Patents

Literature

414results about How to "Improve insulation reliability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

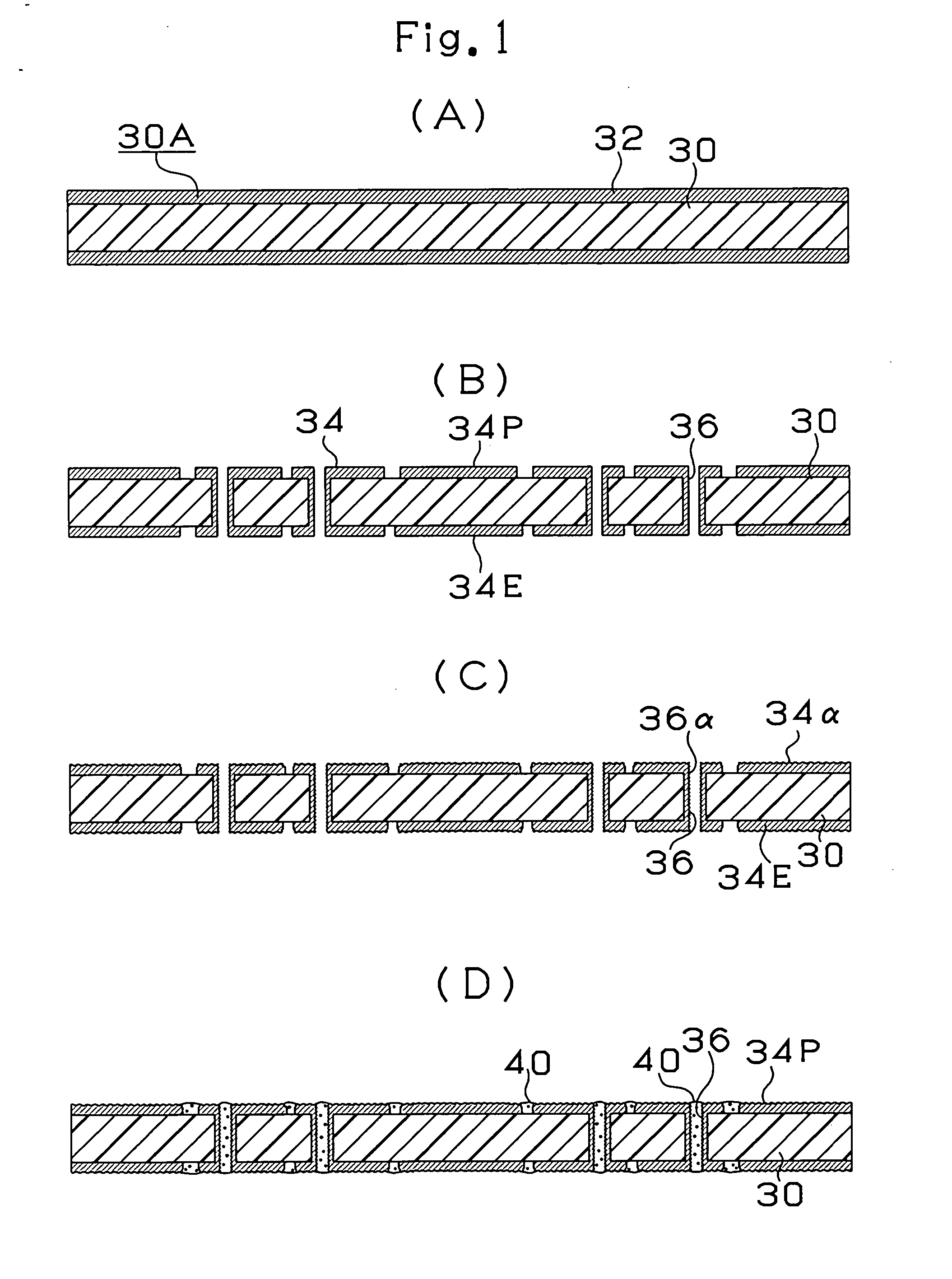

Multilayer printed wiring board

ActiveUS20060243478A1Intensify strengthStress be relaxPrinted electric component incorporationSemiconductor/solid-state device detailsEngineeringElectrical conductor

An IC chip for a high frequency region, particularly a packaged substrate in which no malfunction or error occurs even if 3 GHz is exceeded. A conductive layer on a core substrate is formed at a thickness of 30 μm and a conductor circuit on an interlayer resin insulation layer is formed at a thickness of 15 μm. By thickening the conductive layer, the volume of the conductor can be increased and resistance can be reduced. Further, by using the conductive layer as a power source layer, the capacity of supply of power to an IC chip can be improved.

Owner:IBIDEN CO LTD

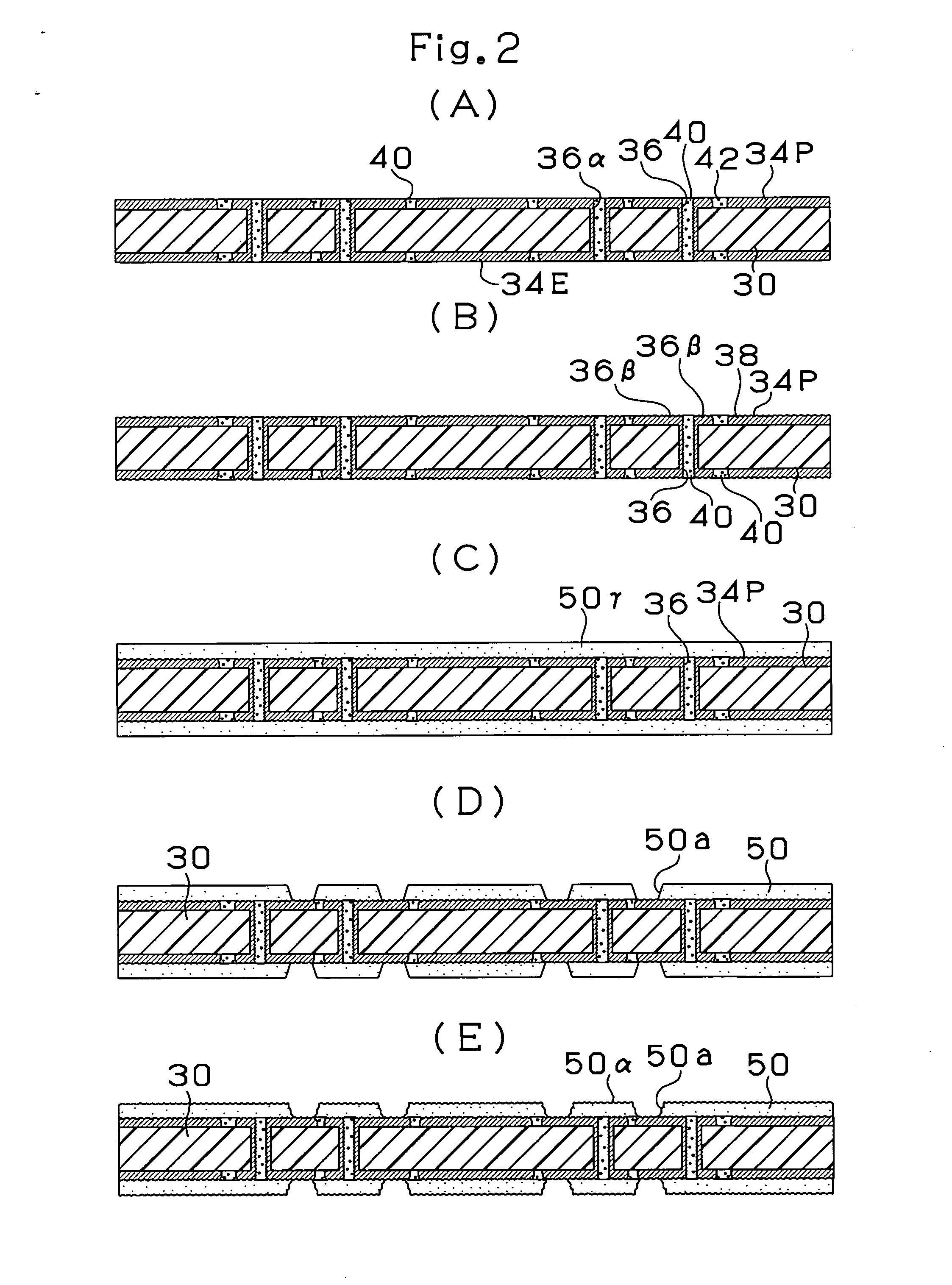

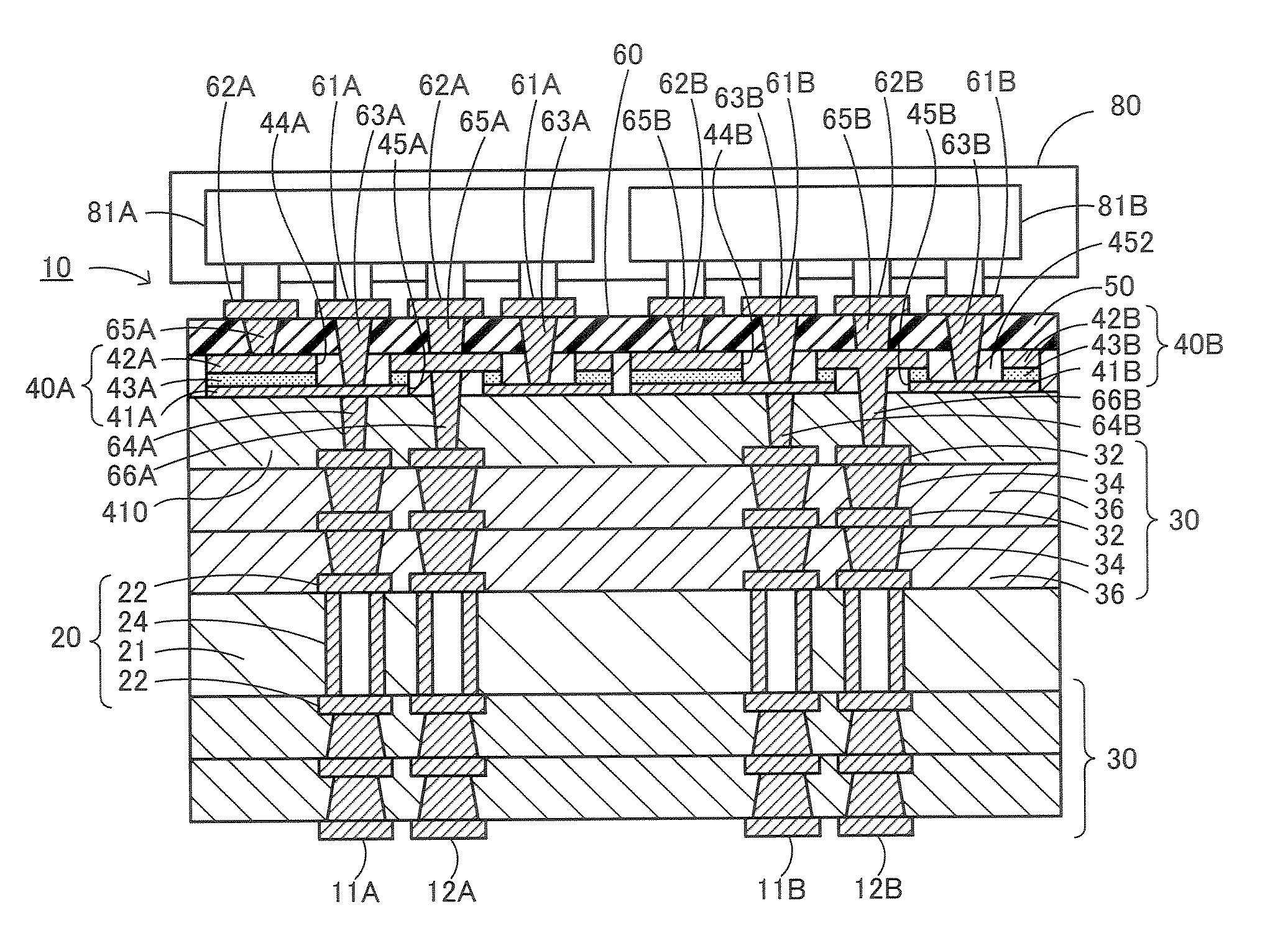

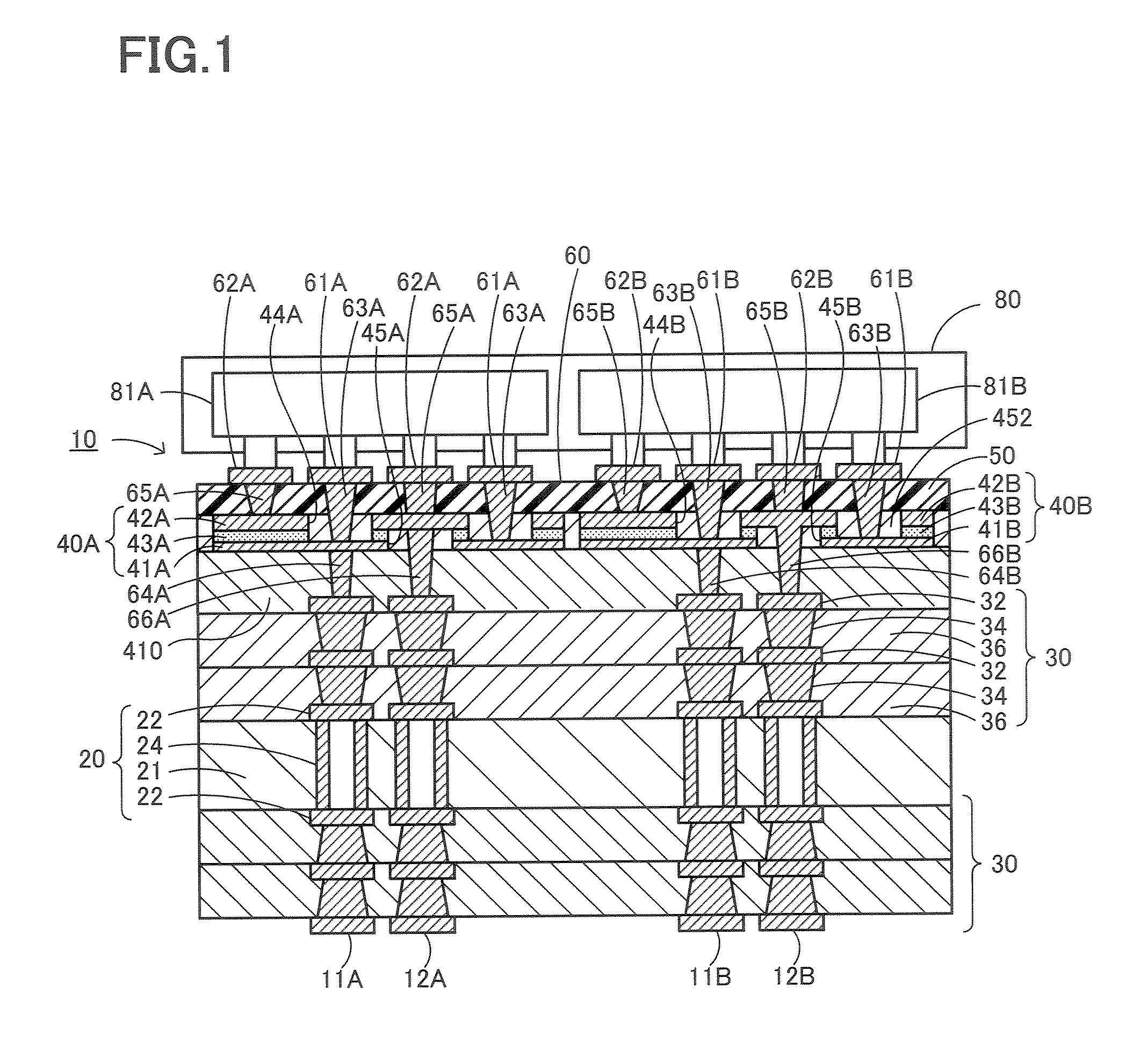

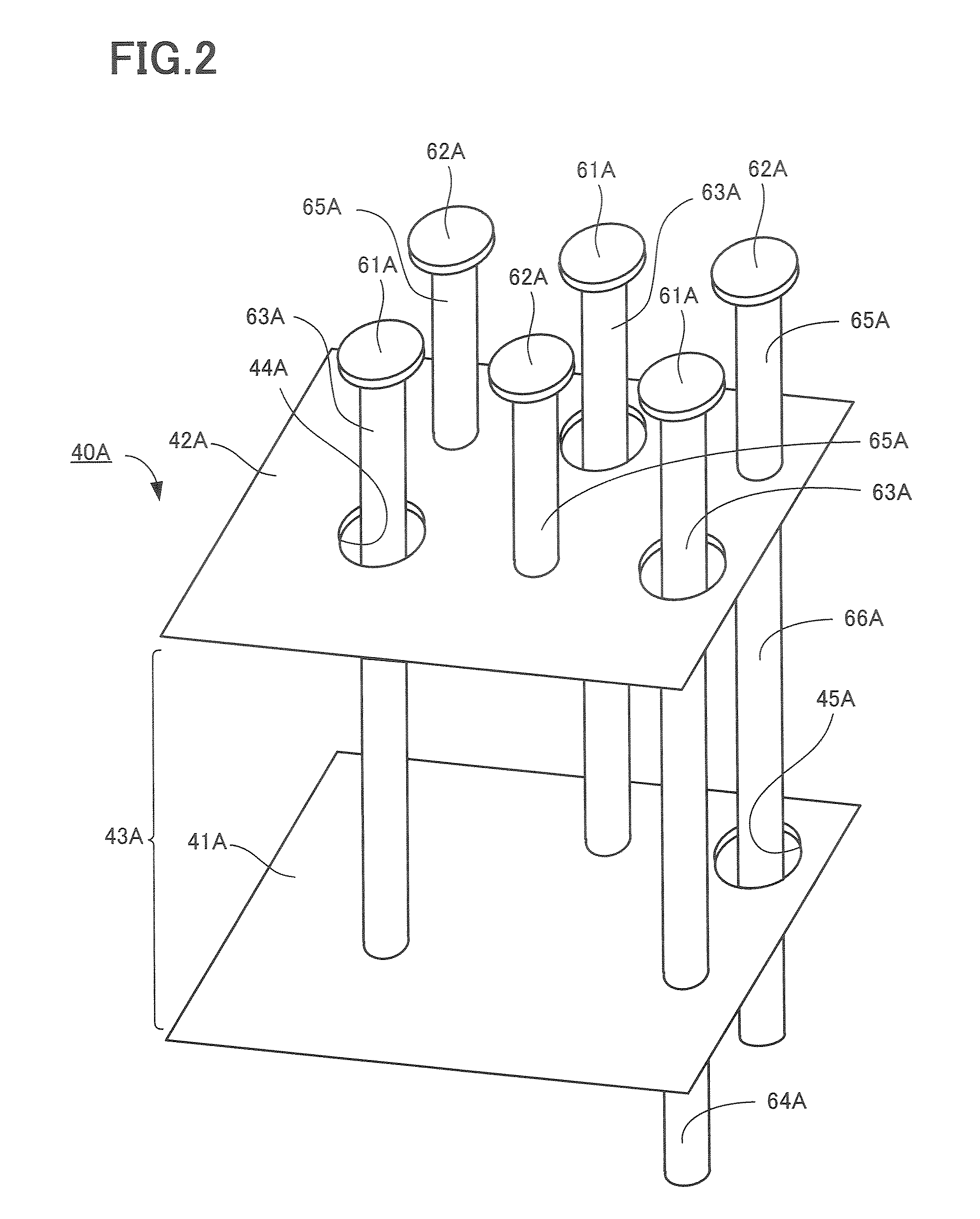

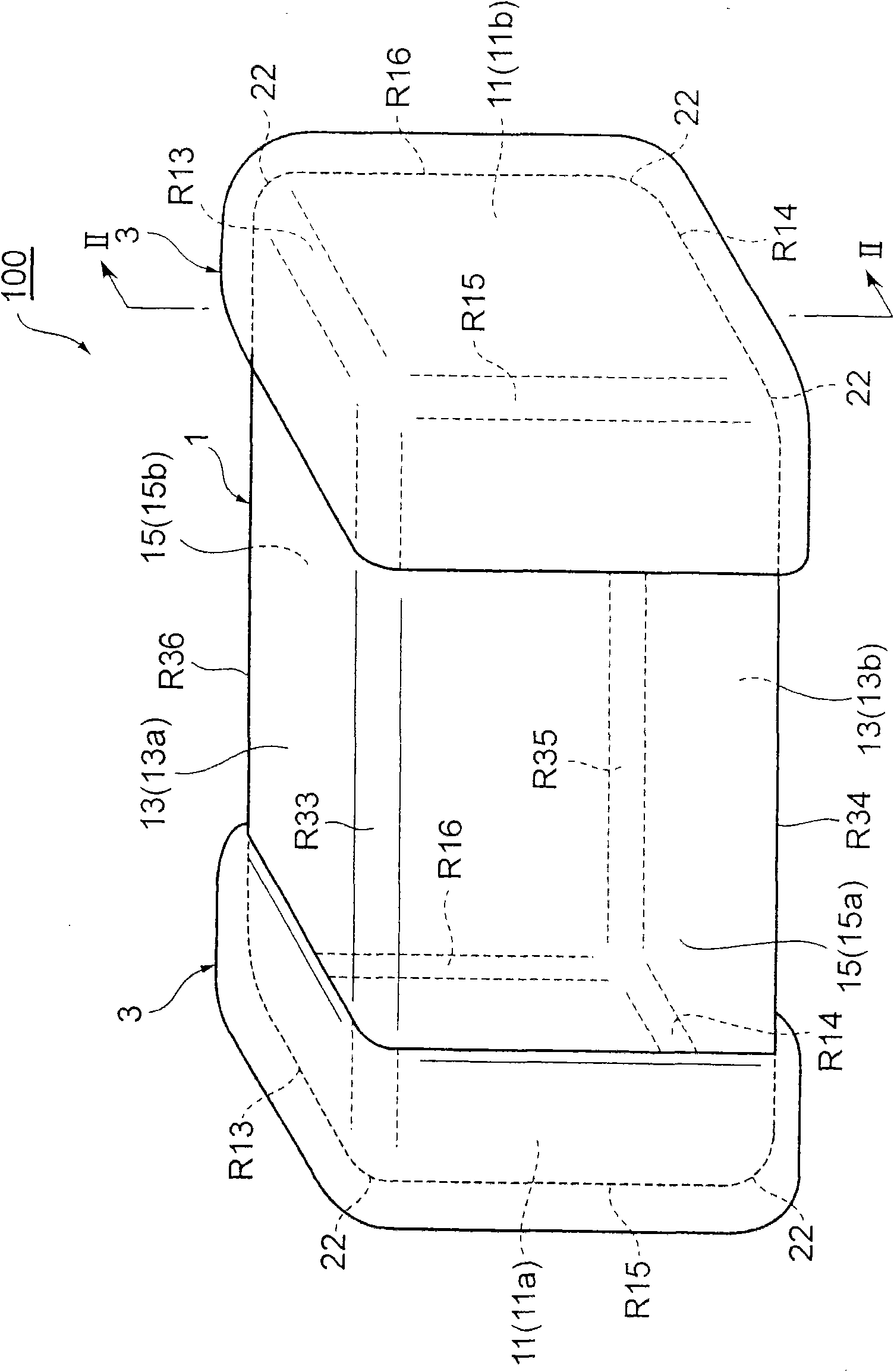

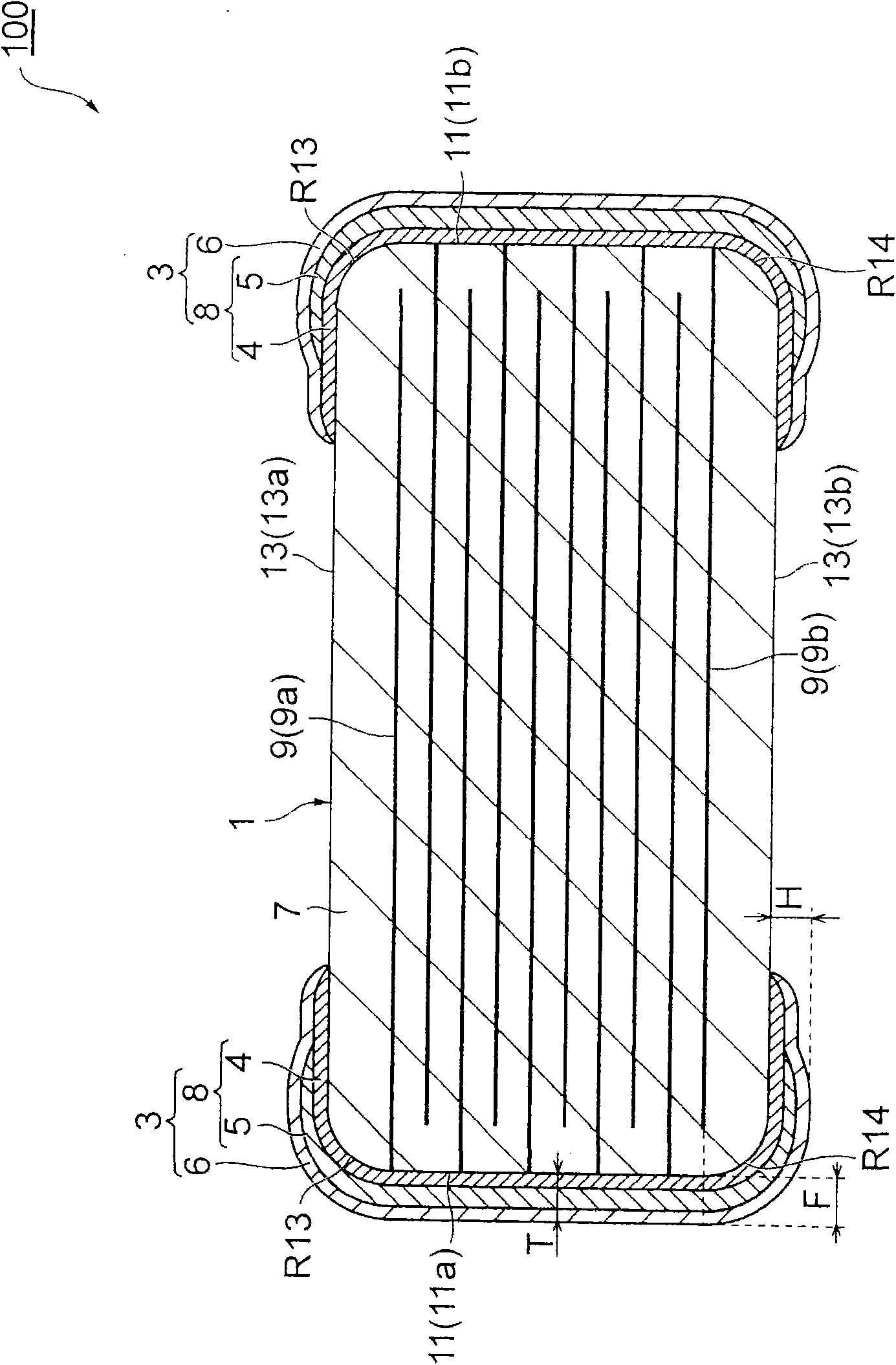

Printed wiring board

ActiveUS20090290316A1Decoupling effect decreaseGood decoupling effectSemiconductor/solid-state device detailsPrinted circuit aspectsDual coreVoltage variation

A printed wiring board includes a mounting portion on which a dual core processor including two processor cores in a single chip can be mounted, power supply lines, ground lines, and a first layered capacitor and a second layered capacitor that are independently provided for each of the processor cores, respectively. Accordingly, even when the electric potentials of the processor cores instantaneously drop, an instantaneous drop of the electric potential can be suppressed by action of the layered capacitors corresponding to the processor cores, respectively. In addition, even when the voltage of one of the processor cores varies, the variation in the voltage does not affect the other processor core, and thus malfunctioning does not occur.

Owner:IBIDEN CO LTD

Adhesiveless Copper Clad Laminates And Method For Manufacturing Thereof

InactiveUS20080090095A1Reduction in heat-resisting peel strength can be avoidedImprove adhesionInsulating substrate metal adhesion improvementVacuum evaporation coatingAdhesiveNickel alloy

The present invention provides adhesiveless copper clad laminates, which does not have defects on a copper film part due to a pin hole generated at the time of forming a base metal layer on an insulating film by dry plating process, has excellent adhesion between the insulating film and the base metal layer and corrosion resistance, and has a copper film layer having high insulation reliability, and provides a method for manufacturing such adhesiveless copper clad laminates. In adhesiveless copper clad laminates according to the present invention provided by forming a base metal layer directly at least on one plane of an insulating film without having an adhesive in between, and then by forming a copper film layer on the base metal layer, the base metal layer having a film thickness of 3 to 50 nm is formed by dry plating method and mainly contains a chrome-molybdenum-nickel alloy wherein the chrome ratio is 4 to 22 weight %, the molybdenum ratio is 5 to 40 weight %, and the balance is nickel.

Owner:SUMITOMO METAL MINING CO LTD

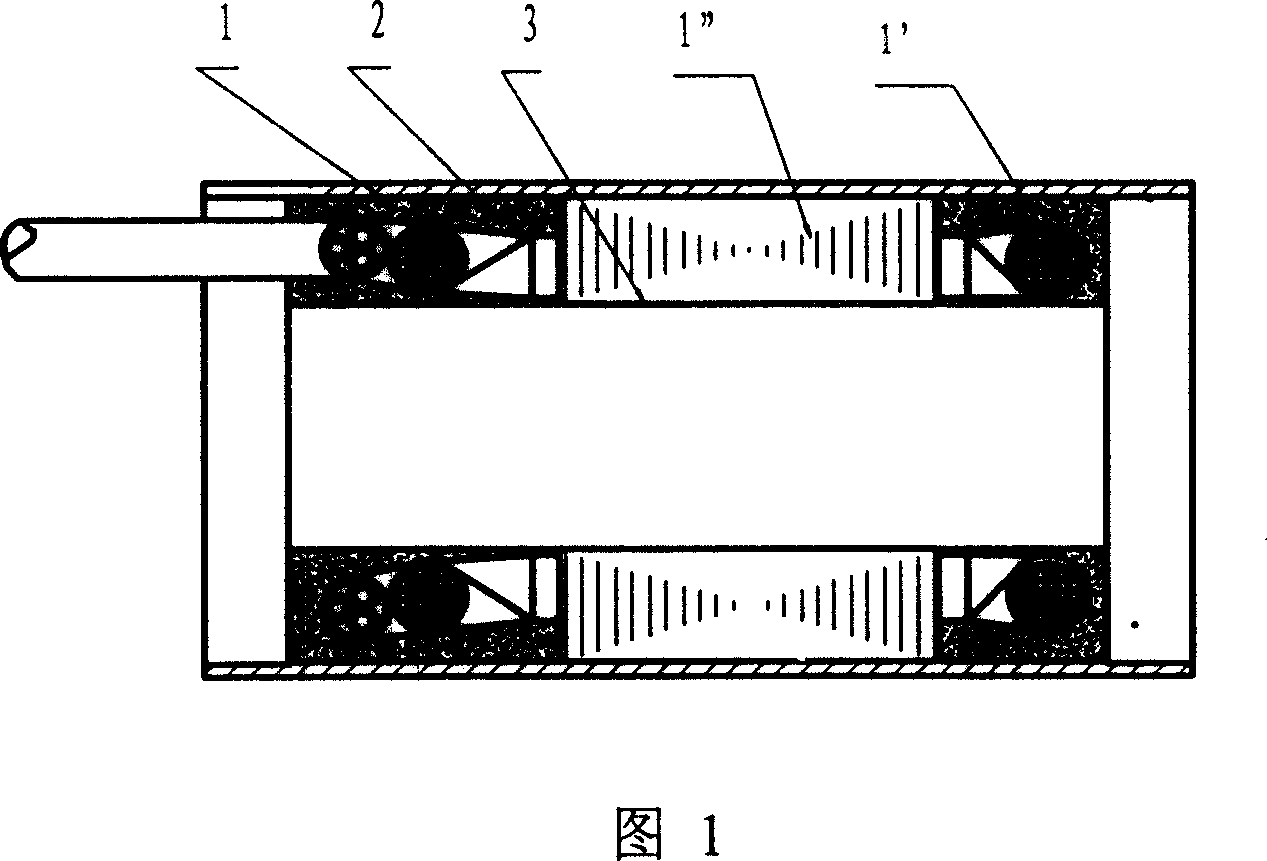

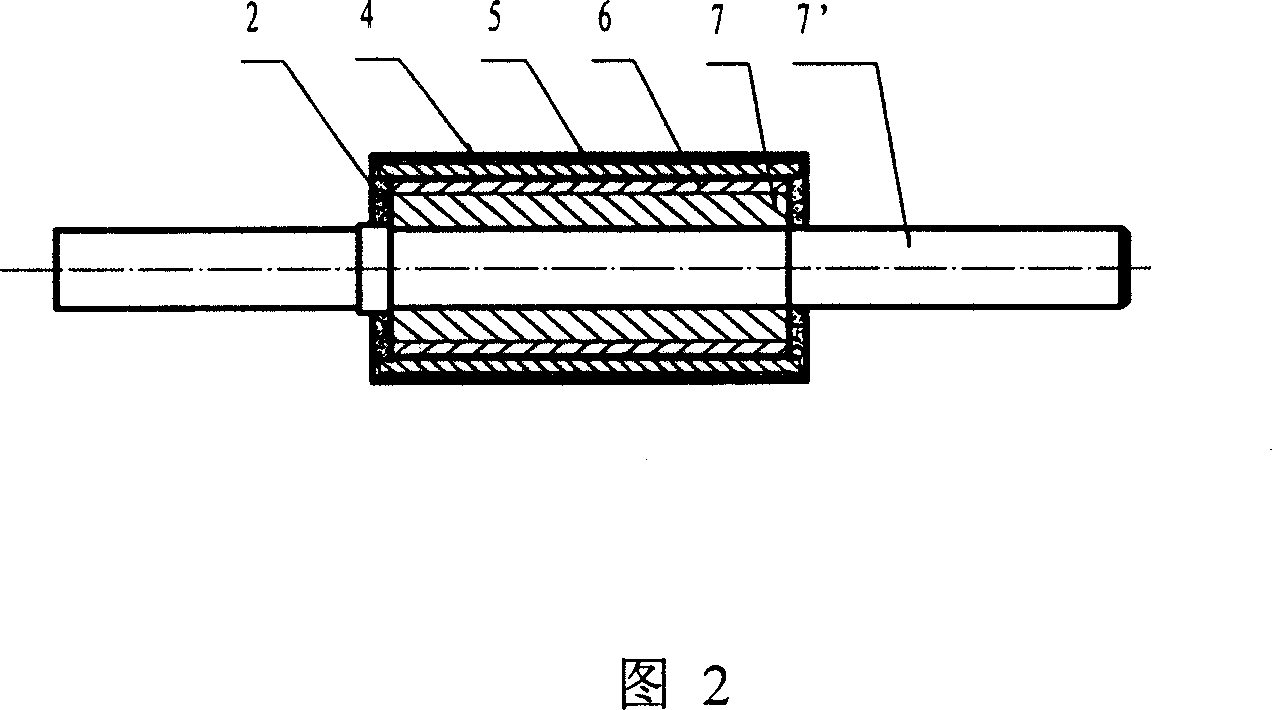

Plastic package material of AC permanent magnet submersible motor, plastic package technique and application

InactiveCN1958706AImprove plastic sealing efficiencyMolding time shortenedOther chemical processesManufacturing dynamo-electric machinesEpoxyTransformer

This invention provides a plastic sealant for AC permanent magnetic submersible motor, its sealing process and application. The plastic sealant is composed of: epoxy resin, diluent, curing agent, and silicon micropowder. The process comprises: (1) preparing the plastic sealant; (2) placing the motor stator in the stator sealing mold, locating, and placing the rotor in the rotor sealing mold; (3) sealing; (4) curing. This invention can be used for sealing AC permanent magnetic submersible motor, permanent magnetic wind power generator, electrical appliance, capacitor, transformer and inducer. This invention can largely shorten the sealing time, and can improve the sealing efficiency of diving motor. The plastic sealant has such advantages as low viscosity, smooth pouring, simple process, high product smoothness, good heat conductivity, good insulation, good waterproof property, no pollution during production and usage, and no toxicity to human bodies, thus is suitable for mass production.

Owner:SUN YAT SEN UNIV

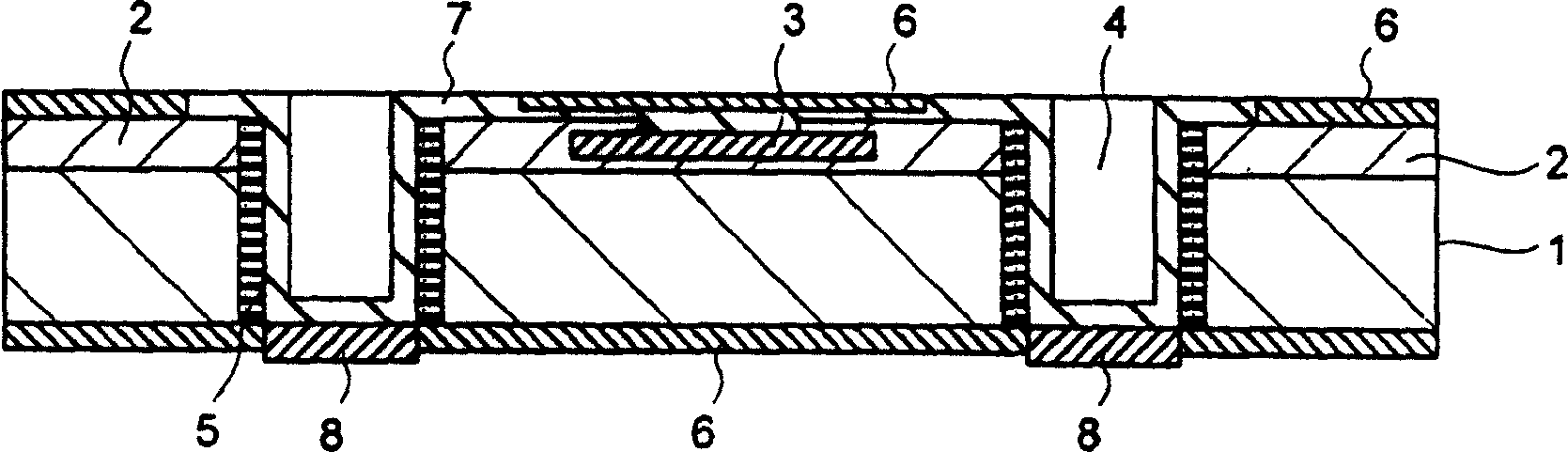

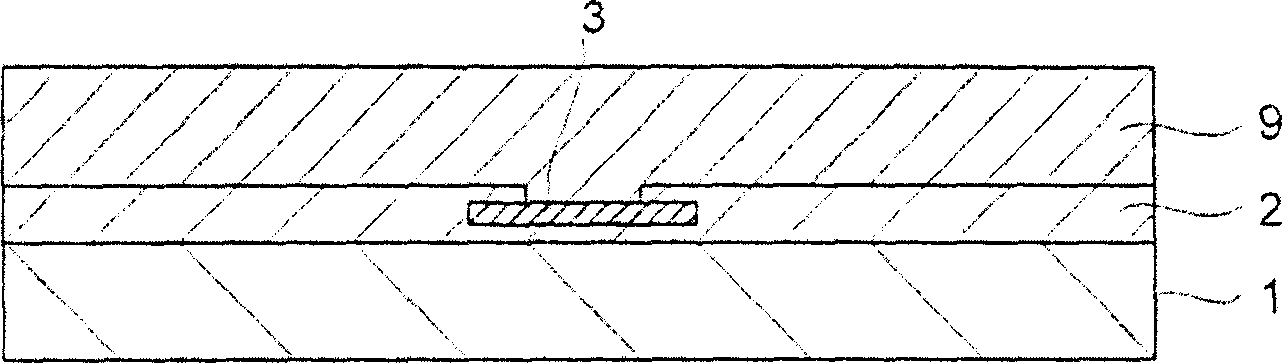

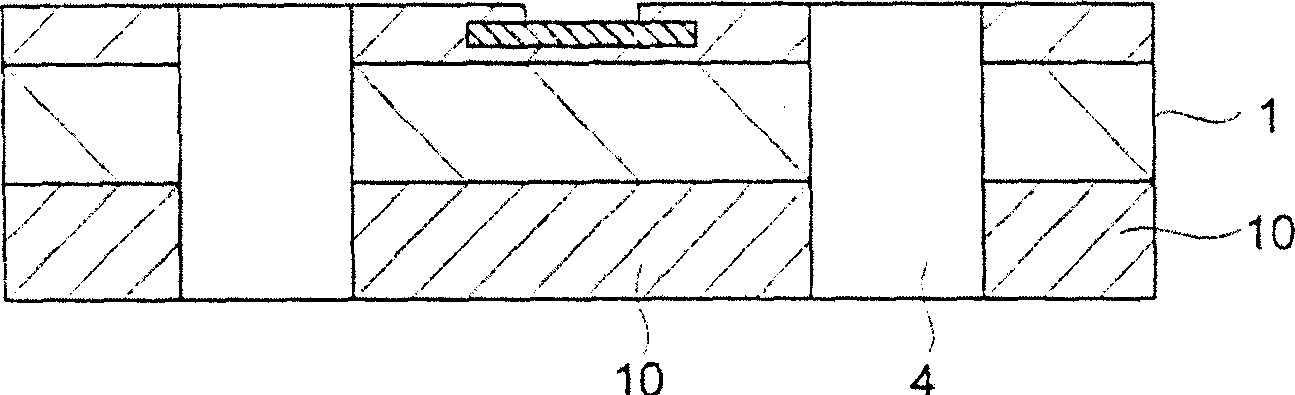

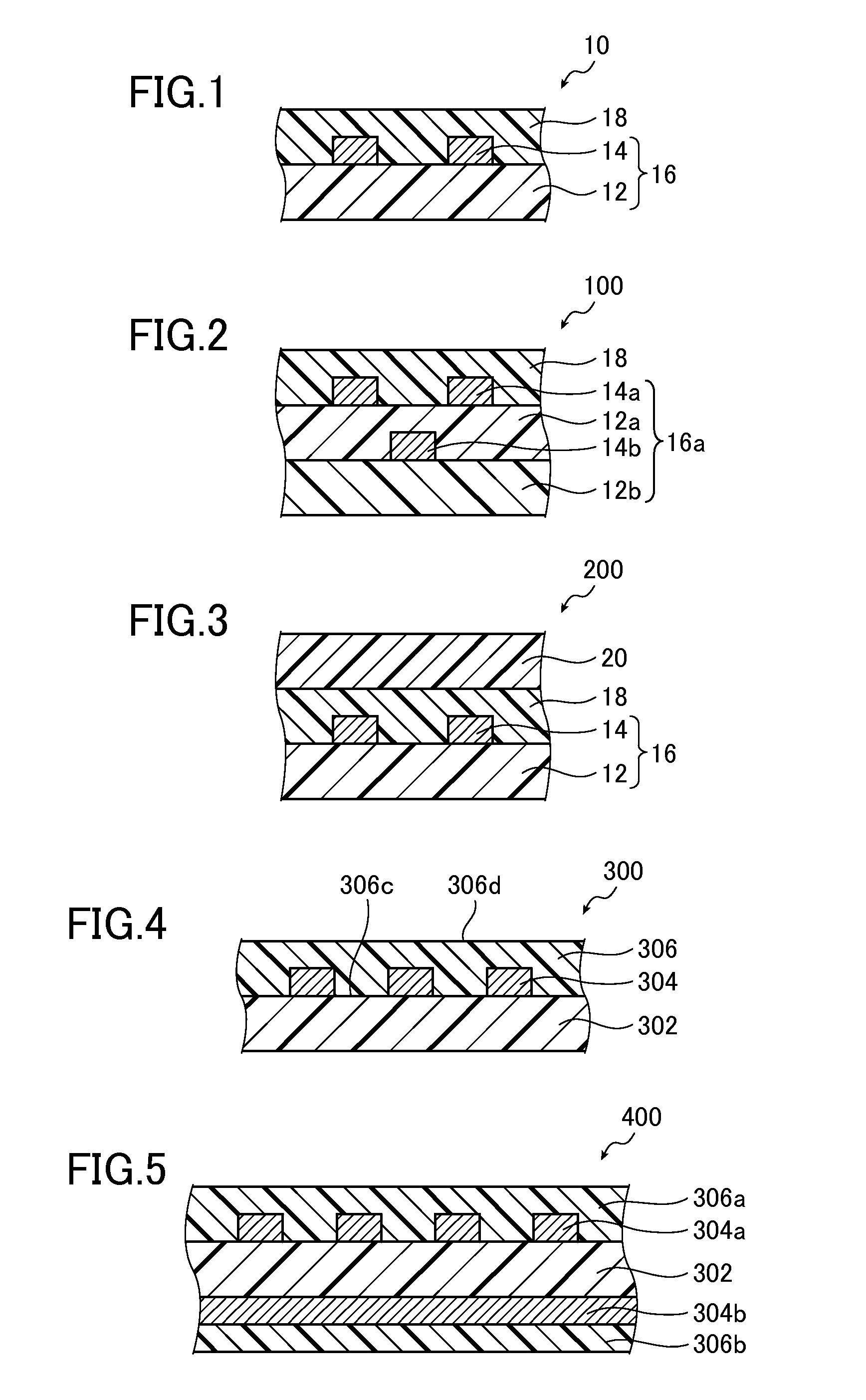

Semiconductor device and manufacturing method thereof

InactiveCN1758430AImprove the ability to formImprove insulation reliabilitySemiconductor/solid-state device detailsSolid-state devicesInsulation layerEngineering

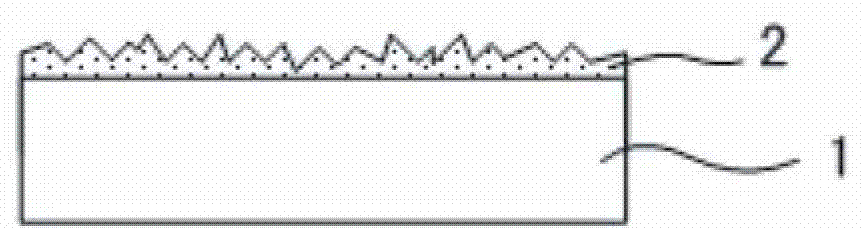

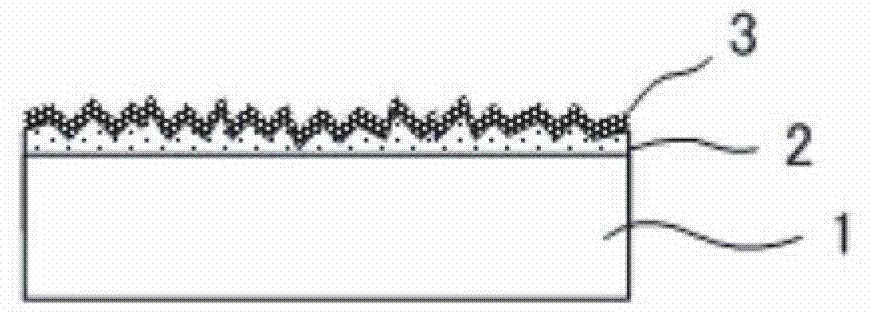

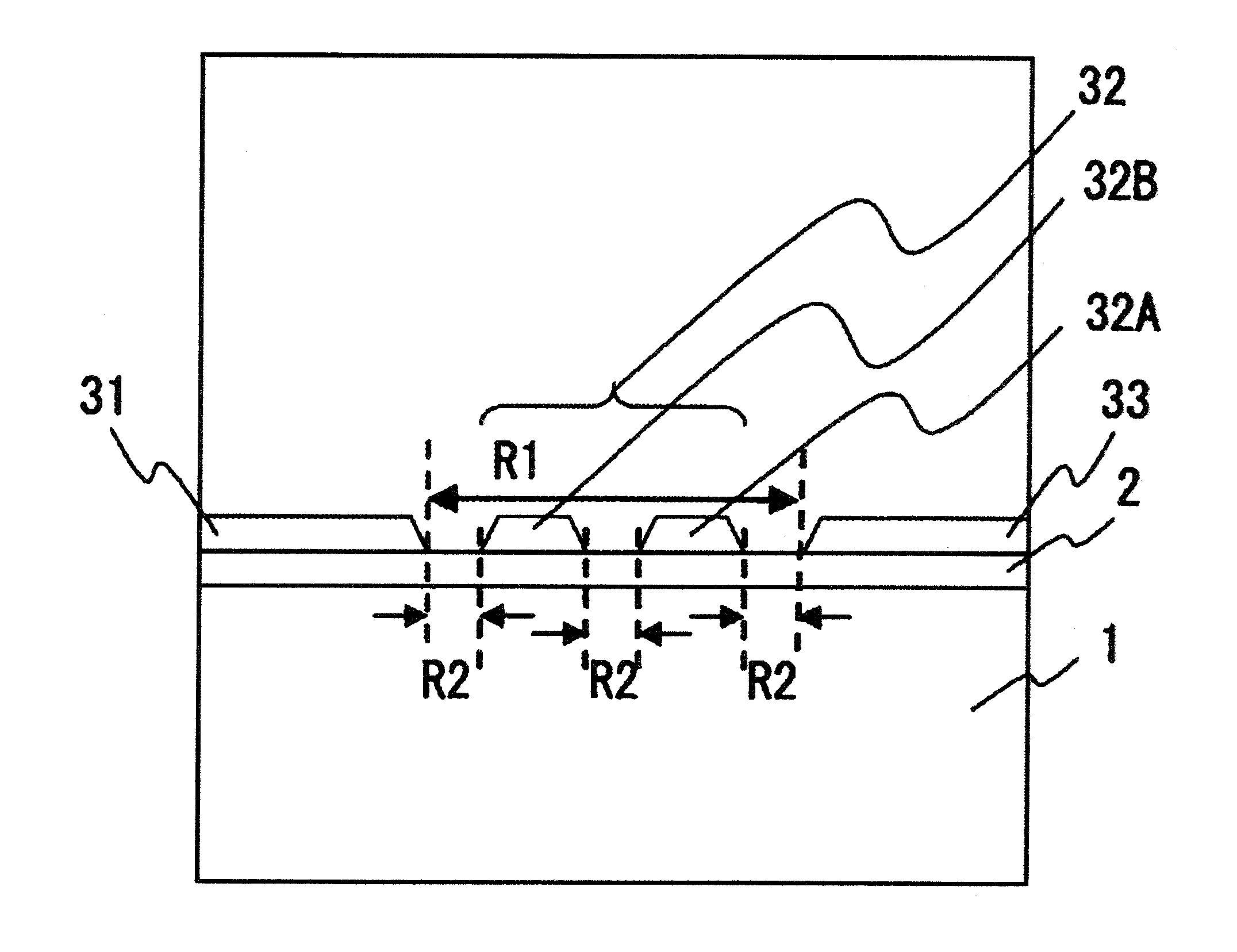

A semiconductor device comprises a semiconductor substrate having an through hole, a first insulation resin layer formed on an inner surface of the through hole, a second insulation resin layer formed on at least one of front and rear surfaces of the semiconductor substrate, and a first conductor layer formed in the through hole to connect at least both front and rear surfaces of the semiconductor substrate and insulated from the inner surface of the through hole with the first insulation resin layer. A second conductor layer (wiring pattern) which is electrically connected to the first conductor layer in the through hole is further provided on the second insulation resin layer. The conductor layer formed in the through hole and constituting a connecting plug has a high insulation reliability. Therefore, a semiconductor device suitable for a multi-chip package and the like can be obtained. Further, since the forming ability of the conductor layer connecting the front and rear surfaces and the insulation layer is high, the manufacturing cost can be reduced.

Owner:KK TOSHIBA

Resin composite and prepreg and laminate materials used thereof

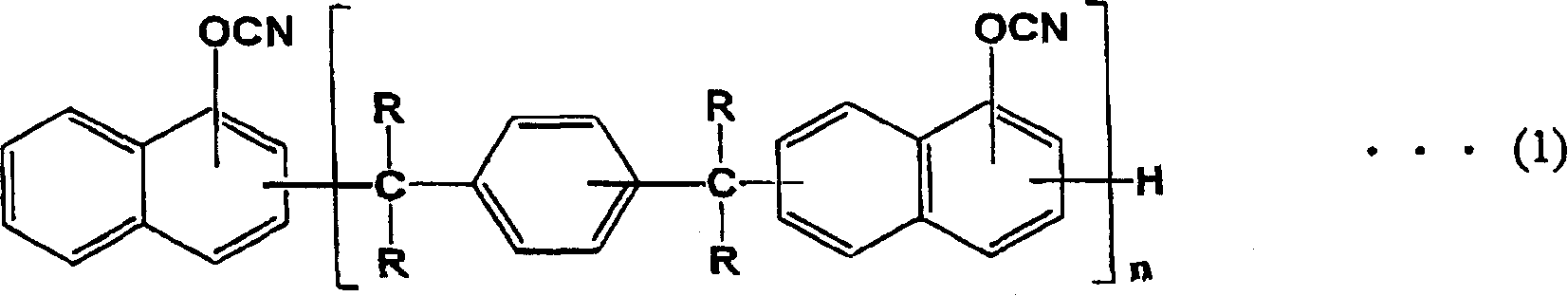

ActiveCN1803916AExcellent curabilityImprove heat resistanceSynthetic resin layered productsHydrogen atomMethyl group

A resin composition containing an epoxy resin (B) and a cyanate ester resin (A) shown in formula (1) as a basic component, wherein R represents a hydrogen atom or a methyl group, and n is an integer of 1 to 50, The premise is that the cyanate resin (A) may be a mixture of compounds of formula (1) having different values of n, and prepregs and laminates using the resin composition.

Owner:MITSUBISHI GAS CHEM CO INC

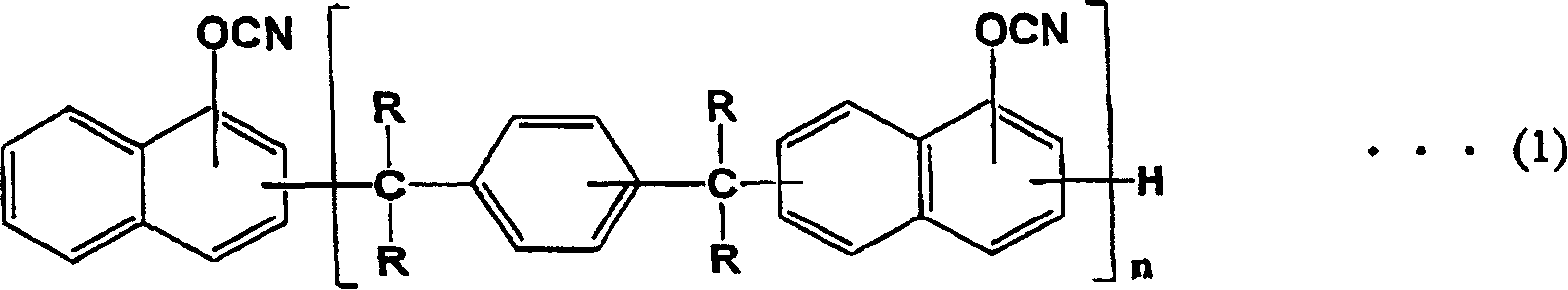

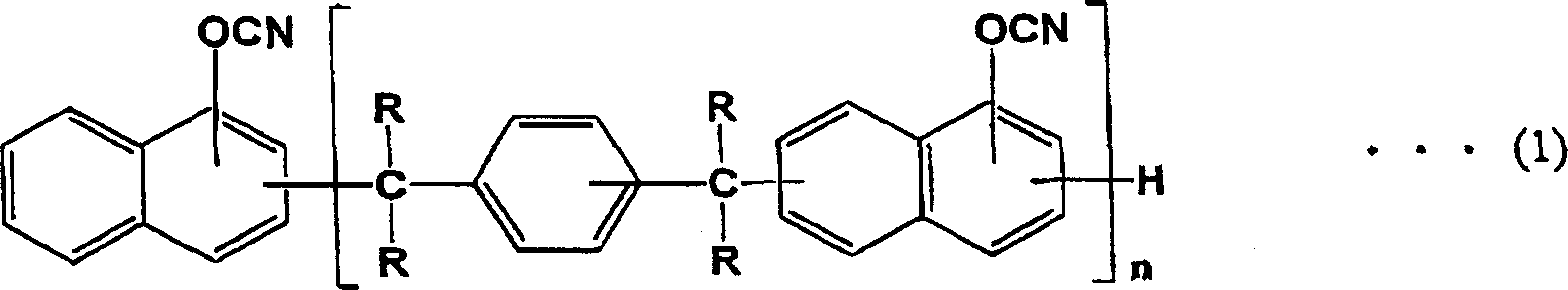

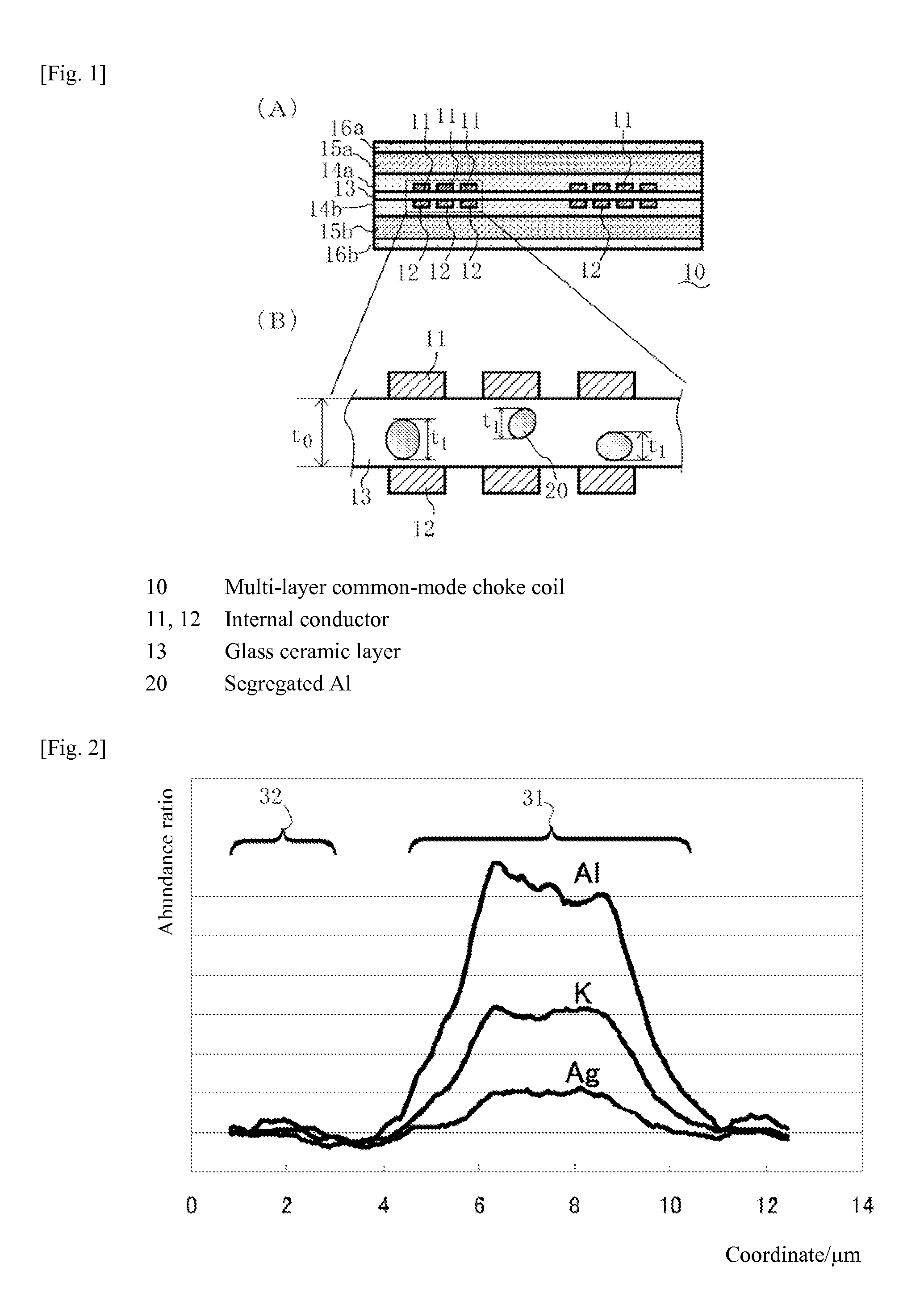

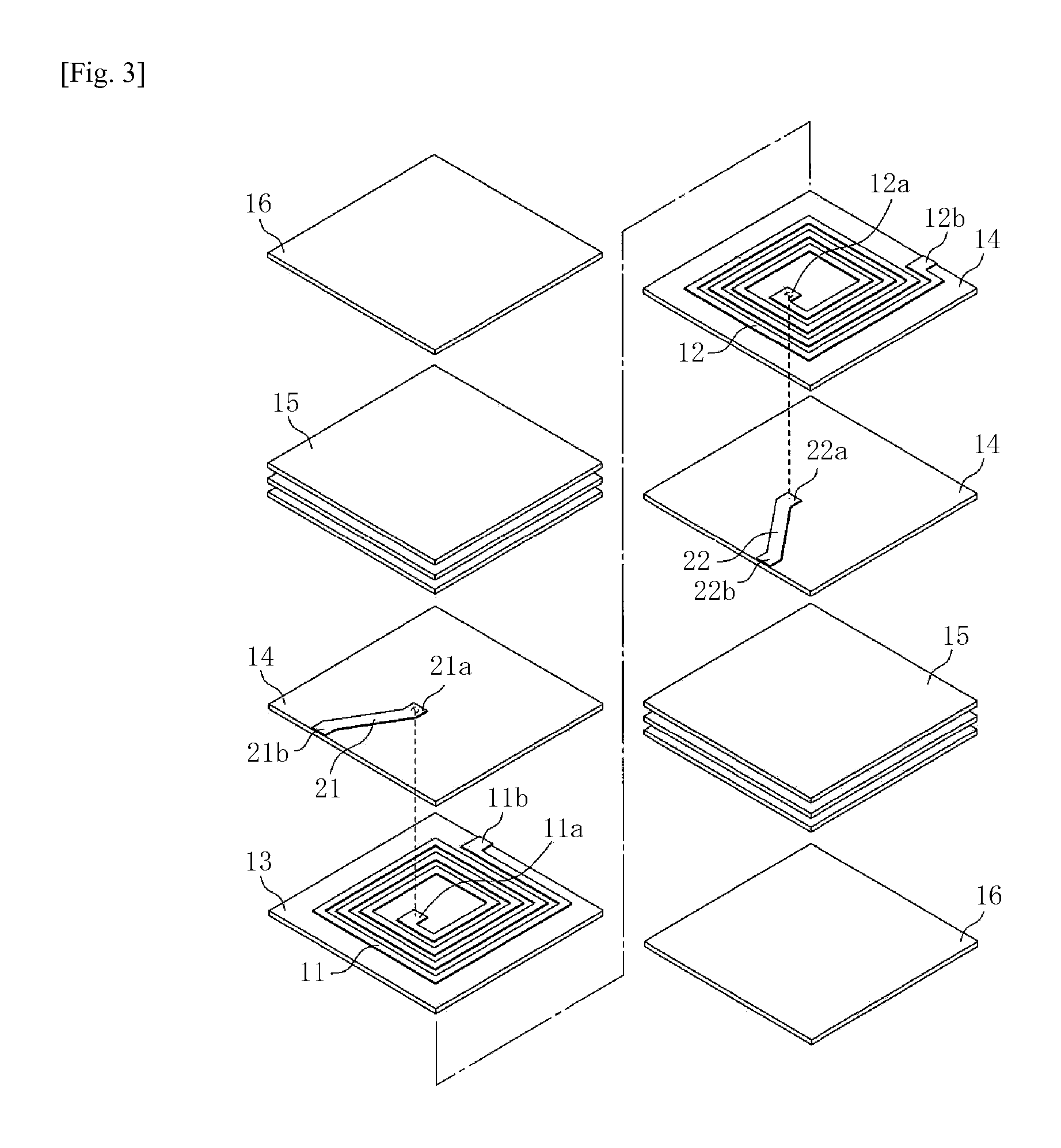

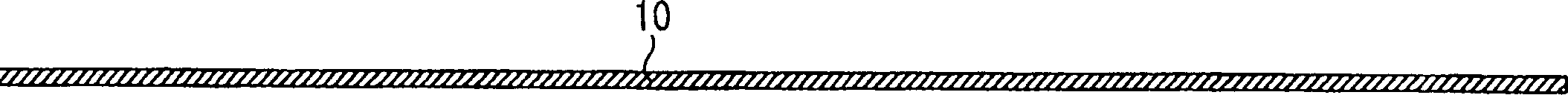

Laminated common-mode choke coil

ActiveUS20130154786A1Insulation property be lowerHigh insulation reliabilityCoilsFixed signal inductancesManufacturing engineeringElectrical conductor

A laminated common-mode choke coil offering higher insulation reliability has a glass ceramic layer, two spiral internal conductors facing each other and sandwiching the glass ceramic layer in between, and insulation layers sandwiching the two internal conductors, wherein the glass ceramic layer contains segregated Al regions and the maximum dimension t1 of each segregated Al region in the glass ceramic layer, in the layer-thickness direction, is no more than 80% of the distance t0 between the two internal conductors.

Owner:TAIYO YUDEN KK

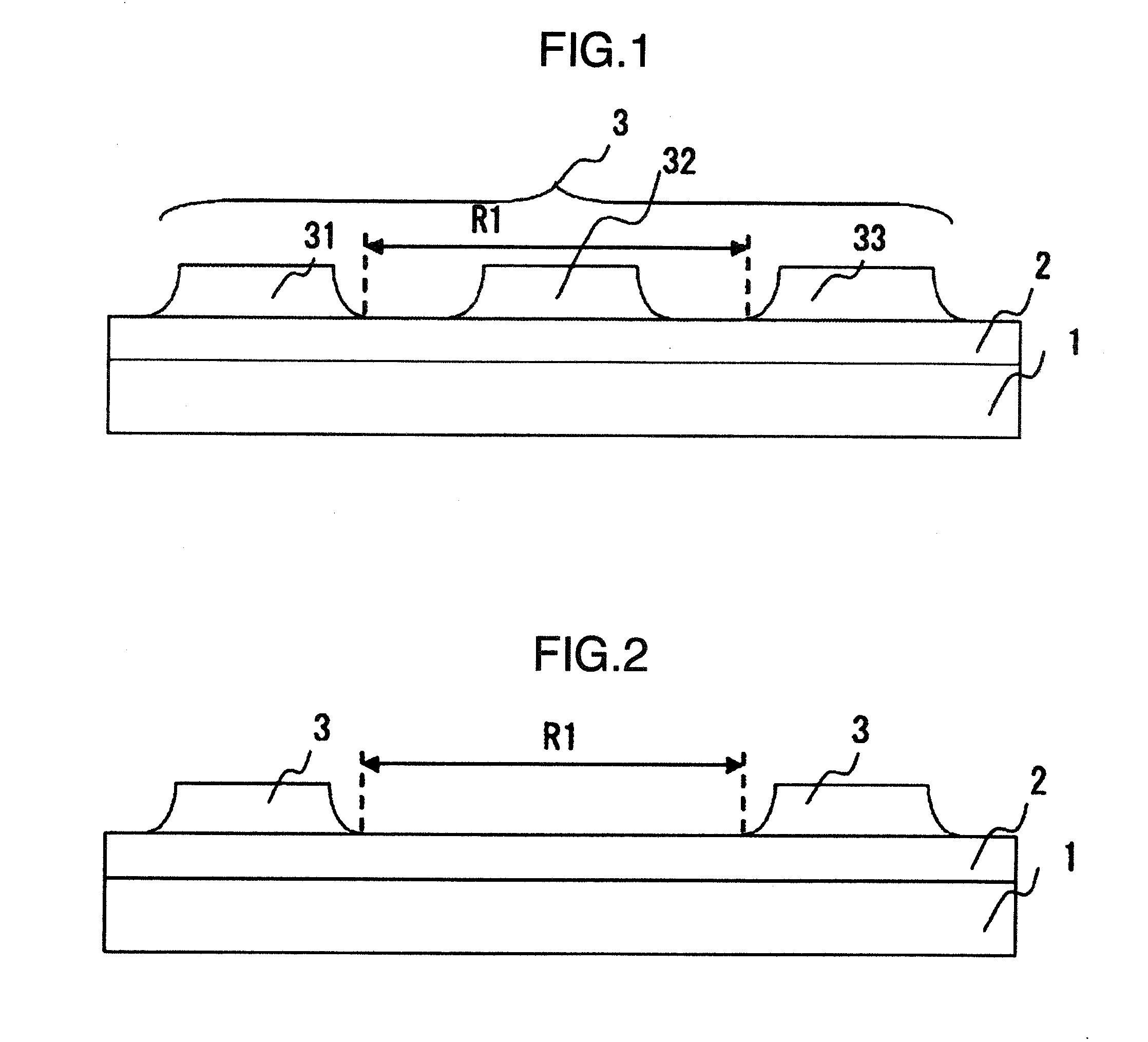

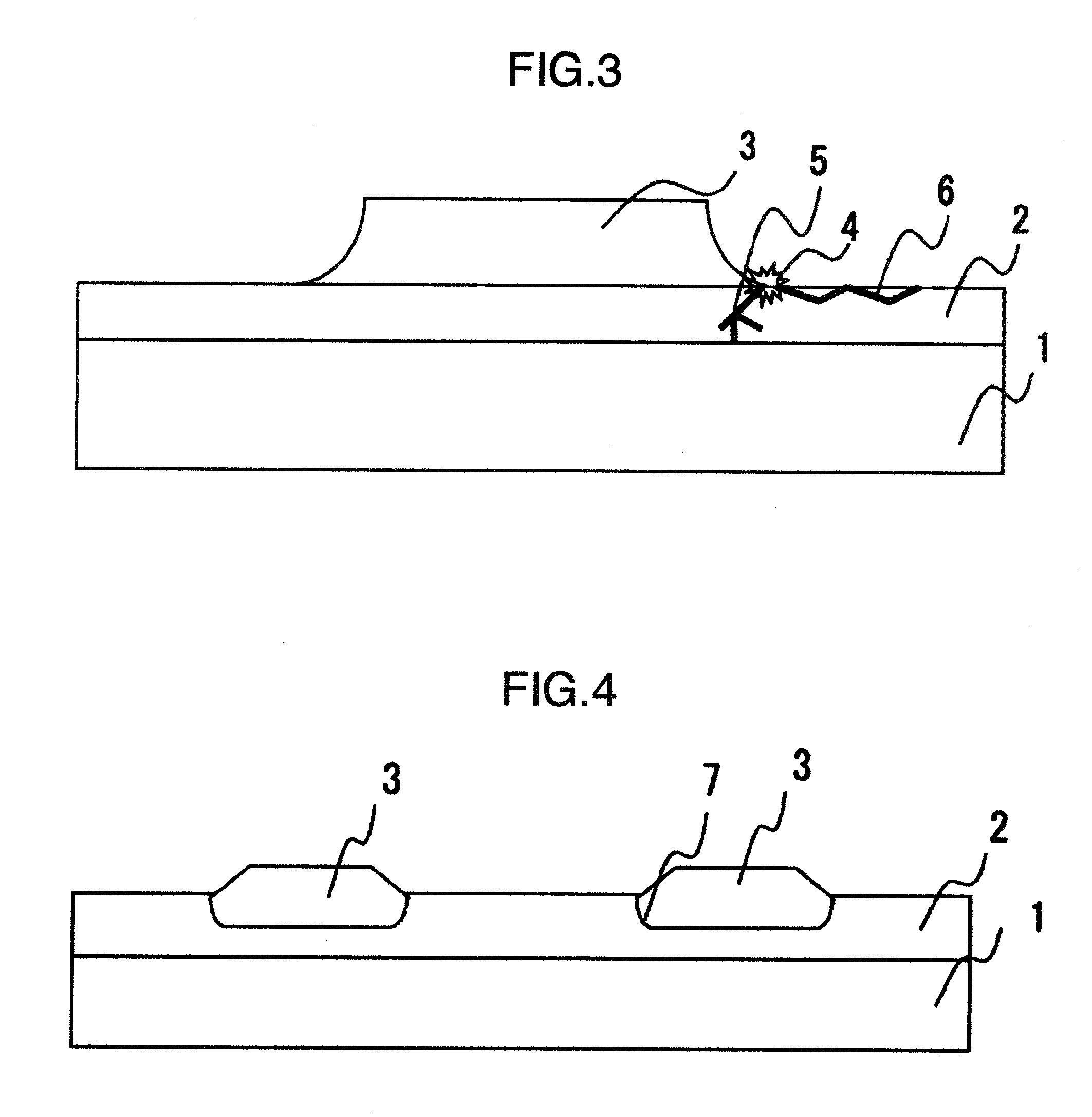

Interlayer insulating layer for printed wiring board, printed wiring board and method for manufacturing same

ActiveCN1823557AInhibit swellingInhibition of contractionMultilayer circuit manufactureEtchingHeat resistance

Disclosed is an interlayer insulating layer for printed wiring boards which is formed on a base and composed of a curing resin wherein scale-like particles are dispersed. Also disclosed is a printed wiring board which is excellently improved in heat cycle resistance and mounting reliability without lowering heat resistance, electrical insulation, heat dissipation, connection reliability or chemical stability. Further disclosed is a method for manufacturing a printed wiring board which enables to transfer a wiring pattern or a via hole to the interlayer insulating layer easily and accurately by an imprinting method wherein a mold having a projected portion corresponding to the wiring pattern is used. The method does not require an optical transfer method or a complicated etching for forming the wiring pattern or via hole. With this method, a printed wiring board having a very fine wiring pattern which is excellent in insulation reliability and interlayer connection can be easily mass-produced at low cost.

Owner:IBIDEN CO LTD

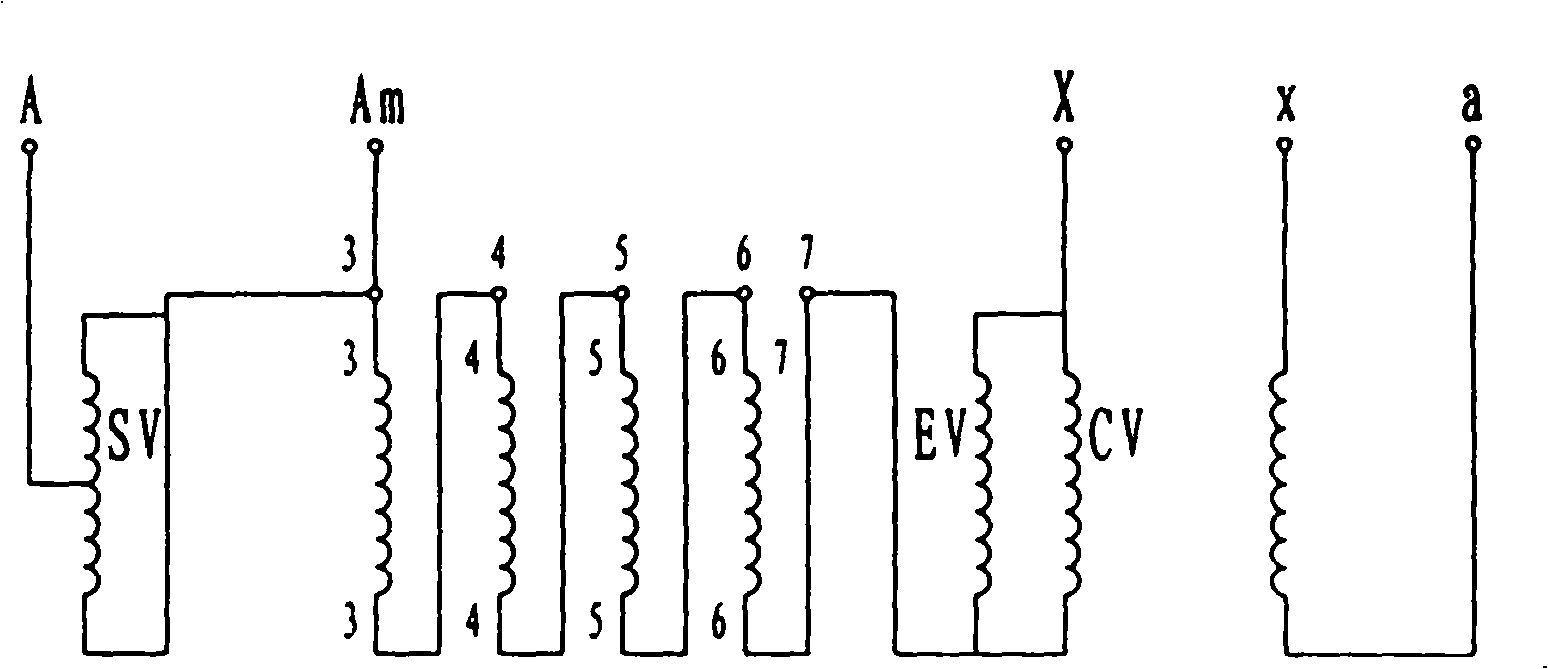

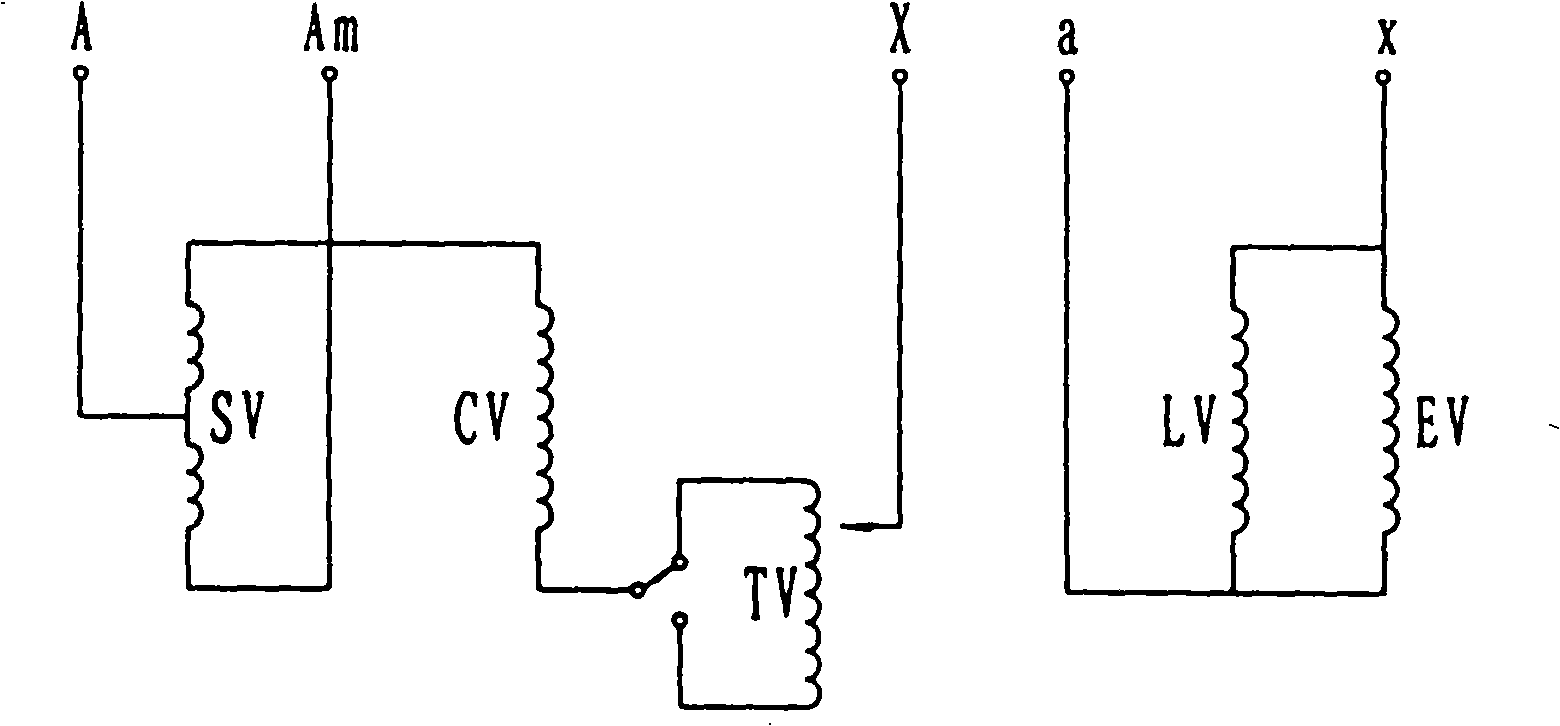

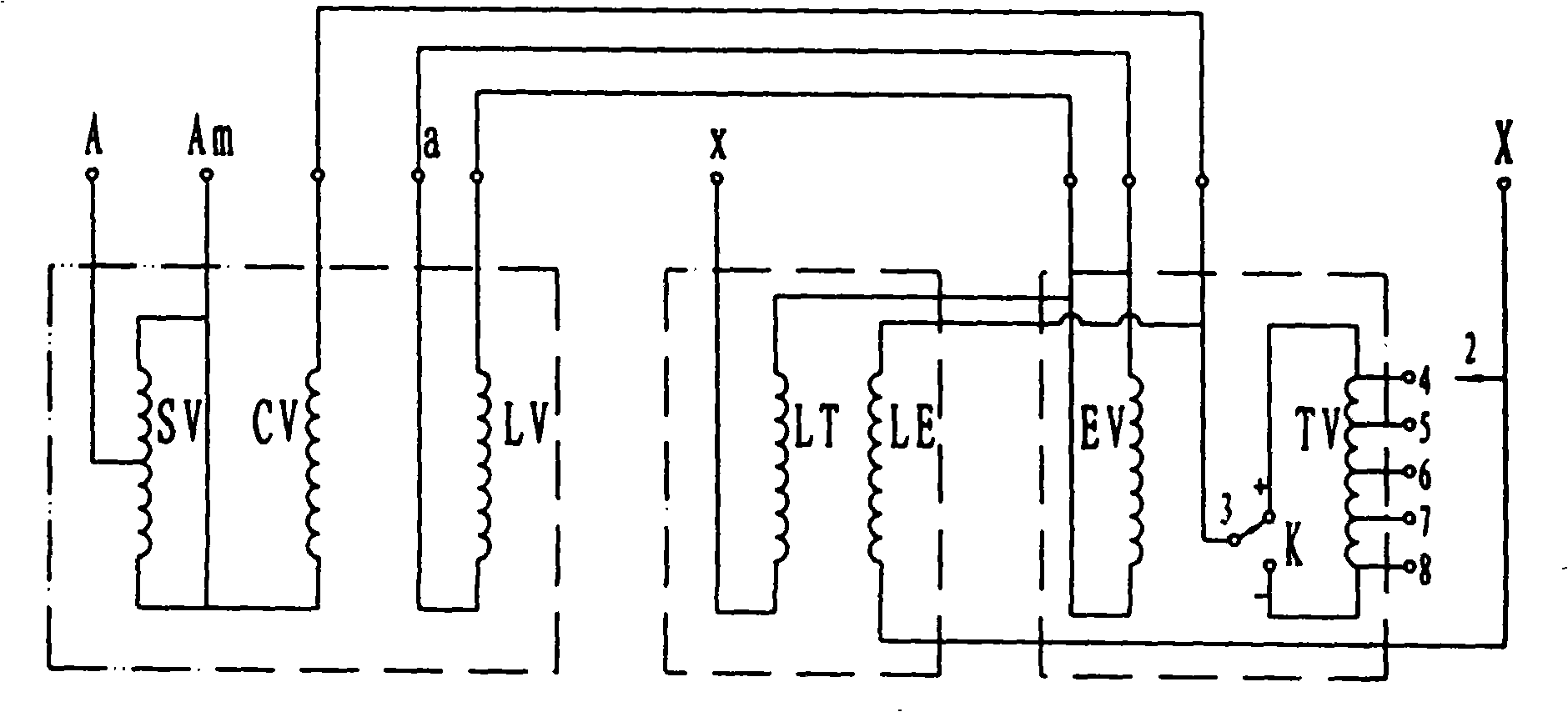

Extra-high voltage single-phase autotransformer

InactiveCN101256891AReduce the voltage levelReduce manufacturing costTransformers/inductances coolingTransformers/inductances coils/windings/connectionsAutotransformerLow voltage

An extra-high voltage single-phase autotransformer belongs to transformer technology field for resolving low-voltage fluctuate problem. The technical scheme is: the transformer consists of autotransformer body, voltage-regulating transformer and low pressure compensate transformer, the autotransformer body is made up of low-pressure winding, public windings and series winding, the voltage-regulating transformer is made up of exciter winding and pressure regulating windings, the low-voltage compensate transformer is made up of low-voltage exciter winding and compensated winding, connected relation of each windings is: pressure regulating windings, public windings and series winding connect input voltage after connecting in series, pressure regulating windings and two terminal of public windings connect output circuit, low-voltage exciter winding and pressure regulating windings are parallel connection, low-pressure winding connects with exciter winding in parallel firstly, secondly, connects with compensated winding in series, then connects compensation network. The present invention can satisfy demand of various users with simple structure, low cost, little low-voltage voltage fluctuation and high insulation reliability.

Owner:BAODING TIANWEI GRP CO LTD +1

A method for manufacturing a base material having gold-coated metallic fine pattern, a base material having gold-coated metallic fine pattern, a printed wiring board, an interposer and a semiconductor device

InactiveCN102893709AImprove insulation reliabilityImprove connection reliabilitySemiconductor/solid-state device detailsPrinted circuit aspectsInterposerSurface roughness

Owner:SUMITOMO BAKELITE CO LTD

Insulation circuit board, and power semiconductor device or inverter module using the same

ActiveUS20120127684A1Low costImprove featuresConversion constructional detailsSemiconductor/solid-state device detailsInsulation layerElectrical conductor

The invention relates to a high-voltage insulation circuit board which is used in an electric power apparatus such as an electric power converter or the like such as power semiconductor device, inverter module, or the like and provides an insulation circuit board in which electric field concentration at the end sections of a wiring pattern is reduced, partial discharging is suppressed, and a reliability is high. According to the invention, there is provided an insulation circuit board having: a metal base substrate; and wiring patterns which are formed onto at least one of the surfaces of the metal base substrate through an insulation layer, characterized in that between two adjacent wiring patterns in which an electric potential difference exists among the wiring patterns, at least one or more wiring patterns or conductors which are in contact with the insulation layer and have an electric potential in a range of the electric potential difference between the adjacent wiring patterns are arranged. According to the invention, the electric field concentration at the end sections of the wiring pattern to which a high voltage is applied is reduced and partial-discharge-resistant characteristics are improved.

Owner:HITACHI LTD

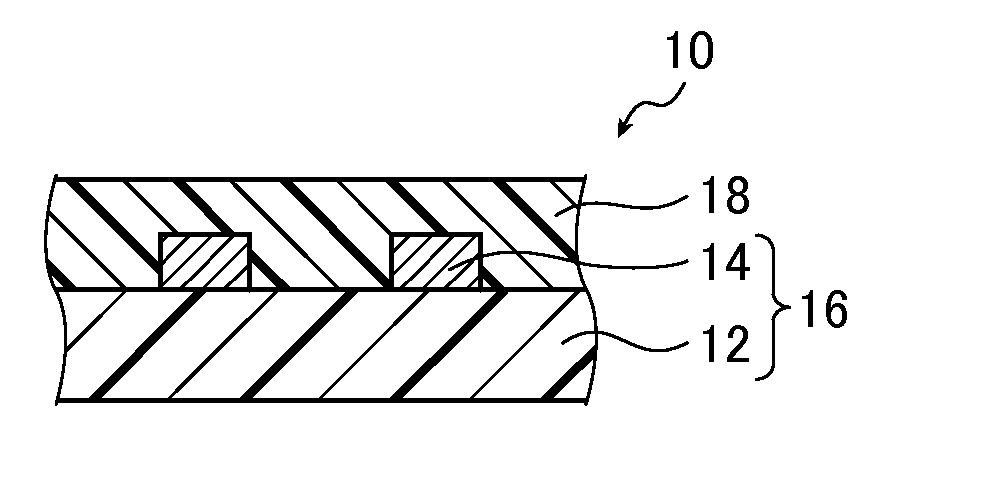

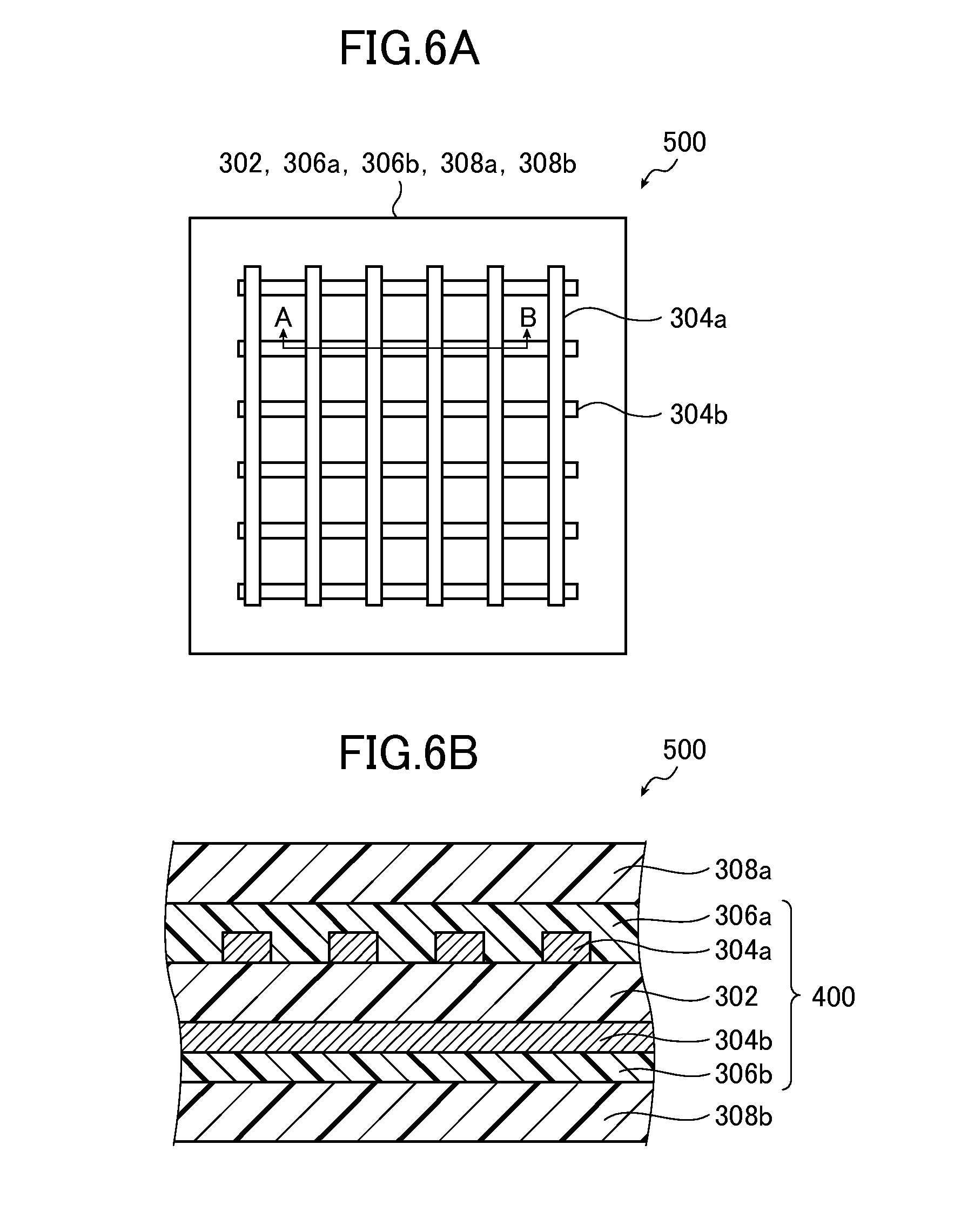

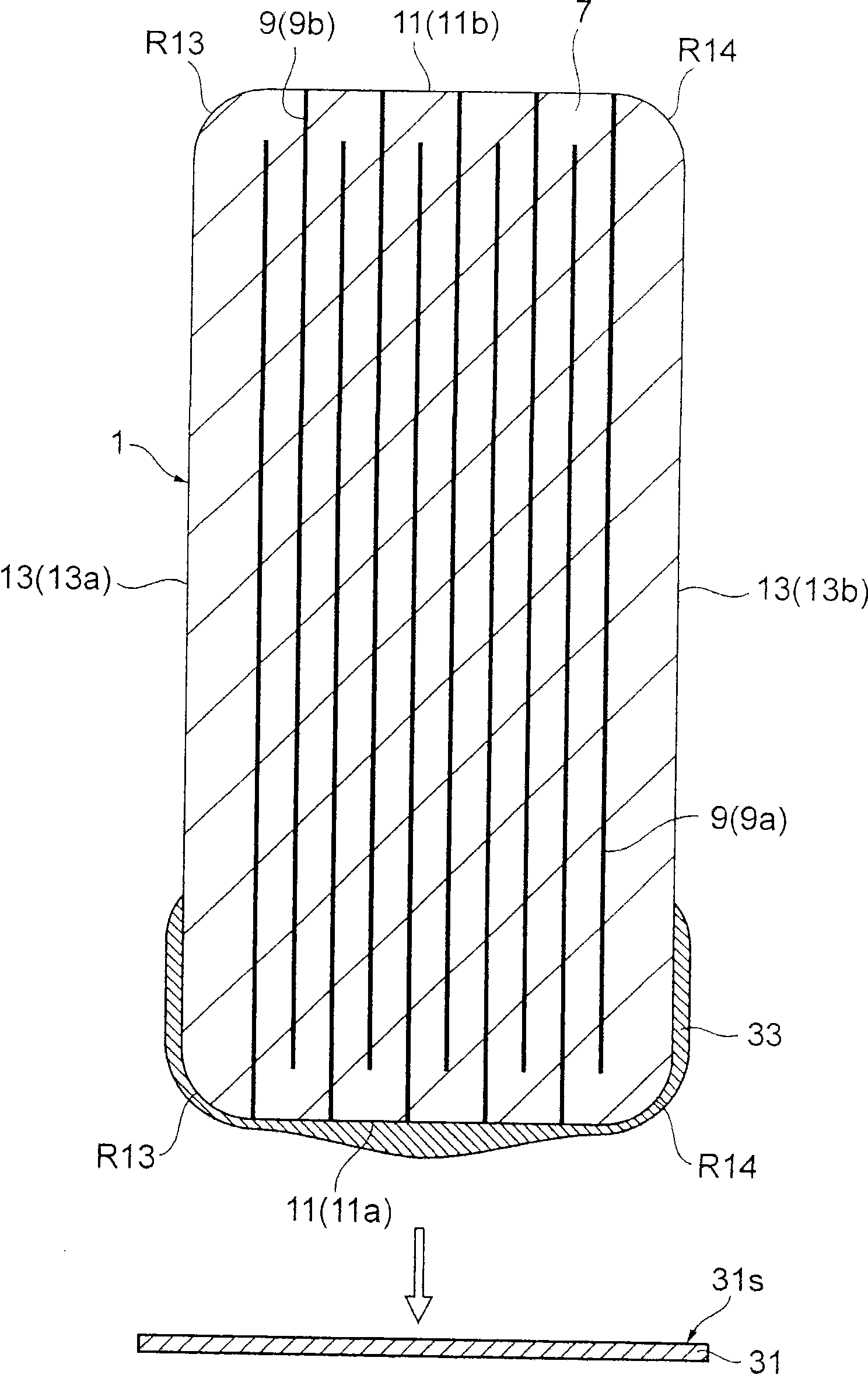

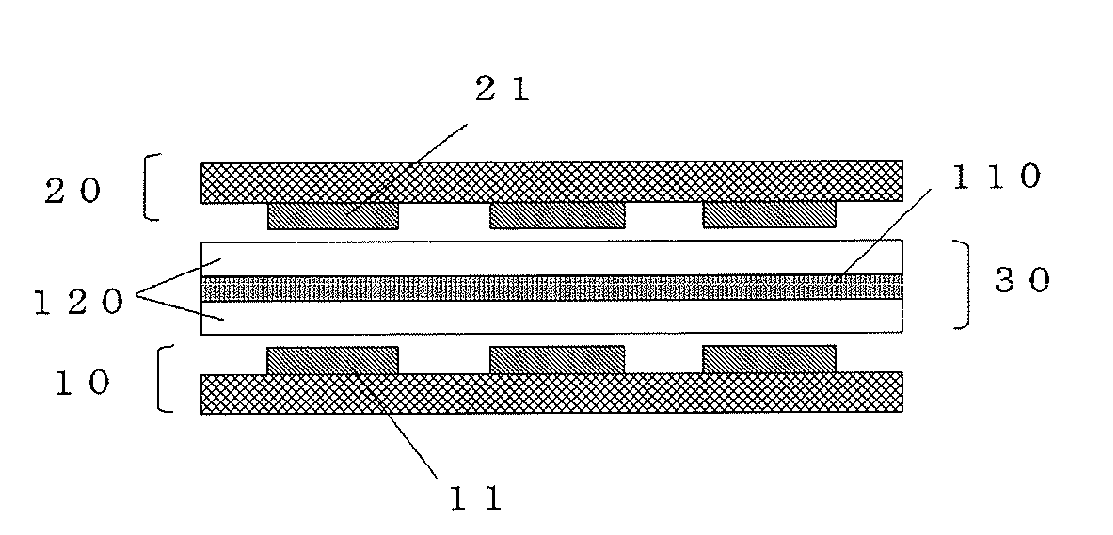

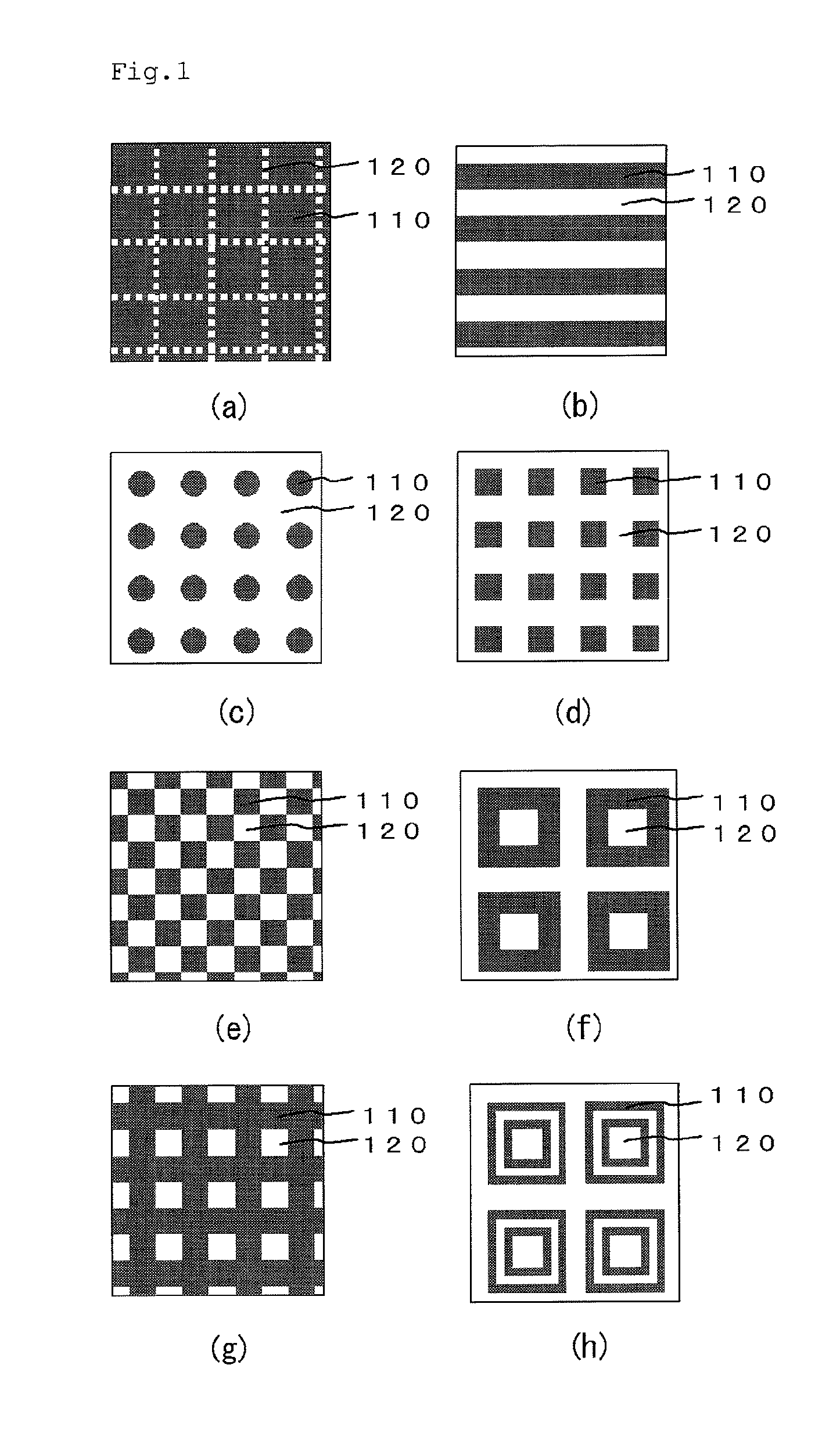

Insulating resin sheet laminate and multi-layer printed circuit board including insulating resin sheet laminate

InactiveUS20100101843A1Improve insulation reliabilityUniform thicknessPig casting plantsSynthetic resin layered productsMetal foilEngineering

Disclosed is an insulating resin sheet laminate (an insulating resin sheet with a film or a metal foil) including an insulating resin layer with a uniform thickness that is formed without repulsion or unevenness in a process of forming the insulating resin layer on a film or a metal foil, and a multi-layer printed circuit board that includes the insulating resin sheet laminate and possesses high insulating reliability. The present invention provides an insulating resin sheet laminate (an insulating resin sheet with a film or a metal foil) obtained by forming an insulating resin layer made of a resin composition on a film or a metal foil, and the resin composition includes an acrylic surfactant.

Owner:SUMITOMO BAKELITE CO LTD

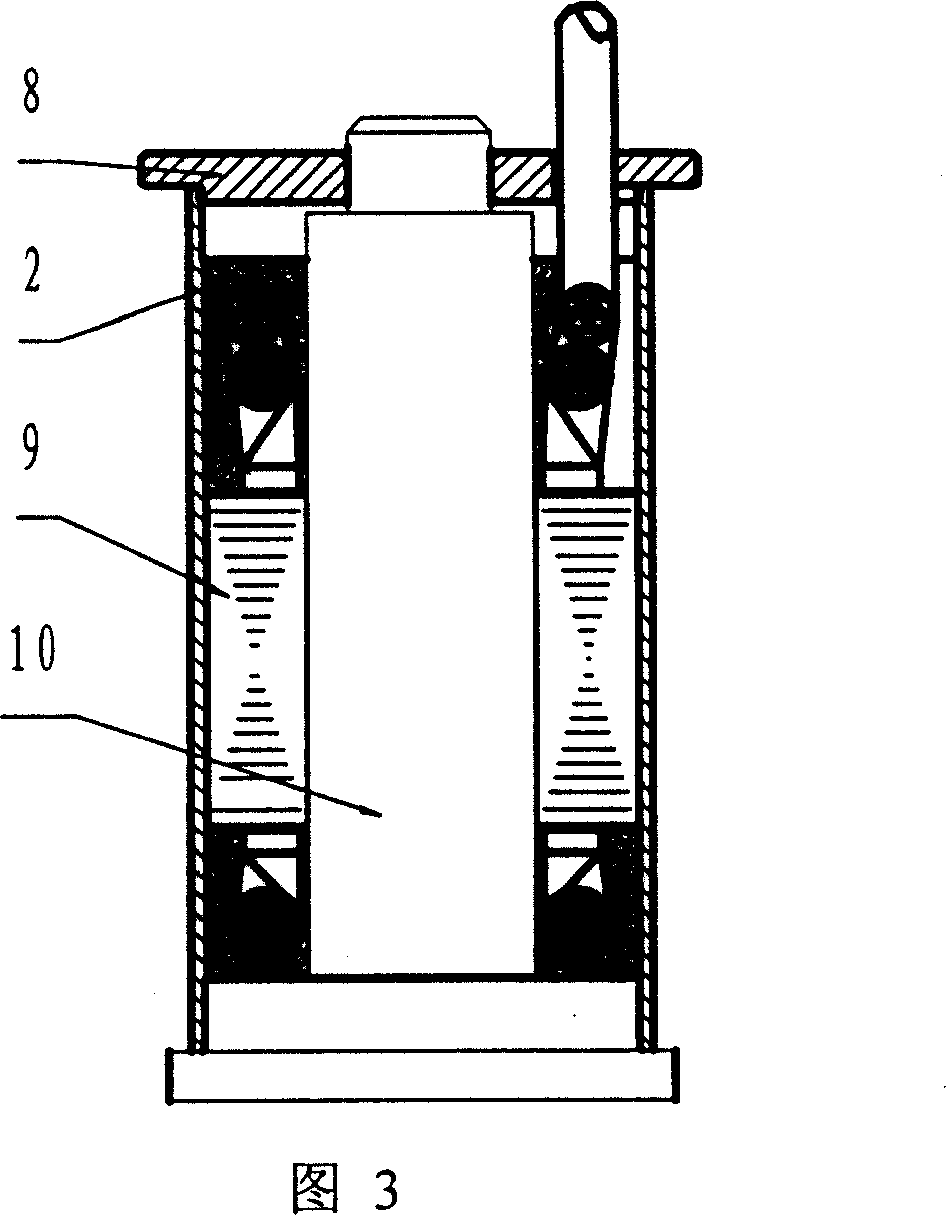

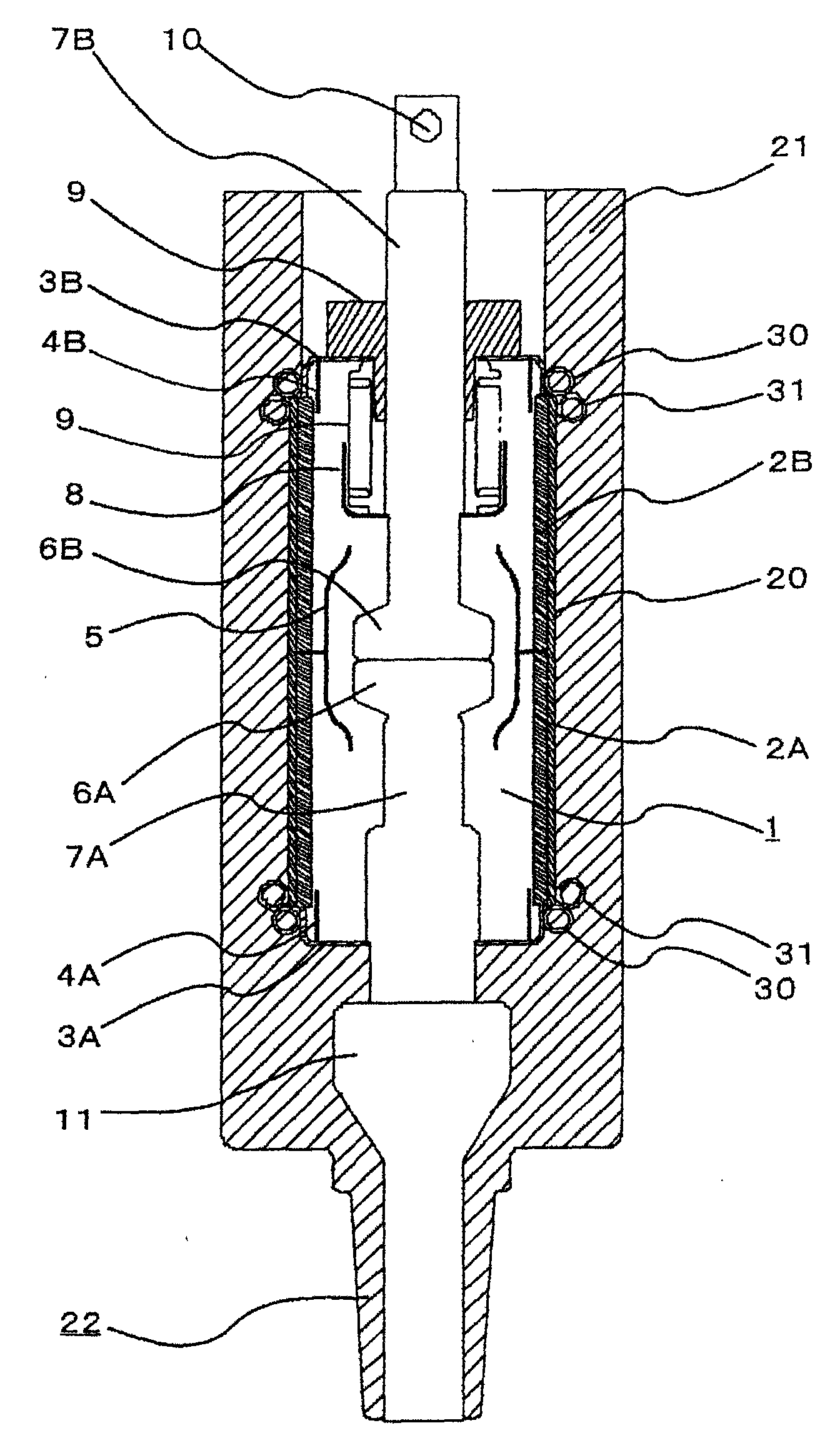

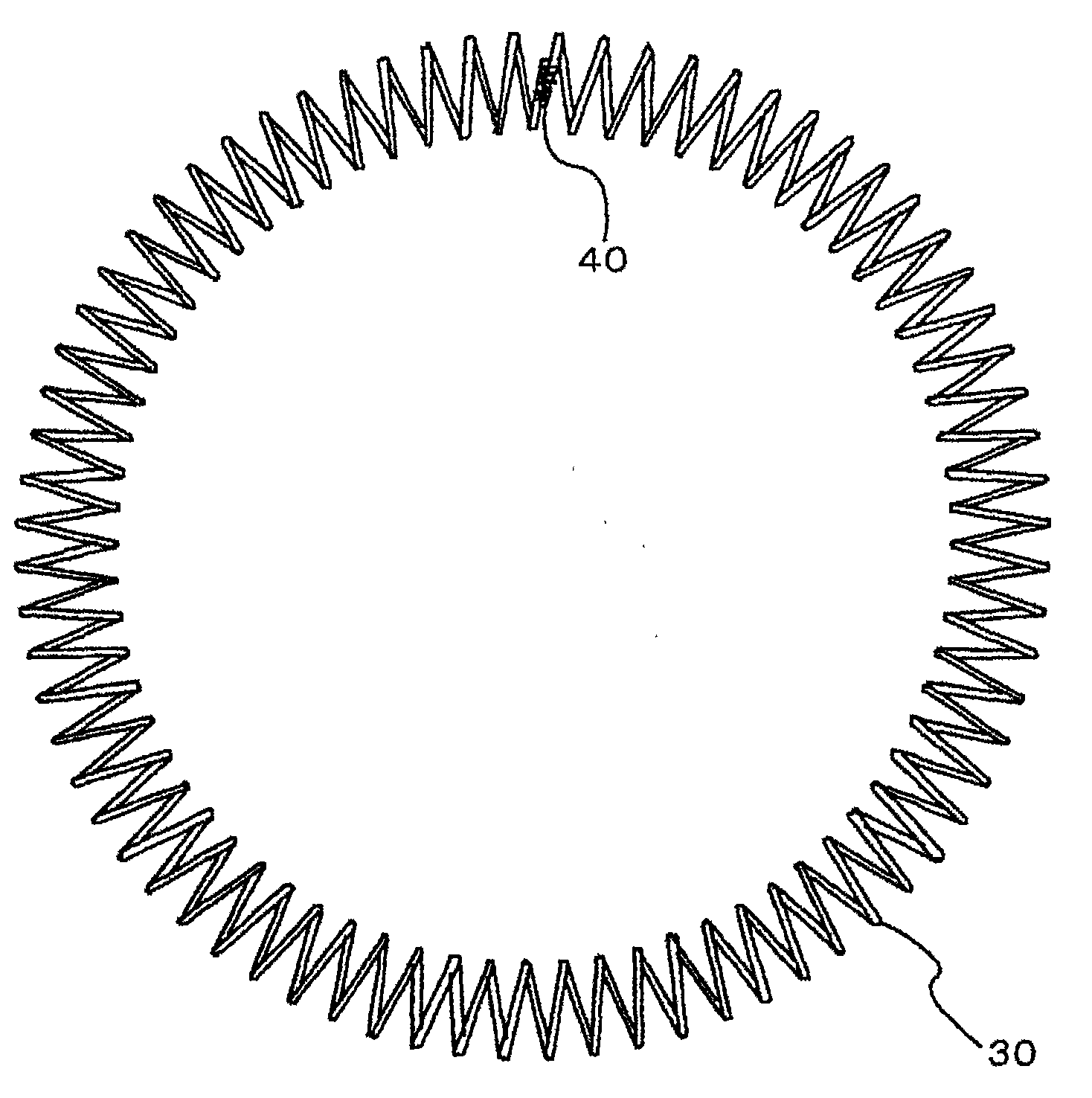

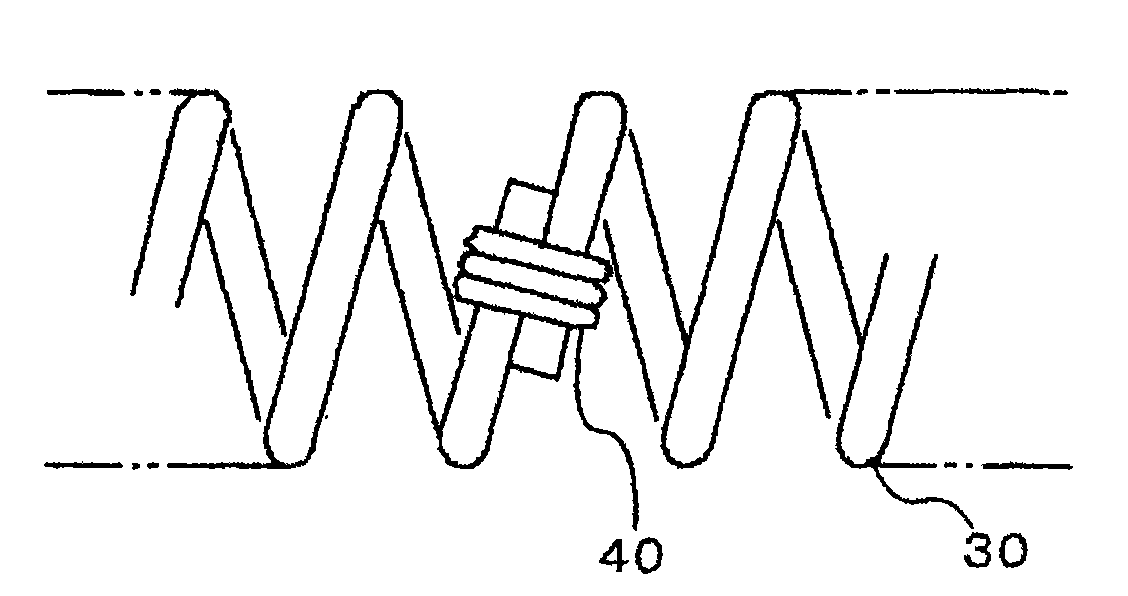

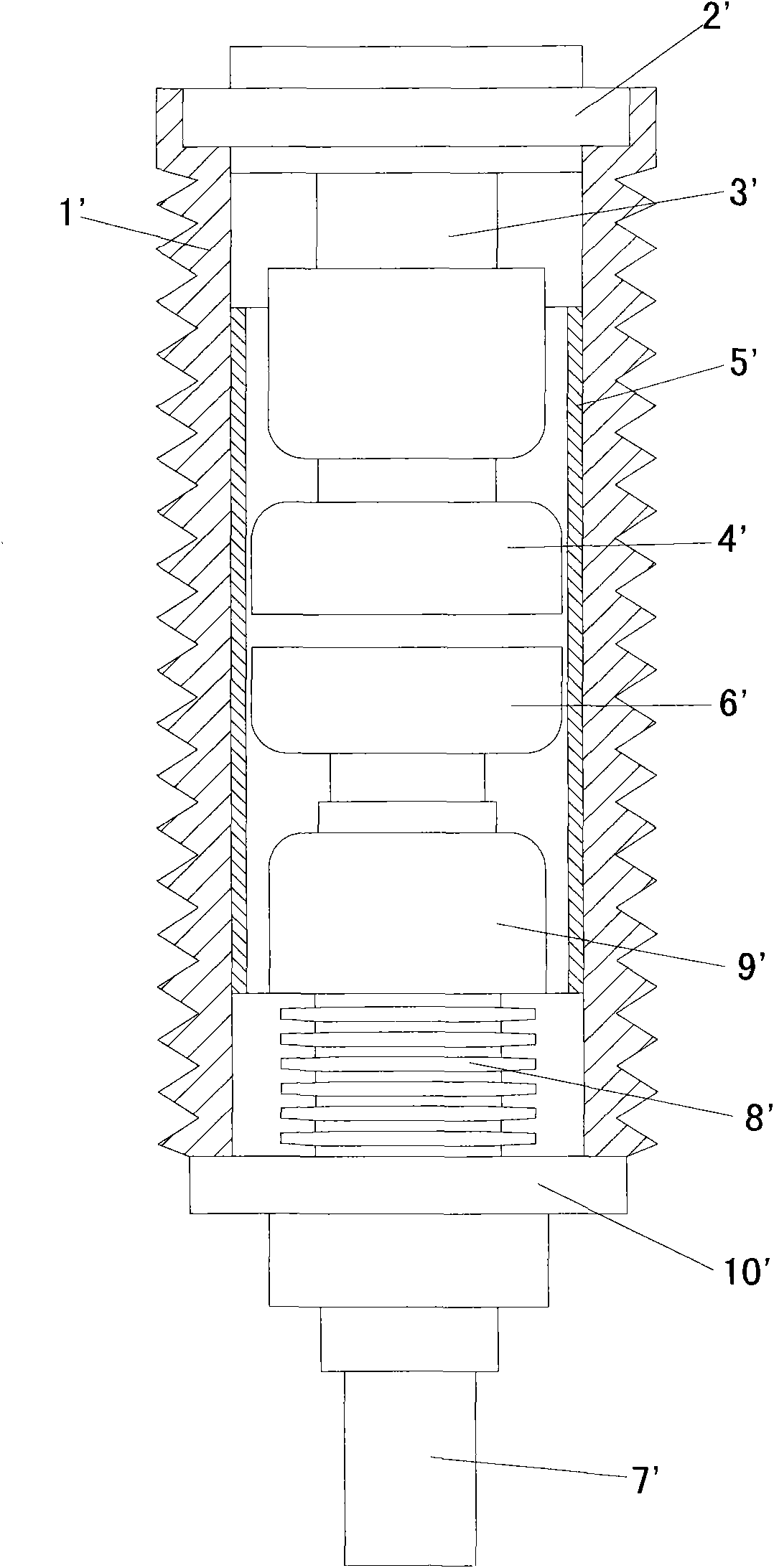

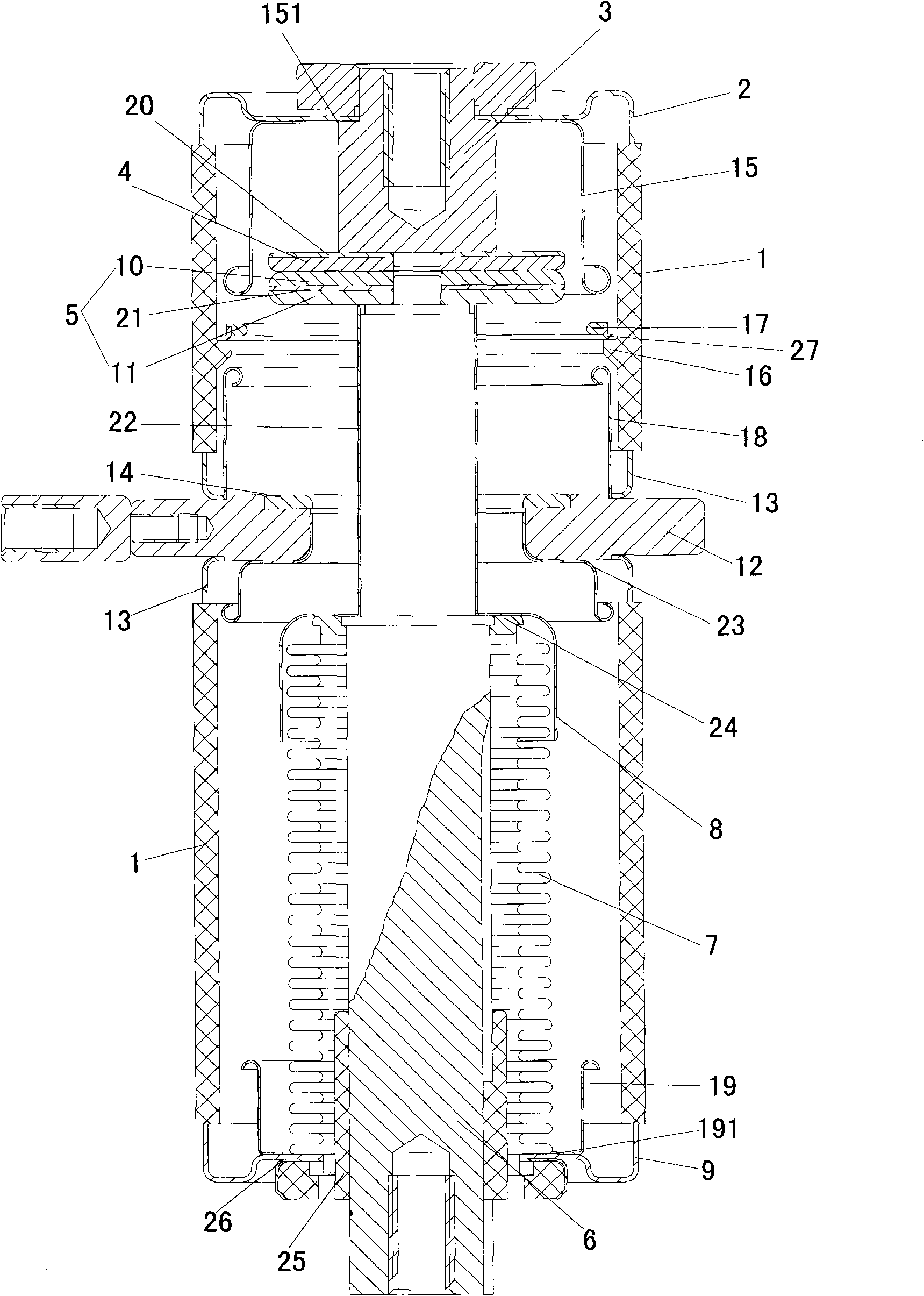

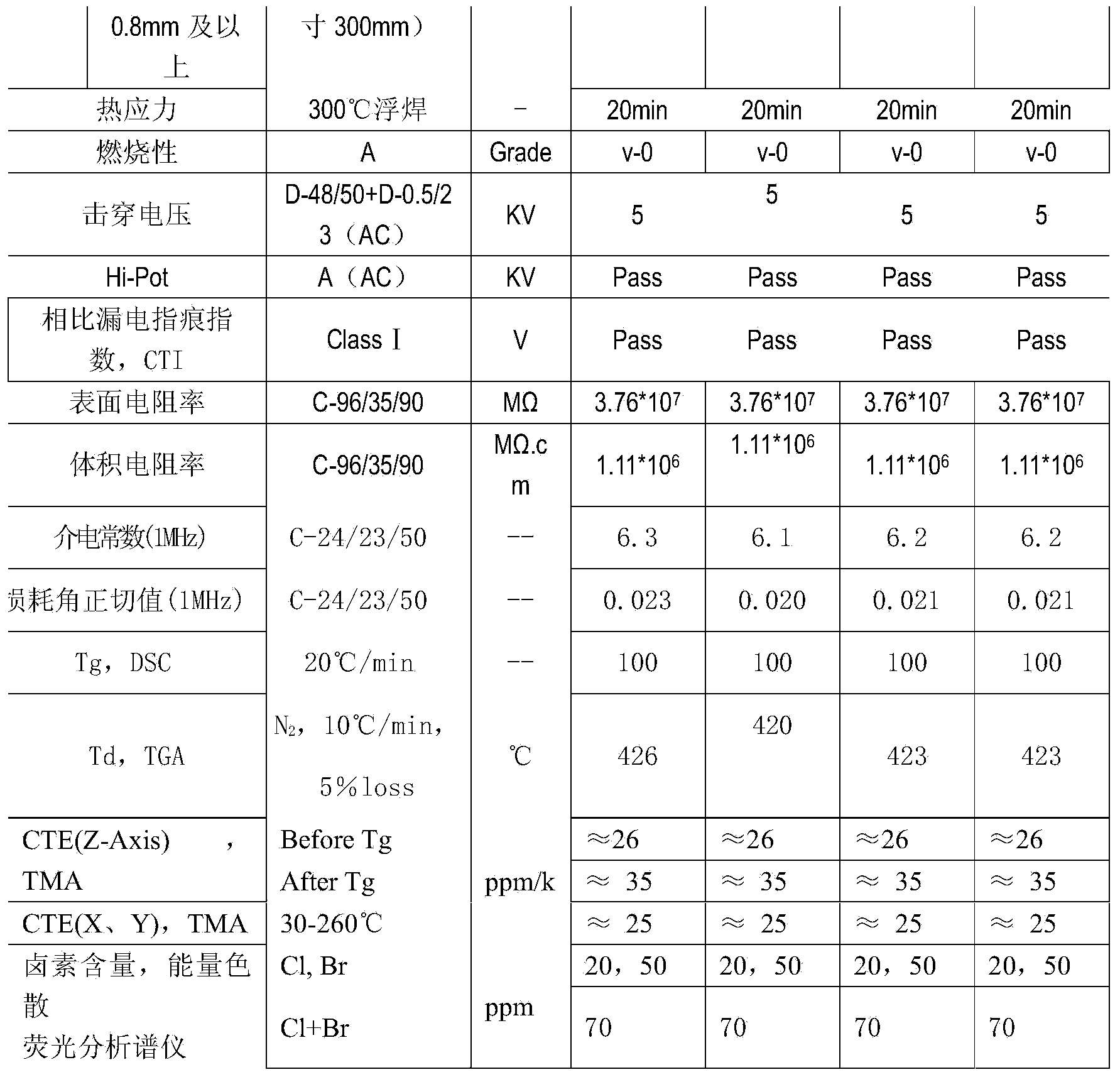

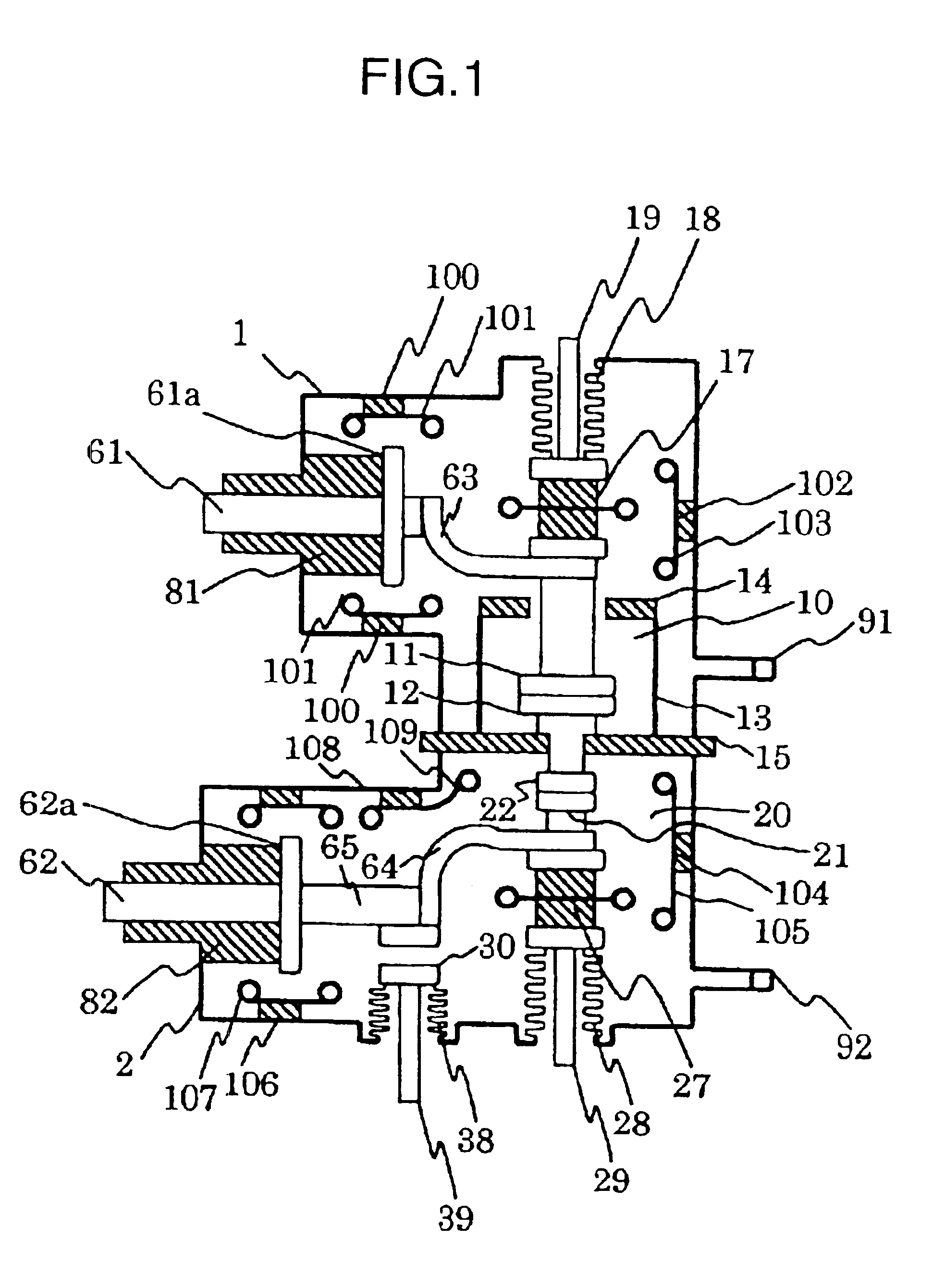

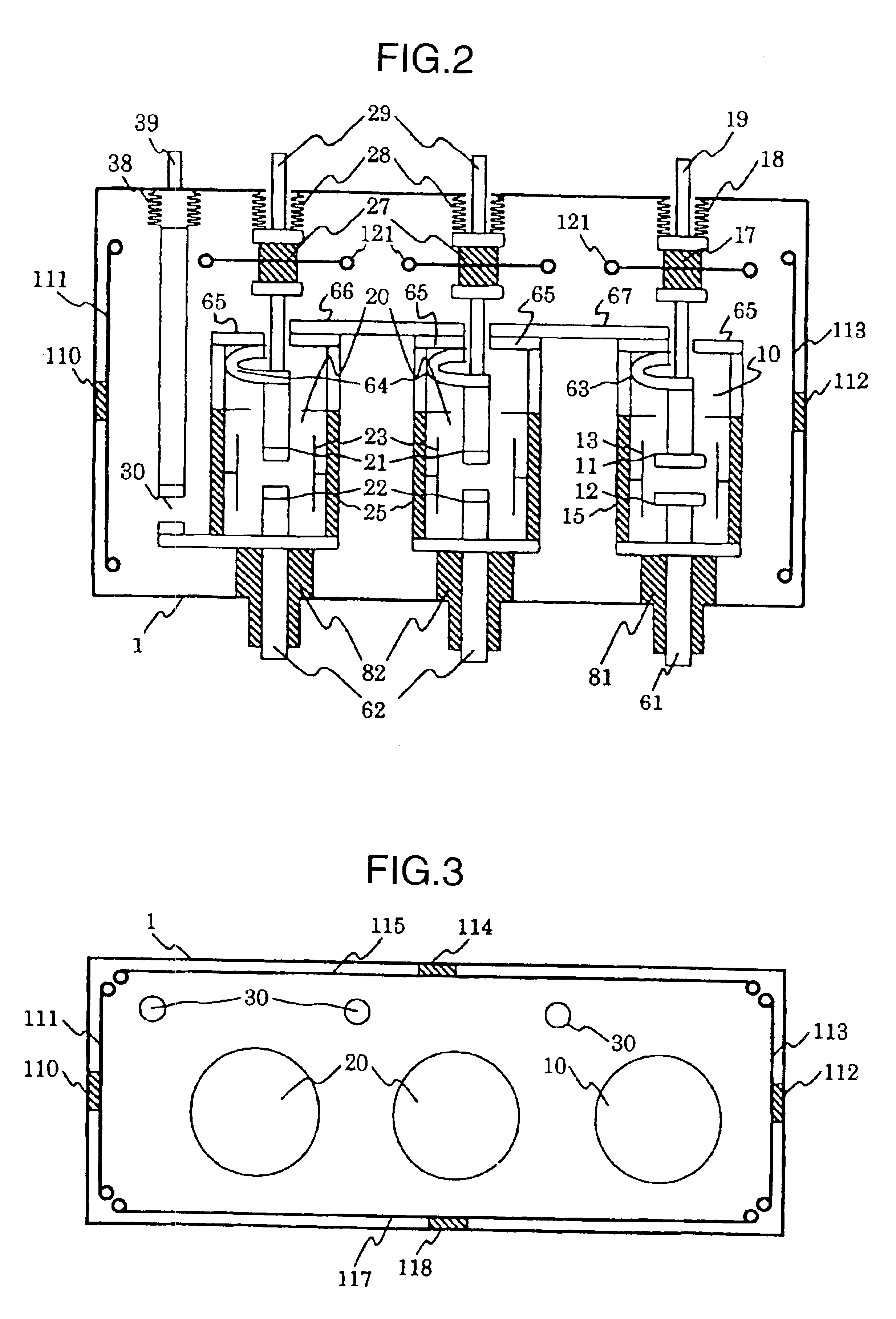

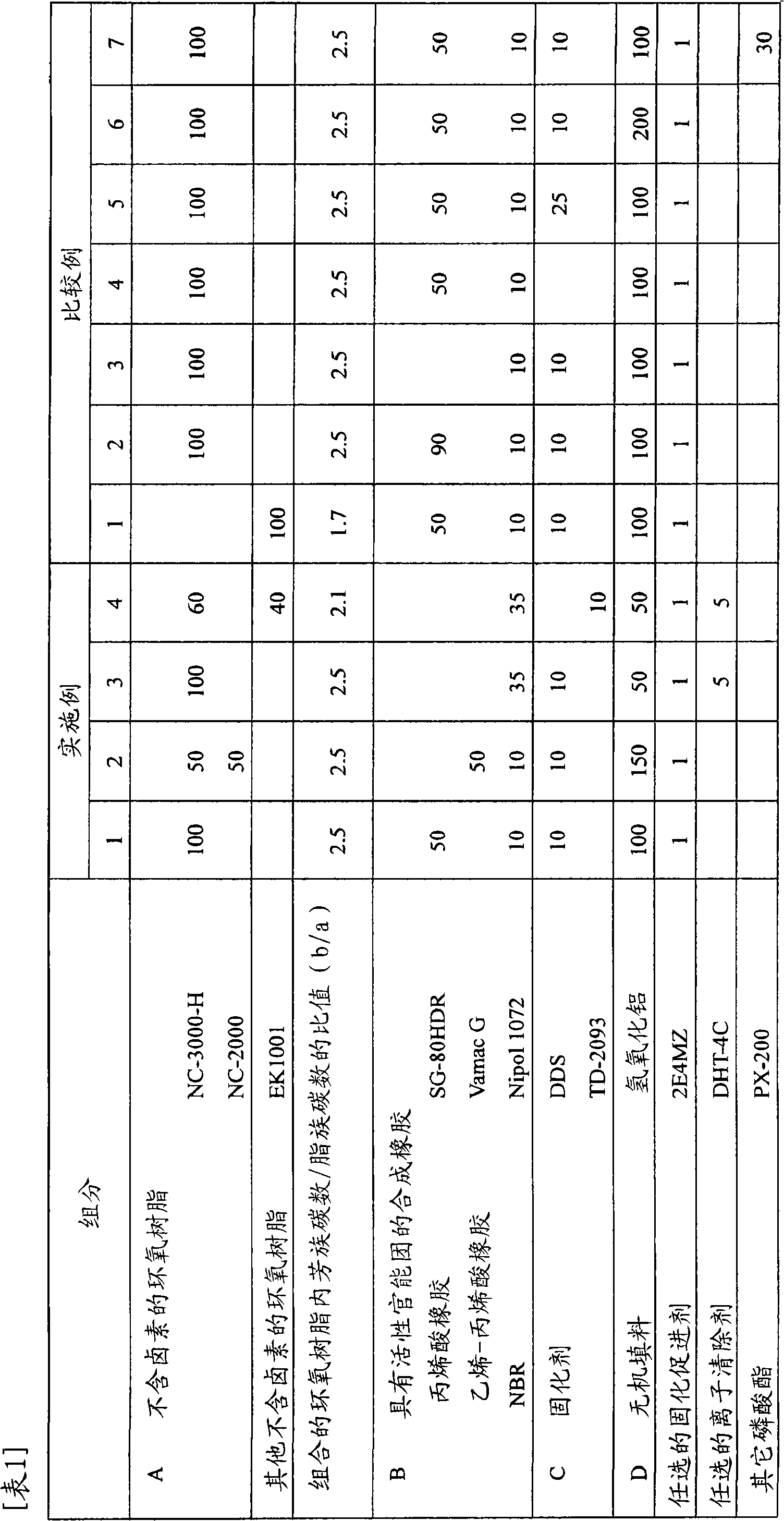

Vacuum switch and vacuum switchgear

InactiveCN101620948AHigher insulation reliabilityImprove insulation reliabilityHigh-tension/heavy-dress switchesAir-break switchesEngineeringCoil spring

The present invention relates to a vacuum switch and a vacuum switchgear. The object of the invention is to provides a vacuum switch covered by solid insulation resin with high insulation performance. The vacuum switch comprises a fixed electrode, a movable electrode facing the fixed electrode, an insulating cylinder, end plates covering both axial ends of the insulating cylinder, a vacuum chamber internally accommodating the fixed electrode and the movable electrode, and a solid isolation resin molded on the outside of the vacuum chamber, characterized in that, a first coil springs, each of which is disposed around the outer circumference of one end plate while touching the end plate and an end face of the insulating cylinder, and a second coil springs, each of which is united to one of the first springs and disposed around the outer circumference of the insulating cylinder so as to cover the angular part of the end face of the insulating cylinder, and the end plates, the end faces of the insulating cylinder, and the first and second coil springs are electrically connected.

Owner:HITACHI IND EQUIP SYST CO LTD

Power module and power conversion device

InactiveCN102414816AImprove insulation reliabilityBoost power moduleAnodisationConversion constructional detailsElectricityInsulation layer

A power module according to the present invention includes: a semiconductor element for converting DC current to AC current by switching operation; an electrical wiring board to which the semiconductor element is electrically connected, with the semiconductor element being disposed upon one of its principal surfaces; an insulating resin layer provided on the other principal surface of the electrical wiring board; a first insulation layer that is disposed opposite from the electrical wiring board, separated by the insulating resin layer, and that is joined to the insulating resin layer; a second insulation layer that is disposed opposite from the insulating resin layer, separated by the first insulation layer, and that ensures electrical insulation of the semiconductor element; and a metallic heat dissipation member that is disposed opposite from the first insulation layer, separated by the second insulation layer, and that radiates heat generated by the semiconductor element via the electrical wiring board, the insulating resin layer, the first insulation layer, and the second insulation layer.

Owner:HITACHI AUTOMOTIVE SYST LTD

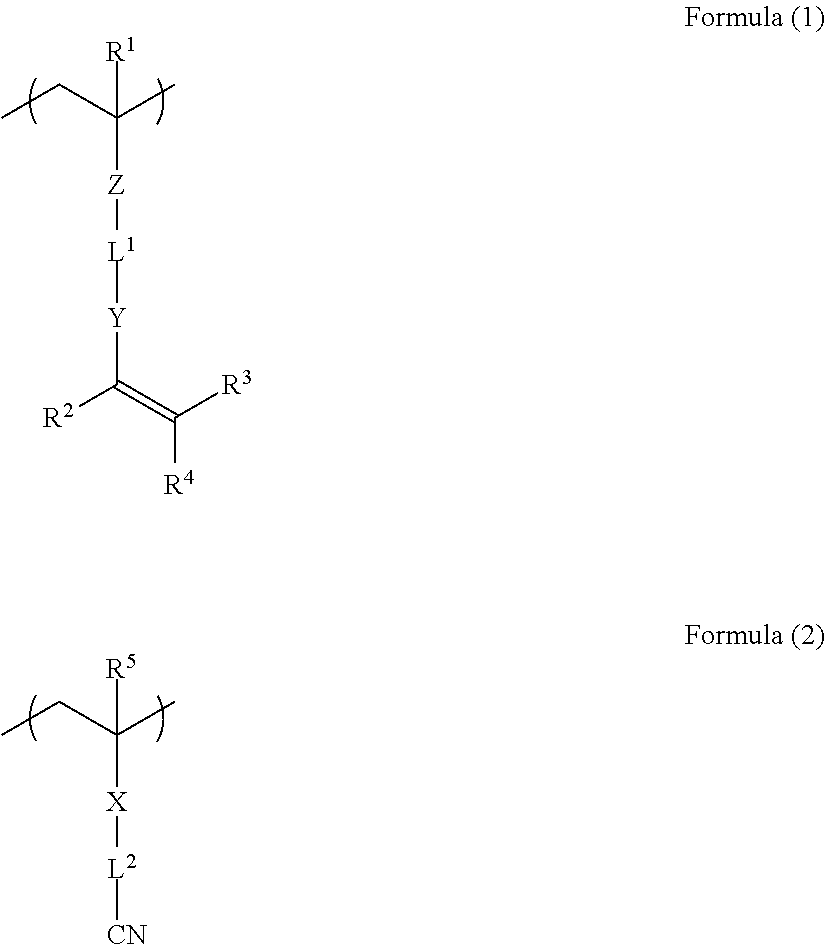

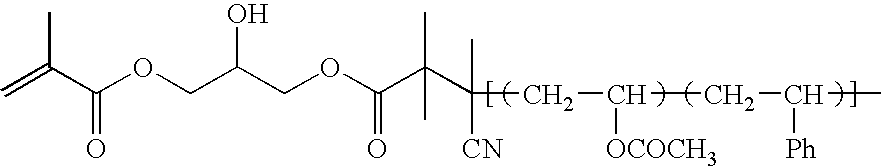

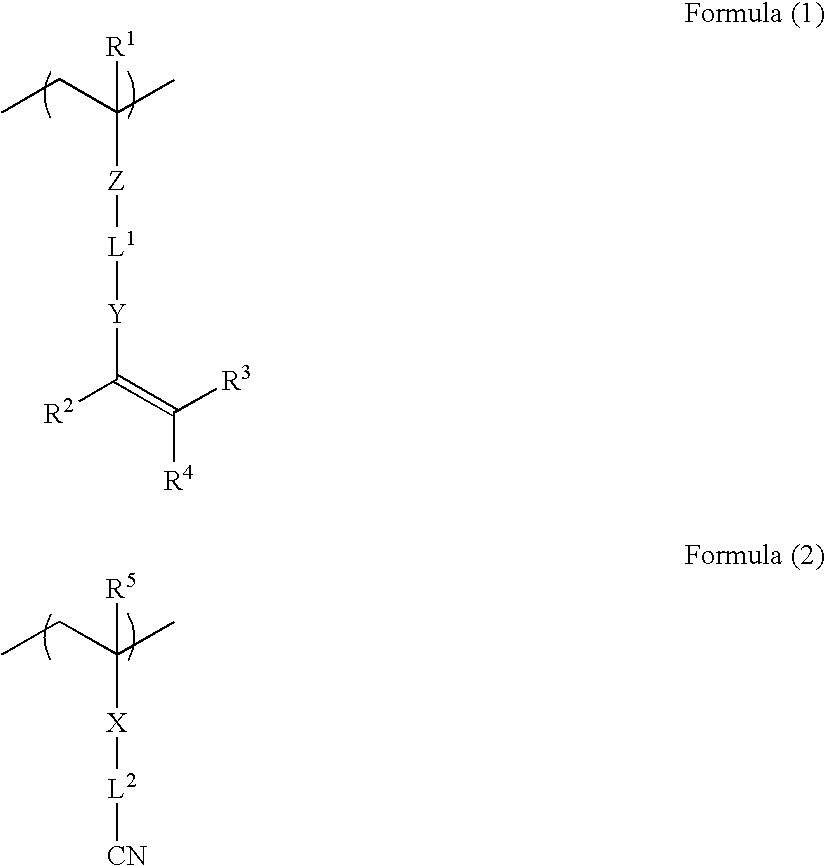

Metal-film-coated material and process for producing the same, metallic-pattern-bearing material and process for producing the same, composition for polymer layer formation, nitrile group-containing polymer and method of synthesizing the same, composition containing nitrile group-containing polymer, and laminate

InactiveUS8084564B2Improve adhesionLess fluctuationSynthetic resin layered productsLiquid/solution decomposition chemical coatingPolymer scienceEther

The invention provides a polymer containing at least a unit represented by the following Formula (1) and a unit represented by the following Formula (2). In Formula (1) and Formula (2), R1 to R5 each independently represent a hydrogen atom or a substituted or unsubstituted alkyl group; X, Y and Z each independently represent a single bond, a substituted or unsubstituted divalent organic group, an ester group, an amide group or an ether group; and L1 and L2 each independently represent a substituted or unsubstituted divalent organic group. The invention provides a method of synthesizing embodiments of the polymer, a composition containing the polymer, and a laminate formed by applying the composition on a resin base material.

Owner:FUJIFILM CORP

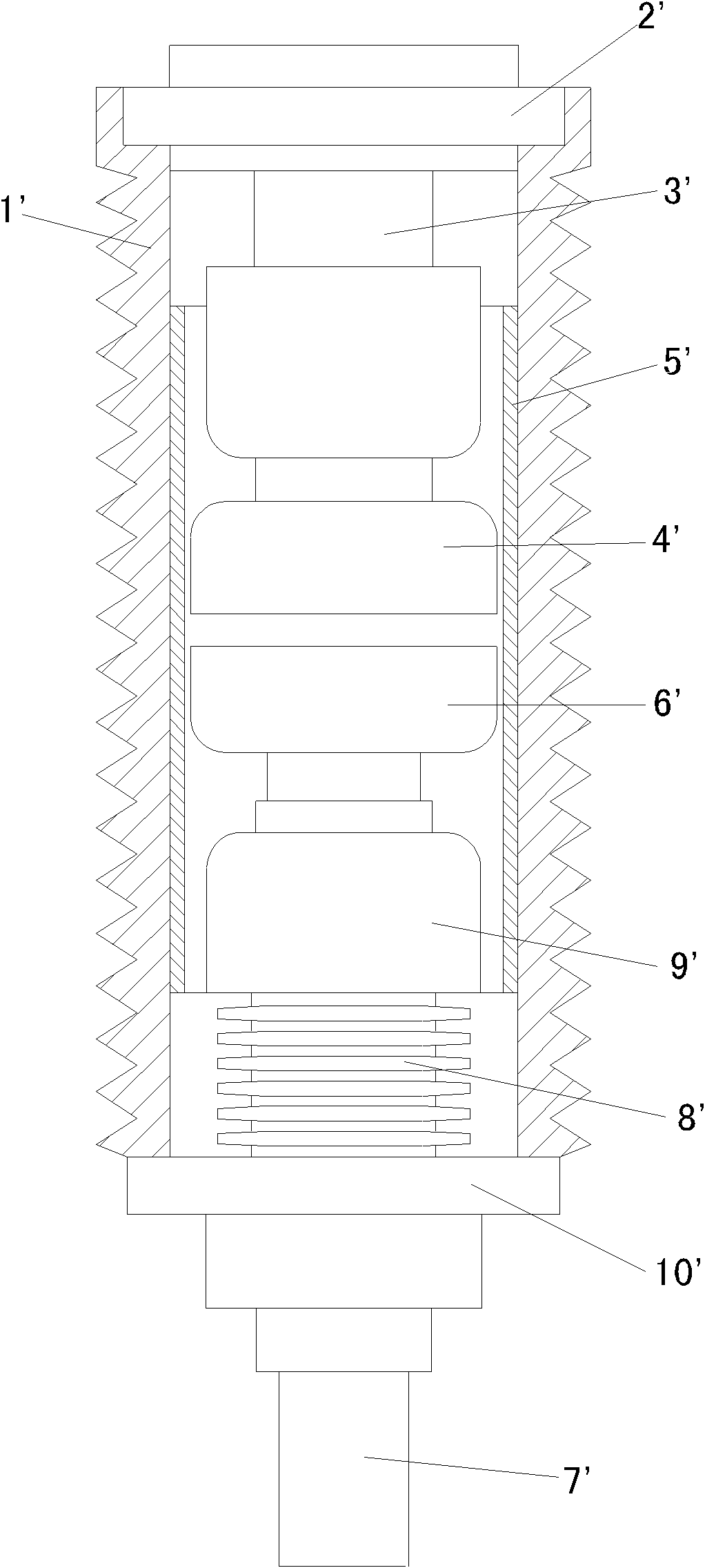

Three-station vacuum arc extinguish chamber for isolated grounding

InactiveCN101819904AImprove insulation reliabilityHigh dielectric strengthHigh-tension/heavy-dress switchesAir-break switchesEngineeringVacuum arc

The invention relates to a three-station vacuum arc extinguish chamber for isolated grounding, which is mainly applied to medium-voltage power switch equipment and comprises an isolated outer shell, a fixed cover plate, a movable cover plate, a fixed end conducting rod, a movable end conducting rod, a fixed contact, a movable contact, a corrugated pipe and a protective cover, wherein the fixed cover plate and the movable cover plate are respectively arranged at the upper end and the lower end of the isolated outer shell, the top of the fixed end conducting rod is welded with the fixed cover plate, and the bottom of the fixed end conducting rod is welded with the fixed contact; the protective cover of the corrugated pipe is arranged outside the corrugated pipe; the movable contact is formed by welding an isolated contact and a movable grounding contact; the middle of the isolated outer shell is provided with a grounding ring, the upper surface and the lower surface of the grounding ring are connected with the isolated outer shell through a sealing ring, and the upper surface of the grounding ring is welded with a fixed grounding contact; the bottom of the fixed cover plate is welded with a fixed end isolated shielding cover, a middle isolated shielding cover is arranged on a bead at the upper part of an inner cavity of the isolated outer shell, and a grounding isolated shielding cover is arranged on the grounding ring; one end of the movable end conducting rod is welded with the movable grounding contact after penetrating through the cover plates, the corrugated pipe, the grounding isolated shielding cover, the middle isolated shielding cover and the fixed end isolated shielding cover, and a movable end voltage-sharing cover is welded on the movable cover plate. The invention has the advantages of simple structure and low cost.

Owner:山东晨鸿电气有限公司 +2

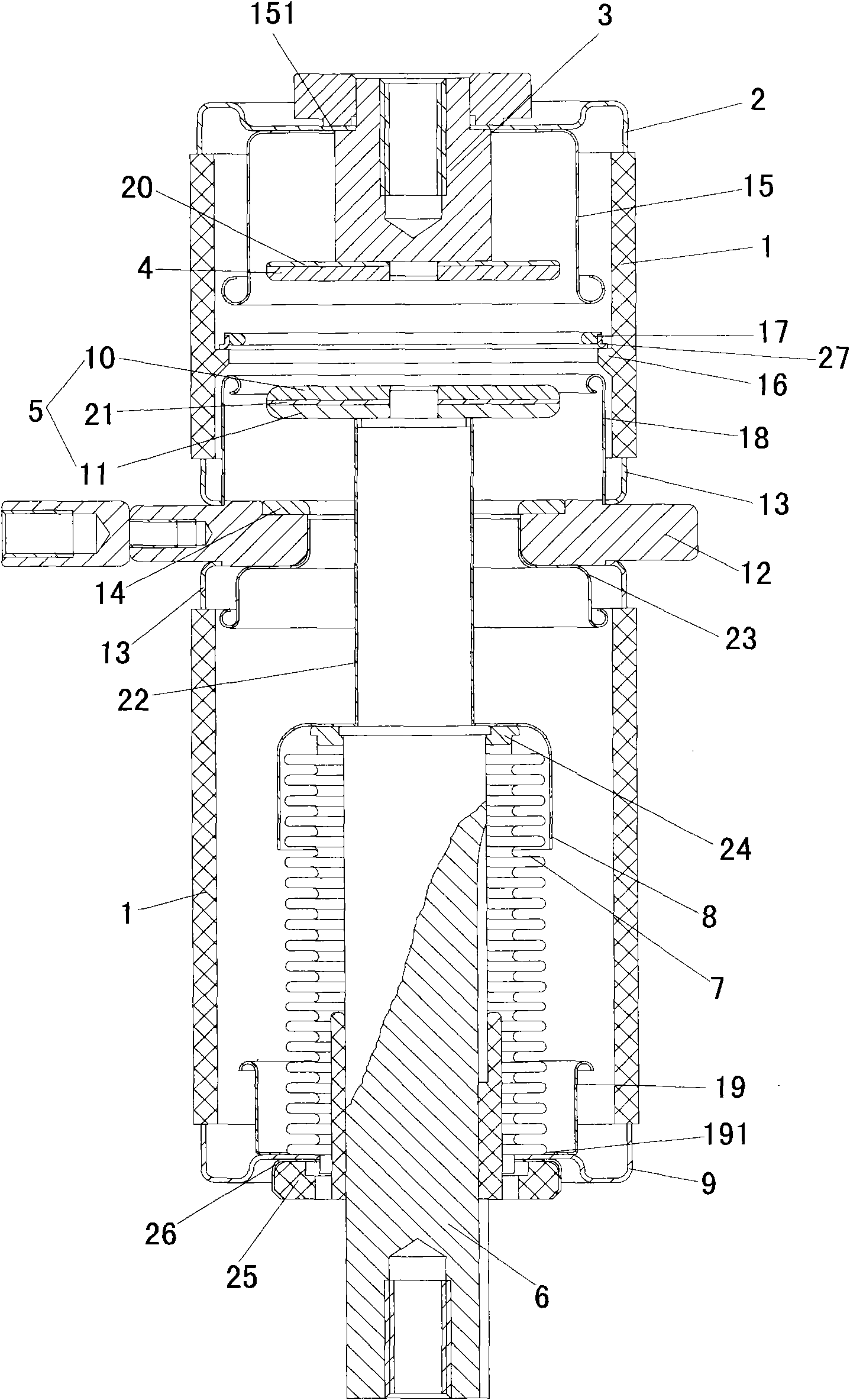

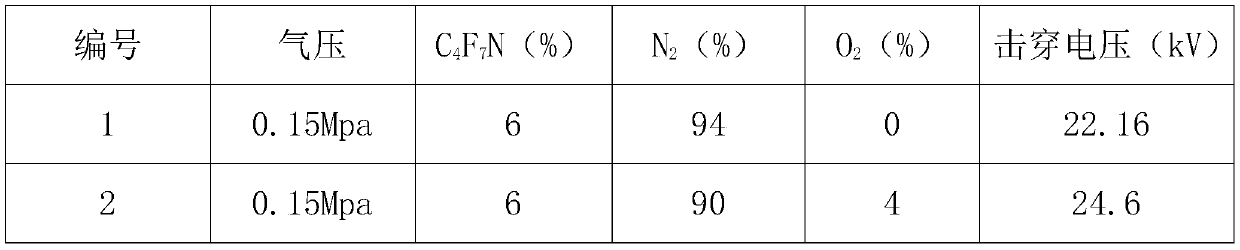

Modified formula of environment-friendly gas insulating medium

InactiveCN109830912AHigh dielectric strengthImprove insulation reliabilitySwitchgear arrangementsOrganic gases insulatorsElectricityPhysical chemistry

The invention provides a modified formula of an environment-friendly gas insulating medium. The modified formula is characterized by comprising an environment-friendly dielectric, a buffer gas and oxygen, wherein the environment-friendly dielectric accounts for 4% to 10% by volume, the buffer gas accounts for 80% to 94% by volume, and the oxygen accounts for 2%to 10% by volume. The environment-friendly dielectric is any one of C4F7N, C5F10O, and C6F12O. The buffer gas is either N2 or CO2. A mixed gas configured according to the modified formula of the environmentally-friendly gas insulating medium of the invention, when used in an electrical device, such as a gas-insulated combined device, using an insulating gas as an insulating medium, has a higher dielectric strength than a unmodified environmentally-friendly dielectric mixed gas. Moreover, the modified environment-friendly dielectric mixed gas can reduce the precipitation of carbon particles and enhance the insulation reliability of the environment-friendly dielectric mixed gas.

Owner:WUHAN UNIV

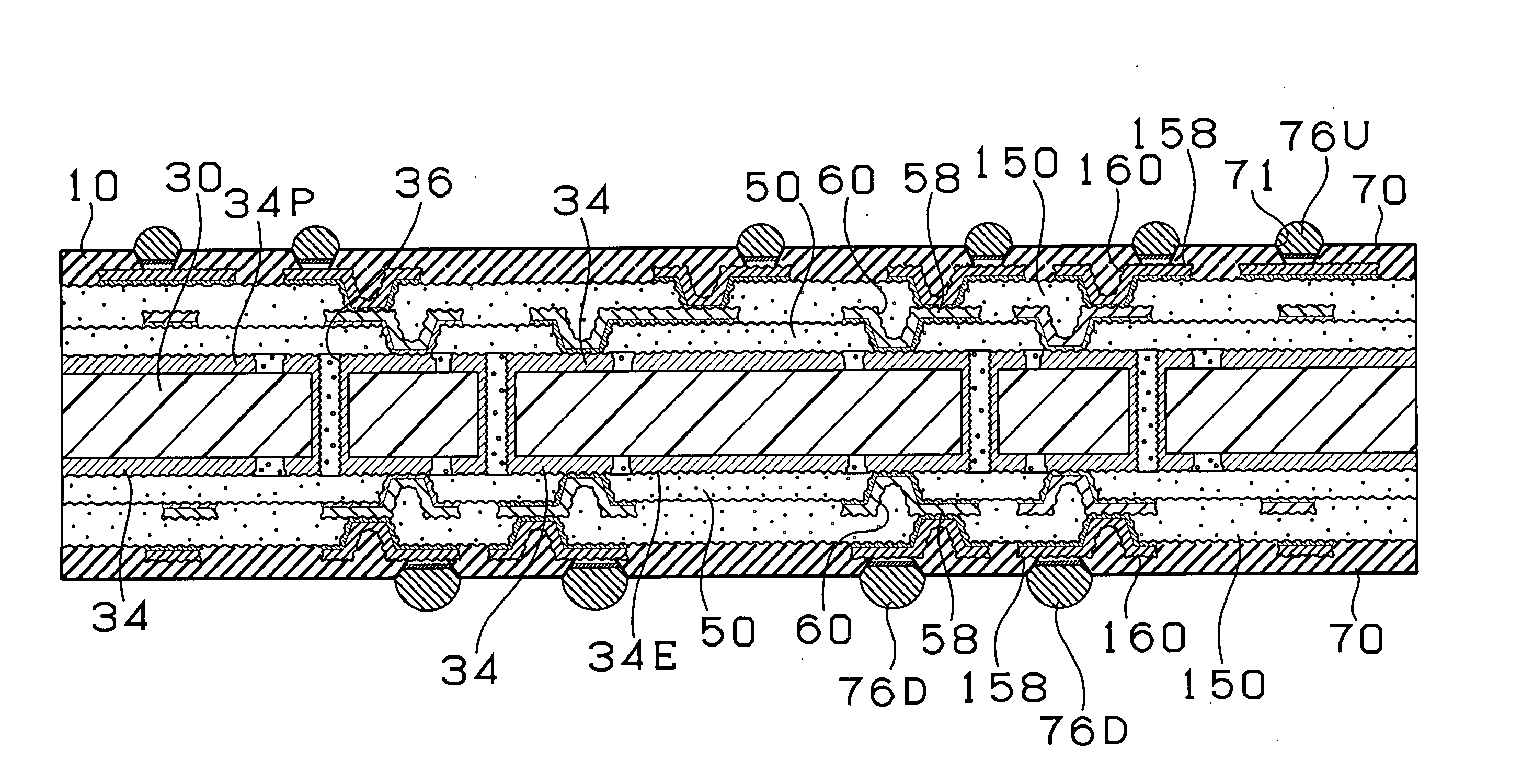

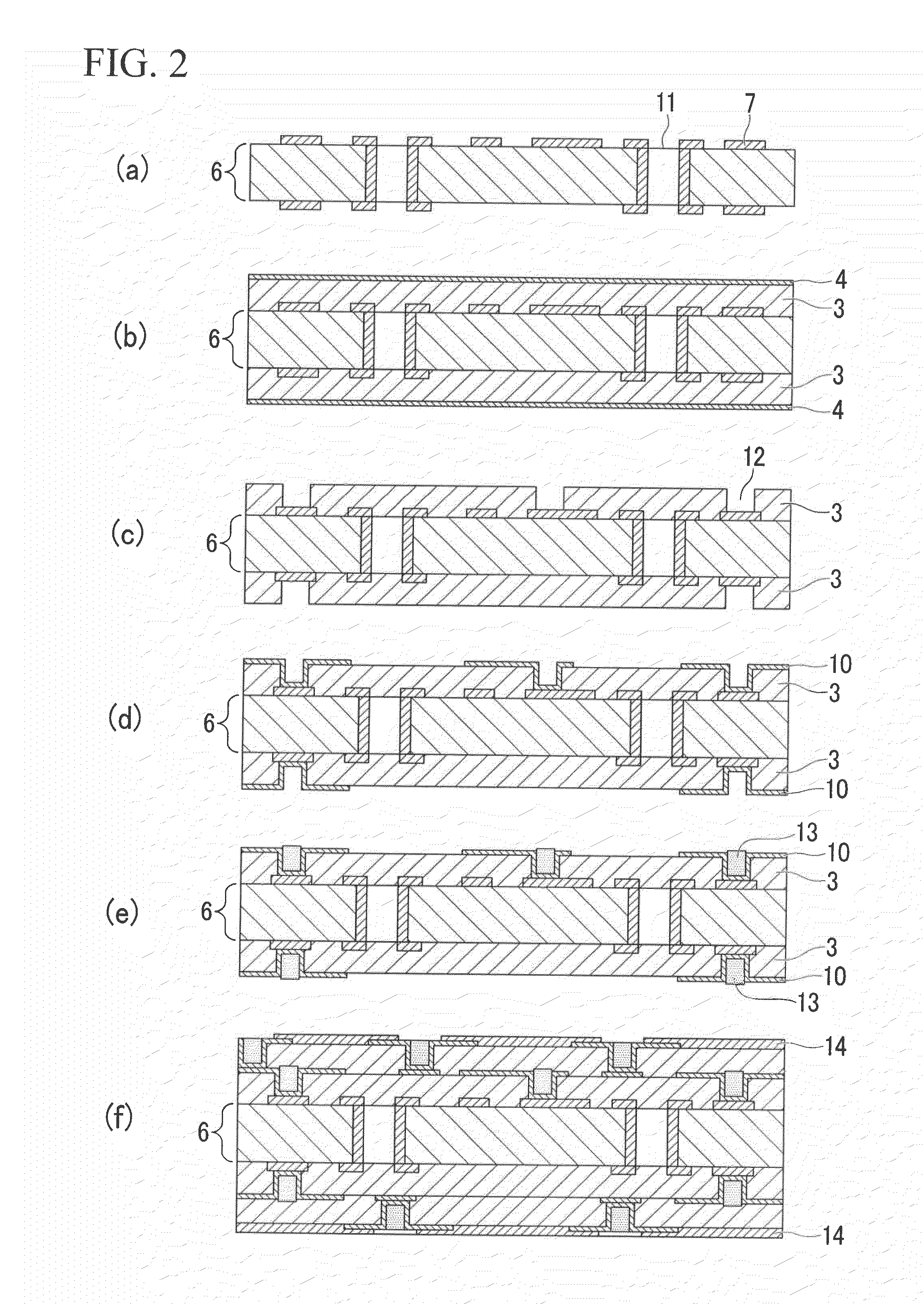

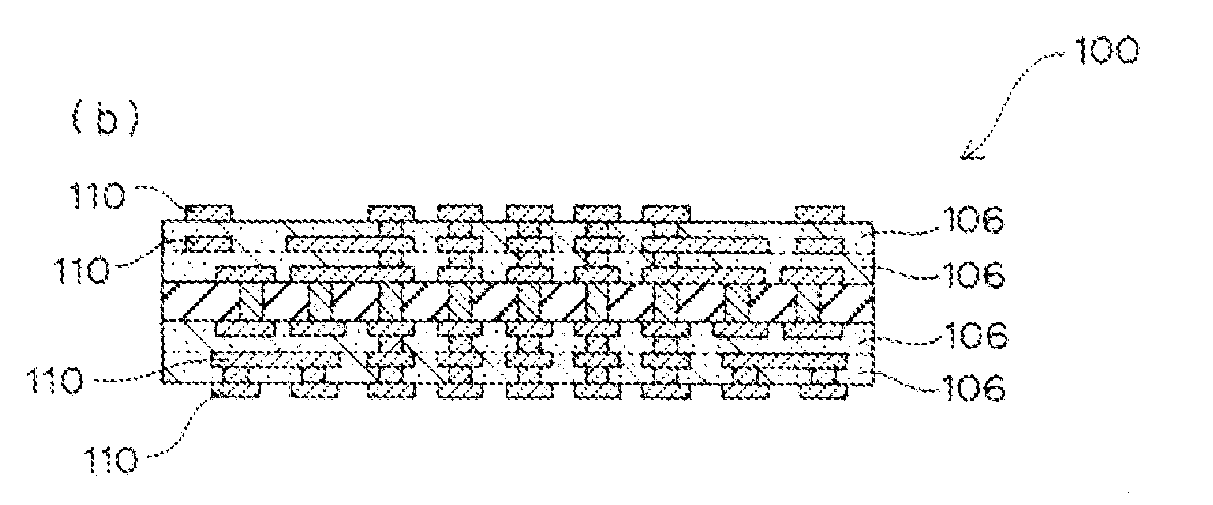

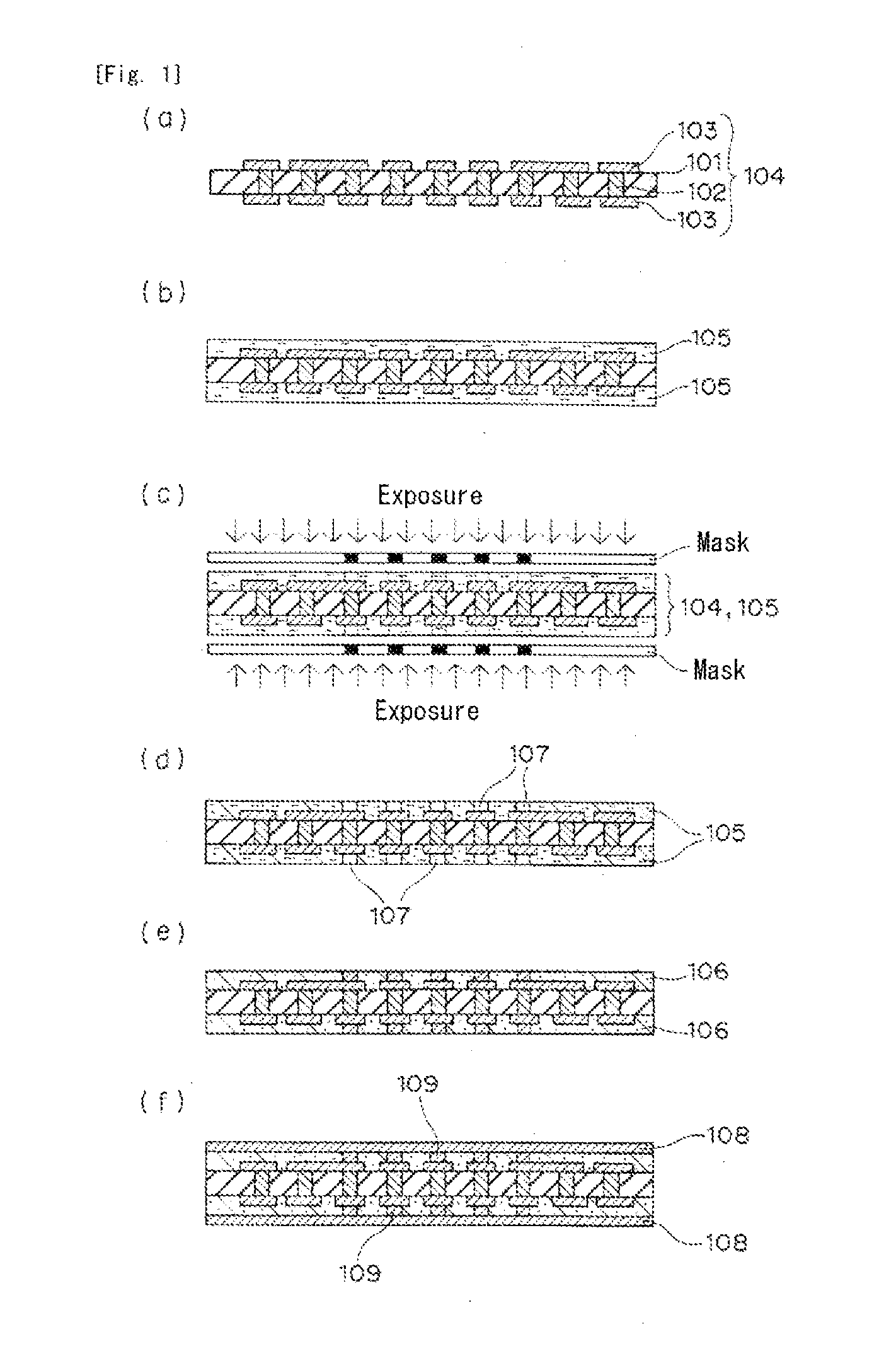

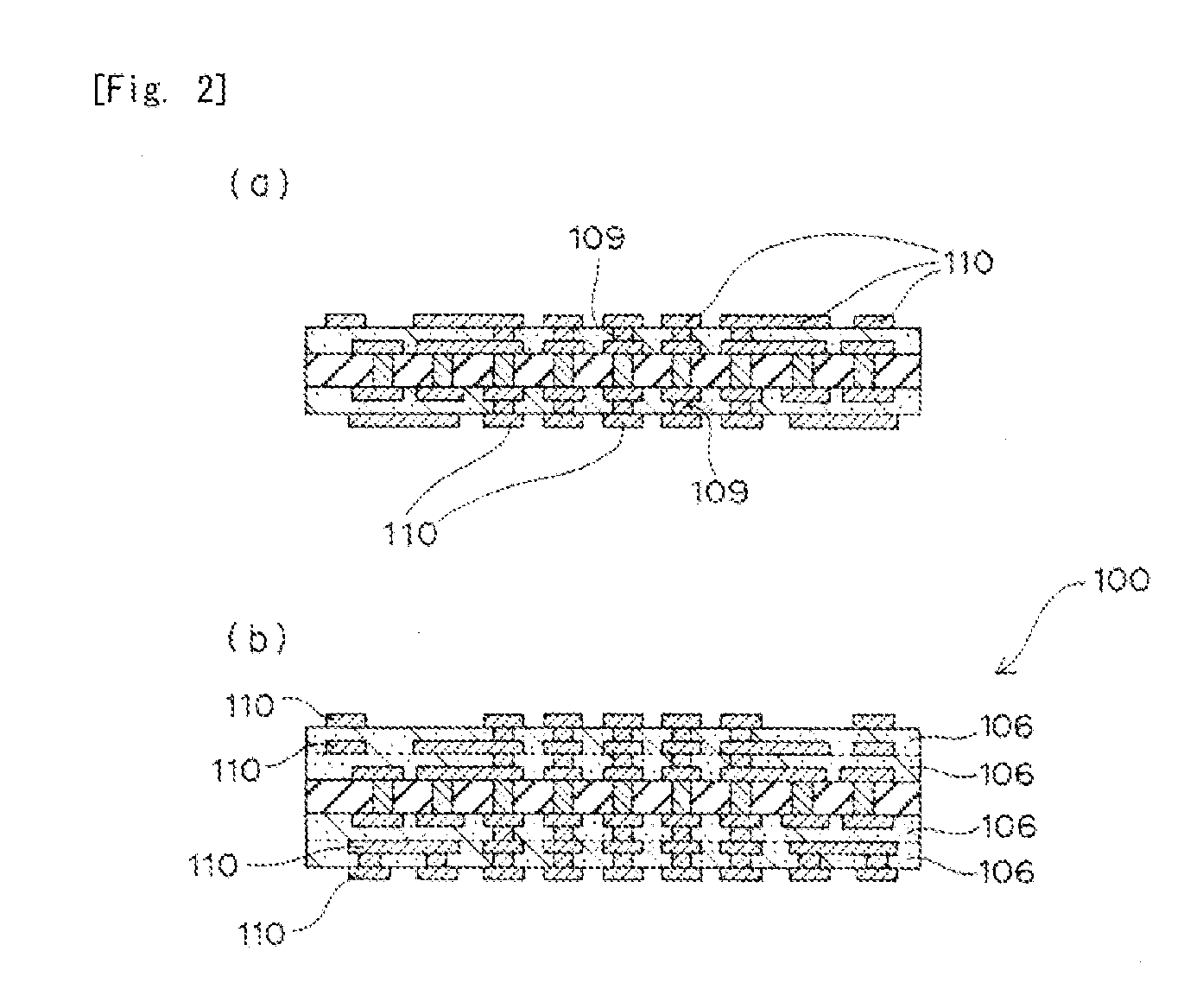

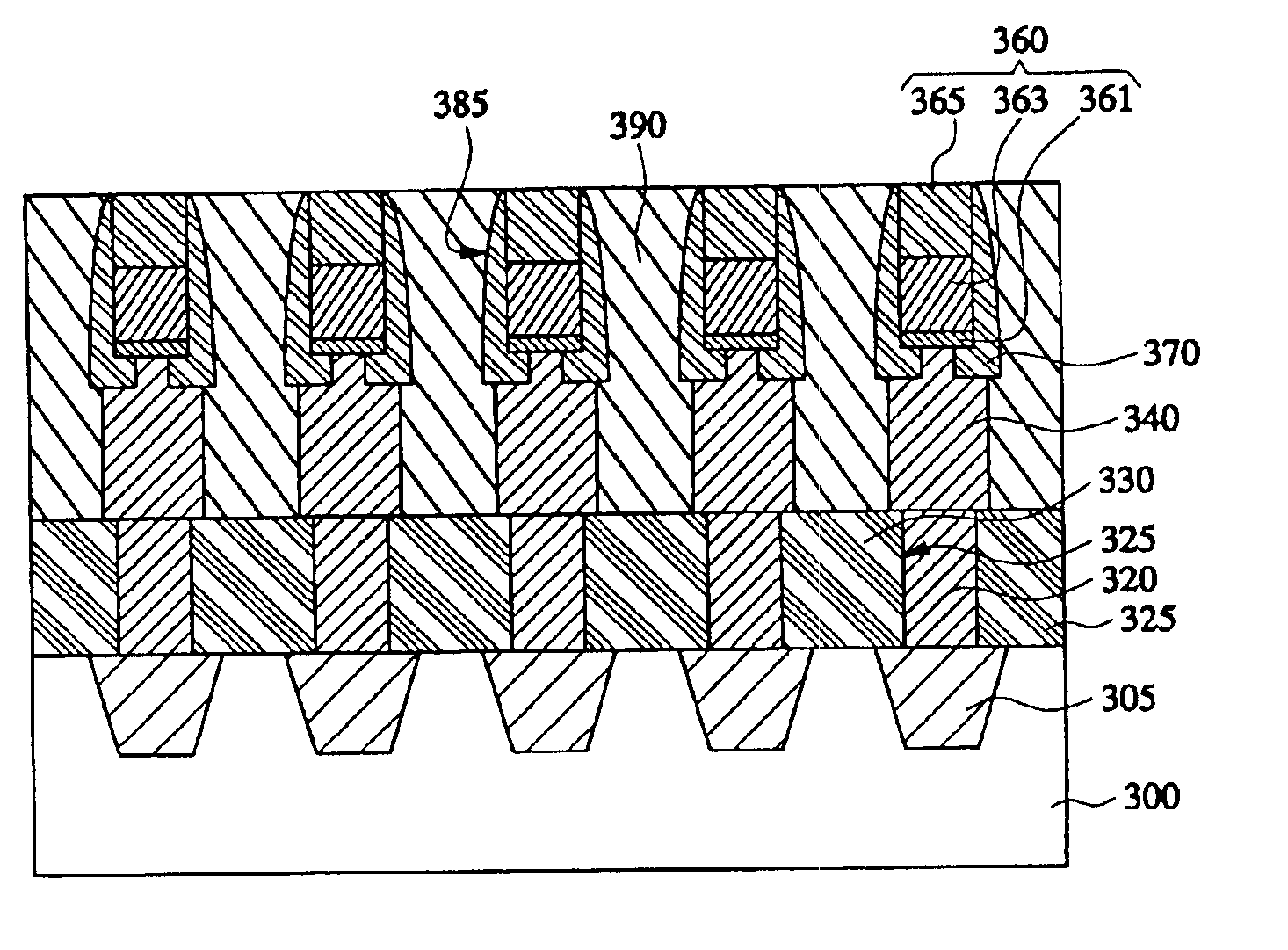

Built-up substrate, method for manufacturing same, and semiconductor integrated circuit package

ActiveUS20140124777A1Improve insulation reliabilityPrecise positioningDielectric materialsSemiconductor/solid-state device detailsEngineeringSemiconductor

A method for manufacturing a build-up substrate, the build-up substrate comprising an insulating layer and a wiring pattern layer stacked over a circuit substrate, said method comprising the steps of: (i) applying a photoactive metal oxide precursor material to one or both sides of the circuit substrate with a wiring pattern, and drying the applied photoactive metal oxide precursor material to form an insulating film; (ii) forming an opening for a via hole in the insulating film by exposure and development of the insulating film; (iii) applying a heat treatment to the insulating film to convert the insulating film into a metal oxide film, thereby forming a build-up insulating layer of the metal oxide film; and (iv) plating the build-up insulating layer to form via holes in the openings, forming a metal layer on the build-up insulating layer, and etching the metal layer to form a build-up wiring pattern; and (v) repeating the steps from (i) to (iv) at least one time.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

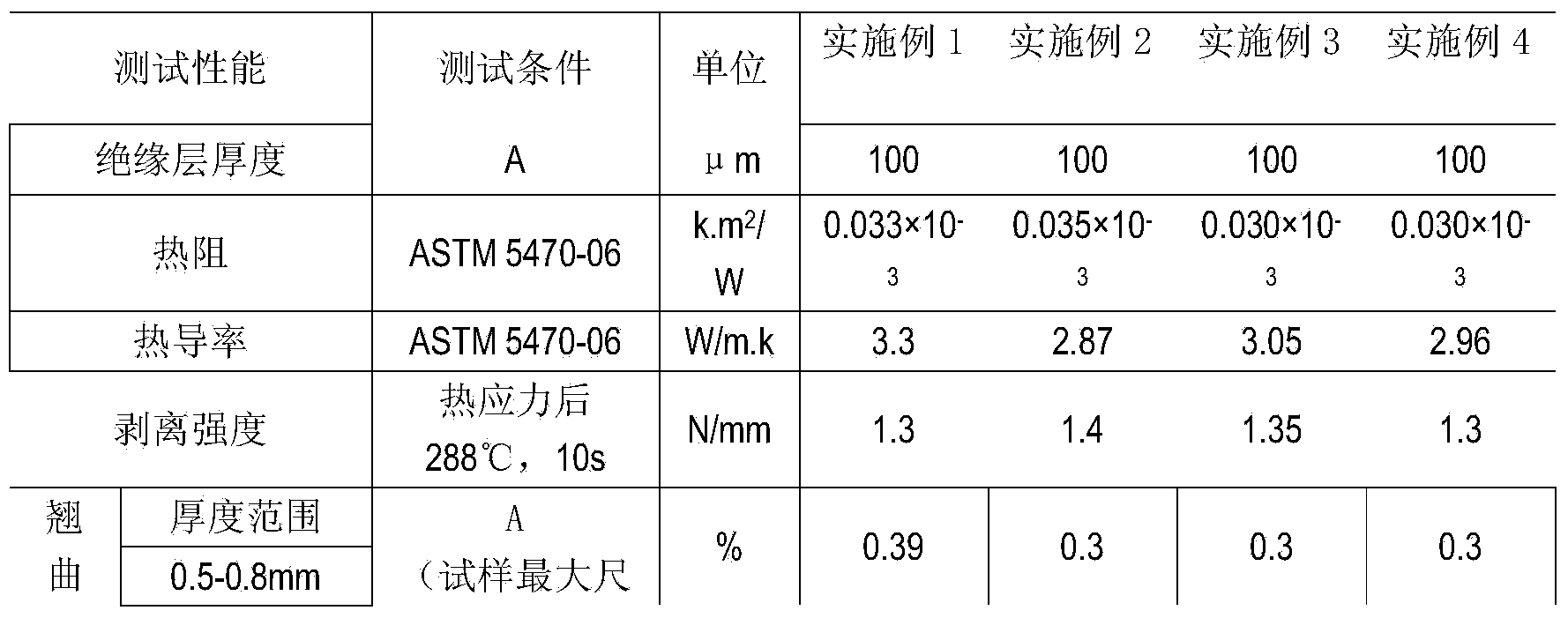

Adhesive and preparation method thereof as well as preparation technology of halogen-free aluminium base copper-clad plate based on adhesive

ActiveCN103773266AFix interface issuesSolve the problem of difficult glue applicationNon-macromolecular adhesive additivesLaminationEpoxyAdhesive

The invention discloses adhesive and a preparation method thereof as well as a preparation technology of a halogen-free aluminium base copper-clad plate based on the adhesive. The adhesive comprises an inorganic filler, KH560 and propylene glycol monomethyl ether, wherein the weight of the KH560 accounts for 0.5%-1% of the total weight of the inorganic filler, and the KH560 and the propylene glycol monomethyl ether are mixed according to a mass ratio being 1: 1; and the inorganic filler is one or combination of several of aluminium oxide, aluminium nitride and boron nitride which are different in grain diameters and are spherical or irregular. The preparation method and the preparation technology have the advantages that the interfacial problem between expoxy resin and the inorganic filler is solved by pretreating the filler, so that the addition rate of the filler in an adhesive system is increased, the heat conductivity of an insulating layer is also obviously improved, and a technology of using silk-screen printing for coating an aluminium plate solves the problem that a thick copper foil aluminium substrate obtained by using a conventional technology is difficult to glue.

Owner:SHAANXI SHENGYI TECH

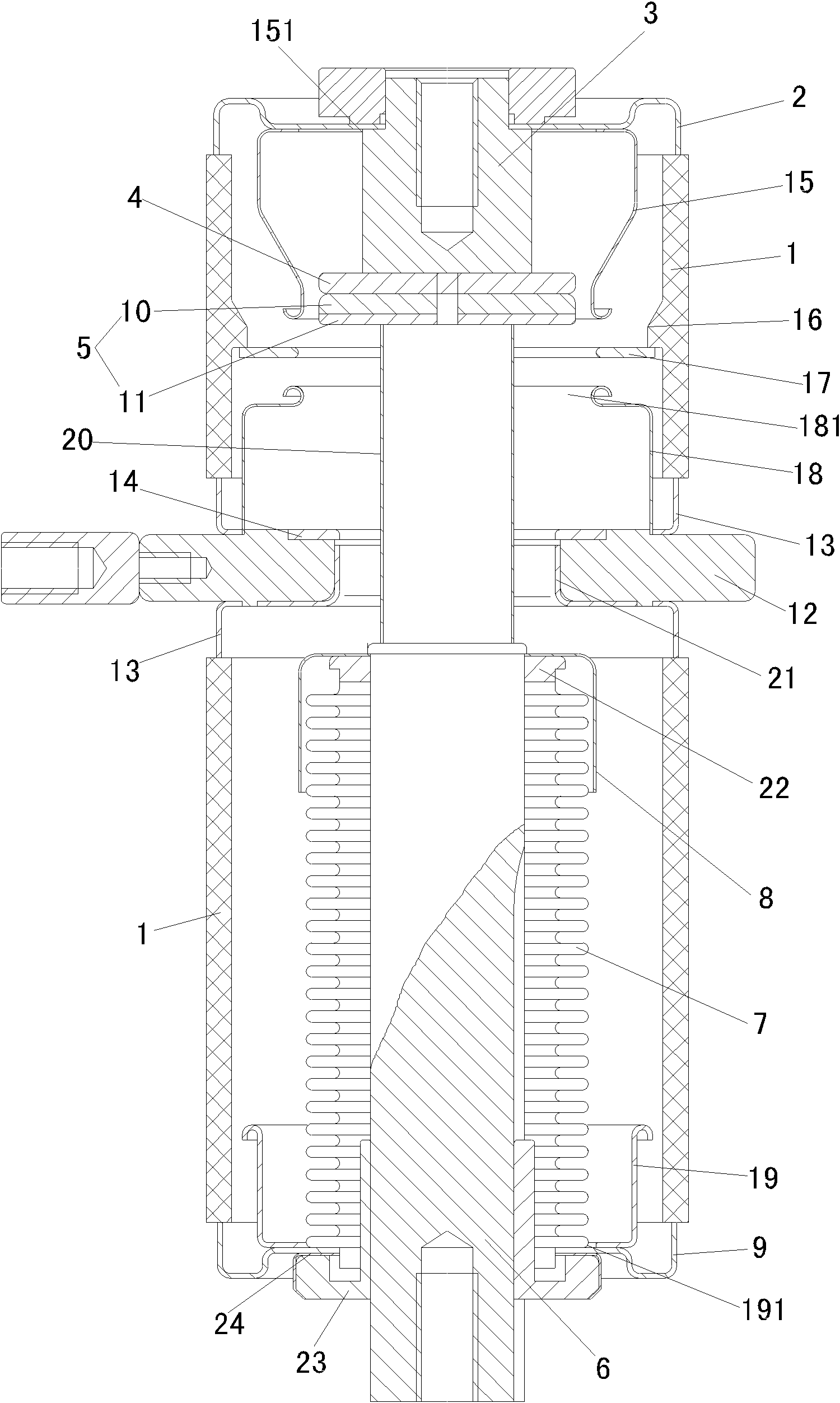

Three-station vacuum arc extinguish chamber for all-solid switch cabinet

ActiveCN101789328AImprove insulation reliabilityHigh dielectric strengthHigh-tension/heavy-dress switchesAir-break switchesGround contactEngineering

The invention discloses a three-station vacuum arc extinguish chamber for an all-solid switch cabinet, which is mainly applied to a medium-voltage power switchgear. The three-station vacuum arc extinguish chamber for the all-solid switch cabinet comprises an insulating shell, fixed and moveable cover plates, fixed and movable end conducting rods, fixed and moveable contacts, a corrugated tube and a protection cover, wherein the fixed and movable cover plates are arranged at the upper and lower ends of the insulating shell respectively; the fixed cover plate is welded on the upside of the fixed end conducting rod, while the fixed contact is welded on the downside; the moveable contact is welded by a movable isolating contact and a movable grounding contact; the middle part of the insulating shell is provided with a ground ring; the upper and lower surfaces of the ground rings are connected with the insulating shell by sealing rings; a fixed ground contact is welded on the upper surface of the ground ring; a cover-shaped fixed end isolating shield is welded on the lower surface of the fixed cover plate, a middle isolating shield is welded on the ledge lower surface at the upper part of an inner chamber of the insulating shell and the upper surface of the ground ring is provided with a ground isolating shield; one end of the moveable end conducting rod runs through the movable cover plate, the corrugated tube, the ground and middle and fixed end isolating shields and then is connected with the movable ground contact; and a movable end grading shield is welded on the upper surface of the movable cover plate. The three-station vacuum arc extinguish chamber specific for the all-solid switch cabinet has the advantages of simple structure and low cost.

Owner:BEIJING SOJO ELECTRIC

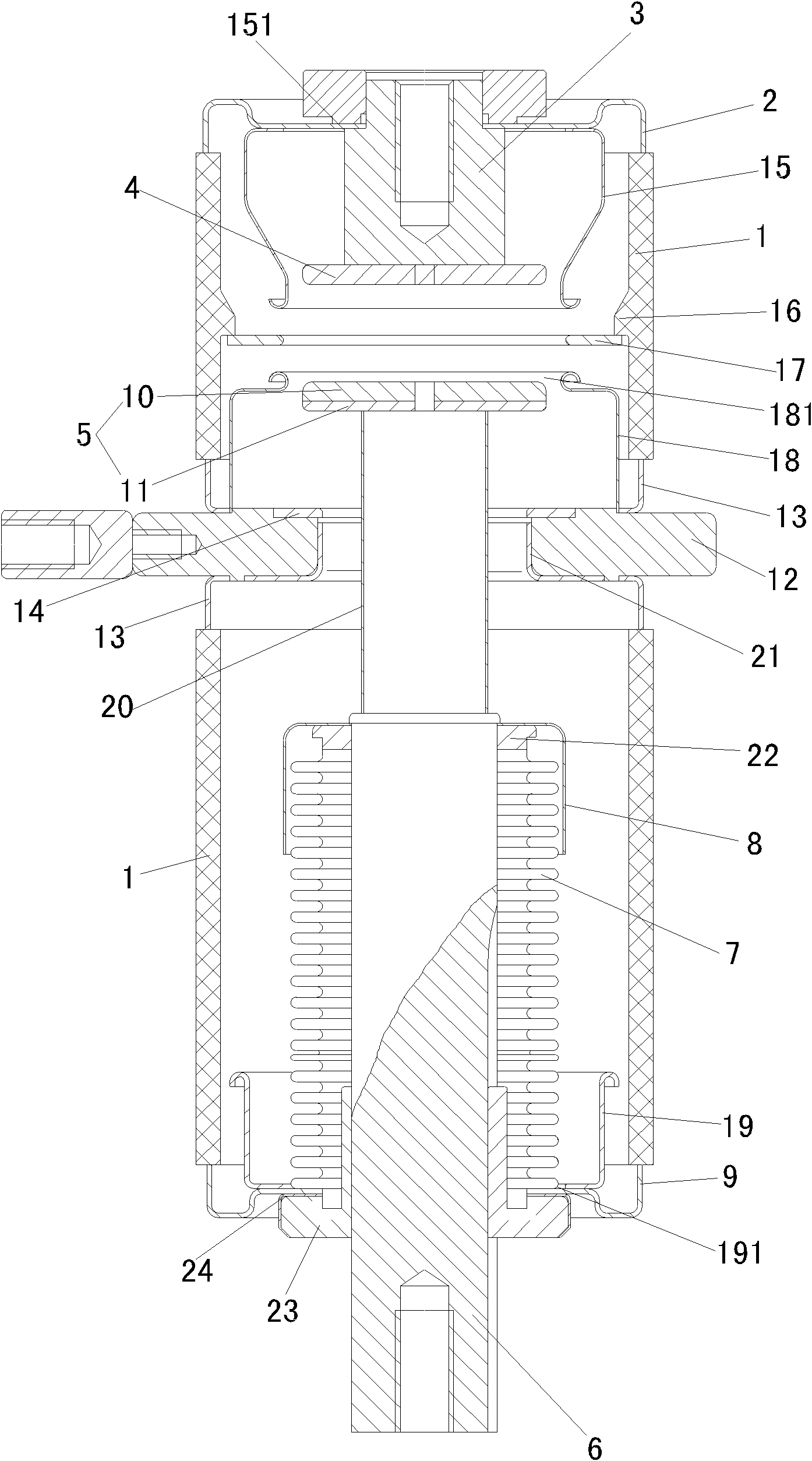

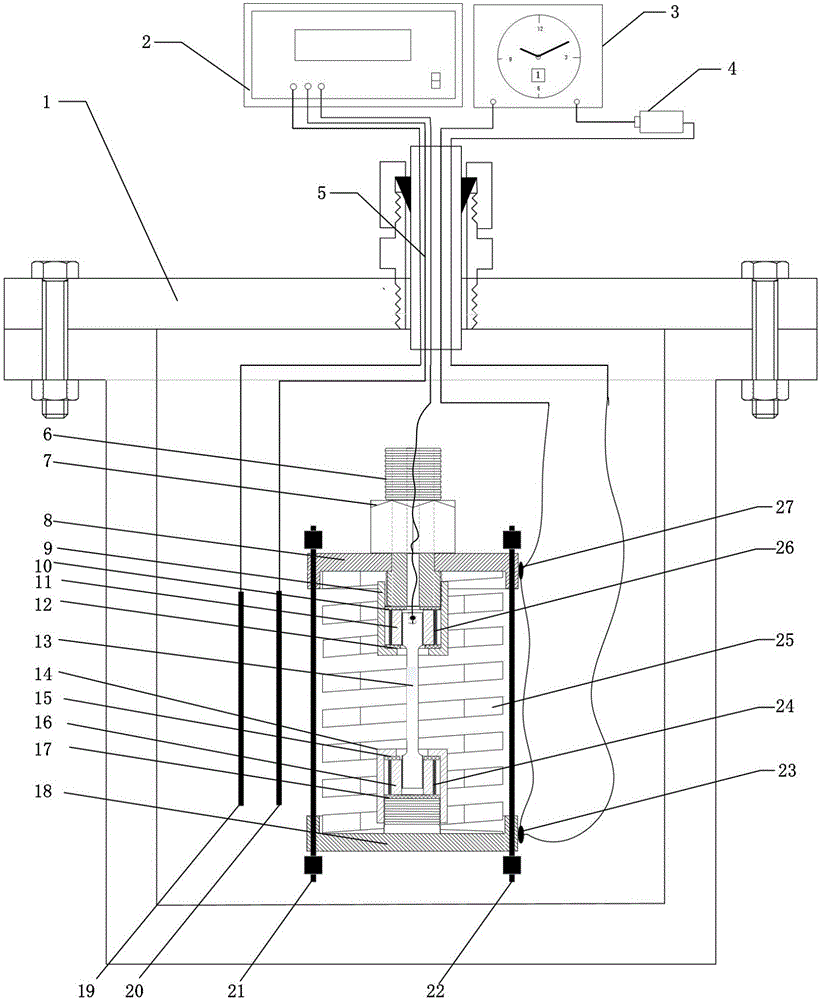

Device for testing stress corrosion behavior of metal material under fluid high pressure

ActiveCN106442136AImprove insulation reliabilitySolve the problem of high stress conduction sealing requirementsWeather/light/corrosion resistanceNuclear energy generationAdhesiveAuxiliary electrode

The invention provides a device for testing the stress corrosion behavior of a metal material under fluid high pressure, belonging to the technical field of metal material test equipment. The device comprises a high-pressure kettle, an electrochemical workstation, a timer, a bundled wire, a stud, a loading nut, a loading device top plate, a closed threaded sleeve, a high-strength insulating spacer, a threaded sleeve, a loading device bottom plate, an auxiliary electrode, a reference electrode, a steel wire rope, a powerful instant adhesive, an insulating coating layer and a rectangular spring and is used for testing the stress corrosion behavior of the metal material under fluid high pressure. The loading way is a constant-load loading way which is implemented by a spring and the stress magnitude of which can be conveniently adjusted. The device can solve the problems of high requirement on stress conduction air tightness between the loading equipment and the high-pressure kettle in the prior art, inconvenience in adjusting the loading stress and electrochemical performance study in a stress corrosion test process of a high-pressure environment.

Owner:UNIV OF SCI & TECH BEIJING

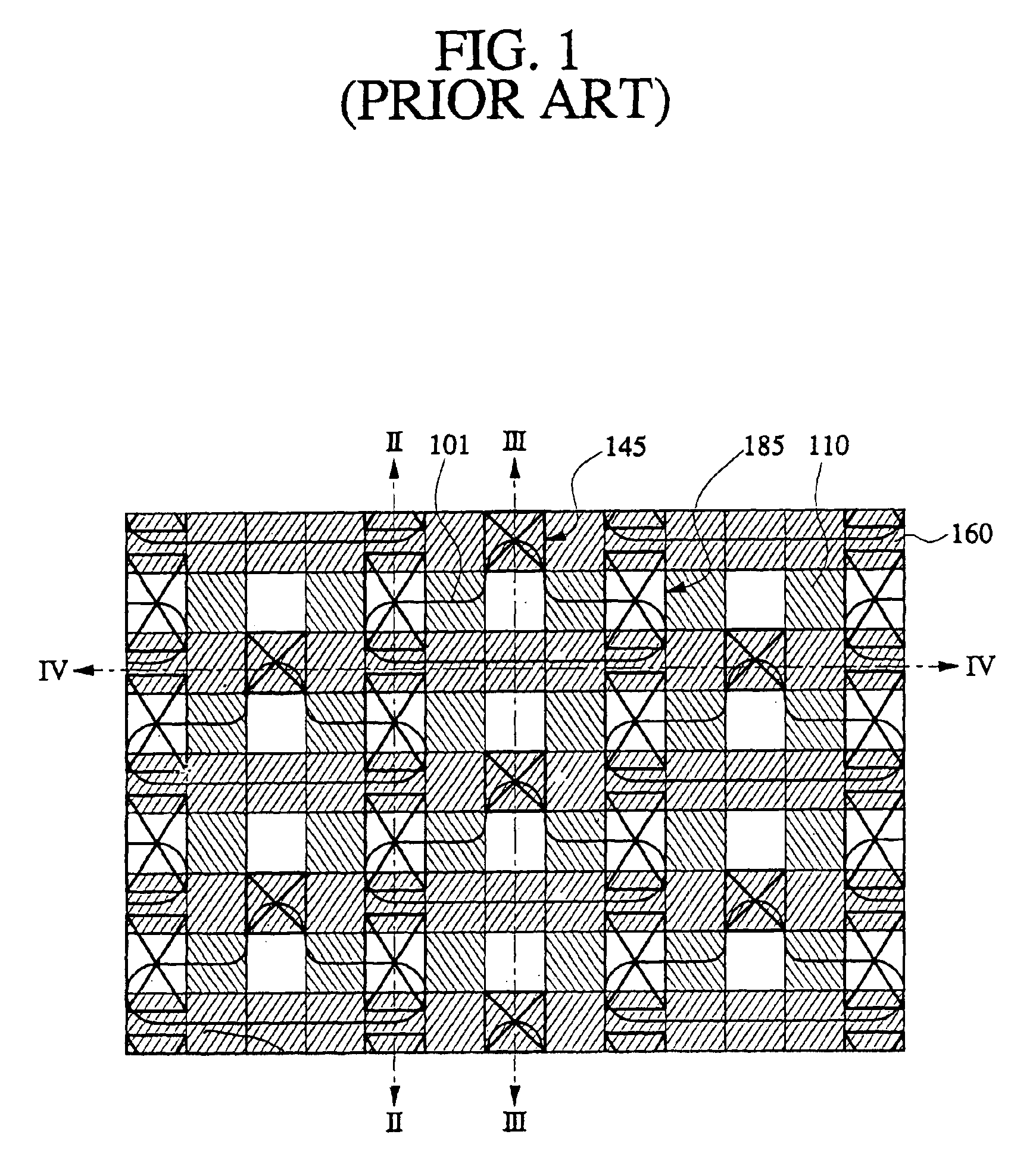

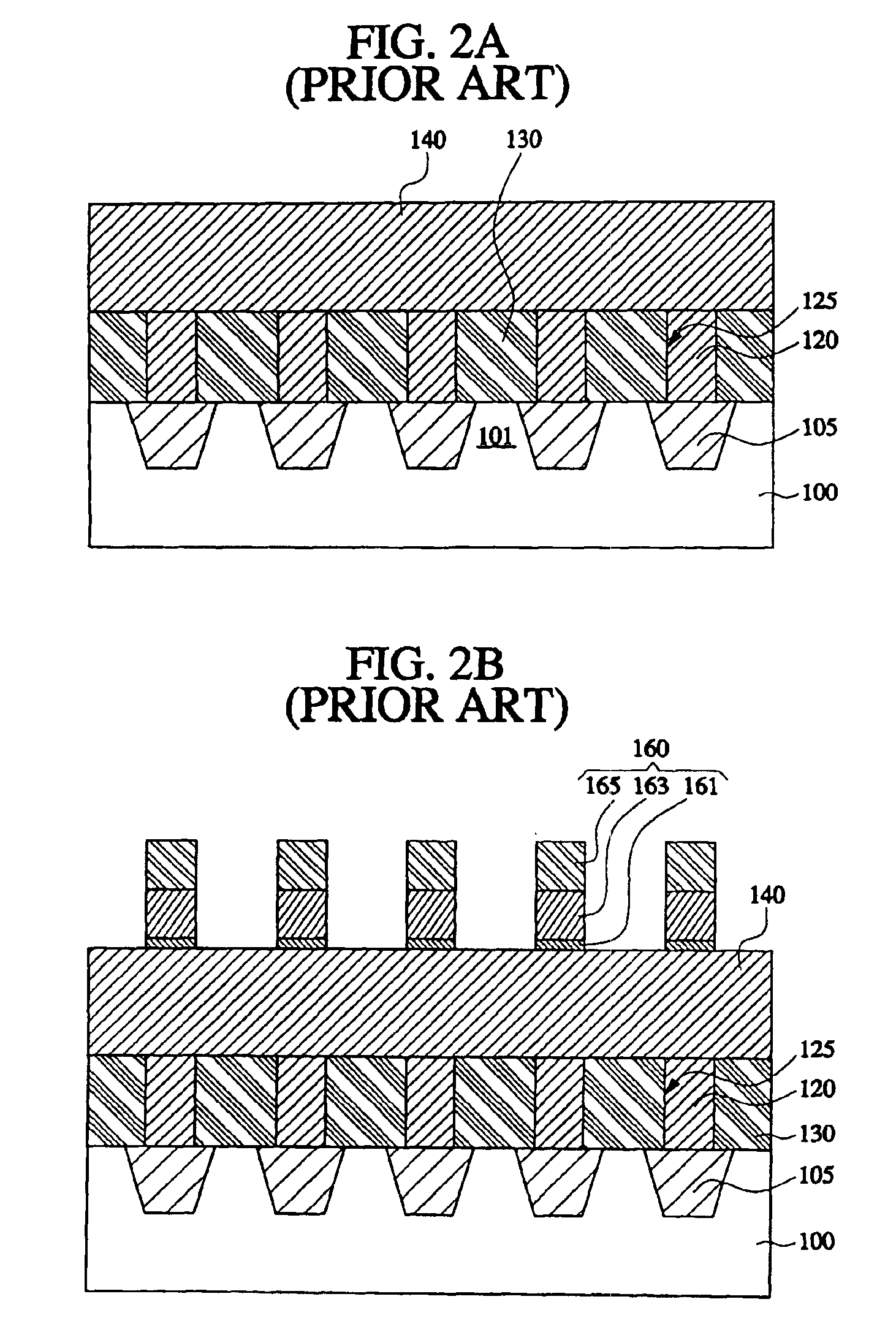

Integrated circuits including insulating spacers that extend beneath a conductive line

InactiveUS6930341B2Improve insulation reliabilityTransistorSemiconductor/solid-state device detailsIntegrated circuit

Integrated circuit devices are fabricated by fabricating a conductive line on an insulating layer on an integrated circuit substrate. The conductive line includes a bottom adjacent the insulating layer, a top remote from the insulating layer and first and second sidewalls therebetween. An insulating spacer is formed to extend along the first and second sidewalls and to also extend along at least a portion of the bottom between the conductive line and the insulating layer. By providing an insulating spacer beneath at least a portion of the conductive line, insulation reliability may be improved even as the spacer may become narrower and / or the contact area may be enlarged.

Owner:SAMSUNG ELECTRONICS CO LTD

Composition for forming silver ion diffusion-suppressing layer, film for silver ion diffusion-suppressing layer, circuit board, electronic device, conductive film laminate, and touch panel

ActiveUS20150014030A1Improve insulation reliabilitySuppresses silver ion migrationPlastic/resin/waxes insulatorsSynthetic resin layered productsMetal interconnectAlloy

A composition for forming a silver ion diffusion-suppressing layer includes an insulating resin and a compound including: a structure selected from the group consisting of a triazole structure, a thiadiazole structure and a benzimidazole structure; a mercapto group; and at least one hydrocarbon group optionally containing a heteroatom, with the total number of carbon atoms in the hydrocarbon group or groups being 5 or more. The composition for forming a silver ion diffusion-suppressing layer allows formation of a silver ion diffusion-suppressing layer capable of suppressing silver ion migration between metal interconnects containing silver or a silver alloy to improve the reliability on the insulation between the metal interconnects.

Owner:FUJIFILM CORP

Ceramic electronic component

ActiveCN101783243AImprove insulation reliabilityStacked capacitorsFixed capacitor terminalsElectronic componentElectrode

Owner:TDK CORPARATION

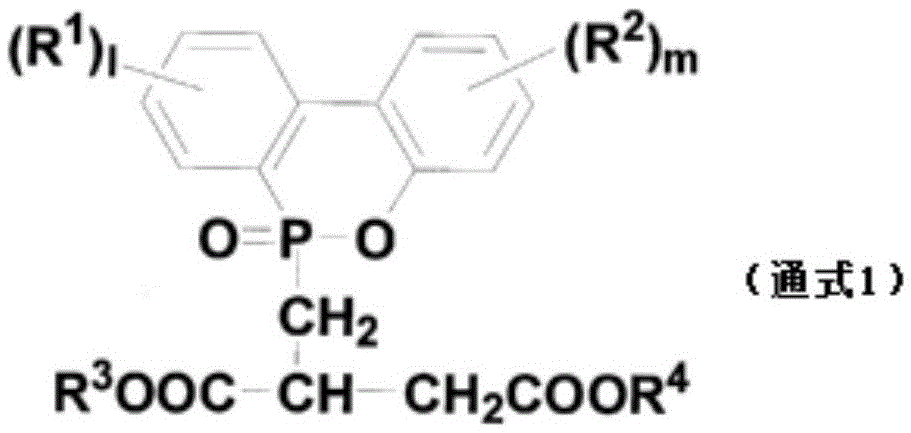

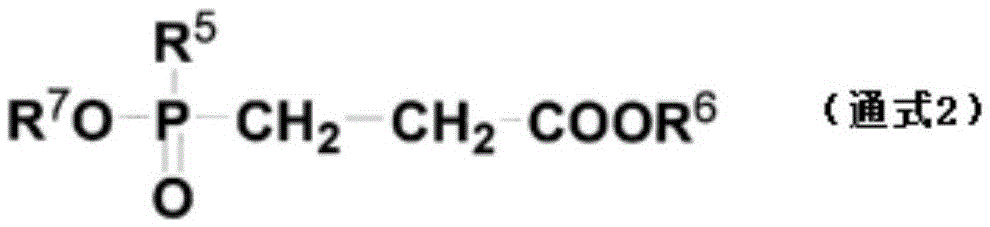

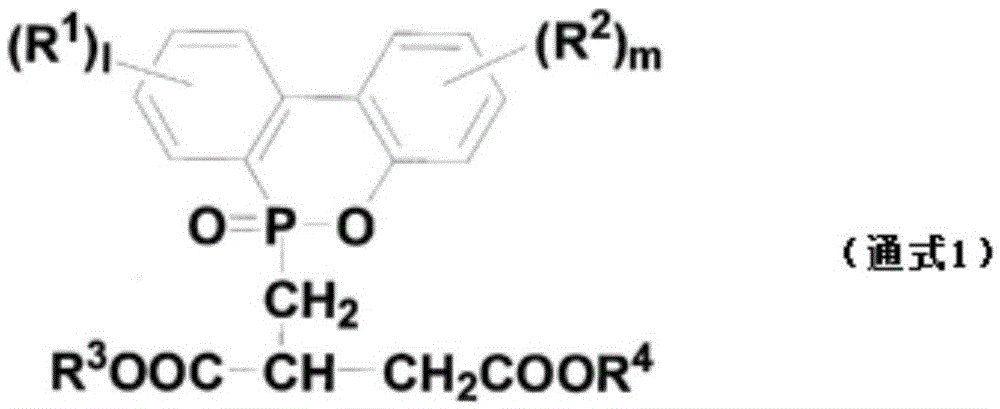

Polyurethane resin composition and adhesive composition, laminate, and printed wiring board using same

ActiveCN105492534AExcellent insulation reliabilityImprove adhesionNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAntimonyHydrocarbon

The present invention provides a polyurethane resin composition having high adhesiveness to various plastic films and metals, high moist heat resistance that can even accommodate soldering after humidification, and excellent flame retardancy without using any halogen or antimony, and an adhesive composition, laminate, and printed wiring board that use the polyurethane composition. A polyurethane resin composition containing a polyurethane resin (A) that satisfies (1)-(3) and an epoxy resin (B). (1) Includes a polyester polyol containing a phosphorus compound residue represented by general formula (1) or general formula (2) as a structural component; (2) an acid value (unit: Eq / 106 g) of from 50 to 1000; (3) a urethane group concentration (unit: Eq / 106 g) of from 100 to 600 (R1 and R2 are each independently a hydrogen atom or hydrocarbon group, R3 and R4 are each independently a hydrogen atom, hydrocarbon group, or hydroxy group-substituted hydrocarbon group, and l and m are integers of 0 to 4.) (R5 is a hydrogen atom or hydrocarbon group, and R6 and R7 are each independently a hydrogen atom, hydrocarbon group, or hydroxy group-substituted hydrocarbon group.)

Owner:TOYO TOYOBO CO LTD

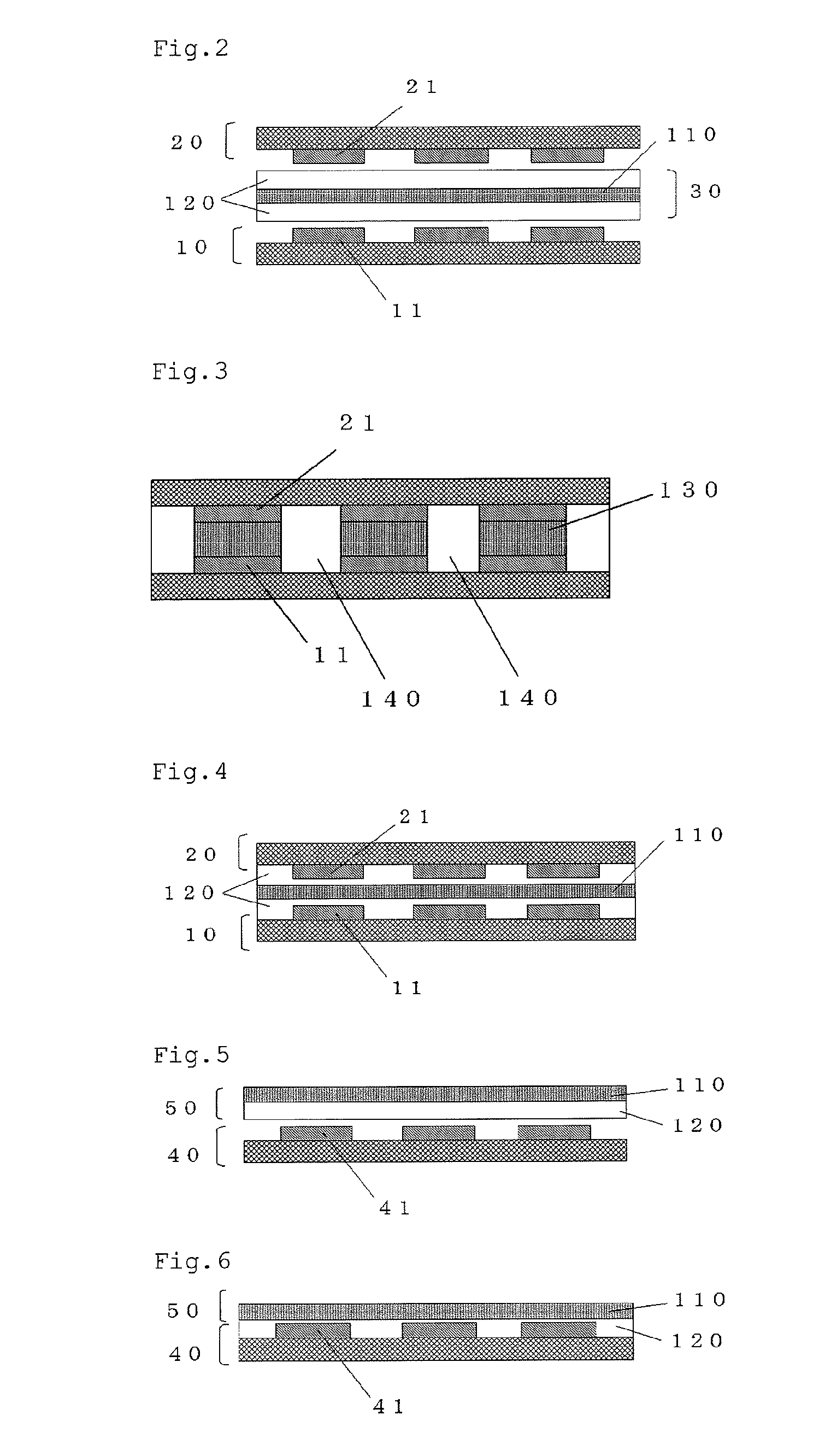

Conductive connecting material, method for producing electronic component, electronic member with conductive connecting material and electronic component

InactiveUS20120261174A1Improve insulation reliabilityReliable electrical connectionSingle bars/rods/wires/strips conductorsSolid-state devicesEngineeringElectronic component

Disclosed is a conductive connecting material 30 used to form conductive portions on a plurality of terminals 11 of an electronic member having a substrate 10 and the plurality of terminals 11 provided on the substrate 10, comprising a metal layer 110 and a resin layer 120 having a resin component and a filler, in which the metal layer is aggregated on each of terminals to form the conductive portions on the plurality of terminals by bringing the conductive connecting material into contact with the plurality of terminals and heating the conductive connecting material.

Owner:SUMITOMO BAKELITE CO LTD

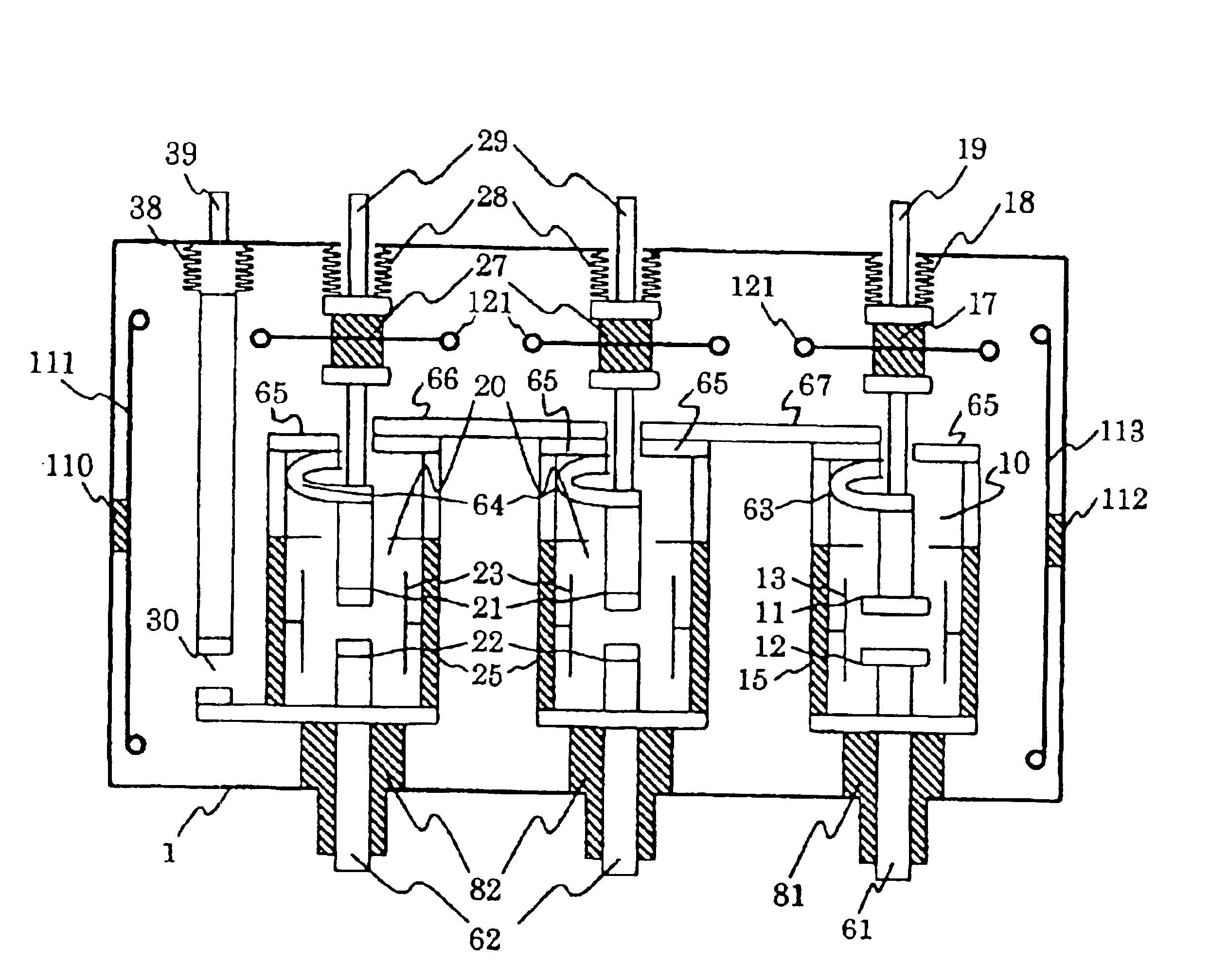

Vacuum switchgear

InactiveUS6884940B1Improve insulation reliabilityAvoid damageMagnetic/electric field screeningConductive materialForeign matterElectrical conductor

A main circuit switching unit and an isolator are accommodated in a vacuum container. A first conductor and a main circuit conductor are arranged to extend in and out of the vacuum container. A movable electrode of the main circuit switching unit is connected to the first conductor through a first flexible conductor, and a movable electrode of the isolator is connected to the main circuit conductor through a second flexible conductor. A shield is arranged around the first conductor and the main circuit conductor. Another shield is arranged around a connecting portion between the first flexible conductor and the movable electrode of the main circuit switching unit. A still another shield is arranged around the isolator. A further another shield is arranged around the second flexible conductor. These shields are secured to the vacuum container through insulating spacers. This arrangement instantly eliminates a dielectric breakdown phenomenon that occurs at electric field concentrated regions by the shields to prevent a dielectric breakdown caused by particulate foreign matters and thereby improve an insulation reliability of the devices.

Owner:HITACHI LTD

Metal-film-coated material and process for producing the same, metallic-pattern-bearing material and process for producing the same, composition for polymer layer formation, nitrile group-containing polymer and method of synthesizing the same, composition containing nitrile group-containing polymer, and laminate

InactiveUS20090214876A1Improve adhesionLess fluctuationSynthetic resin layered productsLiquid/solution decomposition chemical coatingPolymer sciencePtru catalyst

A process for producing a metal film-coated material, the process including: (a1) forming, on a substrate, a polymer layer formed from a polymer which has a functional group capable of interacting with a plating catalyst or a precursor thereof, and is directly chemically bonded to the substrate; (a2) providing a plating catalyst or a precursor thereof to the polymer layer; and (a3) performing plating with respect to the plating catalyst or a precursor thereof. The polymer layer satisfies all of the following requirements (1) to (4): (1) the saturated water absorption coefficient of the polymer layer as measured in an environment of temperature of 25° C. and relative humidity of 50% is 0.01 to 10% by mass; (2) the saturated water absorption coefficient of the polymer layer as measured in an environment of temperature of 25° C. and relative humidity of 95% is 0.05 to 20% by mass; (3) the water absorption coefficient of the polymer layer as measured after 1 hour of immersion in boiling water at 100° C. is 0.1 to 30% by mass; and (4) the surface contact angle of the polymer layer as measured after dropping 5 μL of distilled water thereonto and leaving to stand for 15 seconds in an environment of temperature of 25° C. and relative humidity of 50% is 50 to 150 degrees.

Owner:FUJIFILM CORP

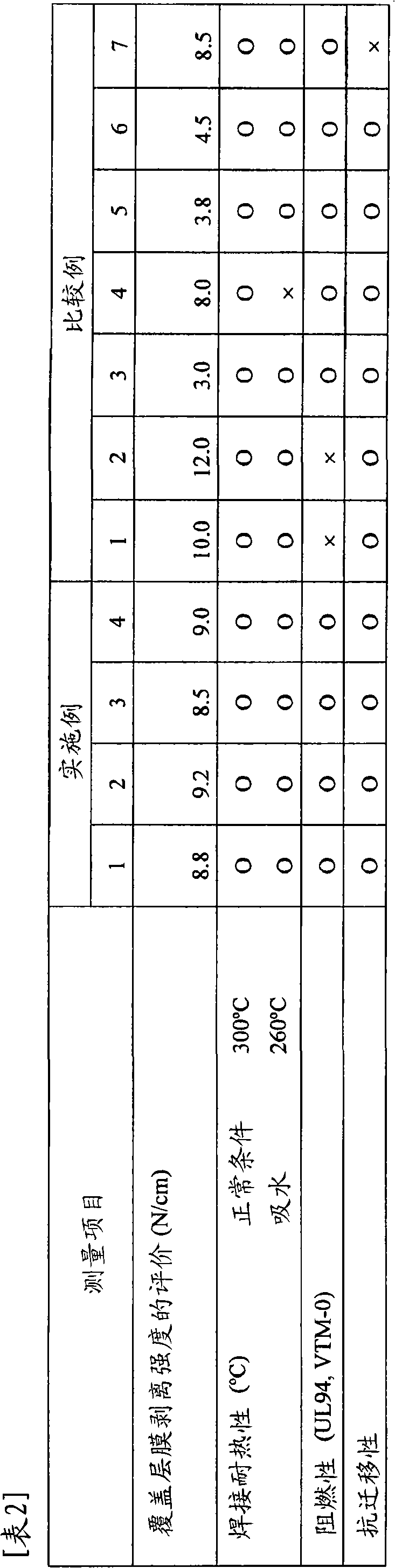

Fire retardant adhesive composition and covering layer film using the same

InactiveCN101314705AImprove flame retardant performanceImprove adhesionNon-macromolecular adhesive additivesFilm/foil adhesivesHydrogen atomHalogen

This invention refers to a fire resistance bond composite and a covering layer film using the same. The fire resistance bond composite without halogen atoms and phosphorus atoms is provided. The composite contains: (A) 100 parts by weight of an epoxide resin without halogen, wherein if the number of the carbon atoms in the aliphatic radical of epoxide resin is a, and the number of carbon atoms in the aromatic radical of the epoxide resin is b, then b / a is not smaller than 2.0, (B) 15 to 70 parts by weight of aromatics rubber with active functional group; (C) 1 to 20 parts by weight of firming agent and (D) 10 to 70 parts by weight of inorganic filling material. This composite has excellent fire resistance, thermal stability and anti-transference property, and a covering layer film using the composite is further provided.

Owner:SHIN ETSU CHEM IND CO LTD

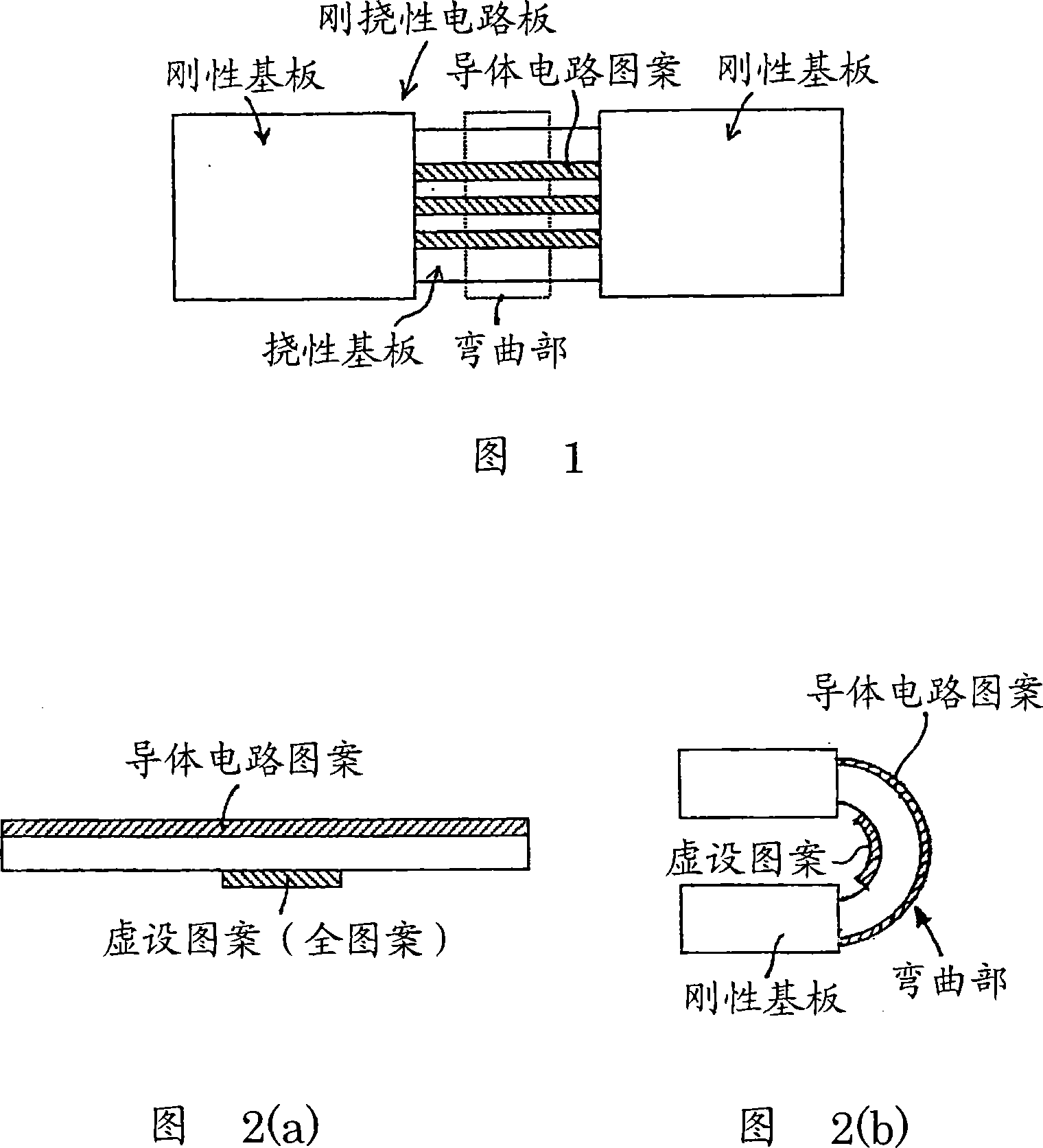

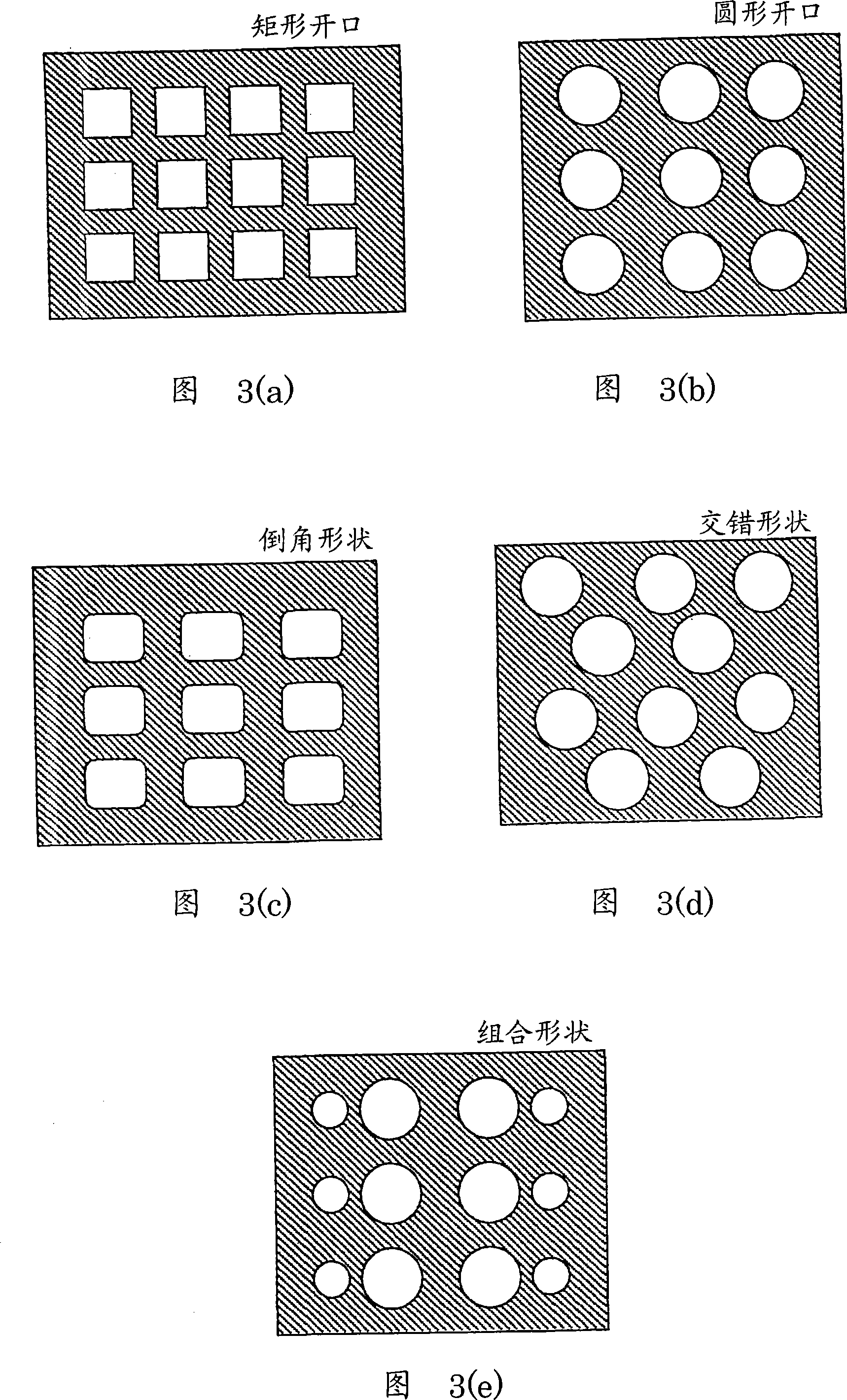

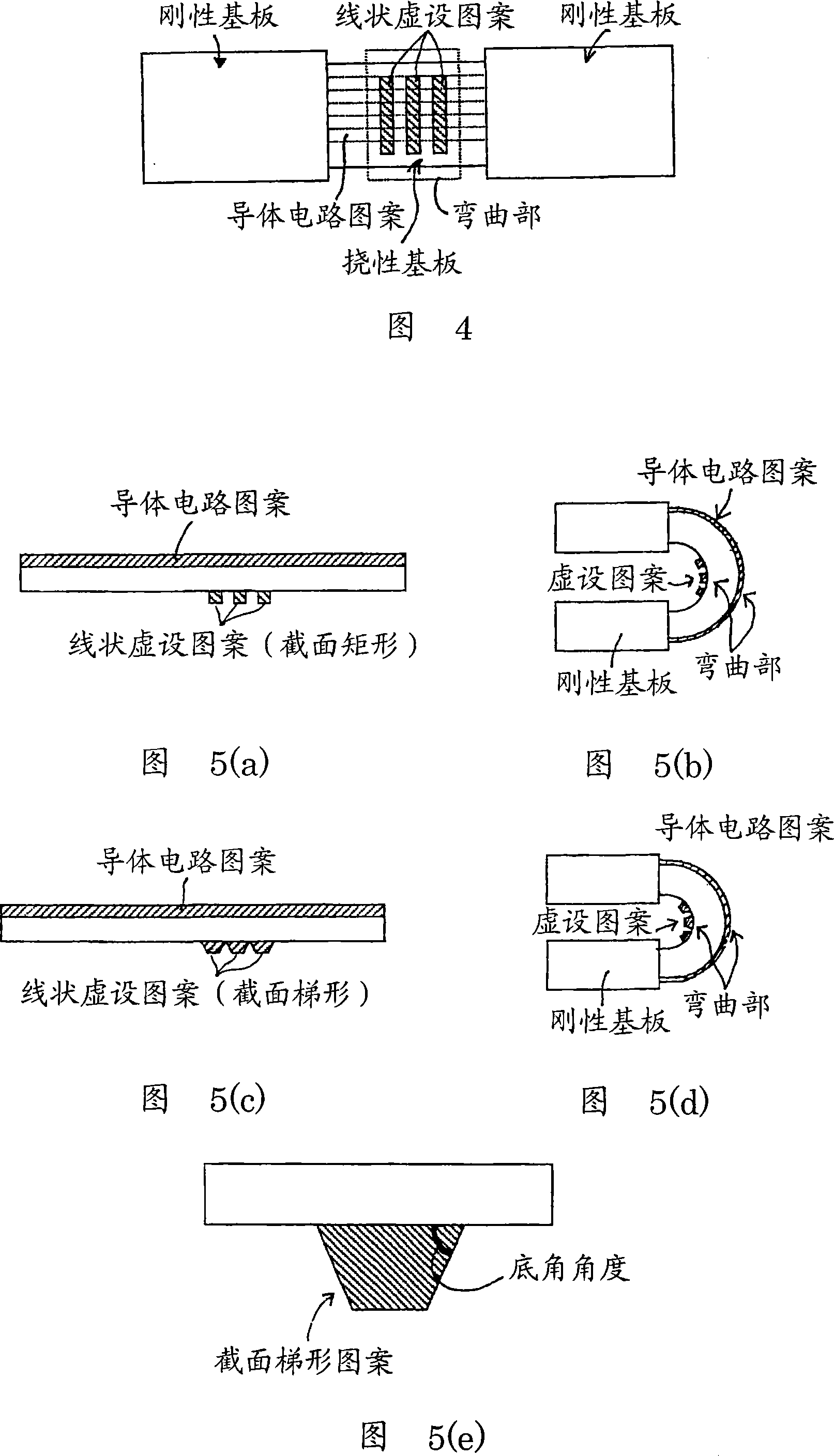

Flex-rigid wiring board and manufacturing method thereof

InactiveCN101002511AImprove insulation reliabilityImprove connection reliabilityCircuit bendability/stretchabilityPrinted circuit aspectsGlass fiberElectrical conductor

A flex-rigid wiring board having excellent connection reliability and a manufacturing method thereof are provided. A flex-rigid wiring board is provided by connecting a hard rigid board wherein a conductor circuit is provided on an insulating board, and a bendable flexible board wherein a conductor circuit is provided on an insulating board and a coverlay is provided to cover the conductor circuit. As an insulating base material of the flexible board, a bendable base material provided by impregnating a glass cloth with a resin and drying it is employed. On one surface of the flexible board, the conductor circuit is formed, and on the other surface, a dummy pattern is formed close to a bending part. Thus, base material deformation easily generated close to the bending part, conductor circuit disconnection, wave formation and the like can be prevented. The equivalent effects can be obtained by increasing the width of a wiring pattern of the conductor circuit or by curving the wiring pattern in the width direction, at the bending part on the flexible board.

Owner:IBIDEN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com