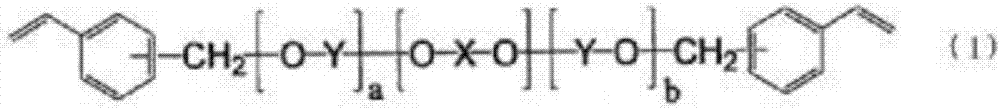

Resin composition, and insulating film and semiconductor device using same

A technology of resin composition and insulating film, which is applied in the direction of electrical components, printed circuits, circuit substrate materials, etc., can solve the problems of toxic hydrofluoric acid, etc., and achieve the effect of good adhesive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

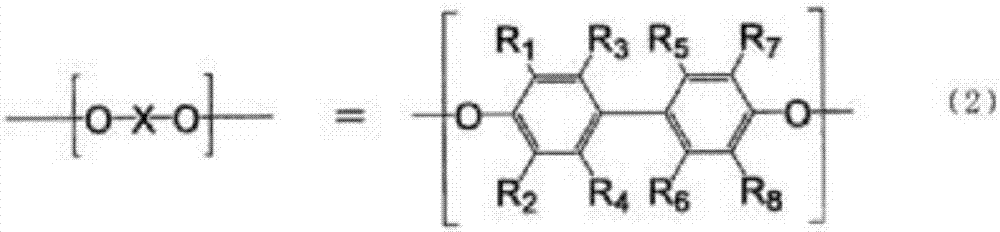

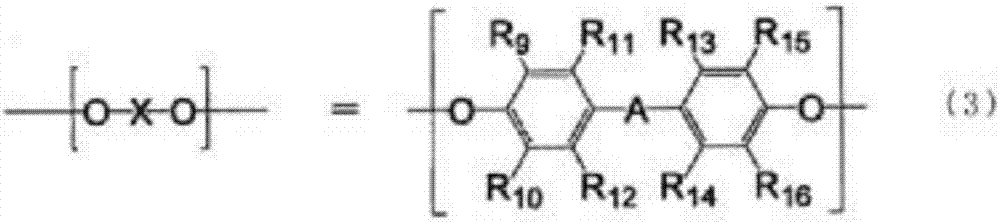

Method used

Image

Examples

Embodiment 1~14

[0134] (Examples 1-14, Comparative Examples 1-5)

[0135]Sample Preparation and Assay Methods

[0136] After measuring and mixing each component so that the mixing ratio (parts by mass) shown in the table below was added, toluene was added, and the above-mentioned material was placed in a reaction vessel heated to 80° C., and the mixture was rotated at 150 rpm for 3 minutes. Hours of atmospheric mixing. Subsequently, the resin composition was dispersed with a wet micronization device (MN2-2000AR, manufactured by Yoshida Kiko Kogyo Co., Ltd.).

[0137] A varnish containing the resin composition obtained in this way was applied to one side of a support (PET film subjected to mold release treatment), and dried at 100°C to obtain an insulating film (thickness: 30 μm) with a support. .

[0138] In addition, the abbreviated symbols in the table represent the following contents, respectively.

[0139] ingredient (A)

[0140] OPE2200: oligophenylene ether (modified polyphenylen...

Embodiment 1

[0174] In Examples 1 to 14, the high-frequency electrical characteristics (dielectric constant (ε), dielectric loss factor (tanδ)) and peel strength were all good. The differences of Examples 2 to 10 with respect to Example 1 are as follows.

Embodiment 2

[0175] Example 2: Combination use of component (B-1) and component (B-2).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com