Patents

Literature

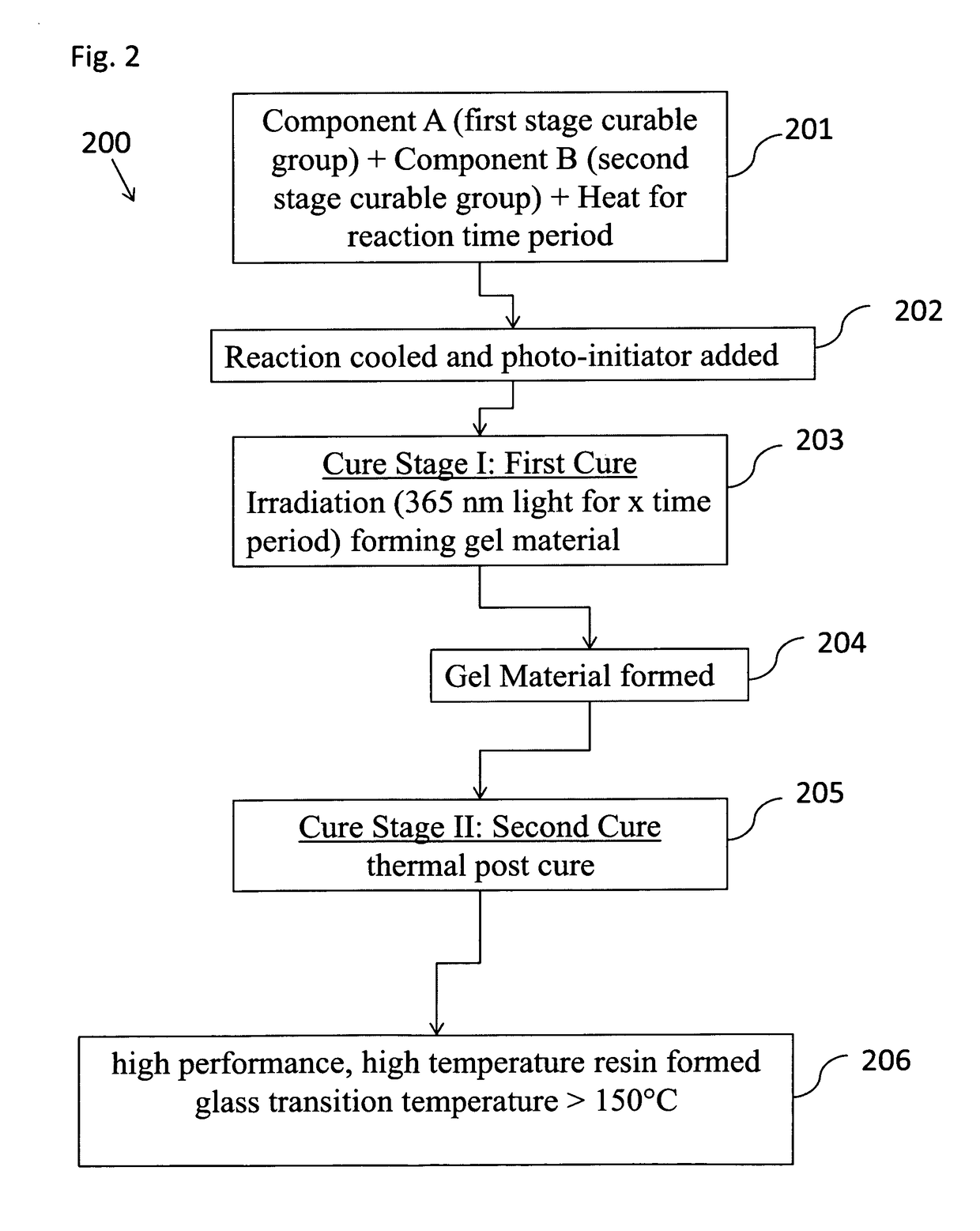

378 results about "Cyanate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The cyanate ion is the anion with the chemical formula written as [OCN]⁻ or [NCO]⁻. In aqueous solution it acts as a base, forming isocyanic acid, HNCO. The cyanate ion is an ambidentate ligand, forming complexes with a metal ion in which either the nitrogen or oxygen atom may be the electron-pair donor. It can also act as a bridging ligand. Organic cyanates are called isocyanates when there is a C−NCO bond and cyanates when there is a C−OCN bond.

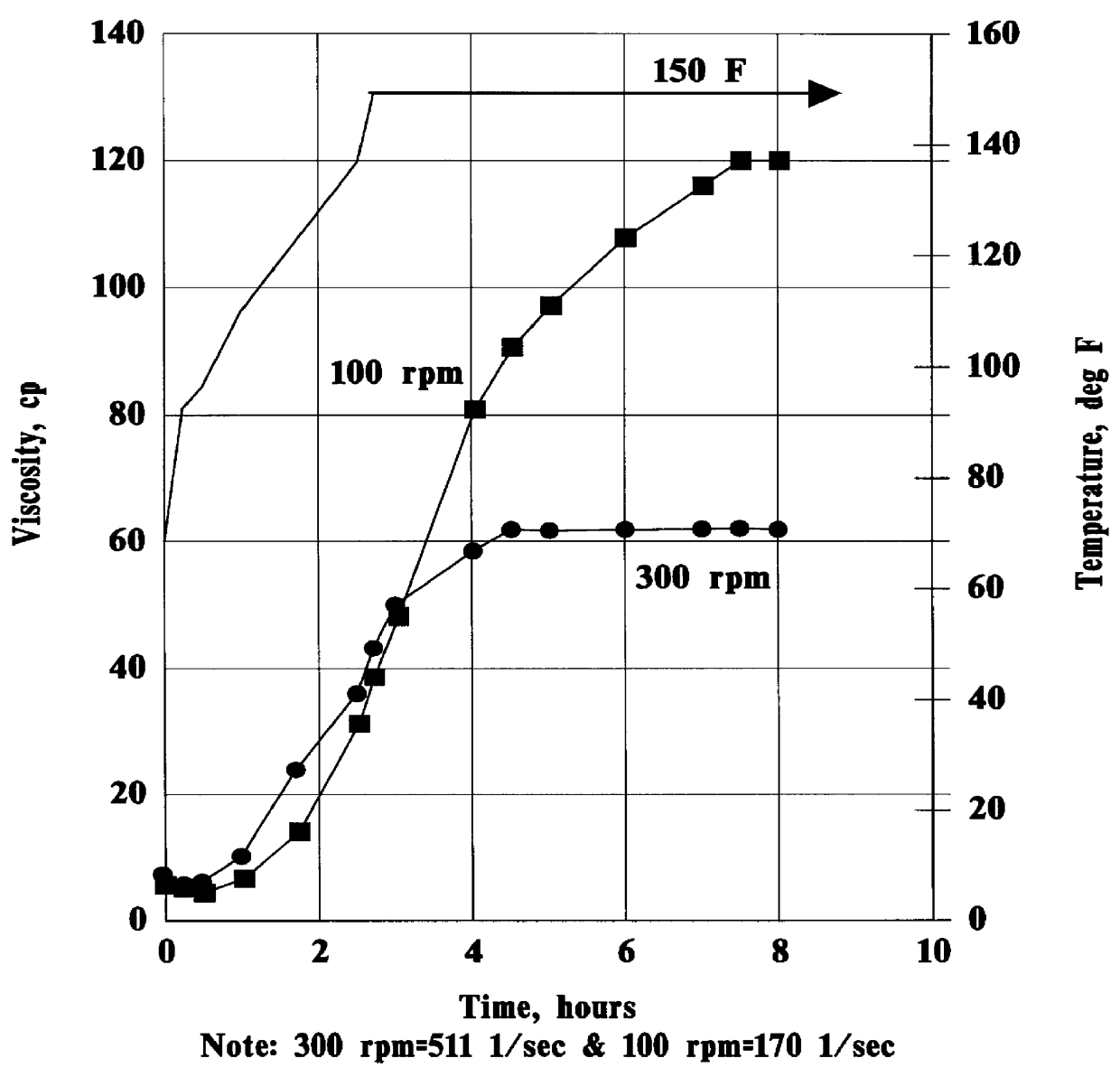

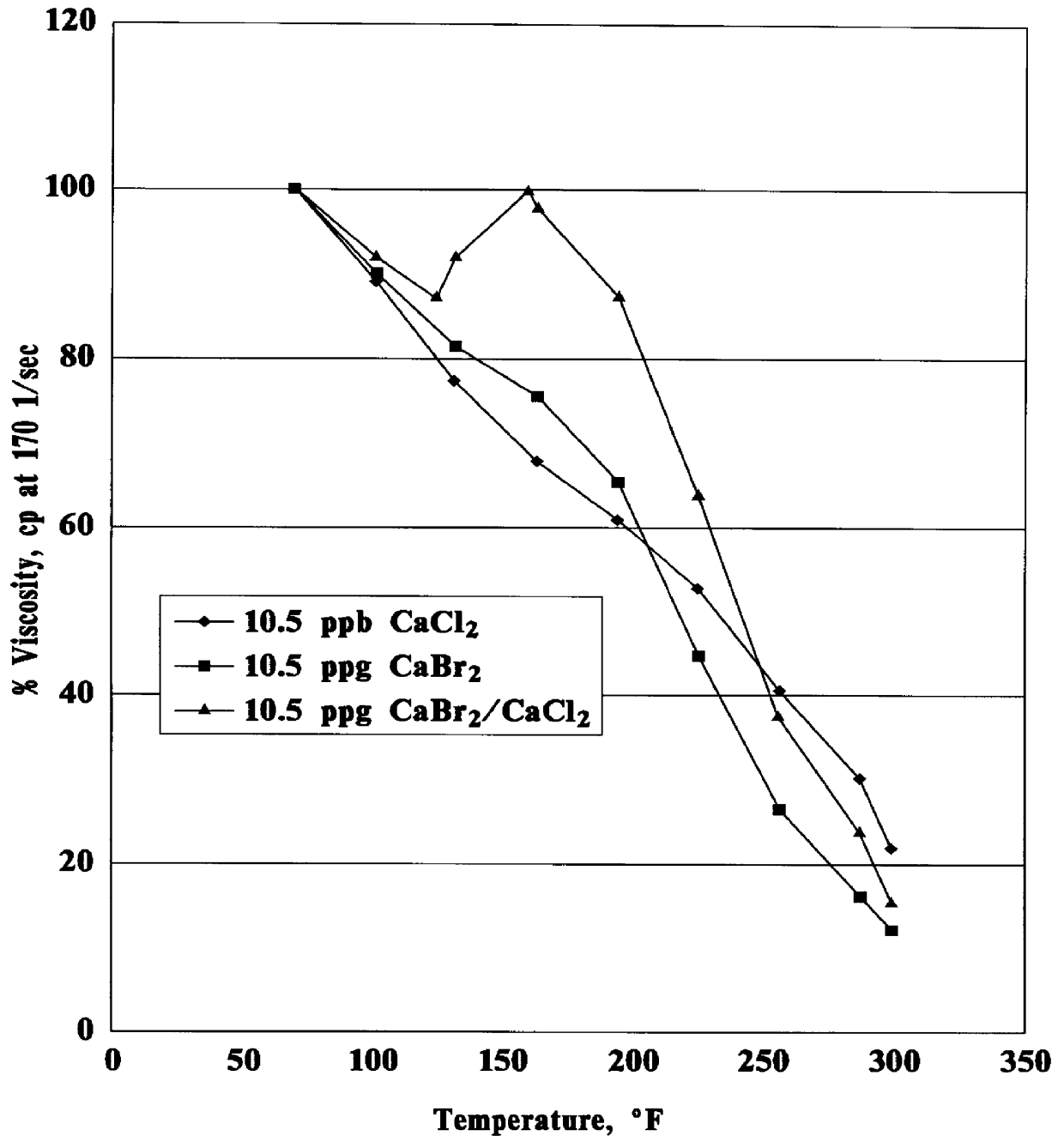

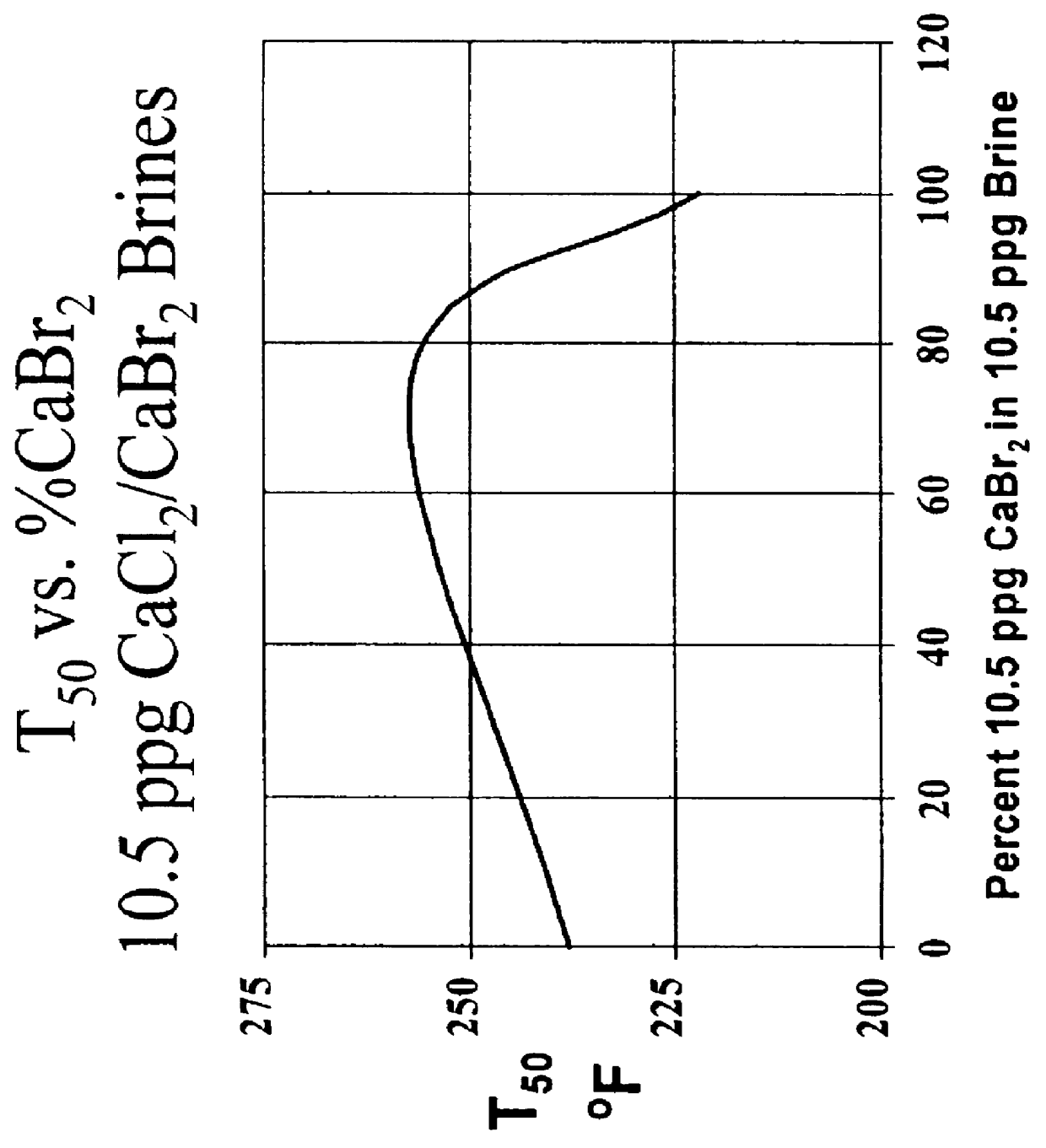

High density, viscosified, aqueous compositions having superior stability under stress conditions

Owner:BJ SERVICES CO

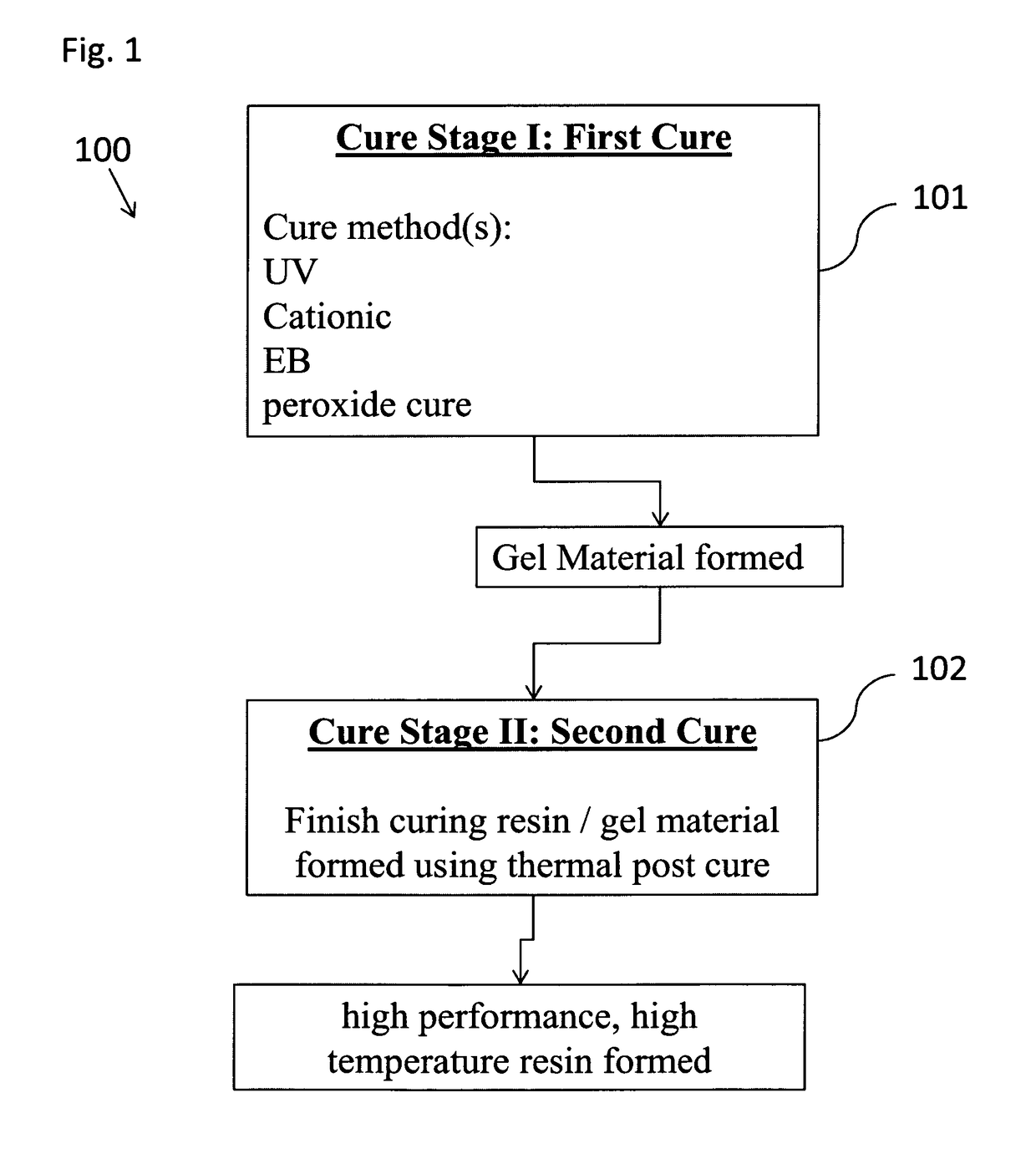

High temperature three dimensional printing compositions

ActiveUS9708440B2Improve performanceHigh-temperature resinAdditive manufacturing apparatusMetal catalystRoom temperature

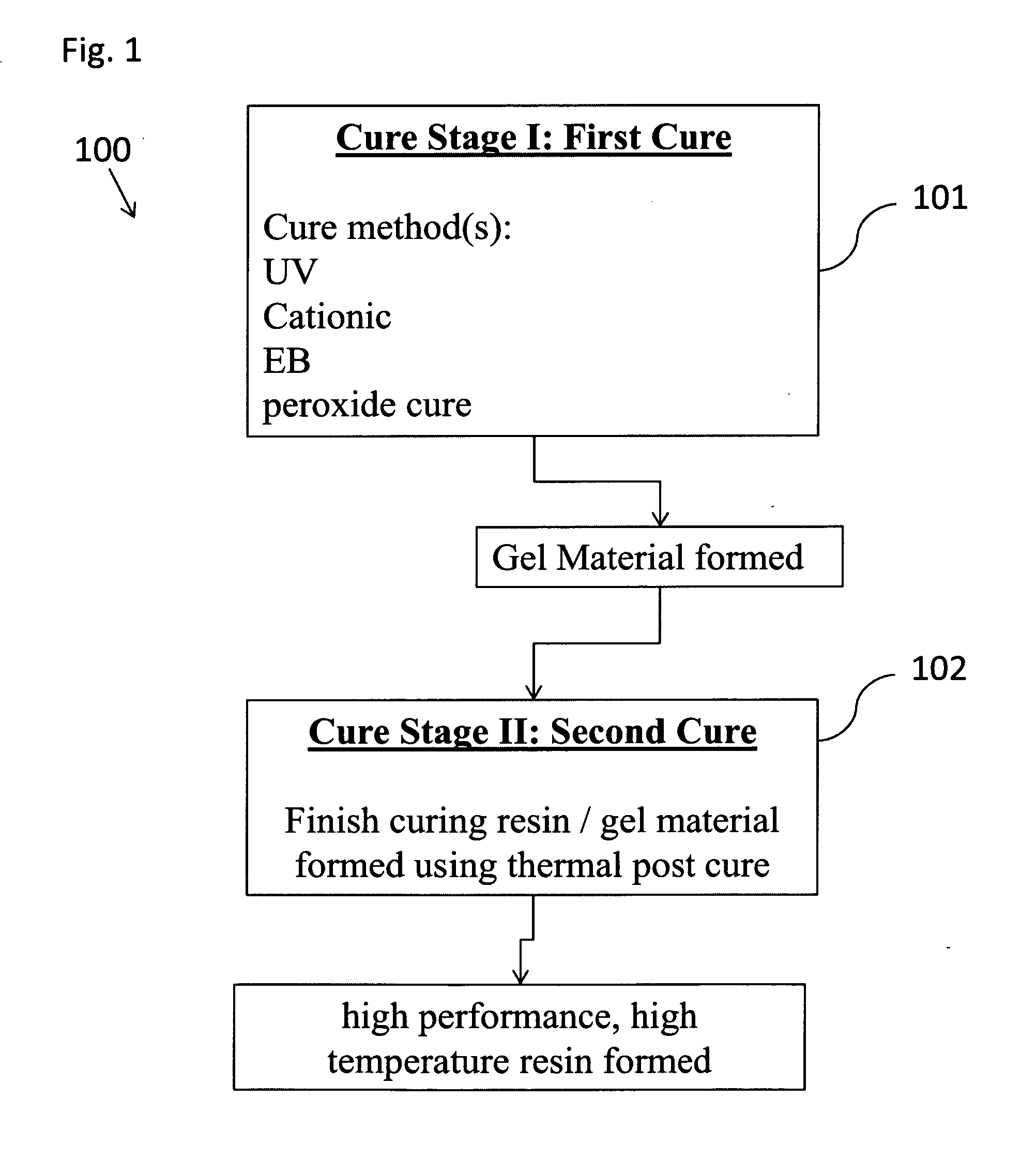

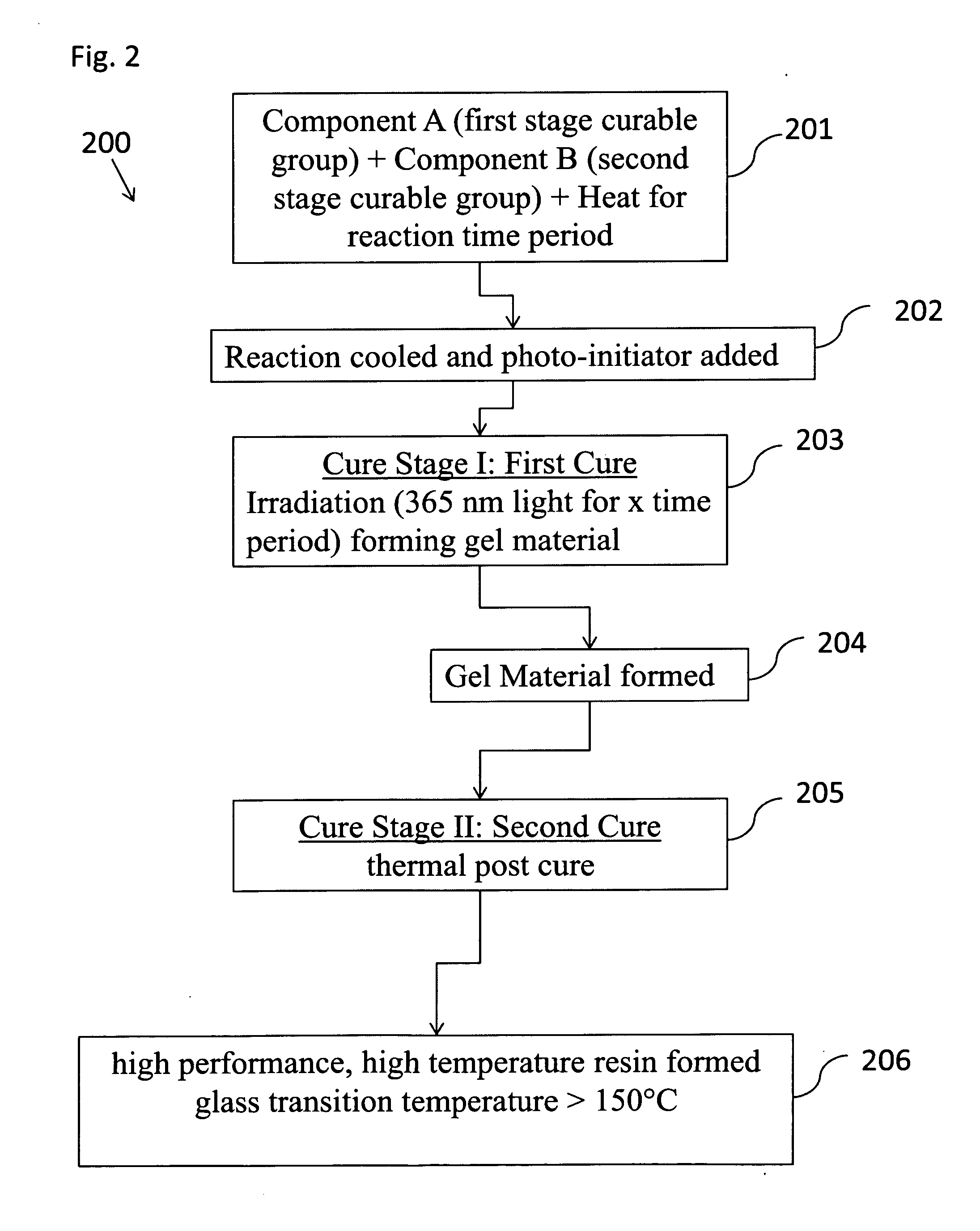

A thermosetting resin composition has particular applications in three dimensional (3-D) printing. The thermosetting resin composition exhibits high performance and is characterized by a high temperature two stage cure resin composition. The thermosetting resin composition comprises cyanate esters and other high temperature resins, photo curable monomers, photo initiator, metal catalyst or ionic liquid catalyst. The thermosetting resin composition cures at room temperature to form 3-D objects and upon further post cure these objects exhibit high temperature properties enabling use at temperatures exceeding 150 C.

Owner:NOVOSET

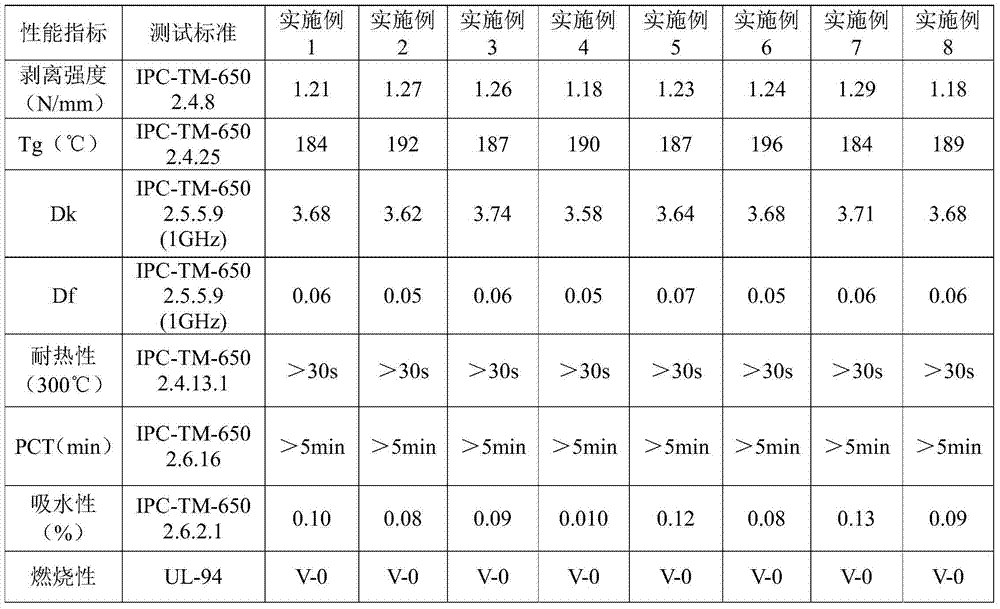

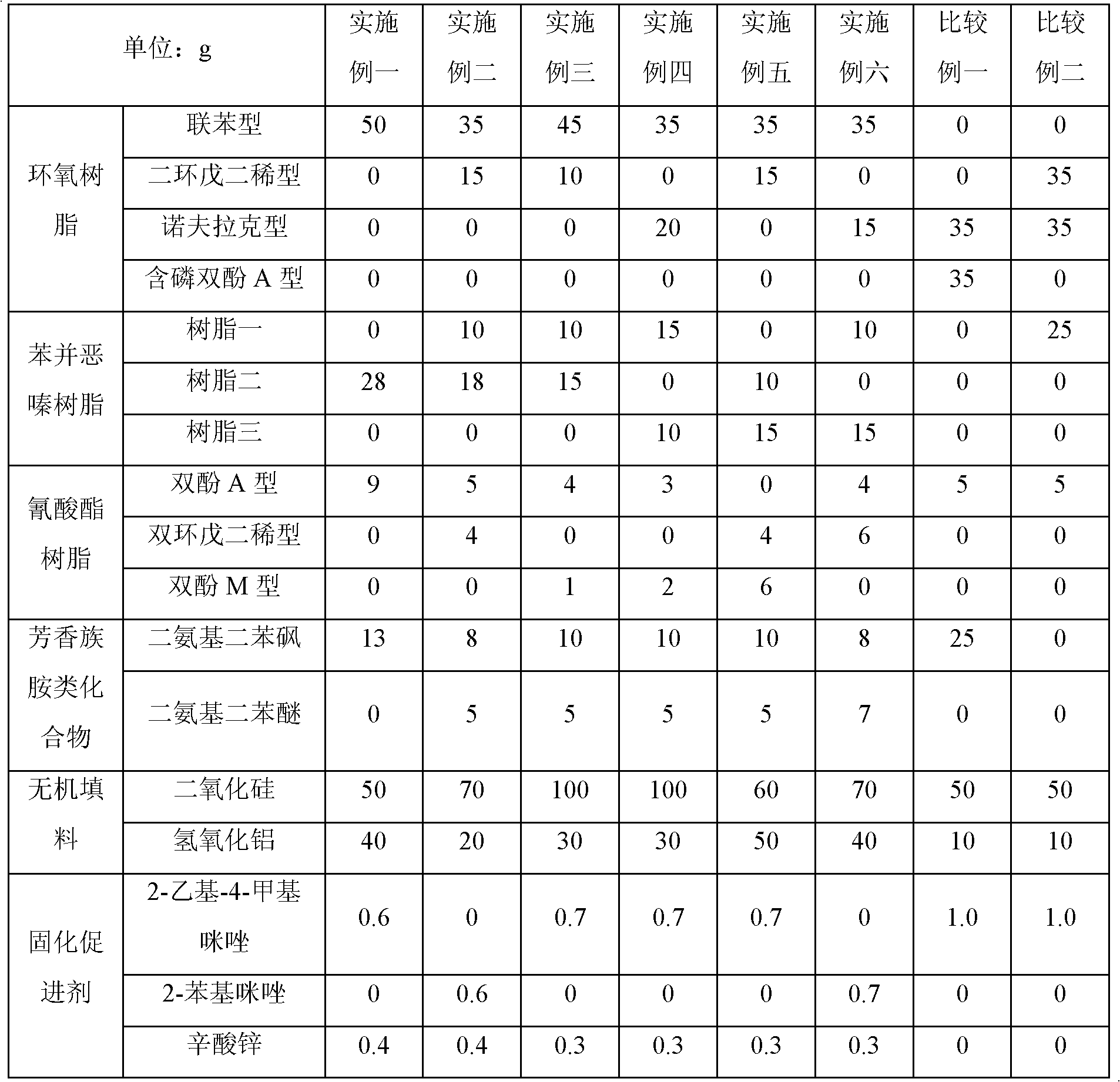

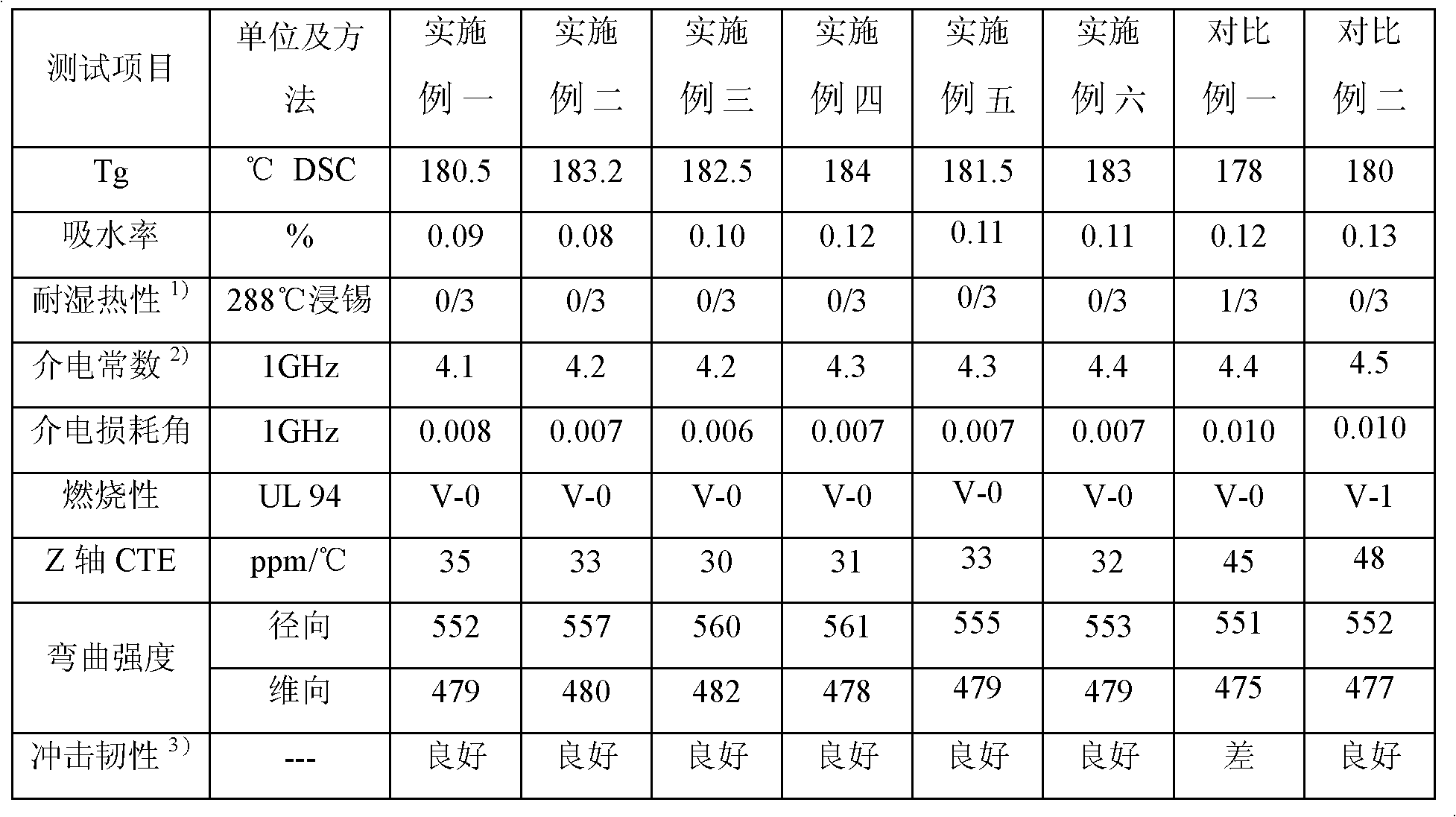

Thermosetting resin composition, prepreg and laminated board

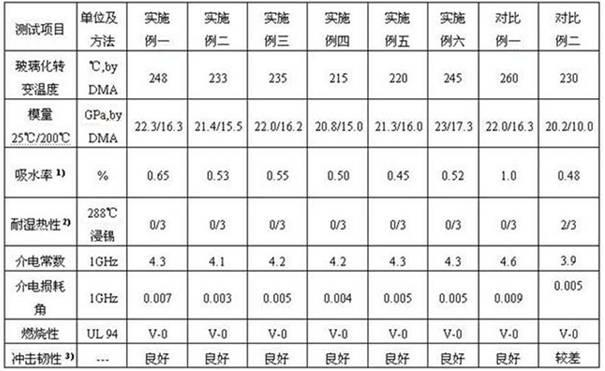

ActiveCN102115600AExcellent heat and humidity resistanceImprove heat resistanceGlass/slag layered productsMetal layered productsEpoxyDielectric loss

The invention discloses a thermosetting resin composition, which is characterized by comprising the following components in part by weight: 8 to 80 parts of allyl modified bismaleimide resin prepolymer, 15 to 60 parts of cyanate resin and 5 to 40 parts of halogen-free epoxy resin, wherein the allyl modified bismaleimide resin prepolymer is prepared by reacting bismaleimide resin with an allylcompound at the temperature of between 110 and 160DEG C for 20 to 100 minutes, and a weight ratio of the bismaleimide resin to the allylcompound is 100:(30-120). The composition can be used for preparing a prepreg and a laminated board. The composition and the laminated board have excellent humidity resistance, high heat resistance, low water absorption rate, high modulus, lower dielectric constant and dielectric loss, and good processing toughness, and can realize halogen-free flame retardancy.

Owner:SHENGYI TECH SUZHOU

High temperature three dimensional printing compositions

ActiveUS20160369040A1High modulusHigh elongationAdditive manufacturing apparatusPolymer scienceMetal catalyst

A thermosetting resin composition has particular applications in three dimensional (3-D) printing. The thermosetting resin composition exhibits high performance and is characterized by a high temperature two stage cure resin composition. The thermosetting resin composition comprises cyanate esters and other high temperature resins, photo curable monomers, photo initiator, metal catalyst or ionic liquid catalyst. The thermosetting resin composition cures at room temperature to form 3-D objects and upon further post cure these objects exhibit high temperature properties enabling use at temperatures exceeding 150C.

Owner:NOVOSET

High index and high impact resistant polythiourethane/urea material, method of manufacturing same and its use in the optical field

A transparent, non elastomeric, high index, impact resistant polythiourethane / urea material comprising the reaction product of: a) at least one (alpha, omega)-diiso(thio)cyanate cycloaliphatic or aromatic prepolymer having a number average molecular weight ranging from 100 to 3000 gmol-1, and b) at least one primary diamine, in an equivalent molar ratio amine function / iso(thio)cyanate function from 0.5 to 2, preferably from 0.90 to 1.10, wherein, said prepolymer and diamine are free from disulfide (-S-S-) linkage and at least one of the prepolymer or the diamine contains one or more S atoms in its chain.

Owner:ESSILOR INT CIE GEN DOPTIQUE

Thermosetting resin composition, prepreg and laminated board

ActiveCN102199351AGood workmanshipExcellent heat and humidity resistanceSynthetic resin layered productsLaminationEpoxyThermal expansion

The invention discloses a thermosetting resin composition which is characterized by comprising the following components in parts by weight: 10-65 parts of alkyl modified bismaleimide resin prepolymer, 5-60 parts of composite cyanate resin and 5-65 parts of halogen-free epoxy resin, wherein the total weight of the resins is 100 parts; the alkyl modified bismaleimide resin prepolymer is obtained byreacting a bismaleimide resin with a diallyl compound for 20-120 minutes at the temperature of 110-160 DEG C and then cooling; and the weight ratio of bismaleimide resin to diallyl compound is 100: (15-120). A prepreg and a laminated board can be prepared by using the composition. The composition, the prepreg and the laminated board have the characteristics of good manufacturability, halogen-free inflaming retardance, excellent humidity resistance and heat resistance, low thermal expansion coefficient and low dielectric constant and dielectric loss, and are suitable for the fields of integrated circuit package, high-frequency, high-speed and high-density interconnection and the like.

Owner:SHENGYI TECH SUZHOU

Halogen-free resin composition and method for manufacturing prepreg and laminated board by using halogen-free resin composition

InactiveCN103937157AImprove heat resistanceHigh glass transition temperatureSynthetic resin layered productsCircuit susbtrate materialsEpoxyCopper foil

The present invention discloses a halogen-free resin composition and a method for manufacturing a prepreg and a laminated board by using the halogen-free resin composition. The halogen-free resin composition is prepared by dispersing the following components in an organic solvent, wherein the components comprise, by weight, 10-100 parts of a halogen-free epoxy resin, 10-80 parts of cyanate, 10-70 parts of an anhydride curing agent, 10-100 parts of a benzoxazine resin, 0.01-1.0 part of a curing accelerator, 1-15 parts of a toughening agent, 0-50 parts of a fire retardation agent, and 0-100 parts of an inorganic filler, and the solid content of the halogen-free resin composition is 30-70 wt%. The prepared prepreg and the copper foil-clad laminated board have characteristics of good heat resistance, high glass-transition temperature, low water absorption rate, excellent fire retardation, low dielectric constant and low dielectric loss factor.

Owner:ZHEJIANG WAZAM NEW MATERIAL CO LTD

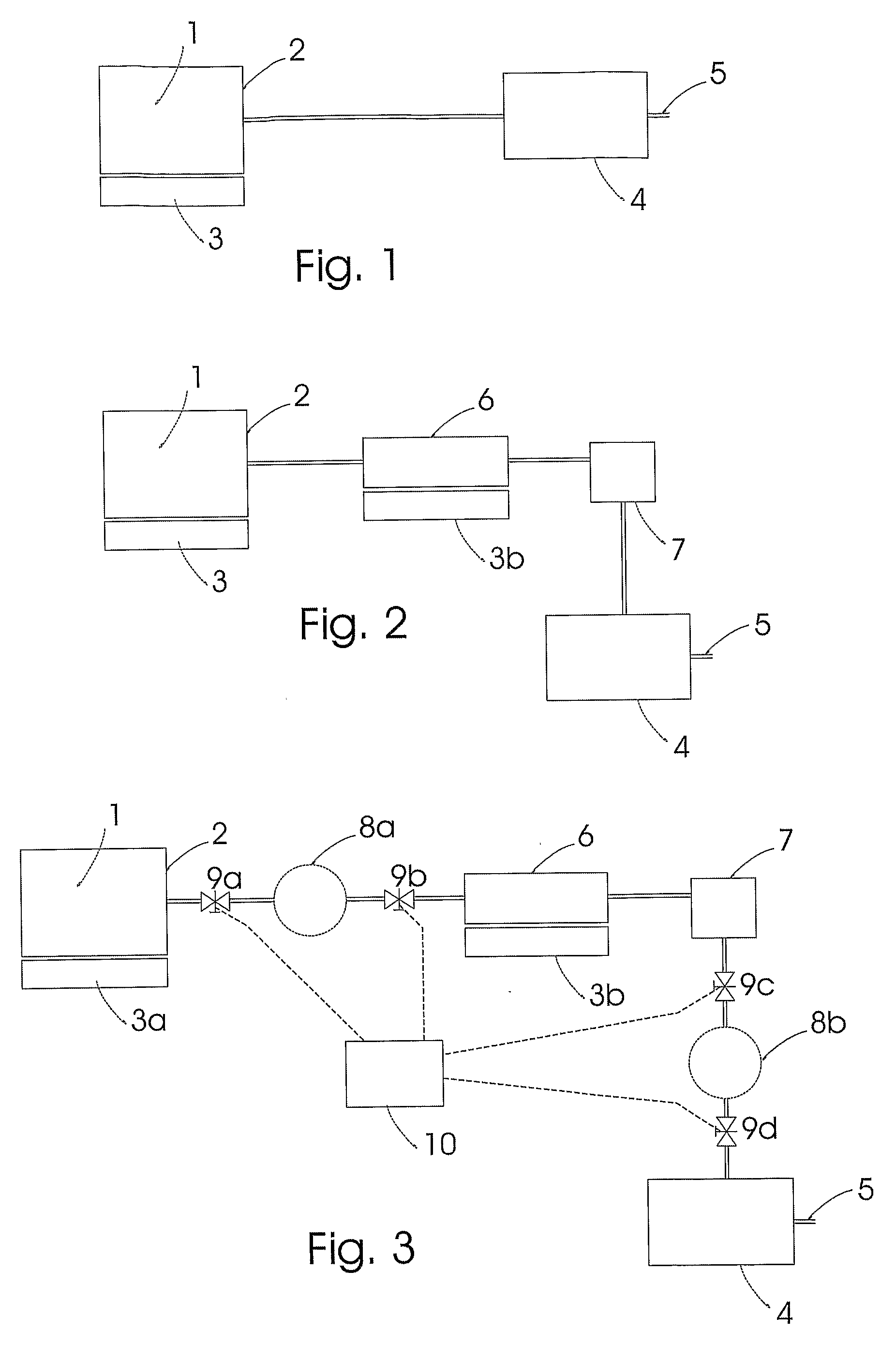

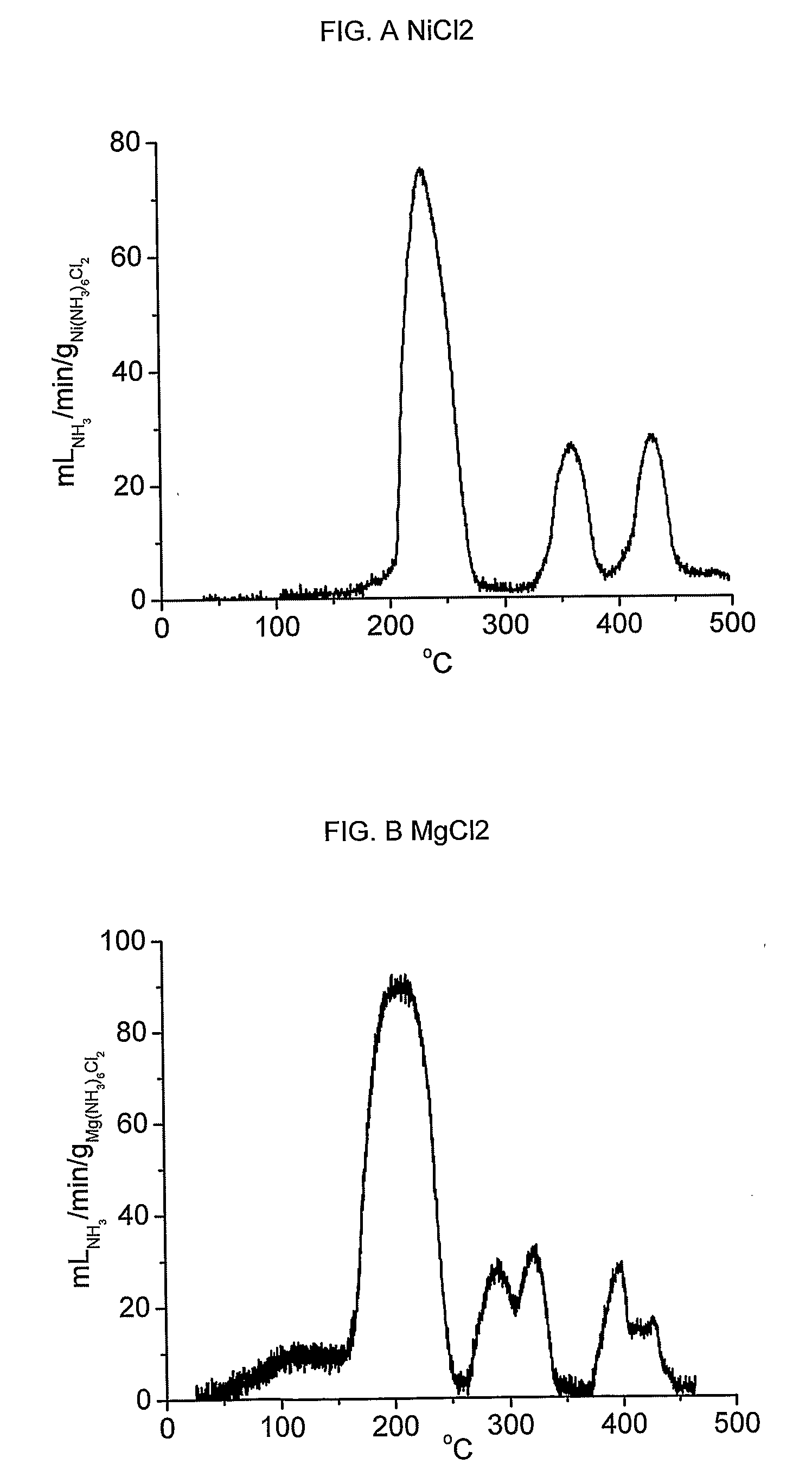

Use Of An Ammonia Storage Device In Production Of Energy

InactiveUS20070207351A1Reactant parameters controlMagnesium halidesAlkaline earth metalAmmonia storage

An electric power generating unit comprising (i) an ammonia storage device in the form of a container comprising an ammonia absorbing and releasing salt of the general formula: Ma(NH3)nXz, wherein M is one or more cations selected from alkali metals, alkaline earth metals, and transition metals such as Li, K, Mg, Ca, V, Cr, Mn, Fe, Co, Ni, Cu or Zn, X is one or more anions selected from fluoride, chloride, bromide, iodide, nitrate, thiocyanate, sulphate, molybdate, phosphate, and chlorate ions, a is the number of cations per salt molecule, Z is the number of anions per salt molecule, and n is the coordination number of 2 to 12. (ii) means for heating said container and ammonia absorbing and releasing salt for releasing ammonia gas and (iiia) a fuel cell for converting ammonia directly into electric power; or (iiib1) a reactor for dissociating ammonia into hydrogen and nitrogen and (iiib2) a fuel cell for converting hydrogen into electric power is useful for large stationary energy producing facilities, but also for use for is useful for large stationary energy producing facilities, but also for use for small rechargeable and / or replaceable power supply units for micro-fabricated or miniaturized ammonia decomposition reactors for use in mobile units and portable devices may be used for large energy producing facilities, and by use of small rechargeable and / or replaceable ammonia storage decomposition reactors, it is also possible to provide energy for mobile units and portable devices.

Owner:AMMINEX

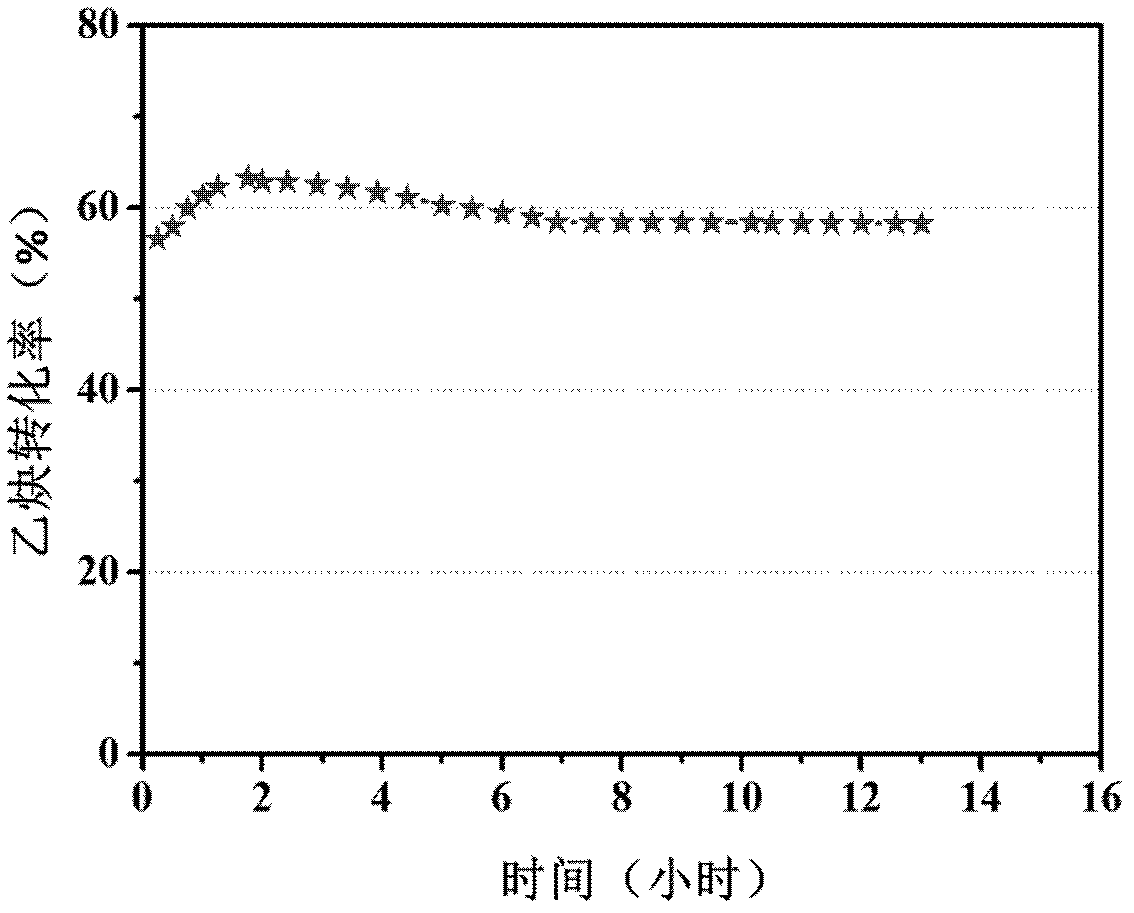

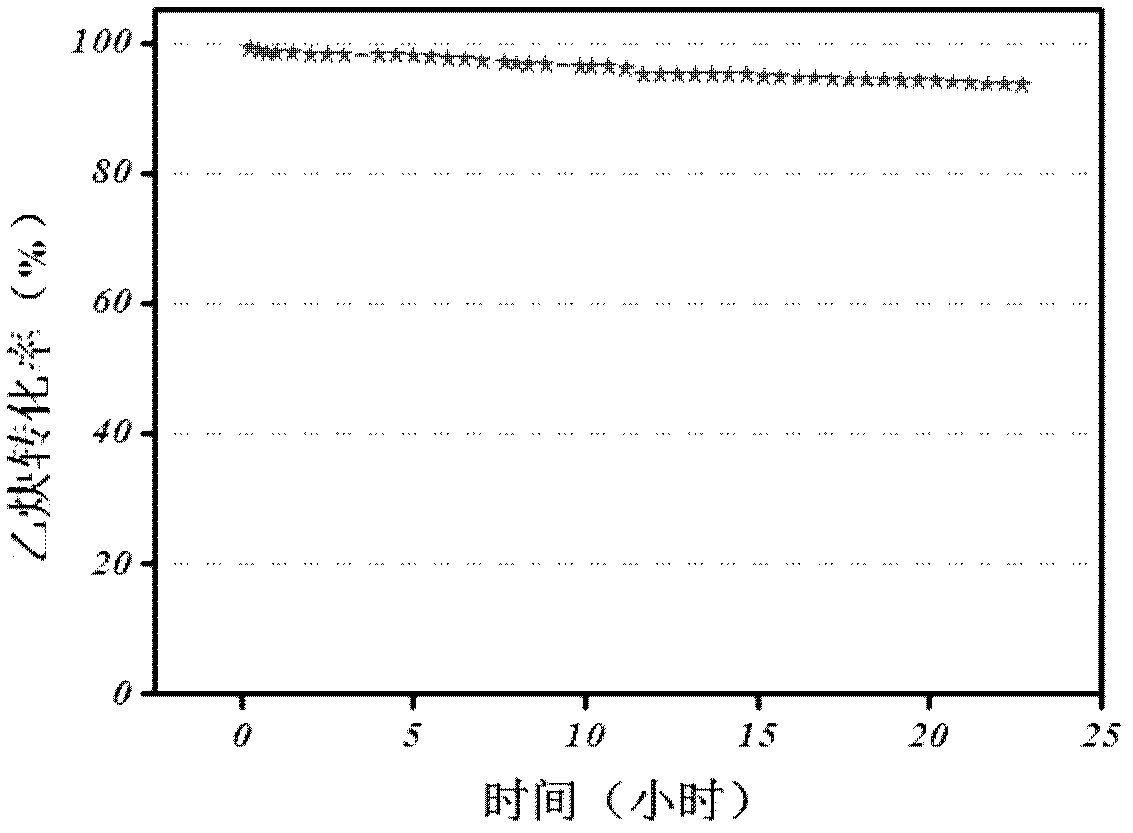

Composite metal salt catalyst for hydrochlorination reaction of acetylene

ActiveCN102631942AGuaranteed stabilityImprove stabilityPhysical/chemical process catalystsPreparation by halogen halide additionPotassiumCarbon nanotube

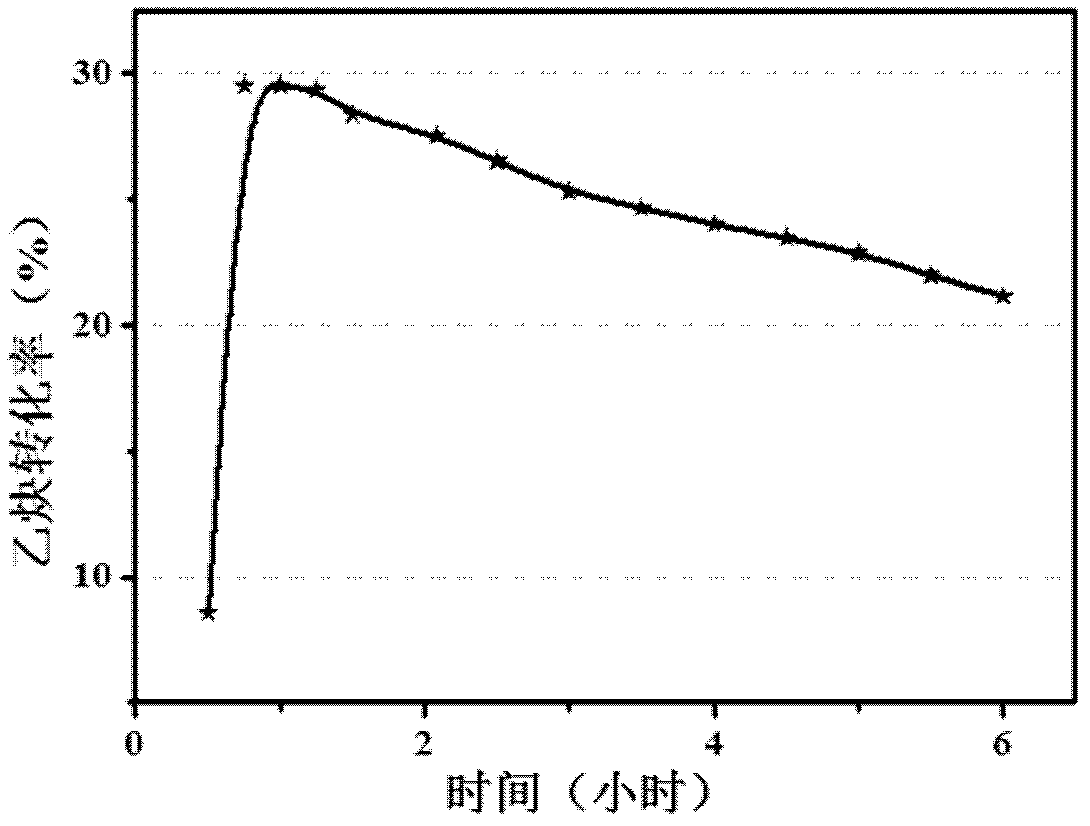

The invention discloses a composite metal salt catalyst for a hydrochlorination reaction of acetylene, belonging to the technical field of catalysts. The composite metal salt catalyst takes gold as active metal, and the reduction deactivation of the composite metal salt catalyst is reduced by reducing reduction potential of metal through a complexing action of a thiocyanate radical or a cyanate radical. Carbon deposition in a reaction process is restrained by introducing one or more of potassium, cerium and lanthanum elements. The composite metal salt catalyst is loaded on active carbon or carbon nanometer pipe with the specific surface area of not less than 100m<2>*g<-1>, wherein the mass fraction of a gold load is 0.05-0.50%, the mass fraction of a copper load is 0.1-5.0%, and the mass fraction of the potassium / cerium / lanthanum load is 0.1-5.0%. In a reaction for preparing vinyl chloride, composite salt of gold and copper has excellent activity, selectivity and stability; furthermore, one or two of cerium and lanthanum are added to a catalyst so as to be capable of effectively restraining the carbon deposition and catalyzing a hydrochlorination process of the acetylene in low cost and high efficiency.

Owner:TSINGHUA UNIV +1

Resin composition, prepreg and metal-foil-clad laminate

ActiveUS20070203308A1Improve heat resistanceImprove practicalityPrinted circuit aspectsThin material handlingPolymer scienceMetal foil

A resin composition excellent in heat resistance after moisture absorption, lead-free solder reflow properties, dimensional stability and electrical characteristics for high-multilayer and high-frequency-capable printed wiring boards, which composition comprises a bisphenol A type epoxy resin (a) having at least two epoxy groups per molecule and a secondary hydroxyl group amount of 0.4 meq / g or less, a novolak type epoxy resin (b) at least two epoxy groups per molecule, a cyanate ester resin (c) having at least two cyanate groups per molecule and spherical silica having an average particle diameter of 4 μm or less, wherein the equivalent ratio of cyanate groups / epoxy groups in the resin composition is in the range of 0.7 to 1.45, and a prepreg and a metal-foil-clad laminate each of which comprises the resin composition.

Owner:MITSUBISHI GAS CHEM CO INC

Production of low-free TDI polyurethane curing agent, curing agent therefrom and its products

A low-free radical TDI polyurethane curing agent, its production and product are disclosed. The process is carried out by putting tolylene-diisoester cyanate, solvent S and catalyst A into reactor, adding into antioxidant and long-chain alcohol, agitating in reactor, heating, keeping temperature, inspecting NCO value, adding into phase-transferring solvent X while reaching NCO value to 20-40%, adding into catalyst B till reaching NCO value to 10-15, adding into inhibitor to stop reaction, adding into solvent S, decreasing pressure, distilling and removing phase-transferring solvent X. It's cheap and convenient.

Owner:BEIJING ZHANCHEN CHEM +2

Canate-bimaleimide resin adhesive and preparation method

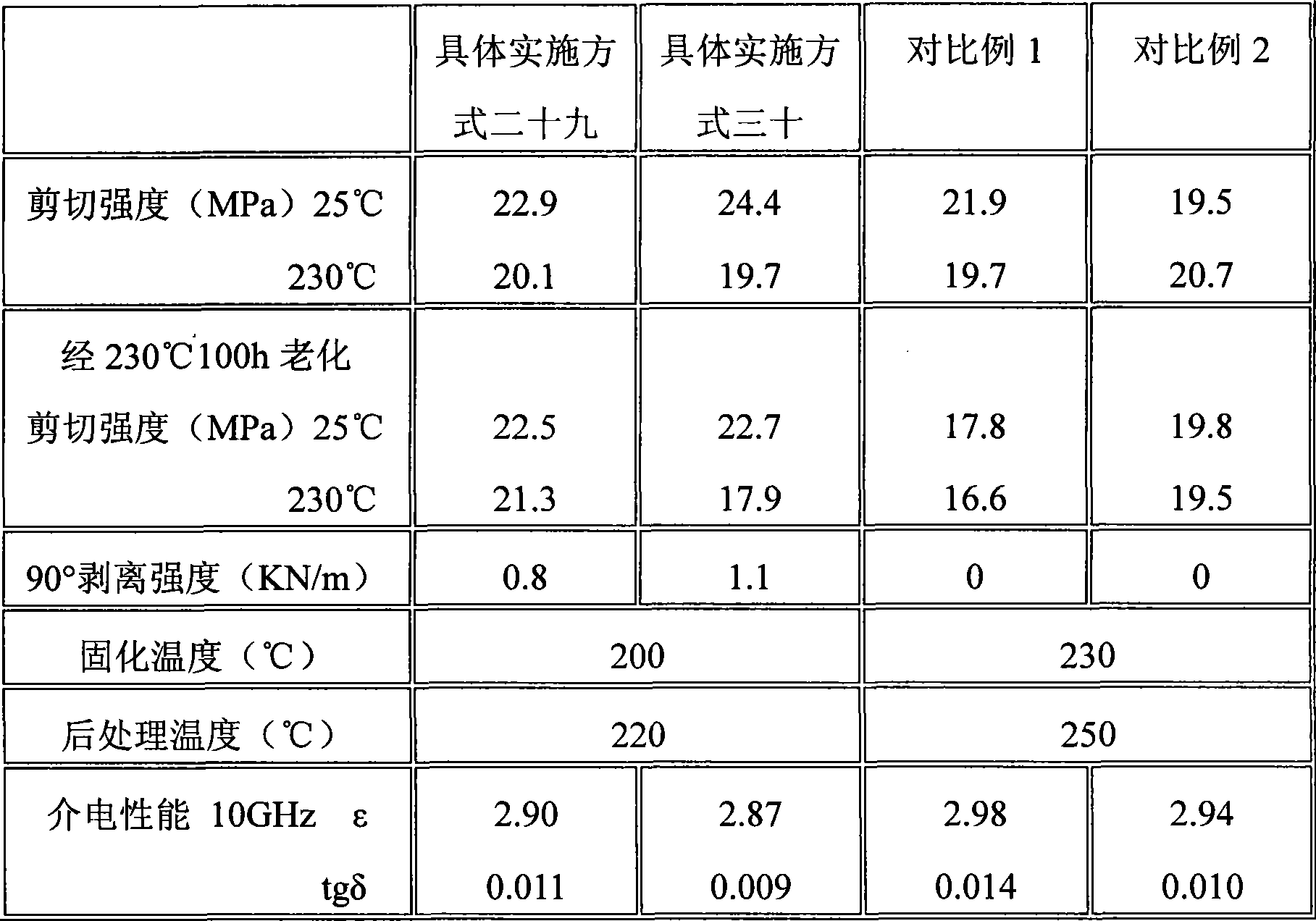

InactiveCN101531880ALow dielectric lossLow dielectric constantAdhesivesCyanate compoundResin adhesive

A cyanate-bimaleimide resin adhesive and a preparation method belong to the adhesive field, solving the problems of poor heat resistance, low dielectric property and poor adhesive property of current high-temperature adhesives. The adhesive of the invention is prepared by a cyanate ester resin, a bismaleimide resin, an internally toughened phenolic resin, an epoxy resin and a catalyst. The preparation method is as follows: 1. carrying out pre-reaction on the epoxy resin and the internally toughened phenolic resin to obtain a prepolymer resin B; 2. carrying out pre-reaction on the cyanate, the bimaleimide and the catalyst to obtain a prepolymer C; 3. carrying out pre-reaction on the prepolymer C and the prepolymer B to prepare the adhesive of the invention. The prepared adhesive has reasonable formulation, good heat resistance, dielectric property, adhesive property and curing process property, can be used for adhesion of high-temperature resistance composite materials with high dielectric property and used as a matrix resin, and is simple in method and easy operation.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

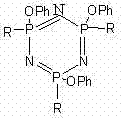

Thermosetting cyanate resin composition and application of thermosetting cyanate resin composition

ActiveCN102942684AOvercome the disadvantage of high water absorptionImprove heat resistanceSynthetic resin layered productsEpoxyCopper coating

The invention relates to a thermosetting cyanate resin composition, which comprises the following components: polyfunctional cyanate, epoxy resin, flame retardant agent and inorganic filler. The thermosetting cyanate resin composition is used for preparing resin substrates, resin compound metal copper foils, prepregs, laminating plates, copper-coating plate laminating plates, printed circuit boards and the like. The thermosetting cyanate resin composition has good heat resistant property, humidity resistant property and flame retardant property and low heat expansion coefficient.

Owner:GUANGDONG SHENGYI SCI TECH

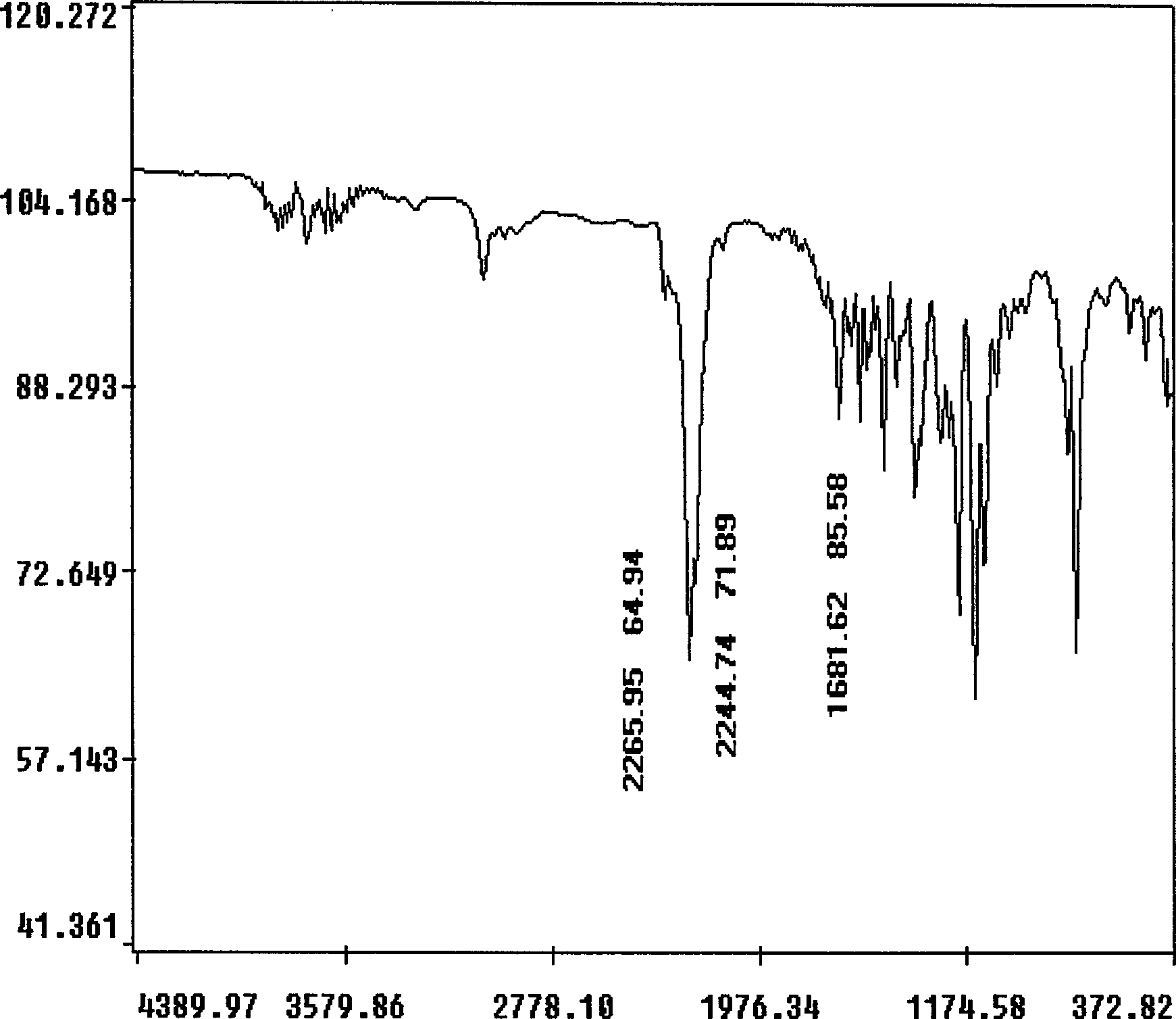

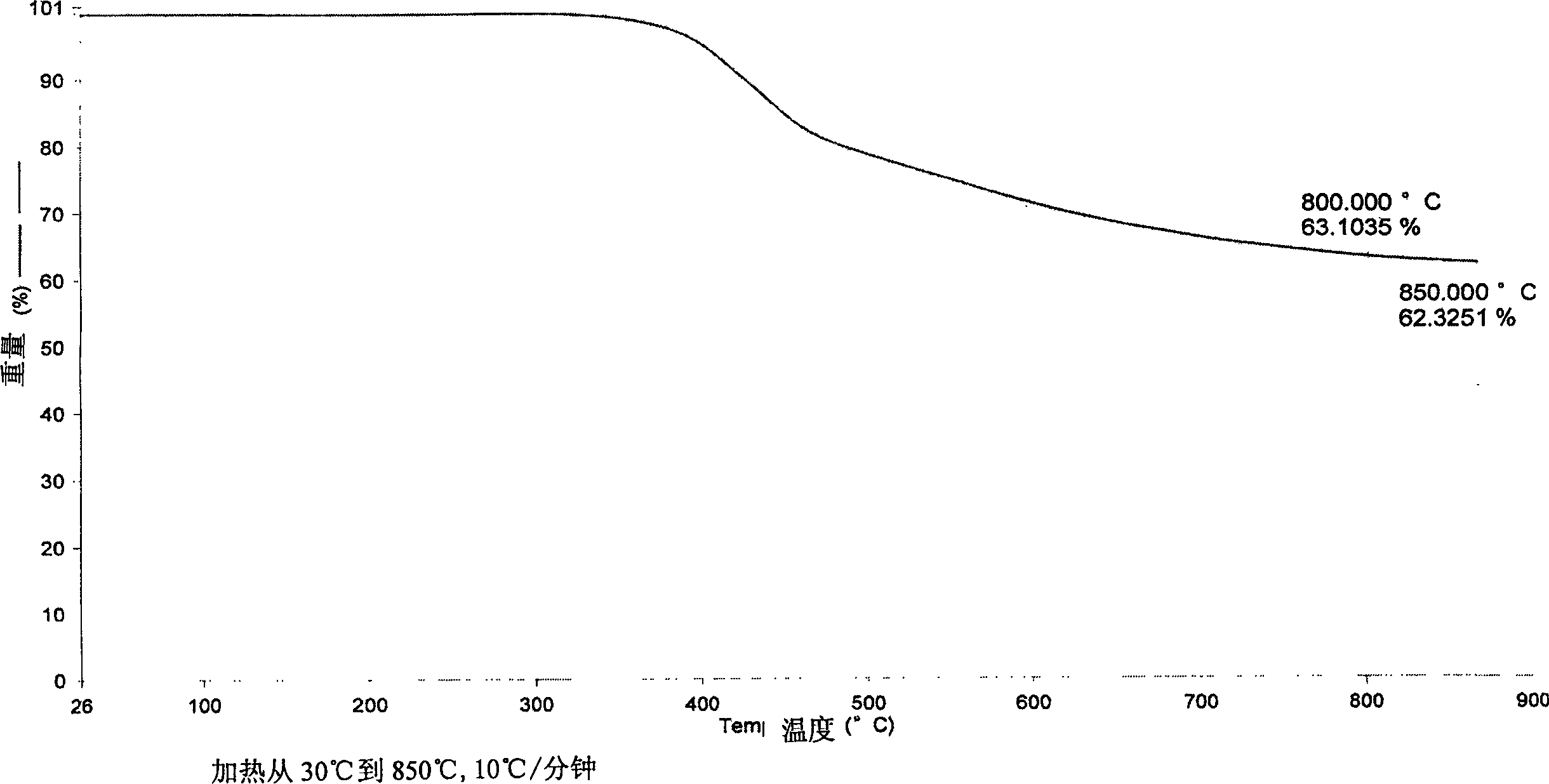

Phenolic cyanate resin and its synthesis method and phenolic cyanate ablative material composite

The present invention discloses a phenol-formaldehyde cyanate resin. It provides its chemical formula and synthesis method, and ablative composite material formed from the the above-mentioned phenol-formaldehyde cyanate resin.

Owner:北京玻钢院复合材料有限公司

Halogen-free and phosphorus-free epoxy resin composition and prepreg and laminated board produced therefrom

InactiveCN102276961AAchieving Flame RetardancyImprove heat resistanceSynthetic resin layered productsMetal layered productsThermal expansionAromatic amine

The invention discloses a halogen-free and phosphorus-free epoxy resin composition, which comprises: (a) epoxy resin: 40-80 parts; (b) cyanate resin: 1-15 parts; (c) benzene Oxazine resin: 10-45 parts; (d) aromatic amine compound: 5-30 parts; (e) inorganic filler; the total amount of the above-mentioned components a, b, c, and d is 100 parts; component e Content: the total amount of the first four components is 70~150:100; the monomer of the epoxy resin contains 2 or more benzene rings. The halogen-free and phosphorus-free epoxy resin composition, prepreg and laminate obtained in the present invention can meet the requirements of halogen-free and phosphorus-free flame retardancy, and the flame retardancy reaches UL94V-O level. It not only has environmental protection characteristics, but also has high heat resistance, low Dielectric constant, low dielectric loss, low thermal expansion coefficient, good drilling processability, low water absorption and other excellent characteristics.

Owner:SHENGYI TECH SUZHOU

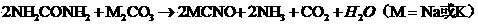

Cyanate resin for hot-melt prepregs and preparation method thereof

The invention relates to a cyanate resin for hot-melt prepregs and a preparation method thereof, belonging to the technical field of hot-melt prepregs. The cyanate resin is composed of 60-95 parts of modified cyanate resin and 5-40 parts of toughener. The cyanate resin for hot-melt prepregs has the advantages of simple technique and no solvent volatilization, and is suitable for industrial production. A hot-melt process can be adopted to prepare the prepreg. The prepreg has favorable manufacturability and long storage period. The prepared cyanate resin fiber composite material has the advantages of higher comprehensive mechanical properties, favorable heat resistance and favorable radiation resistance, can widely satisfy the requirements for high-performance aerospace structure materials, and has favorable application prospects.

Owner:长春长光宇航复合材料有限公司

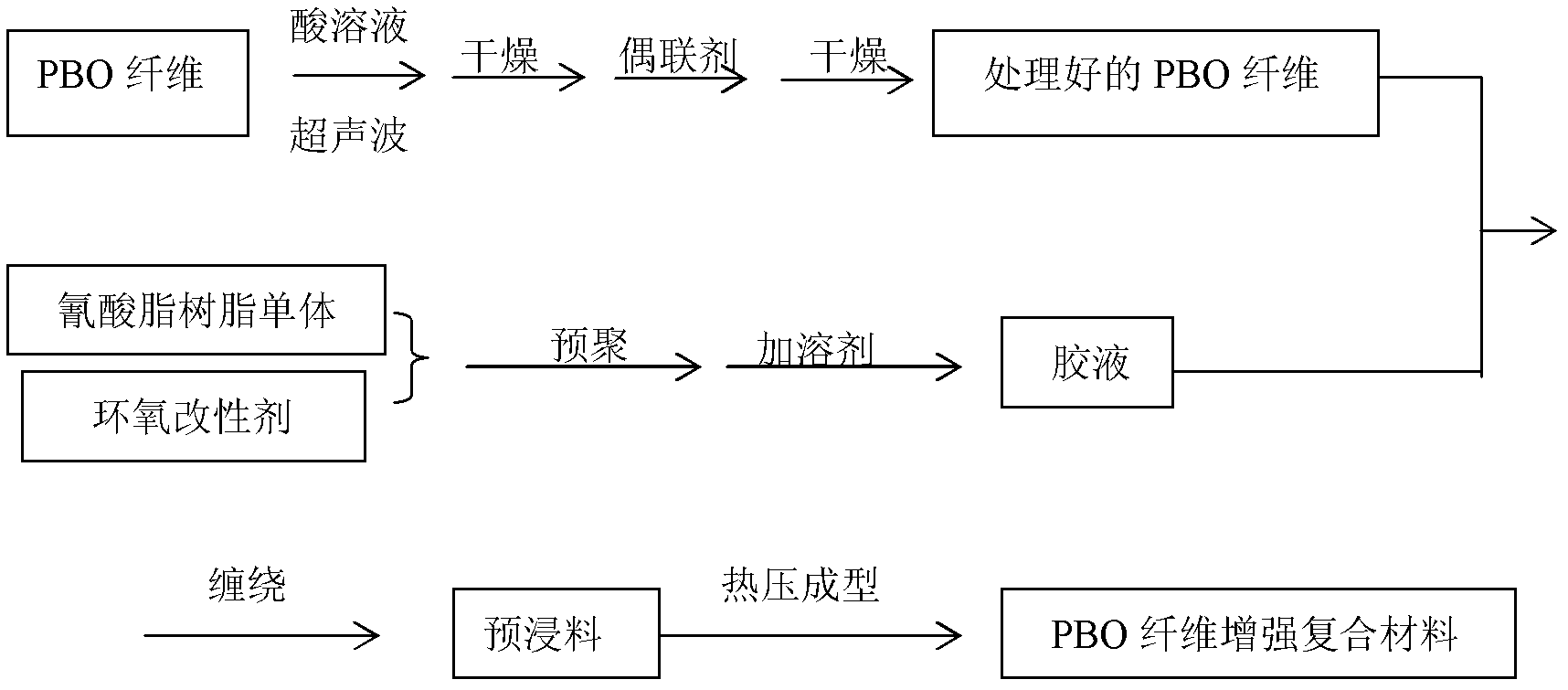

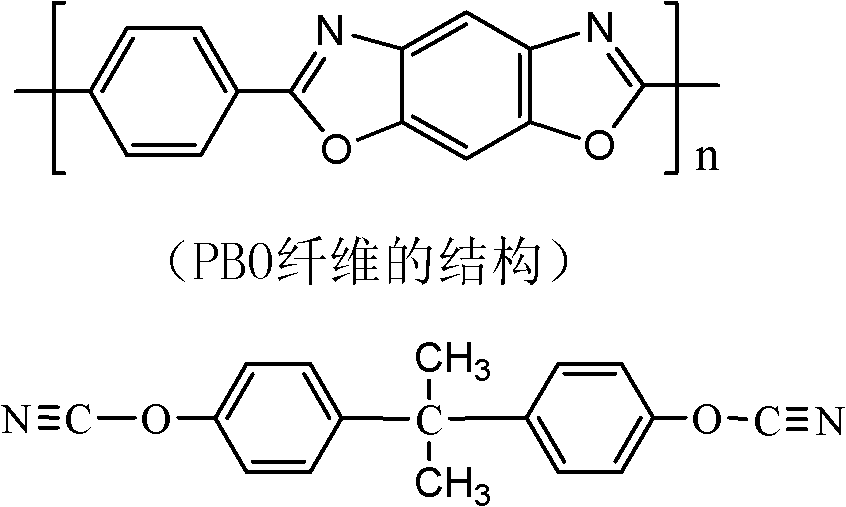

High-performance wave-transmitting composite material based on PBO (poly-p-phenylene benzobisthiazole) fiber and preparation method thereof

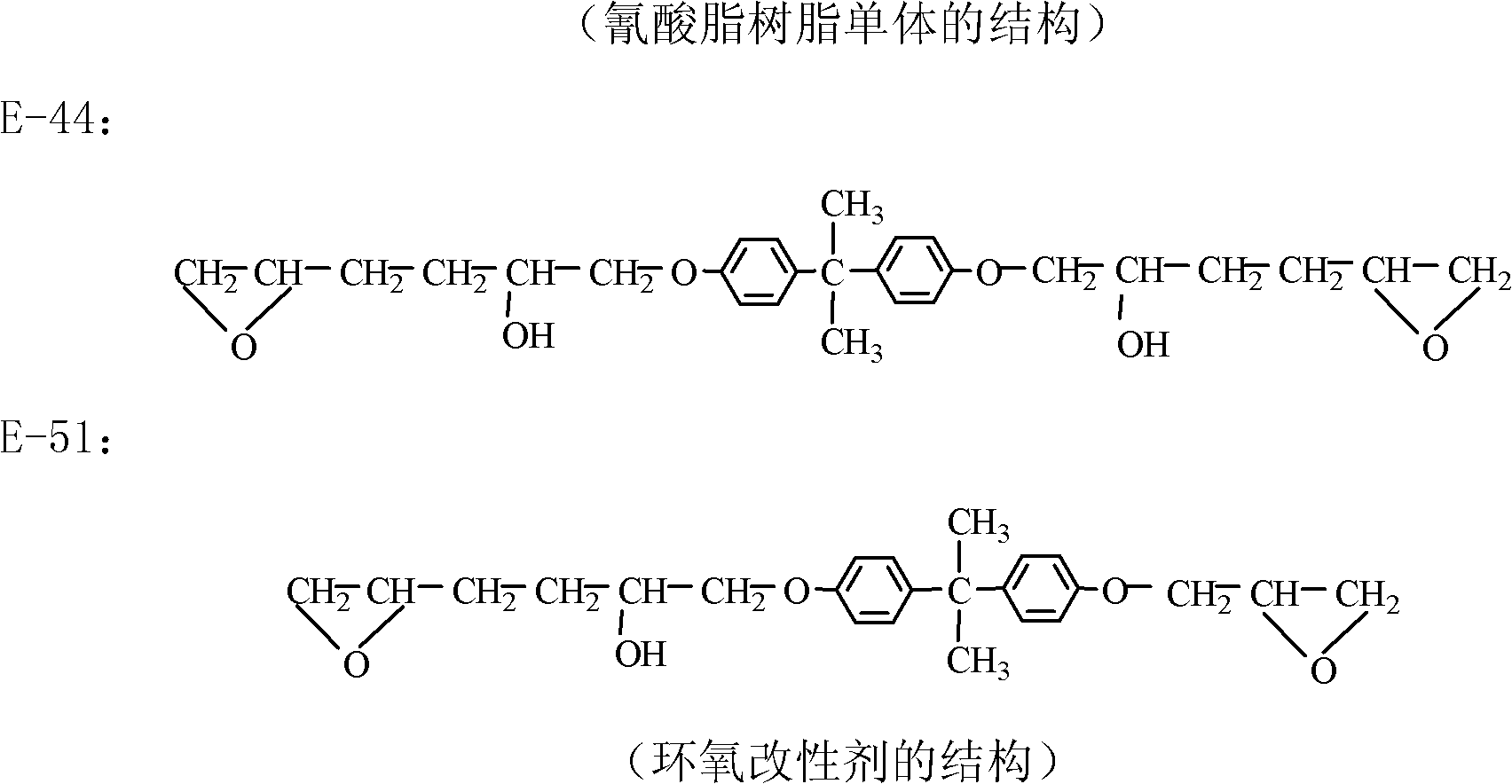

The invention discloses a high-performance wave transmitting composite material based on PBO (poly-p-phenylene benzobisthiazole) fiber and a preparation method of the composite material. The preparation method comprises the steps of: preparing epoxy-modified cyanate resin prepolymer from PBO fiber as a reinforcing material and modified bisphenol A type cyanate resin as a substrate through a heating fusion method, wherein the used cyanate resin contains an epoxy modifier; and adding an organic solvent to prepare liquid glue, immersing and winding treated PBO fiber, obtaining a prepreg after solvent is volatilized, paving the prepreg in a mold, and preparing the PBO fiber-reinforced cyanate composite material by a high-temperature pressure molding method. The high-performance wave transmitting composite material has the advantages of high strength, high modulus, low density, excellent high-temperature resistance and dielectric properties, excellent molding process property and the like.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

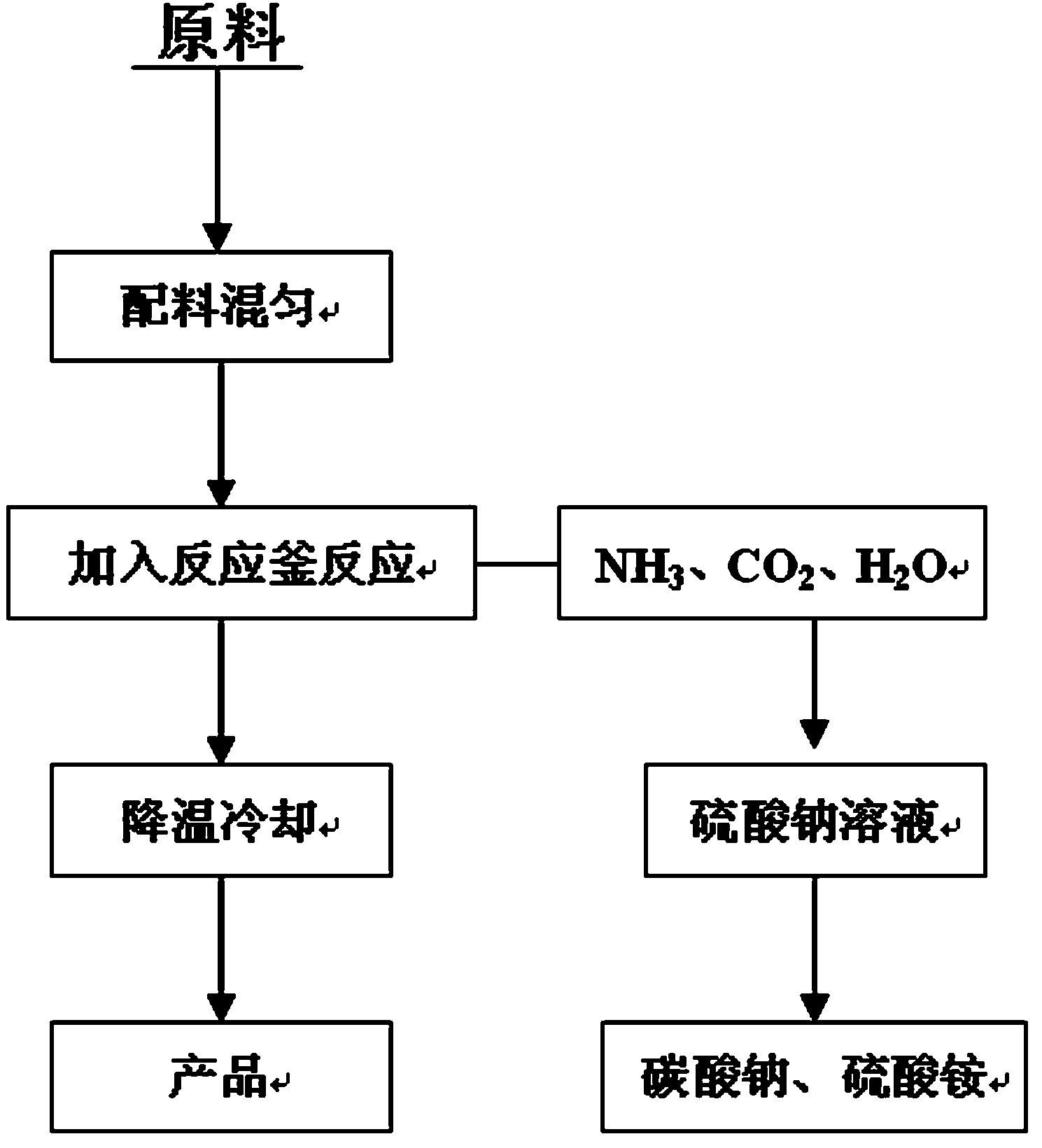

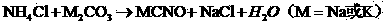

Beneficiation reagent, synthesis method and method for comprehensively utilizing generated waste gases

The invention discloses a beneficiation reagent, a synthesis method and a method for comprehensively utilizing generated waste gases. The beneficiation reagent is formed by solid-phase synthesis of inorganic or organic raw materials and comprises the following raw materials in parts by weight: 300 to 700 parts of a nitrogen-containing compound, 500 to 800 parts of chlorine salt, 400 to 650 parts of carbonate, 80 to 160 parts of strong alkali, 50 to 500 parts of cyanide complex double salt, 0 to 300 parts of cyanate, 5 to 20 parts of potassium sulfide, 50 to 200 parts of carbon and 0 to 100 parts of lime nitrogen. The beneficiation reagent is prepared by the following steps: mixing the raw materials uniformly; adding the mixed raw materials into a reaction kettle; quickly heating to 500 to 1,200 DEG C; maintaining high temperature for 1 to 2 hours; and cooling and crushing to obtain the product. Ammonia gas and carbon dioxide generated in a synthesis process are absorbed by a sodium sulfate solution to generate byproducts sodium carbonate and ammonium sulfate. The invention has the advantages of low production cost, simple operation, low toxicity and easy control. The product can be widely applied to leaching of noble metals such as gold oxide ores and silver oxide ores, floatation inhibitors and metal heat treatment and electroplating industries.

Owner:YUNNAN KEENLY NEW MATERIAL

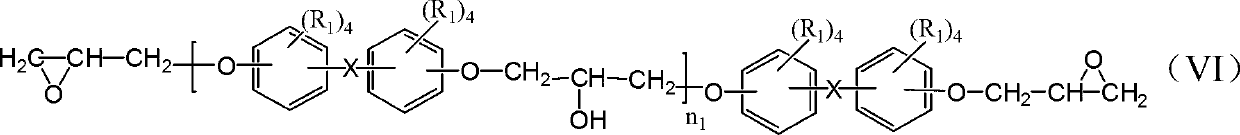

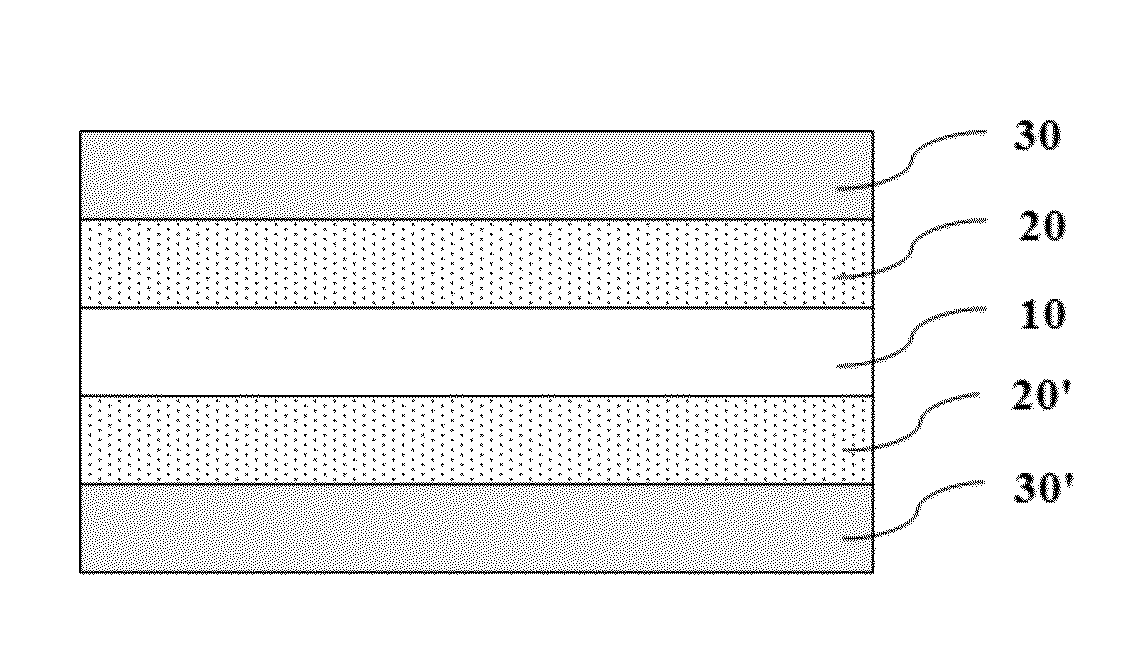

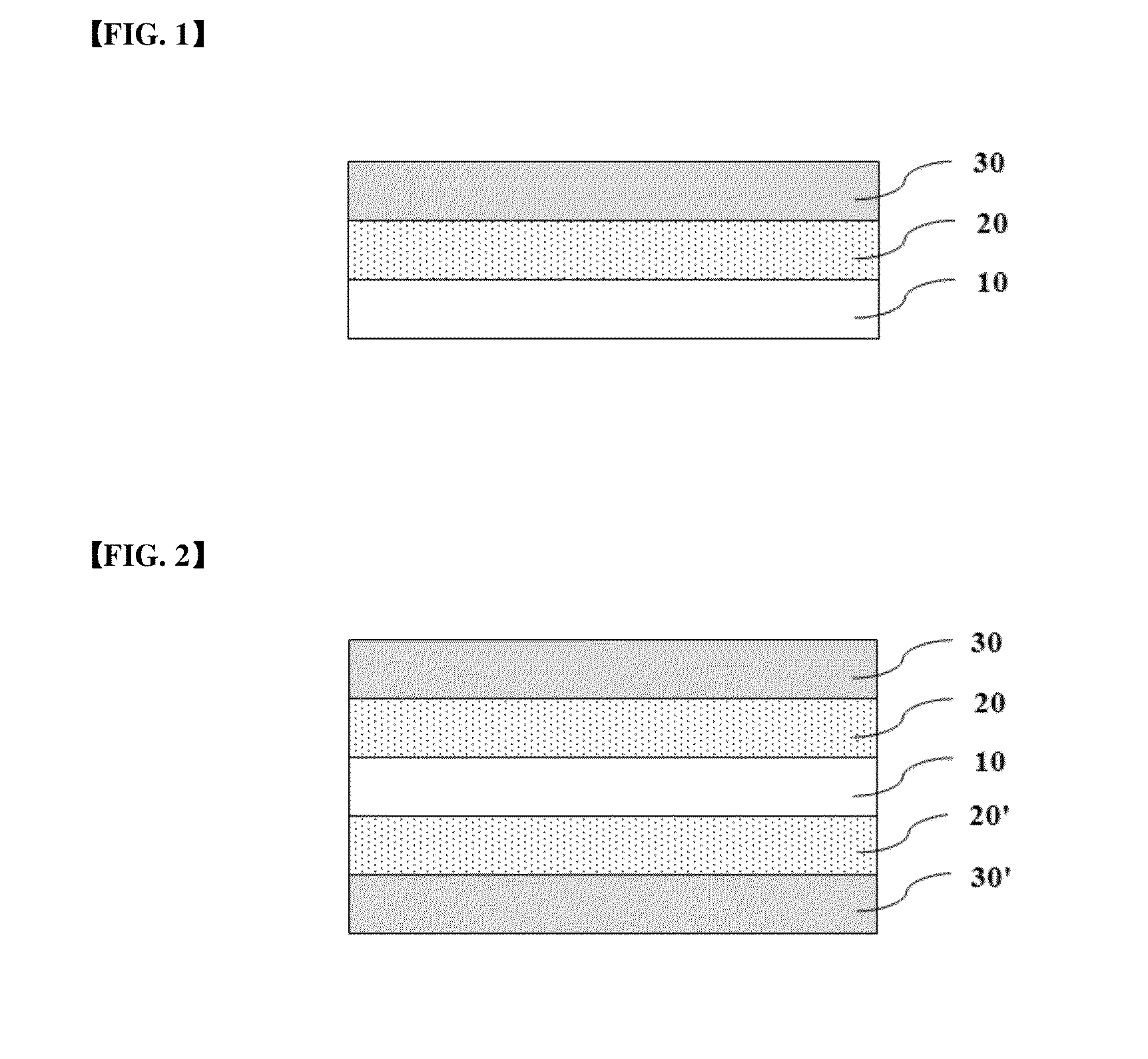

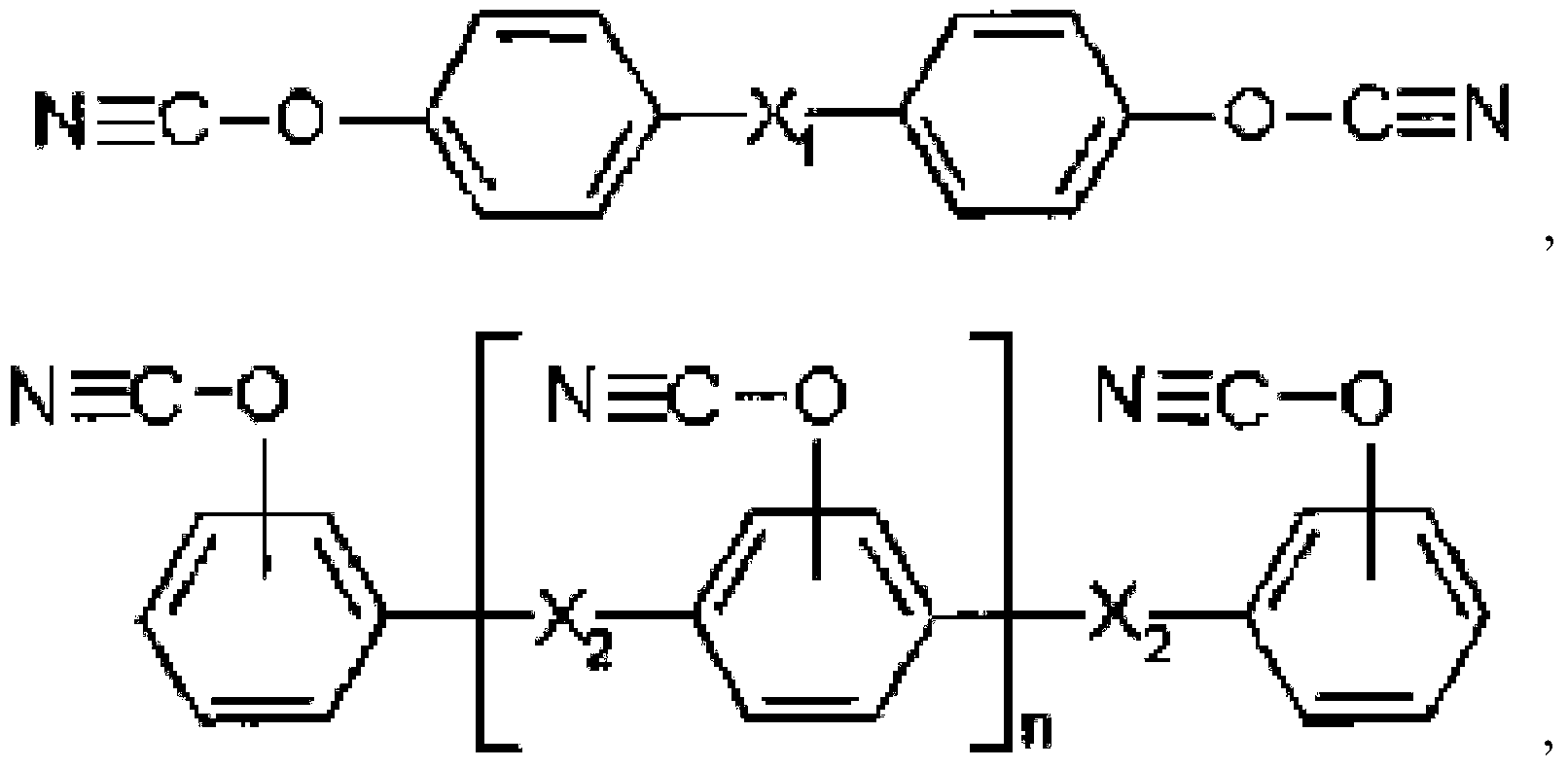

Cyanate esters-based adhesive resin composition for fabrication of circuit board and flexible metal clad laminate comprising the same

InactiveUS20140335341A1Low dielectric constantImprove electrical characteristicsDielectric materialsSynthetic resin layered productsDielectric loss factorMetal

The present invention relates to an adhesive resin composition for fabrication of circuit boards and its use. The adhesive resin composition of the present invention includes a cyanate ester resin, a fluorine-based resin powder dispersed in the cyanate ester resin, and a rubber component and has low dielectric constant and low dielectric loss factor, which enables the fabrication of circuit boards with further enhanced electrical characteristics.

Owner:LG CHEM LTD

Thermosetting resin composition and prepreg and laminate prepared therefrom

InactiveCN104371320ALow dielectric constantSmall dielectric lossSynthetic resin layered productsElectrical equipmentDielectric lossCyanate compound

The invention relates to a thermosetting resin composition and prepreg and laminate prepared therefrom. The thermosetting resin composition contains the following ingredients in parts by weight: 50-150 parts of cyanate, 30-120 parts of epoxy resin, 20-70 parts of allyl benzene-maleic anhydride, 20-100 parts of polyphenyl ether, 30-100 parts of halogen-free flame retardant, 0.05-5 parts of curing accelerator and 50-200 parts of filler. The prepreg and the laminate, which are manufactured from the thermosetting resin composition, have the comprehensive properties of low dielectric constant, low dielectric loss, excellent flame retardance, heat resistance and wet resistance and the like, and are suitable for being applied to halogen-free high-frequency multilayer circuit boards.

Owner:GUANGDONG SHENGYI SCI TECH

Hybrid polymers made of cyanates and silazanes, method for the production and use thereof

InactiveCN102449035AImprove featuresImprove fracture toughnessGlass/slag layered productsThin material handlingPolymer scienceHigh fracture

The invention relates to hybrid pre-polymers and polymers produced by converting difunctional, oligofunctional and / or polyfunctional cyanates and / or pre-polymers thereof with monomer, oligomer and / or polymer silazanes. The polymers are duromers having high glass transition temperature and very high fracture toughness from the respective cyanate output materials. They can be dissolved in a pre-polymerized state in solvents and are therefore suitable as impregnating resins for prepregs, for example. In addition, they can be processed to moulded articles. The fire characteristics thereof are particularly exceptional.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV +1

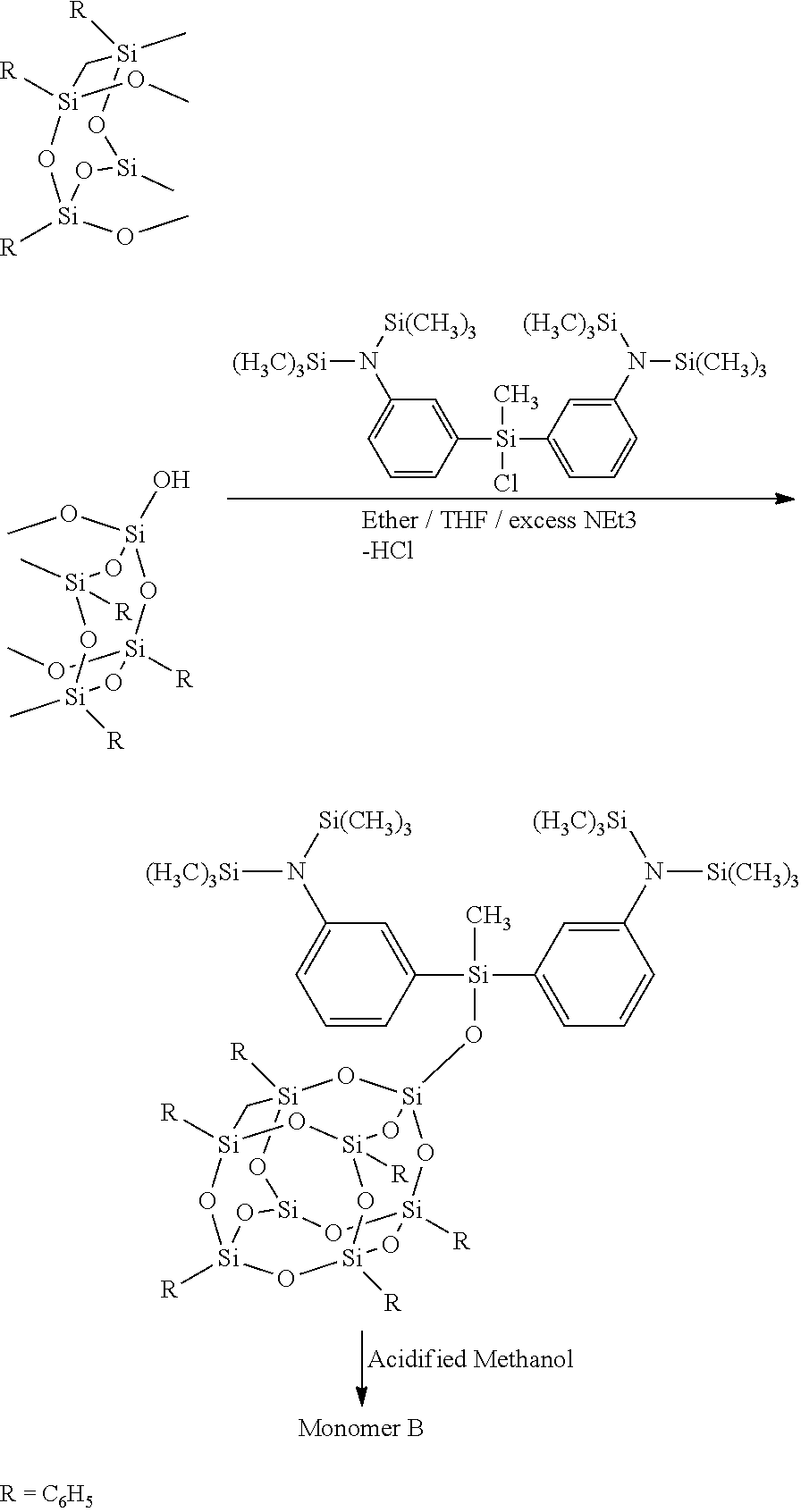

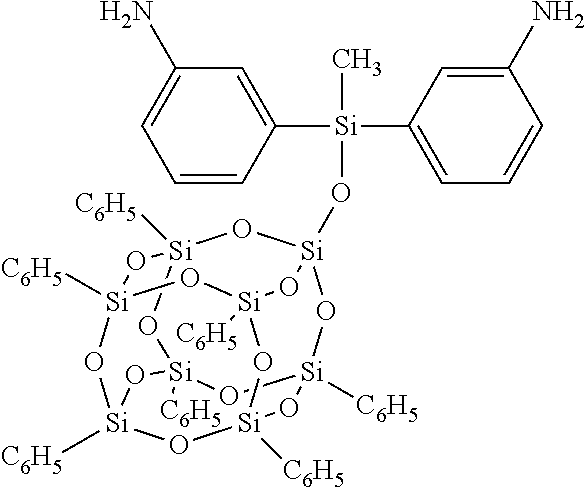

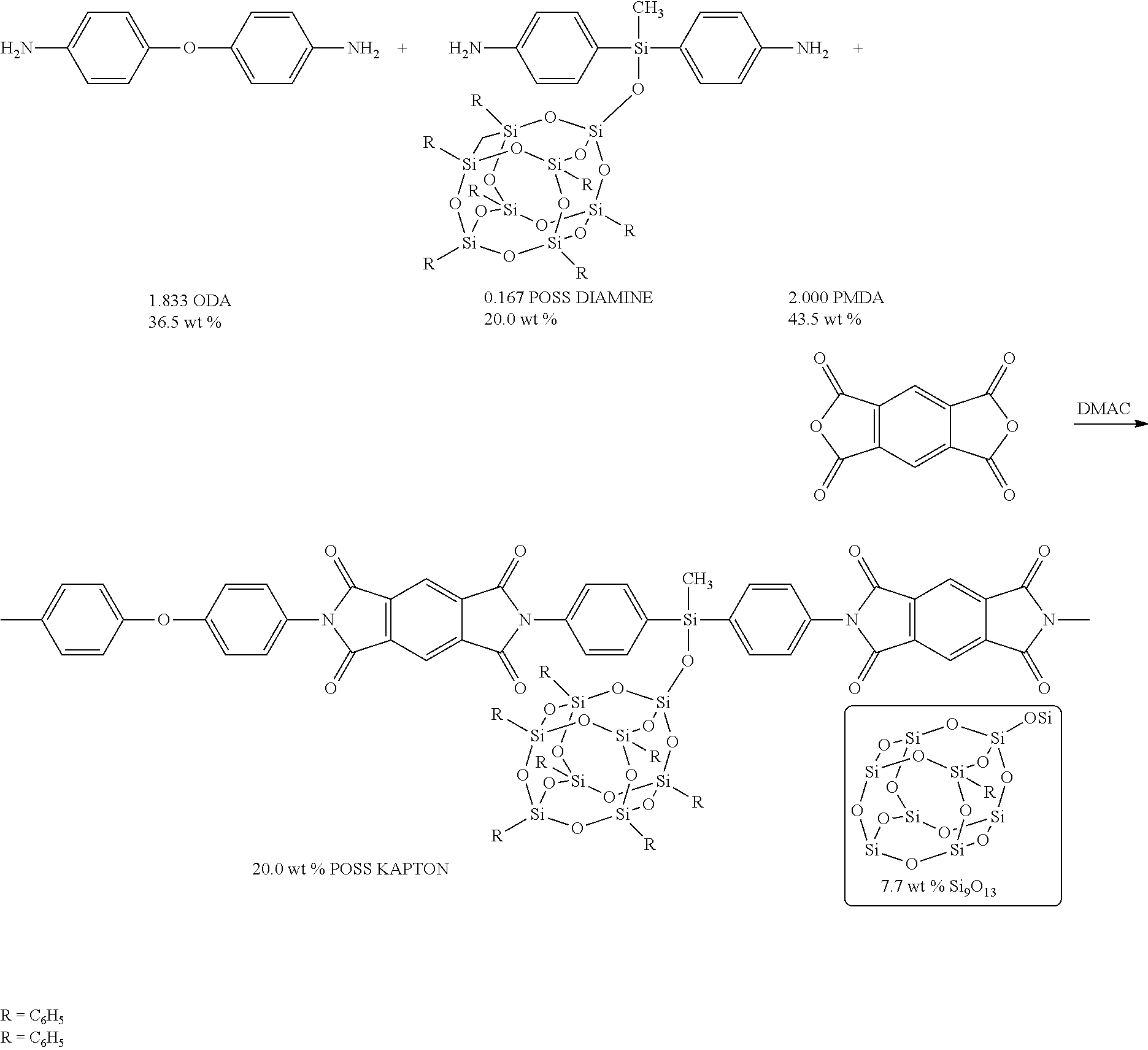

POSS enhanced compositions

A. new compound, a high temperature POSS-dianiline is provided. It is a composition of nanoparticles, which can be incorporated into polymers such as polyimides, polyamides, cyanate esters, and epoxies, for improved properties and performance of such polymers.

Owner:GOVERNMENT OF THE UNITED STATES AS REPRESENTED BY THE SEC OF THE AIR FORCE

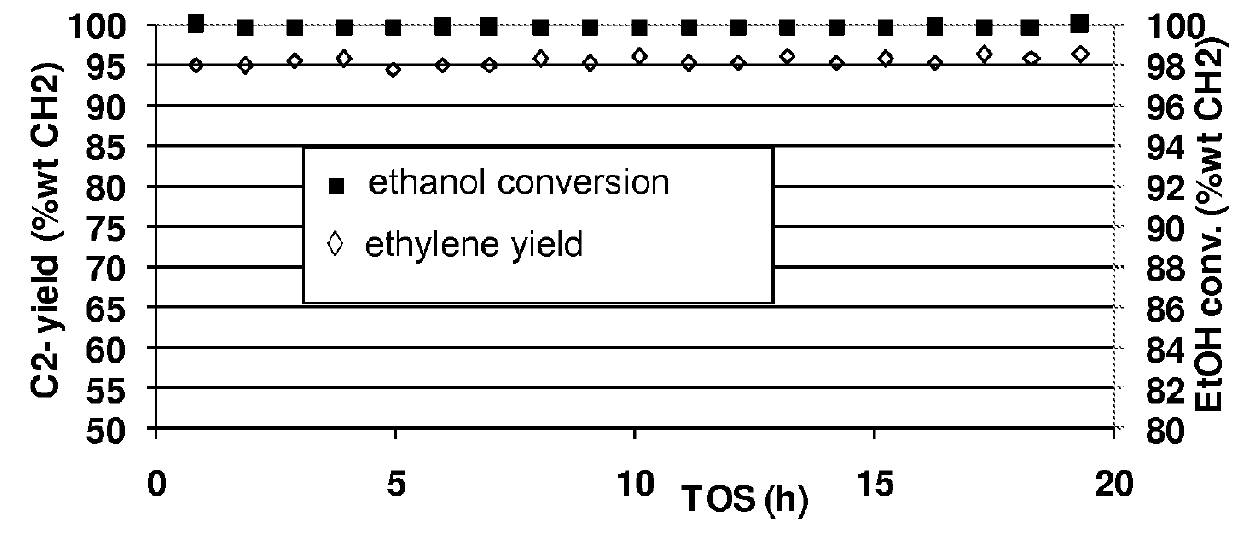

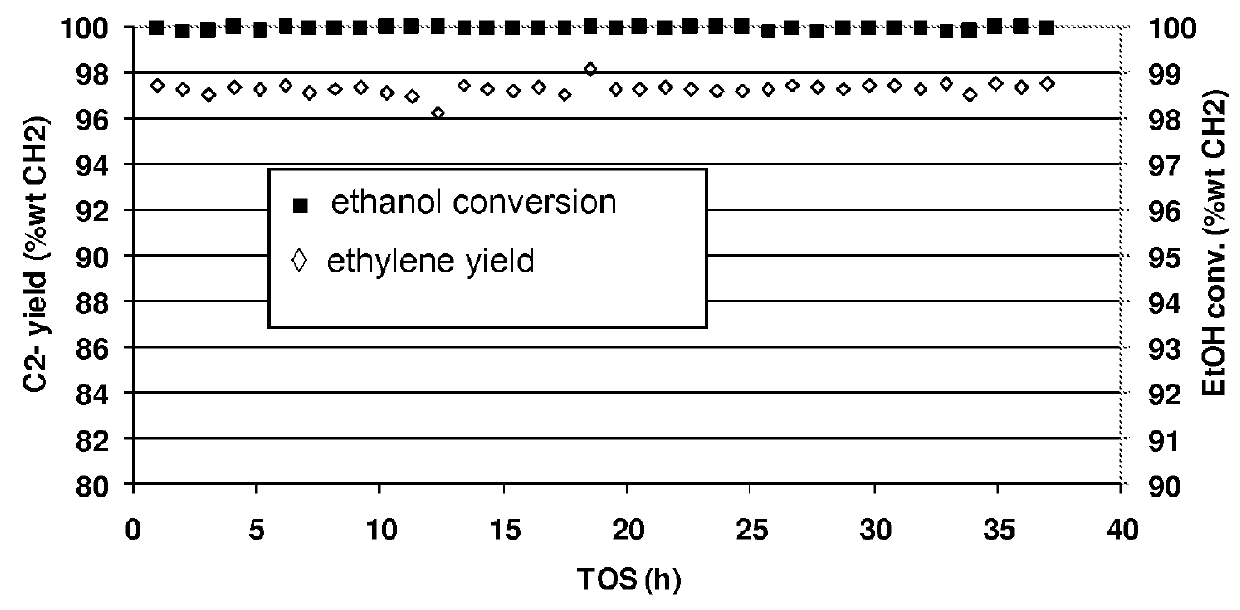

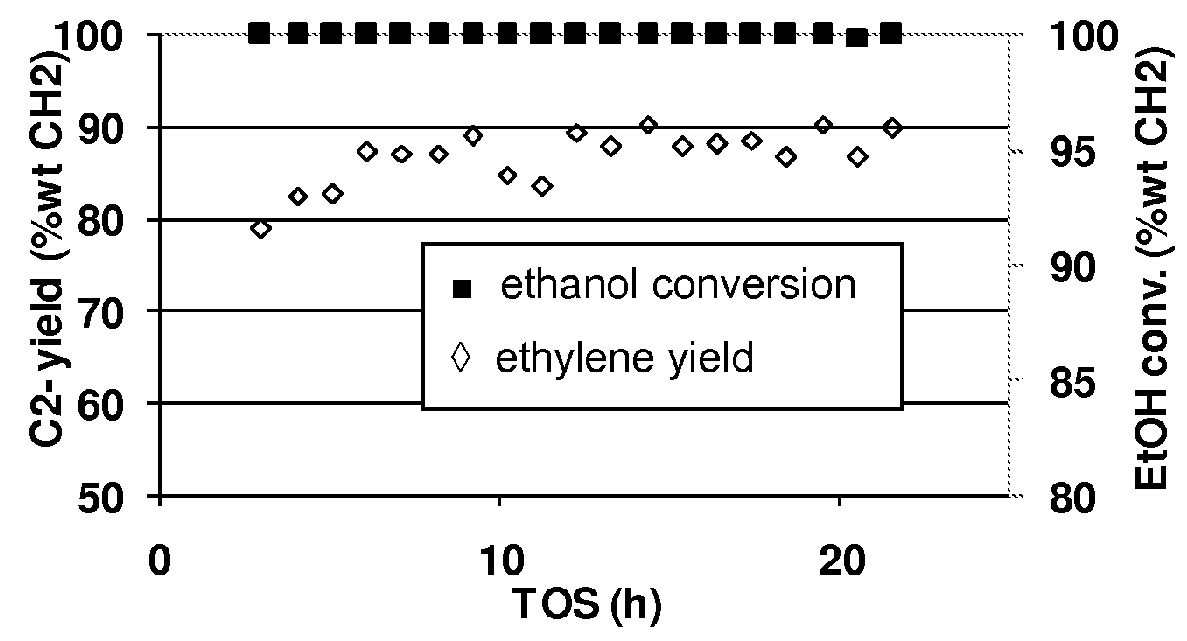

Dehydration of alcohols on acidic catalysts

ActiveUS9249066B2High selectivityMolecular sieve catalystsMolecular sieve catalystKetoneAlkyl nitrites

A dehydration process may include introducing in a reactor an alcohol, and contacting the alcohol with an acidic catalyst to dehydrate the alcohol to make a corresponding olefin. The process may include recovering from the reactor the olefin and water. In the process, an effective amount of a component capable to neutralize a part of the catalyst active site may be introduced. The component may include ammonia, organic ammonium salts, hydrazine, nitriles, amines, amides, imines, di-imines, imides, cyanates, isocyanates, nitrites and nitroso compounds, aldehydes, ketones, carboxylic esters, and their corresponding thio-compounds.

Owner:TOTAL RES & TECH FELUY

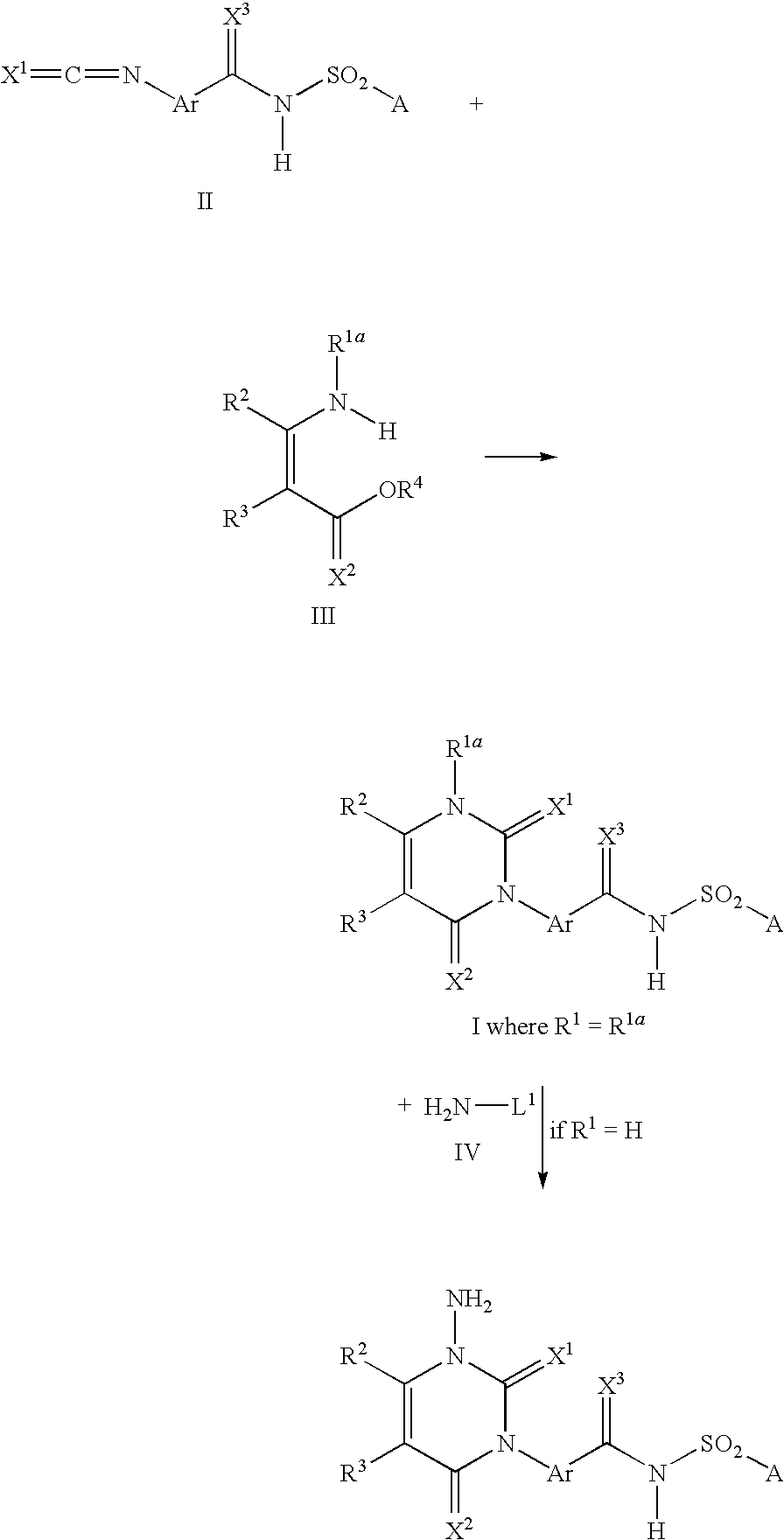

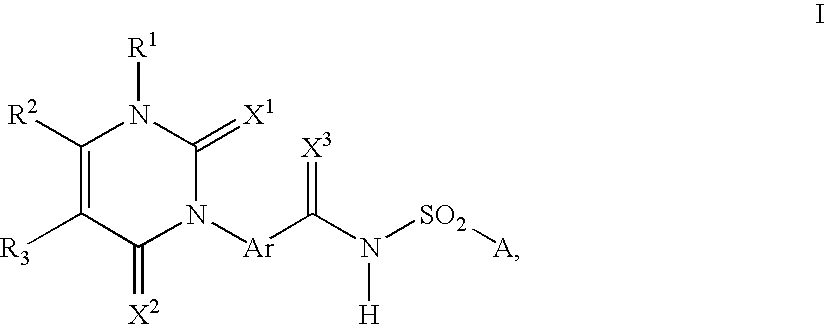

Method for producing 3-phenyl(thio)uracils and 3-phenyldithiouracils

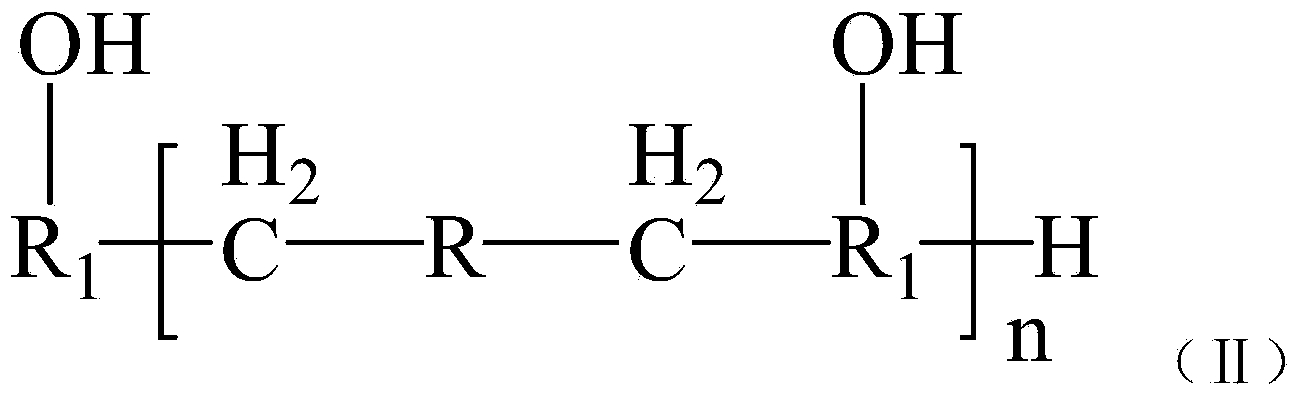

A process is described for preparing 3-phenyl(thio)uracils or 3-phenyldithiouracils of the formula I, by reacting a phenyl iso(thio)cyanate of the formula II with an enamine of the formula III and, if appropriate, in a further step, the resulting 3-phenyl(thio)uracil or 3-phenyldithiouracil of the formula I where R1=R1a, when R1=hydrogen, is reacted with an aminating agent of the formula IV to give 3-phenyl(thio)uracils or 3-phenyldithiouracils of the formula I where R1=aminowhere the variables R1, R1a, R2, R3, R4, X1, X2, X3, Ar, A and L1 are each as defined in claim 1.

Owner:BASF AG

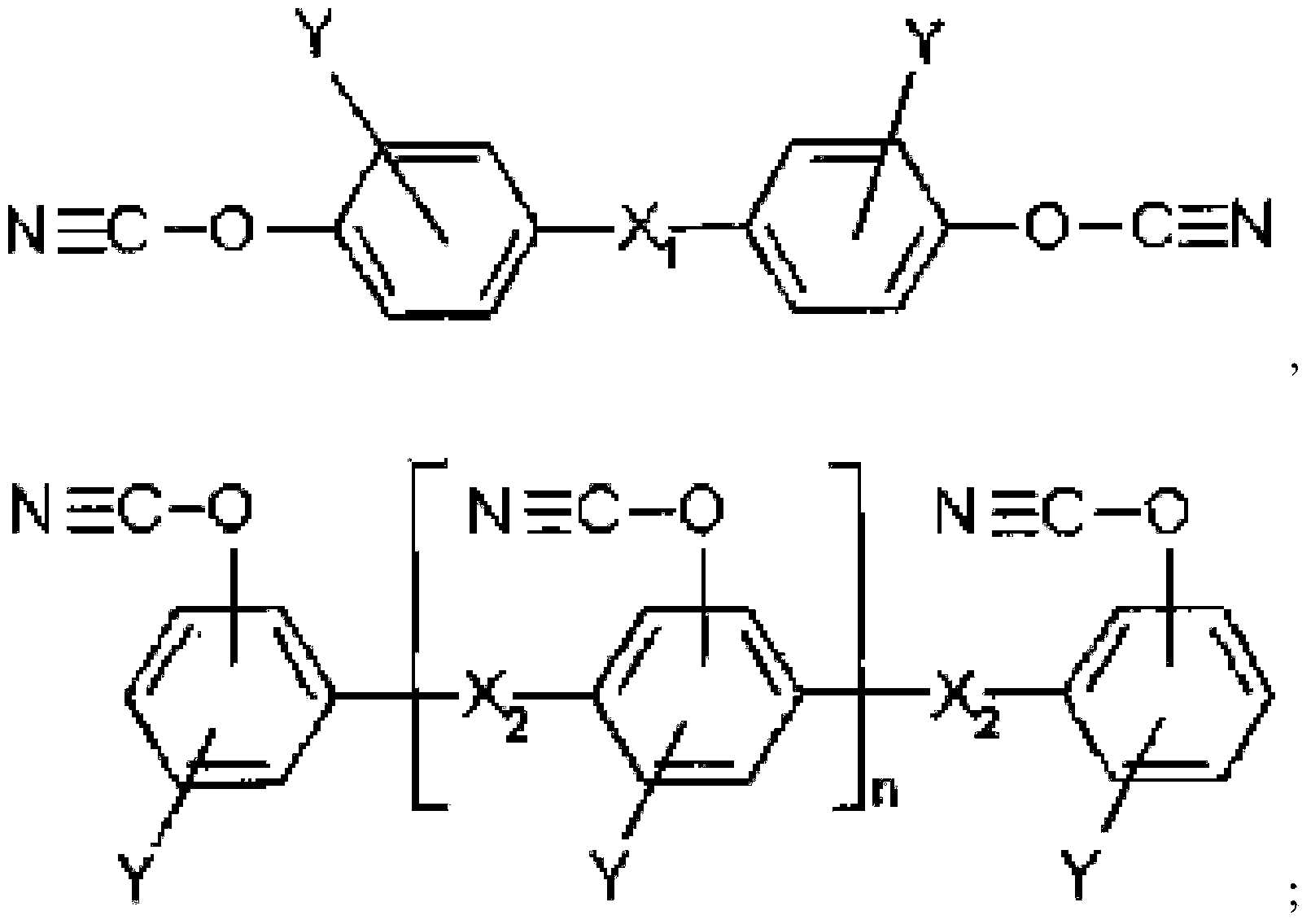

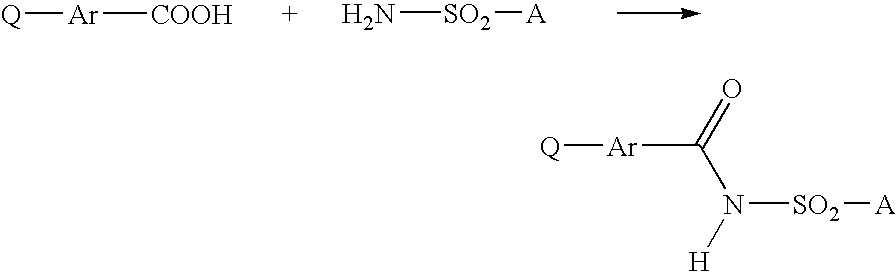

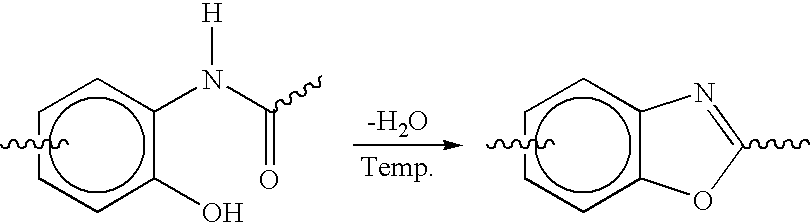

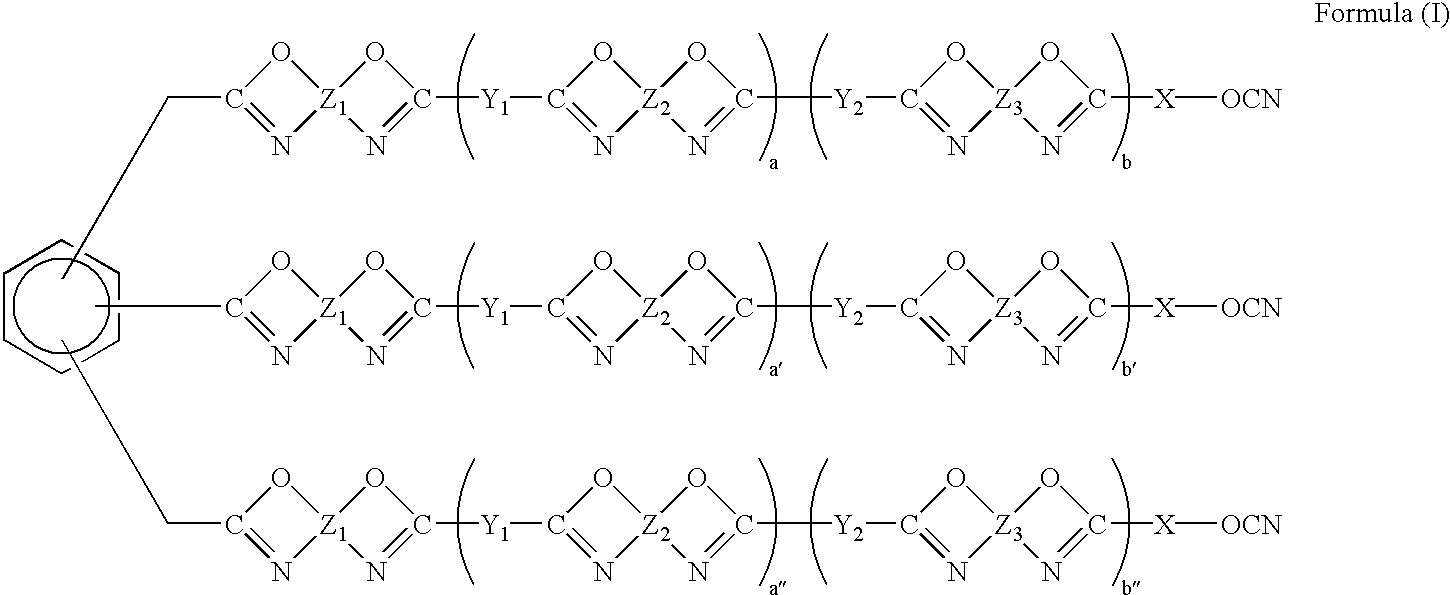

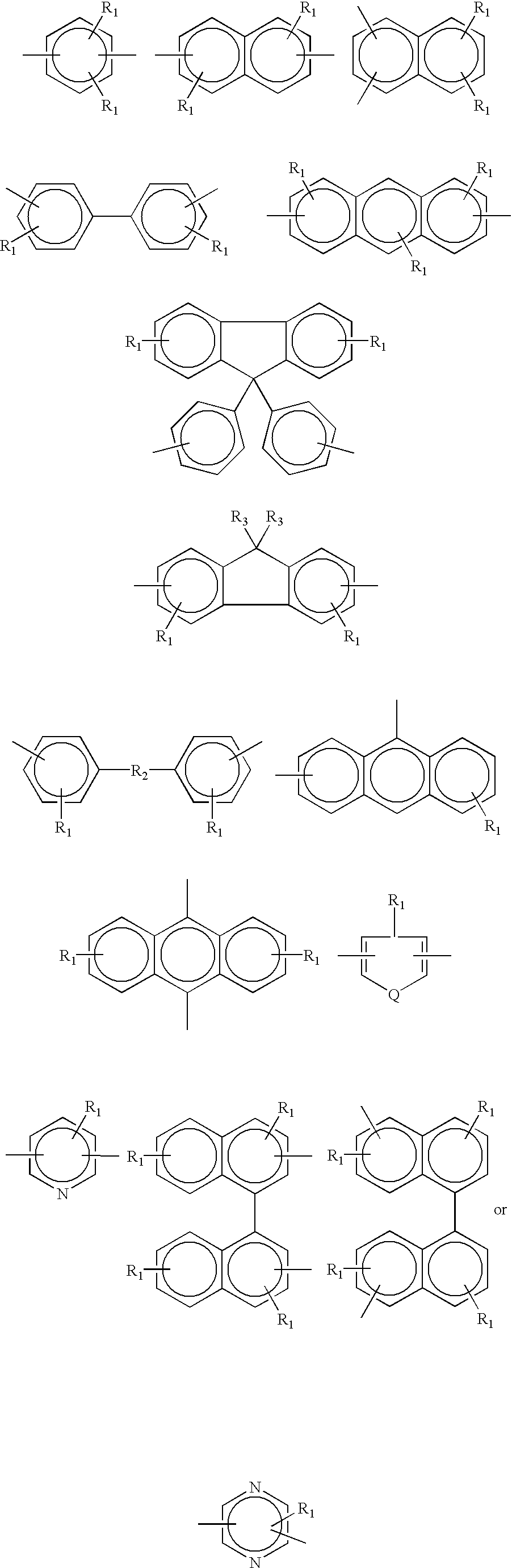

Phenyl-linked oxazole cyanates as dielectrics having good adhesive and filling properties

InactiveUS20030060573A1High bonding strengthPlastic/resin/waxes insulatorsHollow inflatable ballsBenzoxazoleAryl

Owner:POLARIS INNOVATIONS LTD

Chemical Mechanical Planarization for Tungsten-Containing Substrates

InactiveUS20140273458A1Maintaining and boosting tungsten film removal rateHigh selectivitySemiconductor/solid-state device manufacturingSurface treatment compositionsCompound (substance)Cyanate compound

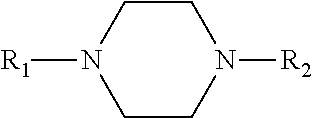

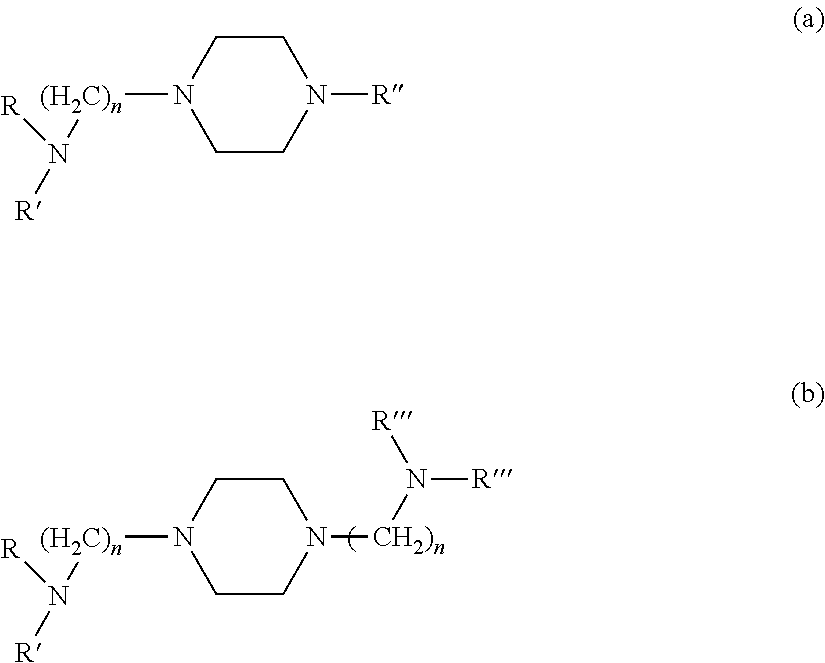

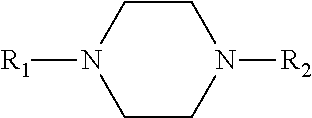

Chemical mechanical polishing (CMP) compositions for polishing tungsten or tungsten-containing substrates comprise an abrasive, at least one solid catalyst, a chemical additive selected from the groups consisting of piperazine derivatives, salts of cyanate, and combinations thereof; and a liquid carrier. Systems and processes use the aqueous formulations for polishing tungsten or tungsten-containing substrates.

Owner:VERSUM MATERIALS US LLC

Modified cyanate coating

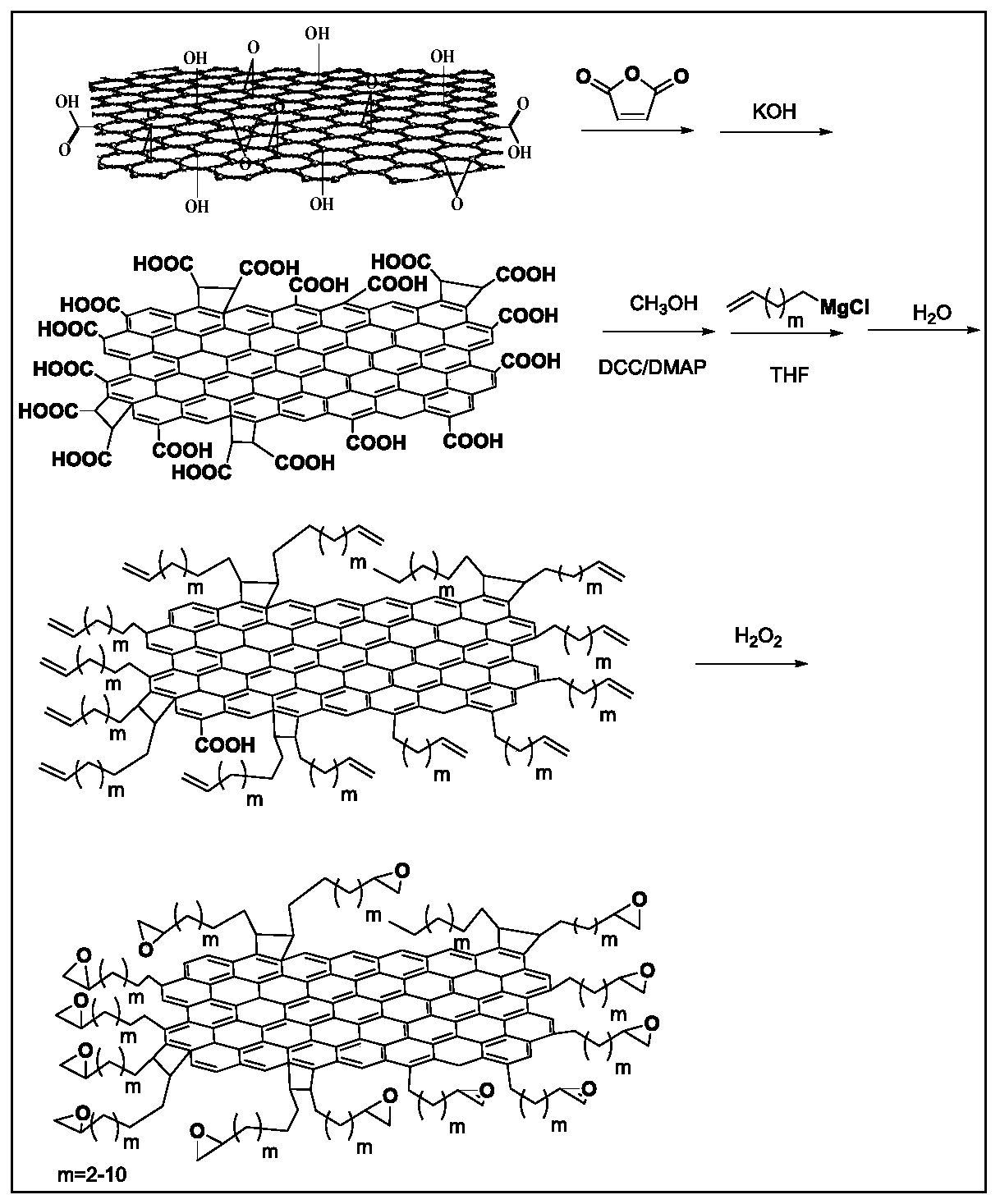

ActiveCN109943223AImprove mechanical propertiesGood thermal propertiesCoatingsReactive diluentGraphene

The invention provides a modified cyanate coating. The modified cyanate coating contains epoxy group-modified graphene, cyanate resin and a non-reactive diluent, namely tetrahydrofuran. Compared withthe prior art, the modified cyanate coating has the advantages that the cyanate coating is modified with epoxy group-modified graphene with a certain chain segment length, and the surface of epoxy group-modified graphene contains a sufficient amount of epoxy chain segments, so that the aggregation among slice layer is blocked, and the sufficient steric hindrance for the dispersion of graphene is realized; and meanwhile, the liquidation of a graphene nano-material can be realized by virtue of an epoxy alkyl chain with a specific length, so that the uniform dispersion of liquefied epoxy group-modified graphene in the cyanate resin is promoted by virtue of the ultralow viscosity of the cyanate resin in a high-temperature curing process; besides, an epoxy functional group on the surface of graphene can react with a cyanate intermediate, namely a triazine ring in the curing process of the cyanate resin, so that the curing process of the cyanate resin is accelerated.

Owner:浙江中科应化科技有限公司

Cyanate resin composition and application for preparing high modulus carbon fiber prepreg by hot-melt method thereof

The invention provides a cyanate resin composition comprising at least one 70-90wt% of cyanate or cyanate prepolymer, 30-10wt% of epoxy resin and 100-500ppm of catalyst. In addition, the invention provides a high modulus carbon fiber prepreg which is prepared by soaking the carbon fiber in the cyanate resin composition without solvent, the prepreg has good operability and long-life property at room temperature, and the mechanical property of the cyanate / high modulus carbon fiber composite material which is through the hot-press forming with a press or through the autoclave forming is greatly increased compared with that of the corresponding epoxy / high modulus carbon fiber.

Owner:EAST CHINA UNIV OF SCI & TECH

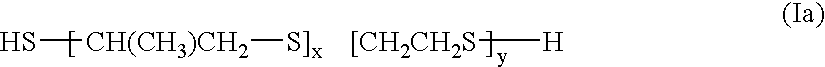

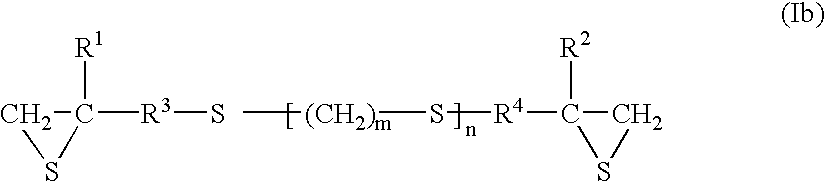

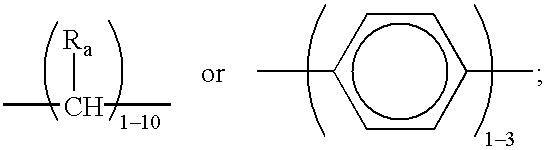

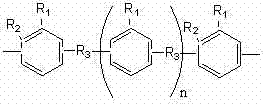

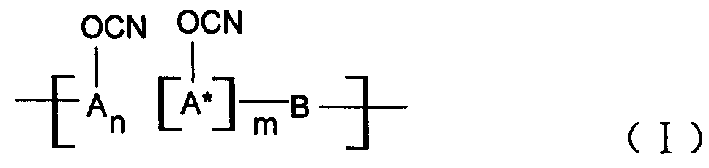

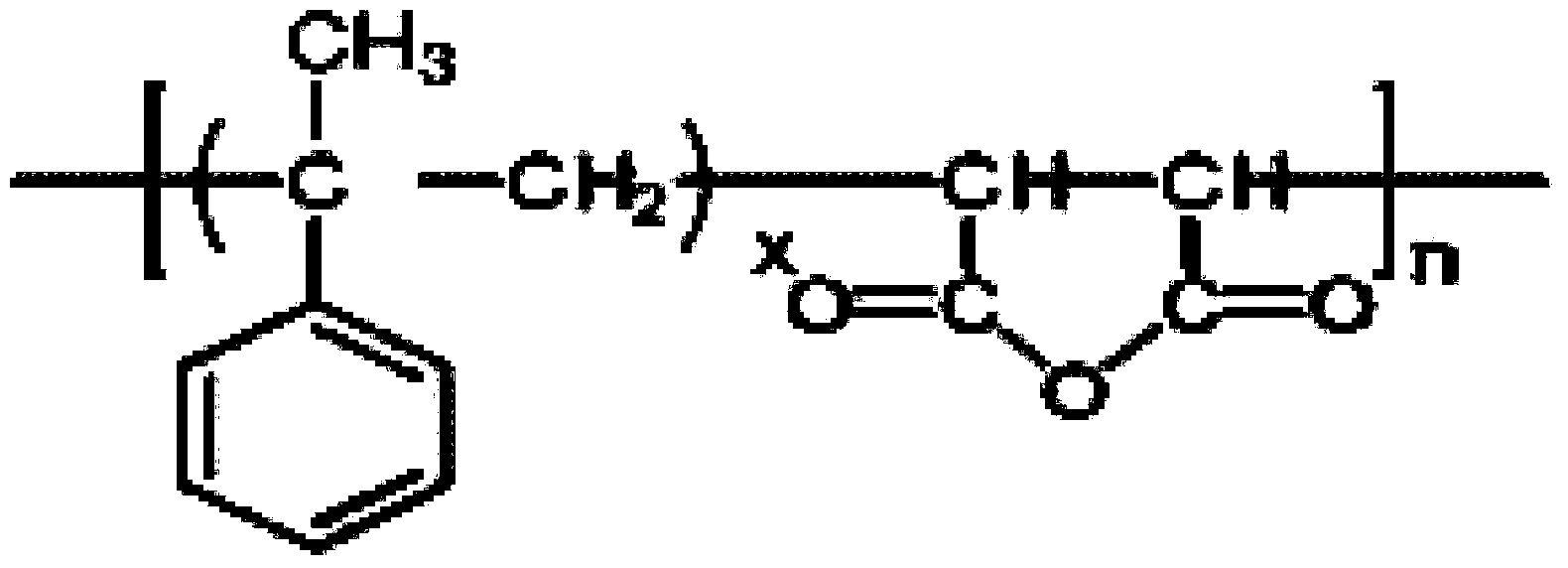

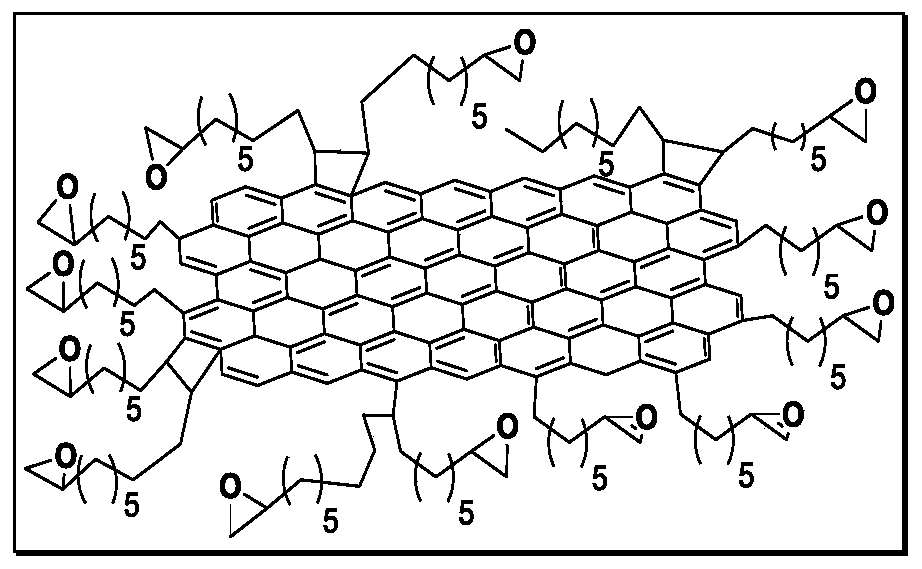

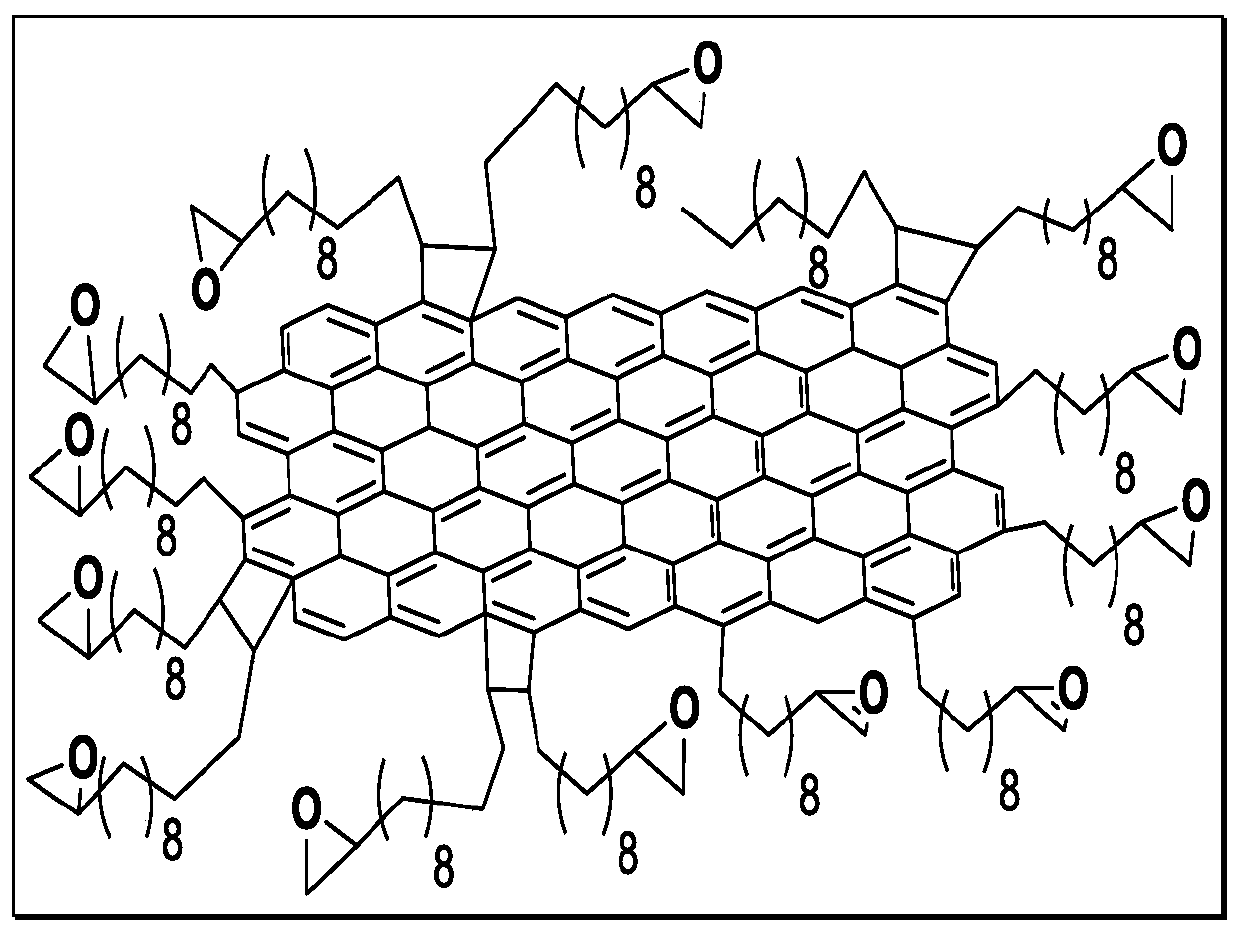

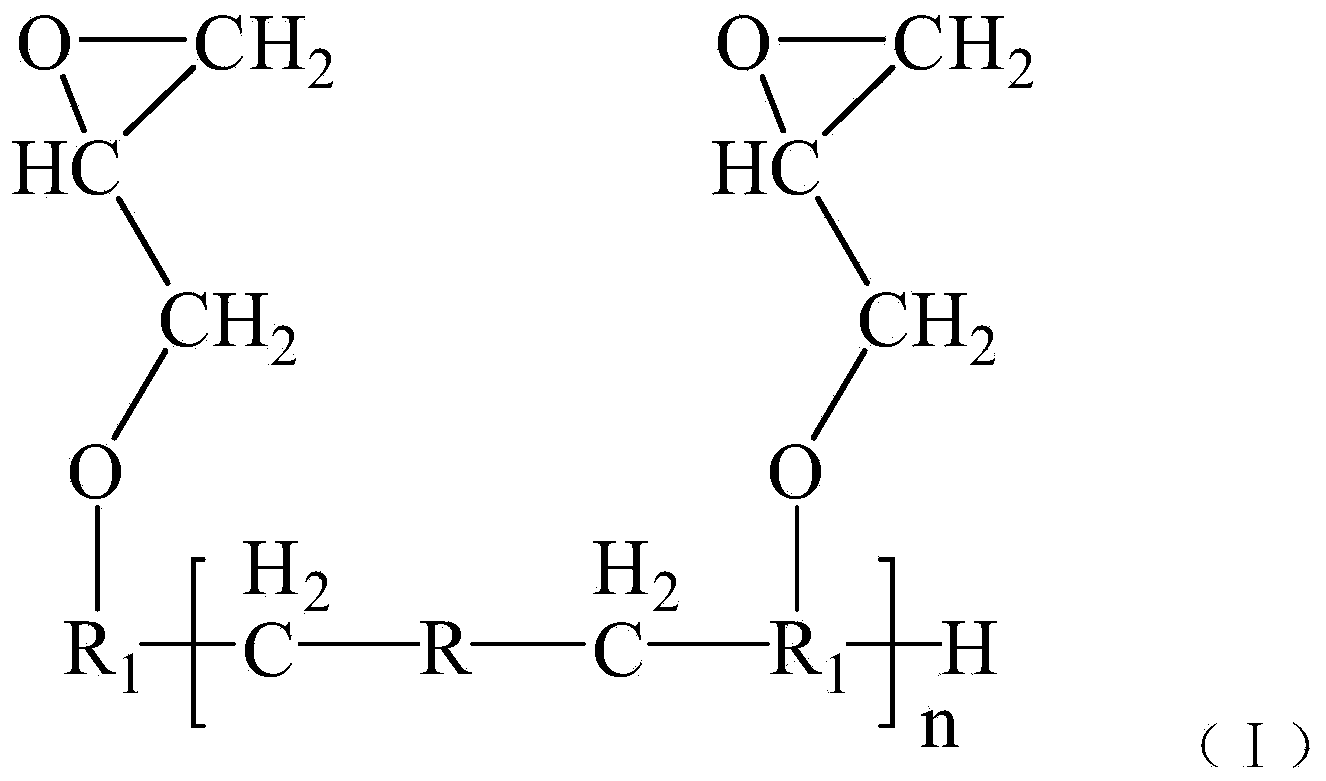

Cyanate resin composition and application thereof

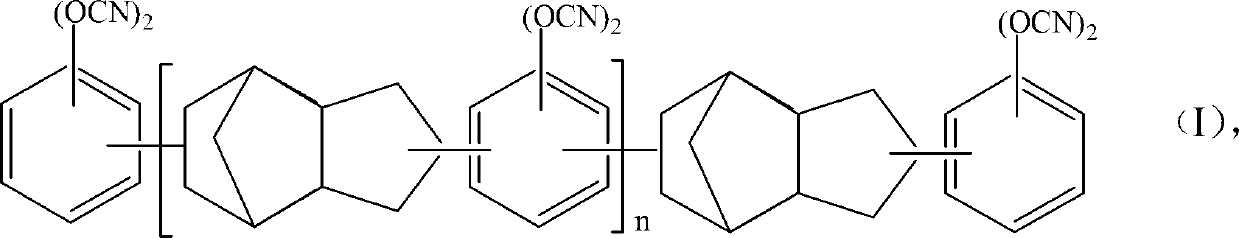

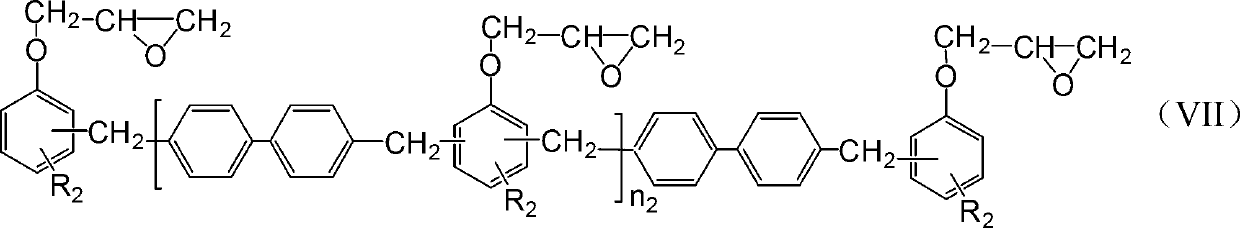

InactiveCN103724999AImprove moisture resistanceImprove heat resistanceSynthetic resin layered productsElectrical equipmentEpoxyHigh density

The invention relates to a cyanate resin composition, and a prepreg, laminated board, metal foil clad laminated board and printed circuit board prepared from the same. The cyanate resin composition comprises a cyanate resin (A), an epoxy resin disclosed as Formula (I) and a maleimide compound (C). The cyanate resin composition, and the prepreg, laminated board, metal foil clad laminated board and printed circuit board prepared from the cyanate resin composition have the advantages of favorable moisture resistance, favorable heat resistance, high flame retardancy, high reliability and low planar thermal expansion coefficient, and is suitable for substrate materials for manufacturing high-density printed circuit boards.

Owner:GUANGDONG SHENGYI SCI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com