Halogen-free resin composition and method for manufacturing prepreg and laminated board by using halogen-free resin composition

A technology of resin composition and manufacturing method, which is applied in the field of manufacturing prepregs, laminates for printed circuits, and halogen-free resin compositions, can solve the problems of loss of dielectric properties of cyanate resin, etc., and achieve low dielectric loss factor and excellent resistance. Effect of flammability, high glass transition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Take 25 parts of dicyclopentadiene (DCPD) type epoxy resin (XD-1000, Nippon Kayaku), 20 parts of phosphorus-containing epoxy resin (XZ92530, DOW), bisphenol A type cyanate resin (BA-3000S, Lonza) 45 parts, anhydride curing agent (SMA EF40, Sartomer) 10 parts, benzoxazine (XTW8291, Huntsman Advanced Materials) 15 parts, 2-methylimidazole (Shikoku Chemicals) 0.08 parts, carboxyl-terminated nitrile rubber (1072CG, Zeon Corporation) 5 parts, spherical silica (SFP-30M, DENKA) 40 parts, the solid content of the resin composition was adjusted to 40wt% with butanone solvent.

[0028] The thermosetting resin composition is impregnated and coated on E-type glass cloth (2116, unit weight 104g / m 2 ) and baked in an oven at 170°C for 4 minutes to obtain a prepreg with a resin content of 50%.

[0029] Put the prepared prepreg with a resin content of 50%, put a piece of copper foil on the upper and lower sides, and press it in a vacuum hot press to obtain a copper-clad laminate. The...

Embodiment 2

[0032] Take 50 parts of biphenyl type epoxy resin (NC-3000, Nippon Kayaku), 30 parts of bisphenol A type cyanate resin (CY-1, Jiangdu Wuqiao Resin Factory), 12 parts of anhydride curing agent (SMA EF40, Sartomer) 40 parts, benzoxazine (XTW8291, Huntsman Advanced Materials) 40 parts, 2-ethyl-4-methylimidazole (Shikoku Chemical) 0.12 parts, core-shell rubber (Fortegra351, Dow Chemical) 3 parts, hypophosphorous acid 5 parts of aluminum (OP935, Clariant, Germany), 50 parts of fused silica powder (Lianyungang Donghai silica powder), 20 parts of boehmite (BS100, Hehe lime), and adjust the solid content of the resin composition to 60wt% with butanone solvent .

[0033] The preparation methods of the prepreg and the copper-clad laminate are the same as in Example 1.

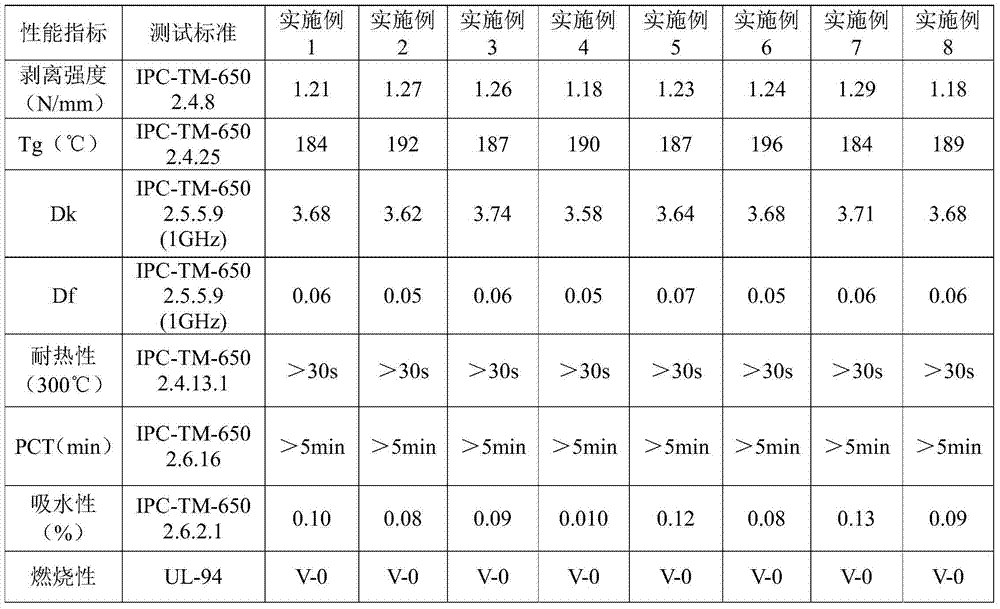

[0034] The properties of copper clad laminates are shown in Table 1.

Embodiment 3

[0036] Take 30 parts of dicyclopentadiene (DCPD) type epoxy resin (XD-1000, Nippon Kayaku), 10 parts of phosphorus-containing epoxy resin (XZ92530, DOW), dicyclopentadiene type cyanate resin (CY-3 , Jiangdu Wuqiao Resin Factory) 50 parts, anhydride curing agent (SMA EF60, Sartomer) 15 parts, benzoxazine (XTW8291, Huntsman Advanced Materials) 20 parts, 2-ethyl-4-methylimidazole (Shikoku Chemicals ) 0.06 parts, rubber modified epoxy resin (EponResin58005, Hexion Specialty Chemicals, Inc.) 10 parts, PX-200 (Japan Daihachi Chemical) 6 parts, spherical silica (SFP-30M, DENKA) 50 parts, with The butanone solvent adjusted the solid content of the resin composition to 50wt%.

[0037] The preparation methods of the prepreg and the copper-clad laminate are the same as in Example 1.

[0038] The properties of copper clad laminates are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com