Patents

Literature

96 results about "Proper function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

PROPER function is categorized as String or Text function in excel. The PROPER function converts the first character to upper case and rests to lower case. Basically, PROPER function in excel is used to convert your input text to proper case.

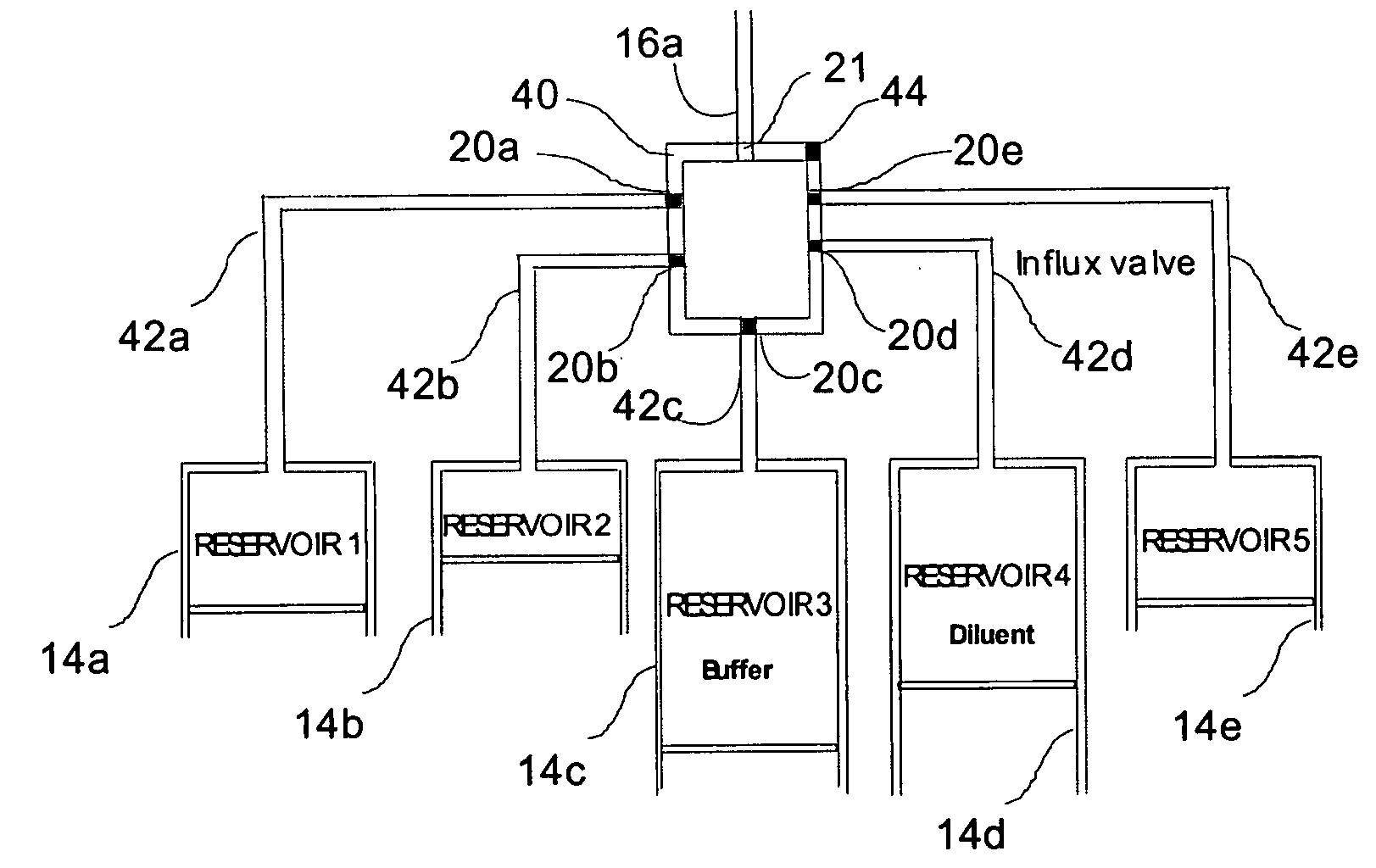

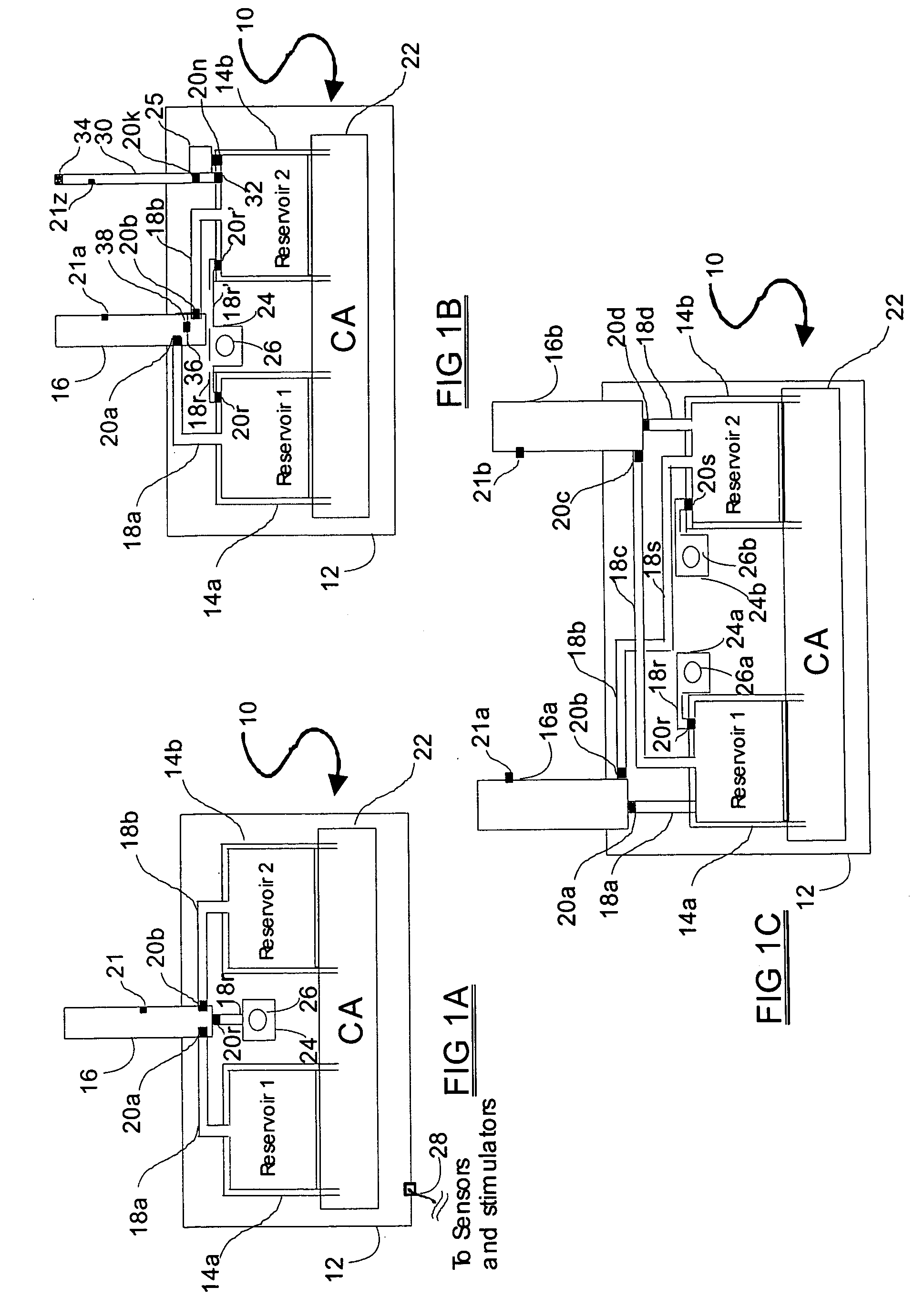

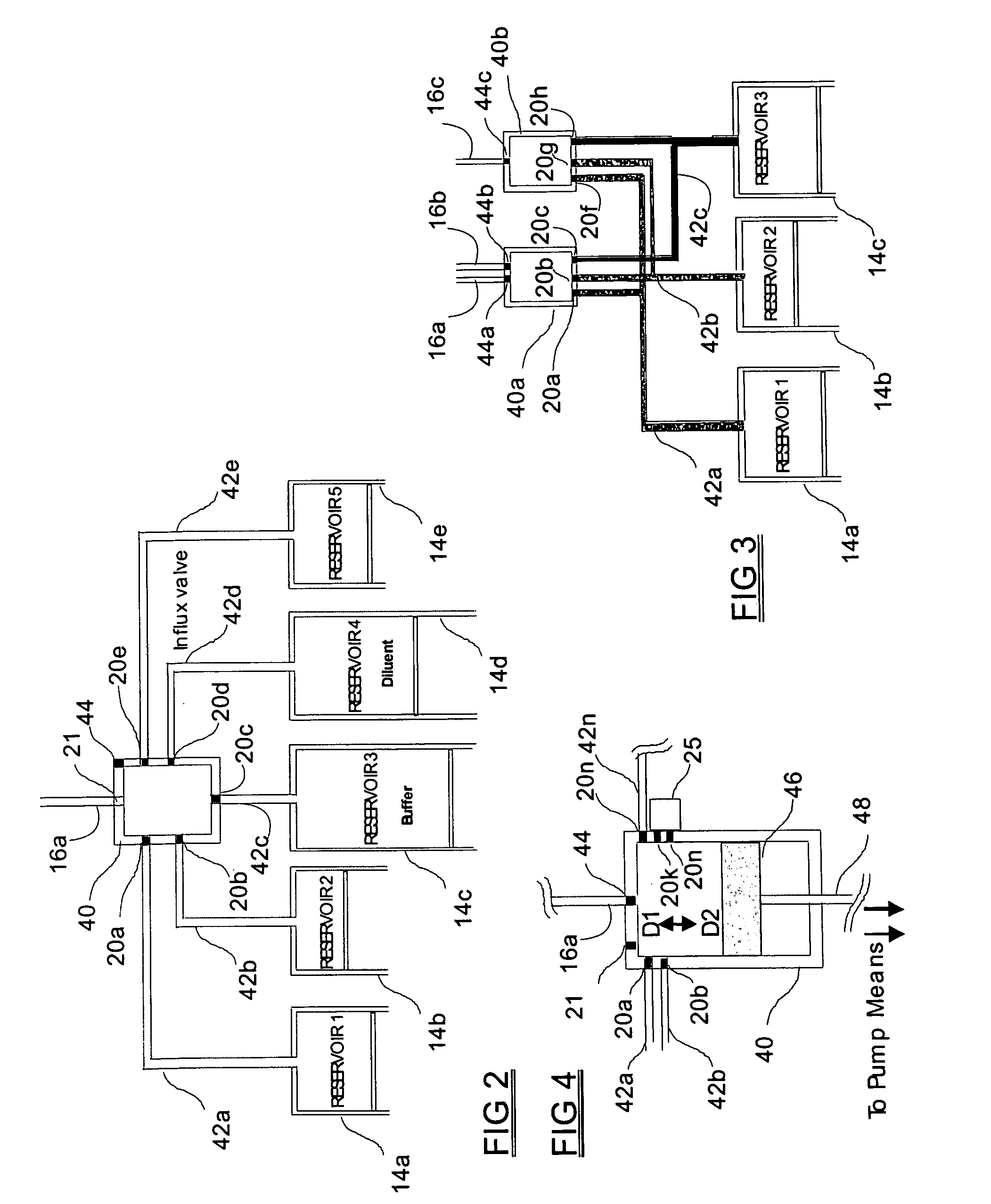

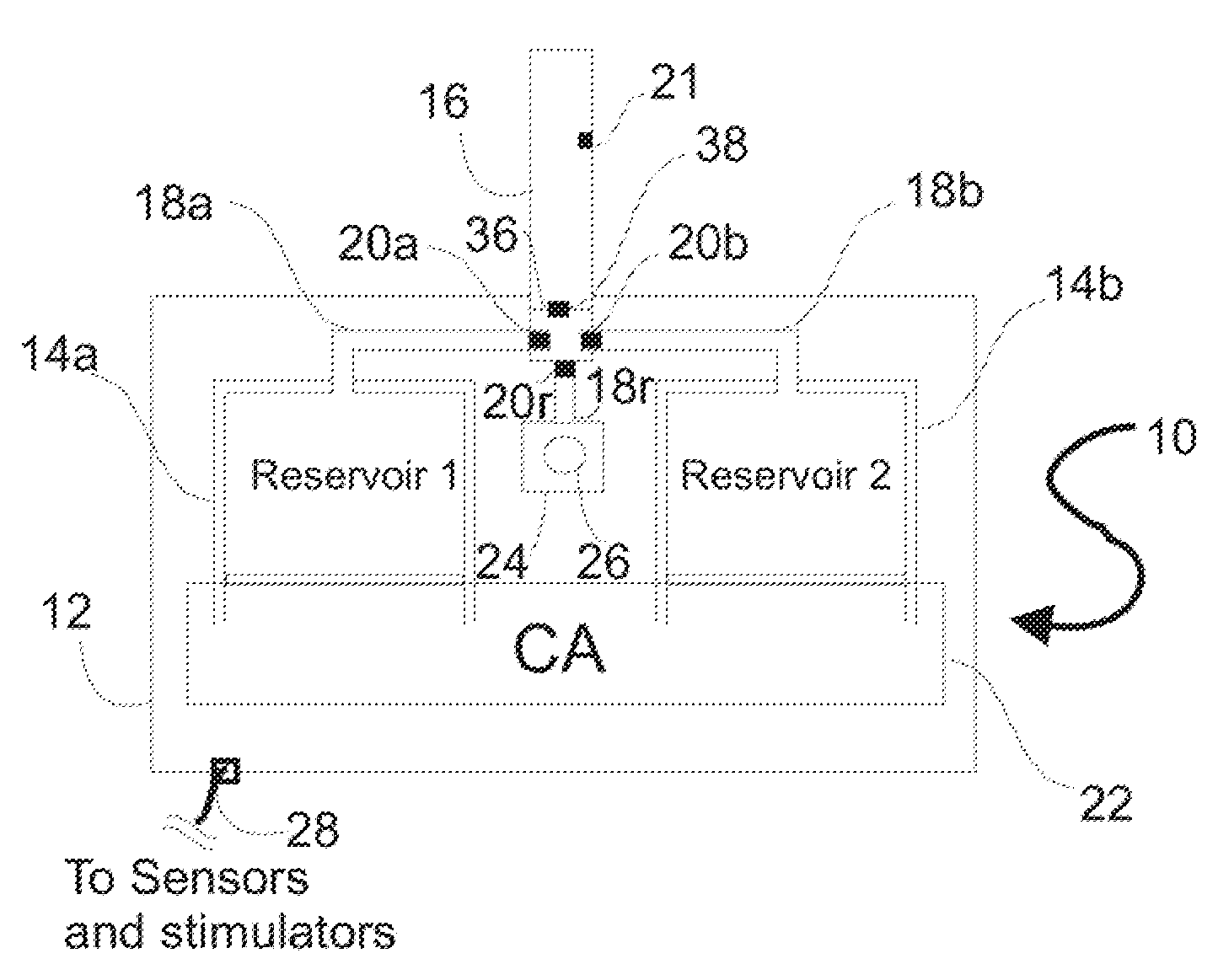

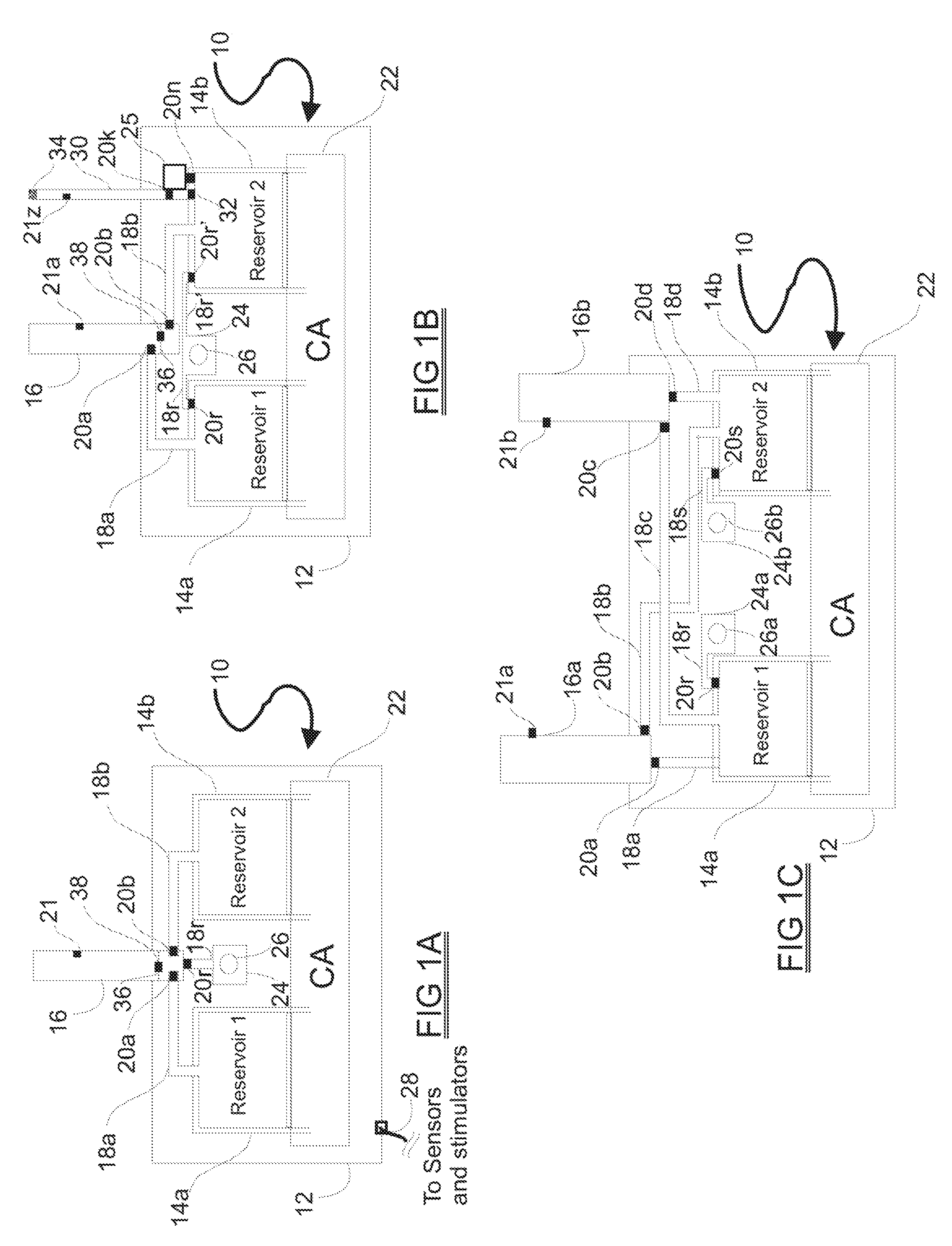

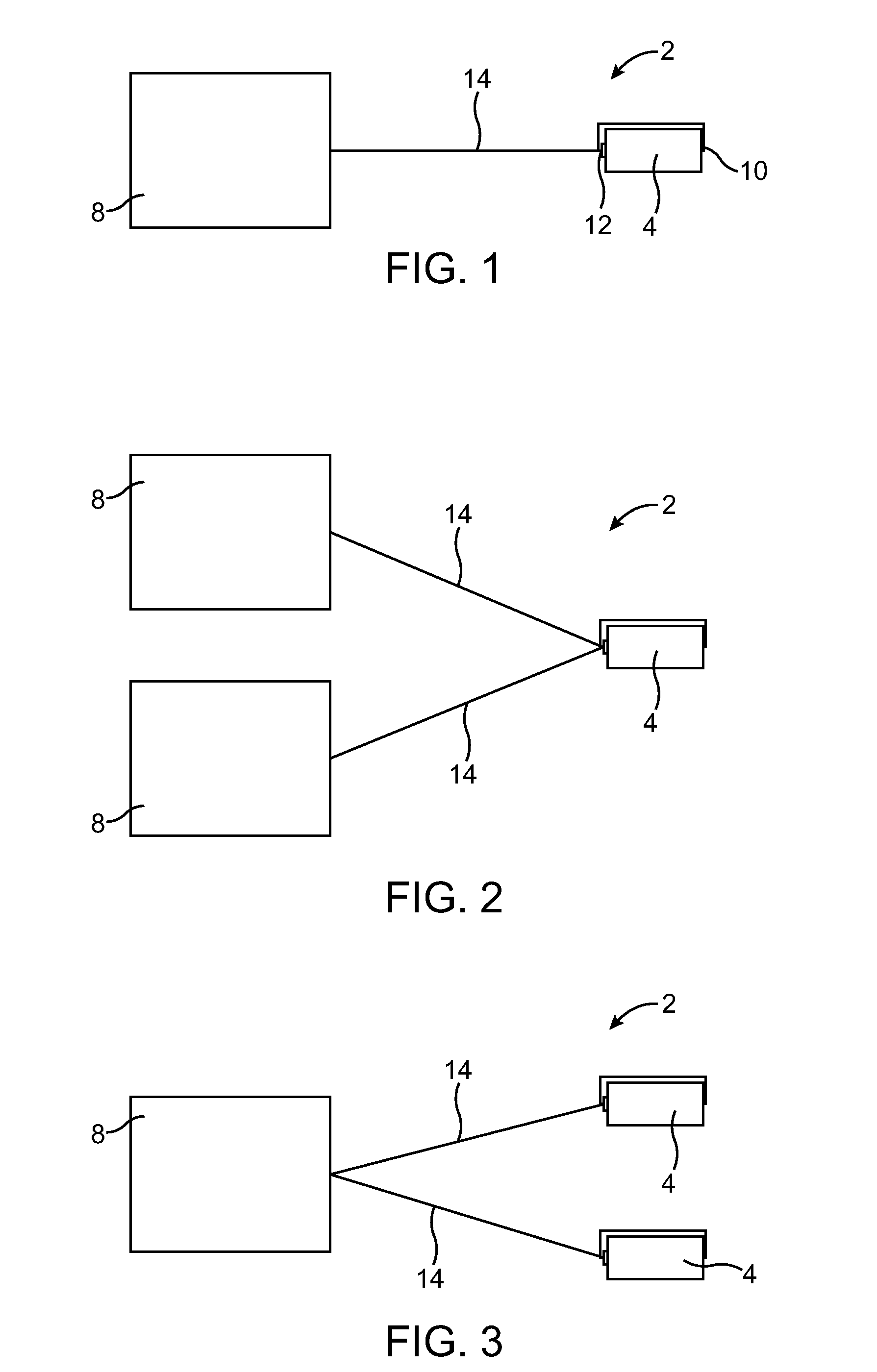

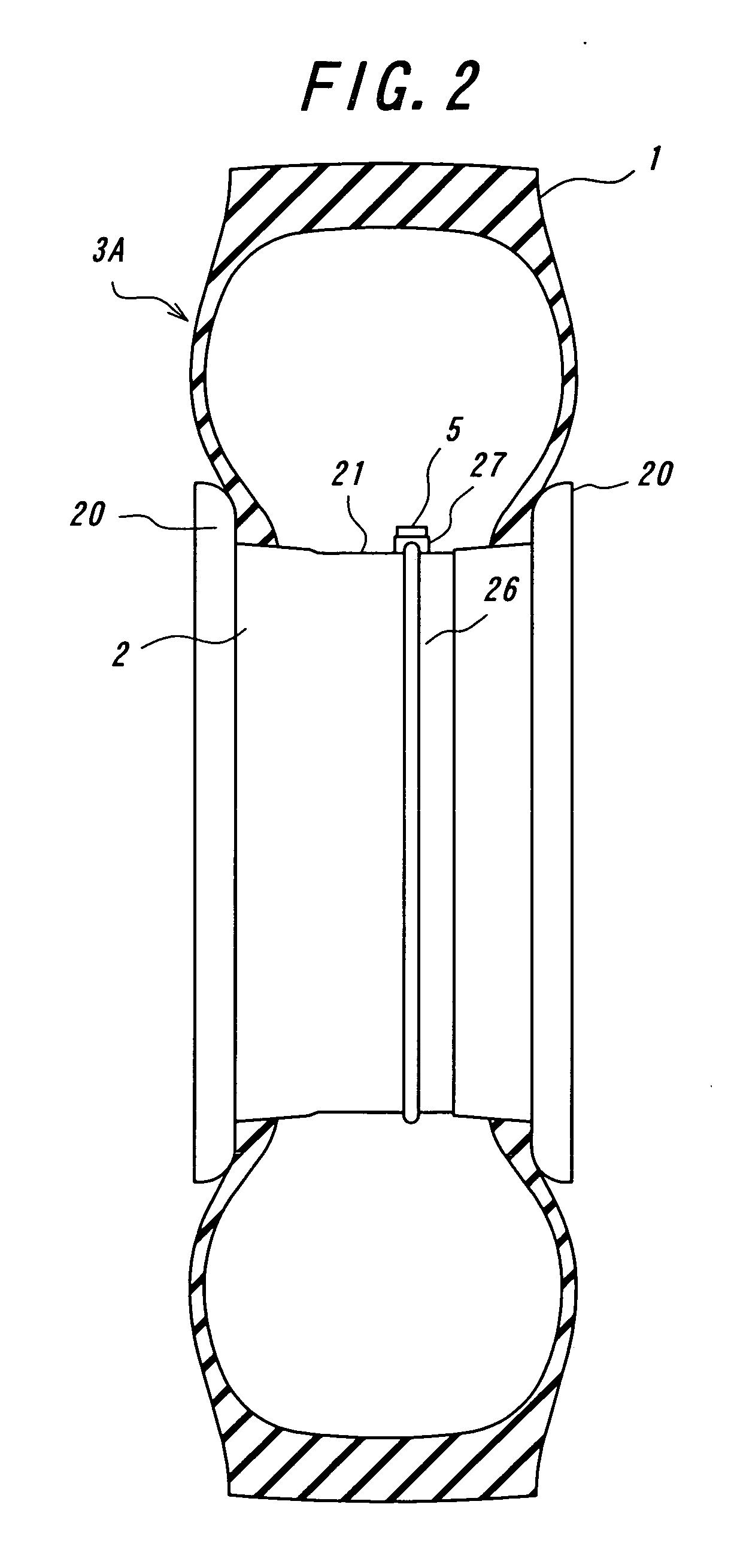

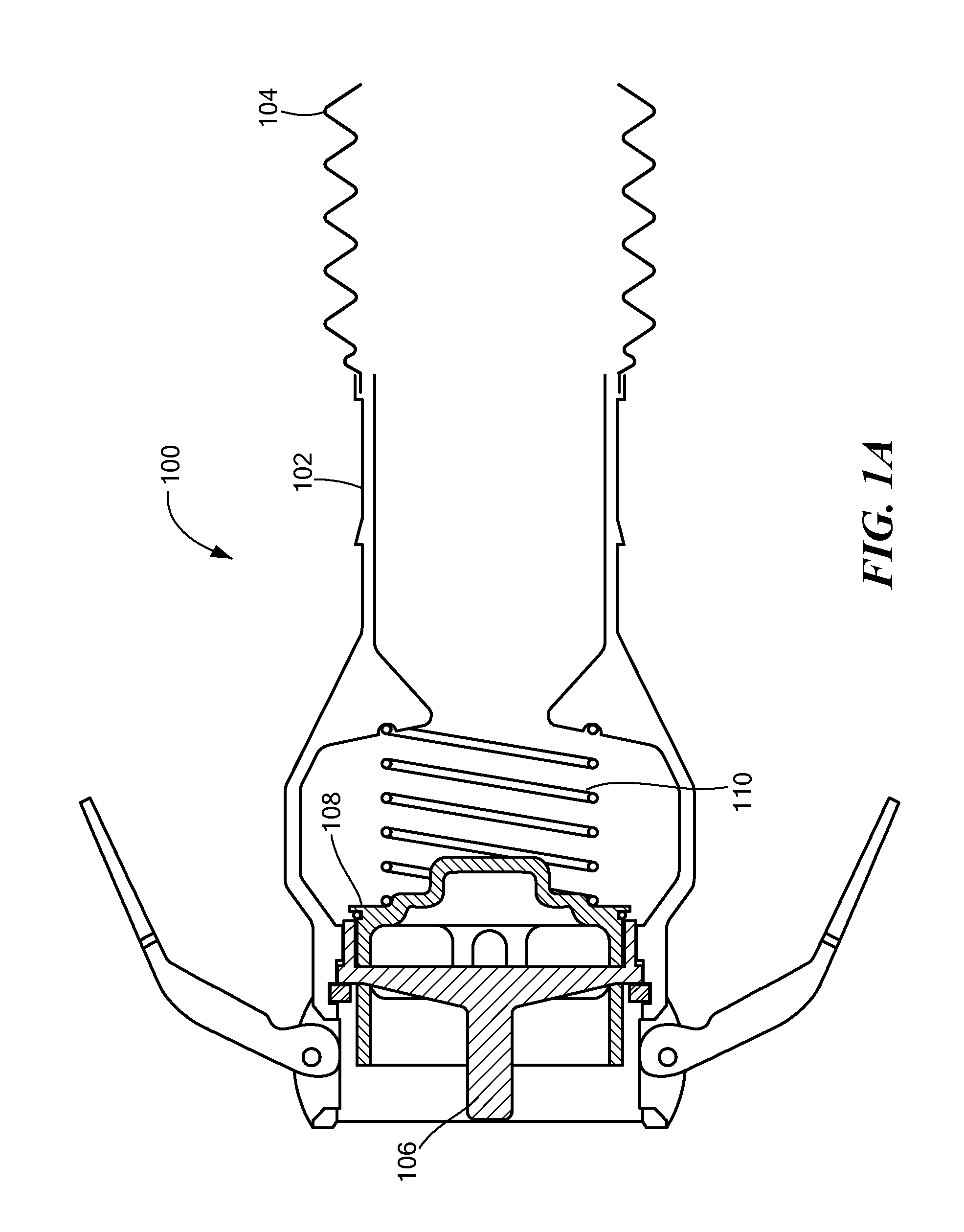

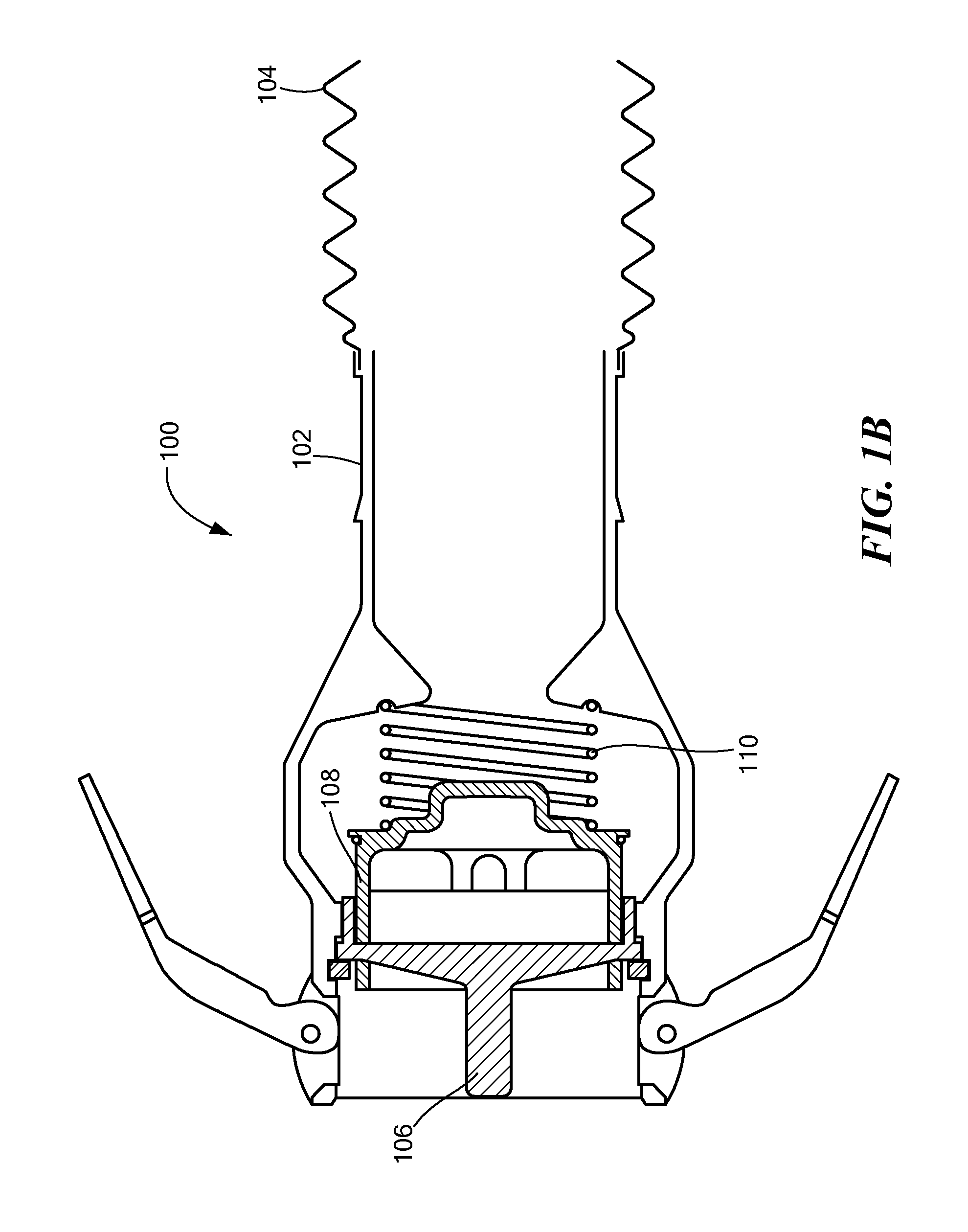

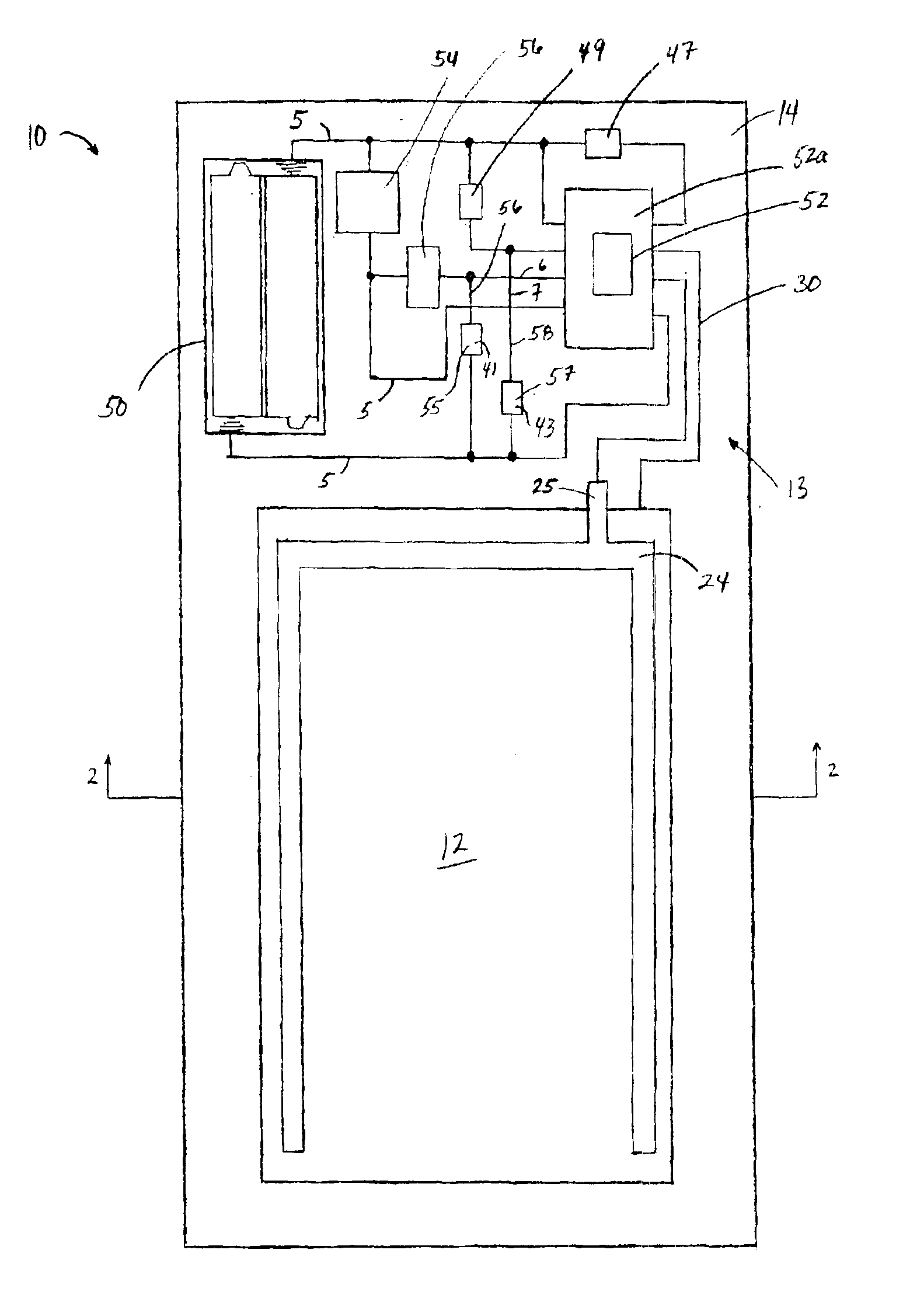

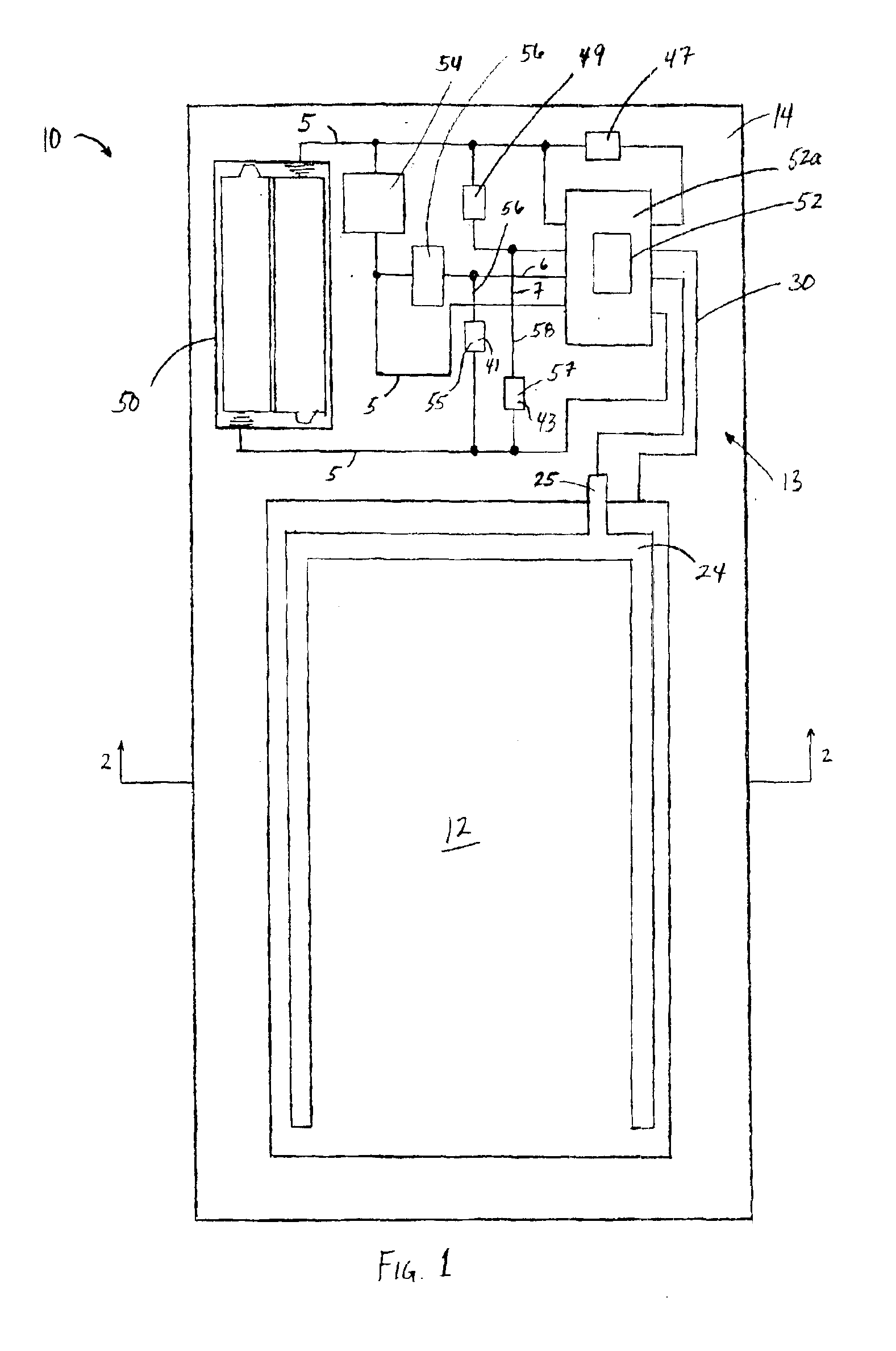

Programmable medical drug delivery systems and methods for delivery of multiple fluids and concentrations

InactiveUS20050277912A1Extension of timeEasy to fillMulti-lumen catheterDrug and medicationsControl mannerDelivery system

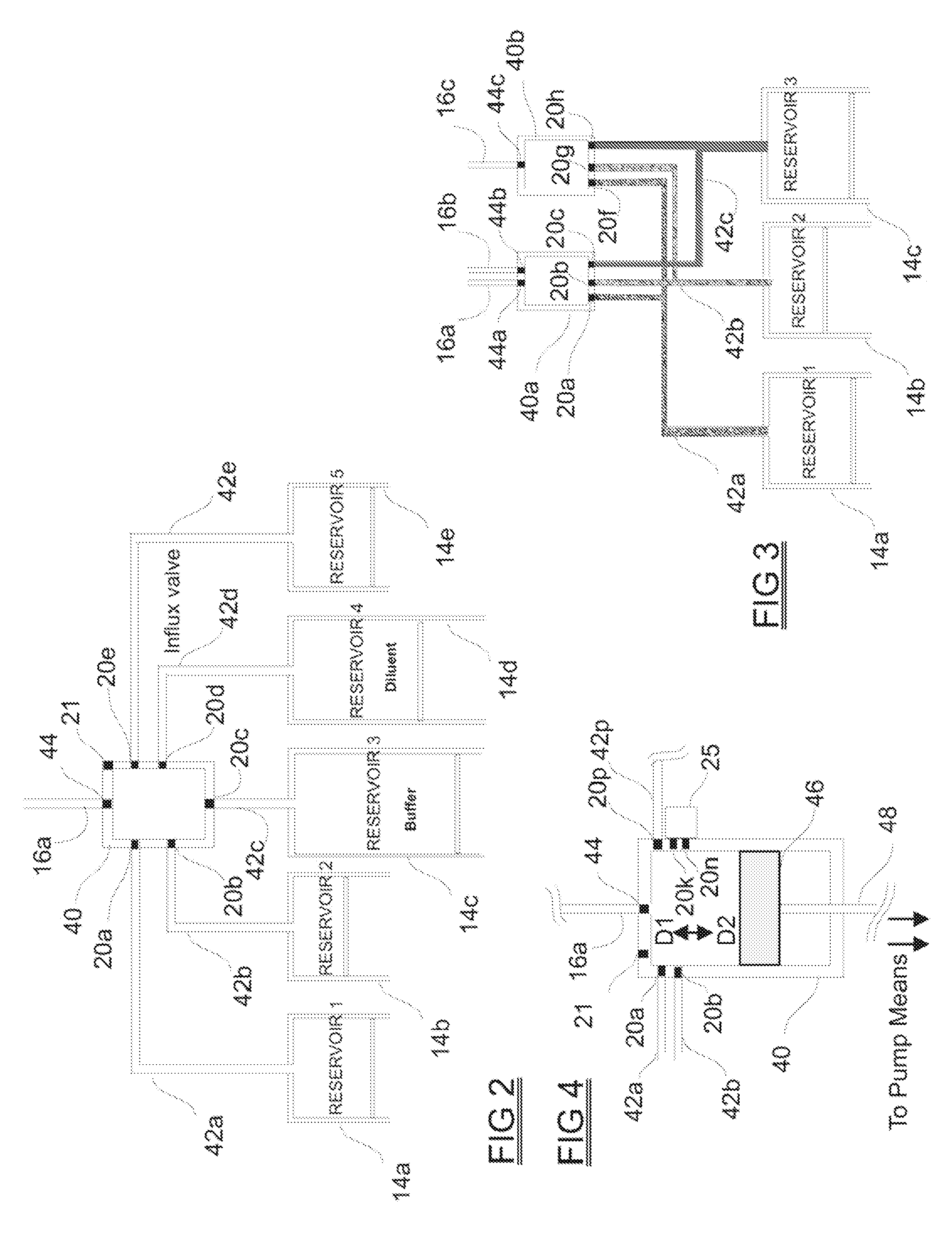

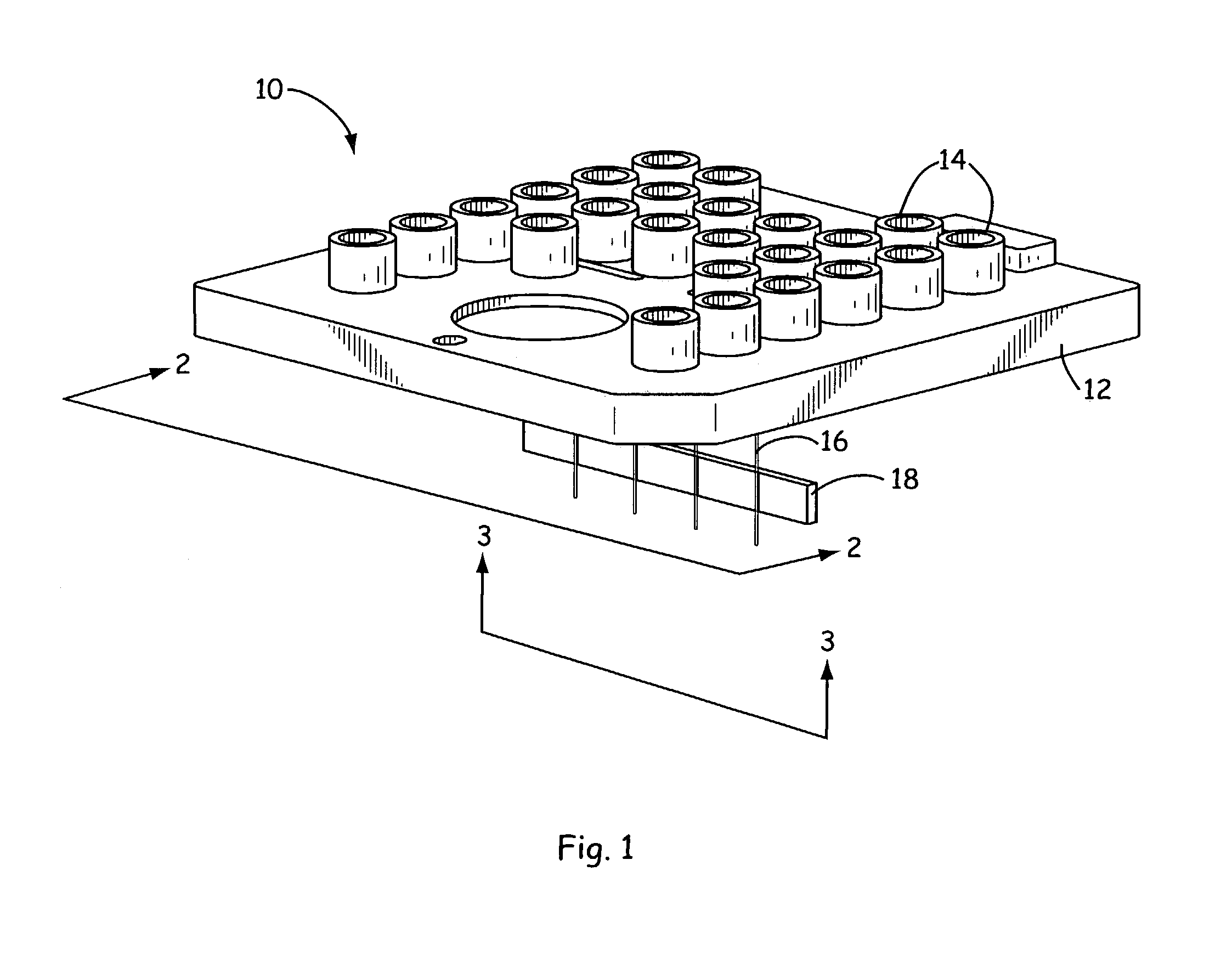

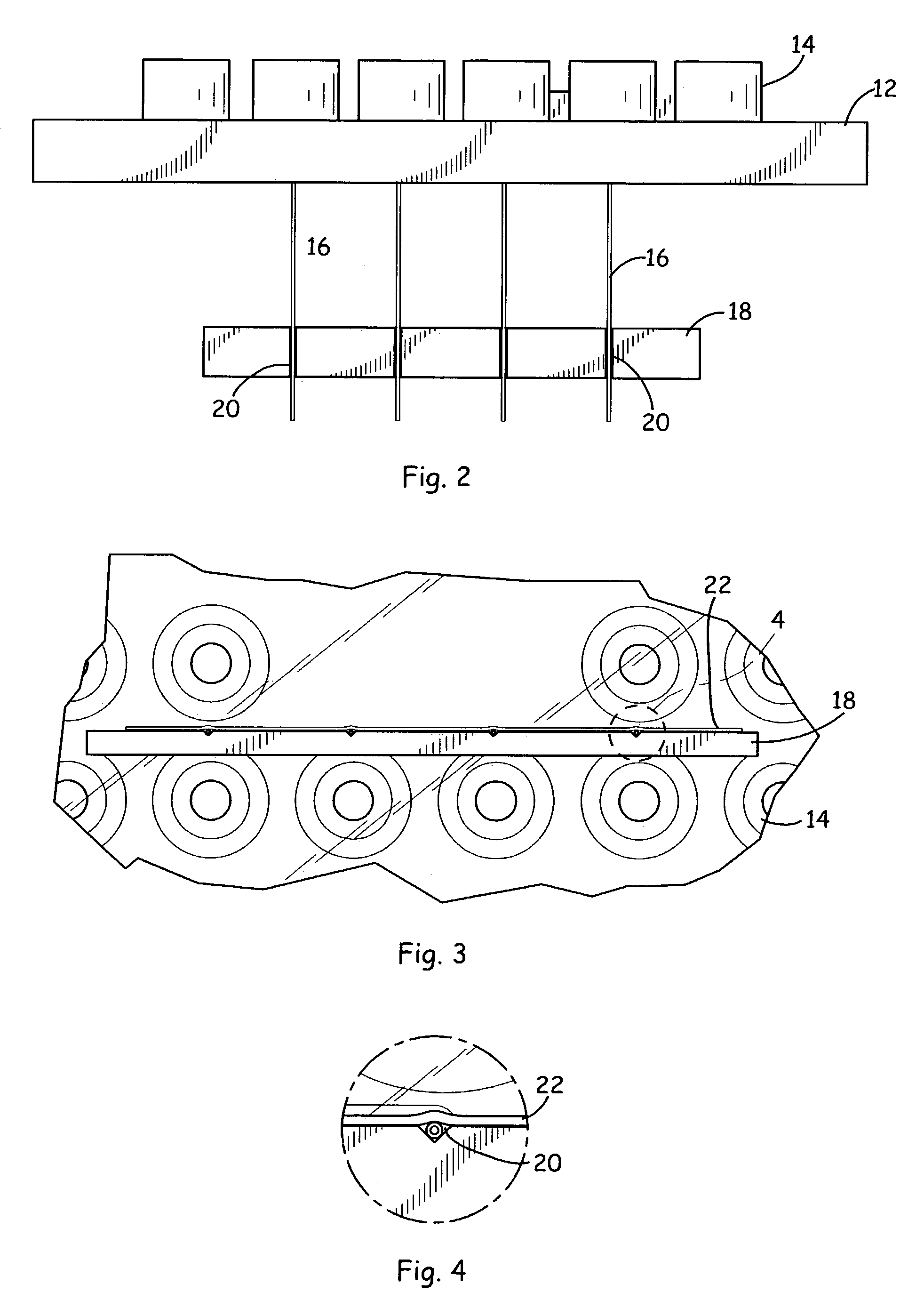

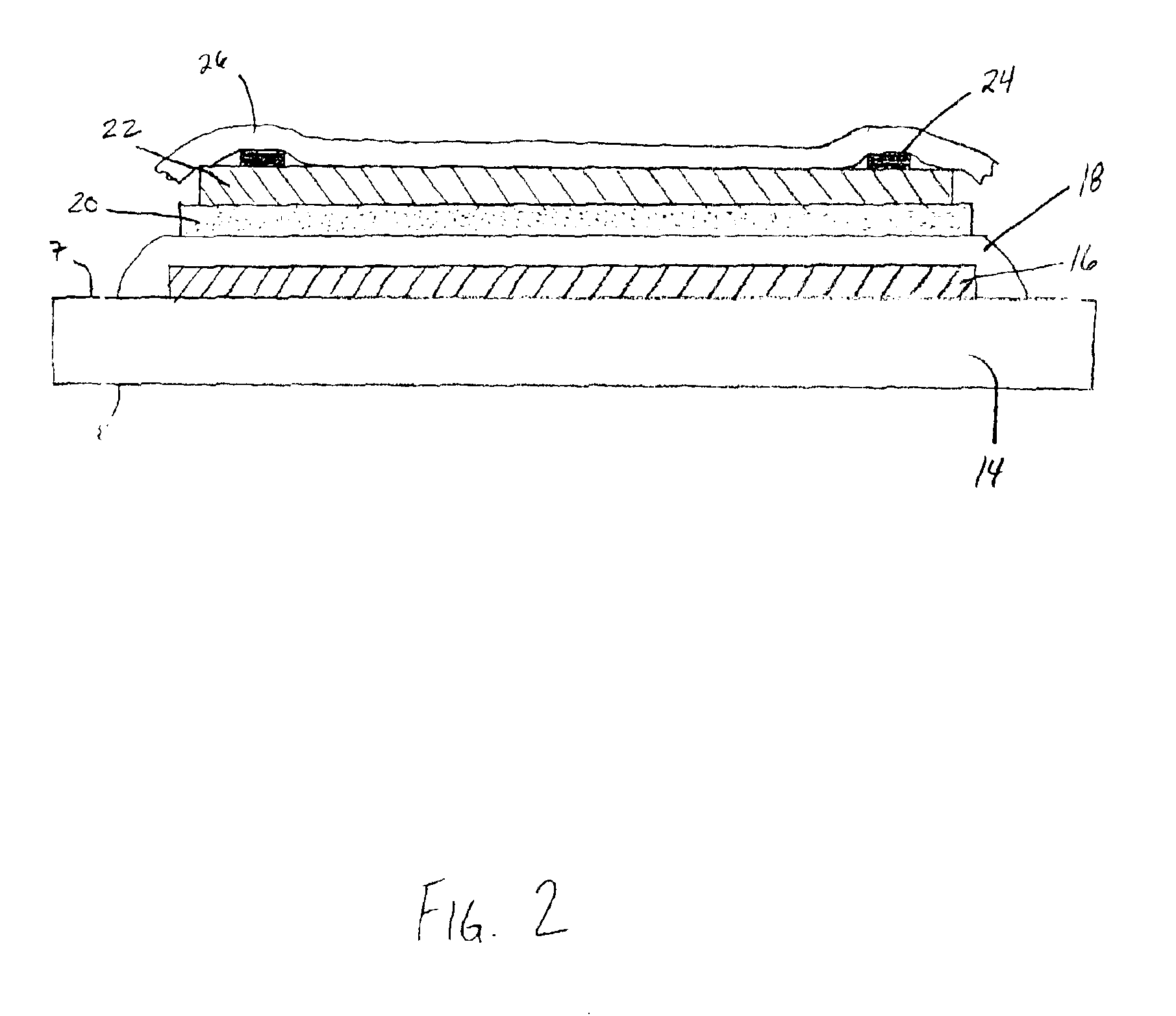

A drug delivery system provides for mixing various drugs in an optimally controlled manner, for using flow controllers to guide multiple drugs into a single or into multiple catheters, for enabling a single lumen catheter to treat a specific region with several drugs, for allowing for dilution of a concentrated drug in order to both increase the time between refilling and also for providing any concentration of a drug that might be desired, for using a buffer fluid to deliver exact amounts of several drugs from the same catheter or to separate several drugs within a single catheter, for using external fluid present in the human body either as a diluent or buffer fluid, and for providing for a drug testing / filler apparatus to be used prior to implant to ensure proper function and easy means of filling multiple reservoirs with different fluids, and also after implant for refilling operations. The drug delivery system (DDS) can perform both bolus and continuous delivery of substances, and enable the measured delivery of any one of several drugs to one or more distal locations at independently programmable rates. New types of catheter systems and uses therefore are also described. Catheter hub assemblies allowing for easy replacement of drug delivery systems offer advantages when replacing drug delivery systems. New methods for using the DDS in the promotion of healthy pregnancy and treatment of a developing fetus are also possible.

Owner:JOHN SASHA

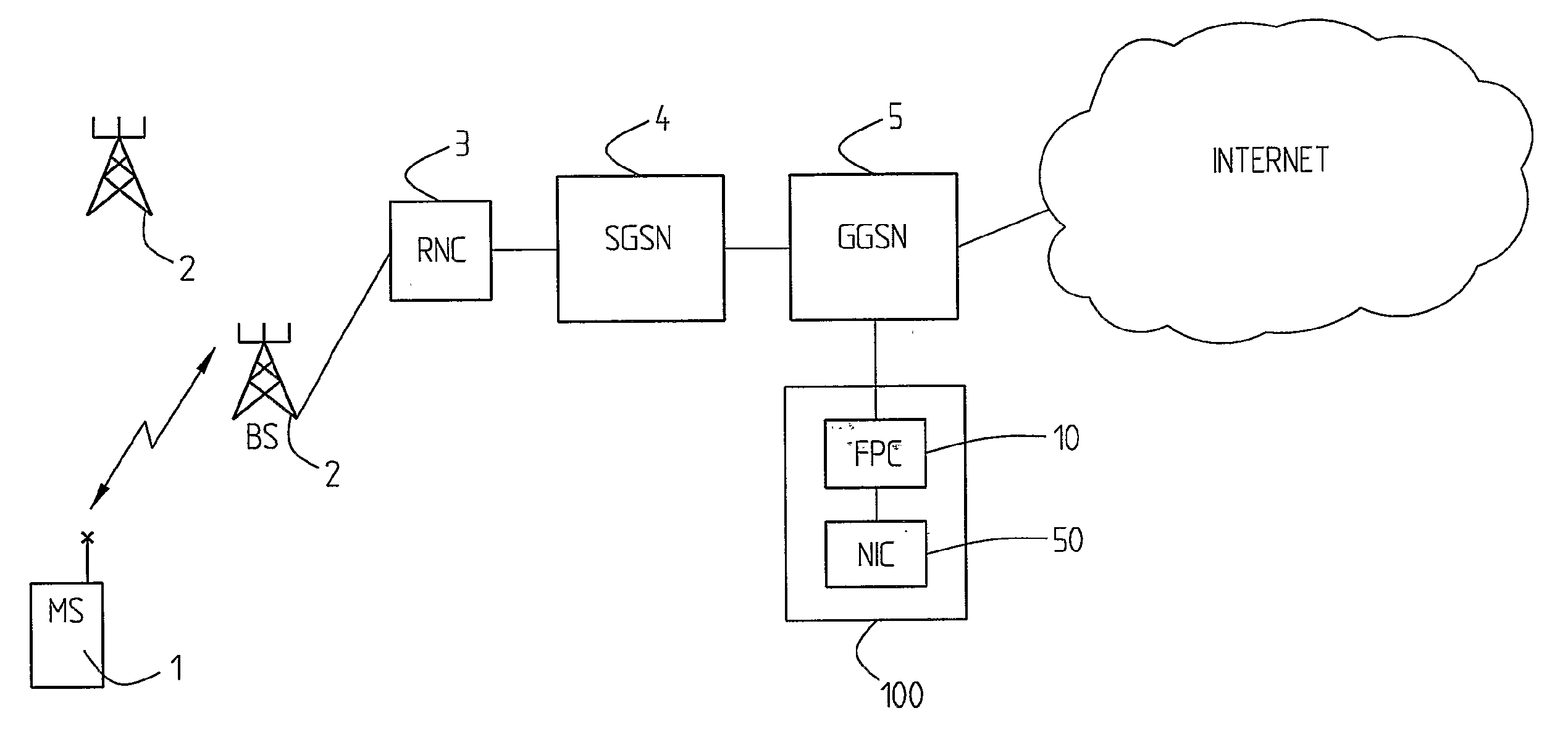

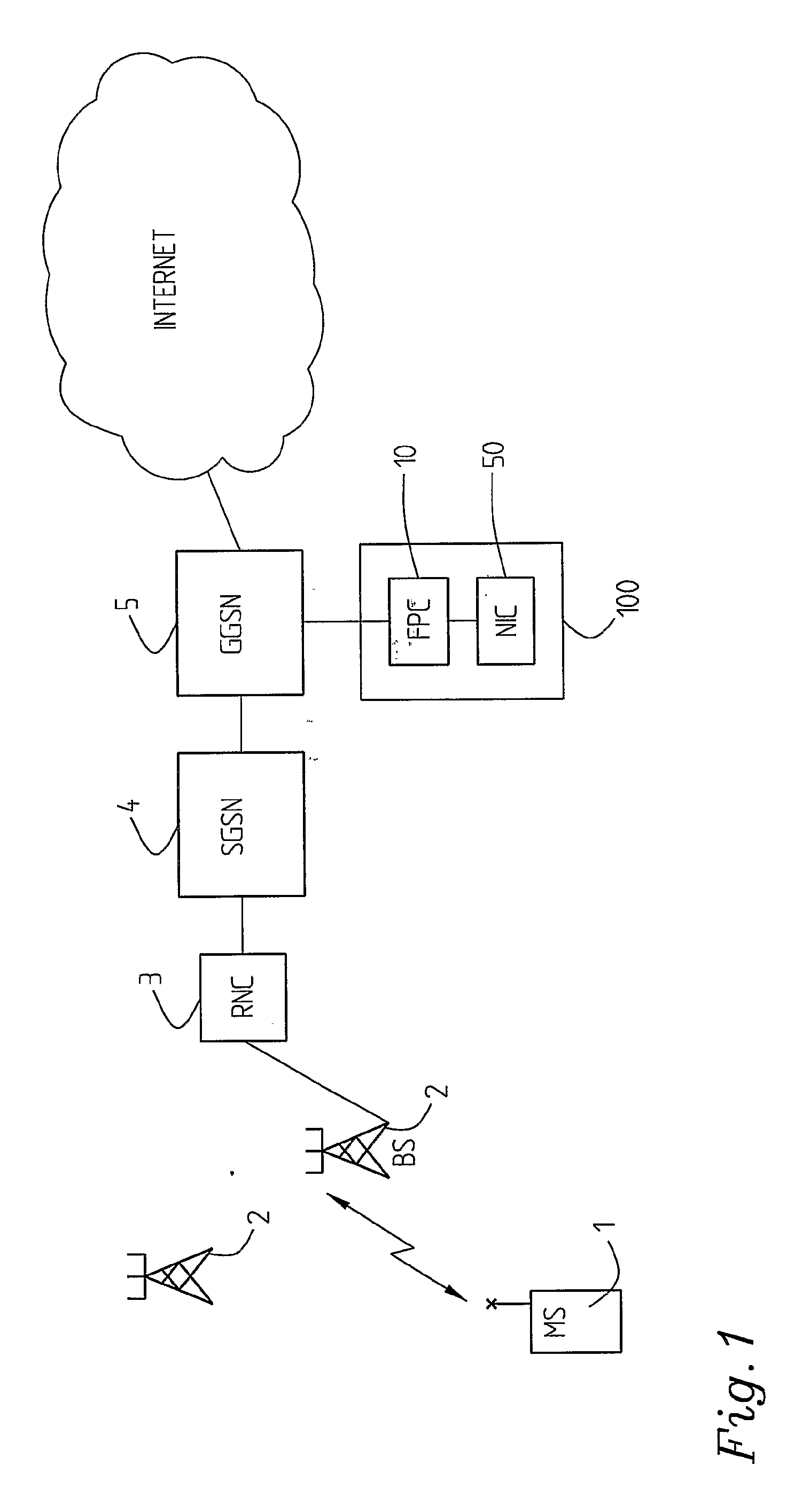

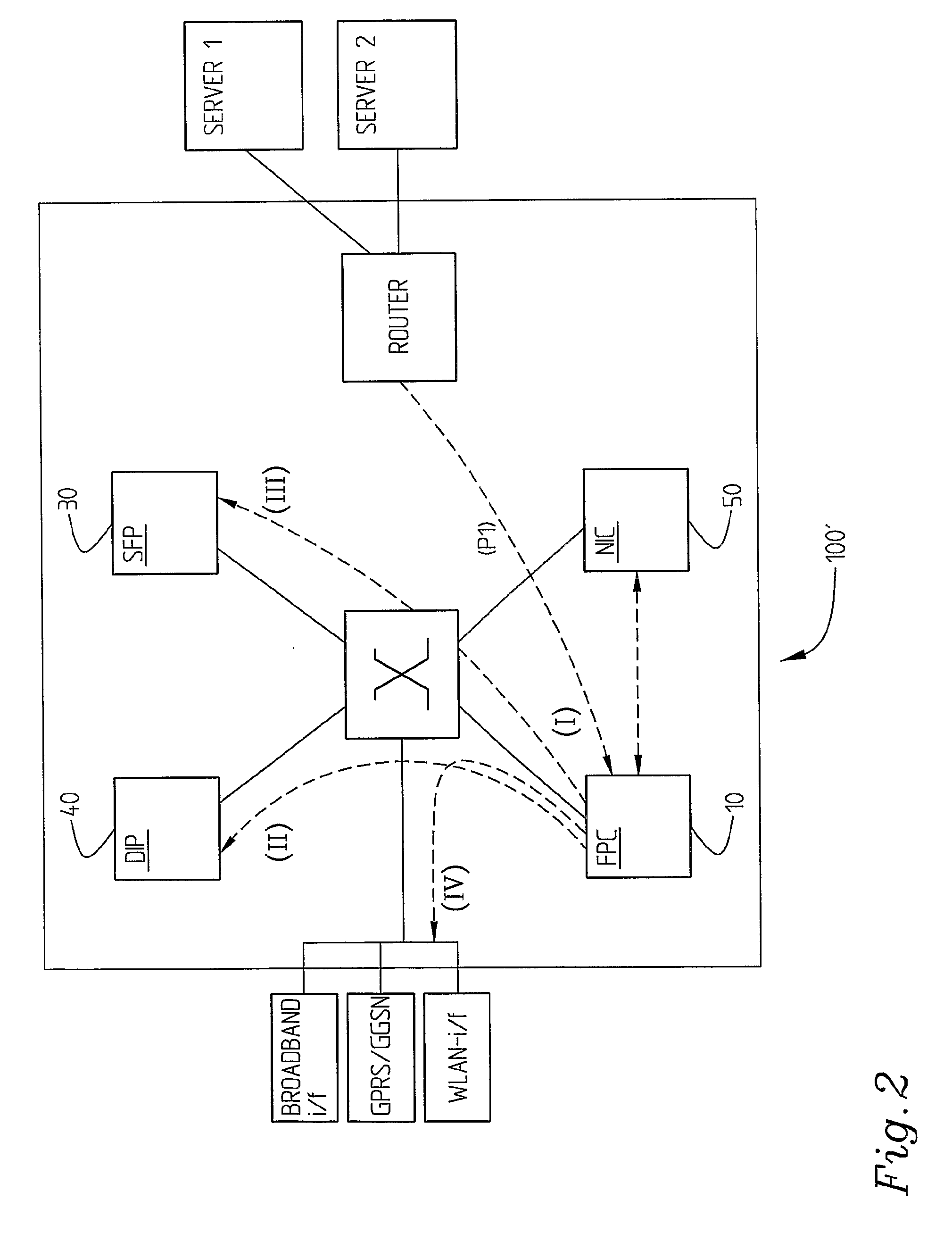

Arrangement and a Method Relating to Flow of Packets in Communication Systems

ActiveUS20080002579A1Precise maintenanceError preventionTransmission systemsProper functionProcessing core

An arrangement, system, and method for switching data packet flows in a communication system. A flow processing core classifies packet flows and defines processing flow sequences applicable to the packet flows. A distributing arrangement directs the packet flows to appropriate functional units or processors according to each packet flow's applicable processing flow sequence. The current position of each packet flow in its respective processing flow sequence is indicated. Packet flow sequence information may be determined so that reclassification of already classified packets is avoided.

Owner:TELEFON AB LM ERICSSON (PUBL)

Programmable medical drug delivery systems and methods for delivery of multiple fluids and concentrations

InactiveUS7811279B2Extension of timeEasy to fillMulti-lumen catheterDrug and medicationsControl mannerDelivery system

A drug delivery system provides for mixing various drugs in an optimally controlled manner, for using flow controllers to guide multiple drugs into a single or into multiple catheters, for enabling a single lumen catheter to treat a specific region with several drugs, for allowing for dilution of a concentrated drug in order to both increase the time between refilling and also for providing any concentration of a drug that might be desired, for using a buffer fluid to deliver exact amounts of several drugs from the same catheter or to separate several drugs within a single catheter, for using external fluid present in the human body either as a diluent or buffer fluid, and for providing for a drug testing / filler apparatus to be used prior to implant to ensure proper function and easy means of filling multiple reservoirs with different fluids, and also after implant for refilling operations. The drug delivery system (DDS) can perform both bolus and continuous delivery of substances, and enable the measured delivery of any one of several drugs to one or more distal locations at independently programmable rates. New types of catheter systems and uses therefore are also described. Catheter hub assemblies allowing for easy replacement of drug delivery systems offer advantages when replacing drug delivery systems. New methods for using the DDS in the promotion of healthy pregnancy and treatment of a developing fetus are also possible.

Owner:JOHN SASHA

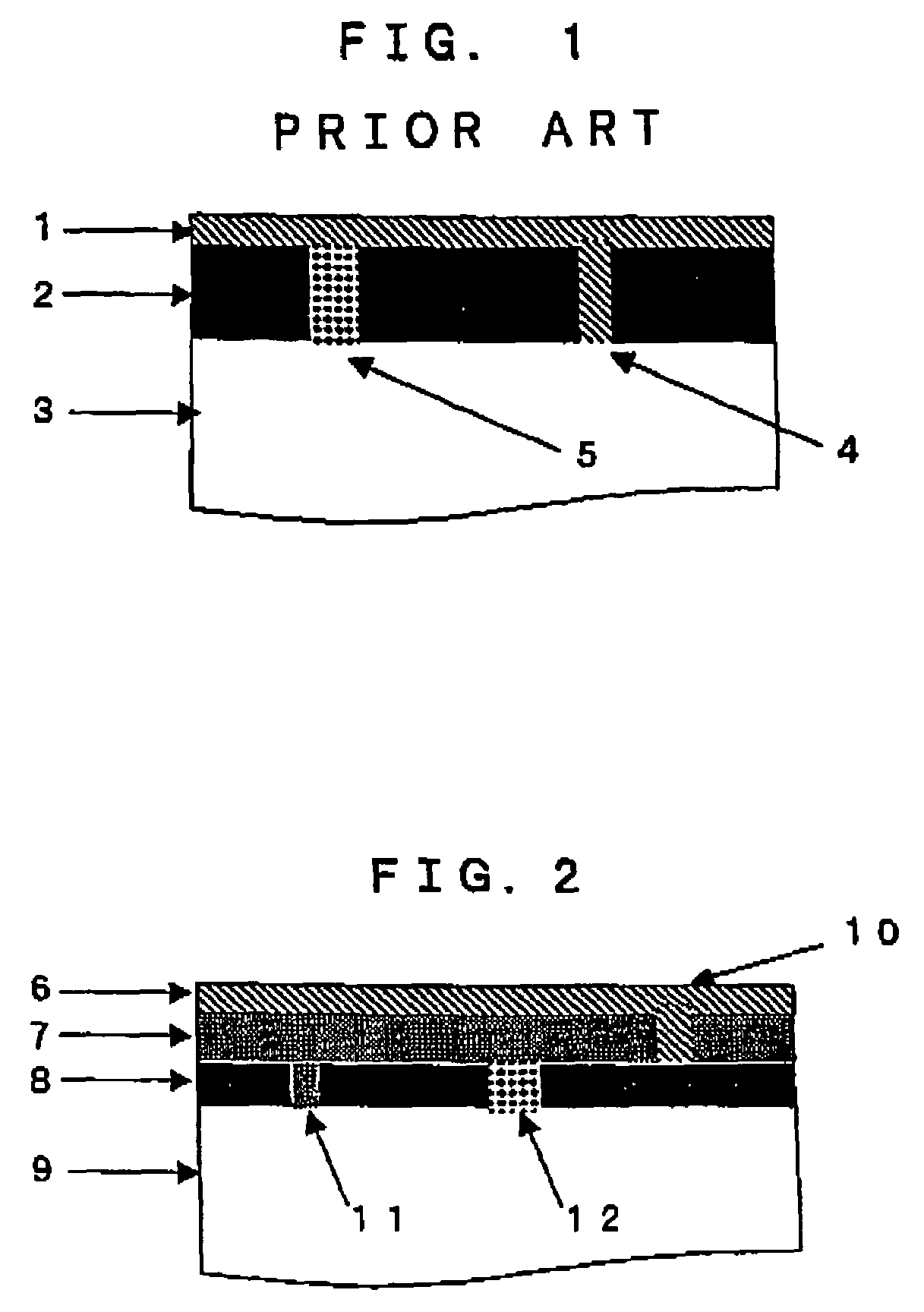

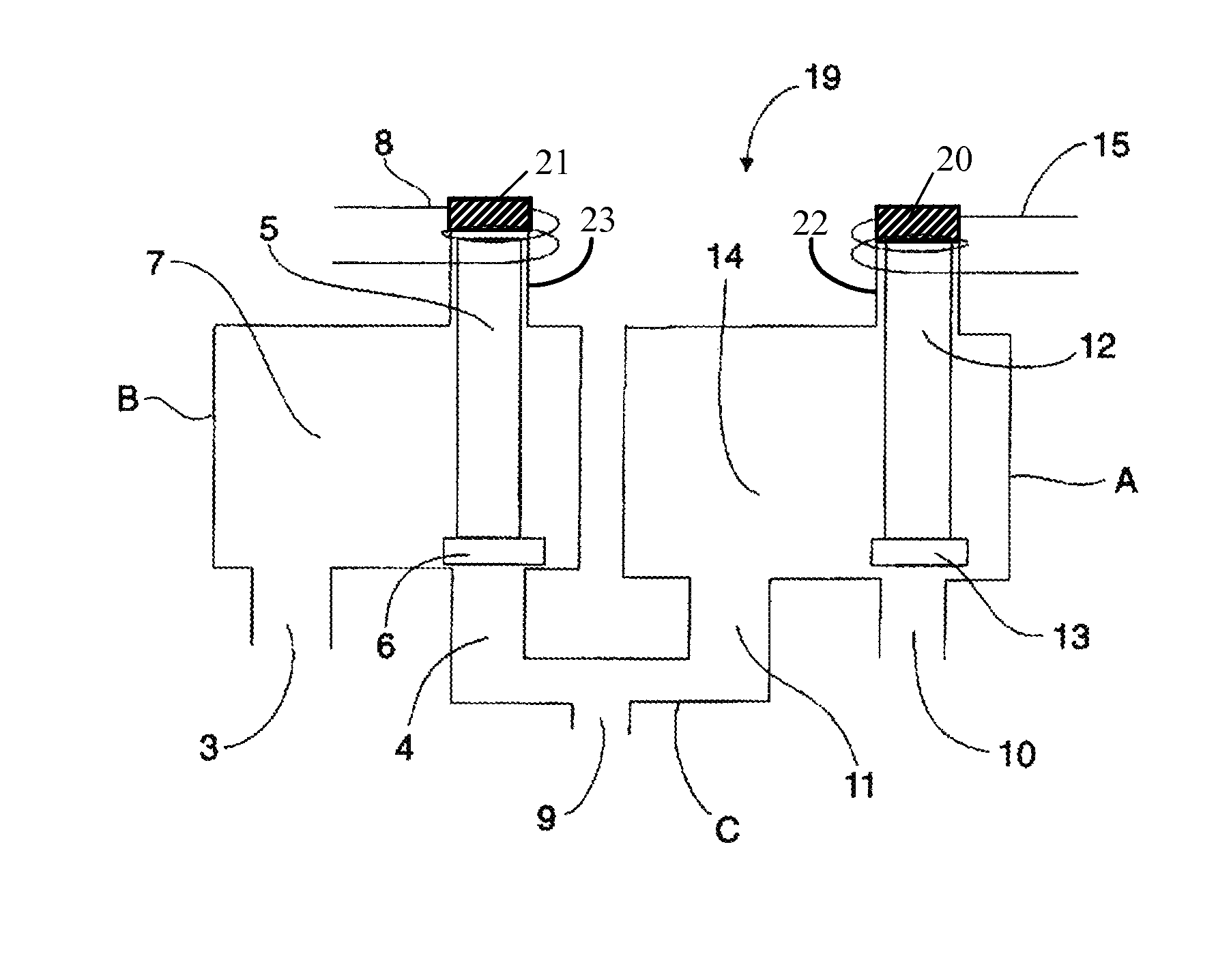

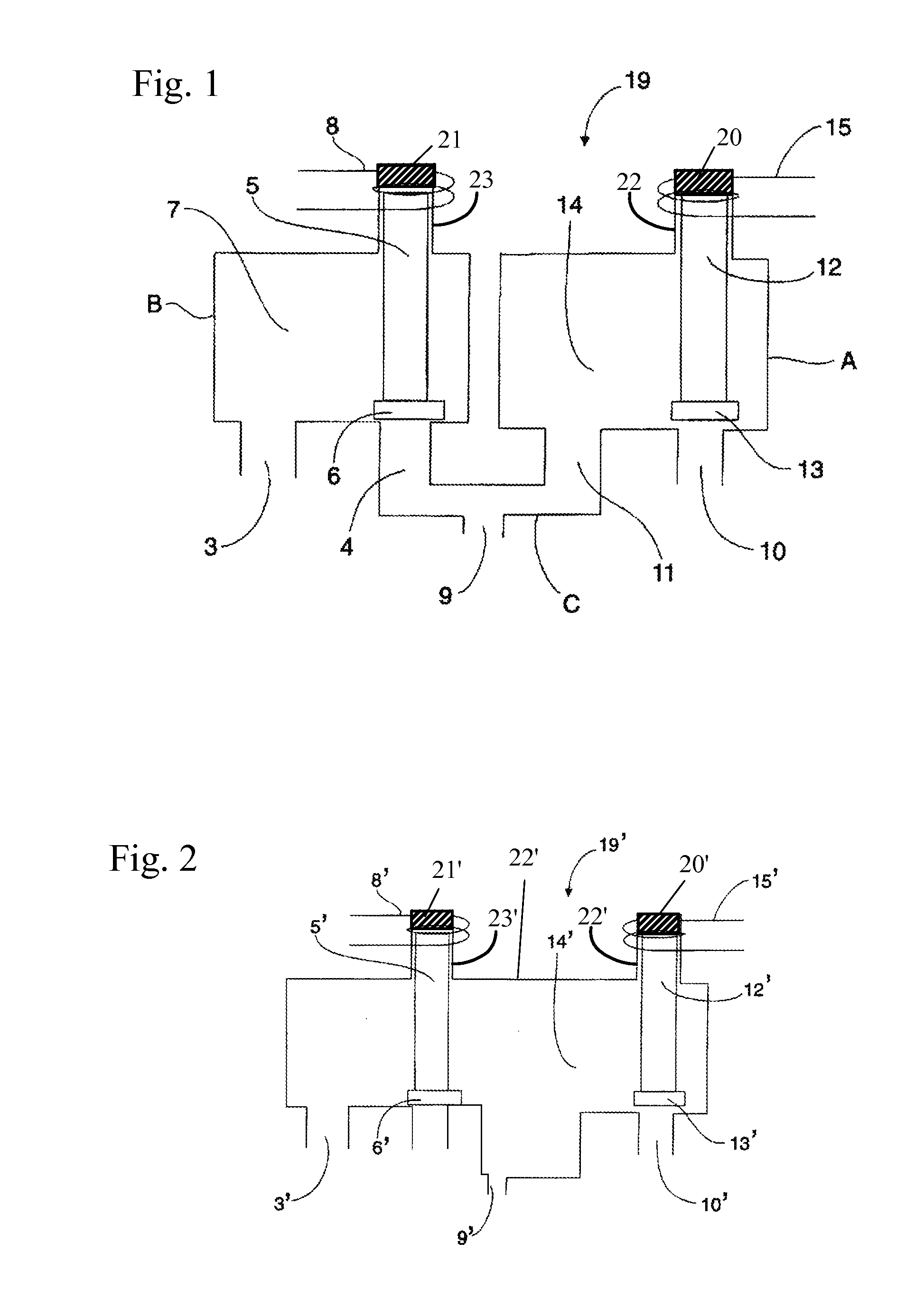

Voltage/current testing equipment for microfluidic devices

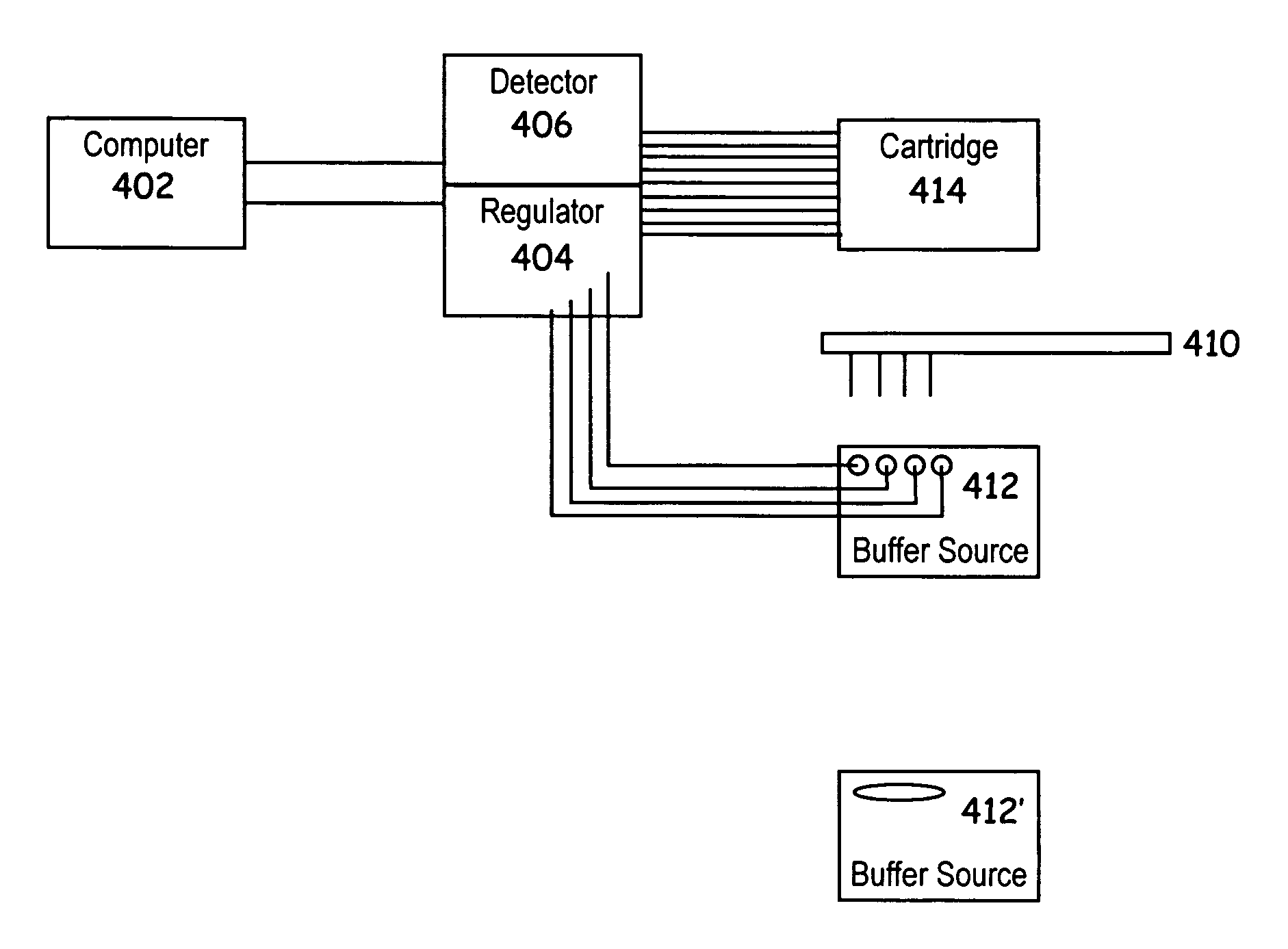

The present invention provides novel methods and devices for testing / verifying the configuration of one or more microfluidic elements in a microfluidic device. In particular the methods and devices of the invention are useful in testing for blockages or the presence of air bubbles in microfluidic elements. For example, a method for verifying the proper function of a microfluidic device is disclosed, which device comprises at least first, second and third fluidic openings, which fluidic openings are fluidly coupled to at least first, second and third microscale channel elements, respectively, the method comprising flowing an electrically conductive buffer through the first, second and third microscale channel elements; setting a known applied voltage potential (or current) between the first and second fluidic openings; setting a current in the third microscale channel element to be approximately zero; detecting a resulting voltage at the third fluidic opening; and, comparing the detected voltage at the third fluidic opening with a calculated target voltage expected at the third fluidic opening to determine whether there is a fault or problem (e.g., air bubble) in at least one of the first and second microscale channel elements. The above method can be repeated one or more times for the other fluidic openings in the microfluidic device to determine whether there is a fault in any one or more microscale elements of the device.

Owner:CAPLIPER LIFE SCI INC

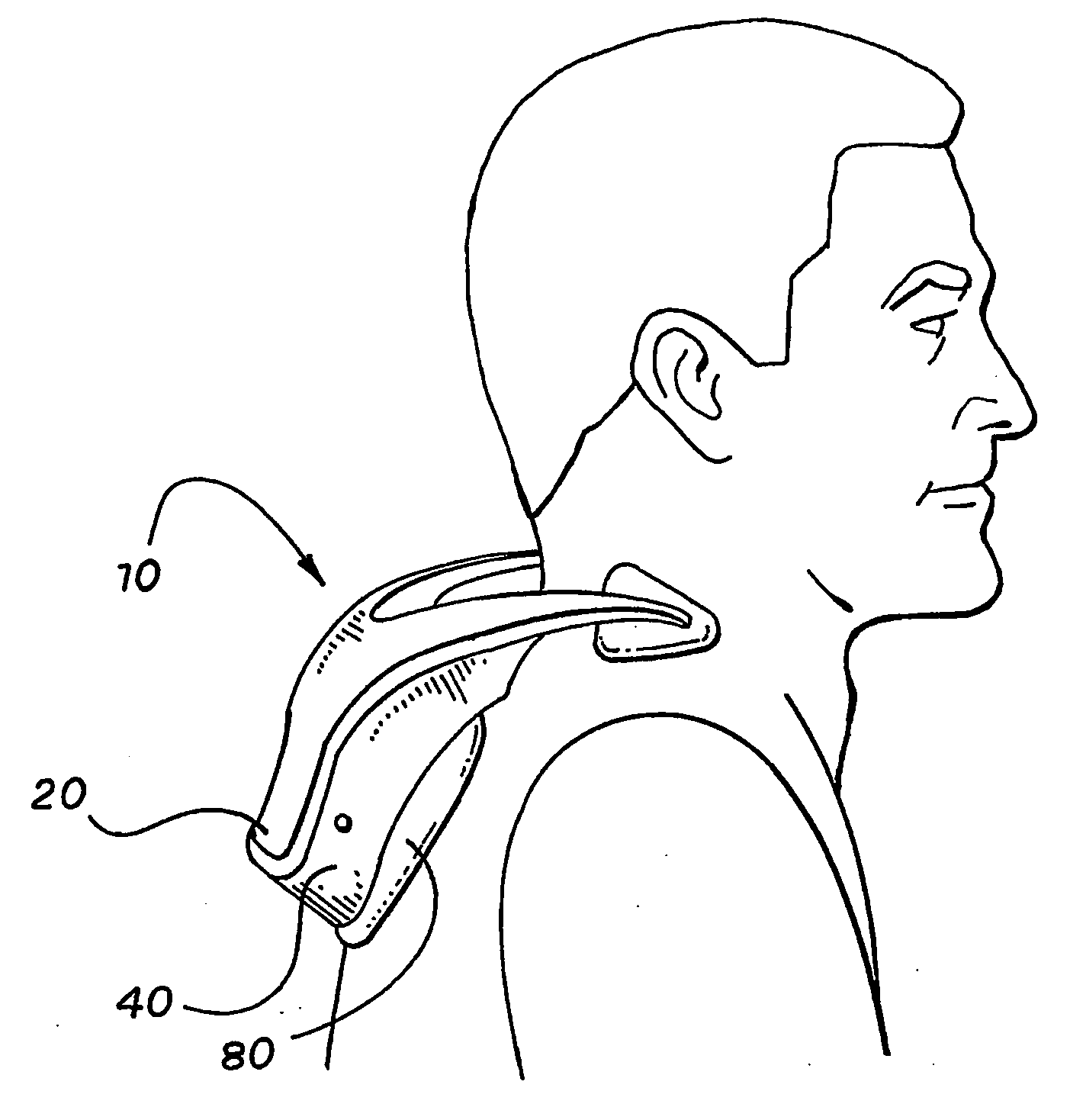

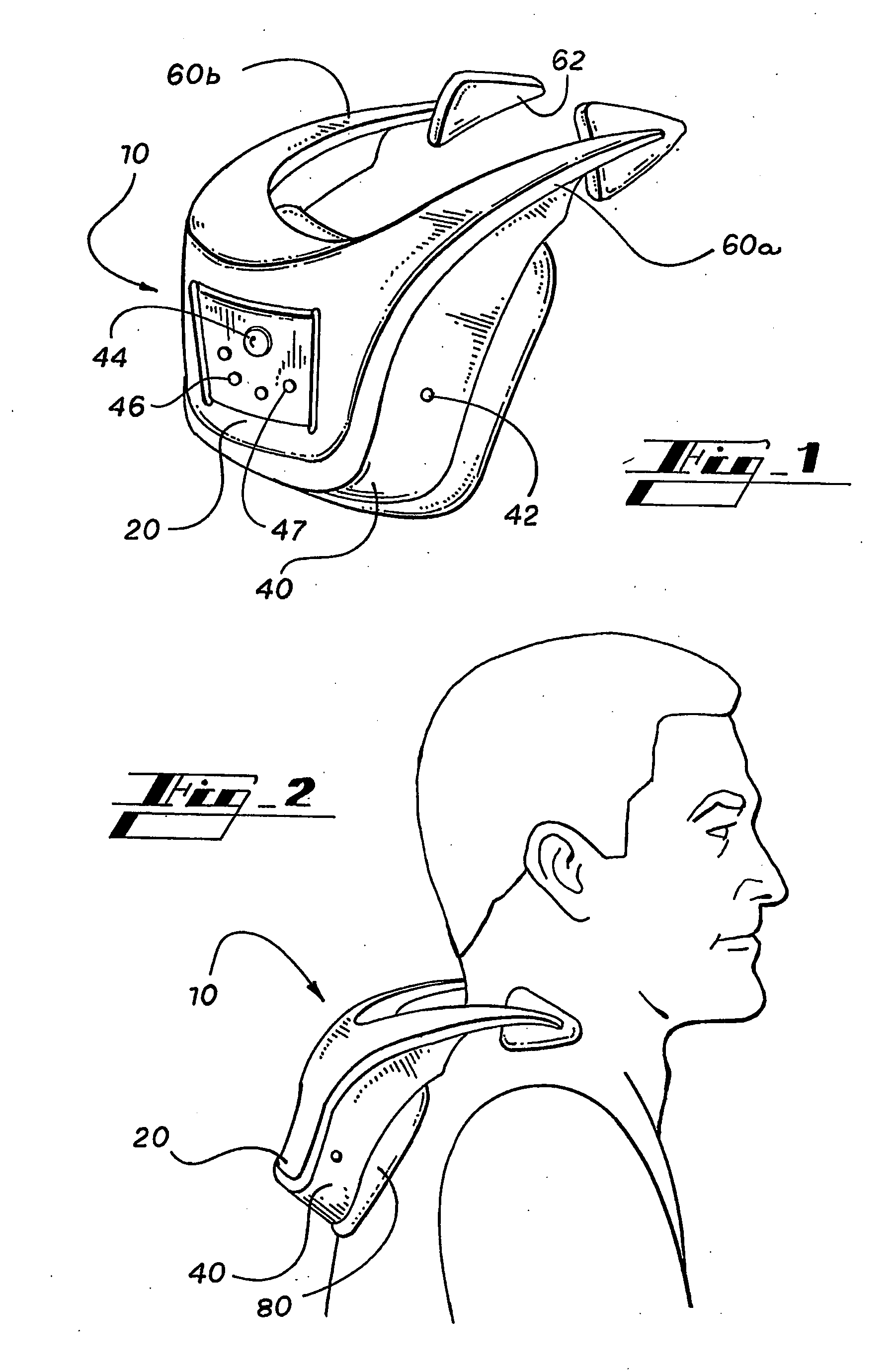

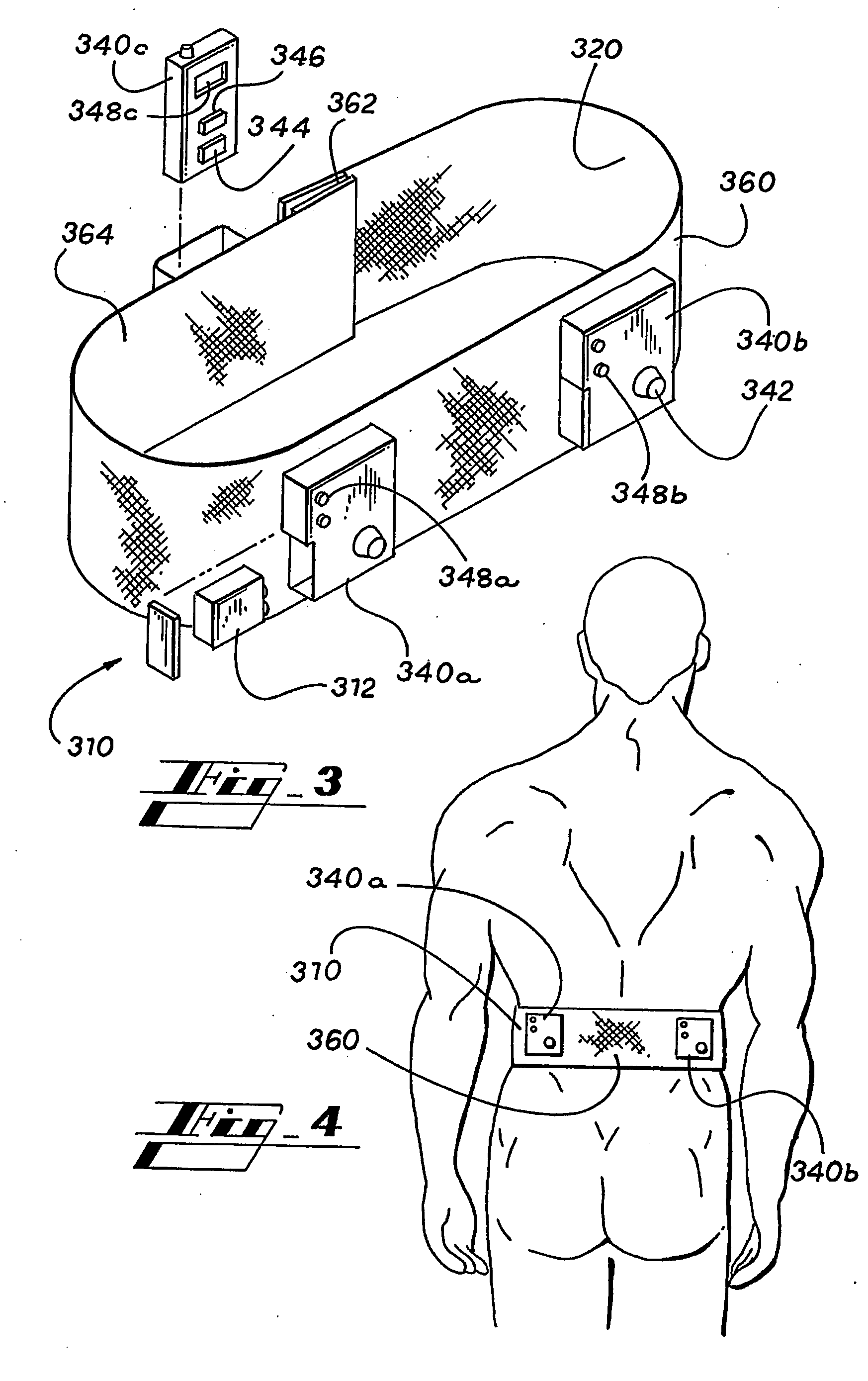

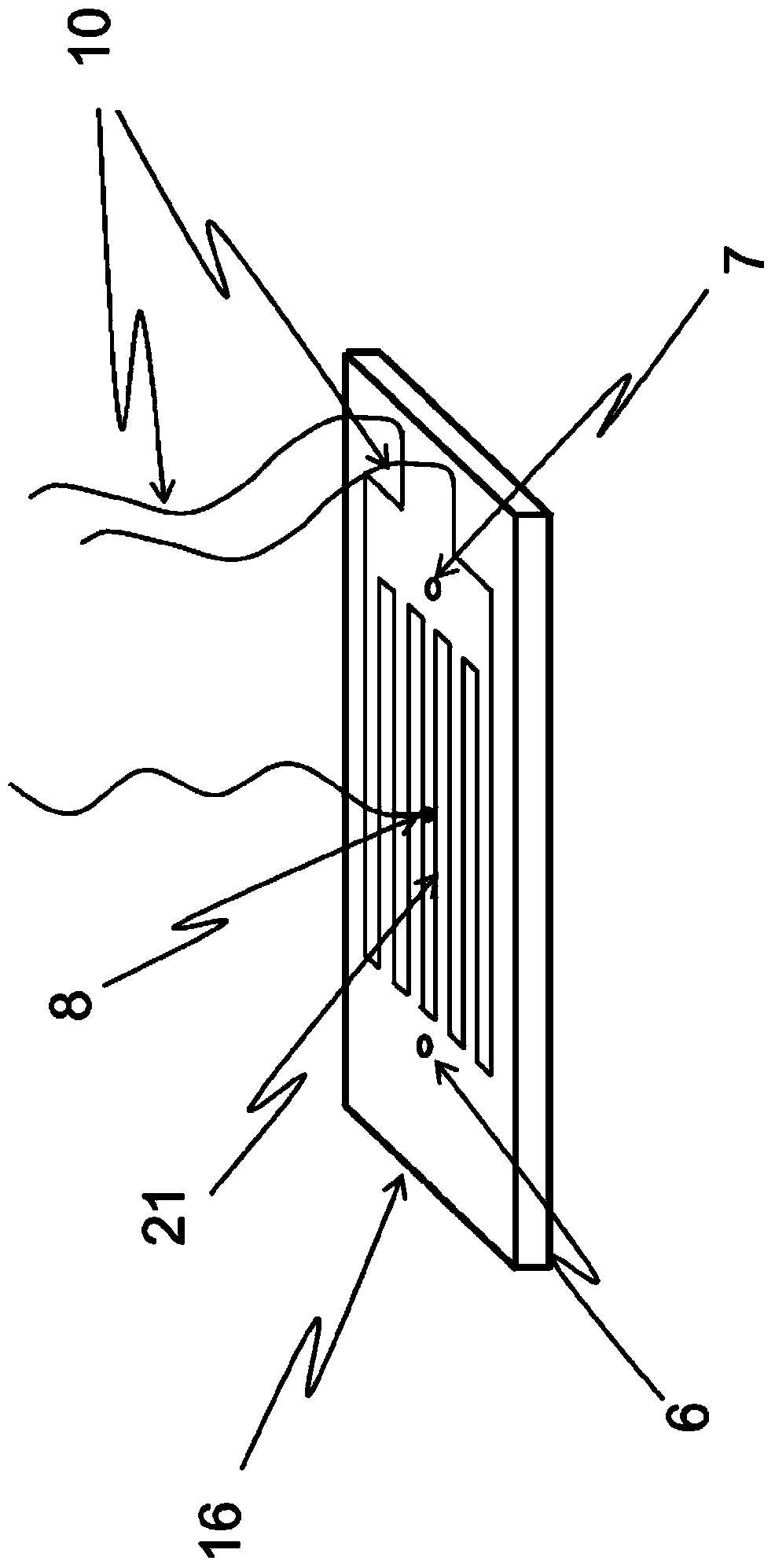

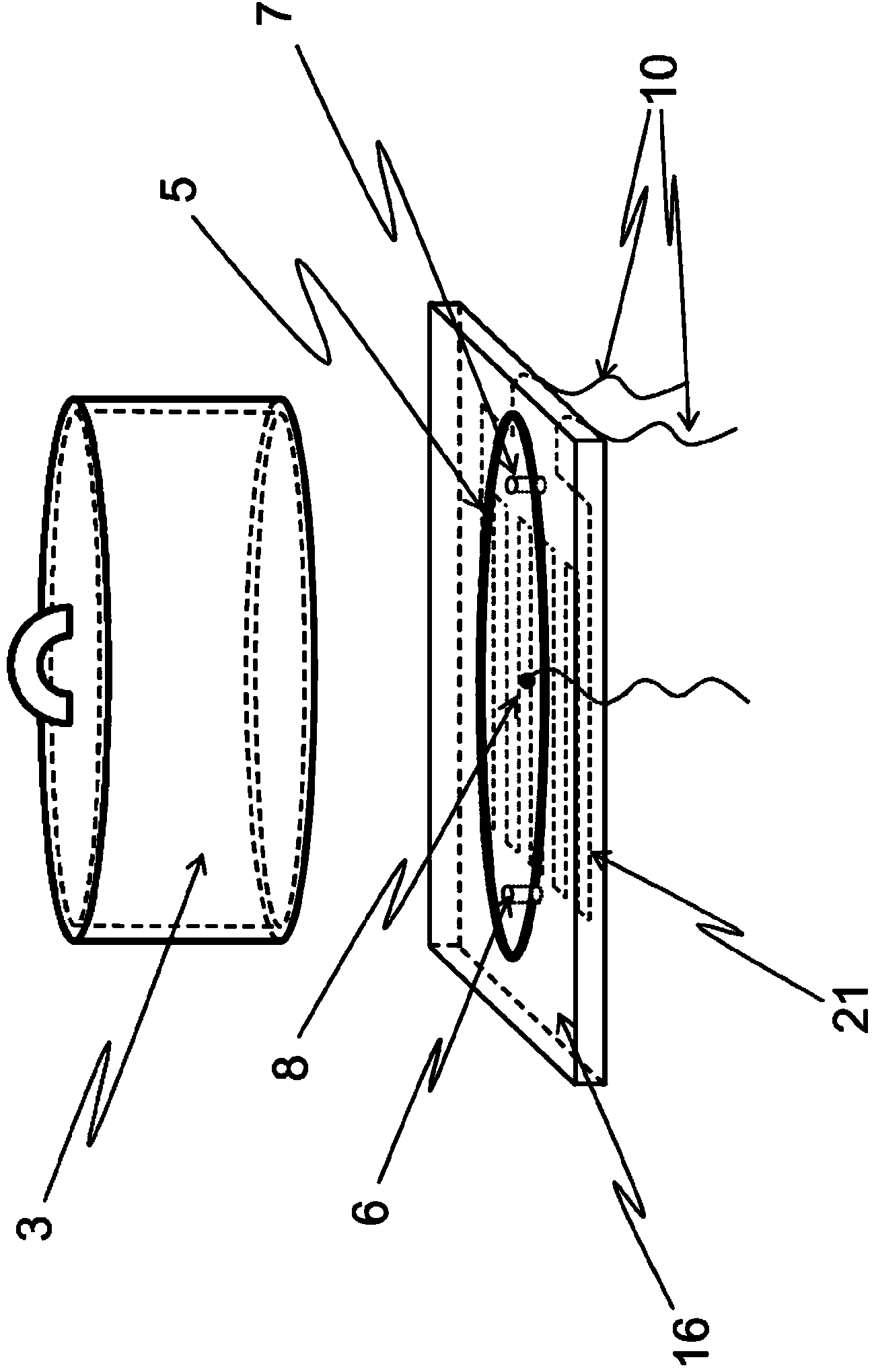

Frequency Stimulation Trainer

InactiveUS20090076421A1Relief the painRelieve painMassage combsMassage beltsRe educationPerformance enhancement

A preferably non-electrical nerve communication enhancement tool that sends specific, pre-timed, controlled vibrational and / or acoustical stimulation frequencies to the body to enhance nerve communication for the purpose of assisting in proper function of skeletal muscle, smooth muscle, sympathetic and parasympathetic nervous systems, and facilitating rapid and improved cerebellar timing circuit and related cerebellar learning mechanism pathways such as the inferior olivary-Purkinje-Thalamus cell system and other similar neuronal pools, to improve muscle memory, coordinated functional neuron-musculo-skeletal performance improvement, enhance blood flow, increased range of motion, flexibility, strength and dexterity, neuromuscular re-education, muscle tone recovery, pain modulation, improved eye-hand coordination, gait improvement, balance and stability gains, kinetic chain integration, neurological performance enhancement, sensory dysfunction reduction, and improvement in mental and cognitive function.

Owner:STIMTRAINER

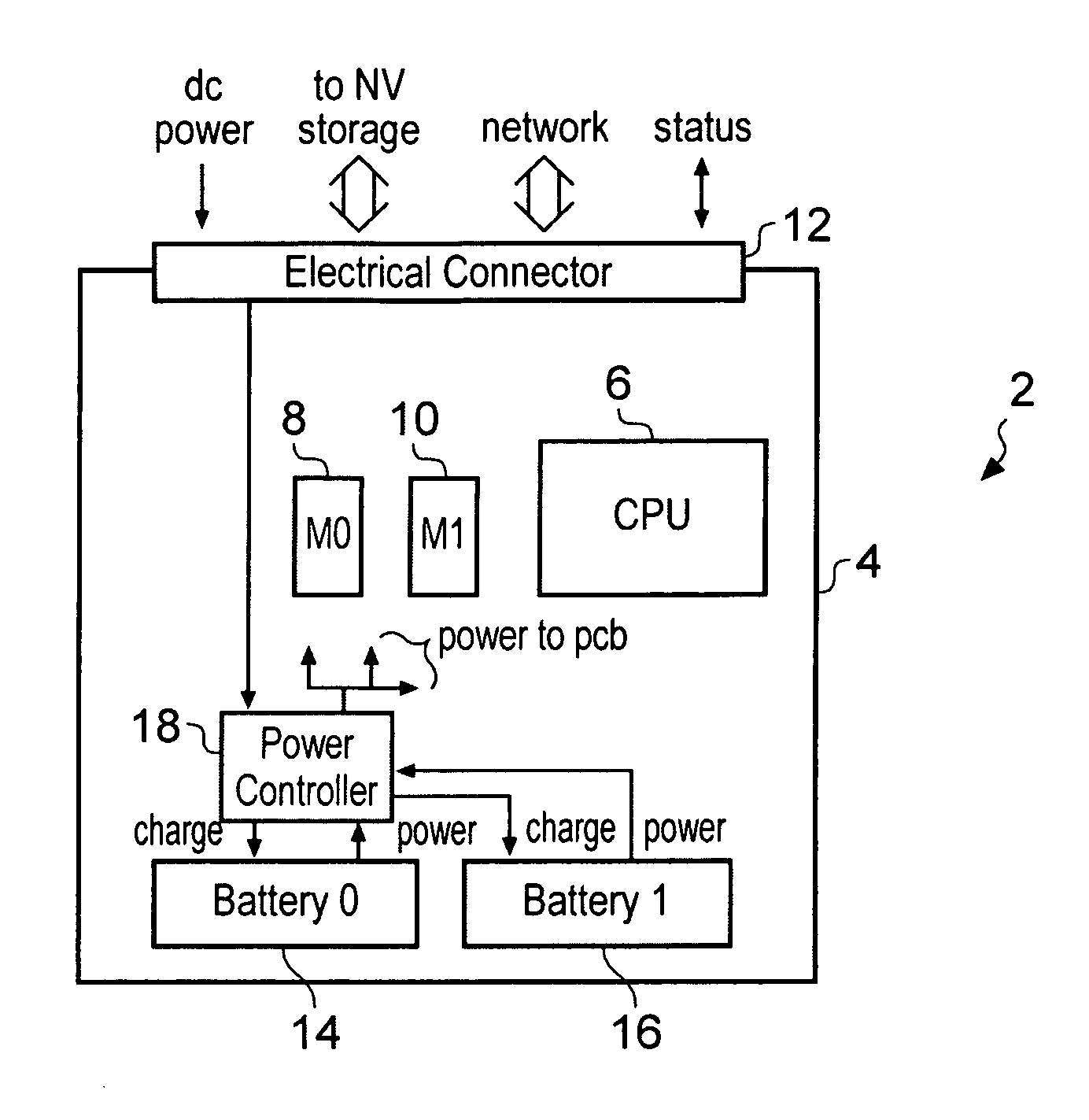

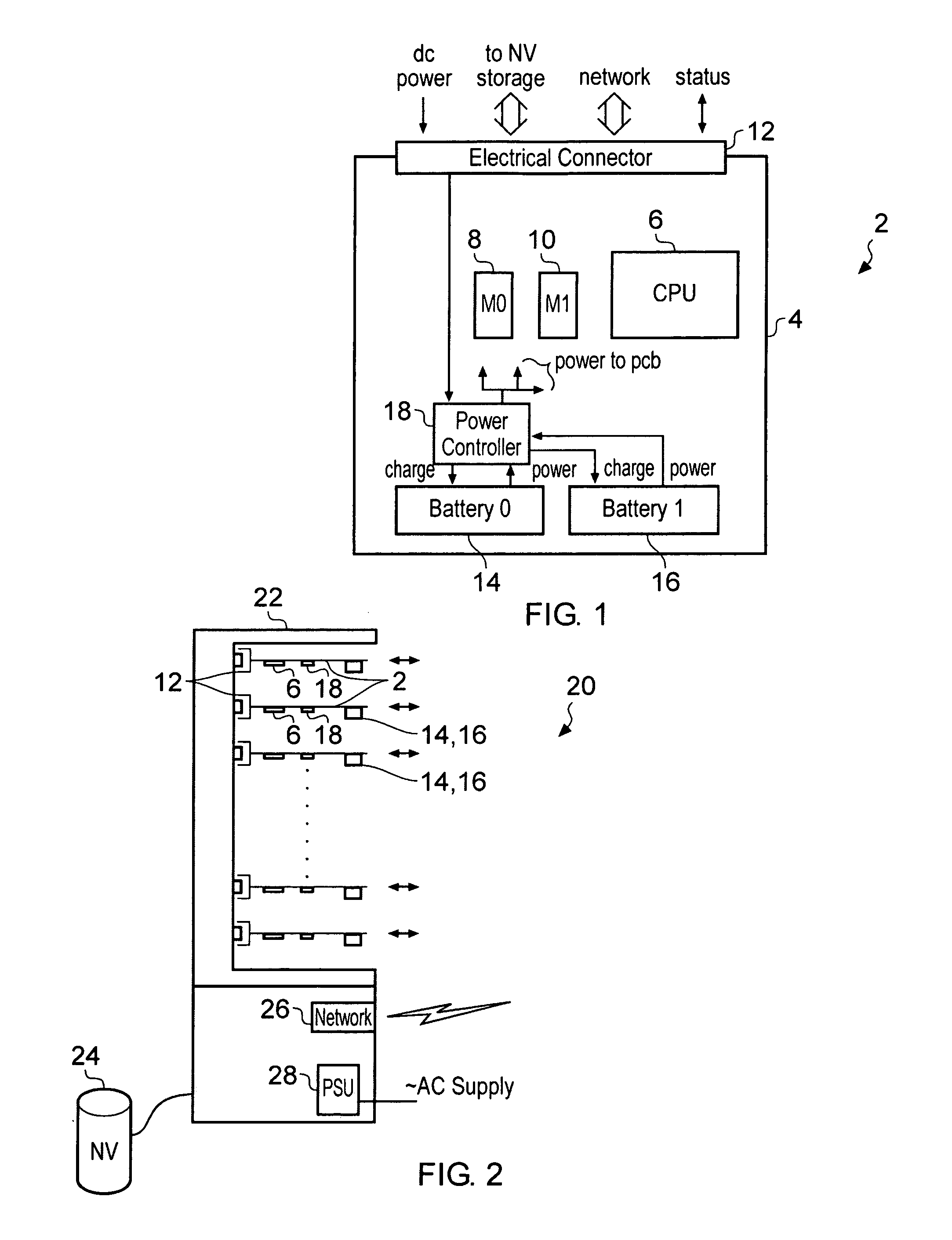

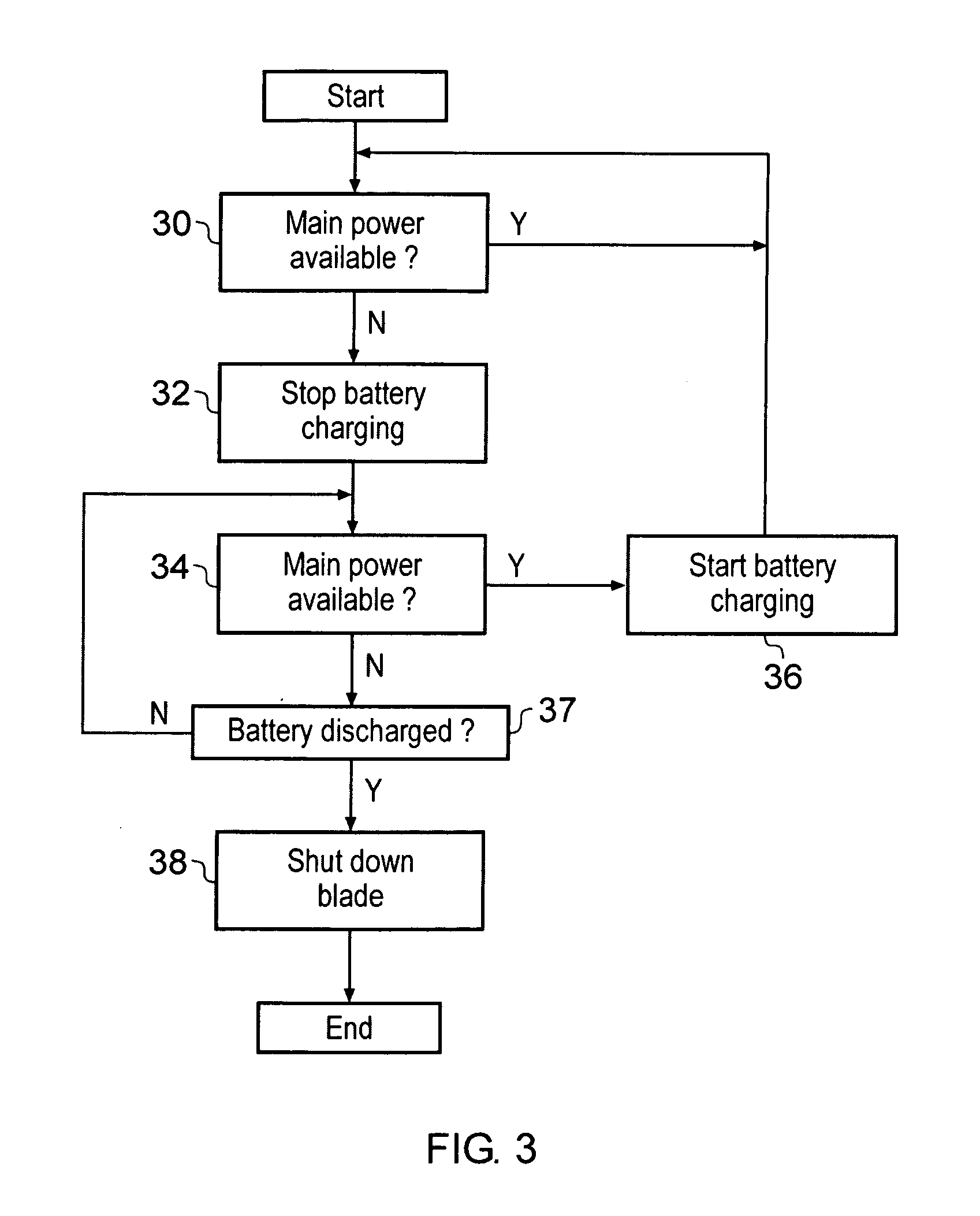

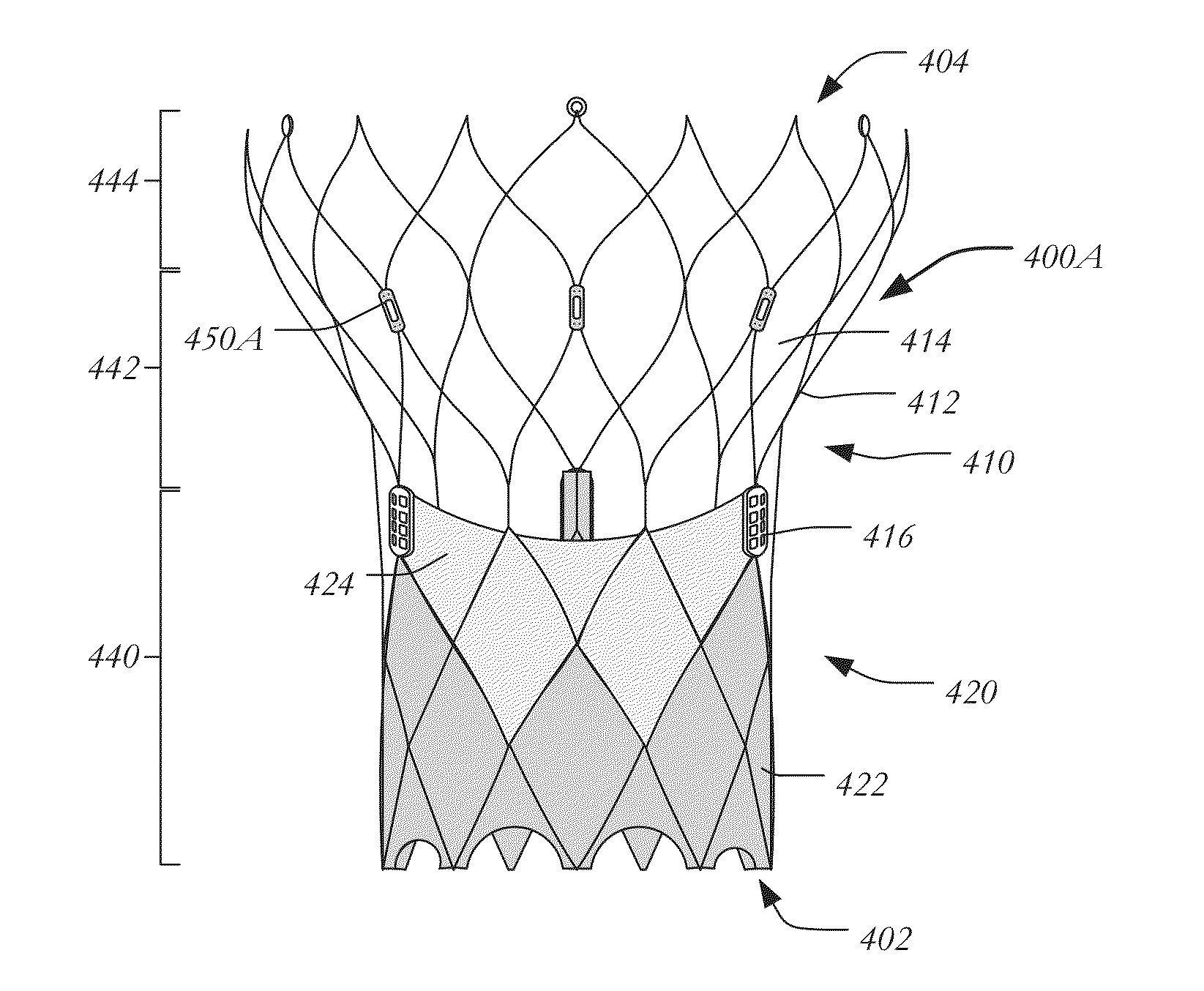

Blade server

InactiveUS20100299548A1Solve insufficient capacityMore power efficientHardware monitoringPower supply for data processingElectricityPower controller

A blade server 2 is provided with a processor 6 for executing program instructions and an electrical connector 12 for connecting to a blade enclosure 22. The blade server 2 also includes a power controller 18 connected to a plurality of power supply batteries 14, 16 which are provided on the blade server 2 itself. If the power controller 18 detects that the main power supply supplied via the electrical connector 12 has been interrupted, then a backup power supply to the processor is provided from the on-board power supply batteries 14, 16. The batteries 14, 16 on each blade are periodically discharged and recharged in turn to check their proper function.

Owner:ARM LTD

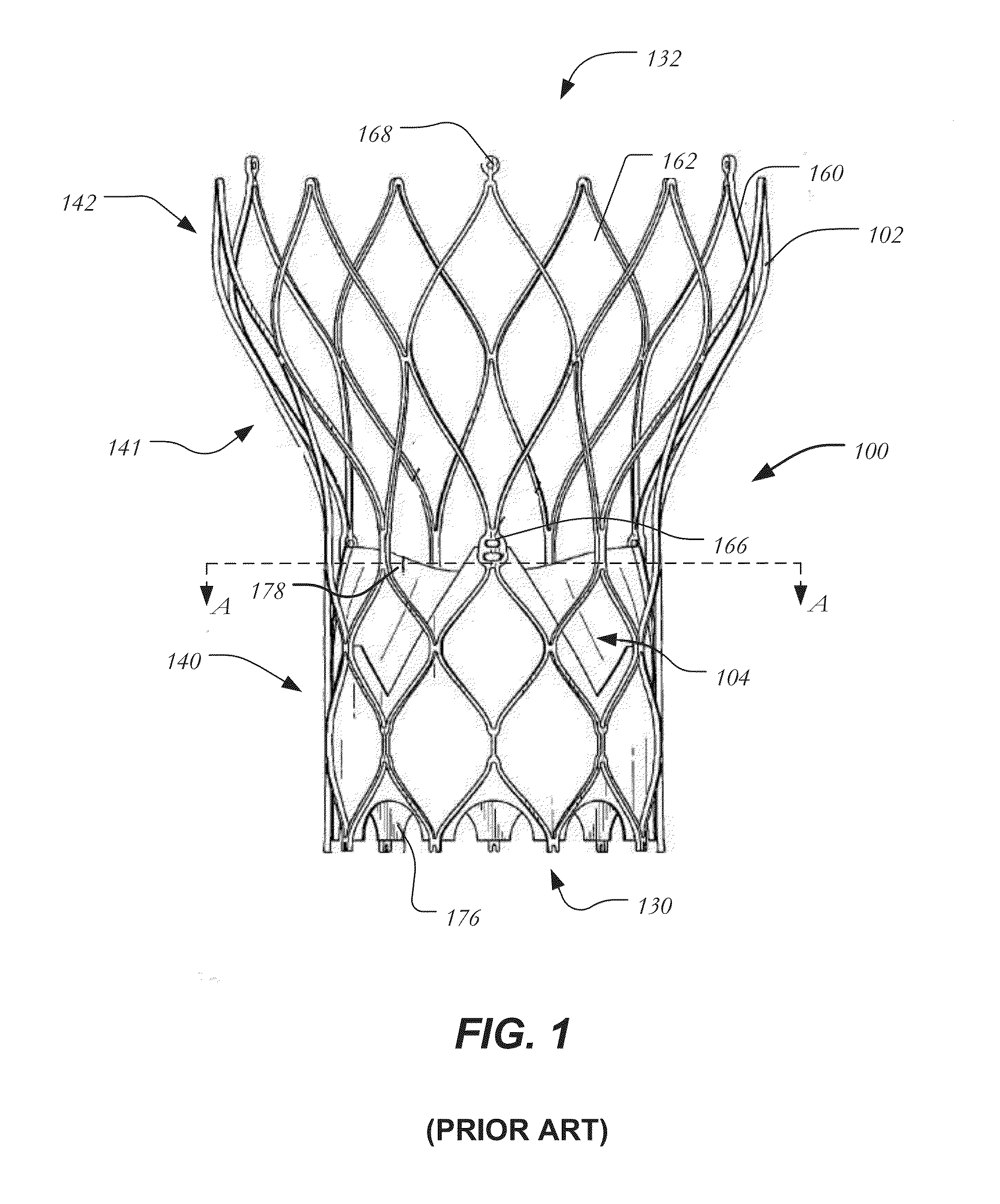

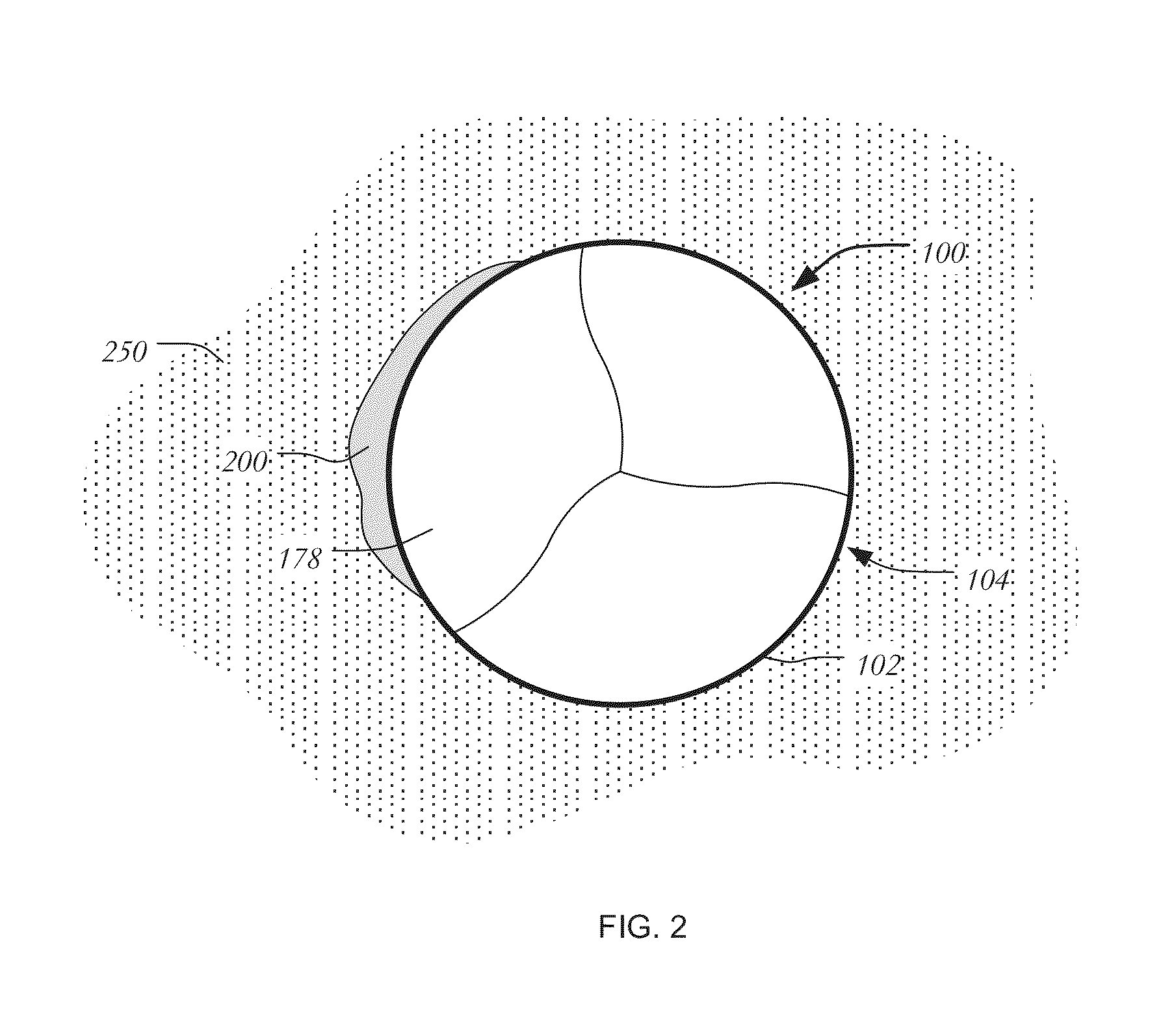

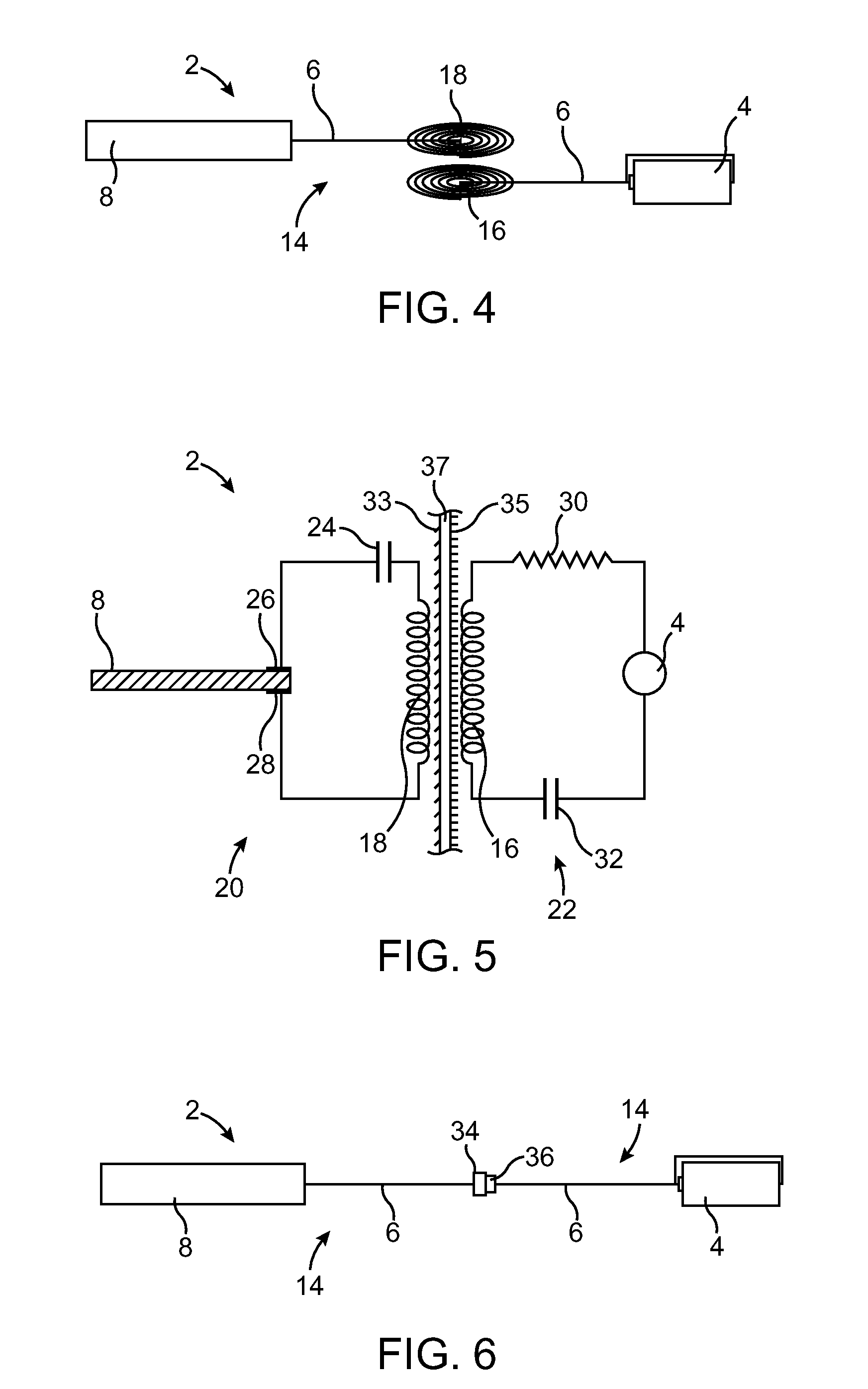

Prosthetic heart devices having diagnostic capabilities

A prosthetic device for implanting in a patient's heart includes (i) a therapeutic device capable of restoring function to a native heart valve; and (ii) at least one sensor including a body, an inductor coil disposed within the body, and a capacitor in communication with the inductor coil, the at least one sensor being coupled to the therapeutic device, and being configured to monitor proper function of the therapeutic device within the patient's heart.

Owner:ST JUDE MEDICAL CARDILOGY DIV INC

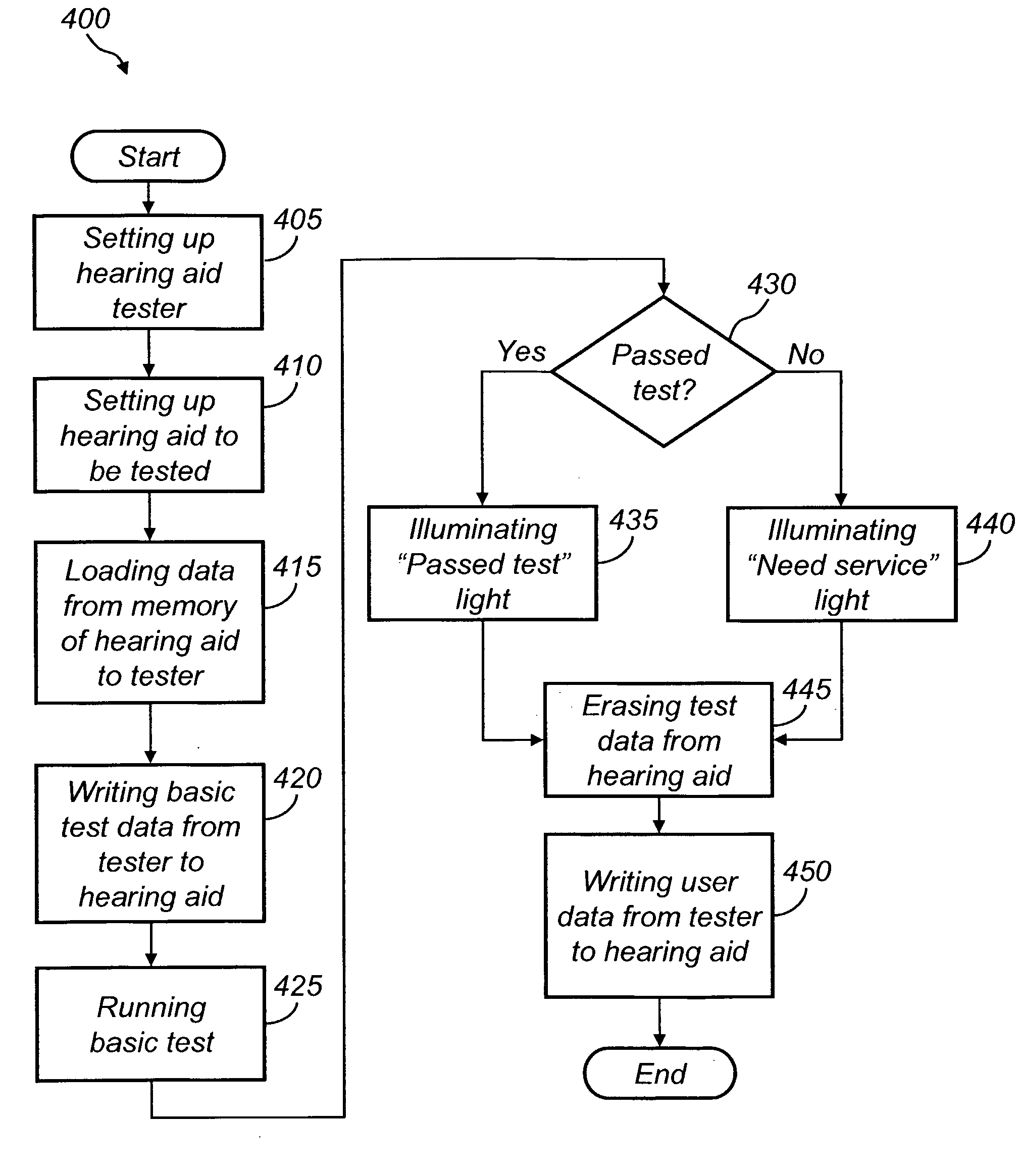

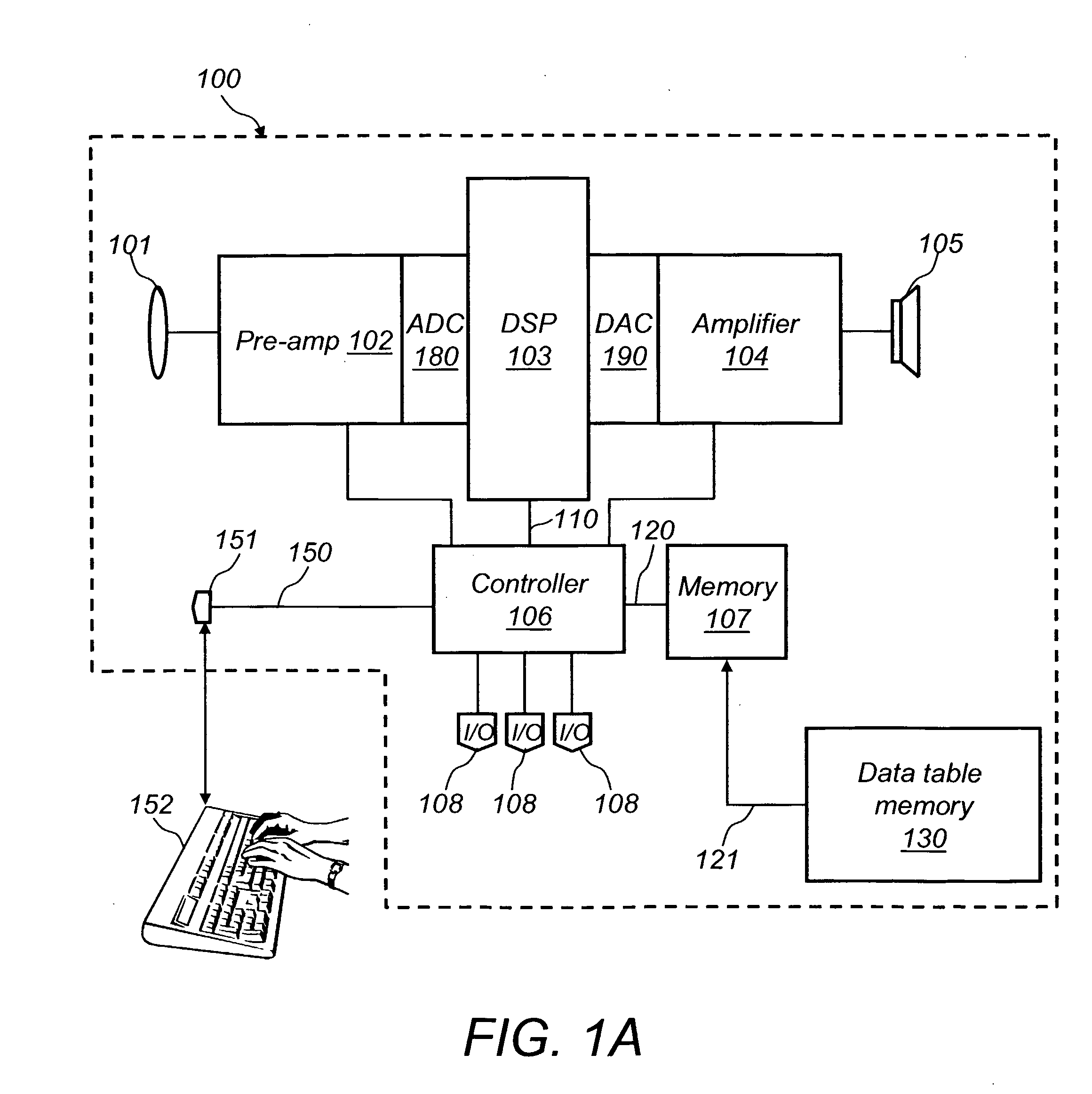

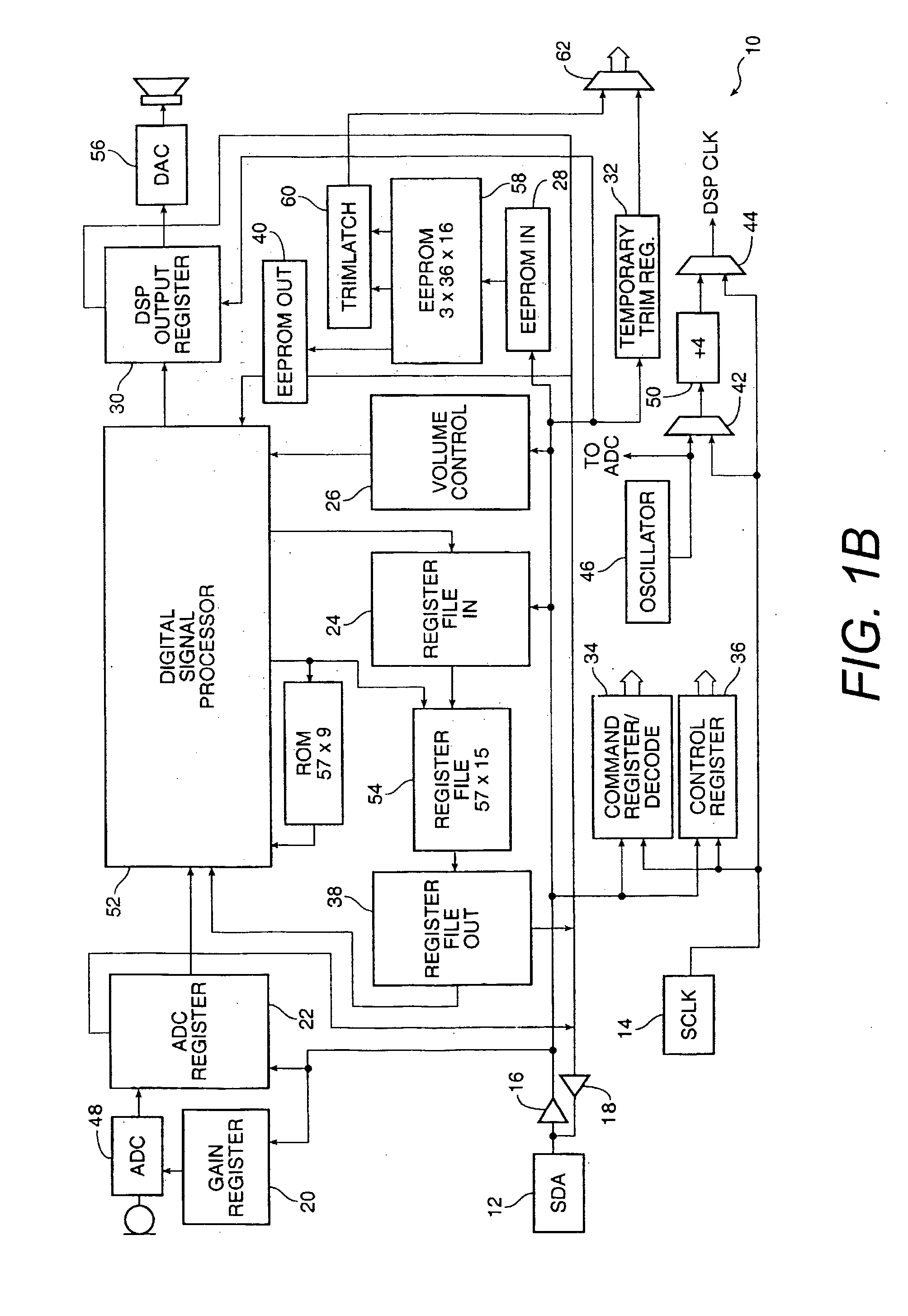

At-Home Hearing Aid Testing and Clearing System

InactiveUS20080253579A1Simple processOptimize locationHearing aids testing/monitoringHearing device specific toolsProper functionQuality of life

The present invention is an apparatus for and method of remotely, automatically, and routinely conducting diagnostic testing on a programmable hearing aid to ensure that it is functioning as intended when optimized for an individual's needs and preferences. Because hearing aids deteriorate with time and buildup of earwax, individuals can be uncertain whether their hearing is worsening or the hearing aid is malfunctioning. The net effect is diminished hearing aid performance and thus diminished quality of life. The present invention tests the hearing aid for proper function as frequently as daily. Additionally, the present invention includes elements (201, 202) that enable the apparatus to perform a cleaning process to effectively remove earwax and other undesirable debris from the hearing aid. The cleaning process can occur prior to the diagnostic testing or as a result of the diagnostic testing.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

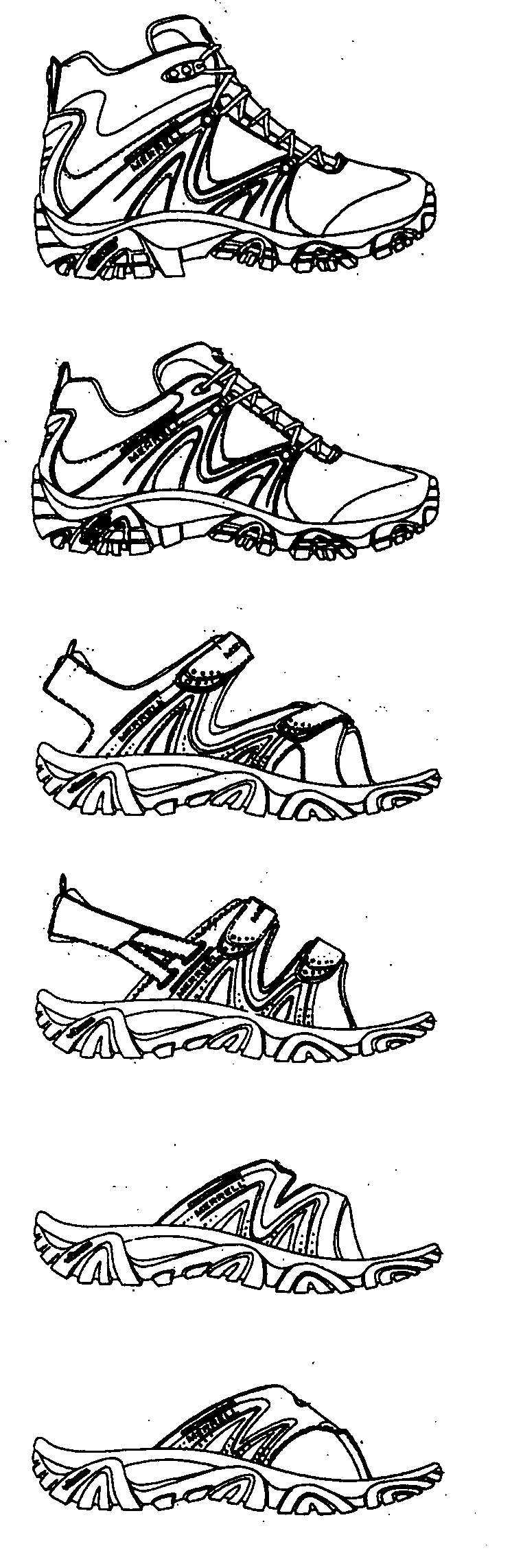

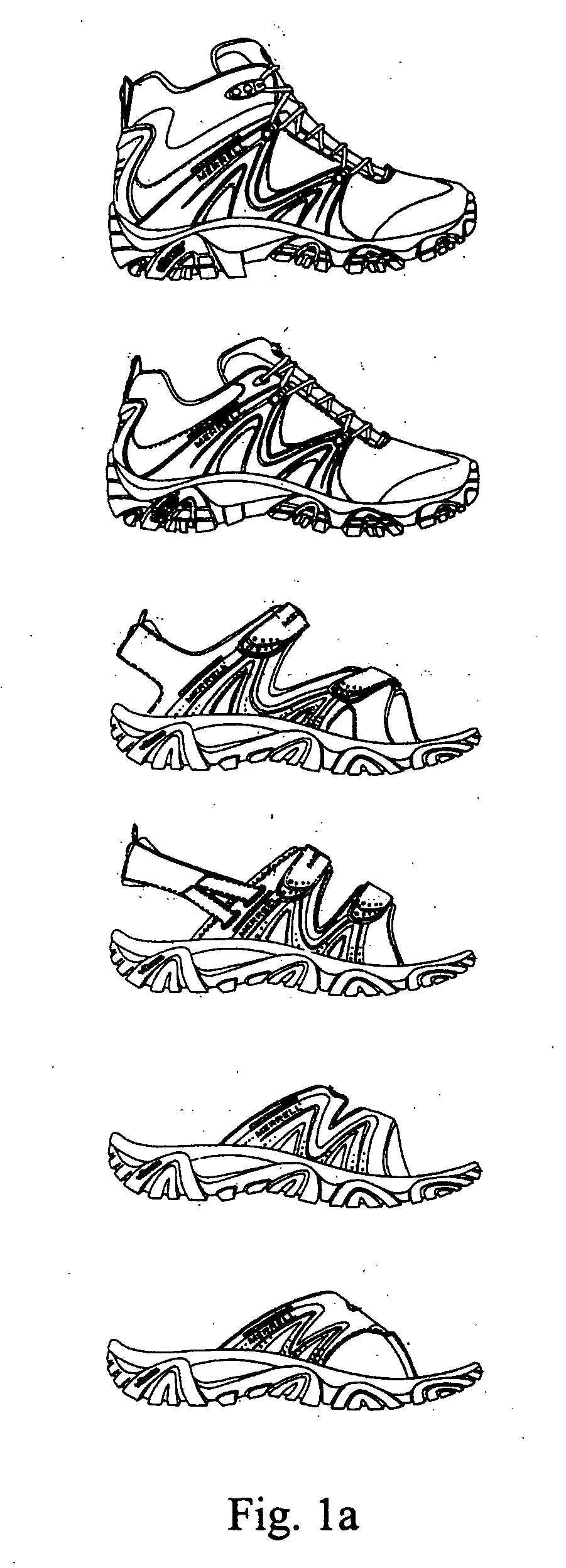

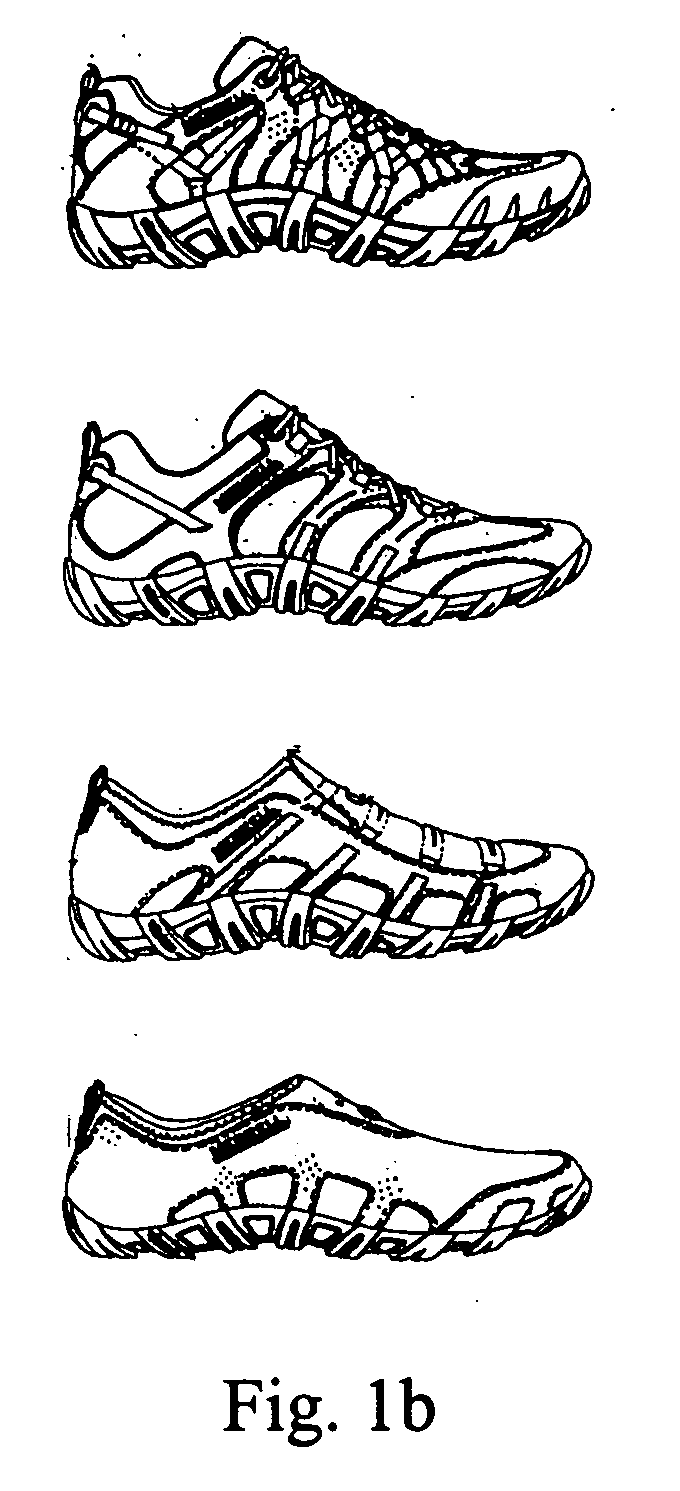

Footwear design and marketing method

InactiveUS20050267775A1Eliminate needSimple designShoemaking devicesSpecial data processing applicationsMorphingProper function

A method for designing a line of products across different functional categories. The method includes the steps of selecting certain performance components and grading the components from one product to the next to tailor the product to the appropriate functional category. At the same time, the products include common, yet varied, design elements that interrelate the products and create a morphing or evolving appearance from one functional category to the next. The present invention further discloses a method for marketing footwear across different functional categories as a line of products by providing the products with evolving or morphing functional and design components.

Owner:WOLVERINE WORLD WIDE

Implant tester

InactiveUS20090069866A1Precise functionElectrotherapySnoring preventionProper functionDetector circuits

An implant testing device and a method of detecting an airway implant are disclosed. The testing device detects the presence of the implant within a patient's body and can be used to determine its location. The testing device also provides an indication of proper function of the implant electronics. A detector circuit of the testing device generates an output signal representative of proximity of the airway implant. A processing circuit receives the output signal and determines proximity of the implant based on one or more detection thresholds. The processing circuit also provides a visual and / or audible alert. In some embodiments, the processing circuit varies the flash rate of one or more light emitting diodes and / or the pitch of an alert tone based on proximity of the implant. Various embodiments of the testing device are adapted for handheld use and can include a handle, elongated portion, and detector element.

Owner:PAVAD MEDICAL

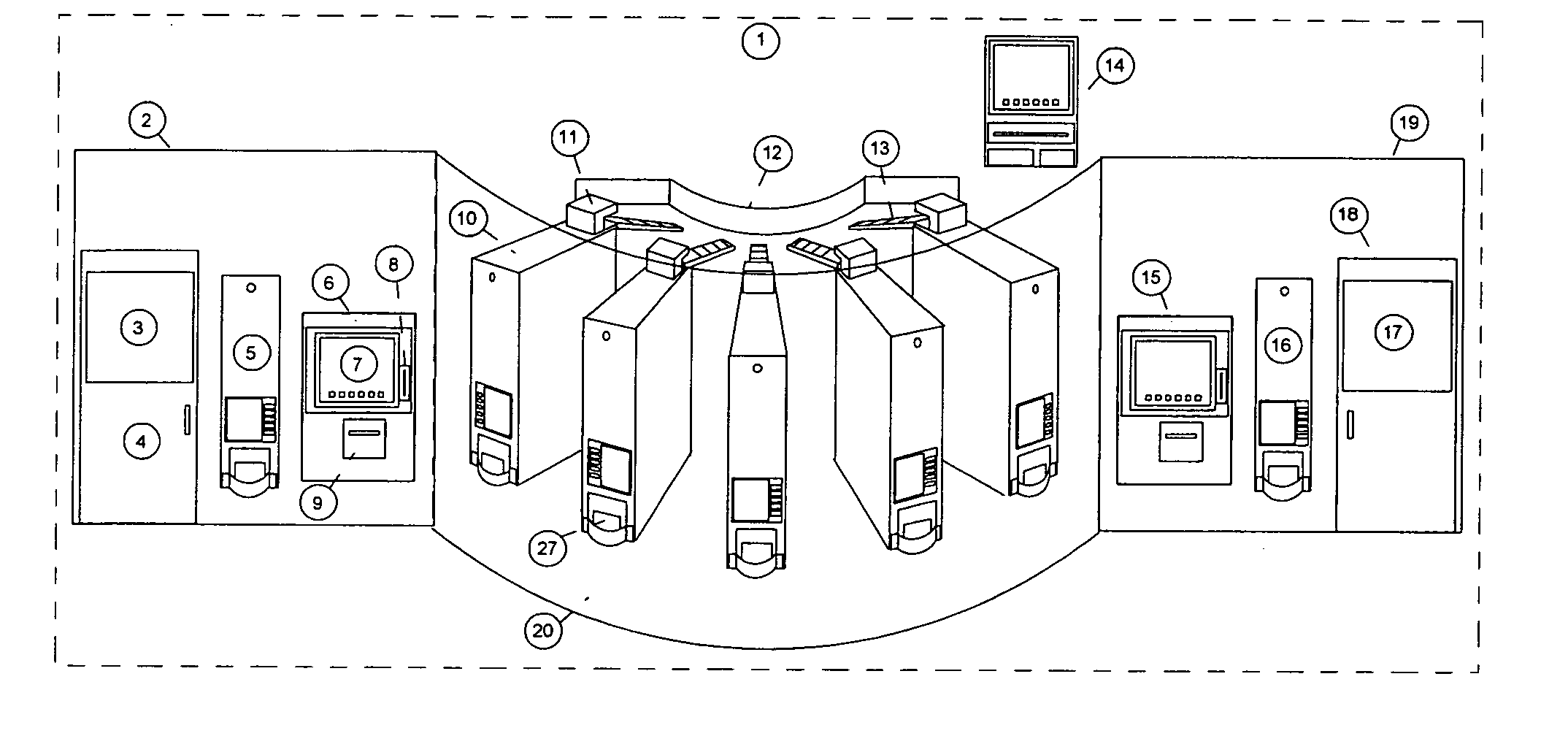

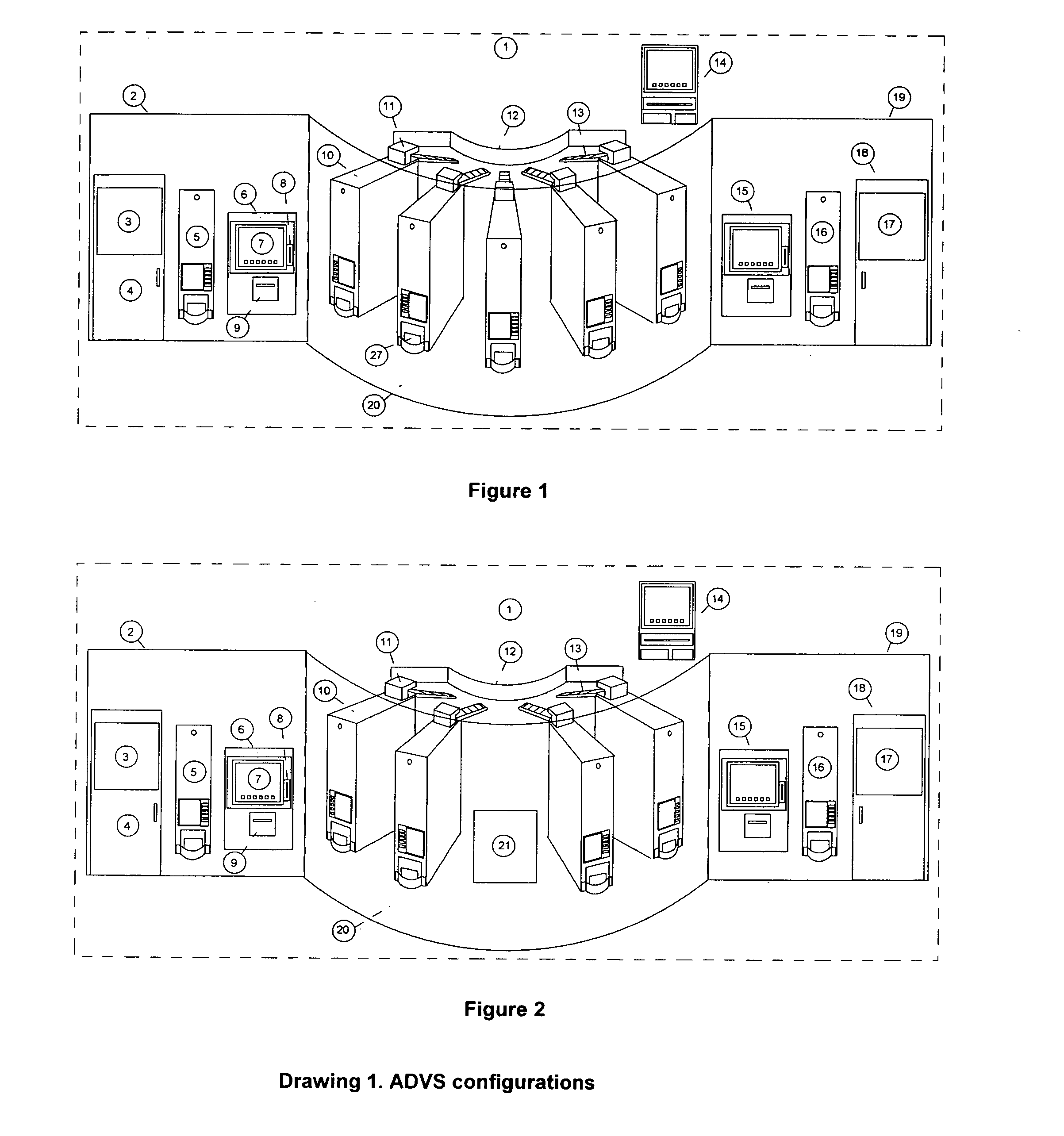

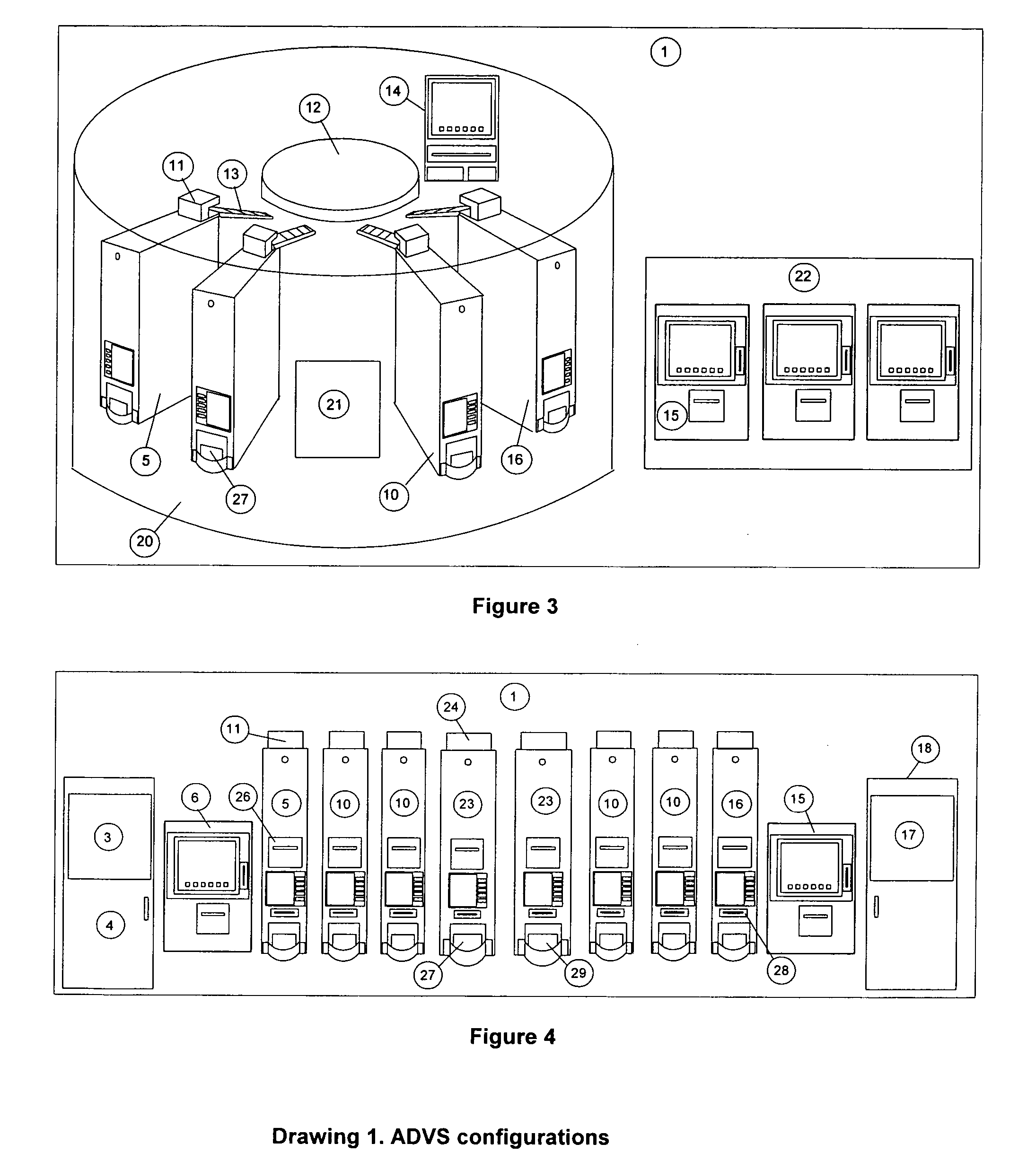

Automatic distributed vending system

InactiveUS20060293784A1Improve efficiencyImprove securityCoin-freed apparatus detailsPayment architectureHuman–machine interfaceSemi automatic

The principals and designs described in my application—provide essential tools for automation of a number of vending applications. It is unique in the way the content (item) is handled, and the levels of flexible, modular automation and security, which together could fully automate the entire process from point of Item manufacturing to point of Item sale, to achieve superior efficiency, compared to any existing or patented methods. An Automatic Distributed Vending System (System) is disclosed that could consist of more than one Automatic Vending Module (Module), support components and more than one Central Computer (Computer), which control entire System. Each Module has a conveyor with a number of linked carriers and with a mechanism and a control system for automatic loading and / or unloading of an Item out of a carrier upon request. Each carrier's inner receptacle could have an insert shaped to match the outline of the carrier's content. Each Item and / or carrier can be identified such as with a barcode label. Module has a Controller consisting of embedded processor or processors, sensors for position and environment, control devices for moving conveyor and other mechanisms, carrier and content identification barcode scanners, human-machine interfaces, status indicators, serial interfaces within Module and to the System local area network. Controller could maintain in real-time inventory and status of all carriers and their content. Controller could execute in real-time required algorithm of operation to support all features of Module. Module's outer enclosure could have one side to be accessible by Provider, and could have the opposite side to be accessible by Customer. Loading of content into carriers could be semi-automatic and / or by automatic mechanism. Module's automatic content loading mechanism could be interfaced with a semi-automatic content feeding mechanism where at one end a content is deposited manually or by an automatic mechanism, and on the other end a content is off-loaded from a content feeding mechanism and loaded into an empty carrier inside Module's inner enclosure. Content could be automatically unloaded from its carrier by Module's unloading mechanism. When a content is requested for unload, the Controller could advance conveyor to position at which the carrier with requested content is at the specified unloading location. At the unloading location controller could perform final inspection of content's barcode label and then could execute appropriate function based on result. Unloading mechanism could deposit content into a pick-up bin, or return “rejected” content back to its carrier, from which it was unloaded. The “rejected” content could be unloaded at a different unloading location within Module. Controller could have interface with content feeding mechanisms, allowing automatic loading of content into empty carriers with proper barcode label. Central computer could obtain from Module's Controller general status of Module, real-time inventory status of Module's content, history of loading and unloading. Module could have different carriers inside, attached to the same conveyor, and recognized by means of barcode labels. Controller could identify each carrier by reading the barcode information, and deposit proper content into each carrier. As result, Module could be loaded with different types of content, which then could be unloaded as needed.

Owner:BRAUNSTEIN ZACHARY L

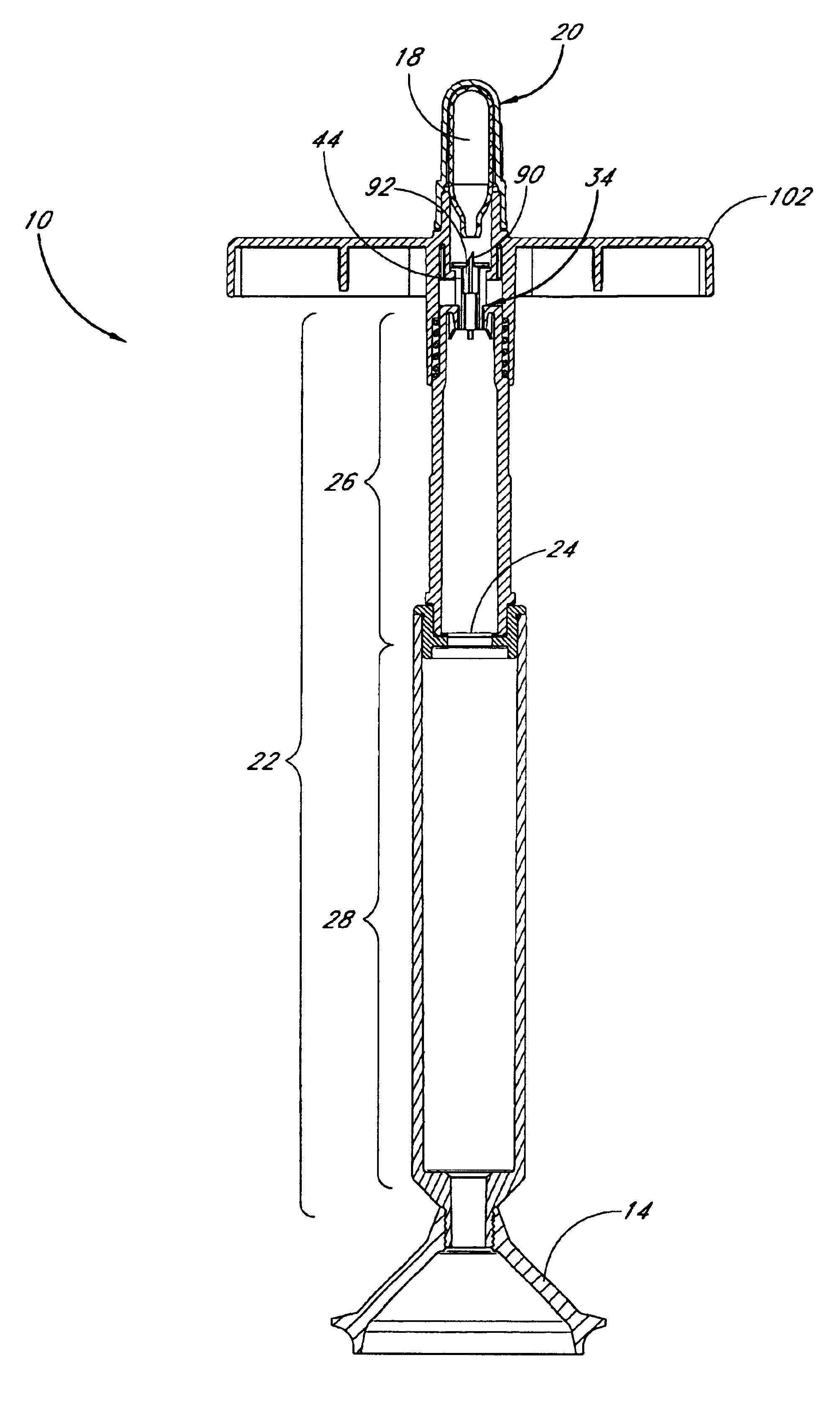

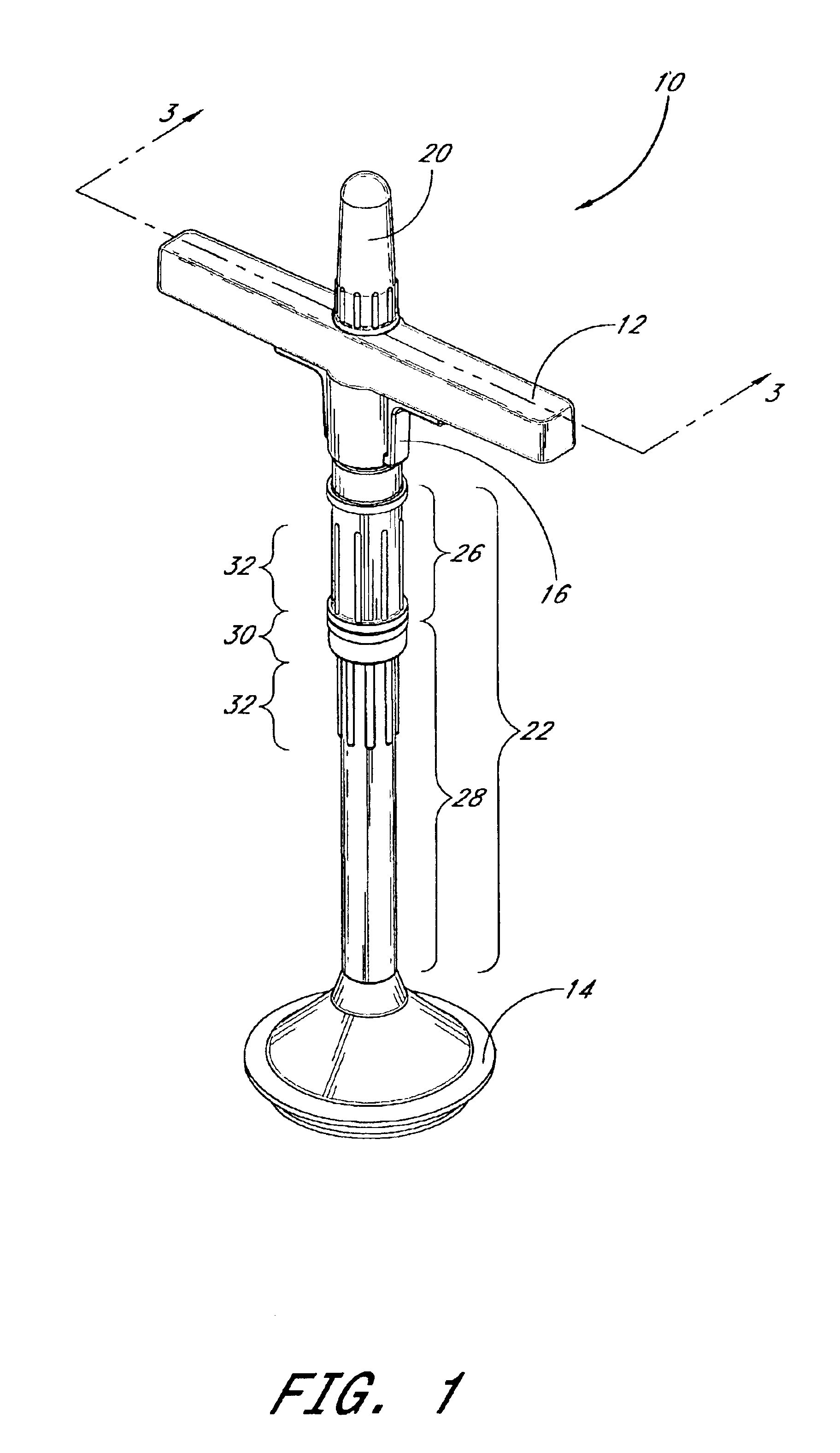

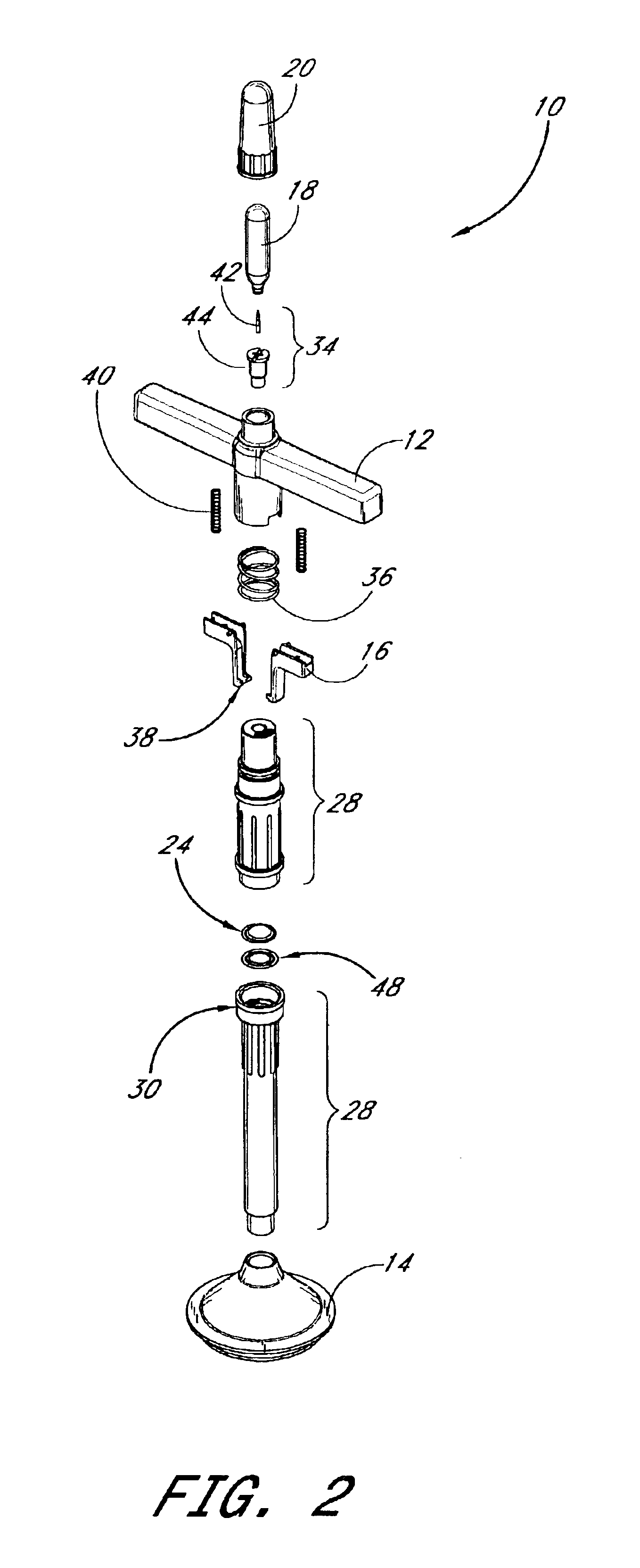

Air-burst drain plunger

An affordable plumbing device that uses a compressed gas and a burst disk having a relatively even surface of substantially uniform thickness to produce a sudden discharge of energy to forcibly act against any obstruction that may interfere with the proper function of a drain. The plumbing device has a cylindrical chamber for receiving the compressed gas and may generally take the shape of a plunger, which is flexible to use and is easy to store. A portion of the chamber forms a receiving chamber with the burst disk for harnessing and directing the energy of the compressed gas to clear the drain.

Owner:THE HOWARD & VERONICA ALLENBAUGH FAMILY TRUST

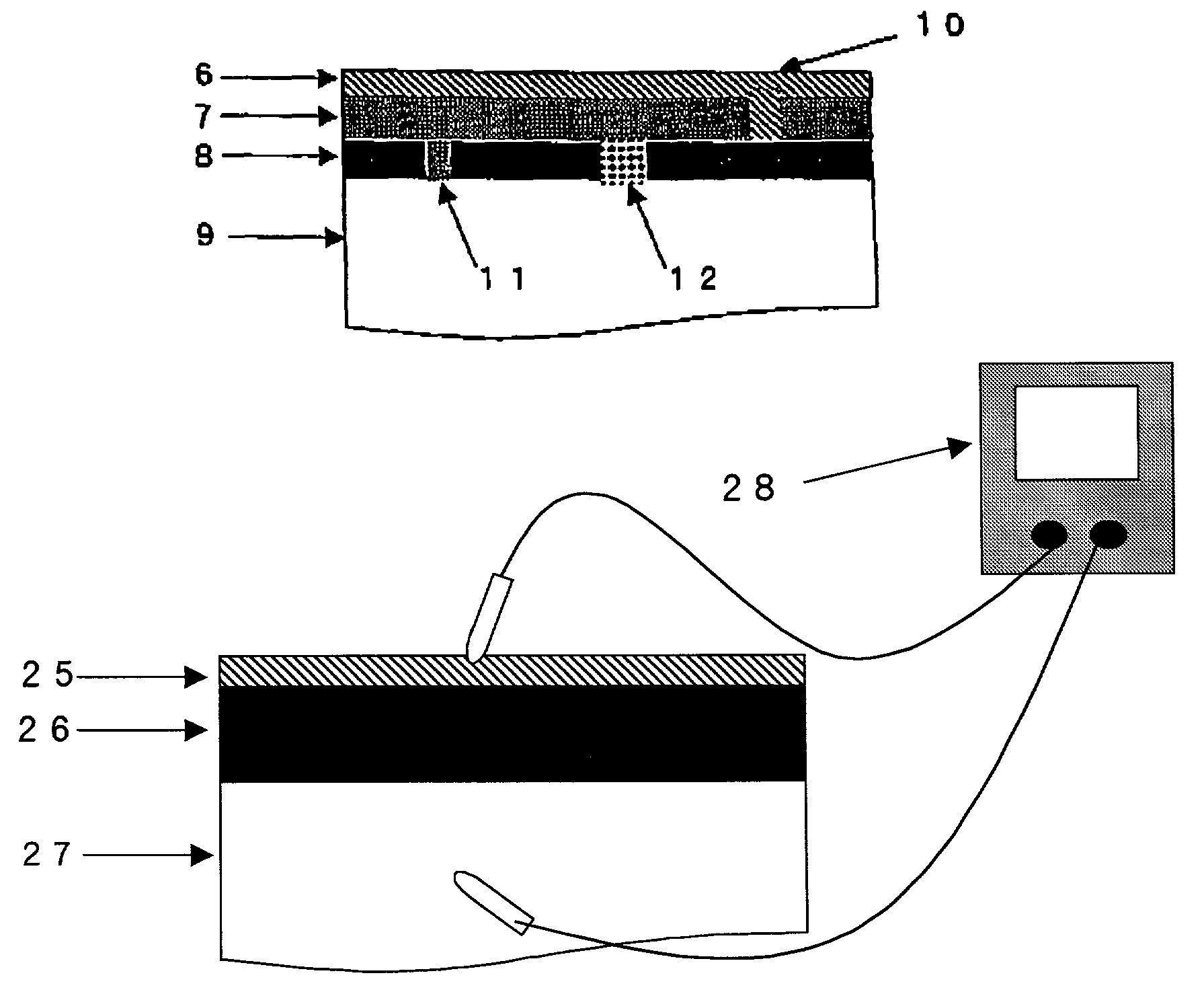

Cutting tool with sensor and production method therefor

InactiveUS7052215B2Improve insulation reliabilityPrecise functionMeasurement/indication equipmentsGrinding feed controlProper functionInsulation layer

A cutting tool with a sensor according to the present invention includes an electrically conductive substrate, an insulation film provided on a surface of the electrically conductive substrate, and a sensor circuit of an electrically conductive film provided on the insulation film. The insulation film includes two consecutive insulation layers. Even if the plural insulation layers each have defects such as cracks and pinholes which possibly impair the insulation property impair the insulation film, the defects present in the plural layers are unlikely to be continuous. Therefore, the insulation film has an improved insulation reliability, thereby ensuring proper function of the sensor circuit in the cutting tool.

Owner:KYOCERA CORP

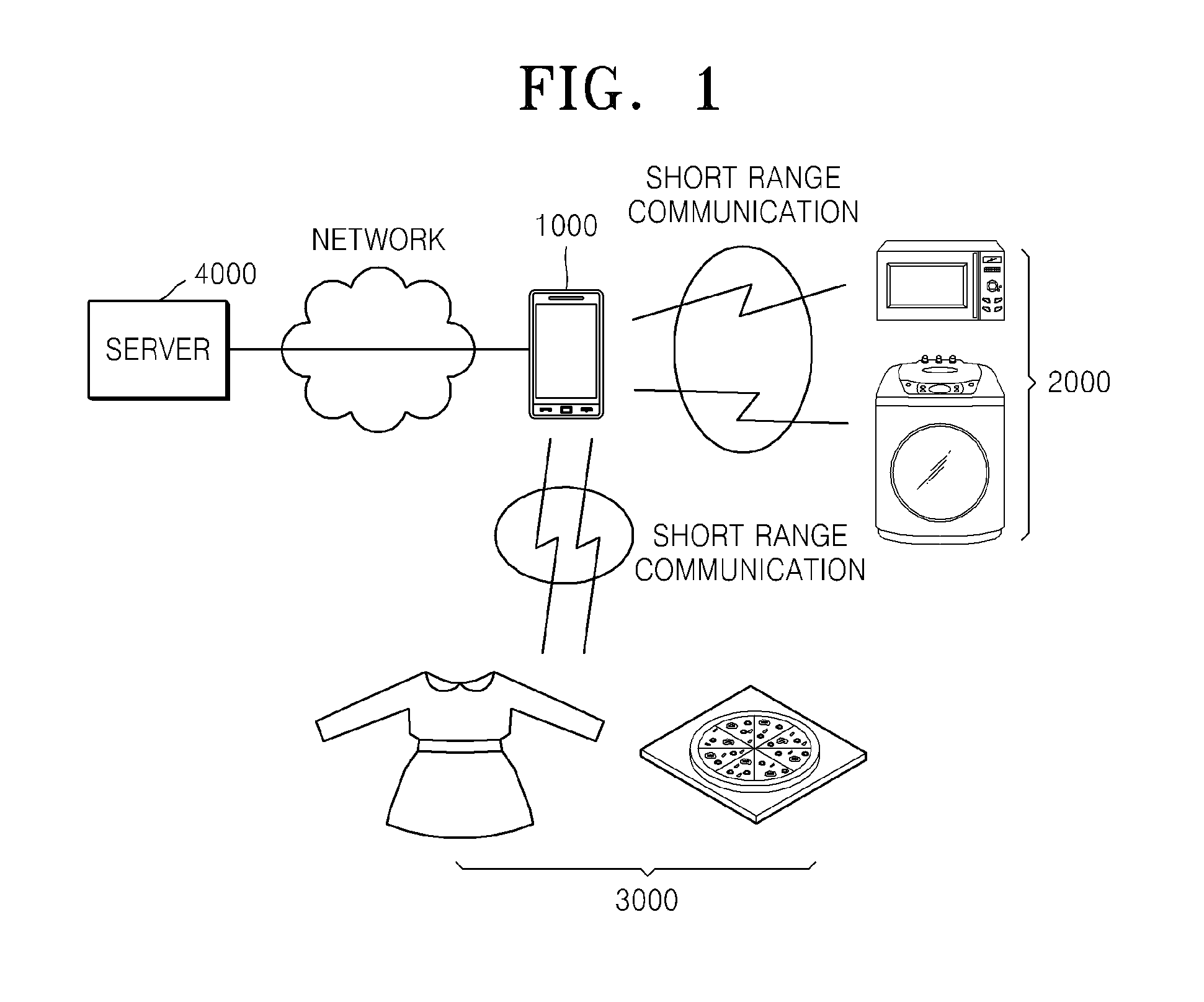

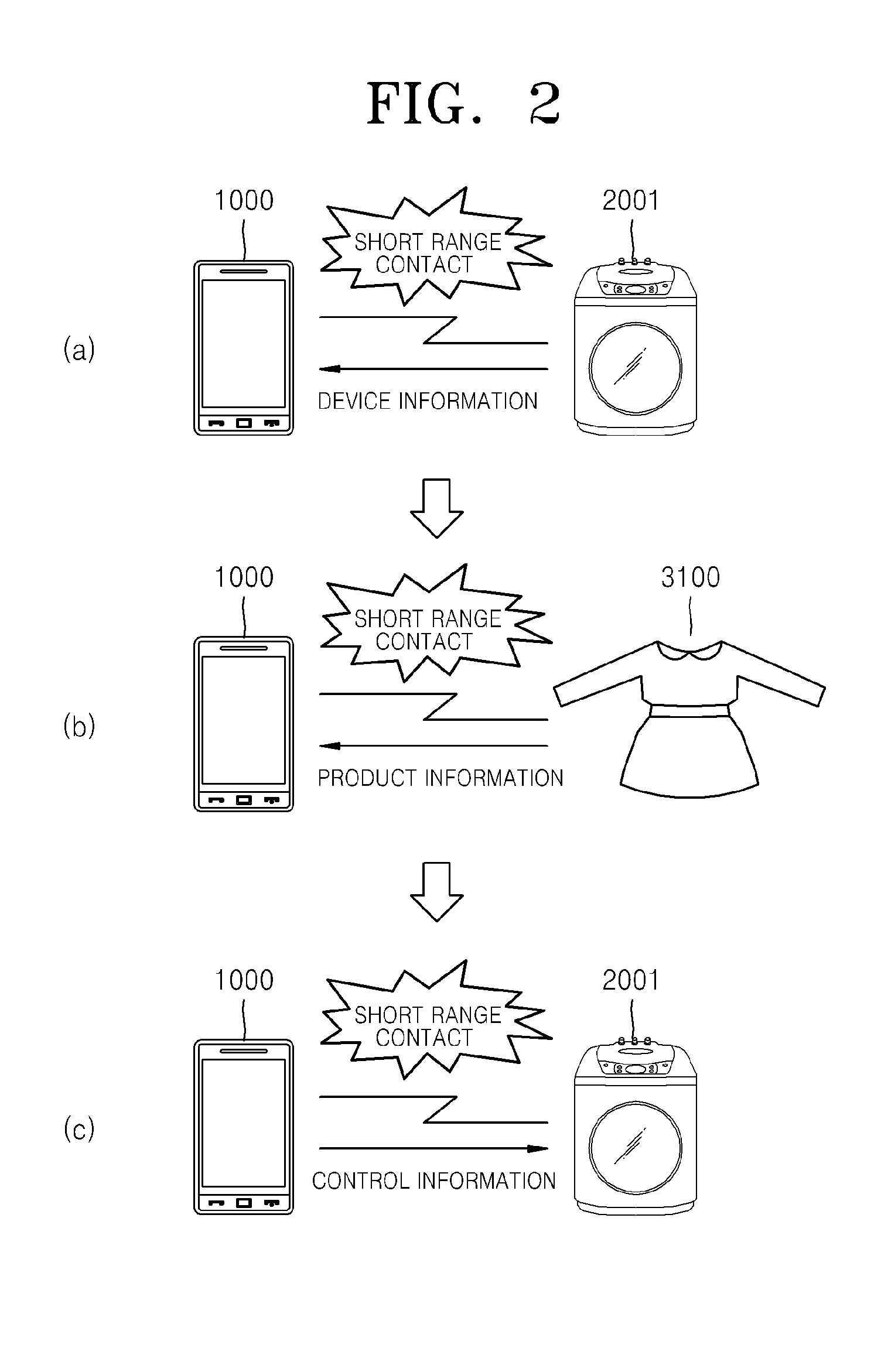

System and method of providing control information to device regarding product

ActiveUS20130264383A1Programme controlDigital data information retrievalProper functionEmbedded system

Controlling a consumer electronic applicant through a mobile terminal to execute functionality appropriate for processing a consumer product is performed by obtaining a device specification of the consumer electronic device and product information on the product to be processed, and generating a command that controls the consumer electronic device to execute the appropriate functionality for processing the product.

Owner:SAMSUNG ELECTRONICS CO LTD

Tired wheel with tire-information sending body, installation instrument and fixing instrument for tire-information sending body, and method of installing tire-information sending body

InactiveUS20050242937A1Precise functionImprove machinabilityTyre measurementsBurglar alarm by hand-portable articles removalProper functionEngineering

Owner:BRIDGESTONE CORP

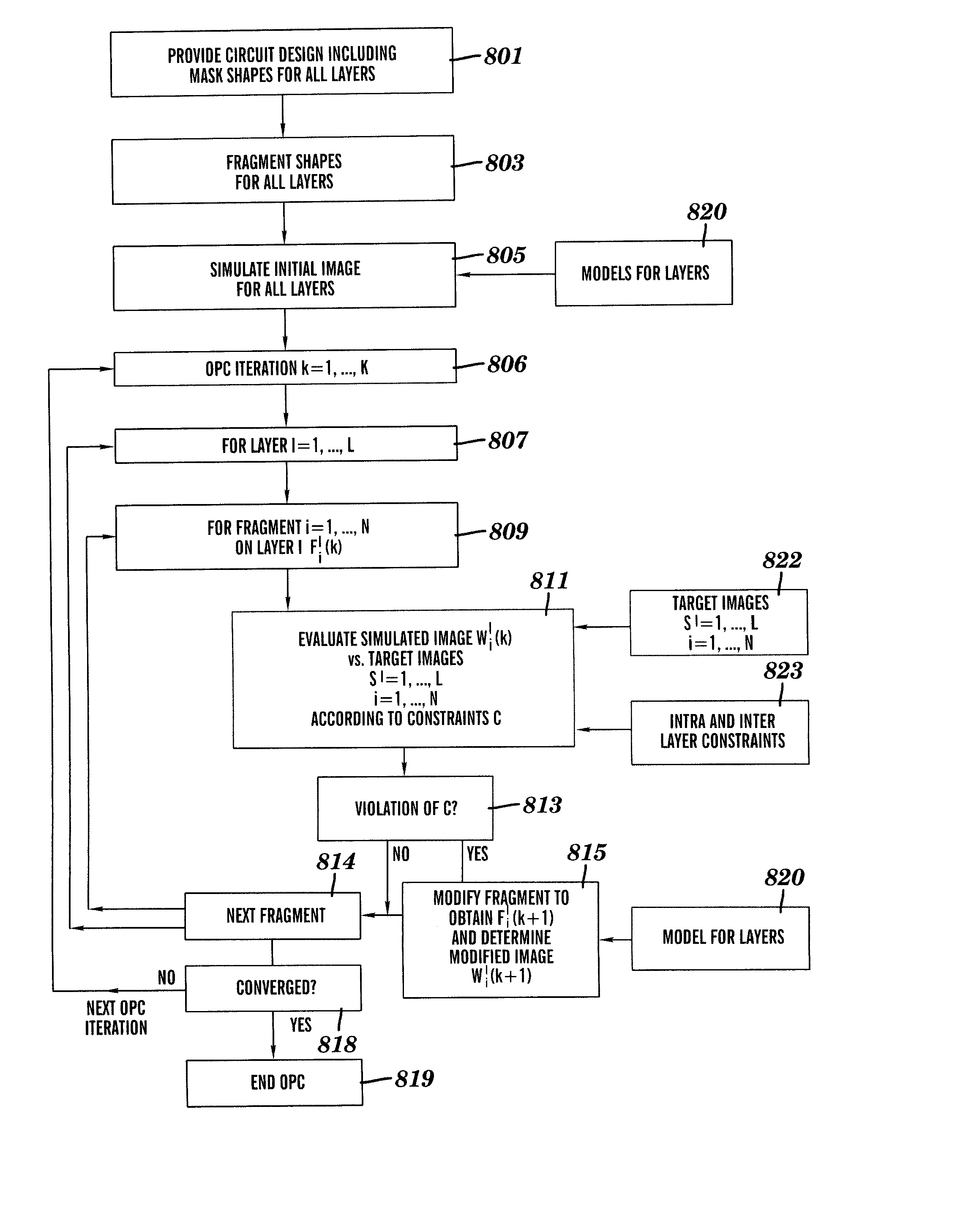

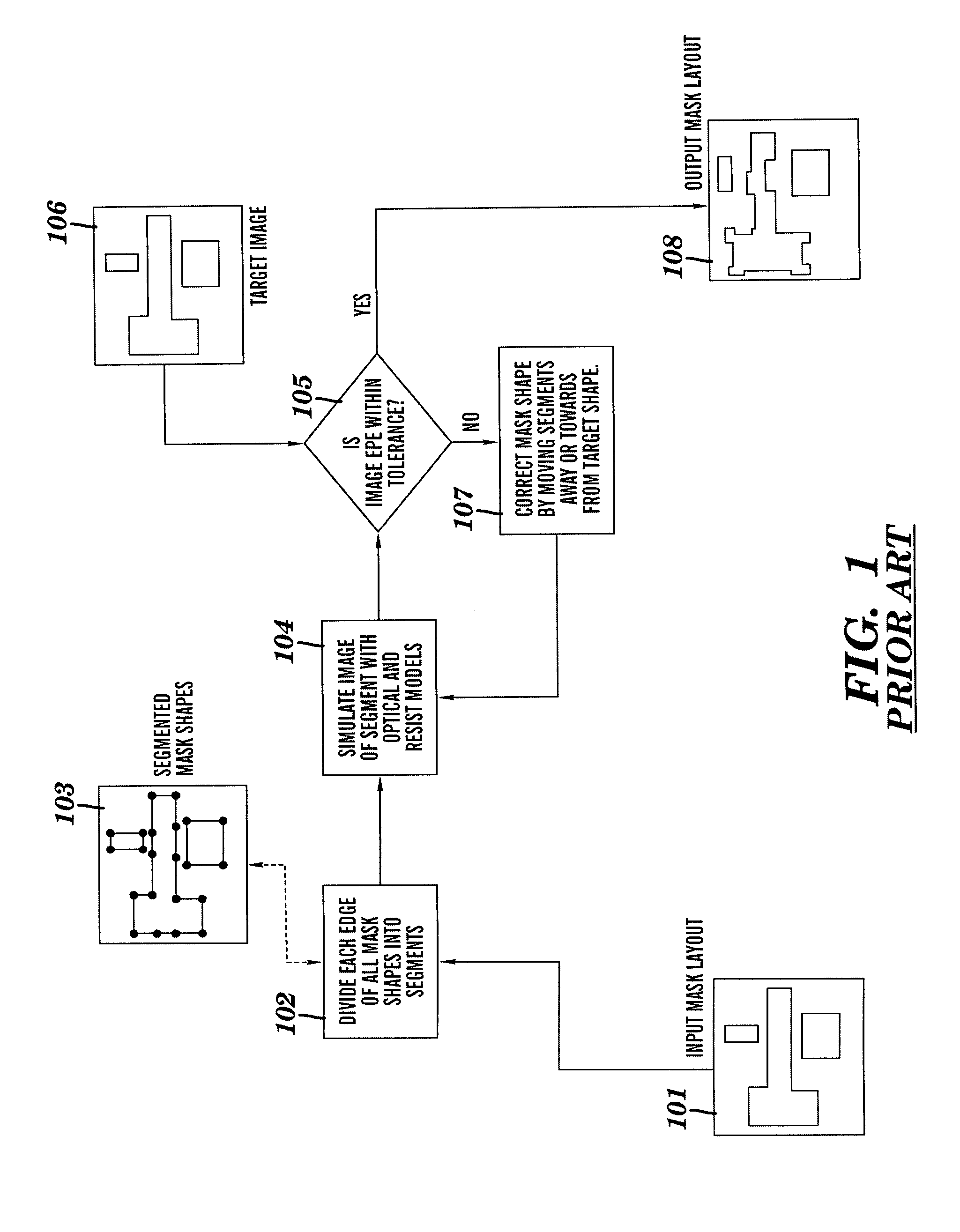

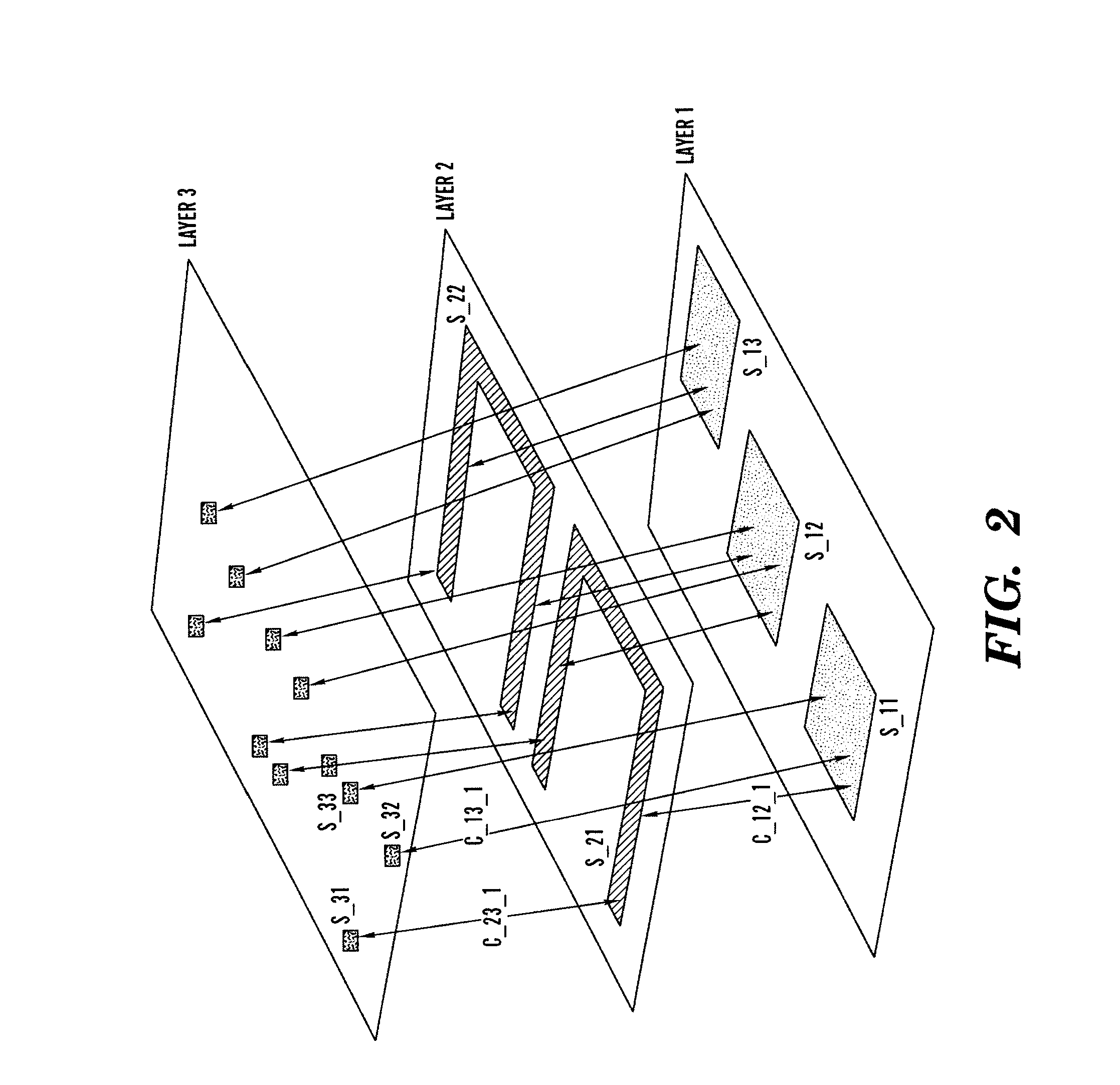

Multilayer OPC for Design Aware Manufacturing

InactiveUS20070220476A1Raise priorityAvoid failureOriginals for photomechanical treatmentSpecial data processing applicationsProper functionInter layer

A method is provided for designing a mask layout for an integrated circuit that ensures proper functional interaction among circuit features by including functional inter-layer and intra-layer constraints on the wafer. The functional constraints used according to the present invention are applied among the simulated wafer images to ensure proper functional interaction, while relaxing or eliminating the EPE constraints on the location of the wafer images.

Owner:GLOBALFOUNDRIES INC

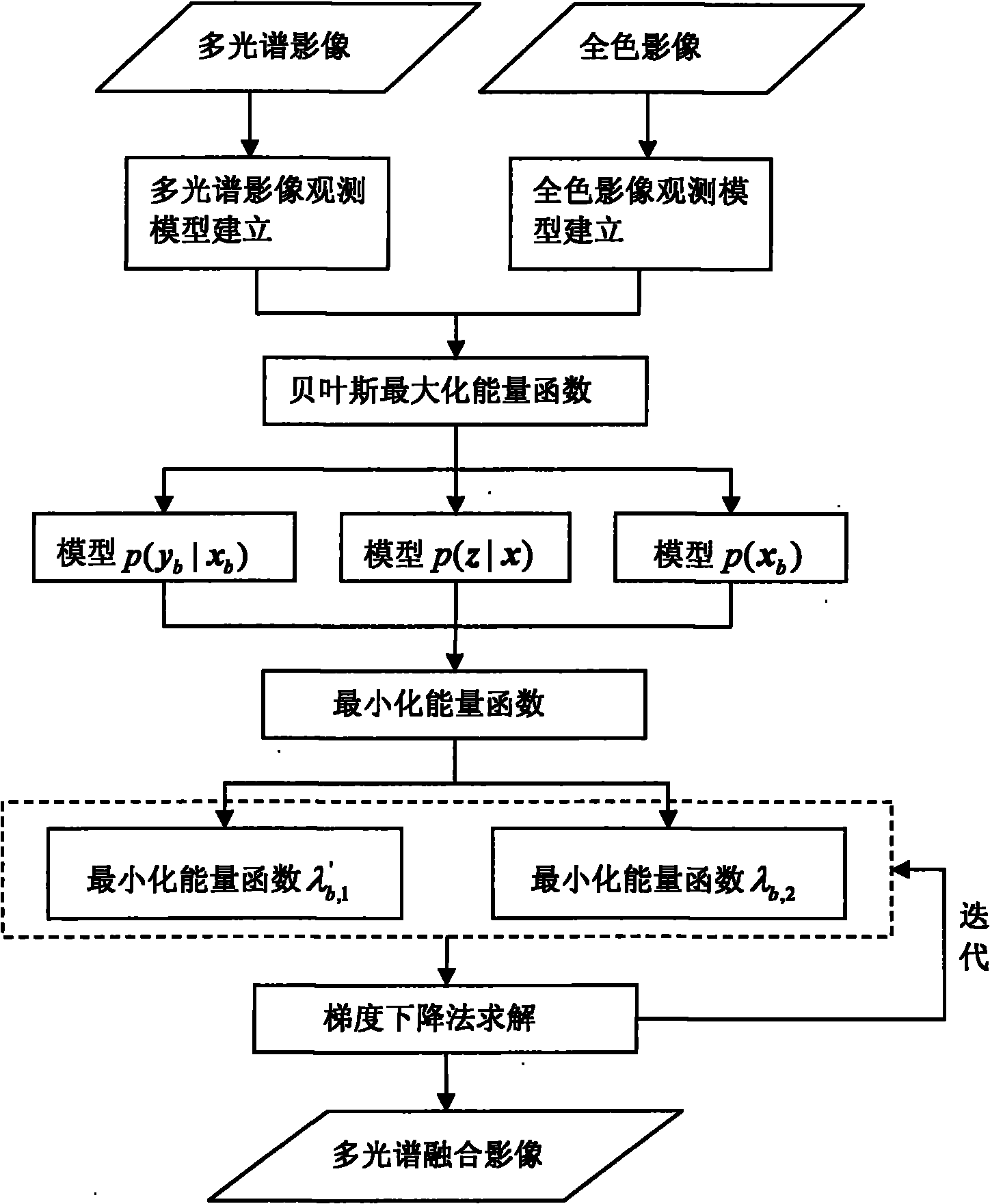

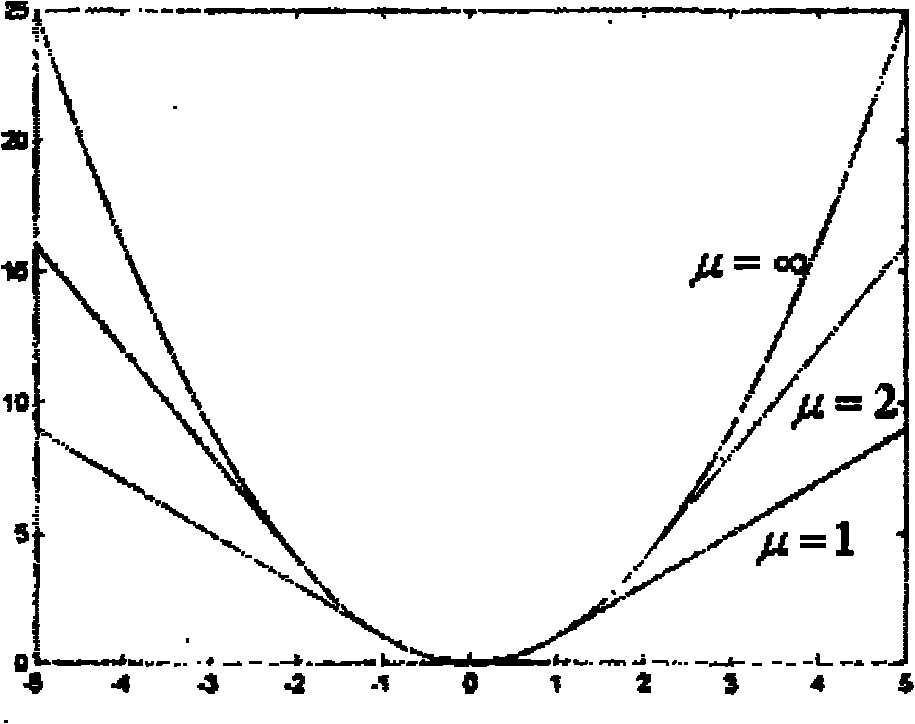

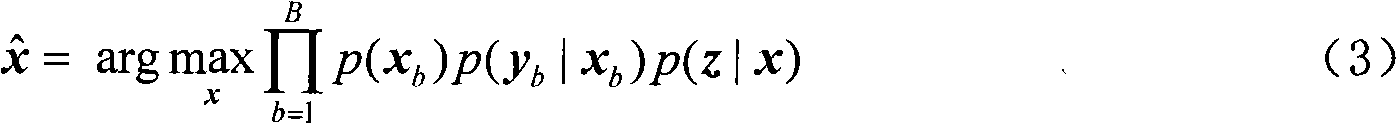

Adaptive variation remotely sensed image fusion method

ActiveCN101894365AHigh degree of integrationStrong adaptive processing abilityImage enhancementRemote sensing image fusionImaging data

The invention provides an adaptive variation remotely sensed image fusion method. In the method, multi-spectrum image and full-color image observation models are respectively established by analyzing the image degrading process, an inverse problem corresponding to the image fusion is described by utilizing a maximum posteriori estimation theoretical frame, and a variation image fusion model consisting of a multi-spectrum image data consistency constraint, a full-color image data consistency constraint and an image transcendental constraint is established; and in the resolving process, iterative solving is carried out by a gradient degressive algorithm, regularization parameters are adaptively solved by establishing a proper function, and an adjustable parameter is reserved simultaneously so as to meet the requirements of different users. The method can improve the original multi-spectrum image space resolution, effectively maintain the conventional spectrum information, and automatically select the proper regularization parameters adaptively according to different image data, so the method has the characteristics of high fidelity, high adaptation degree and the like.

Owner:WUHAN UNIV

Dynamic self-checking interlock monitoring system

ActiveUS20110240136A1Prevent cheatingValve arrangementsHollow article cleaningProper functionProximity sensor

An interlock monitoring system includes a magnetic proximity sensor within a poppet valve type coupler to detect whether the poppet valve is opened or closed. An open poppet valve indicates a proper connection. The sensor consists of dedicated electronics that prevent cheating, or bypassing, by either shorting out or opening the contacts to the sensor. In addition, a ferrous metal proximity switch is used to provide a redundant confirmation of proper connection of the coupler. The ferrous magnetic proximity switch will indicate whether or not the coupler is actually in contact with an appropriate connection. Each of the magnetic proximity sensor and the ferrous magnetic proximity switch must indicate a respective proper condition in order to determine a valid interlock condition.

Owner:SCULLY SIGNAL CO

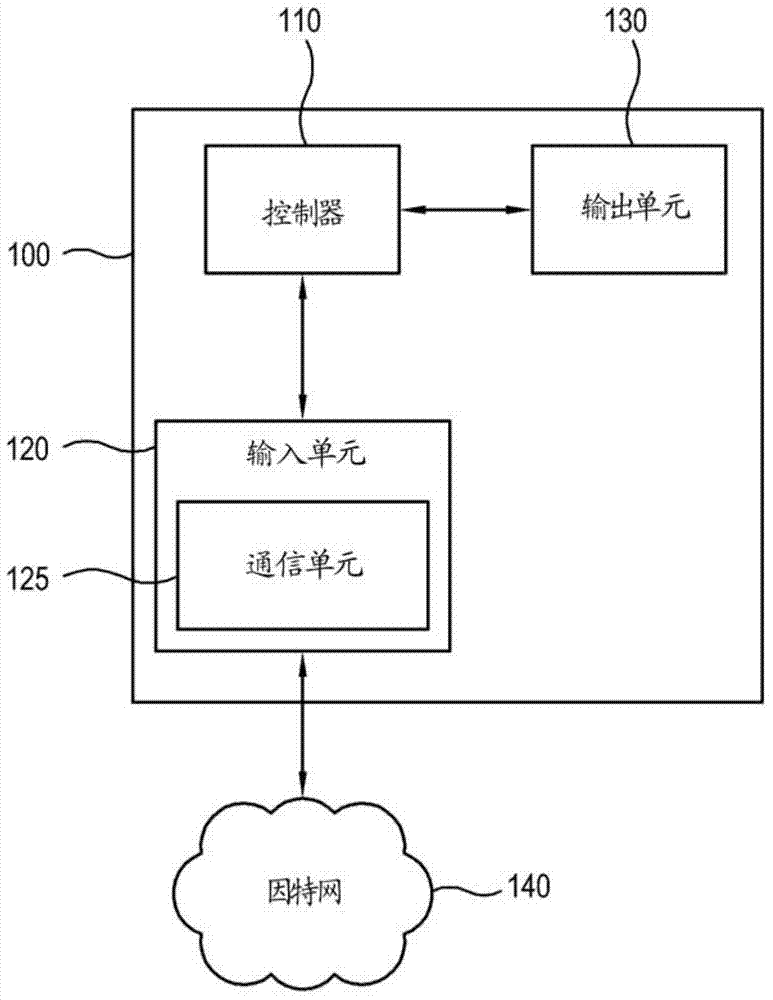

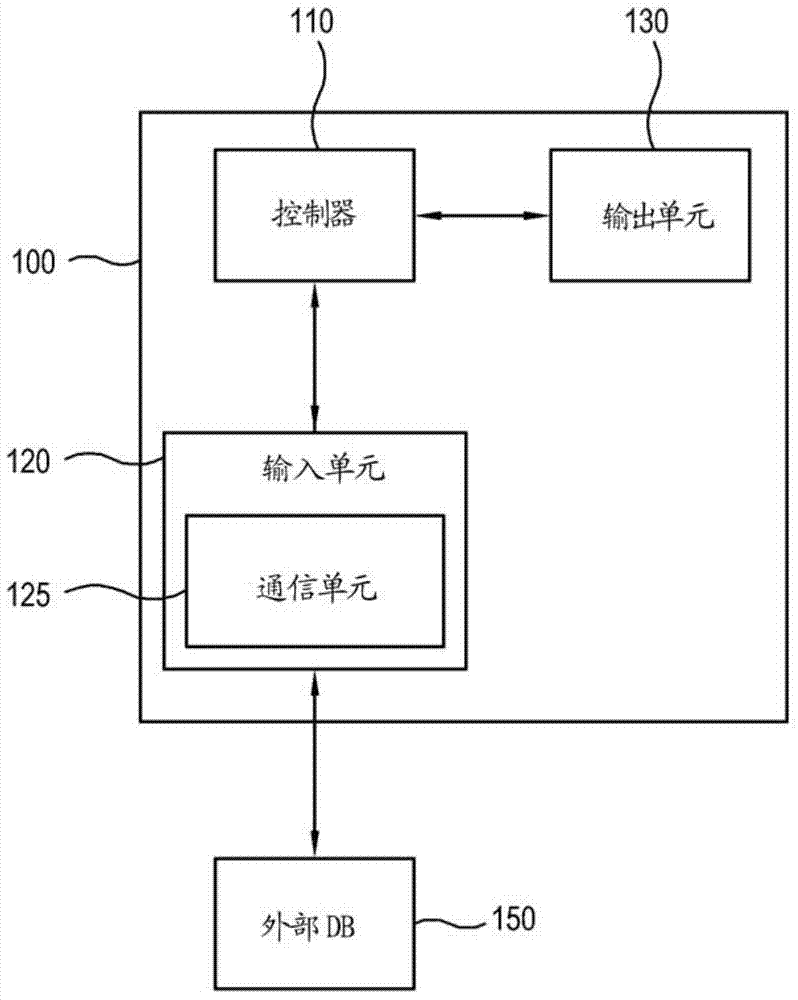

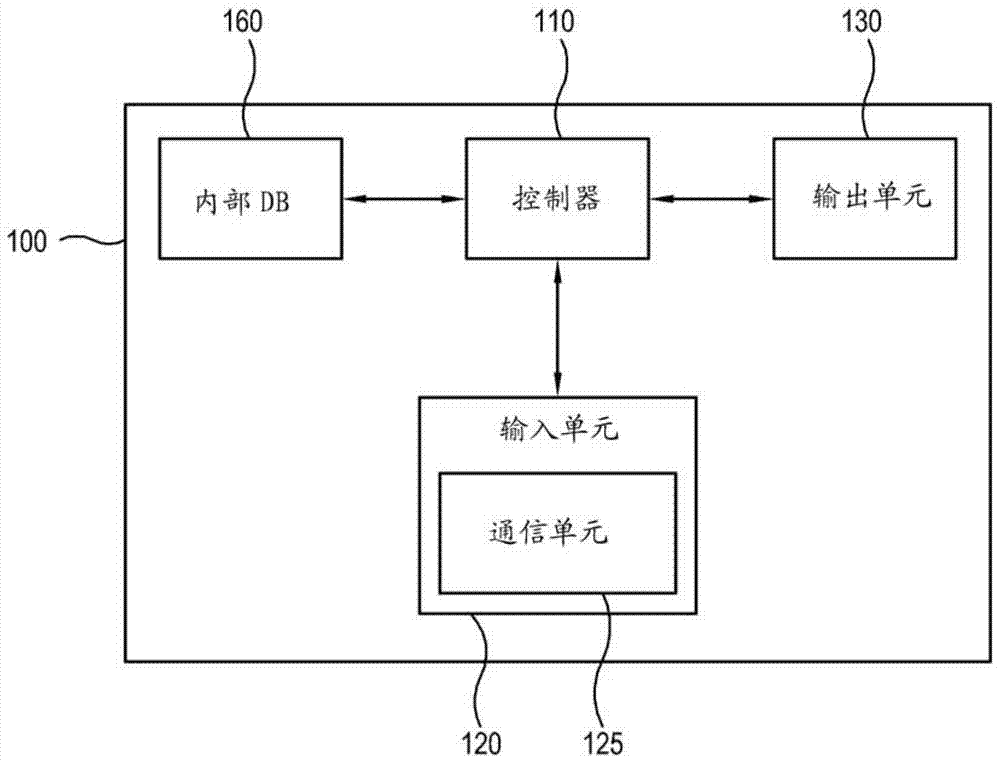

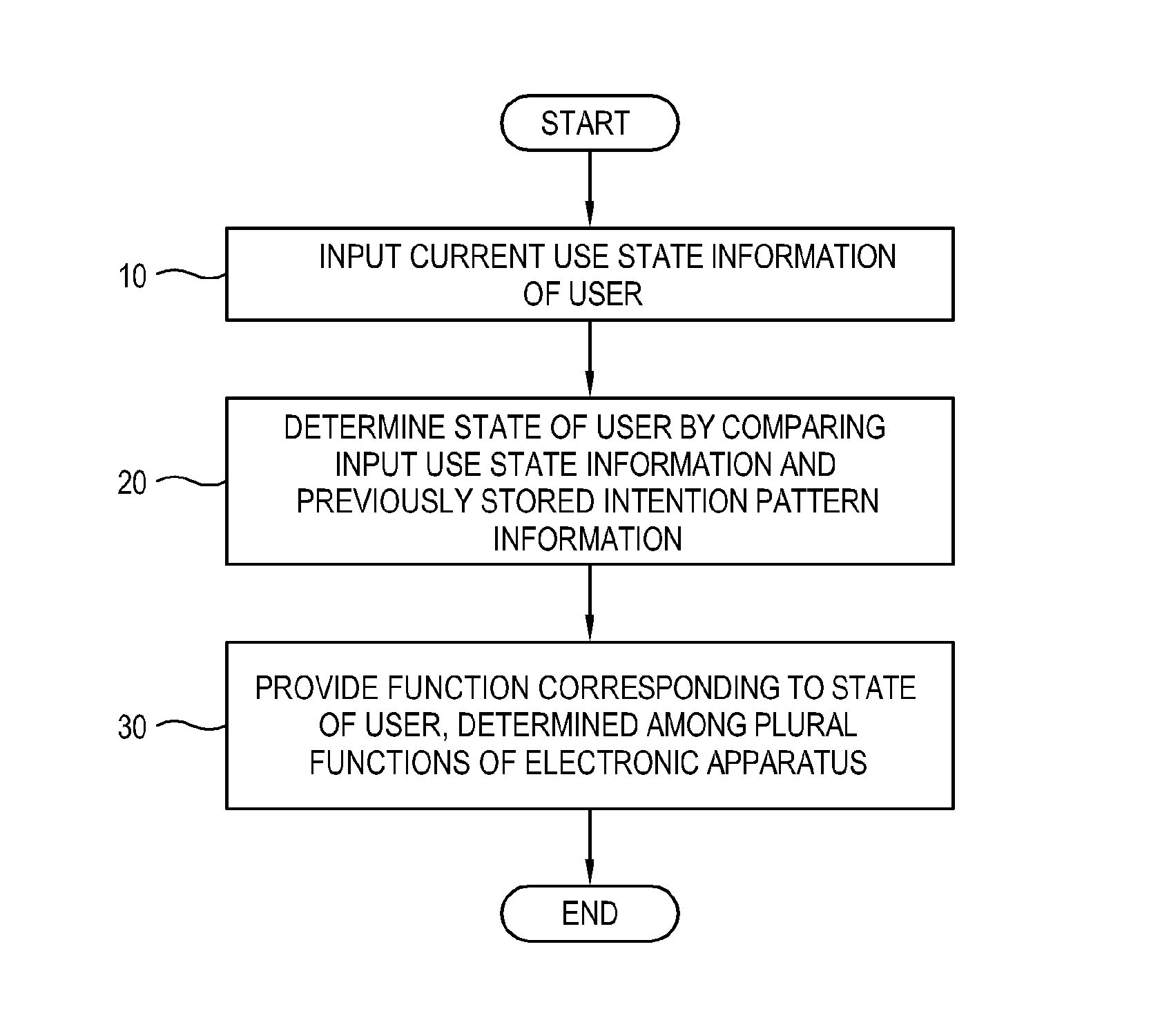

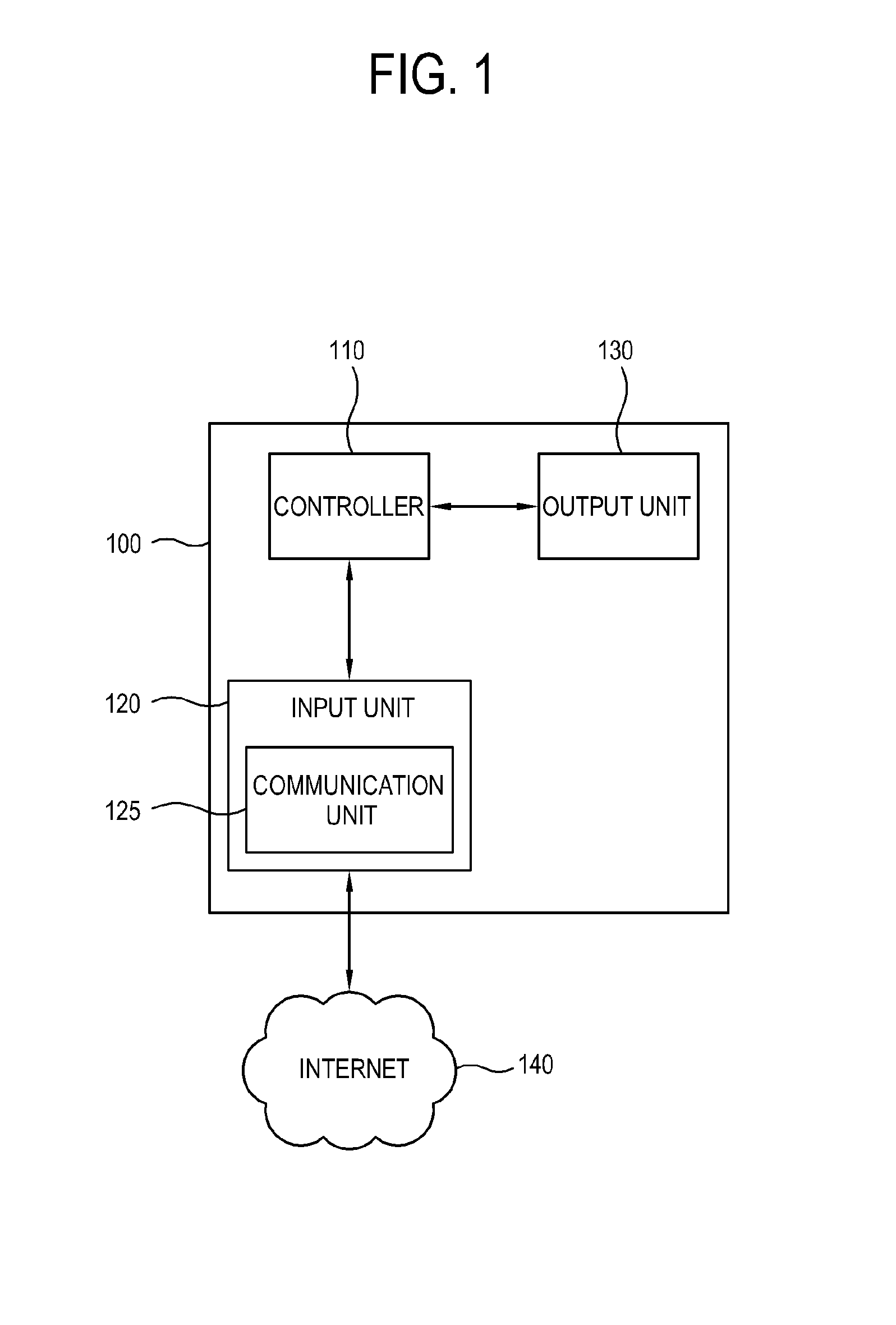

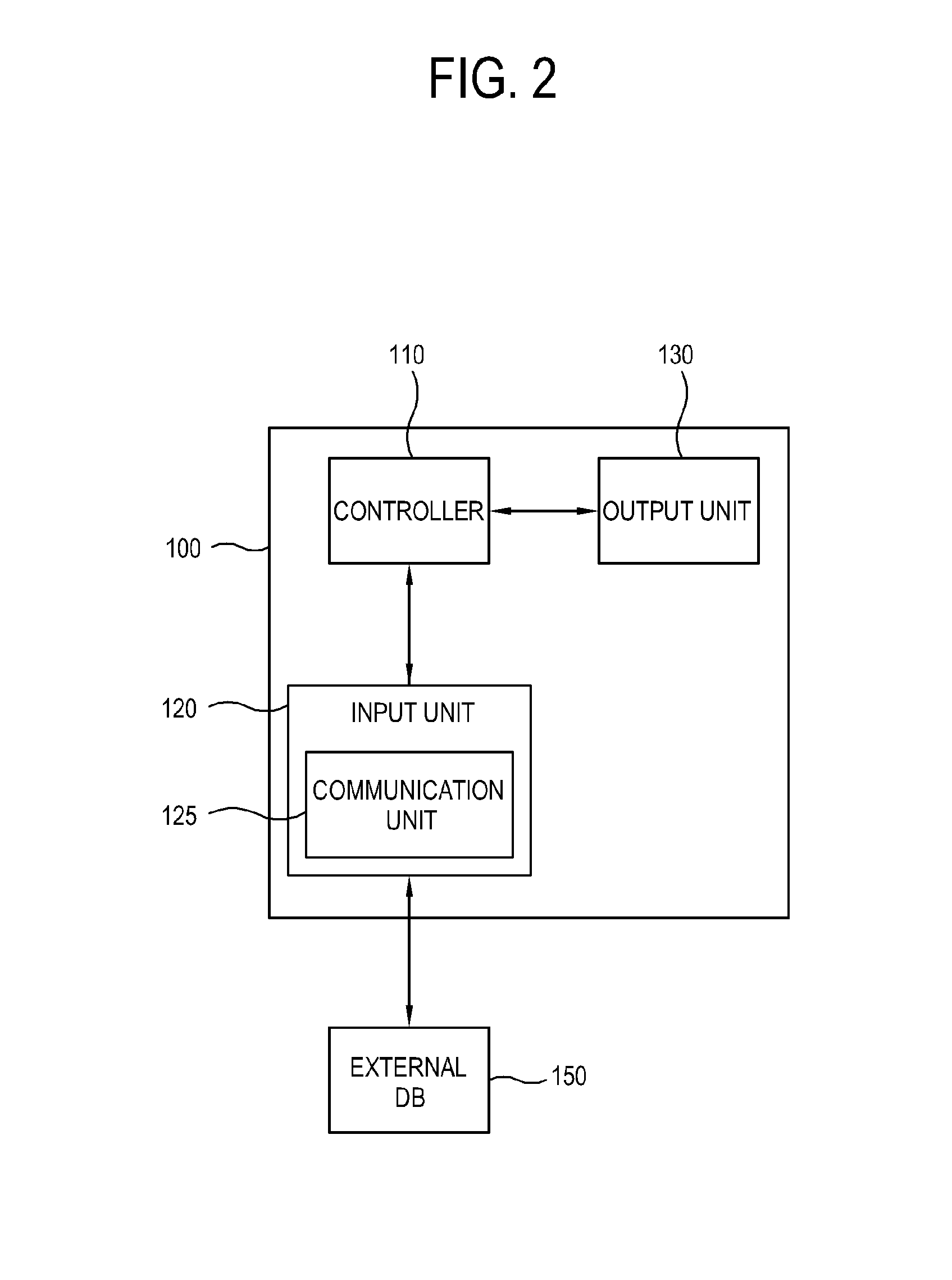

Electronic Apparatus And Method Of Controlling The Same

InactiveCN103929662AInput/output for user-computer interactionSound input/outputProper functionComputer science

An electronic apparatus and a method of controlling the same are provided. The method comprises the steps of receiveing a user's current use state information including at least one of current user information and surrounding environment information, determining a user's current state by comparing the received current use state information with intention pattern information in which a user's intention is patterned and previously stored in association with a plurality of functions or information providable by the electronic apparatus, and automatically proposing a function corresponding to the determined user's state among the plurality of functions or information providable by the electronic apparatus. Thus, a user's intention or needs is determined to actively propose a proper function so that a user can conveniently use the function.

Owner:SAMSUNG ELECTRONICS CO LTD

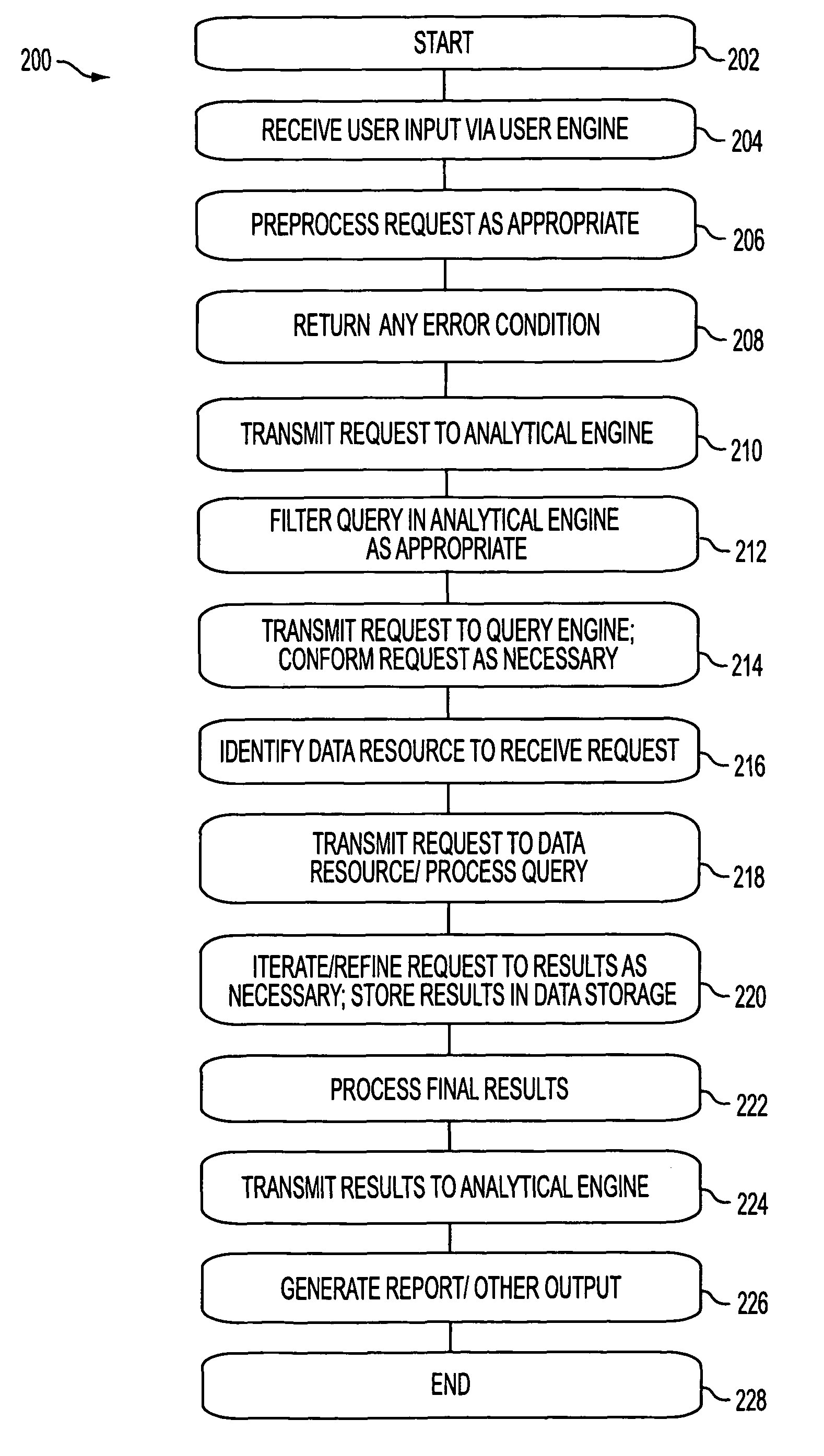

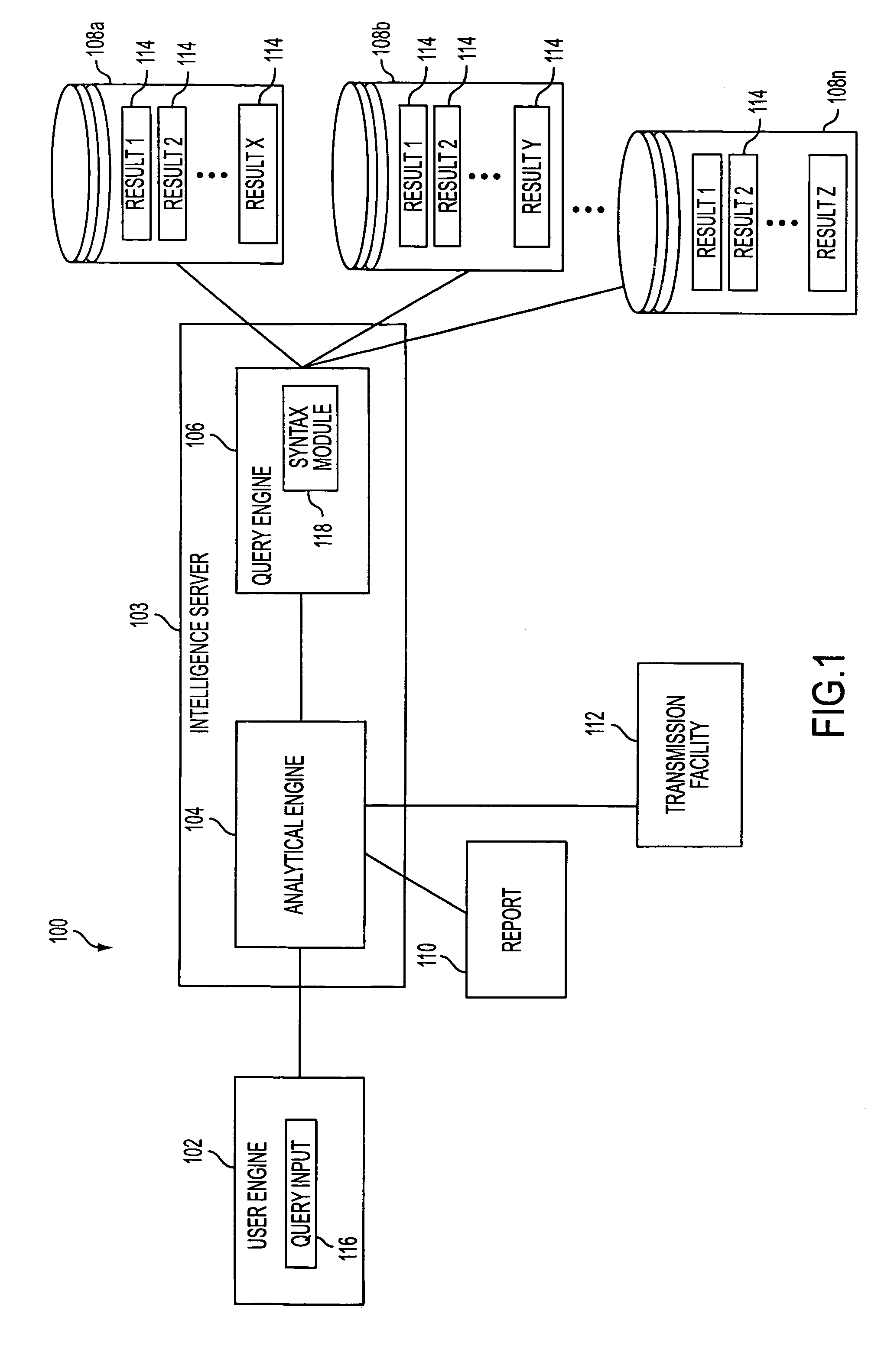

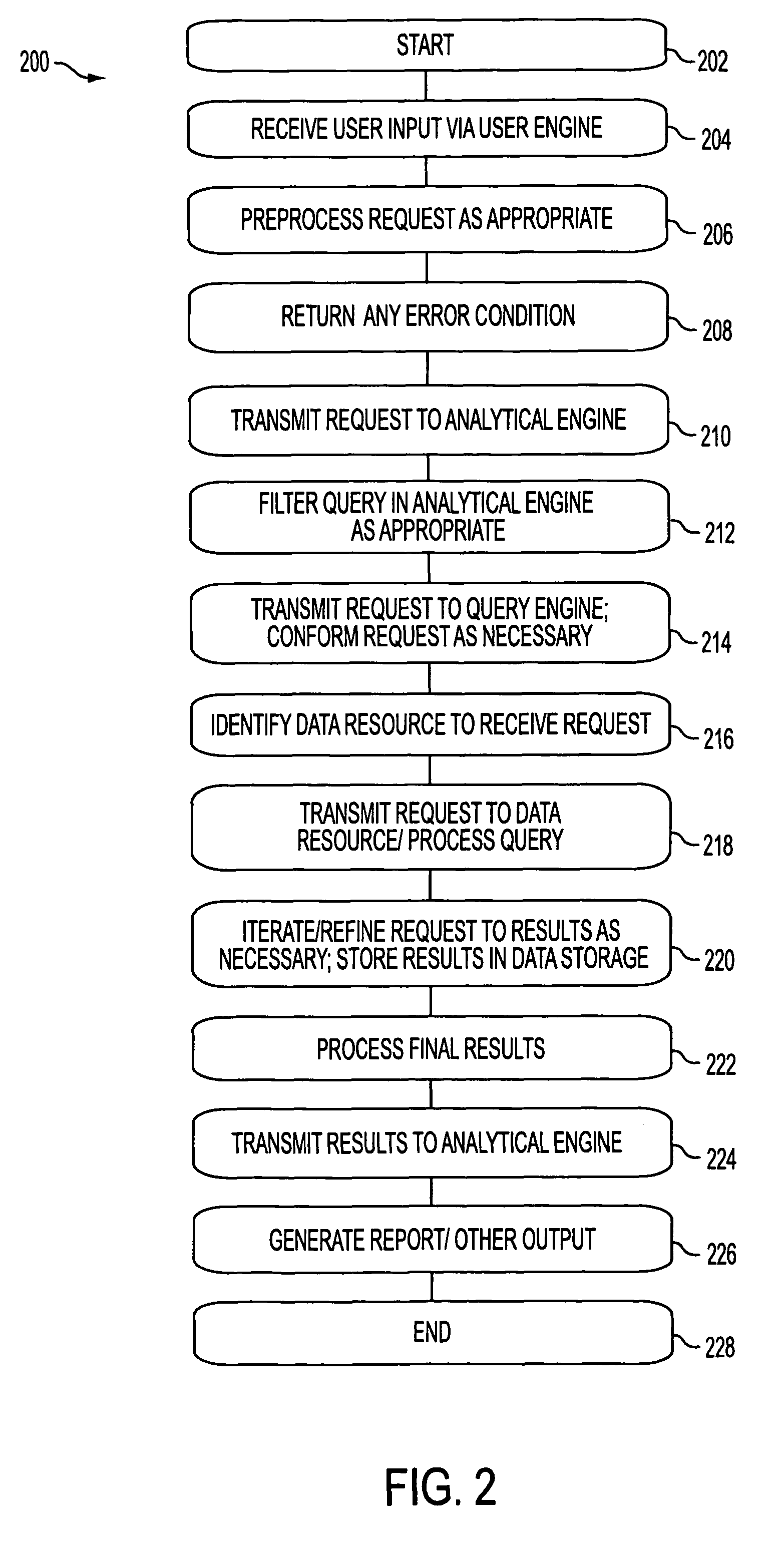

System and method for syntax abstraction in query language generation

ActiveUS8005870B1Improve abilitiesImprove compatibilityDigital data information retrievalDigital data processing detailsProper functionProgramming language

A system and method for syntax abstraction in query language generation in an online analytical processing system, a business intelligence system, a reporting system, or a data mining system. The system generates one or more query language statements that can be run against one or more data sources to return a desired data result set. The system includes a syntax pattern selector module and a statement assembly module. The syntax pattern selector module selects a syntax pattern corresponding to a desired function and a syntax standard. The statement assembly module populates the syntax pattern with an argument data set associated with the desired data set. The result is the generation of one or more query language statements with the correct function, syntax, and data parameters to return the desired data result set from the data sources. A method and medium having processor readable code therein are also described.

Owner:MICROSTRATEGY

Immobilized nuclease and preparing method thereof

The invention belongs to the field of biological medicines and relates to an immobilized nuclease and a preparing method thereof. The immobilized nuclease comprises a nuclease and a solid-phase vector. The nuclease is connected to groups on the solid-phase vector through covalent bonds. The activity of the immobilized nuclease is higher than 500 U / g. A functional pH range of the immobilized nuclease is 6-8. The proper function temperature of the immobilized nuclease is 37 DEG C. The invention also discloses the preparing method of the immobilized nuclease. The immobilized nuclease is applied in processes of medicine products, avoids nuclease residue in a final product during product separation and purification steps, and improves the product quality.

Owner:HANGZHOU JUNFENG BIOENG

Apparatus for monitoring a smoke detector

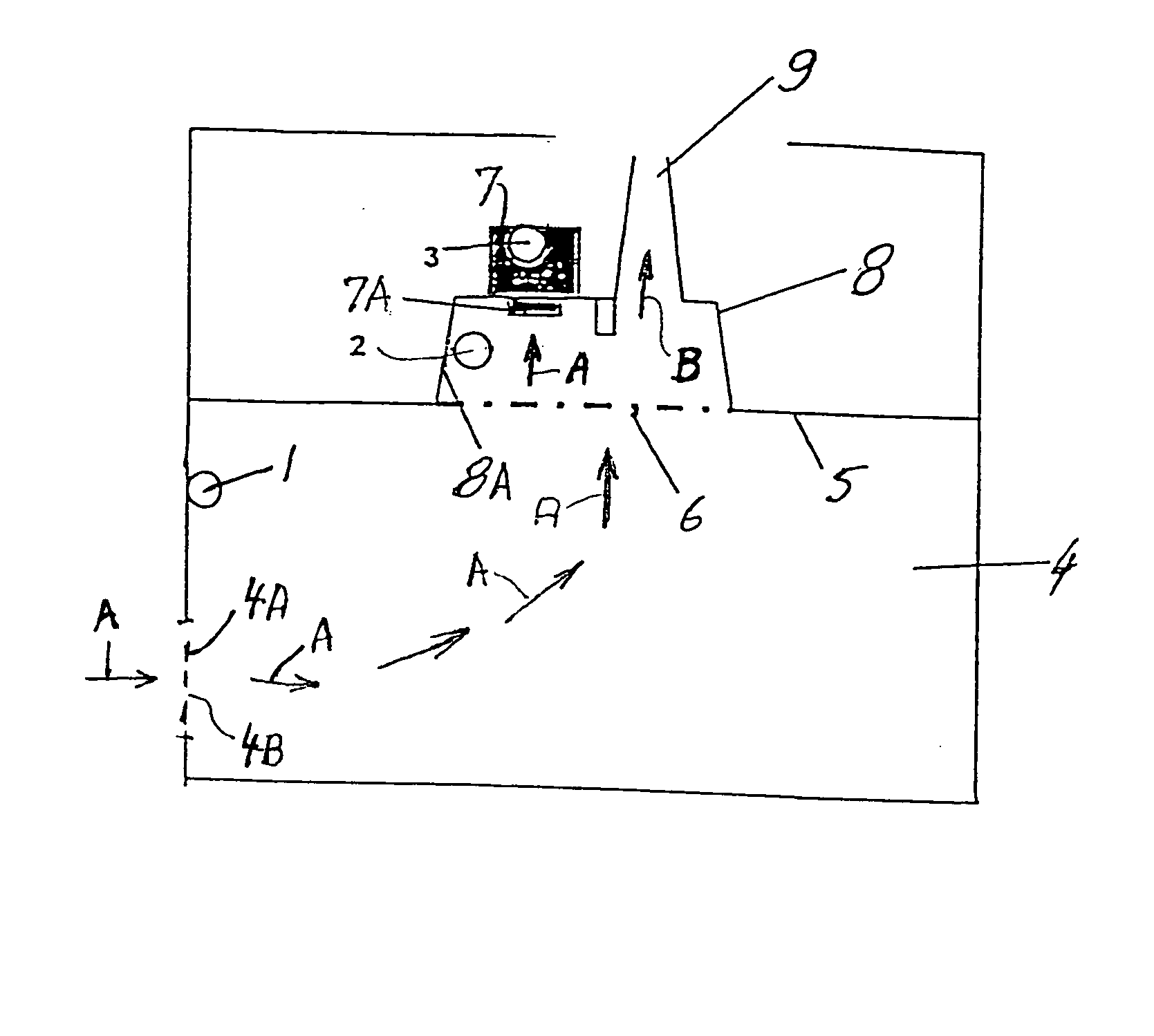

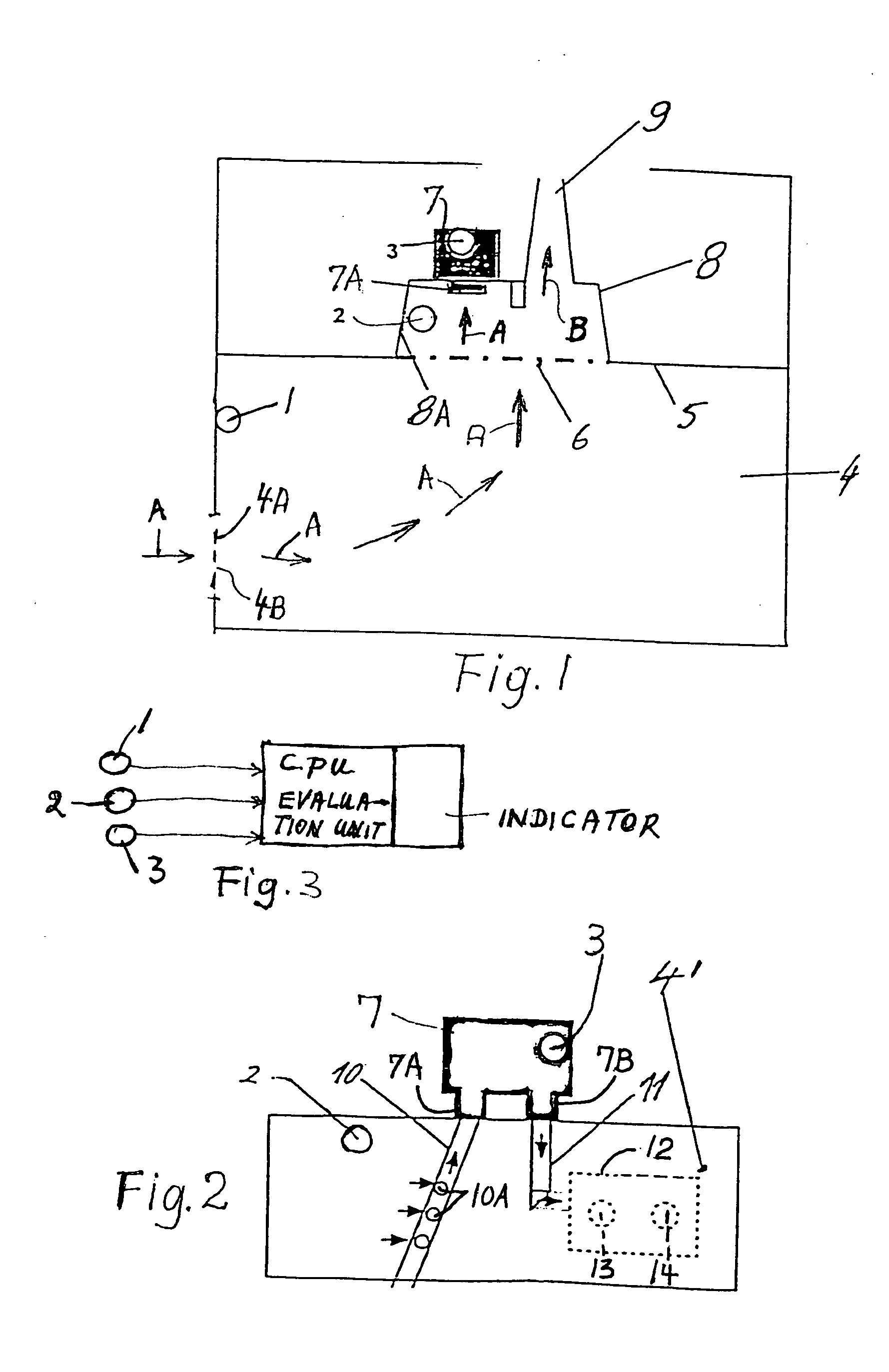

ActiveUS20040246137A1Facilitate a continuous monitoring of the smoke detectorsSolving precise measurementsFire alarm smoke/gas actuationSmoke detectorsProper function

The proper function of a smoke detector of an enclosed space, such as a toilet or freight space or crew quarters in an aircraft, is monitored by at least two air pressure sensors which are so positioned that these air pressure sensors can measure an air pressure differential in the air flow into the smoke detector. If a pressure differential is detected the differential is evaluated in a central processing unit which produces a respective signal that indicates that the air flow and thus the smoke flow into the smoke detector is obstructed, whereby the smoke detector cannot function properly. This signal is visibly or audibly indicated.

Owner:AIRBUS OPERATIONS GMBH

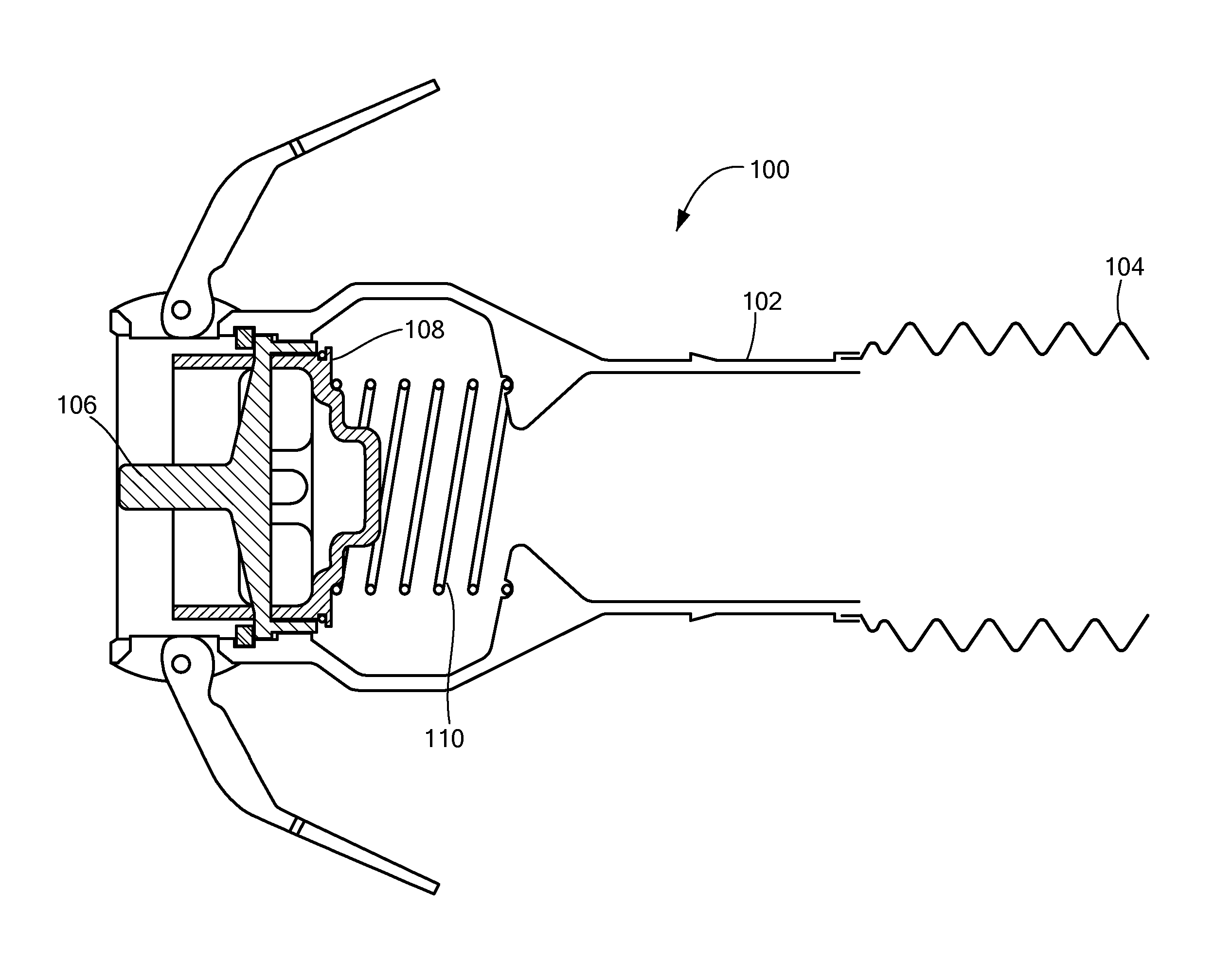

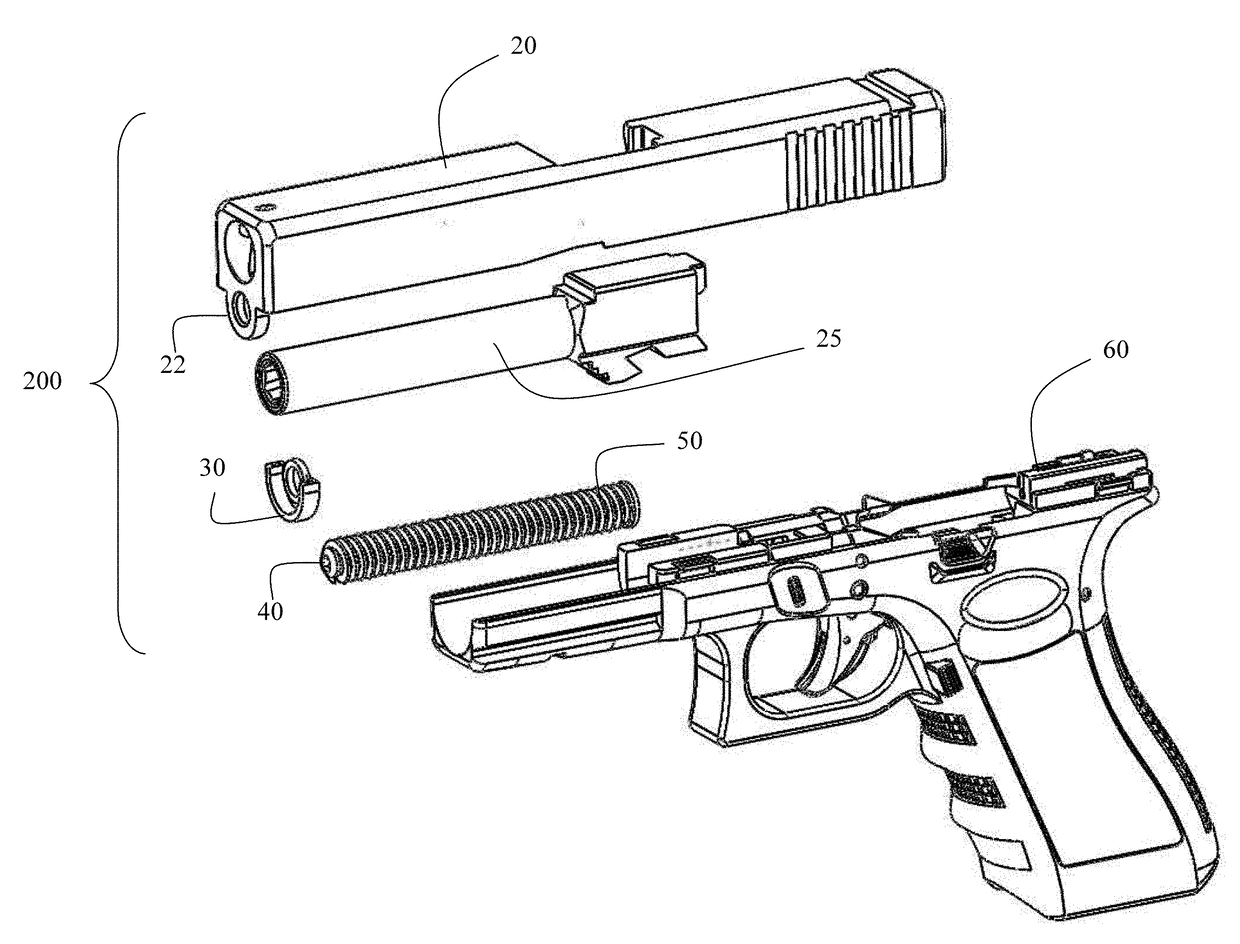

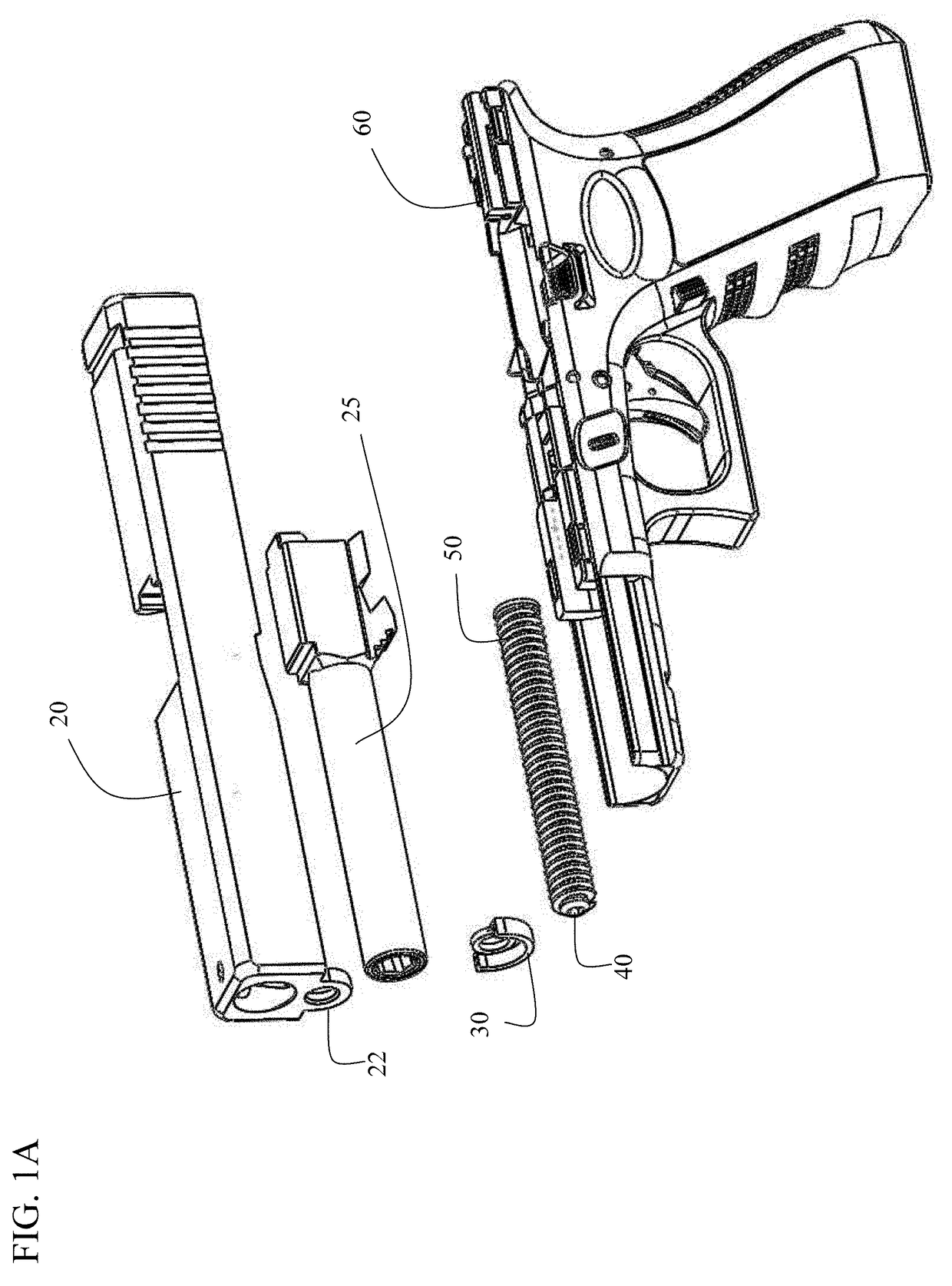

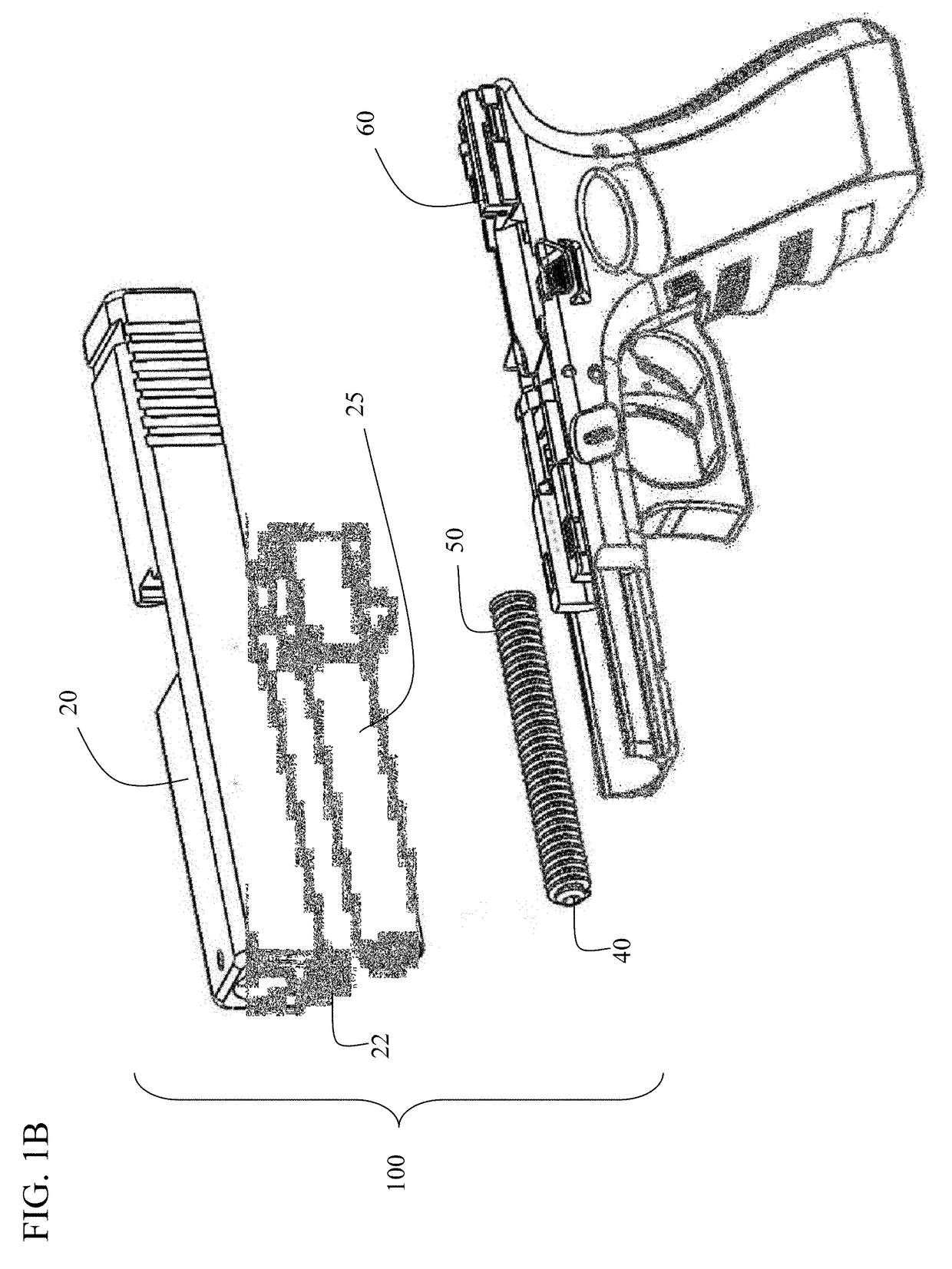

Handgun slide to frame adapter

InactiveUS20170191769A1Improve performanceEnhanced handgun customizationWeapon assembly/disassemblyBreech mechanismsProper functionEarly generation

An adapter for utilizing a handgun slide manufactured for use on a common generation and version of handgun frame to make its use capable on a newer generation or versions frame having different dimensional features. The adapter makes allows use of a slide assembly comprising of a slide, barrel, recoil spring and guide from previous generations on more recent generations of the same handgun. The adapter is mounted on the previous versions dust cover creating a new geometry to allow for proper function inside the newer generation's frame. The adapter includes a bushing. The earlier generation's slides have an outer surface shape smaller than the newer generation slide with the adapter creating the geometry necessary for compatibility.

Owner:ADAMS ARMS

Copulsation milking system

InactiveUS20110168098A1Reduce the impactReducing associated noiseMilking devicesProper functionEngineering

There is provided a method for improving the reliability and performance of a valve device that transitions between the pressure and vacuum phases for the purpose of milking animals. The improvement reduces physical wear of the movable parts within the valve device while ensuring proper function of said movable parts.

Owner:GEHM LANNY +1

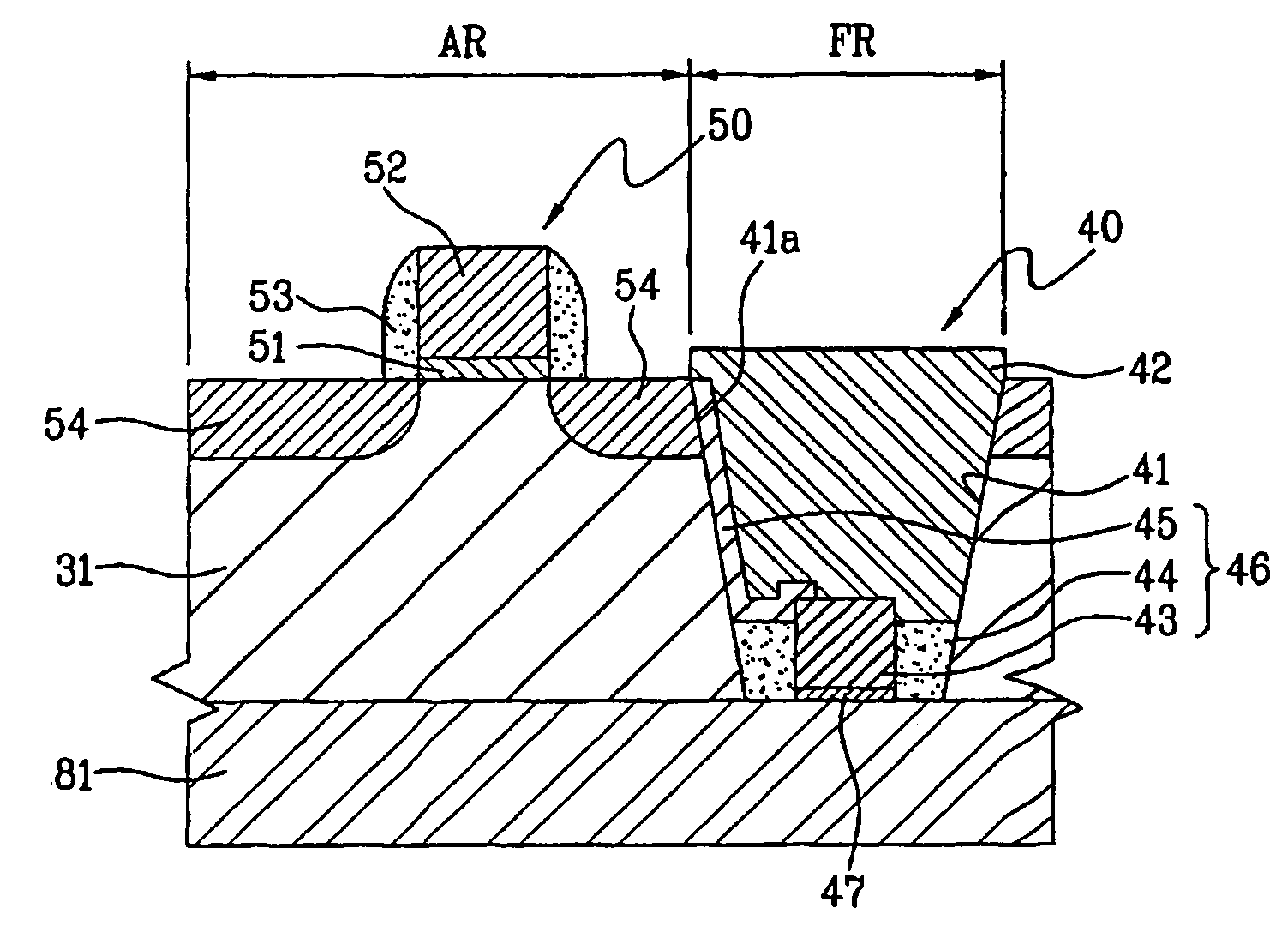

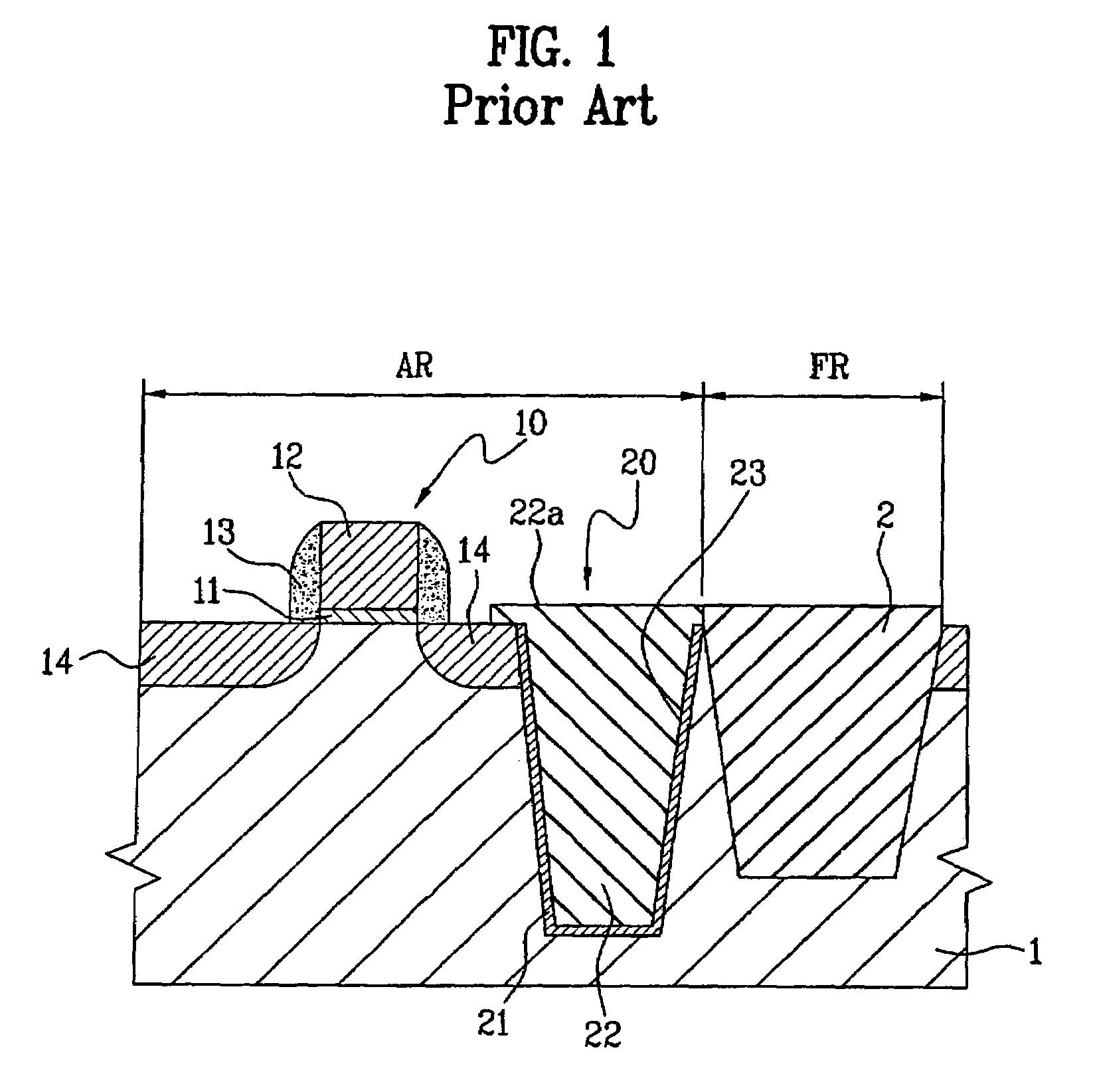

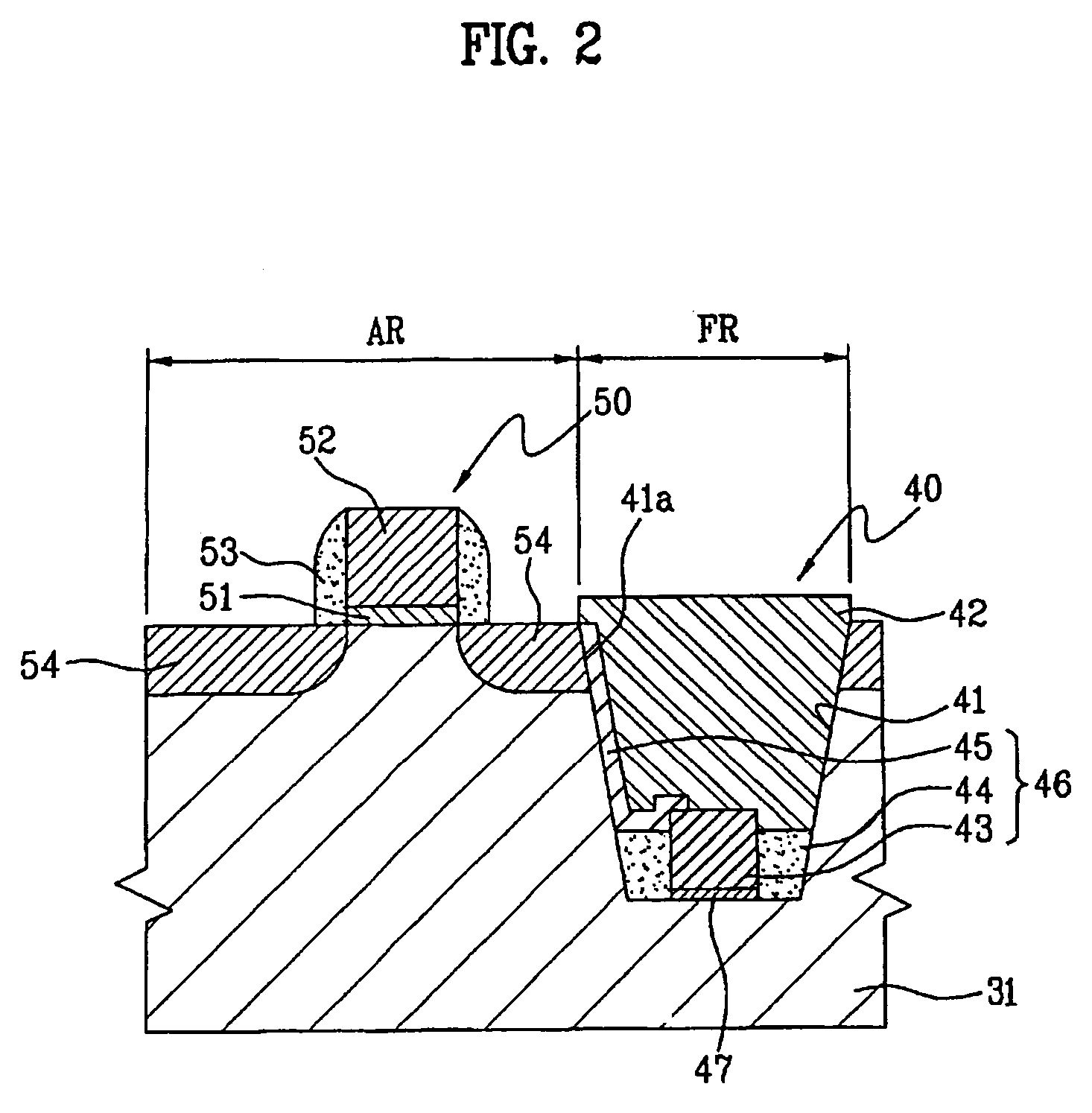

Semiconductor device and method for fabricating the same

InactiveUS7416937B2Minimized in sizeHigh equipment integrationTransistorSolid-state devicesProper functionEngineering

A method creates semiconductor device in which a storage dielectric film and a storage electrode included in the capacitor is transferred from an inactive region of a semiconductor substrate to the active region thereof, i.e., into a device isolating trench such that the capacitor is prevented from unnecessarily occupying an active region of a semiconductor substrate while maintaining its proper function. In contrast to a conventional device where a capacitor is formed in the active region of the semiconductor substrate, to the capacitor is formed in the inactive region according to this process. Accordingly, the capacitor is able to maintain a trench structure without needing to perform a step of removal of a step height difference, and the active region is minimized in size. Therefore, without having a problem of a step height increase, a finished semiconductor device is able to accommodate modern demands for increased device interpretation.

Owner:DONGBU ELECTRONICS CO LTD

Electronic apparatus and method of controlling the same

InactiveUS20140201122A1Input/output for user-computer interactionSound input/outputProper functionModelica

An electronic apparatus and a method of controlling the same, receives a user's current use state information including at least one of current user information and surrounding environment information, determines a user's current state by comparing the received current use state information with intention pattern information in which a user's intention is patterned and previously stored in association with a plurality of functions or information providable by the electronic apparatus, and automatically proposes a function corresponding to the determined user's state among the plurality of functions or information providable by the electronic apparatus. Thus, a user's intention or needs is determined to actively propose a proper function so that a user can conveniently use the function.

Owner:SAMSUNG ELECTRONICS CO LTD

Electroluminescent lamp module and processing method

InactiveUS6922020B2Easy to manufactureIncrease speedPrinted circuit assemblingDischarge tube luminescnet screensElectricityProper function

The present invention is an EL lamp module and a method of producing an EL lamp module. The EL lamp module of the present invention provides both an EL lamp (attachable or printed) and required electrical components for the proper function of the EL lamp in a single structure, thereby eliminating the necessity of separate electrical and mechanical connections for the final application of an EL lamp. The EL lamp module includes a printed circuit pattern and printed electrical components, and / or electrical components that may be connected through conventional printing techniques utilizing conductive and non-conductive pressure sensitive adhesives.

Owner:MORGAN ADHESIVES COMPANY

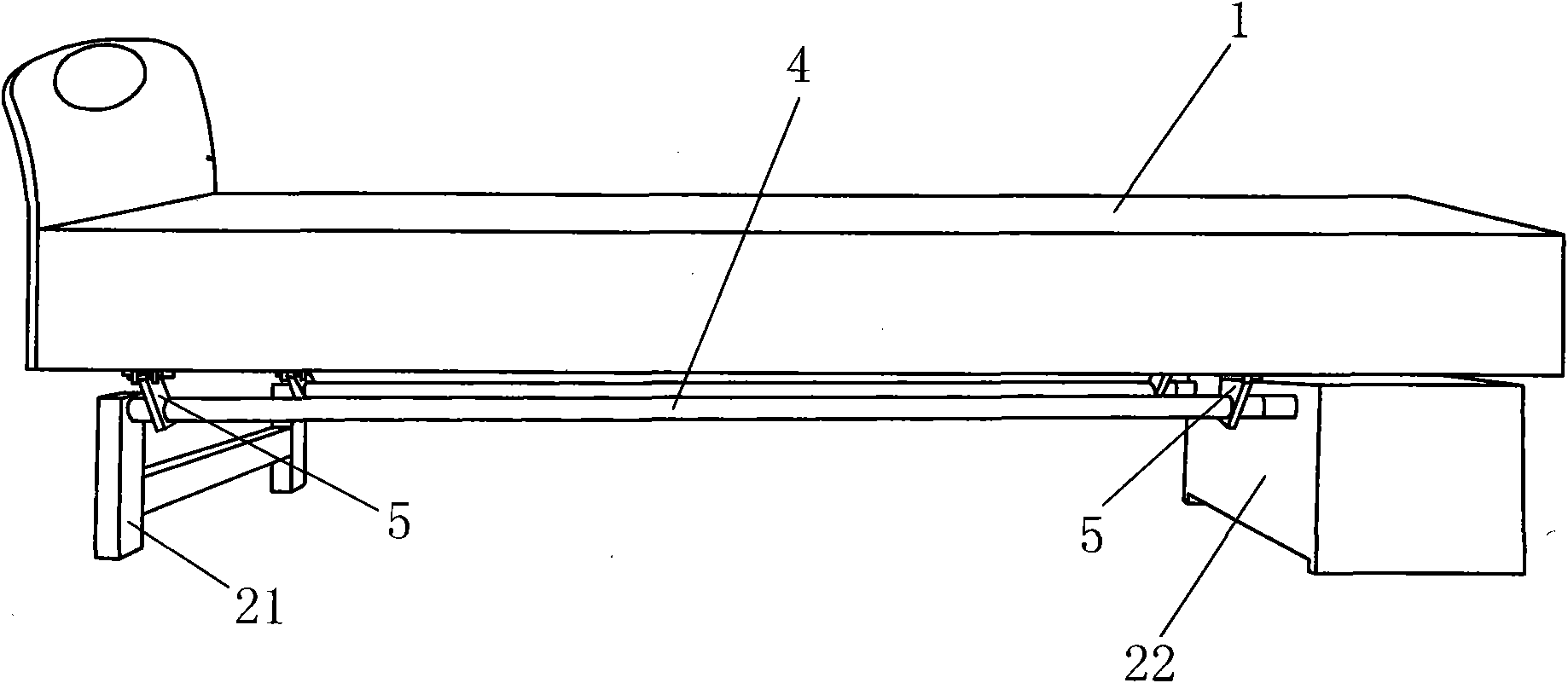

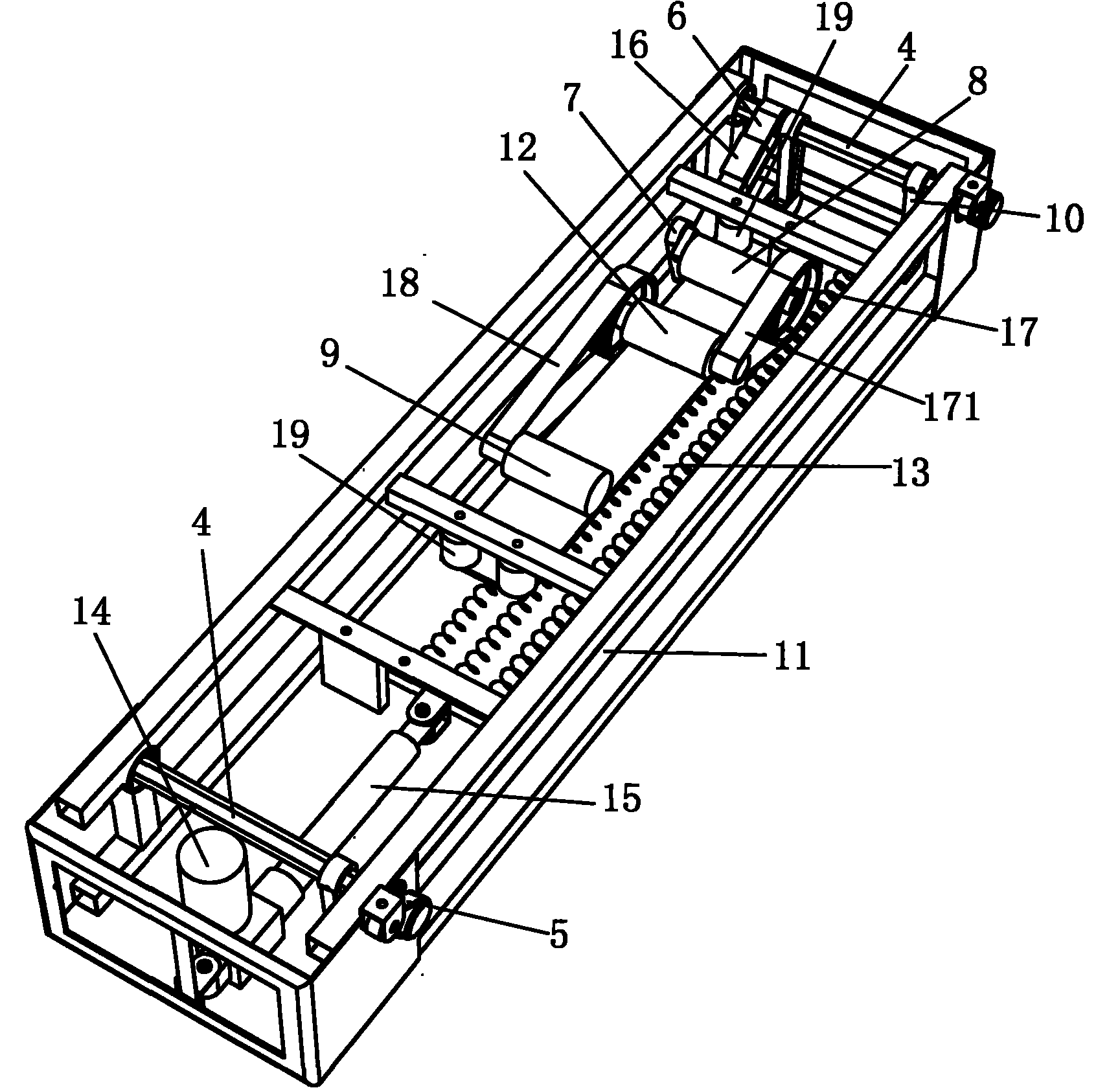

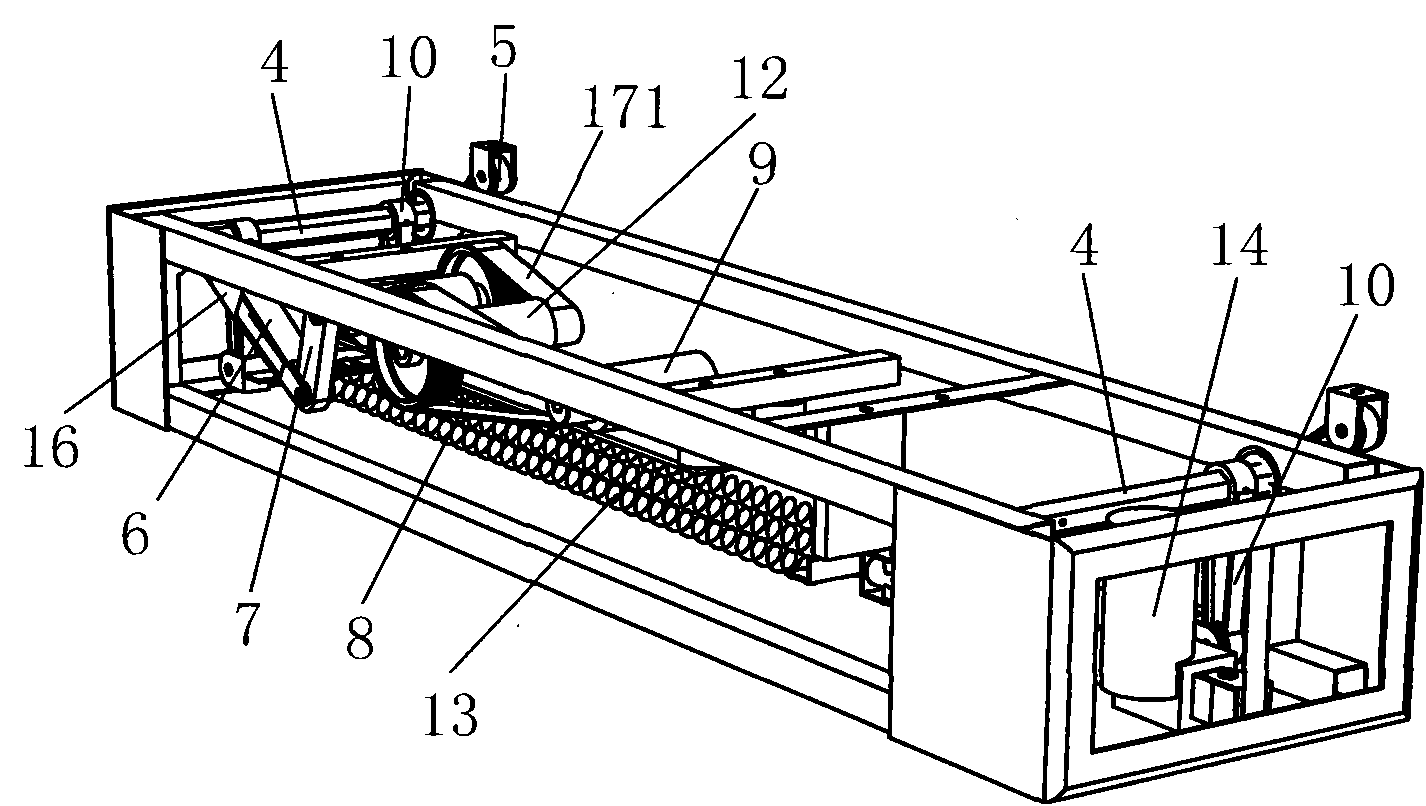

Method for improving human microcirculation through sleeping posture sway, and equipment for implementing same

ActiveCN101836928AAvoid defectsImprove whole body microcirculationChiropractic devicesBedsProper functionEnergy information

The invention discloses a method for improving human microcirculation through sleeping posture sway, which comprises the following steps: preparing an intelligent control system; preparing an electromechanical execution system and fixing a support body on the electromechanical execution system; setting function modes, establishing a database and setting operation parameters; allowing a sensor to acquire per se or manually input physical energy information of a user and inputting the information into the intelligent control system; allowing the intelligent control system to select a proper function mode and drive the electromechanical execution system to operate; allowing a power mechanism to work and output power to drive the support body to swing so as to ensure that a human body regularly sways relative to the support body; allowing the sensor in the intelligent control system to acquire per se, record execution data and feed back the execution data to a core control processor; allowing the core control processor to correct execution errors, automatically adjust the operation parameters, give an alarm through voice prompt and drive the electromechanical execution system to execute; and allowing the intelligent control system to stop the operation of the electromechanical execution system after finishing execution and automatically store main data in the operation process.

Owner:DONGGUAN JIAJIAKANG FITNESS EQUIP

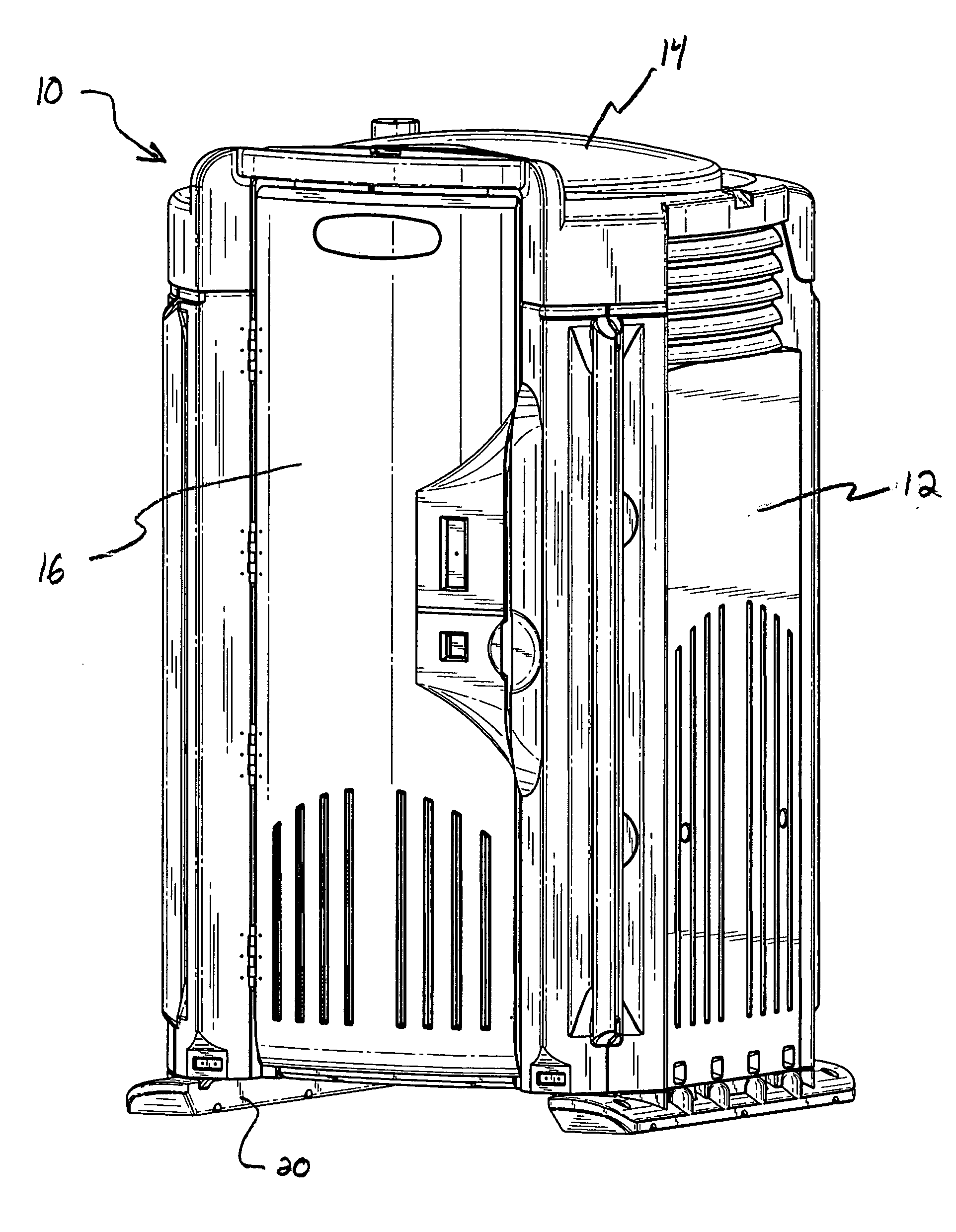

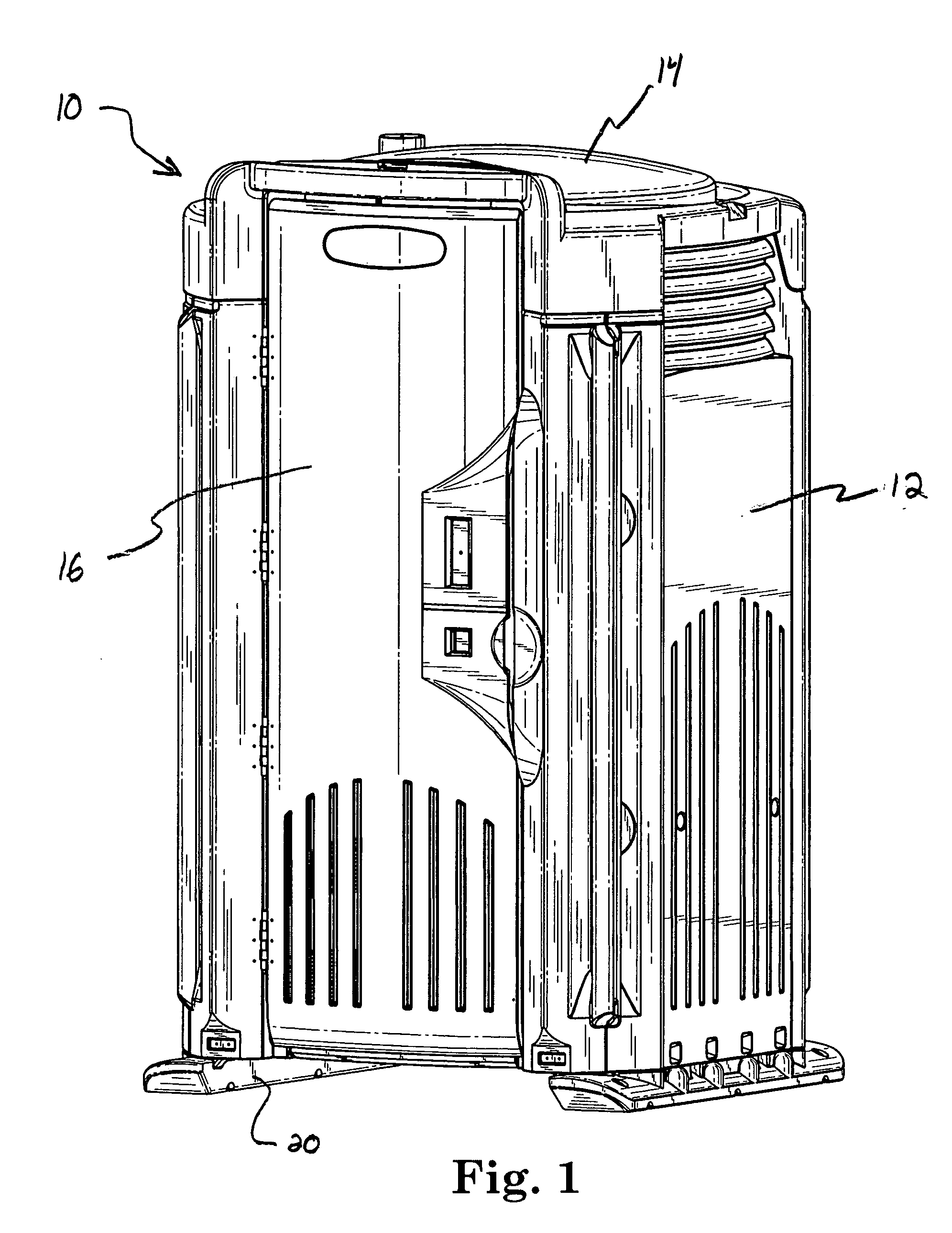

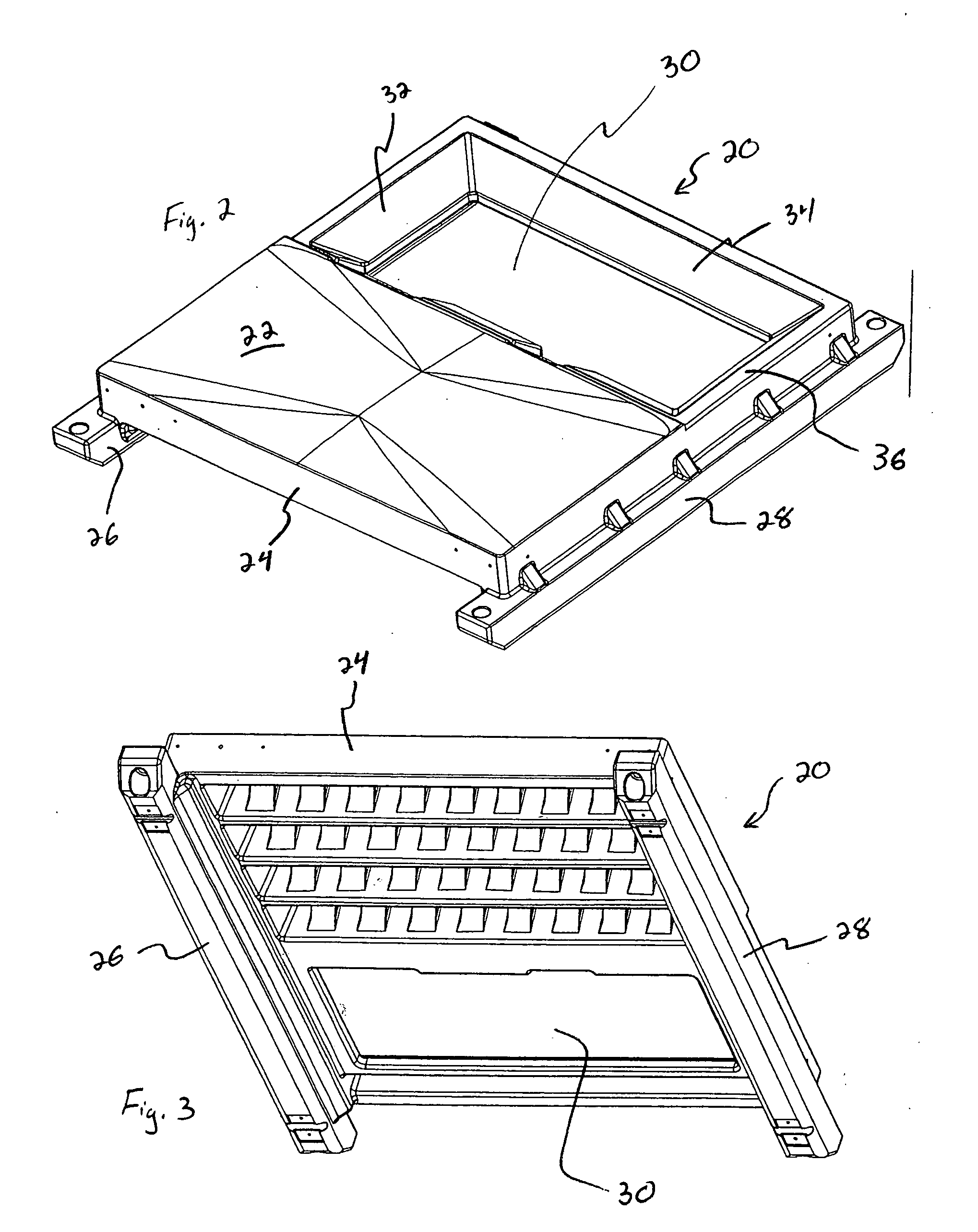

Portable toilet

InactiveUS20070163036A1Improve comfortEfficient use ofPublic buildingsBathroom accessoriesProper functionPortable toilet

A portable restroom is designed to provide features which enhance the comfort and appeal to users. These features include a rigid and stable structure, including a rigid floor structure, thus providing a sense of security to the user. Further, flushing and fresh water capabilities are achieved by using a dual tank structure made capable by the base design itself. This dual tank structure is achieved utilizing a unique siphoning pump to provide appropriate functionality.

Owner:SATELLITE IND

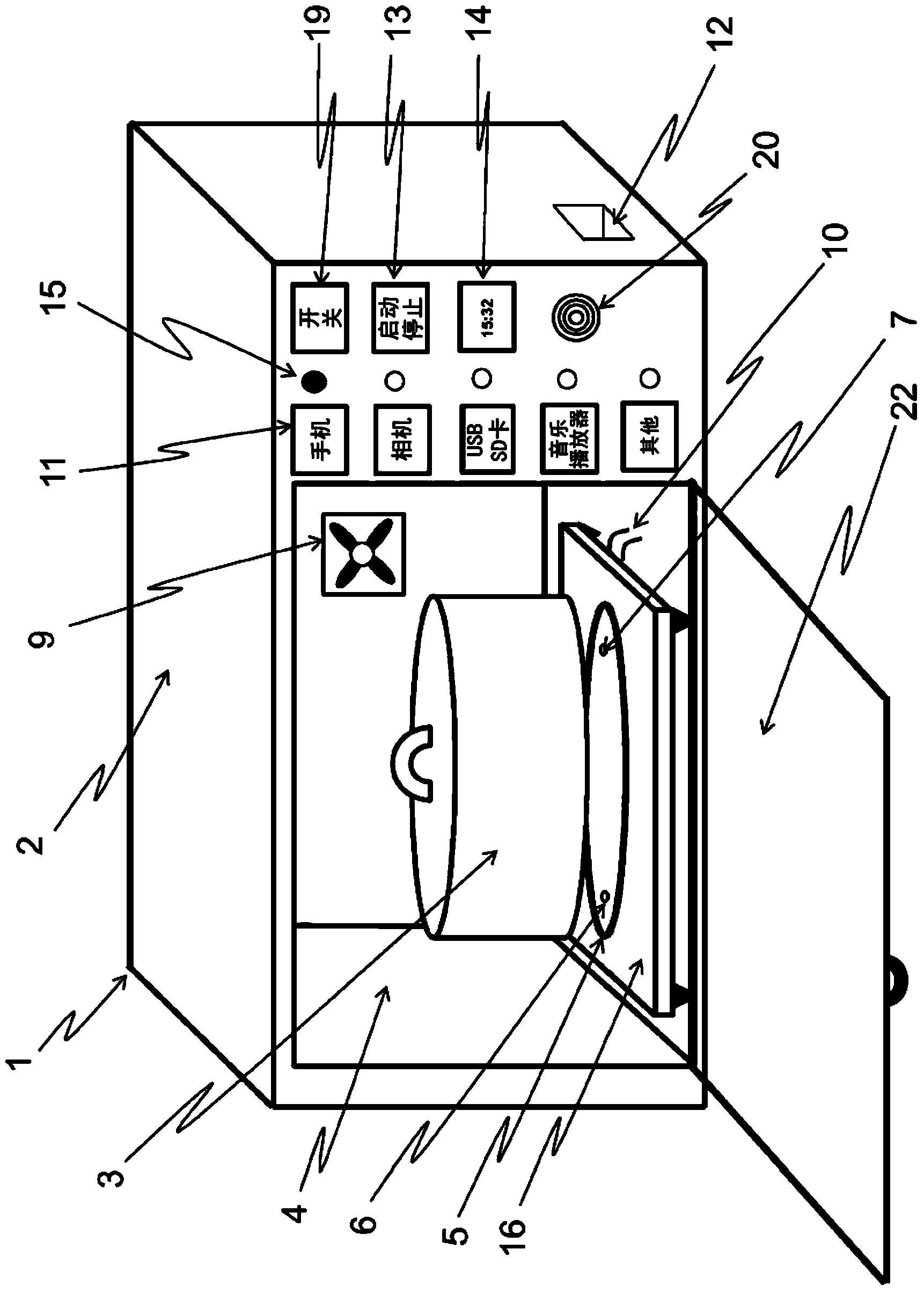

Methods and apparatuses for drying electronic devices

ActiveCN104272048ADrying solid materials with heatDrying solid materials without heatProper functionAutomatic control

Methods and apparatuses for drying electronic devices are disclosed. Embodiments include methods and apparatuses that heat and decrease pressure within the electronic device. Some embodiments increase and decrease pressure while adding heat. Other embodiments include a desiccator for removing moisture from the air being evacuated from the electronic device prior to the air reaching an evacuation pump. Further embodiments detect humidity within the low-pressure chamber and determine when to increase and / or decrease pressure based on the humidity. Still further embodiments determine that the device is sufficiently dry to restore proper function based on the detected humidity, and in some embodiments based on the changes in humidity while pressure is being increased and / or decreased. Still further alternate embodiments automatically control some or all aspects of the drying of the electronic device. Additional embodiment disinfect the electronic device.

Owner:REVIVE ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com