Resin composite and prepreg and laminate materials used thereof

A technology of resin composition and laminated materials, which is applied in the direction of synthetic resin layered products, layered products, chemical instruments and methods, etc., can solve the problems of insufficient performance improvement, and achieve high industrial utility, good curability, and high resistance flammability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

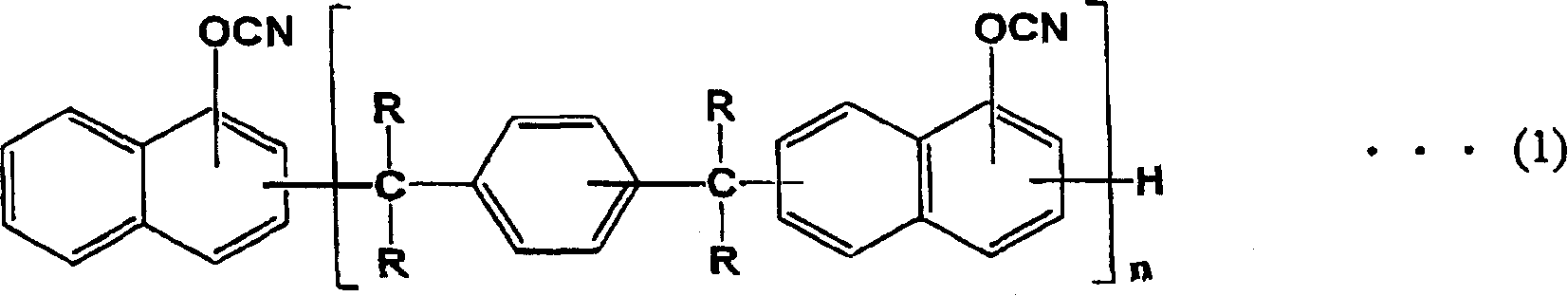

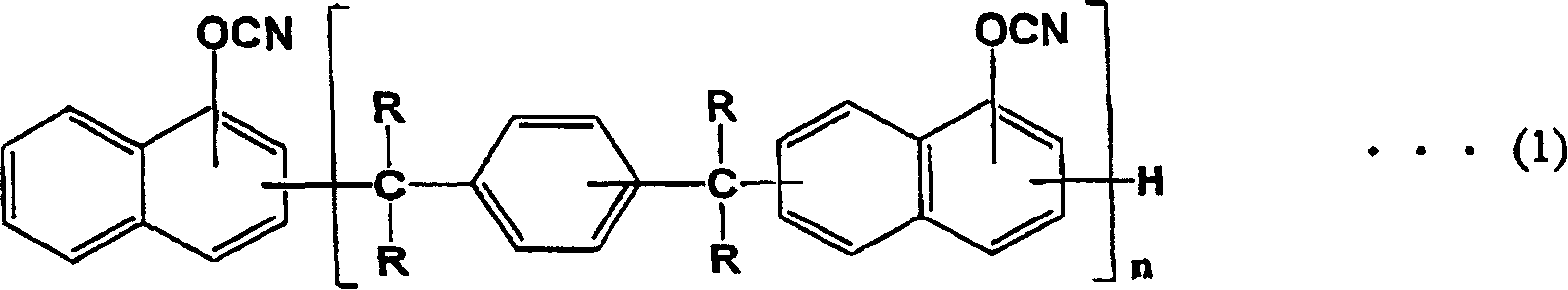

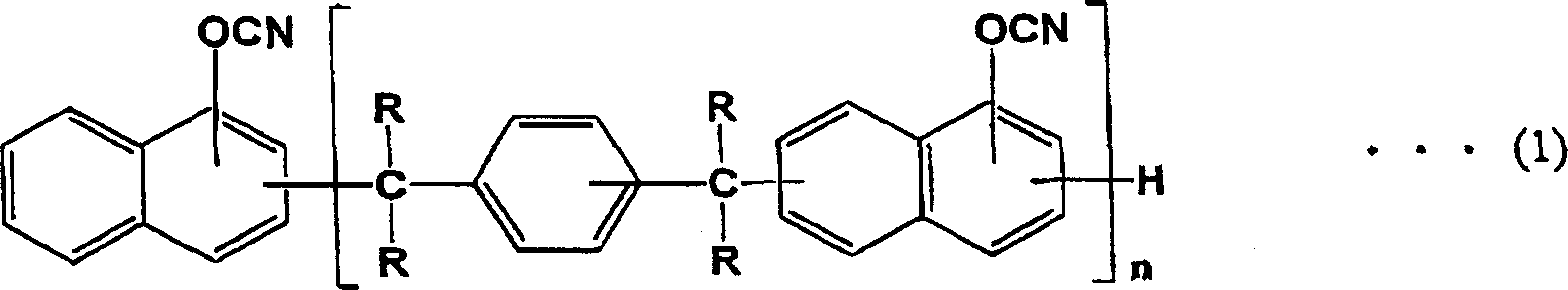

[0057] (Synthesis example 1) Synthesis of α-naphthol aralkyl cyanate ester resin

[0058]

[0059] n=1 to 5 mixture

[0060] 0.47 mol (calculated based on OH group) α-naphthol aralkyl resin (SN475L, OH group equivalent: 216g / eq.) represented by the above formula (3), manufactured by Nippon Steel Chemical Co., Ltd. Provided) Dissolve in 500 ml of chloroform, add 0.7 mole of triethylamine and mix with the resulting solution. To the mixture was added dropwise a solution of 0.93 moles of cyanogen chloride in 300 g of chloroform at -10°C over 1.5 hours. The resulting mixture was stirred for 30 minutes. Then, a mixed solution of 0.1 mole of triethylamine and 30 g of chloroform was added dropwise, and the resulting mixture was stirred for 30 minutes to complete the reaction. The generated triethylamine hydrochloride is separated by filtration. The filtrate thus obtained was washed with 500 ml of 0.1N hydrochloric acid, and then repeatedly washed with 500 ml of water 4 times. After dryi...

Embodiment 1

[0064] 70 parts by weight of α-naphthol aralkyl type cyanate resin obtained in Synthesis Example 1 and 30 parts by weight of bisphenol A type epoxy resin (Epikote 1001, provided by Japan Epoxy Resins Co., Ltd.) were dissolved in Methyl ethyl ketone, and 0.04 parts by weight of zinc octoate were mixed with the resulting solution to obtain a varnish. The varnish was diluted with methyl ethyl ketone solvent, the diluted varnish was immersed in E glass cloth with a thickness of 0.1 mm, and the immersed varnish was heated and dried at 160°C for 4 minutes to obtain a resin content of 41% by weight Of prepreg. Stack the four prepregs and place 18 micron thick electrolytic copper foils on the upper and lower surfaces of the stacked prepregs, with a copper foil on the upper surface and a copper foil on the lower surface, and the resulting Components at 30kgf / cm 2 It was pressed for 120 minutes at a temperature of 220° C. under a pressure of 4 to obtain a copper-clad laminate with a thickne...

Embodiment 2

[0066] 30 parts by weight of the α-naphthol aralkyl type cyanate resin obtained in Synthesis Example 1 and 45 parts by weight of brominated phenol novolac type epoxy resin (BREN-S, provided by Nippon Kayaku Co., Ltd) And 25 parts by weight of cresol novolac type epoxy resin (ESCN-220F, provided by Sumitomo Chemical Co. Ltd.) were dissolved in methyl ethyl ketone, and 0.04 parts by weight of zinc octoate was mixed with the resulting solution to obtain a varnish. Then, except for using the above varnish, a prepreg with a resin content of 43% by weight was obtained in the same manner as in Example 1. The subsequent procedures were performed in the same manner as in Example 1 to obtain a copper-clad laminate with a thickness of 0.4 mm. Table 1 shows the measurement results of the physical properties of the copper clad laminate material thus prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com