Patents

Literature

1342 results about "Ampoule" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An ampoule (also ampul, ampule, or ampulla) is a small sealed vial which is used to contain and preserve a sample, usually a solid or liquid. Ampoules are commonly made of glass, although plastic ampoules do exist.

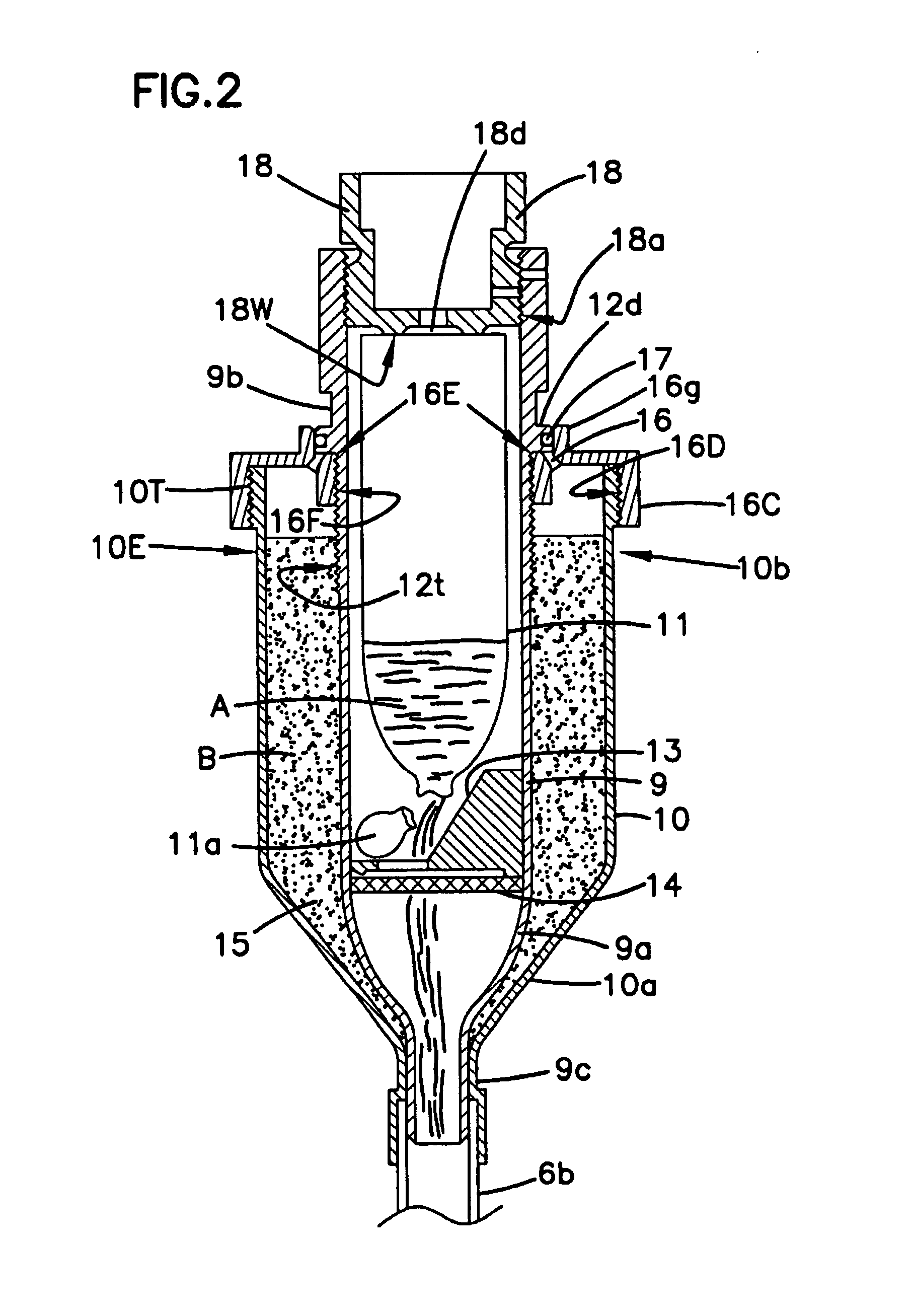

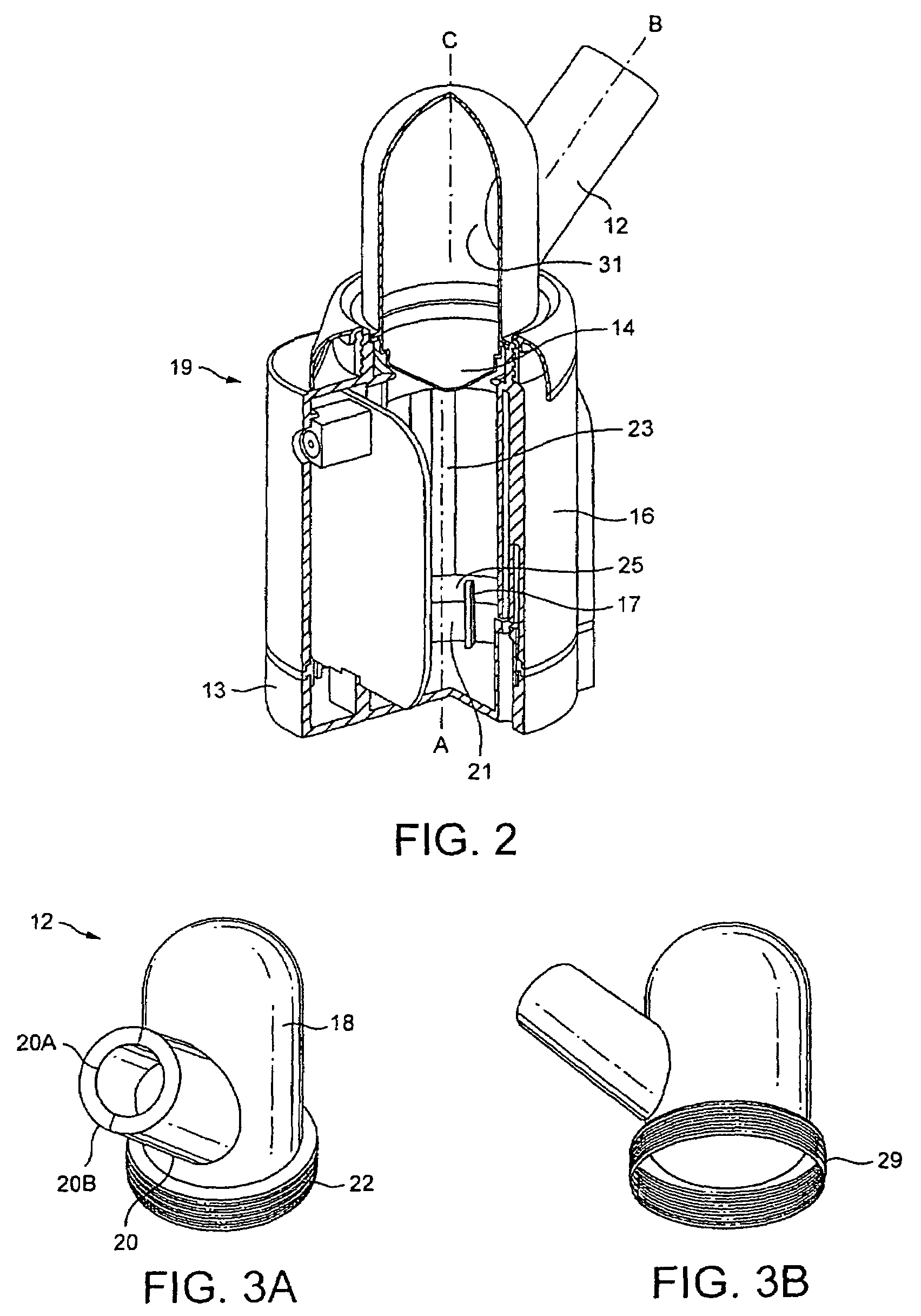

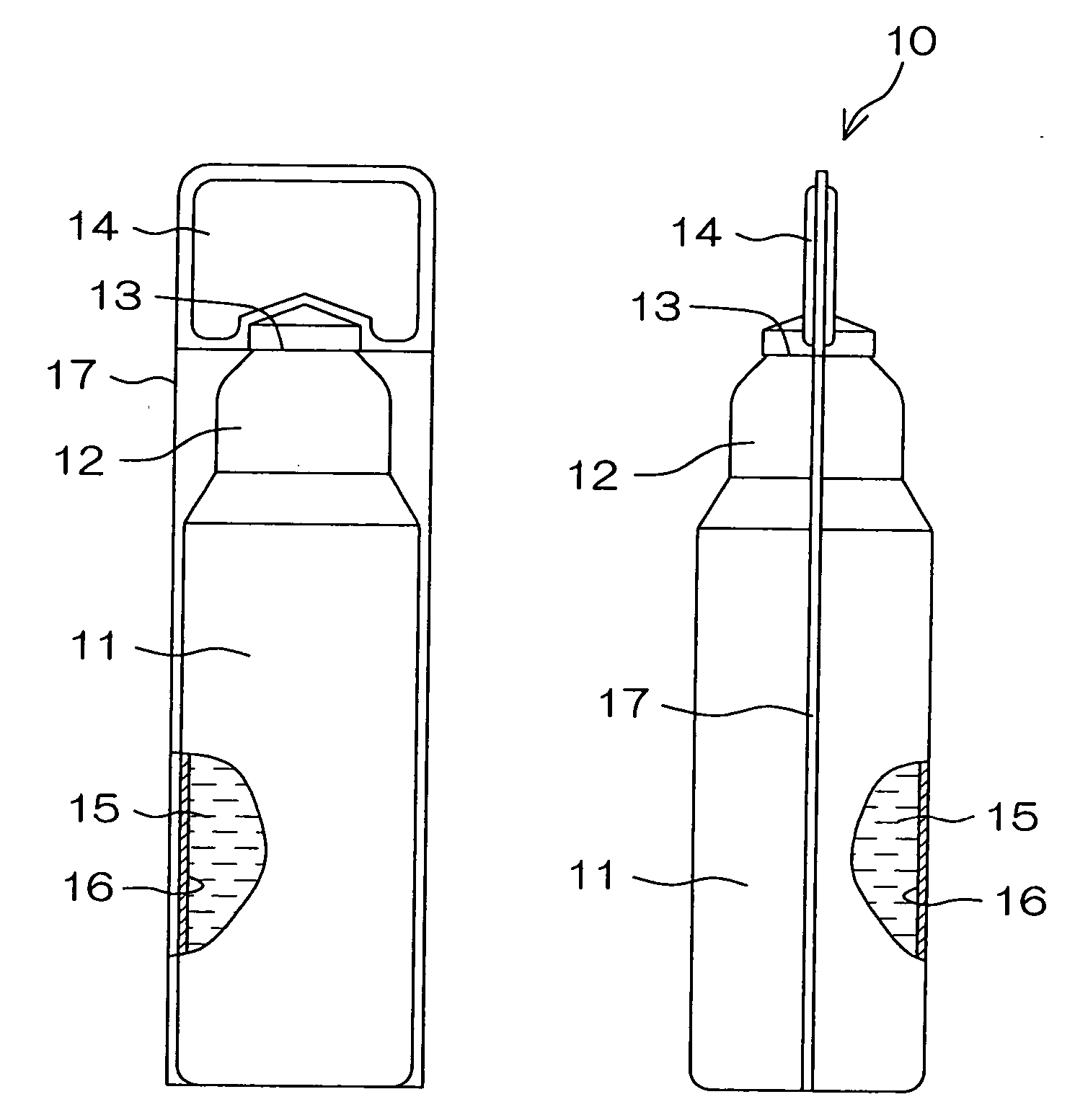

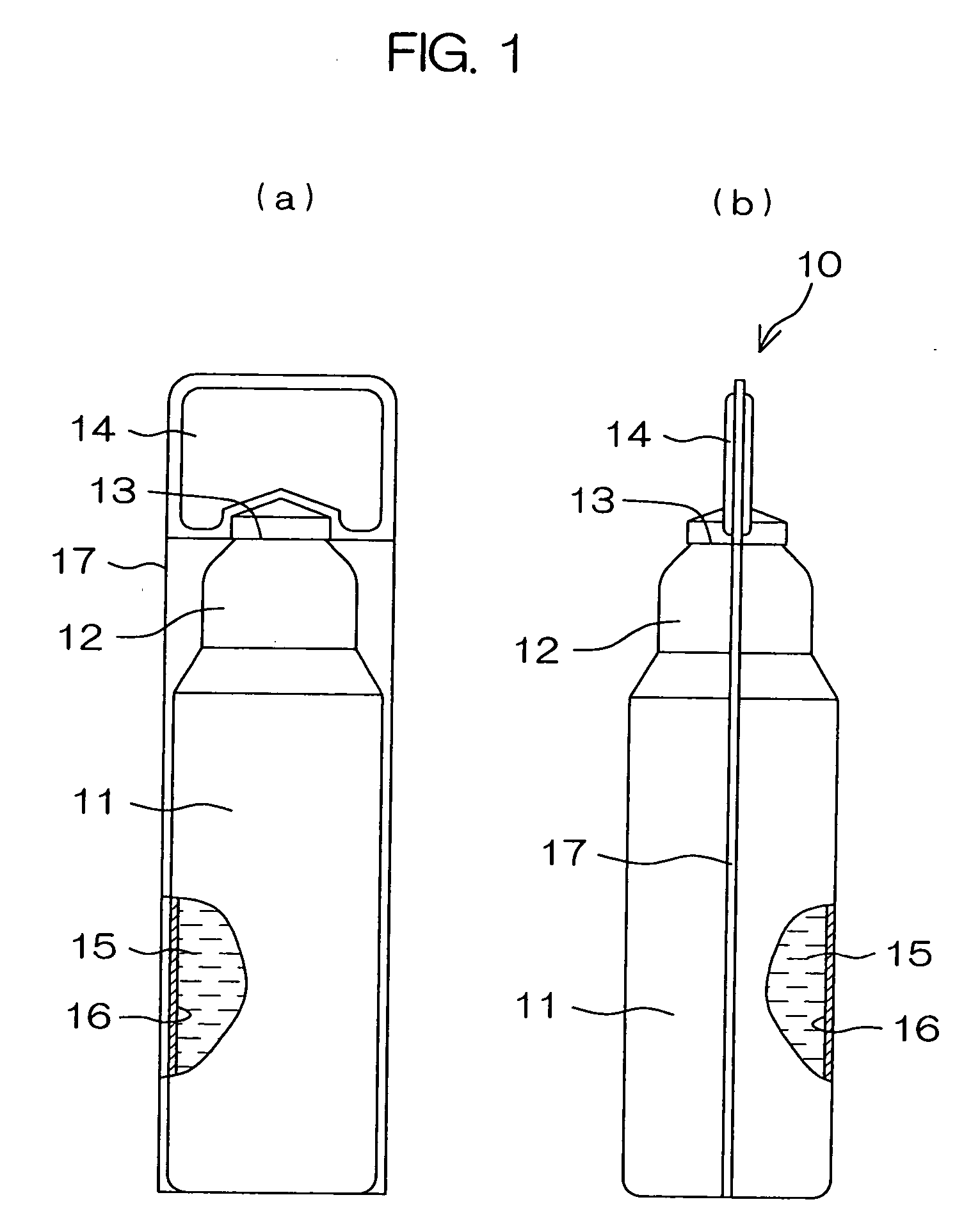

Drug solution filling plastic ampoule and process for producing the same

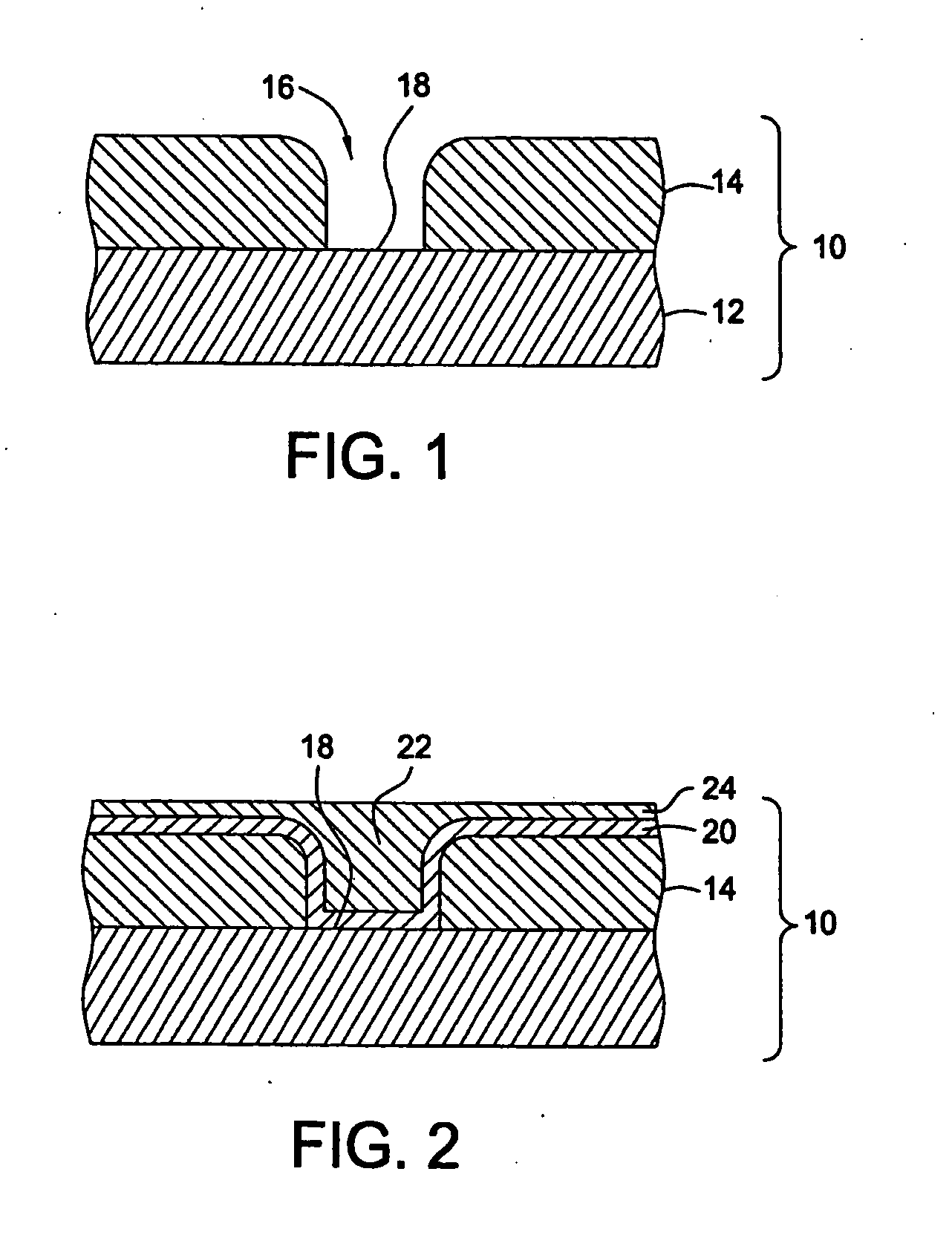

A drug solution filling plastic ampoule having gas, steam and light ray barrier properties, a drug permeation preventing capability and an absorption / adsorption preventing capability, and a production method for the plastic ampoule. The drug solution filling plastic ampoule includes a container body, a fusion-bonded portion which seals a mouth of the container body, and a wrench-off holder tab connected to the fusion-bonded portion. The ampoule is formed from a parison including two or more layers, at least one of which is a functional layer having at least one characteristic property selected from the group consisting of a gas permeation preventing capability, a steam permeation preventing capability, a light ray permeation preventing capability, a drug permeation preventing capability and a drug absorption / adsorption preventing capability.

Owner:OTSUKA PHARM FAB INC

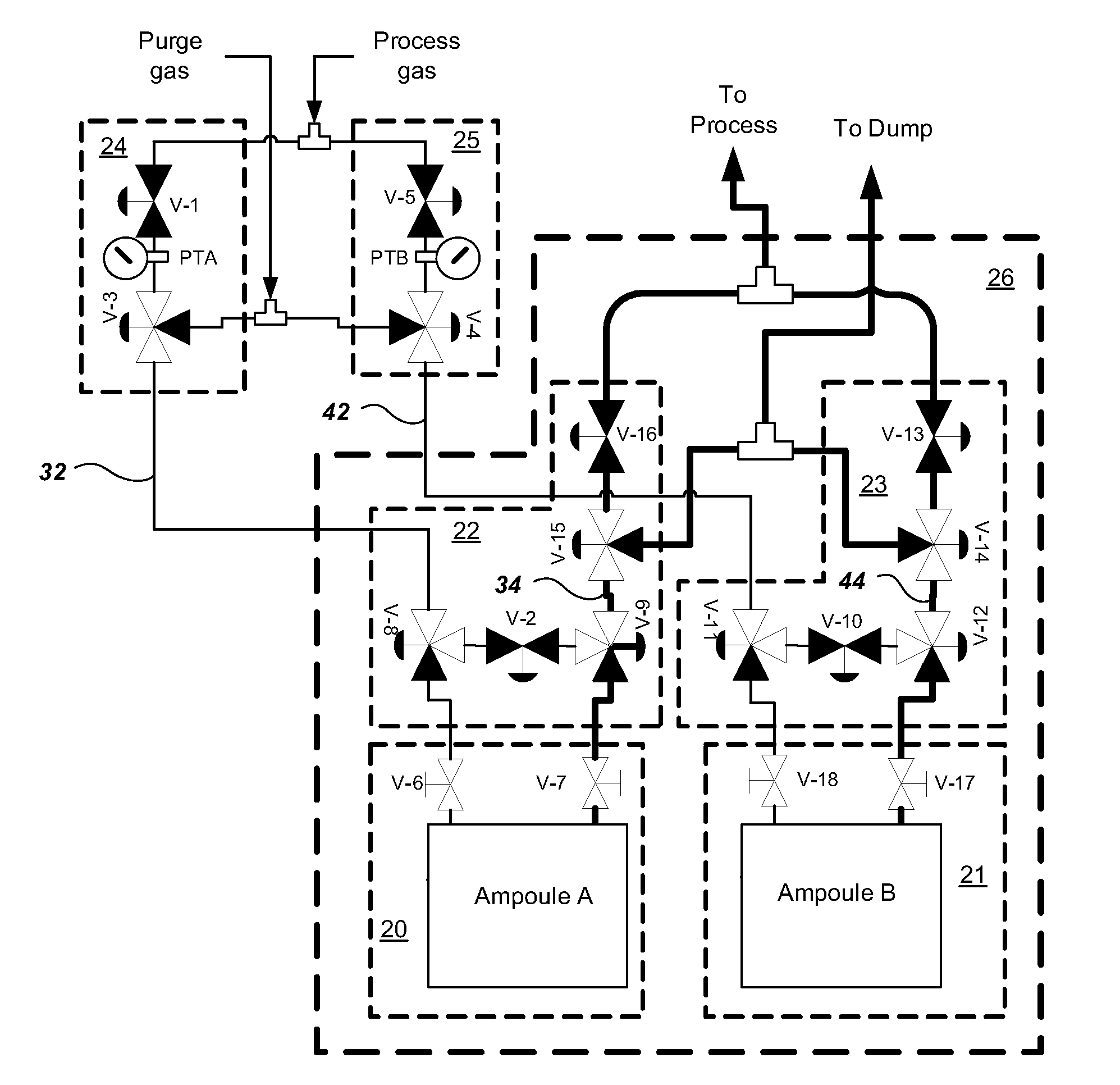

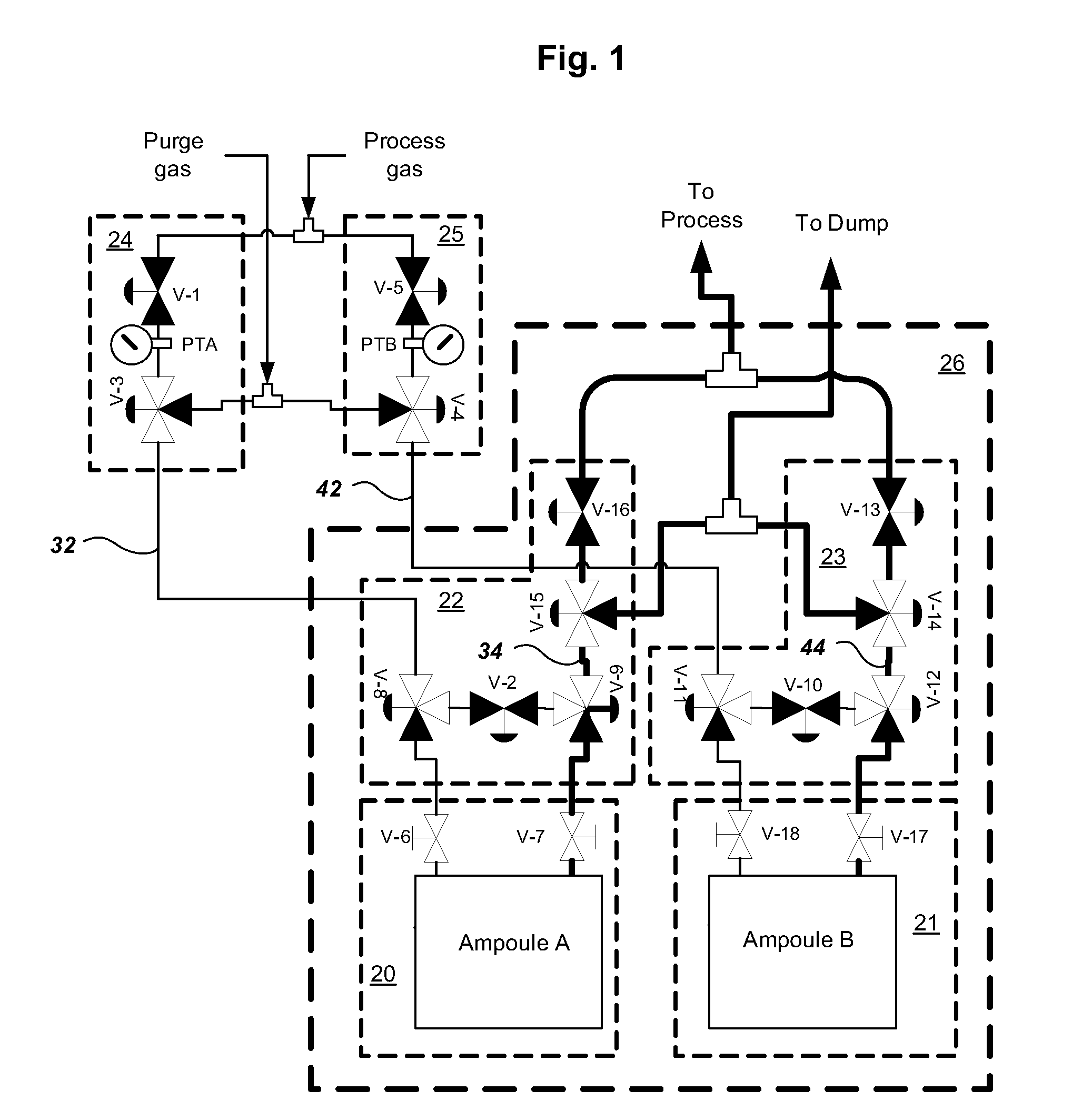

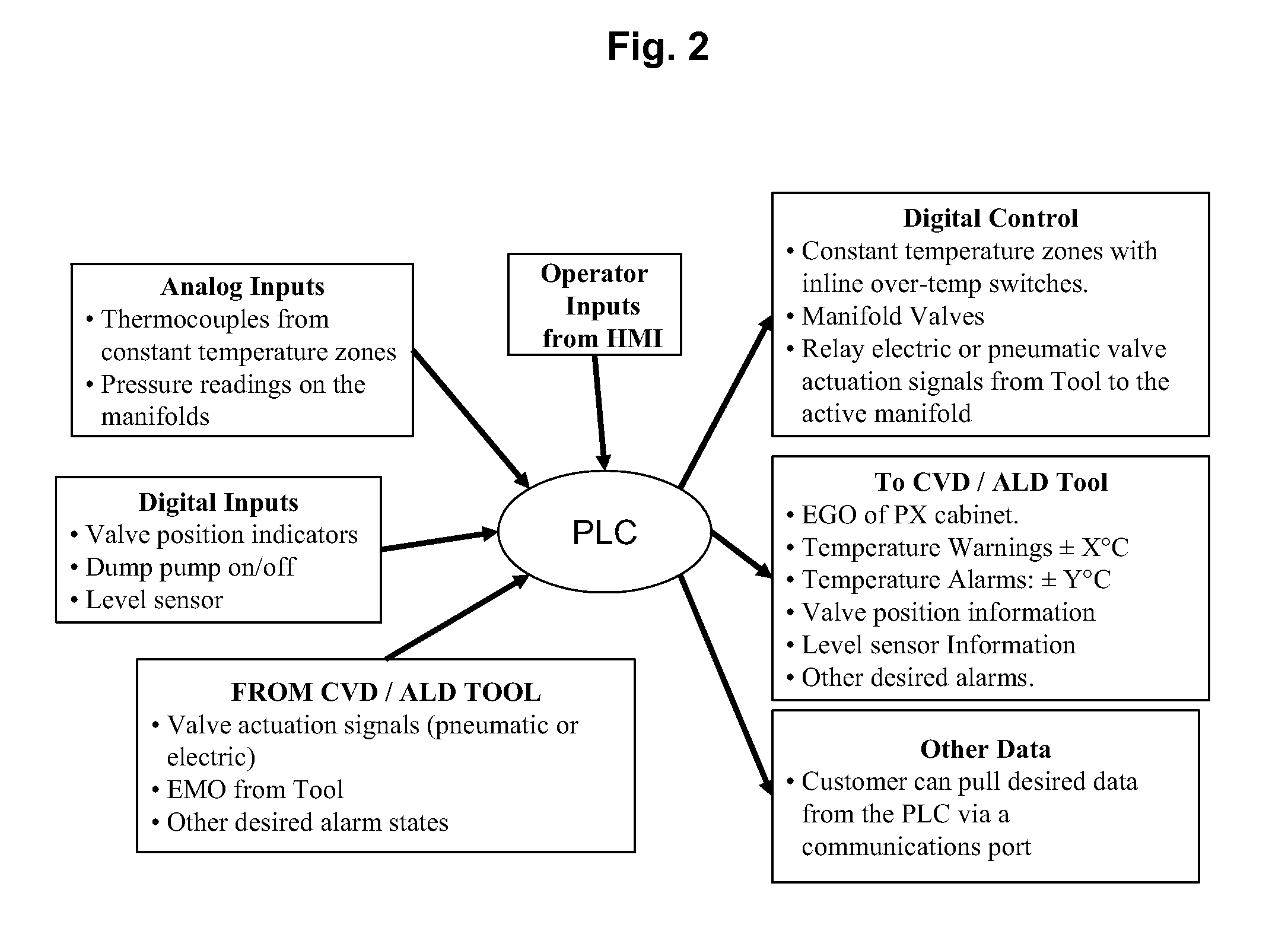

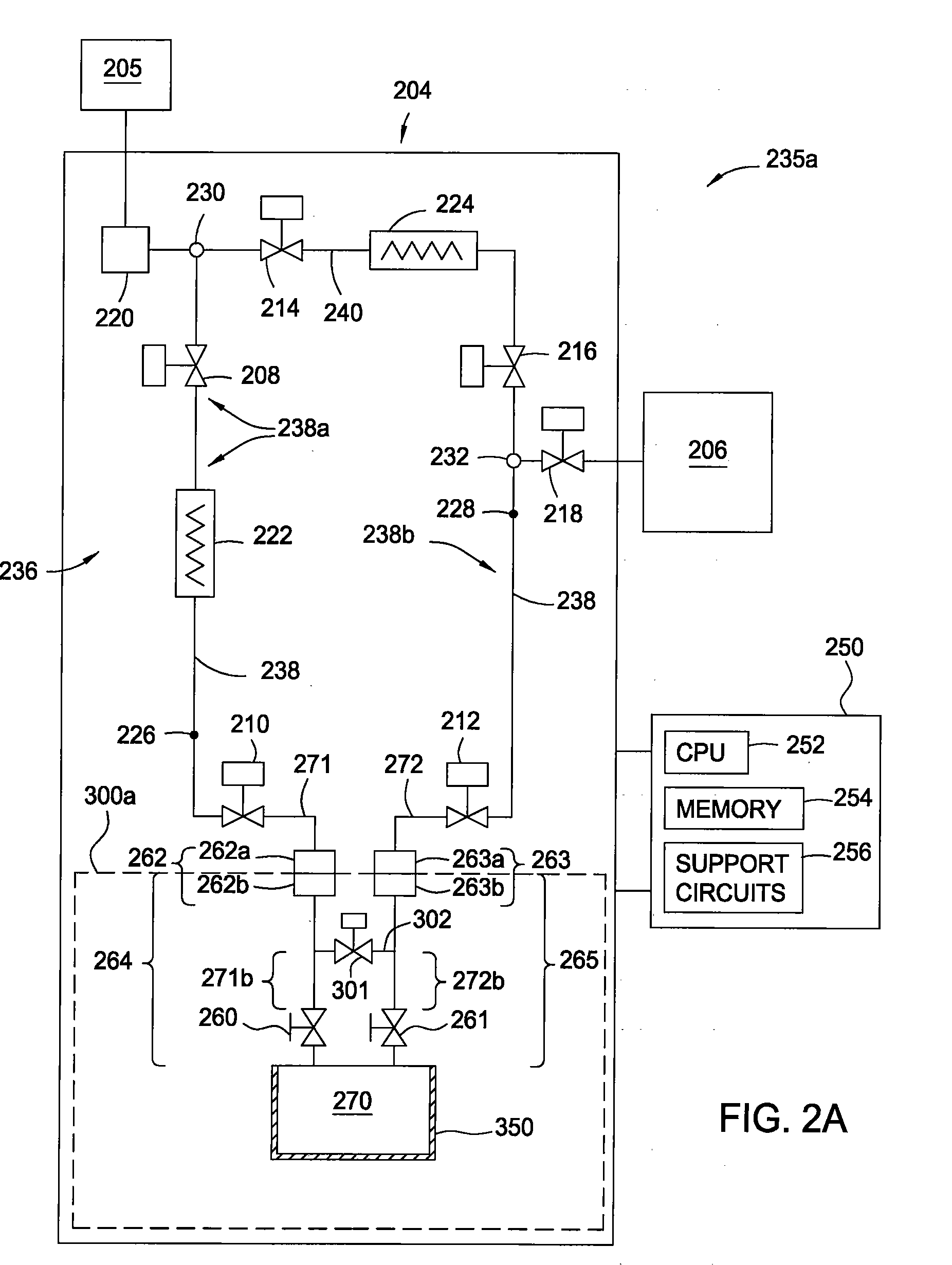

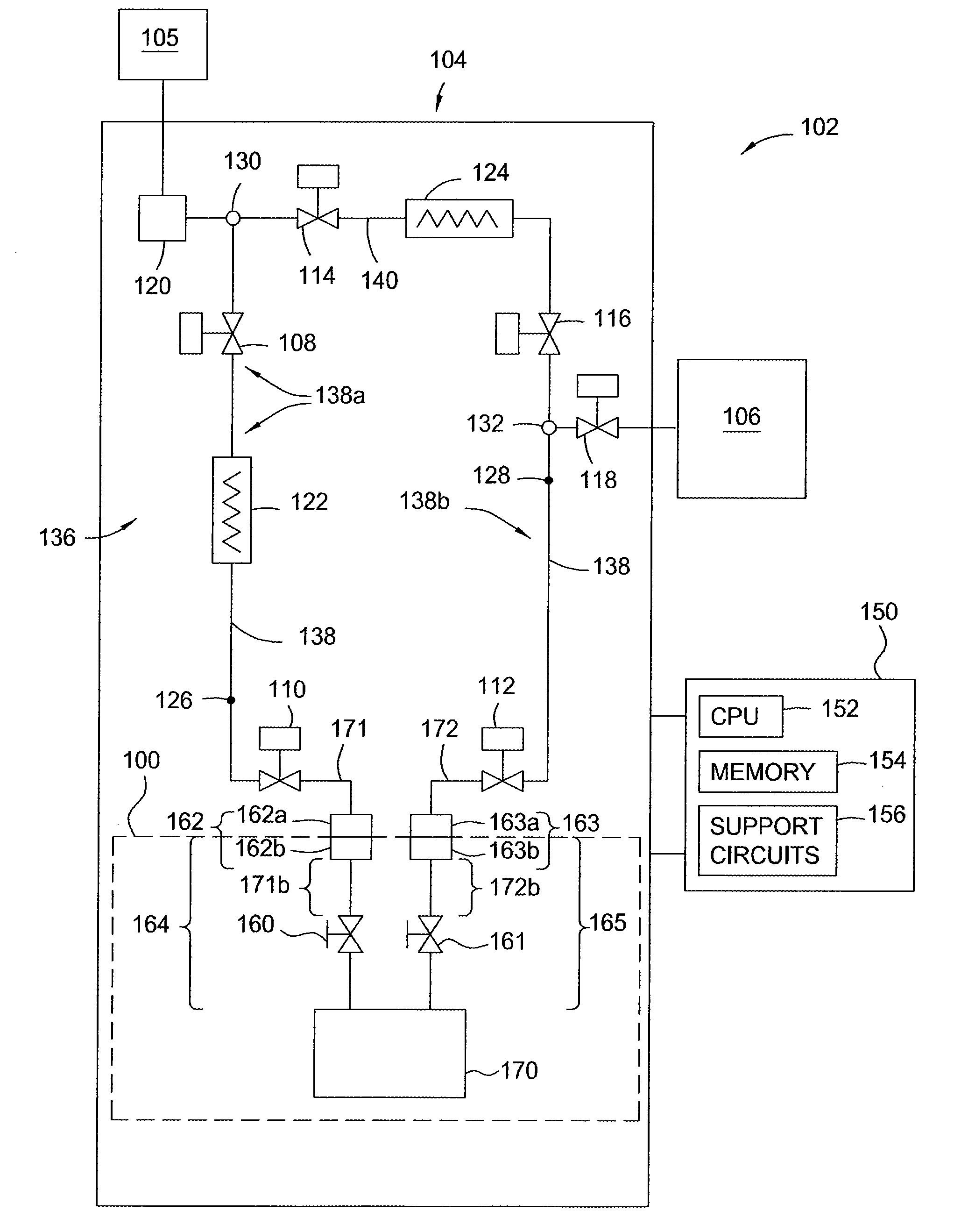

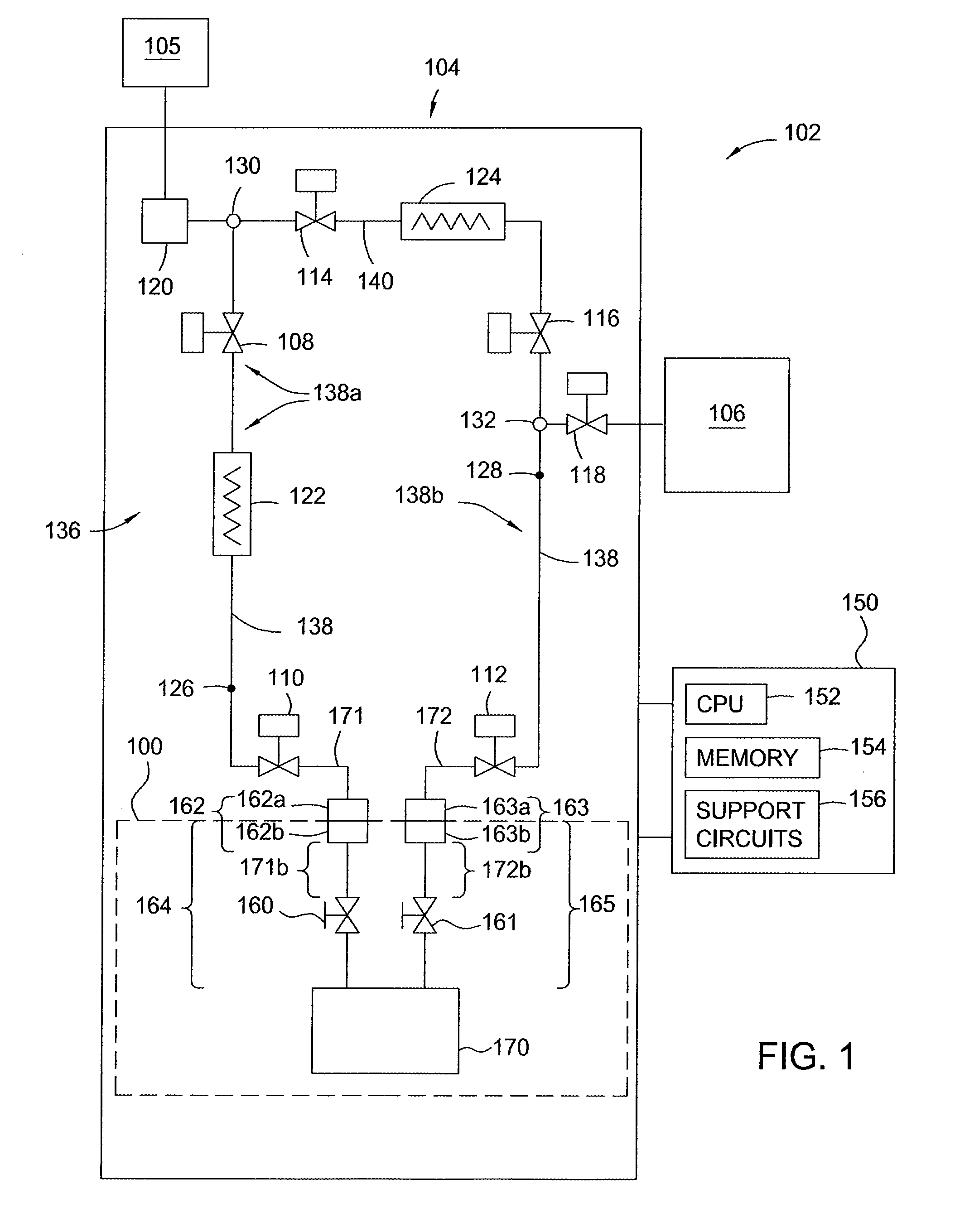

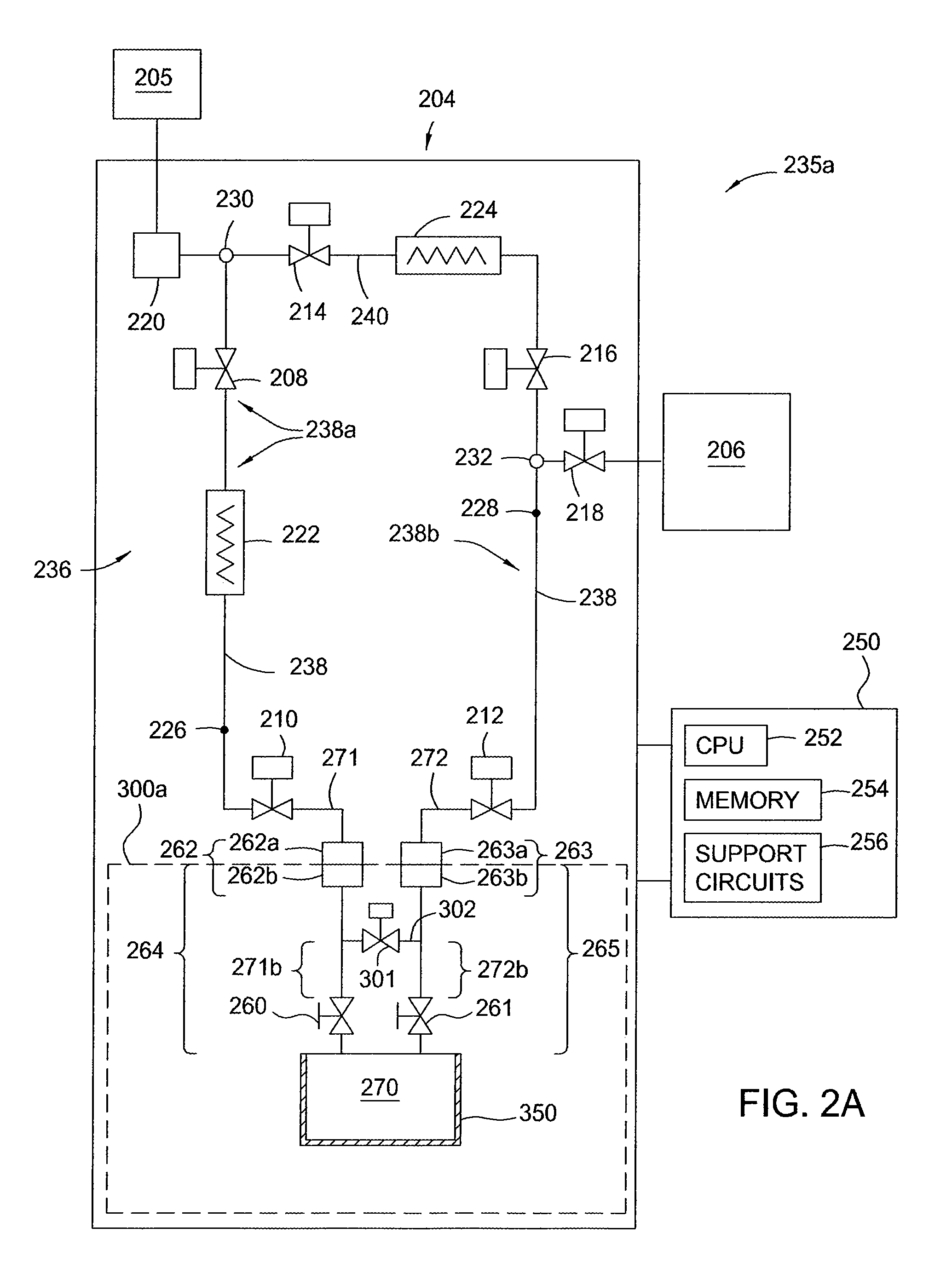

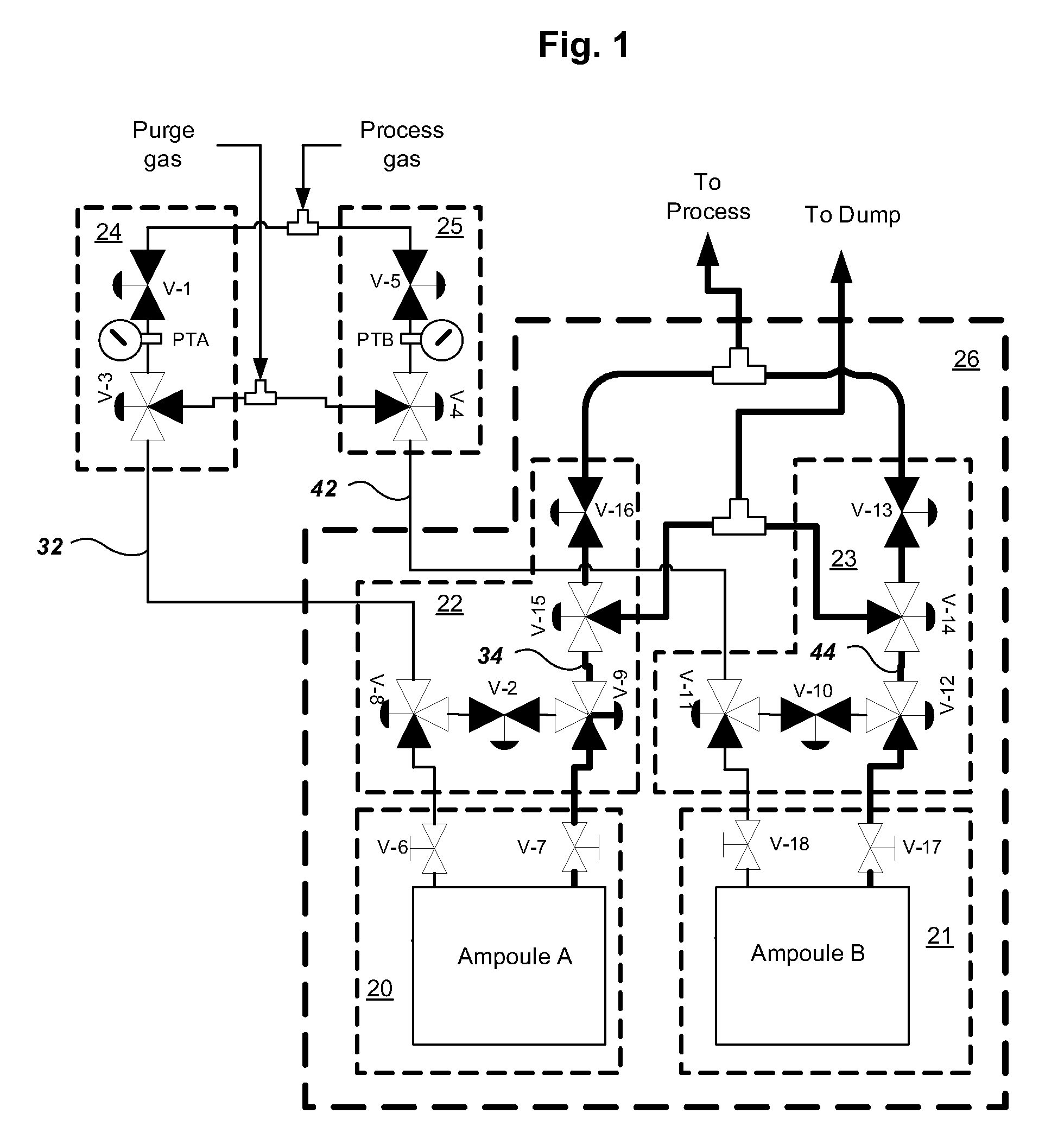

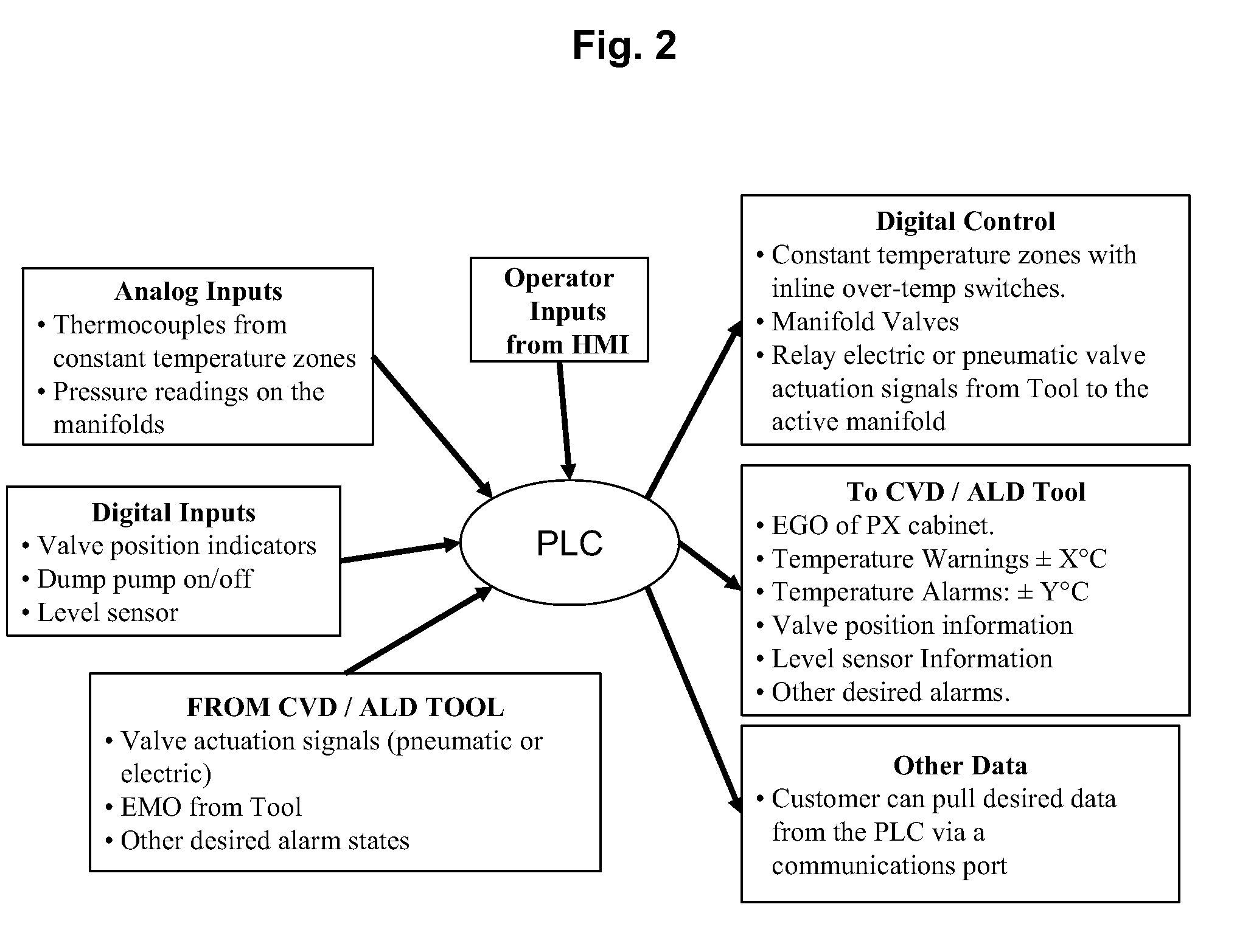

Multiple ampoule delivery systems

InactiveUS20090211525A1Easy to useReduce wasteLiquid surface applicatorsPipeline systemsSemiconductor materialsDelivery system

This invention relates to an integrated vapor or liquid phase reagent dispensing apparatus having a plurality of vessels and a plurality of carrier or inert gas feed / vapor or liquid phase reagent delivery manifolds, that may be used for continuously dispensing vapor or liquid phase reagents such as precursors for deposition of materials in the manufacture of semiconductor materials and devices.

Owner:PRAXAIR TECH INC

Ampoule with a thermally conductive coating

ActiveUS20080149031A1Improve temperature uniformityChemical vapor deposition coatingConductive coatingCompound (substance)

Embodiments of the invention provide an apparatus and a process for generating a chemical precursor used in a vapor deposition processing system. The apparatus includes a canister (e.g., ampoule) having a sidewall, a top, and a bottom encompassing an interior volume therein, inlet and outlet ports in fluid communication with the interior volume, and a thermally conductive coating disposed on or over the outside surface of the canister. The thermally conductive coating is more thermally conductive than the outside surface of the canister. The thermally conductive coating may contain aluminum, aluminum nitride, copper, brass, silver, titanium, silicon nitride, or alloys thereof. In some embodiments, an adhesion layer (e.g., titanium or tantalum) may be disposed between the outside surface of the canister and the thermally conductive coating. In other embodiments, the canister may contain a plurality of baffles or solid heat-transfer particles to help evenly heat a solid precursor therein.

Owner:APPLIED MATERIALS INC

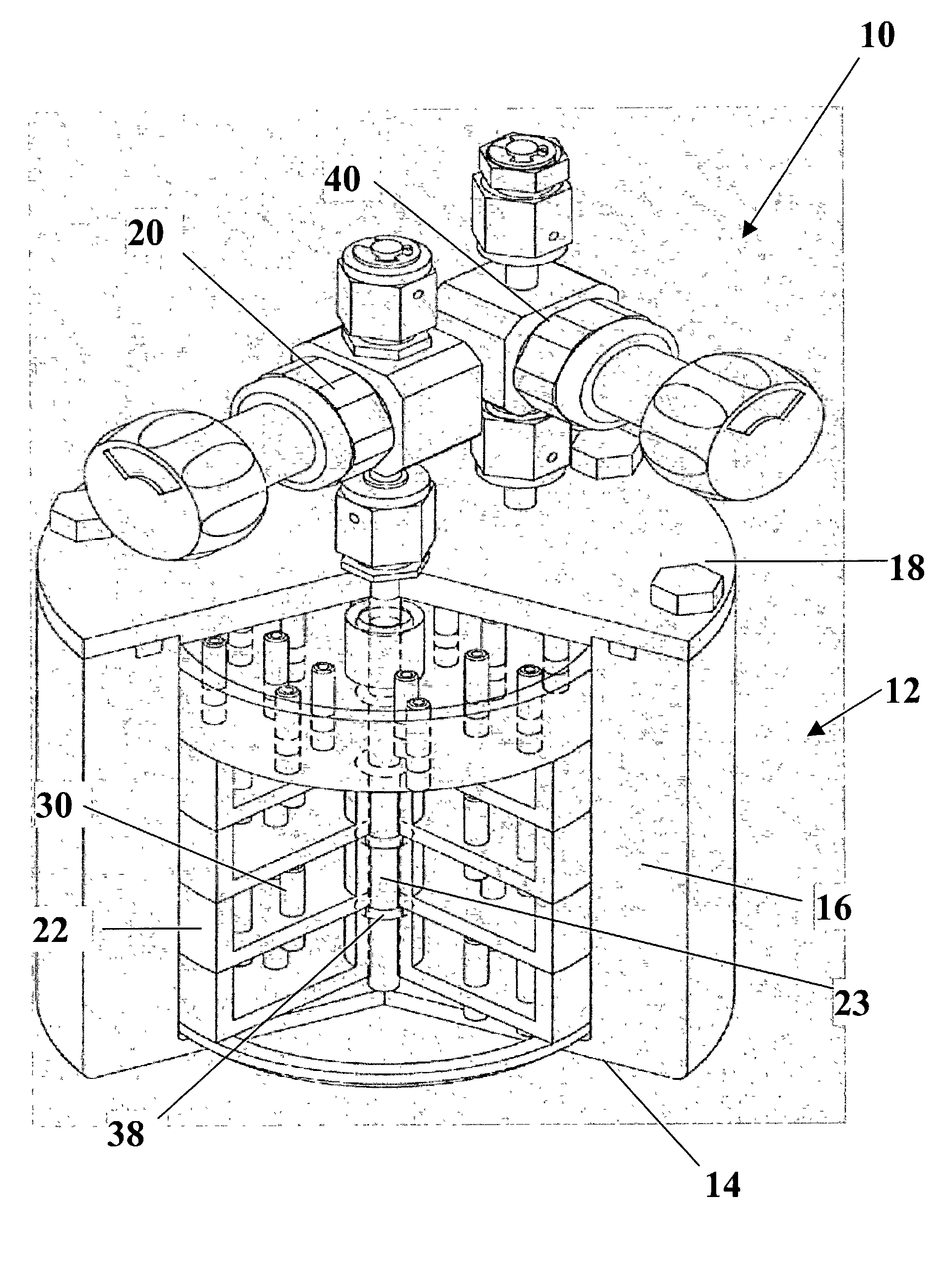

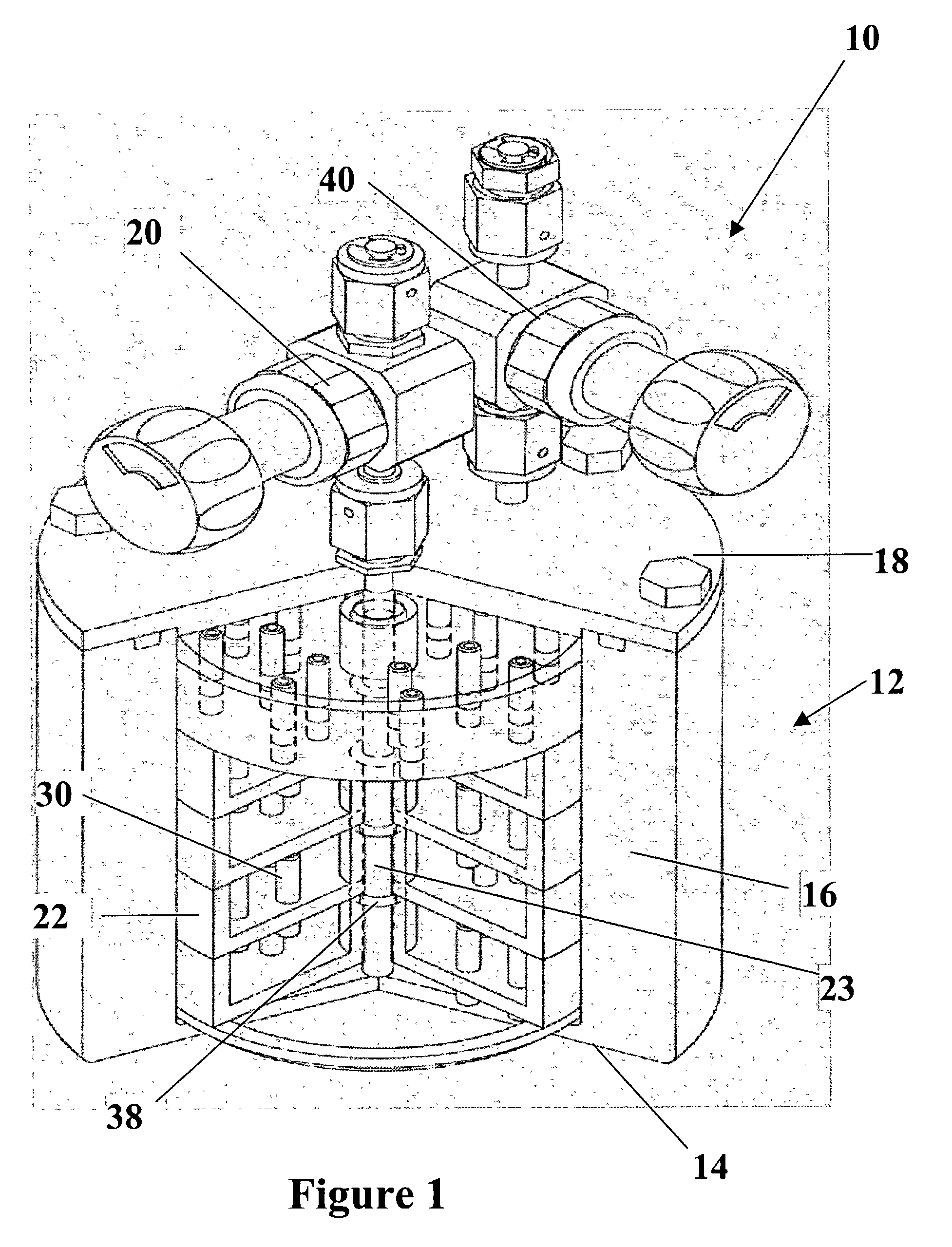

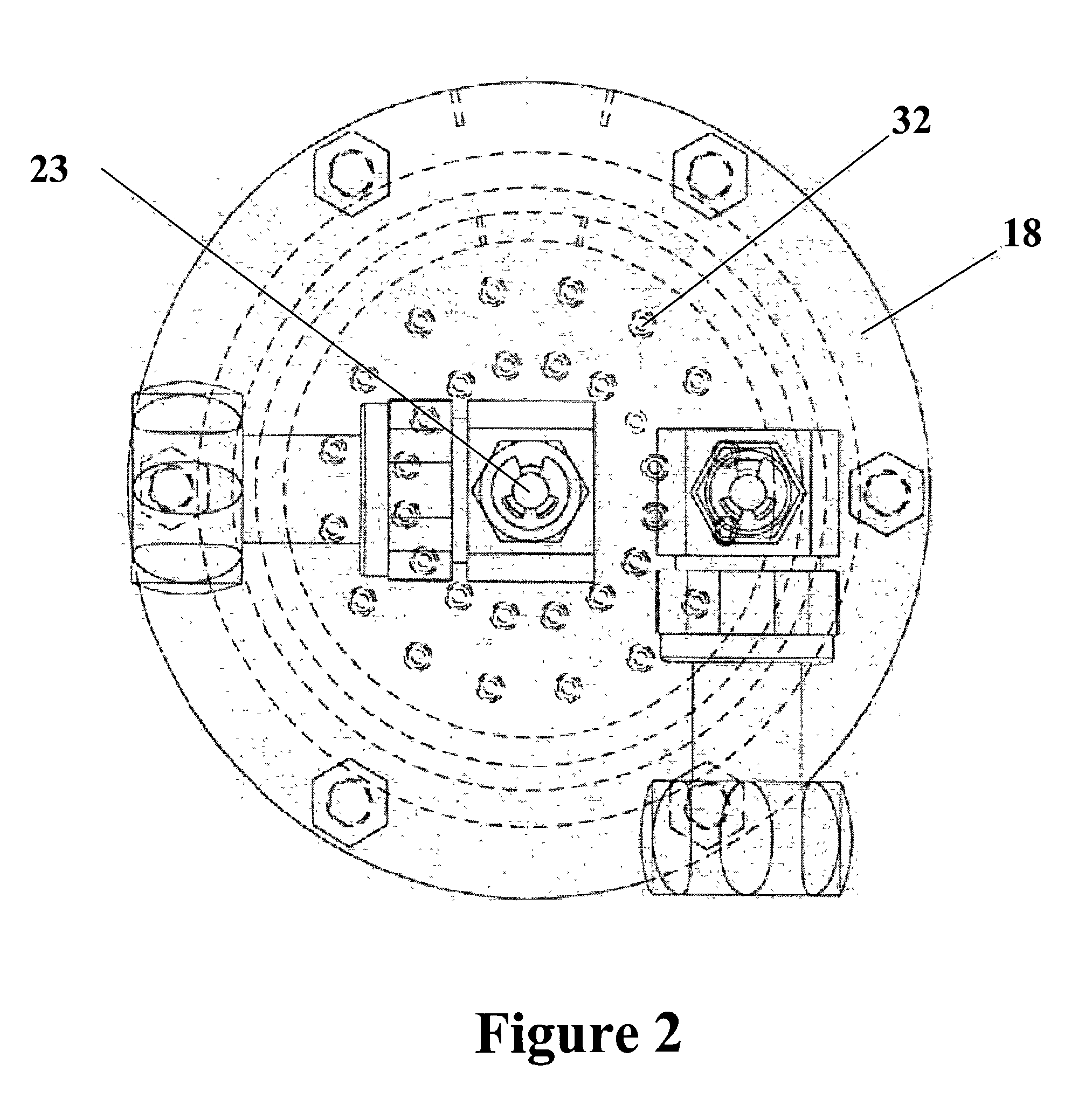

Vaporizer delivery ampoule

InactiveUS20040016404A1Increase the areaShorten closing timeVessel wallsNon-pressured vesselsSource materialEngineering

A vaporizer delivery system for use in semiconductor manufacturing processes including a plurality of vertically stacked containers for holding a vaporizable source material. Each of the vertically stacked containers includes a plurality of vented protuberances extending into the interior of the each stacked container thereby providing channels for passage of a carrier gas between adjacent vertically stacked containers.

Owner:ENTEGRIS INC

Vaporizer delivery ampoule

InactiveUS6921062B2Increase the areaShorten closing timeDrying using combination processesDrying solid materials with heatSource materialEngineering

A vaporizer delivery system for use in semiconductor manufacturing processes including a plurality of vertically stacked containers for holding a vaporizable source material. Each of the vertically stacked containers includes a plurality of vented protuberances extending into the interior of the each stacked container thereby providing channels for passage of a carrier gas between adjacent vertically stacked containers.

Owner:ENTEGRIS INC

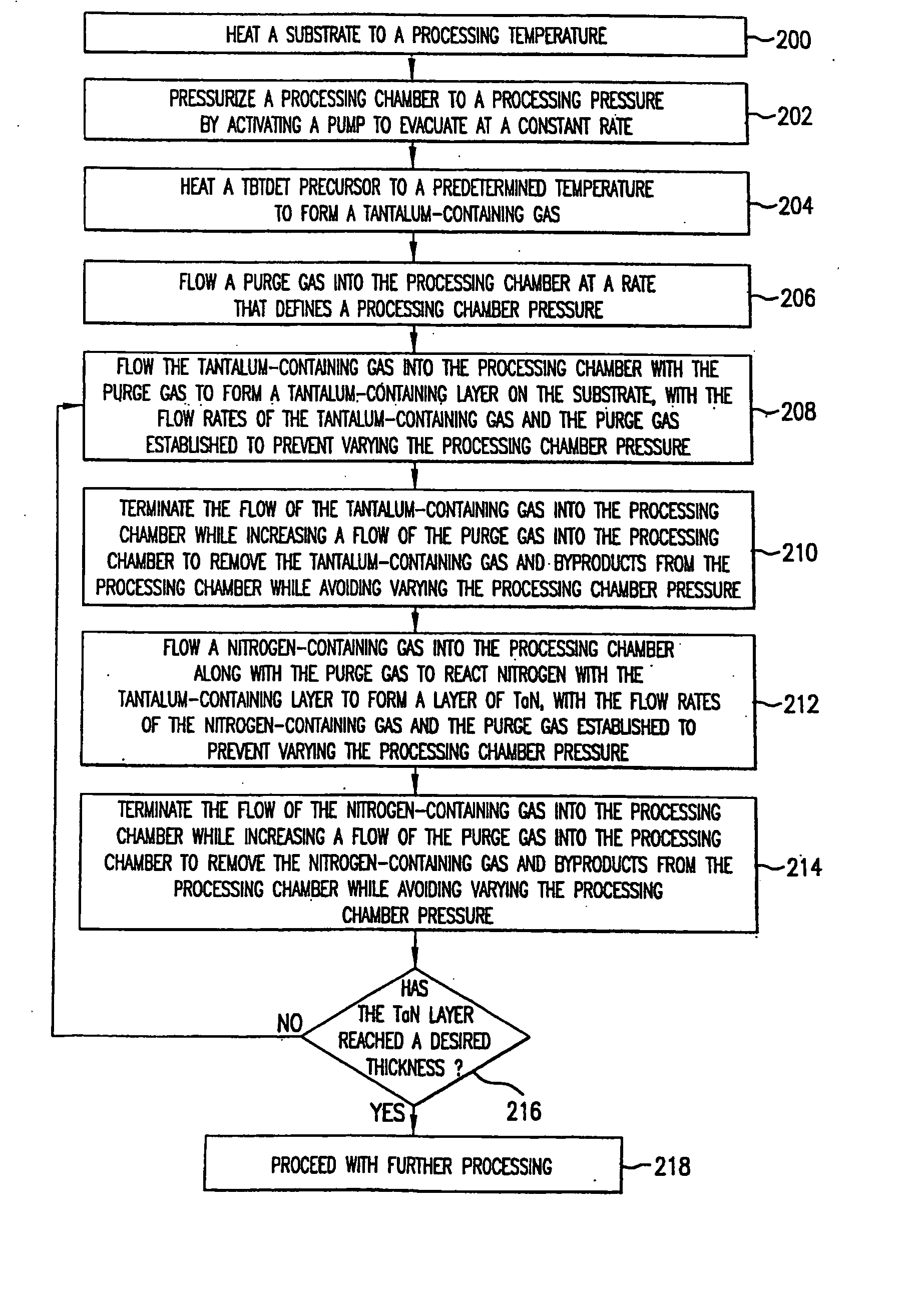

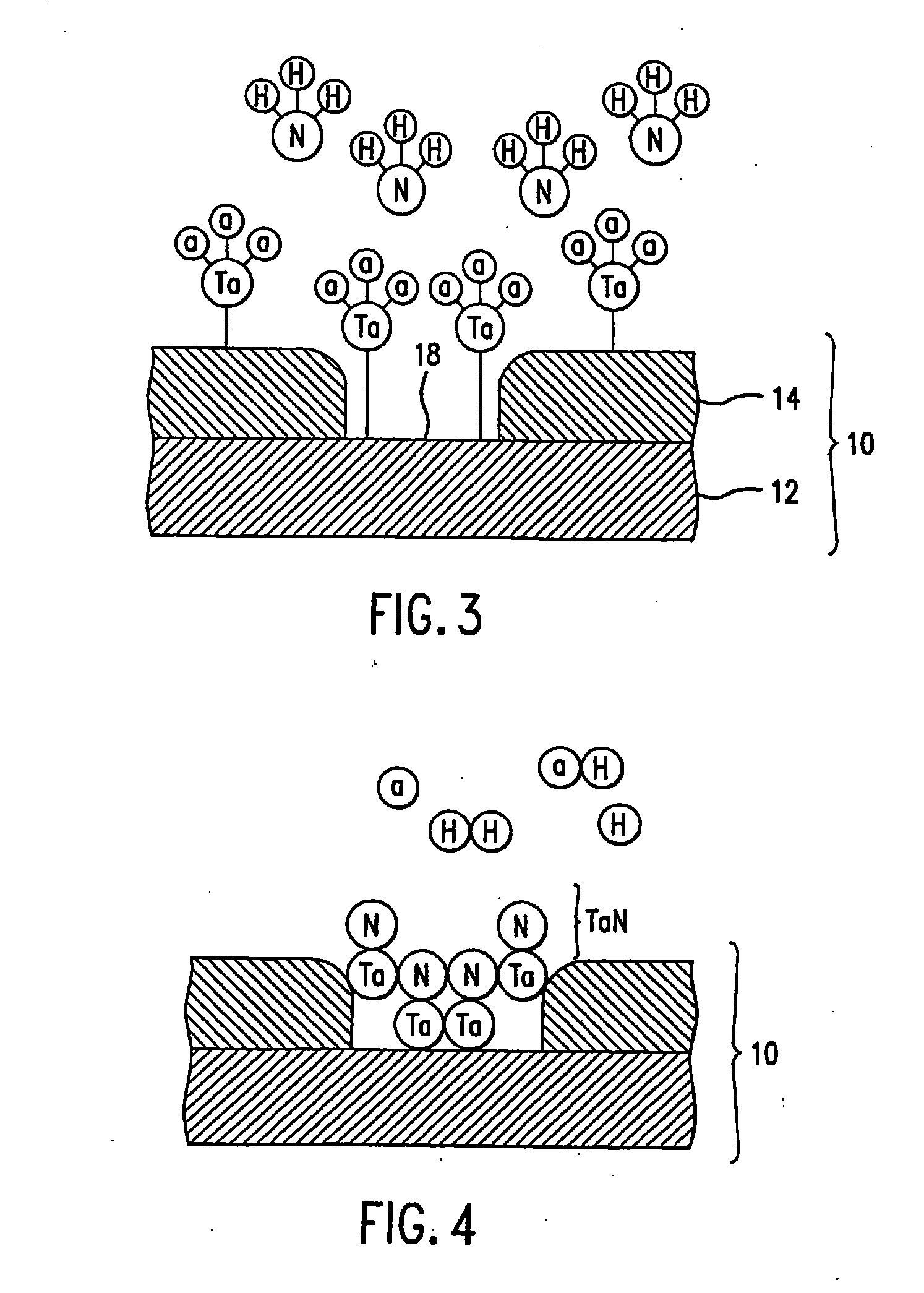

Sequential deposition of tantalum nitride using a tantalum-containing precursor and a nitrogen-containing precursor

InactiveUS20060019494A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingTantalum nitrideNitrogen

Embodiments of the invention provide a method for forming tantalum nitride materials on a substrate by employing an atomic layer deposition (ALD) process. The method includes heating a tantalum precursor within an ampoule to a predetermined temperature to form a tantalum precursor gas and sequentially exposing a substrate to the tantalum precursor gas and a nitrogen precursor to form a tantalum nitride material. Thereafter, a nucleation layer and a bulk layer may be deposited on the substrate. In one example, a radical nitrogen compound may be formed from the nitrogen precursor during a plasma-enhanced ALD process. A nitrogen precursor may include nitrogen or ammonia. In another example, a metal-organic tantalum precursor may be used during the deposition process.

Owner:APPLIED MATERIALS INC

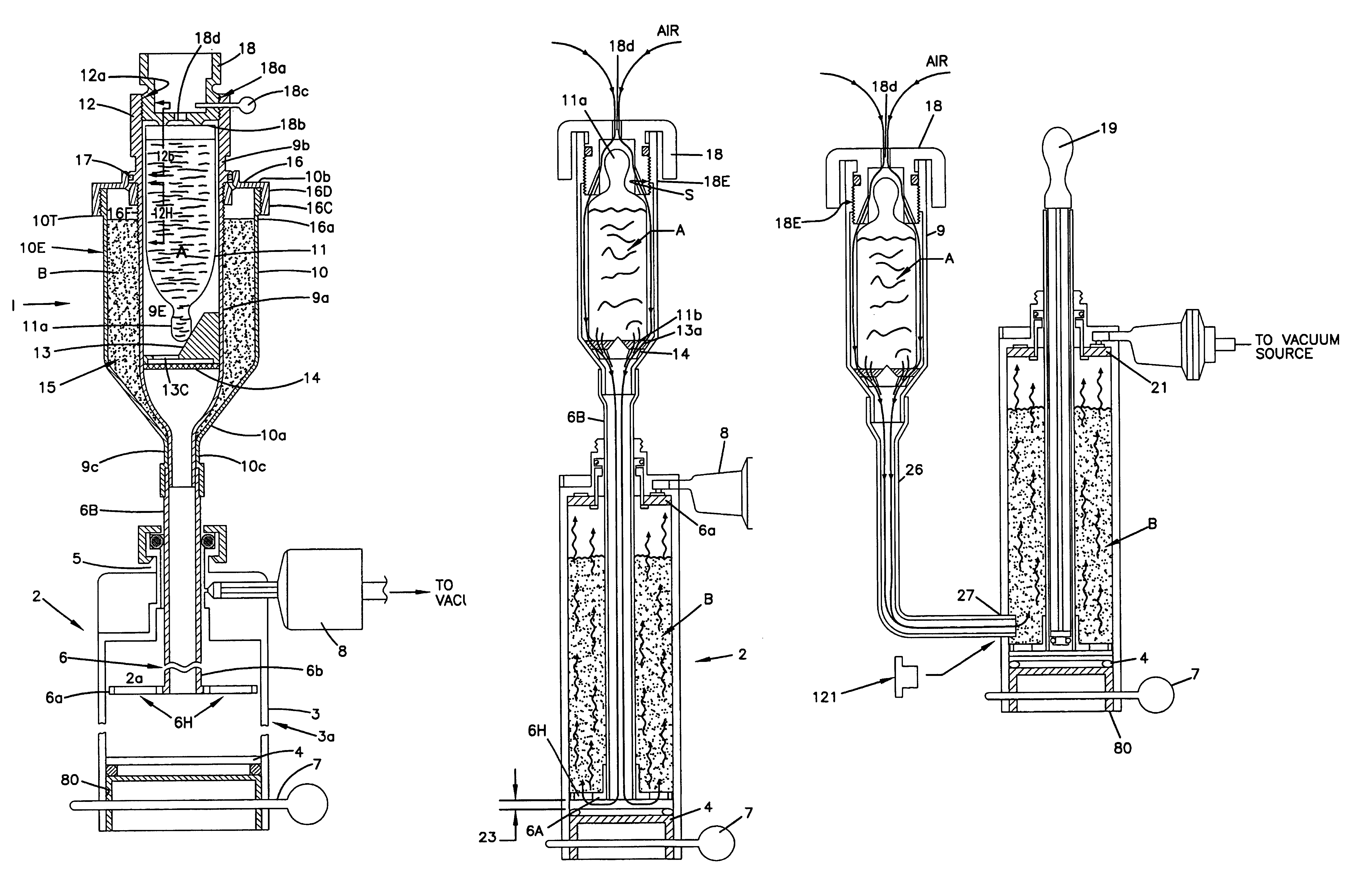

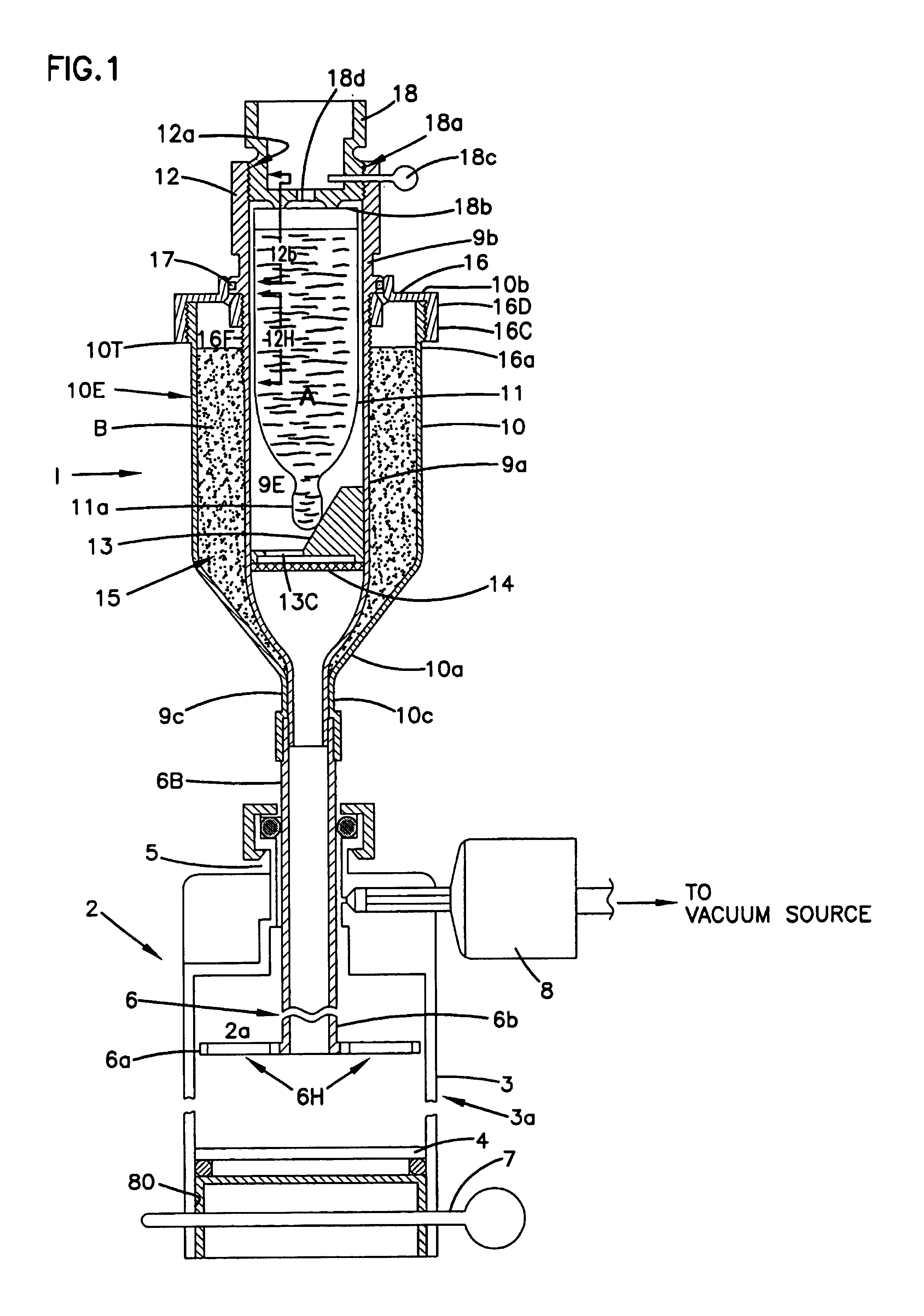

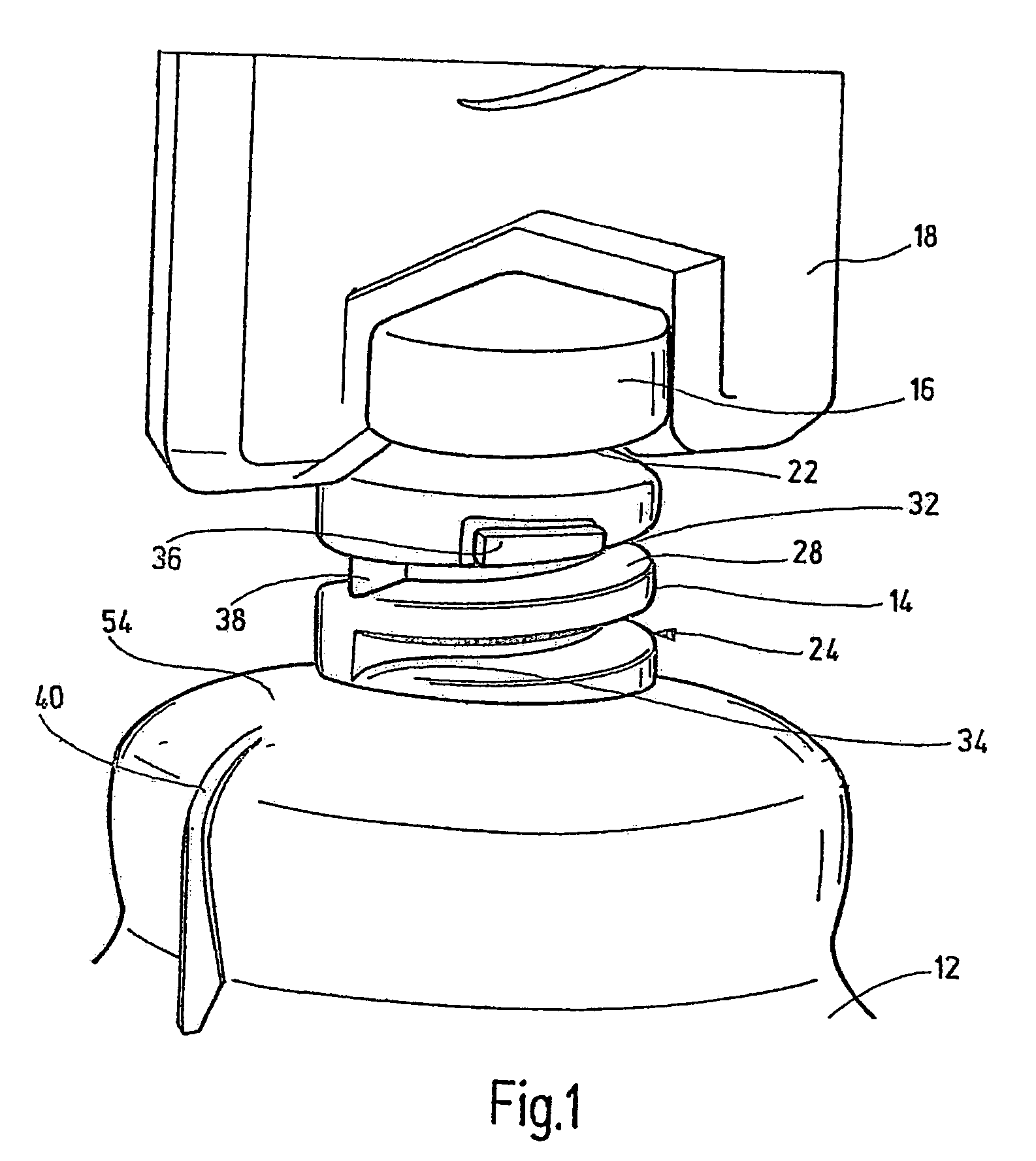

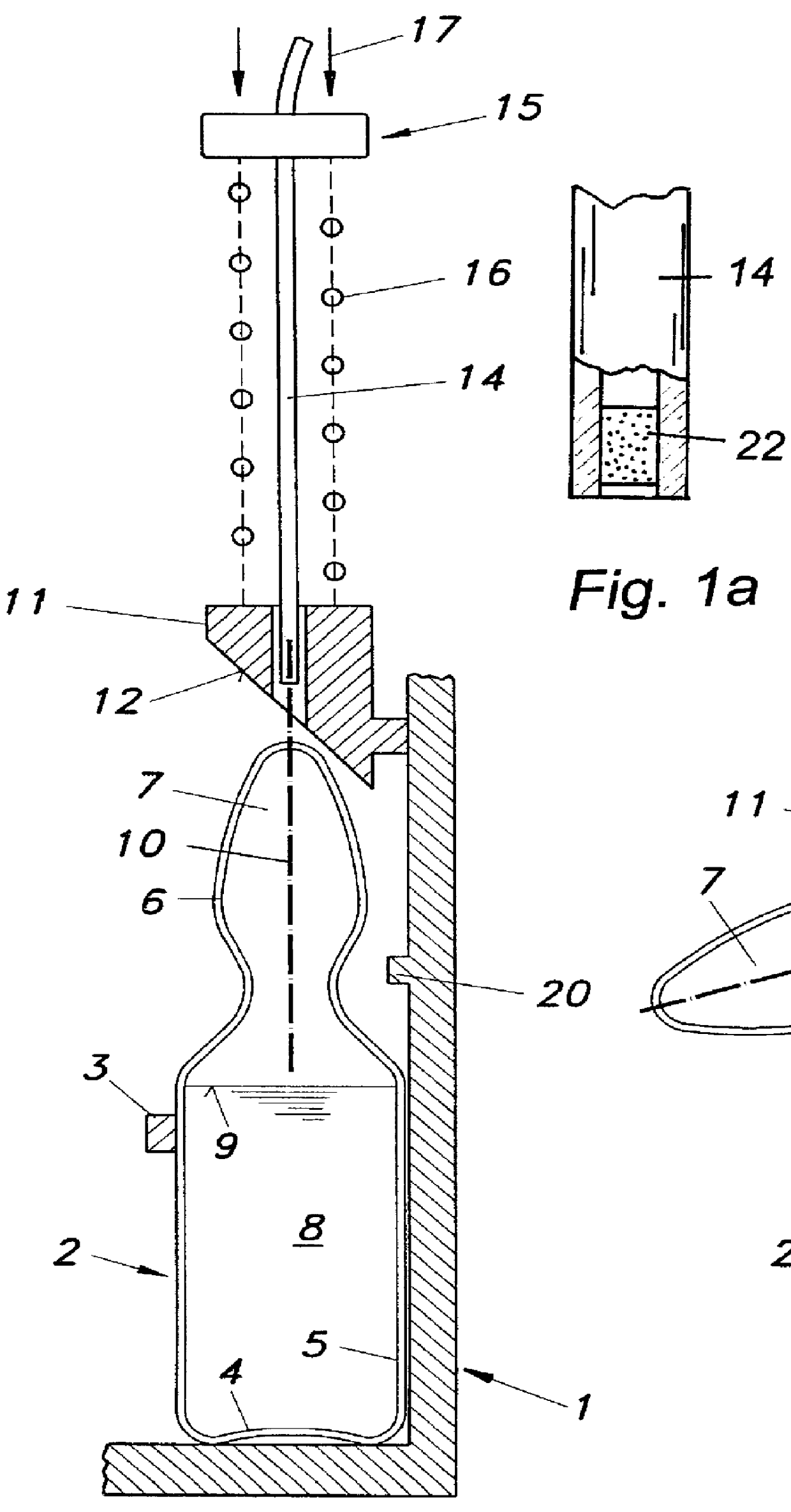

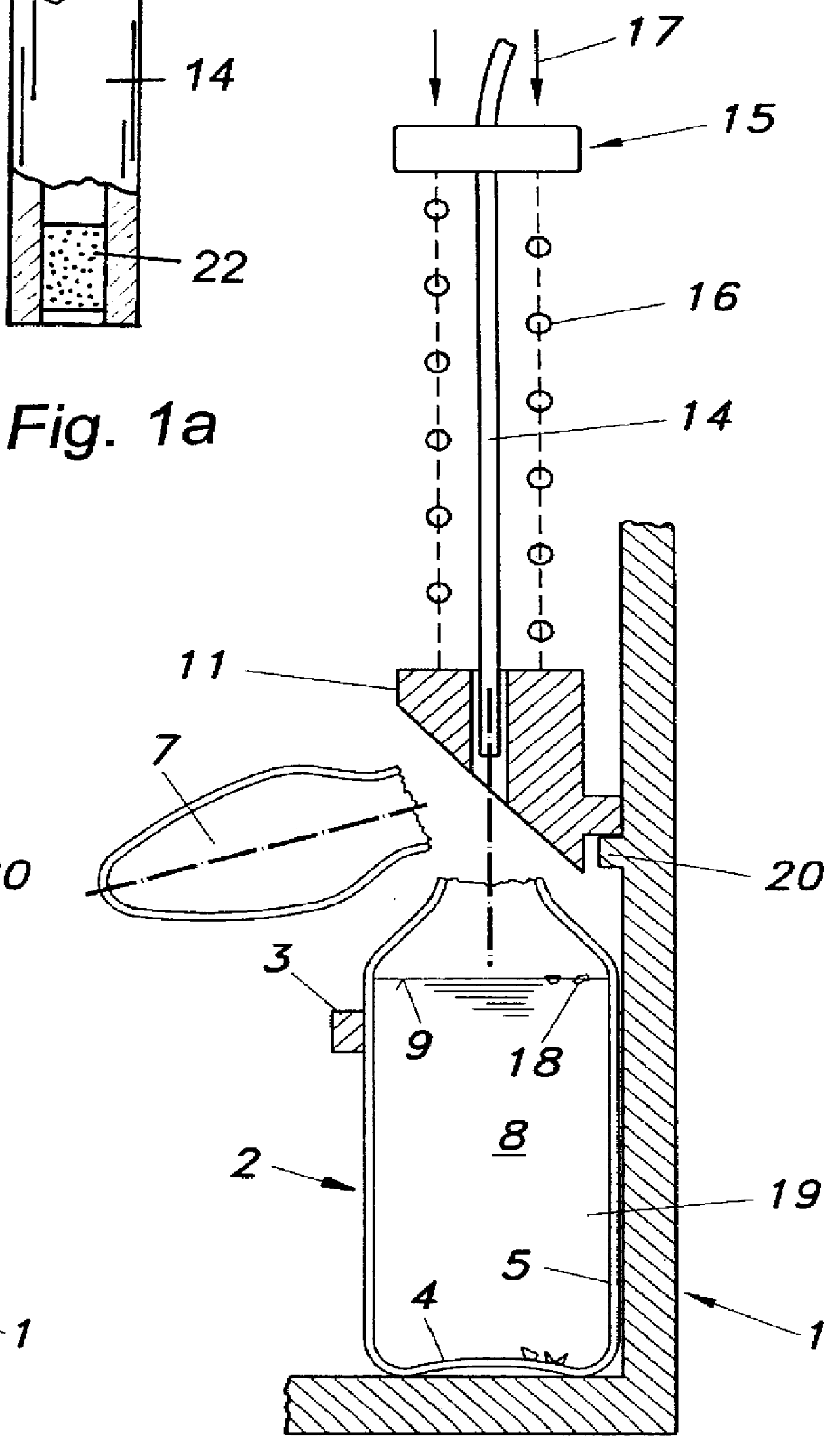

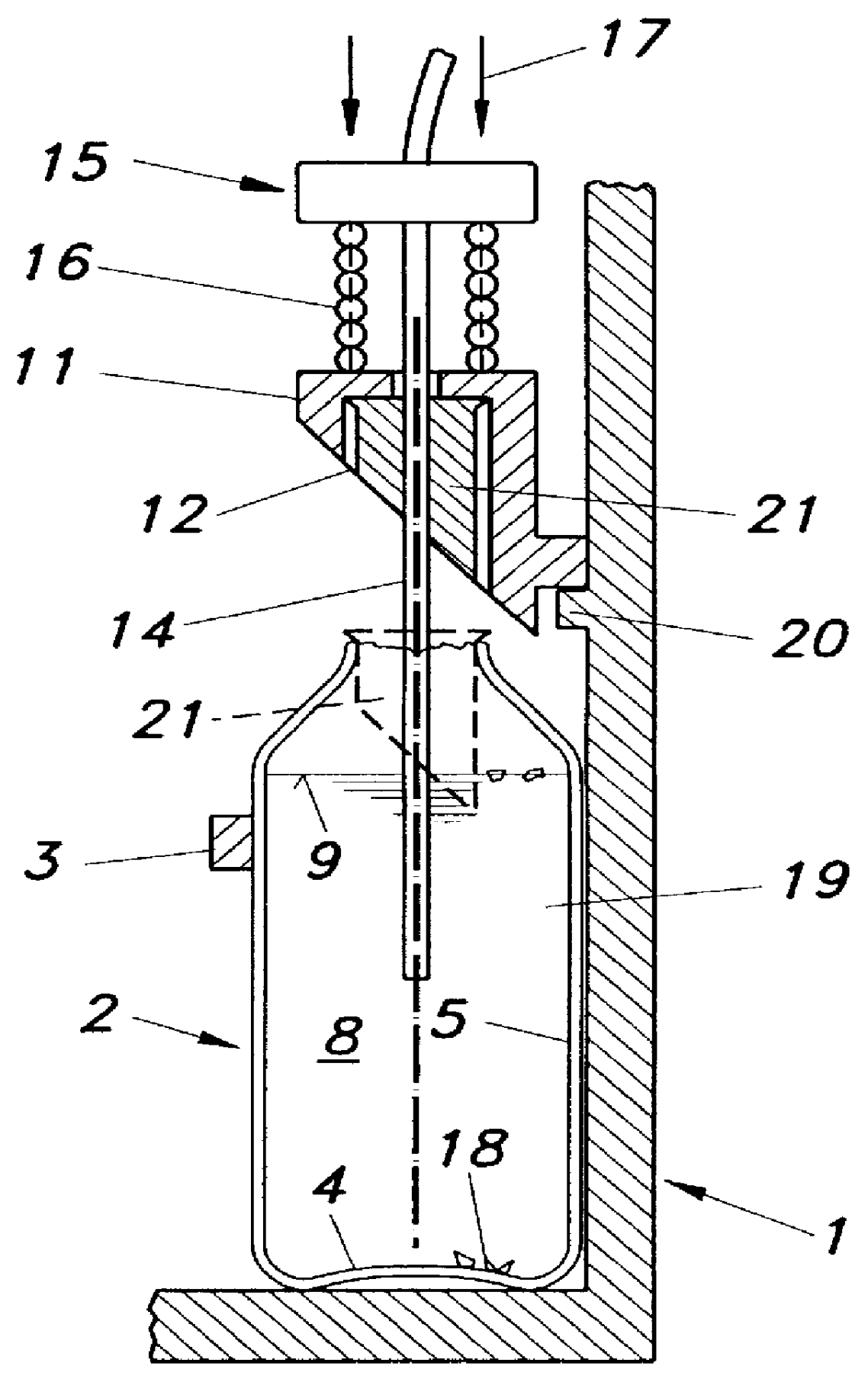

Method and device for feeding components for bone cement into a mixing vessel

InactiveUS7073936B1Reduce riskAvoid communicationShaking/oscillating/vibrating mixersSurgical furnitureEngineeringBone cement

A method and an arrangement for successively feeding batches into a mixing vessel under partial vacuum for the preparation of bone cement. The arrangement includes an inner container communicating with the atmosphere and with the mixing vessel, which container is so arranged as to enclose a glass ampoule containing a liquid bone cement component and, on the other hand, a device for opening the ampoule so that its contents can be sucked into the mixing vessel under partial vacuum. An outer container encloses the inner container at least partially, and is arranged to communicate with the mixing vessel. The inner container, and the outer container, define a space filled with a proportional quantity of a second bone cement component, which is in powder form. The inner container is capable of displacement relative to the outer container between a first position, in which sections of the inner container prevent communication between the mixing vessel and the atmosphere, and a second position, in which communication between both the mixing vessel and the atmosphere is open, so that the powdered bone cement component can be sucked into the mixing chamber under vacuum. The feeding sequence of the bone cement components is arbitrary. In other embodiments, the inner and outer containers are eliminated, or only the inner container is retained.

Owner:CEMVAC SYST

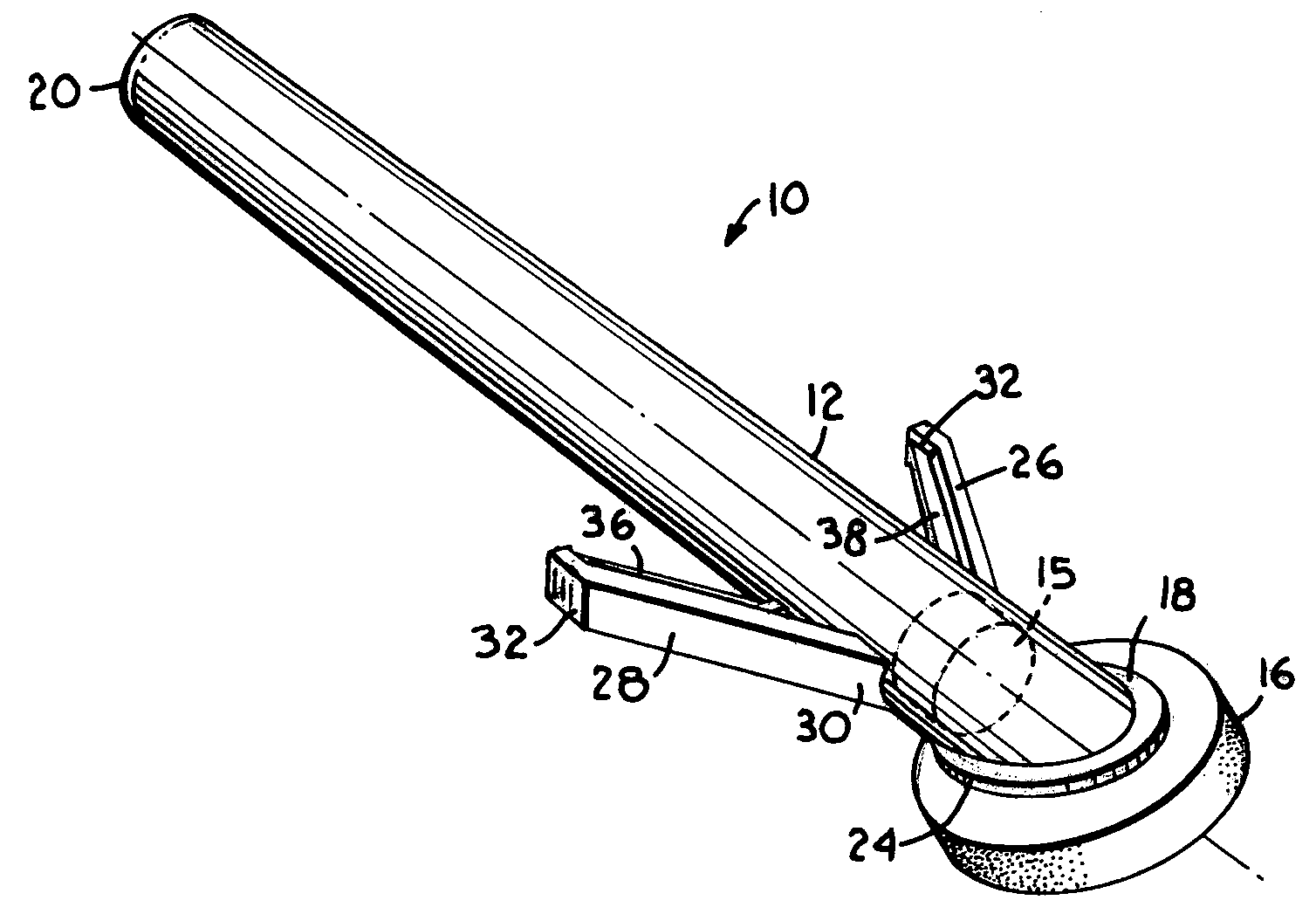

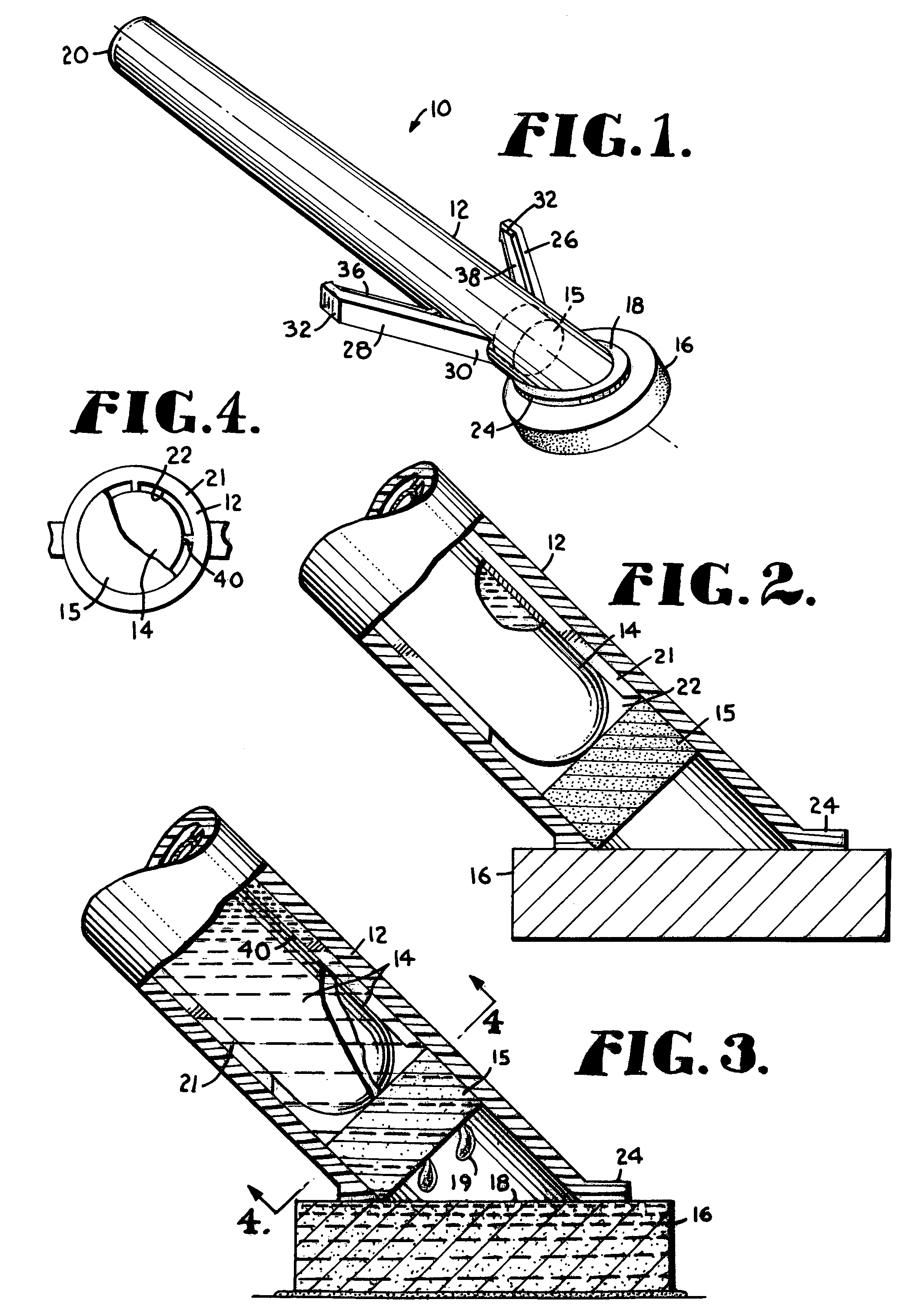

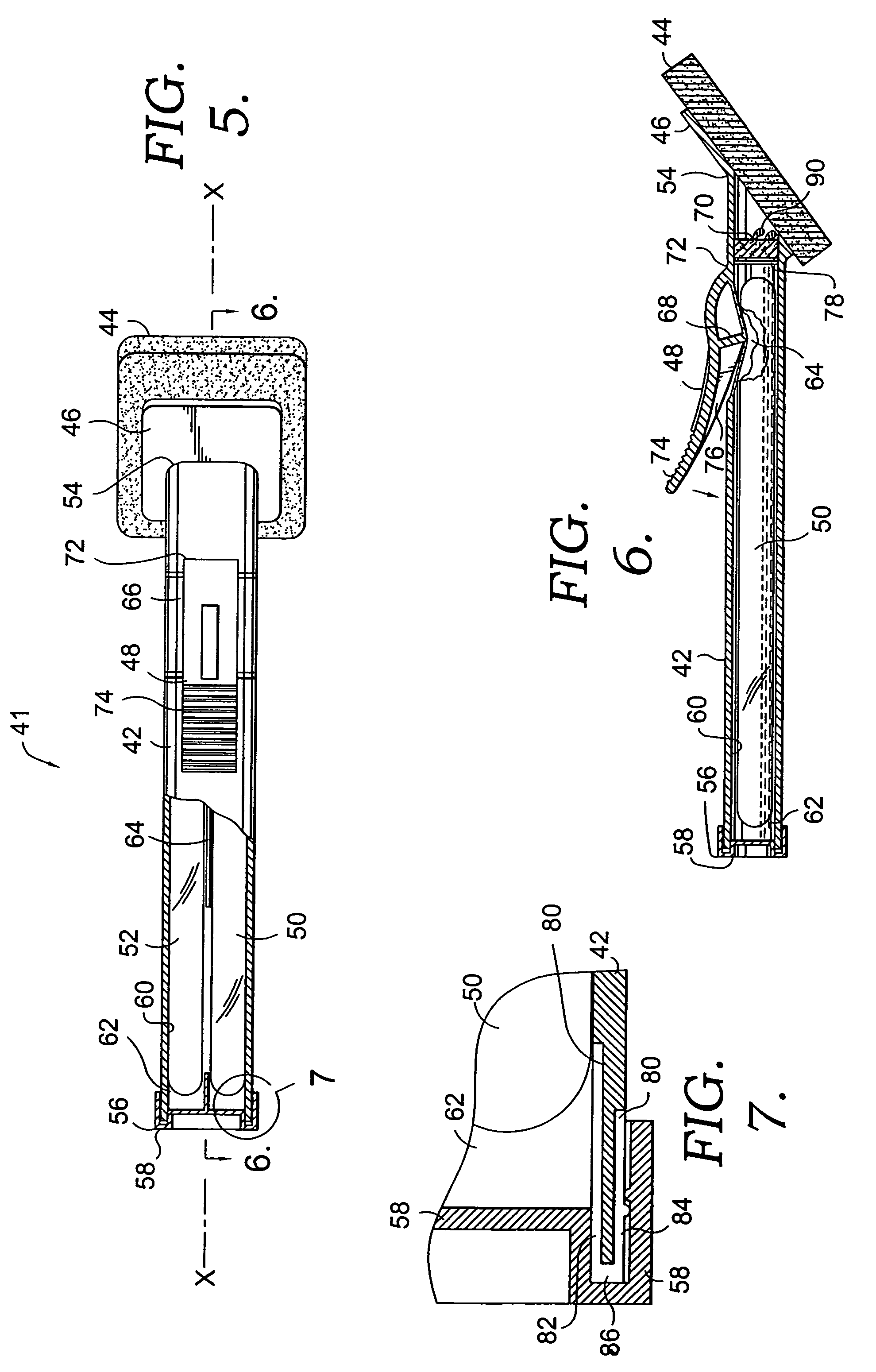

Liquid applicator with a mechanism for fracturing multiple ampoules

Owner:CAREFUSION 2200 INC

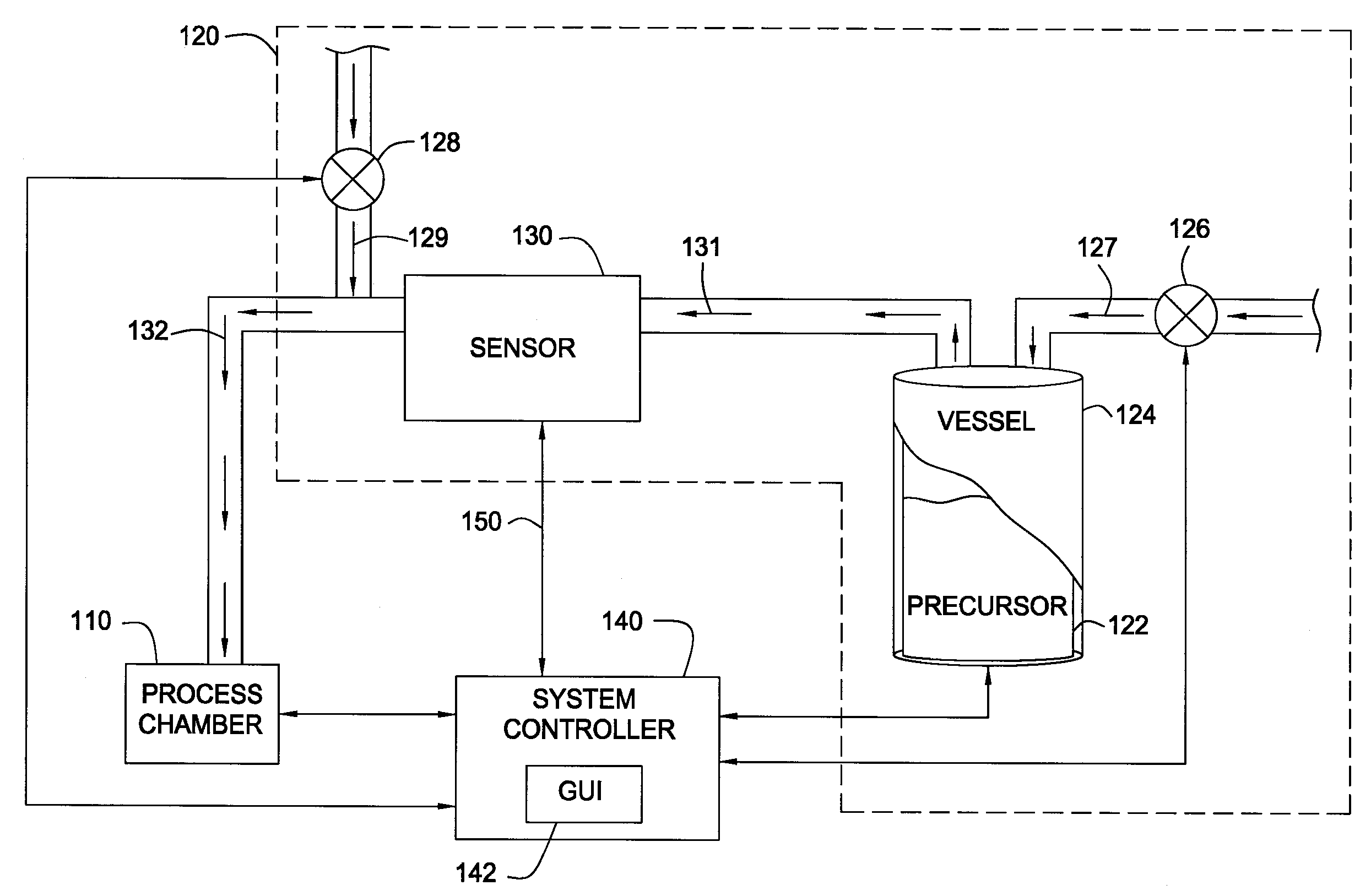

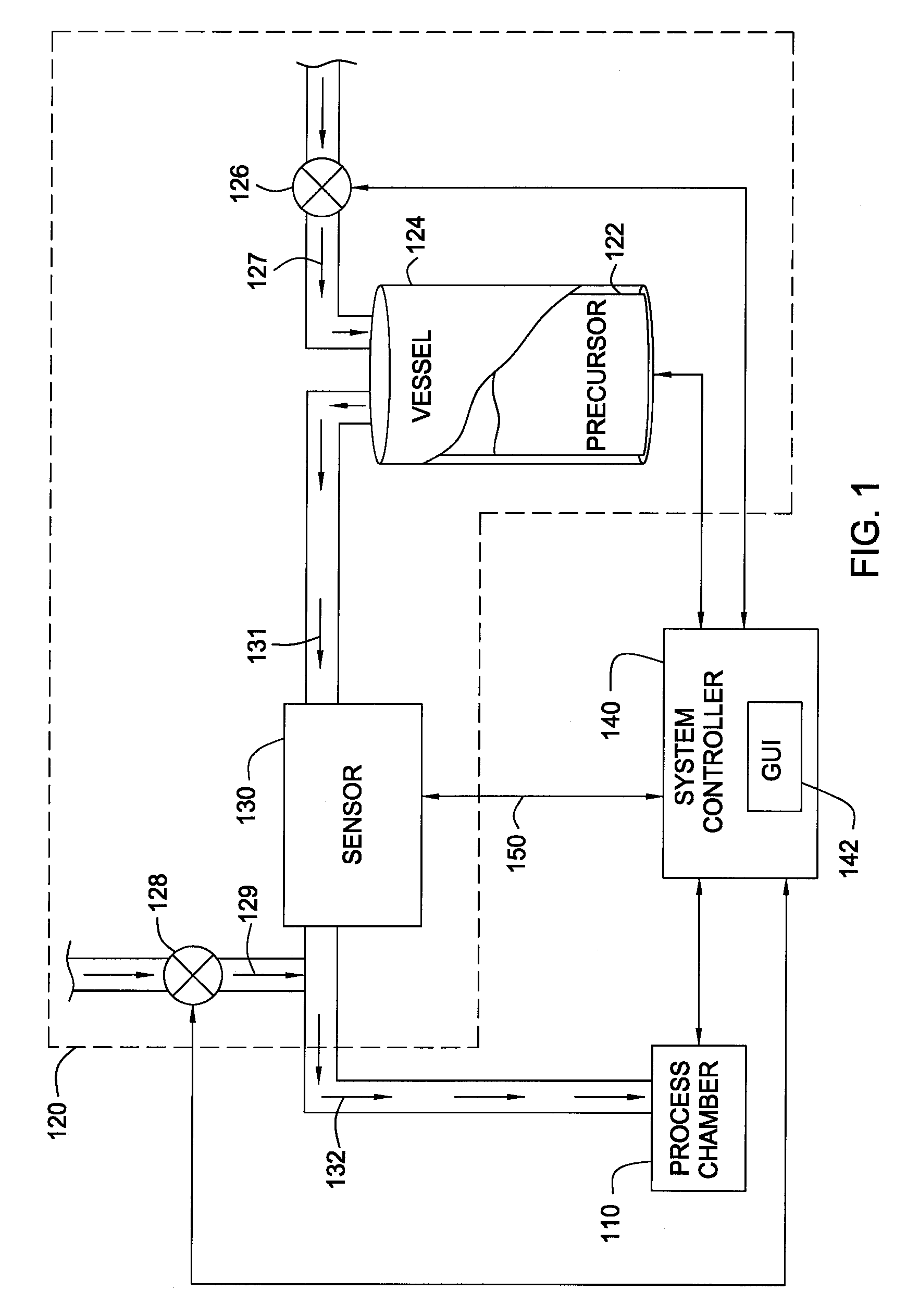

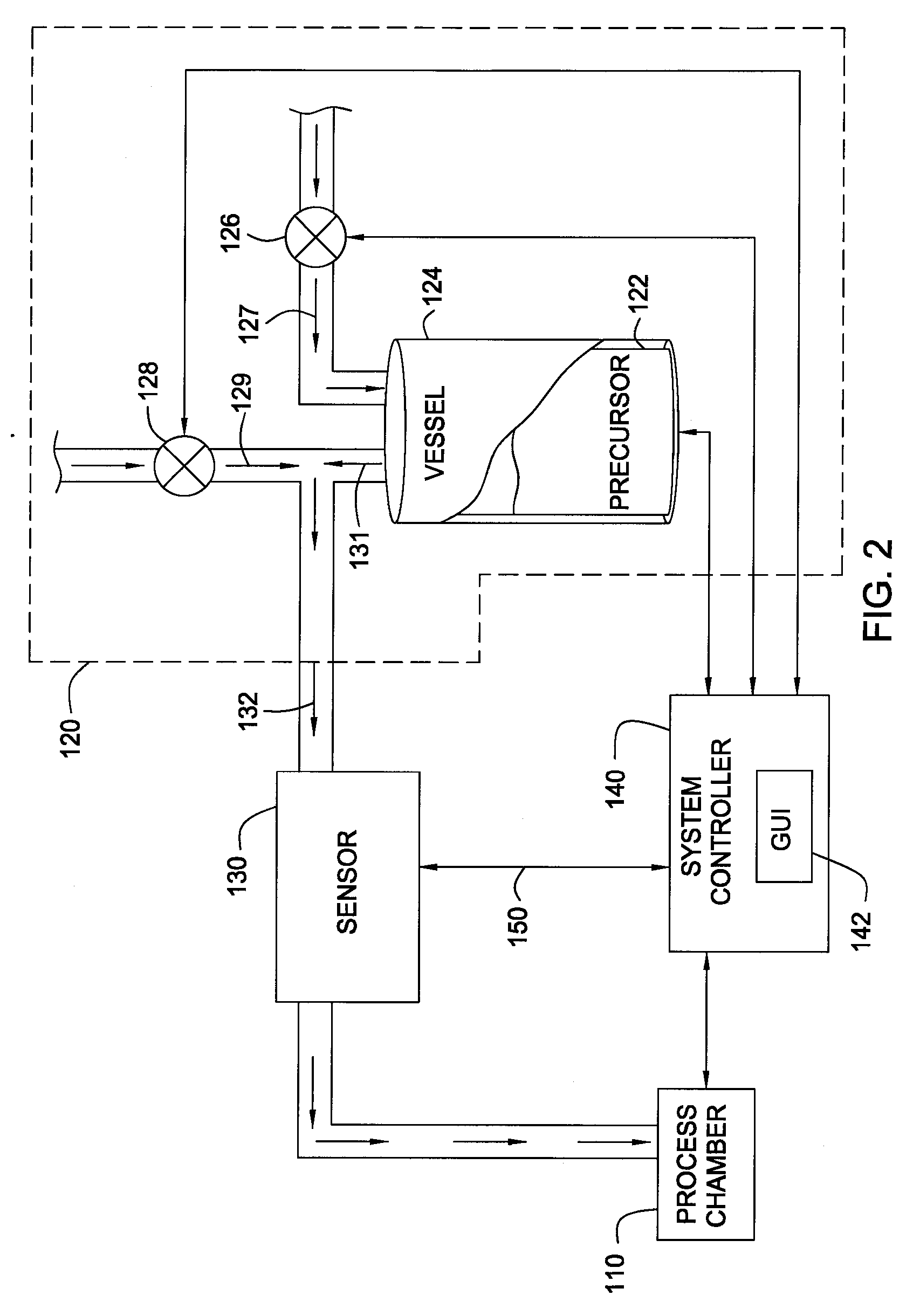

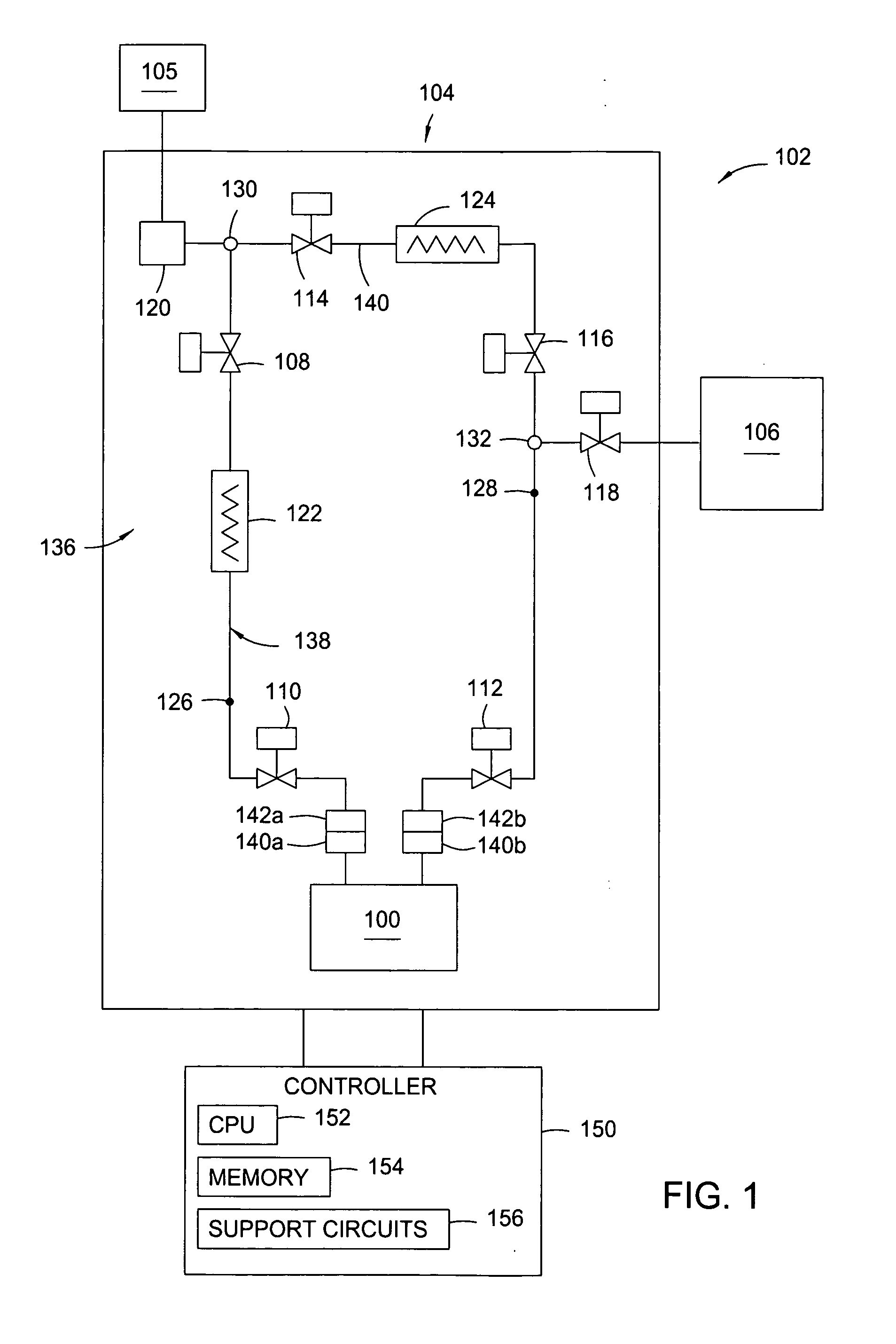

Rate control process for a precursor delivery system

InactiveUS20080044573A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingCompound (substance)Engineering

Embodiments of the invention provide a method for monitoring and controlling delivery of a precursor from an ampoule in a process chamber. In one embodiment, the method provides flowing a first carrier gas at a first flow rate through a vessel containing a chemical precursor to form a first precursor gas, combining a second carrier gas at a second flow rate and the first precursor gas to form a second precursor gas, measuring a concentration of the chemical precursor within the second precursor gas, and calculating a mass flow rate of the chemical precursor. In one example, a tantalum-containing film is deposited on a substrate during an atomic layer deposition process by heating an ampoule containing pentakis(dimethylamido) tantalum to a temperature within a range from about 60° C. to about 75° C., and forming a precursor gas by flowing a carrier gas through the ampoule.

Owner:APPLIED MATERIALS INC

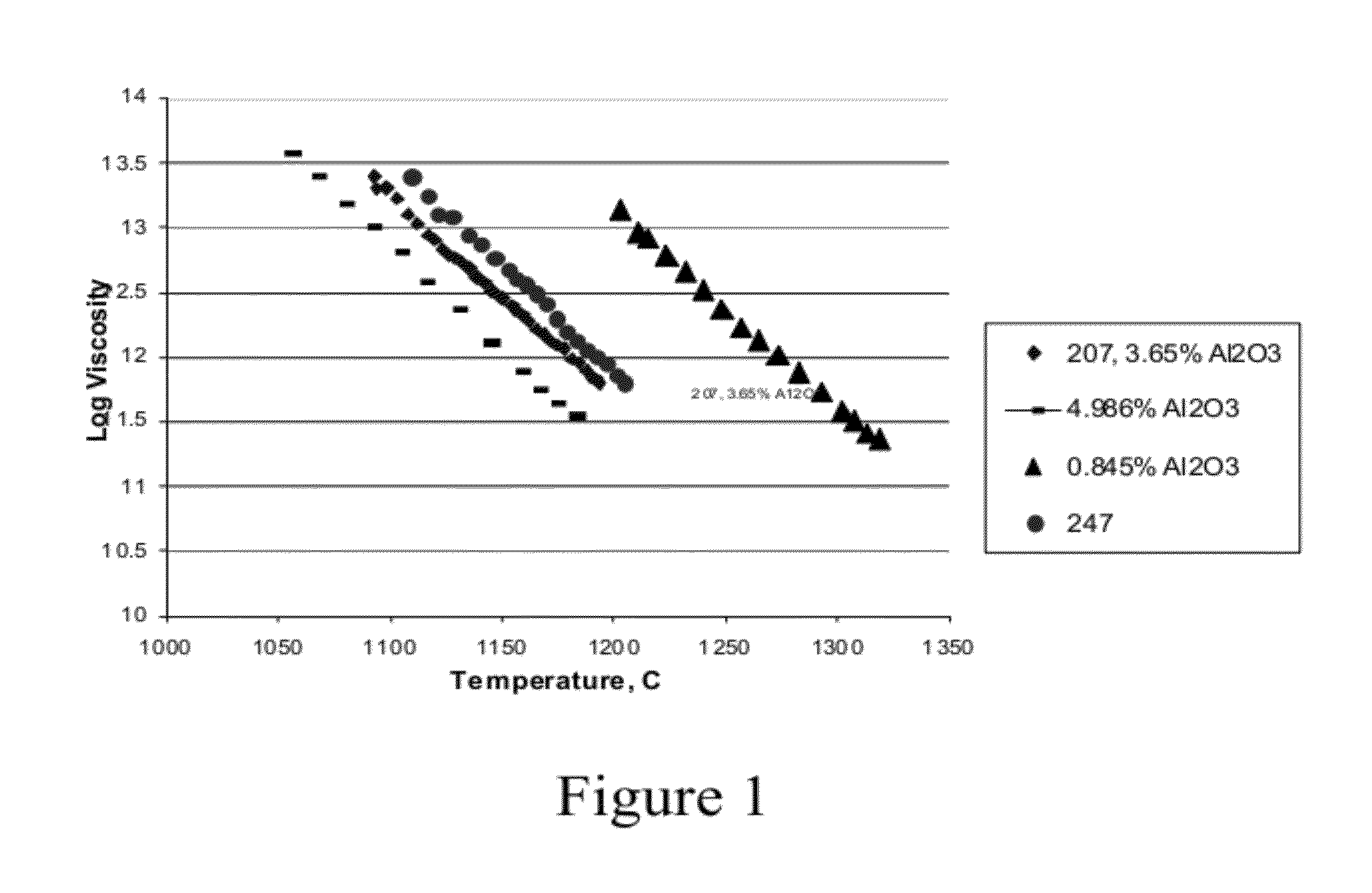

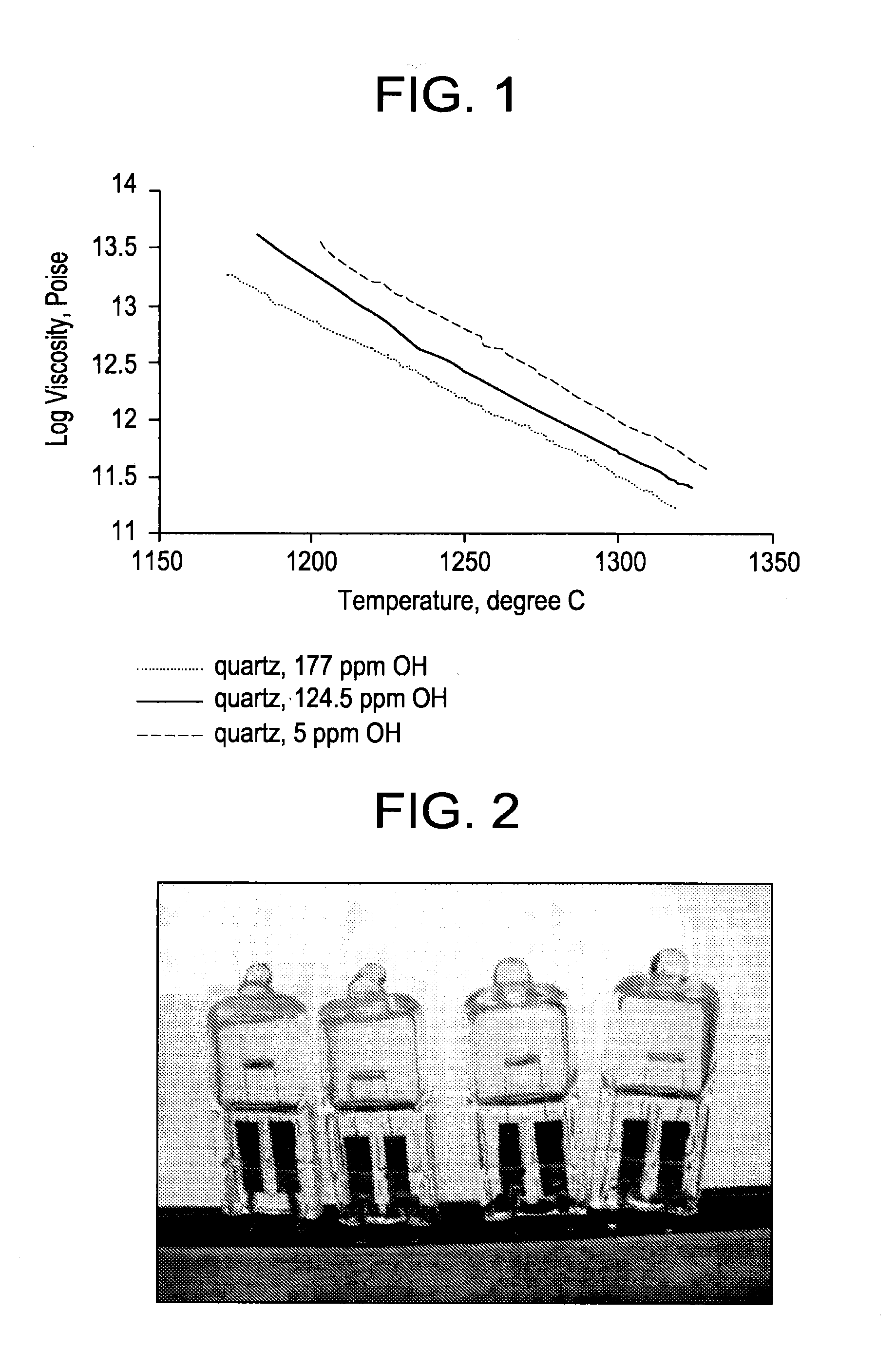

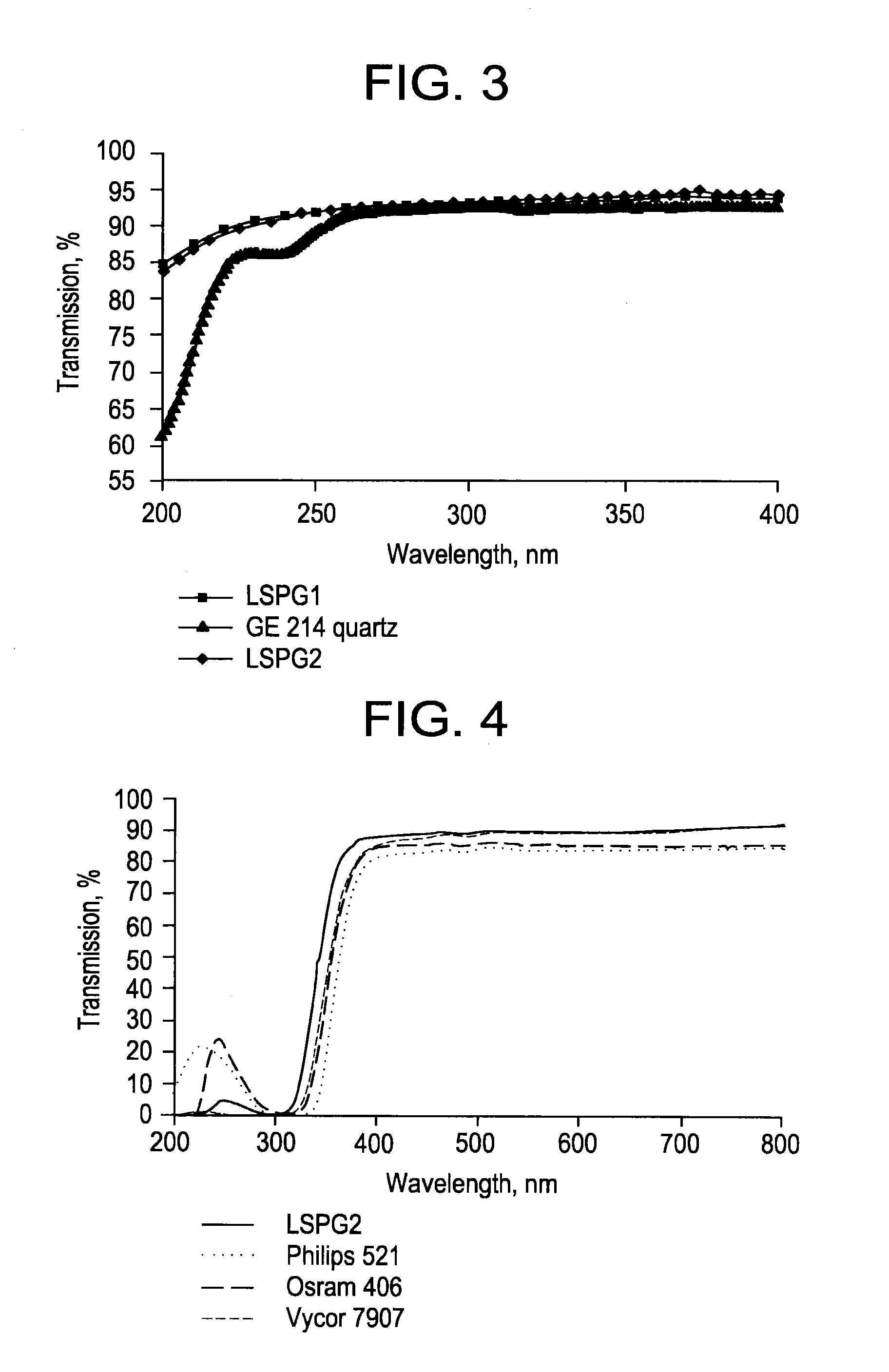

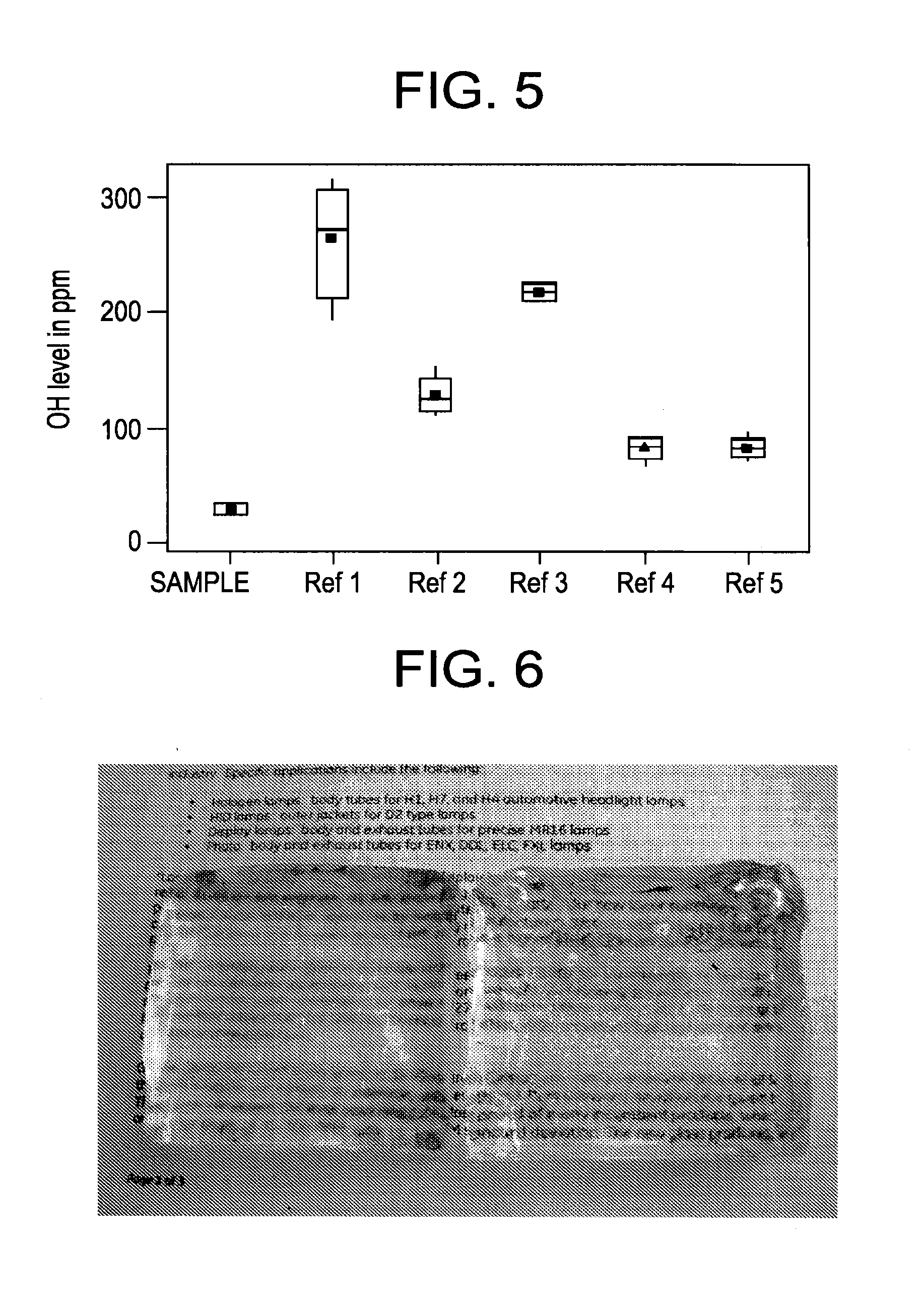

Fused quartz tubing for pharmaceutical packaging

InactiveUS20120148770A1Reduce softeningLow working point temperatureLayered productsPharmaceutical containersRare earthWorking temperature

A high silica glass composition comprising about 82 to about 99.9999 wt. % SiO2 and from about 0.0001 to about 18 wt. % of at least one dopant selected from Al2O3, CeO2, TiO2, La2O3, Y2O3, Nd2O3, other rare earth oxides, and mixtures of two or more thereof. The glass composition has a working point temperature ranging from 600 to 2,000° C. These compositions exhibit stability similar to pure fused quartz, but have a moderate working temperature to enable cost effective fabrication of pharmaceutical packages. The glass is particularly useful as a packaging material for pharmaceutical applications, such as, for example pre-filled syringes, ampoules and vials.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

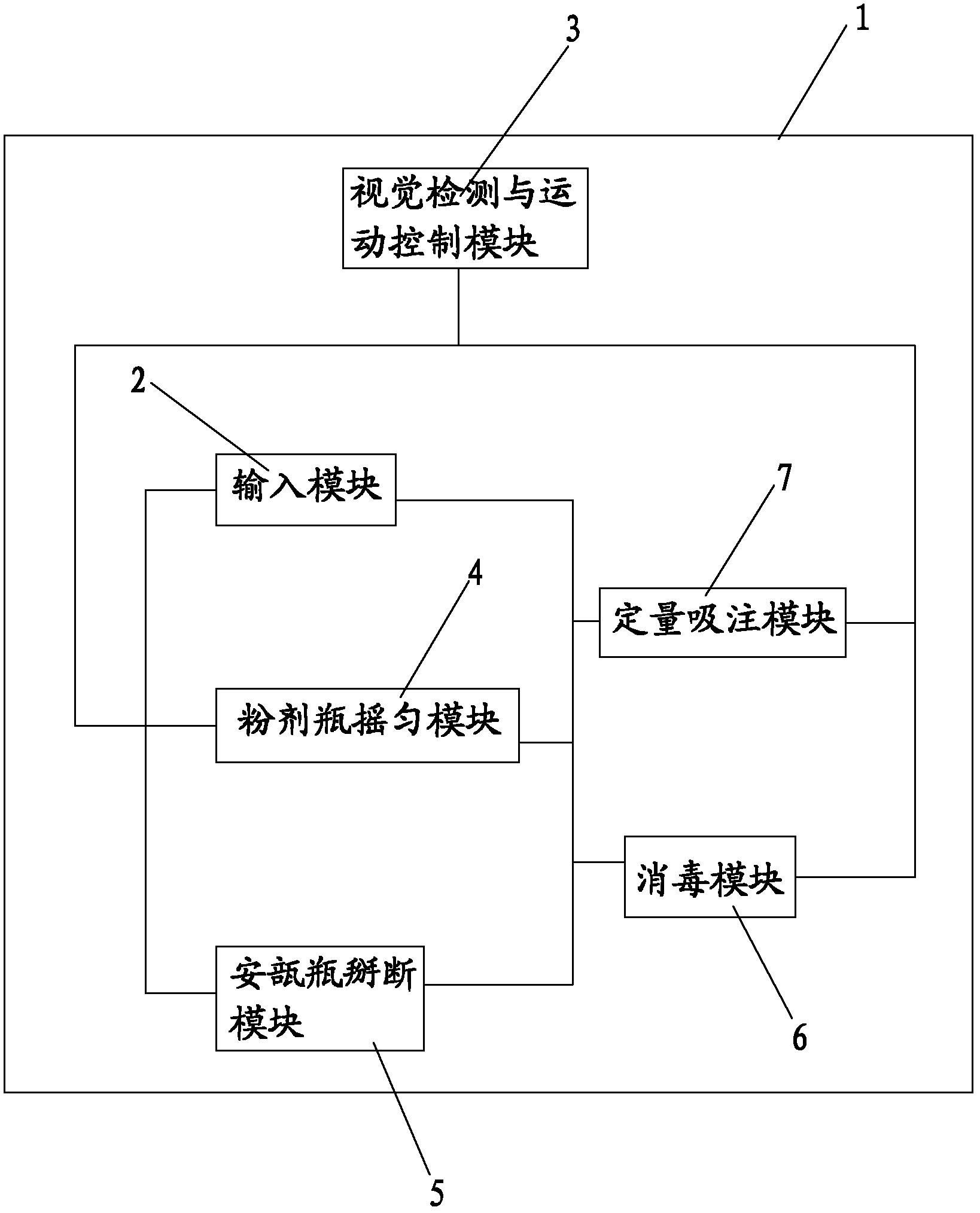

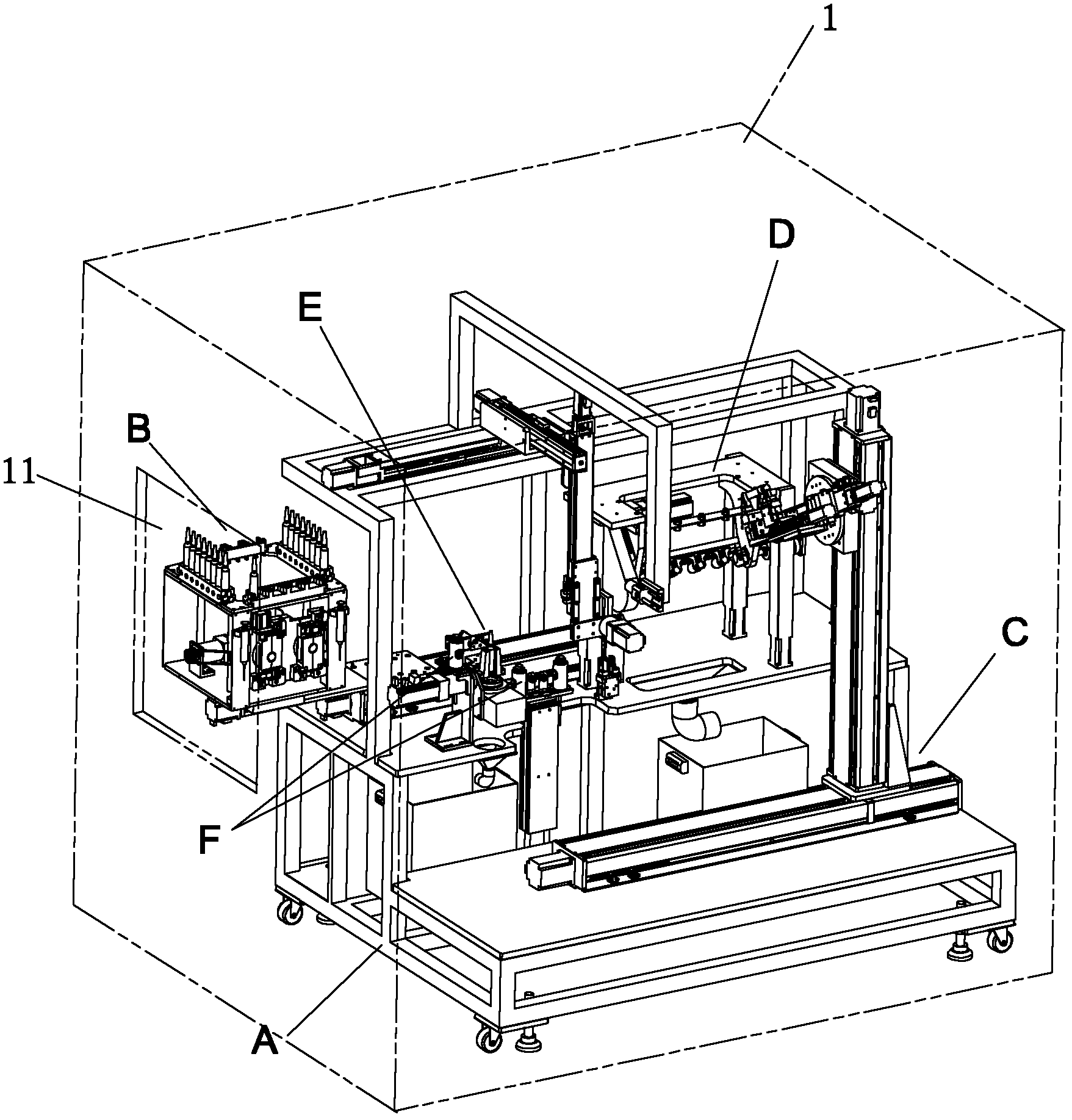

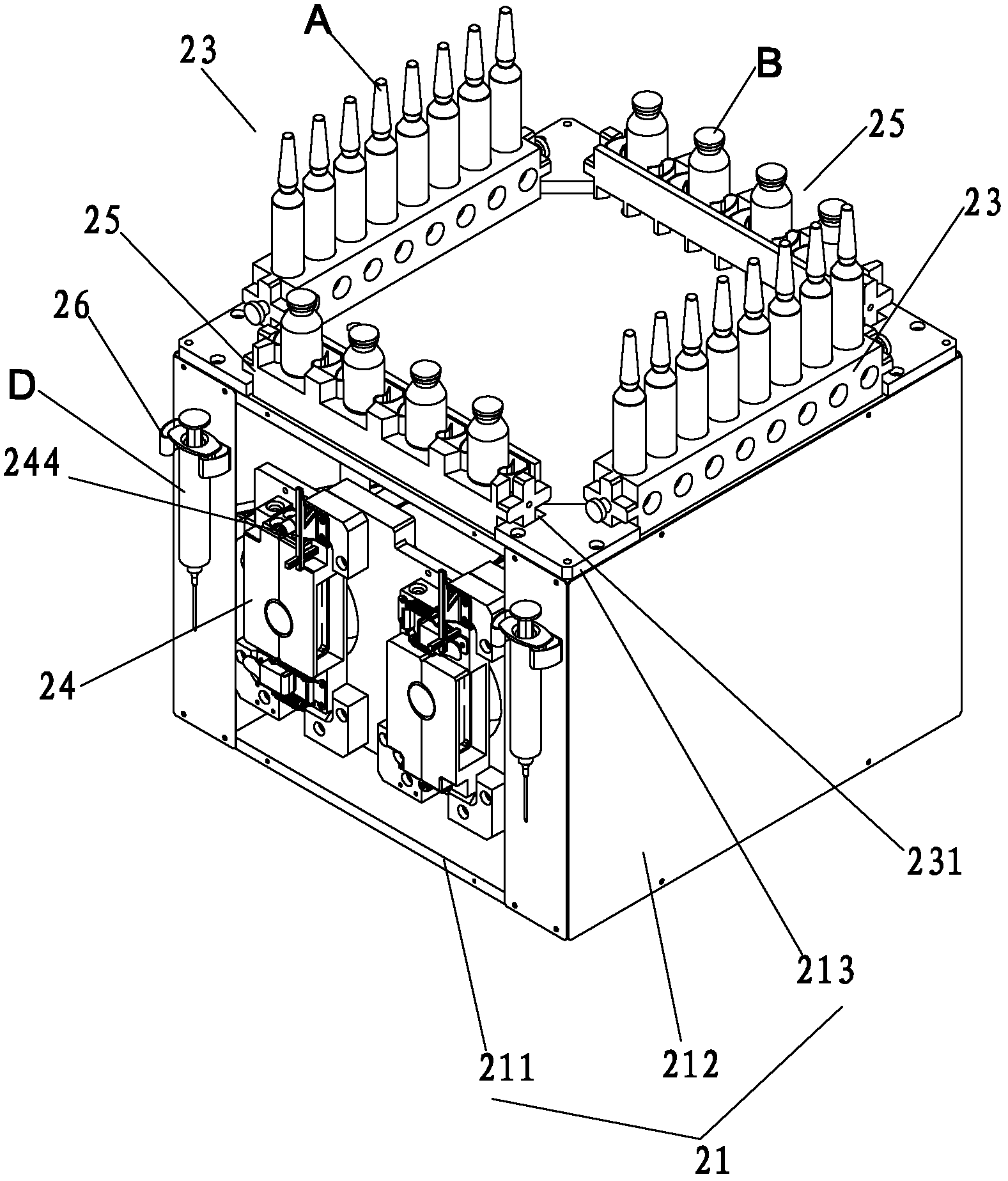

Automatic dispensing robot system and method

ActiveCN103006436AAvoid pollutionAvoid damageMixing methodsPharmaceutical containersHazardous substanceEngineering

The invention discloses an automatic dispensing robot system and an automatic dispensing method, which are used for preparing an intravenous infusion solution. The system comprises a closed cavity, wherein the closed cavity can be opened, and an input module, a powder bottle shaking module, an ampoule bottle breaking module, a disinfection module, a quantitative injection module and a visual detection and motion control module are arranged in the closed cavity. According to the automatic dispensing robot system, the breaking, disinfection and quantitative suction of an ampoule bottle, the disinfection and quantitative suction of a powder bottle and the mixing with a mother solution can be automatically realized, and the solution is prevented from being polluted; additionally, nursing personnel are prevented from being radiated and hurt by harmful substances; the probability of misoperation is reduced; the operating standard of intravenous infusion dispensing is standardized; and the dispensing efficiency is increased.

Owner:SHENZHEN CITY WEIBANG TECH

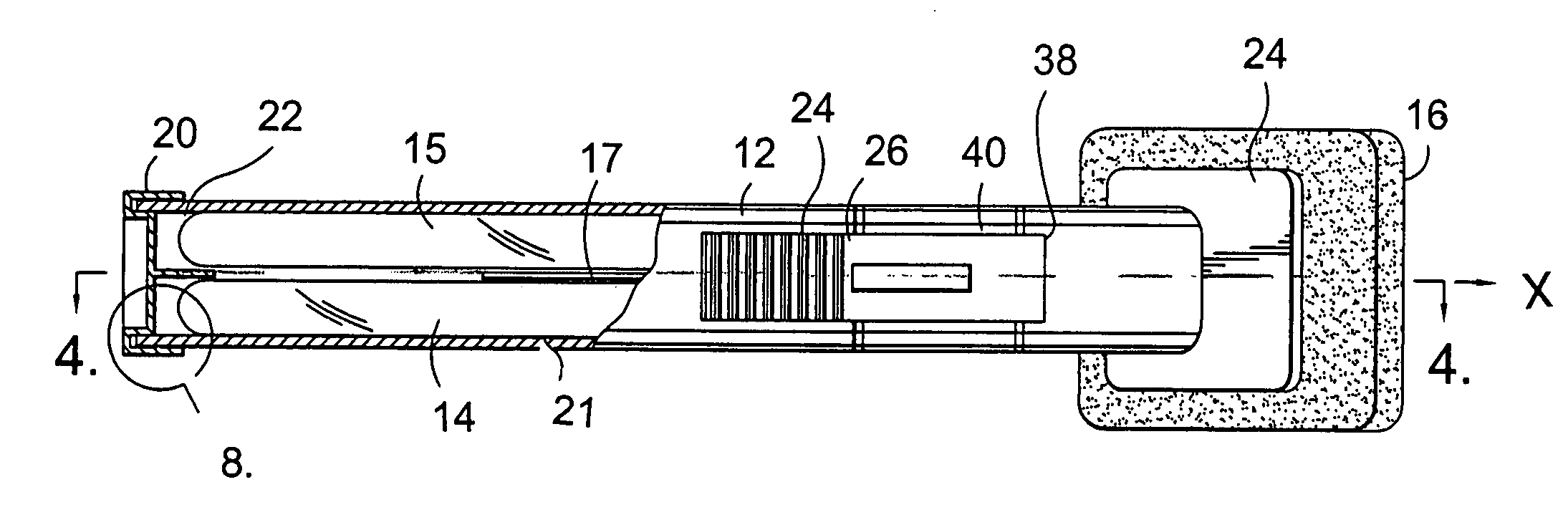

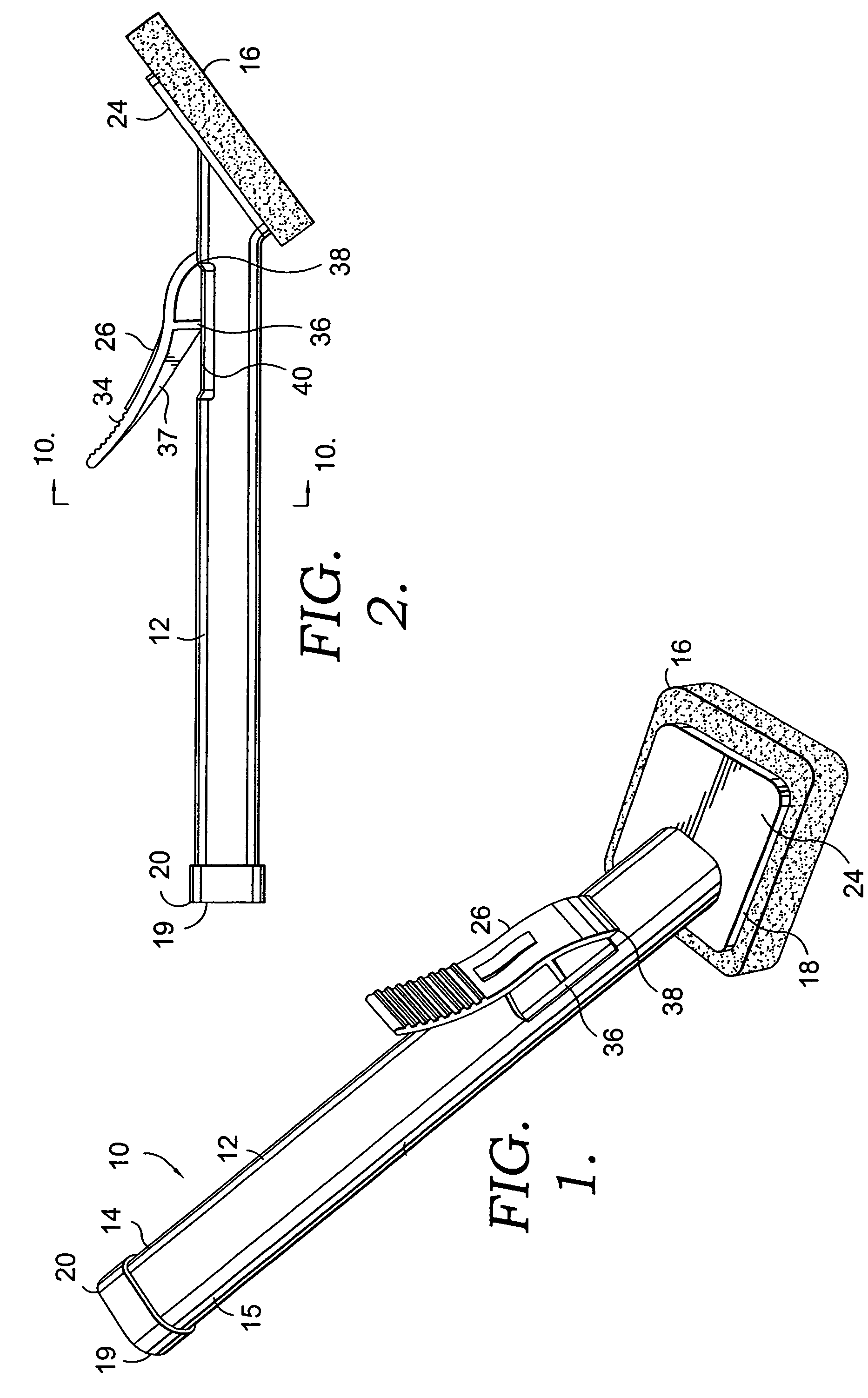

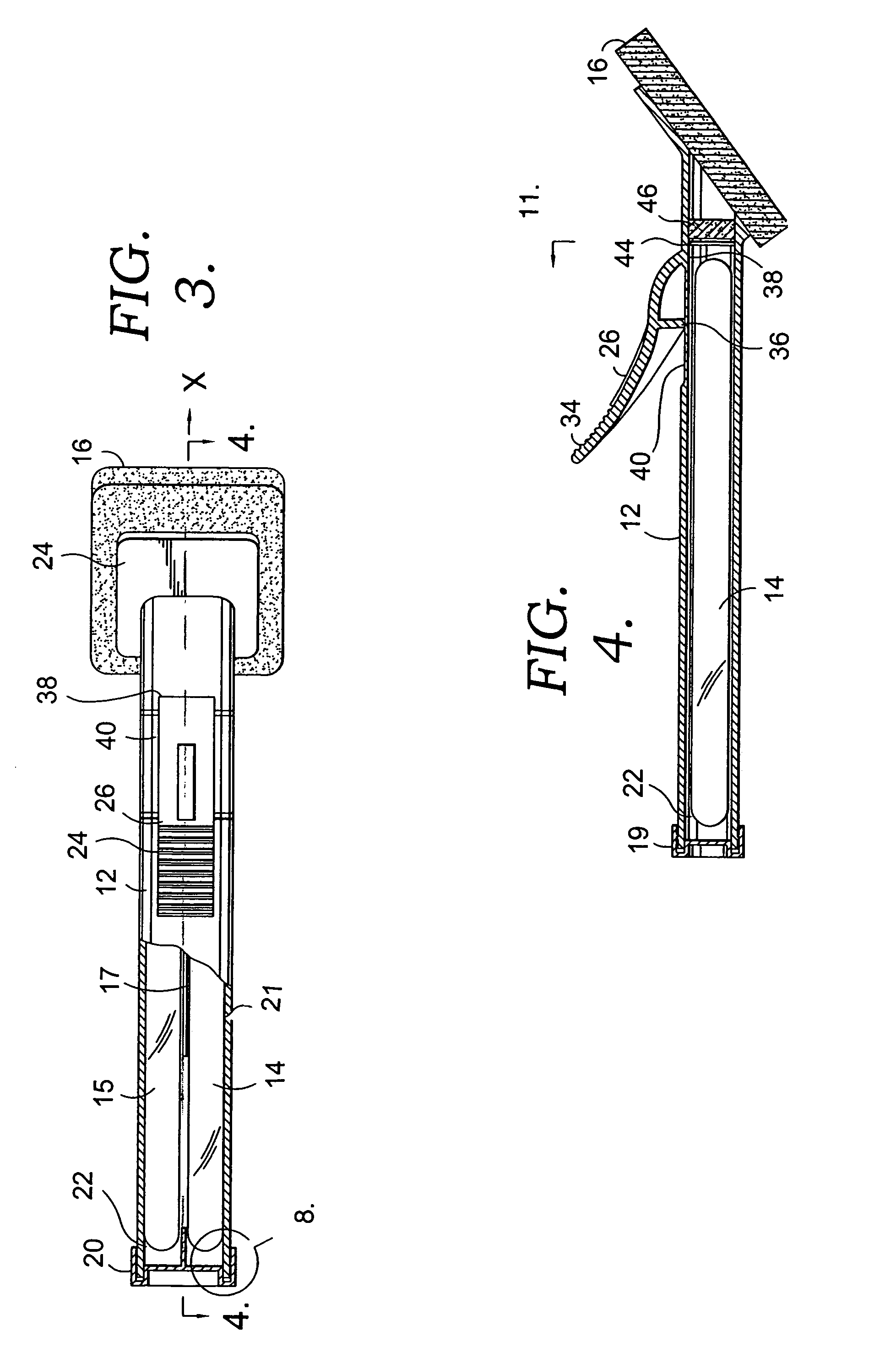

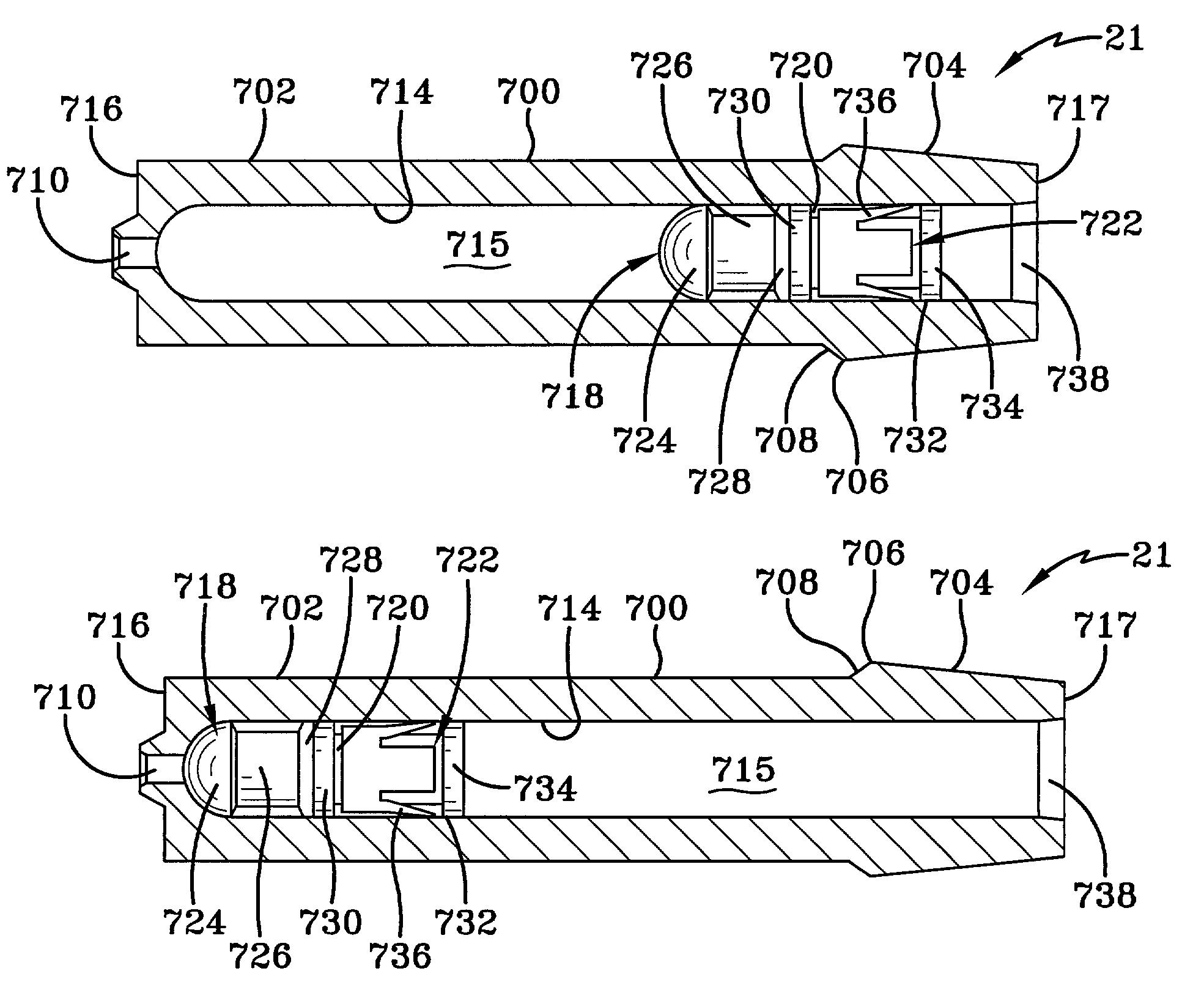

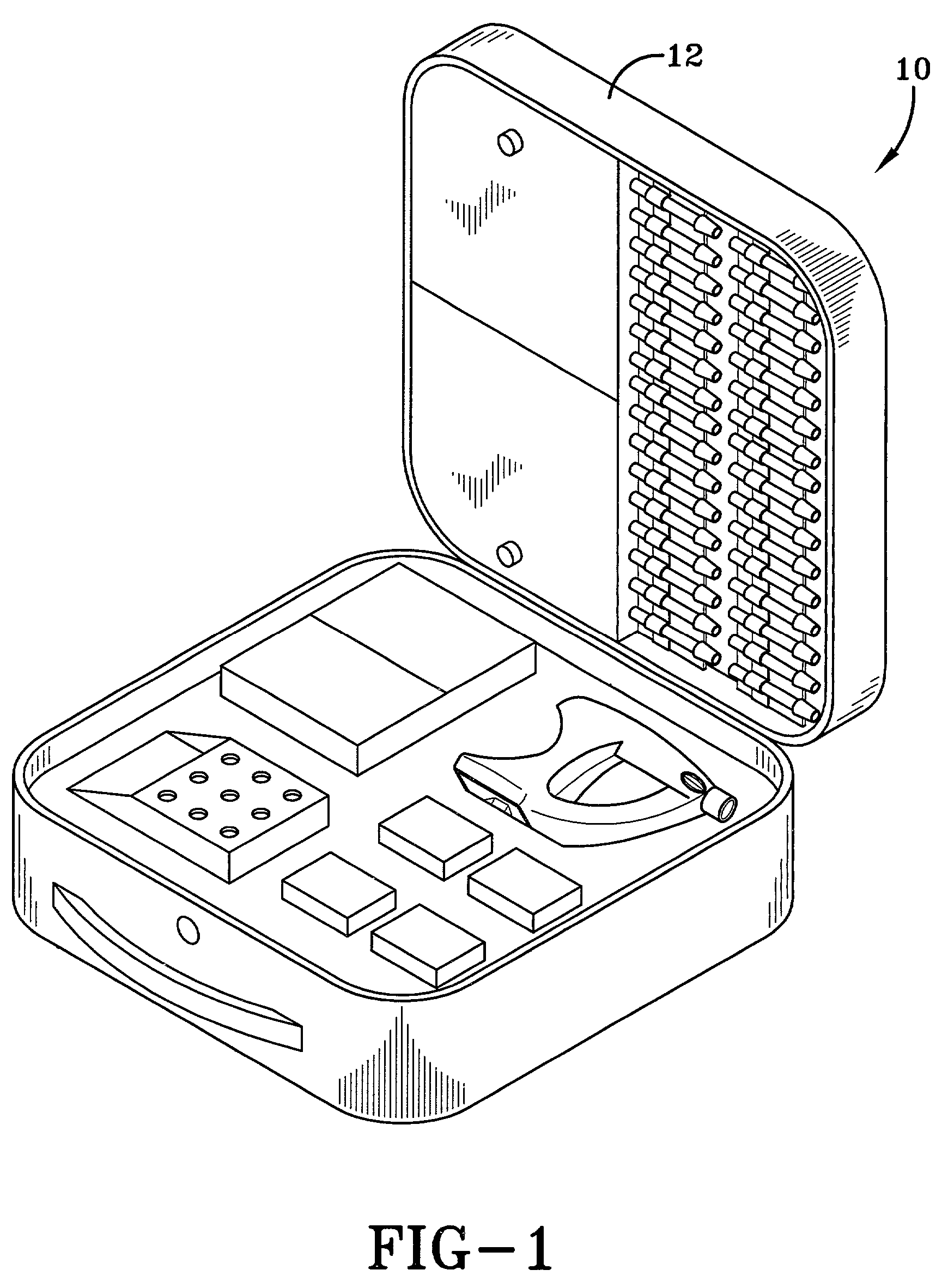

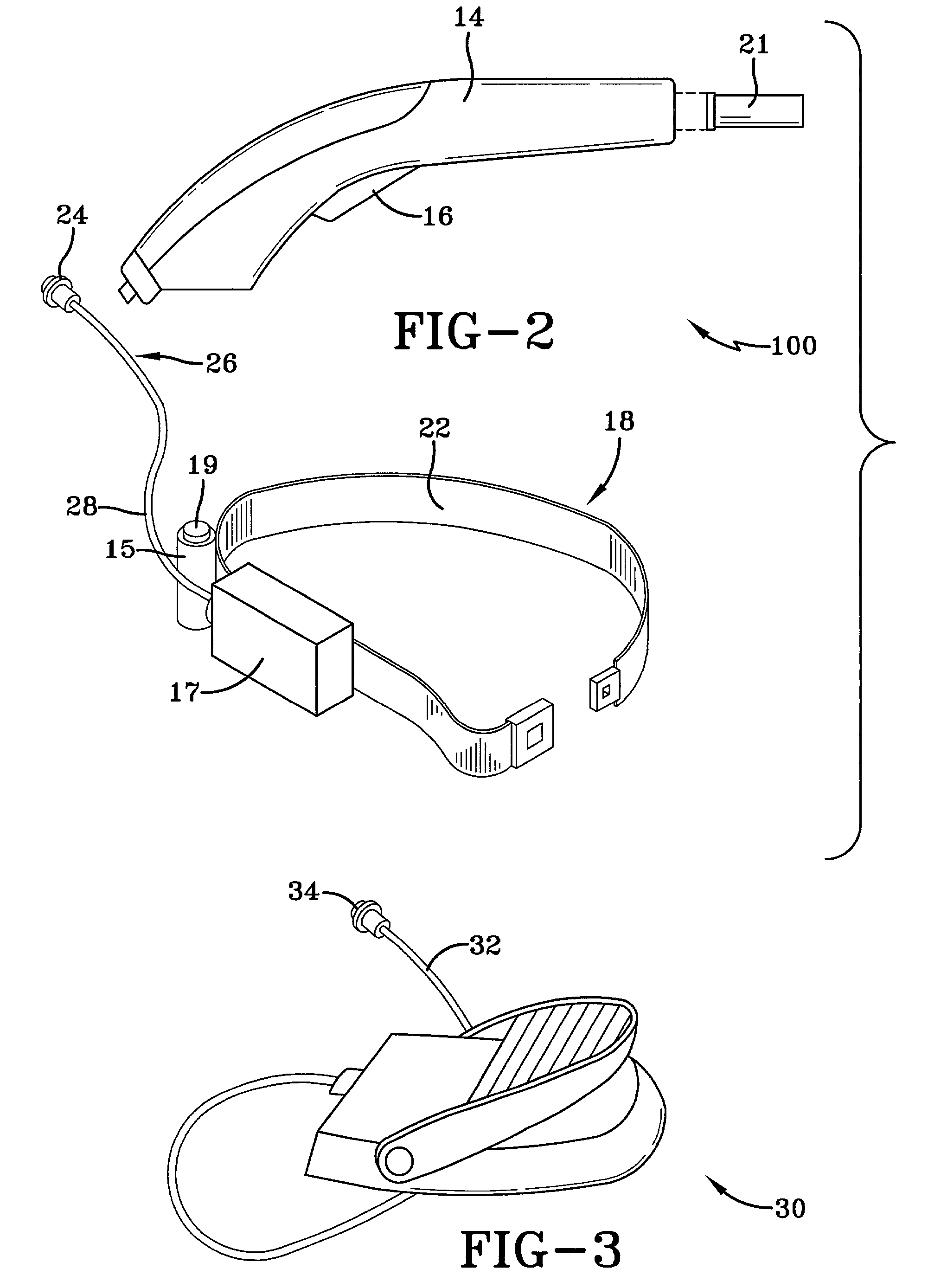

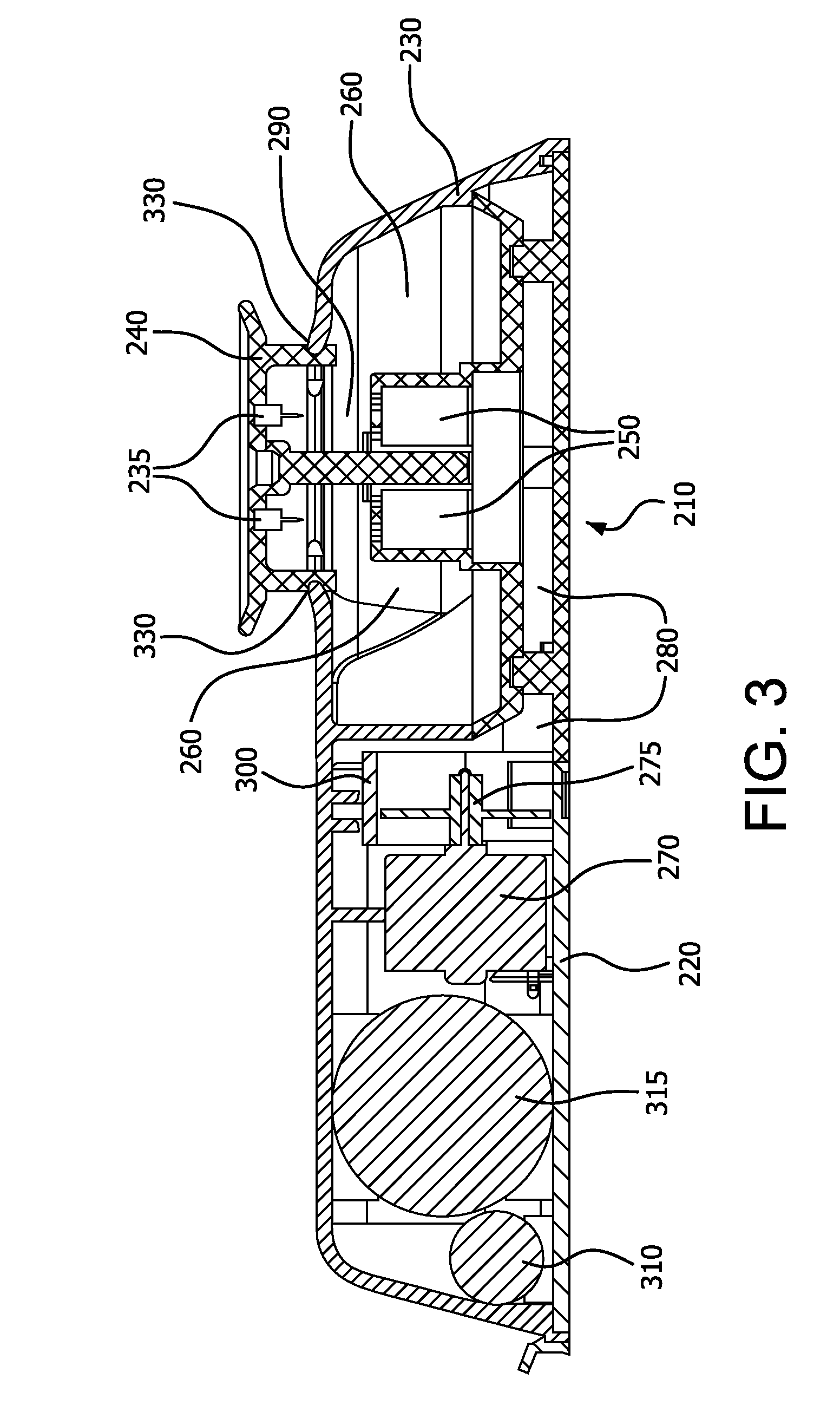

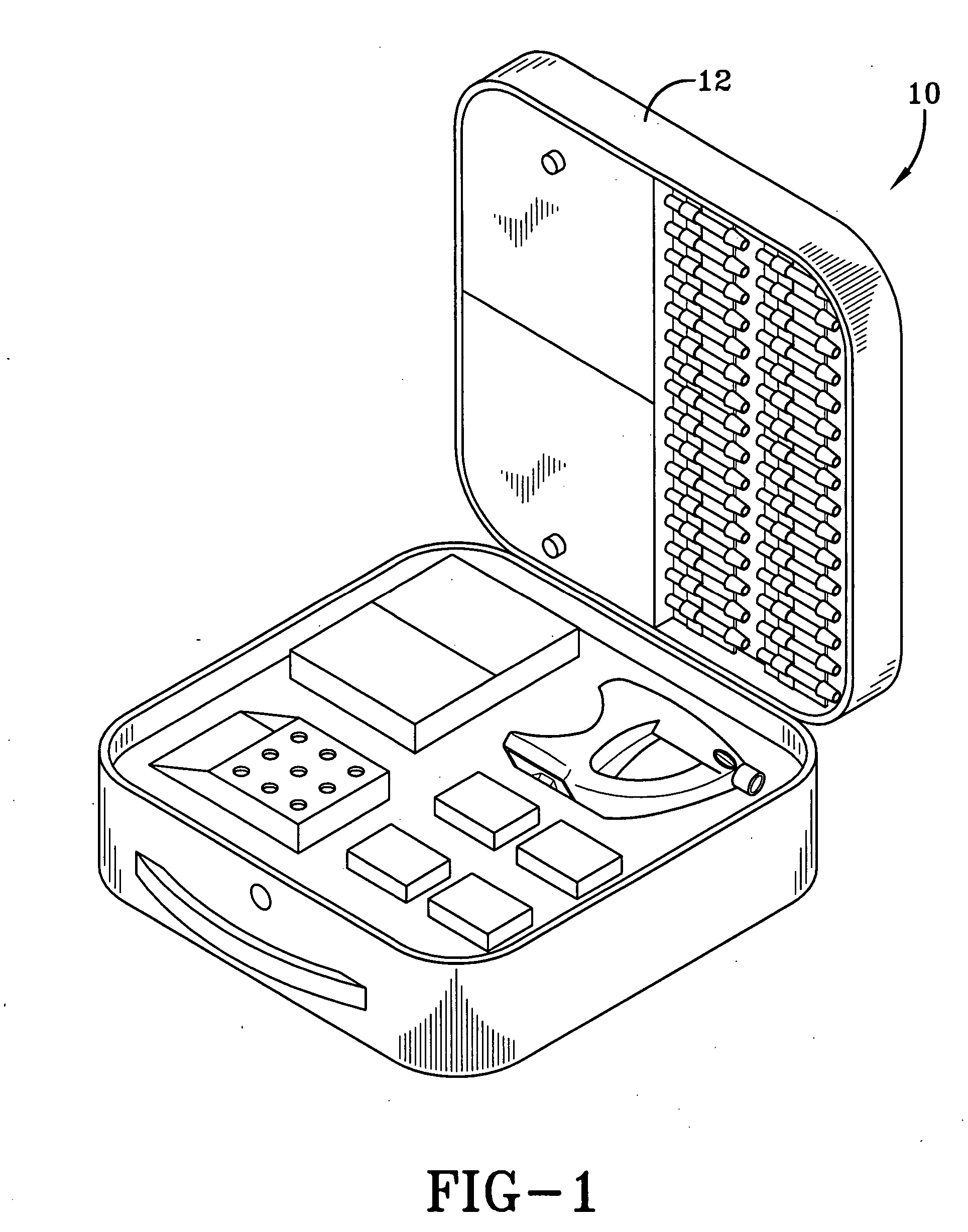

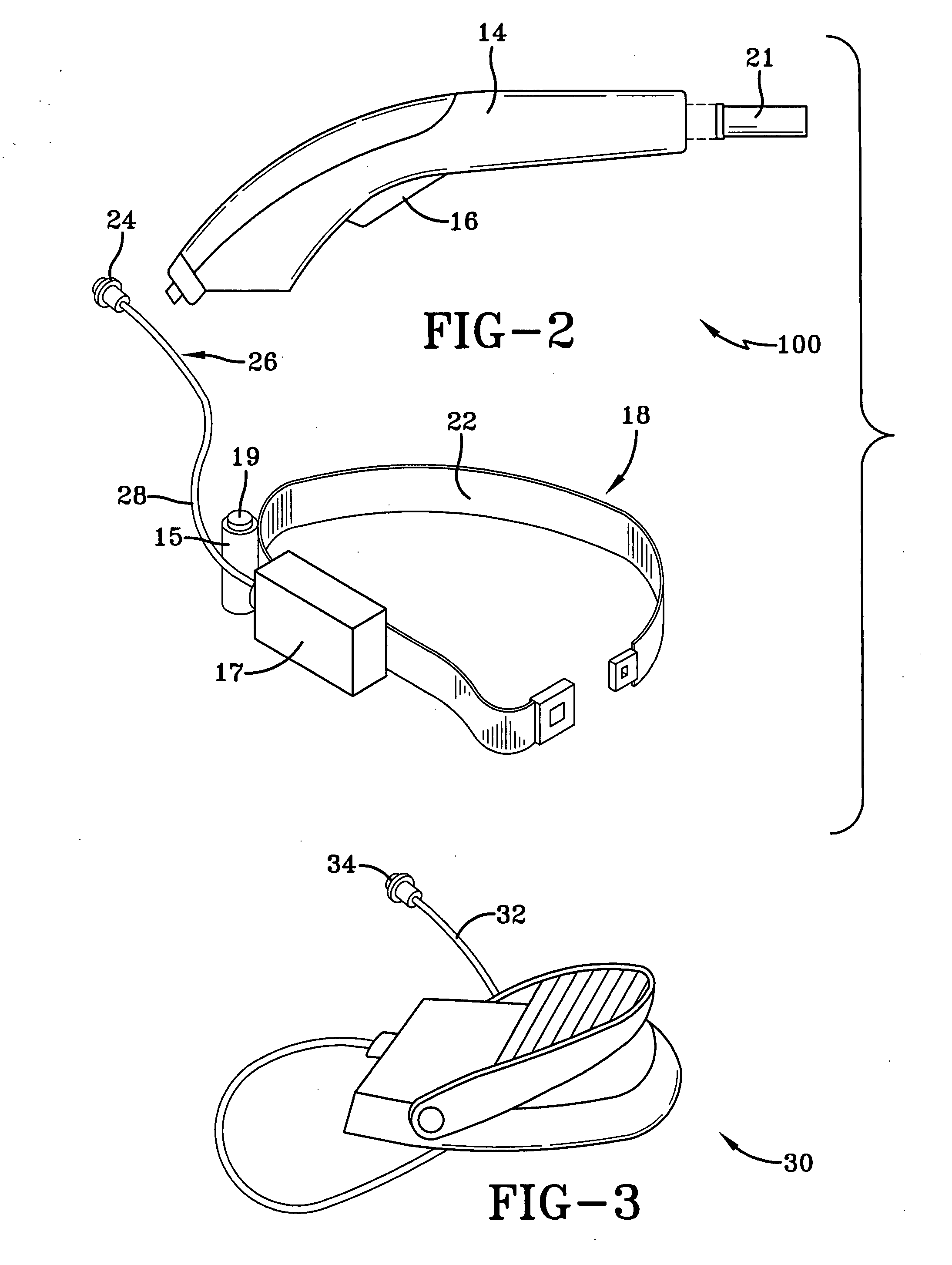

Hypodermic injection system

InactiveUS7235063B2Sufficient forceEliminate the problemAmpoule syringesJet injection syringesMultiple injectionHypodermoclysis

A hypodermic injection system particularly for use in mass immunizations having a handpiece with a grasping mechanism for holding ampules filled with injectate, a plunger for driving into the ampule to discharge the injectate in an injection process, an injection spring mechanism for driving the plunger, a motor and / or manual mechanism for cocking the injection spring mechanism, and an ampule ejection mechanism for ejecting ampules after use under control of a release mechanism. Ampules can be loaded, used and ejected without contact by the user of the system or the patient being injected. Also disclosed are a filling station for filling ampules through their injection orifices, and an arming device for setting the injection spring. Ampules are disclosed having a piston which is drivable towards an orifice to discharge injectate through the orifice. Ampules are also disclosed having enlarged proximal portions for easy grasping by the grasping mechanism of the injector. Ampules are further disclosed with separators for mixing lyophilized medication and a diluent. Further disclosed are magazines for holding ampules for sequential use by the hypodermic injector. The disclosed system finds particular use as a mass immunization kit for making numerous injections in the field.

Owner:DANTONIO CONSULTANTS INT INC

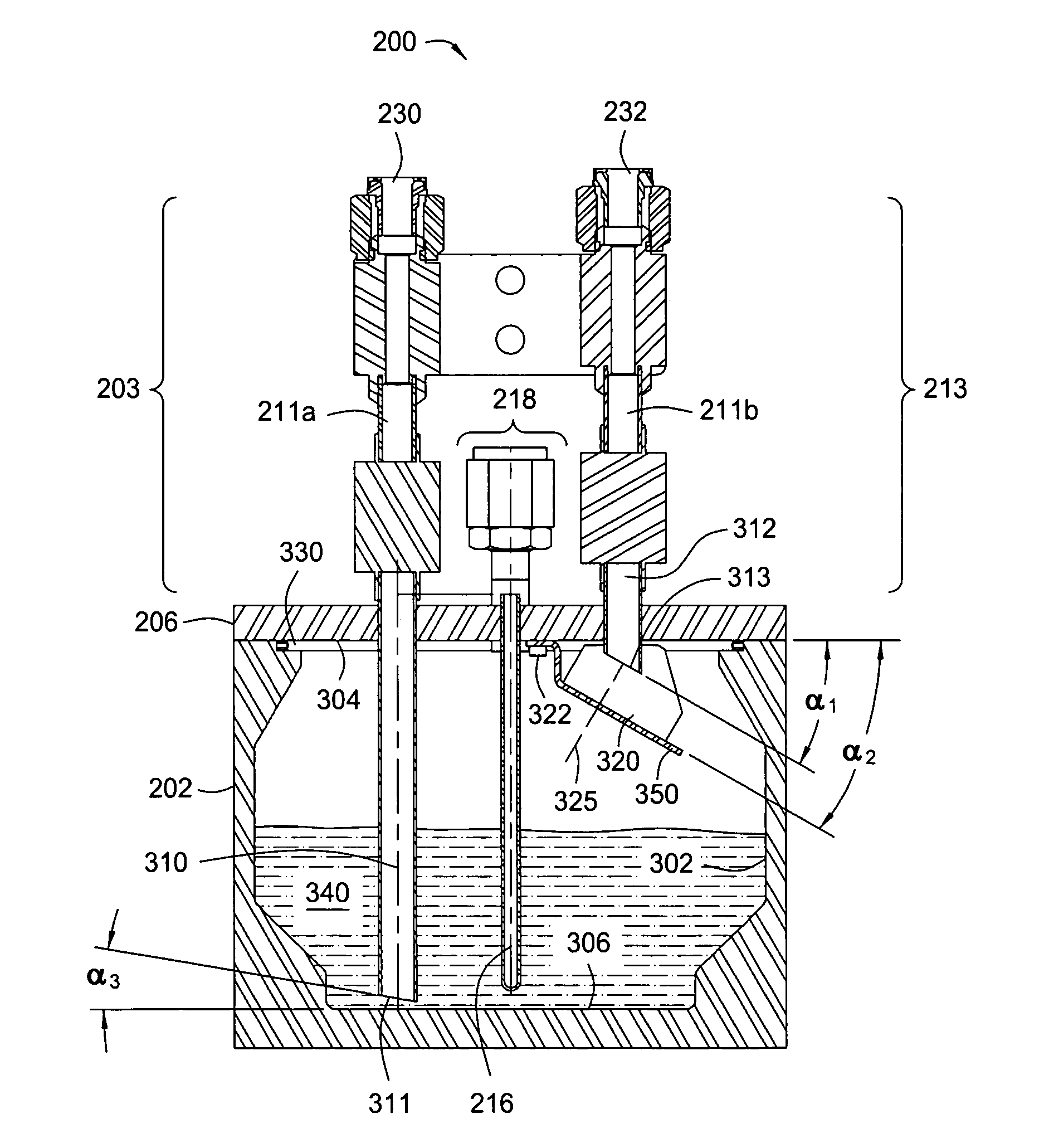

Ampoule splash guard apparatus

Embodiments of the invention provide an apparatus for generating a precursor gas used in a vapor deposition process system. The apparatus contains a canister or an ampoule for containing a chemical precursor and a splash guard contained within the ampoule. The splash guard is positioned to obstruct the chemical precursor in a liquid state from being bumped or splashed into a gas outlet during the introduction of a carrier gas into the ampoule. The carrier gas is usually directed into the ampoule through a gas inlet and combines with the vaporized chemical precursor to form a precursor gas. The splash guard is also positioned to permit the passage of the precursor gas from the gas outlet. In one example, the gas outlet contains a stem with a tapered tip and the splash guard is positioned at an angle parallel to the plane of the tapered tip.

Owner:APPLIED MATERIALS INC

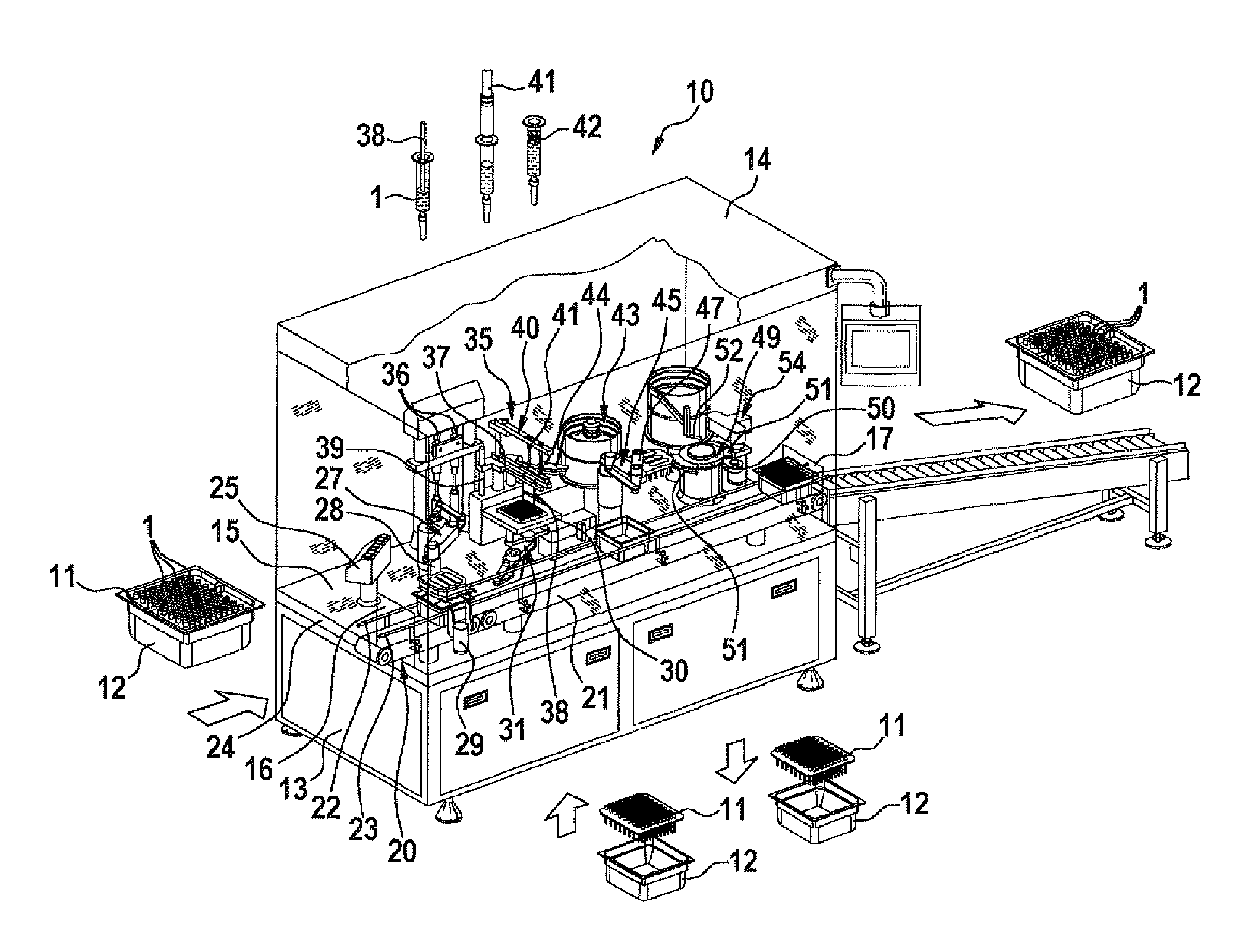

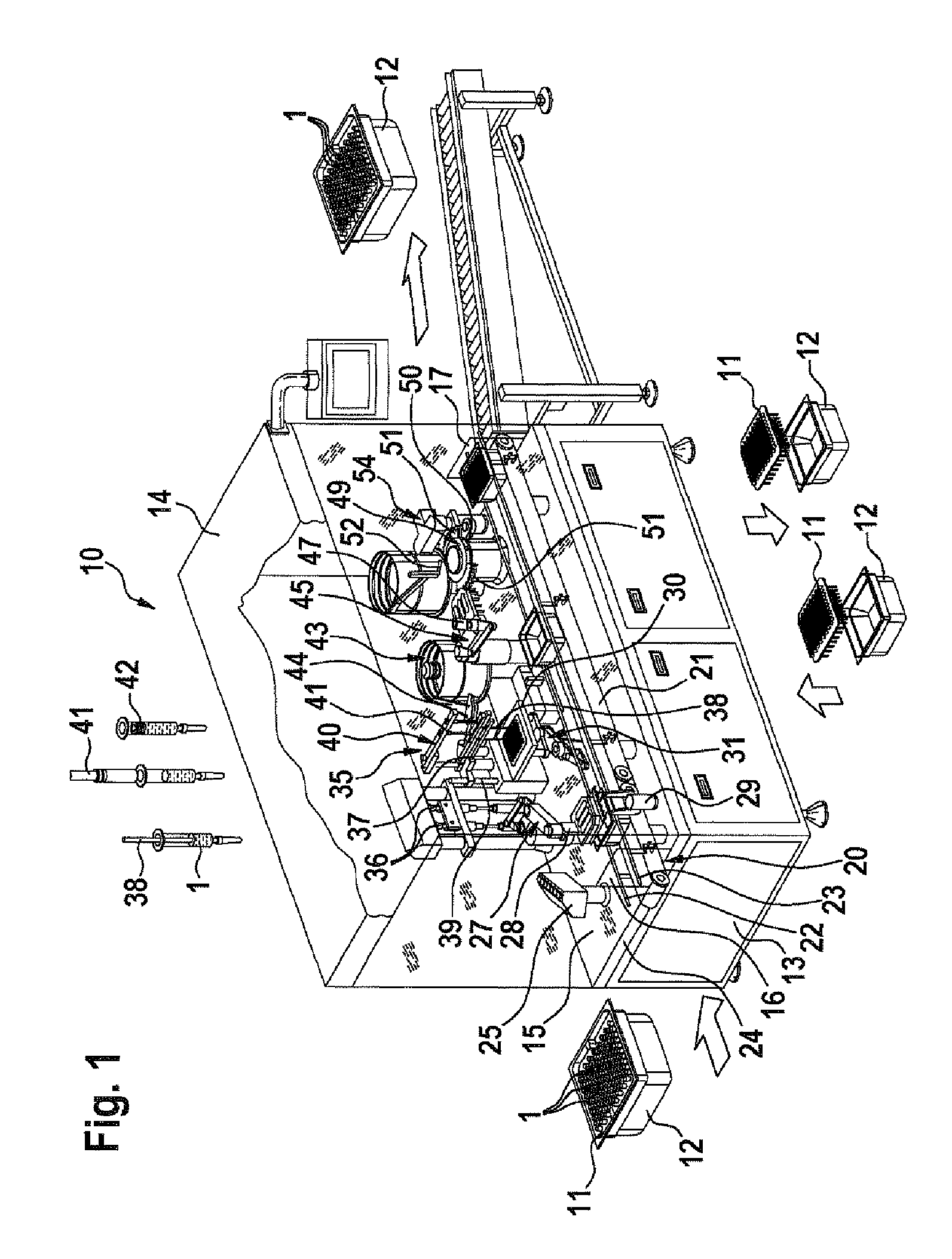

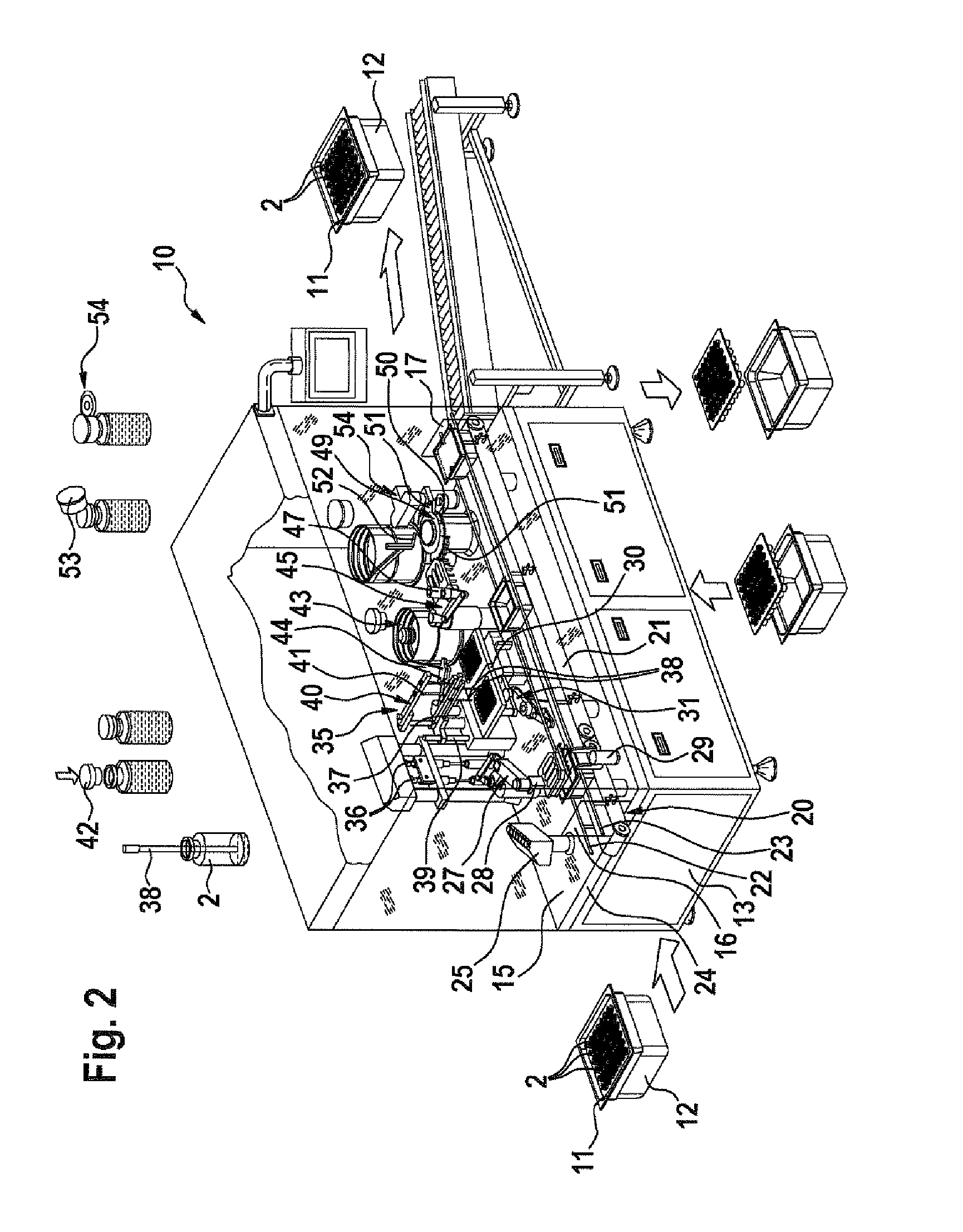

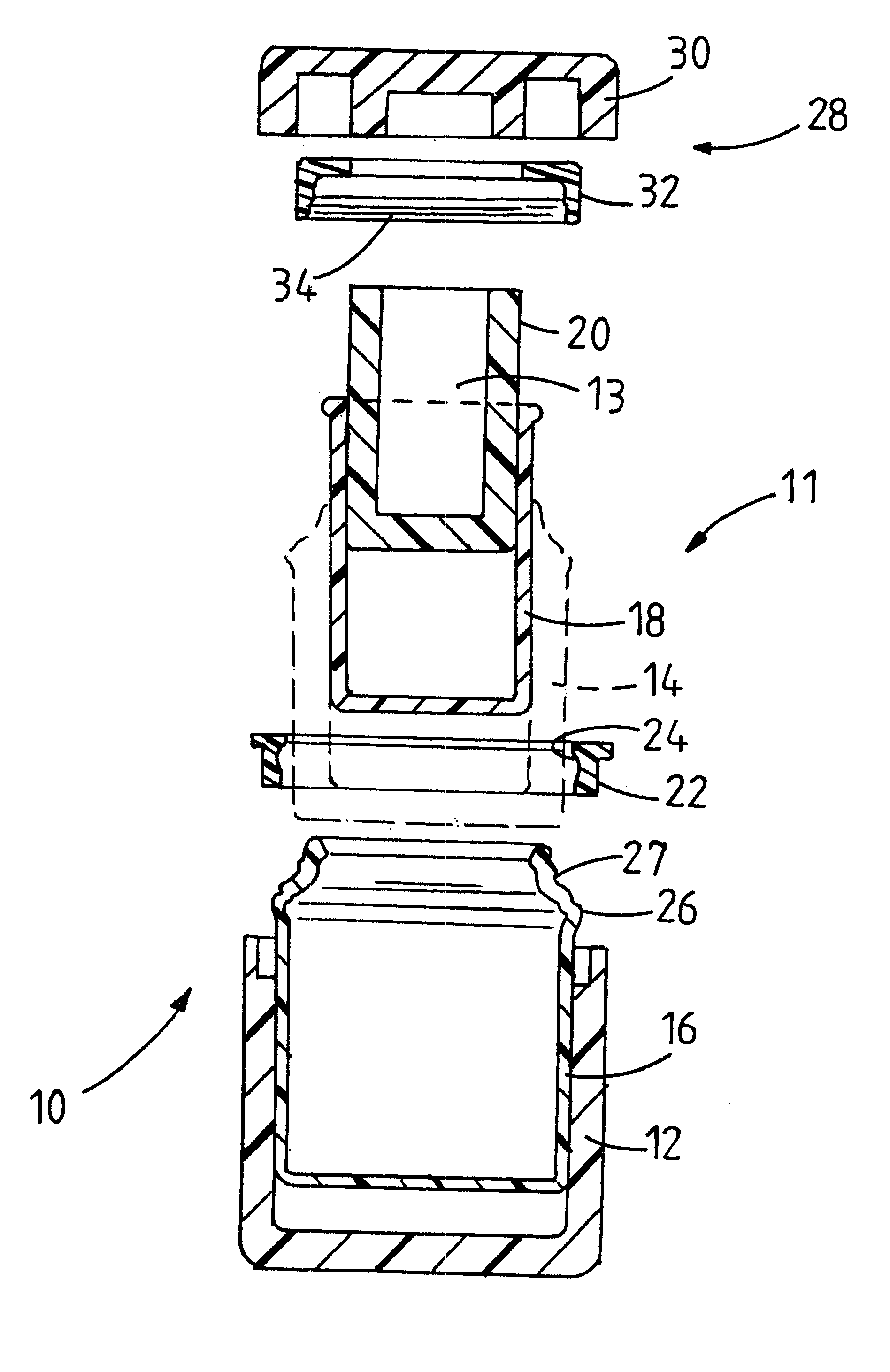

Device for filling and sealing pharmaceutical containers

ActiveUS20120090268A1Chance is lostNo longer be conveyedIntravenous devicesSolid materialAmpouleTreatment unit

The invention relates to a device (10) for filling and sealing pharmaceutical containers, wherein the containers are received in a receptacle (12), which is in particular tub-shaped and in which a carrier element (11) is inserted, said carrier element being removable from the receptacle (12). The containers are arranged in receivers of the carrier element (11) in multiple rows next to one another and behind one another. Said device further comprises a first handling unit (27) for removing the carrier element (11) from the receptacle (12), a filling and sealing device (35) for the containers, and a second handling unit (45) for reinserting the carrier element (11) into the receptacle (12) which is conveyed with the carrier element (11) on a conveying device (20). According to the invention, the containers are embodied as syringe barrels (1) or as containers which are to be provided with crimp caps (53), such as vials (2) or cylindrical ampoules (3), and the second handling device (45) is associated with a crimping device (54). When handling containers which are to be provided with crimp caps, the crimping device is controlled by the second handling device (45) so that the second handling device (45) first feeds the containers into the crimping device (54) then reinserts the containers which were sealed by means of the crimping device (54) into the carrier element (11).

Owner:SYNTEGON TECHNOLOGY GMBH

Fused quartz tubing for pharmaceutical packaging

ActiveUS20130095261A1Low working point temperatureHigh wt % contentDiagnosticsLayered productsDopantWorking temperature

A high silica glass composition comprising about 92 to about 99.9999 wt. % SiO2 and from about 0.0001 to about 8 wt. % of at least one dopant selected from Al2O3, CeO2, TiO2, La2O3, Y2O3, Nd2O3, other rare earth oxides, and mixtures of two or more thereof. The glass composition has a working point temperature ranging from 600 to 2,000° C. These compositions exhibit stability similar to pure fused quartz, but have a moderate working temperature to enable cost effective fabrication of pharmaceutical packages. The glass is particularly useful as a packaging material for pharmaceutical applications, such as, for example pre-filled syringes, ampoules and vials.

Owner:MOMENTIVE PERFORMANCE MATERIALS QUARTZ INC

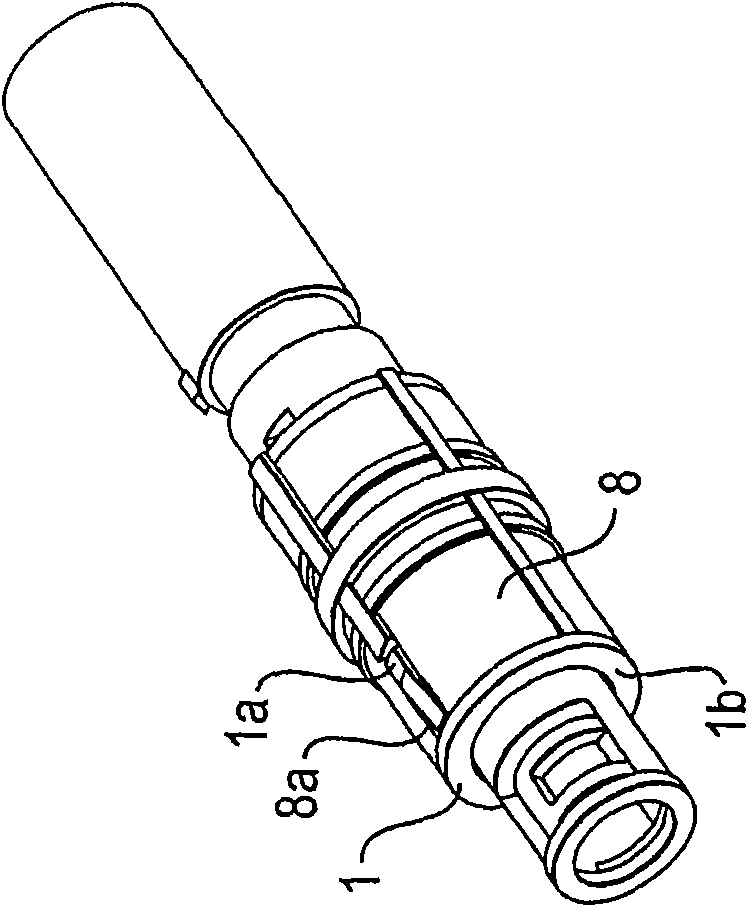

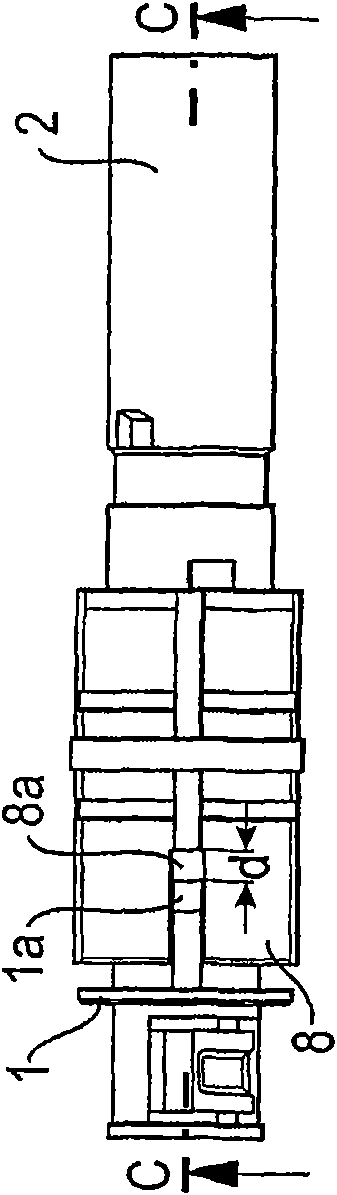

Blocking element for a dosing mechanism

ActiveCN101678172APrevent rotational movementAvoid unpluggingAmpoule syringesIntravenous devicesInjection deviceBiomedical engineering

The invention relates to a blocking element (1) for a dosing mechanism of an injection device with at least one holding element (1a) that can interact with the dosing mechanism, or with a dosing element (2) of the dosing mechanism, in such a way that an adjustment movement of the dosing mechanism or of the dosing element can be prevented in a starting position of the blocking element and is permitted only after a movement or displacement of the blocking element or of the holding element. The invention also relates to a method for preparing an injection device for dispensing a substance from anampoule or two-chamber ampoule (5), wherein the ampoule or two-chamber ampoule is introduced and preferably screwed into the injection device, and the blocking or anti-rotational locking of the dosing or adjusting element or lifting element of the injection device is only released when the ampoule has been introduced so far into the injection device that a substance can be dispensed from the ampoule in a defined or dosed manner, or that the substances contained in the two-chamber ampoule are preferably completely mixed.

Owner:YPSOMED AG

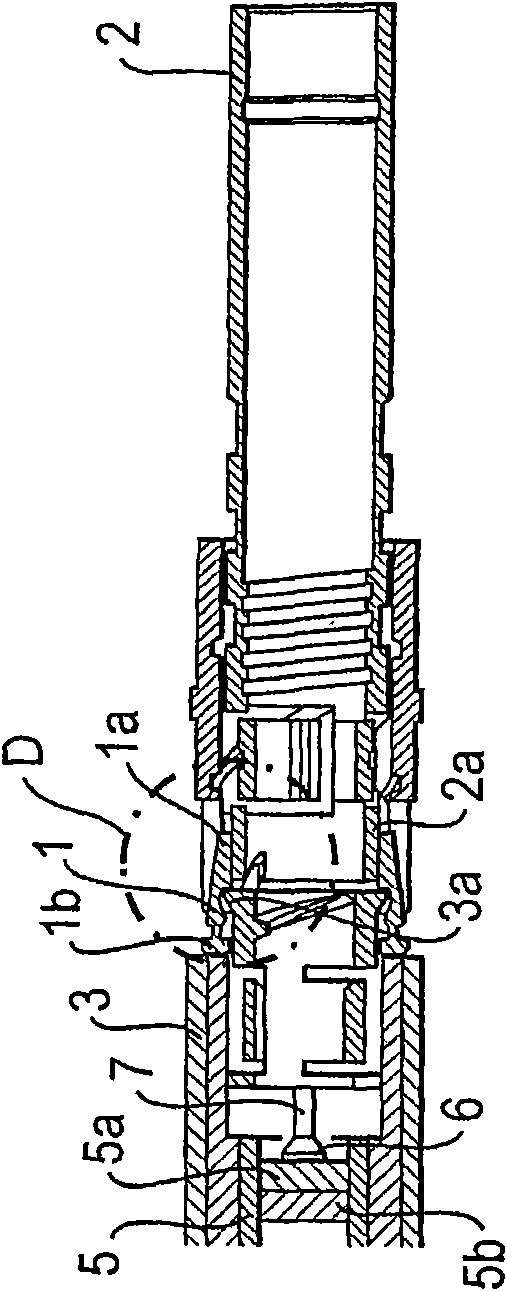

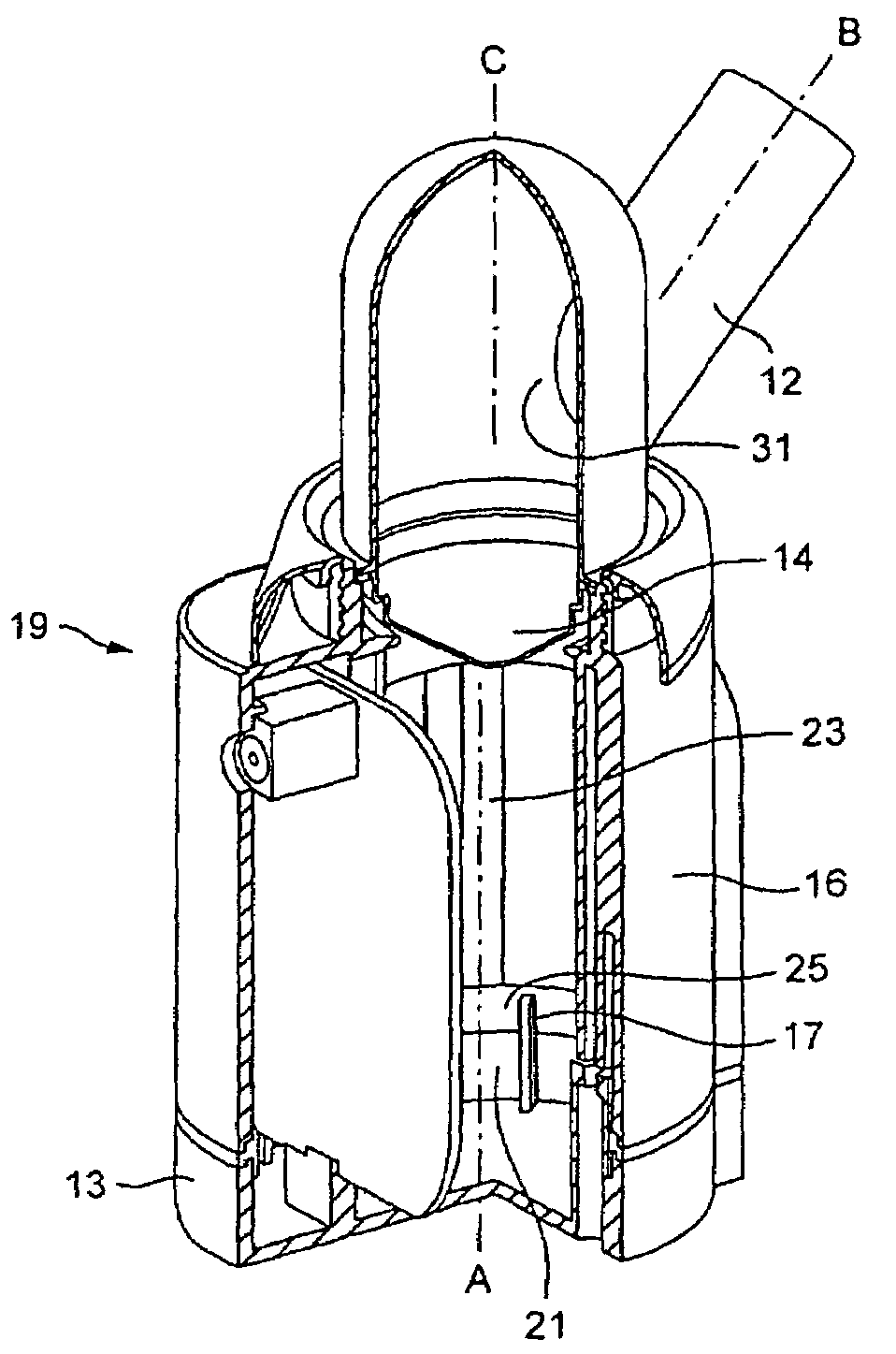

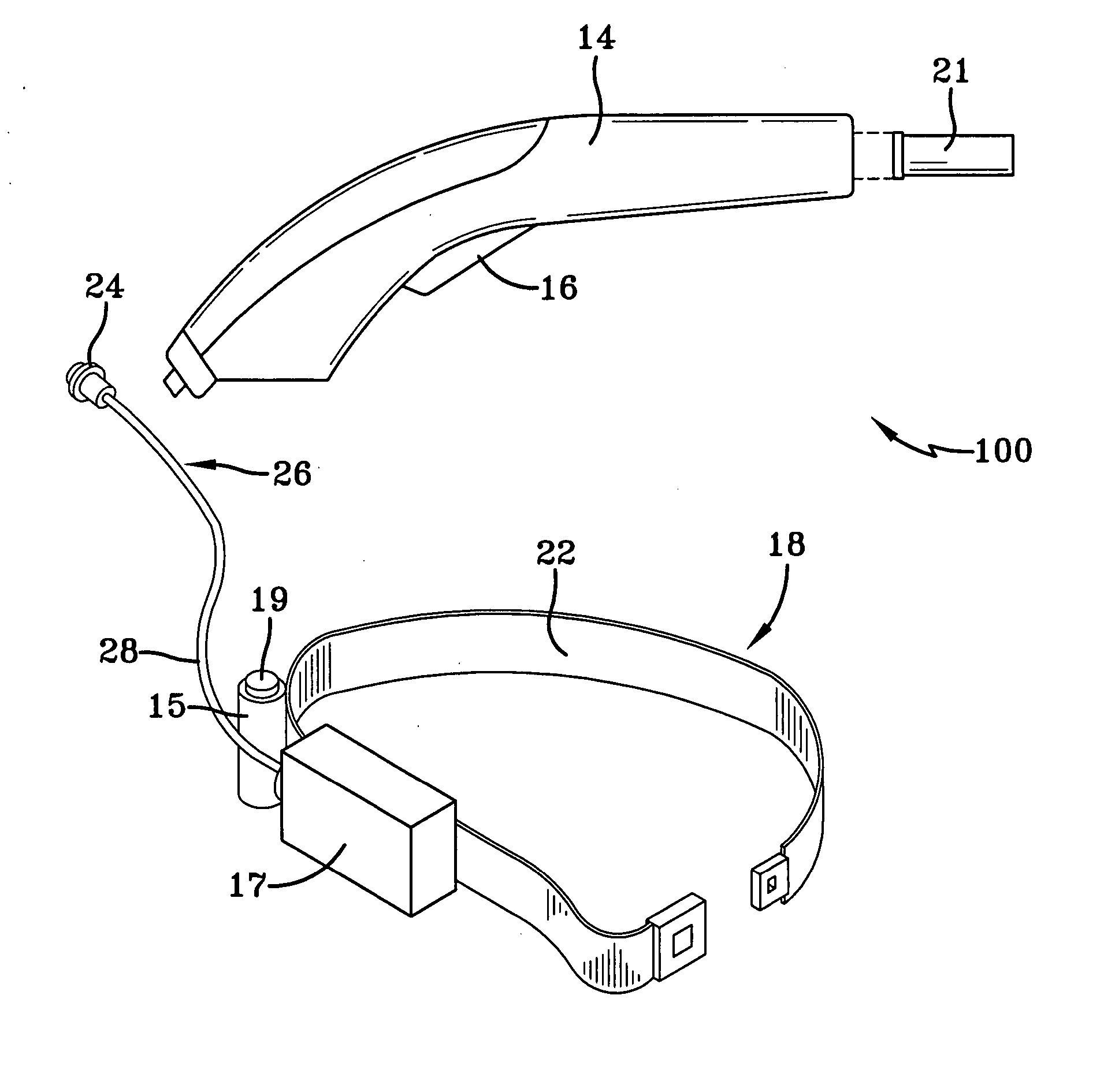

Breath-enhanced ultrasonic nebulizer and dedicated unit dose ampoule

InactiveUS7261102B2Minimizes numberReduce the possibilityRespiratorsMedical devicesSonificationUltrasonic transmission

A medicament delivery system comprises a nebulizer device, an open-faced mist chamber-defining element having a tubular input / output port, a tubular inhalation port connecting to the output port of the mist chamber-defining element, and a sealed unit dose ampoule adapted to fit within the mist chamber-defining element. The nebulizer device includes an ultrasonic transducer responsive to applied electrical energy to generate ultrasonic energy, an ultrasonic transmission horn between an input energy surface at an input end and an energy delivery surface at an output end. The sealed unit dose ampoule can be placed directly into the nebulizer device and acts as both the dose cup and baffle, so that the chance of spillage of drug and the number of components to be cleaned are minimized.

Owner:NORTON HEALTHCARE

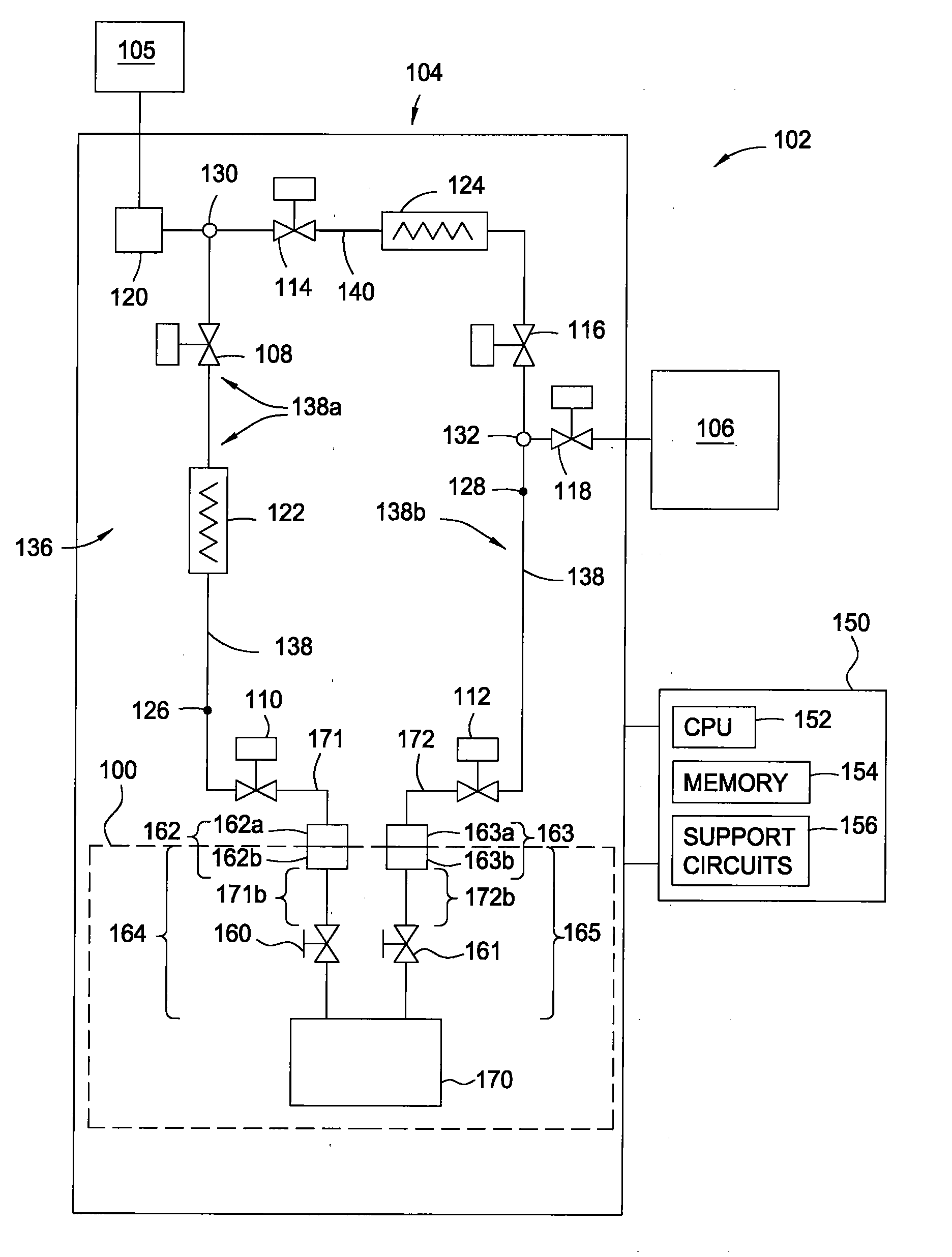

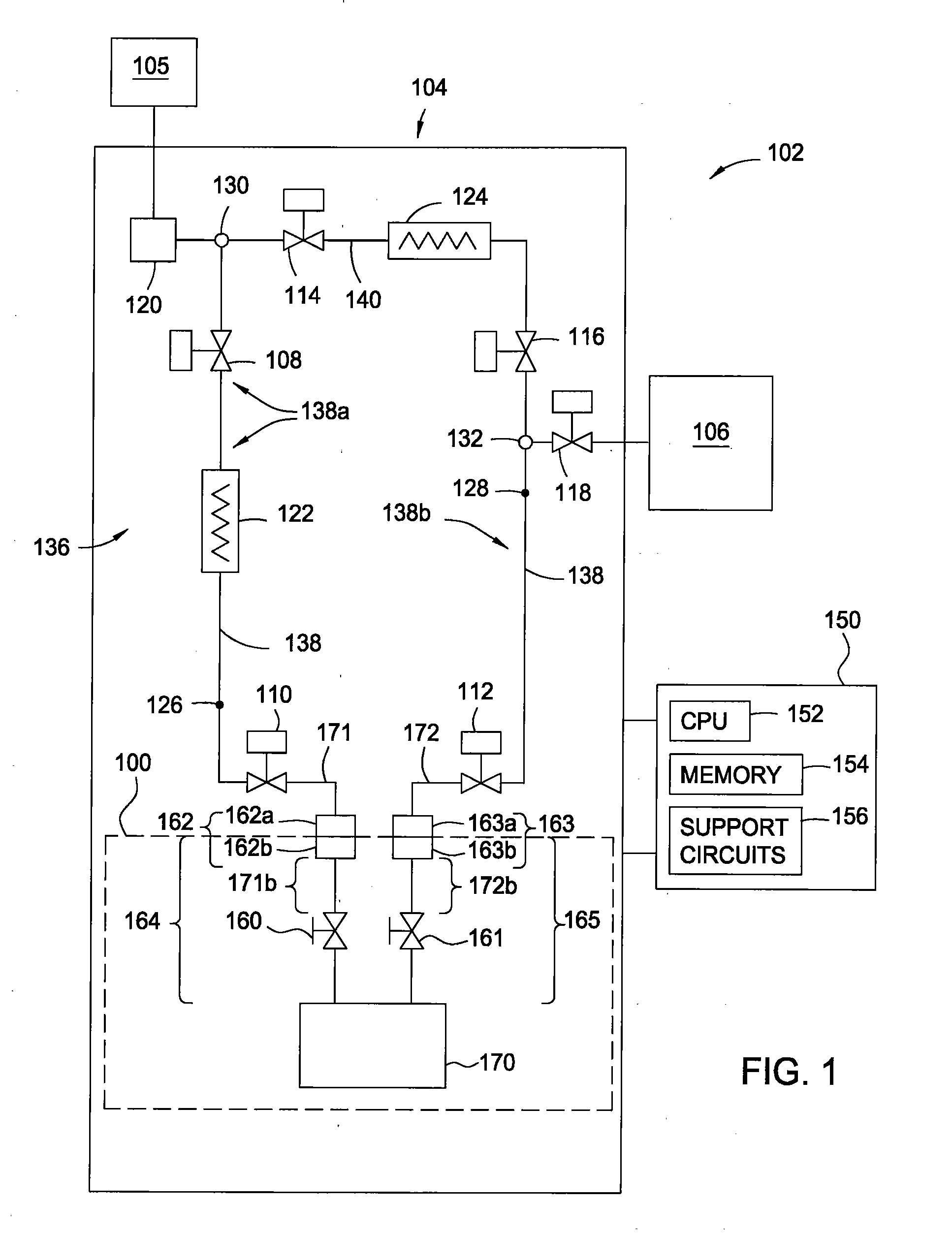

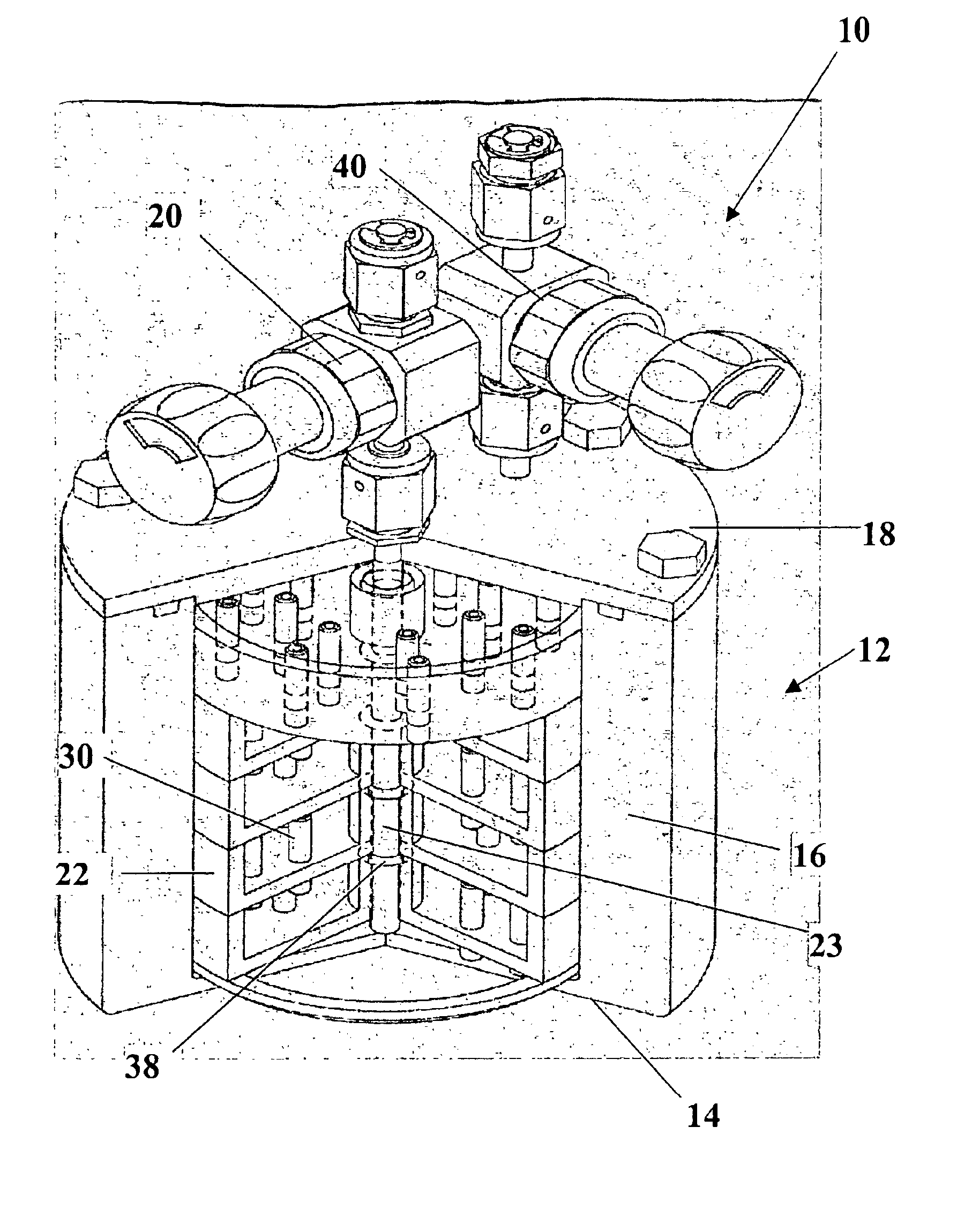

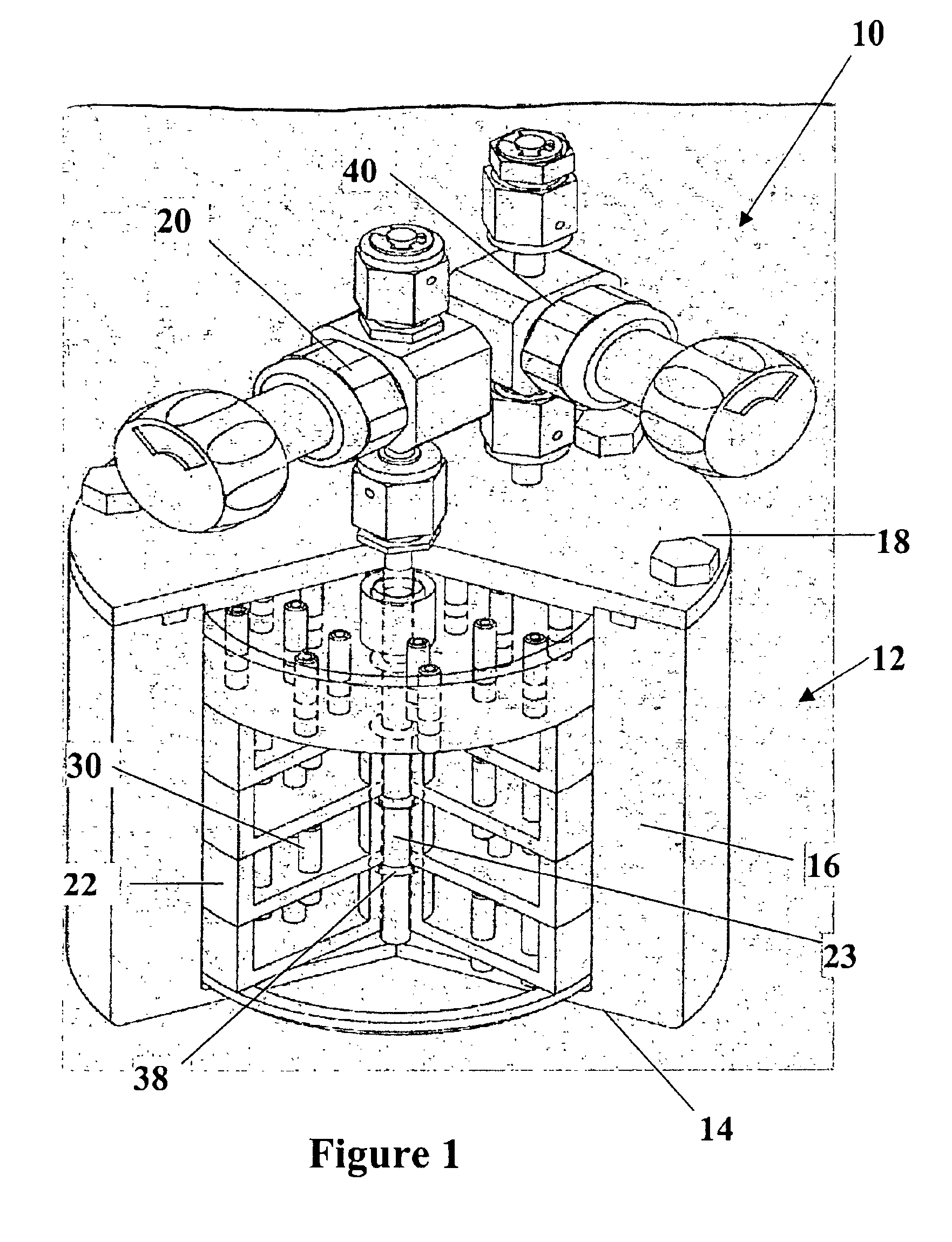

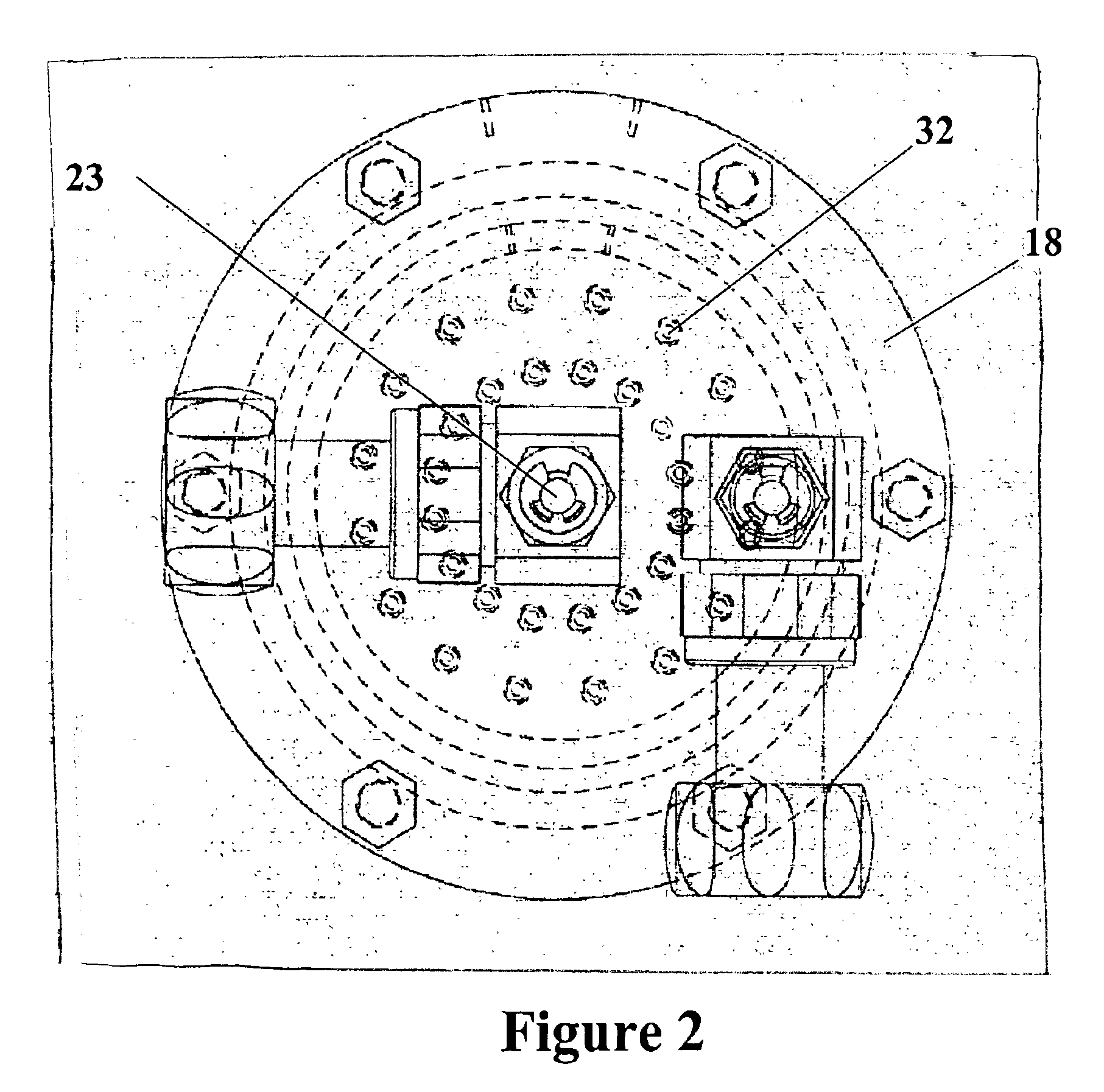

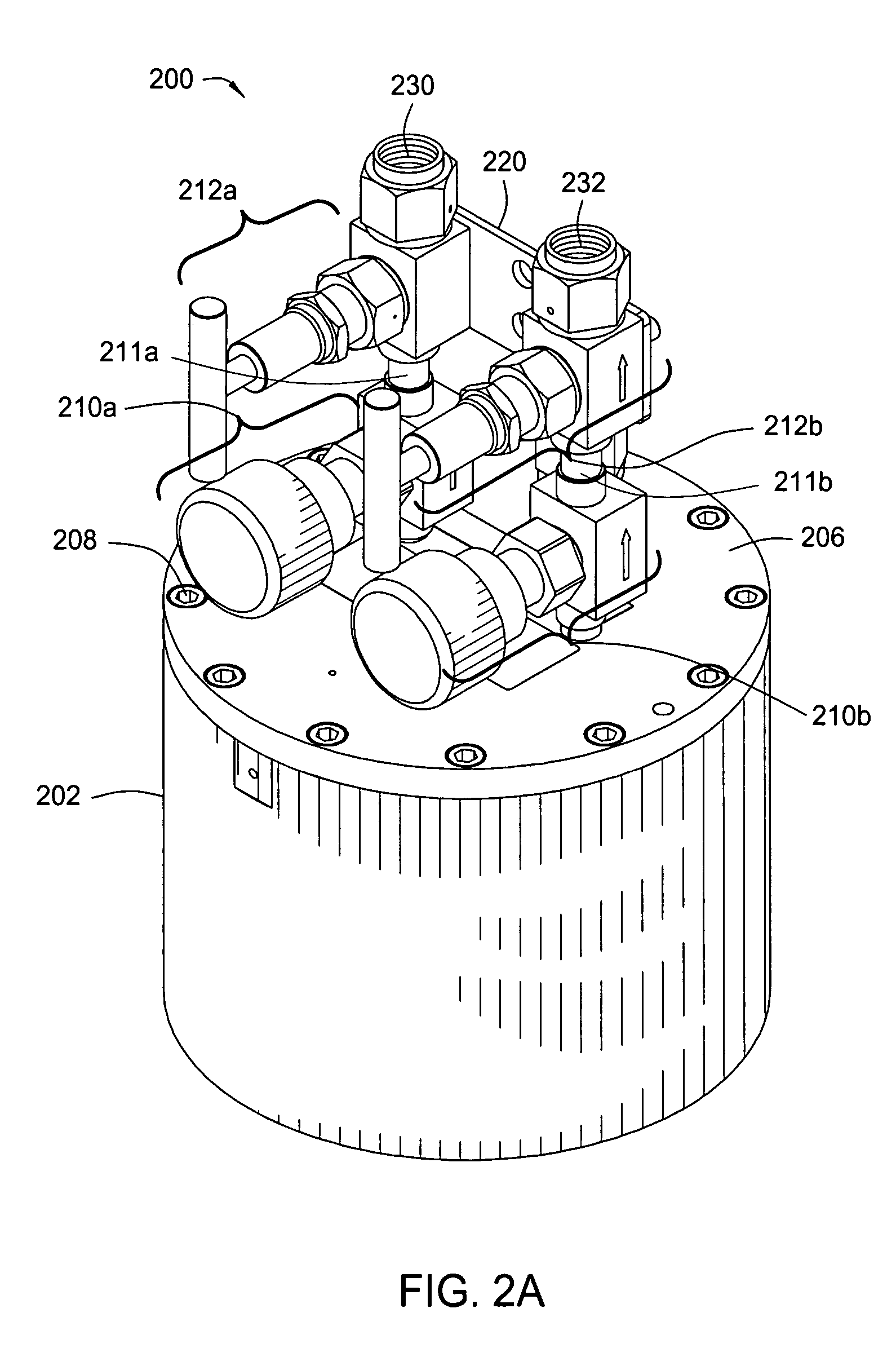

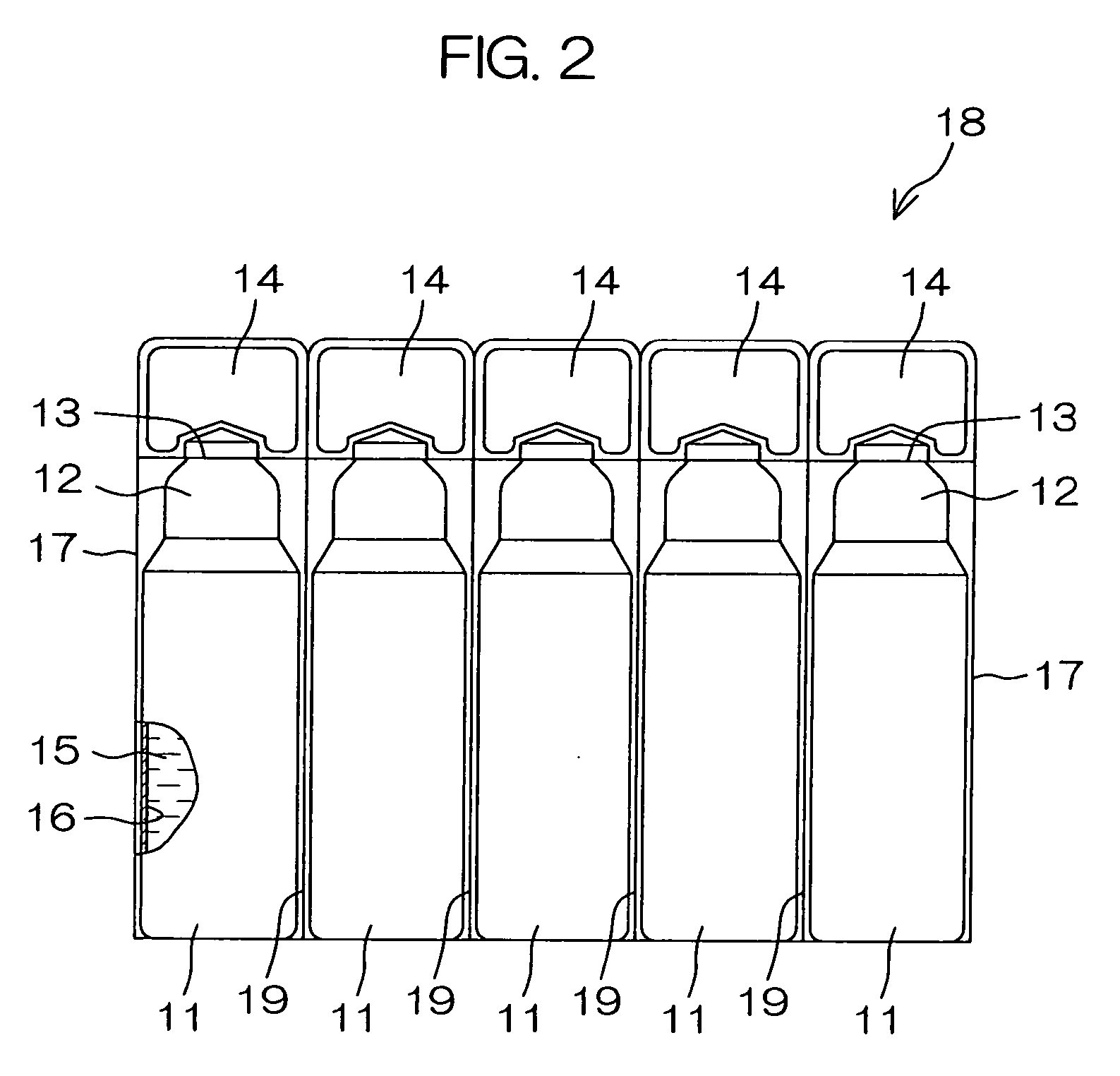

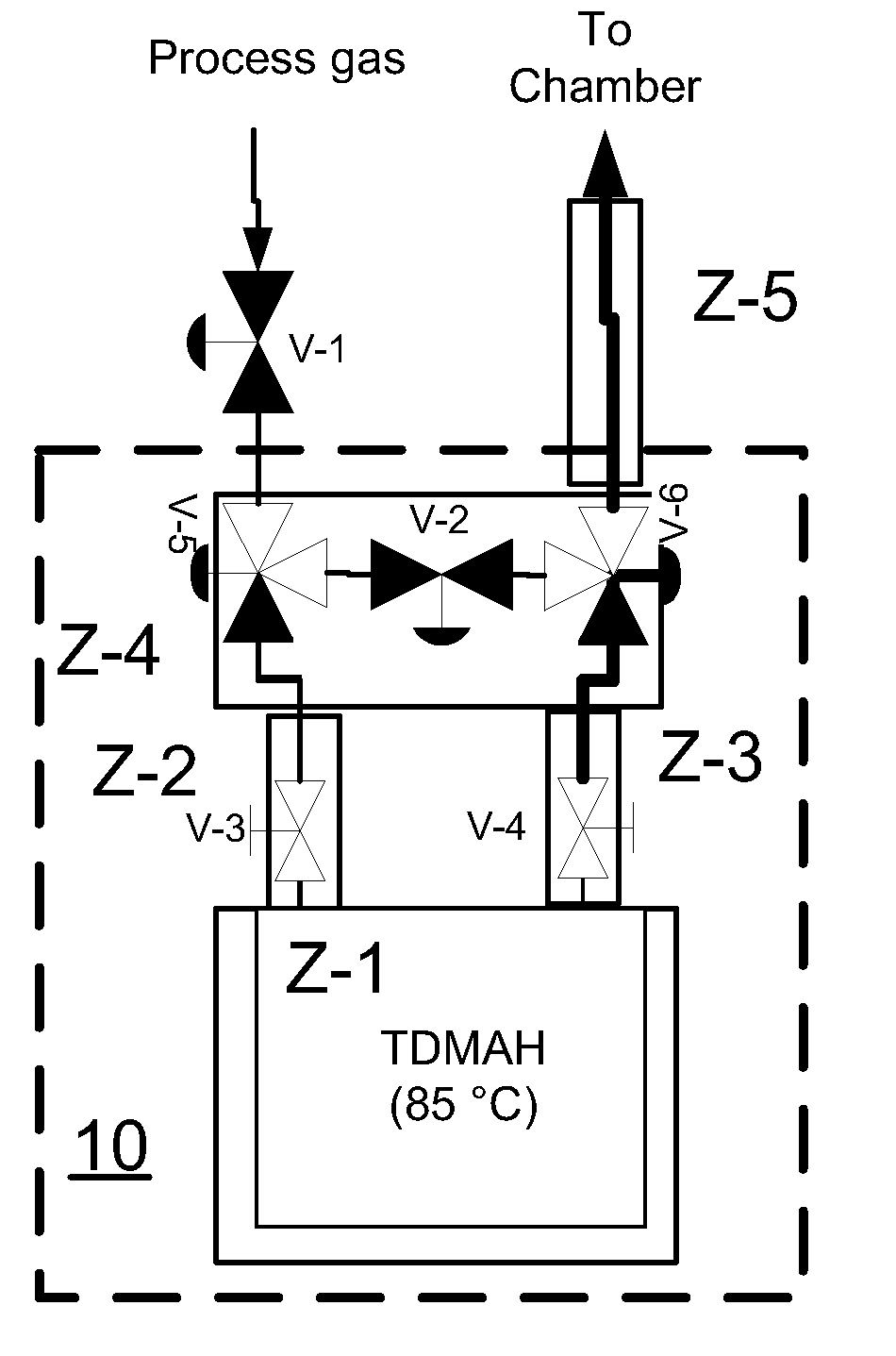

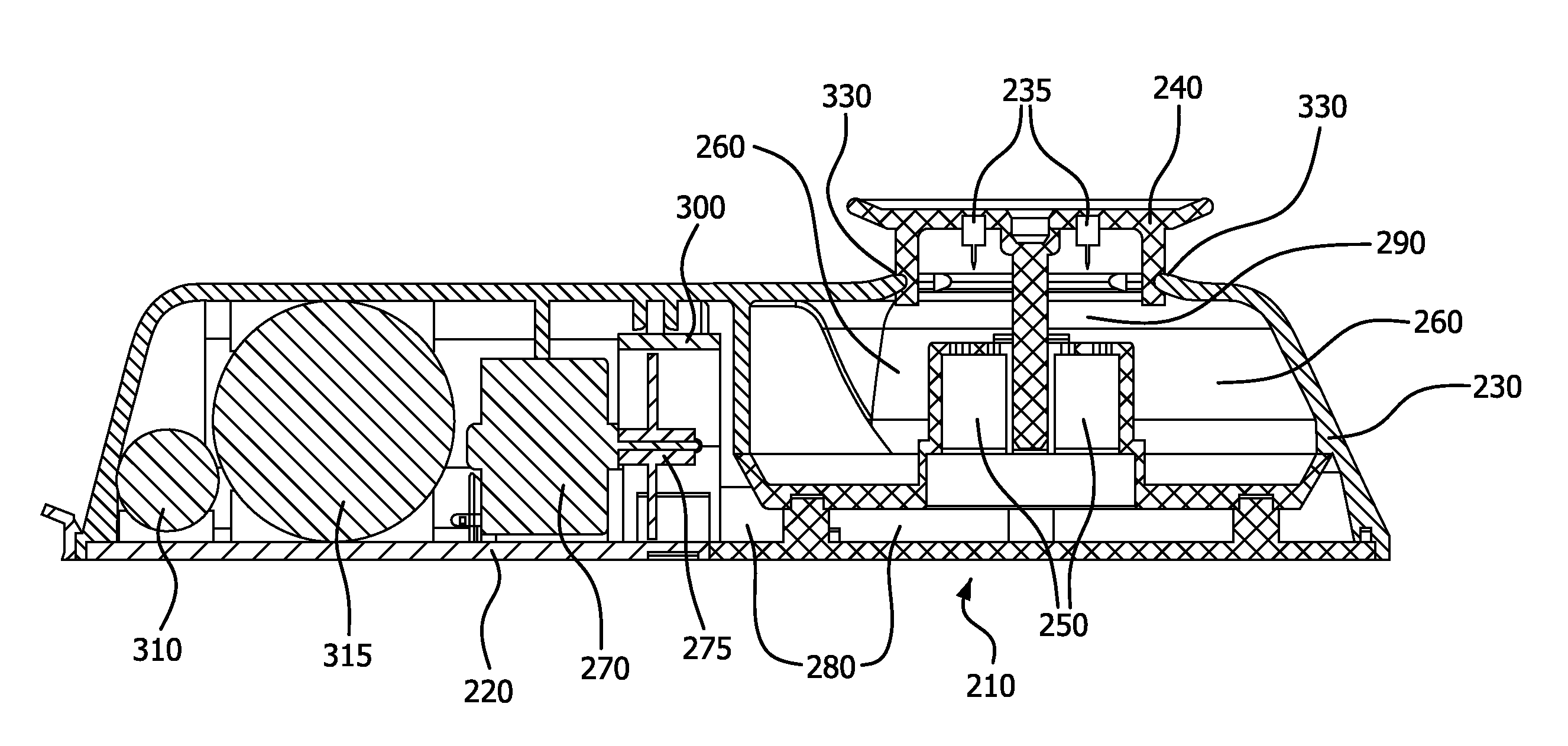

Heated valve manifold for ampoule

InactiveUS20090232986A1Chemical vapor deposition coatingSemiconductor/solid-state device manufacturingInlet channelPneumatic valve

Embodiments of the invention provide an apparatus and a method for generating a gaseous chemical precursor that may be used in a vapor deposition processing system. In one embodiment, the apparatus contains a valve manifold assembly, which includes a valve assembly body having at least one embedded electric heater, an inlet channel passing through the valve assembly body, a first pneumatic valve and a first manual valve coupled to the valve assembly body and positioned to control fluid flow within the inlet channel, an outlet channel passing through the valve assembly body, and a second pneumatic valve and a second manual valve coupled to the valve assembly body and positioned to control fluid flow within the outlet channel. The valve manifold assembly further contains a bypass channel connected to and between the inlet and outlet channels, and containing a bypass valve positioned to control fluid flow within the bypass channel.

Owner:APPLIED MATERIALS INC

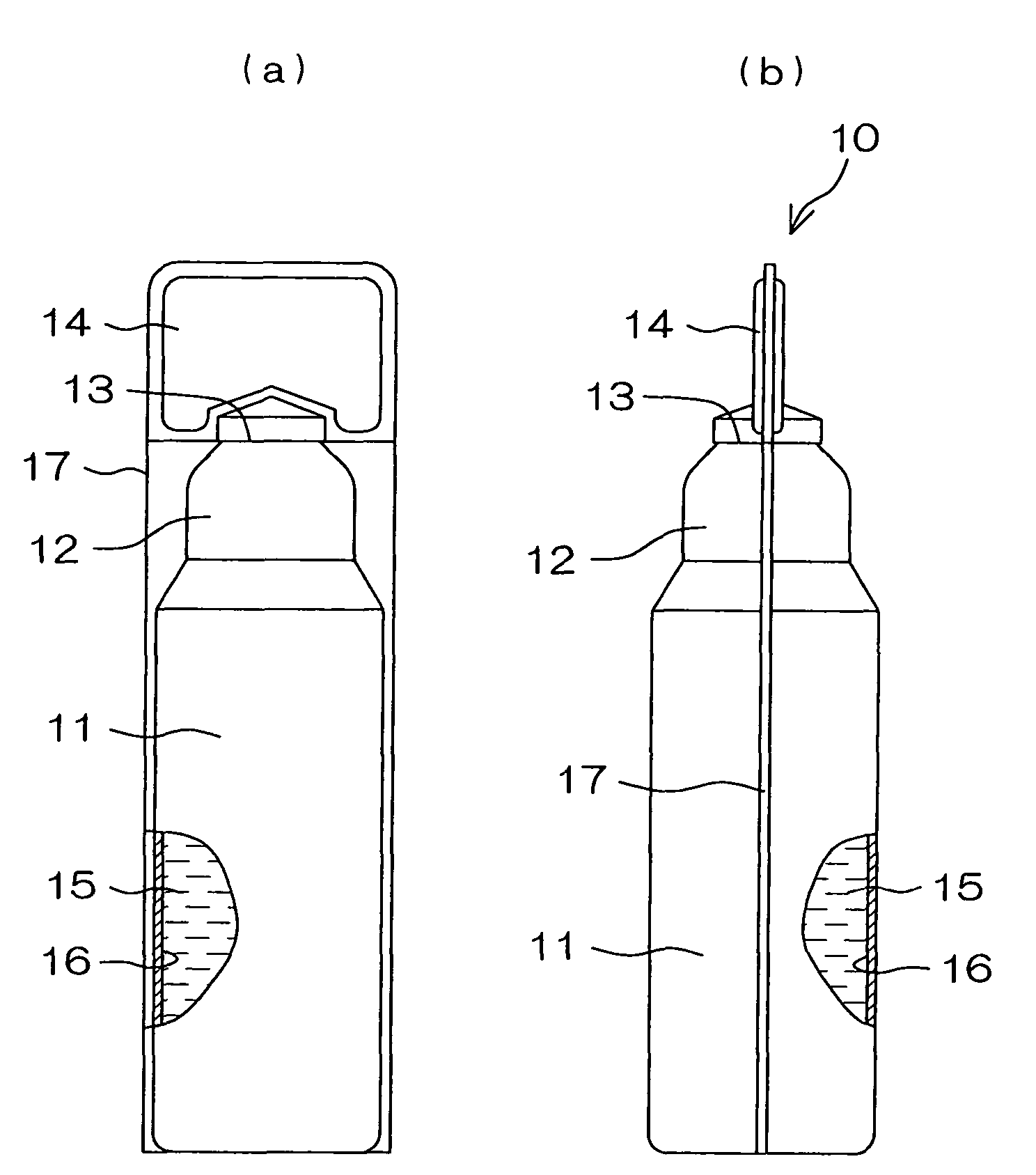

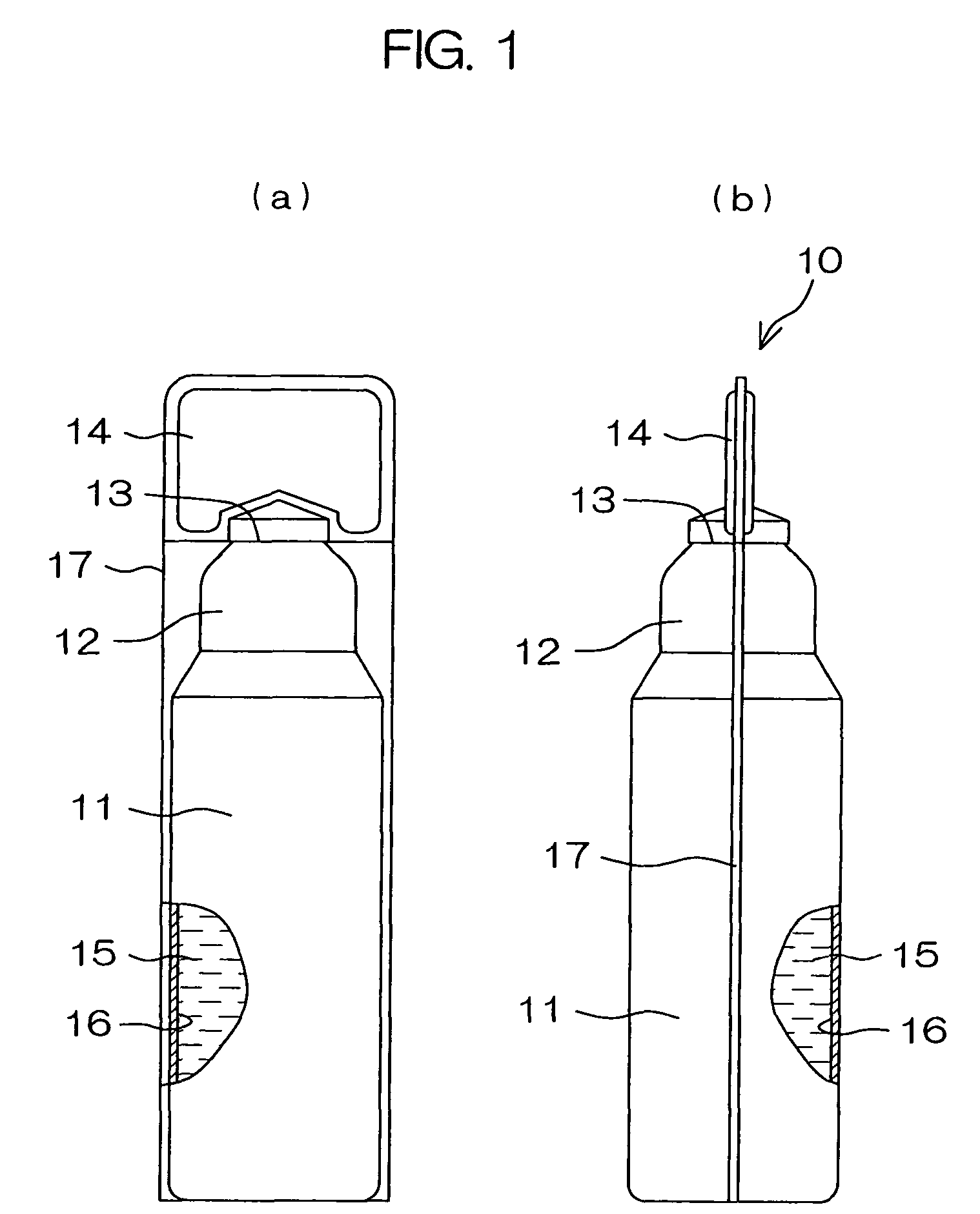

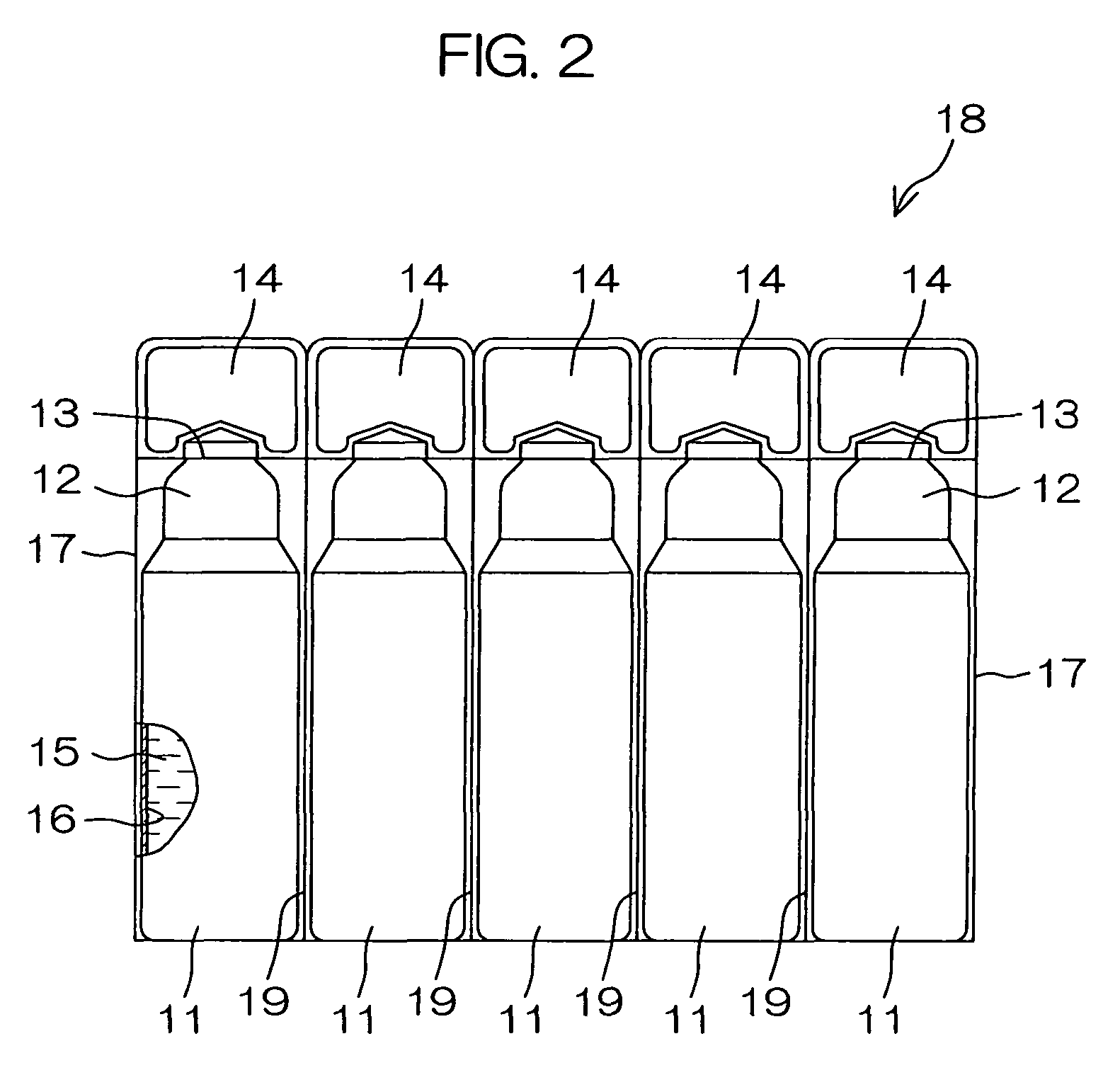

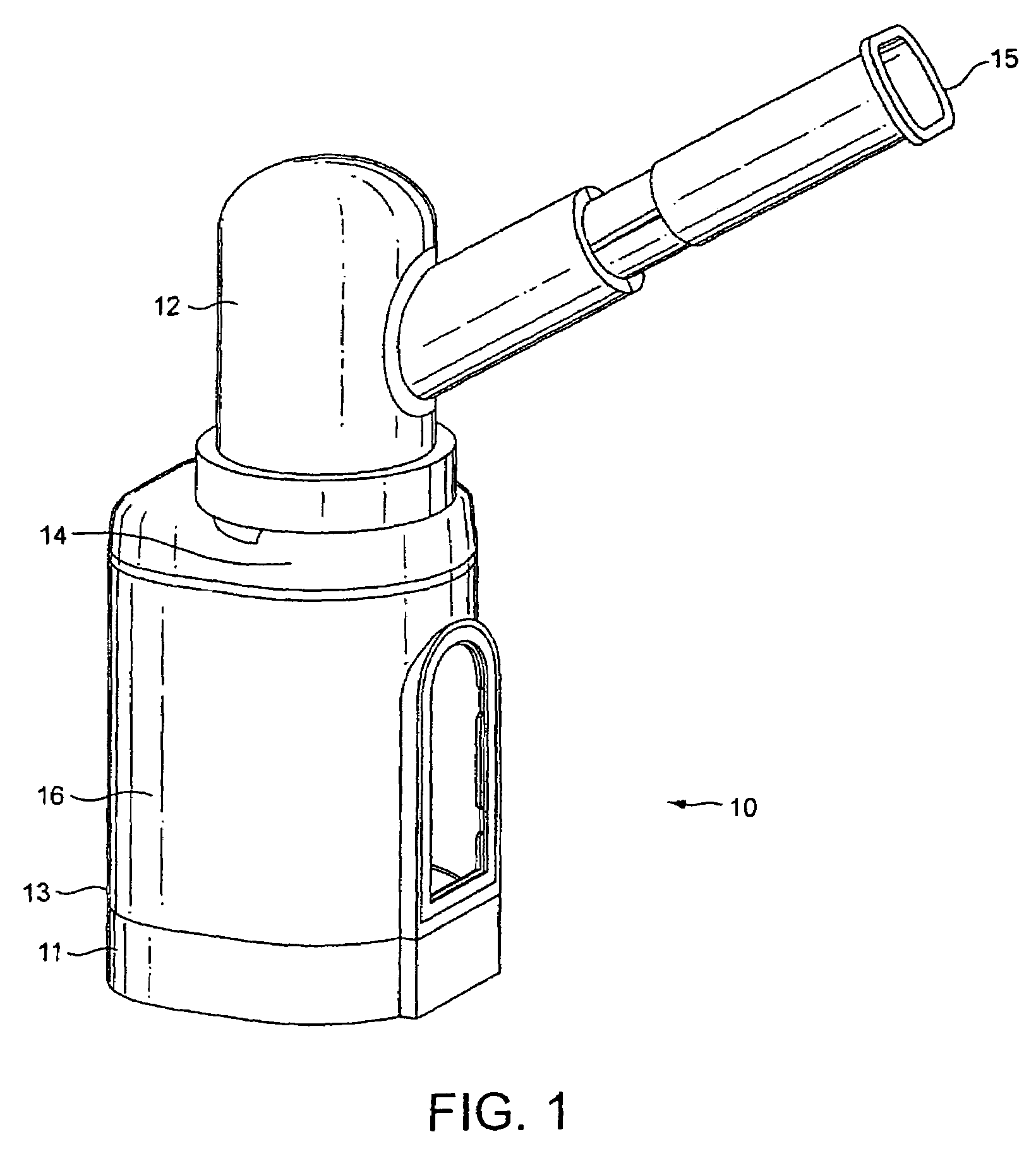

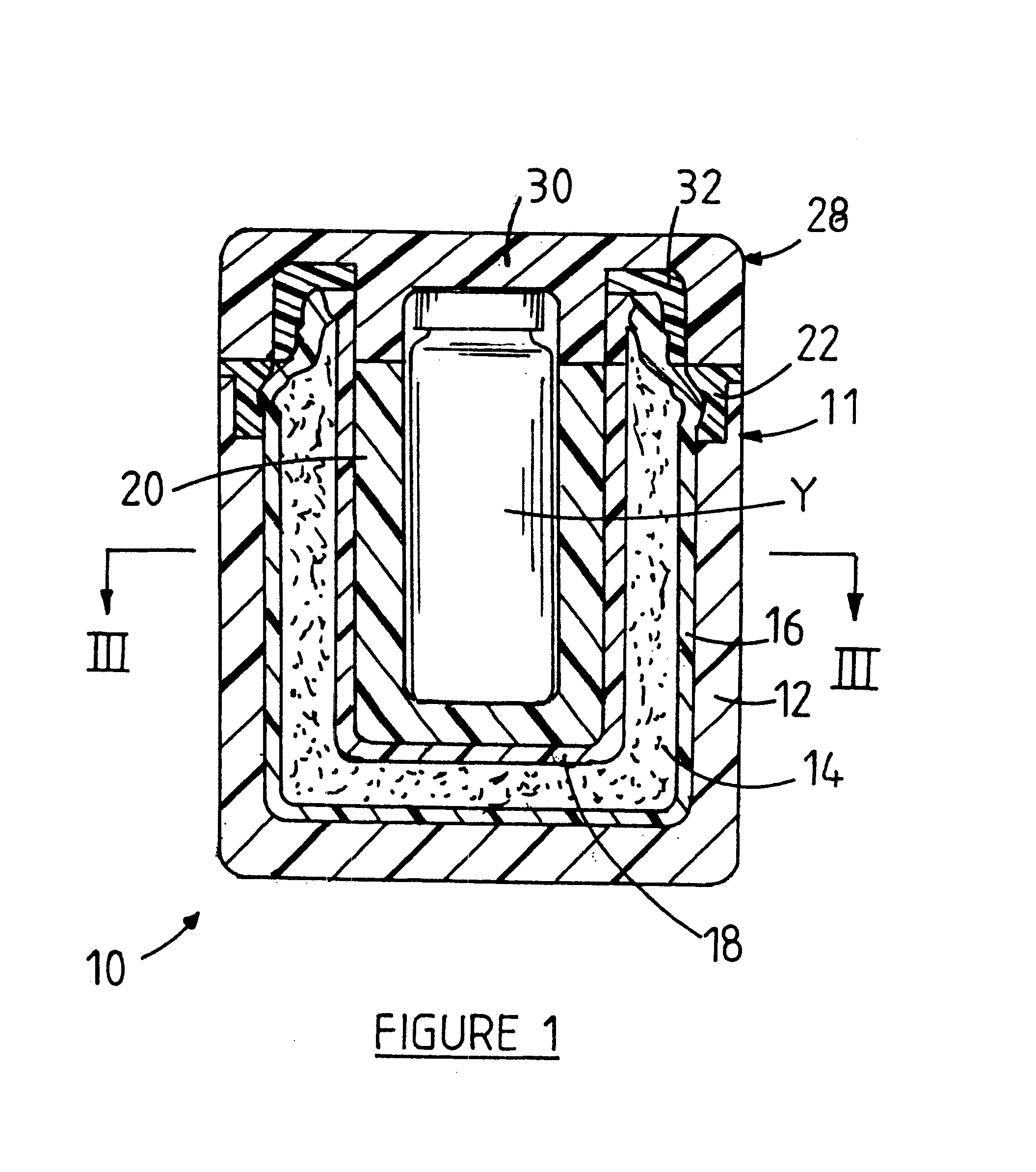

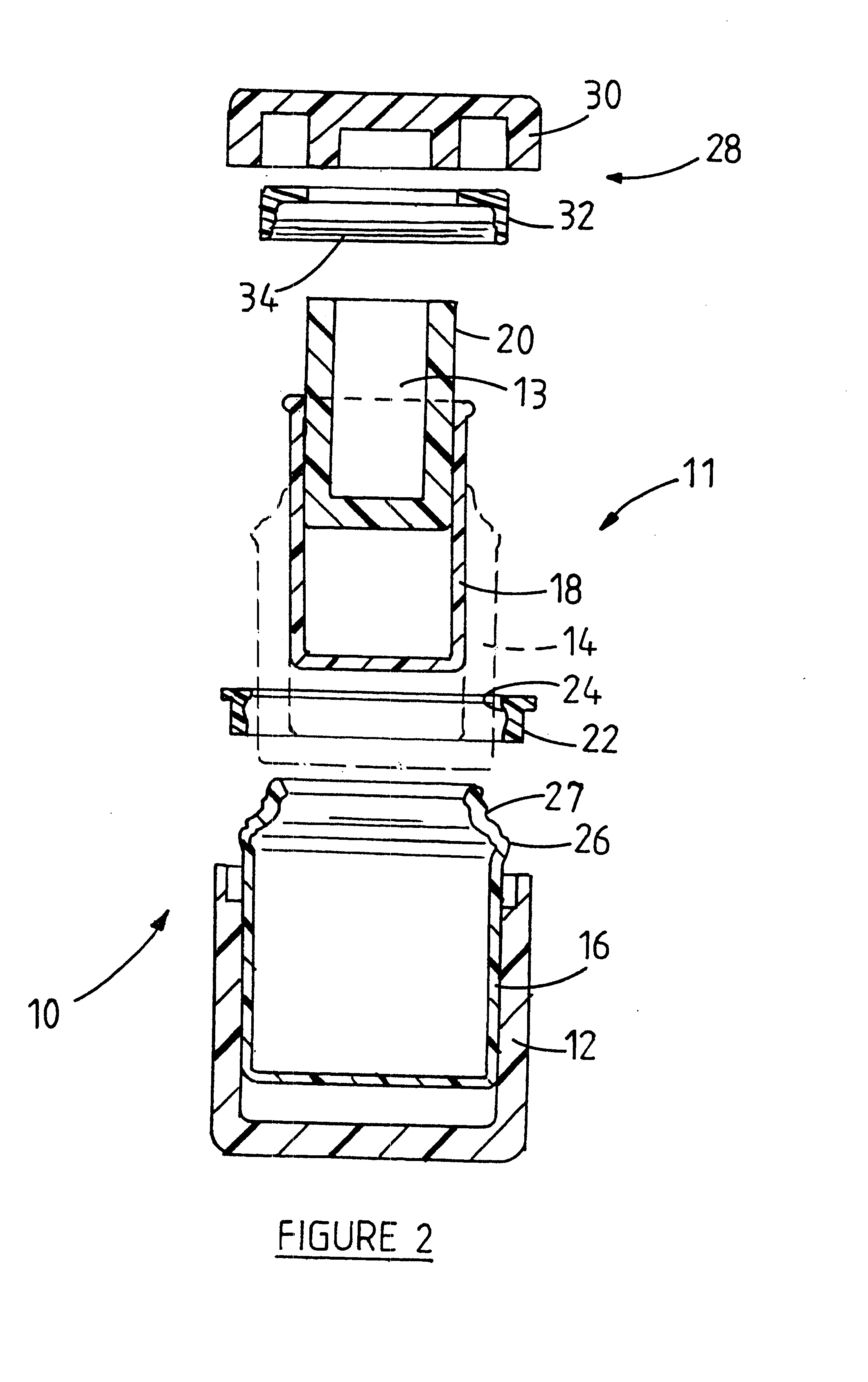

Drug solution filling plastic ampoule and process for producing the same

The present invention provides a drug solution filling plastic ampoule having gas, steam and light ray barrier properties, a drug permeation preventing capability and an absorption / adsorption preventing capability, and a production method for the plastic ampoule. The drug solution filling plastic ampoule (10) according to the present invention includes a container body (11), a fusion-bonded portion (13) which seals a mouth (12) of the container body, and a wrench-off holder tab (14) connected to the fusion-bonded portion. The ampoule (10) is formed from a parison including two or more layers, at least one of which is a functional layer having at least one characteristic property selected from the group consisting of a gas permeation preventing capability, a steam permeation preventing capability, a light ray permeation preventing capability, a drug permeation preventing capability and a drug absorption / adsorption preventing capability. That is, the parison is extruded from a multilayer blow forming die, and then held between lower split mold pieces to be formed into the container body (11). After a drug solution (15) is filled in the container body (11), the mouth (12) is held between upper split mold pieces to form the fusion-bonded portion (13) and the holder tab (14). Thus, the plastic ampoule is provided.

Owner:OTSUKA PHARM FAB INC

Multiple ampoule delivery systems

InactiveUS20090214779A1Easy to useReduce wasteLiquid surface applicatorsChemical vapor deposition coatingSemiconductor materialsDelivery system

This invention relates to an integrated vapor or liquid phase reagent dispensing apparatus having a plurality of vessels and a plurality of carrier or inert gas feed / vapor or liquid phase reagent delivery manifolds, that may be used for continuously dispensing vapor or liquid phase reagents such as precursors for deposition of materials in the manufacture of semiconductor materials and devices.

Owner:PRAXAIR TECH INC

Ampoule for the storage and dispersion of volatile liquids

In one aspect, the present invention is directed to an ampoule for the storage and dispersion of a volatile liquid comprised of (a) an outer shell composed of an impermeable material and defining at least one opening; (b) a porous diffusion member defining an internal reservoir positioned inside said outer shell; (c) a volatile liquid contained within such internal reservoir; and (d) a film member adhered to said outer shell and covering said at least one opening; wherein said film member is disposed such that an air space is present between said porous diffusion member and said film member; and wherein said porous diffusion member is configured such that molecules of the volatile liquid can only enter into said air space via diffusion through said porous diffusion member. Such ampoules are particularly suited for the storage and dispersion of organic chemicals useful as bed bug attractants, especially where such attractants are formulated in a highly volatile liquid, such as a C8-C12 alkane. In another aspect, this invention is directed to a device adapted to receive one or more of such ampoules. In one preferred embodiment, such device is a bed bug capturing device.

Owner:FMC CORP

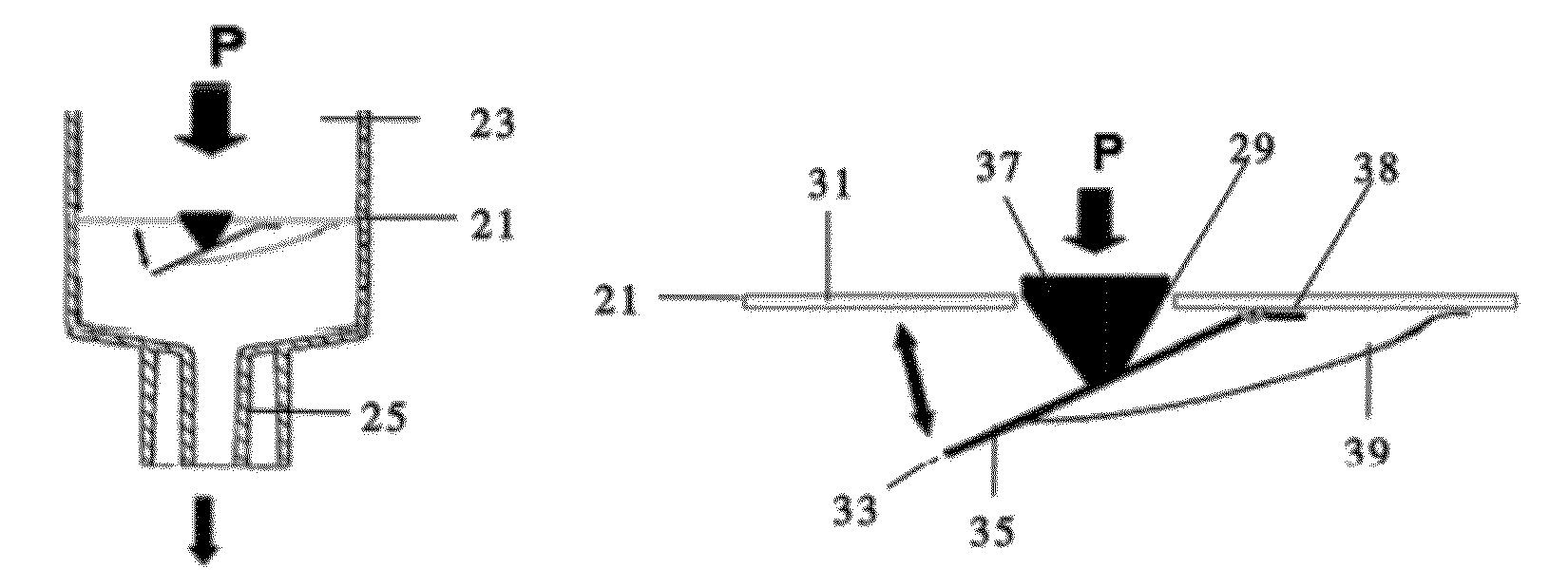

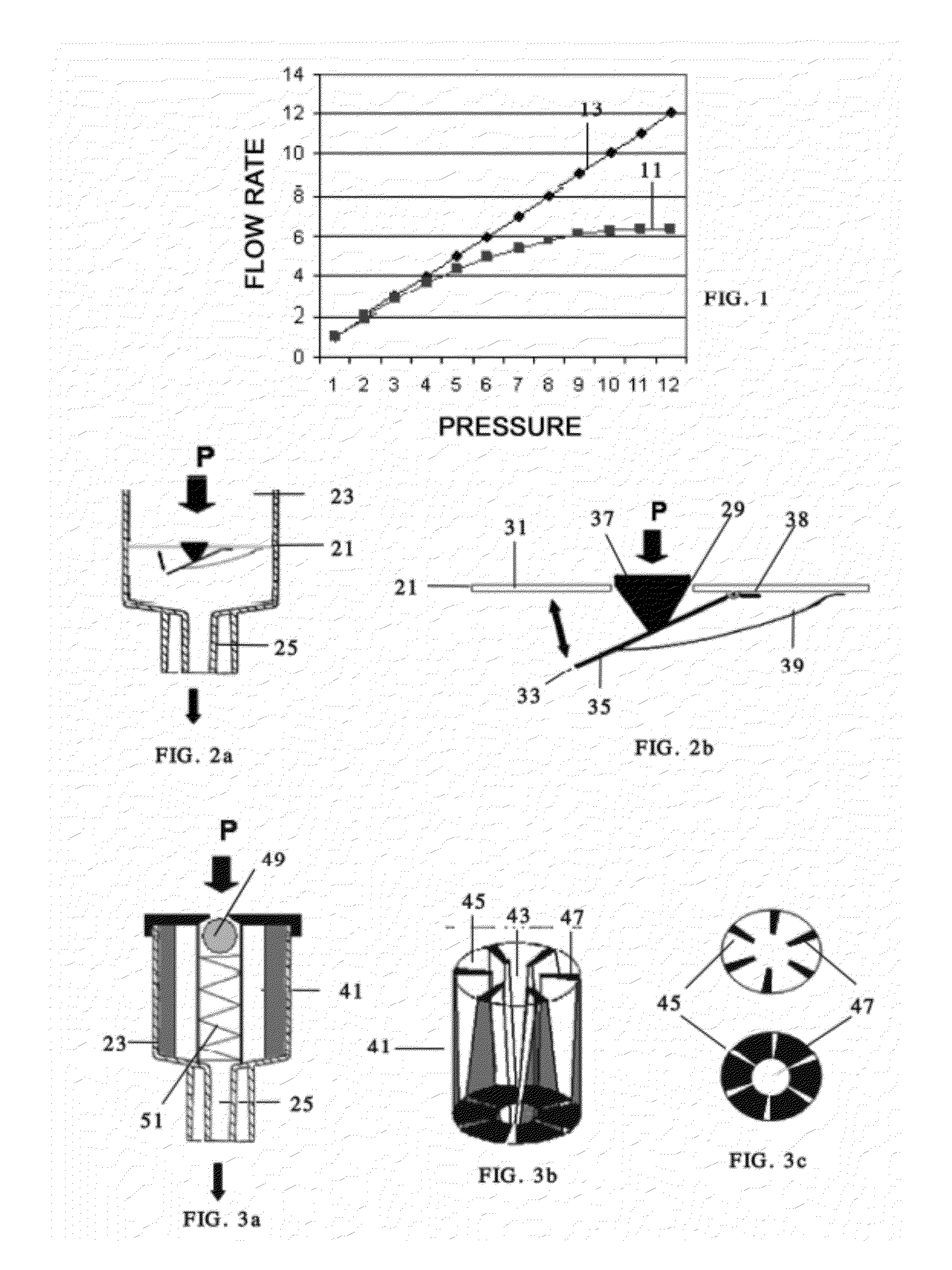

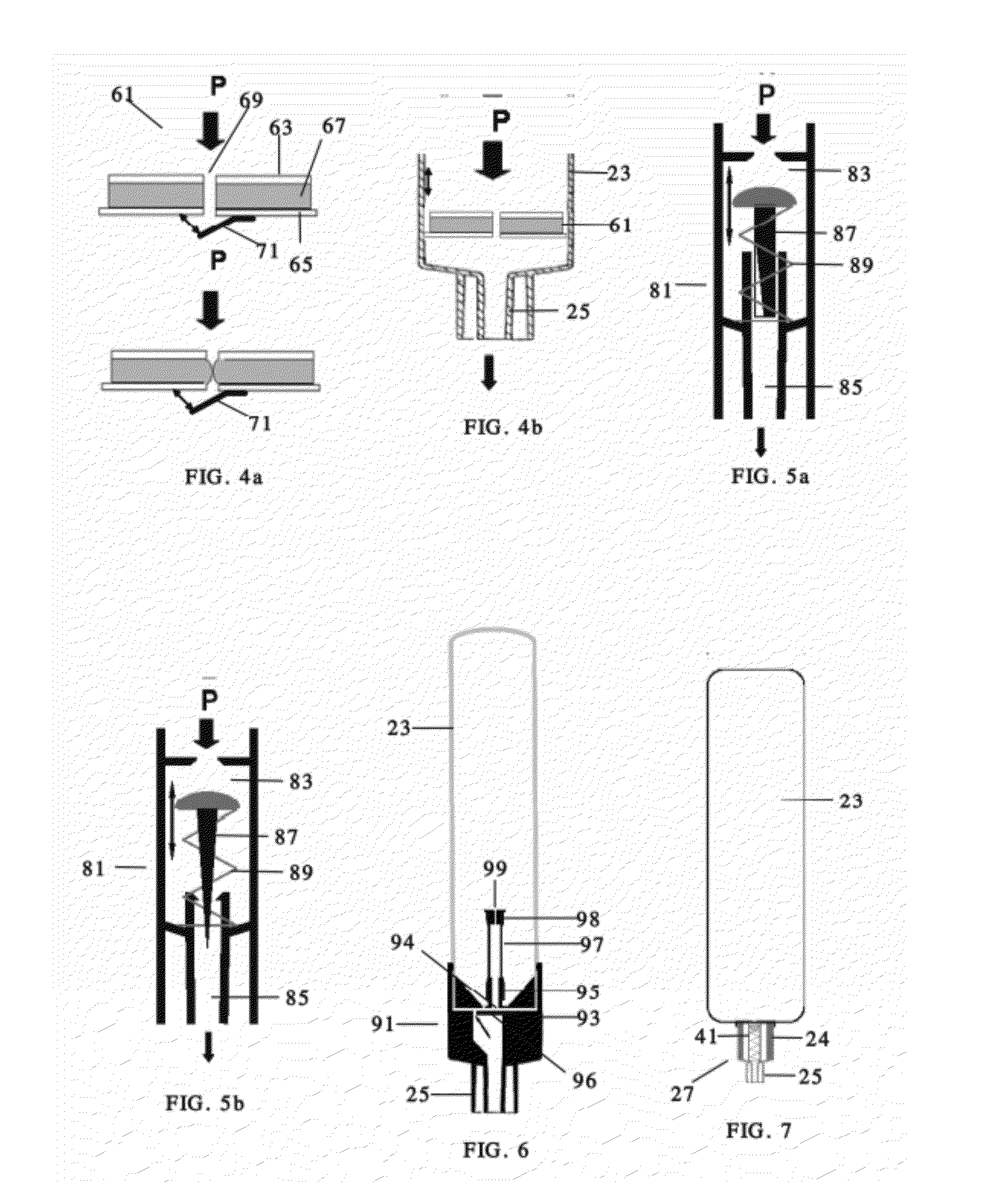

Device for the administration of injectable products with a controlled flow rate

A device is for the administration of injectable products with controlled flow rate, with a container (23) in the form of both a syringe and an ampoule preloaded with the injectable product, an injection port (25) and a control valve (21) for controlling the outlet rate and pressure arranged between the injectable products and the injection port (25). A device for reducing the outlet flow rate depends on the pressure increase applied during the administration of the injectable product, the administration being moderated by closing the valve (21) when the pressure exceeds a predetermined limit. A device prevents the backflow of fluids during the administration of the injectable product. The valve (21) can be positioned both in the container (23) and at an injection end (27) including the injection port (25) which is coupled to the container (23).

Owner:INNOVA SALUD DESARROLLOS SANITARIOS

Liquid applicator for coloring a liquid

InactiveUS6991393B2Non-uniform distributionLiquid surface applicatorsMedical applicatorsAmpouleBiomedical engineering

A method of making a liquid applicator having a flexible hollow body within which a liquid-filled, frangible ampoule is received. The liquid applicator also has a porous element containing colorant positioned such that when the ampoule is fractured, the liquid flows through the porous element containing colorant. Colorant is transferred to the liquid as it flows through the porous element. The resulting colored solution may be applied to a desired surface.

Owner:CAREFUSION 2200 INC

Hypodermic injection system

ActiveUS20080015512A1Increase speedMeet needsAmpoule syringesJet injection syringesMultiple injectionDiluent

A hypodermic injection system particularly for use in mass immunizations having a handpiece with a grasping mechanism for holding ampules filled with injectate, a plunger for driving into the ampule to discharge the injectate in an injection process, an injection spring mechanism for driving the plunger, a motor and / or manual mechanism for cocking the injection spring mechanism, and an ampule ejection mechanism for ejecting ampules after use under control of a release mechanism. Ampules can be loaded, used and ejected without contact by the user of the system or the patient being injected. Also disclosed are a filling station for filling ampules through their injection orifices, and an arming device for setting the injection spring. Ampules are disclosed having a piston which is drivable towards an orifice to discharge injectate through the orifice. Ampules are also disclosed having enlarged proximal portions for easy grasping by the grasping mechanism of the injector. Ampules are further disclosed with separators for mixing lyophilized medication and a diluent. Further disclosed are magazines for holding ampules for sequential use by the hypodermic injector. The disclosed system finds particular use as a mass immunization kit for making numerous injections in the field.

Owner:DANTONIO CONSULTANTS INT INC

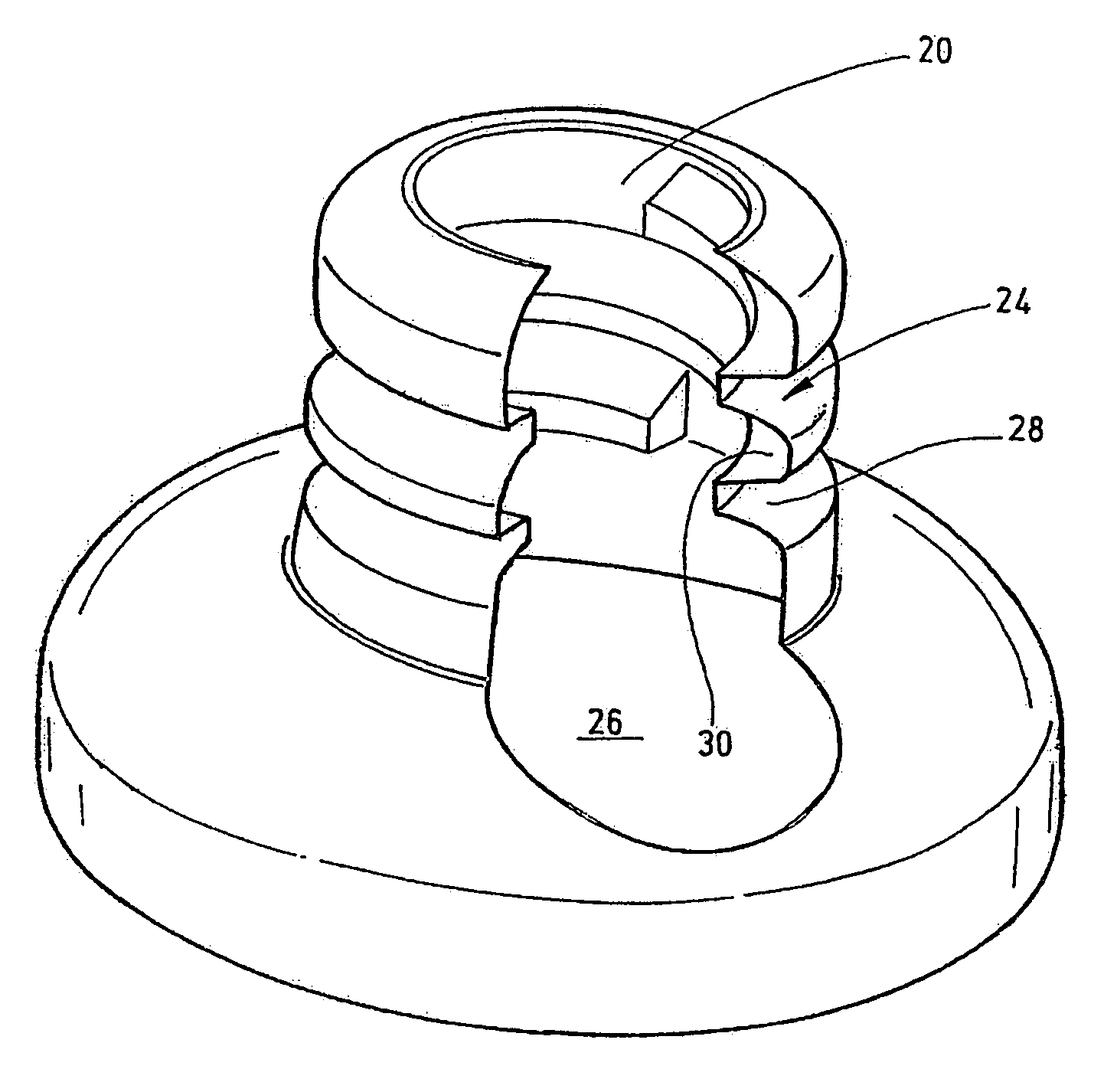

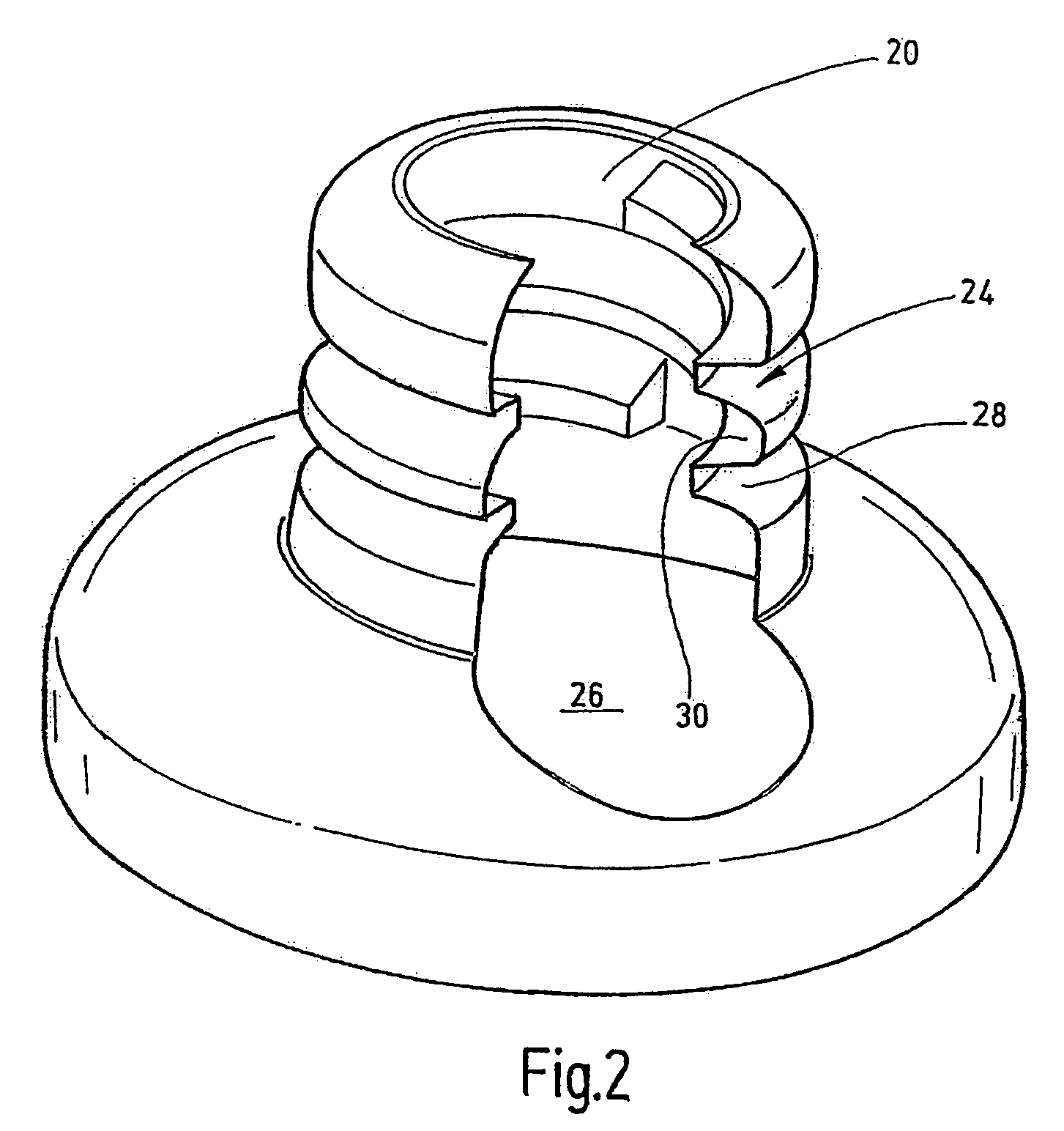

Ampoule

ActiveUS7516846B2Simple designReliable fillingSmall article dispensingBottlesEngineeringChannel types

A plastic ampoule includes a container (12) for receiving a defined fluid, with a neck (14) that can be closed by a head (16). The neck has a channel-type entrance port (24) for air to the interior (26) of the container (12). The fluid can be safely stored and a syringe or needle base is reliably filled at any speed of withdrawal by the syringe or needle base. For this purpose, the entrance port (24) for air includes at least one ring channel (28, 30) that is at least partially disposed on the outer and / or inner periphery of the neck (14).

Owner:HANSEN BERND

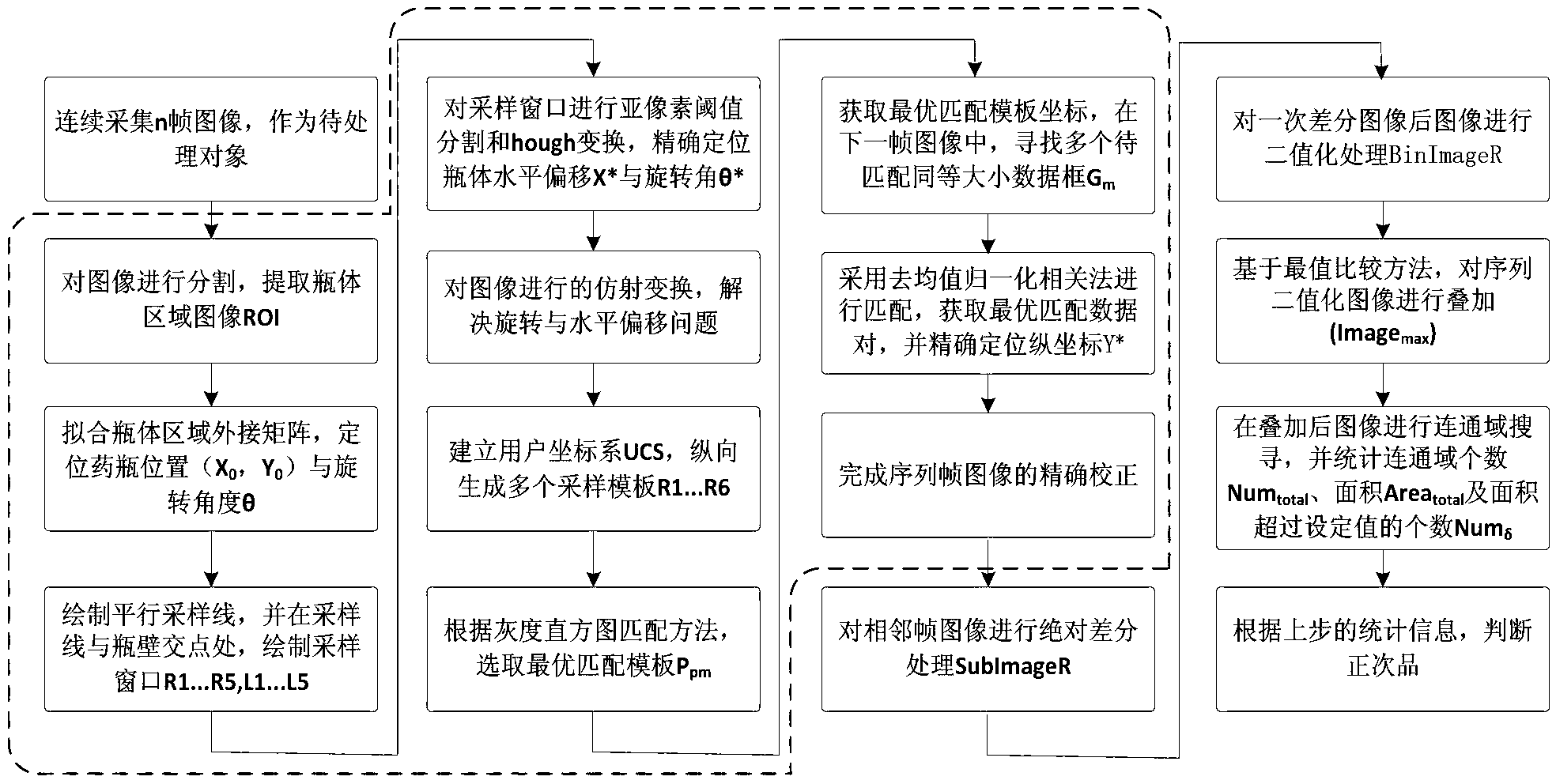

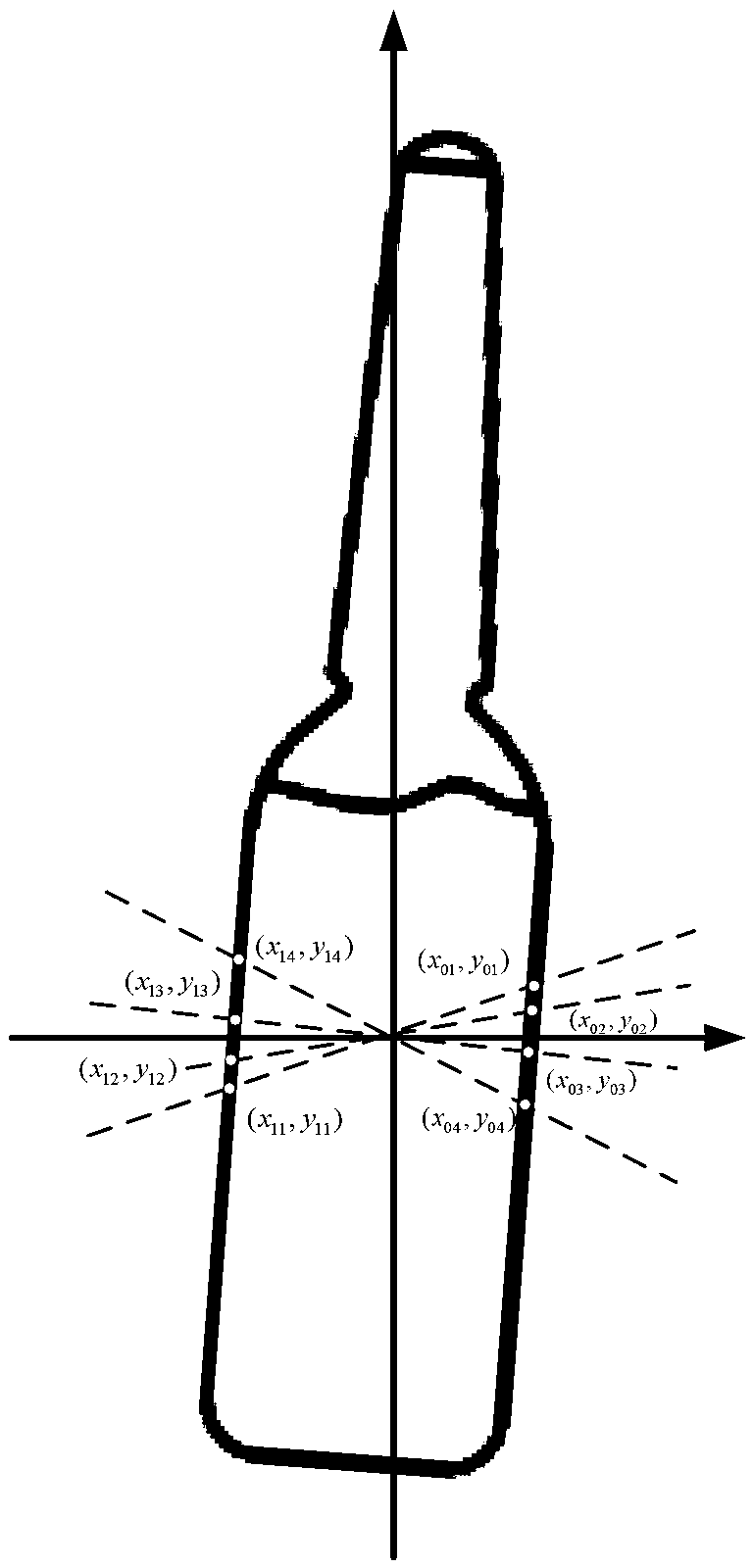

Medicine bottle foreign matter detection method based on medical visual detection robot image correction

ActiveCN103226814ARealize eligibility judgmentImprove detection accuracyImage enhancementForeign matterTemplate matching

The invention discloses a medicine bottle foreign matter detection method based on medical visual detection robot image correction. The method comprises the following steps: accurately calculating the rotating angle and the horizontal offset of a medicine bottle on the basis of determining the characteristic of the medicine bottle; determining the longitudinal offset in a maximal matching degree mode based on a template matching method; realizing precision correction of an image; and realizing eligible judgment of medical foreign matters through differentiation, binaryzation, superposition and the like. The sequence image high-precision registering method can be used under the environment of insufficient medical anti-shaking inhibition, effectively makes up the shortage of hardness, and is suitable for high-speed high-precision detection of a visual detection robot for medical foreign matters of ampoule, infusion solution, oral liquid, soft bags and the like.

Owner:HUNAN UNIV

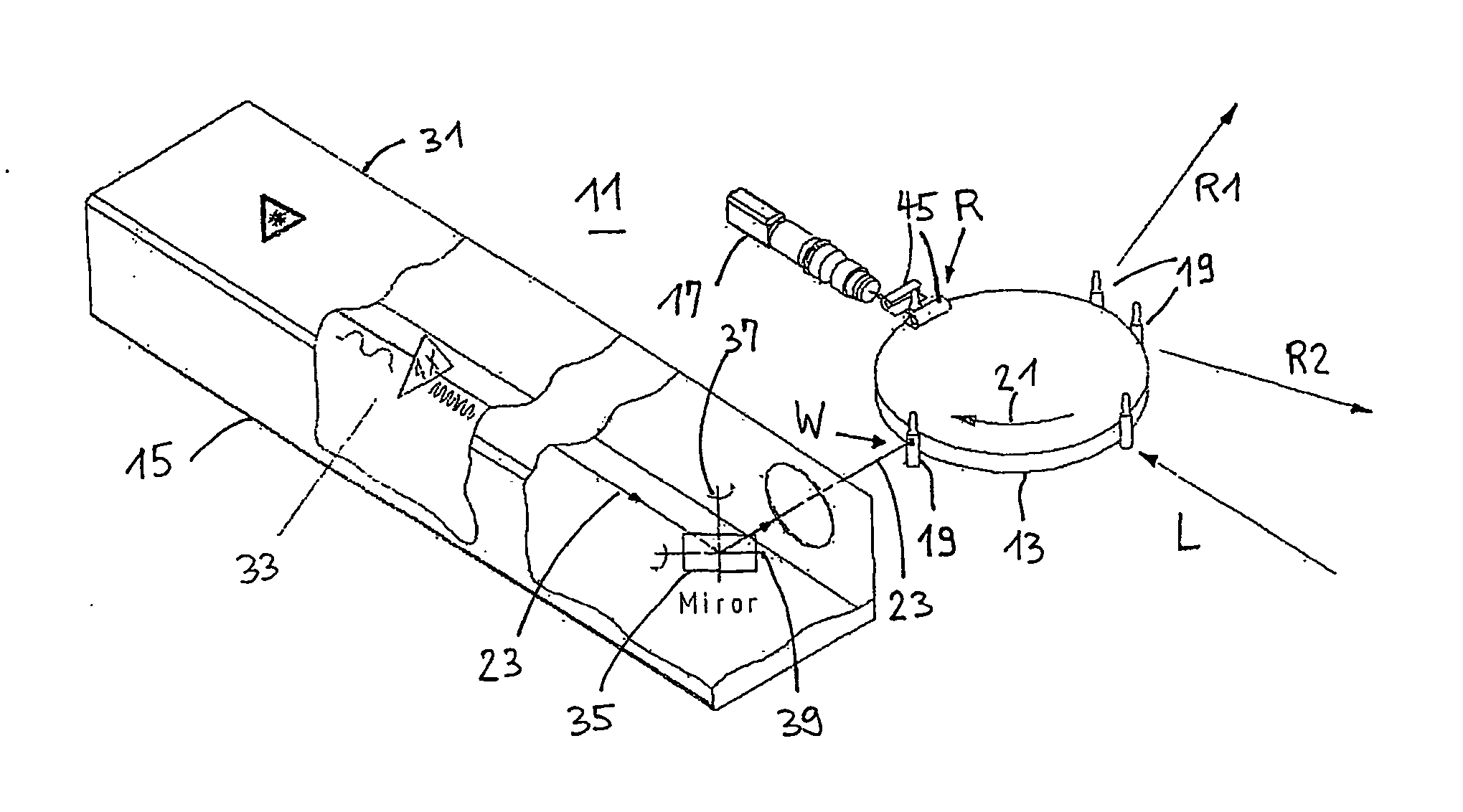

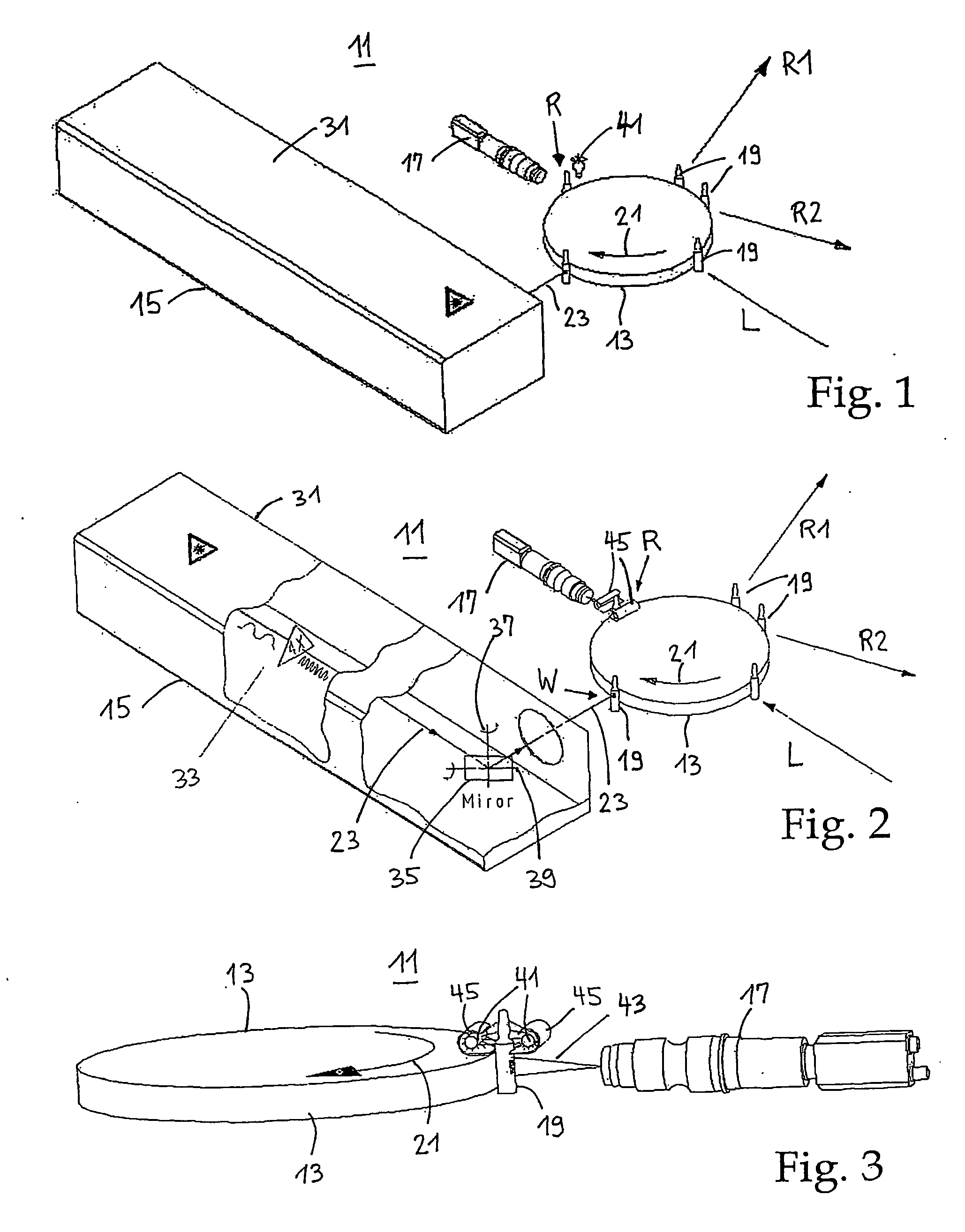

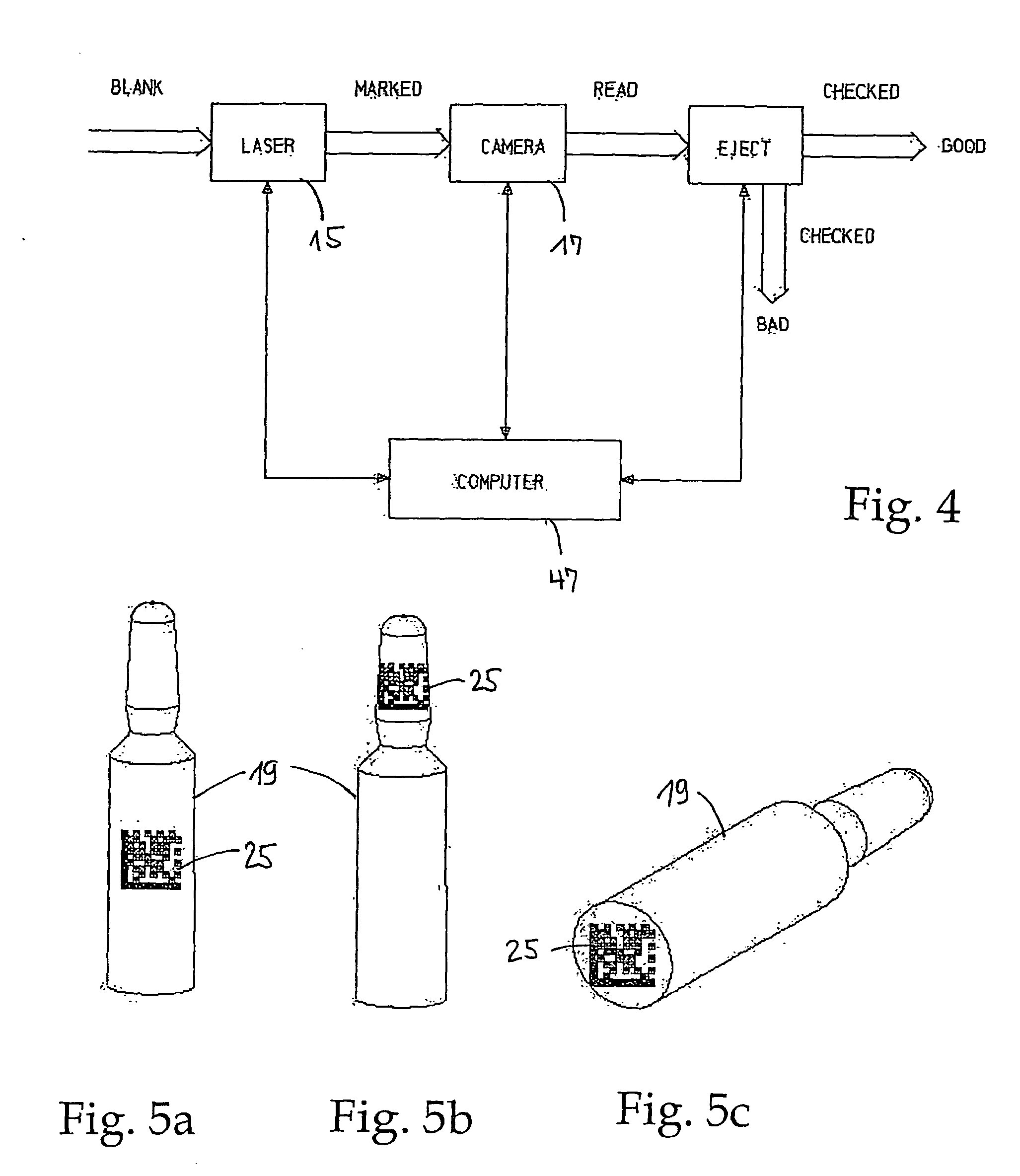

Method and a device for depositing a wipe-proof and rub-proof marking onto transparent glass

InactiveUS20050218126A1Free from damageDigitally marking record carriersDecorative surface effectsControl signalLight beam

A device for depositing a wipe-proof and rub-proof marking or code marking, in particular a two-dimensional matrix or line coding onto glass receptacles such as glass ampoules, glass bottles, vials and likewise, comprises a transport means having a drive, with one or more accommodating devices for objects to be inscribed, a laser system arranged at a distance to the transport means with a laser source for producing a laser light beam of a wavelength <380 nm, said laser light beam in operation being directed onto the transport path and defining an impingement point in the region of at least one accommodating means moved along the transport path, means in order to deflect the laser light beam in a first and in a second direction continuously or in certain incremental intervals, and at least one control unit comprising a memory unit and a microprocessor which is in connection with the laser system and the deflection means, for controlling at least the deflection system and the laser system. The device further comprises a transport means designed for the transport of glass receptacles to be marked, along a transport path, a means for detecting or determining at least the position of at least one accommodating means or a glass receptacle accommodated therein at least one position along the transport path, said means being in connection with the control unit, and a program stored in the memory unit, which triggers the laser in dependence on the position of the glass receptacle to be inscribed, as well as at least one marking pattern, according to which the deflection means for writing the 2D marking is moved in a first and in a second direction. A read means is provided or arranged at a defined read position along the transport path after the laser system in the transport direction, for detecting the marking previously written by the laser system, said read means being in connection with the control unit. In the control unit there is further present a program or a program procedure which compares the stored marking pattern to the marking detected by the read means and provides a control signal in dependence on the result of the comparison, at the output of the control unit.

Owner:FREWITT PRINTING

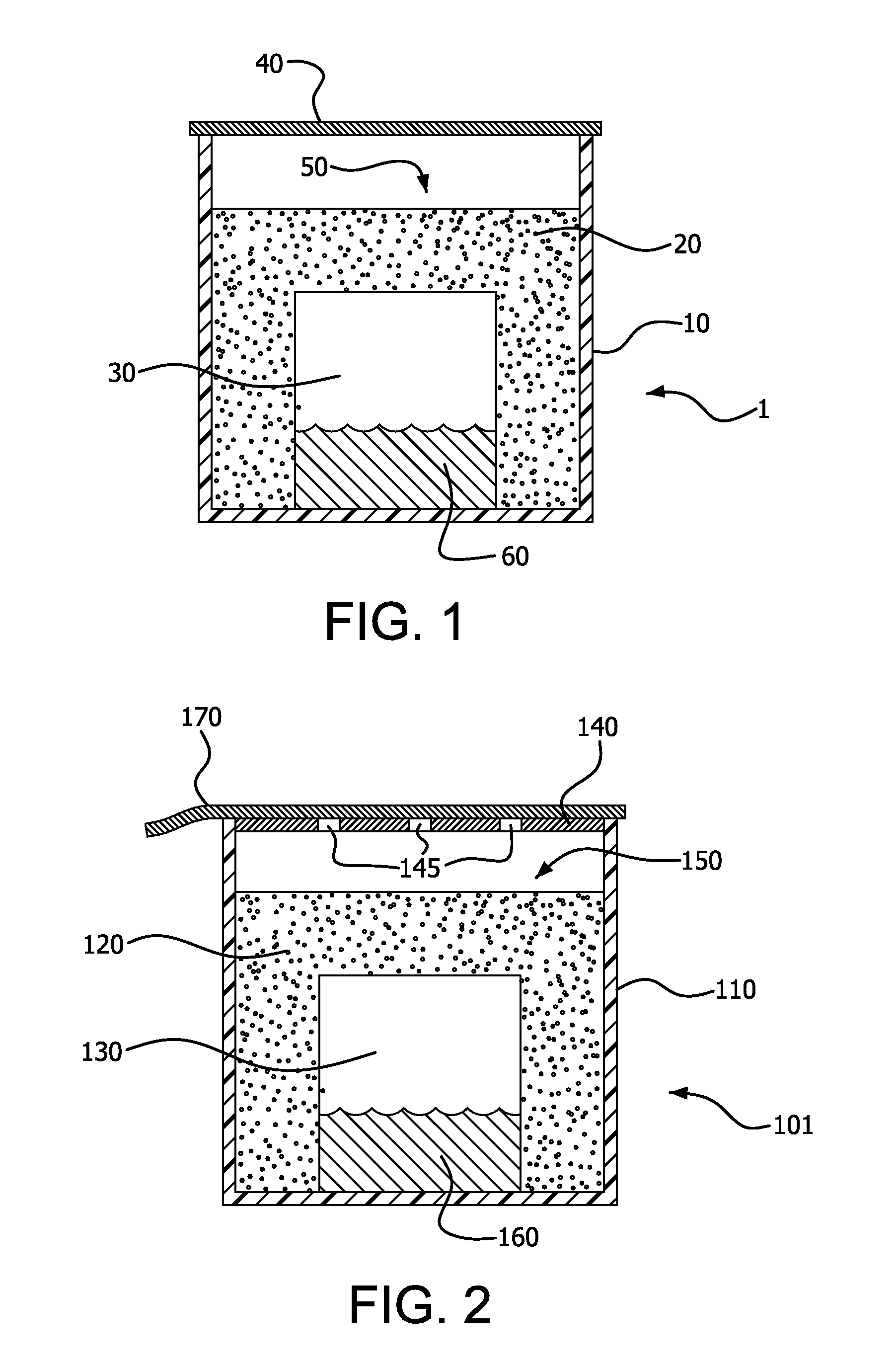

Container for a vial or ampoule

InactiveUS6467299B1Lighting and heating apparatusPharmaceutical containersPlastic materialsEngineering

A portable container (10) suitable for housing and protecting vials (Y) ampoules and other small vessels containing pharmaceutical or veterinary preparations such as vaccines, which are sensitive to changes in temperature or to relatively high temperature, is provided. The container (10) comprises a layered wall (11) defining a centrally located cavity (13) for receiving the vial (Y). The wall (11) includes an outer thermally insulating layer (12) surrounding a substance (14) for providing a passive cold source to the cavity (13) and two spaced inner layers (16 and 18) of a relatively hard plastics material providing an annular chamber wherein the substance (14) is received.

Owner:TRIPLE CCC CC

Device for withdrawing a liquid from a sealed glass ampoule

InactiveUS6099510ASimple designAvoid changeOpening closed containersBottle/container closureEngineeringAmpoule

A device for withdrawing a liquid from a sealed glass ampoule includes a frame holding the sealed glass ampoule in upright or slightly inclined position, such that a tip of the ampoule points upwardly. An element is provided which will press or knock against the side of the tip or neck of the ampoule in order to break the tip of the ampoule in the region of the neck. The device further includes a withdrawing element which can be introduced into the glass ampoule in an area between the bottom of the ampoule and the surface of the liquid therein, and which includes a cannula for withdrawing the liquid.

Owner:AVL MEDICAL INSTR

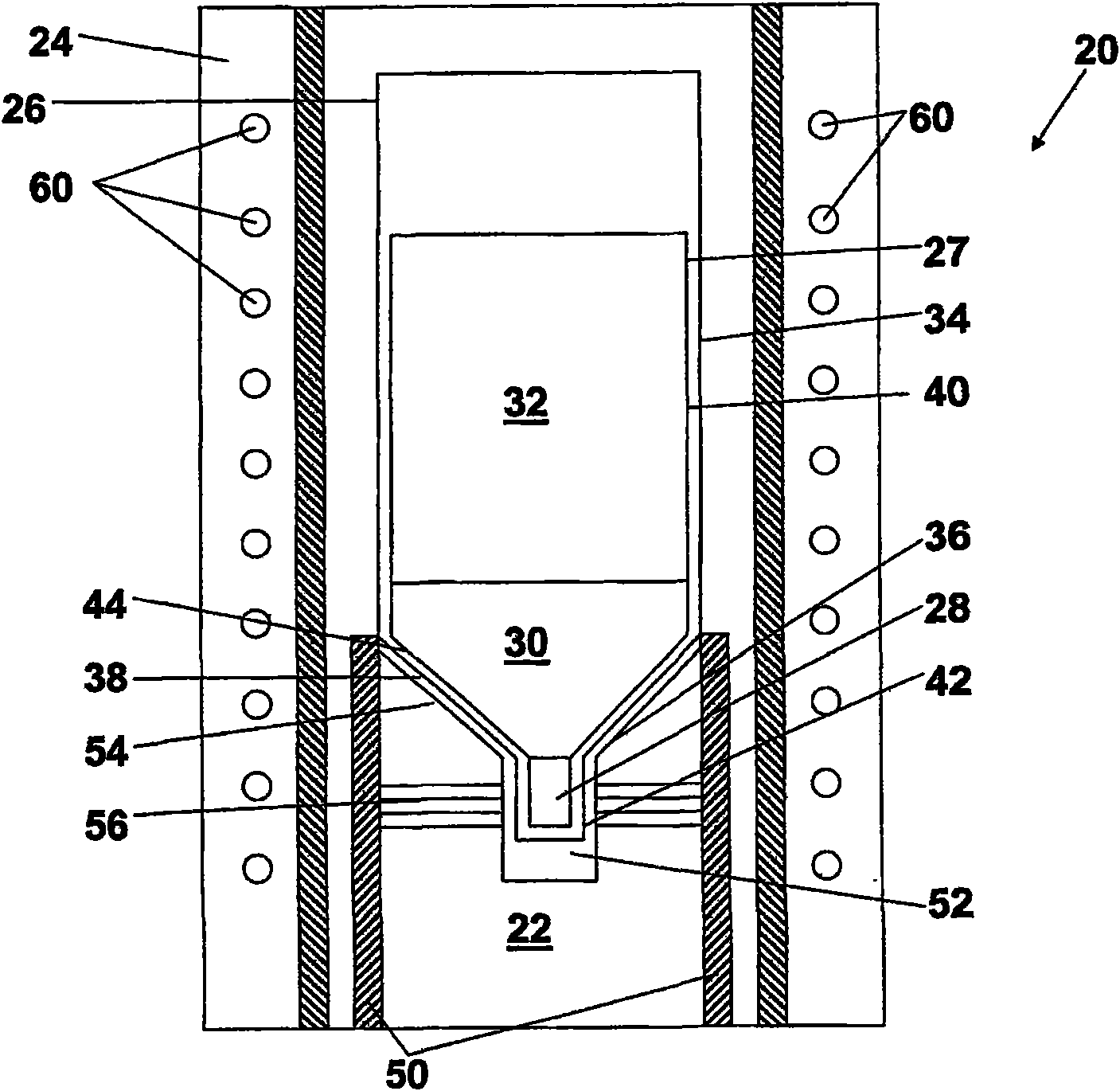

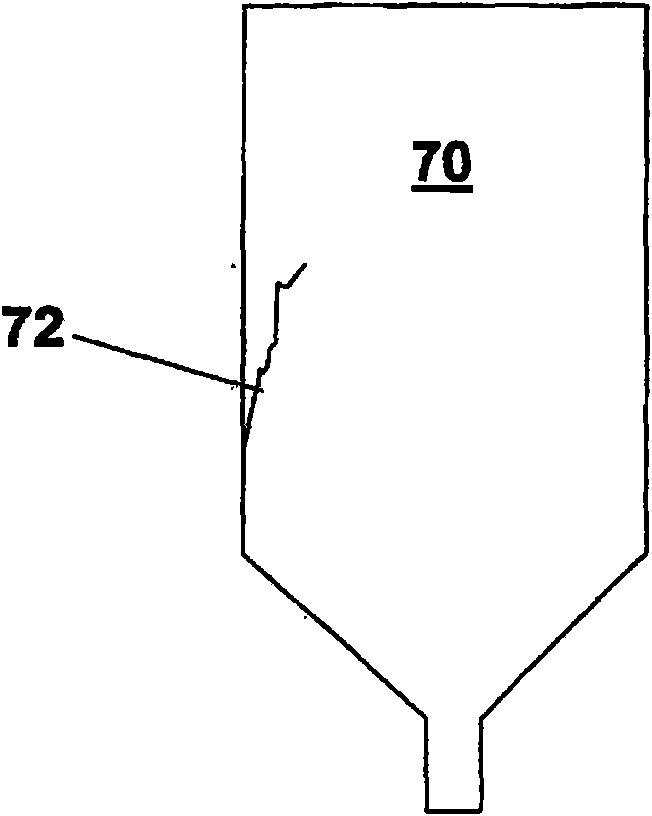

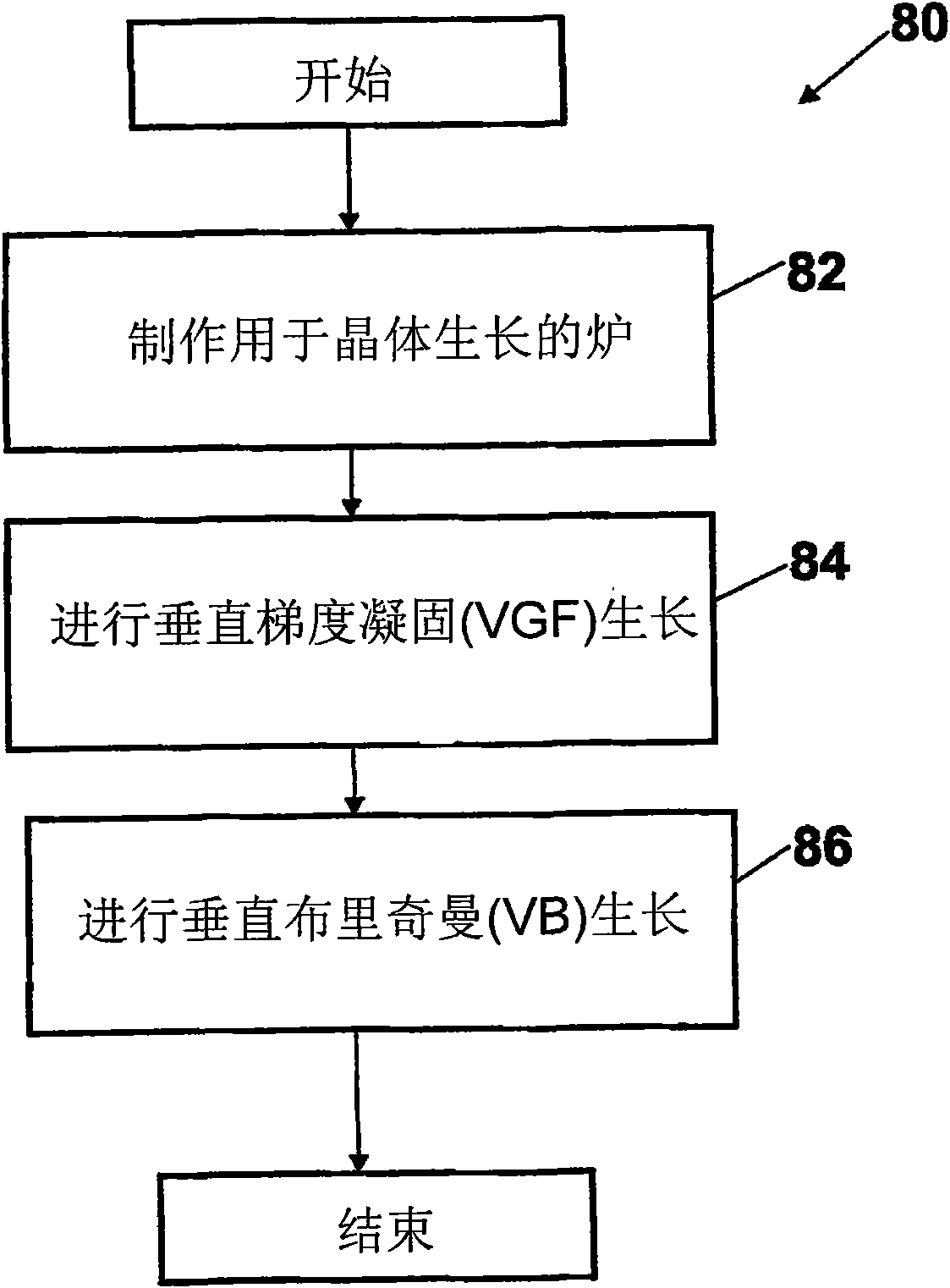

Crystal growing device and method

InactiveCN101555620AAfter-treatment apparatusPolycrystalline material growthVertical gradientCrucible

The invention discloses a system and a method using VGF and VB growing technology to carry out crystal growth to reduce body inlaid crystal. In a demonstration embodiment, an ampoule bottle containing a raw material is inserted into a furnace with a heating resource, and a vertical gradient solidifying technology is used for crystal growth, wherein the crystallizing temperature gradient can move corresponding to the crystal and / or the furnace to melt the raw material and convert the raw material into monocrystal compound; and a vertical Bridgman technology is used for crystal growth on a crucible, wherein the ampoule bottle / heating source can relatively move to continuously melt the raw material and convert the raw material into monocrystal compound.

Owner:AXT INC +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com