Patents

Literature

21119results about How to "Extension of time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

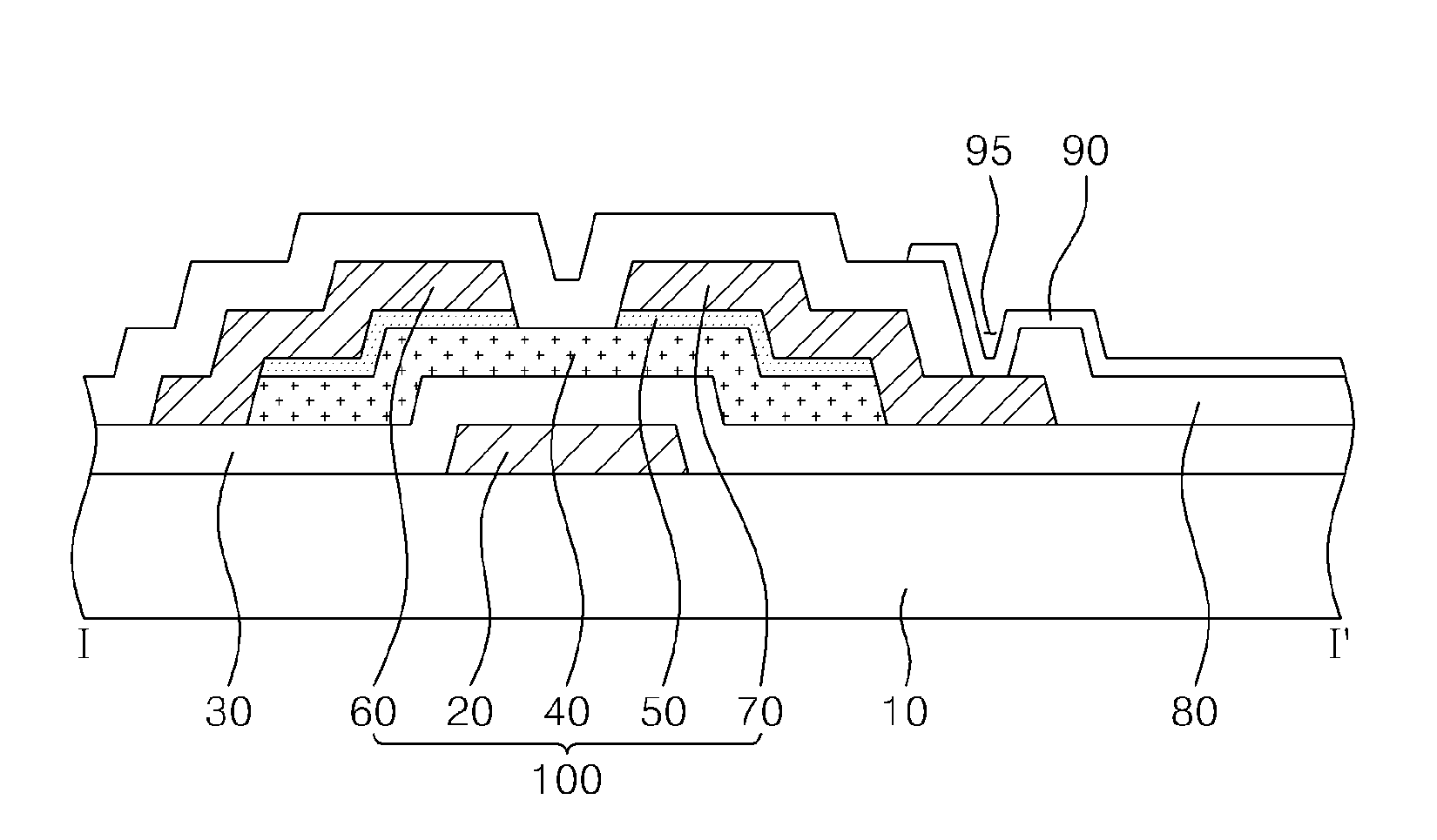

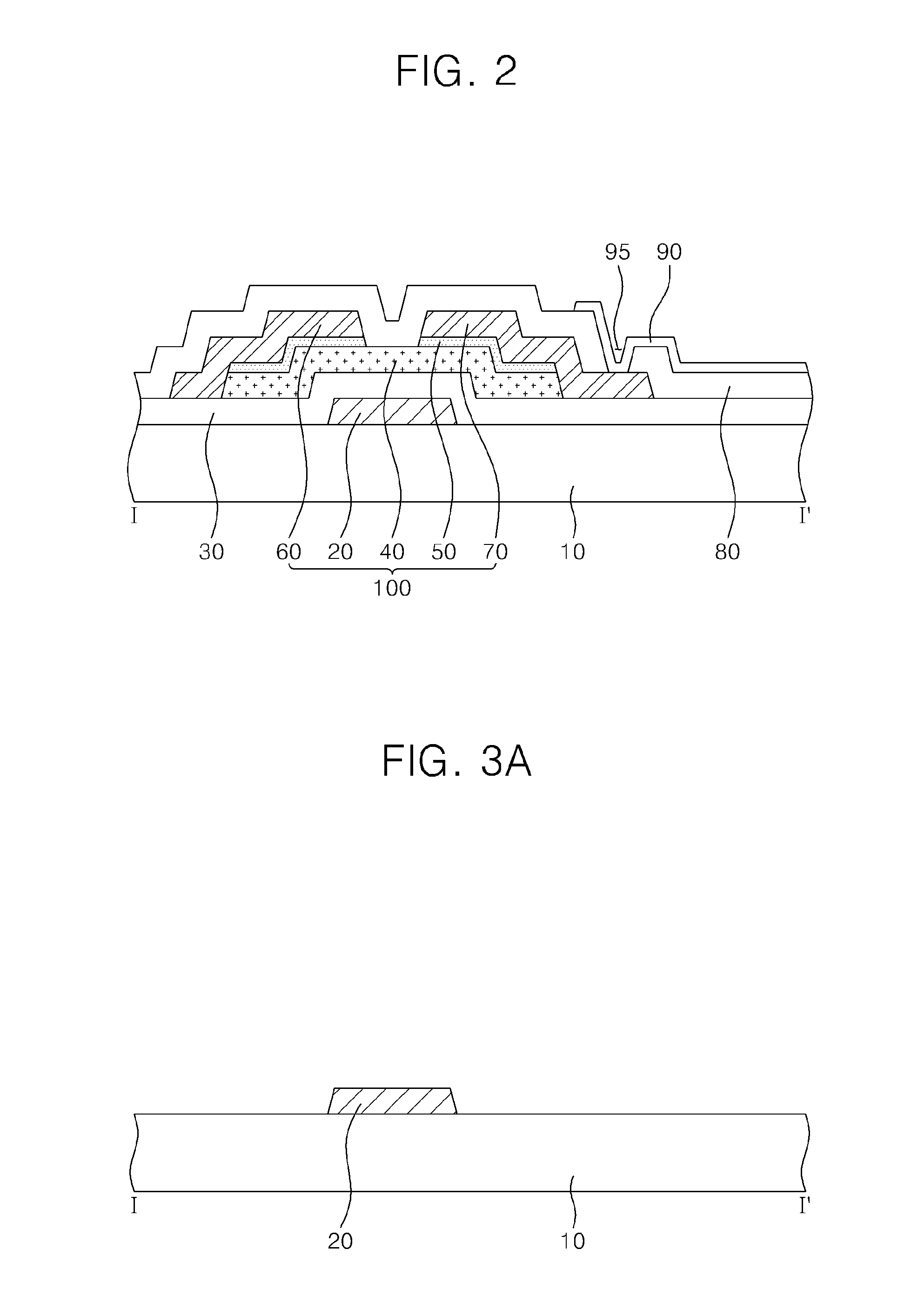

Thin film transitor substrate and method of manufacturing the same

InactiveUS20080258143A1Increases process time and leakage current and serial contact resistanceDegrading property of TFTTransistorSemiconductor/solid-state device manufacturingOxide semiconductorOxide

A method of manufacturing a thin film transistor (“TFT”) substrate includes forming a first conductive pattern group including a gate electrode on a substrate, forming a gate insulating layer on the first conductive pattern group, forming a semiconductor layer and an ohmic contact layer on the gate insulating layer by patterning an amorphous silicon layer and an oxide semiconductor layer, forming a second conductive pattern group including a source electrode and a drain electrode on the ohmic contact layer by patterning a data metal layer, forming a protection layer including a contact hole on the second conductive pattern group, and forming a pixel electrode on the contact hole of the protection layer. The TFT substrate including the ohmic contact layer formed of an oxide semiconductor is further provided.

Owner:SAMSUNG ELECTRONICS CO LTD

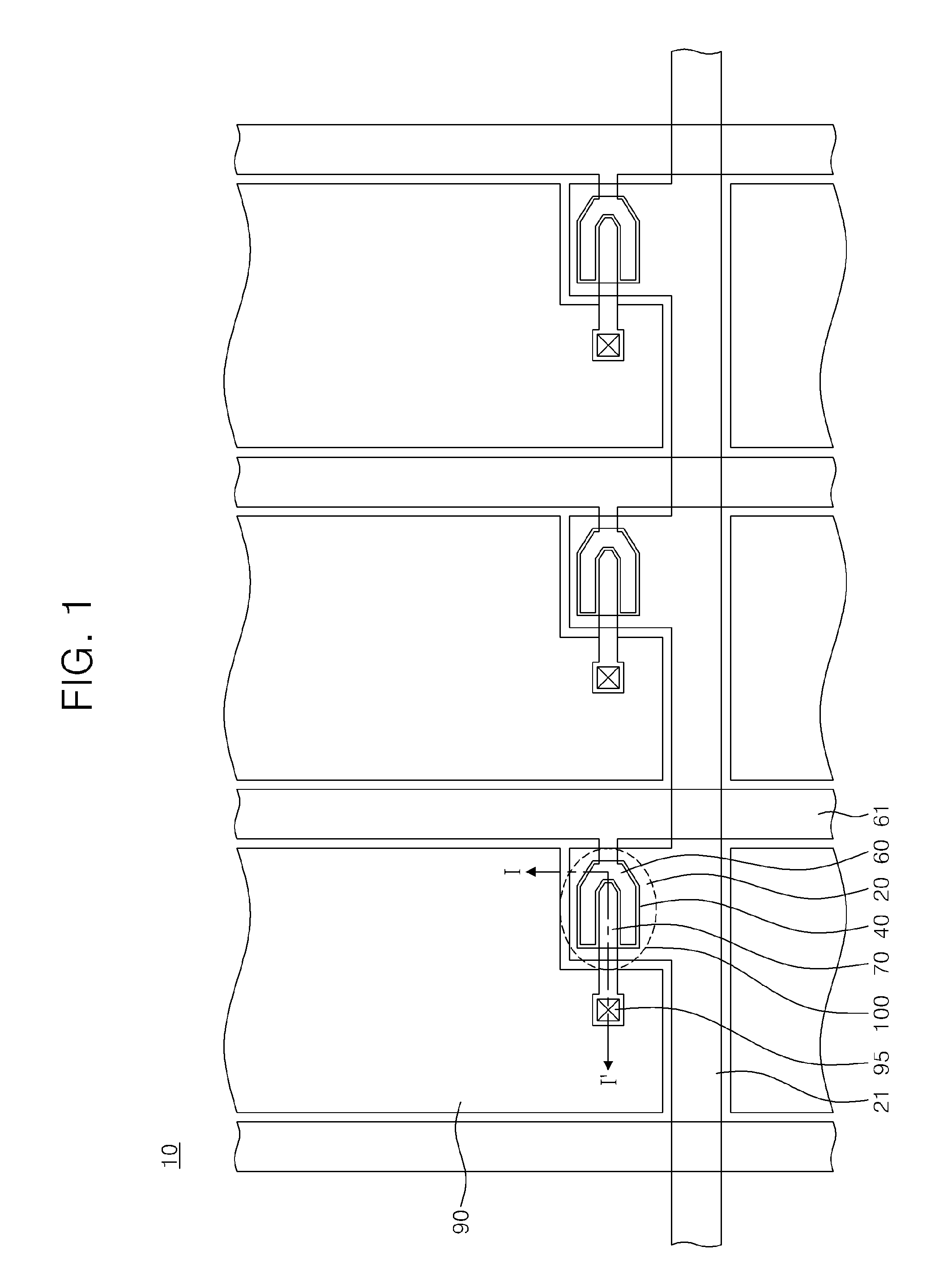

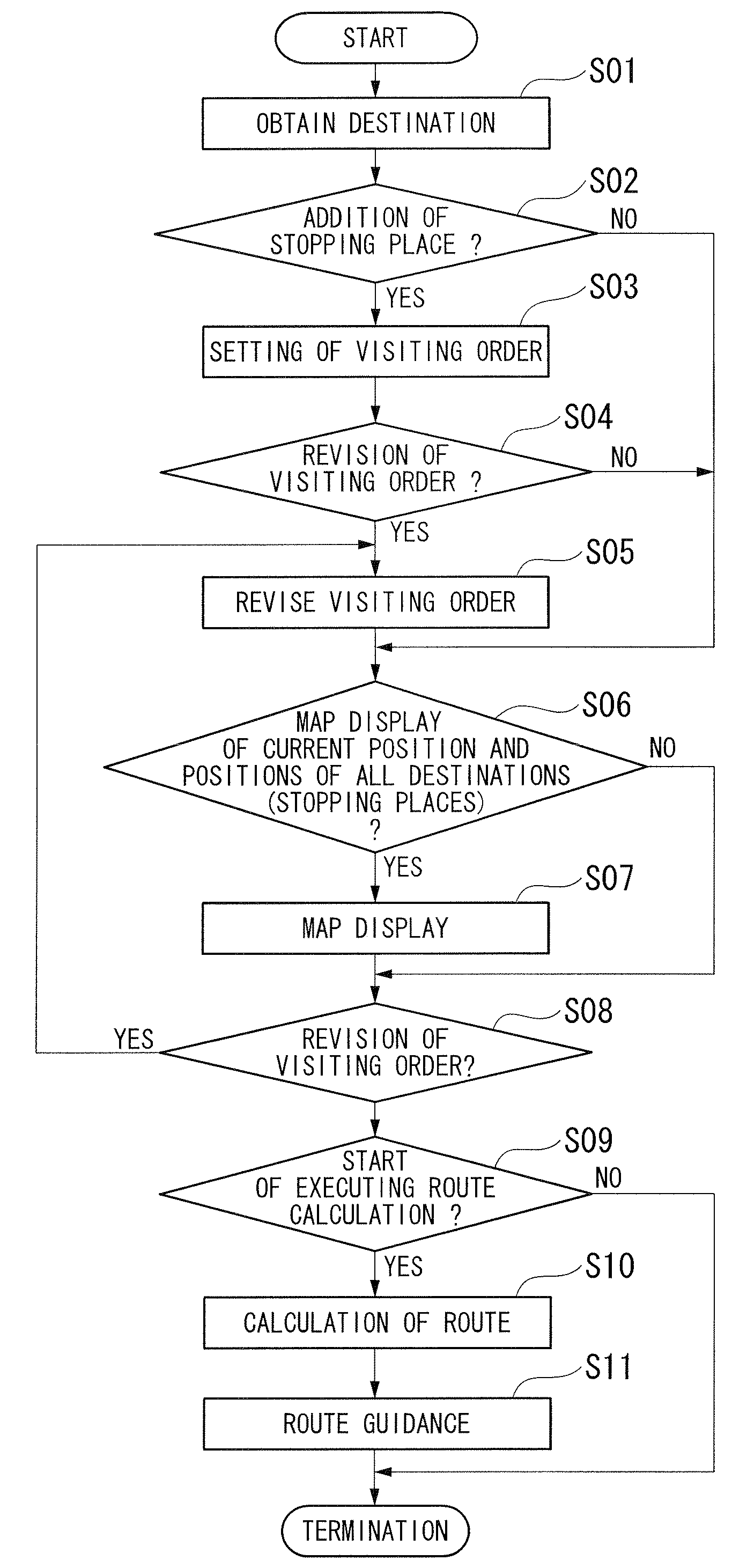

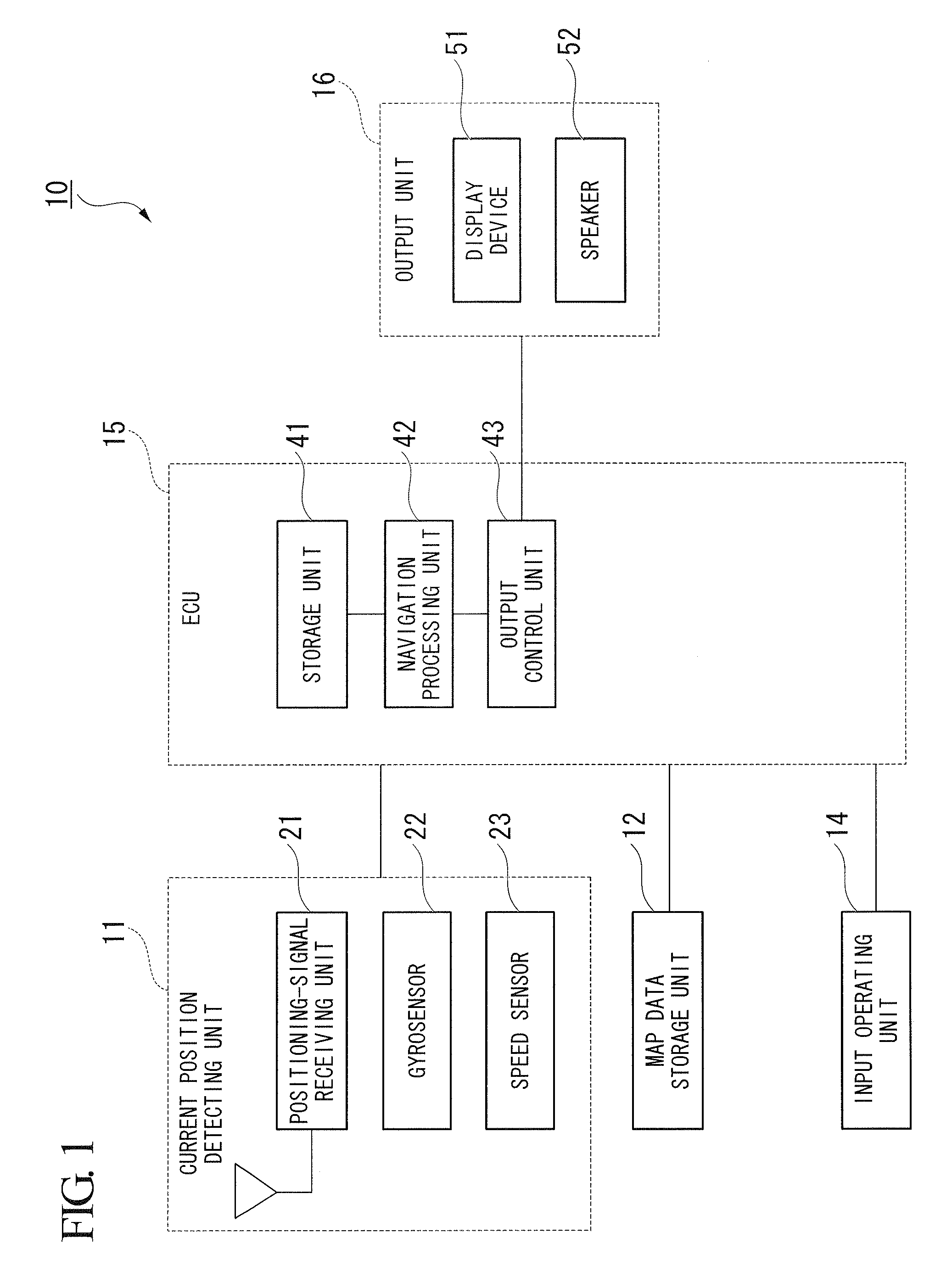

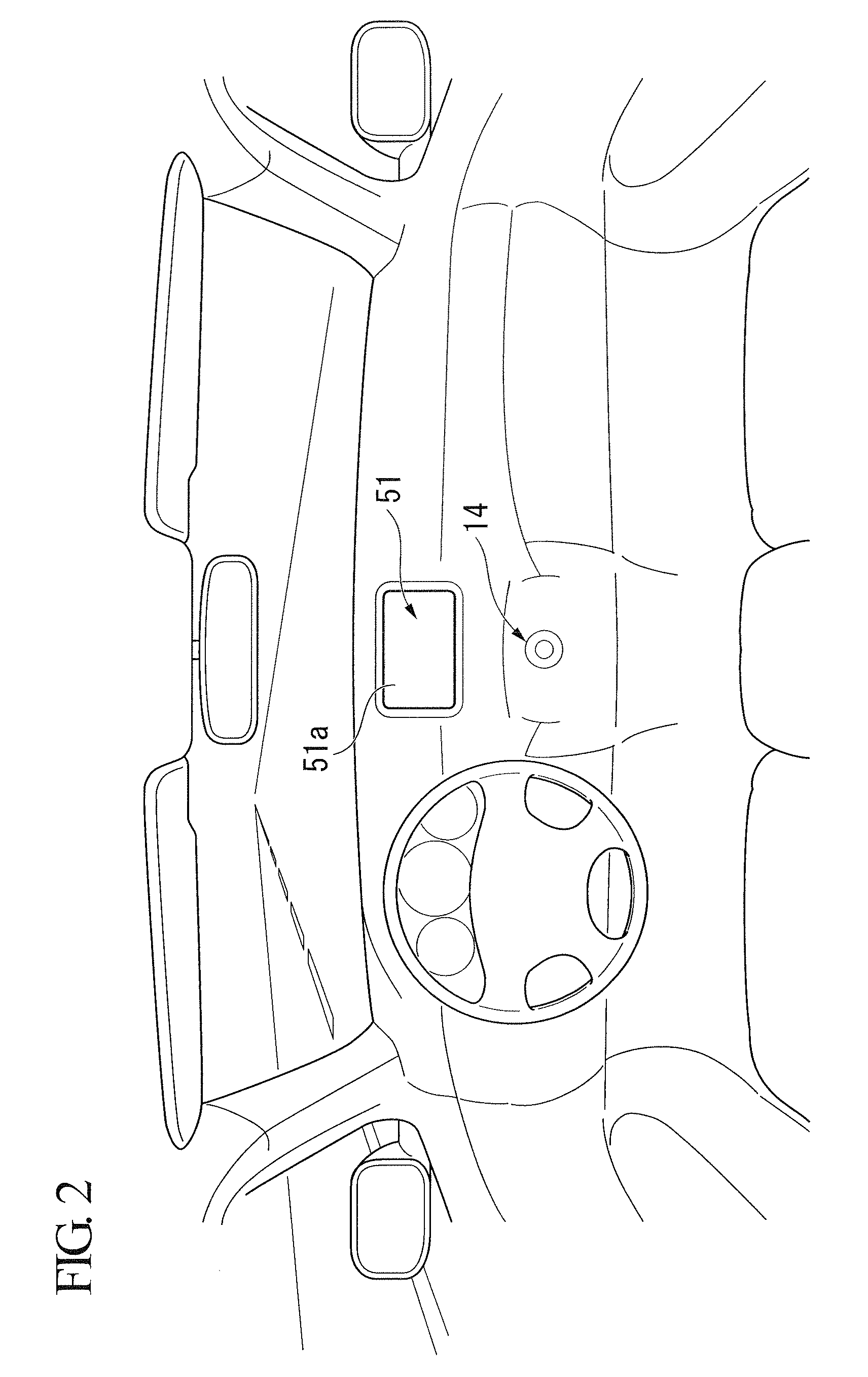

Navigation Apparatus

InactiveUS20090119011A1Improve convenienceEasy to operateManual control with multiple controlled membersInstruments for road network navigationImage storageMarine navigation

A navigation apparatus includes: an input operating unit; a map image storage member; a current position detecting member; a destination determination member; a visiting order determination member which determines a visiting order of each of the plurality of destinations in an revisable manner; a display control member which displays on the display member the map image on which the current position of the user and positions of all of the plurality of destinations are displayed; and a route calculation member which calculates a route from the current position by way of all of the plurality of destinations according to the visiting orders.

Owner:HONDA MOTOR CO LTD

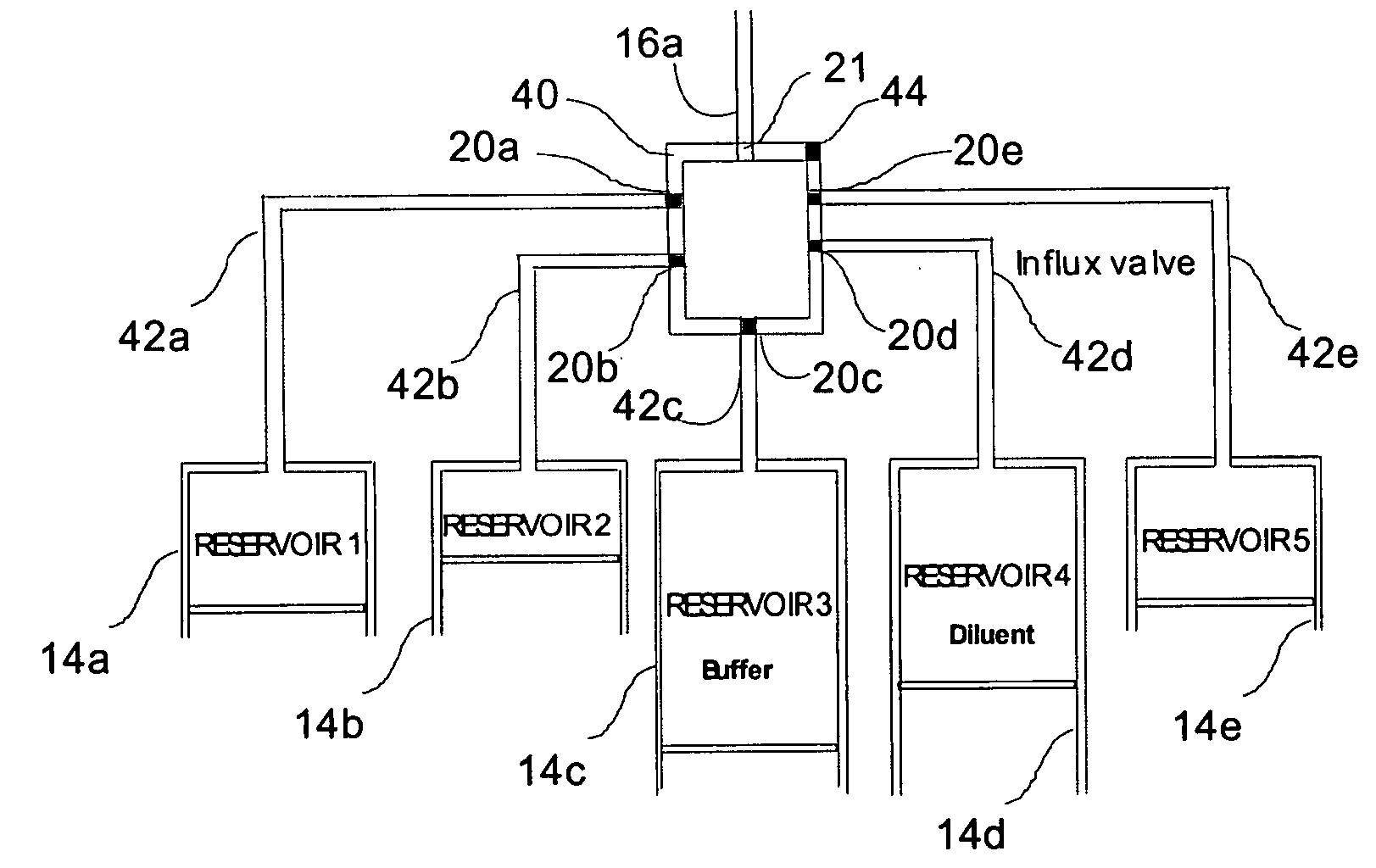

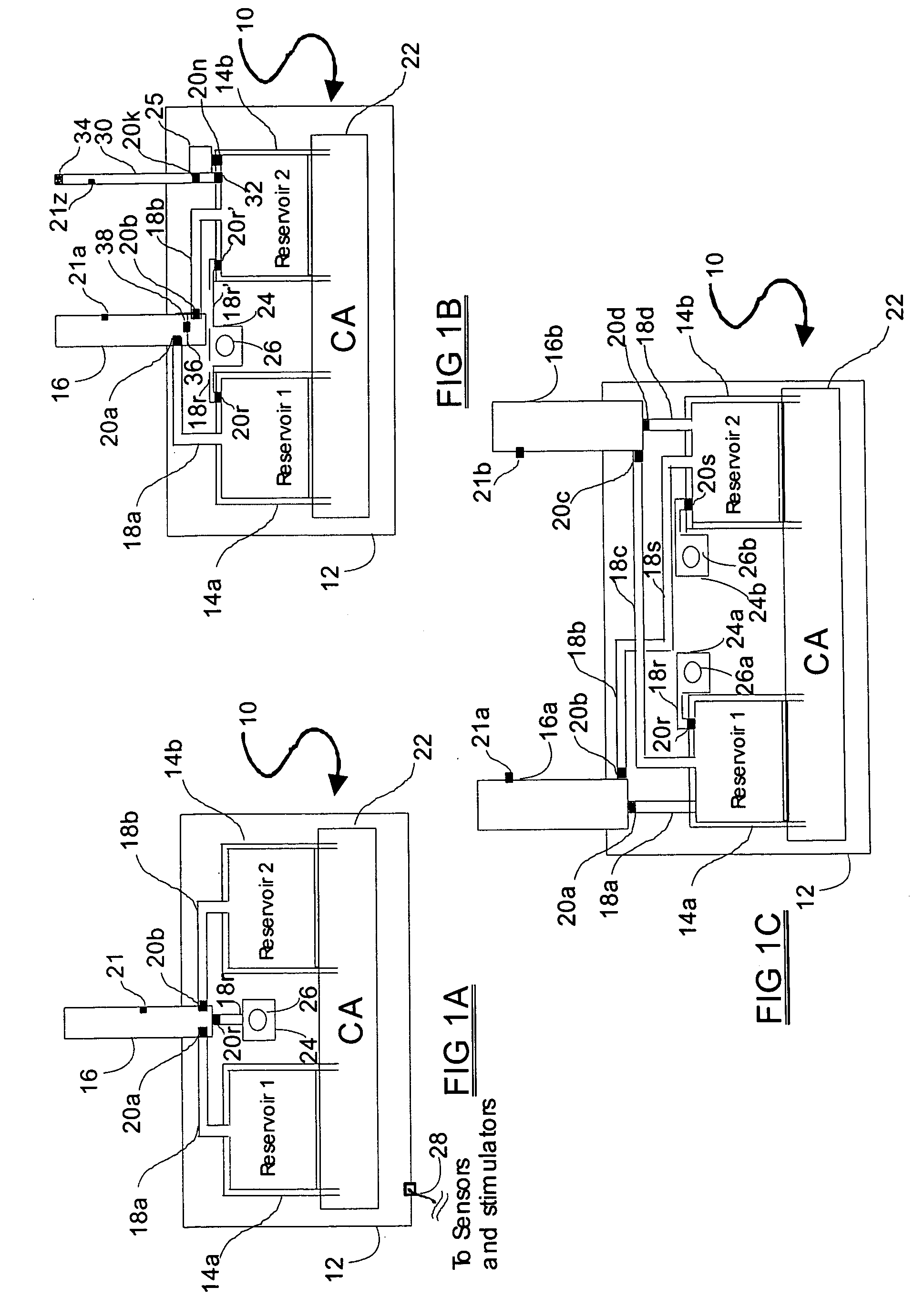

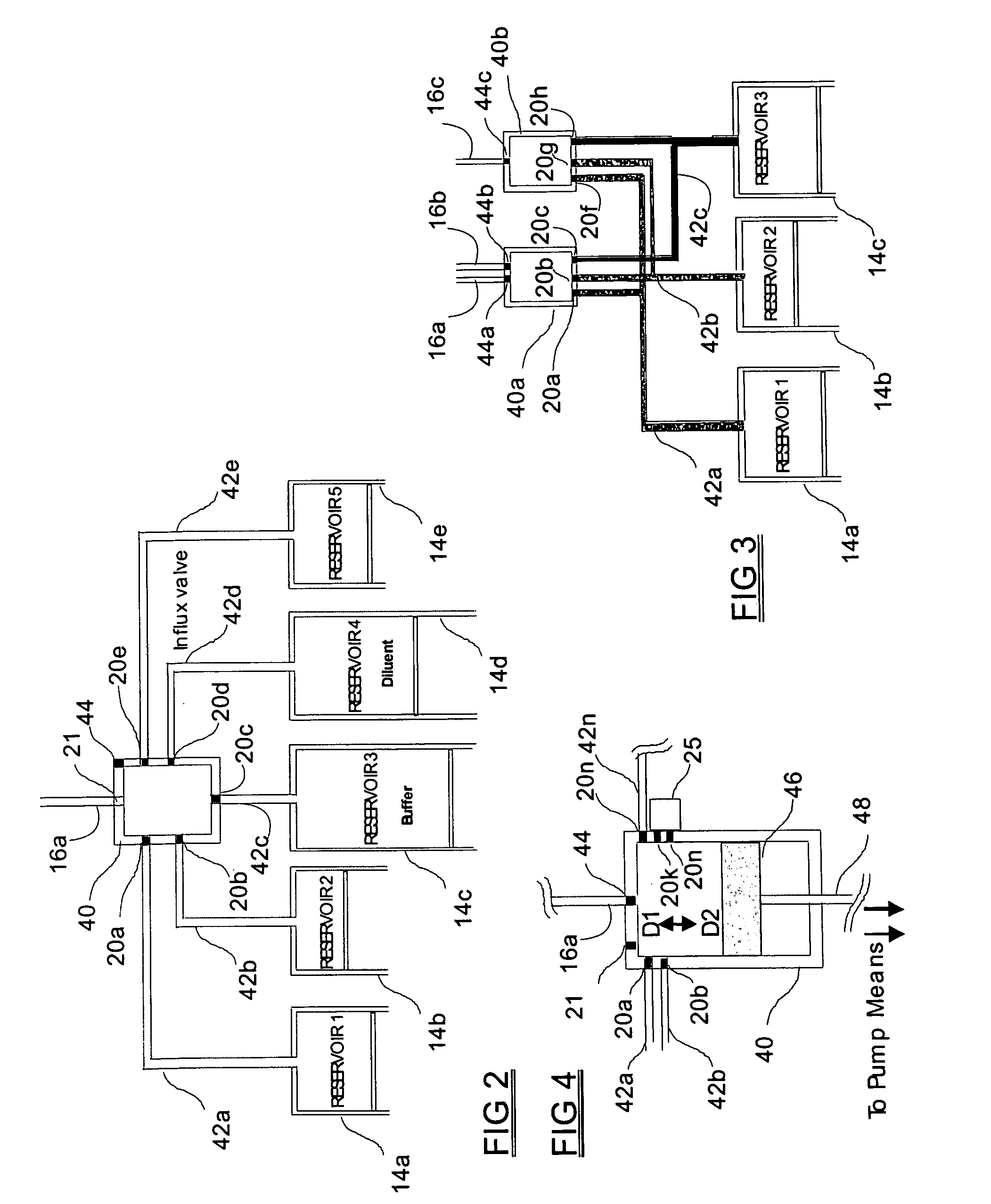

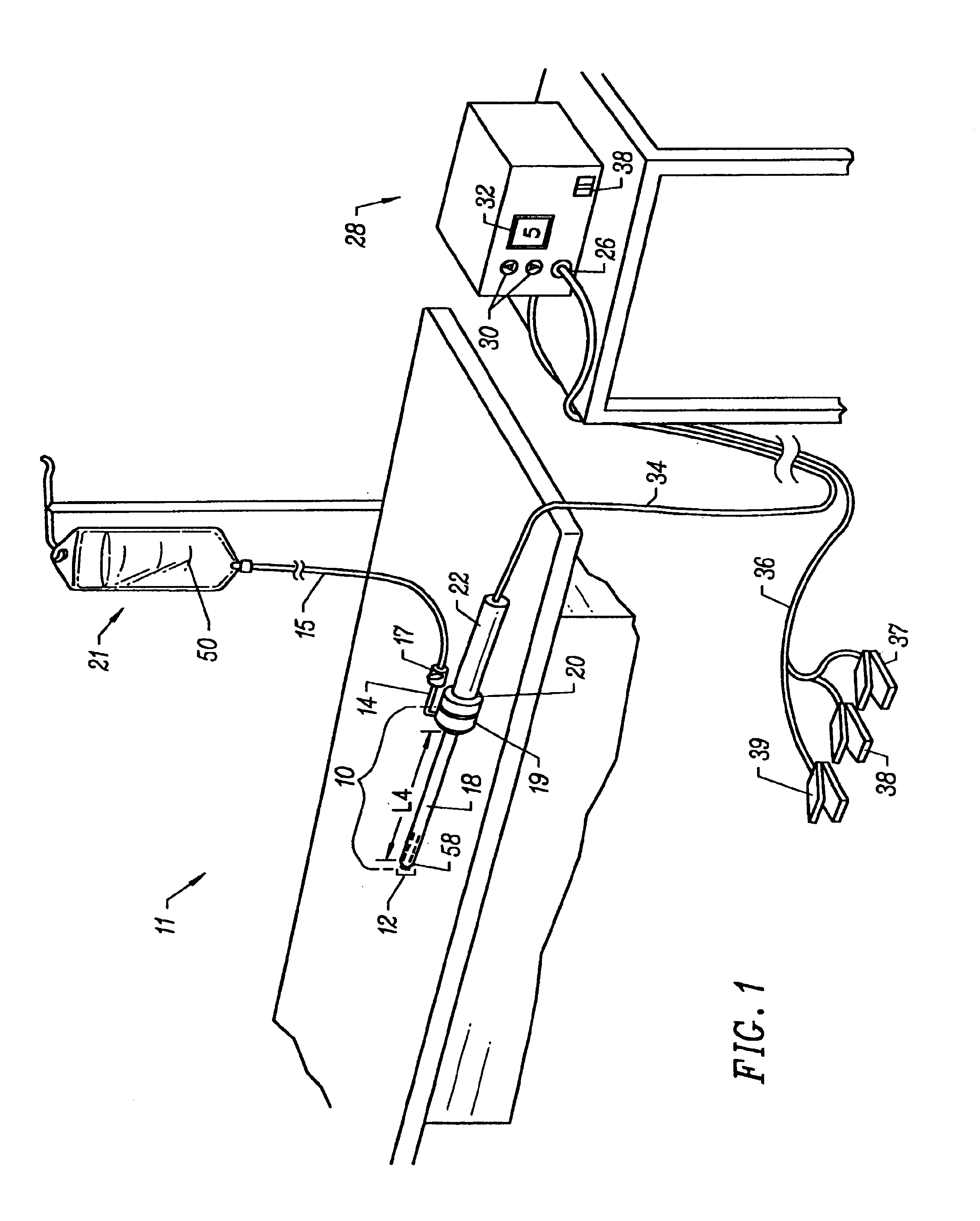

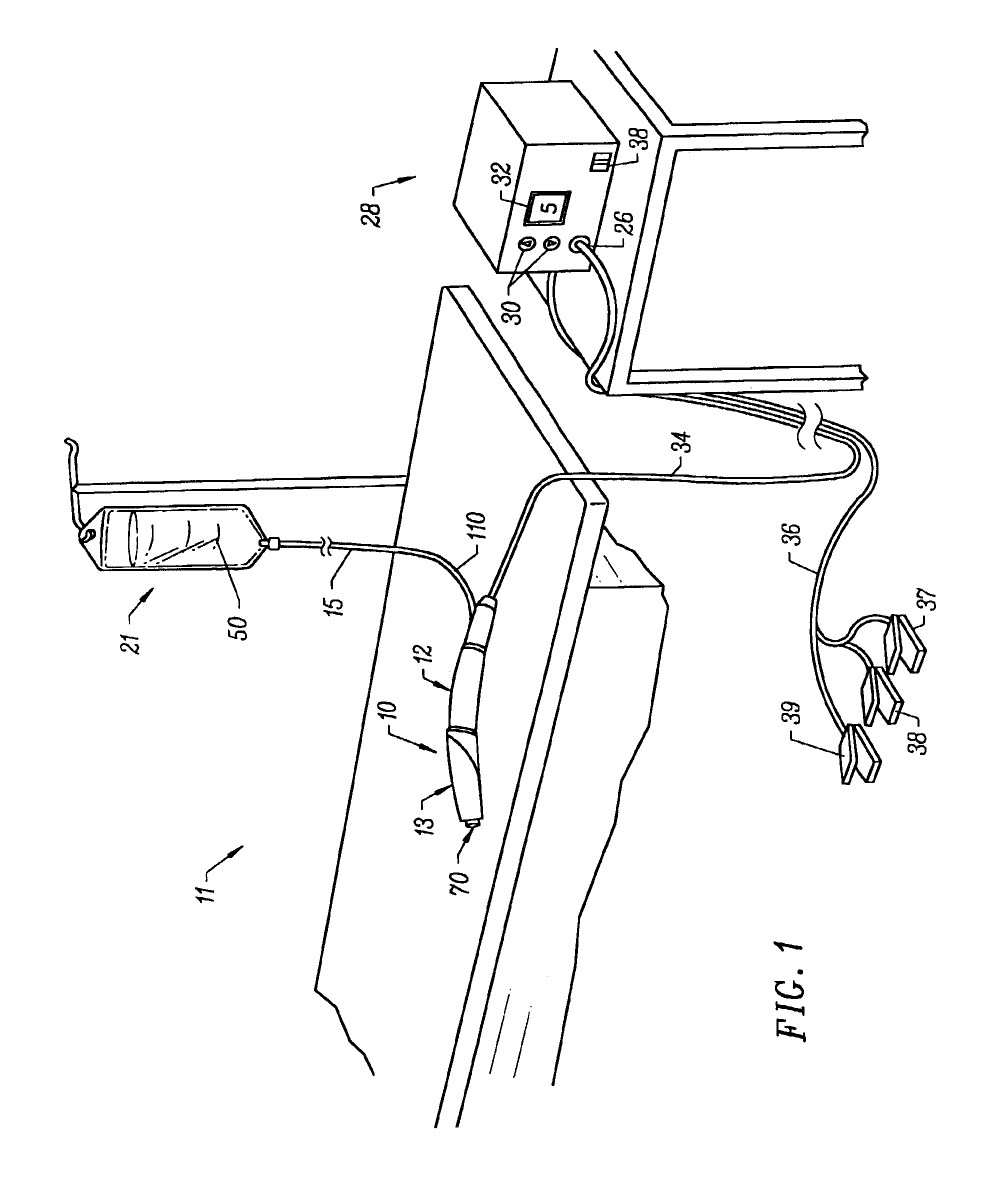

Programmable medical drug delivery systems and methods for delivery of multiple fluids and concentrations

InactiveUS20050277912A1Extension of timeEasy to fillMulti-lumen catheterDrug and medicationsControl mannerDelivery system

A drug delivery system provides for mixing various drugs in an optimally controlled manner, for using flow controllers to guide multiple drugs into a single or into multiple catheters, for enabling a single lumen catheter to treat a specific region with several drugs, for allowing for dilution of a concentrated drug in order to both increase the time between refilling and also for providing any concentration of a drug that might be desired, for using a buffer fluid to deliver exact amounts of several drugs from the same catheter or to separate several drugs within a single catheter, for using external fluid present in the human body either as a diluent or buffer fluid, and for providing for a drug testing / filler apparatus to be used prior to implant to ensure proper function and easy means of filling multiple reservoirs with different fluids, and also after implant for refilling operations. The drug delivery system (DDS) can perform both bolus and continuous delivery of substances, and enable the measured delivery of any one of several drugs to one or more distal locations at independently programmable rates. New types of catheter systems and uses therefore are also described. Catheter hub assemblies allowing for easy replacement of drug delivery systems offer advantages when replacing drug delivery systems. New methods for using the DDS in the promotion of healthy pregnancy and treatment of a developing fetus are also possible.

Owner:JOHN SASHA

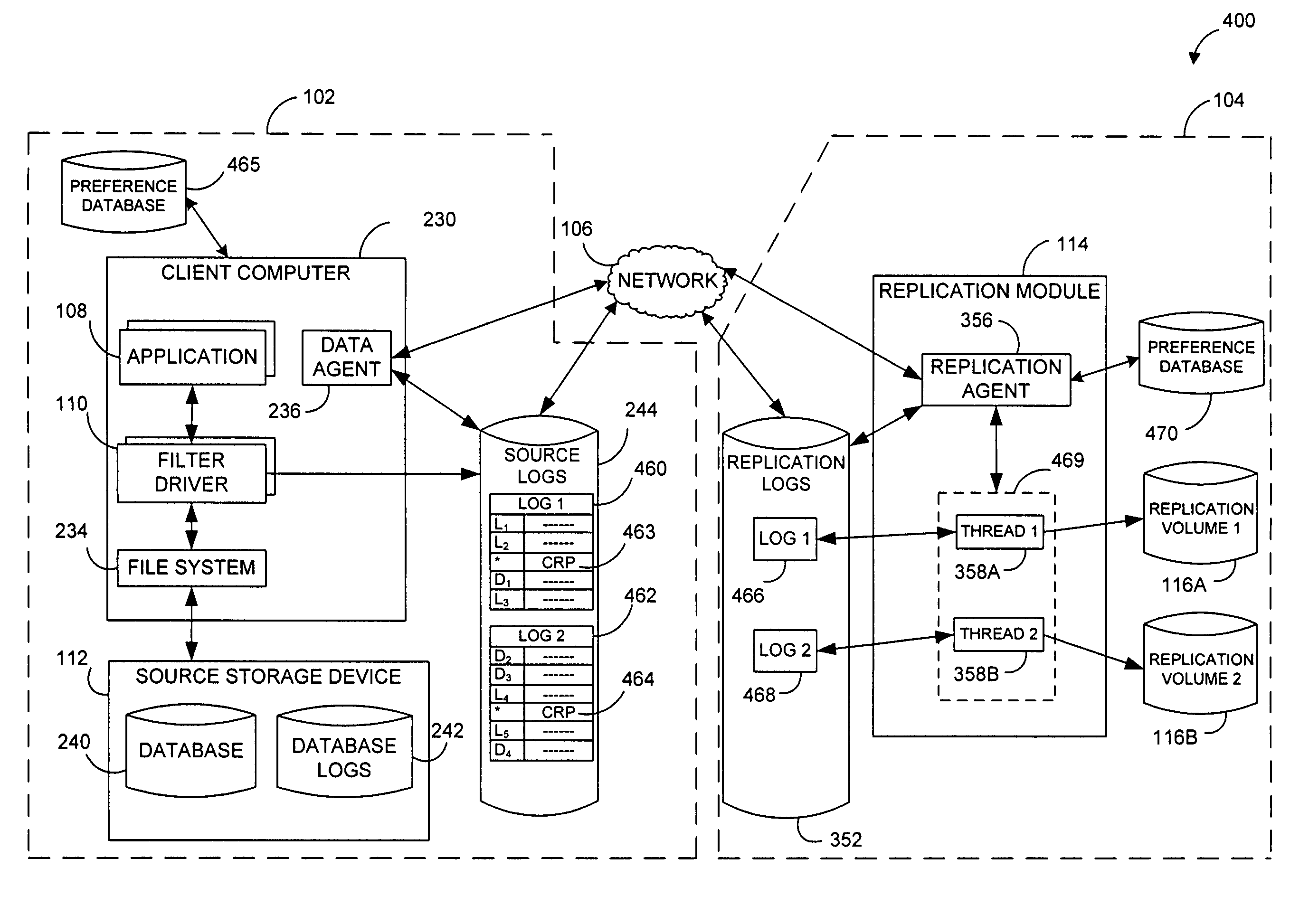

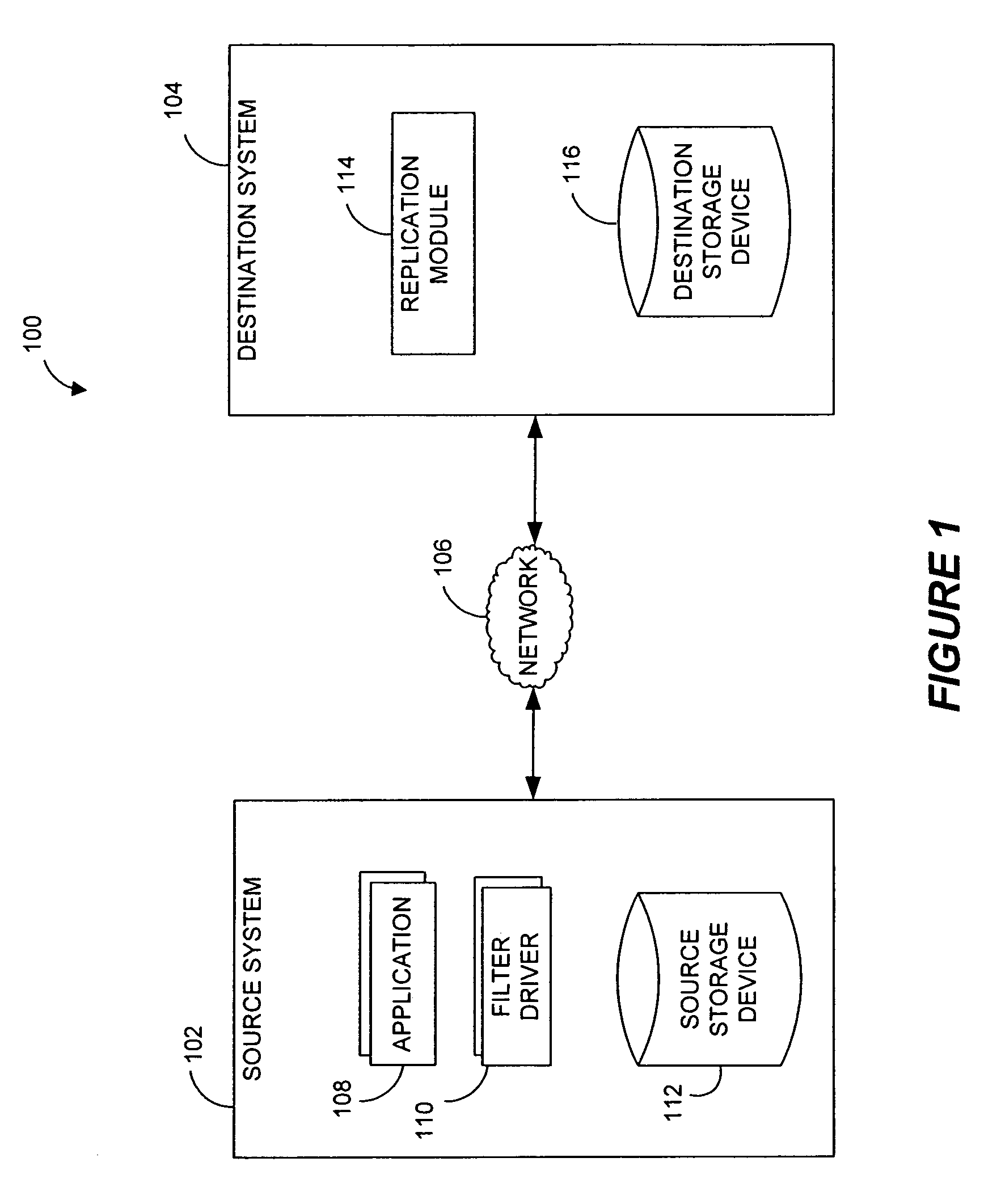

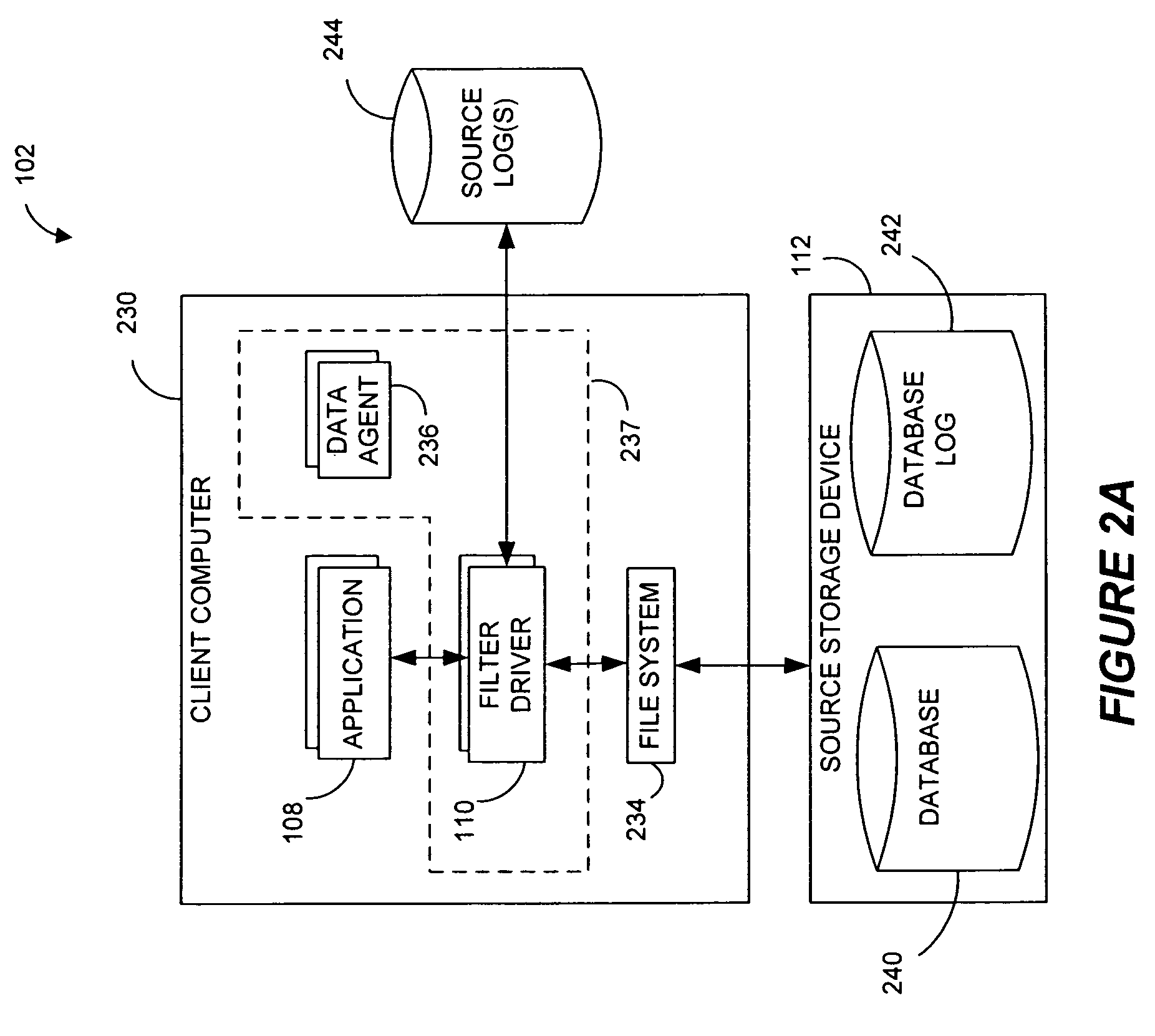

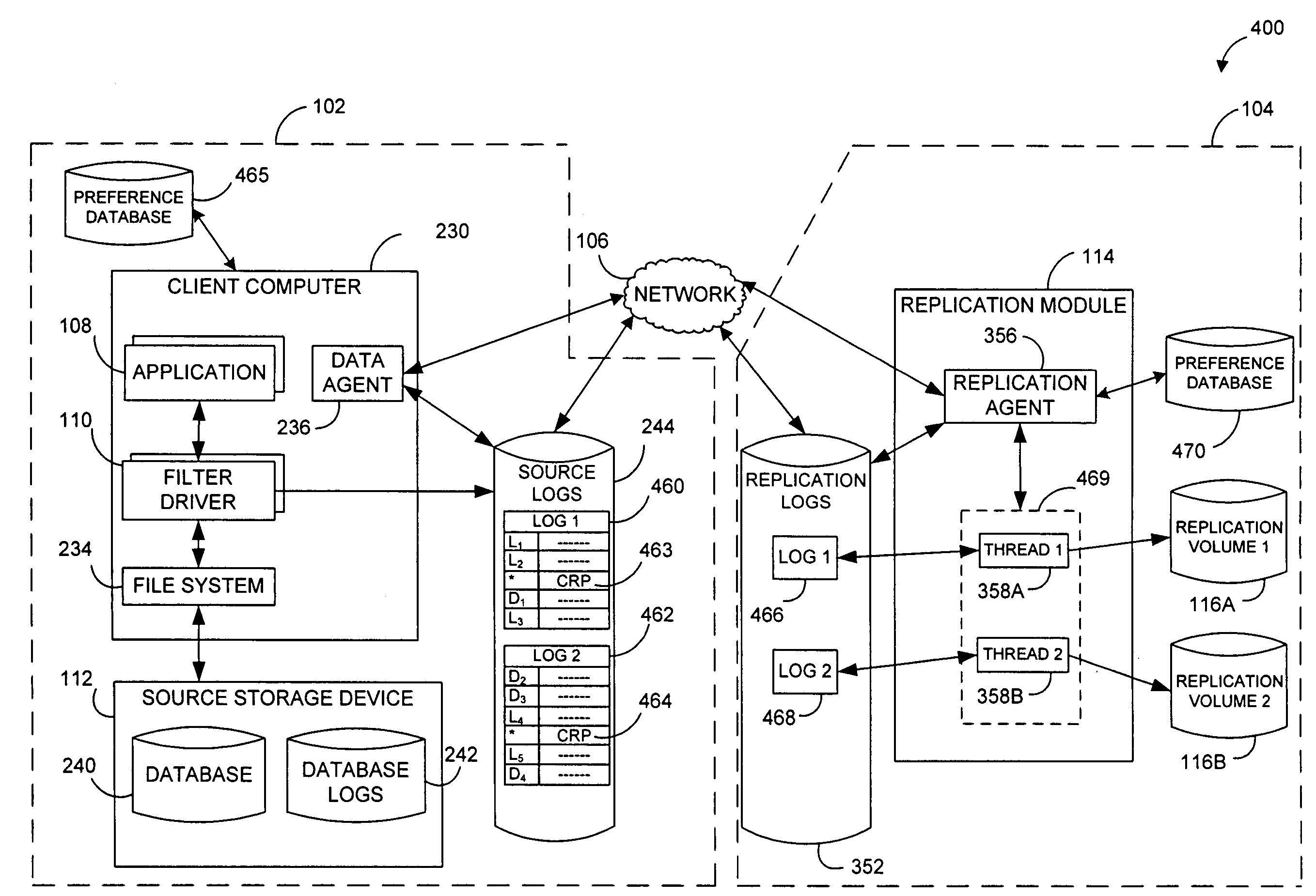

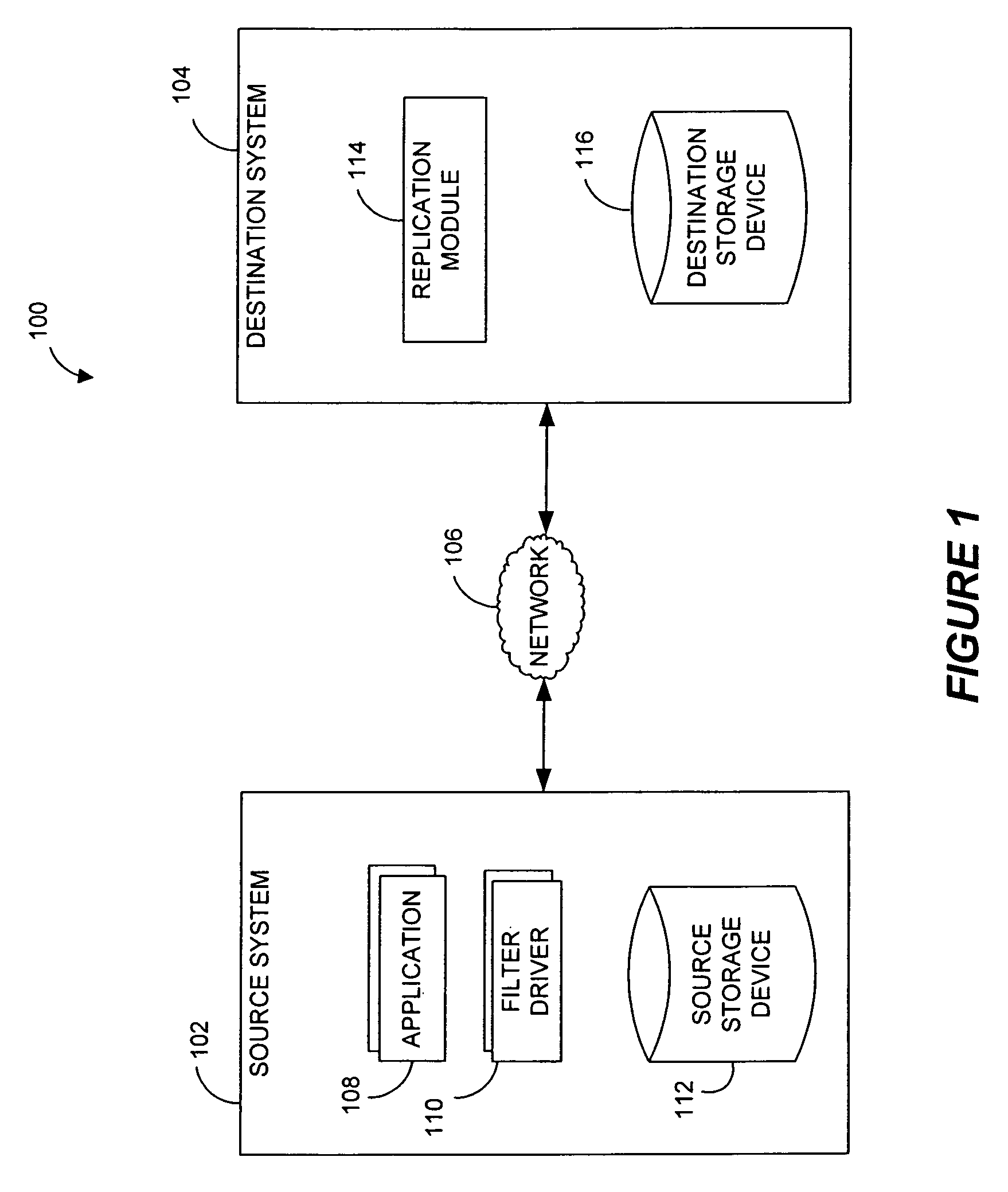

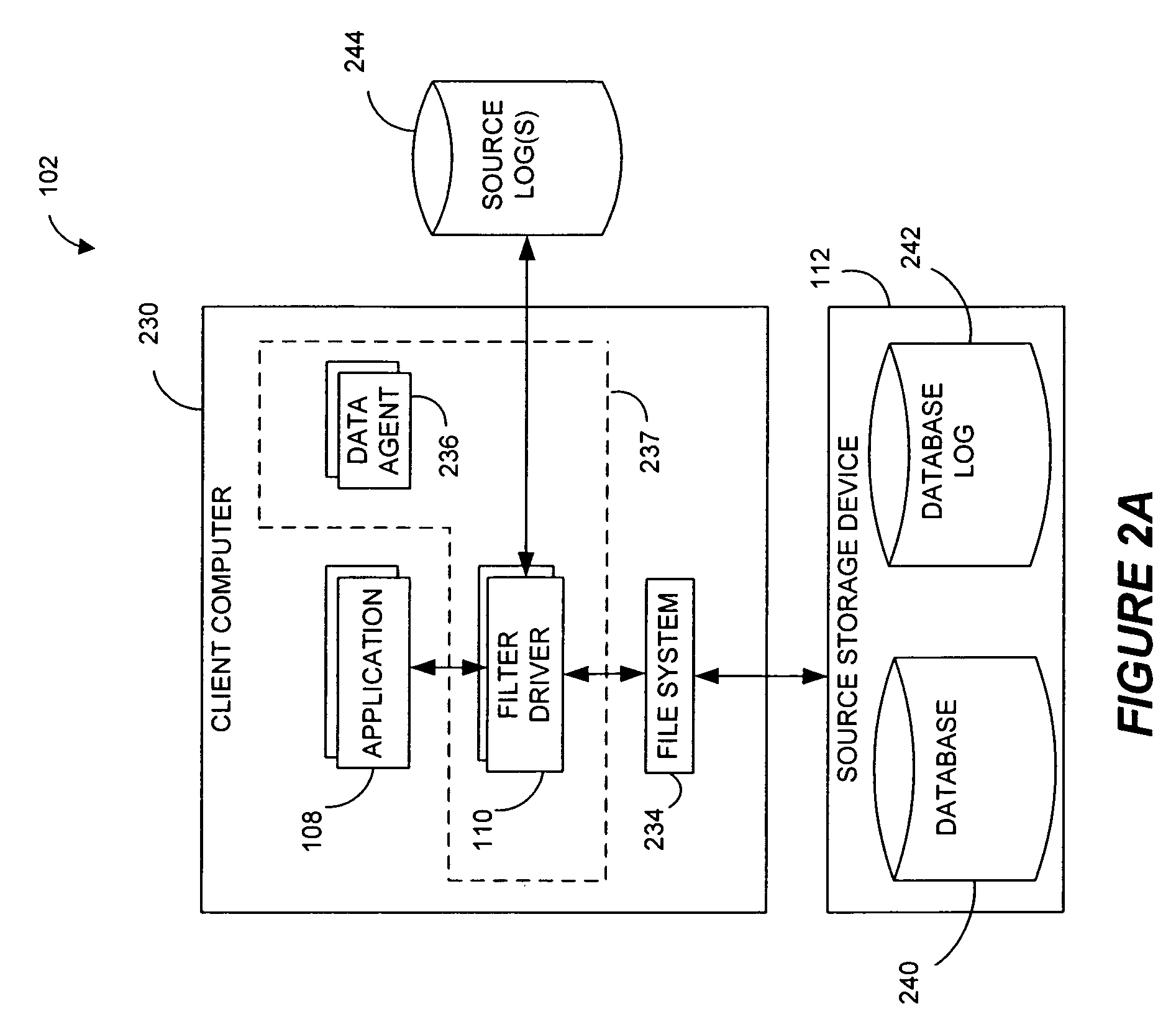

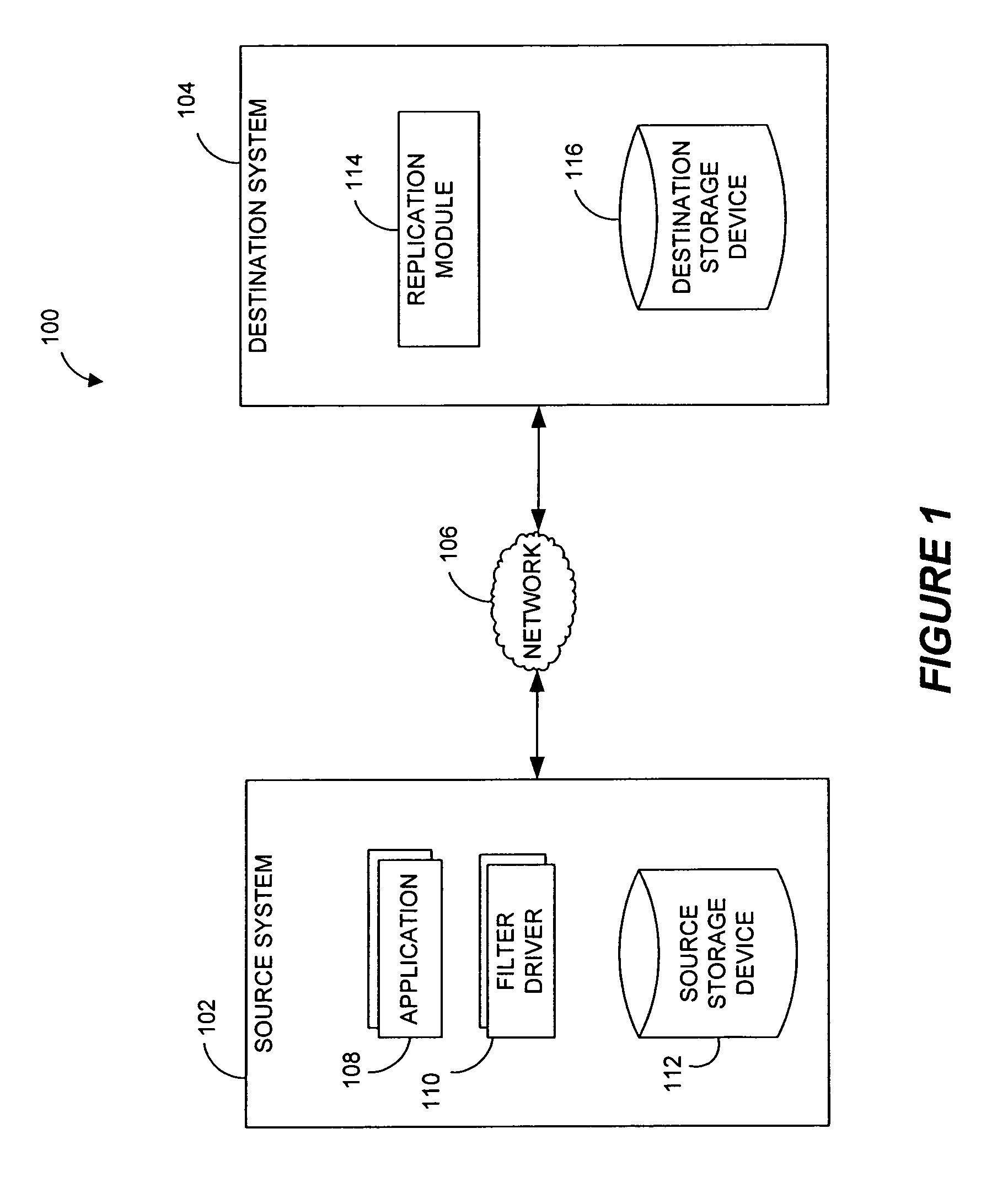

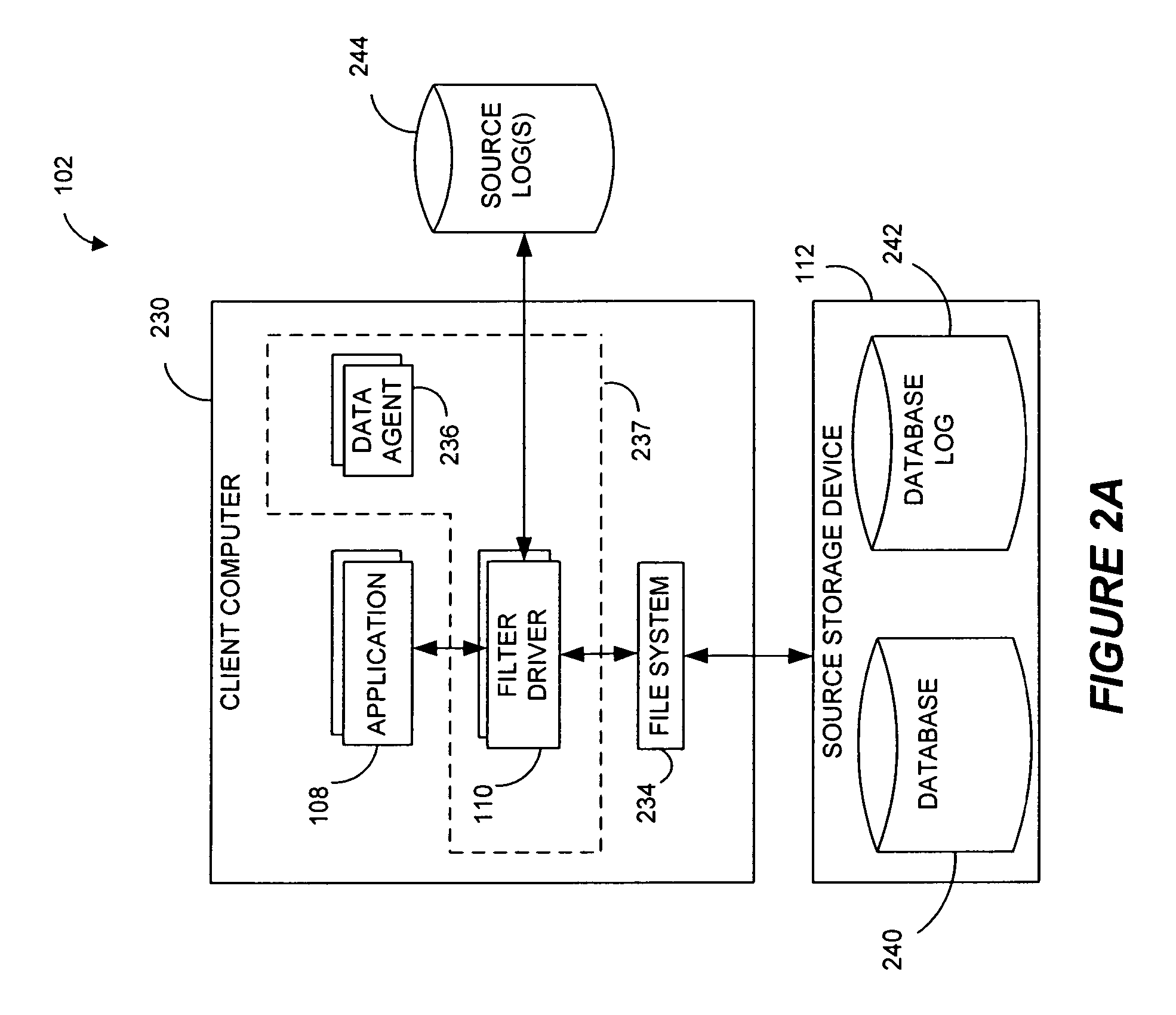

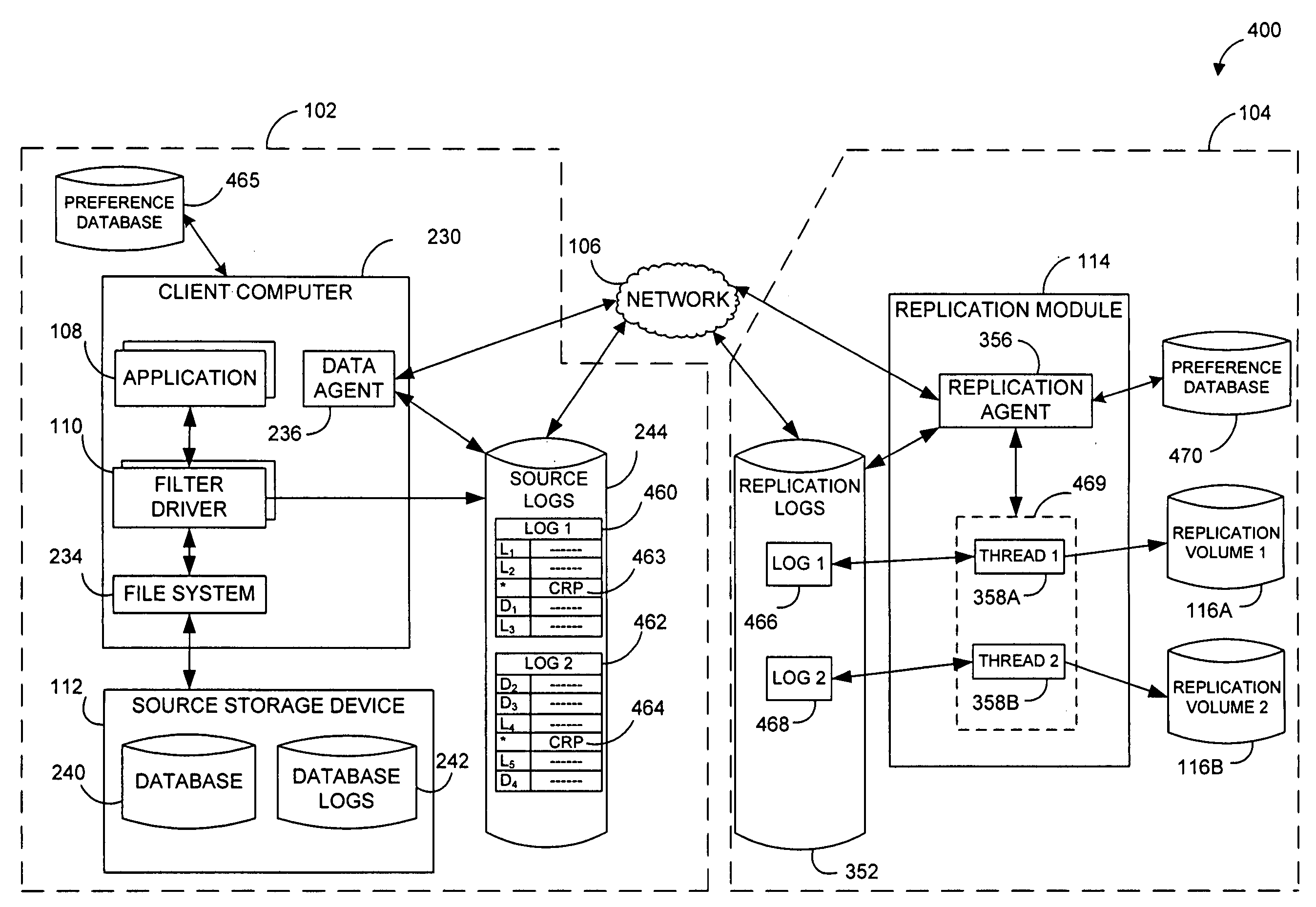

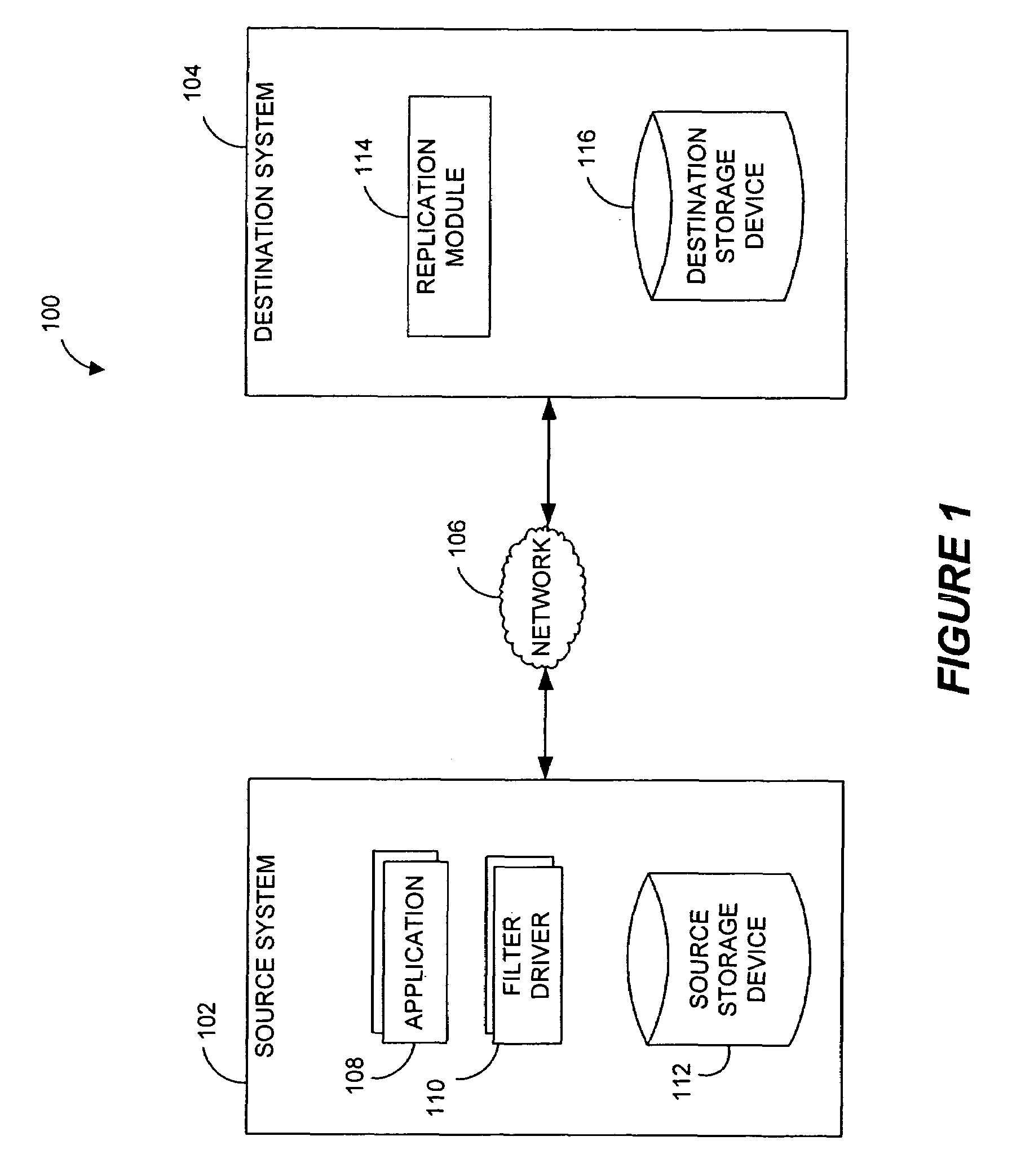

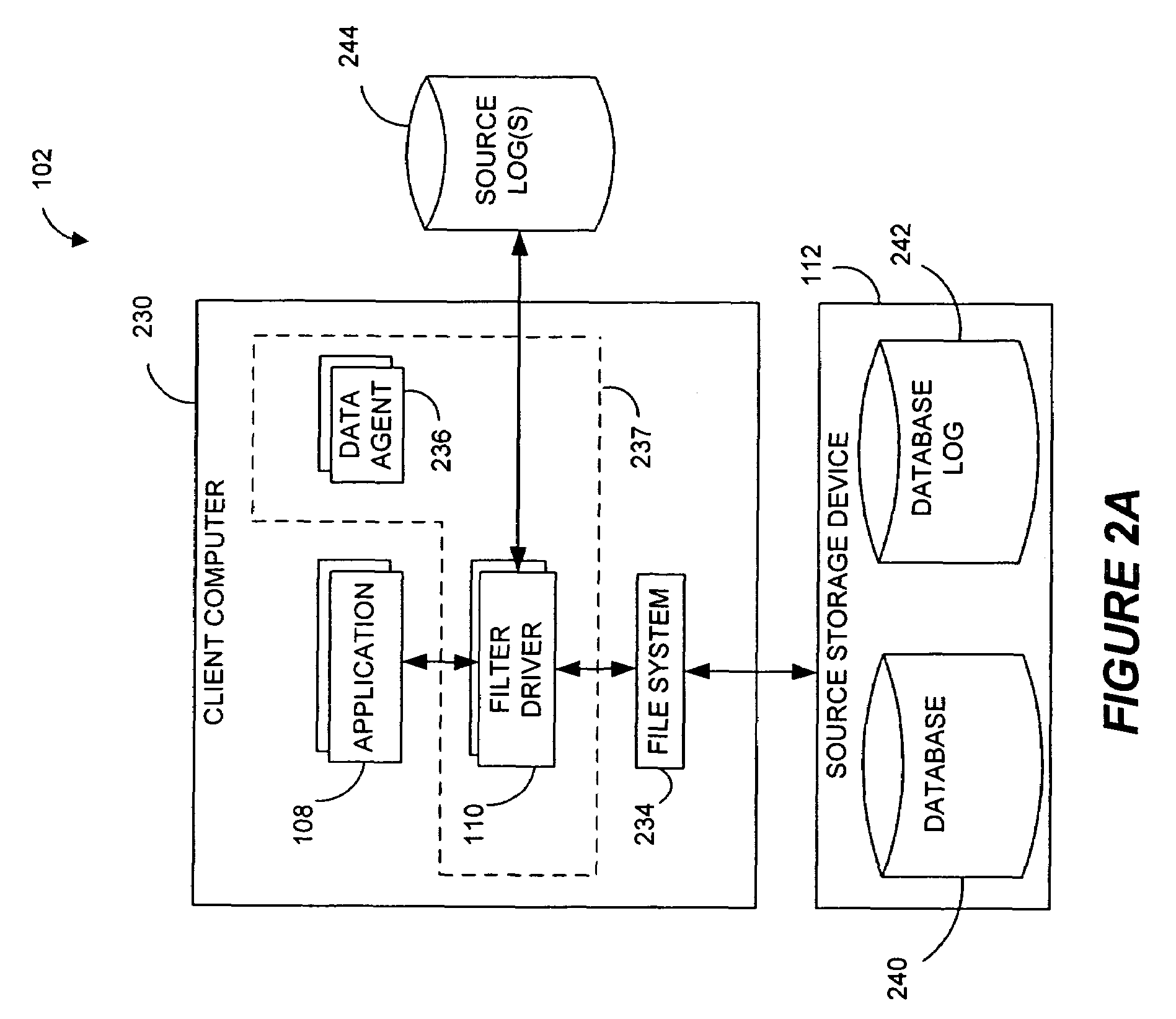

Systems and methods for monitoring application data in a data replication system

InactiveUS7617262B2Reduce impactReduce memory requirementsDigital data information retrievalData processing applicationsTemporal informationData management

Performing data management operations on replicated data in a computer network. Log entries are generated for data management operations of an application executing on a source system. Consistency point entries are used to indicate a time of a known good, or recoverable, state of the application. A destination system is configured to process a copy of the log and consistency point entries to replicate data in a replication volume, the replicated data being a copy of the application data on the source system. When the replicated data represents a known good state of the application, as determined by the consistency point entries, the destination system(s) may perform a storage operation (e.g., snapshot, backup) to copy the replicated data and to logically associate the copied data with a time information (e.g., time stamp) indicative of the source system time when the application was in the known good state.

Owner:COMMVAULT SYST INC

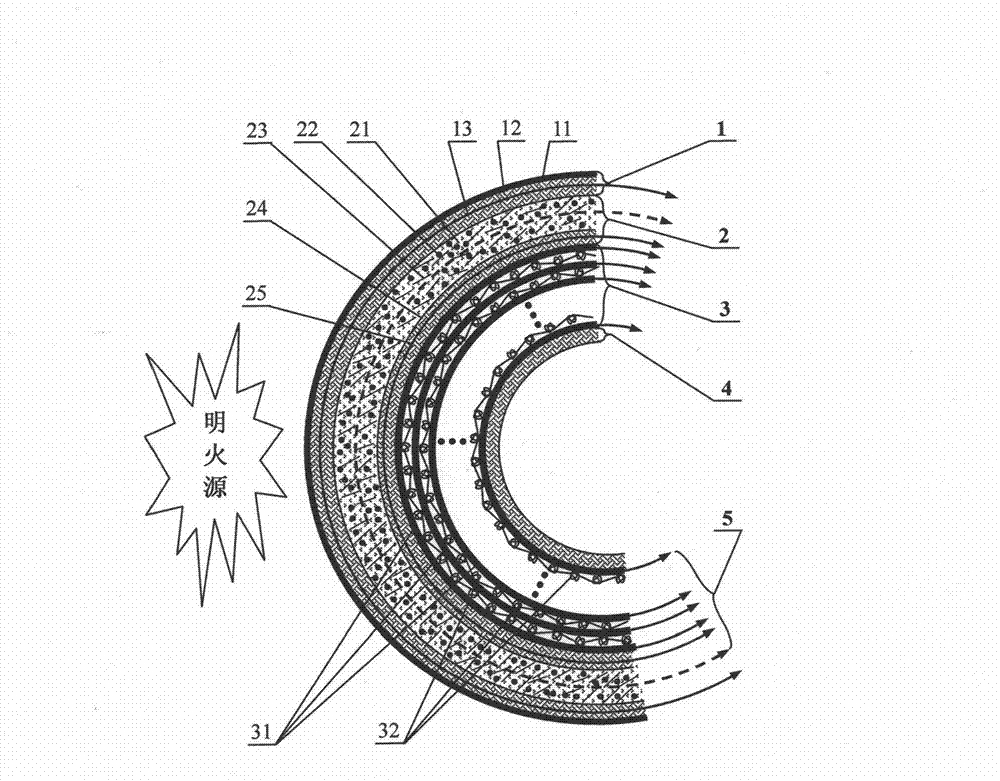

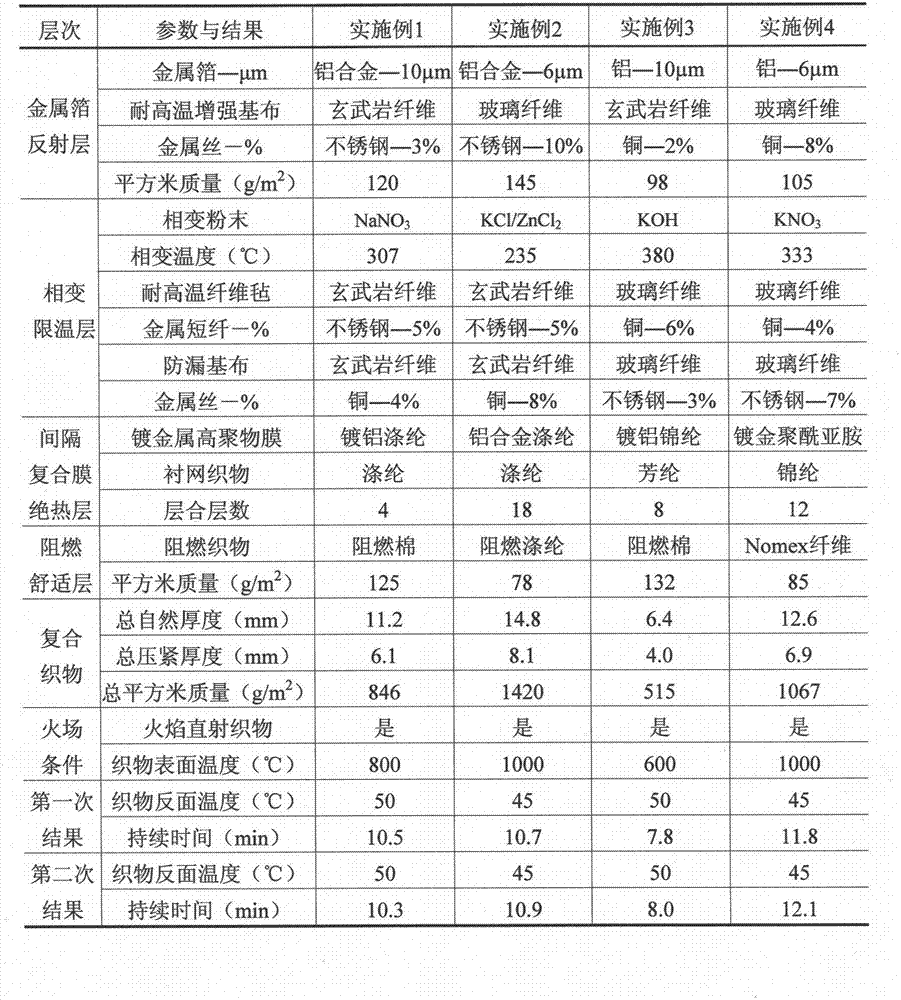

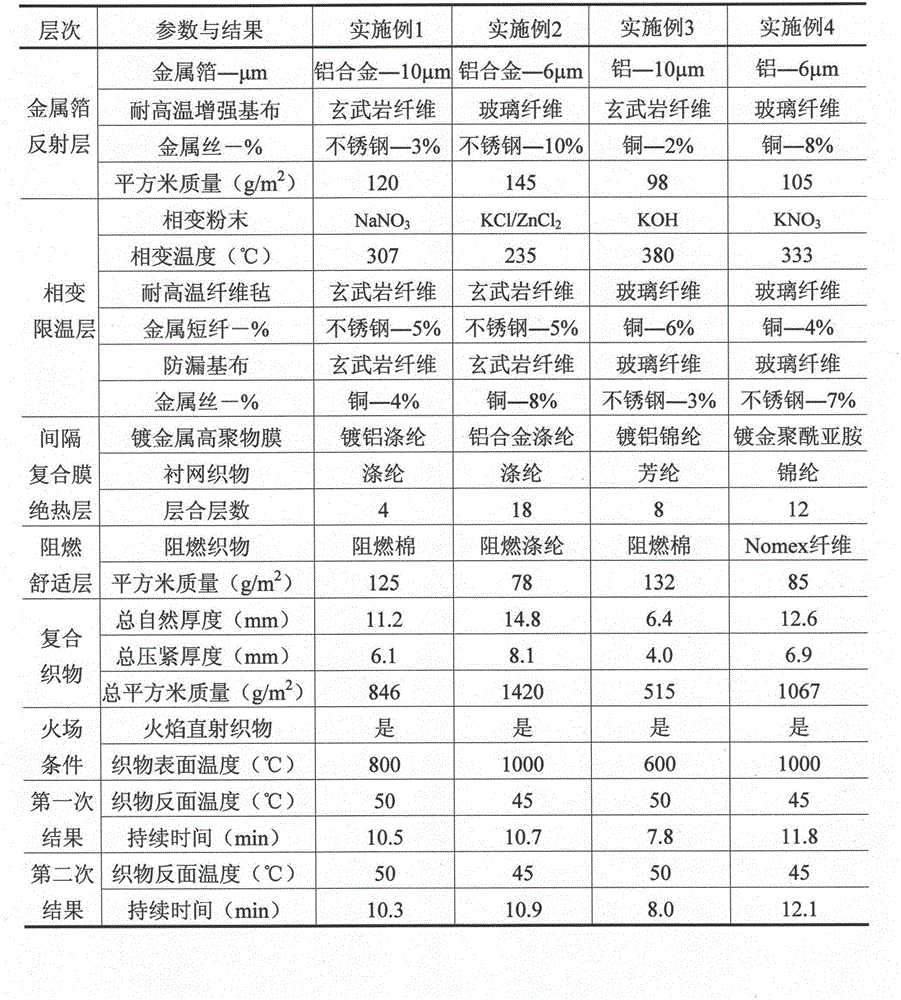

Multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric, preparation method and application

ActiveCN102783741AImprove permeabilityPromote absorptionLaminationLamination apparatusInsulation layerMetal foil

The invention relates to a preparation method and an application of multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric. The multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric is formed by successively arranging and laminating a metal foil reflection layer, a phase change temperature limitation layer, an interval composite membrane heat-insulation layer and a flame-retardant comfortable layer, wherein the metal foil reflection layer has high reflectivity and an enhanced heat-dissipation function; the phase change temperature limitation layer has functions of high energy consumption absorption and evenly-distributed heat conduction; the interval composite membrane heat-insulation layer has the functions of reflection insulation and even distribution of heat; and the flame-retardant comfortable layer has the functions of low-contact heat conduction, heat insulation and comfort. When the front side of the multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric is under the action of open fire and strong heat flow environment, the back side of the multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric can be kept below 50DEG C which is near the safe temperature state of the human skin, and the integral structural form and the mechanical property are stable. The natural thickness of the composite fabric is 5-15mm, the compression thickness of the composite fabric is 3-8mm, and the square meter quality of the composite fabric is 400-1500g / m<2>. The composite fabric is fire-proof heat-insulation material which is totally sealed, stuck and sewn and can be used for individual protection and environment heat insulation in special high-temperature occasions, such as fire control, military, exploration, safe escape and industry and the like.

Owner:DONGHUA UNIV

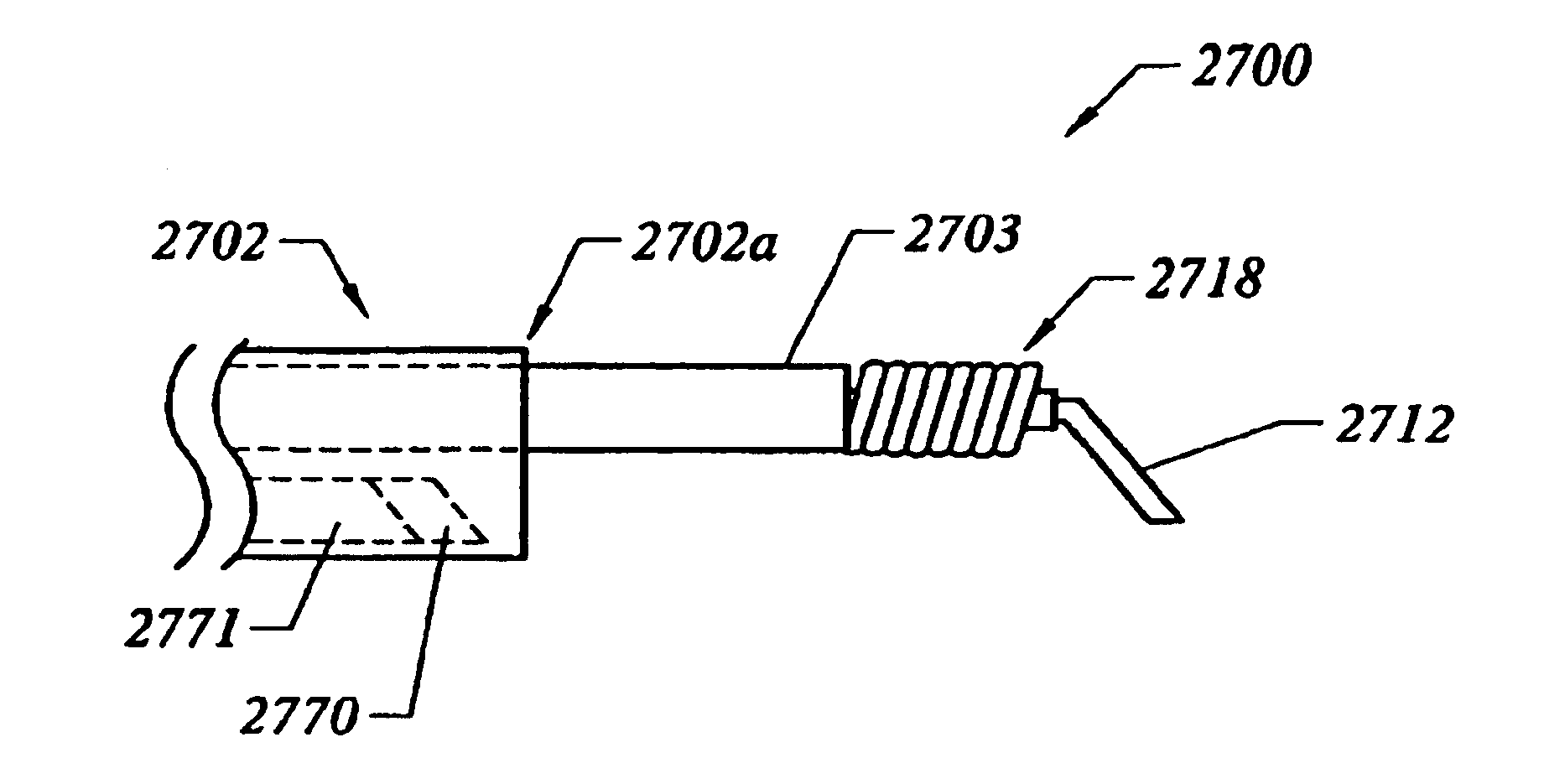

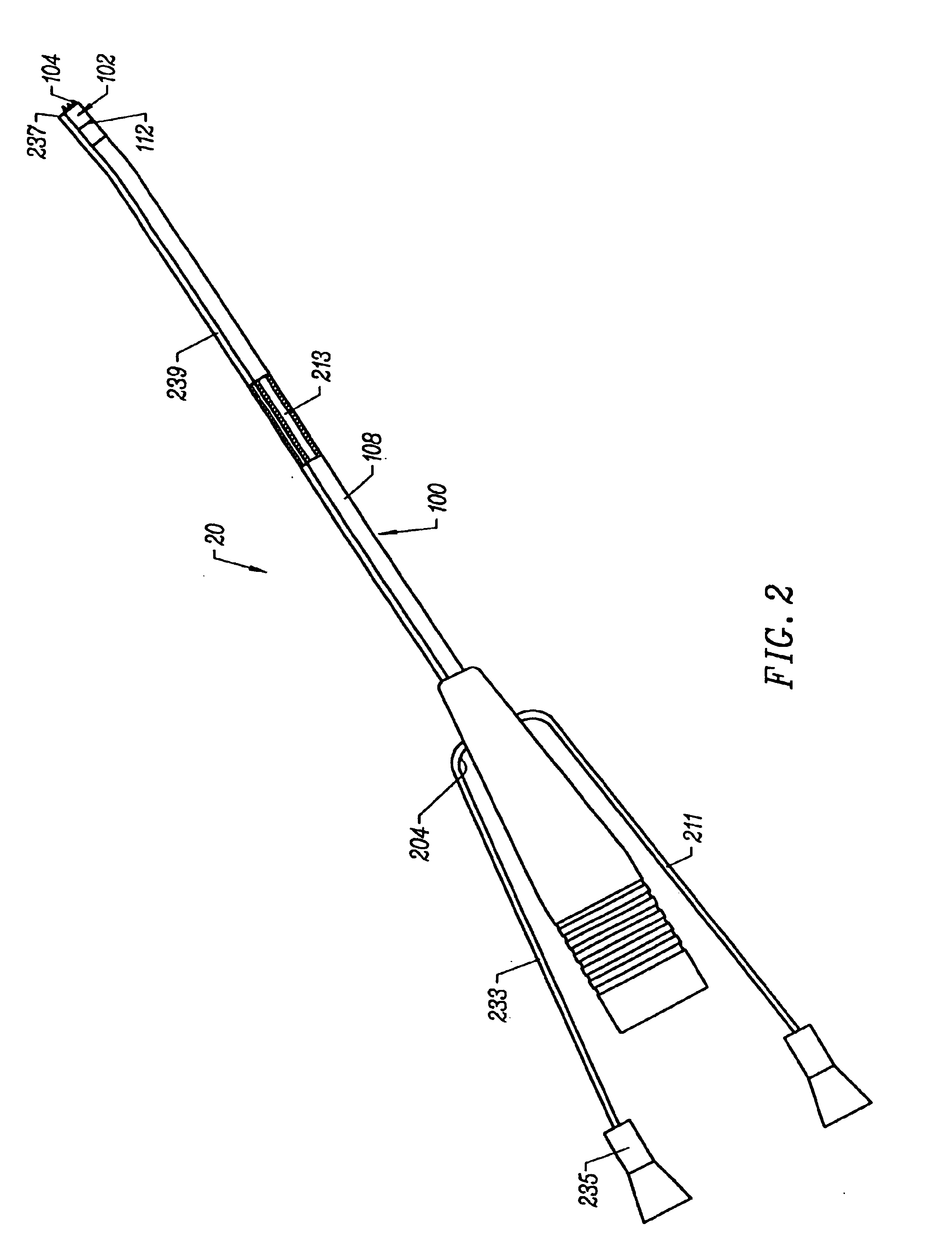

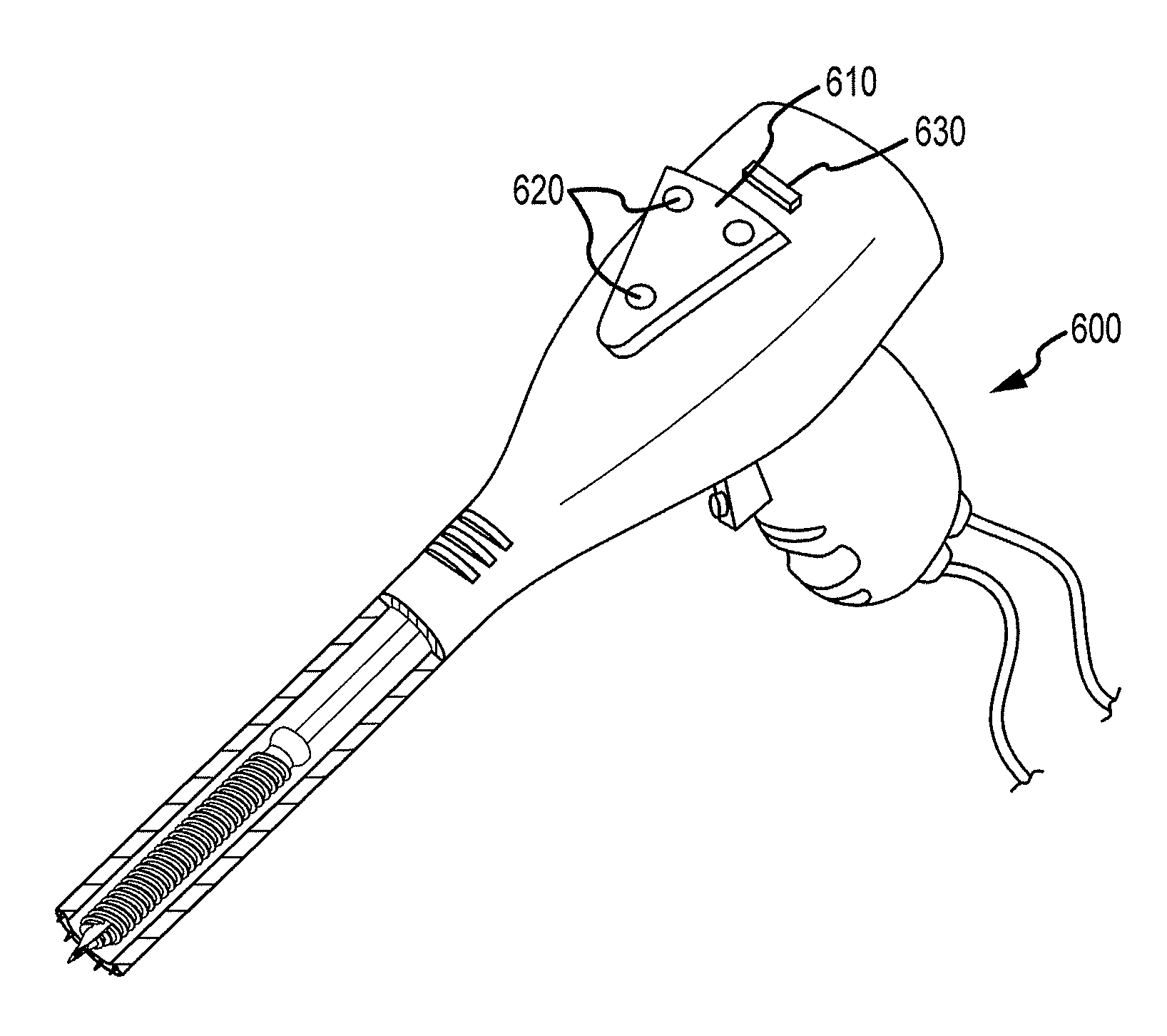

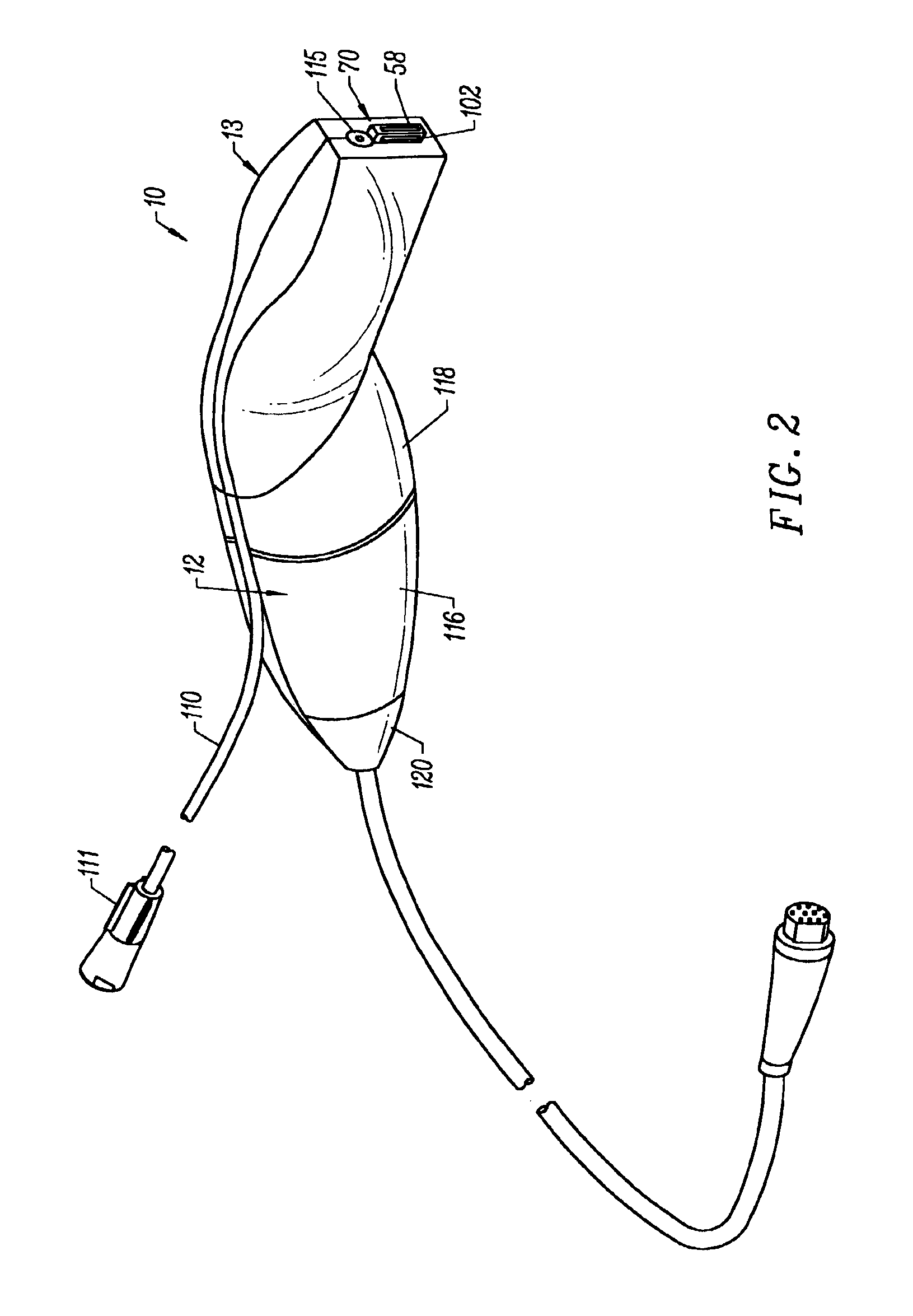

Electrosurgical probe with movable return electrode and methods related thereto

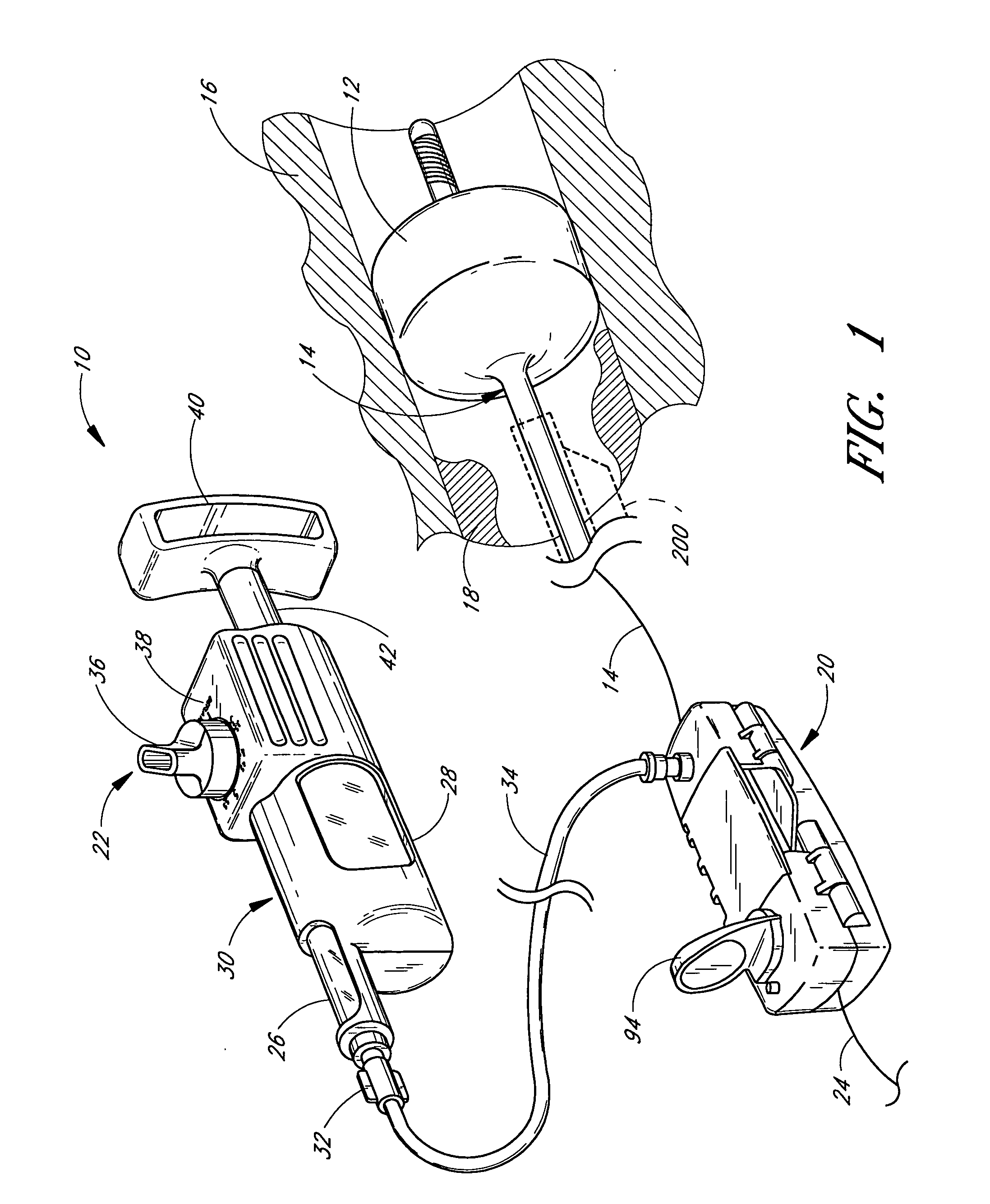

InactiveUS6837888B2Thermal damage is minimizedMinimize damageCannulasEnemata/irrigatorsActive electrodeBiomedical engineering

The present invention provides systems, apparatus, and methods for dissecting, resecting, severing, cutting, contracting, coagulating, or otherwise modifying a tissue or organ of a patient. An apparatus of the invention includes an electrosurgical probe configurable between an open configuration and a closed configuration, the probe including an active electrode terminal, a fixed return electrode disposed proximal to the active electrode terminal, and a movable return electrode configured to move linearly with respect to the active electrode terminal between the open configuration and the closed configuration. A method of the present invention comprises clamping a blood vessel between the active electrode terminal and the movable return electrode, coagulating the clamped blood vessel by application of a first high frequency voltage, and severing the coagulated blood vessel by application of a second high frequency voltage.

Owner:ARTHROCARE

Systems and methods for performing data replication

ActiveUS7651593B2Reduce impactReduce memory requirementsError detection/correctionDistillation separationTemporal informationData management

Owner:COMMVAULT SYST INC

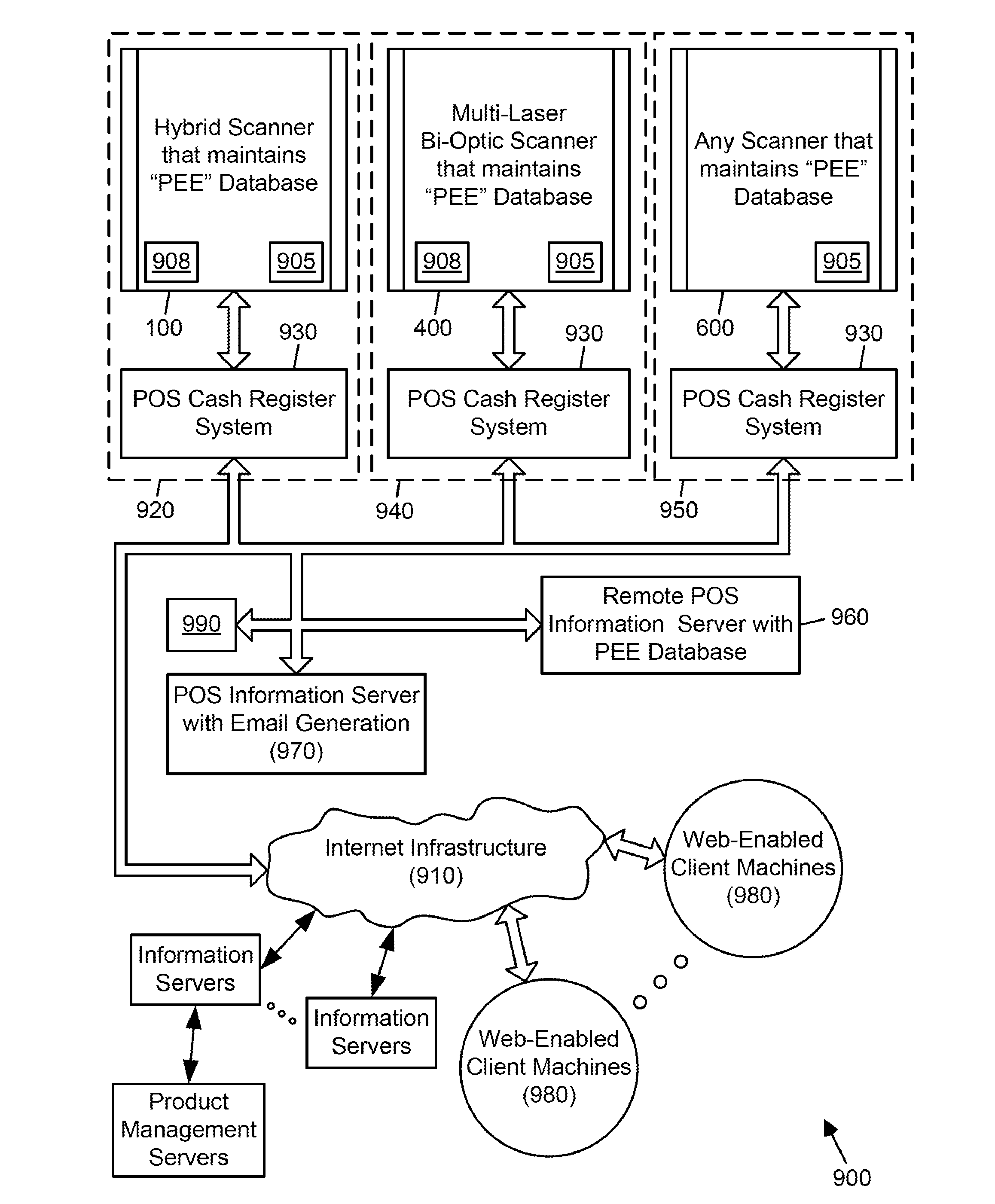

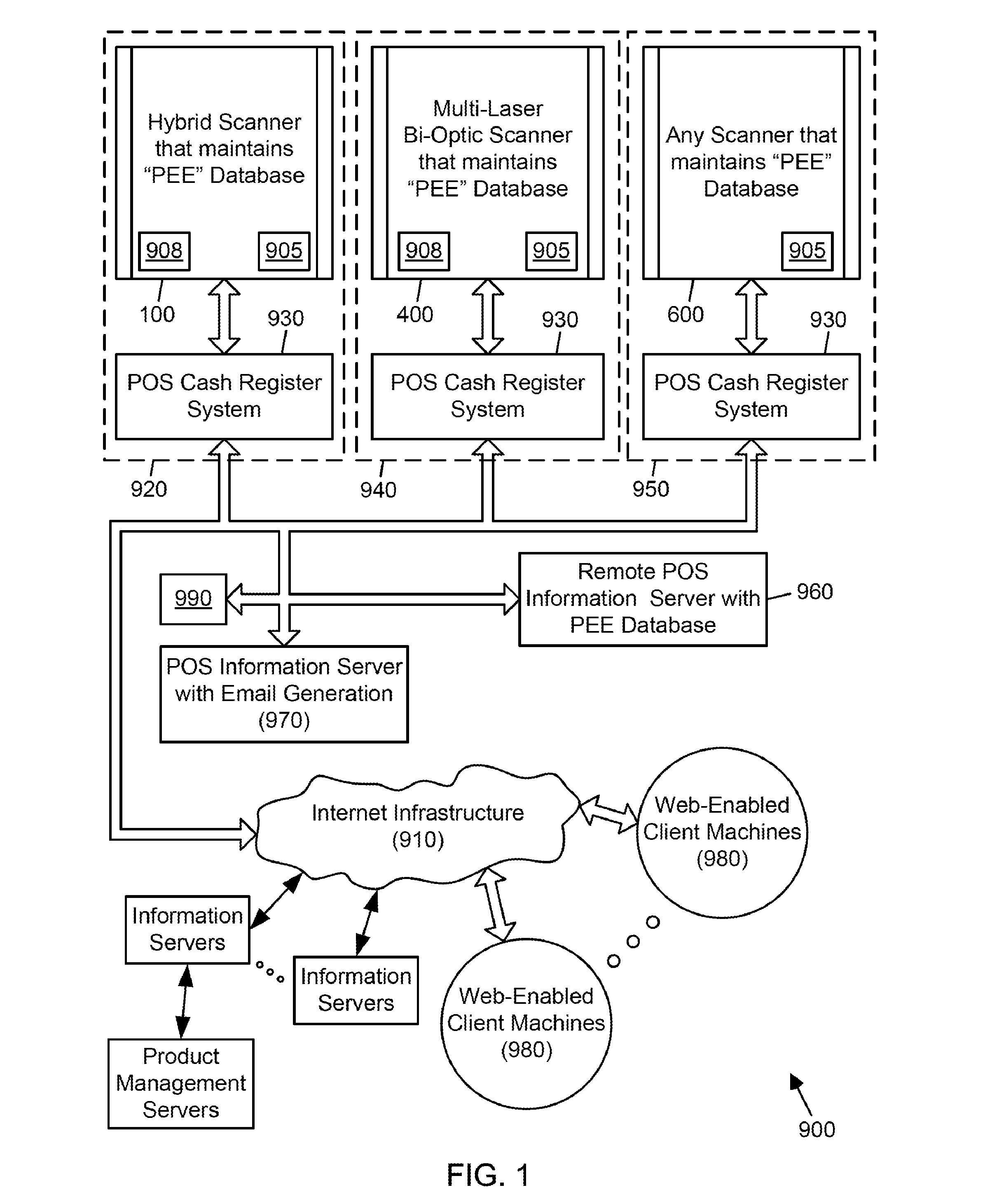

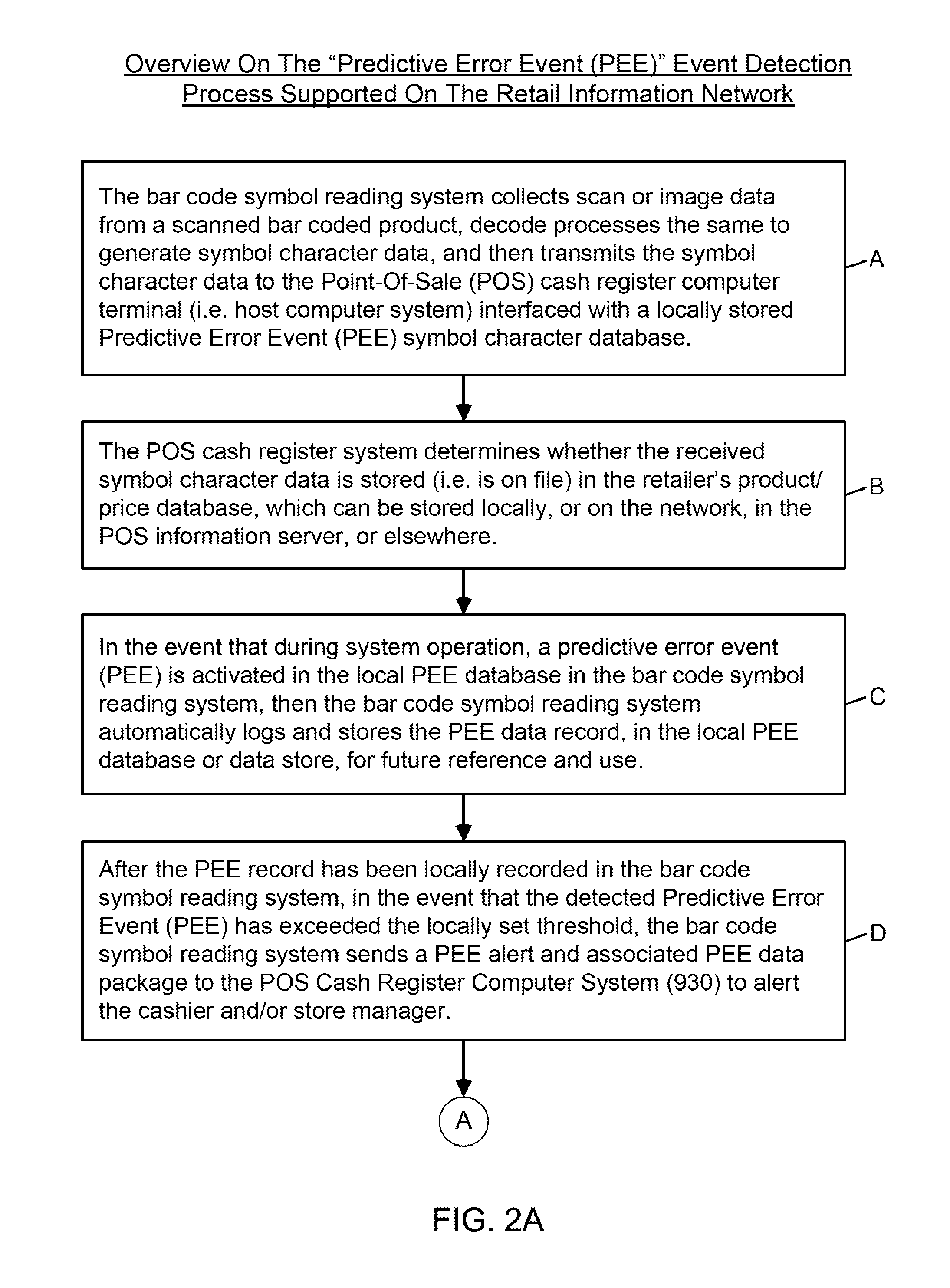

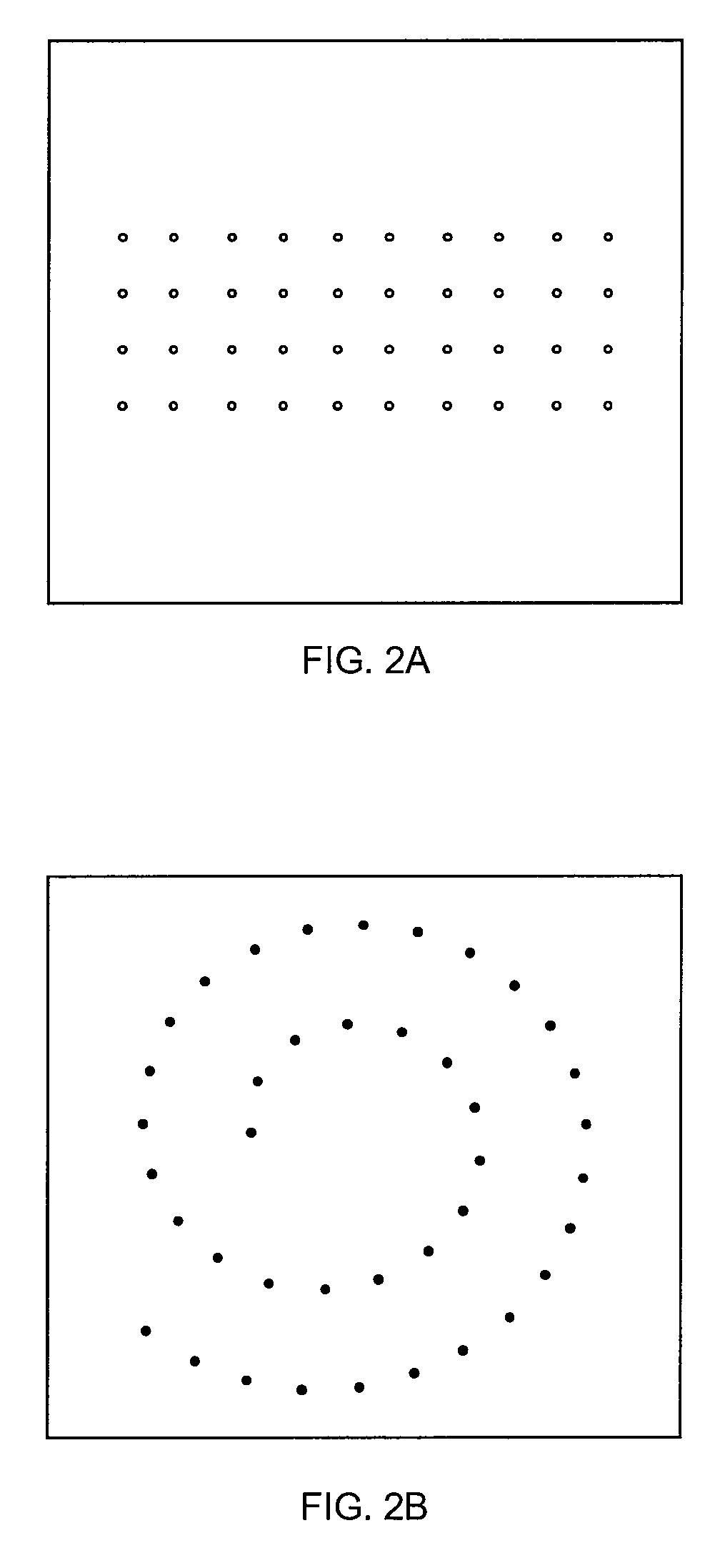

Symbol reading system having predictive diagnostics

ActiveUS9022288B2Improve the level ofEasy maintenanceTesting sensing arrangementsSensing by electromagnetic radiationInformation networksBarcode

A retail information network includes one or more POS scanning and checkout systems, each including (i) a bar code symbol reading subsystem, and (ii) a cash register computer subsystem interfaced with the bar code symbol reading subsystem and a network infrastructure, and each having access to product and price data maintained in a product / price database. The bar code symbol reading subsystem includes a local predictive error event (PEE) data store for logging and storing predictive error events (PEEs) detected within the bar code symbol reading system, wherein said PEEs are subsequently sent to POS information servers used to create predictive error alerts (PEAs) and corresponding instructions to maintain and / or repair certain aspects of the bar code symbol reading system.

Owner:METROLOGIC INSTR

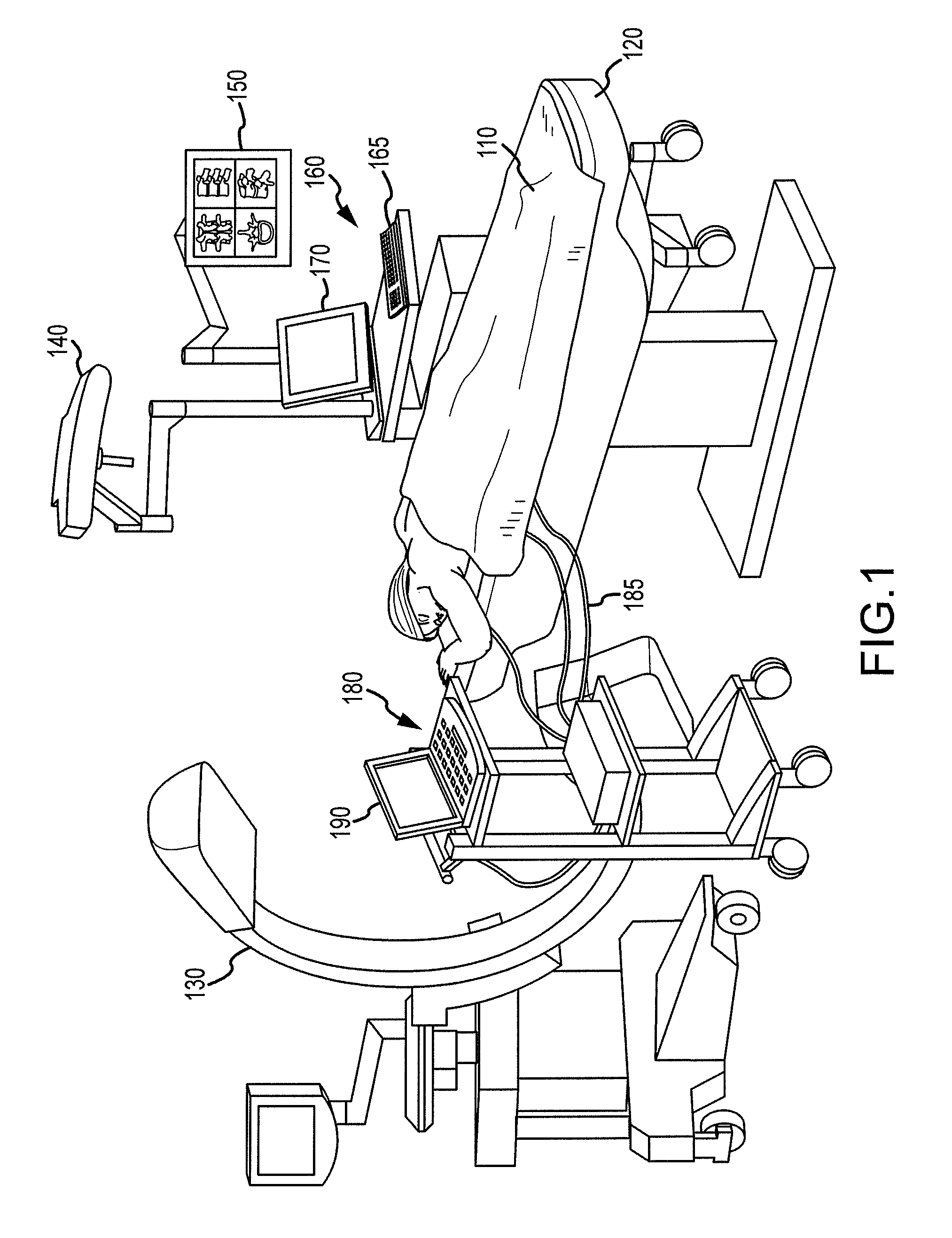

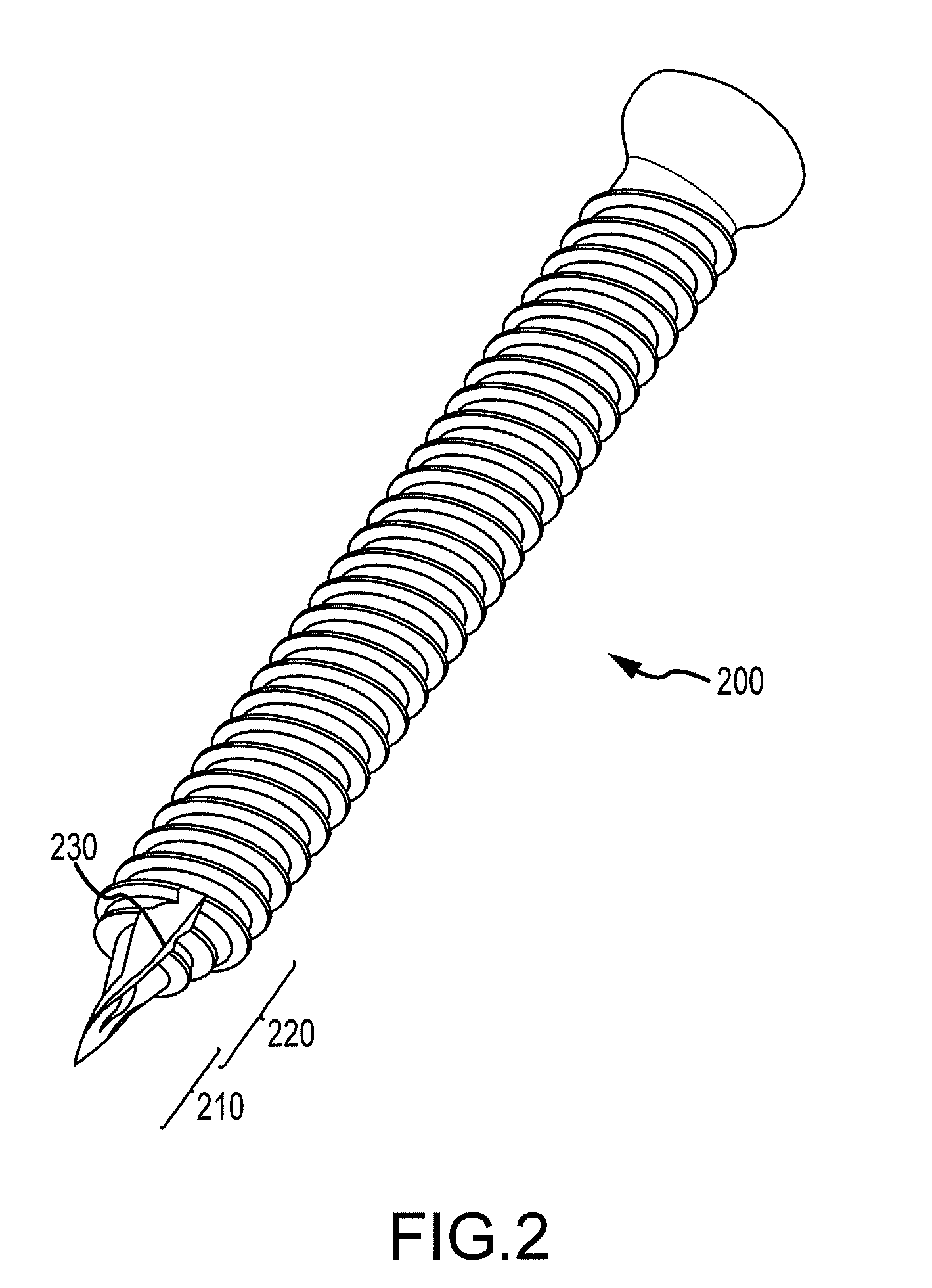

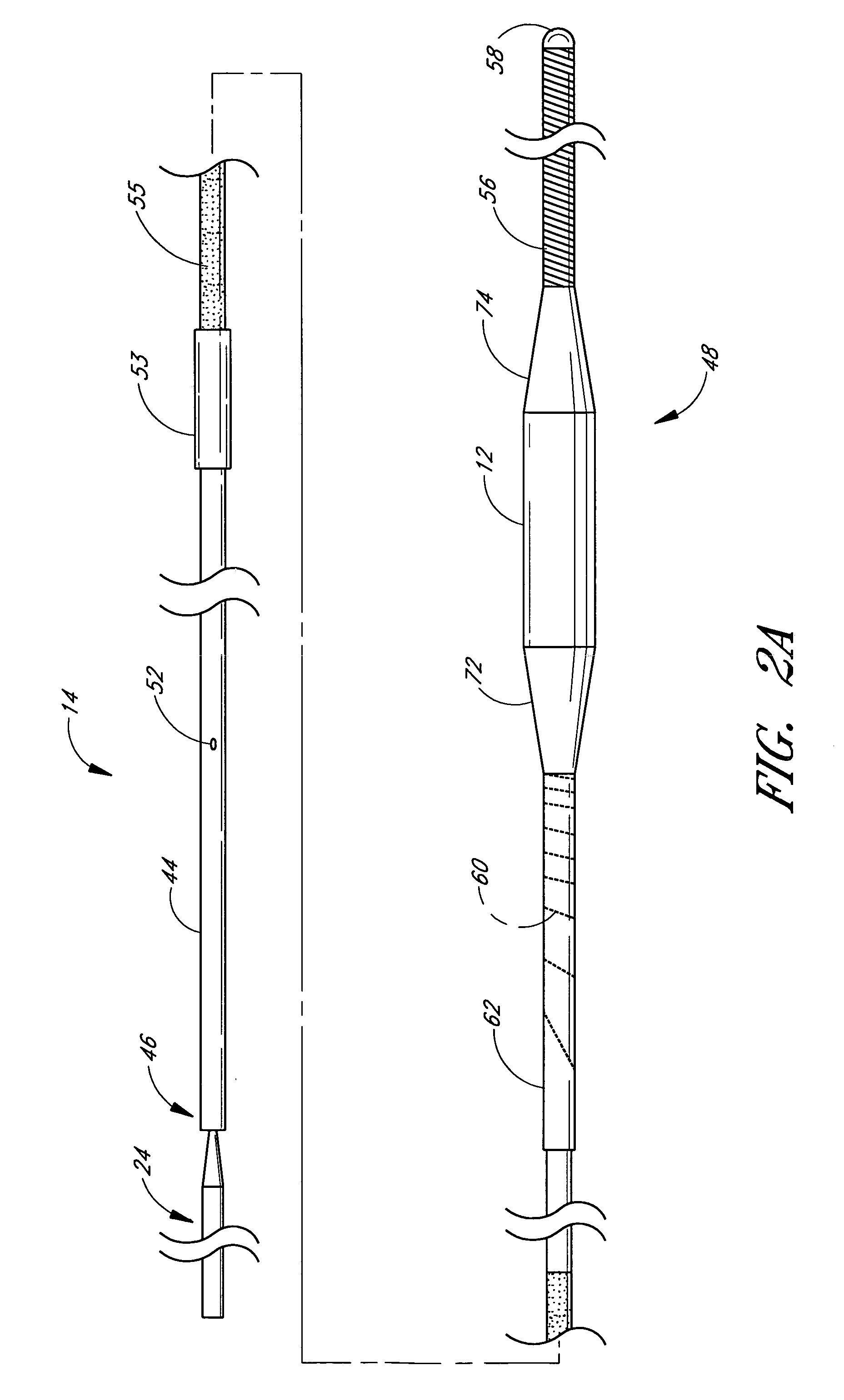

Image-guided minimal-step placement of screw into bone

ActiveUS8366719B2Procedure is time-consumeImprove accuracyInternal osteosythesisDiagnosticsScrew placementMonitoring system

The present disclosure describes a device and methods for safely and accurately placing screws into bones with a powered driving device. By employing multiple layers of fail-safe features and image-guidance systems, the powered driving device provides safe, accurate, and efficient screw placement. That is, the powered driving device may continuously monitor a screw advancement and placement and may automatically shutdown when improper placement is detected. Monitoring placement may be conducted by a microcurrent-monitoring system, by an image-guidance system, or by any other appropriate sensory system. Additionally, upon detecting that screw insertion is complete, the powered driving device may be automatically shutdown. As screw placement is continuously simulated by image-guidance in real time, multiple redundant verification steps are eliminated, providing highly accurate screw placement while decreasing clinician error, device contamination, and surgical time, the decreased surgical time associated with decreased patient-recovery time and associated medical costs.

Owner:INTEGRATED SPINAL CONCEPTS

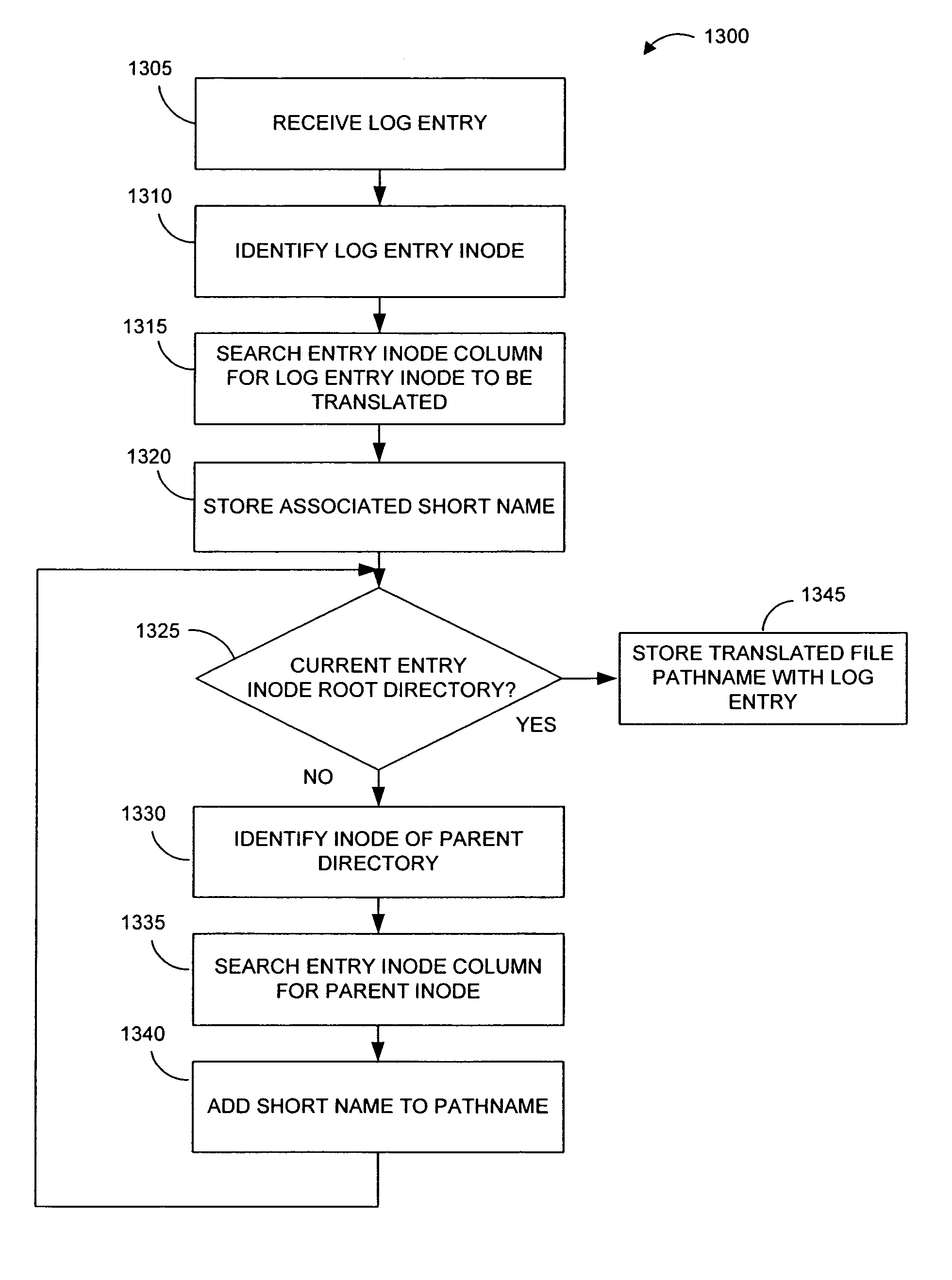

Pathname translation in a data replication system

InactiveUS7636743B2Reduce impactReduce memory requirementsData processing applicationsDigital data information retrievalTemporal informationData management

Owner:COMMVAULT SYST INC

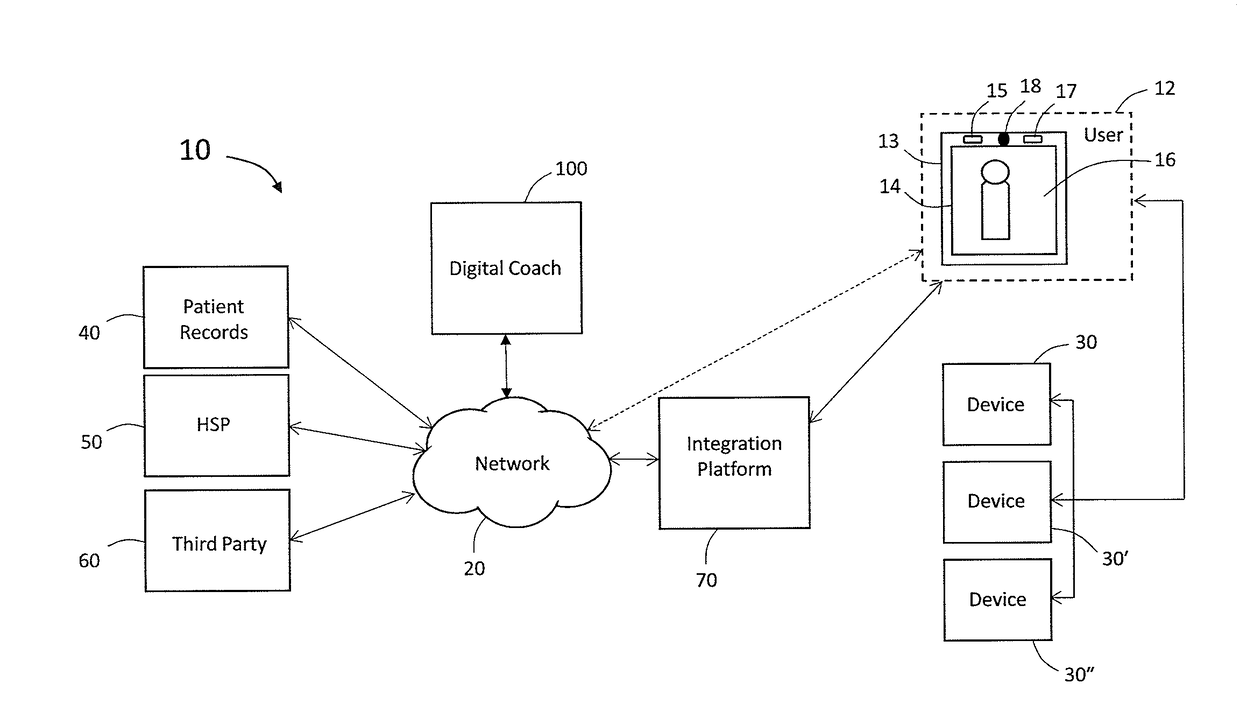

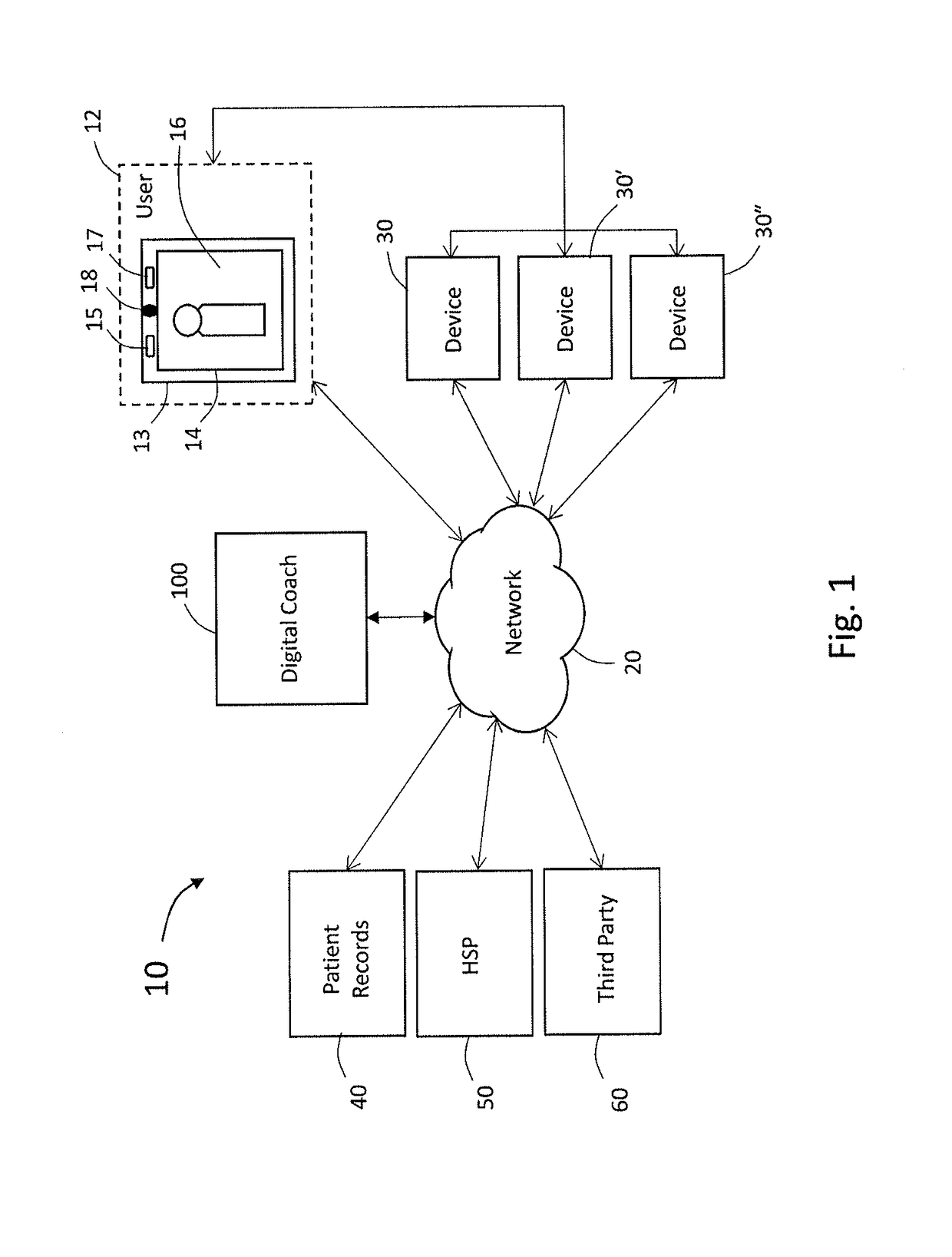

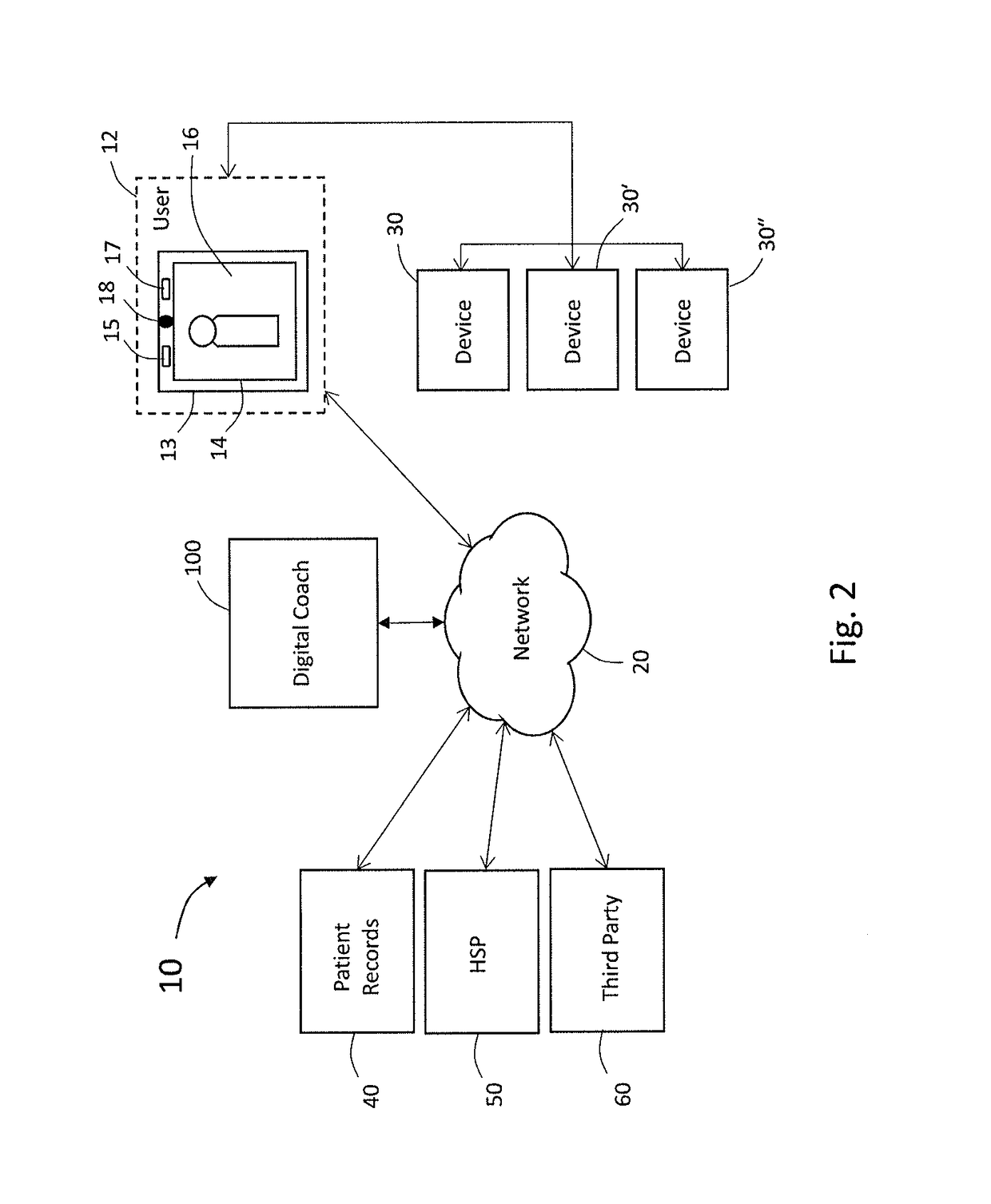

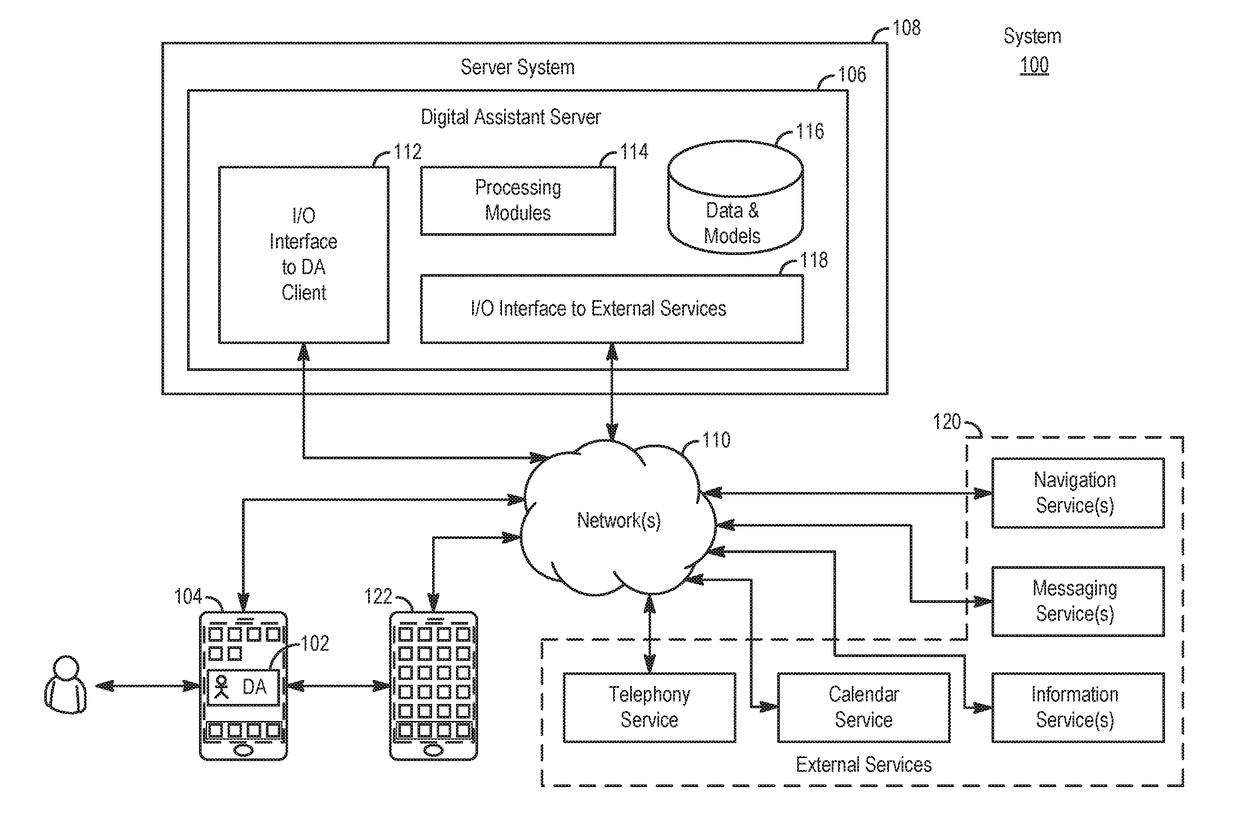

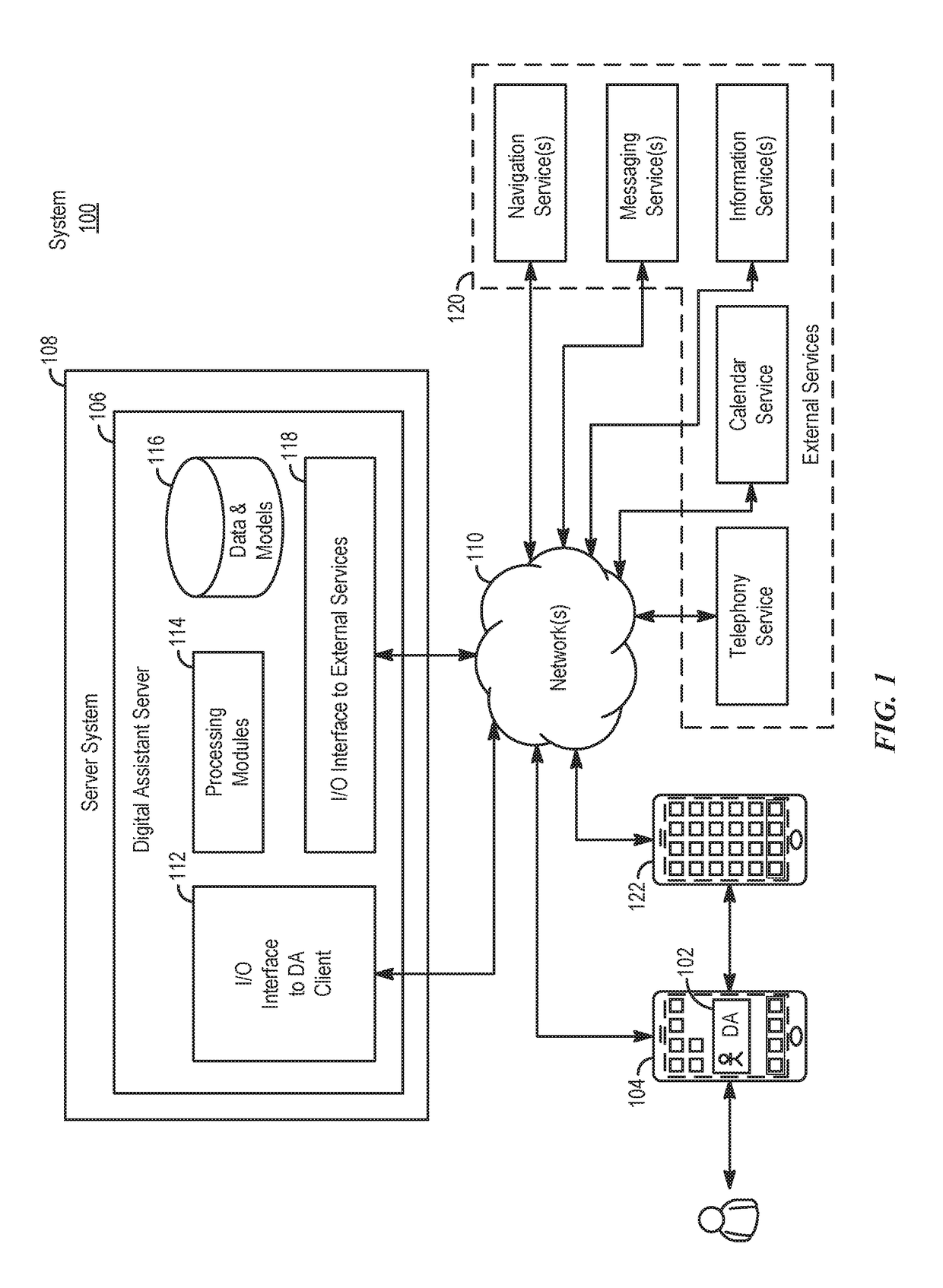

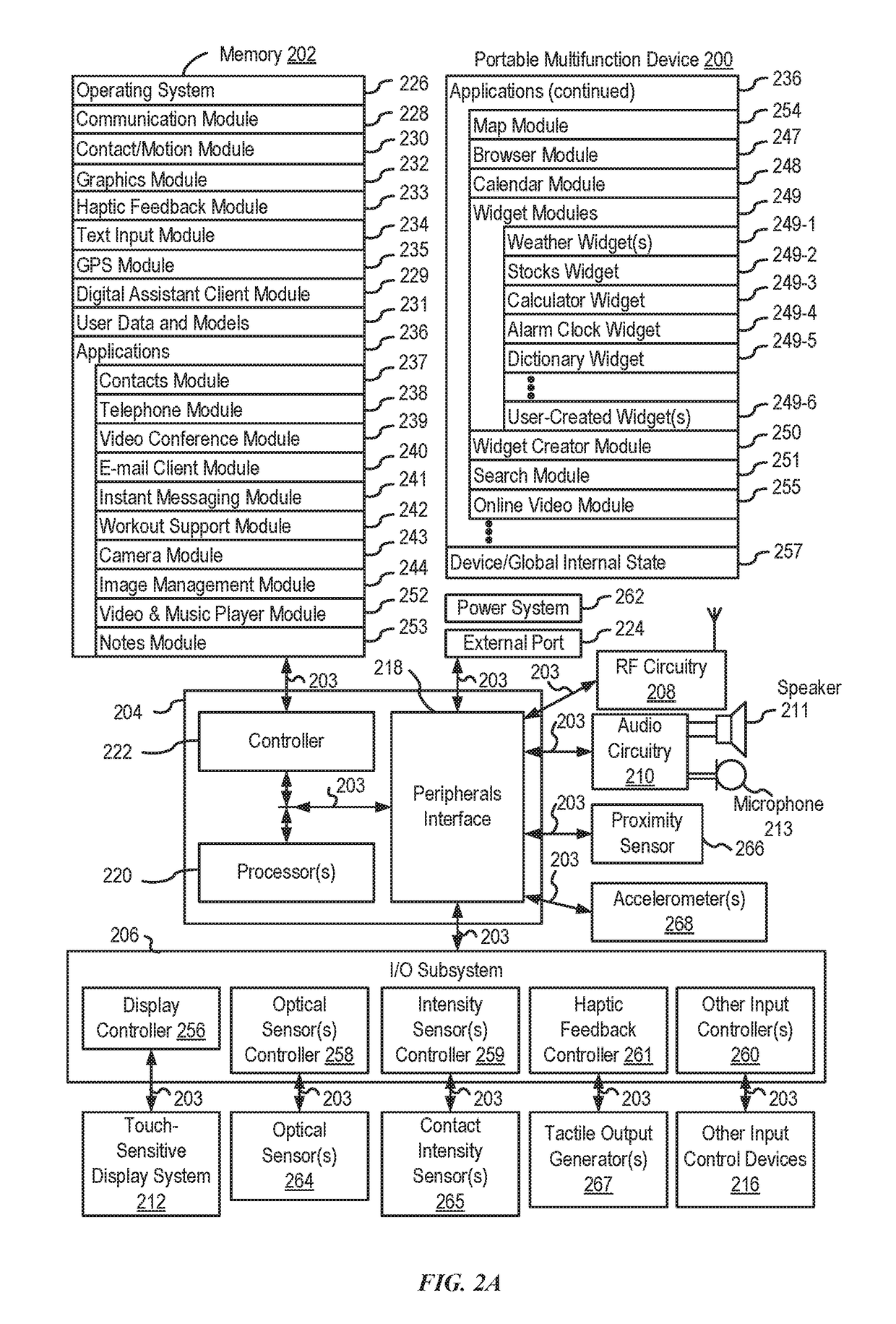

System and Method for Synthetic Interaction with User and Devices

ActiveUS20180114591A1Improve accuracyExtension of timeNatural language translationPhysical therapies and activitiesInteraction deviceMedical procedure

Systems and methods for conducting automated synthetic interactions with a user, such as a patient at home following a medical procedure. A digital coach having a processor and memory initiates a session with a user's interactive device, and presents pre-recorded scripts as video and / or audio through the interactive device. The user's responses are received by the digital coach through the interactive device. Peripheral devices, such as medical devices, may be used by the user or controlled by the digital coach to obtain data measurements regarding the physiological condition of the user. The processor of the digital coach analyzes the data from the user responses and devices, and semantically interprets the responses and data to determine the next action and script to present the user in the session. The digital coach provides a conversational, dynamic, adaptive session with a user based on semantically expanded interpretations of data by the processor.

Owner:PRIBANIC VIRGINIA FLAVIN

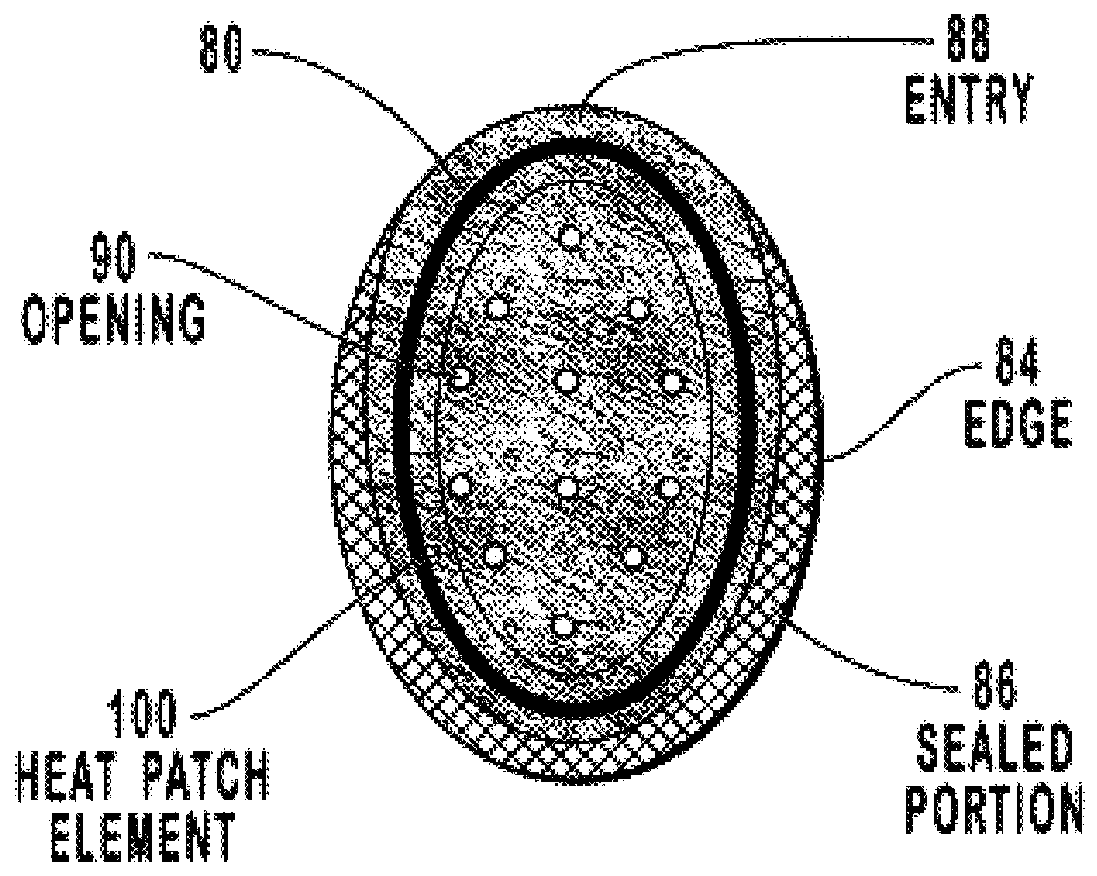

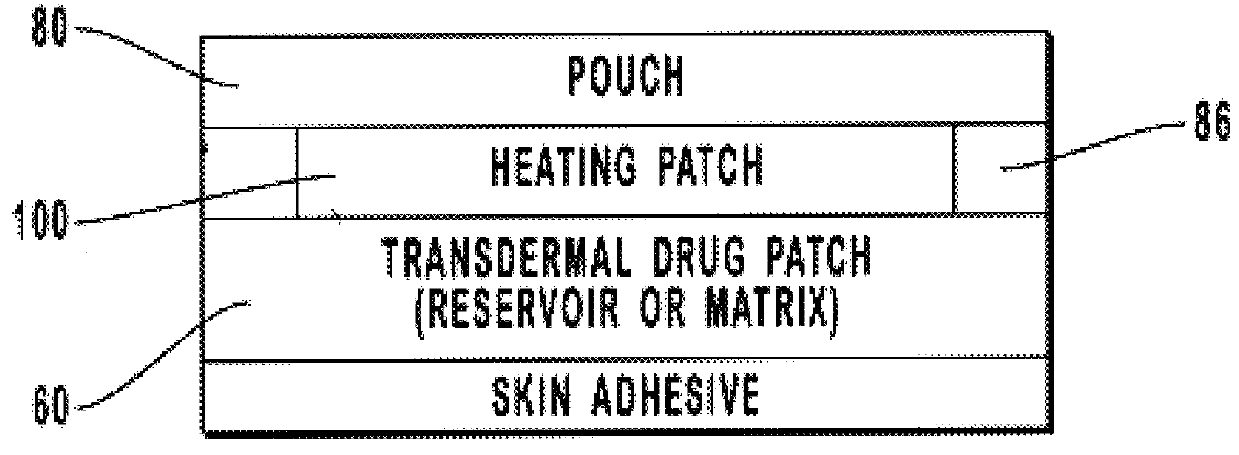

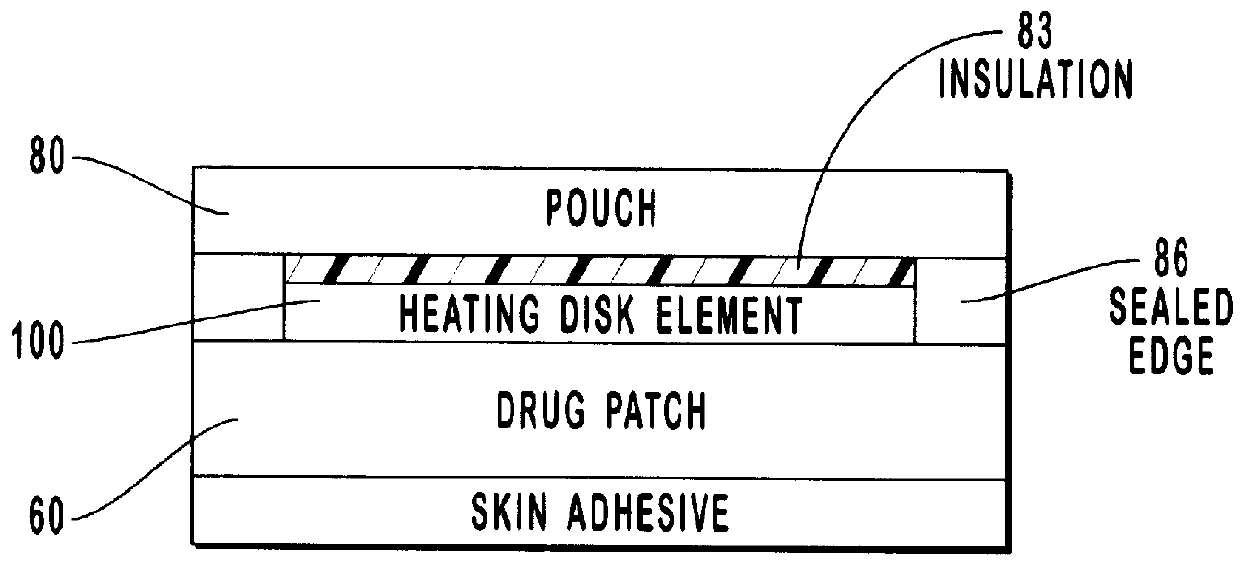

Transdermal drug patch with attached pocket for controlled heating device

InactiveUS6261595B1Shorten the timeEasy to replaceElectrotherapyMedical devicesTransdermal patchDrug administration

The present invention relates to a transdermal drug delivery system comprising a dermal drug delivery patch and a heating element compartment securable to the dermal drug delivery patch. A freely transferrable heating element is securable within the heating element compartment. A drug can be administered transdermally using the present invention by placing the dermal drug delivery patch upon a patient's skin at an administration site. A heating element compartment is secured to the dermal drug delivery patch and a freely transferrable heating element is placed within the heating element compartment. The heating element provides controlled heat to the dermal drug patch and the patient's skin aid thereby improves dermal drug administration.

Owner:ZARS INC

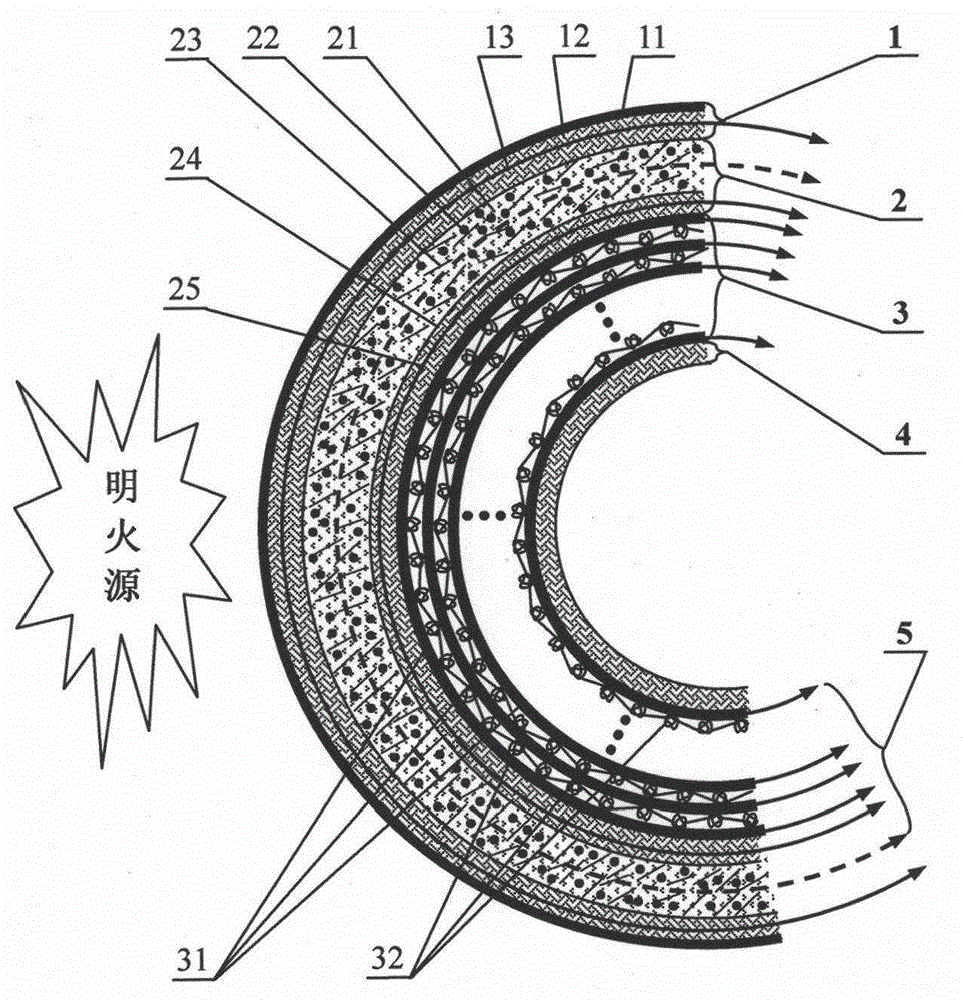

Fire-proof and heat-insulating composite fabric with multi-stage expansion and heat dissipation, preparation method and application

ActiveCN102783741BImprove permeabilityPromote absorptionLaminationLamination apparatusInsulation layerMetal foil

The invention relates to a preparation method and an application of multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric. The multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric is formed by successively arranging and laminating a metal foil reflection layer, a phase change temperature limitation layer, an interval composite membrane heat-insulation layer and a flame-retardant comfortable layer, wherein the metal foil reflection layer has high reflectivity and an enhanced heat-dissipation function; the phase change temperature limitation layer has functions of high energy consumption absorption and evenly-distributed heat conduction; the interval composite membrane heat-insulation layer has the functions of reflection insulation and even distribution of heat; and the flame-retardant comfortable layer has the functions of low-contact heat conduction, heat insulation and comfort. When the front side of the multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric is under the action of open fire and strong heat flow environment, the back side of the multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric can be kept below 50DEG C which is near the safe temperature state of the human skin, and the integral structural form and the mechanical property are stable. The natural thickness of the composite fabric is 5-15mm, the compression thickness of the composite fabric is 3-8mm, and the square meter quality of the composite fabric is 400-1500g / m<2>. The composite fabric is fire-proof heat-insulation material which is totally sealed, stuck and sewn and can be used for individual protection and environment heat insulation in special high-temperature occasions, such as fire control, military, exploration, safe escape and industry and the like.

Owner:DONGHUA UNIV

Destination systems and methods for performing data replication

InactiveUS7617253B2Reduce impactReduce memory requirementsData processing applicationsDigital data information retrievalTemporal informationData management

Performing data management operations on replicated data in a computer network. Log entries are generated for data management operations of an application executing on a source system. Consistency point entries are used to indicate a time of a known good, or recoverable, state of the application. A destination system is configured to process a copy of the log and consistency point entries to replicate data in a replication volume, the replicated data being a copy of the application data on the source system. When the replicated data represents a known good state of the application, as determined by the consistency point entries, the destination system(s) may perform a storage operation (e.g., snapshot, backup) to copy the replicated data and to logically associate the copied data with a time information (e.g., time stamp) indicative of the source system time when the application was in the known good state.

Owner:COMMVAULT SYST INC

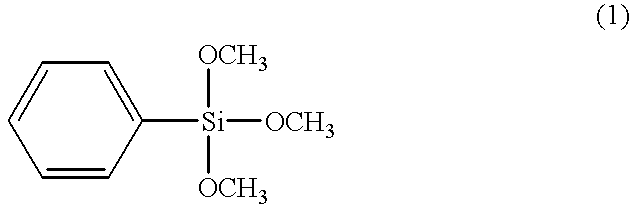

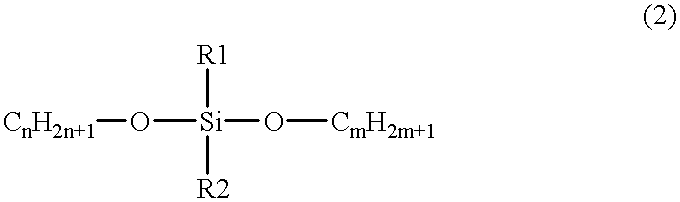

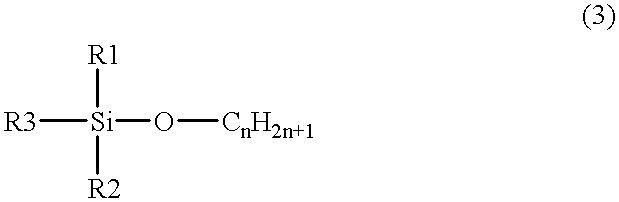

Silicone polymer insulation film on semiconductor substrate and method for forming the film

InactiveUS6352945B1Low dielectric constantImprove thermal stabilityLiquid surface applicatorsSemiconductor/solid-state device detailsPolymer scienceHigh humidity

A method for forming a silicone polymer insulation film having a low relative dielectric constant, high thermal stability and high humidity-resistance on a semiconductor substrate is applied to a plasma CVD apparatus. The first step is introducing a silicon-containing hydrocarbon compound expressed by the general formula SialphaObetaCxHy (alpha, beta, x, and y are integers) to the reaction chamber of the plasma CVD apparatus. The silicon-containing hydrocarbon compound has at most two O-CnH2n+1 bonds and at least two hydrocarbon radicals bonded to the silicon. The residence time of the material gas is lengthened by, for example, reducing the total flow of the reaction gas, in such a way as to form a silicone polymer film having a micropore porous structure with a low relative dielectric constant.

Owner:ASM JAPAN

Speaker recognition

InactiveUS20170092278A1Increased efficiency , effectiveness , and user satisfactionFaster and efficient method and interfaceSpeech recognitionAcoustic propertyNatural language

A non-transitory computer-readable storage medium stores one or more programs including instructions, which when executed by an electronic device, cause the electronic device to receive natural-language speech input from one of a plurality of users, the natural-language speech input having a set of acoustic properties; and determine whether the natural-language speech input corresponds to both a user-customizable lexical trigger and a set of acoustic properties associated with the user; where in accordance with a determination that the natural language speech input corresponds to both a user-customizable lexical trigger and a set of acoustic properties associated with the user, invoke a virtual assistant; and in accordance with a determination that either the natural language speech input fails to correspond to a user-customizable lexical trigger or the natural-language speech input fails to have a set of acoustic properties associated with the user, forego invocation of a virtual assistant.

Owner:APPLE INC

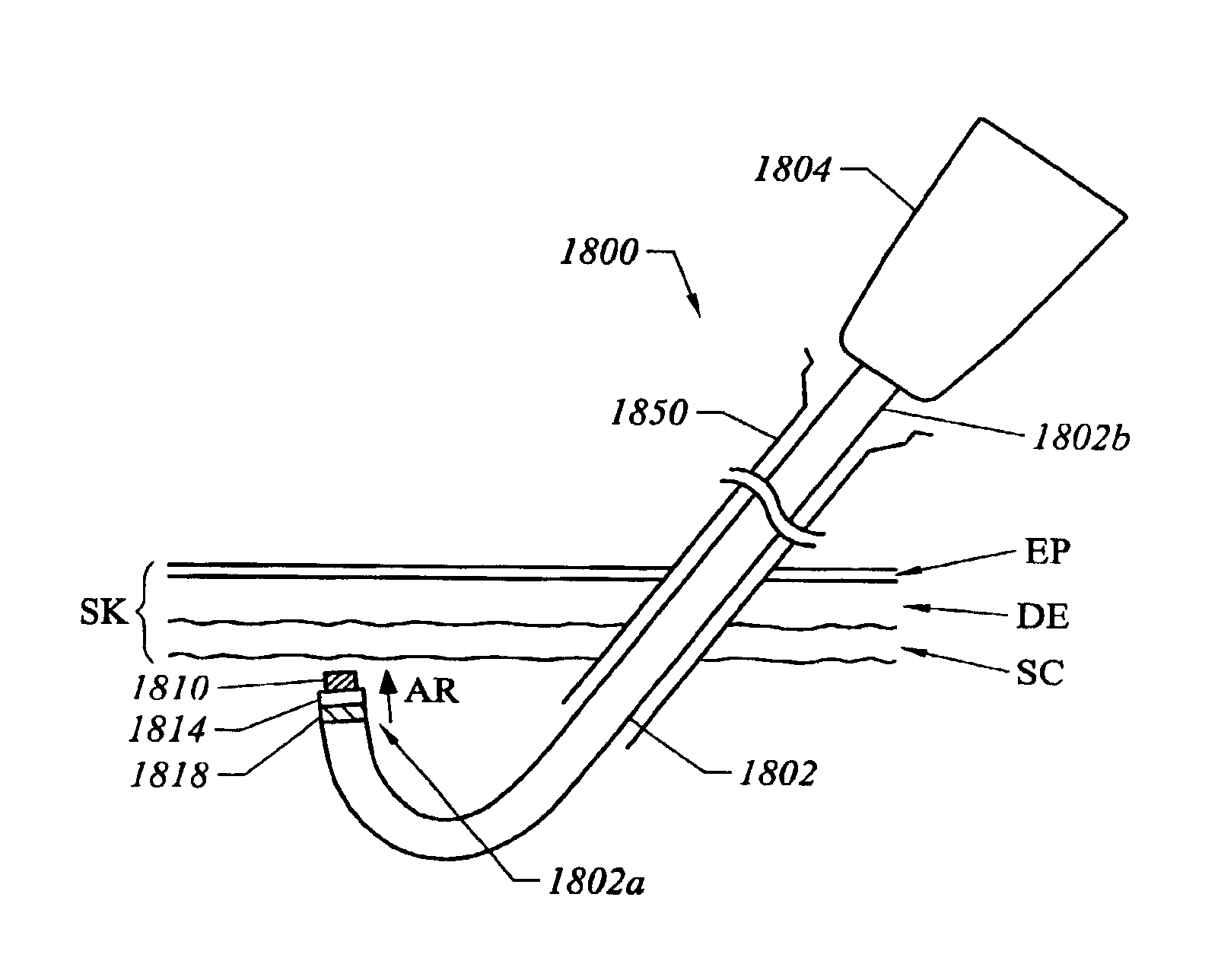

Methods and apparatus for skin treatment

InactiveUS6920883B2Thermal damage is minimizedMinimizes and avoids damageDiagnosticsSurgical instruments for heatingDermisFace lifting

Methods and apparatus for electrosurgically treating human skin. The skin may be treated by applying thermal energy to the dermis to shrink the skin following liposuction, or to induce collagen deposition at the site of a wrinkle for wrinkle reduction or removal. In another embodiment, a method involves electrosurgically removing or modifying tissue in the head or neck to provide a face-lift or a neck-lift. In one embodiment, the working end of an electrosurgical instrument is positioned in at least close proximity to the dermis by approaching the dermis from the underside (reverse side) of the skin.

Owner:ARTHROCARE

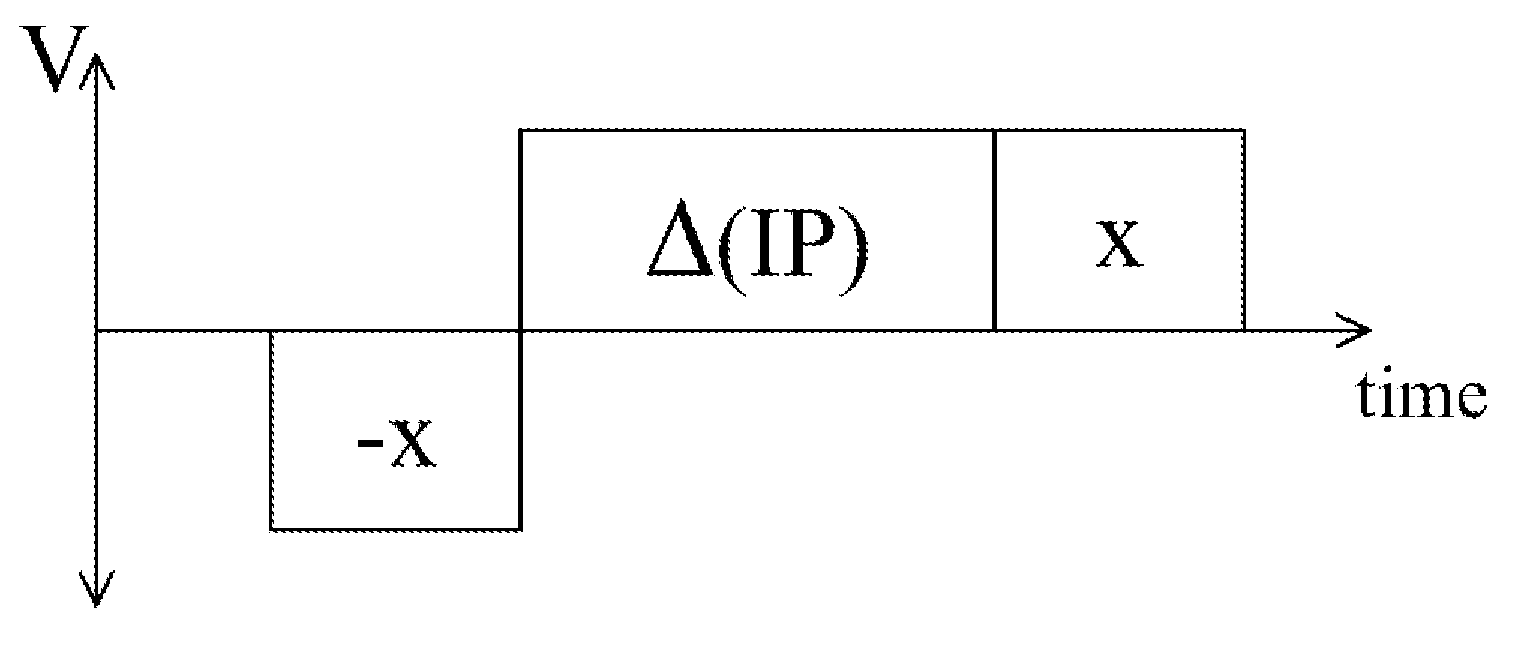

Electrophoretic displays using gaseous fluids

InactiveUS20080024429A1Reduce the impactIncrease the lengthStatic indicating devicesElectrophoresisDisplay device

An electrophoretic display comprises a pair of facing substrates, at least one of which is transparent, a plurality of particles and a gas between the substrates, and means for applying an electric field to cause the particles to move and thus change the electro-optic state of the display. The electric field means is arranged to increase the impulse applied to the display with increasing time since a reference time, or with increasing number of images written on the display. In another embodiment, an alternating current pulse is applied to the display, and the duration and / or amplitude of the alternating current pulse is increased with increasing time since a reference time.

Owner:E INK CORPORATION

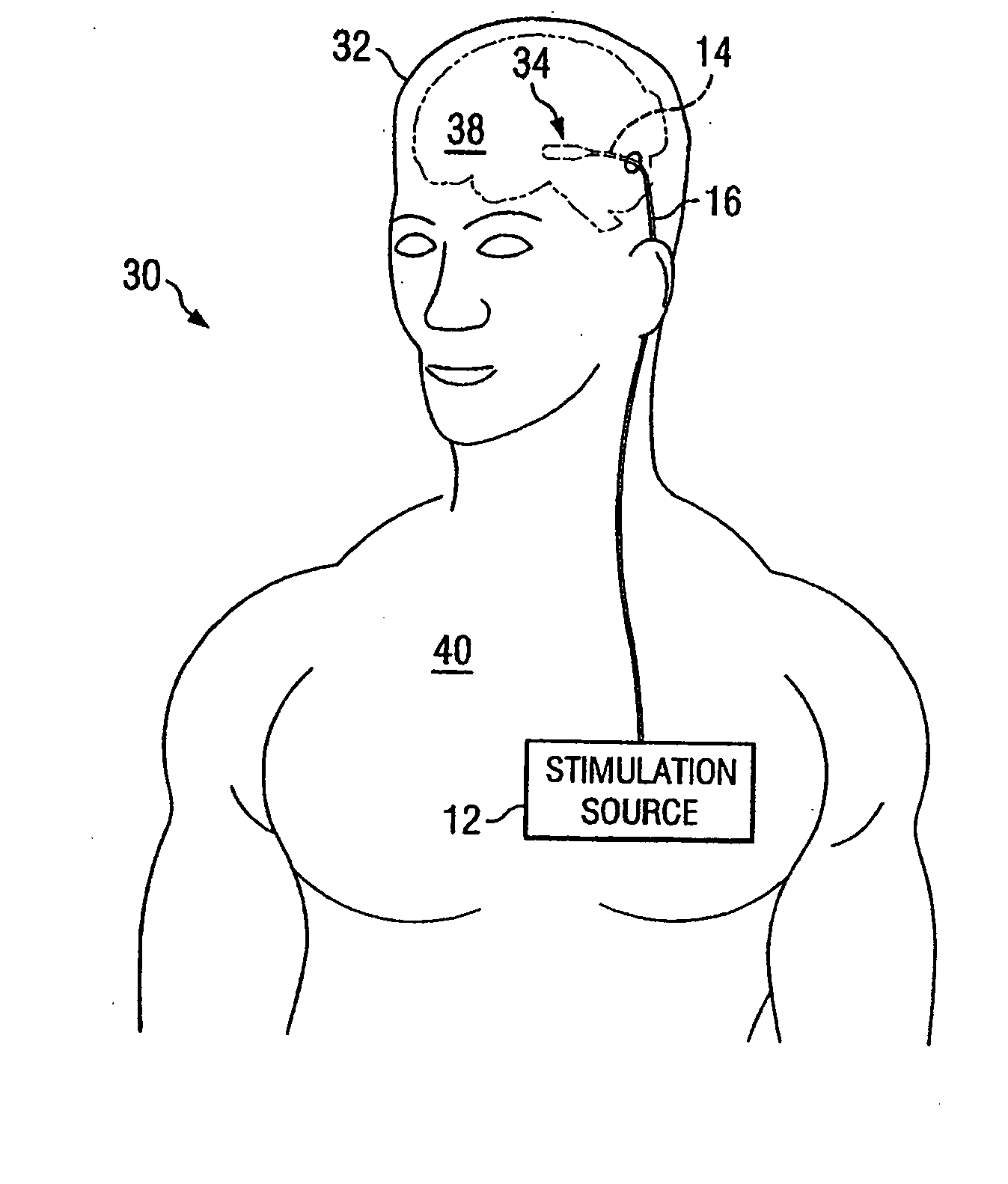

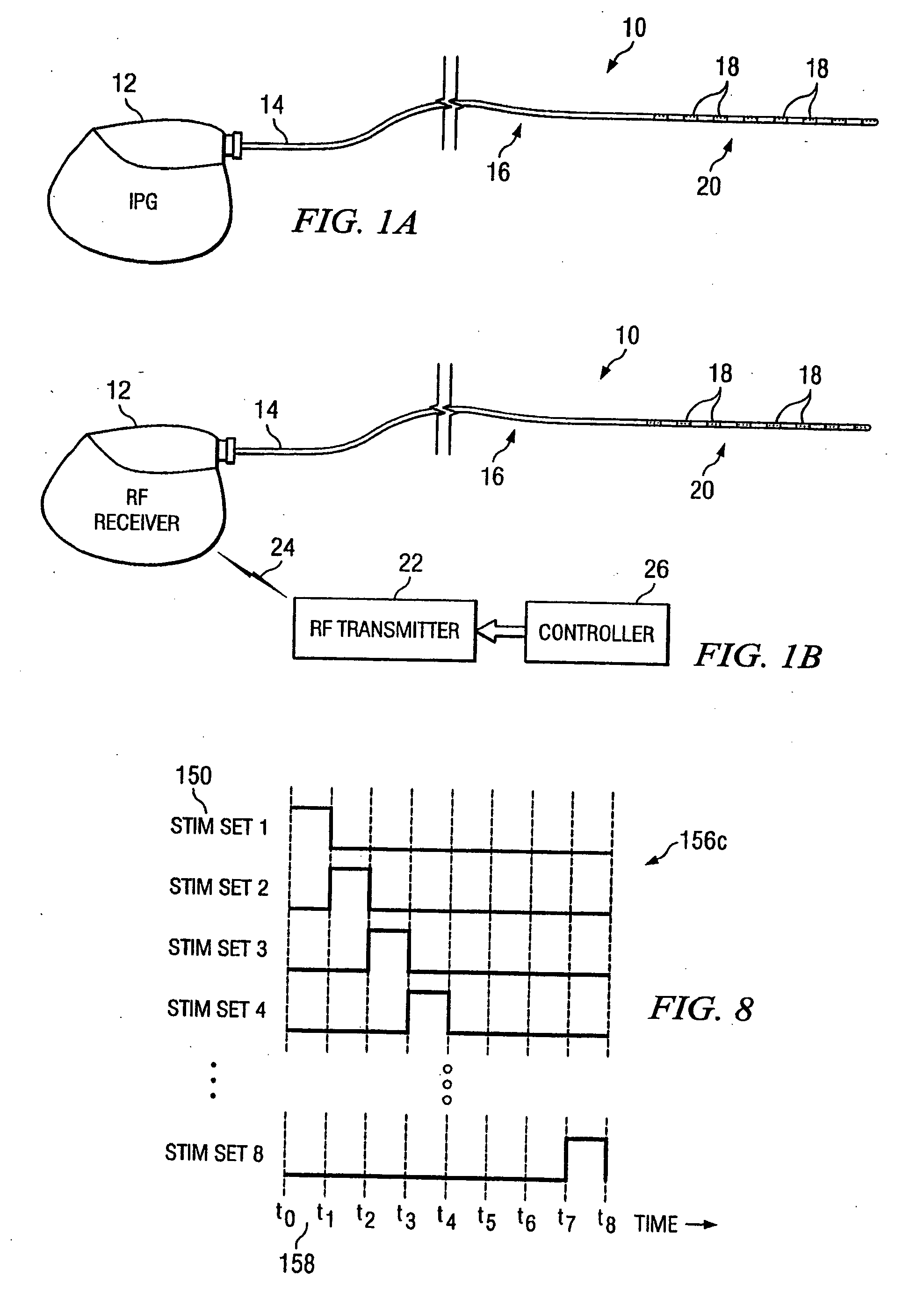

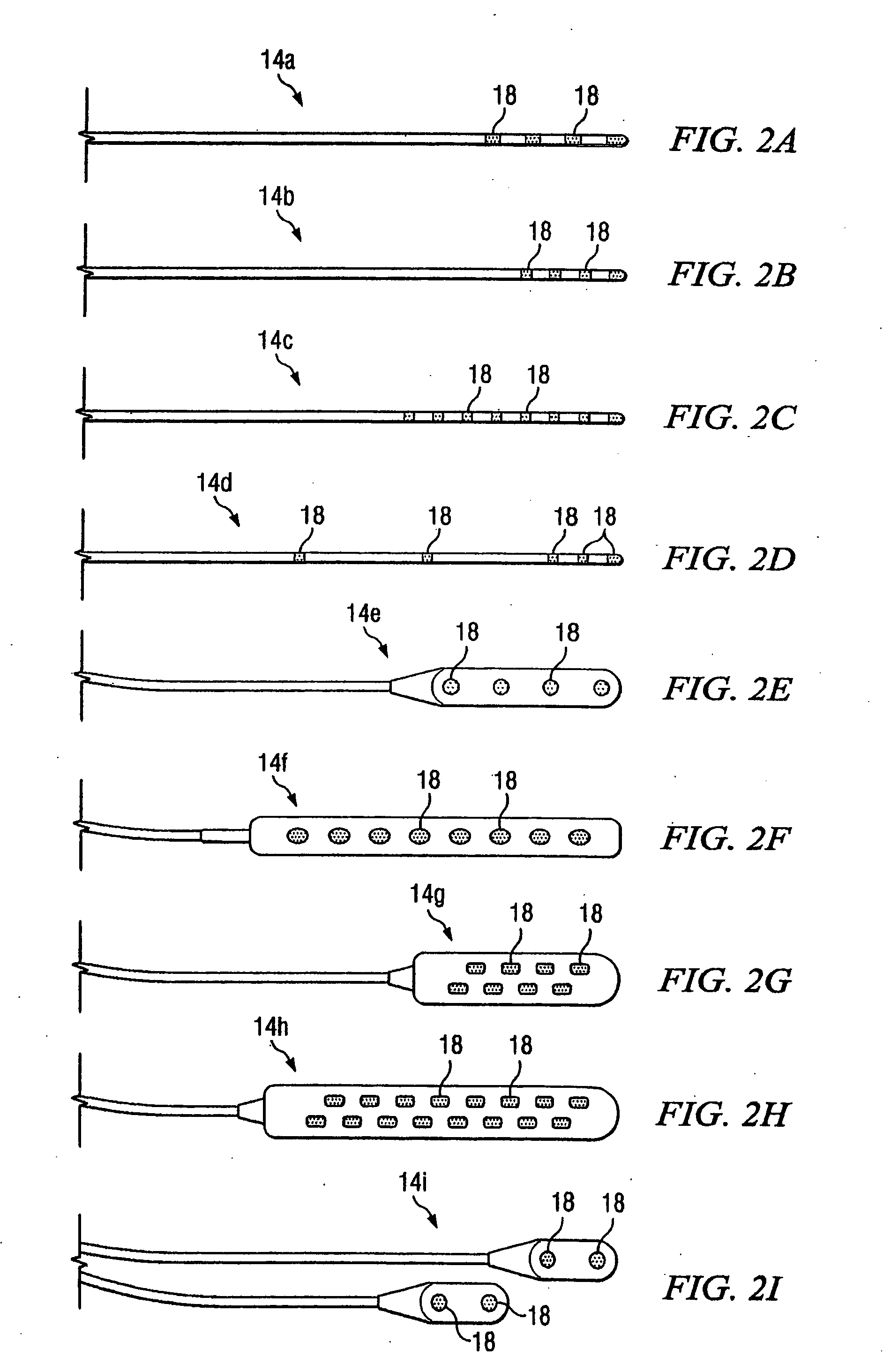

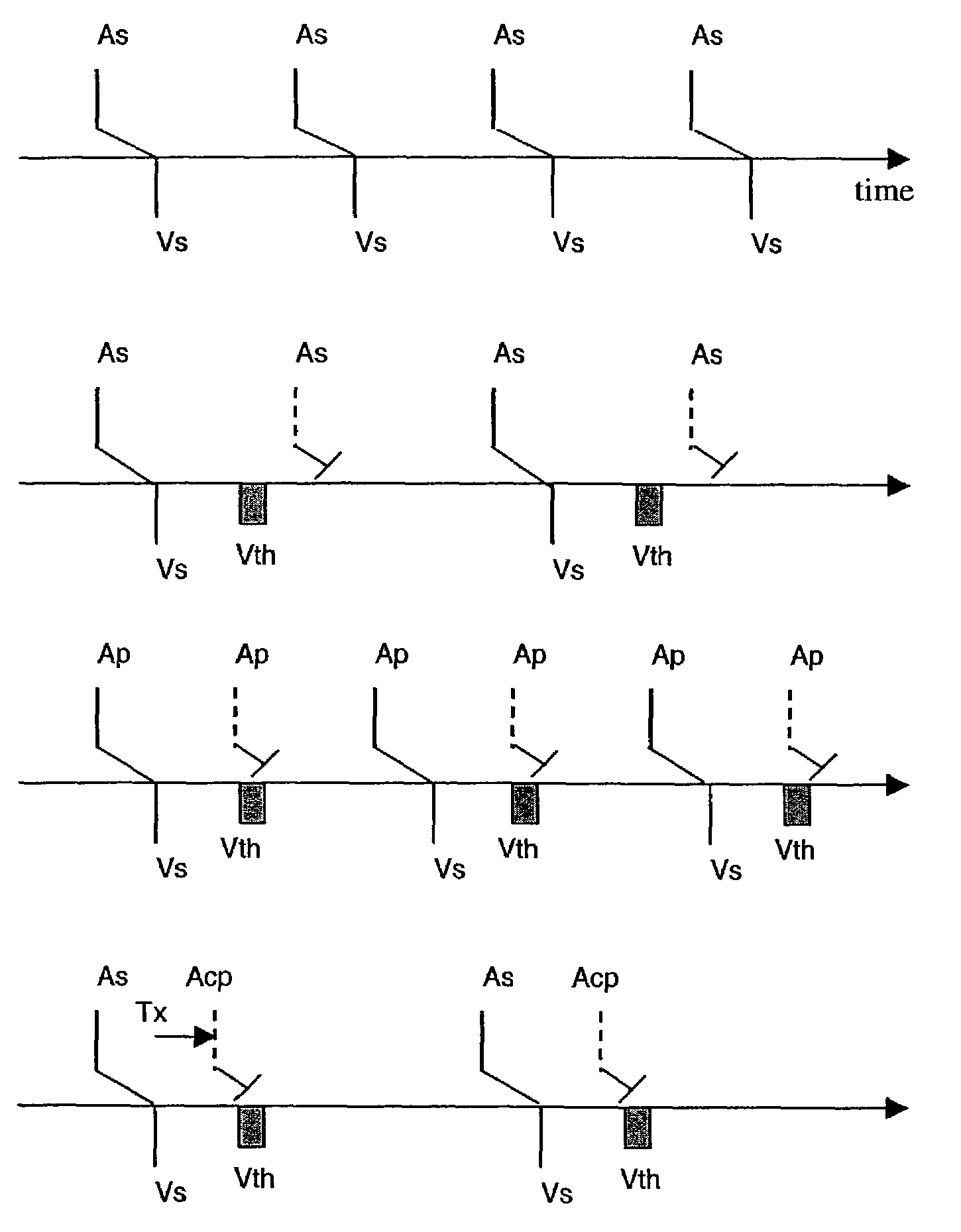

Electrical stimulation system and method for stimulating tissue in the brain to treat a neurological condition

InactiveUS20060004422A1Reduce and eliminate certain problem and disadvantageRemissionSpinal electrodesHead electrodesElectricityMedicine

According to one aspect, a stimulation system is provided for electrically stimulating a predetermined site to treat a neurological condition. The system includes an electrical stimulation lead adapted for implantation in communication with a predetermined site, wherein the site is brain tissue site. The stimulation lead includes one or more stimulation electrodes adapted to be positioned in the predetermined site. The system also includes a stimulation source that generates the stimulation pulses for transmission to the one or more stimulation electrodes of the stimulation lead to deliver the stimulation pulses to the predetermined site to treat a neurological disorder or condition.

Owner:ADVANCED NEUROMODULATION SYST INC

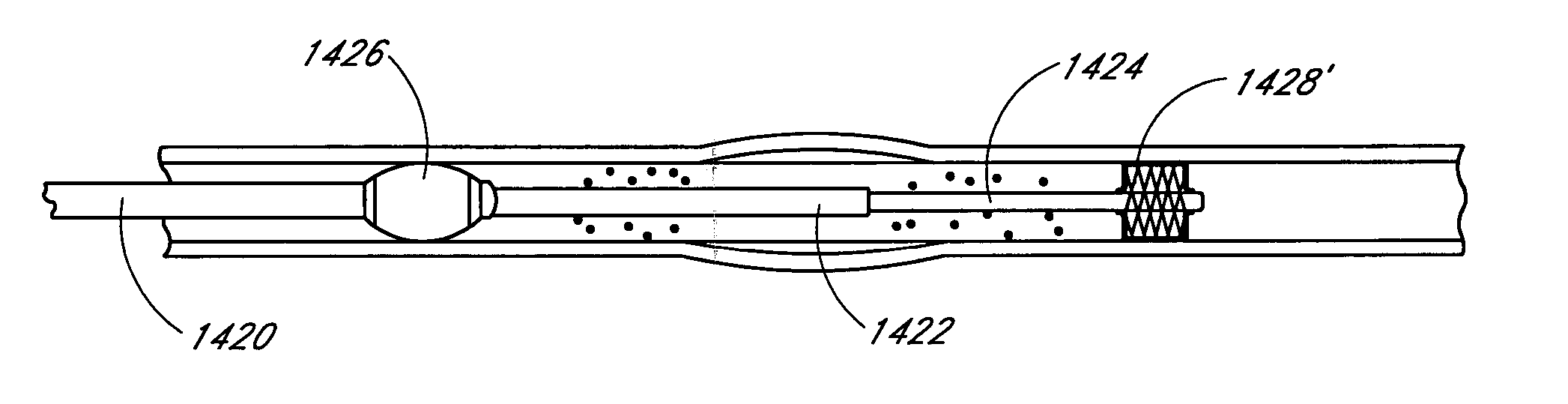

Method and apparatuses for treating an intravascular occlusion

InactiveUS20060200191A1Minimize timeReduce amountBalloon catheterMulti-lumen catheterThree vesselsExternal carotid artery

Methods for an intravascular occlusion are provided. A guidewire having an occlusive device such as balloon or a filter at one end is advanced across the occlusion using a guide catheter, and the occlusive device is expanded distal to the occlusion to occlude the blood vessel. The guide catheter may also have an occlusive device to occlude the vessel proximal to the occlusion. In a treatment method for the carotid arteries, occlusive devices may be provided in the external carotid artery, in the internal carotid artery, and in the common carotid artery.

Owner:ZADNO AZIZI GHOLAM REZA

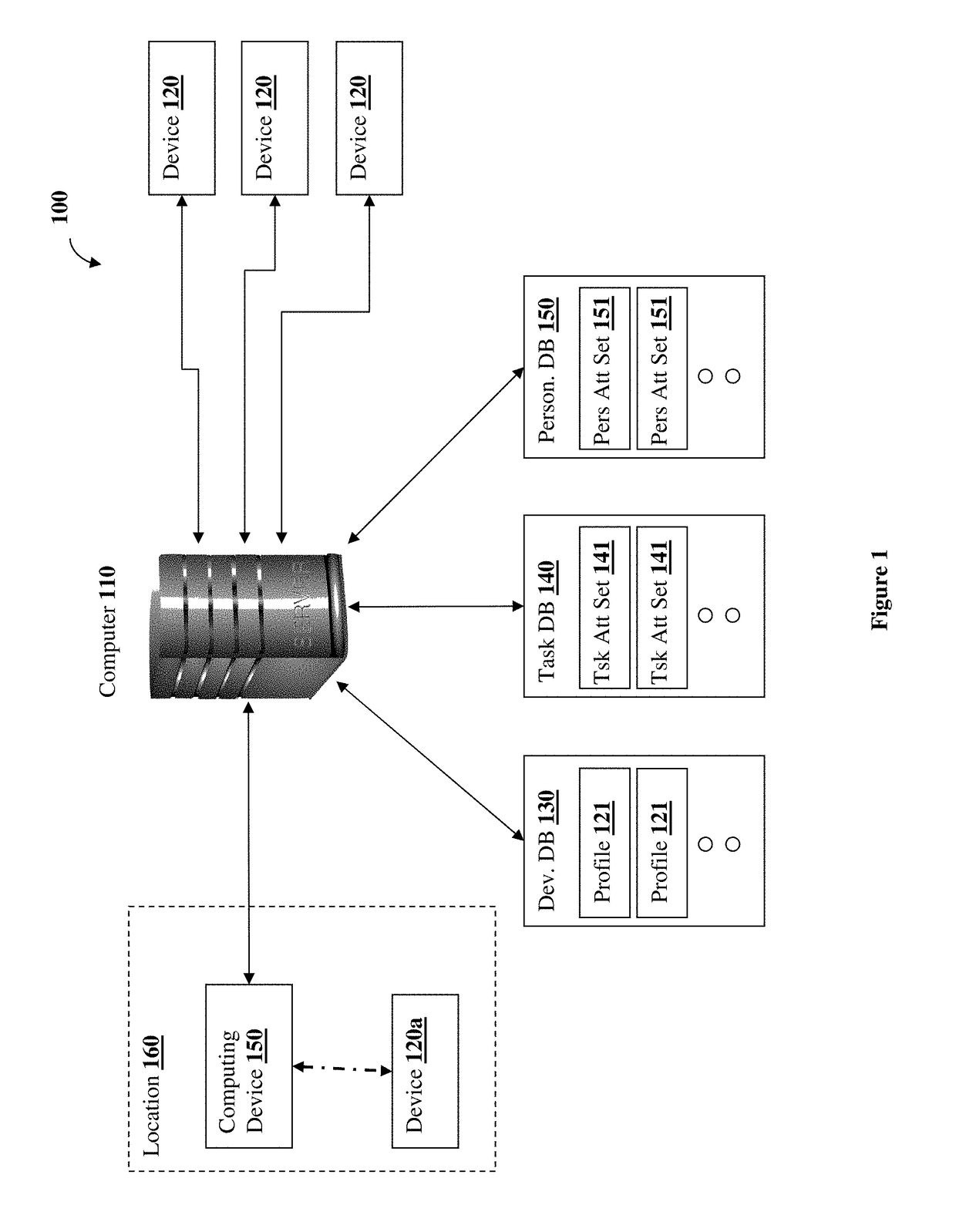

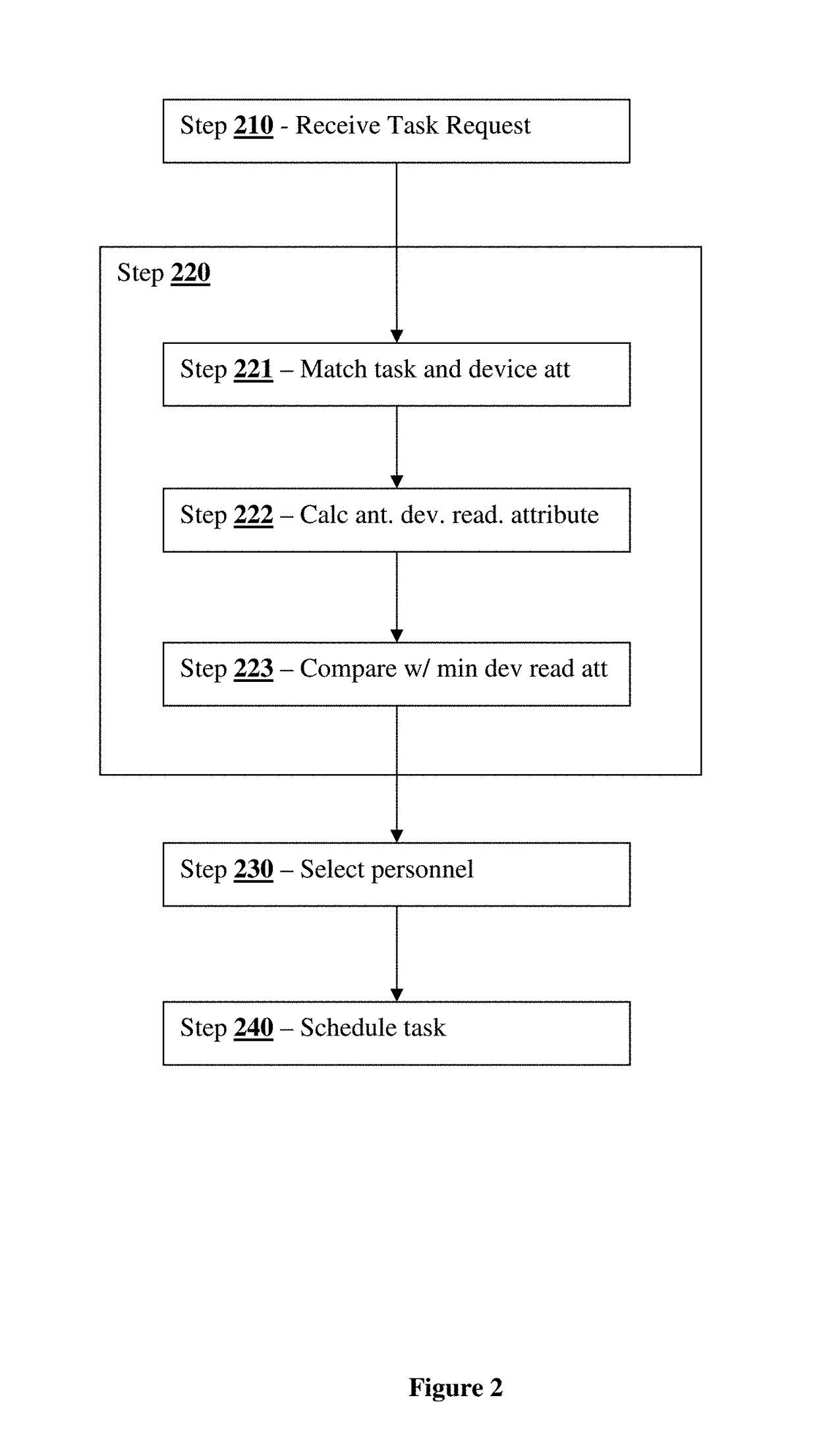

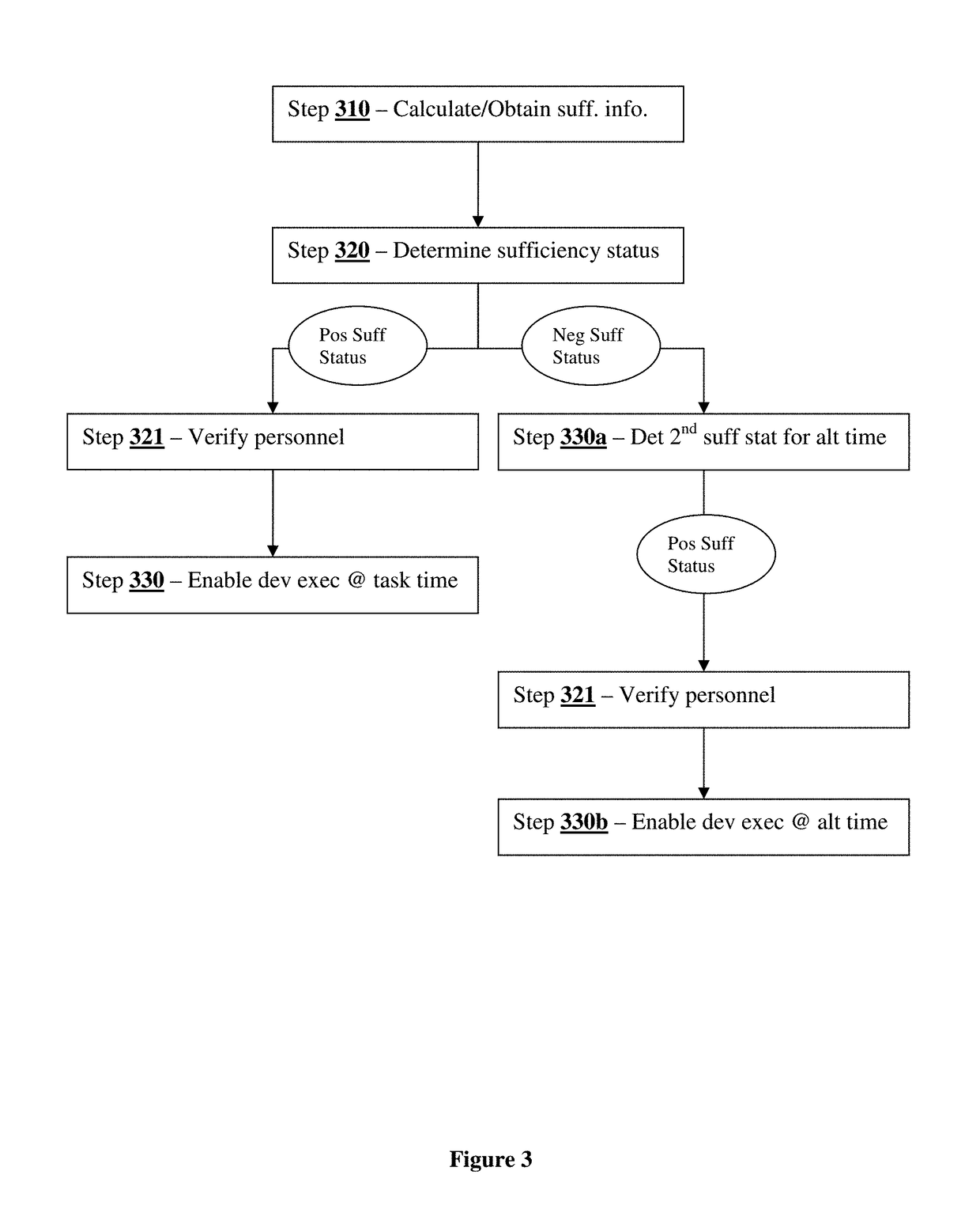

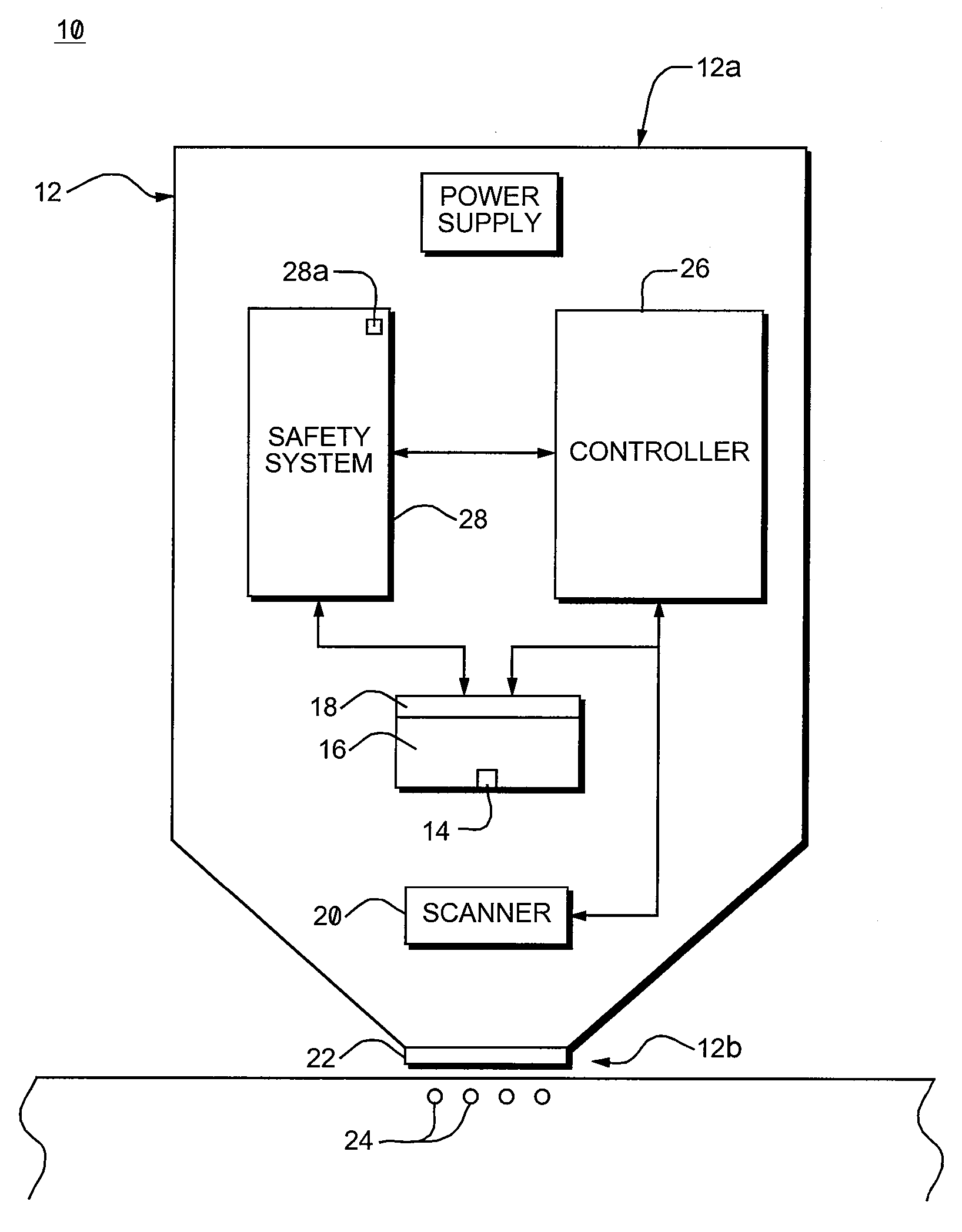

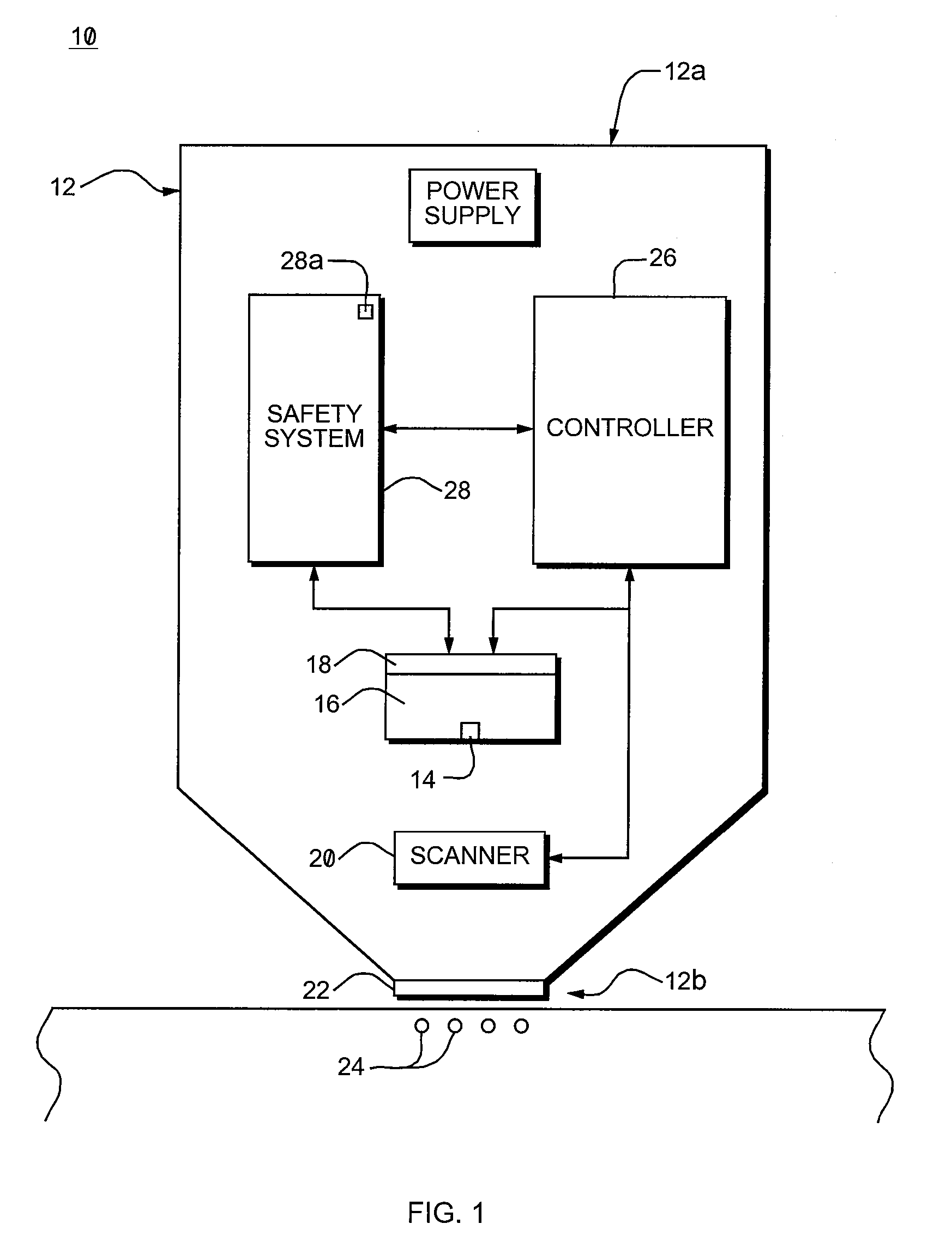

Systems and methods of ensuring and maintaining equipment viability for a task

ActiveUS10163065B1Adjust in timeExtension of timeProgram initiation/switchingOffice automationMonitor equipmentSTAFFING SCHEDULING

A device management system that is capable of scheduling connected devices and personnel for tasks, monitoring the ability of the devices to perform the scheduled task by checking in with the devices based on their uses and locations, and to modify the functioning of the devices according to the tasks scheduled for the devices and their uses. Additionally, the system can incorporate uncommunicated “dumb” devices into the scheduling of tasks and track and manage those devices.

Owner:NMETRIC

Handheld Photocosmetic Device

InactiveUS20080058783A1Maintain and improve benefitSimple designDiagnosticsControlling energy of instrumentHand heldDermatology

The present invention discloses handheld photocosmetic devices that can be utilized to apply EMR to the skin, e.g., to achieve fractional treatment of the skin. The invention discloses effective fractional photocosmetic devices for use in by a consumer in a non-medical and or non-professional setting. Thus, embodiments of such devices are disclosed herein that have one or more of the following attributes: capable of performing one or more cosmetic and / or dermatological treatments; efficacious for such treatments; durable; relatively inexpensive; relatively simple in design; smaller than existing professional devices (with some embodiments being completely self-contained and hand-held); safe for use by non-professionals; and / or not painful to use (or only mildly painful).

Owner:PALOMAR MEDICAL TECH

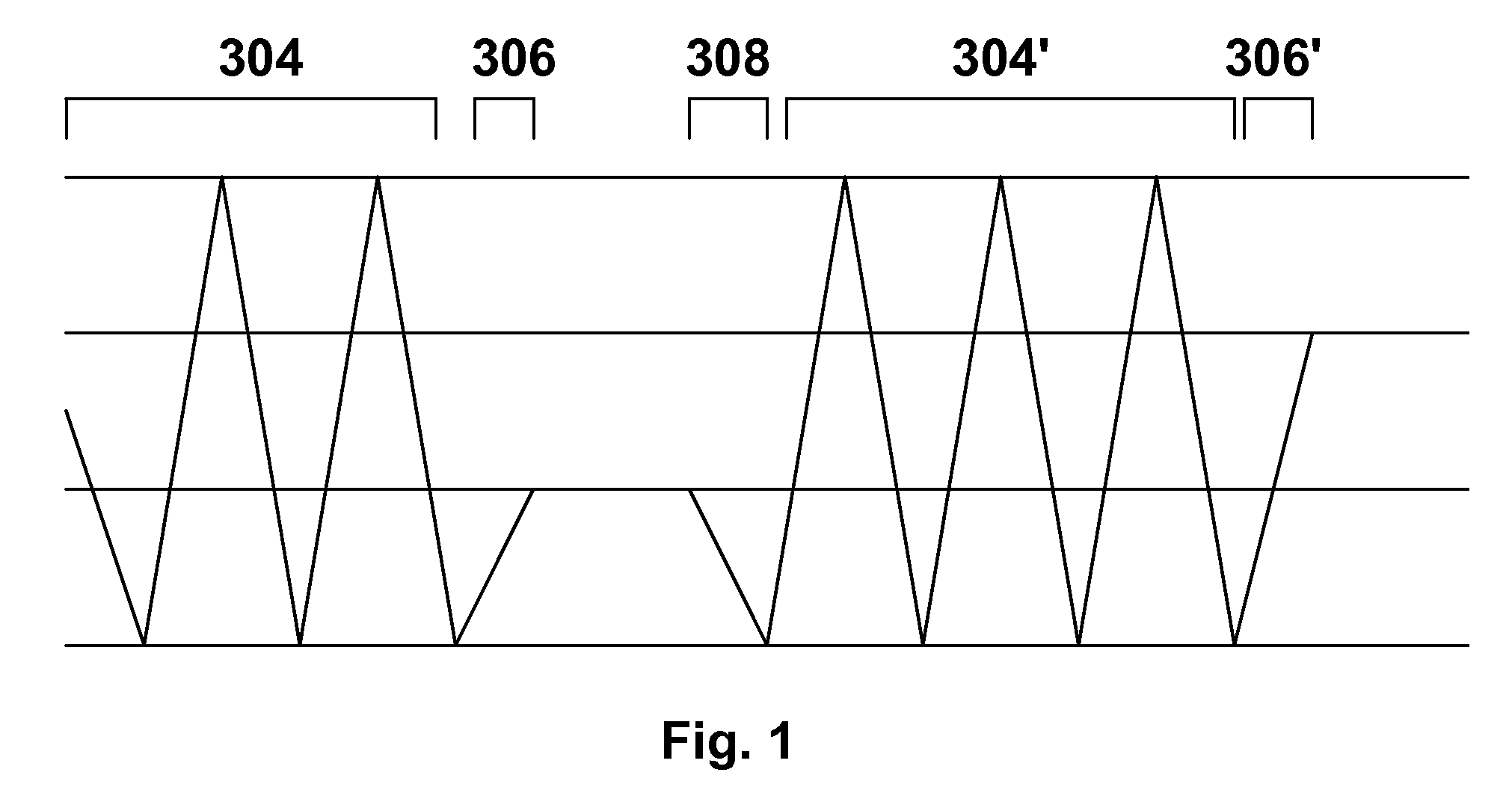

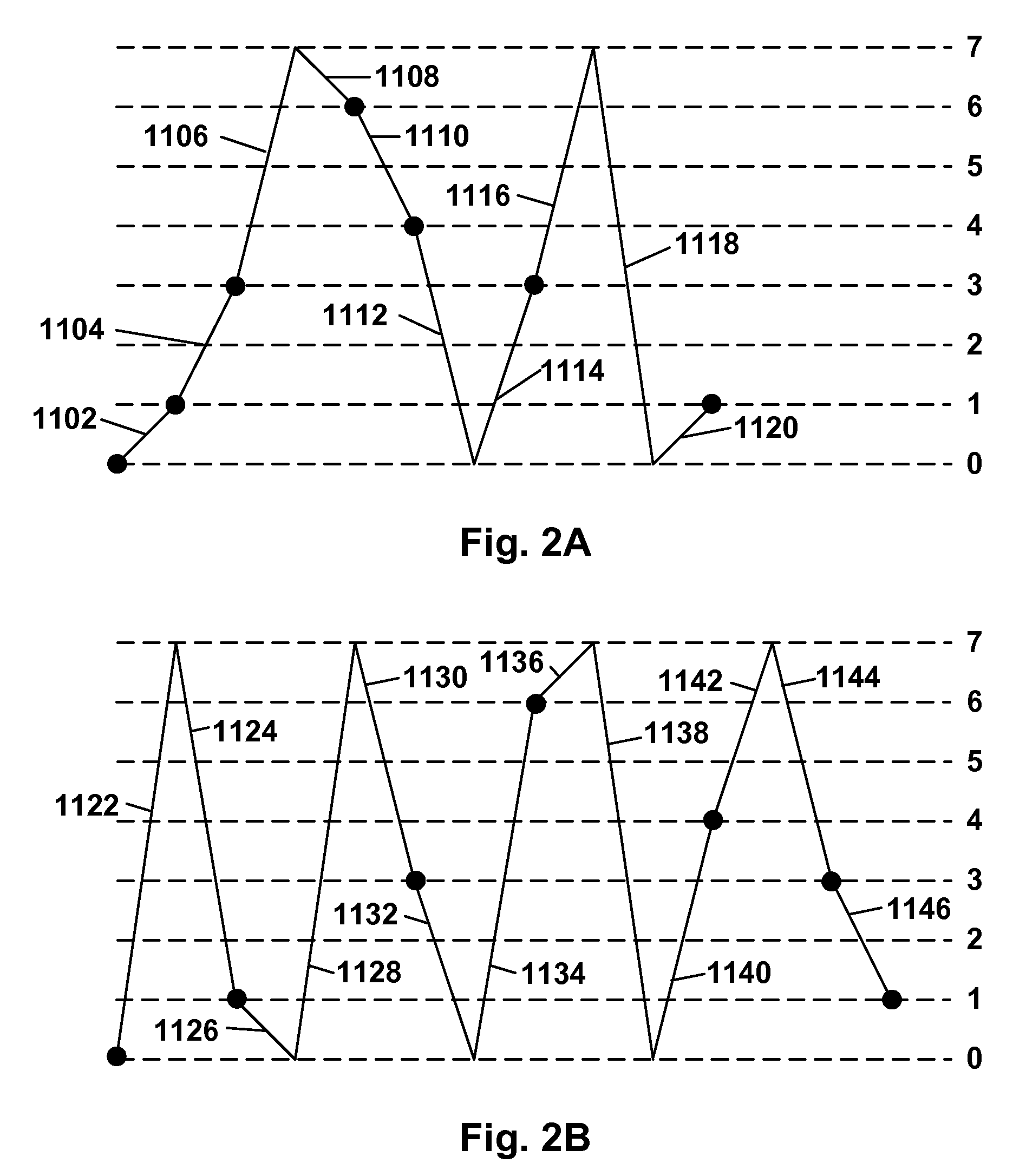

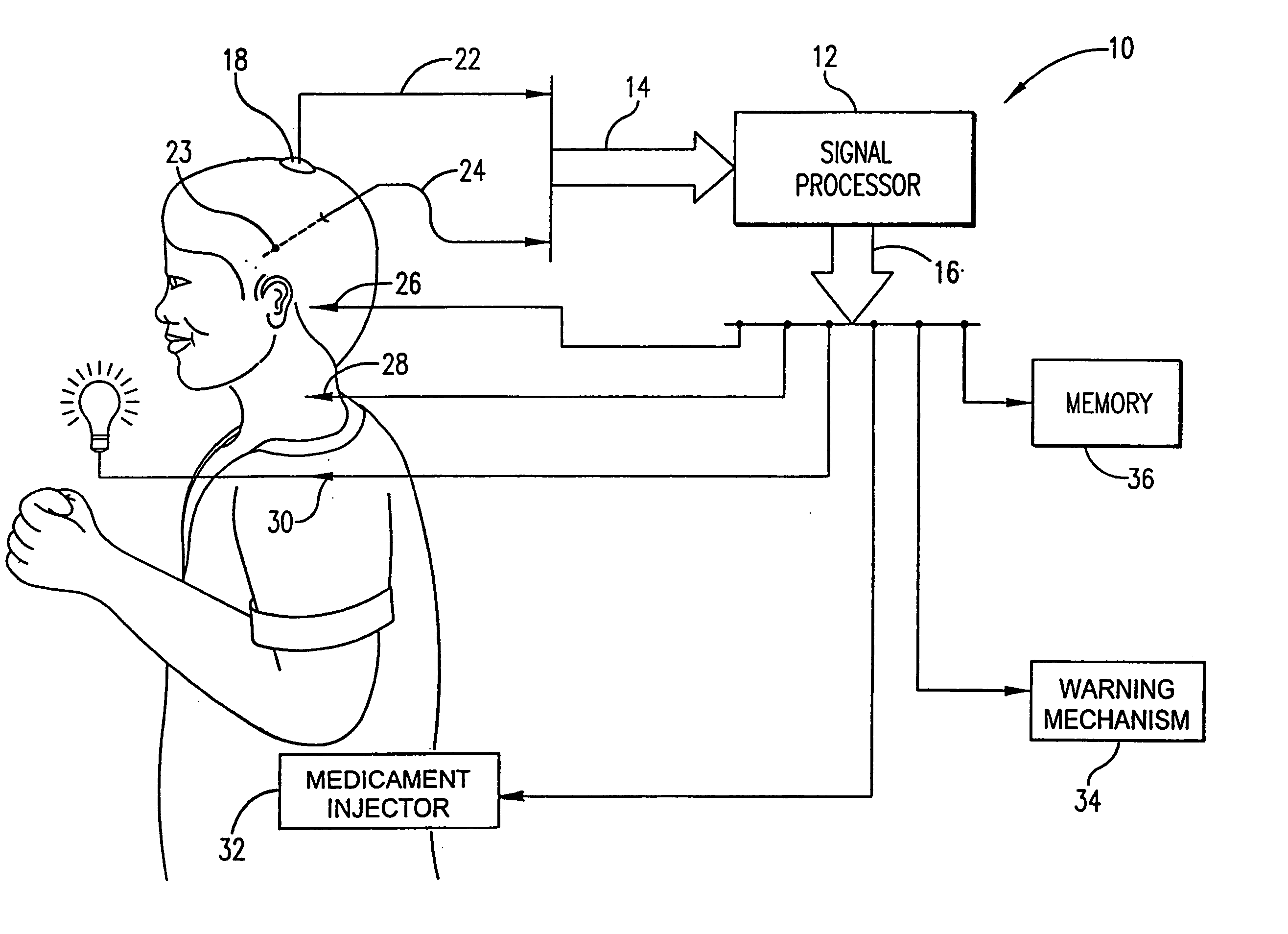

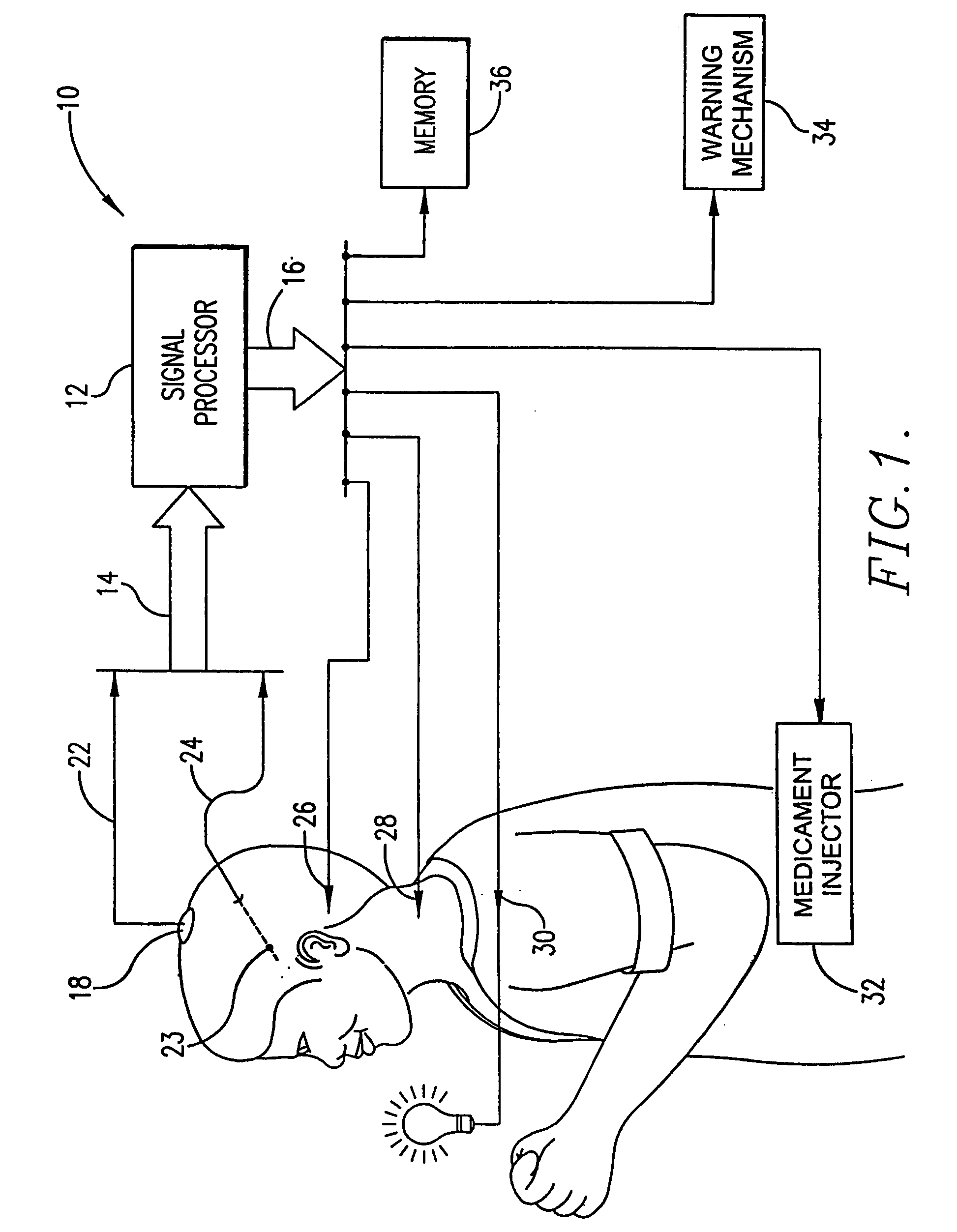

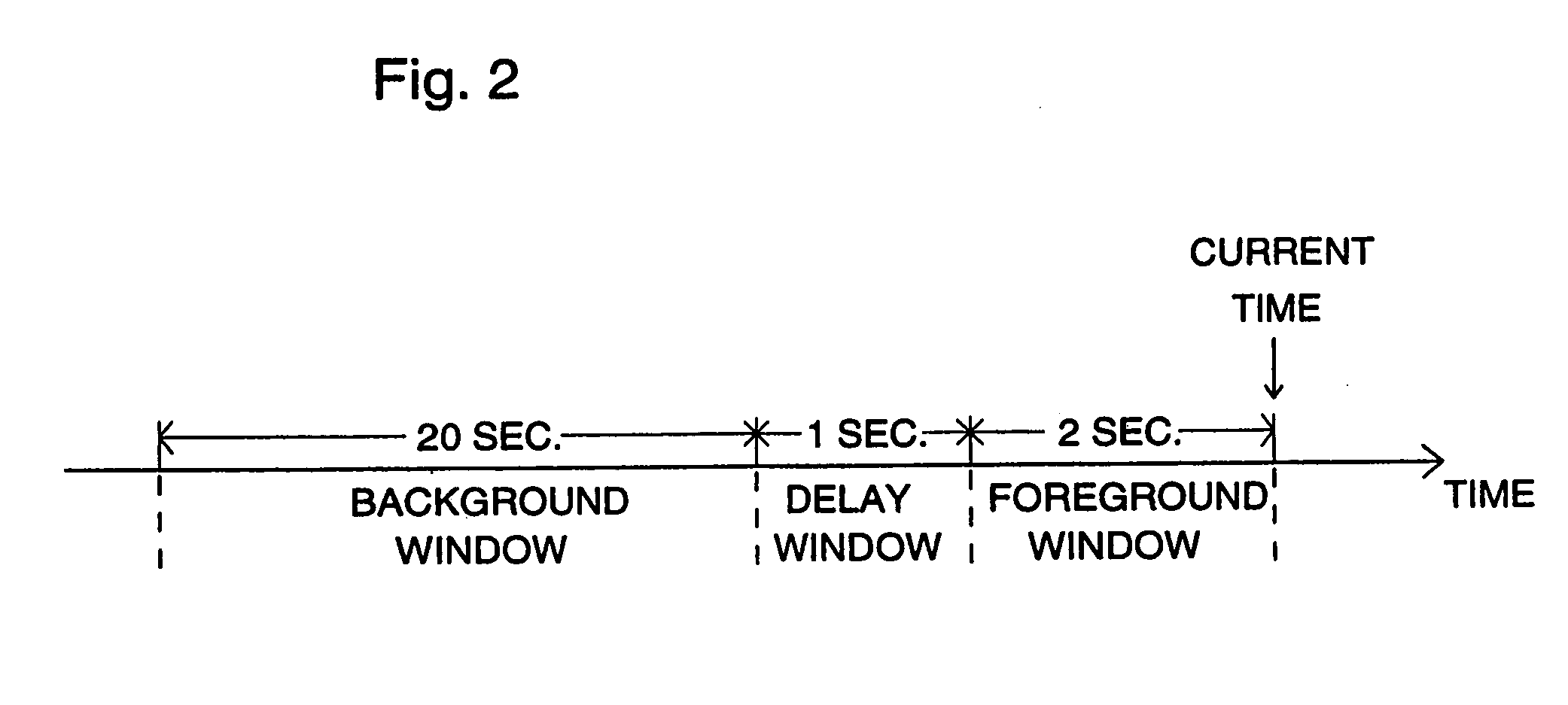

System for the prediction, rapid detection, warning, prevention, or control of changes in activity states in the brain of a subject

InactiveUS20050197590A1Improve predictive timeImprove reliabilityElectroencephalographyElectrotherapyNonlinear filterReal time analysis

A system (10) analyzes signals representative of a subject's brain activity in a signal processor (12) for information indicating the subject's current activity state and for predicting a change in the activity state. One preferred embodiment uses a combination of nonlinear filtering methods to perform real-time analysis of the electro-encephalogram (EEG) or electro-corticogram (ECoG) signals from a subject patient for information indicative of or predictive of a seizure, and to complete the needed analysis at least before clinical seizure onset. The preferred system then performs an output task for prevention or abatement of the seizure, or for recording pertinent data.

Owner:FLINT HILLS SCI L L C

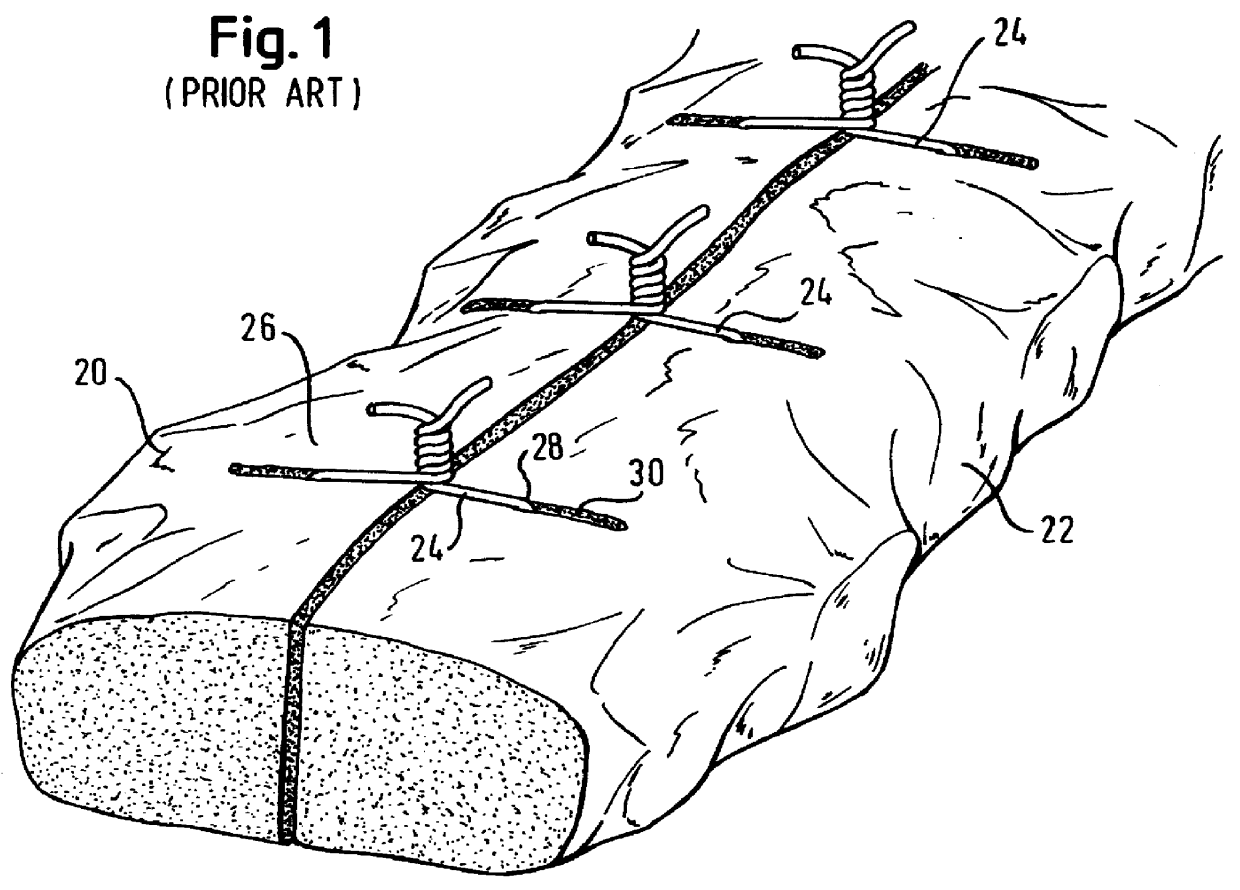

Sternal closure technique and kit for performing same

InactiveUS6030410AReduce riskExtension of timeSuture equipmentsInternal osteosythesisSternal bodyReduction procedure

An improved method of reducing and stabilizing the sternum after a sternotomy includes fixing a staple at the anterior surface of the sternum adjacent to each outlet for trans-sternal wire sutures. The staples are applied to the sternal halves to reinforce the bone adjacent to the suture outlets so as to prevent the suture from cutting into the bone. As each suture loop is tightened to adapt the sternum, the suture loop abuts the staples adjacent the suture outlets. The staples are deformed under force applied by the suture loop to indicate that the loop has been tightened to an optimum degree. A sterile surgical staple gun is employed to install the staples in the sternal halves. A kit for performing the improved sternal reduction procedure includes a pre-sterilized staple gun loaded with surgical staples, as well as suture / needle assemblies.

Owner:ZURBRUGG HEINZ ROBERT

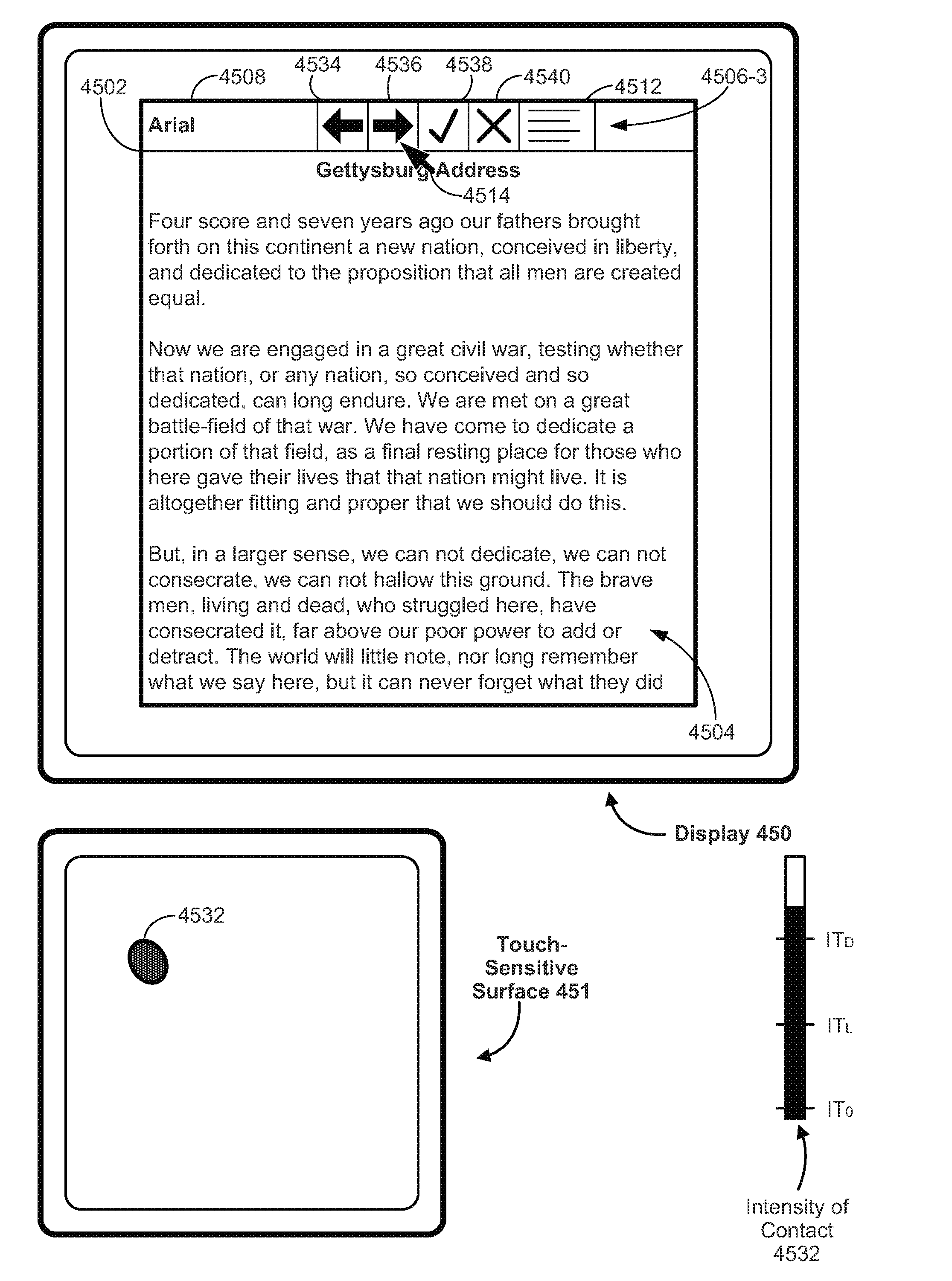

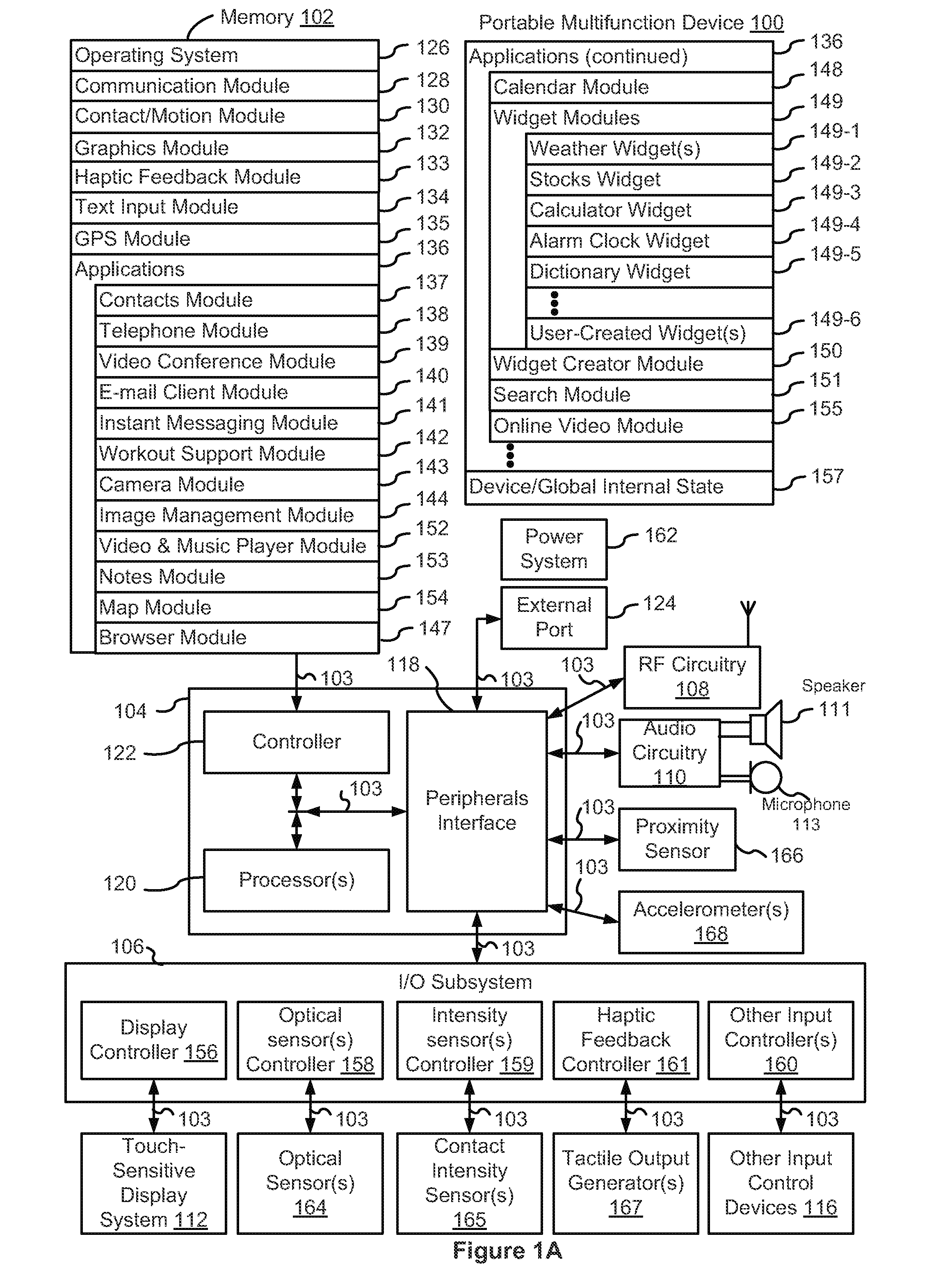

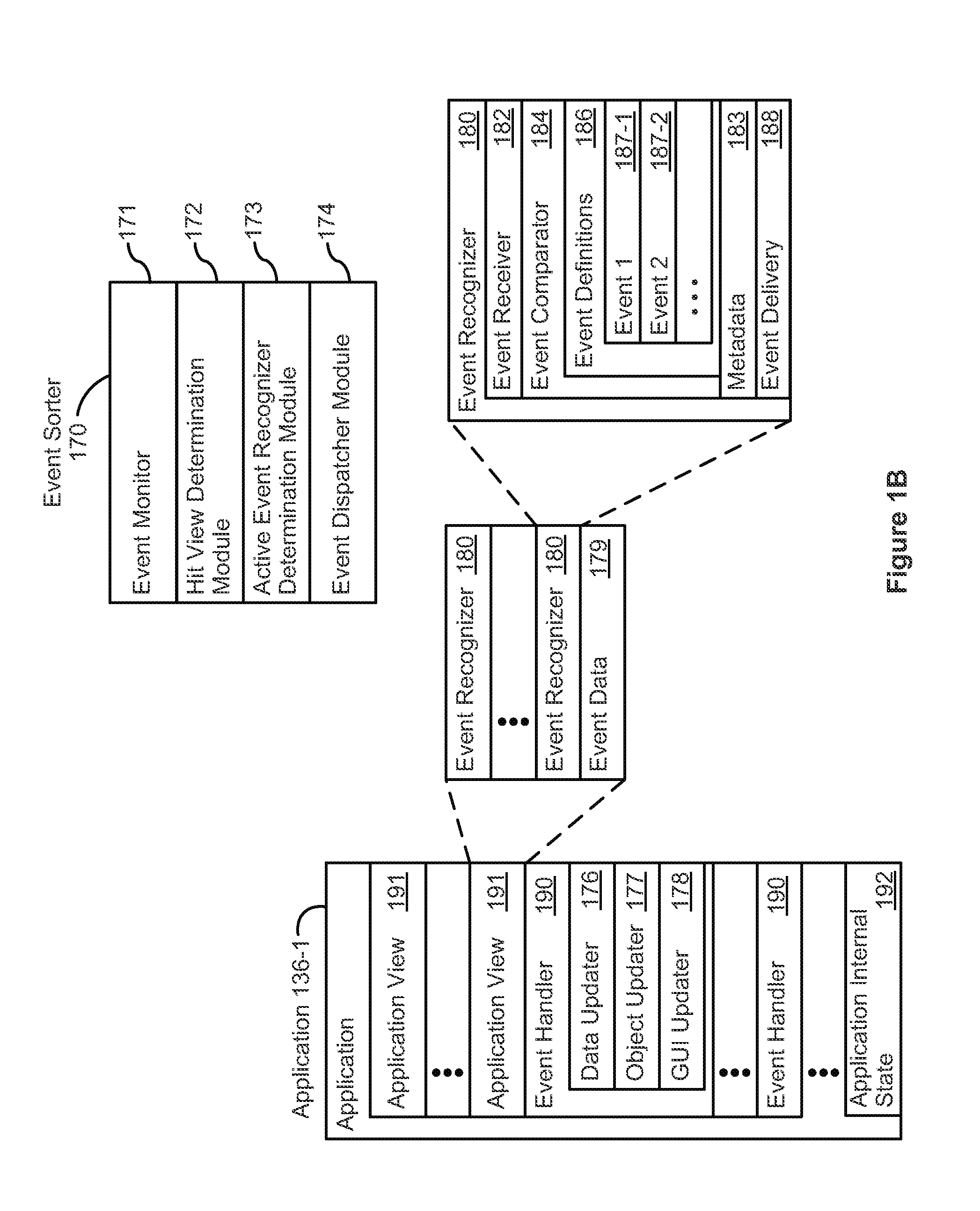

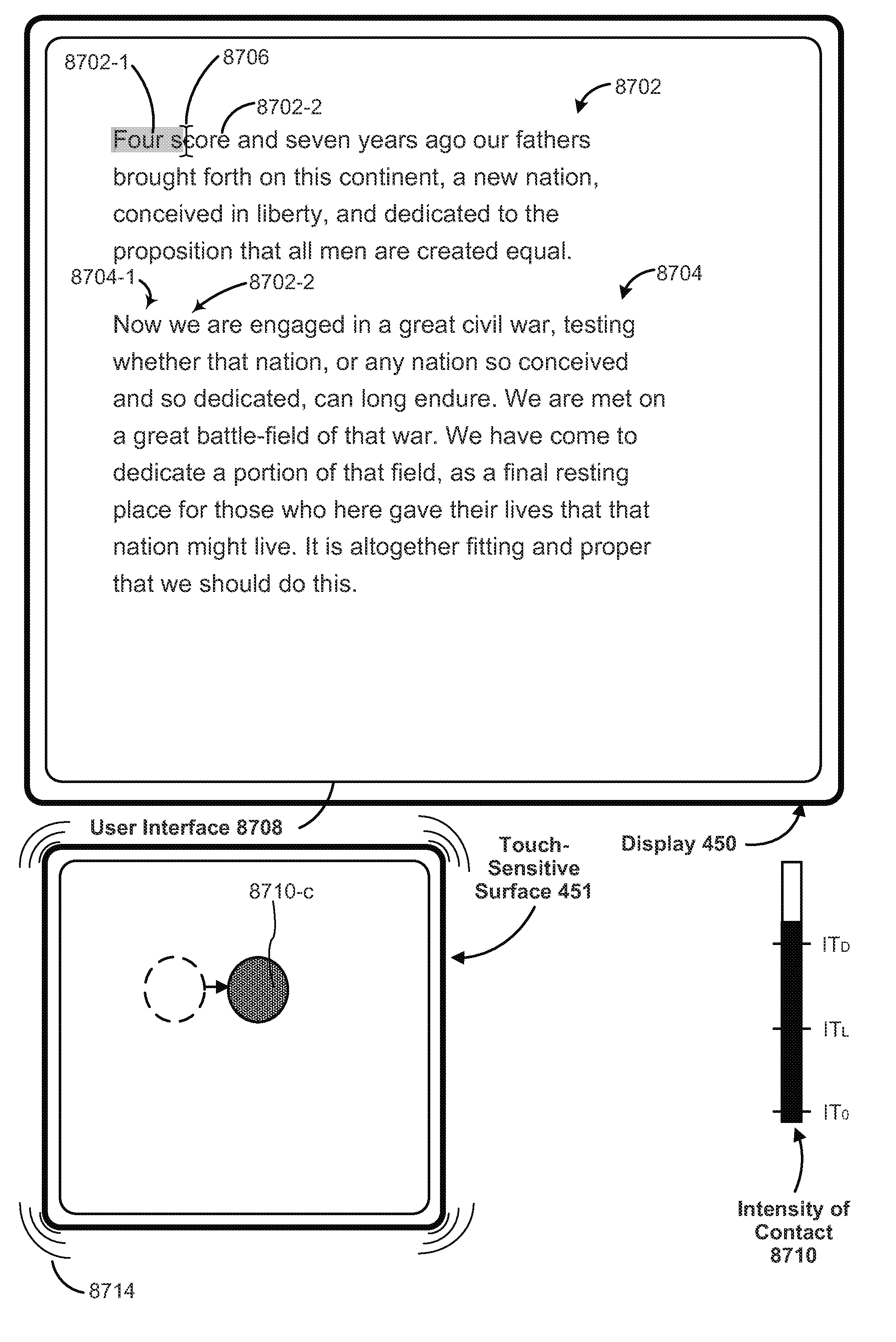

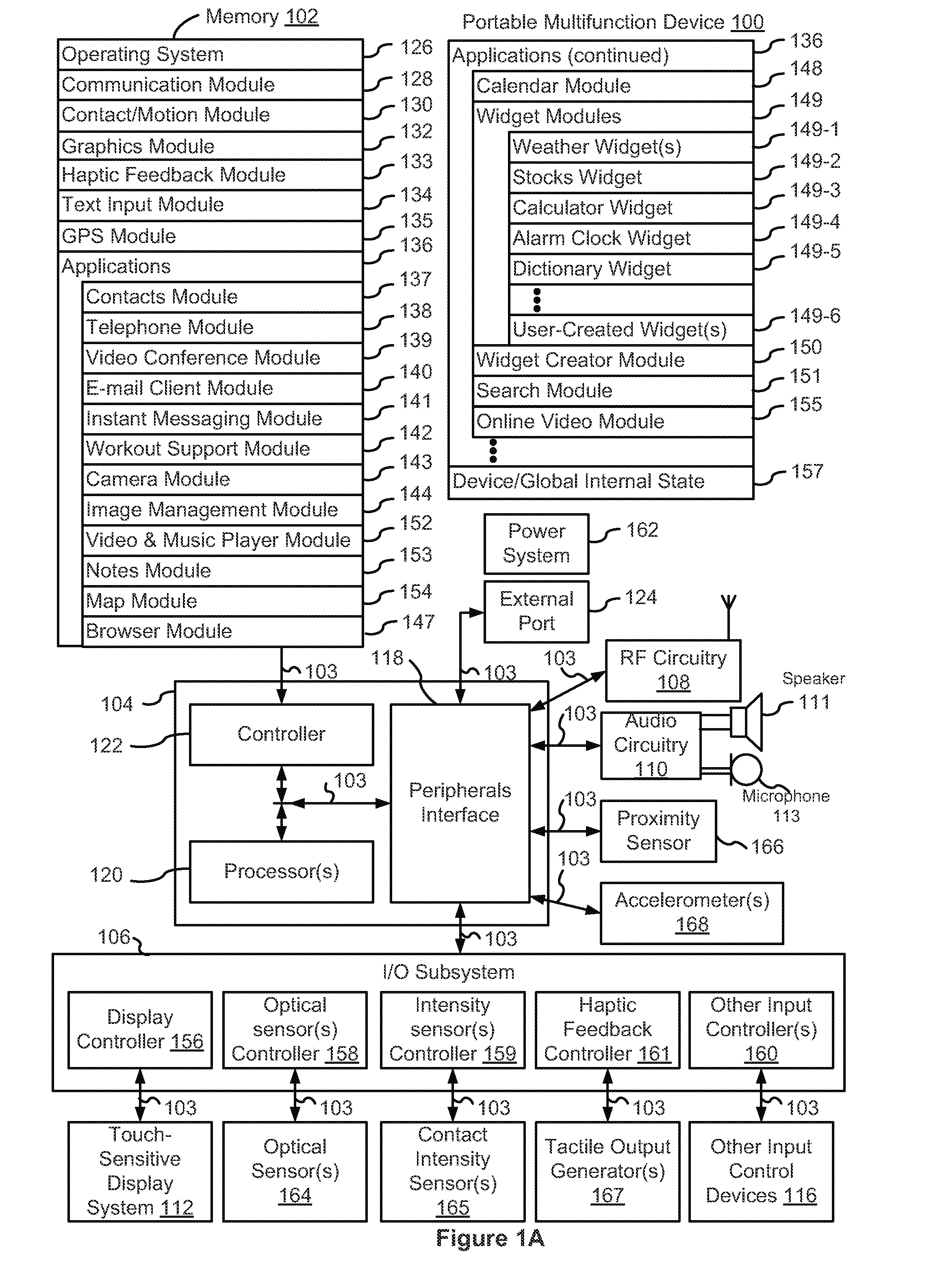

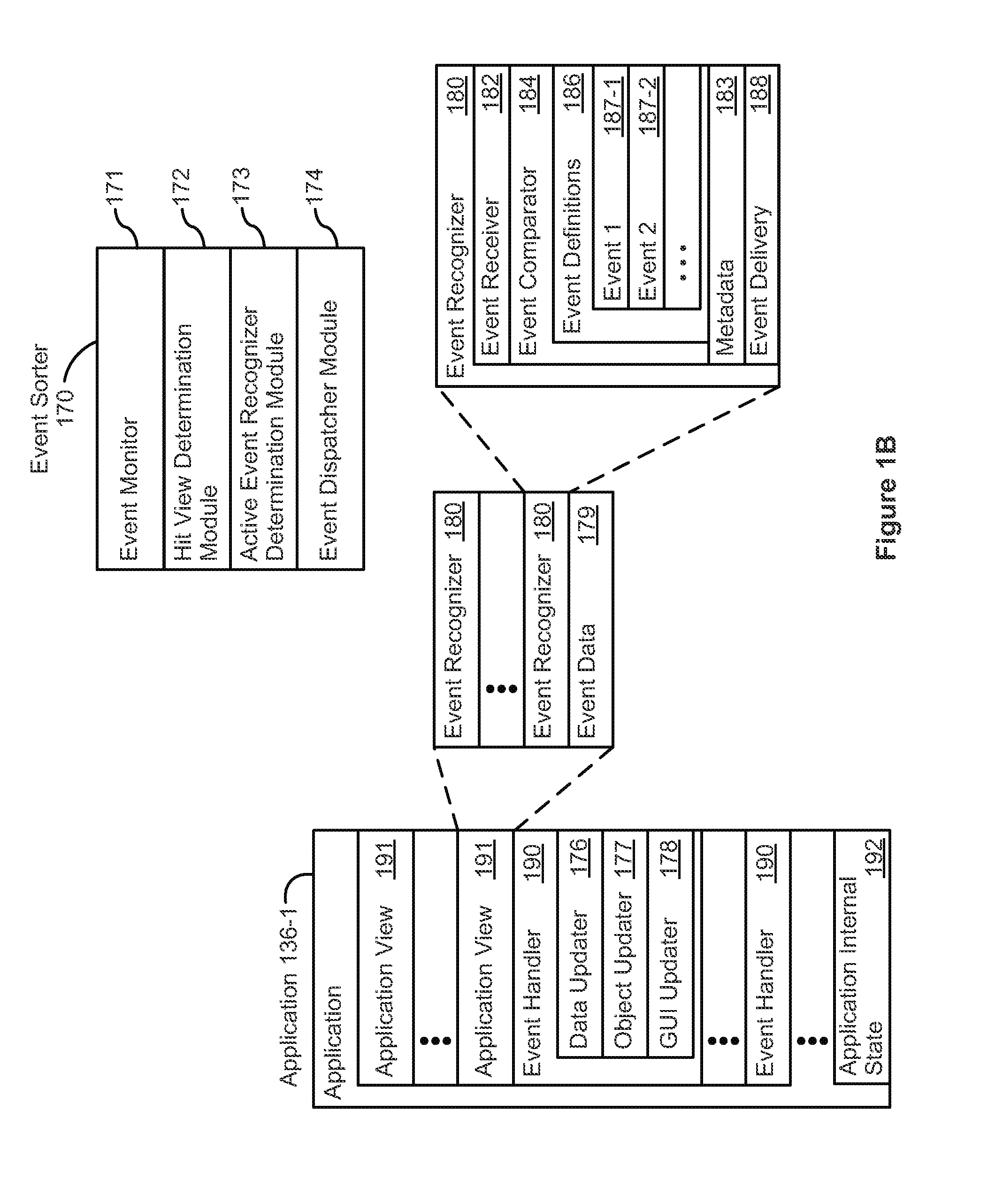

Device, Method, and Graphical User Interface for Facilitating User Interaction with Controls in a User Interface

ActiveUS20150067513A1Faster and efficient methodFaster and efficient and interfaceInput/output processes for data processingPictoral communicationGraphicsGraphical user interface

An electronic device, with a touch-sensitive surface and a display, includes one or more sensors to detect intensity of contacts with the touch-sensitive surface. The device displays, on the display, a first control for controlling a first operation. The device detects, on the touch-sensitive surface, a first input that corresponds to the first control; and in response to detecting the first input: in accordance with a determination that the first input meets first control-activation criteria but does not include a contact with a maximum intensity above a respective intensity threshold, the device performs the first operation; and in accordance with a determination that the first input includes a contact with an intensity above the respective intensity threshold, the device displays a second control for performing a second operation associated with the first operation.

Owner:APPLE INC

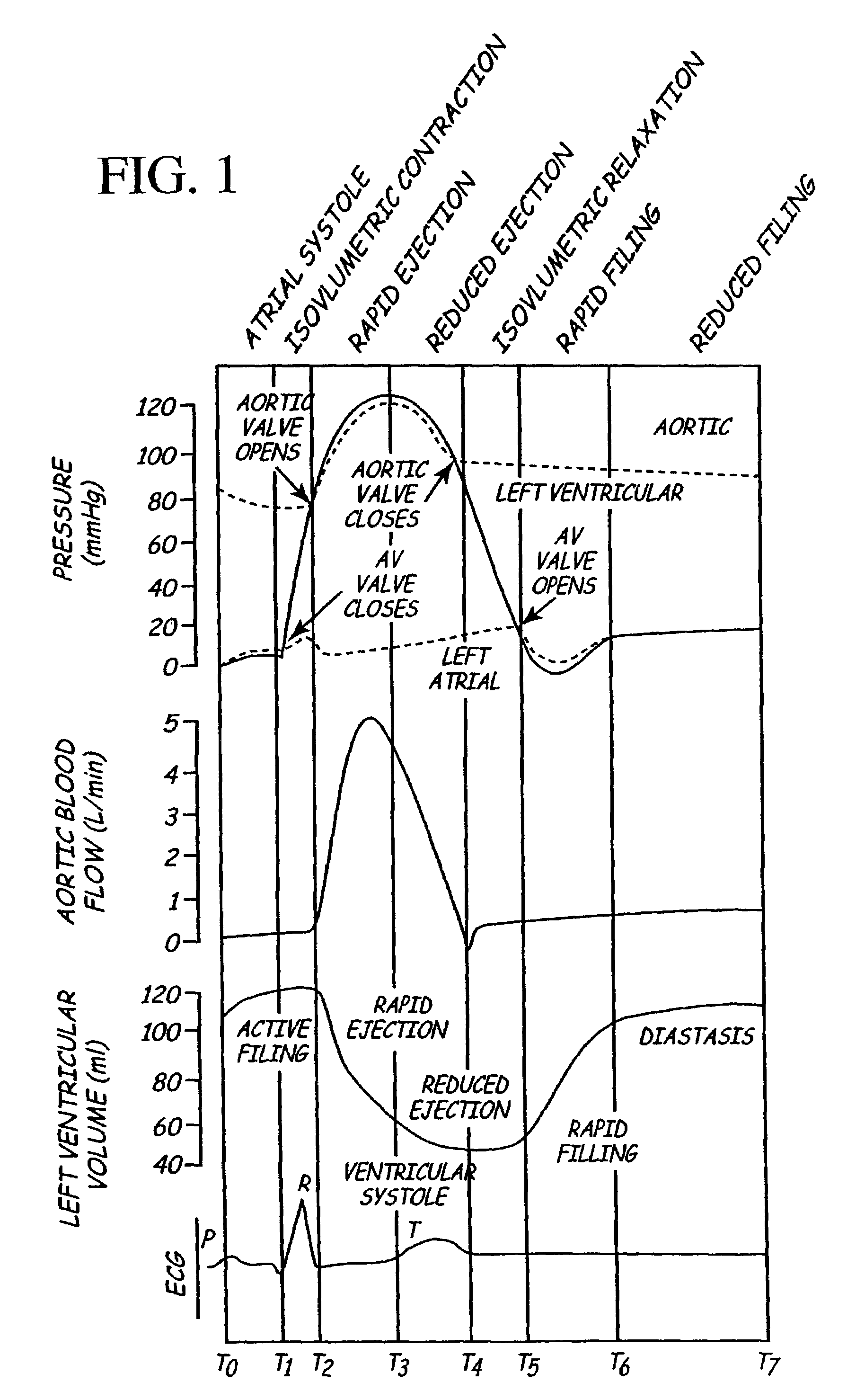

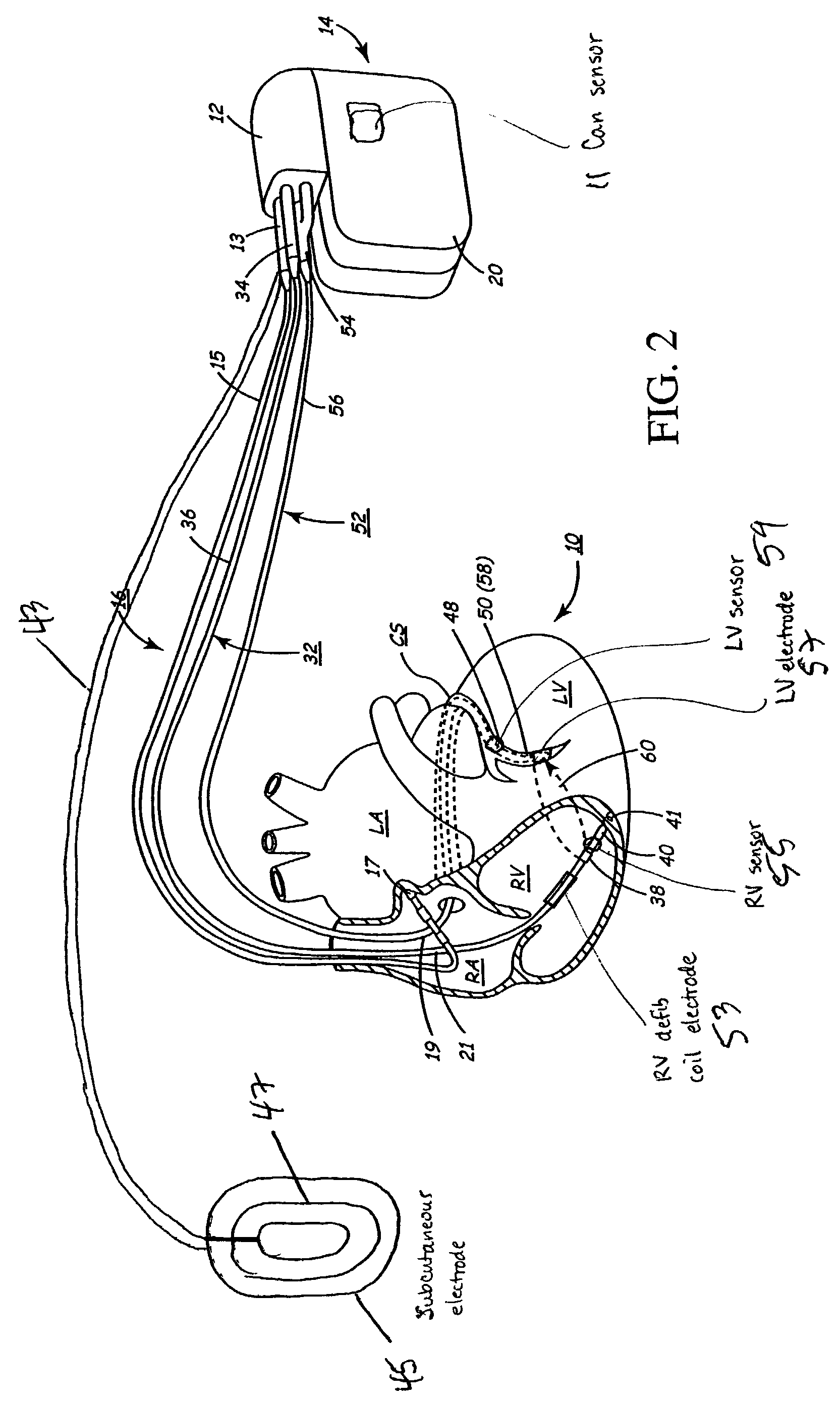

Implantable medical device for treating cardiac mechanical dysfunction by electrical stimulation

InactiveUS7096064B2Improve toleranceExtension of timeHeart defibrillatorsHeart stimulatorsCardiac dysfunctionElectrical stimulations

The disclosure provides methods and apparatus of particular benefit for patients suffering heart failure including cardiac dysfunction, chronic HF, and the like and all variants thereof. According to the disclosure monitoring and therapy delivery for a wide variety of acute and chronic cardiac dysfunctions are described and depicted. Various forms of paired or coupled pacing therapy delivery provided alone or in combination with neurostimulation therapy delivered by both implantable and external apparatus, including defibrillation therapy are also provided herein.

Owner:MEDTRONIC INC

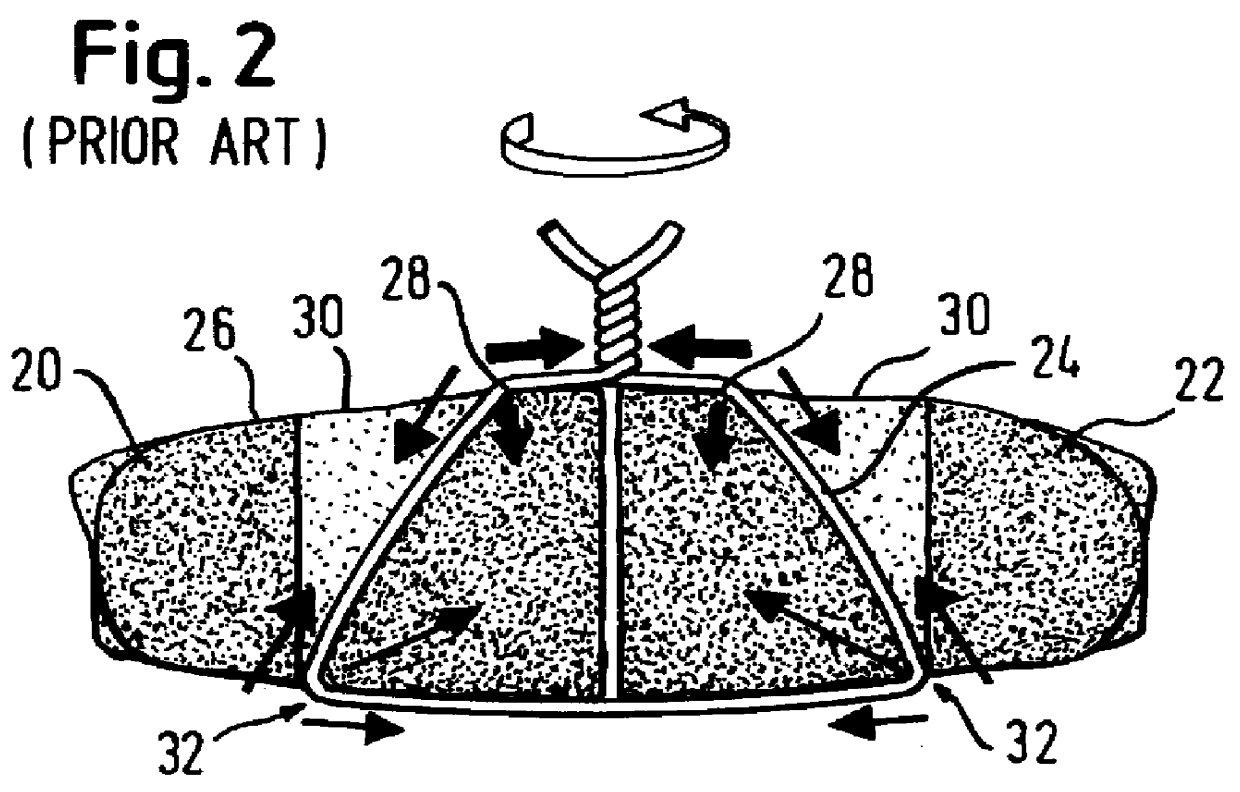

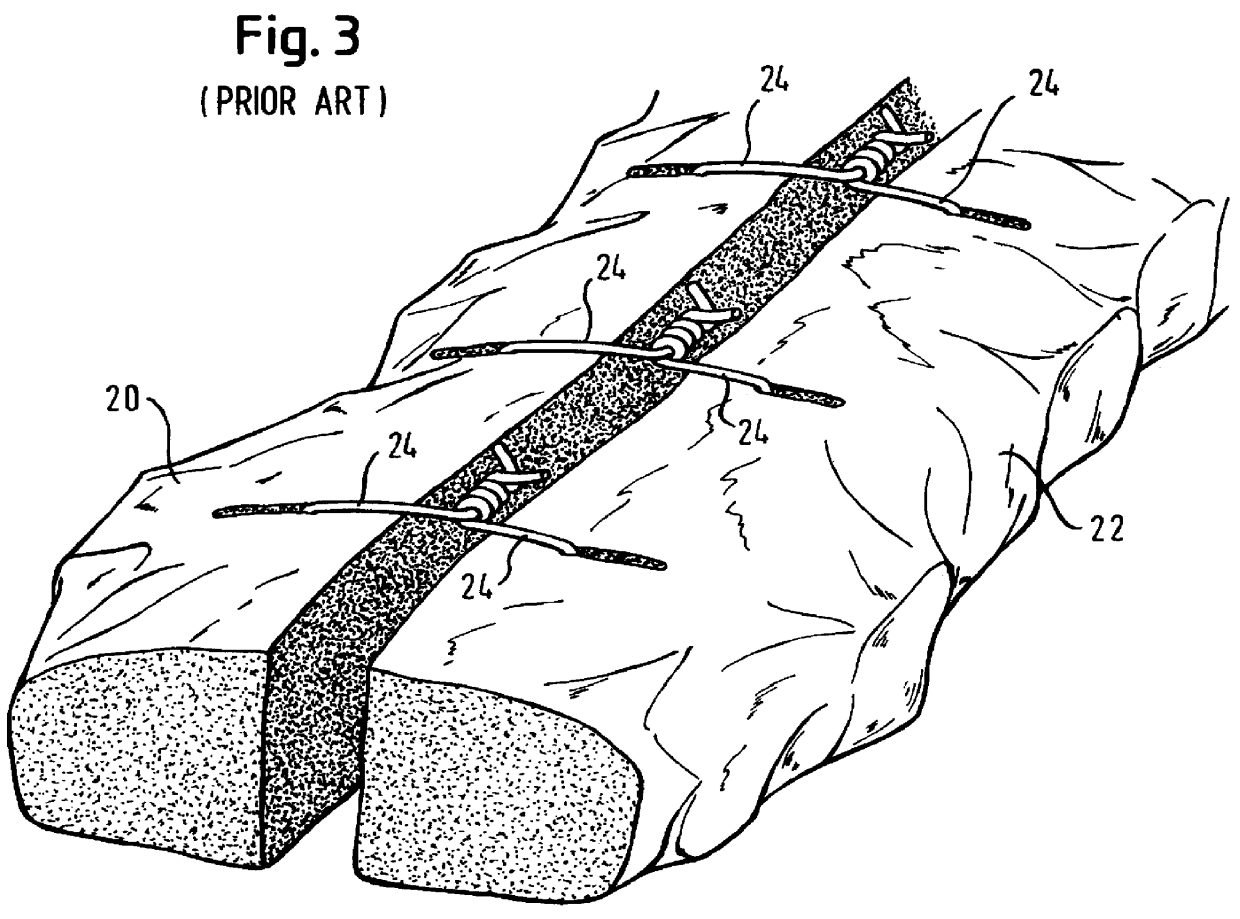

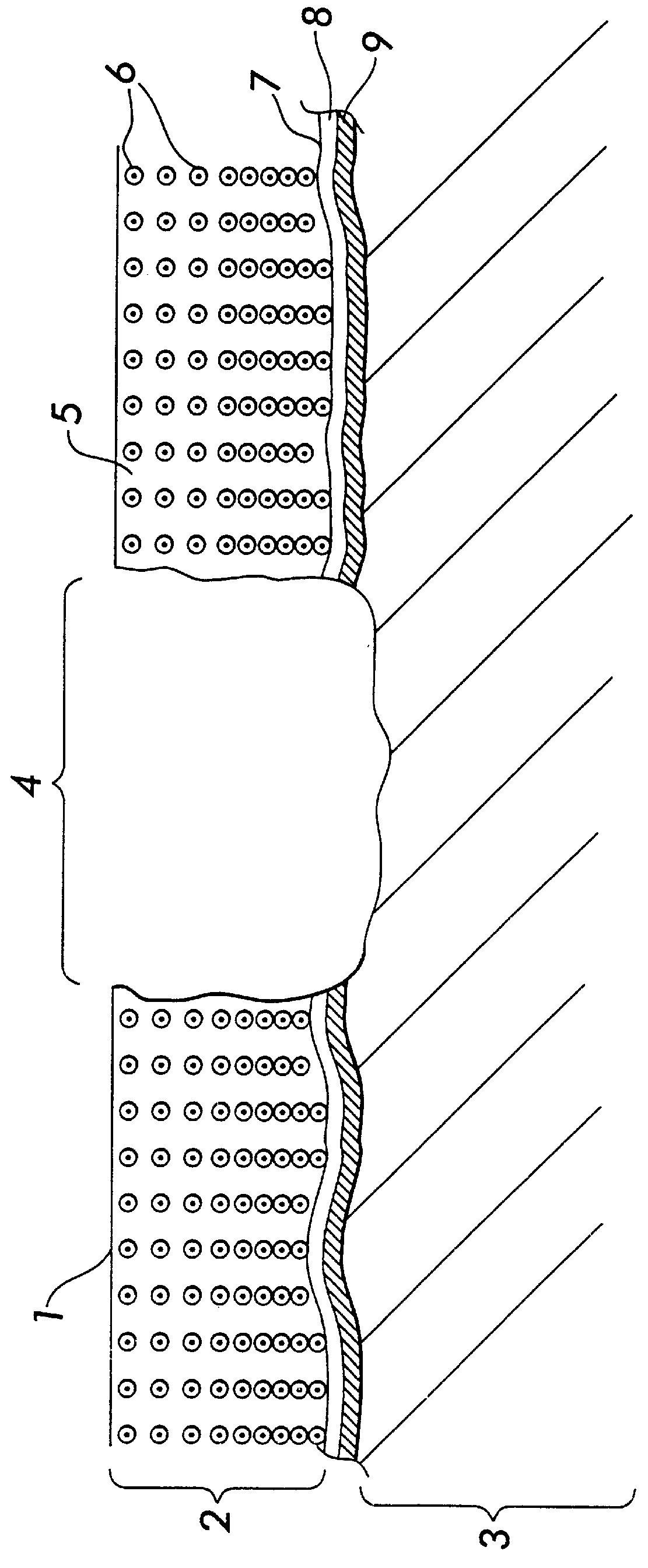

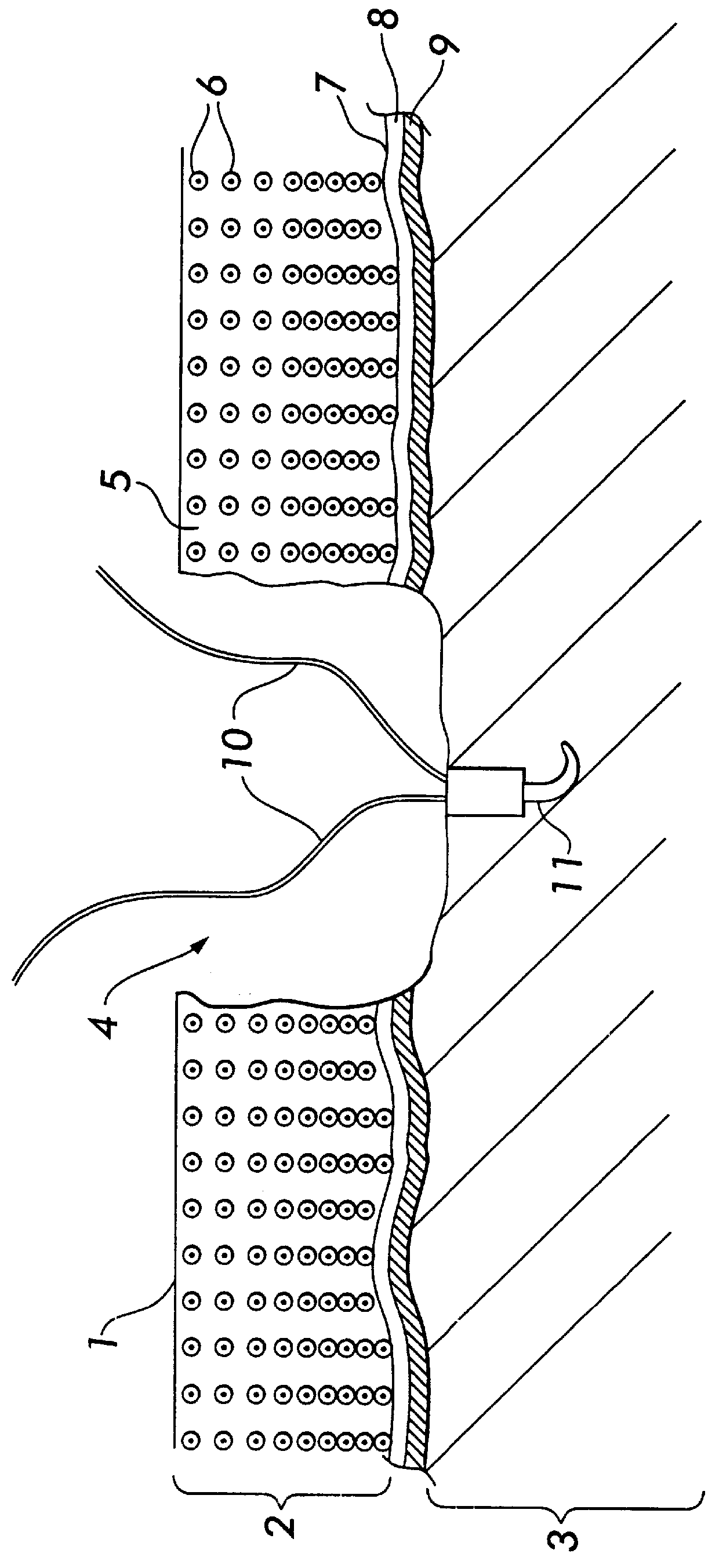

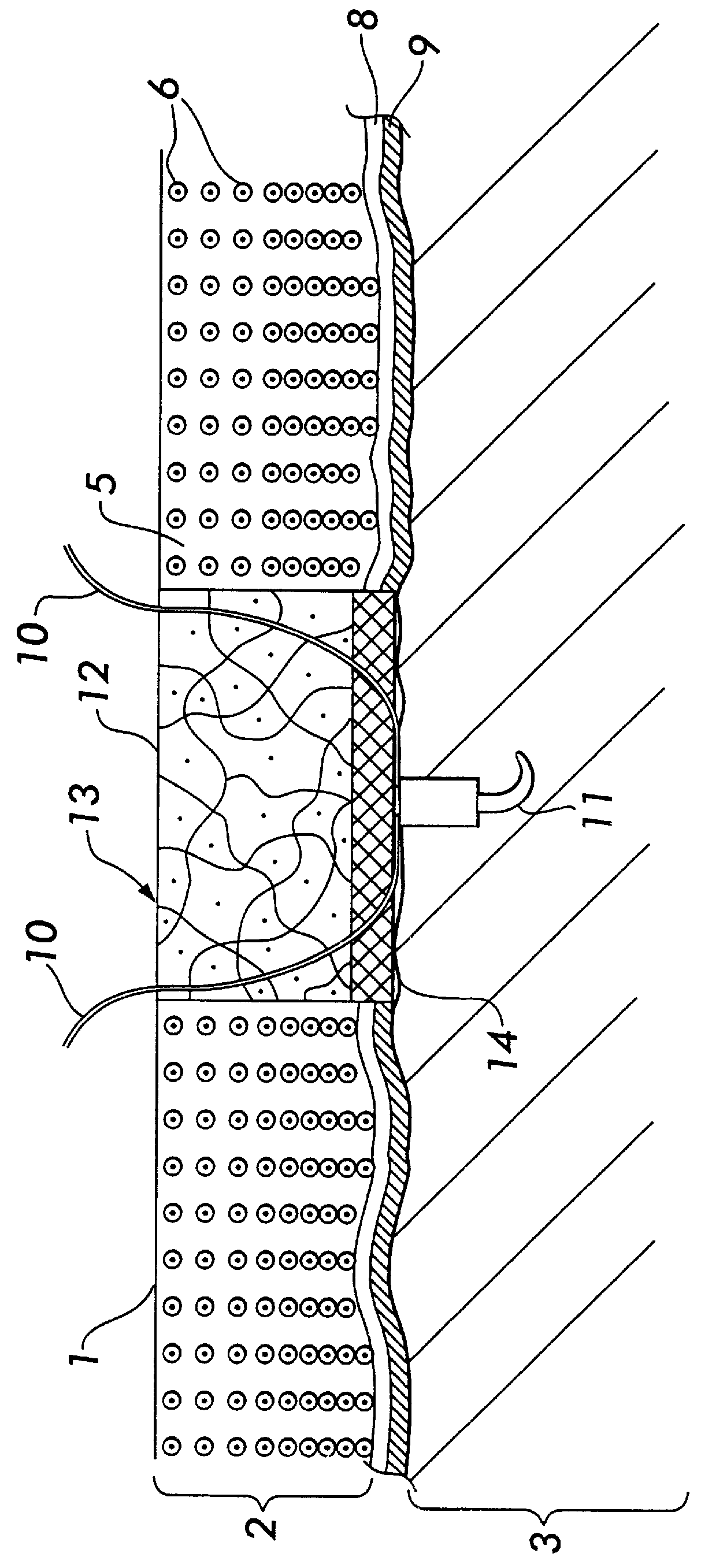

Multi-stage collagen-based template or implant for use in the repair of cartilage lesions

InactiveUS6080194ASafe and effectiveDefect in be healSuture equipmentsBone implantNutrientSacroiliac joint

The invention is a template to aid in the regeneration of articular cartilage. The template is formed by combining a porous collagen sponge ("collagen matrix") with a dense collagen membrane. The dense collagen membrane is placed on the surface of the cartilage defect to prevent cell migration from the subchondral plate and vasculature. The collagen membrane will allow movement and exchange of fluids, nutrients, cytokines and other factors necessary for cartilage regeneration. The collagen matrix has been developed to allow attachment and growth of cells, specifically chondrocytes which are normally found in articular cartilage. The collagen matrix can be combined with chondrocytes in vitro, and therefore serve to transport cultured cells to the defect site and to retain the cells in position following implantation. Procedures are described to effectively use the two-staged template, and to fix the template to the repair site.

Owner:HOSPITAL FOR JOINT DISEASES ORTHOPEDIC INST

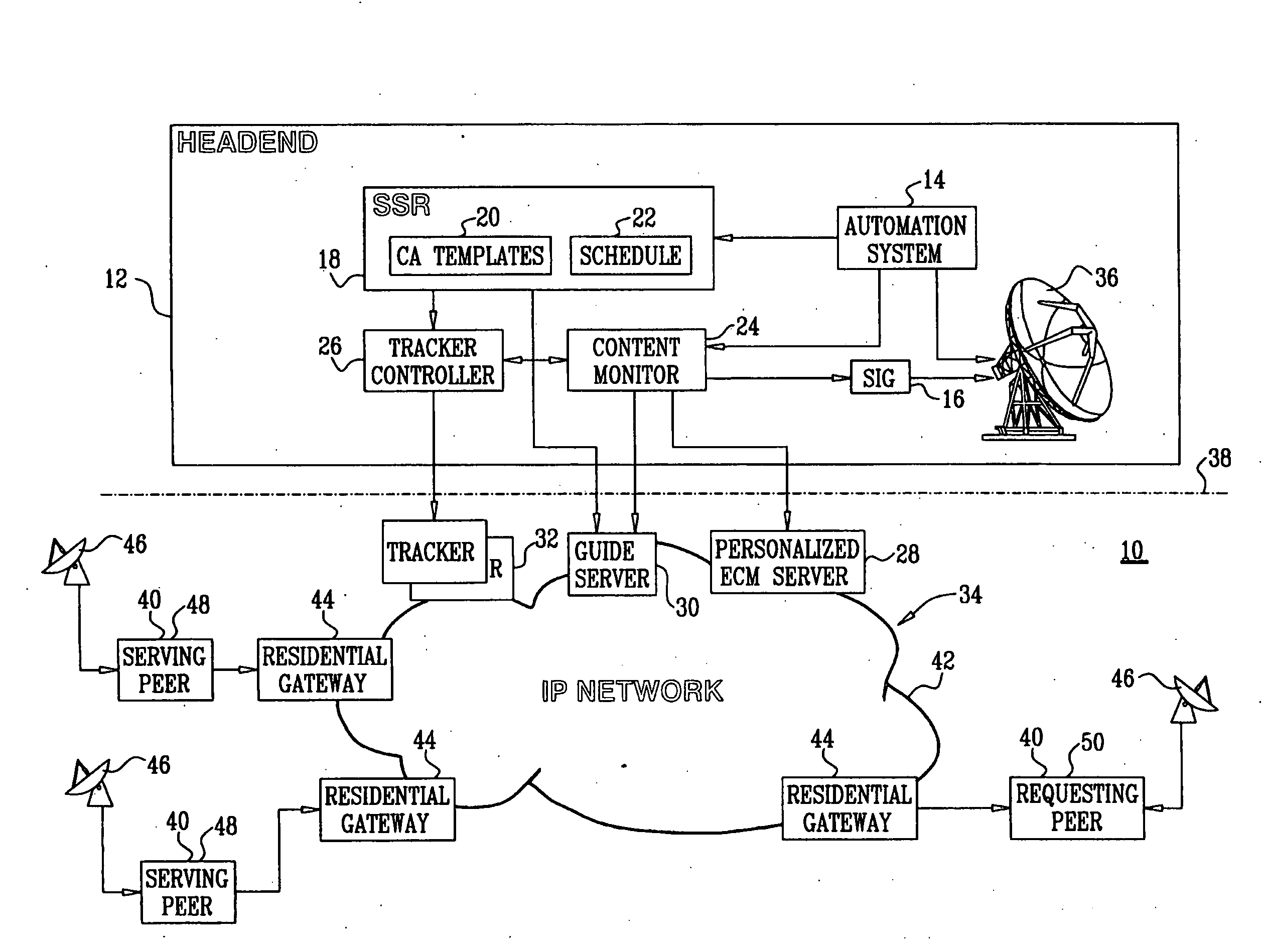

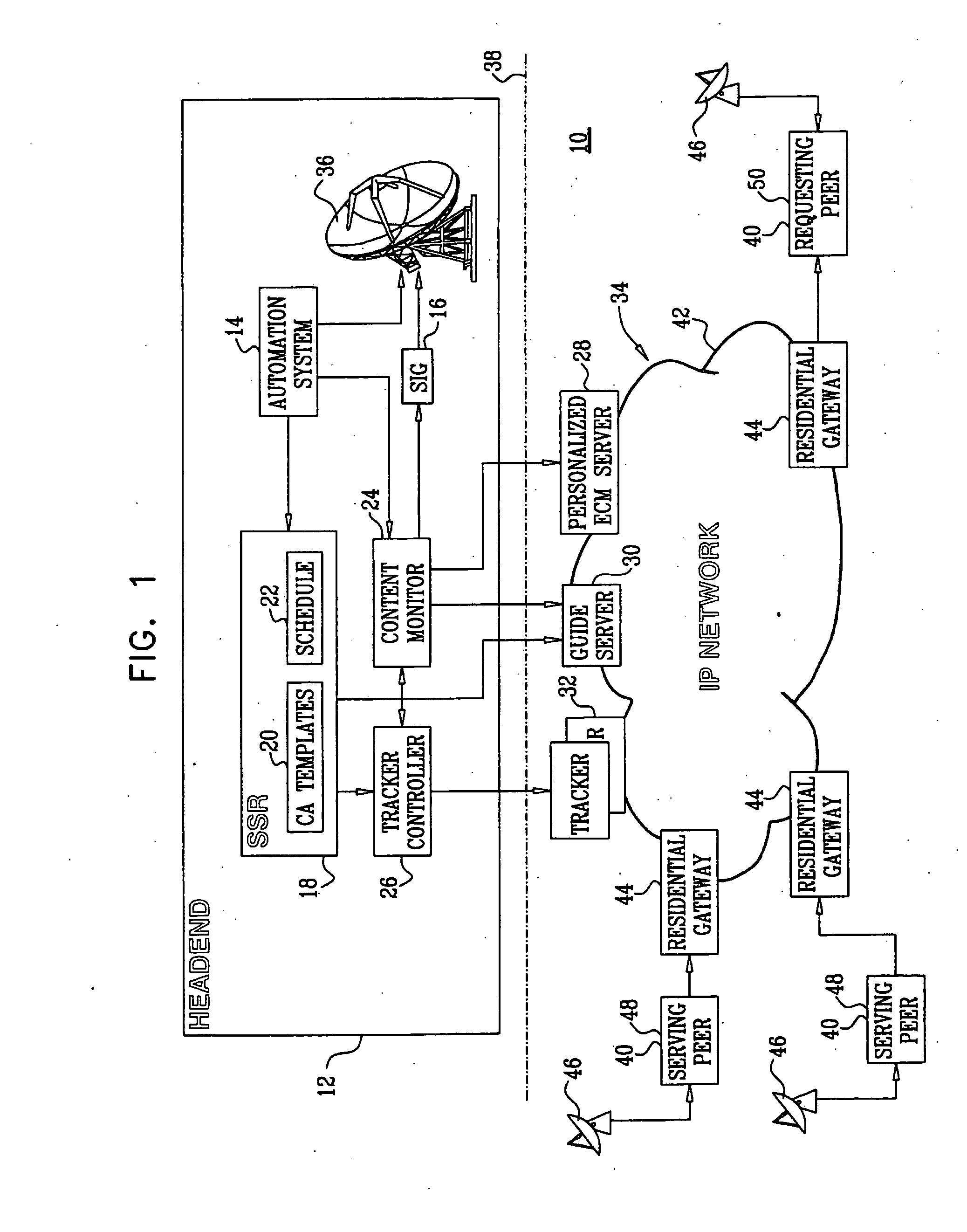

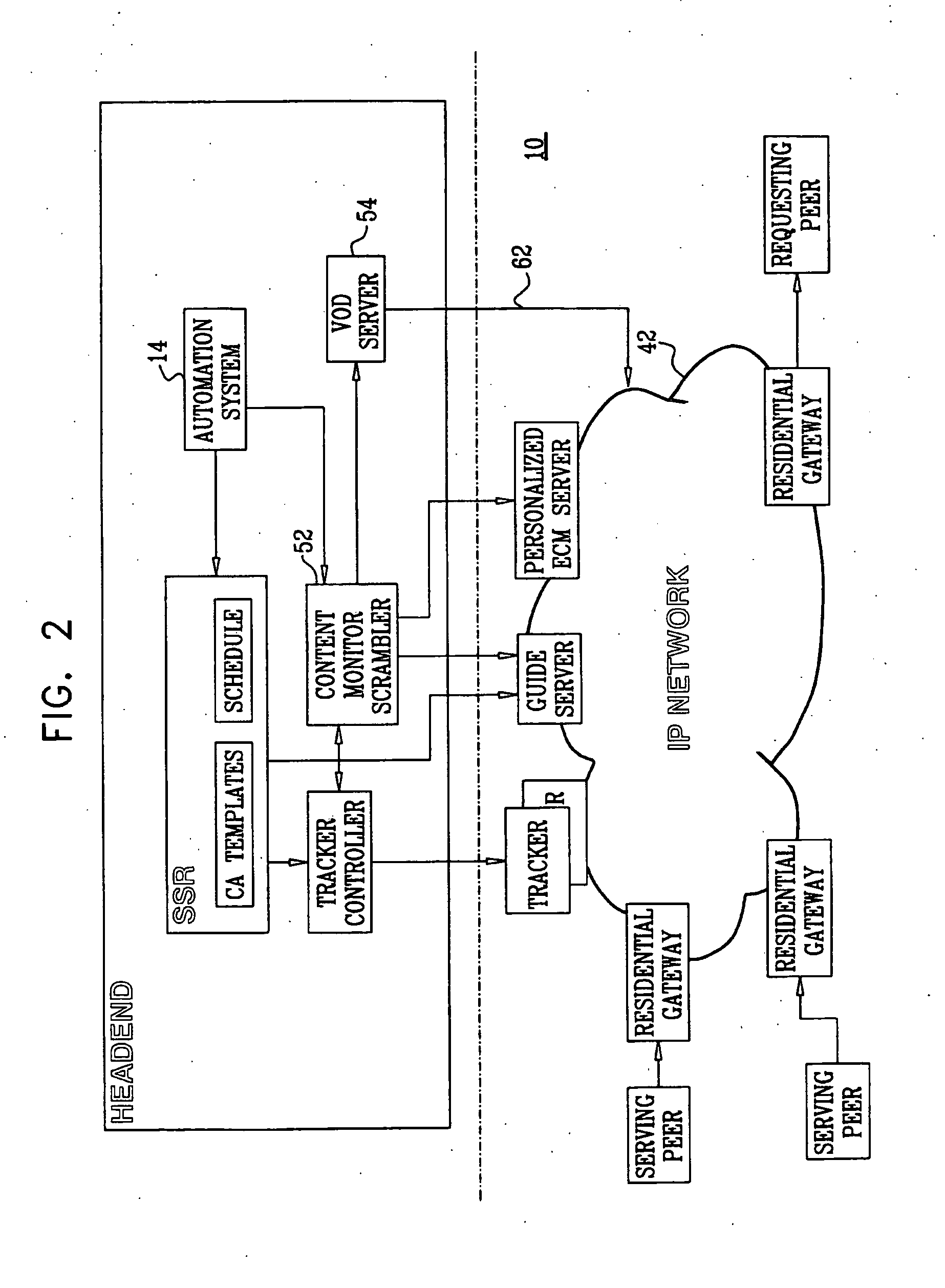

Peer- to- peer set-top box system

InactiveUS20090300673A1Easy to shareDecreasing download bandwidthTelevision system detailsColor television detailsContent sharingMetadata

A content sharing system, for implementation in a requesting peer, to receive at least a part of a chunk from a serving peer, the chunk being part of a content item, the requesting peer being operationally connected to a plurality of peers including the serving peer via a communications network, the content item being media content originally broadcast in a media stream by a Headend to at least some of the peers, the system including a metadata module to receive chunk metadata identifying the location of the chunk based on an identifier in the media stream originally broadcast by the Headend, a content transfer module to request the at least part of the chunk from the serving peer based on the chunk metadata, and receive the at least part of the chunk from the serving peer. Related apparatus and methods are also described.

Owner:CISCO TECH INC

Device, Method, and Graphical User Interface for Forgoing Generation of Tactile Output for a Multi-Contact Gesture

ActiveUS20150149899A1Improve effectivenessImprove efficiencyInput/output for user-computer interactionPower supply for data processingGraphicsGraphical user interface

Owner:APPLE INC

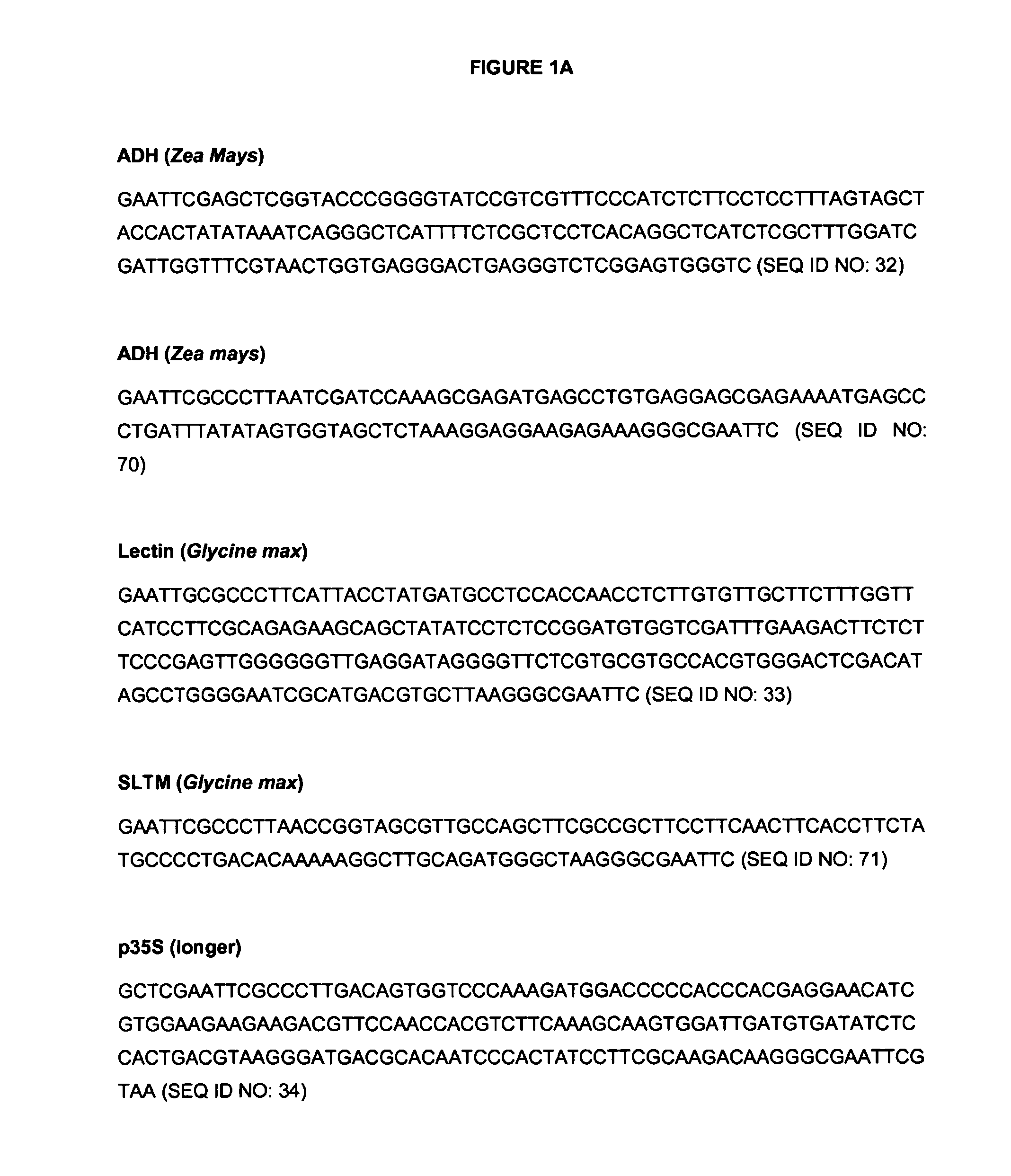

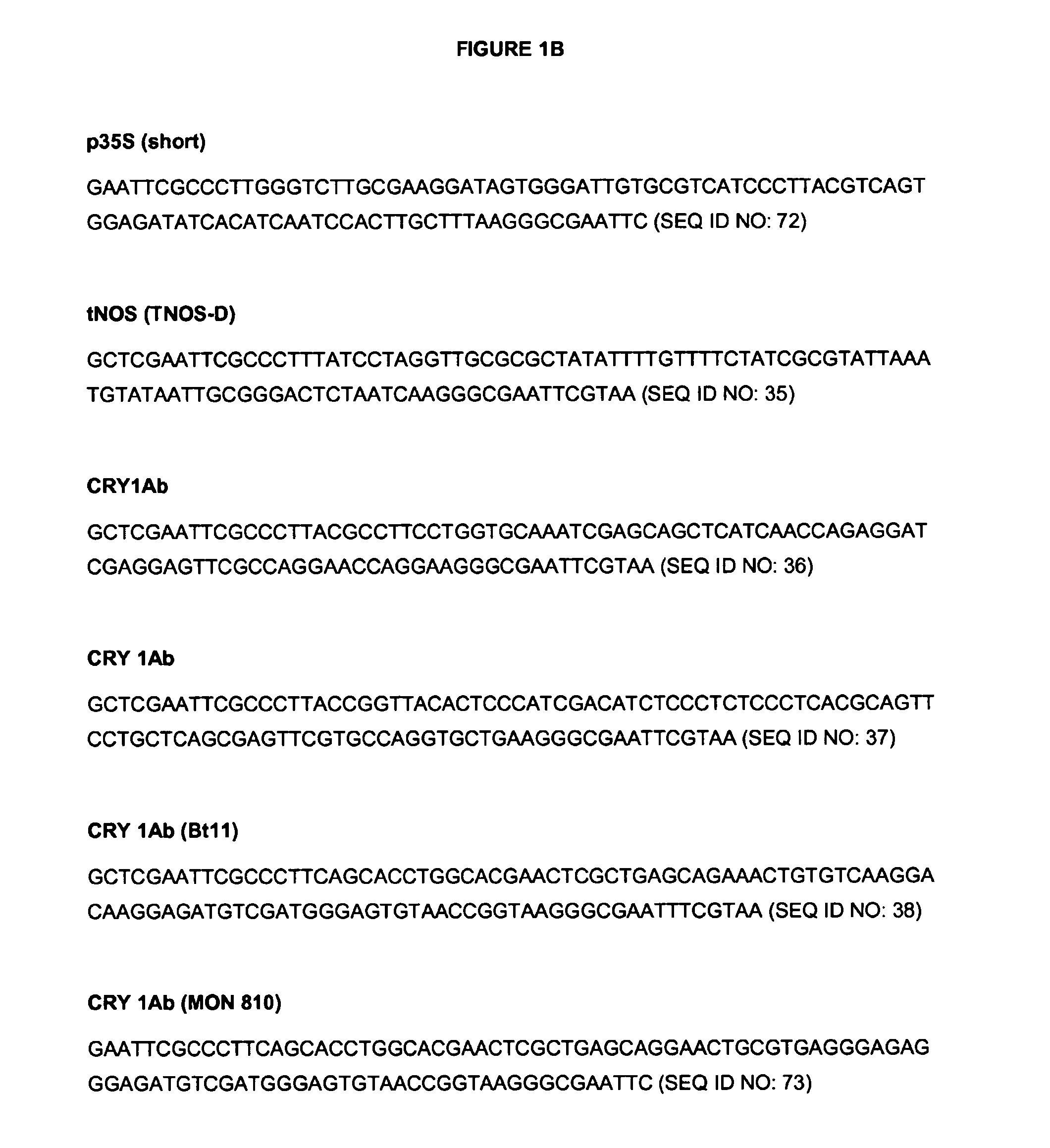

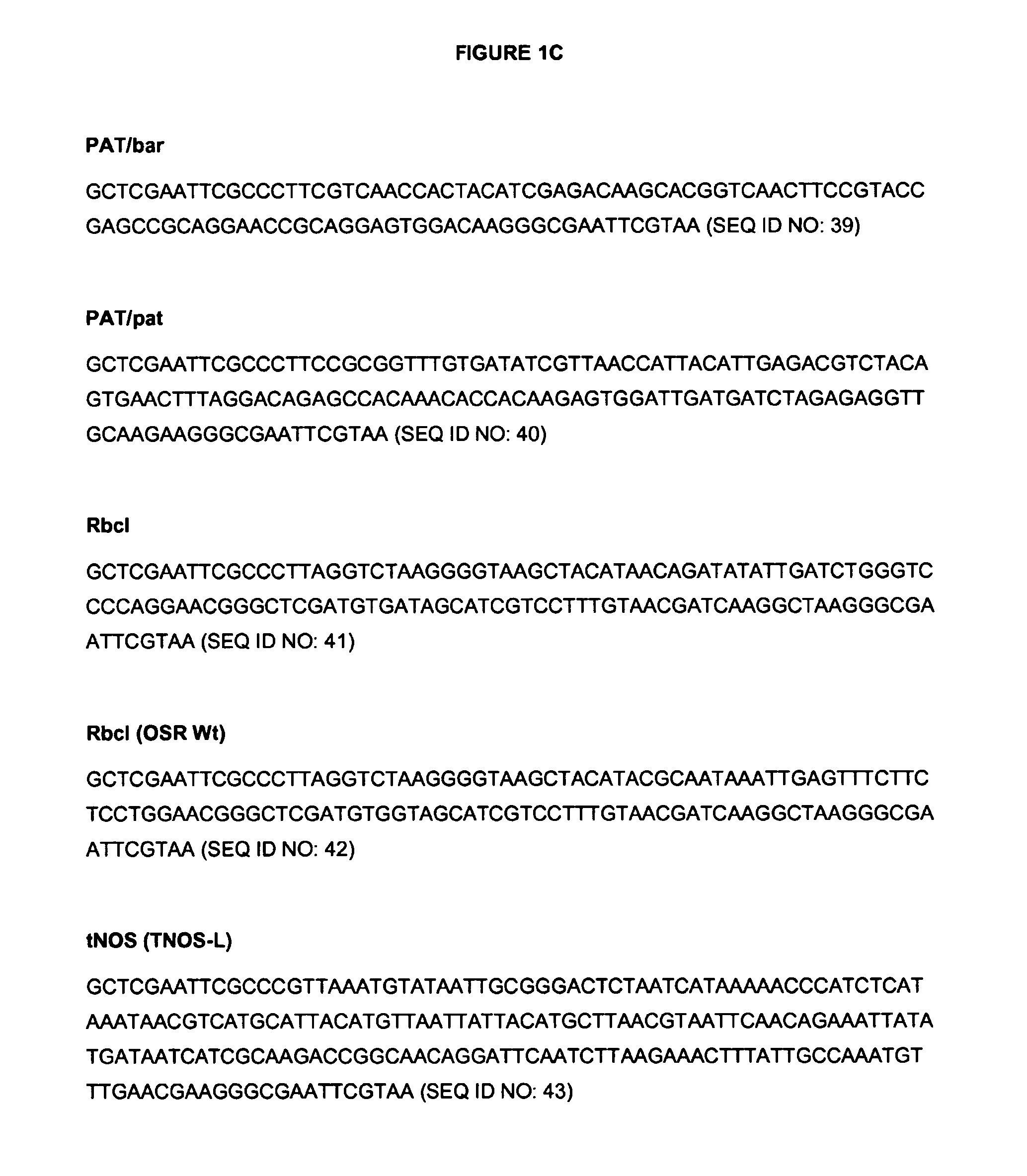

Transgenic plant event detection

ActiveUS8700336B2Reduce in quantityExtension of timeMicrobiological testing/measurementClimate change adaptationGenetic MaterialsTransgene

The present invention relates to detection of materials derived from transgenic plant events. In particular, the invention provides methods, reagents, kits and reference materials for detecting the presence or absence in a sample of genetic material derived from and attributable to select transgenic plant events.

Owner:SCIENSANO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com