Patents

Literature

1458results about "Additive mnaufacturing with solid and fluid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

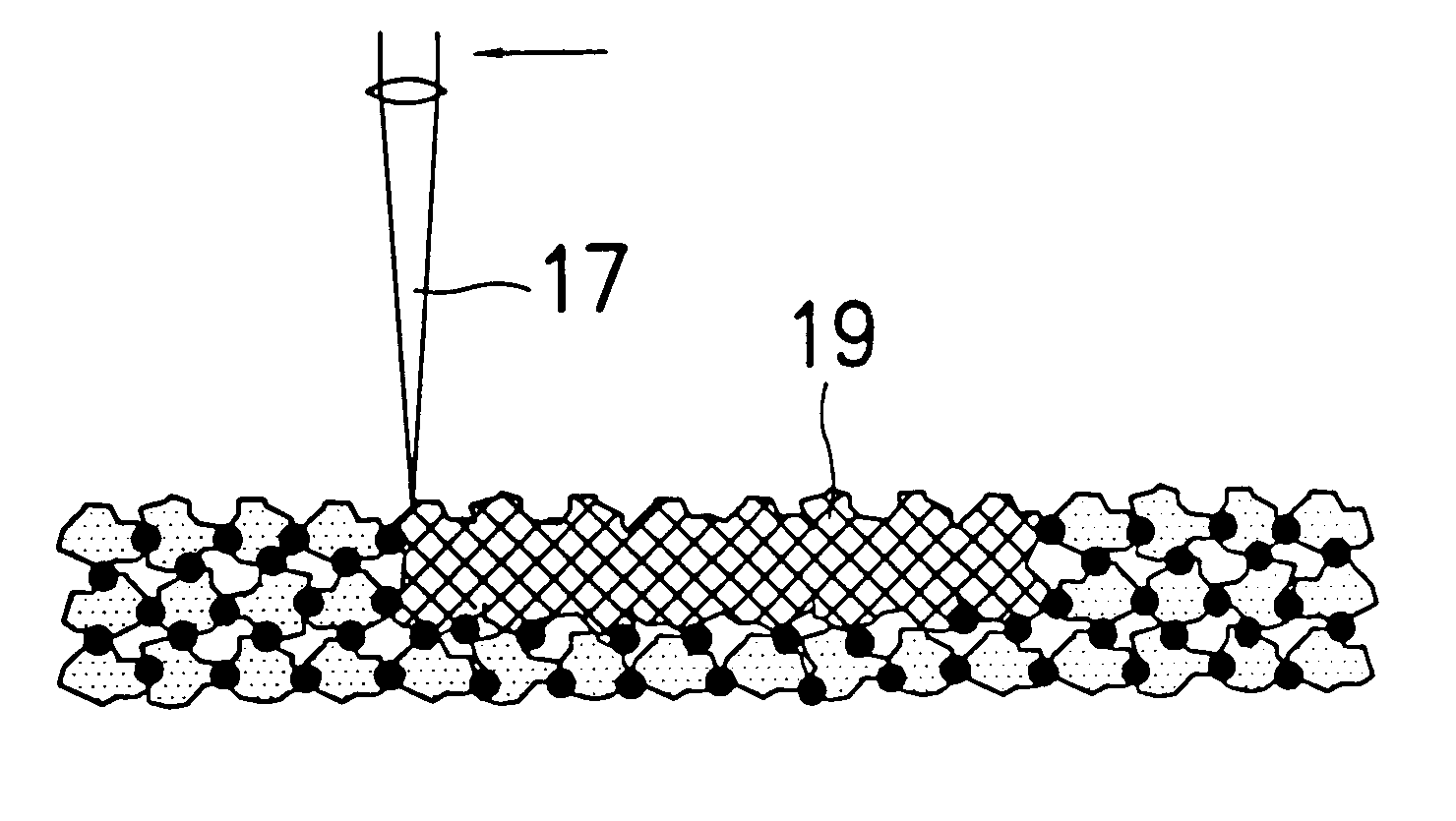

Production of three-dimensional objects by use of electromagnetic radiation

InactiveUS20070241482A1Reduce contractionReduce expansionElectrographic process apparatusAdditive mnaufacturing with solid and fluidEngineeringElectromagnetic radiation

Process, materials, and equipment for producing three-dimensional objects from a particulate material by melting and adhering, for example, by fusion or sintering, portions of the particulate material.

Owner:Z CORPORATION

Solid free-form fabrication methods for the production of dental restorations

InactiveUS20050023710A1Improve bindingImpression capsCeramic shaping apparatusPolymer scienceFree form

Solid free form fabrication techniques can be utilized indirectly to manufacture substrates, dies, models, near-net shapes, shells, and wax-ups that are then used in the manufacture of dental articles. Digital light processing is the most preferred indirect method for the production of substrates. After the substrates are produced, various coating or deposition techniques such as gel casting, slip casting, slurry casting, pressure infiltration, dipping, colloidal spray deposition or electrophoretic deposition are used to manufacture the dental article.

Owner:IVOCLAR VIVADENT AG

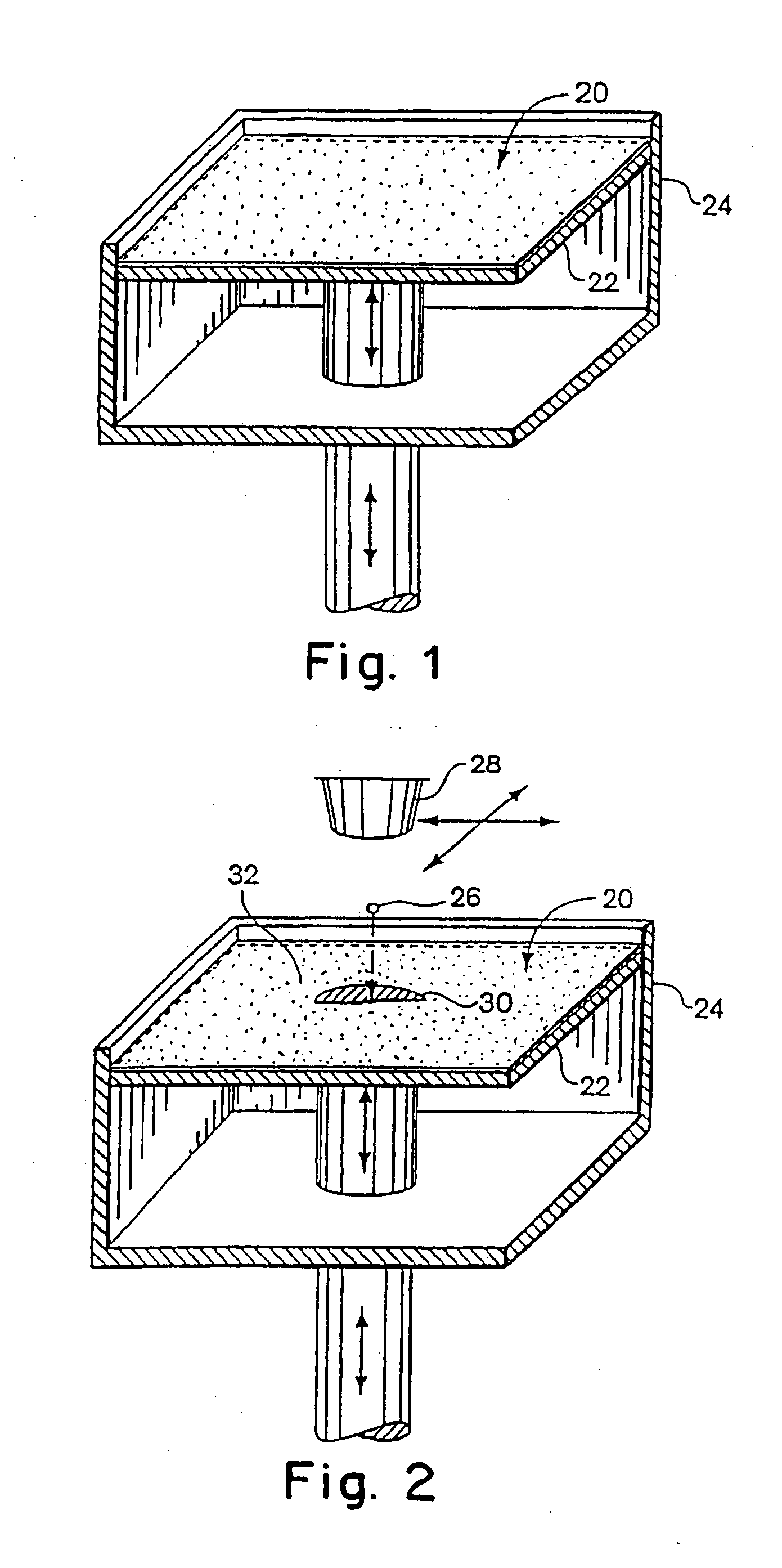

Methods and systems for the manufacture of layered three-dimensional forms

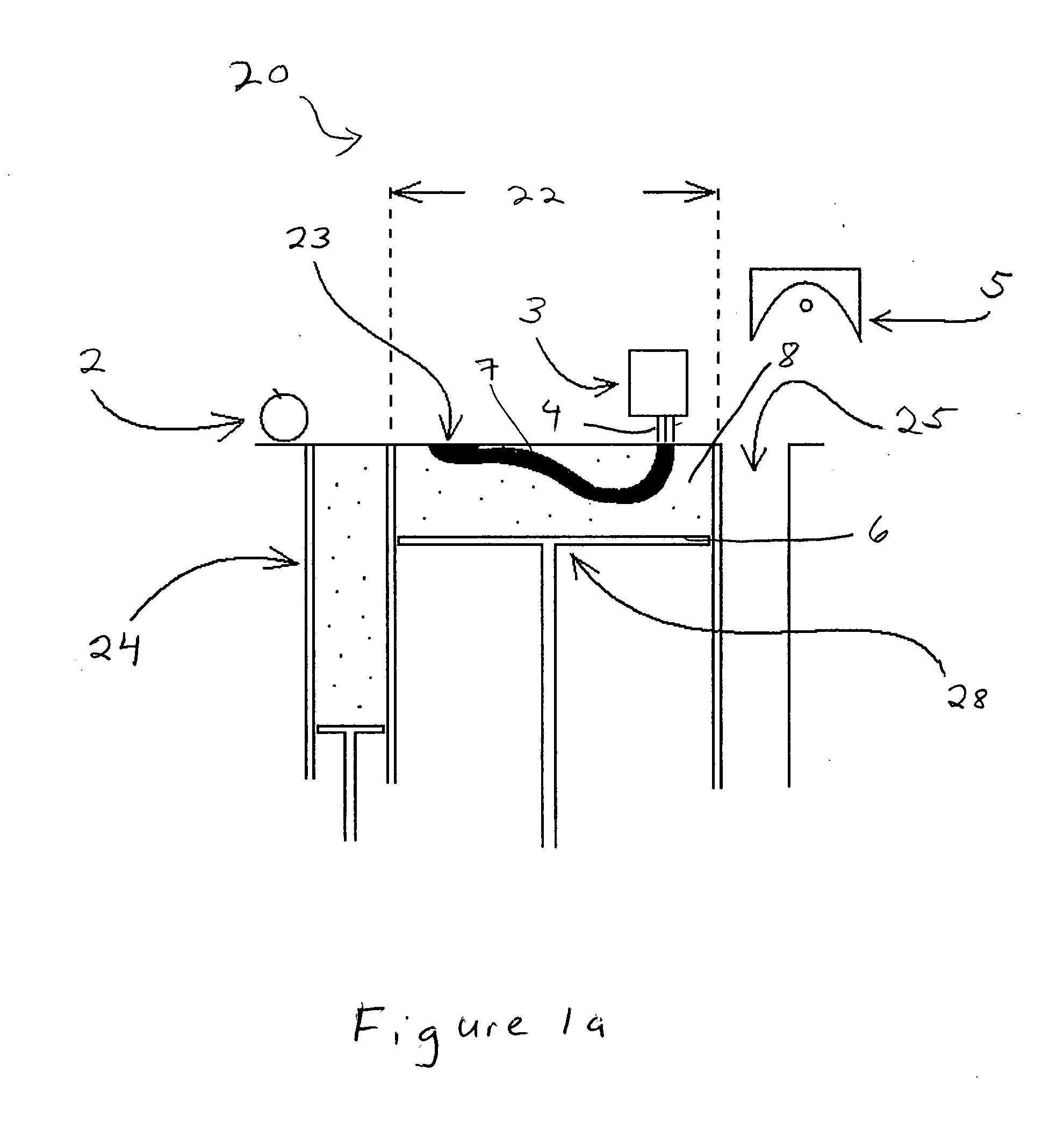

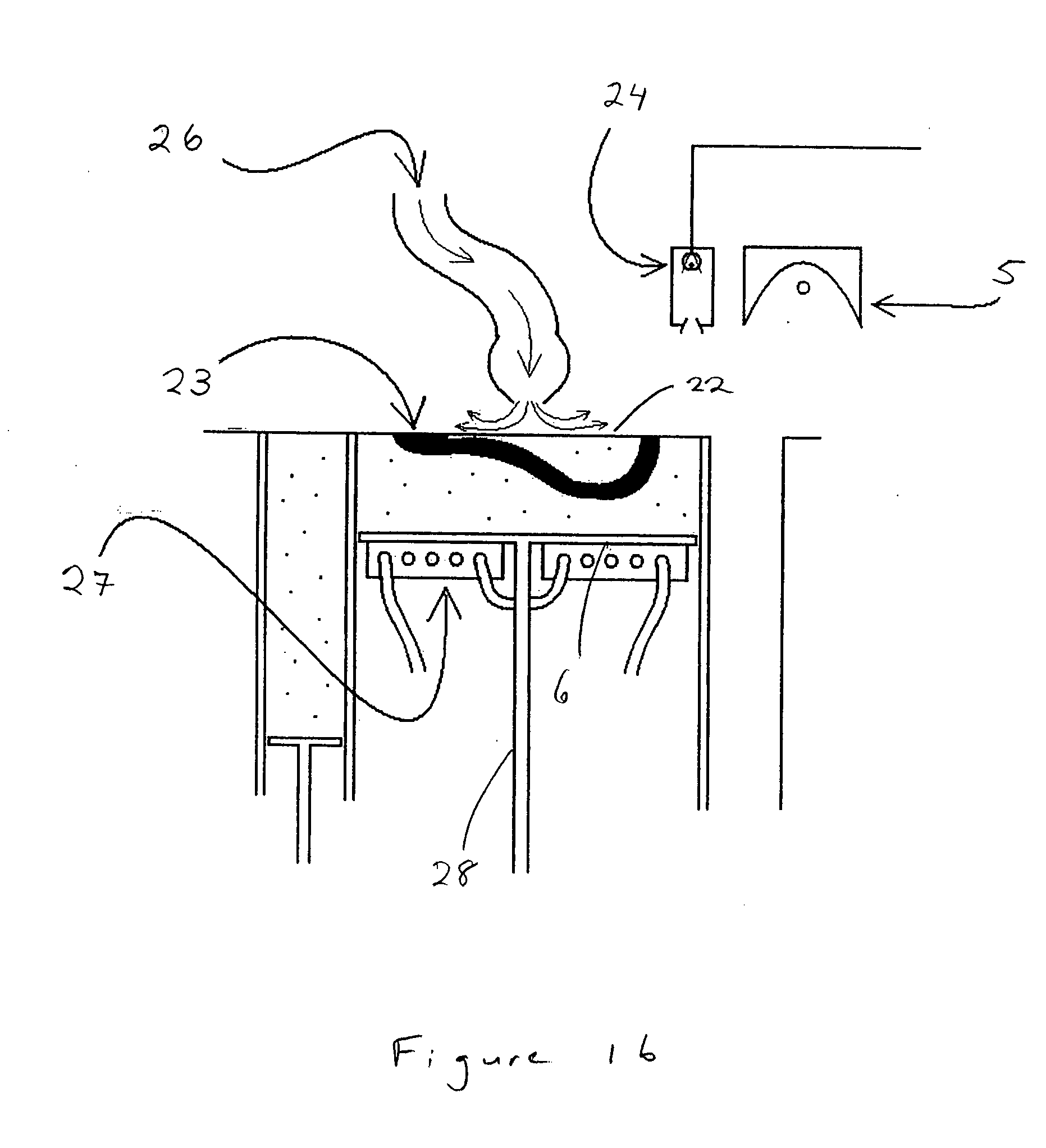

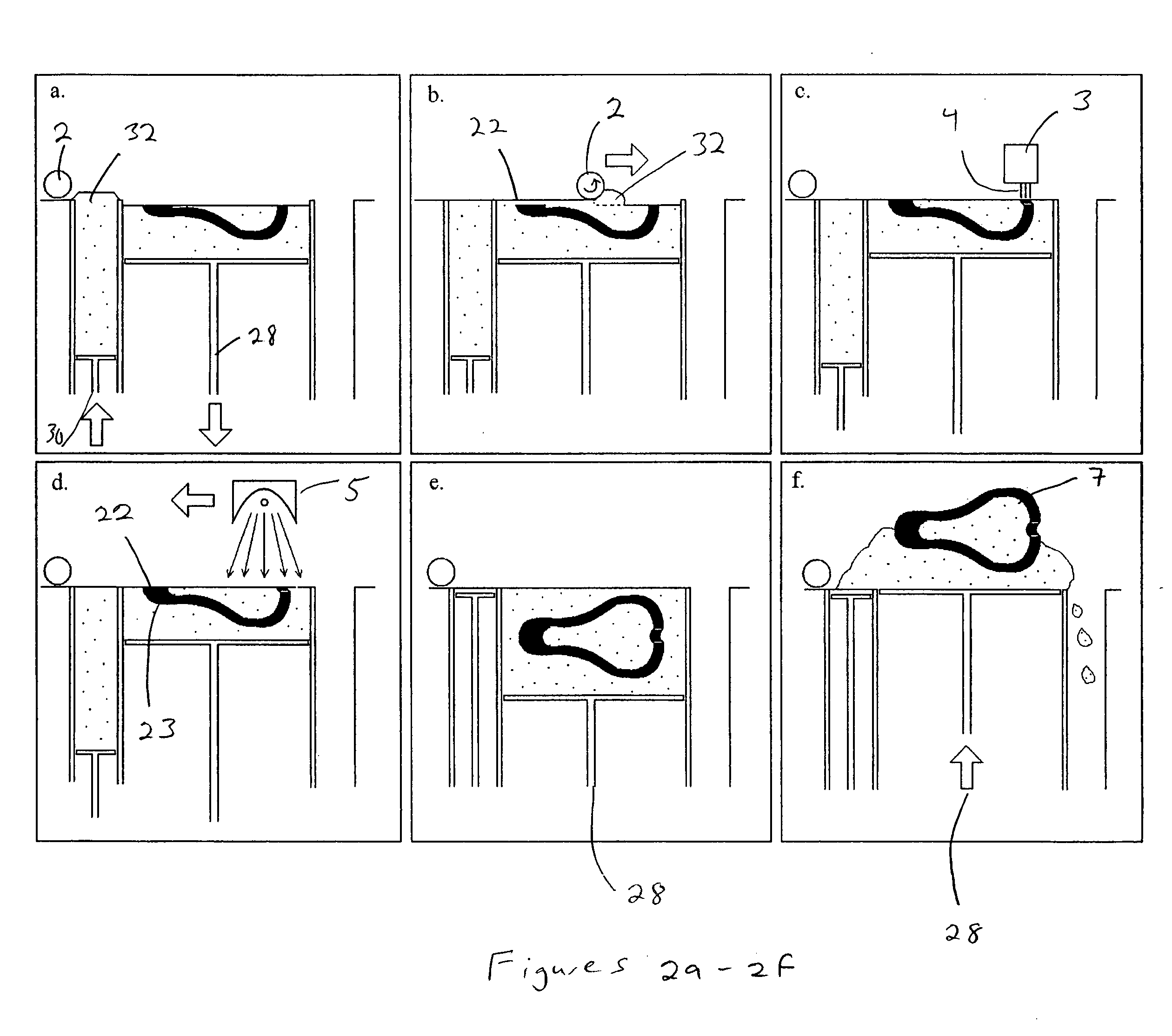

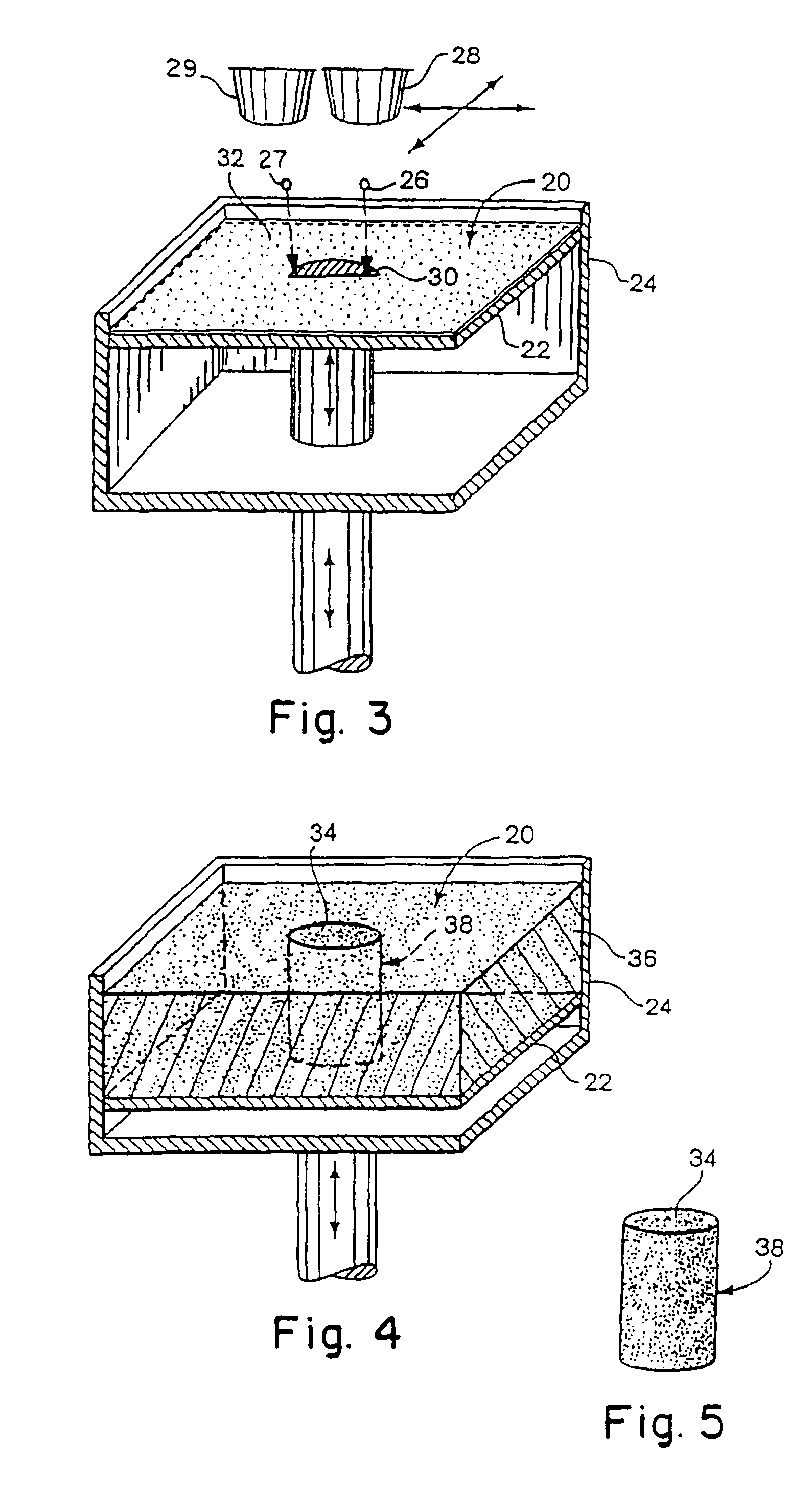

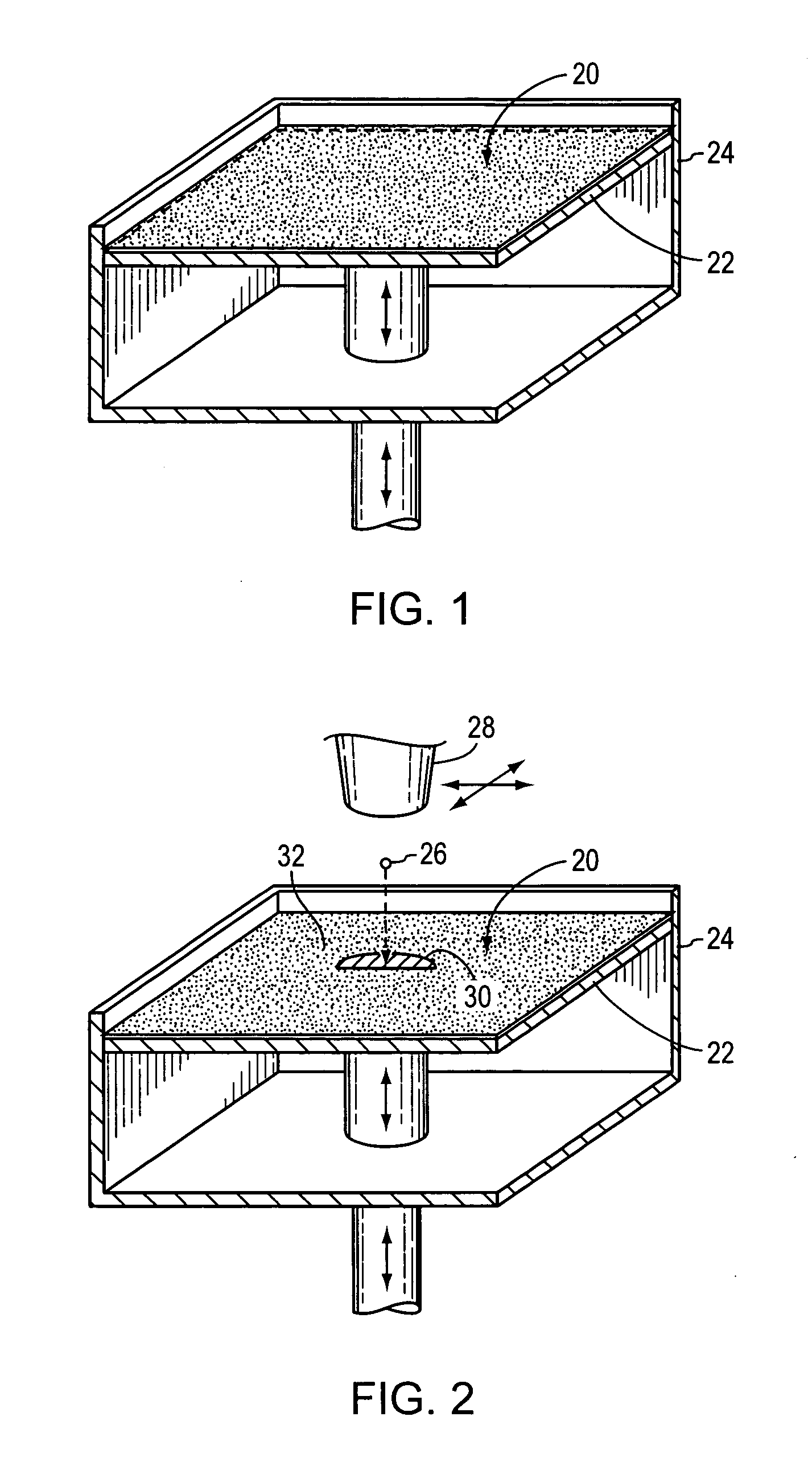

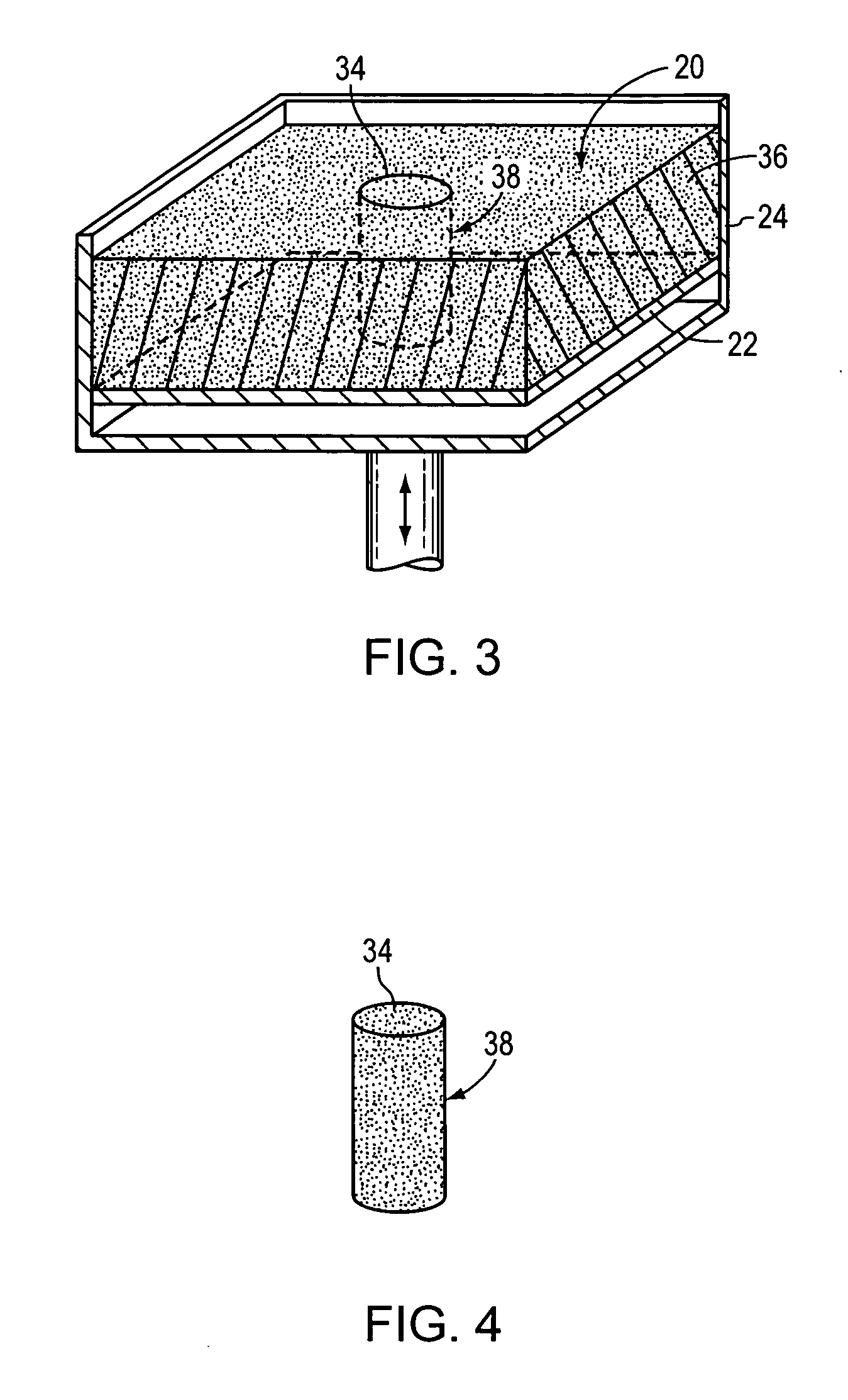

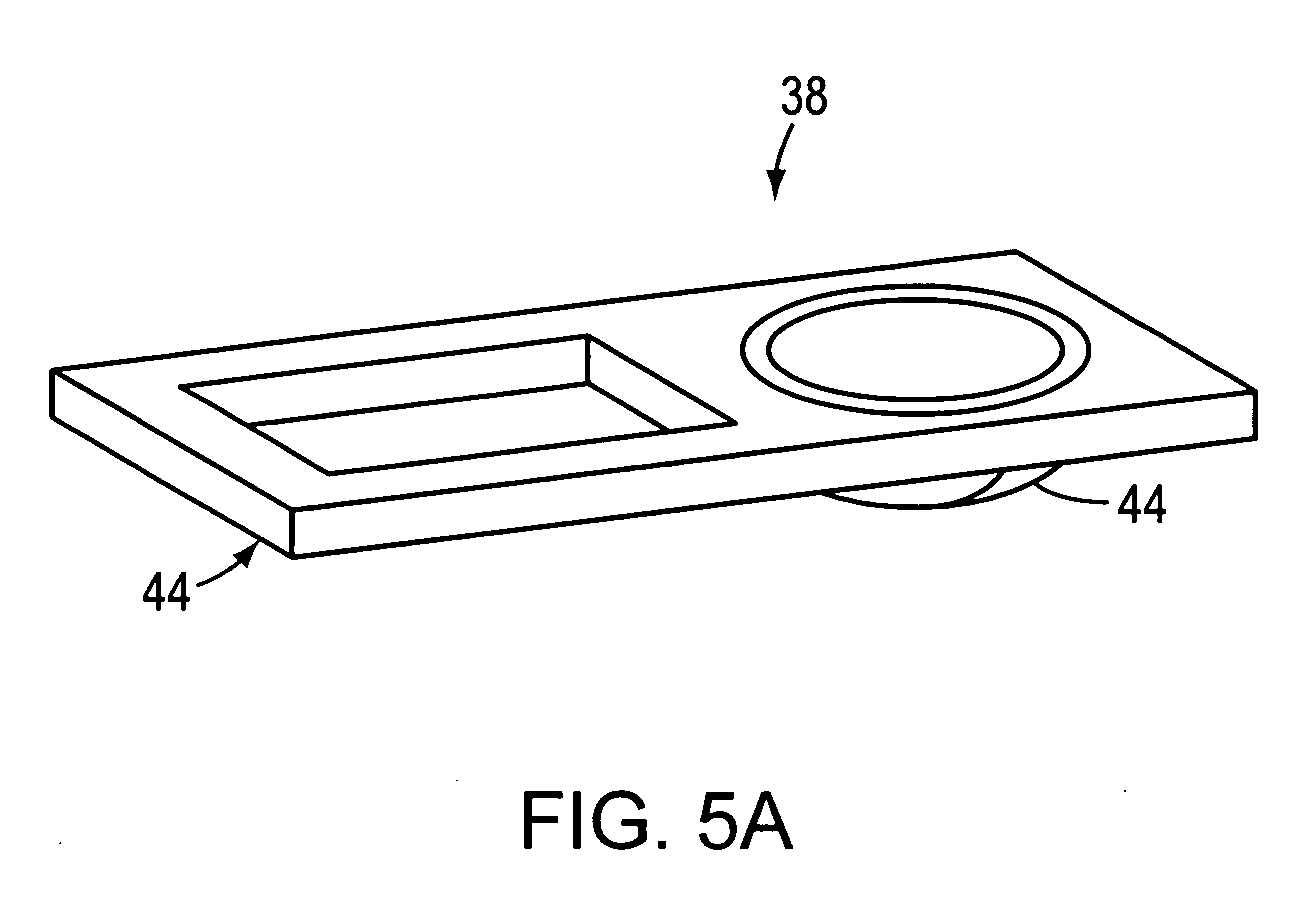

ActiveUS20050017394A1Lower potentialEasy to controlConfectionerySweetmeatsParticulatesBiological activation

New methods and systems for manufacturing a three-dimensional form, comprising steps of providing a plurality of particulates; contacting the particulates with an activation agent; contacting particulates having the activation agent with a binder material that is activatable by the activation agent; at least partially hardening the binder for forming a layer of the three-dimensional form; and repeating these steps to form the remainder of the three-dimensional form. Following sequential application of all required layers and binder material to make the form, the unbound particles are appropriately removed (and optionally re-used), to result in the desired three-dimensional form. The invention also contemplates a novel method for preparing a form, where unbound particulates free of binder material are re-claimed.

Owner:EXONE

Material systems and methods of three-dimensional printing

InactiveUS7795349B2Adhesive processesAdditive manufacturing apparatusEngineering3 dimensional printing

The present invention is directed to three-dimensional printing material systems and method, and an article made therefrom. The method of the present invention includes building cross-sectional portions of a three-dimensional article, and assembling the individual cross-sectional areas in a layer-wise fashion to form a final article. The individual cross-sectional areas are built by using an ink-jet printhead to deliver a fluid to a particulate material that includes particulate material.

Owner:3D SYST INC

Absorbent fillers for three-dimensional printing

InactiveUS20050059757A1Quick and reliable and safe and inexpensiveSmooth surface finishPigmenting treatmentAdditive manufacturing apparatusParticulatesEngineering

A materials system and methods are provided to enable the formation of articles by three-dimensional printing. The materials system includes an absorbent particulate filler that facilitates absorption of infiltrants, thereby allowing the accurate definition of articles with enhanced mechanical and structural characteristics. The methods include the use of phase-change materials to bind a powder, as well as the formation of support structures to improve the control of the shape of the articles.

Owner:Z CORPORATION

Method for rapid forming of a ceramic work piece

InactiveUS6217816B1Rapid productionPrevent dislocationAdditive manufacturing apparatusFeeding arrangmentsHeat fusionLaser beams

An inorganic binder and a dissolving agent are put into ceramic powder. They are mixed to form a plastic green mixture. Then the said mixture is formed into a thin green layer. Preferably, this thin green layer will be preheated and dried such that the thin green layer will be hardened due to the bonding effect of the inorganic binder. A portion of the thin green layer exposed under a directed high-energy beam is sintered, preferably by a laser beam, to cause ceramic molecules to bond together locally due to heat fusion. By controlling the scanning path of the high-energy beam, a two-dimensional thin cross section of the ceramic part in arbitrary form can be produced. A second thin ceramic layer can be built onto the first thin ceramic layer and bonded to it by the same method. After multiple repetitions of this procedure a three dimensional ceramic part can be fabricated layer upon layer. The green portion, which is not scanned by the high-energy beam, will be removed with suitable method. A ceramic part can be rapidly produced in this way.

Owner:NAT SCI COUNCIL

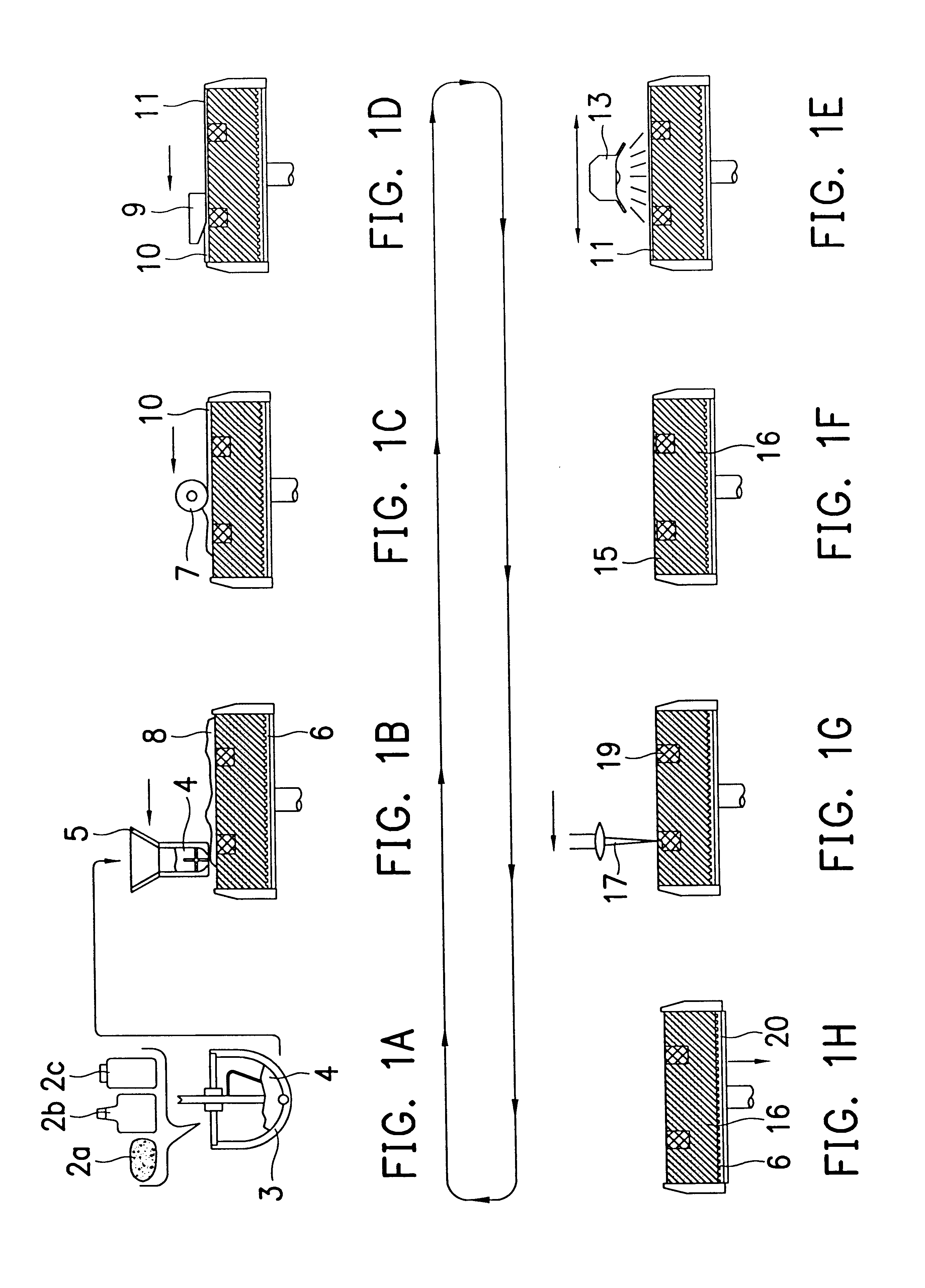

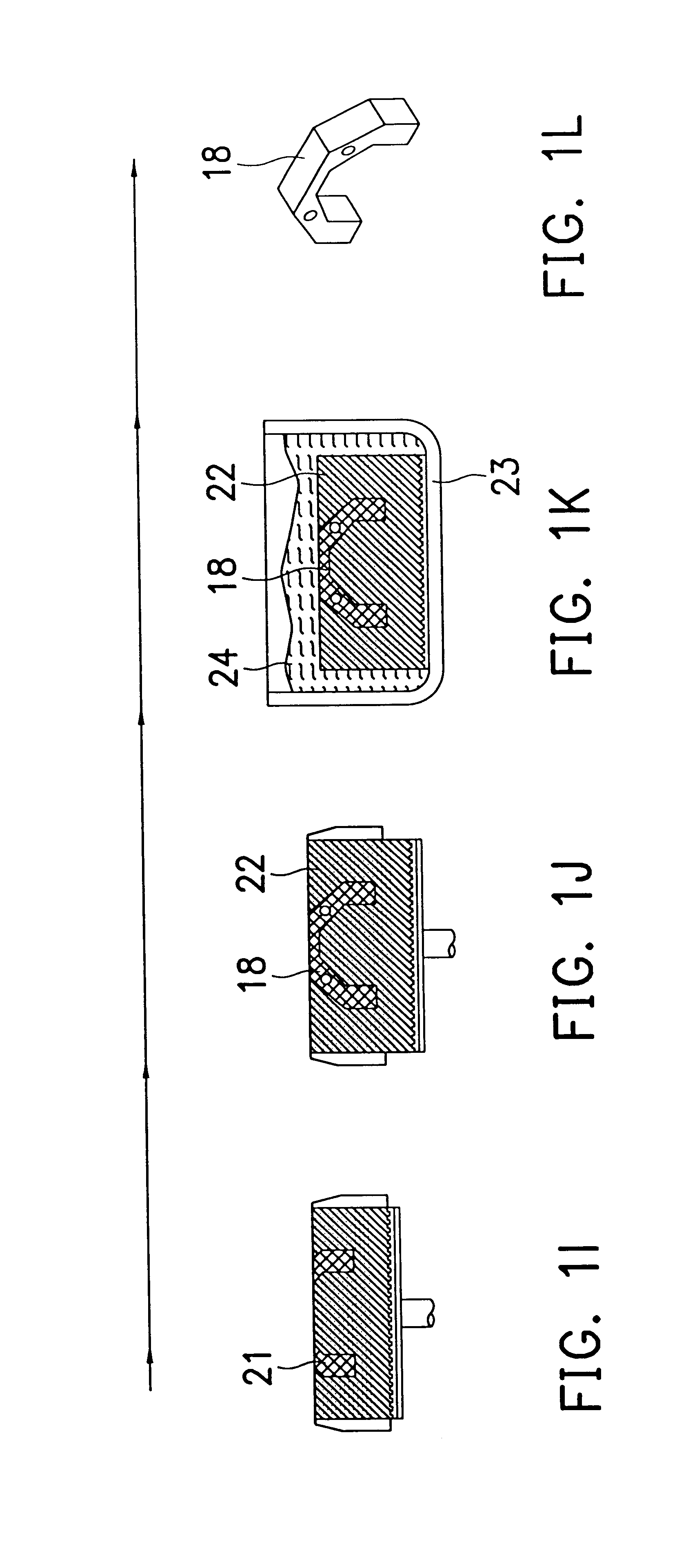

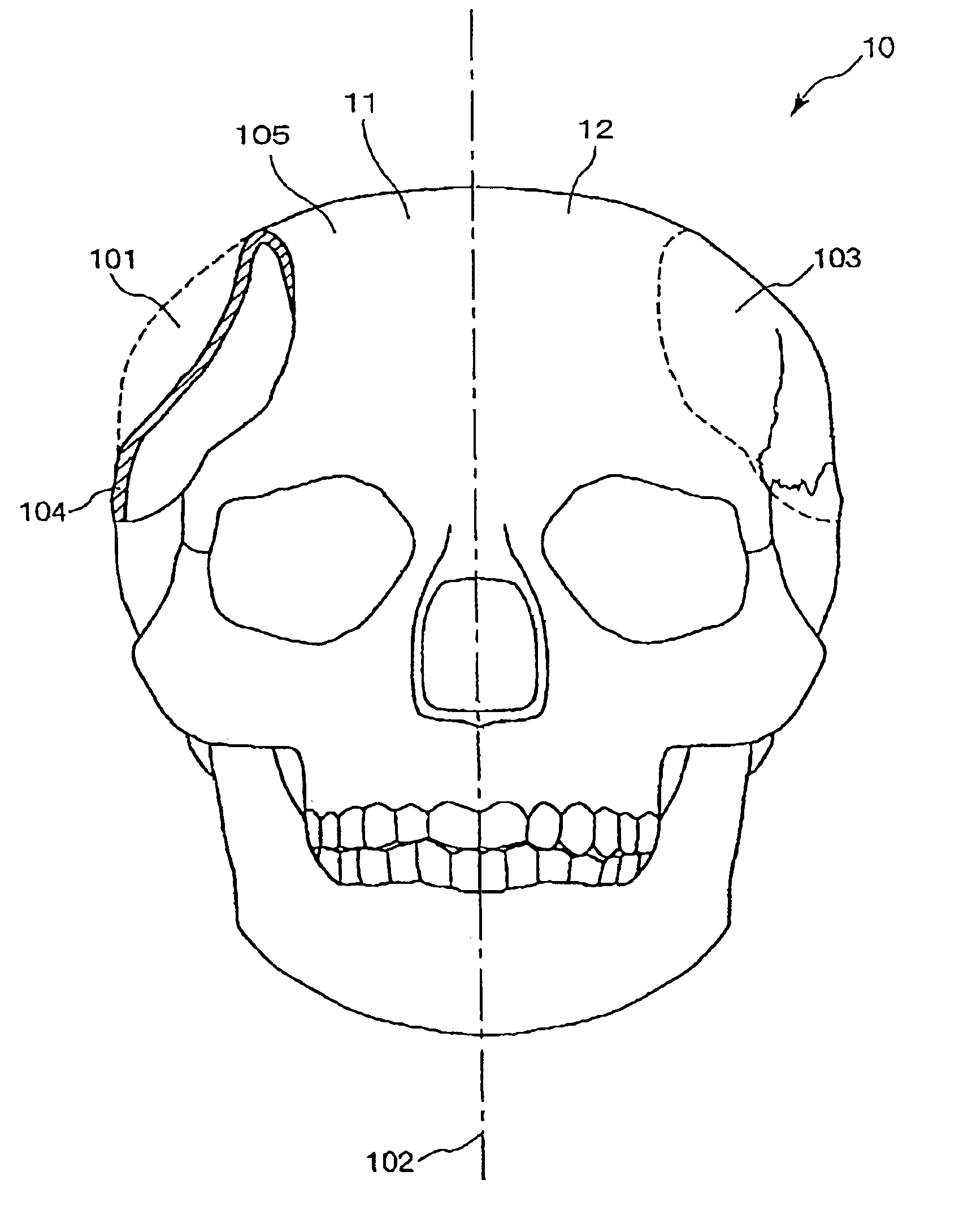

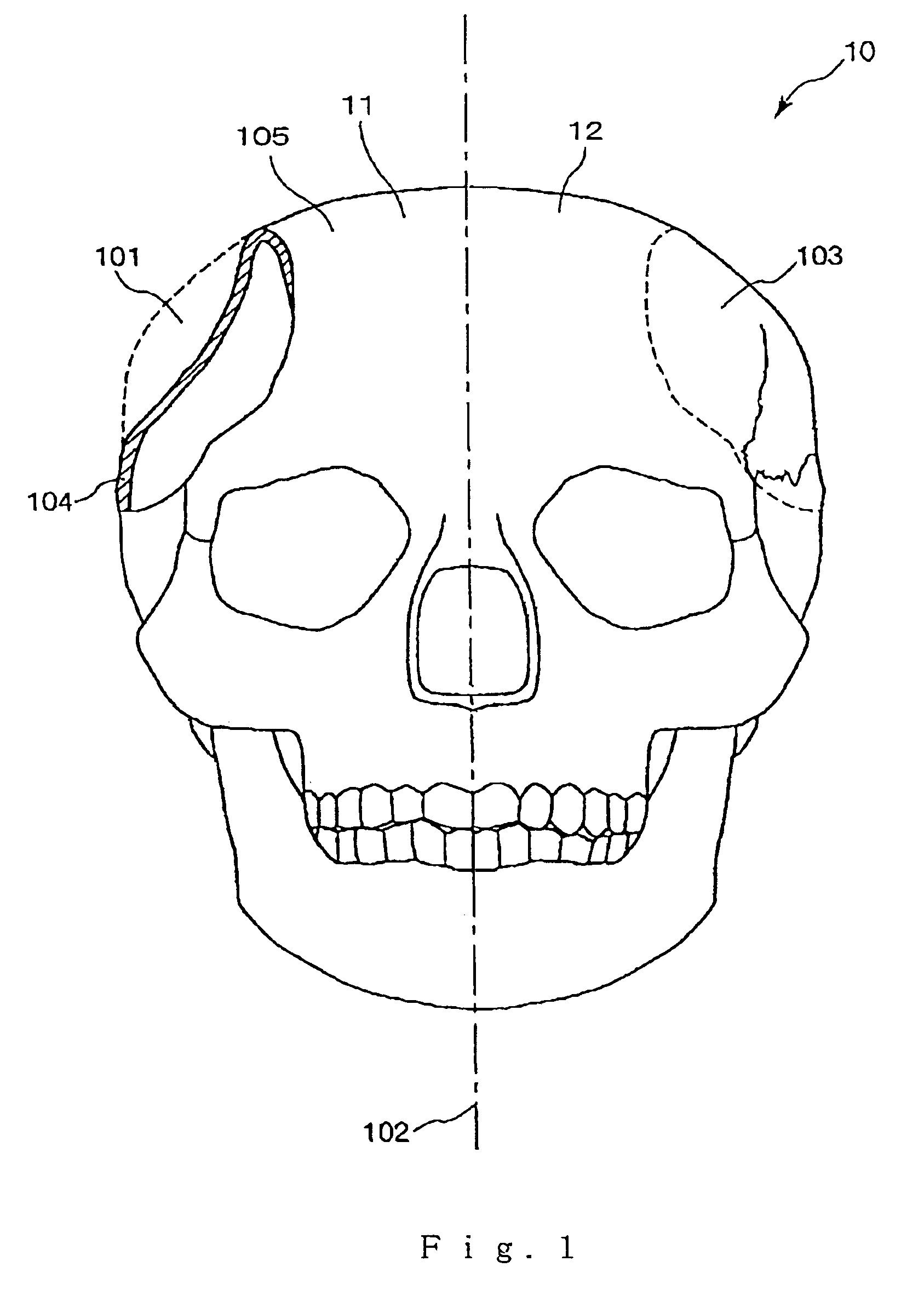

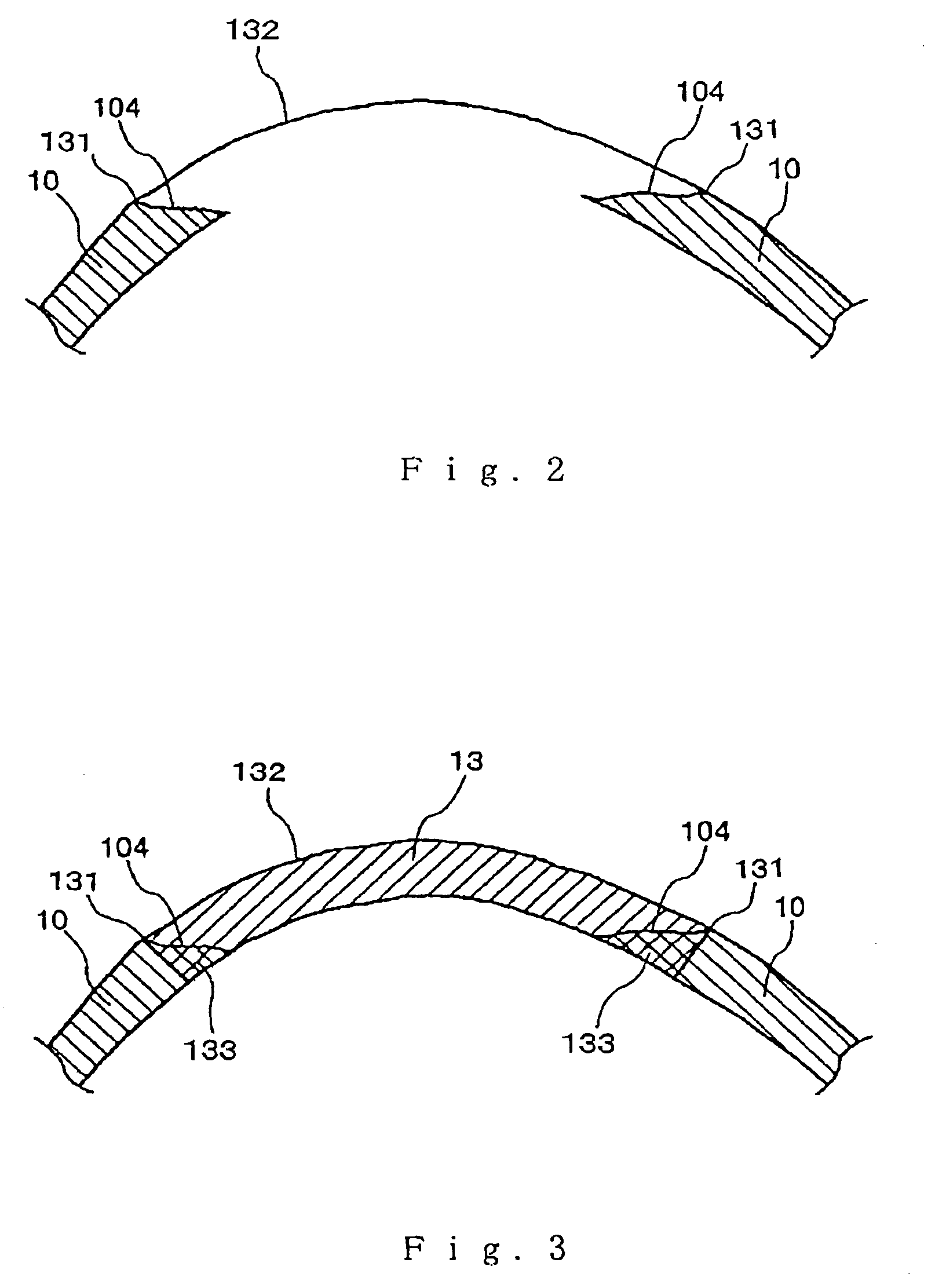

Method for modeling an implant and an implant manufactured by the method

InactiveUS7050877B2Good biocompatibilityStrong shape adaptabilitySurgeryPerson identificationTomographic imageBiomedical engineering

A method for modeling an implant to be applied to a defect of a bone comprises the steps of obtaining a plurality of tomographic image data of the bone based on measurement data by MRI, producing three-dimensional image data of the bone based on the plurality of tomographic image data, and estimating a shape of a missing born that was previously present or should have been present in the defect of the bone to obtain three-dimensional data of the implant. The estimating step comprises the steps of estimating a provisional shape of the implant which has a contour conformable with the shape of a contour of periphery of the side walls of the defect at the distal surface of the bone and has a predetermined thickness; and deleting data of portions of the provisional shape of the implant that overlap the bone from the data of the provisional shape of the implant so that the three-dimensional data of the implant has an outer peripheral shape that is conformable with the shape of the side walls of the defect.

Owner:ASAHI KOGAKU KOGYO KK +1

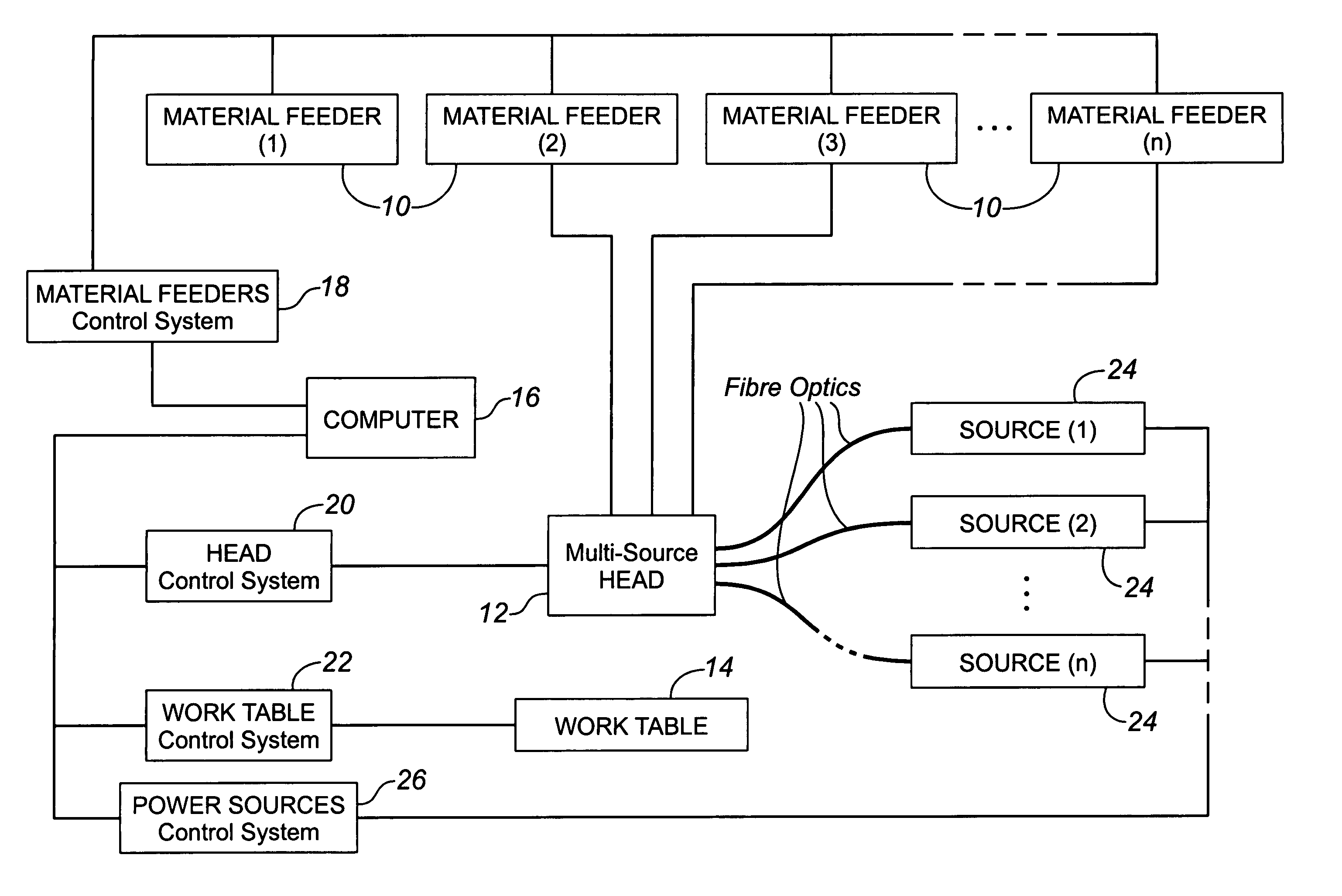

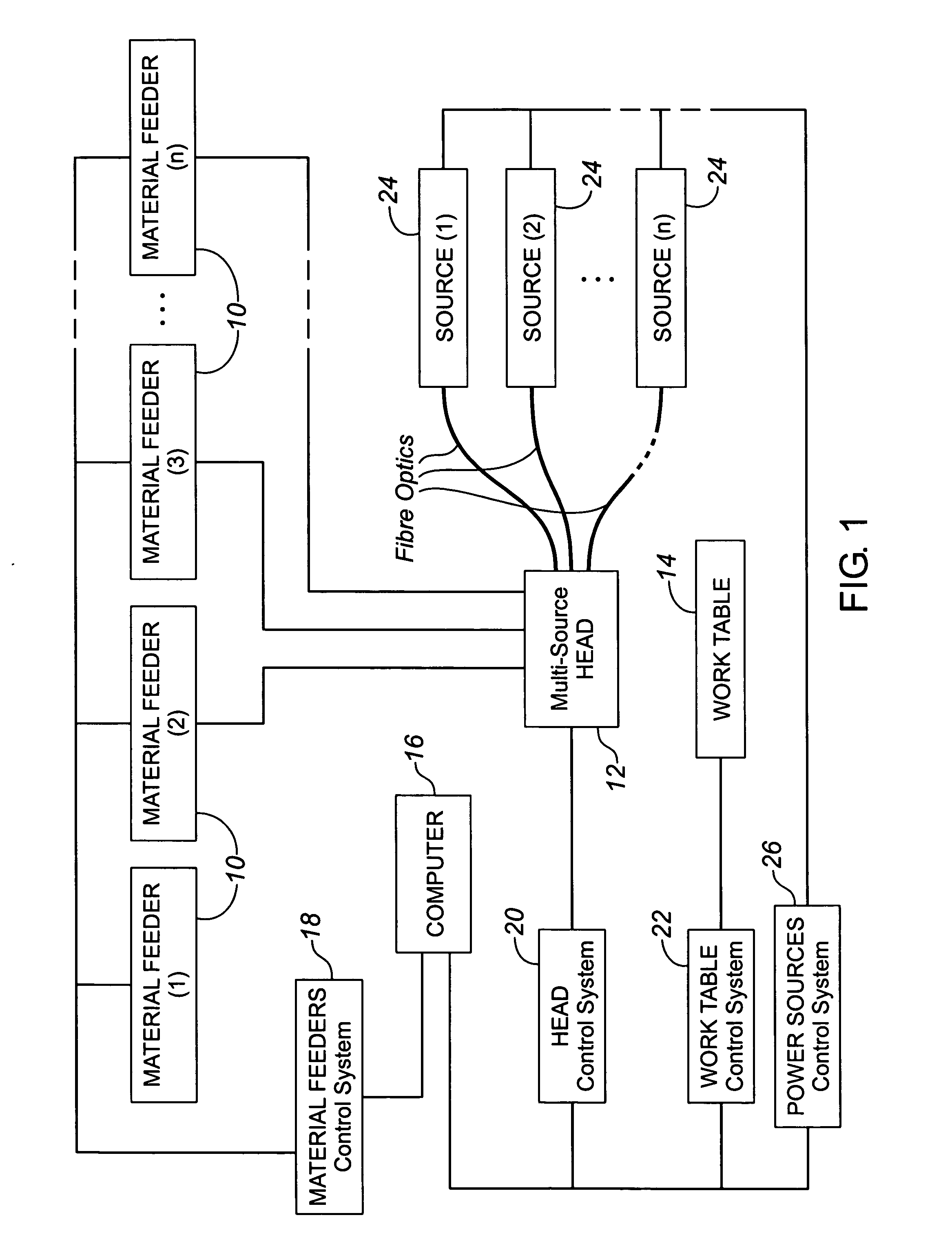

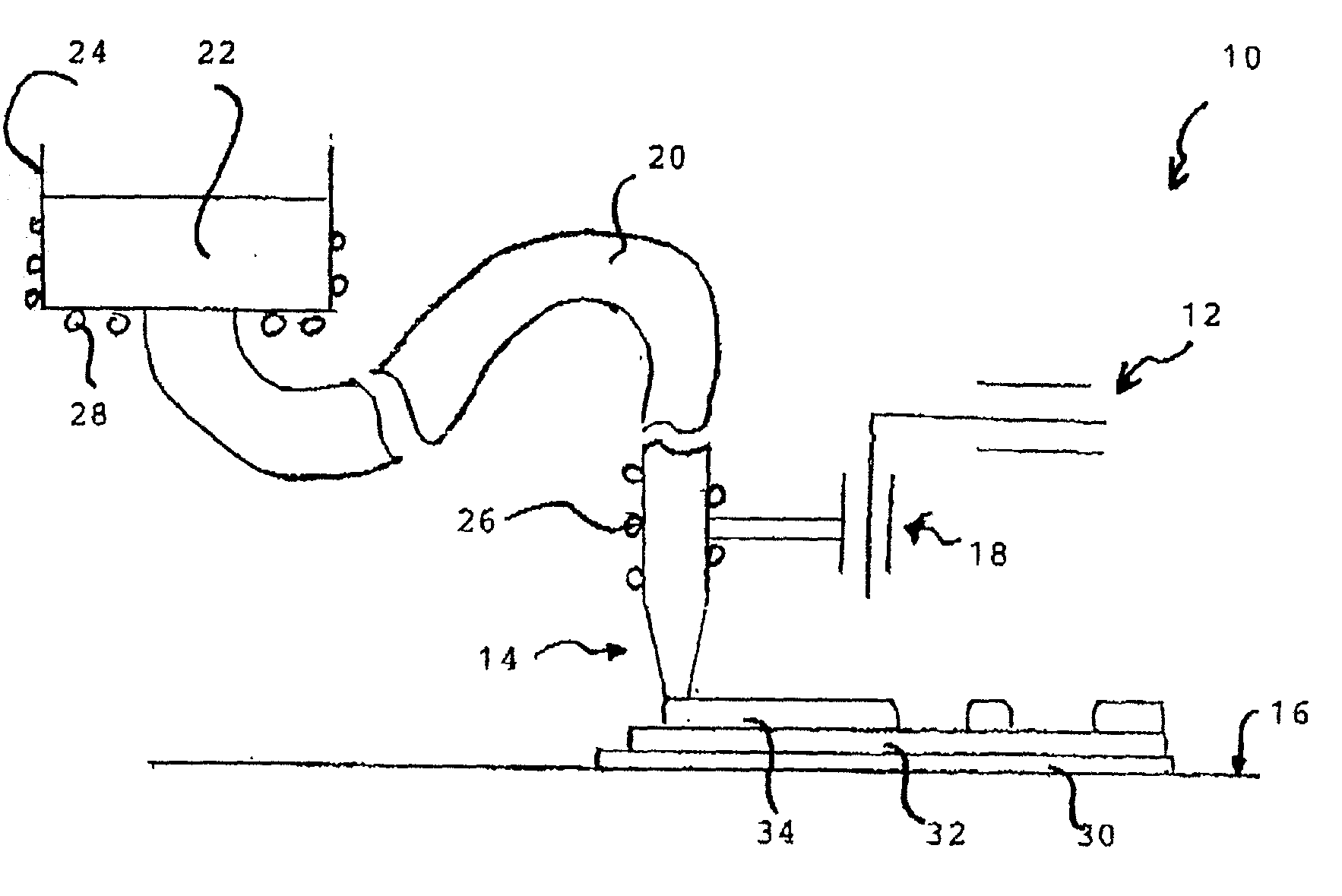

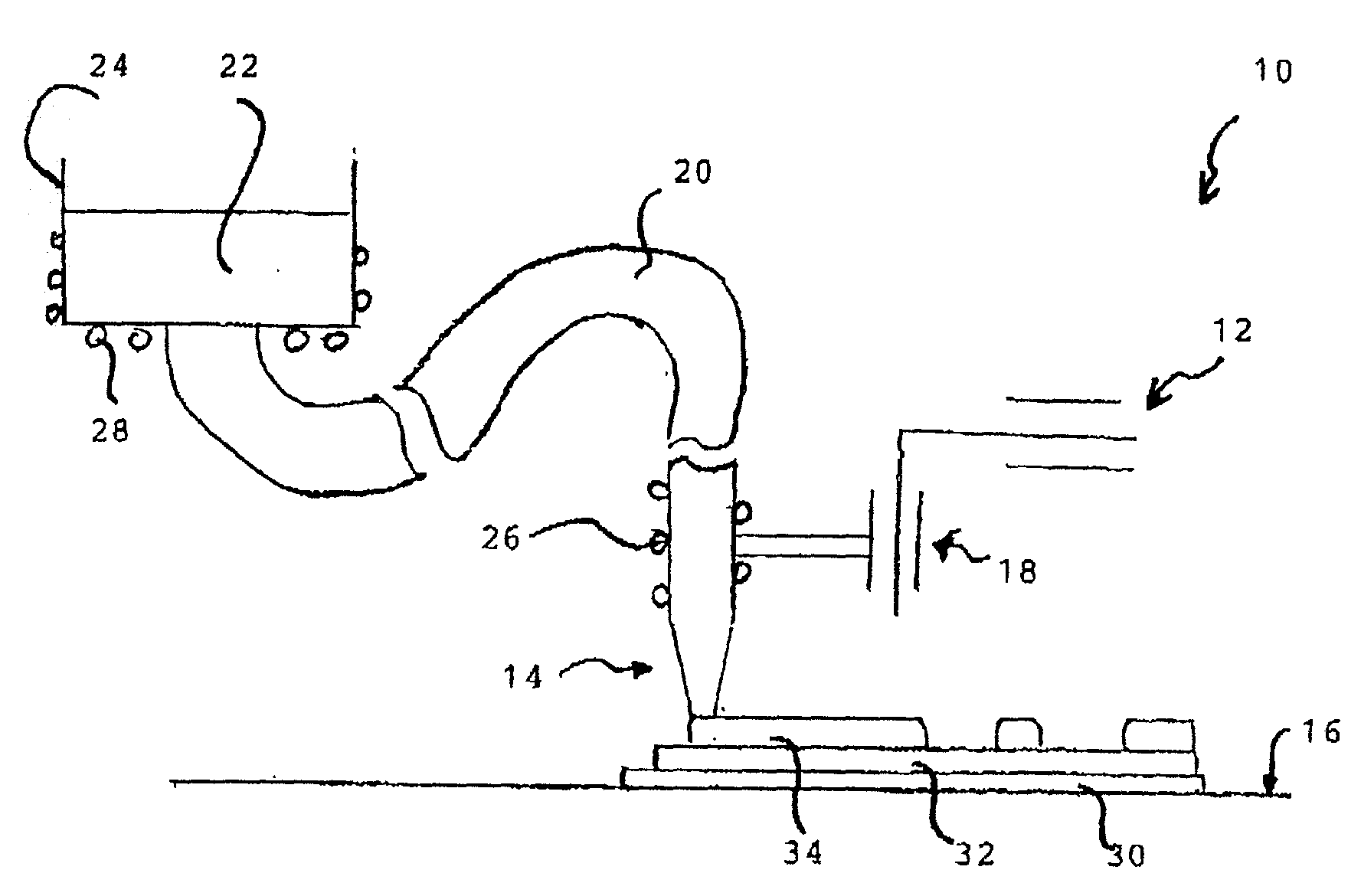

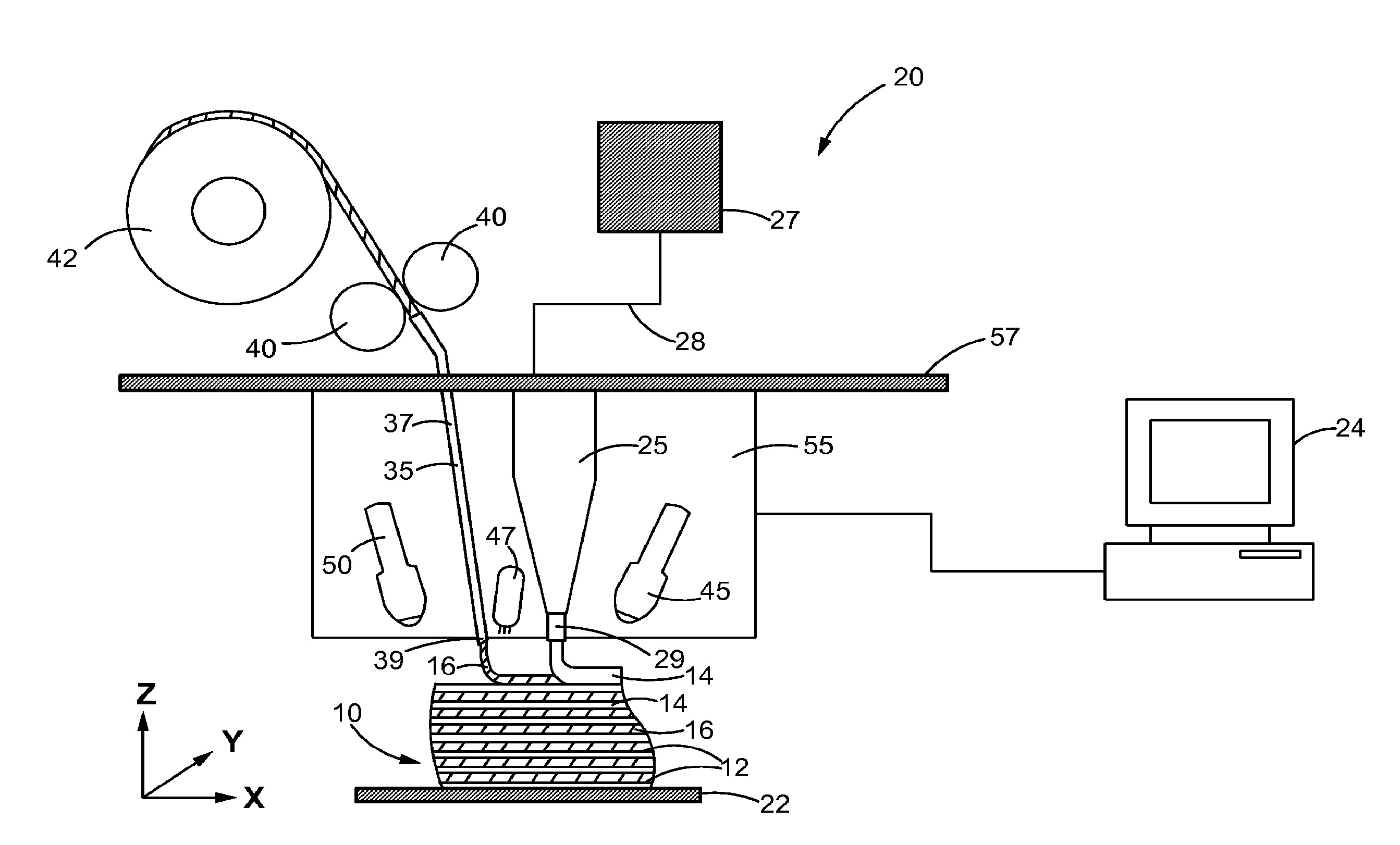

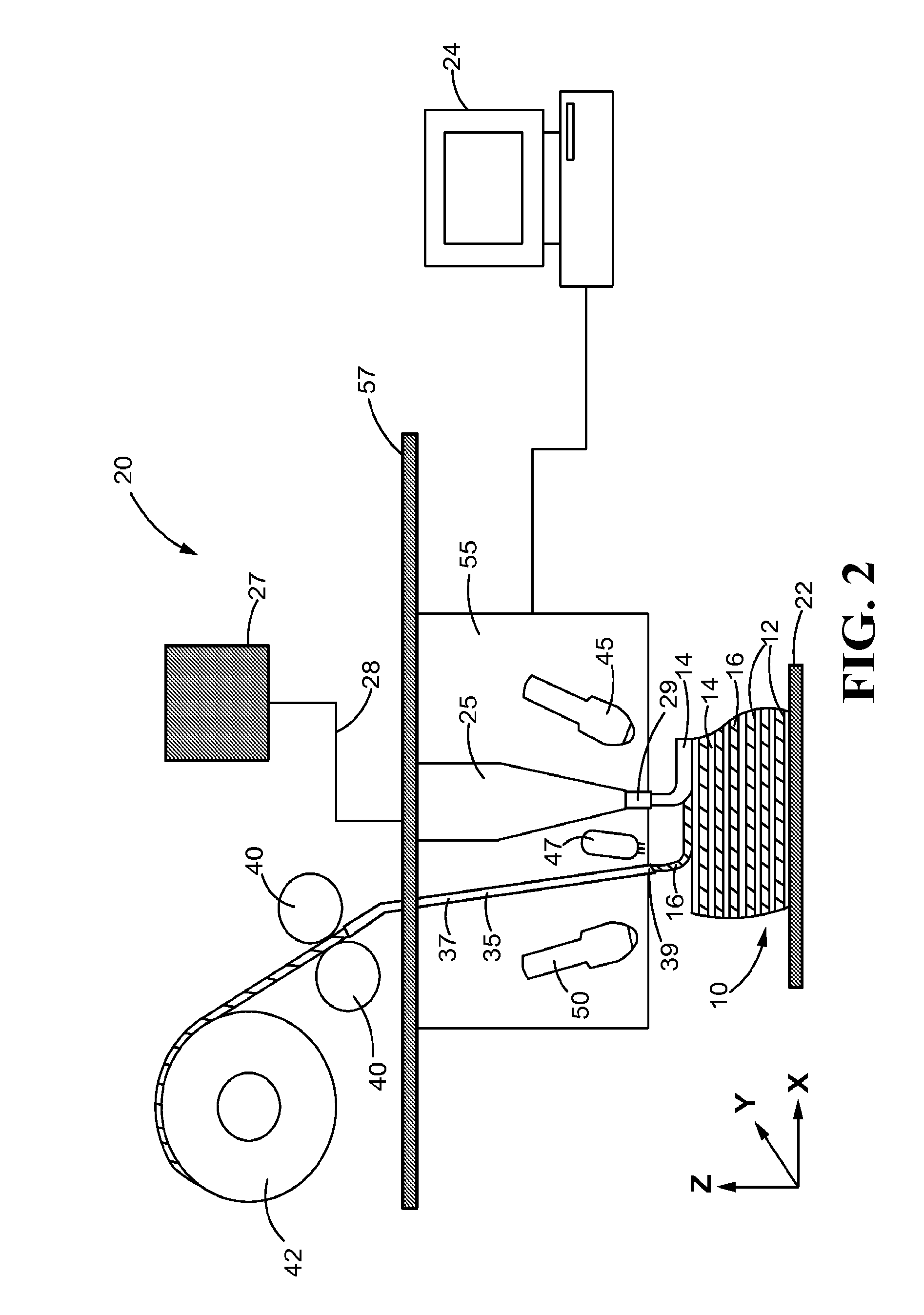

Multisource and multimaterial freeform fabrication

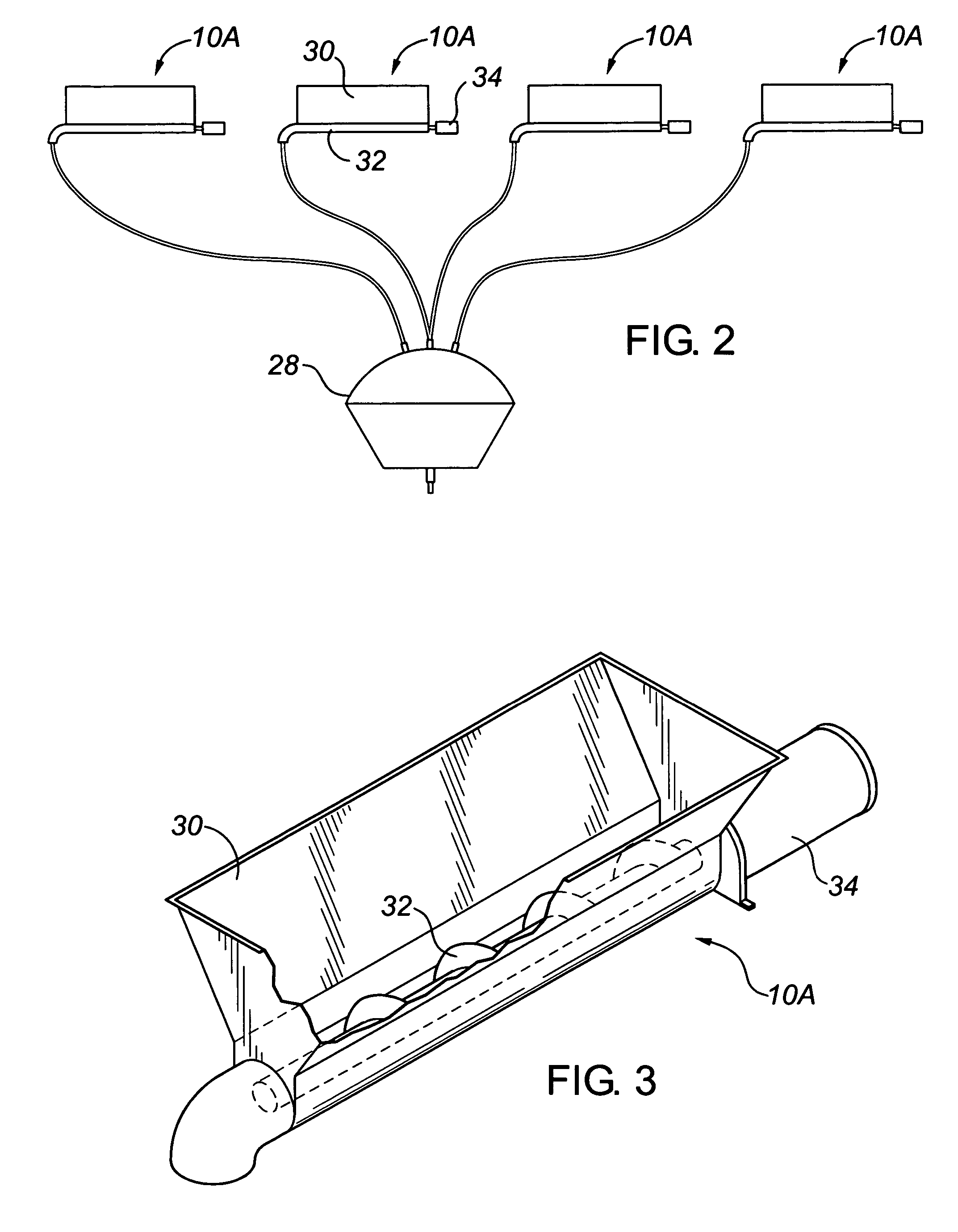

InactiveUS20050104257A1Liquid surface applicatorsMechanical working/deformationControl systemEngineering

An apparatus for forming freeform solid articles includes a head unit having a plurality of arc-shaped support arms. The support arms mount material feeders and power sources which are directed at a work table. The material feeders, power sources and movement of the head unit and work table are controlled by a computerized control system.

Owner:UNIV TECH INT

Method and Apparatus for Additive Mechanical Growth of Tubular Structures

InactiveUS20160031155A1High strengthEliminate needLiquid surface applicatorsManufacturing driving meansAdditive layer manufacturing3D printing

Owner:CONTINUOUS COMPOSITES INC

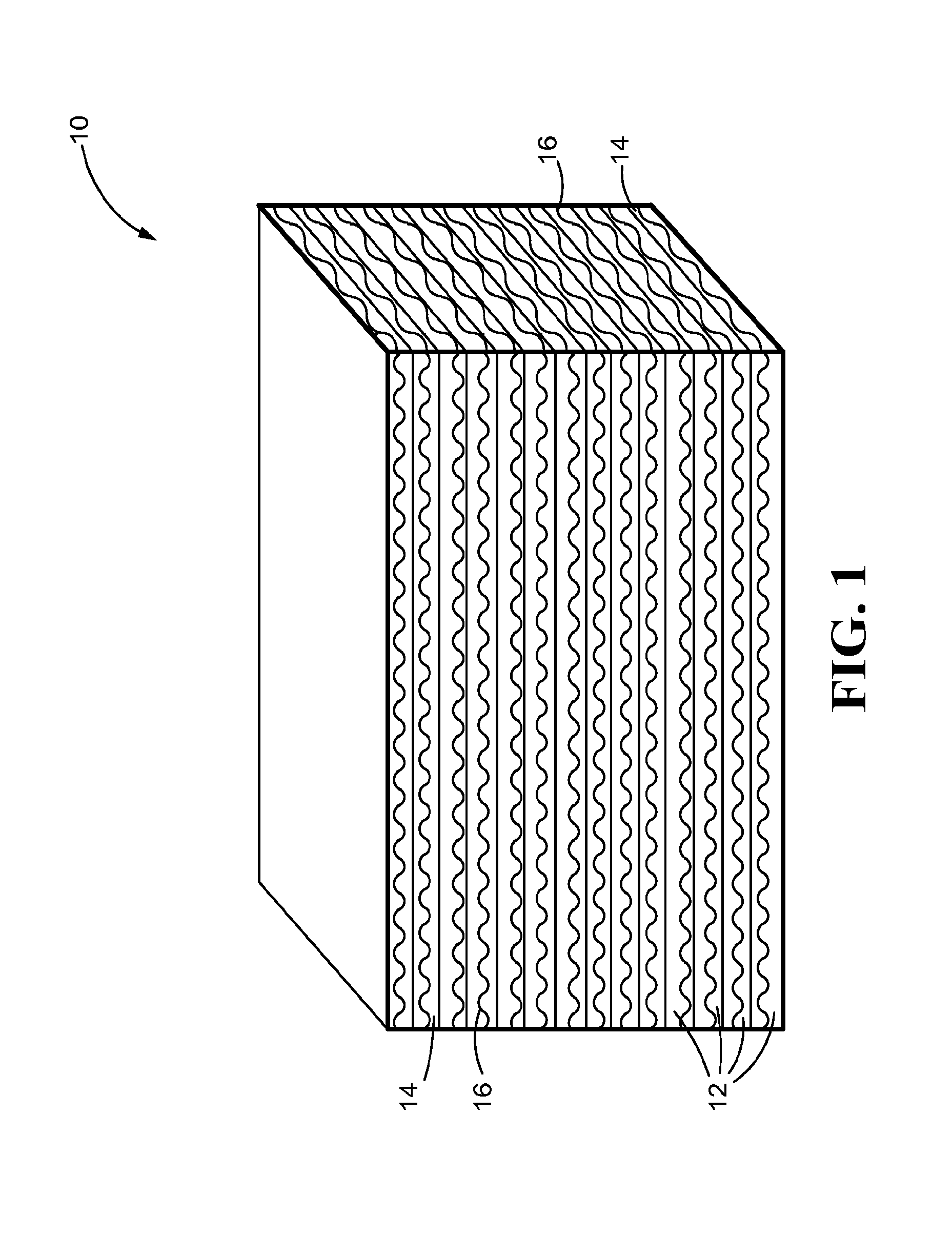

Fibers and methods for use in solid freeform fabrication

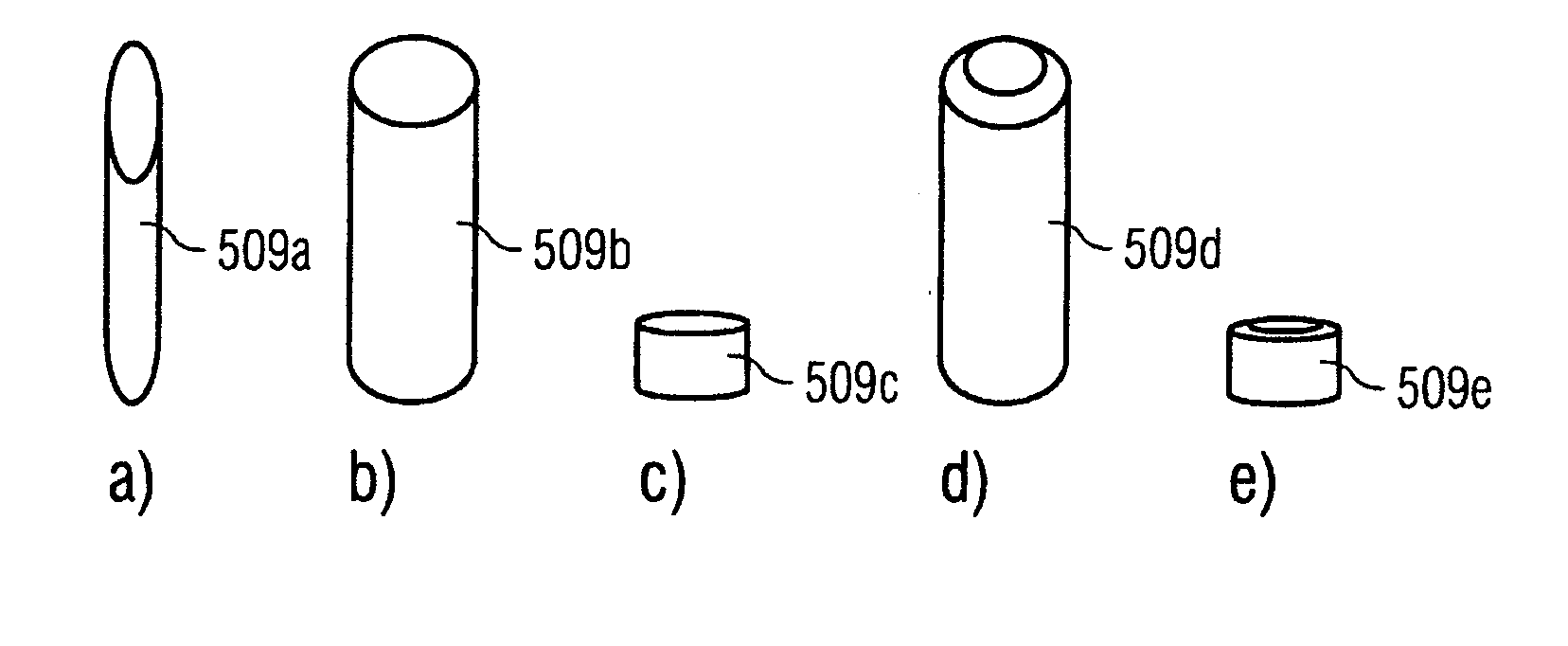

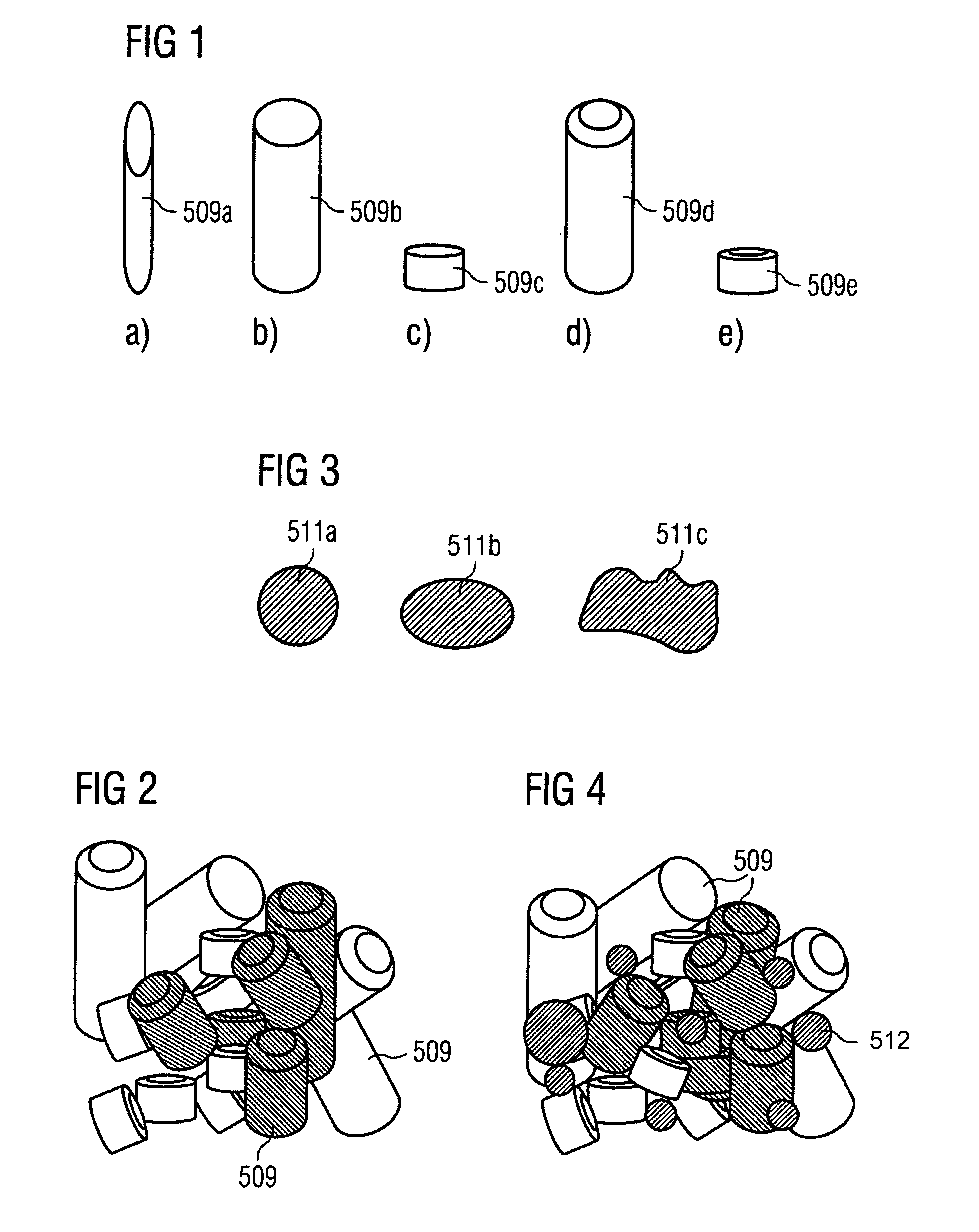

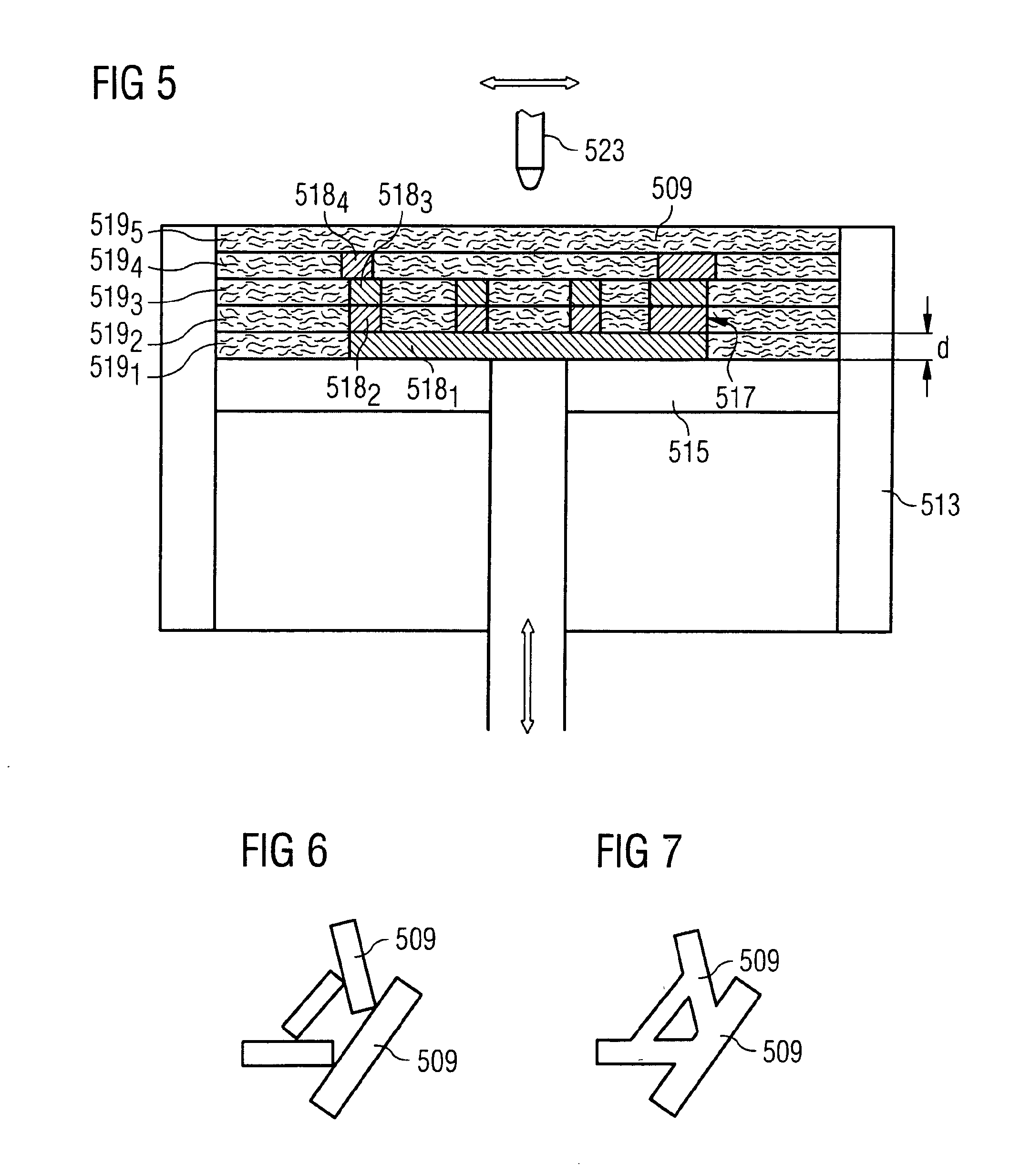

ActiveUS20110143108A1Easy to produceSpecific characteristicAdditive manufacturing apparatusSynthetic resin layered productsFiberRapid prototyping

A shaped body comprised of individual, interconnected layers may be produced from fibers in accordance with a solid freeform fabrication or rapid prototyping method. The fibers may be produced by extrusion molding a thermoplastic material.

Owner:EVONIK OPERATIONS GMBH

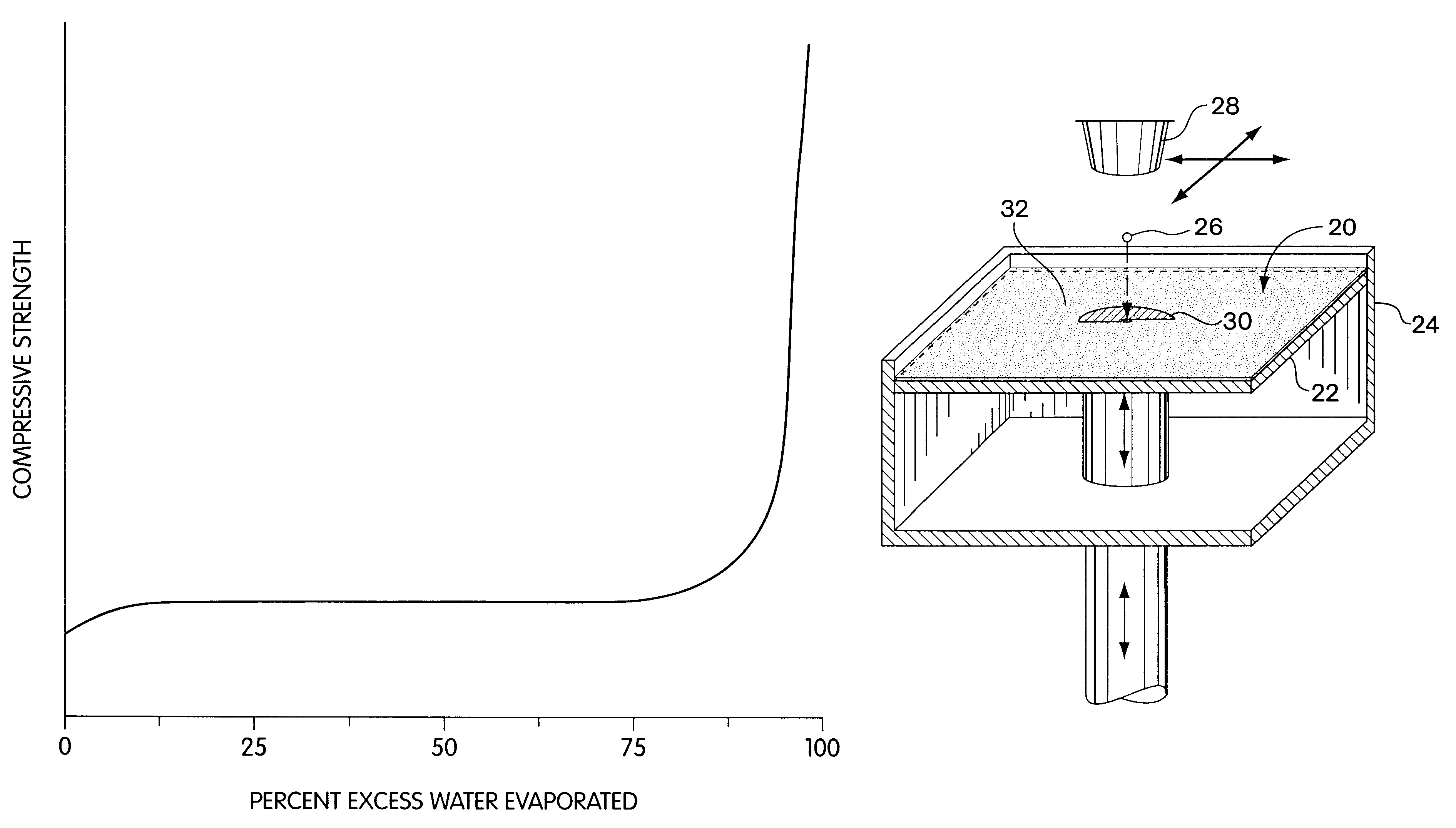

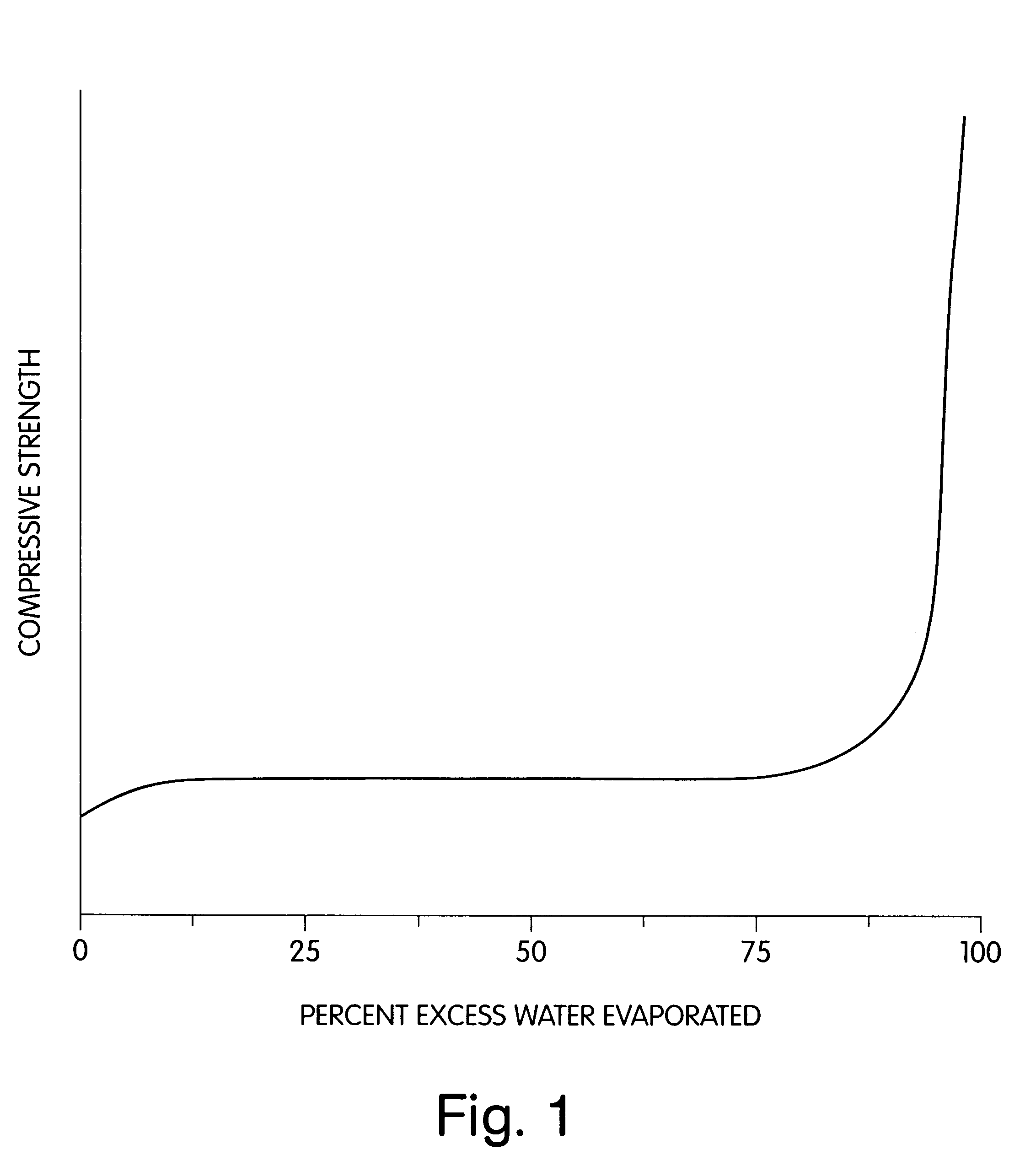

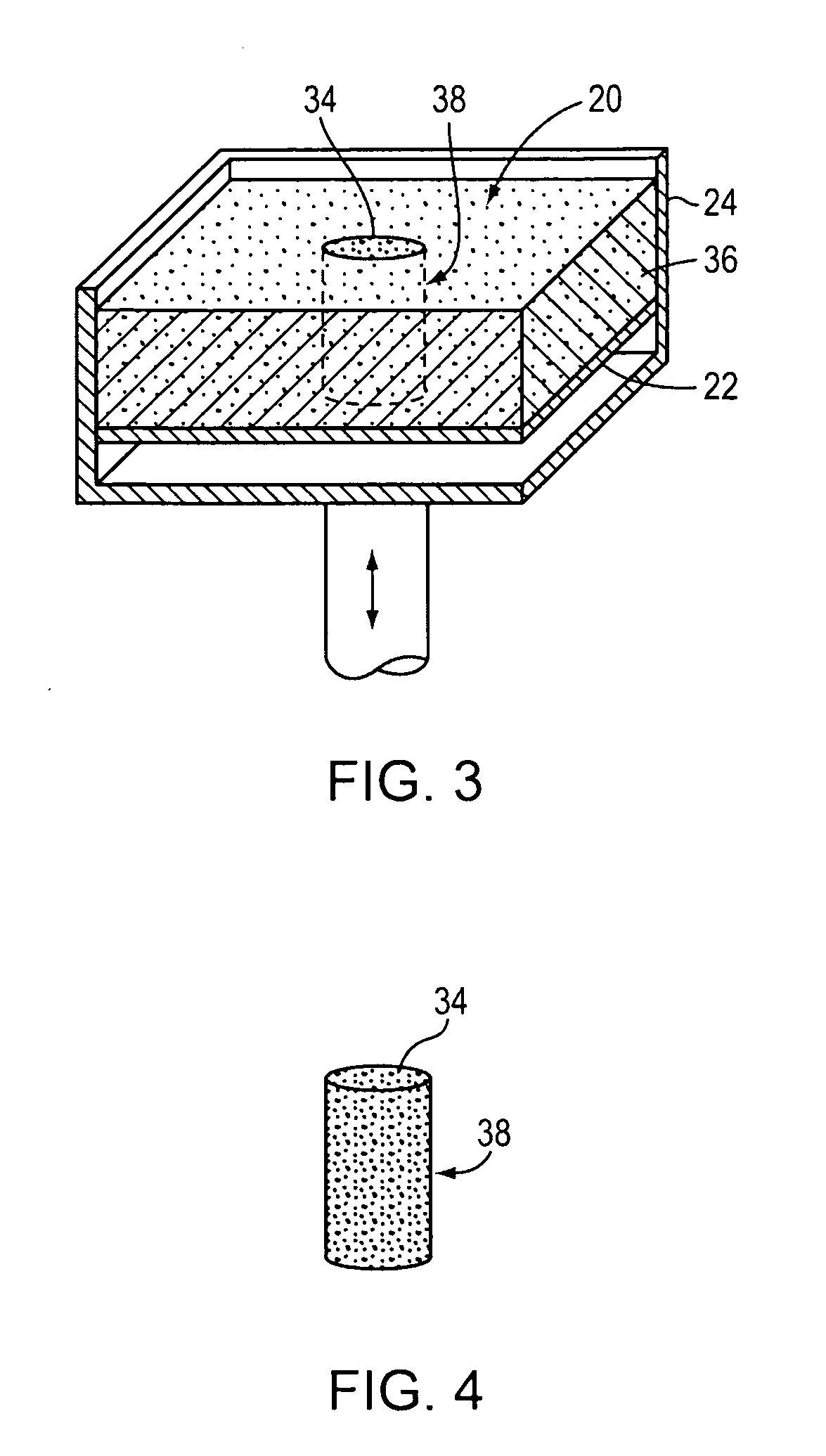

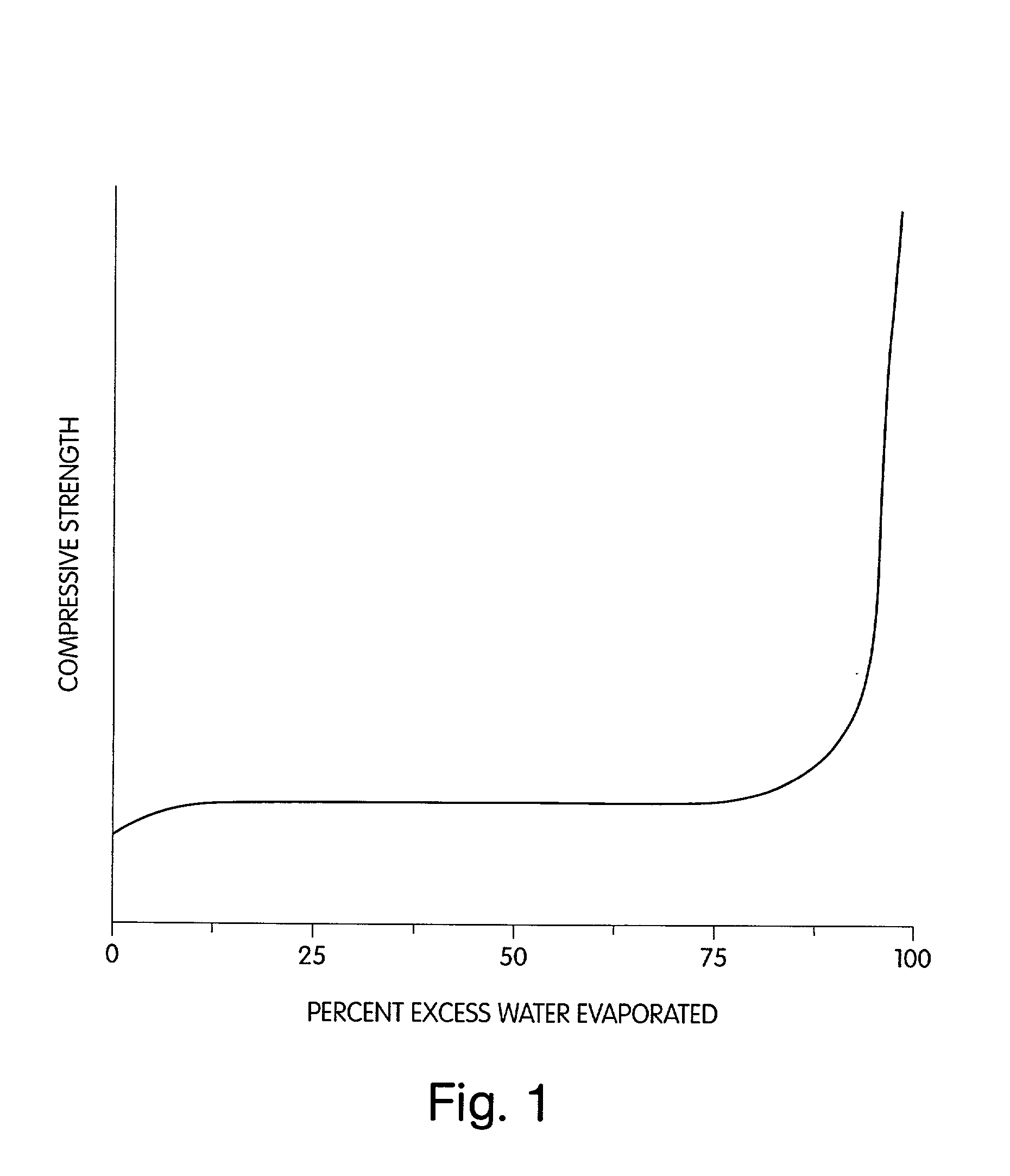

Three dimensional printing material system and method

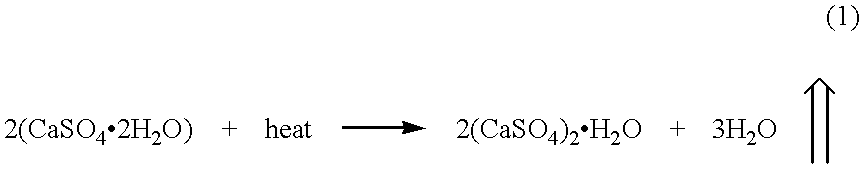

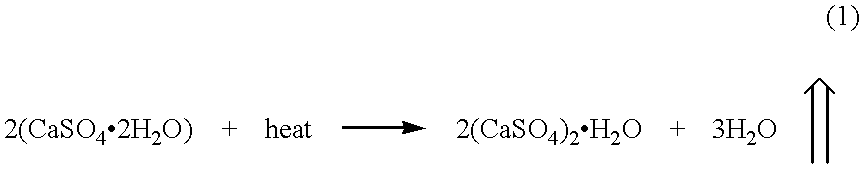

InactiveUS6610429B2High strengthReduce the amount of solutionAdditive manufacturing apparatusLamination ancillary operationsEngineeringLayer wise

The present invention is directed to a 3DP(TM) material system ad method, and an article made therefrom. The method of the present invention includes building cross-sectional portions of a three-dimensional article, and assembling the individual cross-sectional areas in a layer-wise fashion to form a final article. The individual cross-sectional areas are built by using an ink-jet printhead to deliver an aqueous fluid to a particulate material that includes plaster.

Owner:3D SYST INC

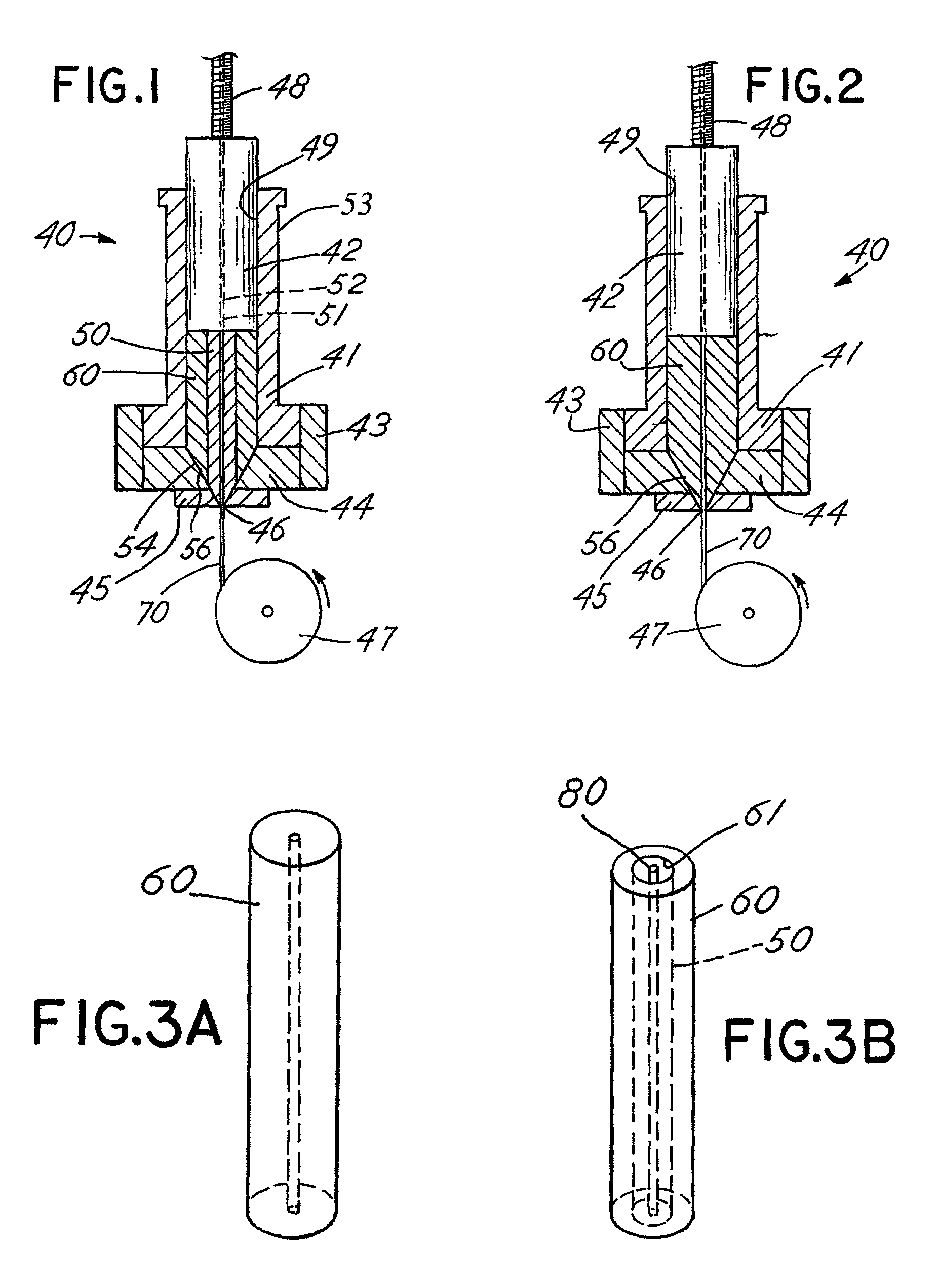

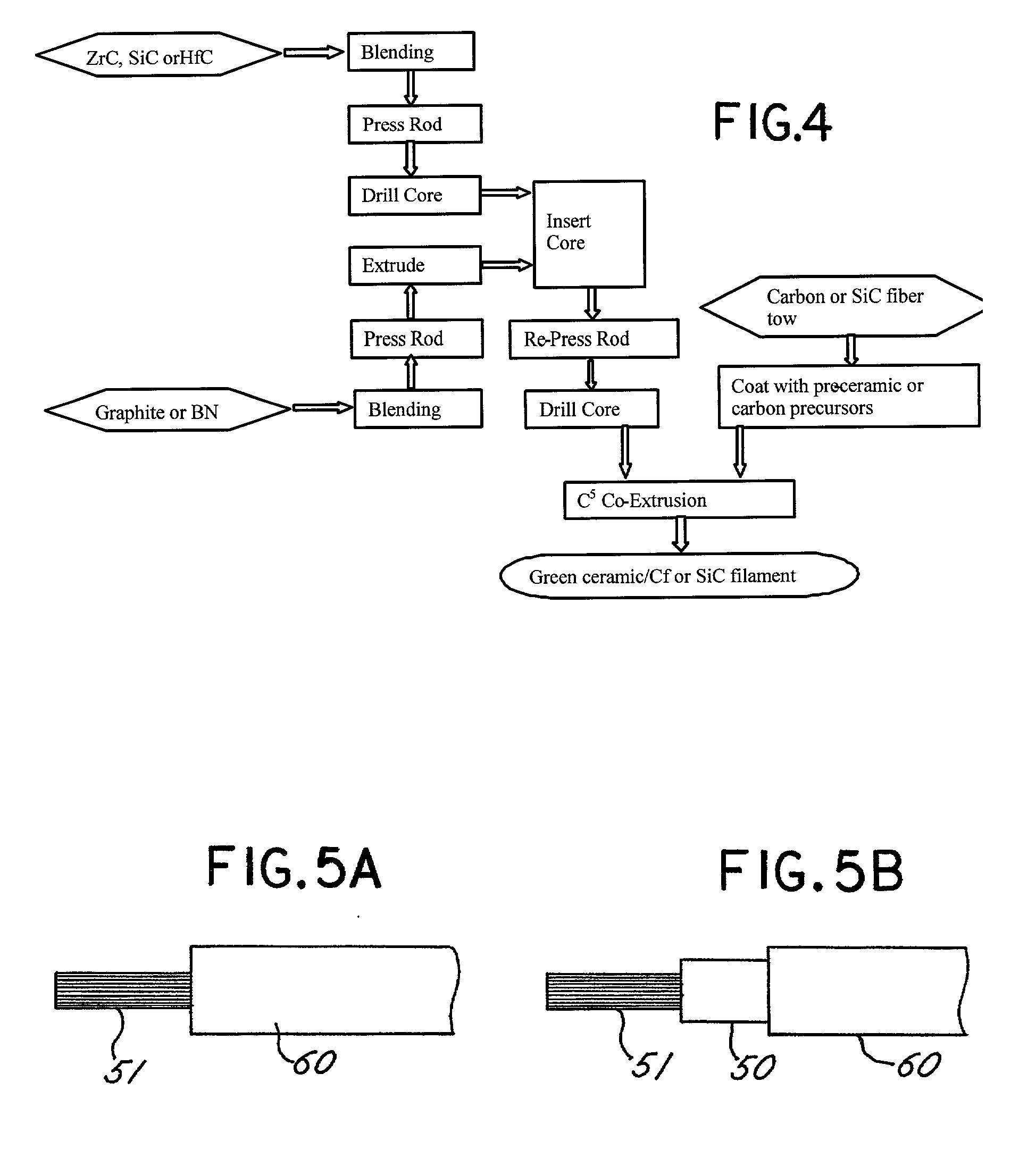

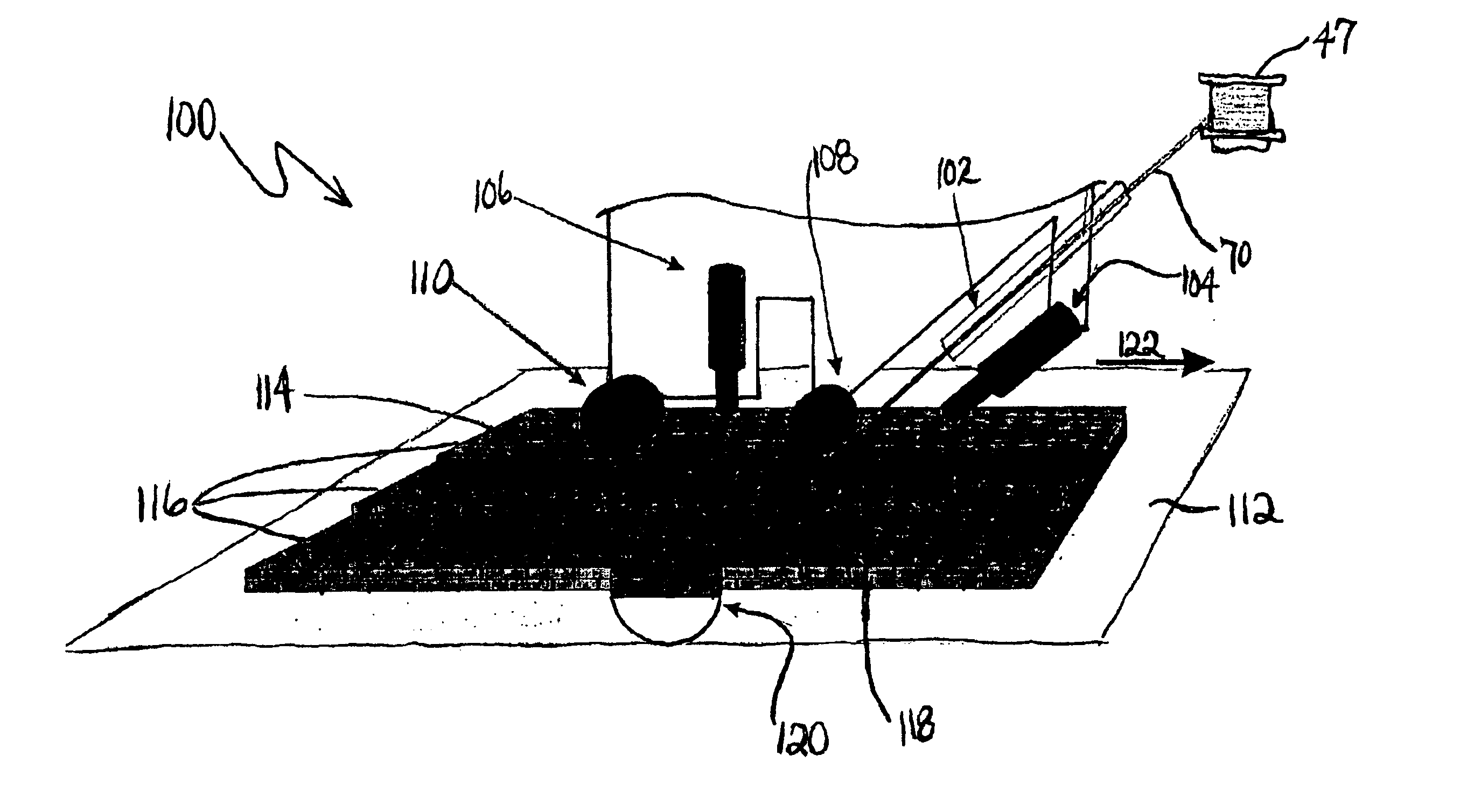

Continuous fiber reinforced composites and methods, apparatuses, and compositions for making the same

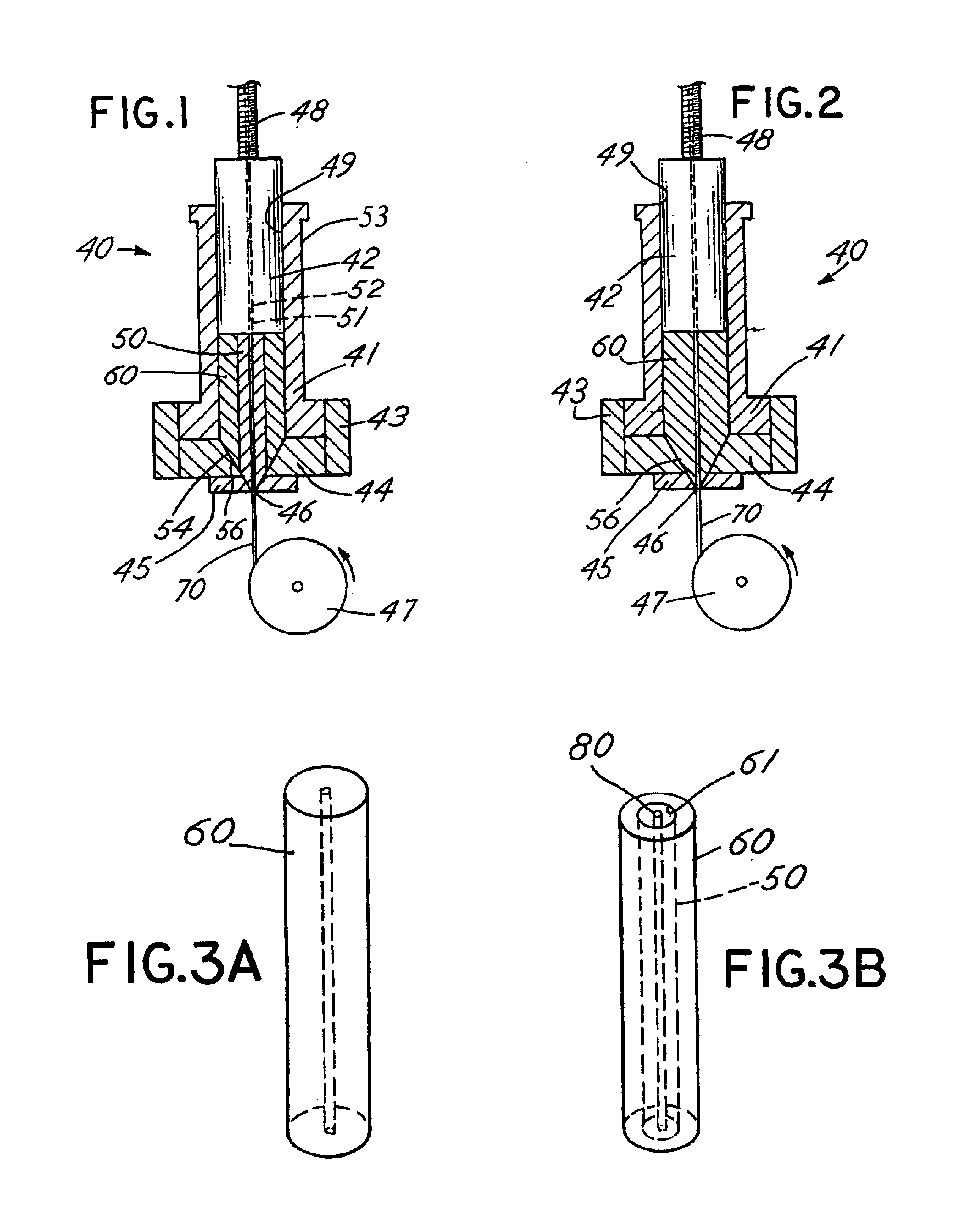

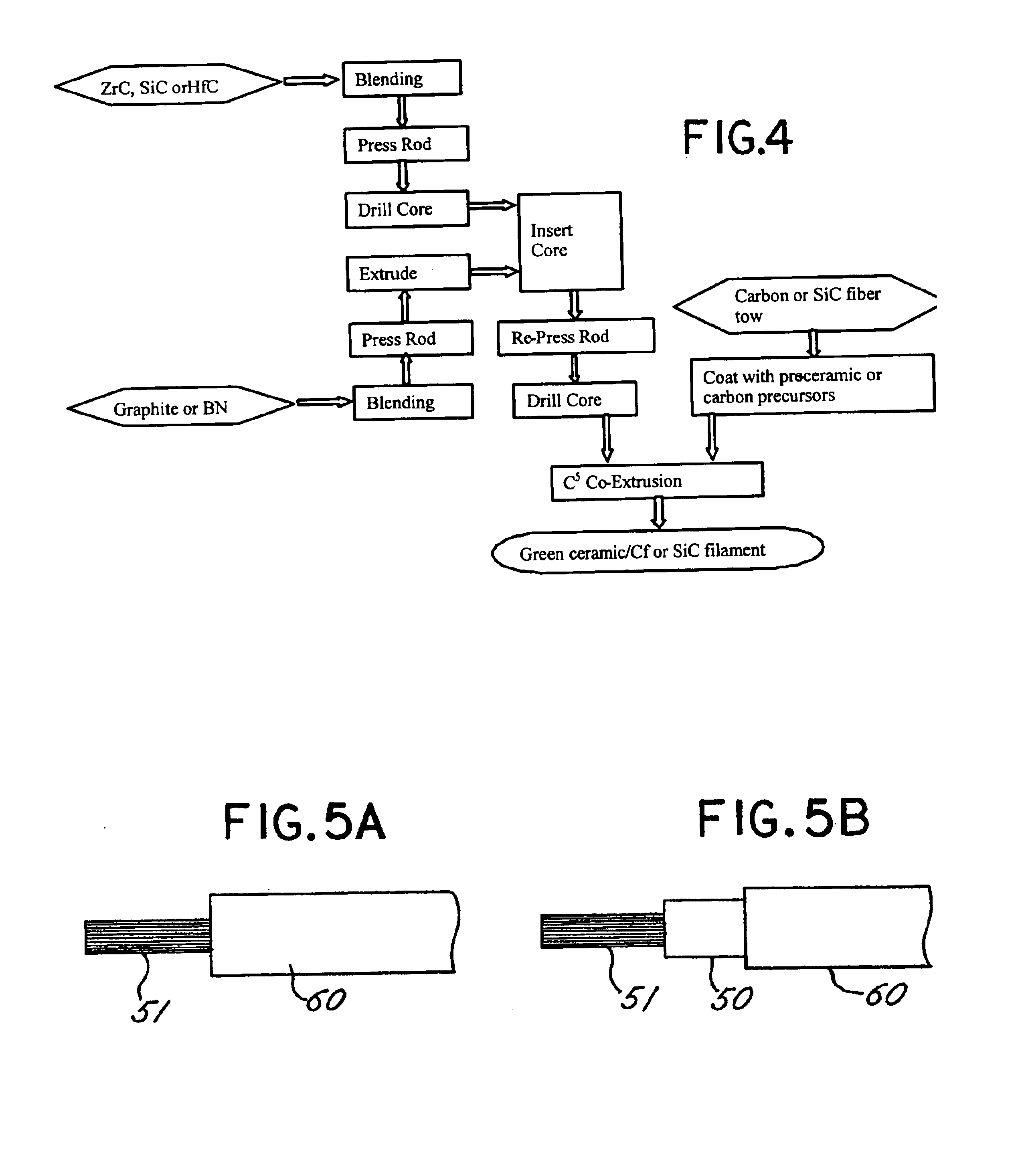

A process for continuous composite coextrusion comprising: (a) forming first a material-laden composition comprising a thermoplastic polymer and at least about 40 volume % of a ceramic or metallic particulate in a manner such that the composition has a substantially cylindrical geometry and thus can be used as a substantially cylindrical feed rod; (b) forming a hole down the symmetrical axis of the feed rod; (c) inserting the start of a continuous spool of ceramic fiber, metal fiber or carbon fiber through the hole in the feed rod; (d) extruding the feed rod and spool simultaneously to form a continuous filament consisting of a green matrix material completely surrounding a dense fiber reinforcement and said filament having an average diameter that is less than the average diameter of the feed rod; and (e) depositing the continuous filament into a desired architecture which preferably is determined from specific loading conditions of the desired object and CAD design of the object to provide a green fiber reinforced composite object.

Owner:ADVANCED CERAMICS

Desktop process for producing dental products by means of 3-dimensional plotting

InactiveUS20020167100A1High viscosityLess resourcesAdditive manufacturing apparatusImpression capsChemical reactionOligomer

A process for fabricating dental form pieces for dental restoration and replacement parts is provided and includes the step of applying a material, on a firm support or a fluid medium, by a three dimensional plotting technology in a layer by layer manner. The material has micro cords and / or micro drops which include at least one of a meltable, polymerizable, polycondensable, and polyaddable constituent element that is an unfilled monomer, a reinforced monomer, oligomer, polymer, or a ceramic element. The process also includes the step of hardening the applied material by cooling of the material, chemical reaction, polymerization with thermal handling, or polymerization by irradiation of the material with UV or visible light.

Owner:IVOCLAR VIVADENT AG

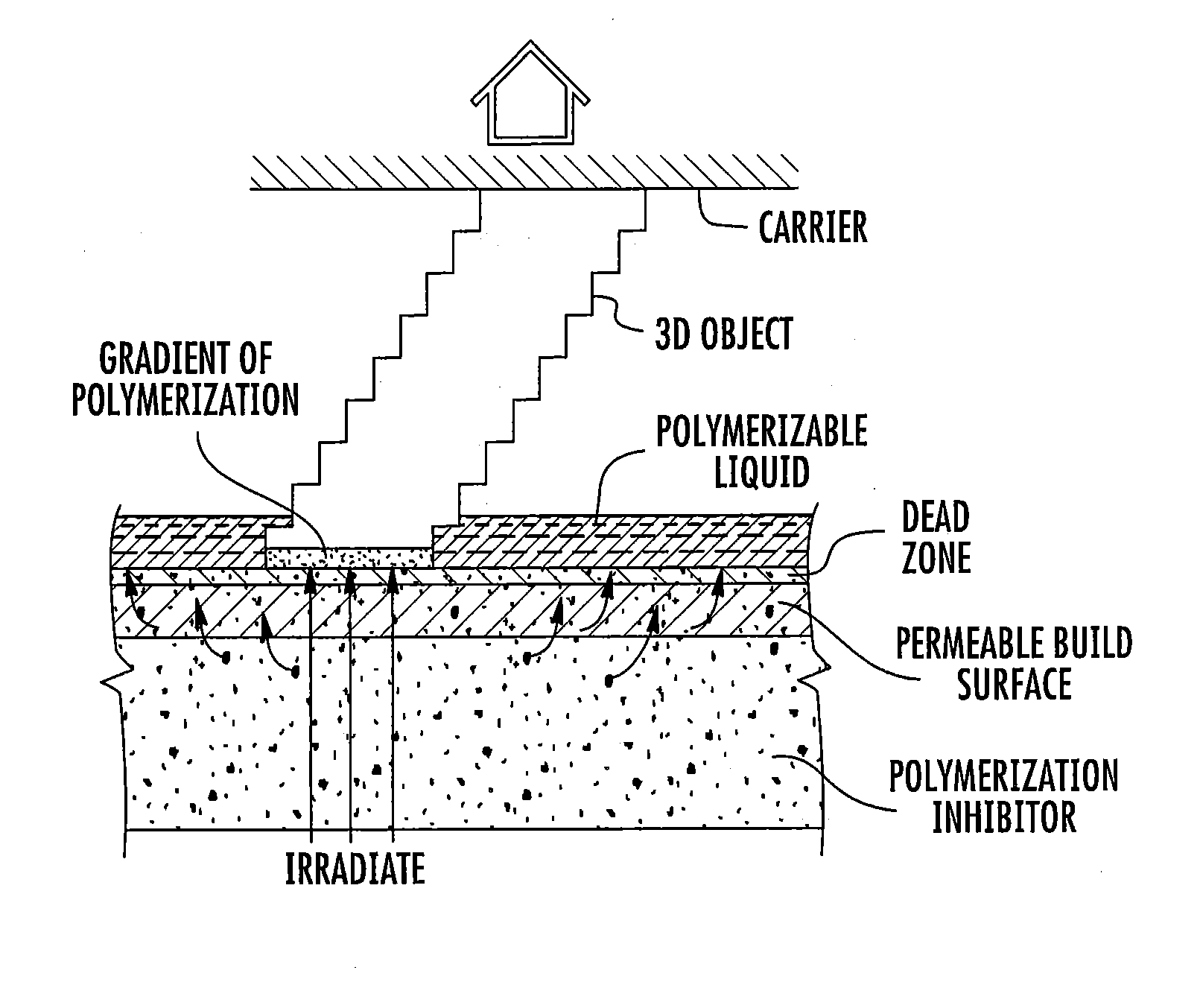

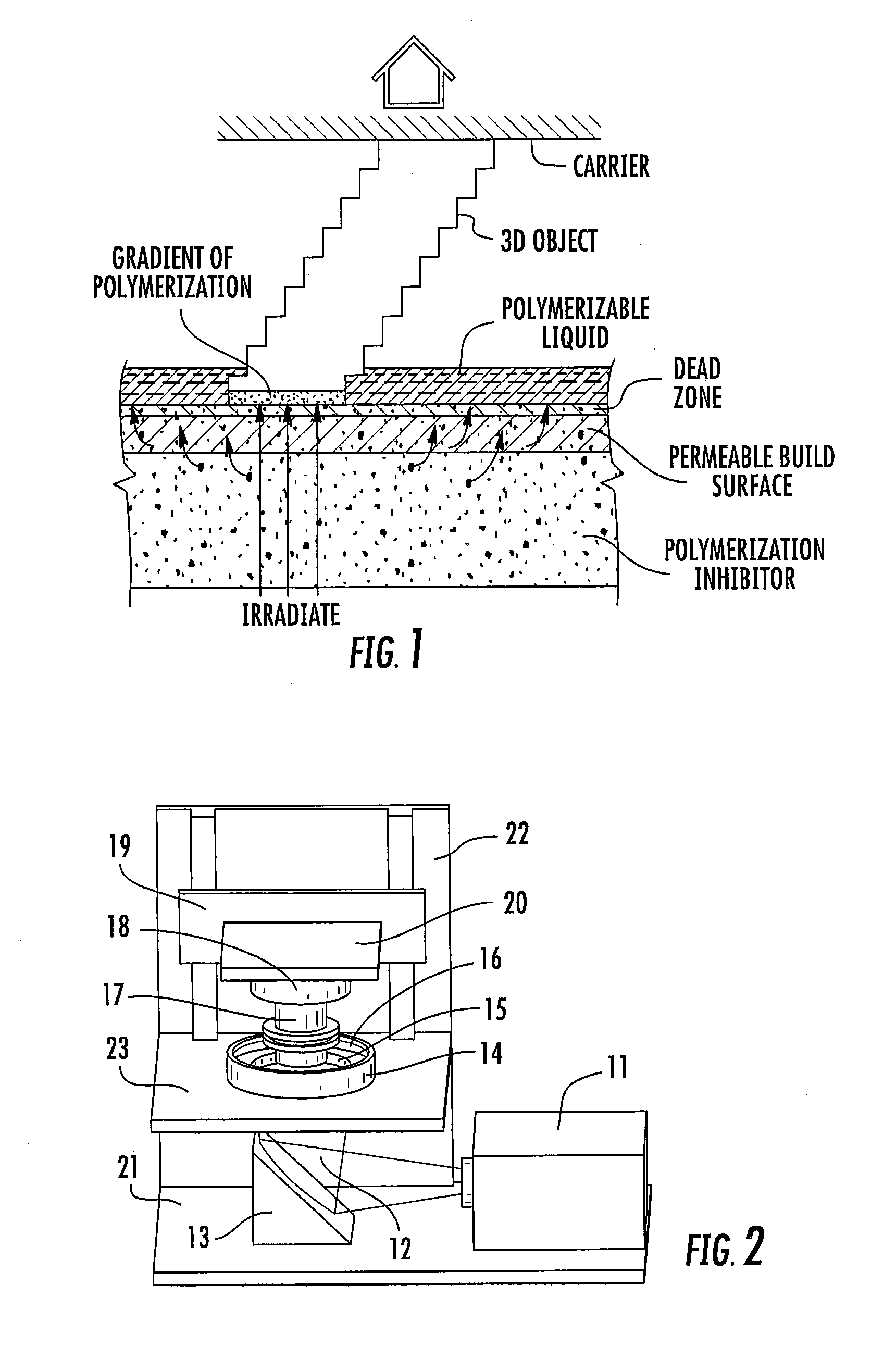

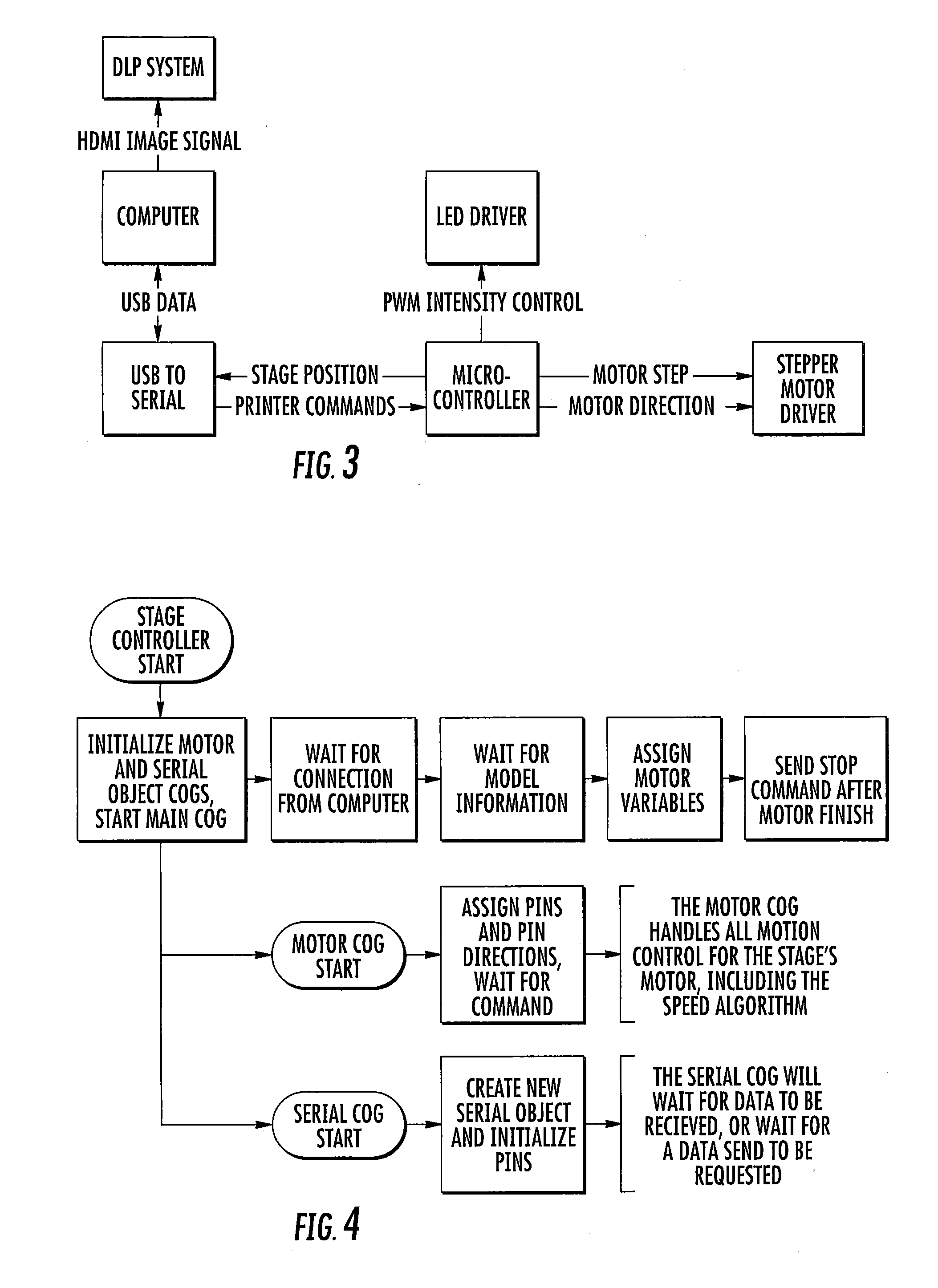

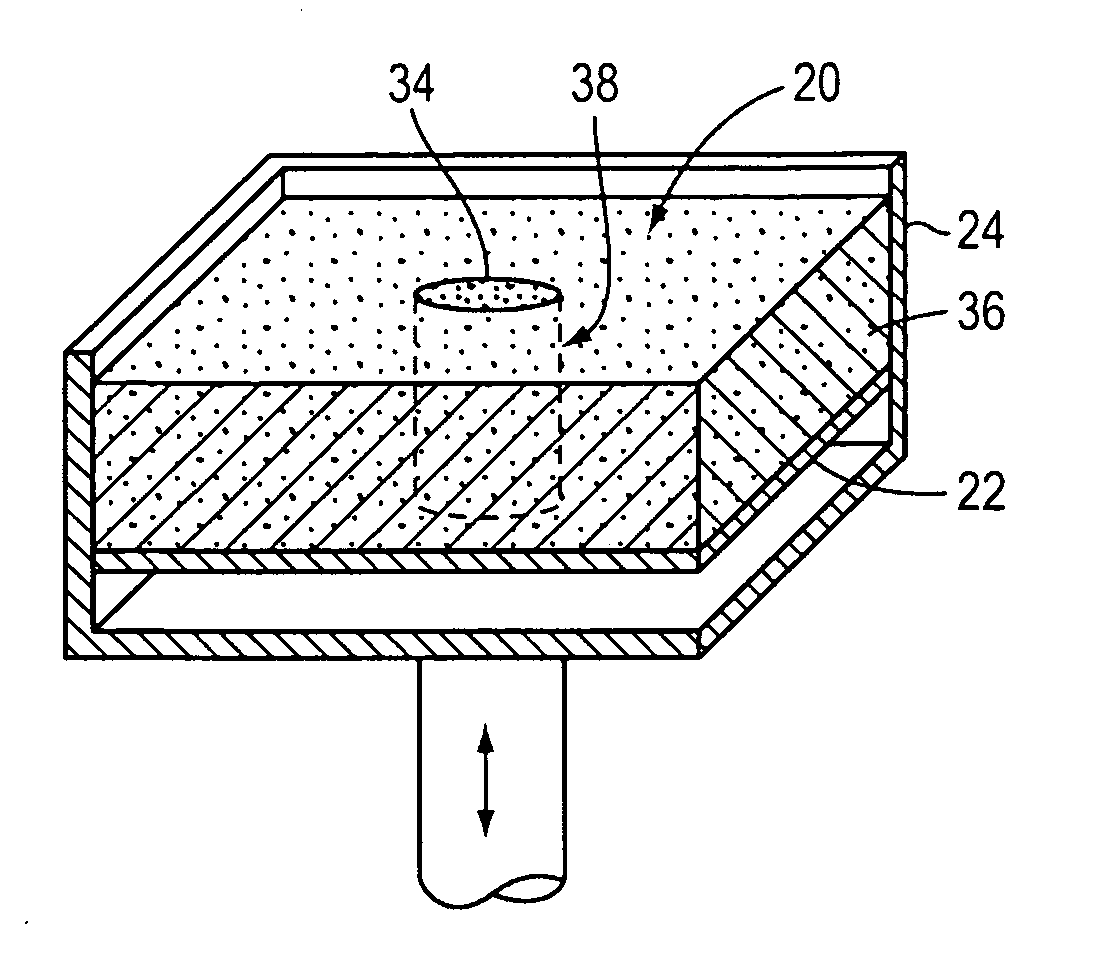

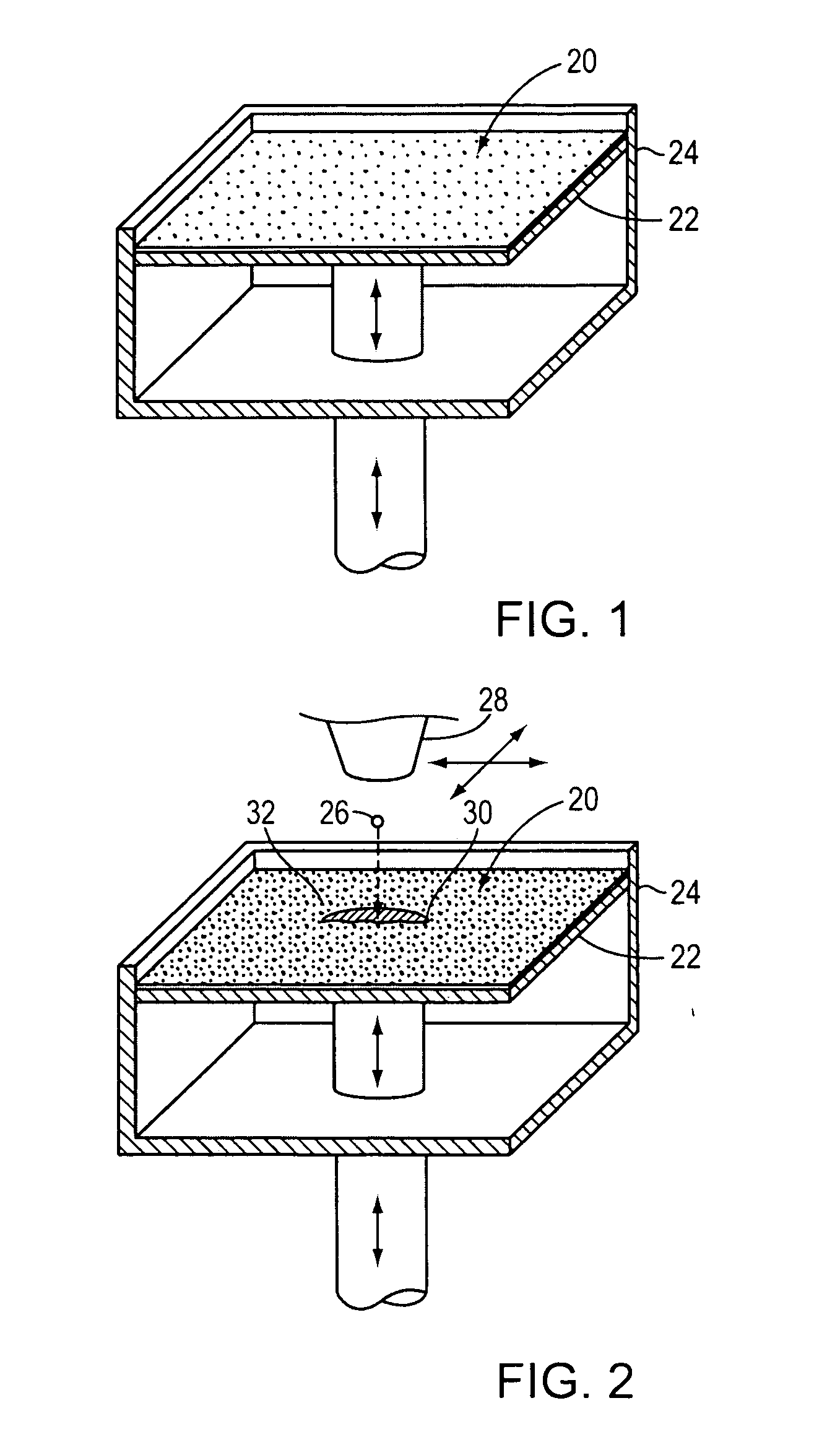

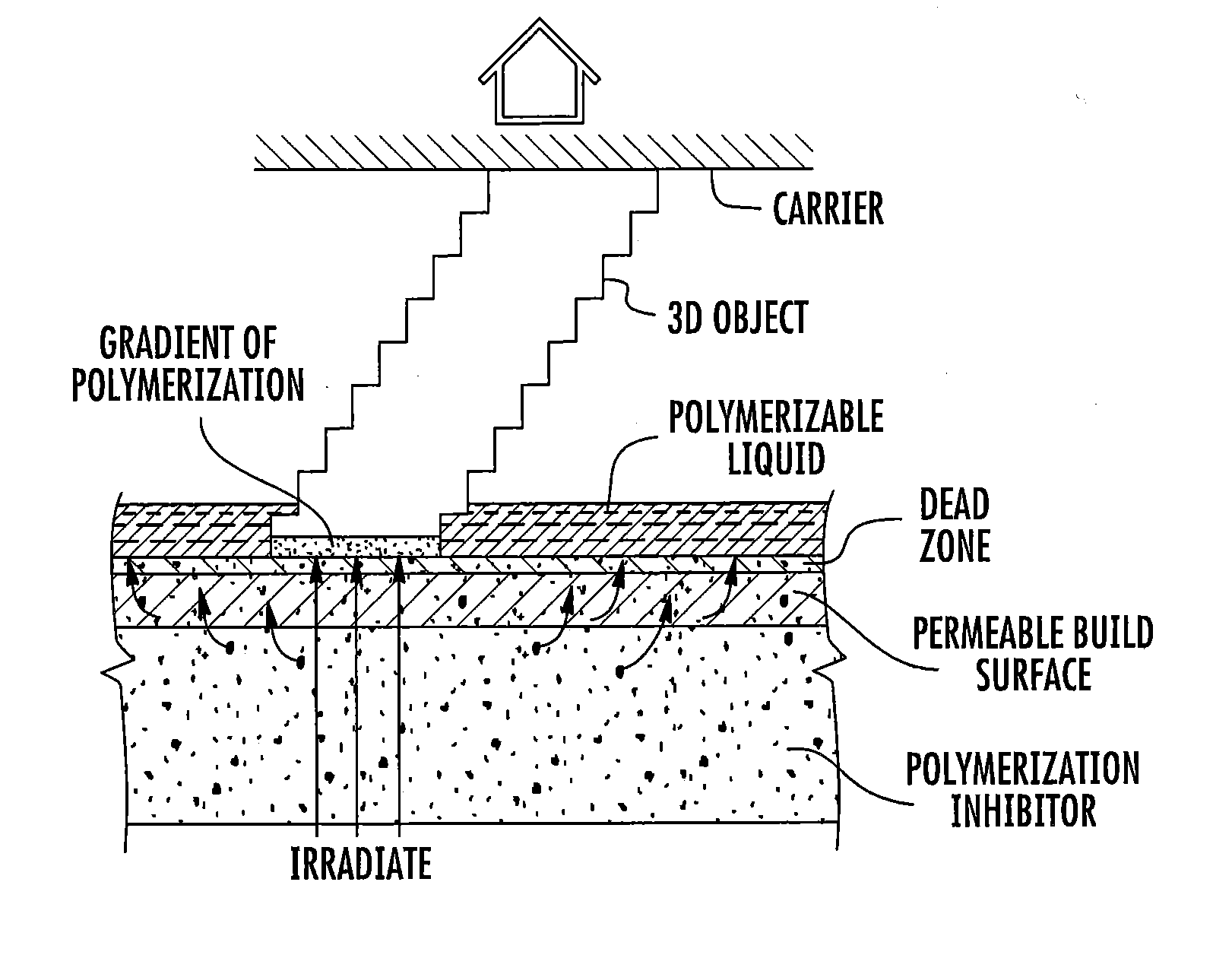

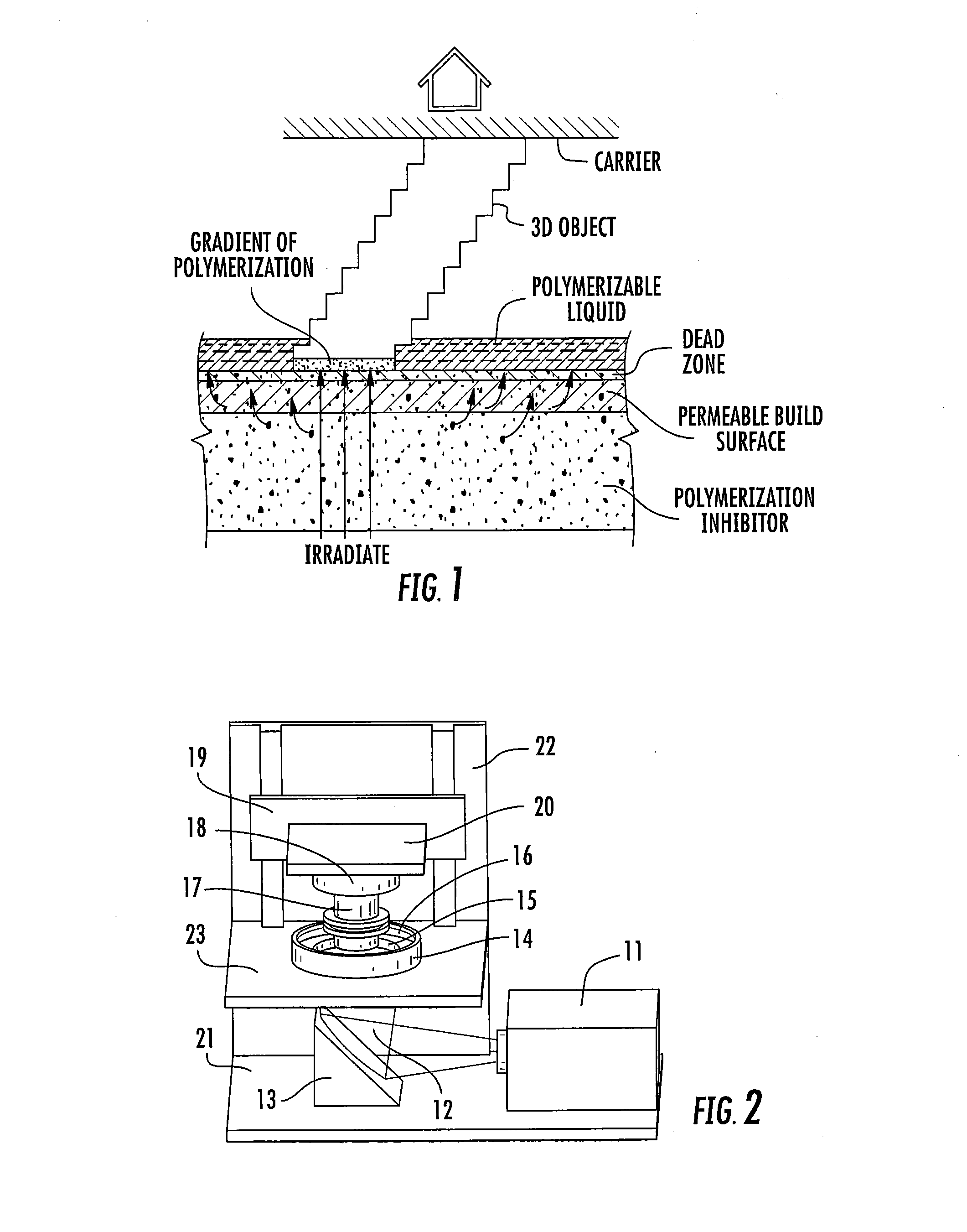

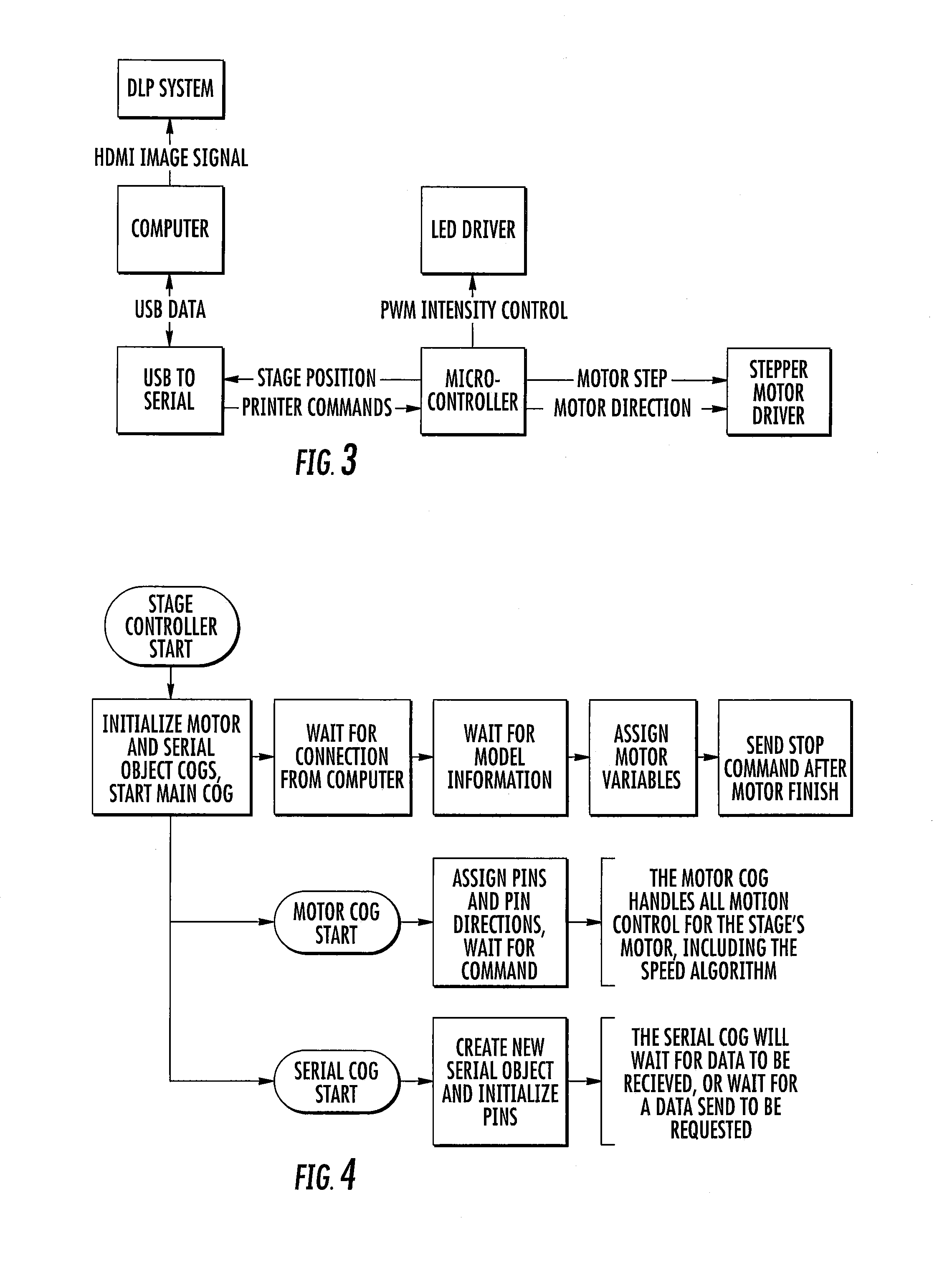

Methods of producing three-dimensional objects from materials having multiple mechanisms of hardening

ActiveUS20160136889A1Increased formationEnhance or speed the refilling of the build regionManufacturing enclosuresOptical articlesPolymer scaffoldChemistry

A method of forming a three-dimensional object is carried out by: (a) providing a carrier and an optically transparent member having a build surface, the carrier and the build surface defining a build region therebetween; (b) filling the build region with a polymerizable liquid, the polymerizable liquid including a mixture of (i) a light polymerizable liquid first component, and (ii) a second solidifiable component that is different from the first component; (c) irradiating the build region with light through the optically transparent member to form a solid polymer scaffold from the first component and also advancing the carrier away from the build surface to form a three-dimensional intermediate having the same shape as, or a shape to be imparted to, the three-dimensional object, and containing the second solidifiable component carried in the scaffold in unsolidified and / or uncured form; and (d) concurrently with or subsequent to the irradiating step, solidifying and / or curing the second solidifiable component in the three-dimensional intermediate to form the three-dimensional object.

Owner:CARBON INC

Three Dimensional Printing Material System and Method Using Peroxide Cure

ActiveUS20080138515A1High strengthEliminate needAdditive manufacturing apparatusLiquid surface applicatorsPeroxideParticulate material

A materials system and methods are provided to enable the formation of articles by Three Dimensional Printing. The materials system includes a transition metal catalyst that facilitates the reaction of an acrylate-containing binder with a particulate material.

Owner:3D SYST INC

Continuous fiber-reinforced component fabrication

ActiveUS20160114532A1Additive manufacturing apparatusTailstocks/centresAdditive layer manufacturingElectrical and Electronics engineering

A machine for fabricating a fiber-reinforced component by additive manufacturing is disclosed. The machine may have a surface, a matrix feed configured to deposit a plurality of matrix layers on the surface, and a fiber feed configured to deposit a fiber layer on at least one of the plurality of matrix layers. The deposition of the plurality of matrix layers and the fiber layer may be controlled by a computer.

Owner:RTX CORP

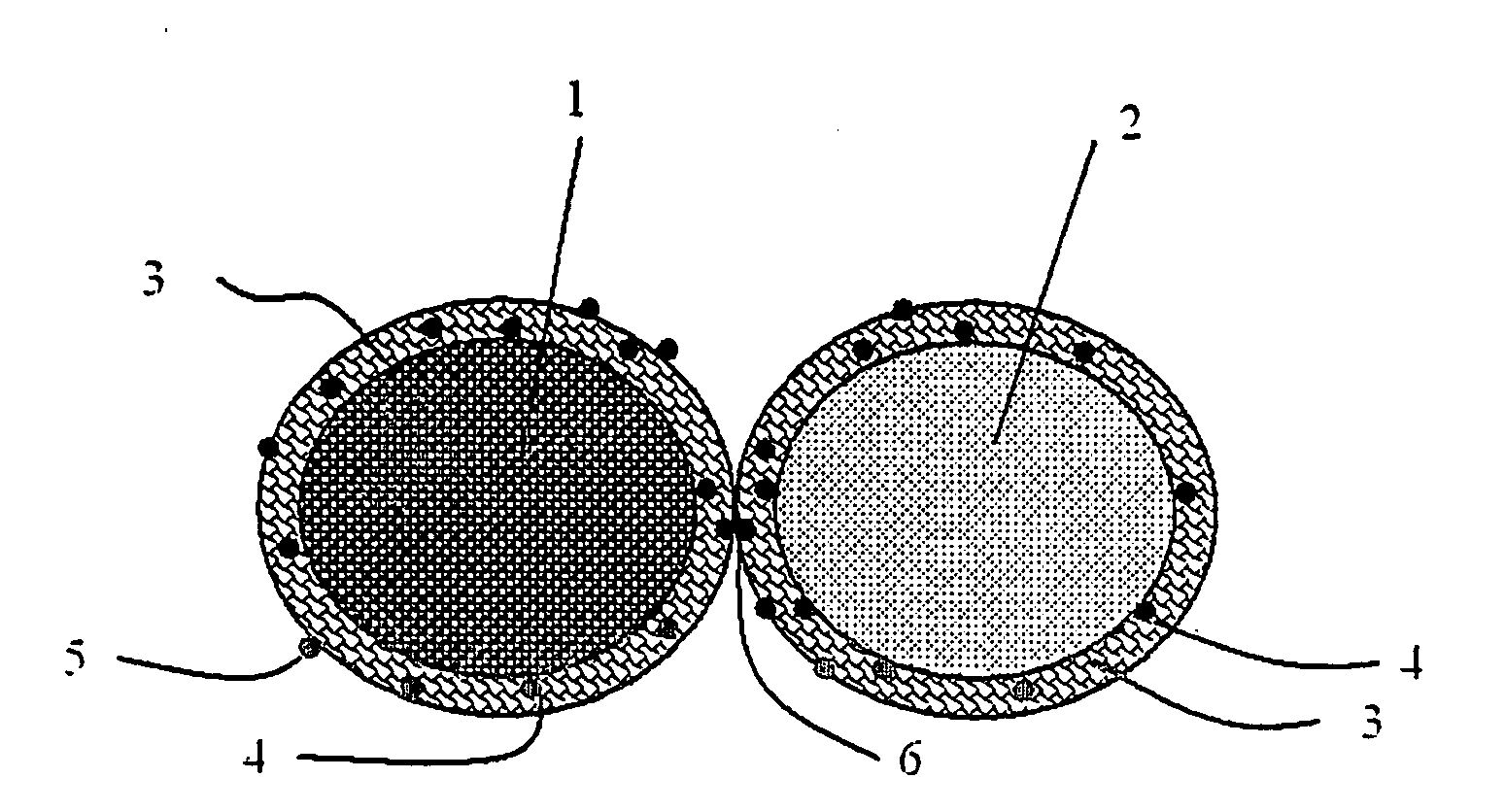

Coated powder particles for producing three-dimensional bodies by means of a layer constituting method

InactiveUS20060251535A1Good storage stabilityHigh distinctnessAdditive manufacturing apparatusTransportation and packagingOrganic solventLaser light

The invention relates a powder material consisting of coated particles for a powder-based rapid generative prototyping methods, in particular by compressing a 3D binder. Said powder material consists of individual plastic, metal and / or ceramic particles and / or granules. A coating essentially consists of an adhesive agent which can be activated by a liquid binder, light or laser light, and of sinterable or glass-forming fine-grained material. Said invention also relates to a method for compressing 3D binder with the aid of an organic solvent having a water content less than 45% and to sintered bodies, in particular for moulding or precision mechanical engineering, which are fixed to each other by sintering or glass formation from a fine grained material.

Owner:PFEIFER ROLF +2

Apparatus and process for forming three-dimensional objects

ActiveUS20170021565A1Additive manufacturing apparatusAdditive manufacturing with liquidsFiberBiomedical engineering

An apparatus for forming a three-dimensional (3D) object includes a 3D printing head, for fabricating a first portion of the 3D object by forming a plurality of successive layers of a first material. The apparatus also includes a delivery head for fabricating a second portion of the 3D object by dispensing onto the first portion of the 3D object a plurality of layers of a continuous-fiber reinforced second material. Further, the delivery head includes comprising a roller for pressing the continuous-fiber rein-forced second material into place during the dispensing thereof. A controller controls the 3D printing head and the delivery head to cooperatively form the 3D object, based on a dataset corresponding to a 3D object model.

Owner:MAGNA INTERNATIONAL INC

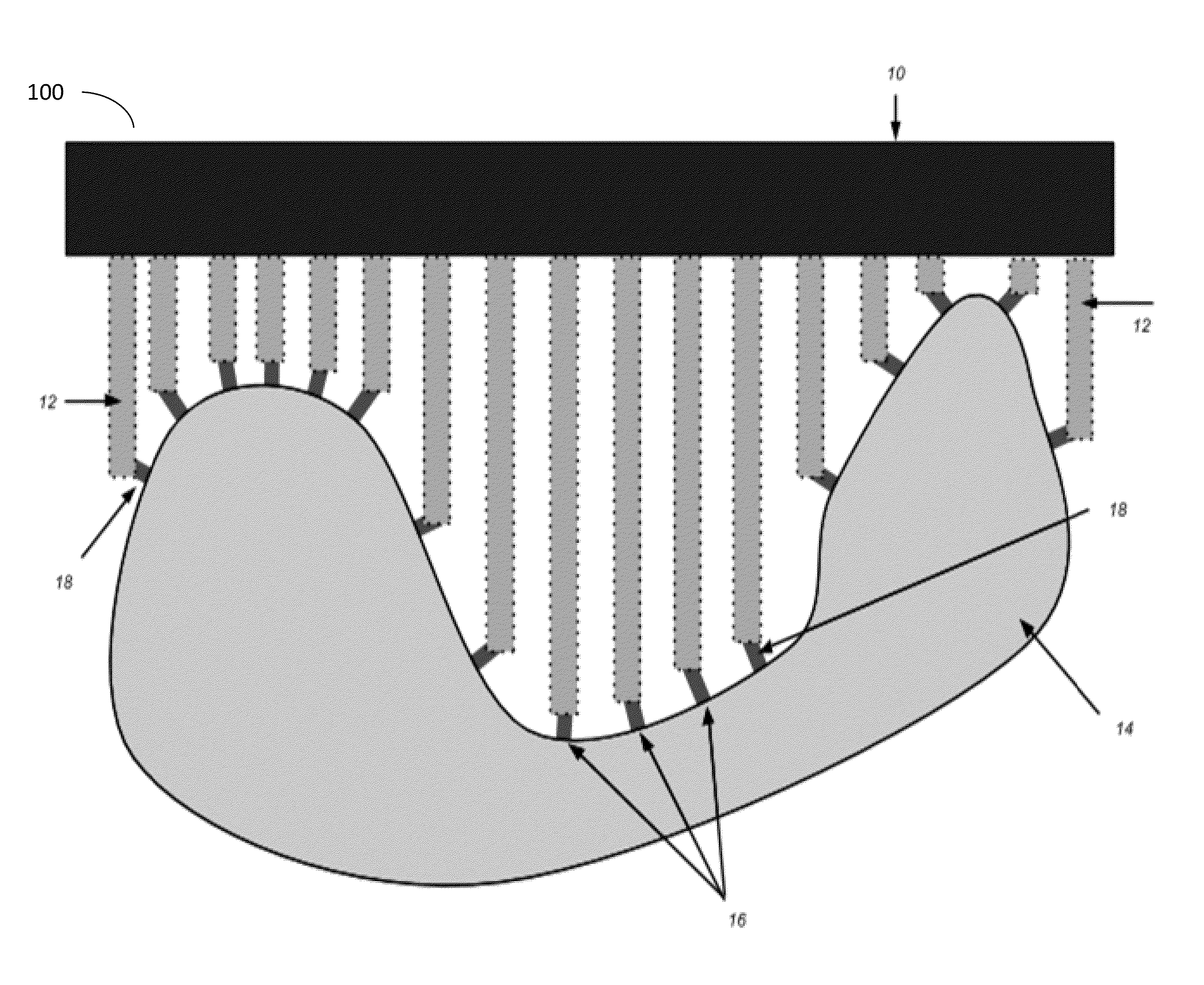

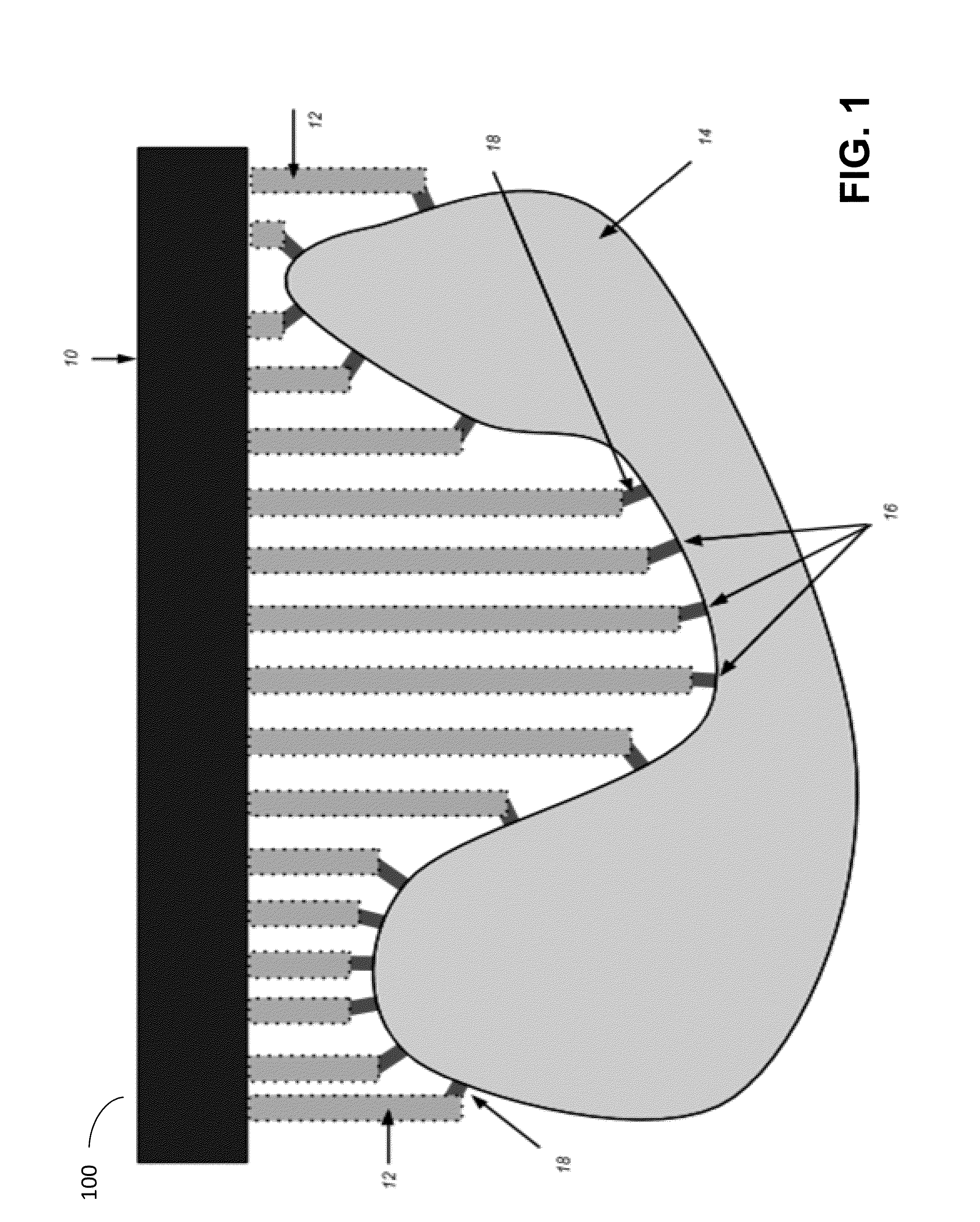

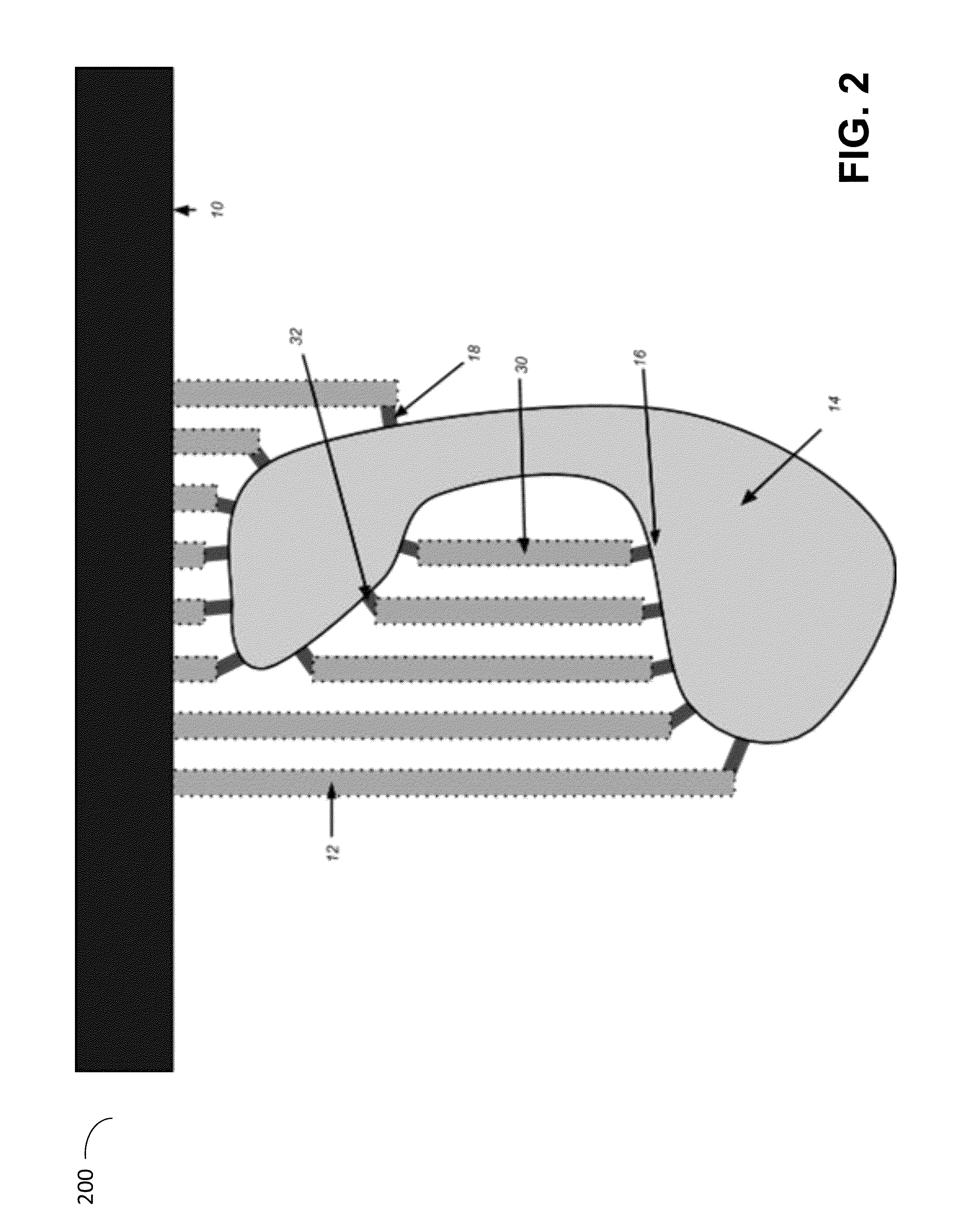

Additive fabrication support structures

ActiveUS20140300017A1Minimize contactProgramme controlAdditive manufacturing apparatusManufacturing technologyEngineering

Some aspects provide a method of generating a support structure for an object, the support structure and the object to be fabricated via one or more additive fabrication techniques, comprising identifying one or more regions of the object as one or more regions to which mechanical support is to be provided, identifying one or more support points within at least a first region of the one or more regions, and generating the support structure for the object, the support structure comprising one or more support tips coupled to the object at the one or more support points, the support tips being generated based at least in part on a direction normal to the surface of the object at the respective support point.

Owner:FORMLABS INC

Three dimensional printing material system and method

InactiveUS20020026982A1High strengthReduce the amount of solutionSolid waste managementCeramic shaping apparatusEngineeringLayer wise

The present invention is directed to a 3DP(TM) material system ad method, and an article made therefrom. The method of the present invention includes building cross-sectional portions of a three-dimensional article, and assembling the individual cross-sectional areas in a layer-wise fashion to form a final article. The individual cross-sectional areas are built by using an ink-jet printhead to deliver an aqueous fluid to a particulate material that includes plaster.

Owner:3D SYST INC

Material systems and methods of three-dimensional printing

ActiveUS20060208388A1Adhesive processesAdditive manufacturing apparatusEngineering3 dimensional printing

The present invention is directed to three-dimensional printing material systems and method, and an article made therefrom. The method of the present invention includes building cross-sectional portions of a three-dimensional article, and assembling the individual cross-sectional areas in a layer-wise fashion to form a final article. The individual cross-sectional areas are built by using an ink-jet printhead to deliver a fluid to a particulate material that includes particulate material.

Owner:3D SYST INC

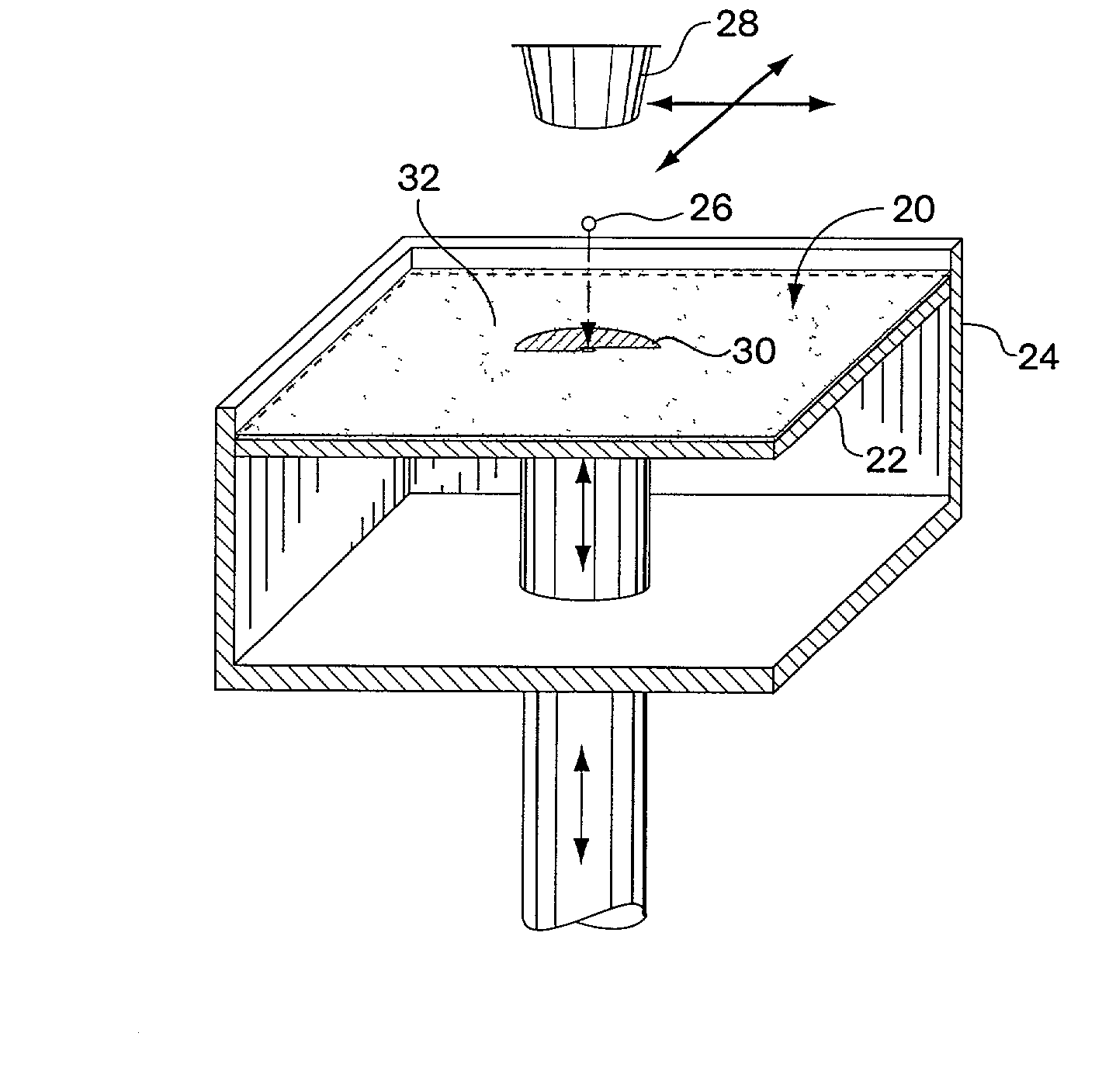

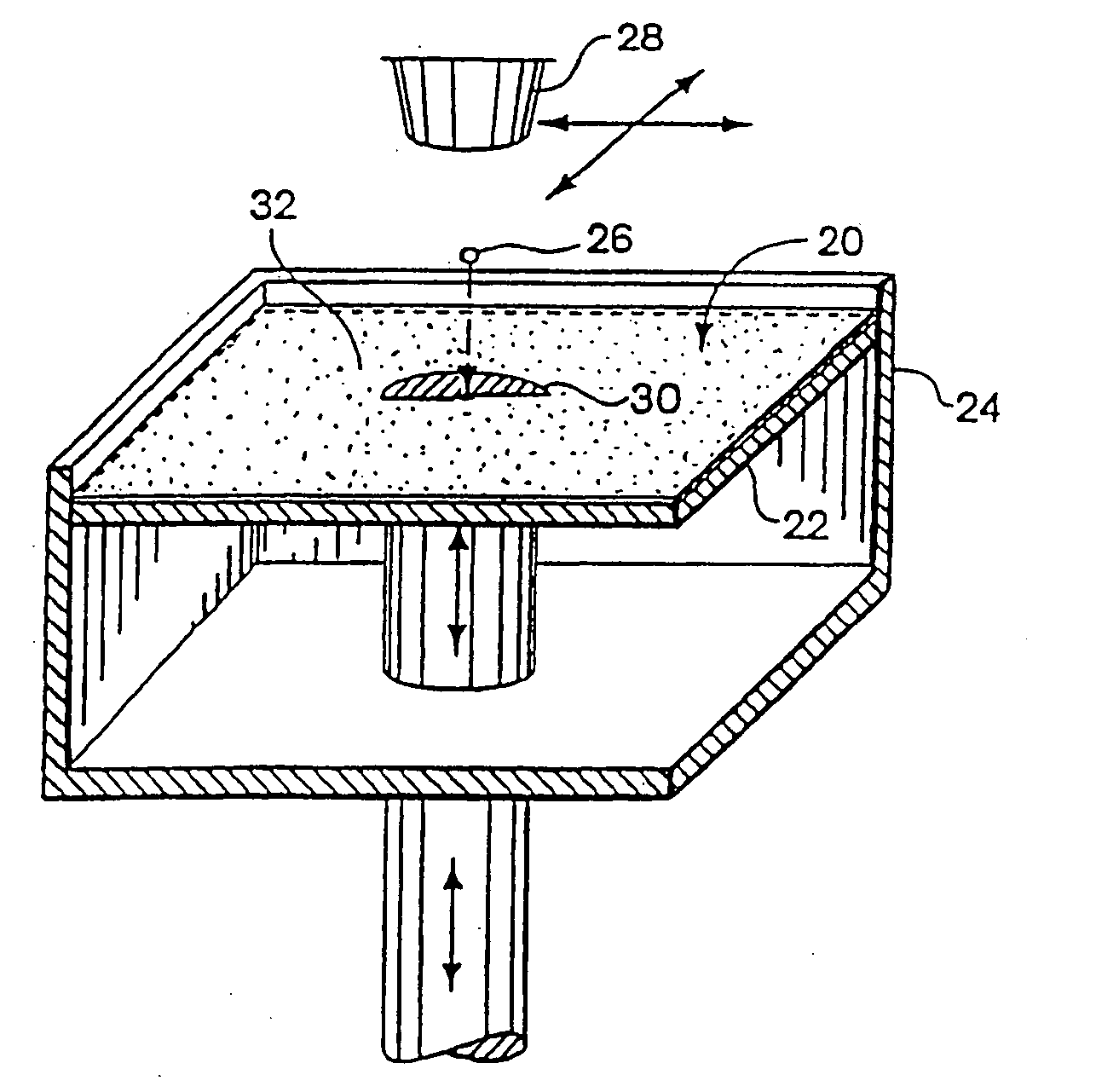

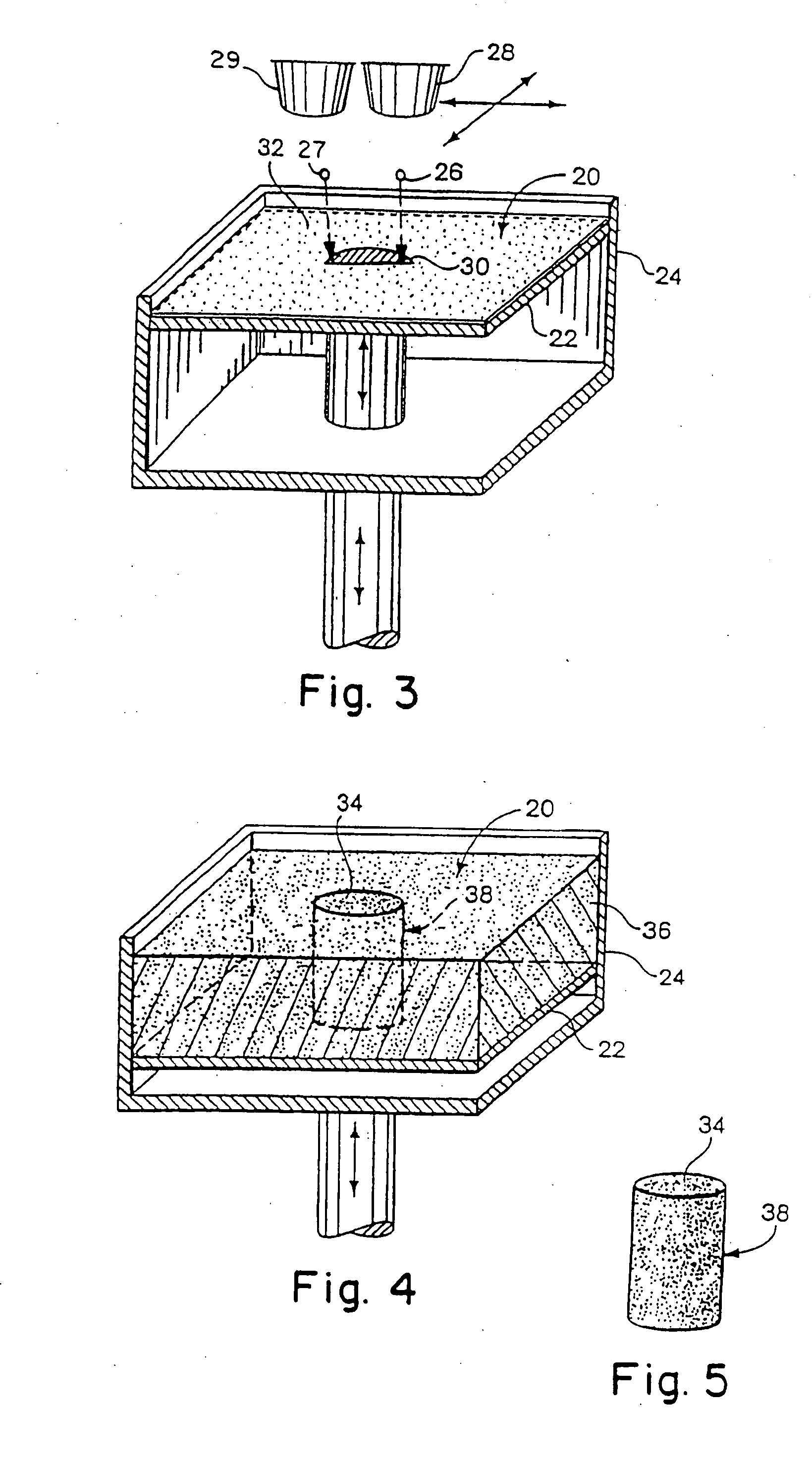

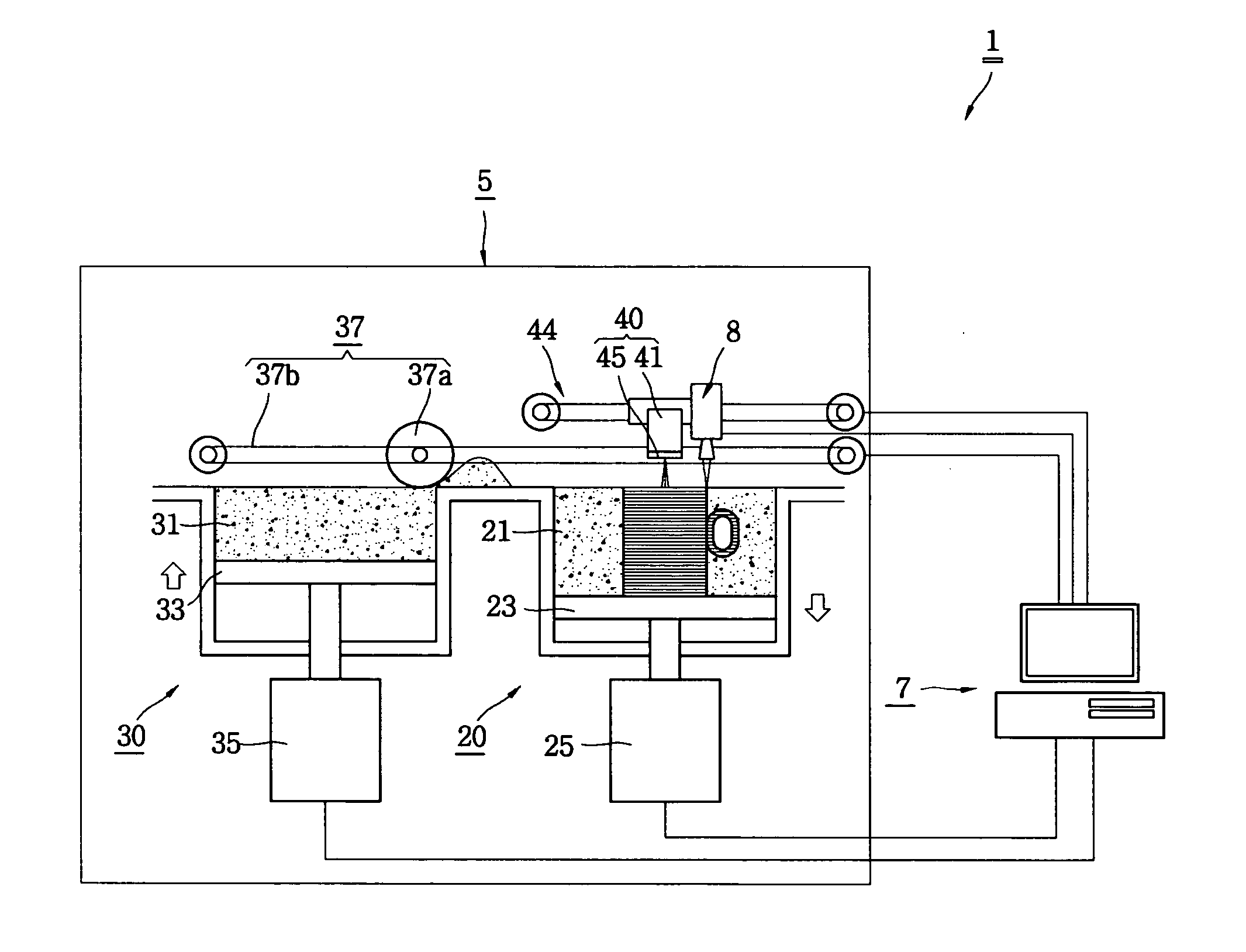

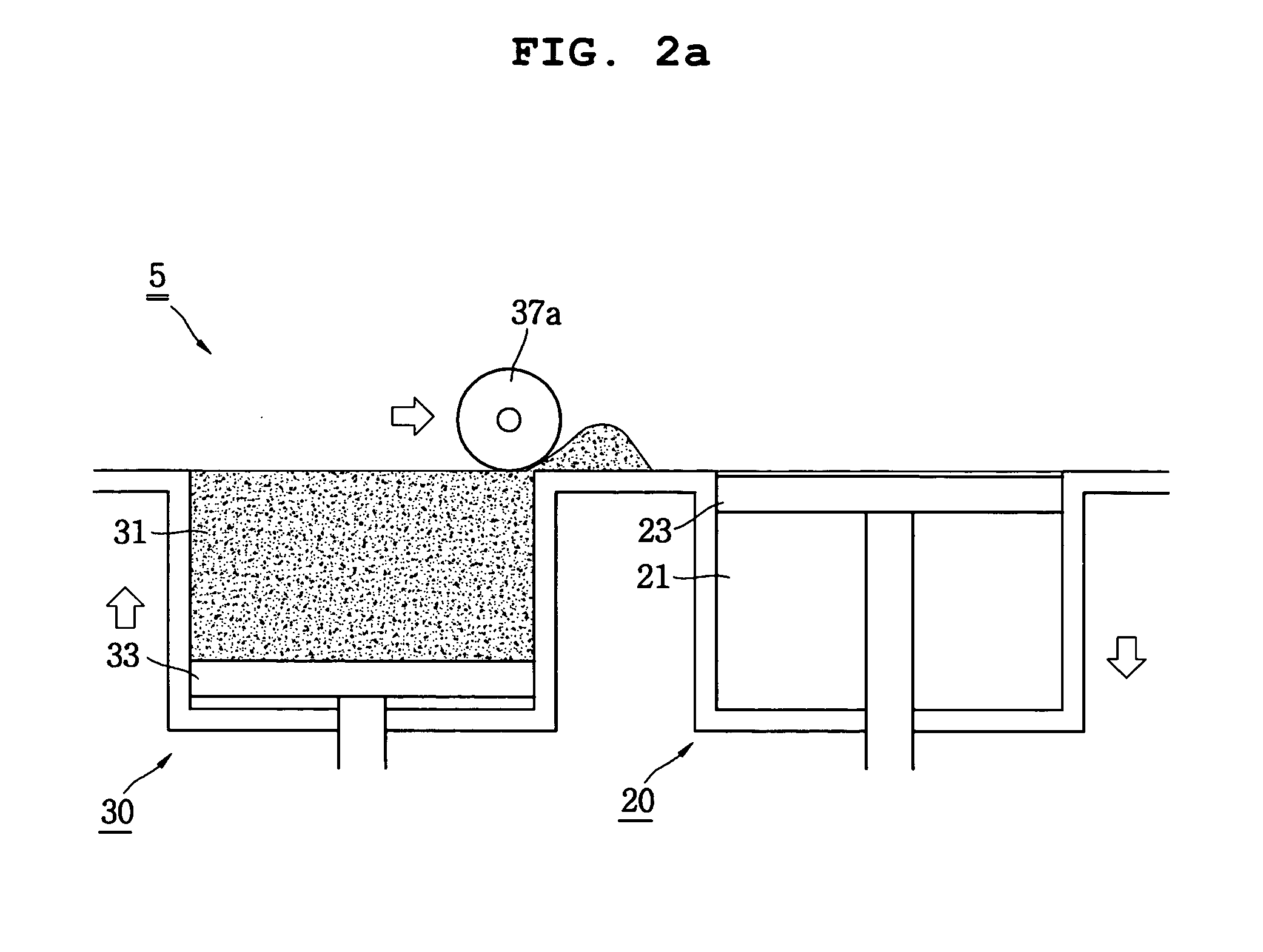

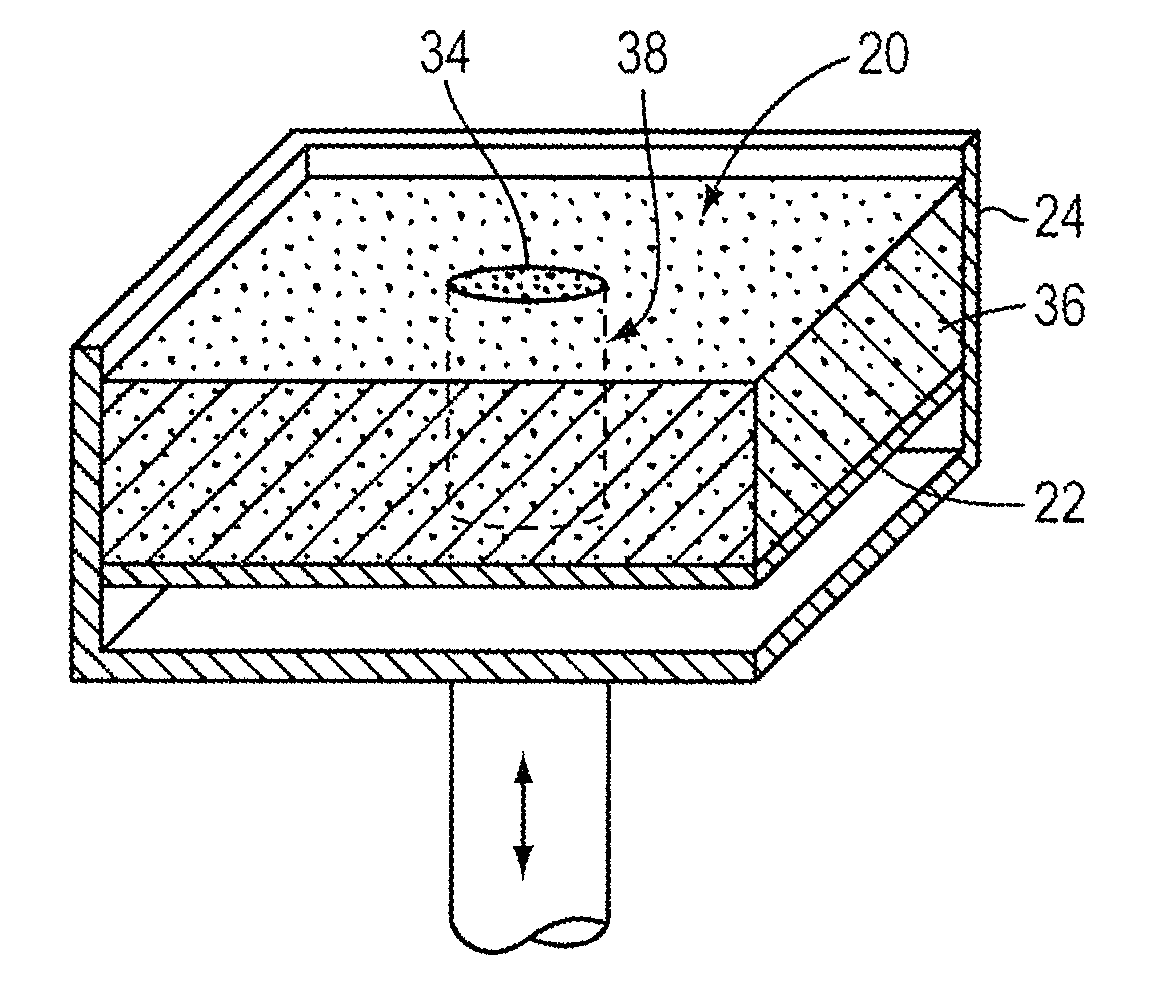

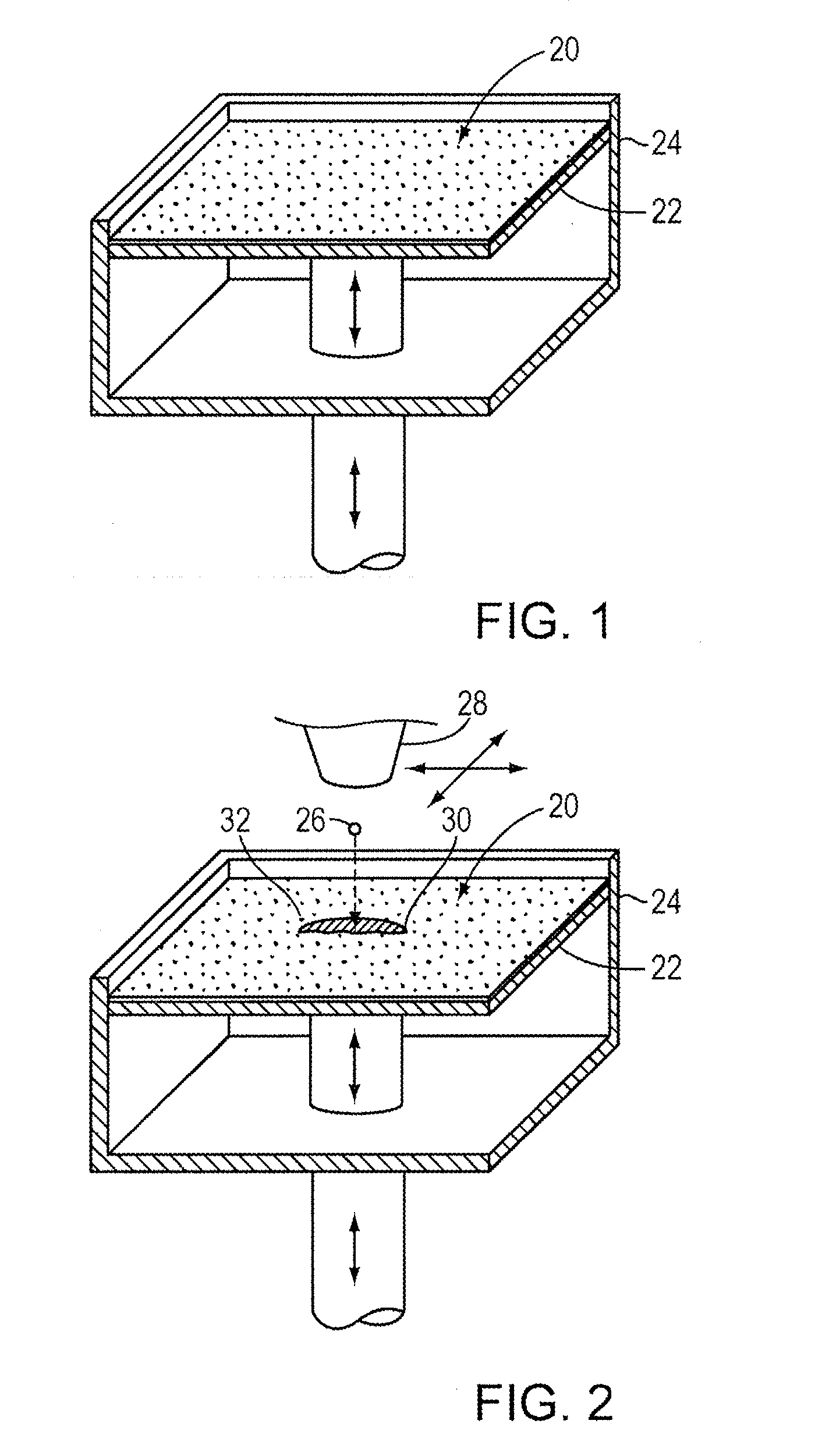

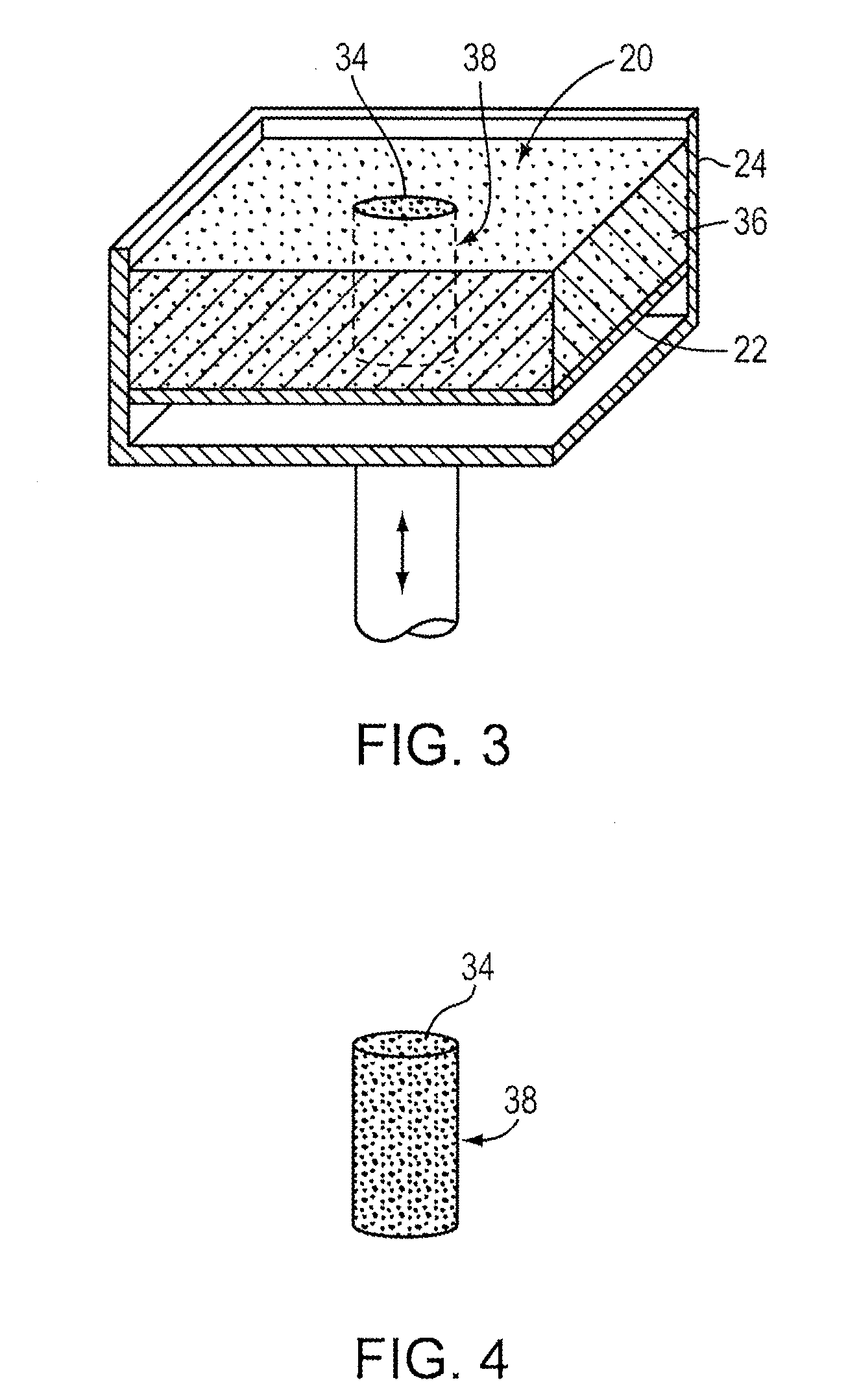

Three-dimensional printing prototyping system

InactiveUS20060099287A1Shorten the time periodLow viscosityConfectionerySweetmeatsEngineeringMaterial supply

The present invention relates to a three-dimensional printing prototyping system which includes a prototyping chamber having a prototyping table capable of moving up and down by a predetermined range, a material containing chamber containing a powder material and having a material supply table capable of moving up and down by a predetermined range, and a material supplying means for supplying the powder material contained in the material containing chamber to the prototyping table as much as a sectional thickness corresponding to divided section data of a three-dimensional prototype to be prototyped. The system of the present invention comprises a printing head for injecting a photocuring adhesive material to a region, corresponding to the sectional data, on the powder material supplied to the prototyping table; a curing device for photocuring at least the region on which the adhesive material is injected; and a control computer for controlling the printing head and the curing device such that the adhesive material is injected and cured, respectively, on the region corresponding to the divided section data of the three-dimensional prototype. According to the present invention, a period of time required in curing a three-dimensional prototype can be remarkably shortened and the three-dimensional prototype with its superior solidity can be obtained.

Owner:KOREA INST OF MACHINERY & MATERIALS

Three-Dimensional Printing Material System With Improved Color, Article Performance, and Ease of Use

ActiveUS20080187711A1Strong and durable prototypeHigh green part strengthAdditive manufacturing apparatusOther chemical processesParticulatesWhitening Agents

A materials system and methods are provided to enable the formation of articles by three dimensional printing. The materials system includes particulate mixtures having a whitening agent and a solid particulate additive comprising an acid, the latter adapted for modifying a cure rate of an infiltrant. The materials system also includes aqueous fluids including optical brightening agents.

Owner:3D SYST INC

Inserting inhibitor to create part boundary isolation during 3D printing

A 3D printing system may print a desired 3D object. A fusible powder may fuse when subjected to a fusing condition. A deposition system may deposit portions of the fusible powder on a substrate. A fusing system may apply the fusing condition to the deposited fusible powder. Inhibitor material may not fuse when subjected to the fusing condition. An insertion system may insert a portion of the inhibitor material between portions of the deposited fusible powder after having been deposited by the deposition system, but before being fused by the fusing system, so as to form a boundary that defines at least a portion of a surface of the desired 3D object.

Owner:UNIV OF SOUTHERN CALIFORNIA

Dental restorations formed by solid free-form fabrication methods

InactiveUS6994549B2Manufacture of restorationAdditive manufacturing apparatusImpression capsFree formThin layer

Solid free form fabrication techniques such as fused deposition modeling and three-dimensional printing are used to create a dental restoration. Three-dimensional printing comprises inkjet printing a binder into selected areas of sequentially deposited layers of powder. Each layer is created by spreading a thin layer of powder over the surface of a powder bed. Instructions for each layer may be derived directly from a CAD representation of the restoration. The area to be printed is obtained by computing the area of intersection between the desired plane and the CAD representation of the object. All the layers required for an aesthetically sound restoration can be deposited concurrently slice after slice and sintered / cured simultaneously. The amount of green body oversize is equivalent to the amount of shrinkage which occurs during sintering or curing. While the layers become hardened or at least partially hardened as each of the layers is laid down, once the desired final shaped configuration is achieved and the layering process is complete, in some applications it may be desirable that the form and its contents be heated or cured at a suitably selected temperature to further promote binding of the powder particles.

Owner:JENERICPENTRON

Three-dimensional objects produced from materials having multiple mechanisms of hardening

InactiveUS20160160077A1Enhance or speed the refilling of the build regionIncreased formationManufacturing enclosuresLayered productsPolymer scienceCationic polymerization

A three dimensional object includes (a) a light polymerized first component; and (b) a second solidified component different from the first component. The object is preferably of a polymer blend formed from the first component and the second component, with the polymer blend as an interpenetrating polymer network, a semi-interpenetrating polymer network, or a sequential interpenetrating polymer network. In some preferred embodiments, the second component does not contain a cationic polymerization photoinitiator. In some preferred embodiments, the three dimensional object is produced by the process of continuous liquid interface production.

Owner:CARBON INC

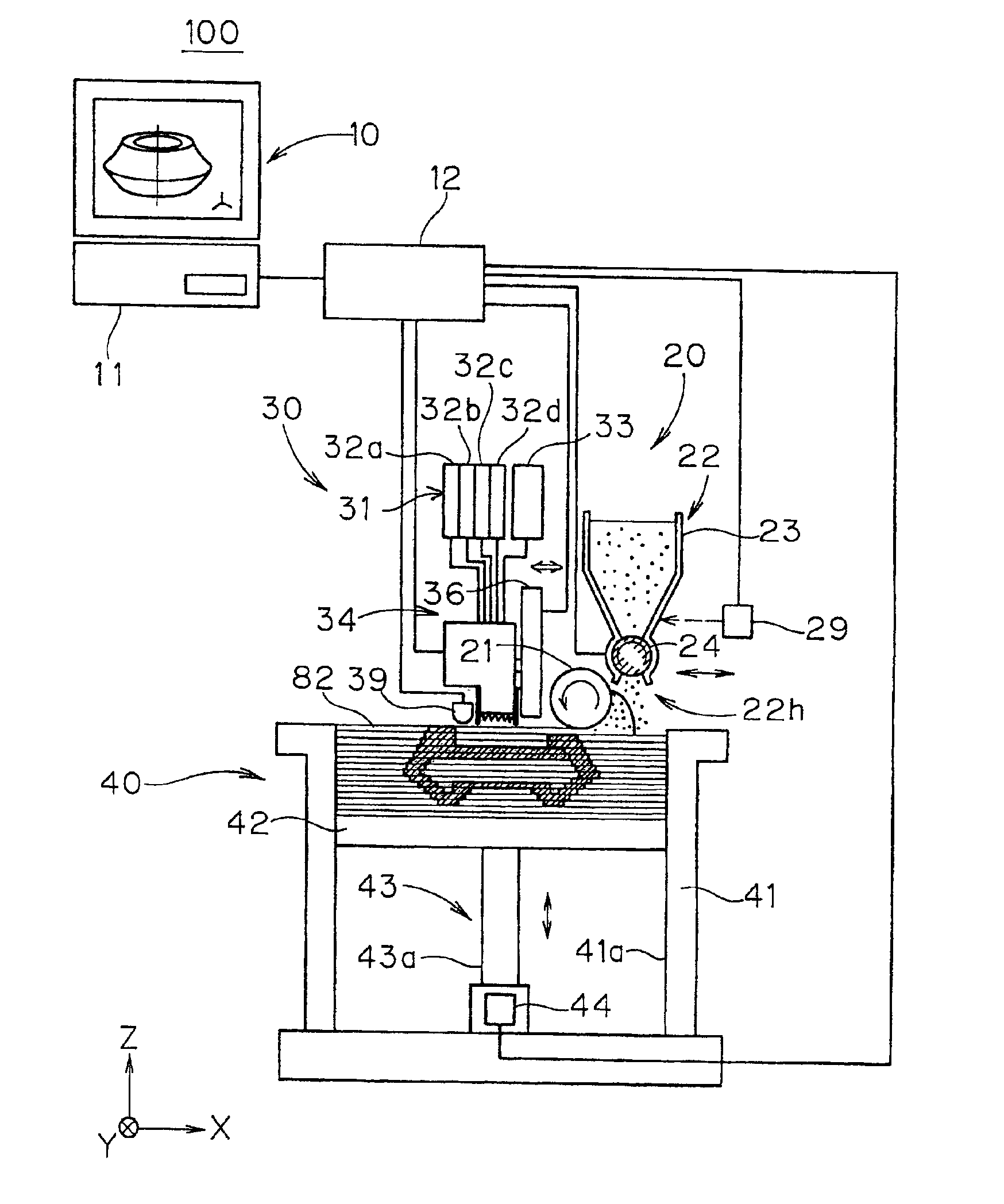

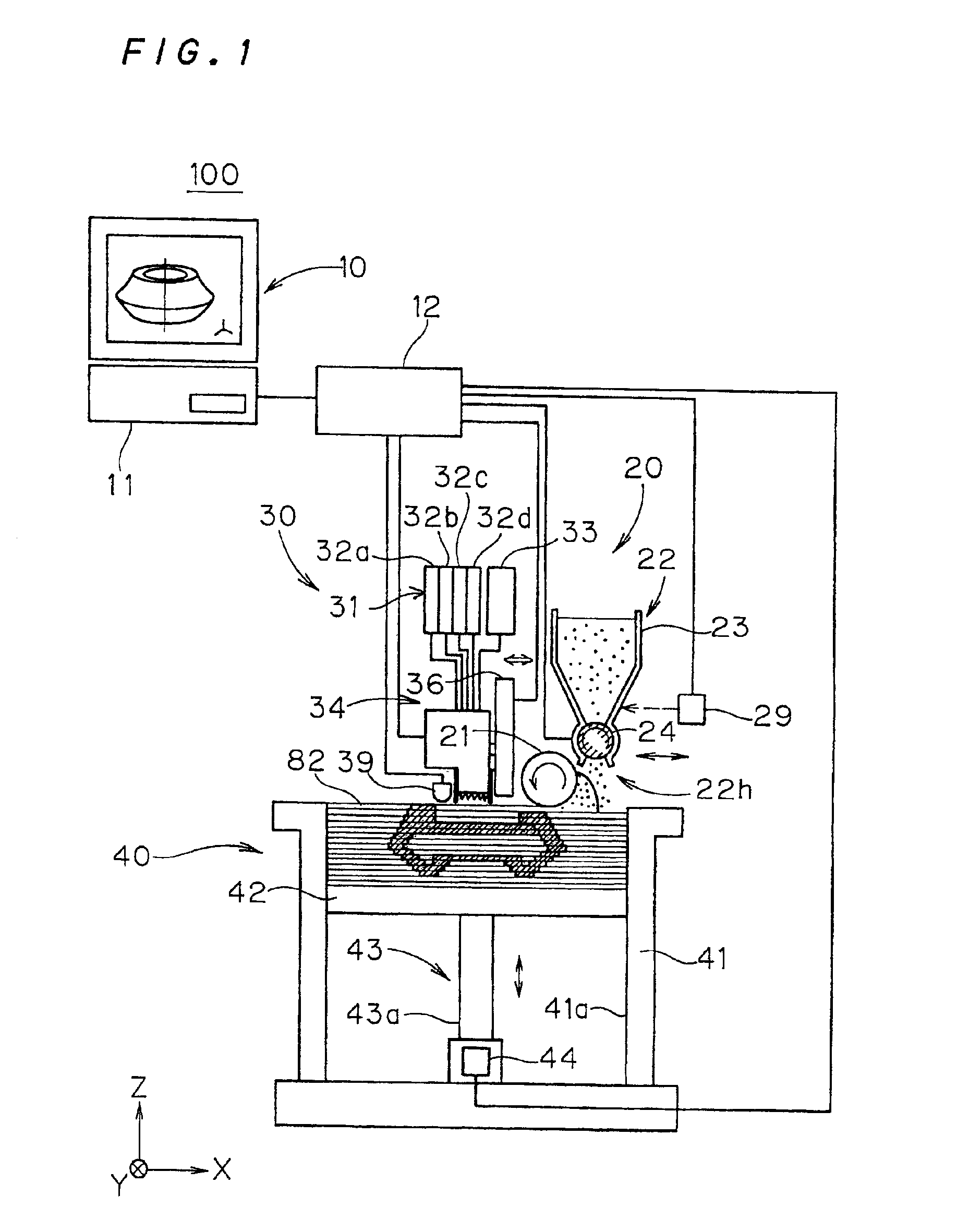

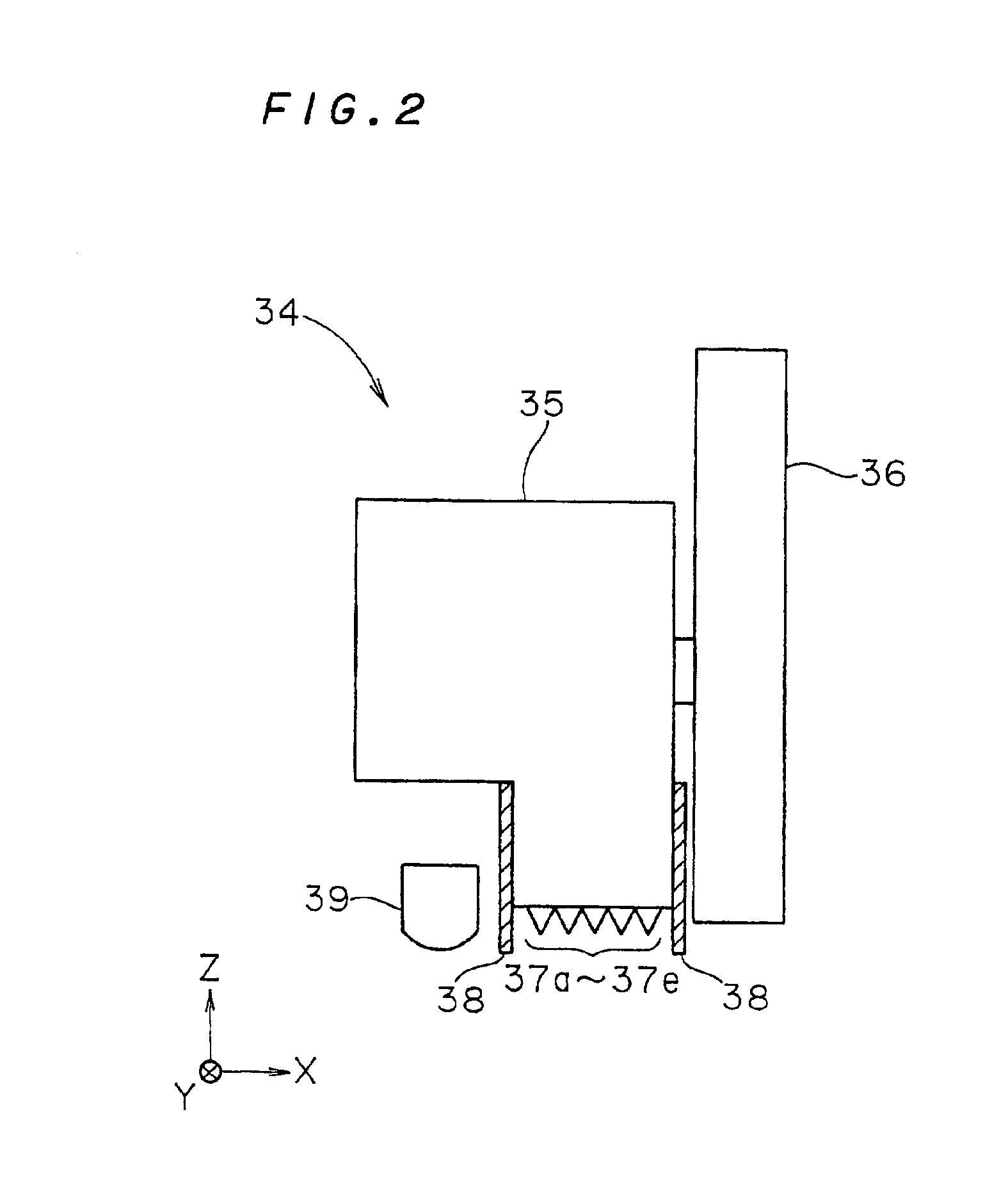

Three-dimensional molding apparatus and three-dimensional molding method

To provide a three-dimensional molding technique capable of generating a three-dimensional molded article in short time.In a three-dimensional molding apparatus, a powder material is allowed to drop via an opening while moving a thin layer formation section in the +X direction, thereby forming a powder layer on a molding stage. With respect to a selected region in the powder layer, a binder of ultraviolet-ray hardening resin is discharged from a head section. Then, the powder layer is irradiated with ultraviolet rays from an ultraviolet irradiation section, making the ultraviolet-ray hardening resin applied on the powder layer harden to thereby bind the powder material. By repeating this operation with respect to the powder layer which is sequentially formed, a three-dimensional molded article is formed. In this way, since an ultraviolet-ray hardening resin is used as a binder and a powder material can be bound rapidly by ultraviolet irradiation, it is possible to generate a three-dimensional molded article in short time.

Owner:MINOLTA CO LTD

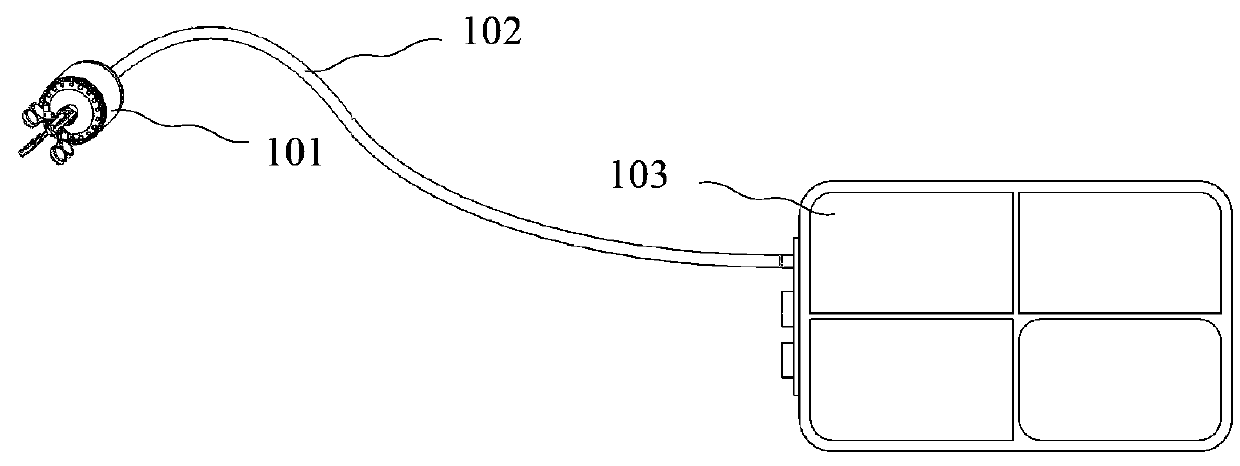

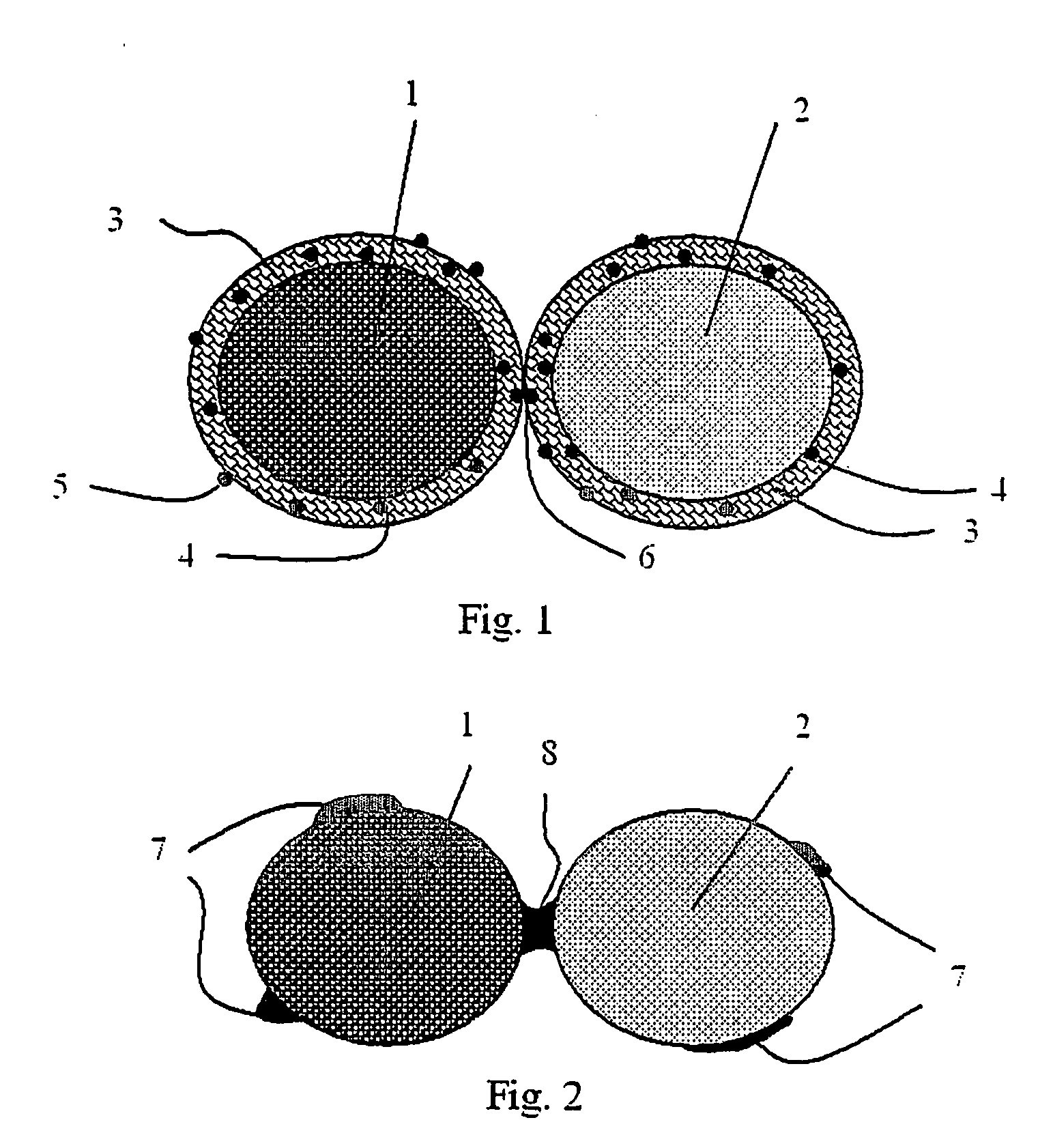

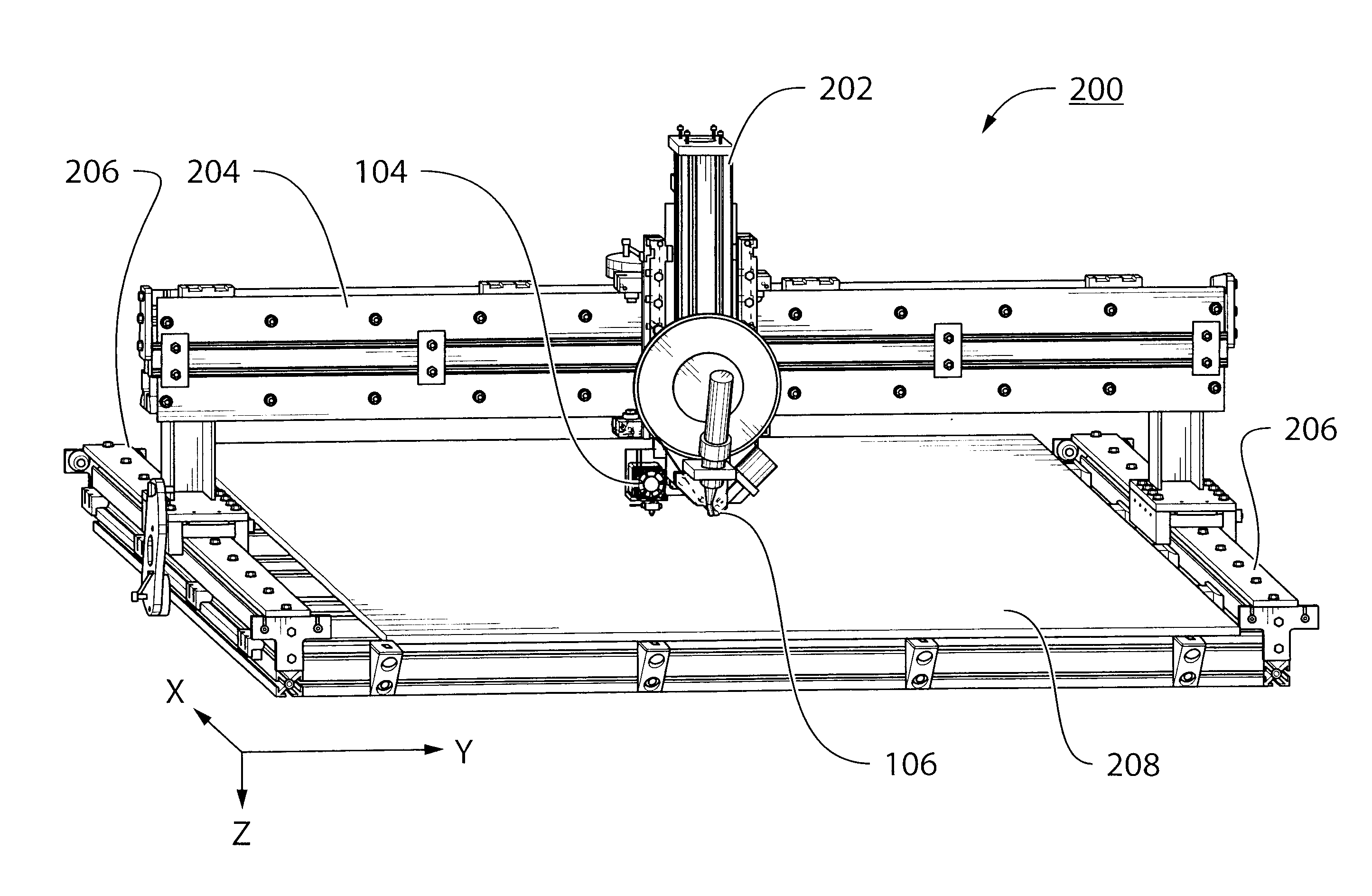

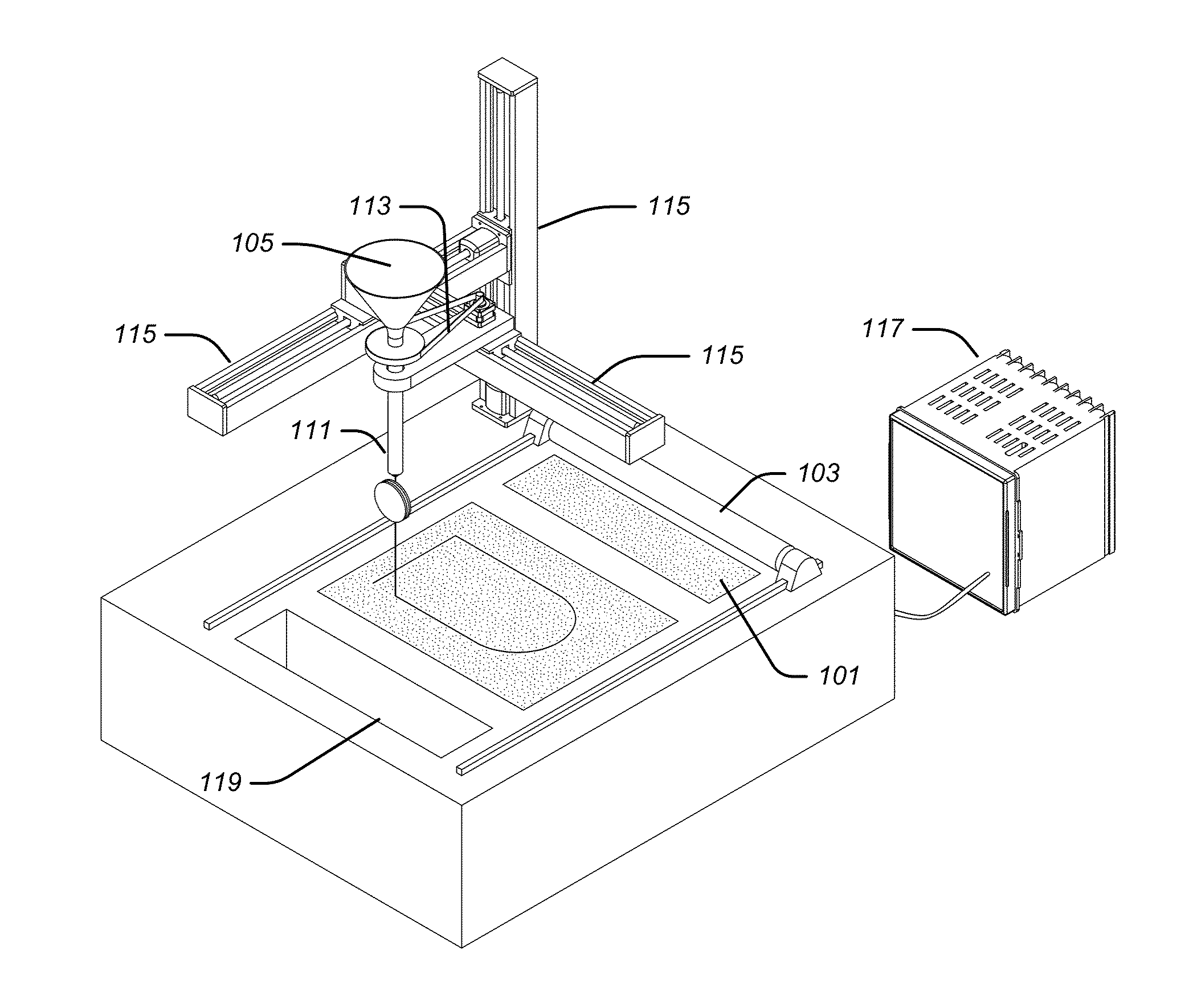

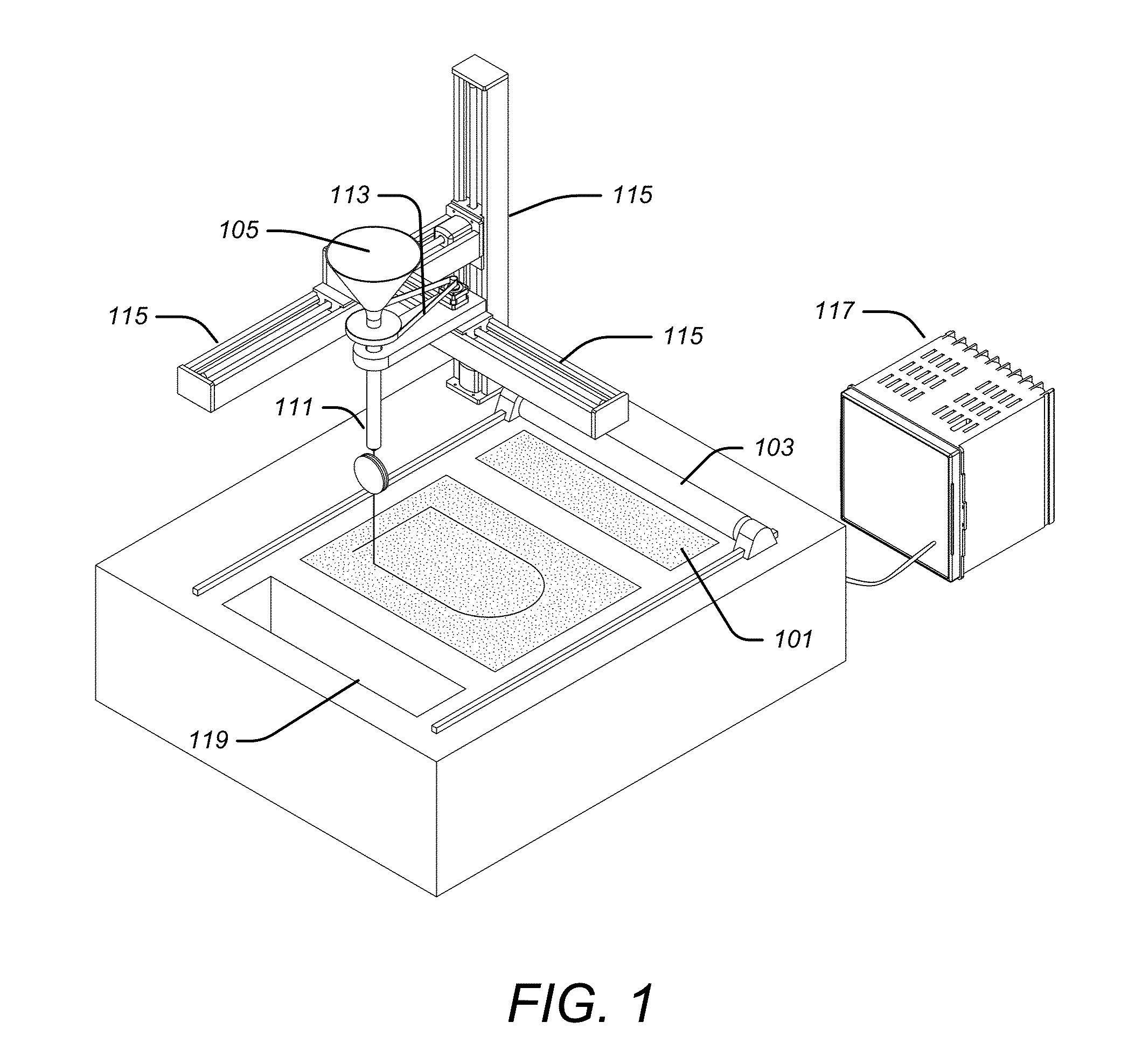

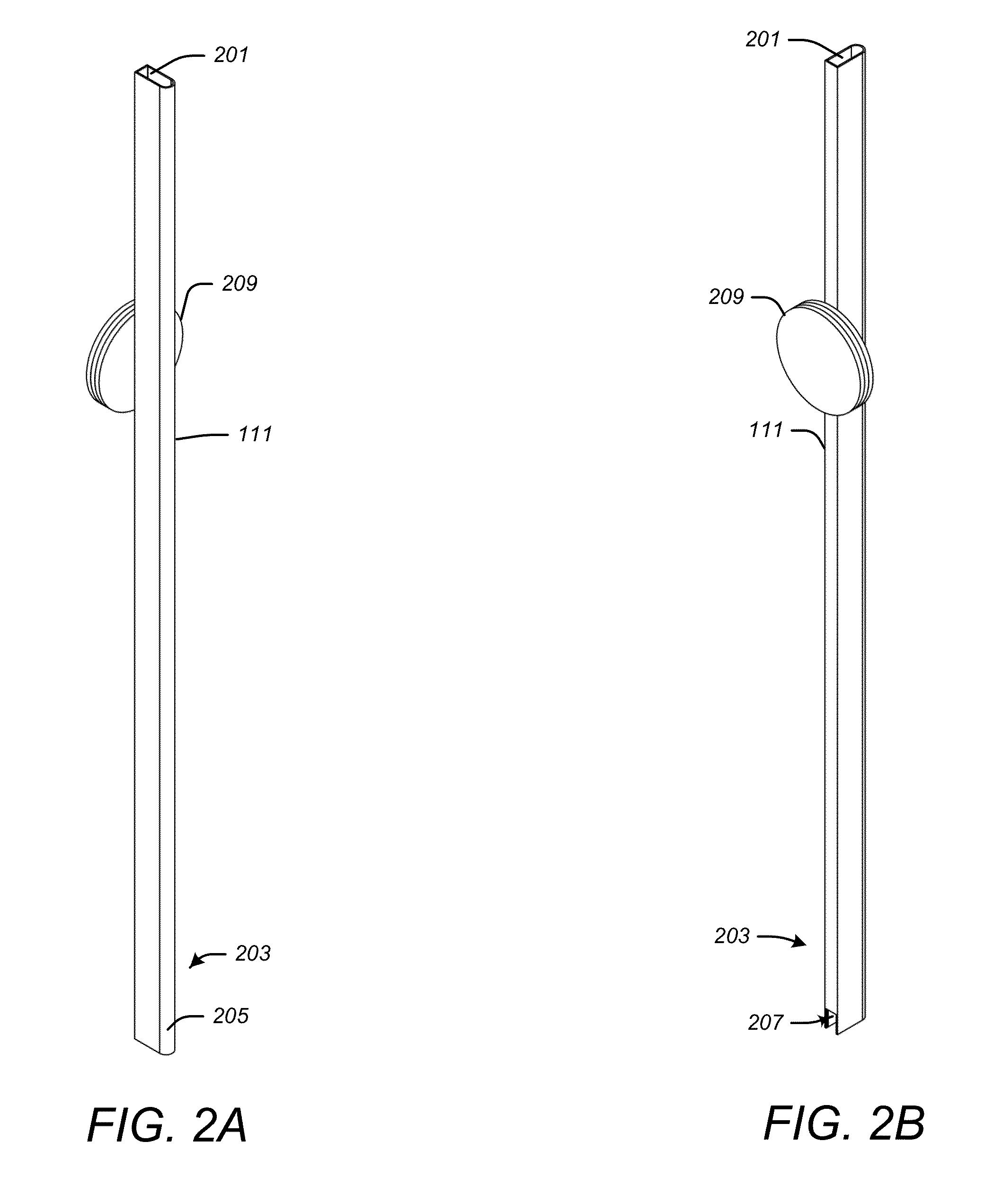

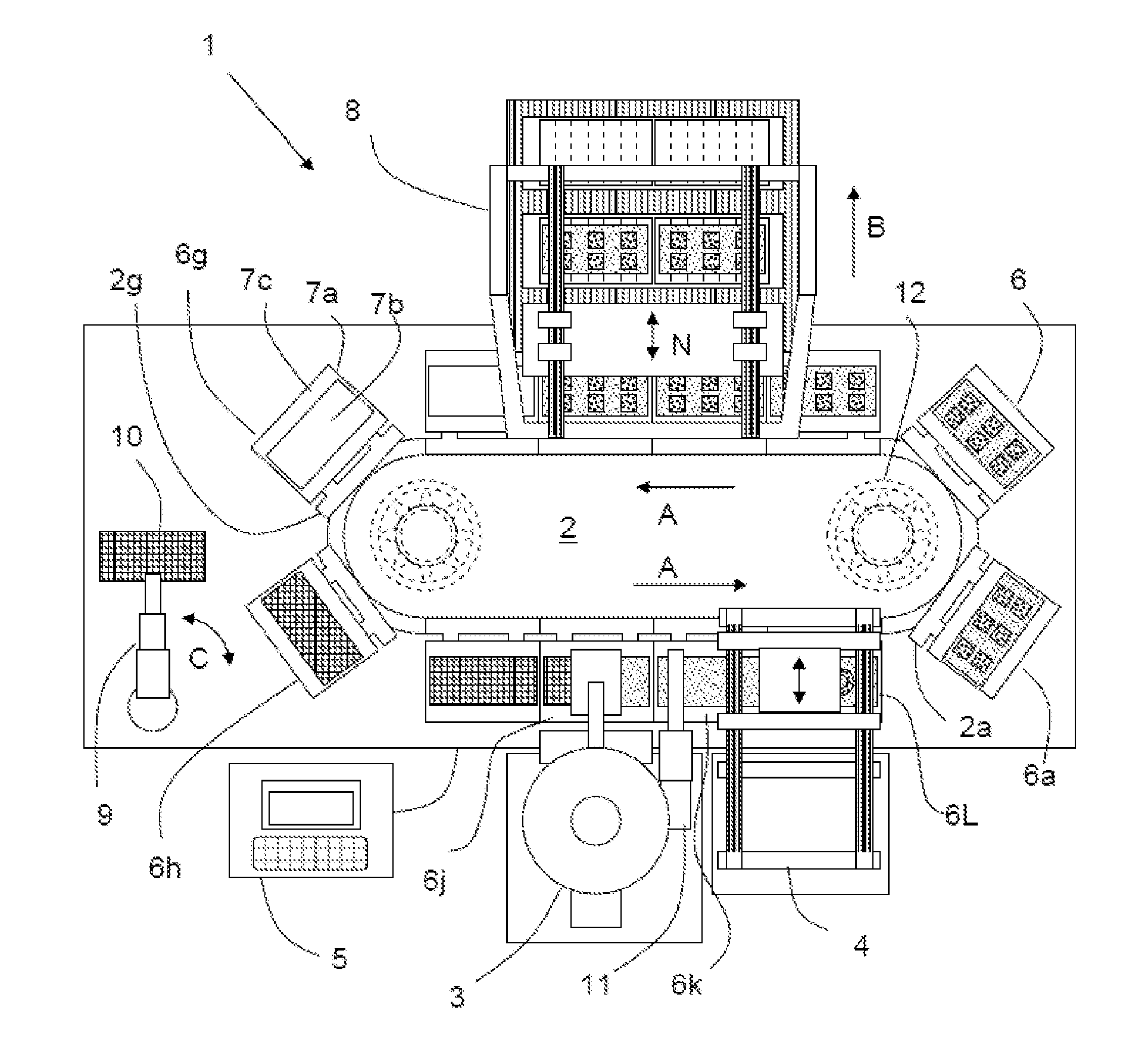

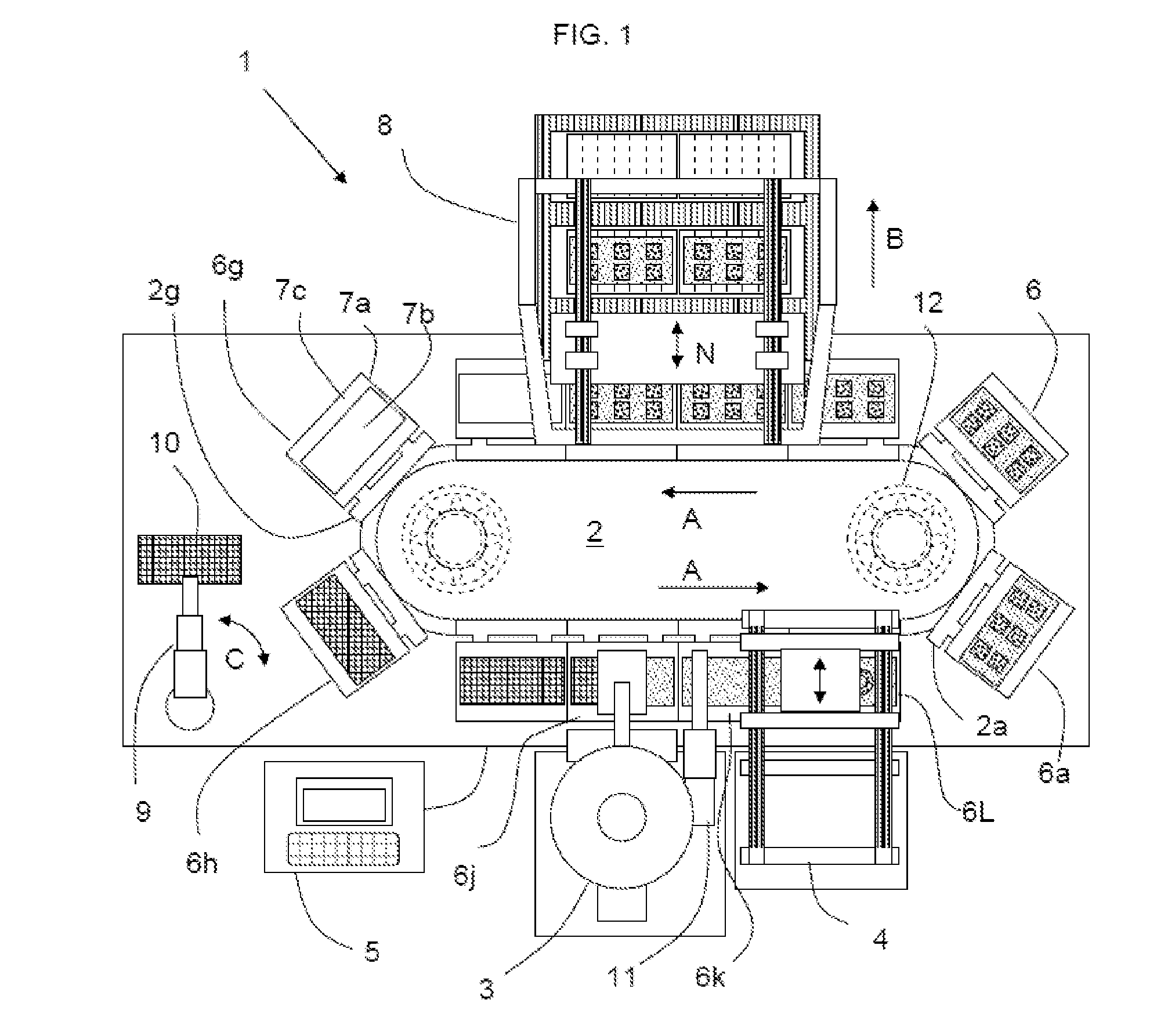

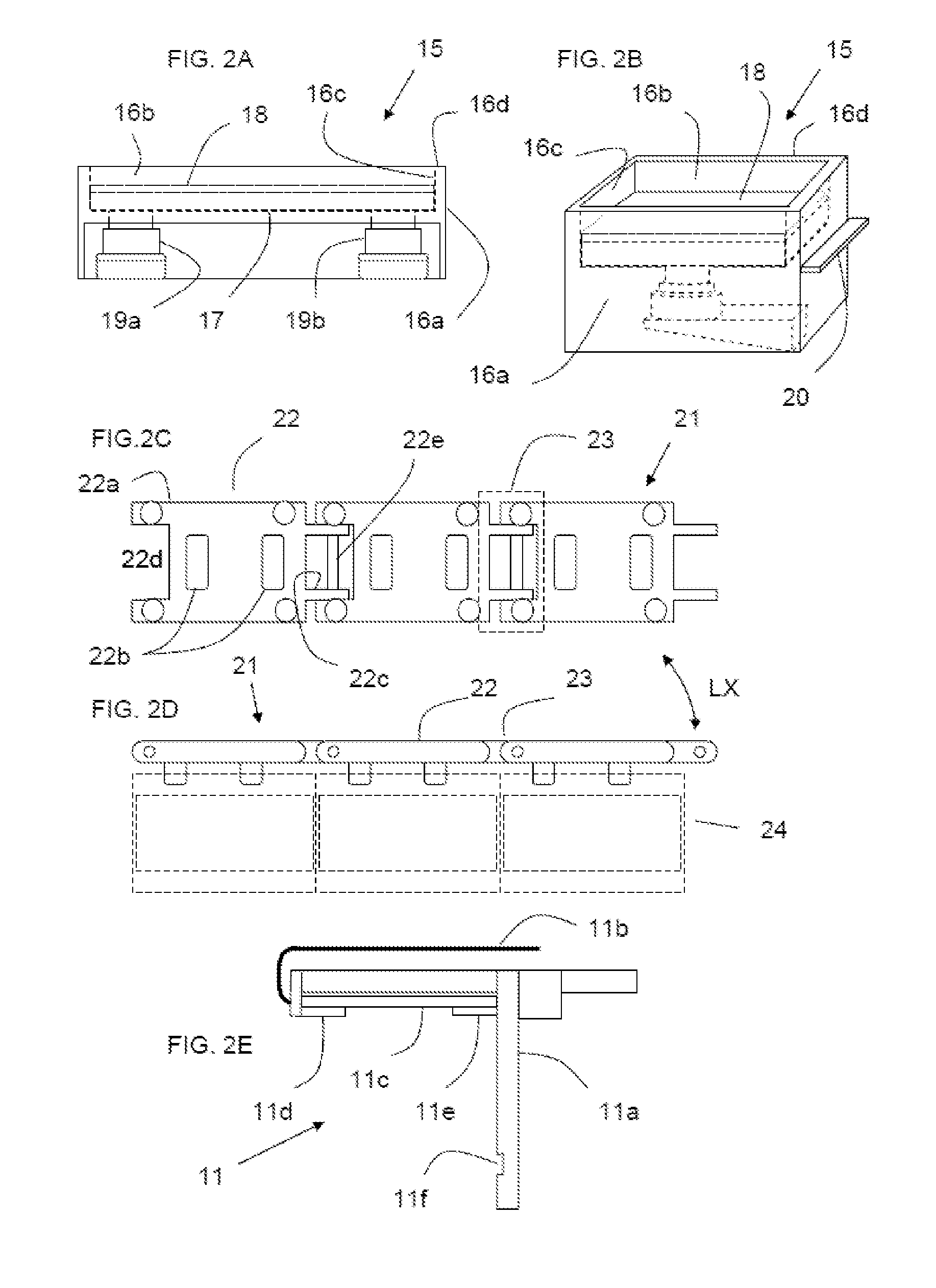

Three-dimensional printing system and equipment assembly

ActiveUS8888480B2Loss of productionImprove efficiencyManufacturing platforms/substratesConfectioneryDevice Subassembly3 dimensional printing

Owner:APRECIA PHARMA LLC

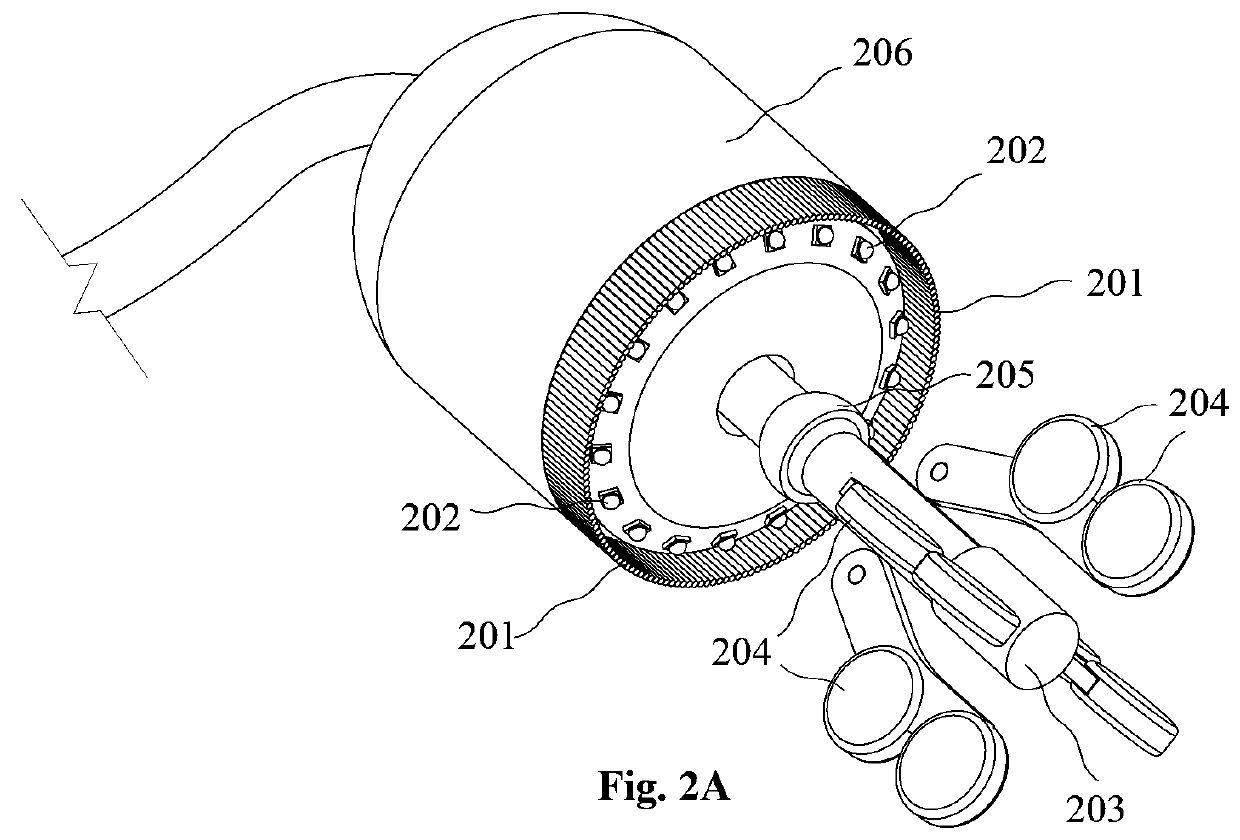

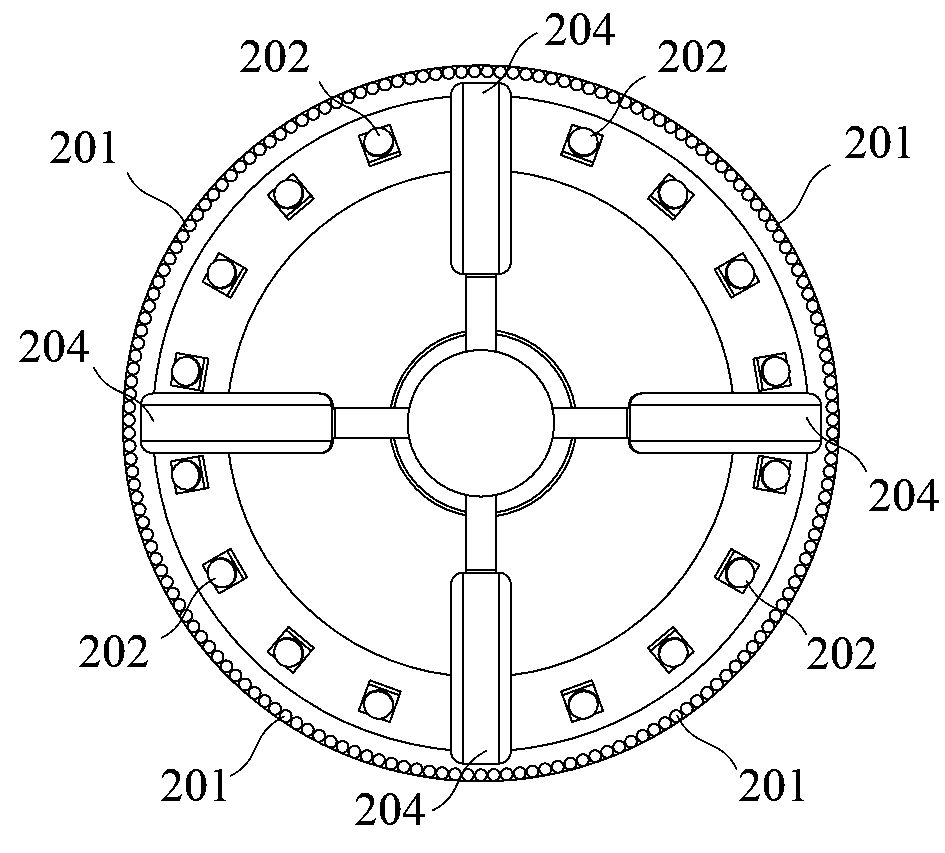

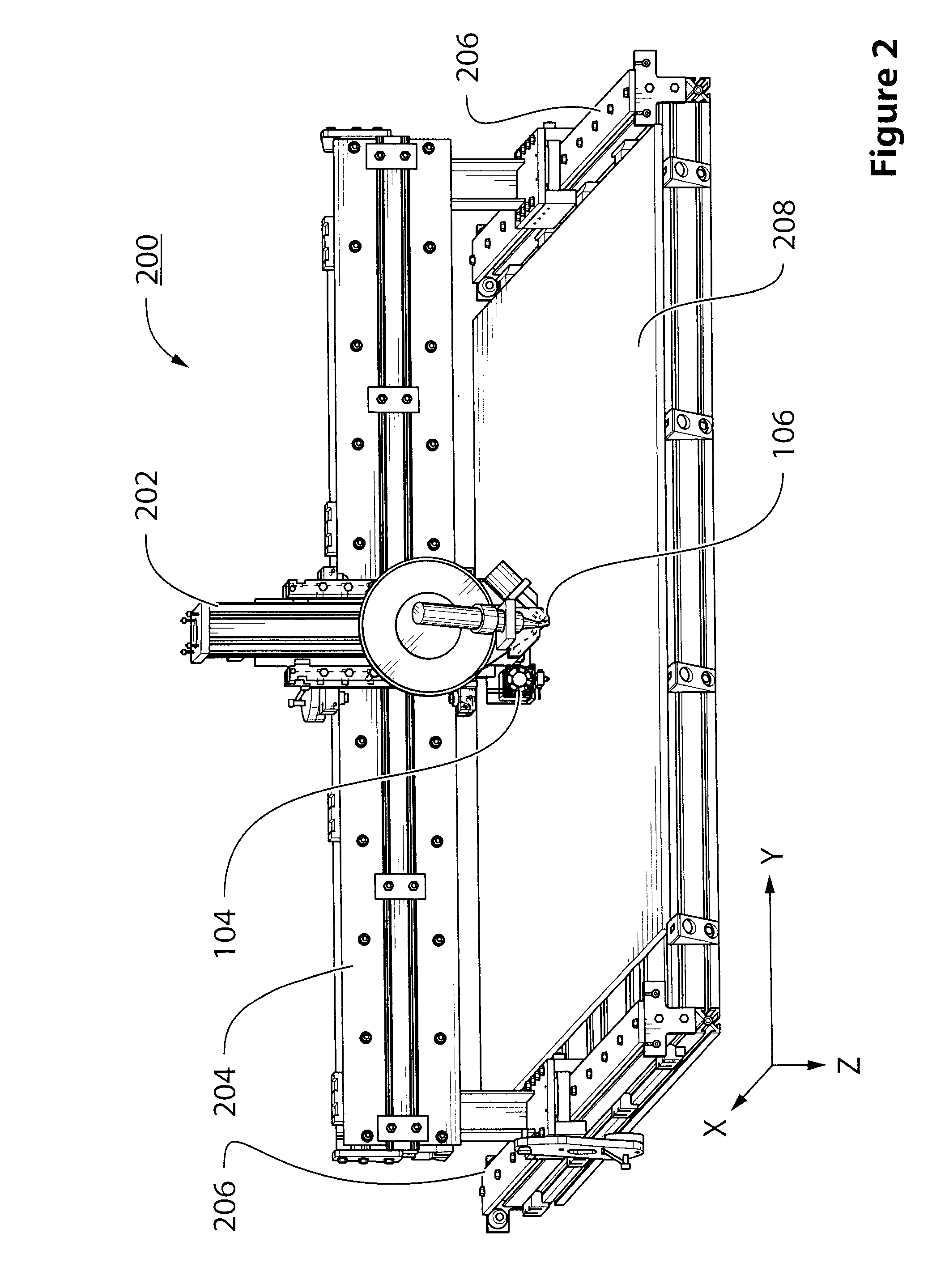

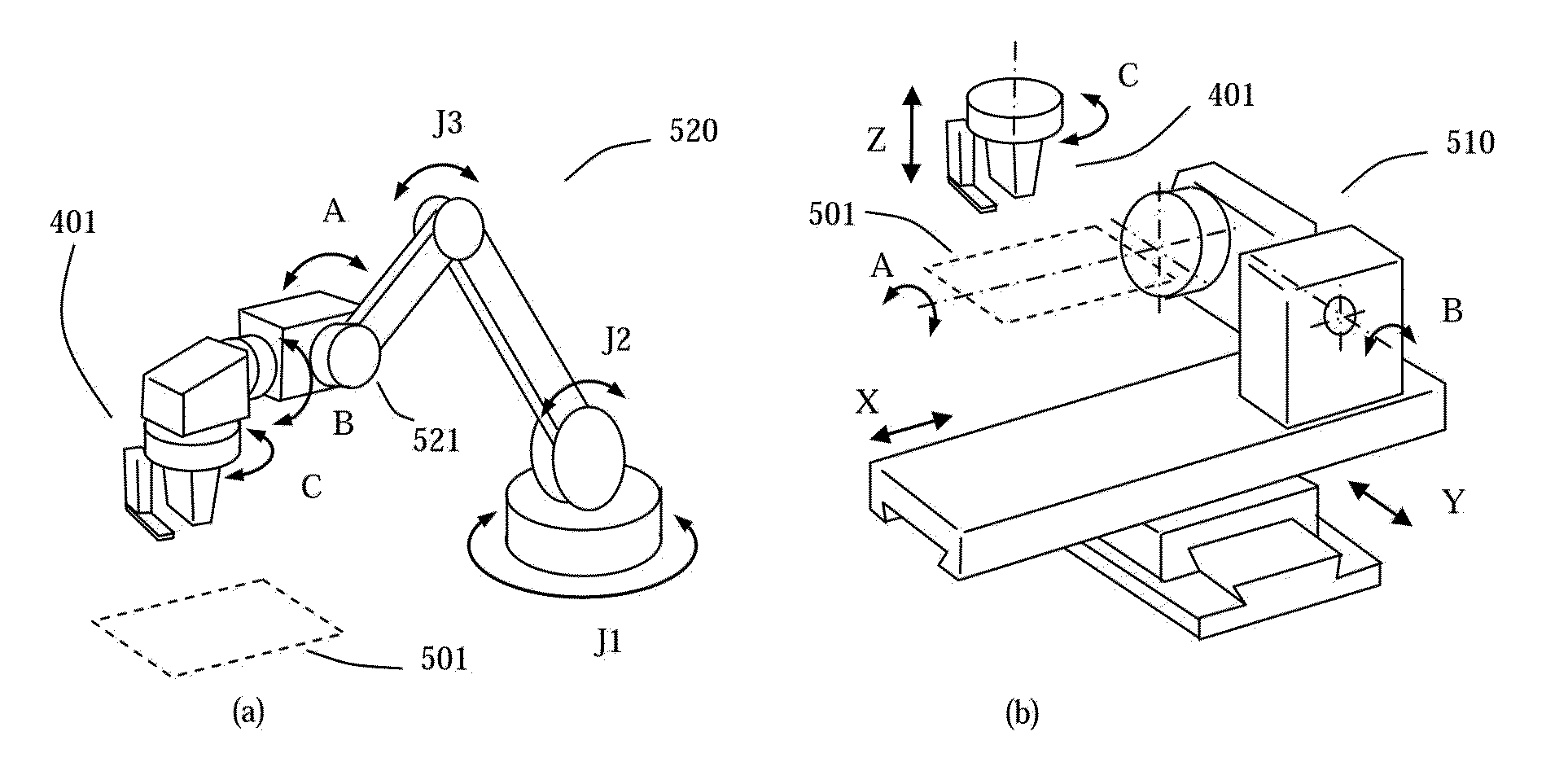

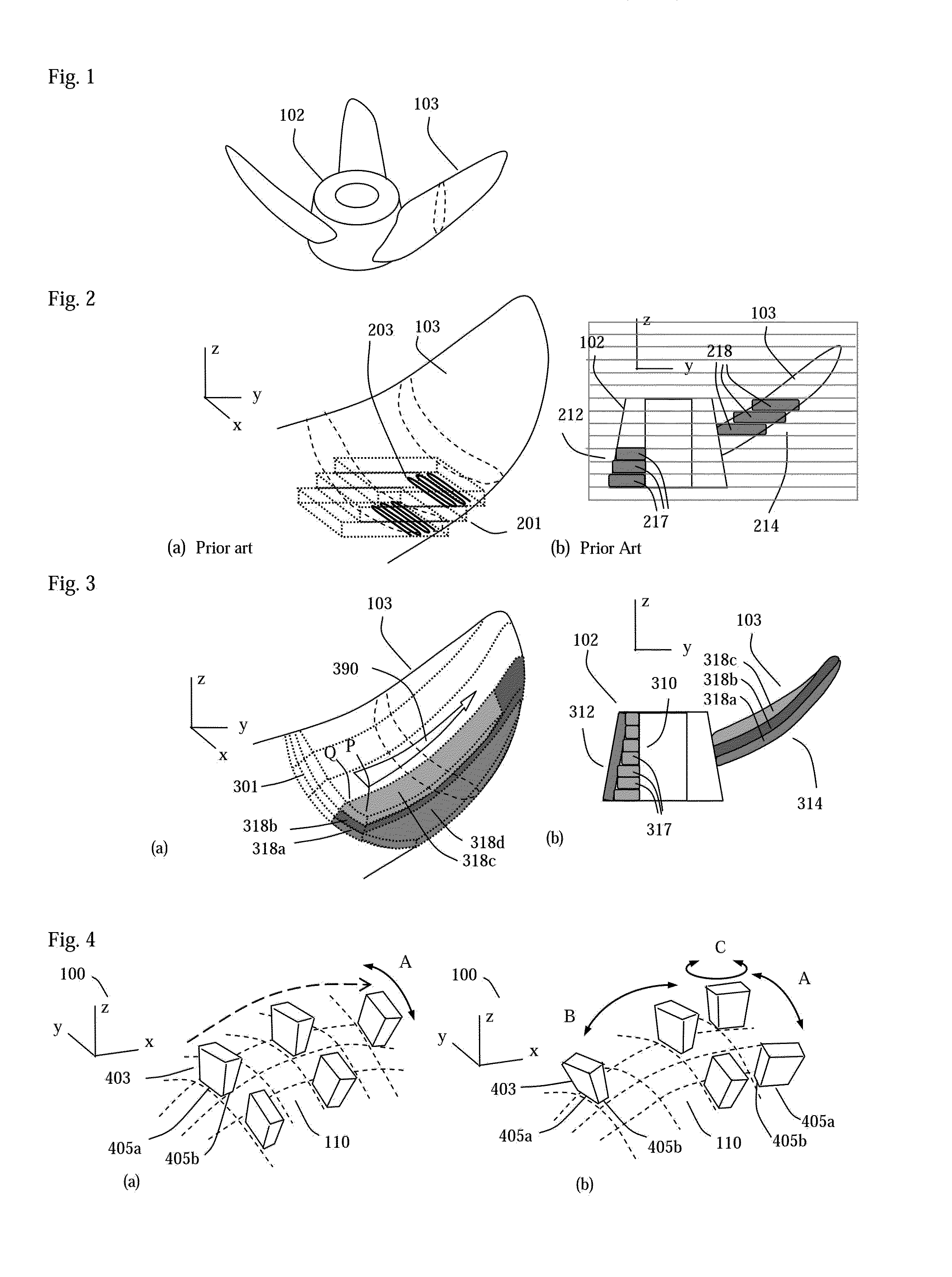

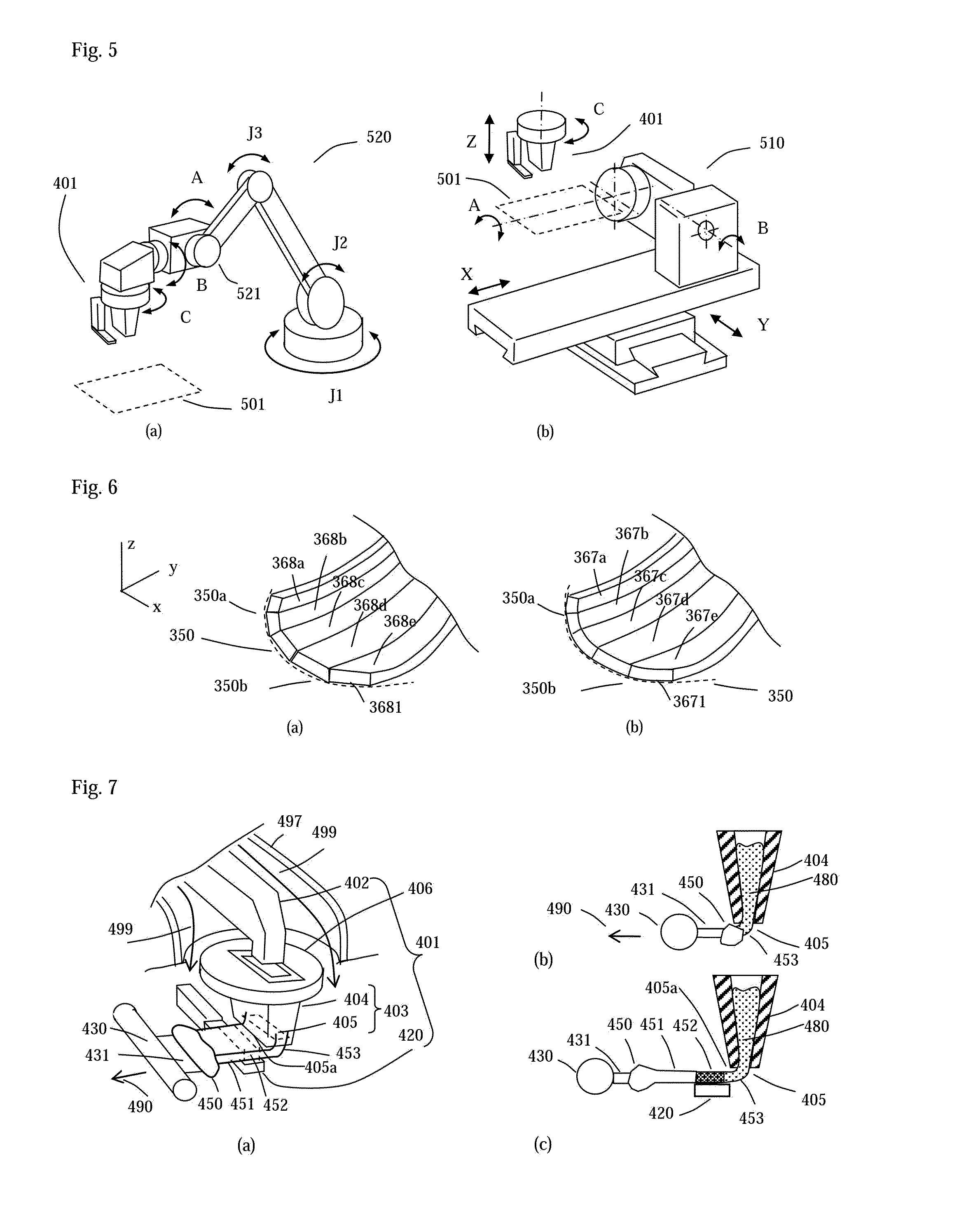

Flexible 3D Freeform Techniques

ActiveUS20160151833A1Improve manufacturing speedBuild fine and complexConfectioneryGlass forming apparatusEngineeringInjection molding machine

This invention relates to processes and systems of rapid prototyping and production. Its features includes flexible material deposition along tangential directions of surfaces of a part to be made, thereby eliminating stair-shape surface due to uniform horizontal layer deposition, increasing width of material deposition to increase build up rate, applying the principles of traditional forming / joining processes, such as casting, fusion welding, plastic extrusion and injection molding in the fabrication process so that various industrial materials can be processed, applying comparatively low cost heating sources, such as induction heating and arc-heating. Additional features include varying width and size of material deposition in accordance with geometry to be formed and applying a differential molding means for improved shape formation and surface finishing.

Owner:NATIONAL TSING HUA UNIVERSITY

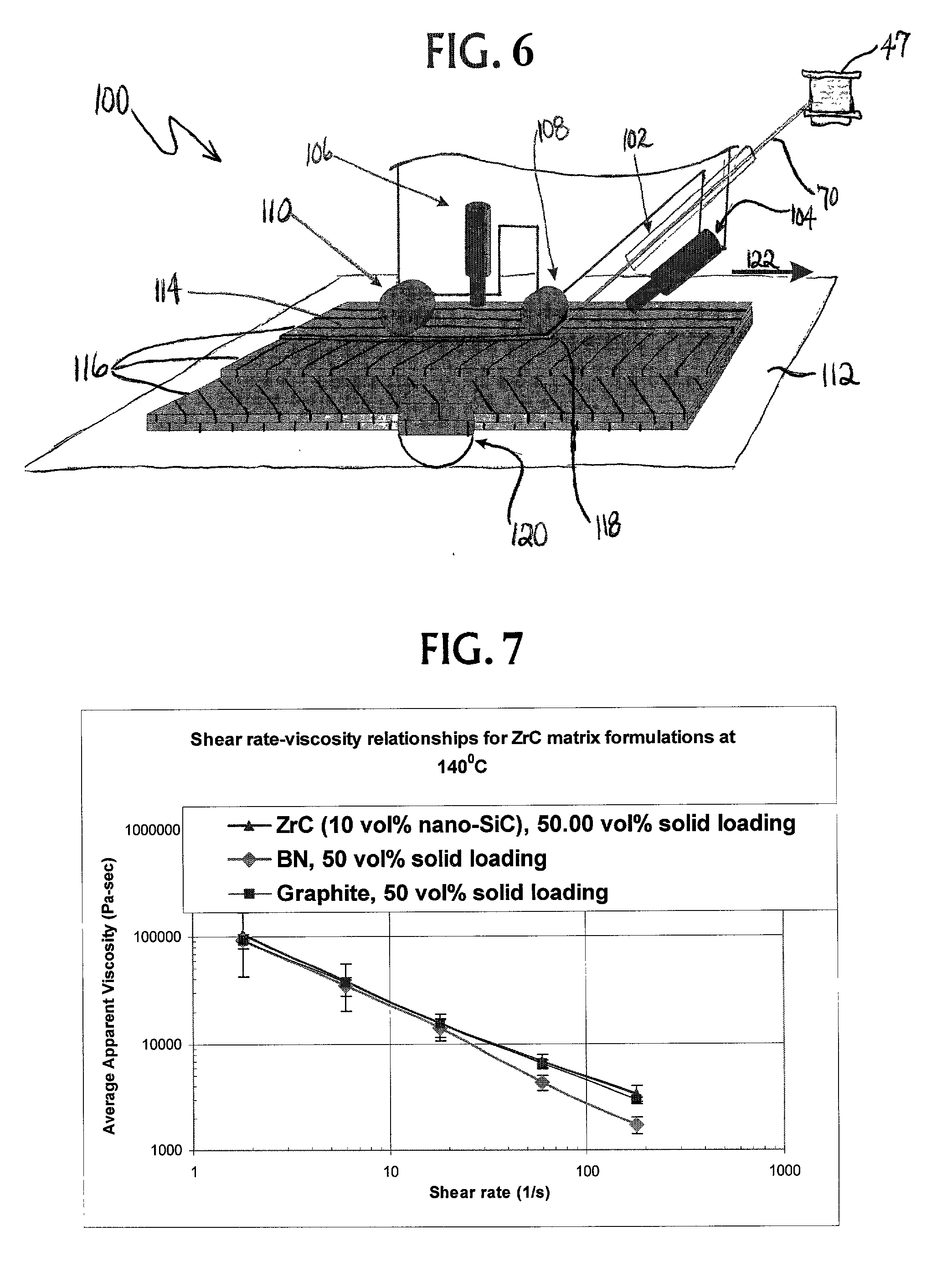

Continuous fiber reinforced composites and methods, apparatuses, and compositions for making the same

InactiveUS6899777B2Improved non-brittle failure characteristicFast preparationCeramic shaping apparatusCoatingsMetal fiberPolymer science

A process for continuous composite coextrusion comprising: (a) forming first a material-laden composition comprising a thermoplastic polymer and at least about 40 volume % of a ceramic or metallic particulate in a manner such that the composition has a substantially cylindrical geometry and thus can be used as a substantially cylindrical feed rod; (b) forming a hole down the symmetrical axis of the feed rod; (c) inserting the start of a continuous spool of ceramic fiber, metal fiber or carbon fiber through the hole in the feed rod; (d) extruding the feed rod and spool simultaneously to form a continuous filament consisting of a green matrix material completely surrounding a dense fiber reinforcement and said filament having an average diameter that is less than the average diameter of the feed rod; and (e) depositing the continuous filament into a desired architecture which preferably is determined from specific loading conditions of the desired object and CAD design of the object to provide a green fiber reinforced composite object.

Owner:ADVANCED CERAMICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com