Patents

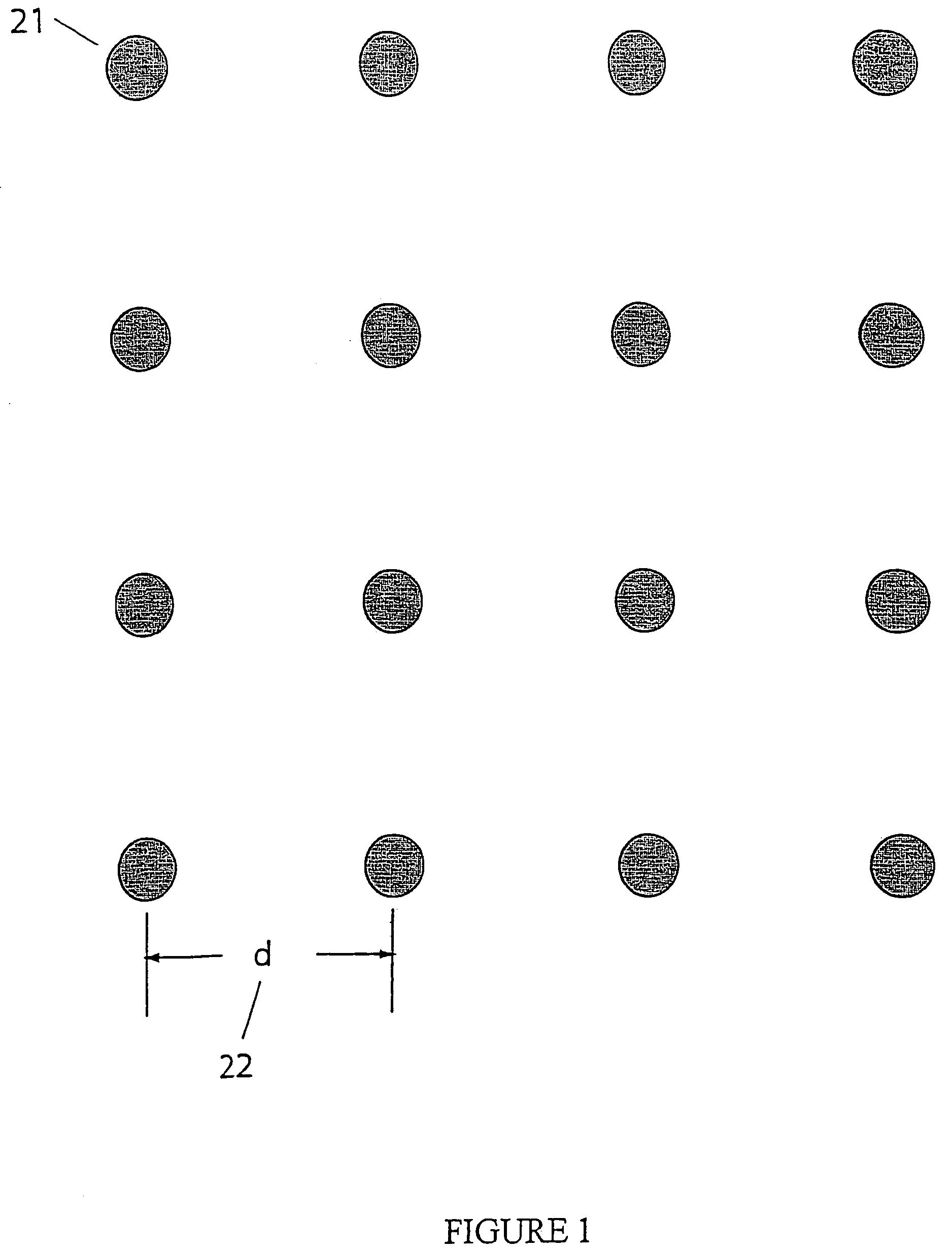

Literature

70020 results about "Analytical chemistry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Analytical chemistry studies and uses instruments and methods used to separate, identify, and quantify matter. In practice, separation, identification or quantification may constitute the entire analysis or be combined with another method. Separation isolates analytes. Qualitative analysis identifies analytes, while quantitative analysis determines the numerical amount or concentration.

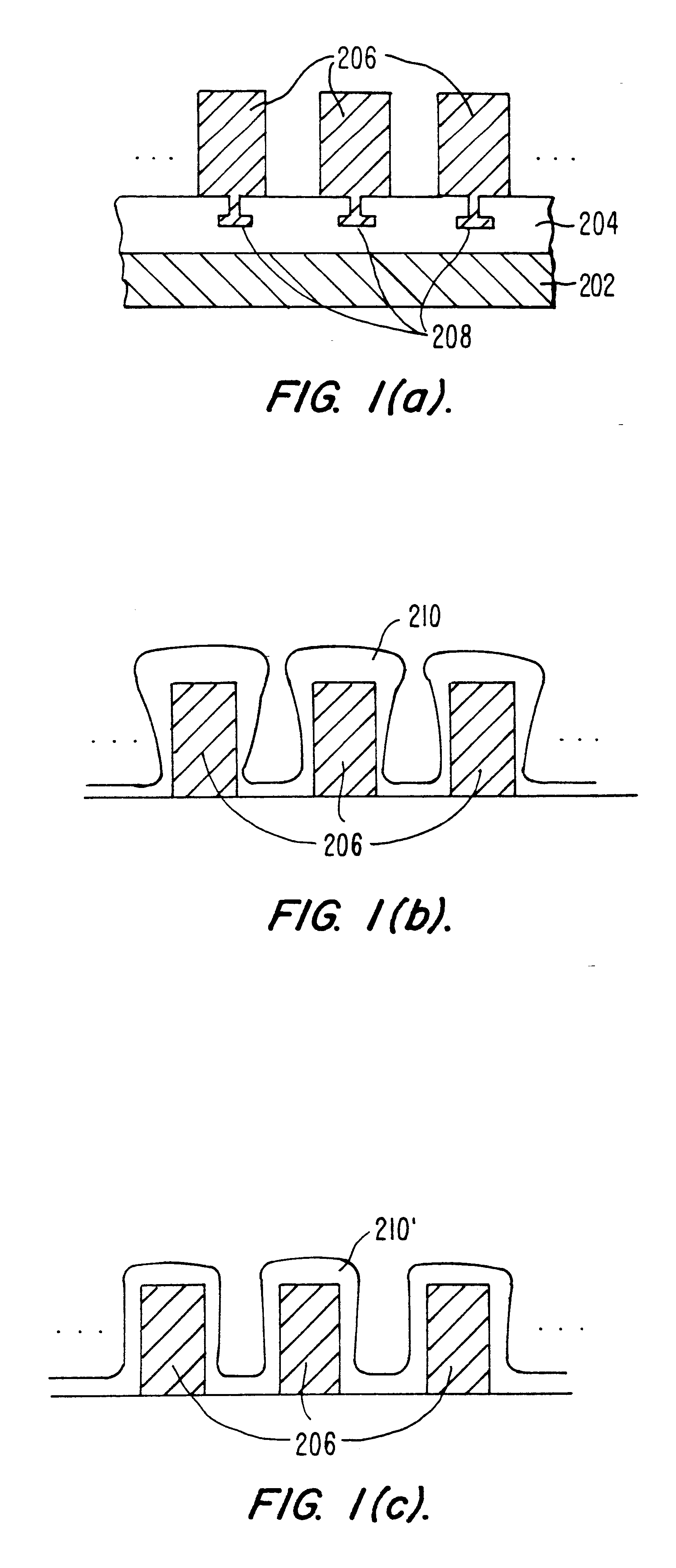

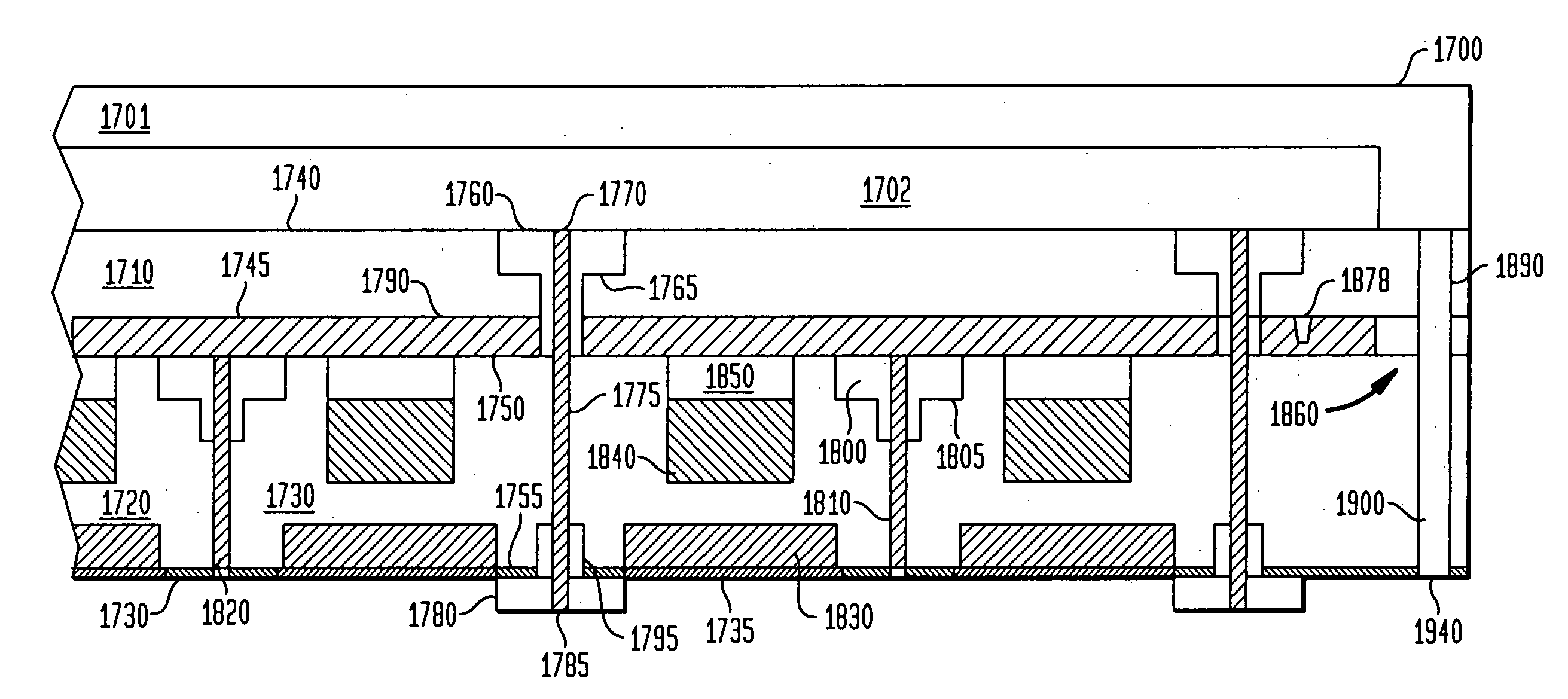

Electrochemical analyte sensor

InactiveUS6484046B1Avoid and reduce corrosionMicrobiological testing/measurementMaterial analysis by electric/magnetic meansAnalyteElectrolysis

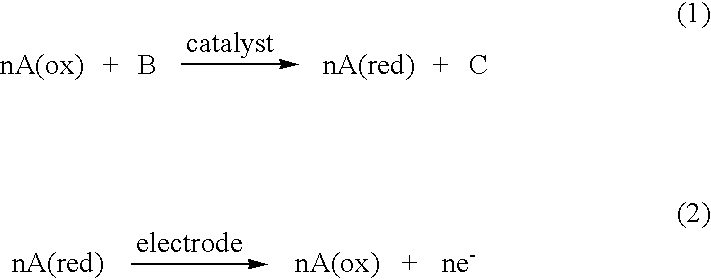

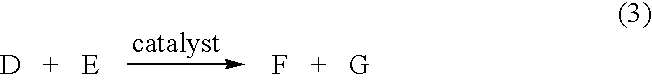

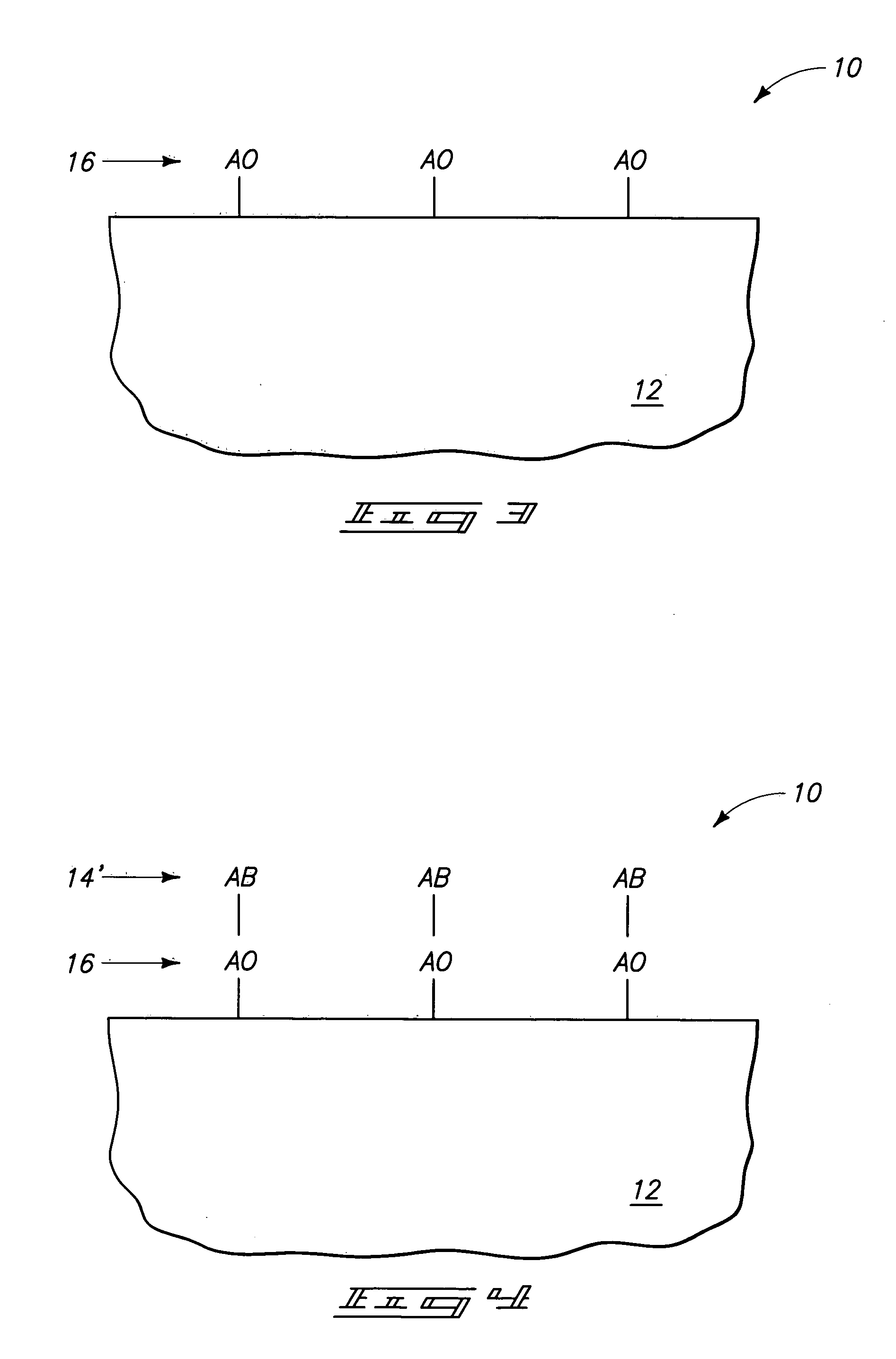

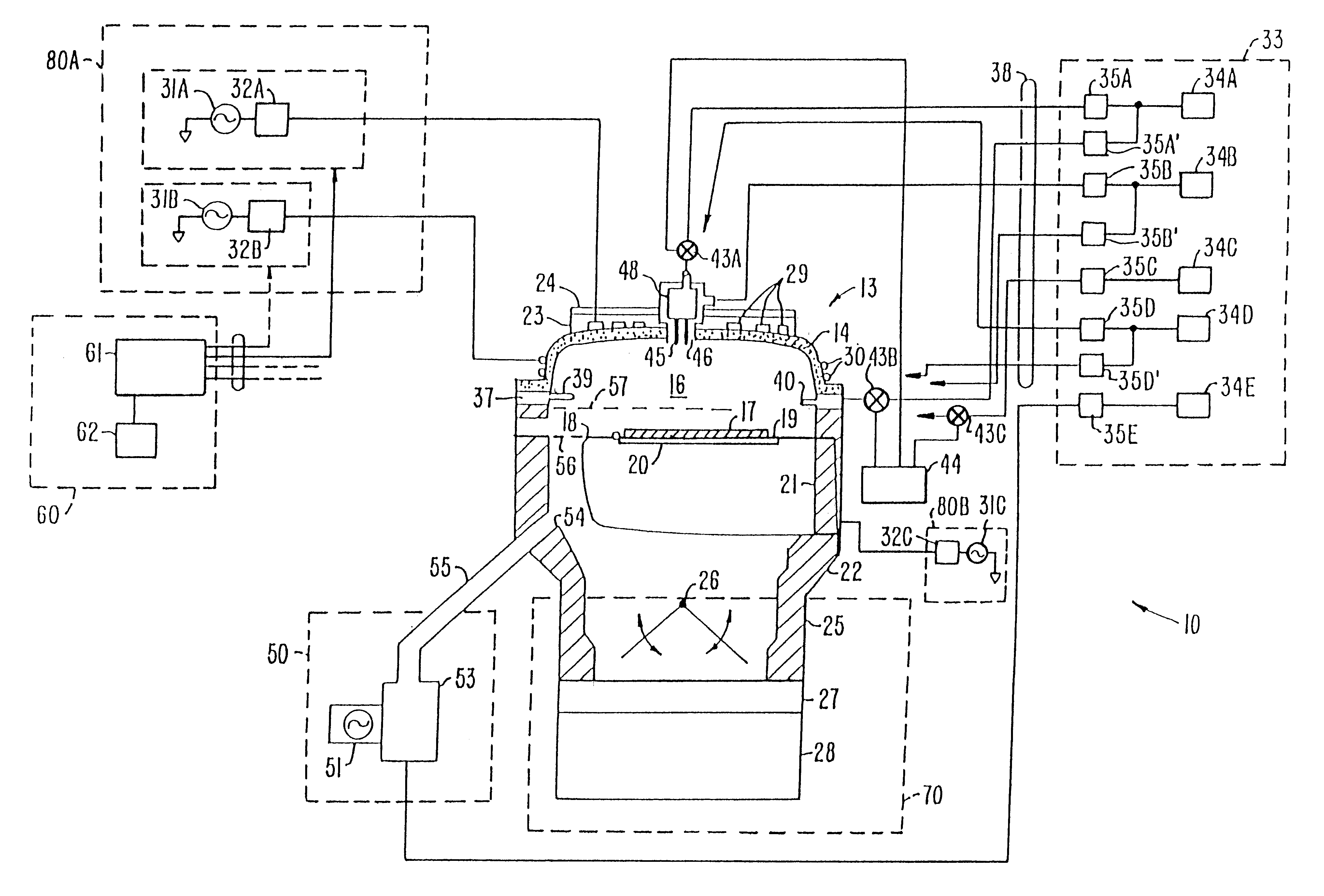

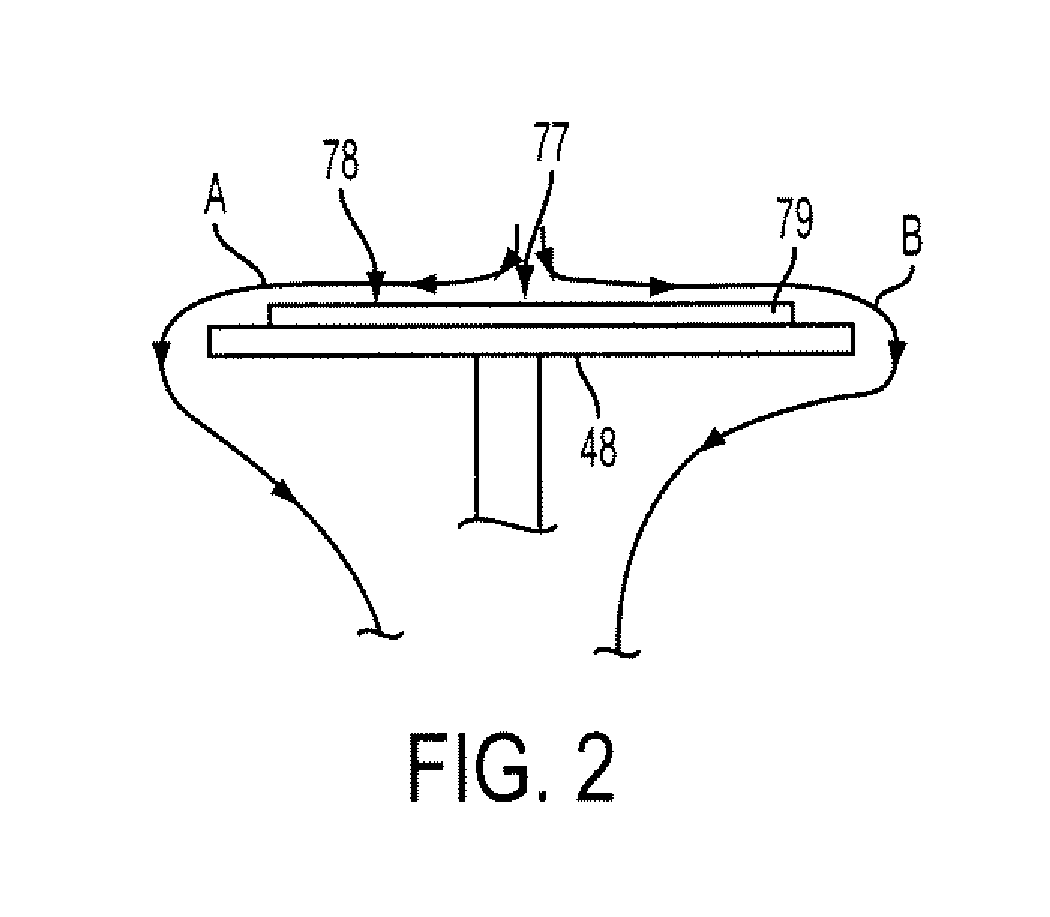

An electrochemical analyte sensor having conductive traces on a substrate is used to determine a level of analyte in in vitro or in vivo analyte-containing fluids. The electrochemical analyte sensor includes a substrate and conductive material disposed on the substrate, the conductive material forming a working electrode. In some sensors, the conductive material is disposed in recessed channels formed in a surface of the sensor. An electron transfer agent and / or catalyst may be provided to facilitate the electrolysis of the analyte or of a second compound whose level depends on the level of the analyte. A potential is formed between the working electrode and a reference electrode or counter / reference electrode and the resulting current is a function of the concentration of the analyte in the fluid.

Owner:ABBOTT DIABETES CARE INC

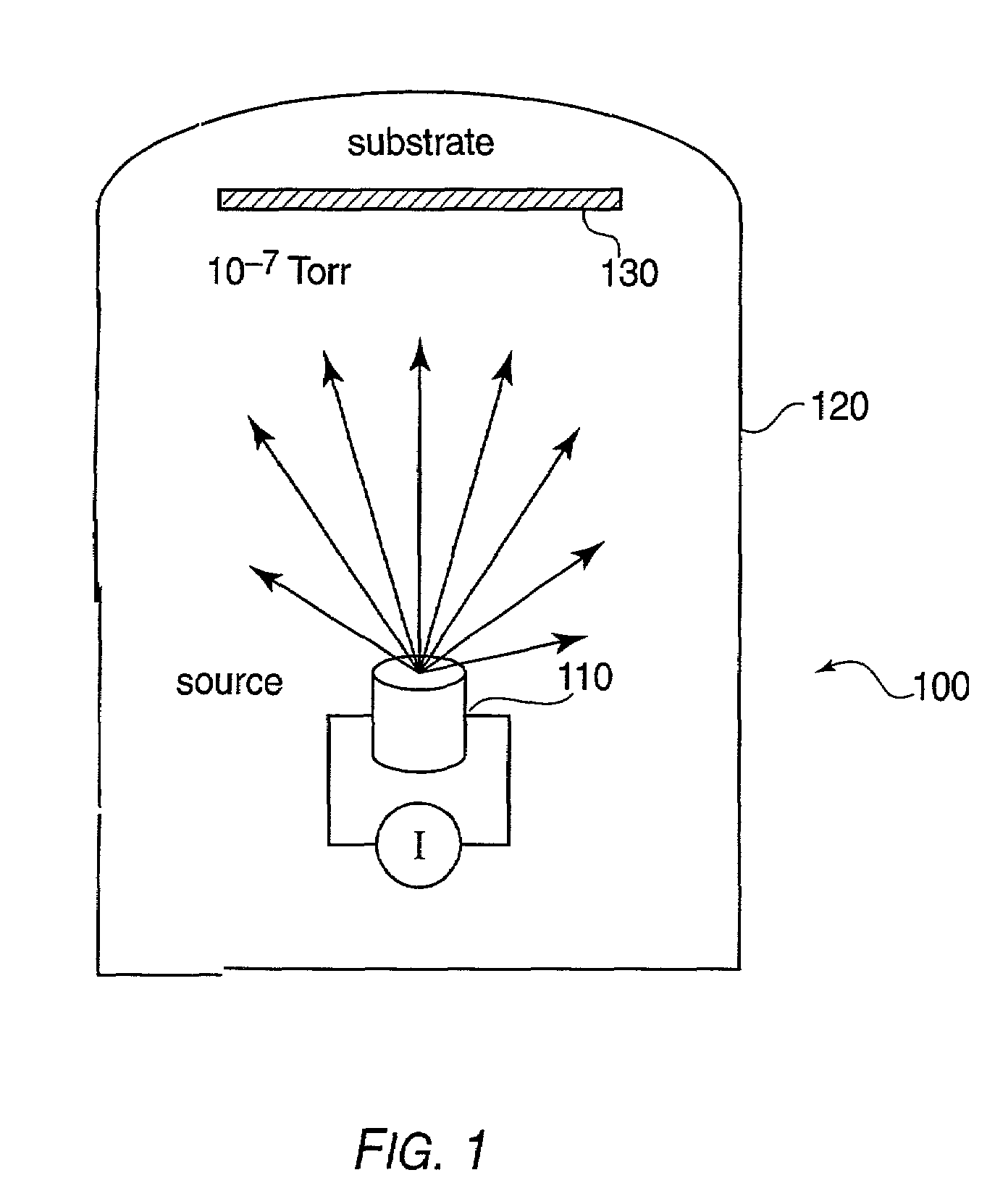

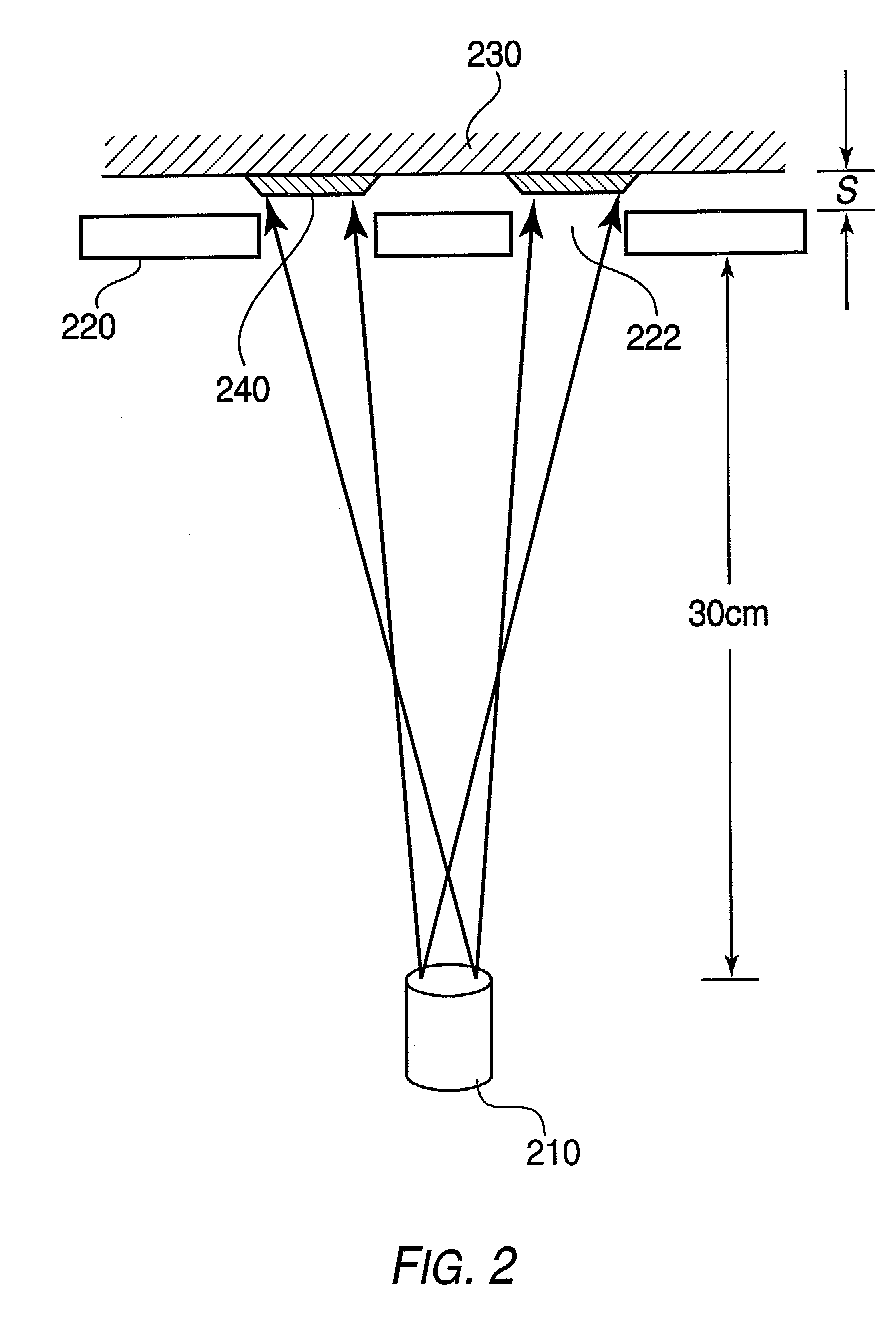

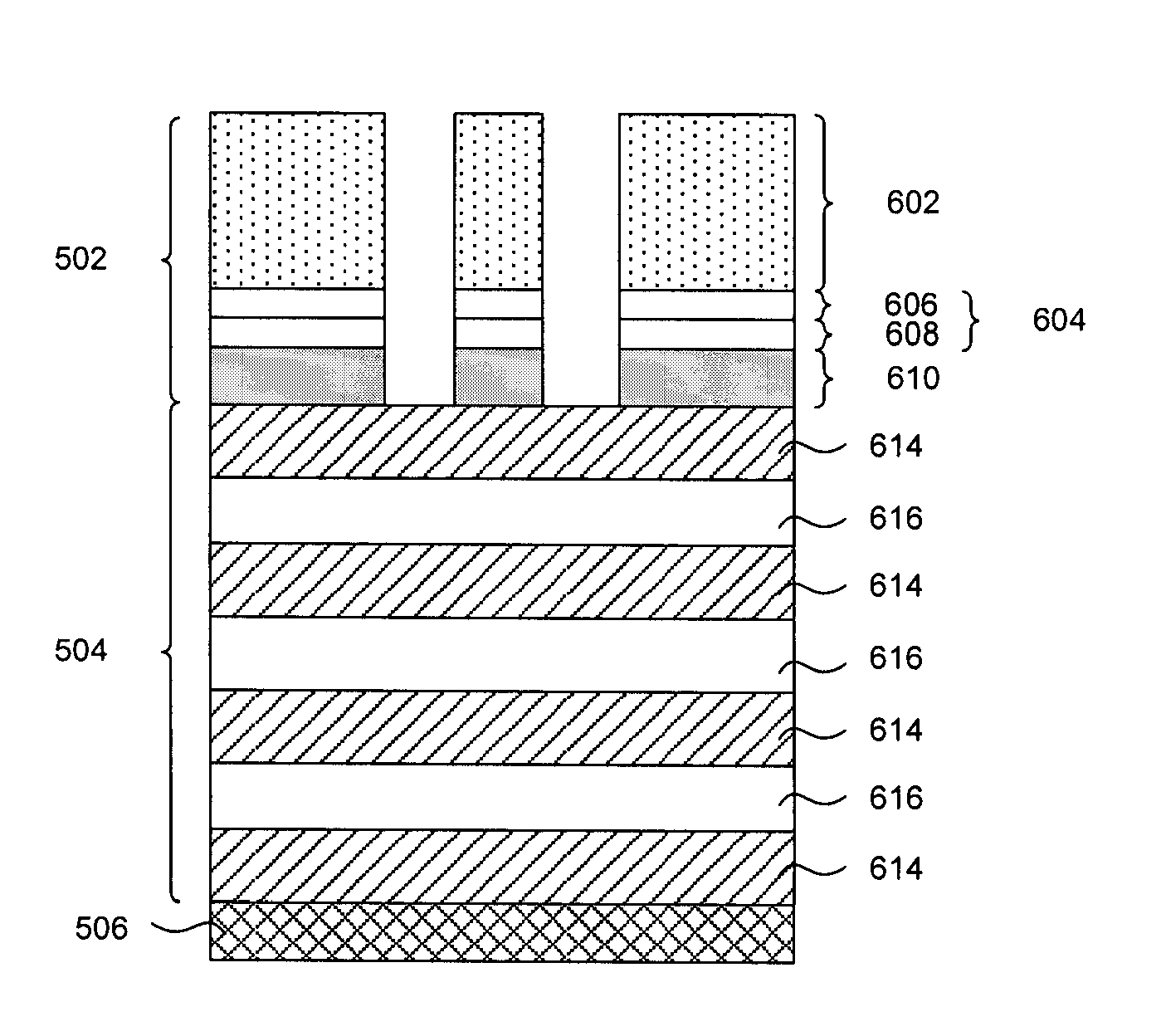

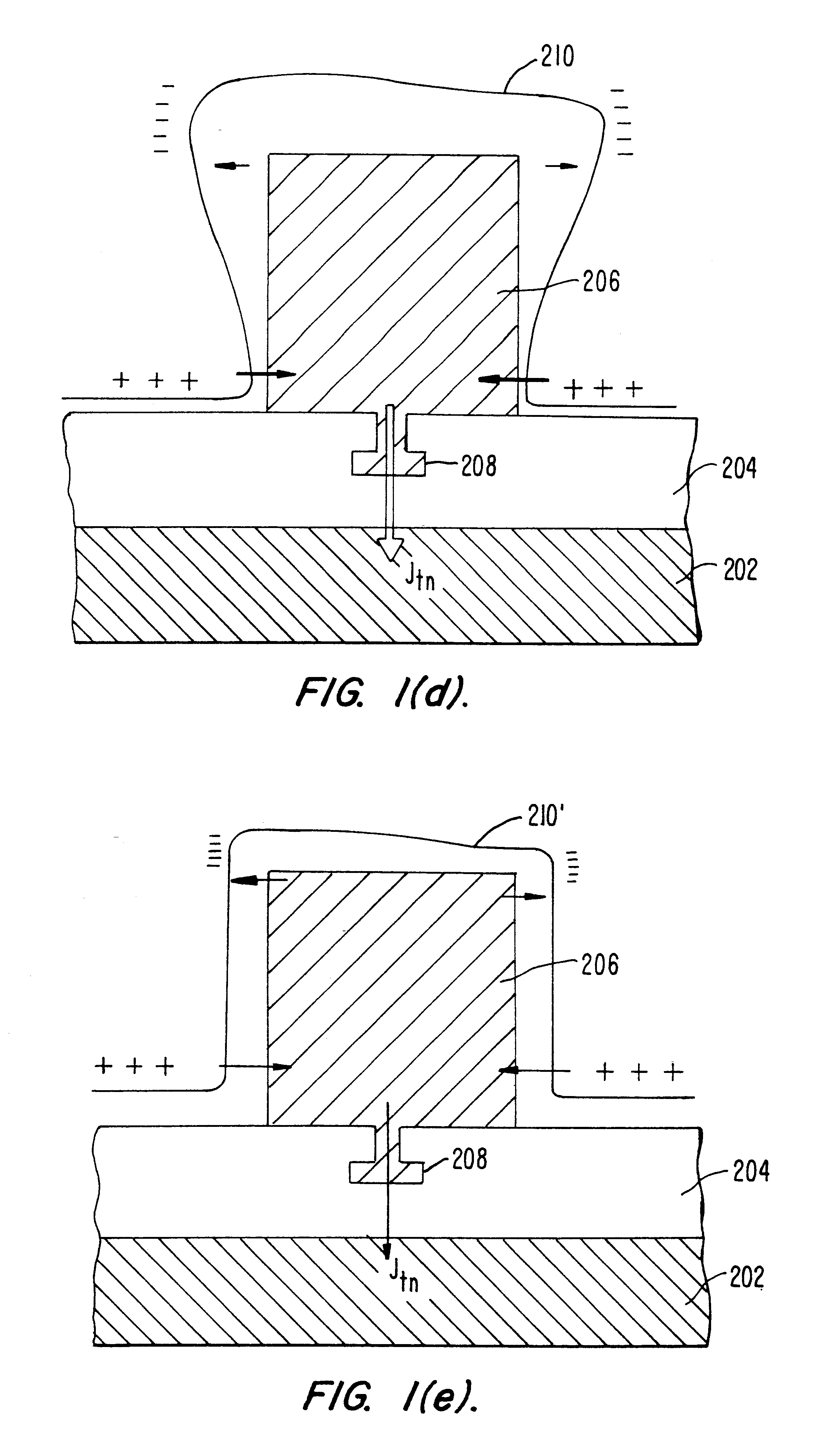

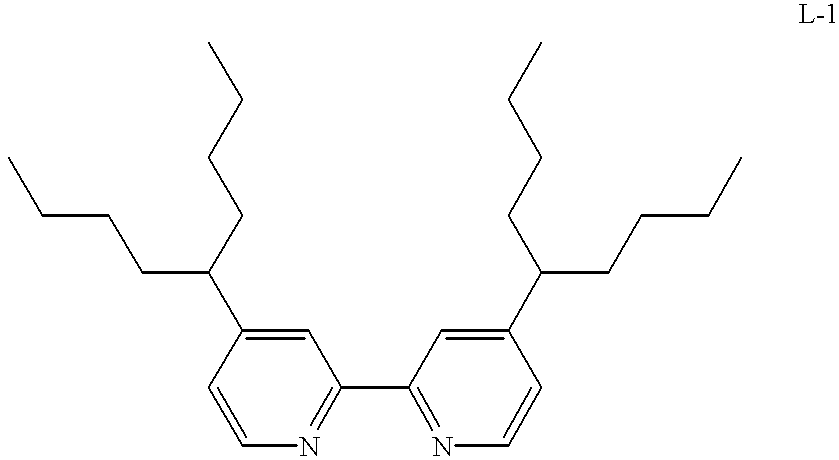

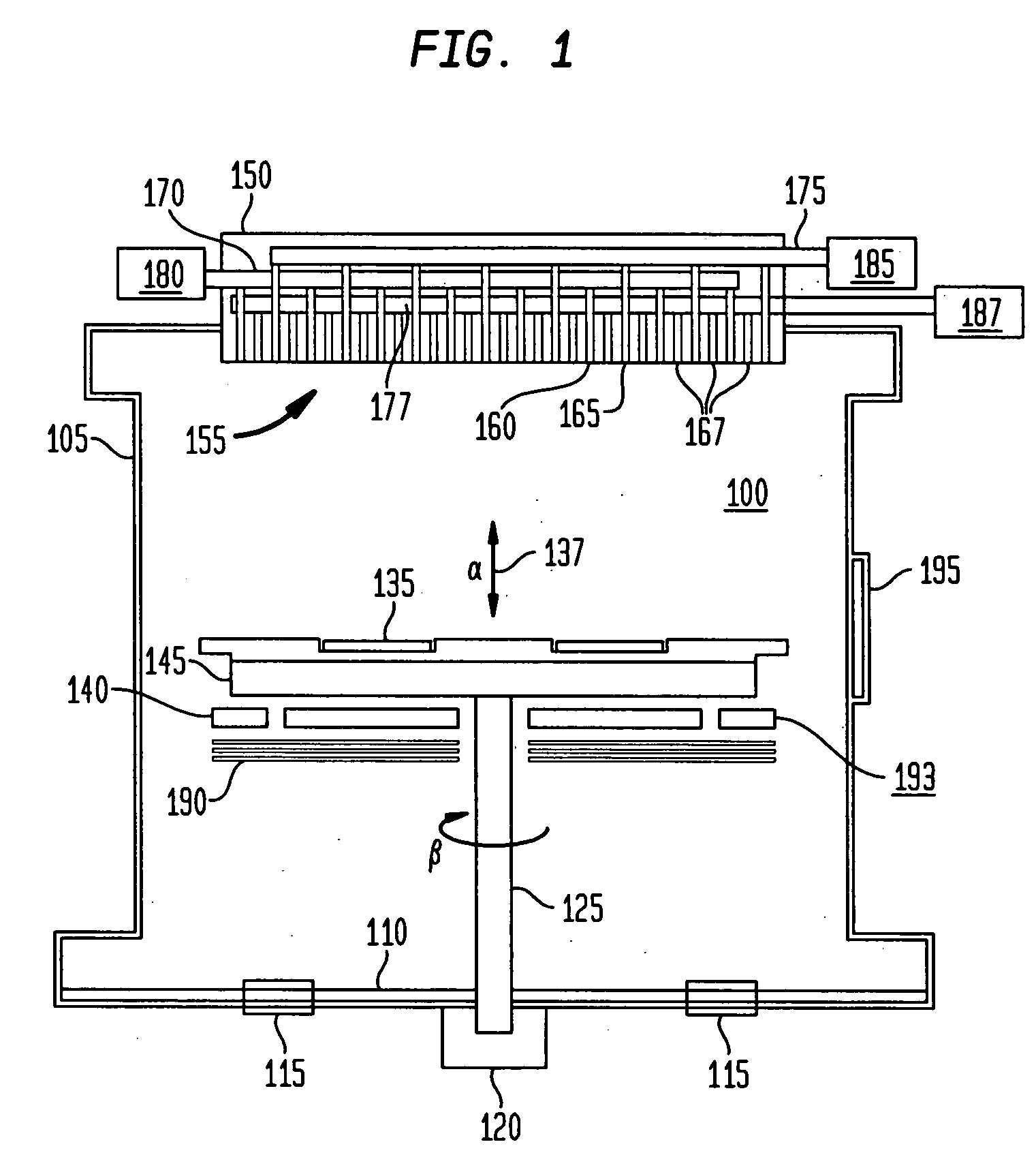

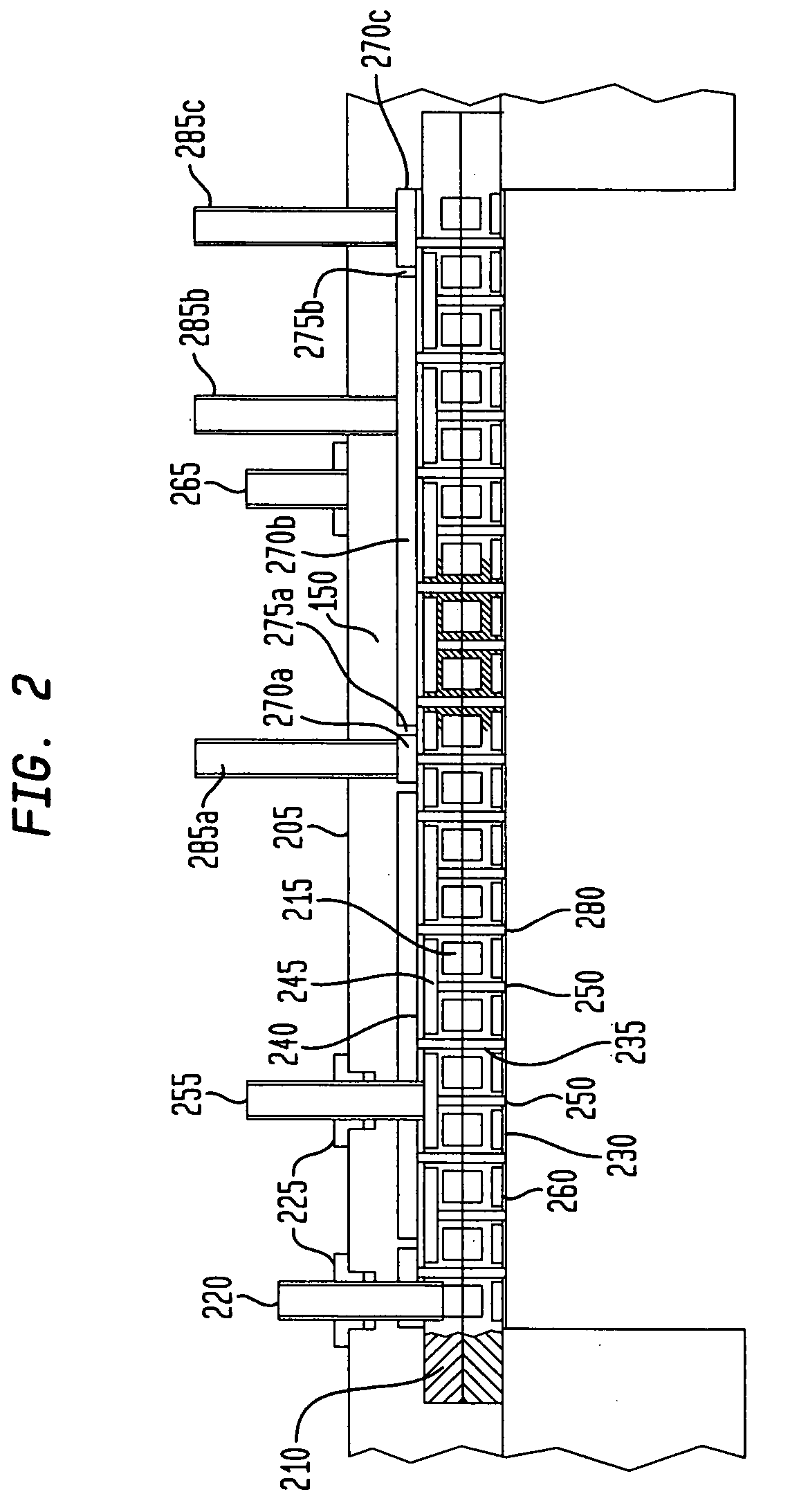

Process and apparatus for organic vapor jet deposition

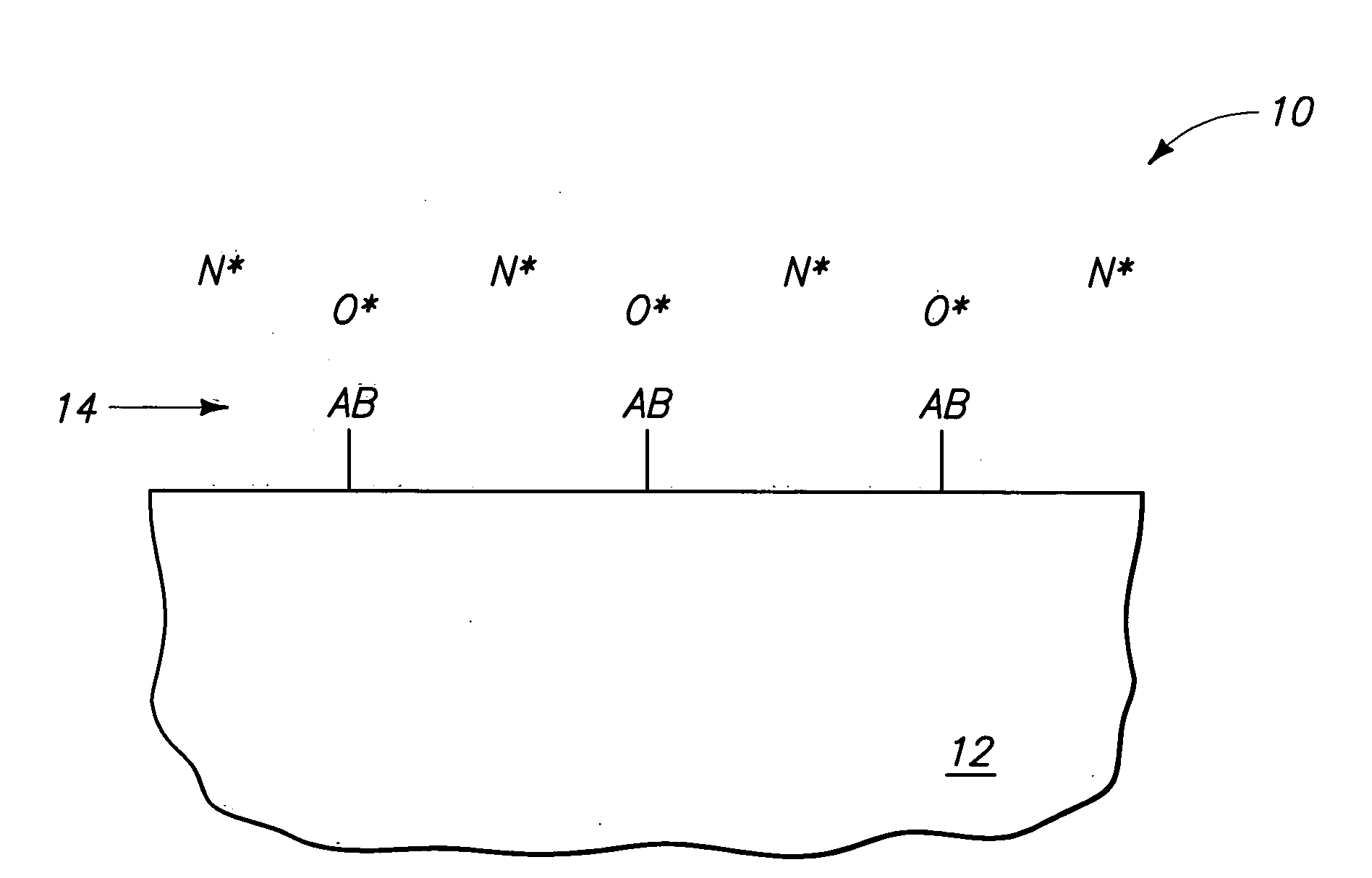

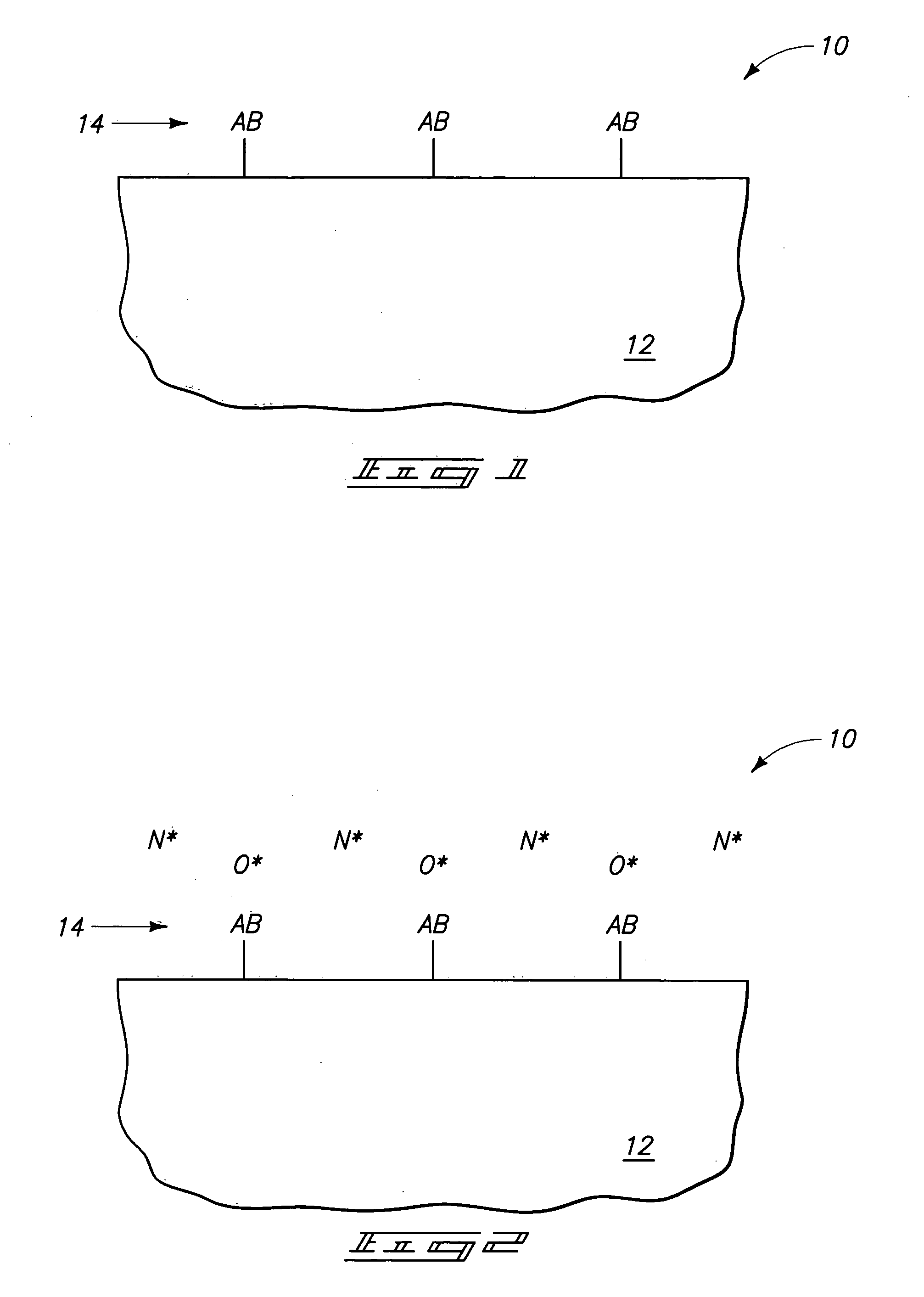

ActiveUS7431968B1Good directionSharp pixelVacuum evaporation coatingSputtering coatingOrganic filmVacuum chamber

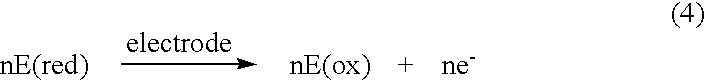

A method of fabricating an organic film is provided. A non-reactive carrier gas is used to transport an organic vapor. The organic vapor is ejected through a nozzle block onto a cooled substrate, to form a patterned organic film. A device for carrying out the method is also provided. The device includes a source of organic vapors, a source of carrier gas and a vacuum chamber. A heated nozzle block attached to the source of organic vapors and the source of carrier gas has at least one nozzle adapted to eject carrier gas and organic vapors onto a cooled substrate disposed within the vacuum chamber.

Owner:THE TRUSTEES FOR PRINCETON UNIV

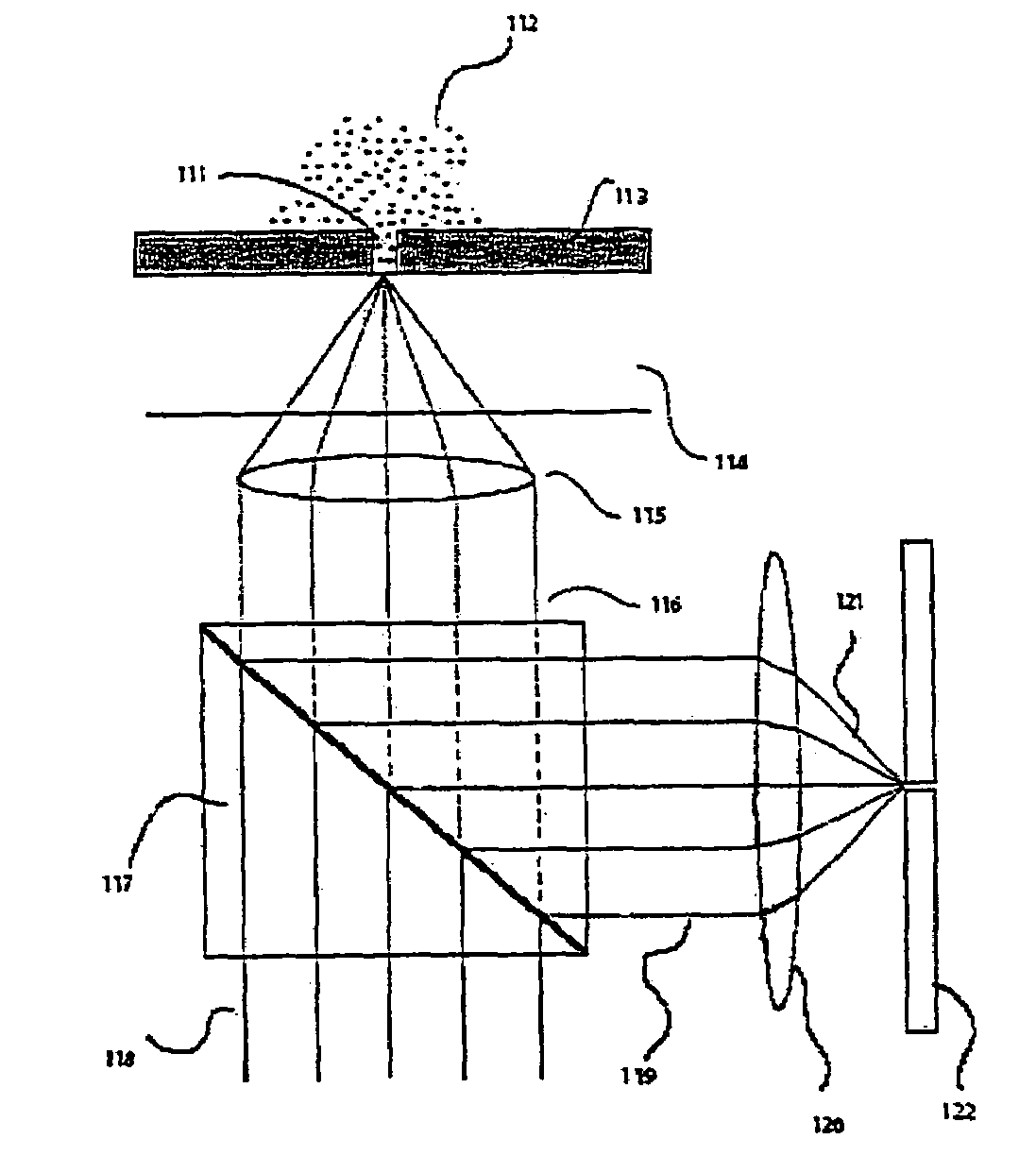

Apparatus and methods for optical analysis of molecules

ActiveUS7170050B2Small volumeEffective volumeRadiation pyrometryLaser detailsMolecular analysisChemical reaction

The present invention relates to optical confinements, methods of preparing and methods of using them for analyzing molecules and / or monitoring chemical reactions. The apparatus and methods embodied in the present invention are particularly useful for high-throughout and low-cost single-molecular analysis.

Owner:NANOFLUIDICS INC +1

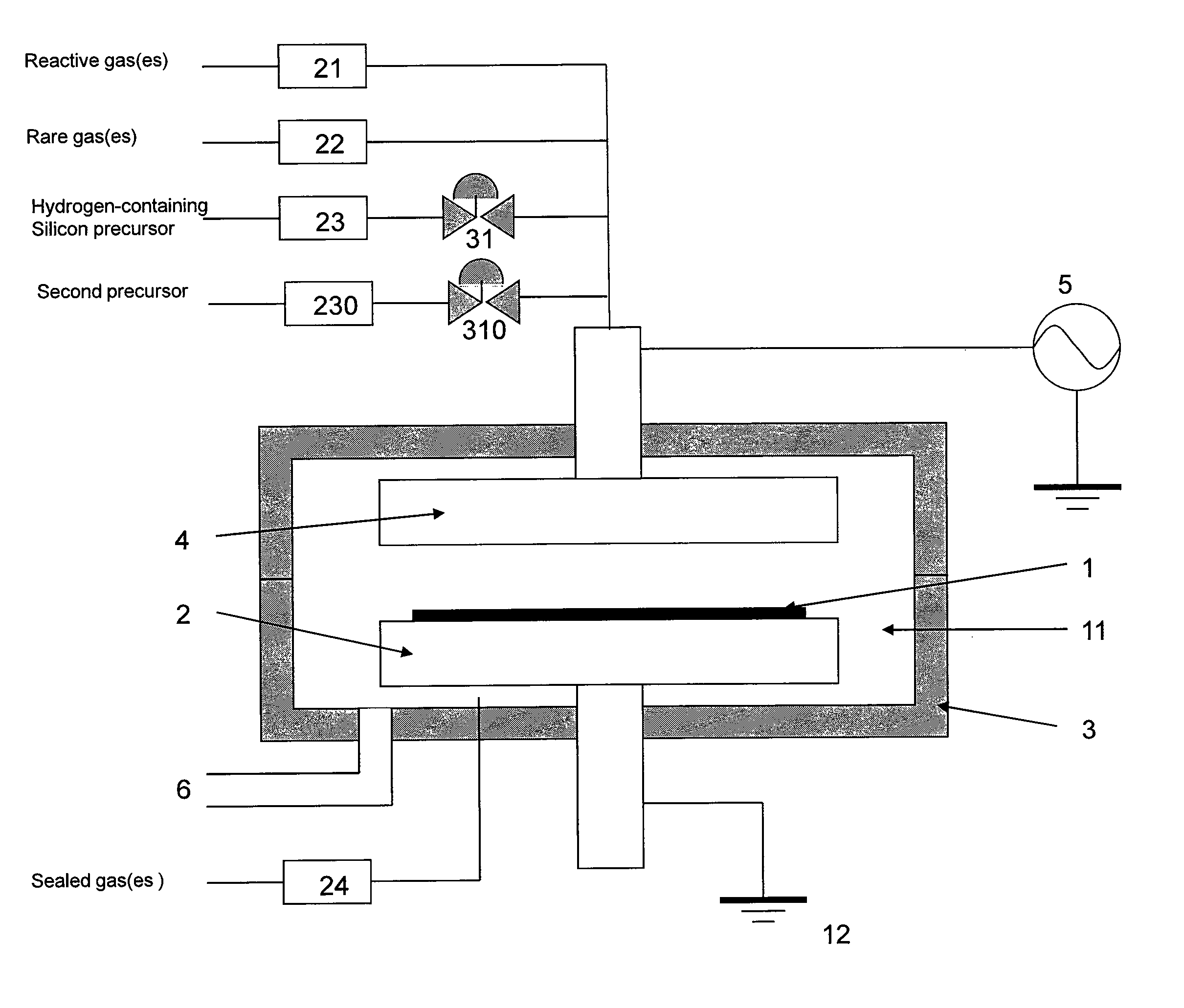

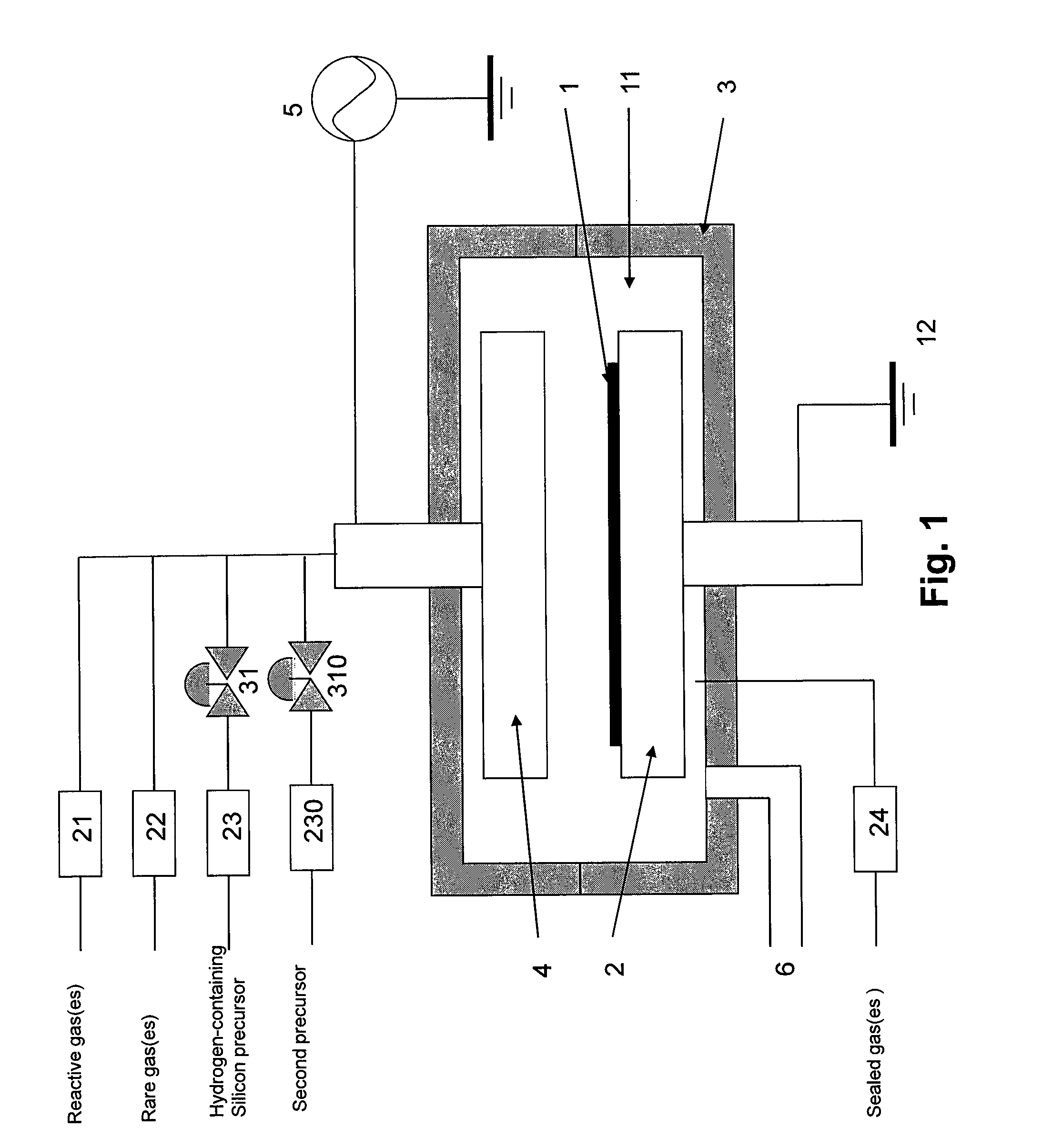

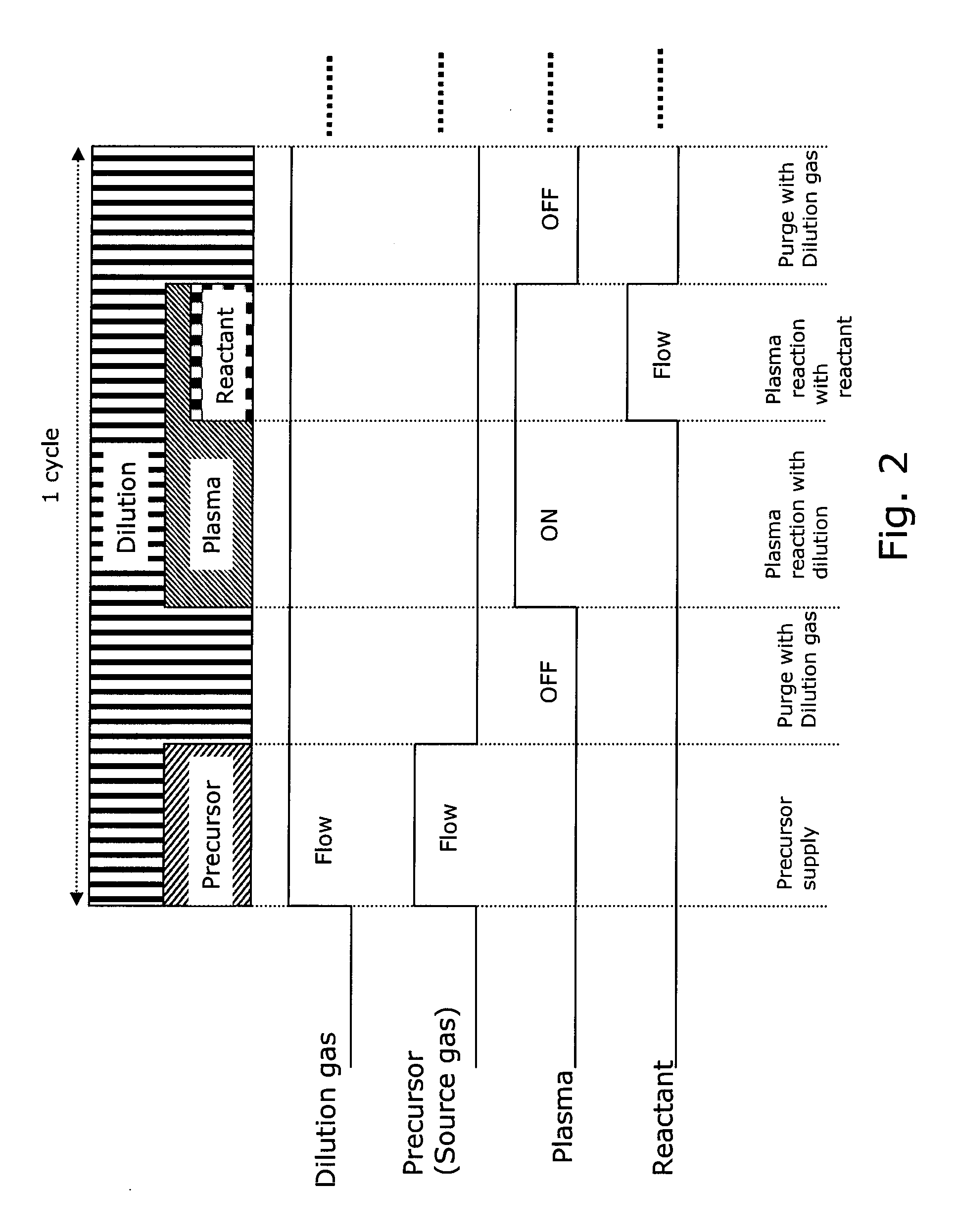

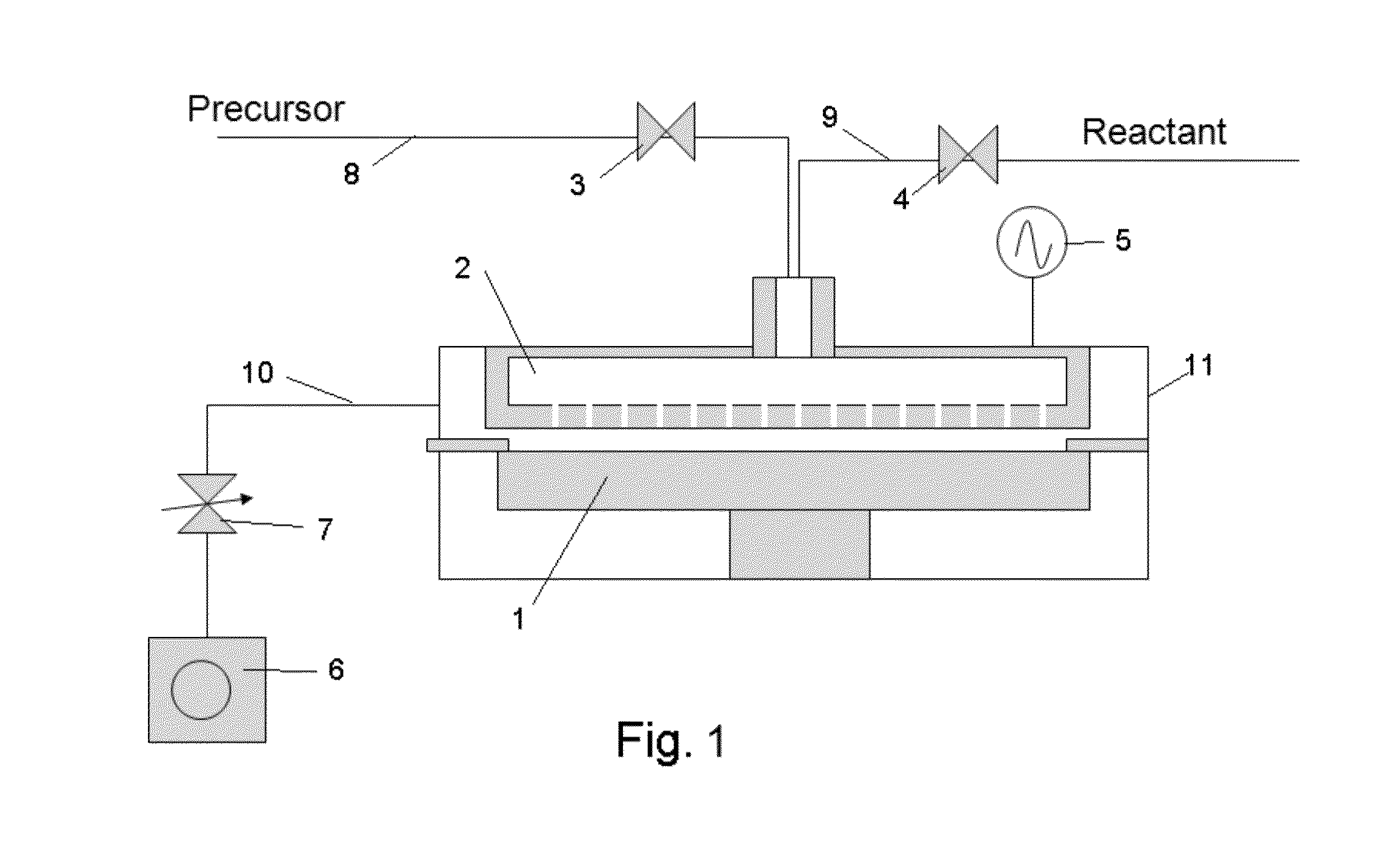

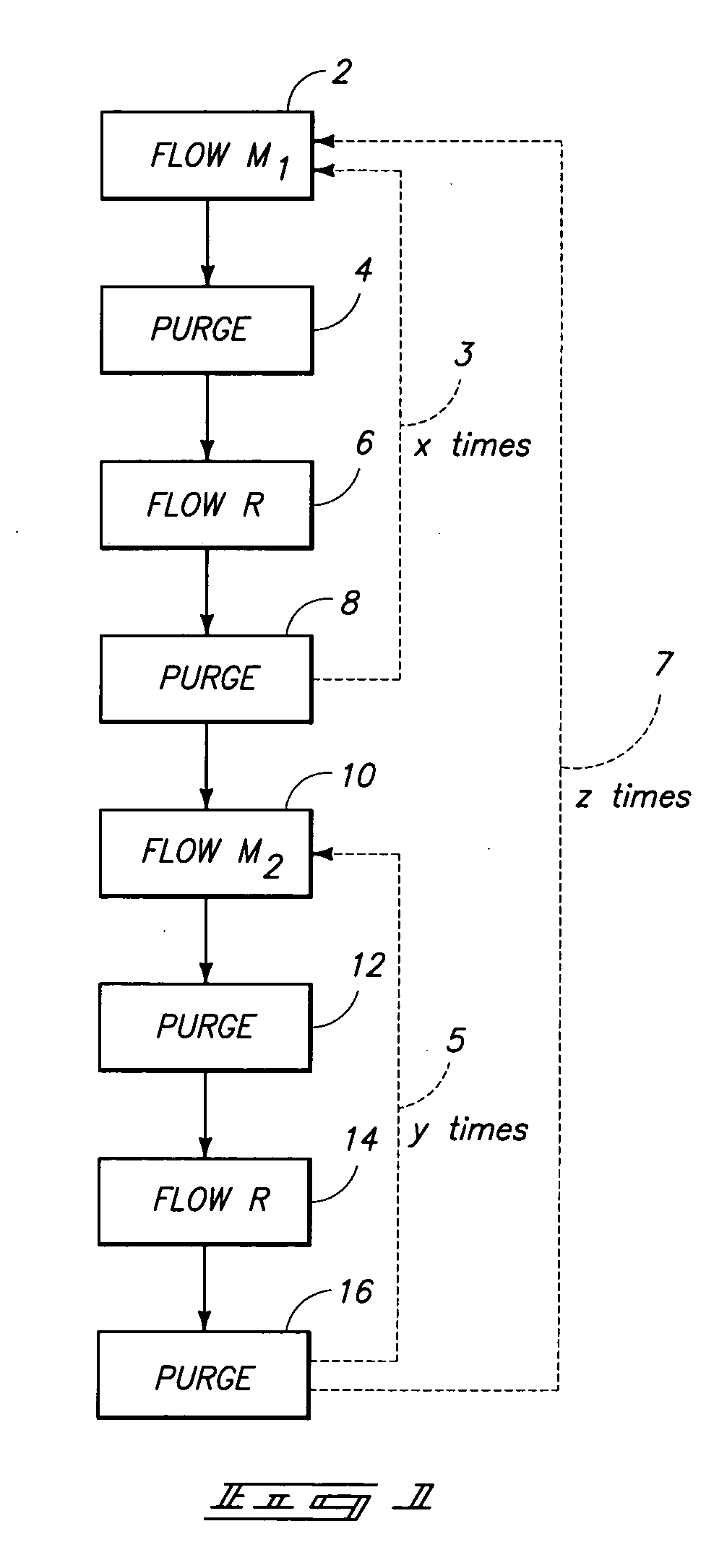

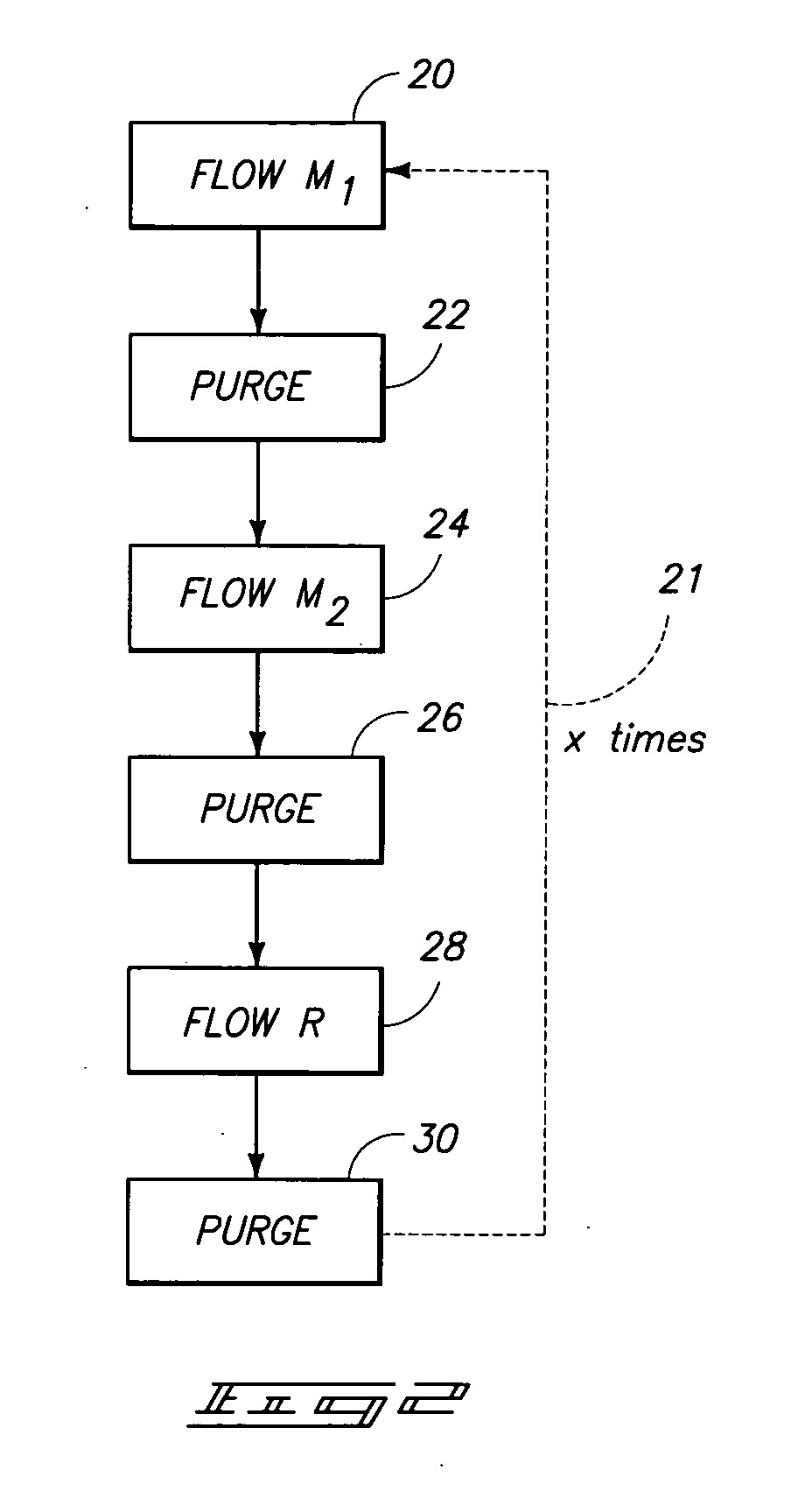

Method of Forming Insulation Film by Modified PEALD

ActiveUS20100124621A1Increase coverageImprove throughputSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringPhysical chemistry

Owner:ASM JAPAN

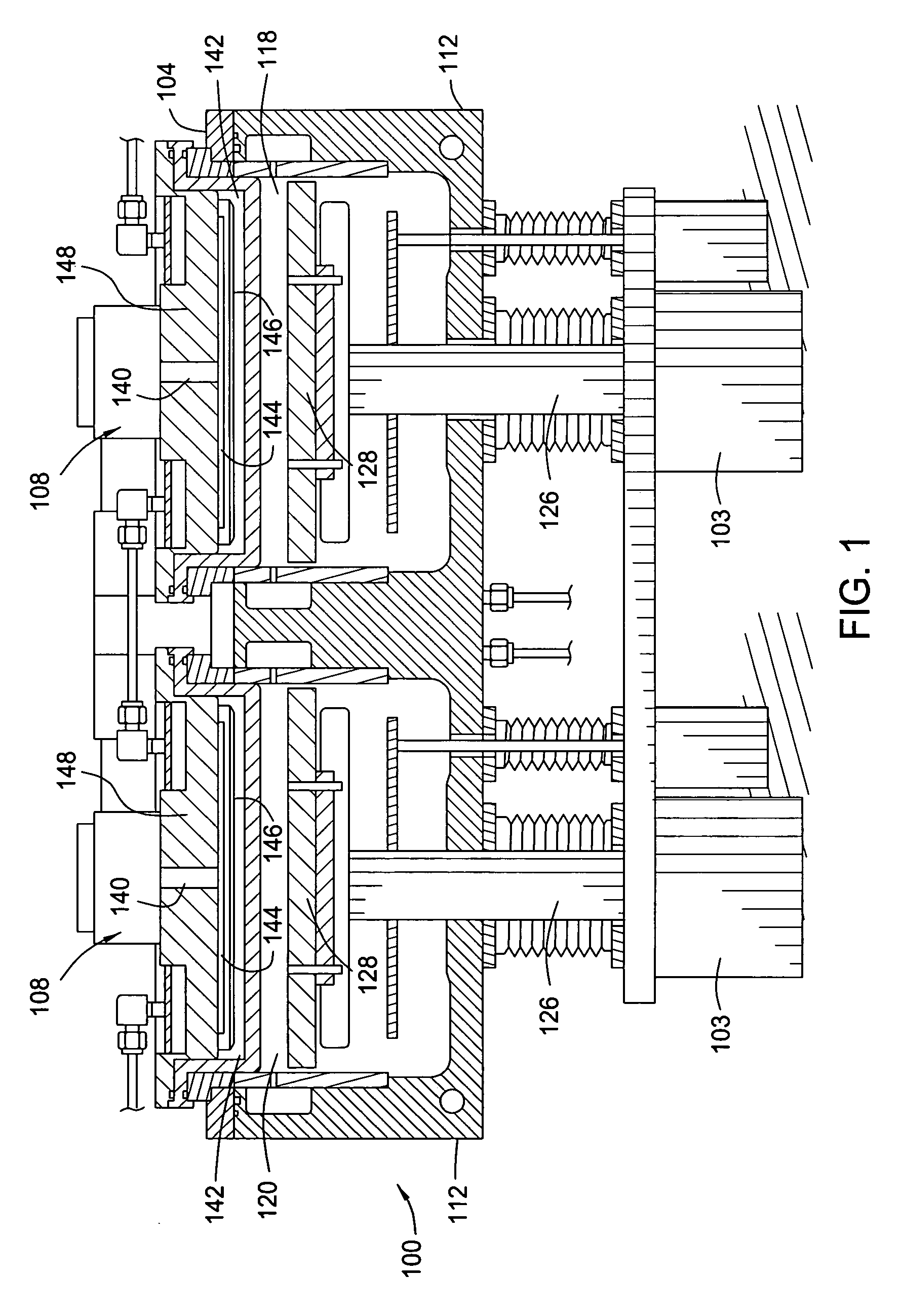

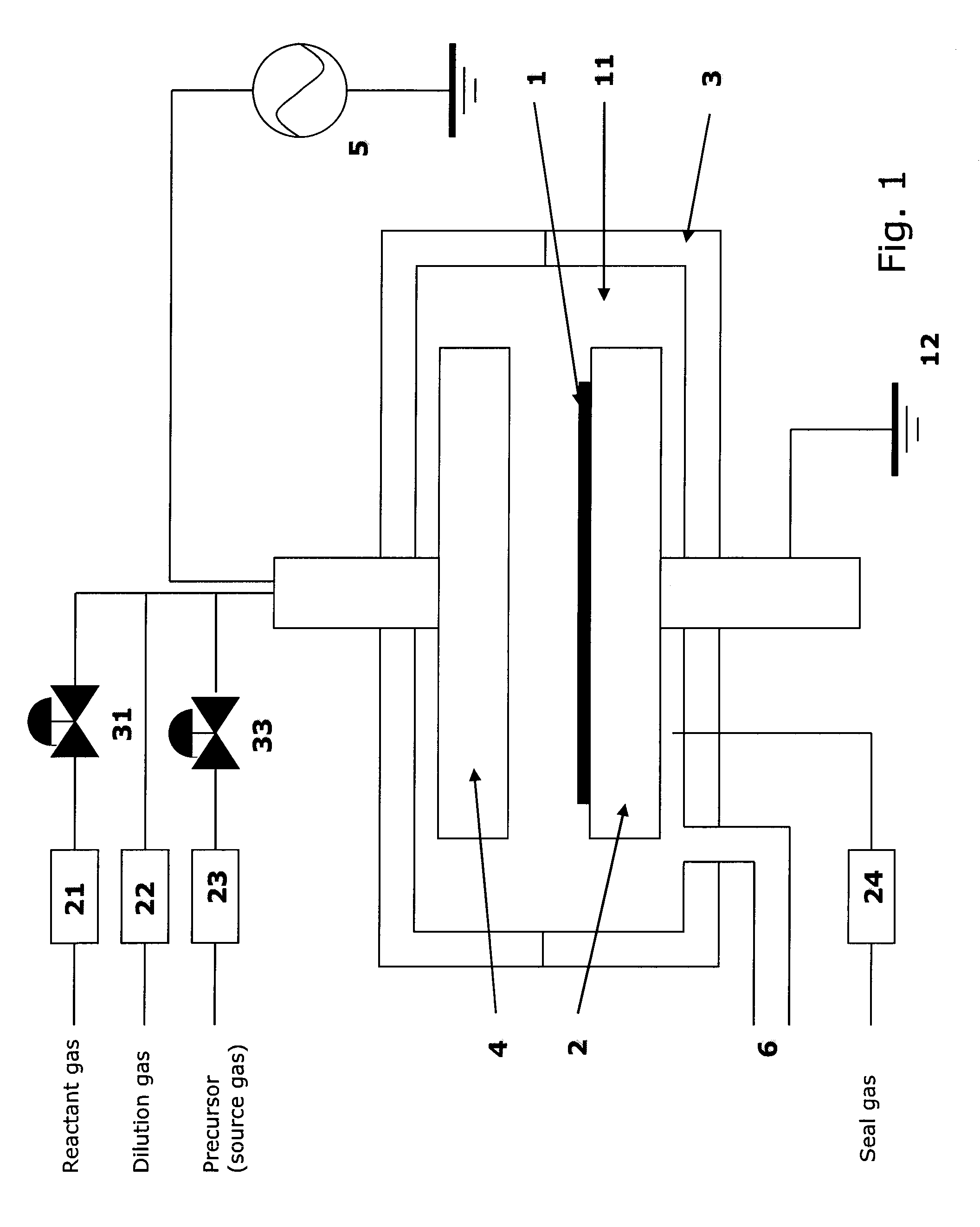

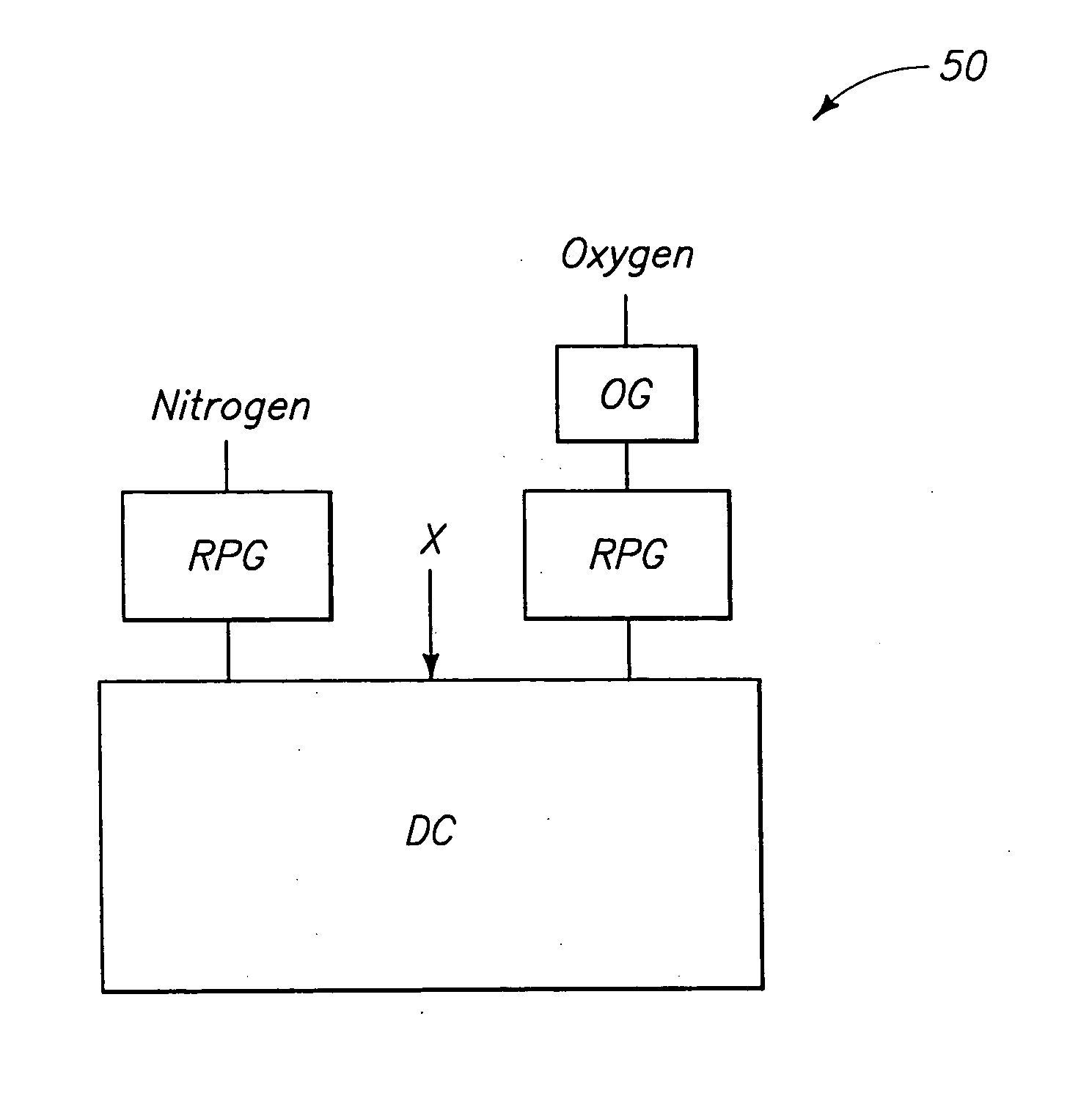

Radical Reactor with Multiple Plasma Chambers

InactiveUS20120114877A1Well mixedElectric discharge tubesChemical vapor deposition coatingAtomic layer depositionPlasma chamber

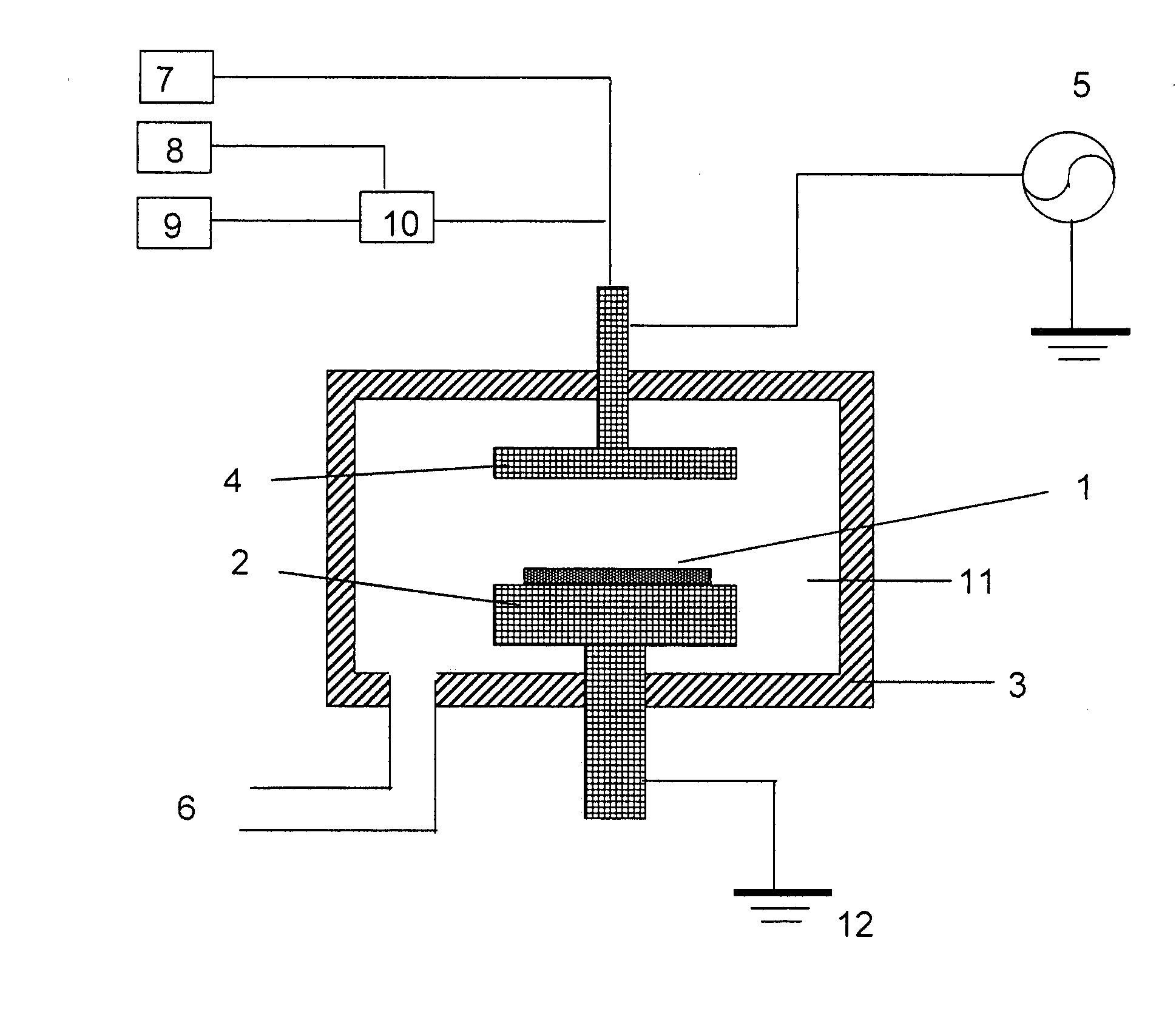

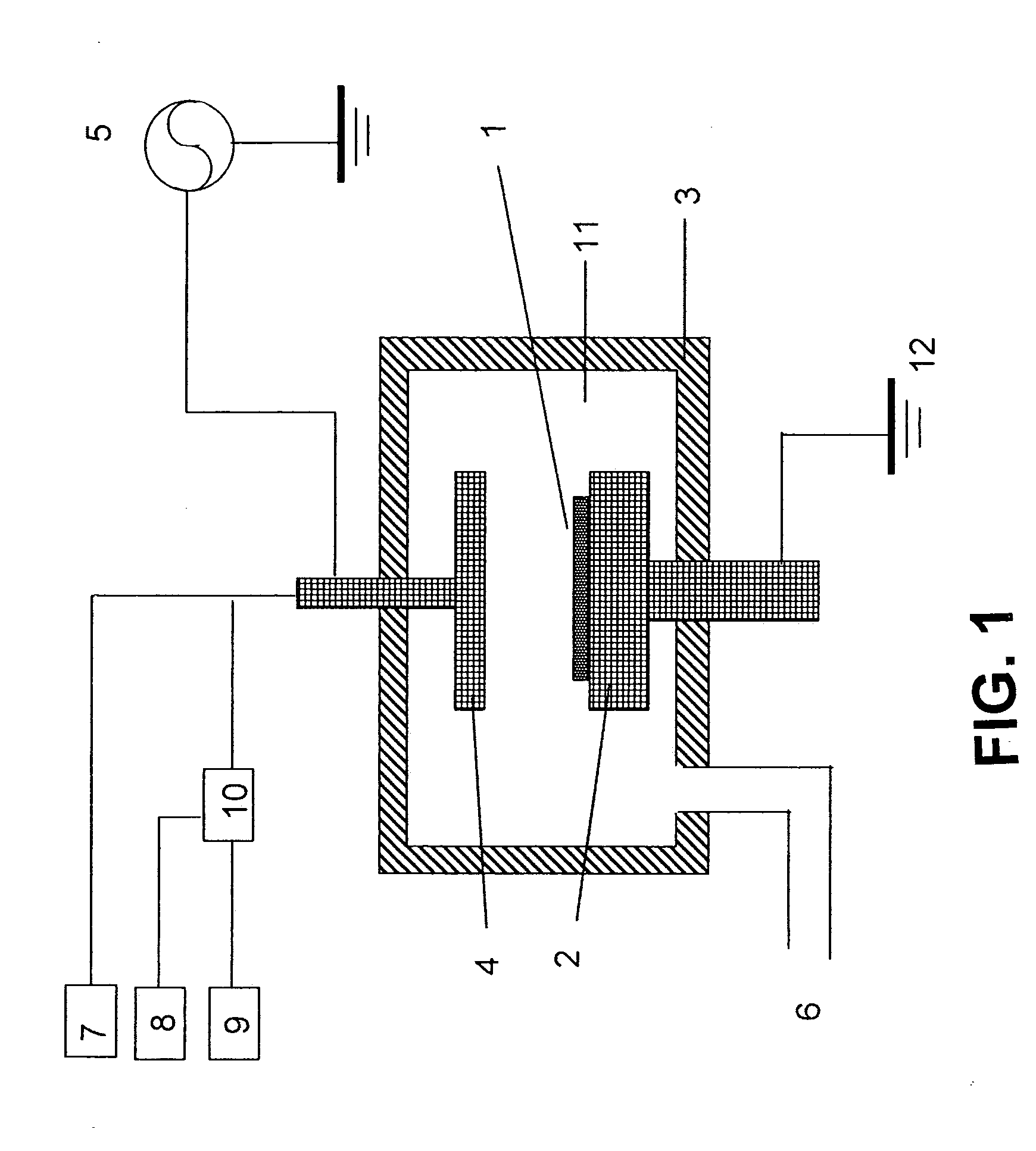

Two or more plasma chambers are provided in a radical reactor to generate radicals of gases under different conditions for use in atomic layer deposition (ALD) process. The radical reactor has a body with multiple channels and corresponding process chambers. Each plasma chamber is surrounded by an outer electrode and has an inner electrode extending through the chamber. When voltage is applied across the outer electrode and the inner electrode with gas present in the plasma chamber, radicals of the gas is generated in the plasma chamber. The radicals generated in the plasma chamber are then injected into a mixing chamber for mixing with radicals of another gas from another plasma chamber, and injected onto the substrate. By providing two or more plasma chambers, different radicals of gases can be generated within the same radical reactor, which obviates the need for separate radical generators.

Owner:VEECO ALD

Apparatus and method for analysis of molecules

ActiveUS7302146B2Improve accuracyEasy to implementMaterial nanotechnologyCladded optical fibreMolecular analysisChemical reaction

Owner:PACIFIC BIOSCIENCES

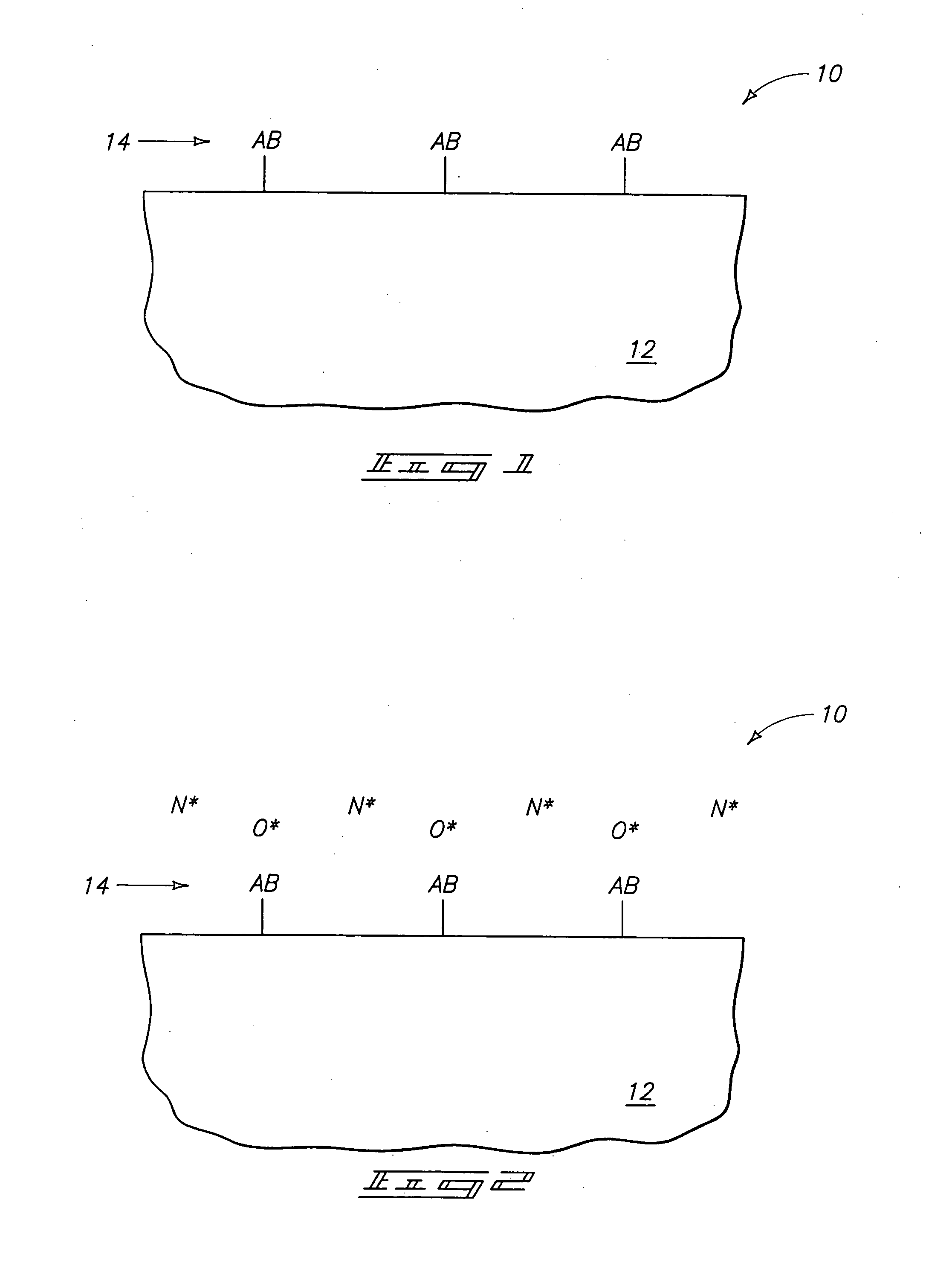

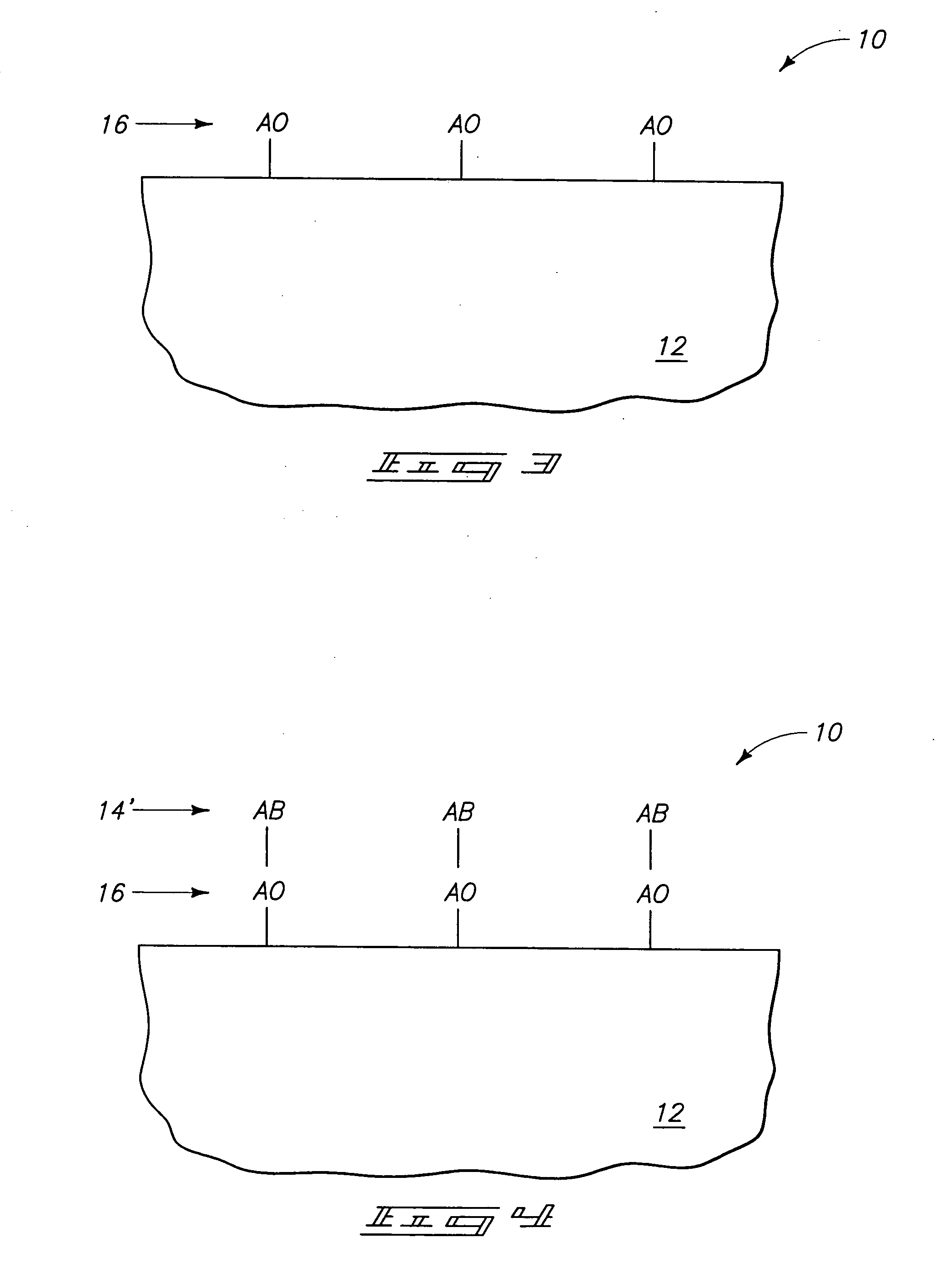

Atomic layer deposition method of depositing an oxide on a substrate

The invention includes atomic layer deposition methods of depositing an oxide on a substrate. In one implementation, a substrate is positioned within a deposition chamber. A first species is chemisorbed onto the substrate to form a first species monolayer within the deposition chamber from a gaseous precursor. The chemisorbed first species is contacted with remote plasma oxygen derived at least in part from at least one of O2 and O3 and with remote plasma nitrogen effective to react with the first species to form a monolayer comprising an oxide of a component of the first species monolayer. The chemisorbing and the contacting with remote plasma oxygen and with remote plasma nitrogen are successively repeated effective to form porous oxide on the substrate. Other aspects and implementations are contemplated.

Owner:MICRON TECH INC

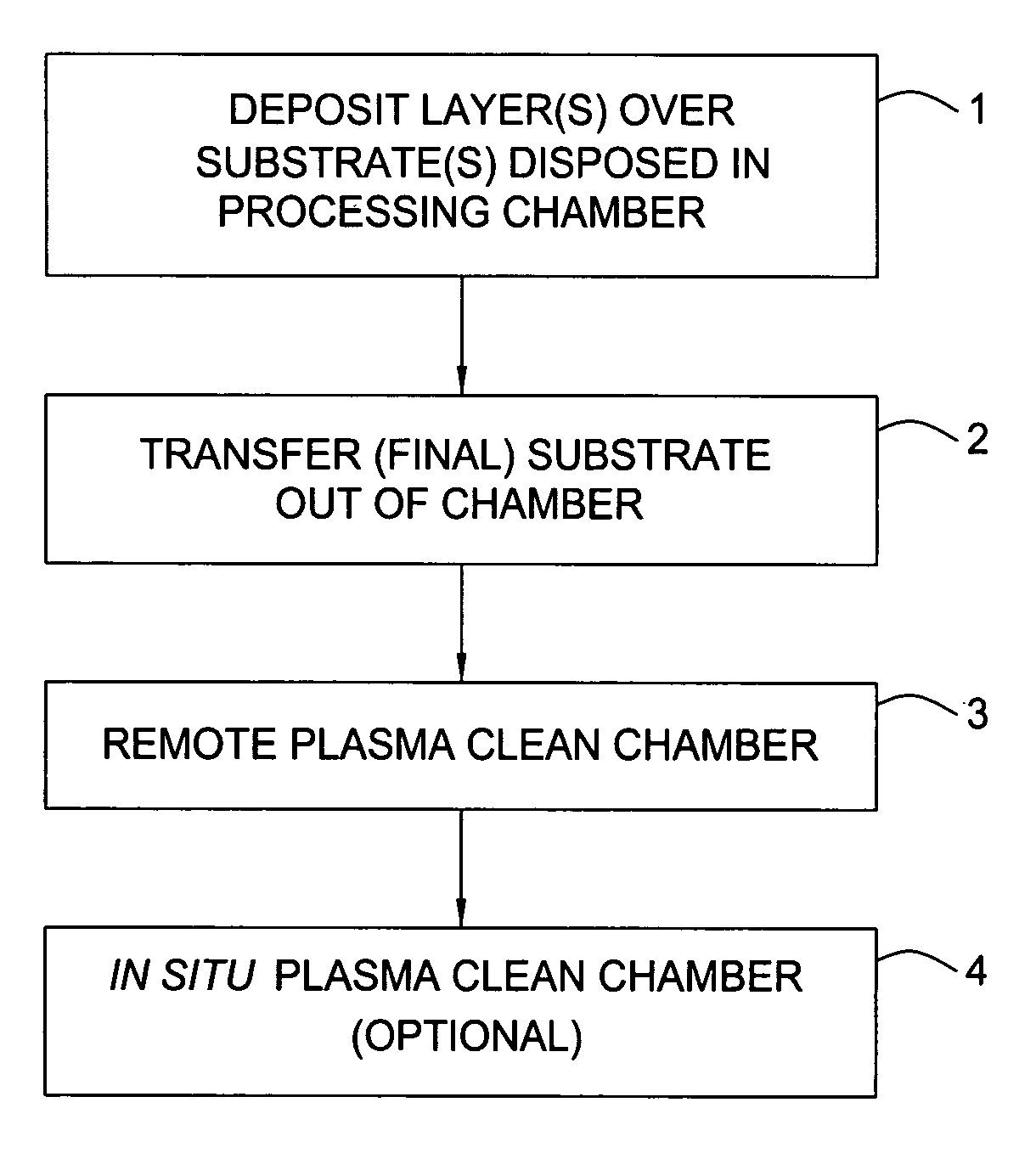

High-power dielectric seasoning for stable wafer-to-wafer thickness uniformity of dielectric CVD films

InactiveUS20060093756A1Liquid surface applicatorsSemiconductor/solid-state device manufacturingDielectricCleaning methods

A method for seasoning a deposition chamber wherein the chamber components and walls are densely coated with a material that does not contain carbon prior to deposition of an organo-silicon material on a substrate. An optional carbon-containing layer may be deposited therebetween. A chamber cleaning method using low energy plasma and low pressure to remove residue from internal chamber surfaces is provided and may be combined with the seasoning process.

Owner:APPLIED MATERIALS INC

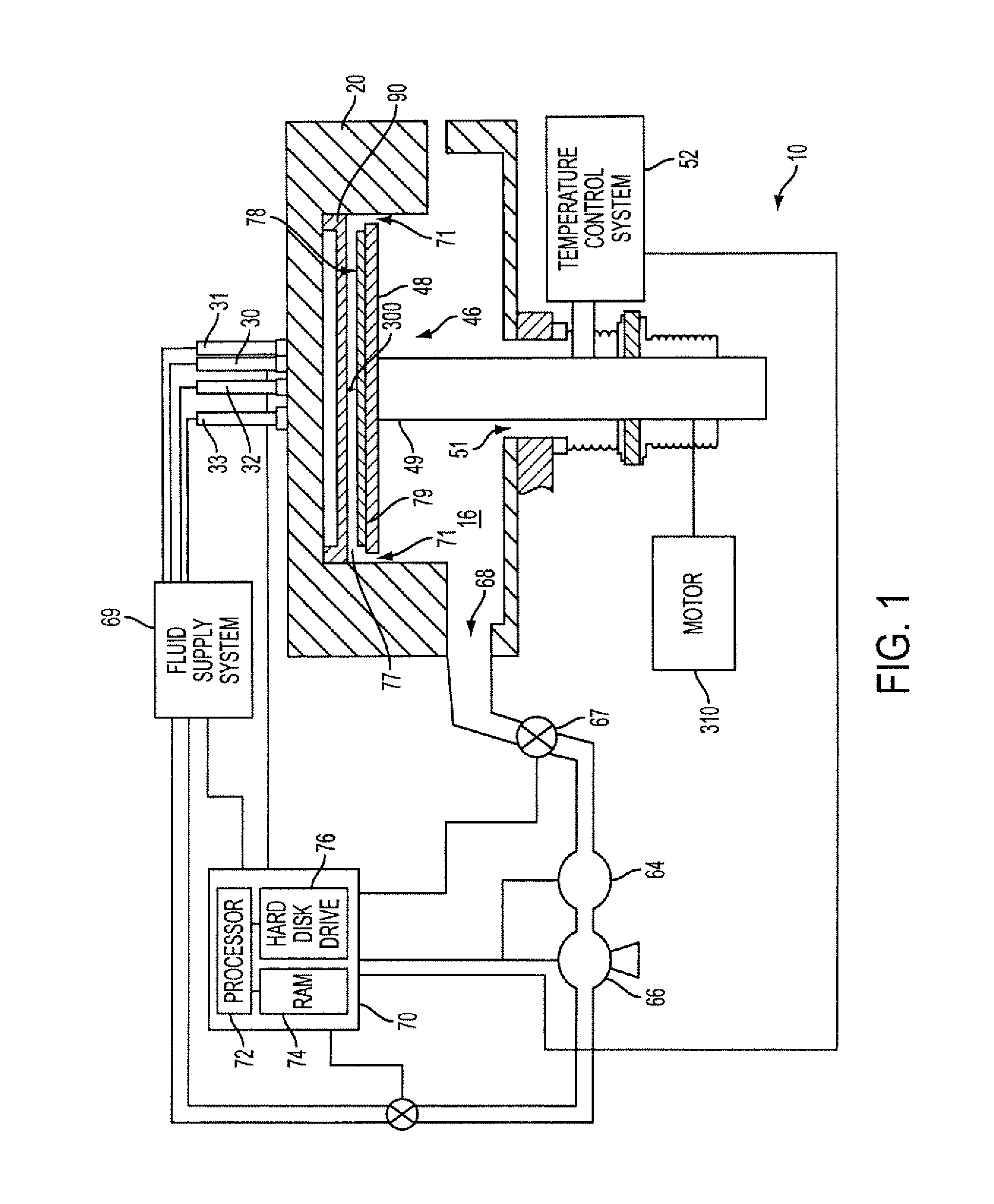

Reaction system for growing a thin film

ActiveUS20050241176A1Extension of timeLong stepDrying using combination processesDrying solid materials with heatControl systemDiffusion barrier

A reactor defines a reaction chamber for processing a substrate. The reactor comprises a first inlet for providing a first reactant and to the reaction chamber and a second inlet for a second reactant to the reaction chamber. A first exhaust outlet removes gases from the reaction chamber. A second exhaust outlet removes gases from the reaction chamber. A flow control system is configured to alternately constrict flow through the first and second exhaust outlets. The reactor chamber is configured to for a diffusion barrier within the reaction chamber.

Owner:ASM IP HLDG BV

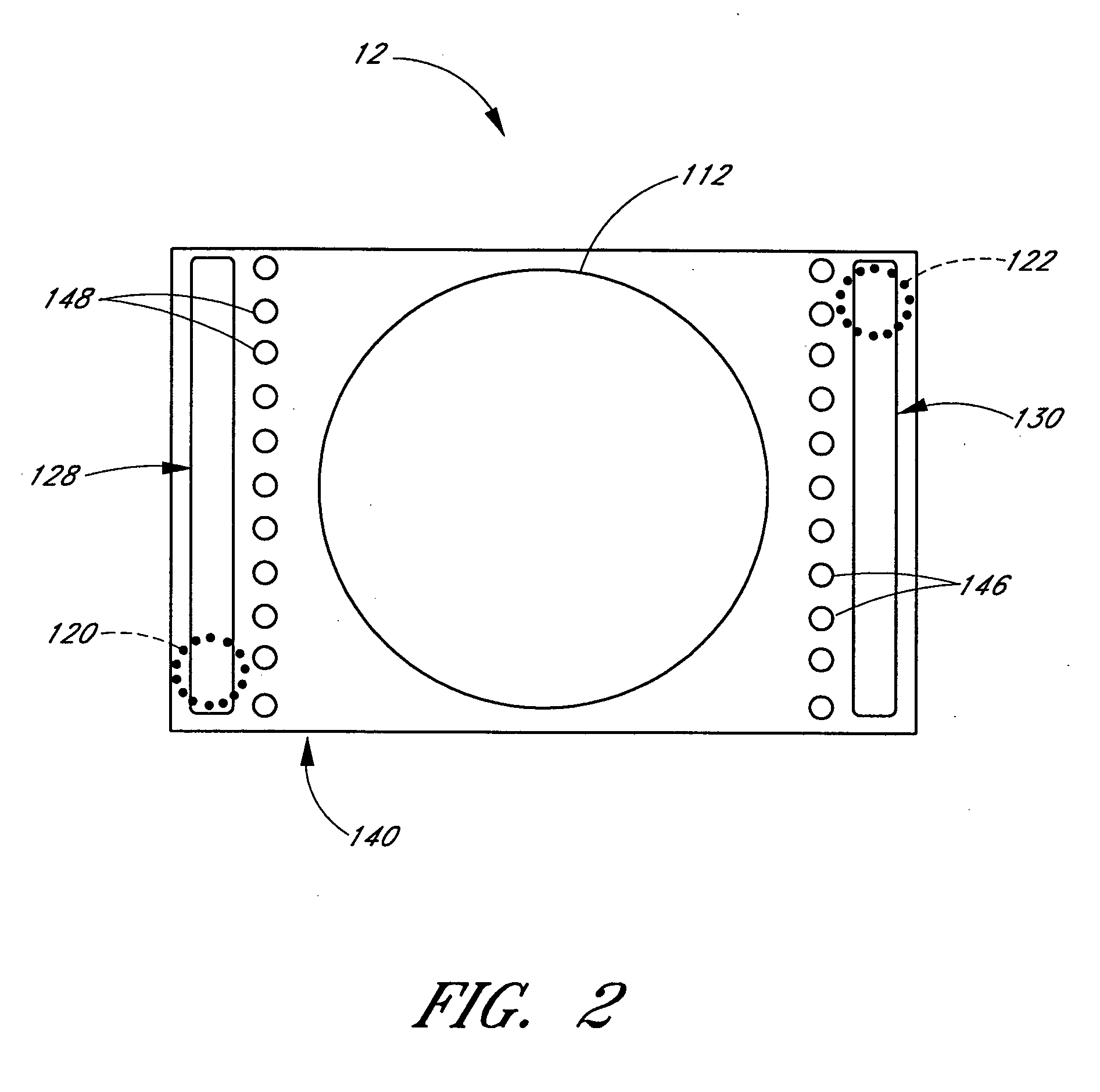

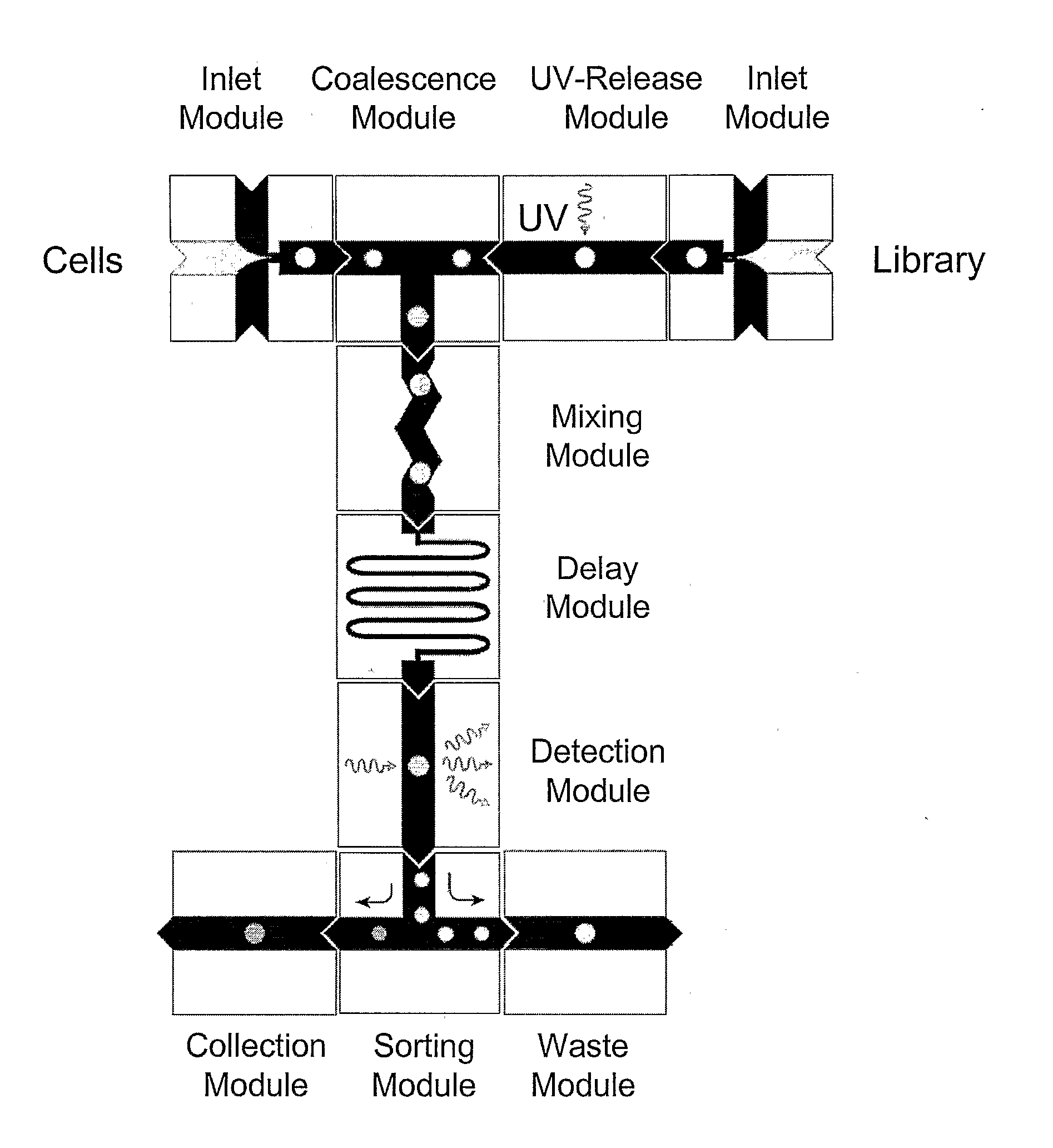

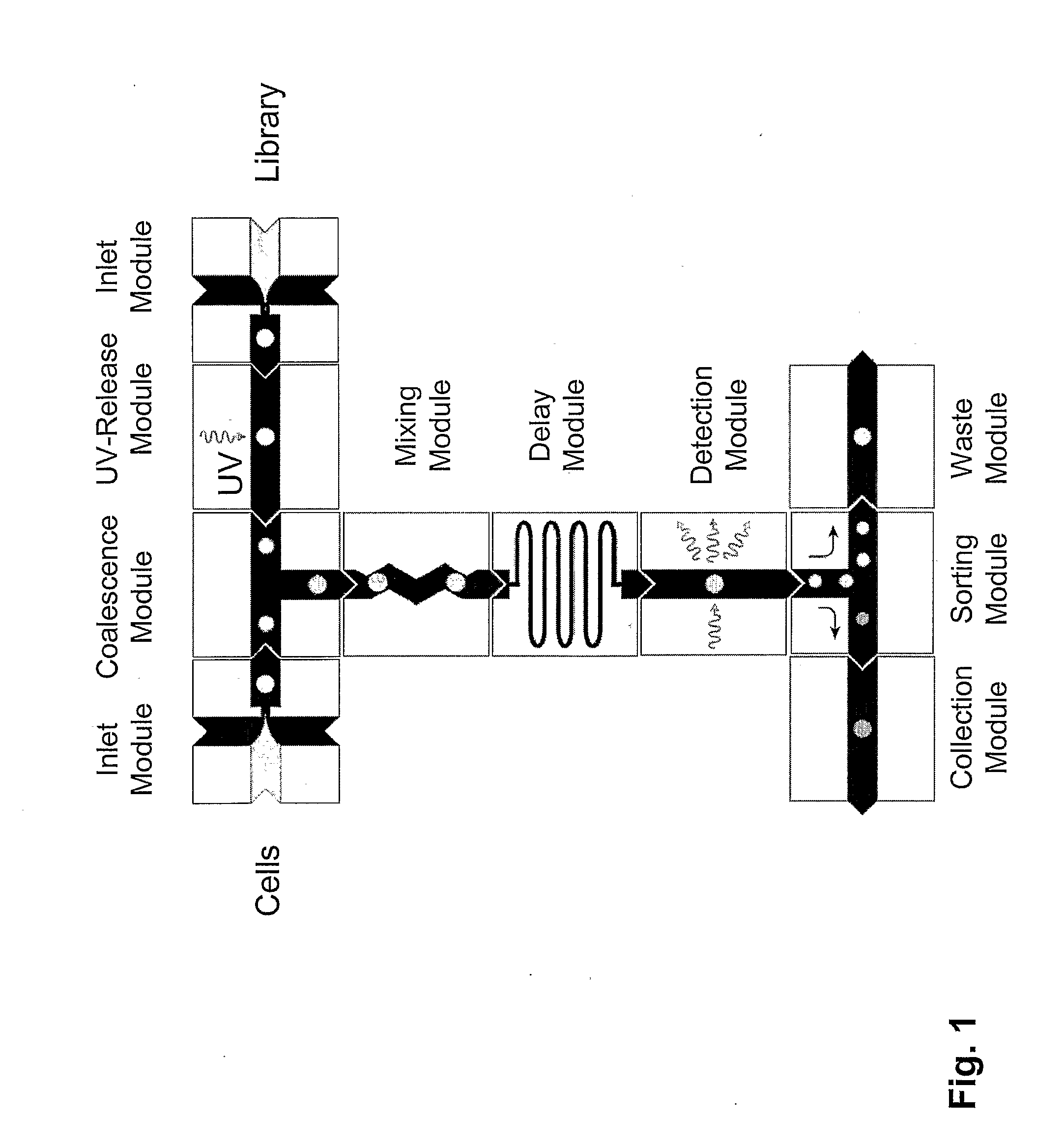

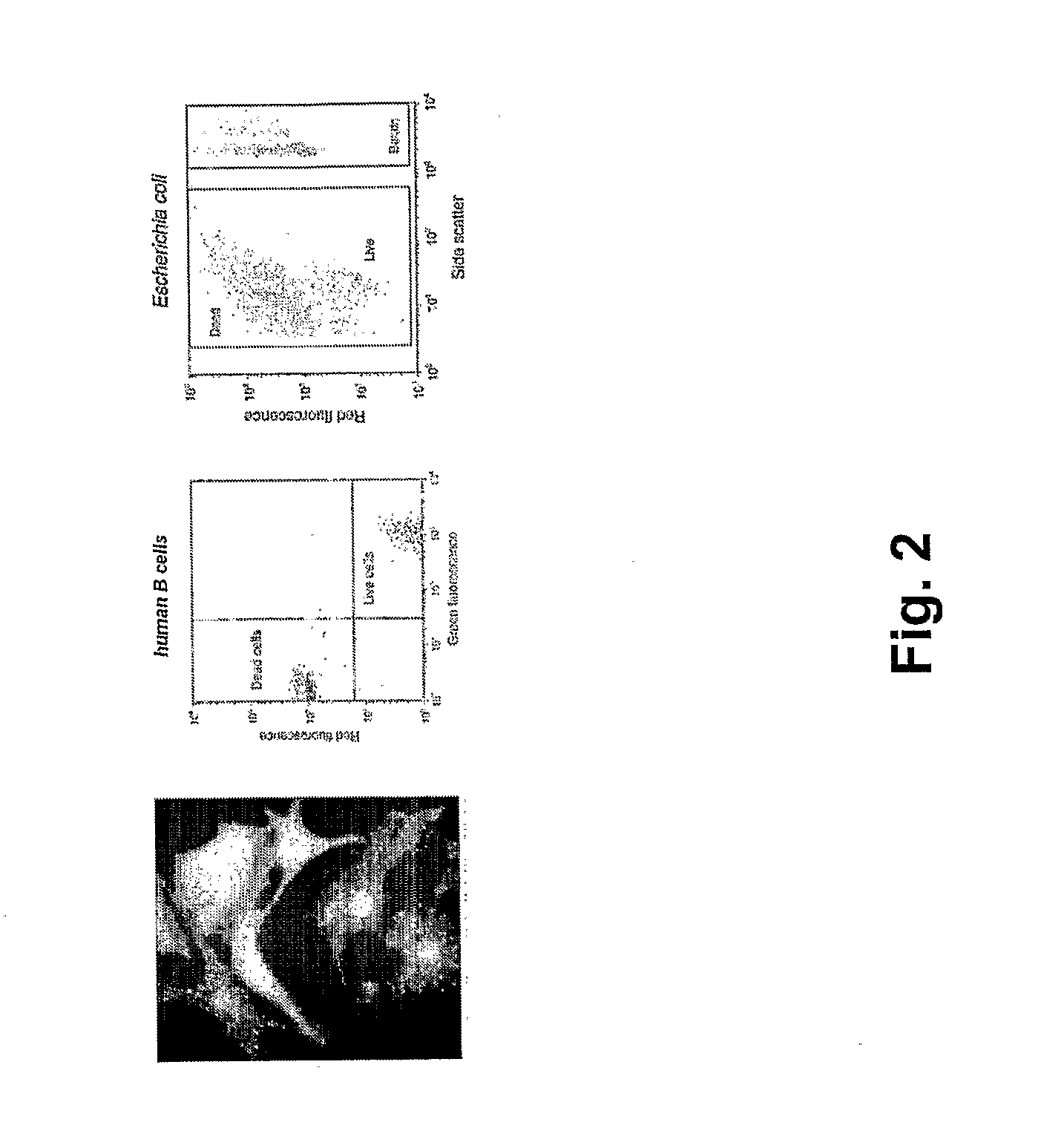

Microfluidic Devices and Methods of Use in The Formation and Control of Nanoreactors

InactiveUS20100137163A1Material nanotechnologyCompound screeningHigh-Throughput Screening AssaysEmulsion

The present invention provides novel microfluidic devices and methods that are useful for performing high-throughput screening assays and combinatorial chemistry. Such methods can include labeling a library of compounds by emulsifying aqueous solutions of the compounds and aqueous solutions of unique liquid labels on a microfluidic device, which includes a plurality of electrically addressable, channel bearing fluidic modules integrally arranged on a microfabricated substrate such that a continuous channel is provided for flow of immiscible fluids, whereby each compound is labeled with a unique liquid label, pooling the labeled emulsions, coalescing the labeled emulsions with emulsions containing a specific cell or enzyme, thereby forming a nanoreactor, screening the nanoreactors for a desirable reaction between the contents of the nanoreactor, and decoding the liquid label, thereby identifying a single compound from a library of compounds.

Owner:BIO RAD LAB INC

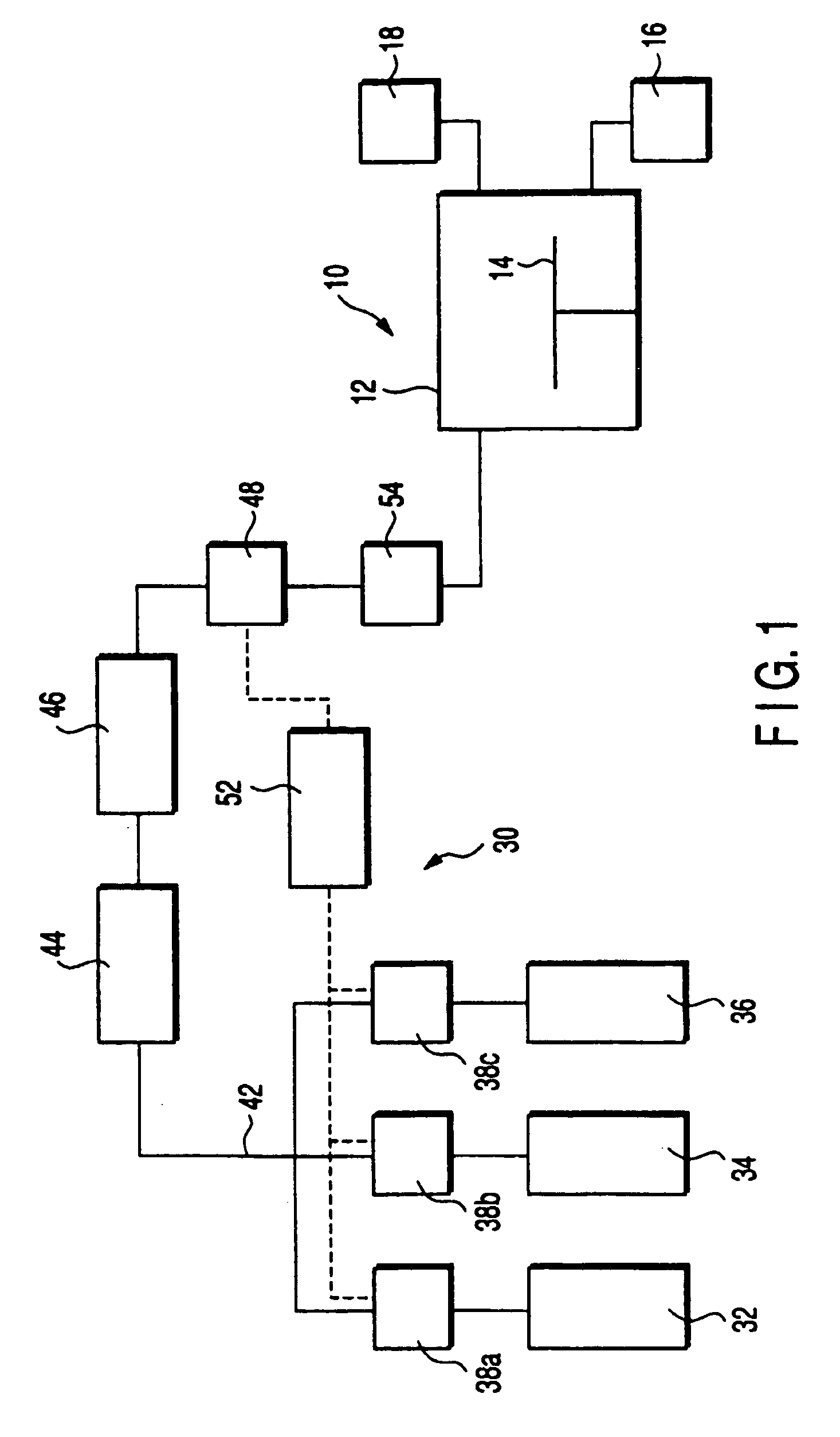

Method and apparatus for cleaning and method and apparatus for etching

InactiveUS20050020071A1Increase flexibilityImprove securitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingProcess engineeringForming gas

A cleaning apparatus (30) is connected to a treating chamber (12) of a CVD apparatus (10) for forming a silicon film. The cleaning apparatus (30) has a first, a second, and a third gas sources (32, 34, 36) and a chlorine gas, a fluorine gas, and an inert gas are introduced from the gas sources through FMC (38a, 38b, 38c), respectively, with flow rates controlled independently from one another. Those gases are gathered at a pipe (42) and mixed into a mixed gas. The mixed gas is passed through a heated reactor (44) such as a heat exchanger to thereby react the chlorine gas with the fluorine gas and form a formed gas containing fluorinated chlorine gas such as CIF3. The formed gas is supplied to the treating chamber (12) through a cooler (46), an analyzer (48) and a buffer (54).

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

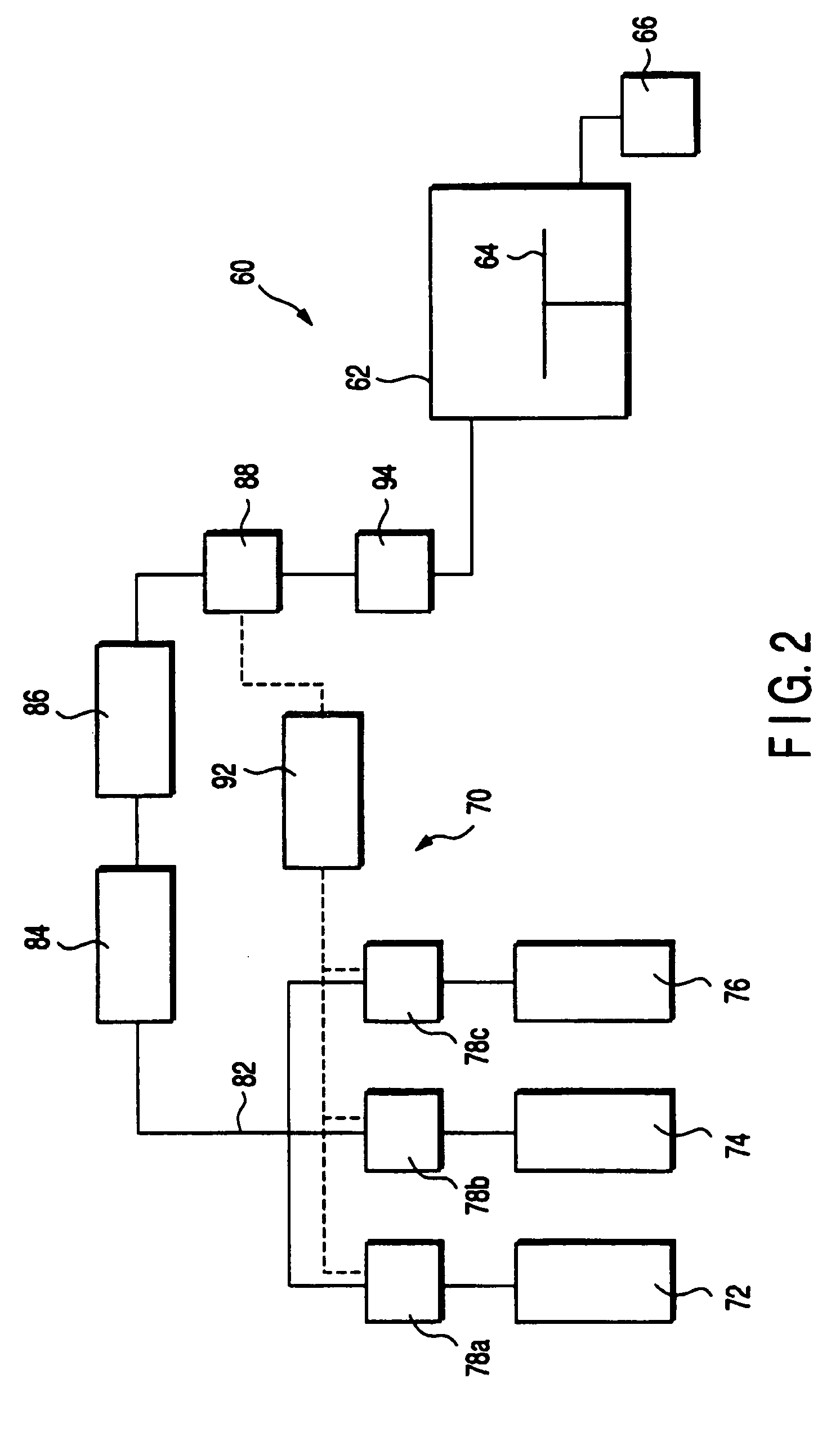

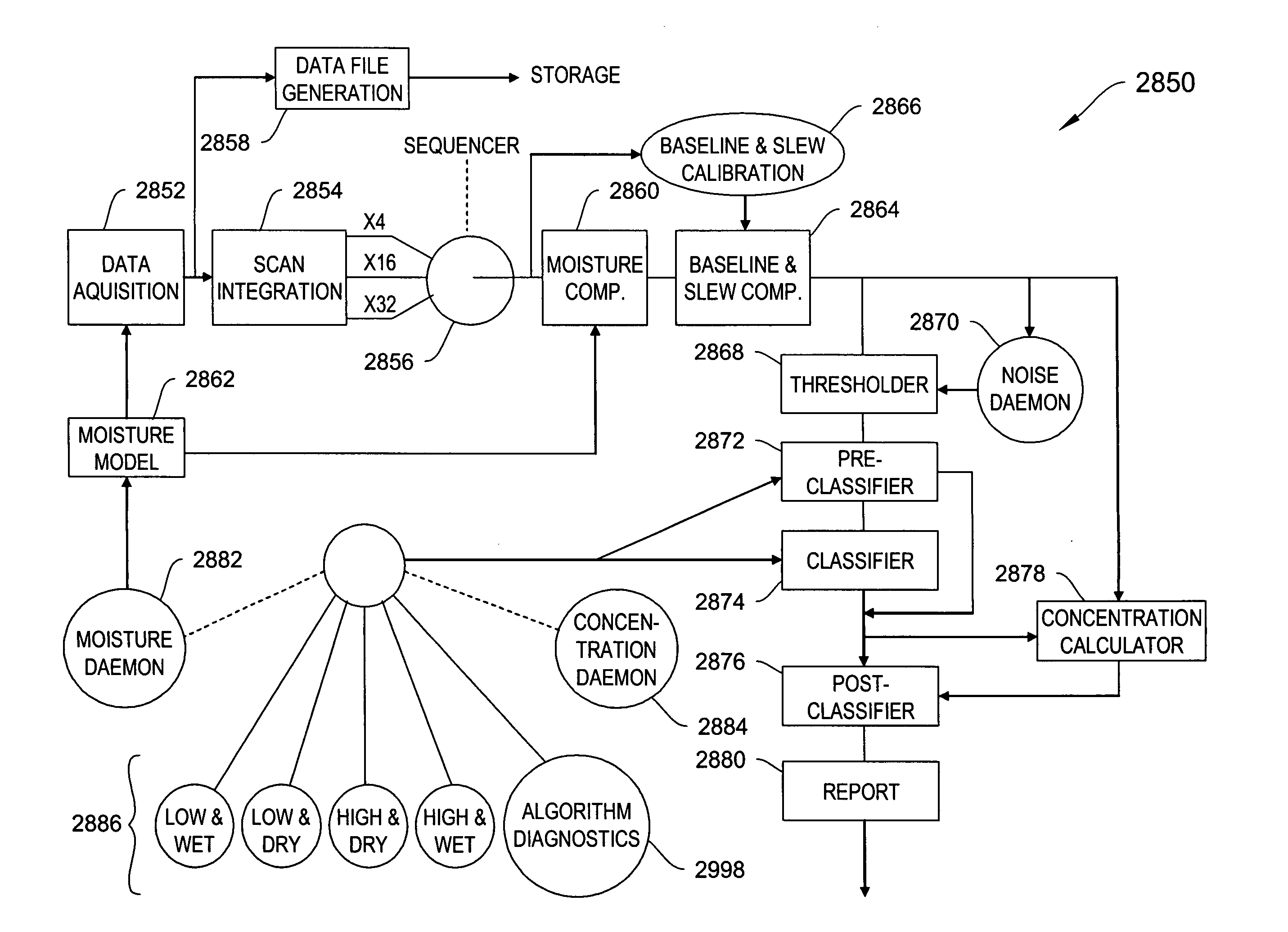

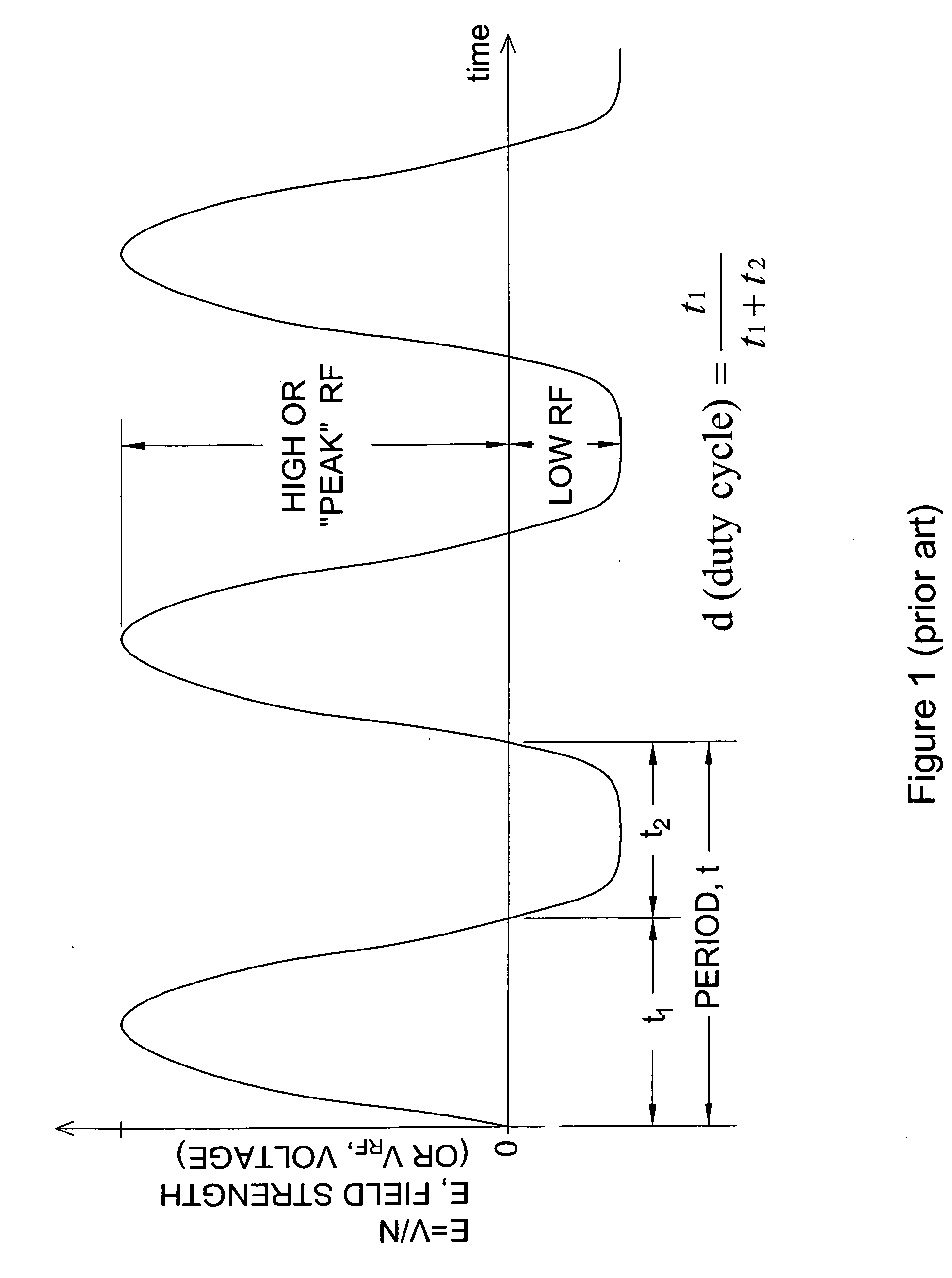

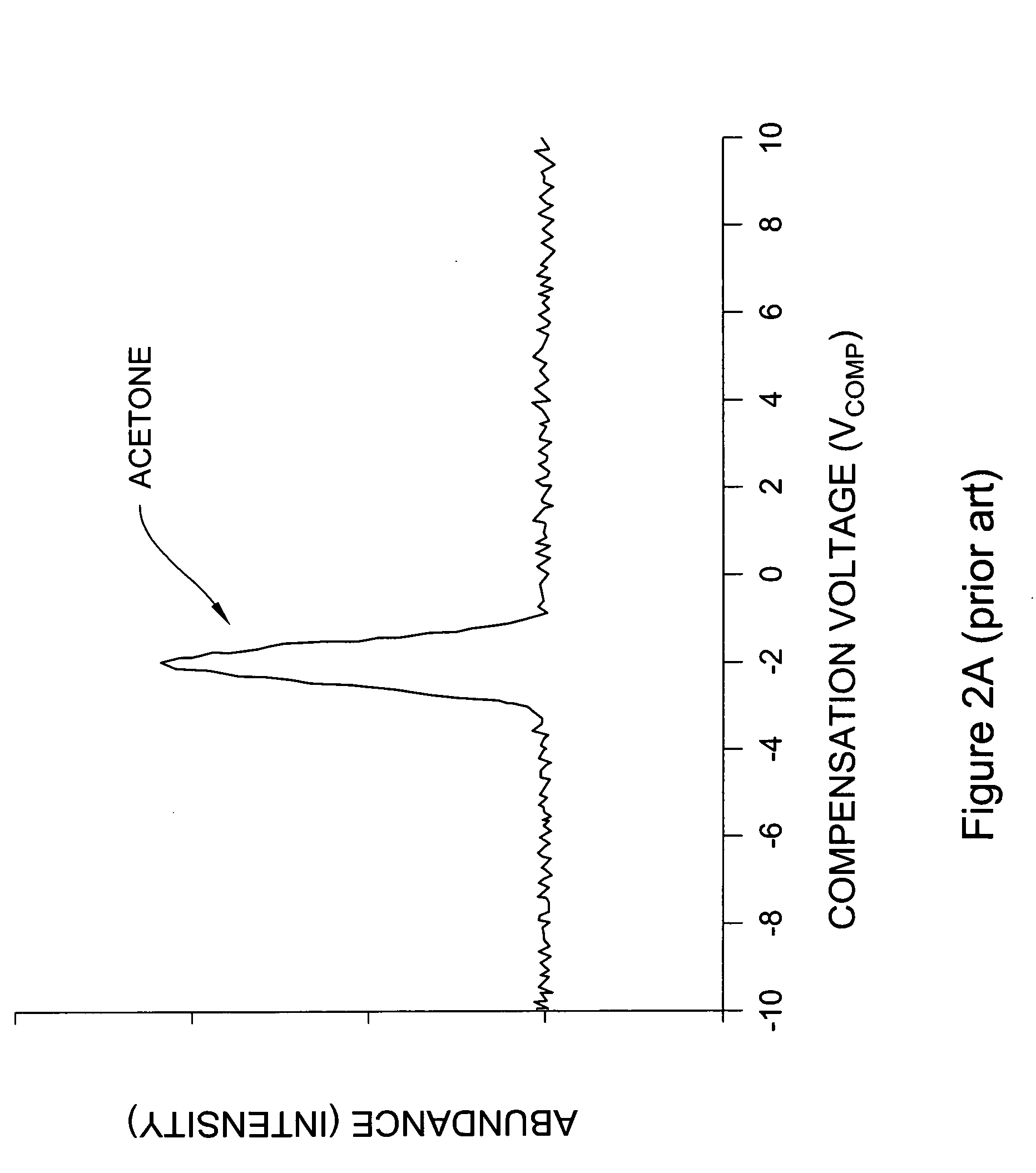

Systems and methods for ion species analysis with enhanced condition control and data interpretation

ActiveUS20050253061A1Reduces spectral peak overlapHigh resolutionTime-of-flight spectrometersMaterial analysis by electric/magnetic meansSystems approachesComputer science

The invention relates generally to ion mobility based systems, methods and devices for analyzing samples and, more particularly, to sample detection using enhanced condition control and data interpretation.

Owner:DH TECH DEVMENT PTE

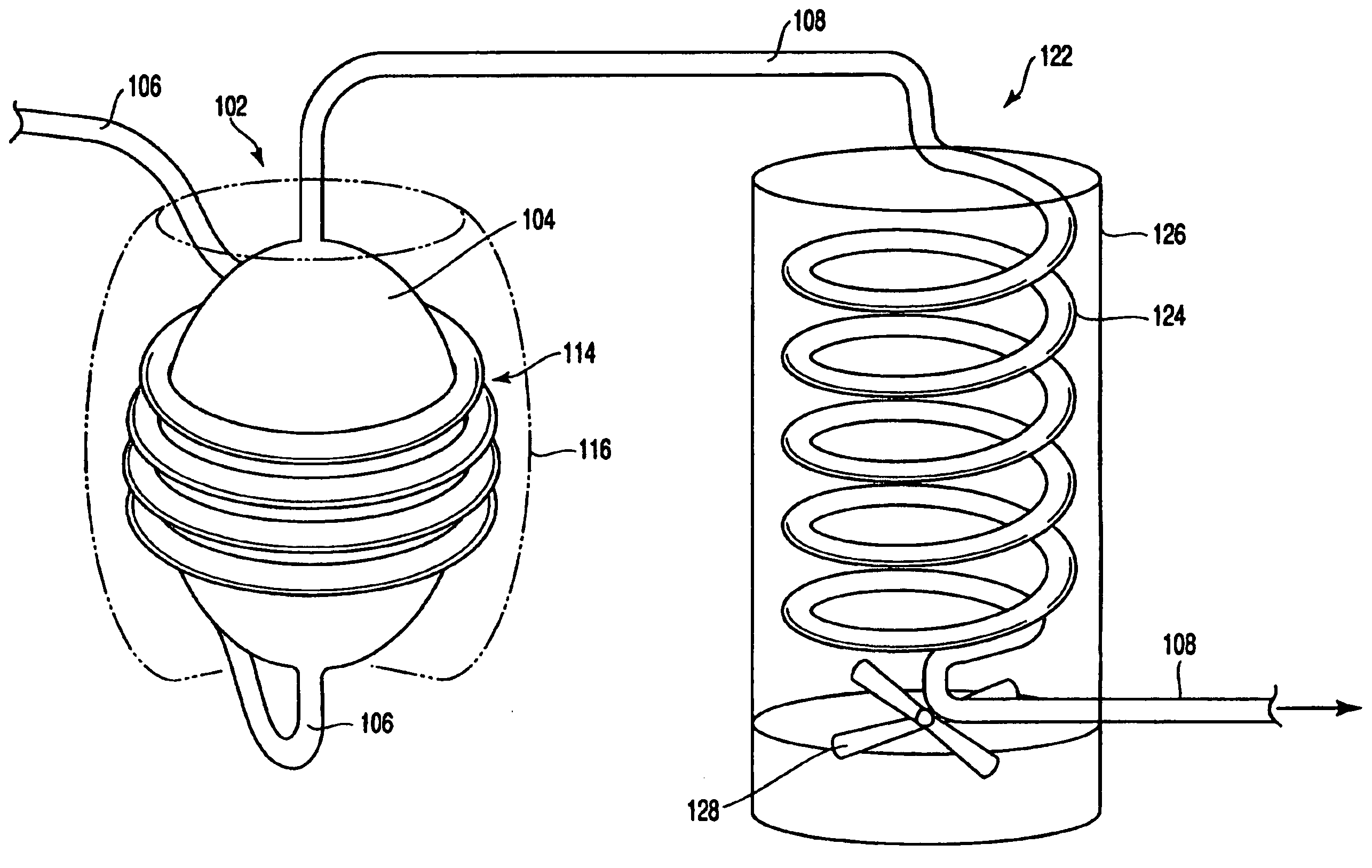

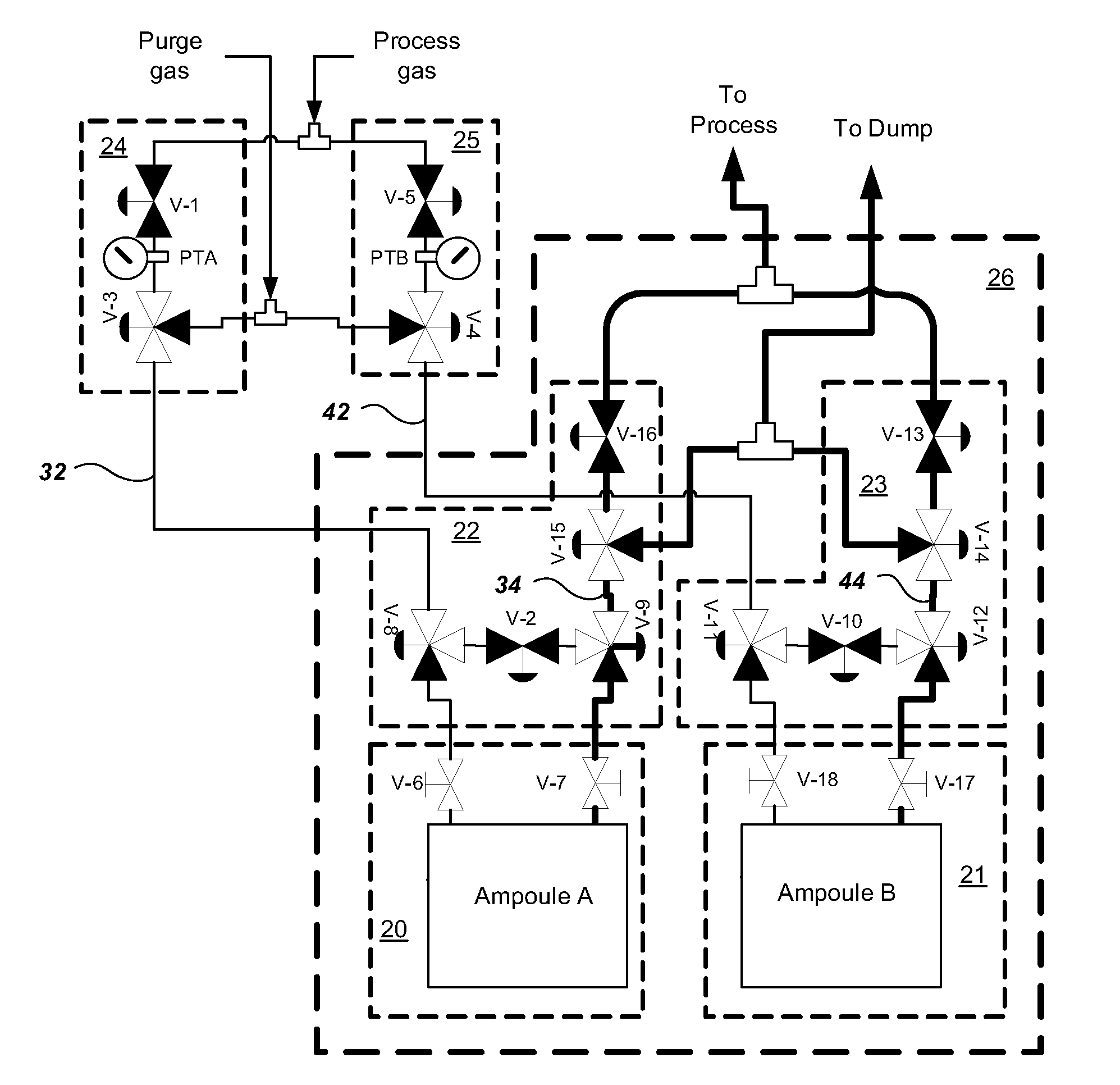

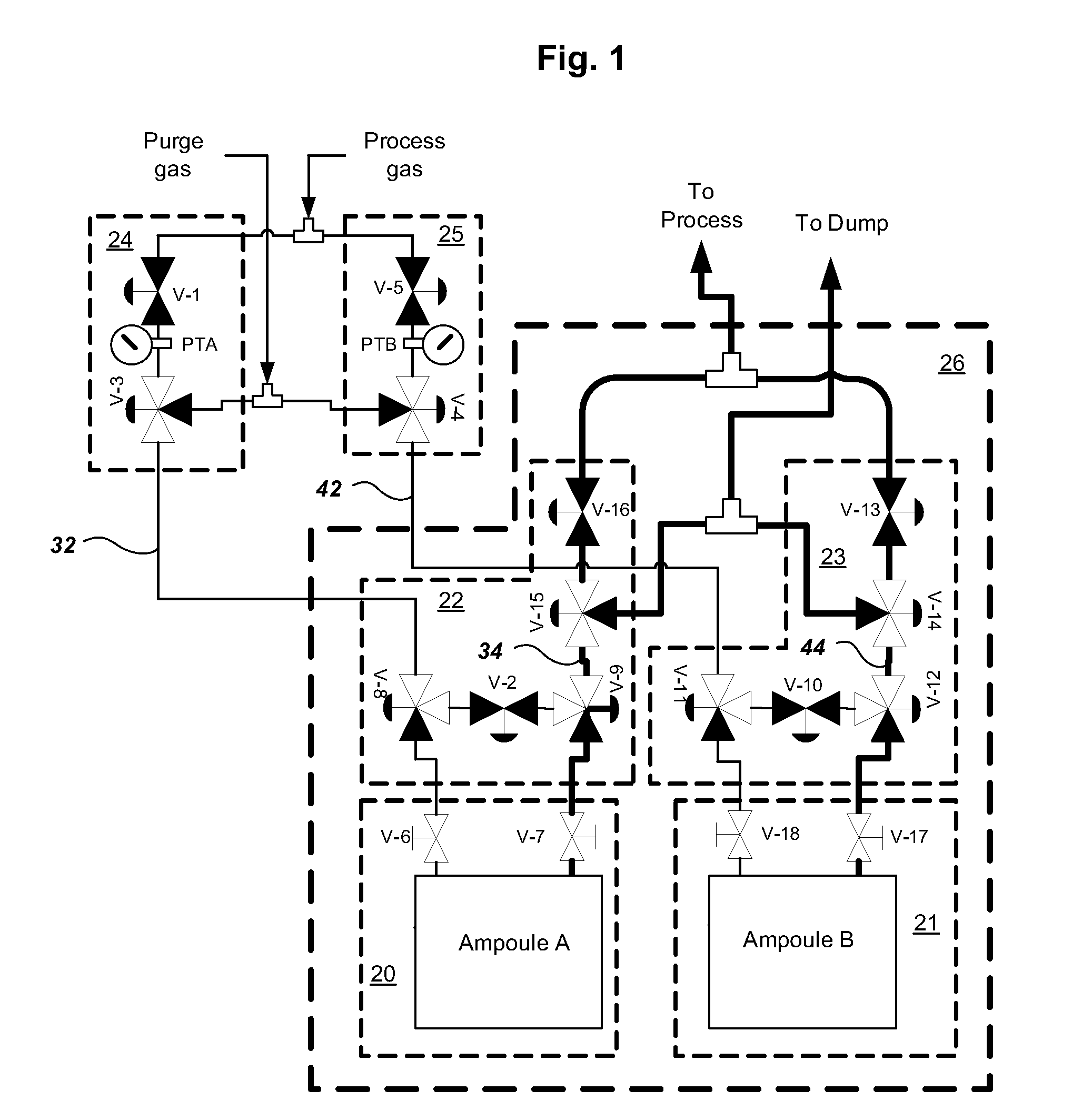

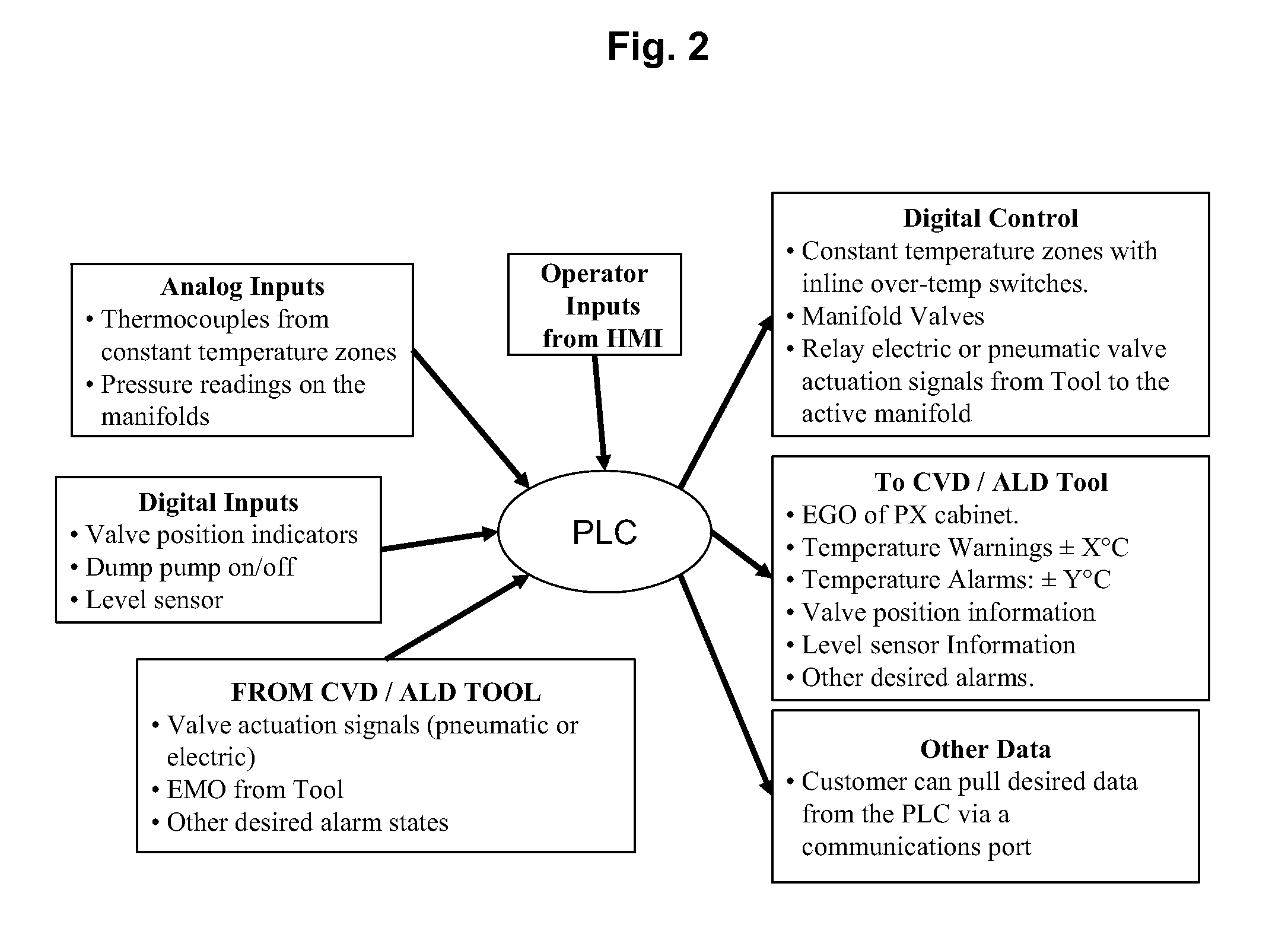

Multiple ampoule delivery systems

InactiveUS20090211525A1Easy to useReduce wasteLiquid surface applicatorsPipeline systemsSemiconductor materialsDelivery system

This invention relates to an integrated vapor or liquid phase reagent dispensing apparatus having a plurality of vessels and a plurality of carrier or inert gas feed / vapor or liquid phase reagent delivery manifolds, that may be used for continuously dispensing vapor or liquid phase reagents such as precursors for deposition of materials in the manufacture of semiconductor materials and devices.

Owner:PRAXAIR TECH INC

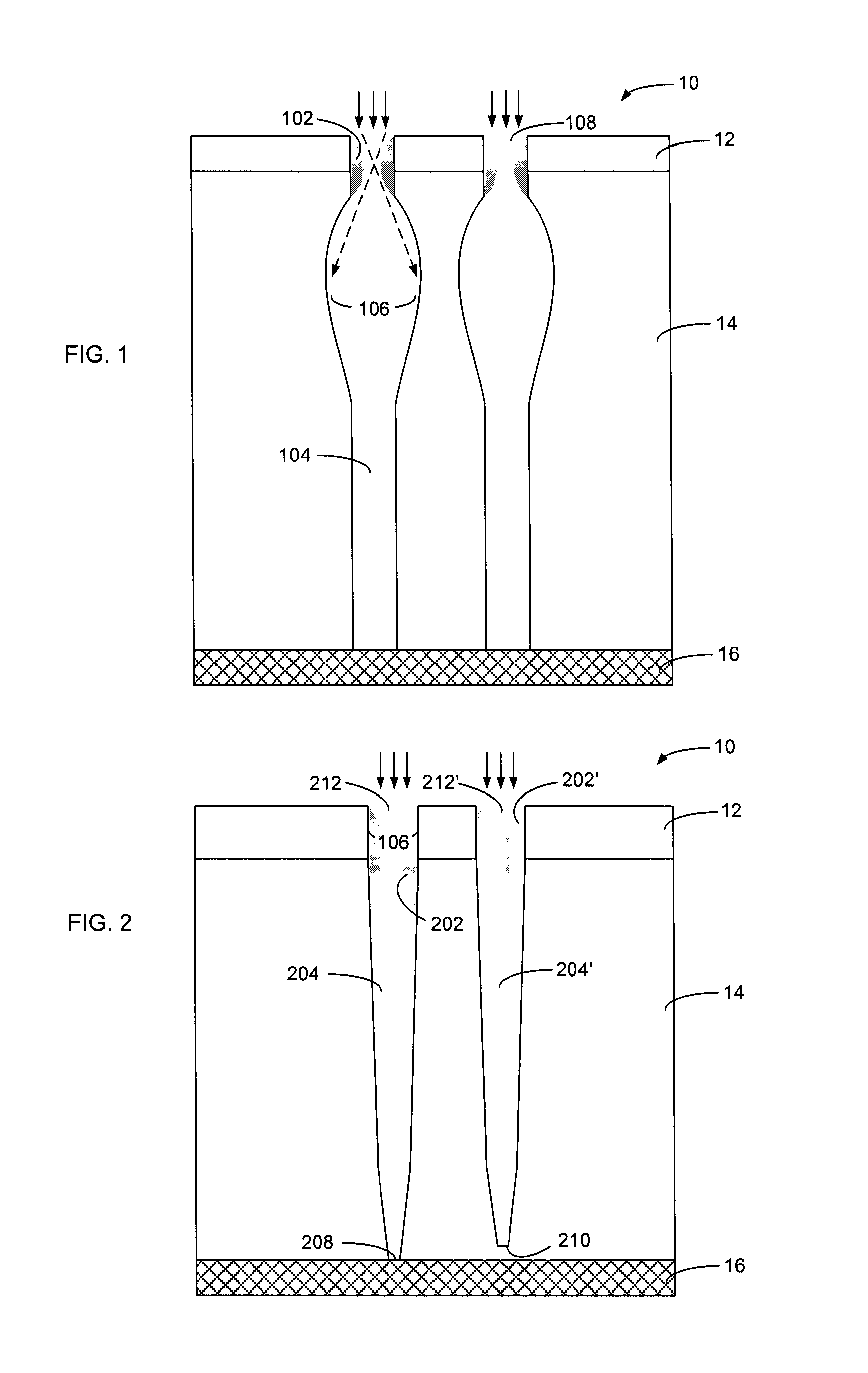

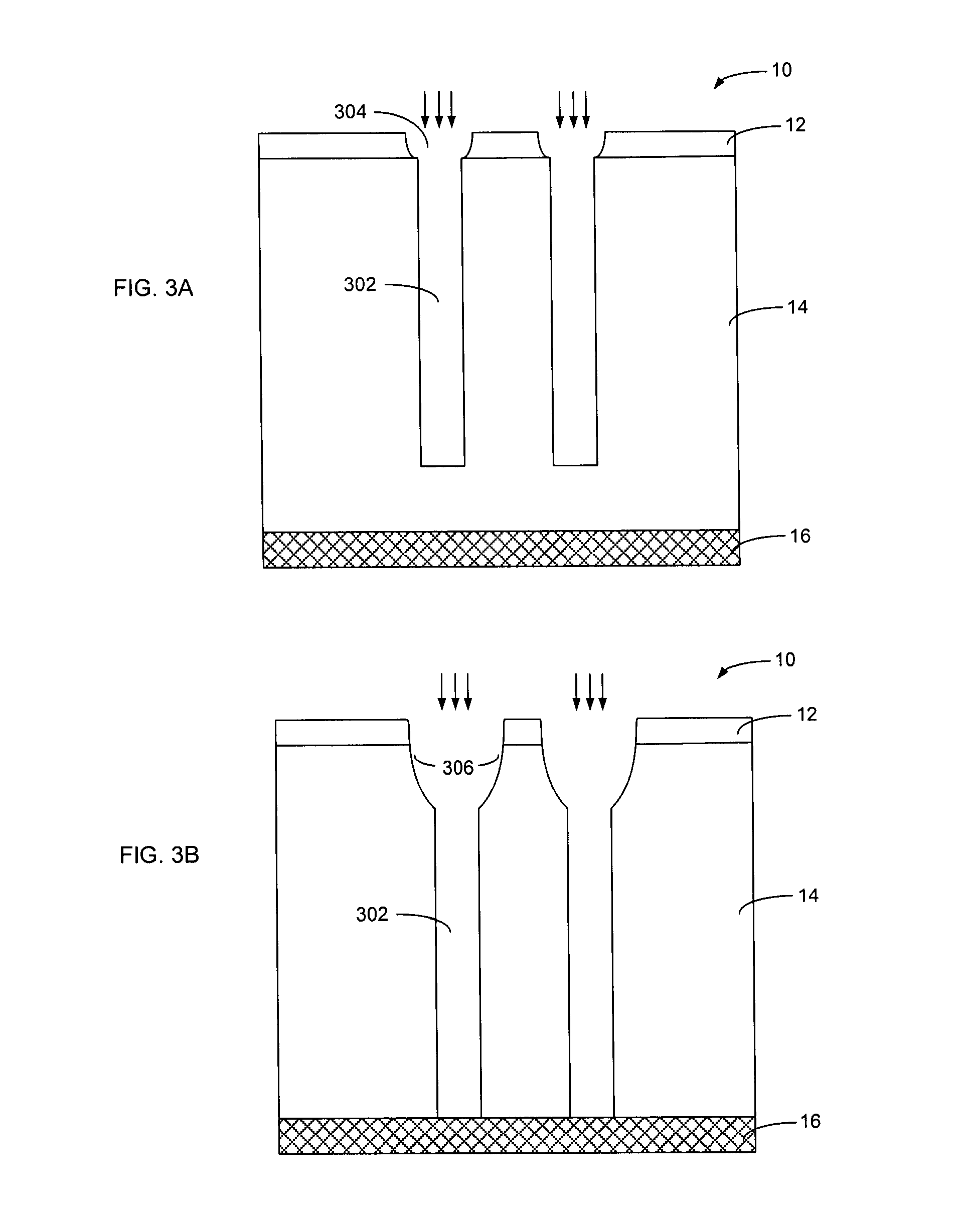

Method of etching high aspect ratio features in a dielectric layer

Methods of etching HAR features in a dielectric layer are described. In one embodiment, a substrate is provided into an etch chamber. The substrate has a patterned mask disposed on a dielectric layer formed thereon where the patterned mask has openings. A gas mixture is provided into the etch chamber, the gas mixture includes CO, O2, a fluorocarbon gas, and an optional inert gas. A plasma is formed from the gas mixture. Features are etched in the dielectric layer through the openings in the presence of the plasma

Owner:APPLIED MATERIALS INC

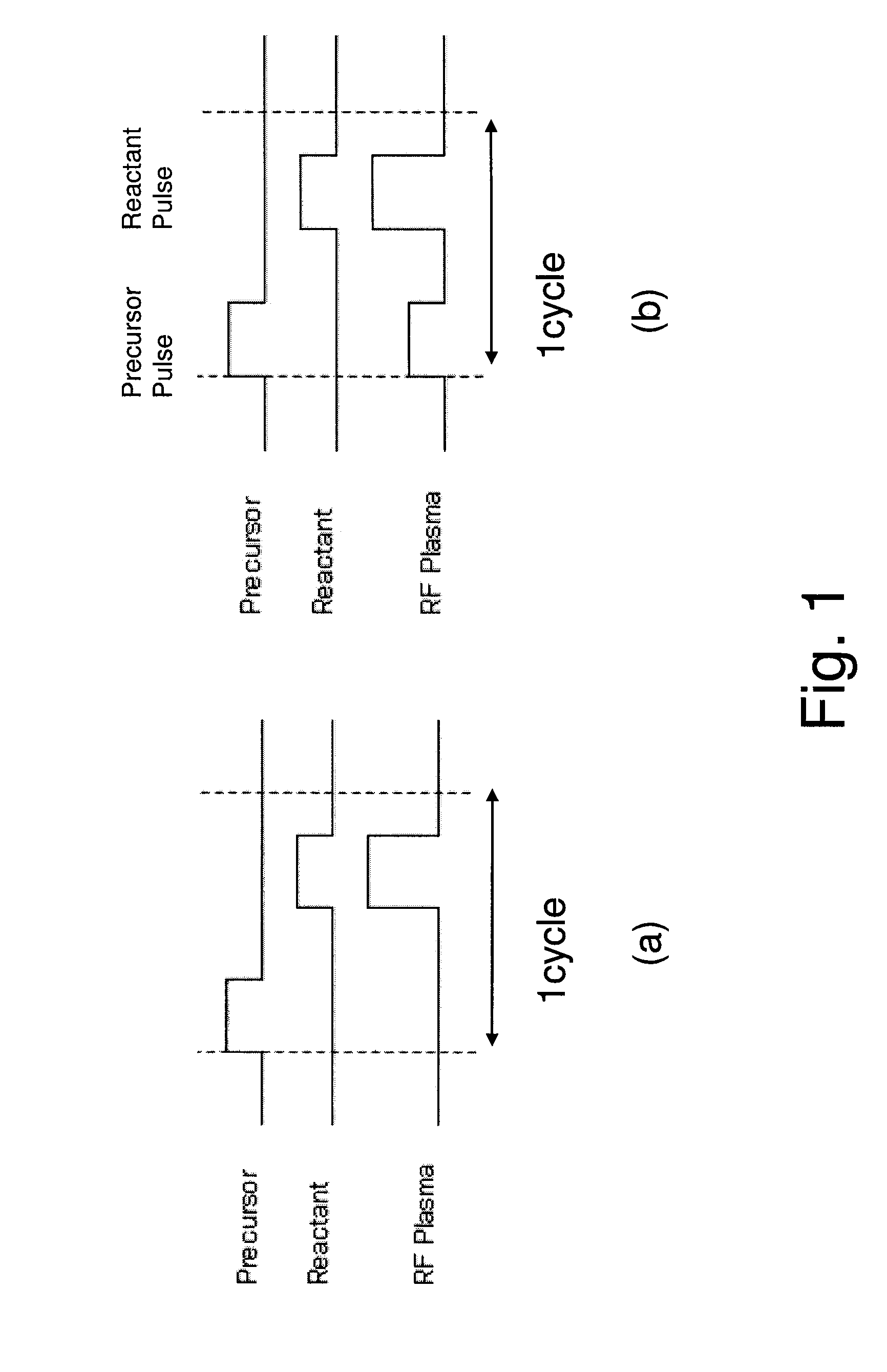

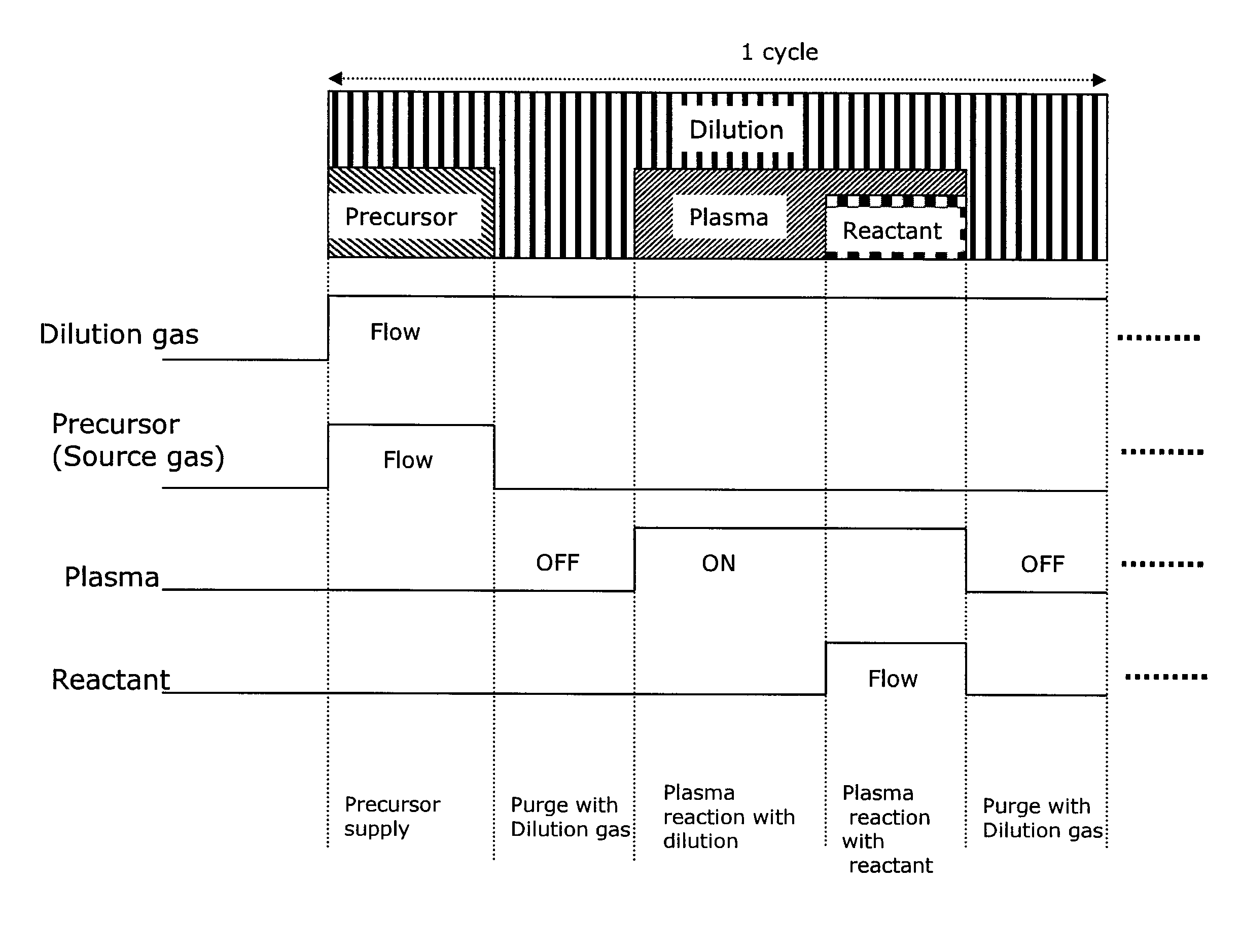

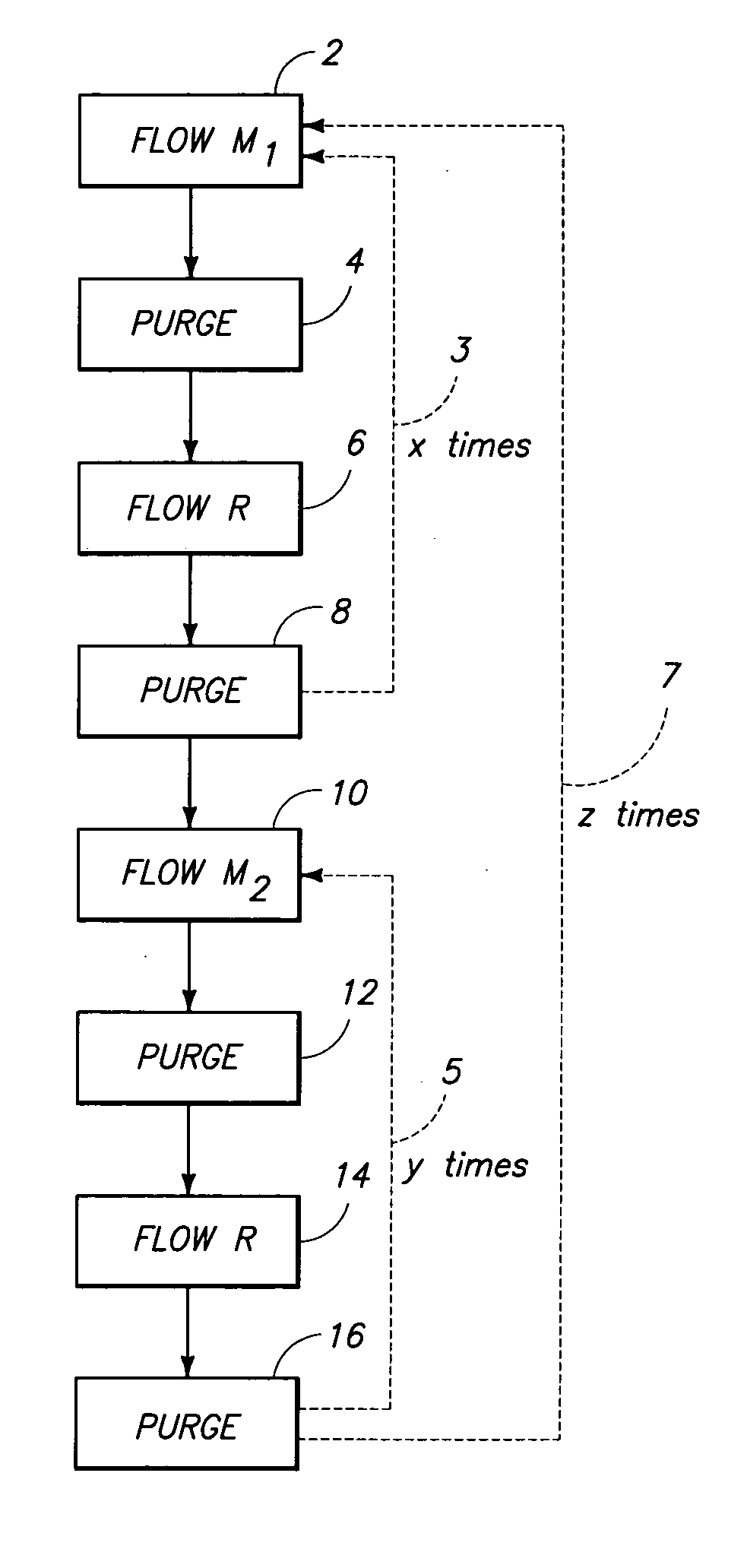

Method for forming thin film

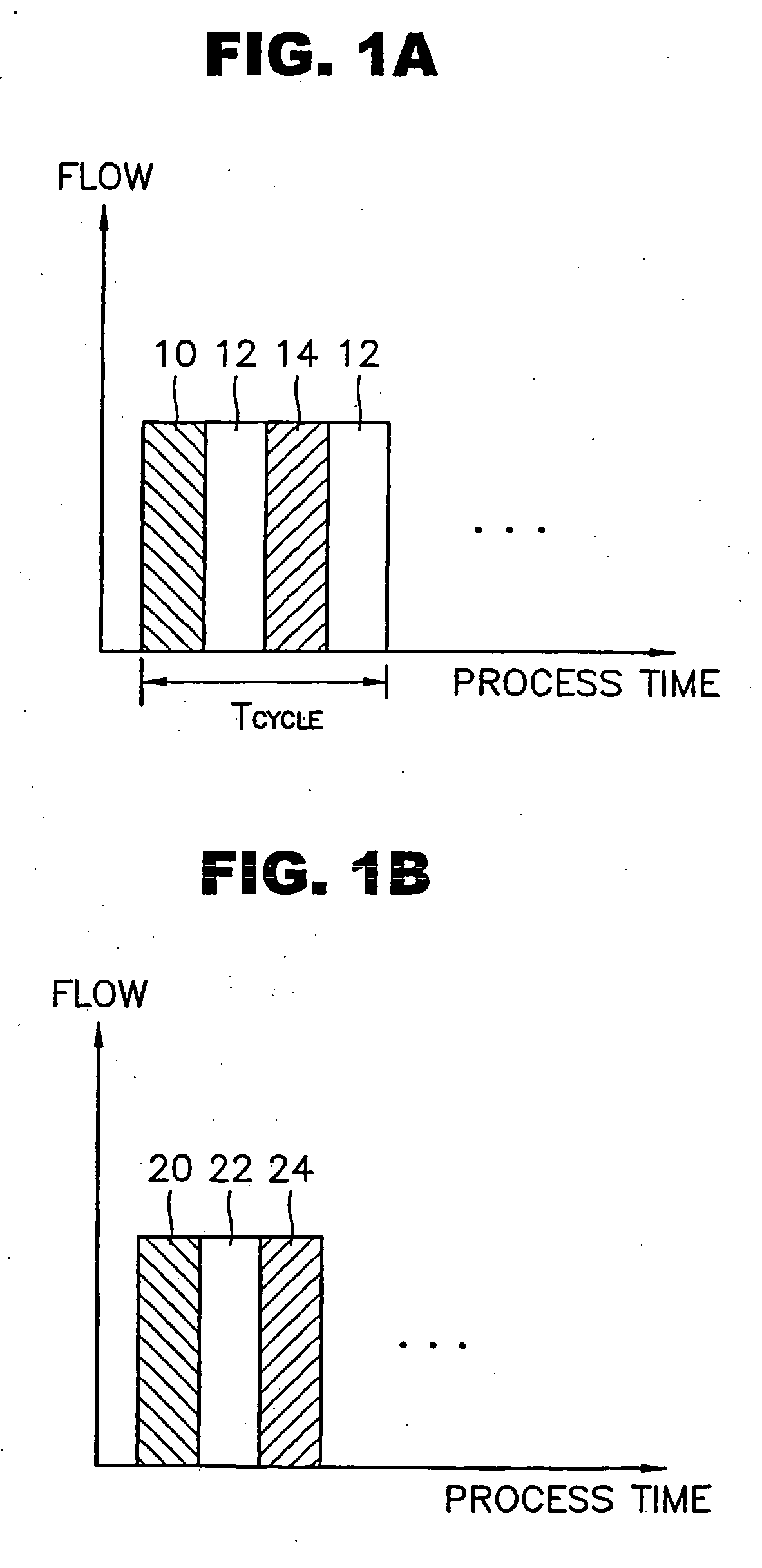

InactiveUS20050037154A1Prolonged durationIncrease ratingsSemiconductor/solid-state device manufacturingChemical vapor deposition coatingThin layerProduct gas

Method for forming a thin film at low temperature by using plasma pulses is disclosed. While a purge gas or a reactant purge gas activated by plasma is continuously supplied into a reactor, a source gas is supplied intermittently into the reactor during which period plasma is generated in the reactor so that the source gas and the purge gas activated by plasma reacts, so that a thin film is formed according to the method. Also, a method for forming a thin layer of film containing a plural of metallic elements, a method for forming a thin metallic film containing varied contents by amount of the metallic elements by using a supercycle Tsupercycle comprising a combination of simple gas supply cycles Tcycle, . . . , and a method for forming a thin film containing continuously varying compositions of the constituent elements by using a supercycle Tsupercycle comprising a combination of simple gas supply cycles Tcycle, . . . , are disclosed. The methods for forming thin films disclosed here allows to shorten the purge cycle duration even if the reactivity between the source gases is high, to reduce the contaminants caused by the gas remaining in the reactor, to form a thin film at low temperature even if the reactivity between the source gases is low, and also to increase the rate of thin film formation.

Owner:ASM GENITECH KOREA

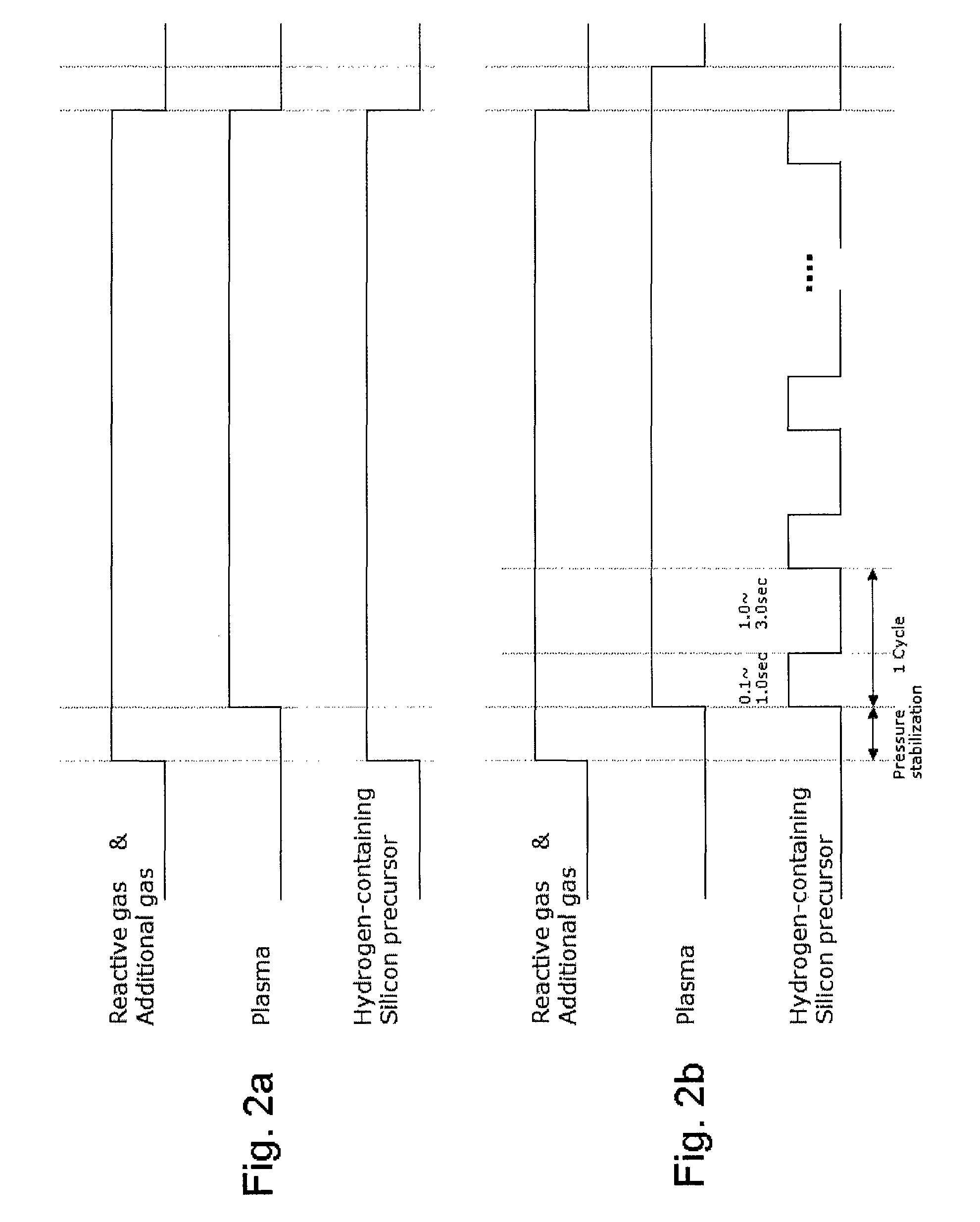

Method of forming conformal dielectric film having Si-N bonds by PECVD

ActiveUS7972980B2Increase deposition rateHigh conformalitySemiconductor/solid-state device detailsSolid-state devicesDielectricNoble gas

Owner:ASM JAPAN

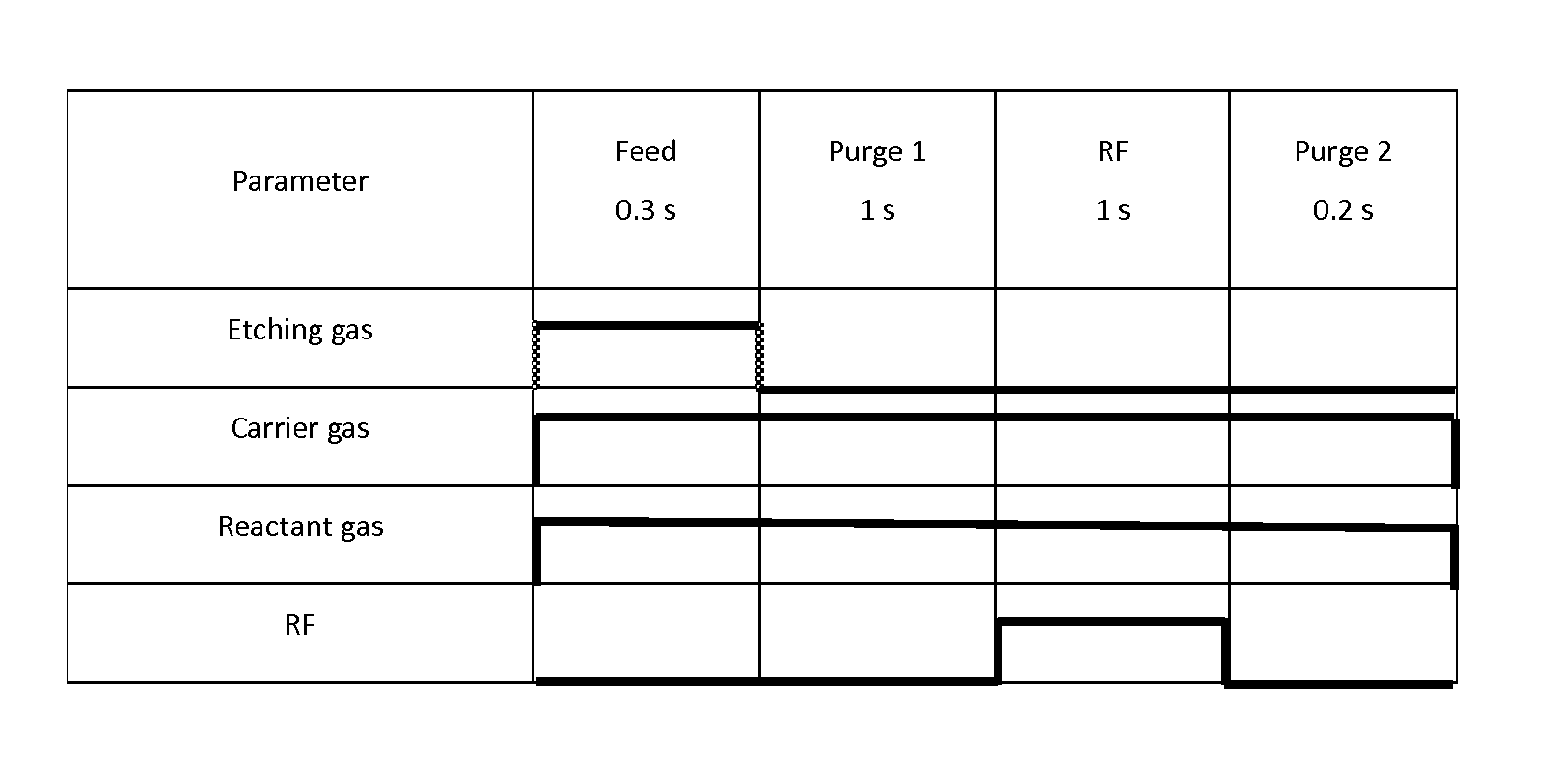

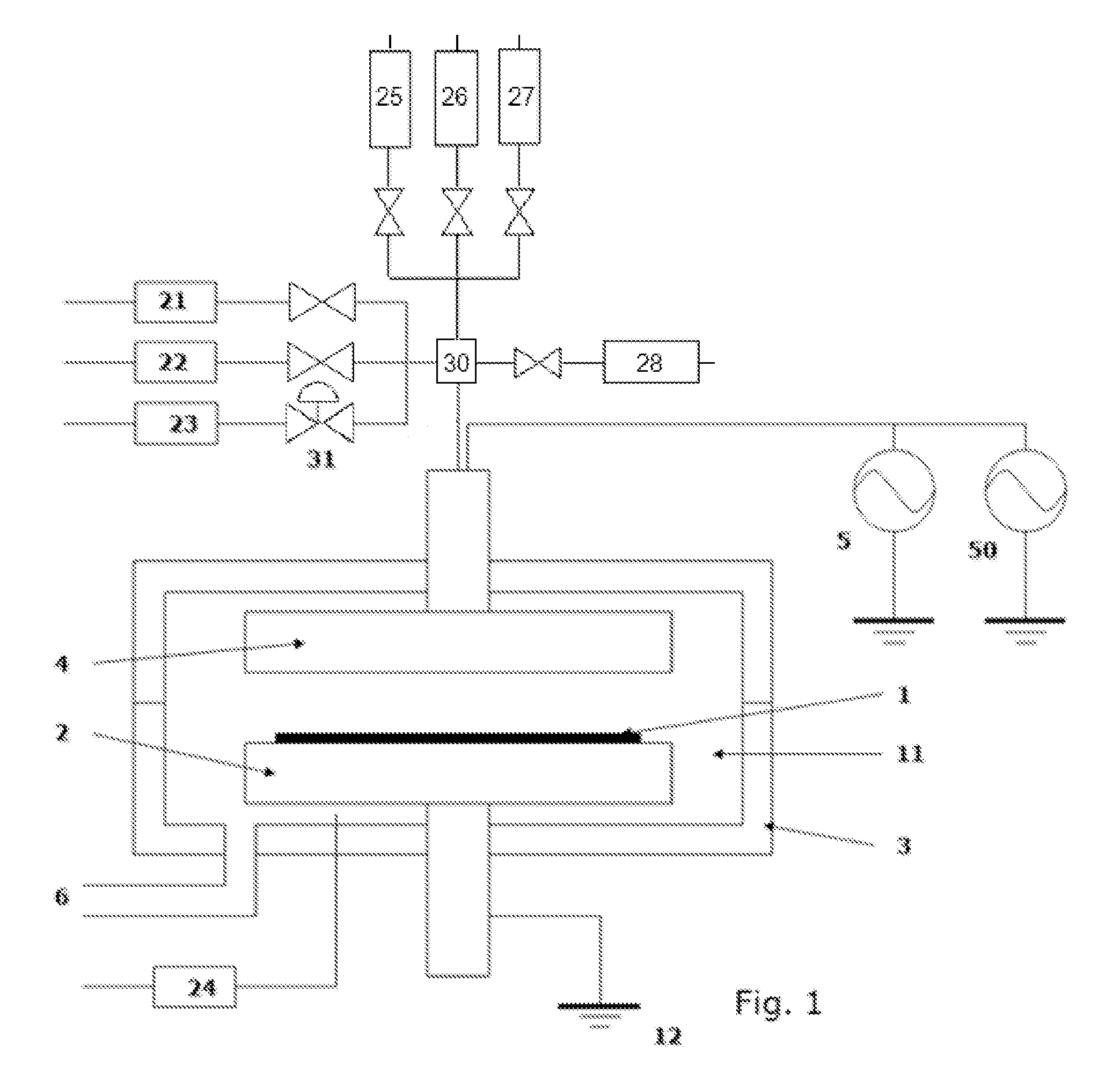

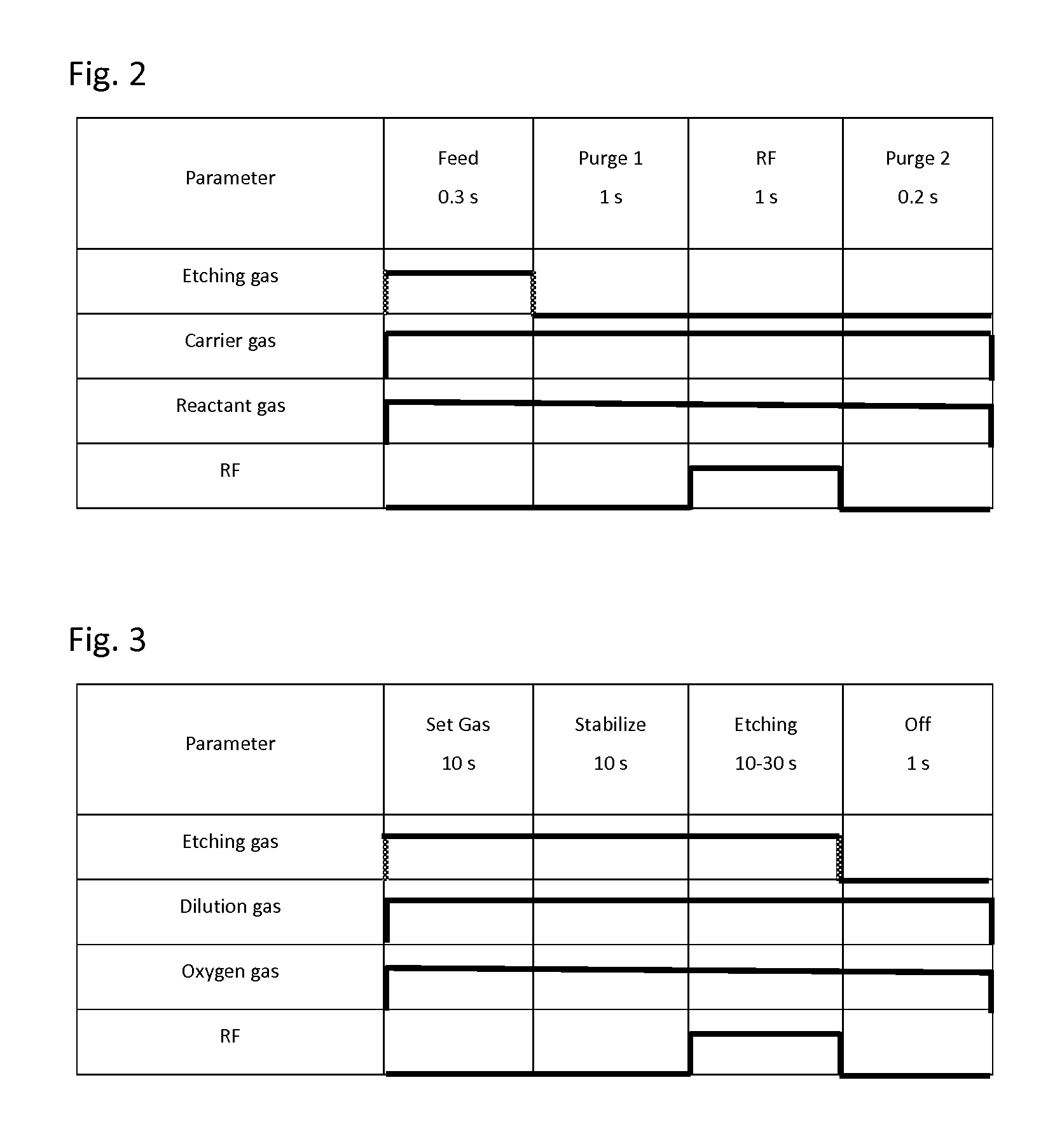

Method of plasma-enhanced atomic layer etching

ActiveUS9396956B1Increase efficiencyImprove efficiencyElectric discharge tubesSemiconductor/solid-state device manufacturingChemistryAmount of substance

A method for etching a layer on a substrate includes at least one etching cycle, wherein an etching cycle includes: continuously providing an inert gas into the reaction space; providing a pulse of an etching gas into the continuous inert gas flow upstream of the reaction space to chemisorb the etching gas in an unexcited state on a surface of the substrate; and providing a pulse of RF power discharge between electrodes to generate a reactive species of the inert gas in the reaction space so that the layer on the substrate is etched.

Owner:ASM IP HLDG BV

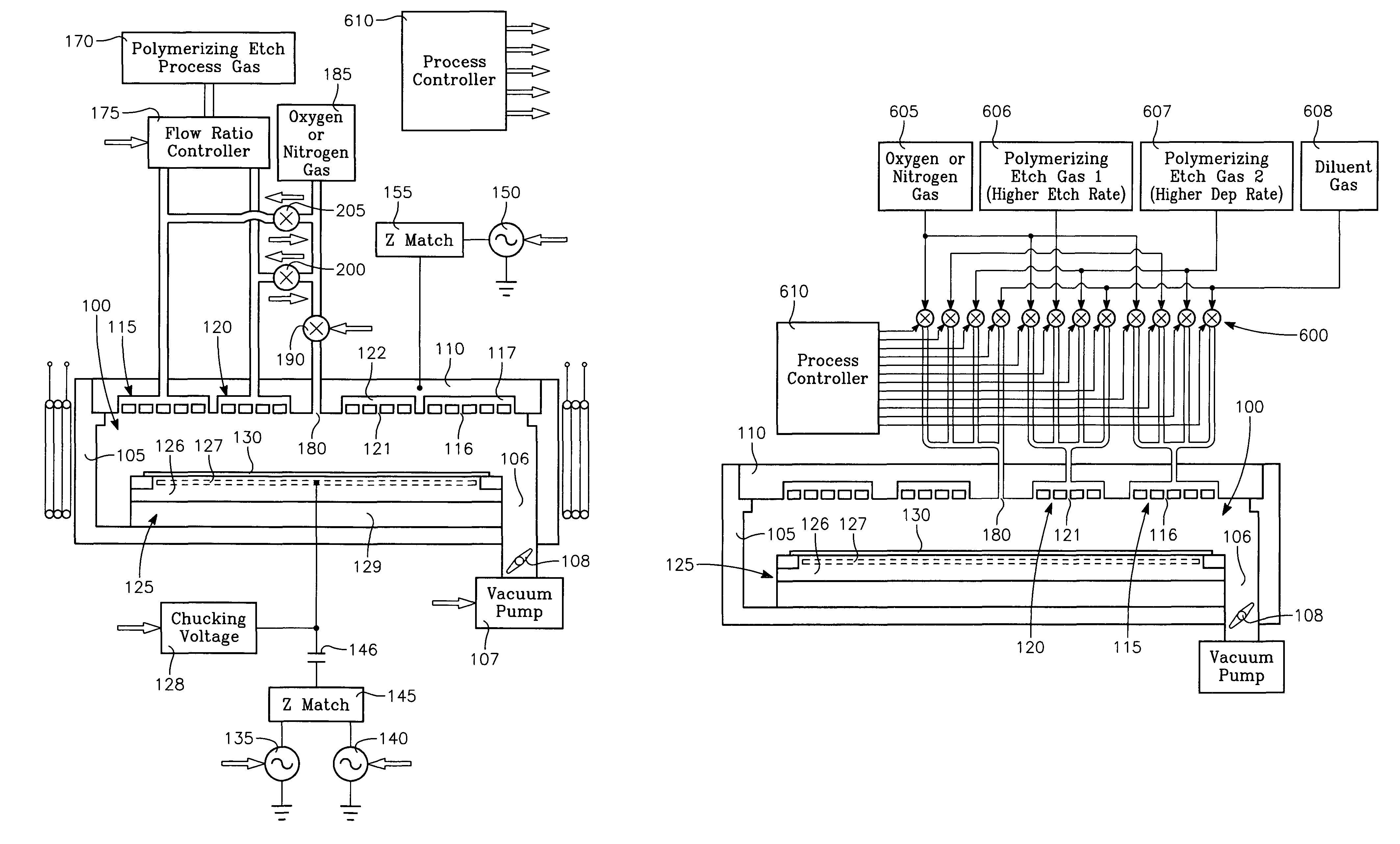

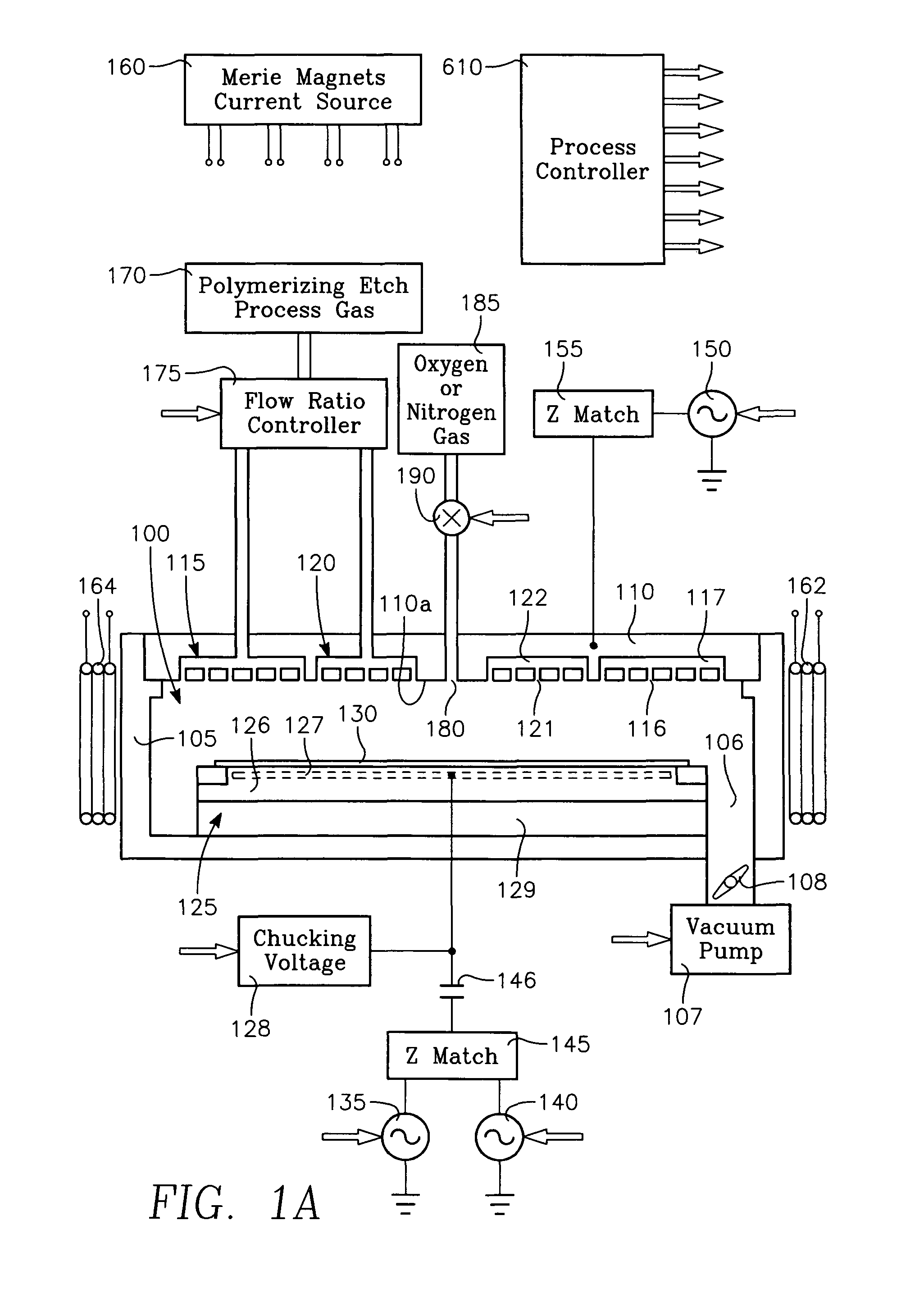

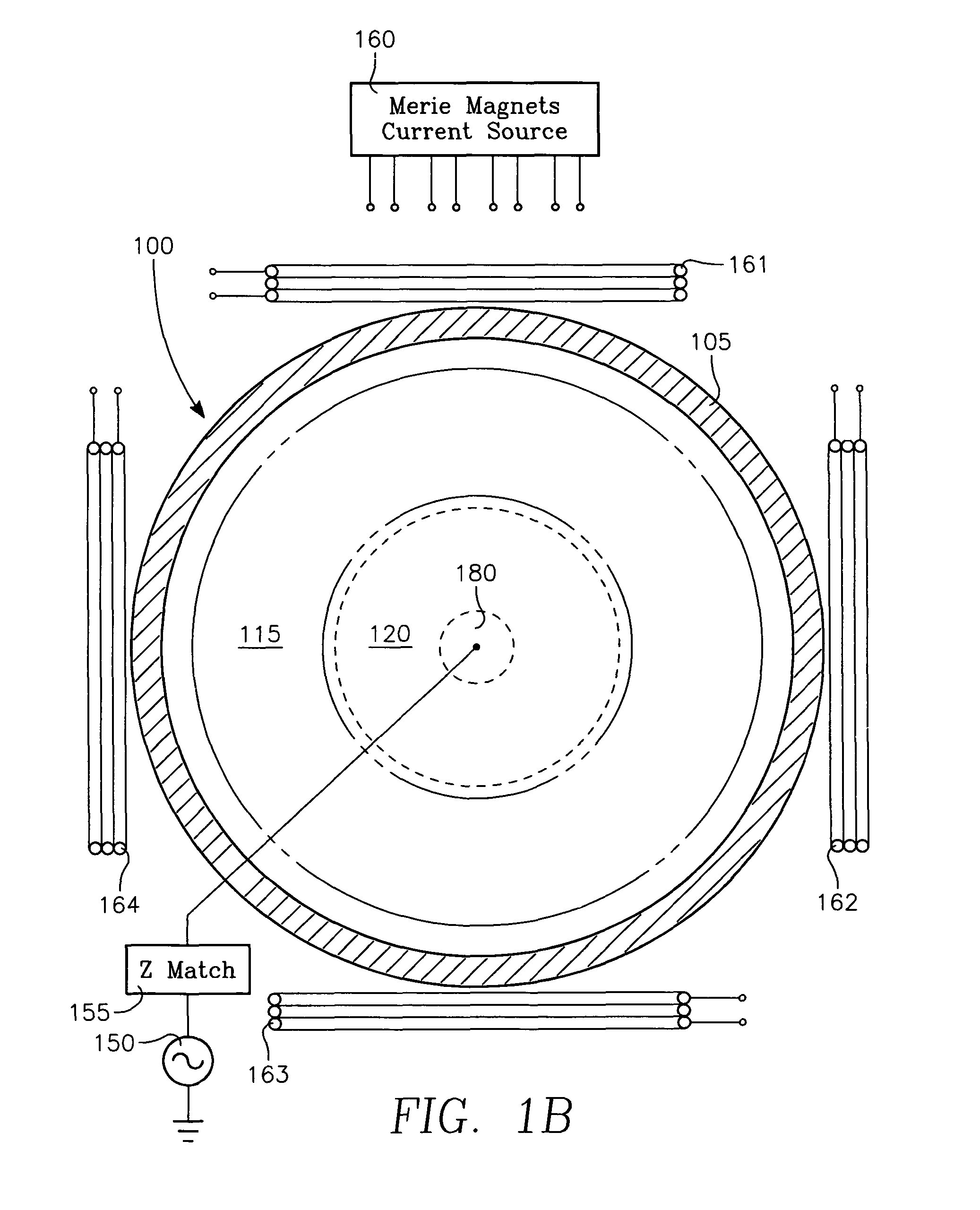

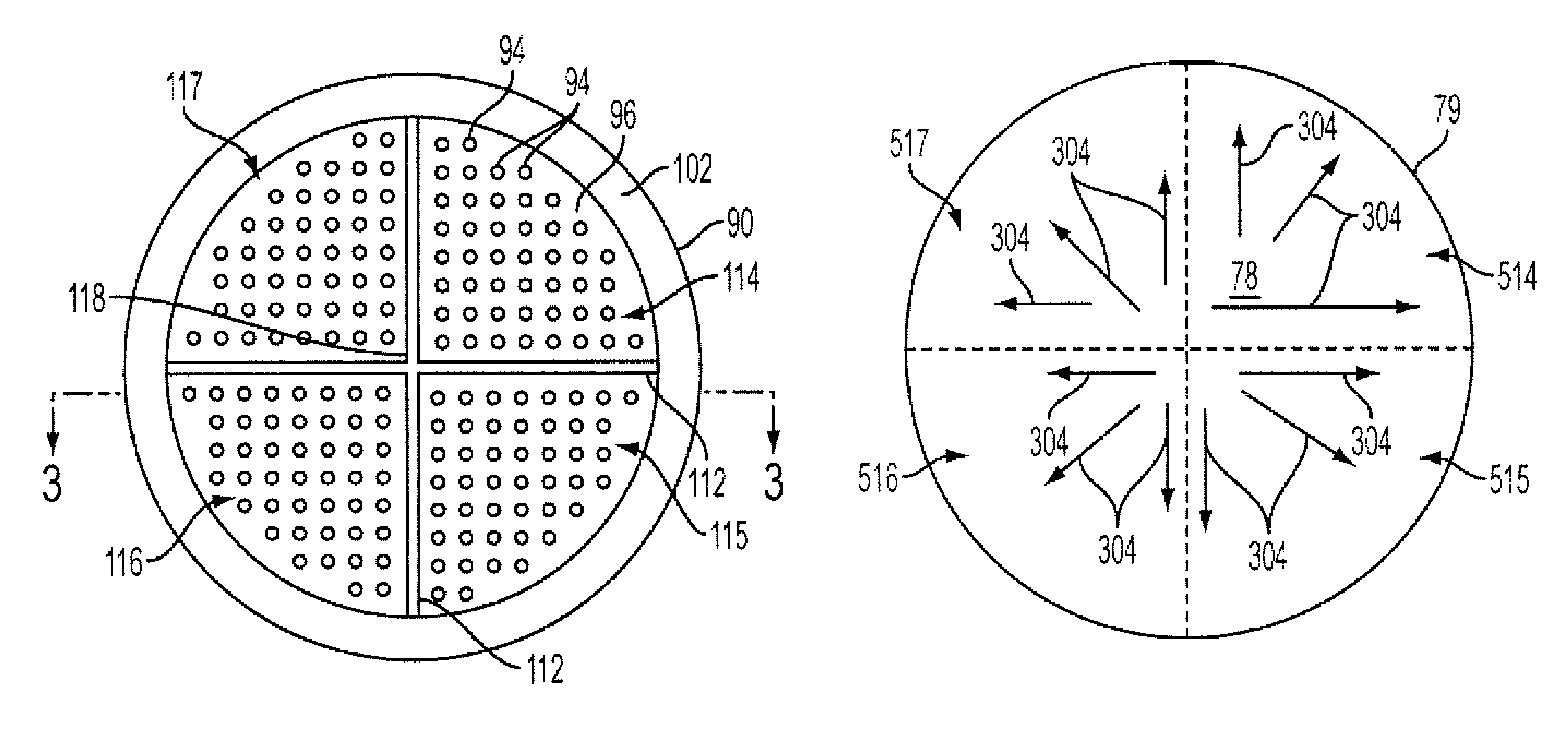

Plasma reactor apparatus with multiple gas injection zones having time-changing separate configurable gas compositions for each zone

ActiveUS8231799B2Electric discharge tubesVacuum gauge using ionisation effectsGas compositionEngineering

Owner:APPLIED MATERIALS INC

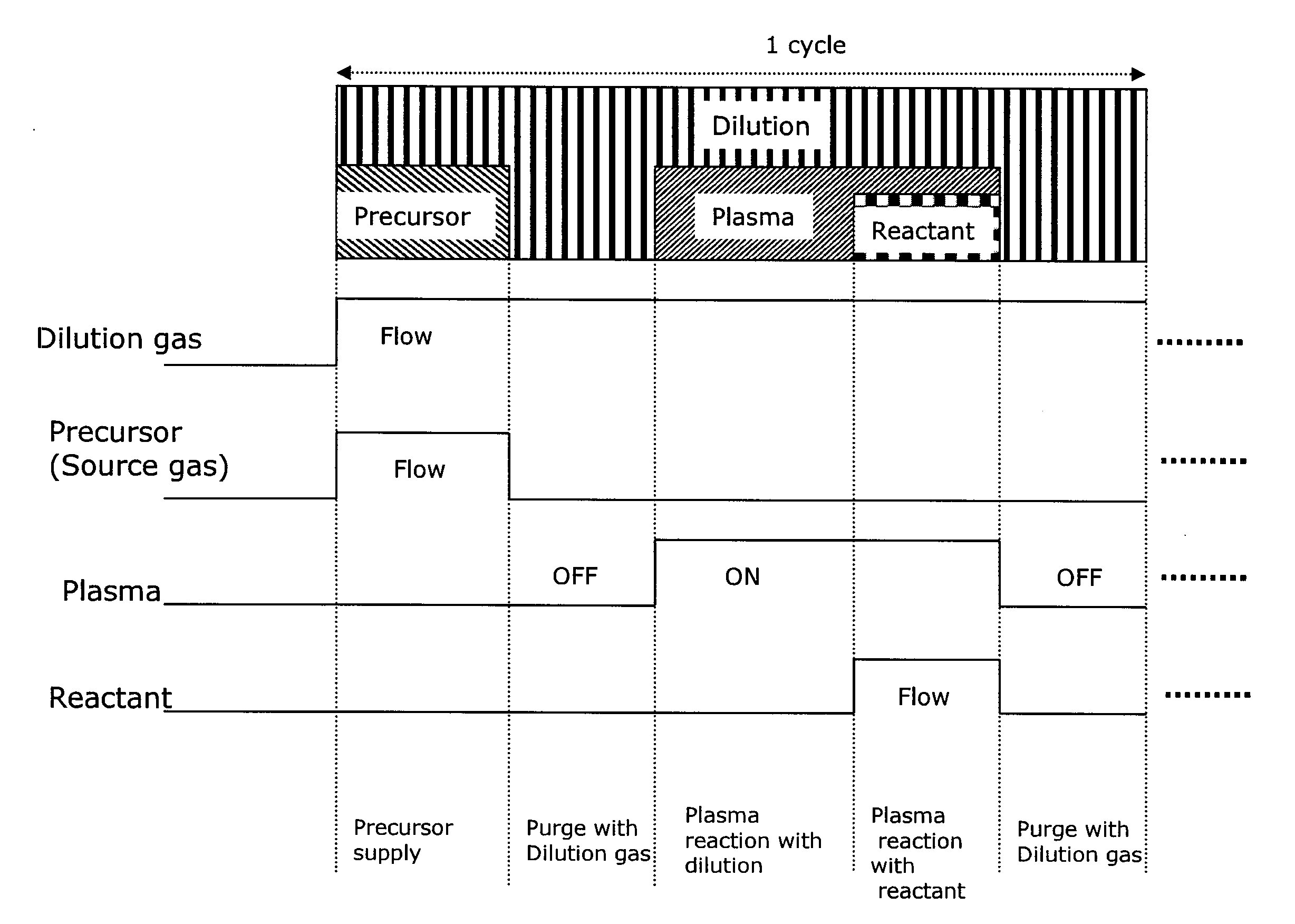

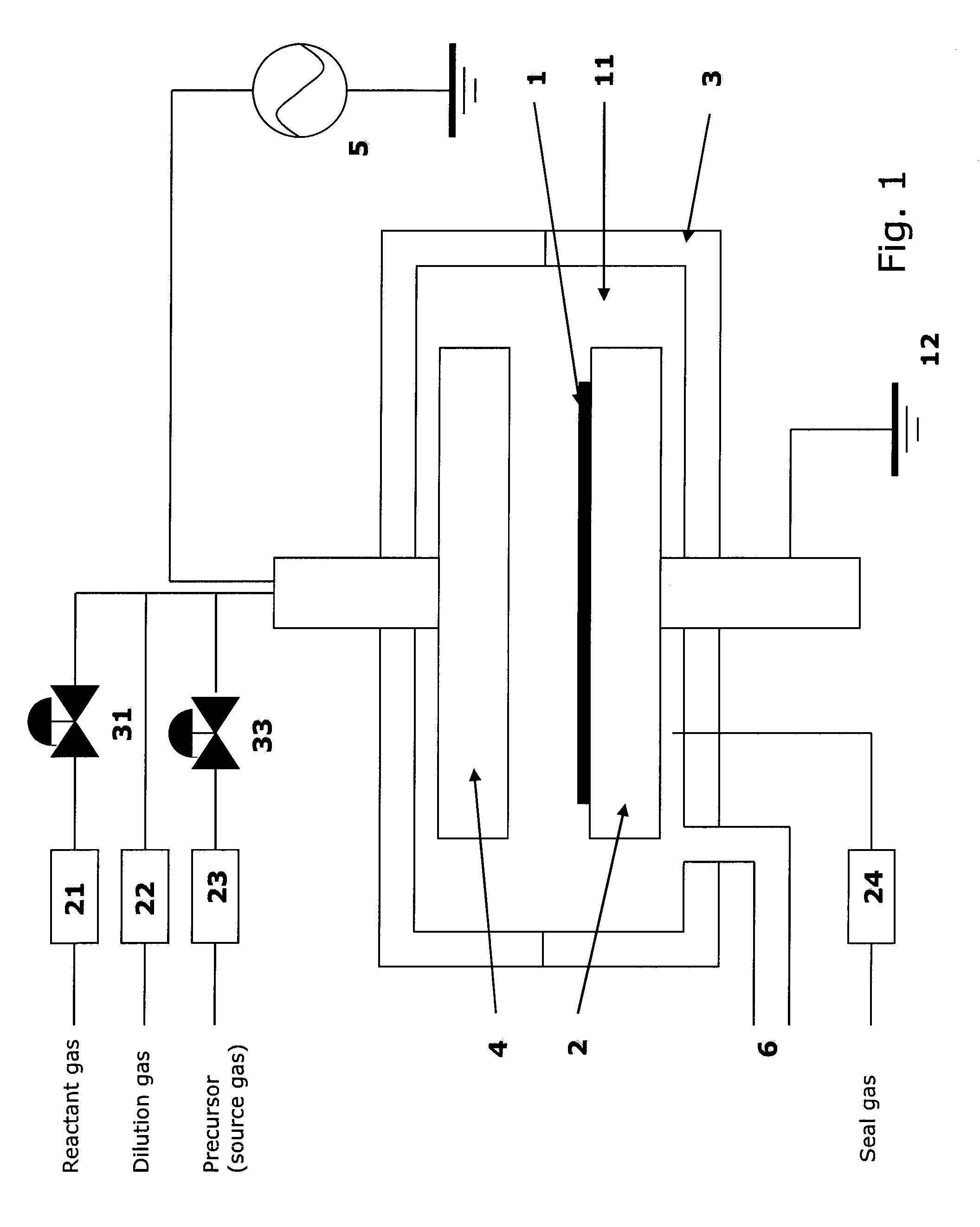

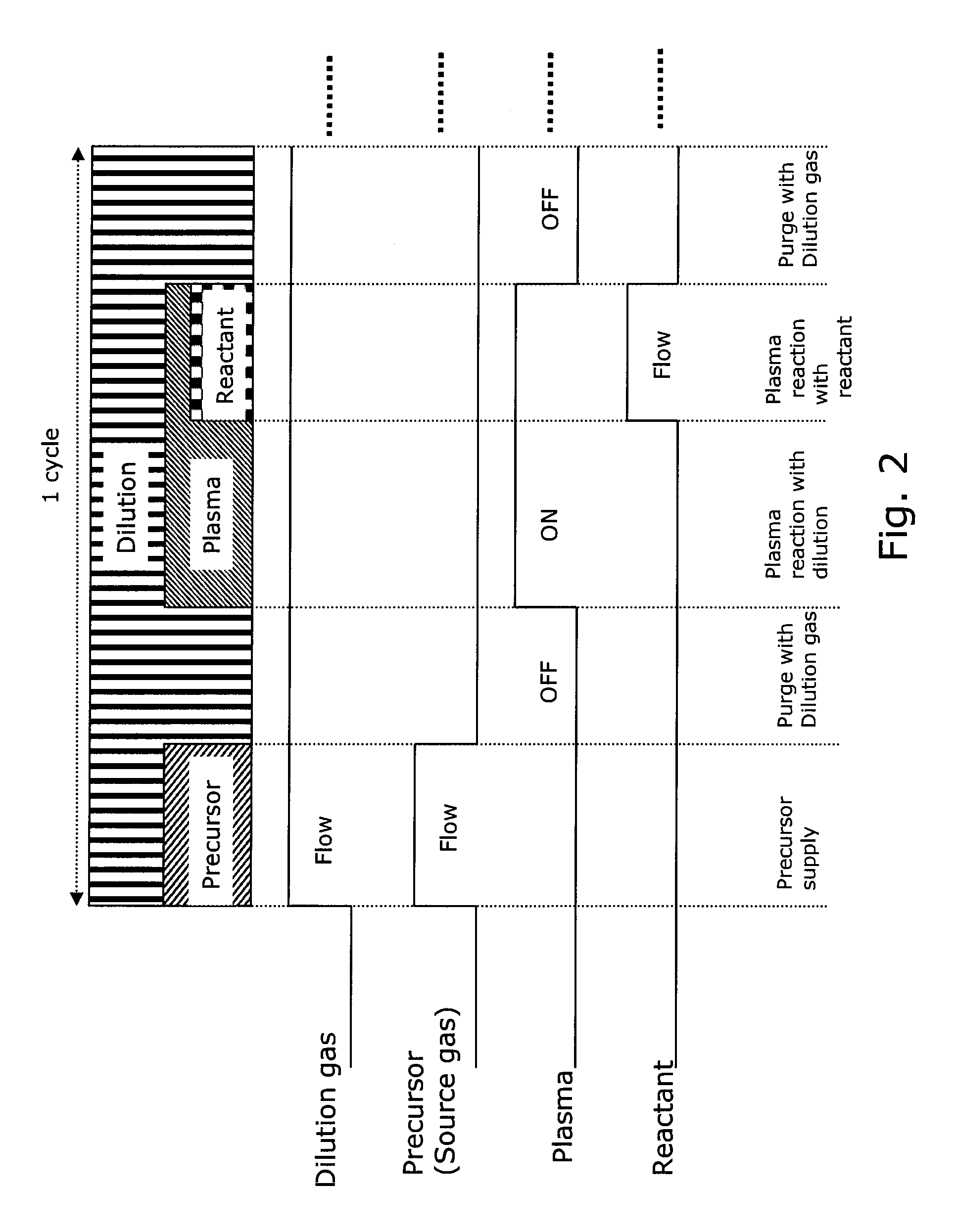

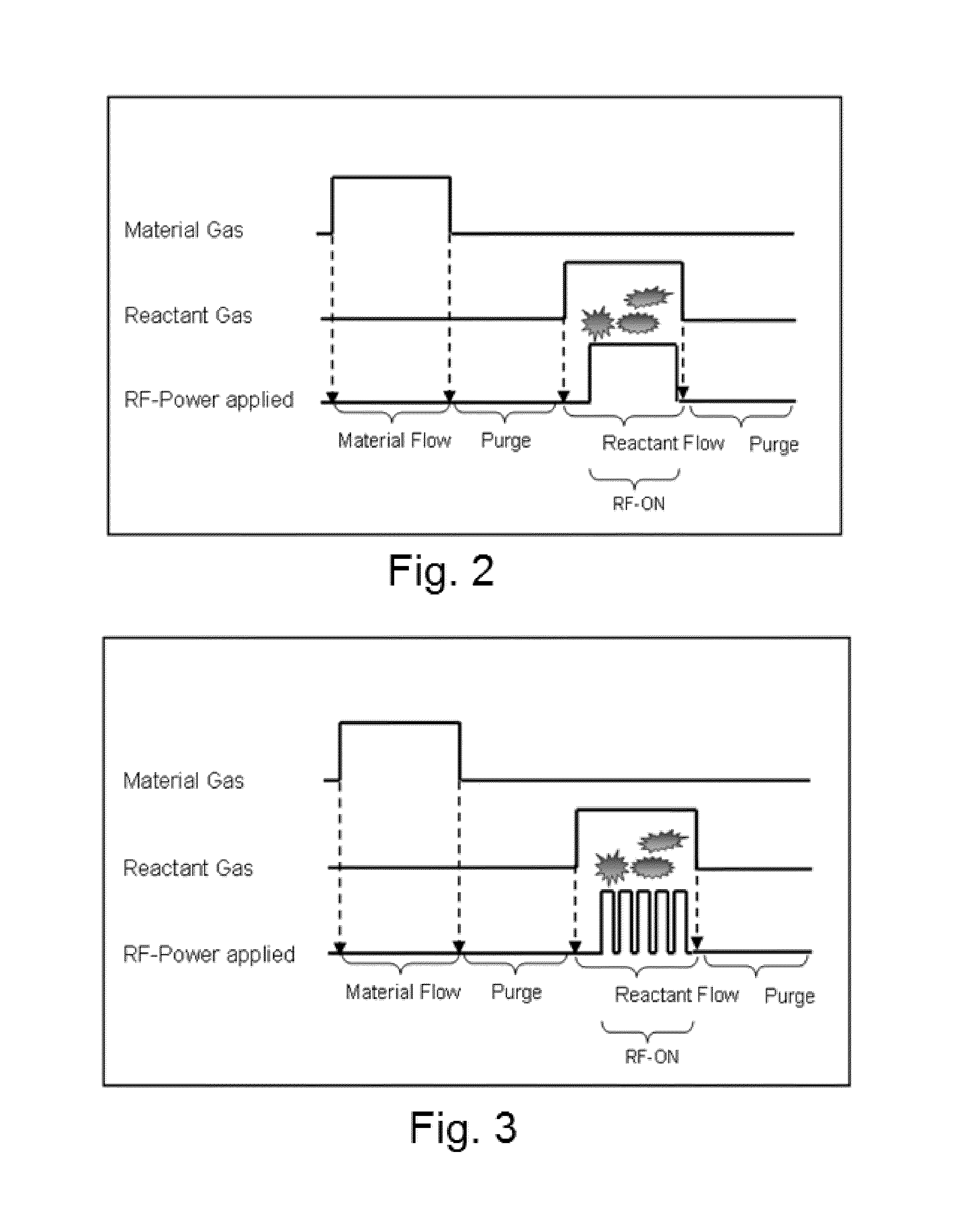

Method for Forming Single-Phase Multi-Element Film by PEALD

ActiveUS20130084714A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingReaction zoneGas plasma

A method for forming a single-phase multi-element film on a substrate in a reaction zone by PEALD repeating a single deposition cycle. The single deposition cycle includes: adsorbing a precursor on the substrate in the absence of reactant and plasma; decomposing the precursor adsorbed on the substrate by an inert gas plasma; and reacting the decomposed precursor with a reactant gas plasma in the presence of the inert gas plasma. The multi-element film contains silicon and at least two non-metal elements constituting a matrix of the film, the precursor contains silicon and optionally at least one non-metal element to be incorporated in the matrix, and the reactant gas contains at least one non-metal element to be incorporated in the matrix.

Owner:ASM JAPAN

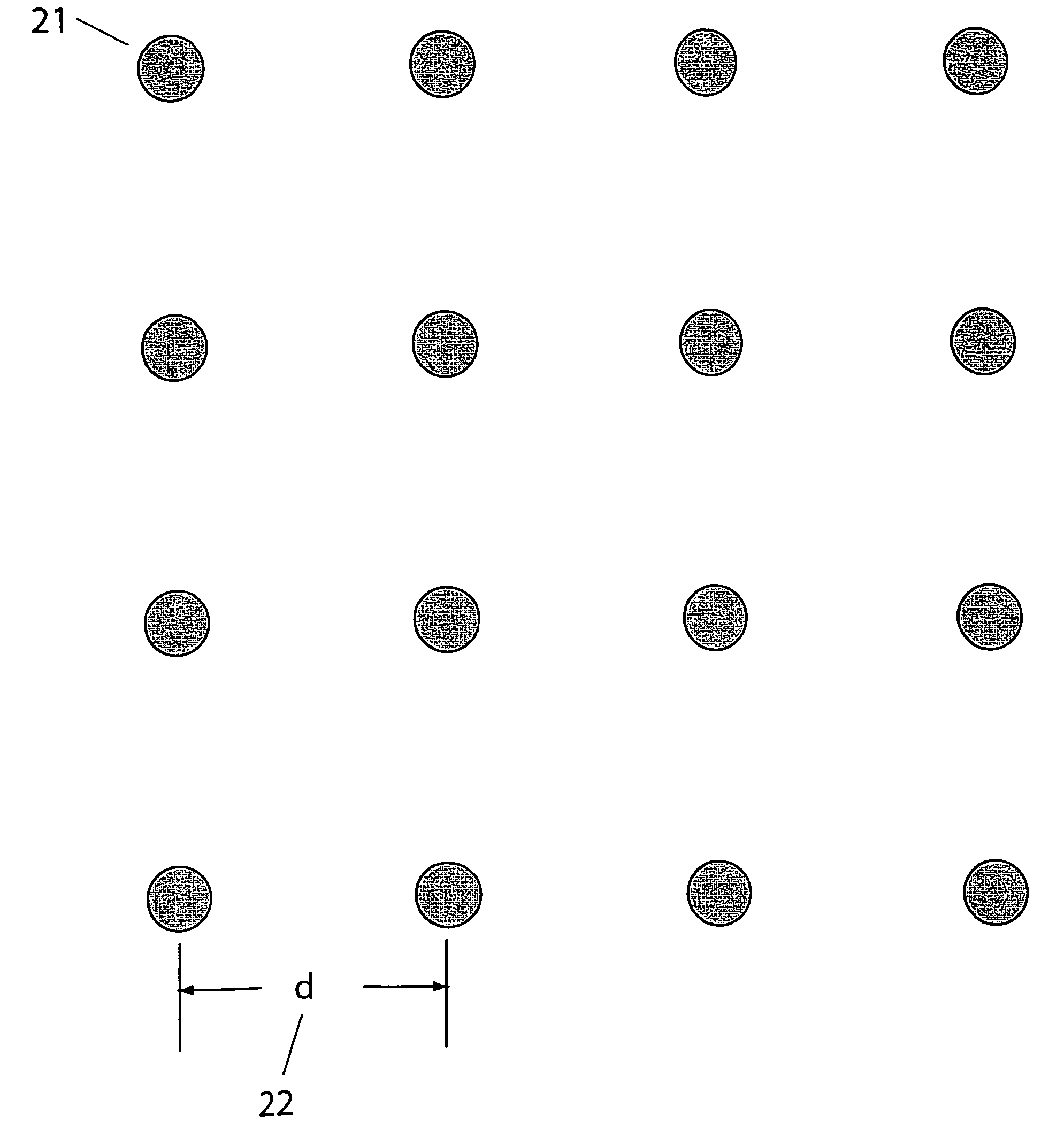

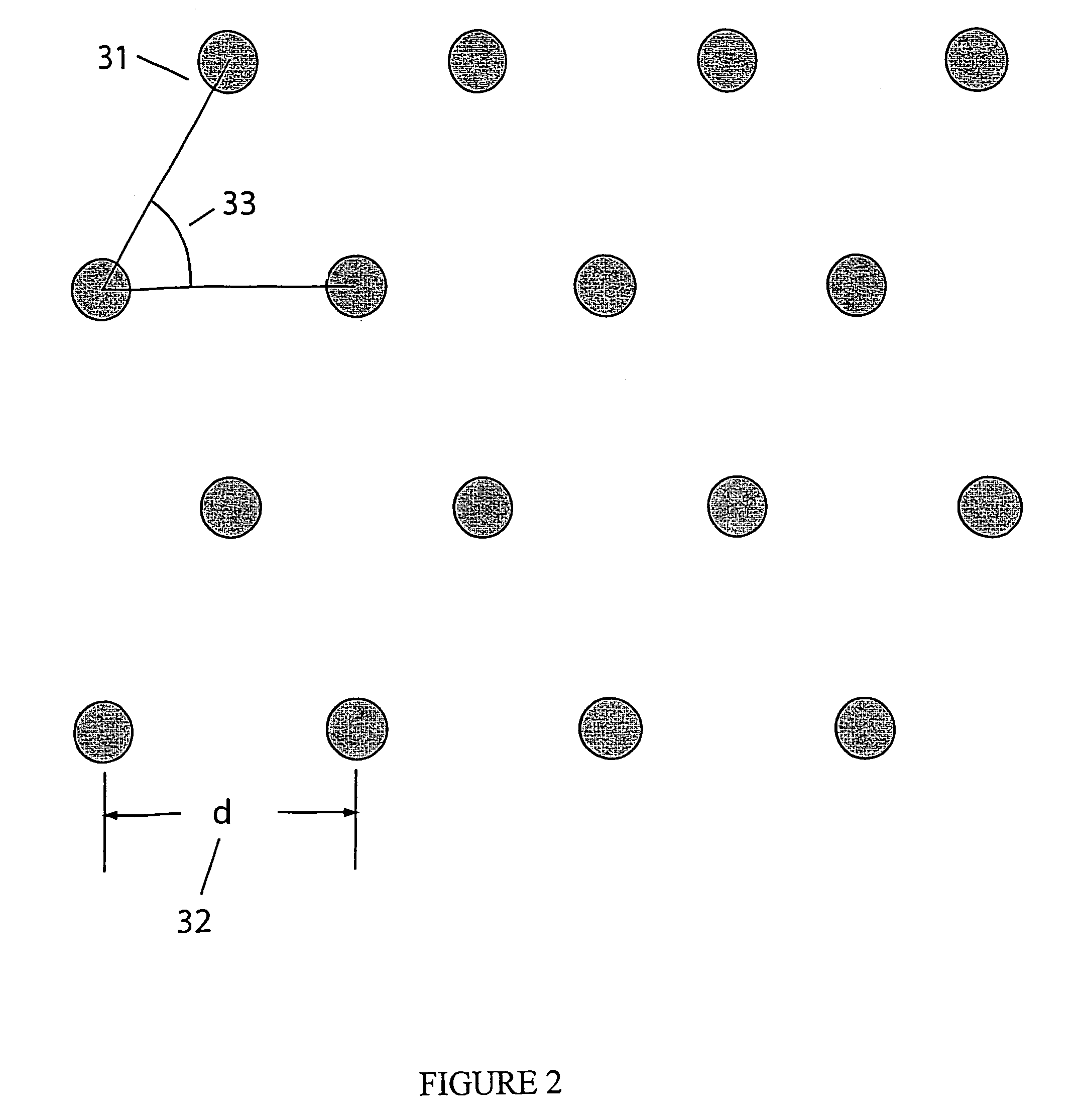

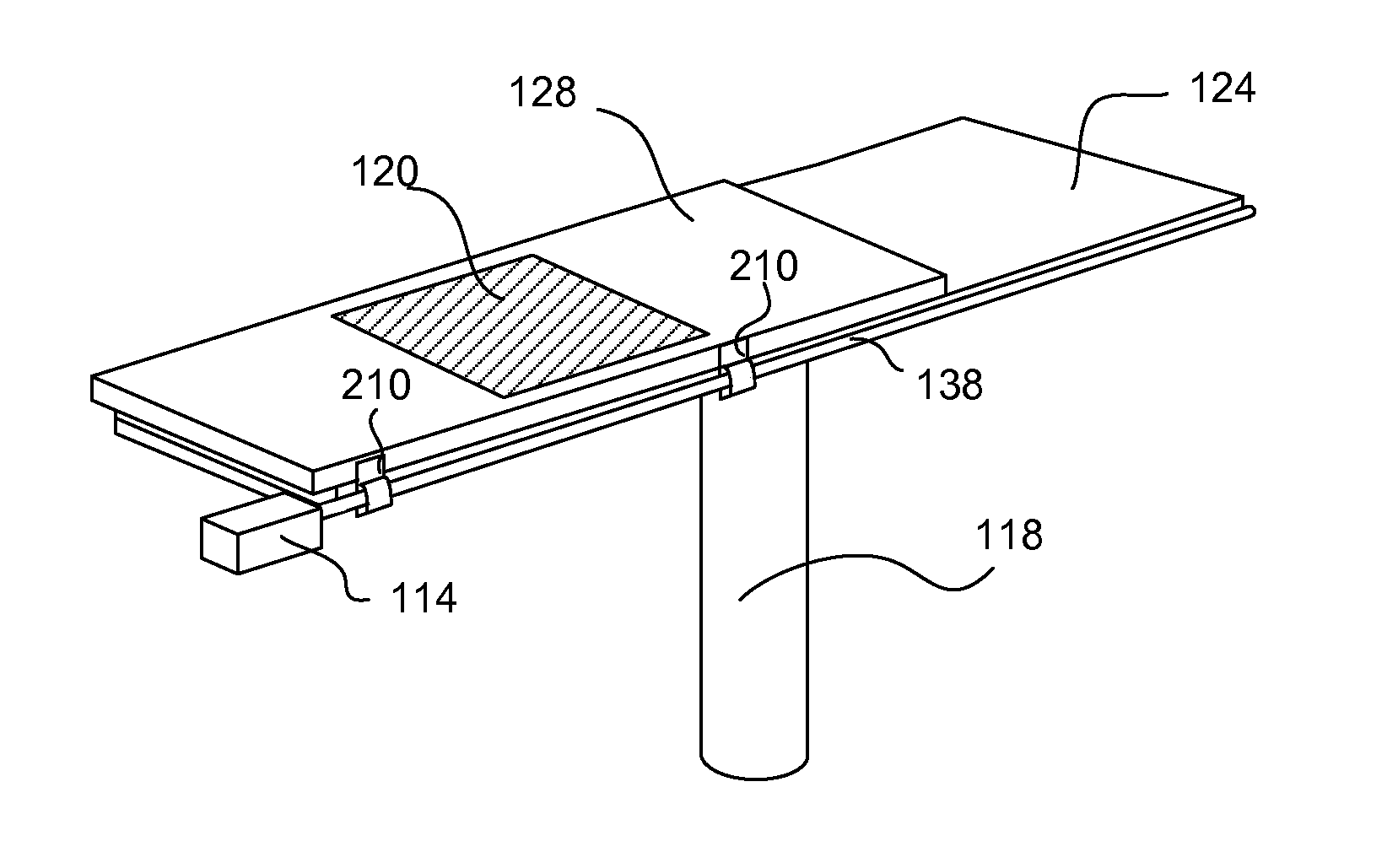

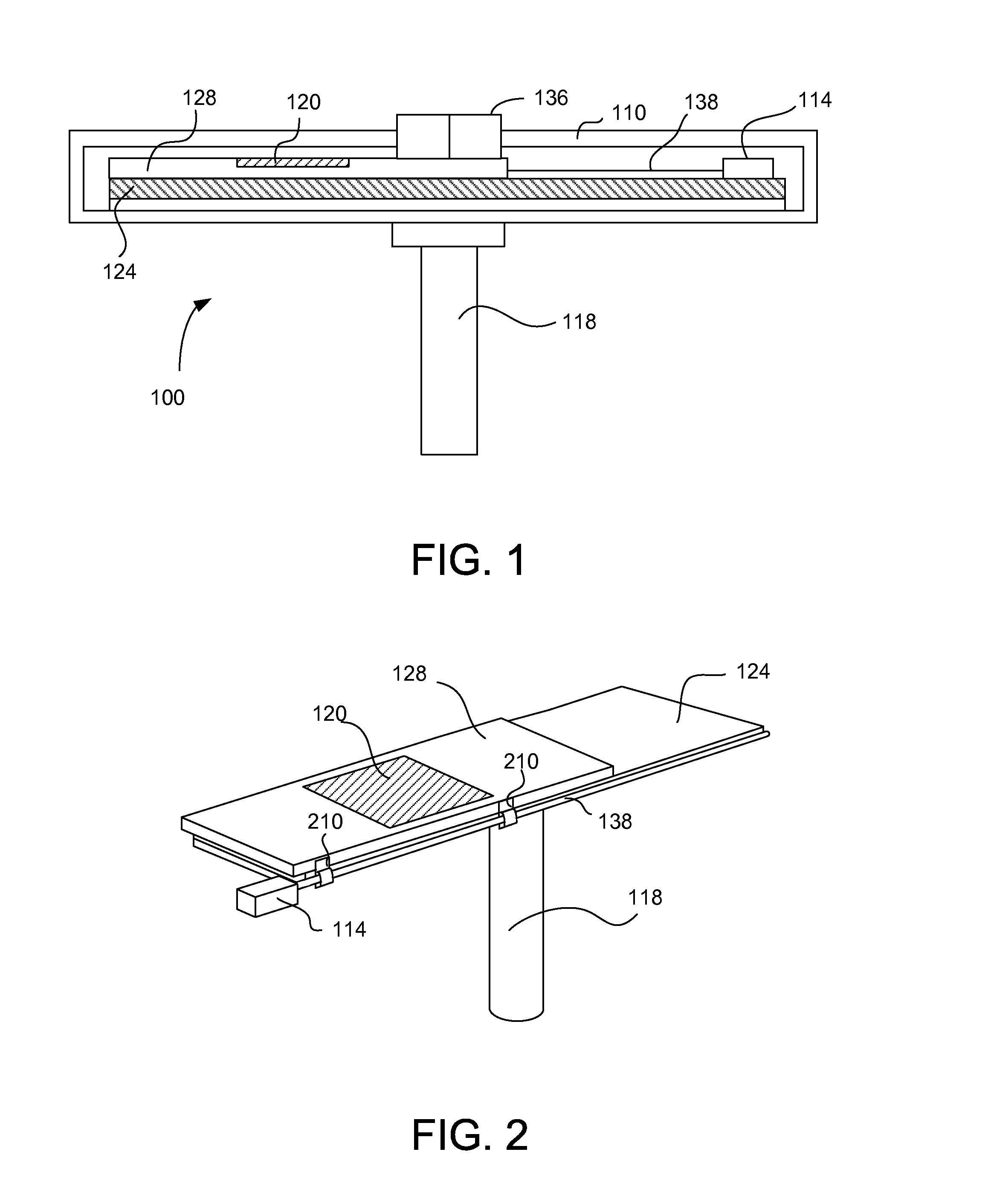

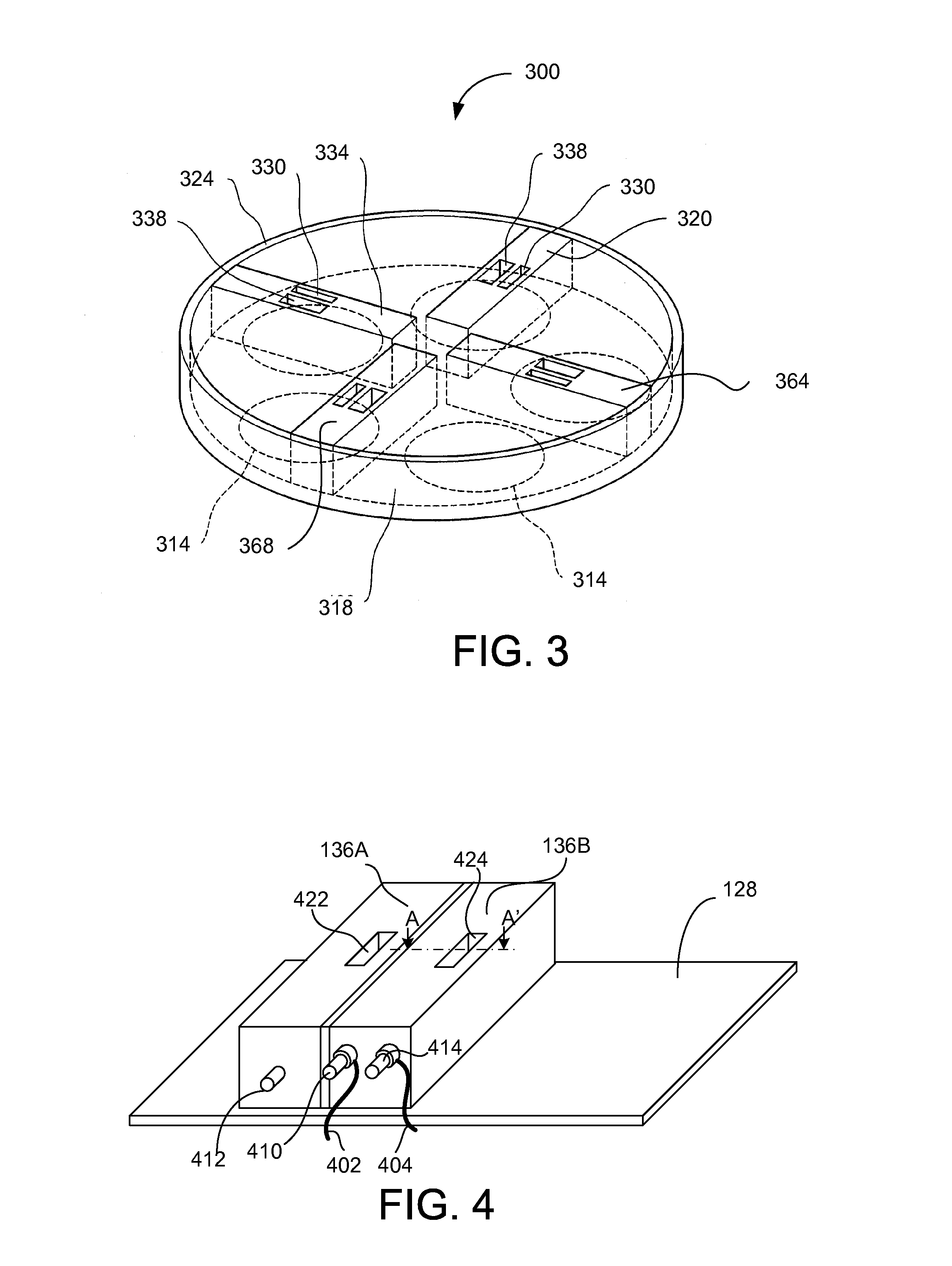

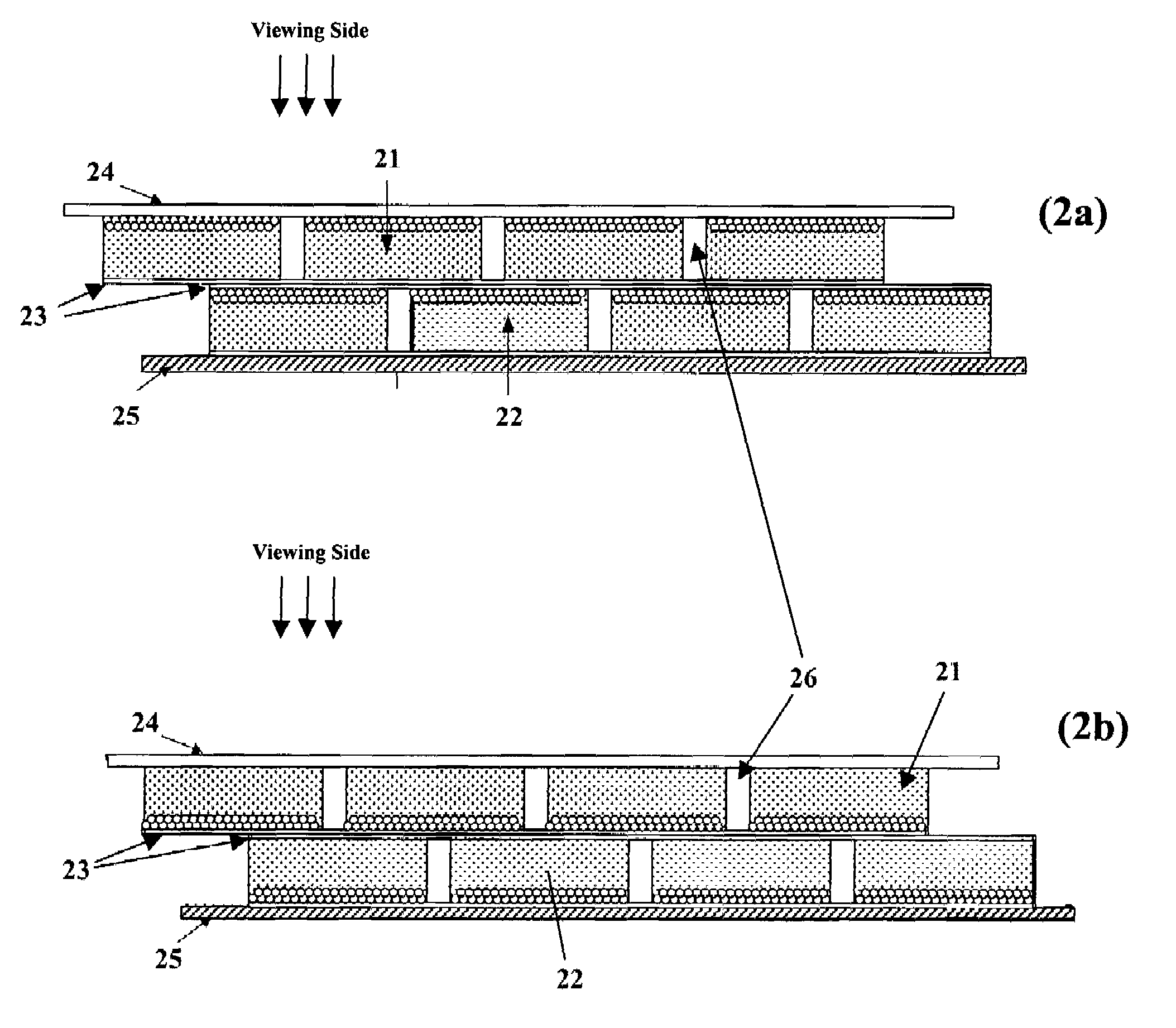

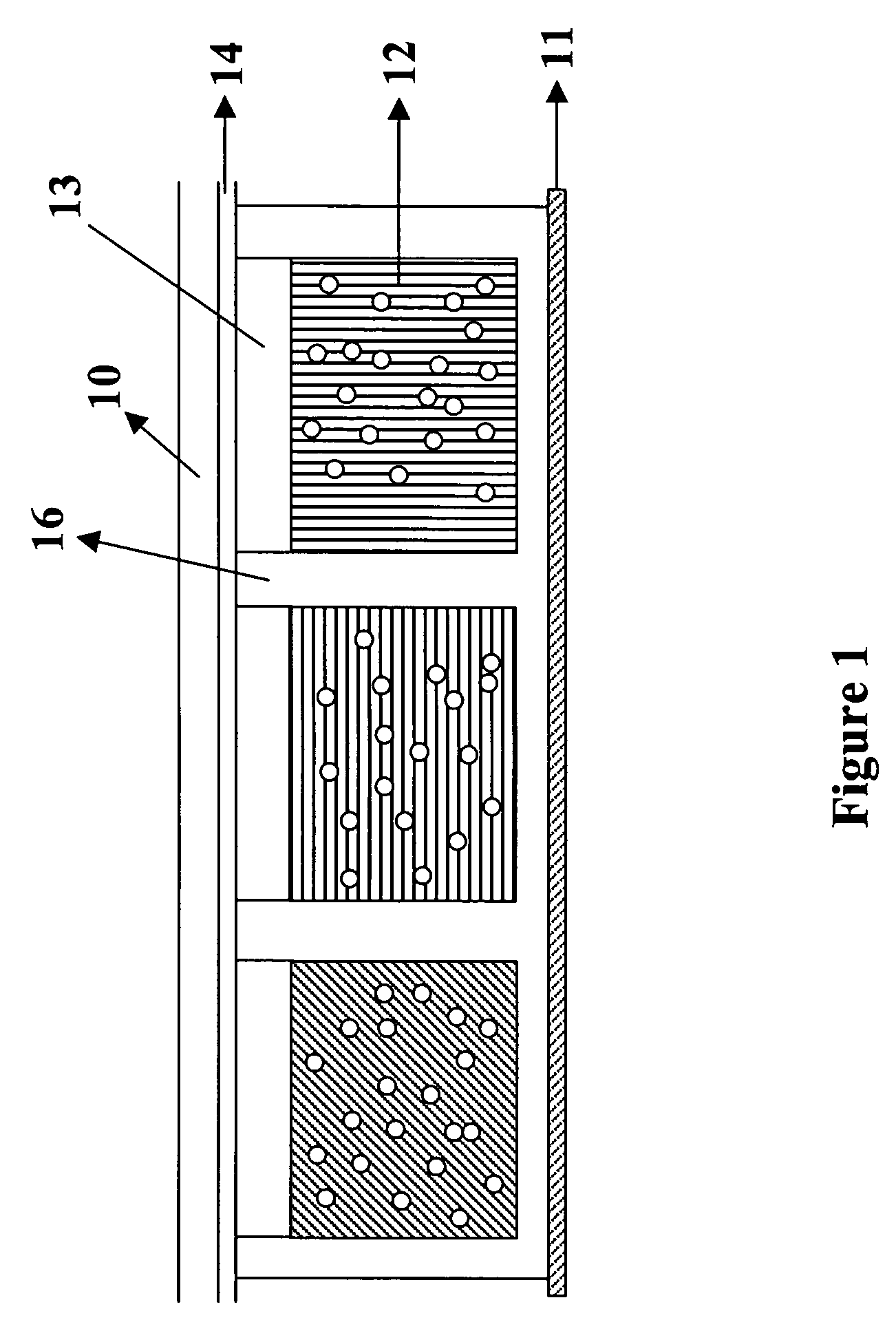

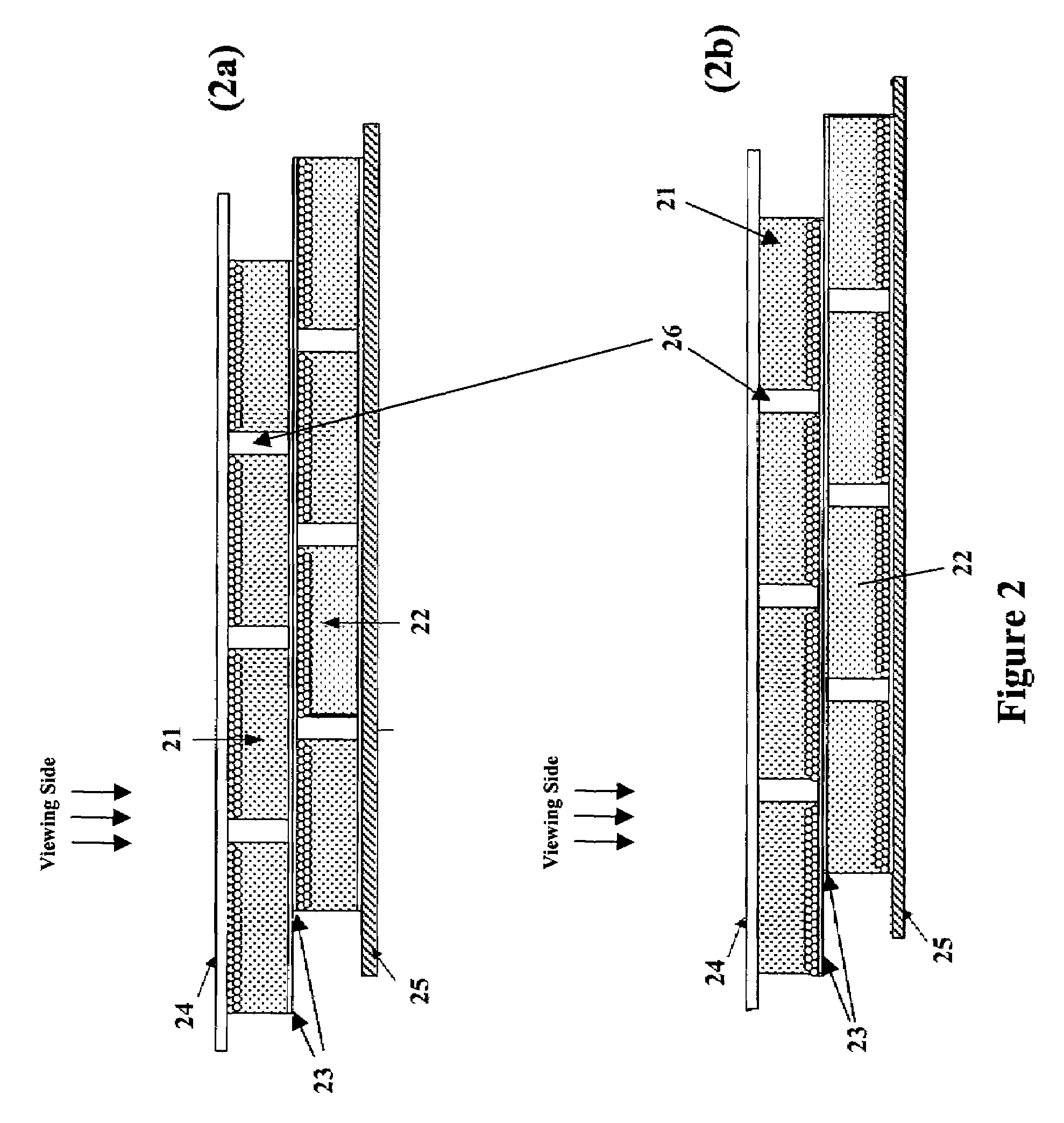

Electrophoretic display and novel process for its manufacture

ActiveUS7072095B2Improve contrast ratioImprove switching performanceStatic indicating devicesElectrographic processes using photoelectrophoresisElectrophoresisDisplay device

This invention relates to an electrophoretic display with improved contrast ratio, switching performance, reflectivity at the Dmin state and structural integrity, and methods for its manufacture.

Owner:E INK CALIFORNIA

Atomic layer deposition method of depositing an oxide on a substrate

The invention includes atomic layer deposition methods of depositing an oxide on a substrate. In one implementation, a substrate is positioned within a deposition chamber. A first species is chemisorbed onto the substrate to form a first species monolayer within the deposition chamber from a gaseous precursor. The chemisorbed first species is contacted with remote plasma oxygen derived at least in part from at least one of O2 and O3 and with remote plasma nitrogen effective to react with the first species to form a monolayer comprising an oxide of a component of the first species monolayer. The chemisorbing and the contacting with remote plasma oxygen and with remote plasma nitrogen are successively repeated effective to form porous oxide on the substrate. Other aspects and implementations are contemplated.

Owner:MICRON TECH INC

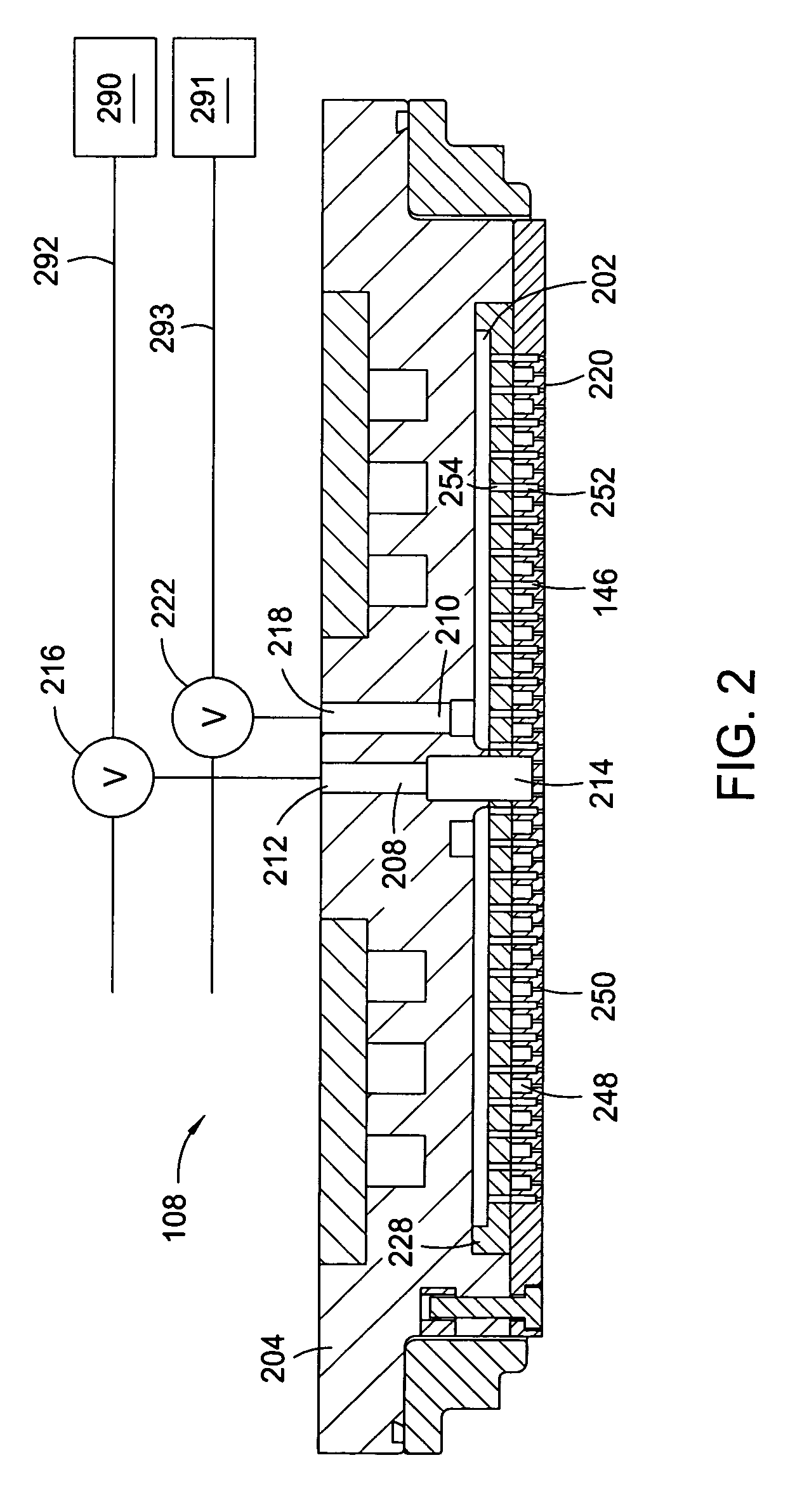

Apparatus for reducing plasma charge damage for plasma processes

InactiveUS7036453B2Reducing plasma discharge damageReduce morbidityElectric discharge tubesSemiconductor/solid-state device manufacturingMaterials sciencePhysical chemistry

A method is provided for depositing a thin film on a substrate in a process chamber with reduced incidence of plasma charge damage. A process gas containing a precursor gases suitable for forming a plasma is flowed into a process chamber, and a plasma is generated from the process gas to deposit the thin film on the substrate. The precursor gases are flowed into the process chamber such that the thin film is deposited at the center of the substrate more rapidly than at an edge of the substrate.

Owner:APPLIED MATERIALS INC

Rapid characterization of polymers

InactiveUS6406632B1More separatedHigh sample throughputSequential/parallel process reactionsSamplingFluid phasePhysical chemistry

Rapid characterization and screening of polymer samples to determine average molecular weight, molecular weight distribution and other properties is disclosed. Rapid flow characterization systems and methods, including liquid chromatography and flow-injection analysis systems and methods are preferably employed. High throughput, automated sampling systems and methods, high-temperature characterization systems and methods, and rapid, indirect calibration compositions and methods are also disclosed. The described methods, systems, and devices have primary applications in combinatorial polymer research and in industrial process control.

Owner:INTERMOLECULAR

Method for forming single-phase multi-element film by PEALD

ActiveUS8569184B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingReaction zoneGas plasma

Owner:ASM JAPAN

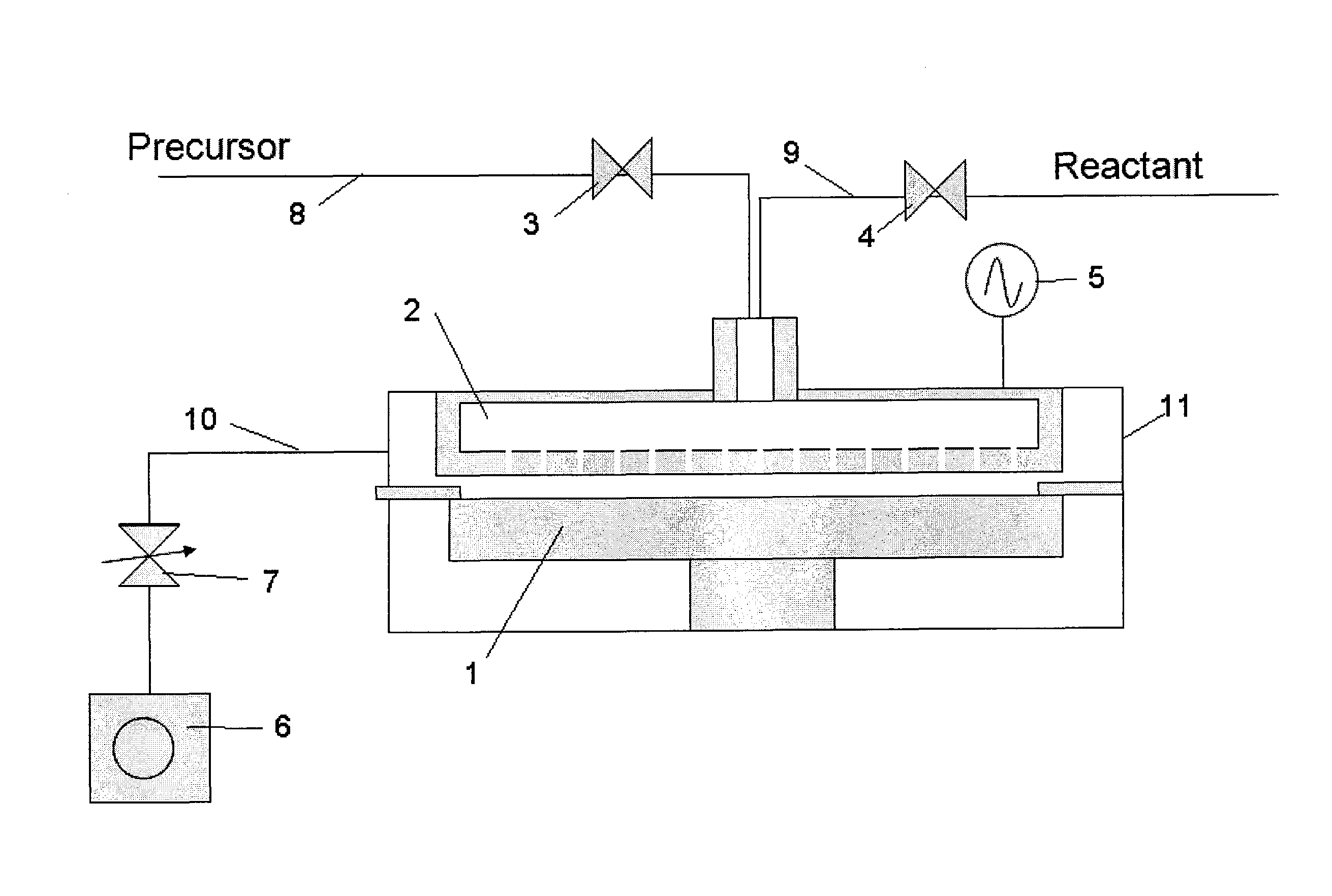

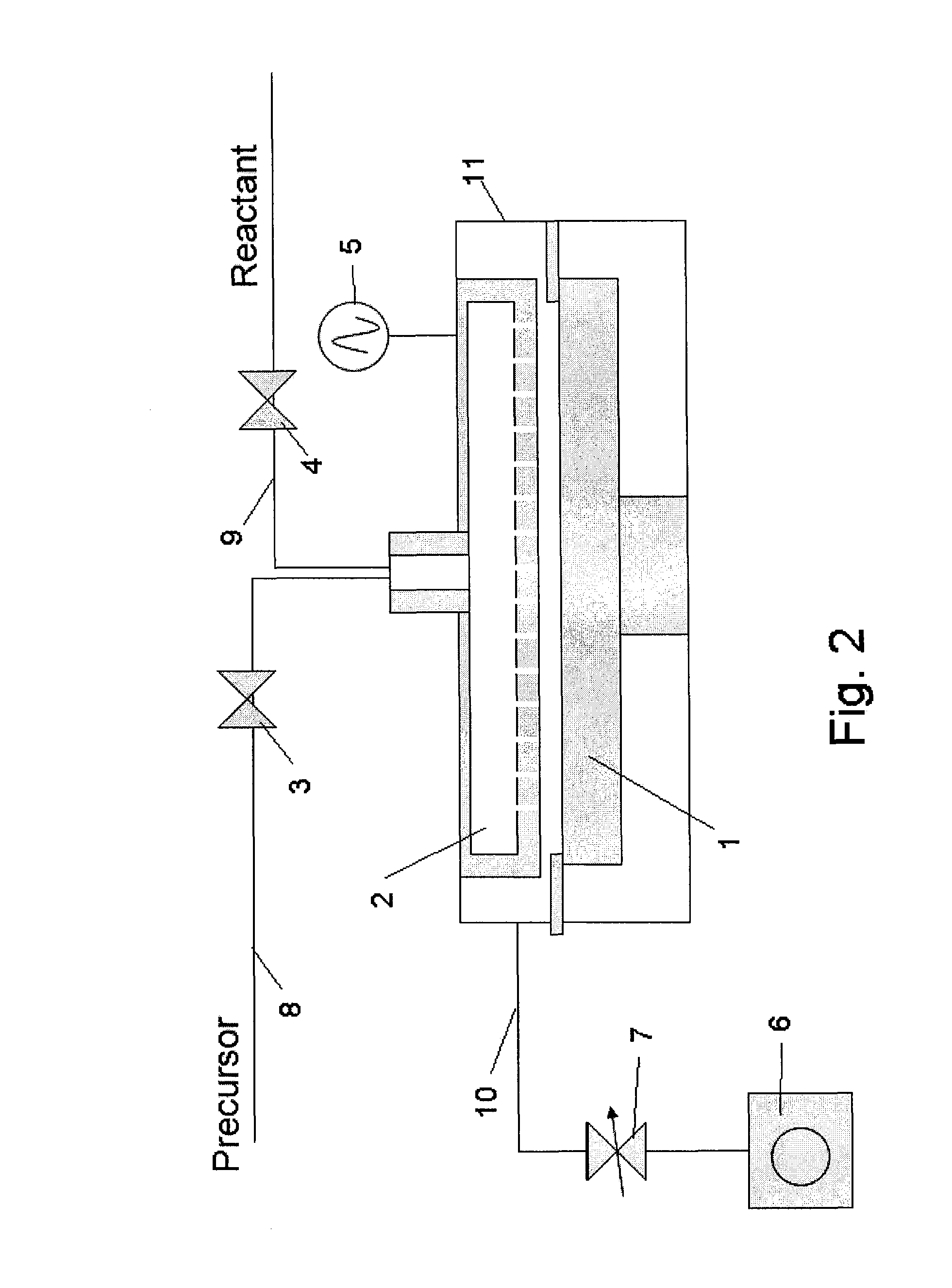

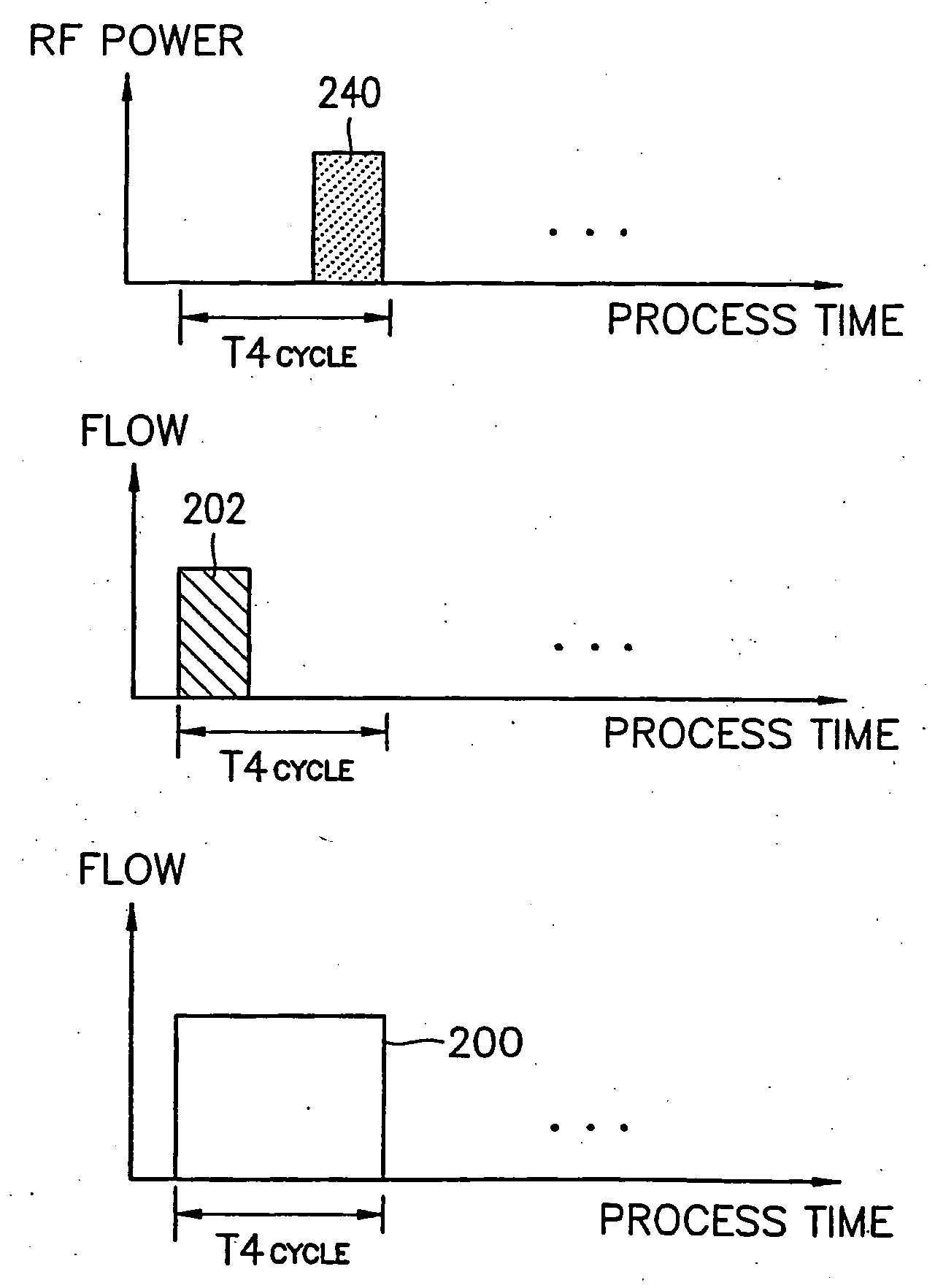

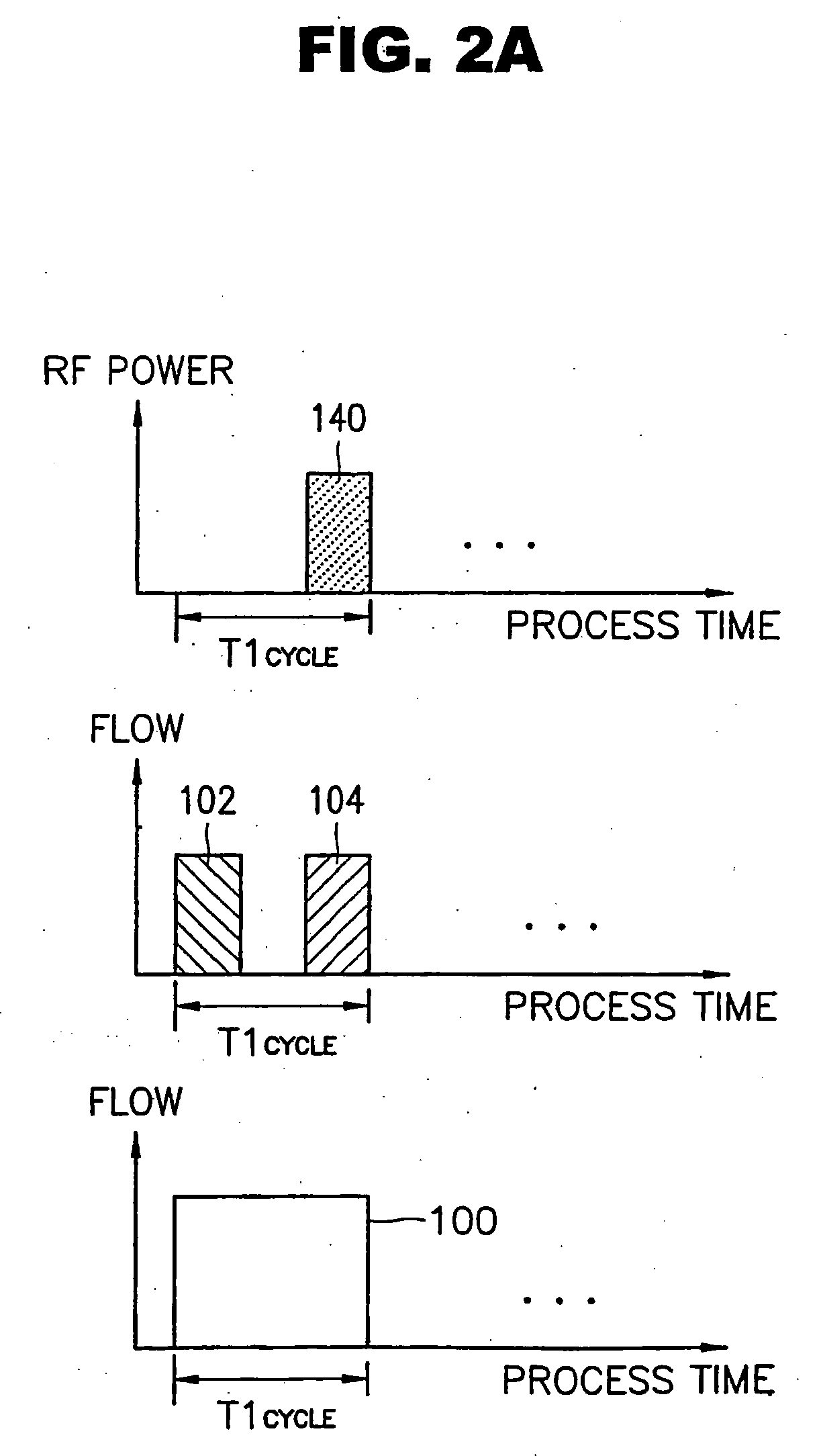

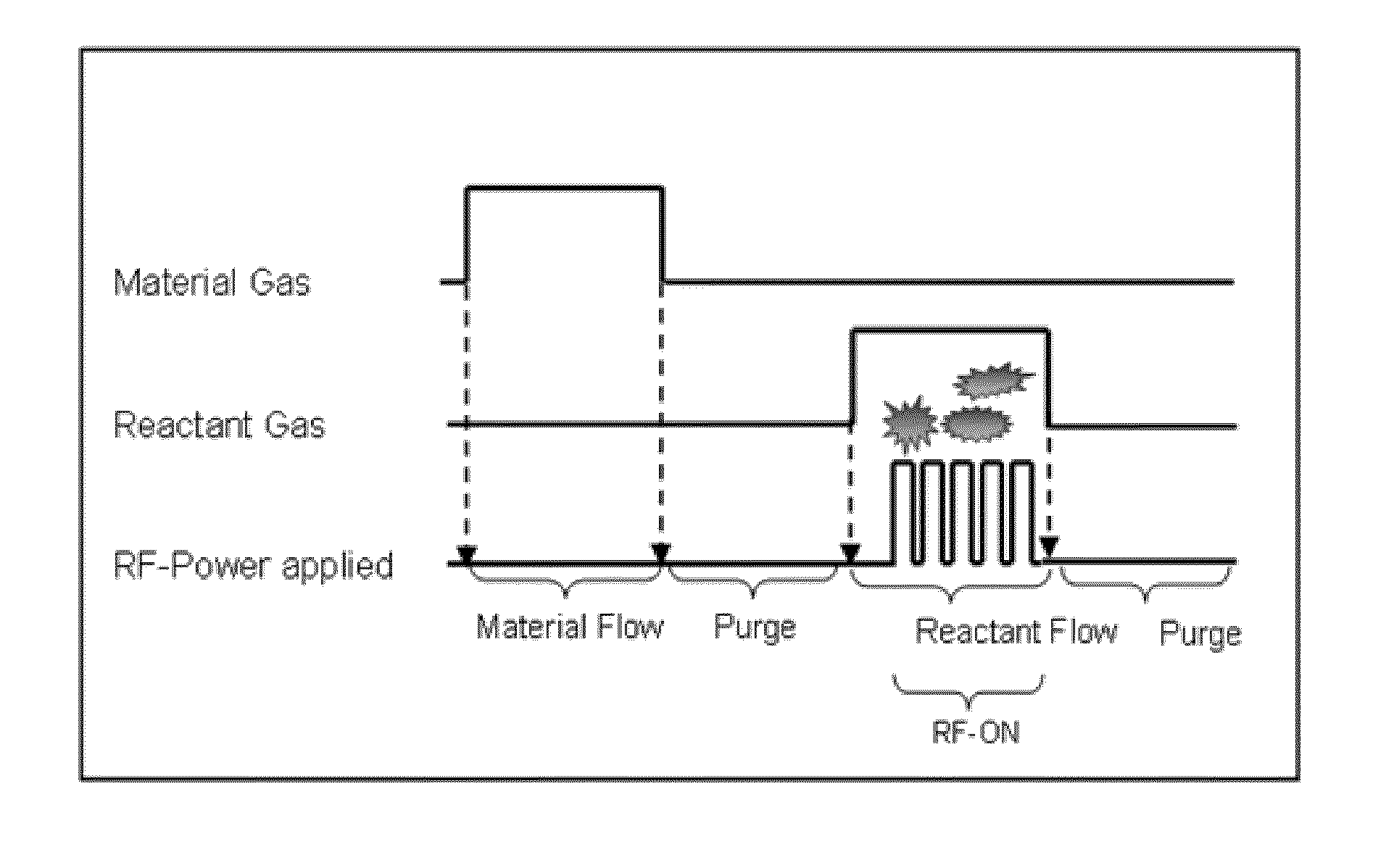

Method of depositing film by atomic layer deposition with pulse-time-modulated plasma

ActiveUS8465811B2Improve in-plane uniformityUniform supplyPretreated surfacesChemical vapor deposition coatingPulse time modulationAtomic layer deposition

A thin film is formed by alternating multiple times, respectively, a process of adsorbing a precursor onto a substrate and a process of treating the adsorbed surface using a reactant gas and a plasma, wherein the reactant gas is supplied substantially uniformly over the substrate, and the plasma is pulse-time-modulated and applied in the process of supplying the reactant gas.

Owner:ASM JAPAN

Methods of forming material over substrates

InactiveUS20070252244A1Speed up pressure saturationSemiconductor/solid-state device detailsSolid-state devicesHafnium oxideAnalytical chemistry

The invention includes ALD-type methods in which two or more different precursors are utilized with one or more reactants to form a material. In particular aspects, the precursors are hafnium and aluminum, the only reactant is ozone, and the material is hafnium oxide predominantly in a tetragonal crystalline phase.

Owner:ROUND ROCK RES LLC

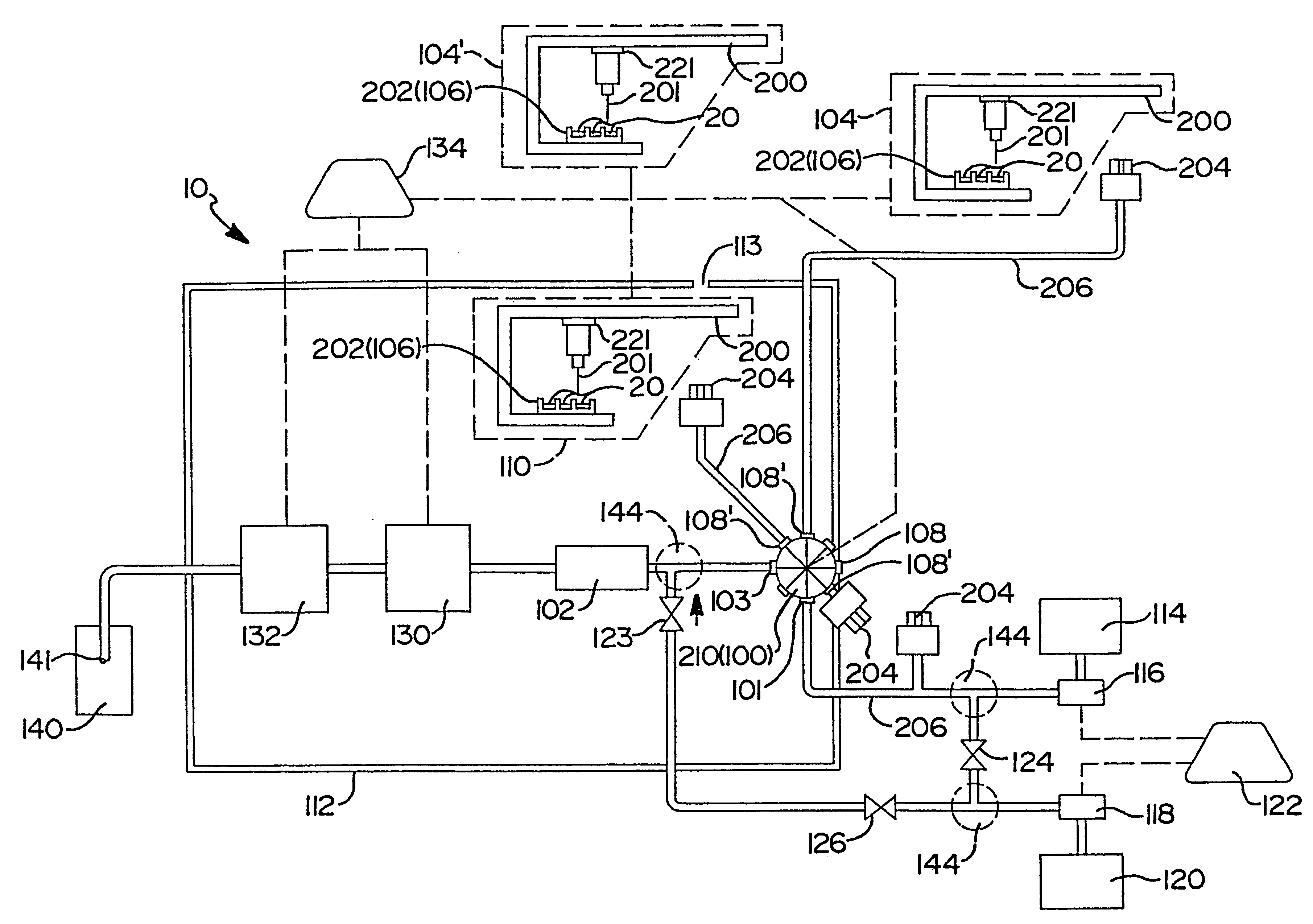

Vapor based combinatorial processing

A combinatorial processing chamber and method are provided. In the method a fluid volume flows over a surface of a substrate with differing portions of the fluid volume having different constituent components to concurrently expose segregated regions of the substrate to a mixture of the constituent components that differ from constituent components to which adjacent regions are exposed. Differently processed segregated regions are generated through the multiple flowings.

Owner:INTERMOLECULAR

Method of forming a carbon polymer film using plasma CVD

ActiveUS20070218705A1Improve featuresFunction increaseLiquid surface applicatorsPhotomechanical apparatusCapacitanceBoiling point

A method forms a hydrocarbon-containing polymer film on a semiconductor substrate by a capacitively-coupled plasma CVD apparatus. The method includes the steps of: vaporizing a hydrocarbon-containing liquid monomer (CαHβXγ, wherein α and β are natural numbers of 5 or more; γ is an integer including zero; X is O, N or F) having a boiling point of about 20° C. to about 350° C.; introducing the vaporized gas into a CVD reaction chamber inside which a substrate is placed; and forming a hydrocarbon-containing polymer film on the substrate by plasma polymerization of the gas.

Owner:ASM JAPAN

Multi-gas distribution injector for chemical vapor deposition reactors

A gas distribution injector for chemical vapor deposition reactors has precursor gas inlets disposed at spaced-apart locations on an inner surface facing downstream toward a substrate carrier, and has carrier openings disposed between the precursor gas inlets. One or more precursor gases are introduced through the precursor gas inlets, and a carrier gas substantially nonreactive with the precursor gases is introduced through the carrier gas openings. The carrier gas minimizes deposit formation on the injector. The carrier gas openings may be provided by a porous plate defining the surface or via carrier inlets interspersed between precursor inlets. The gas inlets may removable or coaxial.

Owner:VEECO INSTR

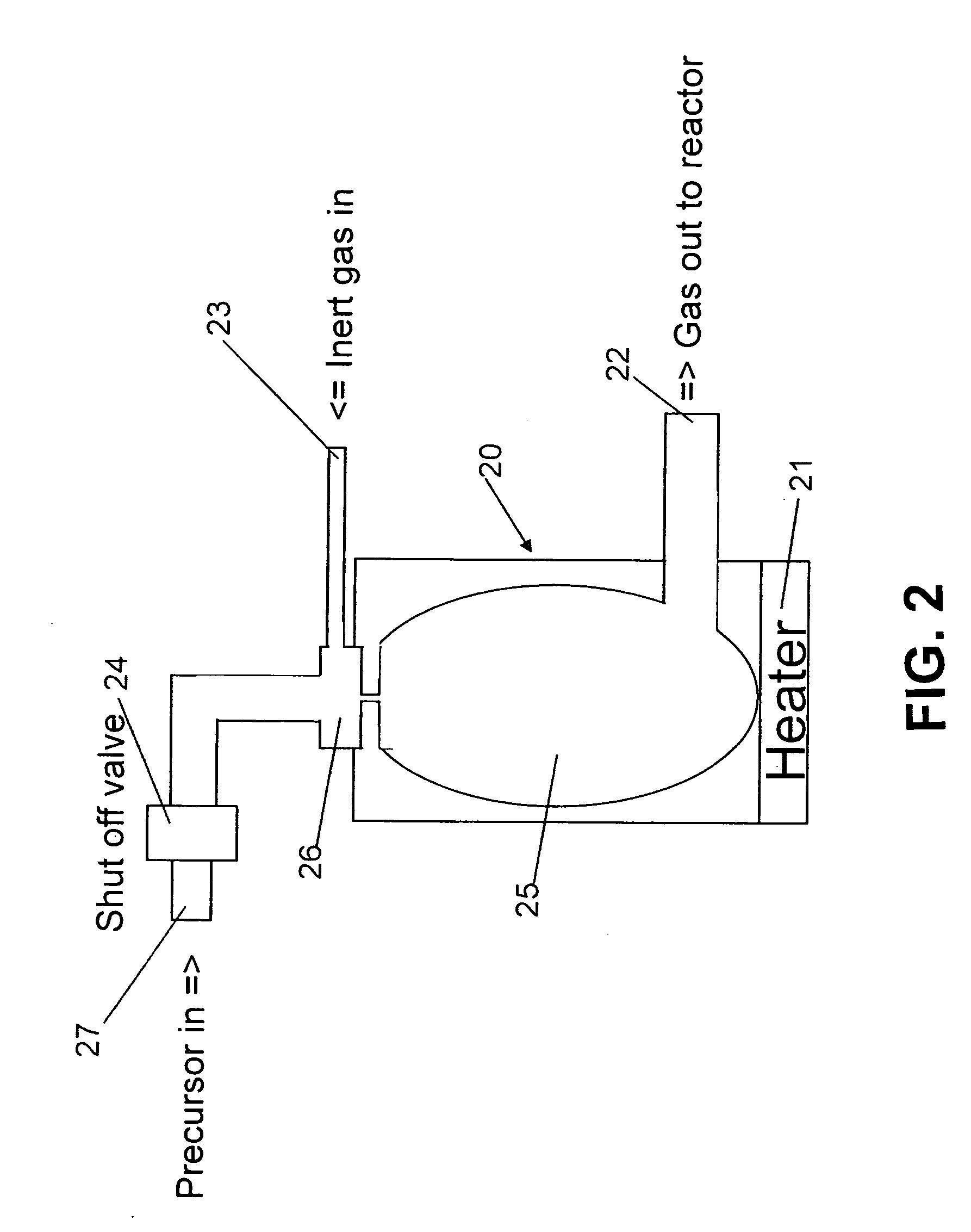

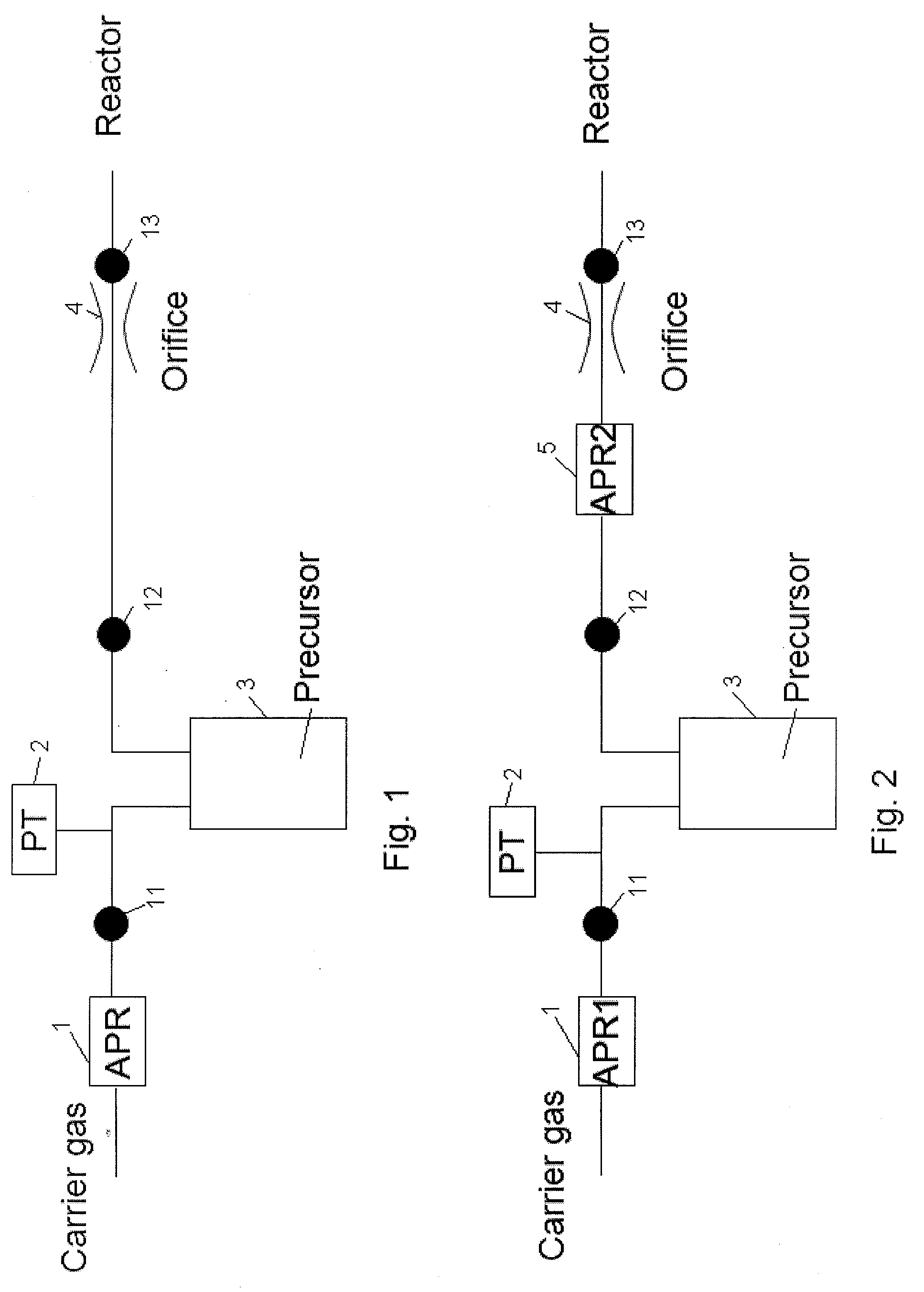

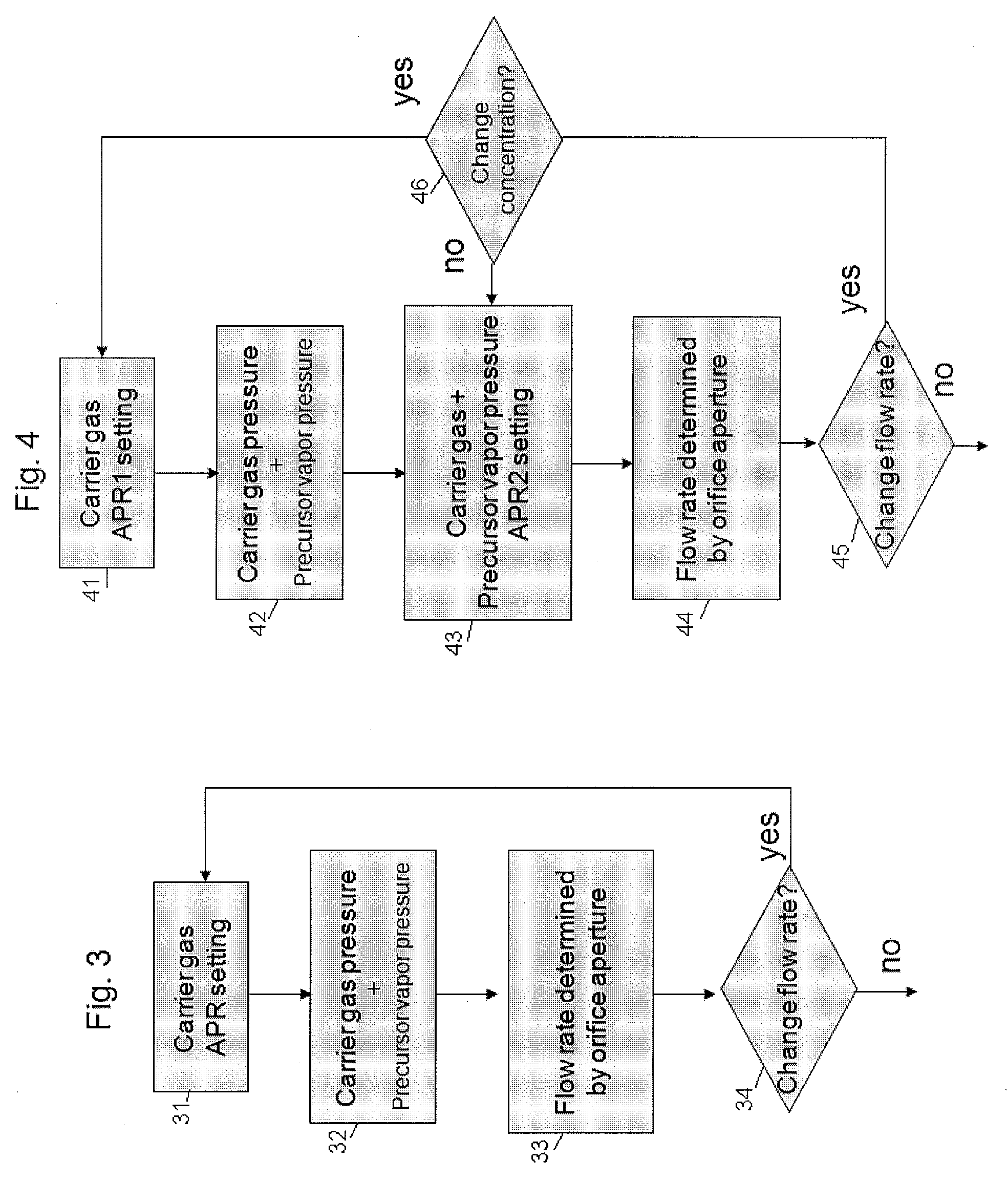

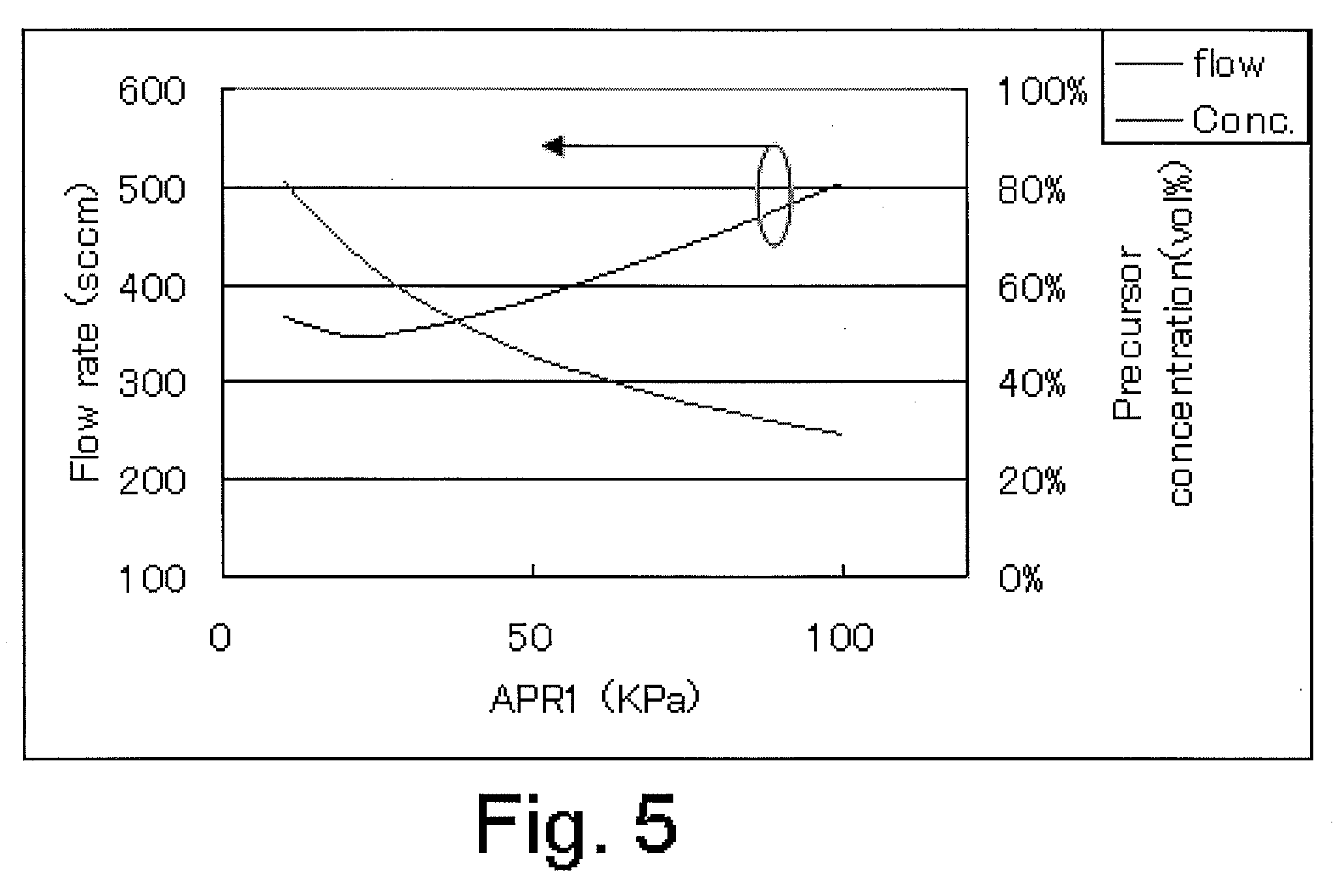

Method for controlling flow and concentration of liquid precursor

ActiveUS20100178423A1Material concentration can be controlledLine pressure can be accuratelyLiquid surface applicatorsVacuum evaporation coatingControl flowPressure regulator

A method for controlling flow and concentration of a liquid precursor includes: supplying a carrier gas to a first auto-pressure regulator and outputting therefrom the carrier gas at a first pressure to a precursor reservoir; outputting the mixture of the vaporized precursor and the carrier gas from the precursor reservoir; and supplying the mixture to a second auto-pressure regulator and outputting therefrom the mixture at a second pressure to a reactor via an orifice.

Owner:ASM JAPAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com