Patents

Literature

798 results about "Polyaryletherketone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

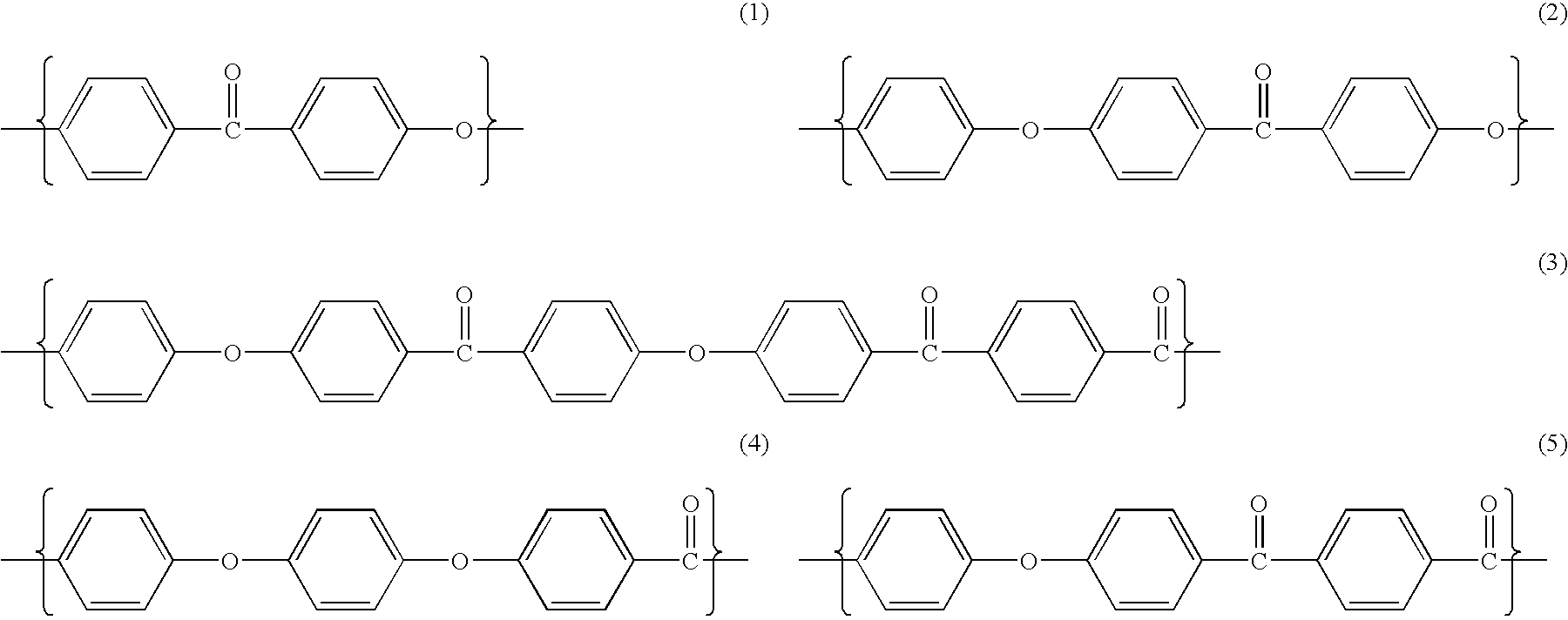

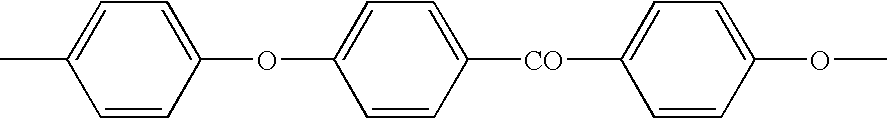

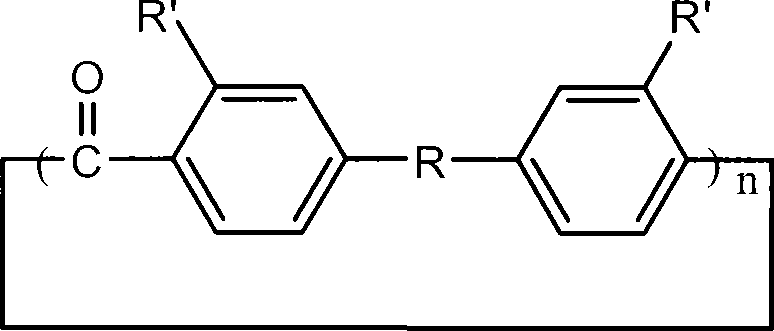

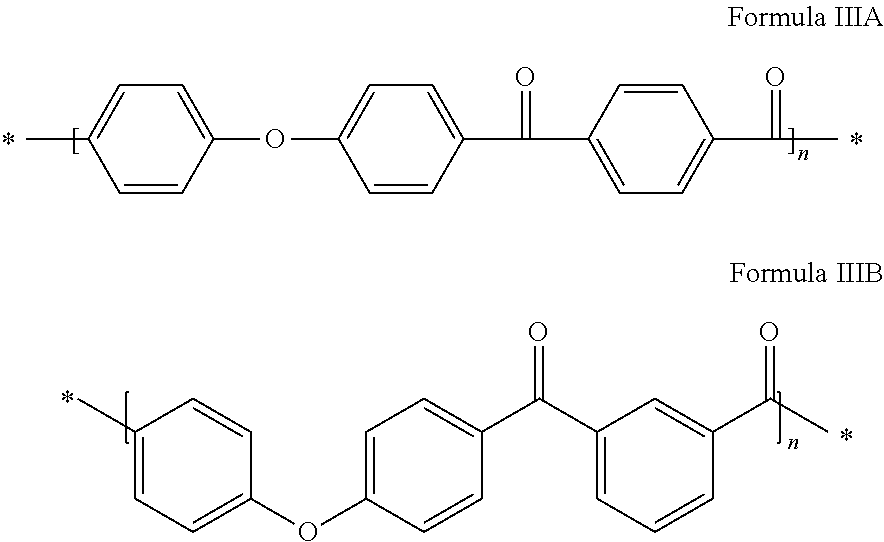

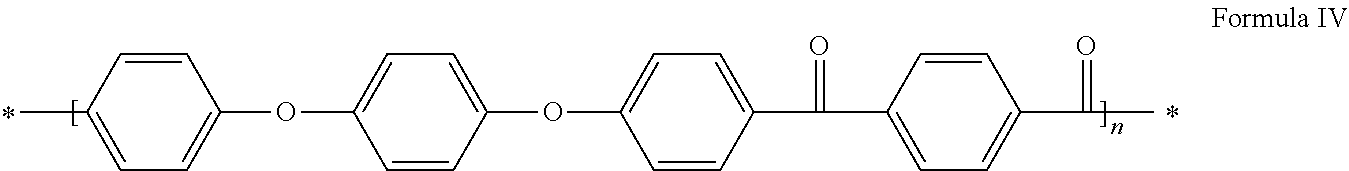

Polyaryletherketone (PAEK) is a family of semi-crystalline thermoplastics with high-temperature stability and high mechanical strength whose molecular backbone contains alternately ketone (R-CO-R) and ether groups (R-O-R). The linking group R between the functional groups consists of a 1,4-substituted aryl group.

Surgical implant and manufacturing method

InactiveUS20070185488A1High elongationBone implantJoint implantsEthylene HomopolymersBiomedical engineering

A surgical implant and a method for manufacturing the same. The surgical implant has a body comprising polyaryletherketone (PAEK). Said polyaryletherketone is a homopolymer and a first section of the body comprises a polyaryletherketone that has a crystallization peak in its DSC-curve.

Owner:INION

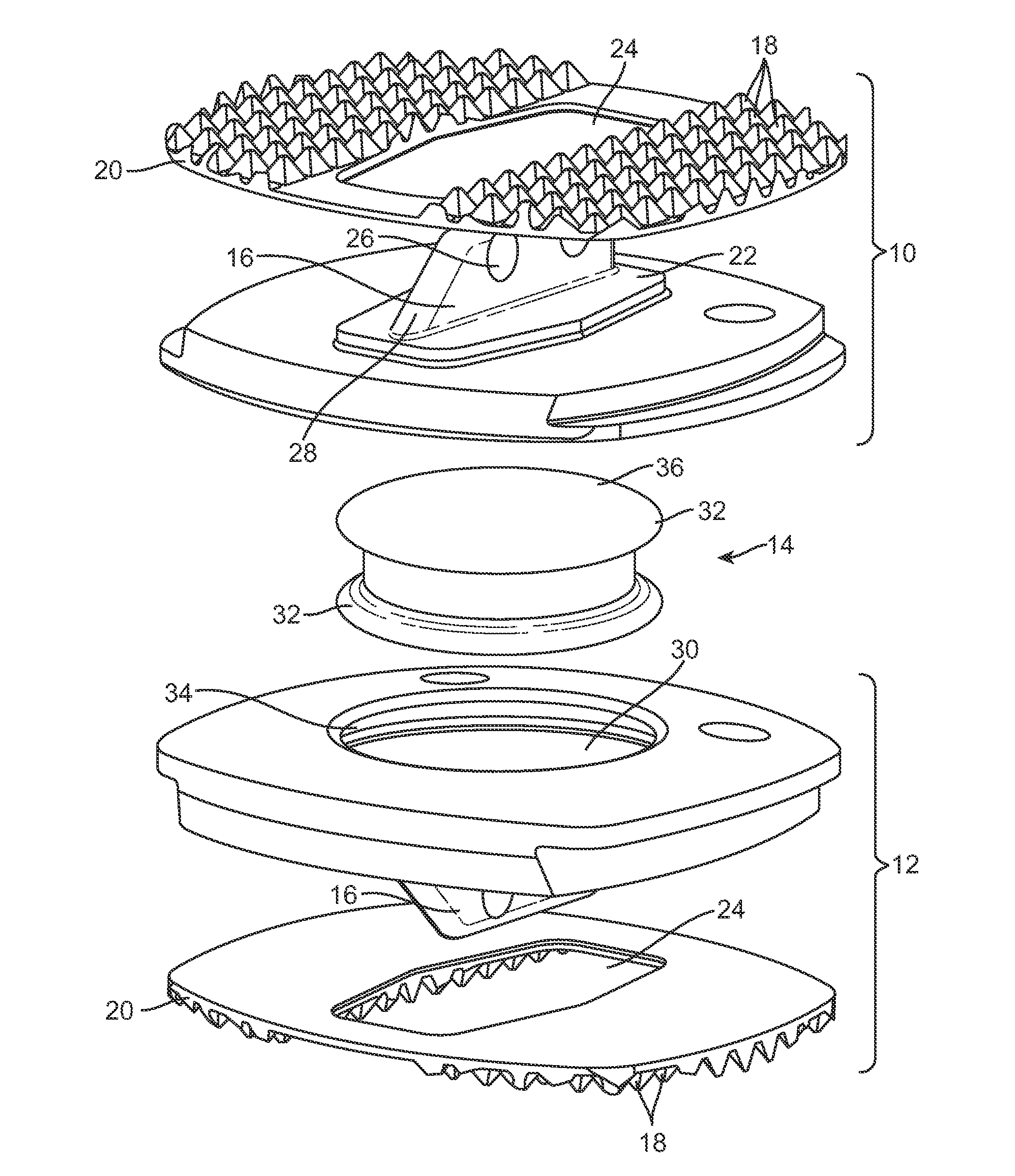

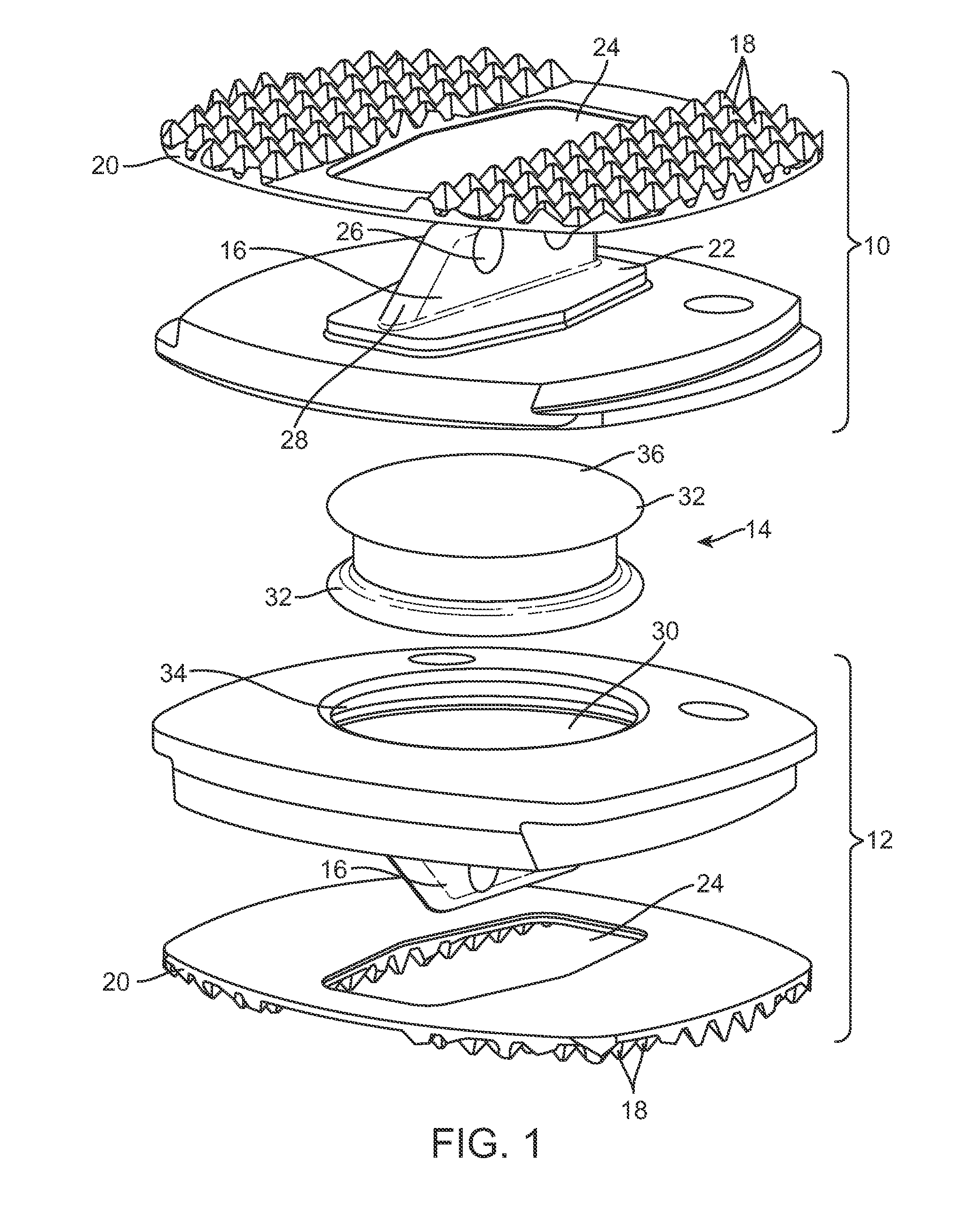

Polyaryletherketone artificial intervertebral disc

An intervertebral prosthesis for insertion between adjacent vertebrae, in one embodiment, includes upper and lower prosthesis plates and a movable core. The prosthesis plates and optionally the core are formed of polyaryletherketone (PAEK) for improved imaging properties. A metallic insert is provided on each of the PAEK prosthesis plates providing a bone ongrowth surface.

Owner:SIMPLIFY MEDICAL PTY LTD

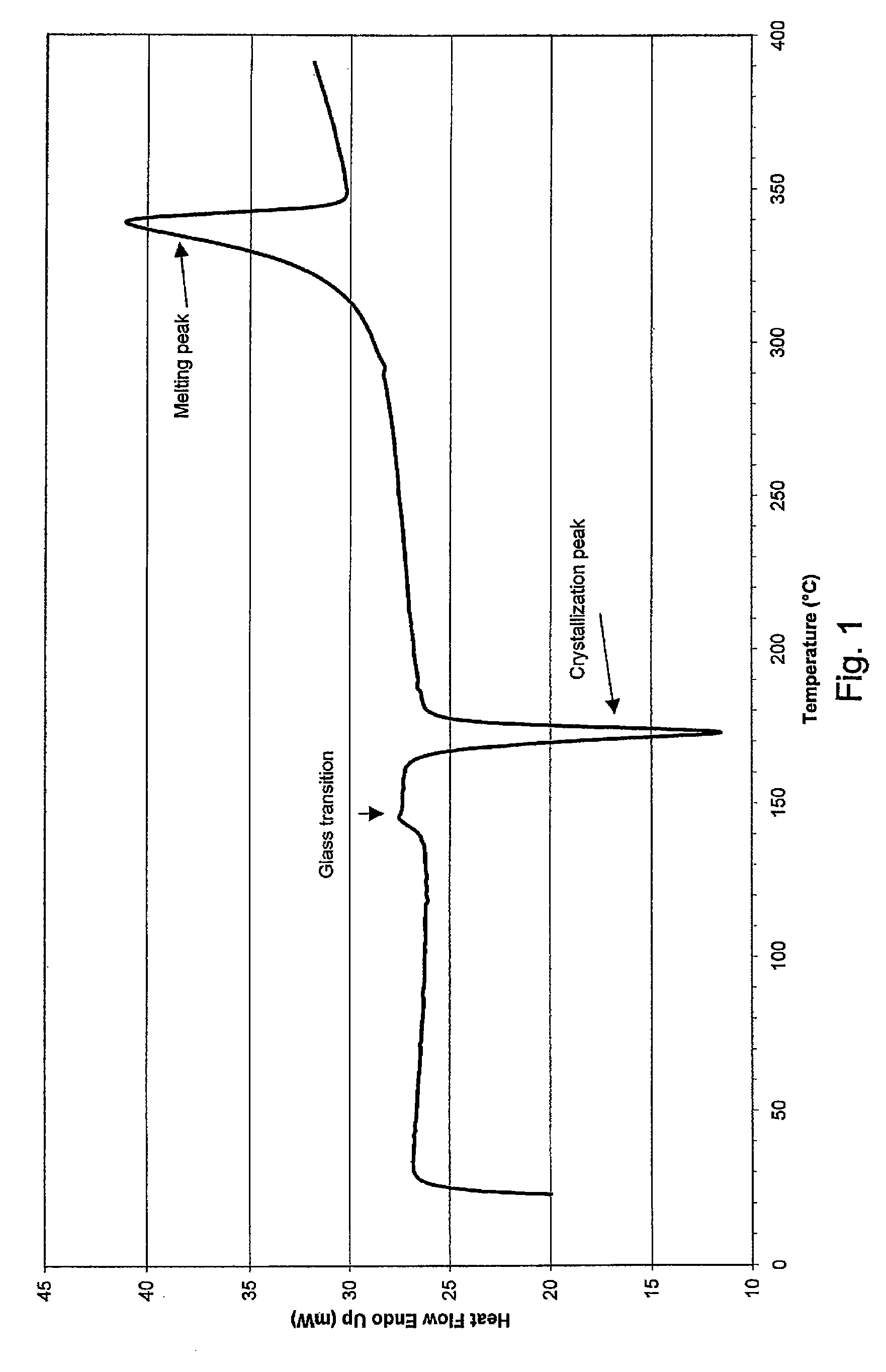

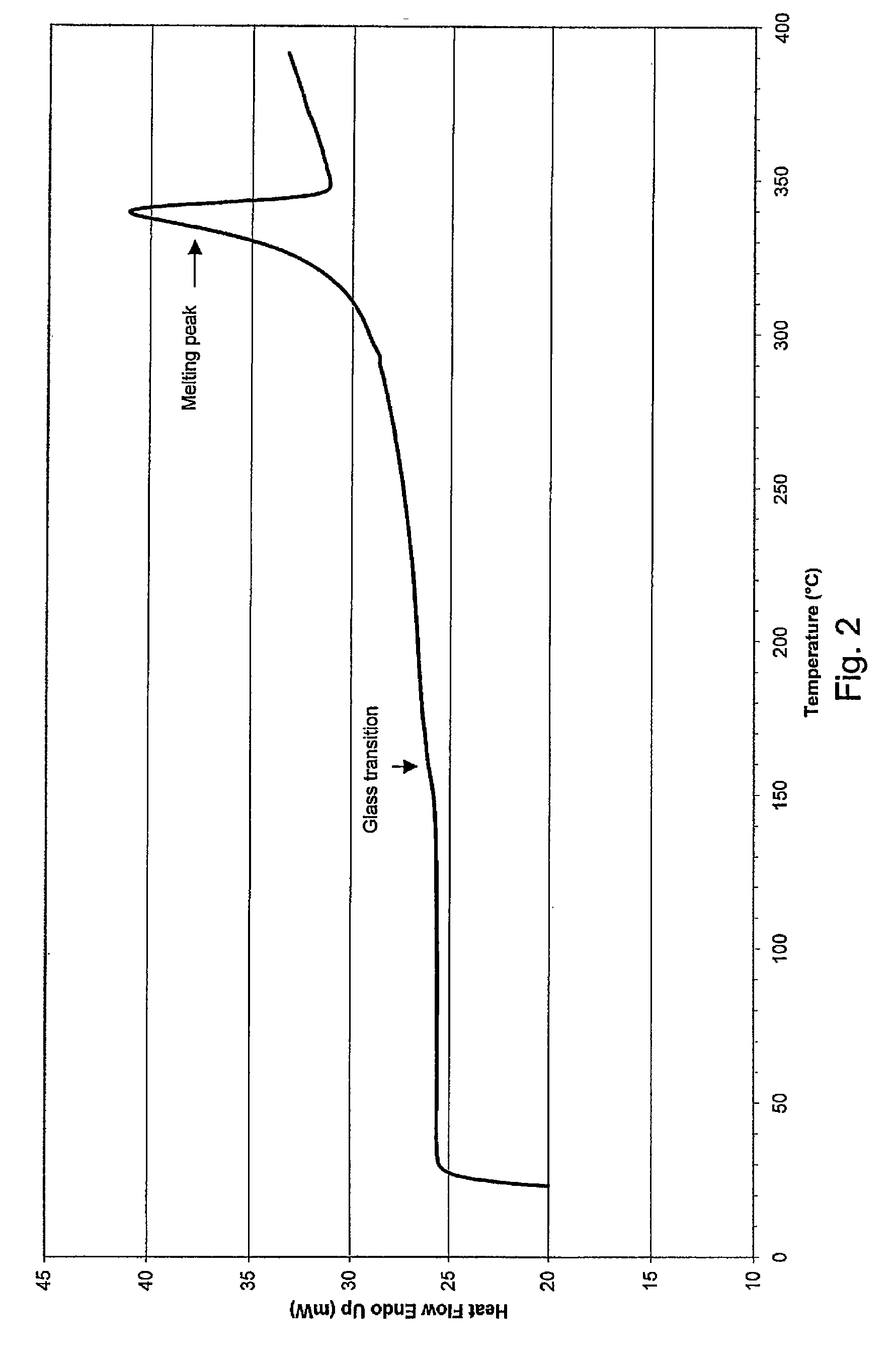

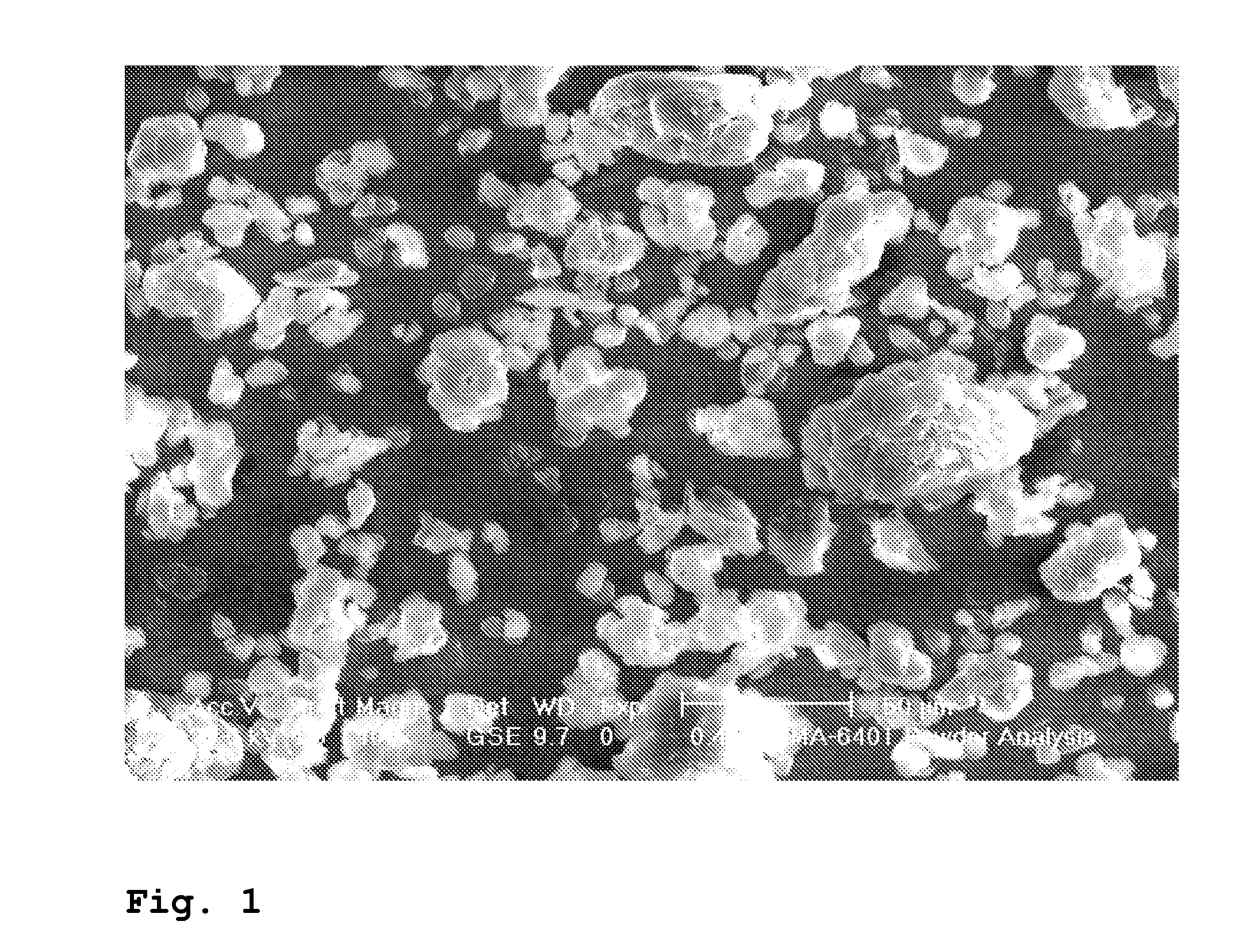

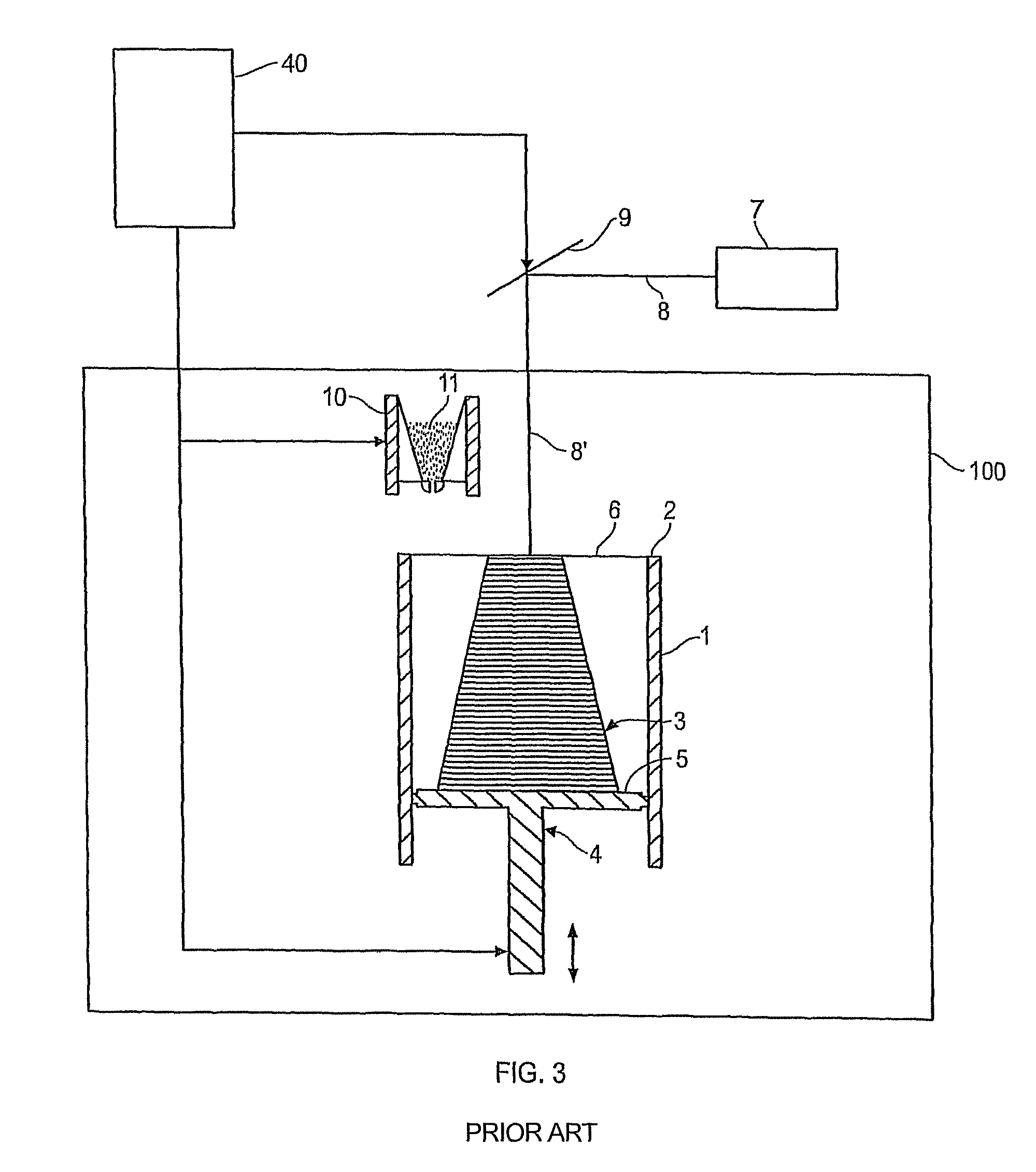

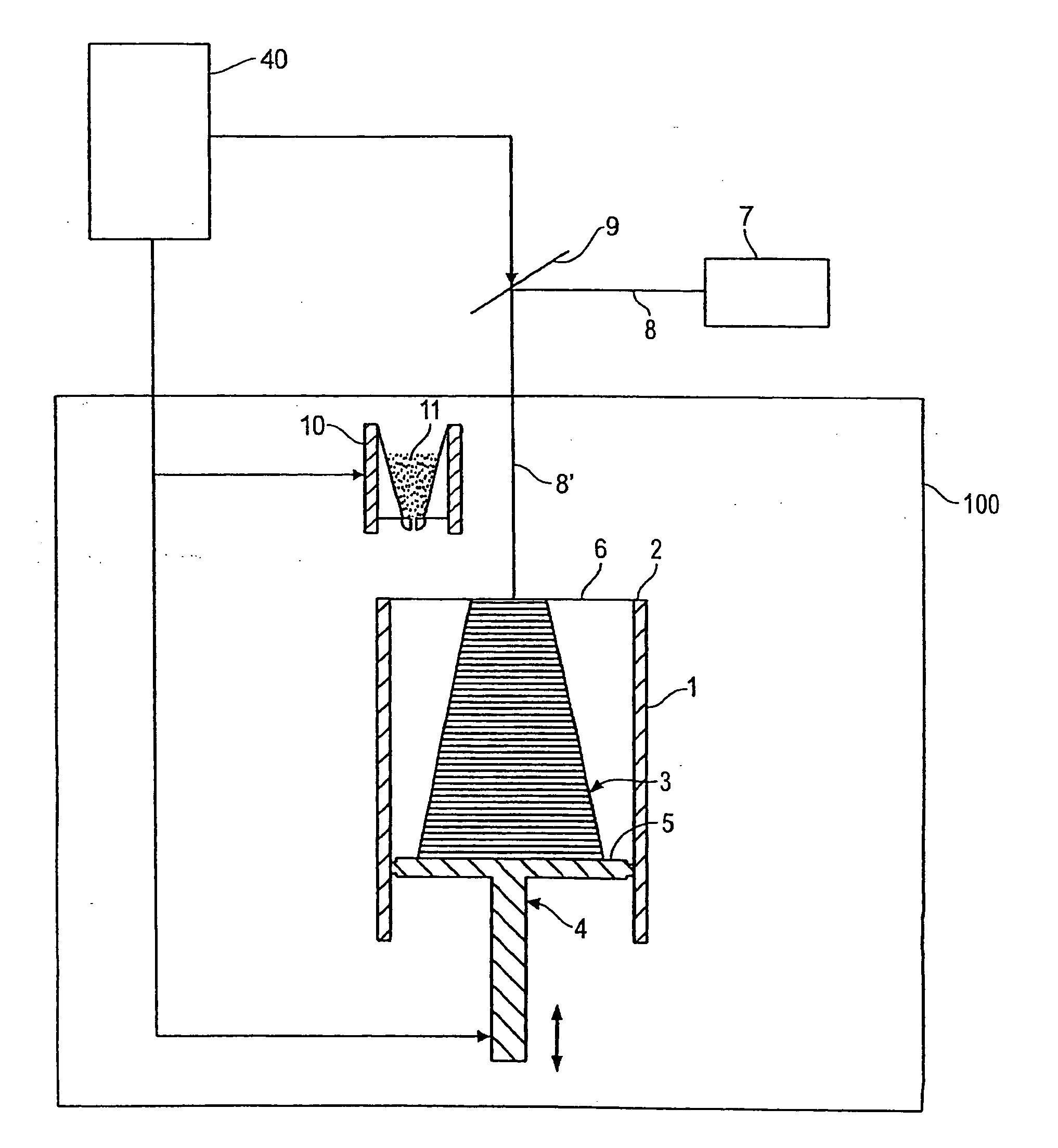

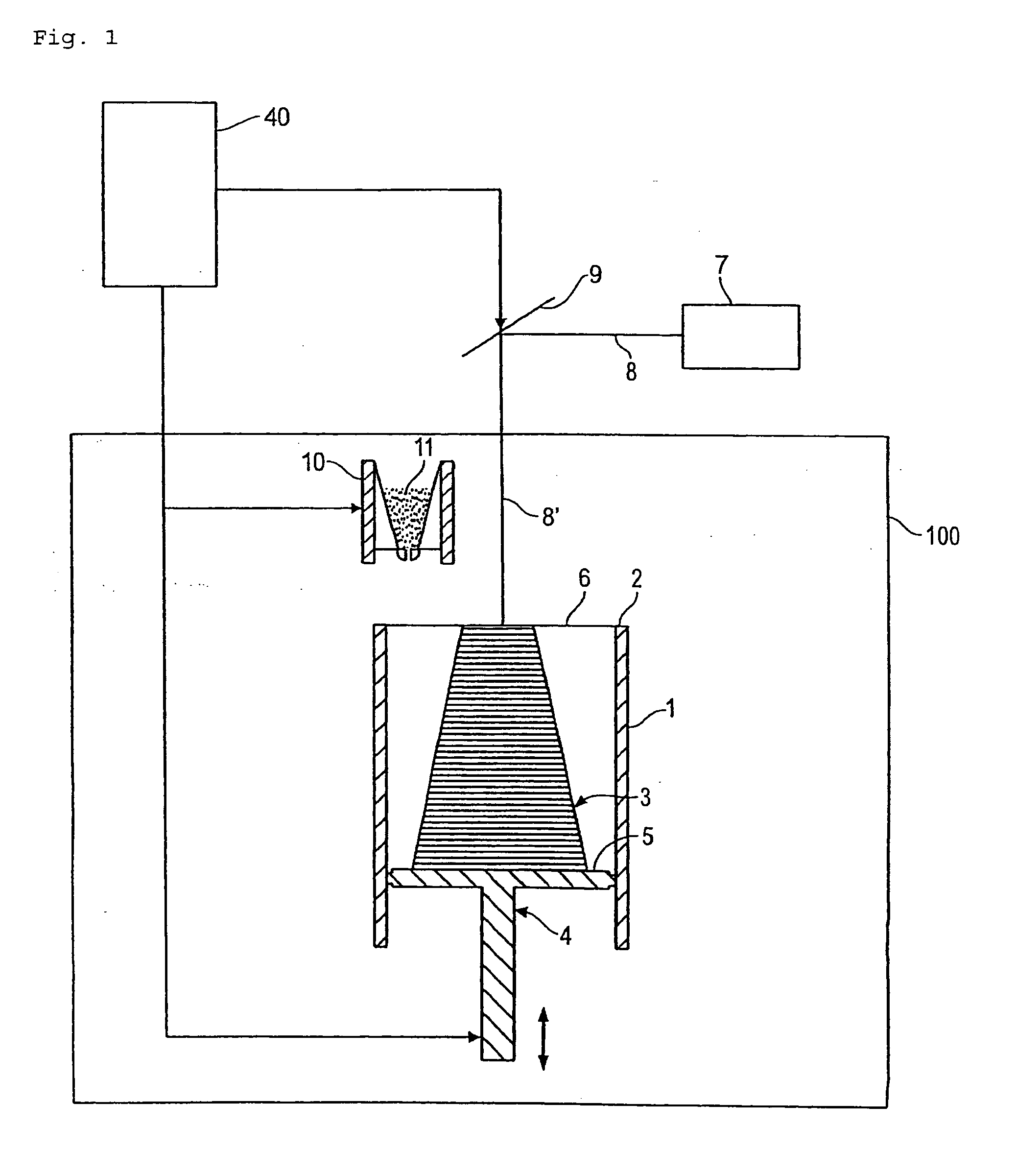

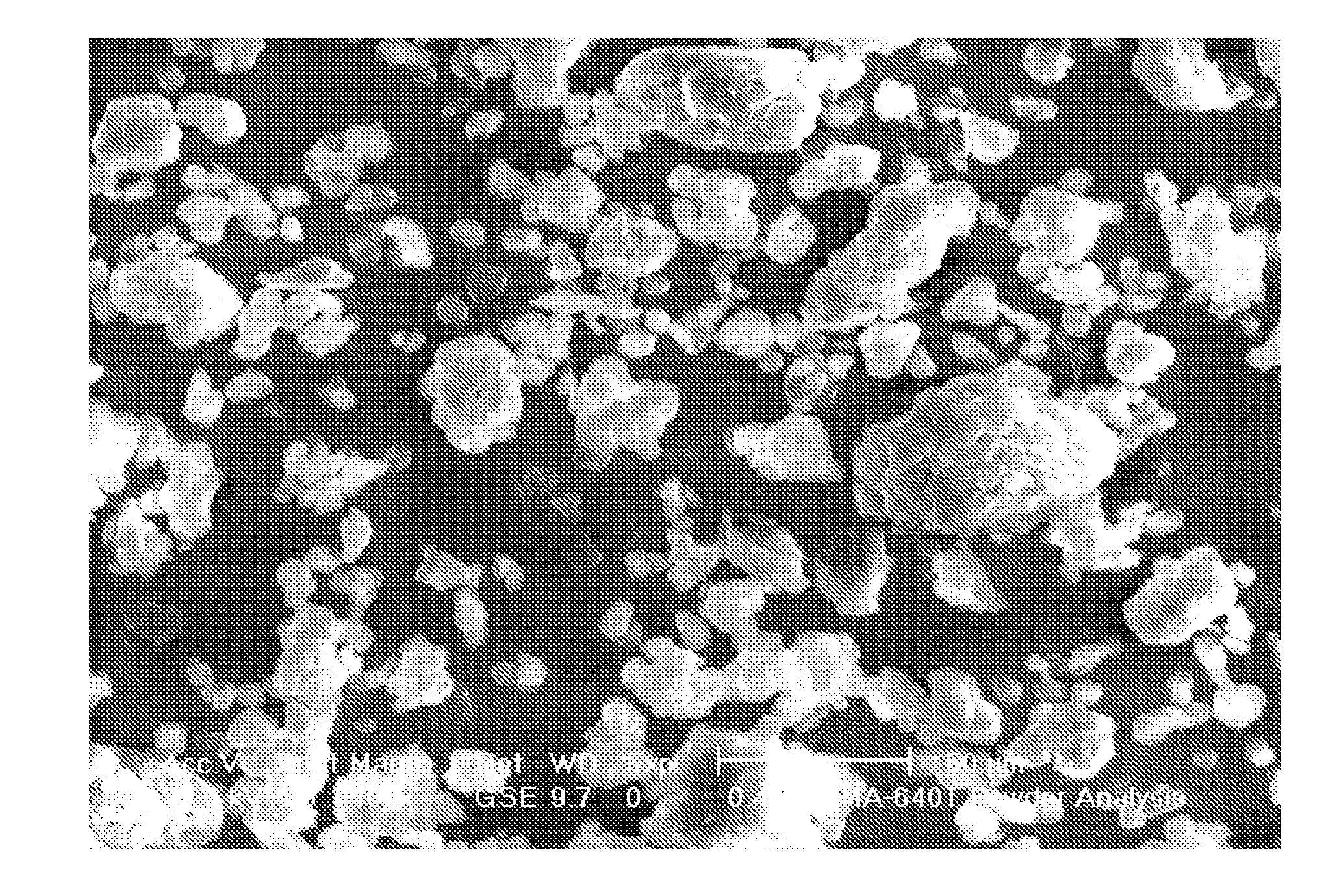

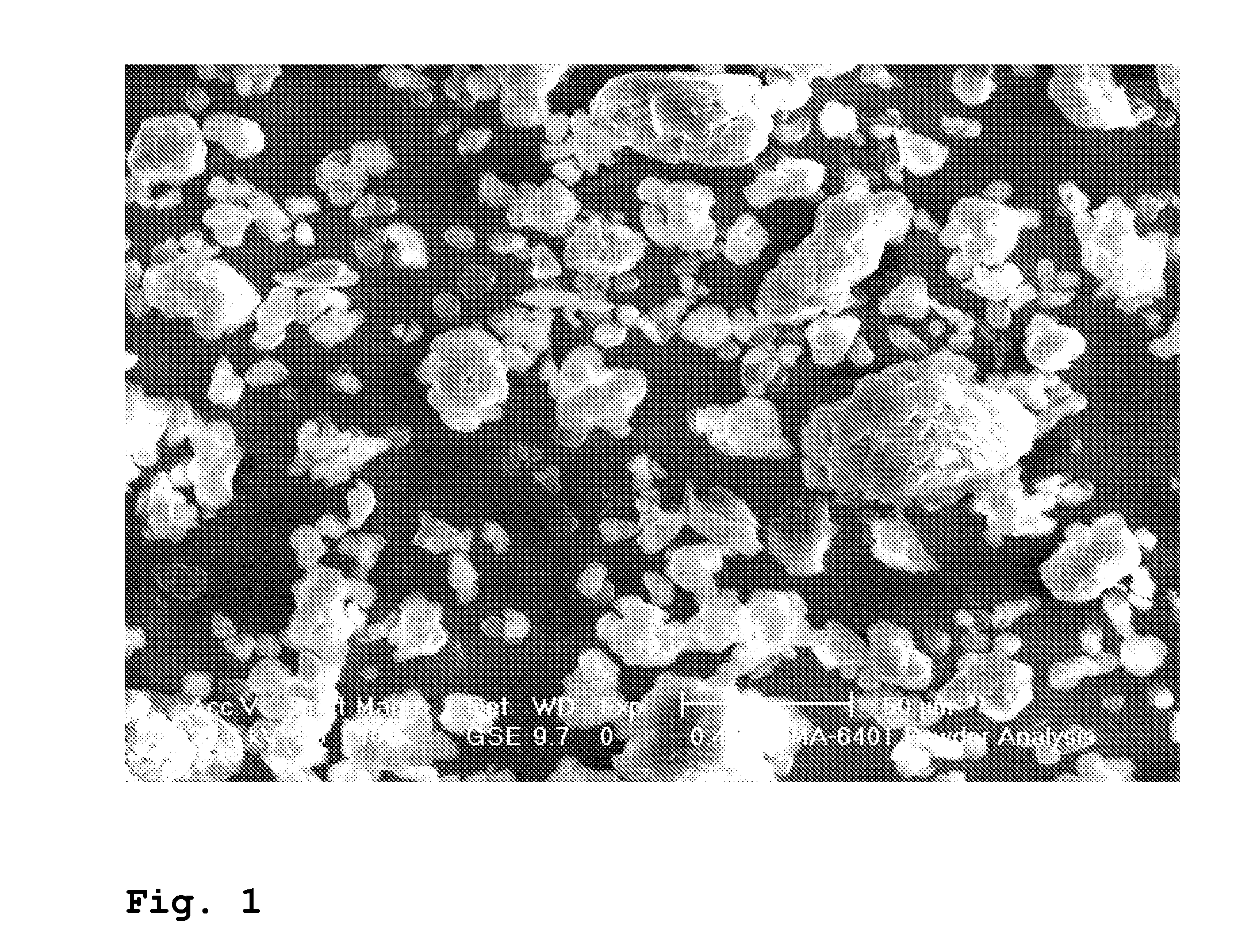

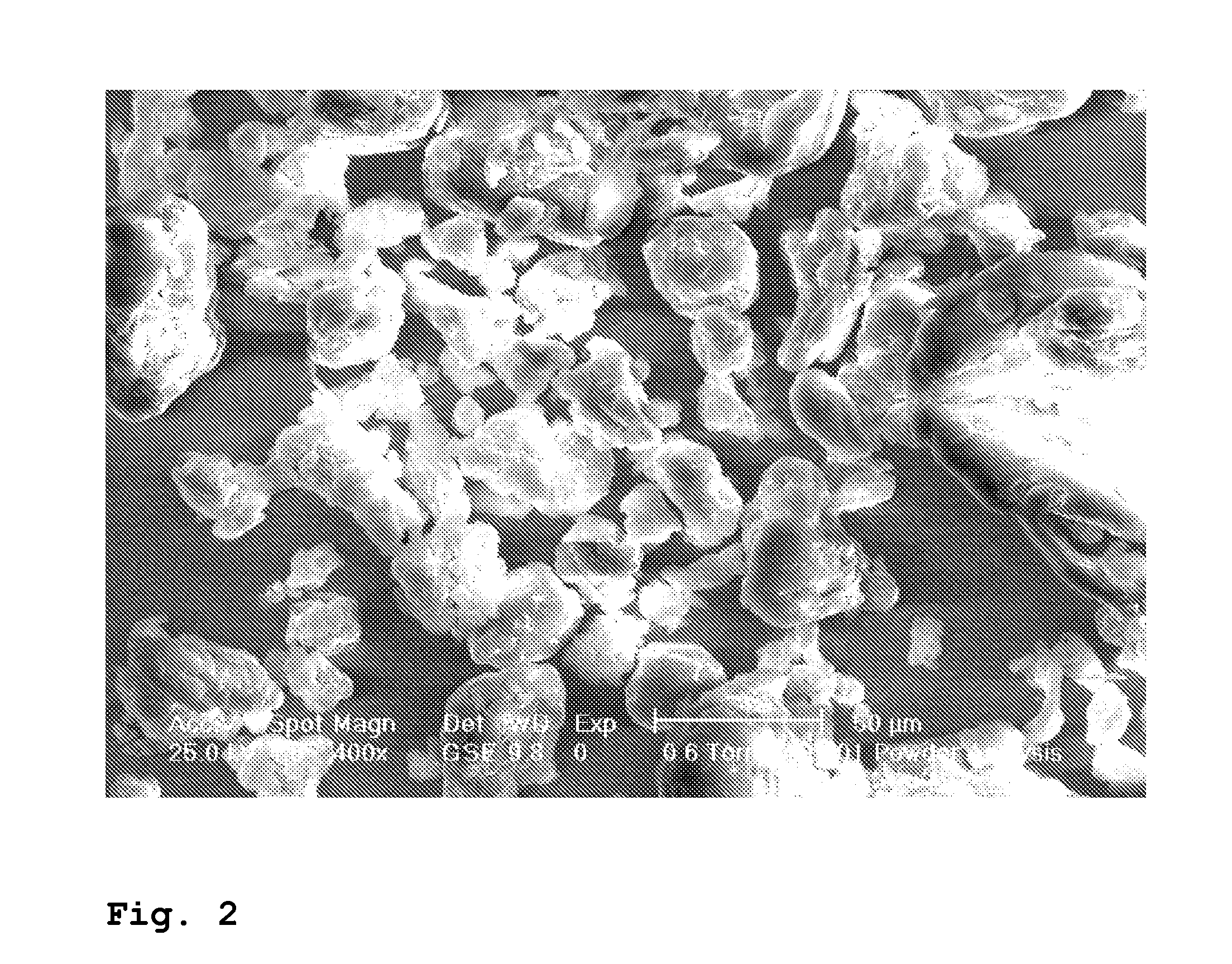

PAEK powder, in particular for the use in a method for a layer-wise manufacturing of a three-dimensional object, as well as method for producing it

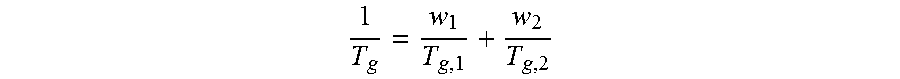

ActiveUS7847057B2Additive manufacturing apparatusSynthetic resin layered productsMetallurgyGlass transition

By a temper treatment a polyaryletherketone powder is processed such that it is particularly suited for the use in a method for a layer-wise manufacturing of a three-dimensional object. To this effect the powder is tempered at a temperature that is at least 20° C. above the glass transition temperature for at least 30 minutes before it is used as building material.

Owner:EOS ELECTRO OPTICAL SYST

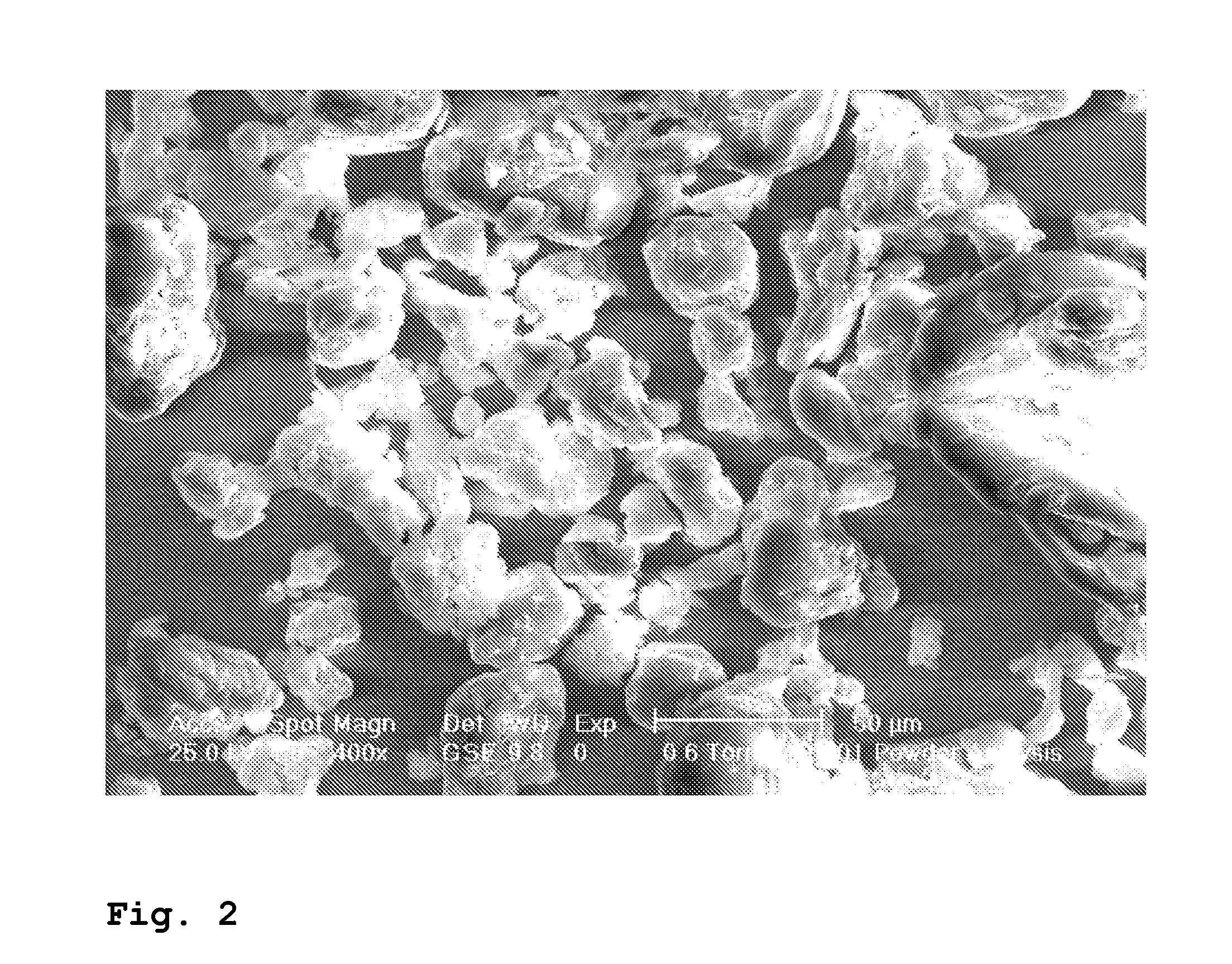

Selective sintering of structurally modified polymers

ActiveUS20090295042A1Improve mechanical propertiesSpeed up the processAdditive manufacturing apparatusLiquid surface applicatorsSelective laser sinteringPolymer science

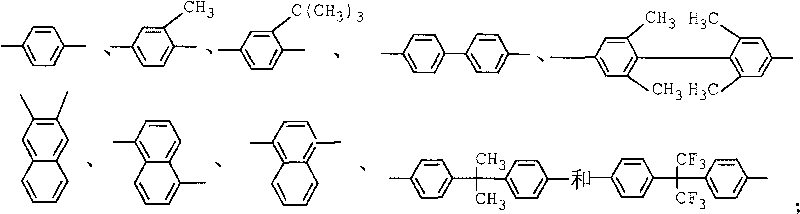

A three-dimensional object is manufactured by selective sintering by means of electromagnetic radiation, wherein the powder comprises a polymer or copolymer having at least one of the following structural characteristics:(i) at least one branching group in the backbone chain of the polymer or copolymer, provided that in case of the use of polyaryletherketones (PAEK) the branching group is an aromatic structural unit in the backbone chain of the polymer or copolymer;(ii) modification of at least one end group of the backbone chain of the polymer or copolymer;(iii) at least one bulky group within the backbone chain of the polymer of copolymer, provided that in case of the use of polyaryletherketones (PAEK) the bulky group is not selected from the group consisting of phenylene, biphenylene, naphthalene and CH2— or isopropylidene-linked aromatics;(iv) at least one aromatic group non-linearly linking the backbone chain.

Owner:EOS ELECTRO OPTICAL SYST

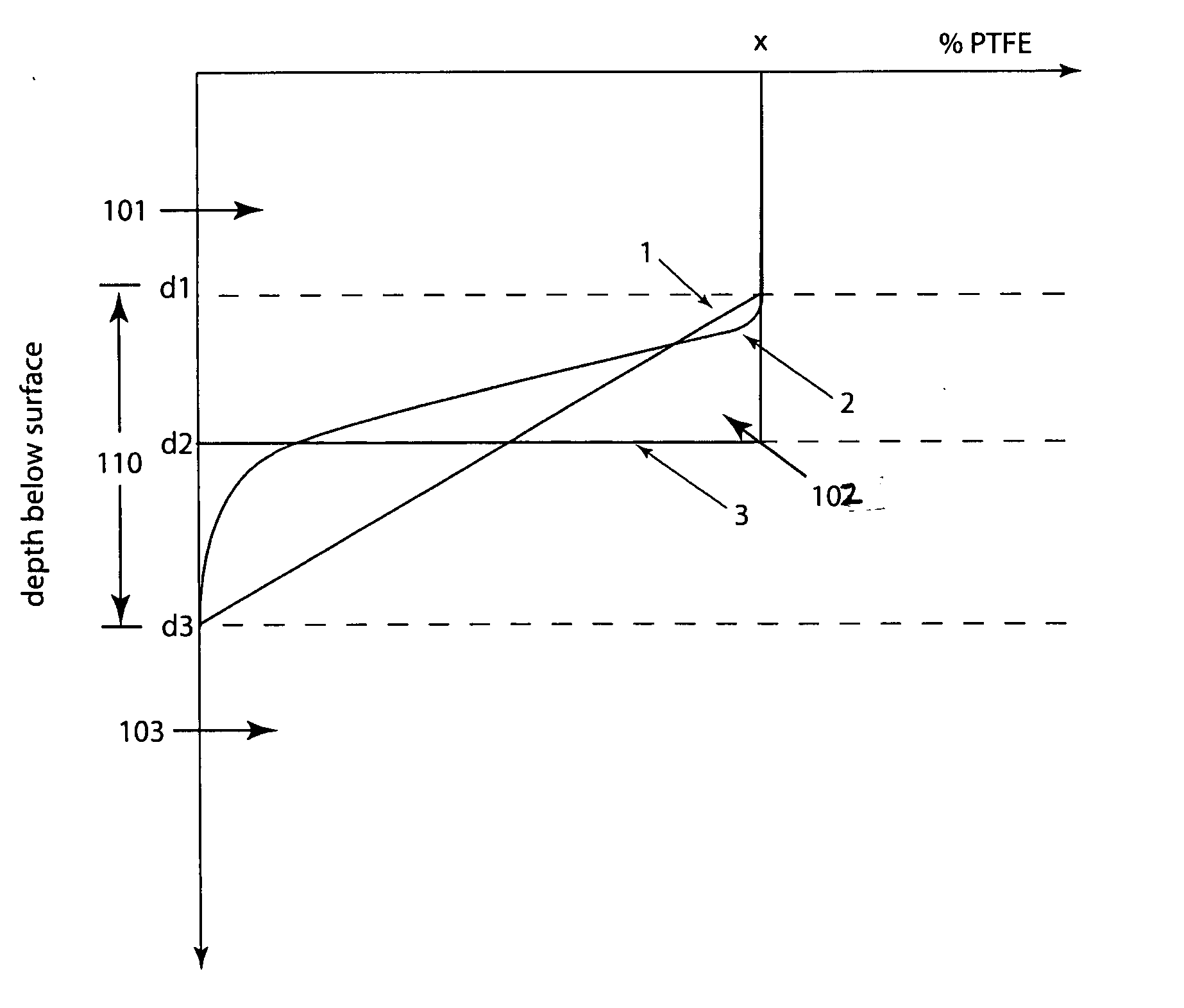

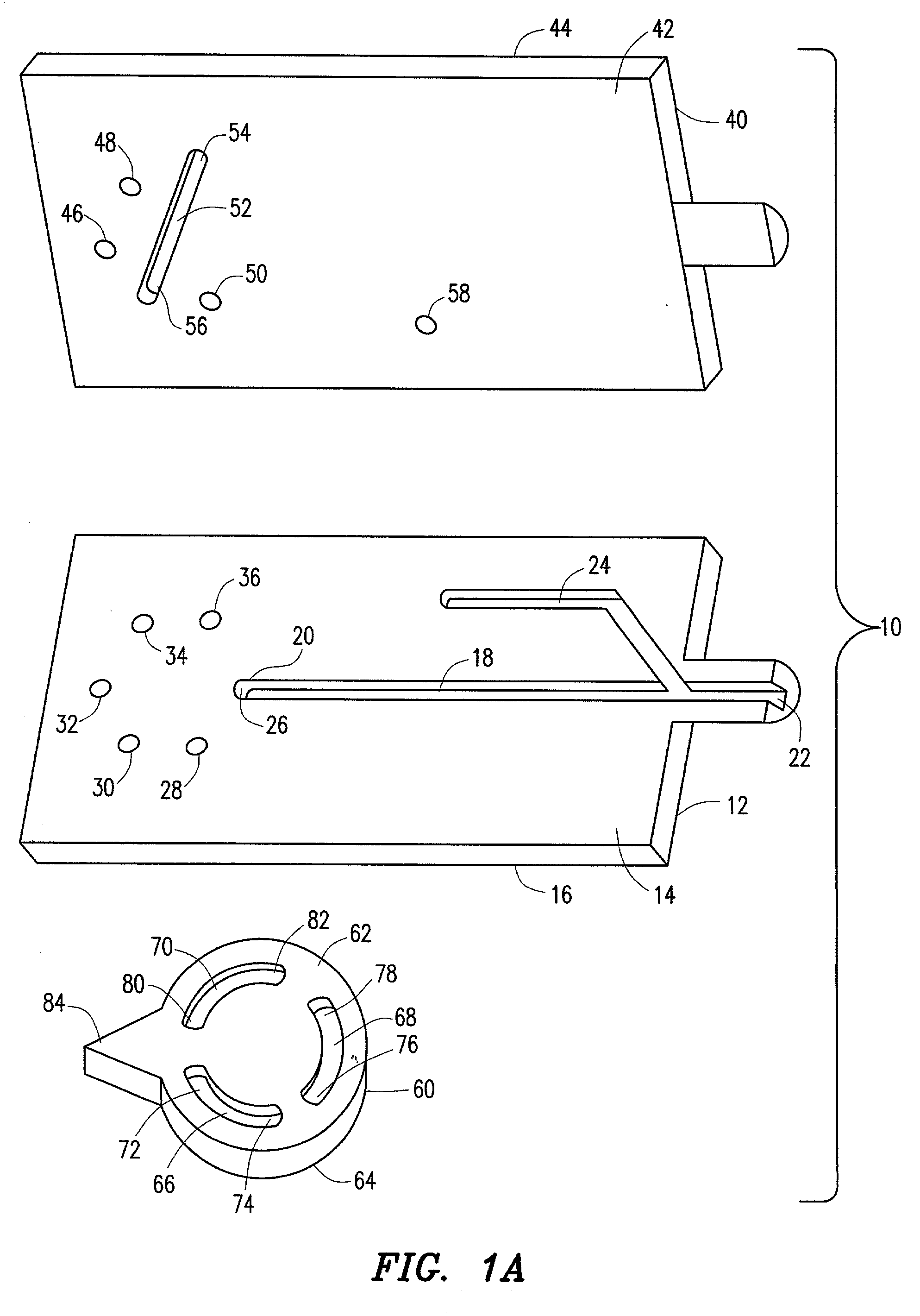

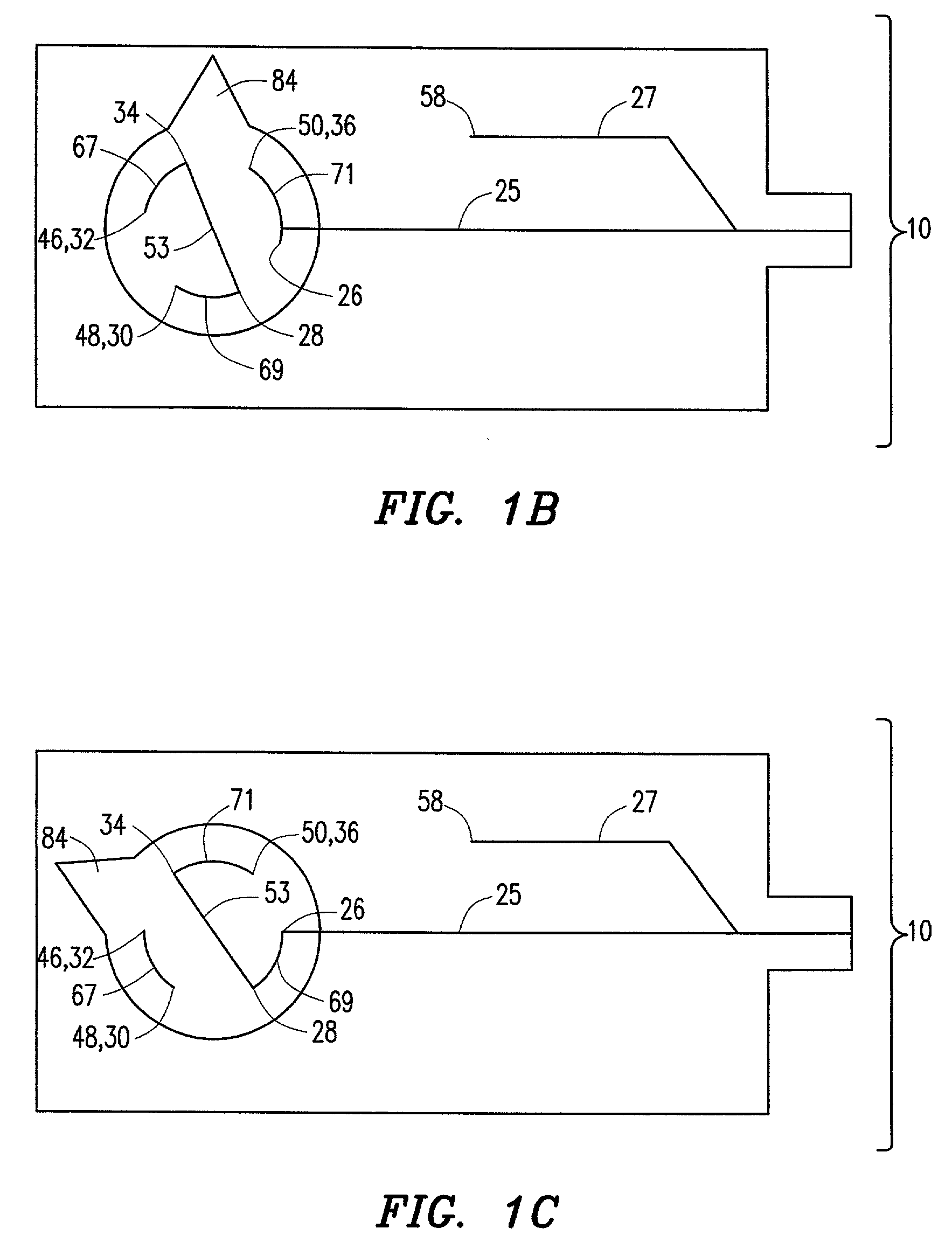

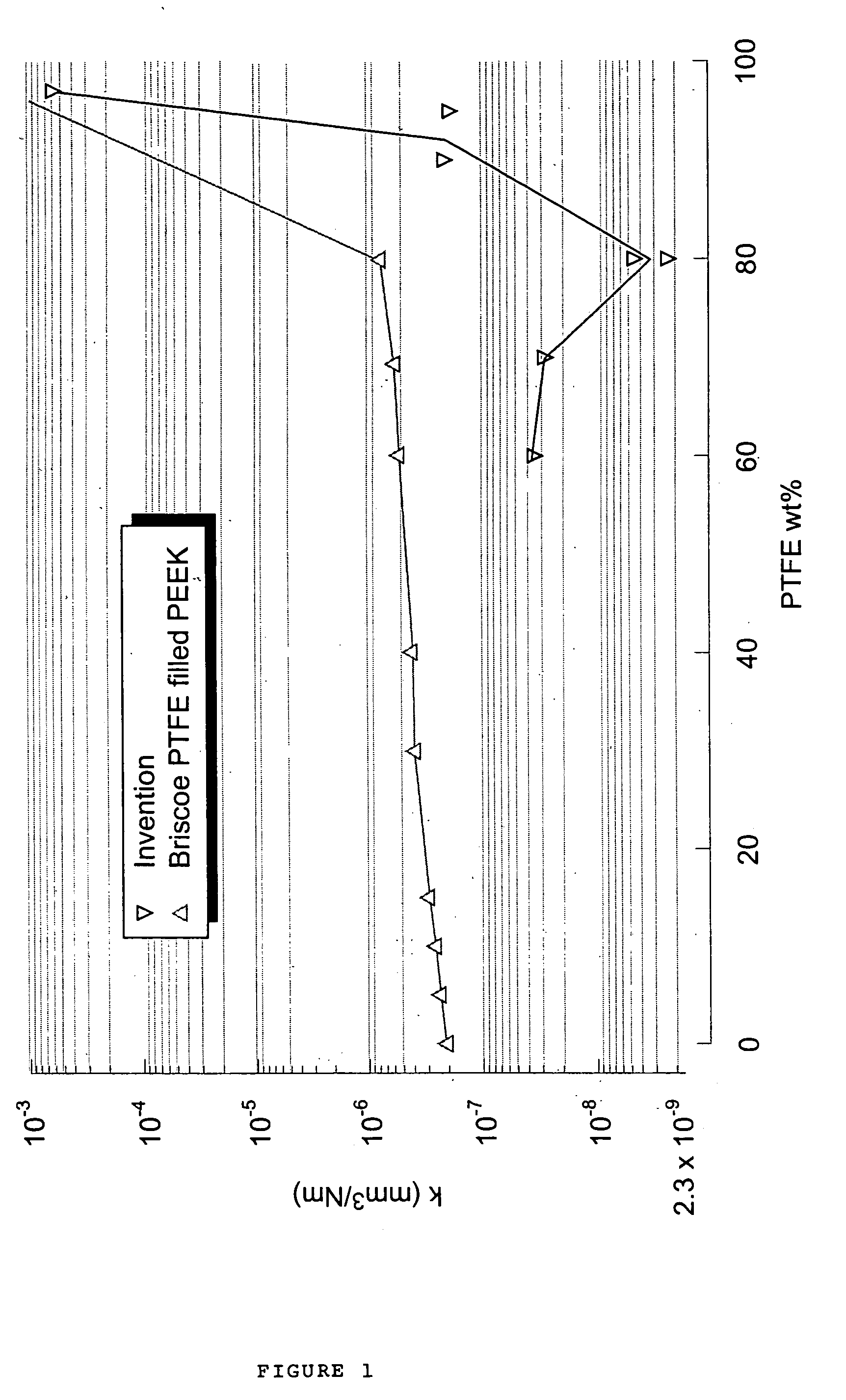

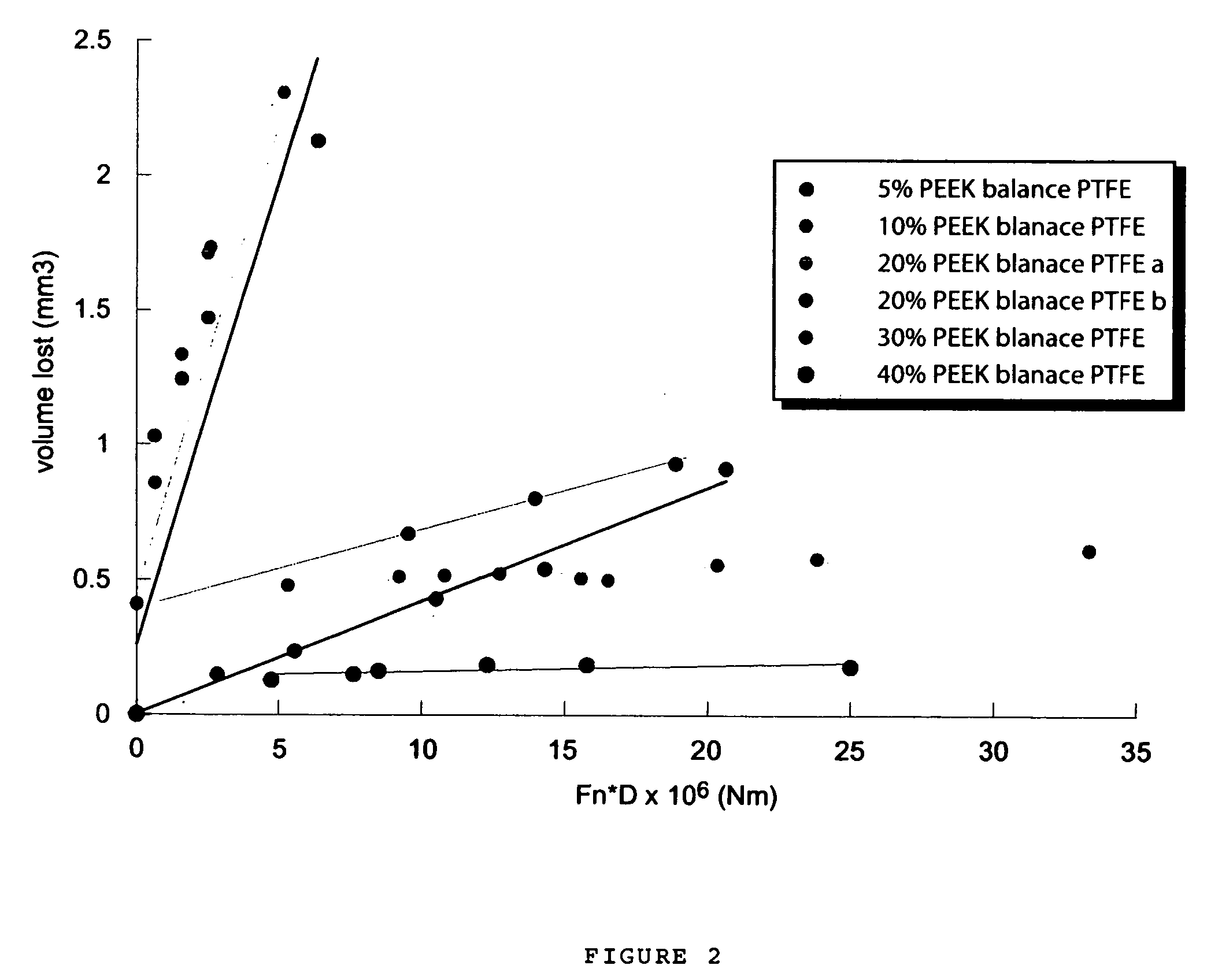

Multi-layer low friction and low wear polymer/polymer composites having compositionally graded interfaces

InactiveUS20060029795A1Reduce wearReduce frictionLiquid surface applicatorsSynthetic resin layered productsPolymer sciencePolyether ether ketone

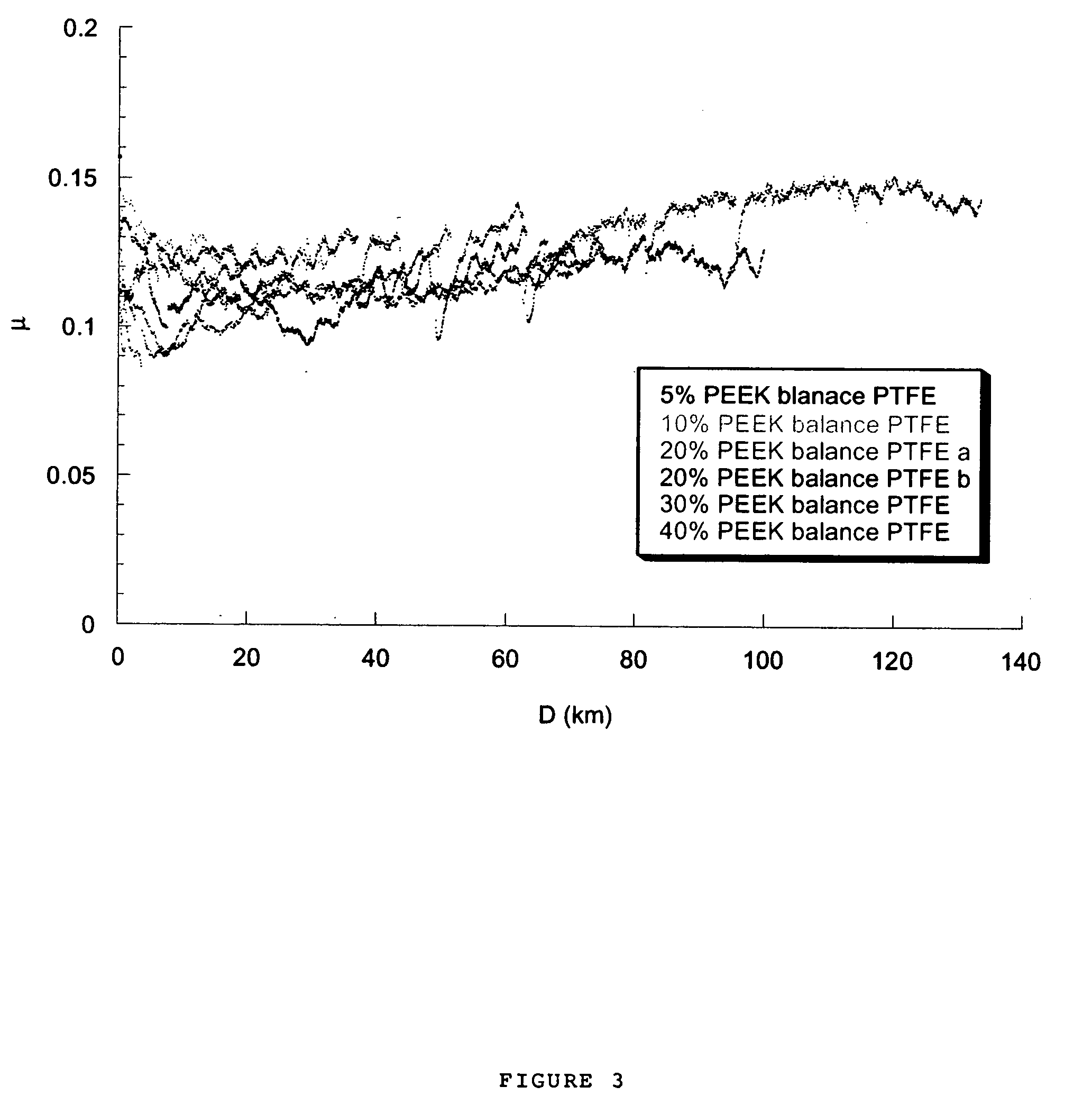

A high strength multi-layer polymeric article having a low wear surface includes a base polymer layer, and a polymer composite capping layer disposed on the base polymer layer. The capping layer includes a first polymer including a transfer film forming polymer, and a second polymer different from the first polymer for strengthening this polymer composite mixed with the first polymer. The first polymer provides at least 10 weight % of the composite capping layer. A transition layer composite including the first and second polymer is interposed between the capping layer and the base polymer layer, at least a portion of the transition layer providing a non-constant first or second polymer concentration. A wear rate of the article is <10−7 mm3 / Nm. The first polymer can be PTFE and the second polymer can be a polyaryletherketone (PEEK).

Owner:UNIV OF FLORIDA RES FOUNDATION INC

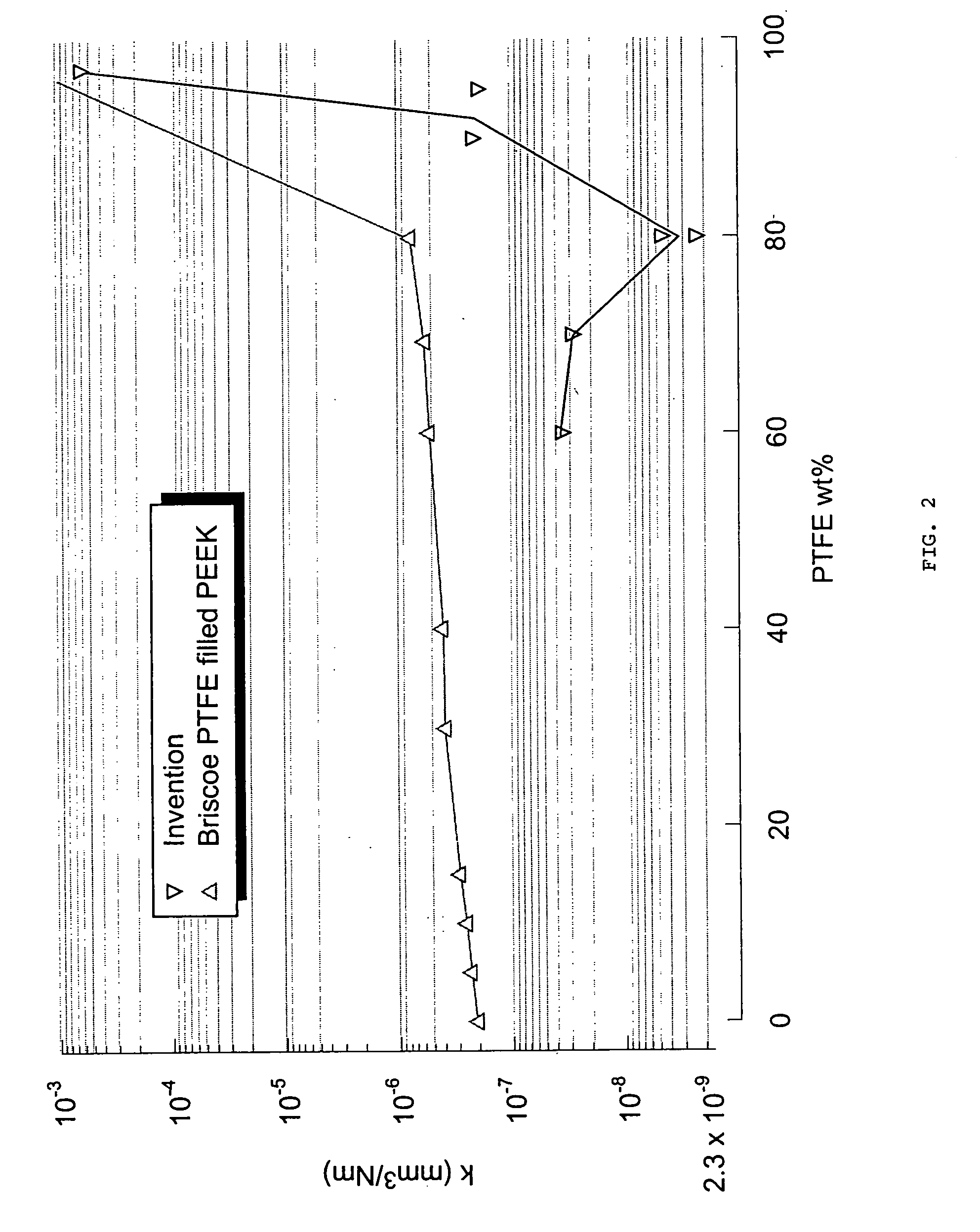

Poly aryl ether ketone polymer blends

Filled phase-separated blends of polyaryl ether ketones, polyaryl ketones, polyether ketones, polyether ether ketones and mixtures thereof with at least one polysulfone etherimide, wherein the polysulfone etherimide has greater than or equal to 50 mole % of the polymer linkages contain at least one aryl sulfone group are described. Such filled blends have improved load-bearing capability at high temperature. In another aspect the filled blends have a higher crystallization temperature, especially at fast cooling rates.

Owner:SABIC GLOBAL TECH BV

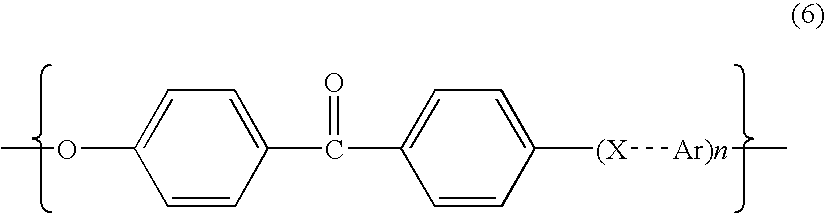

Method for reducing metal impurities in poly(aryl ether ketone) polymer

The invention belongs to the technical field of polymer material, and relates to a method, used in a production process, for reducing metal impurities in poly(aryl ether ketone). The method comprises the following steps: 1) purification: fully mixing poly(aryl ether ketone) with hydroxy ethidene diphosphonic acid aqueous solution with mass concentration of 0.1-2% at 40-100 DEG C for 0.5-3 h, wherein time for mixing and stirring is preferably 1-2 h, and filtering; 2) washing: washing the purified poly(aryl ether ketone) with distilled water, until conductivity of the aqueous solution is below 20 muS / cm; and 3) drying: drying the washed poly(aryl ether ketone) at 120-140 DEG C for 4-6 h to obtain poly(aryl ether ketone) with metal impurities removed. The method can not only reduce content of the metal impurities in the poly(aryl ether ketone) and improve product quality; besides the used reagents have excellent chemical stability, small dosage, and no self toxicity or pollution, can be treated with biochemical degradation in a later period of production, and will not harm the environment.

Owner:ZHEJIANG PFLUON TECH CO LTD +1

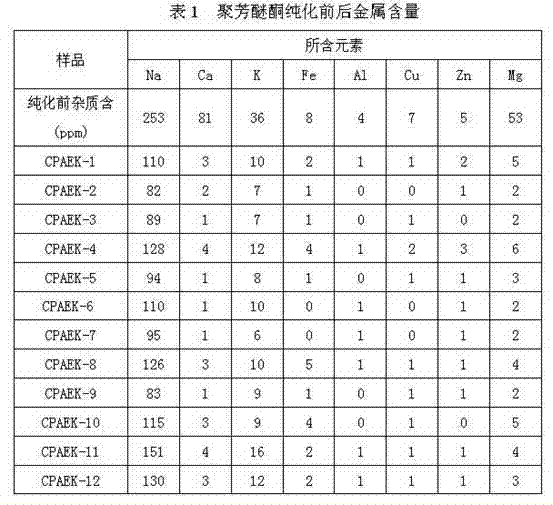

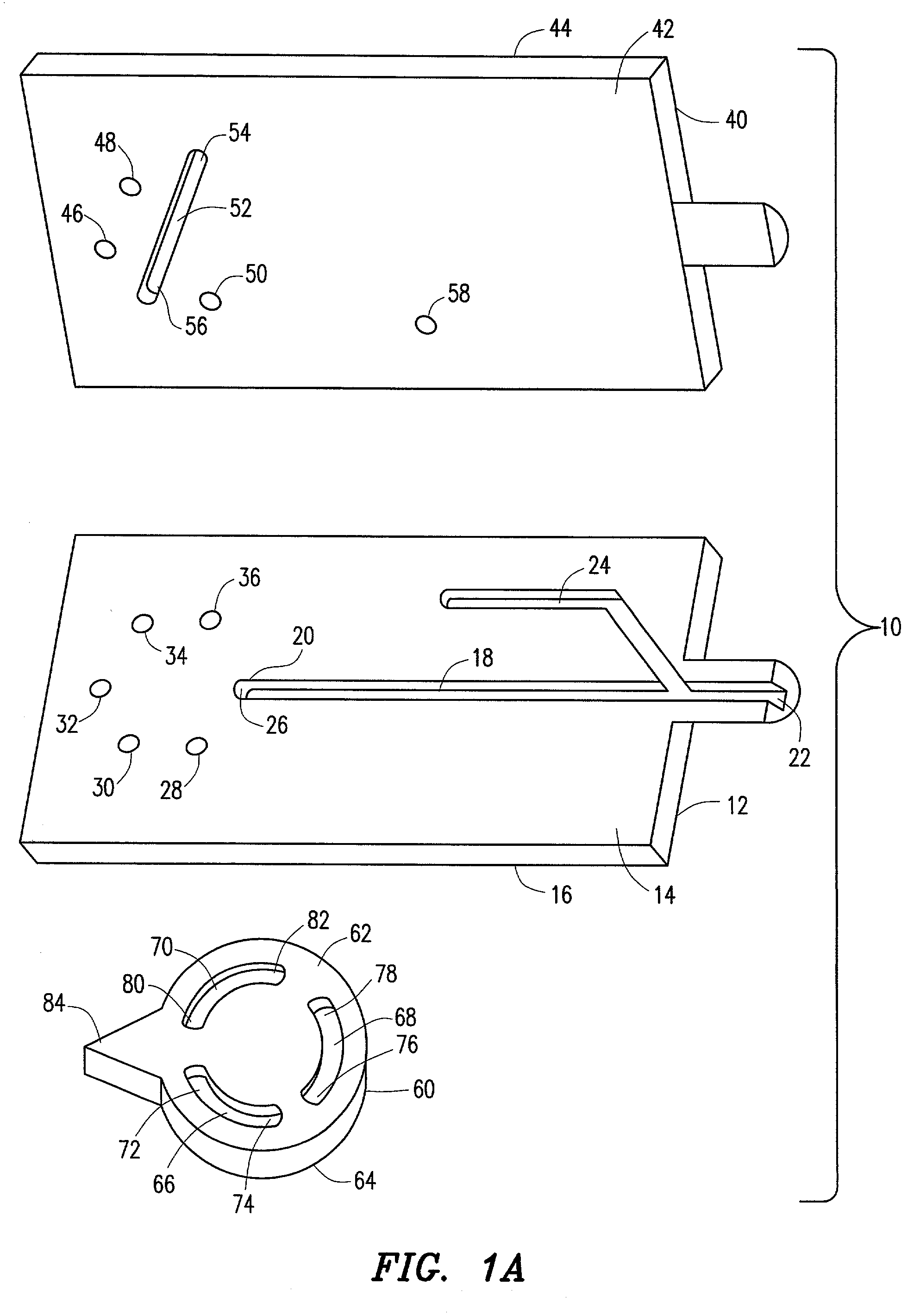

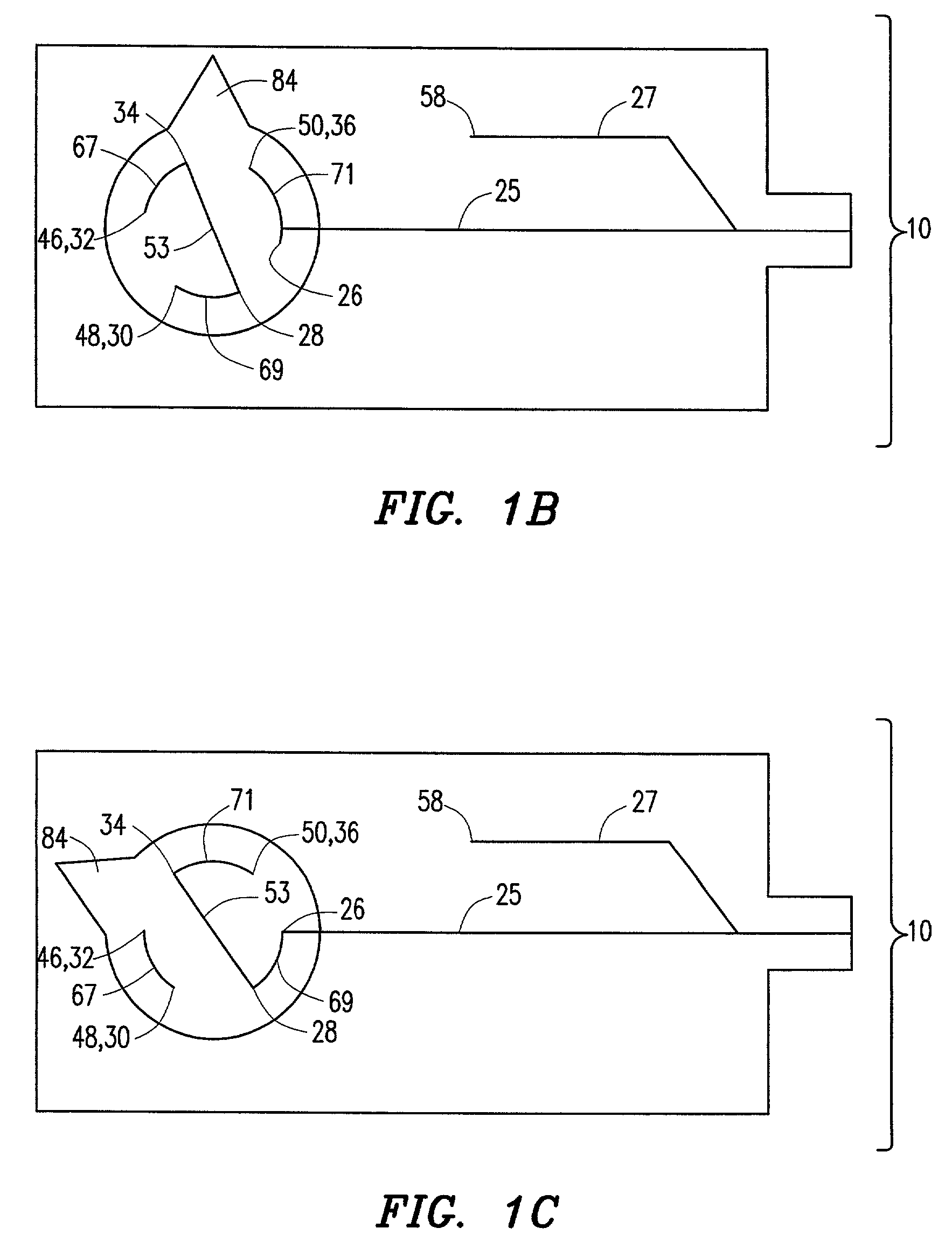

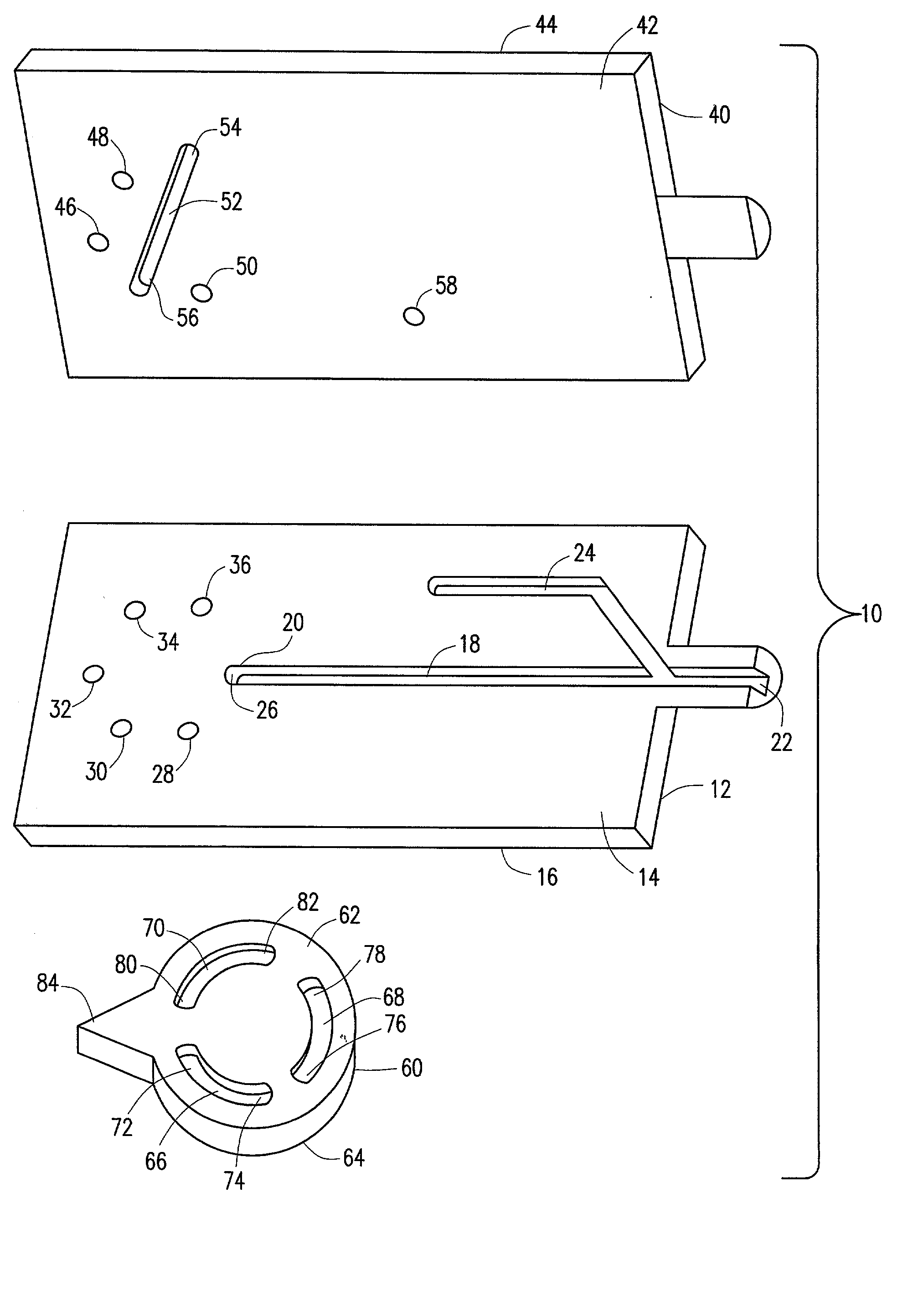

Paek embossing and adhesion for microfluidic devices

InactiveUS7314599B2Narrow rangeMechanical working/deformationFixed microstructural devicesVitrificationAdhesive

A fabrication and adhesion method for a polyaryl-ether-ketone (PAEK) device, such as a microfluidic device, is disclosed. At least one glassy uncrystallized PAEK substrate is heated up to near or above the glass transition temperature to allow the substrate to crystallize from the glass state, while embossing the substrate with patterns. Bonding the PAEK substrate to another substrate is accomplished using a solvent-resistant adhesive, such as a polyimide-based adhesive, in combination with an adhesion enhancement treatment. In certain embodiments, the adhesion enhancement treatment is a plasma treatment or a chemical sulfonation treatment.

Owner:AGILENT TECH INC

PAEK powder, in particular for the use in a method for a layer-wise manufacturing of a three-dimensional object, as well as method for producing it

ActiveUS20080258330A1Additive manufacturing apparatusSynthetic resin layered productsVitrificationMetallurgy

By a temper treatment a polyaryletherketone powder is processed such that it is particularly suited for the use in a method for a layer-wise manufacturing of a three-dimensional object. To this effect the powder is tempered at a temperature that is at least 20° C. above the glass transition temperature for at least 30 minutes before it is used as building material.

Owner:EOS ELECTRO OPTICAL SYST

Functionalized porous poly(aryl ether ketone) materials and their use

ActiveUS20060094852A1Good chemical resistanceSimple and cost-effective and industrially feasibleMembranesSemi-permeable membranesPolymer scienceHydrazine compound

Functionalized porous poly(aryl ether ketone) articles are prepared by reacting ketone groups in the backbone of poly(aryl ether ketone) polymer with a primary amine reagent. Preferred functional primary amines are primary aliphatic amines or substituted hydrazines containing one or more target functional groups including polar groups, such as hydroxyl groups, ˜OH, amino groups, ˜NH2, ˜NHR, ˜NRR′, and ethylene oxide groups, ˜OCH2CH2—, negatively or positively charged ionic groups, such as ˜SO3−, ˜COO−, and ˜NH4+ groups, hydrophobic groups such as siloxane or perfluorcarbone groups, and non-polar groups, such as linear or branched hydrocarbon groups. The functionalized porous poly(aryl ether ketone) article can be prepared by reacting primary amine with a pre-formed, shaped porous poly(aryl ether ketone) article or by functionalizing the surface of a non-porous precursor article that is subsequently converted into a porous article.

Owner:MASSACHUSETTS DEV FINANCE AGENCY

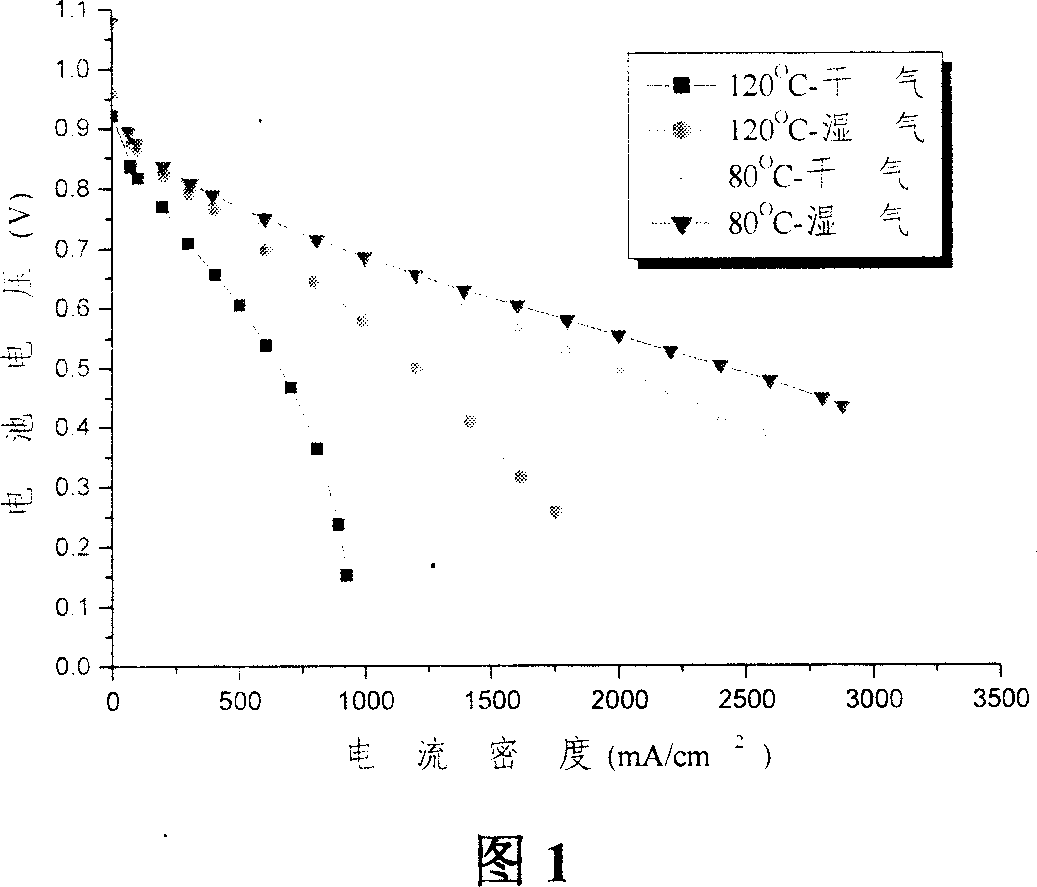

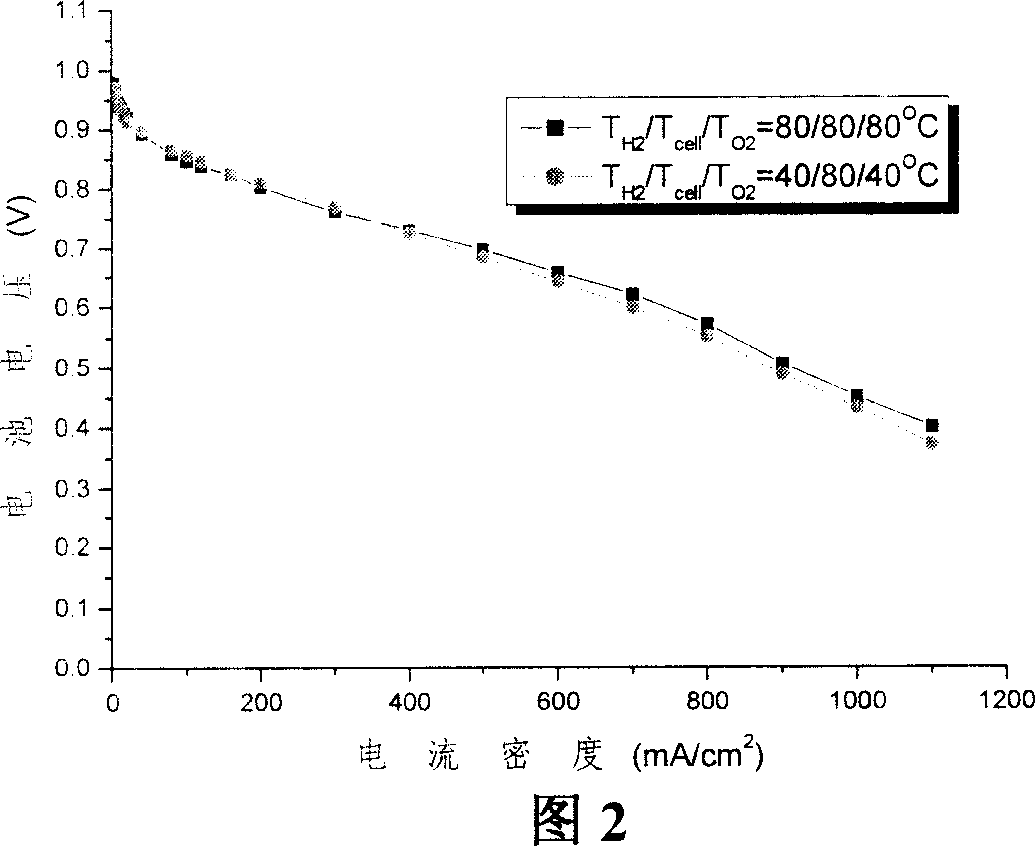

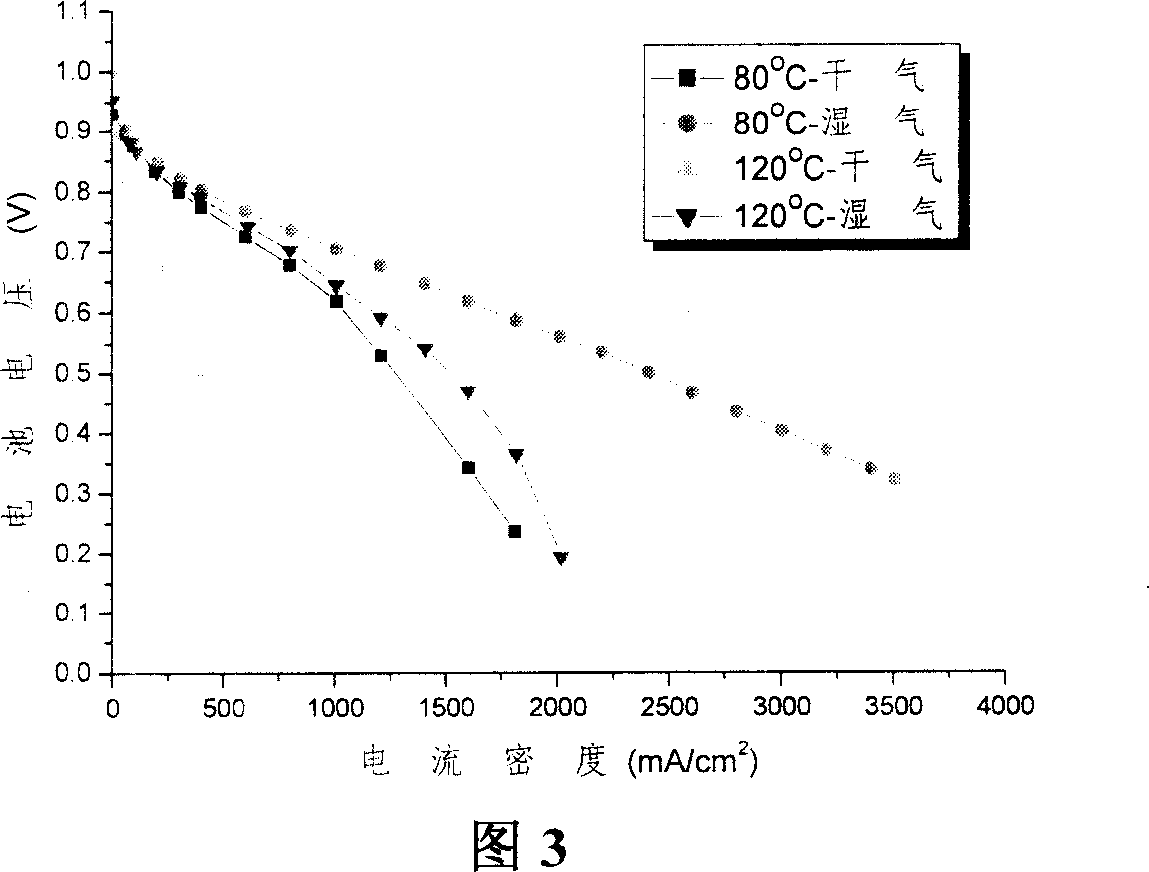

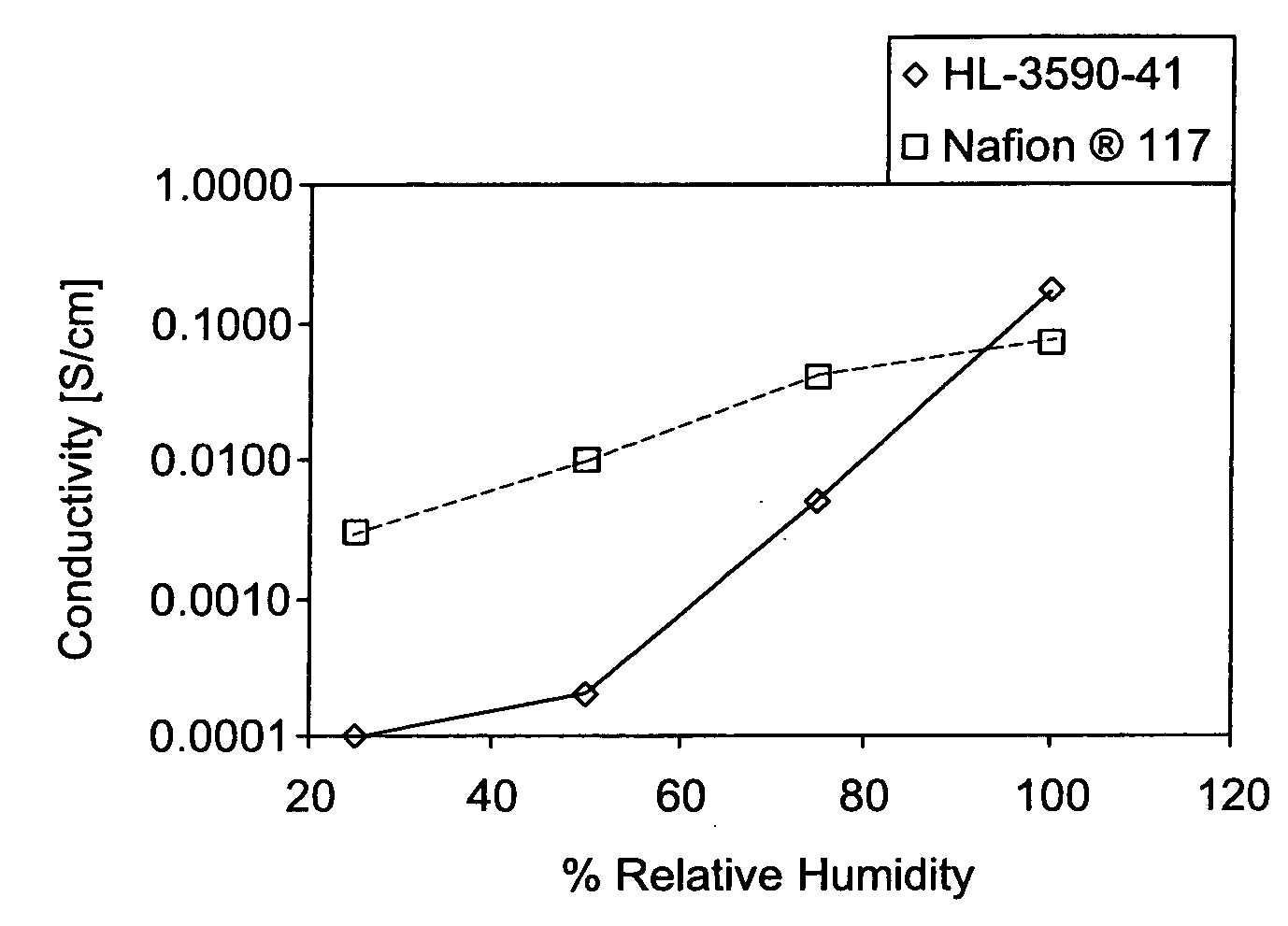

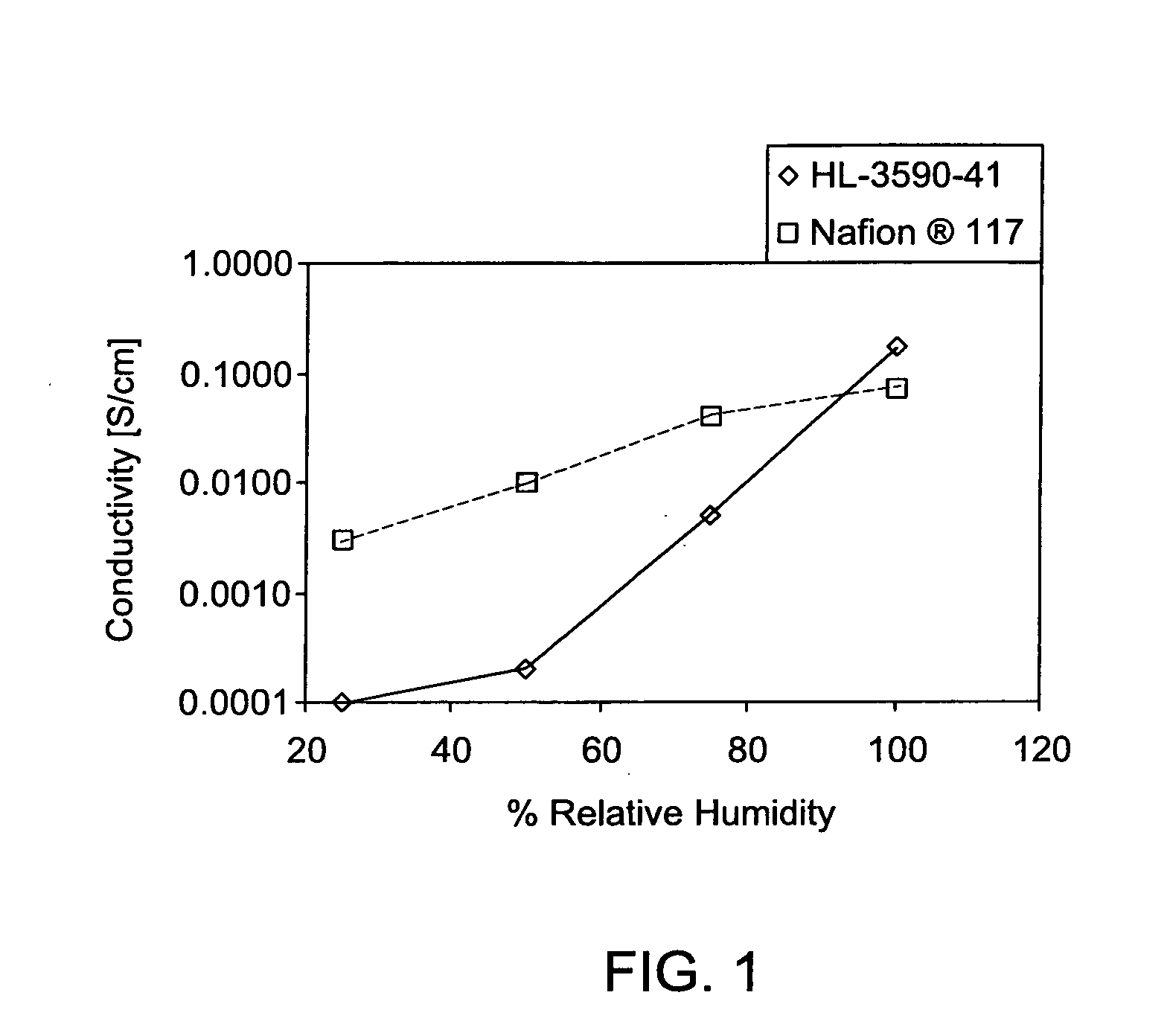

Multi-layer moisture making compound film for proton exchange film fuel cell and its making method

InactiveCN101079487ALow costImprove thermal stabilityFinal product manufactureSolid electrolyte fuel cellsPolystyreneAccelerant

The invention relates to a multiple-layer complex proton exchange film for the fuel battery in particular to a multiple-layer self-humidifying complex film and preparing method for the proton exchange film fuel battery. The complex film comprises the following parts: a porous strengthening film and a self-humidifying complex layer, wherein the proton exchange film resin is poured and painted on the porous strengthening film and the strengthening complex film is formed, the self-humidifying complex layer is poured and painted at two sides of the strengthening complex film, the self-humidifying complex layer is comprised by the metal accelerant and the proton exchange film resin(the mass ratio of the accelerant(pt) and the proton exchange film resin is 0.0005:1-0.01:1), the proton exchange film resin can be perfluorine sulfonic acid resin, sulfonated polyarylethersulfone, sulfonated polyetheretherketone, partial sulfonated polystyrene fluoride, partial sulfonated polyarylethersulfone fluoride, or partial polyaryletheretherketone fluoride. The multiple-layer self-humidifying complex film is provided with the good steady, the high proton conductivity and the good self-humidifying property.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Paek embossing and adhesion for microfluidic devices

InactiveUS20030017305A1Mechanical working/deformationFixed microstructural devicesVitrificationAdhesive

A fabrication and adhesion method for a polyaryl-ether-ketone (PAEK) device, such as a microfluidic device, is disclosed. At least one glassy uncrystallized PAEK substrate is heated up to near or above the glass transition temperature to allow the substrate to crystallize from the glass state, while embossing the substrate with patterns. Bonding the PAEK substrate to another substrate is accomplished using a solvent-resistant adhesive, such as a polyimide-based adhesive, in combination with an adhesion enhancement treatment. In certain embodiments, the adhesion enhancement treatment is a plasma treatment or a chemical sulfonation treatment.

Owner:AGILENT TECH INC

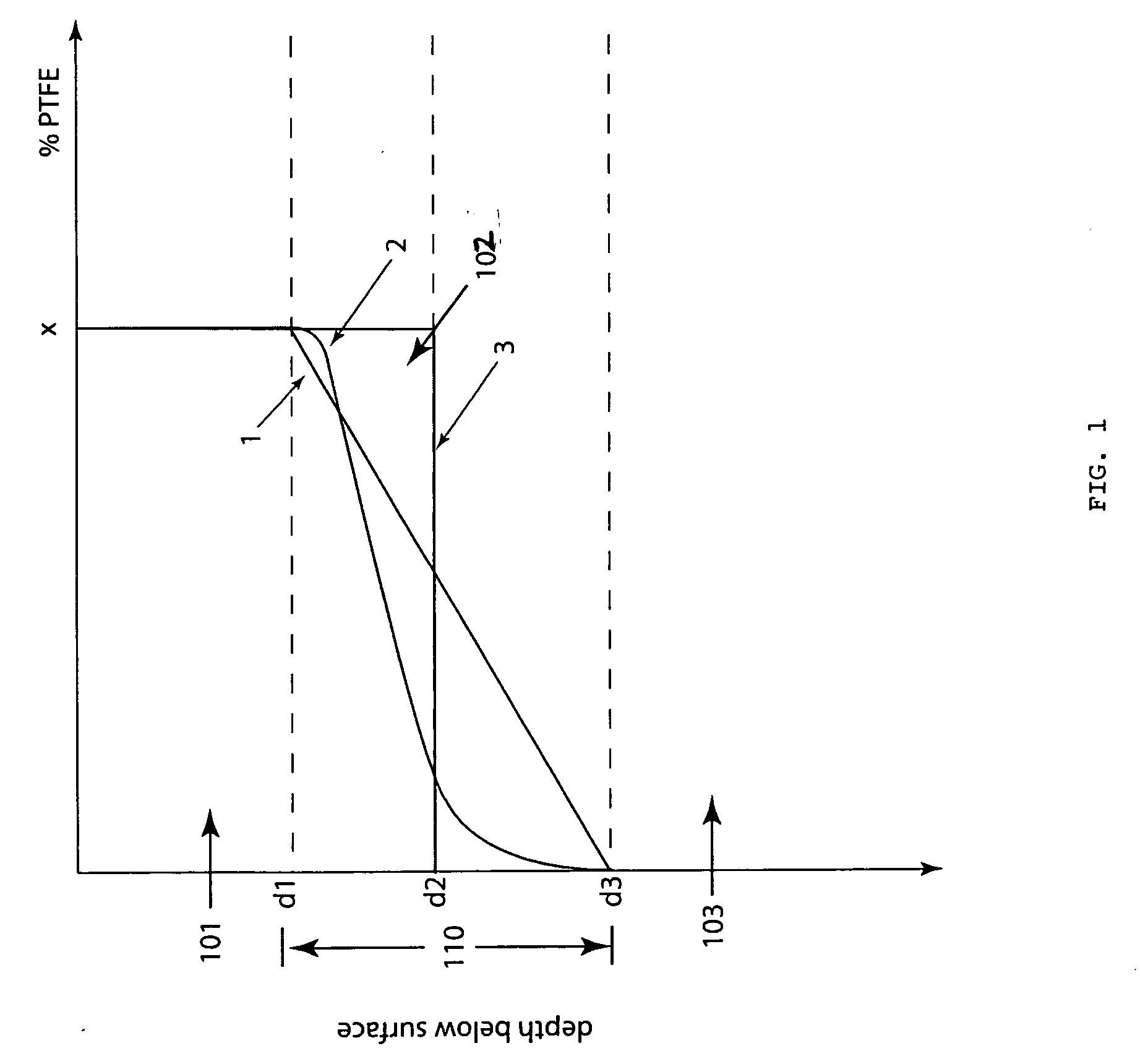

Low friction and low wear polymer/polymer composites

InactiveUS20060030681A1Improve tribological propertiesReduce wearCoatingsSpecial surfacesPolymer sciencePolyether ether ketone

A composite material having superior tribological properties includes a first polymer being a transfer film forming polymer and a second polymer mixed with the first polymer. The first polymer is at least 10 weight % of the composite and the composite provides a wear rate of <10−7 mm3 / Nm and an average friction coefficient of said composite no more than 0.15. The first polymer can be PTFE and the second polymer a polyaryletherketone (PEEK). A method of forming composites includes the steps of providing a plurality of transfer film forming polymer particles and second polymer particles, and molding or extruding the particles at a temperature sufficient to allow softening and mobilization of at least one of the transfer film forming polymer particles and the plurality of strengthening phase polymer particles to form an interconnected network, wherein the composite formed provides a wear rate of <10−7 mm3 / Nm.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

Fiducial marker

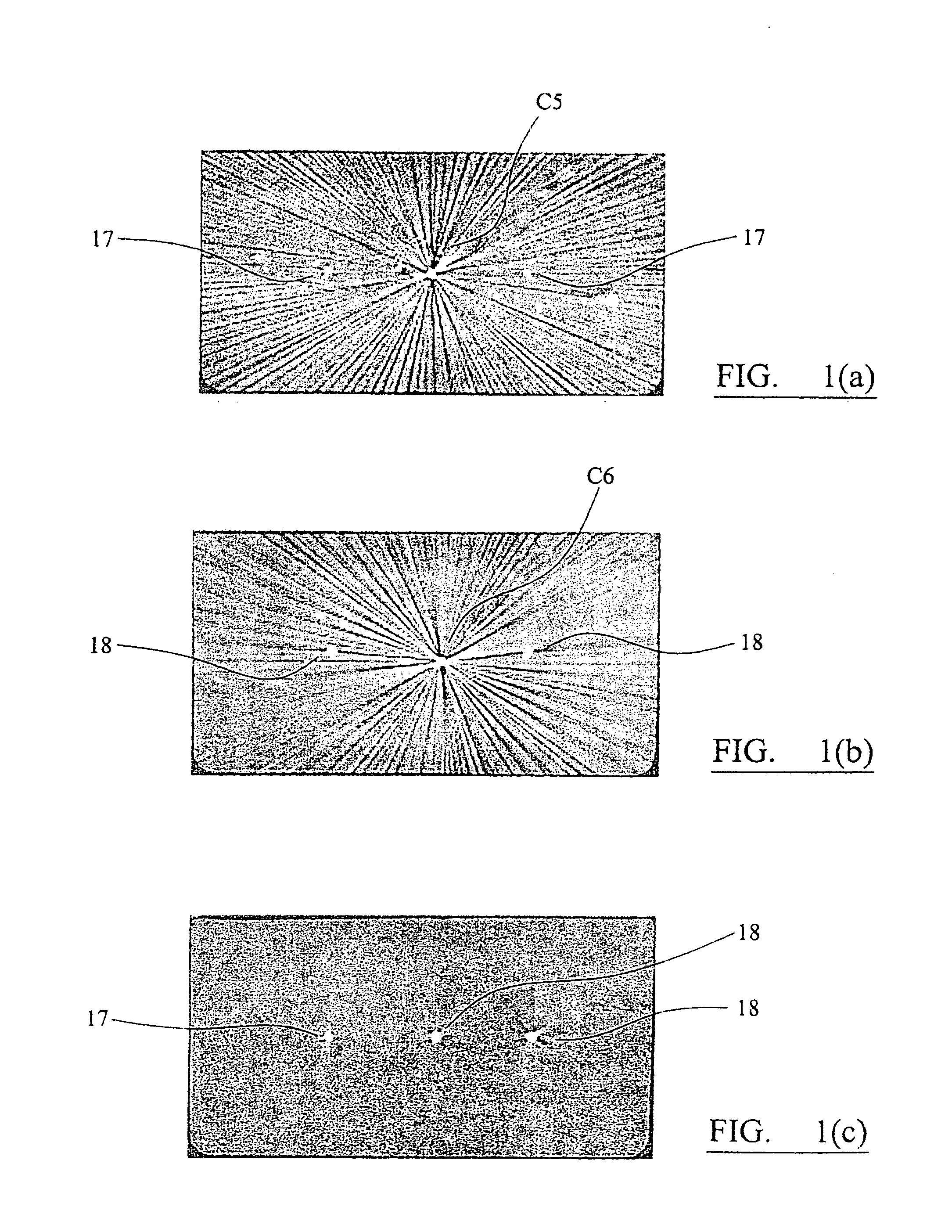

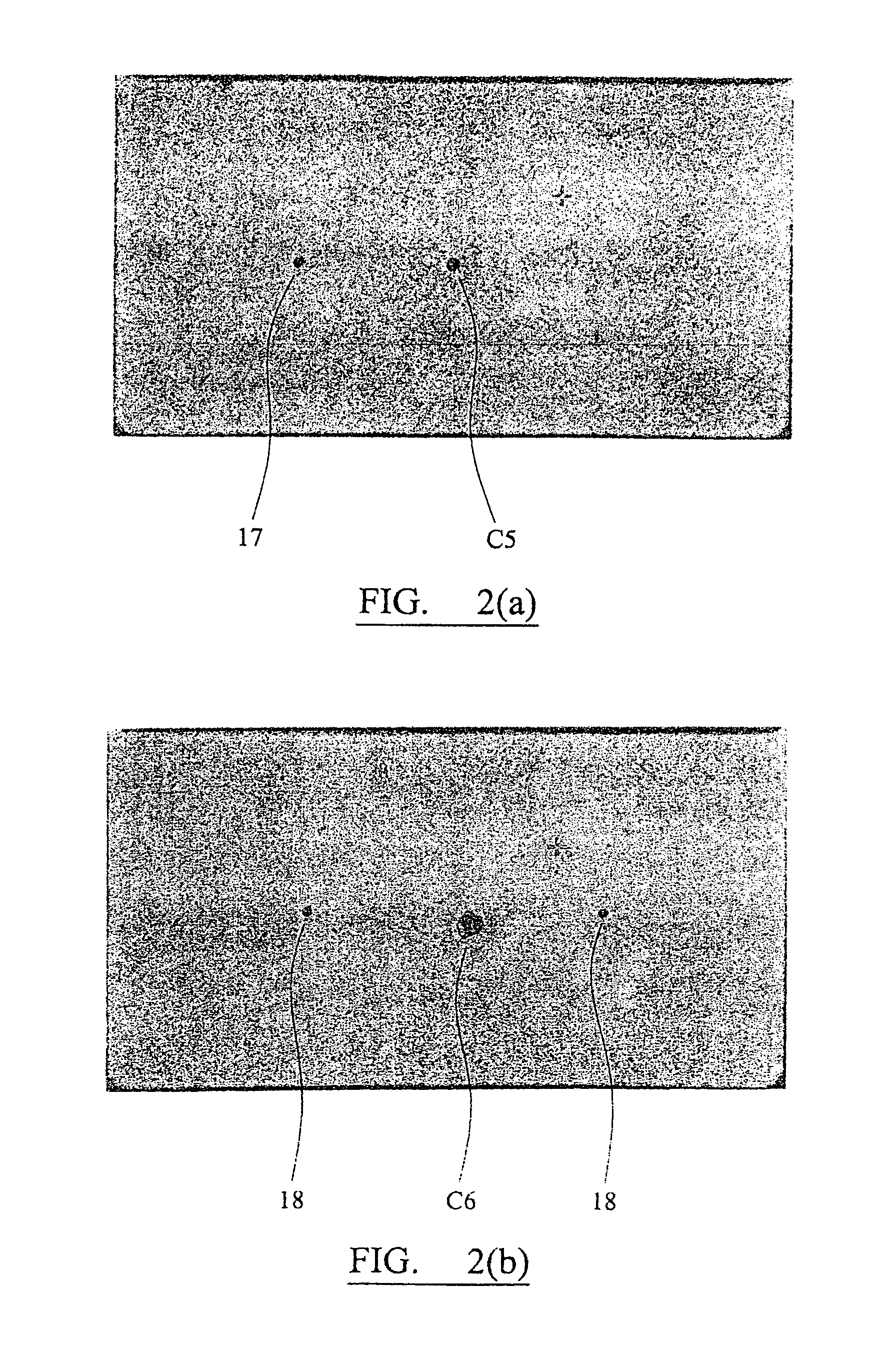

InactiveUS20080234532A1Minimise patients' discomfortImprove radiopacitySurgeryDiagnostic markersImaging techniqueNuclear medicine

A fiducial marker which is visible to a wide range of imaging techniques, comprises a radiopaque material, such as barium sulphate or a metal wire, encapsulated in a biocompatible polymeric material, for example a polyaryletherketone such as polyetheretherketone.

Owner:INVIBIO

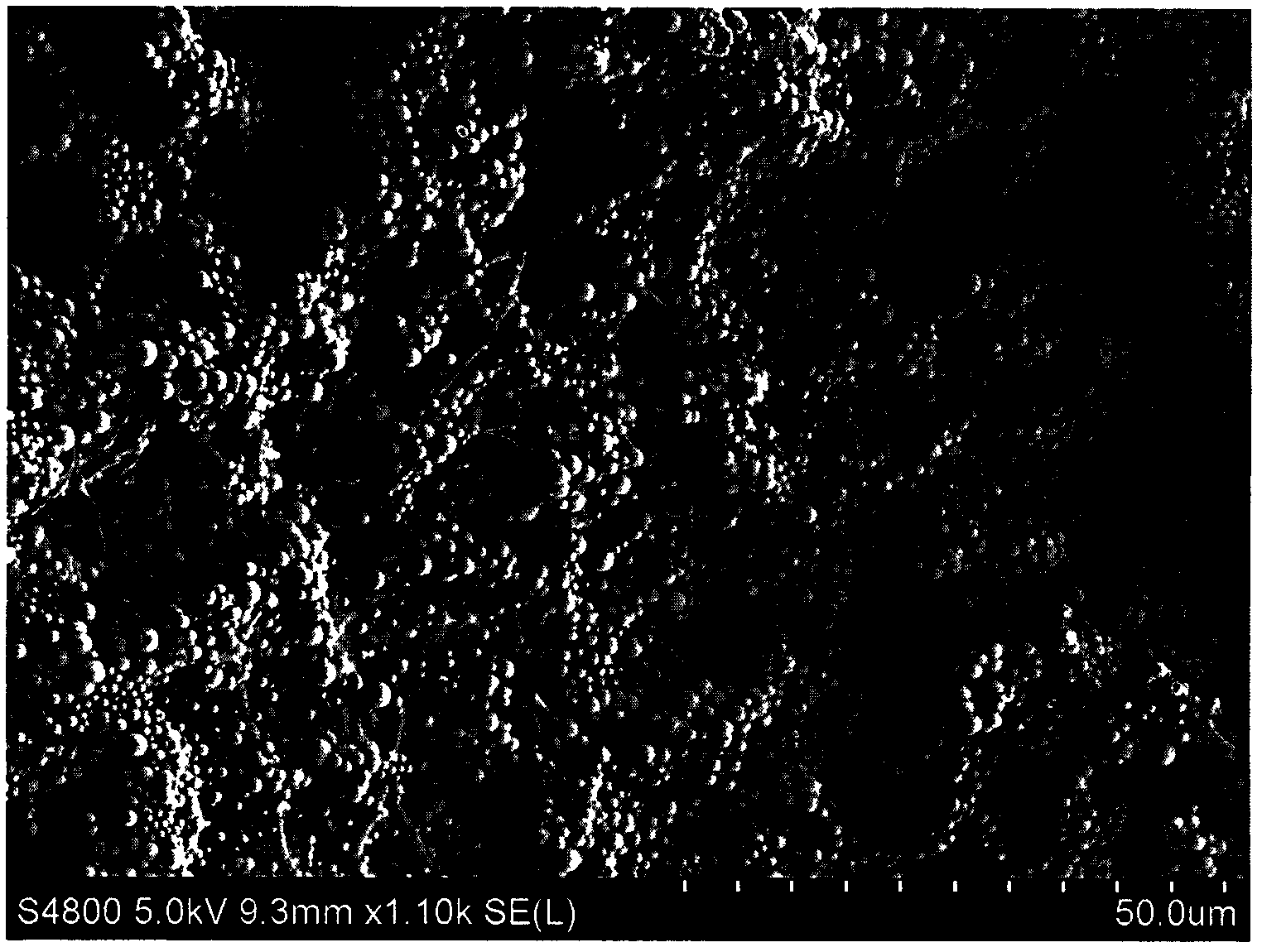

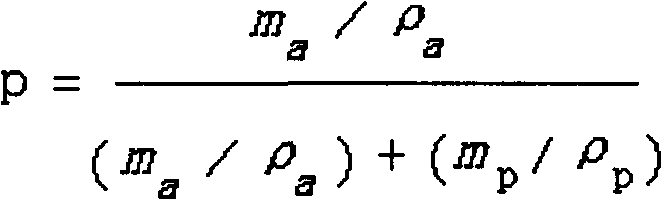

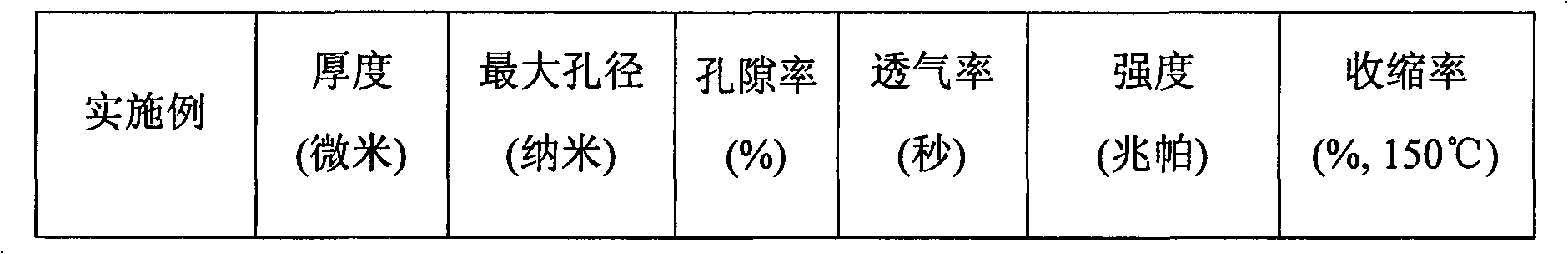

Biomass cellulose porous composite diaphragm used for lithium ion secondary cell

ActiveCN102516585AUniform pore structureEvenly distributedCell component detailsCellulosePolyaryletherketone

The invention discloses a cellulose porous membrane able to be used for a lithium ion secondary cell diaphragm. Two side surfaces of the membrane are coated with sodium alginate, a fluorine-containing polymer, polyaryletherketone, polyimide, polynorbornene or inorganic nanoparticles and other structure enhanced and interface stable components. The membrane has thickness of 15-100 micrometers, and air permeability of 2-500s. The upper and lower surfaces as well as inner pores of the membrane are symmetrically and uniformly distributed, with an average pore size of 20-200 nanometers and tensile strength of 50-250MPa. The invention also discloses a preparation method of the cellulose porous membrane. The membrane of the invention can be used as a lithium ion cell diaphragm and has good heat resistance, and even if at a temperature of 150DEG C, a cell short circuit phenomenon cannot occur. Therefore, the cell diaphragm provided in the invention is especially suitable for large capacity and power lithium ion cells. In addition, employment of biomass cellulose that has the largest output in the nature as the raw material for producing the lithium ion cell diaphragm has the advantages of low cost, sustainability and environmental protection.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

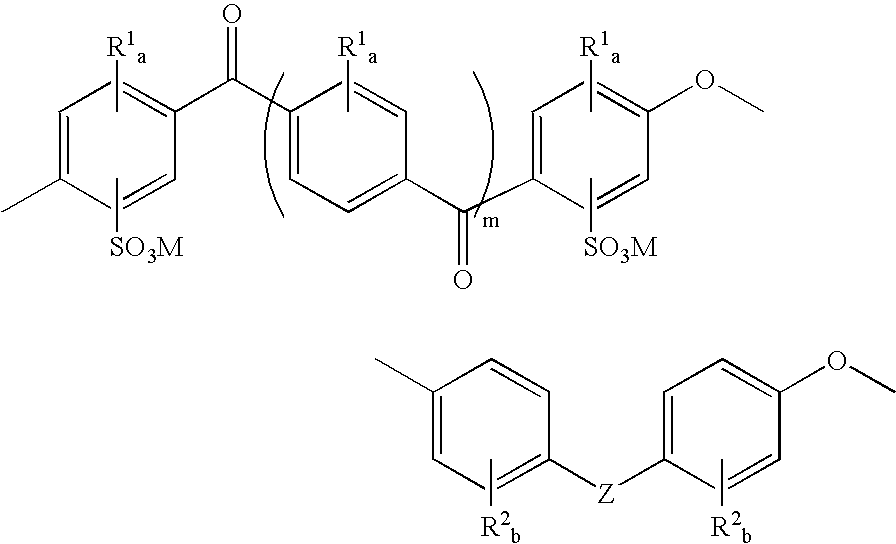

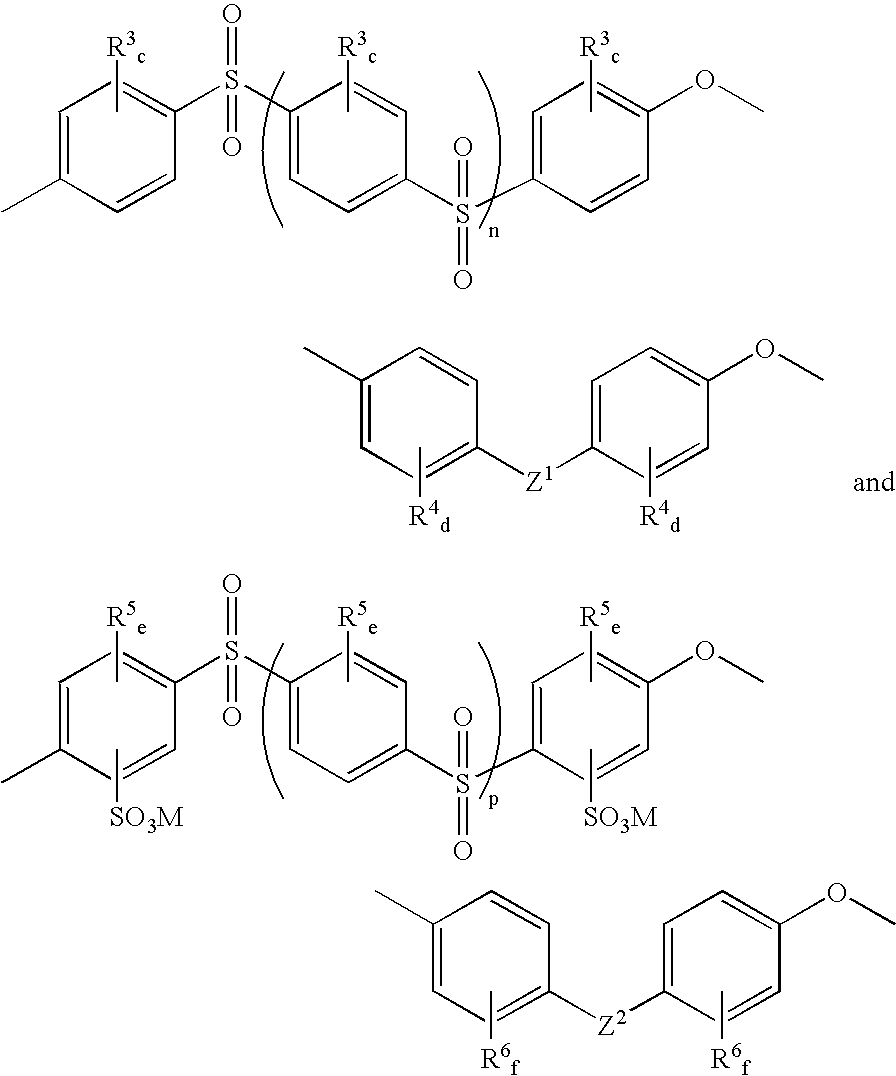

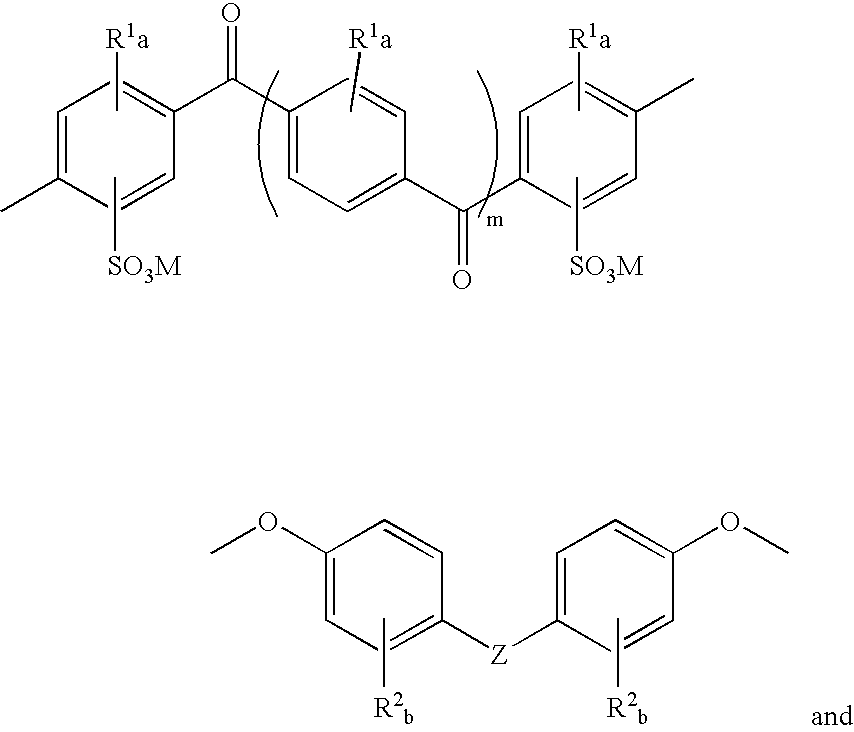

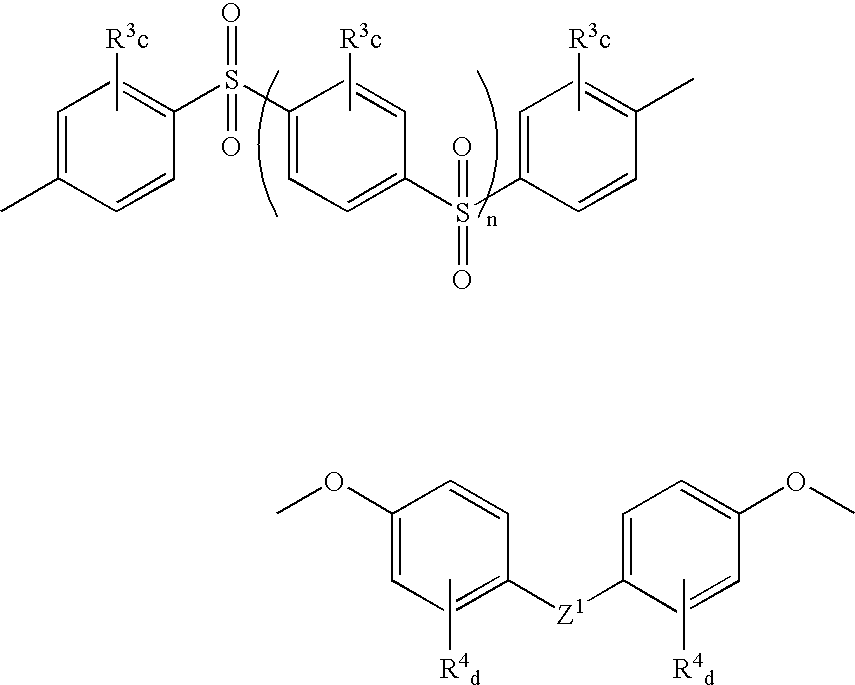

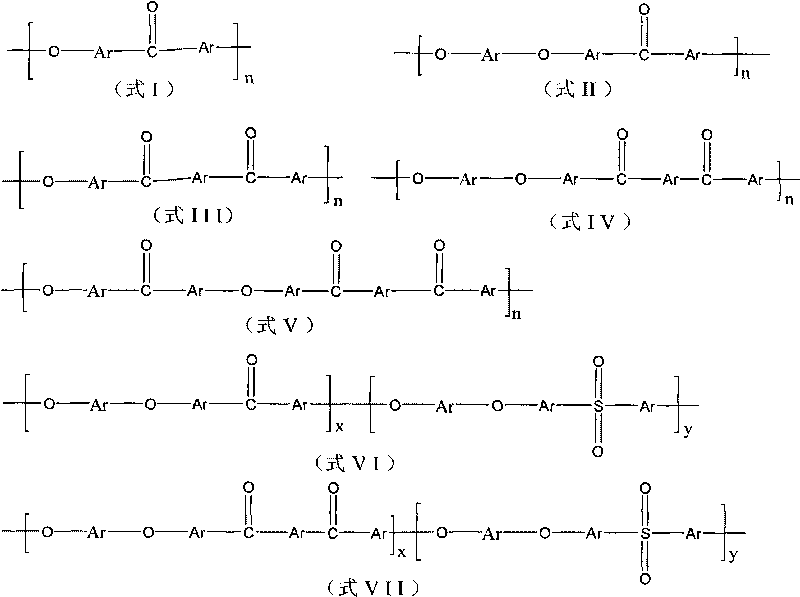

Mixed-sulfonation block copolymers

Sulfonated block copolymers that may be used as membranes for fuel cells include sulfonated polyaryletherketone blocks and lightly sulfonated polyethersulfone blocks. The sulfonated polyaryletherketone blocks include structural units of formula and the lightly sulfonated polyethersulfone blocks include structural units of formula wherein R1, R2, R3, R4, R5 and R6 are independently C1-C10 alkyl, C3-C12 cycloalkyl, C6-C14 aryl, allyl, alkenyl, alkoxy, halo, or cyano; Z, Z1 and Z2 are independently a direct bond or O, S, (CH2)r, (CF2)r, C(CH3)2, C(CF3)2, or a combination thereof; M is H, a metal cation, a non-metallic inorganic cation, an organic cation or a mixture thereof; a and e are independently 0 or an integer from 1 to 3; b, c, d, and f are independently 0 or an integer from 1 to 4; m, n and p are independently 0 or 1; and r is an integer from 1 to 5.

Owner:GENERAL ELECTRIC CO

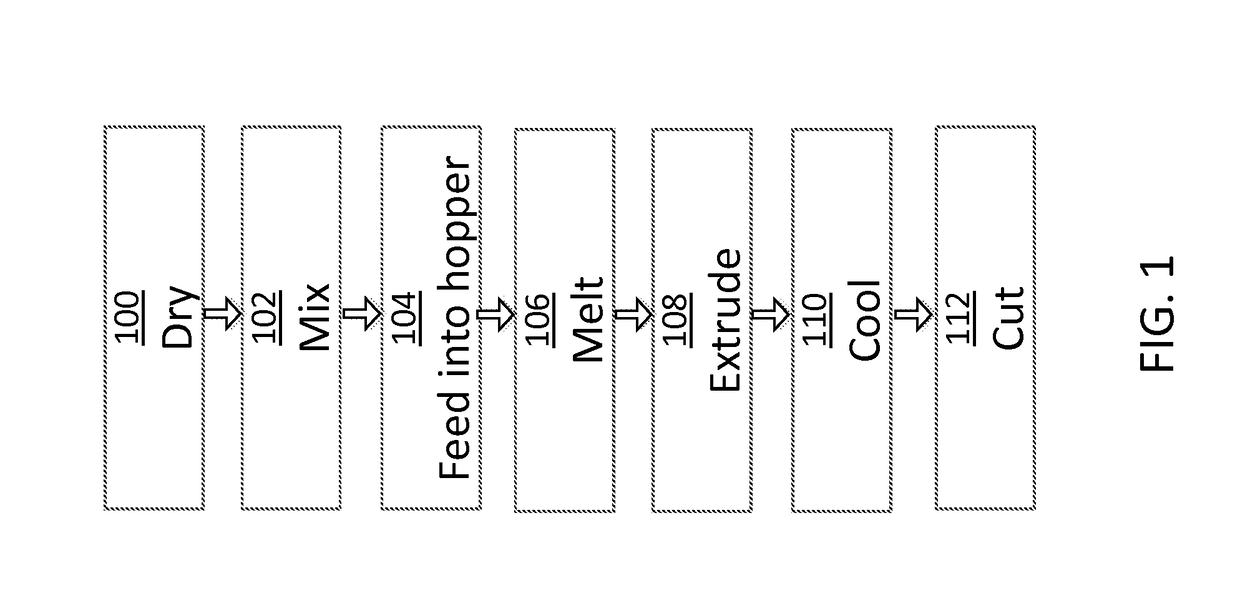

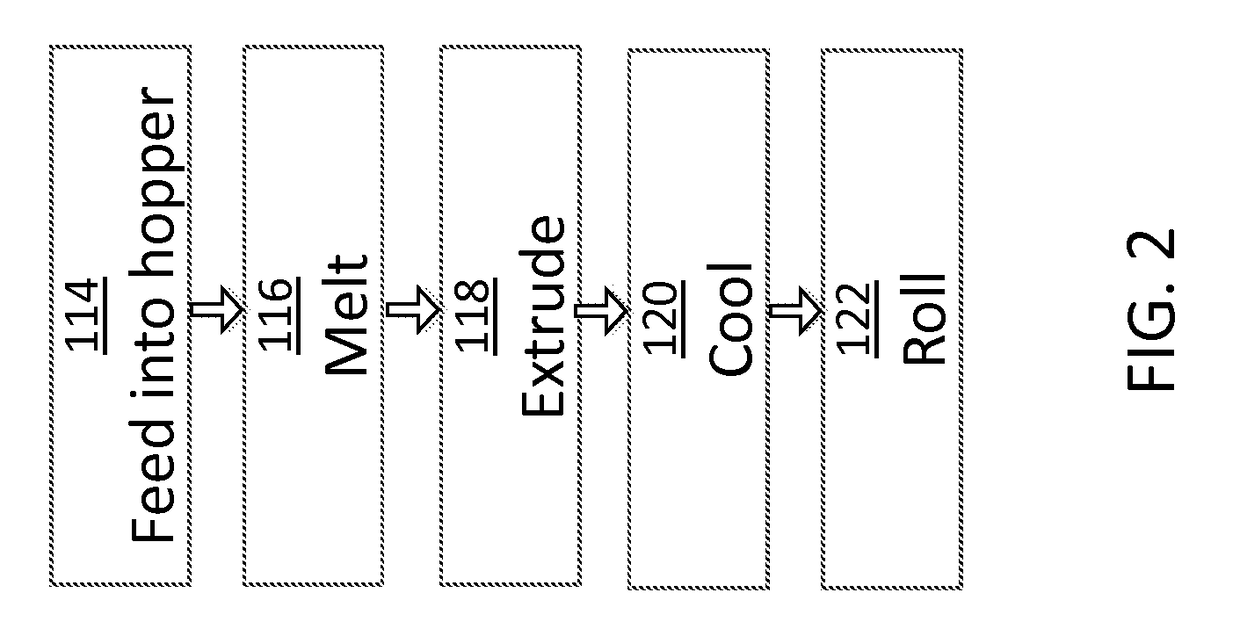

Amorphous polyaryletherketone and blends thereof for use in additive manufacturing

ActiveUS20170096576A1High melt flowHigh viscosityAdditive manufacturing apparatusAdditive manufacturing with liquidsFused filament fabricationAdditive layer manufacturing

A material for use in a fused filament fabrication (FFF) printer comprises a polyaryletherketone (PAEK) having an amorphous morphology. In some embodiments, the material also includes a PAEK having a semi-crystalline morphology.

Owner:AREVO INC

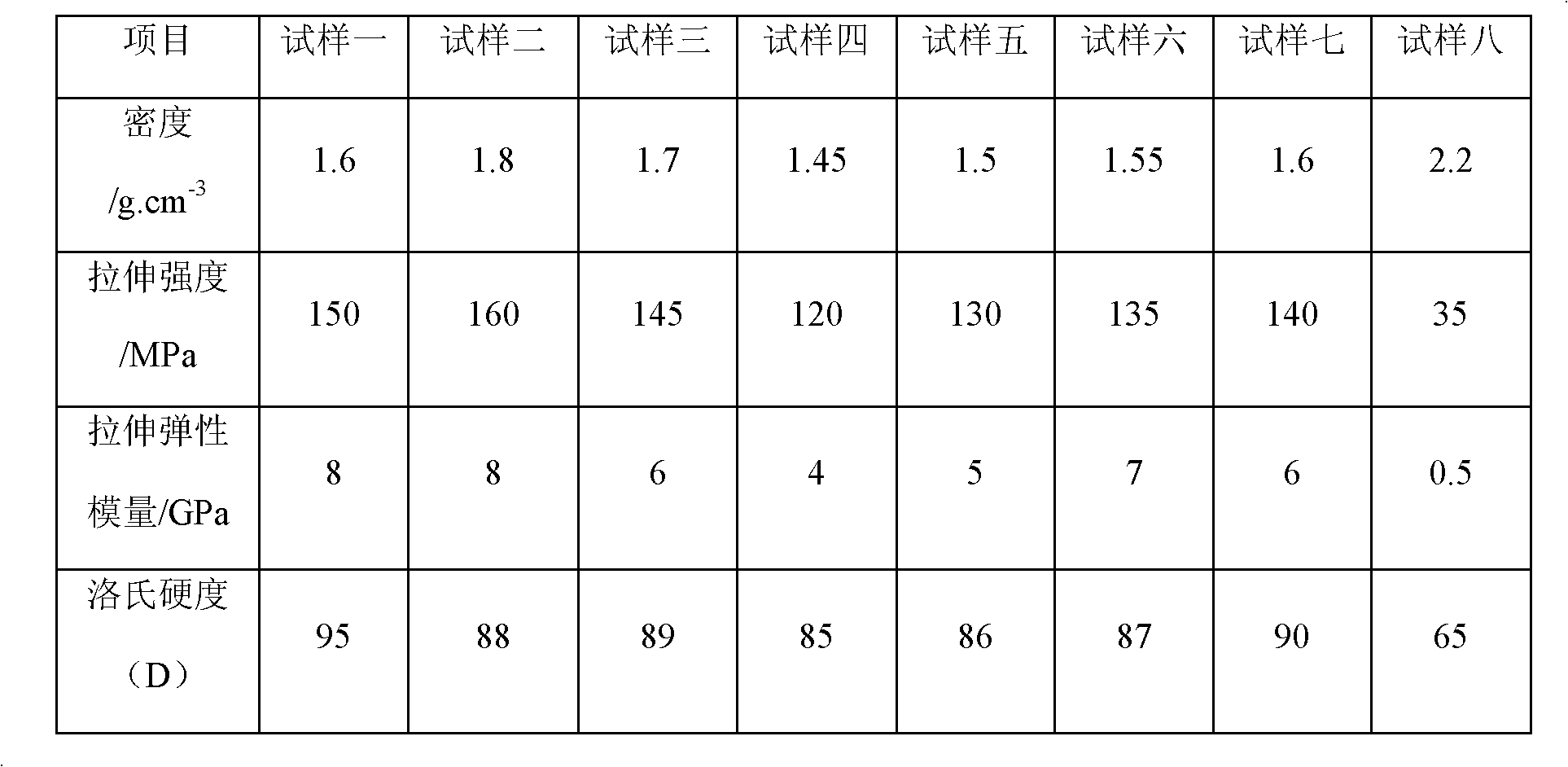

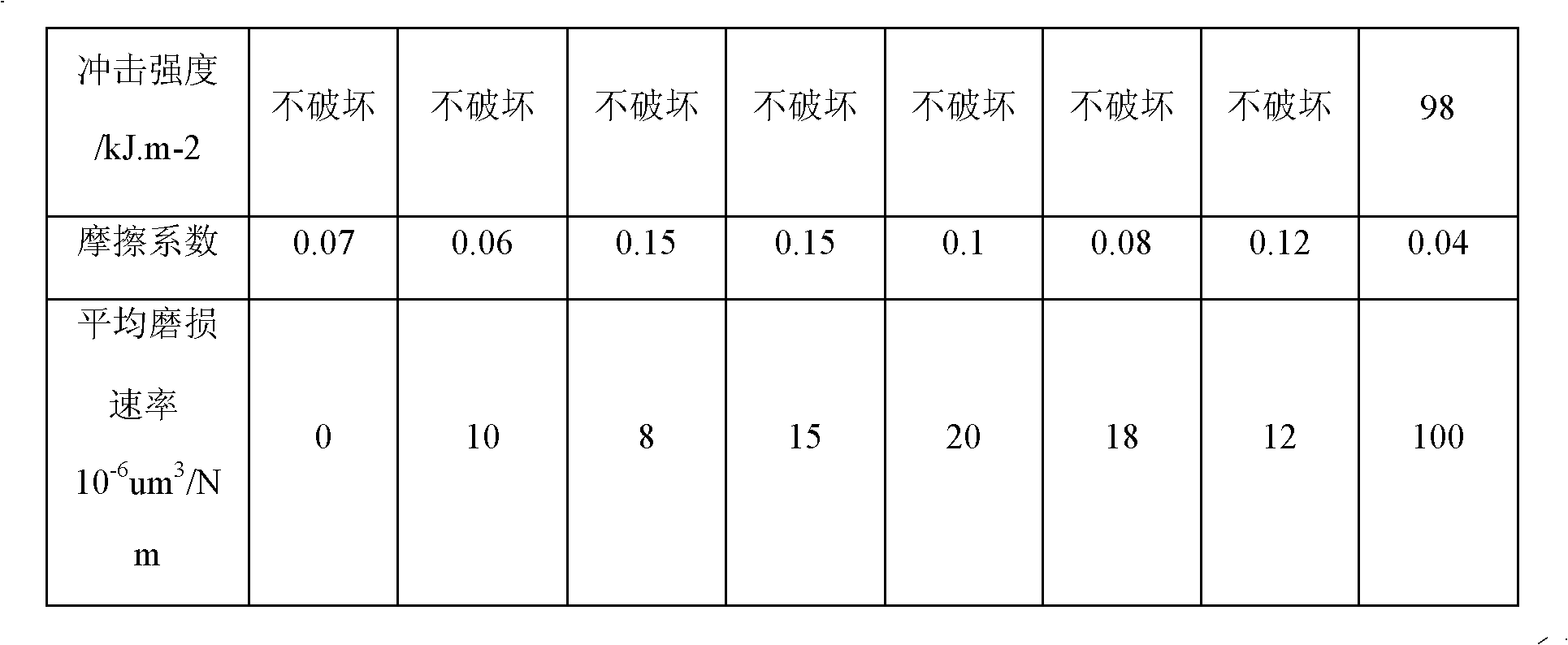

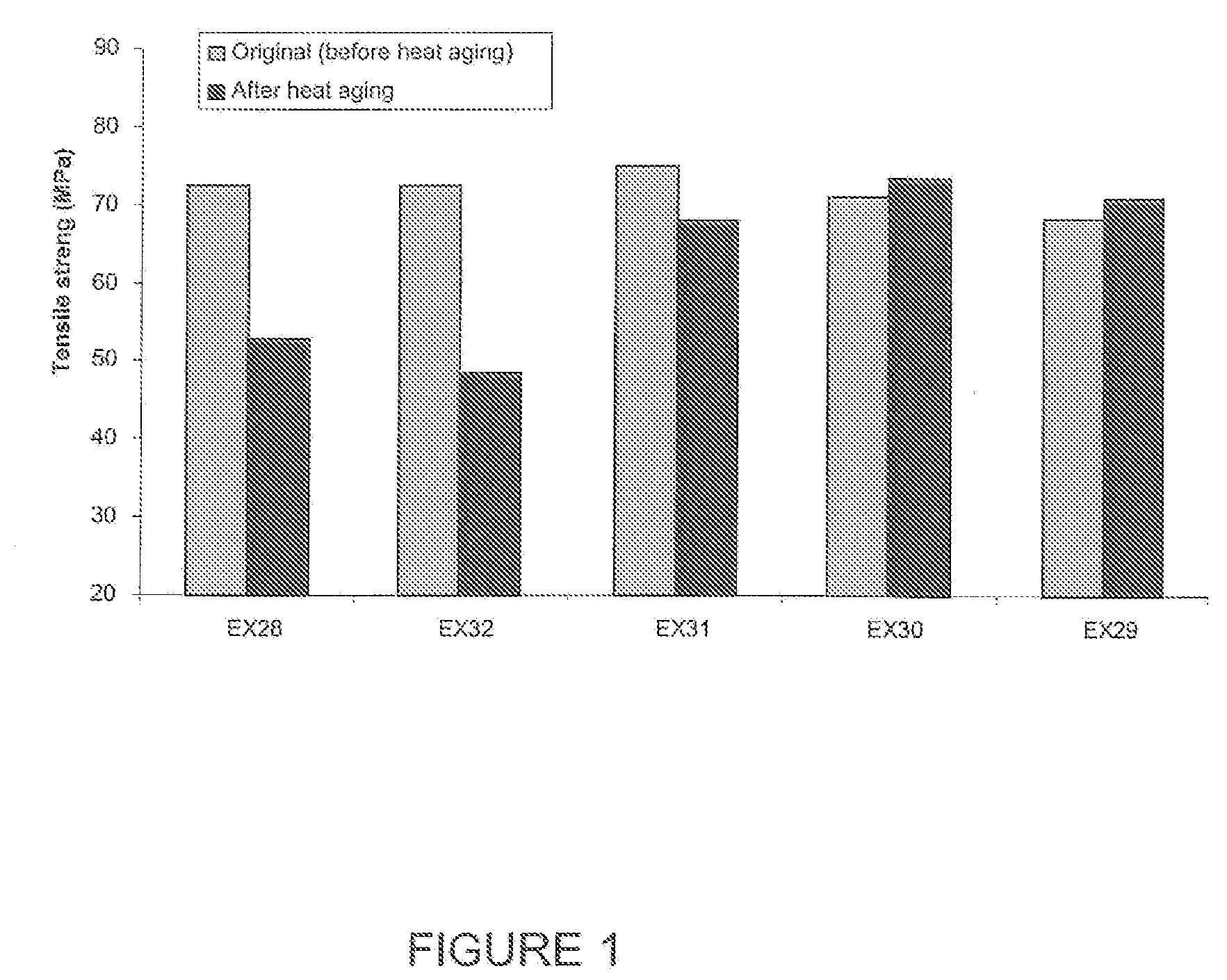

Polyaryletherketone composite material and application of the same in bridge bearing

InactiveCN103013090AImprove wear resistanceImprove the lubrication effectBridge structural detailsBridge materialsFiberHigh wear resistance

The present invention discloses a polyaryletherketone composite material and a preparation method thereof. The polyaryletherketone composite material comprises the following components, by weight, 40-99.8 parts of a polyaryletherketone resin, 0.1-20 parts of a polytetrafluoroethylene resin, 0-20 parts of fibers, 0.1-30 parts of a solid lubricant, and 0-15 parts of a filler, wherein various components are completely mixed and grinded into fine powder, and the fine powder is subjected to molding forming to prepare the material. According to the present invention, polyaryletherketone modification is performed so as to prepare the polyaryletherketone composite material with characteristics of high wear resistance and good lubricity; test results show that an average friction coefficient of the composite material is not higher than 0.15, and an average wear rate is less than 10<-8> mm<3> / Nm; and the polyaryletherketone composite material is made into a bridge bearing used in the bridge field, and a high elasticity polyurethane is matchedly adopted as a pressure bearing plate and sealing ring buffer material so as to substantially improve mechanical properties of the bridge bearing and improve a service life of the bridge bearing.

Owner:CHONGQING CINWO PLASTICS +2

Polyether Ether Ketone/Polyphenylene Sulfide Blend

InactiveUS20080258337A1High retention rateGood chemical resistanceCeramic shaping apparatusPolyether coatingsElectrical conductorPoly ether ether ketone

The present description discloses a polymeric composition which is a melt-processed alloy comprised of (a) a polyarylene sulfide resin, (b) a polyaryl-ether-ketone resin, and a reactive compound which results in (c) a graft copolymer of the polyarylene sulfide resin and / or the polyaryl-ether-ketone resin in addition to the starting resins. Exemplary melt-processed polymeric compositions can be made by reacting an alkoxy silane with the polyarylene sulfide resin and / or the polyaryl-ether-ketone resin to produce a graft copolymer of a portion of one or both of the resins, sufficient to render the composition uniform and homogeneous. It is normally preferred for the exemplary organosilane compound, to be an amino silane. The subject invention further reveals an insulated wire comprising (1) an electrical conductor and (2) a layer of the melt-processed alloy composition; and fiber reinforced composites comprising fibers substantially fully impregnated with the alloy polymeric composition.

Owner:TICONA LLC

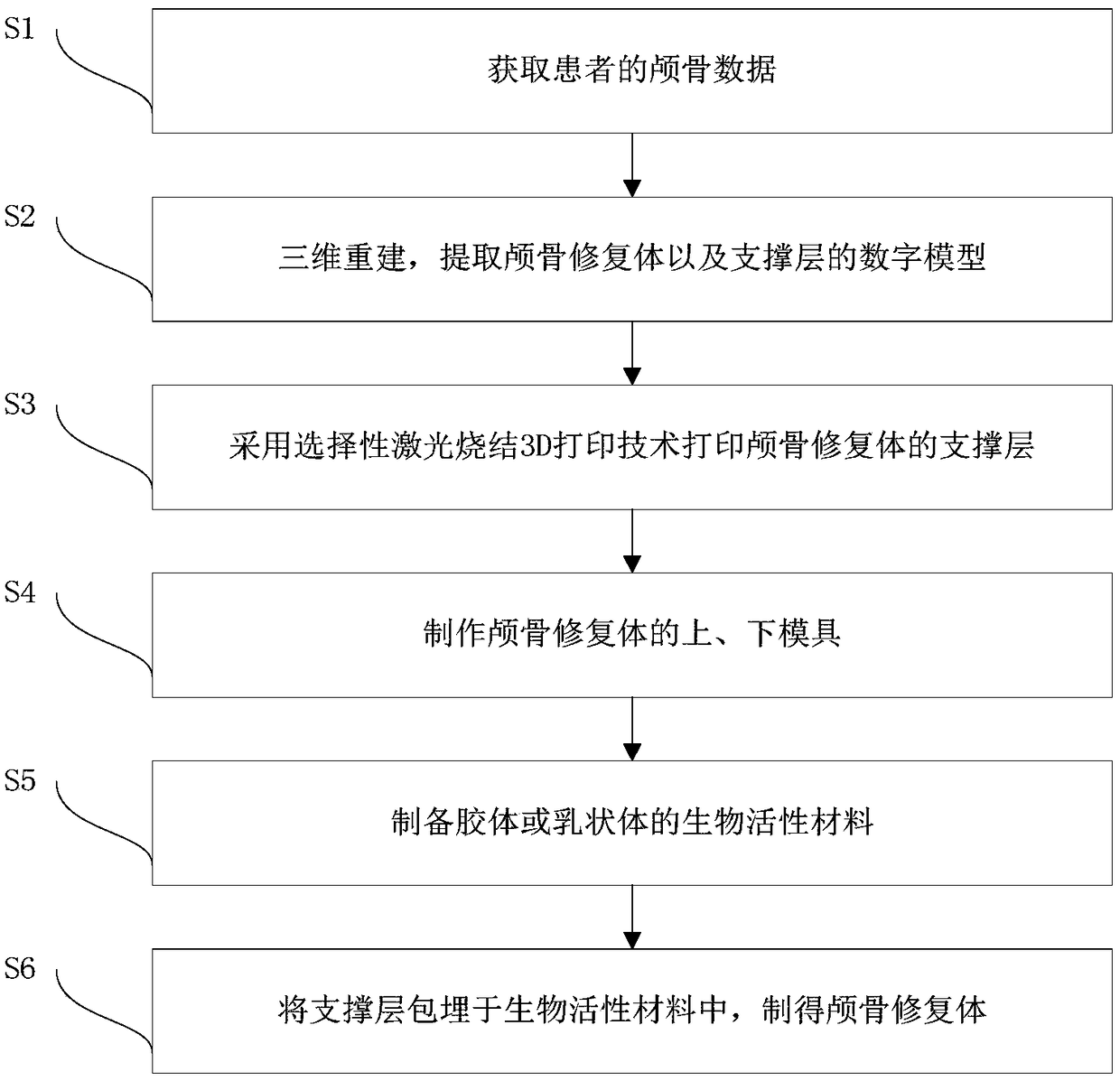

Cranioplasty prosthesis with biological activity and preparation method of cranioplasty prosthesis

InactiveCN104667345AFast productionSmall sizeAdditive manufacturing apparatusCoatingsBiocompatibility TestingDrug biological activity

The invention relates to cranioplasty prosthesis with biological activity and a preparation method of the cranioplasty prosthesis. The cranioplasty prosthesis with biological activity sequentially comprises an unmodified cranioplasty prosthesis layer, a modified cranioplasty prosthesis layer and a nanofiber membrane layer from inside to outside. The invention further provides a preparation method of the cranioplasty prosthesis. By virtue of a three-layer structure and polyaryletherketone materials which are equivalent to a bone of a human body in hardness, strength and weight, are good in biocompatibility, and a 3D printing technology, a cranioplasty prosthesis implant has reliably safety and effectivity and high matching degree. The cranioplasty prosthesis provided by the invention is capable of loading a plurality of bionic scaffolds and bioactive substances, and promoting exchange of nutrient substances inside and outside the prosthesis, and is beneficial to growth of tissues.

Owner:MEDPRINSHENZHEN REGENERATIVEA MEDICAL TECH CO LTD

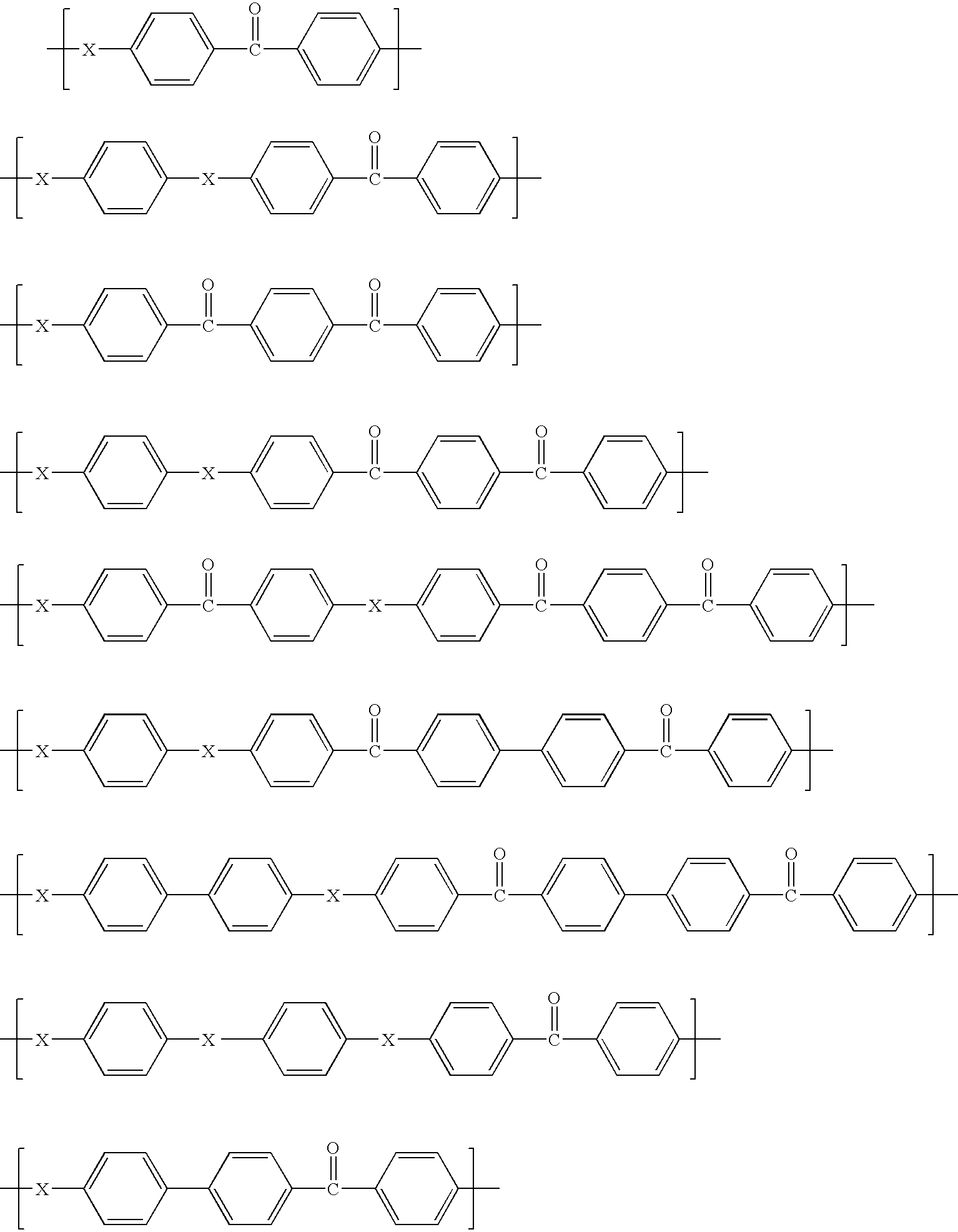

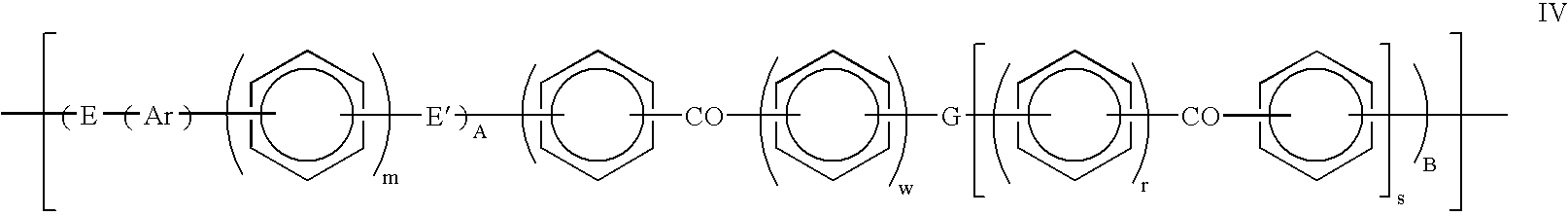

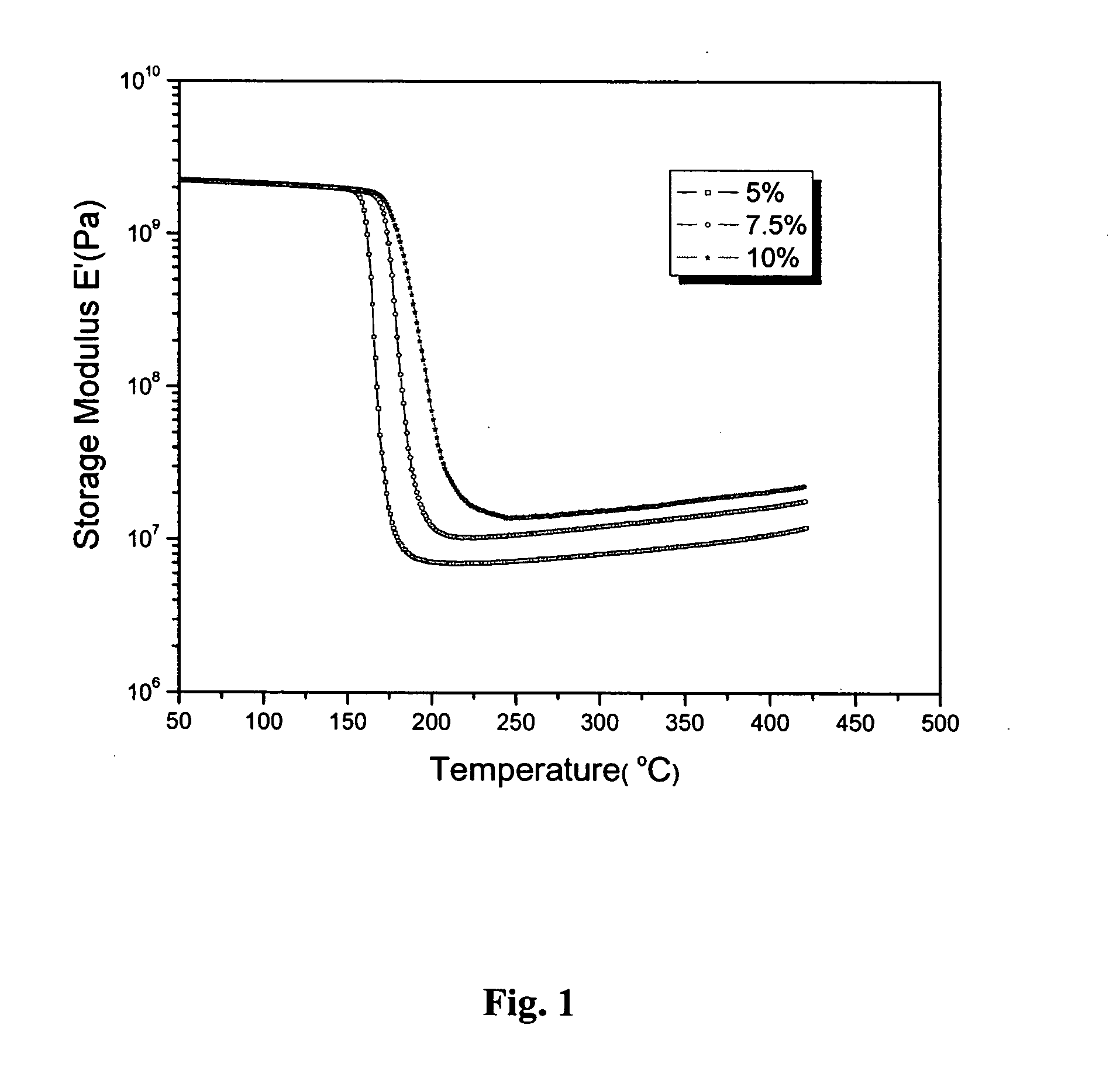

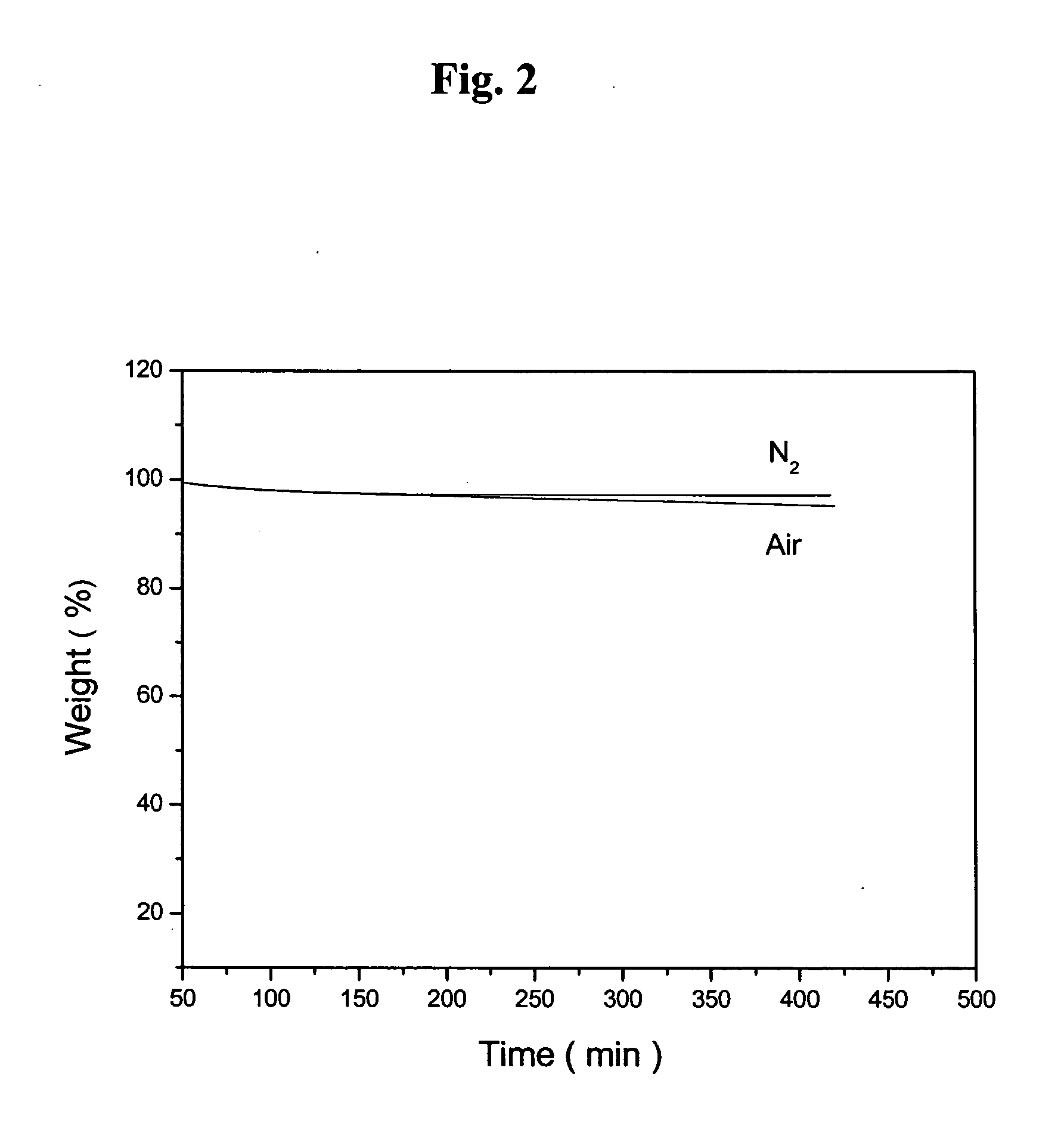

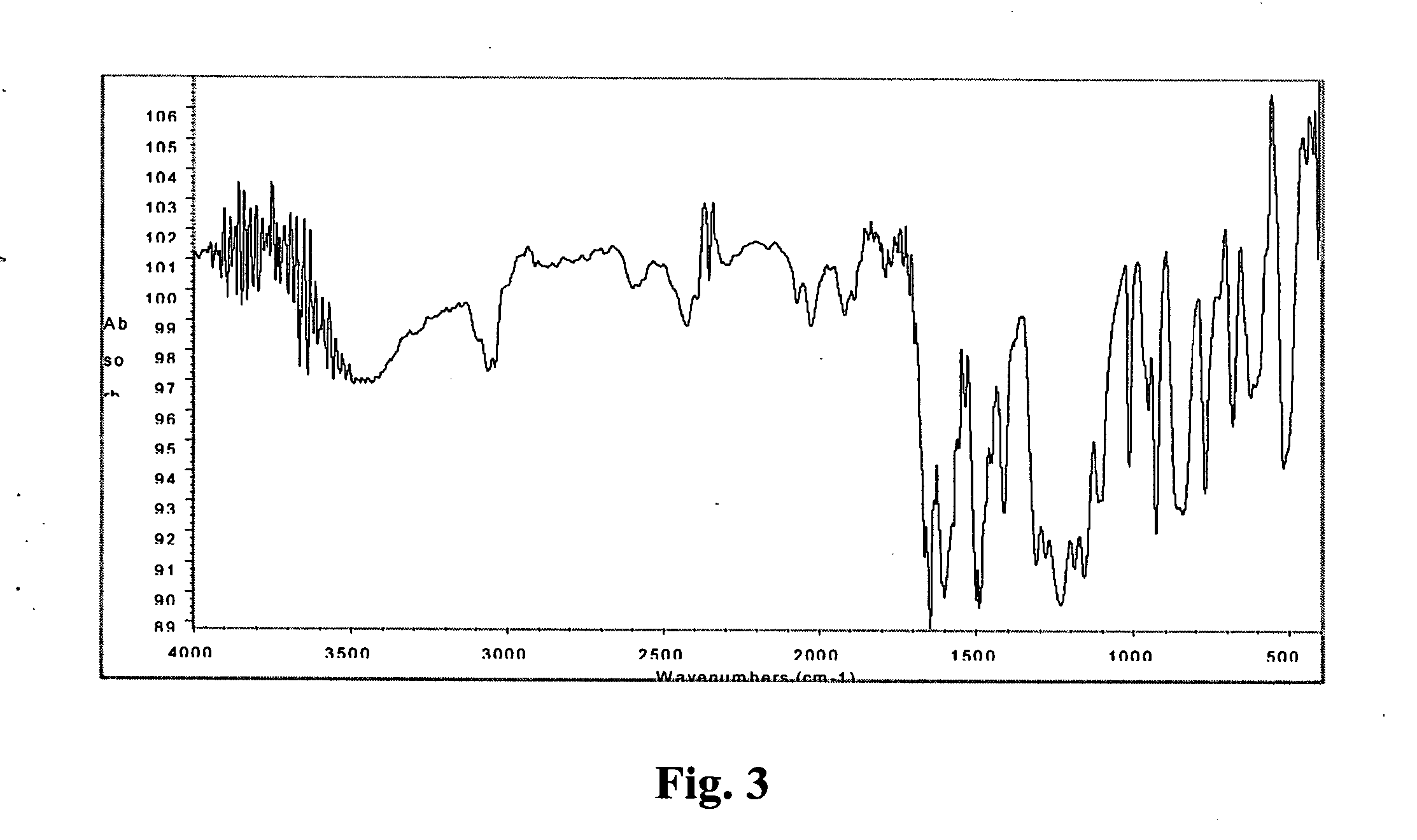

Novel controlled crosslinked polyaryletherketone material with improved properties and a process for producing the same

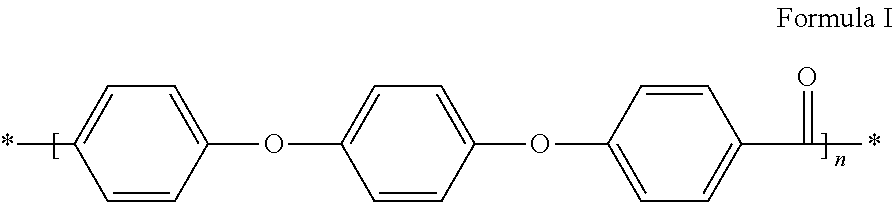

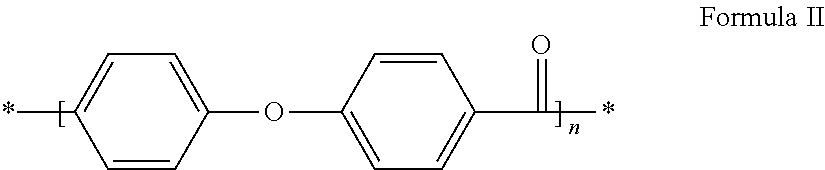

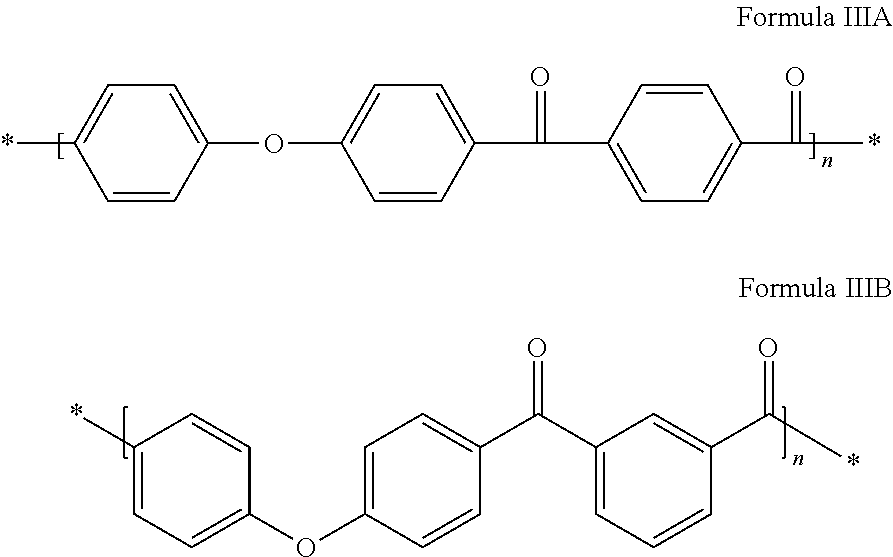

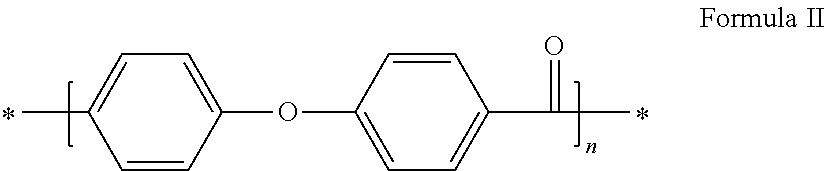

The present invention relates to a controllable crosslinking polyaryletherketone with improved properties such as stiffness, heat resistance, and stability as shown by any one of the following structures:

Owner:JILIN UNIV

Aromatic ring-shaped polyether-ketone oligomer and preparation method thereof

The invention relates to an aromatic ring-shaped polyether-ketone oligomer and a preparation method thereof. Under 'pseudo-high dilution' condition, Friedel-Crafts-Karrer electrophilic reaction is utilized to open up a new route of taking carbon tetrachloride and substituted aromatic hydrocarbon monomers as basic raw materials to synthesize commercial, helicrystalline macrocylic oligomers of high-performance PEEK and PEK, namely the aromatic ring-shaped polyether-ketone oligomer with high yield. The aromatic ring-shaped oligomer can be melted and subjected to ring opening polymerization under the initiation of an anion initiator to obtain high-performance linear polyaryletherketone by using a cyclic structure and low melt viscosity peculiar to the aromatic ring-shaped oligomer. By the combination of low cost and high performance, the aromatic ring-shaped polyether-ketone oligomer and the synthetic route thereof has important application in the field of preparation of high-performance composite materials.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

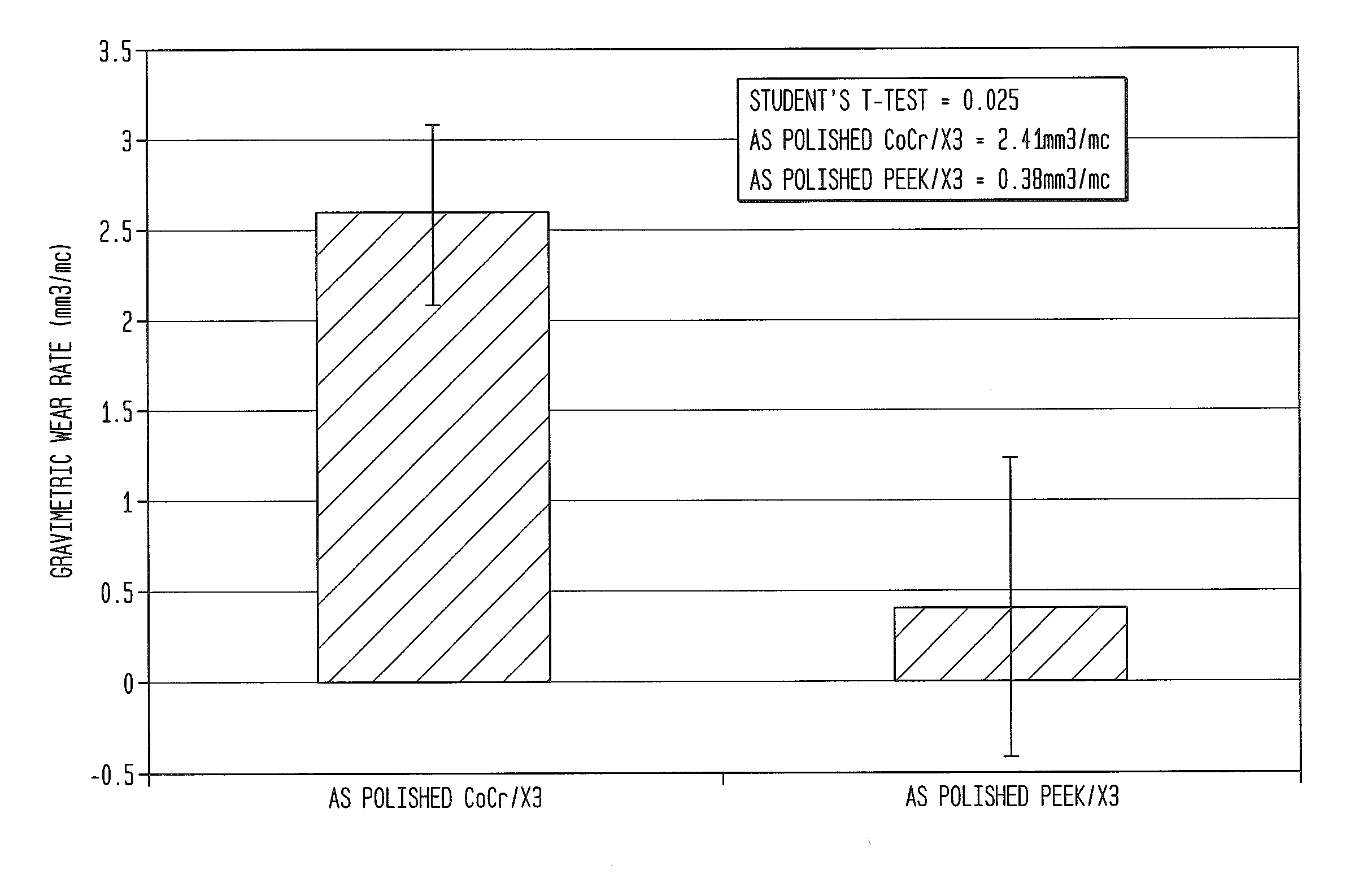

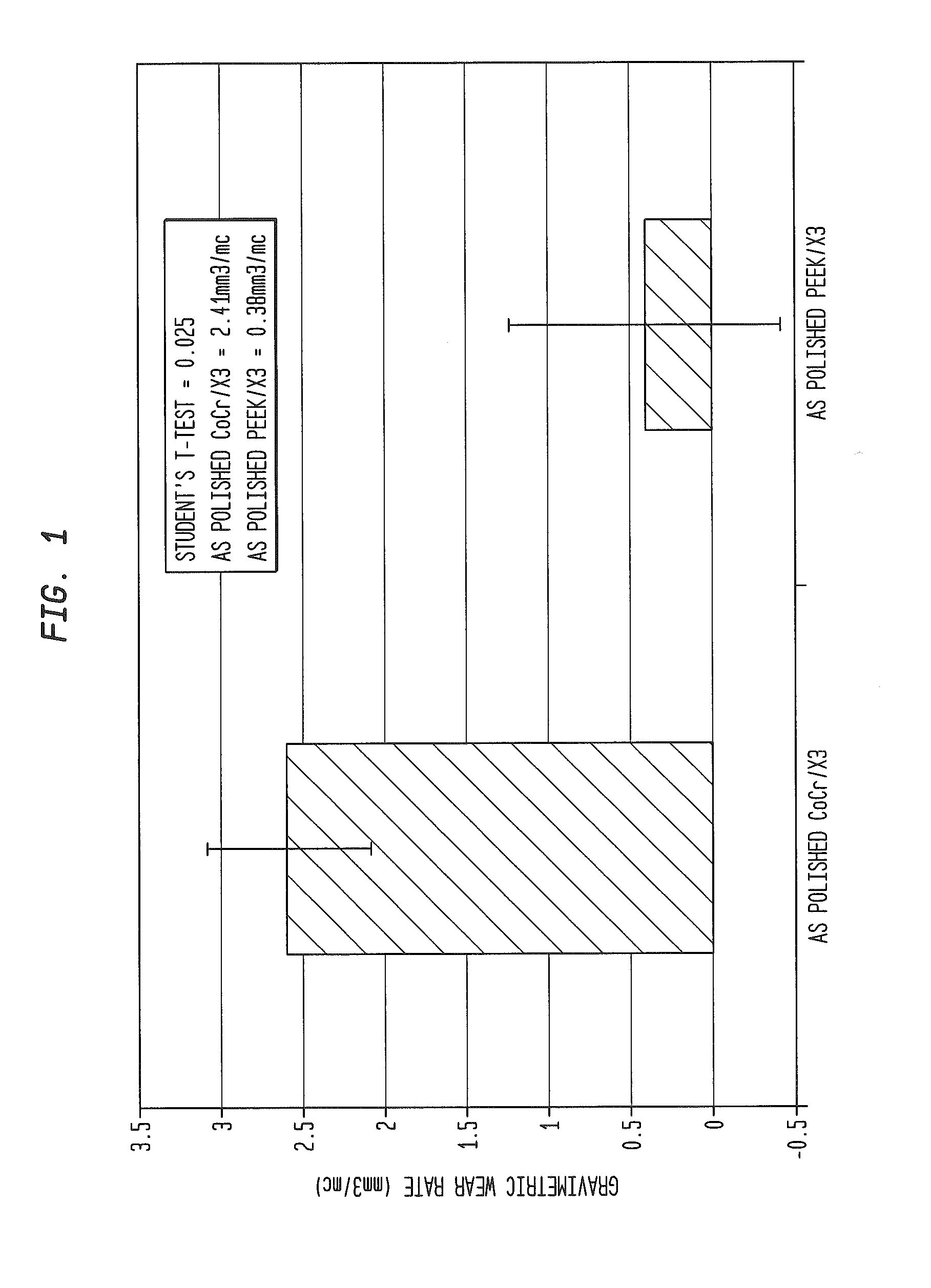

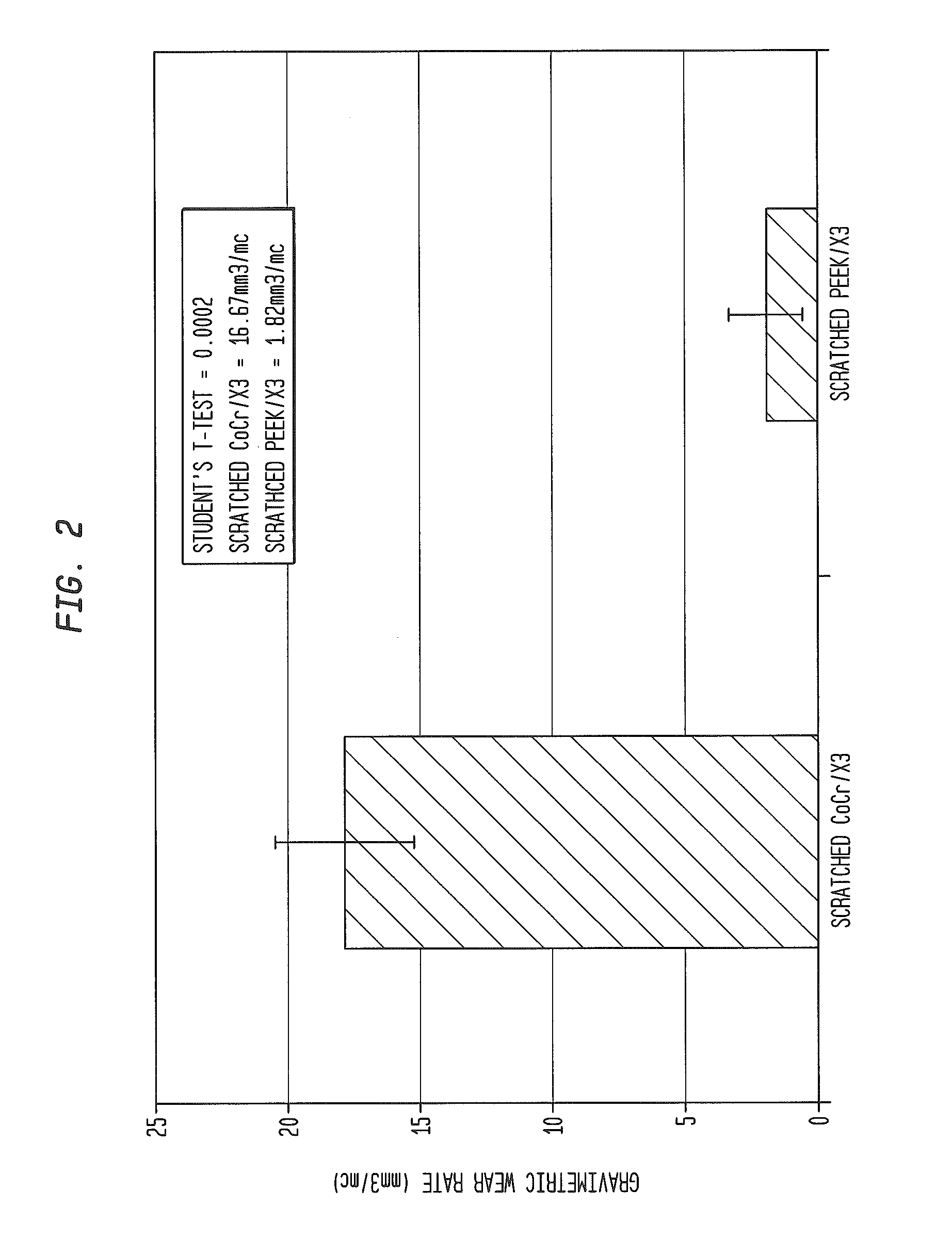

Orthopedic paek-on-polymer bearings

ActiveUS20100312348A1Eliminate the problemNo releaseAnkle jointsJoint implantsJoint componentProsthesis

An orthopedic prosthetic joint comprising a joint couple having a first bearing surface made of a poly aryl ether ketone (PAEK) and a second joint component having a second bearing made of a polymer that is softer than the PAEK such as UHMWPE the first and second bearing surfaces in sliding engagement with one another.

Owner:HOWMEDICA OSTEONICS CORP

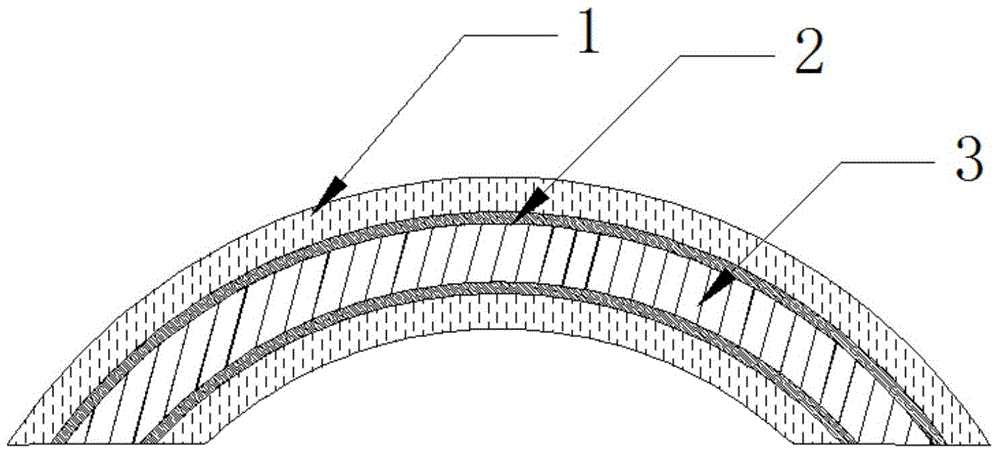

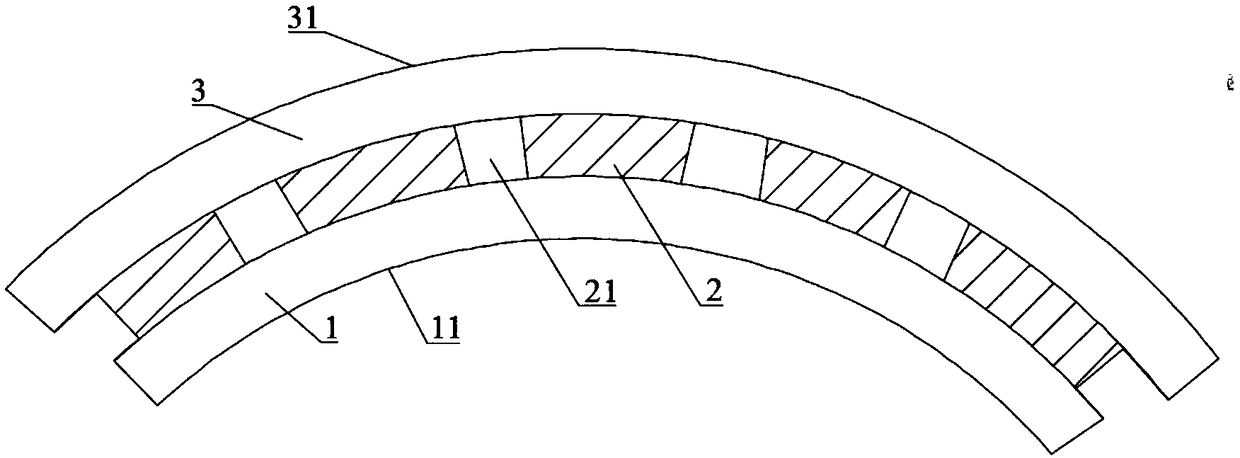

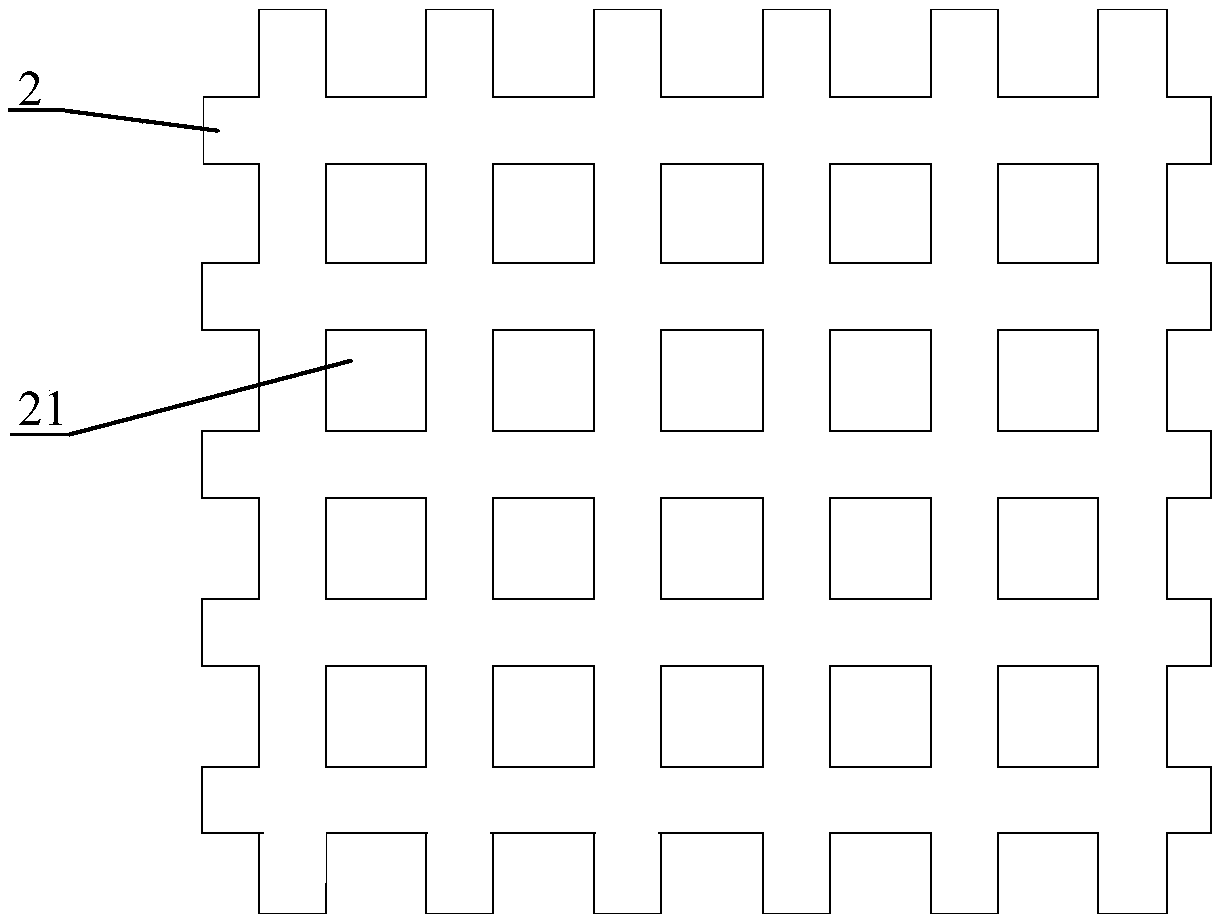

A skull restoration body for inducing bone regeneration and a preparation method thereof

PendingCN109223248APromote ingrowthImprove biological activityJoint implantsTomographyBone tissueProsthesis

The invention relates to the technical field of medical devices, in particular to a skull restoration body for inducing bone tissue regeneration and a preparation method thereof. The skull restorationbody has biological activity and comprises an inner inducing layer, a supporting layer and an outer inducing layer sequentially from the inside to the outside. The support layer is made of polyaryletherketone material which is equivalent to human bone strength, hardness and weight, and plays a supporting role. The inner inducing layer and the outer inducing layer are made of bioactive material, respectively arranged on the inner surface and the outer surface of the supporting layer, have good bioactivity and osteoinductivity, and can induce bone tissue regeneration. The support layer is provided with a plurality of mesh holes, and each mesh hole is filled with a bioactive material, which can promote the exchange of nutrients inside and outside the skull repair body, and is conducive to the growth of tissue. The preparation method of the skull prosthesis builds a digital model according to the skull data of the patient, so that the skull prosthesis and the skull defect part have high matching degree, and the operation difficulty is reduced.

Owner:BEIJING ALLGENS MEDICAL SCI & TECH

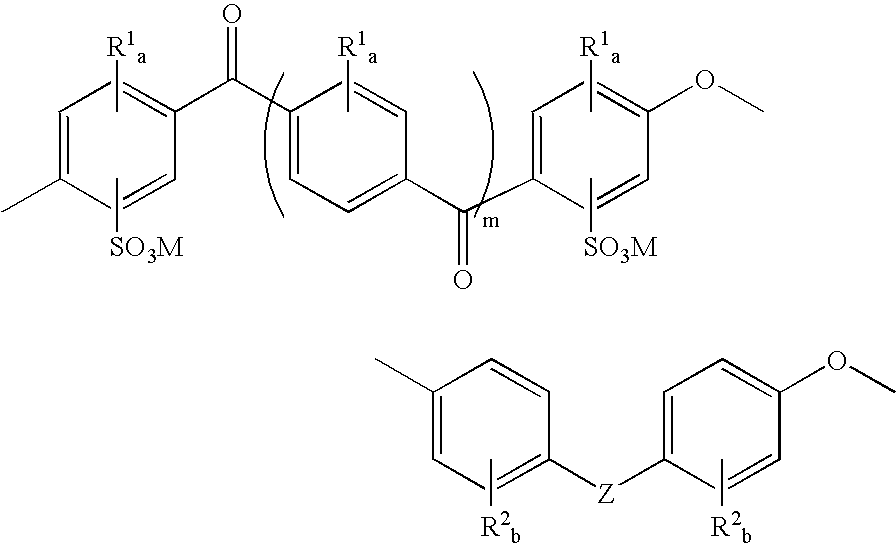

Sulfonated polyaryletherketone-polyethersulfone block copolymers

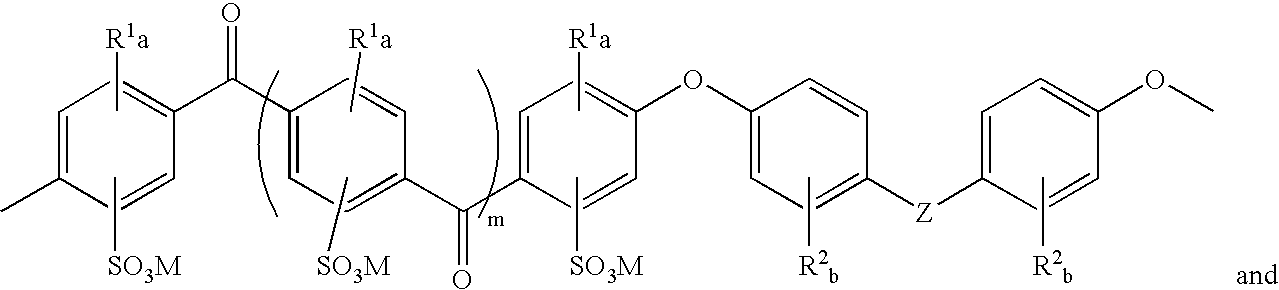

Sulfonated block copolymer suitable for use as proton exchange membranes for fuel cells comprise sulfonated polyaryletherketone blocks and polyethersulfone blocks. The sulfonated polyaryletherketone blocks comprise structural units of formula the polyethersulfone blocks comprising structural units of formula wherein R1, R2, R3 and R4 are independently C1-C10 alkyl, C3-C12 cycloalkyl, C6-C14 aryl, allyl, alkenyl, alkoxy, halo, or cyano; Z and Z1 are independently a direct bond or O, S, (CH2)r, (CF2)r, C(CH3)2, C(CF3)2, or a combination thereof; M is H, a metal cation, a non-metallic inorganic cation, an organic cation or a mixture thereof a is 0 or an integer from 1 to 3; b, c and d are independently 0 or an integer from 1 to 4; m and n are independently 0 or 1; and r is an integer from 1 to 5.

Owner:GENERAL ELECTRIC CO

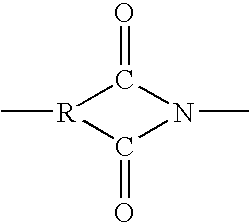

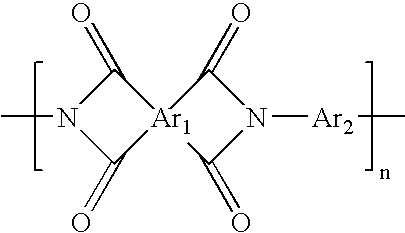

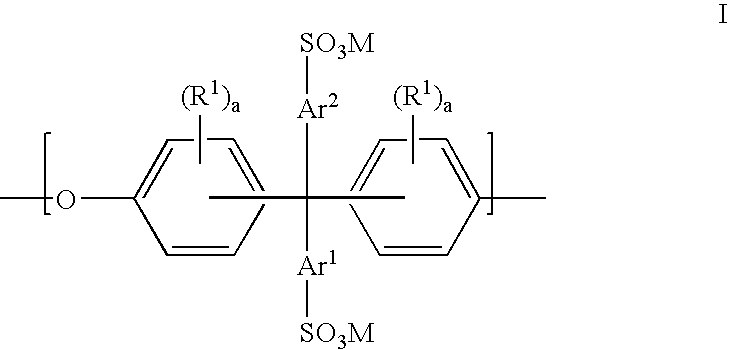

Sulfonated polyaryletherketone-block-polyethersulfone copolymers

Sulfonated block copolymer suitable for use as proton exchange membranes for fuel cells comprise sulfonated polyaryletherketone blocks and polyethersulfone blocks. The sulfonated polyaryletherketone blocks comprise structural units of formula Iwherein R1 is C1-C10 alkyl, C3-C12 cycloalkyl, C6-C14 aryl, allyl, alkenyl, alkoxy, halo, or cyano;Ar1 and Ar2 are each independently C6-C20 aromatic radicals, or Ar1 and Ar2, taken together with an intervening carbon atom, form a bicyclic C6-C20 aromatic radical or a tricyclic C6-C20 aromatic radical;M is H, a metal cation, a non-metallic inorganic cation, an organic cation or a mixture thereof; anda is 0 or an integer from 1 to 4.

Owner:GENERAL ELECTRIC CO

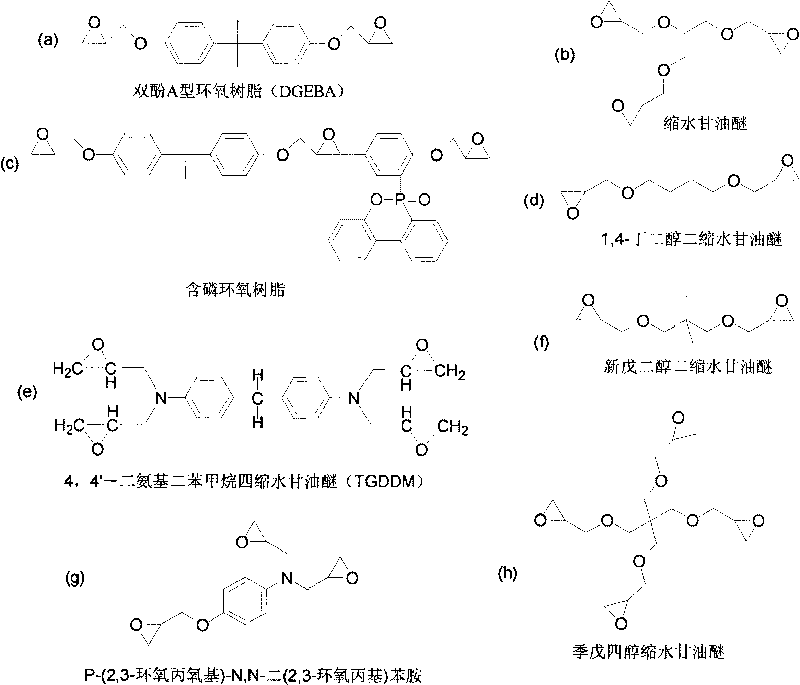

Epoxy crosslinking sulfonated polyaryletherketone proton exchange membrane material and preparation method thereof

InactiveCN101724165AHigh mechanical strengthImprove conductivitySemi-permeable membranesFuel cell detailsCross-linkEpoxy

The invention discloses an epoxy crosslinking sulfonated polyaryletherketone proton exchange membrane material and a preparation method thereof. The preparation of the material comprises the following steps: reducing and modifying sulfonated polyaryletherketone to obtain hydroxide radical functionalized sulfonated polyaryletherketone; then preparing the modified polymer into solution and adding moderate amount of epoxy resin and catalyst to the solution; finishing solvent removing and cross-linking reaction in the process of membrane formation so as to obtain epoxy cross-linking polymer electrolyte membrane material. The electrolyte membrane material of the invention features good dimensional stability, electrical conductivity, alcohol-preventing property, mechanical strength and heat-resistant quality and enjoys significant application value in fields such as Proton Exchange Membrane Fuel Cells (PEMFC), Direct Methanol Fuel Cells (DMFC), ion exchange resin, sensors membrane separation and the like.

Owner:TSINGHUA UNIV

Method of grinding poly(aryl ether ketones)

The present invention relates to an improved method of grinding polyaryletherketones, providing very good yields and the production of powders of polyaryletherketones with an average diameter below 100 μm having a narrow size distribution with few fine particles (Dv10>15 μm).

Owner:ARKEMA FRANCE SA

Method for synthesizing polyaryletherketones

InactiveUS20150183918A1Reduce depositionImprove thermal stabilityAdditive manufacturing with solidsEtherKetone

The invention relates to a process for synthesizing polyaryl ether ketones with low contents of residual materials, whether they are residual monomers or solvents of the synthetic process.

Owner:ARKEMA FRANCE SA

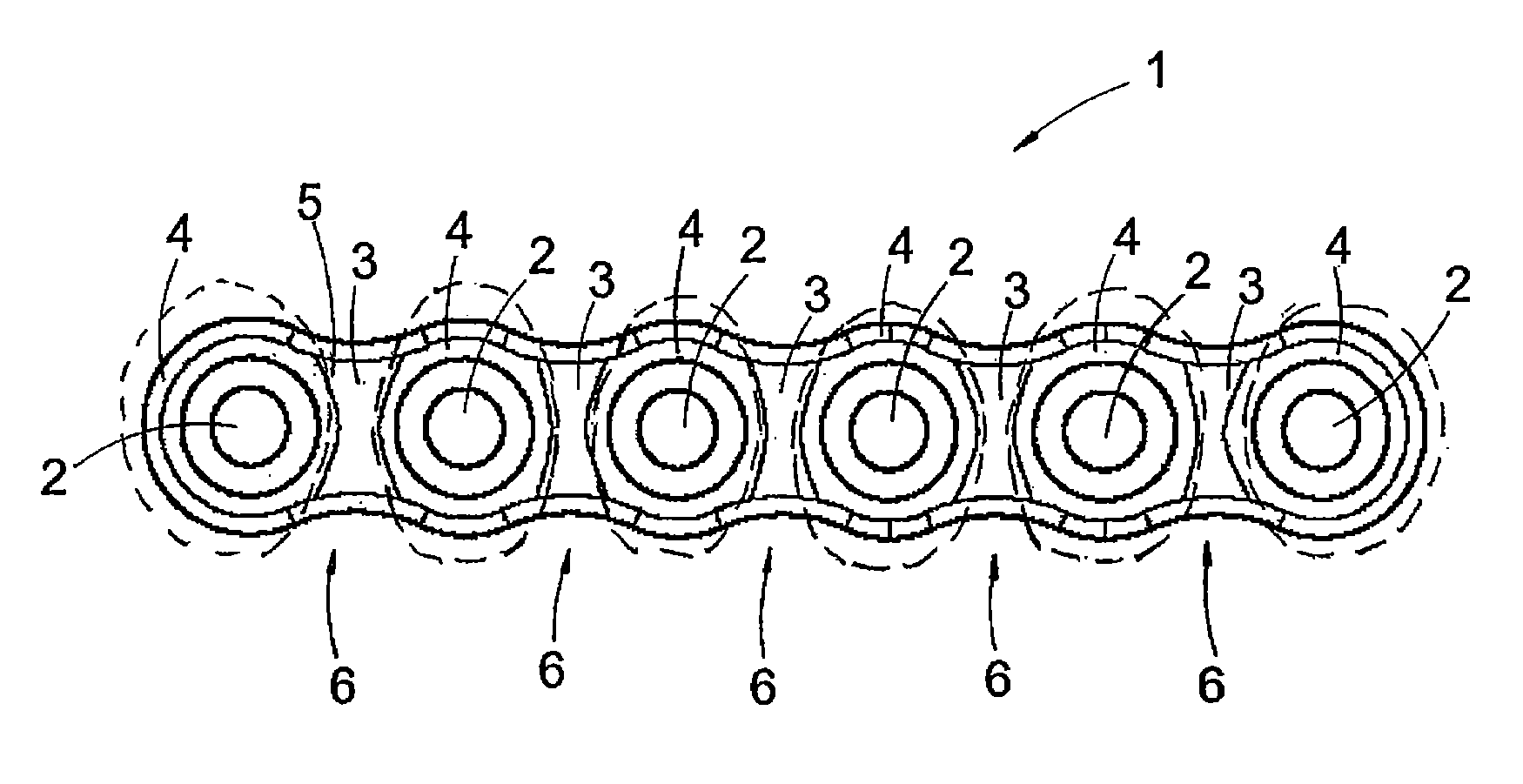

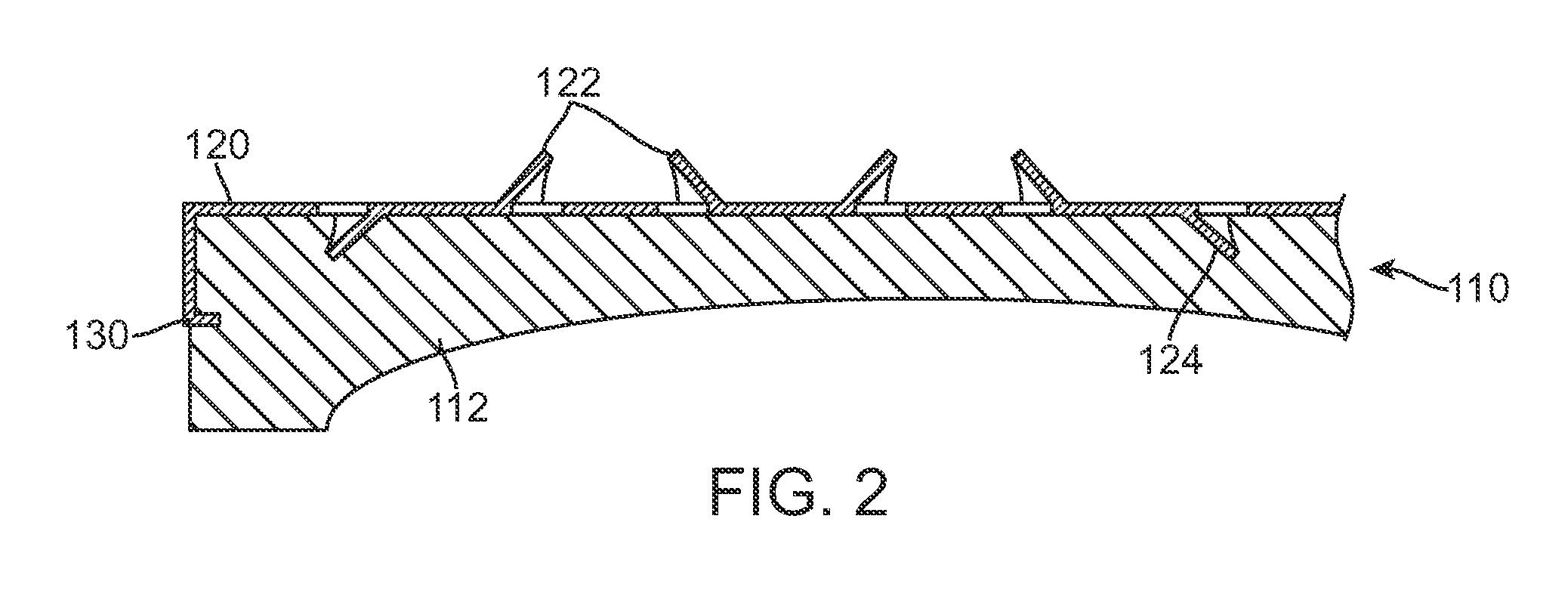

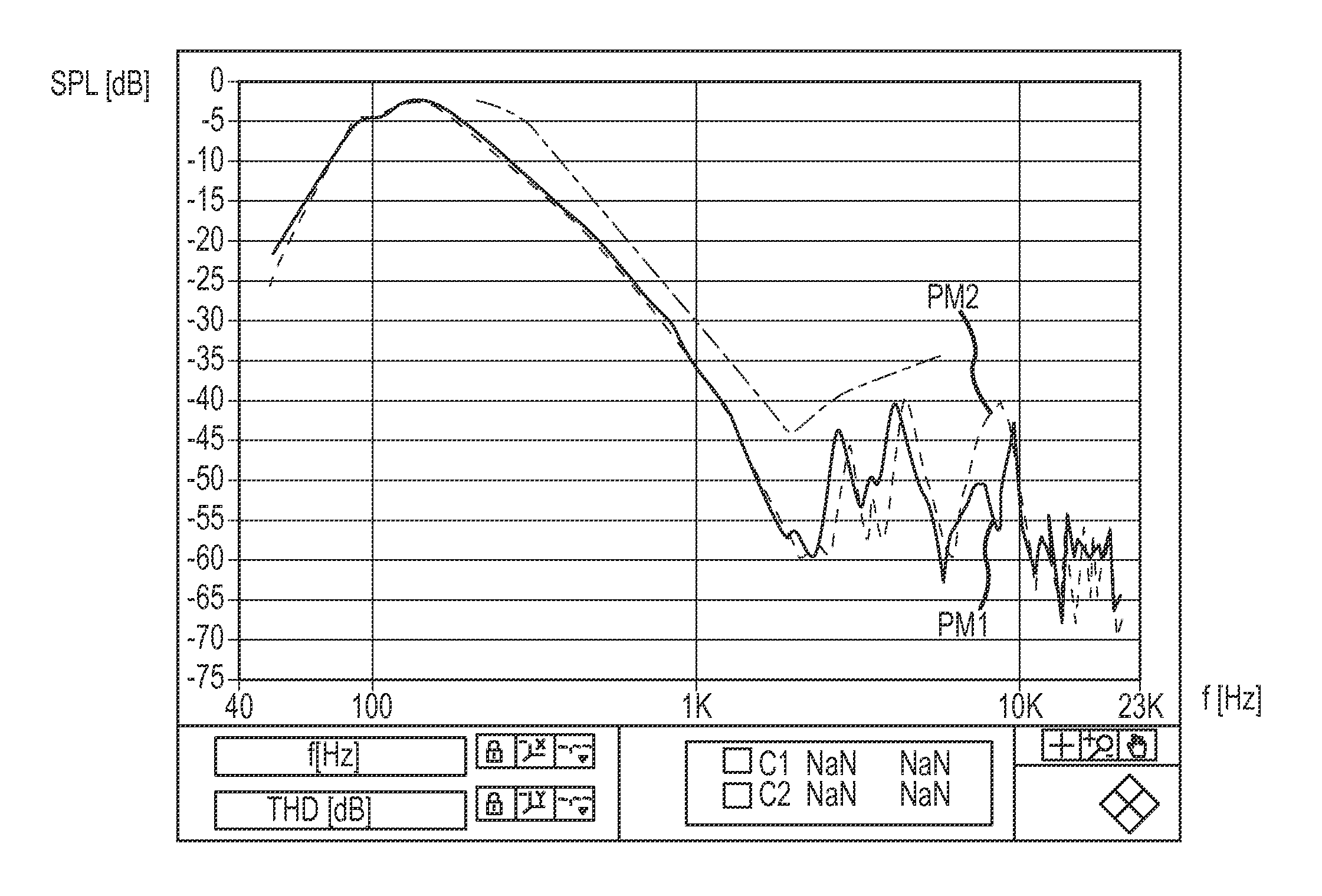

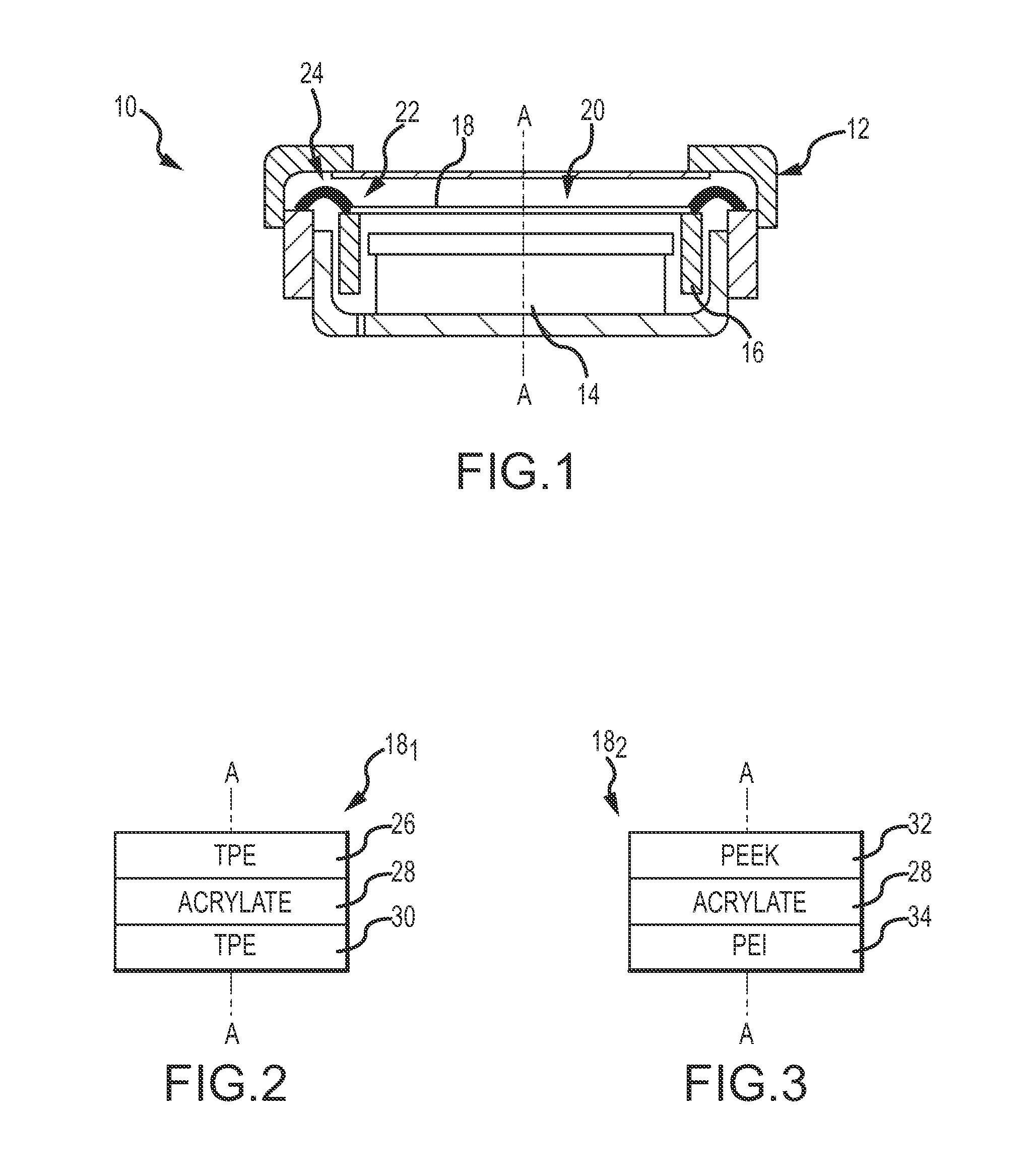

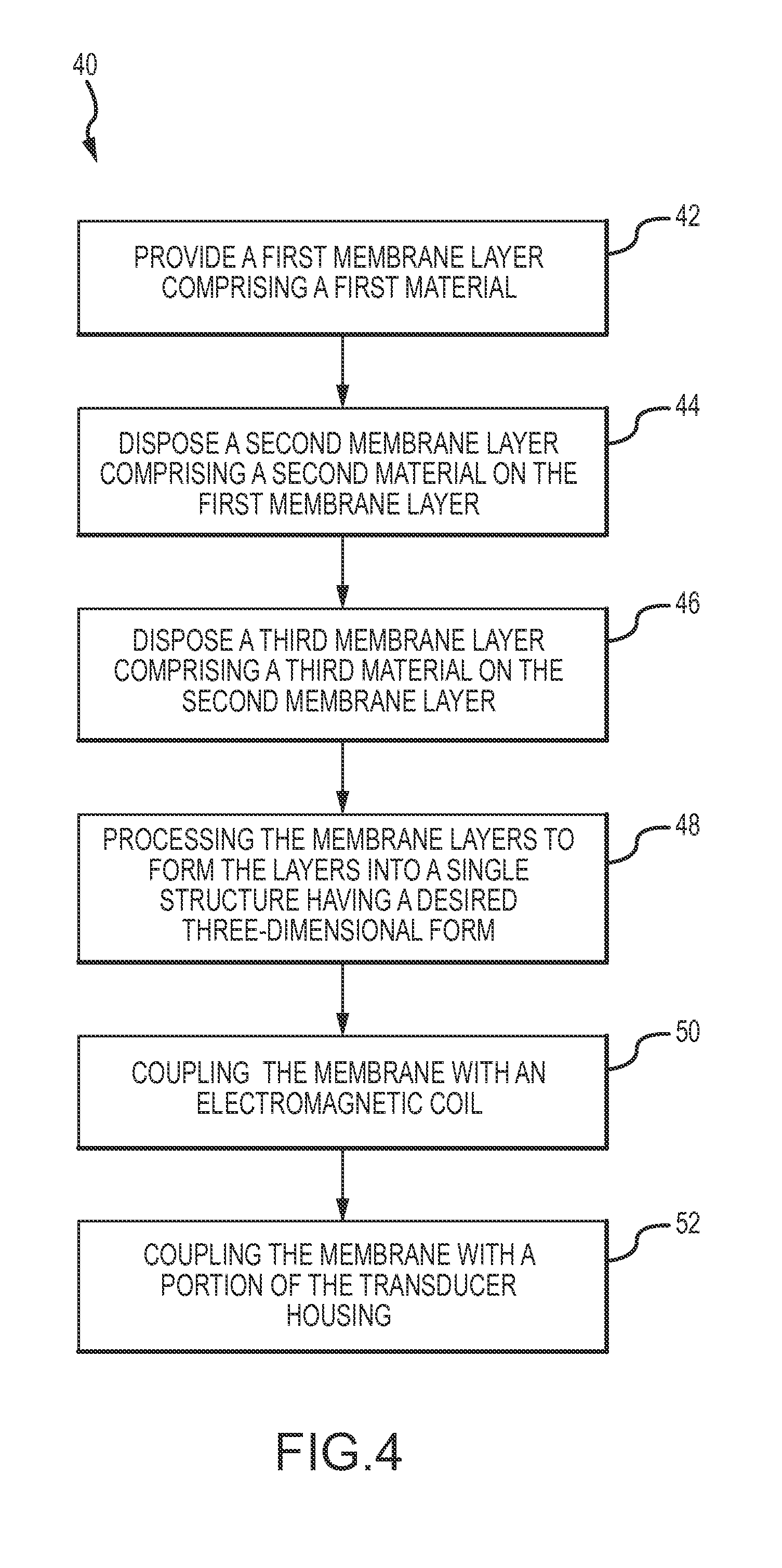

Acoustic membrane with asymmetric layer arrangement

InactiveUS20150312660A1Improve sound reproductionImprove thermal stabilityEngine sealsTransducer detailsPolyetherimideTransducer

A membrane for an acoustic transducer may comprise a first layer comprising a first material, a second layer disposed on the first layer, the second layer comprising a second material that is different from the first material, and a third layer disposed on the second layer, the third layer comprising a third material that is different from the first material and the second material, the third layer configured to be coupled with a moveable coil. The first material may be a polyaryletherketone (PAEK), the second material may be acrylate, and the third material may be polyetherimide (PEI), polycarbonate (PC), or another similar material.

Owner:SOUND SOLUTIONS INTERNATIONAL COMPANY LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com