Patents

Literature

15729 results about "Polytetrafluoroethylene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polytetrafluoroethylene (PTFE) is a synthetic fluoropolymer of tetrafluoroethylene that has numerous applications. The well-known brand name of PTFE-based formulas is Teflon by Chemours. Chemours was a spin-off from DuPont, which originally discovered the compound in 1938. Another popular brand name of PTFE is Syncolon by Synco Chemical Corporation.

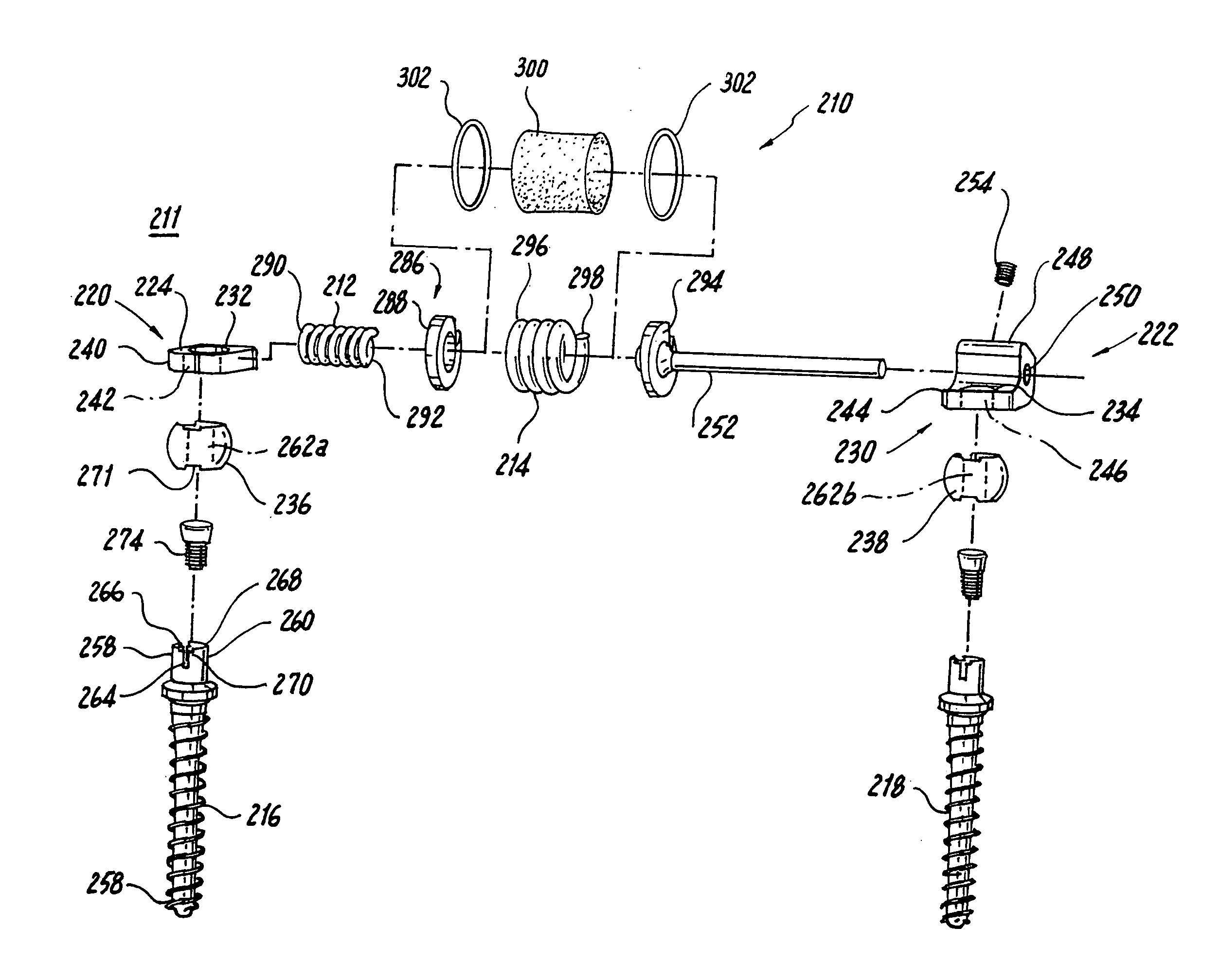

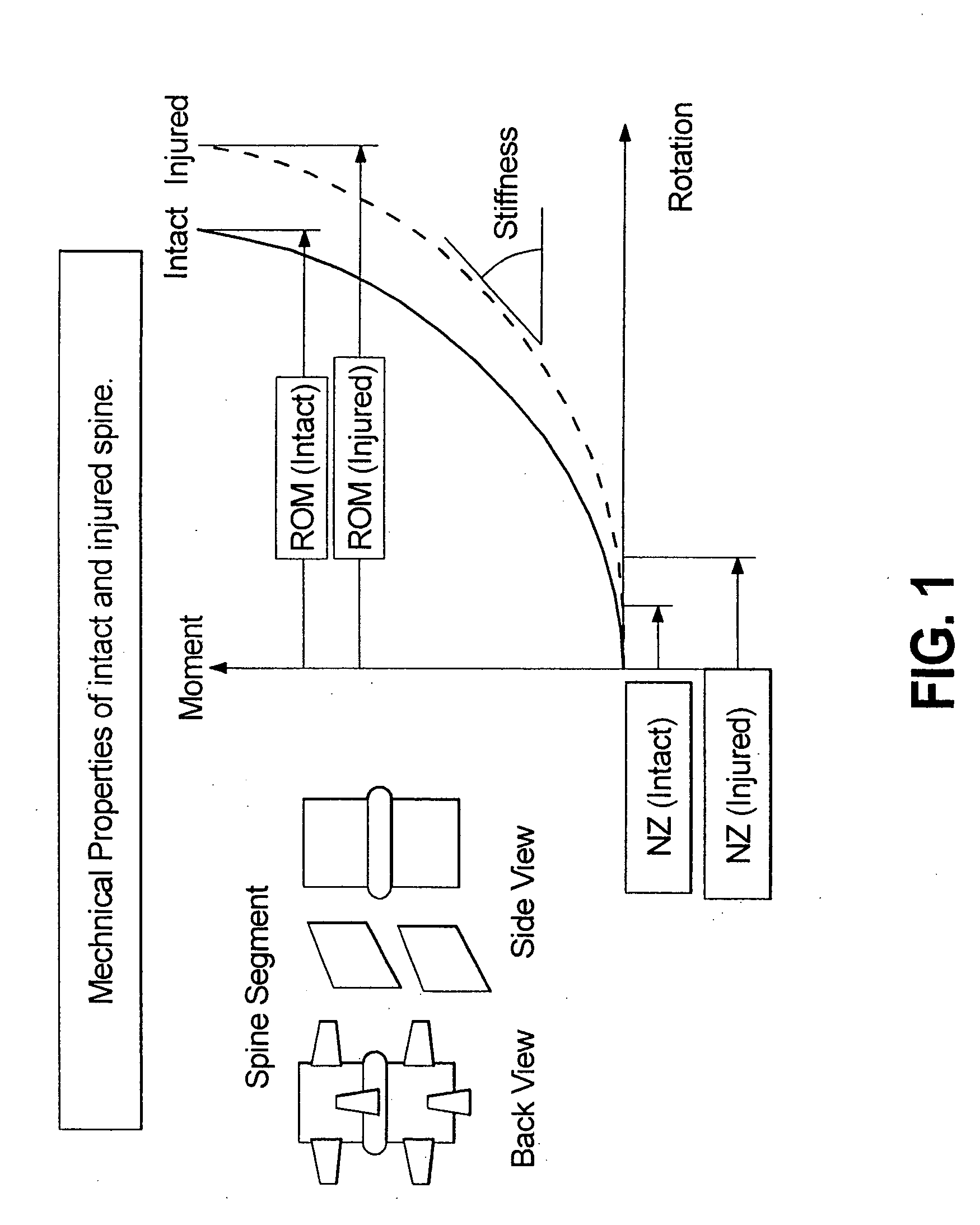

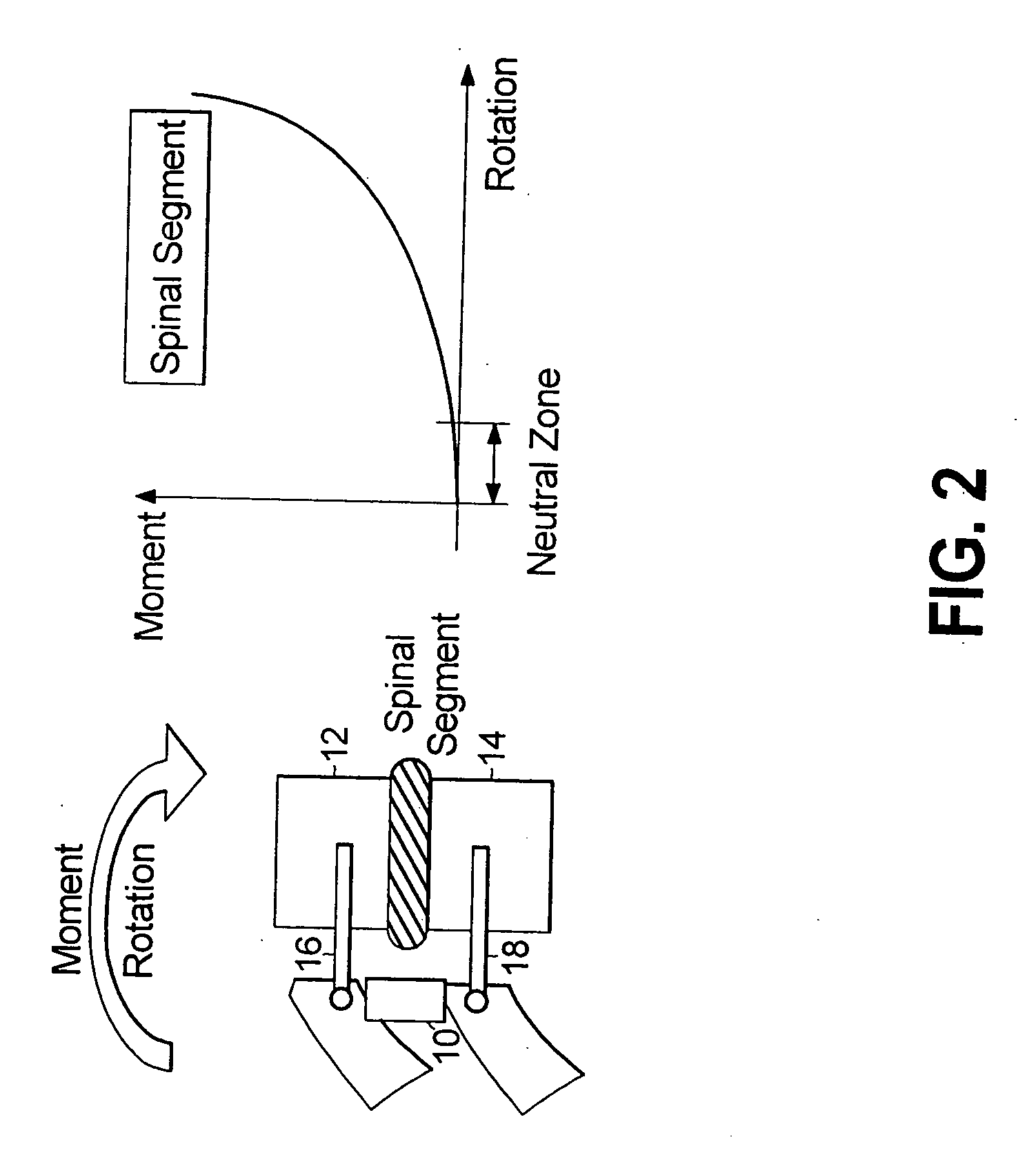

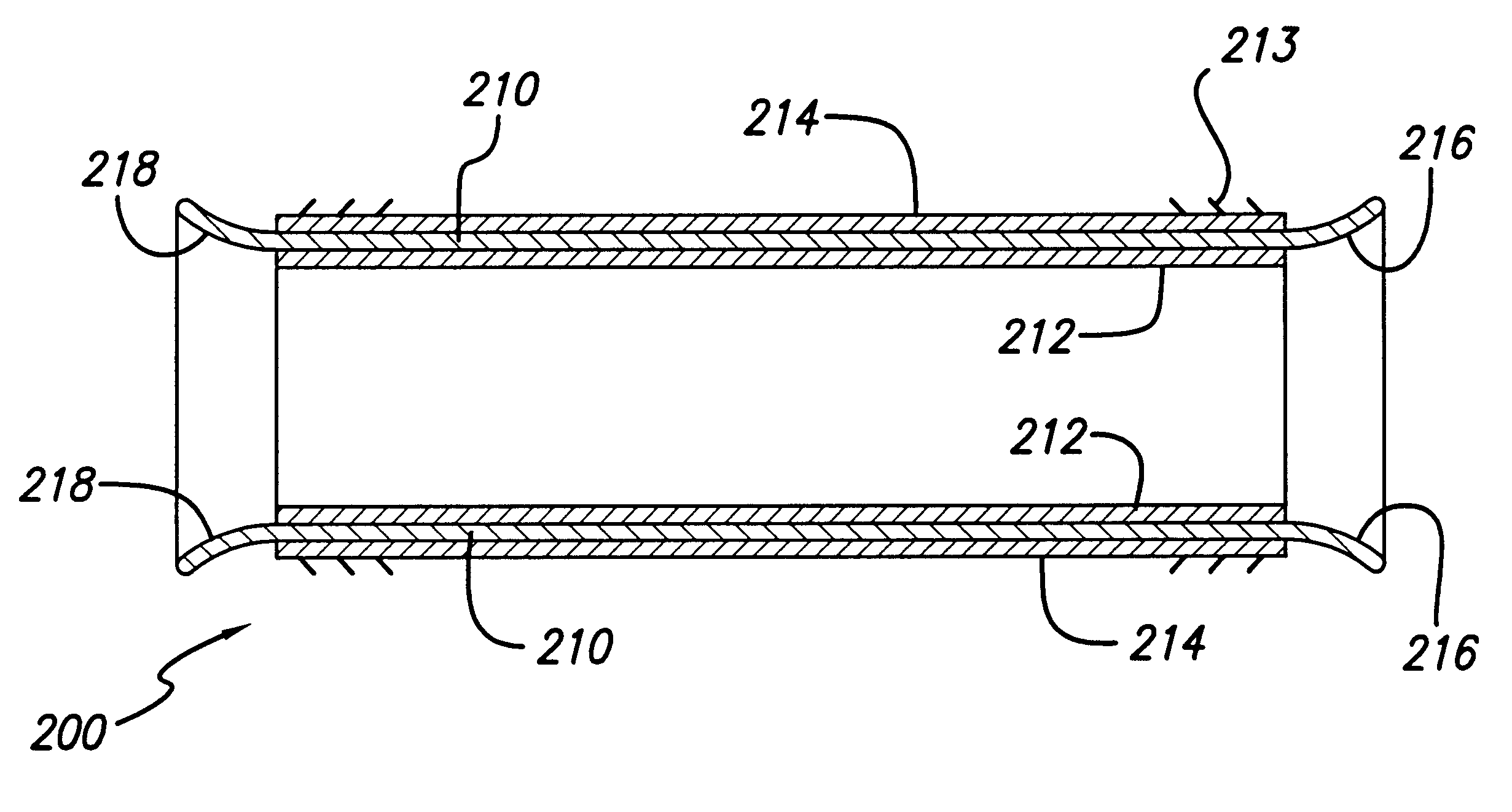

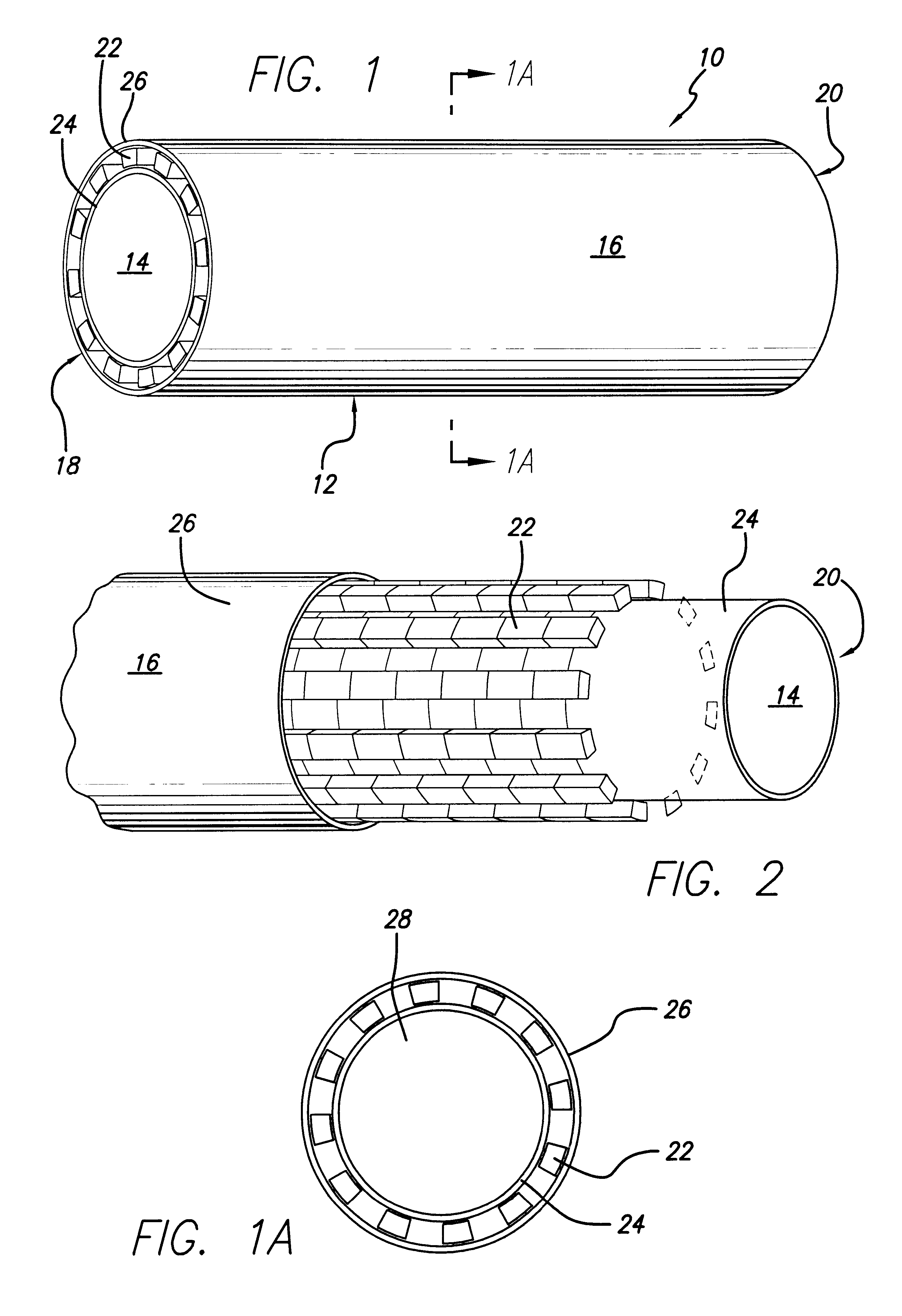

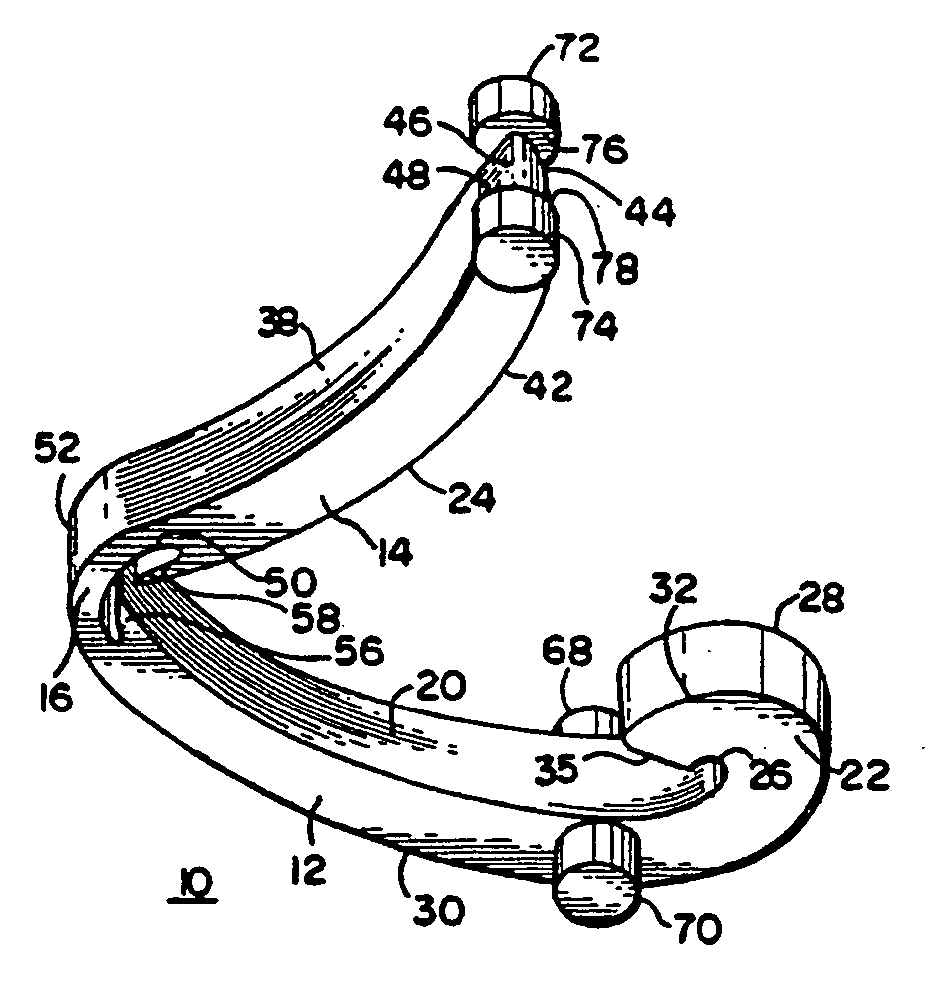

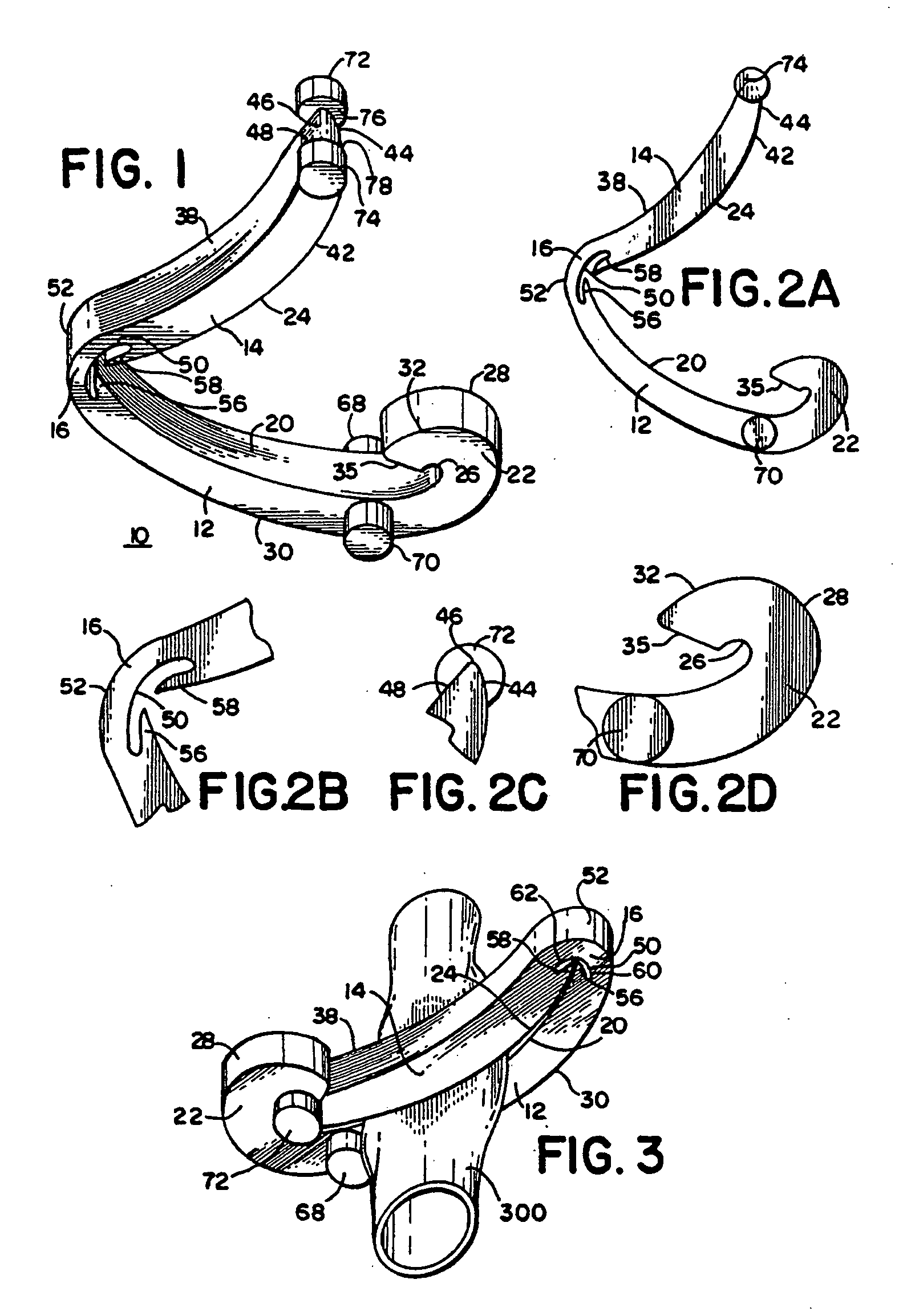

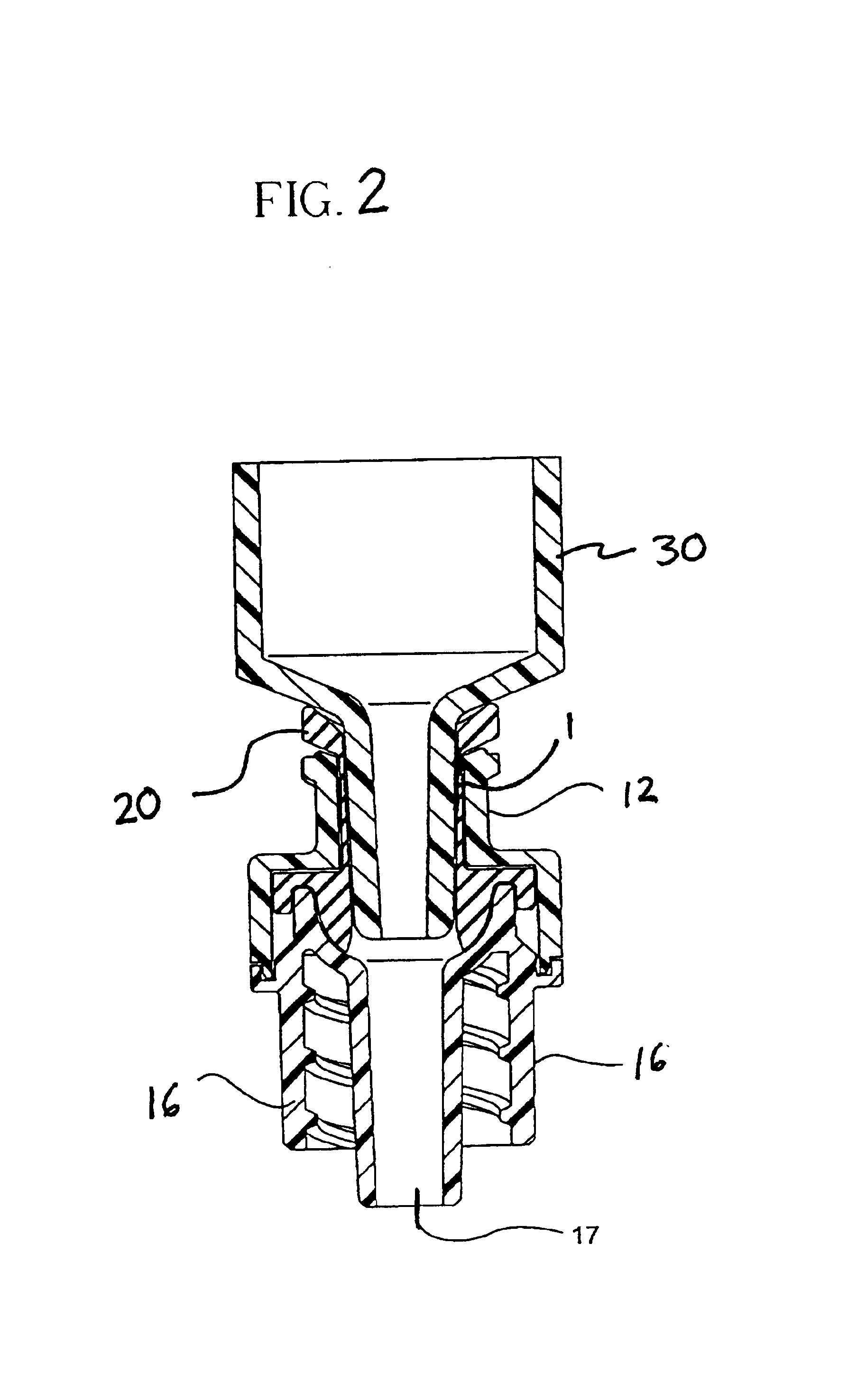

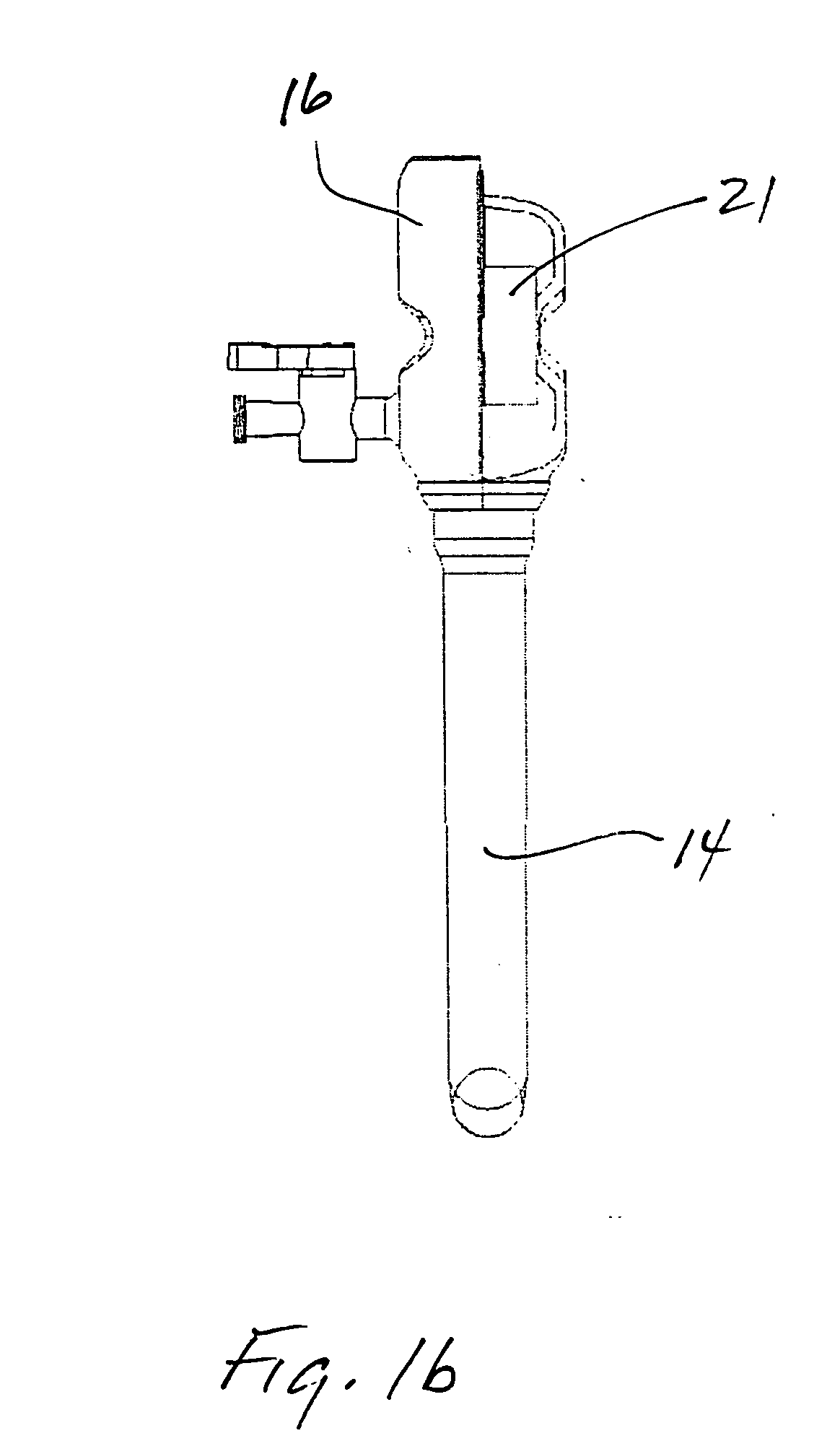

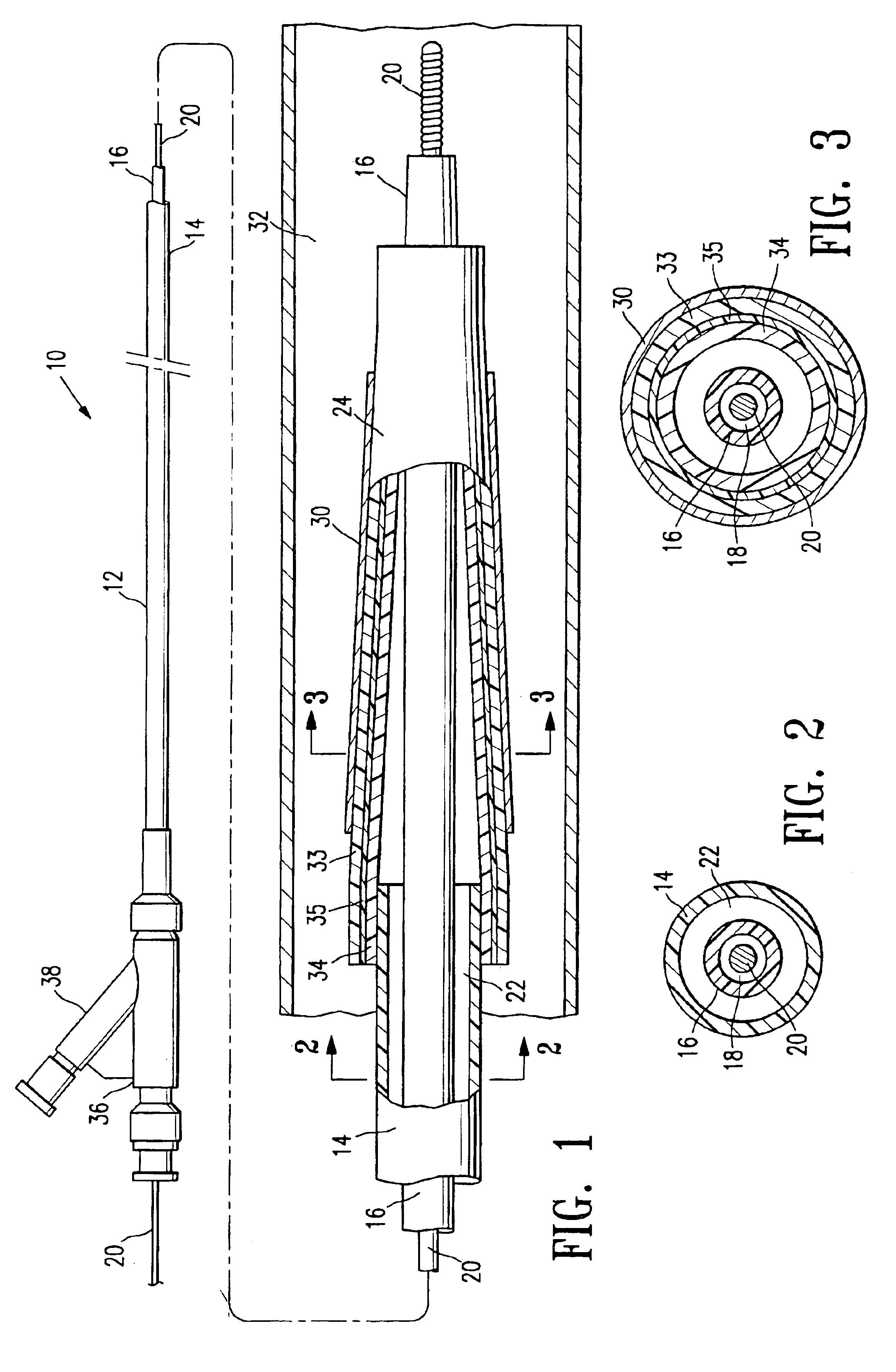

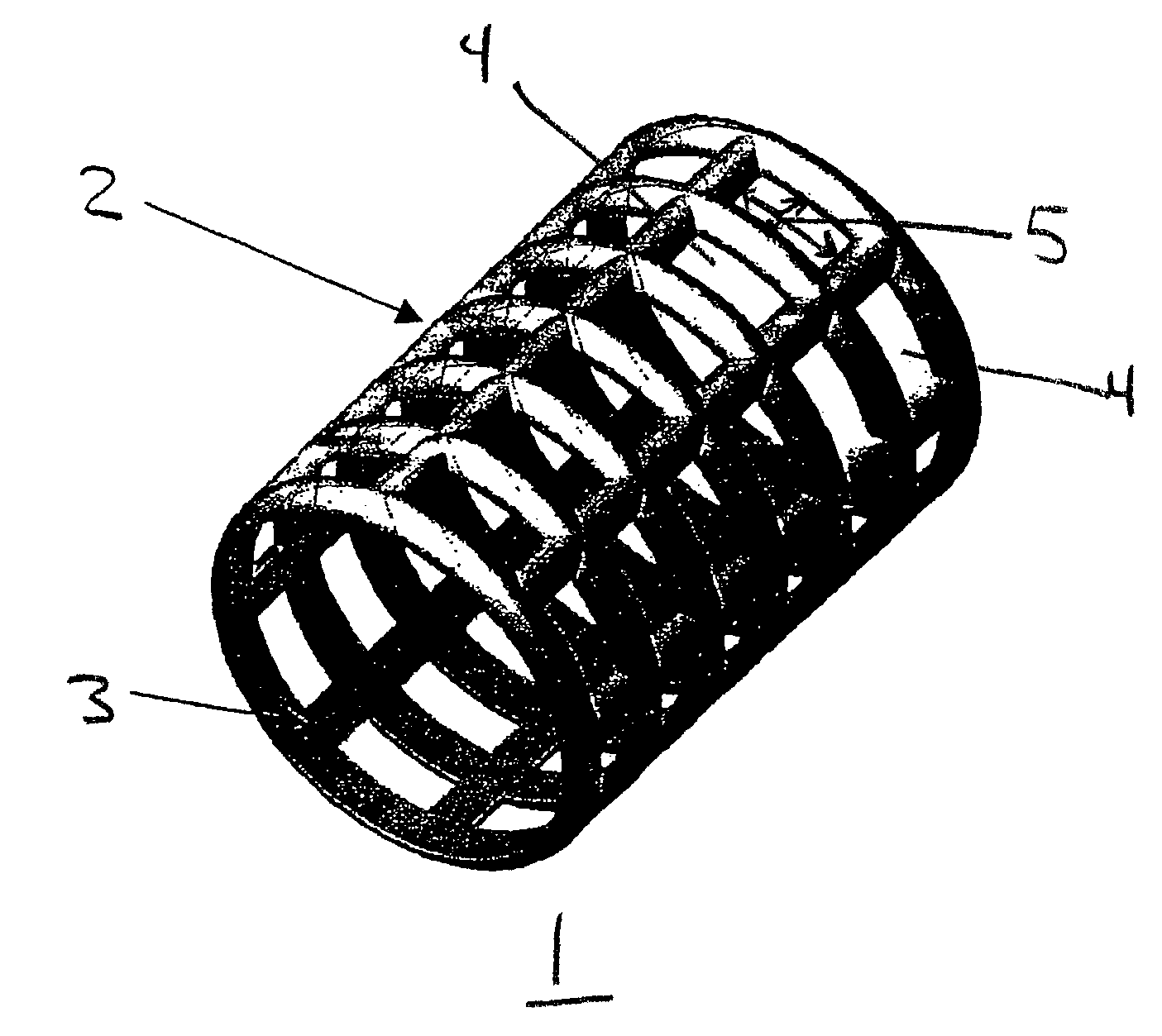

Surgical implant devices and systems including a sheath member

InactiveUS20050177156A1Easy to installImprove clinical outcomesSuture equipmentsInternal osteosythesisAnatomical structuresSpinal column

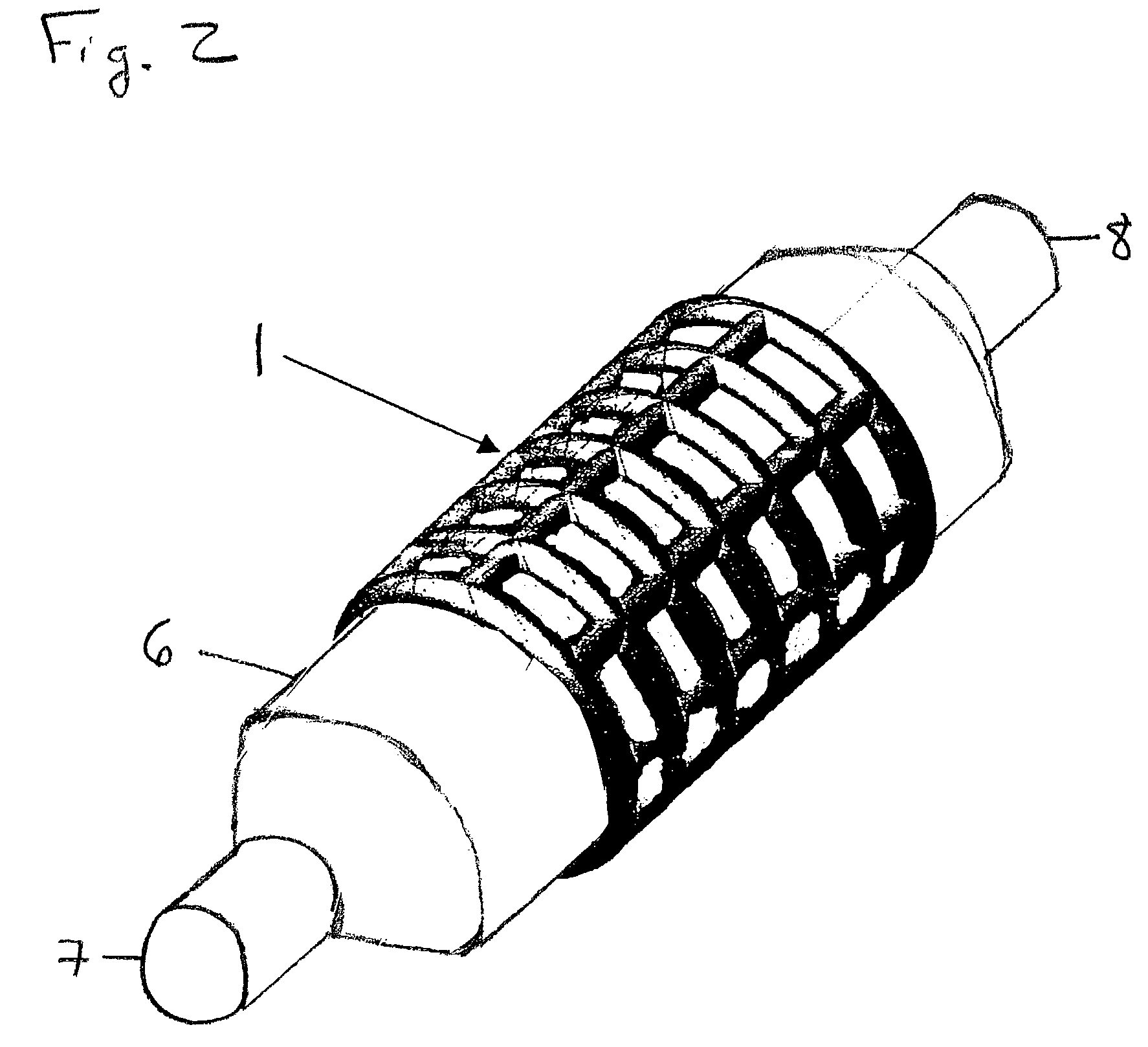

A surgical implant is provided that includes first and second abutment surfaces between which are positioned a force imparting mechanism. A sheath is positioned between the first and second abutment surfaces, and surrounds the force imparting mechanism. The sheath is fabricated from a material that accommodates relative movement of the abutment members, while exhibiting substantially inert behavior relative to surrounding anatomical structures. The sheath is generally fabricated from expanded polytetrafluoroethylene, ultra-high molecular weight polyethylene, a copolymer of polycarbonate and a urethane, or a blend of a polycarbonate and a urethane. The force imparting member may include one or more springs, e.g., a pair of nested springs. The surgical implant may be a dynamic spine stabilizing member that is advantageously incorporated into a spine stabilization system to offer clinically efficacious results.

Owner:RACHIOTEK

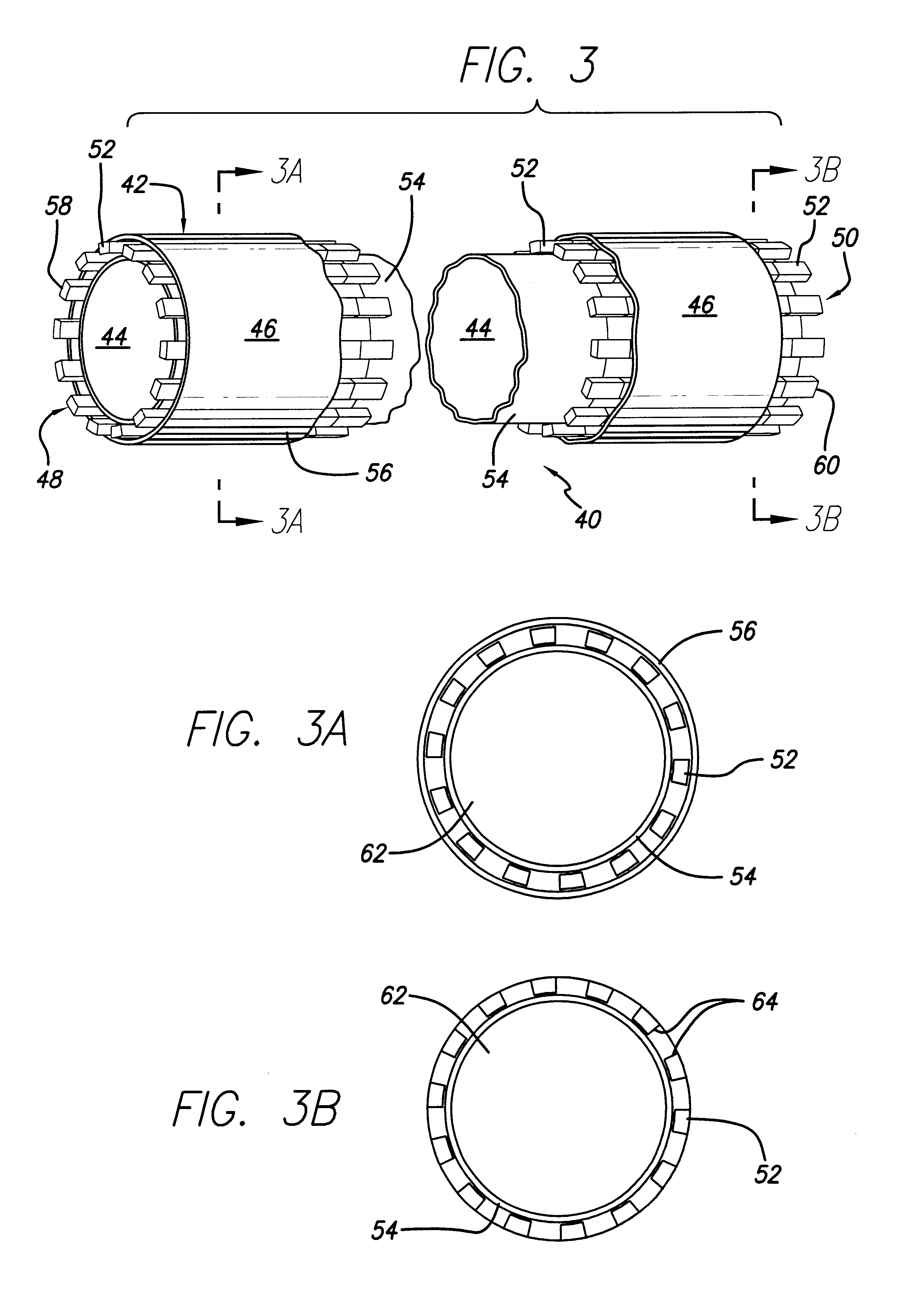

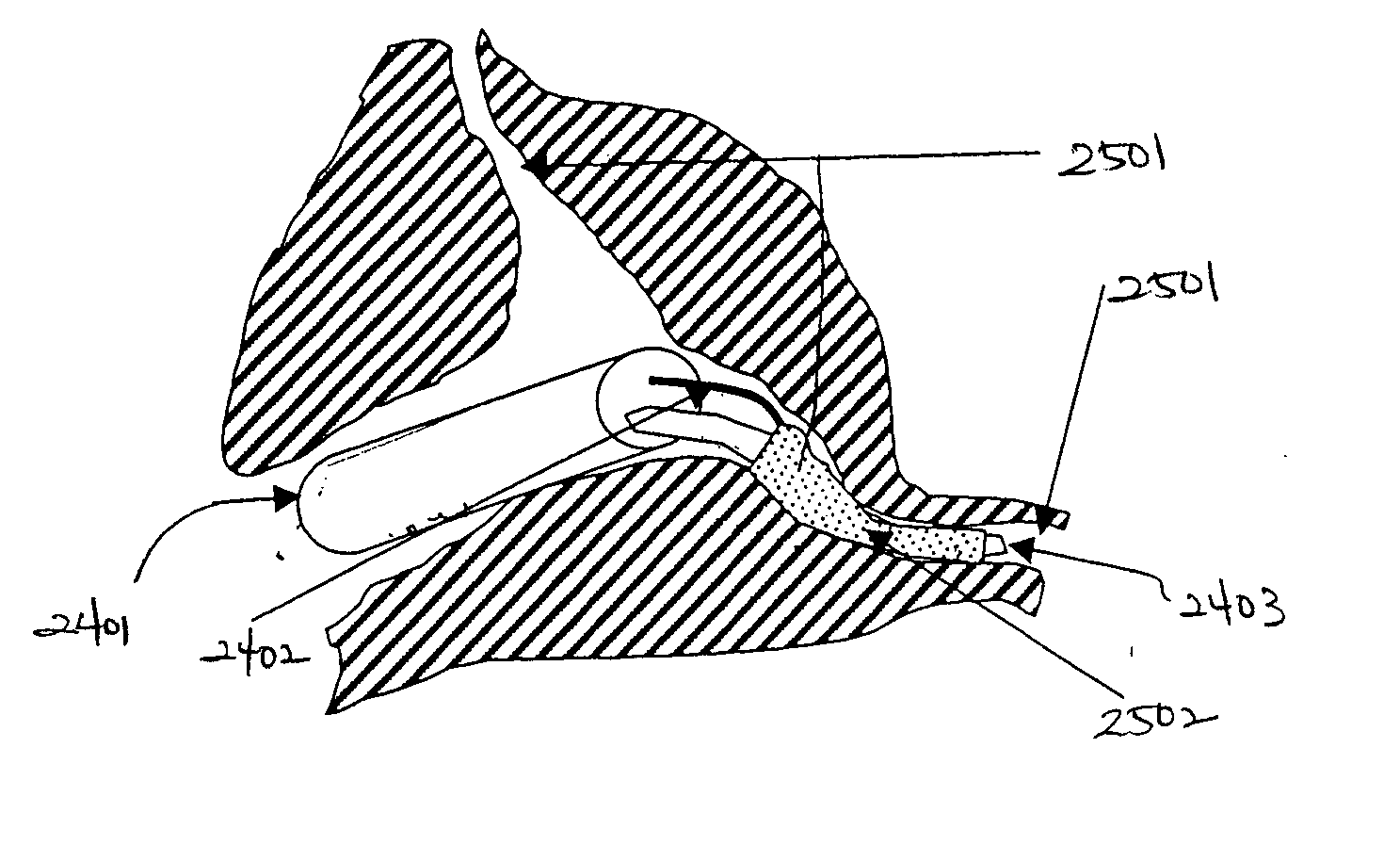

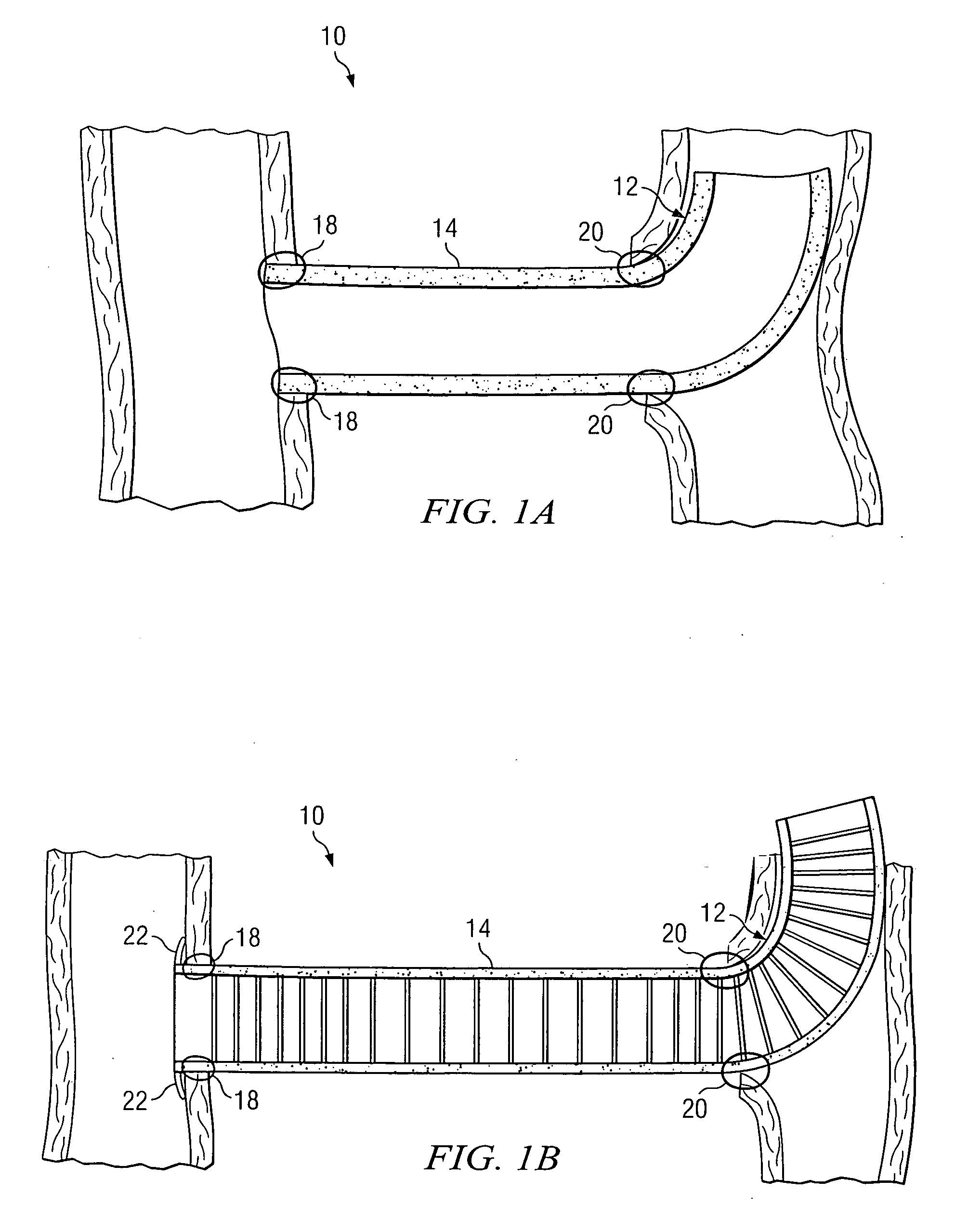

Encapsulated stent

InactiveUS6383214B1Reduce thrombosisEasy to separateStentsBlood vesselsStent graftingPolytetrafluoroethylene

An encapsulated stent having a stent or structural support layer sandwiched between two biocompatible flexible layers. One preferred embodiment has a stent cover which includes a tubular shaped stent that is concentrically retained between two tubular shaped grafts comprised of expanded polytetrafluoroethylene. Another preferred embodiment has a stent graft which includes at least one stent sandwiched between the ends of two tubular shaped grafts wherein at least a portion of the grafts are unsupported by the stent. Still another embodiment includes an articulating stented graft which includes a plurality of stents spaced apart from one another at a predetermined distance wherein each stent is contained between two elongated biocompatible tubular members. The graft / stent / graft assemblies all have inseparable layers.

Owner:BARD PERIPHERAL VASCULAR

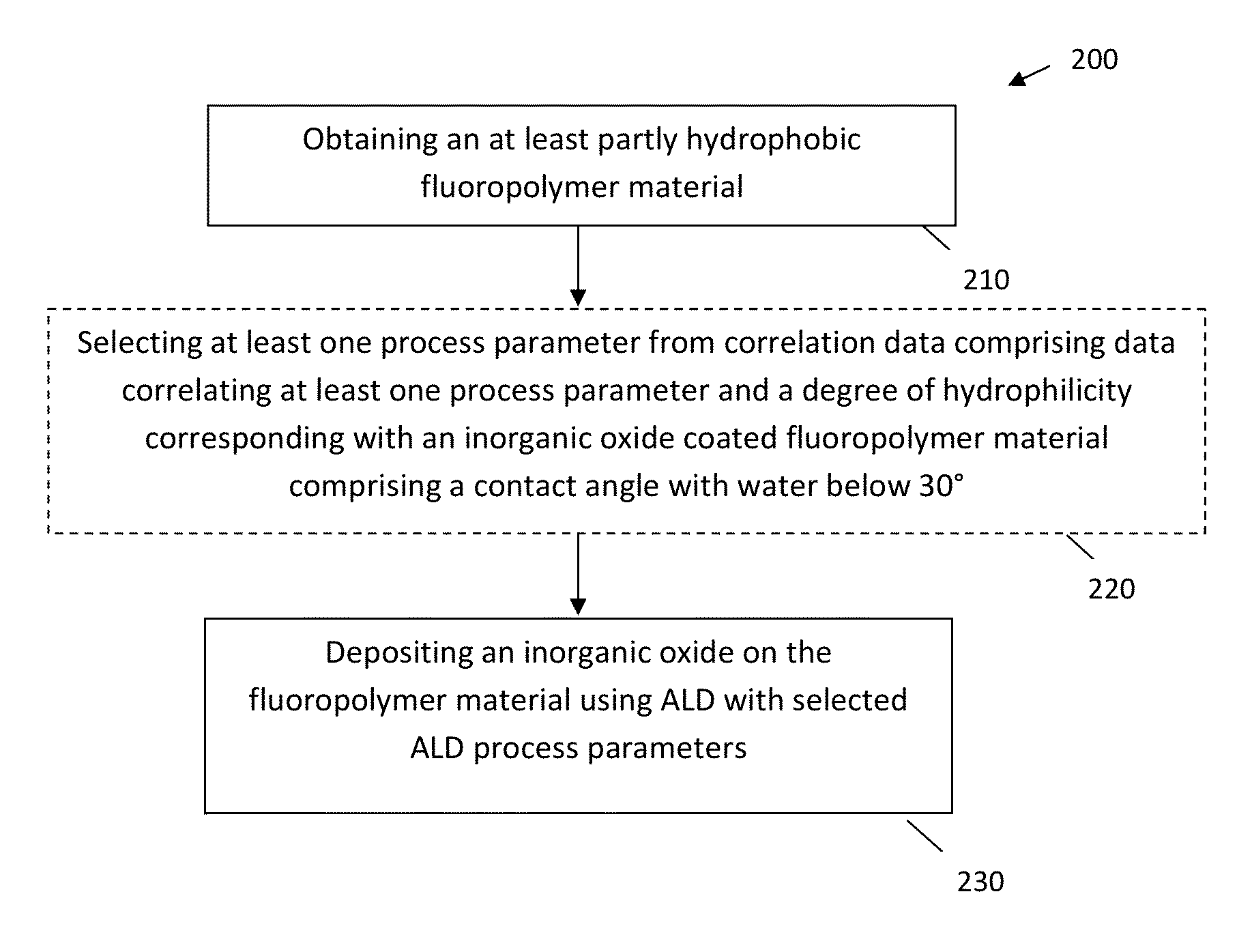

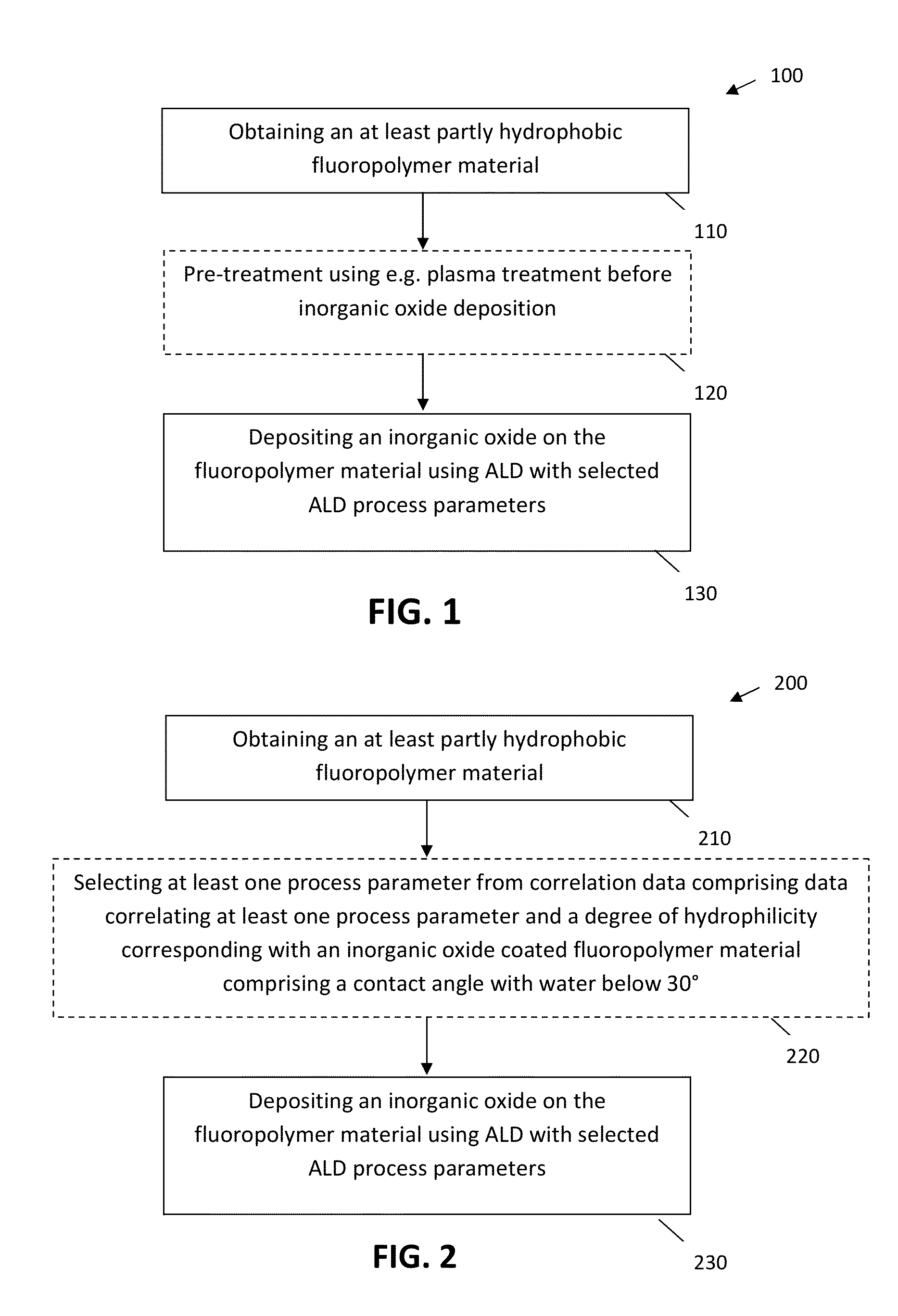

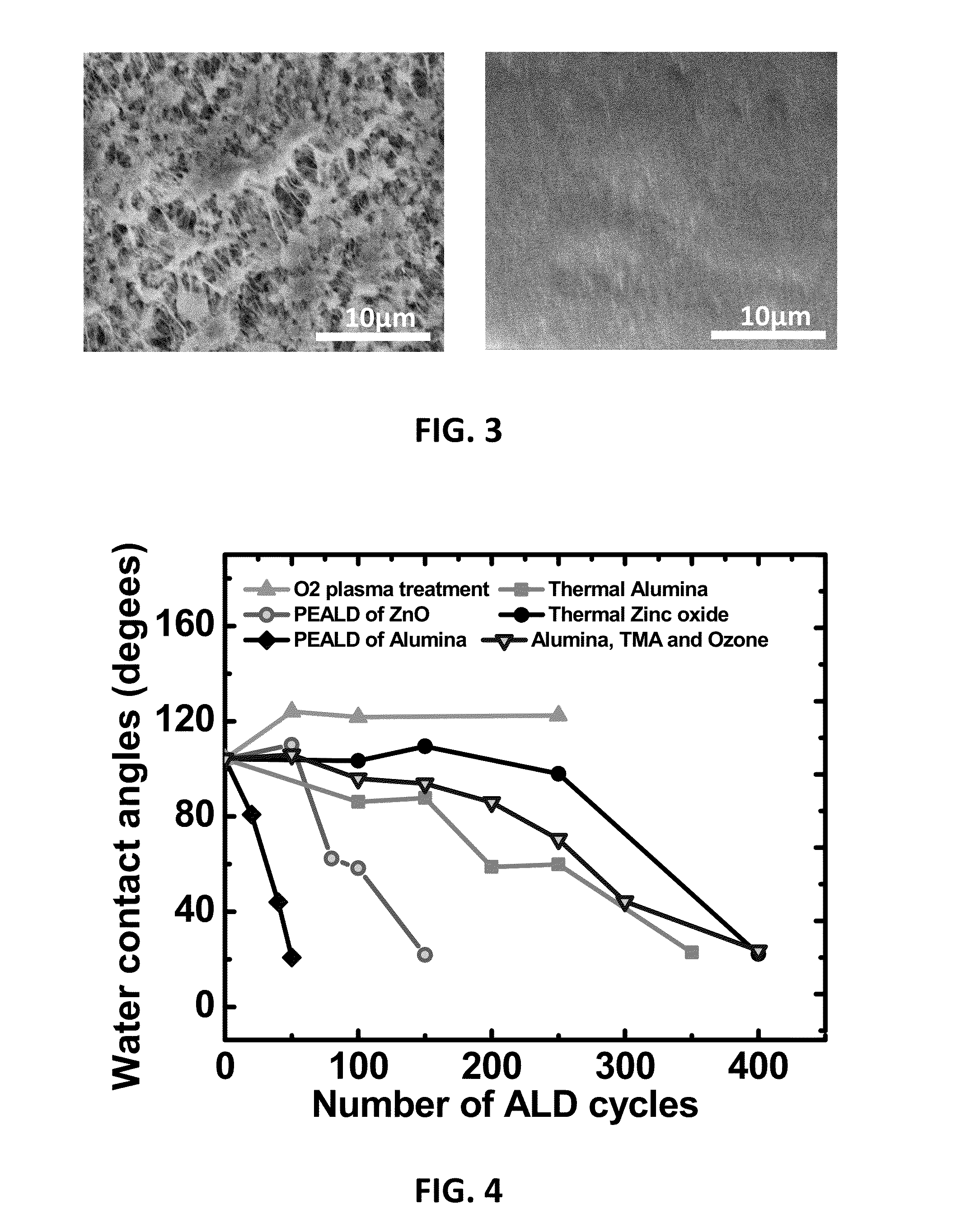

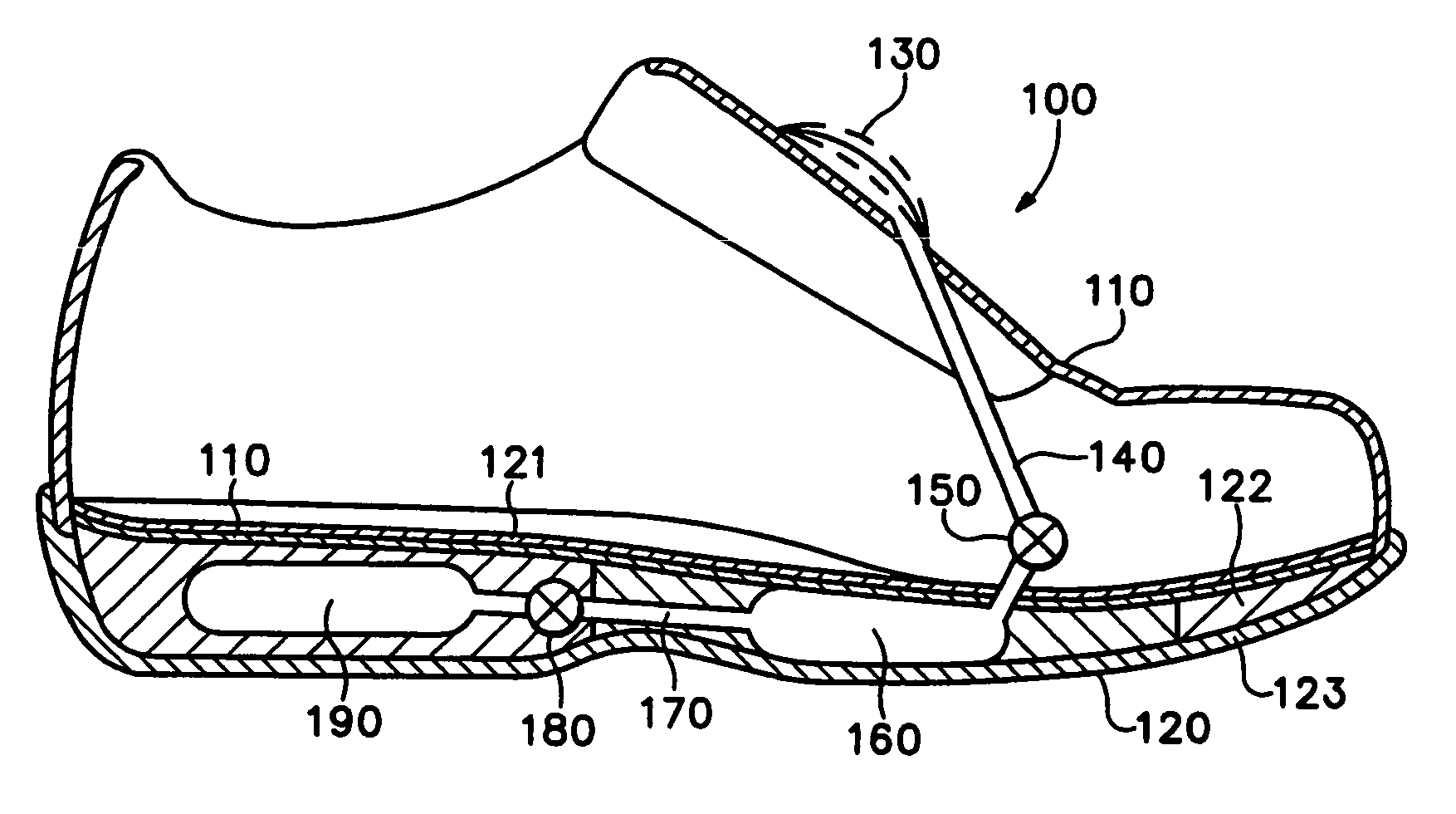

Methods for Obtaining Hydrophilic Fluoropolymers

InactiveUS20150345018A1Rendering fluoropolymers hydrophilicSimple methodSynthetic resin layered productsChemical vapor deposition coatingFluoropolymerPlasma activation

A method is described for providing a hydrophilic effect to a fluoropolymer, e.g. polytetrafluoroethylene (PTFE) material. The method comprises obtaining an at least partly hydrophobic fluoropolymer material, applying a plasma and / or ozone activation step and depositing an inorganic coating using an atomic layer deposition process. Plasma activation step and / or said atomic layer deposition process thereby comprises using process parameters determining a high interaction probability between one or more precursors for the atomic layer deposition process and the fluoropolymer material so as to obtain a coated fluoropolymer material having a contact angle with water below 30°.

Owner:UNIV GENT

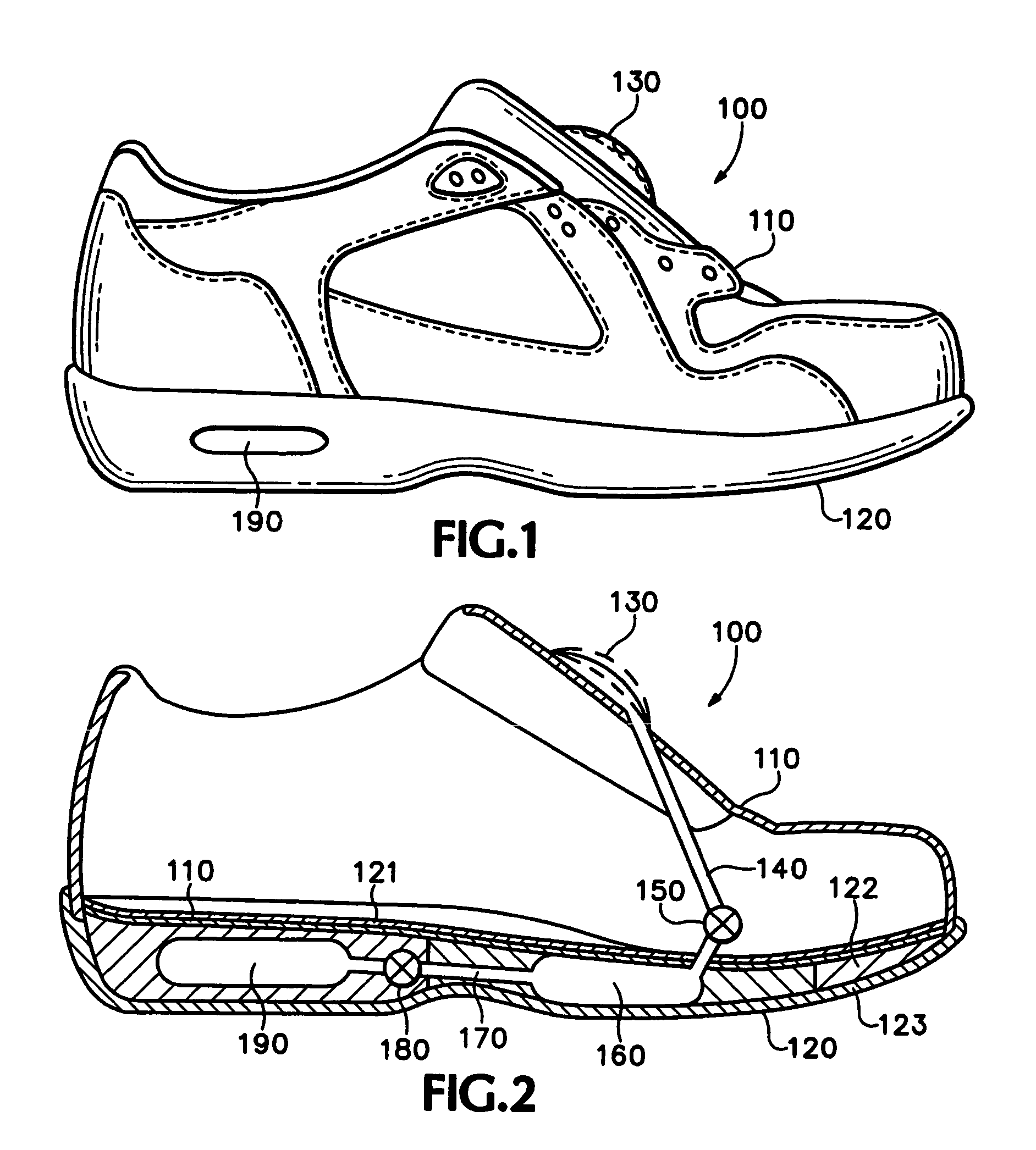

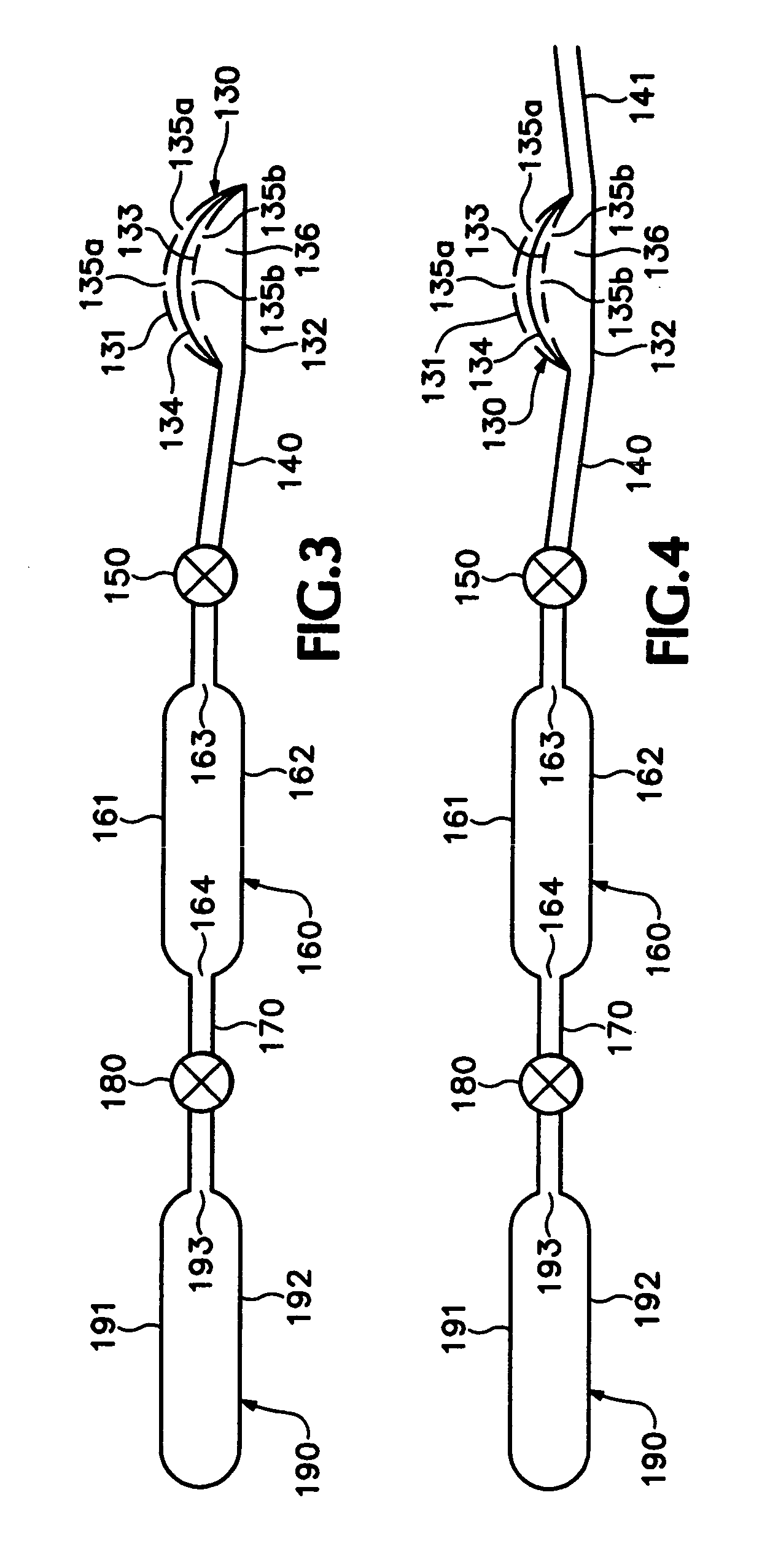

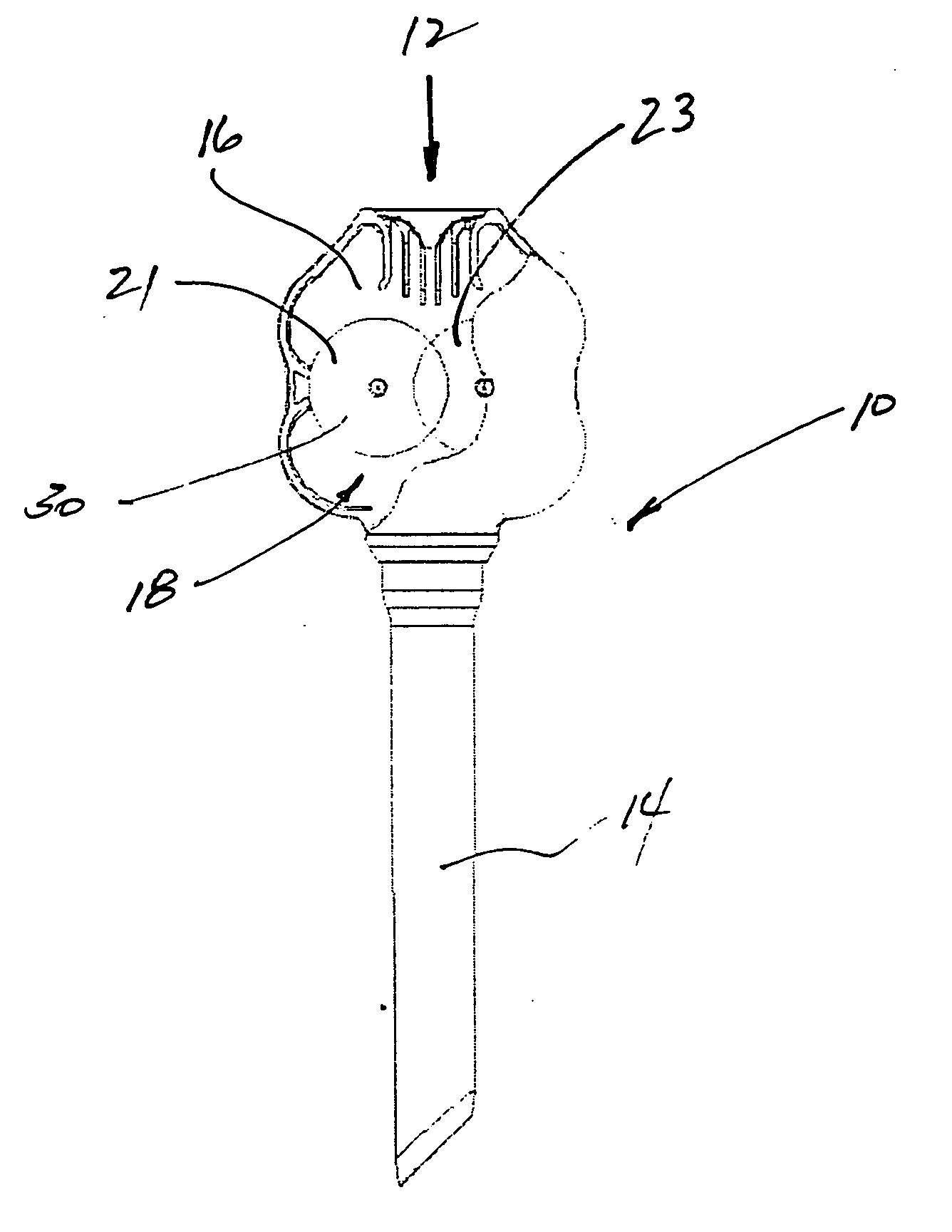

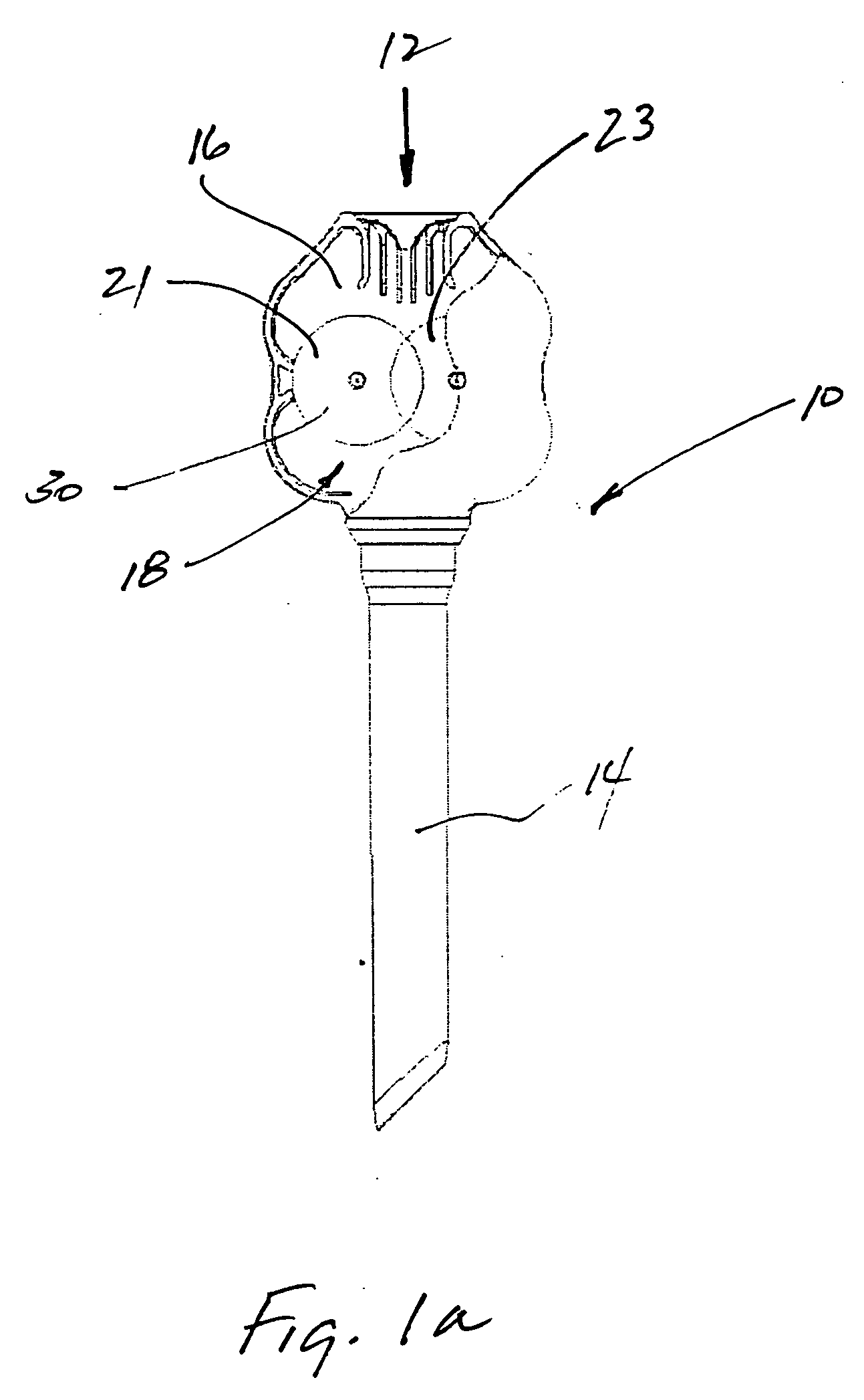

Footwear with bladder filter

An article of athletic footwear having an air-filled bladder disposed in a sole structure is disclosed. The air-filled bladder is in fluid communication with ambient air through a filter that permits ambient air to enter the bladder but restricts liquids and particulates from entering the bladder. In operation, the filter and bladder may be portions of a bladder system that absorb shock when the footwear contacts a playing surface. Alternatively, the filter and bladder may be portions of a bladder system that ventilates the interior of the footwear. The filter may be formed of a material such as expanded polytetrafluoroethylene that is attached to a carrier.

Owner:NIKE INC

Coated ligating clip

A polymeric, surgical clip having first and second curved leg members joined at their proximal end by a hinge portion and movable from an open position to a closed position for clamping a vessel between curved opposing inner surfaces. The clip includes a coating on its exterior which reduces the friction between the leg members and complementary locking mechanisms disposed at the distal end portions of the leg members, and stabilizes closing of the clip. The coating can be any coating, including a polymer coating such as one which includes polytetrafluoroethylene. The coating may be applied using a solvent such as HFC43-10.

Owner:PILLING WECK INC

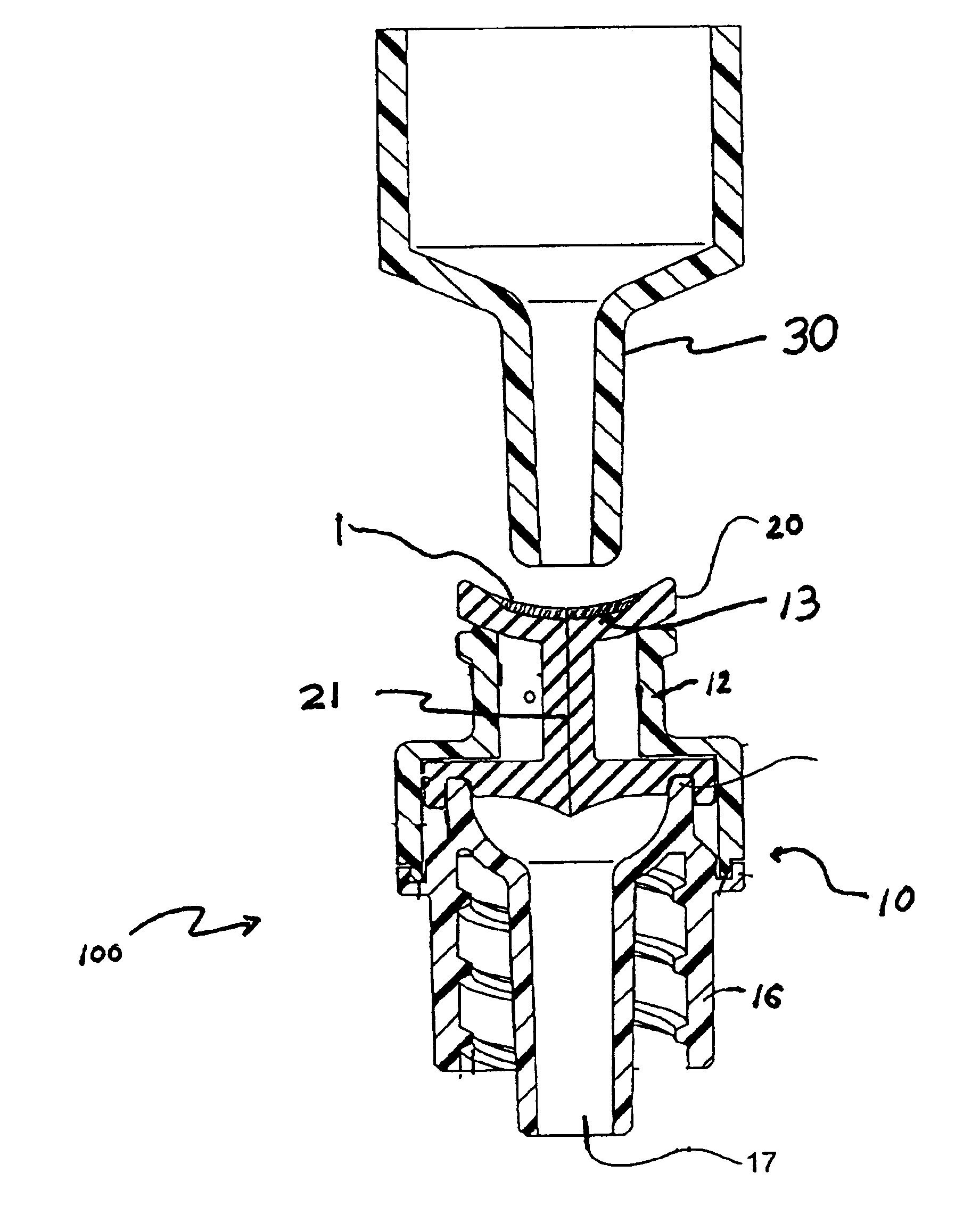

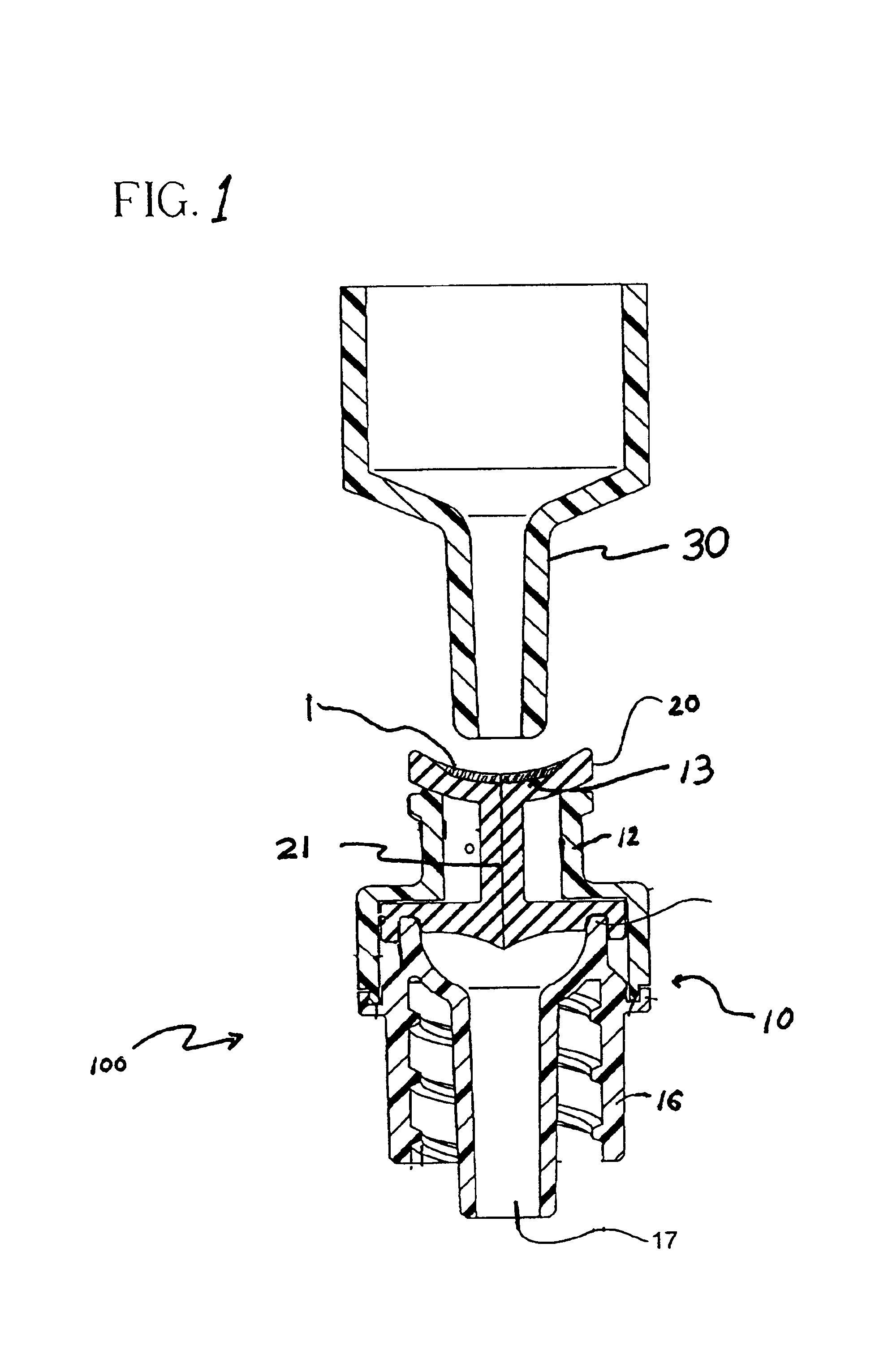

Lubricious coating for a medical device

InactiveUS6866656B2Reduce frictionNot degradedFilm/foil adhesivesSynthetic resin layered productsElastomerChemical Linkage

A lubrication system is disclosed which minimizes friction and that is useful for application on the surface of a flexible portion of a medical device. Such a lubrication system includes a lubricant that is able to move when the flexible portion of the medical device flexes and is biocompatible and is not degraded by the application of alcohol or other conventional medical sterilizing and cleaning agents. The lubricant is bonded to the surface of the flexible portion of the medical device. The lubrication system may be used on an elastomeric septum, such as a silicone rubber elastomer. The lubricant coating may be any type of coating that can be chemically bonded to the elastomer, such as di-paraxylene, poly-(p-xylene), polytetrafluoroethylene, or polyvinylpyrrolidone.

Owner:BECTON DICKINSON & CO

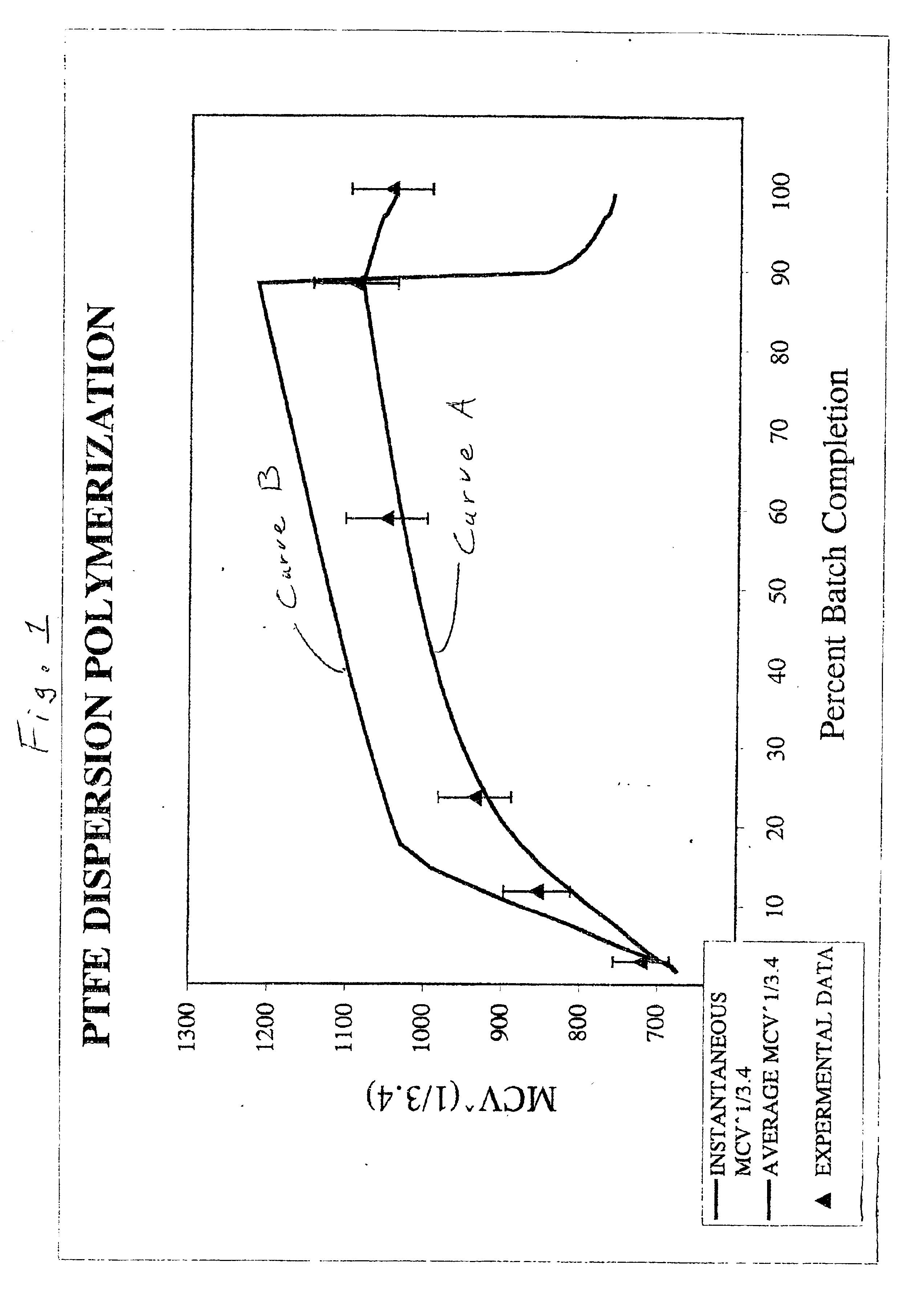

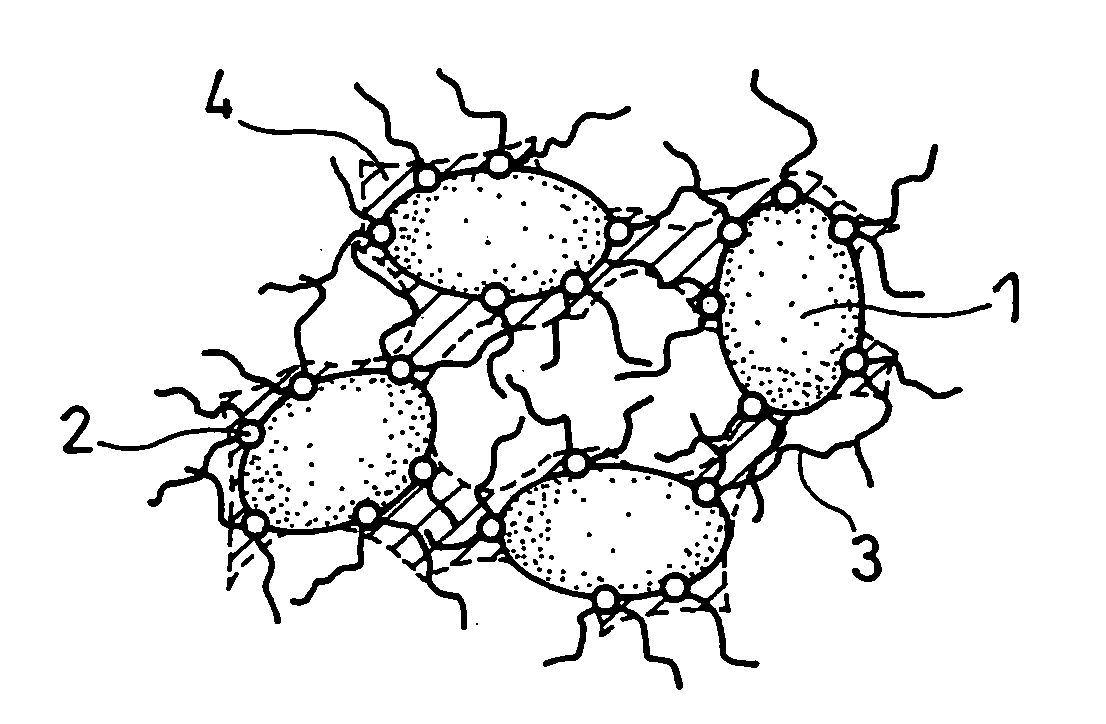

Core-shell fluoropolymer dispersions

InactiveUS6841594B2High shear stabilityExtend elastic lifeSynthetic resin layered productsCellulosic plastic layered productsTetrafluoroethylenePolymer science

A dispersion of non-melt-processible fluoropolymer particles having an SSG of less than about 2.225 in aqueous medium. The fluoropolymer particles comprise a core of high molecular weight polytetrafluoroethylene having an average melt creep viscosity greater than about 1.5×1010 Pa·s and a shell of lower molecular weight polytetrafluoroethylene or modified polytetrafluoroethylene. The shell has an average melt creep viscosity greater than about 9×109 Pa·s and comprises about 5 to about 30% by weight of the particles. The fluoropolymer in the dispersion of the invention is fibrillating.

Owner:THE CHEMOURS CO FC LLC

Surgical device with tack-free gel and method of manufacture

InactiveUS20050033246A1Significant drag forceImprove complianceCannulasSurgical needlesMolten stateLow-density polyethylene

A process of making a tack-free gel is disclosed comprising the steps of providing a mold defining a mold cavity, the mold cavity comprising a plastic material; pouring or injecting a molten gel having a high molding temperature into the mold cavity; and forming the tack-free gel as a thin layer of plastic of the mold cavity is melted over the gel. The forming step further comprises cooling the gel from the molten state to a solidified state. The melting temperature of the plastic material is lower than the molding temperature of the gel; and the higher the temperature differential, the greater the melting of the plastic material and the thicker the layer of the plastic material on the surface of the gel. The mold may be formed of low-density polyethylene (LDPE). With the process of the invention, the heat of the molten gel at its molding temperature is transferred to the surface of the LDPE mold so as to melt a thin layer of the LDPE. The mold may comprise a mold base having a plurality of mold holes forming a plurality of mold cavities, each of the mold holes comprising an axial pin to mold an axial hole through a center of the gel, an LDPE cylinder providing a predetermined inside diameter for the mold, and an LDPE disc mounted on the axial pin and disposed at the bottom of each mold cavity in the mold base. The process may further comprise the step of dabbing the gel in a low-friction powder such as polytetrafluoroethylene (PTFE) and a lubricant. The mold may further comprise a mold top disposed axially of the mold base and comprises a plurality of holes forming a plurality of cavities, each of the mold top holes is adapted to receive the LDPE cylinder, and a second LDPE disc disposed at the top of each mold cavity of the mold top.

Owner:APPL MEDICAL RESOURCES CORP

Encapsulation device and methods of use

An encapsulation device having an expandable, porous body with a cavity, the body having a sealed end and a sealable end, where the body is configured to receive one or more fluids through a port in the sealable end, the body is configured to expand to conform to a shape of a target, and where the sealable end may be sealed to prevent leakage into the body, and a method if using the encapsulation device, is disclosed. The body may comprise porous membrane including expanded Polytetrafluoroethylene (ePTFE), polyester fiberfill, metal / polymer mesh, and perforated or porous polymer / metal. The target may include a location within the human body. The port in the sealable end is configured to receive a first fluid into the cavity to expand the body to conform to the shape of the target, and the port is further configured to receive a second fluid into the cavity which displaces the first fluid by diffusing the first fluid through the pores in the body and which cures (such as, by an ultraviolet light source) to secure the body to the target. Optionally, the introduction of the second fluid may be unnecessary when the first fluid includes the desired filler material for the encapsulation device.

Owner:DEBEER NICHOLAS

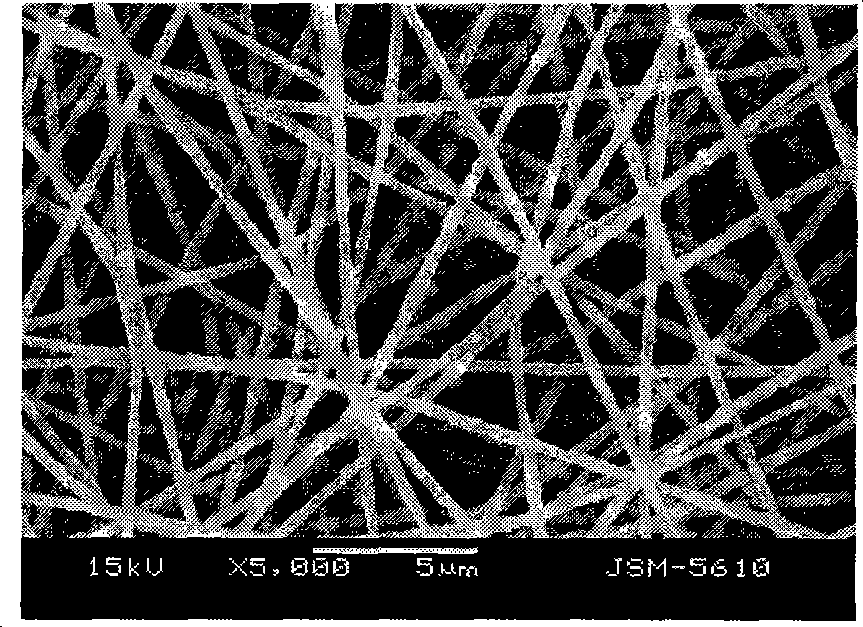

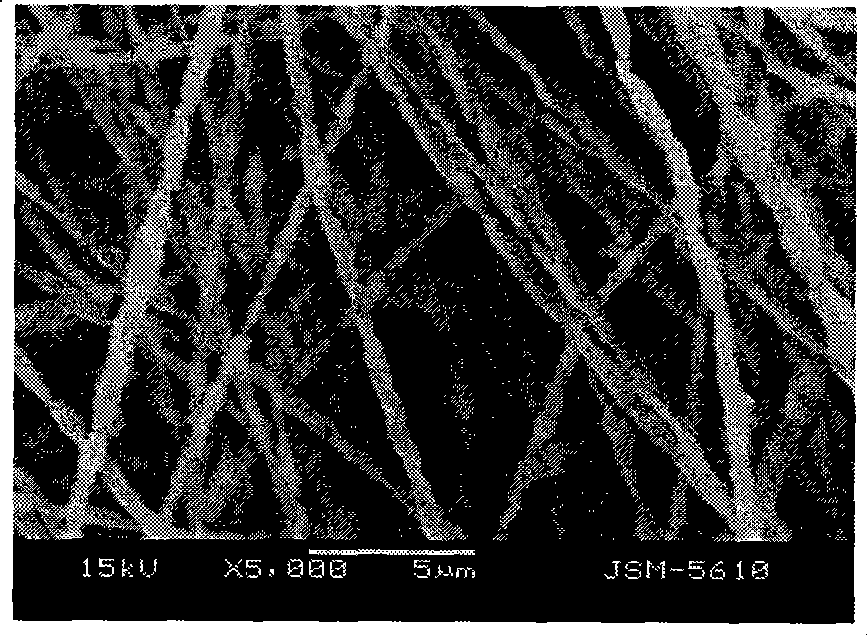

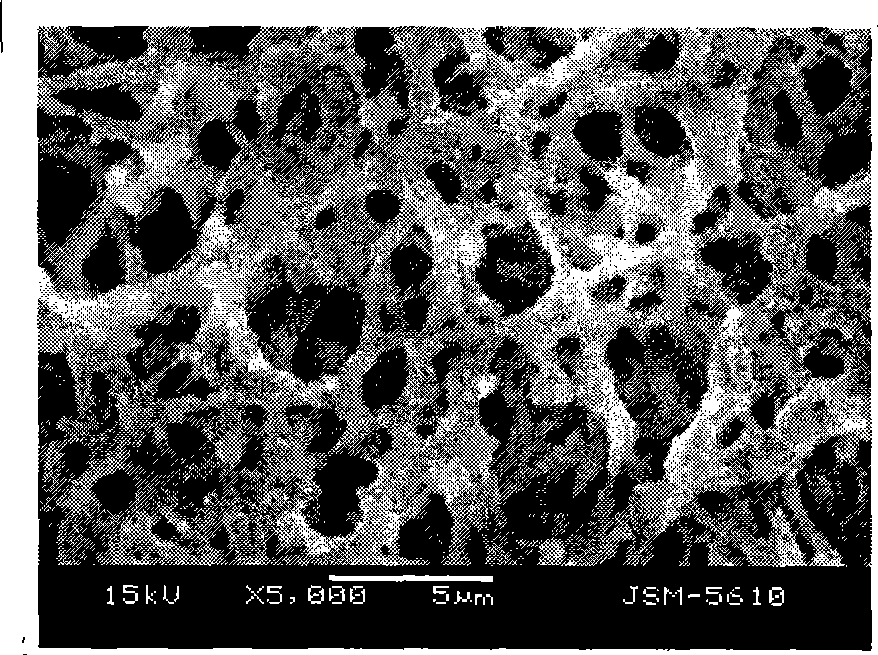

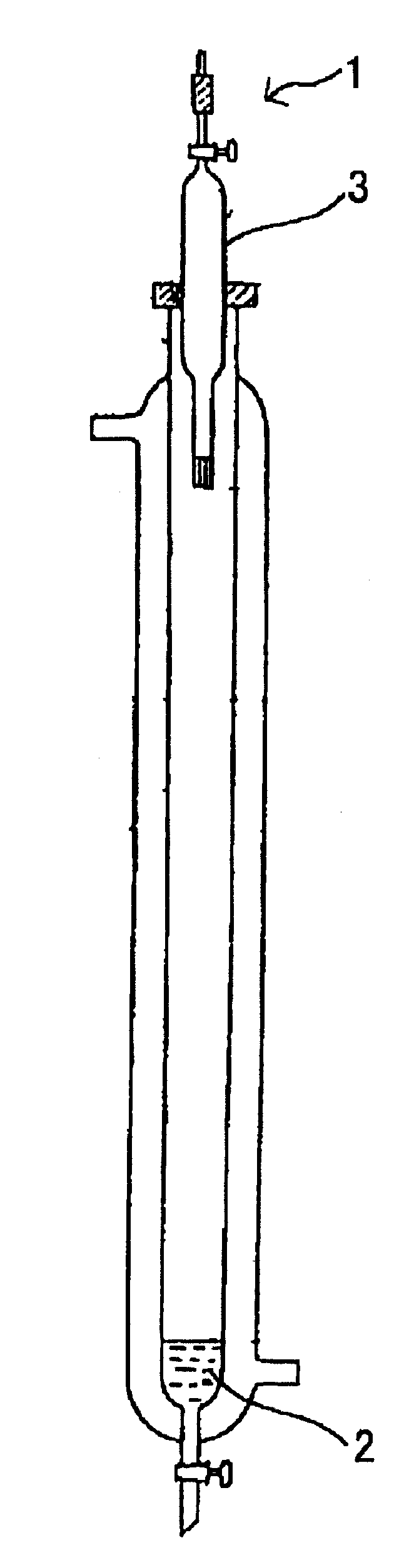

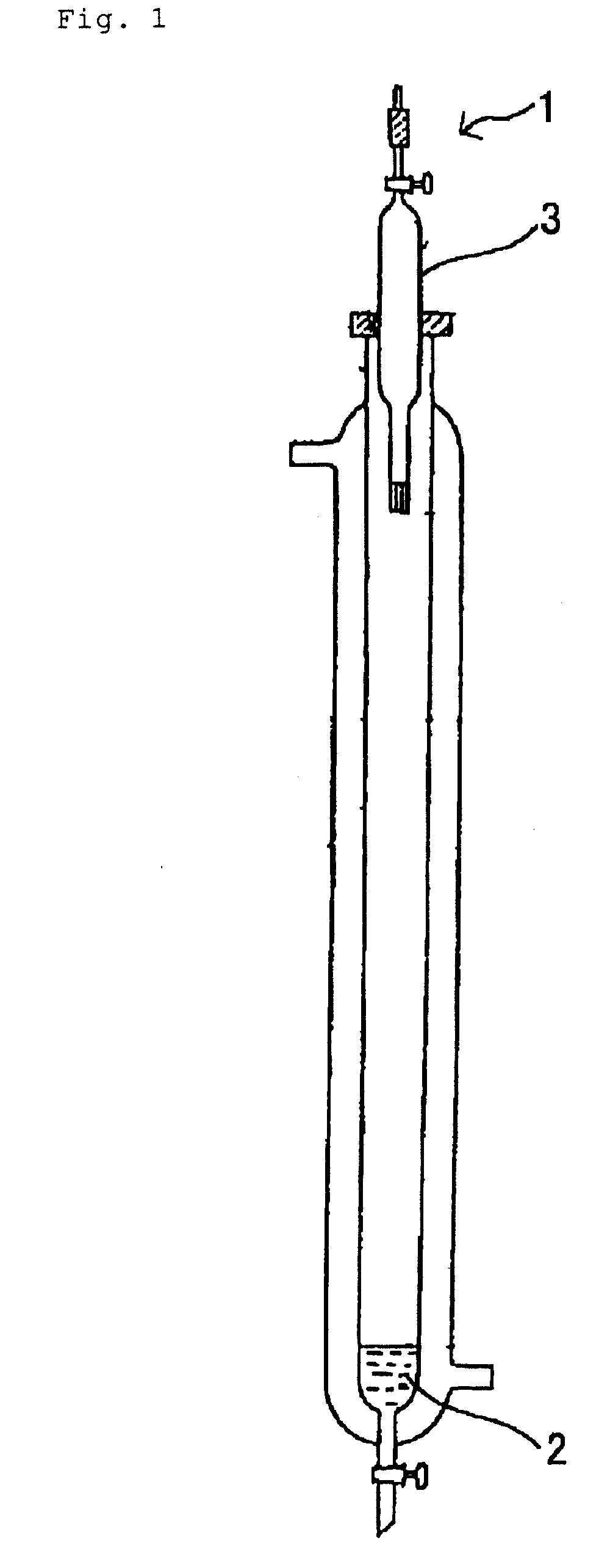

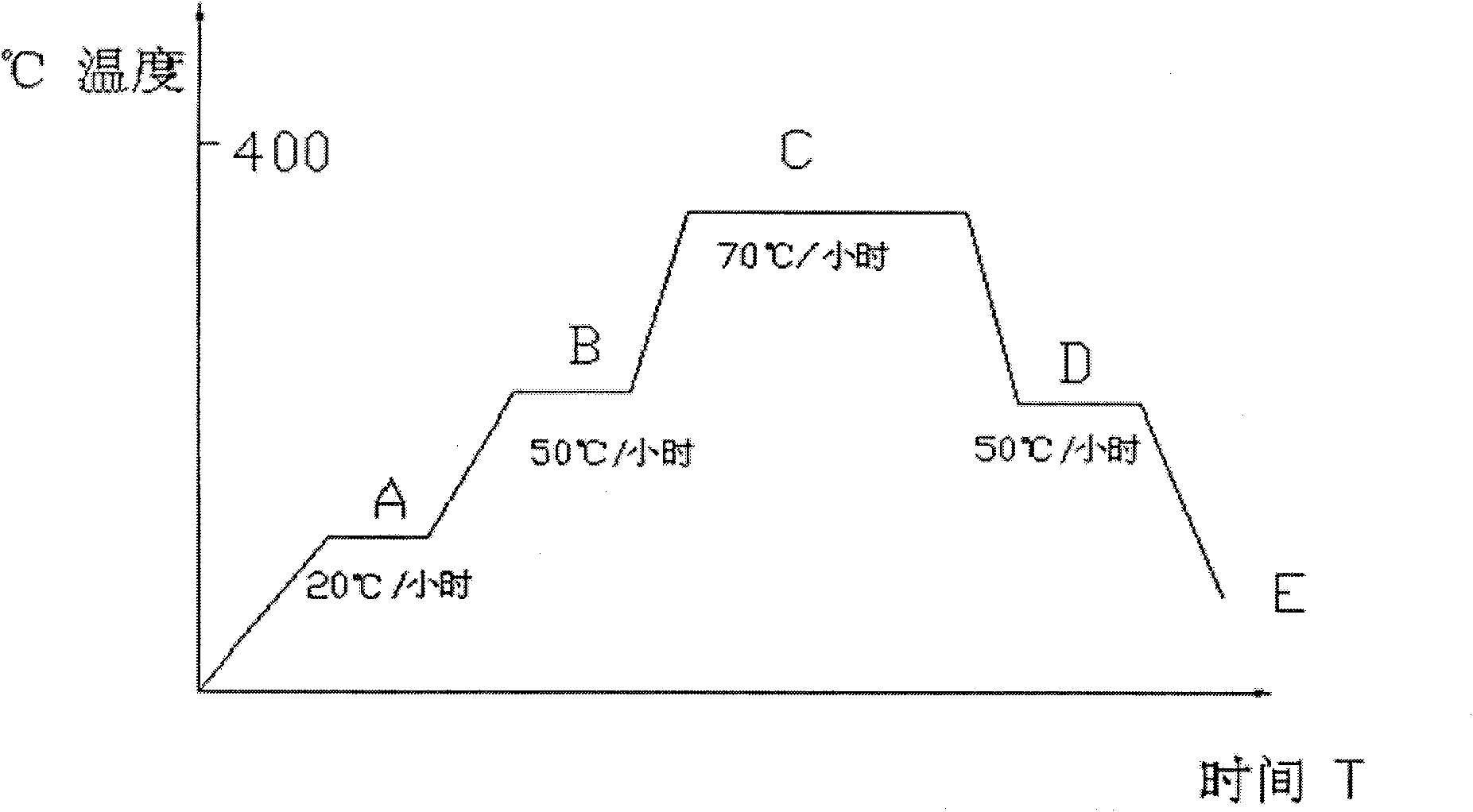

Preparation method of polytetrafluoroethylene superfine fiber porous membrane

InactiveCN101530750AUniform pore sizeHigh porositySemi-permeable membranesHigh concentrationVoid ratio

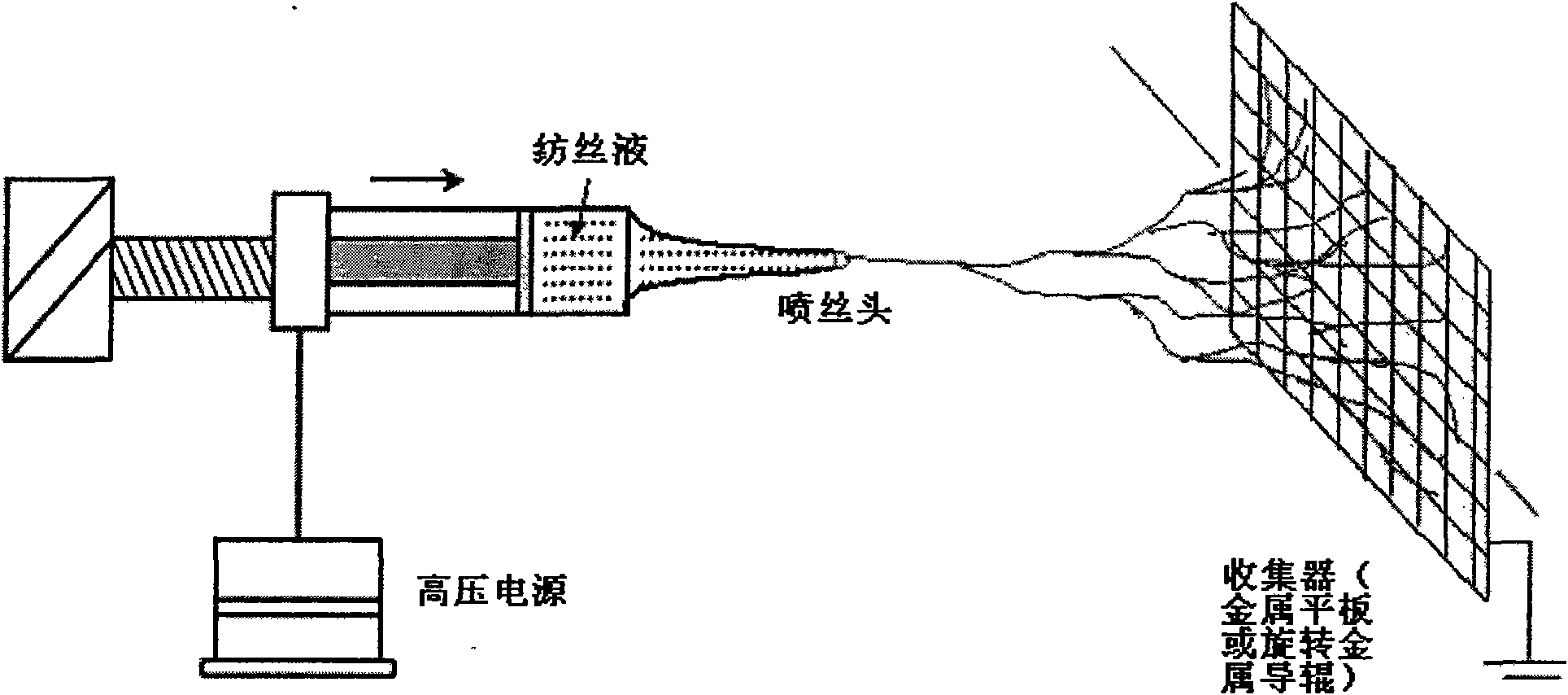

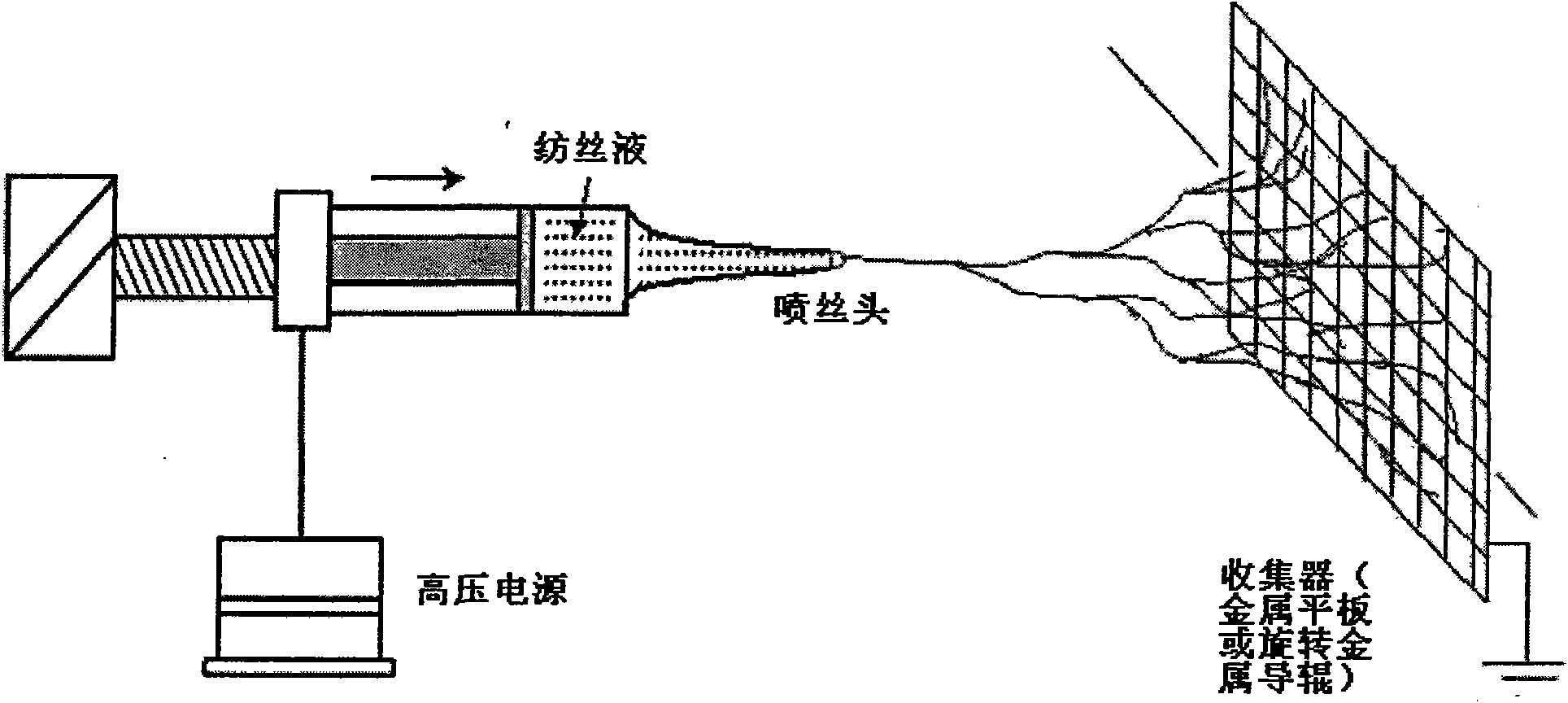

The invention discloses a preparation method of polytetrafluoroethylene superfine fiber porous membrane. In the method, high concentration polytetrafluoroethylene aqueous emulsion is mixed with matrix polymer uniformly to prepare spinning solution. With the effect of high voltage electric field, polytetrafluoroethylene / matrix polymer composite superfine fiber porous membrane with the diameter of 100 nm to 2 [mu]m is obtained by electrostatic spinning, and then polytetrafluoroethylene superfine fiber porous membrane is formed at the conditions of sintering temperature being 330 to 500 DEG C and the sintering time lasting 30s to 5min so that the aperture diameter is 100 nm to 10 [mu]m and the porosity is 50% to 80%. The polytetrafluoroethylene superfine fiber porous membrane prepared by using the method has uniform aperture diameter and high porosity, and can be widely applied to filter material. Compared with the existing technology, the preparation method has the characteristics of simple processing technology, short process and low cost.

Owner:ZHEJIANG SCI-TECH UNIV

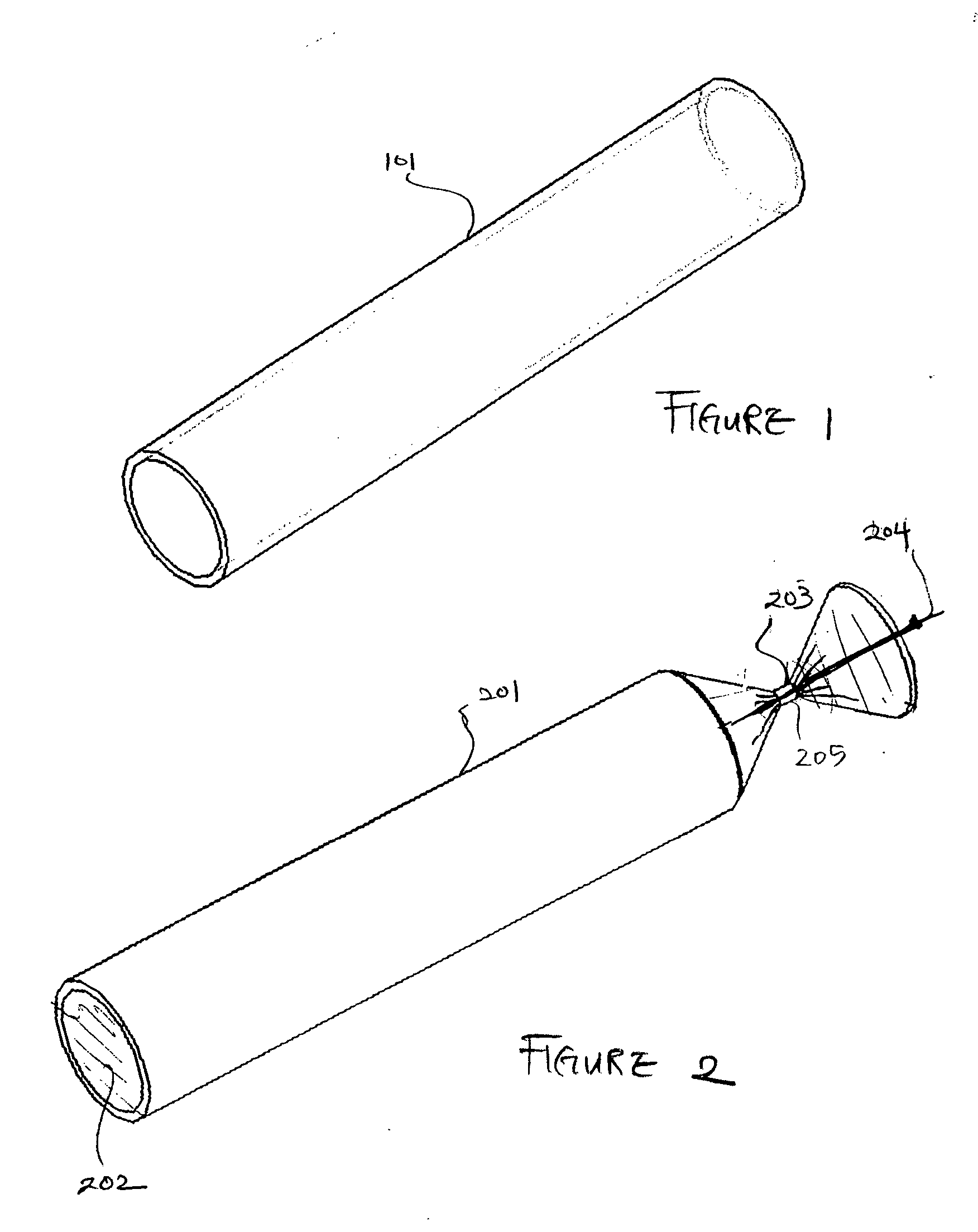

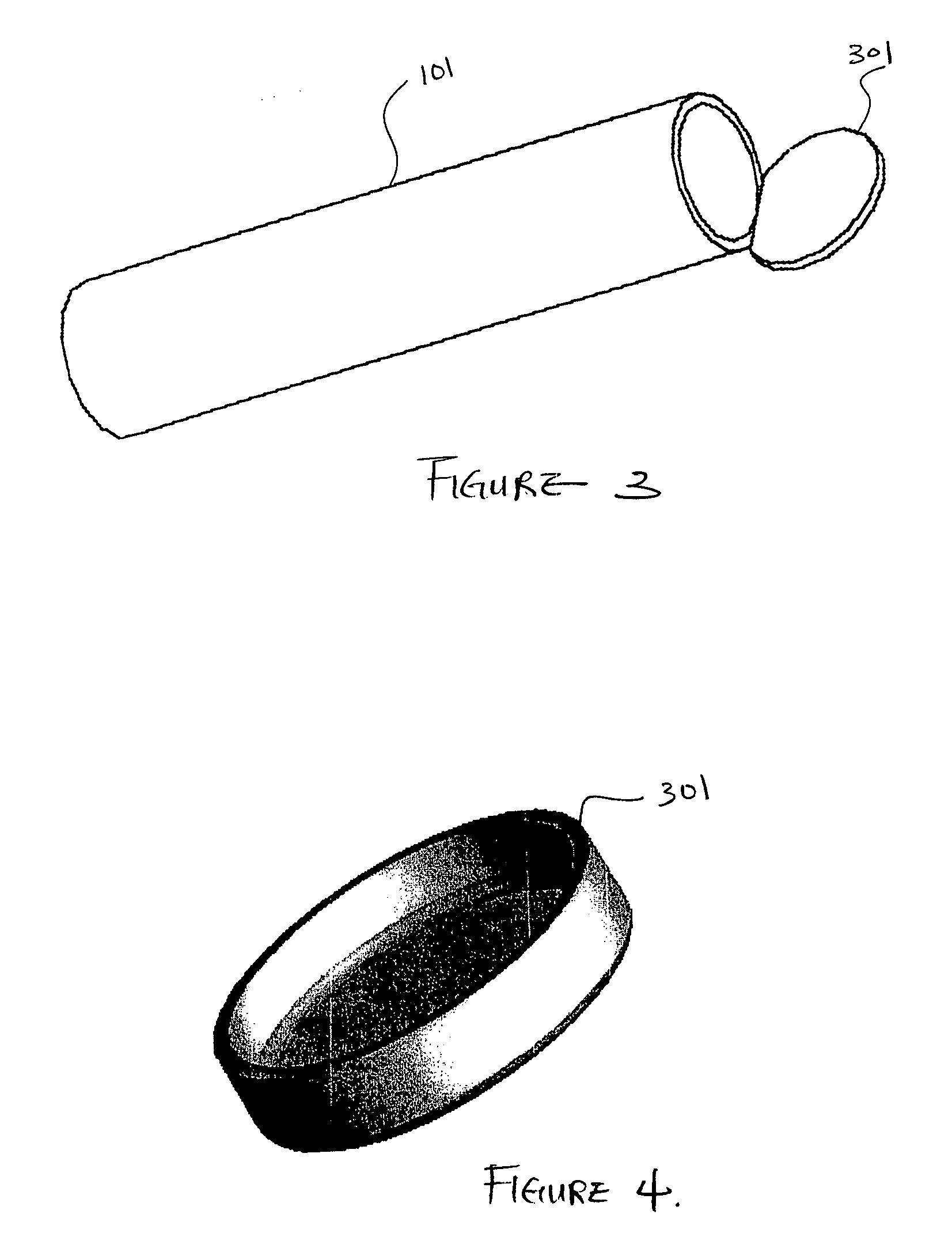

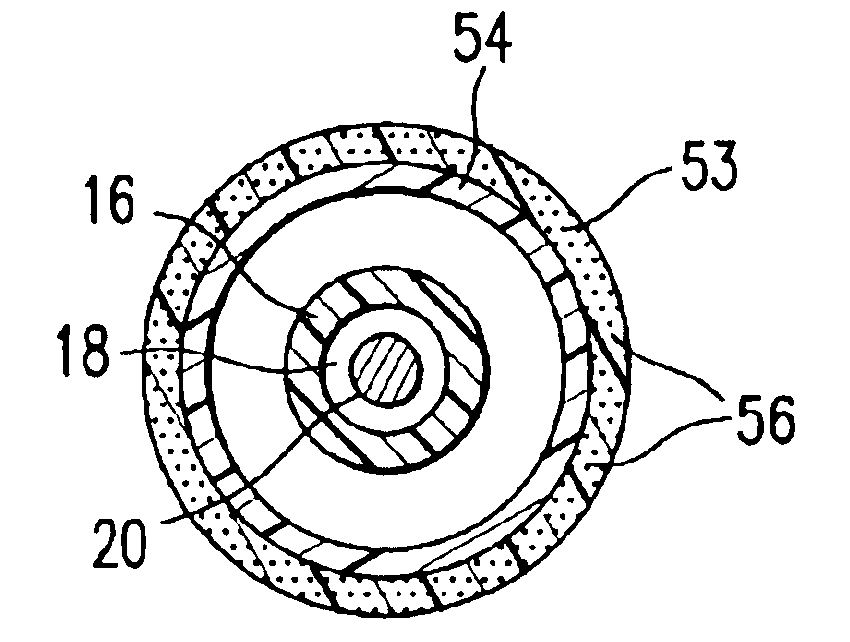

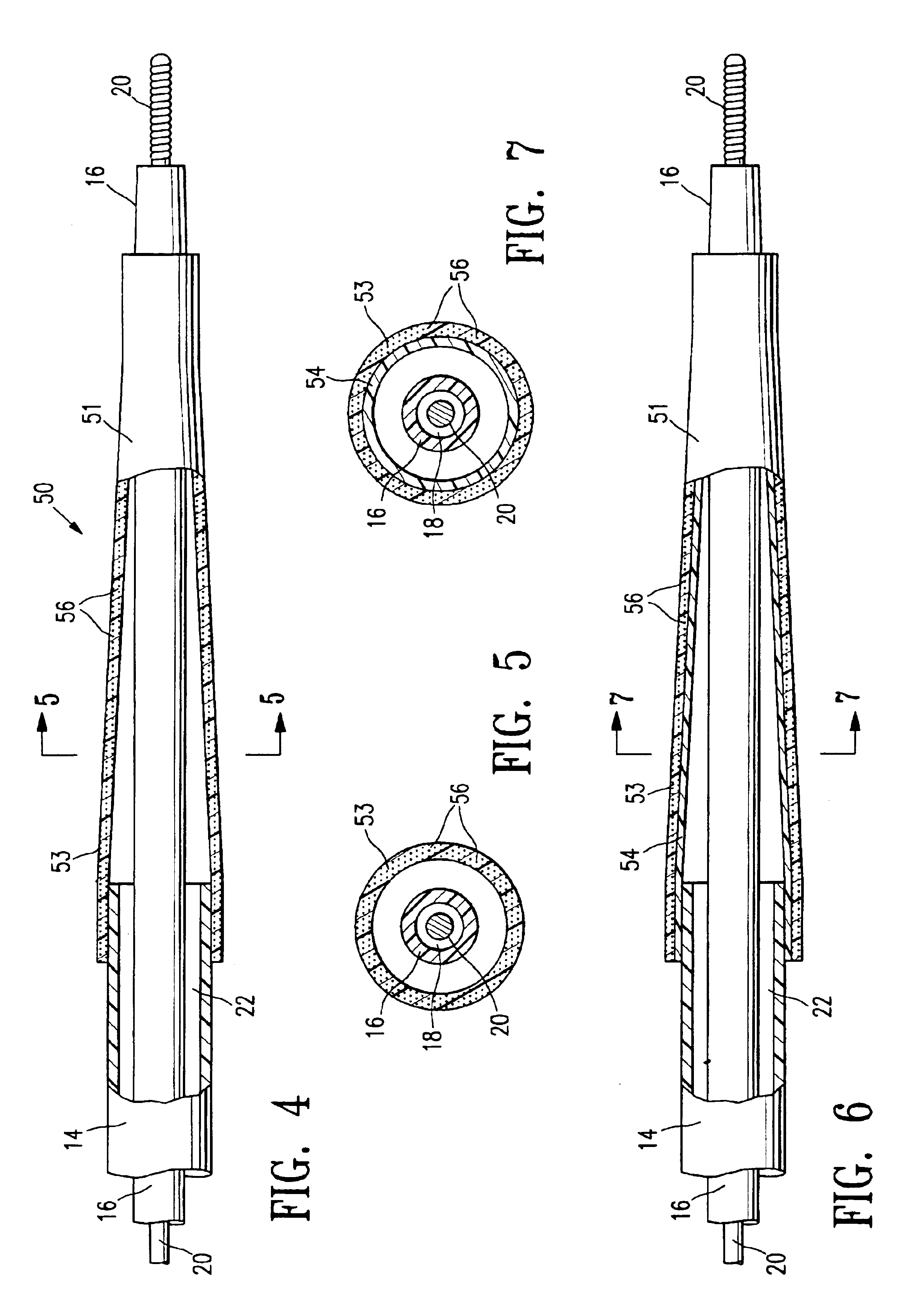

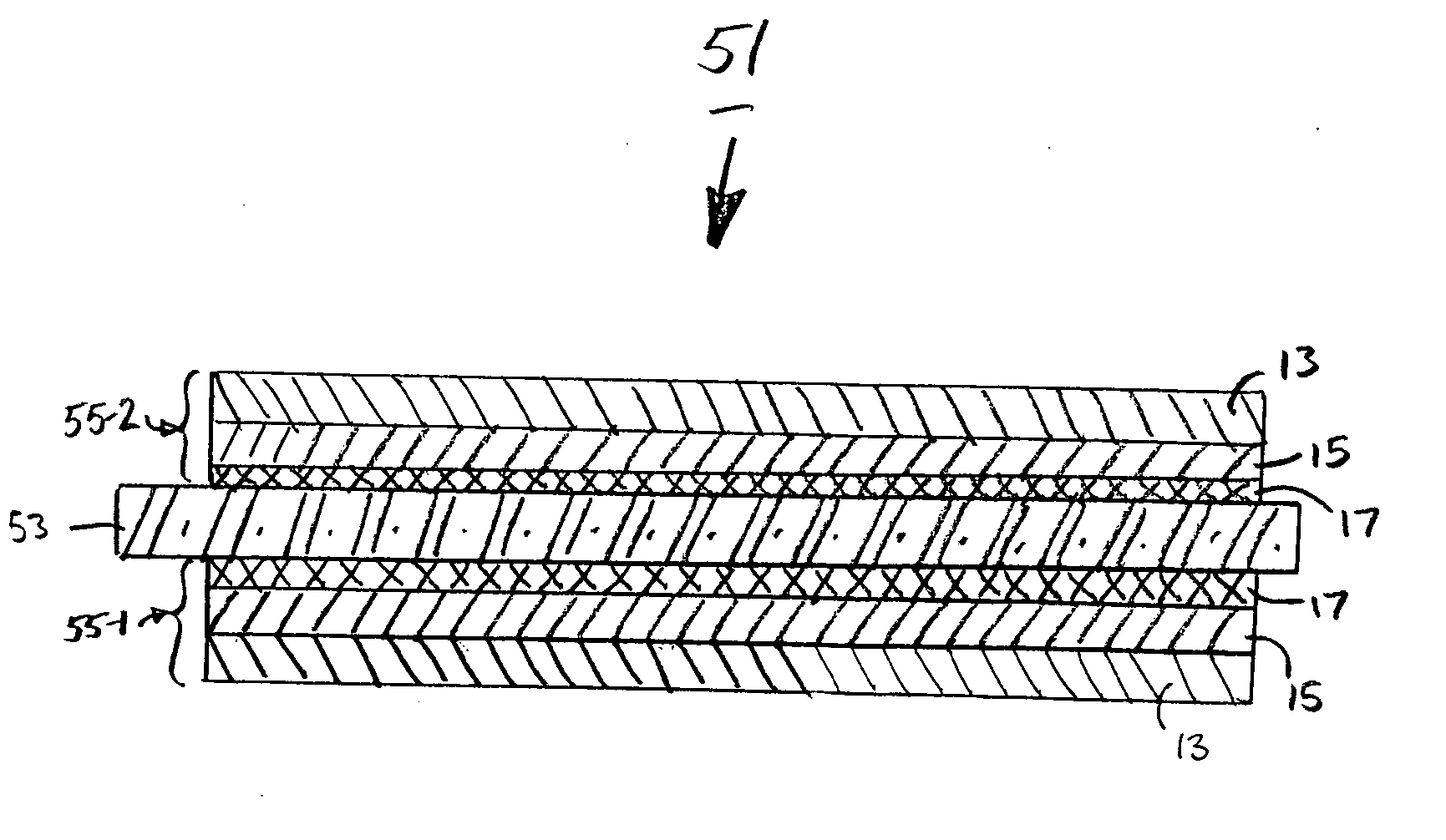

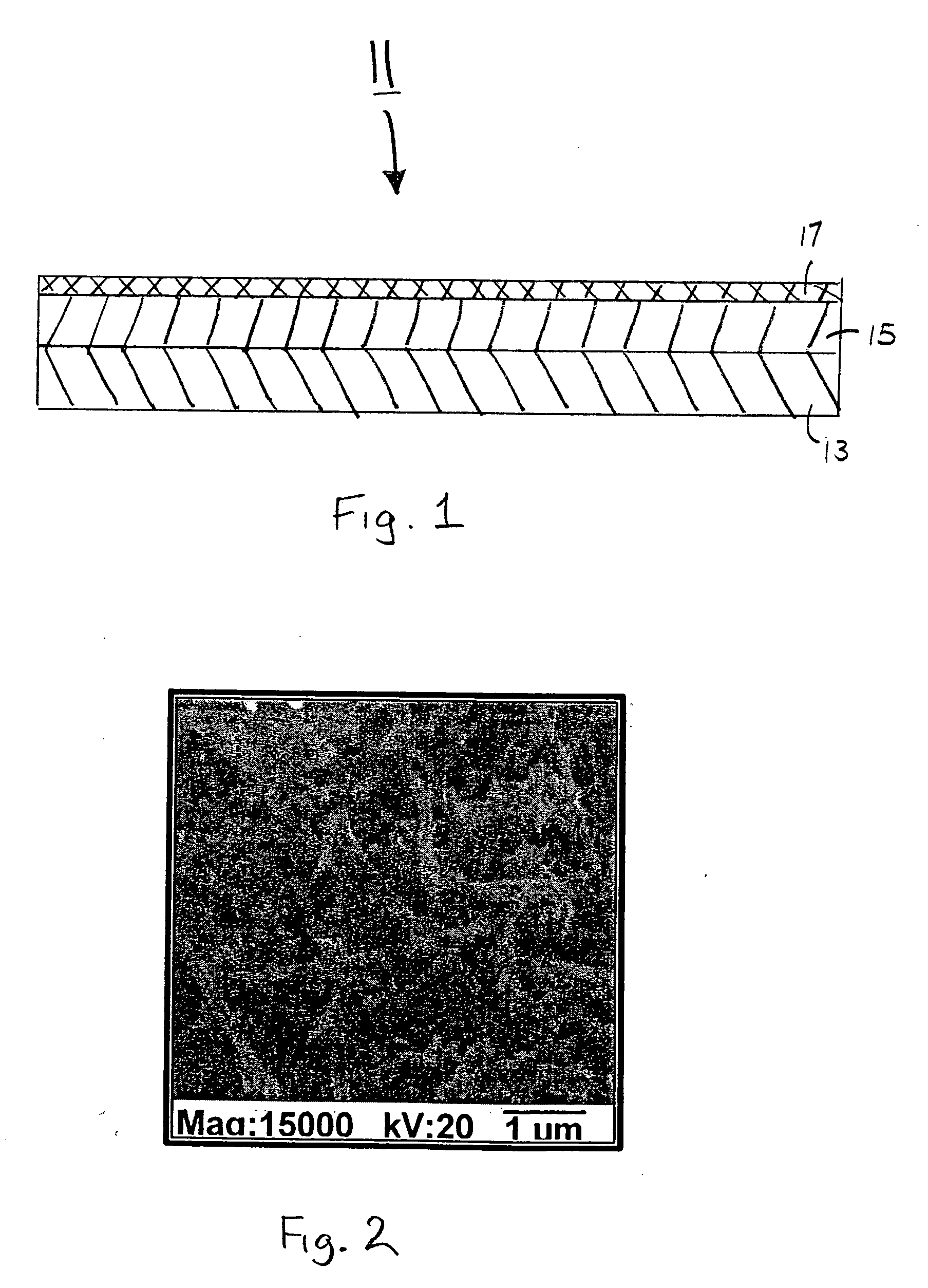

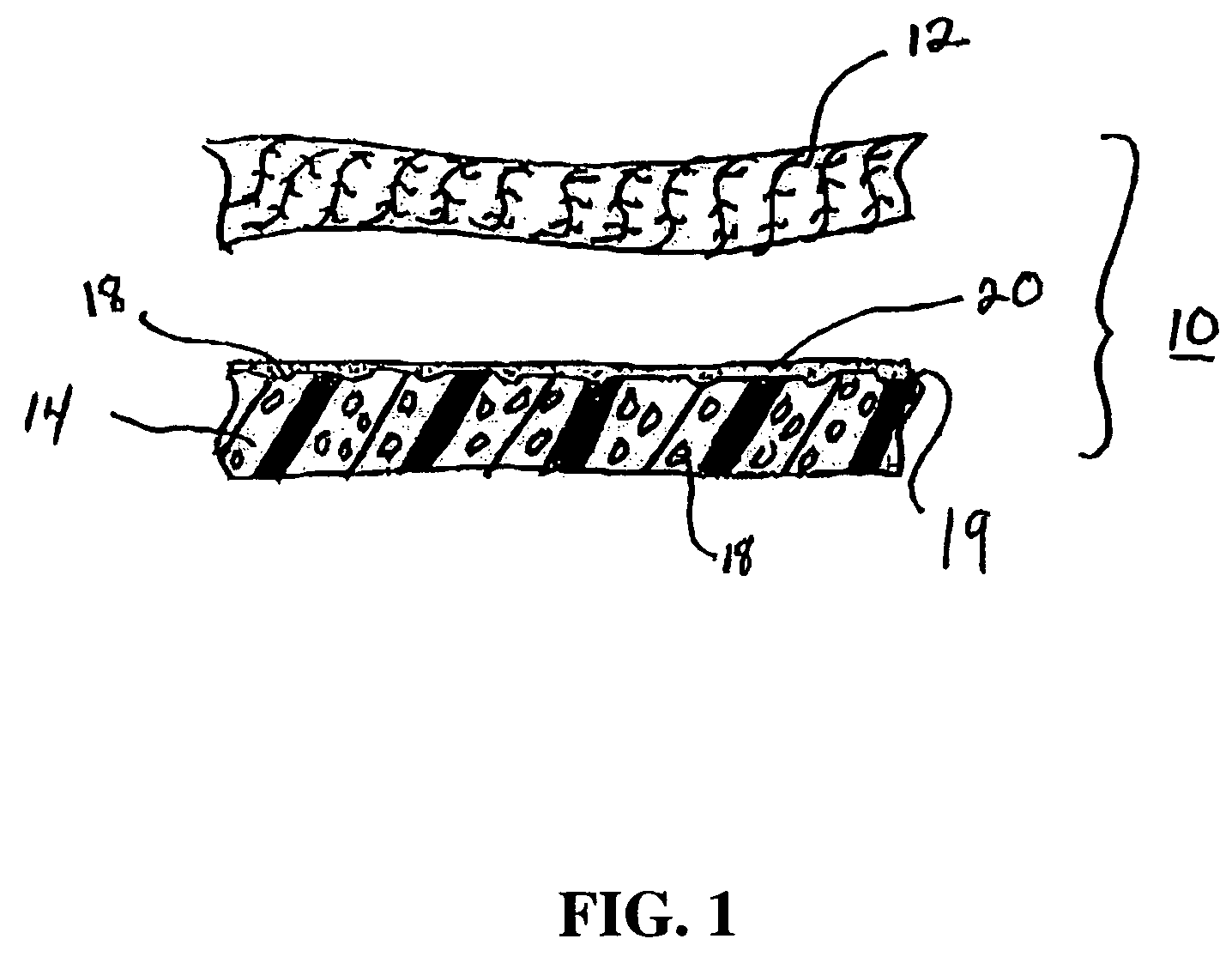

Catheter balloon formed of ePTFE and a diene polymer

InactiveUS6946173B2Improve performanceImprove adhesionEnvelopes/bags making machineryMouldsElastomerTetrafluoroethylene

A catheter balloon formed of a polymeric material such as expanded polytetrafluoroethylene (ePTFE) bonded to a second layer formed of a low tensile set polymer and / or impregnated with a low tensile set polymer. In a presently preferred embodiment, the low tensile set polymer is a silicone-polyurethane copolymer elastomer or a diene polymer elastomer. The low tensile set polymer has high strength, low modulus, high elongation, and low tensile set. The diene or silicone-polyurethane has a low tensile set, which facilitates deflation of the balloon to a low profile deflated configuration. One aspect of the invention provides improved attachment of the diene to the ePTFE. In one embodiment, the second layer is formed of a diene mixed with a bonding promoter such as a vulcanizing agent which is covalently bonded to the diene.

Owner:ABBOTT CARDIOVASCULAR

Method for preparing PTFE film material for air degerming

The invention discloses a method to manufacture polytetrafluoroethylene film material used for air degerming. The invention mixes polytetrafluoroethylene resin powder and liquid lubricant, and is gained after extruding, rolling, longitudinal stretching, lateral stretching and hot shaping. It is simple technology and low cost. It could be used for air degerming and has great social and economic benefits.

Owner:ZHEJIANG SCI-TECH UNIV

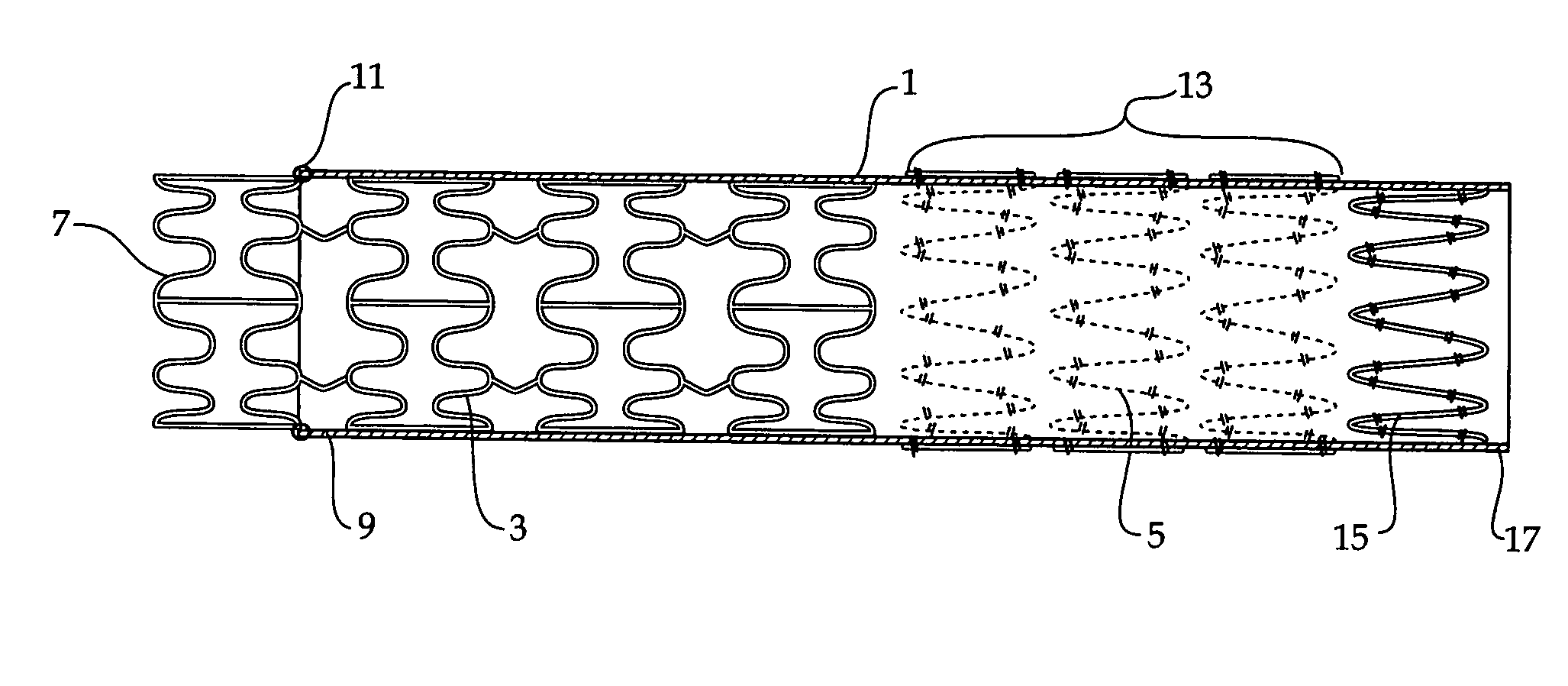

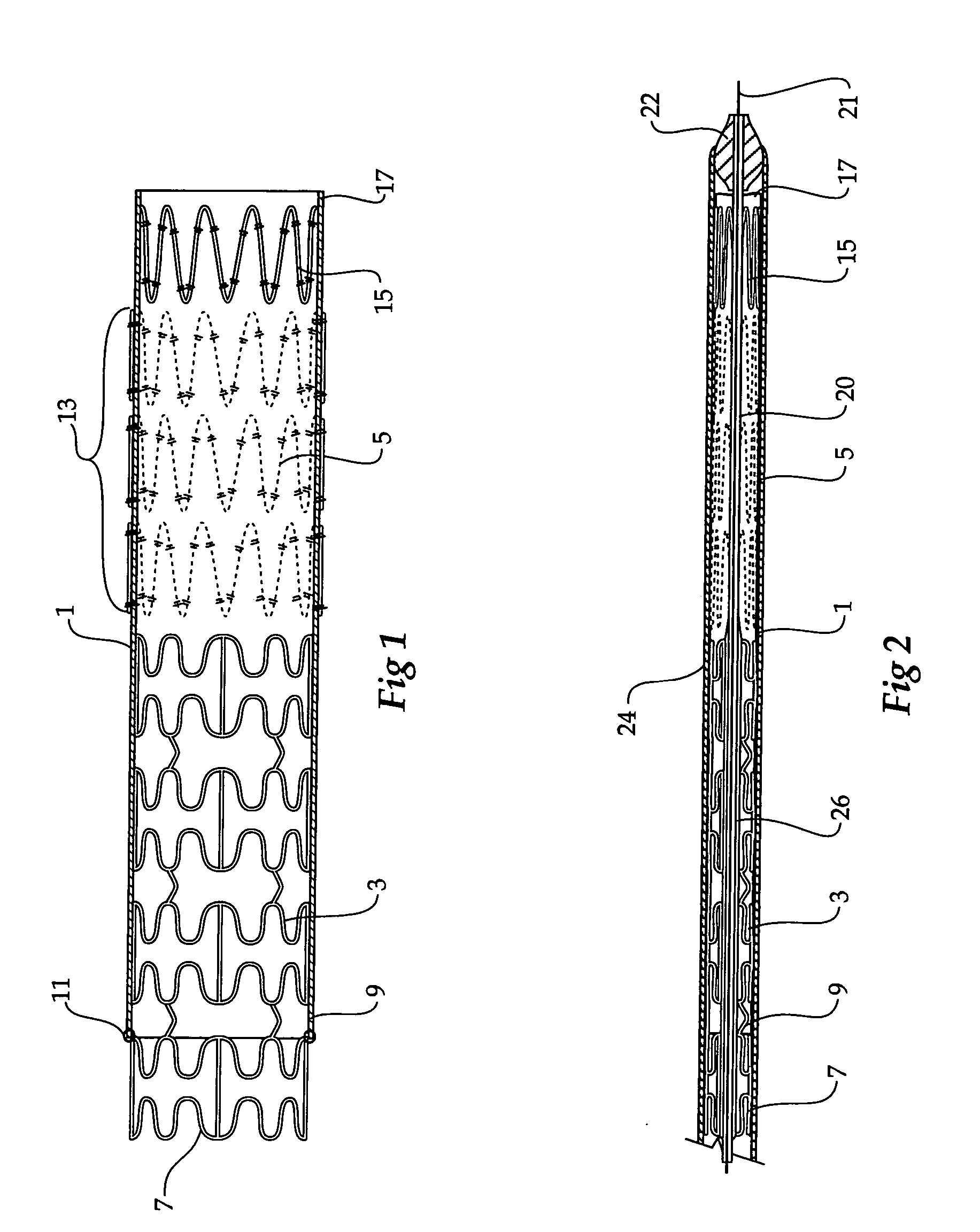

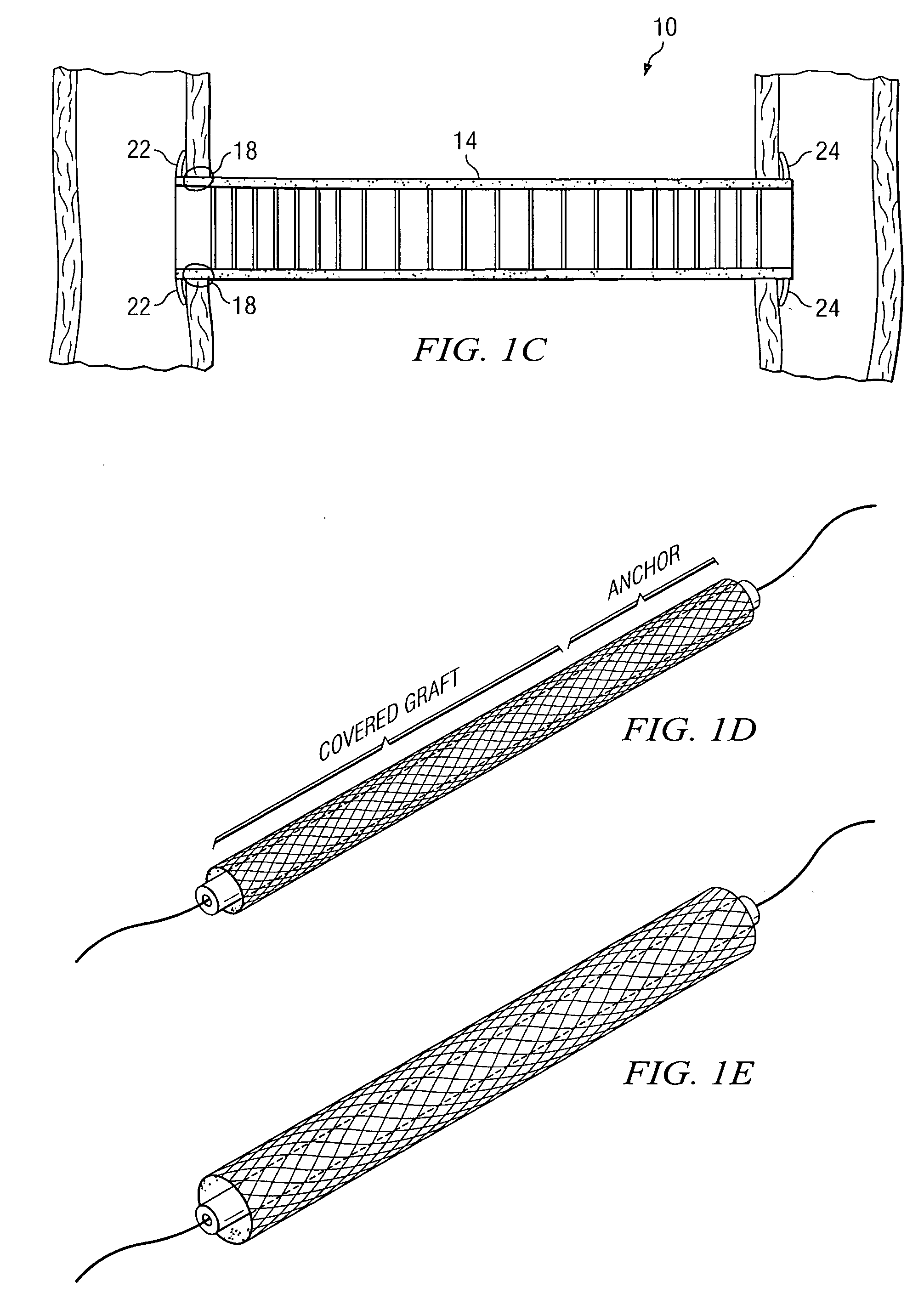

Composite stent graft

A composite stent graft has a balloon expandable stent portion ( 3 ), a tubular graft material portion ( 1 ) inside or outside of the balloon expandable stent portion and self expanding stents ( 5 ) associated with the tubular graft material portion. Part ( 7 ) of the balloon expandable stent portion can extend beyond the proximal end ( 9 ) of the tubular graft material portion. The tubular graft material can be polytetrafluoroethylene, Dacron, Thoralon(TM), polyamide, small intestine submucosa, collagenous extracellular matrix material, or any other suitable biocompatible material. A method of deploying which includes flaring a part ( 7 ) of the balloon expandable stent portion is also discussed.

Owner:COOK MEDICAL TECH LLC

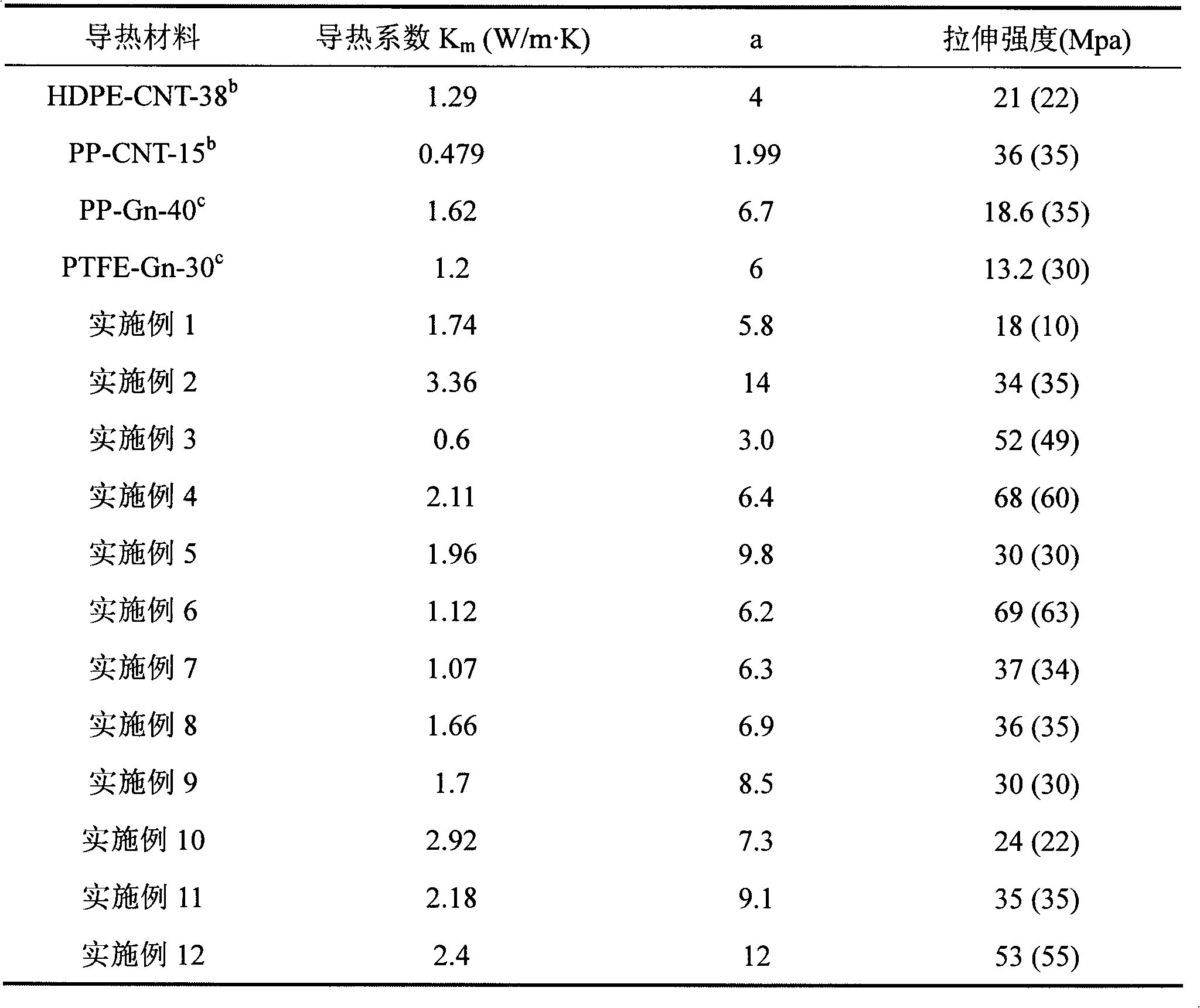

High-heat-conductivity composite material and preparation method thereof

InactiveCN102040761AImprove thermal conductivitySmall amount of thermally conductive fillerFiberCarbon fibers

The invention discloses a high-heat-conductivity composite material and a preparation method thereof. The preparation method comprises the following steps: evenly mixing fibrous heat-conduction filler and high-heat-conductivity filler graphene in a mass ratio of 1:1-1:200 with thermoplastic polymer, dispersing for 0.5-24 hours, granulating to obtain high-heat-conductivity composite grains, and putting the grains in a die to carry out hot molding at 170-280 DEG C under the pressure of 10-18 MPa. The thermoplastic polymer is any one of polyethylene, polypropylene, polyvinylidene fluoride, polytetrafluoroethylene, polyperfluoroalkoxy ester, nylon, polymethyl methacrylate, polycarbonate and polyvinyl chloride. The fibrous heat-conduction filler is carbon fiber or carbon nanotube, and the high-heat-conductivity filler accounts for 5-35 wt% of the high-heat-conductivity composite material. The high-heat-conductivity composite material has the advantages of excellent heat-conduction property, low consumption of heat-conduction filler, favorable mechanical properties, simple preparation technique and low cost.

Owner:SOUTH CHINA UNIV OF TECH

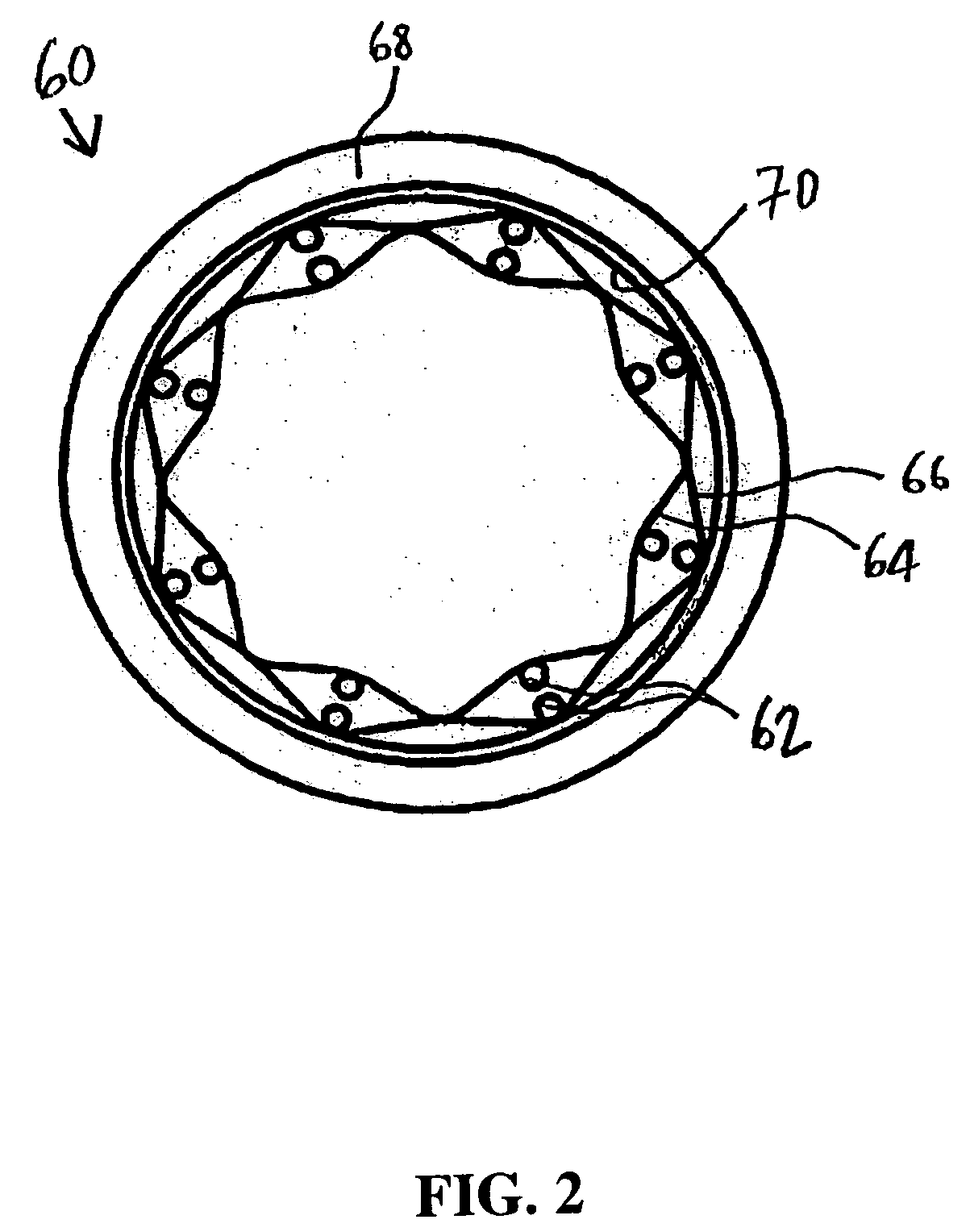

Expandable mask stent coating method

InactiveUS7482034B2Quickly made available for reuseIncrease chanceSpraying apparatusPharmaceutical containersPolytetrafluoroethyleneMesh grid

A system and method for selective masking of stents using an expandable masking balloon to prevent deposition of therapeutic or protective coatings on portions of the stent during a coating application process. An expandable balloon is located within the inner region of a stent, the balloon is inflated until its outer surface contacts and the inner surface of the stent lattice in the areas in which the stent coating is not to be applied, thereby masking the stent inner surface from deposition of stent coating material during a stent coating process, and the coating is applied to the remaining exposed surfaces of the stent, for example by spraying or dipping the stent. The balloon is then deflated and removed from the coated stent. The balloon may be coated with, or formed from, a material impregnated with polytetrafluoroethylene to discourage adherence of the coating material to the balloon's outer surface in order to minimize coating waste and bridging of stent lattice openings by coating films.

Owner:BOSTON SCI SCIMED INC

Glycosaminoglycan and Synthetic Polymer Material for Blood-Contacting Applications

ActiveUS20150196688A1Improve surface chemistryFeasible at commercial productionSuture equipmentsOrganic active ingredientsLow-density polyethyleneLinear low-density polyethylene

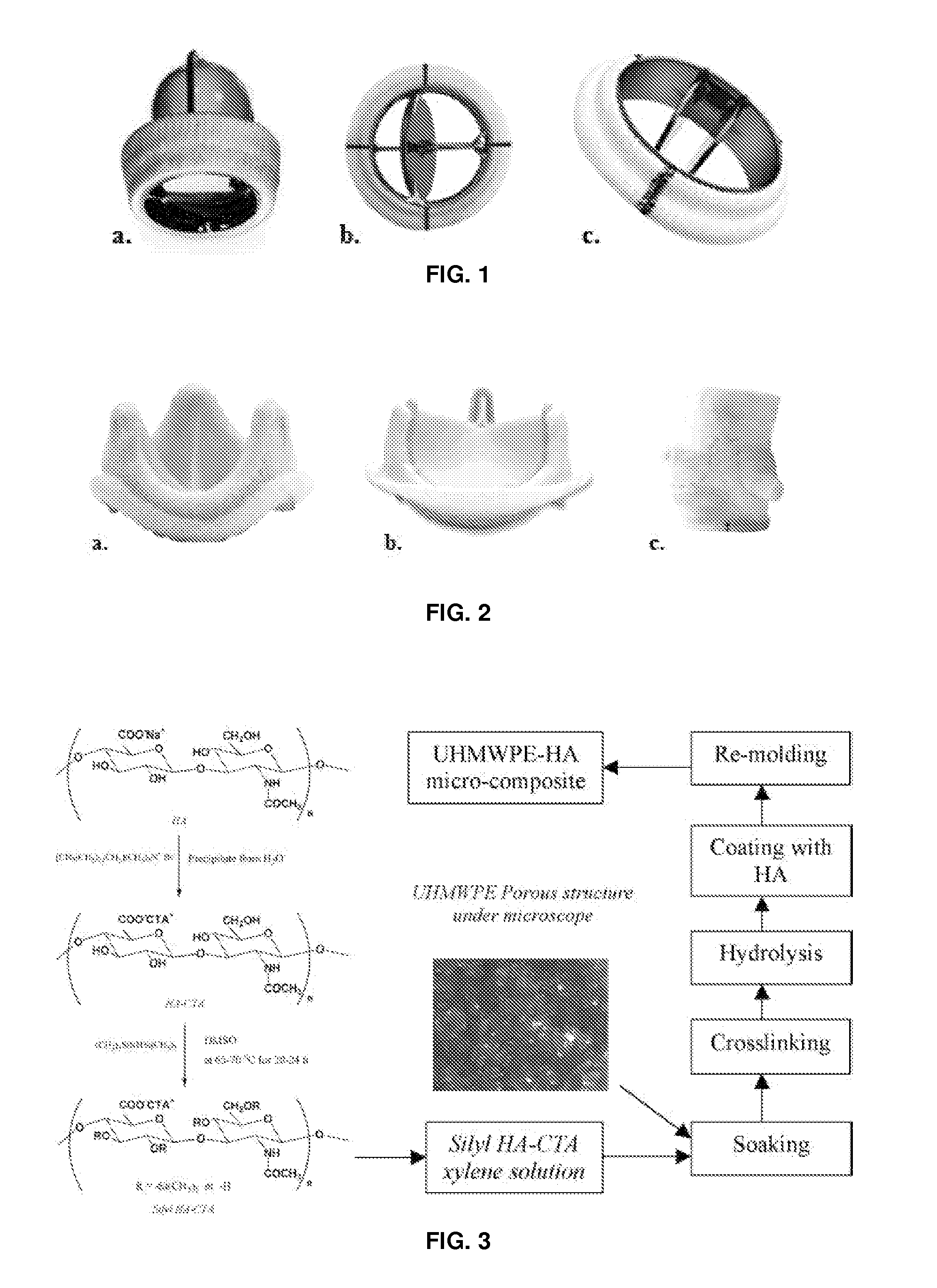

Provided herein is a composite, comprising: a polymer host selected from the group consisting of low-density polyethylene (LDPE), linear low-density polyethylene (LLDPE), polyethylene terephthalate (PET), polytetrafluoroethylene (PTFE), and polypropylene (PP), polyurethane, polycaprolactone (PCL), polydimethylsiloxane (PDMS), polymethylmethacrylate (PMMA), and polyoxymethylene (POM); and a guest molecule comprising hyaluronic acid; wherein the guest molecule is disposed within the polymer host, and wherein the guest molecule is covalently bonded to at least one other guest molecule. Also provided herein are methods for forming the composite, and blood-contracting devices made from the composite, such as heart valves and vascular grafts.

Owner:COLORADO STATE UNIVERSITY

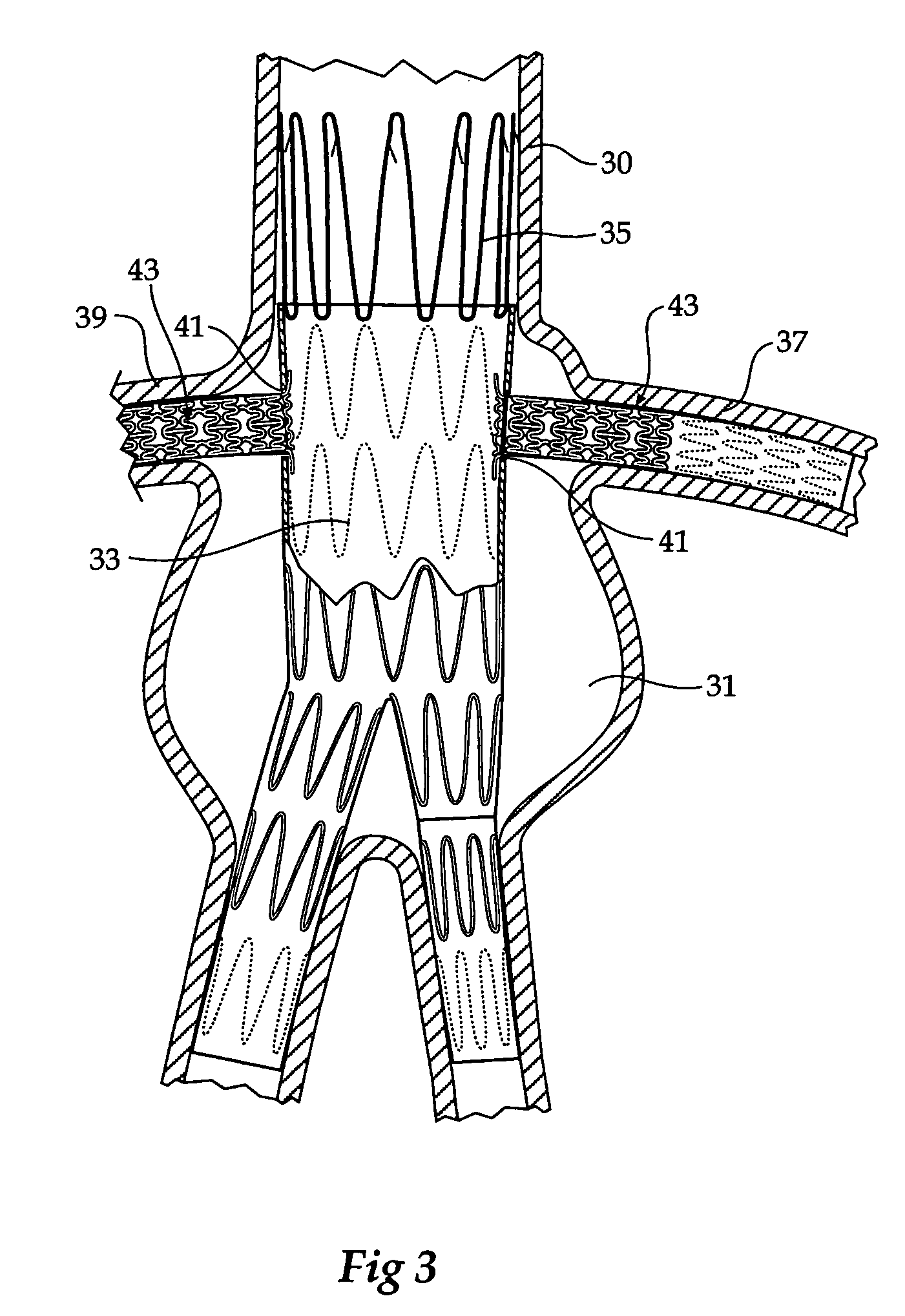

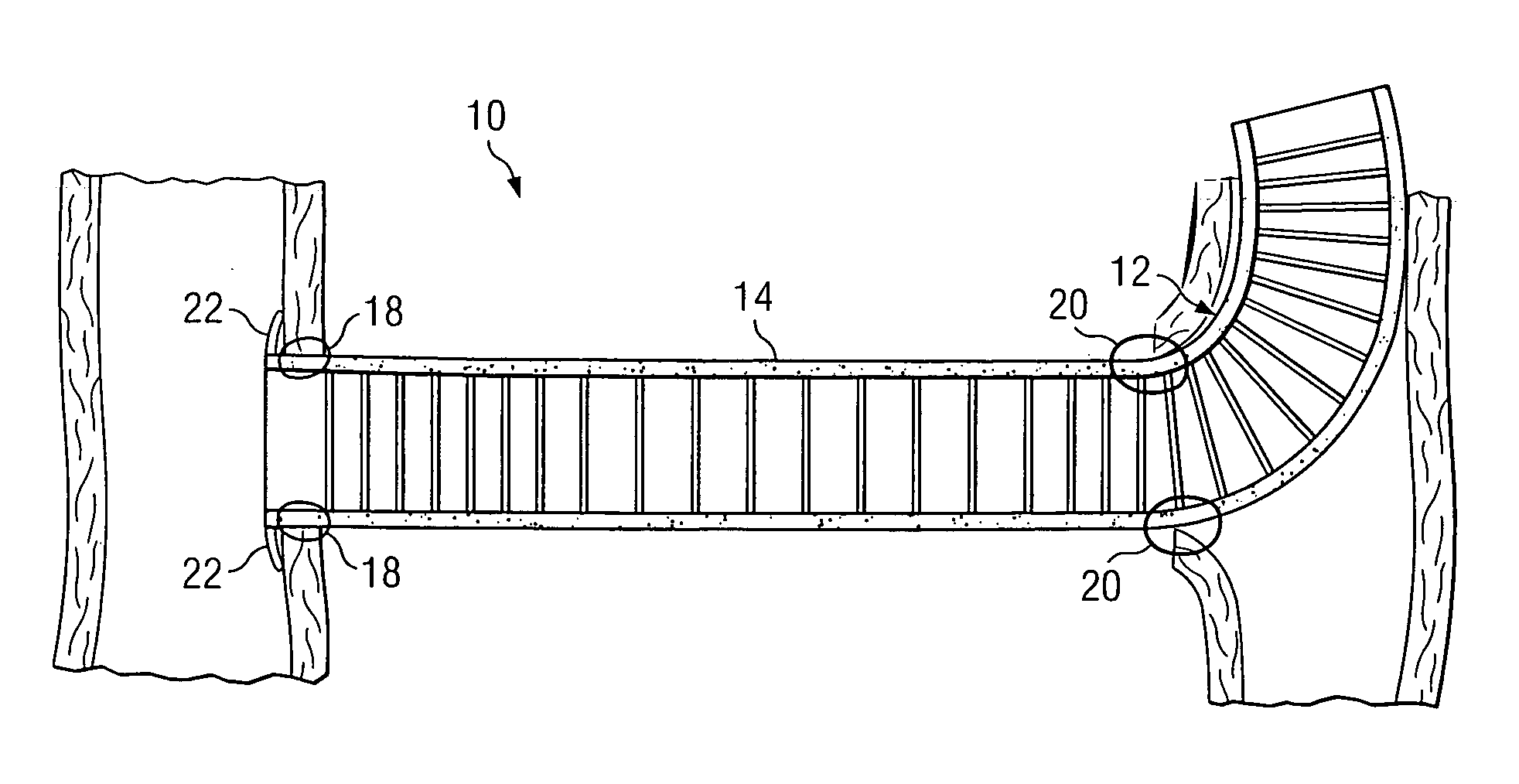

System and method for providing a graft in a vascular environment

InactiveUS20080009781A1Easy to moveMinimal stenosisStentsEar treatmentBiodegradable scaffoldCatheter

An apparatus is provided that includes a graft for coupling two vascular conduits within a patient. The graft includes: 1) an anchor system that forms an arc at one end of the conduits; and 2) a body element coupled to the anchor system. The anchor system comprises a biodegradable stent. In particular embodiments, portions of the graft are either self-expandable or balloon-expandable. In still other embodiments, anchor system includes NITINOL and the anchor system is substantially self-sealing at one end of the conduits. In one embodiment, the body element comprises polytetrafluoroethylene (PTFE) or expanded polytetrafluoroethylene (EPTFE). In yet other embodiments, the body element includes either a gelatinous or an elastomeric coating disposed on its surface.

Owner:GRAFTECH INT HLDG INC

Carbon fiber reinforced composite and preparation thereof

The invention discloses carbon fiber reinforced thermoplastic resin composite material which is composed of the components according to the percentage by weight: carbon fibers with the surface modified accounting for 5 percent to 50 percent, thermoplastic resin accounting for 44 percent to 75 percent, polytetrafluoroethylene accounting for 5 percent to 15 percent and processing auxiliary agent accounting for 1 percent to 5 percent; the carbon fibers with the surface modified is manufactured by processing the carbon fibers in specially mixed acidic solution under the temperature of 40 DEG C to 80 DEG C for 30 minutes to 120 minutes and dried at the temperature of 80 DEG C to 150 DEG C. The invention also discloses the preparation method of the carbon fiber reinforced thermoplastic resin composite material. The carbon fibers of the carbon fiber reinforced thermoplastic resin composite material provided by the invention are dispersed in a state of 3 mm to 5 mm in a resin matrix, the original high intensity of the carbon fibers is maintained to the maximum, so as to ensure the prepared composite material to have high intensity, high modulus, high heat resistant and high wear resistant performances.

Owner:宁波益德新材料有限公司

Antimicrobial medical articles containing a combination of anti-infective compounds, octoxyglycerin, salicylic acid, and sesquiterpenoids

Medical articles impregnated with antimicrobial compositions containing synergistic combinations of octoxyglycerin and other anti-infective compounds are disclosed. Such medical articles may include urinary catheters, central venous catheters, tracheal catheters, arterial grafts, wound dressings, sutures, or any other medical articles derived from polymeric substrates such as biomedical polyurethane, biomedical polyvinylchloride (PVC), biomedical silicon, biodegradable polymers, polytetrafluoroethylene (PTFE), etc. or from natural products including natural rubber, silk or cotton fiber. Antimicrobial compositions comprising salicylic acid and sesquiterpenoids are also disclosed.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

Polytetrafluoroethylene aqueous dispersion composition, polytetrafluoroethylene resin film and polytetrafluoroethylene resin impregnated article

ActiveUS20090035582A1Improve mechanical stabilityReduce formationNon-fibrous pulp additionSynthetic resin layered productsMechanical stabilityWater soluble

The invention provides a PTFE-containing aqueous dispersion composition which is excellent in mechanical stability and scarcely allows the formation of agglomerates due to fibrillation of the PTFE resin during transportation or processing thereof. This invention is a polytetrafluoroethylene-containing aqueous dispersion composition comprising a polytetrafluoroethylene resin (A), a hydrocarbon-derived nonionic compound (B) and a water-soluble high-molecular compound (C) having no oxygen atom in the main chain thereof.

Owner:DAIKIN IND LTD

Preparation method for high strength macro graphene conductive fiber

ActiveCN102534868AEasy to manufactureImprove solubilityArtificial filament chemical after-treatmentFiberCarbon fibers

The invention discloses a preparation method for high strength macro graphene conductive fiber. According to the method, graphite is oxidized to obtain a graphene oxide; the graphene oxide is dispersed in water or a polar organic solvent to prepare a spinning liquid sol with the mass concentration of 1-20%; the spinning liquid sol is transferred to a spinning device; the spinning liquid is continuously extruded from a spinning head capillary at a uniform speed; the extruded spinning liquid enters a solidification liquid; the solidified primary fiber is collected by using a polytetrafluoroethylene roller; a drying treatment is performed to obtain the graphene oxide fiber; the graphene oxide fiber is subjected to chemical reduction to obtain the graphene fiber. According to the present invention, the spinning process is simple; the operation is performed at the room temperature; no strong corrosive reagent is used; the process has the characteristics of green environmental protection; the prepared graphene fiber has characteristics of good conductivity, excellent mechanical property and good toughness, can be woven into the pure graphene fiber cloth, can further be woven into various fabrics with other fibers, and can further be added to the polymer as the conduction enhancing additive and the like; the prepared graphene fiber can replace the carbon fiber to use in a plurality of fields.

Owner:杭州德烯科技集团有限公司

Scratch-resistant modified polypropylene composite material and preparation method thereof

The invention belongs to the field of modified polypropylene composite materials and relates to a scratch-resistant modified polypropylene composite material which is applicable to manufacturing automotive interior parts and comprises the following components by parts by weight: 60-90 parts of polypropylene, 5-20 parts of plasticizer, 5-20 parts of mineral filler, 0.1-4 parts of wear-resistant agent / scratch-resistant agents and 0.1-3 parts of additives, wherein the wear-resistant agent / scratch-resistant agents can be selected from the mixture of nano-polytetrafluoroethylene superfine micro-powder, organic matter-modified siloxane, modified silicone mixture and reactive modified polysiloxane. The prepared modified polypropylene composite material has high surface gloss and better impact-resistant performance, strength, melt fluidity and mechanical performance; furthermore, due to the use of the various wear-resistant agents / scratch-resistant agents, the scratch-resistant performance of the product is excellent; and the resources of the required raw materials are simultaneously extensive and easy to obtain.

Owner:SUZHOU SUNWAY POLYMER

Article of manufacture and process for anodically coating an aluminum substrate with ceramic oxides prior to polytetrafluoroethylene or silicone coating

InactiveUS20050115840A1AnodisationElectrolytic inorganic material coatingCeramic coatingSilicone coating

Owner:HENKEL KGAA

Method for preparing polytetrafluoroethylene superfine fiber

InactiveCN101994161AEasy to prepareArtificial filament washing/dryingFilament/thread formingFiberElectrospinning

The invention discloses a method for preparing a polytetrafluoroethylene superfine fiber, comprising the following steps of: firstly dissolving polyvinyl alcohol into water to prepare a polyvinyl alcohol solution, then evenly mixing the polyvinyl alcohol solution with polytetrafluoroethylene concentrated dispersion to prepare a spinning solution; then making the spinning solution into a polytetrafluoroethylene / polyvinyl alcohol superfine fiber by adopting an electrostatic spinning method; and finally, carrying out polyvinyl alcohol removal aftertreatment on the prepared polytetrafluoroethylene / polyvinyl alcohol superfine fiber to obtain the polytetrafluoroethylene superfine fiber. The prepared polytetrafluoroethylene superfine fiber is white or dark brown, and the diameter of the fiber is 30-2000nm.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Gas diffusion electrode and method of making the same

ActiveUS20060078784A1Porosity adjustableNatural cellulose pulp/paperFinal product manufactureFiberPorous substrate

A gas diffusion electrode and method of making the same. According to one embodiment, the electrode comprises a support layer, a first cushioning layer positioned on top of the support layer, a second cushioning layer positioned on top of the first cushioning layer, and a catalyst layer positioned on top of the second cushioning layer. The support layer is a mechanically stable, electrically-conductive, gas porous substrate, such as carbon fiber paper. The first cushioning layer, which is also gas porous, comprises a non-woven mat of electrically-conductive, chemically-inert fibers, preferably carbon nanofibers, bound together with a polymeric binder, such as polytetrafluoroethylene. The second cushioning layer is similar to the first cushioning layer, except that carbon black or a similar electrically-conductive, chemically-inert particulate material is included in addition to or instead of the fibrous material for the purpose of fine-tuning pore size.

Owner:PLUG POWER

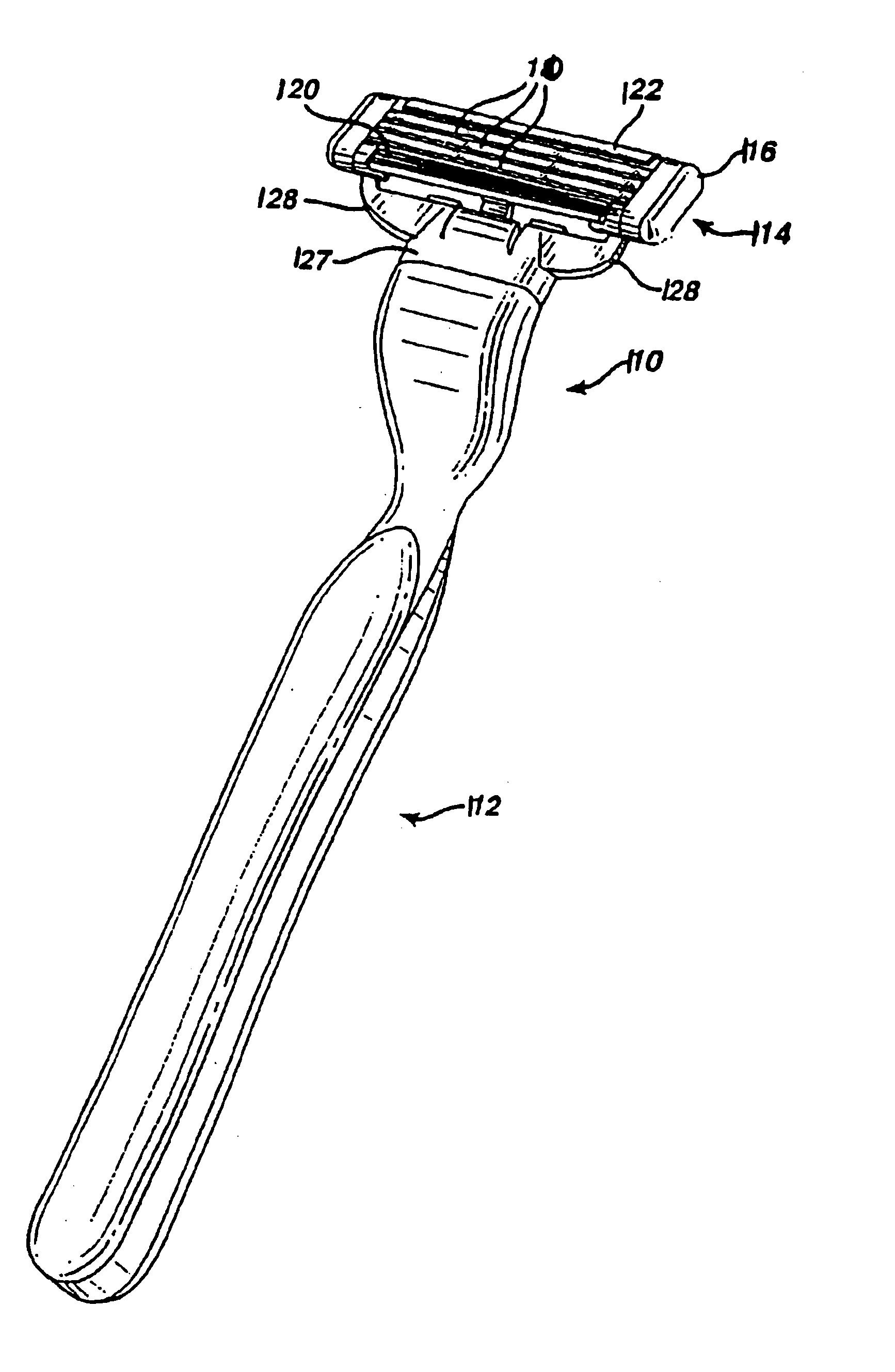

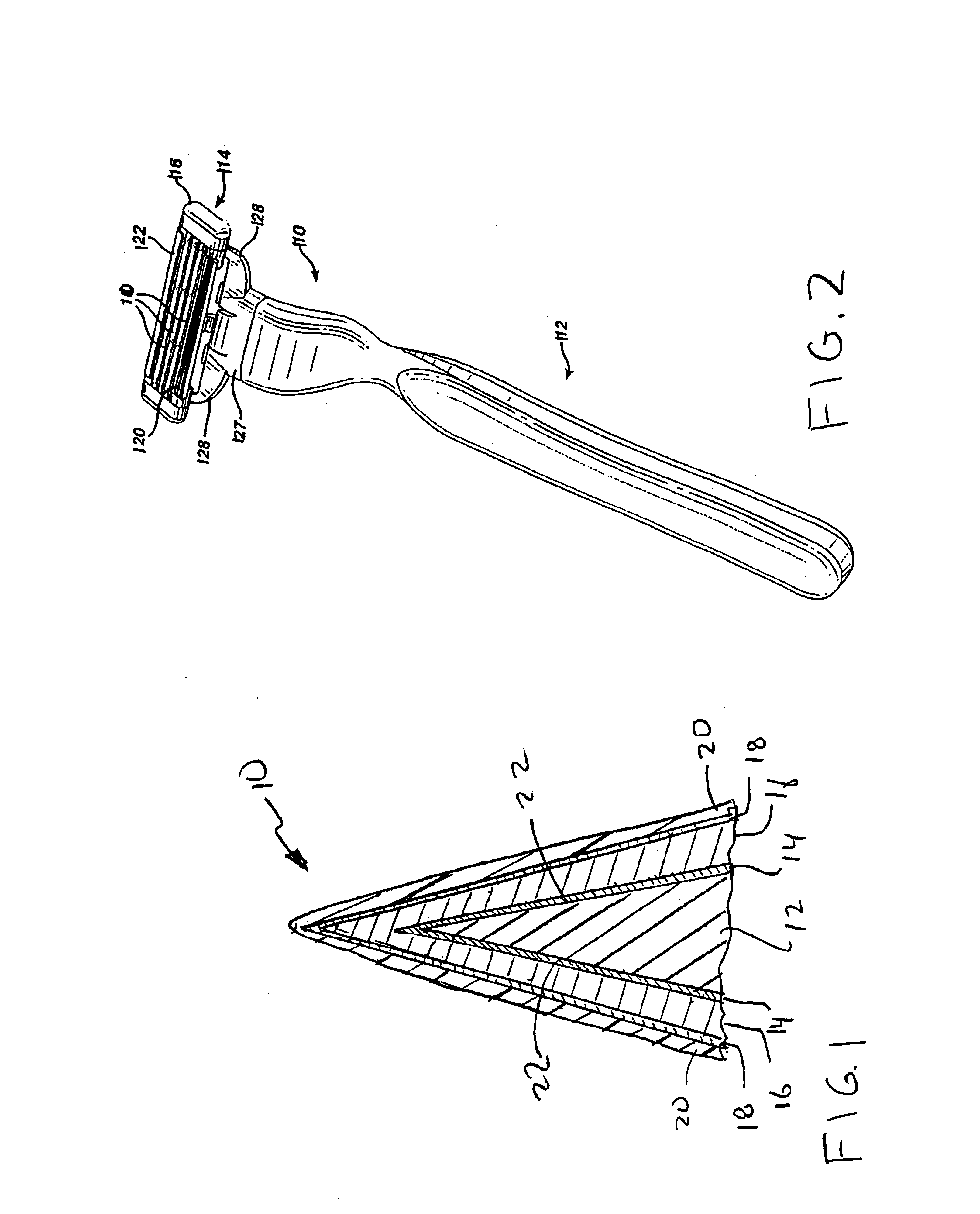

Razor blade technology

InactiveUS6866894B2Improve adhesionReduced tip roundingPretreated surfacesCoatingsCarbon coatingChromium

A razor blade including a substrate with a cutting edge defined by a sharpened tip and adjacent facets, a layer of hard coating on the cutting edge, an overcoat layer of a chromium containing material on the layer of hard carbon coating, and an outer layer of polytetrafluoroethylene coating over the overcoat layer. Also disclosed is a method of making a razor blade including providing a substrate with a cutting edge defined by a sharpened tip and adjacent facets, and applying an aqueous solution including polytetrafluoroethylene coating over the sharpened tip to result in an outer layer, the polytetrafluoroethylene having a molecular weight of about 45,000.

Owner:THE GILLETTE CO

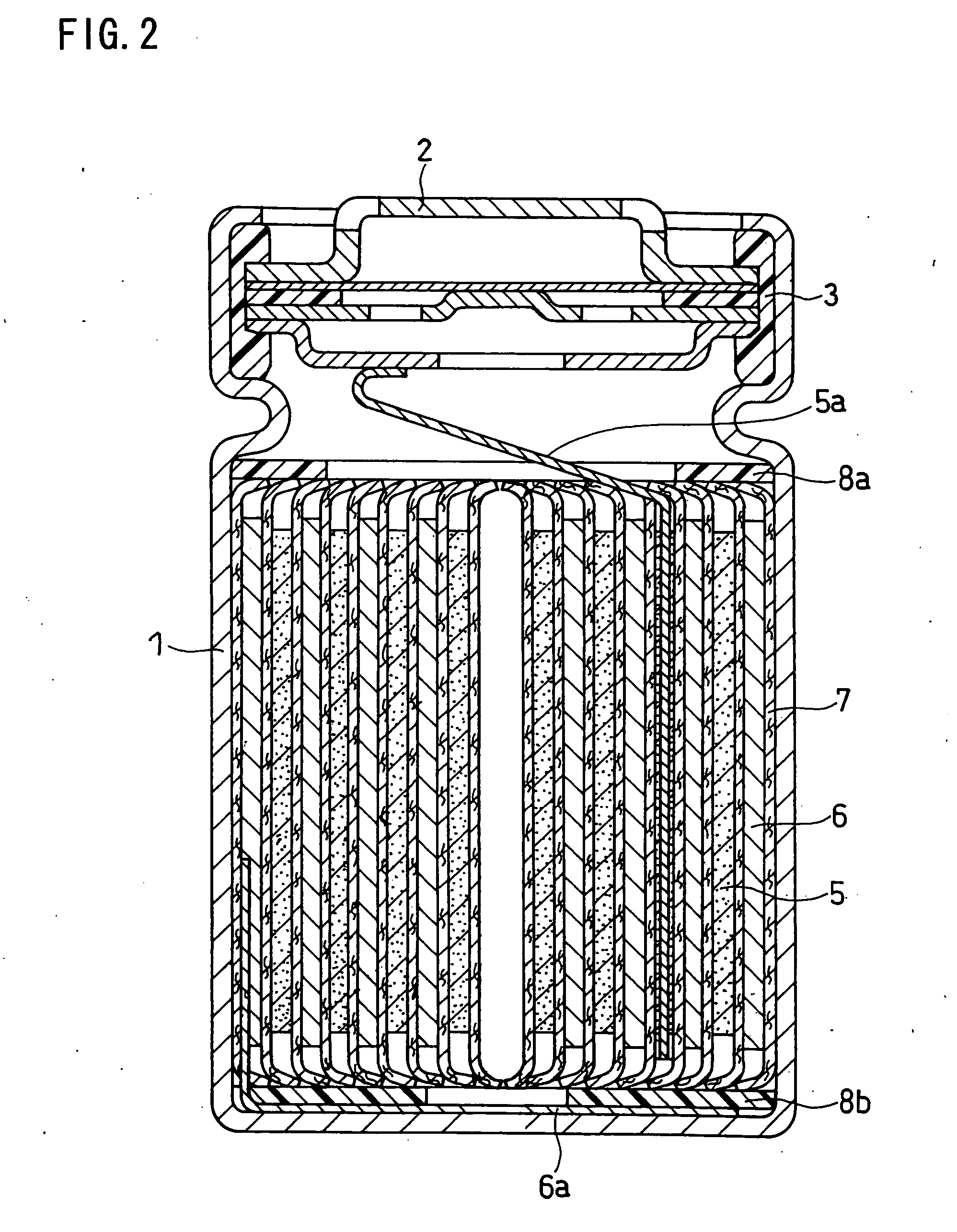

Non-aqueous electrolyte secondary battery

InactiveUS20070099081A1Improve reliabilityHigh charge and discharge capacityMaterial nanotechnologyNon-aqueous electrolyte accumulatorsPolyetherimidePolyamide

A non-aqueous electrolyte secondary battery including a positive electrode, a negative electrode, a separator interposed between the positive and negative electrodes, and a non-aqueous electrolyte. The negative electrode includes composite particles and a binder. Each of the composite particles includes: a negative electrode active material including an element capable of being alloyed with lithium; carbon nanofibers that are grown from a surface of the negative electrode active material; and a catalyst element for promoting the growth of the carbon nanofibers. The binder comprises at least one polymer selected from the group consisting of polyimide, polyamide imide, polyamide, aramid, polyarylate, polyether ether ketone, polyether imide, polyether sulfone, polysulfone, polyphenylene sulfide, and polytetrafluoroethylene.

Owner:PANASONIC CORP

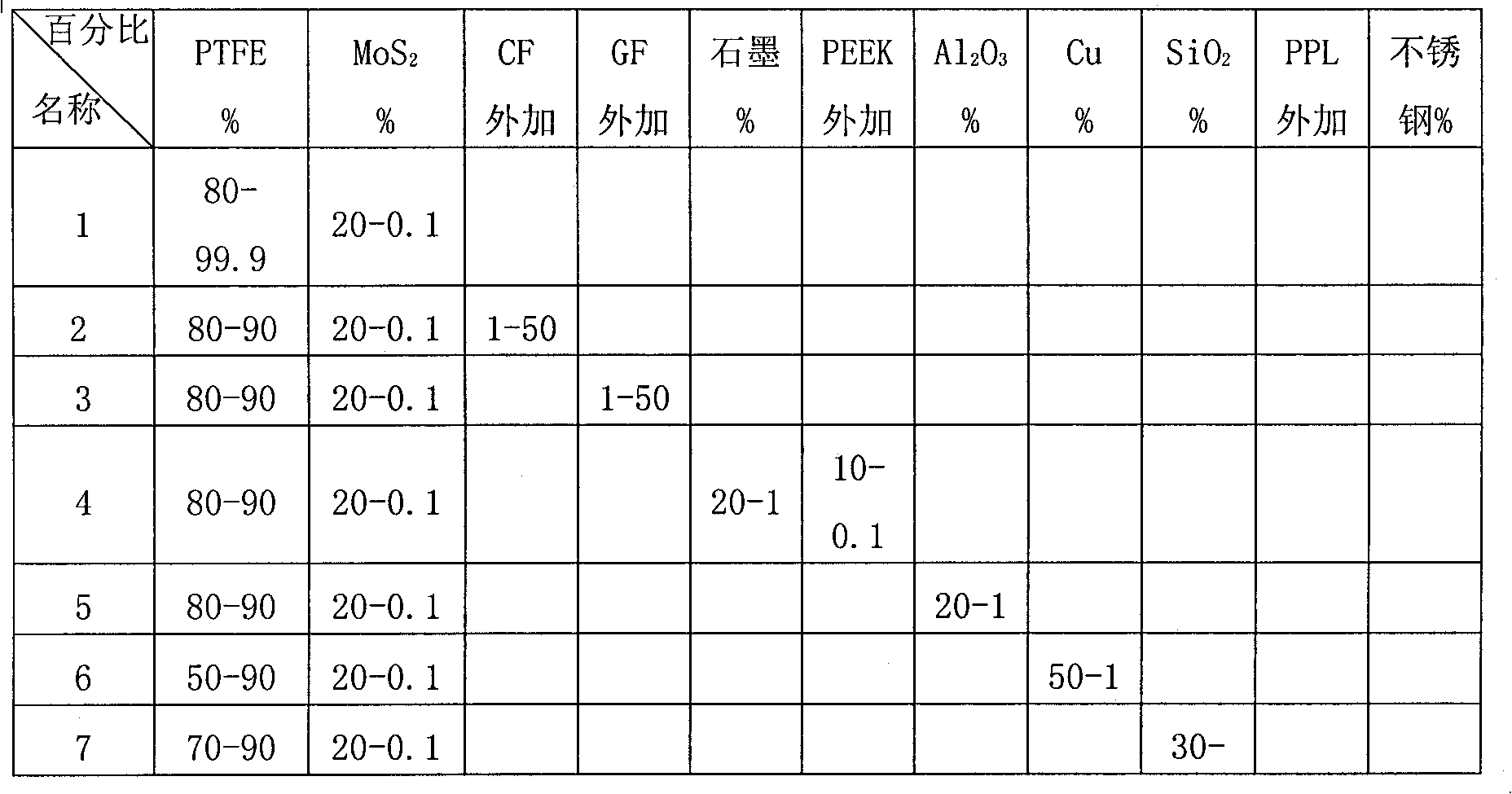

Polytetrafluoroethylene composite material and product preparation method thereof

ActiveCN101775186AImprove thermal conductivityImproved ball compressive strengthFiberTetrafluoroethylene

The invention discloses a polytetrafluoroethylene composite material, which comprises one or more of molybdenum disulfide, aluminum sesquioxide, copper powder, graphite, silicon dioxide and stainless steel powder and polytetrafluoroethylene, wherein the polytetrafluoroethylene composite material is a binary polytetrafluoroethylene composite material, which comprises 80 to 99.9 weight percent of the polytetrafluoroethylene, and the balance of other components. A product preparation method for the material comprises the following steps: compounding the materials of polytetrafluoroethylene (PTFE), molybdenum disulfide (MoS2), aluminium oxide (Al2O3), Cu powder, silicon dioxide (SiO2), polyphenylester (PPL), stainless steel powder, carbon fiber (CF), glass fiber (GF) and the like, molding the materials by a mold pressing sintering method, and then mechanically machining the materials to form an L-shaped sealing element.

Owner:NANJING COMPTECH MATERIALS

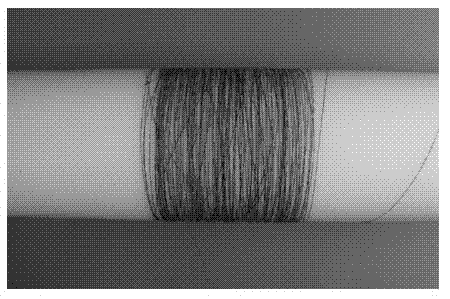

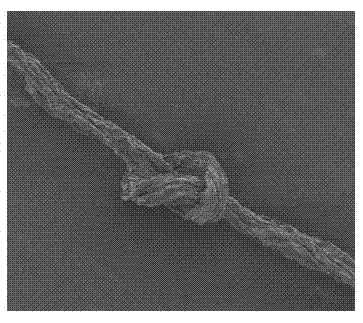

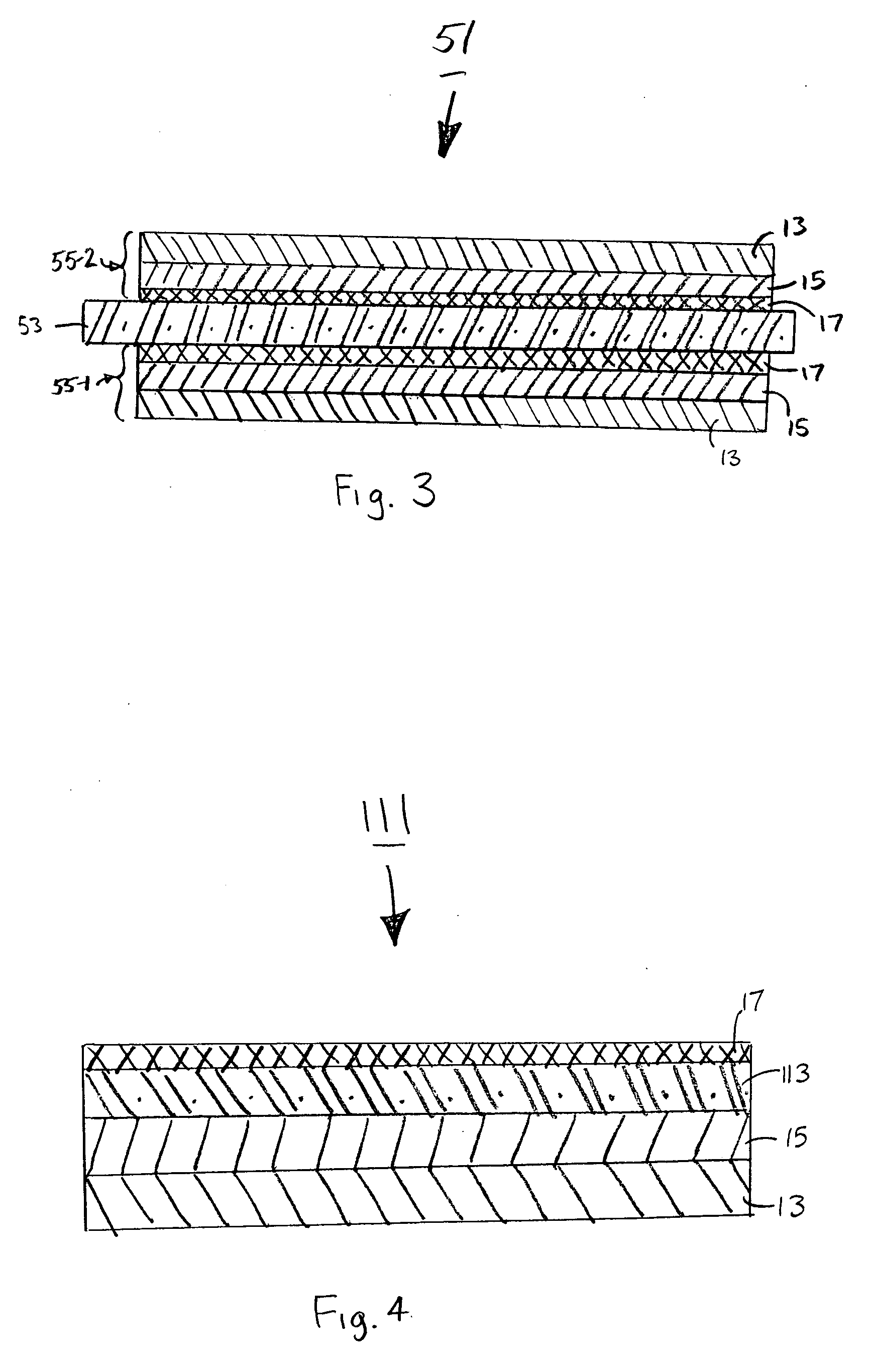

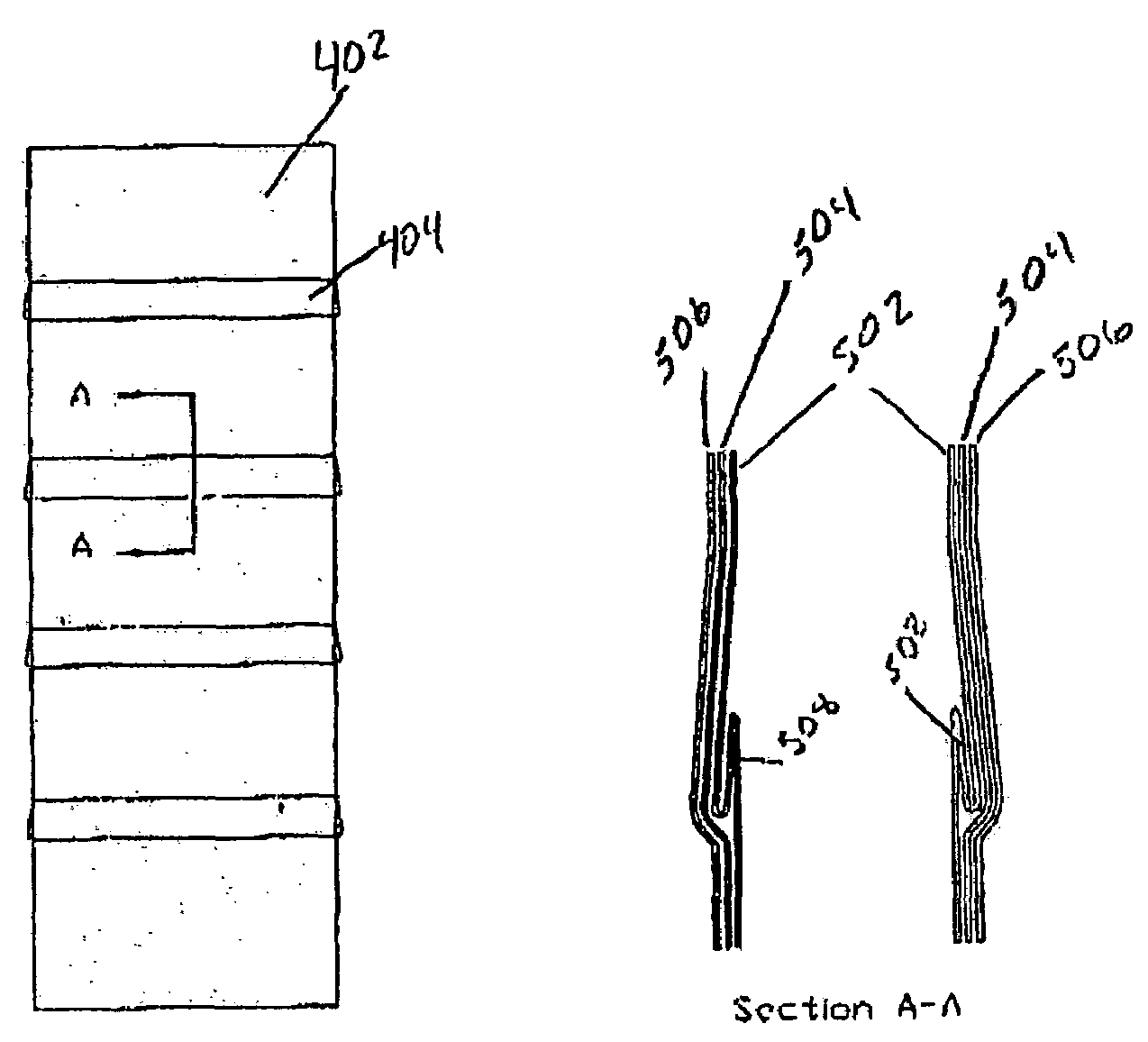

Pleated composite ePTFE/textile hybrid covering

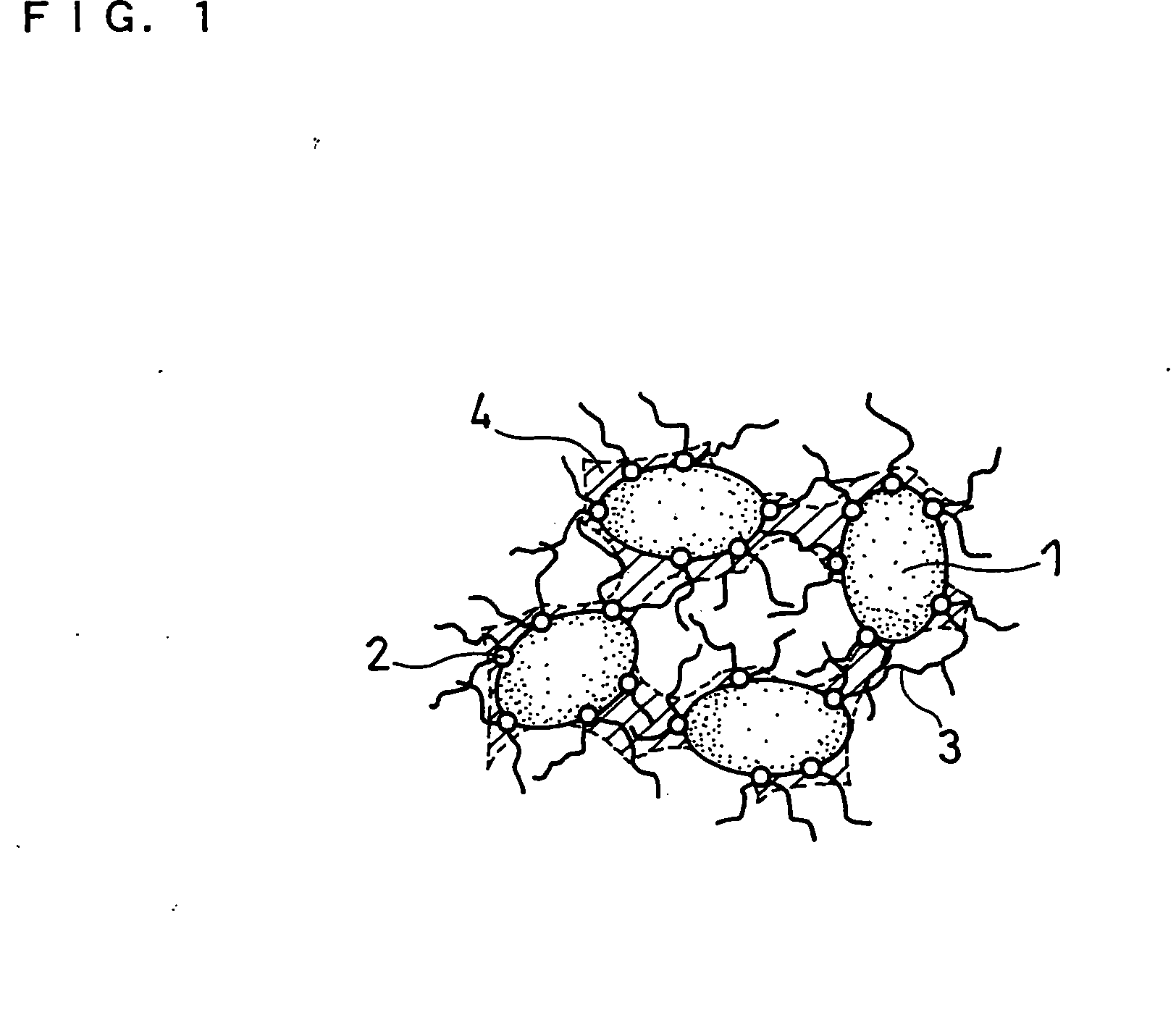

InactiveUS7510571B2Enhanced tissue ingrowthHigh suture retention strengthStentsLayered productsFiberFibril

A composite multilayer implantable material having a first inner tubular layer formed of expanded polytetrafluoroethyene having a porous microstructure defined by nodes interconnected by fibrils, wherein said first layer has a plurality of pleated folds, a second tubular layer formed of textile material circumferentially disposed exteriorly to said first layer; and having an elastomeric bonding agent applied to one of said first layer or second layer and disposed within the pores of said microstructure for securing said first layer to said second layer.

Owner:LIFESHIELD SCI

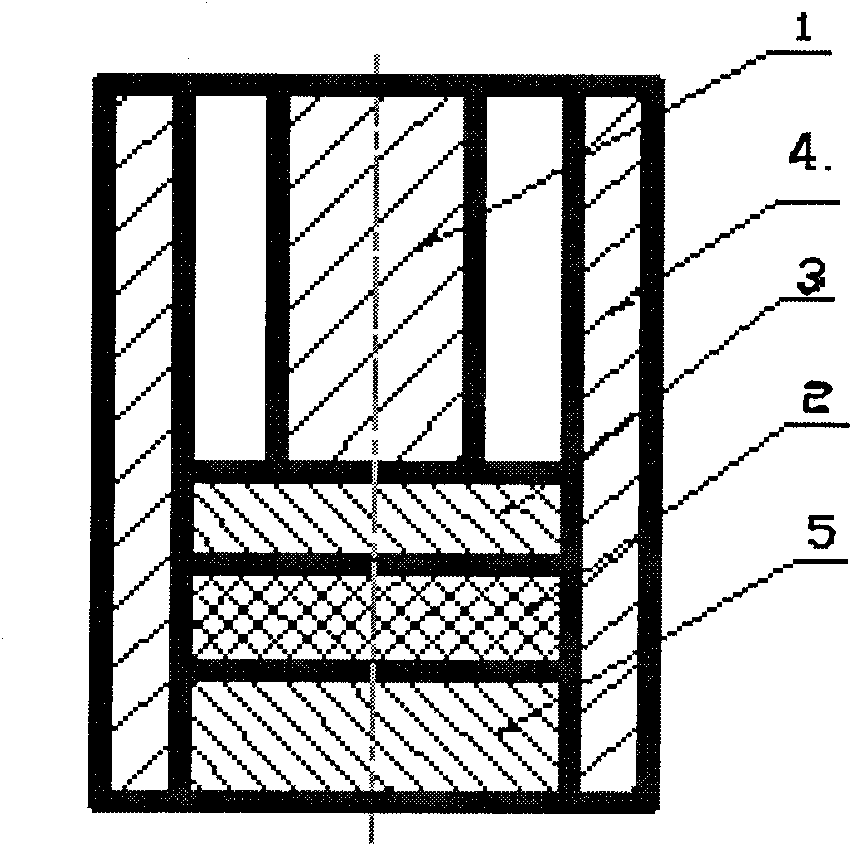

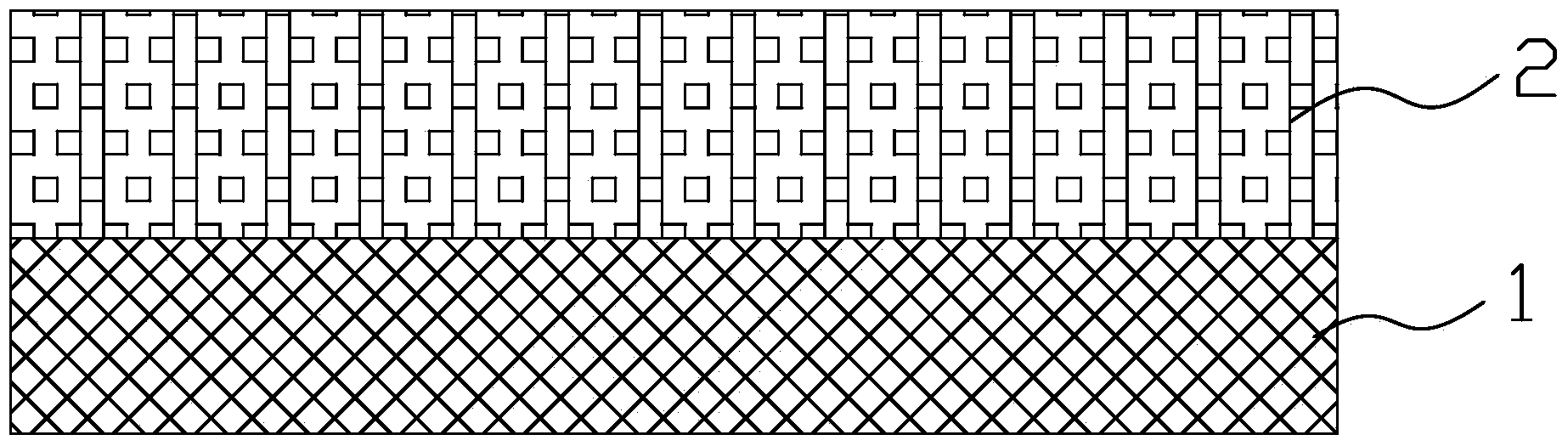

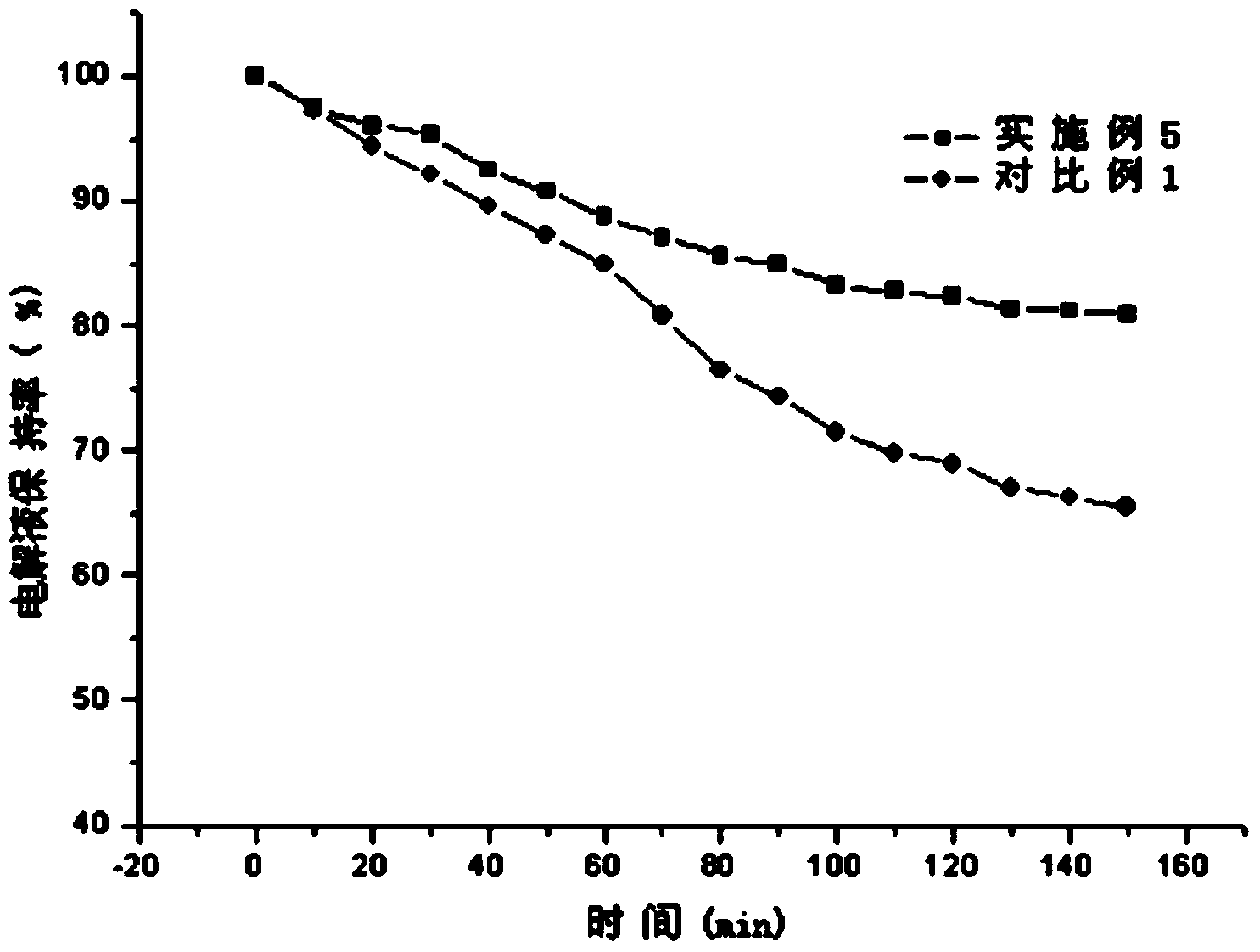

Composite diaphragm and method for preparing same

ActiveCN103515564AImprove thermal safetyImprove wettabilityCell seperators/membranes/diaphragms/spacersPorosityAdhesive

The invention discloses a composite diaphragm which comprises a supporting layer and an organic / inorganic particle blended coating layer, laminated; the coating layer comprises a polymer particle and an inorganic particle, uniformly mixed in an adhesive; micropore structures are arranged on the surface and at the inner part of the coating layer; the porosity is 20%-80%; the aperture average is 0.01 to 10 micrometers; the polymer particle comprises one or more of polytetrafluoroethylene, polyvinylidene fluoride, polyvinylidene fluoride-hexafluoropropylene copolymer, polyimide, polyacrylonitrile and aramid fiber resin; the particle size of the polymer particle is 0.01-10 micrometers; the inorganic particle comprises any one or more of SiO2, Al2O3, CaO, TiO2, MgO, ZnO, SnO2 and ZrO2; the particle size of the inorganic particle is 0.01-10 micrometers; the mass ratio of the polymer particle to the inorganic particle is (1:10) to (10:1). The invention further discloses a method for preparing the composite diaphragm. The composite diaphragm and the method have good thermal safety and strong in electrolyte absorption stiffness value, and meanwhile, and can achieve the advantages of low cost and low pollution.

Owner:SHENZHEN SENIOR TECH MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com