Patents

Literature

102results about How to "Low dielectric dissipation factor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Halogen-free resin composition and method for manufacturing prepreg and laminated board by using halogen-free resin composition

InactiveCN103937157AImprove heat resistanceHigh glass transition temperatureSynthetic resin layered productsCircuit susbtrate materialsEpoxyCopper foil

The present invention discloses a halogen-free resin composition and a method for manufacturing a prepreg and a laminated board by using the halogen-free resin composition. The halogen-free resin composition is prepared by dispersing the following components in an organic solvent, wherein the components comprise, by weight, 10-100 parts of a halogen-free epoxy resin, 10-80 parts of cyanate, 10-70 parts of an anhydride curing agent, 10-100 parts of a benzoxazine resin, 0.01-1.0 part of a curing accelerator, 1-15 parts of a toughening agent, 0-50 parts of a fire retardation agent, and 0-100 parts of an inorganic filler, and the solid content of the halogen-free resin composition is 30-70 wt%. The prepared prepreg and the copper foil-clad laminated board have characteristics of good heat resistance, high glass-transition temperature, low water absorption rate, excellent fire retardation, low dielectric constant and low dielectric loss factor.

Owner:ZHEJIANG WAZAM NEW MATERIAL CO LTD

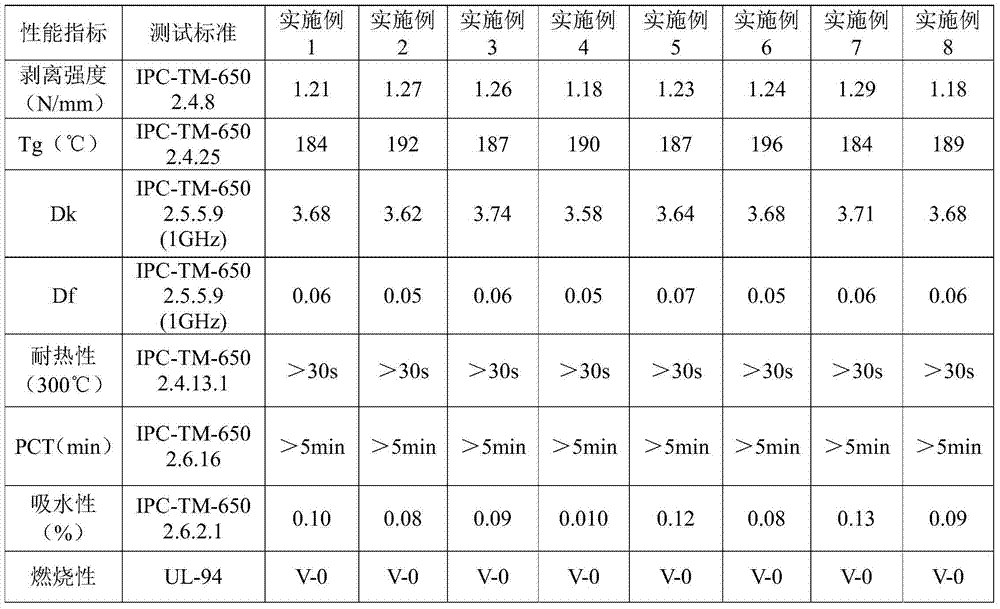

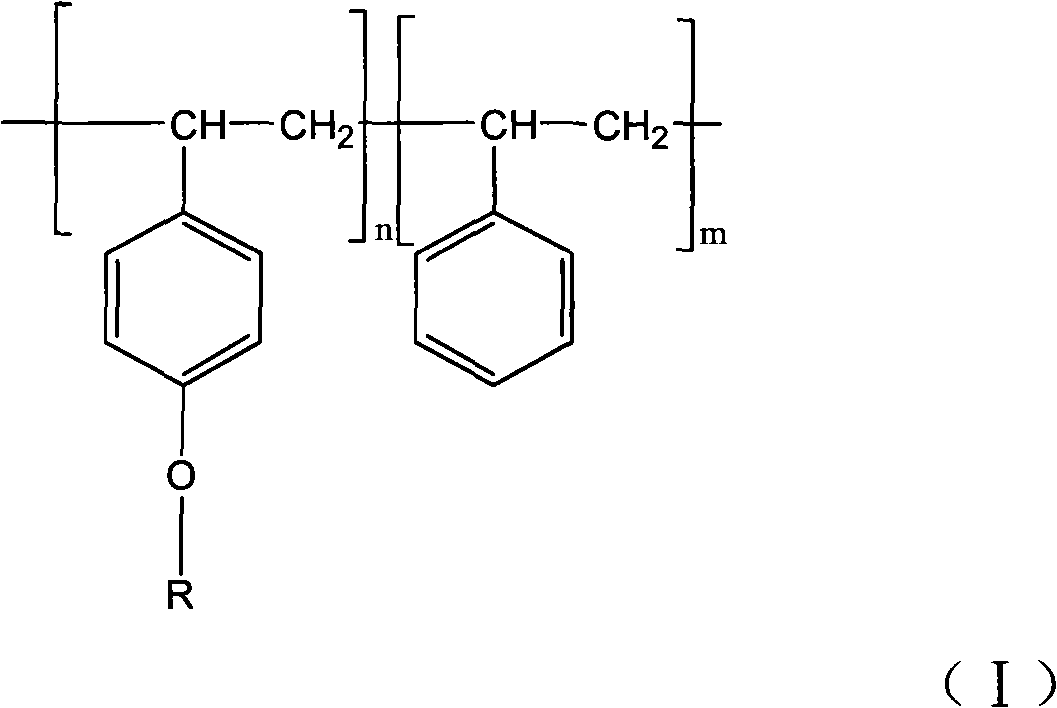

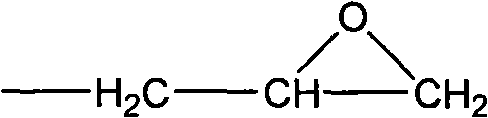

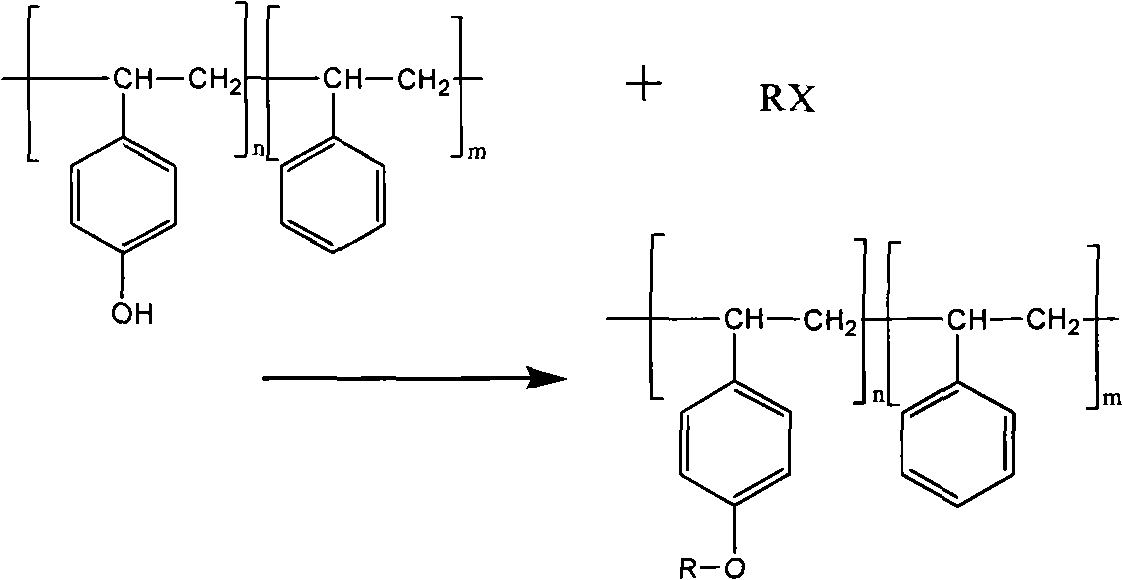

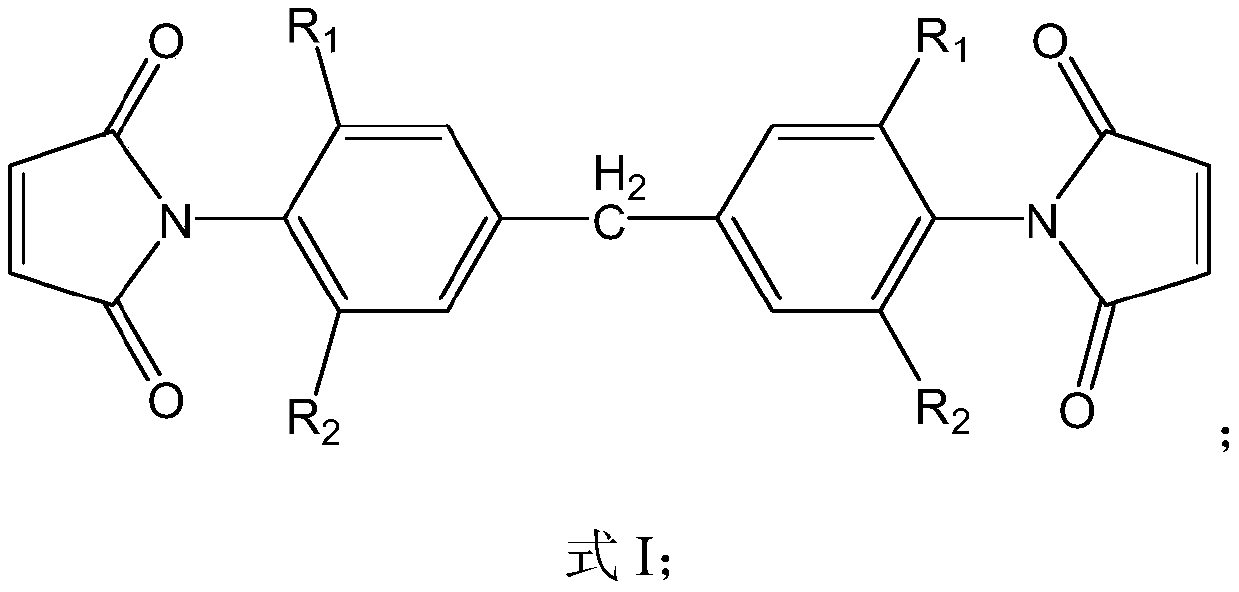

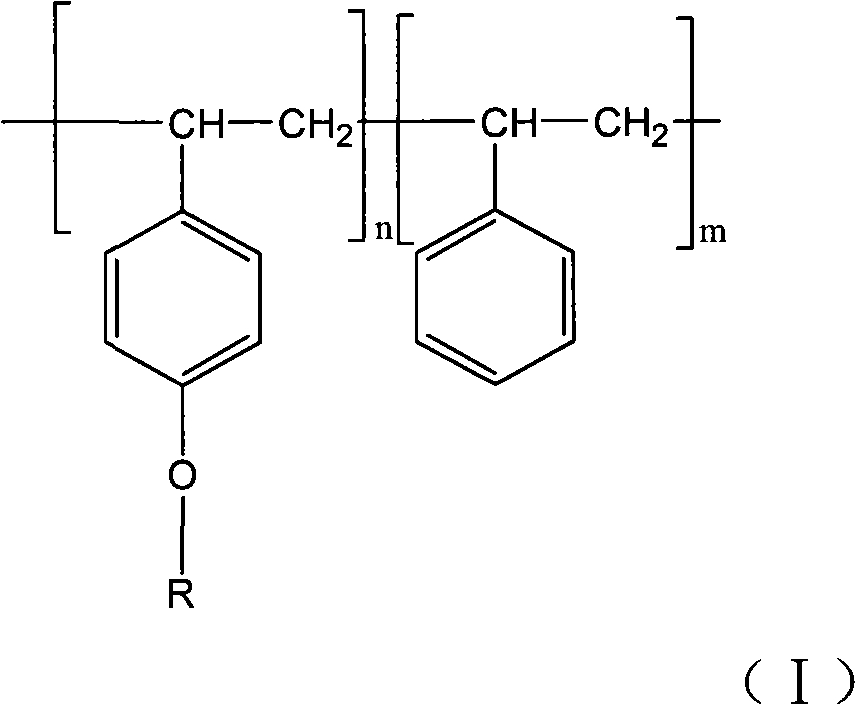

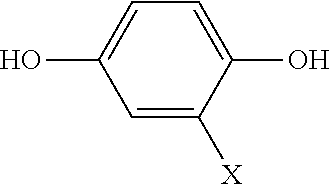

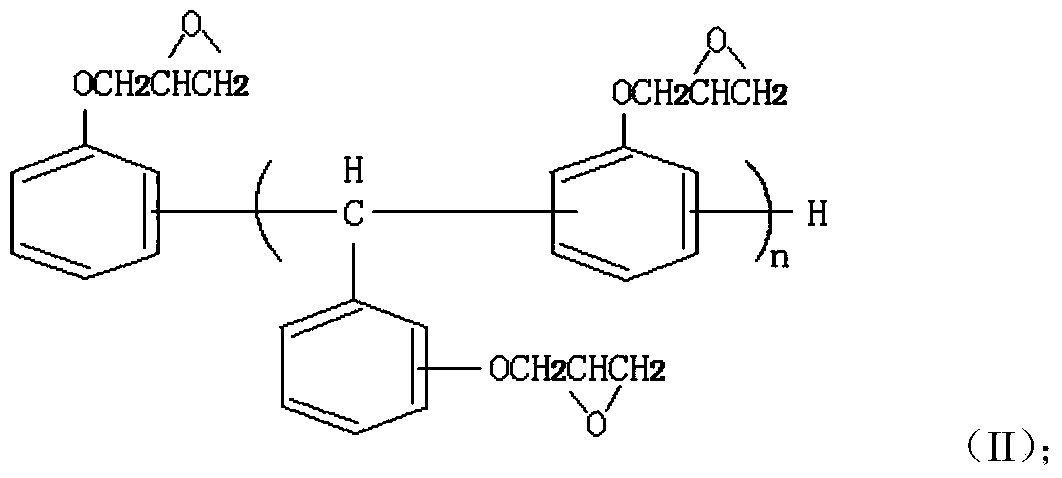

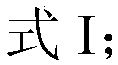

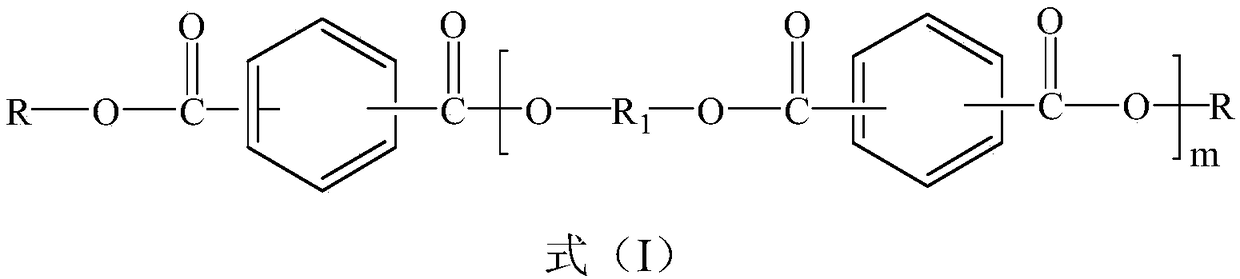

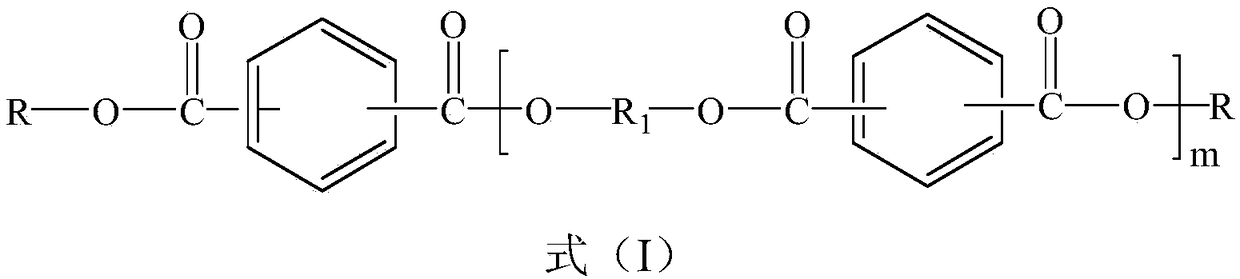

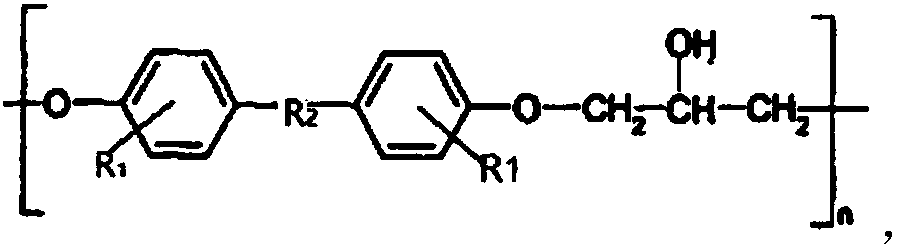

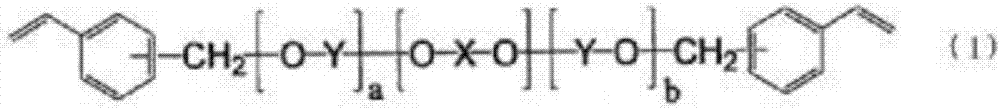

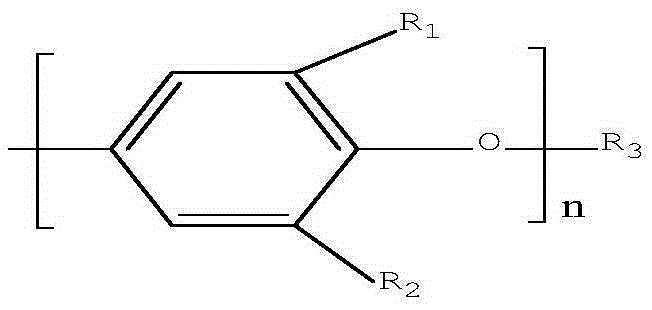

Thermosetting resin composition and prepreg and laminate for printed circuits thereby

InactiveCN101643571AExcellent dielectric propertiesImprove thermal stabilityCircuit susbtrate materialsMetal layered productsEpoxyDip soldering

The invention relates to a thermosetting resin composition and a prepreg and a laminate for printed circuits thereby. The thermosetting resin composition comprises at least an epoxy resin with a component being the structural formula (I) and a curing agent. The molecular structure of the epoxy resin composition of the invention contains the low-polarity styrene structure, therefore, the dielectricproperty of the resin is optimized. The dielectric constant and the dielectric loss angle tangent are reduced compared with those of the common epoxy resins. The prepreg obtained by coating the resincomposition on the substrates and the laminate manufactured by laminating the prepreg simultaneously have the characteristics of low dielectric constant, low dielectric dissipation factors, good heatresistance, good dip soldering resistance, good moisture resistance, good humidity resistance and good cohesiveness with copper foils. The resin composition of the invention can be also used for manufacturing the resin sheets, resin composition copper foils, the laminate and the printed circuit boards. R is (a), and n and m are natural numbers.

Owner:GUANGDONG SHENGYI SCI TECH

Thermosetting resin composition, prepreg comprising same, metal-foil-coated laminate and printed circuit board

ActiveCN109825081AHigh glass transition temperatureImprove heat resistancePrinted circuit aspectsSynthetic resin layered productsBenzoxazoleEpoxy

Owner:GUANGDONG SHENGYI SCI TECH

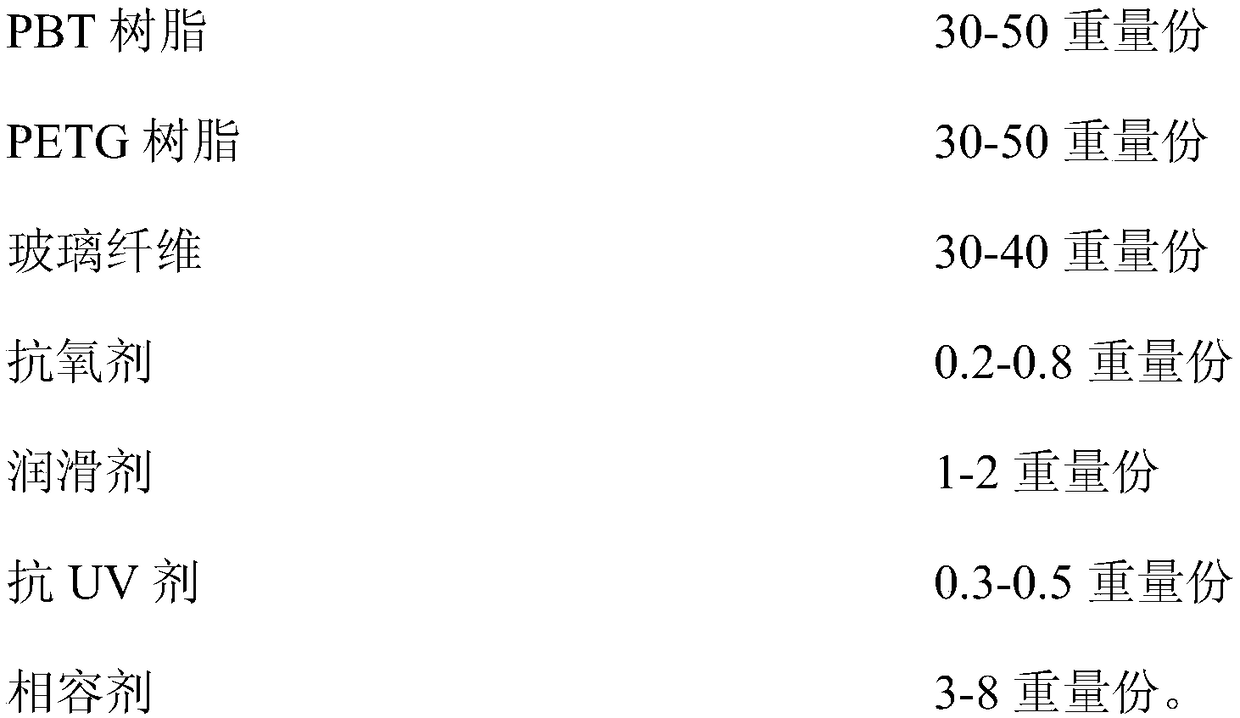

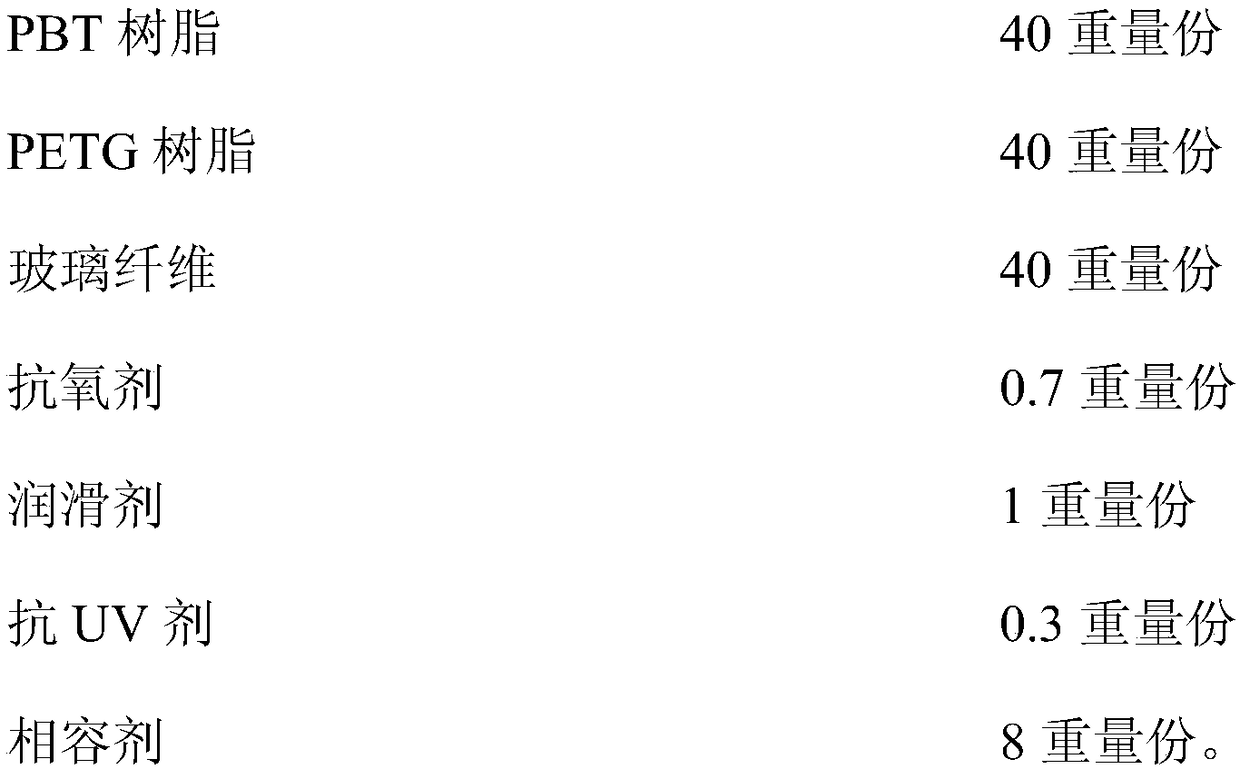

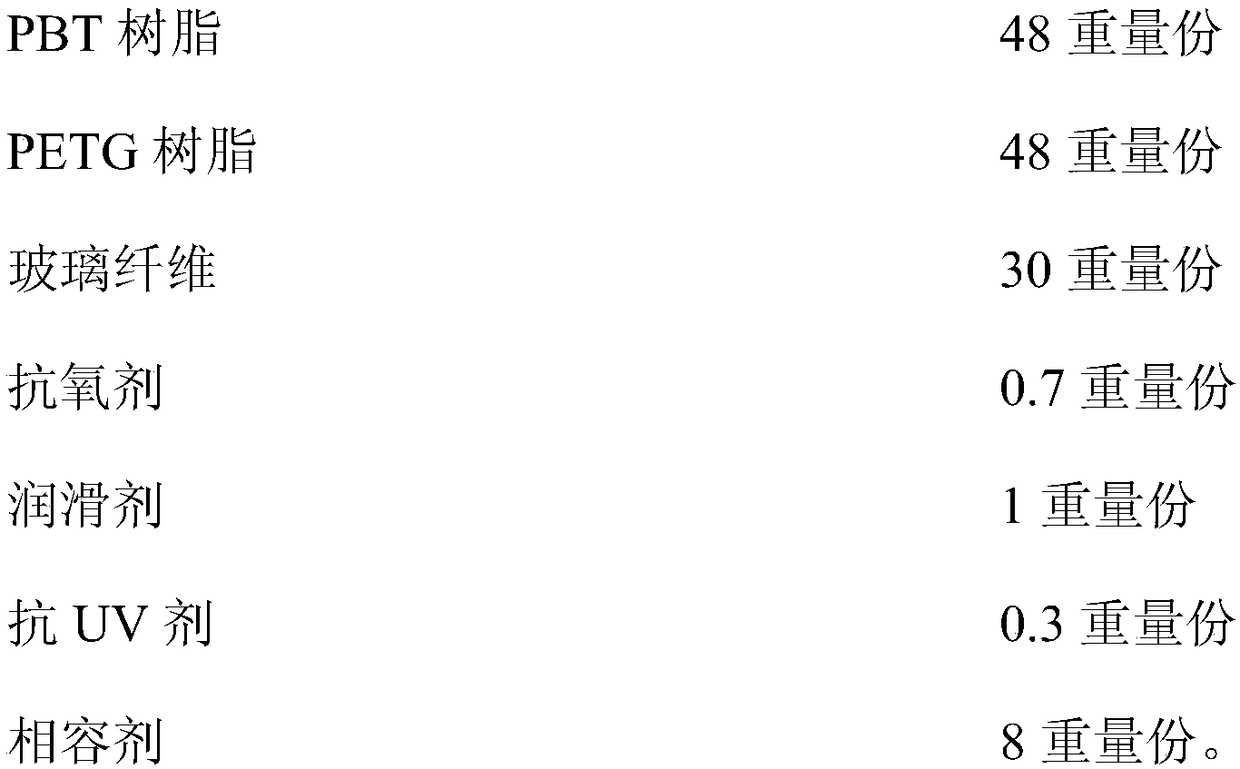

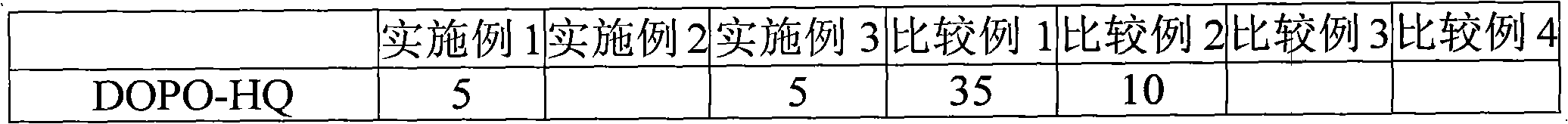

Low dielectric PBT/PETG alloy nanometer injection molding composite material as well as preparation method and application thereof

The invention provides a low dielectric PBT / PETG alloy nanometer injection molding composite material as well as a preparation method and application thereof. The preparation raw materials of the PBT / PETG alloy nanometer injection molding composite material comprise the following components in parts by weight: 30 to 50 parts of PBT resin, 30 to 50 parts of PETG resin, 30 to 40 parts of glass fiber, 0.2 to 0.8 part of an antioxidant, 1 to 2 parts of a lubricating agent, 0.3 to 0.5 part of an anti-UV agent and 3 to 8 parts of a compatilizer. The PBT / PETG alloy nanometer injection molding composite material has high mechanical performance, heat resistance, chemical resistance and machinability, has relatively low dielectric constant and relatively low dielectric dissipation factor, and is applicable to the preparation of low dielectric materials or electric equipment products.

Owner:SINOPLAST NEW MATERIAL

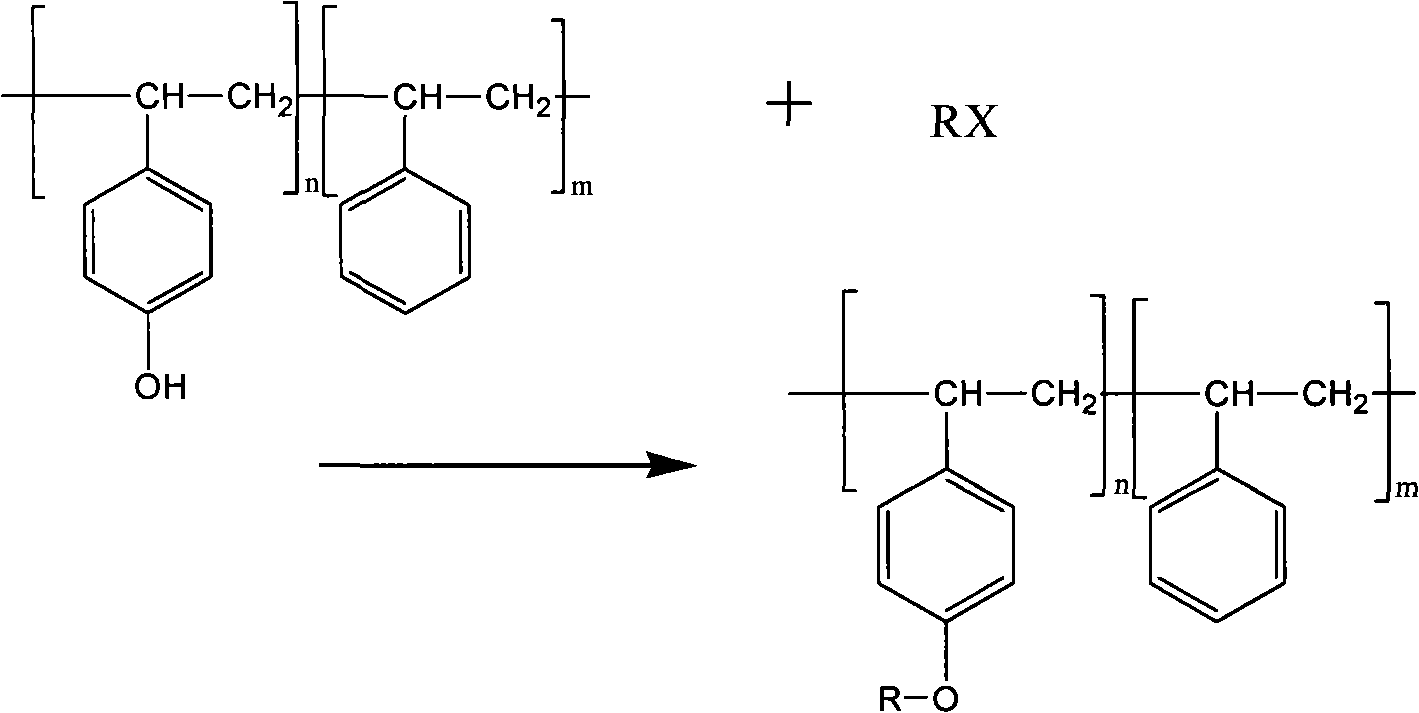

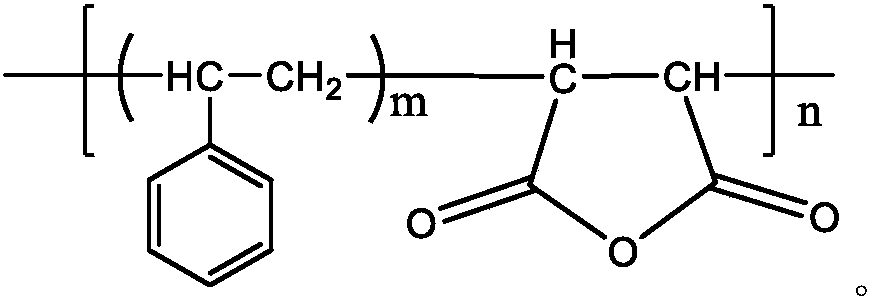

Halogen-free thermosetting resin composition, prepreg and metal clad foil laminated plate manufactured by using same

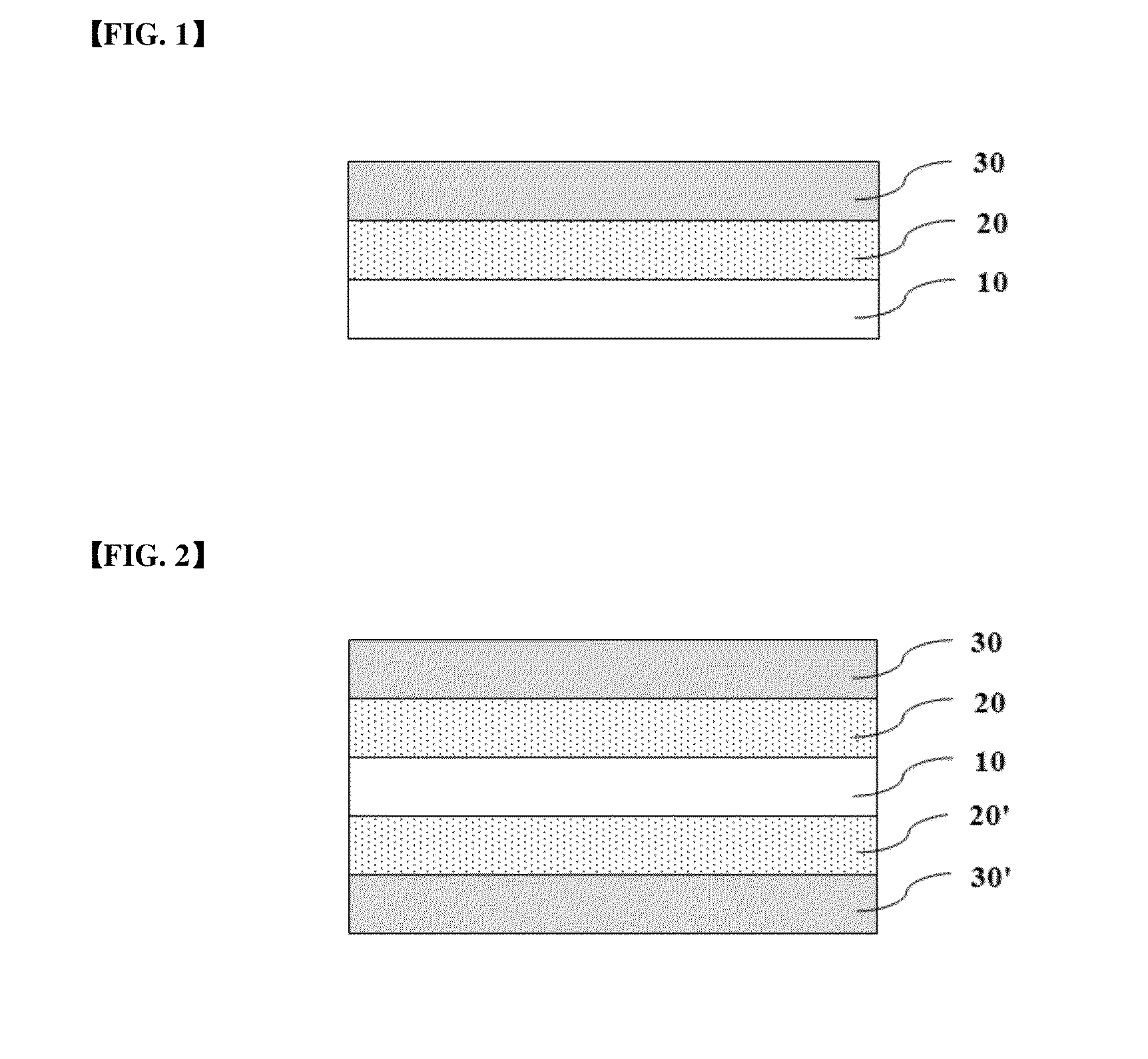

InactiveCN101928444AHeat resistantSolder dip resistantSynthetic resin layered productsMetal layered productsEpoxyHalogen

The invention relates to a halogen-free thermosetting resin composition, and a prepreg and a metal clad foil laminated plate manufactured by using the same. The halogen-free thermosetting resin composition comprises the following components in part by weight: 10 to 70 parts of bifunctional or multi-functional epoxy resin with a halogen-free molecular structure, 10 to 60 parts of styrene-maleic anhydride copolymer and 3 to 20 parts of co-curing agent, wherein the co-curing agent is halogen-free phenolic compound or phenolic resin. The prepreg manufactured by using the halogen-free thermosetting resin composition comprises a base material and the halogen-free thermosetting resin composition attached to the base material after impregnation drying. The metal clad foil laminated plate manufactured by using the halogen-free thermosetting resin composition comprises a plurality of layers of mutually overlapped prepregs and a metal foil pressed on one side or two sides of the overlapped prepregs, wherein each prepreg comprises the base material and the halogen-free thermosetting resin composition attached to the base material after impregnation drying.

Owner:GUANGDONG SHENGYI SCI TECH

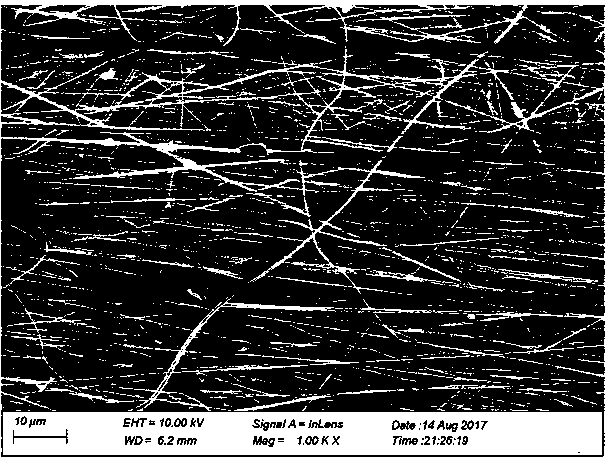

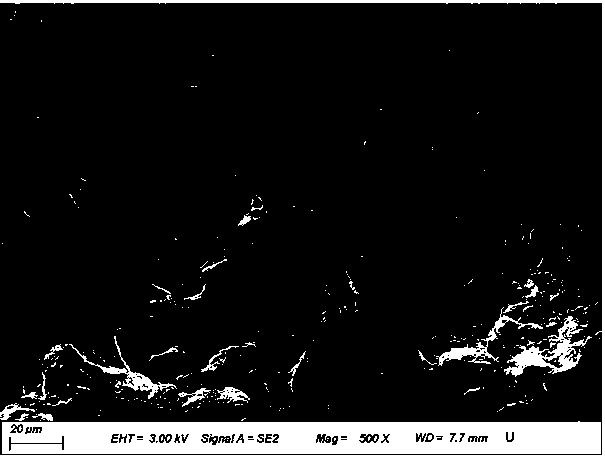

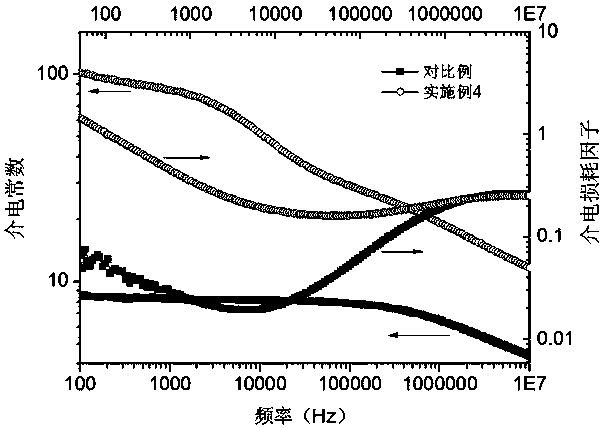

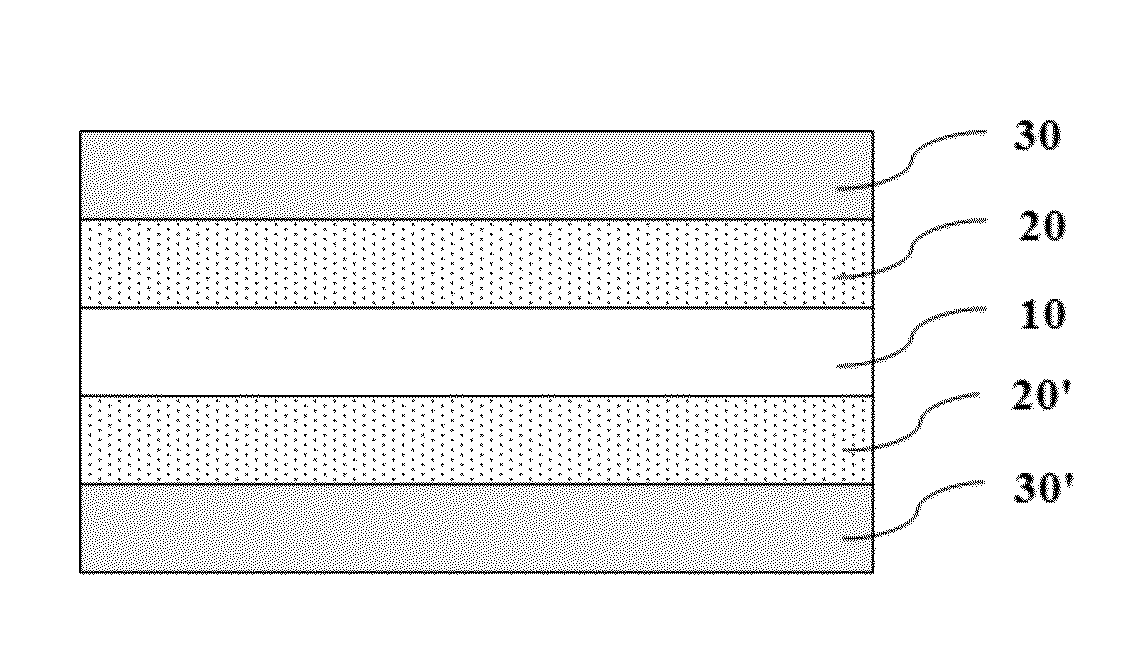

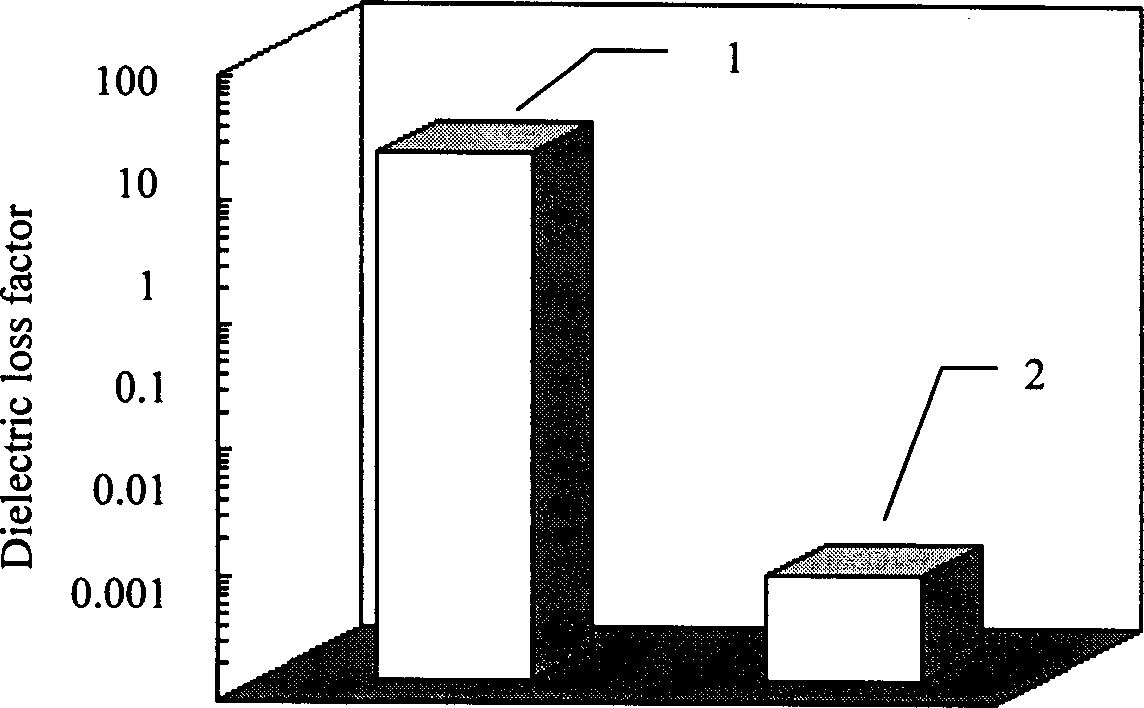

Polymer modified graphene/polyvinylidene fluoride high-dielectric composite material and preparation method thereof

InactiveCN107618243AEvenly dispersedHigh dielectric constantSynthetic resin layered productsLaminationPolymer modifiedPolymer science

The invention discloses a polymer modified graphene / polyvinylidene fluoride high-dielectric composite material and a preparation method thereof. The composite material is prepared by taking polyvinylidene fluoride as a matrix and taking graphene subjected to graft modification by aminosilane and polymer sequentially as dielectric enhancement functional filler through solution blending, electrostatic spinning and laminar hot-press molding sequentially. On the basis of dual regulation of interface and spatial microstructures, uniform dispersion of high-filling-volume graphene filler in the polyvinylidene fluoride matrix is effectively realized according to a graphene surface polymer grafting modification and electrostatic spinning combined method, and the dielectric constant of the obtainedgraphene / polyvinylidene fluoride composite material is evidently increased while a small dielectric dissipation factor is achieved, so that the polymer modified graphene / polyvinylidene fluoride high-dielectric composite material is applicable to fields of embedded capacitors, high-energy-density energy accumulators and the like.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

Process for preparing high performance copper-clad polytetrafluoroethylene plate

InactiveCN1586876AReduce void volumeLow dielectric dissipation factorSynthetic resin layered productsCopper foilPTFE - Polytetrafluoroethylene

The preparation process of novel high performance copper-clad PTFE plate includes the following steps: preparing inner layer of glass fiber fabric; preparing outer layer of glass fiber fabric; and cladding copper foil on two sides of the outer layer of glass fiber fabric. The copper-clad PTFE plate of the present invention has excellent electric performance, heat performance and mechanical performance, high bending strength, high size stability and high comprehensive performance.

Owner:SOUTH CHINA UNIV OF TECH

Cyanate esters-based adhesive resin composition for fabrication of circuit board and flexible metal clad laminate comprising the same

InactiveUS20140335341A1Low dielectric constantImprove electrical characteristicsDielectric materialsSynthetic resin layered productsDielectric loss factorMetal

The present invention relates to an adhesive resin composition for fabrication of circuit boards and its use. The adhesive resin composition of the present invention includes a cyanate ester resin, a fluorine-based resin powder dispersed in the cyanate ester resin, and a rubber component and has low dielectric constant and low dielectric loss factor, which enables the fabrication of circuit boards with further enhanced electrical characteristics.

Owner:LG CHEM LTD

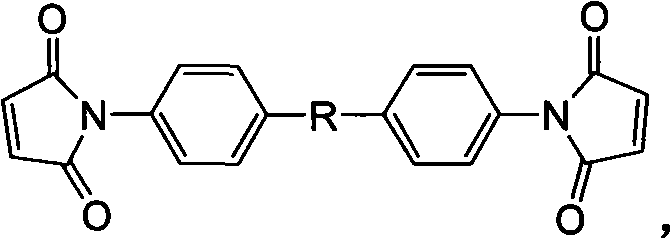

Halogen-free flam retardant prepolymer, preparation method thereof and application of halogen-free flam retardant prepolymer in copper clad laminate (CCL)

ActiveCN101974156AGuaranteed performanceImprove flame retardant performanceLaminationLamination apparatusCopper foilChemistry

The invention particularly relates to a halogen-free flame retardant prepolymer, and an application thereof in the manufacture of the copper clad laminate (CCL). The manufacture of the CCL comprises the following steps: taking and reacting the bismaleimides, allyl compound and phosphorus-containing compound for 10 to 120 minutes at the temperature of 80 to 160 DEG C to obtain the halogen-free flame retardant prepolymer; preparing the prepolymer into solution, stirring uniformly the solution to obtain a glue solution, coating the glue solution uniformly on an E-glass fiber cloth with smooth surface, and then baking the E-glass fiber cloth to prepare a B-rank prepreg; and cutting the B-rank prepreg into proper size according to the size of a pressing machine, overlapping a certain amount of prepregs, and pressing the prepregs with a copper foil with the same size on the top and a copper foil with the same size at the bottom in a hot pressing machine to obtain the CCL. The CCL has good flame retardant effect, no release of harmful gases during the burning, and the product after the solidification of the CCL has the advantages of good toughness, higher thermal decomposition temperature and lower dielectric loss.

Owner:SHENGYI TECH SUZHOU

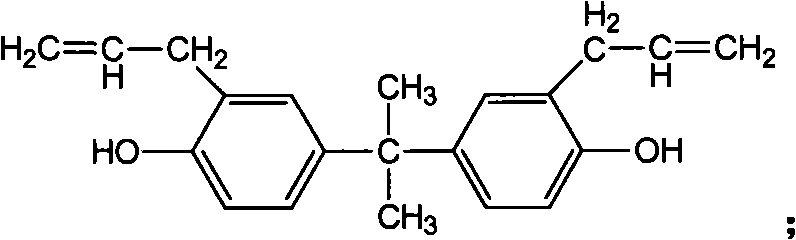

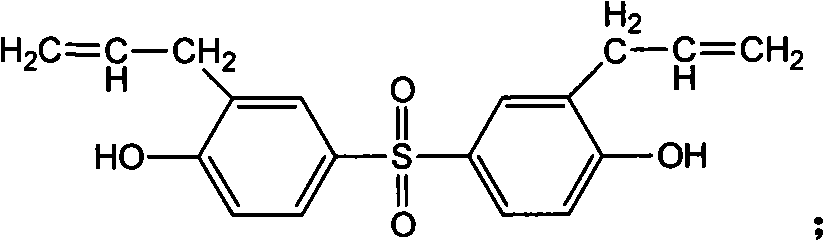

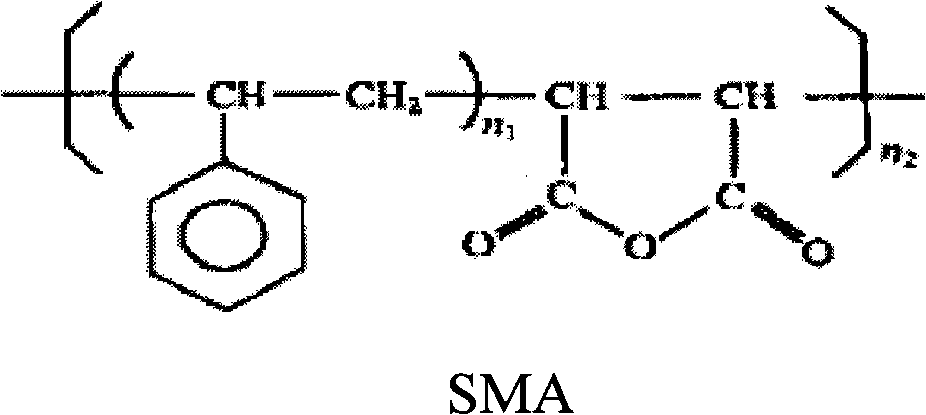

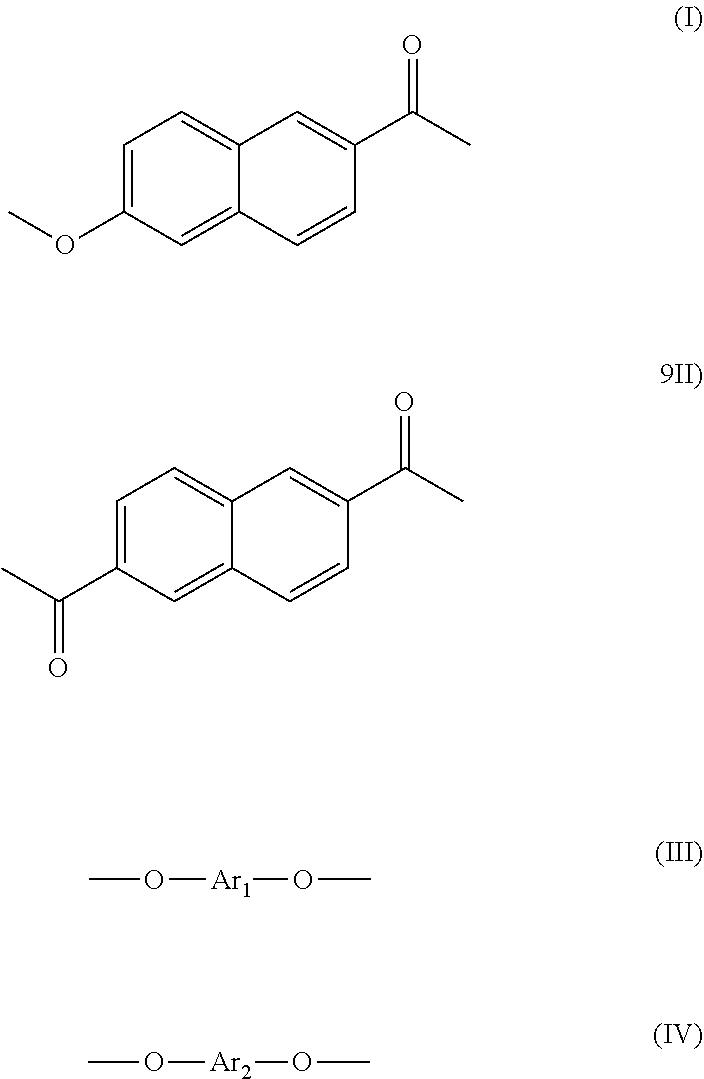

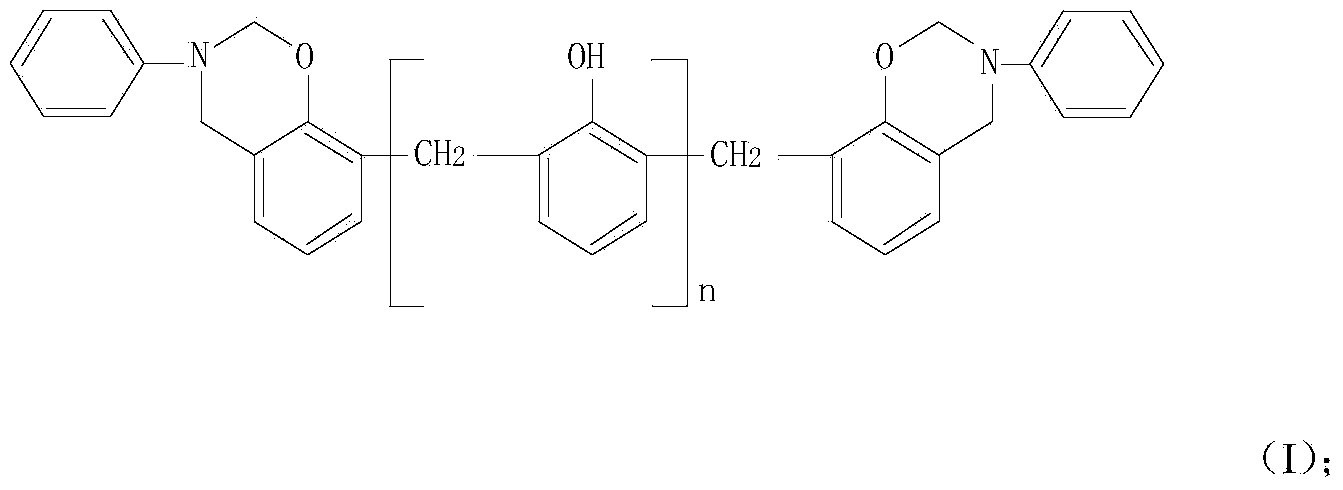

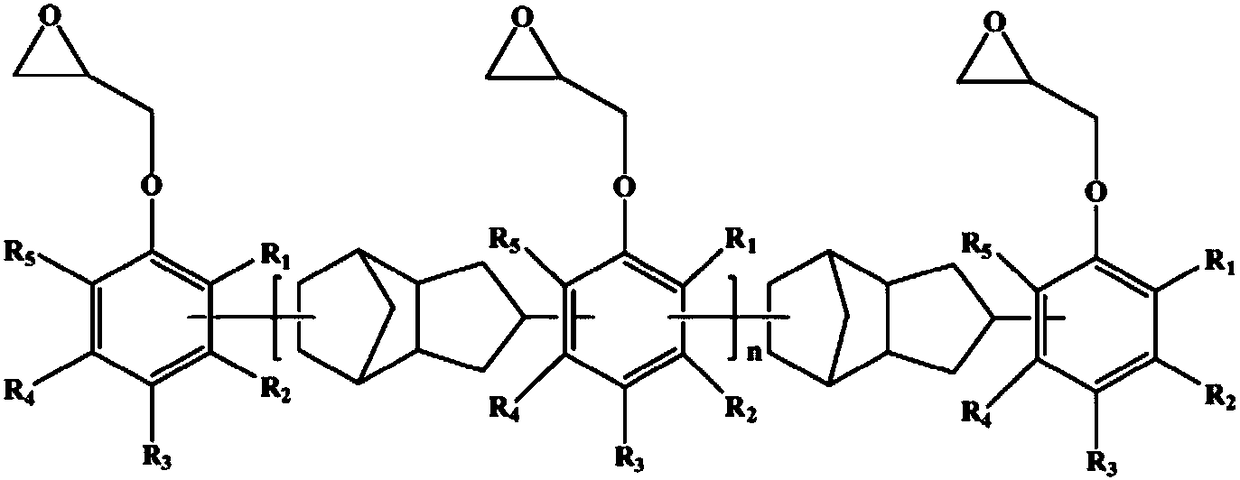

Thermosetting resin composition and prepreg and laminate for printed circuits thereby

InactiveCN101643572AExcellent dielectric propertiesImprove thermal stabilityCircuit susbtrate materialsMetal layered productsCopper foilCyanate compound

The invention relates to a thermosetting resin composition and a prepreg and a laminate for printed circuits thereby. The thermosetting resin composition comprises at least an epoxy resin of the structural formula (I) and a cyanate resin. The thermosetting resin composition of the invention has high heat resistance, low dielectric constant and low dielectric dissipation factors, thus being used for manufacturing the resin sheets, resin composition copper foils, the prepregs, the laminate and the printed circuit boards. R is (a), and n and m are natural numbers.

Owner:GUANGDONG SHENGYI SCI TECH

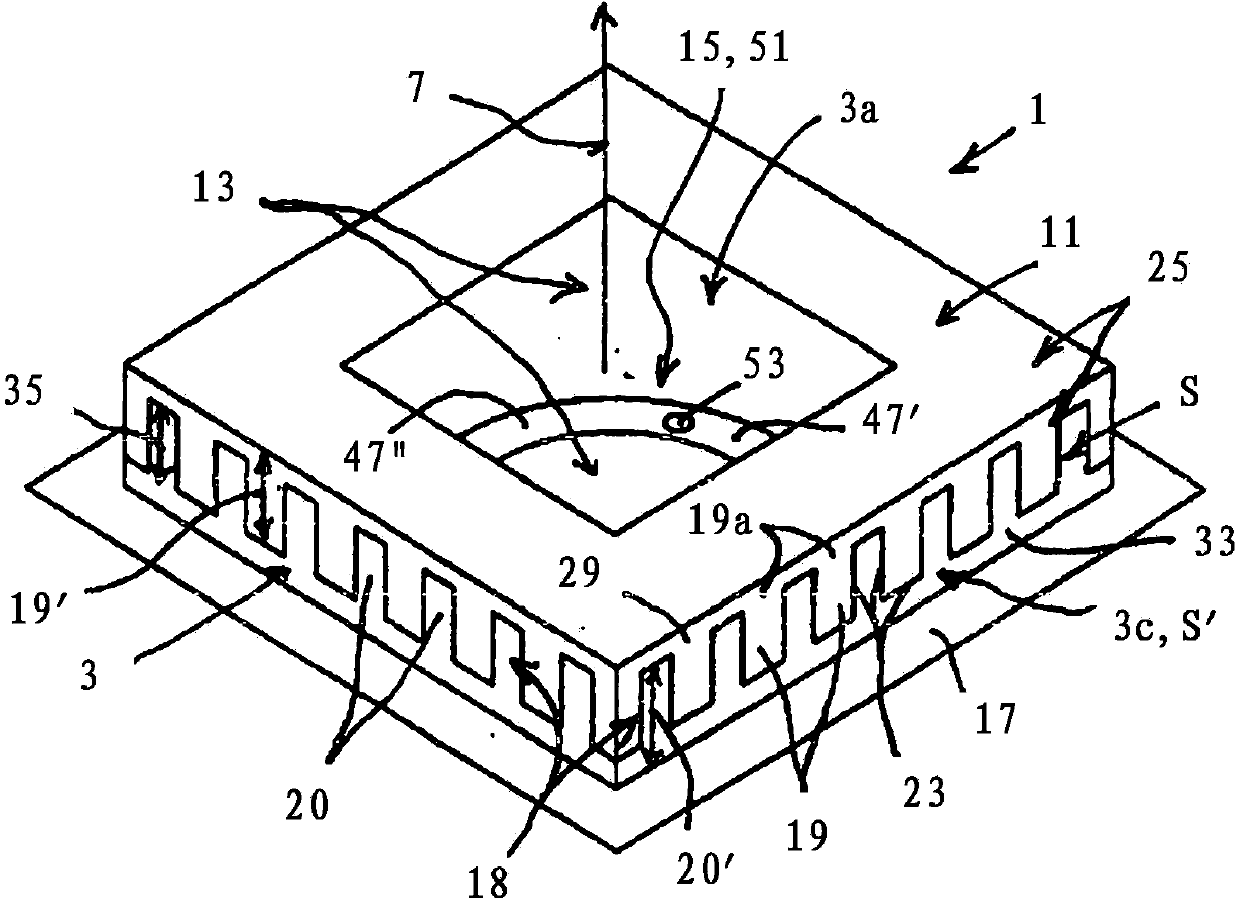

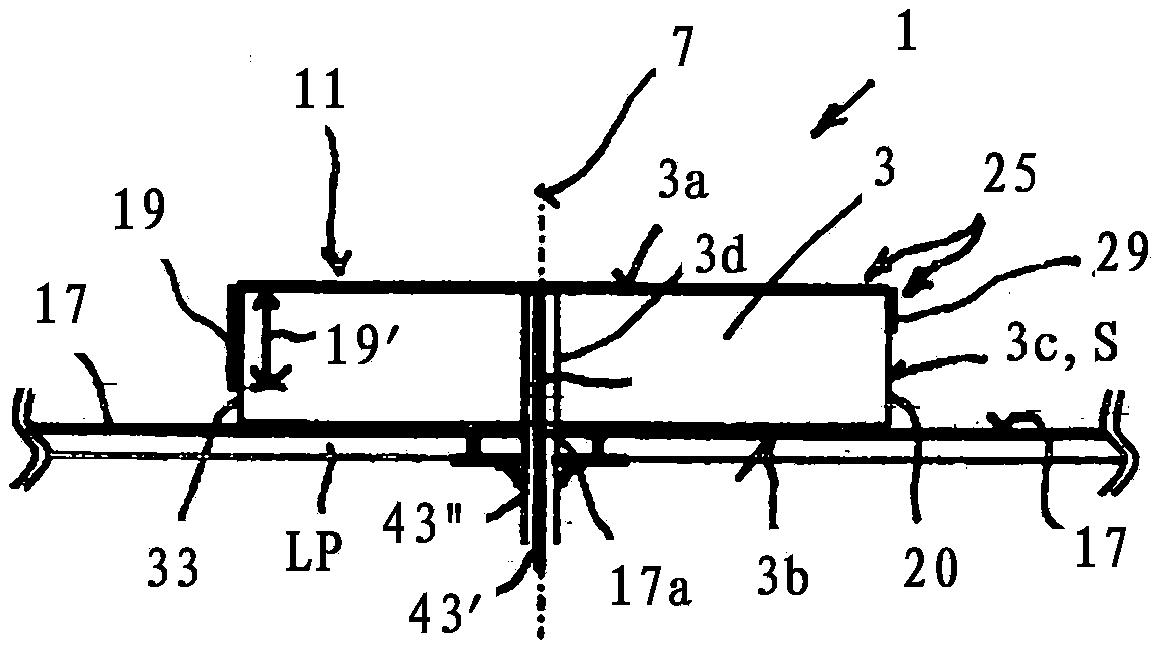

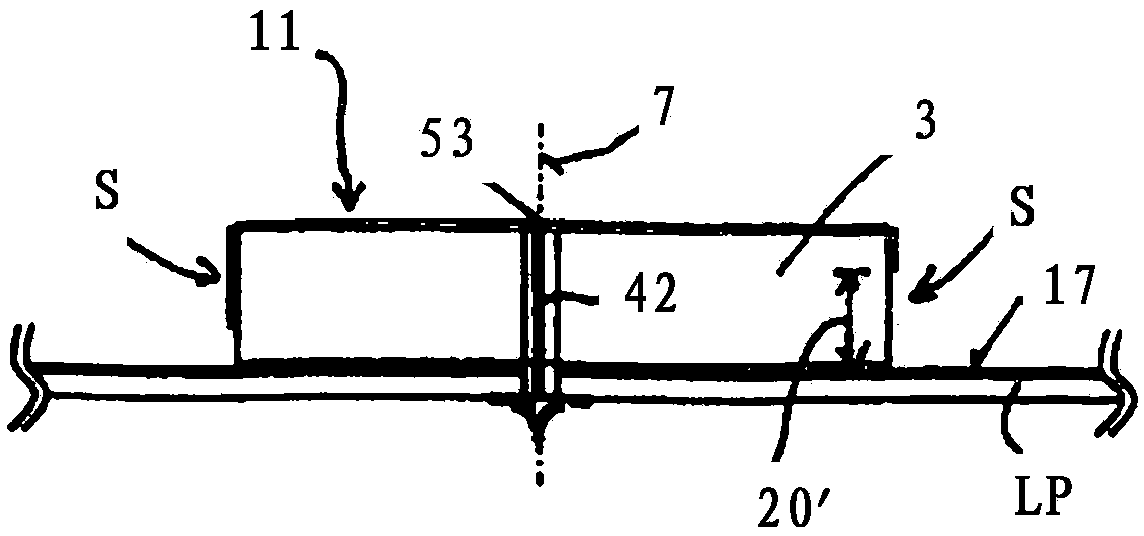

Patch radiator

ActiveCN103959557AGood broadband performanceEnhanced Vertically Polarized ComponentSimultaneous aerial operationsRadiating elements structural formsEngineering

An improved patch radiator is characterised by the following additional features: the radiator surface (11) is designed as an annular and / or frame-shaped radiator surface (11), extending around a recess area (13), - the radiator surface (11) is extended so as to transition into the lateral surfaces or lateral walls (3c), and on the lateral surfaces or lateral walls (3c), a lateral surface radiator structure (18) electrically connected to the radiator surface (11) is formed, comprising, in the peripheral direction of the lateral surfaces or lateral walls (3c), lateral radiator surface sections (19), between which electrically non-conductive recess areas (20) are provided.

Owner:KATHREIN AUTOMOTIVE GMBH

Preparation method of polyimide film with low dielectric constant and low dielectric loss factor

ActiveCN106366334AImprove mechanical propertiesGood mechanical propertiesDielectric loss factorSilicon dioxide

The invention discloses a preparation method of a polyimide film with a low dielectric constant and a low dielectric loss factor. Dianhydride and diamine are adopted for preparing a polyamide acid solution, and the polyamide acid solution and additives such as nanometer fluorine-containing macromolecule powder, nanometer aluminum oxide powder and nanometer silicon dioxide powder are prepared into the polyimide film. The preparation method is characterized in that the additives account for 10-50% of the weight of polyamide acid. The obtained polyimide film with the low dielectric constant and the lower dielectric loss factor can achieve the effects that the dielectric constant is smaller than or equal to 2.6, the dielectric loss factor is smaller than or equal to 0.003 on the basis of keeping good mechanical properties, the technology is simple, and raw materials are easy to purchase and low in price.

Owner:NINGBO JINSHAN NEW MATERIAL

Thermoplastic liquid crystal polymer and film of same

ActiveUS20200017769A1Low dielectric dissipation factorLow melting pointLiquid crystal compositionsWave based measurement systemsPolymer scienceDielectric loss factor

Provided are a thermoplastic polymer capable of reducing a dielectric dissipation factor in high frequency bands and a film thereof. The thermoplastic liquid crystal polymer includes repeating units represented by the following formulae (I), (II), (III) and (IV), in which a molar ratio of a total amount of the repeating units represented by formulae (I) and (II) to a total amount of all the repeating units in the thermoplastic liquid crystal polymer is 50 to 90 mol %, and a molar ratio of the repeating unit represented by formula (III) to the repeating unit represented by formula (IV) is the former / the latter=23 / 77 to 77 / 23.

Owner:KURARAY CO LTD

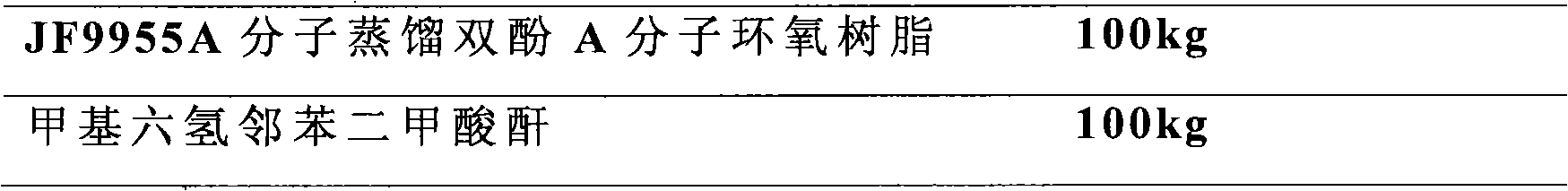

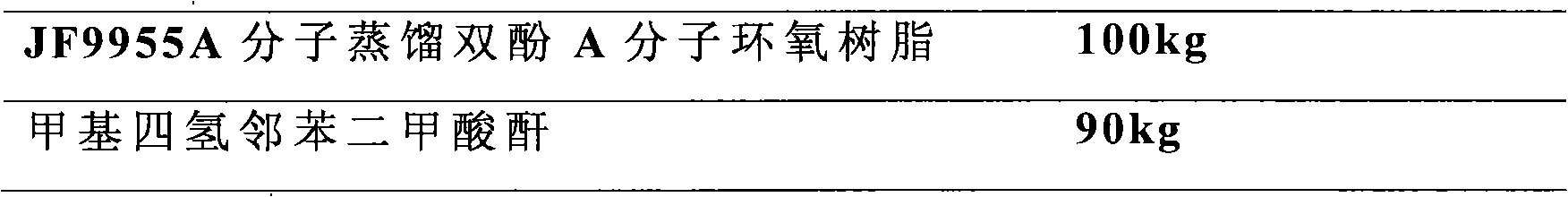

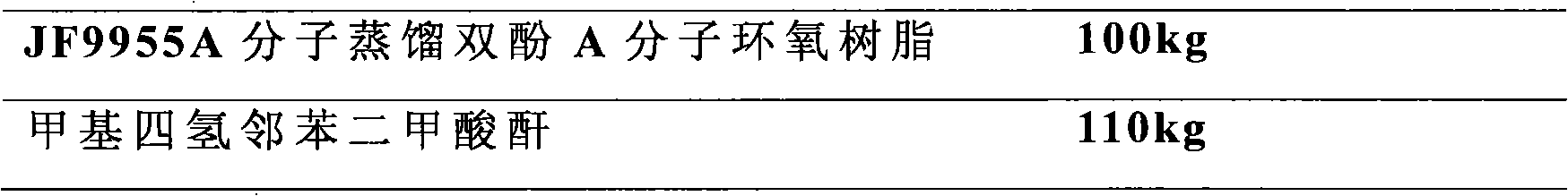

Heat-resistant epoxy anhydride resin suitable for vacuum pressure impregnation (VPI) and preparing method and application thereof

InactiveCN101864059ALow heat resistanceImprove heat resistancePlastic/resin/waxes insulatorsManufacturing dynamo-electric machinesNuclear powerHigh voltage

The invention discloses heat-resistant epoxy anhydride resin suitable for vacuum pressure impregnation (VPI), which is characterized by comprising bisphenol A-type epoxy resin and liquid anhydride which are at the weight ratio of 1:0.8-1.2. The heat-resistant epoxy anhydride resin comprises no volatile cinnamic activated diluents, the cured heat-resistant epoxy anhydride resin has good resistance, high mechanical strength and low dielectric loss factor. The heat-resistant epoxy anhydride resin is suitable for the VPI insulation of the high-voltage motor, the wind power motor, the nuclear power motor and the coil and the impregnation of the electric generator and can meet the technical requirement for the insulation of the single coil bar for the large-scale hydroelectric generating unit and the steam-turbine generatoing unit.

Owner:SUZHOU JUFENG ELECTRICAL INSULATION SYST

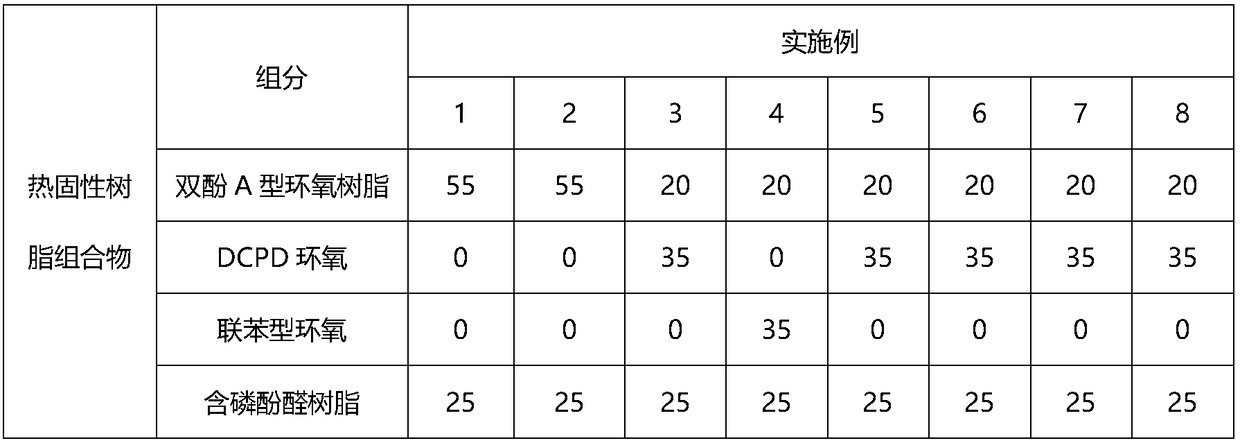

Halogen-free low water-absorbent thermosetting flame retardant resin composition and application thereof

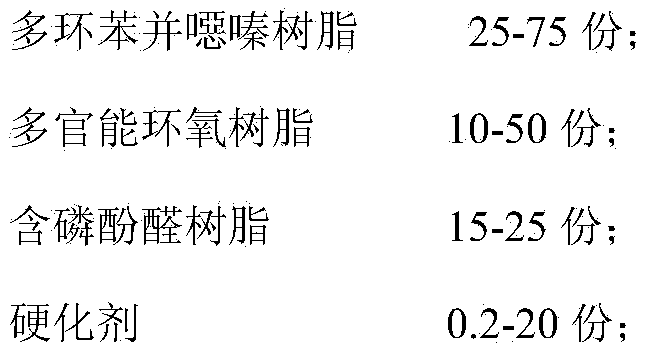

InactiveCN103724997AIncrease crosslink densityGood heat resistanceSynthetic resin layered productsElectrical equipmentDielectric lossChemistry

The invention discloses a halogen-free low water-absorbent thermosetting flame retardant resin composition. The composition consists of the following components in parts by weight: 25-75 parts of polycyclic benzoxazine resin, 10-50 parts of multi-functional epoxy resin, 15-25 parts of phosphorus containing phenolic resin and 0.2-20 parts of hardening agent. The halogen-free low water-absorbent thermosetting flame retardant resin composition disclosed by the invention can be prepared into a bonding sheet and a copper-clad plate; the copper-clad plate is high in heat resistance, low in expansion rate, low in dielectric dissipation factor, low in water-absorbing quality and good in processing performance, and flame retardant property can satisfy UL94-V0.

Owner:FUJIAN NEW CENTURY ELECTRONICS MATERIAL

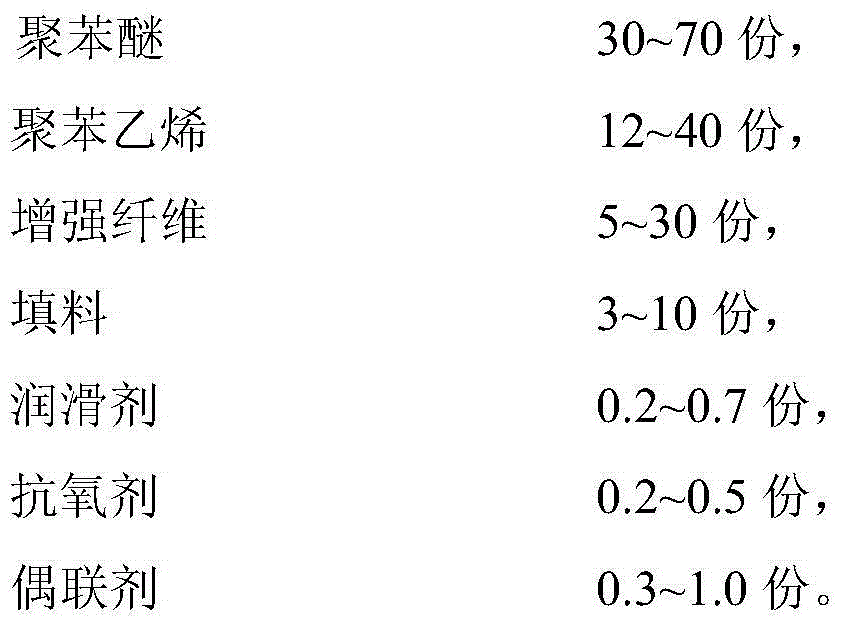

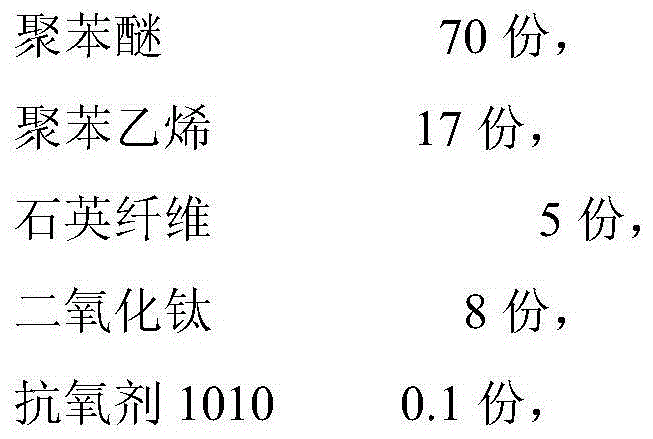

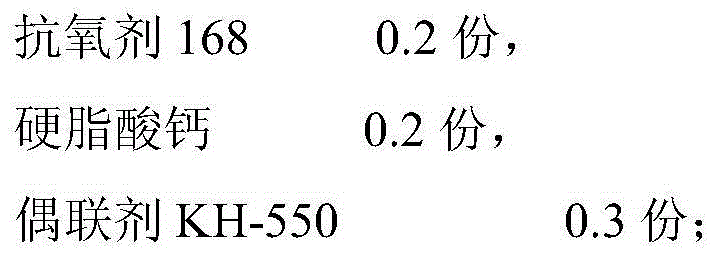

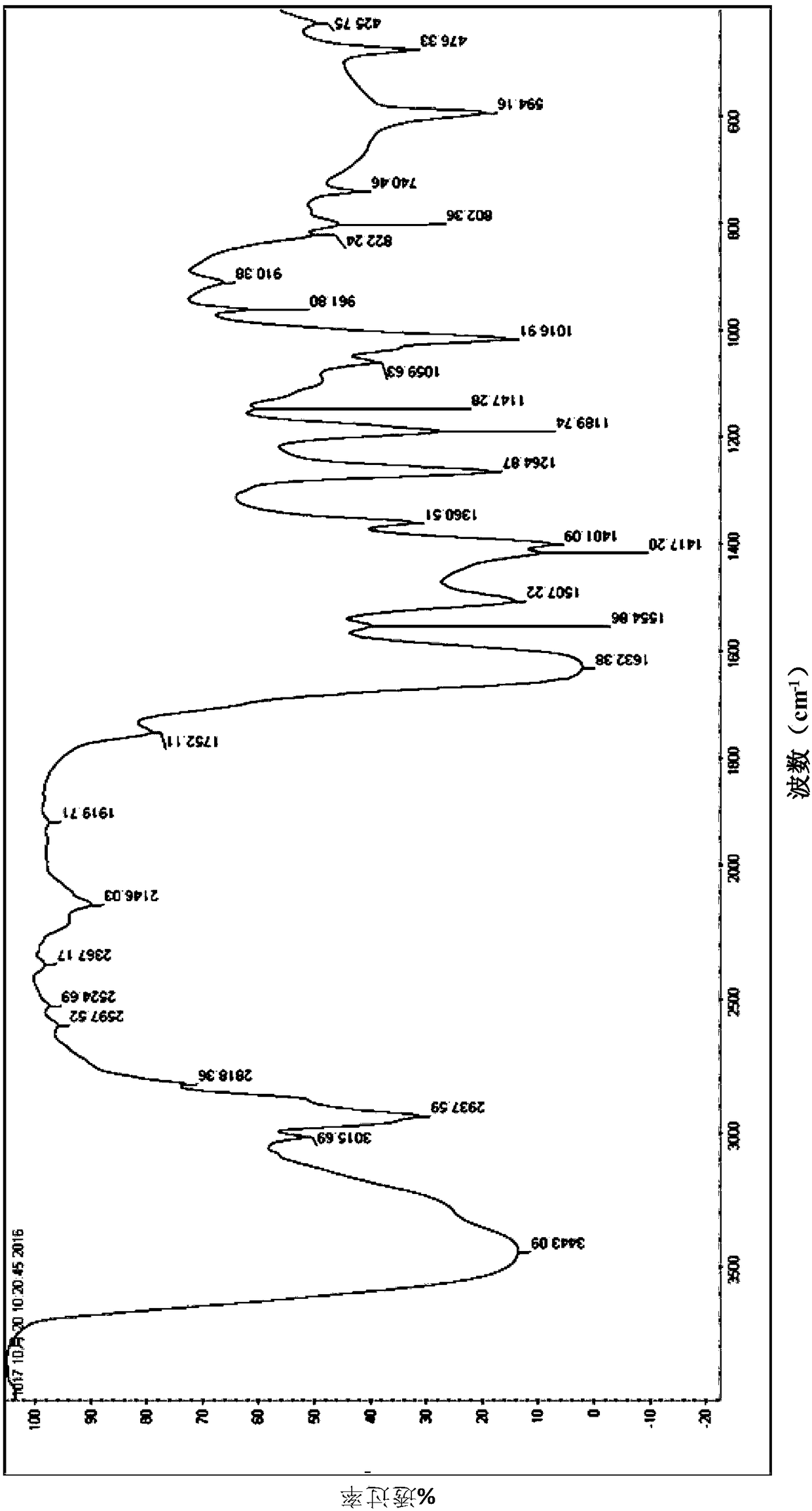

A modified polyphenylene oxide material with high strength and low dielectric loss and a preparing method thereof

A modified polyphenylene oxide material is provided. The modified polyphenylene oxide material is prepared from 30-70 parts by weight of polyphenylene oxide, 12-40 parts by weight of polystyrene, 5-30 parts by weight of reinforcing fibers, 3-10 parts by weight of a filler, 0.2-0.7 part of a lubricant, 0.2-0.5 part by weight of an antioxidant and 0.3-1.0 part by weight of a coupling agent. A preparing method of the modified polyphenylene oxide material is also disclosed. The method includes weighing the 30-70 parts by weight of the polyphenylene oxide, the 12-40 parts by weight of the polystyrene, the 3-10 parts by weight of the filler, the 0.2-0.7 part of the lubricant, the 0.2-0.5 part by weight of the antioxidant and the 0.3-1.0 part by weight of the coupling agent, fully mixing through a high-speed mixer, adding the mixture into a screw extruder, feeding the 5-30 parts by weight of the reinforcing fibers through a side feeding port of the extruder, drawing into bars through the screw extruder, and granulating to obtain the modified polyphenylene oxide material. The polyphenylene oxide is adopted as a base material. The polyphenylene oxide has good electric properties, has the minimum dielectric loss factor in engineering plastics, and is low in influences by frequency and temperature. Products of the material can be widely used for electrommunication products.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

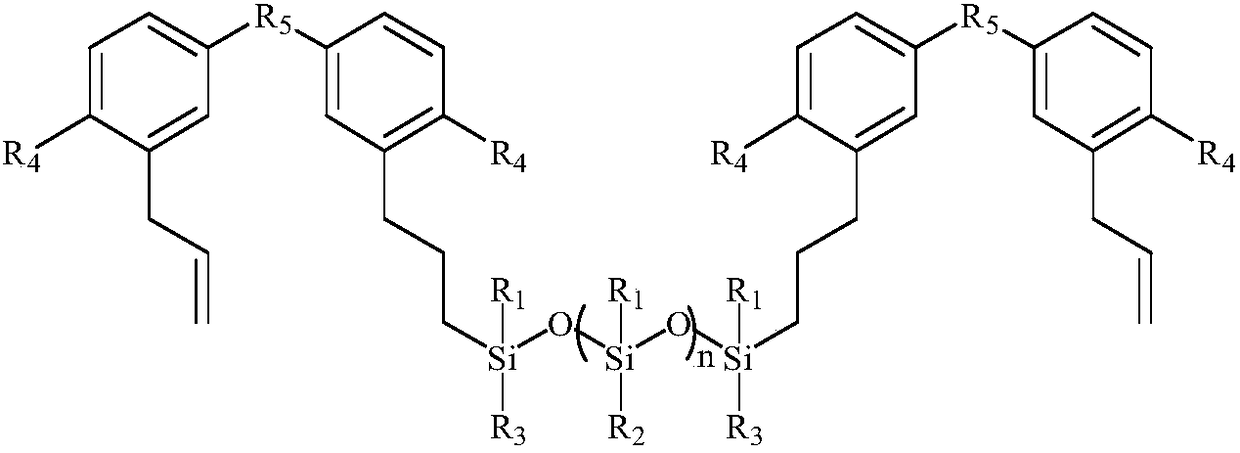

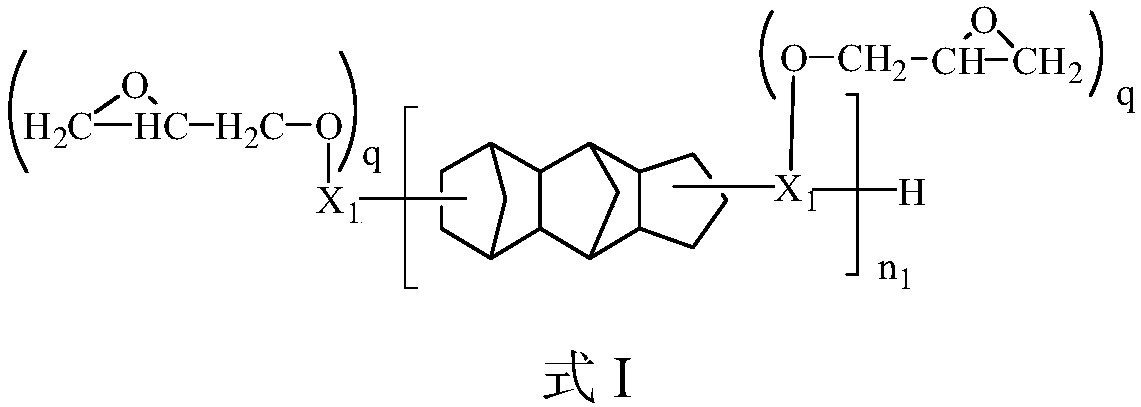

Polysiloxane-allyl compound modified polyphenylene ether resin composition, and prepreg, laminated board and printed circuit board thereof

ActiveCN108250716ALow dielectric constantLow dielectric dissipation factorSynthetic resin layered productsPrinted circuit aspectsDielectric loss factorCombustion

The invention provides a polysiloxane-allyl compound modified polyphenylene ether resin composition, and a prepreg, a laminated board and a printed circuit board thereof. The polysiloxane-allyl compound modified polyphenylene ether resin composition comprises polyphenylene ether resin and a polysiloxane-allyl compound having a structure represented by formula I, and the composition concretely comprises 100 parts by weight of the polyphenylene ether resin and 15-80 parts by weight of the polysiloxane-allyl compound. After the polysiloxane-allyl compound is added to the polyphenylene ether resincomposition, the obtained composition has a low dielectric constant, a low dielectric loss factor, excellent heat resistance and excellent moisture absorption performance, overcomes the application disadvantage of poor adhesion between the composition and metal foil, improves the interlayer adhesion of a copper-clad plate, can achieve the UL94V-0 combustion grade without an additional flame retardant, and truly achieves halogen-free, phosphorus-free and flame-retardant effects.

Owner:GUANGDONG SHENGYI SCI TECH

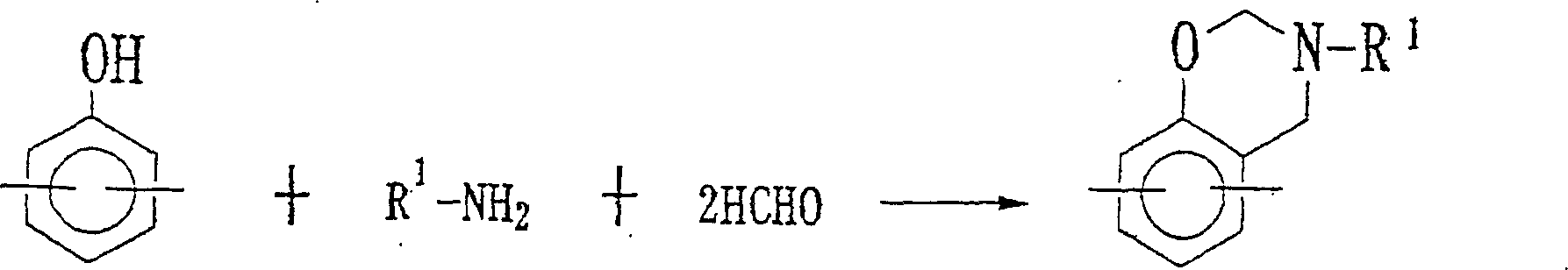

Thermosetting resin composition and prepreg laminate for circuit board and printed circuit board each made therewith

InactiveCN1484674AEasy to processLow dielectric dissipation factorSynthetic resin layered productsThin material handlingPolymer scienceTriazine

The present invention discloses a thermosetting resin composition which comprises (A) 35 to 75 parts by weight of a thermosetting resin comprising a compound having a dihydrobenzoxazine ring as a main component, (B) 10 to 25 parts by weight of a polycondensation product of a phenol, a compound having a triazine ring and an aldehyde, and (C) 10 to 45 parts by weight of an epoxy resin, based on 100 parts by weight of the total amount of organic solid components of Components (A), (B) and (C), and (i) a bisphenol F epoxy resin having a weight average molecular weight of 1,000 to 3,000, or (ii) a mixed epoxy resin of bisphenol F epoxy resin and bisphenol A epoxy resin having a weight average molecular weight of 1,000 to 3,000, is contained in Component (C) in an amount of 0 to 100% by weight of Component (C); and a prepreg, a laminated board for a wiring board and a wiring board using the same.

Owner:RESONAC CORP

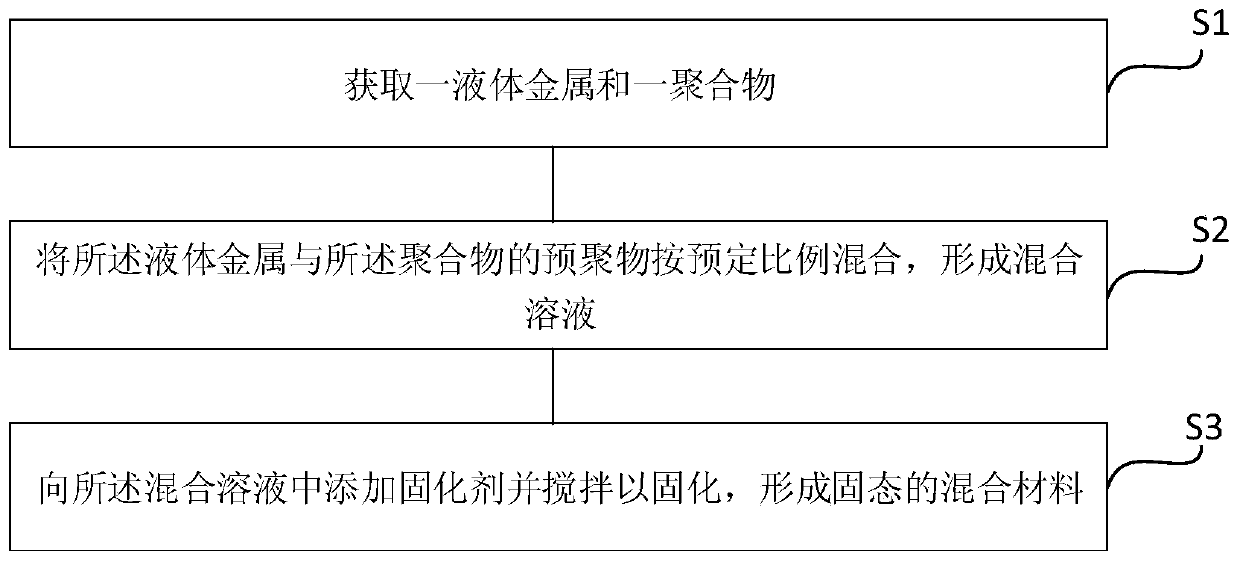

Liquid metal polymer mixed material and preparation method thereof

InactiveCN110564157AHigh dielectric constantLow dielectric dissipation factorForce measurementLiquid metalMixed materials

The invention discloses a liquid metal polymer mixed material and a preparation method thereof. The preparation method comprises the following steps: obtaining a liquid metal and a polymer; mixing theliquid metal with a prepolymer of the polymer according to a preset proportion to form a mixed solution; adding a curing agent into the mixed solution, and stirring for curing to form a solid mixed material. According to the mixed material, the problem that rigid fillers in a traditional metal polymer mixed material do not match the internal flexibility of the polymer is solved, the mechanical property of a base material is kept, and unique combination of low mechanical rigidity and a high dielectric constant is achieved.

Owner:XIDIAN UNIV

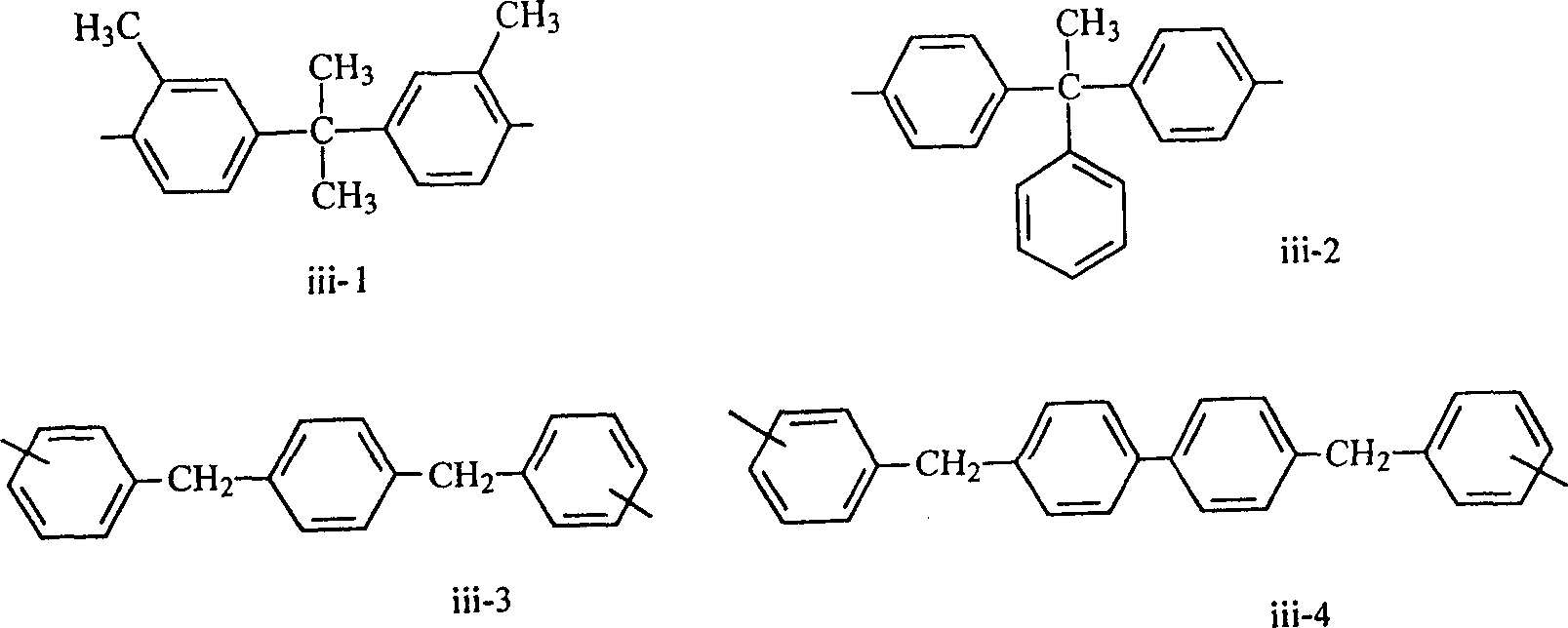

Phosphorus-containing active ester and halogen-free composition thereof, and copper-clad laminate

ActiveCN108250675AImprove electrical performanceHalogen freeGroup 5/15 element organic compoundsSynthetic resin layered productsDielectric loss factorHalogen

The invention provides a phosphorus-containing active ester and a halogen-free resin composition thereof, and a prepreg and a laminated board using the halogen-free resin composition. The halogen-freeresin composition comprises (A) thermosetting resin, and (B) phosphorus-containing active ester resin. The prepreg and the laminated board prepared by using the halogen-free resin composition have low dielectric loss factors and can achieve halogen-free flame retardancy.

Owner:GUANGDONG SHENGYI SCI TECH

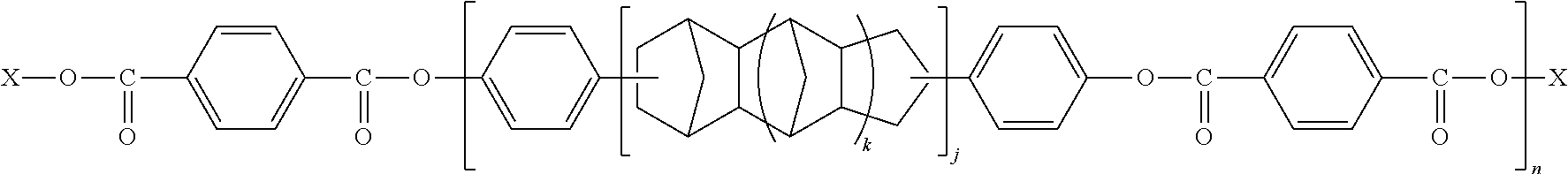

Epoxy resin composition

InactiveCN1521210AImprove heat resistanceLow dielectric dissipation factorCircuit susbtrate materialsLow dissipationEpoxy

An epoxy resin cured article has a high glass transition temperature and low dissipation factor. An epoxy resin composition from which the cured article can be having excellent solubility in solvents is used to produce the cured articles. A polyester as a curing agent of an epoxy resin composition having an aromatic polyhydroxy coumpound residue including an aryloxycarbonyl group at the molecule of the terminal, an aromatic polyvalent hydrocarbon group residue, and bulky structure, is used. Since the curing agent behaves as a polyfunctional curing agent, a cured article produced therefrom has a high crosslink density. Since highly polar hydroxyl groups are not formed during curing, a cured article has high glass transition temperature and a low dissipation factor. The cured article does not release low molecular weight carboxylic acids though hydrolysis of ester bonds at crosslinked bonds. Since the polyester has a bulky structure, the crystallization of the molecular chain is prevented and the solubility of the epoxy resin composition containing the polyester is excellent.

Owner:DAINIPPON INK & CHEM INC

Low-dielectric-constant halogen-free resin composition and low-flowability prepreg with same

ActiveCN108410132ALow dielectric constantImprove wettabilitySynthetic resin layered productsElectrical equipmentChemistryDielectric loss factor

The invention discloses a low-dielectric-constant halogen-free resin composition and a low-flowability prepreg with the same. The low-dielectric-constant halogen-free resin composition comprises, by weight, 10-80 parts of epoxy resin, 5-30 parts of phenoxy resin, 10-50 parts of flame retardants, 5-50 parts of curing agents, 0-5 parts of curing accelerators, 10-80 parts of fillers, 5-30 parts of toughening agents and 0-80 parts of additives. The low-dielectric-constant halogen-free resin composition and the low-flowability prepreg have the advantages that the low-dielectric-constant halogen-free resin composition is good in wettability and sufficiently low in dielectric constant and dielectric loss tangent, and the low-flowability prepreg prepared from the low-dielectric-constant halogen-free resin composition is good in heat resistance after being cured, is low in dielectric constant and dielectric loss factor, excellent in flame retardance and good in water resistance, water absorption and cohesiveness.

Owner:ZHEJIANG WAZAM NEW MATERIAL CO LTD +1

Special-shaped glass fiber and preparation method thereof

The invention provides a special-shaped glass fiber and a preparation method thereof. The special-shaped glass fiber comprises the following components in percentage by mole: 52-58% of SiO2, 16-24% of B2O3, 13-19% of Al2O3, 1-5% of CaO, 4.2-8% of MgO, 0.4-2% of F2, 0-0.5% of Li2O, 0-0.4% of Fe2O3, 0-0.2% of K2O and 0-0.2% of Na2O. Compared with the prior art, the special-shaped glass fiber with a relatively-low dielectric constant and dielectric loss factor is prepared by controlling components in a formula and the contents of all the components, and meanwhile, the special-shaped glass fiber has relatively-high mechanical property, filling rate and special-shaped rate. Experiment results prove that the special-shaped glass fiber provided by the invention has the dielectric constant of smaller than 4.7 and the dielectric loss factor of smaller than 10<-3>.

Owner:CHONGQING POLYCOMP INT

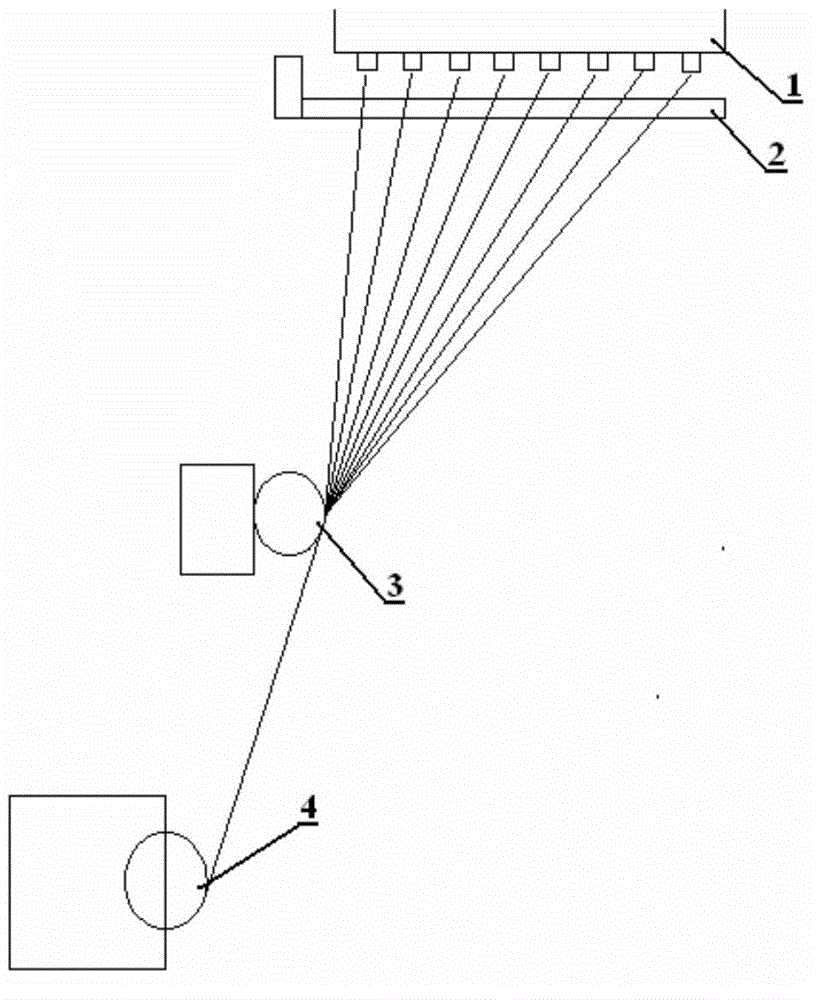

Prep. of preparing fiber reinforced silica-base composite material

InactiveCN1448369AMeet the requirements of wave-transparent materialsMeet needsChemical vapor deposition coatingOxygenChemical vapor infiltration

The present invention is the making process of wave-permeating fiber reinforced silica-base composite material. With oxide fiber fabric as prefabricated matter, organosilicon alkoxide as precursor and high-purity argon and oxygen as carrier gas and carbon eliminating gas, part with complicated shape, thin wall and relatively precise sizes may be produced in chemical vapor permeating furnace as making equipment, and its dielectric performance can meet the requirement as antenna hood and other astronautic wave-permeating material.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Resin composition, and insulating film and semiconductor device using same

ActiveCN107075222AImprove adhesion strengthLow dielectric constantCircuit susbtrate materialsNon-metallic protective coating applicationDevice materialMetal foil

Provided are: an insulating film having excellent adhesive strength to metal foil that forms FPC wiring and to FPC substrate material such as polyimide film and exhibiting electrical characteristics in the high frequency range, specifically, low dielectric constant (epsilon) and low dielectric tangent (tan delta) in the 1-10 GHz frequency range; and a resin composition used in manufacturing said insulating film. This resin composition contains (A) a thermosetting resin having styrene groups on the ends and having a phenylene ether backbone, (B) a hydrogenated styrene thermoplastic elastomer, and (C) a polytetrafluoroethylene filler, and contains 40 mass% to 80 mass% of the component (C) with respect to the total mass of the components (A)-(C).

Owner:NAMICS CORPORATION

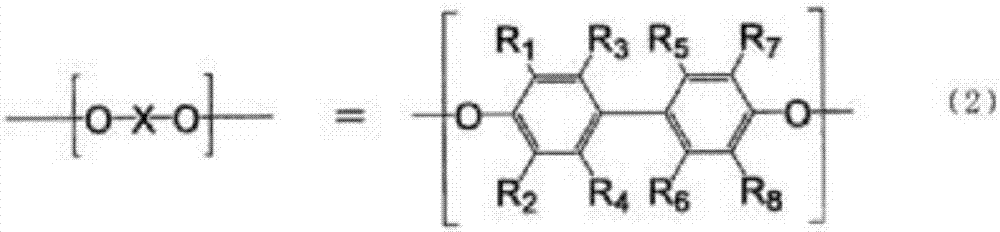

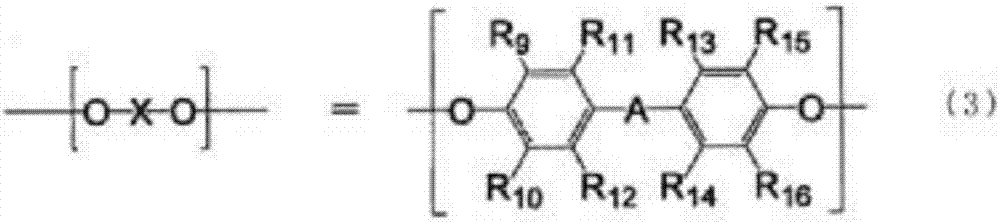

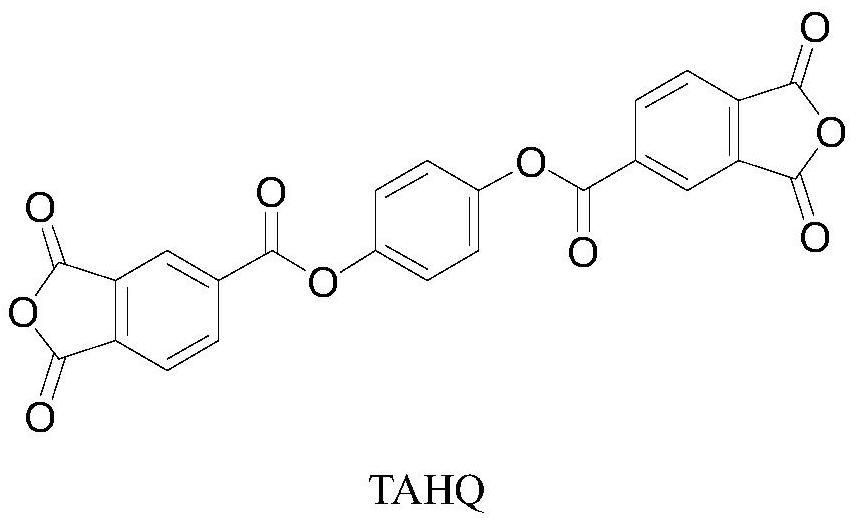

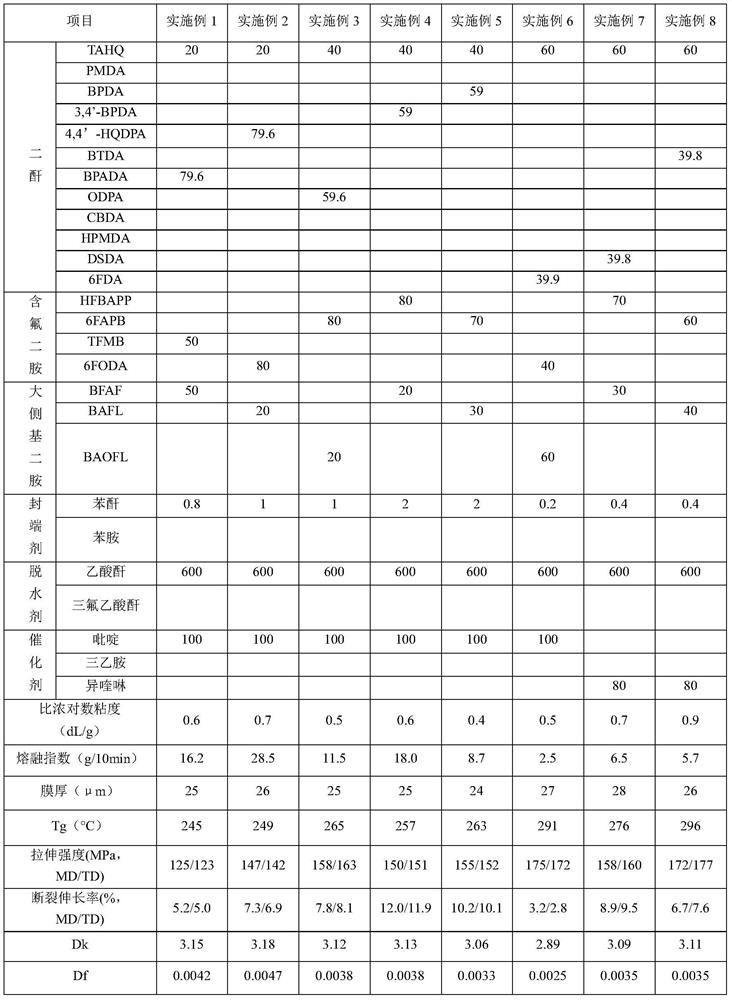

Thermoplastic polyimide resin composite film with low dielectric property and preparation method thereof

The invention relates to a thermoplastic polyimide resin composite film with low dielectric property, and belongs to the technical field of composite film materials, the polyimide resin composite film is prepared by blending and modifying polyimide resin and LCP resin, according to the parts by weight, the polyimide resin is prepared from the following components in parts by weight: 20 to 100 parts of p-phenylene-biphenyl trimellitate dianhydride monomer, 0 to 80 parts of other copolymerized dianhydride monomer, 20 to 80 parts of diamine monomer containing fluorine group, and 20 to 80 parts of diamine monomer containing large side group. The polyimide resin has the characteristics of good solubility and good melt processability, the processing cost of polyimide is reduced, the molecular structure contains ester groups, the compatibility can be improved by blending modification with the LCP resin, the anisotropy problem caused by crystal orientation of the LCP resin is improved, the composite film is prepared, the dielectric property is further improved, and the water absorption rate is further reduced.

Owner:烟台丰鲁精细化工有限责任公司

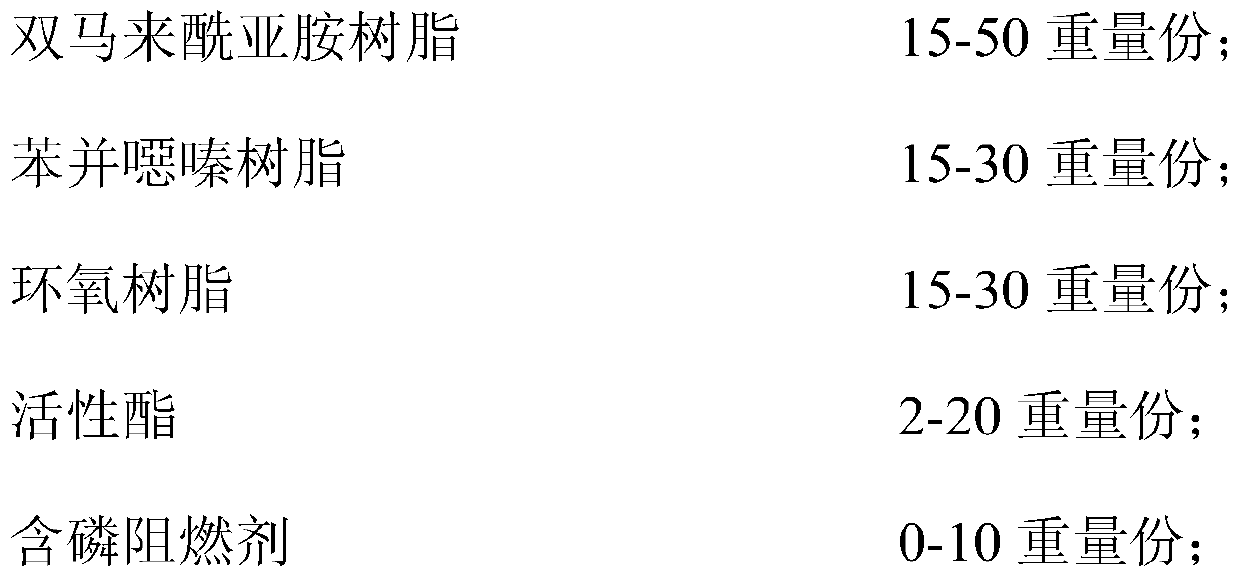

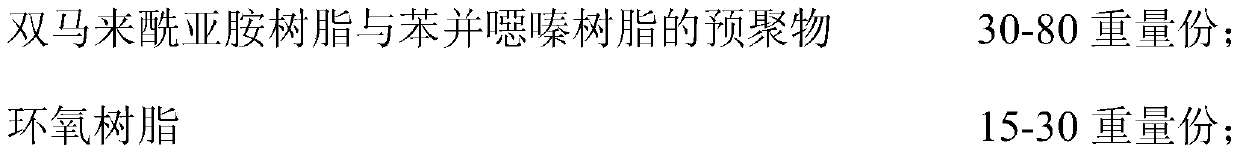

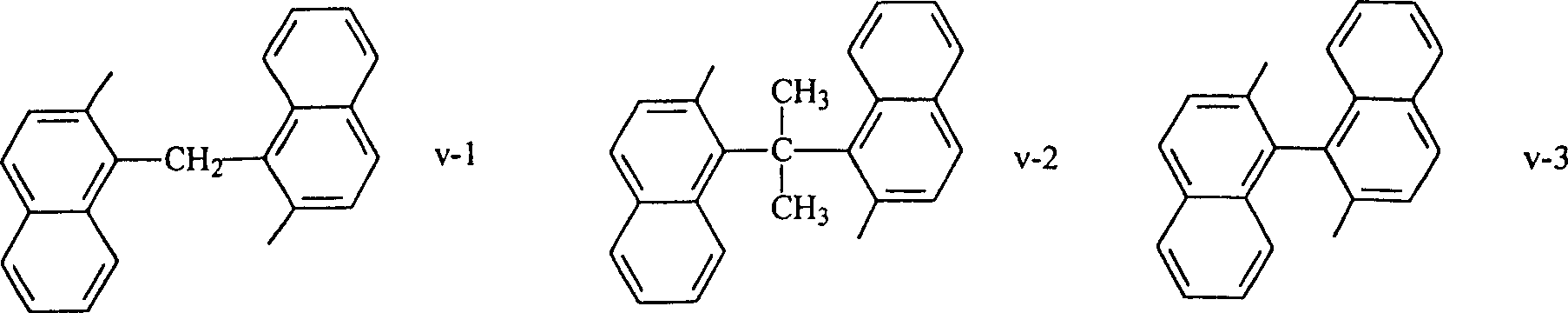

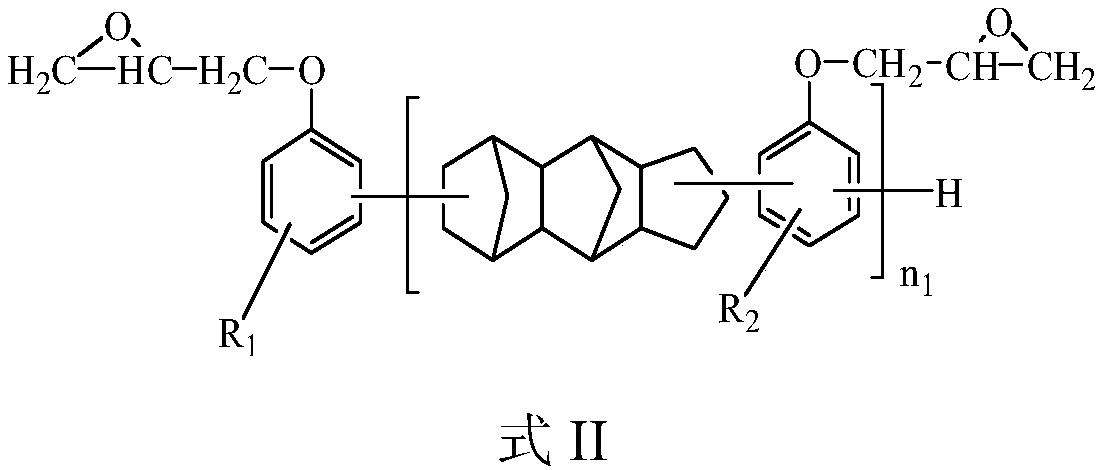

Halogen-free resin composition and uses thereof

InactiveUS20160272808A1Low dielectric constantLow dielectric dissipation factorLayered productsElectrical equipmentEpoxyHigh dimensional

Disclosed is a halogen-free resin composition. The halogen-free resin composition comprises: (A) 10-60 parts by weight of dicyclopentadiene benzoxazine resin, (B) an epoxy resin, (C) an active ester curing agent, and (D) a phosphorus-containing flame retardant, based on 100 parts by weight of the total amount of total organic solid matters of (A), (B), (C), and (D). A prepreg and a laminate which are prepared using the halogen-free resin composition have low dielectric constant, low dielectric loss factor, low water absorption, high dimensional stability, high thermal resistance and good flame retardancy, processability and chemical resistance.

Owner:GUANGDONG SHENGYI SCI TECH

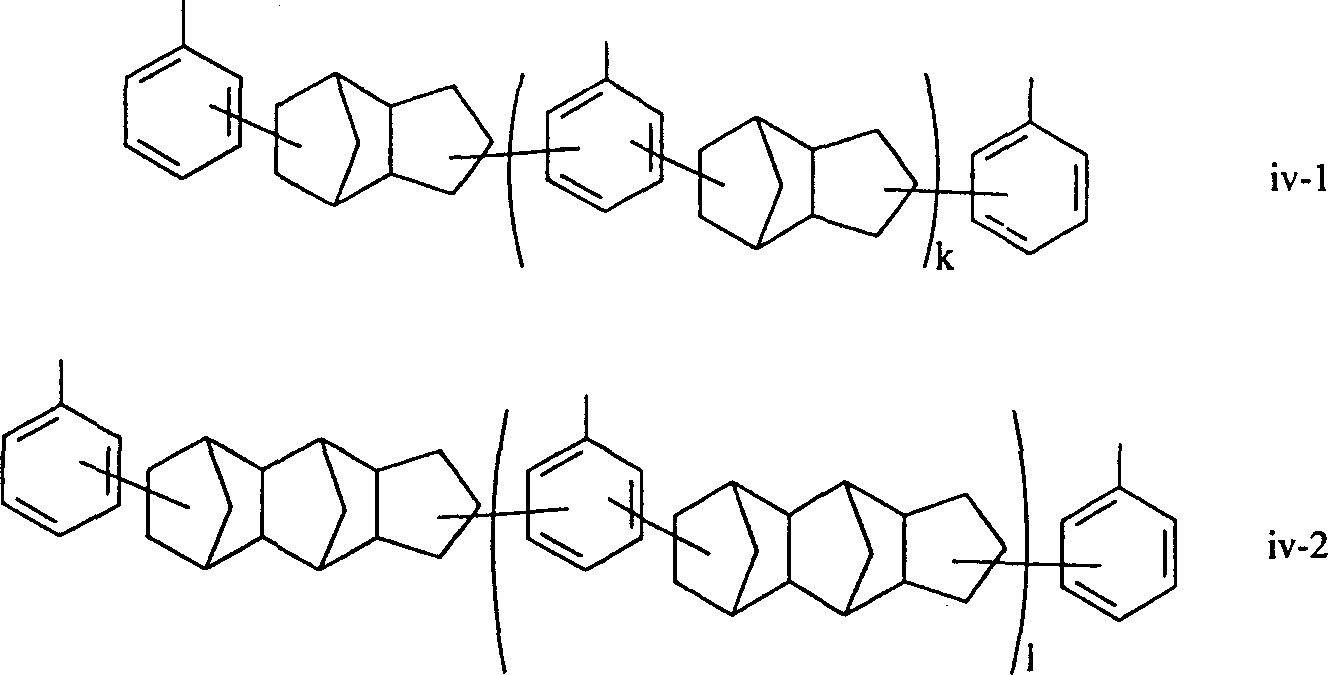

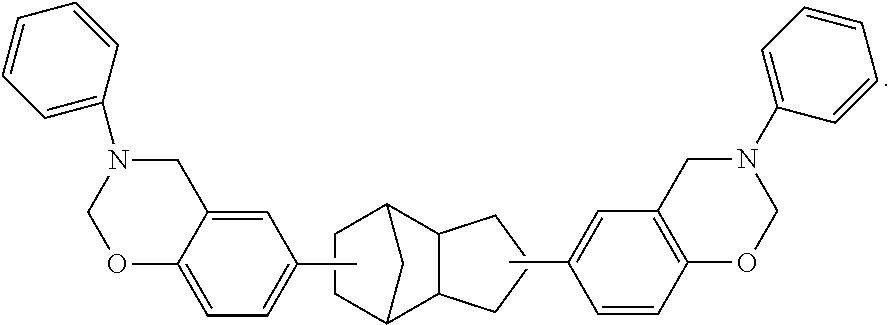

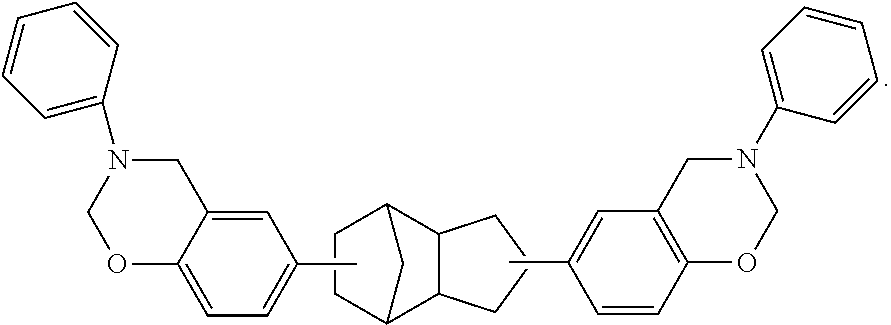

Epoxy resin containing TCPD structure, epoxy resin composition, prepreg, laminated board and printing circuit board

ActiveCN108864410AImprove heat resistanceSmall expansion coefficientElectrical equipmentGlass/slag layered productsAbsorption rateChemistry

The invention relates to an epoxy resin containing a TCPD structure, an epoxy resin composition, a prepreg, a laminated board and a printing circuit board. The laminated board manufactured by the epoxy resin containing the TCPD structure or the epoxy resin composition has the advantages of high glass-transition temperature, high thermal decomposition temperature, low thermal expansion coefficients, low dielectric constant, low dielectric loss factors, and low water absorption rate.

Owner:GUANGDONG SHENGYI SCI TECH

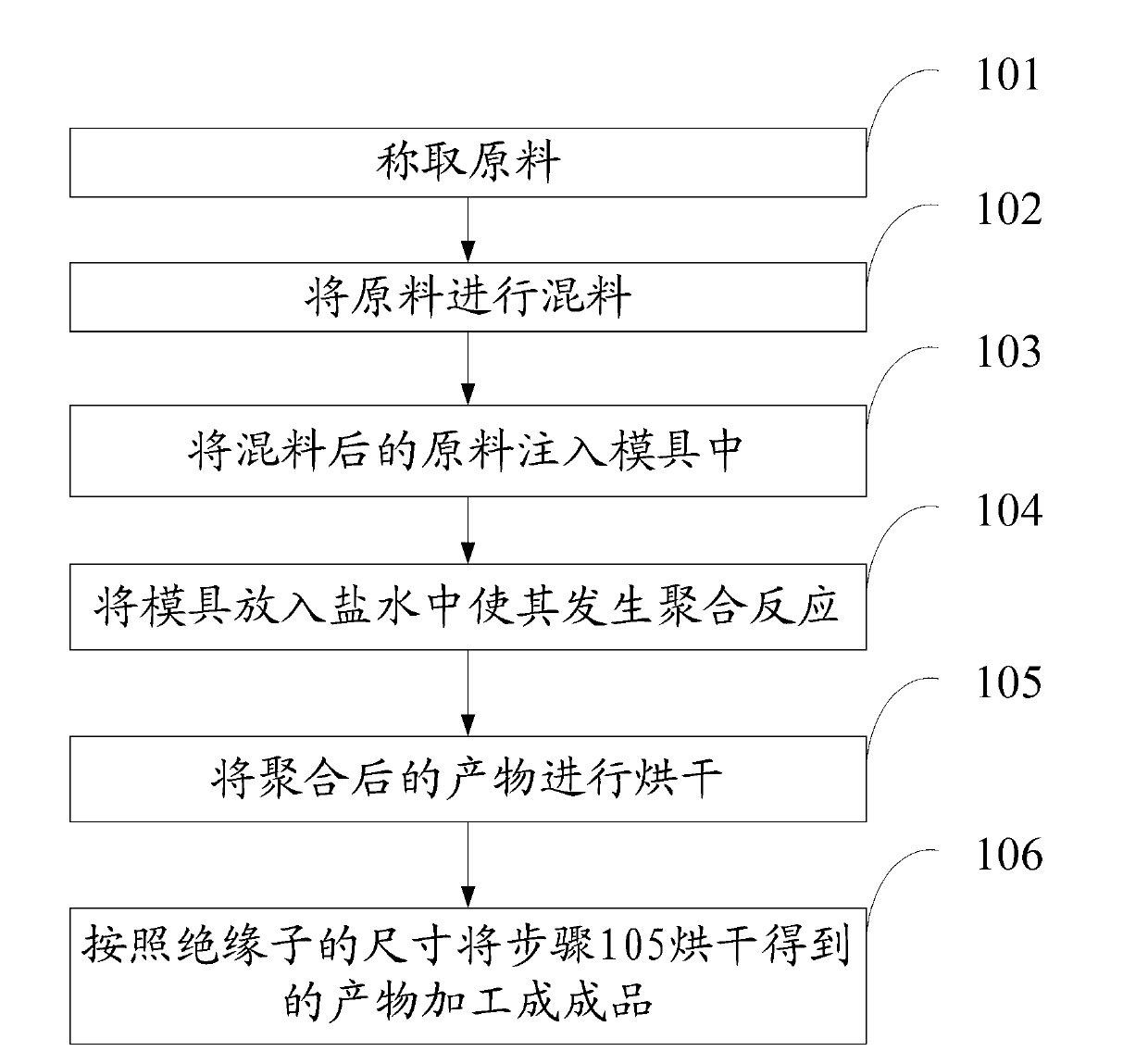

Crosslinked polystyrene, high-power pulse vacuum insulator and preparation method

InactiveCN103012646AImprove performance indicatorsComprehensive performance index of high power pulse vacuum insulator with large diameterInsulatorsPolystyreneDivinyl benzene

The invention relates to the chemical field, and in particular relates to crosslinked polystyrene, a high-power pulse vacuum insulator and a preparation method. The crosslinked polystyrene comprises the following raw materials by mass percent: 85-98% of styrene, 1-10% of divinyl benzene, and 0.5-5% of azobisisobutyronitrile; the preparation method of the crosslinked polystyrene comprises the steps of weighing the raw materials, and mixing the raw materials; injecting the mixed raw materials into a mould; placing the mould into brine so as to conduct polymerization reaction; and drying the polymerized product. The diameter of the high-power pulse vacuum insulator is greater than 1m; the thickness of the high-power pulse vacuum insulator is greater than 0.1m; and the preparation method of the high-power pulse vacuum insulator comprises the crosslinked polystyrene preparation method, the product dried is processed into a finished product according to the size of the insulator. The crosslinked polystyrene, the high-power pulse vacuum insulator and the preparation method are applicable to insulation of the high-power pulse vacuum environment.

Owner:四川中久红宇科技有限公司

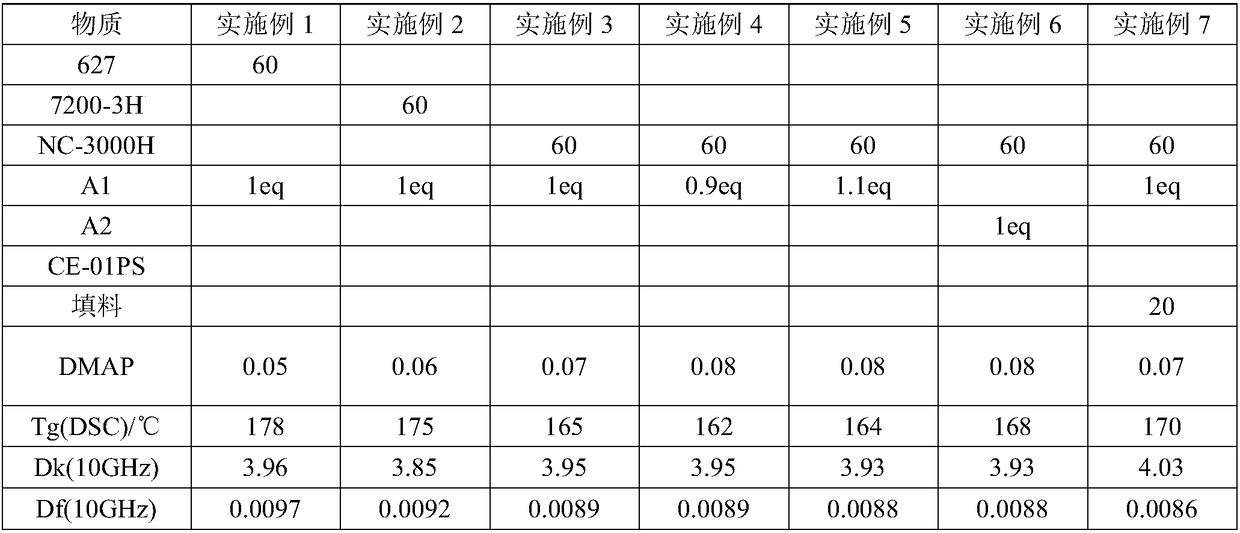

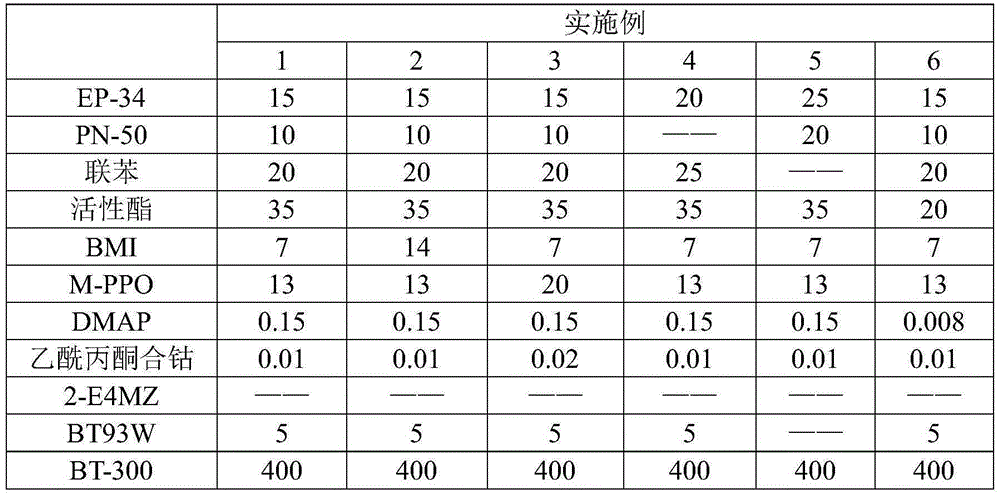

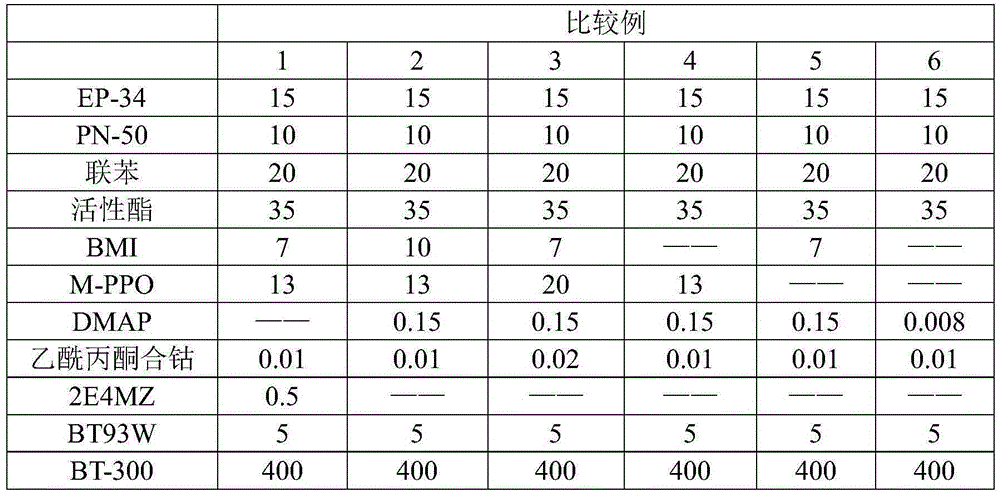

High dielectric thermosetting resin composition and laminated board for substrate

InactiveCN105385107AImprove heat resistanceHigh glass transition temperatureLamination ancillary operationsSynthetic resin layered productsHeat resistanceFilling materials

The invention discloses a high dielectric thermosetting resin composition and laminated board for substrate. The thermosetting resin composition comprises 300 to 550 parts of filling material with a high dielectric constant and 100 parts of organic solid constituent; wherein the 100 parts of organic solid constituent comprise: 30 to 50 parts of epoxy resin composition, 18 to 35 parts of active ester curing agent, 4 to 15 parts of bismaleimide resin, 4 to 20 parts of cyanate ester modified polyphenyl ether resin, and 0.01 to 2 parts of promoter namely dimethylamino pyridine. The provided thermosetting resin composition has the advantages of high dielectric constant, excellent heat-resistant performance, and high glass-transition temperature, and can meet the requirements of miniaturization development of wireless navigation equipment.

Owner:ZHEJIANG WAZAM NEW MATERIAL CO LTD +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com