Patents

Literature

746 results about "Layer wise" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

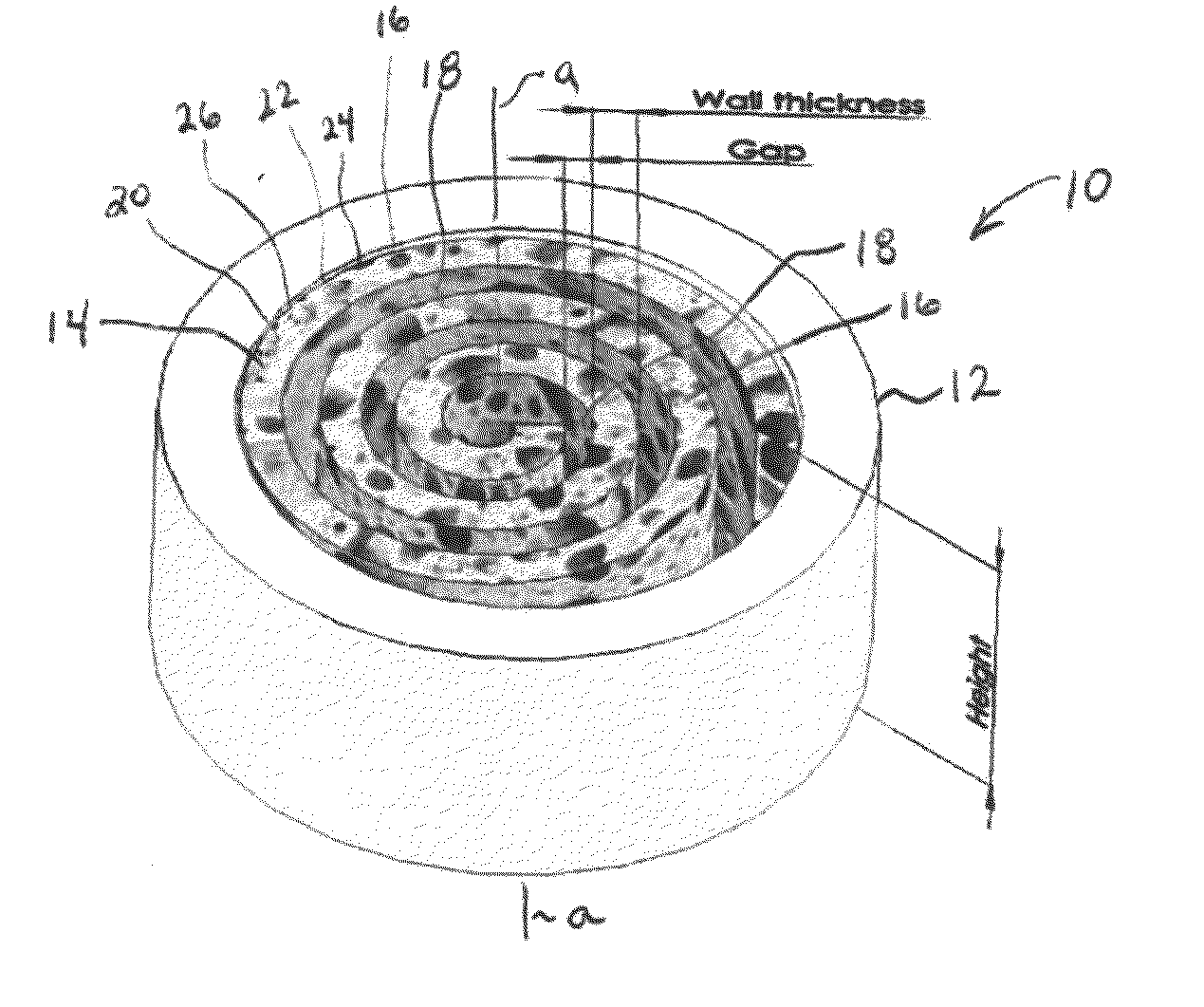

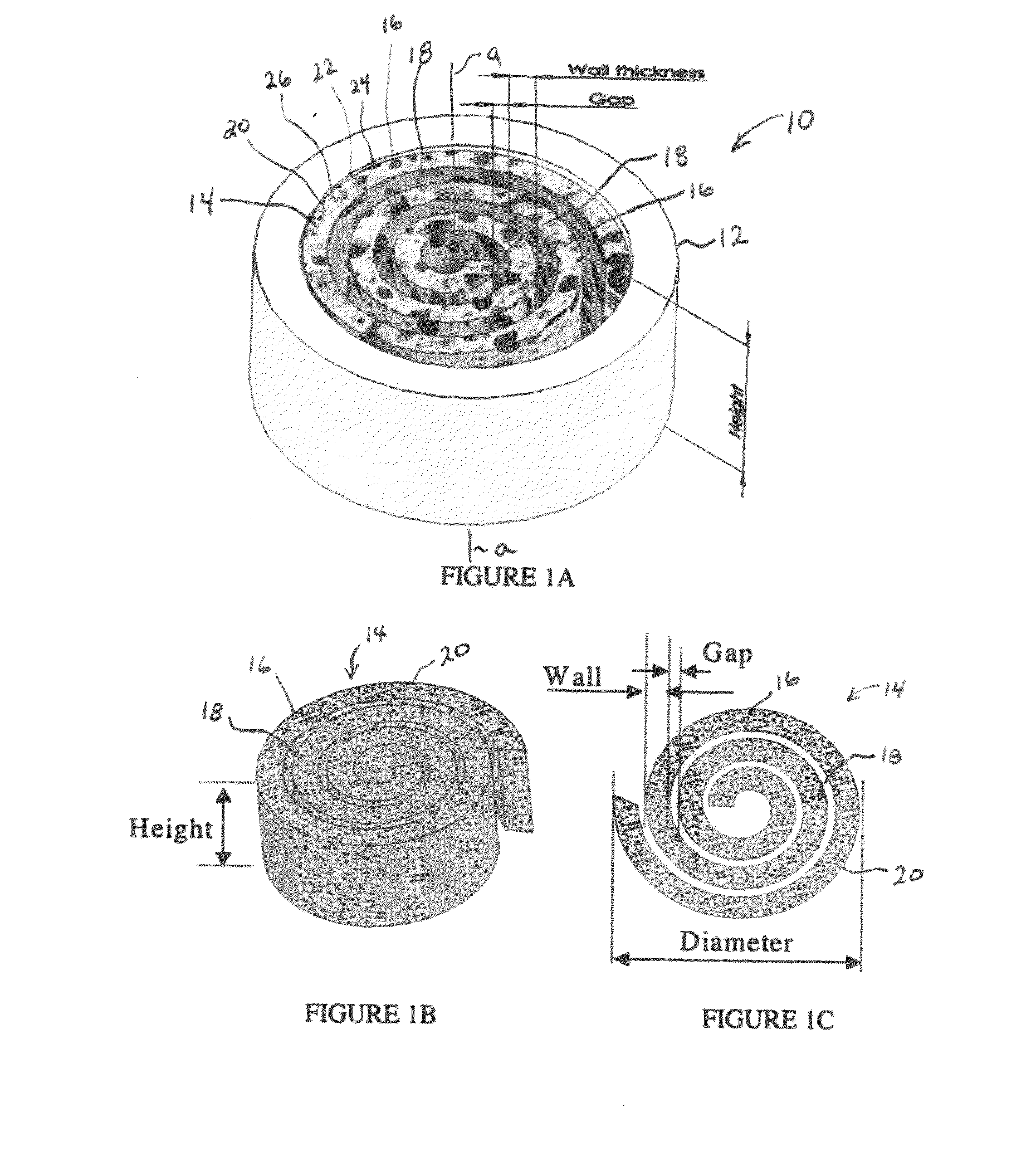

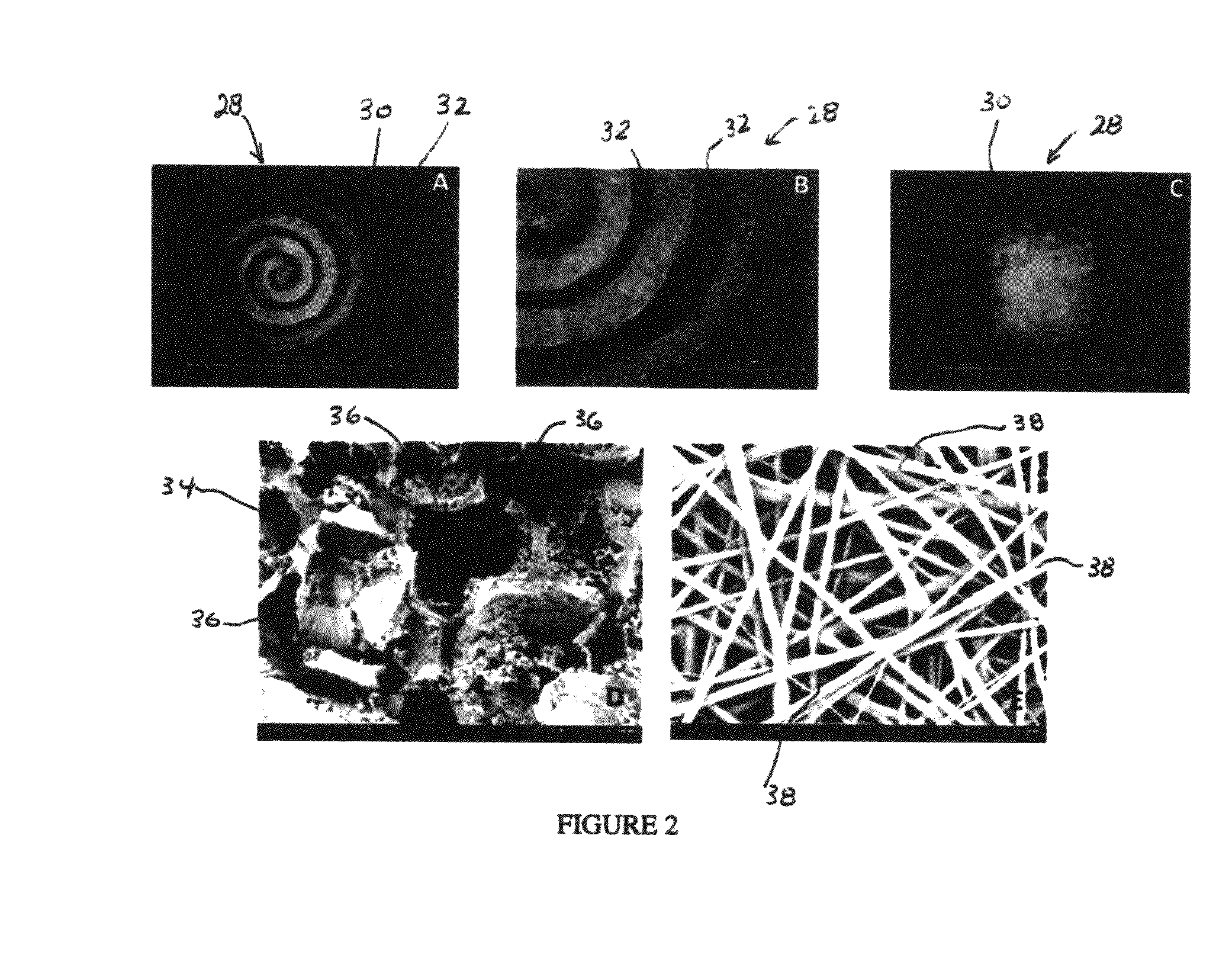

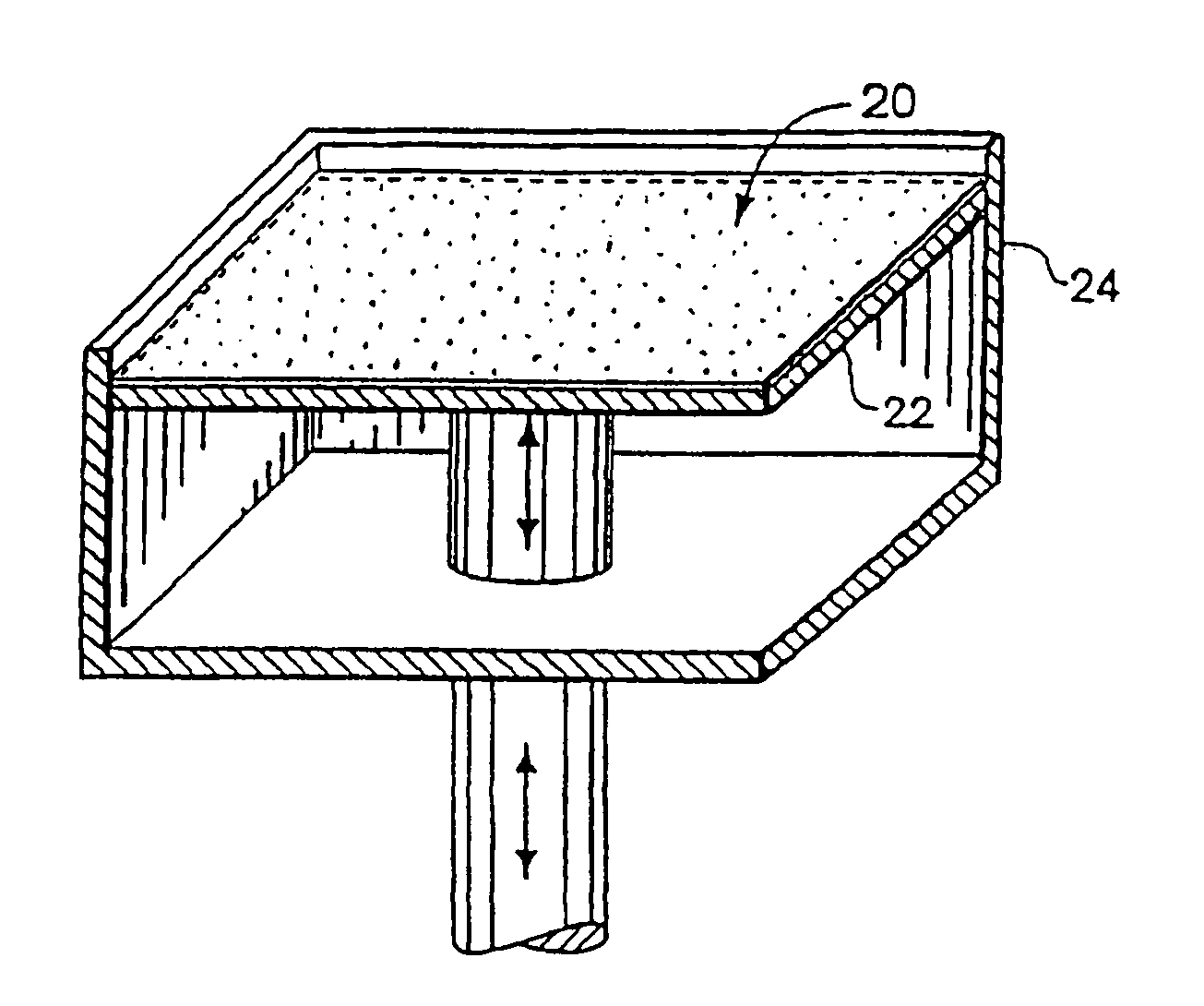

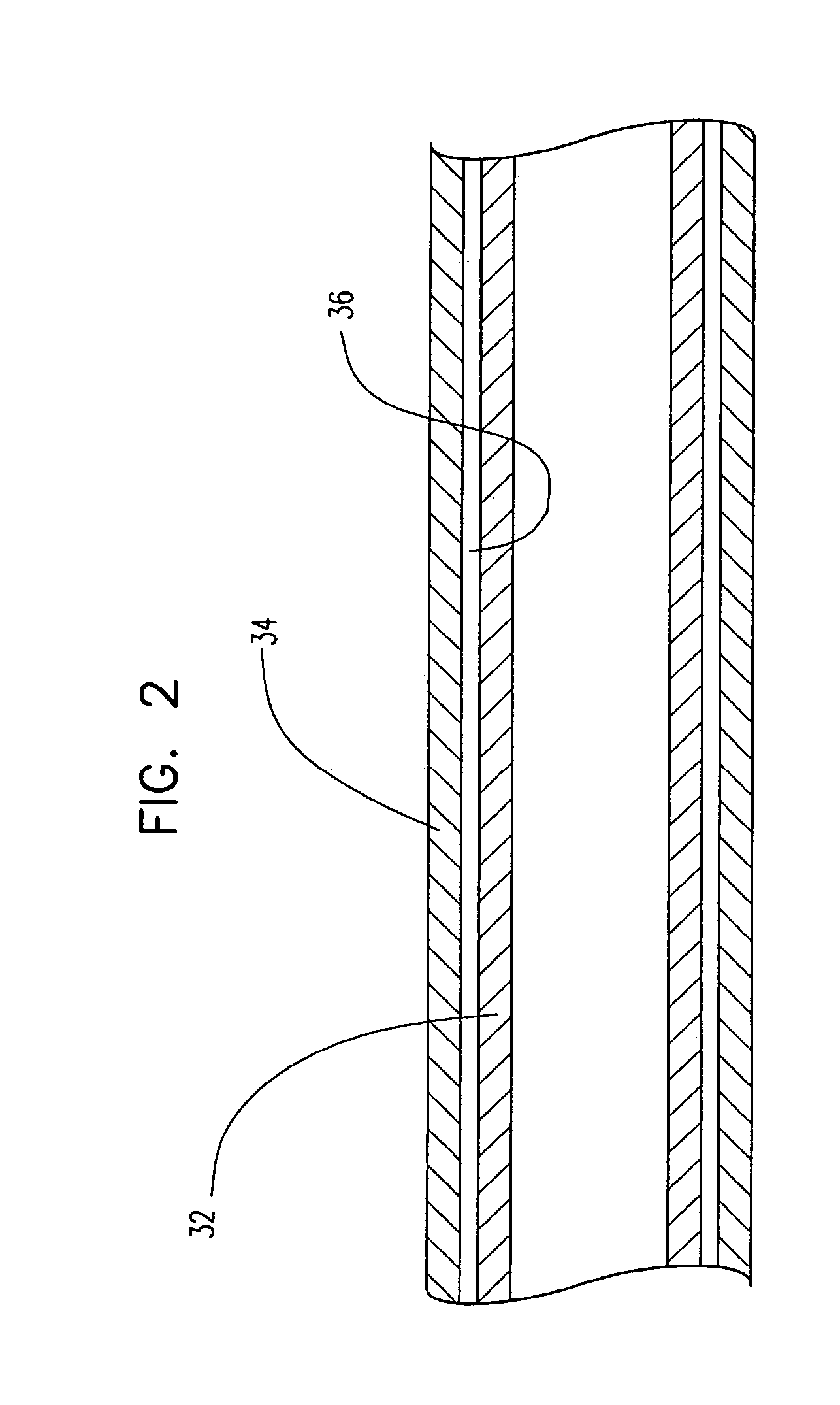

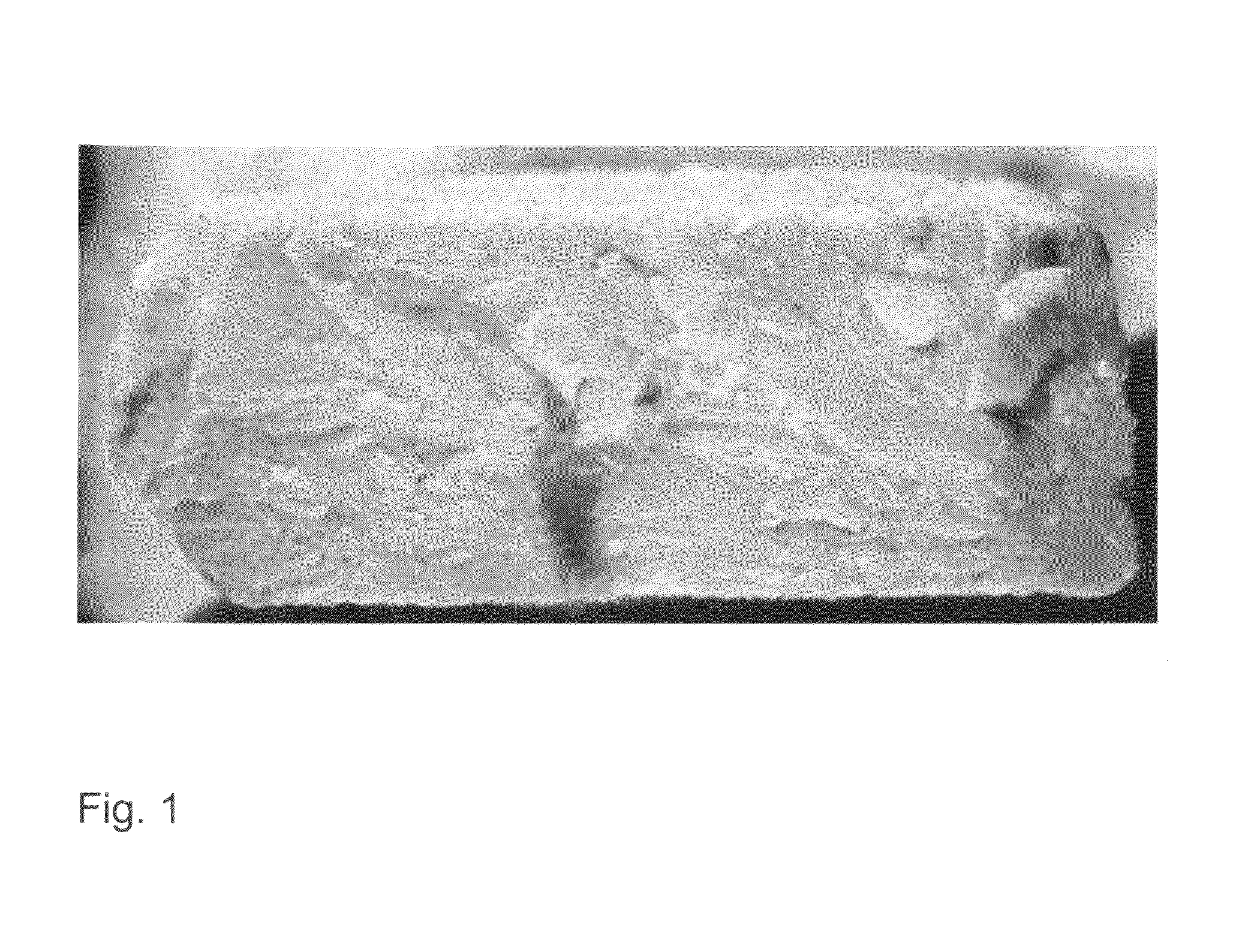

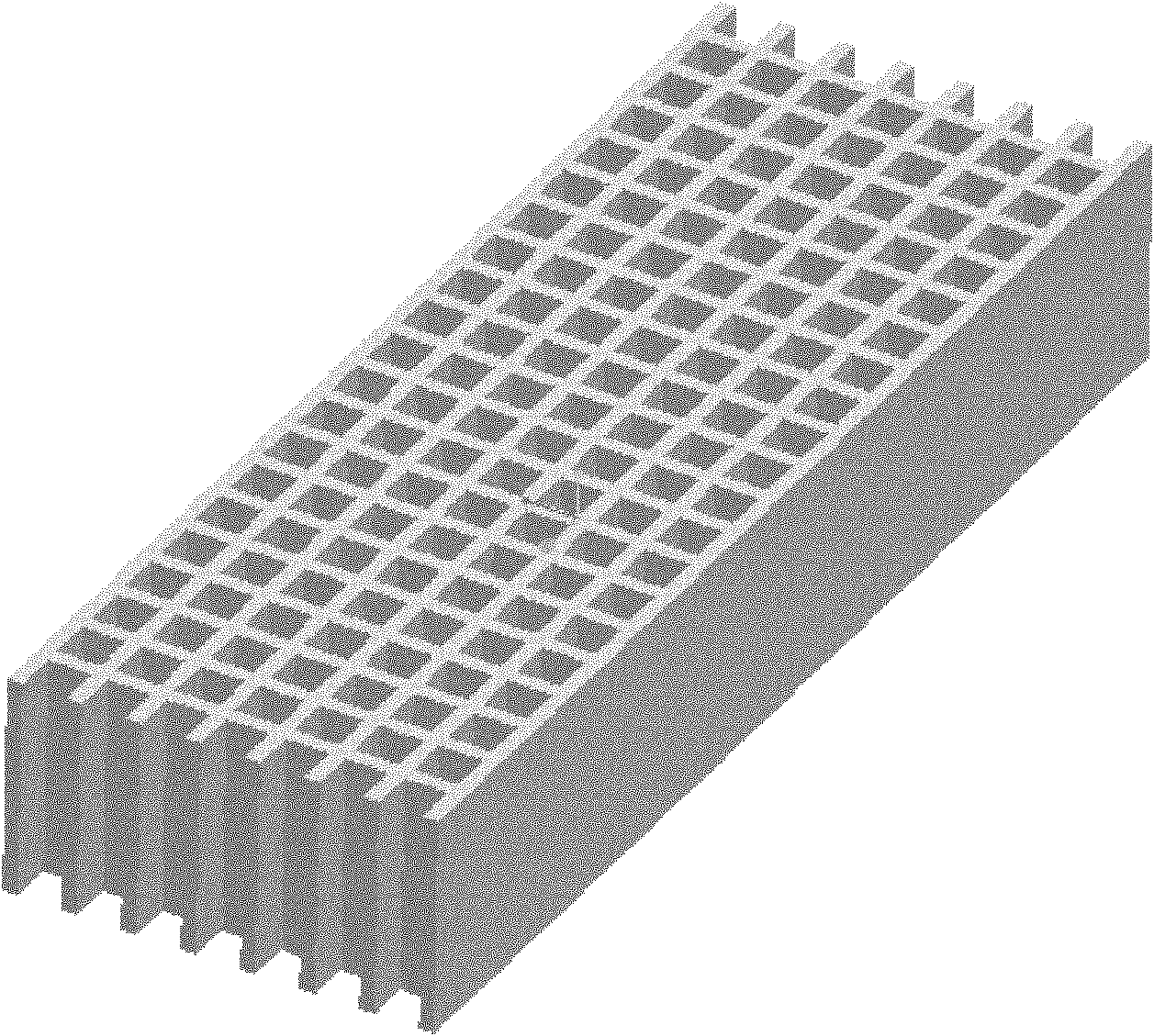

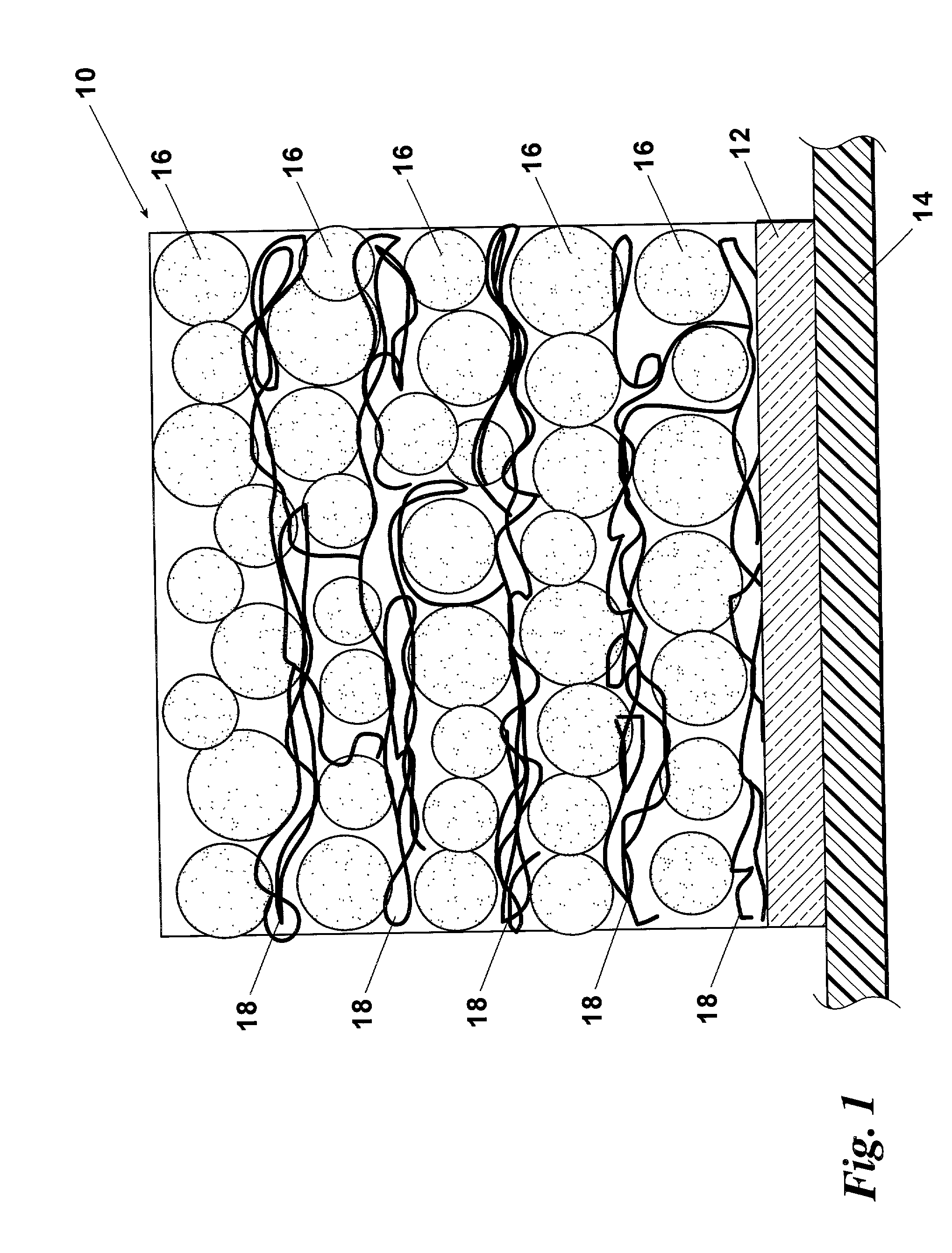

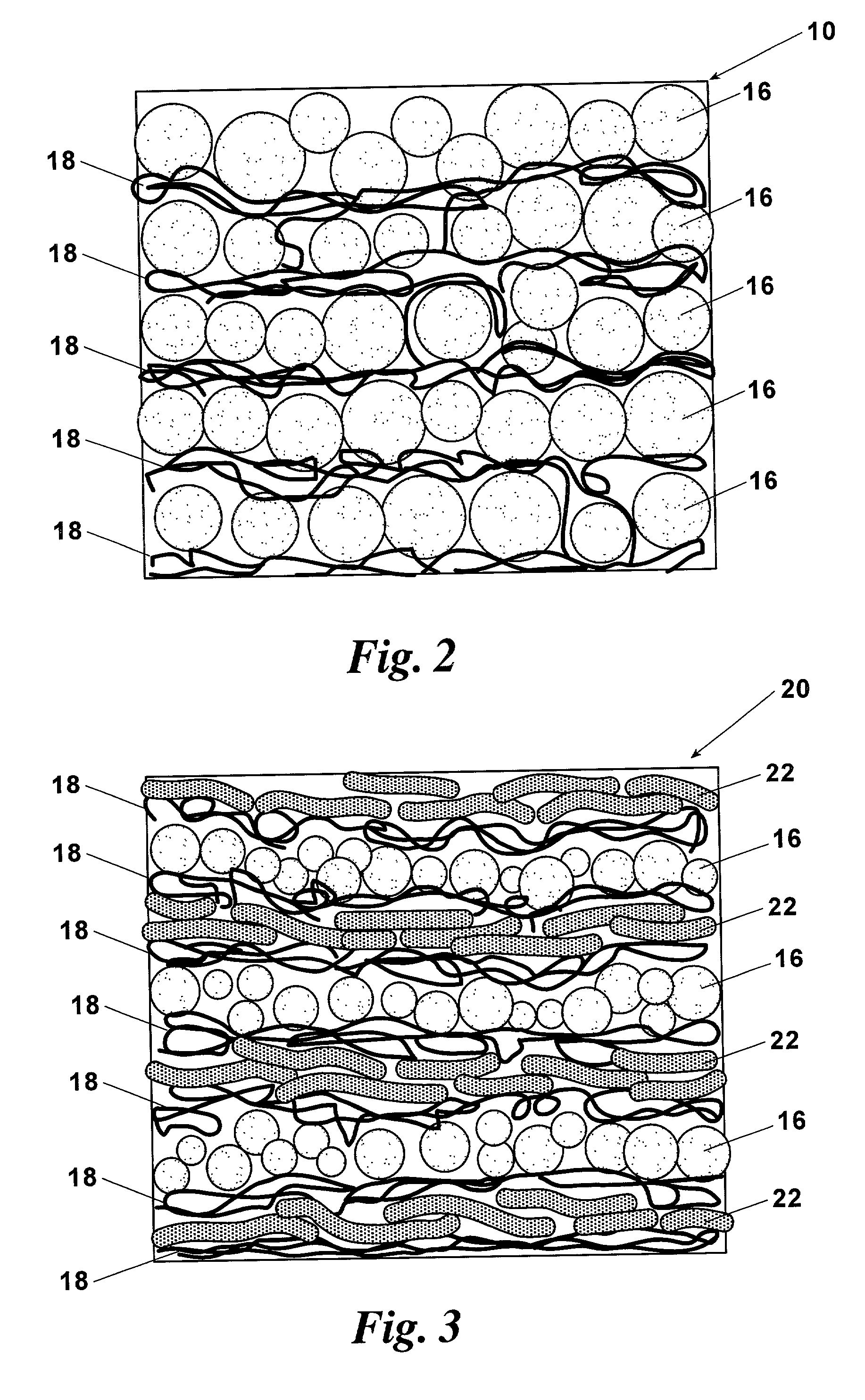

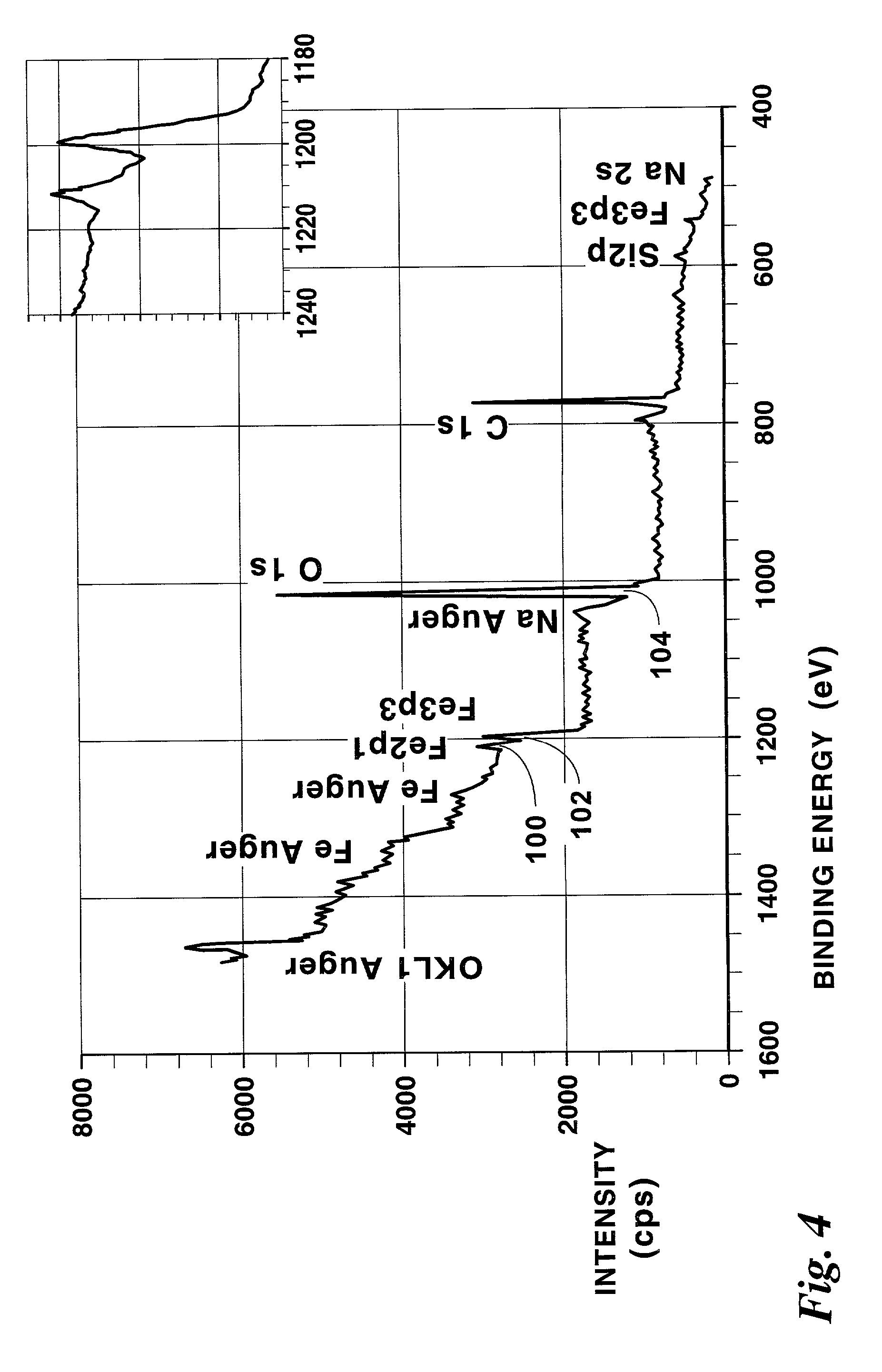

Synergetic functionalized spiral-in-tubular bone scaffolds

InactiveUS20100310623A1Increase the number ofIncrease alkaline phosphatase activityPeptide/protein ingredientsBone implantPorous sheetCell seeding

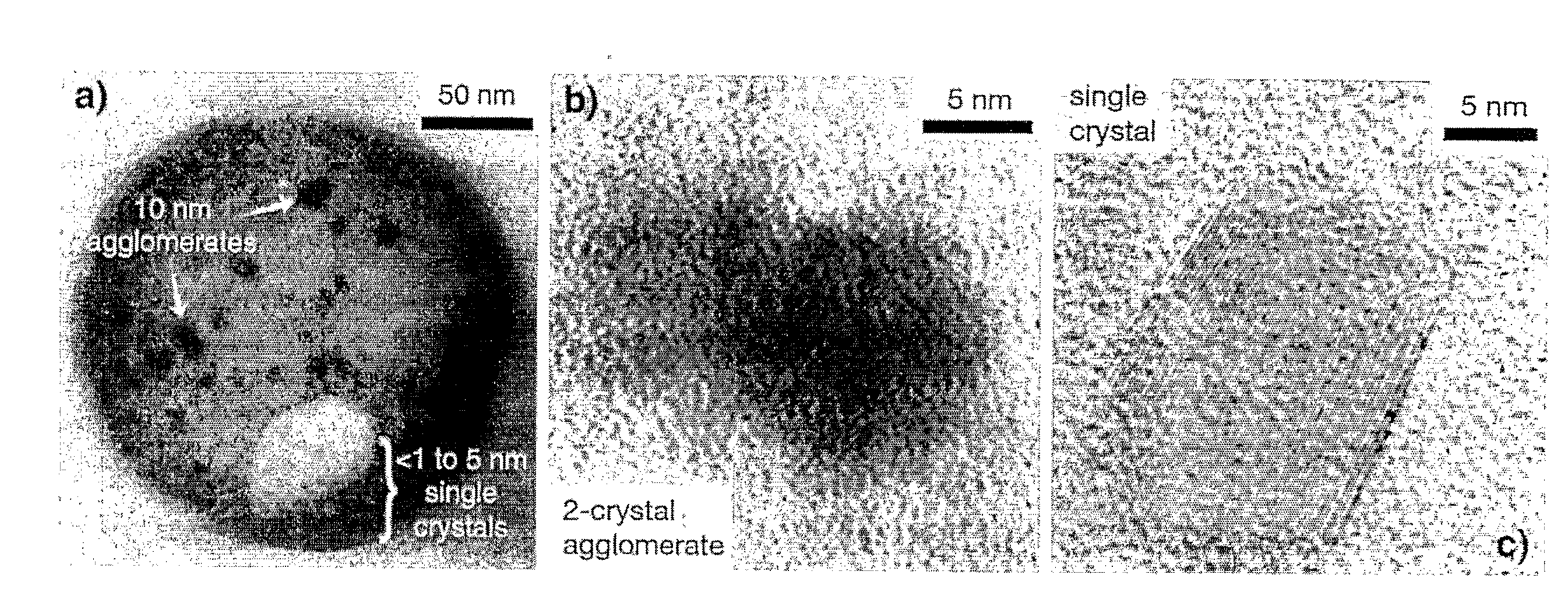

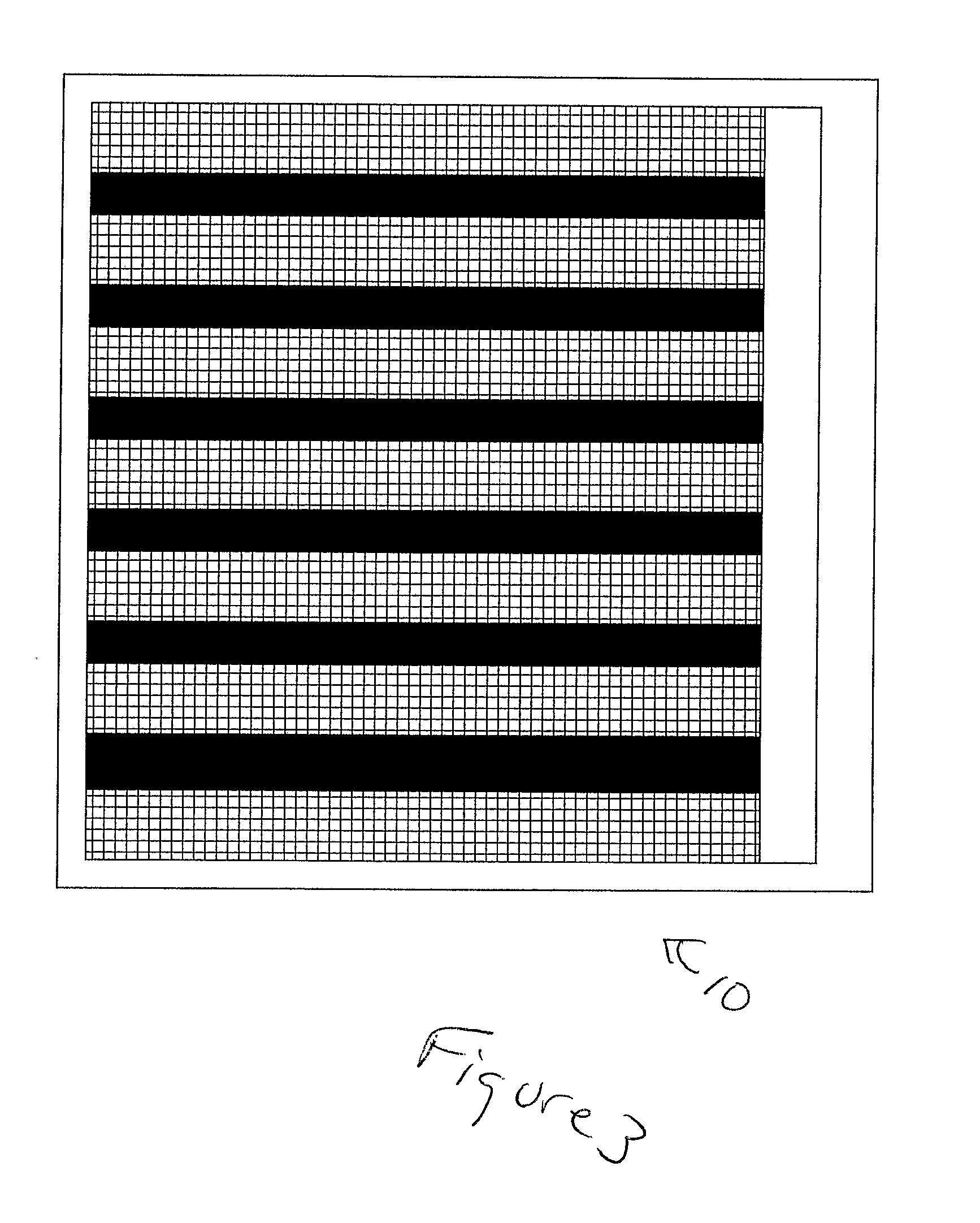

An integrated scaffold for bone tissue engineering has a tubular outer shell and a spiral scaffold made of a porous sheet. The spiral scaffold is formed such that the porous sheet defines a series of spiral coils with gaps of controlled width between the coils to provide an open geometry for enhanced cell growth. The spiral scaffold resides within the bore of the shell and is integrated with the shell to fix the geometry of the spiral scaffold. Nanofibers may be deposited on the porous sheet to enhance cell penetration into the spiral scaffold. The spiral scaffold may have alternating layers of polymer and ceramic on the porous sheet that have been built up using a layer-by-layer method. The spiral scaffold may be seeded with cells by growing a cell sheet and placing the cell sheet on the porous sheet before it is rolled.

Owner:UNIV OF CONNECTICUT

Material systems and methods of three-dimensional printing

InactiveUS7795349B2Adhesive processesAdditive manufacturing apparatusEngineering3 dimensional printing

The present invention is directed to three-dimensional printing material systems and method, and an article made therefrom. The method of the present invention includes building cross-sectional portions of a three-dimensional article, and assembling the individual cross-sectional areas in a layer-wise fashion to form a final article. The individual cross-sectional areas are built by using an ink-jet printhead to deliver a fluid to a particulate material that includes particulate material.

Owner:3D SYST INC

Three dimensional printing material system and method

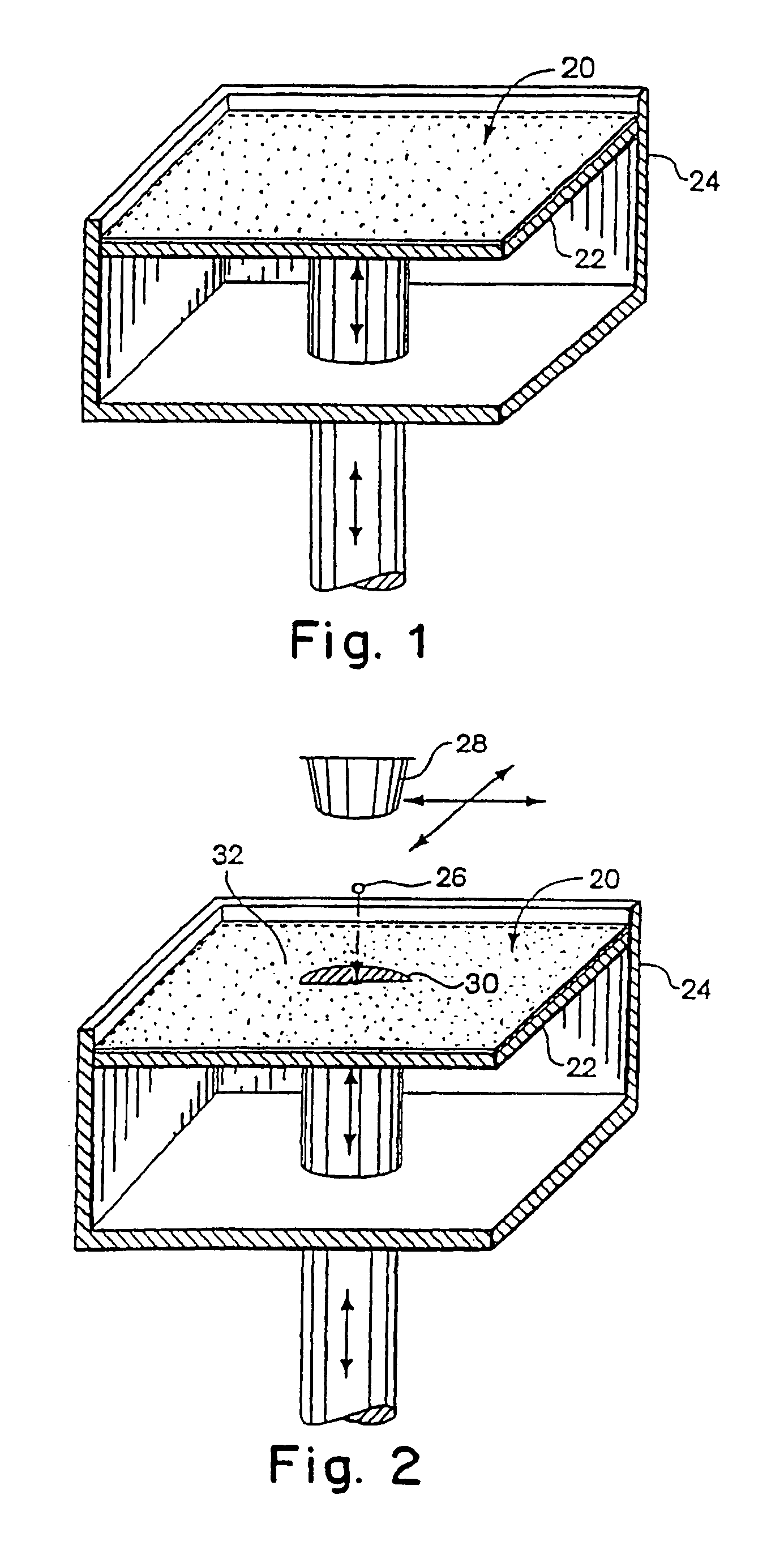

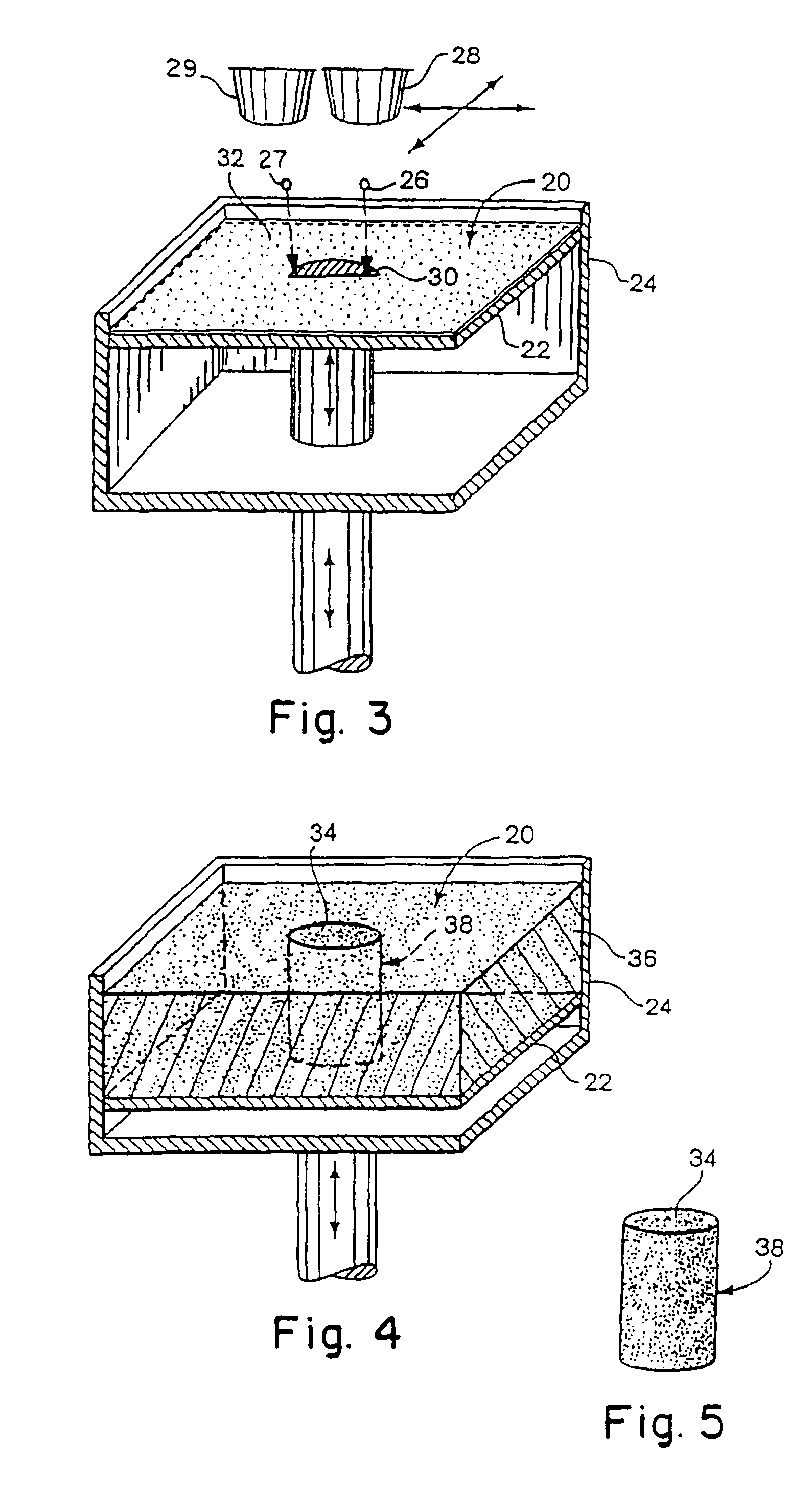

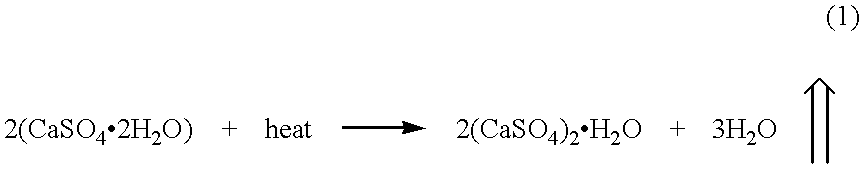

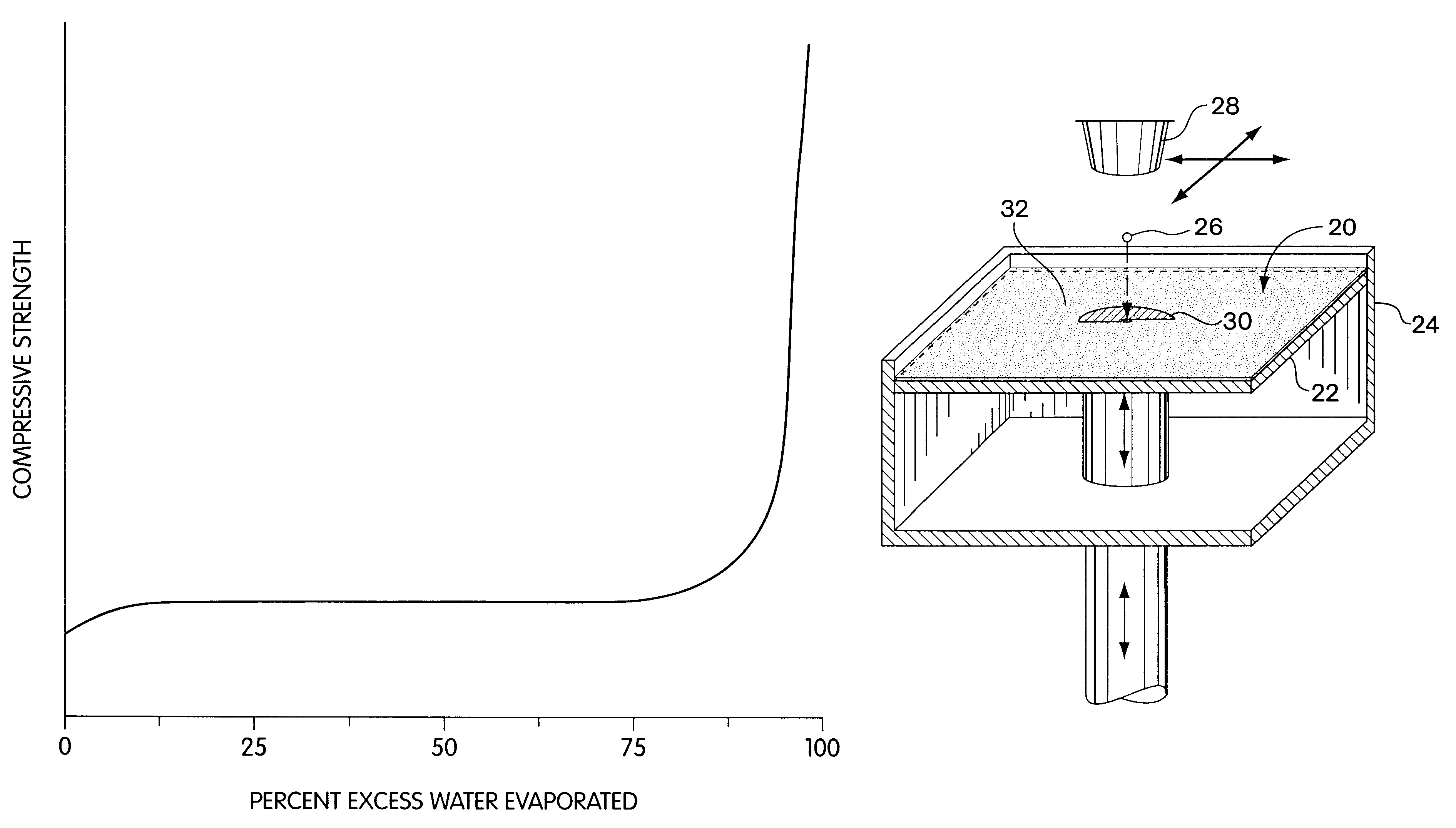

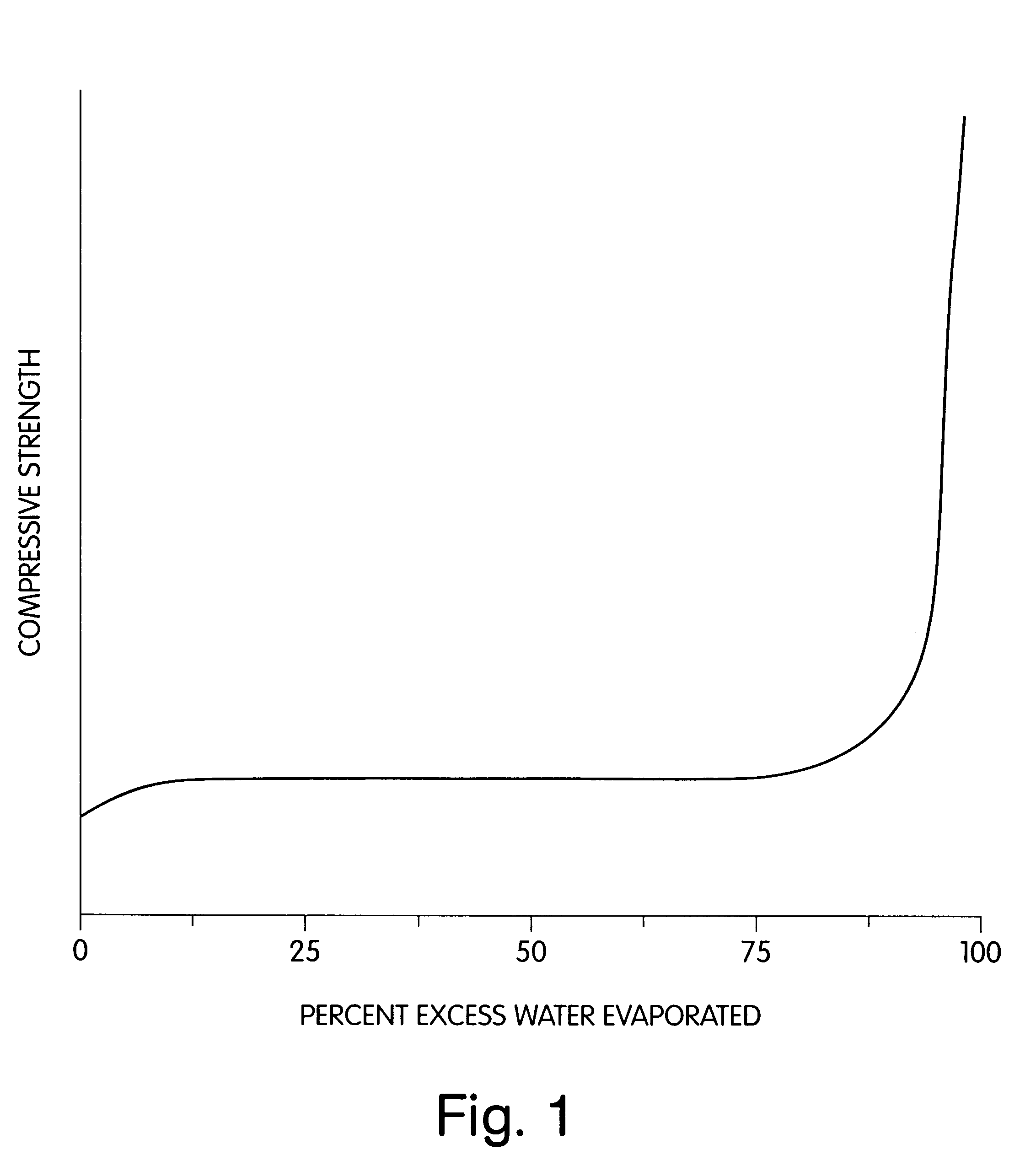

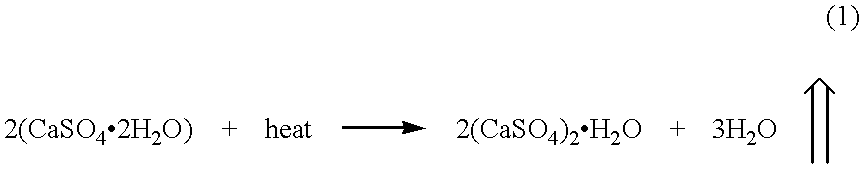

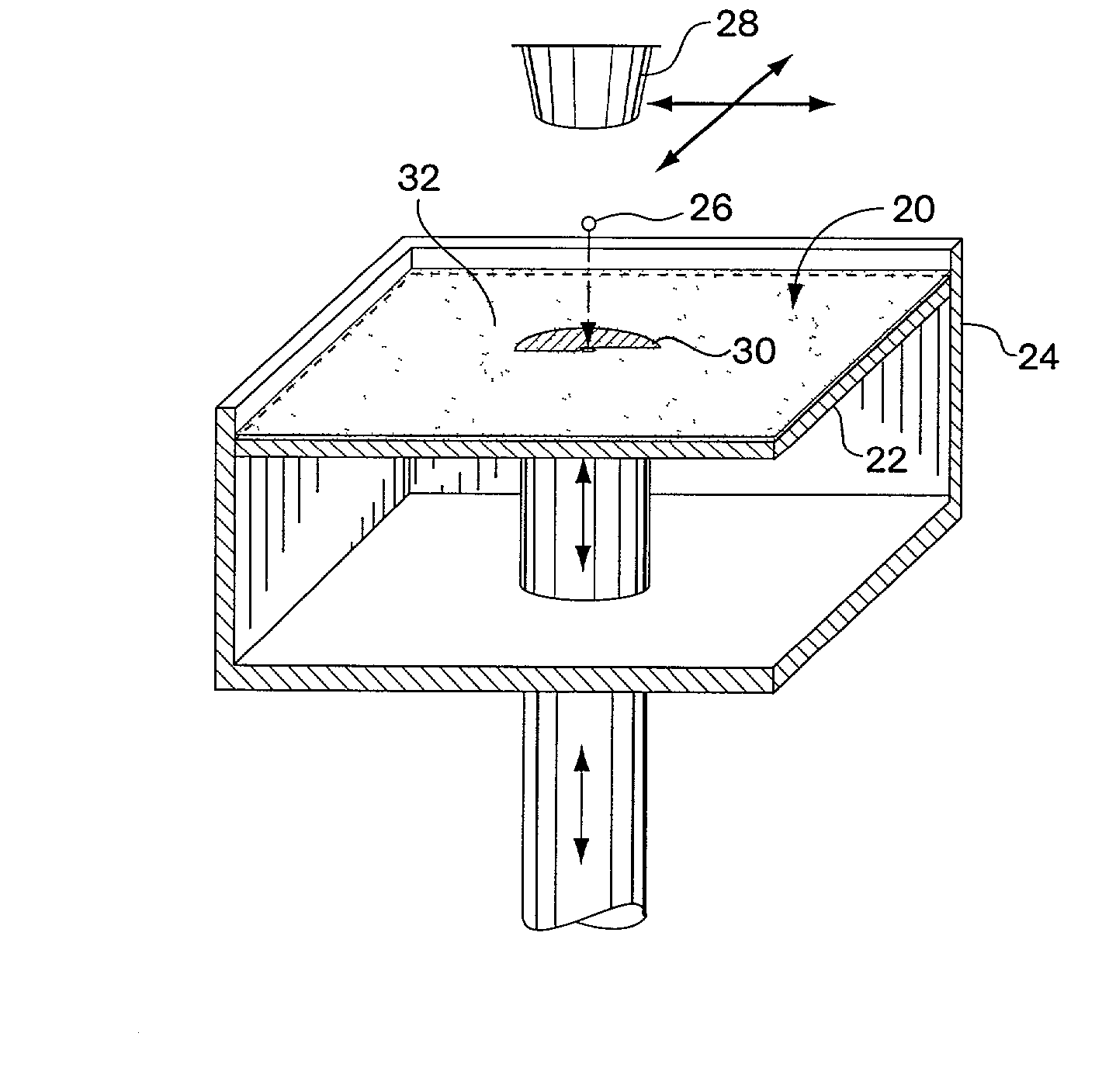

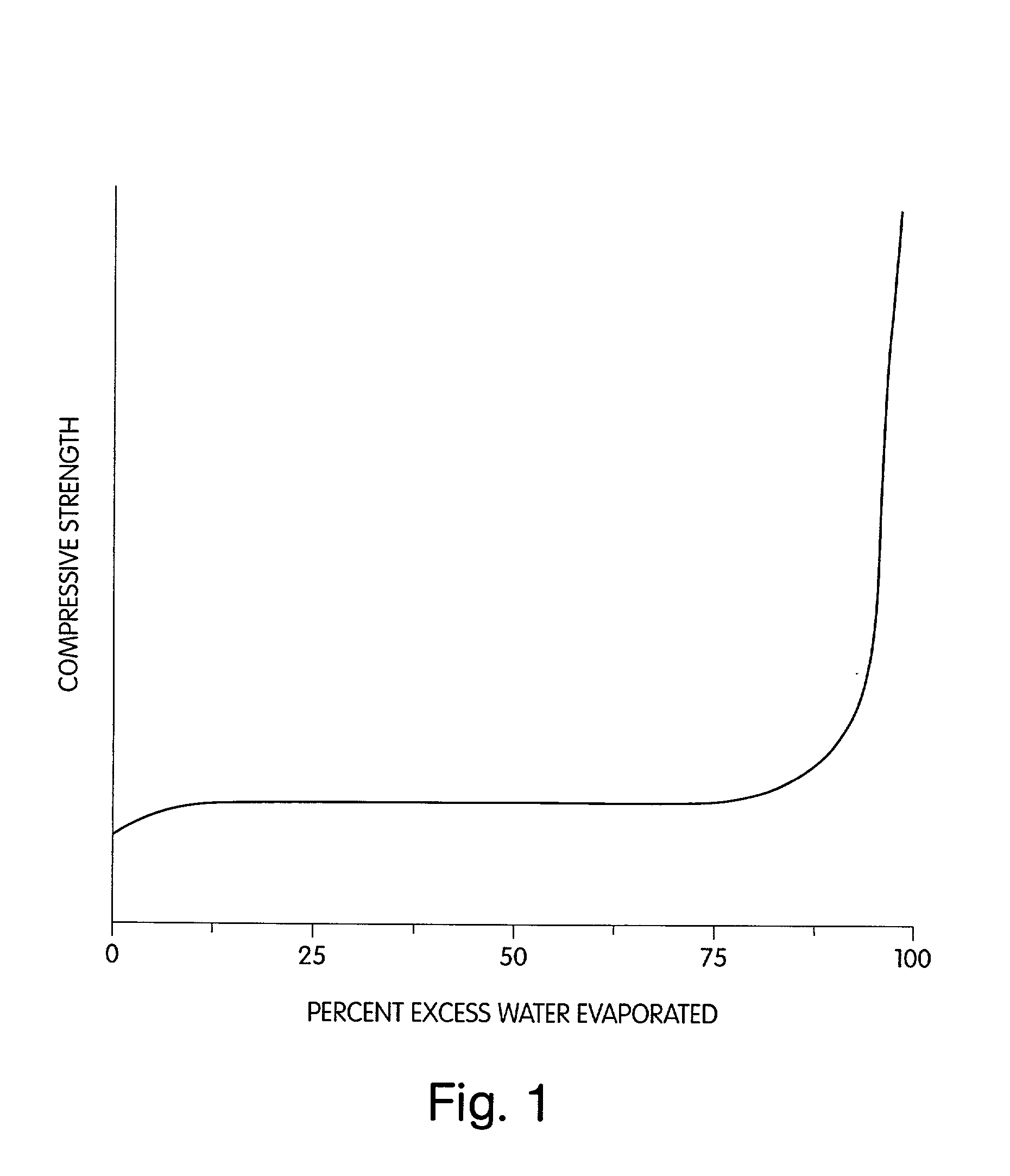

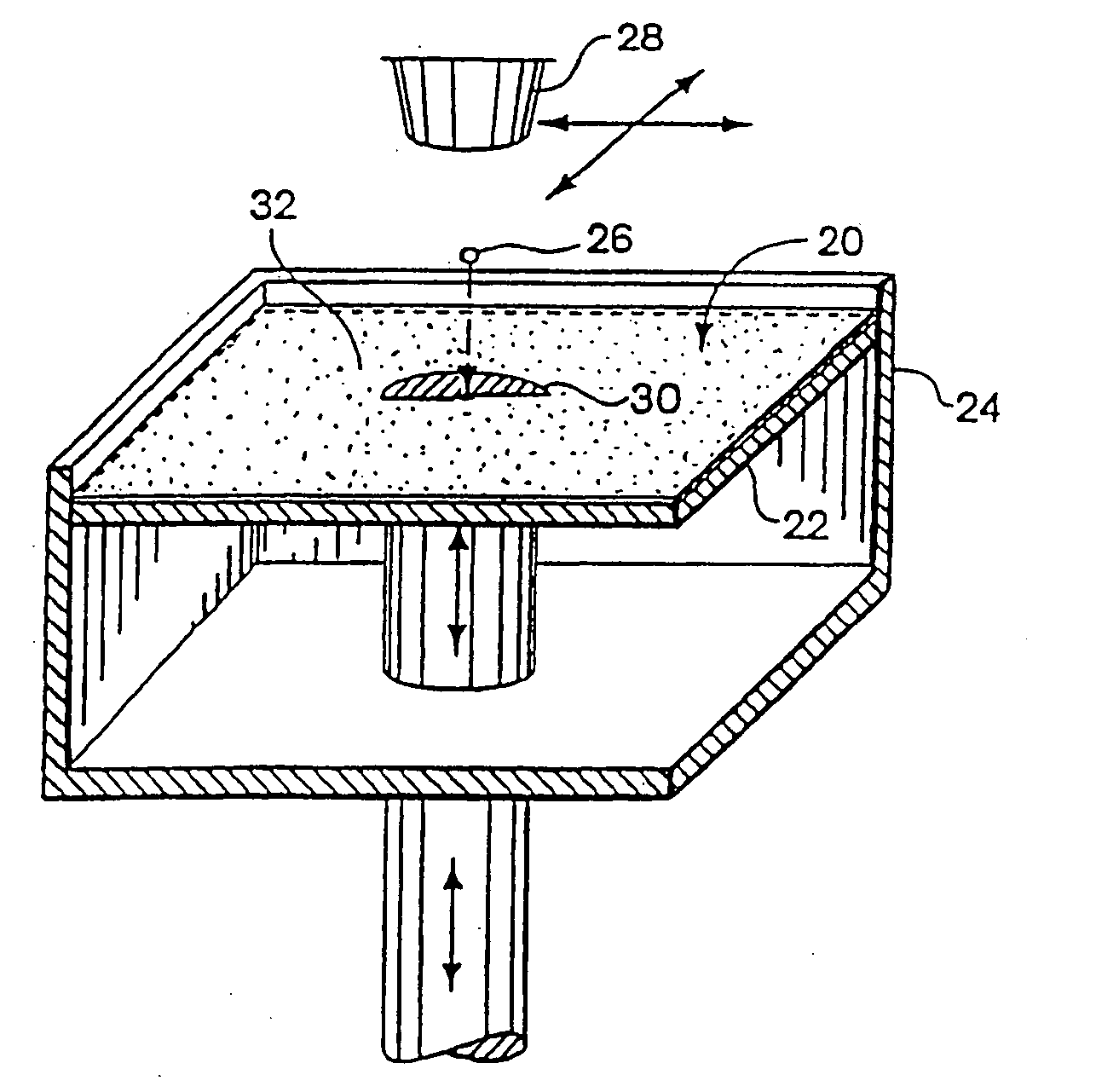

InactiveUS6610429B2High strengthReduce the amount of solutionAdditive manufacturing apparatusLamination ancillary operationsEngineeringLayer wise

The present invention is directed to a 3DP(TM) material system ad method, and an article made therefrom. The method of the present invention includes building cross-sectional portions of a three-dimensional article, and assembling the individual cross-sectional areas in a layer-wise fashion to form a final article. The individual cross-sectional areas are built by using an ink-jet printhead to deliver an aqueous fluid to a particulate material that includes plaster.

Owner:3D SYST INC

Method and apparatus for forming a three-dimensional article

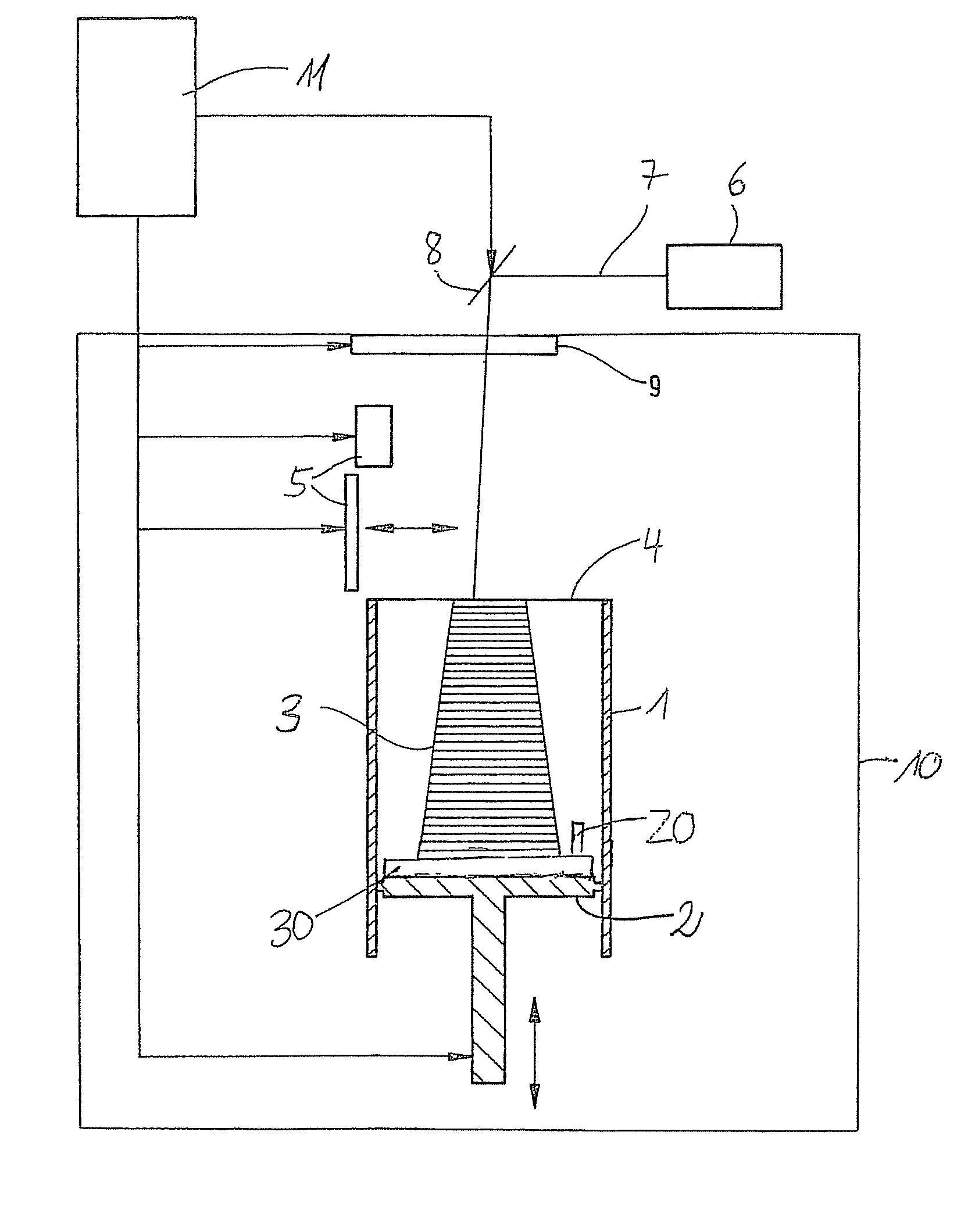

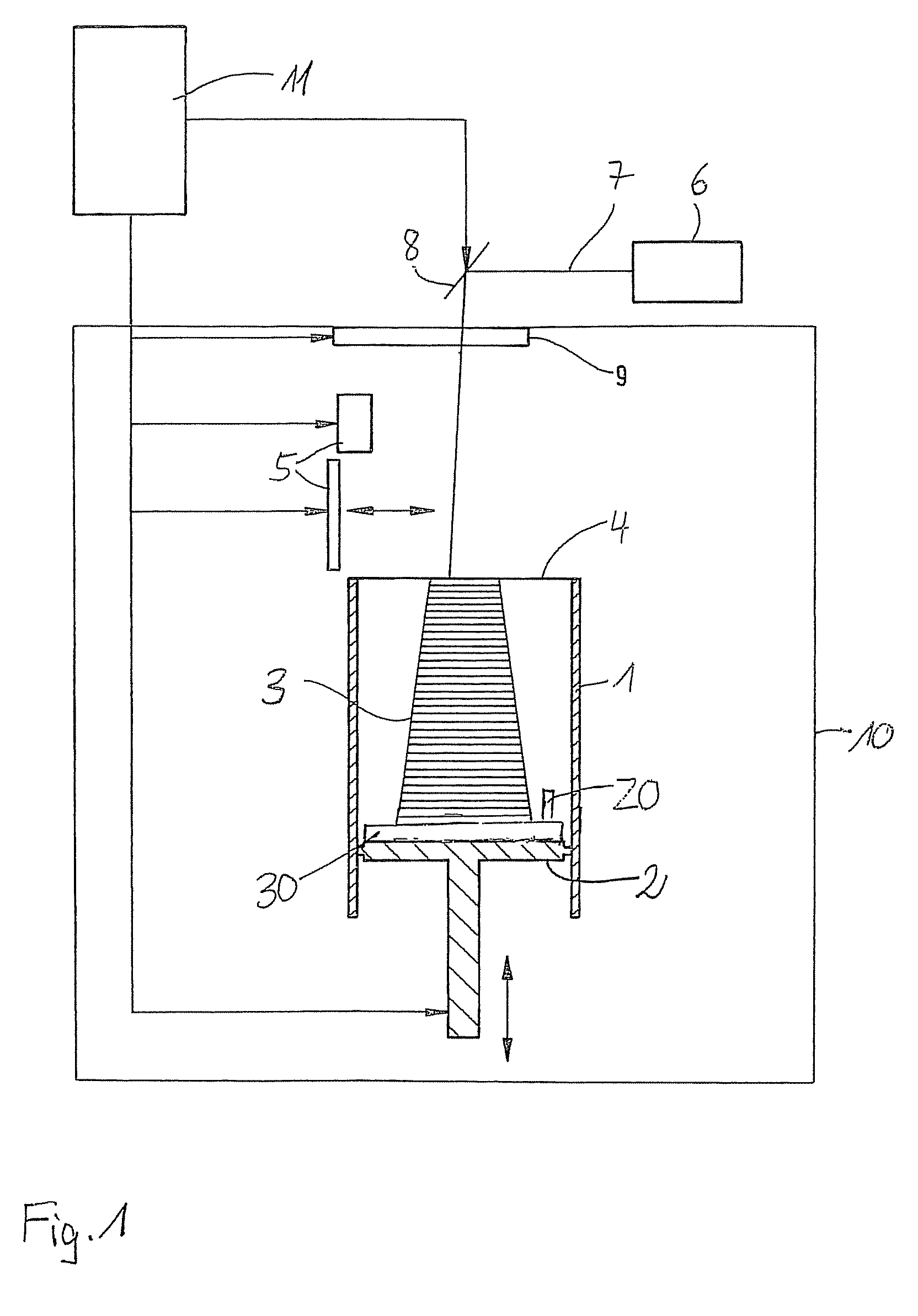

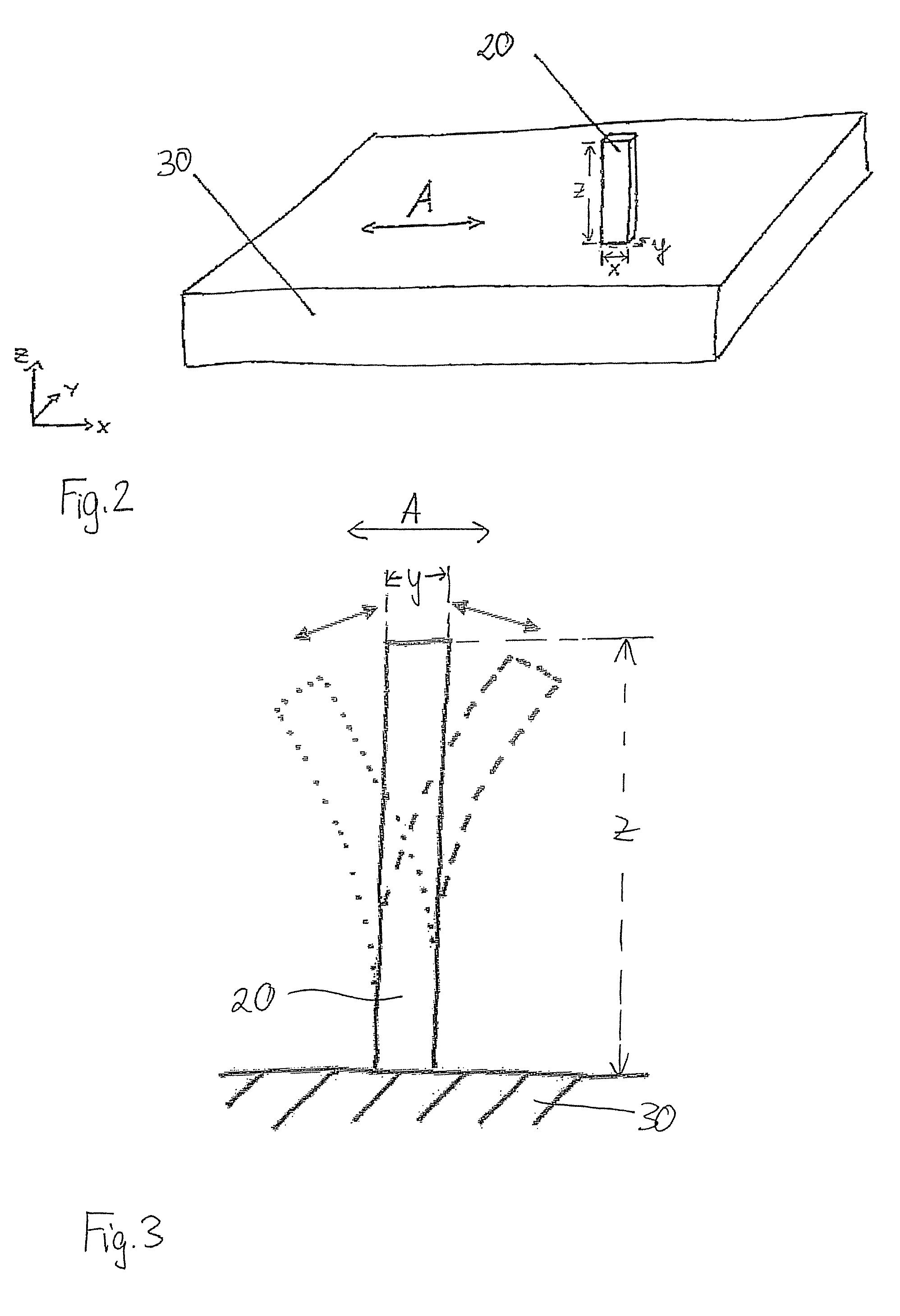

ActiveUS20140314609A1Improve compactionIncrease flexibilityAdditive manufacturing apparatusElectric discharge tubesMetallurgyDistributor

An apparatus for forming at least one three-dimensional article by fusing parts of a powder bed layer-wise. The apparatus comprising a powder distributor and an energy beam for fusing the powder layer. Said powder distributor comprises a first part being an elongated rod provided movable at a predetermined distance above the powder bed and with its central axis in parallel with a top surface of said work table and second part being a metal foil having at least a first and a second opposite edge portions. Said metal foil is provided between said elongated rod and said work table, said first and second opposite edge portions are attached to said elongated rod so that a distance between said first and second edge portions is smaller than the distance between said first and second edge portions of said metal foil when said metal foil is in a flat position.

Owner:ARCAM AB

Three dimensional printing material system and method

InactiveUS20020026982A1High strengthReduce the amount of solutionSolid waste managementCeramic shaping apparatusEngineeringLayer wise

The present invention is directed to a 3DP(TM) material system ad method, and an article made therefrom. The method of the present invention includes building cross-sectional portions of a three-dimensional article, and assembling the individual cross-sectional areas in a layer-wise fashion to form a final article. The individual cross-sectional areas are built by using an ink-jet printhead to deliver an aqueous fluid to a particulate material that includes plaster.

Owner:3D SYST INC

Material systems and methods of three-dimensional printing

ActiveUS20060208388A1Adhesive processesAdditive manufacturing apparatusEngineering3 dimensional printing

The present invention is directed to three-dimensional printing material systems and method, and an article made therefrom. The method of the present invention includes building cross-sectional portions of a three-dimensional article, and assembling the individual cross-sectional areas in a layer-wise fashion to form a final article. The individual cross-sectional areas are built by using an ink-jet printhead to deliver a fluid to a particulate material that includes particulate material.

Owner:3D SYST INC

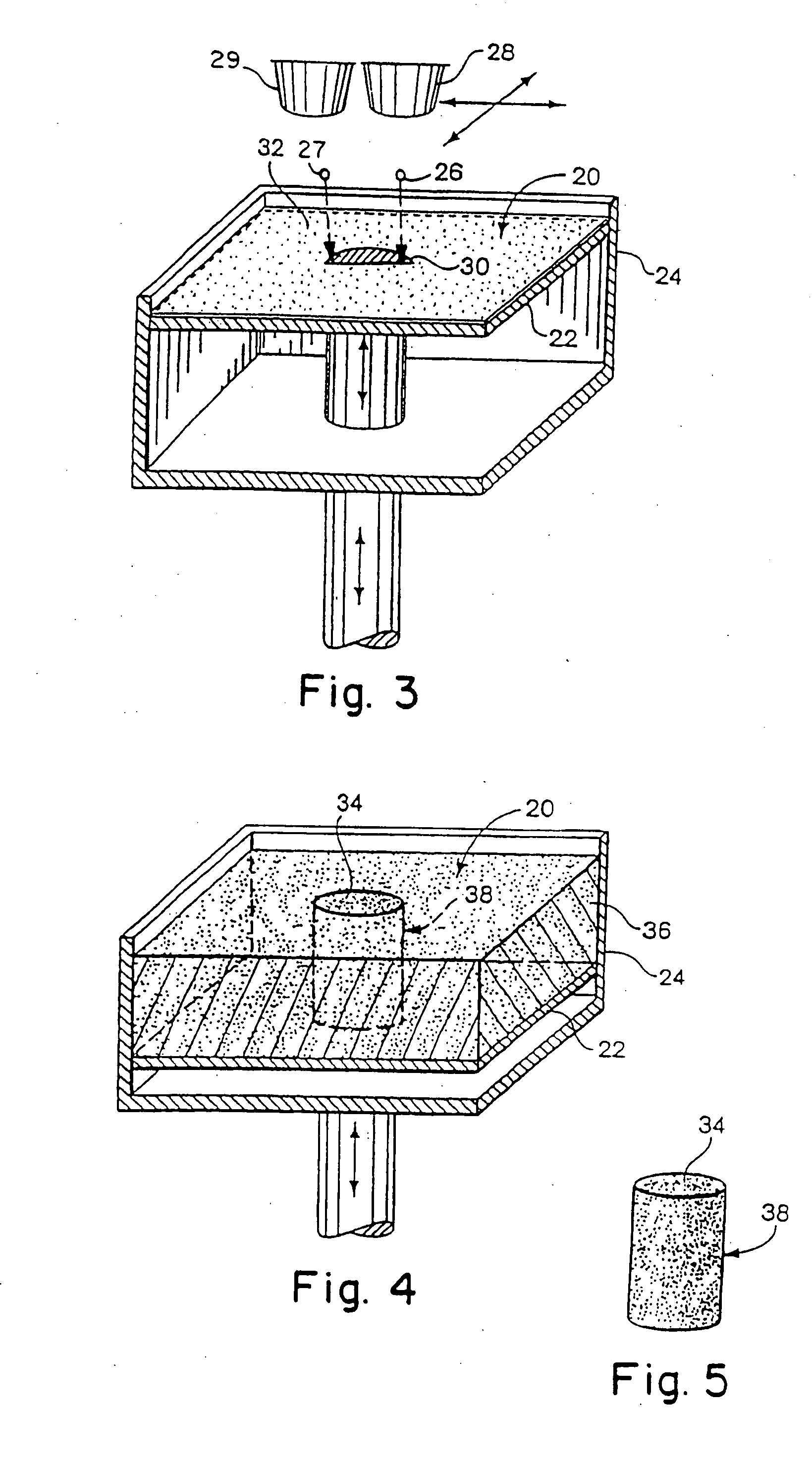

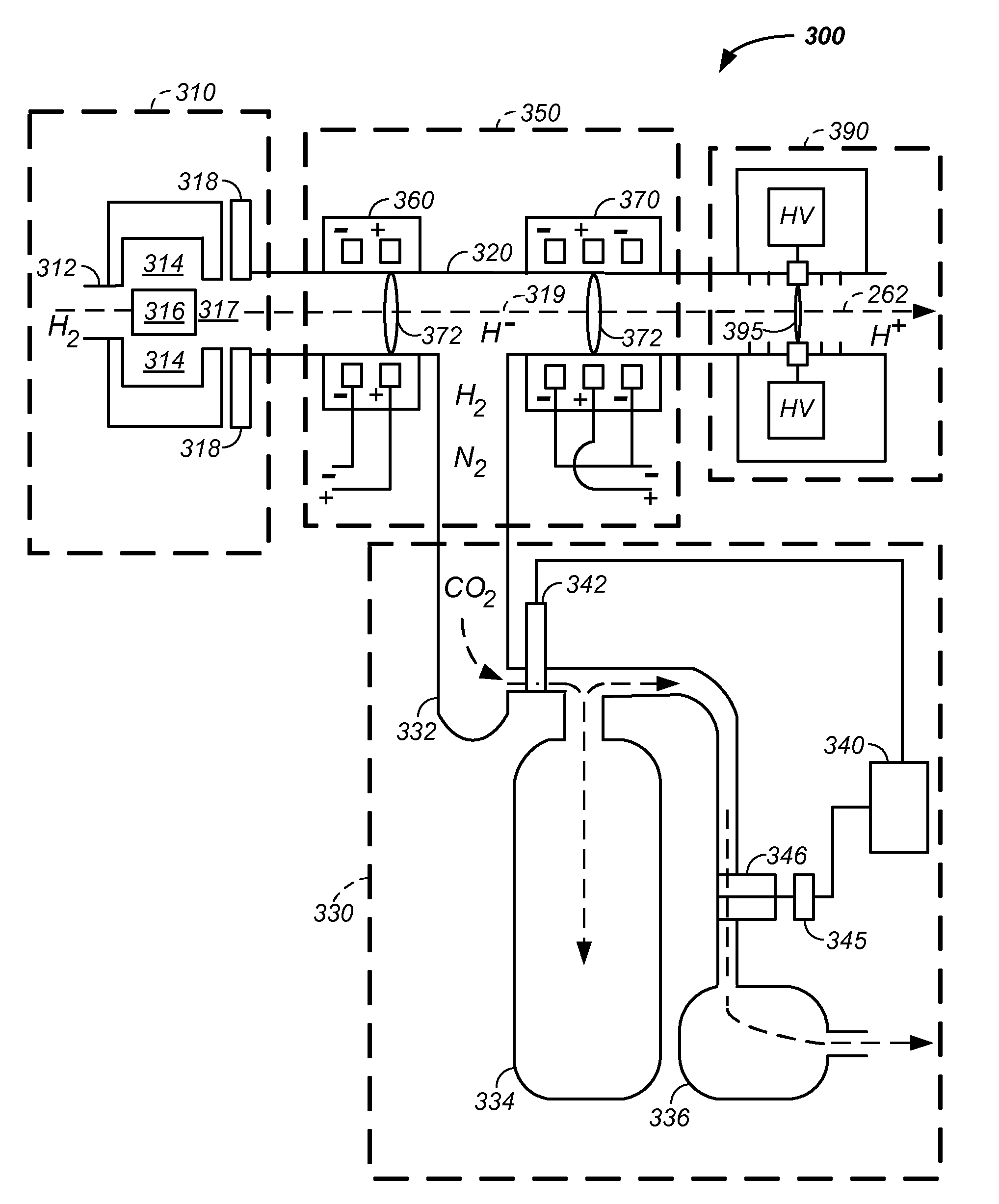

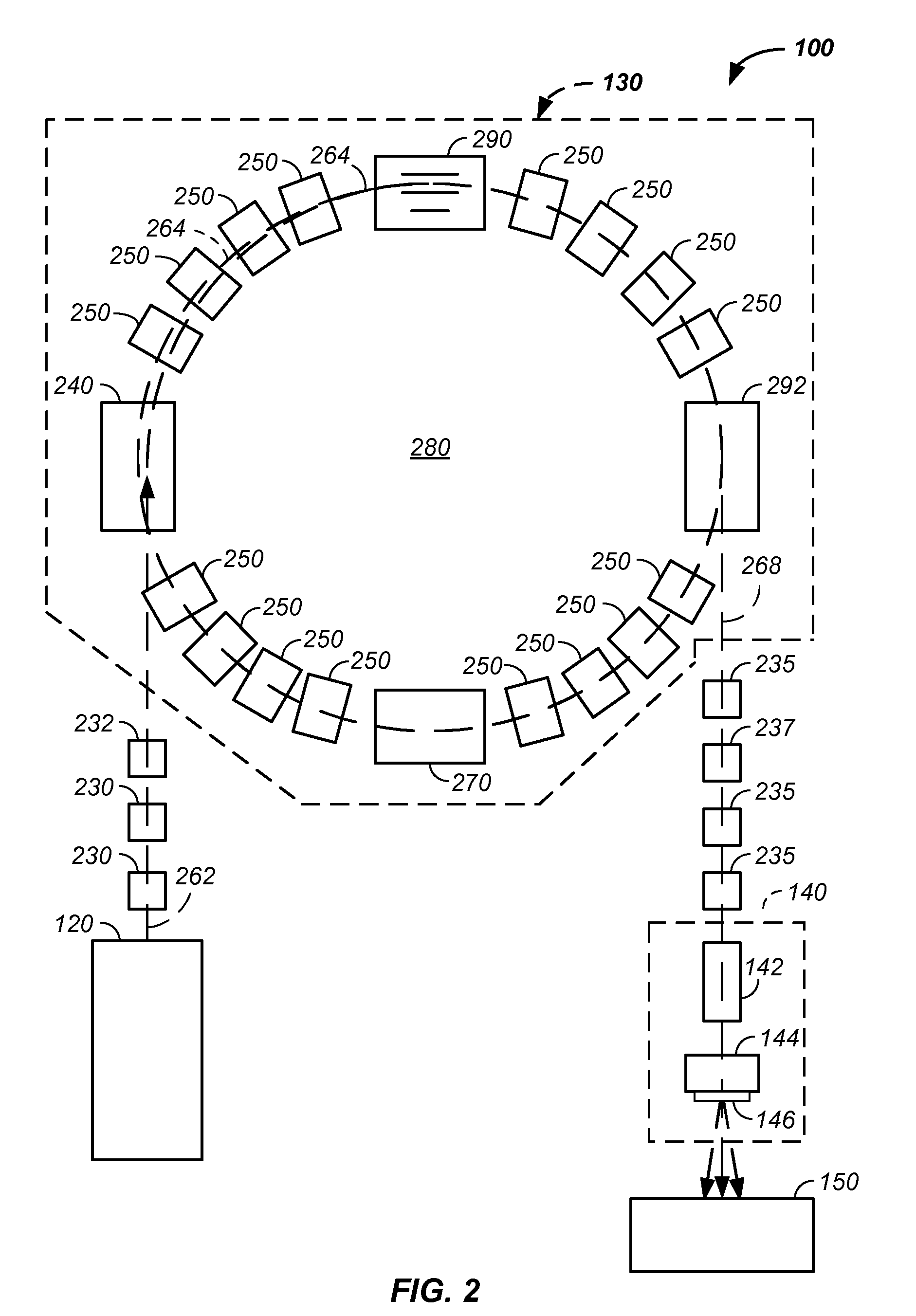

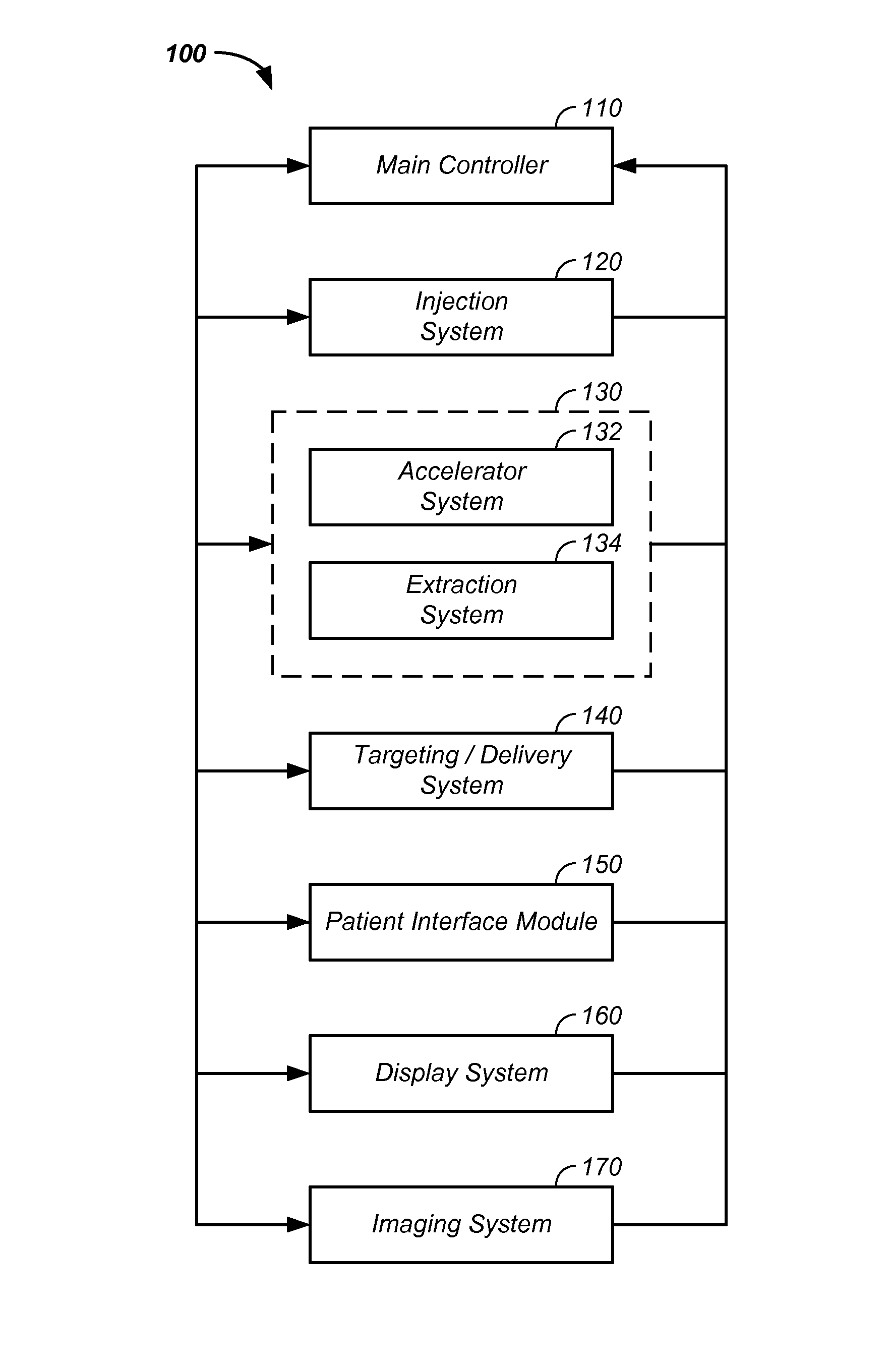

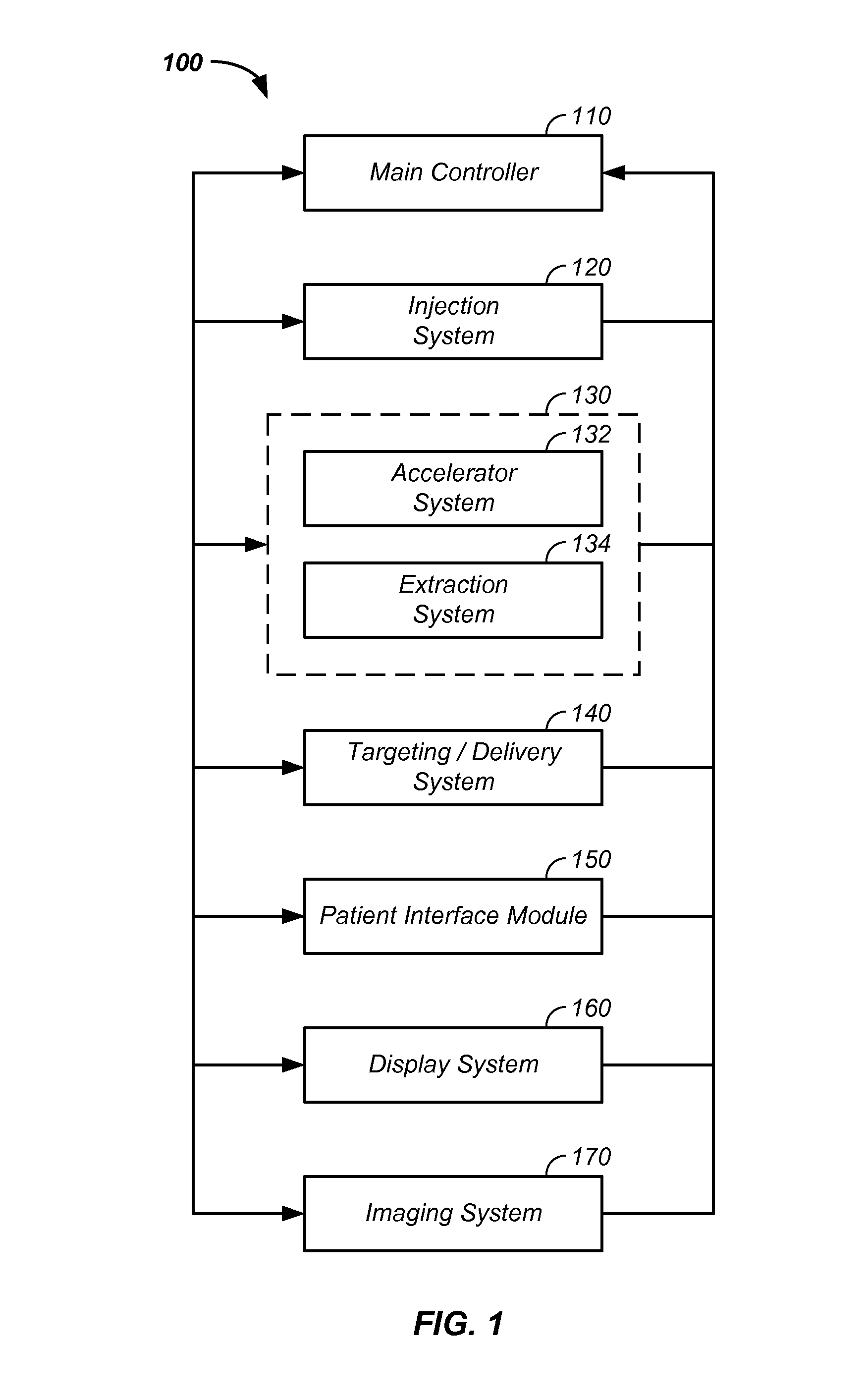

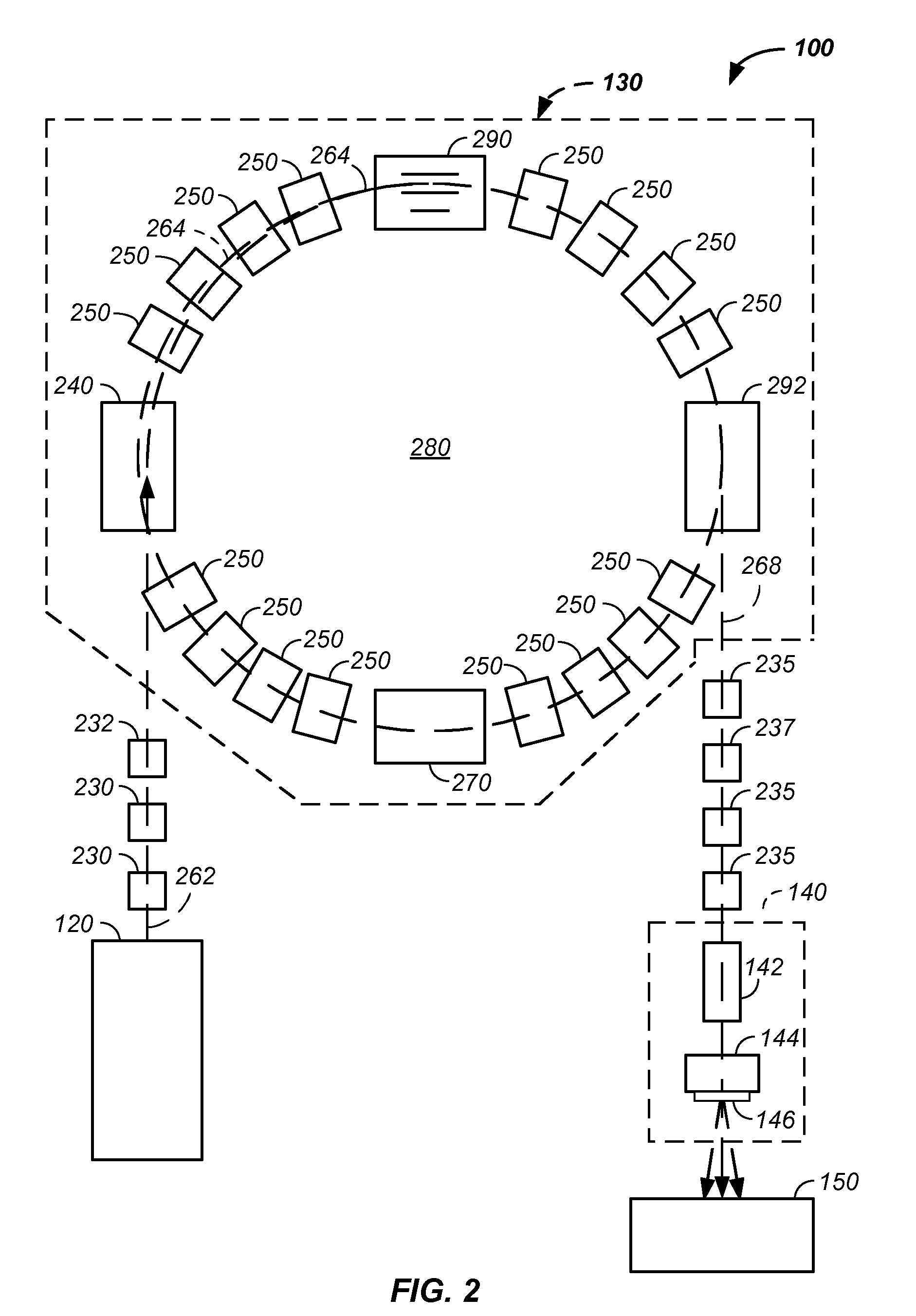

Multi-field charged particle cancer therapy method and apparatus

ActiveUS20100090122A1Discharge tube luminescnet screensElectric discharge tubesAbnormal tissue growthBragg peak

The invention relates to treatment of solid cancers. More particularly, the invention relates to a combined rotation / raster method, referred to as multi-field charged particle cancer therapy. The system uses a fixed orientation proton source relative to a rotating patient to yield tumor irradiation from multiple directions. The system combines layer-wise tumor irradiation from many directions with controlled energy proton irradiation to deliver peak proton beam energy within a selected tumor volume or irradiated slice. Optionally, the selected tumor volume for irradiation from a given angle is a distal portion of the tumor. In this manner ingress Bragg peak energy is circumferentially spread about the tumor minimizing damage to healthy tissue and peak proton energy is efficiently, accurately, and precisely delivered to the tumor.

Owner:BALAKIN ANDREY VLADIMIROVICH +1

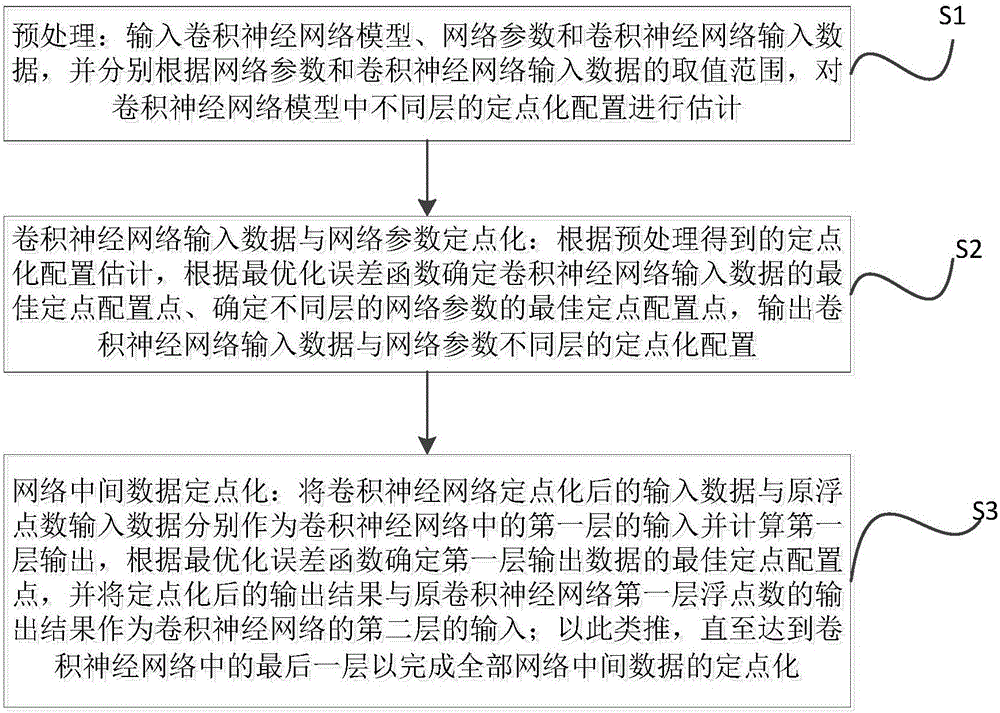

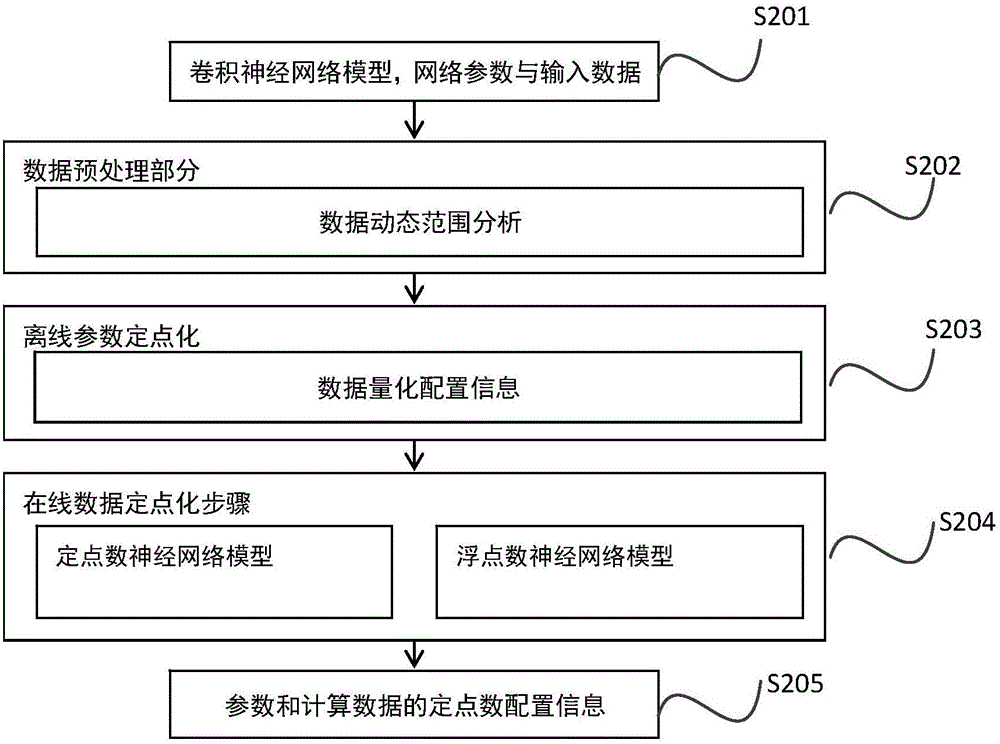

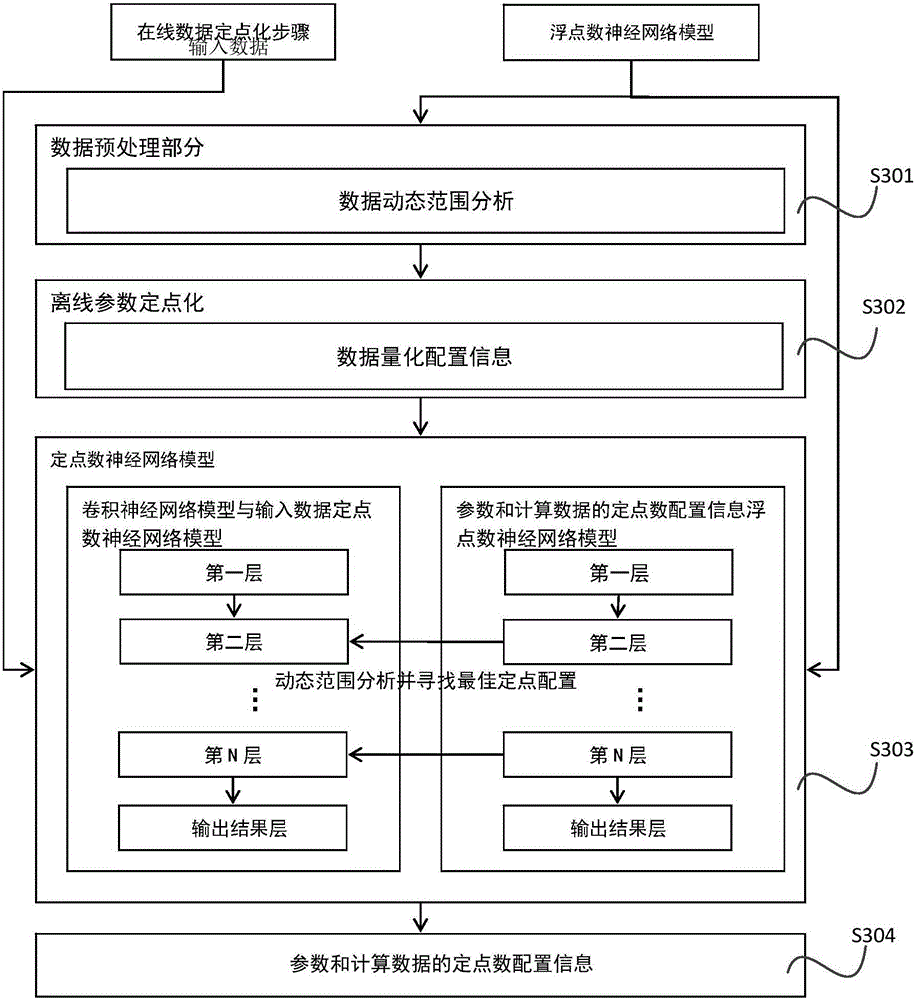

Method and apparatus for fixed-pointing layer-wise variable precision in convolutional neural network

InactiveCN105760933AReduce precision lossFast transmissionNeural learning methodsFloating pointNetwork data

The invention discloses a method and an apparatus for fixed-pointing the layer-wise variable precision in a convolutional neural network. The method comprises the following steps: estimating fixed-pointing configuration input to various layers in the convolutional neural network model respectively in accordance with input network parameters and a value range of input data; based on the acquired fixed-point configuration estimation and the optimal error function, determining the best fixed-point configuration points of the input data and network parameters of various layers and outputting the best fixed-point configuration points; inputting respectively the input data which is subject to fixed-pointing and an input data of an original floating-point number as a first layer in the convolutional neural network and computing the optimal fixed-point configuration point of the output data of the layer, and inputting the output result and an output result of the original first layer floating-point number as a second layer. The rest of the steps can be done in the aforementioned manner until the last layer completes the whole fixed-pointing. The method of the invention guarantees the minimum precision loss of each layer subject to fixed-pointing of the convolutional neural network, can explicitly lower space required by storing network data, and can increase transmitting velocity of network parameters.

Owner:BEIJING DEEPHI INTELLIGENT TECH CO LTD

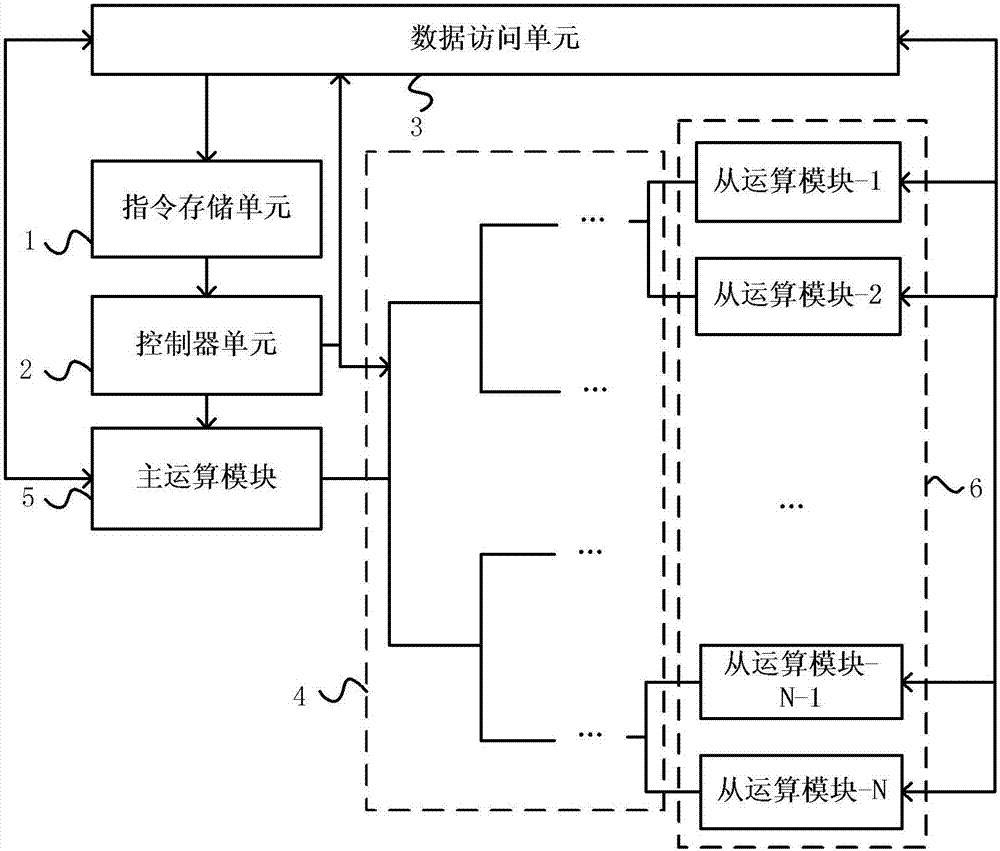

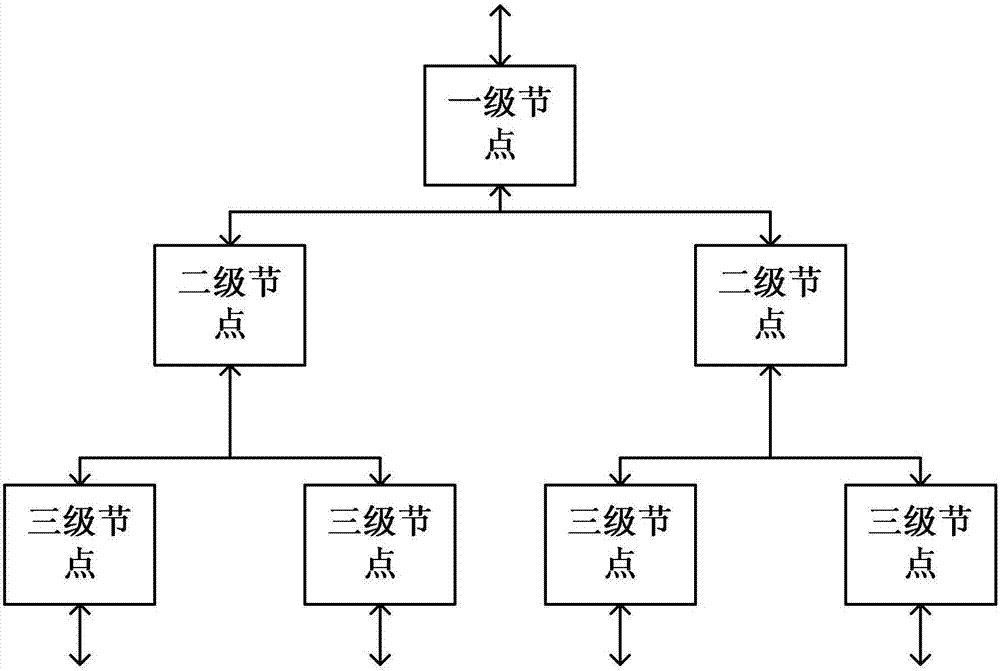

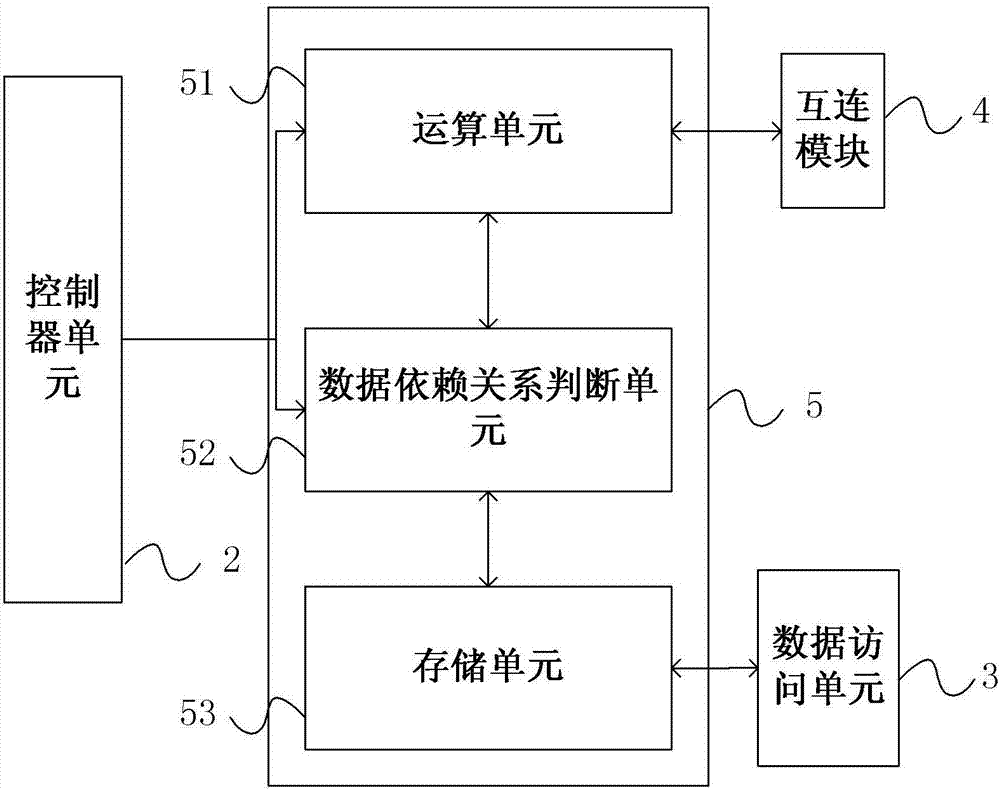

Device and method for executing artificial neural network self-learning operation

ActiveCN107316078ASimplified front-end decoding overheadHigh performance per wattPhysical realisationNeural learning methodsHidden layerNerve network

The invention discloses a device and method for executing artificial neural network self-learning operation. The device comprises an instruction storage unit, a controller unit, a data access unit, an interconnection module, a primary operation module and a plurality of secondary operation modules. According to the device and method, the self-learning pre-training of a multilayer neural network can adopt a layer-by-layer training manner; for each layer of network, the self-learning pre-training is completed after multiple operations are iterated until the weight is updated to be smaller than a certain threshold value. Each iteration process can be divided into four stages, calculation is carried out in the first three stages to respectively generate a first-order hidden layer median, a first-order visible layer median and a second-order hidden layer median, and the weight is updated in the last stage by utilizing the medians in the first three stages.

Owner:CAMBRICON TECH CO LTD

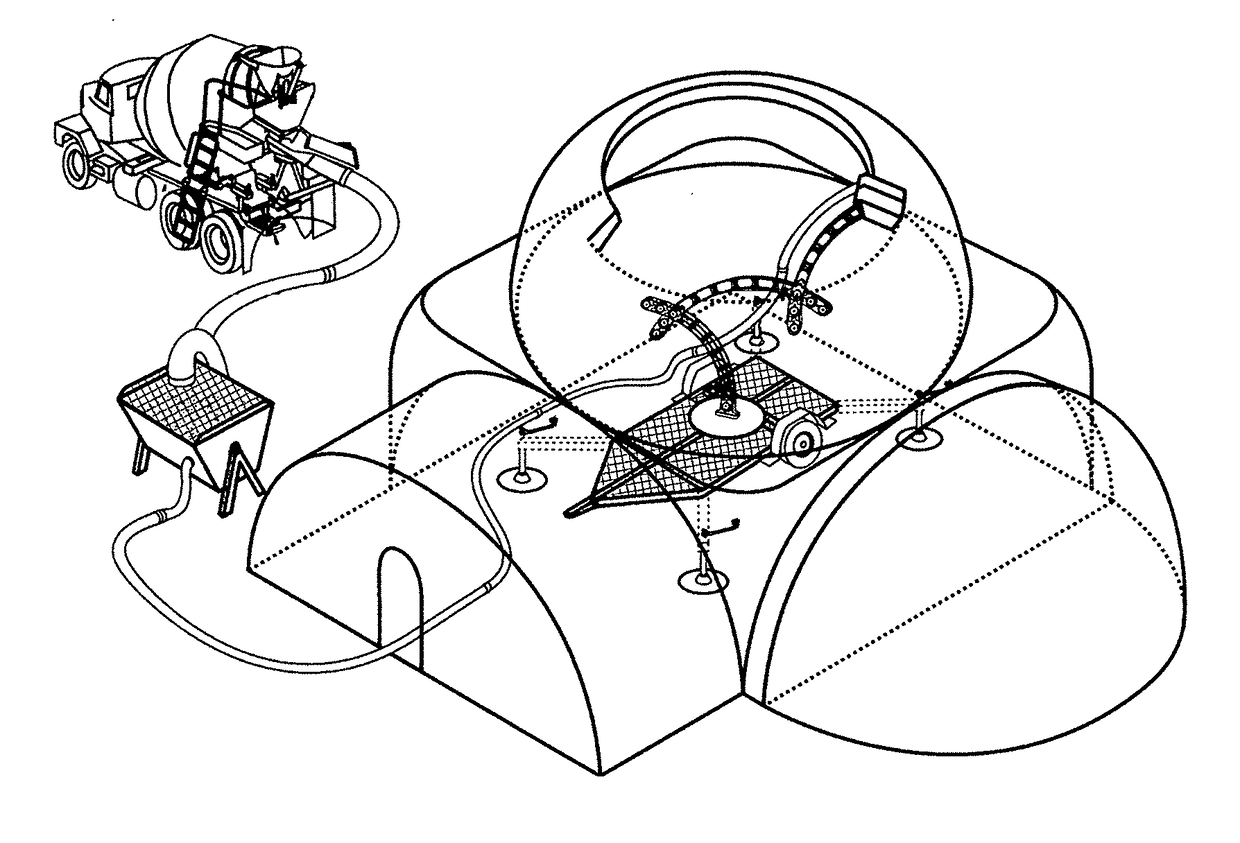

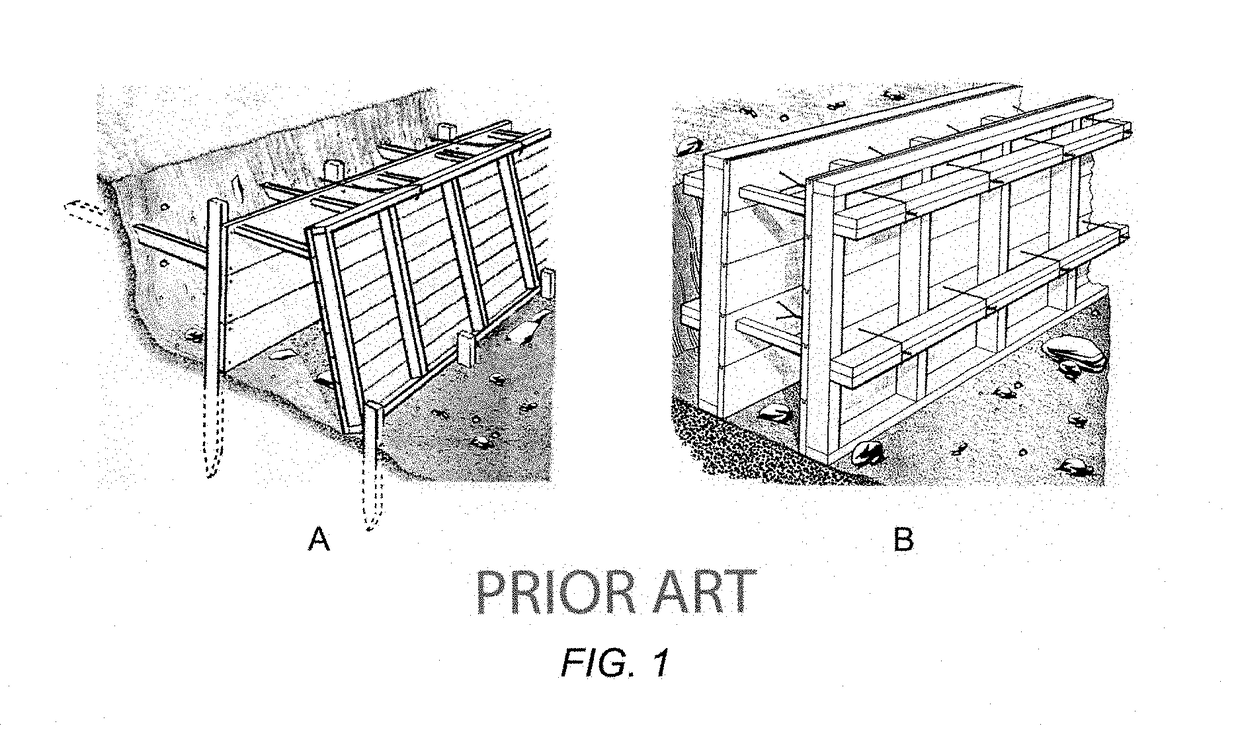

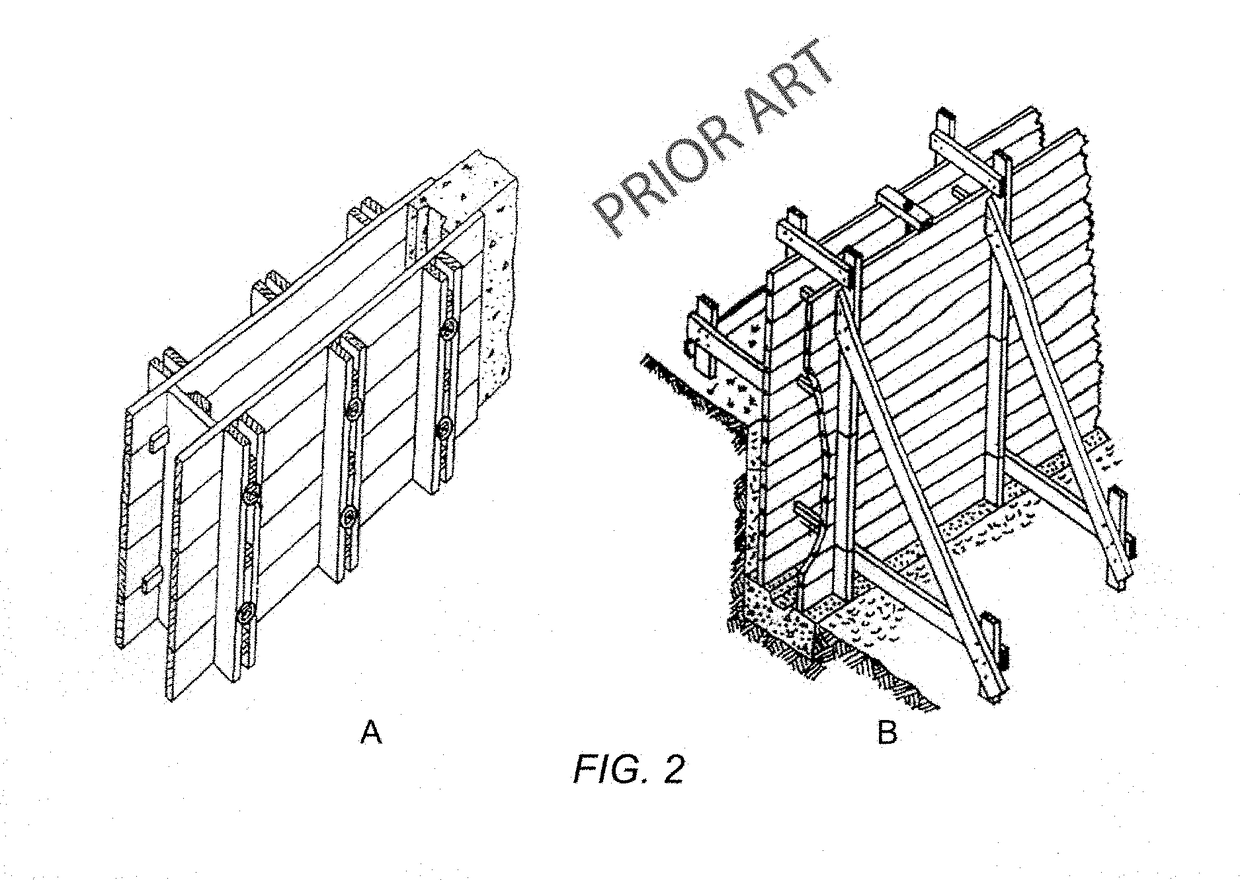

Method of reinforced cementitious constrauction by high speed extrusion printing and apparatus for using same

ActiveUS20180071949A1Low costAdditive manufacturing apparatusConstruction materialReinforced concreteBrick

The present invention relates to methods and apparatuses for an automated reinforced concrete construction system for onsite slip-form molding and casting a variety of cementitious mixes in a cast in place leave in place externally moldable flexible reinforced containment sleeve providing a wide variety of interchangeable full-scale molding configurations simultaneously optimizing a wide variety of cementitious mix curing characteristics, further having optional internal reinforcement net(s), for layer wise interlocking additive printed brick deposition providing improved slip-form mold casting of a wide variety of reinforced concrete structures; the present invention further includes a variety of operating platforms suitable for on and offsite construction as disclosed herein.

Owner:ARMATRON SYST LLC

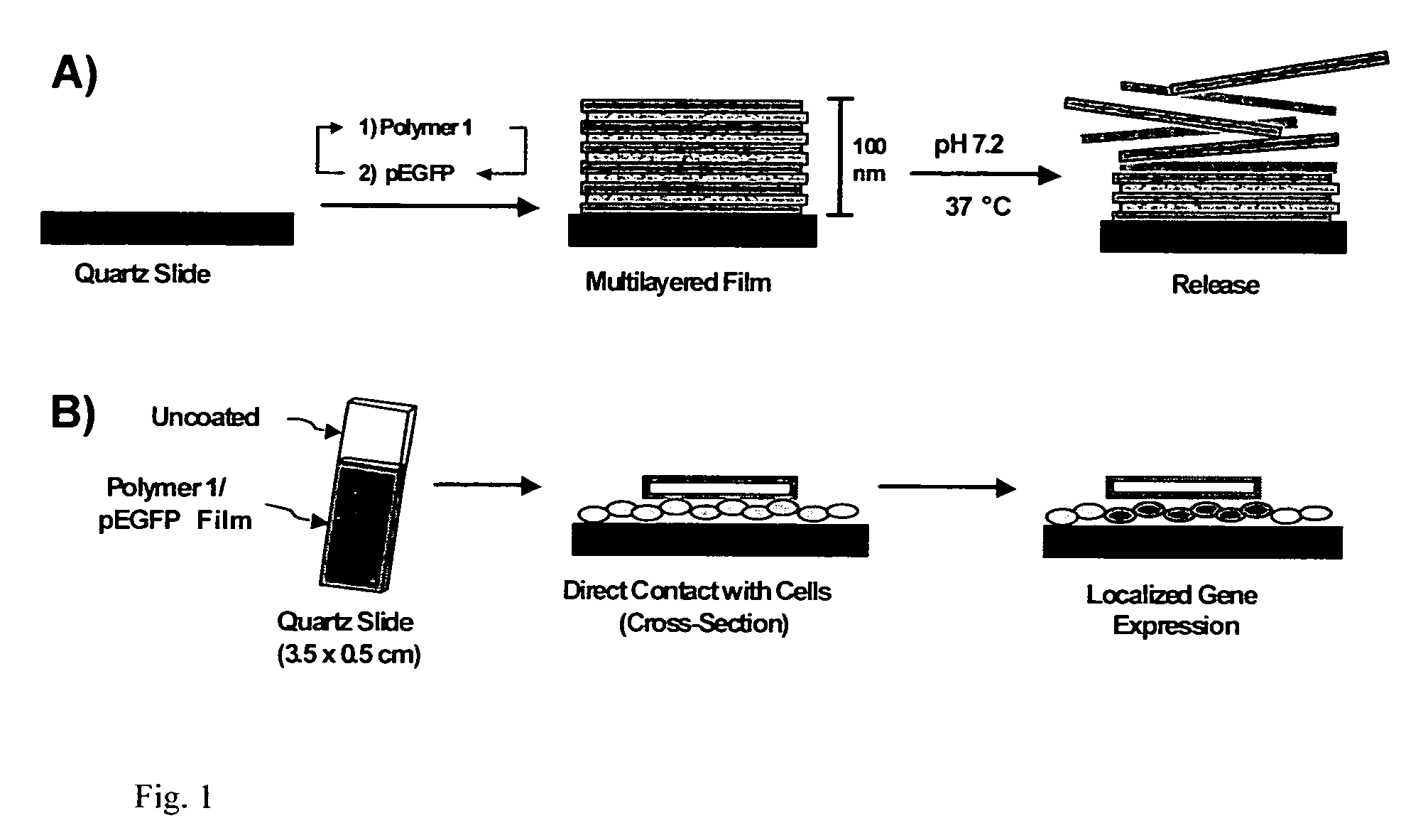

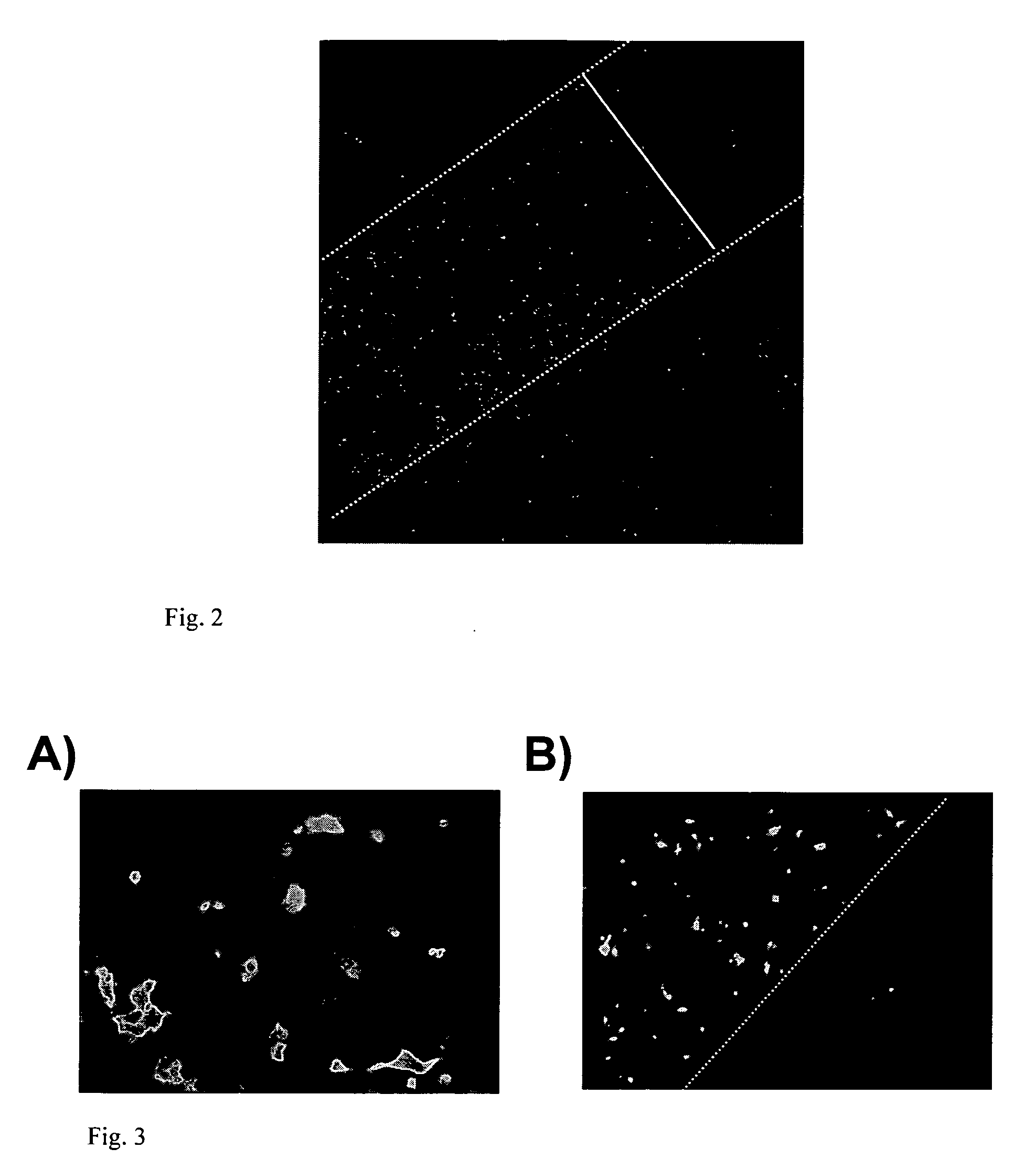

Localized delivery of nucleic acid by polyelectrolyte assemblies

ActiveUS20060251701A1Strong therapeutic activityReduce inflammationSurgeryNon-active genetic ingredientsPolyelectrolyteMedical device

The present invention provides implantable medical devices coated with polyelectrolyte assemblies that are fabricated by layer-by-layer deposition of nucleic acid and polycation. Such devices facilitate the local delivery of a nucleic acid contained in the polyelectrolyte assembly into a cell or tissue at an implantation site. Also provided are methods of fabricating and using implantable medical devices according to the invention.

Owner:WISCONSIN ALUMNI RES FOUND

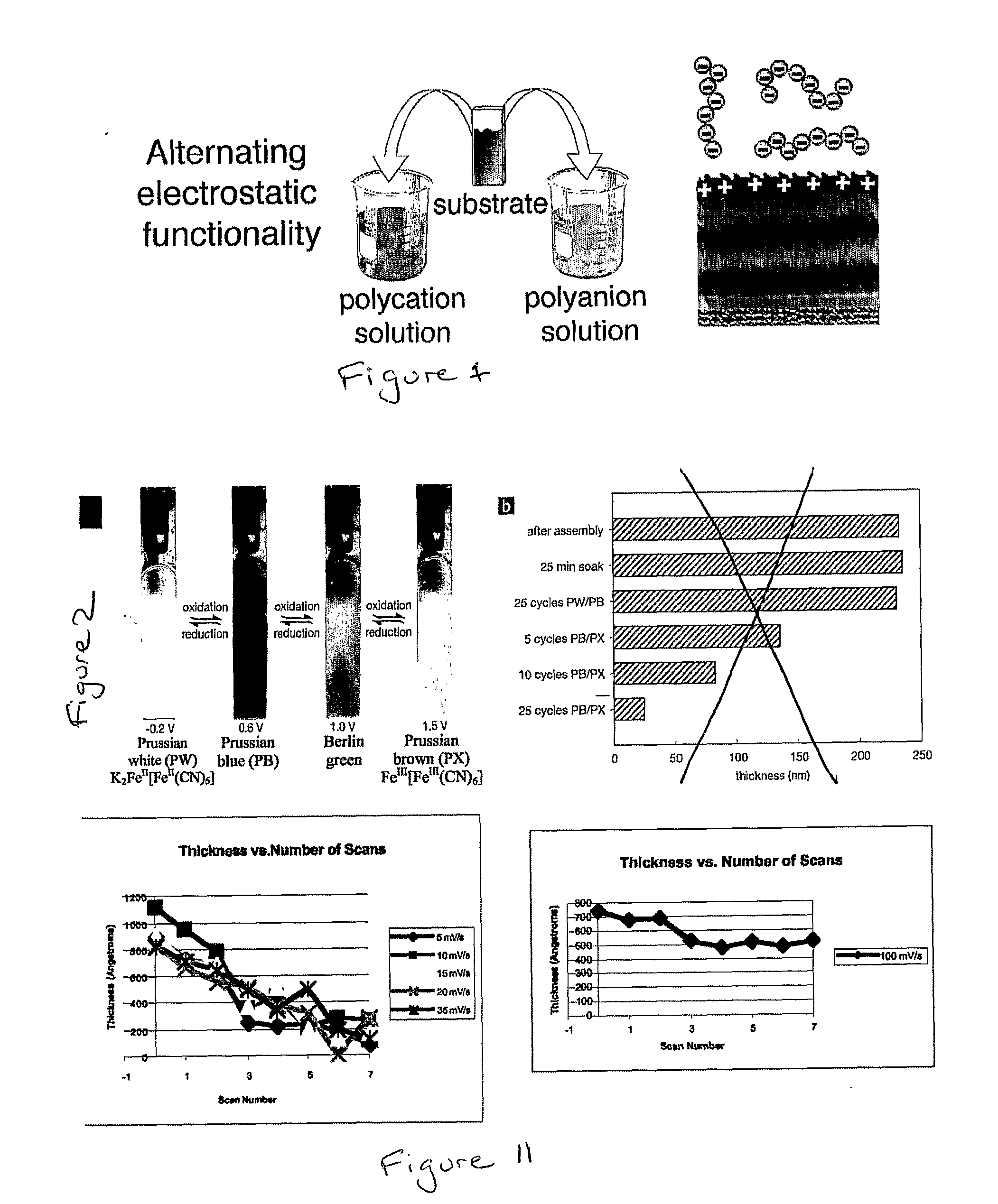

Electronically-Degradable Layer-by-Layer Thin Films

A decomposable thin film comprising a plurality of alternating layers of net positive and negative charge. At least a portion of the positive layers, the negative layers, or both, comprise a polyelectrolyte.

Owner:MASSACHUSETTS INST OF TECH

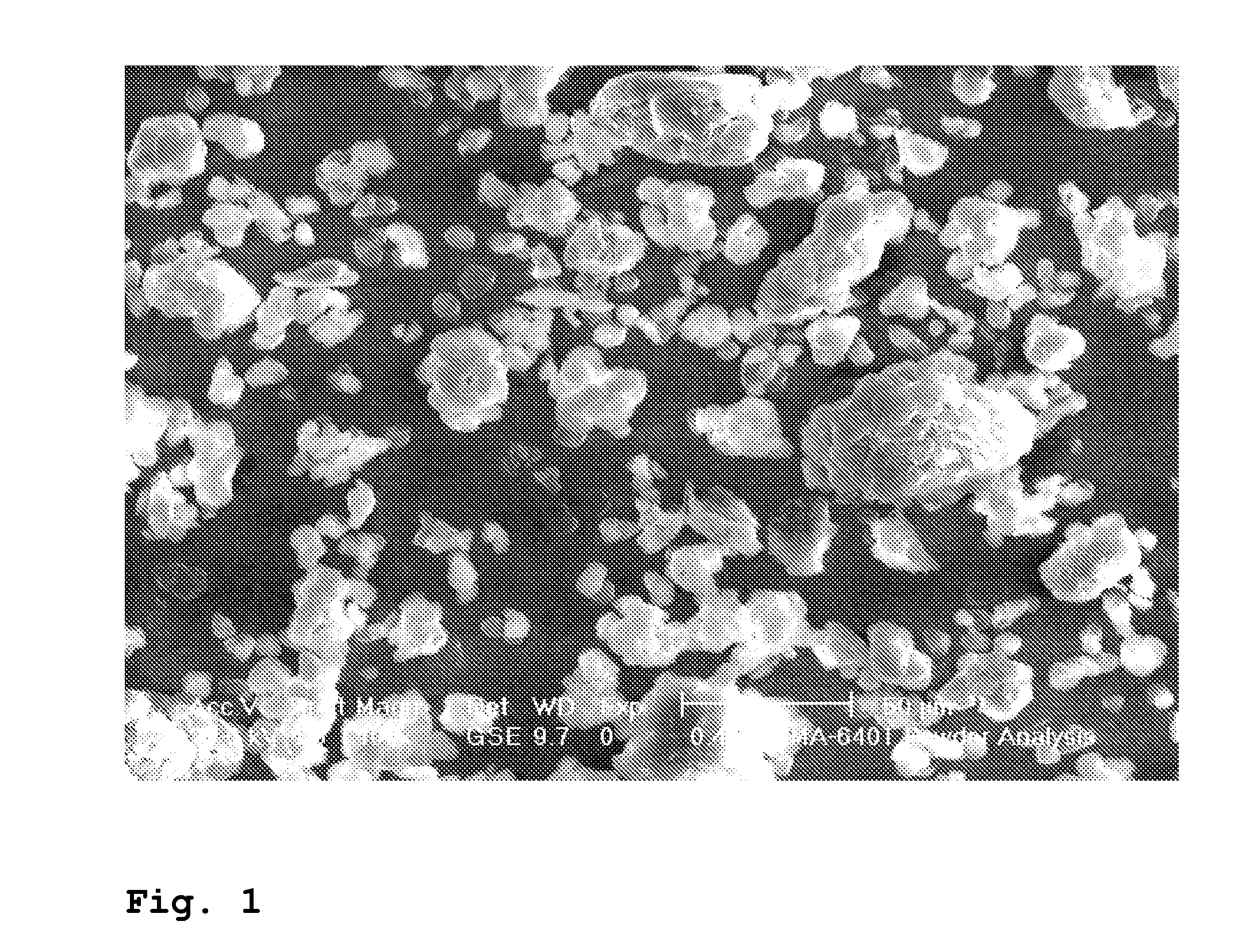

Polymer powder, process for production of and use of this powder, and resultant shaped articles

InactiveUS20070232753A1Low costWide applicationSynthetic resin layered productsPolymer sciencePolyvinyl alcohol

A process for production of a powder suitable for use in a process for the layer-by-layer moldless production of a three-dimensional shaped article, in which regions of the respective powder layer are selectively melted via input of electromagnetic energy, comprising mixing of a polymer or copolymer with at least one water-soluble polymeric polyol, the dissolution of the mixture in water to form a dispersion, the isolation of the polymer particles or copolymer particles from the dispersion, and the washing and drying of the isolated polymer particles or isolated copolymer particles; a powder which comprises a polymer powder or copolymer powder with from 0.001% by weight to 5% by weight content of at least one polymeric polyol, the polymeric polyol having been selected from the group consisting of polyethylene glycols and polyvinyl alcohols; the powder formed from the process; method of using the powder; and a shaped article formed from the powder.

Owner:EVONIK DEGUSSA GMBH

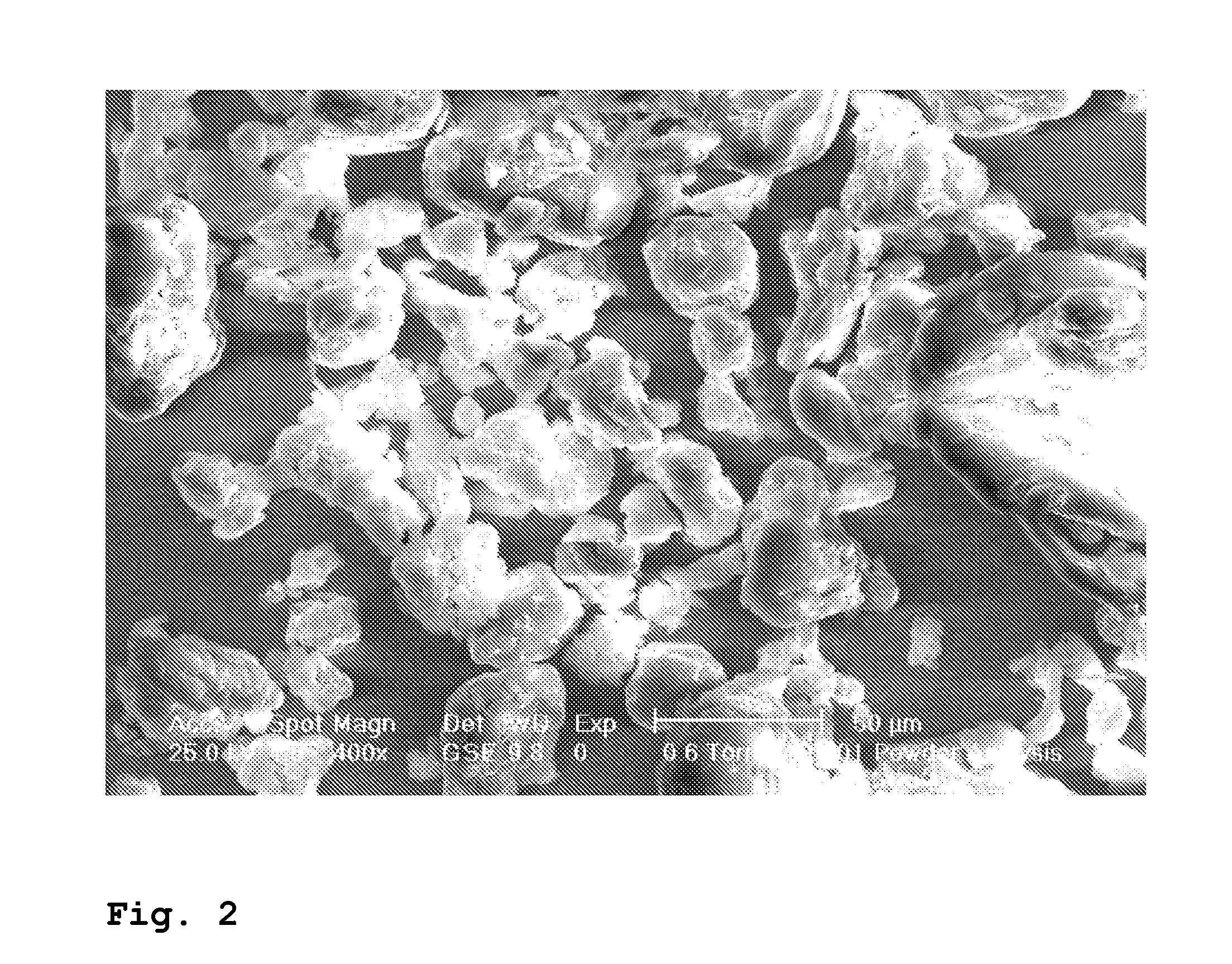

Polymer powder with phosphonate-based flame retardant, process for its production, and moldings produced from this polymer power

ActiveUS20050027047A1UL® classificationMaintain mechanical propertiesAdditive manufacturing apparatus3D object support structuresPolymer sciencePolyamide

The present invention relates to a polymer powder composed of polyamide or of copolyamides, which also comprises flame retardant, in particular phosphonates, to a layer-by-layer process which selectively melts regions or selectively binds them, and also to moldings produced from this polymer powder. Compared with conventional products, the moldings constructed using the powder of the invention exhibit marked advantages in flammability and combustibility and drop behavior, particularly with respect to UL® (Underwriters Laboratories) classification. Furthermore, moldings produced from polymer powder of the invention have adequately good mechanical properties when compared with moldings based on polymer powders without flame retardant, in particular in terms of modulus of elasticity and tensile strain at break. In addition, these moldings also have a density close to that of injection moldings.

Owner:EVONIK OPERATIONS GMBH

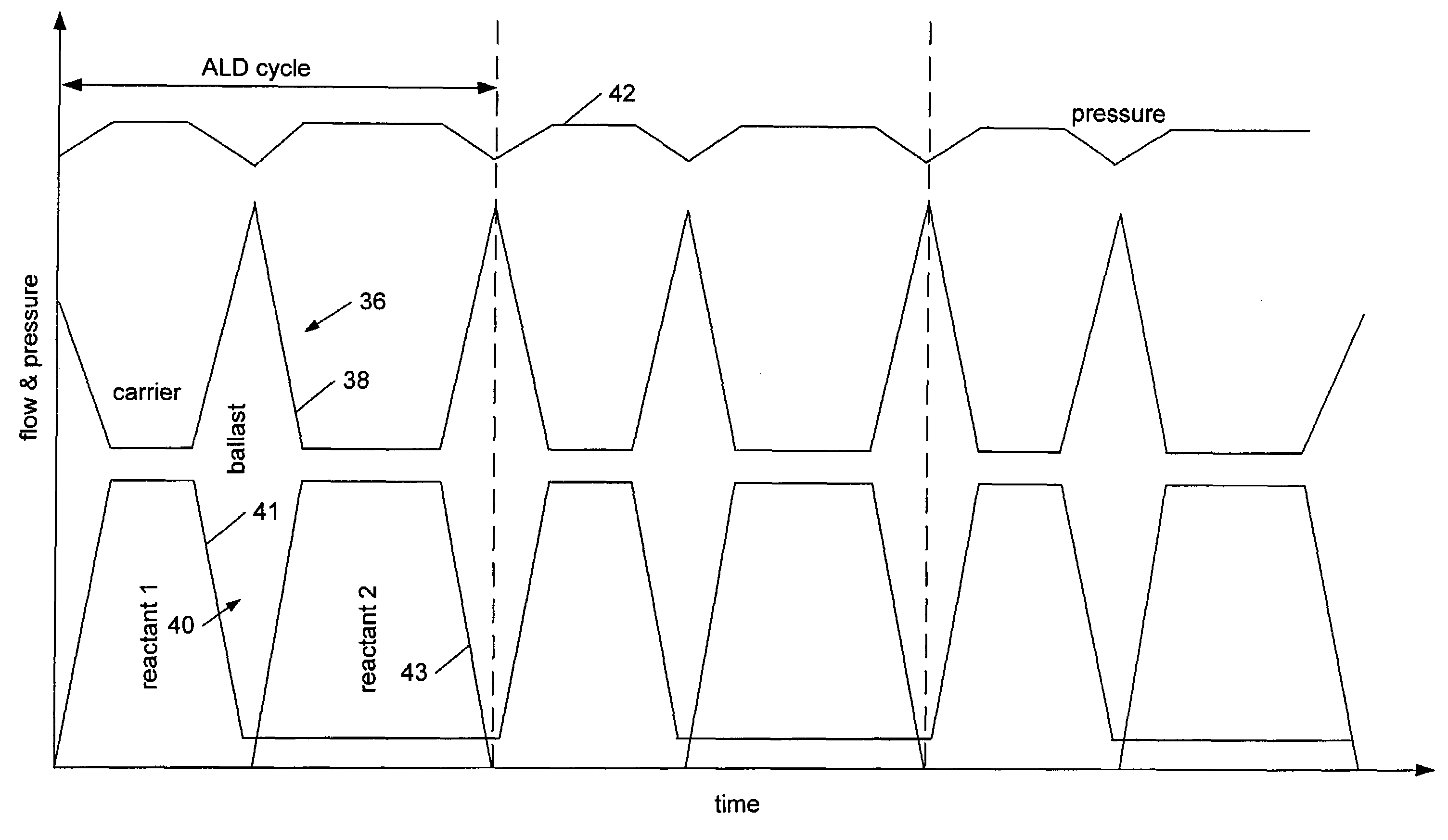

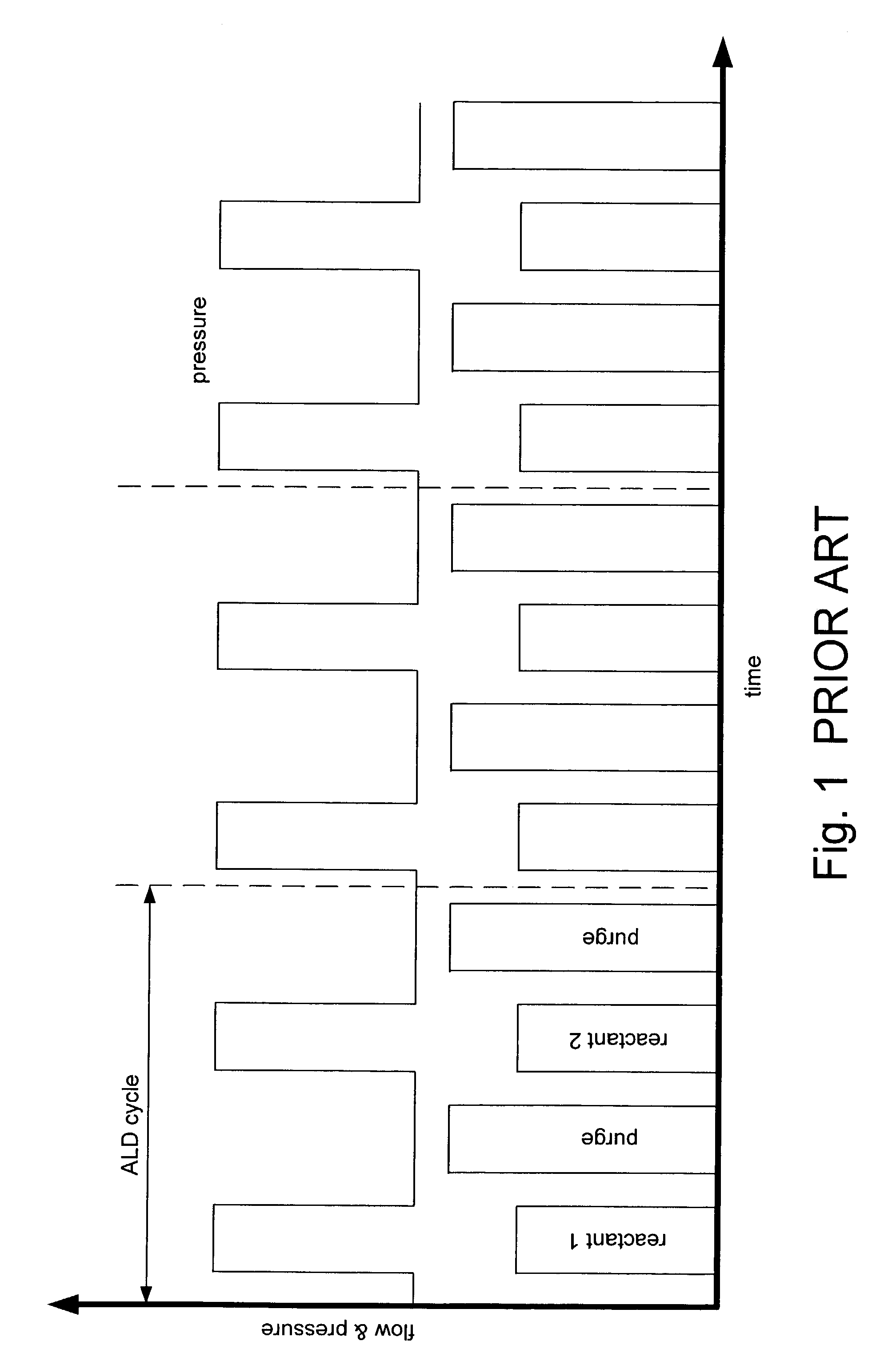

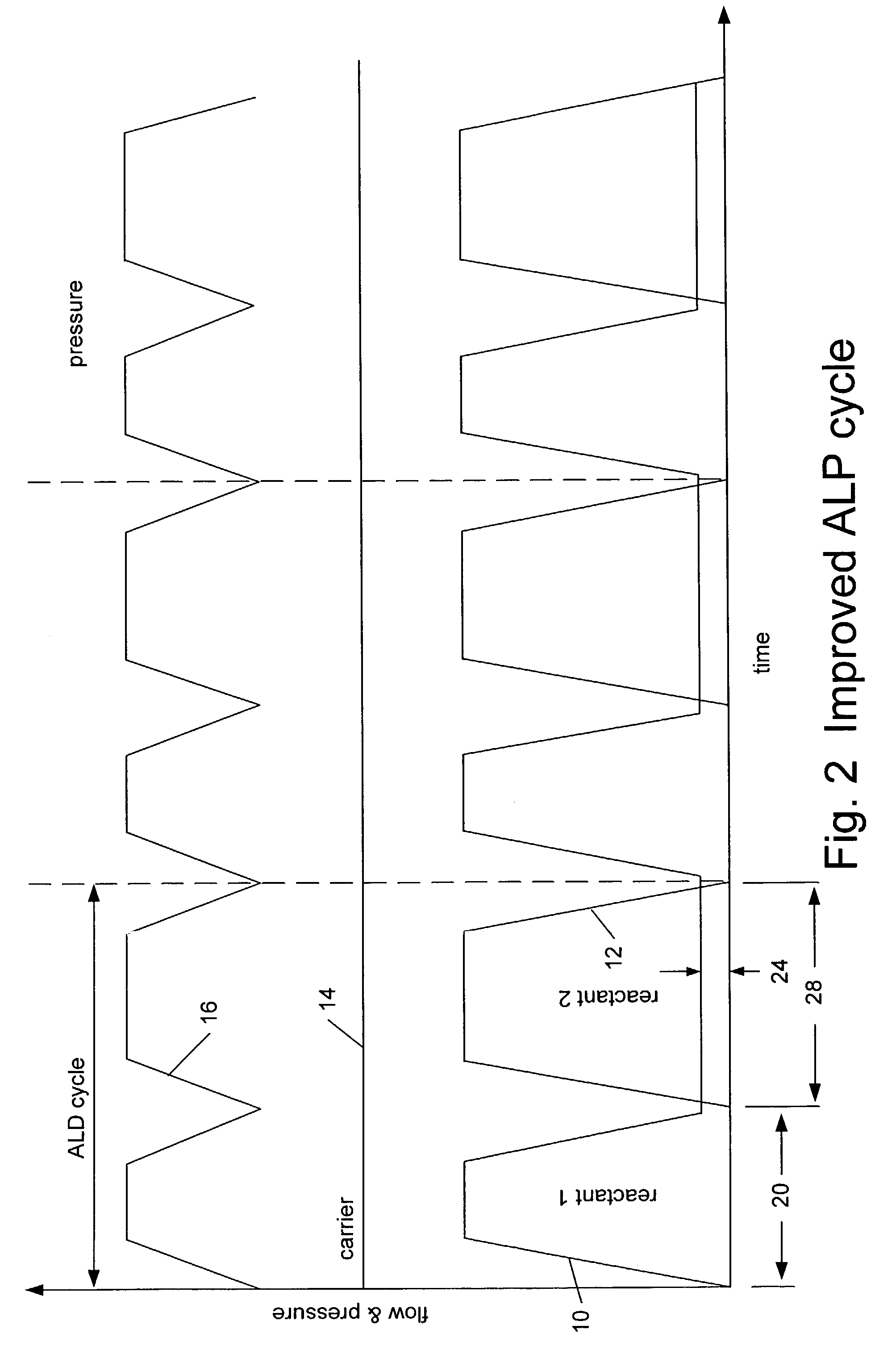

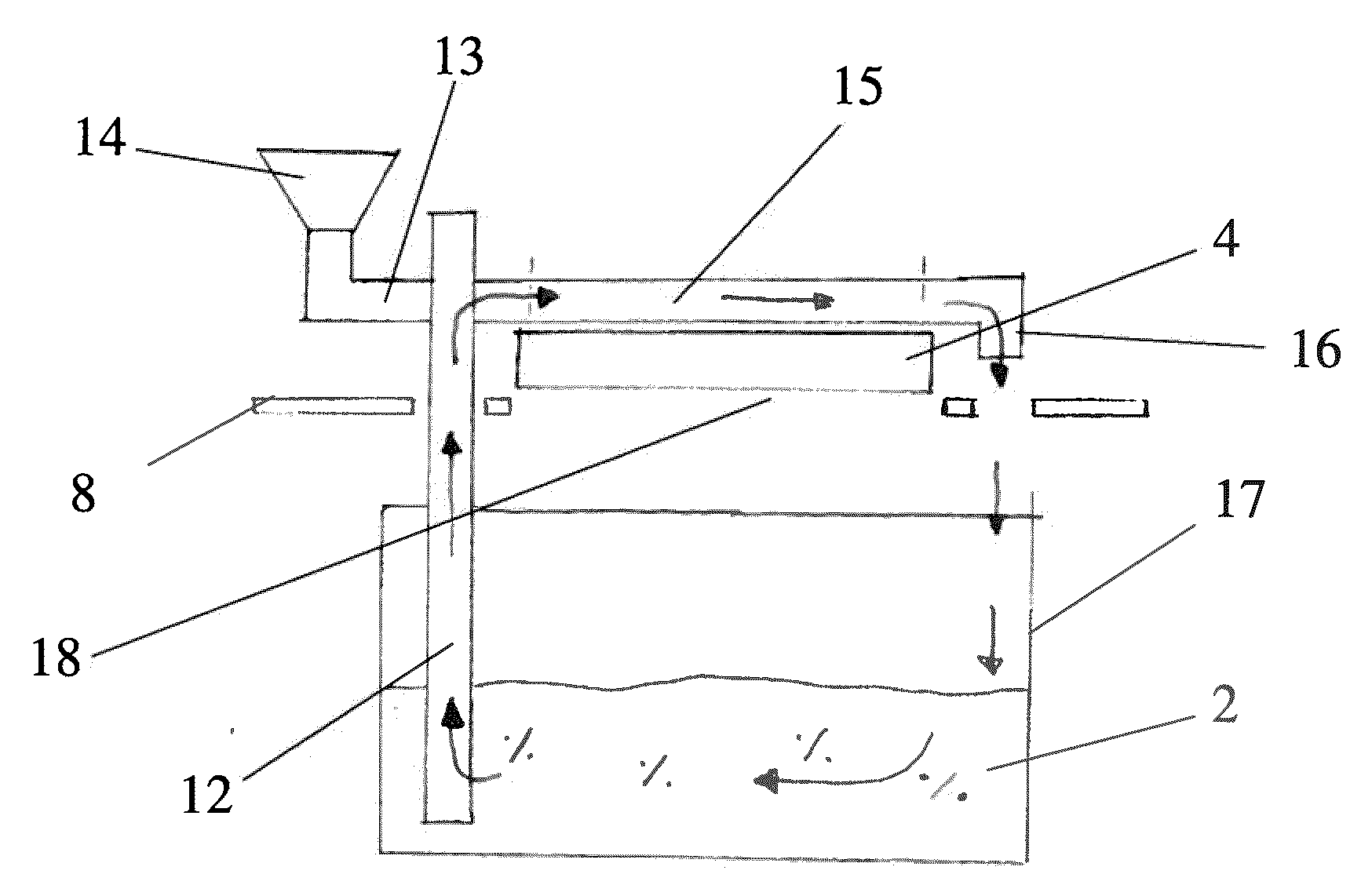

Method and apparatus for layer by layer deposition of thin films

InactiveUS7393561B2Increase wafer throughputImprove throughputElectric discharge tubesSemiconductor/solid-state device manufacturingChemisorptionEngineering

A method of increasing ALP briefly, a preferred embodiment of the present invention includes a method of increasing ALP throughput by continuously modulating gas flow in a reactor to achieve layer by layer growth on a wafer. A first reactant is introduced with a percentage of a carrier gas. After a first time interval, the first reactant flow is reduced while the carrier gas flow is increased so as to maintain an approximately constant total gas flow. When the first reactant flow reaches a minimal, predetermined amount, a second reactant flow is initiated and increased while the carrier gas flow is decreased so as to continue a constant total gas flow. The method alternatively includes introducing a substance that enhances reactant adsorption and chemisorption, either as a first applied gas that reacts with the surface or as an added ligand to the reactant. Still further alternatives include a periodic rapid thermo anneal for improving film properties, parallel wafer processing and a reactant reservoir.

Owner:APPLIED MATERIALS INC

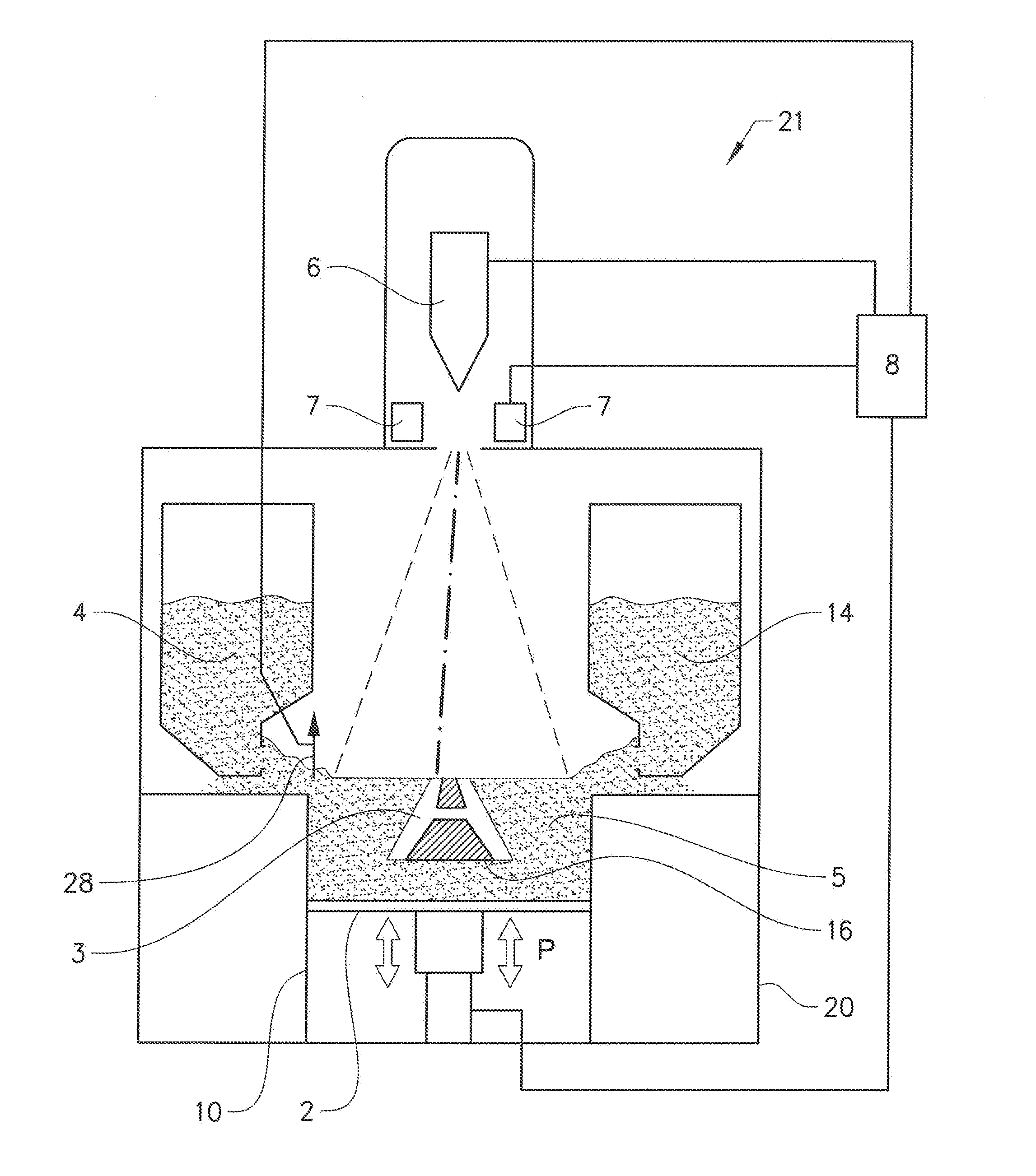

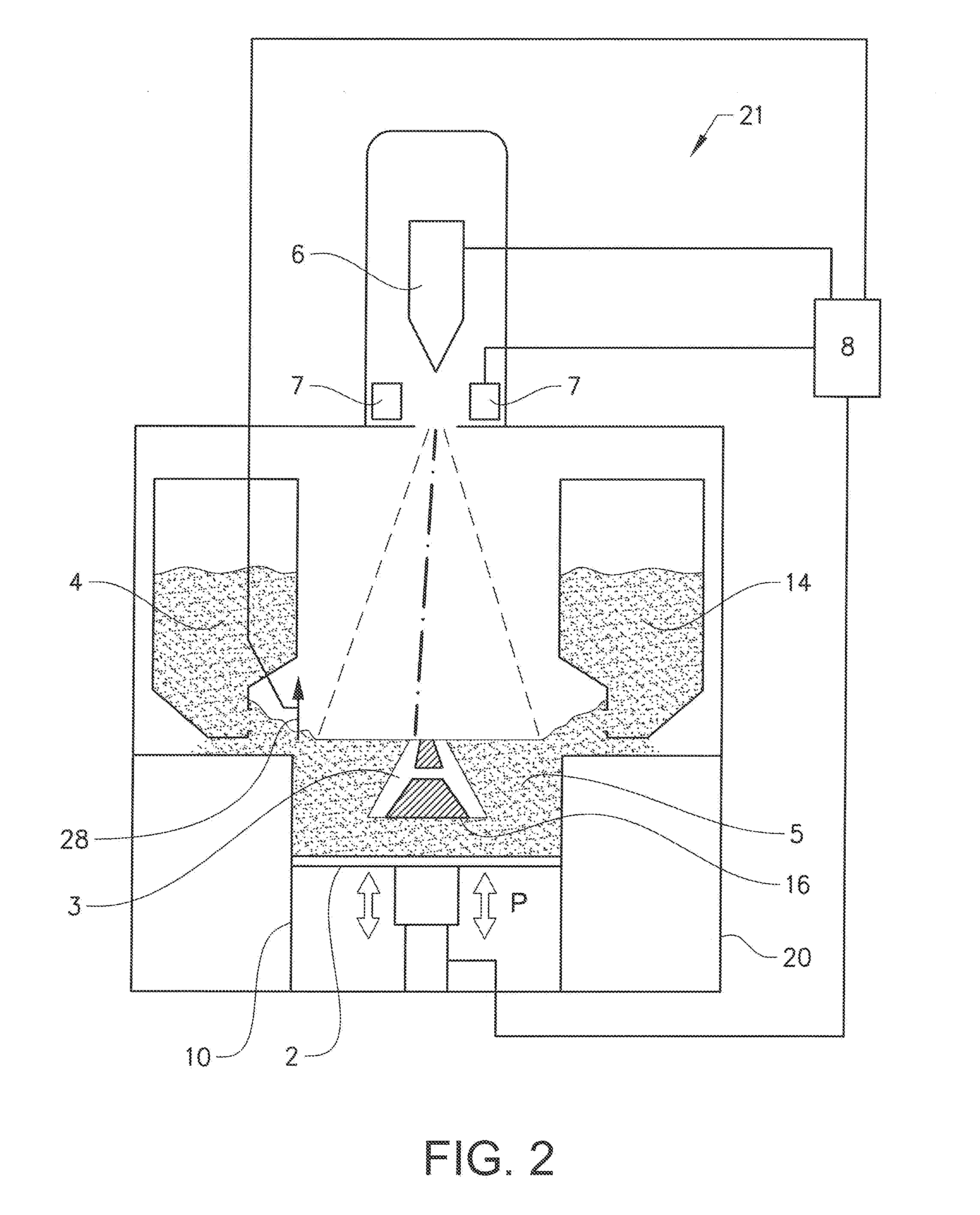

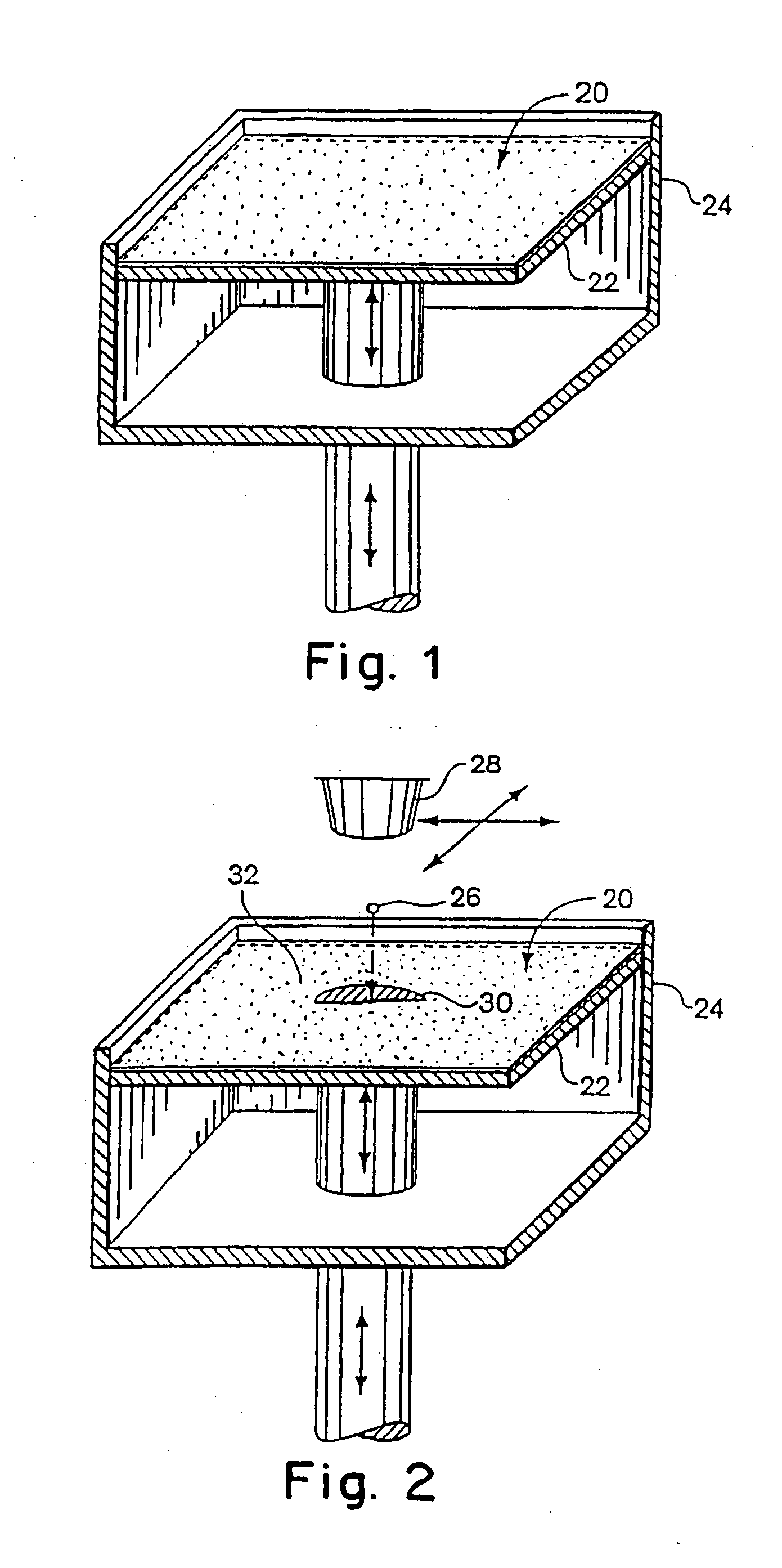

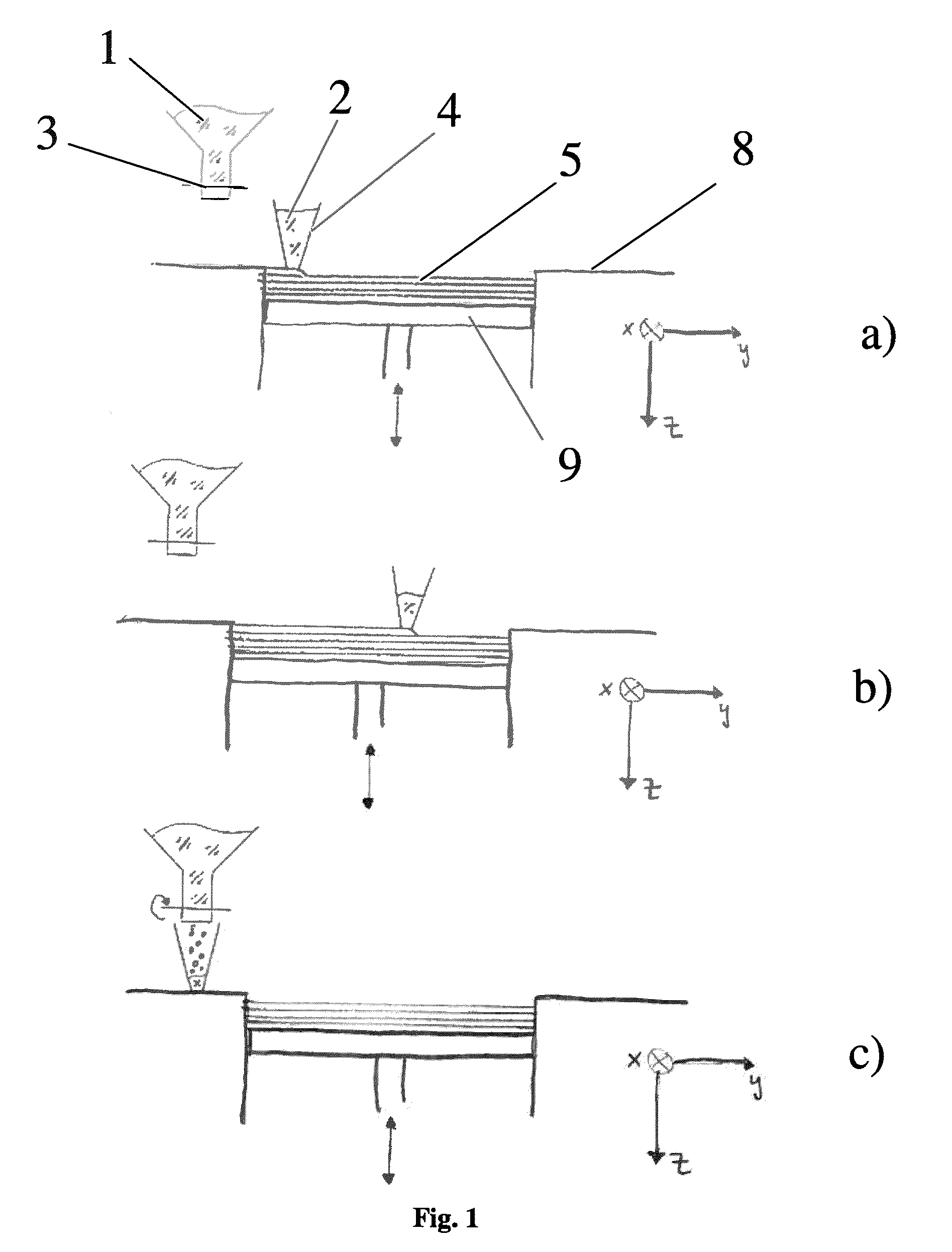

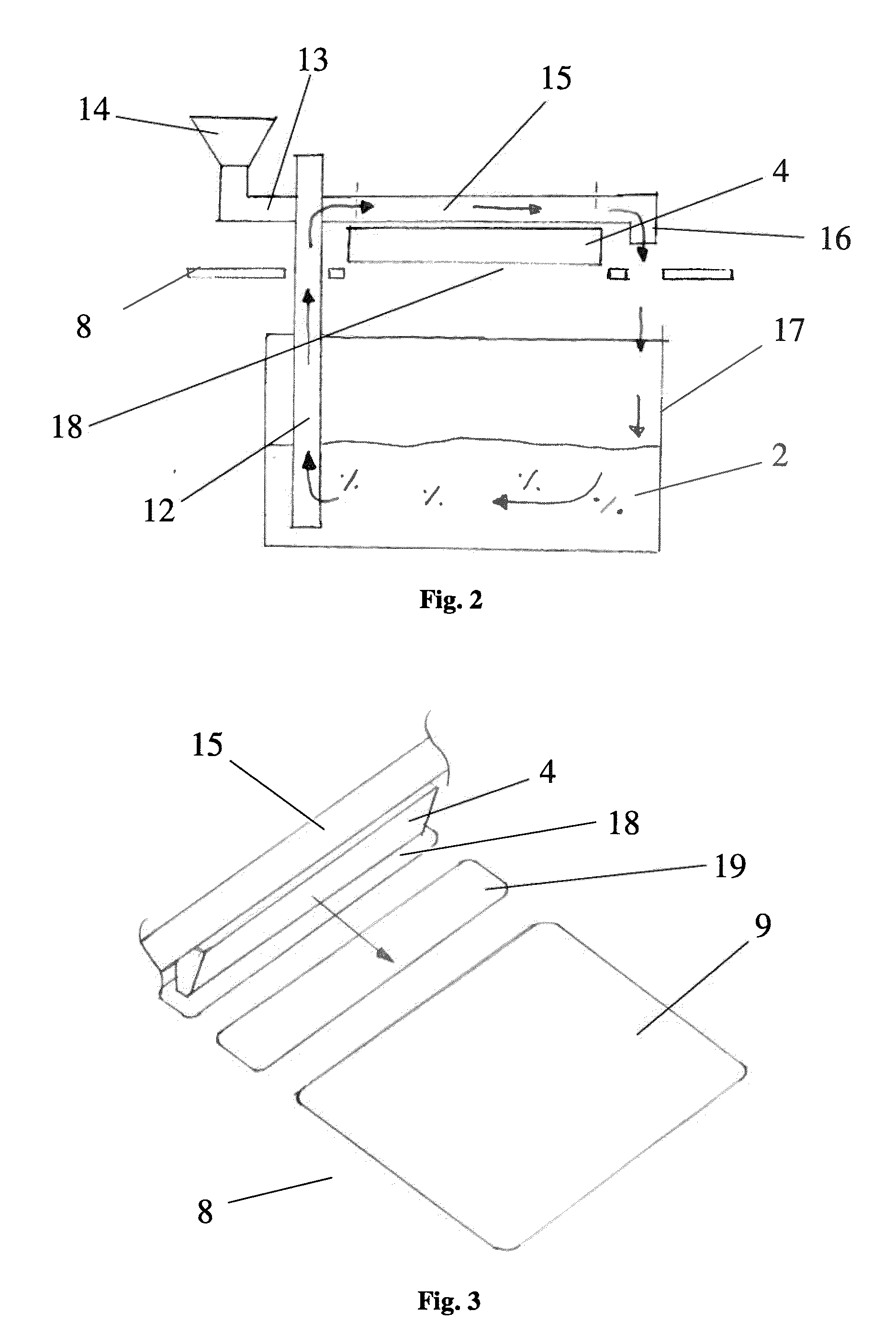

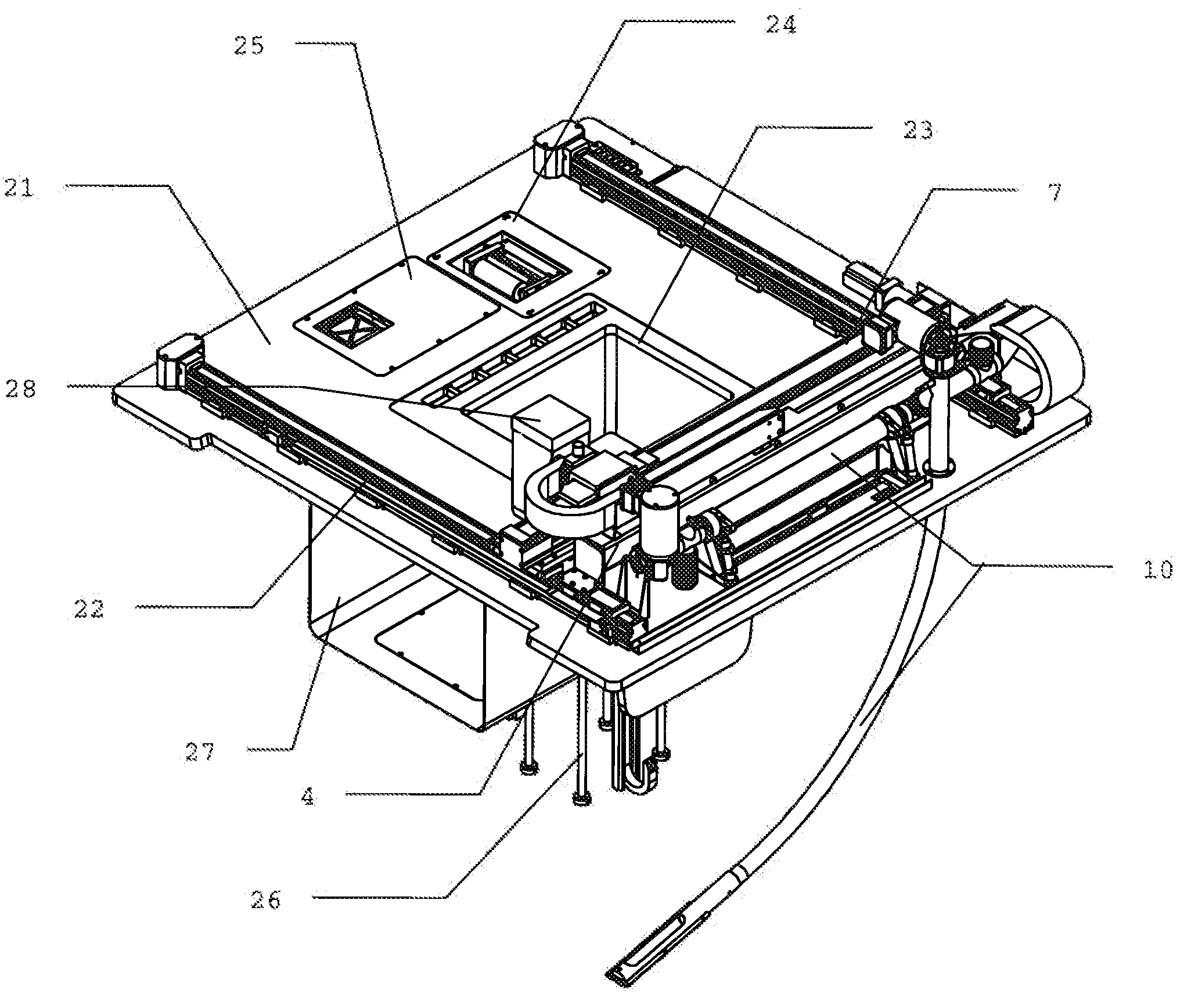

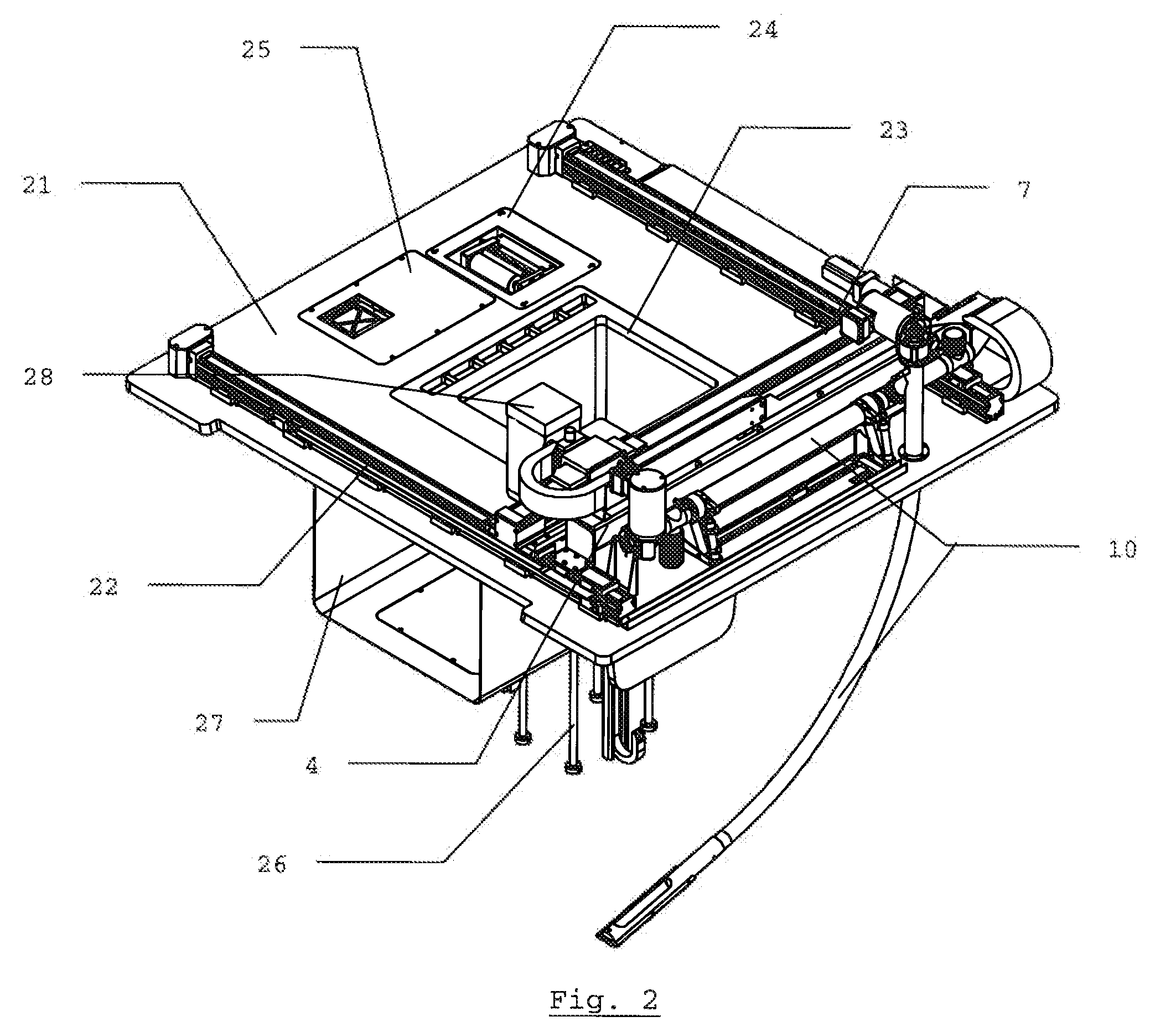

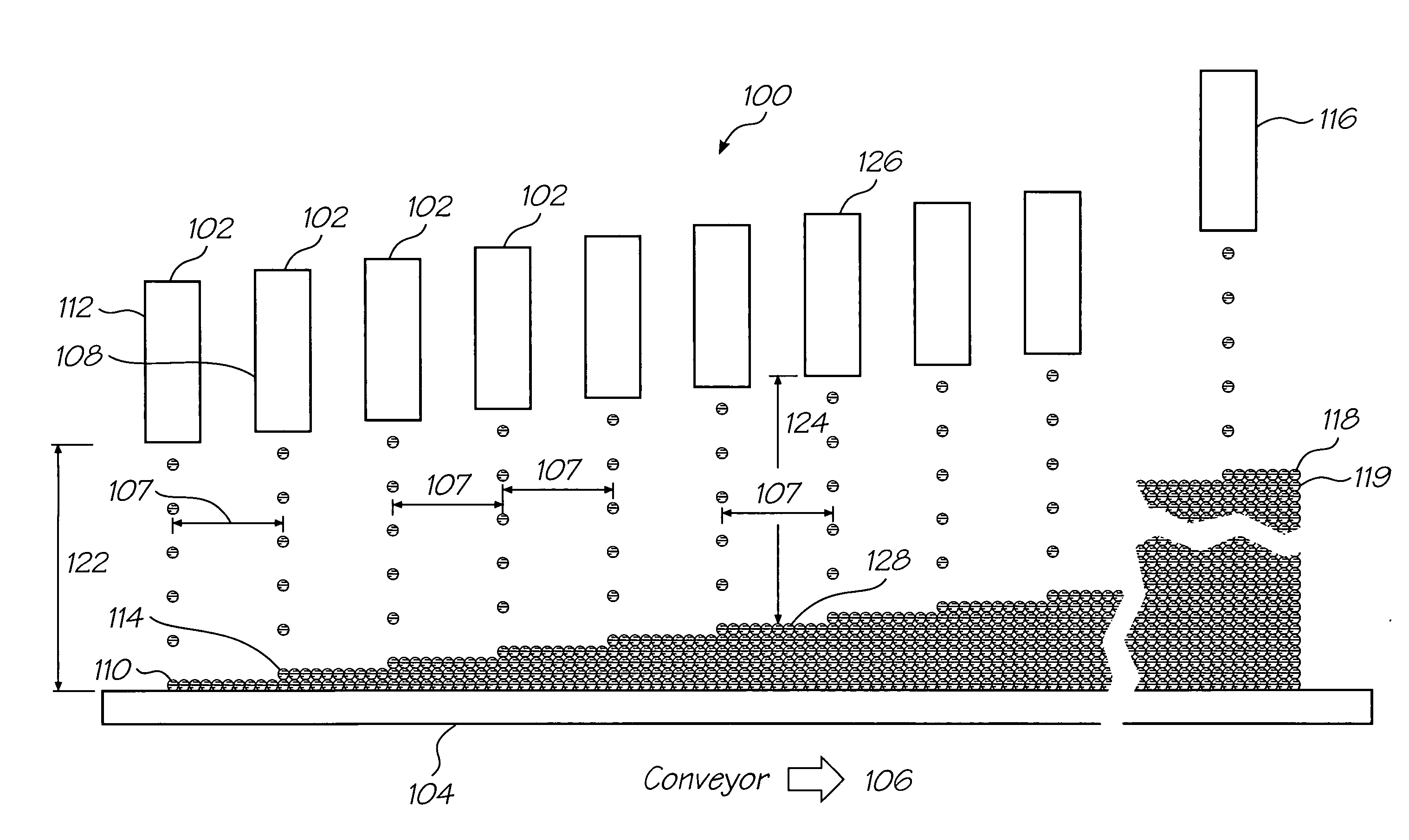

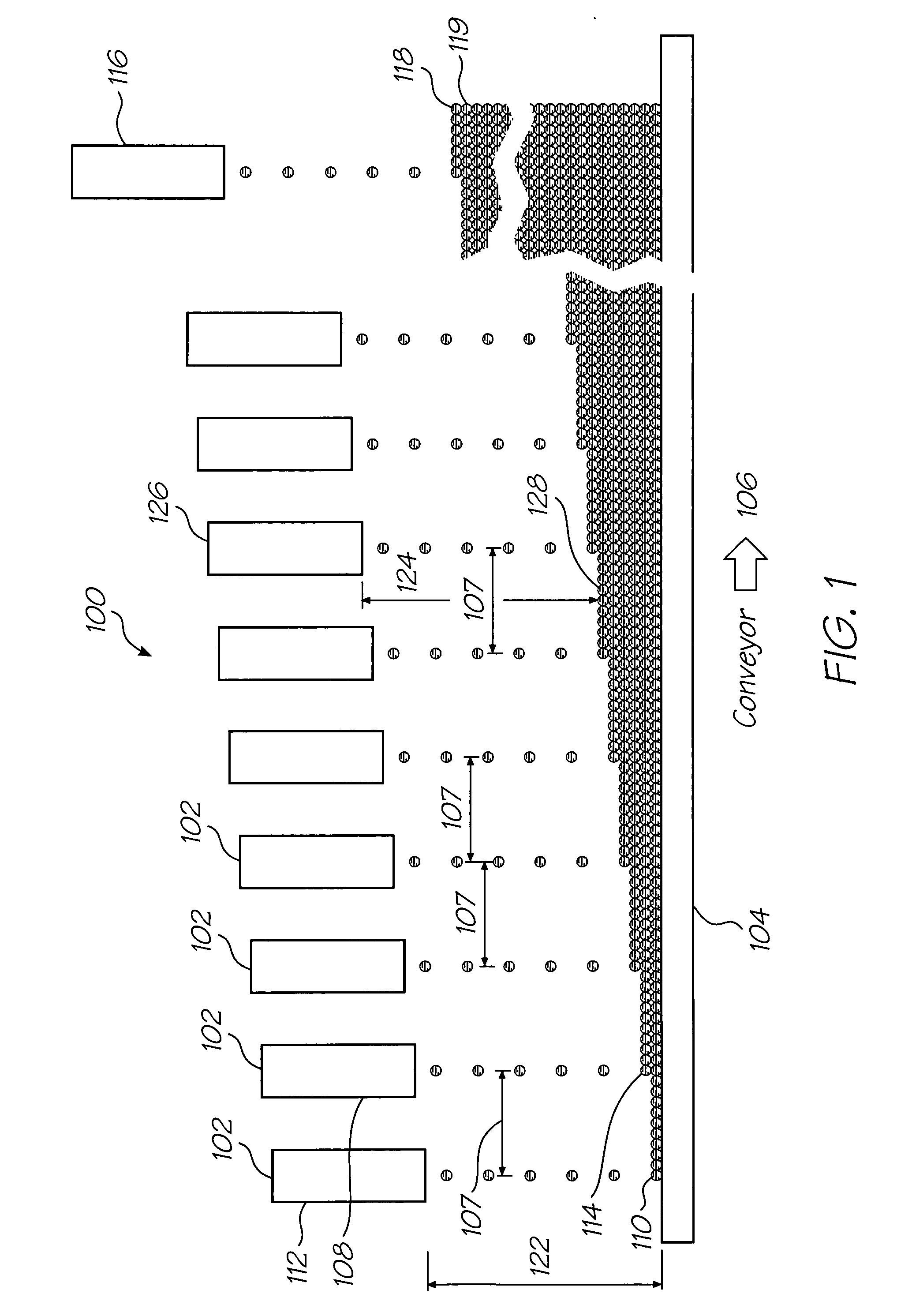

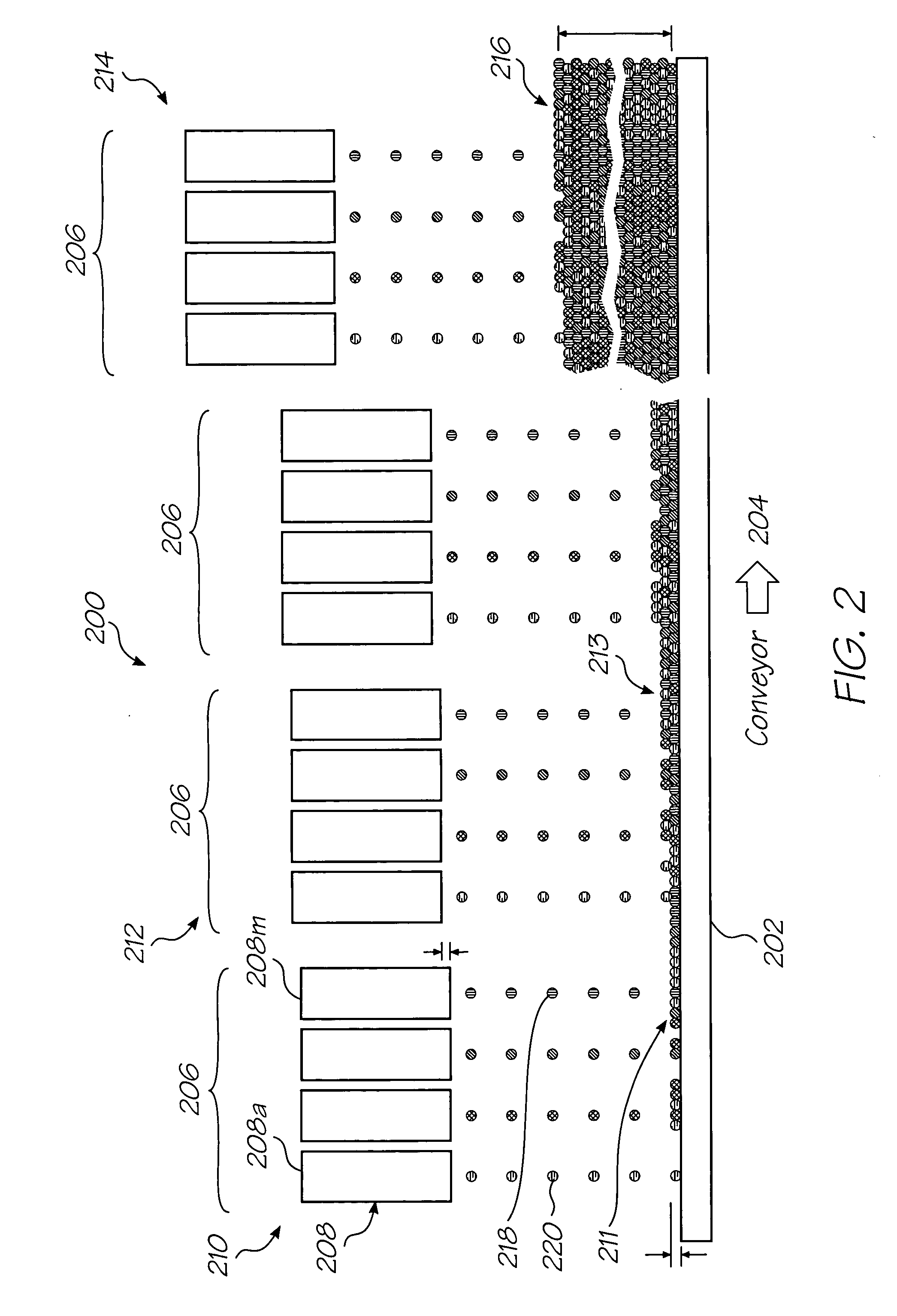

Method and device for conveying particulate material during the layer-wise production of patterns

ActiveUS20100272519A1Evenly filledAdditive manufacturing apparatusLiquid surface applicatorsEngineeringMechanical engineering

The present invention relates to a method for conveying particulate material during the manufacture of patterns in layers, wherein powder is conveyed out of a reservoir into a spreader unit and, if applicable, excess powder fed to the spreader unit is again conveyed back into the reservoir and wherein this conveying takes place in a closed conveying circuit.

Owner:VOXELJET AG

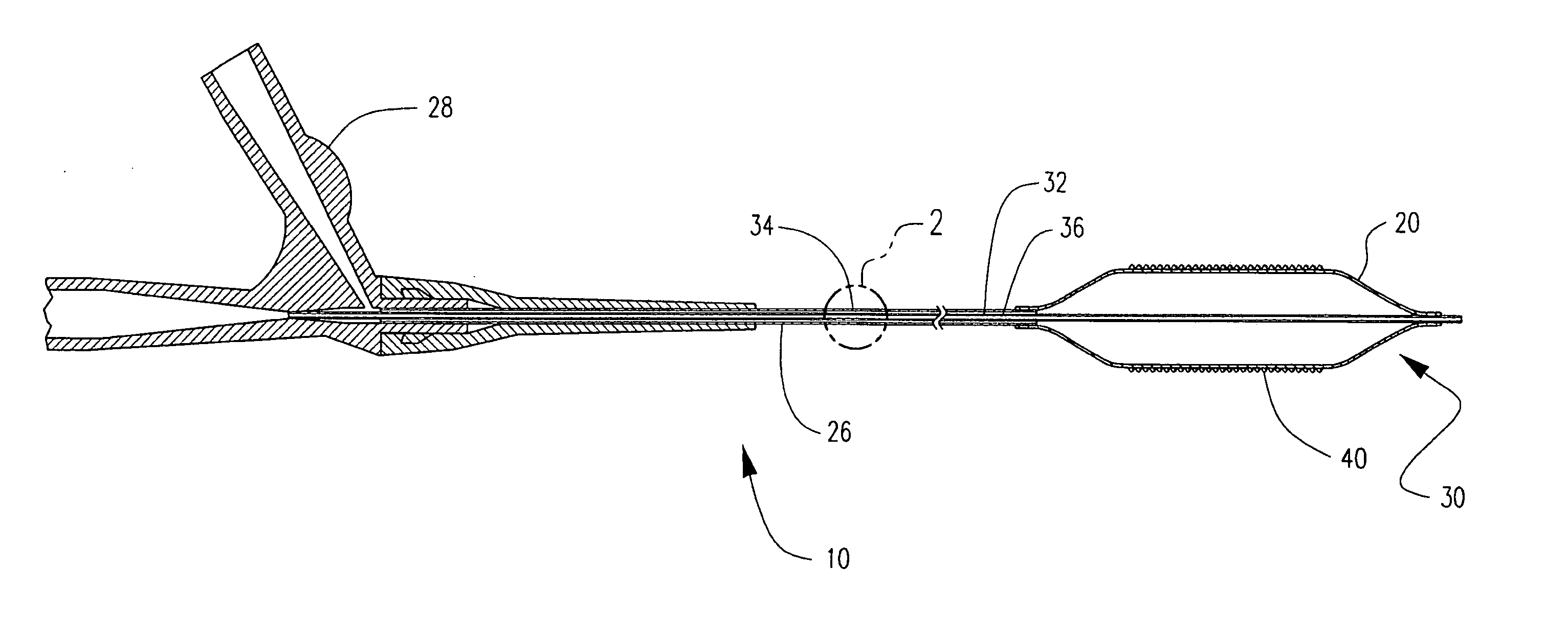

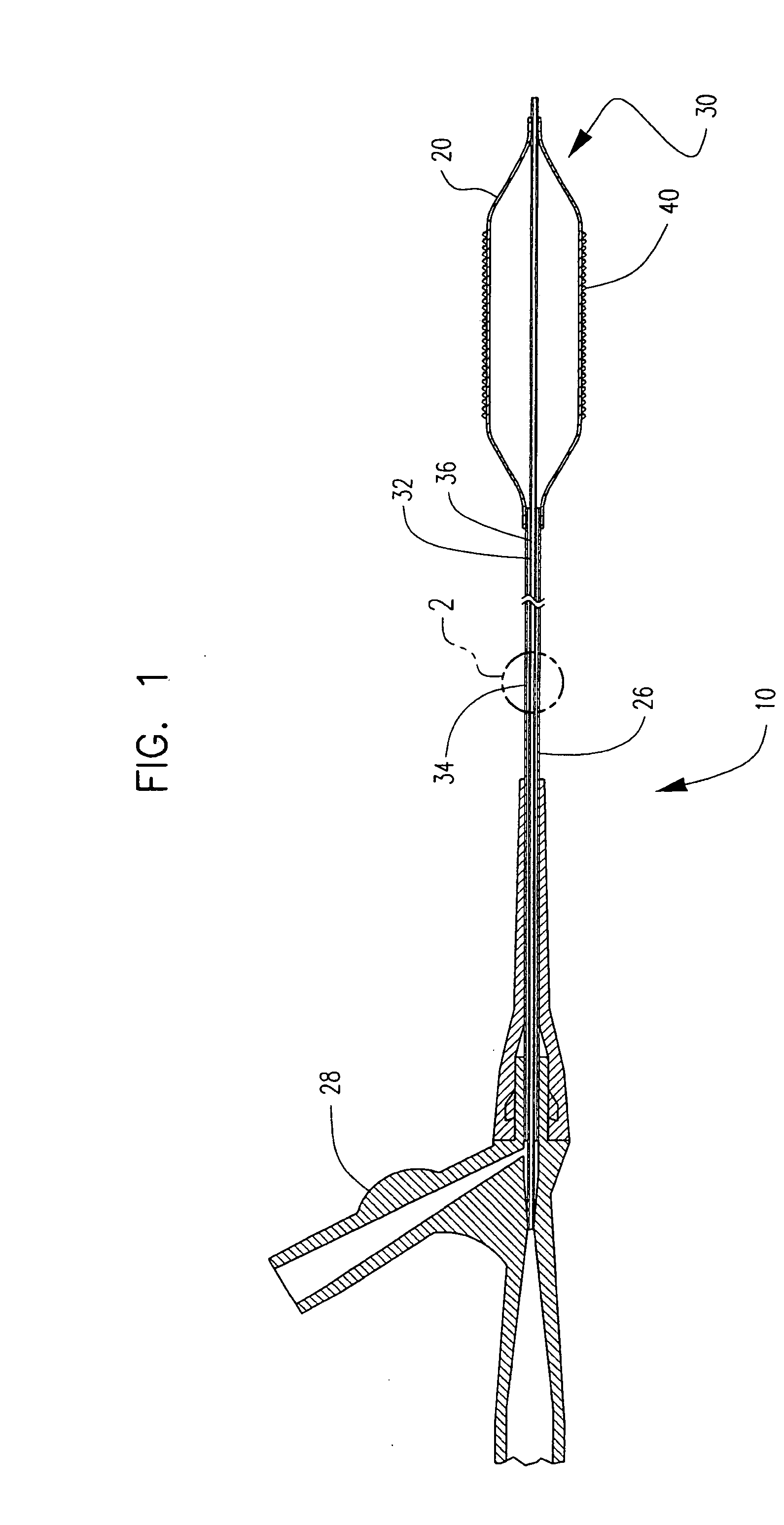

Coatings for use on medical devices

InactiveUS20060212106A1Improve medical device deployment accuracyPrevent slippingStentsBalloon catheterMedical deviceBiomedical engineering

A medical device at least a portion of which has a degradable coating, the coating degrading in an aqueous environment, and to methods of making and using the same. The coating may be a layer-by-layer coating, the first layer comprising a material having a positive charge and the second layer comprising a material having a negative charge.

Owner:BOSTON SCI SCIMED INC

PAEK powder, in particular for the use in a method for a layer-wise manufacturing of a three-dimensional object, as well as method for producing it

ActiveUS7847057B2Additive manufacturing apparatusSynthetic resin layered productsMetallurgyGlass transition

By a temper treatment a polyaryletherketone powder is processed such that it is particularly suited for the use in a method for a layer-wise manufacturing of a three-dimensional object. To this effect the powder is tempered at a temperature that is at least 20° C. above the glass transition temperature for at least 30 minutes before it is used as building material.

Owner:EOS ELECTRO OPTICAL SYST

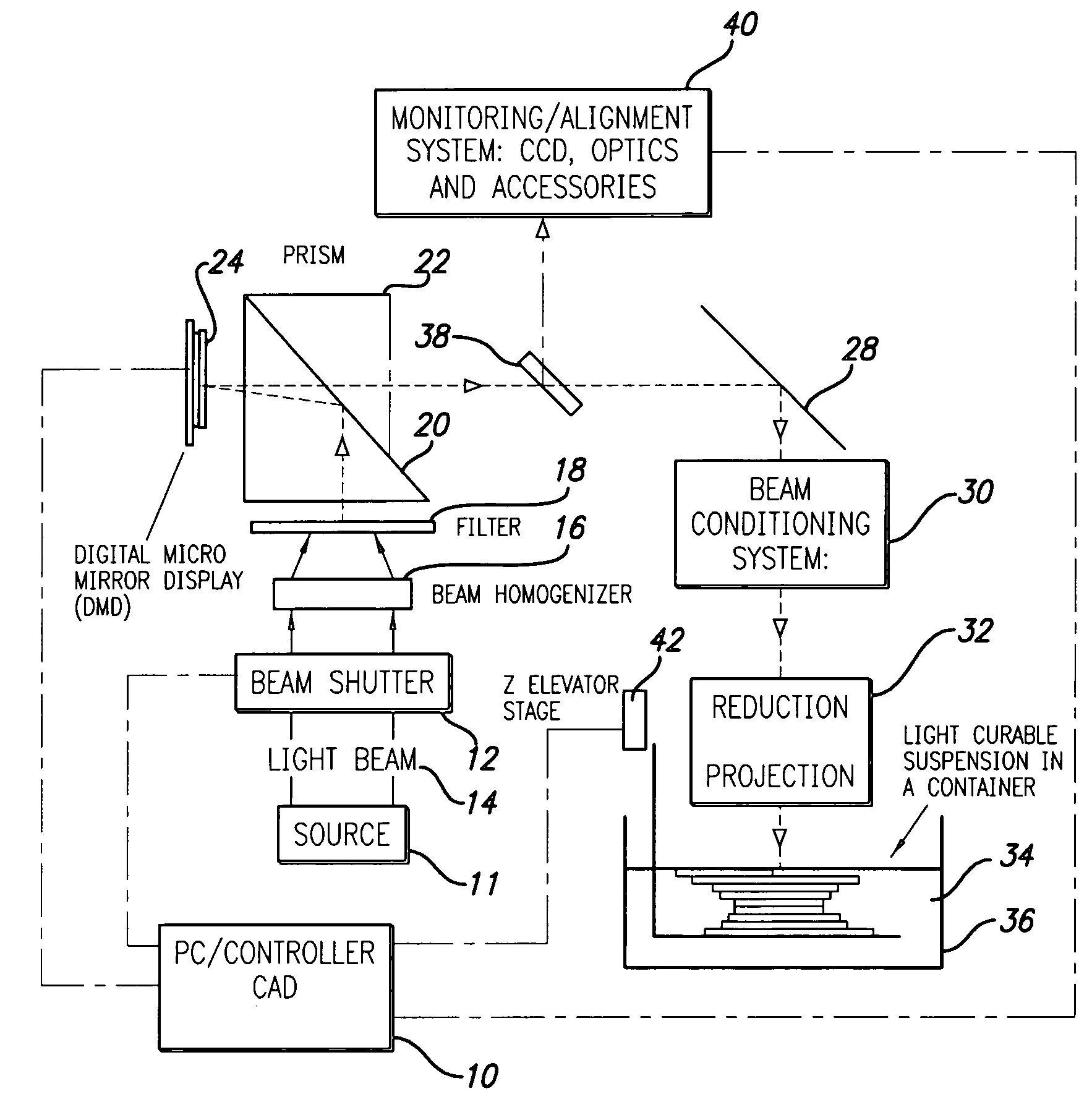

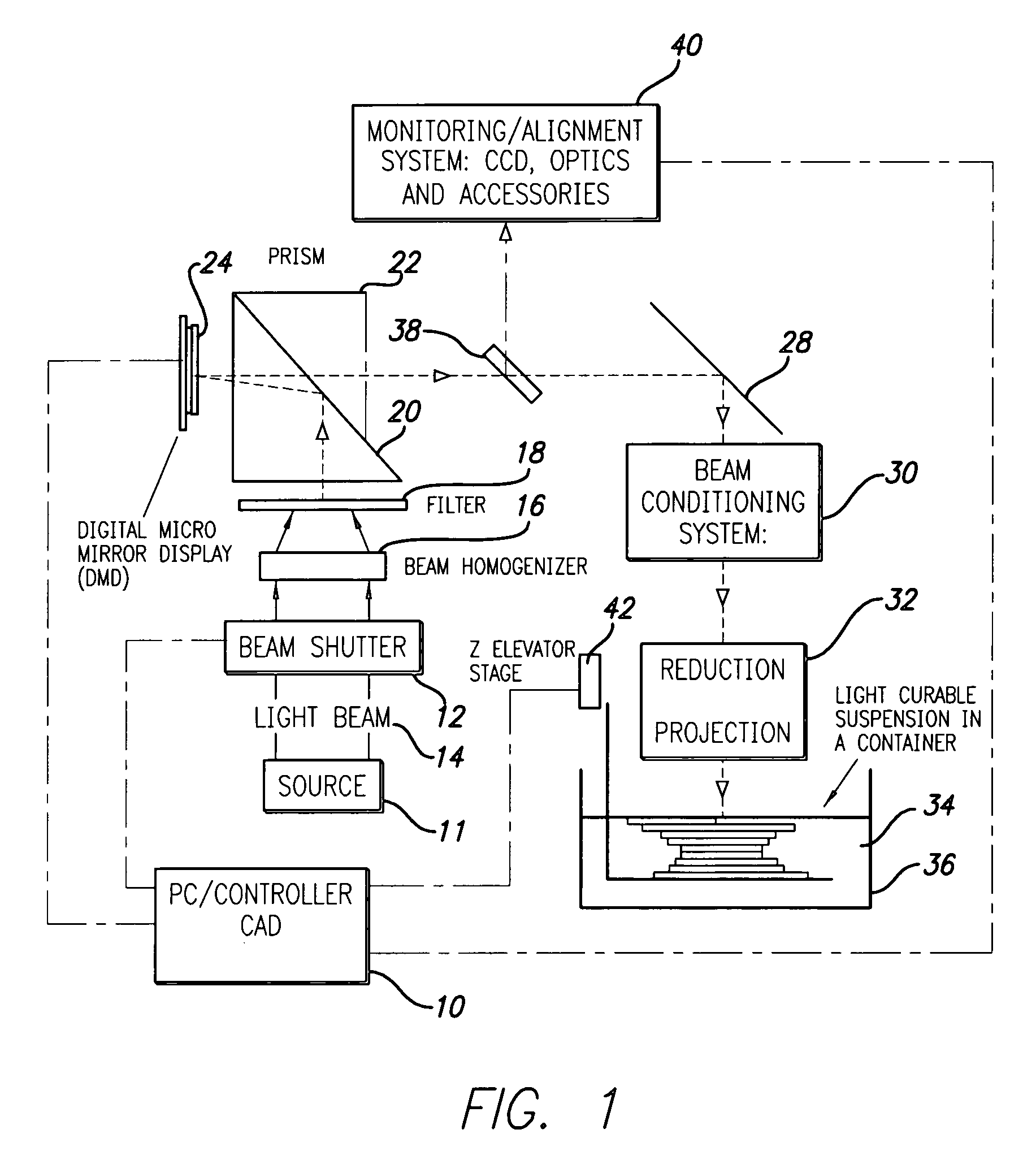

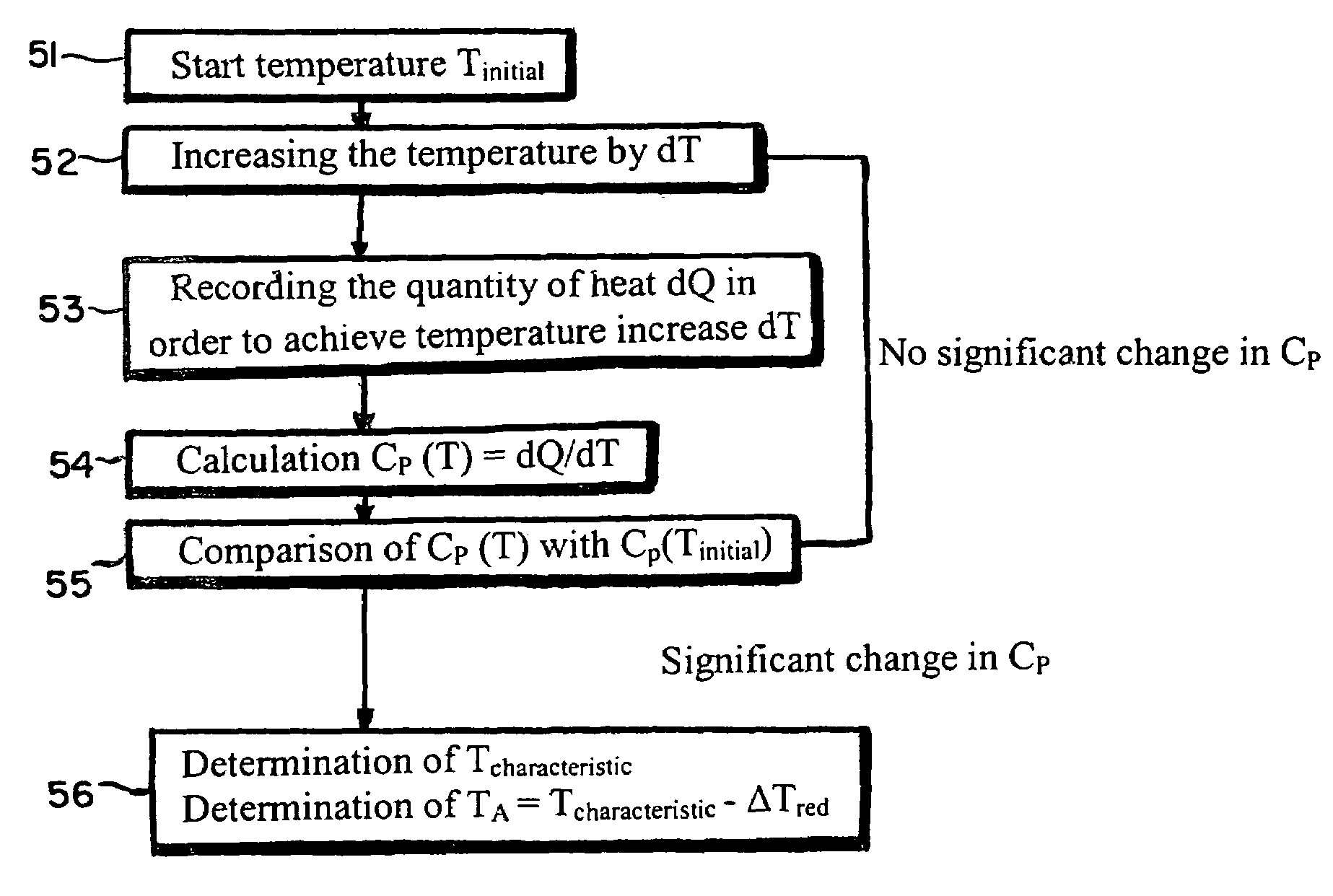

Dynamic mask projection stereo micro lithography

InactiveUS7088432B2Additive manufacturing apparatusPhotomechanical exposure apparatusComputer graphics (images)Software design

Three-dimensional structures are fabricated by a process in which a 3D solid model is designed by software at a PC and sliced into a series of 2D layers. Each 2D layer is displayed at a dynamic mask via micro-mirror deflections projected onto a photoresist to form a layer, which is lowered and the process is repeated to build the object layer by layer.

Owner:RGT UNIV OF CALIFORNIA

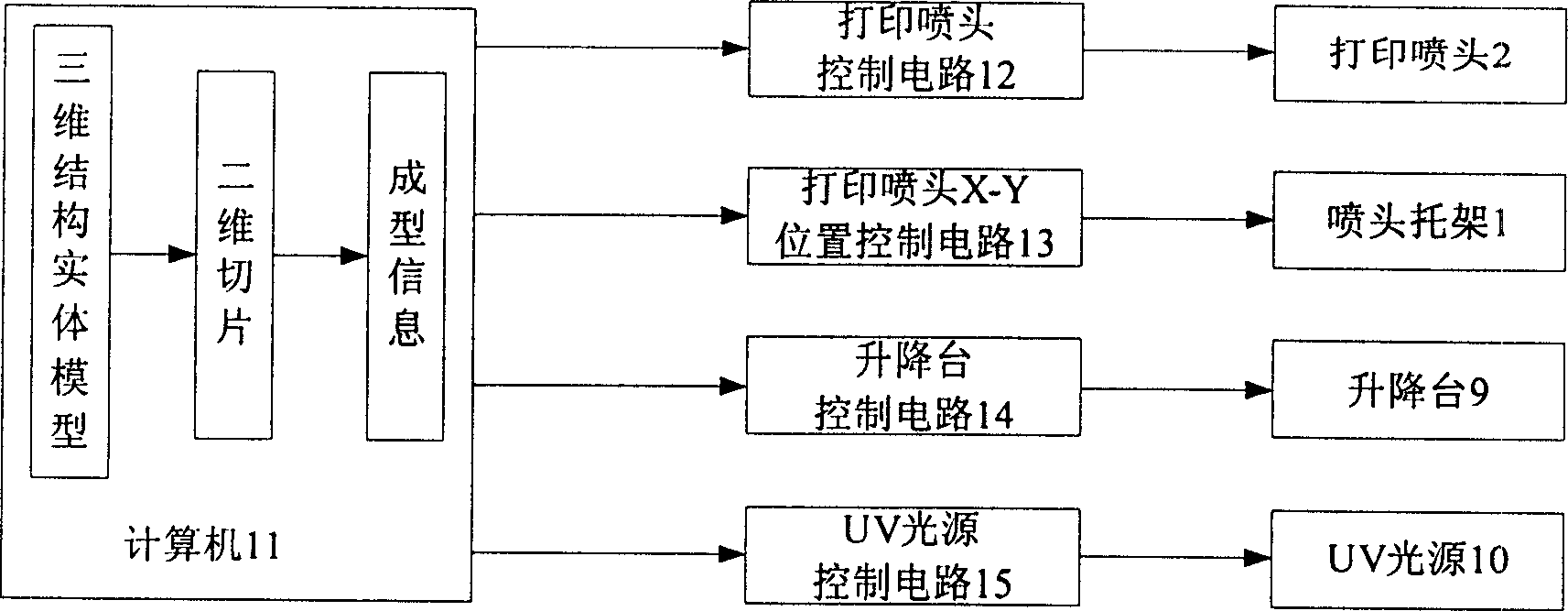

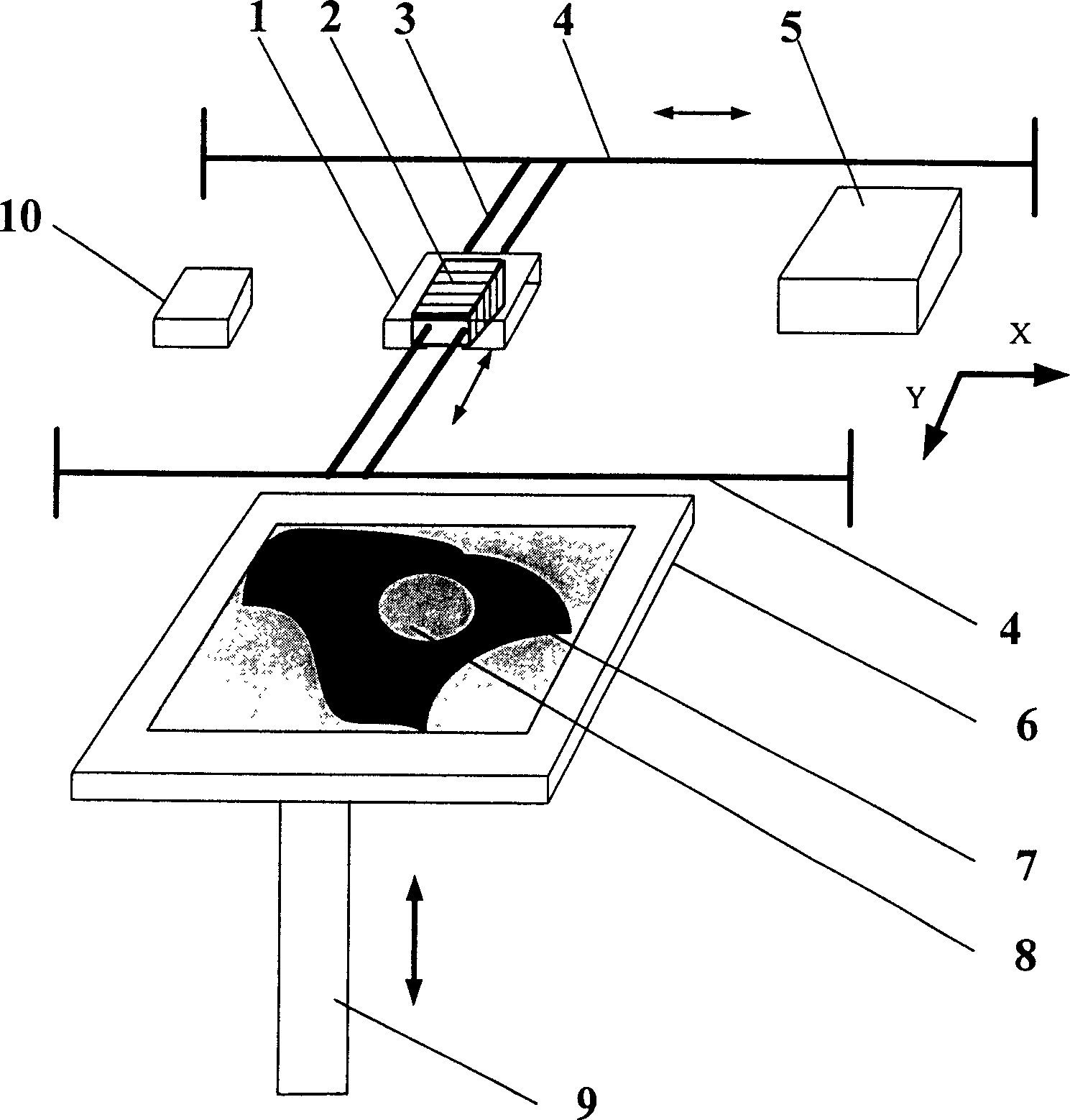

Method for manufacturing three-dimensional object by use of spray coating successively

The invention discloses a method for producing three-dimensional matter via plating layer-to-layer, which comprises following steps: building a computer solid model of three-dimensional matter to be sliced and layered; the computer controls the operation of printing injector and injecting UV liquid material according to the molding information of each layer to be solidified via ultraviolet light to form a layer with the same shape and strength of molding information; injecting support material in the non-injected area as support; adhering each layer to produce designed three-dimensional matter; removing filled support material of each layer to attain the three-dimensional matter of said computer solid model. The invention can quickly, reliably, and safely produce complex three-dimensional matter and composite color three-dimensional matter with lower cost. Wherein, the molding material in said invention is innocuous, therefore, the invention can be used in office.

Owner:NANJING NORMAL UNIVERSITY

Device for the layer-wise production of patterns

ActiveUS20100212584A1Low production costMinimize effortManufacturing platforms/substratesLiquid surface applicatorsPorosityEngineering

The instant invention relates to a method for changing characteristics of a plastic component, wherein a medium is introduced into the plastic component, which encompasses a porosity and wherein the medium forms a homogenous compound with the plastic component by at least partially dissolving the plastic component.

Owner:VOXELJET AG

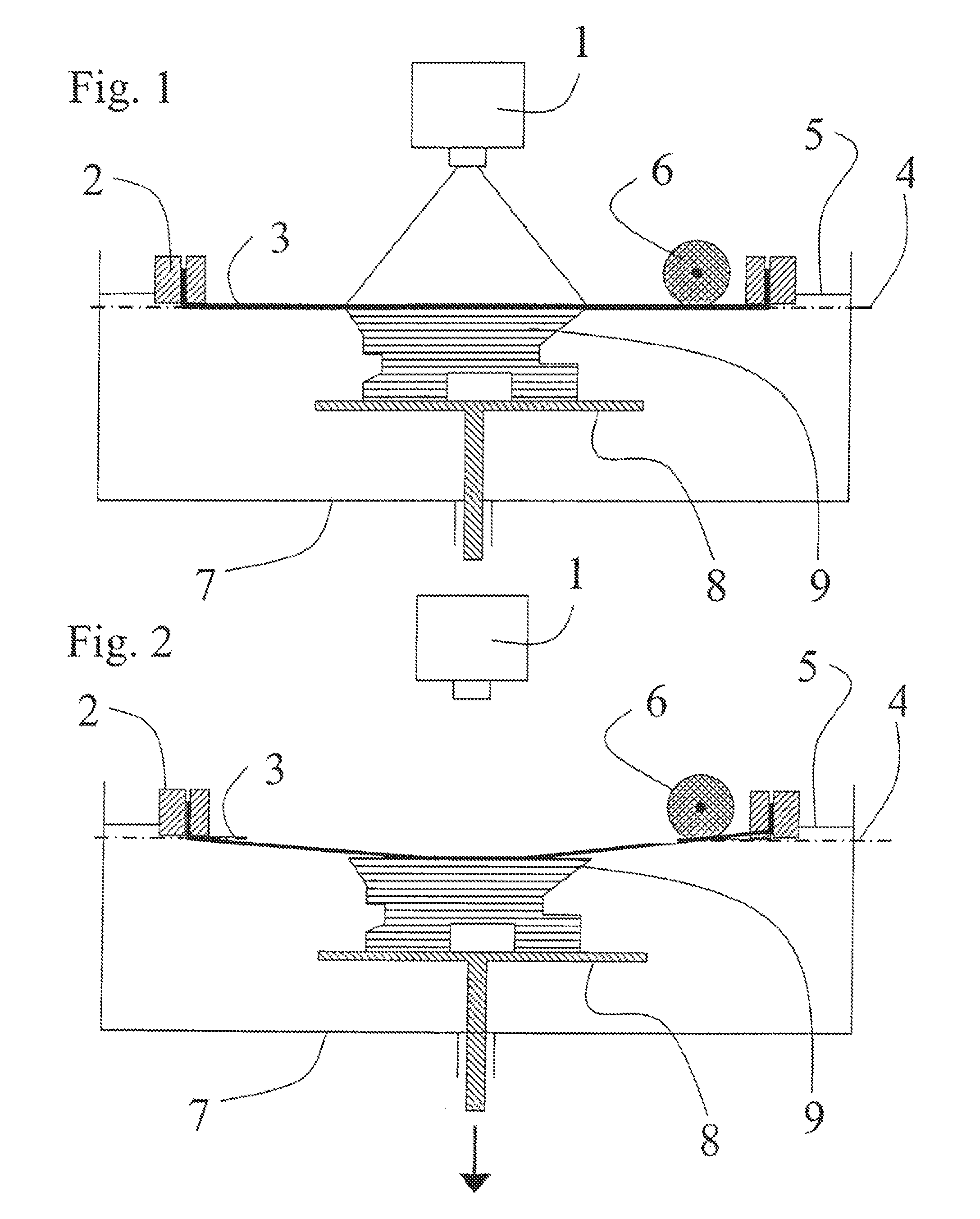

Process for the production of a three-dimensional object with an improved separation of hardened material layers from a construction plane

ActiveUS8394313B2Reduce in quantityModel are minimized.Additive manufacturing apparatusAuxillary shaping apparatusElastomerStructure of the Earth

Owner:ENVISIONTEC GMBH DE

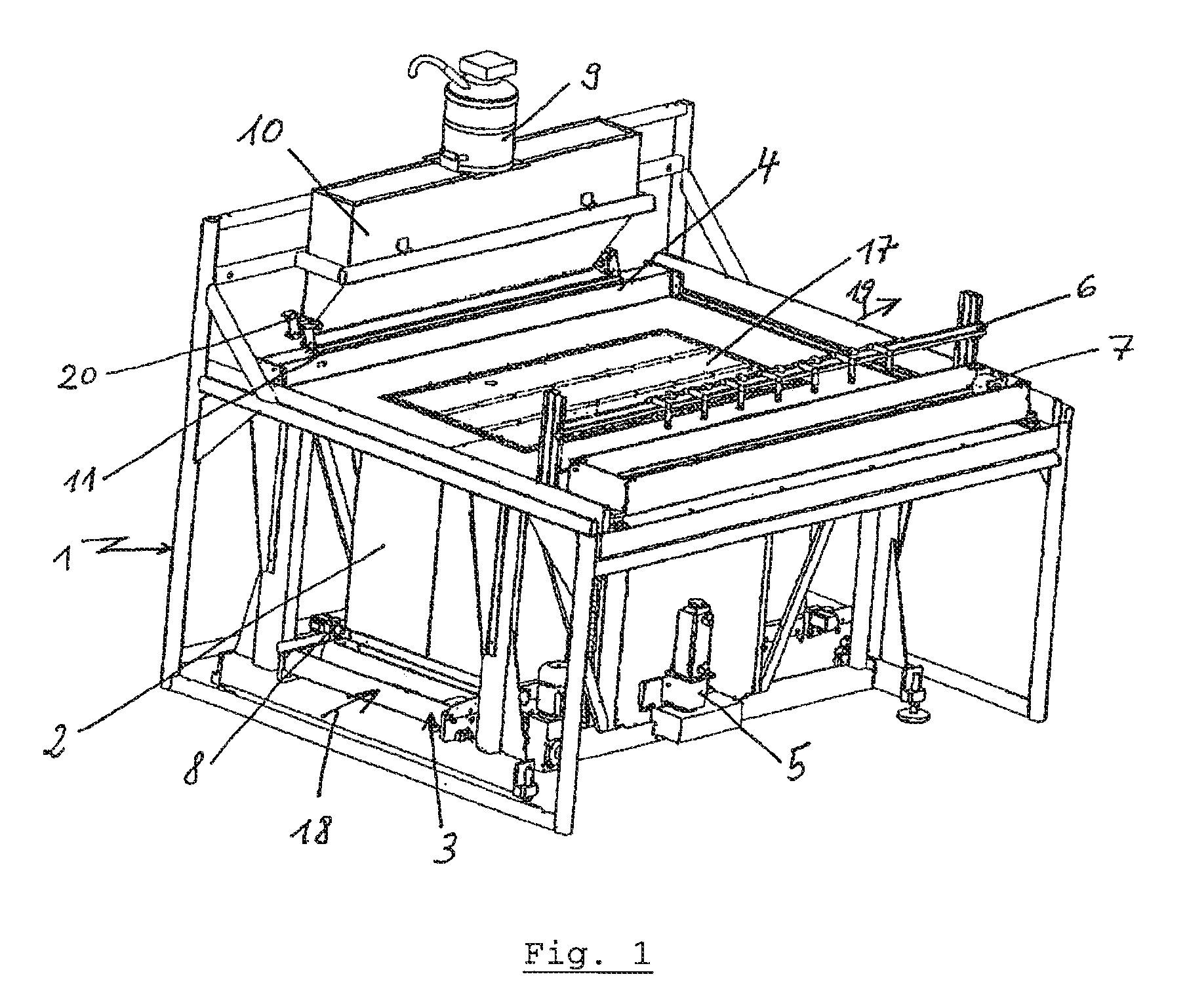

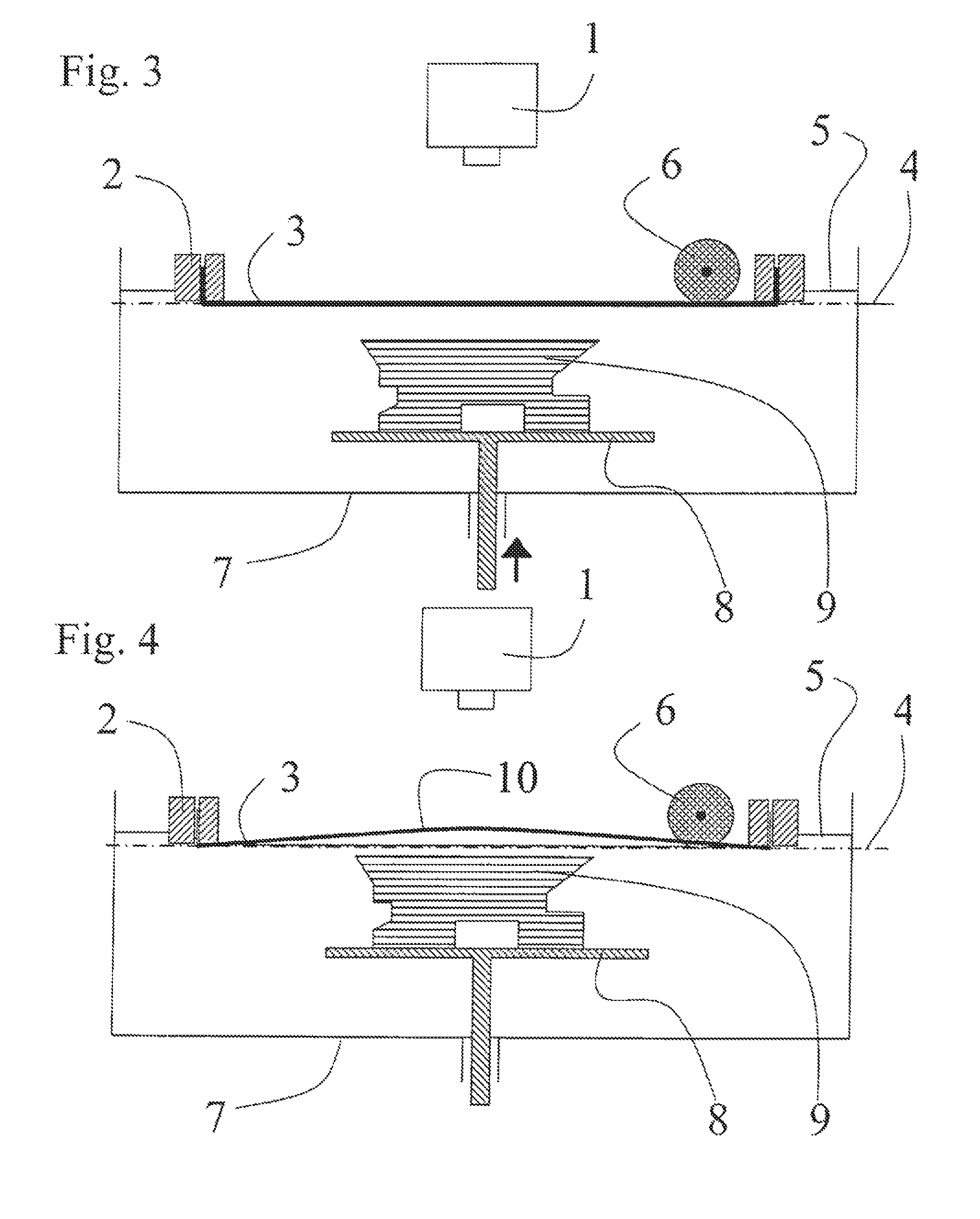

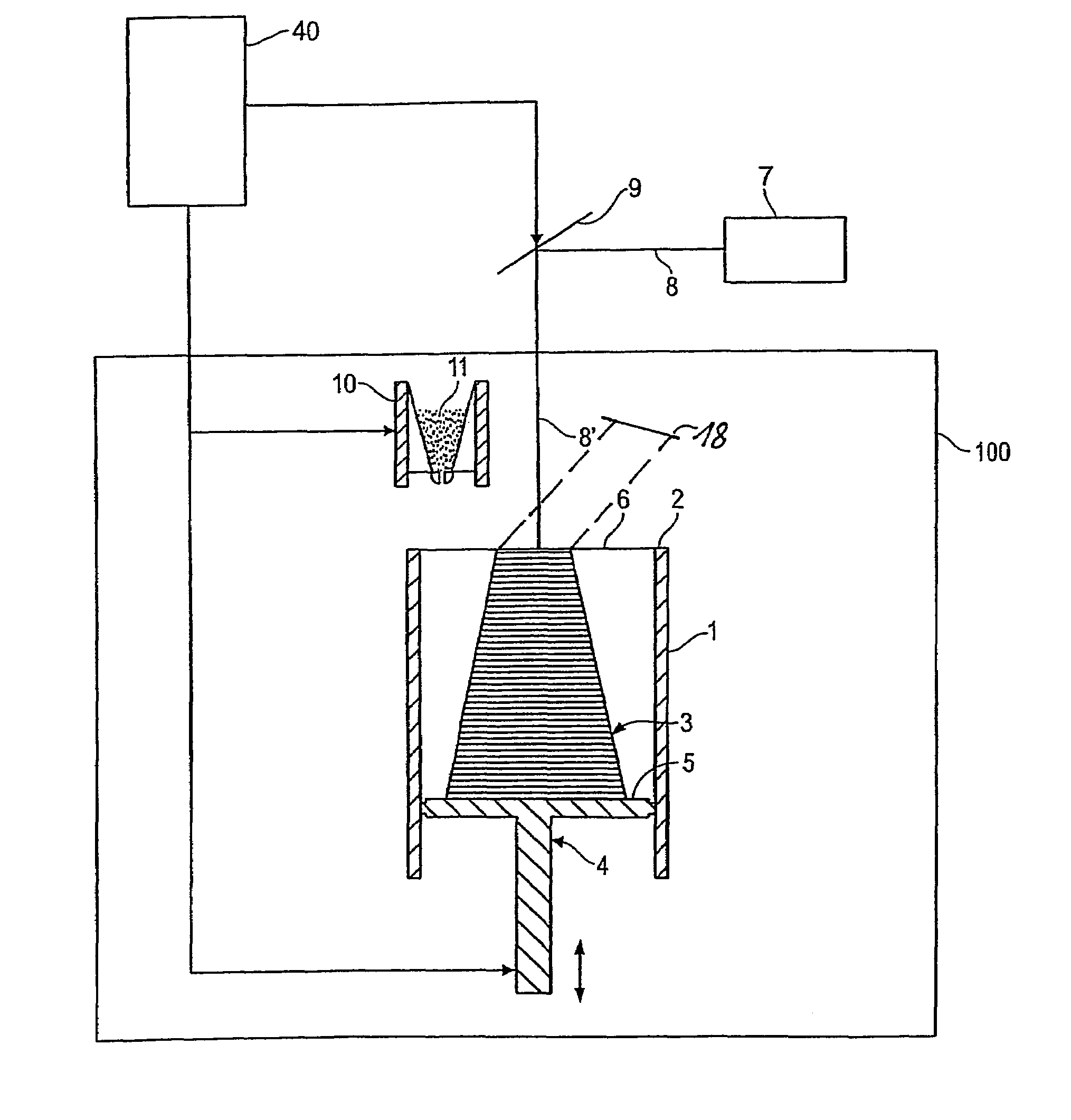

Method and device for the production of a three-dimensional object by means of sintering

InactiveUS7419632B2Quality improvementAvoid disadvantagesConfectioneryManufacturing heating elementsMetallurgyWorking temperature

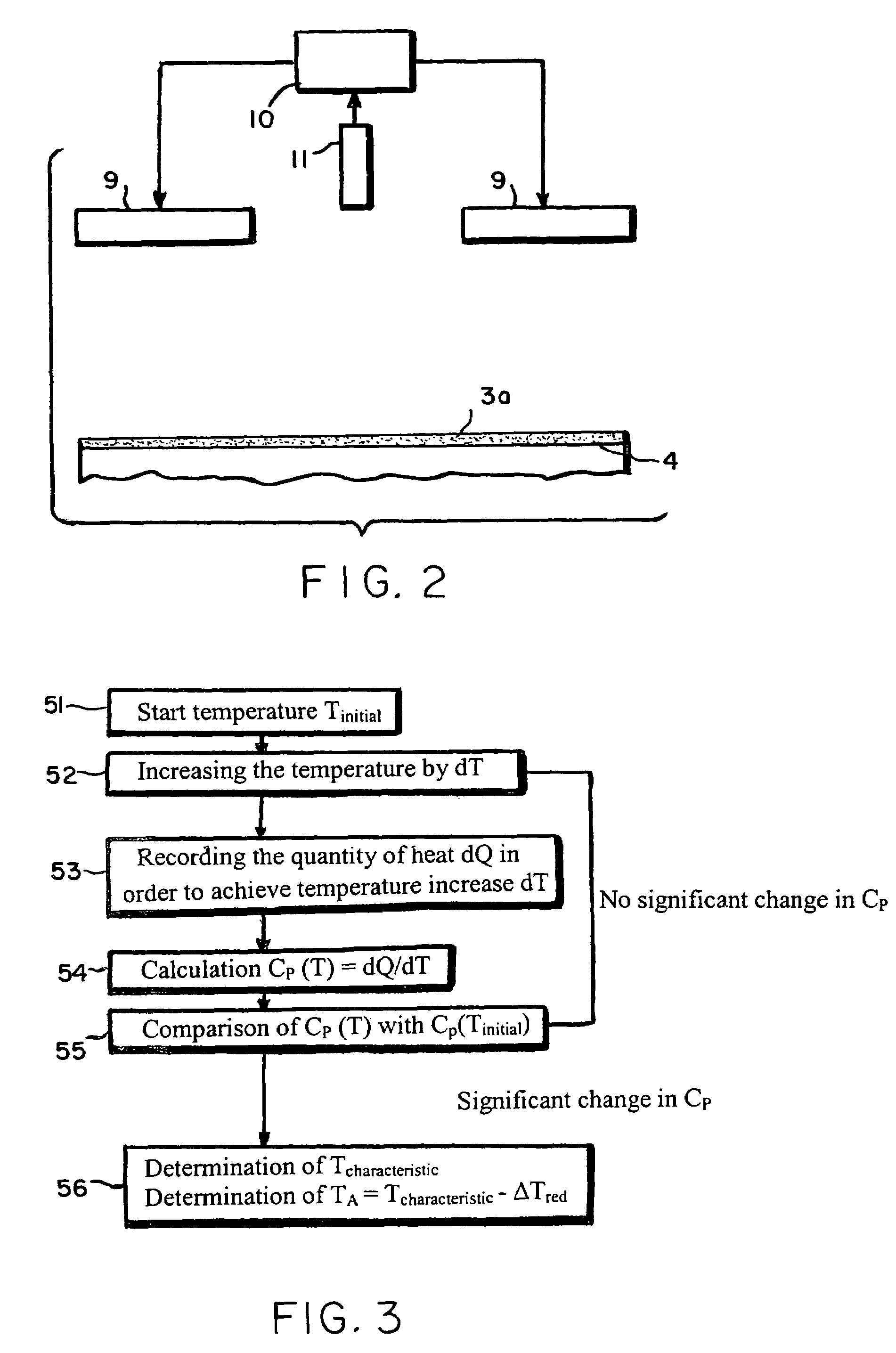

A process and a device for producing a three-dimensional object is provided, with which process or device the object is produced by layer-wise solidification of a pulverulent material by sintering of the material at the points corresponding to the cross-section of the object by means of the action of radiation energy. The process comprises the application of a layer of the pulverulent material onto a substrate or a previously sintered layer, pre-heating of the pulverulent material to a working temperature below the temperature at which the powder is sintered and sintering of the material at the points corresponding to the cross-section of the object in the layer, wherein a step of controlled heating of an applied powder layer and of determining the quantity of heat taken up by the powder per (FIG. 3) temperature interval for at least two temperature intervals is carried out.

Owner:EOS ELECTRO OPTICAL SYST

Method for manufacturing a three-dimensional object

InactiveUS8501075B2Convenient, fast and accurate detectionAdditive manufacturing apparatusAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterials scienceLayer wise

Method of manufacturing a three-dimensional object according to which the object is built layer-wise by solidification of a building material, wherein a test specimen is built which is excited to oscillate after being built and wherein natural frequencies of the oscillations are determined.

Owner:EOS ELECTRO OPTICAL SYST

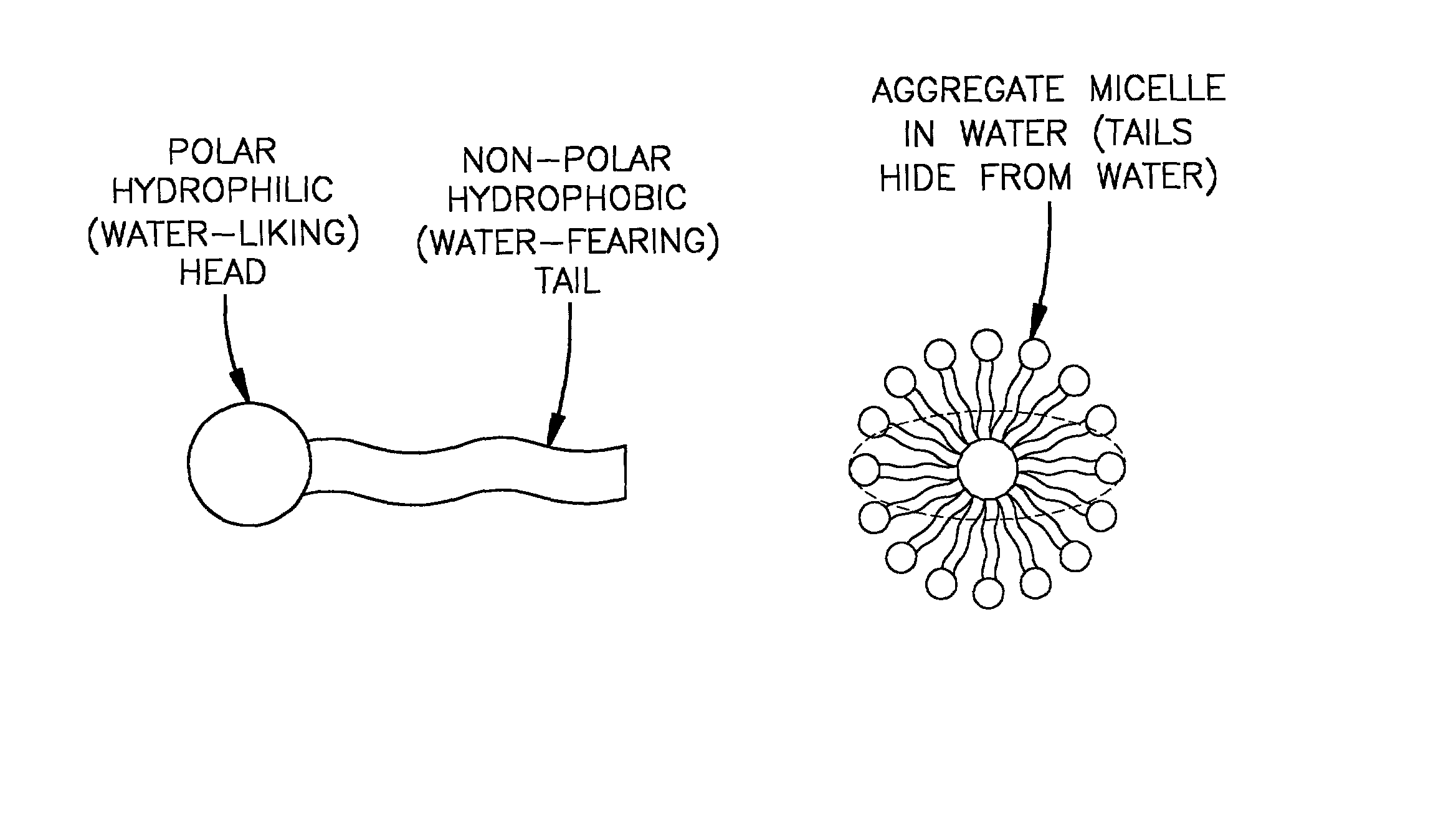

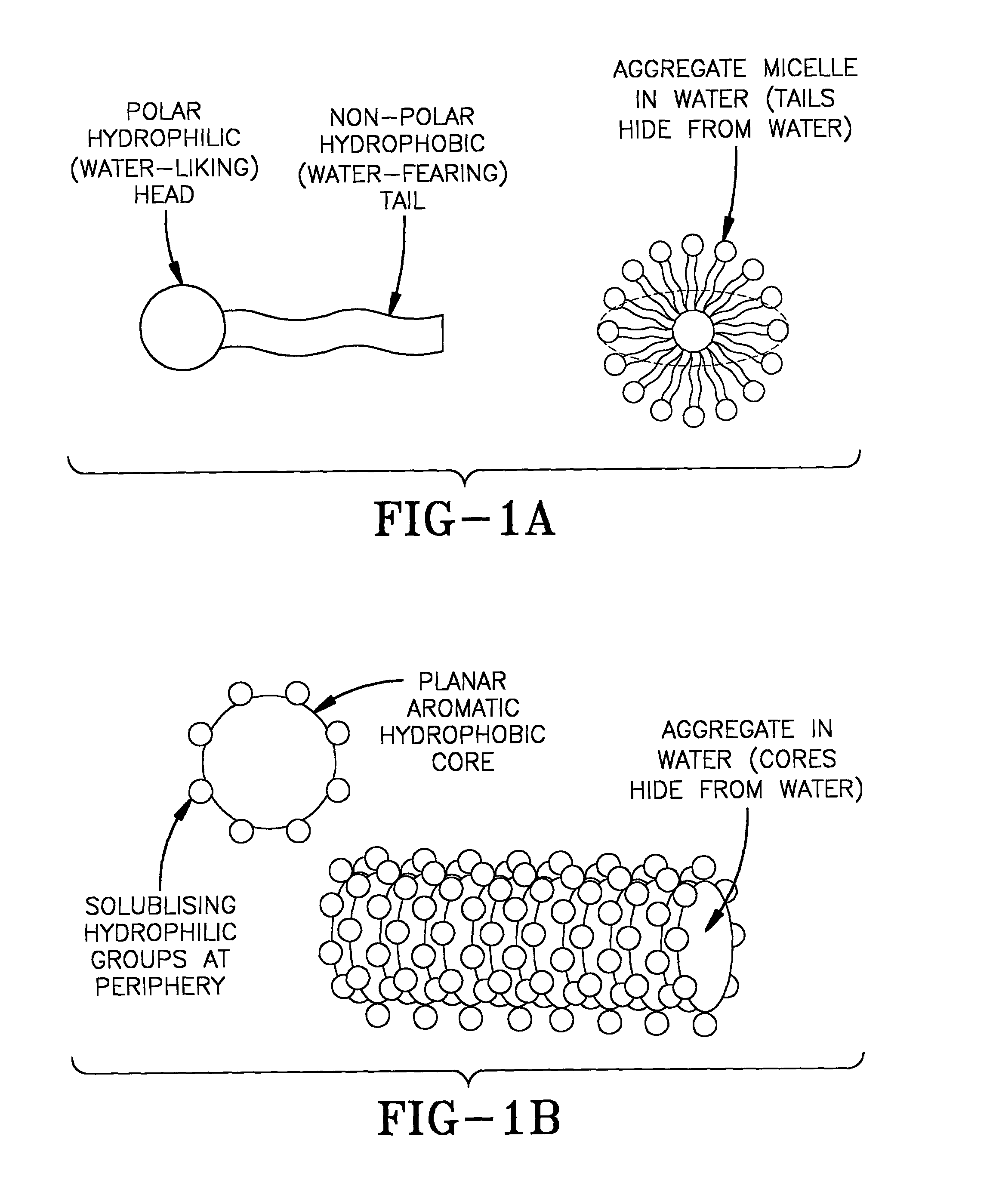

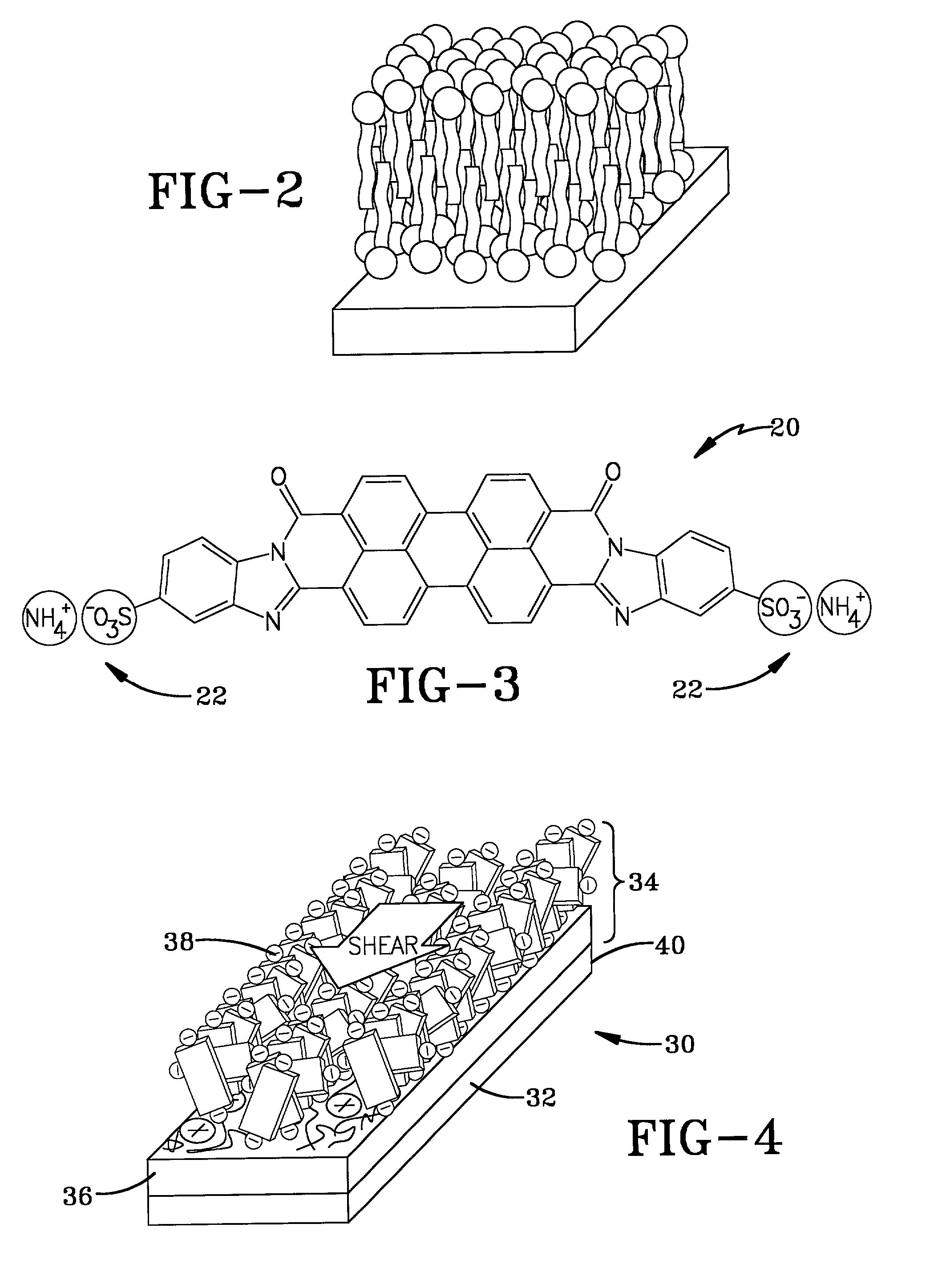

Alignment of lyotropic chromonic liquid crystals at surfaces as monolayers and multilayered stacks

InactiveUS20020168511A1Easy fashionLiquid crystal compositionsMaterial nanotechnologyIn planeLiquid crystalline

A broad class of lyotropic liquid crystals of a non-surfactant nature, the so-called lyotropic chromonic liquid crystals (LCLCs), are alignable with the techniques, in particular, LCLCs can be aligned at a surface as one monomolecular layer as a stack of monomolecular layers. The method for monolayer alignment is based on alternate layer-by-layer adsorption of polyions and dyes from aqueous solutions that have liquid crystalline structure. Using this method, one is able to stack alternate monolayers of dye and polyion while controlling the long-range in-plane orientation of the dye molecules within the plane of each layer. The feature of controlling the alignment of LCLCs enables one to create practical devices from them. For example, alignment of multilayered stacks allows one to use the resulting dried LCLC films in optical devices, for example, as internal polarizers, color filters, optical compensators, band-gap filters, and the like.

Owner:KENT STATE UNIV

Digitally active 3-D object creation system

ActiveUS20040141030A1Increased substrate speedIncrease speedLiquid surface applicatorsConfectioneryEngineeringMultiple layer

Owner:3D SYST INC

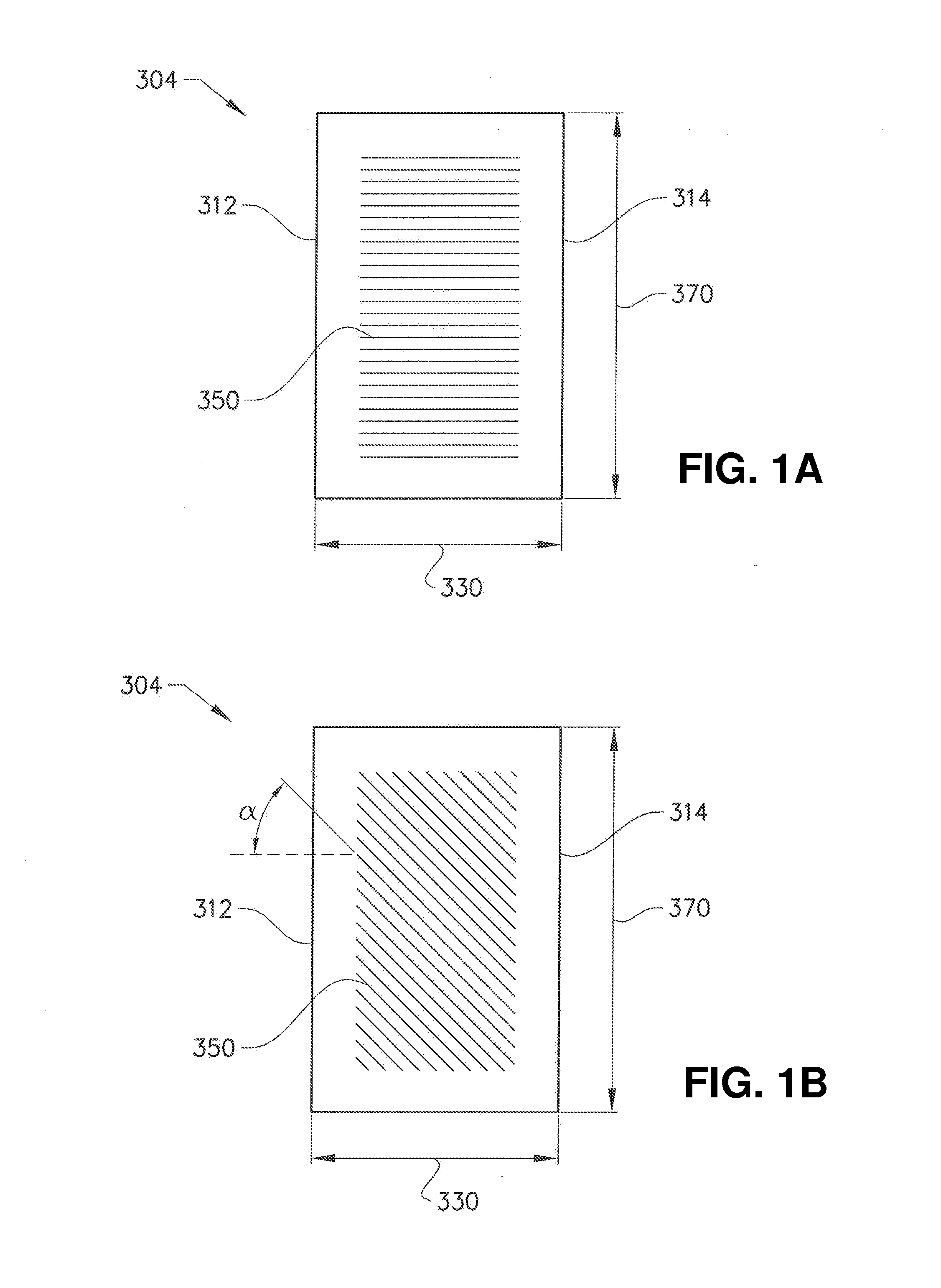

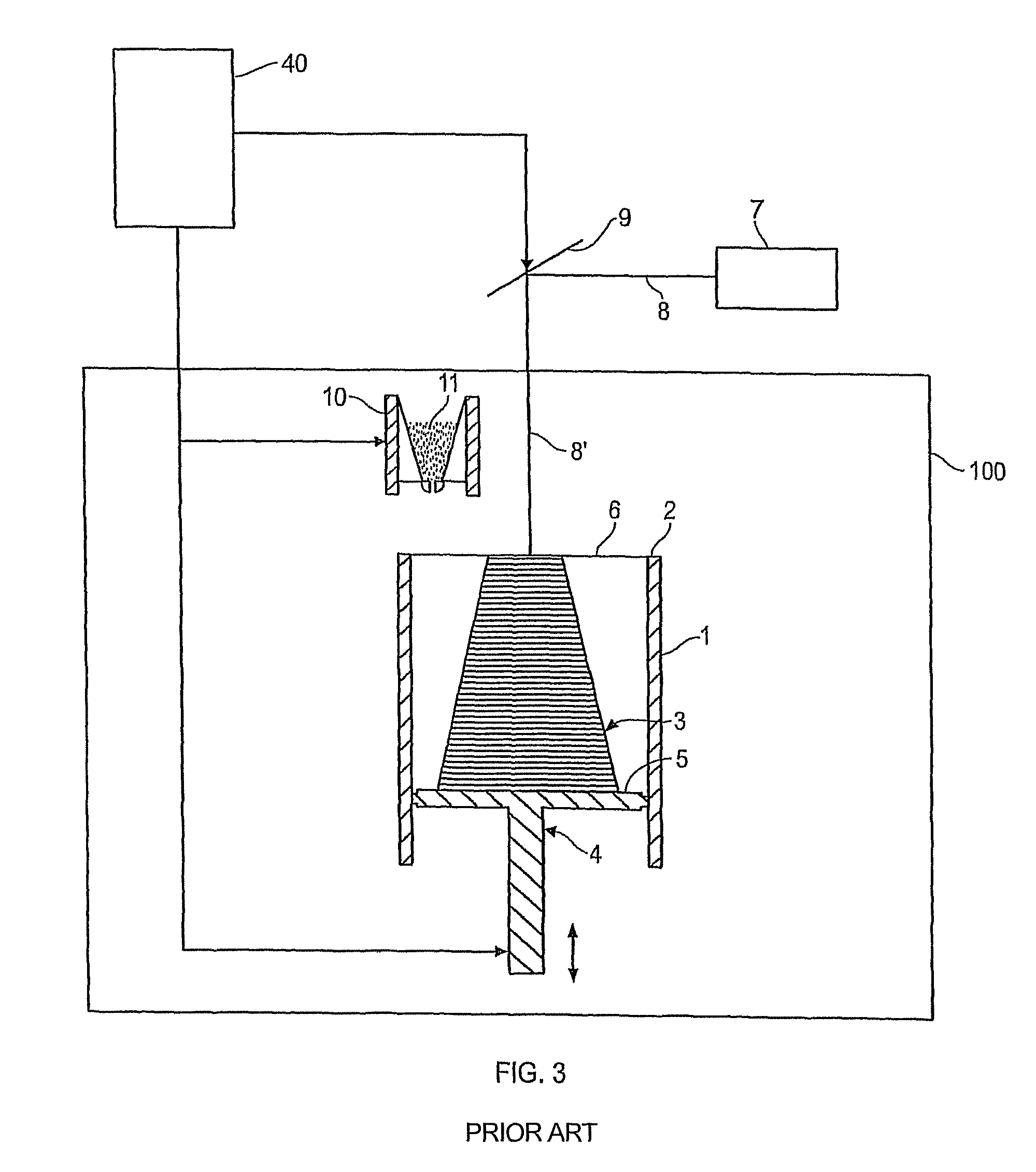

Method for a layer-wise manufacturing of a three-dimensional object

ActiveUS9011982B2Shorten the durationShorten the timeAdditive manufacturing apparatusPretreated surfacesParticle beamElectromagnetic radiation

A method for a layer-wise manufacturing of a three-dimensional object has a first step of providing a layer of a material in powder form or a liquid material on a support or a layer that has already been solidified at selected positions previously and a second step of directing a focussed photon or particle beam (8′) selectively at selected positions of the layer. In the second step, the photon or particle beam is selected such that it brings about a change of the absorption of the material when hitting the layer. After the termination of the second step, a third step is carried out, in which the layer is irradiated by means of electromagnetic radiation (18′) such that the material is homogenously solidified at those positions of the layer that correspond to the cross-section of the object to be formed.

Owner:EOS ELECTRO OPTICAL SYST

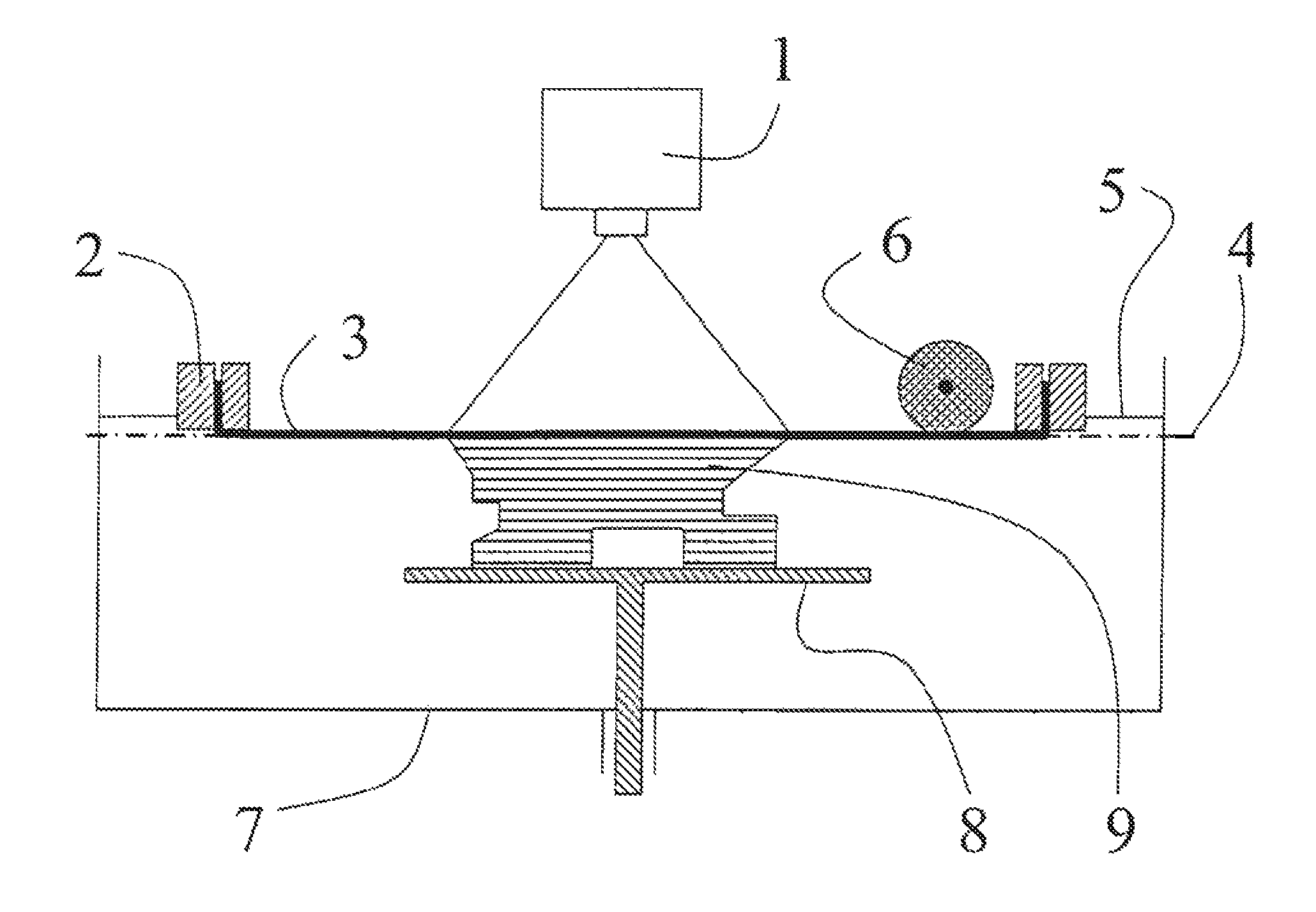

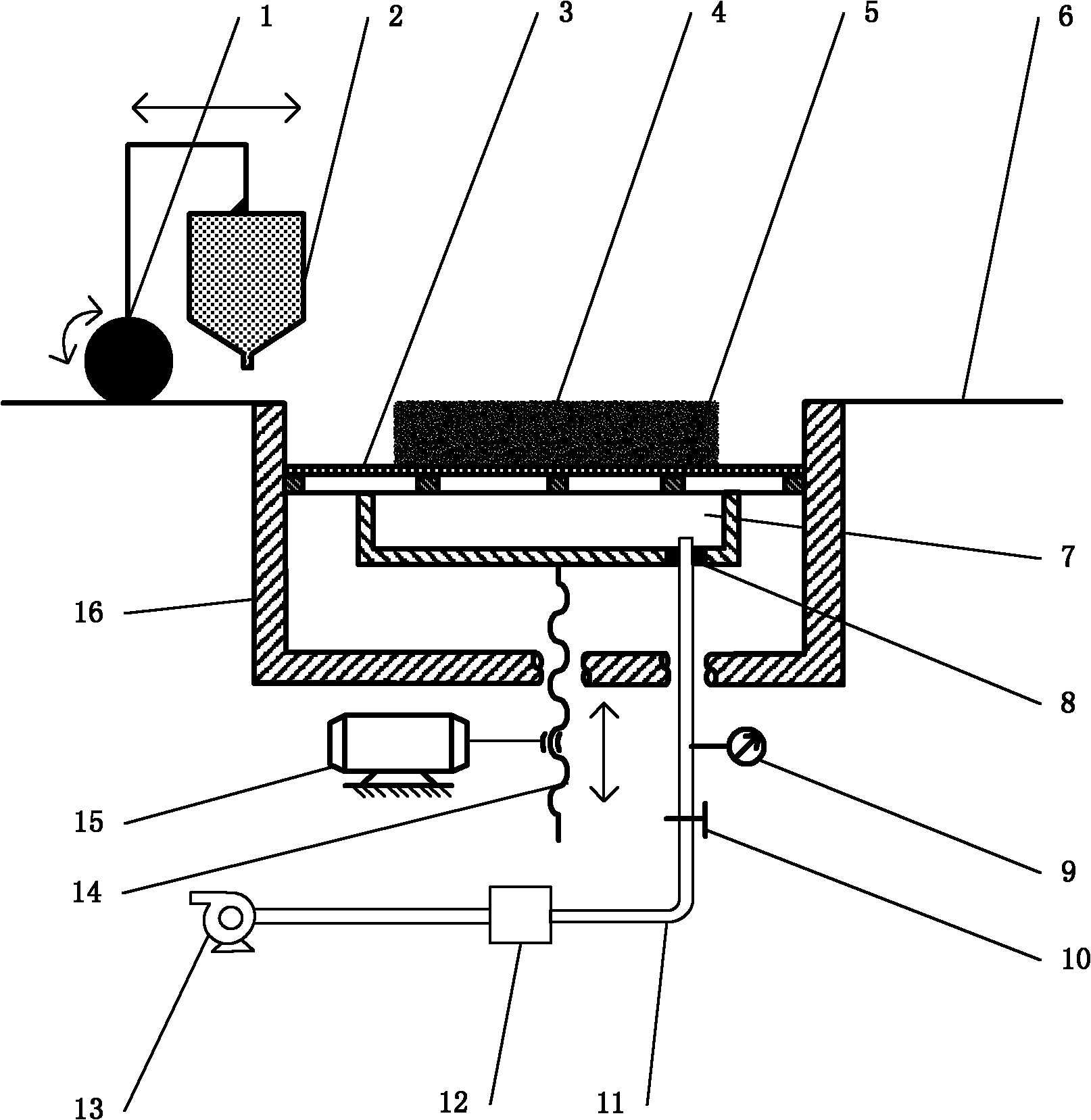

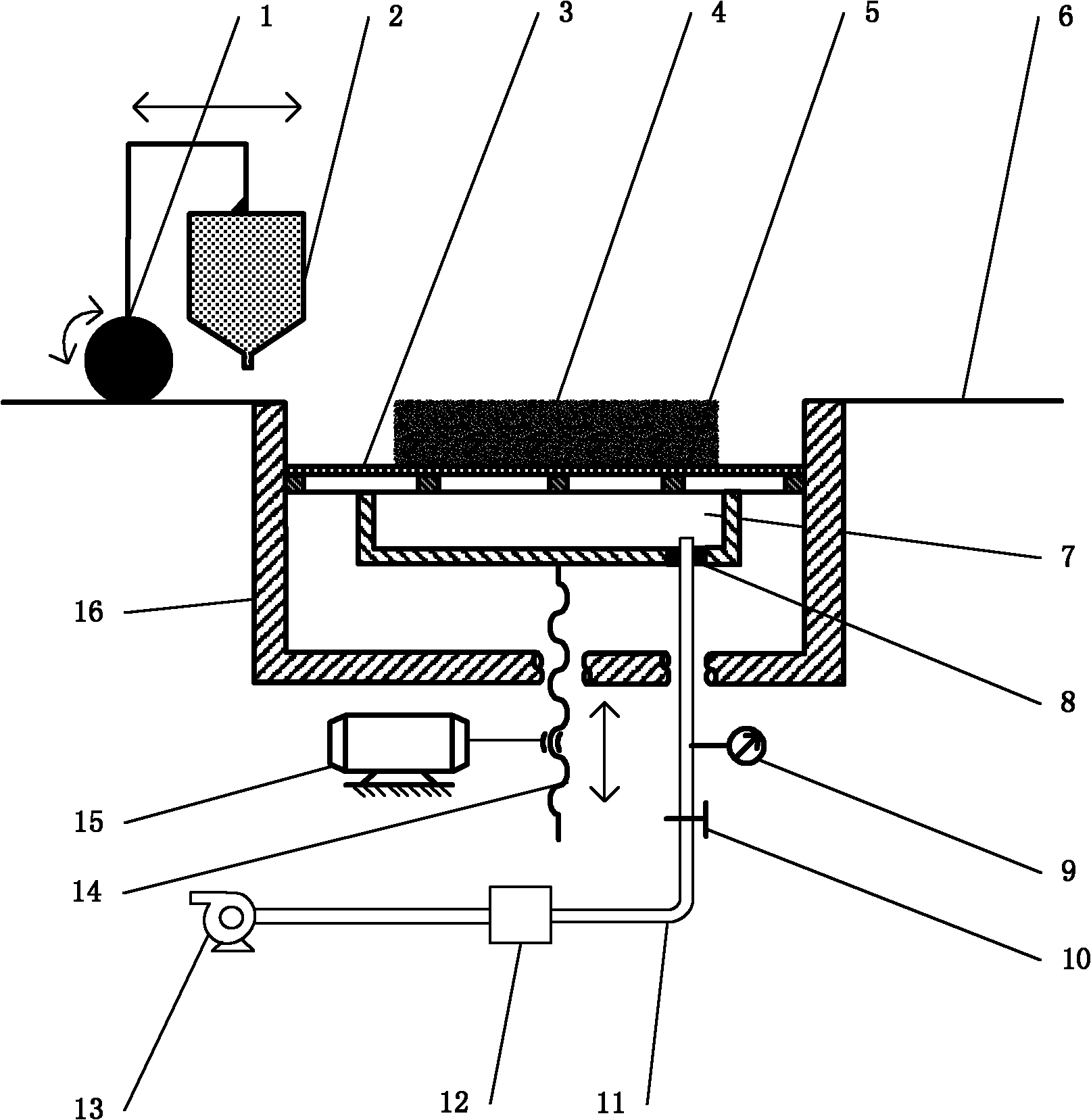

Negative pressure-based device and method for manufacturing porous textures by laser sintering and quick molding

InactiveCN102029389AFast molding speedGuaranteed porosityIncreasing energy efficiencySelective laser sinteringReciprocating motion

The invention relates to a negative pressure-based device and a negative pressure-based method for manufacturing porous textures by laser sintering and quick molding. The device comprises an X-Y workbench, wherein a pair of guide rails is arranged on the workbench, and the guide rails have a powder spreading roller and a power spreading groove which can move reciprocally along the guide rails; the X-Y workbench is provided with a molding tank, and a molding workbench capable of moving vertically is arranged in the molding tank; the molding workbench consists of a screen with holes distributed densely and a carriage, and a negative pressure chamber is formed on the lower surface of the molding workbench; the bottom end of the negative pressure chamber is connected with a screw and a servo motor in turn; an absorption tube is communicated with the negative pressure chamber through an opening; and the other end of the absorption tube is connected with a filter and a vacuum pump in turn. In the invention, based on a negative pressure absorption principle, powder which is not sintered on each layer is removed and recycled through an absorption tube; and through layer-by-layer absorption, the powder which is not sintered and solidified is cleaned completely, while the sintered and solidified powder is continuously stacked and overlaid to form parts, so that the manufacturing of the porous texture with an aperture of less than 1mm is realized through selective laser sintering and quick molding.

Owner:NANJING HONNY 3 DIMENSIONAL TECH

Assembly of free-standing films using a layer-by-layer process

InactiveUS20010046564A1Easy to controlRetain biological activityMaterial nanotechnologyMouldsCross-linkEngineering

A method for the layer-by-layer assembly of a free standing thin film includes the steps of preparing a support with a suitable substrate; forming a thin film having a plurality of layers onto the substrate utilizing a layer-by-layer assembly process; removing the substrate and thin film from the support; and separating the substrate from the thin film. Various compounds improving the strength, flexibility, tension and other mechanical properties may be included in the assembly to improve the structural quality of the film. Similar effect may also be achieved by cross-linking the applied layers.

Owner:BOARD OF REGENTS FOR OKLAHOMA STATE UNIVERSITY +1

Multi-field charged particle cancer therapy method and apparatus

ActiveUS8436327B2Stability-of-path spectrometersMaterial analysis by optical meansBragg peakBeam energy

The invention relates to treatment of solid cancers. More particularly, the invention relates to a combined rotation / raster method, referred to as multi-field charged particle cancer therapy. The system uses a fixed orientation proton source relative to a rotating patient to yield tumor irradiation from multiple directions. The system combines layer-wise tumor irradiation from many directions with controlled energy proton irradiation to deliver peak proton beam energy within a selected tumor volume or irradiated slice. Optionally, the selected tumor volume for irradiation from a given angle is a distal portion of the tumor. In this manner ingress Bragg peak energy is circumferentially spread about the tumor minimizing damage to healthy tissue and peak proton energy is efficiently, accurately, and precisely delivered to the tumor.

Owner:BALAKIN ANDREY VLADIMIROVICH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com