Patents

Literature

6601 results about "Closed cavity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

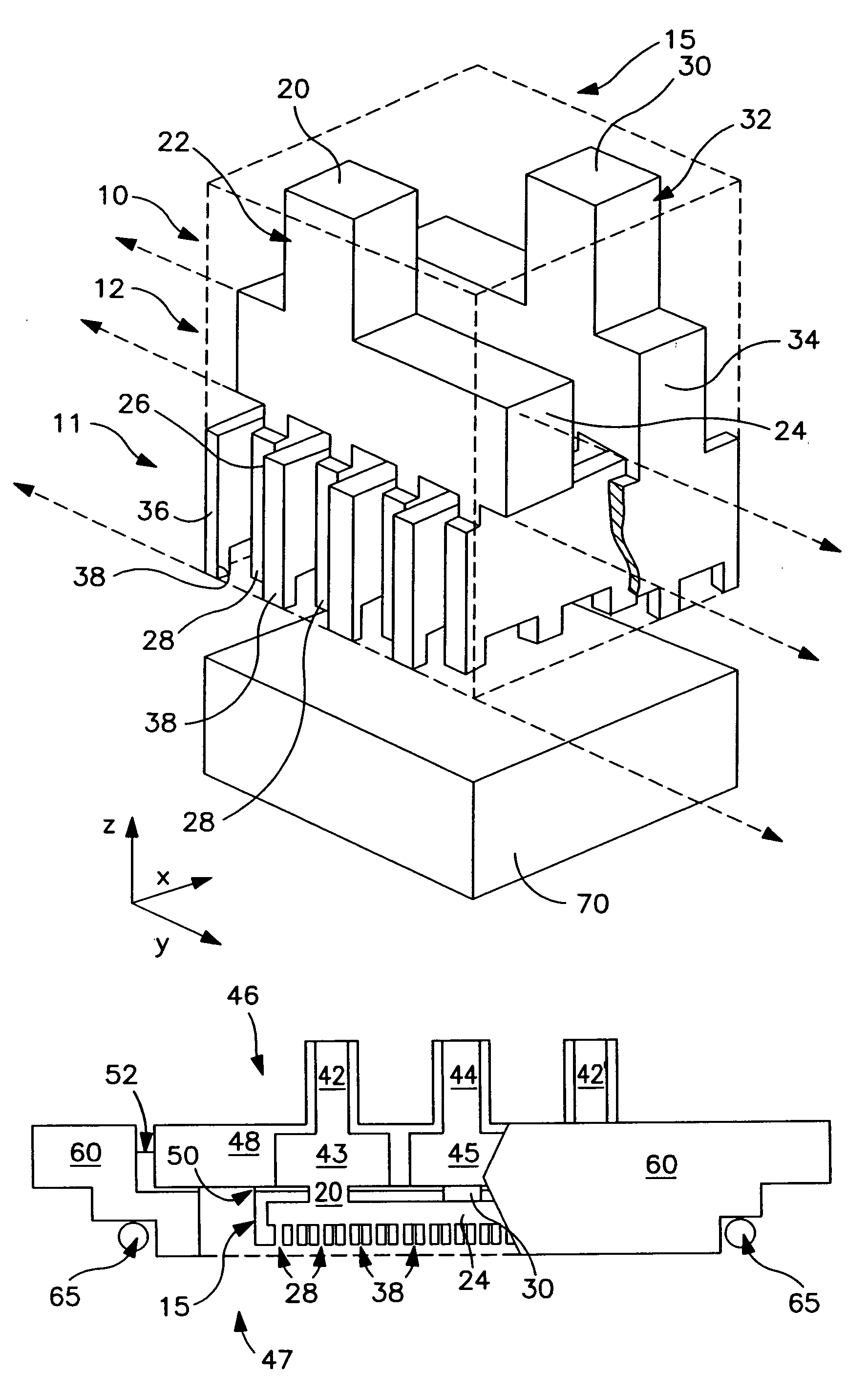

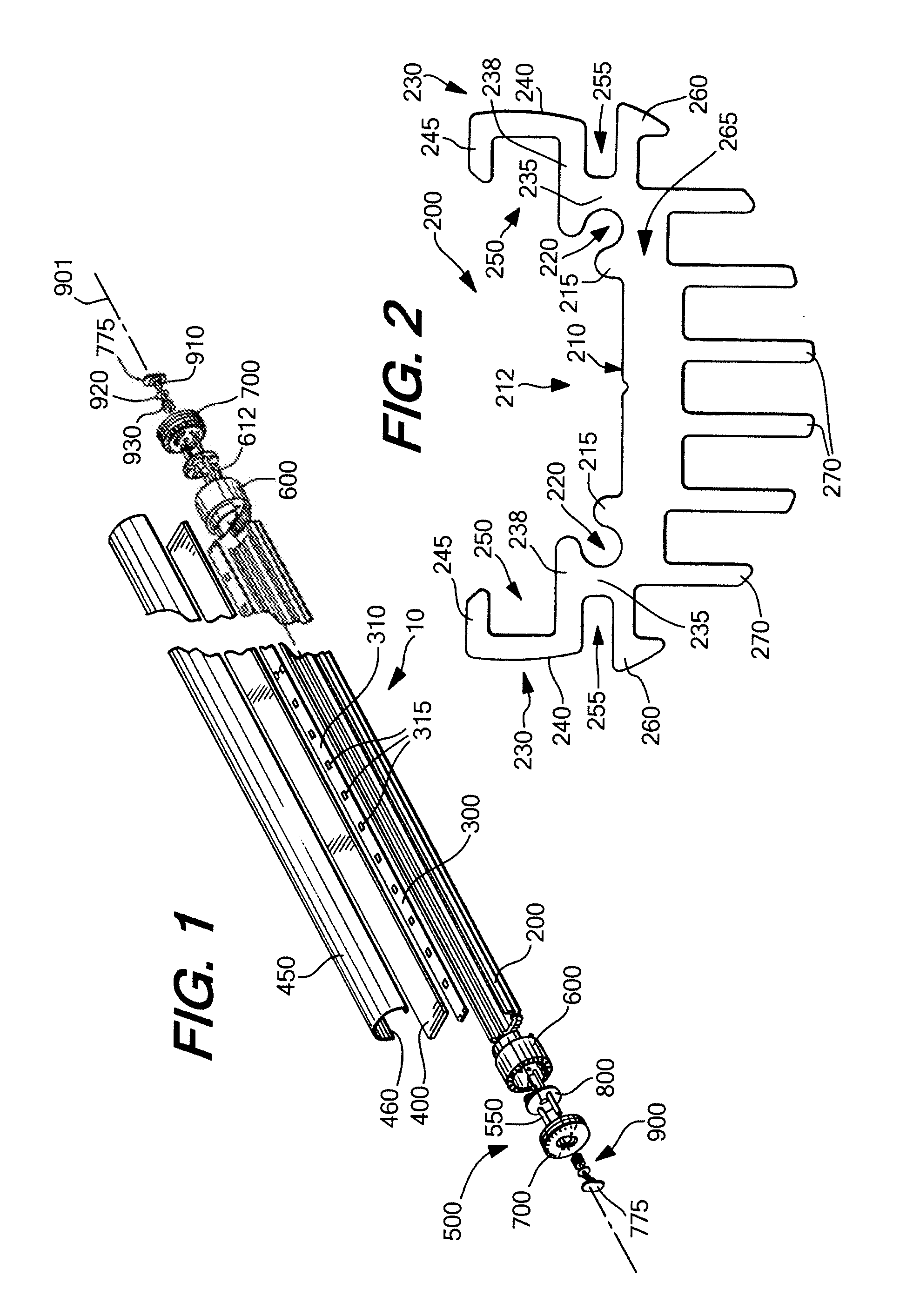

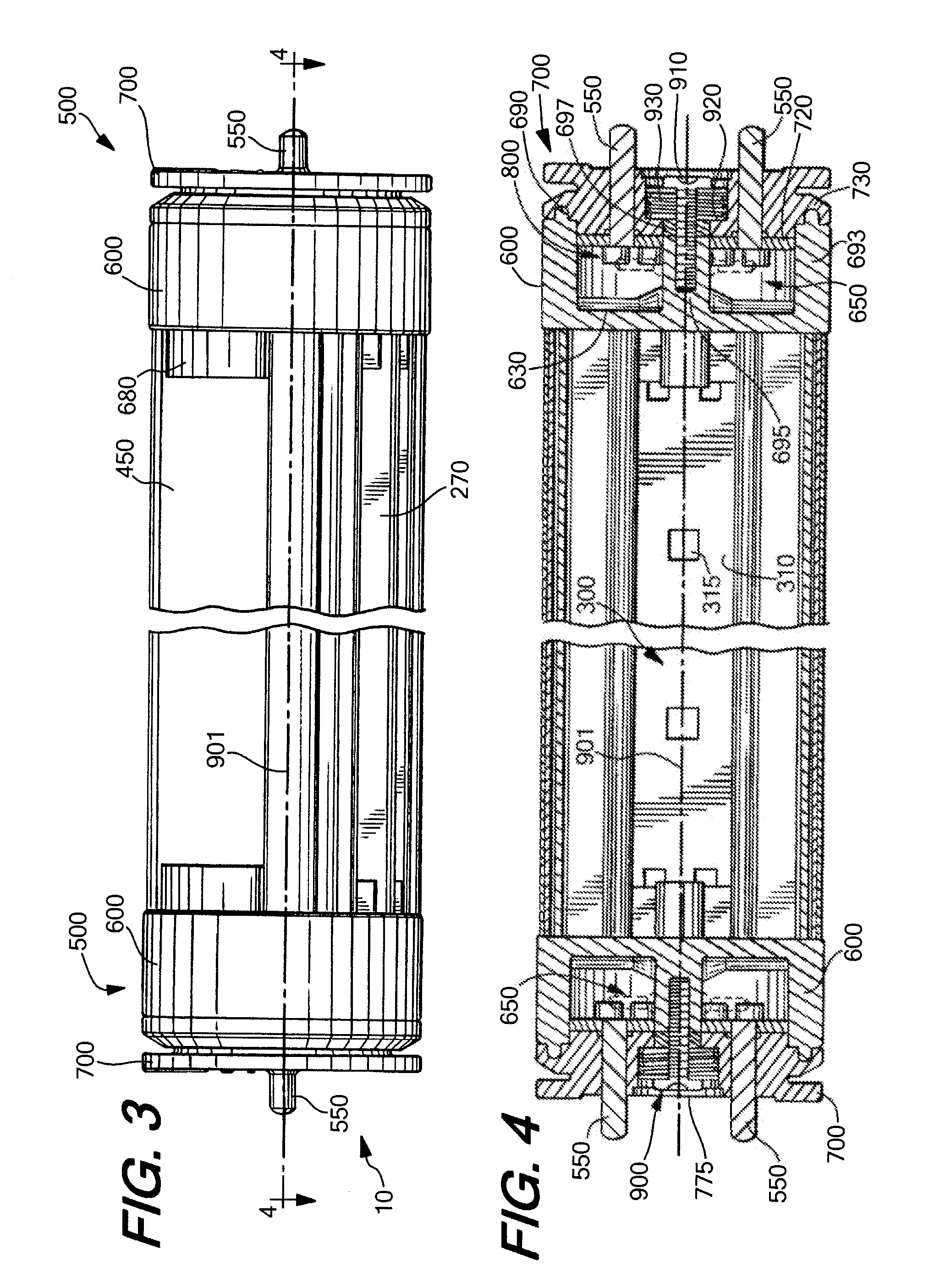

Actuation sled having a curved guide member and method

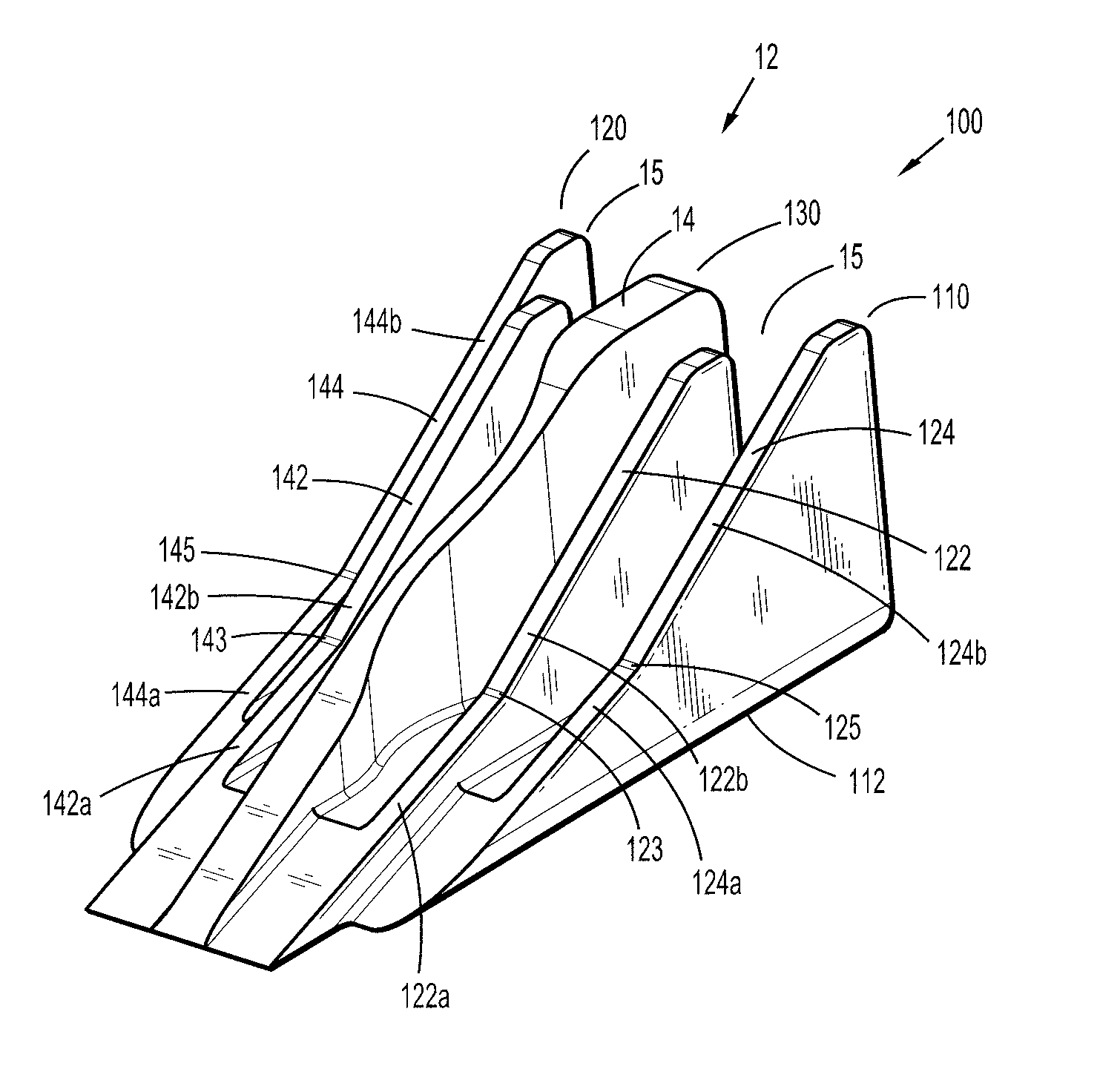

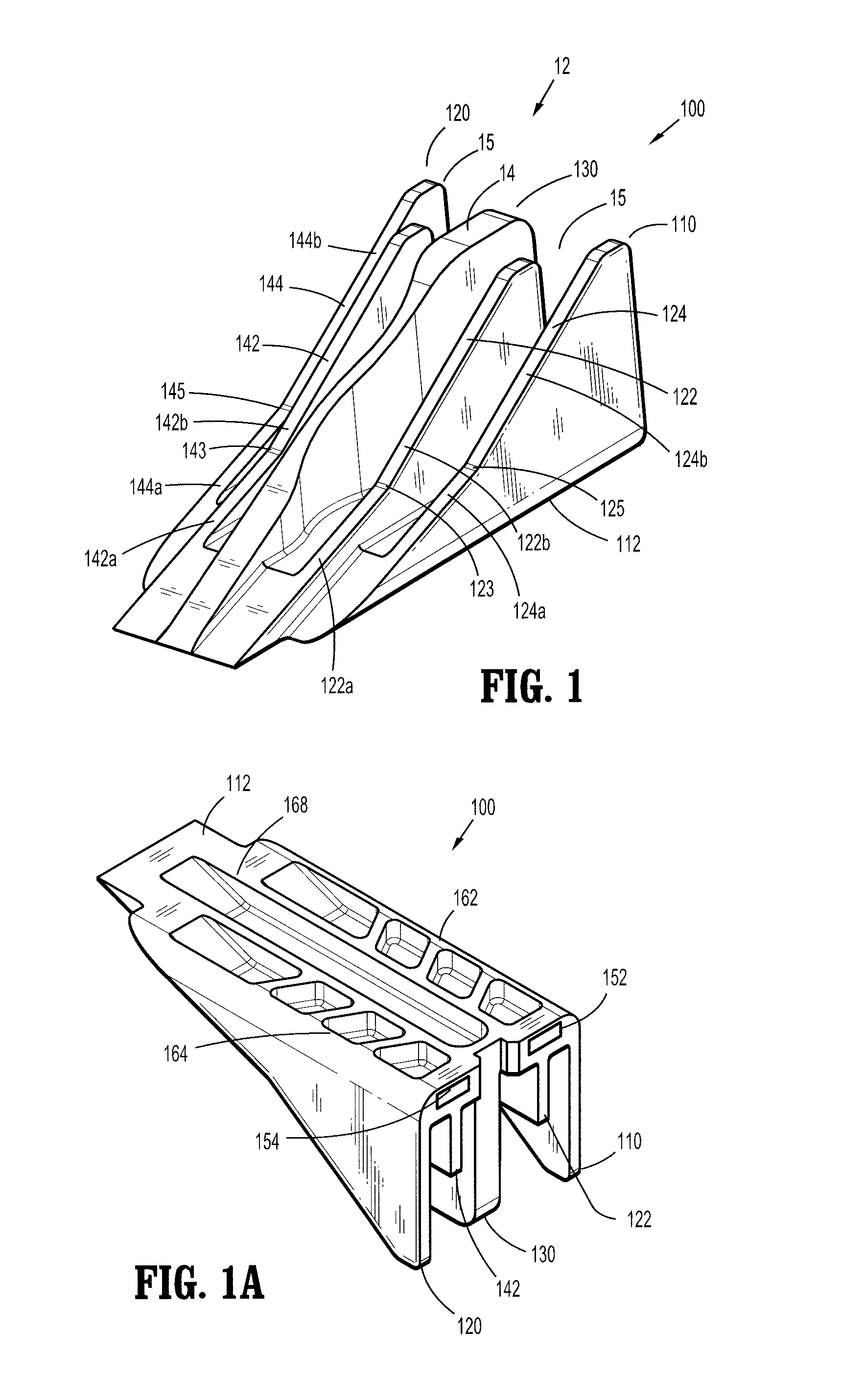

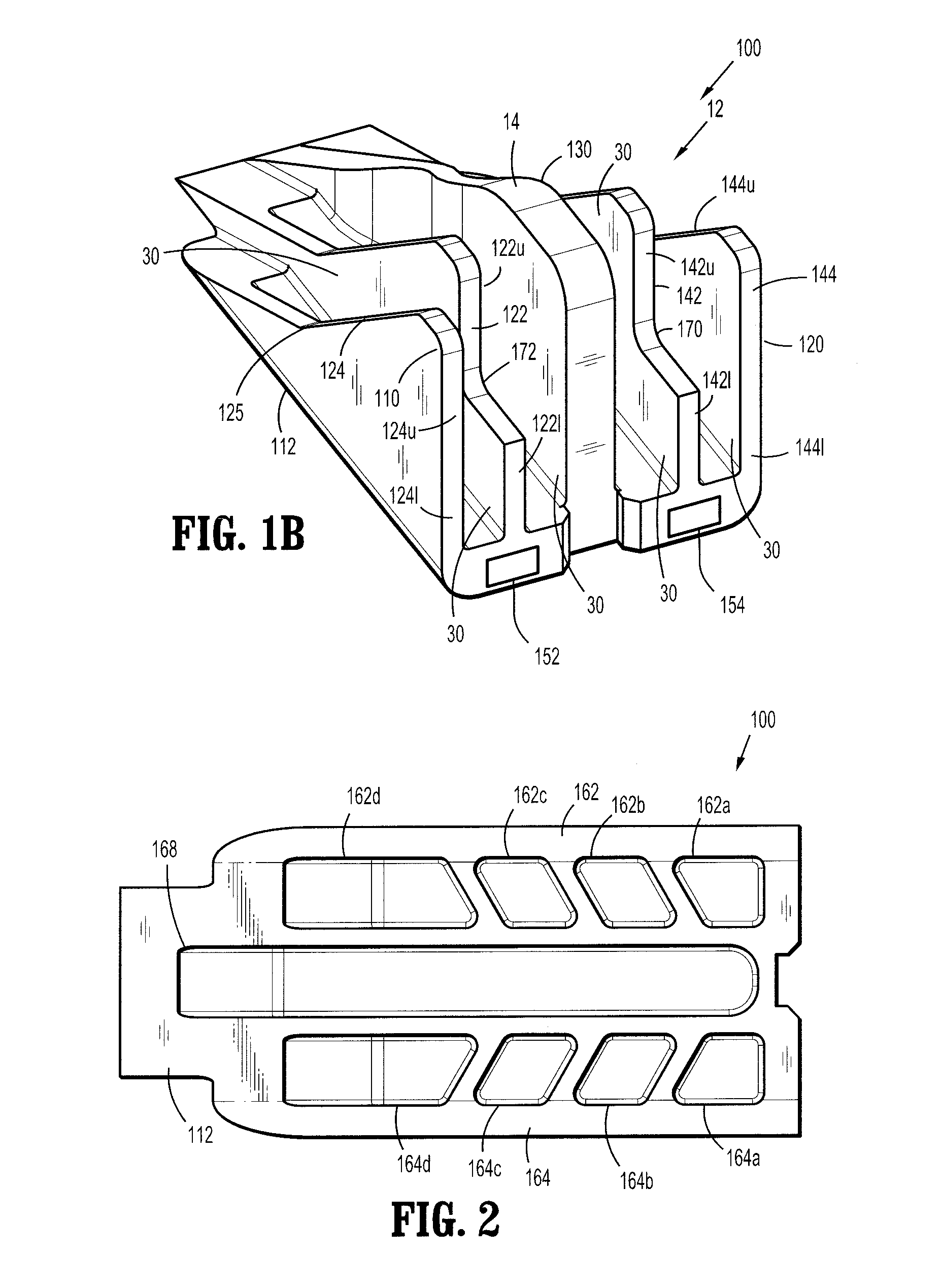

An apparatus for injection molding includes at least one mold part having at least one surface. The mold part includes at least one mold part having at least one substantially central, sloping, non-linear surface, the at least one mold part including at least one shaped portion. The mold part further includes at least one substantially closed cavity region disposed within the at least one substantially central, sloping, non-linear surface. The mold part further includes at least one gate disposed on a base portion of the mold part for providing fluid communication to the at least one cavity region, the base portion having a plurality of recesses / depressions extending longitudinally along the length of the mold part. Additionally, at least one flow restrictor may be positioned on the mold part for initially directing flow of injected fluid to the at least one shaped portion.

Owner:COVIDIEN LP

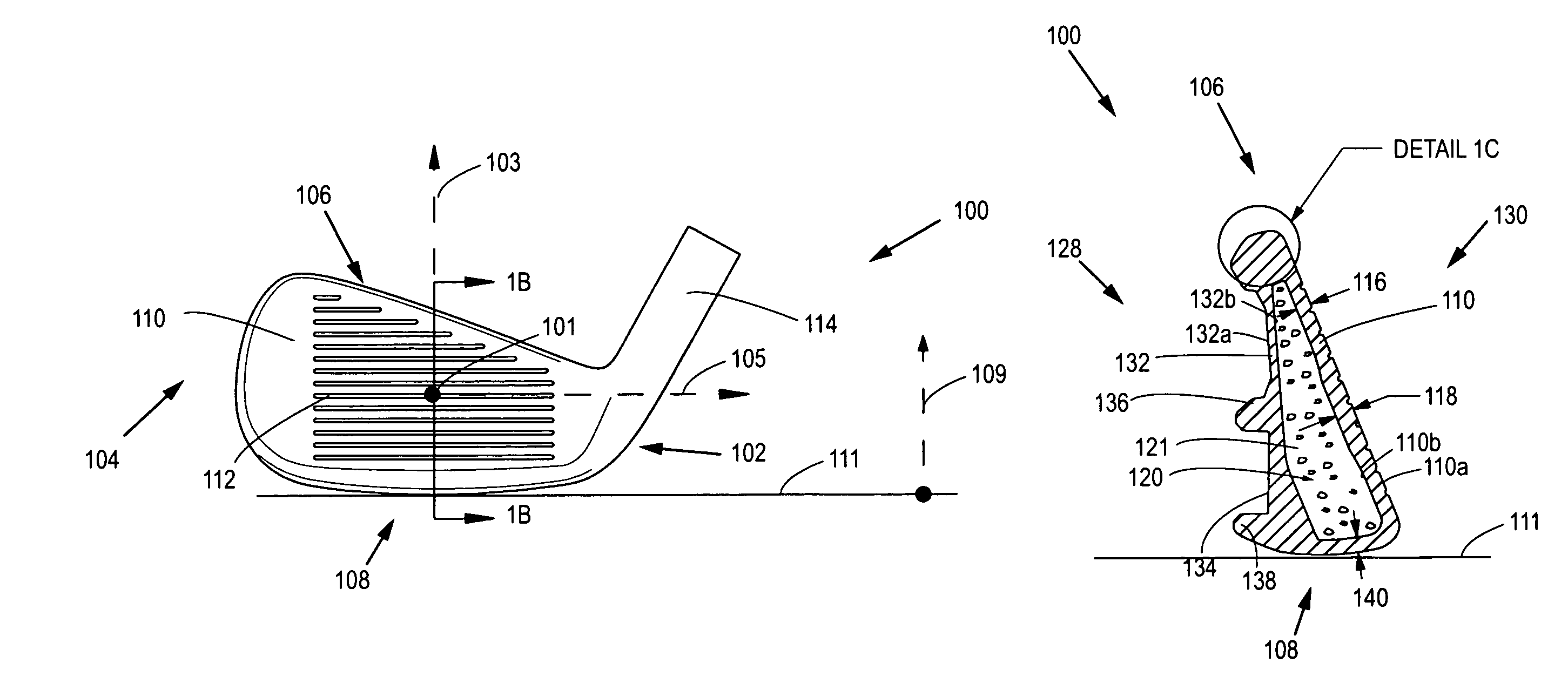

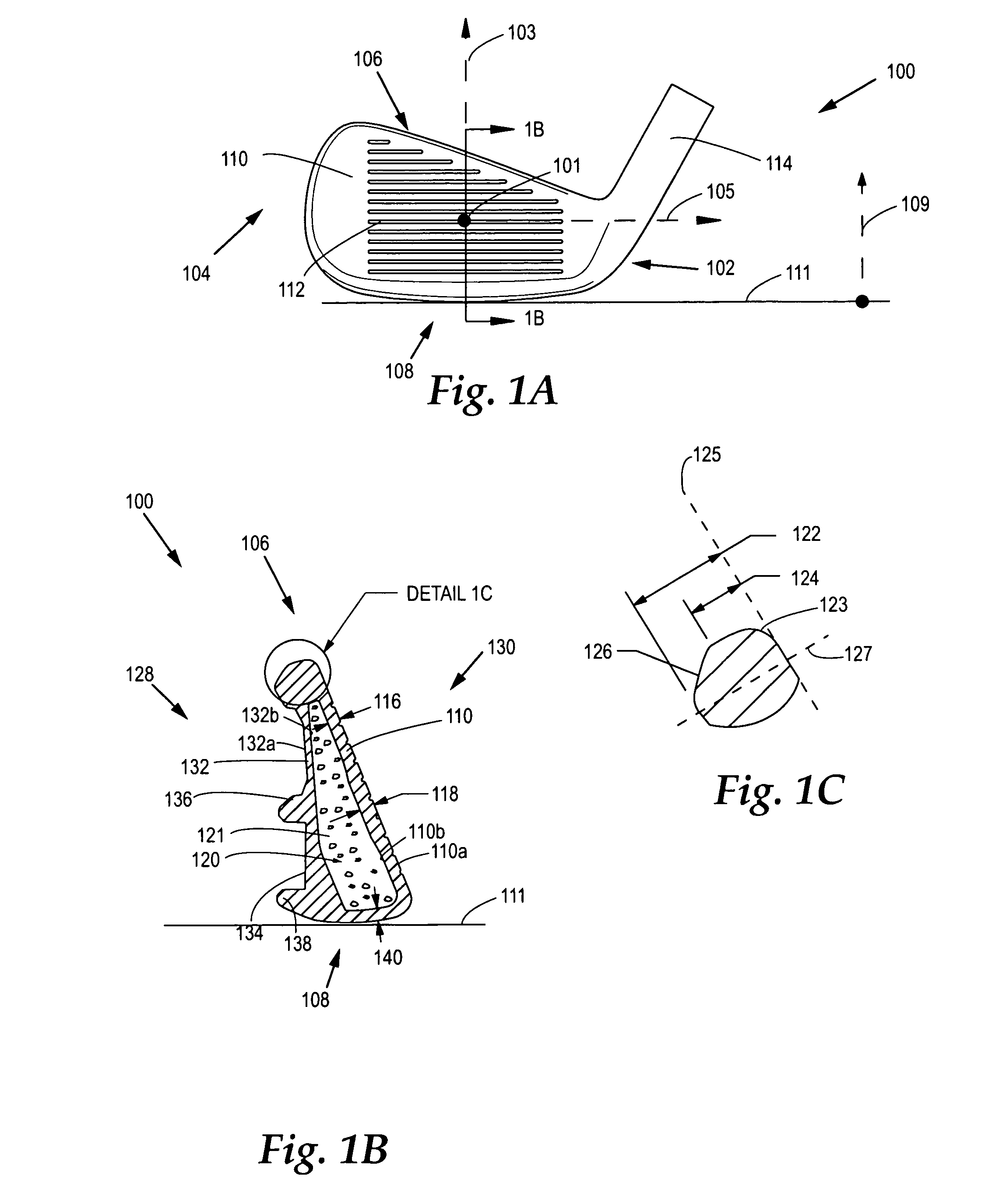

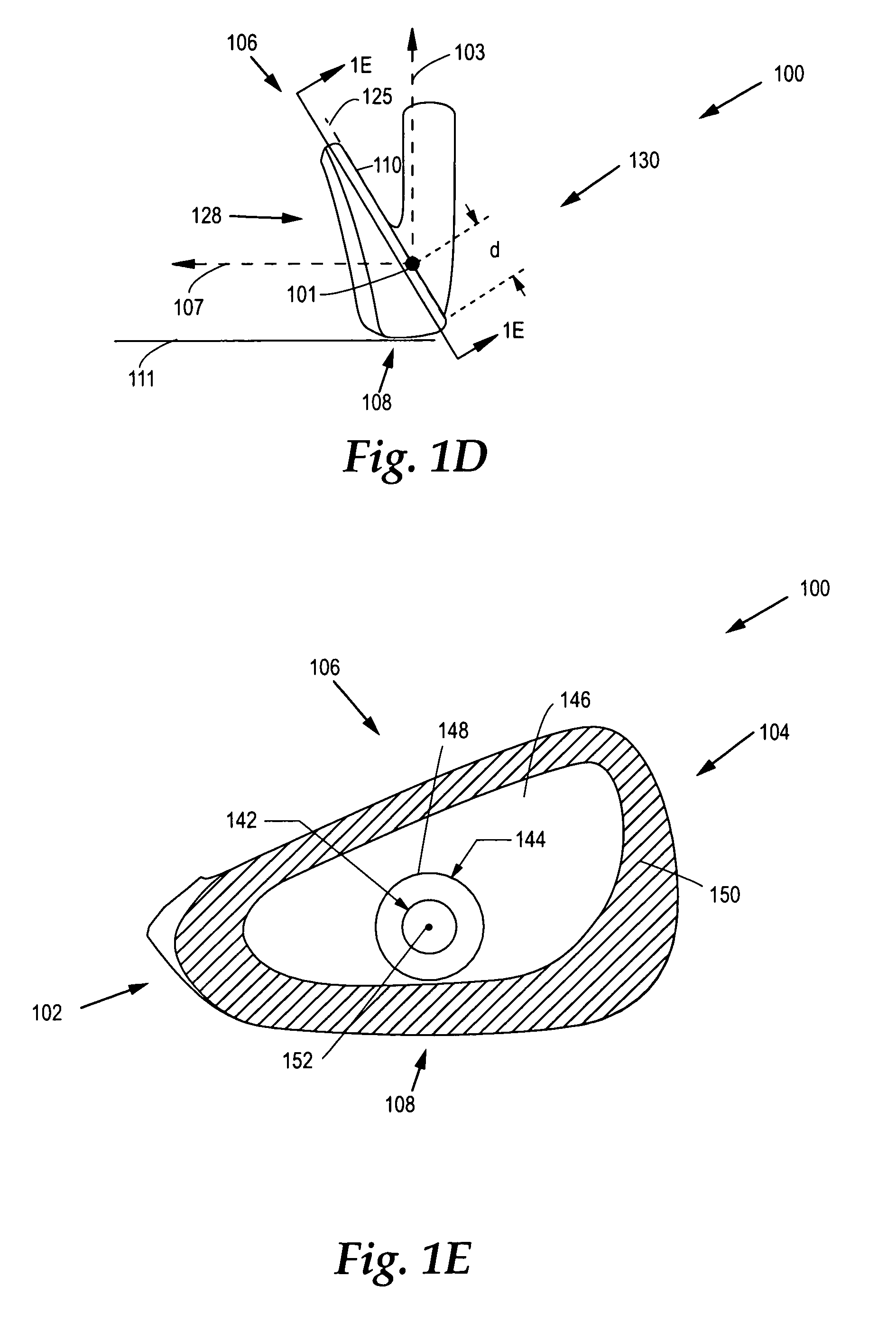

Golf club head

An iron-type golf club head is disclosed having a heel portion, a sole portion, a toe portion, a top-line portion, a front portion, a rear portion, and a striking face. A back wall is also disclosed in the rear portion enclosing a portion of the rear portion to create an enclosed cavity. The cavity is defined by at least a rear surface of the striking face, an inner back wall surface, and the sole portion. A plug and a filler material is located within the enclosed cavity. The filler material surrounds the plug and is configured to hold the plug in place. The plug is lighter than the filler material.

Owner:TAYLOR MADE GOLF

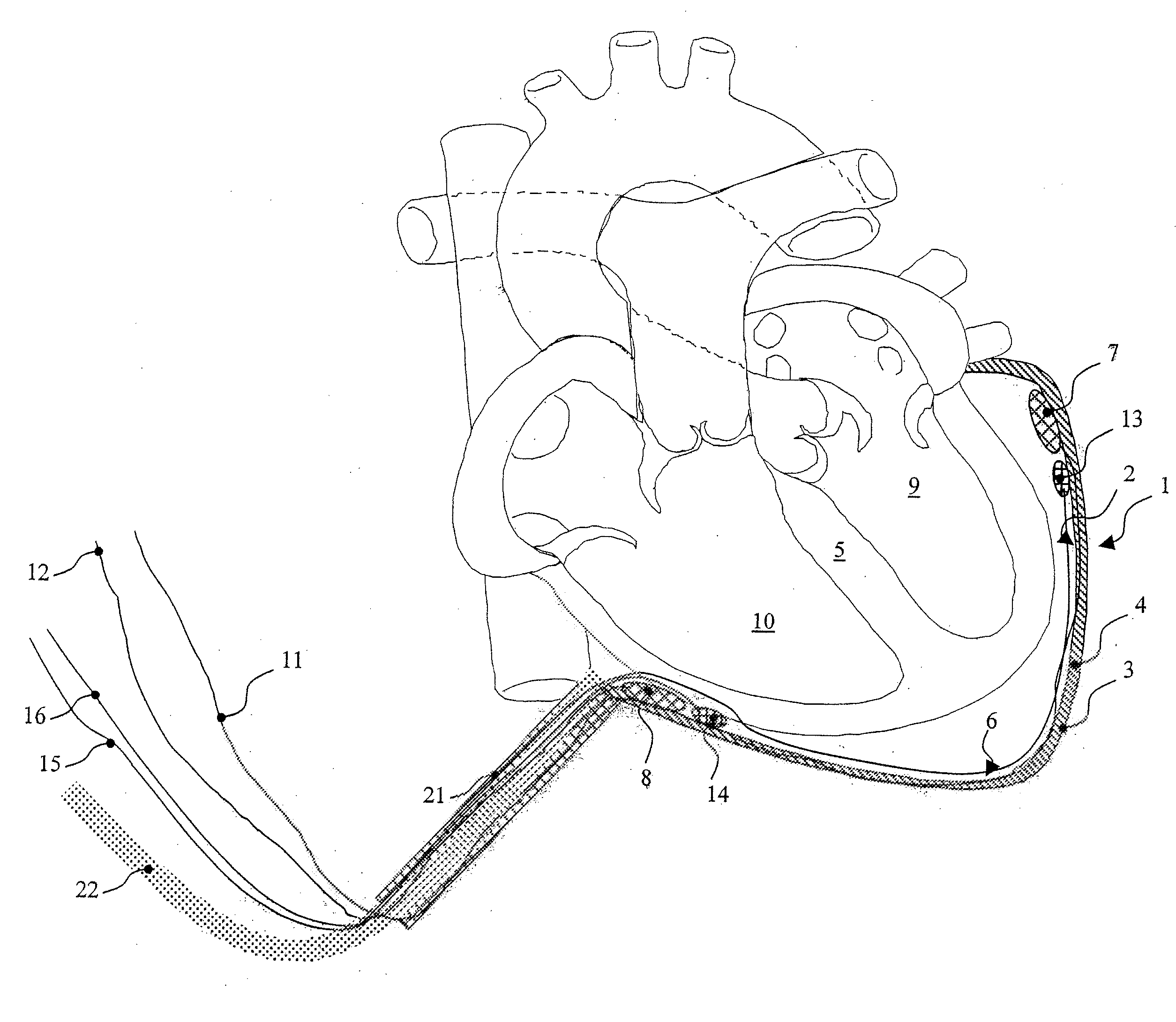

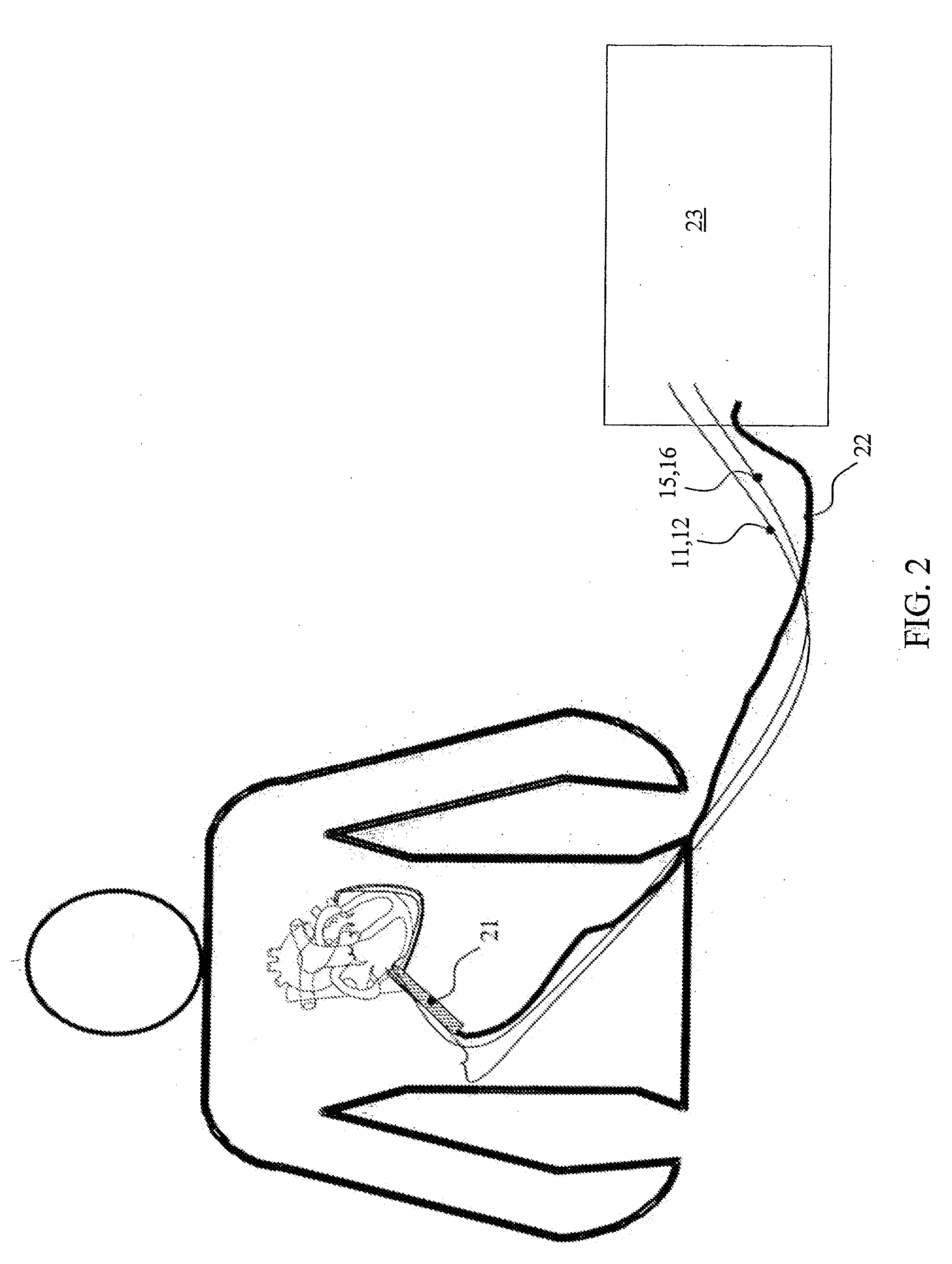

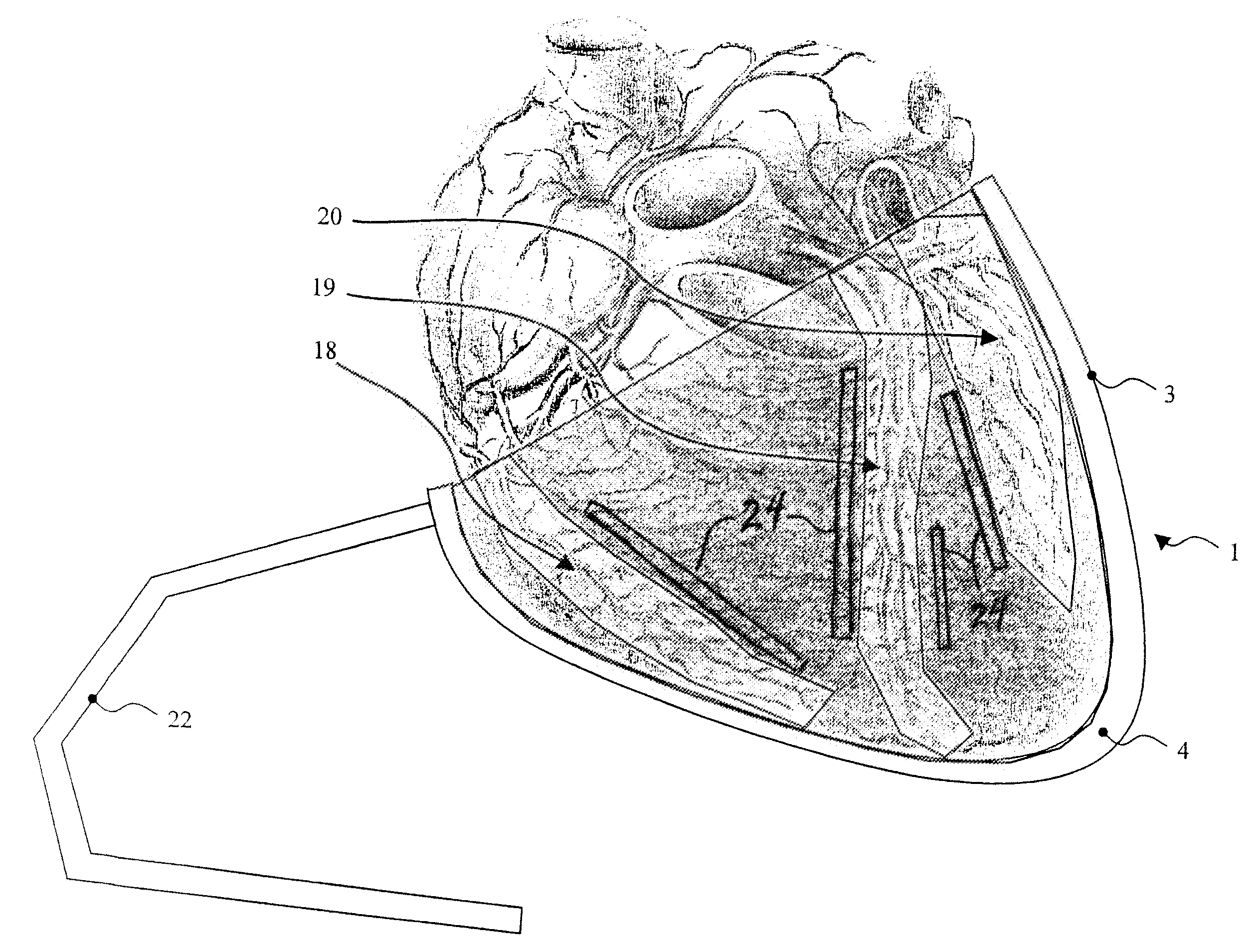

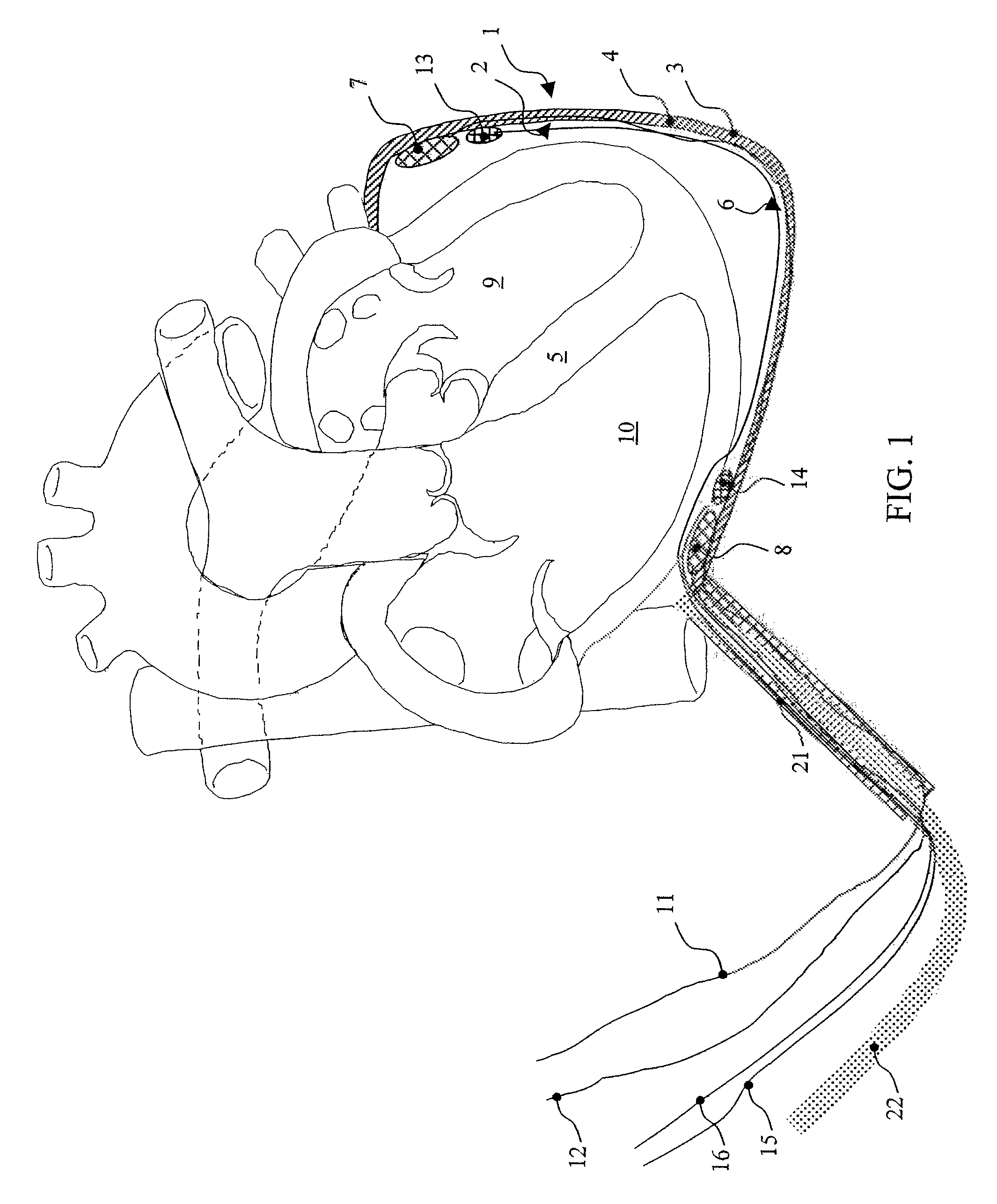

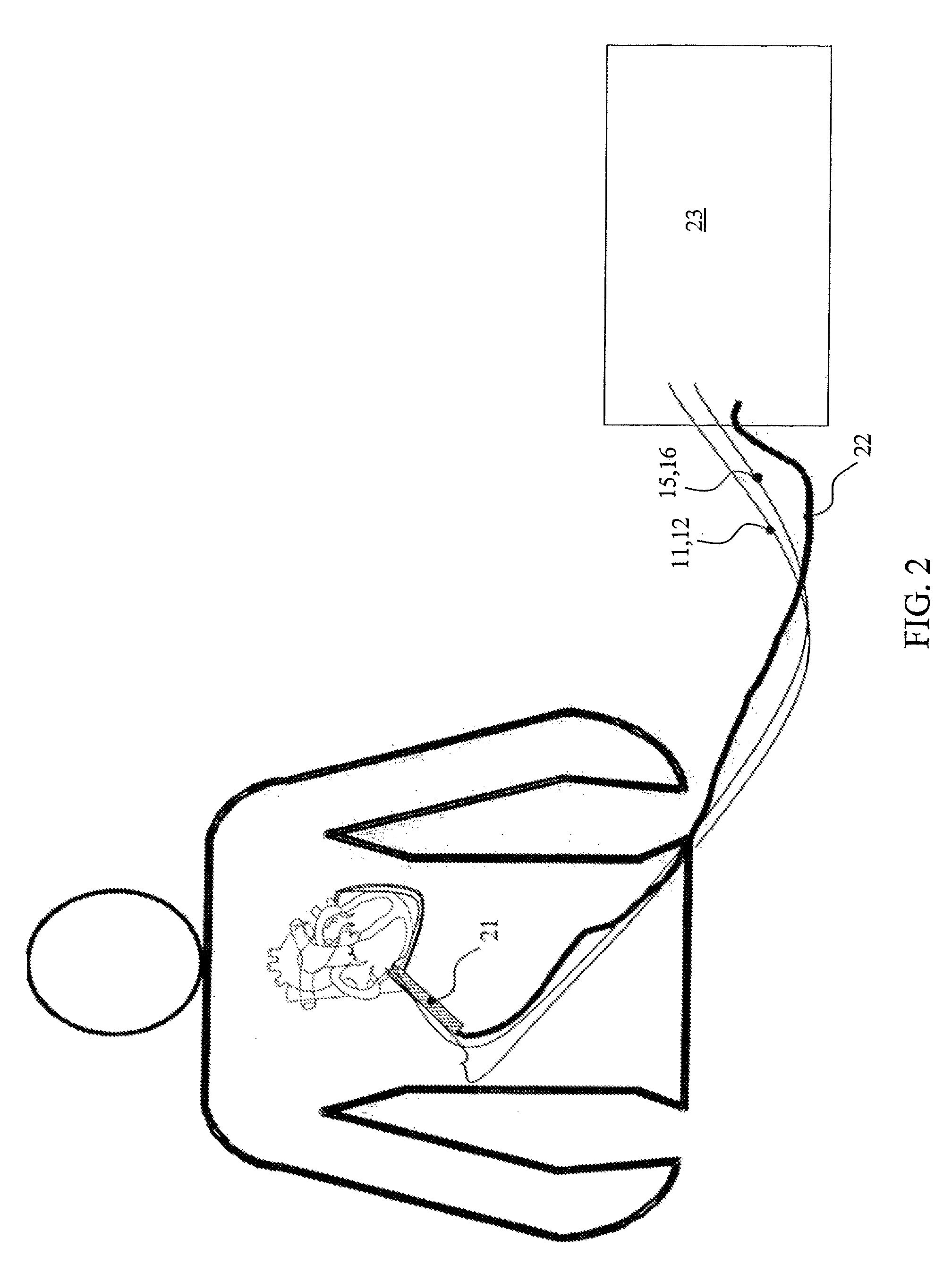

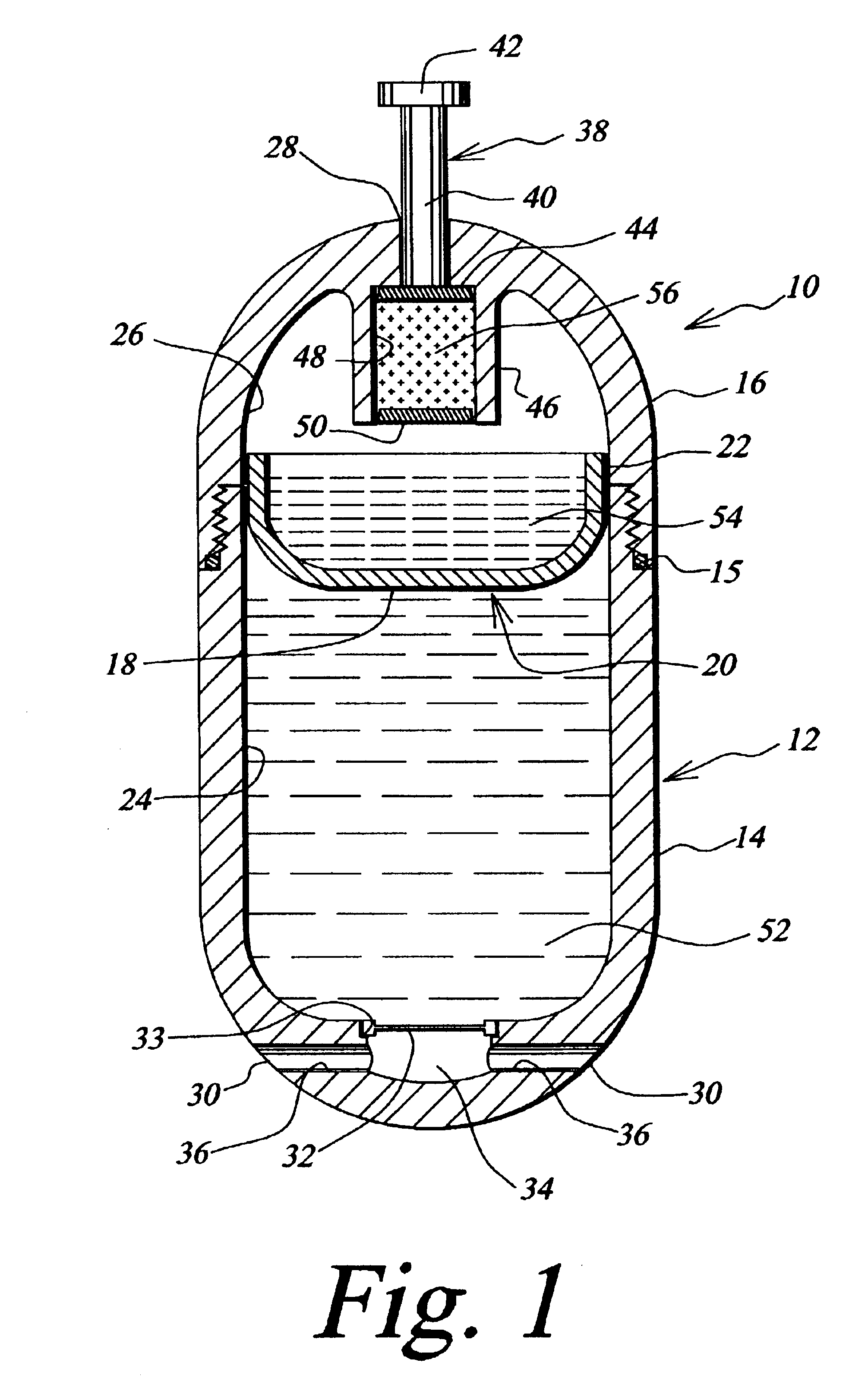

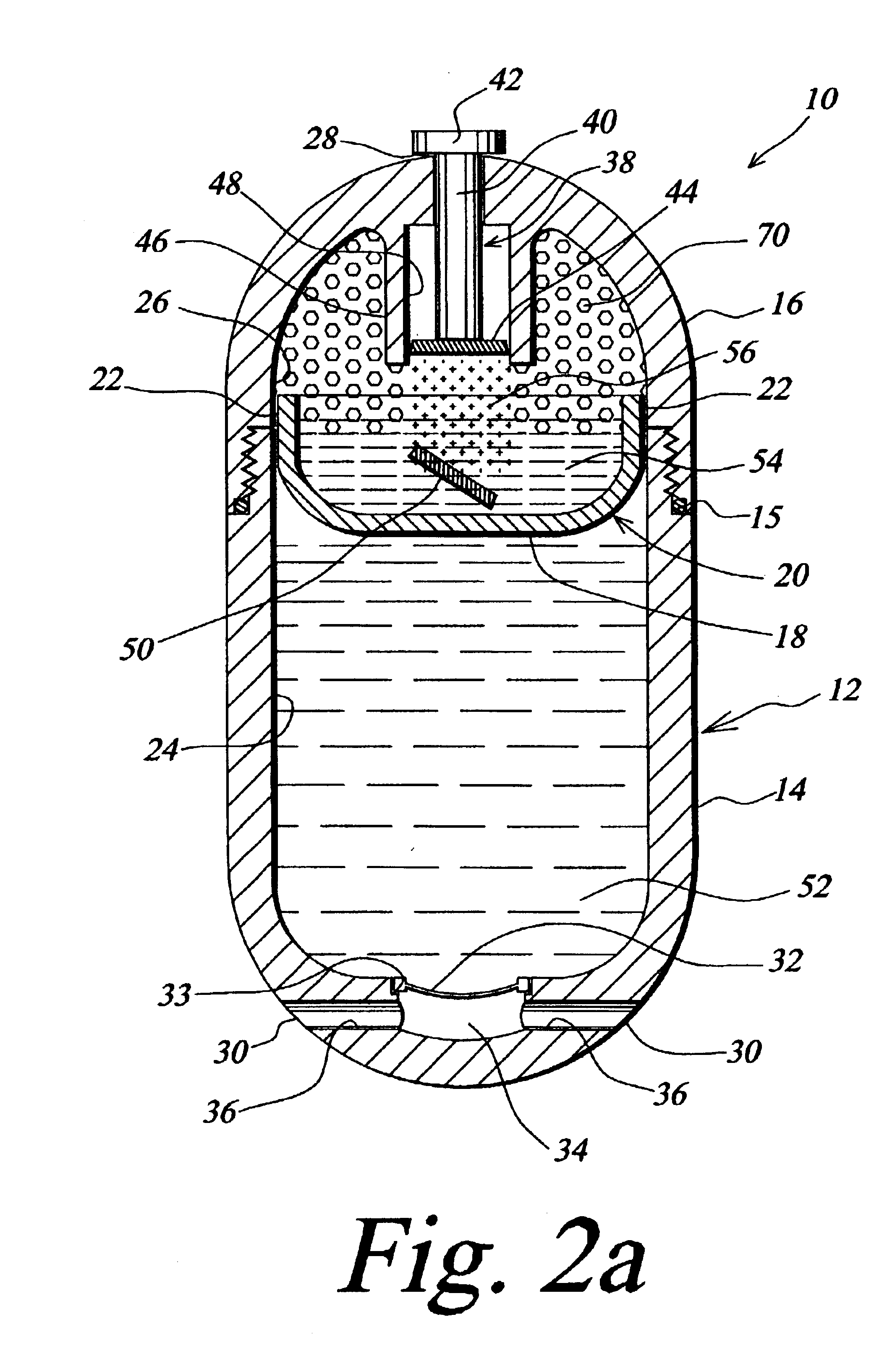

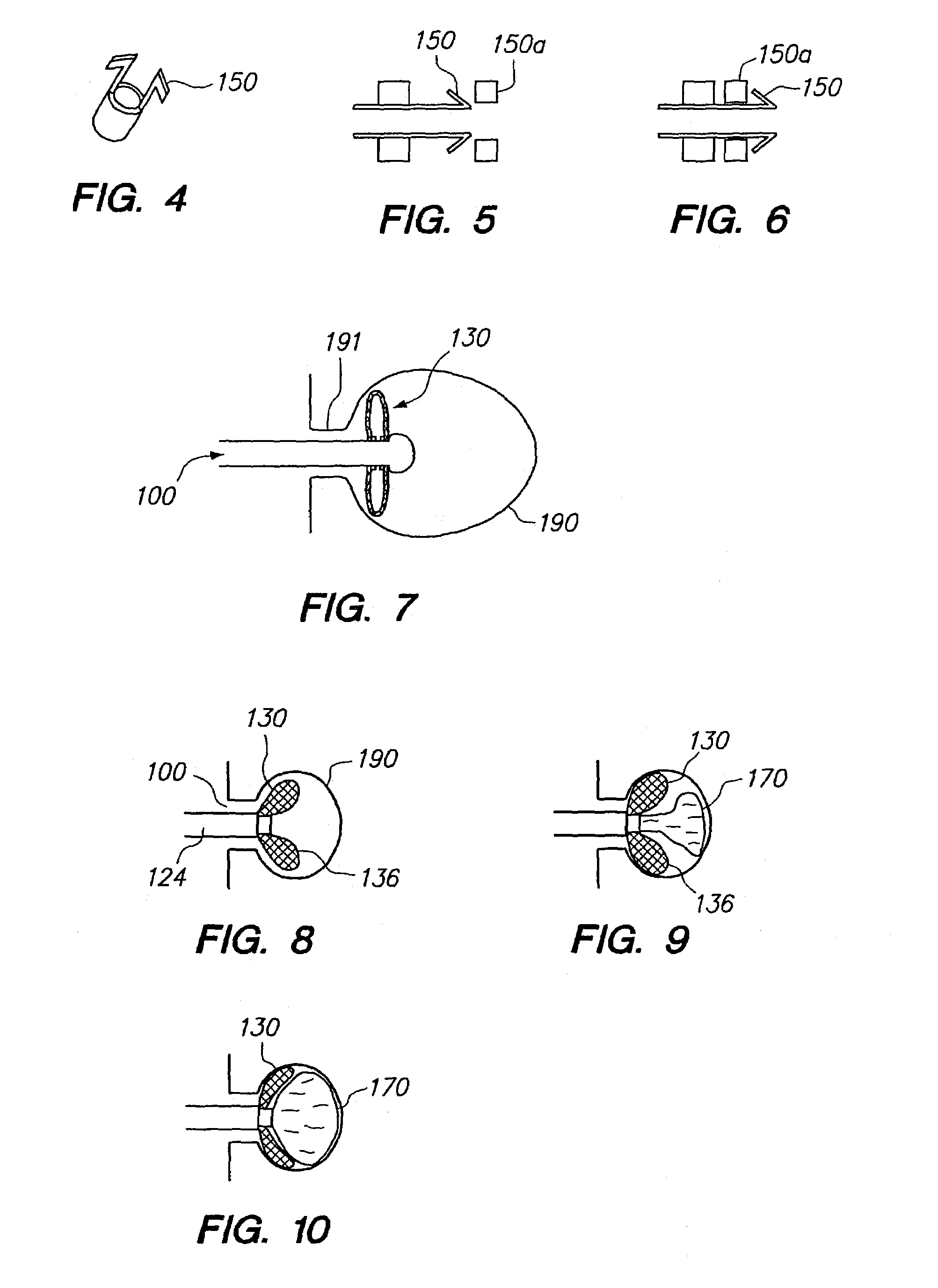

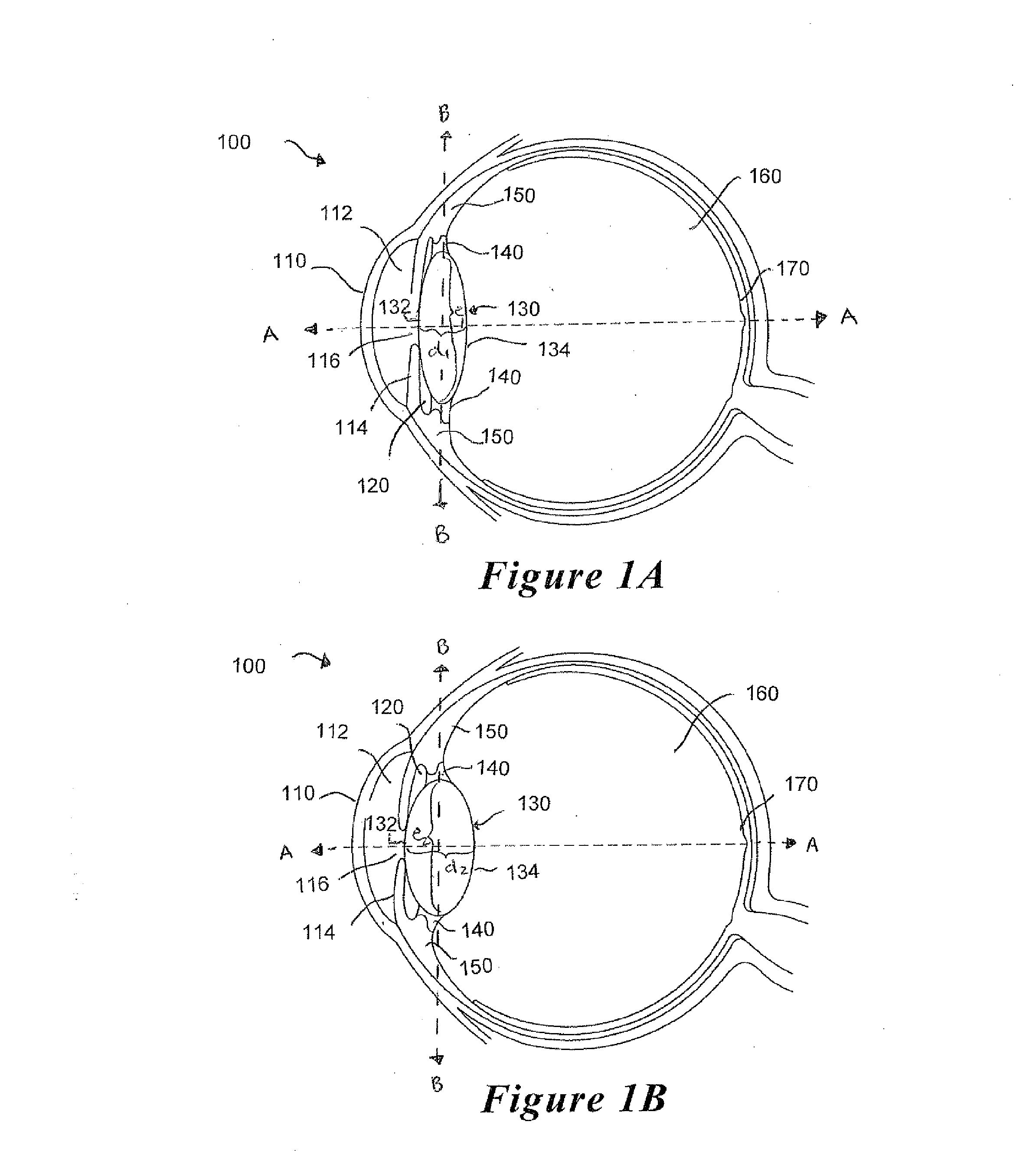

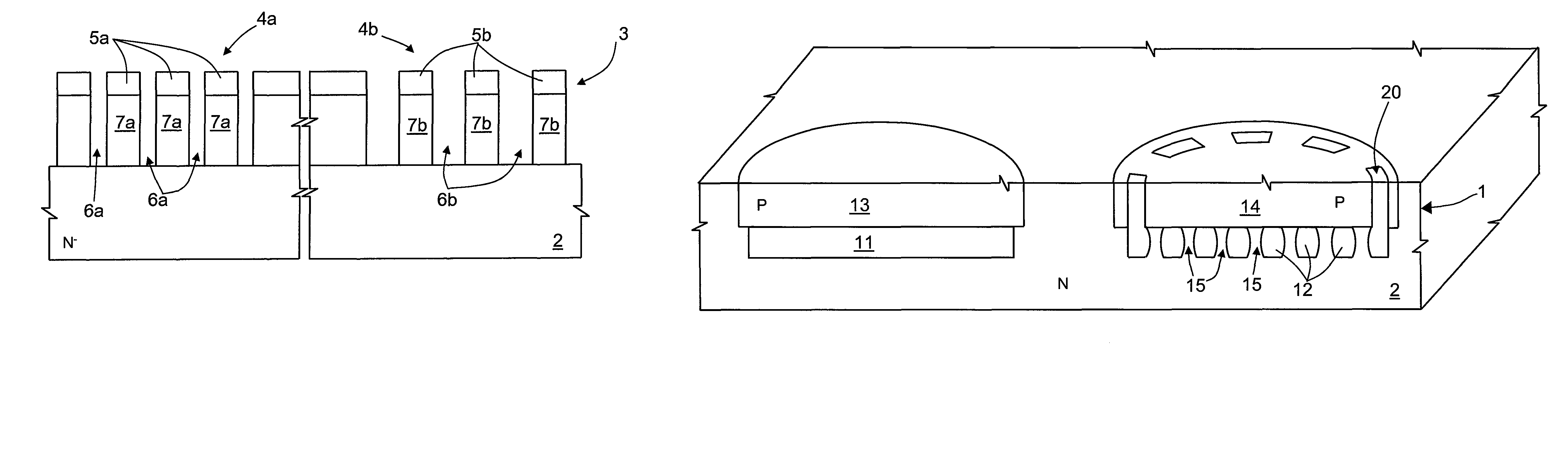

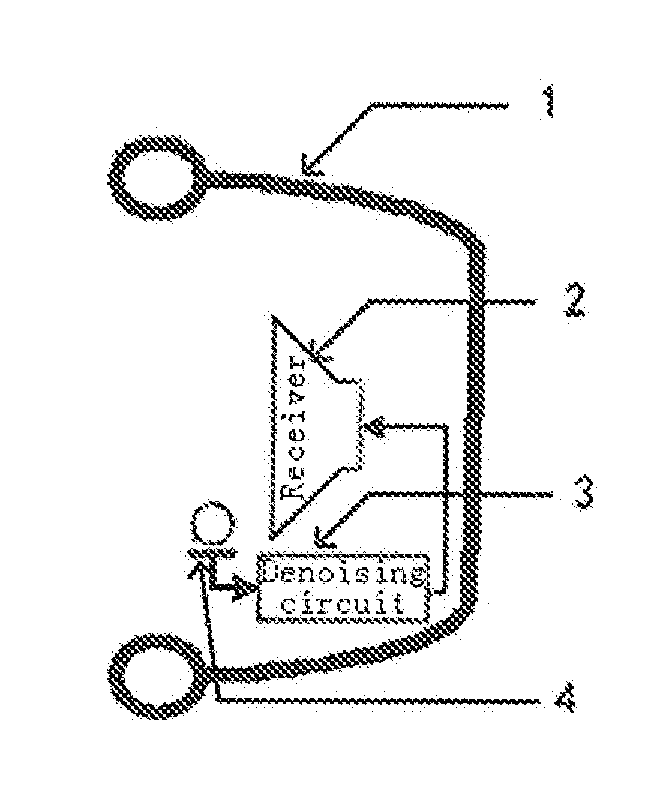

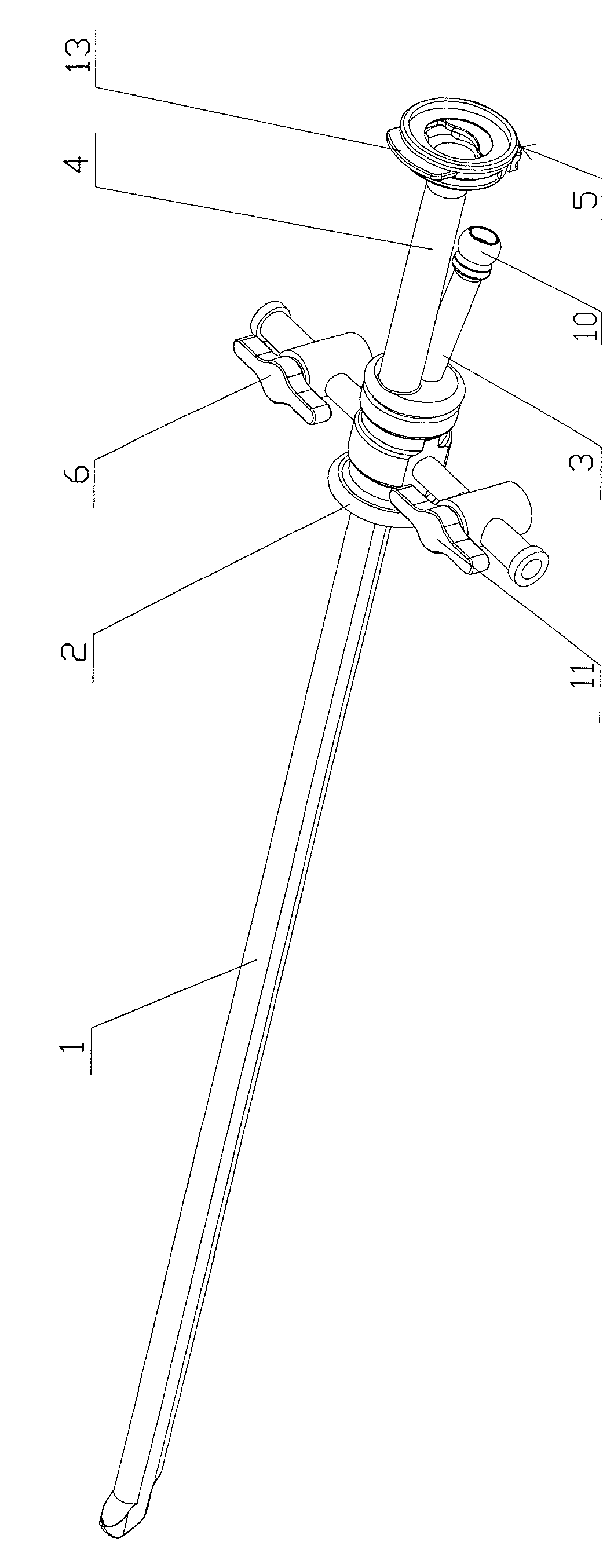

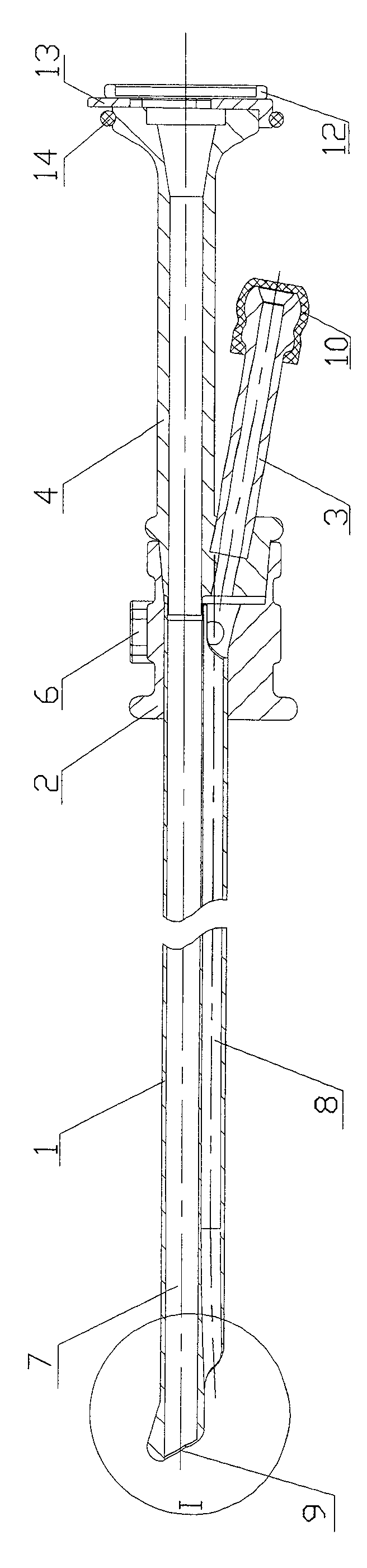

Device for the Epicardial Support and/or Resumption of Cardiac Activity

InactiveUS20070225545A1Good choiceEpicardial electrodesControl devicesCardiac pacemaker electrodeEcg lead

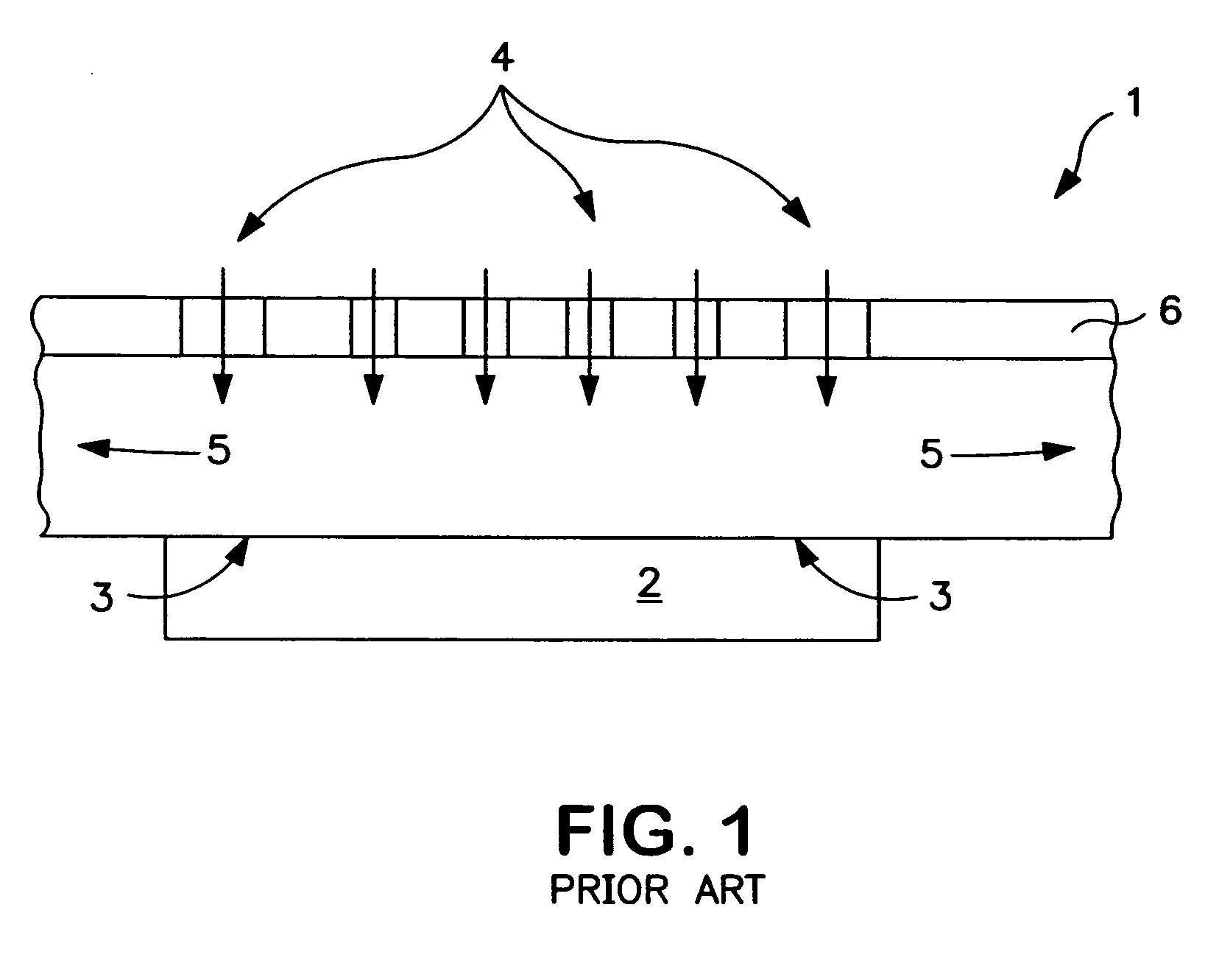

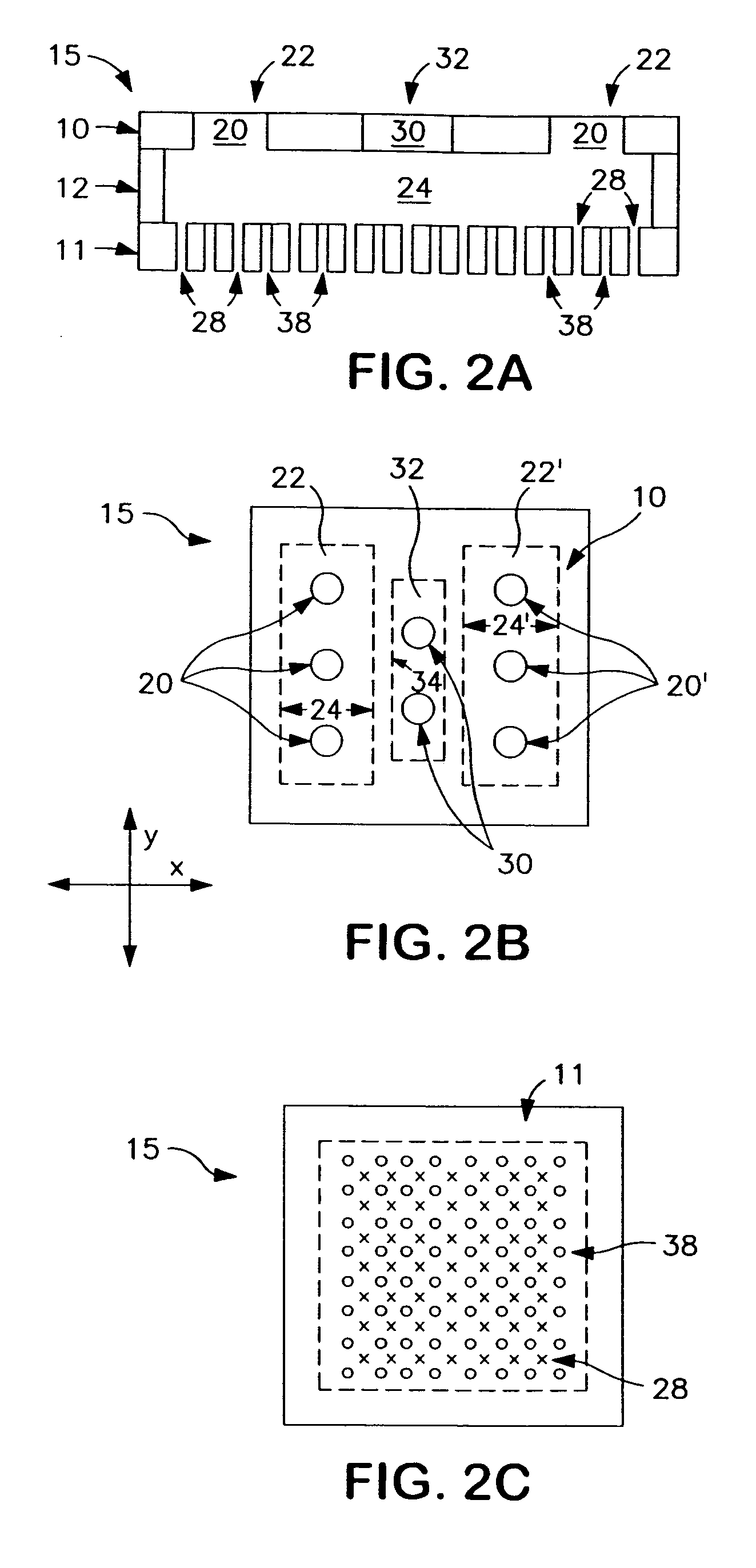

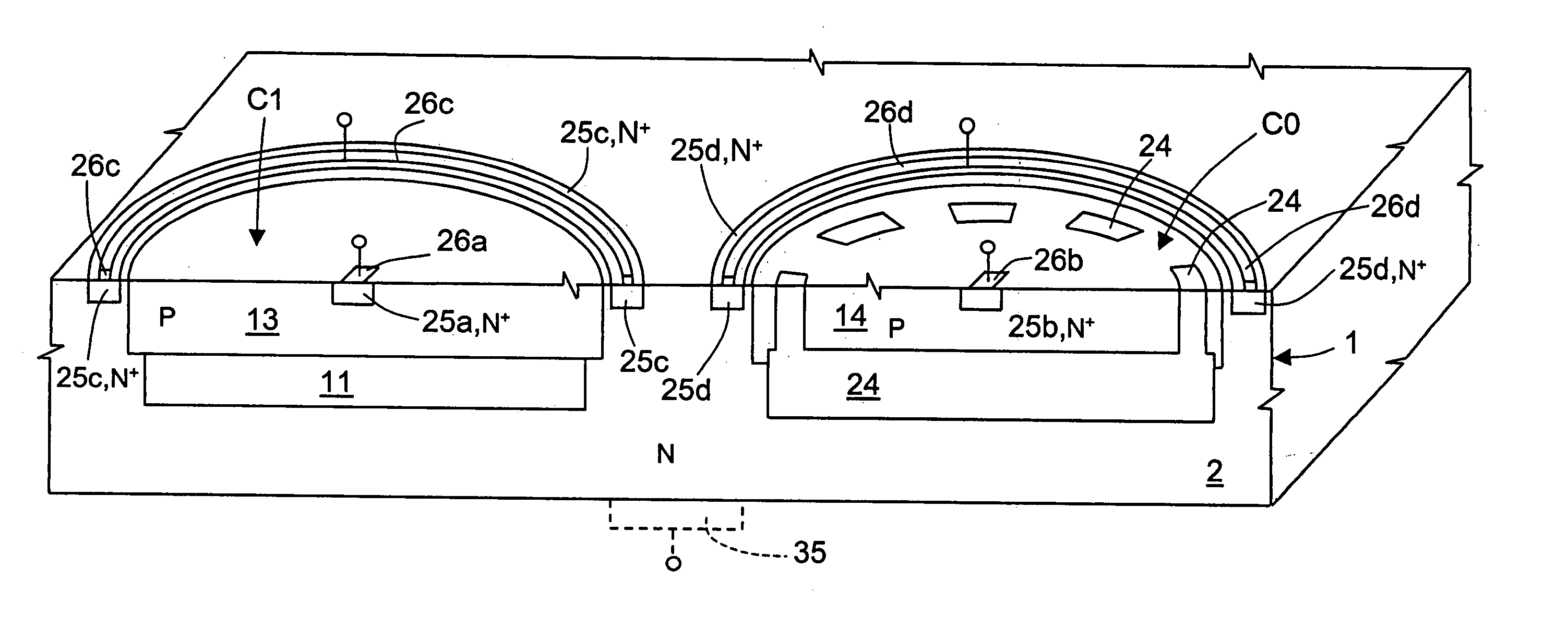

A device for epicardial support and / or the assuming of cardiac activity having a double membrane (1) consisting of an elastic inner membrane (2) and a non-expandable outer membrane (3) as well as a closed cavity (4) formed therebetween which can be inflated and deflated by means of a fluid. With the objective of further developing a device of the type as indicated at the outset which provides a simpler possibility of stimulating the heart in the critical post-operative phase, it is provided for at least one probe / electrode unit (7, 8) to be arranged on the inward facing side (6) of the inner membrane (2) to the heart (5) for epicardial ECG leads and / or signal transmission / conversion of an external pacemaker.

Owner:PPA TECH GMBH

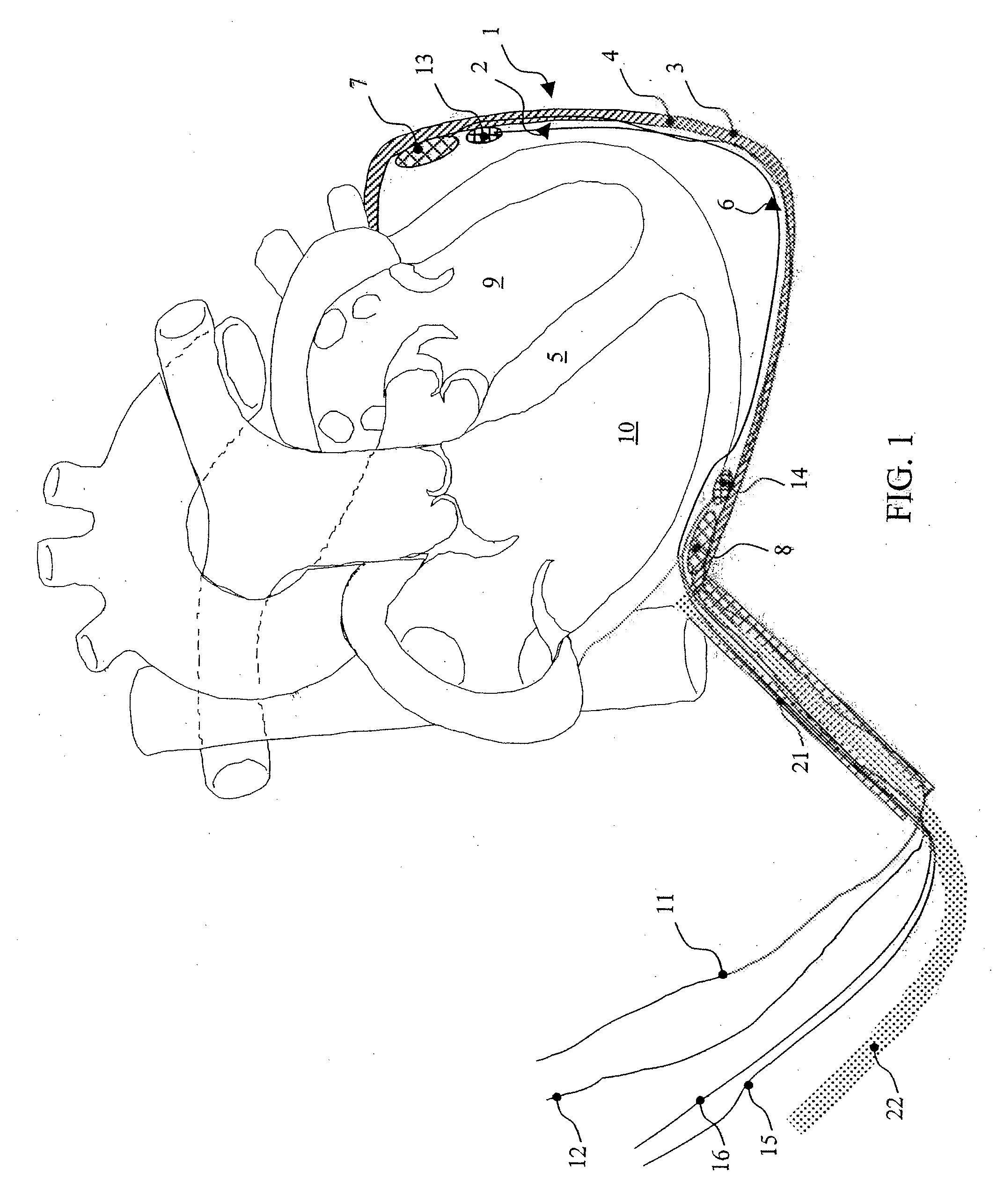

Device for the epicardial support and/or resumption of cardiac activity

InactiveUS7691047B2Good choiceEpicardial electrodesControl devicesCardiac pacemaker electrodeEcg lead

A device for epicardial support and / or the assuming of cardiac activity having a double membrane (1) consisting of an elastic inner membrane (2) and a non-expandable outer membrane (3) as well as a closed cavity (4) formed therebetween which can be inflated and deflated by means of a fluid. With the objective of further developing a device of the type as indicated at the outset which provides a simpler possibility of stimulating the heart in the critical post-operative phase, it is provided for at least one probe / electrode unit (7, 8) to be arranged on the inward facing side (6) of the inner membrane (2) to the heart (5) for epicardial ECG leads and / or signal transmission / conversion of an external pacemaker.

Owner:PPA TECH GMBH

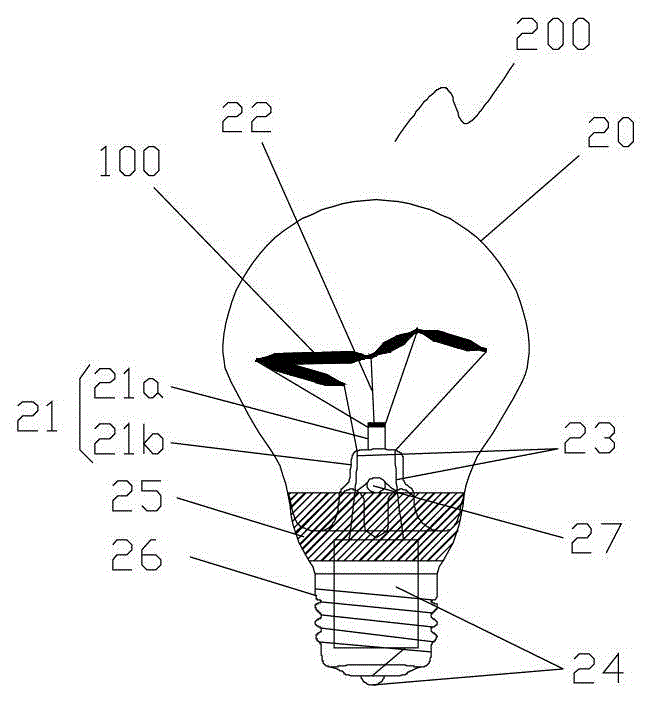

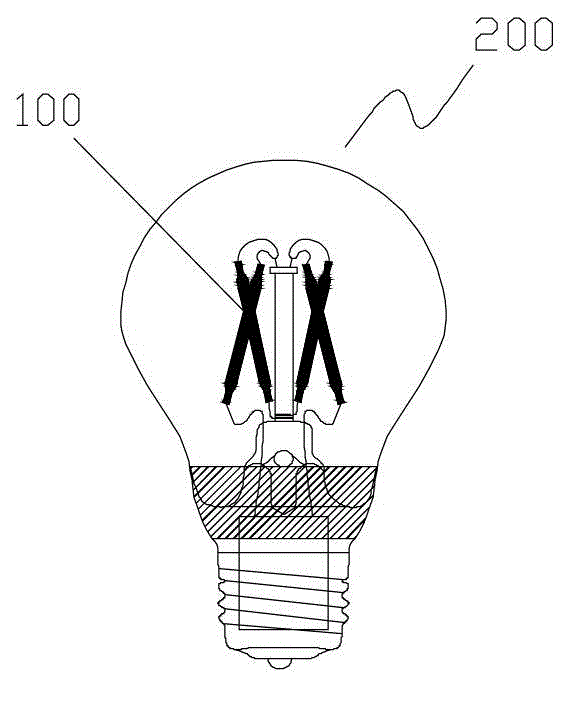

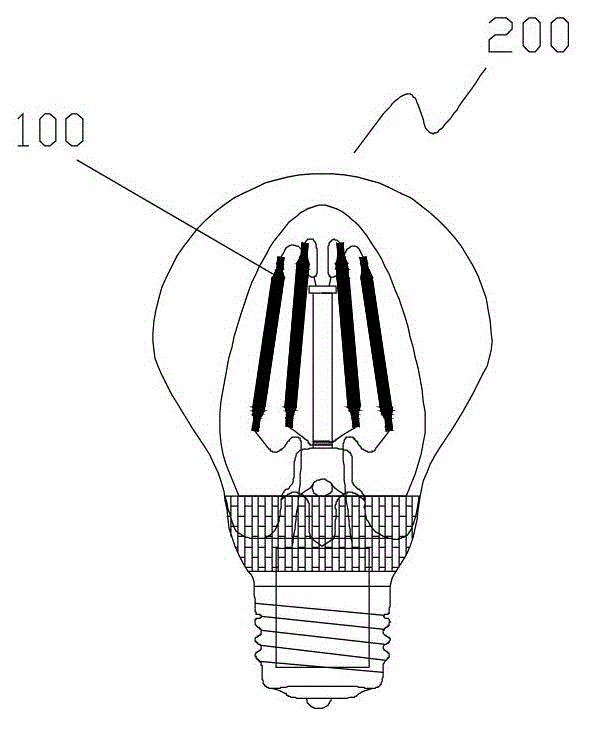

LED lighting device

InactiveCN103939758AImprove aestheticsImprove securityPoint-like light sourceLighting heating/cooling arrangementsEffect lightEngineering

The invention relates to the field of LED lighting, and particularly provides an LED lighting device. The LED lighting device comprises a transparent outer shell, an LED luminescent device and a support, wherein the transparent outer shell and the support form a closed cavity and the LED luminescent device is located inside the cavity and fixed onto the support. The LED lighting device is characterized in that the cavity is filled with inert gas which is used for transmitting heat generated by the LED luminescent device to the outer portion of the transparent outer shell. According to the LED lighting device, through the inert gas arranged in the cavity in a filled mode, the heat generated by the LED luminescent device can be transmitted to the outer portion of the LED lighting device without adopting a heat dissipation body, and therefore the shape, the size and the weight of the LED lighting device cannot be limited by the heat dissipating body. Thus, the attractiveness, the safety and the installation convenience of the LED lighting device can be improved.

Owner:ZHEJIANG ZHONGZHOU LIGHTING TECH

Reusable paint grenade

A reusable paint dispersing grenade of the type employed in paint ball games is constructed in such a manner as to avoid the use of any combustible materials, and also to avoid the requirement for access to a source of compressed air for operation. The paint grenade of the invention has a hollow, fluid-tight casing defining an enclosed cavity that is divided internally into a marking paint chamber, a first propellant component chamber, and a second propellant component chamber. The propellant component chambers are each filled separately with propellant components, but remain isolated from each other until the paint dispersing grenade is used. At that time the propellant components chemically react with each other in a noncombustible manner to produce a quantity of gas under pressure. The expanding gas produced by the chemical reaction builds to a pressure sufficient to break a paint seal in the casing or a gas seal initially separating the gas from the paint, whereupon the gas under pressure forces the paint out through one or more paint expulsion ports. The device may be recharged with marking paint and the chemically reactive propellant components any number of times.

Owner:ESTRELLA RANDALL P

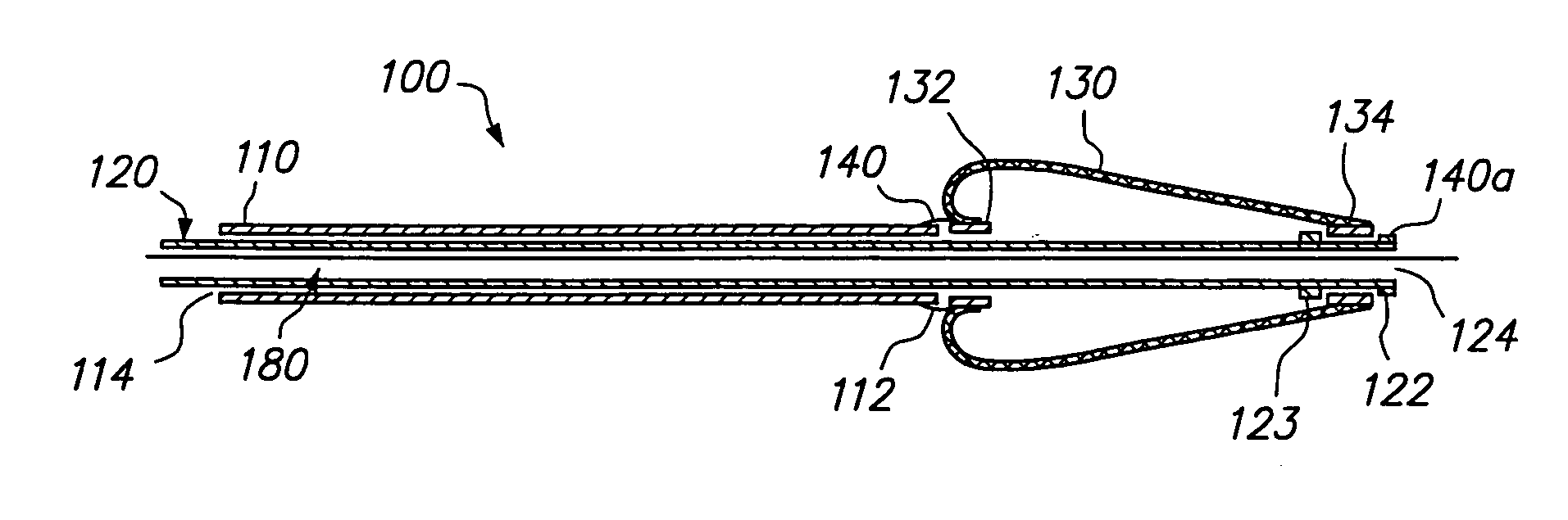

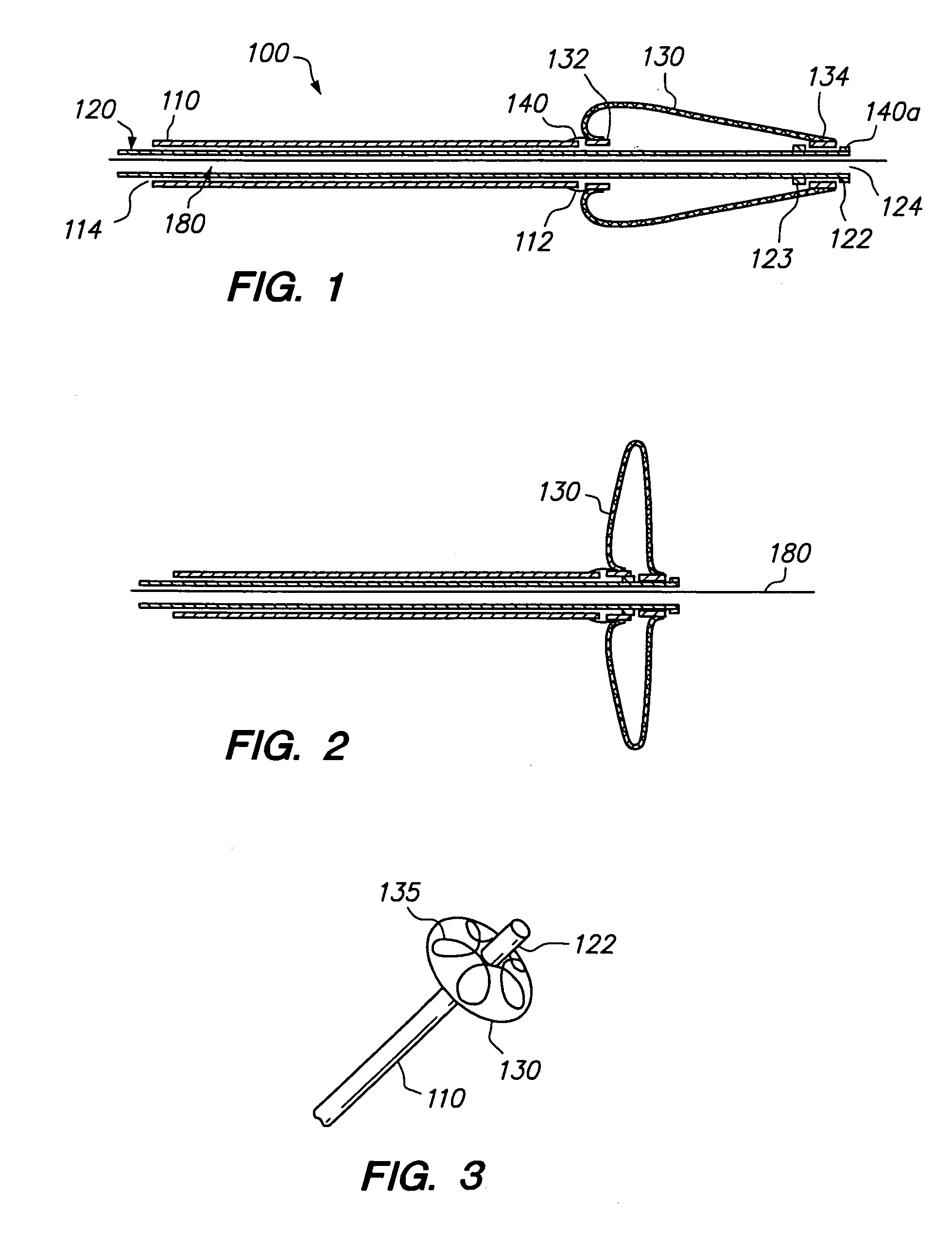

Occlusive cinching devices and methods of use

Methods and devices for blocking orifices and occluding cavities within a patient are provided. The device in one variation comprises first and second tubular members attached to a collapsible sealing element. The device can be placed through an orifice and the collapsible sealing element can be collapsed to seal the orifice. An embolic may be introduced distal to the sealing element to occlude a cavity. The device may incorporate a locking mechanism which can be engaged to lock the sealing element into the collapsed position. The device may incorporate a valve to prevent flow through the tubular members, for example to prevent egress of the embolic from a cavity. The device can be detached to provide a permanent seal of the orifice, and can retain the embolic within the cavity. The device may be used in conjunction with a stent or other retention device to assist the sealing element in maintaining the seal.

Owner:STRYKER EURO OPERATIONS HLDG LLC +1

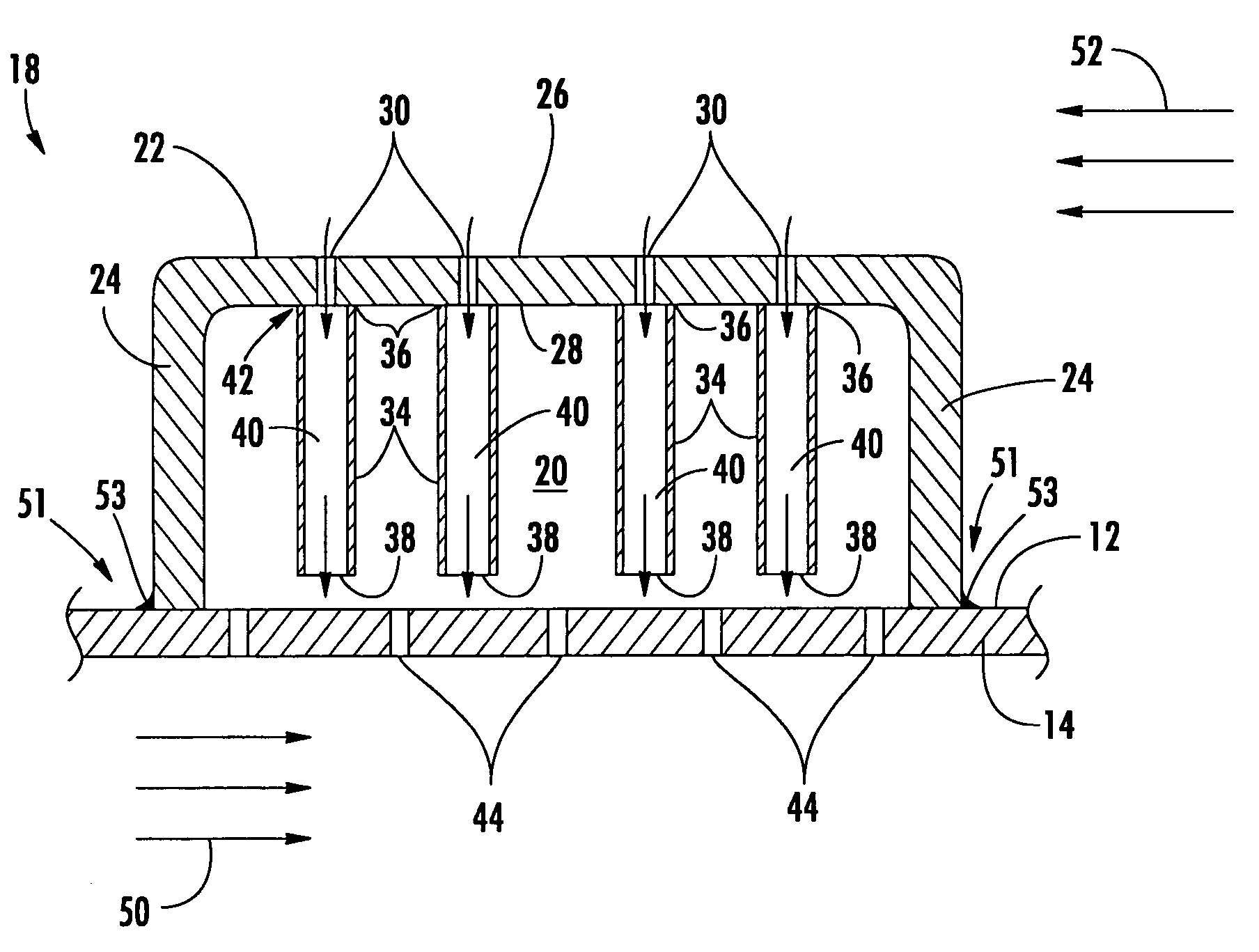

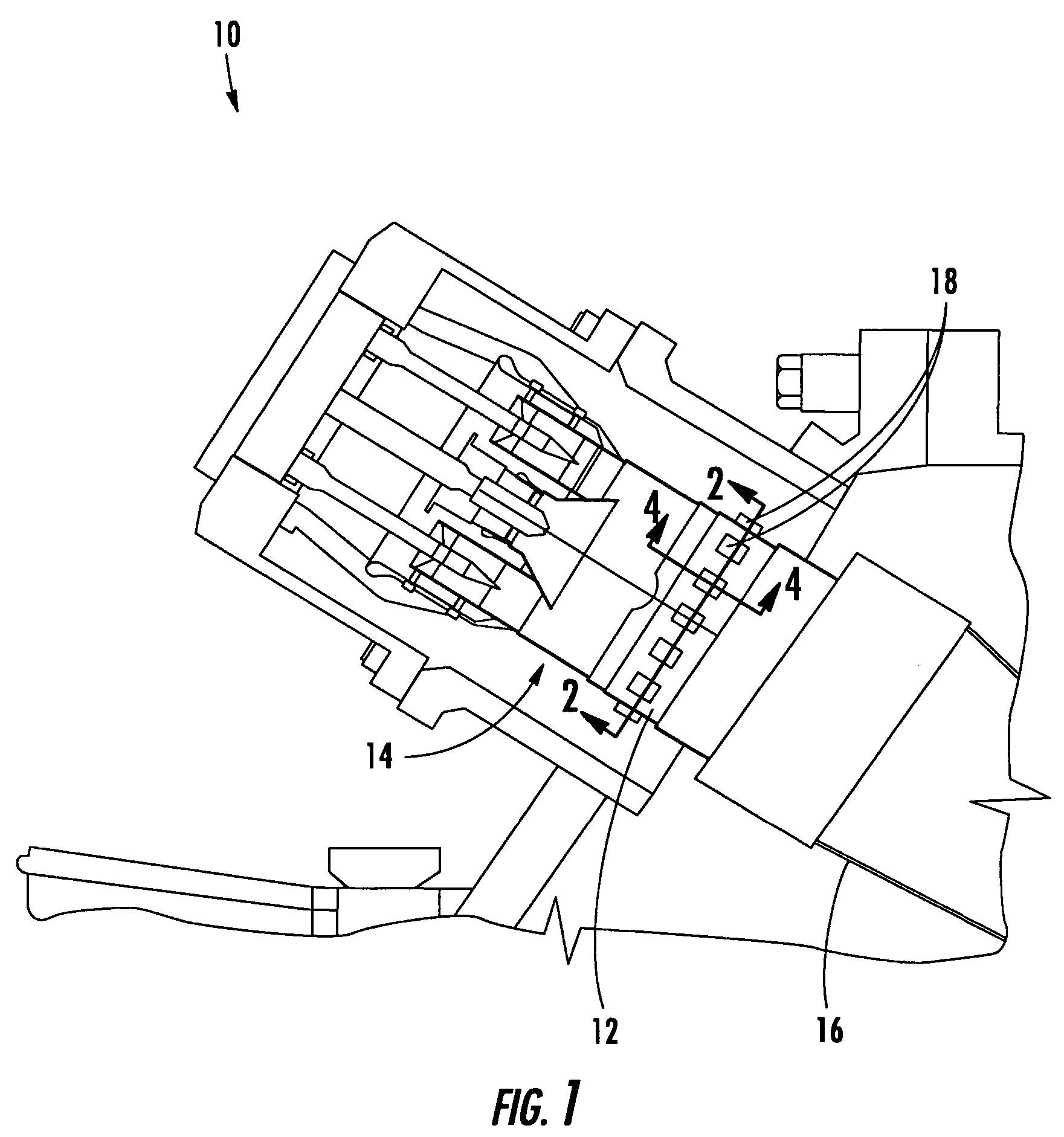

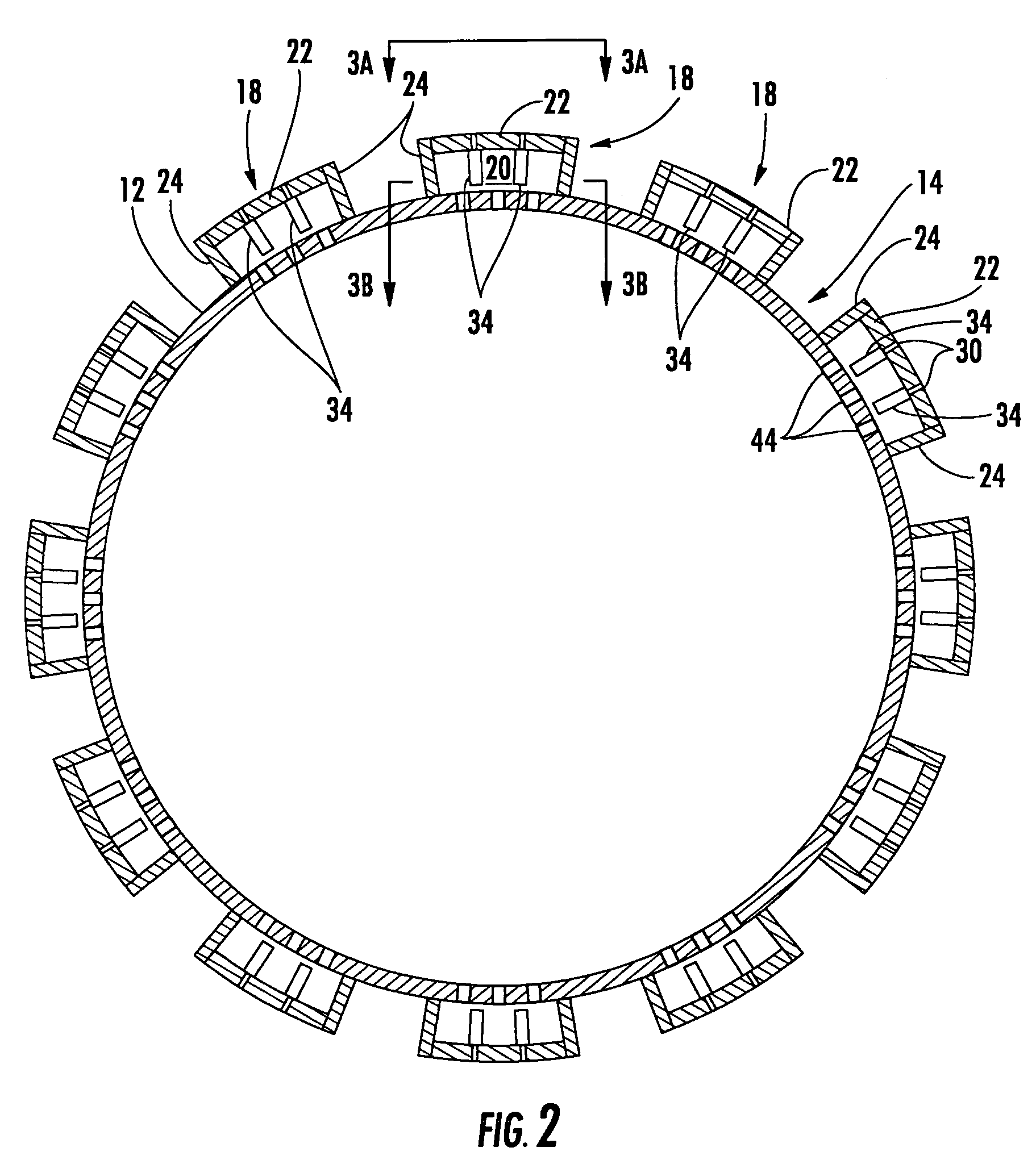

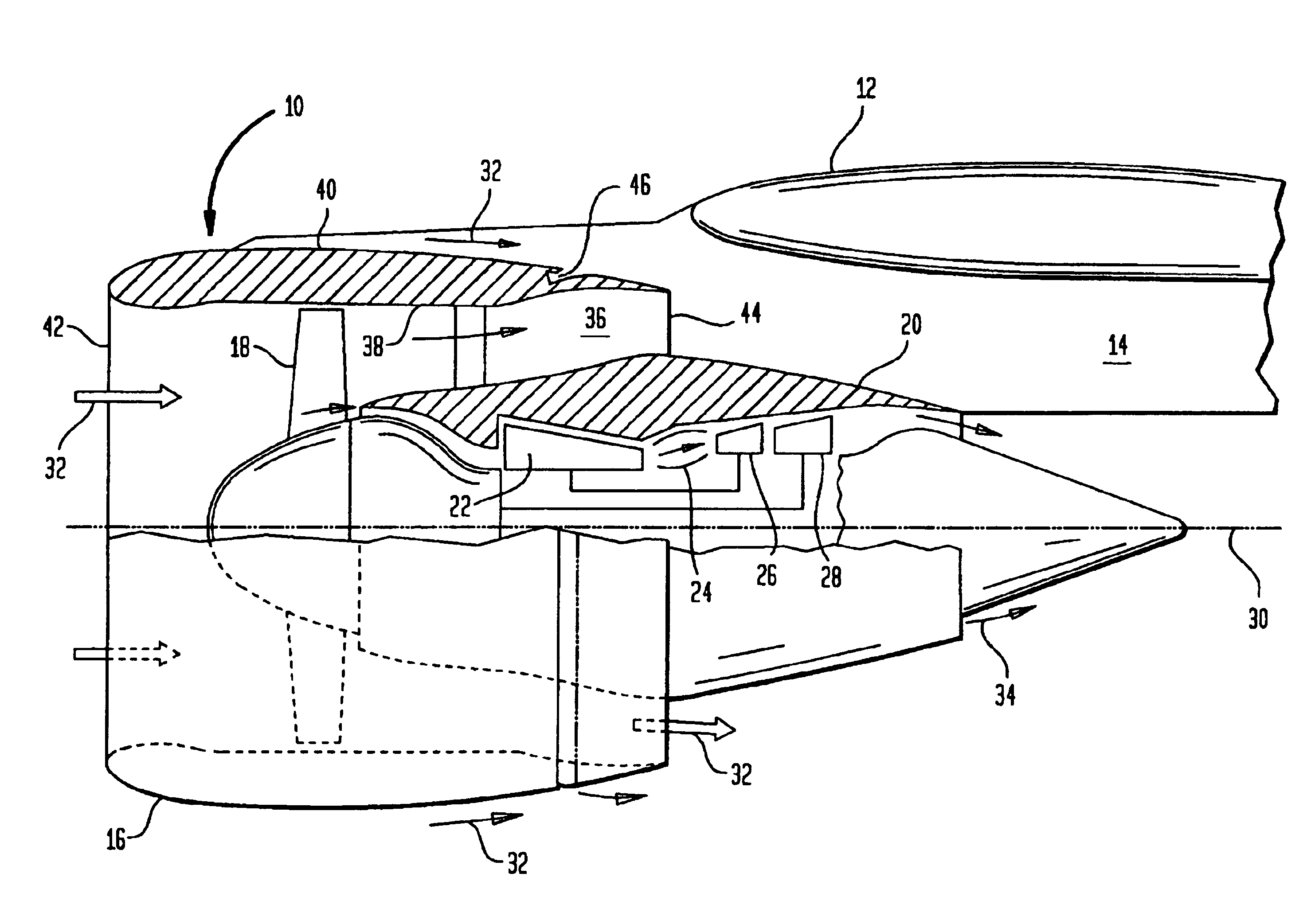

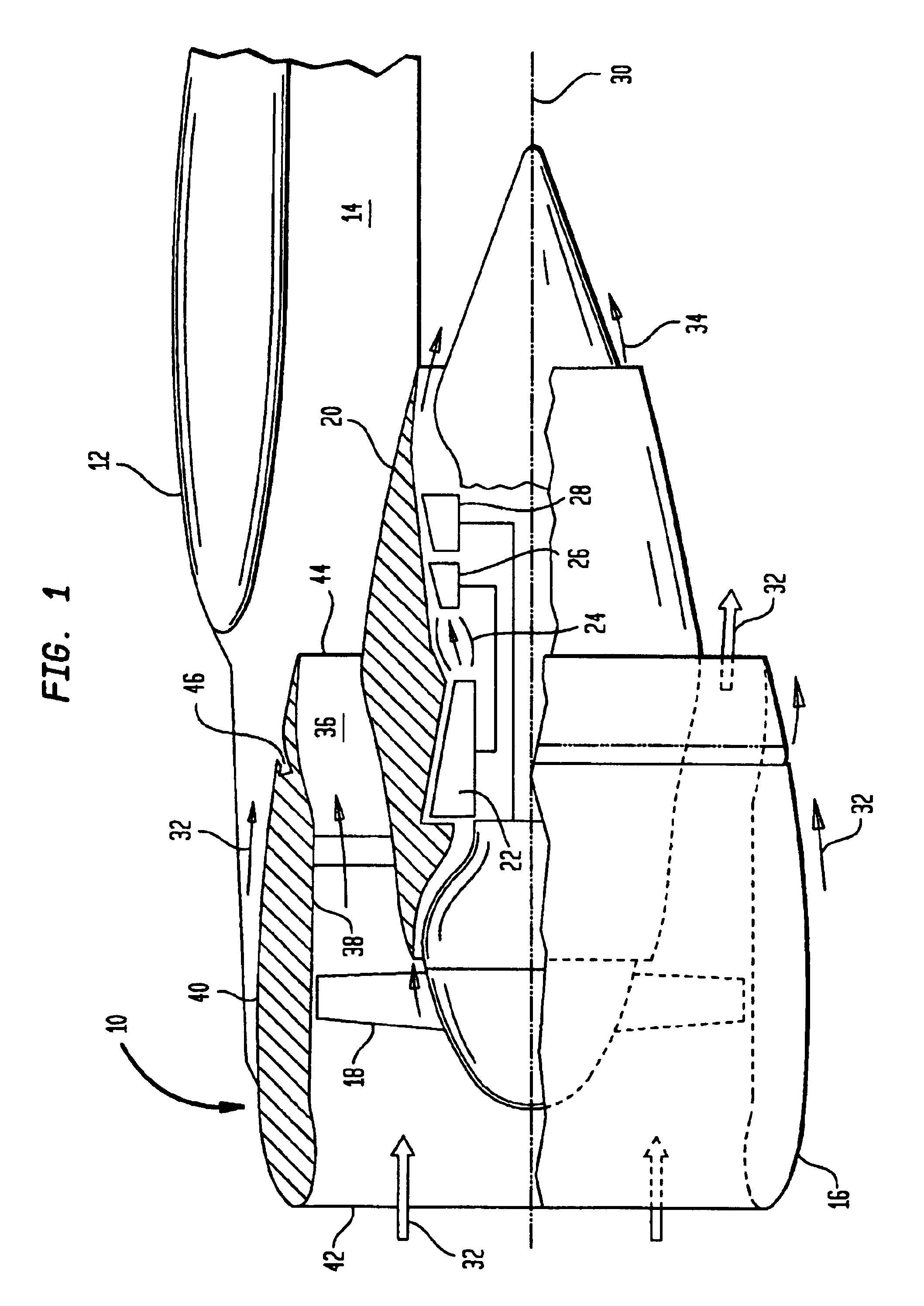

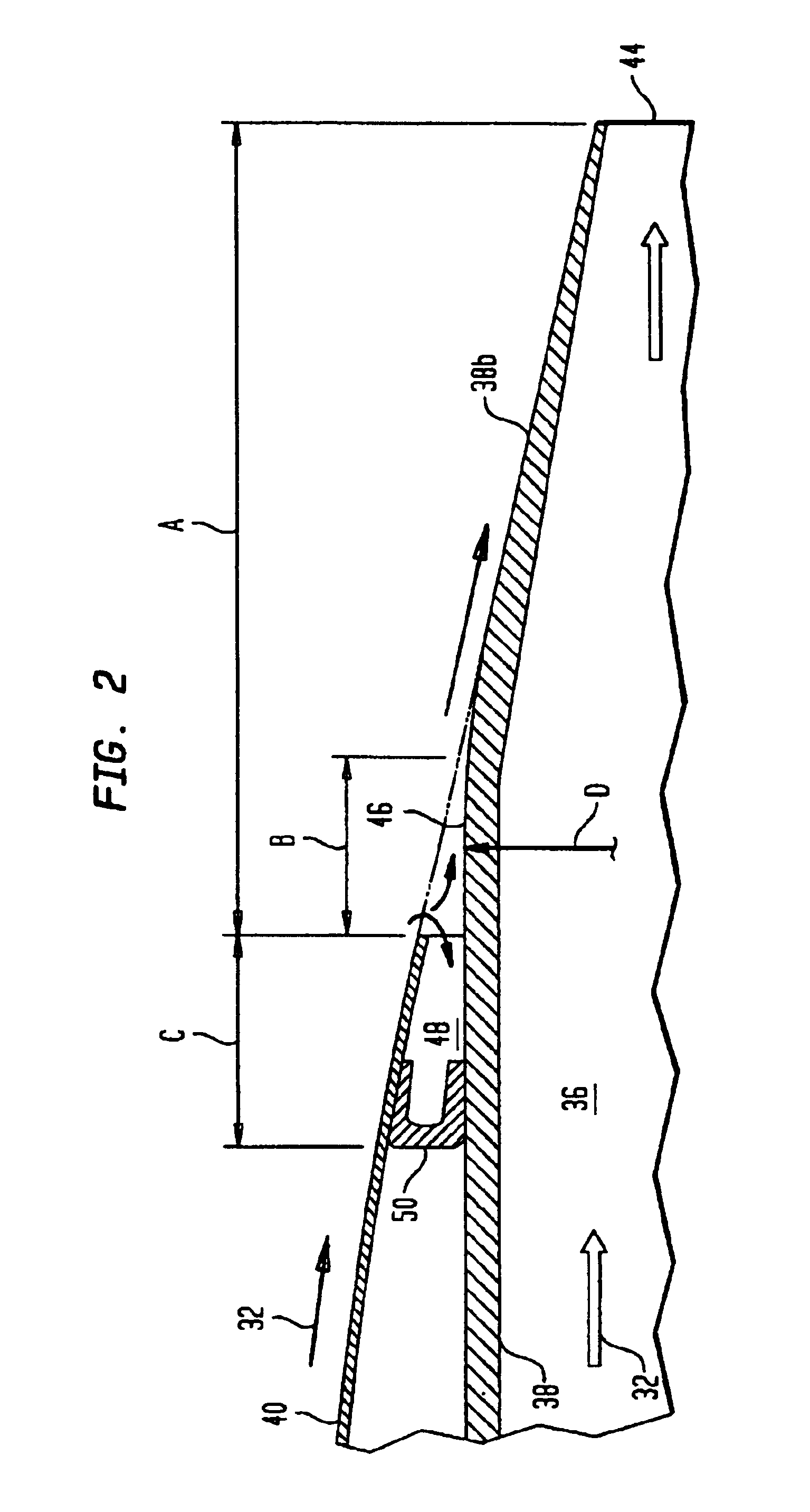

Acoustic resonator with impingement cooling tubes

Aspects of the invention are directed to an acoustic resonator with improved impingement cooling effectiveness. The resonator includes a plate with an inside face and an outside face. A plurality of passages extend through the plate. The resonator includes a side wall that extends from and about the plate. A plurality of cooling tubes are attached to the resonator plate such that an inner passage of each cooling tube is in fluid communication with a respective passage in the resonator plate. The resonator can be secured to a surface of a turbine engine combustor component to define a closed cavity. The ends of the cooling tubes are spaced from the surface. Thus, a coolant can enter the passages in the plate and can be directed to the surface so as to impingement cool the surface. The cooling tubes can minimize coolant loss by dispersion in the cavity.

Owner:SIEMENS ENERGY INC

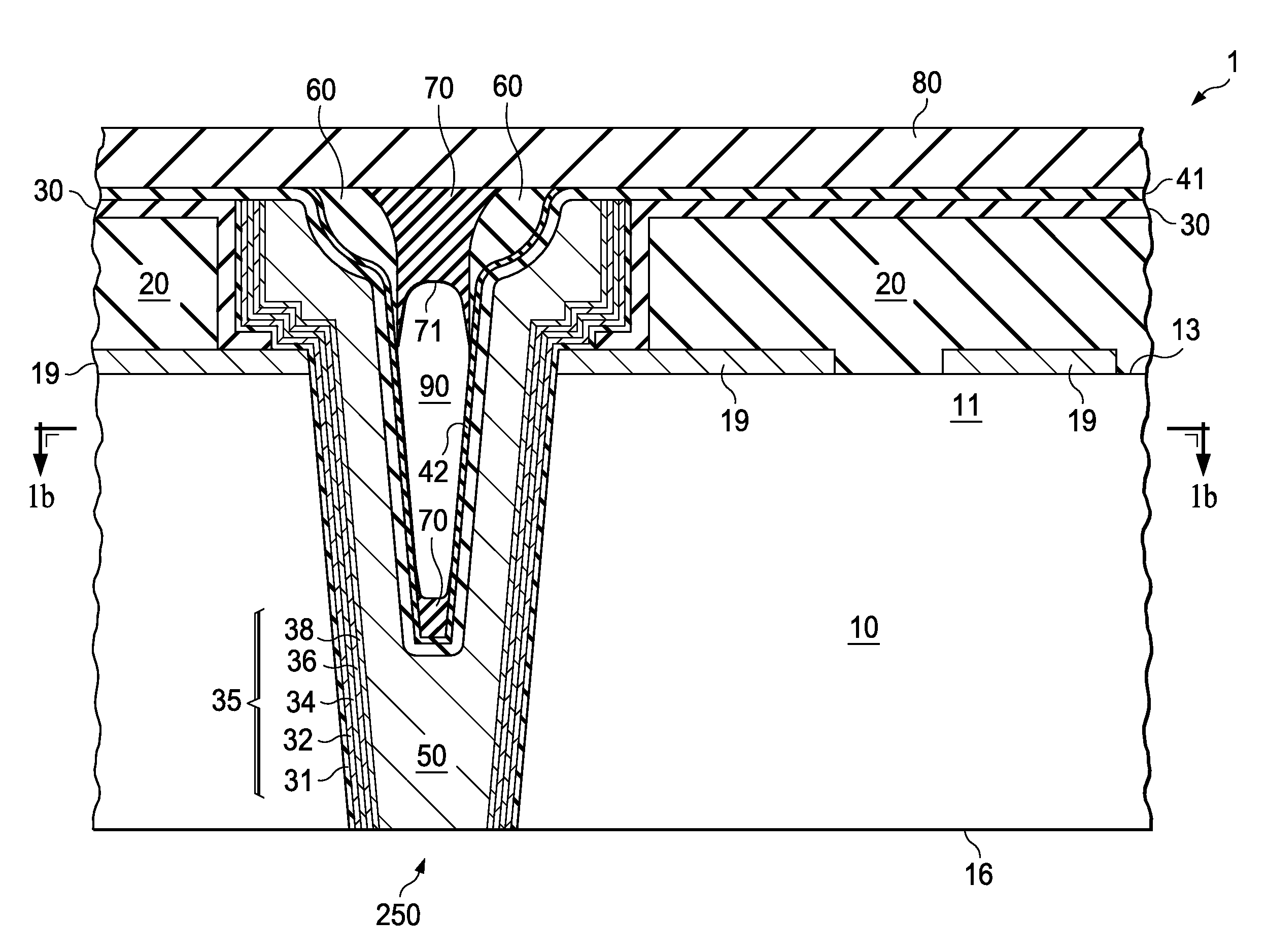

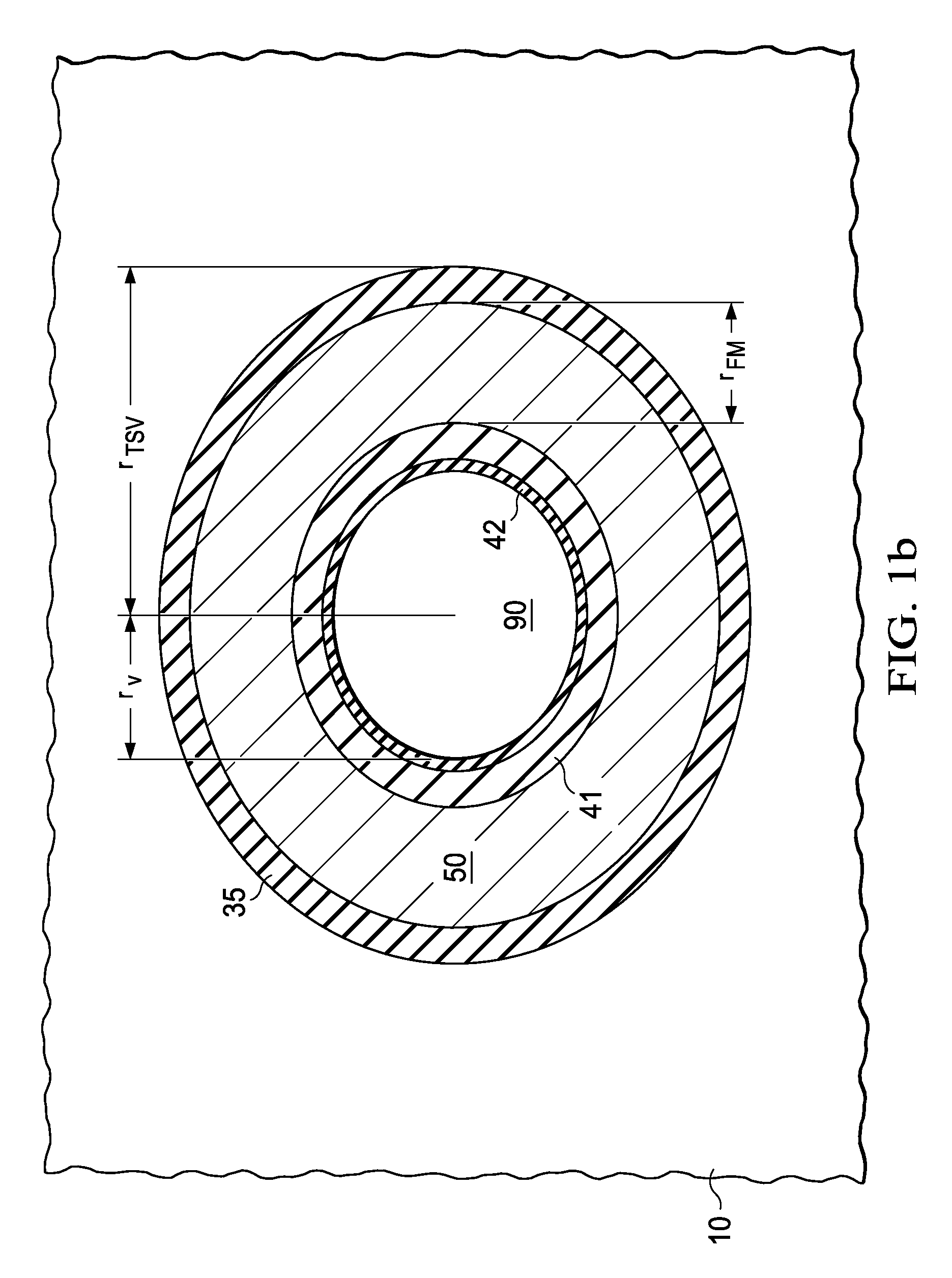

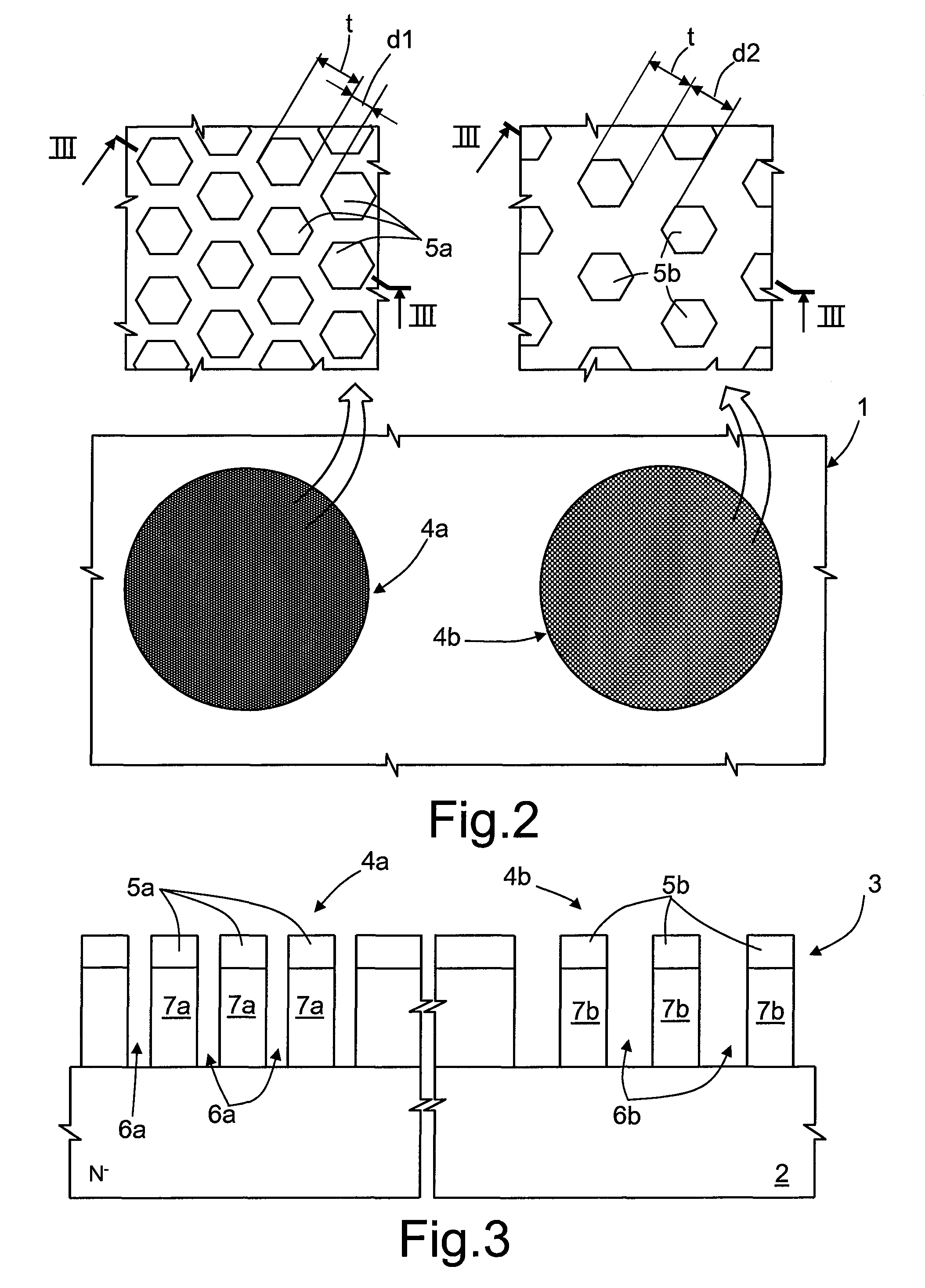

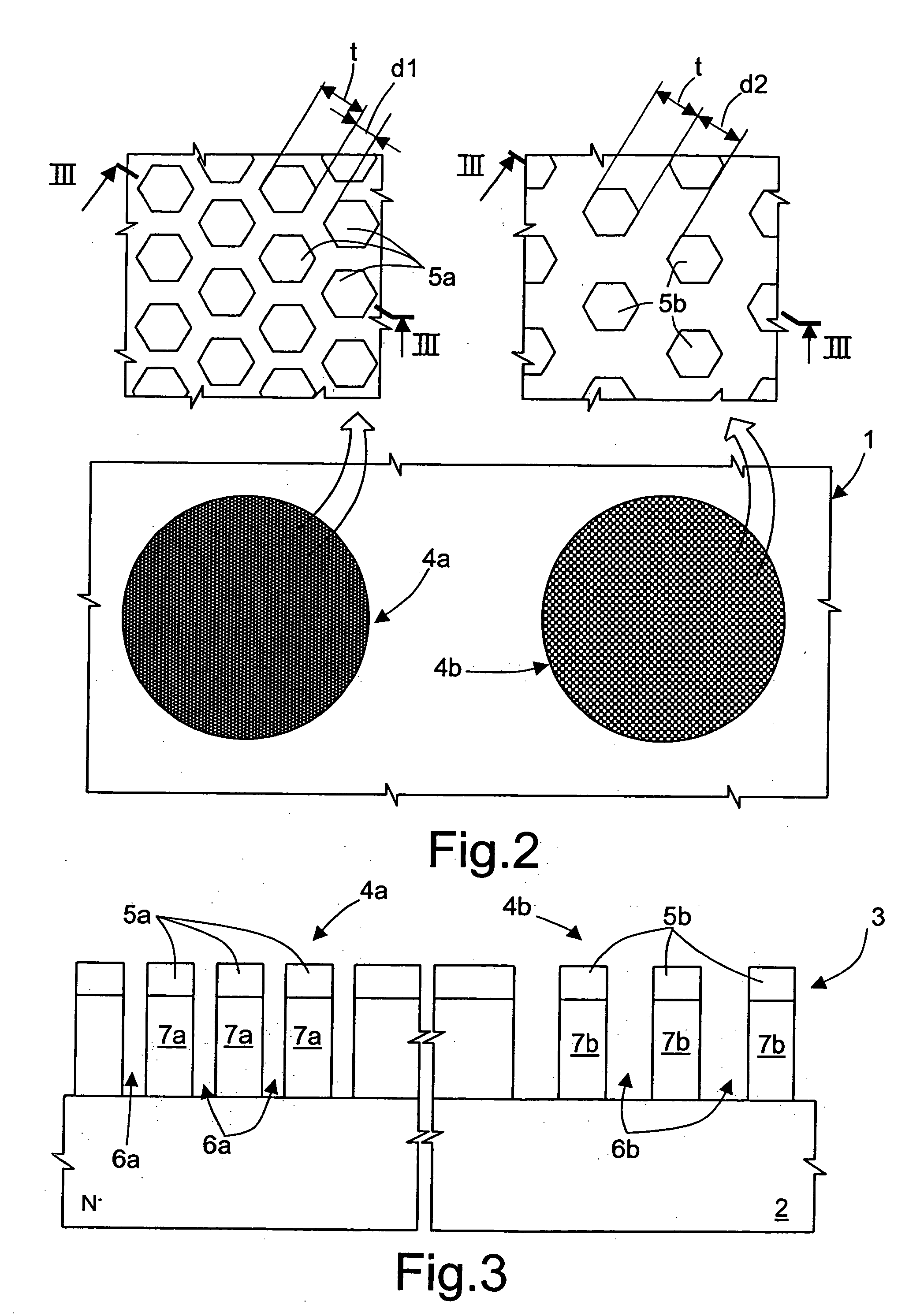

Through Substrate Via Semiconductor Components

ActiveUS20090302480A1Semiconductor/solid-state device detailsSolid-state devicesFirst FillFilling materials

A structure and method of forming through substrate vias in forming semiconductor components are described. In one embodiment, the invention describes a method of forming a through substrate via by partially filling an opening with a fill material, and forming a first insulating layer over the first fill material thereby forming a gap over the opening. The method further includes forming a second insulating layer to close the gap thereby forming an enclosed cavity within the opening.

Owner:INFINEON TECH AG

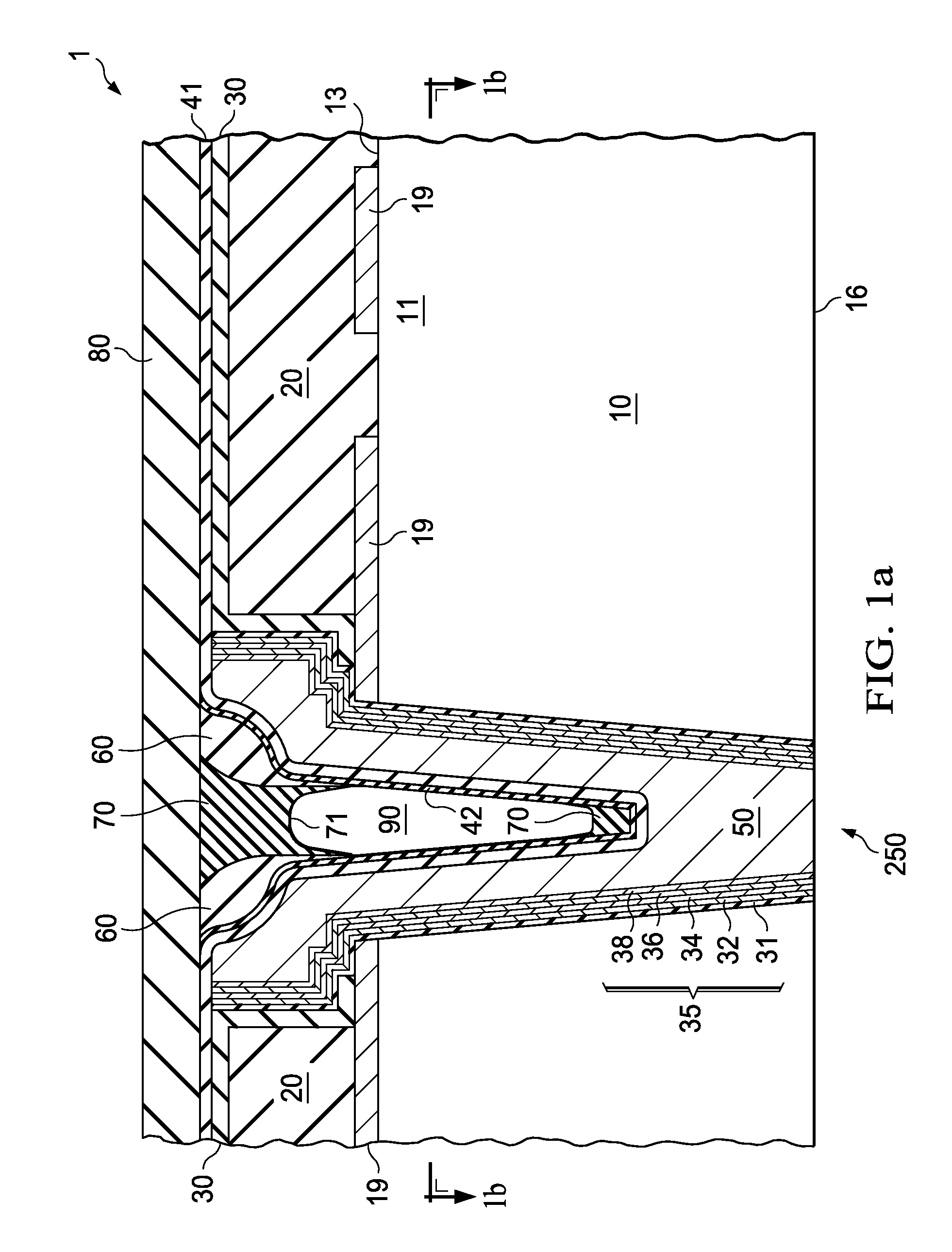

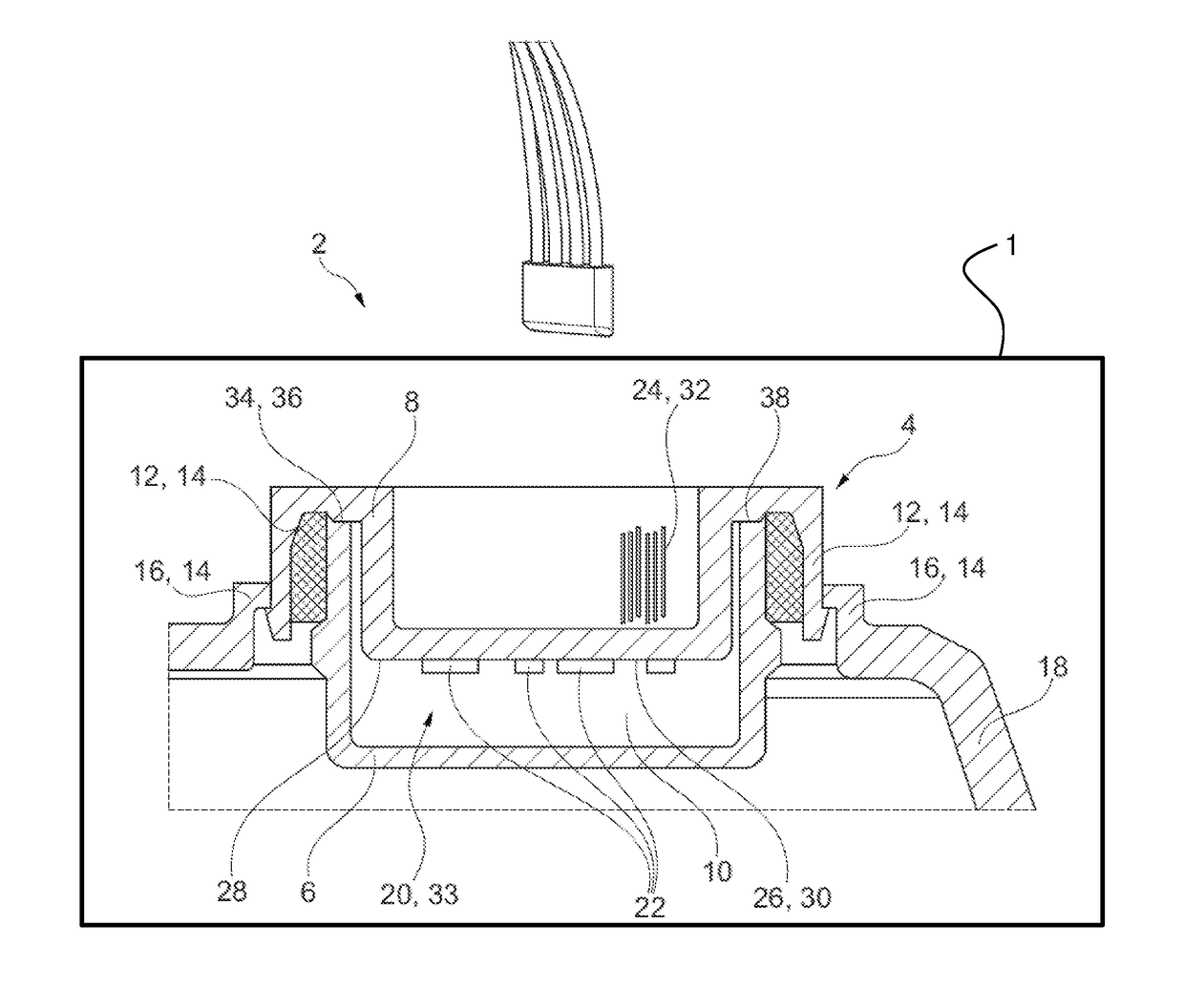

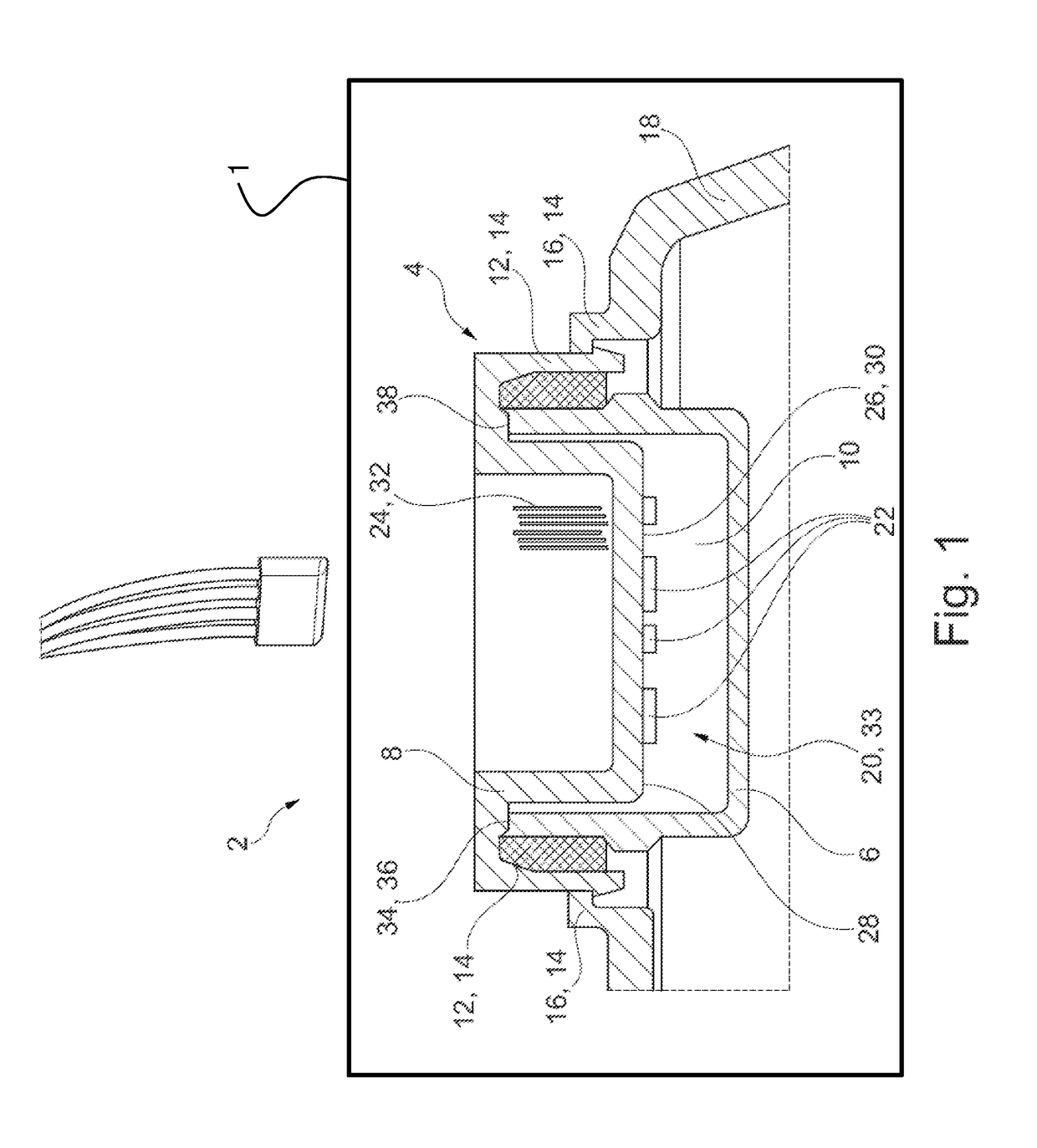

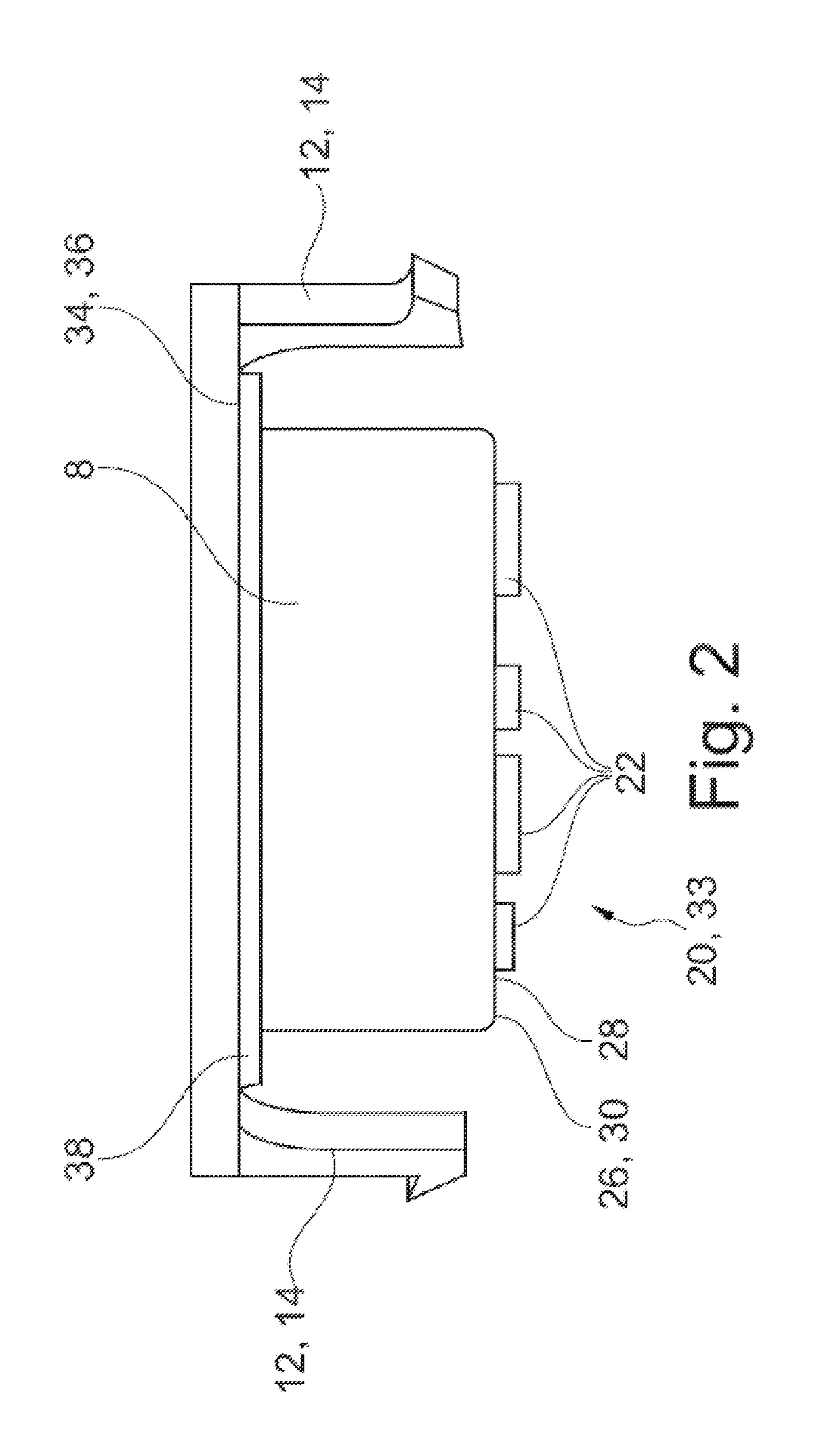

Electronic Device And Rear-View Device

ActiveUS20170066379A1Reduce in quantityReduce spacing3D rigid printed circuitsElectric circuit arrangementsElectrical conductorComputer module

An improved rear-view device for a motor vehicle includes an electronic device with at least one housing device, comprising at least one floor piece and a cover piece configured to be arranged on the floor piece. The floor piece and the cover piece, in the joined state, delimit an at least almost completely closed cavity. At least one first retaining means of a retaining unit, fixes the housing device in or on the rear-view device. At least one electronic module comprises at least one conductor unit and at least one contact means connected with the conductor unit. The conductor unit is arranged on a surface of the floor piece and / or cover piece and turned towards the cavity. The conductor unit comprises at least one carrier and at least one conductor track applied directly to the carrier. The contact means extends through the cover piece and / or through the floor piece with at least one protruding contact section and is accessible externally. The at least one carrier of the at least one conductor unit is formed at least in sections by a functional surface of the floor piece and / or the cover piece adjacent to the cavity and turned towards the cavity. The cover piece and / or floor piece forms a common component with the at least one first retaining means of the retaining unit.

Owner:SMR PATENTS S A R L

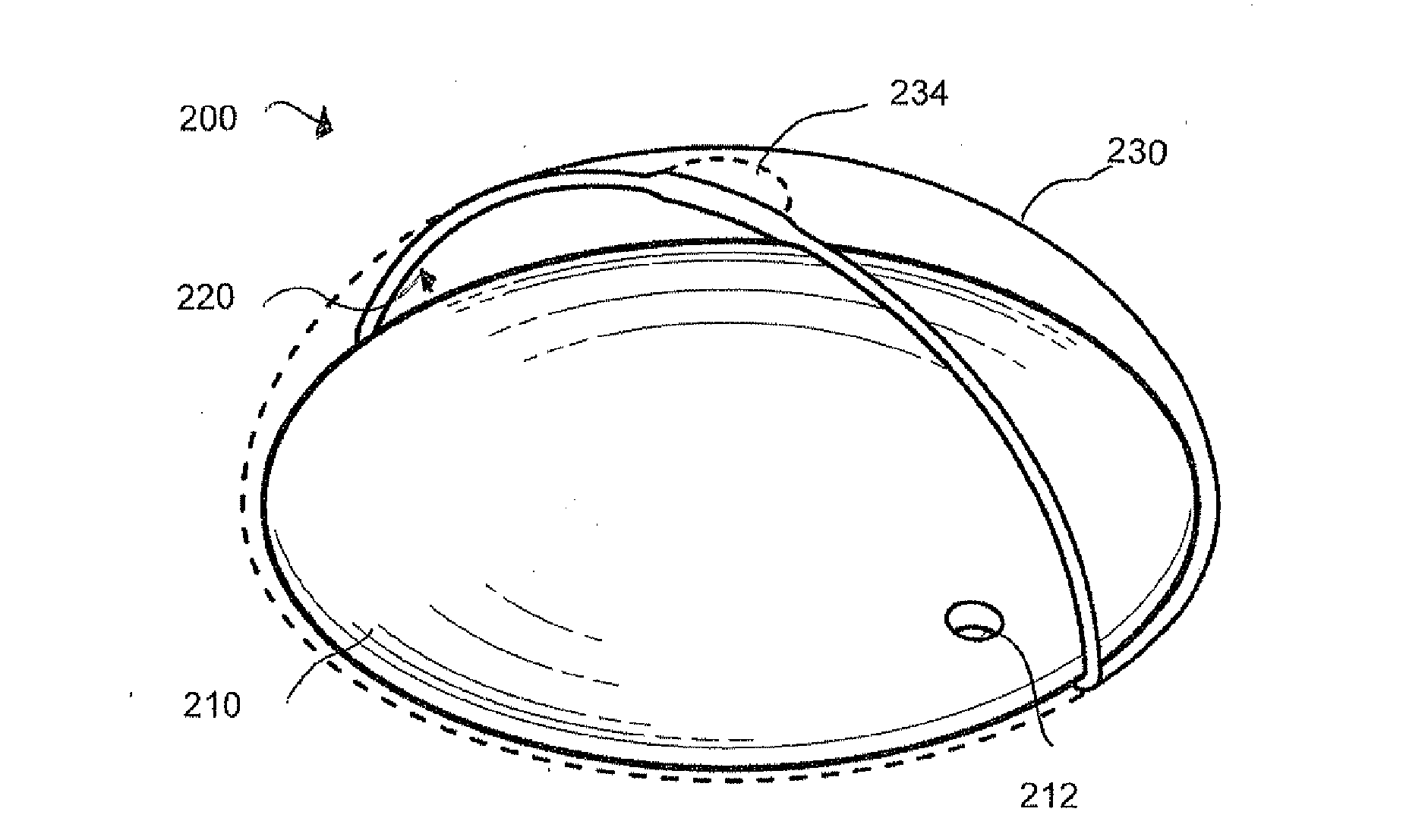

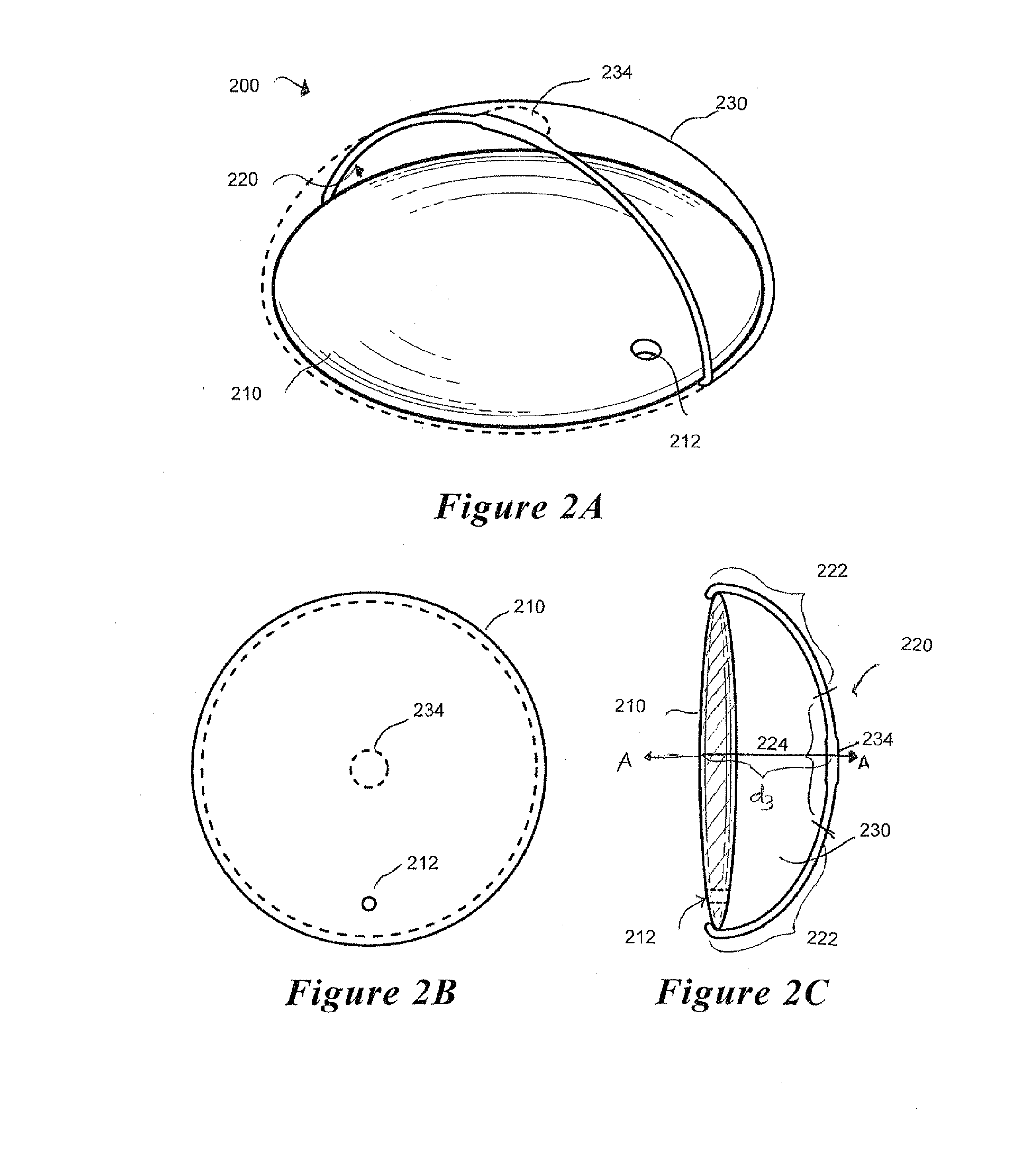

Accommodating intraocular lens device

An accommodating intraocular lens (IOL) device adapted for implantation in the lens capsule of a subject's eye. The IOL device includes an anterior refractive optical element and a membrane coupled to the refractive optical element. The anterior refractive optical element and the membrane define an enclosed cavity configured to contain a fluid. At least a portion of the membrane is configured to contact a posterior area of the lens capsule adjoining the vitreous body of the subject's eye. The fluid contained in the enclosed cavity exerts a deforming or displacing force on the anterior refractive optical element in response to an anterior force exerted on the membrane by the vitreous body. The IOL device may further include a haptic system to position the anterior refractive optical element and also to engage the zonules and ciliary muscles to provide additional means for accommodation.

Owner:LENSGEN INC

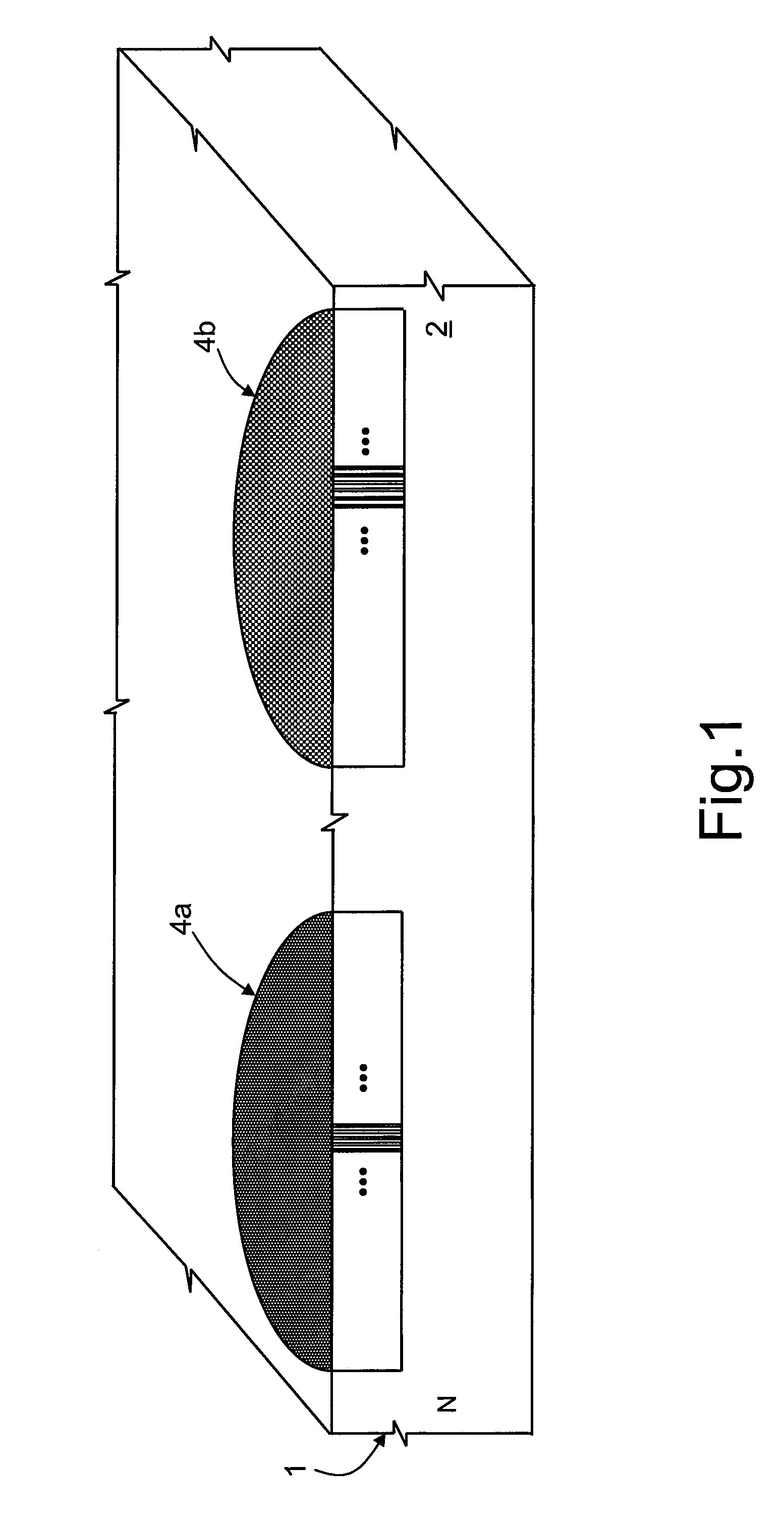

Method for manufacturing a semiconductor pressure sensor

ActiveUS8173513B2Overcome disadvantagesFluid pressure measurement by electric/magnetic elementsSemiconductor/solid-state device manufacturingForce sensorSemiconductor

Method for manufacturing a semiconductor pressure sensor, wherein, in a silicon substrate, trenches are dug and delimit walls; a closing layer is epitaxially grown, that closes the trenches at the top and forms a suspended membrane; a heat treatment is performed so as to cause migration of the silicon of the walls and to form a closed cavity underneath the suspended membrane; and structures are formed for transducing the deflection of the suspended membrane into electrical signals.

Owner:STMICROELECTRONICS SRL

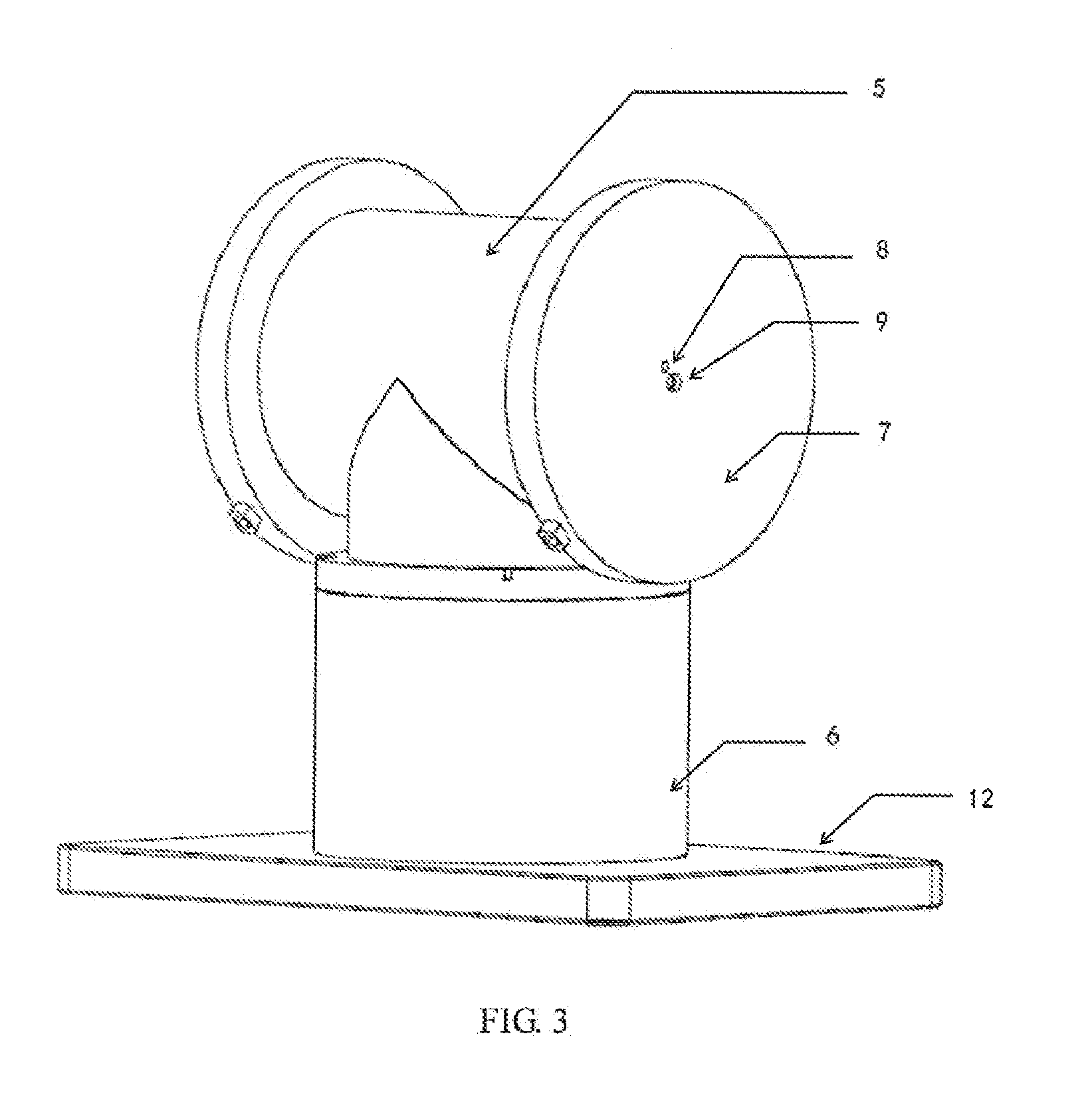

Test Device And Test Method For Active Noise Reduction Headphone

ActiveUS20140146973A1Reduce background noiseReduce test complexityEarpiece/earphone noise reductionAcoustic transmissionEngineering

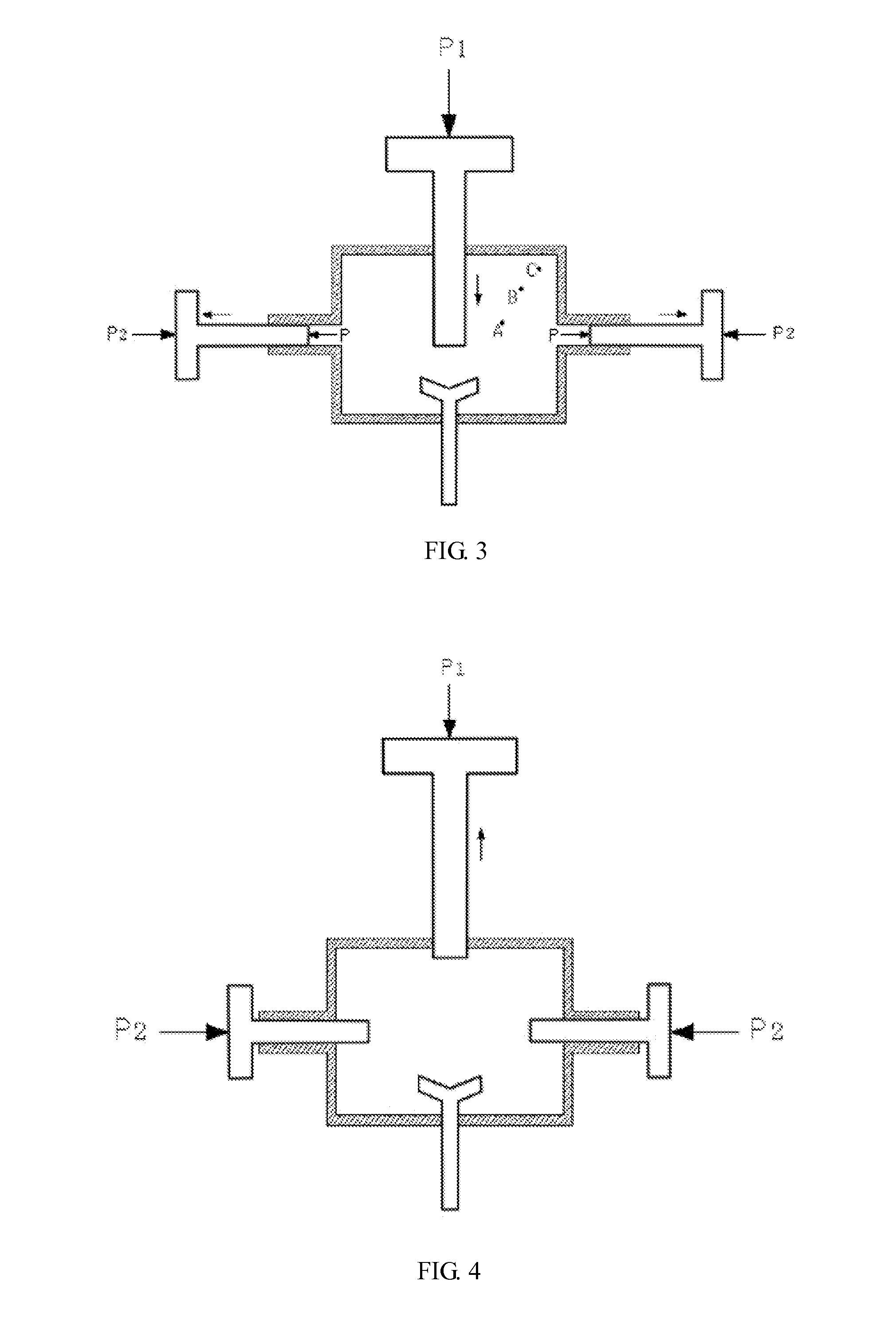

The present invention discloses a test device and test method for the noise reduction headphone. The test device comprises: an enclosed cavity, a noise source, a test panel, a measuring microphone and a measure comparison module connected with the measuring microphone. The sound emitted from the noise source is sealed within the enclosed cavity. The test panel can cooperate with the noise reduction headphone to form a coupling cavity in the test. The test panel has a sound guiding hole in the common part with the enclosed cavity for transmitting the sound of the noise source into the interior of the coupling cavity. The test panel also has a mounting hole, and the measuring microphone is mounted on the mourning hole towards the direction of the coupling cavity. The measuring microphone records noise signals before and after the noise reduction function of the noise reduction headphone is activated. The measure comparison module receives the signals recorded these two times by the measuring microphone and performs comparison processing to obtain noise reduction amount of the noise reduction headphone. The technical solution of the present invention solves the problem of noise pollution caused by high-power external noise sources to the surrounding environment during the test process of noise reduction amount of the headphone, meanwhile, no special shielding room is required, and the requirement on test environment is relieved.

Owner:GOERTEK INC

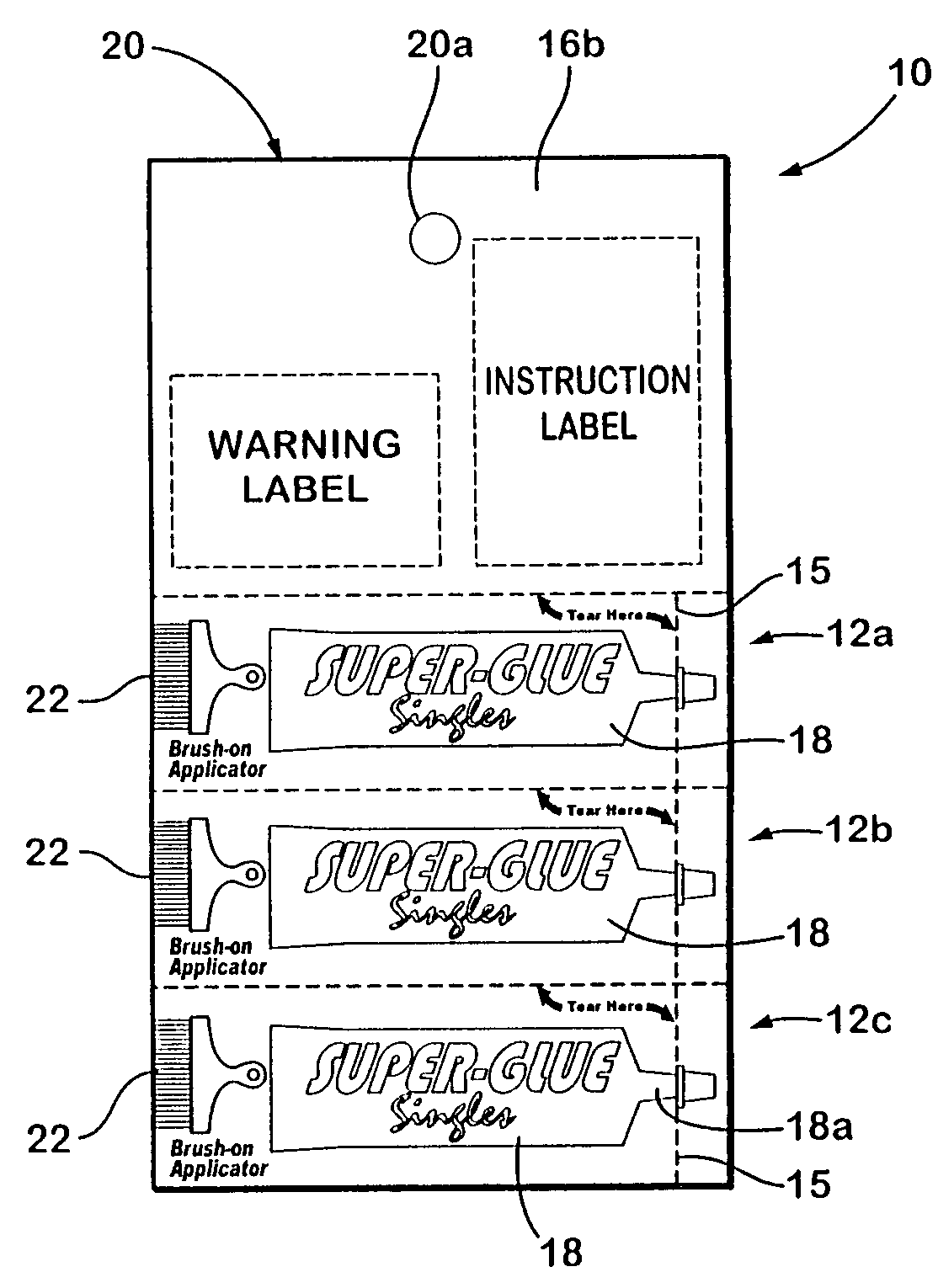

Container for flowable products

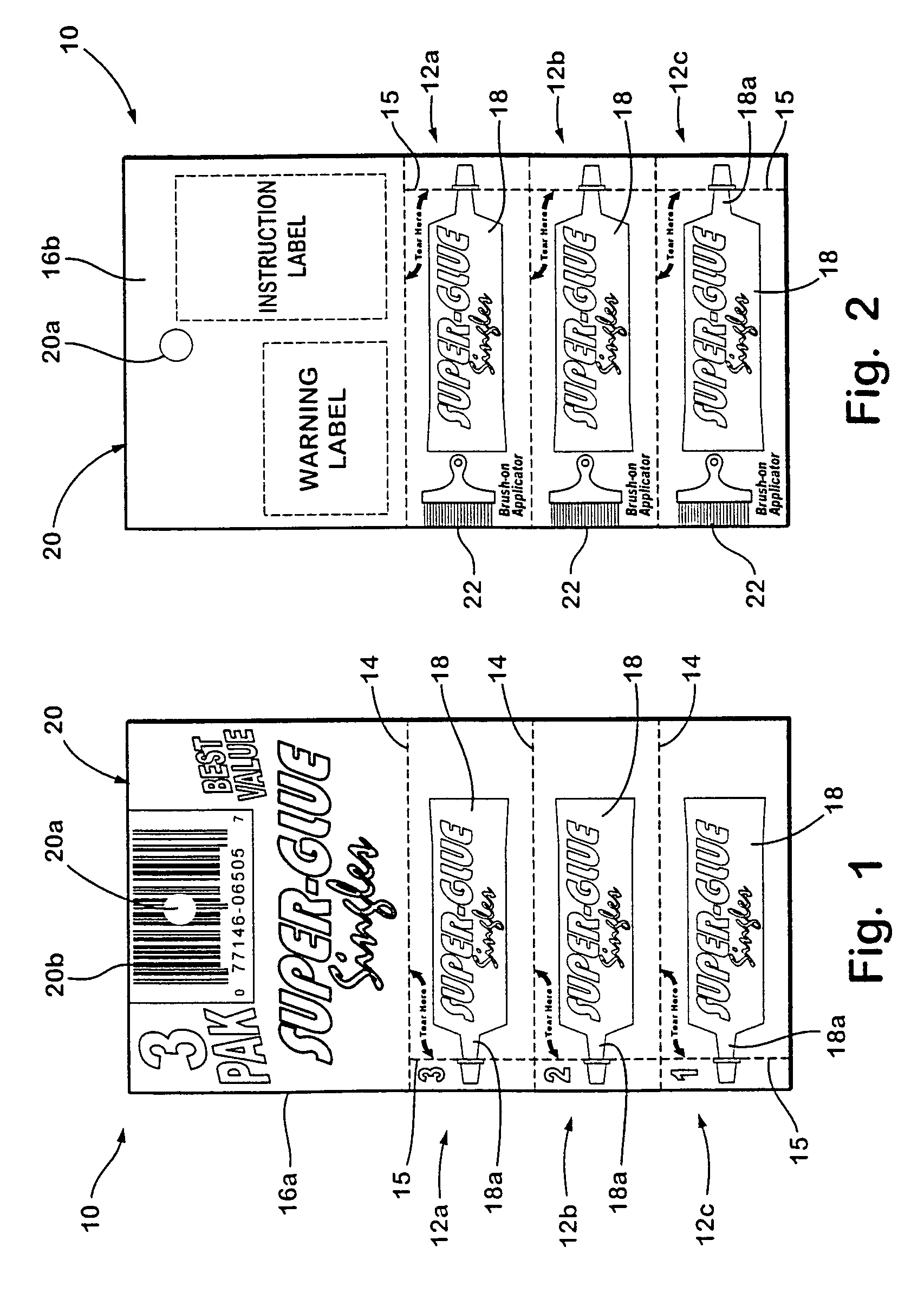

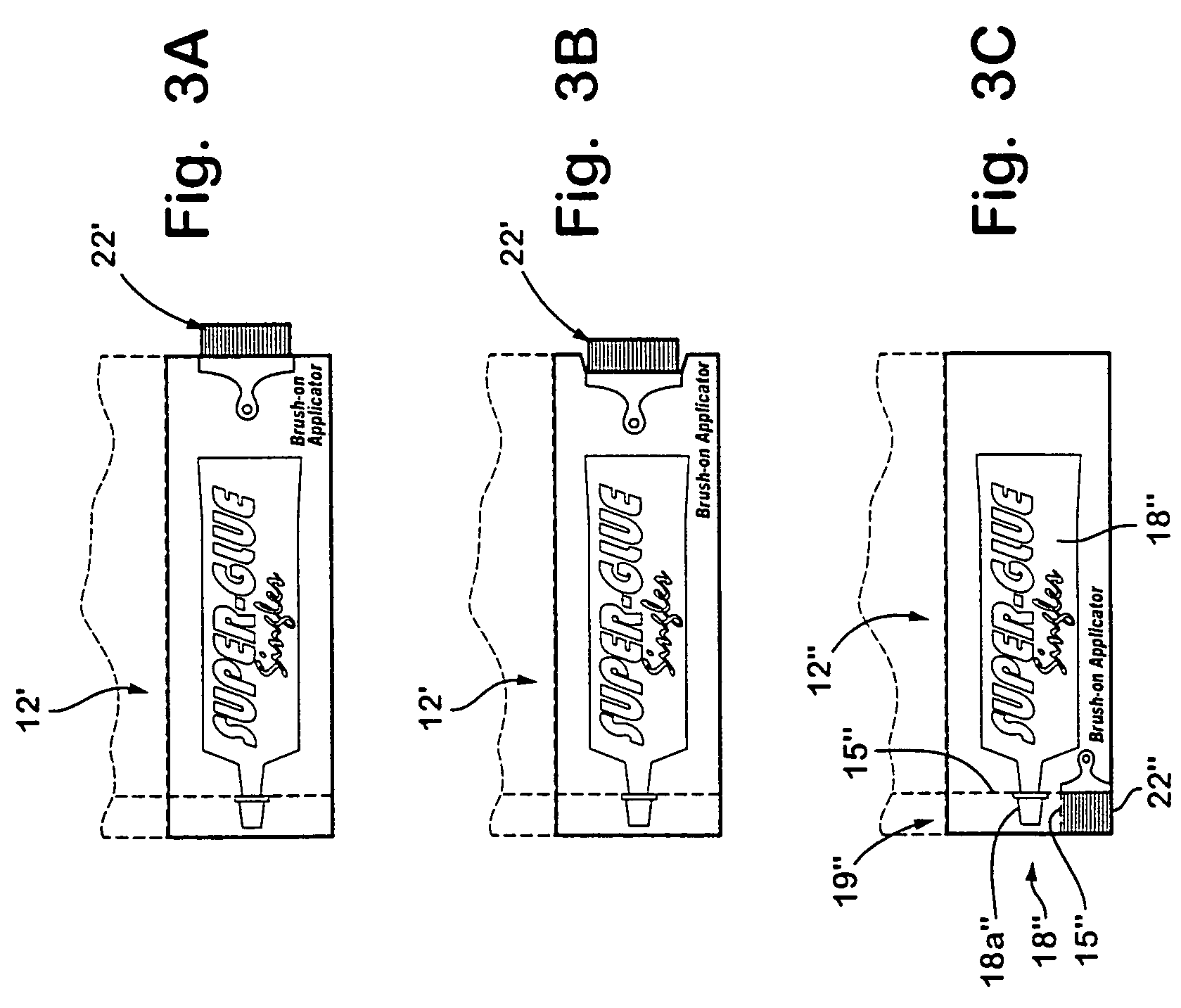

InactiveUS7241066B1Avoid hard activationAddress rising pricesClosuresBrushesIndustrial engineeringClosed cavity

A compartmentalized container for holding and dispensing flowable material and method for making such a compartmentalized container includes opposite sheet portions selectively sealed together to define a plurality of single use dispensers and a header portion that is integral with the dispensers. Each of the dispensers includes a closed cavity defined by an area of the sheet portions that is not sealed together. Each of the dispensers is separable from the container and openable to dispense the flowable material from a respective one of the cavities. The dispensers may be separable from the container via cutting or tearing the dispensers from one another or from the header portion. The header portion may include product information and may include a means for hanging the container. Each of the dispensers may include an applicator brush formed or defined at an edge portion of the dispenser.

Owner:AGS CO AUTOMOTIVE SOLUTIONS LLC

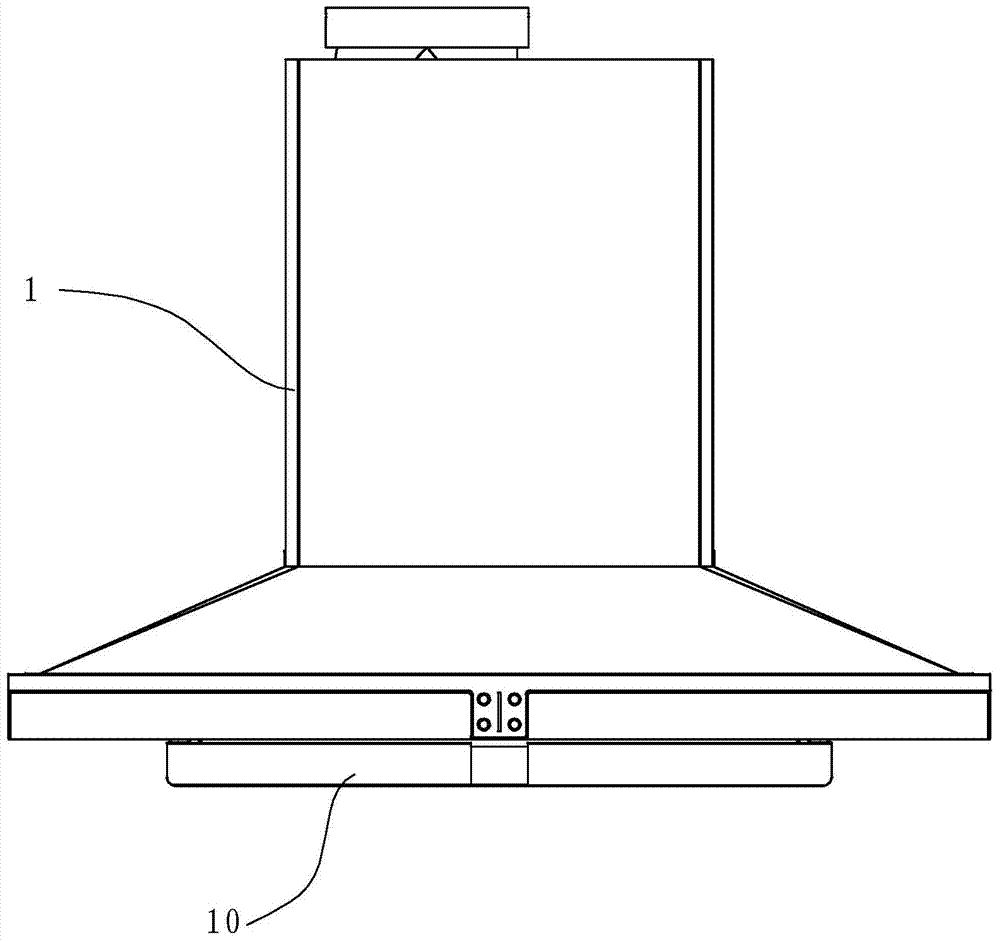

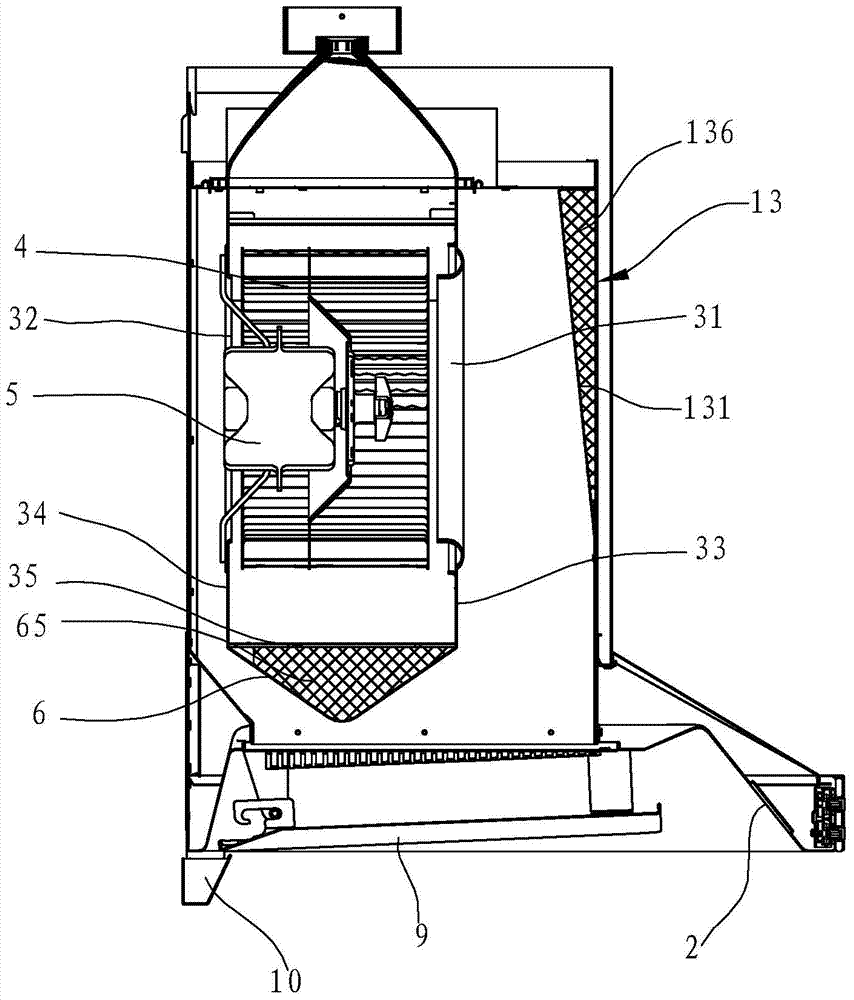

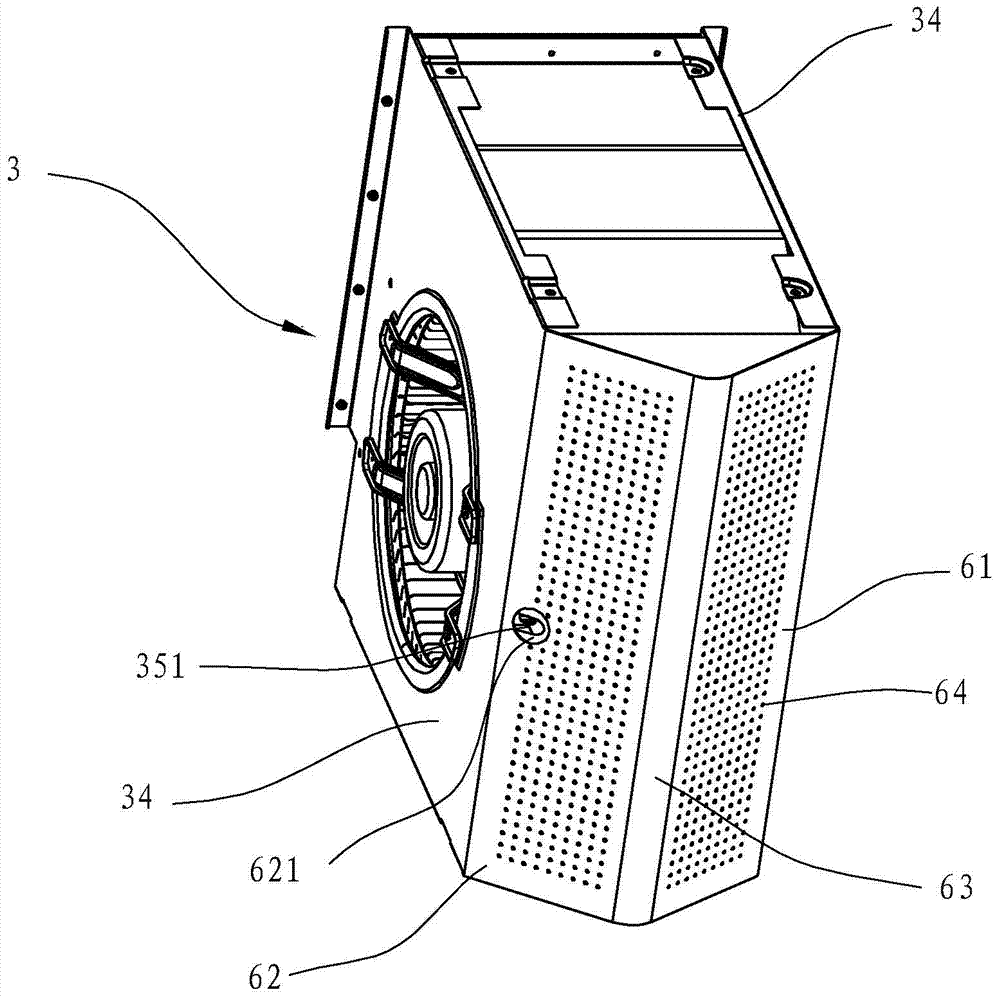

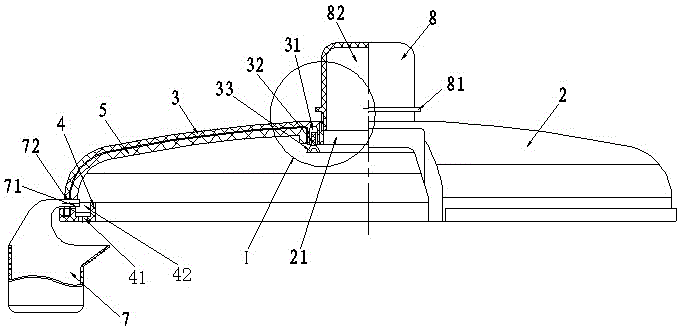

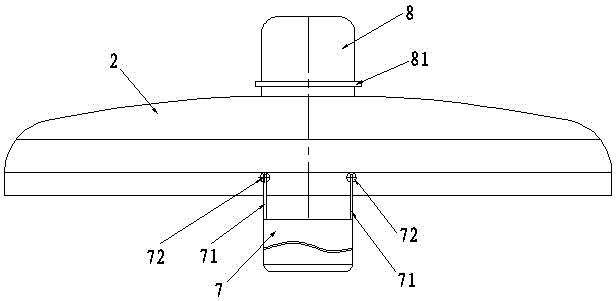

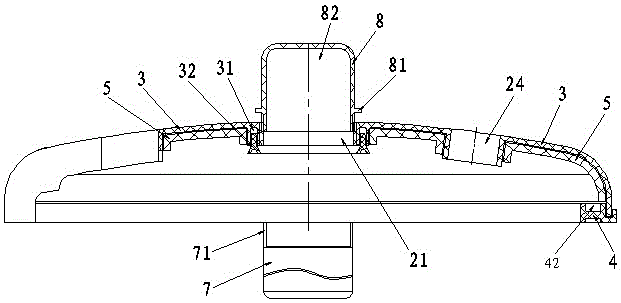

Silent range hood

InactiveCN103697512ASmooth entryPlay the role of diversionDomestic stoves or rangesLighting and heating apparatusExhaust fumesMedium frequency

The invention discloses a silent range hood comprising a machine enclosure and an exhaust fume collecting hood with an air inlet, wherein a spiral casing is arranged in the machine enclosure and is provided with a front air inlet and a back air inlet. The silent range hood is characterized in that a sound absorption flow guide hood is arranged on a front cover plate of the machine enclosure and is just opposite to the front air inlet of the spiral casing, a closed cavity is formed between the sound absorption flow guide hood and the front cover plate of the machine enclosure, a plurality of first micro-pores communicated with the closed cavity are formed in a back panel, opposite to the front air inlet, of the sound absorption flow guide hood, and the closed cavity is filled with first sound absorbing cotton. According to the invention, the sound absorption flow guide hood is just opposite to the front air inlet of the spiral casing and is provided with the micro-pores and the closed cavity is filled with the sound absorbing cotton, so that most of low-frequency, medium-frequency and high-frequency noise radiated outwards from the front air inlet can be absorbed; by reasonable selections of the aperture and the center distance of the micro-pores and the filling area of the sound absorbing cotton, the sound absorbing effect can be further strengthened.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

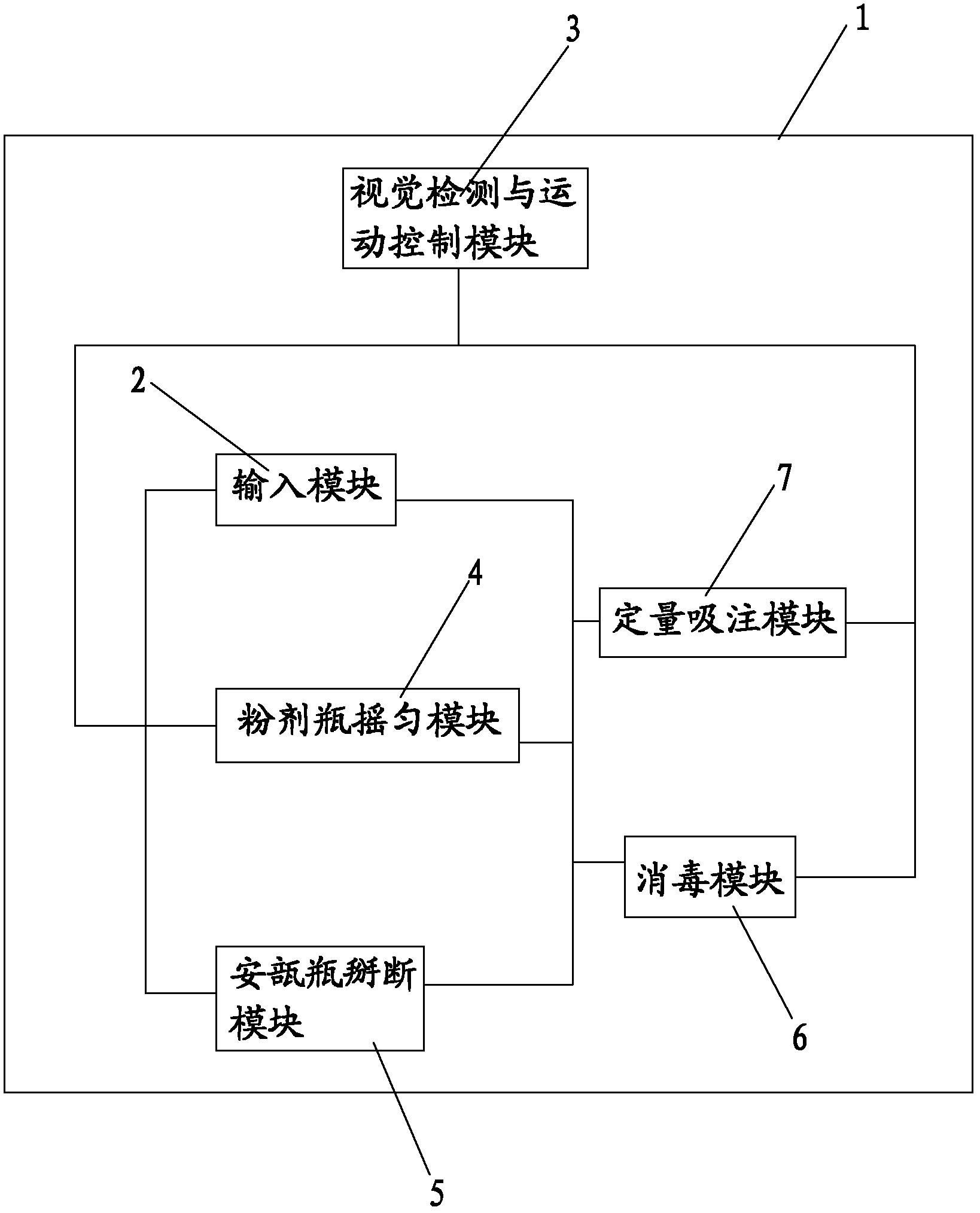

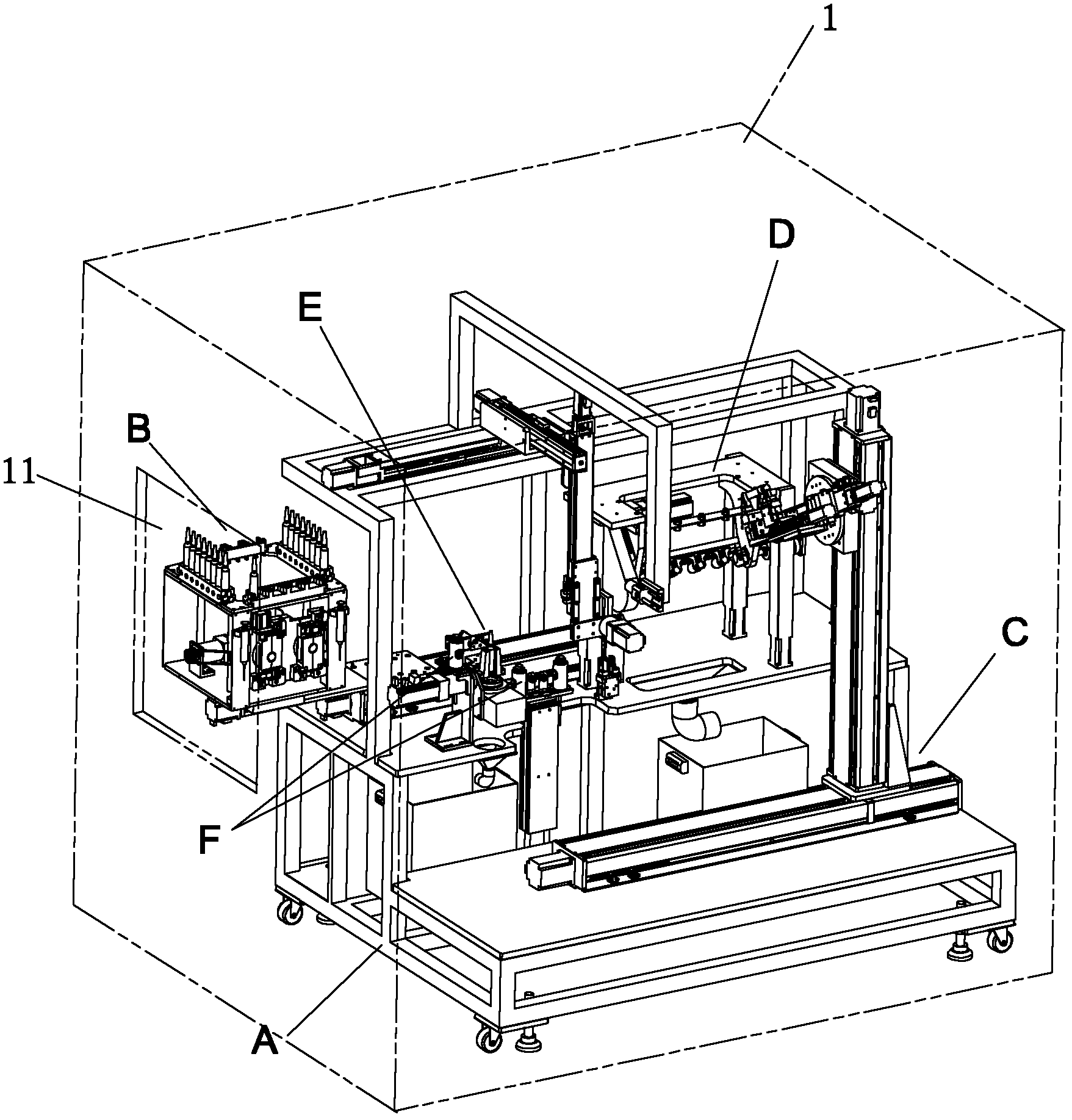

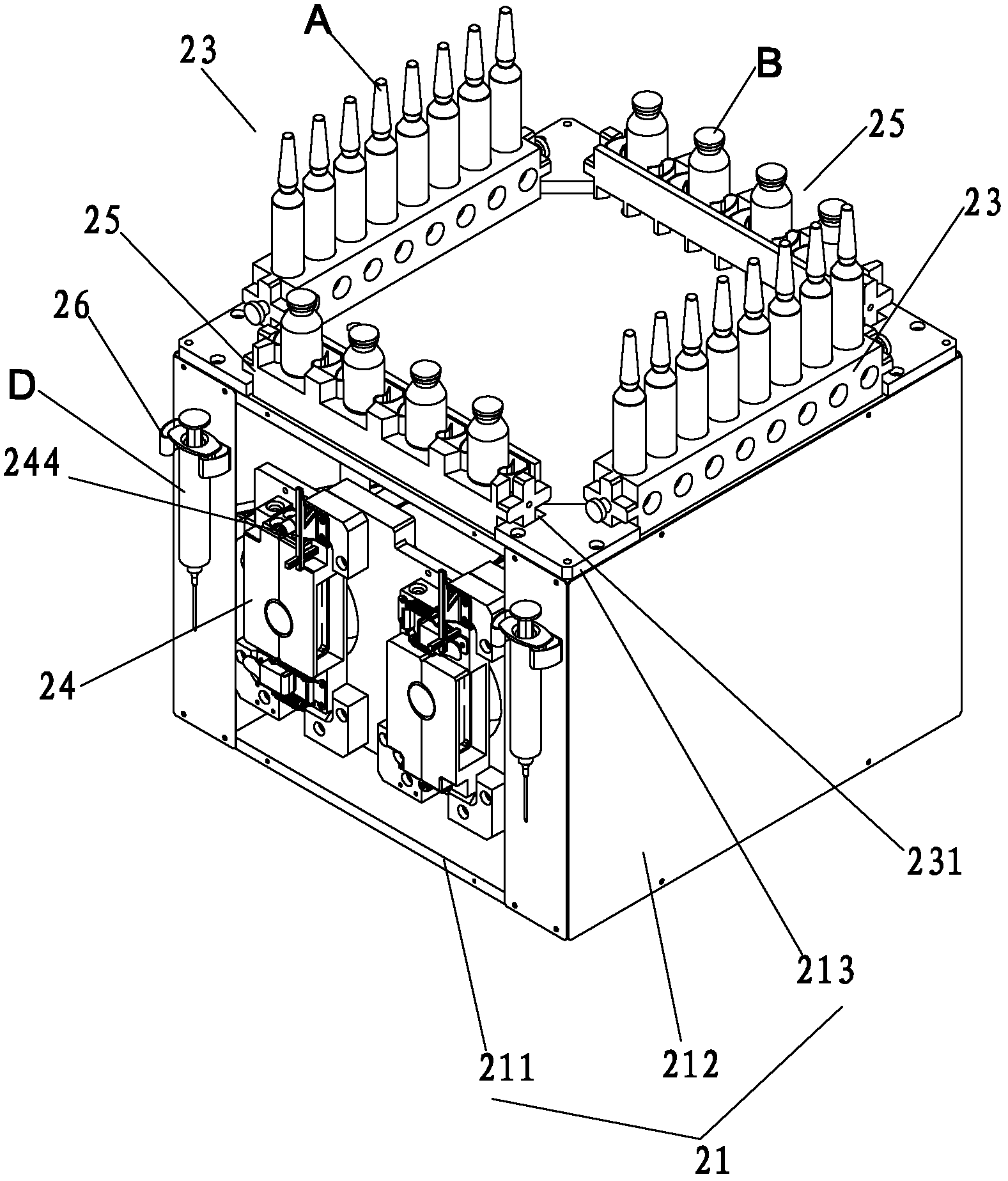

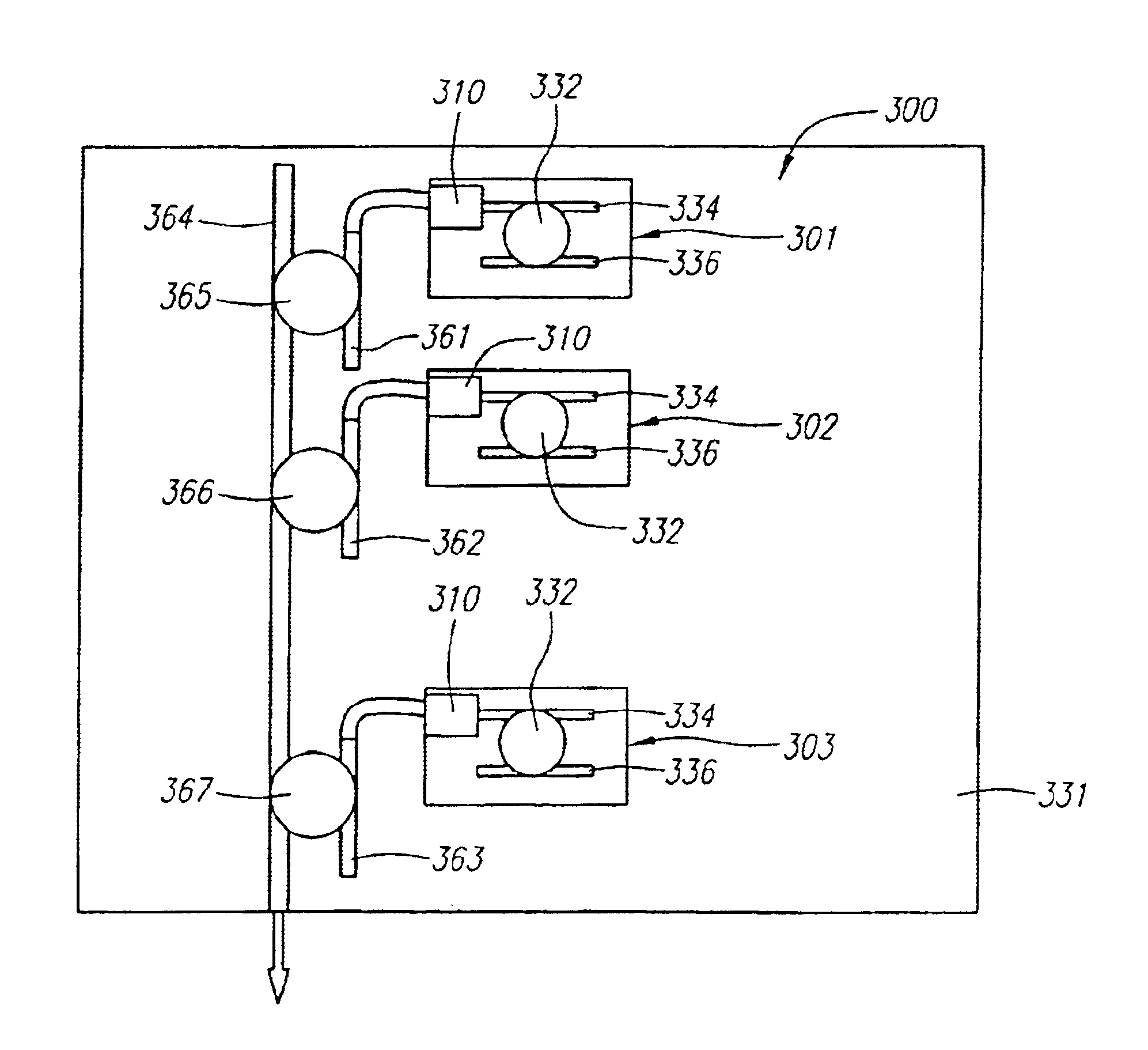

Automatic dispensing robot system and method

ActiveCN103006436AAvoid pollutionAvoid damageMixing methodsPharmaceutical containersHazardous substanceEngineering

The invention discloses an automatic dispensing robot system and an automatic dispensing method, which are used for preparing an intravenous infusion solution. The system comprises a closed cavity, wherein the closed cavity can be opened, and an input module, a powder bottle shaking module, an ampoule bottle breaking module, a disinfection module, a quantitative injection module and a visual detection and motion control module are arranged in the closed cavity. According to the automatic dispensing robot system, the breaking, disinfection and quantitative suction of an ampoule bottle, the disinfection and quantitative suction of a powder bottle and the mixing with a mother solution can be automatically realized, and the solution is prevented from being polluted; additionally, nursing personnel are prevented from being radiated and hurt by harmful substances; the probability of misoperation is reduced; the operating standard of intravenous infusion dispensing is standardized; and the dispensing efficiency is increased.

Owner:SHENZHEN CITY WEIBANG TECH

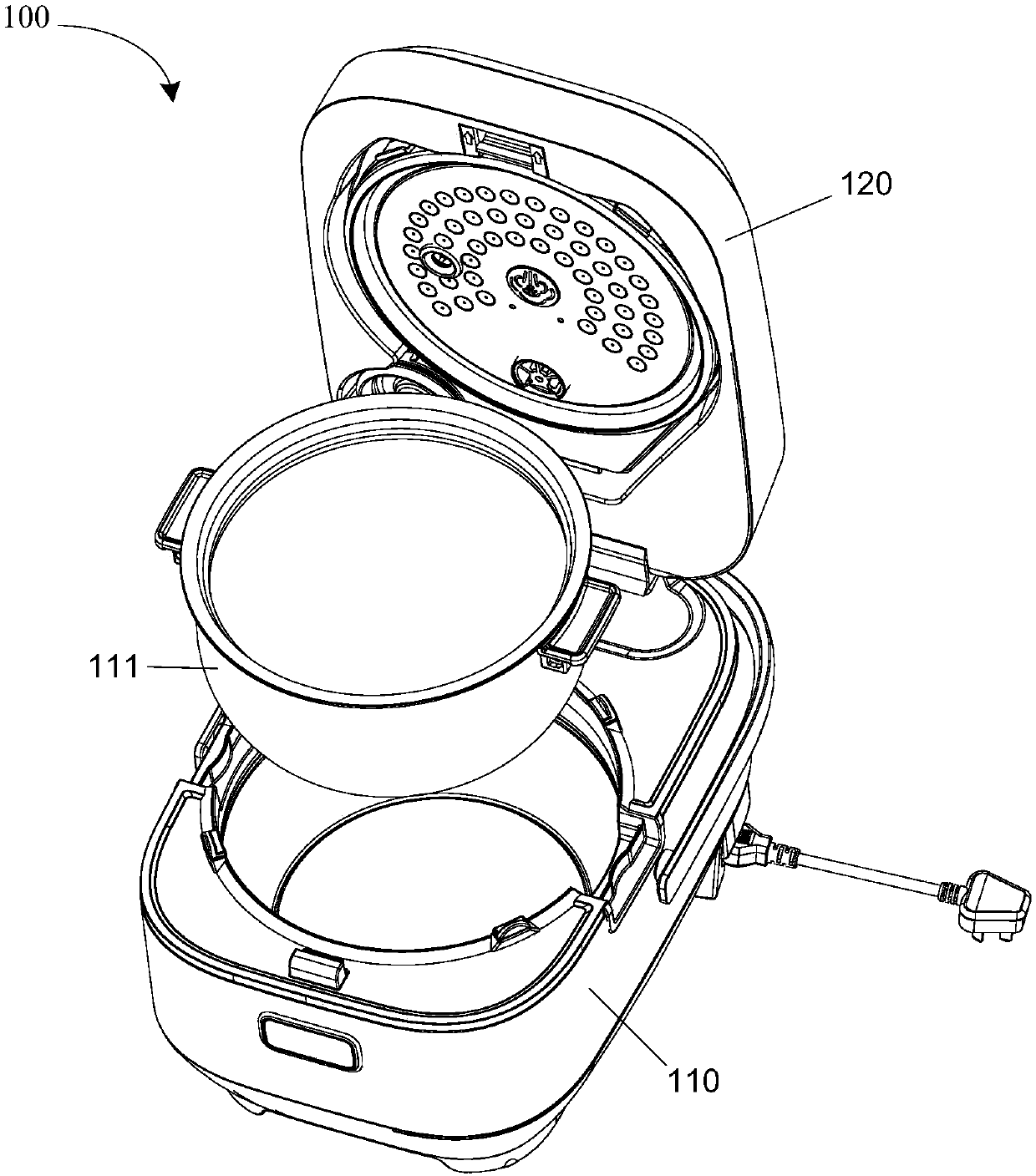

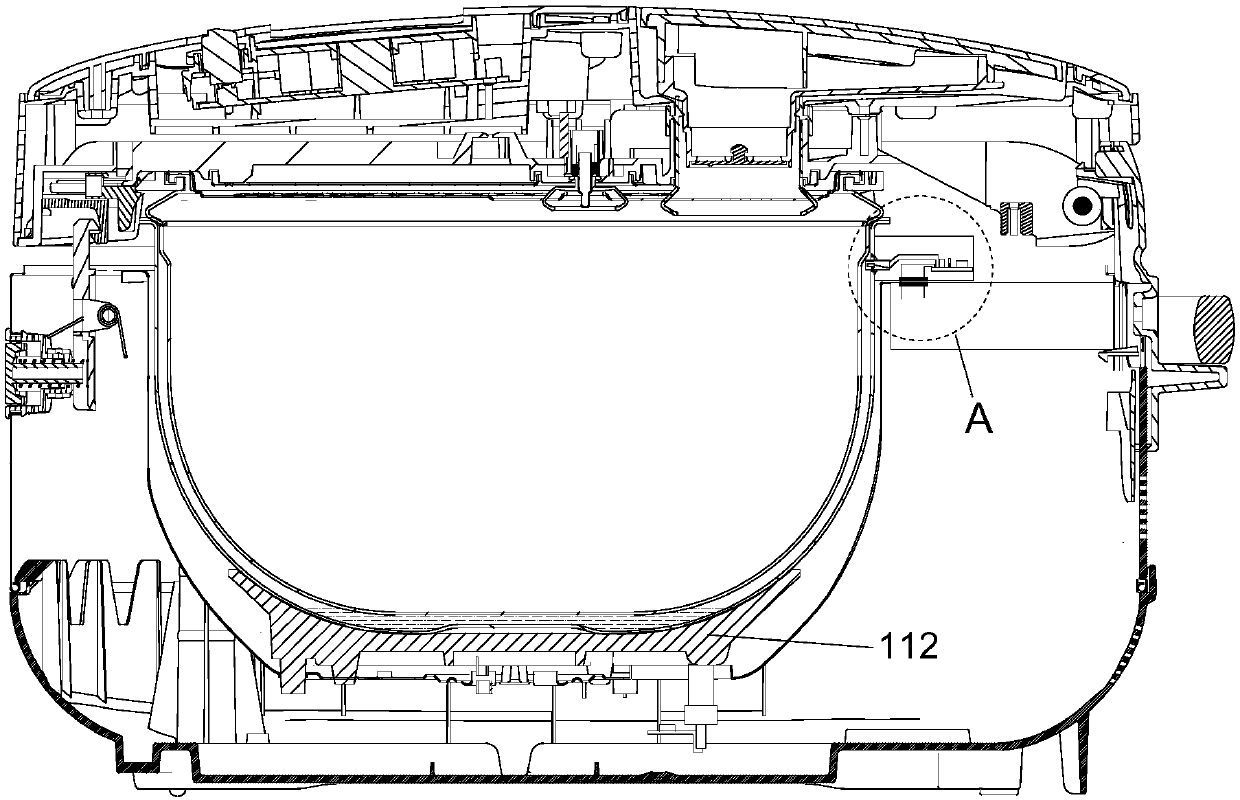

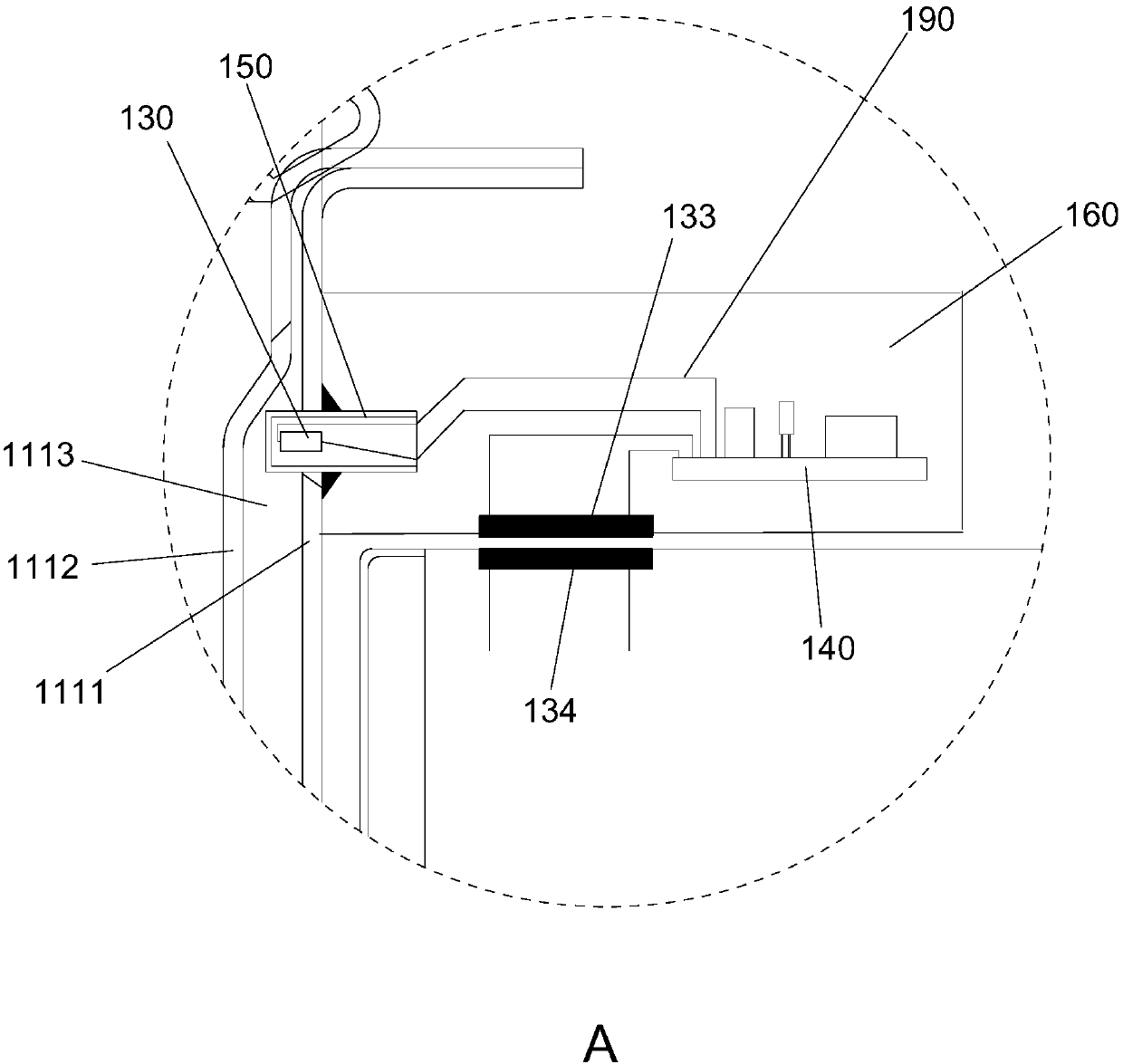

Temperature sensing device and cooking utensil

PendingCN107811517AGuaranteed accuracyAvoid complex structuresCooking-vessel materialsVessels with intergral heatingMaterials scienceClosed cavity

The invention provides a temperature sensing device and a cooking utensil. The temperature sensing device is used for the cooking utensil with an inner pot. The inner pot is provided with an outer-layer pot wall and an inner-layer pot wall, a closed cavity is formed between the outer-layer pot wall and the inner-layer pot wall, and a medium capable of transferring heat is arranged in the closed cavity. The temperature sensing device comprises a temperature sensing element which is used for sensing the temperature of the medium. According to the temperature sensing device and the cooking utensil, it can be ensured that the temperature on the surface of the inner pot is consistently and stably sampled by the temperature sensing element.

Owner:ZHEJIANG SUPOR ELECTRICAL APPLIANCES MFG CO LTD

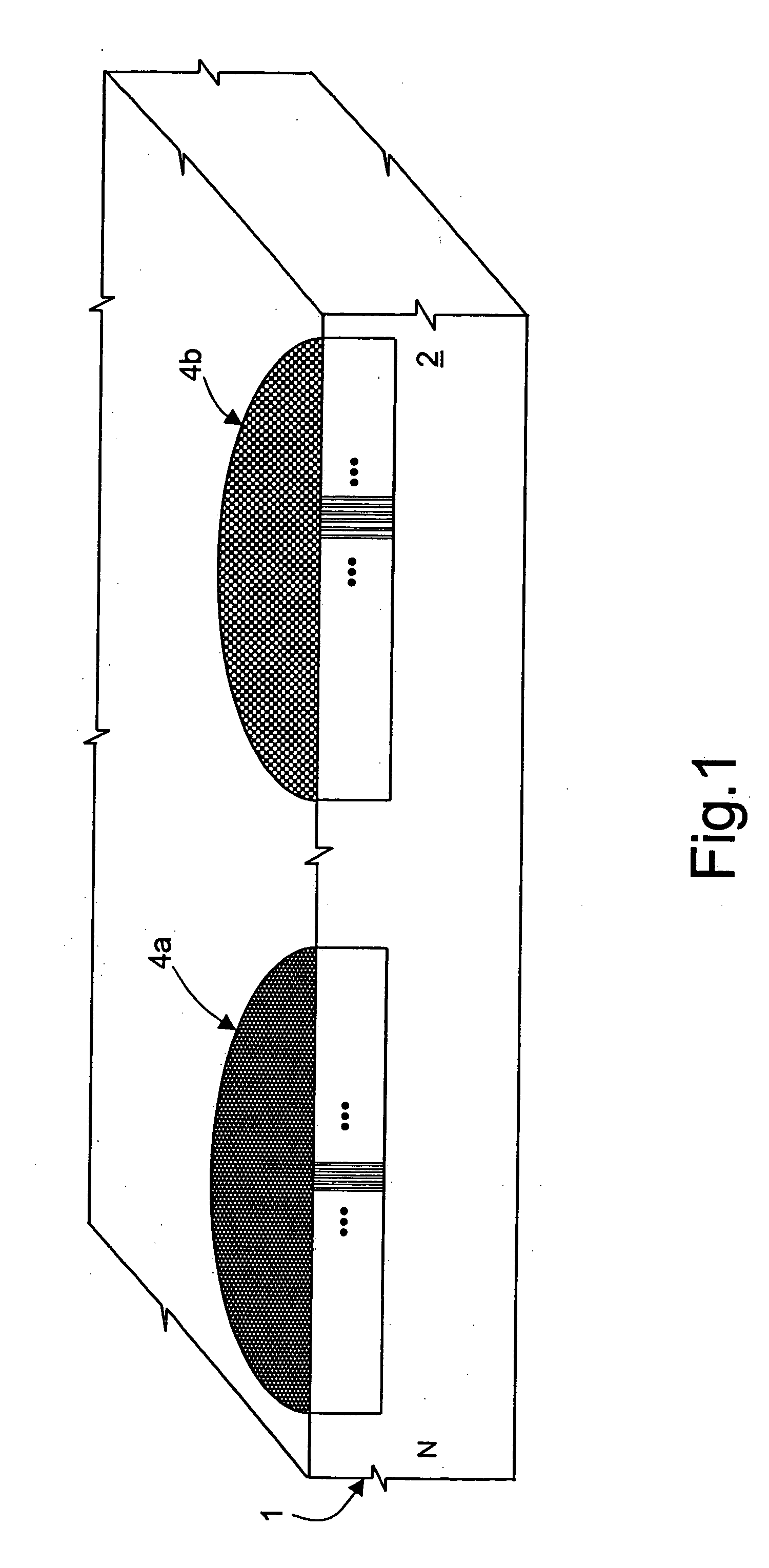

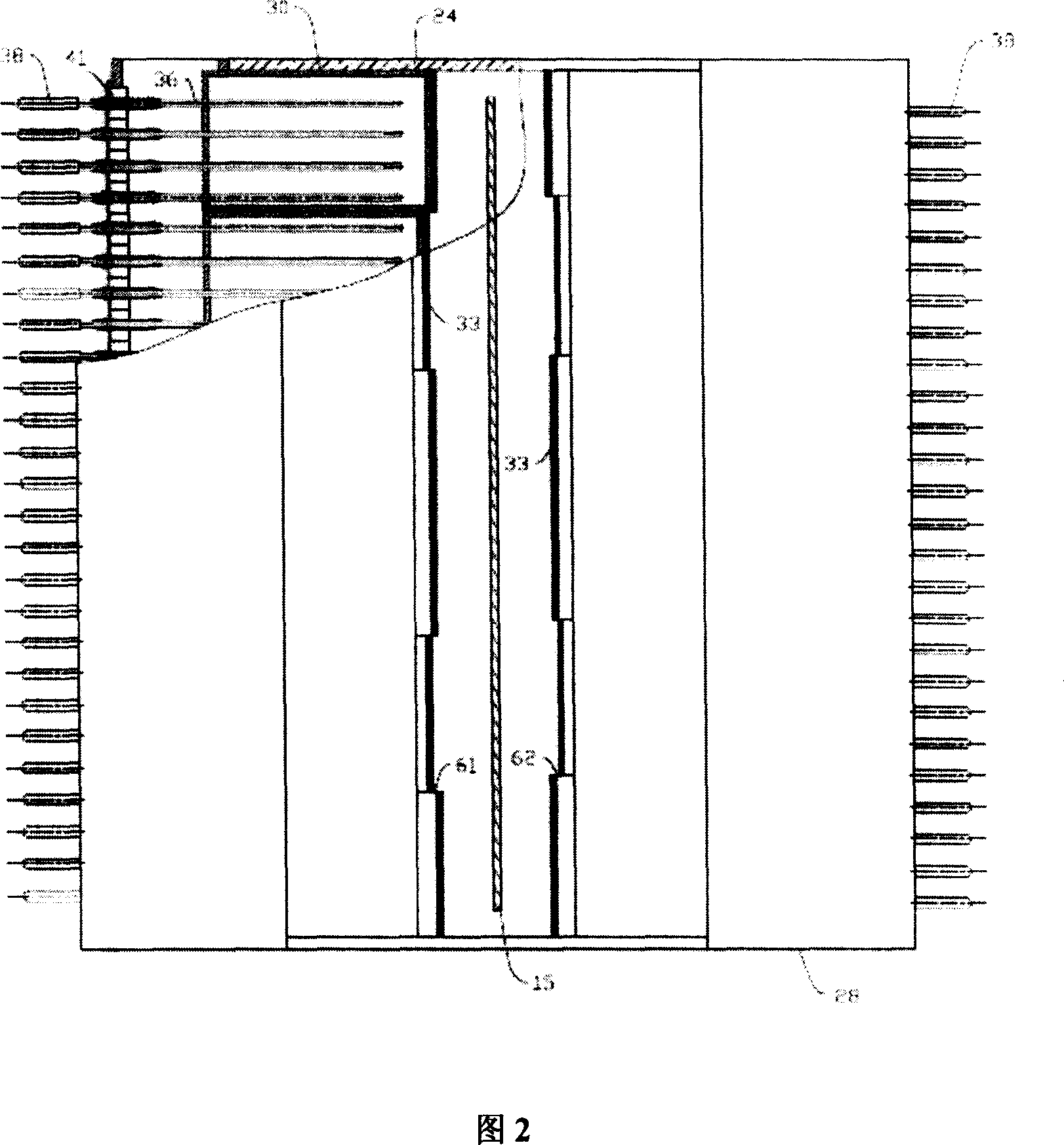

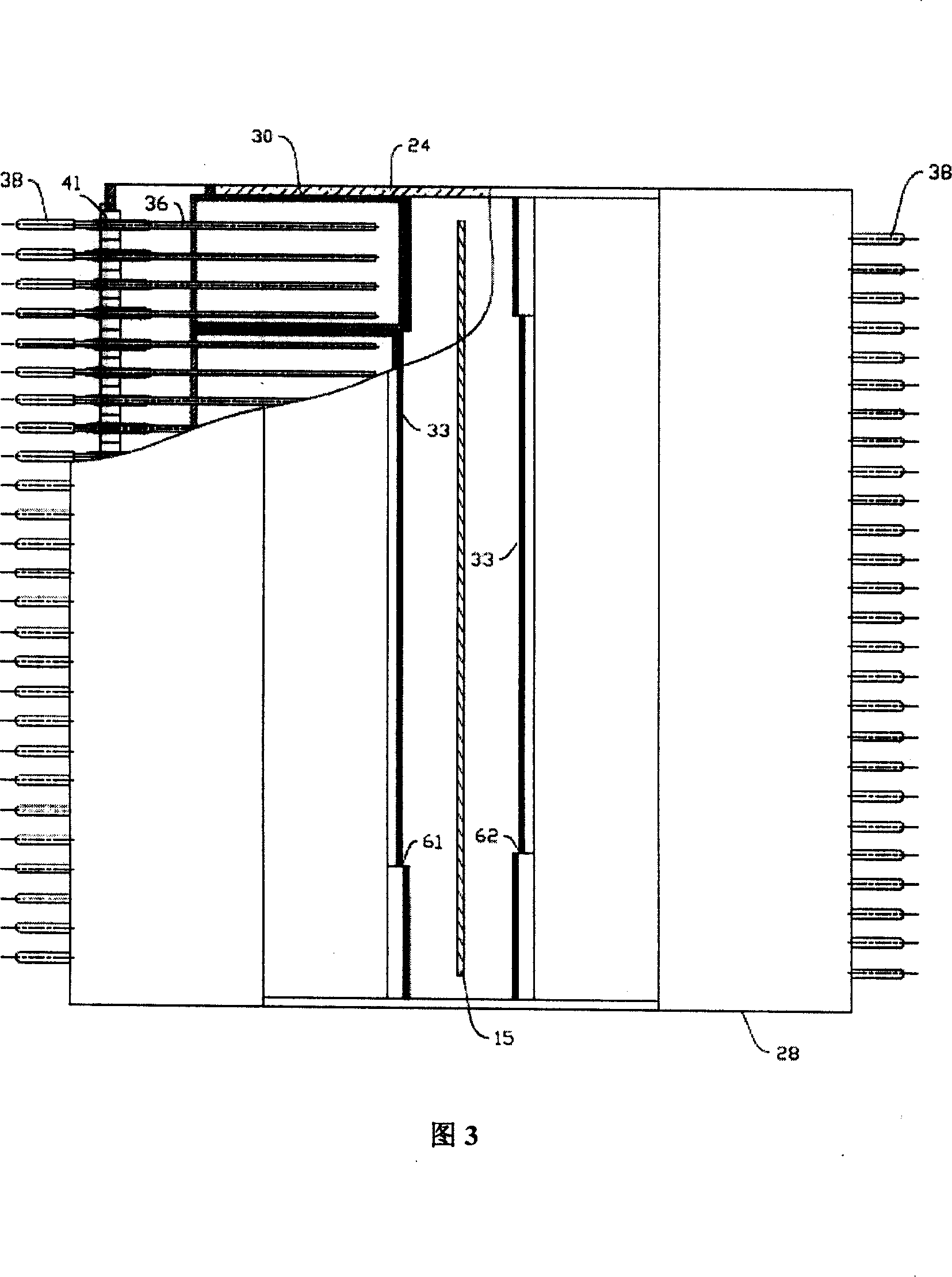

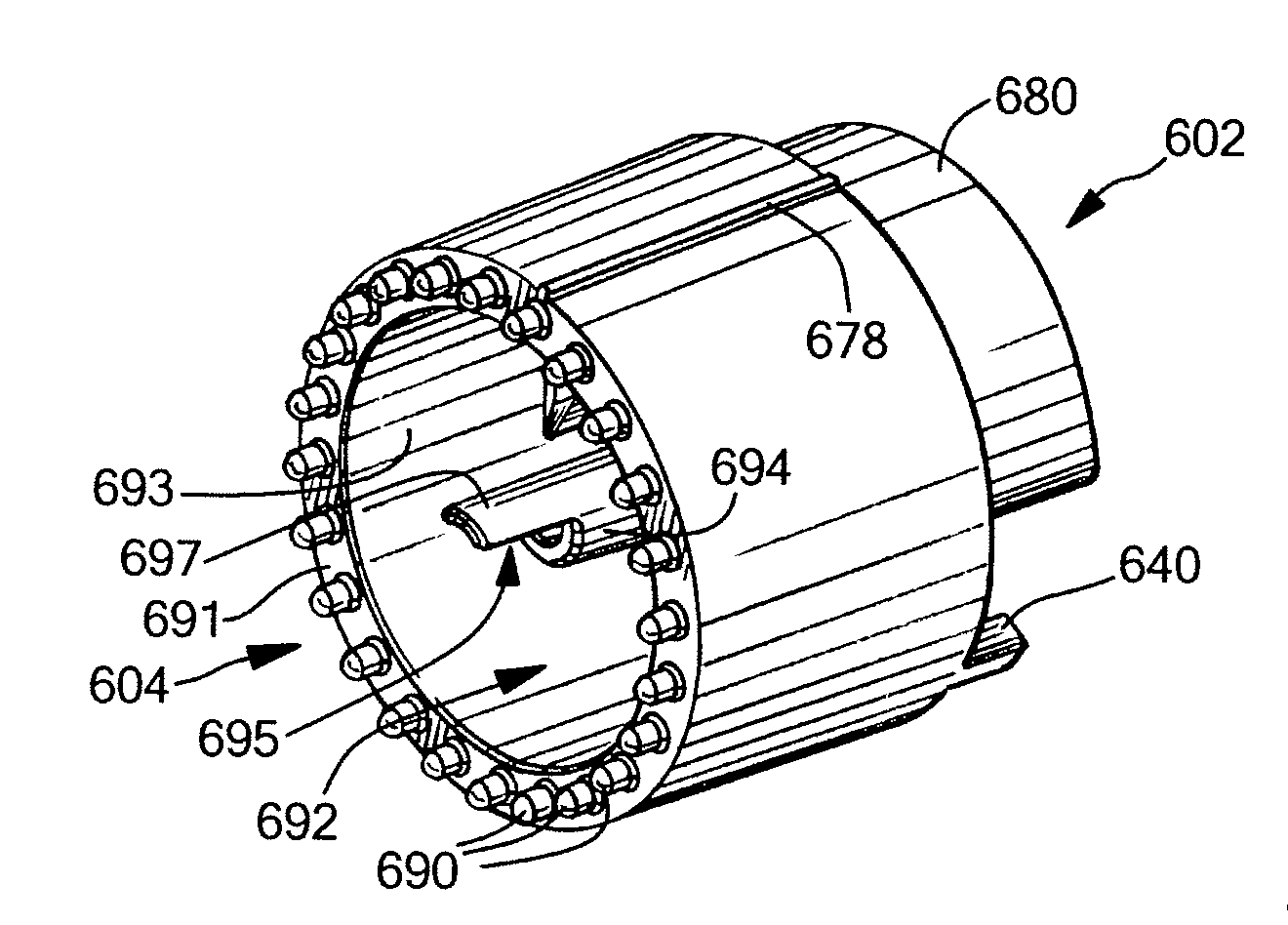

Microjet module assembly

InactiveUS7516776B2Maximize heat transfer ratePrevent liquid leakageSemiconductor/solid-state device detailsSolid-state devicesTarget surfacePower flux

Owner:GLOBALFOUNDRIES INC

Method for manufacturing a semiconductor pressure sensor

InactiveUS20050208696A1Overcome disadvantagesFluid pressure measurement by electric/magnetic elementsSemiconductor/solid-state device manufacturingEngineeringForce sensor

Method for manufacturing a semiconductor pressure sensor, wherein, in a silicon substrate, trenches are dug and delimit walls; a closing layer is epitaxially grown, that closes the trenches at the top and forms a suspended membrane; a heat treatment is performed so as to cause migration of the silicon of the walls and to form a closed cavity underneath the suspended membrane; and structures are formed for transducing the deflection of the suspended membrane into electrical signals.

Owner:STMICROELECTRONICS SRL

Protective energy-saving hood of pressure cooker

InactiveCN105725829AReduce surface temperatureImprove the protective effectCooking-vessel materialsCooking utensils shields/jacketsEngineeringEnergy conservation

The invention provides a protective energy-saving hood of a pressure cooker.The protective energy-saving hood of the pressure cooker comprises a housing 2 arranged on a cooker cover 1 in a sleeving mode and composed of shells 3 and side encircling sleeves 4; the shells 3 and the side encircling sleeves 4 are both made from plastic cement; the side encircling sleeves 4 are closely matched with the shells 3 and sealed to the cooker cover 1; each shell 3 is provided with a clearance groove 22, a valve position hole 21 and other clearance hole grooves, and the lower end faces of the clearance hole grooves are sealed to the surface of the cooker cover 1; a closed cavity 23 is defined by the housing 2 and the cooker cover 1; the peripheral edge of the upper end of each valve position hole 21 is not higher than the lower edge of a cap hole 12; the inner side wall of each shell 3 is provided with a liner 5 made from foaming plastic cement.The protective energy-saving hood is used on the pressure cooker cover in a matched mode and has the safety protection effect and the energy-saving and heat-preserving effects, cooking of the pressure cooker can be made convenient, and the protective energy-saving hood facilitates energy conservation and emission reduction, so that the protective energy-saving hood has application and popularization value.

Owner:戴梦云

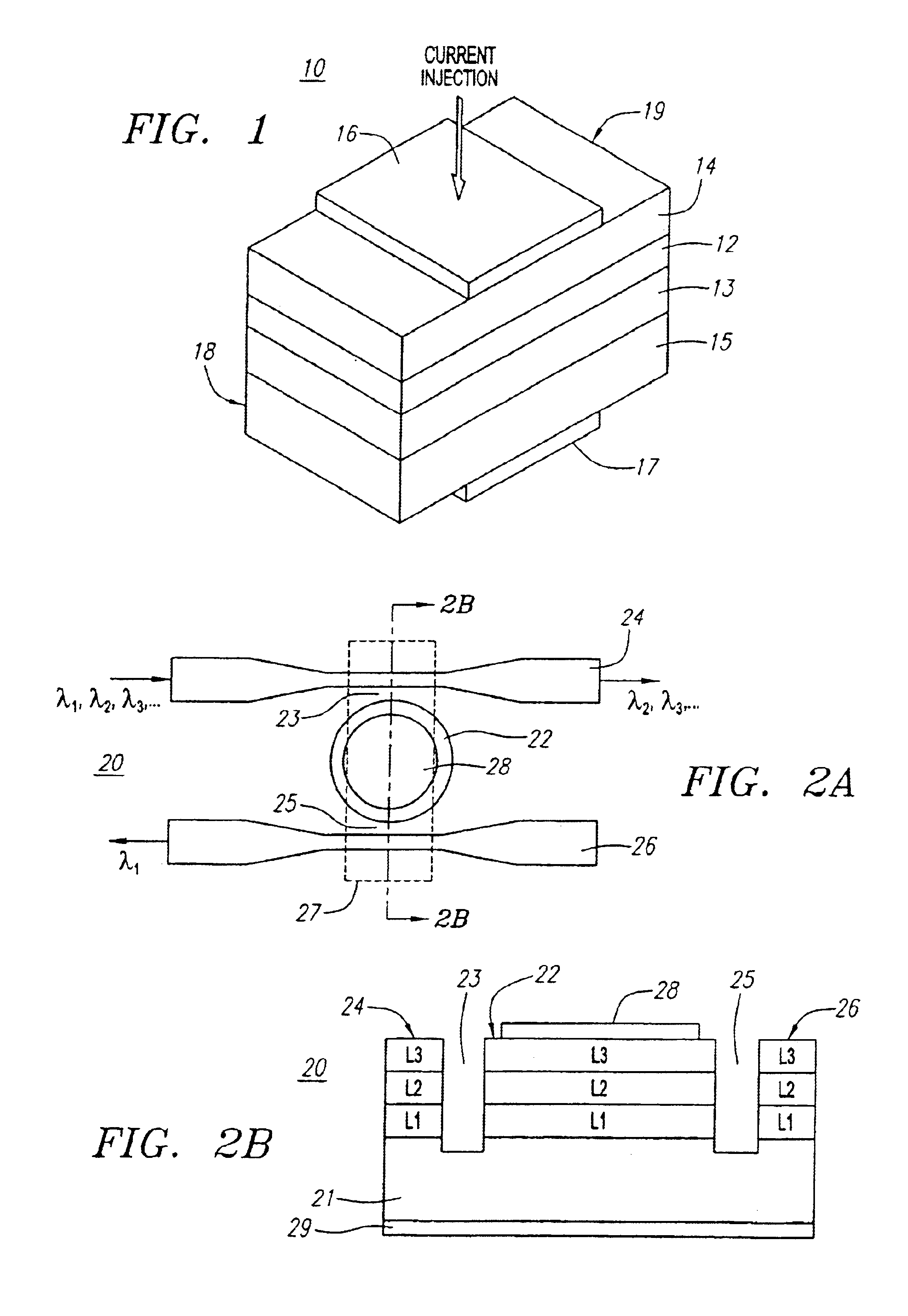

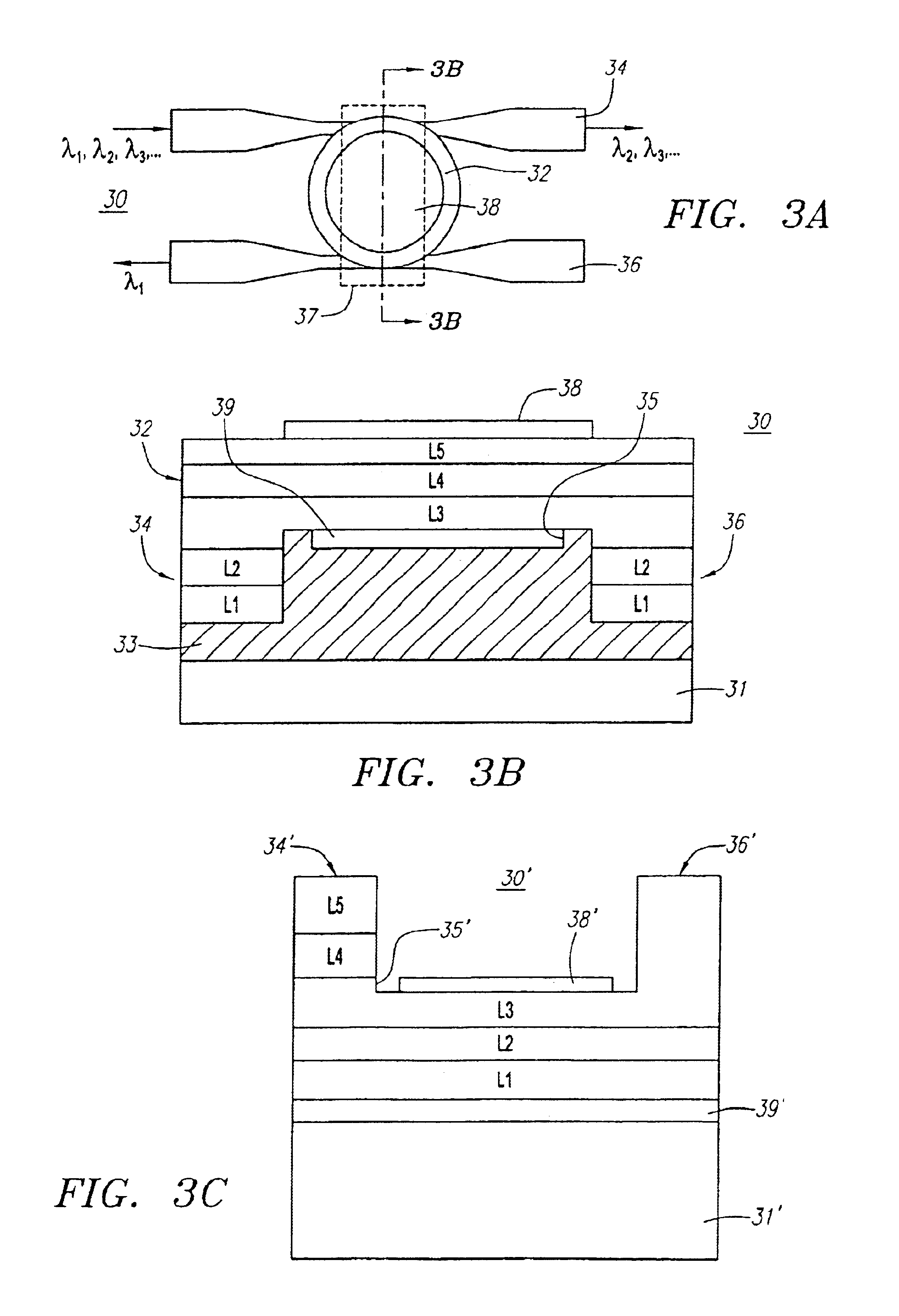

Wavelength tunable laser

InactiveUS6891865B1Increase speedBroad band wavelength tuningLaser optical resonator constructionLaser using scattering effectsResonance wavelengthWaveguide

A wavelength tunable laser comprising a laser diode and a closed external cavity formed by one or more optical resonators either horizontally or vertically coupled to adjacent waveguides. The optical resonator primarily functions as a wavelength selector and may be in the form of disk, ring or other closed cavity geometries. The emission from one end of the laser diode is coupled into the first waveguide using optical lens or butt-joint method and transferred to the second waveguide through evanescent coupling between the waveguides and optical resonator. A mirror system or high reflection coating at the end of the second waveguide reflects the light backwards into the system resulting in a closed optical cavity. Lasing can be achieved when the optical gain overcomes the optical loss in this closed cavity for a certain resonance wavelength which is tunable by changing the resonance condition of the optical resonator through reversed biased voltage or current injection. Multiple optical resonators may be used to reduce the lasing threshold and provide higher power output. With monolithic integration, more optical devices can be integrated with the tunable laser into the same substrate to produce optical devices that are capable of more complex functions, such as tunable transmitters or waveguide buses.

Owner:MIND FUSION LLC +1

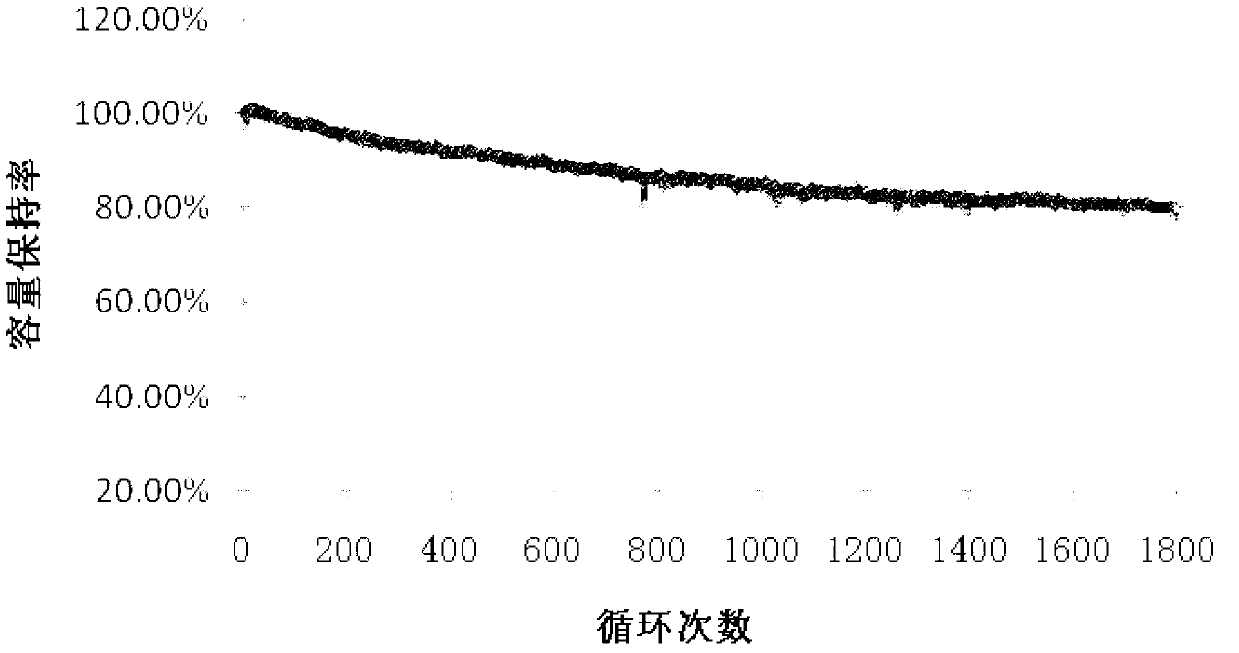

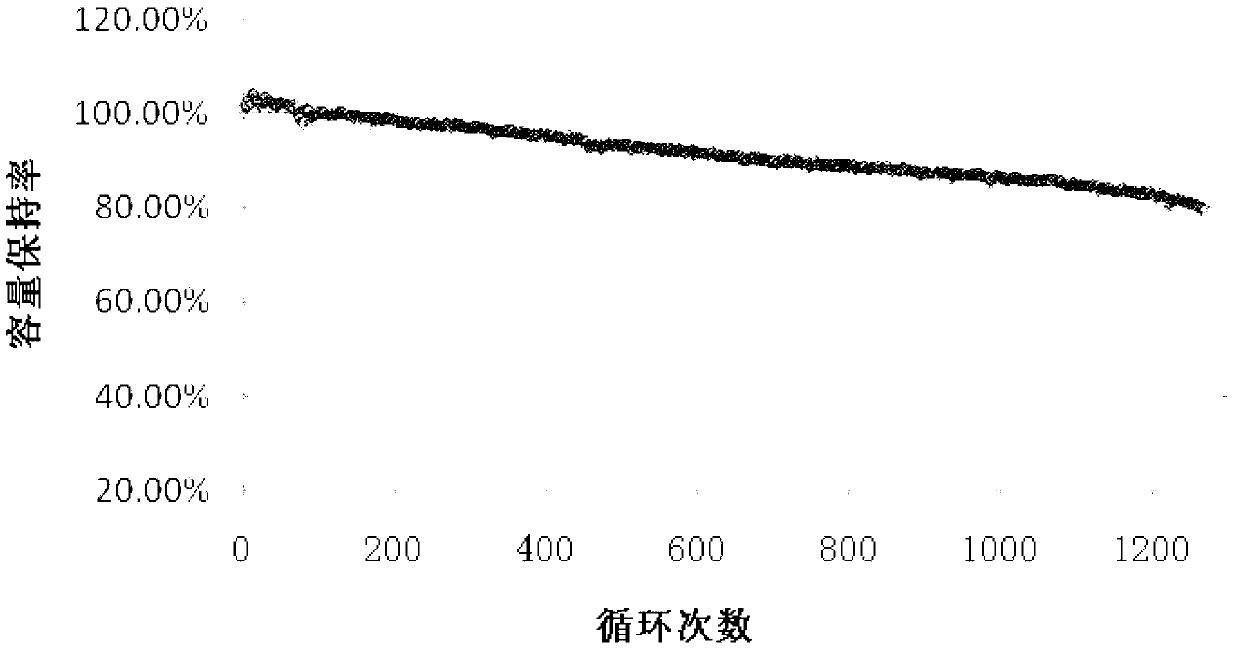

Drying method of lithium-ion battery electric core

ActiveCN102735023AGood water contentReduce labor loadFinal product manufactureDrying solid materials without heatVacuum pumpingElectrical battery

The invention relates to the field of battery manufacturing and particularly relates to a drying method of a lithium-ion battery electric core. The method comprises the following steps that: the electric core to be dried is placed in a closed cavity; constant temperature of the cavity is set; multiple times of vacuum pumping and vacuum relieving are cyclingly carried out; and a cycling air flow is formed in the closed cavity and the electric core is dried. When the lithium-ion battery electric core adopts the drying method provided by the invention, cycling of air pumping and air changing is introduced in the process of vacuum drying, and water content in the lithium-ion battery electric core can be reduced in a relatively short period of time, and operation processes are simplified and work load of an operator is reduced.

Owner:DONGGUAN AMPEREX TECH +1

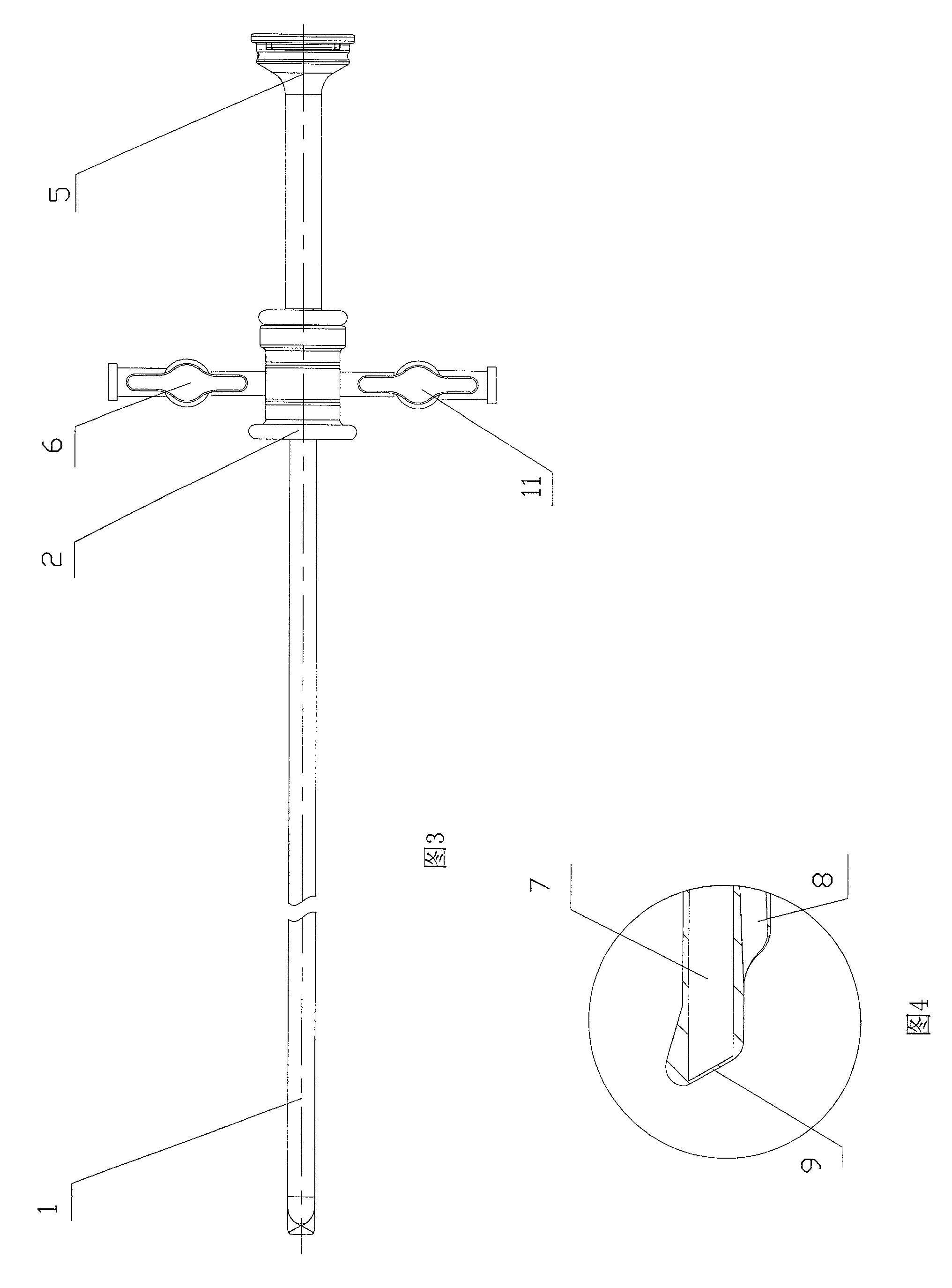

Disposal vesica urinaria examination mirror sheath

The invention relates to a disposable cystoscope sheath. To solve the problem of mutual cross-infection during medical inspection. The technical solution adopted is: a disposable bladder inspection mirror sheath, including a sheath tube, a sheath main body, an instrument valve, a short bridge, a water inlet valve and a water outlet valve, and it is characterized in that: said sheath tubes are provided with independent speculum cavities And the instrument channel, the front end of the speculum cavity is provided with a transparent window for sealing the speculum cavity, the front end of the instrument channel is open, the front section of the instrument channel is curved, and forms a certain angle with the front section of the speculum cavity; It is connected with the instrument channel and the main body of the sheath, and the speculum cavity is connected and communicated with the short bridge connected in the main body of the sheath; one end of the instrument valve is inserted in the main body of the sheath, and the other end of the instrument valve is equipped with a rubber cap; the main body of the sheath is provided with an inlet The water valve and the water outlet valve; the water inlet valve, the water outlet valve, the instrument channel and the main body of the sheath communicate with each other. The invention creates an integrated structure, which is simple and convenient to operate, economical, practical and safe.

Owner:SHENYANG SHENGSHI MEDICAL TECH CO LTD

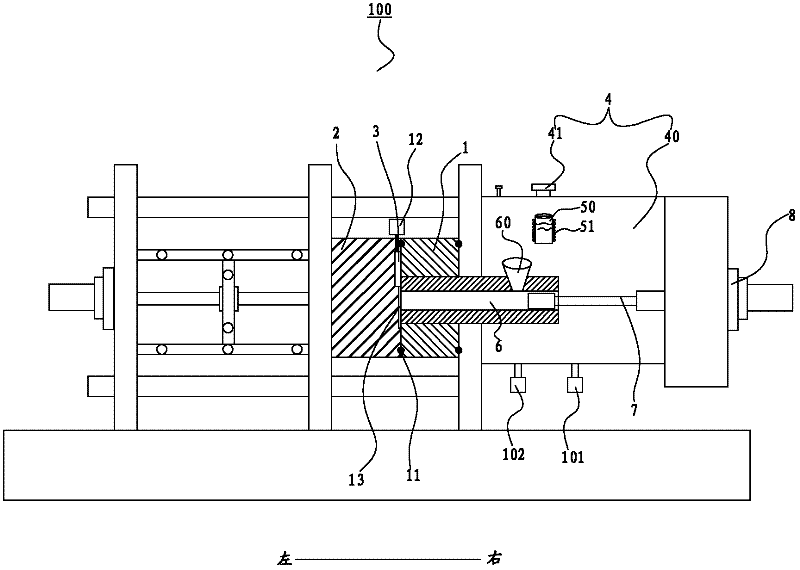

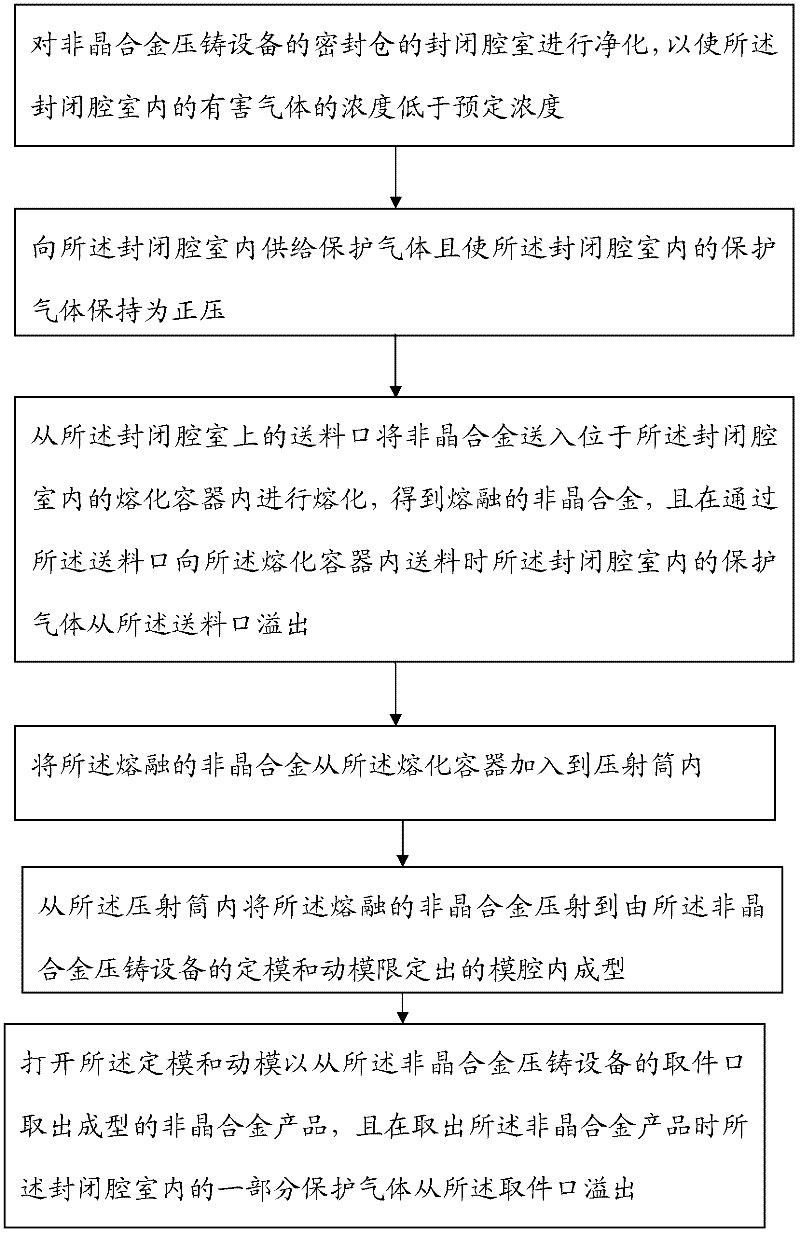

Amorphous alloy diecasting equipment and amorphous alloy diecasting process

ActiveCN102527982ACritical dimension reductionSimple structureMelt-holding vesselsMolten metal conveying equipmentsPositive pressureShielding gas

The invention discloses an amorphous alloy diecasting equipment and an amorphous alloy diecasting process. The amorphous alloy diecasting equipment comprises a fixed die, a movable die, a sealed bin, a protection-gas supplying device, a melting container, a pressing and ejecting cylinder, a driving device and a harmful-gas purifying device; the fixed die and the movable die can be opened and closed, and a die cavity is formed between the fixed die and the movable die in a defining way when the fixed die and the movable die are closed; a sealed chamber is formed in the sealed bin in a defining way, and the sealed bin is provided with a feeding opening; the protection-gas supplying device is connected with the sealed chamber and used for supplying a protection gas to the sealed chamber, wherein the protection gas in the sealed chamber is at positive pressure; the melting container is arranged in the sealed bin; the pressing and ejecting cylinder is communicated with the die cavity and provided with a melt inlet; the pressing and ejecting cylinder is internally provided with a pressing and ejecting piston used for ejecting the melted amorphous alloy into the die cavity; and the harmful-gas purifying device is connected with the sealed chamber and used for purifying the harmful gas in the sealed chamber. The amorphous alloy diecasting equipment disclosed by the embodiment of the invention has a simple structure, adopts the protective gas at positive pressure, does not need to establish a high vacuum degree and has low manufacturing and maintaining cost.

Owner:BYD CO LTD

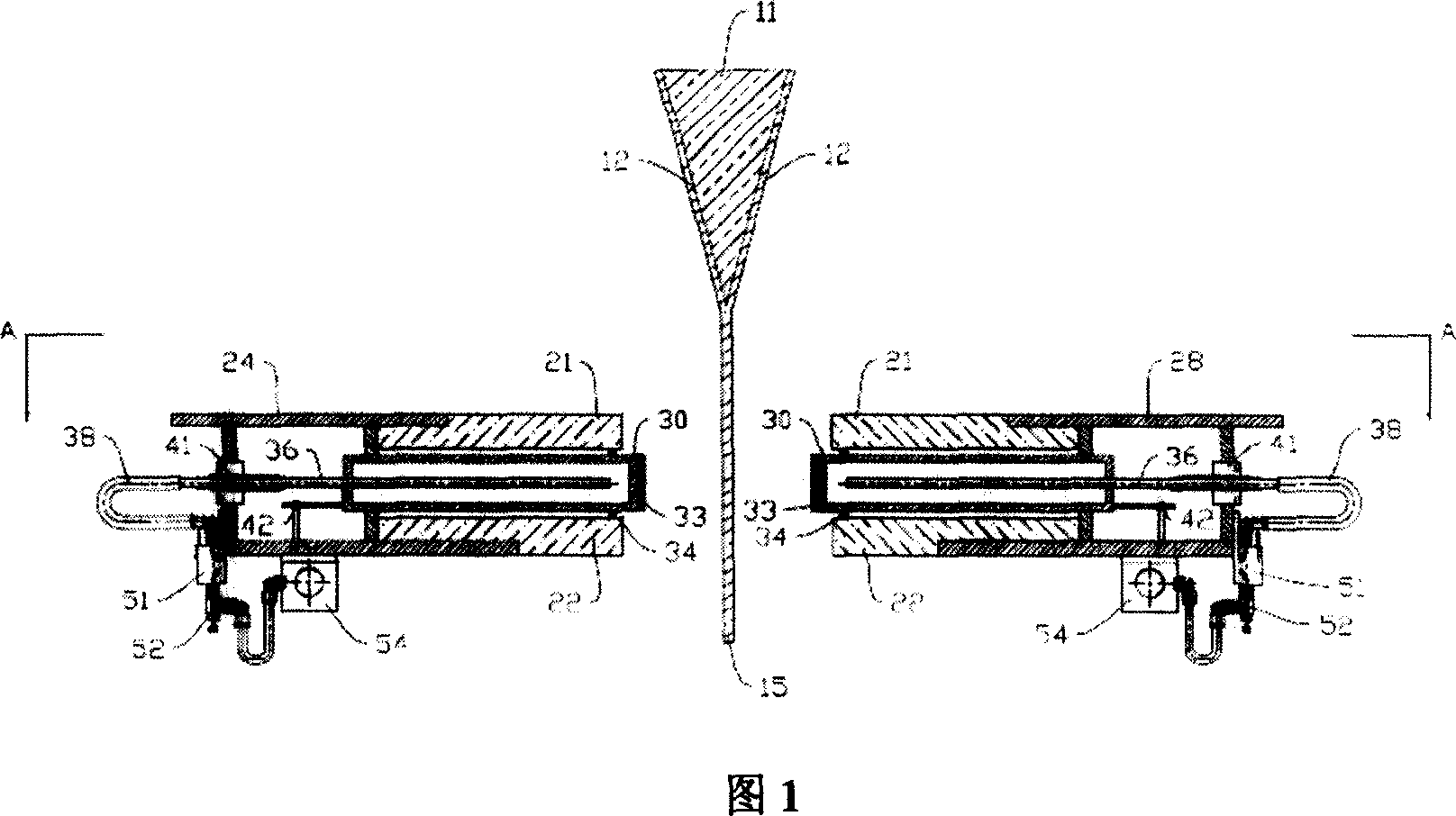

Device and method for controlling glass-board thickness evenness

InactiveCN101028964AControl the degree of heat transferHigh blacknessGlass forming apparatusThermal energyBrick

An apparatus for controlling the thickness uniformity of glass plate is composed of supporting frame, the upper, lower, left and right insulating refractory brick layers for enclosing whole apparatus, and two closed cavities containing at least one fluid tube and arranged at both sides of glass plate for collecting the heat to heat the fused glass in irradiation mode. Its method features that the distance between said apparatus and fused glass and the relative position between fused glass and heating element are regulated for controlling the temp of fused glass.

Owner:HENAN ANCAI HI-TECH +1

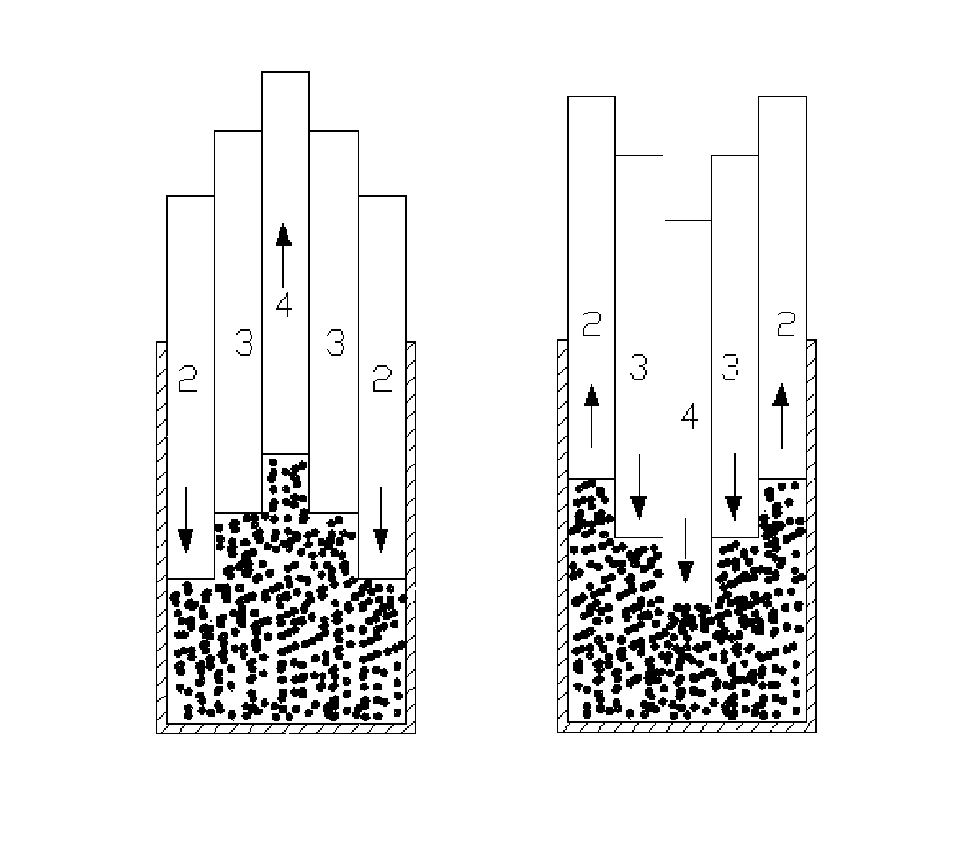

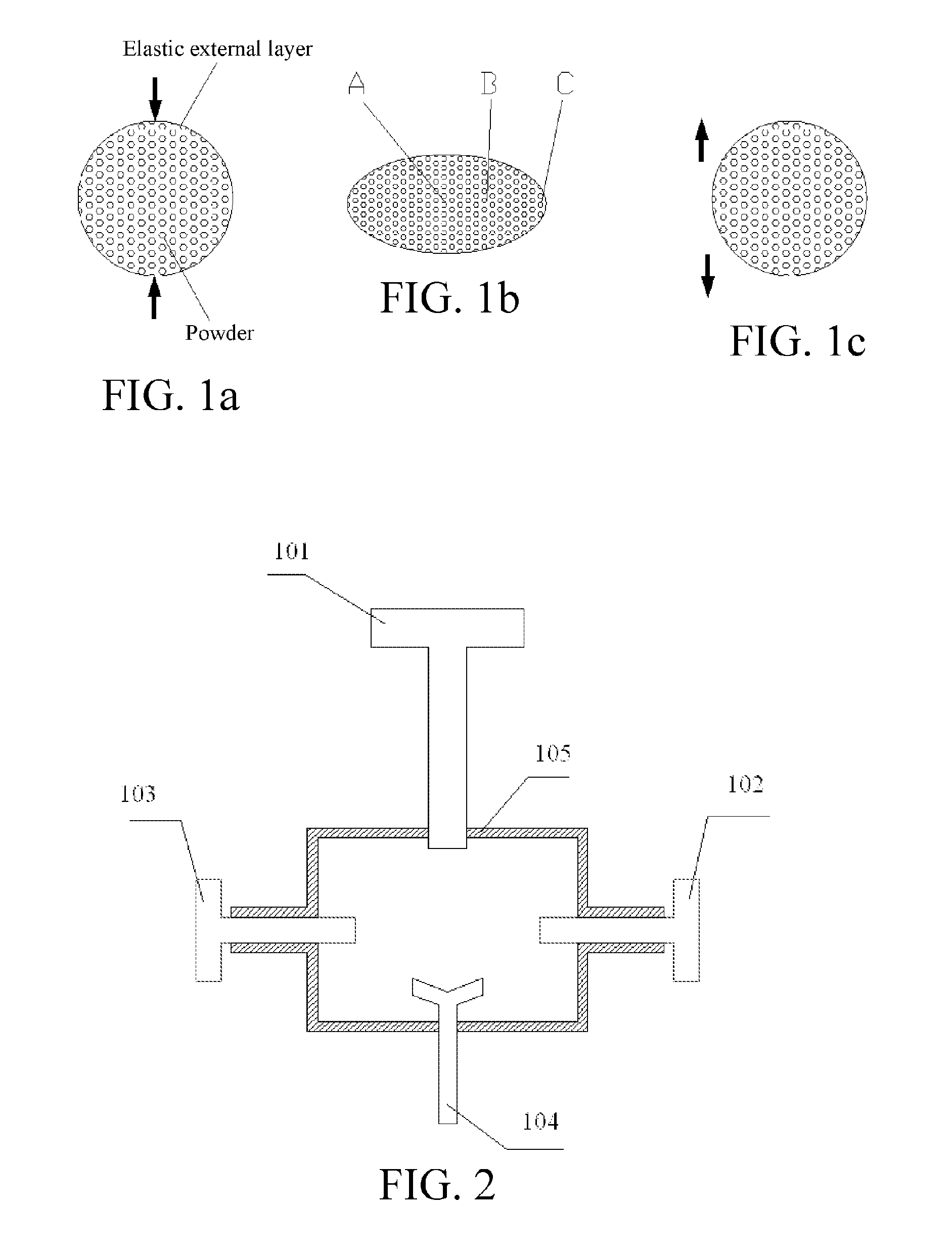

Powder particle shaping device and method

ActiveUS8343395B2Reduced controllabilityEliminate the effects ofConfectioneryFilament/thread formingShape changeMachining process

A powder particle shaping device includes a closed cavity capable of changing between multiple shapes as an external pressure changes, and the closed cavity compresses and moves powder particles with which the closed cavity is filled full while the shape changes. A powder particle shaping method is further provided, which includes a. filling a cavity full with powder particles to be shaped; and b. applying a varying external pressure to make the cavity change repeatedly between multiple shapes, thereby making the powder particles under compression move and be subject to friction, where the cavity is kept in a closed state during an effective processing process. The shaping device and method have highly controllable shaping processing intensity of powder particles and stable processing strength, and thus are applicable to shaping and pulverization of various powder particles, and also applicable to pulverization and further shaping processing of dispersed agglomerates.

Owner:HU XINYU +1

Multi-adjustable replacement LED lighting element

An LED lighting element is configured to receive electrical power from a fluorescent lighting fixture ballast. The LED lighting element includes a base and a light engine coupled to the base. The light engine includes at least one LED. An end cap is coupled to the base and defines an enclosed chamber. A converter module is housed within the enclosed chamber and is electrically coupled to the light engine. The converter module is configured to convert AC power from the fluorescent lighting fixture ballast to DC power for powering the at least one LED.

Owner:THOMAS JAMES +4

Composite sound-absorbing device with built in resonant cavity

InactiveUS20120247867A1Increased acoustic impedancePromote absorptionExhaust apparatusSilencing apparatusResonant cavityEngineering

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

Lithium ion battery cell drying method and lithium ion battery

ActiveCN103344097APrevent agingSave energyDrying using combination processesFinal product manufactureVacuum pumpingEngineering

The invention discloses a lithium ion battery cell drying method and a lithium ion battery. The method includes the following steps that a battery cell is placed in a closed cavity, vacuum pumping is conducted on the cavity, and the vacuum pumping operation lasts for 3-10 minutes after the vacuum degree in the cavity reaches-0.1--0.12 MPa; the battery cell is heated at the temperature ranging from 75-85 DEG C for 2-5 hours; non-oxide gas is inflated in the cavity until the vacuum degree in the cavity reaches-0.01--0.02 MPa; the battery cell is heated at the temperature ranging from 75-85 DEG C for 20-40 minutes; vacuum pumping is conducted on the cavity, and the vacuum pumping operation lasts for 3-10 minutes after the vacuum degree in the cavity reaches-0.1--0.12 MPa. The vacuum pumping operation and gas changing are conducted in a step-by-step mode, so that energy is greatly saved, and drying efficiency is improved.

Owner:奇瑞新能源汽车股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com