Patents

Literature

3657 results about "Particulate material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Particulate Material. Definition - What does Particulate Material mean? Particulate material or particulate matter (PM) refers to very small liquid or solid particles which are pollutants or cause air pollution.

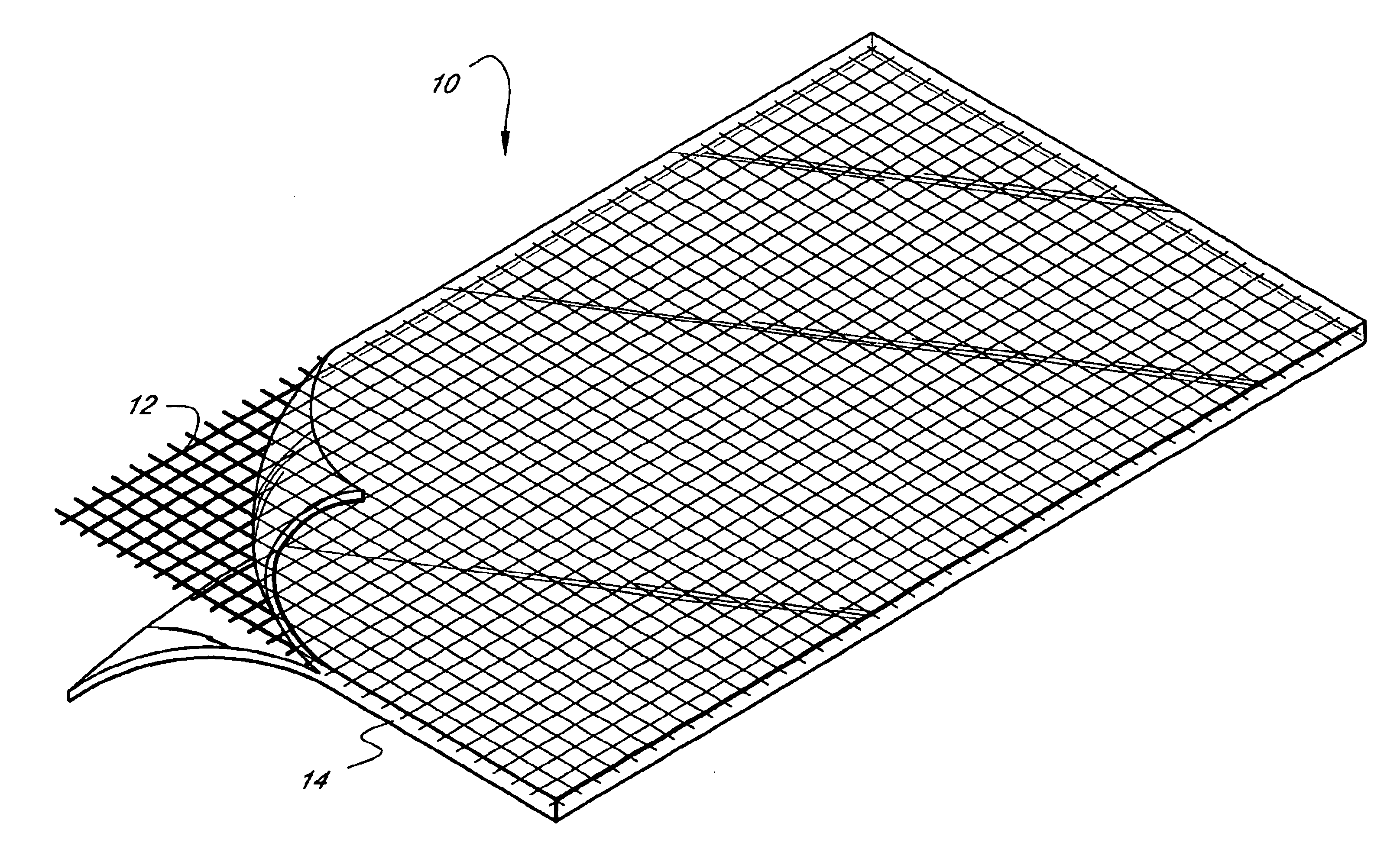

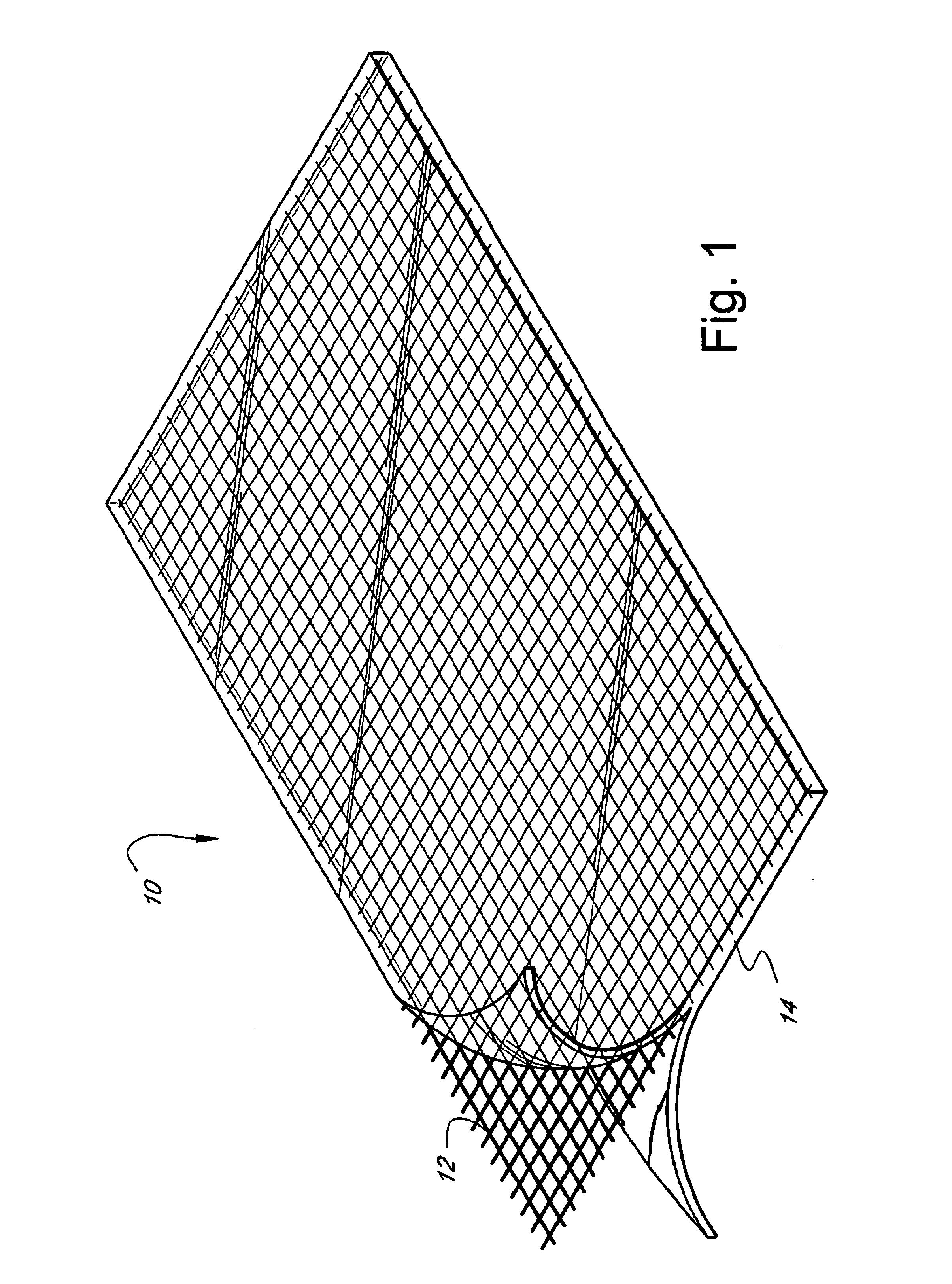

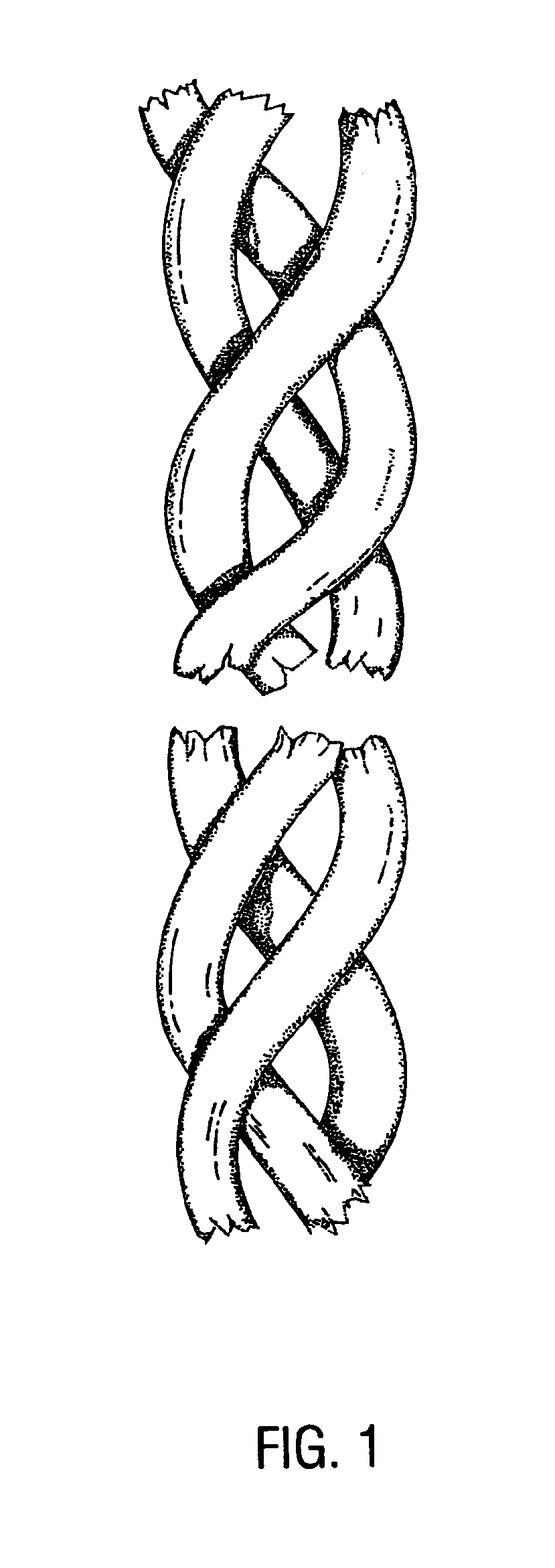

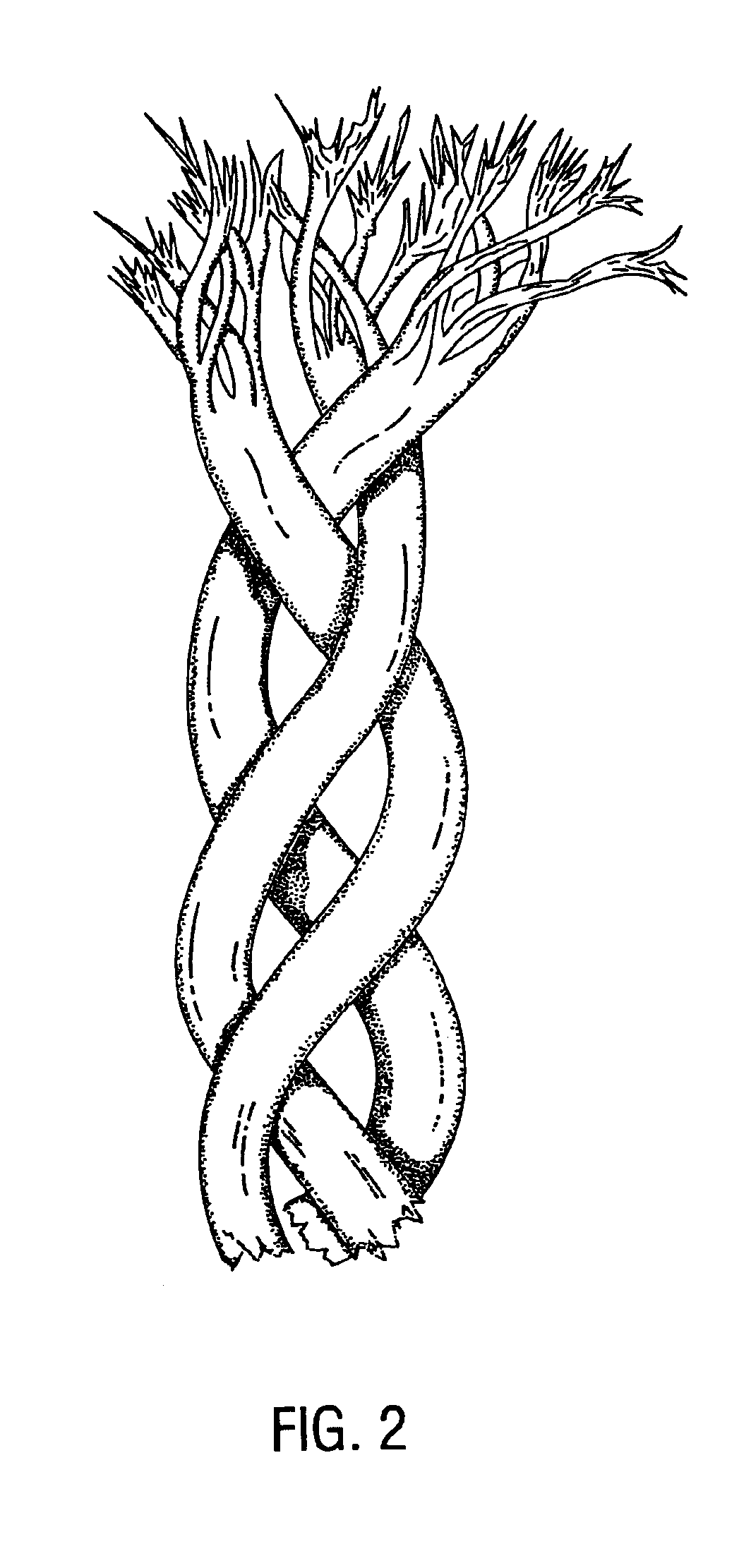

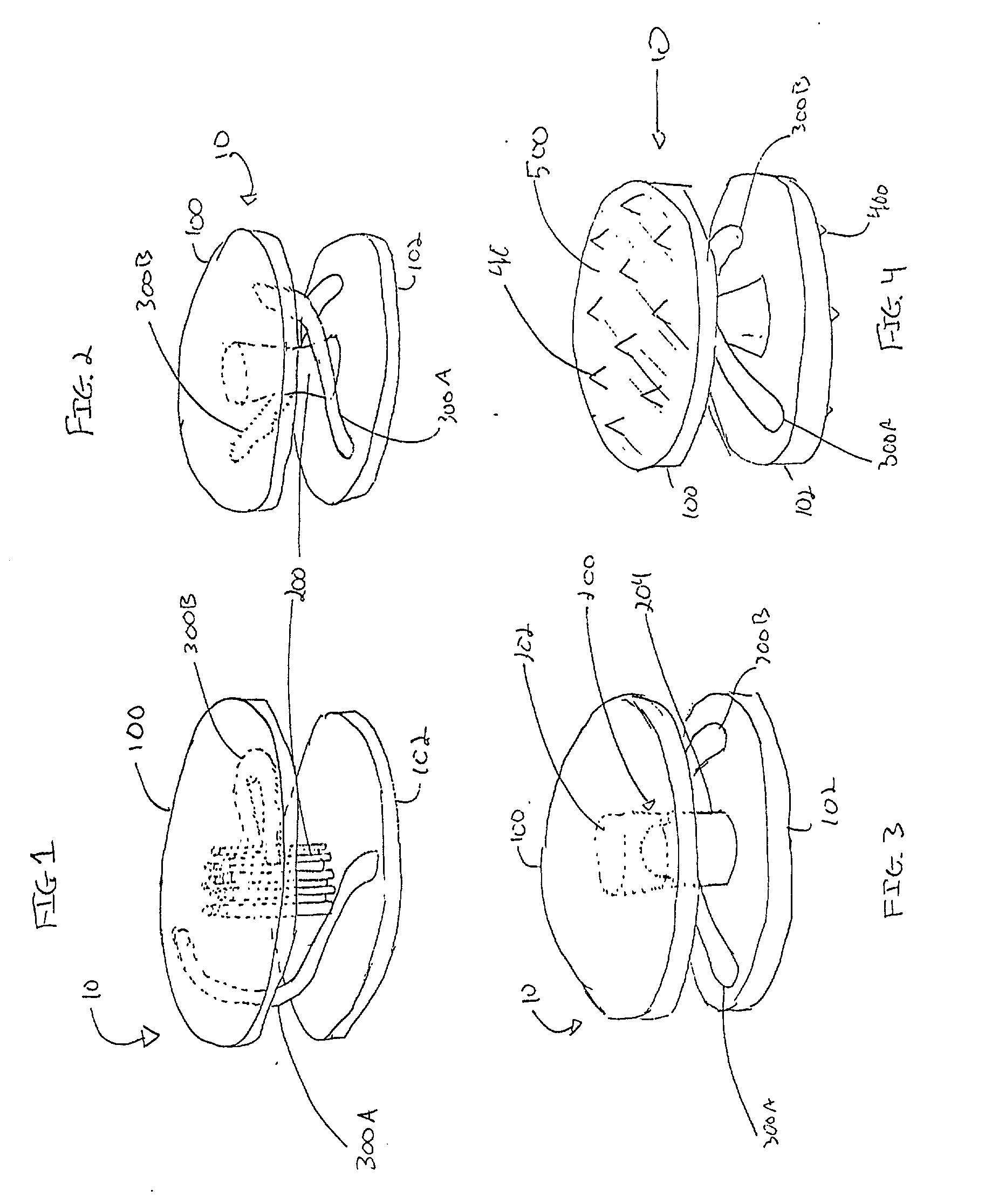

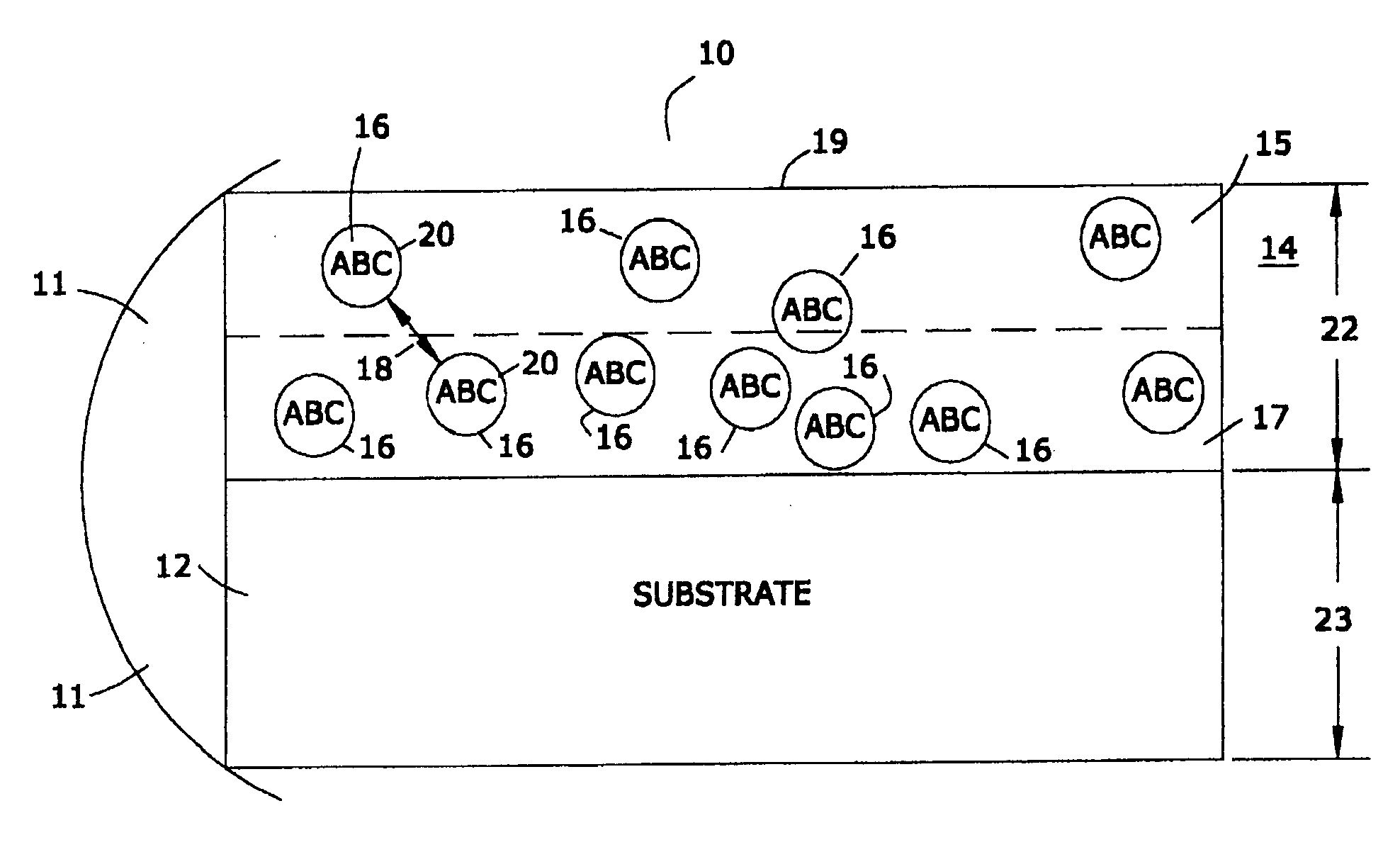

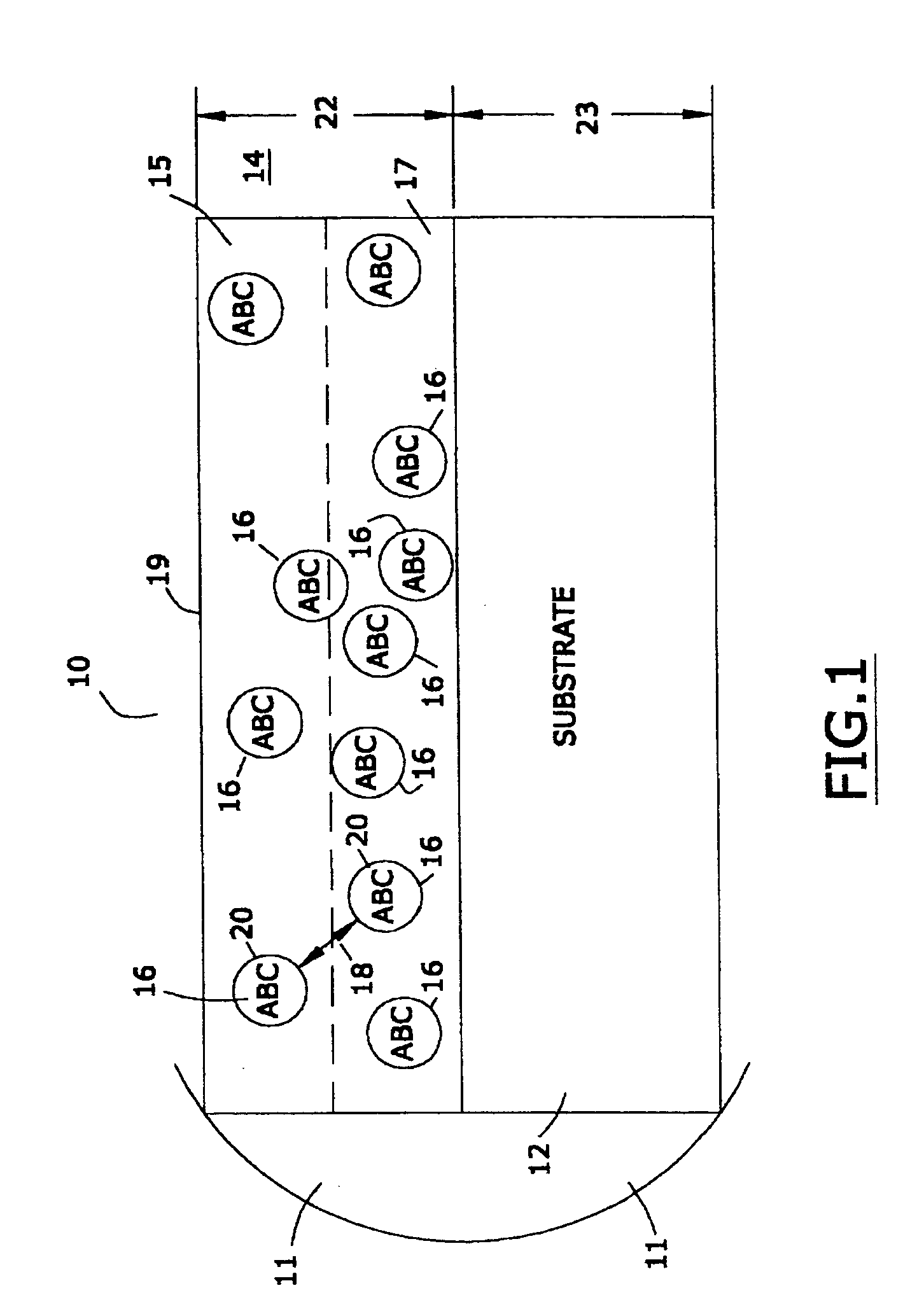

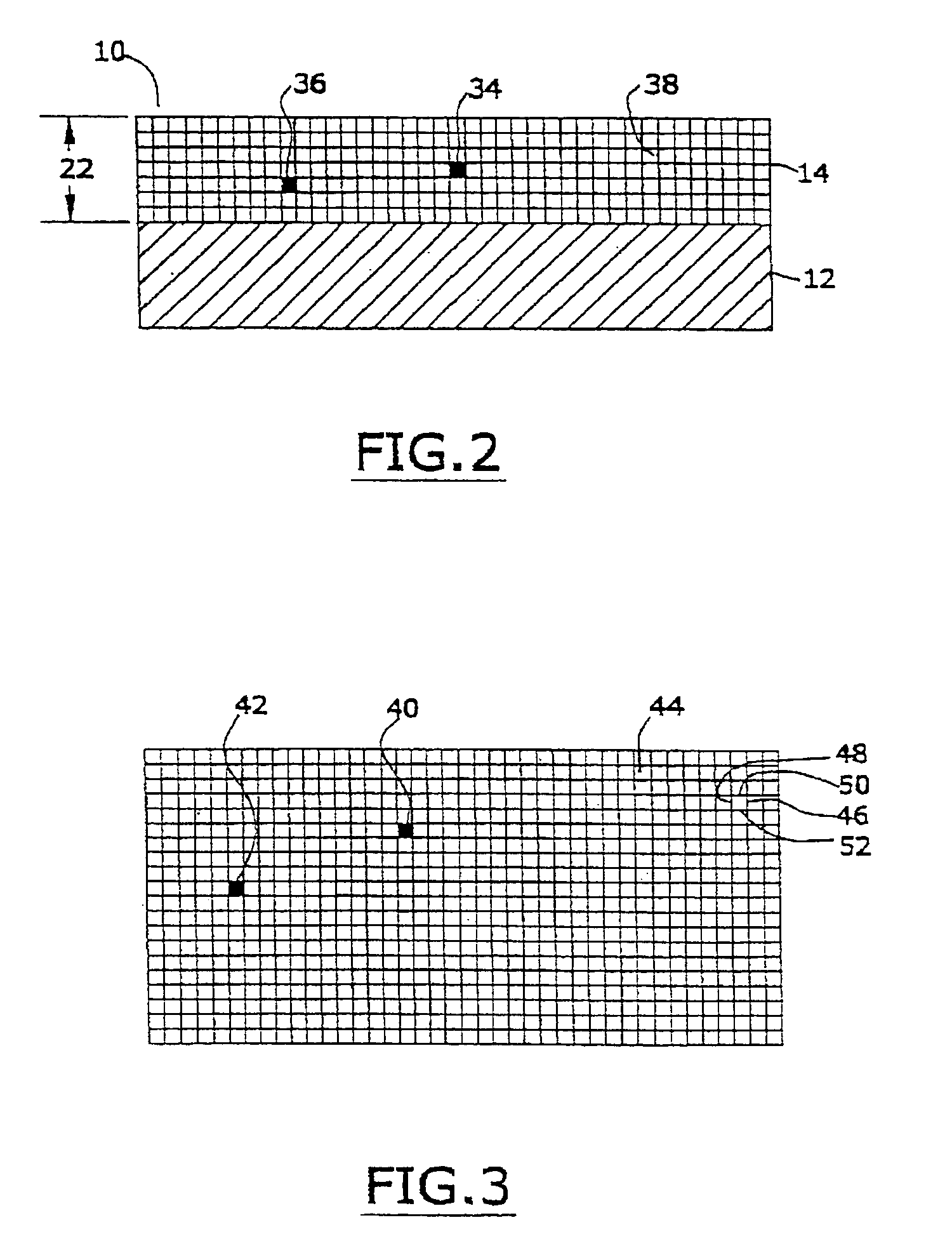

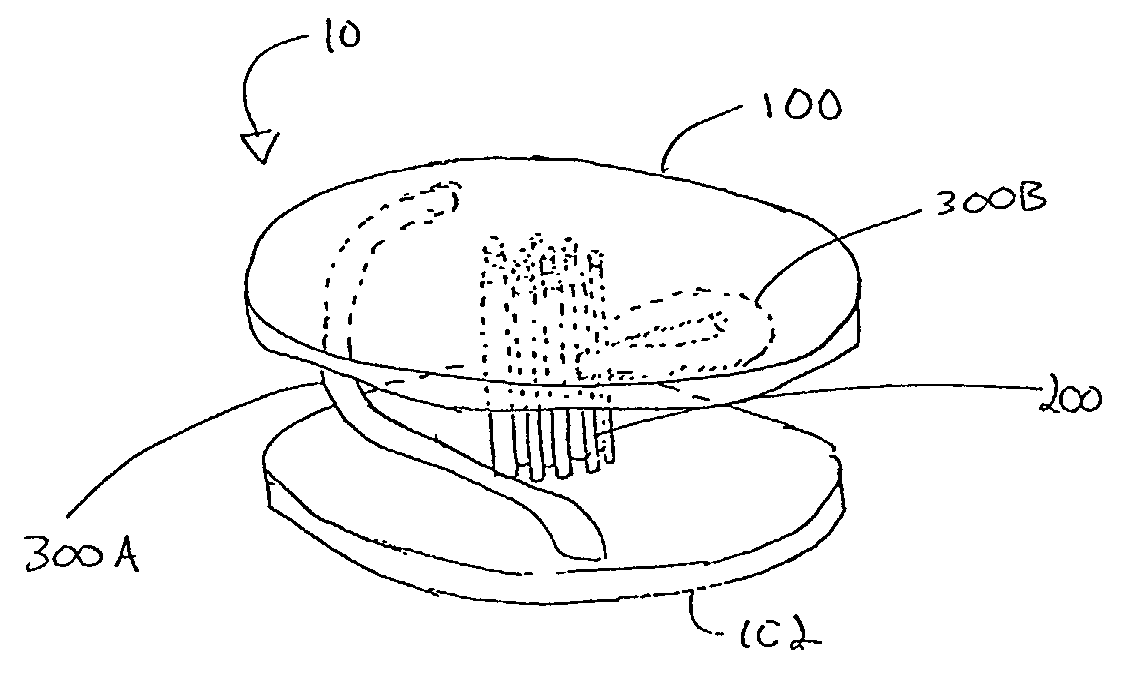

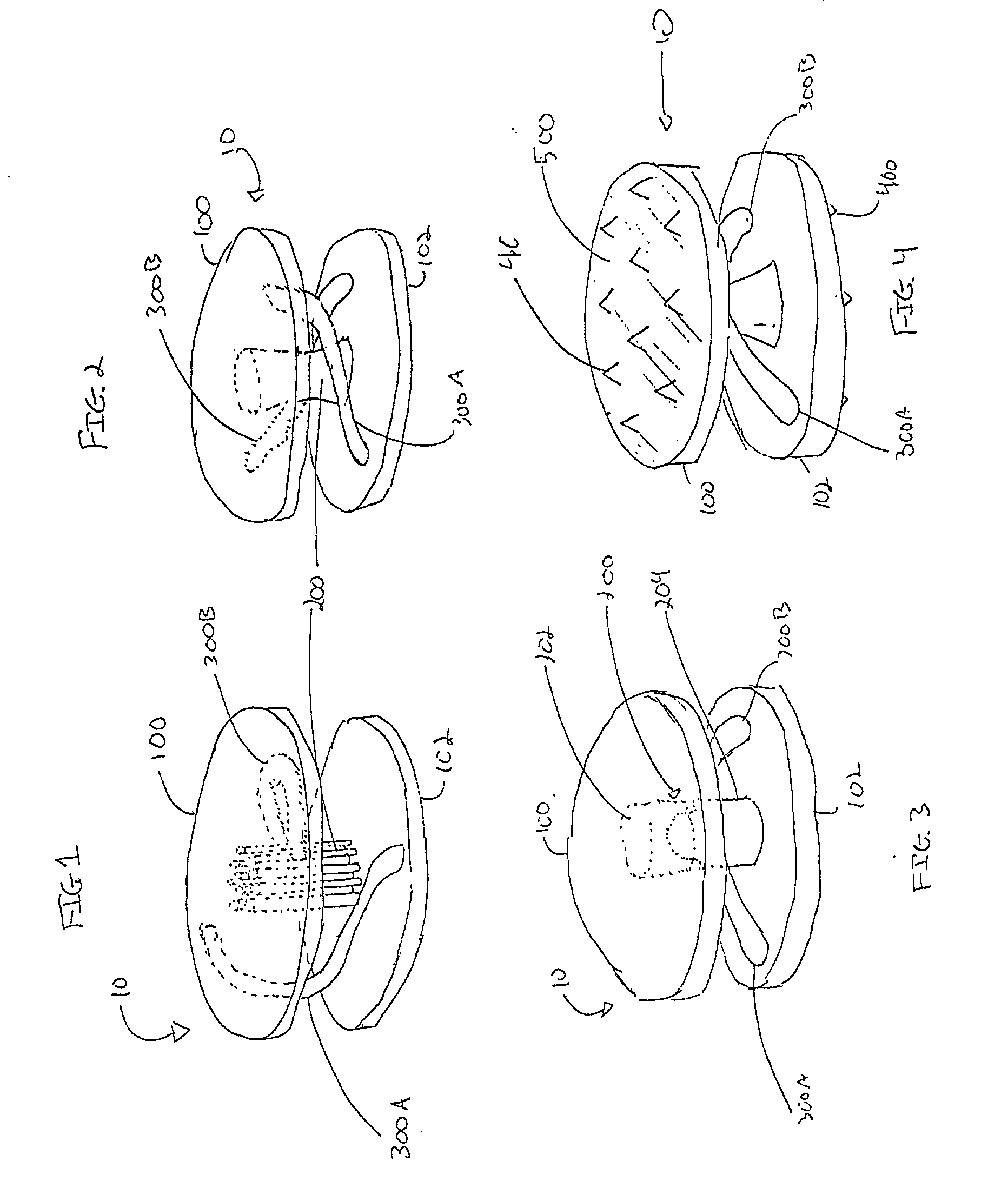

Self-supporting, shaped, three-dimensional biopolymeric materials and methods

Self-supporting, shaped, three-dimensional cross-linked proteinaceous biopolymeric materials that may be implanted in vivo, and methods of making such materials are disclosed. The biopolymeric materials most preferably include reinforcing media, such as biocompatible fibrous or particulate materials. In use, the preformed, shaped biopolymeric materials may be applied to tissue in need of repair and then sealed around its edges with a liquid bioadhesive. In such a manner, repaired tissue which is capable of withstanding physiological pressures may be provided.

Owner:CRYOLIFE

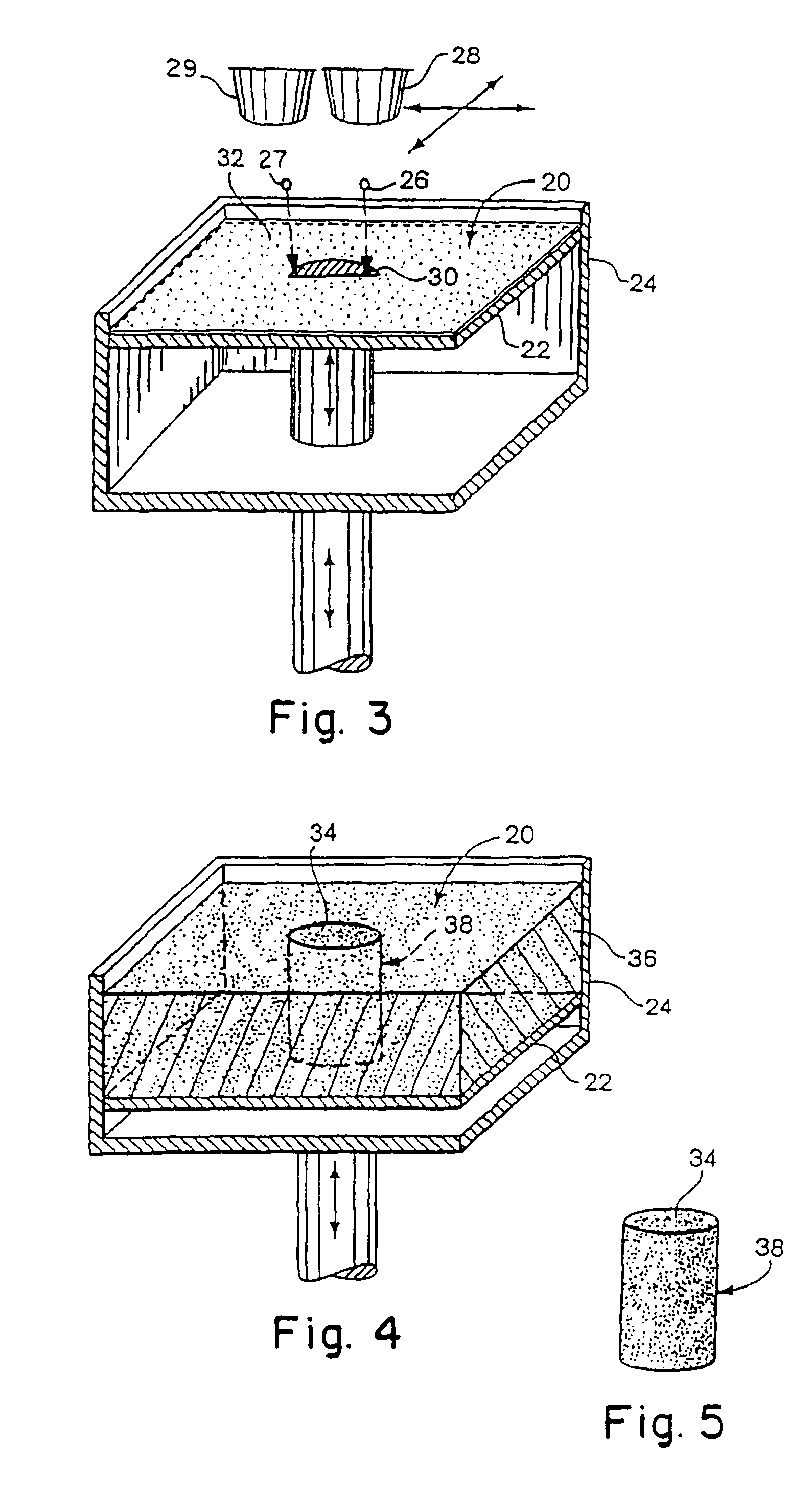

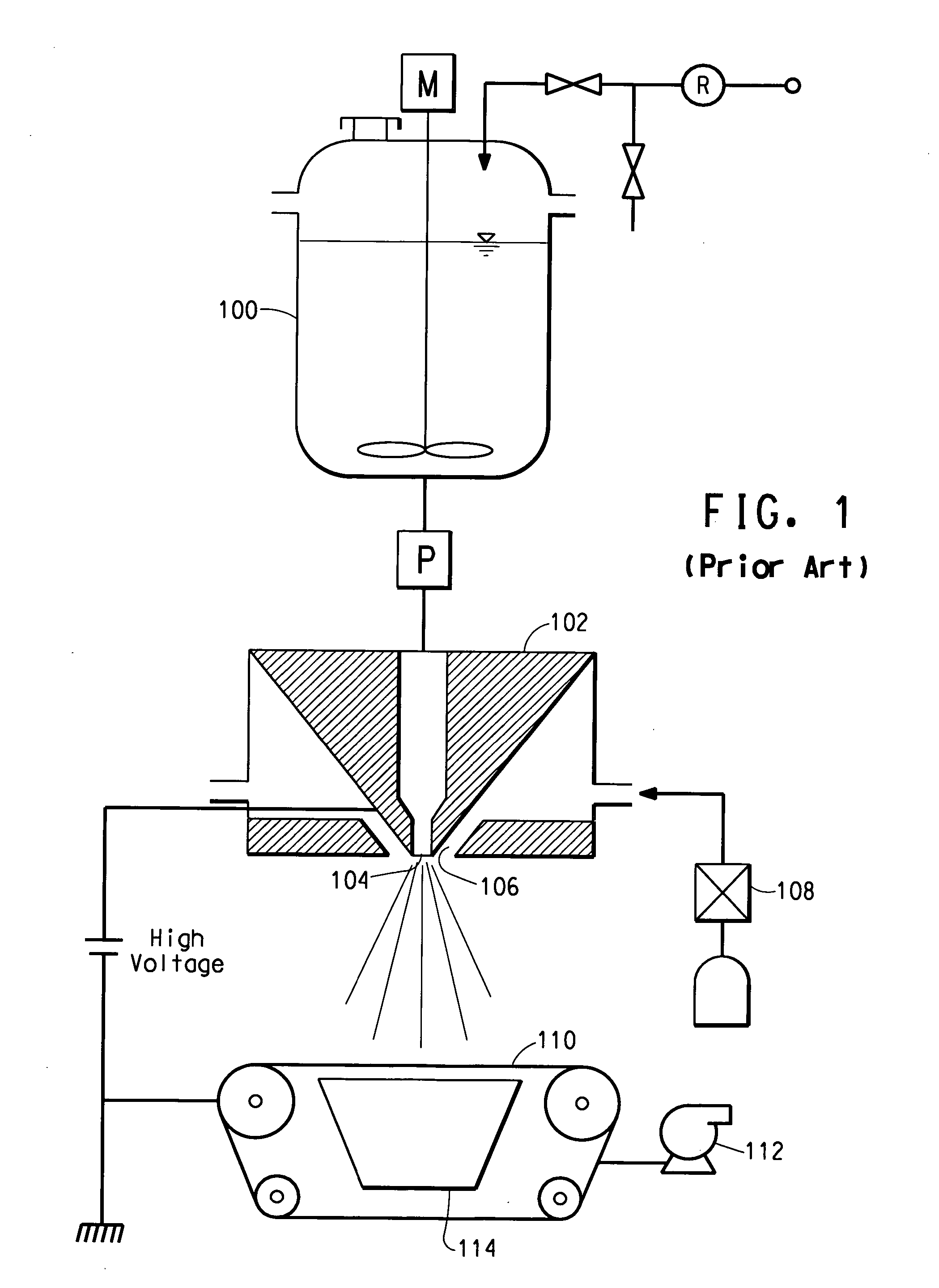

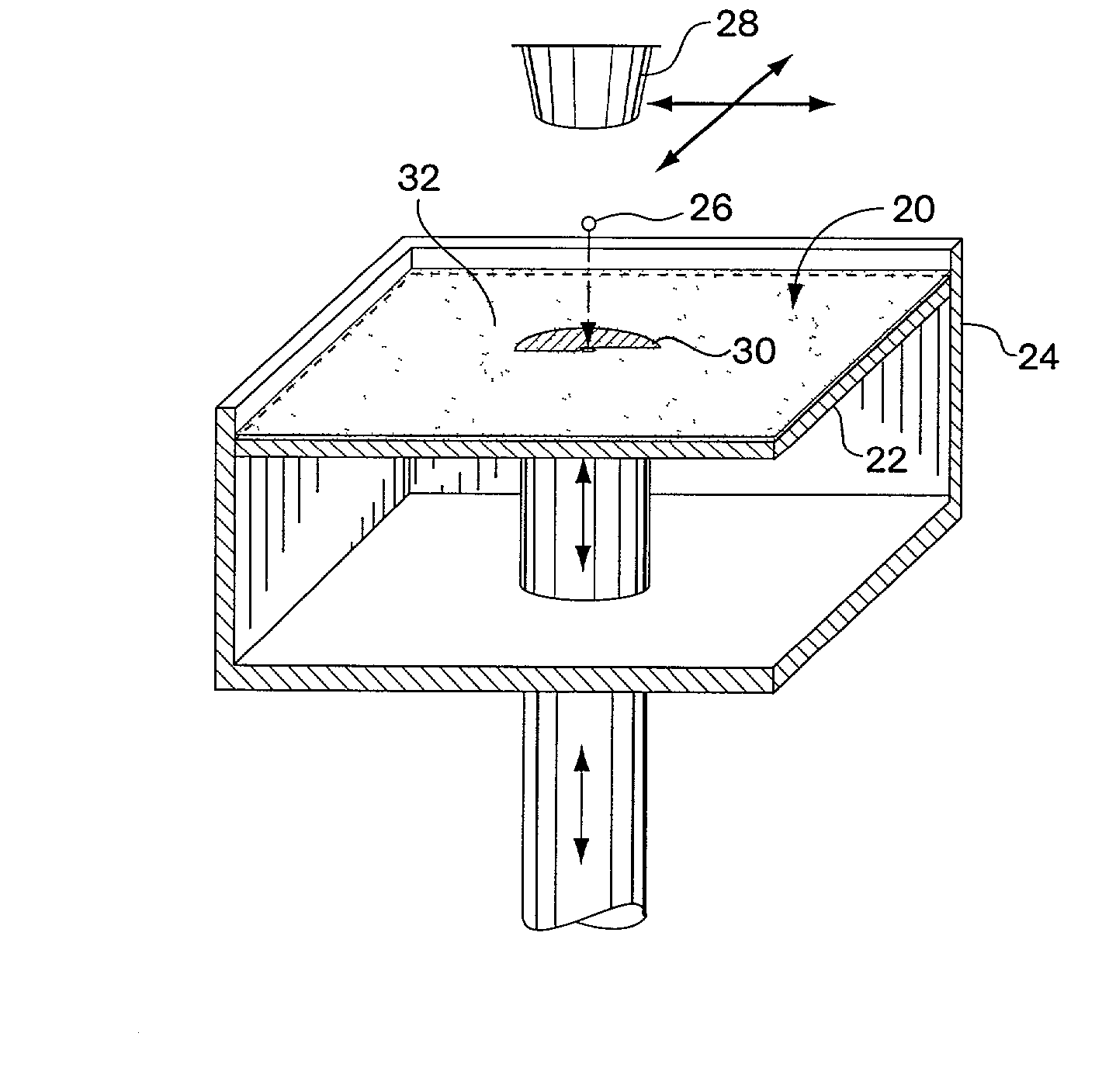

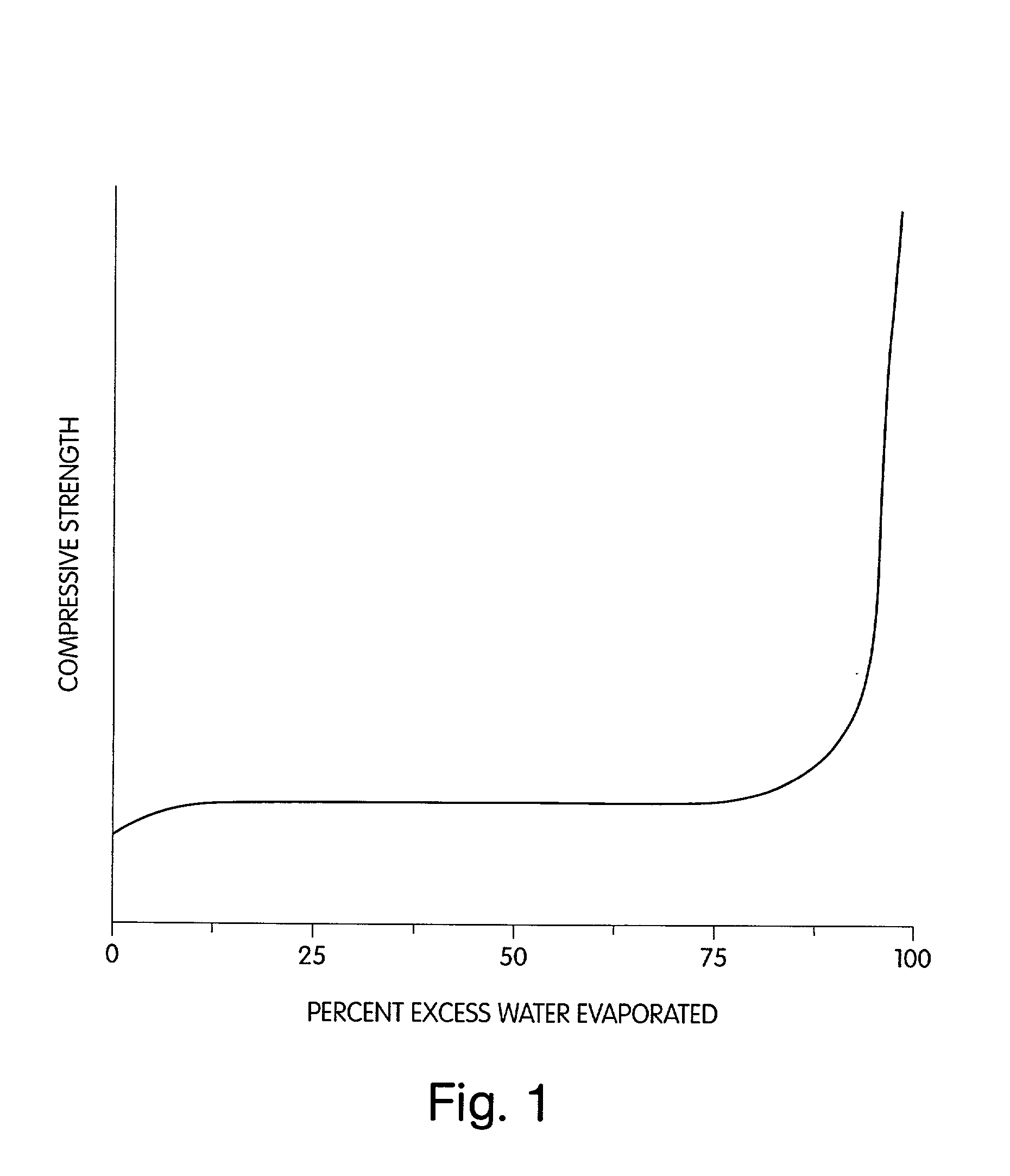

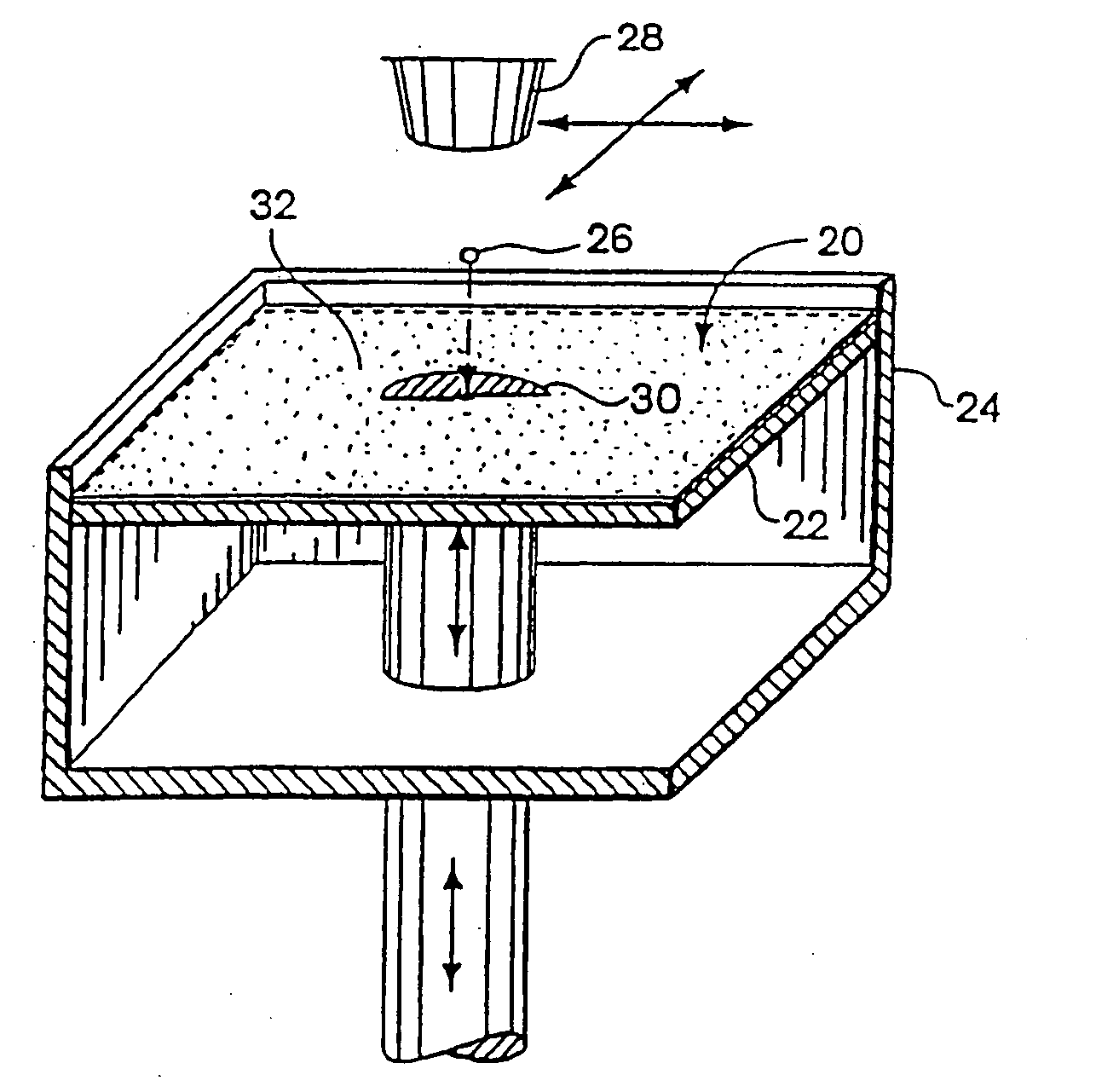

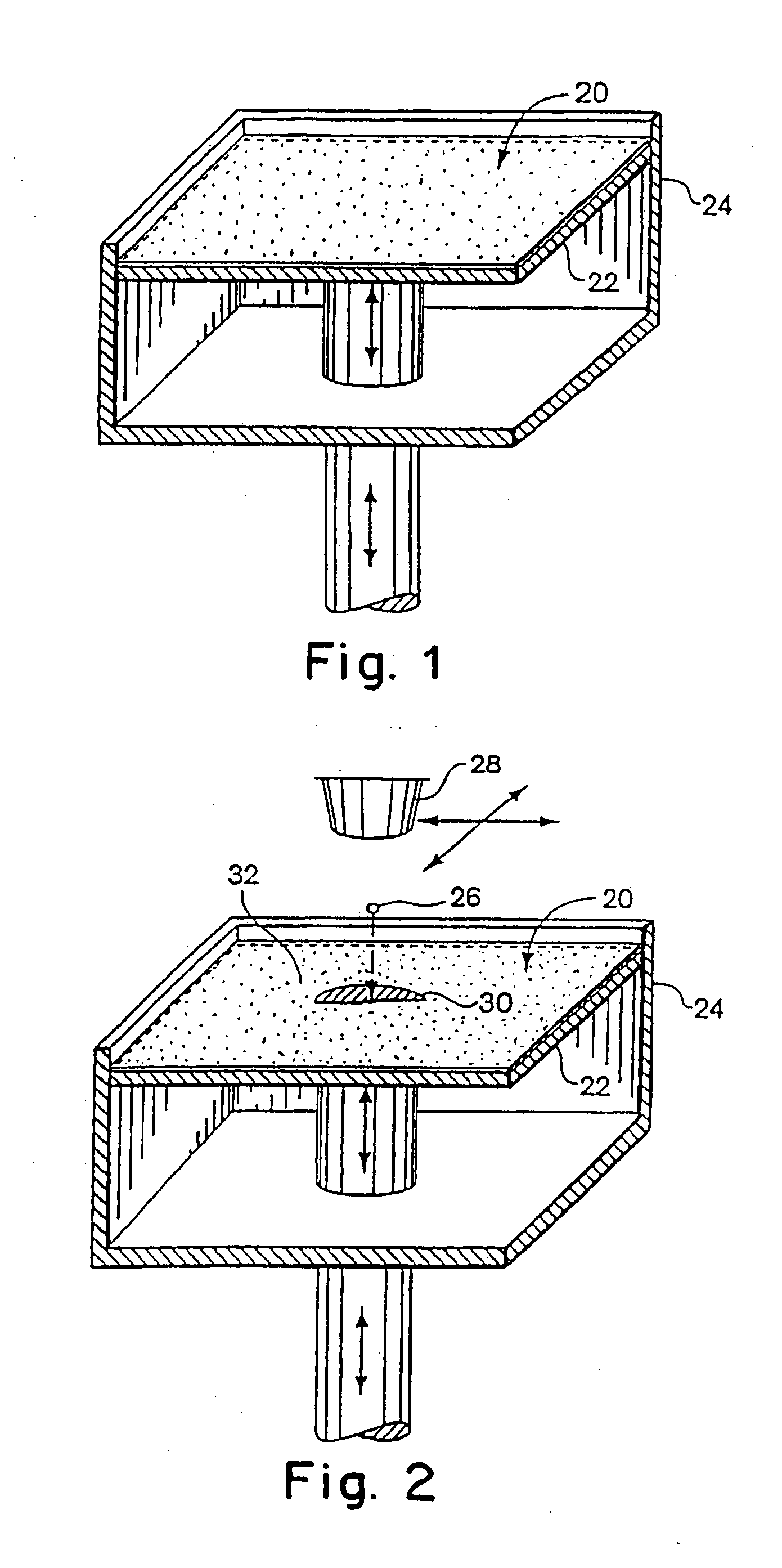

Production of three-dimensional objects by use of electromagnetic radiation

InactiveUS20070241482A1Reduce contractionReduce expansionElectrographic process apparatusAdditive mnaufacturing with solid and fluidEngineeringElectromagnetic radiation

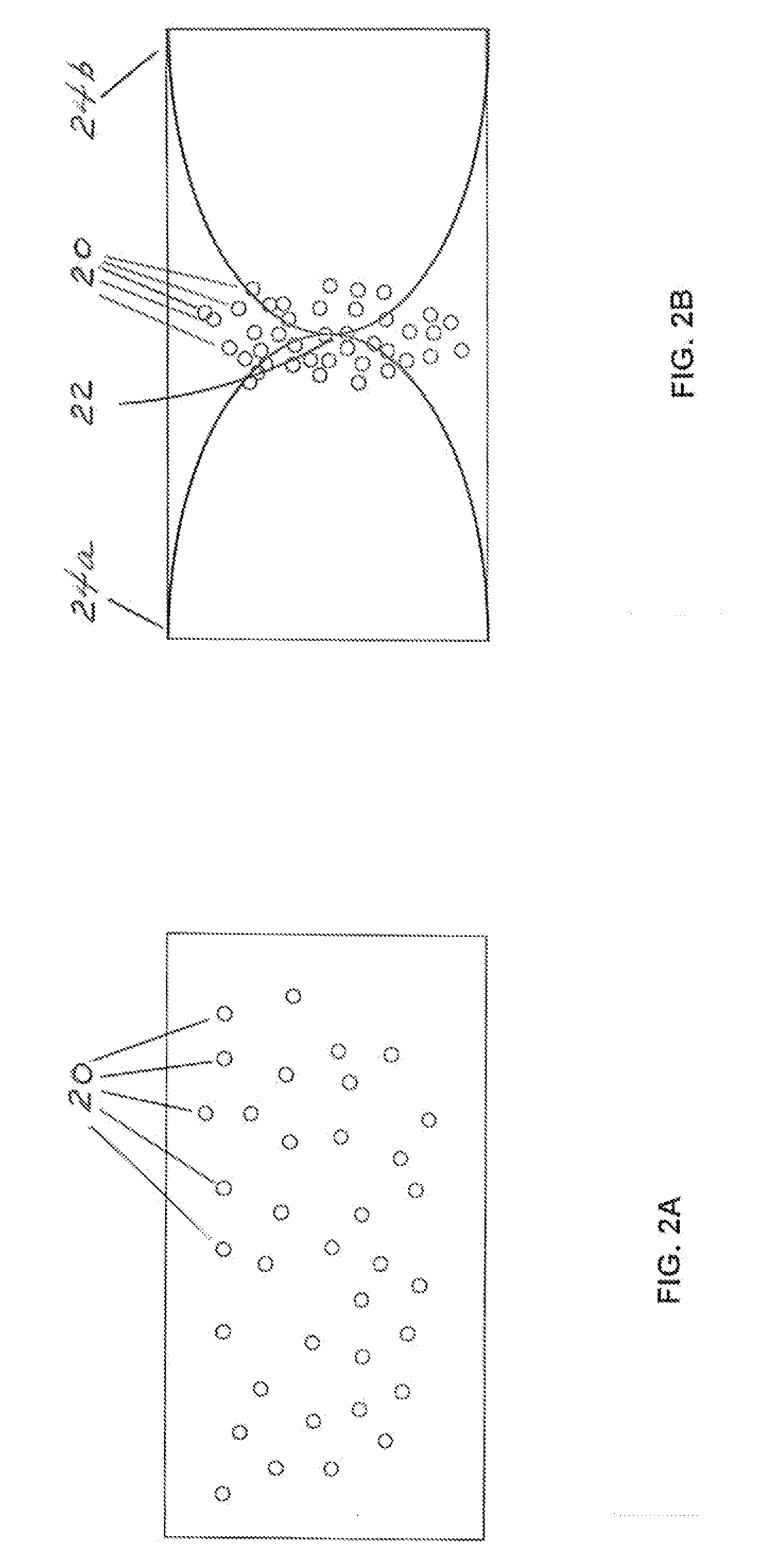

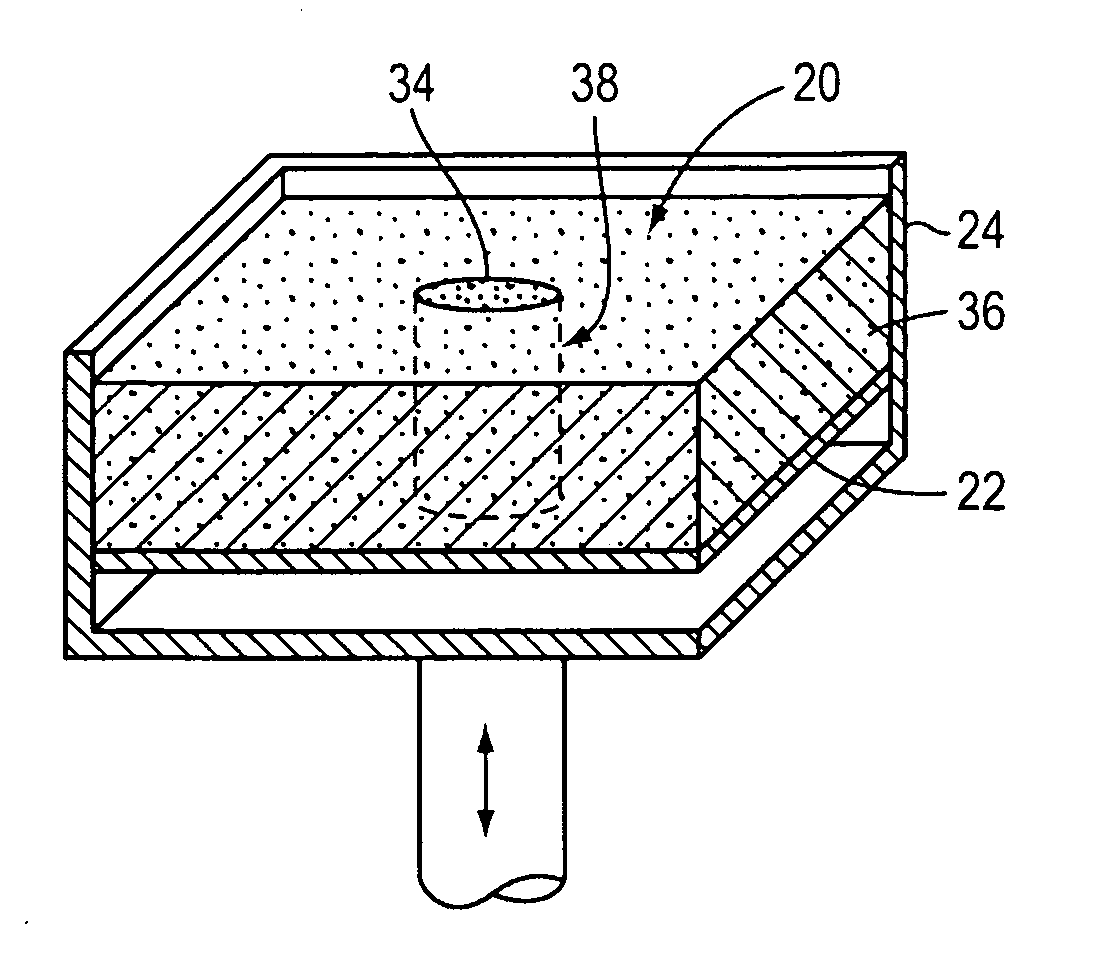

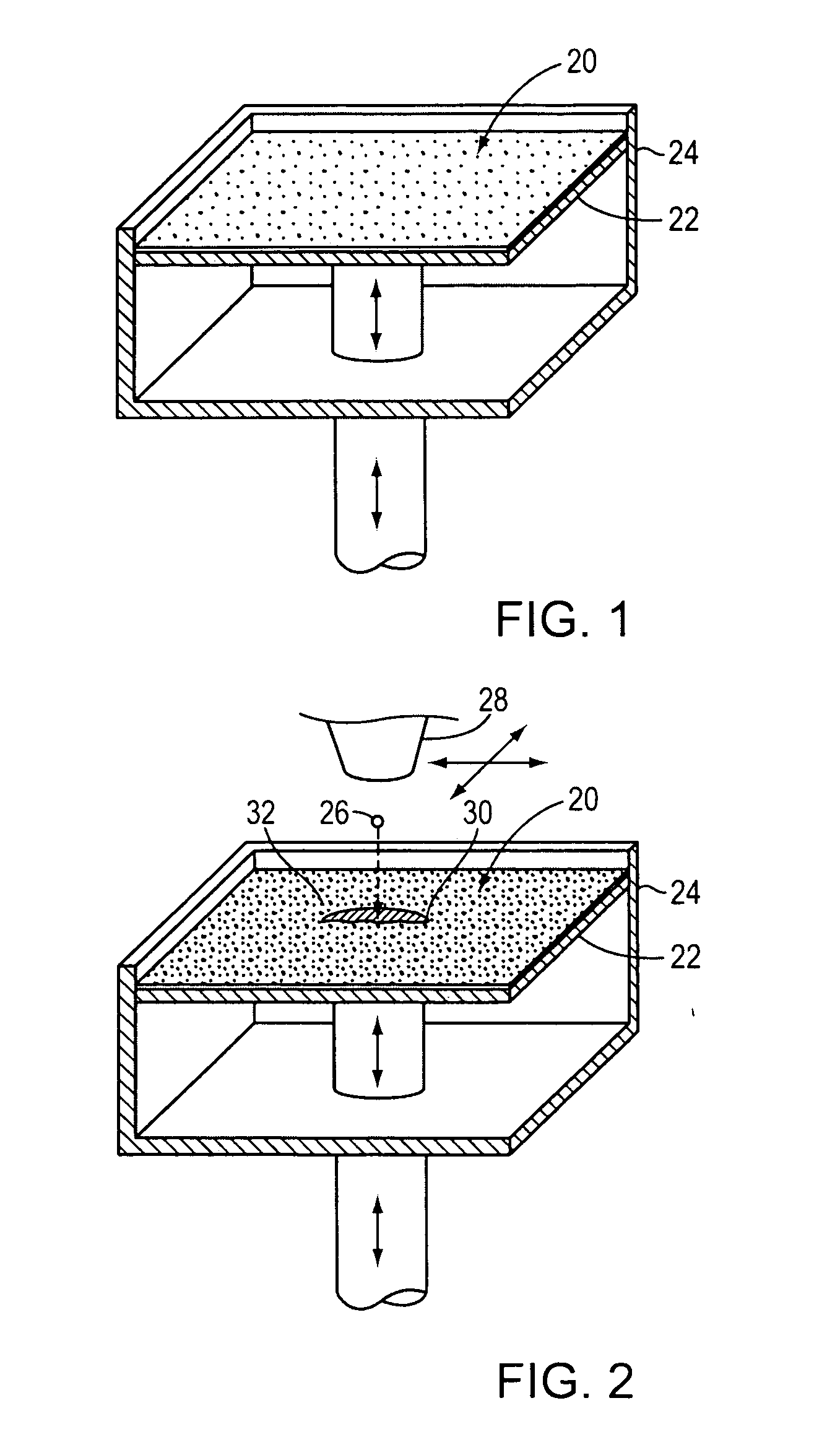

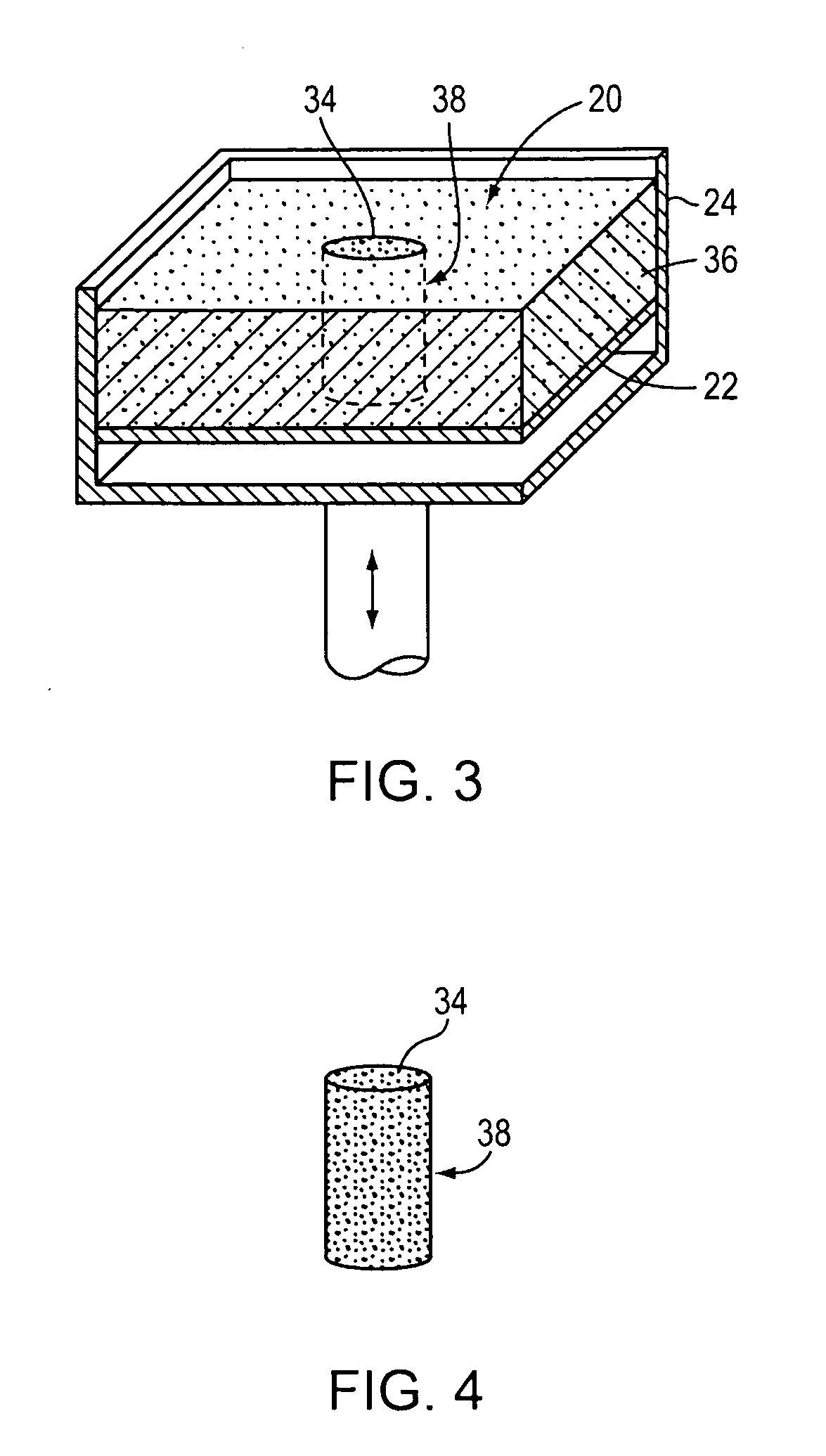

Process, materials, and equipment for producing three-dimensional objects from a particulate material by melting and adhering, for example, by fusion or sintering, portions of the particulate material.

Owner:Z CORPORATION

Particulate acellular tissue matrix

A method of processing an acellular tissue matrix to give a particulate acellular tissue matrix includes: cutting sheets of dry acellular tissue matrix into strips; cryofracturing the dry acellular tissue matrix strips at cryogenic temperatures; separating the resulting particles by size at cryogenic temperatures; and freeze drying the fraction of particles desired size to remove any moisture that may have been absorbed to give a dry particulate acellular tissue matrix. Rehydration of the dry particulate acellular tissue matrix may take place just prior to use. The particulate acellular tissue may be applied to a recipient site, by way of injection, spraying, layering, packing, in-casing or combinations thereof. The particulate acellular tissue may further include growth and stimulating agents selected from epidermal growth factor, fibroblast growth factor, nerve growth factor, keratinocyte growth factor, platelet derived growth factor, vasoactive intestinal peptide, stem cell factor, bone morphogetic proteins, chondrocyte growth factor and combinations thereof. Other pharmaceutically active compounds may be combined with the rehydrated particulate material including: analgesic drugs; hemostatic drugs; antibiotic drugs; local anesthetics and the like to enhance the acceptance of the implanted particulate material. The particulate material product may also be combined with stem cells selected from mesenchymal stem cells, epidermal stem cells, cartilage stem cells, hematopoietic stem cells and combinations thereof.

Owner:LIFECELL

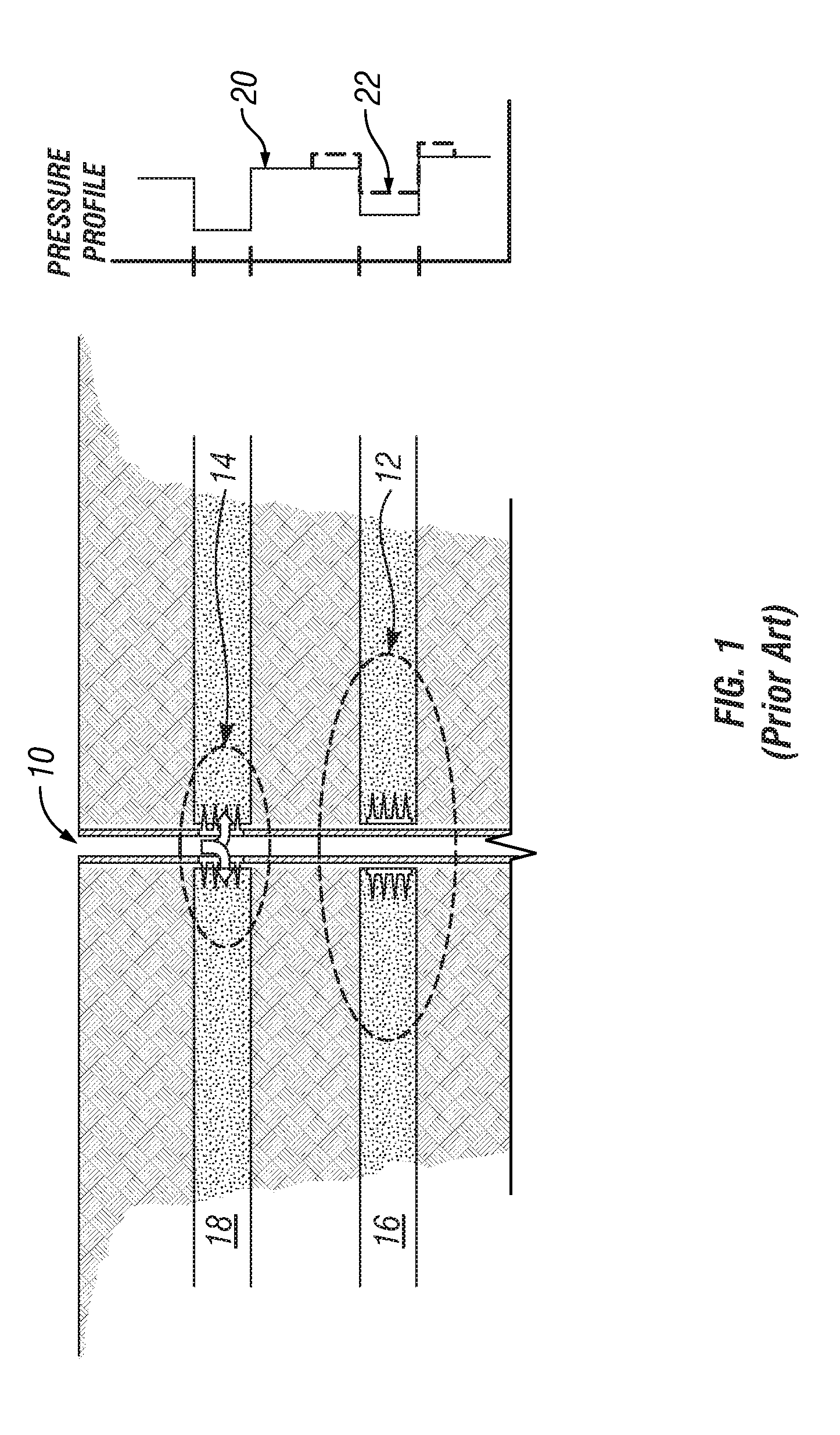

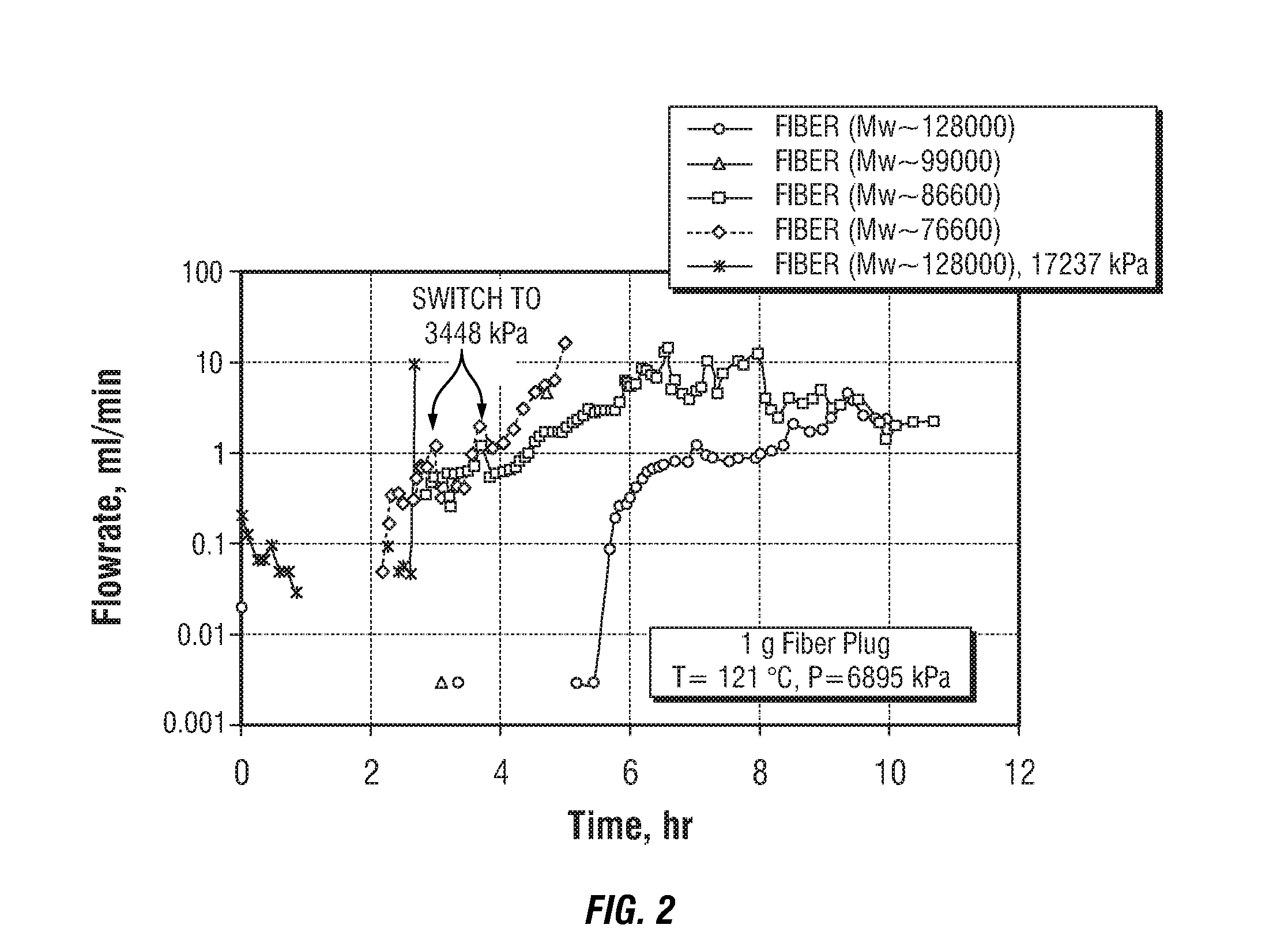

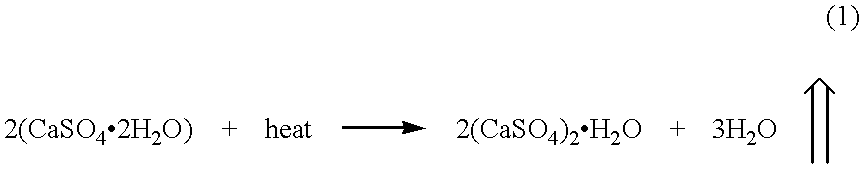

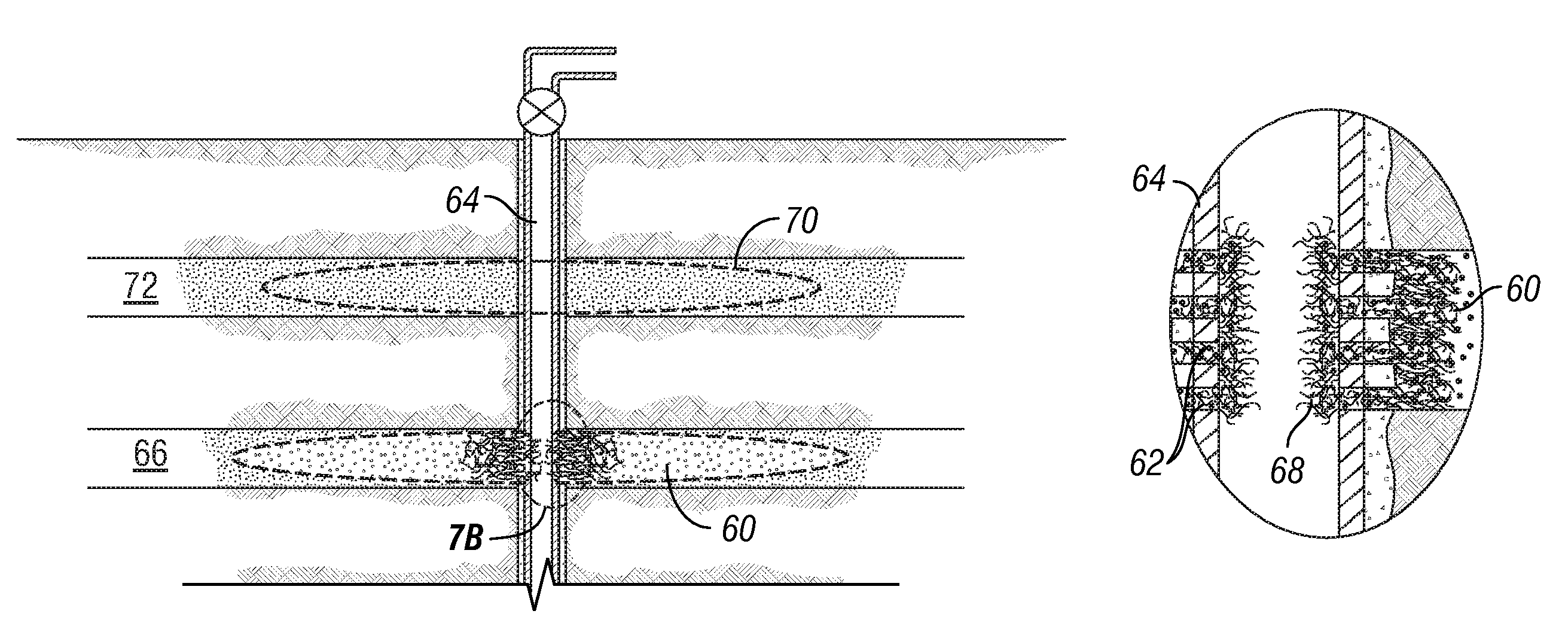

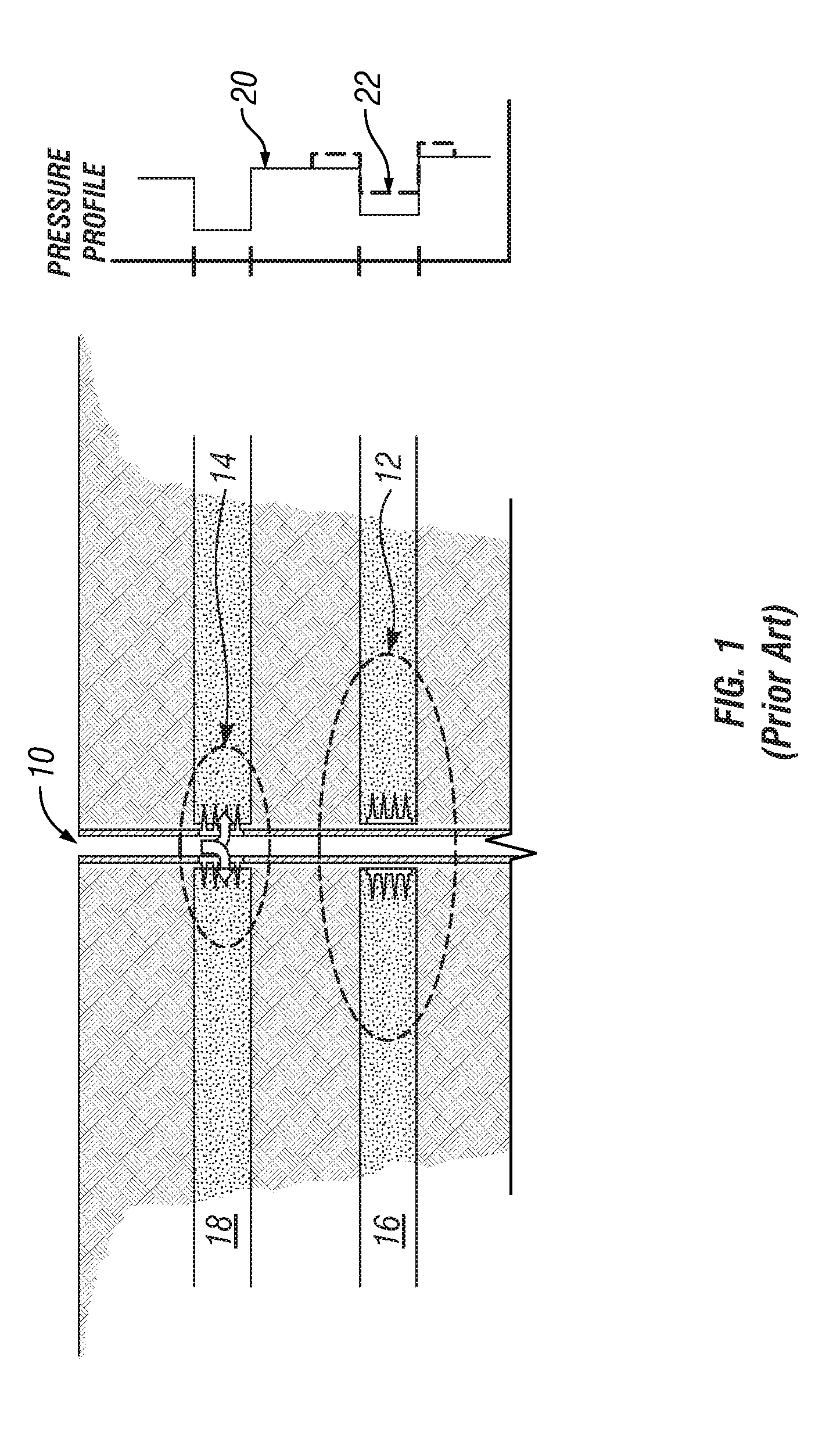

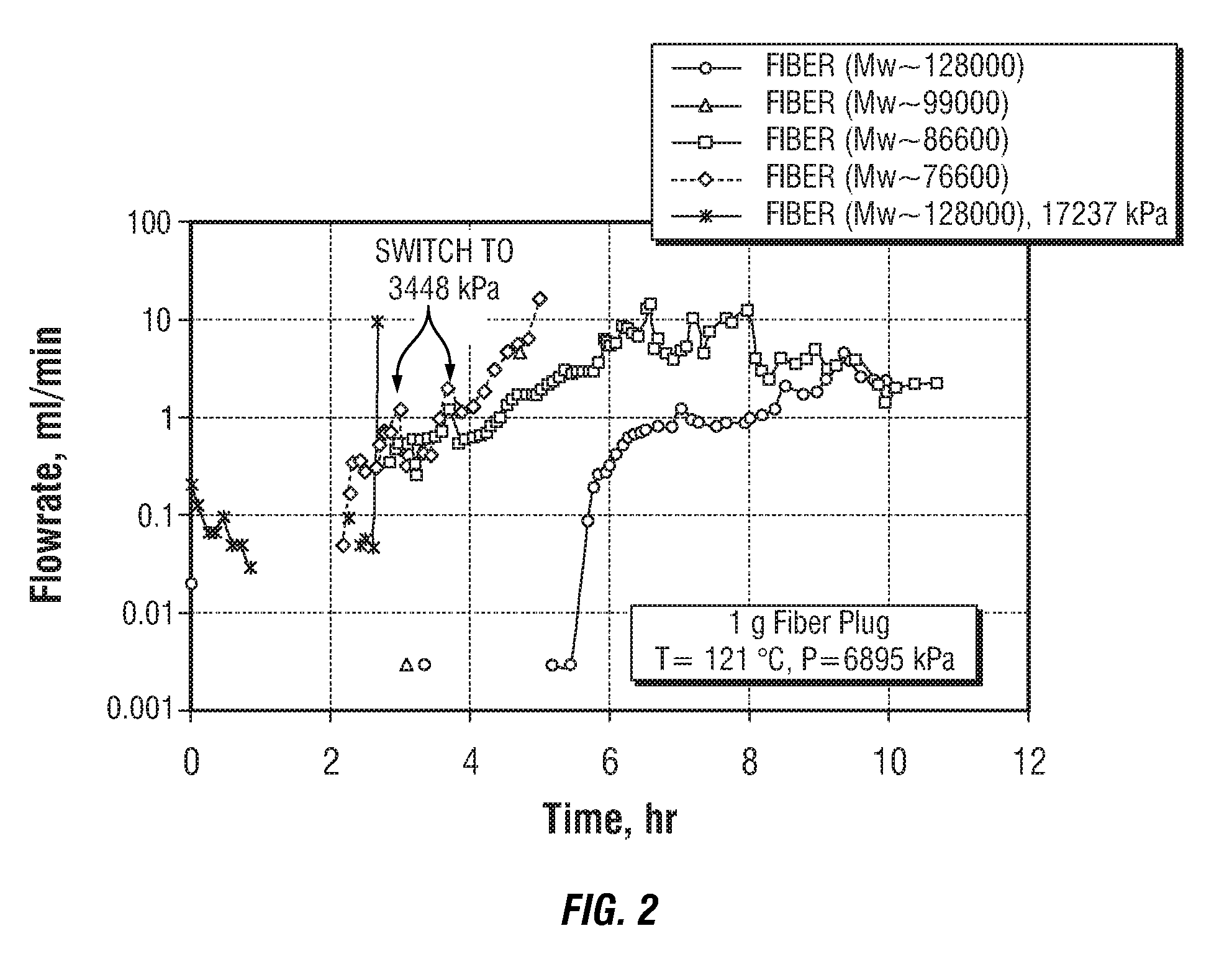

Degradable Material Assisted Diversion

Degradable material assisted diversion (DMAD) methods for well treatment, DMAD treatment fluids, and removable plugs for DMAD in downhole operations. A slurry of solid degradable material is injected into the well, a plug of the degradable material is formed, a downhole operation is performed around the plug diverter, and the plug is then degraded for removal. Degradation triggers can be temperature or chemical reactants, with optional accelerators or retarders to provide the desired timing for plug removal. In multilayer formation DMAD fracturing, the plug isolates a completed fracture while additional layers are sequentially fractured and plugged, and then the plugs are removed for flowback from the fractured layers. In DMAD fluids, an aqueous slurry can have a solids phase including a degradable material and a fluid phase including a viscoelastic surfactant. The solids phase can be a mixture of fibers and a particulate material.

Owner:SCHLUMBERGER TECH CORP

Compositions and methods for controlling the release of chemicals placed on particulates

InactiveUS20050028976A1Simple methodSynthetic resin layered productsCellulosic plastic layered productsParticulatesCompound (substance)

The present invention relates to methods and compositions for creating and using particulate materials having treating agents absorbed thereon and coated with a degradable coating material. One embodiment of a method of the present invention provides a method treating to a subterranean formation comprising placing a coated, treated particulate into a subterranean formation wherein the coated, treated particulate comprises a particulate material having a treating agent placed thereon and a substantially complete layer of a degradable coating material coated placed thereon over the treating agent.

Owner:HALLIBURTON ENERGY SERVICES INC

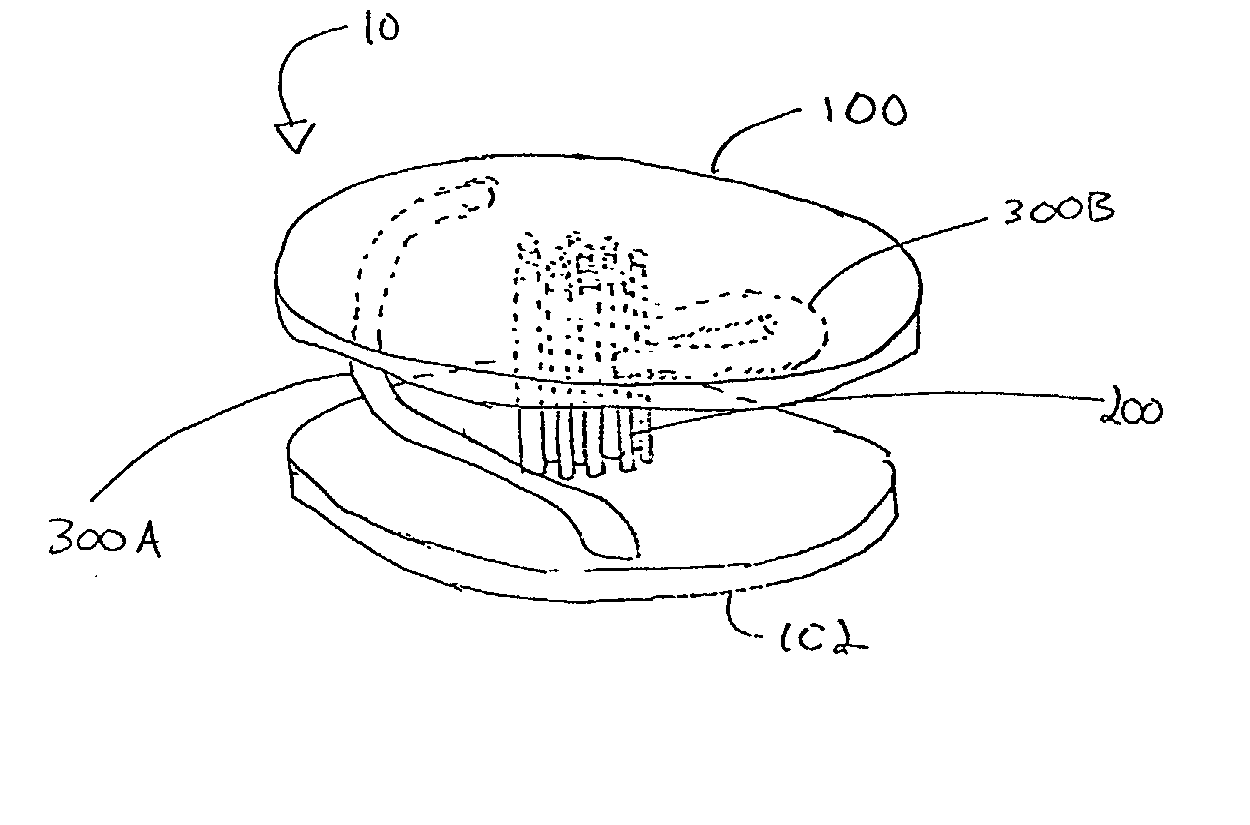

Orthopedic implant and method of making metal articles

The present application is directed to an orthopedic implant. More specifically, the orthopedic implant is suitable for arthroplasty procedures where optimized multifunctional behavior of the implant is desired. In some embodiments the implant is suitable for the replacement of a spinal disc. In one embodiment, the present application is directed to an orthopedic implant including a first plate a second plate and a flexible support. The flexible support may have a single connection to the first plate and a single connection to the second plate and may vary in cross section. The first plate, the second plate and the flexible support may be unitarily formed. This application is also directed to methods of producing metal articles having microstructure for improved mechanical properties. Such methods may be suitable for the production of medical devices. In one embodiment, the method includes directing a stream including a particulate material in a pattern corresponding to at least a portion of a structure of an orthopedic implant and fusing at least a portion of the particulate material with a laser.

Owner:DEPUY ACROMED INC

Material systems and methods of three-dimensional printing

InactiveUS7795349B2Adhesive processesAdditive manufacturing apparatusEngineering3 dimensional printing

The present invention is directed to three-dimensional printing material systems and method, and an article made therefrom. The method of the present invention includes building cross-sectional portions of a three-dimensional article, and assembling the individual cross-sectional areas in a layer-wise fashion to form a final article. The individual cross-sectional areas are built by using an ink-jet printhead to deliver a fluid to a particulate material that includes particulate material.

Owner:3D SYST INC

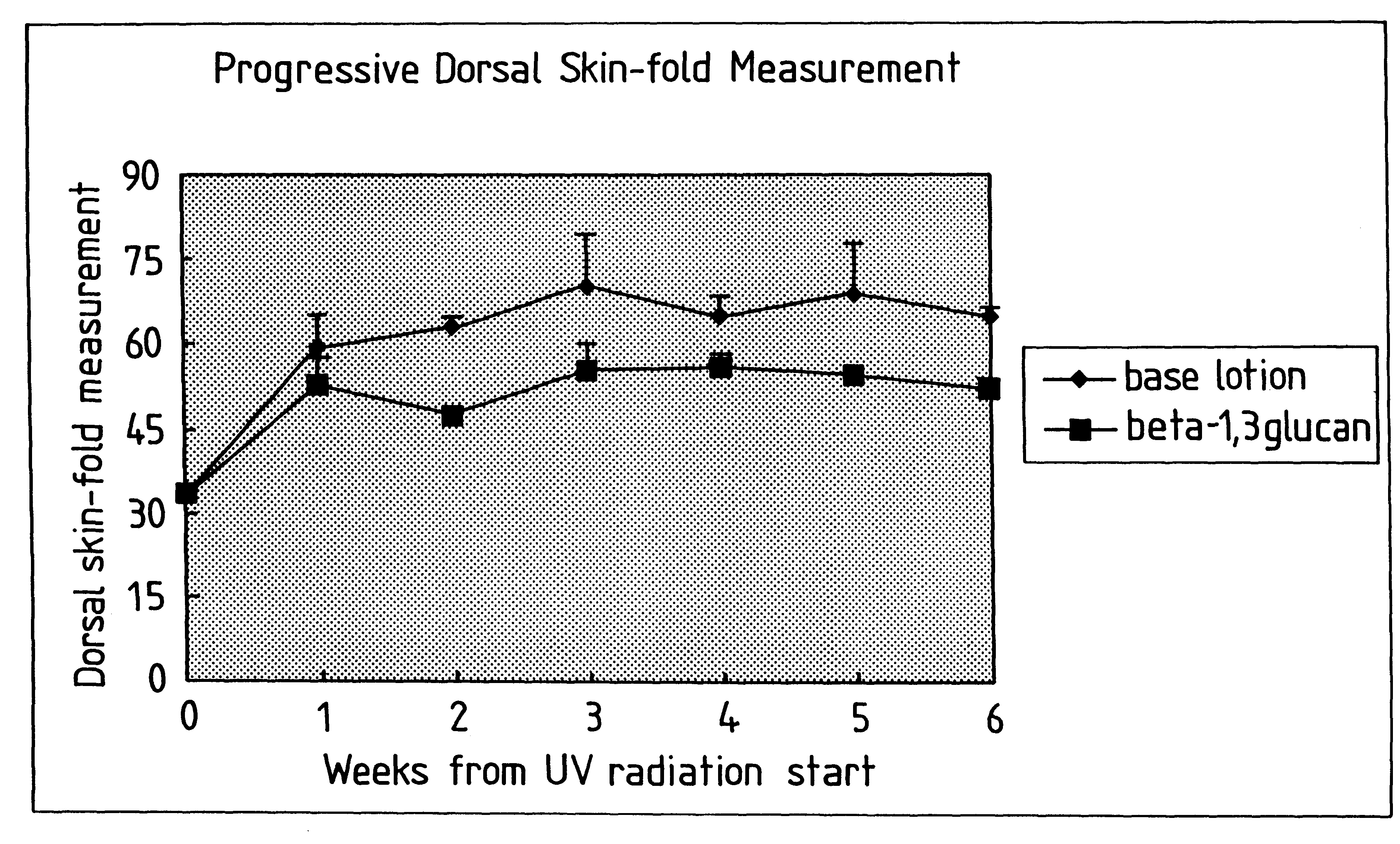

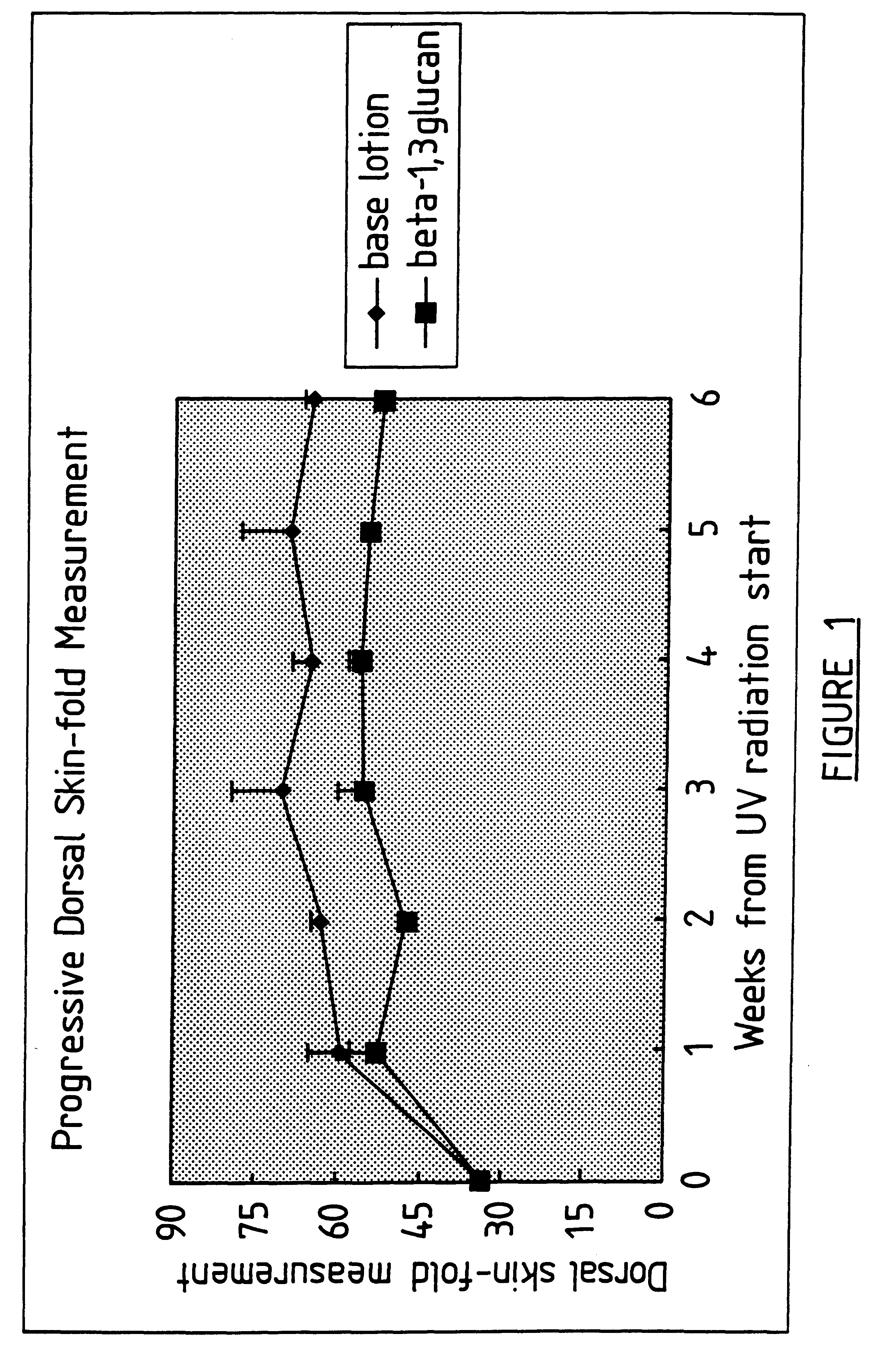

Process for glucan preparation and therapeutic uses of glucan

InactiveUS6242594B1Low costSuitable solubility characteristicAntibacterial agentsOrganic active ingredientsOrganic solventMicroparticle

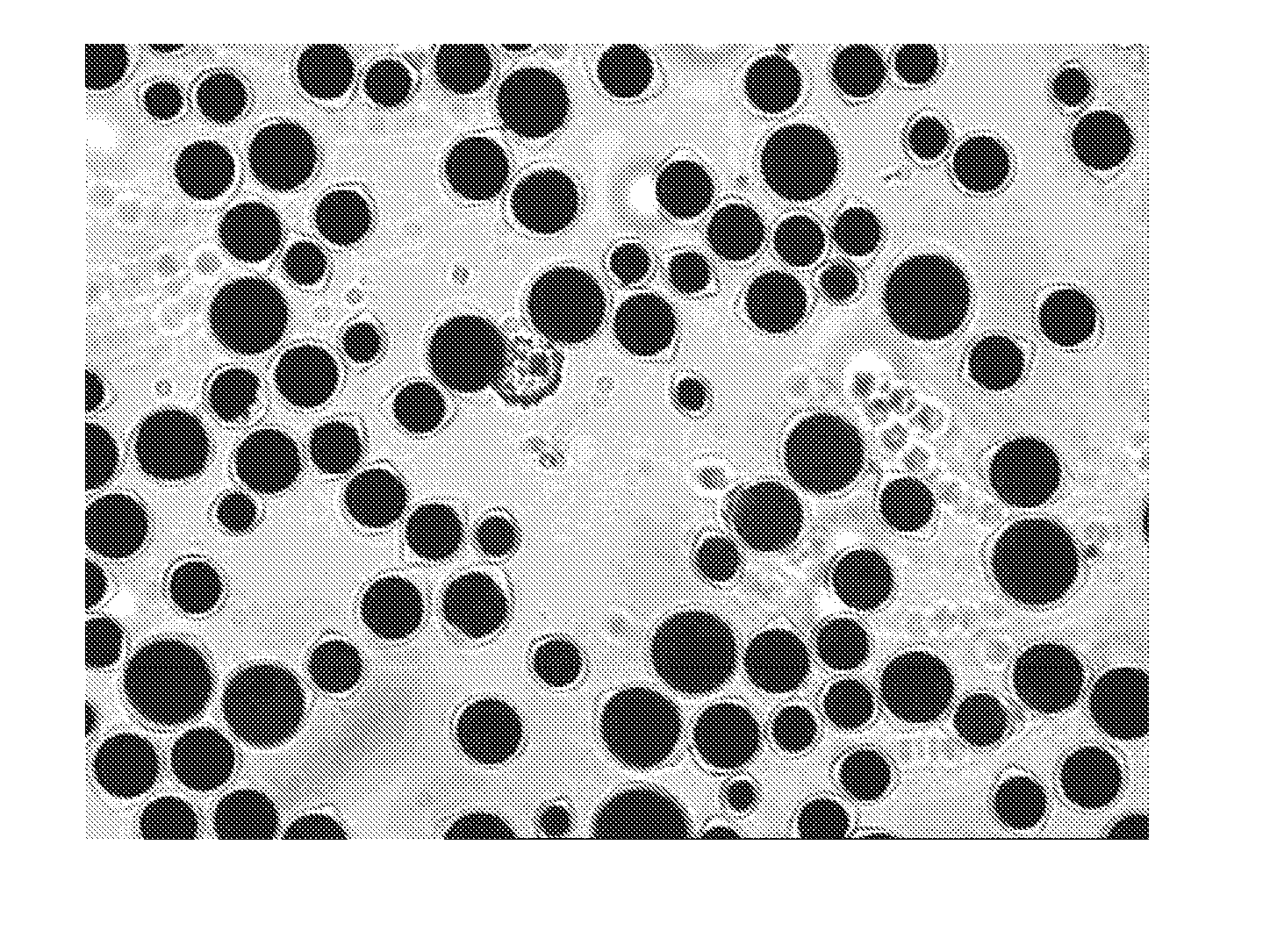

A process for the production of beta-3-(1,3)(1,6) glucan from a glucan containing cellular source is described, together with compositions and uses / methods of treatment involving glucan. The process of the invention comprises the steps of: (a) extracting glucan containing cells with alkali and heat, in order to remove alkali soluble components; (b) acid extracting the cells of step (a) with an acid and heat to form a suspension; (c) extracting the suspension obtained of step (b) or recovered hydrolyzed cells with an organic solvent which is non-miscible with water and which has a density greater than that of water separating the resultant aqueous phase, solvent containing phase and interface so that substantially only the aqueous phase comprising beta-(1,3)(1,6) glucan particulate material remains; wherein the extraction with said organic solvent provides separation of glucan subgroups comprising branched beta-(1,3)(1,6)-glucan, and essentially unbranched beta-(1,3) glucan which is associated with residual non-glucan contaminents; and (d) drying the glucan material from step (c) to give microparticulate glucan.

Owner:TR THERAPEUTICS

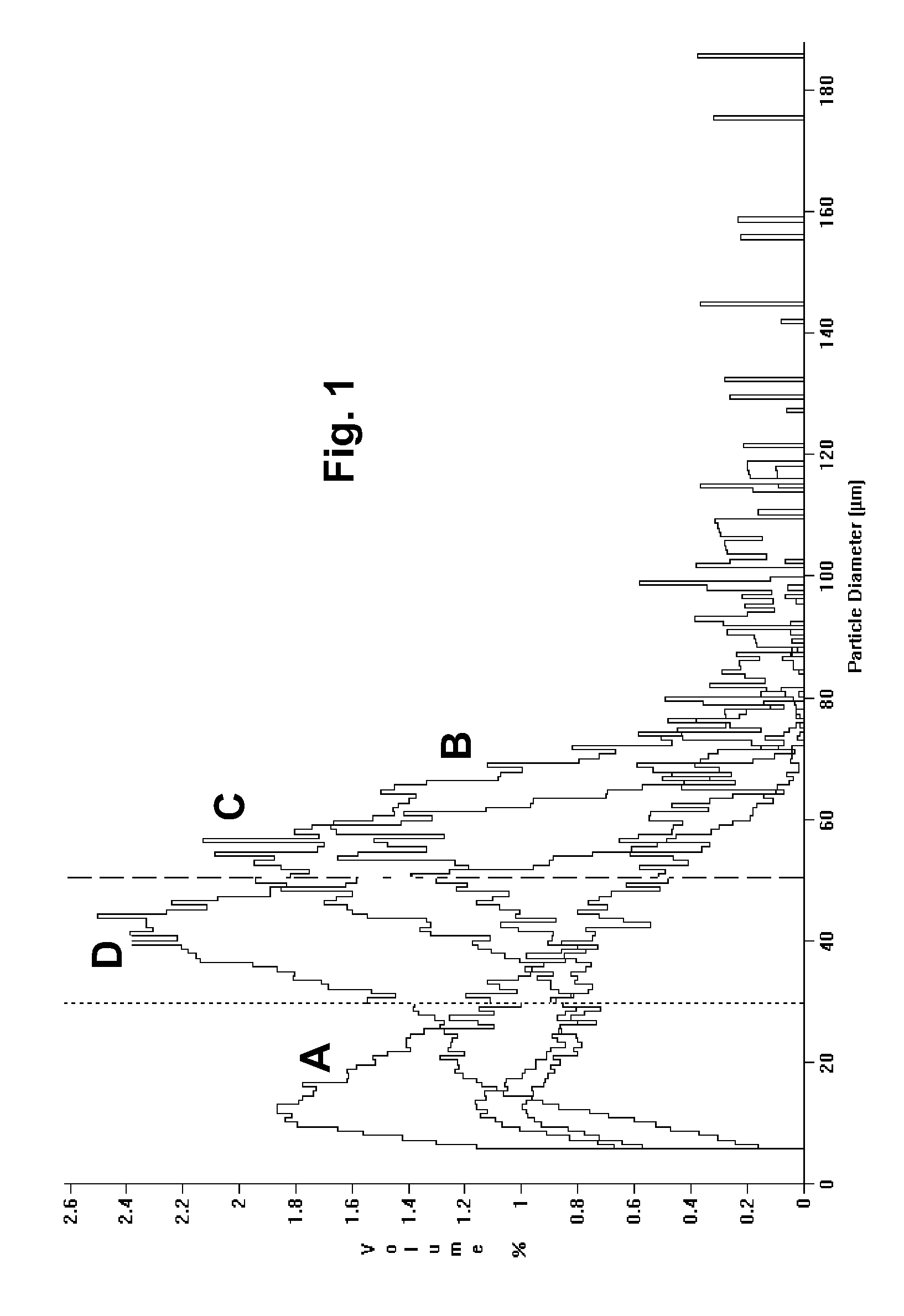

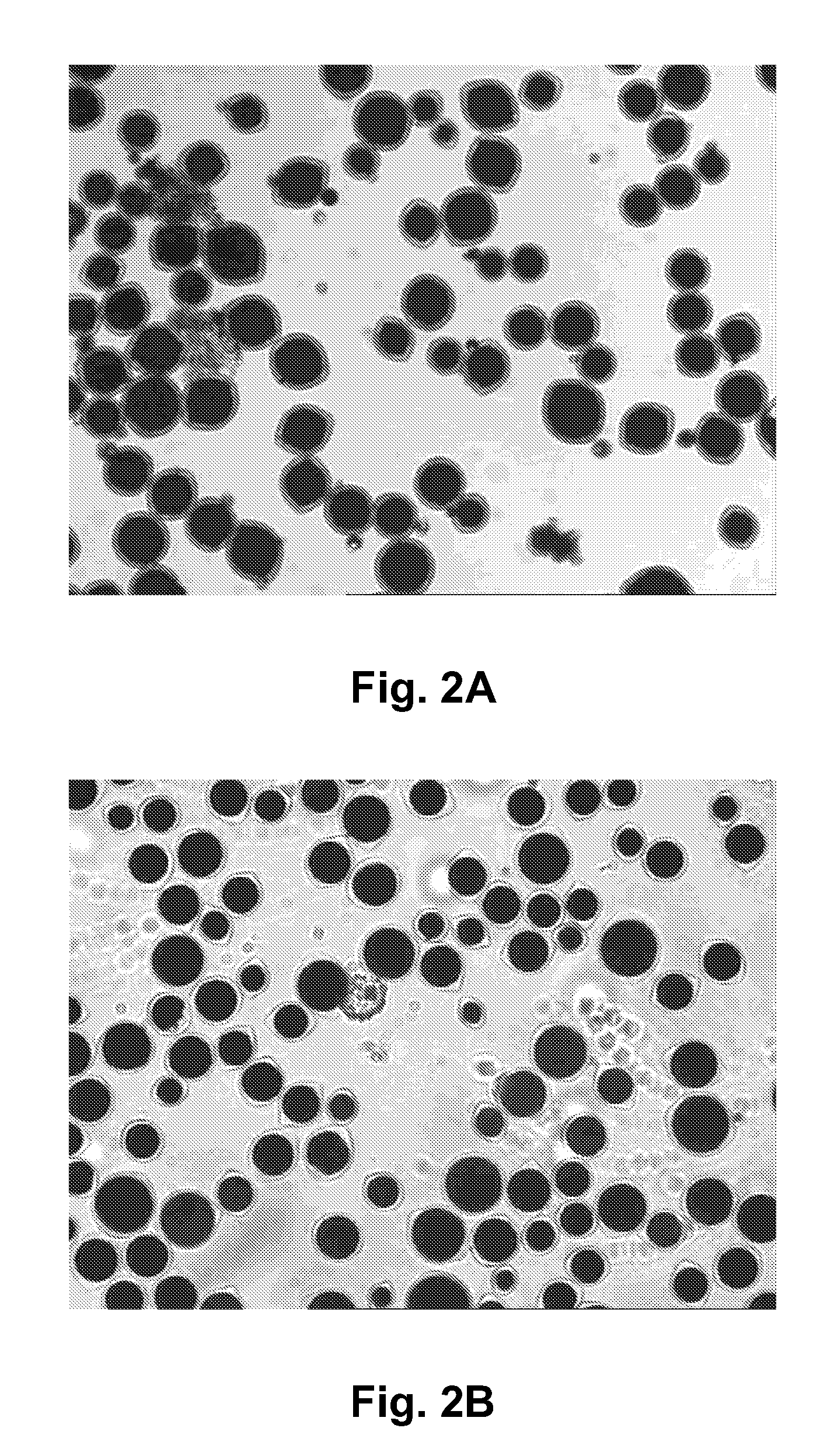

Preparation of capsules

Prior art processes for producing protein-based capsules (for example, capsules for use in electrophoretic media) tend to be wasteful because they produce many capsules outside the desired size range, which is typically about 20 to 50 μm. Capsule size distribution and yields can be improved by either (a) emulsifying a water-immiscible phase in a preformed coacervate of the protein; or (b) using a limited coalescence process with colloidal alumina as the surface-active particulate material.

Owner:E INK CORPORATION

Superabsorbent polymers having anti-caking characteristics

InactiveUS6124391ALittle and no caking problemEliminate the problemPigmenting treatmentAbsorbent padsPolymer scienceSuperabsorbent polymer

A particulate material composition of superabsorbent polymer particles, wherein less than about 60% by weight of the superabsorbent polymer particles will pass through a U.S. Standard 50 mesh sieve. The composition has anti-caking properties and also reduced dusting. The composition can be produced by mixing the superabsorbent polymer particles with an inorganic powder, such as clay.

Owner:EVONIK DEGUSSA GMBH

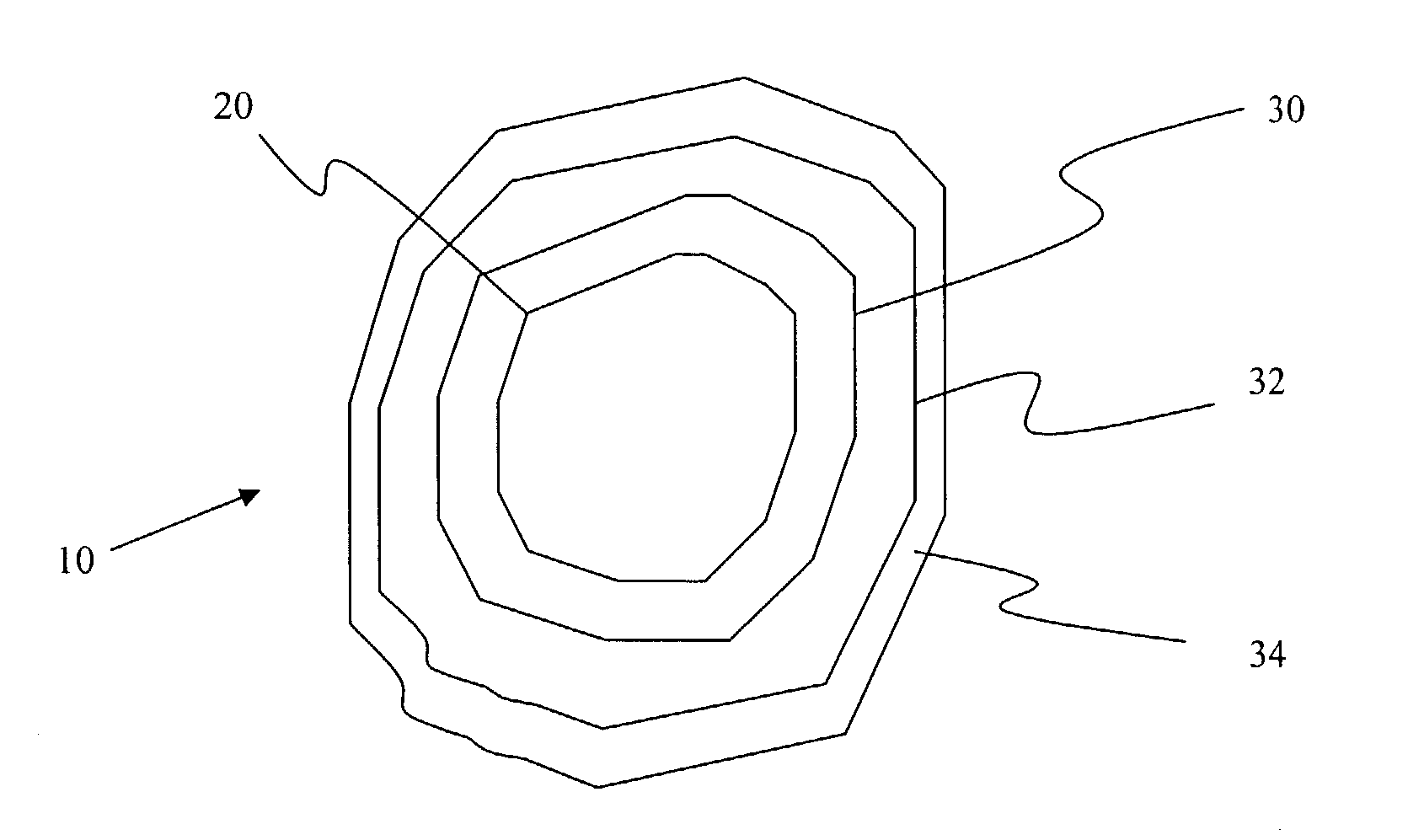

Particulate material having multiple curable coatings and methods for making and using same

InactiveUS7153575B2Retain it curabilityCurability potentialLiquid surface applicatorsSynthetic resin layered productsFuranPolymer science

The present invention relates to coated particulate matter wherein the particles are individually coated with a first set of one or more layers of a curable resin, for example, a combination of phenolic / furan resin or furan resin or phenolic-furan-formaldehyde terpolymer, on a proppant such as sand, and the first set of layers is coated with a second set of one or more layers of a curable resin, for example, a novolac resin with curative. Methods for making and using this coated product as a proppant, gravel pack and for sand control are also disclosed.

Owner:HEXION INC

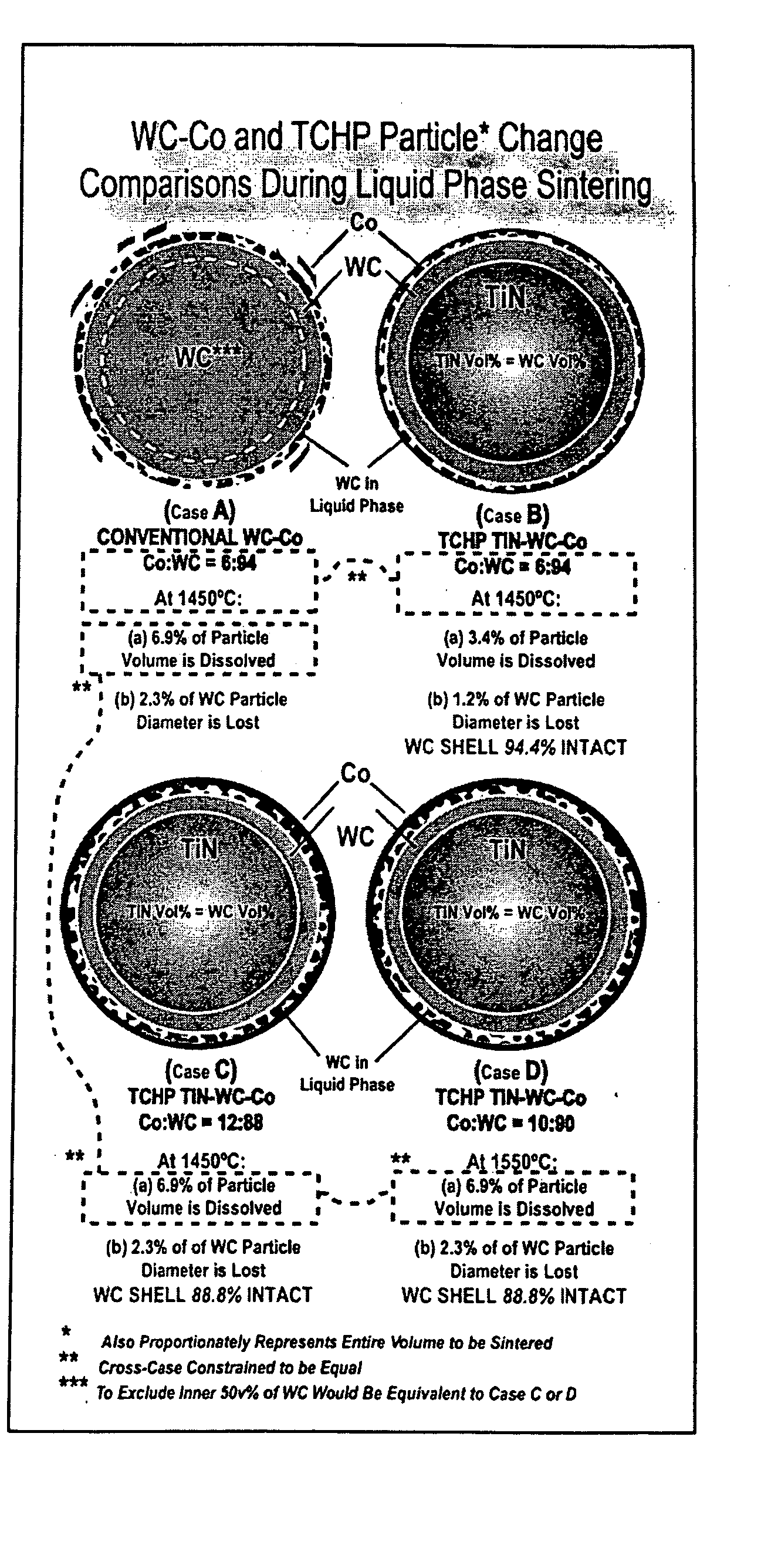

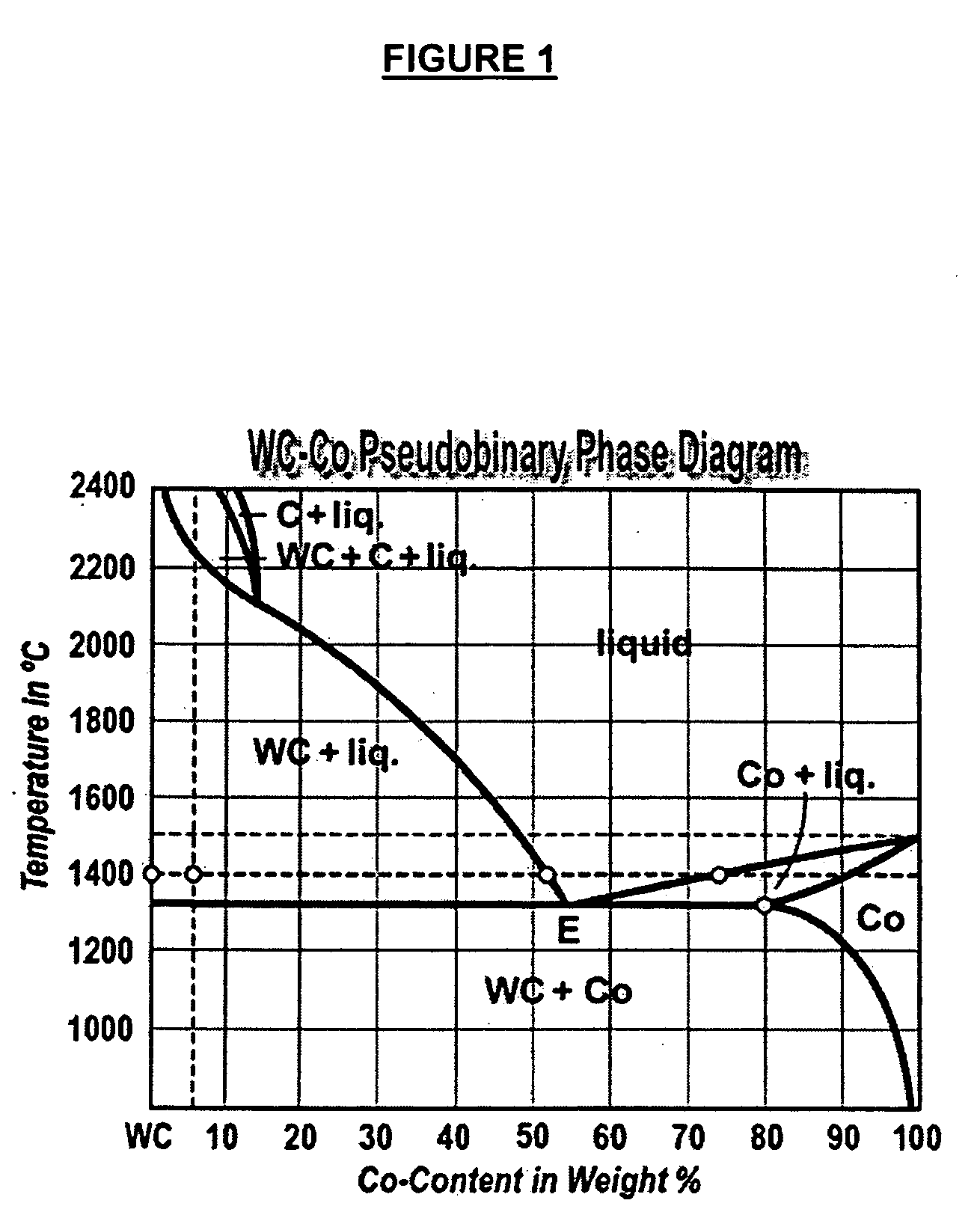

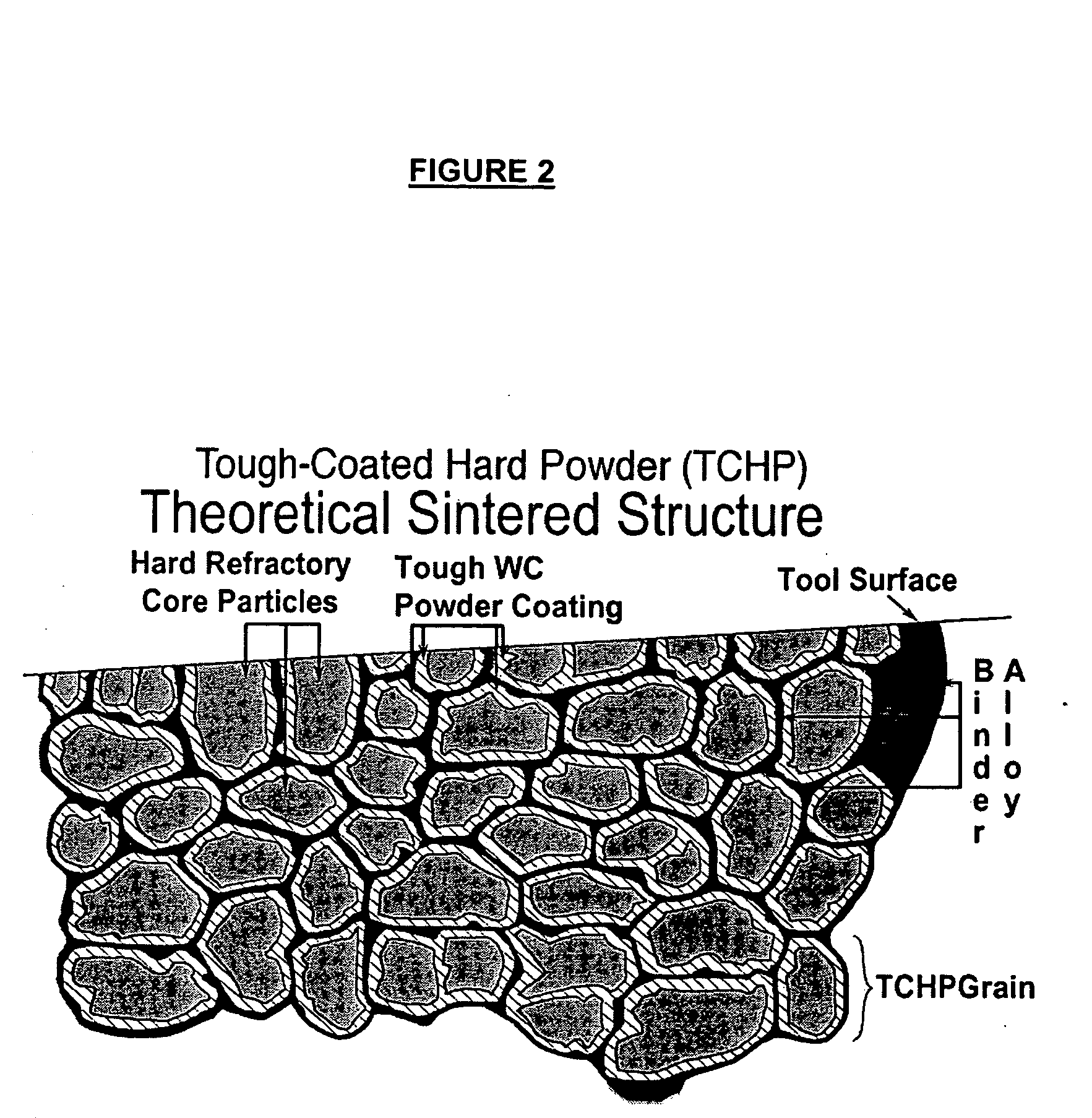

Method for consolidating tough coated hard powders

A method of consolidating particulate materials into articles having combinations of properties not available by conventional processes by liquid phase sintering. These particulate materials are comprised of core particles individually coated with layers of a metal compound having a relatively higher fracture toughness than the core, such as WC or TaC. These coated particles include an outer layer comprised a metal, such as Co or Ni. The particles with these coatings are pressed to form an article and the article densified at pressures and temperatures where full density is achieved without the degradation of the material forming the core particle.

Owner:ETERNALOY HLDG GMBH

Method for fracturing subterranean formations

InactiveUS6875728B2Reduce speedReduce the amount of waterFluid removalFlushingInorganic saltsFracturing fluid

A method of fracturing a formation with a fracturing fluid wherein the formation has particulate material that swells or migrates upon exposure to the fracturing fluid comprises preparing a fracturing fluid comprising (1) a thickening compound comprising a first surfactant selected from the group consisting of a cationic surfactant having only a single cationic group, an amphoteric surfactant and a mixture thereof; and, an anionic surfactant; and, (2) water, wherein no or essentially no inorganic salt is added to the fracturing fluid; and using the fracturing fluid to fracture the formation. A method for recycling a fracturing fluid is also provided.

Owner:BAKER HUGHES INC

Three dimensional printing material system and method

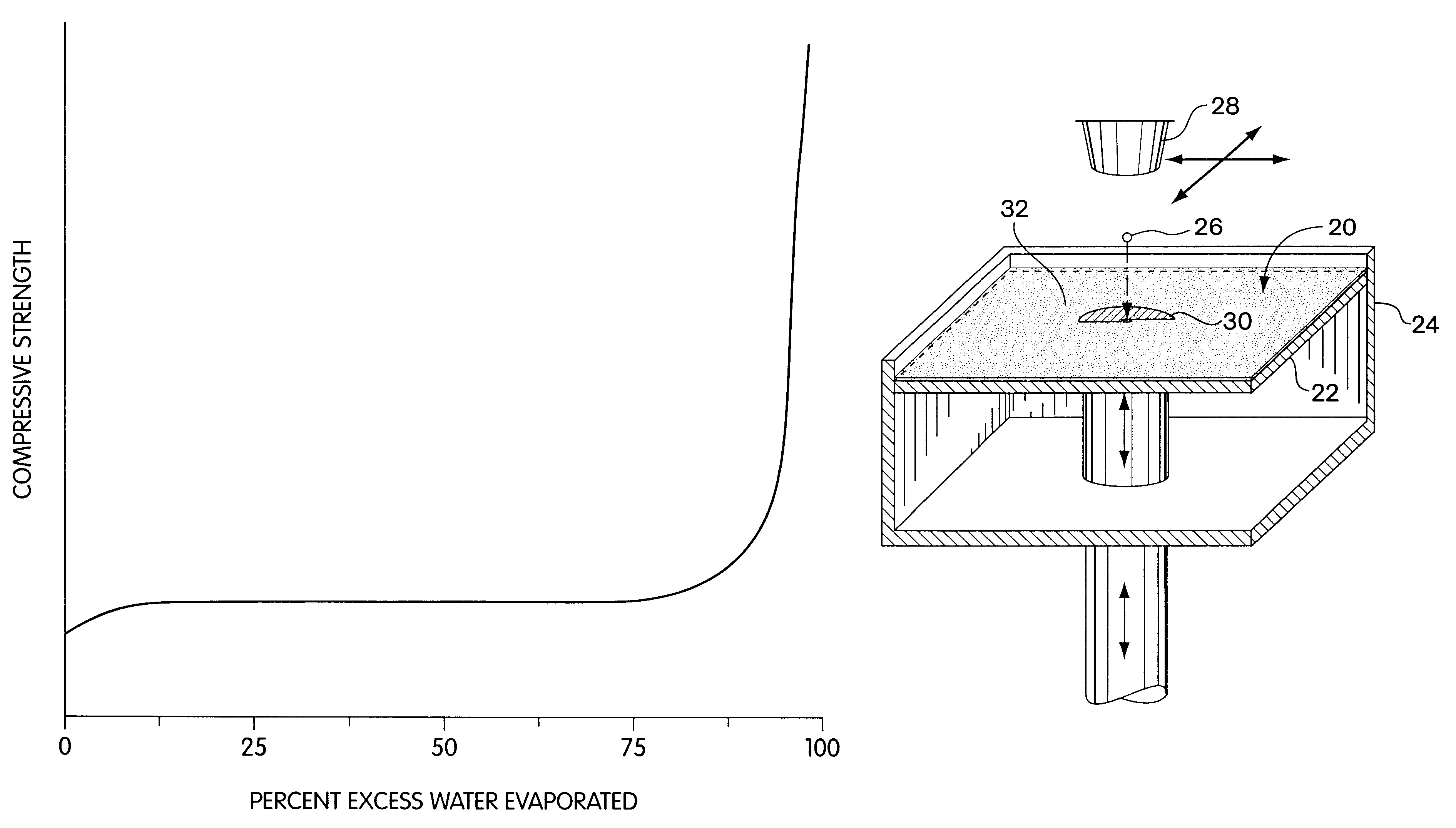

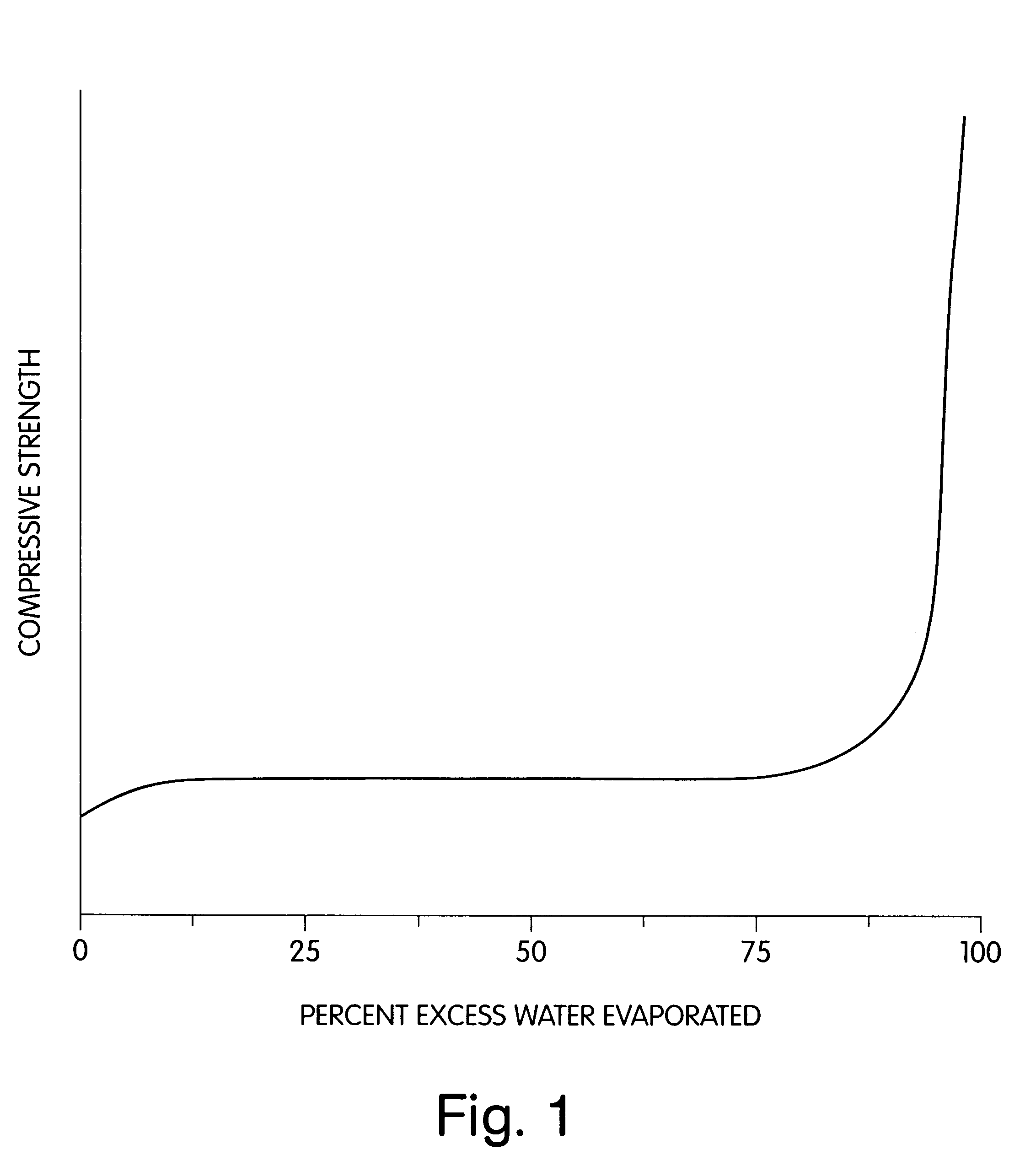

InactiveUS6610429B2High strengthReduce the amount of solutionAdditive manufacturing apparatusLamination ancillary operationsEngineeringLayer wise

The present invention is directed to a 3DP(TM) material system ad method, and an article made therefrom. The method of the present invention includes building cross-sectional portions of a three-dimensional article, and assembling the individual cross-sectional areas in a layer-wise fashion to form a final article. The individual cross-sectional areas are built by using an ink-jet printhead to deliver an aqueous fluid to a particulate material that includes plaster.

Owner:3D SYST INC

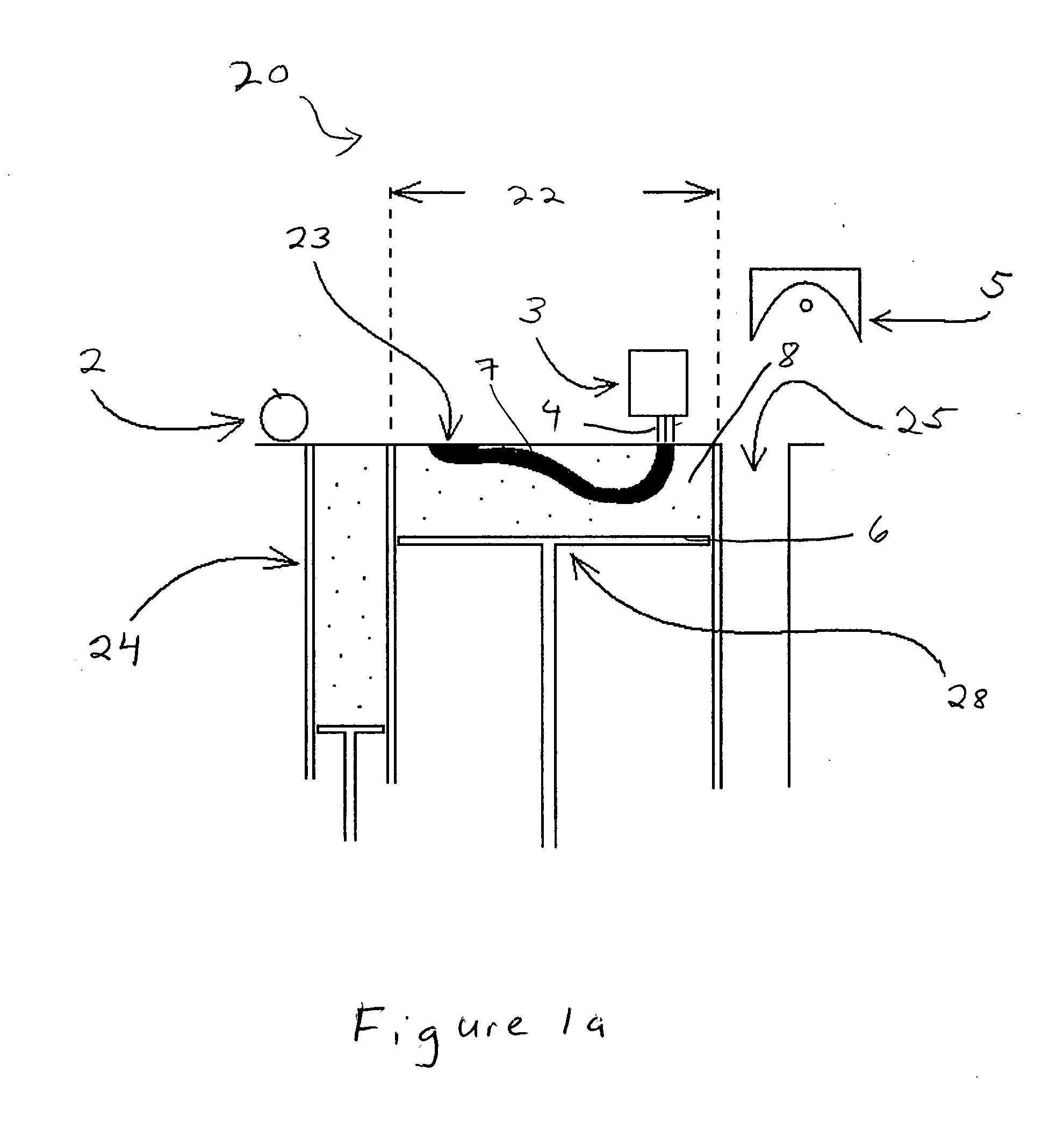

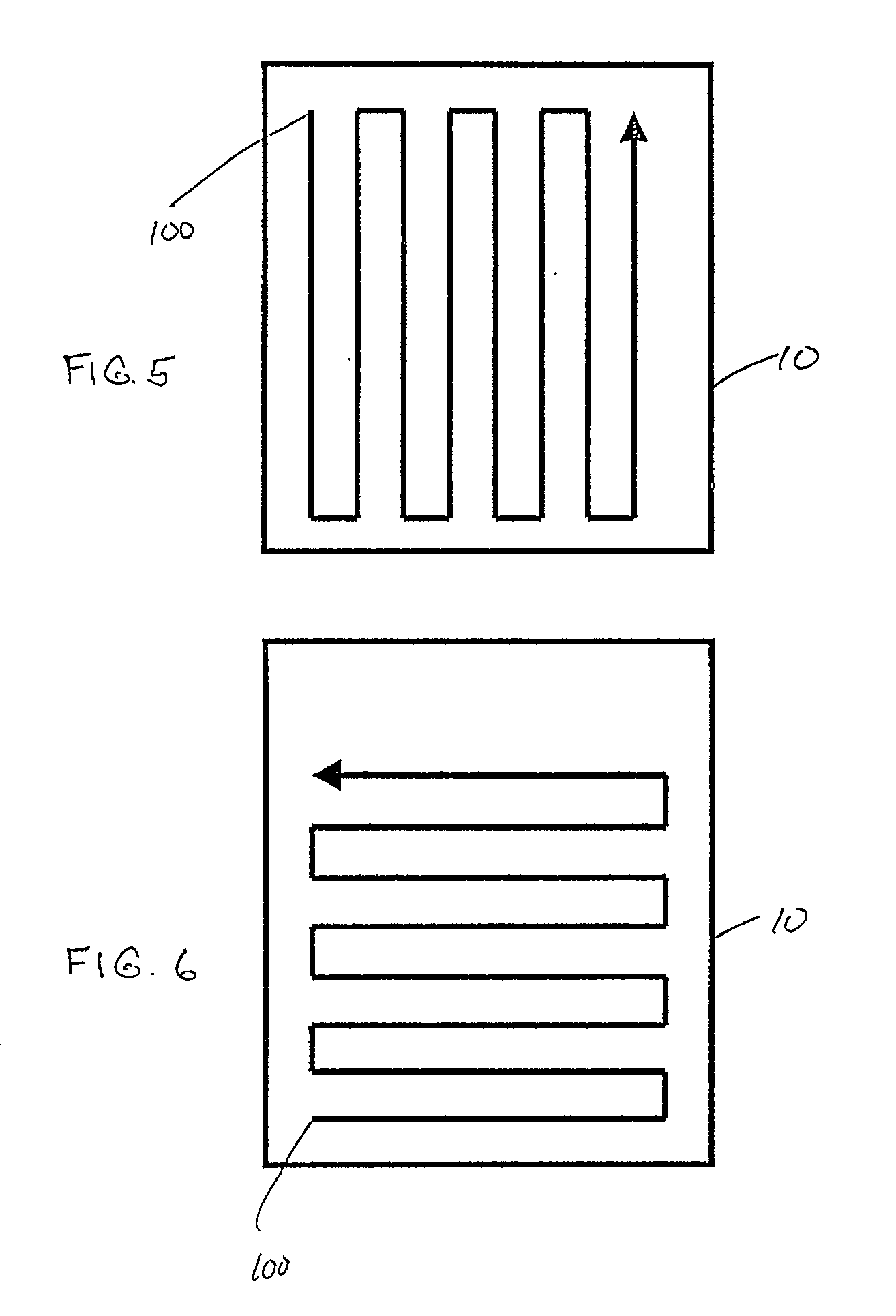

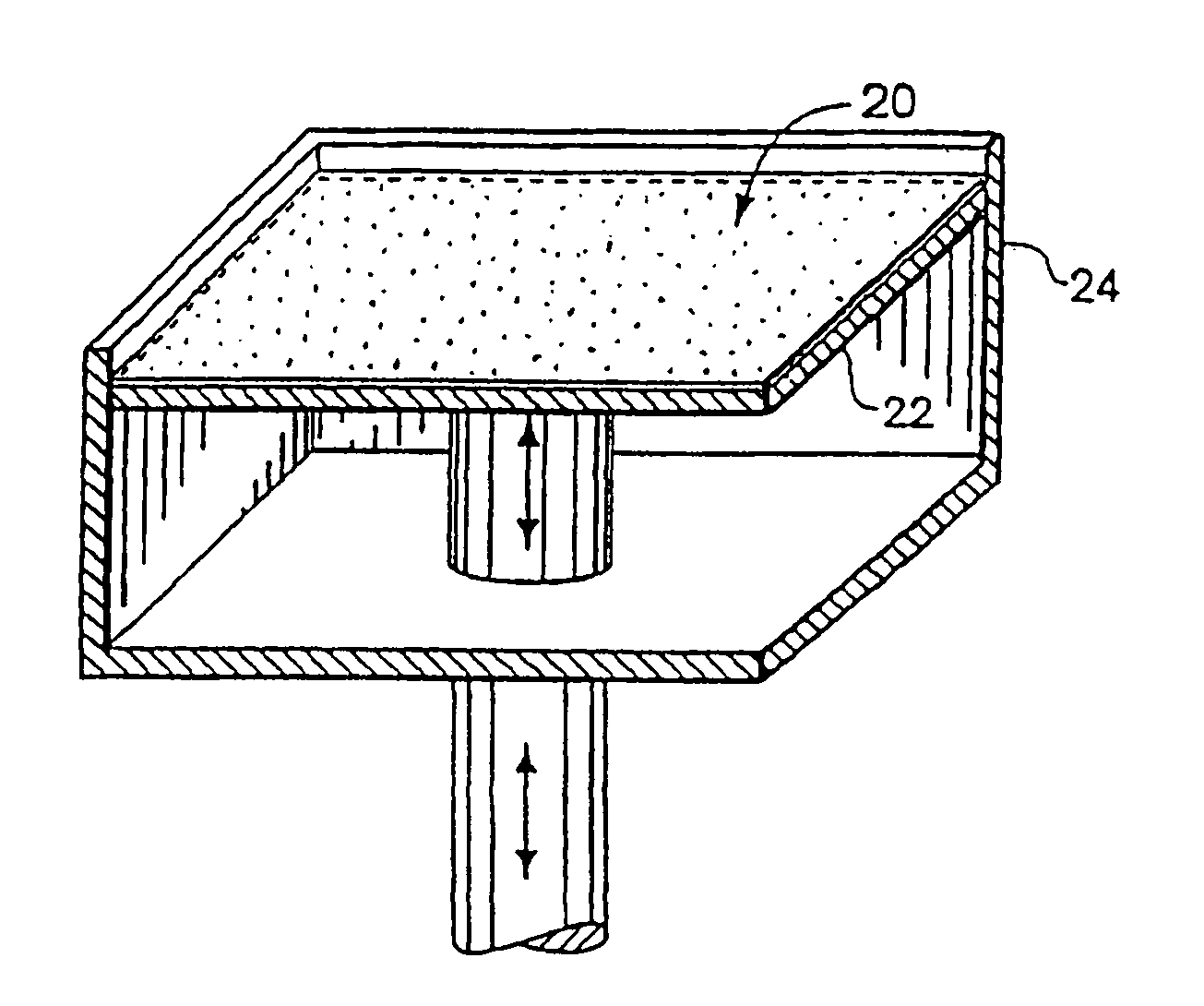

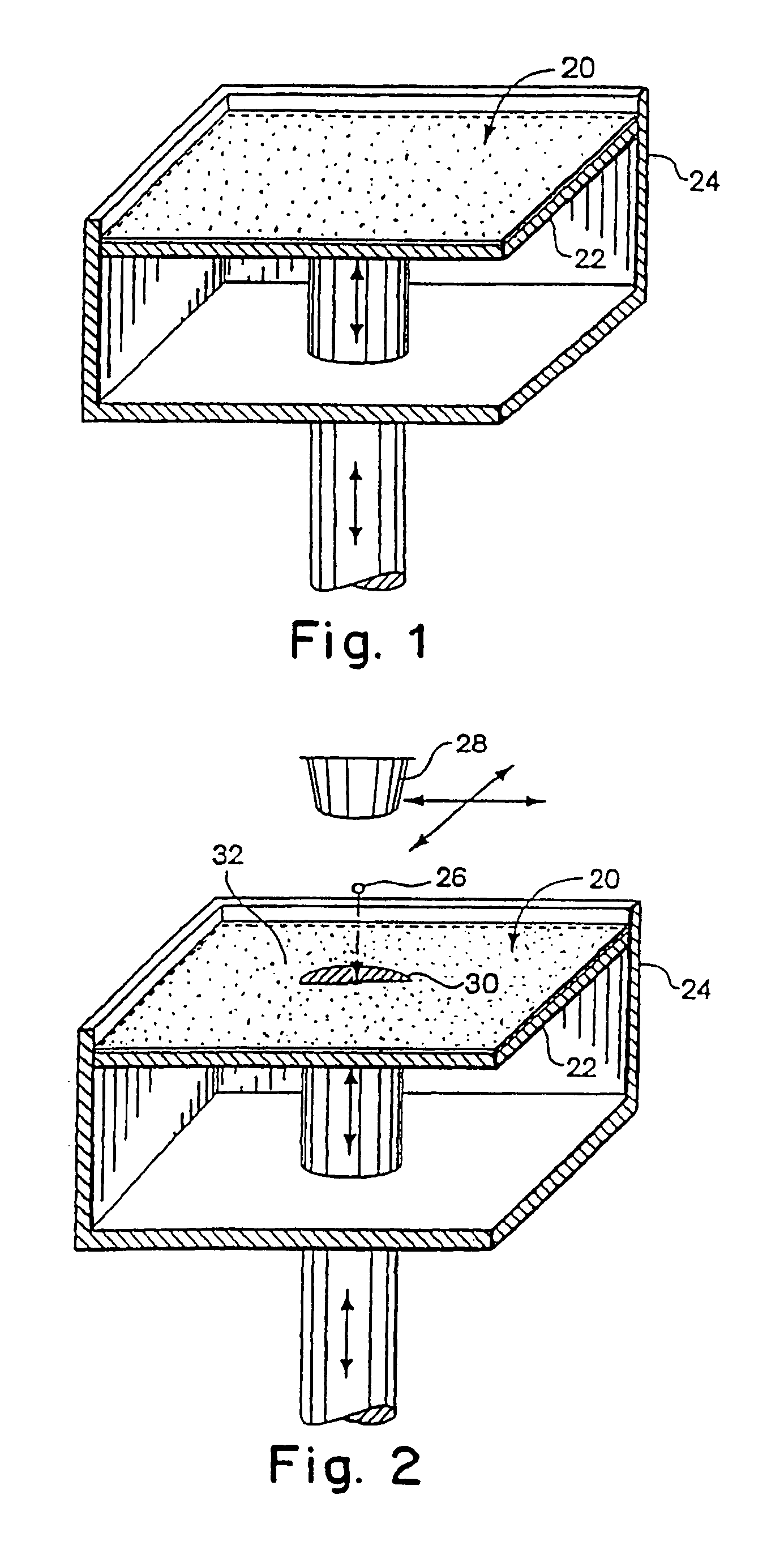

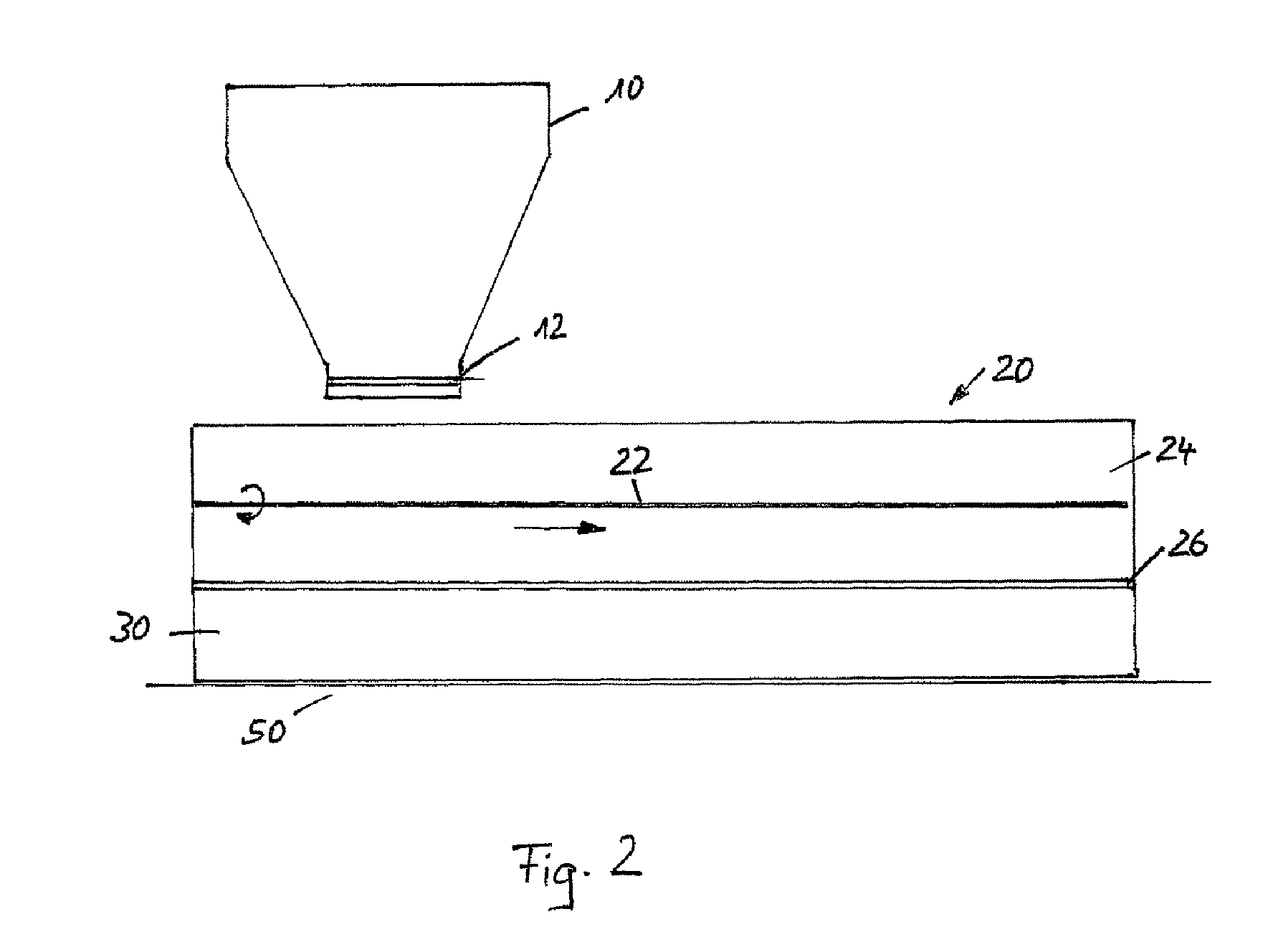

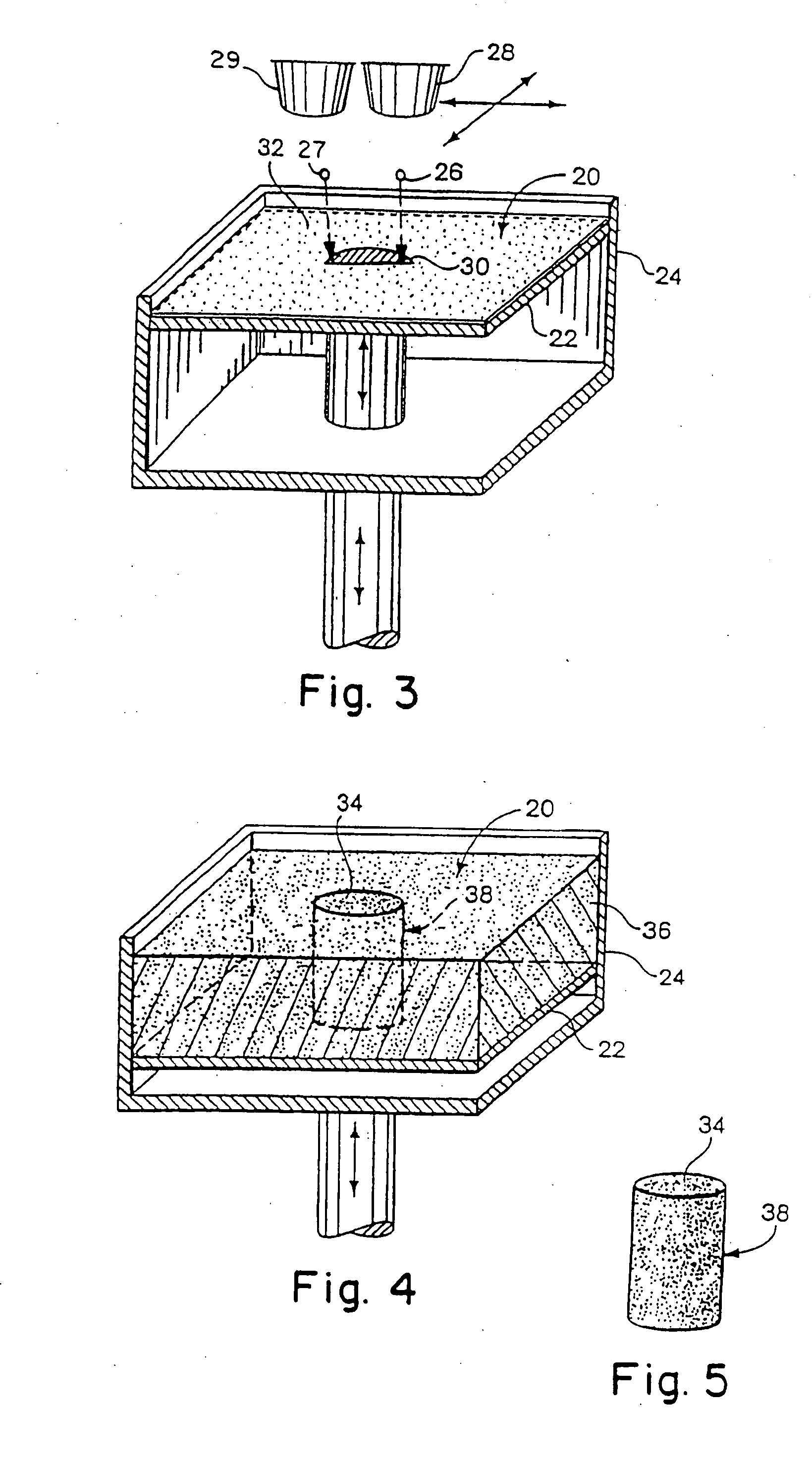

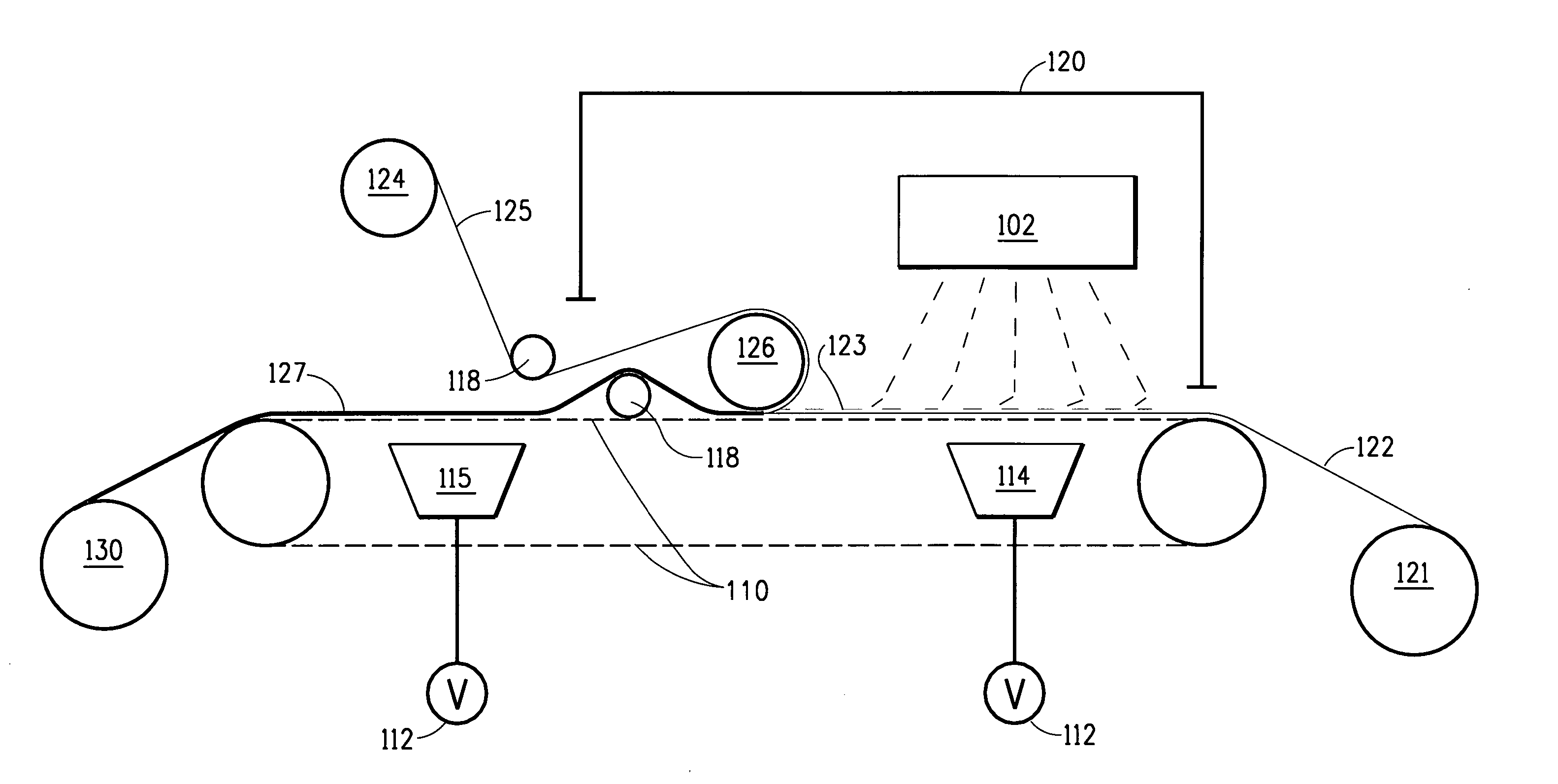

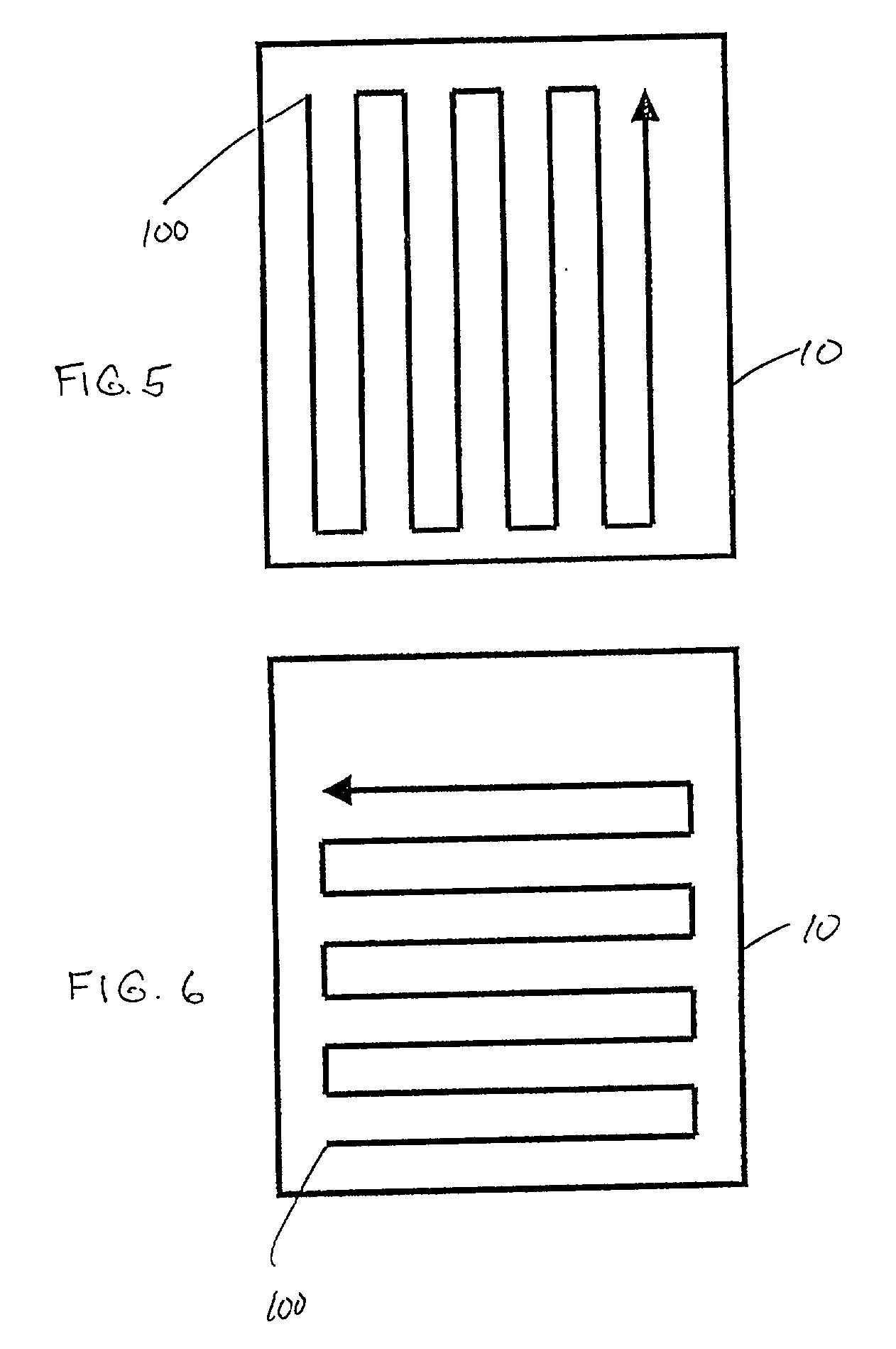

Method of, and apparatus for, applying flowable material across a surface

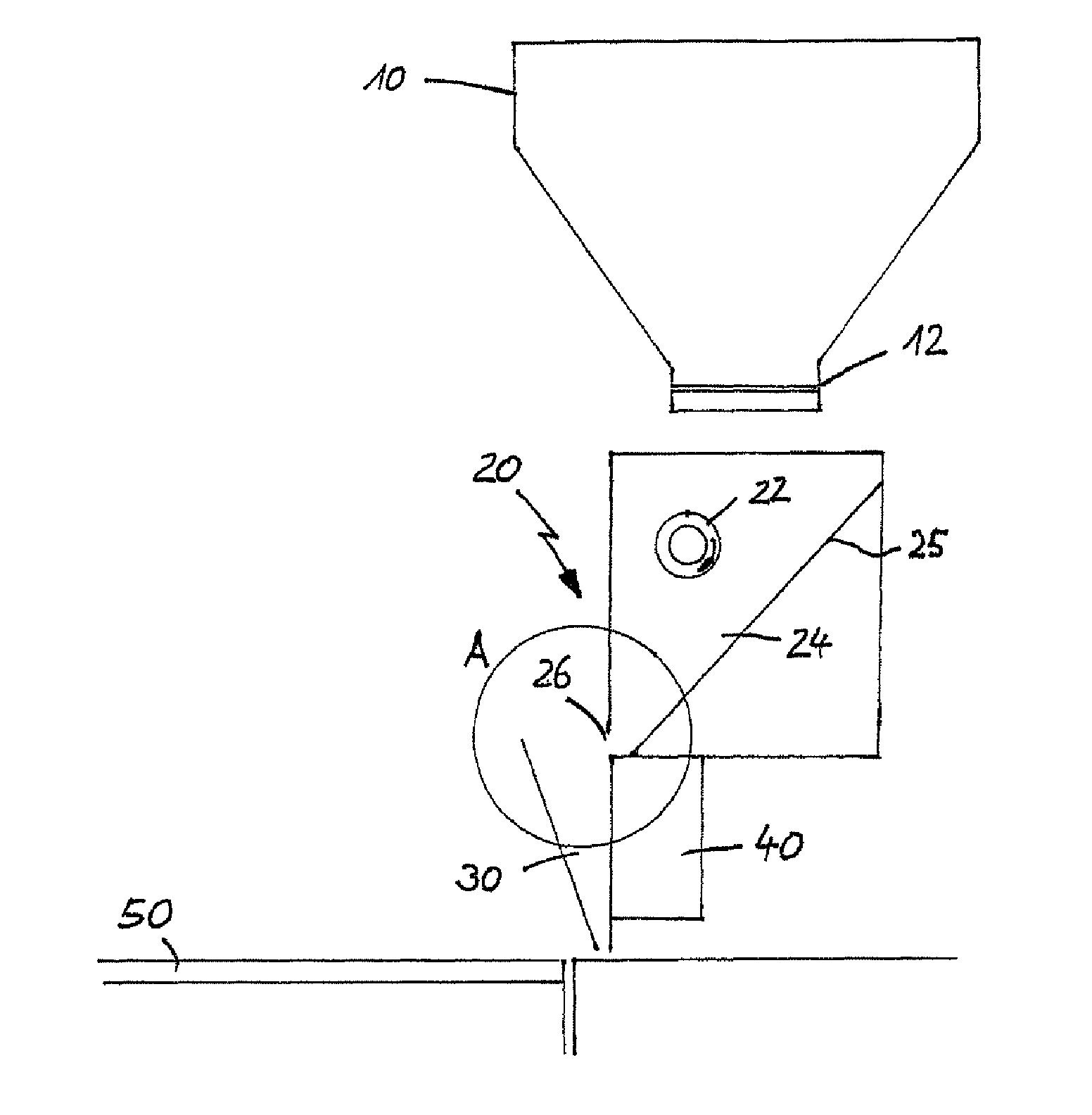

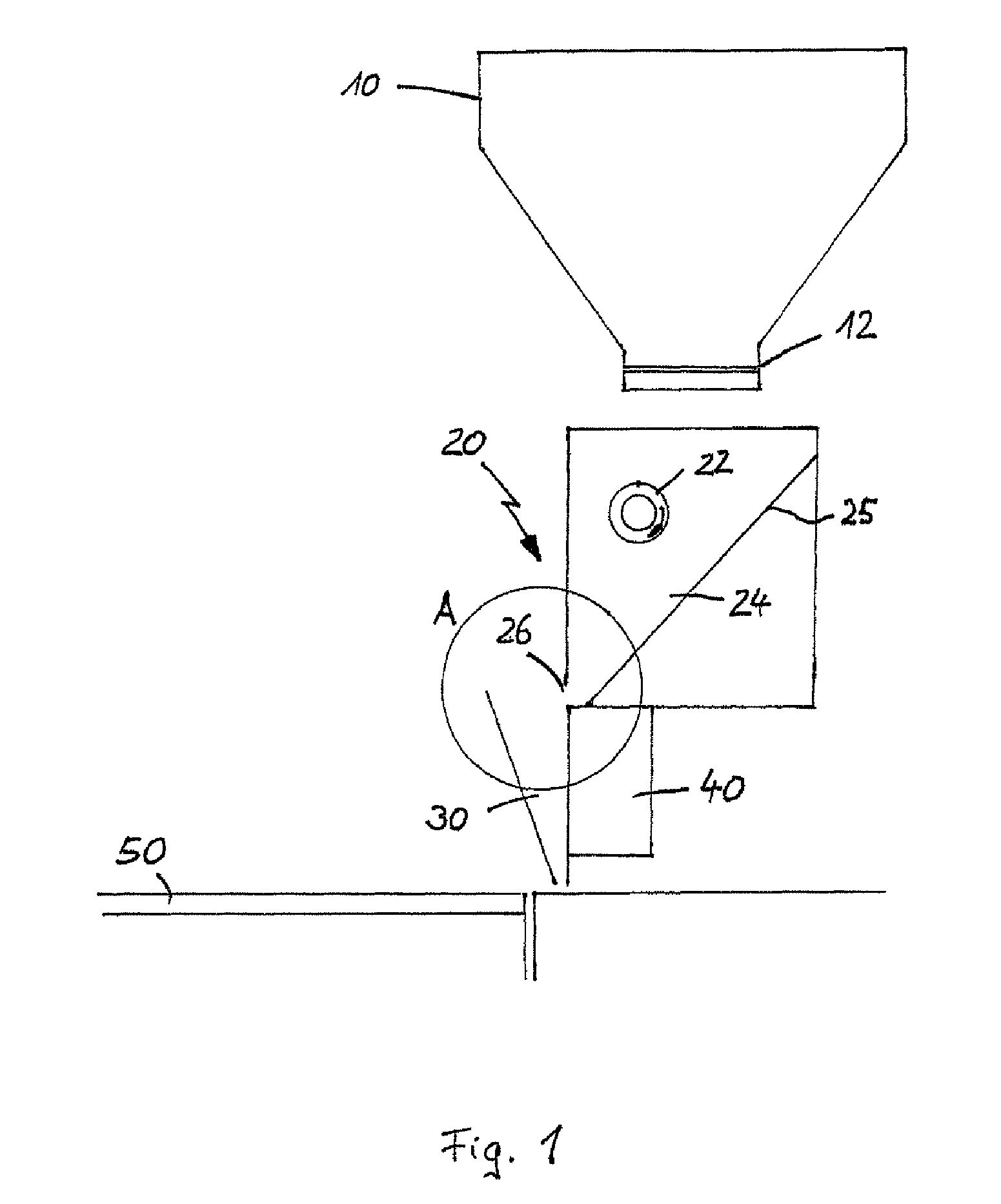

ActiveUS7799253B2Reduce volume of containerReduce in quantityAdditive manufacturing apparatusLiquid surface applicatorsFirst FillEngineering

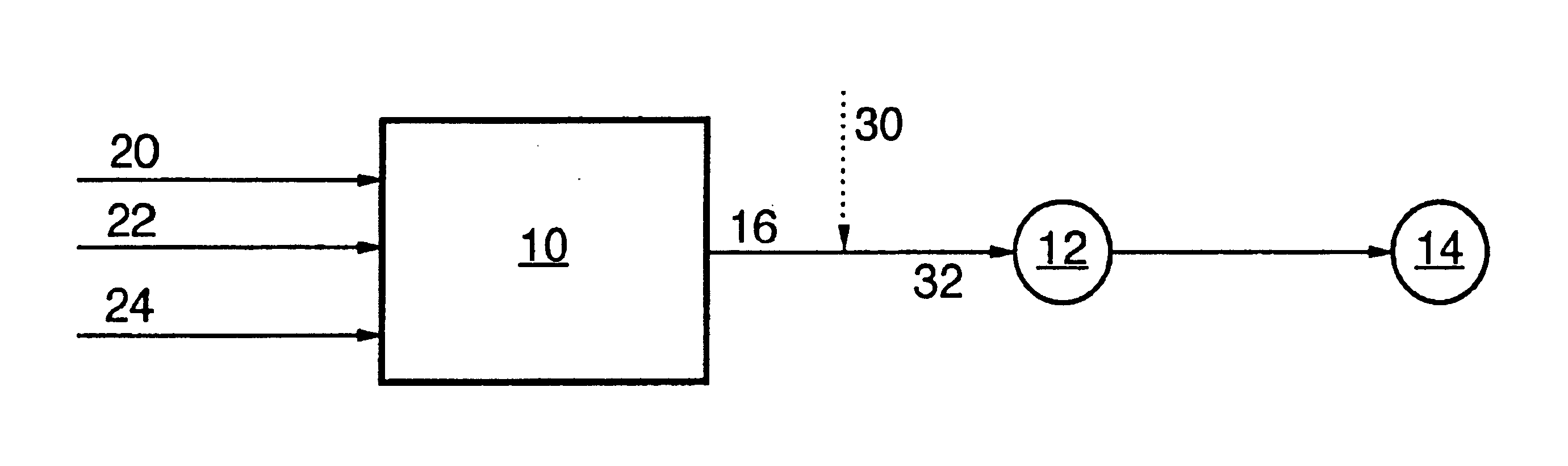

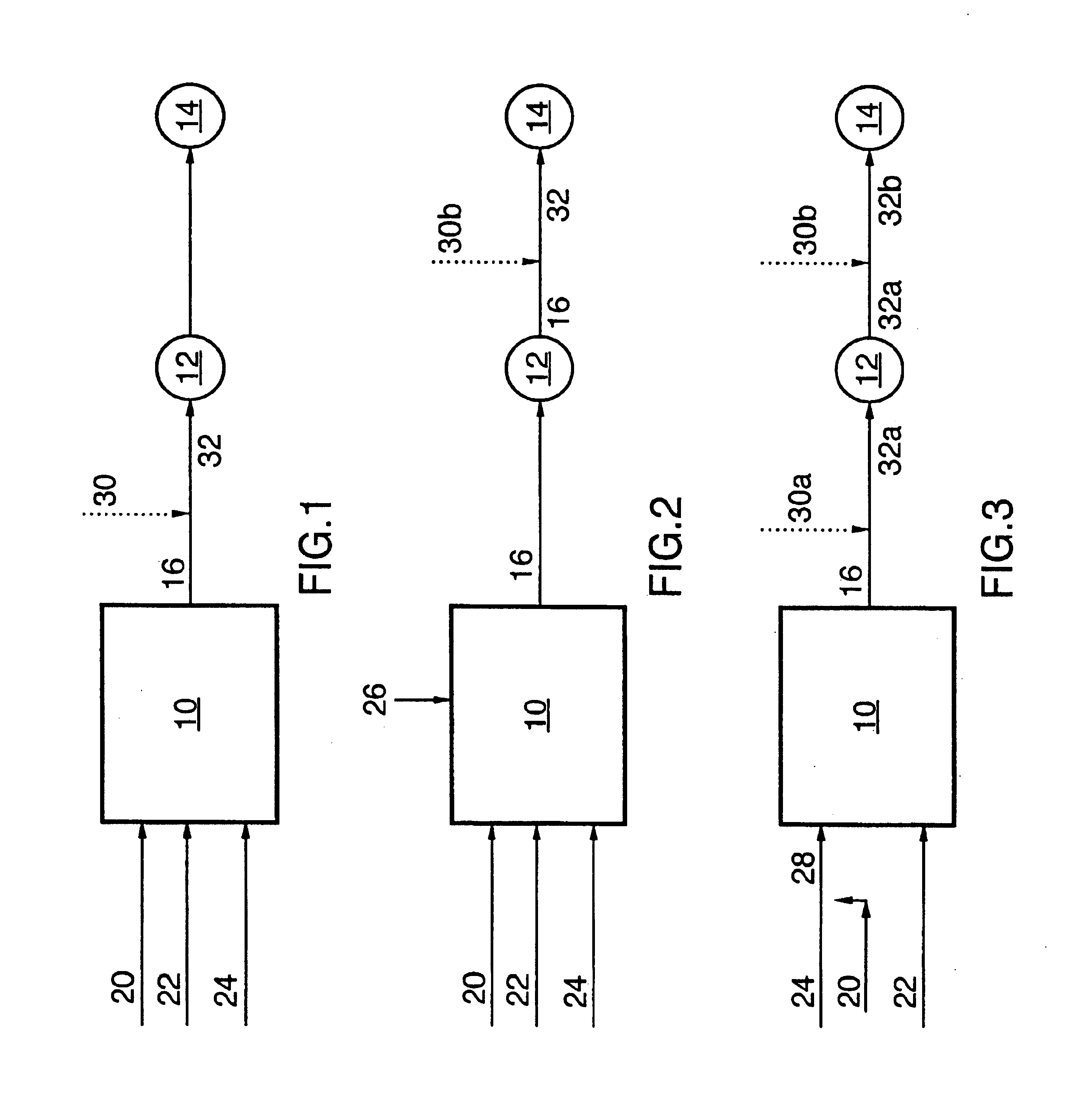

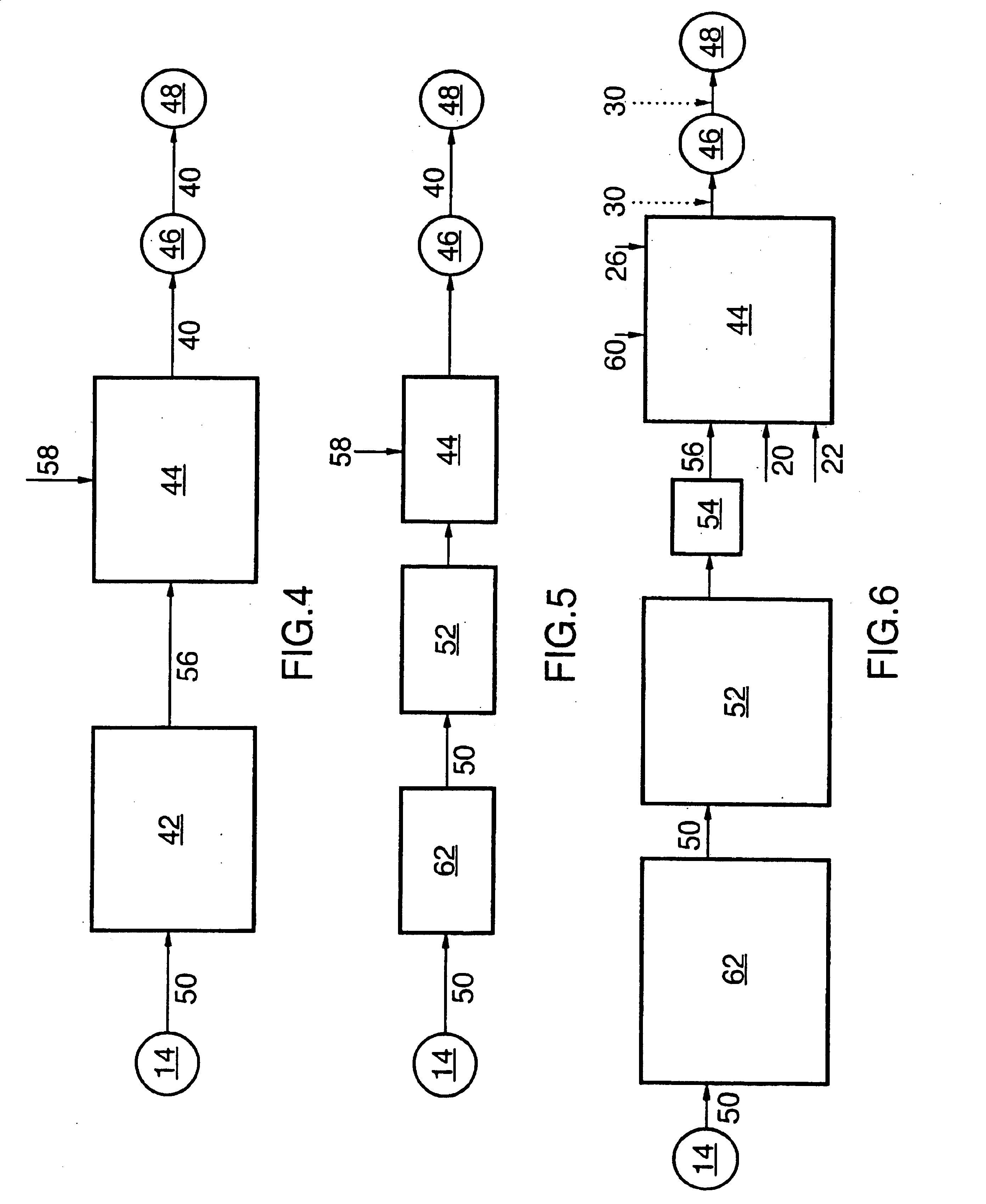

The invention relates to a method and a device for applying for a flowable material, especially a particulate material, in individual superimposed layers across a support (50), the flowable material being first filled from a stationary feed station (10) into a storage container (24) of an application device. In the application device (30), which travels back and forth across the support, the flowable material is distributed inside the storage container across the entire length of the device and is then metered through a slot into a metering shaft in such a manner that the filling level in the metering shaft remains constant during application of the flowable material from the metering shaft onto the support.

Owner:EXONE

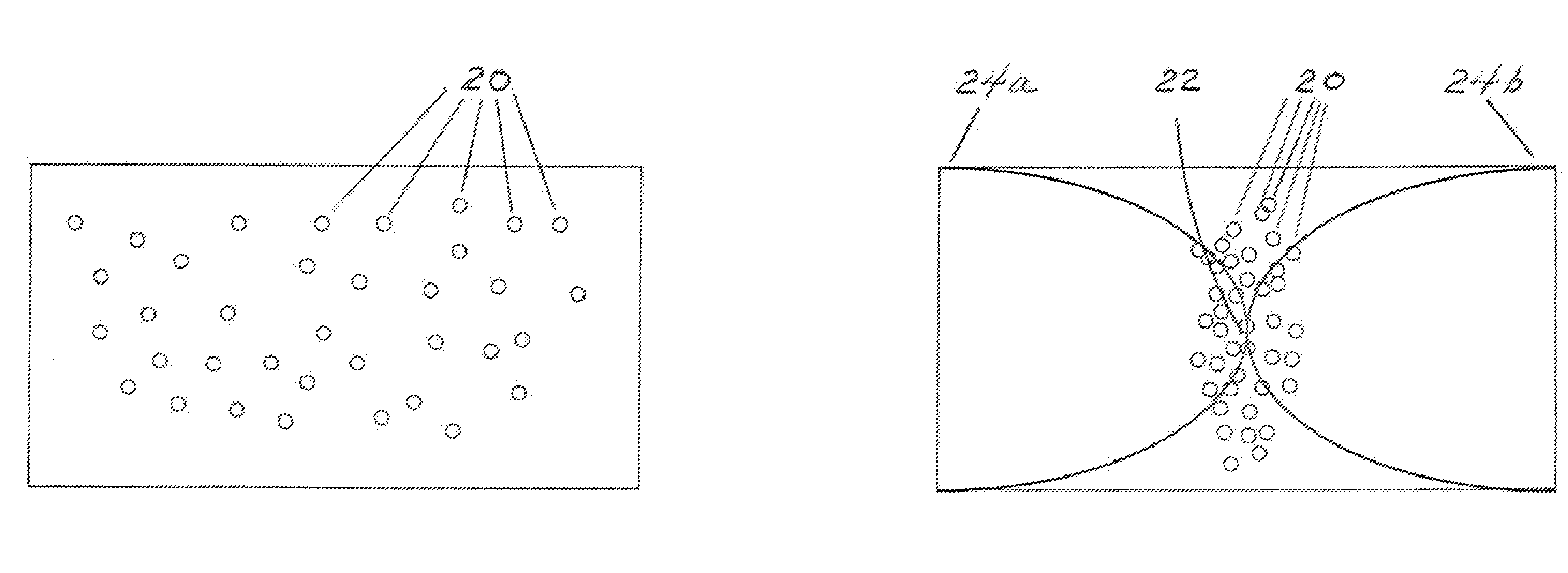

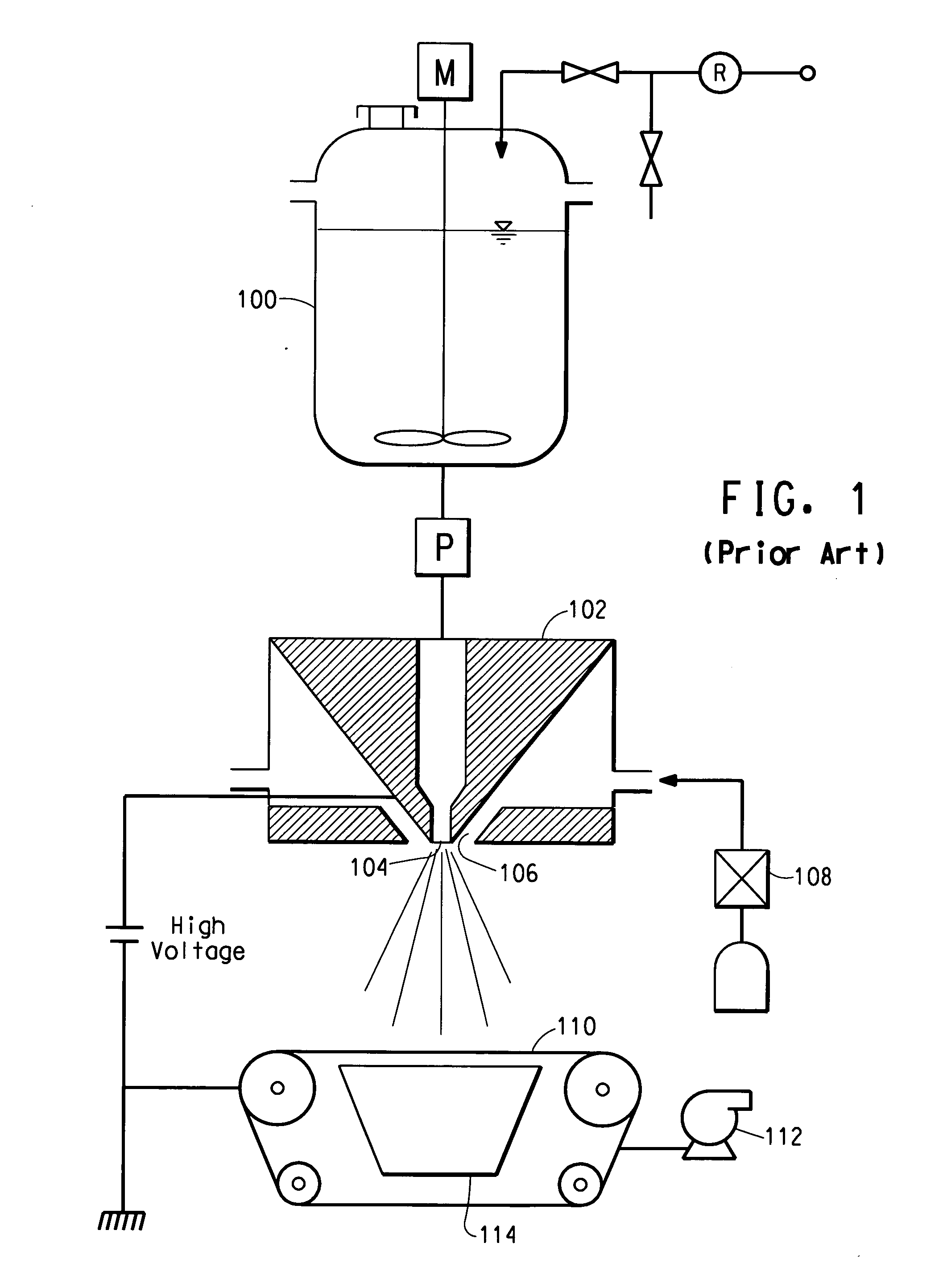

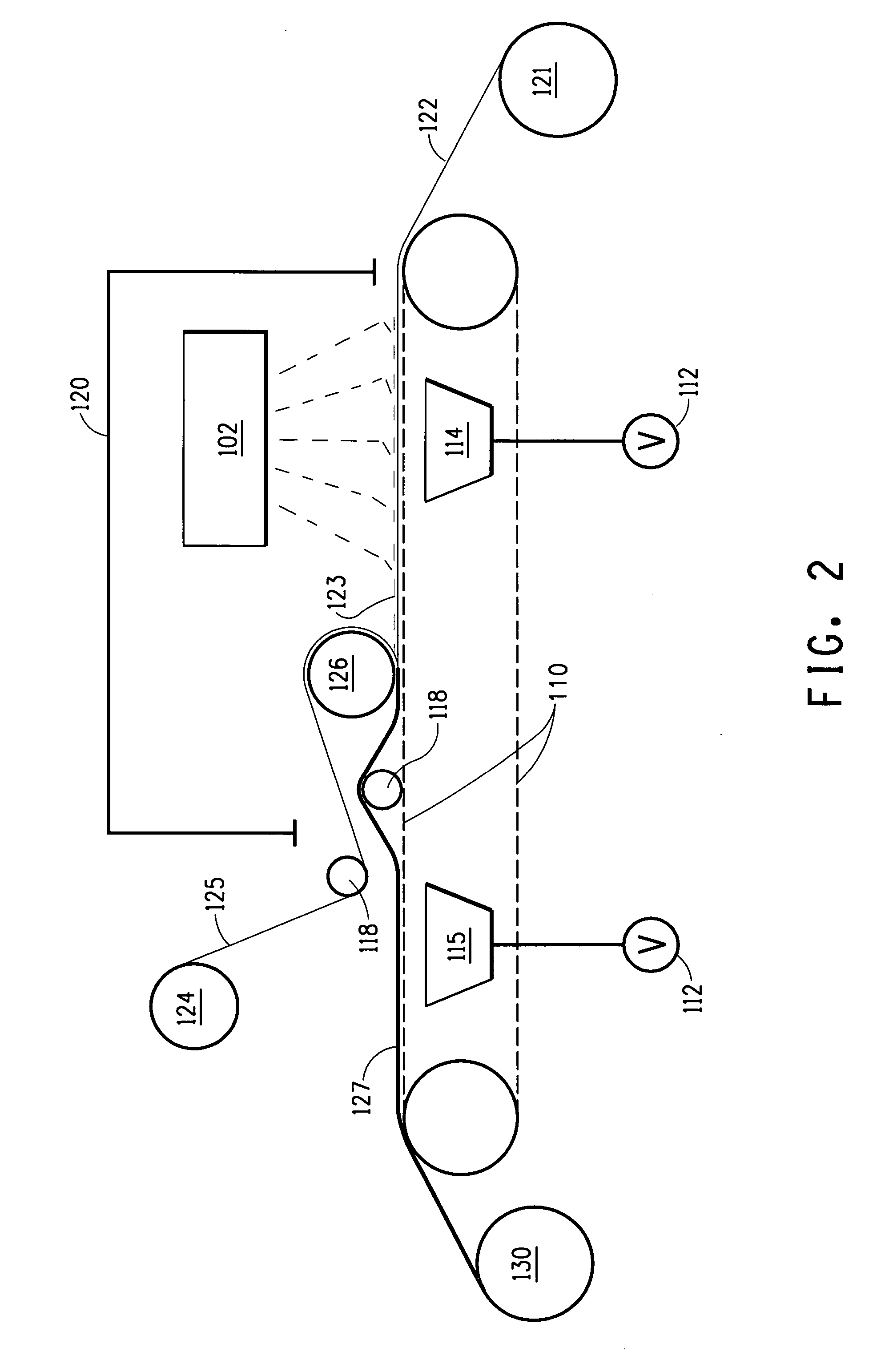

Filtration media for filtering particulate material from gas streams

A filtration medium is disclosed for use in air filters used in heating, ventilating and air conditioning systems. The medium contains at least one nanofiber layer of fibers having diameters less than 1 μm and at least one carrier layer, each nanofiber layer having a basis weight of at least about 2.5 g / m2, and up to about 25 g / m2. The medium has sufficient stiffness to be formed into a pleated configuration.

Owner:EI DU PONT DE NEMOURS & CO

Apparatus and method for separation of particles suspended in a liquid from the liquid in which they are suspended

InactiveUS20100078384A1Improve concentrationAvoid turbulenceSemi-permeable membranesLiquid separation by electricityUltrasonic sensorCompressibility

A method for separating, or removing, particulate material, e.g., blood cells, from a sample of fluid, e.g., whole blood of a patient, in which the particulate material is suspended. In the case of separating blood cells from blood plasma or blood serum, the resulting samples of blood plasma or blood serum can be used for in vitro diagnostic applications. In normal practice, a whole blood sample of a patient are provided and then introduced into an apparatus that contains a flow channel. An acoustic field, which contains acoustic standing waves from external ultrasonic transducers, is located within the flow channel. Laminar flow is maintained in the flow channel. Blood cells and platelets are separated from blood plasma or blood serum at the end of the flow channel and collected. The method described herein allows fluid components to differentially migrate to areas of preferred acoustic interaction. The parameters that affect separation of particles are size, density, compressibility of the particles, and the fluid surrounding the particles.

Owner:ABBOTT LAB INC

Three Dimensional Printing Material System and Method Using Peroxide Cure

ActiveUS20080138515A1High strengthEliminate needAdditive manufacturing apparatusLiquid surface applicatorsPeroxideParticulate material

A materials system and methods are provided to enable the formation of articles by Three Dimensional Printing. The materials system includes a transition metal catalyst that facilitates the reaction of an acrylate-containing binder with a particulate material.

Owner:3D SYST INC

Markers for visualizing interventional medical devices

InactiveUS20050149002A1Avoid transmissionStentsSurgeryDiagnostic Radiology ModalityImaging modalities

A marking material that, when disposed upon medical devices used during interventional medical procedures with imaging modalities such as X-ray Fluoroscopy and Magnetic Resonance Imaging, renders such medical devices visible with minimal imaging artifacts. The material comprises a particulate material with generally higher atomic weight disposed within a matrix material with generally lower atomic weight. In one embodiment the particulate material is magnetic. In another embodiment the particulate material is non-magnetic.

Owner:BIOPHAN TECH

Three dimensional printing material system and method

InactiveUS20020026982A1High strengthReduce the amount of solutionSolid waste managementCeramic shaping apparatusEngineeringLayer wise

The present invention is directed to a 3DP(TM) material system ad method, and an article made therefrom. The method of the present invention includes building cross-sectional portions of a three-dimensional article, and assembling the individual cross-sectional areas in a layer-wise fashion to form a final article. The individual cross-sectional areas are built by using an ink-jet printhead to deliver an aqueous fluid to a particulate material that includes plaster.

Owner:3D SYST INC

Material systems and methods of three-dimensional printing

ActiveUS20060208388A1Adhesive processesAdditive manufacturing apparatusEngineering3 dimensional printing

The present invention is directed to three-dimensional printing material systems and method, and an article made therefrom. The method of the present invention includes building cross-sectional portions of a three-dimensional article, and assembling the individual cross-sectional areas in a layer-wise fashion to form a final article. The individual cross-sectional areas are built by using an ink-jet printhead to deliver a fluid to a particulate material that includes particulate material.

Owner:3D SYST INC

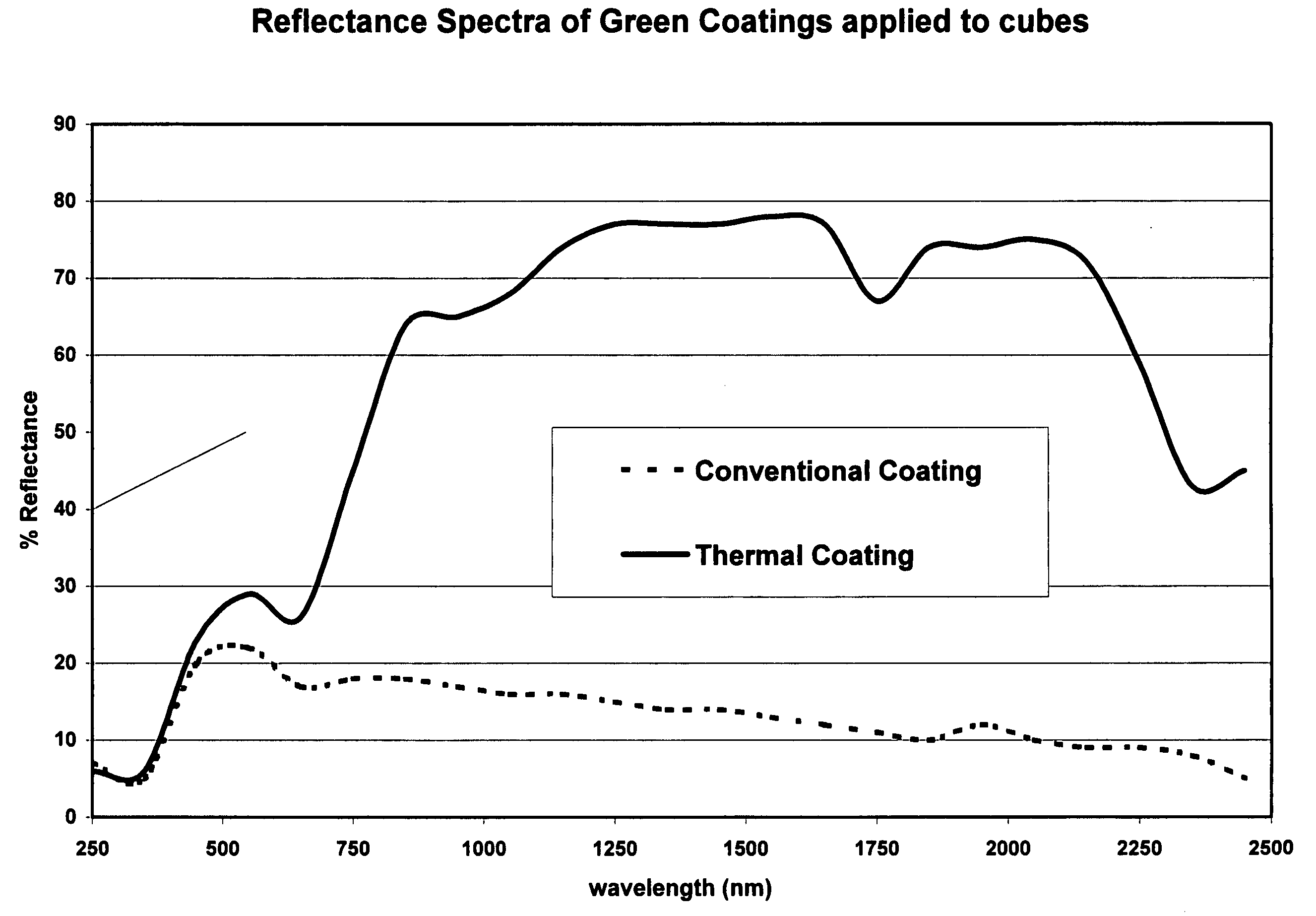

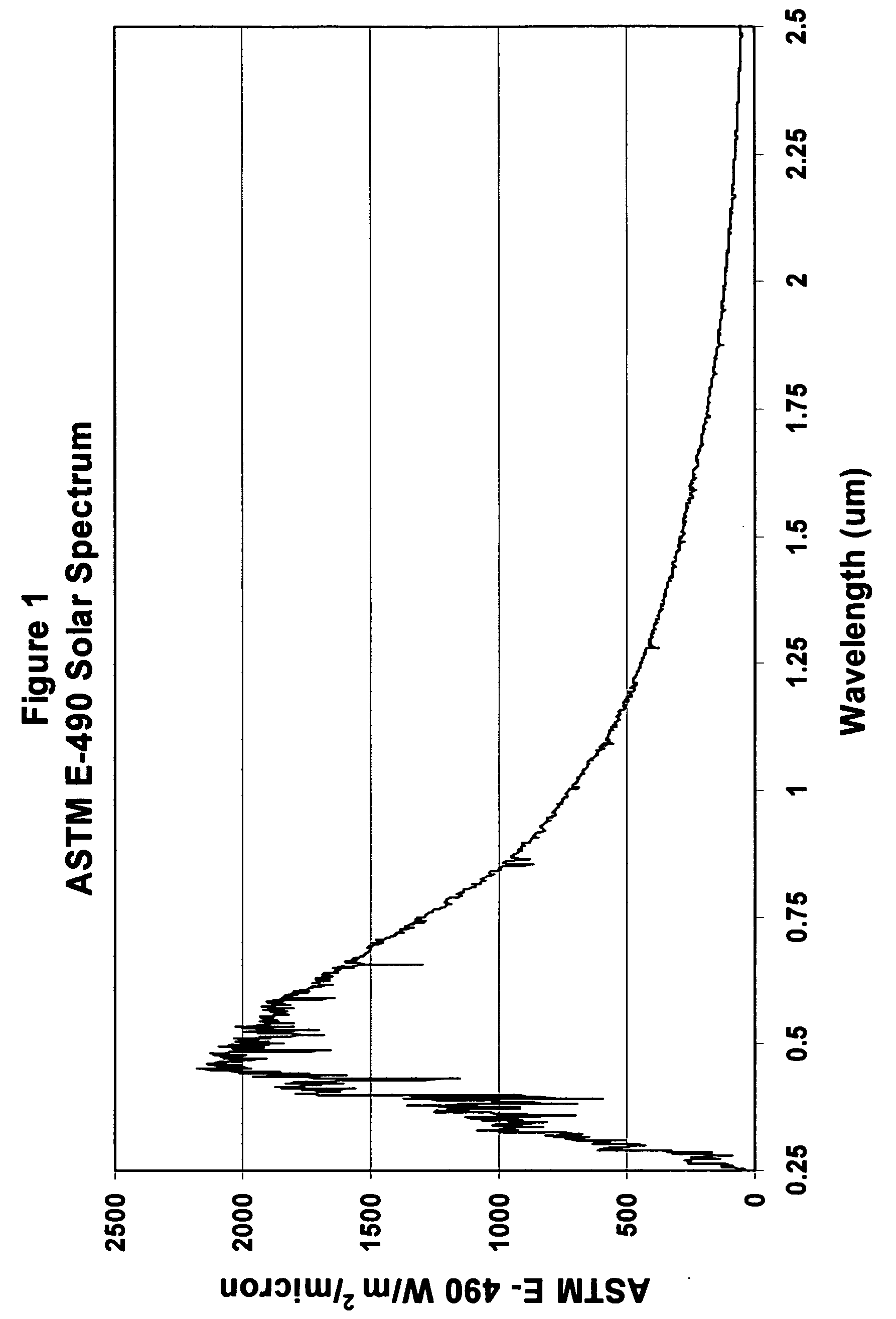

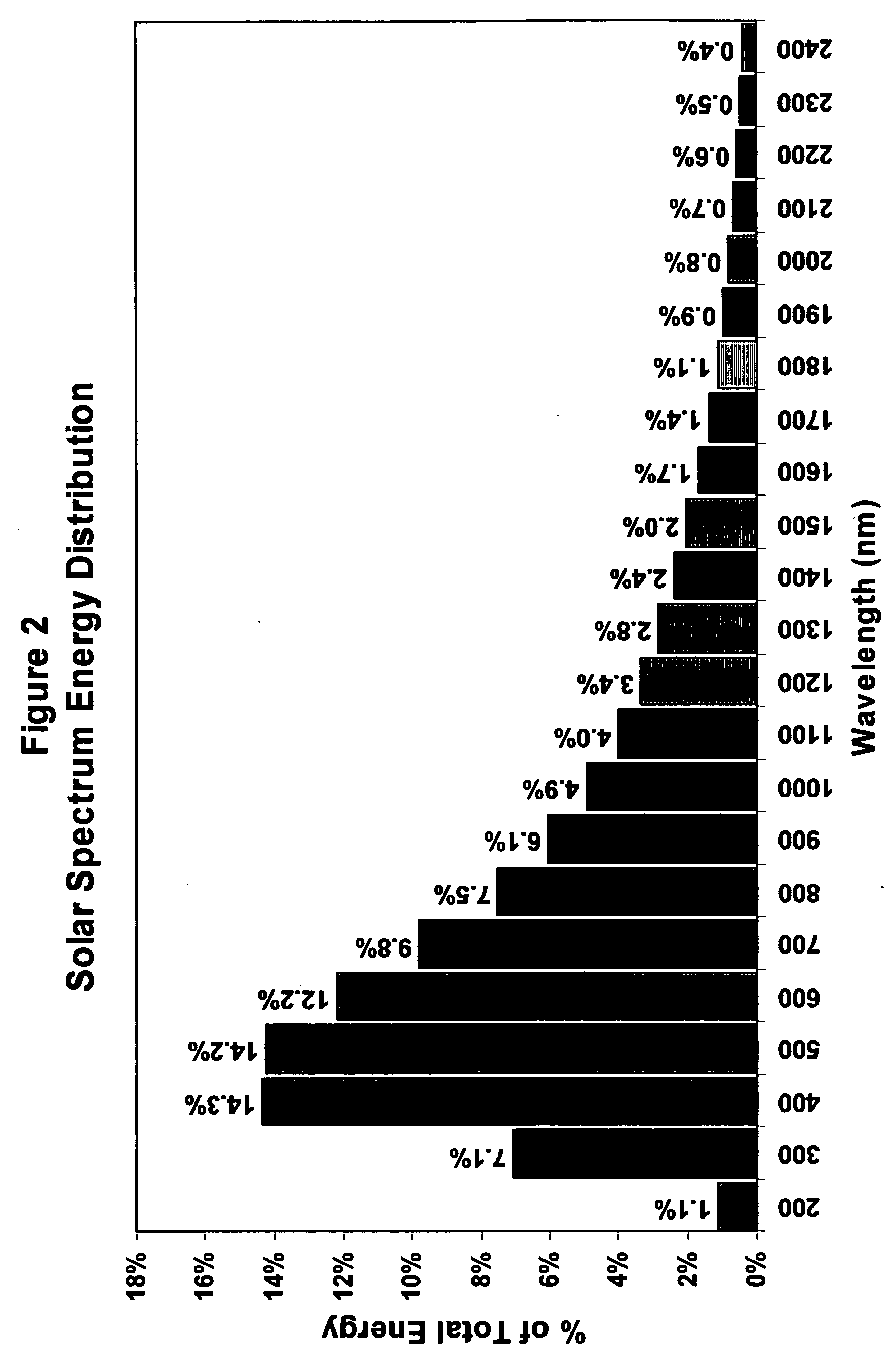

Composition of a thermaly insulating coating system

InactiveUS20050126441A1High infrared reflectivityLow thermal conductivityPigmenting treatmentCeramic layered productsCoating systemSolar spectra

A composition for a Coating System (paint) which forms an insulating material being designed to both reflect infrared radiation and have reduced thermal conductivity. The coating system may be either a single Thermal Coating or may be a Thermal Coating used in combination with a Thermal Primer. The Thermal Coating is formulated using conventional techniques and a resin used in paint manufacture, but utilizes primary pigments and extender mineral pigments which preferentially reflect in the infra red area of the solar spectrum. A method of characterizing particulate materials for their infra red reflectivity is described, which provides a means for preferential selection of particulate additives based on their relative visible light and infrared reflectivity. Additionally the incorporation of hollow micro-spheres is desired to reduce thermal conductivity. The Thermal Primer is designed to provide adhesion between the Thermal Coating and the substrate on which it is applied and uses conventional techniques to achieve those properties. However it has been found advantageous to incorporate hollow micro-spheres with low thermal conductivity, such as glass, ceramic or polymeric micro-spheres and / or an extender pigment with low thermal conductivity such as calcined clay to further reduce heat flow through the Coating System.

Owner:ANTHONY DAVID SKELHORN

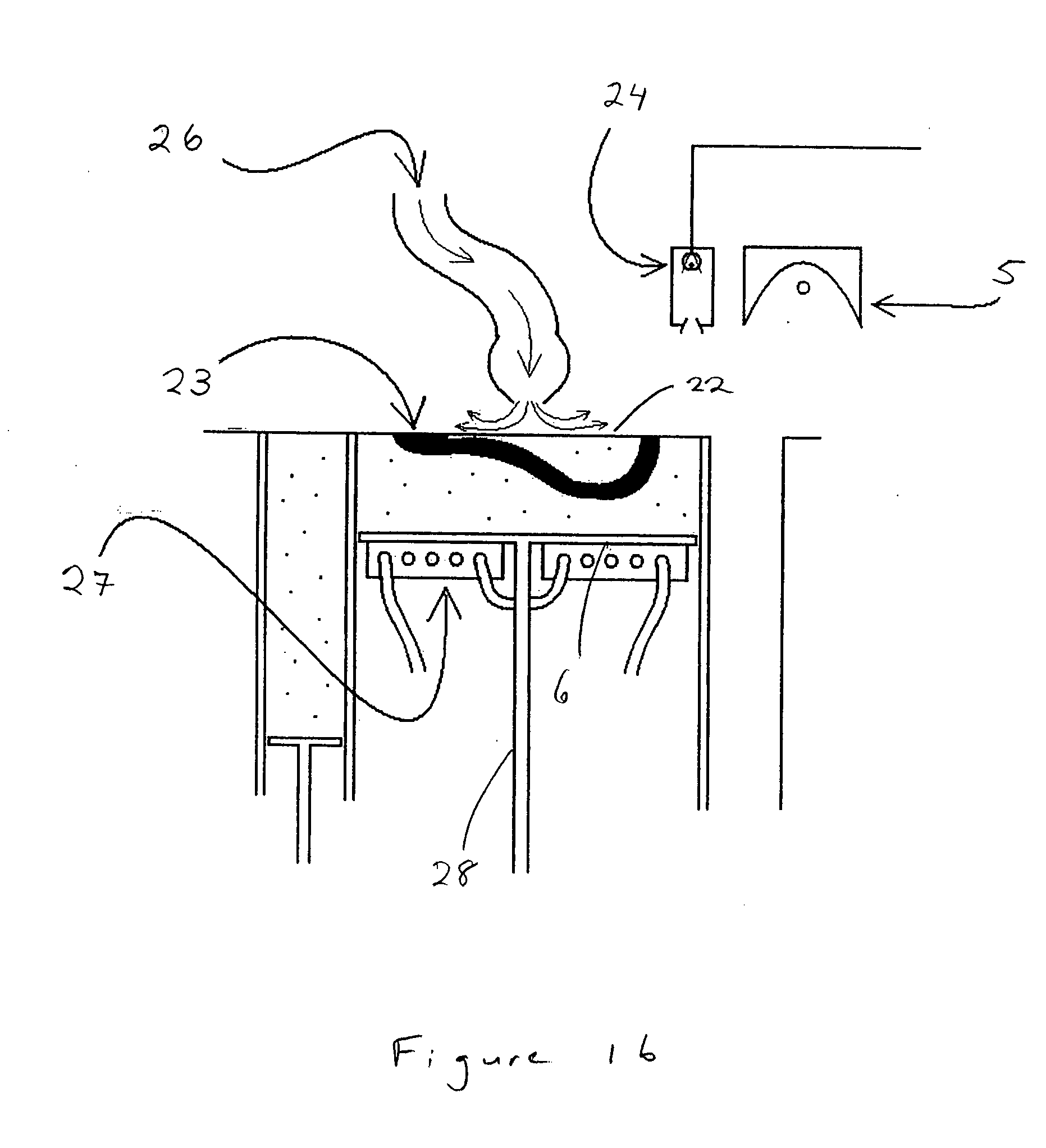

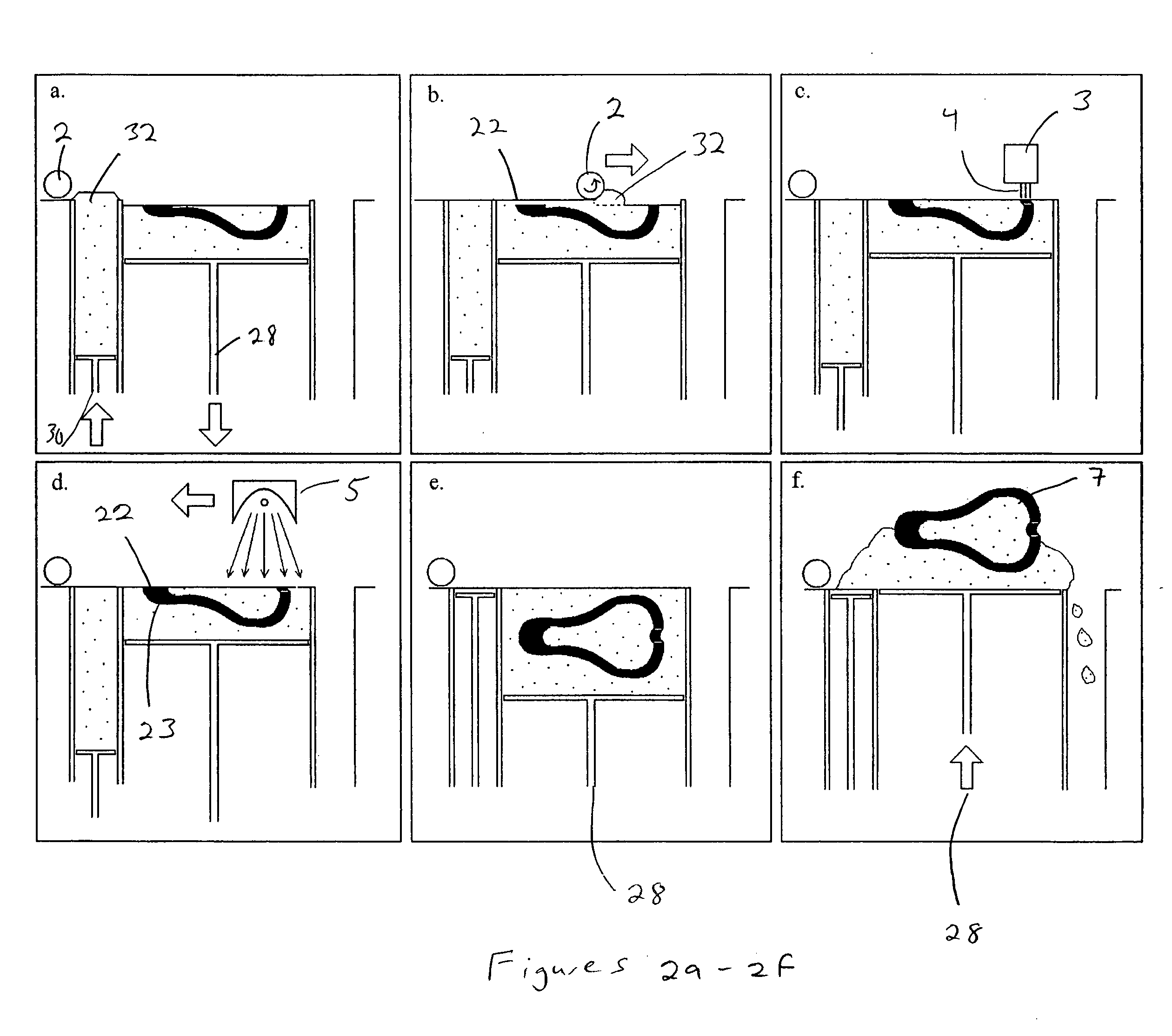

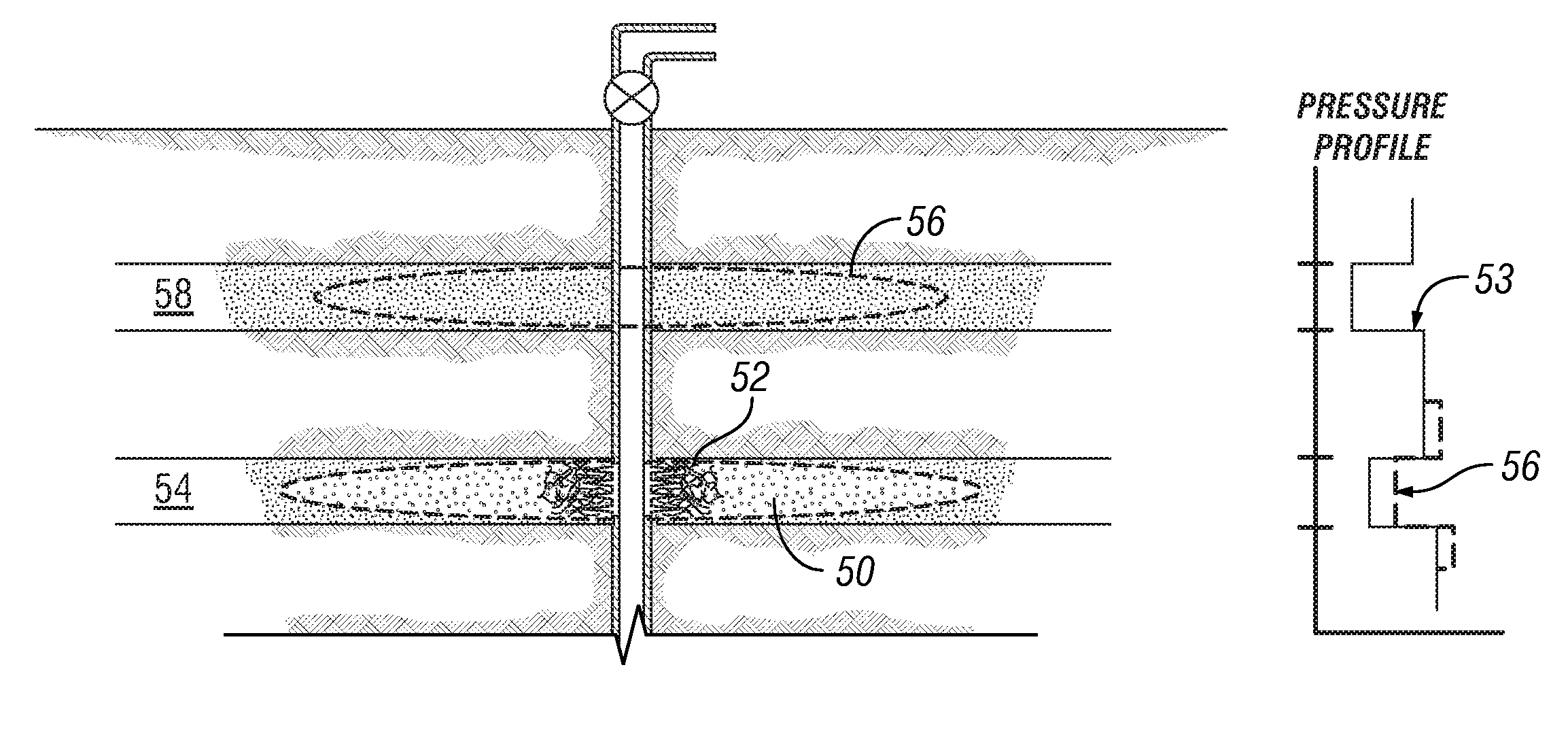

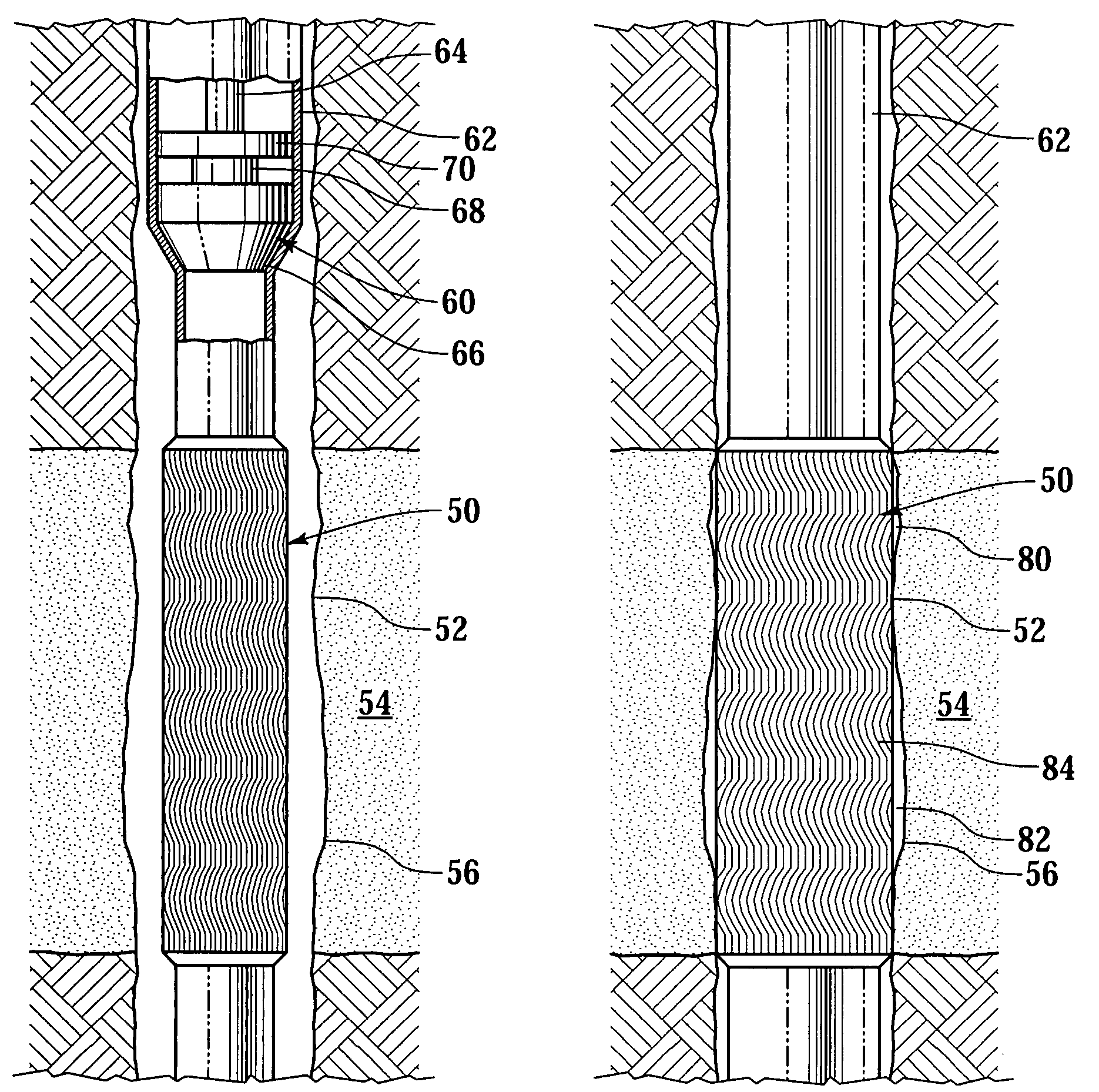

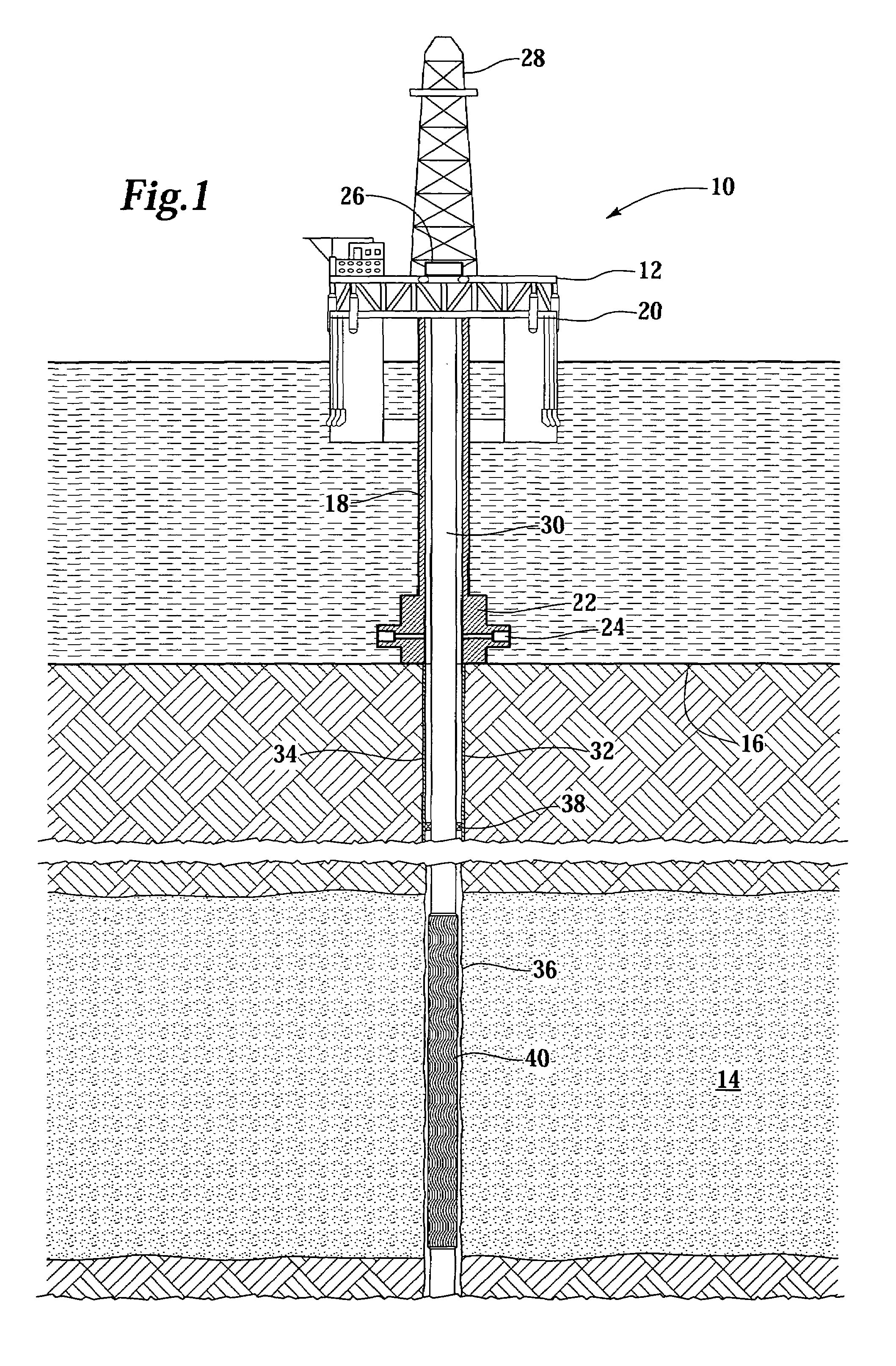

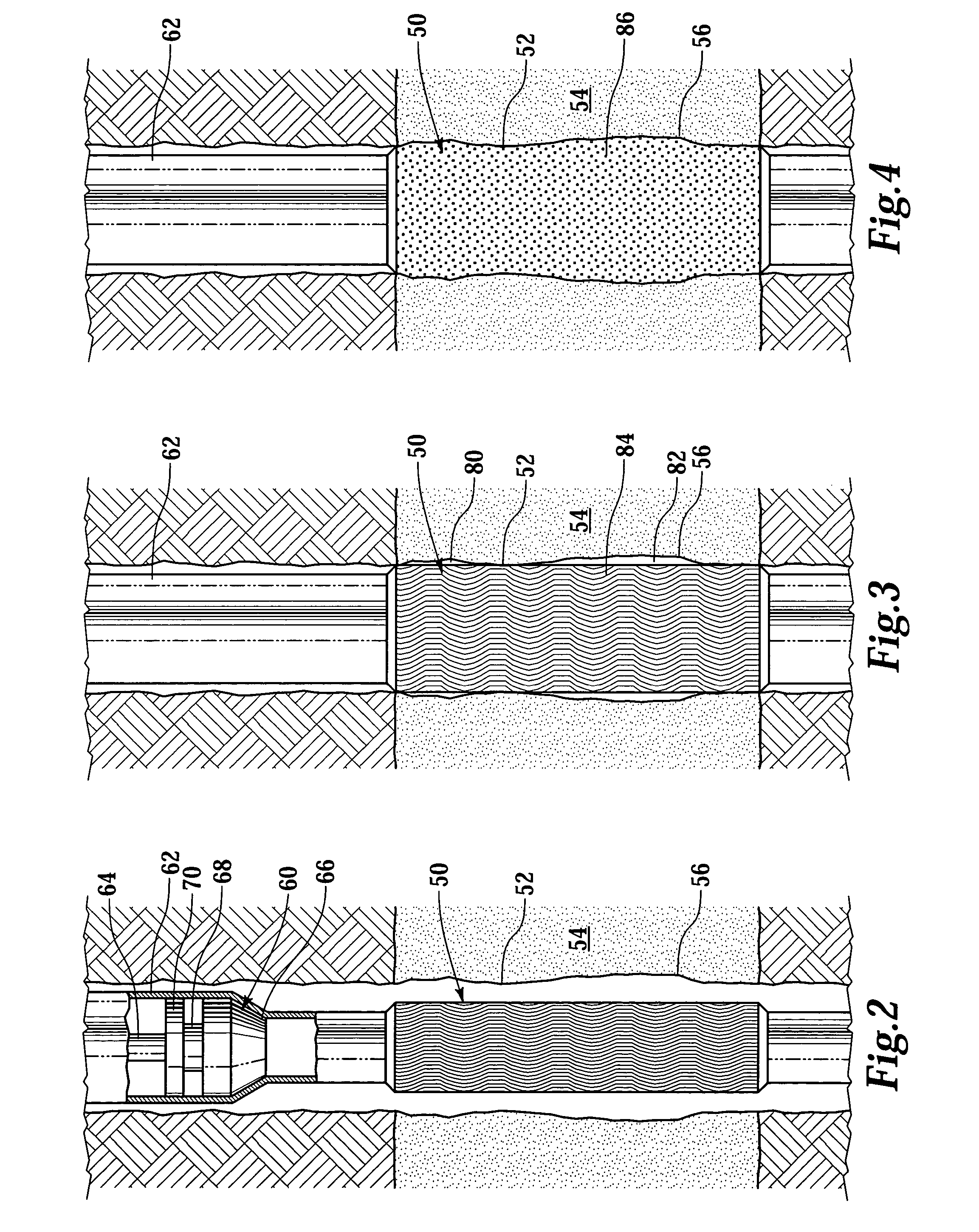

Degradable material assisted diversion

Degradable material assisted diversion (DMAD) methods for well treatment, DMAD treatment fluids, and removable plugs for DMAD in downhole operations. A slurry of solid degradable material is injected into the well, a plug of the degradable material is formed, a downhole operation is performed around the plug diverter, and the plug is then degraded for removal. Degradation triggers can be temperature or chemical reactants, with optional accelerators or retarders to provide the desired timing for plug removal. In multilayer formation DMAD fracturing, the plug isolates a completed fracture while additional layers are sequentially fractured and plugged, and then the plugs are removed for flowback from the fractured layers. In DMAD fluids, an aqueous slurry can have a solids phase including a degradable material and a fluid phase including a viscoelastic surfactant. The solids phase can be a mixture of fibers and a particulate material.

Owner:SCHLUMBERGER TECH CORP

Filtration media for filtering particulate material from gas streams

A composite fabric formed by depositing a web of nanofibers electroblown from a first polymer onto a first support web comprising fibers of larger average diameter than the nanofibers spun from a compatible material, in the absence of an adhesive between the webs, and solvent-bonding the webs together.

Owner:DUPONT SAFETY & CONSTR INC

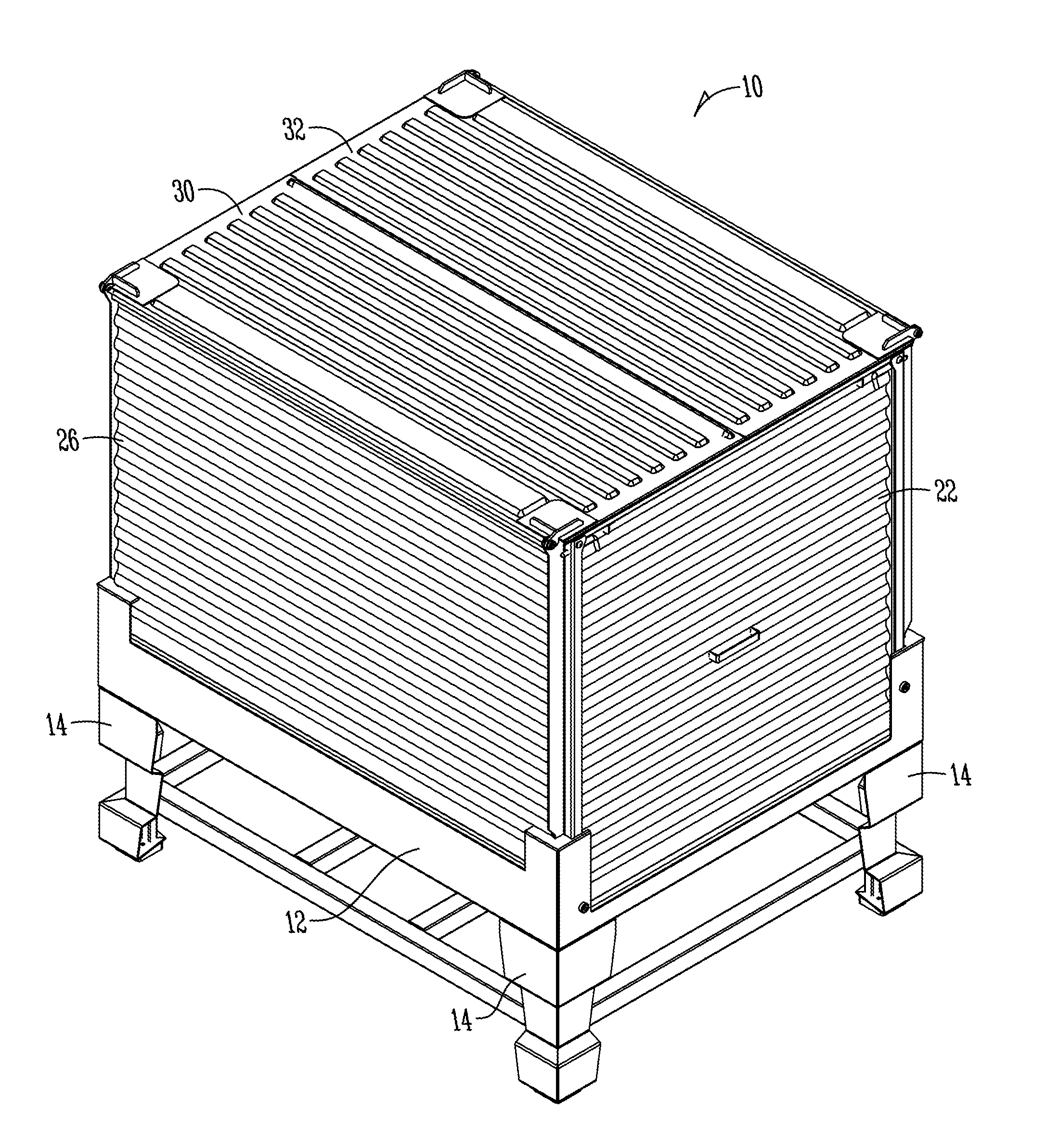

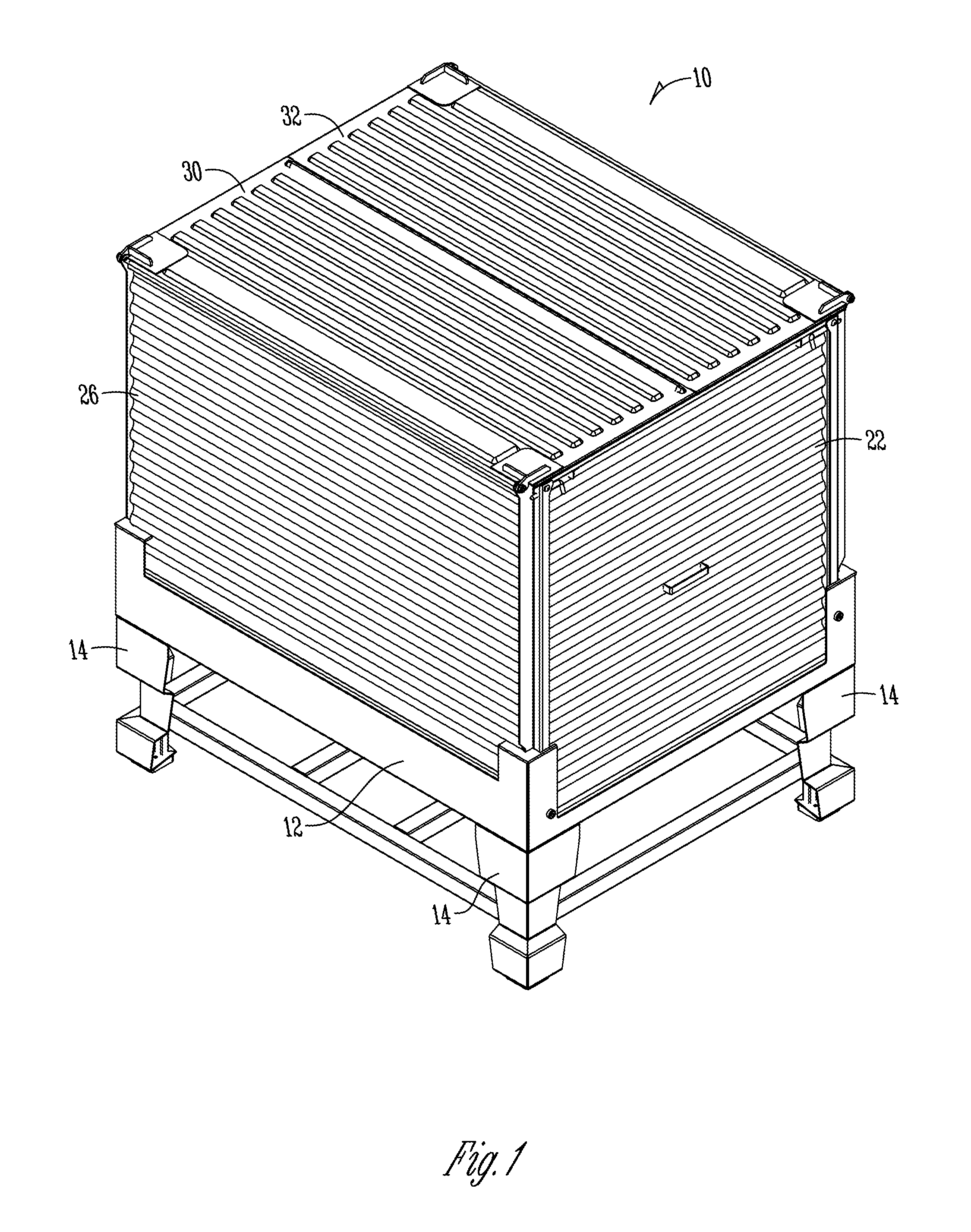

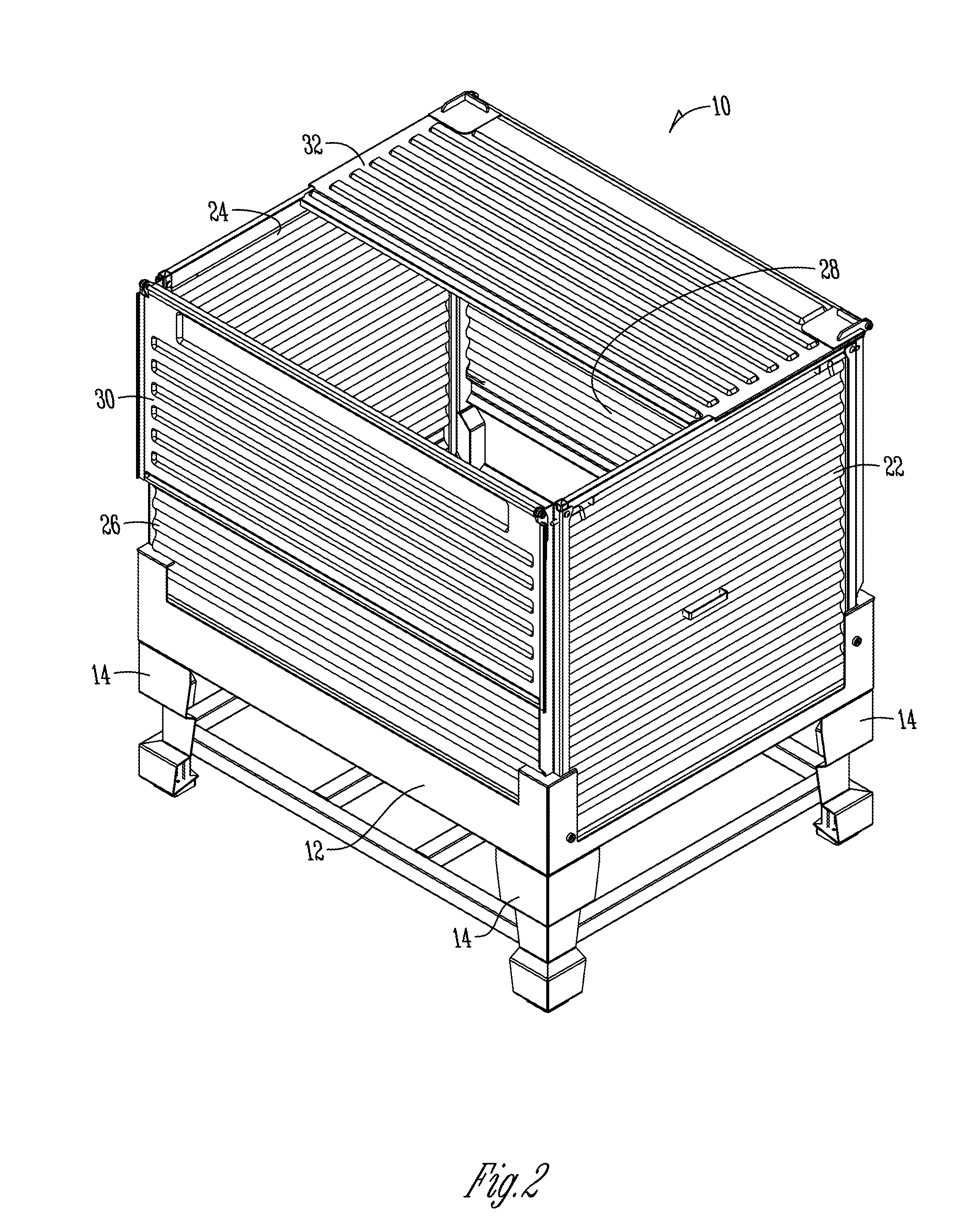

Folding seed box with fork lift base

InactiveUS20110168593A1Easy to removeQuick breakOther accessoriesContainer/bottle contructionEngineeringTruck

A collapsible bulk container for dry, flowable particulate material is provided with a frame to support a bottom wall having a discharge opening and a gate moveable between opened and closed positions relative to the discharge opening. Four side walls are pivotally connected to the frame, with the pivot axes being at different elevations, such that the side walls can be folded between an upright use position and a substantially flat storage position. A lid is pivotally connected to opposite side walls for moving between an open position adjacent the connected side wall and a closed position over the bottom wall. Multiple containers can be stacked one upon another in both the use and storage positions. The base or frame of the container can receive forks from a lift truck on all four sides of the container.

Owner:WOODHAVEN CAPITAL

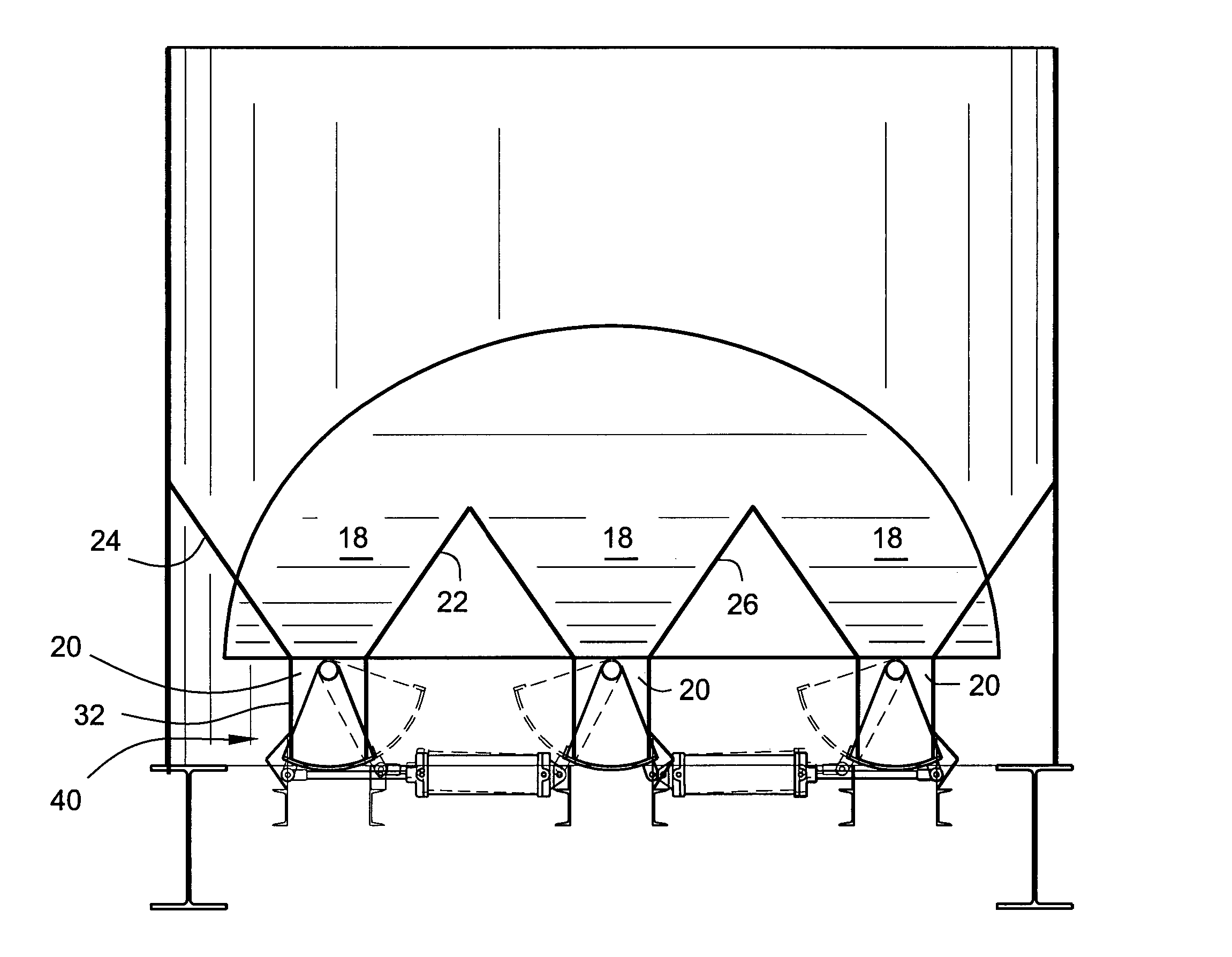

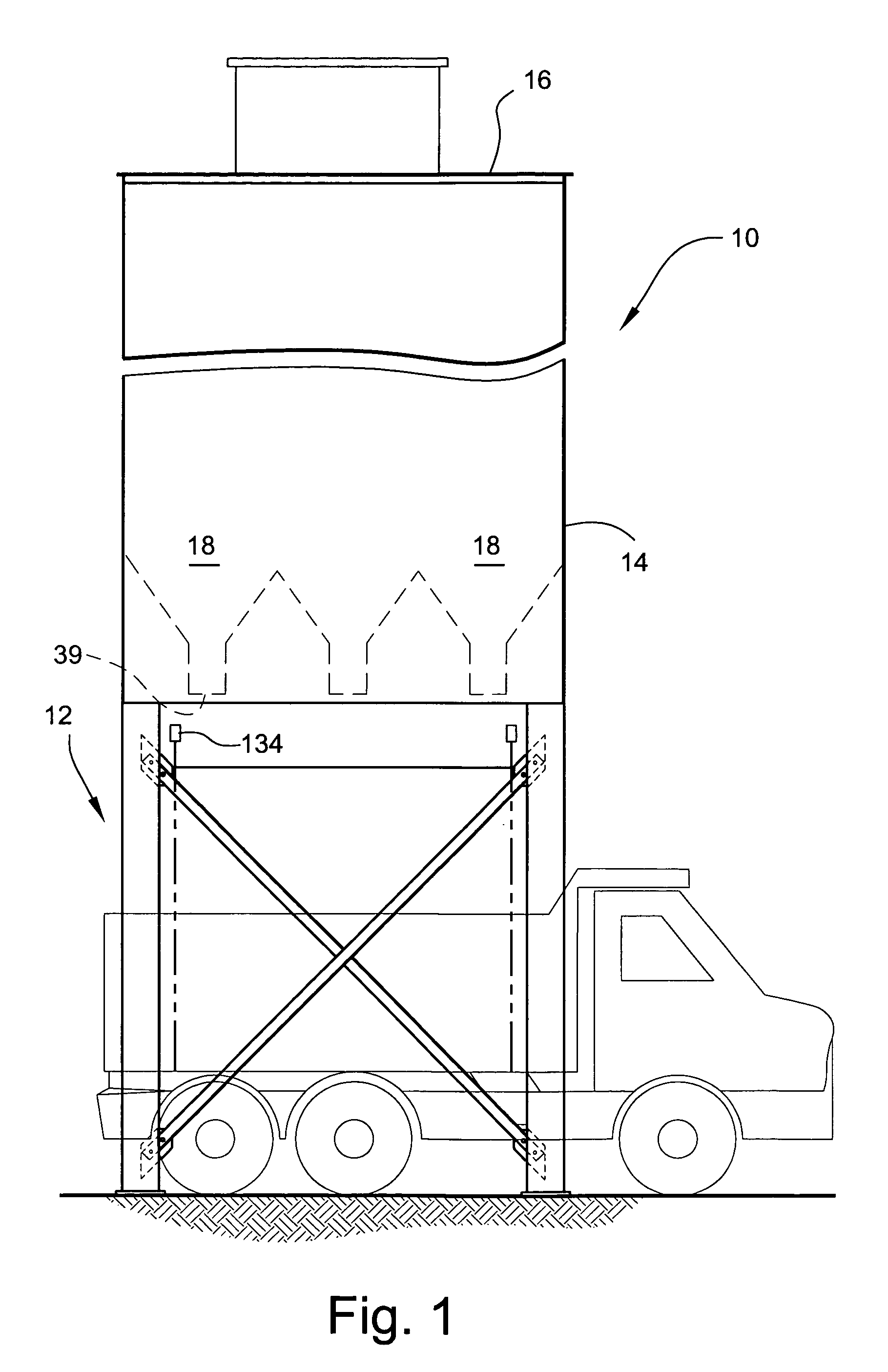

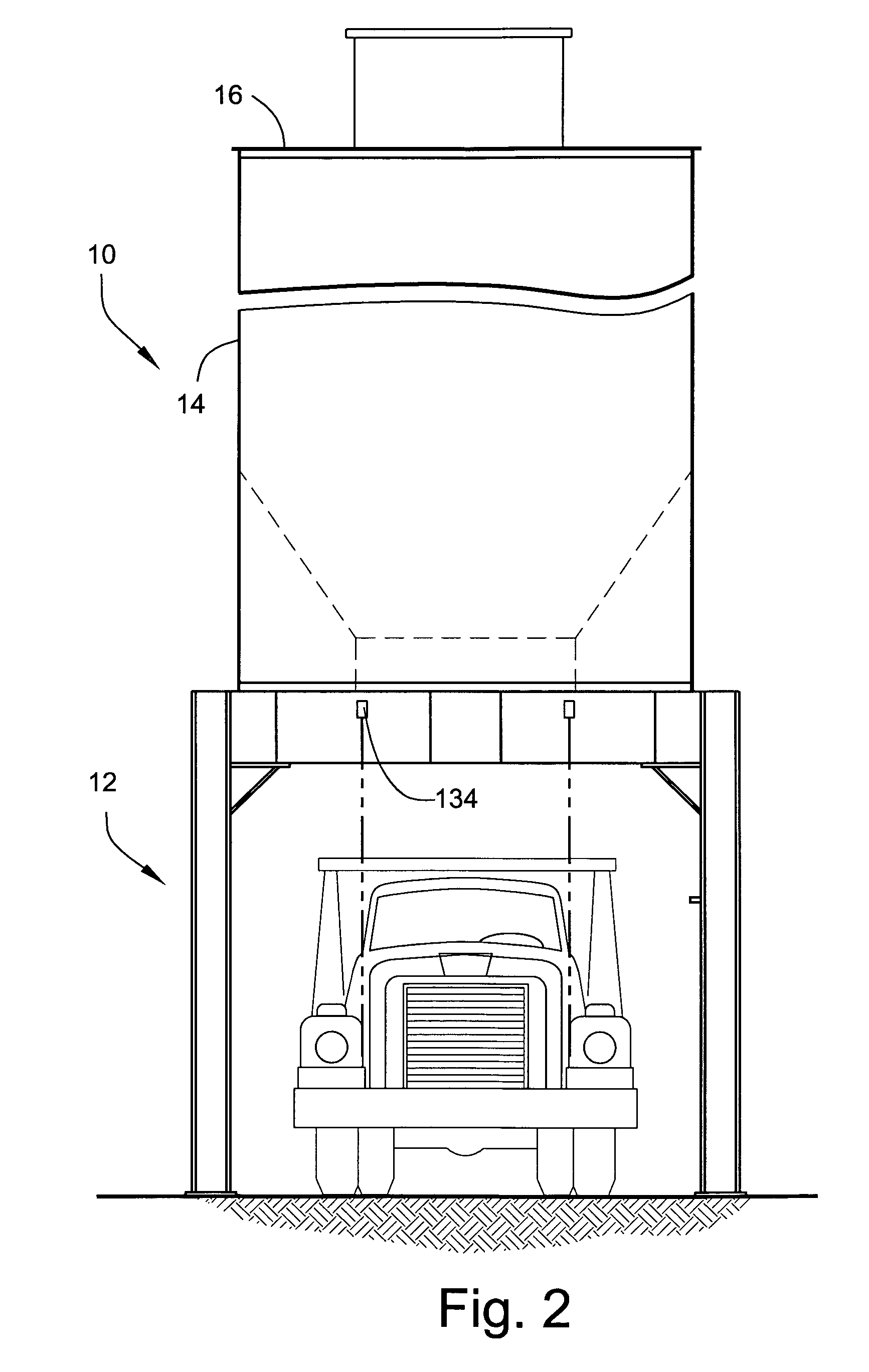

Apparatus and methods for discharging particulate material from storage silos

The silo includes at least three hoppers terminating in rectilinear discharge openings extending lengthwise transversely of a loading area below the discharge openings. Clam gates are movable between open and closed positions to discharge material. The discharge area at the bottom of the silo is increased, facilitating faster loading of trucks with the particulate material.

Owner:GENCOR IND INC

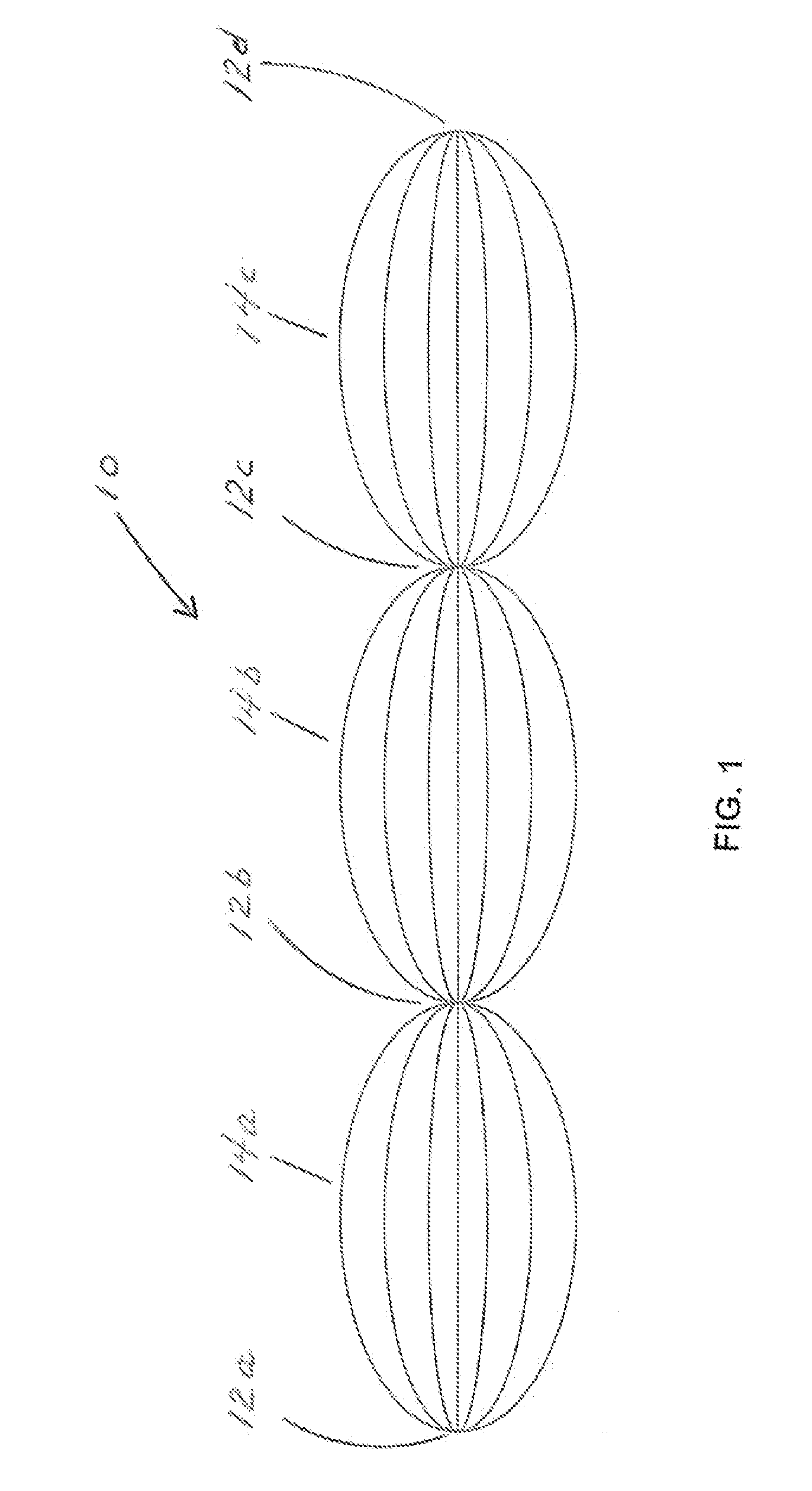

At least partly fused particulates and methods of making them by flame fusion

InactiveUS6045913AEfficient meltingFast heat transferSynthetic resin layered productsCellulosic plastic layered productsEllipsoidal particleProduct gas

The disclosure describes methods for producing bulk, particulate material that includes solid, generally ellipsoidal particles. Irregularly shaped feed particles with average particle sizes of up to 25 microns on a volume basis are dispersed in at least a portion of a combustible gas mixture by application of force and / or fluidizing agents. The combustible mixture with particles in suspension is then delivered, while controlling agglomeration or re-agglomeration of the particles, to at least one flame front. There, the mixture and suspended particles are uniformly distributed across the surface(s) of and passed through the flame front(s) with a high concentration of particles in the mixture. This flame front and the resultant flame(s) with suspended particles are located in at least one "wall free" zone. In such zone(s) the flame(s) may expand while the particles are maintained in dispersion and heated, with controlled and highly efficient application of heating energy. At least partial fusion occurs within at least the surfaces of the particles at high thermal efficiencies, while agglomeration of particles during fusion is inhibited.

Owner:3M CO

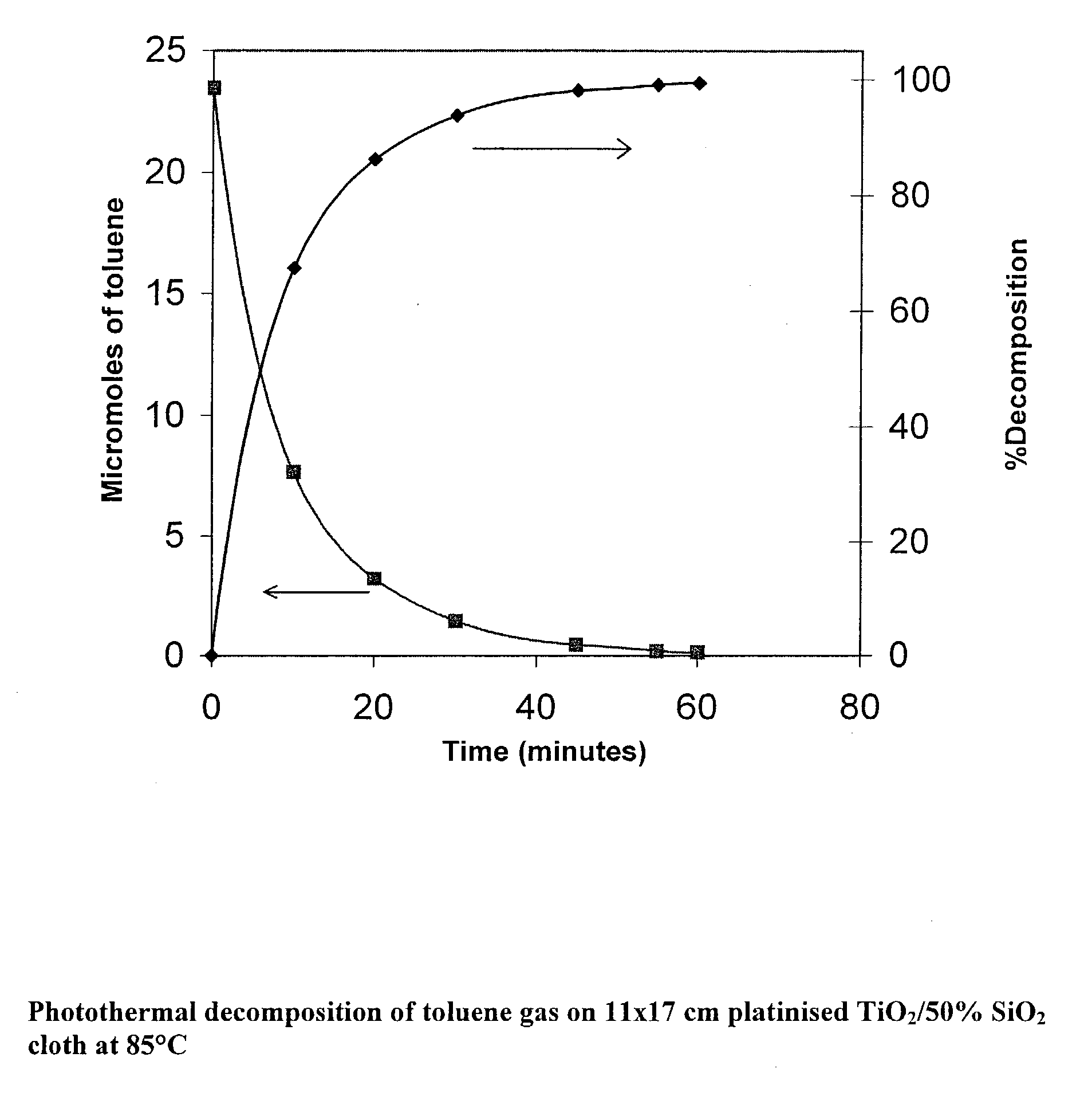

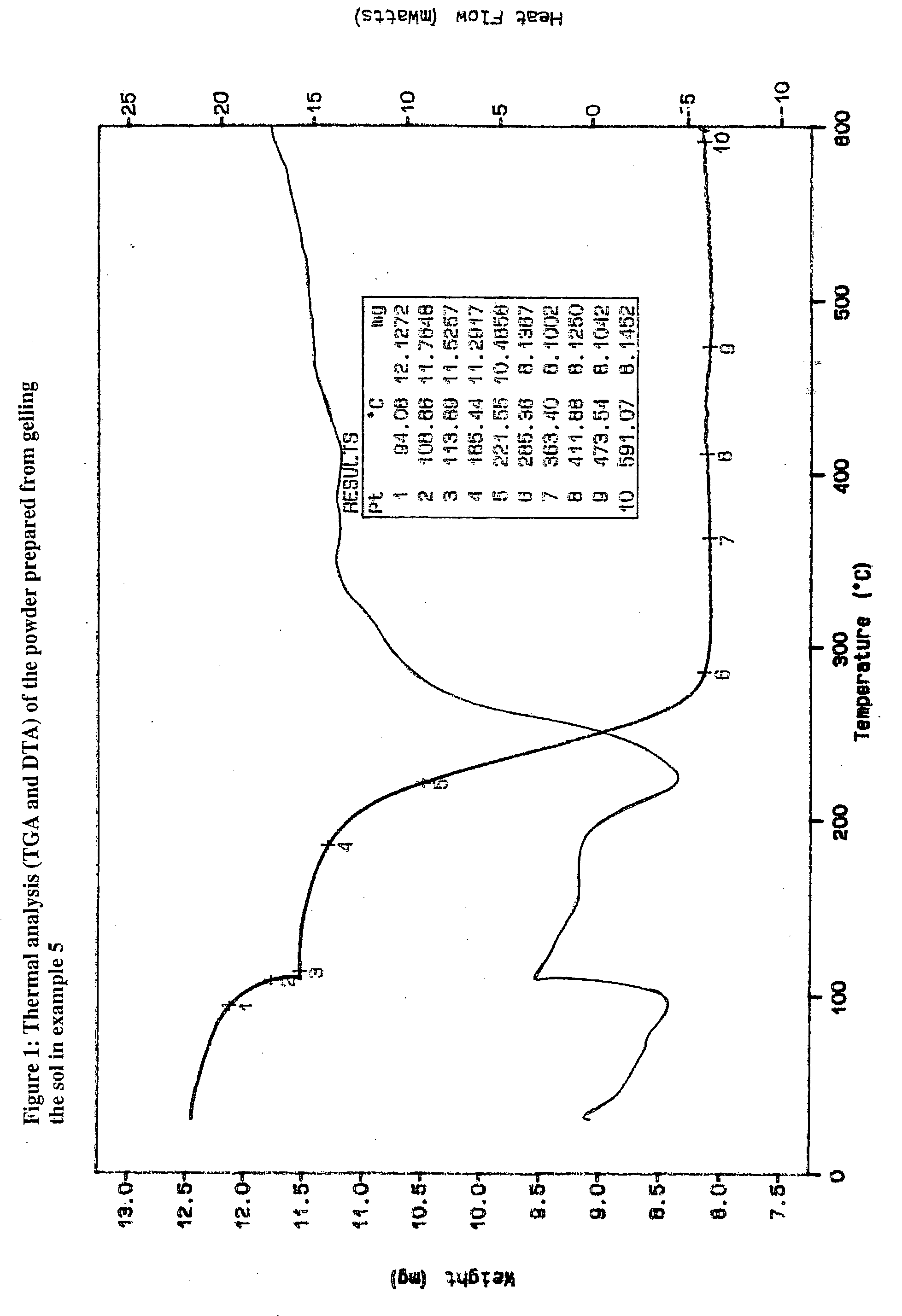

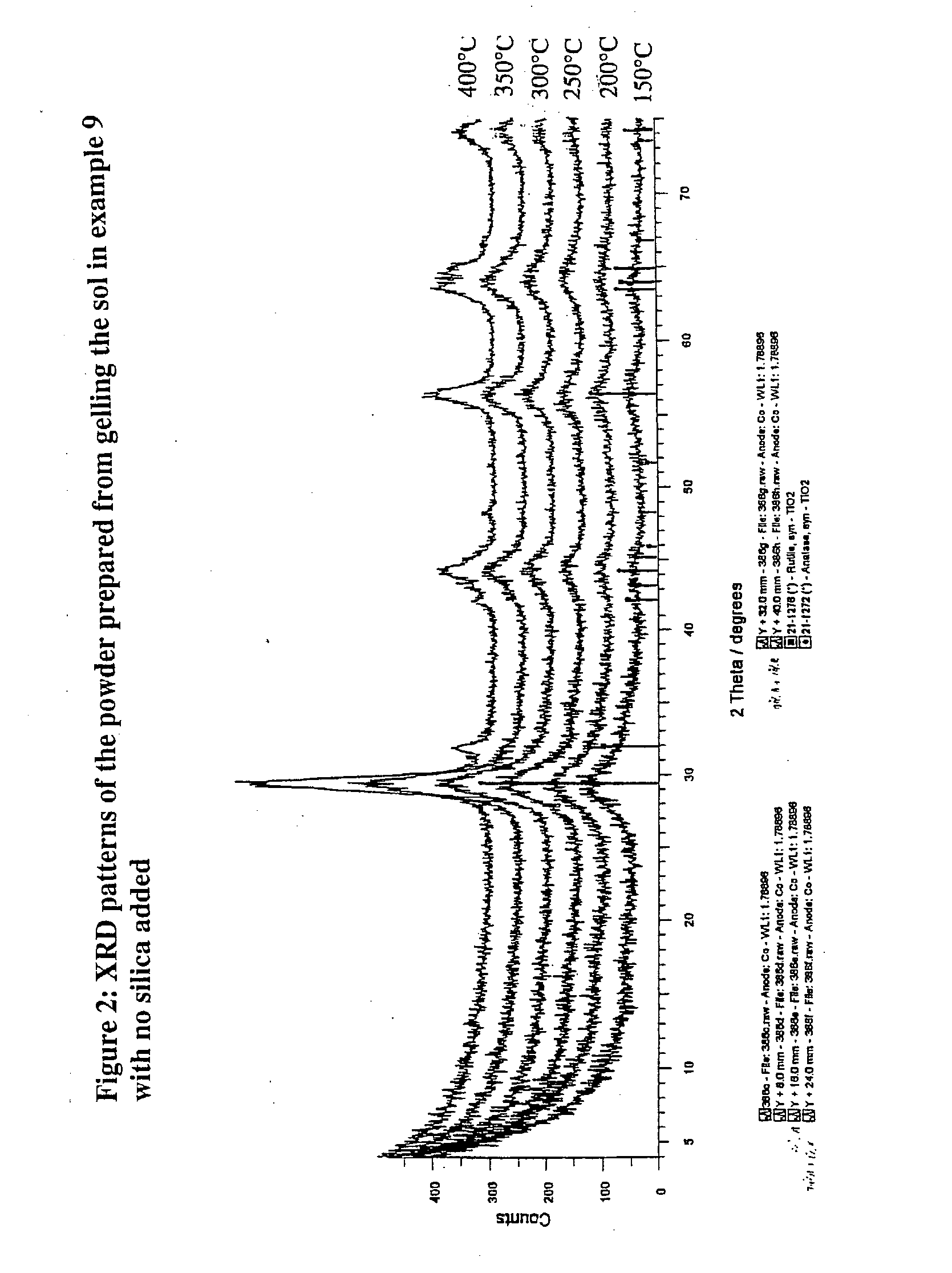

Titanium-containing materials

The invention relates to a method of preparing a solution containing colloidal particles which contain crystalline titanium dioxide wherein one or more hydrolysable titanium-containing compound(s) is stabilised by oxalic acid in a reaction medium. The reaction further relates to the preparation of titania materials (including particulate materials, coating solutions and films) which comprise or include anatase phase titania, and so are suitable in photocatalytic applications. The invention also deals with a method of preparing B-phase titania.

Owner:IND RES LTD

Orthopedic implant and method of making metal articles

The present application is directed to an orthopedic implant. More specifically, the orthopedic implant is suitable for arthroplasty procedures where optimized multifunctional behavior of the implant is desired. In some embodiments the implant is suitable for the replacement of a spinal disc. In one embodiment, the present application is directed to an orthopedic implant including a first plate a second plate and a flexible support. The flexible support may have a single connection to the first plate and a single connection to the second plate and may vary in cross section. The first plate, the second plate and the flexible support may be unitarily formed. This application is also directed to methods of producing metal articles having microstructure for improved mechanical properties. Such methods may be suitable for the production of medical devices. In one embodiment, the method includes directing a stream including a particulate material in a pattern corresponding to at least a portion of a structure of an orthopedic implant and fusing at least a portion of the particulate material with a laser.

Owner:MANASAS MARK +7

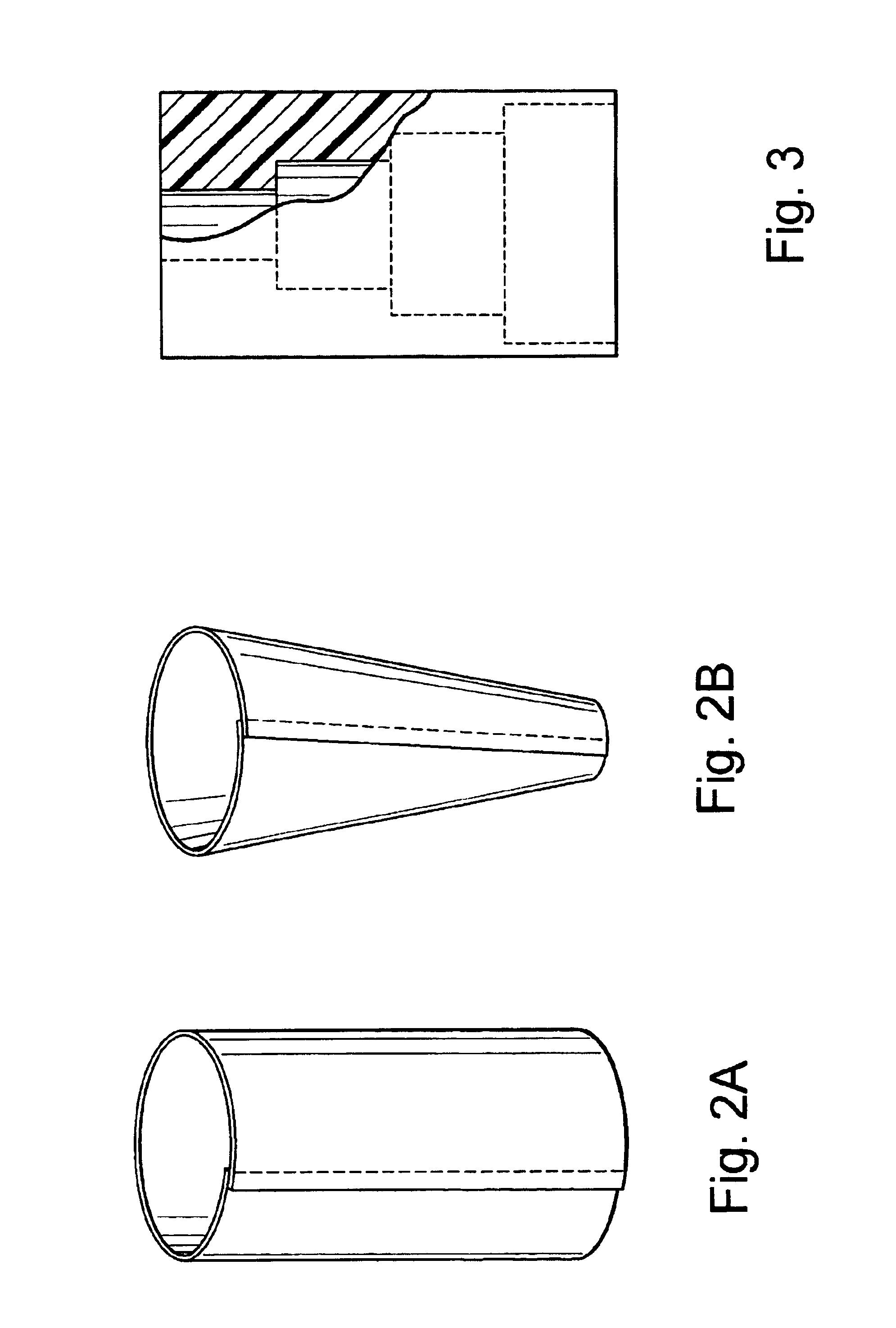

Expandable sand control screen and method for use of same

ActiveUS7048048B2Prevent crashAvoid flowFluid removalDrinking water installationFilter mediaEngineering

An expandable sand control screen (100) that is positionable within a wellbore comprises a fluid permeable generally tubular member (102) that is expanded downhole. A filtering assembly is disposed exteriorly of the generally tubular member (102). The filtering assembly includes a filter medium (106) that prevents the flow of particulate material of a predetermined size therethrough but allows the flow of production fluids therethrough. The filtering assembly also includes a compliable member (118) that has a thickness that is radially variable downhole. During or after expansion of the expandable sand control screen (100), the radial variability of the thickness of the compliable member (118) allows the expandable sand control screen (100) to comply with any irregularities in the wellbore profile, thereby preventing any void regions between the expandable sand control screen (100) and the wellbore.

Owner:HALLIBURTON ENERGY SERVICES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com