Patents

Literature

1146 results about "Poly ether ether ketone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyether ether ketone (PEEK) is a high performance thermally stable thermoplastic. It is strong, stiff, and hard, has good chemical resistance, and inherently low flammability and smoke emission.

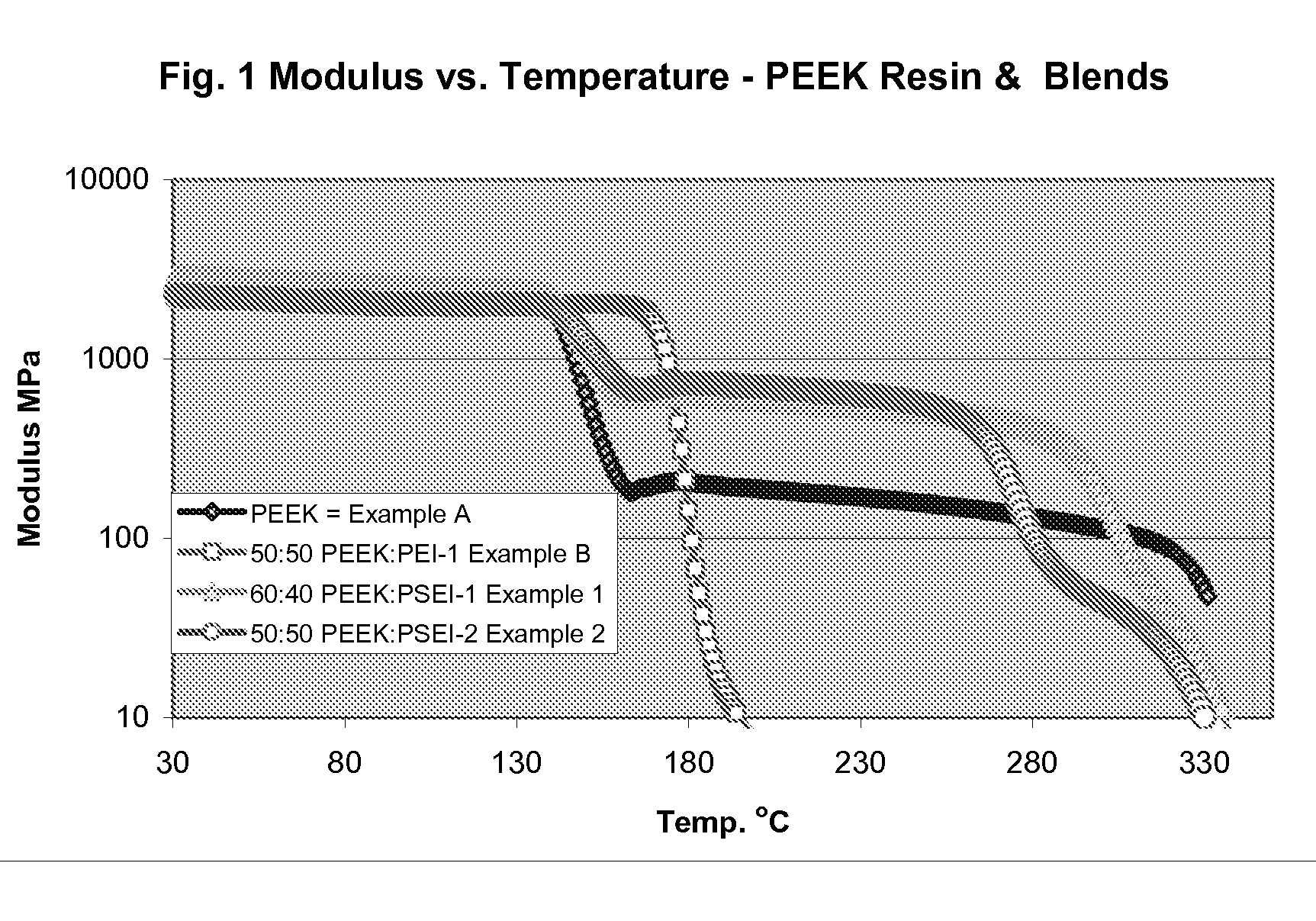

Poly aryl ether ketone polymer blends

Filled phase-separated blends of polyaryl ether ketones, polyaryl ketones, polyether ketones, polyether ether ketones and mixtures thereof with at least one polysulfone etherimide, wherein the polysulfone etherimide has greater than or equal to 50 mole % of the polymer linkages contain at least one aryl sulfone group are described. Such filled blends have improved load-bearing capability at high temperature. In another aspect the filled blends have a higher crystallization temperature, especially at fast cooling rates.

Owner:SABIC GLOBAL TECH BV

Method for purifying poly ether-ether-ketone

InactiveCN1640911AEasy to buyEase of industrial mass productionChemical recyclingVitrificationPoly ether ether ketone

The normal pressure poly(ether-ether-ketone) purifying process includes the technological steps of purification, suction filtering and washing, and drying. During purification, metered poly(ether-ether-ketone) and metered organic solvent and surfactant used as purifying treating agent and purifying assistant separately inside reactor are heated at normal pressure to the temperature between the vitrification point of poly(ether-ether-ketone) and the boiling point of the purifying treating agent for purification for at least 1 hr. Then, the temperature is lowered to below 100 deg.c, and the product is suction filtered, washed with boiling acetone, absolute alcohol and deionized water, and dried to obtain high purity poly(ether-ether-ketone) product. The said process can lower the content of inorganic ion in poly(ether-ether-ketone) product.

Owner:SICHUAN UNIV

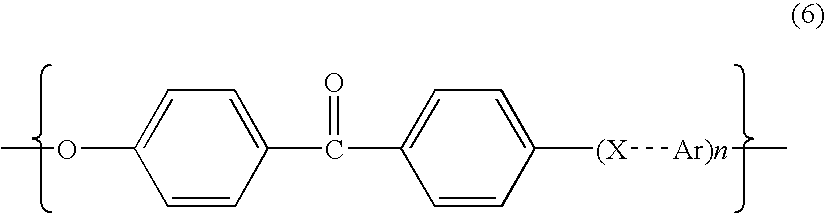

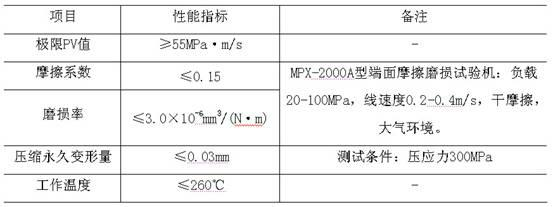

Poly(ether-ether-ketone) composite material, production method and application of sealing member

The invention relates to a polyether-ether-ketone composite material which consists of polyether-ether-ketone, nanoparticles, filling materials and addition agent materials. The composite material comprises 75 to 95 portions of polyether-ether-ketone powders, 5 to 10 portions of the nanoparticles, 10 to 20 portions of the filling materials and 2 to 5 portions of the additive agents by weight. The filling materials are glass fiber, carbon fiber, quartz powder and MoS2 or toner. A method of compression moulding forming adopted is that: materials is prepared according to the formula; materials are mixed: the materials prepared according to designed requirements poured into an automatic material mixing machine for evenly mixing, the mixing time is between 0.5 minute and 3 minutes, then compressing process is carried out, and the blended mixture is sent to a mould cavity for moulding. The material can be used for sealing materials products. Various valve sealing elements produced by the invention has properties of creep resisting, corrosion resistance, heat resistance and pressurization, etc.; the ability of pressurization and wear resistance of the material are improved, and at the same time the cost is lowered by 10 to 20 percent or even higher, thus being beneficial to using and promotion of the materials.

Owner:NANJING COMPTECH COMPOSITES CORP

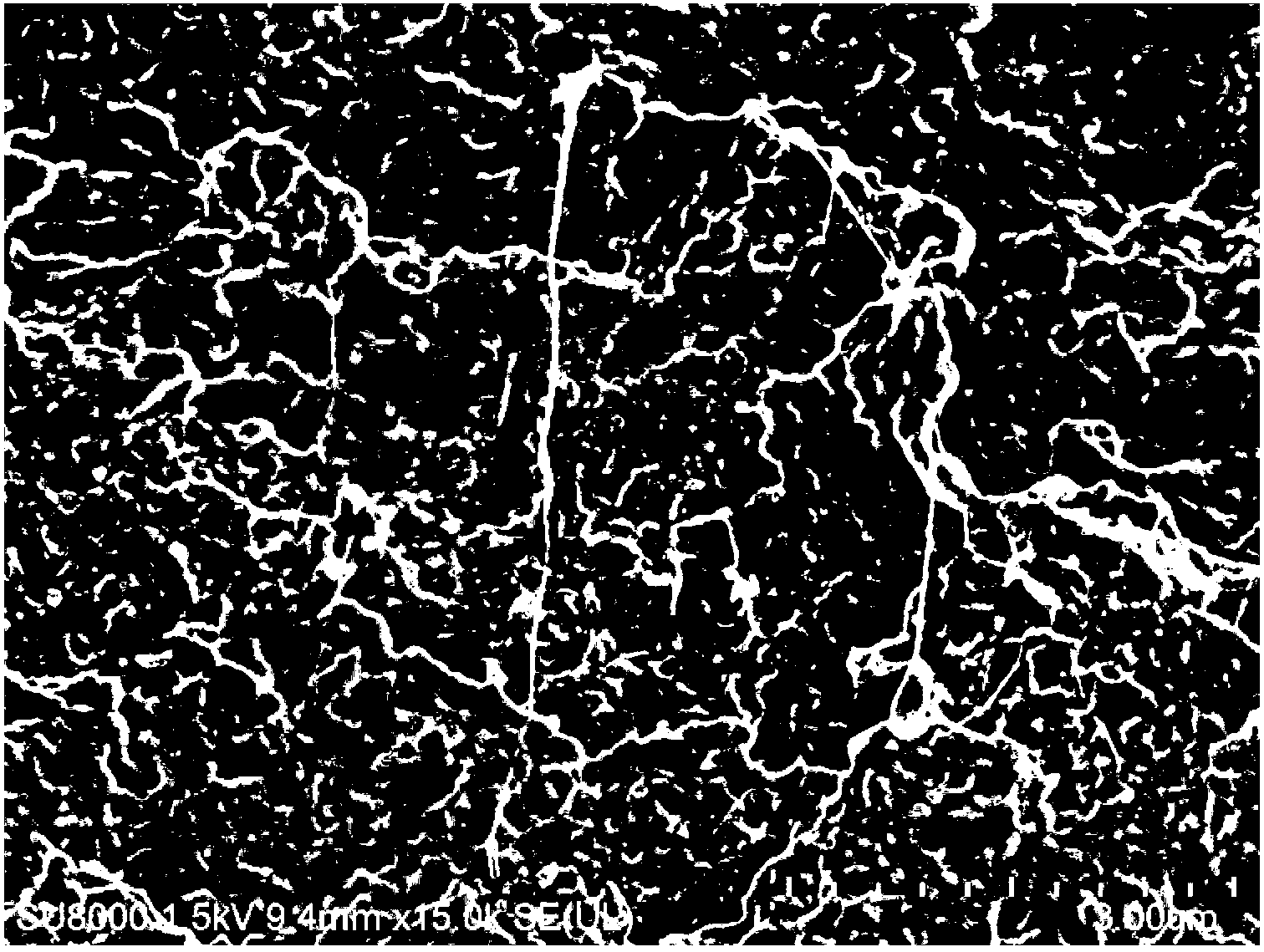

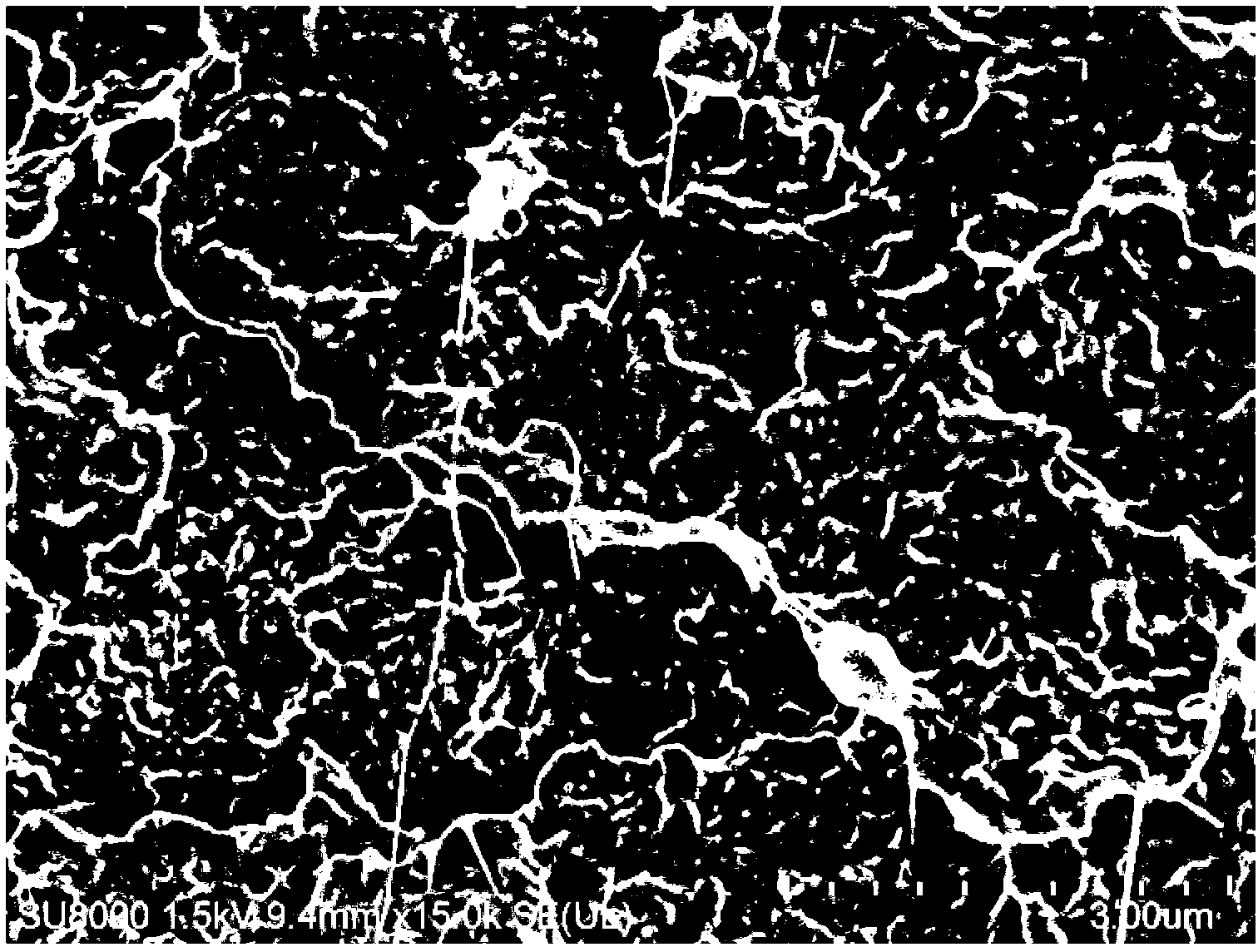

Preparation method of polyether-ether-ketone/graphene oxide nano-composite film

InactiveCN102827386ASolve the problem of fragmentationSimple processPolymer sciencePoly ether ether ketone

The invention belongs to a preparation method of a functional polymer and relates to a preparation method of a polyether-ether-ketone / graphene oxide nano-composite film. The polyether-ether-ketone / graphene oxide nano-composite film is prepared by blending graphene oxide treated by a silane coupling agent, and sulfonated polyether-ether-ketone by a tape casting method, and has high strength and good anti-wear and friction reduction effects. The polyether-ether-ketone / graphene oxide nano-composite film obtained by the preparation method solves the problem of organic and inorganic interface dispersion caused by other preparation methods, and realizes organic / inorganic nano-material compounding in a molecular level. The preparation method has simple processes, is convenient for operation, can be industrialized easily, and has potential application values in fields of structural materials, friction materials, heat-resistant materials and barrier materials.

Owner:JIANGSU UNIV

Coated Implants

InactiveUS20090276053A1Increase pressureGood adhesionBone implantJoint implantsPoly ether ether ketoneMedicine

An implantable device which provides structural support for the skeletal system, such as the spine, coated with hydroxyapatite (HA). This invention provides a mechanically and bioactively functional coating of hydroxyapatite (HA) without altering the biocompatibility profile of the poly-ether-ether-ketone (PEEK) substrate.

Owner:PIONEER SURGICAL TECH INC

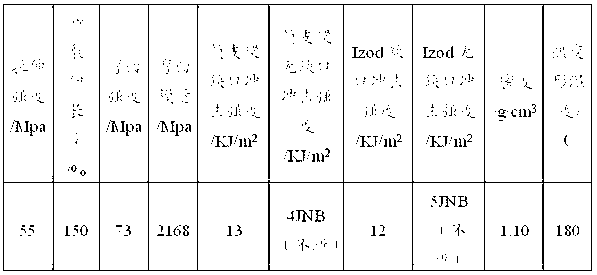

Polyphenylene oxide/polyamide 6 blend alloy as well as preparation method and application for same

The invention discloses a polyphenylene oxide / polyamide 6 blend alloy. The polyphenylene oxide / polyamide 6 blend alloy is prepared from the components in the following parts by weight: 20-80 parts of polyphenylene oxide, 10-40 parts of polyamide 6, 5-35 parts of compatilizer, 5-15 parts of toughener, 0.2-0.5 parts of antioxidant, 0.2-0.7 parts of lubricant, and 3-35.5 parts of auxiliaries. The invention further discloses a preparation method for the polyphenylene oxide / polyamide 6 blend alloy and an application for the polyphenylene oxide / polyamide 6 blend alloy as an extruded profile material. The PPO / PA6 (polyphenylene oxide / polyamide 6) blend alloy material disclosed by the invention is high in strength, good in toughness, excellent in corrosion resistance and insulativity, capable of replacing a steel plate or a special engineering plastic, thus realizing the purpose of replacing steel by plastic. Moreover, the PPO / PA6 blend alloy material can be popularized to extruded profiles, as well as is good in wear resistance, heat resistance and dimensional stability, easy to machine and form, and capable of being used by replacing the profiles of stainless steel, PEEK (poly ether ether ketone) and the like in a very large range, thus greatly reducing cost.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Method for preparing sulfonated polymer films

InactiveCN101531765AHigh retention rateIncrease water fluxSemi-permeable membranesPoly ether ether ketonePolymer science

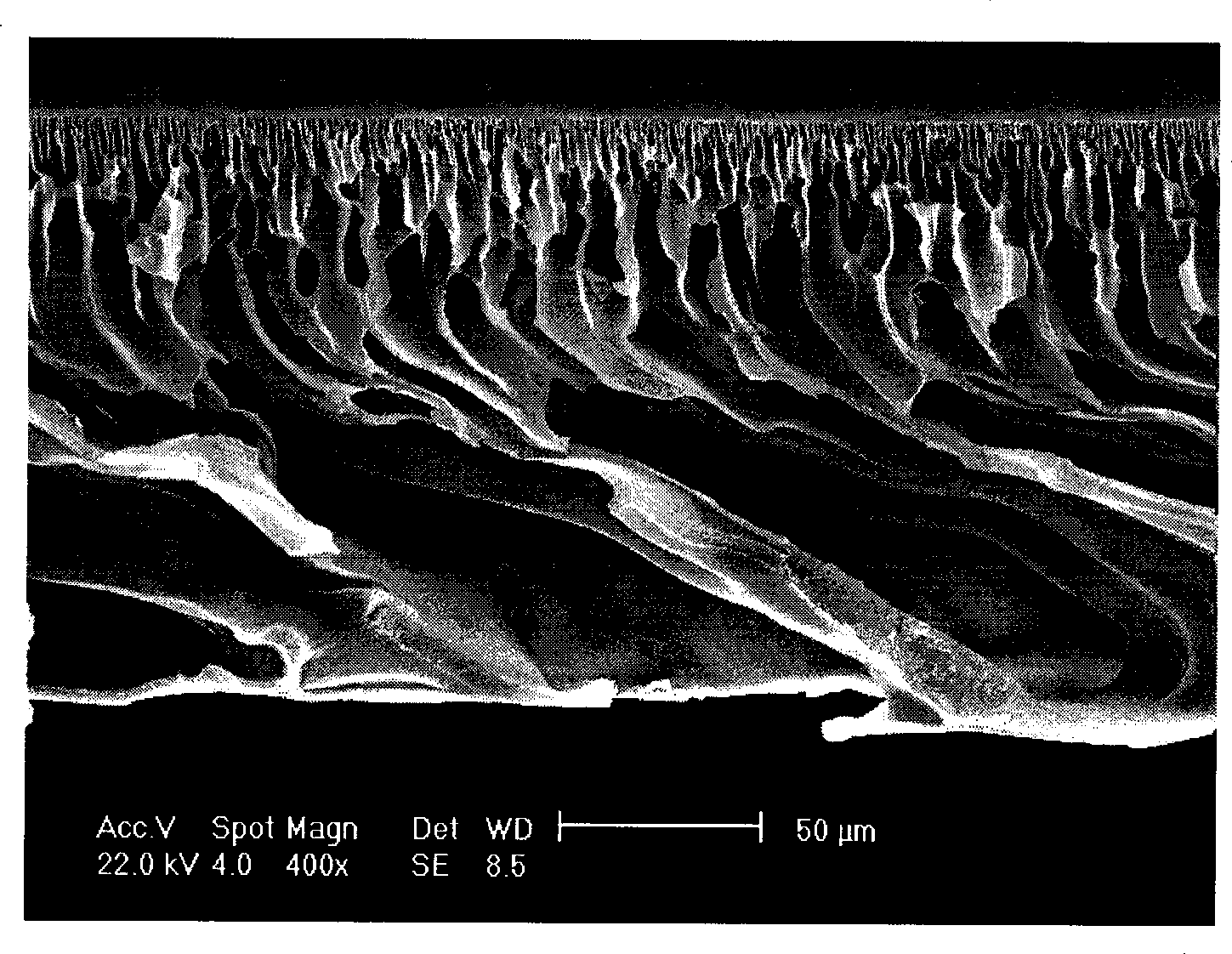

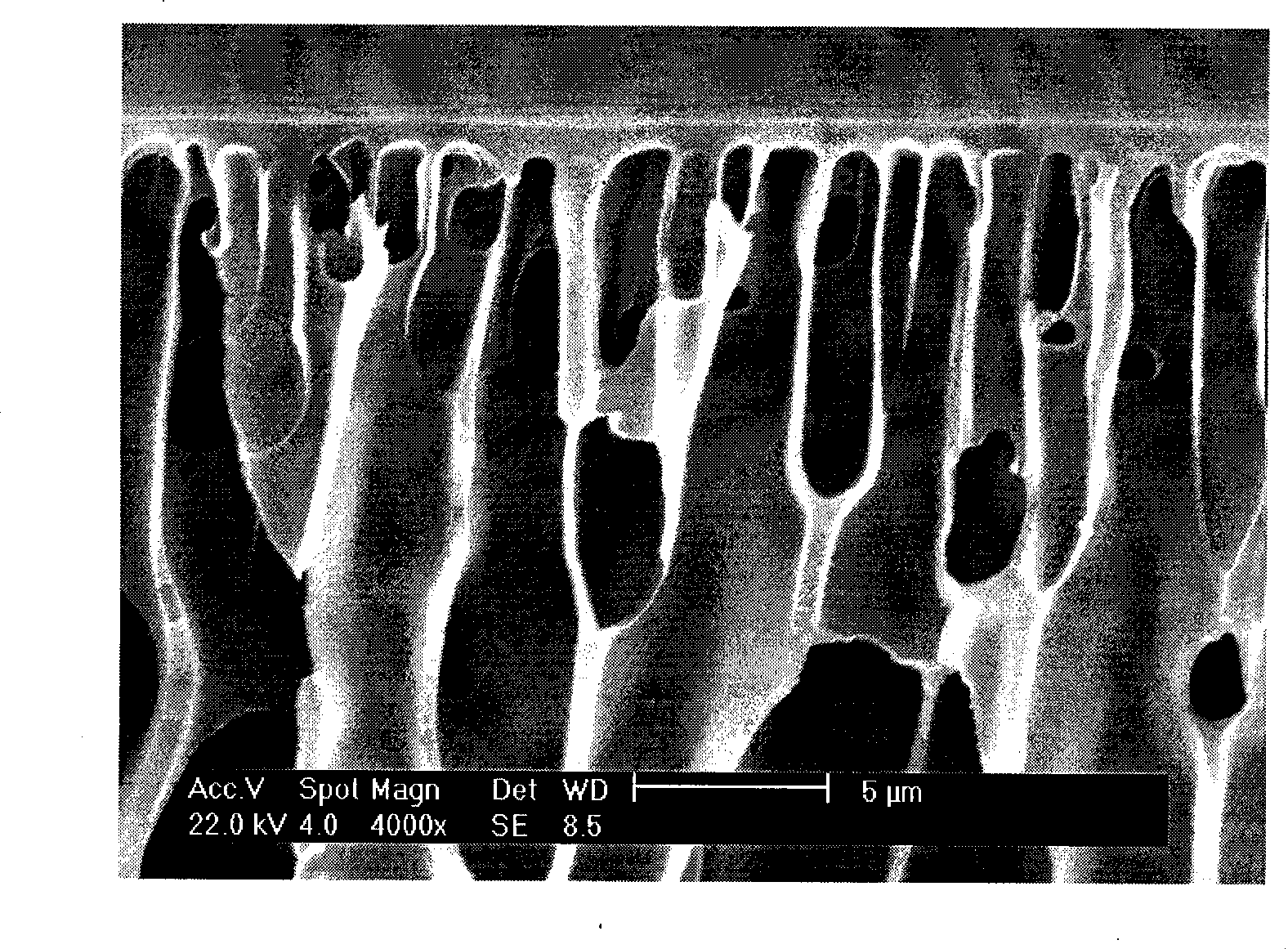

The invention discloses a method for preparing sulfonated polymer films, which comprises the following steps: preparing a casting solution and film-forming on the basis of phase-inversion. The sulfonation reaction is carried out between one or two of polyether-ether-ketone (PEEK), phenolphthalein polyaryl ether sulfone (PES-C) or polystyrene (PS) and concentrated sulfuric acid, fuming sulfuric acid or chlorosulfonic acid to obtain a sulfonated polymer solution in the preparation of the casting solution; and then, the film is directly formed on the basis of the phase-inversion method. The sulfonated polymer film prepared by the invention has higher pure water flux and protein retention rate, furthermore, the method has the advantages of good anti-pollution performance, higher mechanical strength and simple preparation process.

Owner:TIANJIN UNIV

Polymer Composition

Polymer composition (C) comprisinga poly(aryl ether ketone) (P1) chosen from polyetheretherketones, polyetherketoneketones and polyetheretherketone-polyetherketoneketone copolymers,a polyphenylsulfone (P2), anda reinforcing fiber (F),with the exception ofa polymer composition consisting of90 wt %, based on the total weight of the polymer composition, of a polymer blend consisting of 85 parts by weight of a polyphenylsulfone and 15 parts by weight of a polyetheretherketone, and10 wt %, based on the total weight of the polymer composition, of glass fiber.

Owner:SOLVAY ADVANCED POLYMERS LLC

Polyether Ether Ketone/Polyphenylene Sulfide Blend

InactiveUS20080258337A1High retention rateGood chemical resistanceCeramic shaping apparatusPolyether coatingsElectrical conductorPoly ether ether ketone

The present description discloses a polymeric composition which is a melt-processed alloy comprised of (a) a polyarylene sulfide resin, (b) a polyaryl-ether-ketone resin, and a reactive compound which results in (c) a graft copolymer of the polyarylene sulfide resin and / or the polyaryl-ether-ketone resin in addition to the starting resins. Exemplary melt-processed polymeric compositions can be made by reacting an alkoxy silane with the polyarylene sulfide resin and / or the polyaryl-ether-ketone resin to produce a graft copolymer of a portion of one or both of the resins, sufficient to render the composition uniform and homogeneous. It is normally preferred for the exemplary organosilane compound, to be an amino silane. The subject invention further reveals an insulated wire comprising (1) an electrical conductor and (2) a layer of the melt-processed alloy composition; and fiber reinforced composites comprising fibers substantially fully impregnated with the alloy polymeric composition.

Owner:TICONA LLC

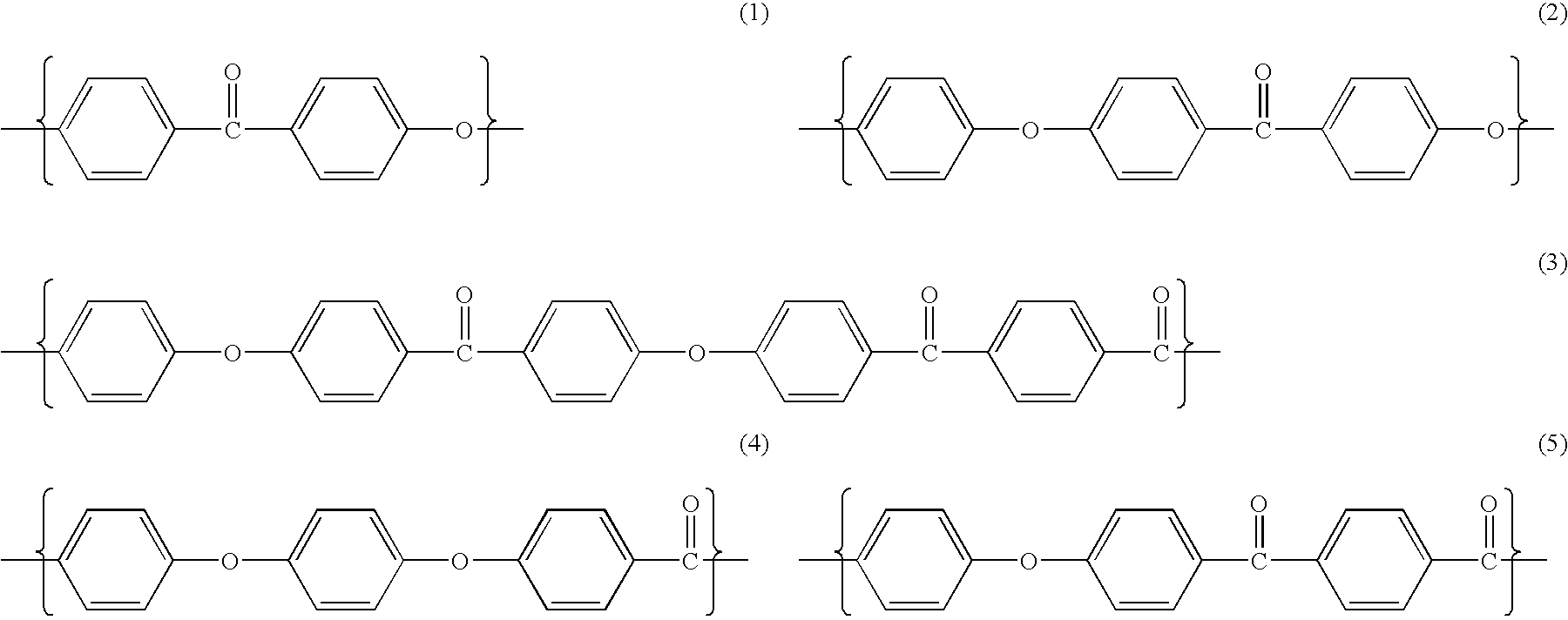

High temperature polymer blends of poly(aryl ether ketone phthalazinone)

The present invention provides high temperature compositions comprising blends of a first polymer, poly(aryl ether ketone phthalazinone)s, and a second polymer, selected from poly(aryl ether ketone)s, poly(aryl ketone)s, poly(ether ether ketone)s, poly(ether ketone ketone)s, or polybenzimidazoles, thermoplastic polyimides, polyetherimides, poly(aryl ether sulfone)s, poly(phenylene sulfide)s, and mixtures thereof. The compositions have improved high temperature characteristics, e.g., improved high temperature load capability and improved high temperature melt processibility.

Owner:POLYMER INSTR & CONSULTING SERVICES LTD

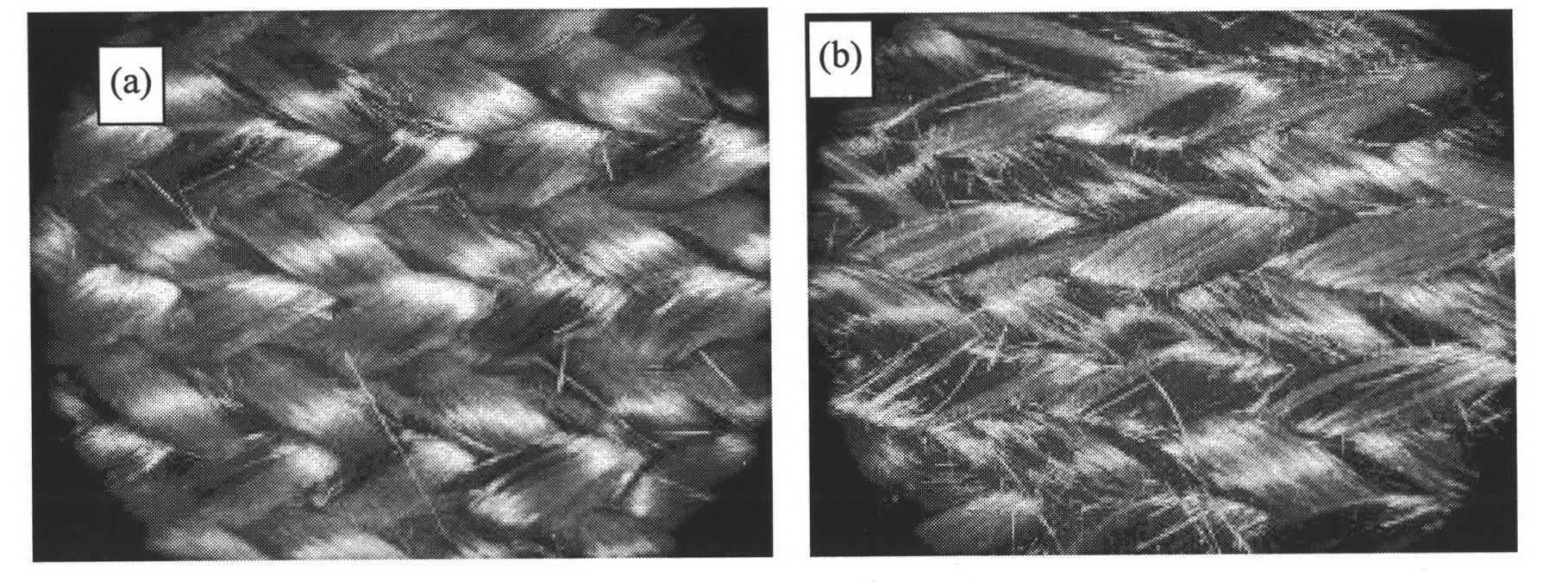

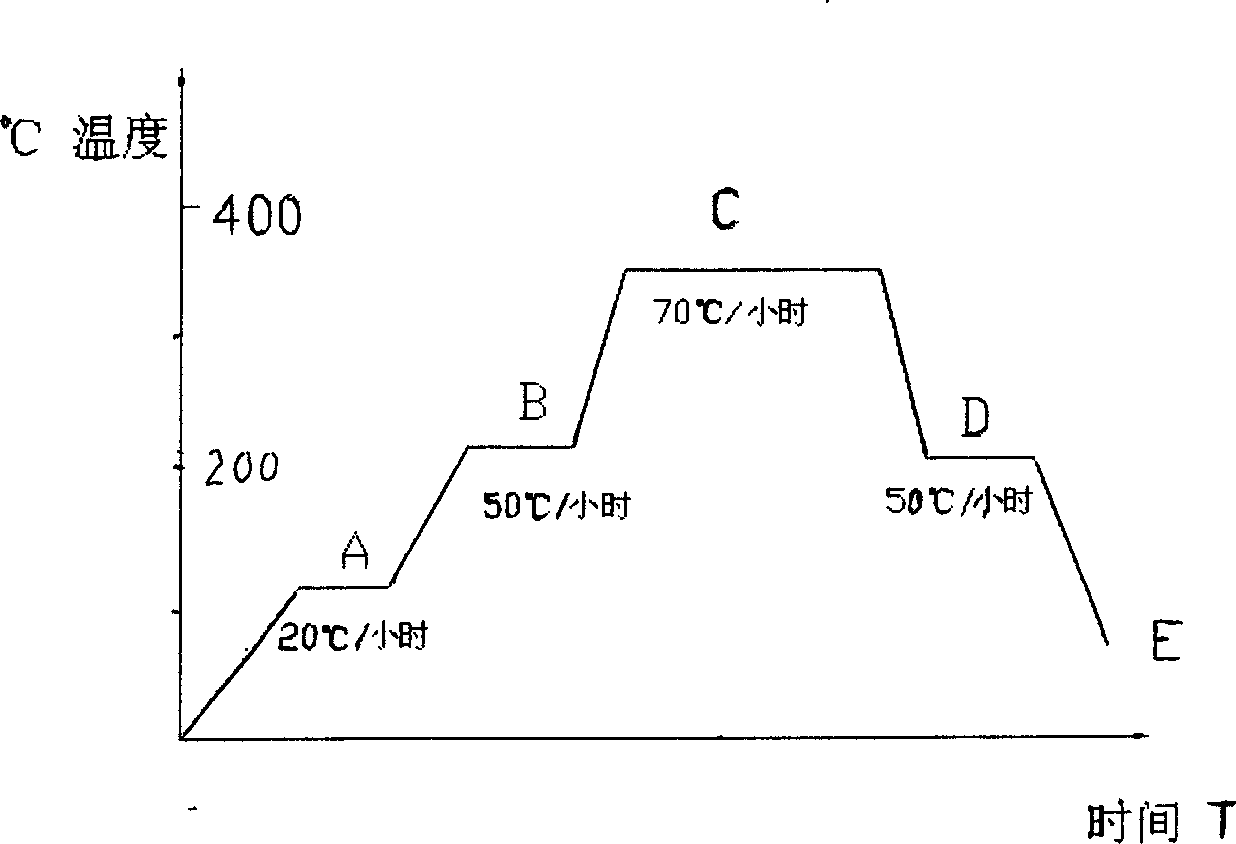

Three-dimensional braided carbon fiber reinforced polyetheretherketone composite material and preparation method thereof

InactiveCN102134372AAvoid difficultiesGood mechanical propertiesCarbon fibresPoly ether ether ketoneDistilled water

The invention relates to a three-dimensional braided carbon fiber reinforced polyetheretherketone composite material and a preparation method thereof. Carbon fiber reinforced polyetheretherketone fiber, and carbon fiber which is used as the raw material and accounts for 18-54% by volume, are mixed and braided in a three-dimensional five-direction mode to obtain the three-dimensional braided carbon fiber reinforced polyetheretherketone composite material. The three-dimensional braided carbon fiber reinforced polyetheretherketone composite material is prepared from fibers by a braiding and hot compaction combined technique. The technological process comprises the following steps: carrying out three-dimensional mixing and braiding on the polyetheretherketone fiber and carbon fiber, carrying out solution oxidation pretreatment on the mixed fabric, repeatedly flushing with distilled water, drying, putting the mixed fabric into a die, and carrying out hot compaction. The invention can effectively overcome the difficulties in the preparation of the three-dimensional braided composite material due to the thermoplastic property of the polyetheretherketone, thereby obtaining the three-dimensional braided carbon fiber reinforced polyetheretherketone composite material which has the advantages of sufficient fiber immersion and excellent mechanical properties.

Owner:江苏飞荣达新材料科技有限公司

Titanium base whisker reinforced polyether ether ketone wearable composite material and its preparation method

The invention relates to polyether ether-ketone wear-resisting compound material which is strengthened by titanium base crystal as well as preparative method. The mentioned titanium base crystal has a diameter of 0.5-3.0 mum, length-diameter ratio of 5-50 and its surface reshaped. The ingredient of the compound material includes titanium base crystal, polytef and PEEK, it's shaped by hot mould pressing or pouring so it has very good strength, and abradability. Compared to the carbon fiber strengthened polyether ether-ketone of the same content, the abradability of the invention has been increased by 10 times, the frictional coefficient has been decreased by 30% and the temperature of the friction surface has been lowered by half. The invention has very good alkali resistance, so it is adaptable to be the ware and wear-resisting material in lye; it's also applicable to special conditions such as high temperature, vacuum, radiation and causticity; it can be widely used as piston link, filling, sliding piece and valve piece, the service life of the material in the invention has been greatly prolonged.

Owner:NANJING UNIV OF TECH

Wear-resistant, high-strength and light-weight poly (ether-ether-ketone) composite material

The invention discloses a wear-resistant, high-strength and light-weight poly (ether-ether-ketone) composite material. The poly (ether-ether-ketone) composite material comprises the following raw materials in parts by weight: 71-83 parts by weight of poly (ether-ether-ketone) resin, 5-10 parts by weight of suspension polytetrafluoroethylene resin, 7-12 parts by weight of carbon fiber powder and 5-7 parts by weight of aluminum oxide powder, as well as a silane coupling agent with the adding quantity of 0.8-1.5% of the weight of the aluminum oxide powder. The poly (ether-ether-ketone) composite material disclosed by the invention has the performance characteristics of wear resistance, high strength, self-lubrication, light weight, corrosion resistance and the like, is used for replacing a hard alloy and a metal framework to assemble a novel sliding bearing, effectively reduces the cost and weight of a bearing product (the weight is reduced by 30%) under the situation of meeting the requirements for service life, and can obviously reduce the power consumption and noise of a pump and achieve the purposes of saving energy and reducing consumption.

Owner:HEFEI GENERAL MACHINERY RES INST

Preparation method of carbon fiber/polyetheretherketone composite material

The invention relates to a preparation method of carbon fiber / polyetheretherketone composite material. The preparation method comprises the following steps of: mechanical blending the following materials: 10 to 20 percent of carbon fiber, 79 to 89 percent of polyetheretherketone and 1 to 10 percent of carbon nanotube according to weight proportion; arranging prepared particles in an air circulating furnace for drying, placing for 3h under the temperature of 150 DEG C plus or minus 3 DEG C, or placing for 2h under the temperature of 160 DEG C plus or minus 3 DEG C till the weight proportion of water is less than 0.02 percent; taking out the particle materials, arranging the particle materials in a material barrel, heating by three sections; wherein the temperature of the rear section is 350 DEG C, cooling water is used for cooling so as to prevent the material from bridging, the temperature of the middle section is 360 to 370 DEG C, the temperature of the front section is 380 to 390 DEG C, the temperature of the mold is 200 to 220 DEG C and the rotating speed of a screw is 50 to 60r / min; injection-molding and preparing fiber / polyetheretherketone composite material. The prepared composite material has good electrical conductivity and can be used for the fields of military industry, aerospace and the like.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

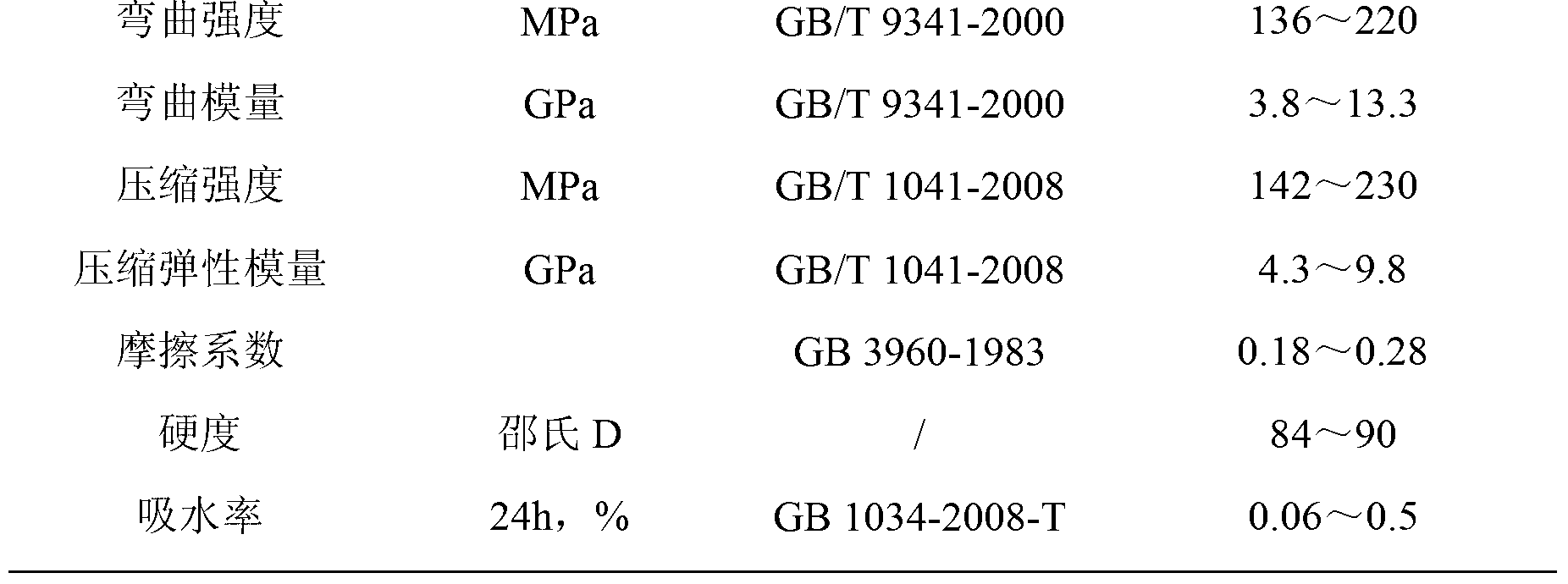

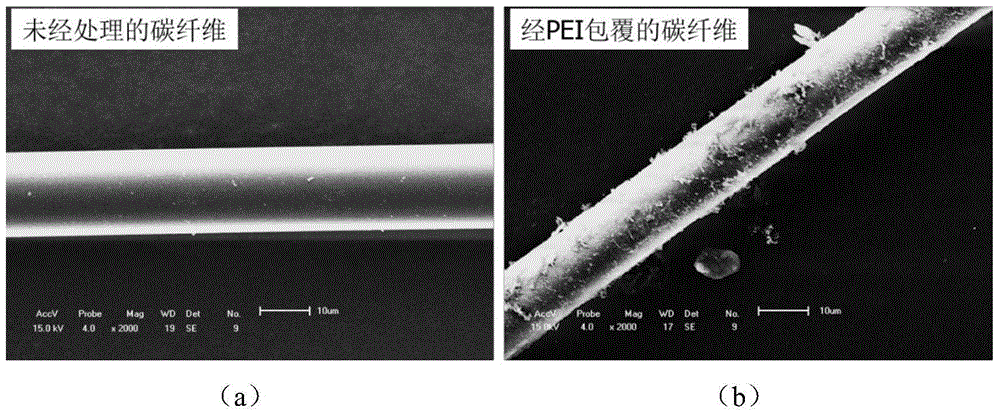

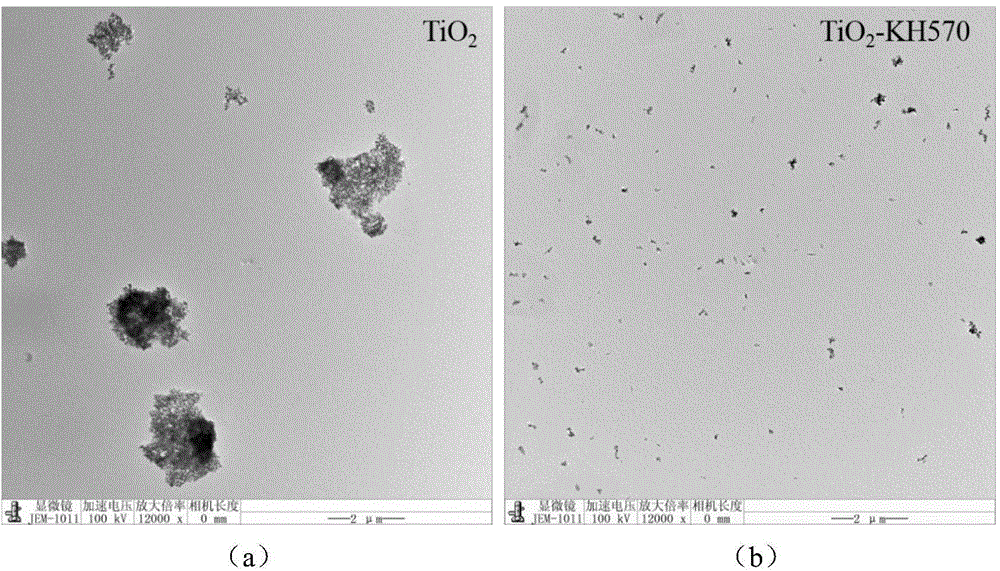

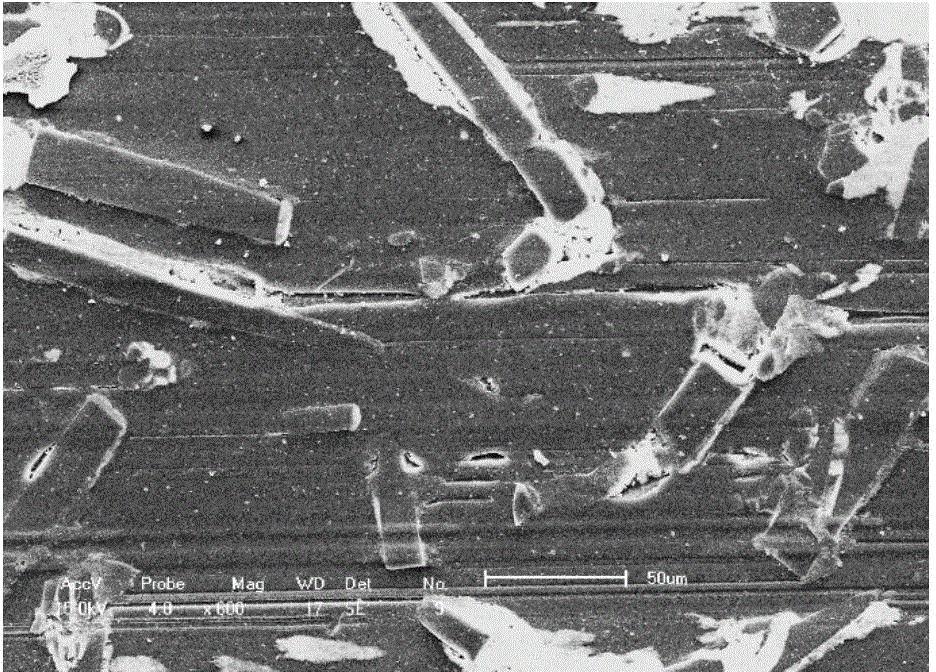

Polyetheretherketone-base composite, preparing method thereof and application thereof in friction reduction and wear resistance

InactiveCN104927298AReduce coefficient of frictionReduce wear rateOther chemical processesDispersityFiber

The invention relates to a polyetheretherketone-base composite, a preparing method thereof and application thereof in friction reduction and wear resistance and belongs to the technical field of polymer composites. The polyetheretherketone-base composite, by 100% weight, 65% to 87% of polyetheretherketone, 10% to 30% of polyetherimide-coated carbon fiber, and 3% to 5% of coupler-modified titanium dioxide. In order to optimize the dispersity of micrometer chopped carbon fiber, polyetherimide which is well compatible with the polyetheretherketone and resistant to high temperature is used to coat the carbon fiber; the nano titanium dioxide is subjected to coupler inarching to reduce its agglomeration degree. Compared with fillers subjected to no treatment, the carbon fiber has the advantages such as uniform dispersity in composites and high interfacial action with matrixes. By adding the coated carbon fiber and the coupler-modified titanium dioxide, the friction and wear performance of the polyetheretherketone-base composite can be effectively improved, and the application in the friction-reducing wear-resistant environments is satisfied.

Owner:JILIN UNIV

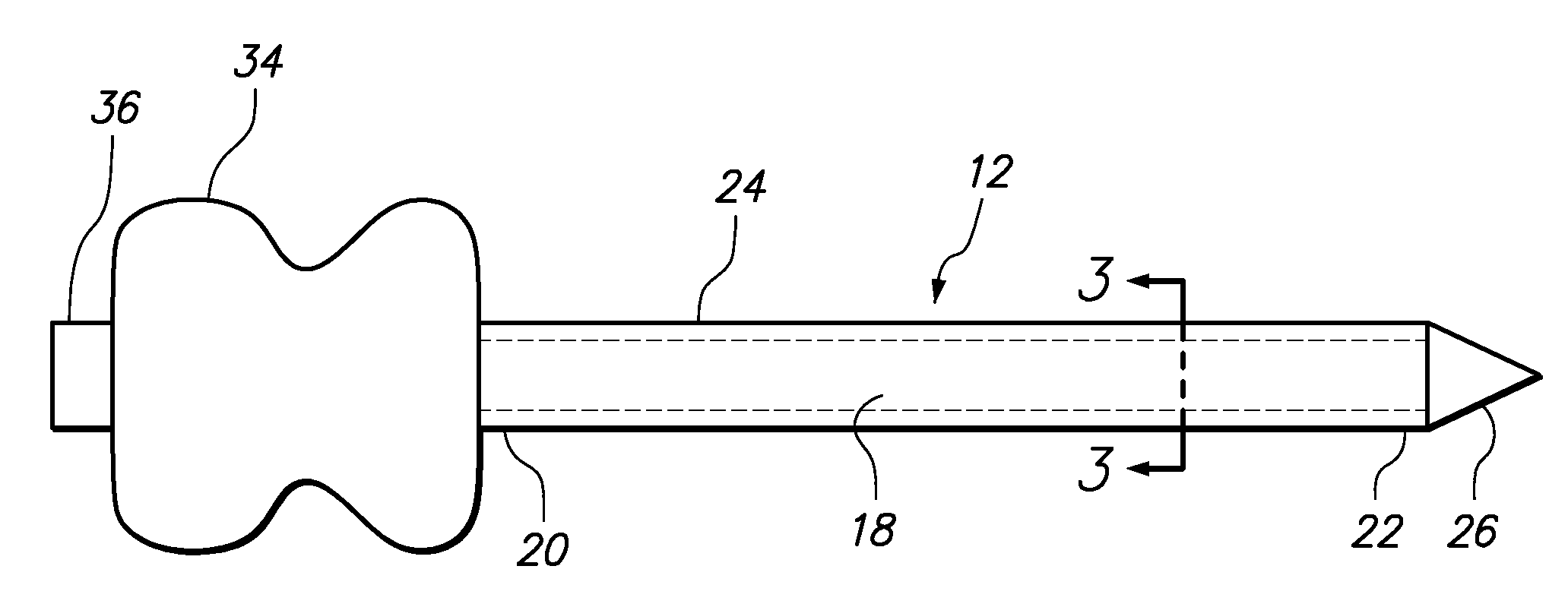

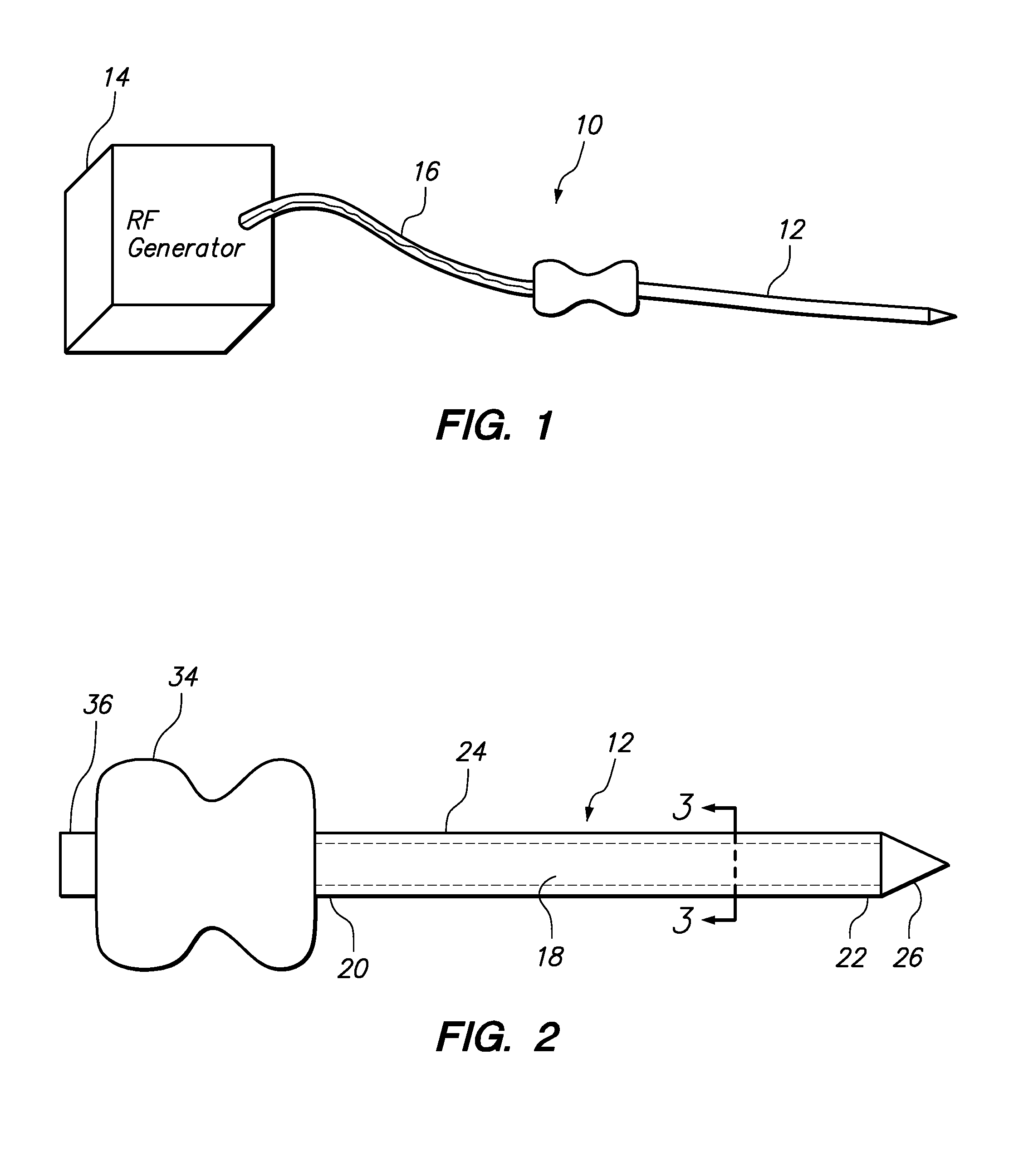

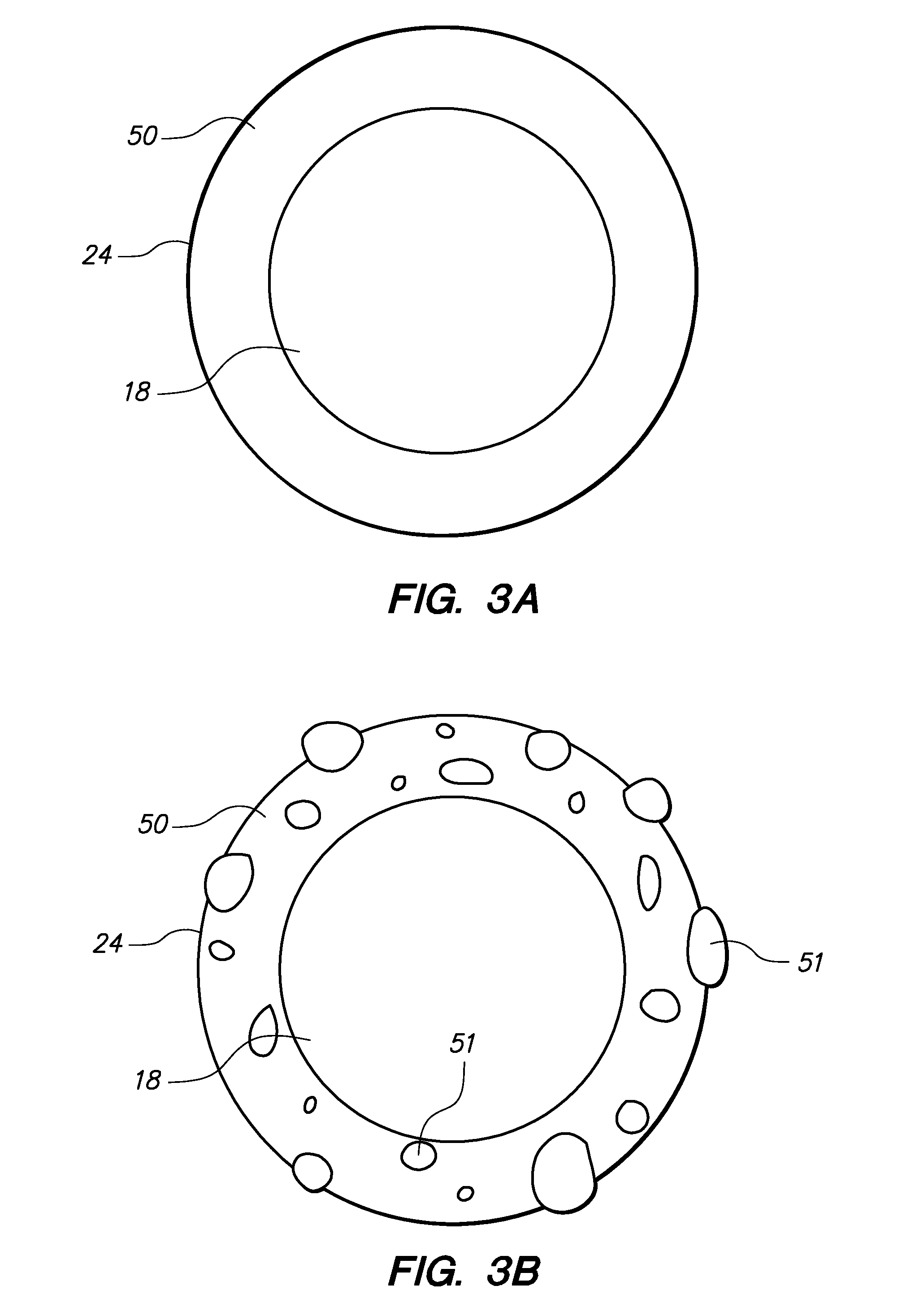

Ablation with echogenic insulative sheath

InactiveUS20080009852A1Diameter minimizationIncrease echogenicityUltrasonic/sonic/infrasonic diagnosticsSurgical needlesPolyether ether ketoneTissue ablation

Tissue ablation probes are provided. Each tissue ablation probe comprises an electrically conductive probe shaft, at least one tissue ablation electrode carried by a distal end of the probe shaft, and an electrically insulative outer sheath disposed on the probe shaft. The sheath is at least partially composed of polyether ether ketone (PEEK) and another material comprising condensed-phase particles interspersed throughout the PEEK to increase the echogenicity of the outer sheath. The durability of the PEEK allows the sheath to be formed as thinly as possible, thereby minimizing the diameter of the ablation probe, while the inclusion of condensed-phase particles within the PEEK does not significantly degrade the durability of the sheath.

Owner:BOSTON SCI SCIMED INC

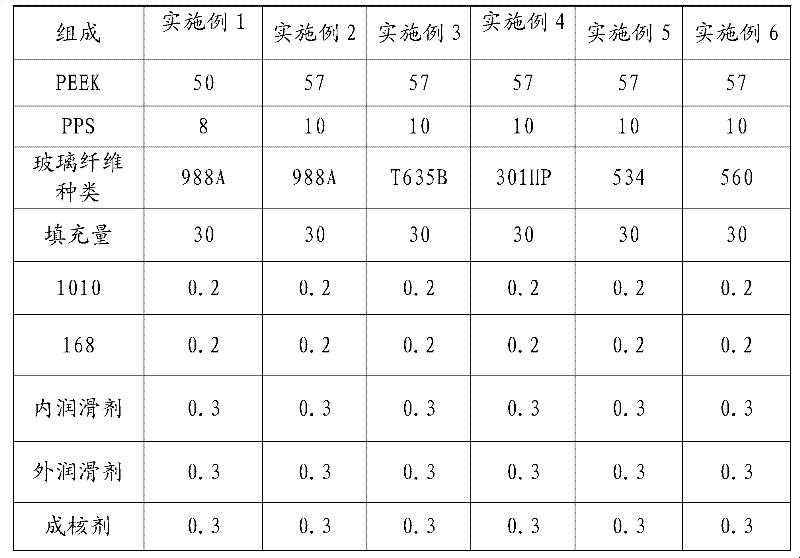

Modification-enhanced polyether ether ketone material and preparation method thereof

InactiveCN102329477AOvercome the disadvantage of poor liquidityReduce processing temperatureAntioxidantEconomic benefits

The invention discloses a modification-enhanced polyether ether ketone material and a preparation method thereof. The modification-enhanced polyether ether ketone material is prepared from the following components in parts by weight: 50-60 parts of polyether ether ketone, 8-15 parts of polyphenylene sulfide, 30-35 parts of filling enhancer, 0.2-0.6 part of antioxidant, 0.2-0.8 part of lubricant and 0.3-0.6 part of nucleating agent. The invention has the characteristics that: the defect of poor fluidity of polyether ether ketone is overcome by adding polyphenylene sulfide, and the processing temperature and difficulty of the polyether ether ketone are greatly reduced; because the polyether ether ketone is expensive, the production cost is greatly lowered by introducing polyphenylene sulfide; and the preparation process disclosed by the invention is simple, low in cost and high in benefit and can obtain good economic benefit.

Owner:SHENZHEN KEJU NEW MATERIAL

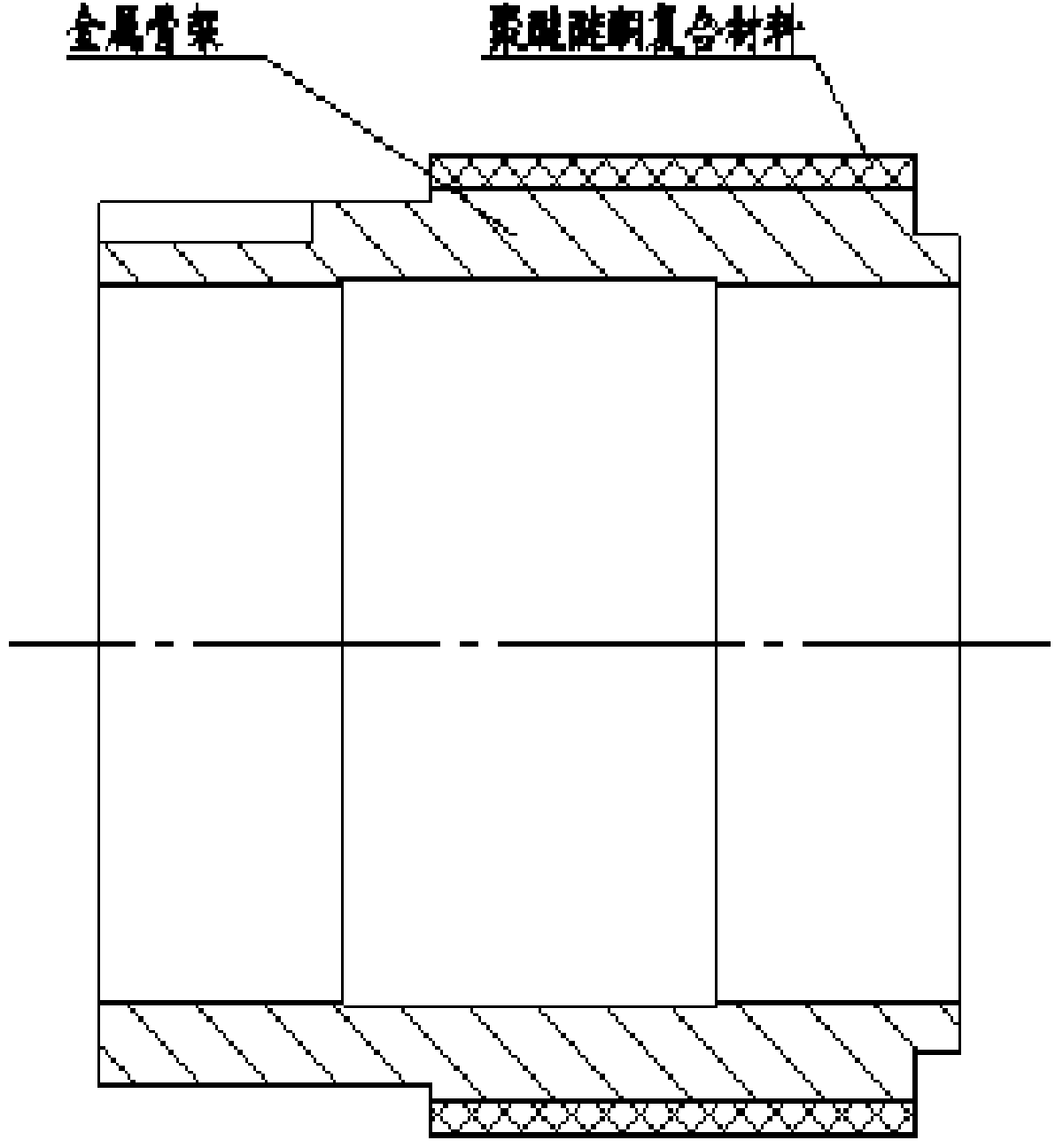

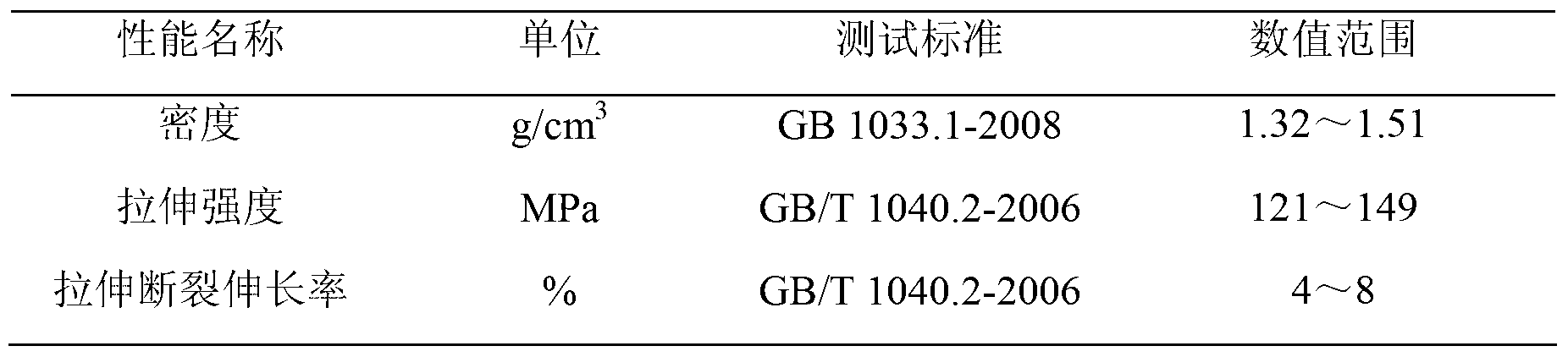

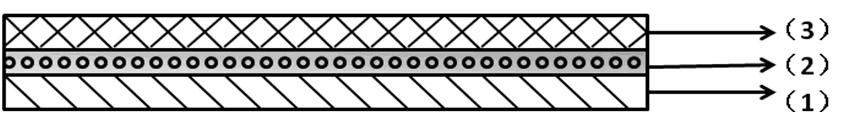

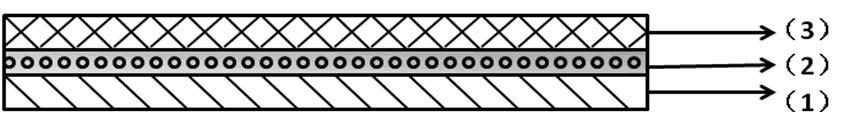

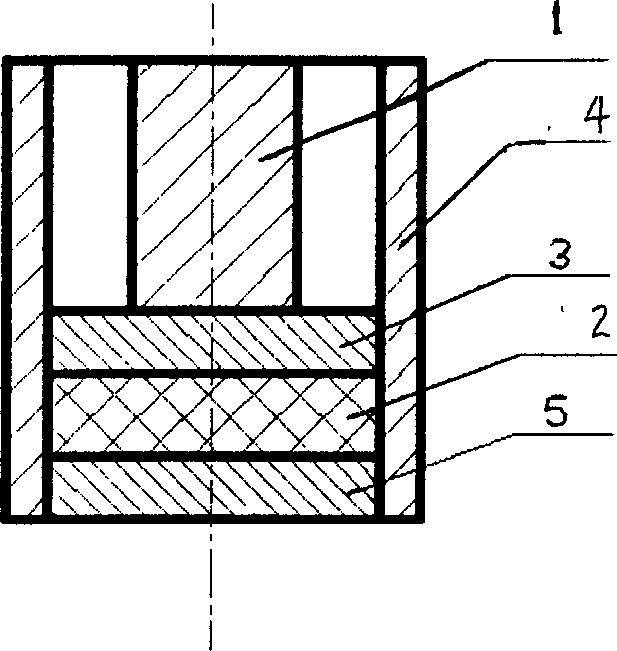

Composite material of high-temperature resistant metal-fabric/resin self-lubricating bearing and preparation method of composite material

InactiveCN102145556AGuaranteed bonding performanceSolve the problem of low bonding strengthSynthetic resin layered productsMetal layered productsPoly ether ether ketoneResin composite

The invention belongs to the technical field of polymer composite materials and in particular relates to a composite material of a high-temperature resistant metal-fabric / resin self-lubricating bearing and a preparation method of the composite material. The composite material comprises three layers, wherein the bottom layer is a metal plate; the middle layer is a porous sintered tin bronze powder layer, and self-lubricating wear-resisting resin is impregnated in a pore; the surface layer is made of the composite material of mixed fabric and self-lubricating wear-resisting resin; the mixed weaved fabric is the composition of at least two materials of polytetrafluoroethylene fiber, carbon fiber, aramid fiber, polybenzimidazole fiber and glass fiber; and the self-lubricating wear-resisting resin is the blend of one or more of polyphenylene sulfide, polytetrafluoroethylene, polyether-ether-ketone and nylon. The composite material of the bearing has good high-temperature resistance, high loading capacity, good wear resistance and good self-lubricating property, solves the problems of high wear rate, poor wear resistance, low-temperature resistance and the like of the material of a DU bearing, and realizes the excellent frictional property and using reliability under high temperature of the material of the bearing. The composite material is applicable to the self-lubricating bearings in the fields of aeronautics and astronautics, machinery, automobiles, home appliances, office facilities and the like.

Owner:FUDAN UNIV

Polyether ether ketone composite material and preparation method thereof

The invention belongs to the fields of science and technology of polyether ether ketone composite material and discloses a polyether ether ketone composite material and a preparation method thereof. The polyether ether ketone composite material comprises the following components by weight: 64.5 to 89.3 parts of polyether ether ketone, 0.5 to 5 parts of nanodiamond powder, 10 to 30 parts of chopped carbon fiber and 0.2 to 0.5 part of antioxidant. The preparation method for the polyether ether ketone composite material comprises the following steps: adding 64.5 to 89.3 parts of polyether ether ketone, 0.5 to 5 parts of pretreated nanodiamond powder and 0.2 to 0.5 part of antioxidant into a high-speed mixing machine and mixing at the temperature of 80 to 100 DEG C and at high speed for 10 to 30 minutes; and feeding the mixed materials through a feeding port, starting a double-screw extruder, adding 10 to 30 parts of chopped carbon fiber form a lateral feeding port, and extruding and pelleting. The polyether ether ketone composite material prepared by the method has the characteristics of excellent heat resistance and dimensional stability, low water absorption and the like, has extremely excellent comprehensive performance and greatly enlarges the application range of the polyether ether ketone composite material.

Owner:汤原县海瑞特工程塑料有限公司

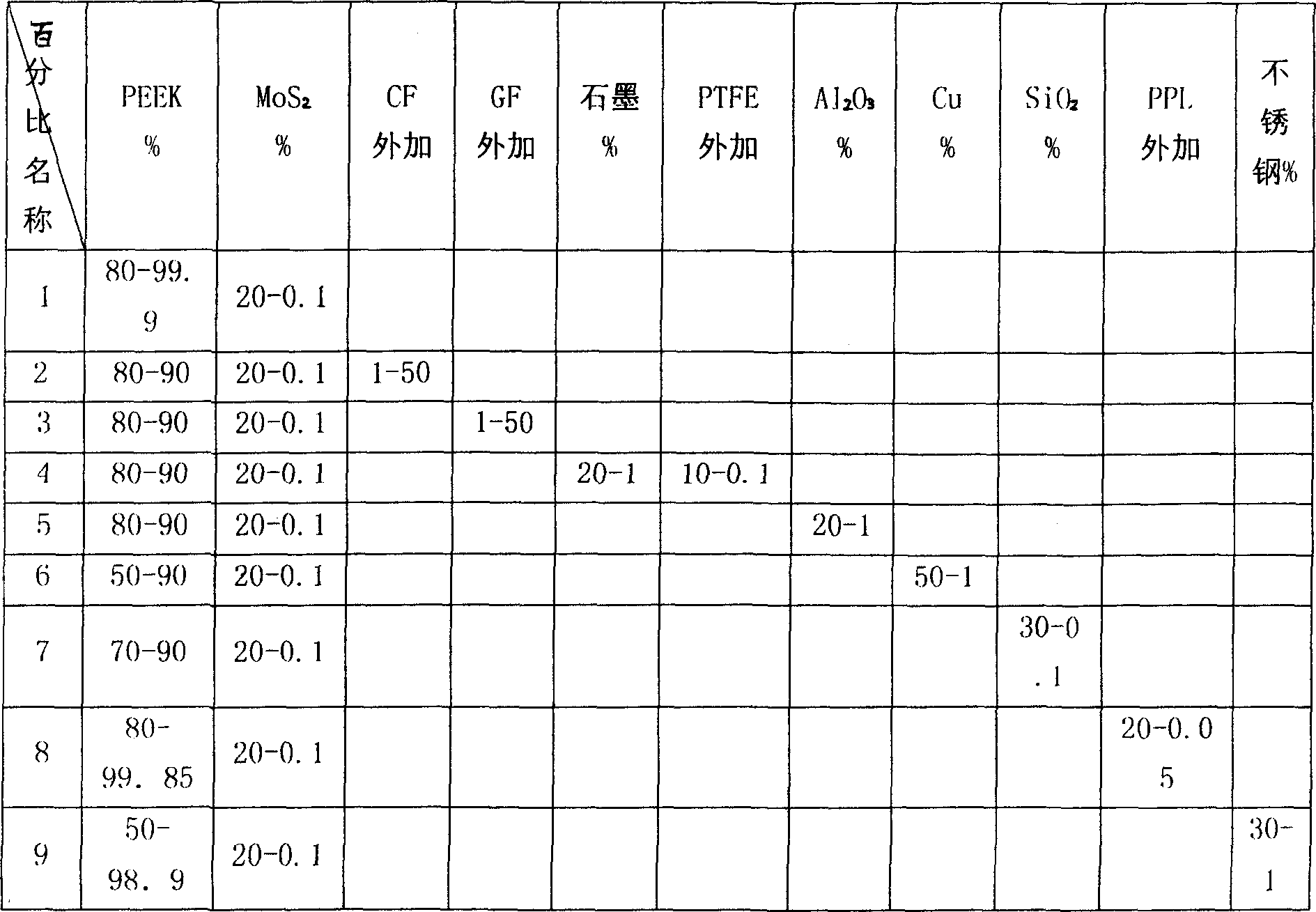

Polyetheretherketone composite material and method of its manufacture

ActiveCN1880372AImprove thermal conductivityImproved ball pressure hardnessFiberPoly ether ether ketone

This invention relates to a polyetheretherketone composite material, composed of a binary composite of polyetheretherketone and one of molybdenum disulfide, aluminium trioxide, copper powder, silica dioxide or stainless steel powder, with weight ratio of 80-99.9:0.1-20. On the base of the above weight as 100%, it continues to add polytetrafluoroethylene or polyphenyl ester, with weight ratio of 0.1-80% and 0.1-20% respectively, to form the ternary polyetheretherketone composite material. On the base of the above binary or ternary composite weight, it continues to add carbon fiber or glass fiber, with weight ratio of 0.1-50%. This invented composite material is characterized of increased thermal conductivity factor, distinct improvement of tensile strength, ball indentation hardness, frictional factor and linear expansibility, and cost reducing.

Owner:NANJING COMPTECH COMPOSITES CORP

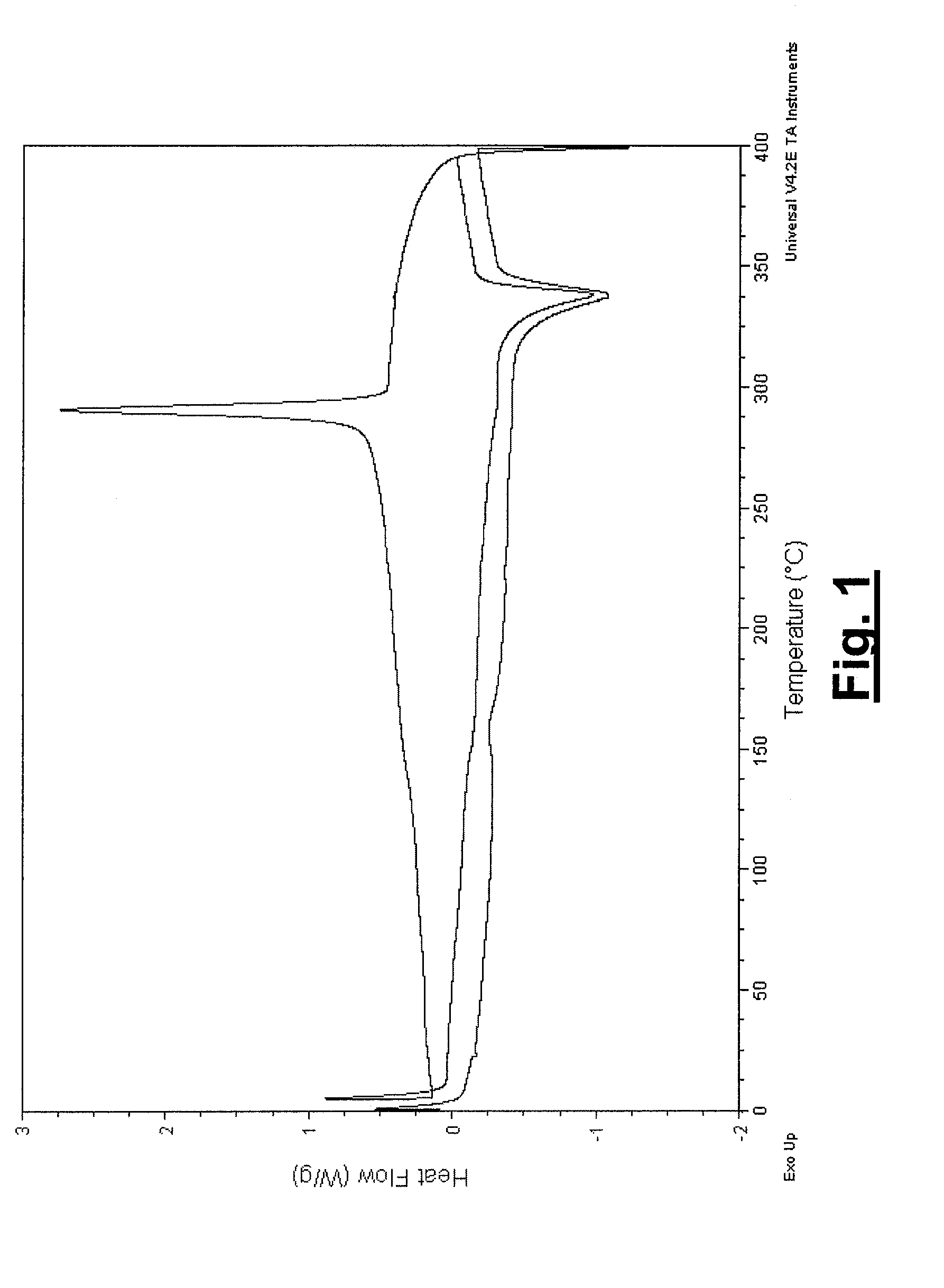

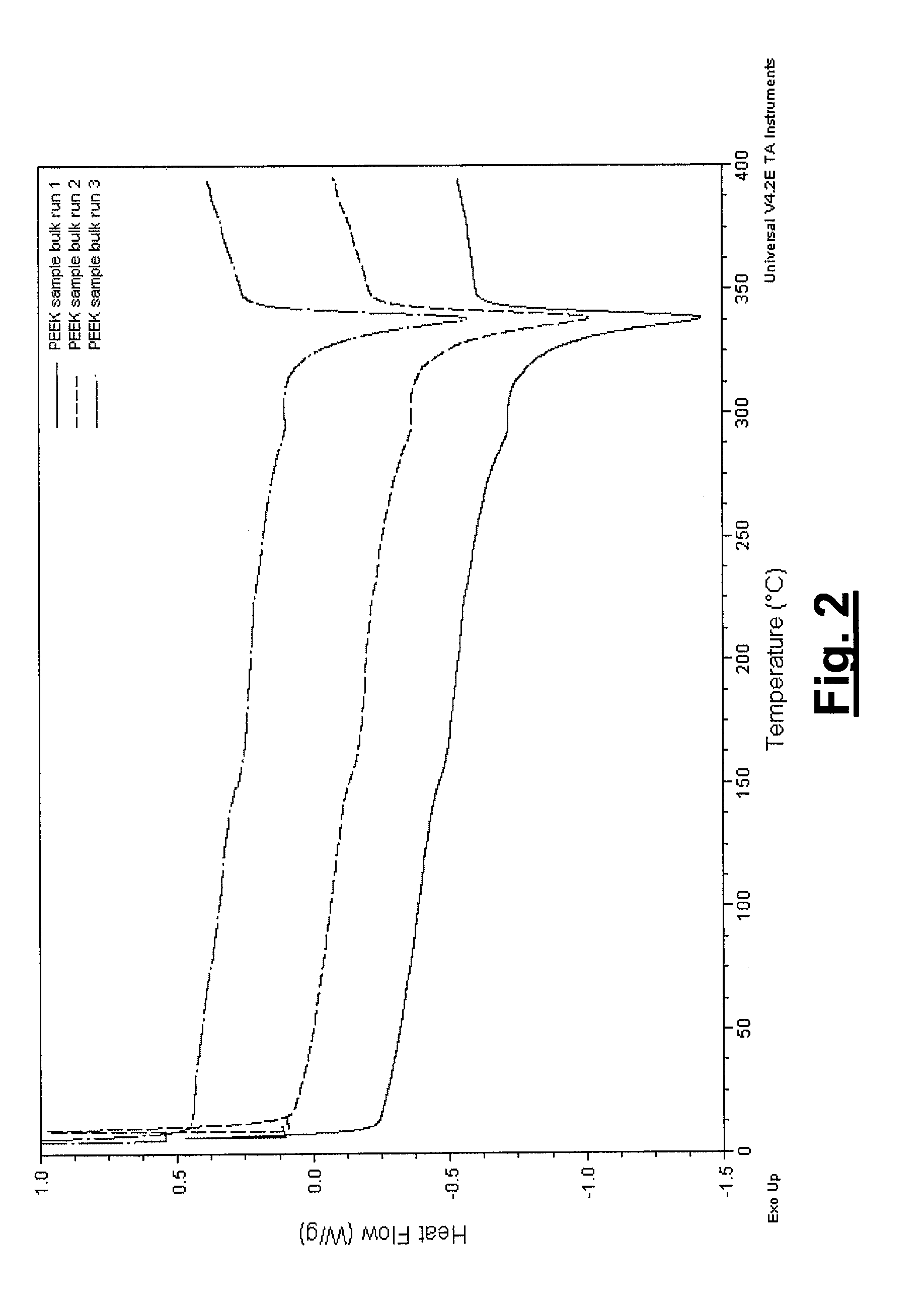

Polyetheretherketone steel bar and preparation method and uses thereof

The invention discloses a novel polyether-ether-ketone (peek) bar which is designed for solving the problems of slow crystallization speed caused by too large viscosity during processing and being too difficult to be processed caused by good metal cohesiveness after the forming by processing existing in a present PEEK bar. The invention comprises the following components according to weight proportion: 55.5 parts to 100 parts of peek resin, 2 parts to 4 parts of lubricant, 0.05 part to 0.5 part of nucleating agent and 0.05 part to 43 parts of filler. The invention also discloses the preparation method and use of the bar and has the advantages of fast molding, good processing performance and wide use.

Owner:南京金紫鑫工程塑料有限公司

A composite material used for a special cable, a preparing method thereof and the special cable

InactiveCN105400131AImprove performanceGuaranteed mechanical propertiesClimate change adaptationInsulated cablesPolymer sciencePoly ether ether ketone

A composite material used for a special cable, a preparing method thereof and the special cable are disclosed. According to the composite material, polyether ether ketone, polyethylene and polyimide are mixed according to a ratio and adopted as a substrate material, ethylene-vinyl acetate copolymer modified geopolymers, molybdenum trioxide and magnesium oxide are processed by a coupling agent and then adopted as a flame retardant additive, dicumyl peroxide is adopted as a crosslinking catalyst, silicon nitride whiskers are adopted as a fortifier, and the composite material is formed by melting and blending. The composite material has good high-temperature resistance and improved flame retardant effects, and can achieve no performance stability decrease under severe working conditions. In addition, the composite material is used for preparing an outer sheath of the special cable, and durability, fire resistance and stability of the special cable are improved.

Owner:YANCHENG KEHENGDA MATERIALS CO LTD

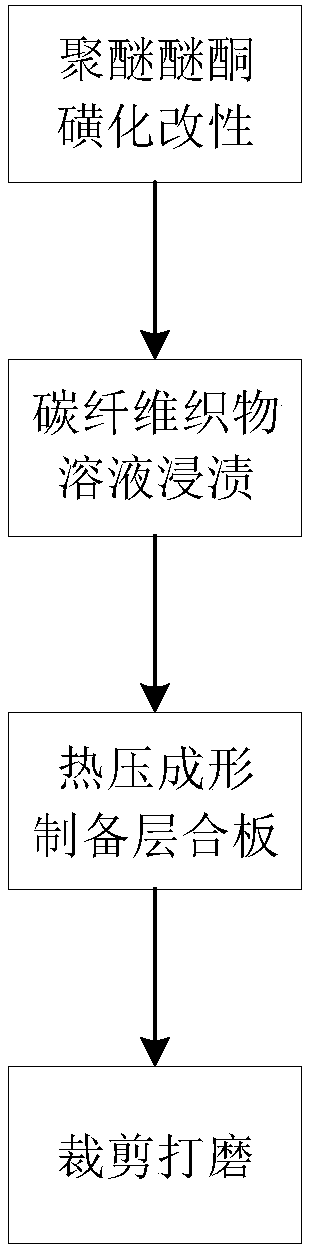

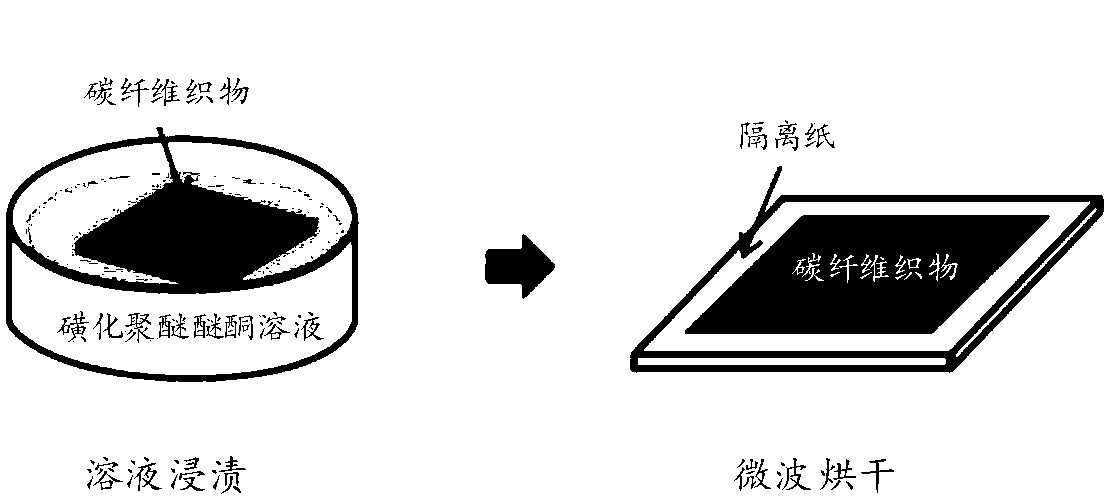

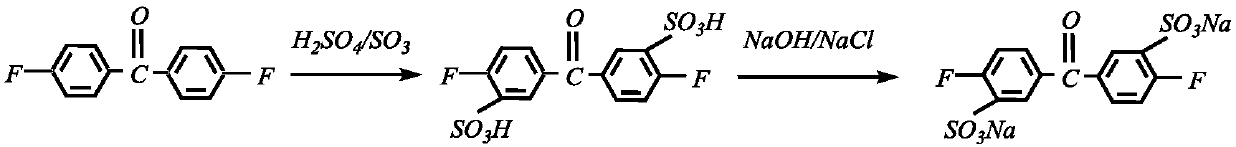

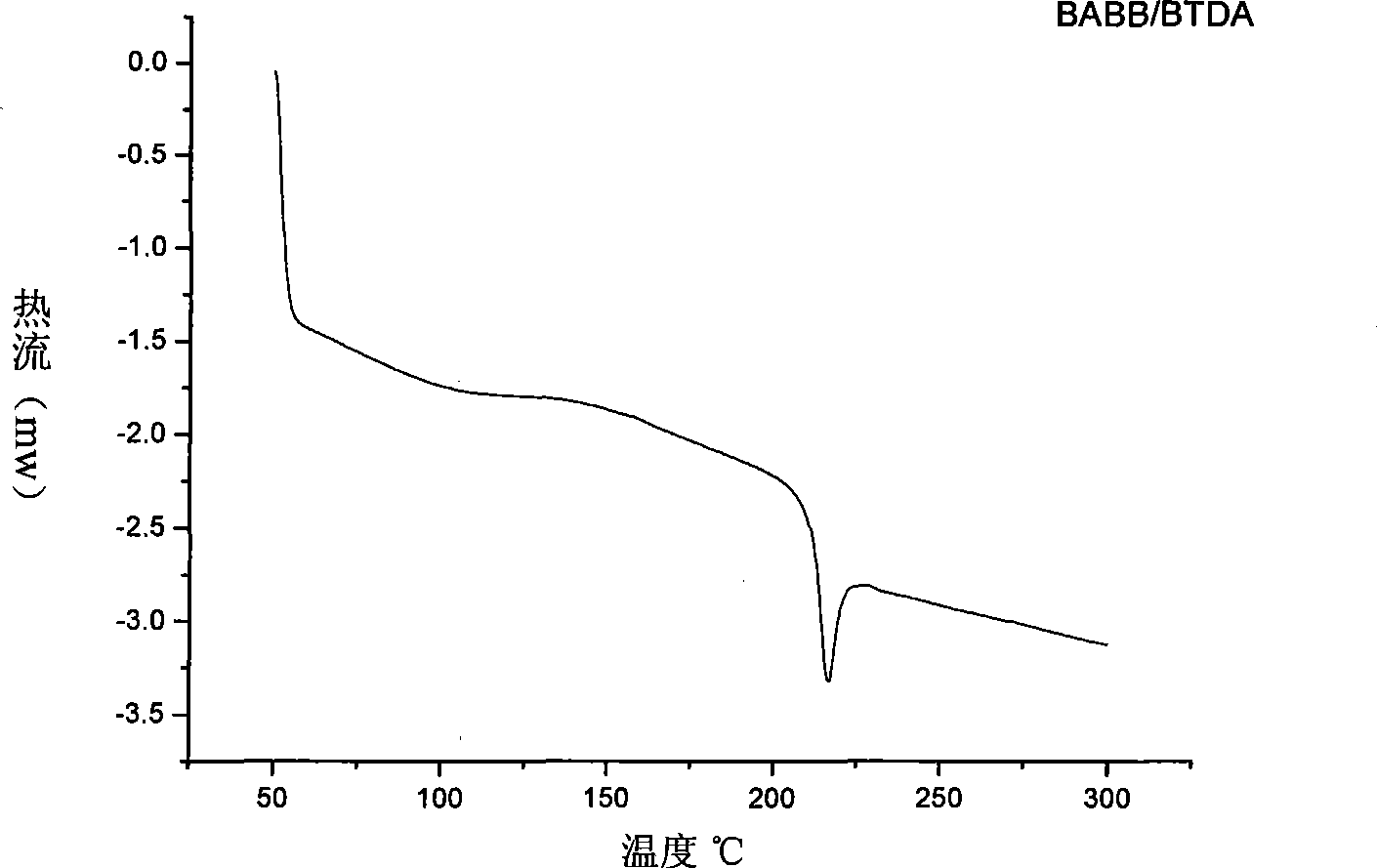

Preparation method of continuous carbon fiber reinforced poly(ether ether ketone) composite material and product

InactiveCN108047470ASolve the problem of being insoluble in any solventImprove mechanical propertiesCarbon fibersPolymer science

The invention belongs to the field of fiber reinforced resin based composite materials, and discloses a preparation method of a continuous carbon fiber reinforced poly(ether ether ketone) composite material and a product. The preparation method comprises the following steps: finishing modification by sulphonation on the poly(ether ether ketone) by copolymerization of sulfonated monomers; preparinga composite material prepreg tape by using solution impregnation; and preparing the continuous carbon fiber reinforced poly(ether ether ketone) composite material by a hot pressing forming process. The invention further discloses the product obtained according to the preparation method. By the preparation method, the problem that the poly(ether ether ketone) is hardly dissolved in any solvents issolved, the method for preparing the prepreg tape by solution impregnation is proposed, the problem of preparation of the continuous carbon fiber reinforced poly(ether ether ketone) composite material is solved, meanwhile, by sulfonated poly(ether ether ketone), the ability of binding of a polymer base body and a fiber interface can be improved, and therefore, the mechanical property of the fiberreinforced poly(ether ether ketone) composite material is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

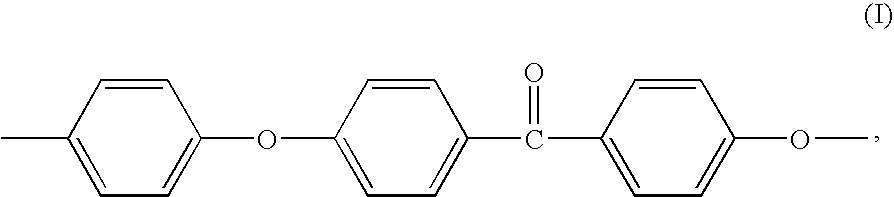

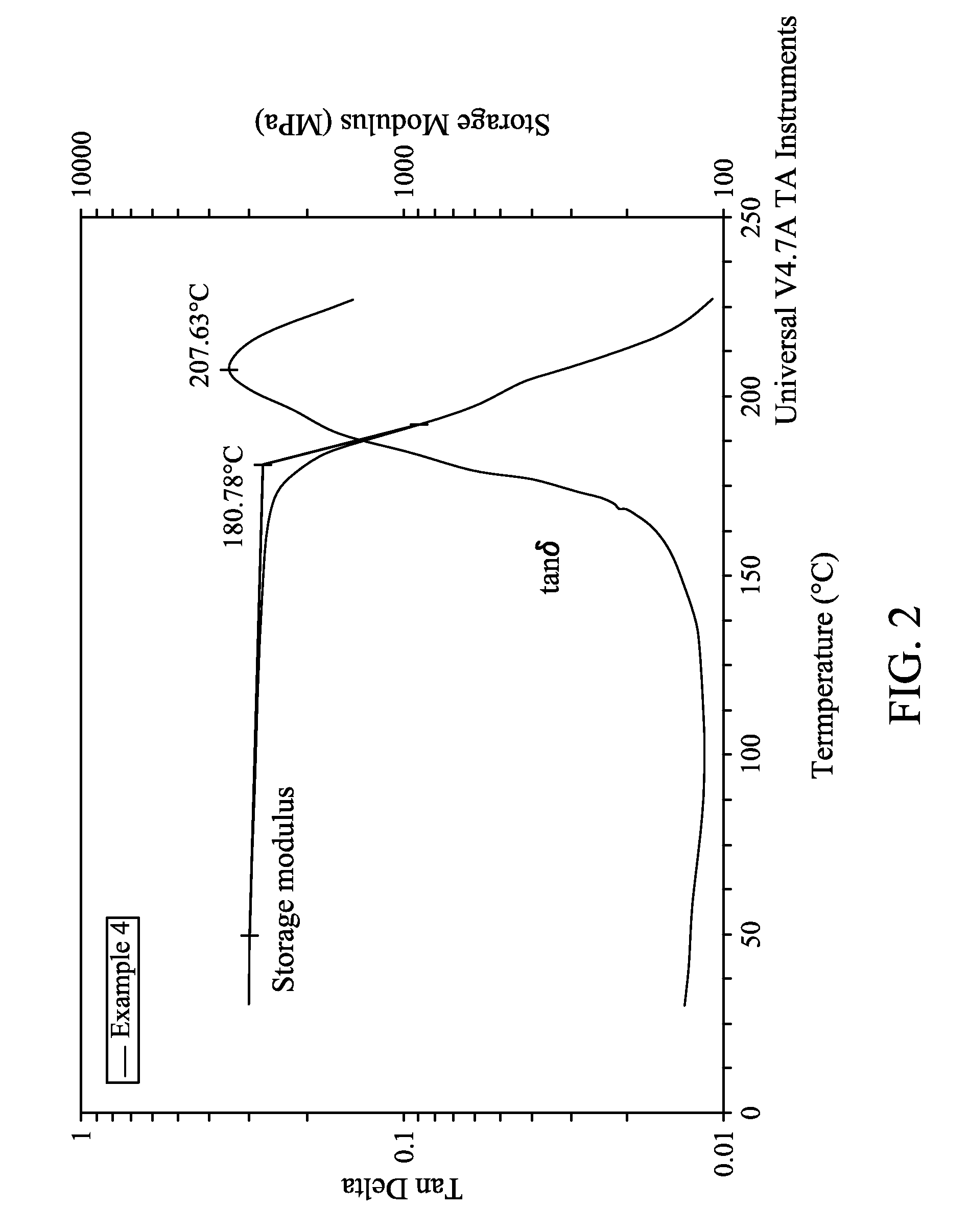

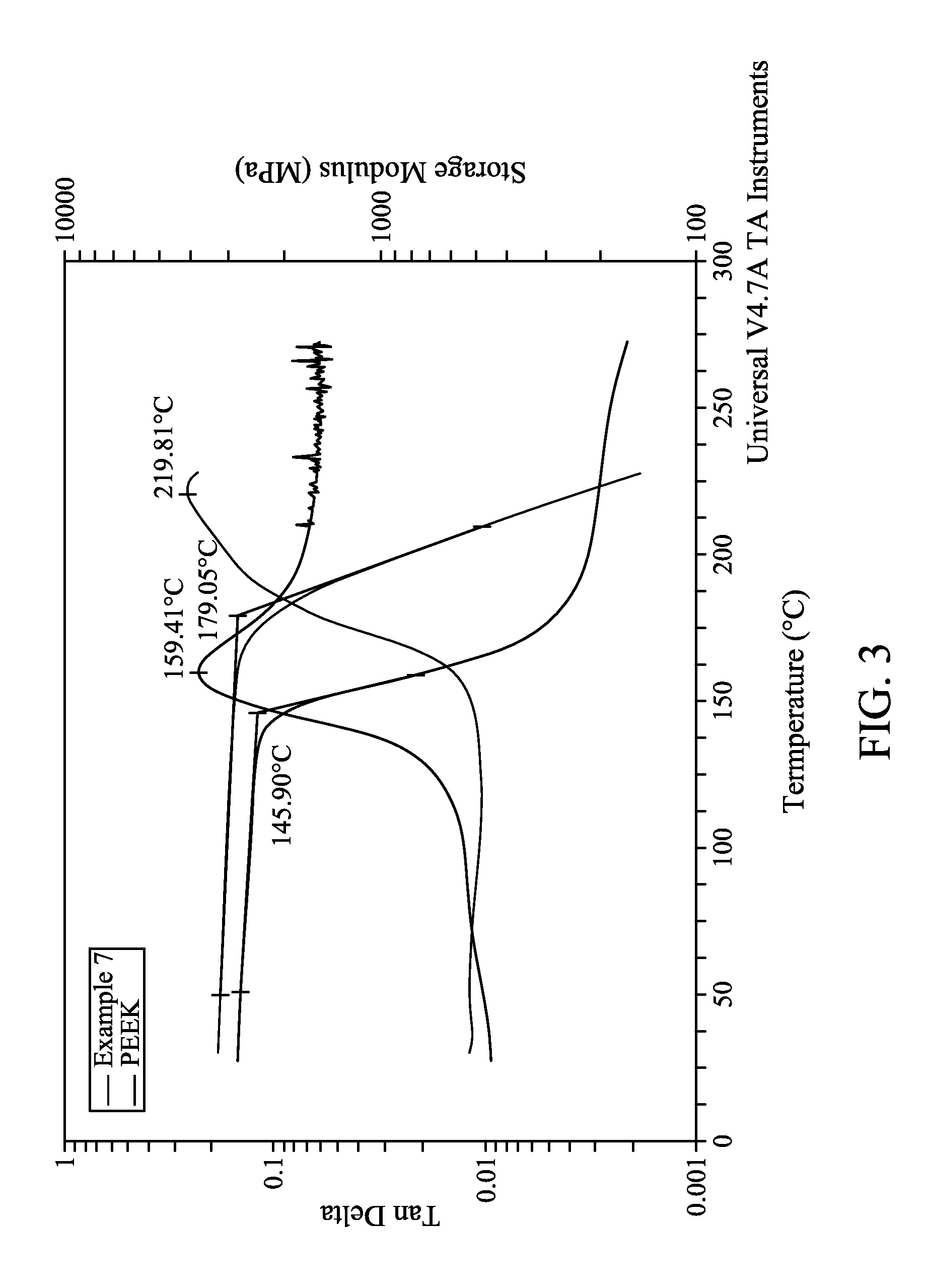

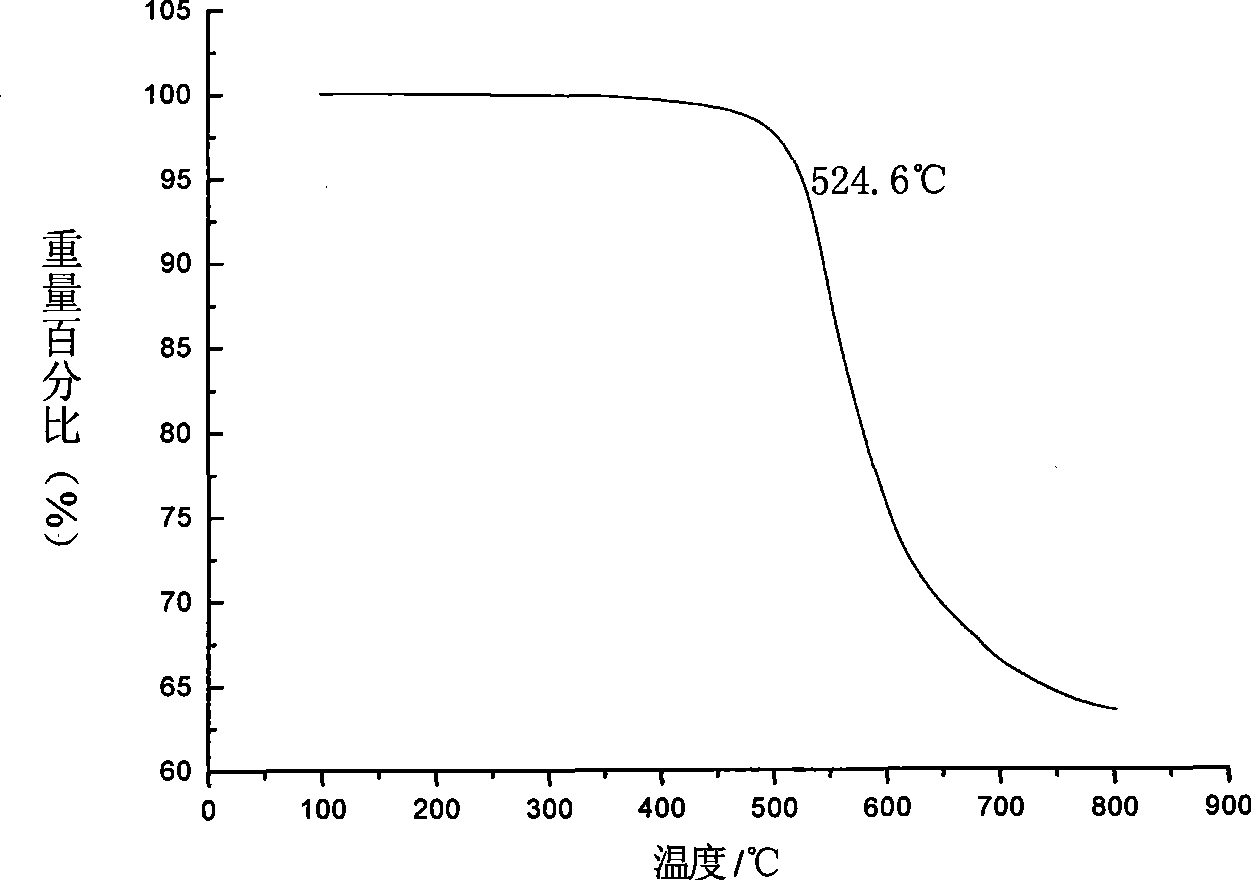

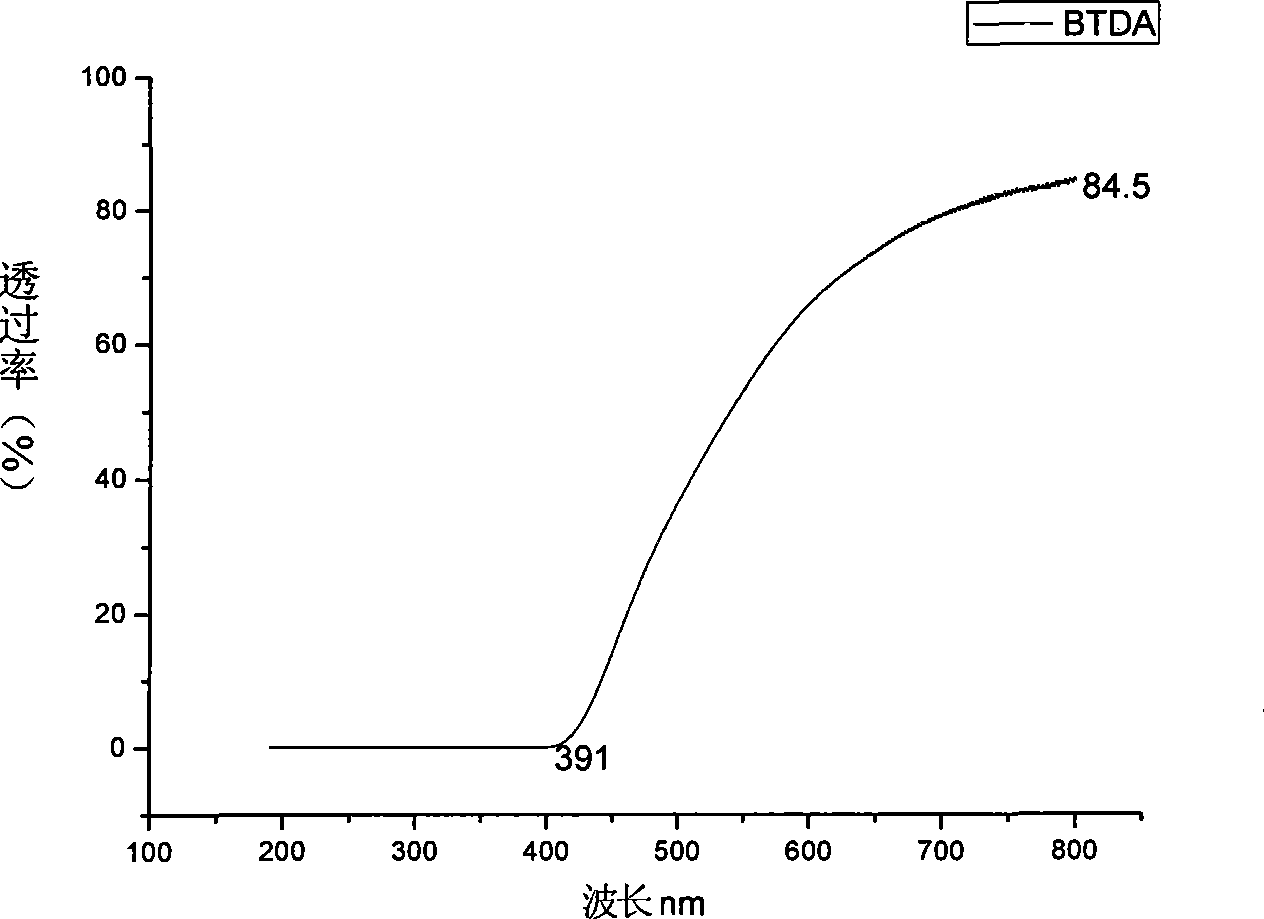

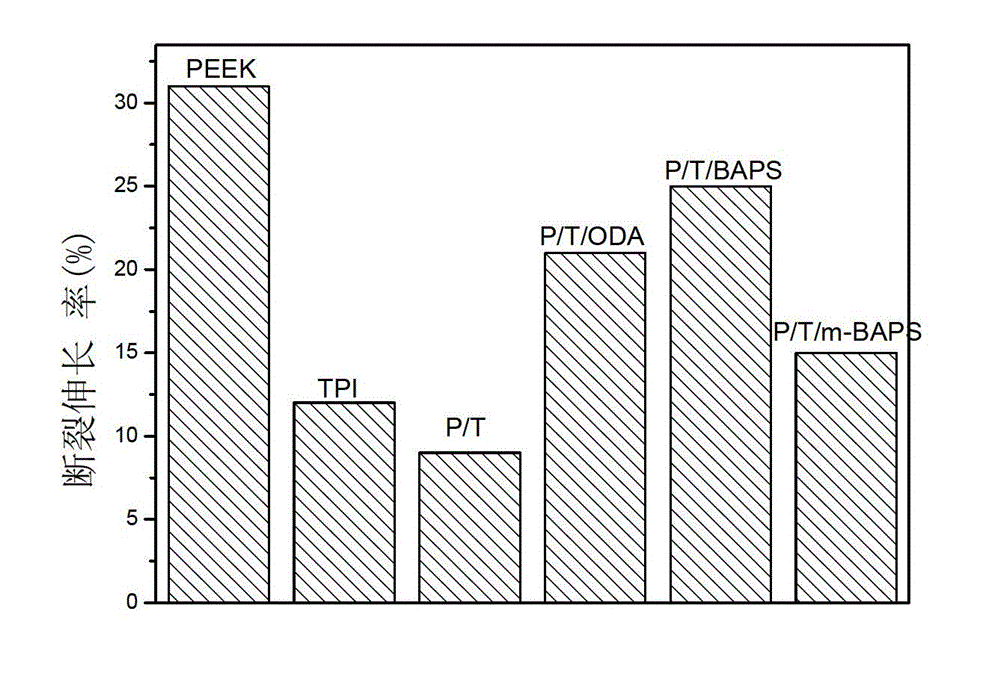

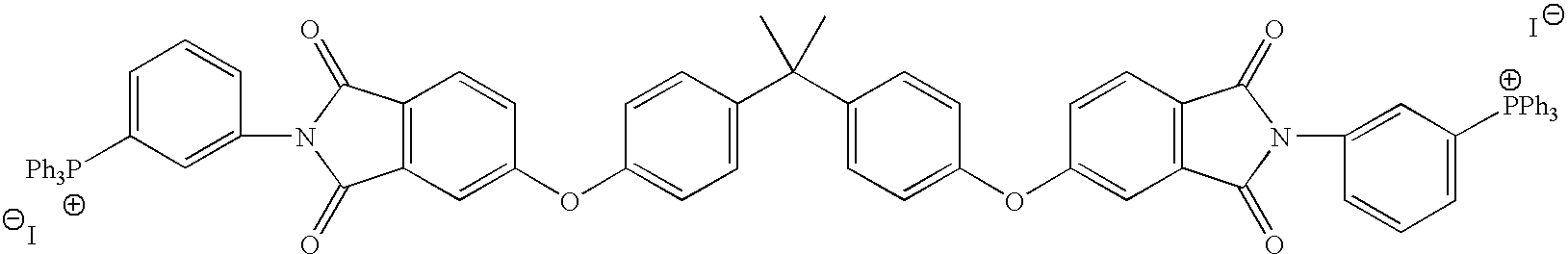

Thermoplastic poly(ether-ether-ketone) type polyimide and preparation method thereof

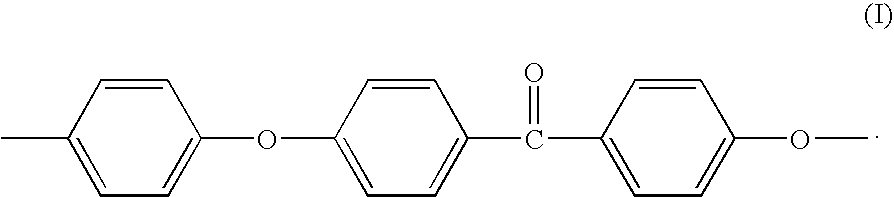

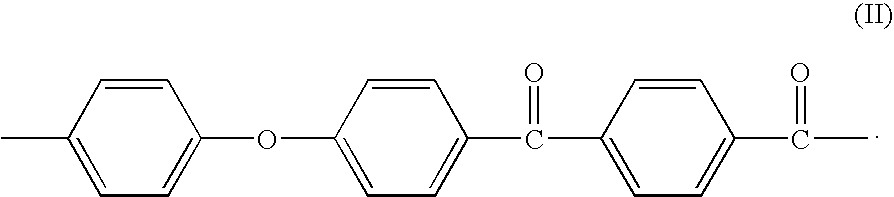

The invention belongs to the field of high polymer material, and in particular relates to a few kinds of polyimide with lower glass transition temperature as well as good mechanical properties, thermal stability and high UV transmittance and a method for preparing the same. The method comprises the steps of adding diamine 1,3-bis (3-amino phenoxy-4'-benzoyl) benzene, dianhydride (s-BPDA, a-BPDA, i-BPDA, BTDA, PMDA, ODPA, BPADA or 6FDA) into an organic solvent (DMF, DMAc or NMP ) to react for 2 to 24 hours in an ice-water bath at room temperature under nitrogen protection, or adding end-capping agent aniline or phthalic anhydride so as to obtain polyamic acid solution; then pouring the polyamic acid solution onto a clean glass sheet to remove the organic solvent in an oven after even scrapping; and then performing imidization on the polyamic acid solution in a vacuum oven to obtain a polyimide polymer film of no-sealed end, aniline sealed end, phthalic anhydride sealed end or dianhydride sealed end.

Owner:JILIN UNIV

Porous-grade polyether-ether-ketone self-lubricating wear-resistant composite material and preparation method thereof

InactiveCN102504478AExtended service lifeStable and good lubricationCoatingsPoly ether ether ketoneCarbon nanotube

The invention relates to a porous-grade polyether-ether-ketone self-lubricating wear-resistant composite material and a preparation method thereof, which are used for solving the problems of simple pore forming way and over single pore canal structure existing in a polyether-ether-ketone porous material. The method comprises the following steps of: adding micron and nano-pore forming agents into polyether-ether-ketone, sintering and molding to obtain a substrate; and filling lubricating oil or grease into holes inside the substrate, wherein the nano-pore forming agent is one or a mixture of certain of mesoporous titanium oxide crystal whiskers of which the specific surface area is more than or equal to 50 m<2> / g, a molecular sieve or a carbon nanotube. In the composite material, a stable lubricating oil film is formed on a friction surface in a friction process, so that stable and good lubricating functions are realized; the composite material is suitable to be applied in special environments such as high temperatures, vacuum, corrosion, radiation and the like; and friction can be reduced remarkably, and the service life of a device is prolonged greatly.

Owner:NORTHEAST GASOLINEEUM UNIV

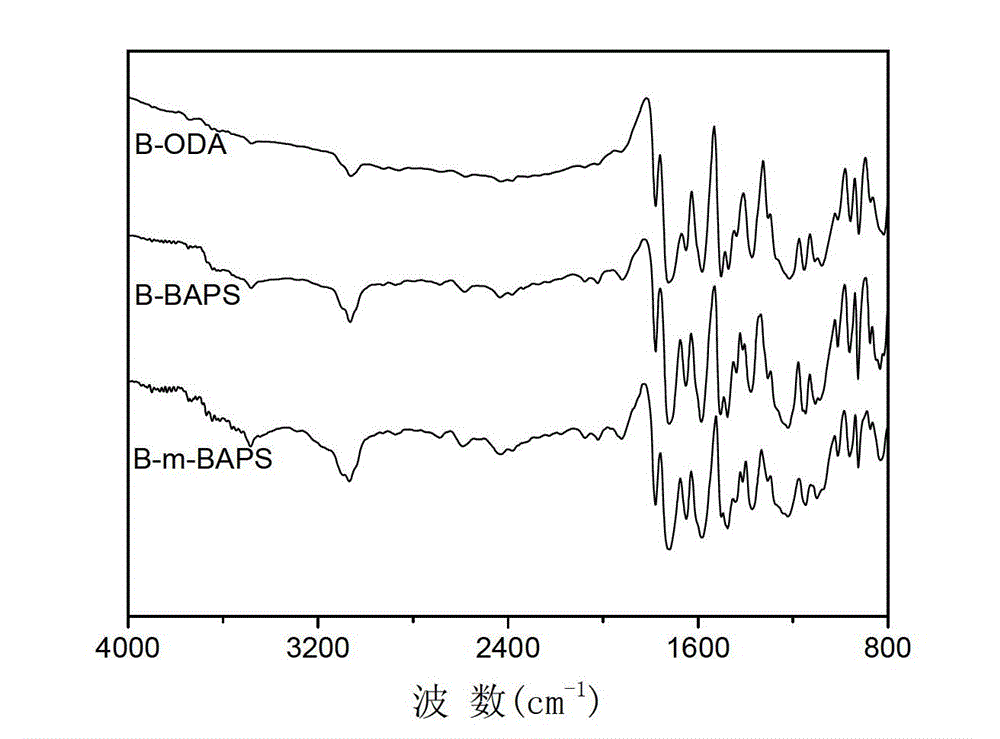

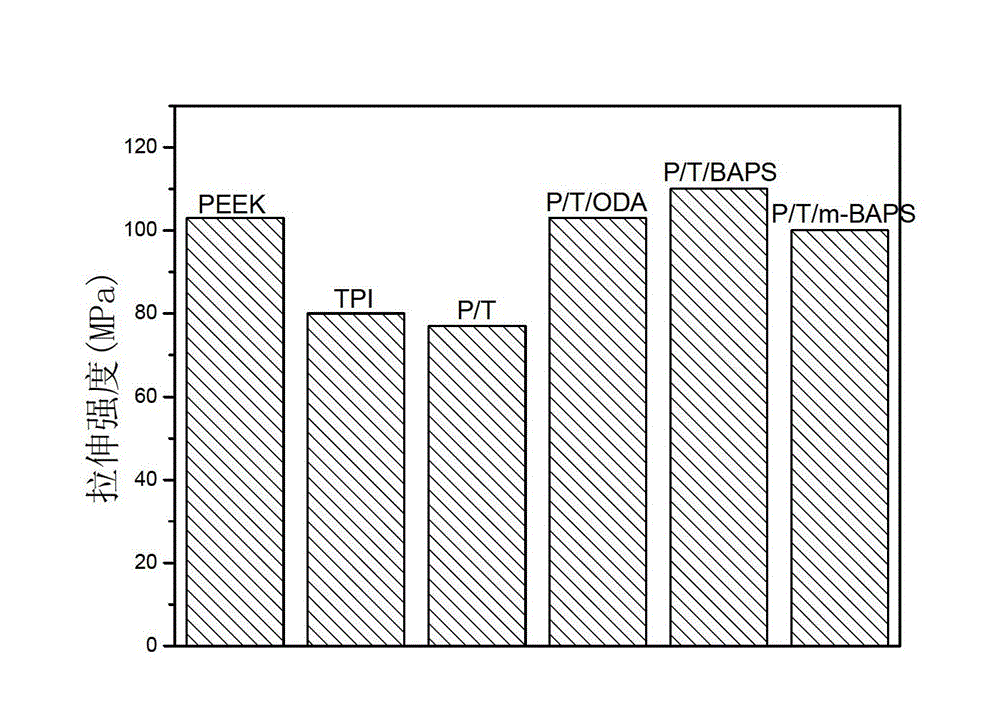

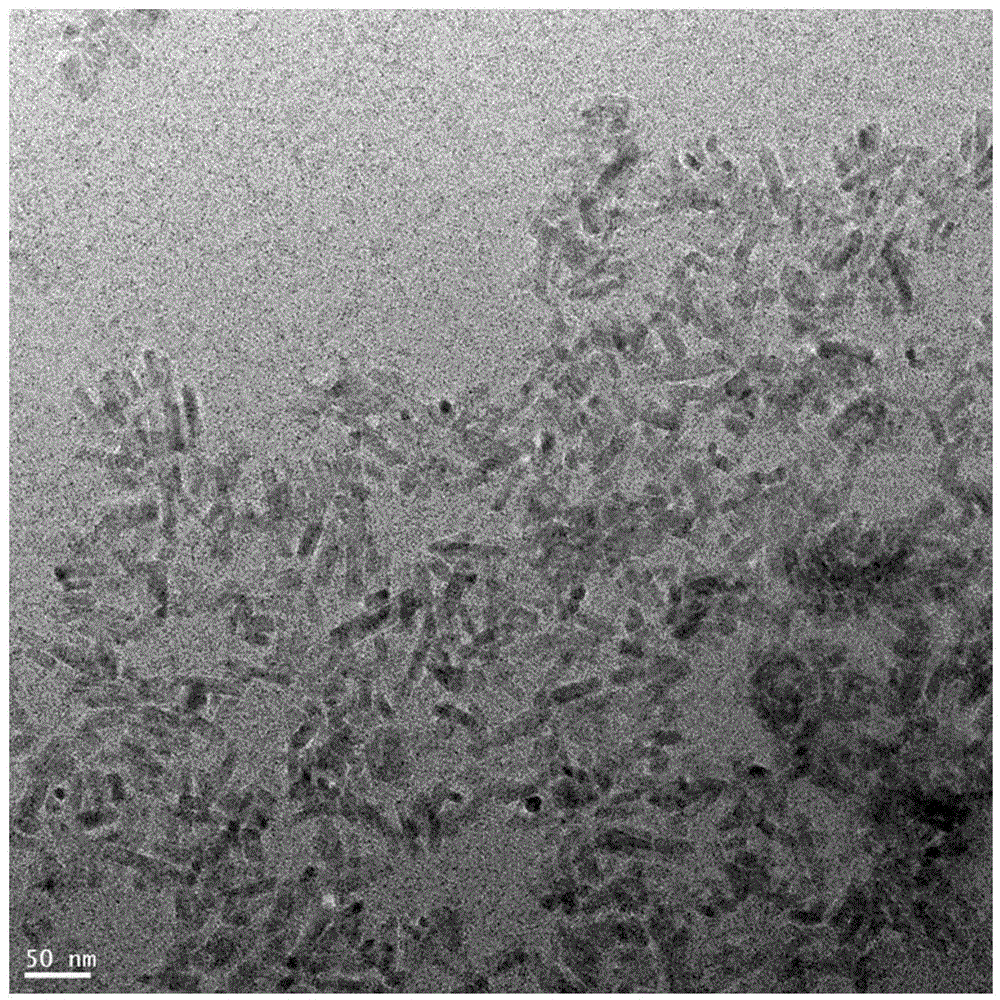

Aromatic polyetheretherketone-polyimide block polymer, and preparation method and application thereof

InactiveCN102875819AGood compatibilityImprove mechanical propertiesPolymer sciencePoly ether ether ketone

The invention relates to an aromatic block polymer, and a preparation method and application thereof as a compatibilizer. Amino-terminated polyetheretherketone oligomer and acid-anhydride-terminated polyimide oligomer are subjected to nucleophilic polycondensation reaction in an organic solvent to obtain the polyetheretherketone-polyimide block polymer. The polymerization degree of the two oligomers can be regulated to prepare the block polymer, so that the number-average molecular weight of the prepared polyetheretherketone block and polyimide block is 1000-6000, and the number-average molecular weight of the block polymer is 20000-40000. When being adding into a polyetheretherketone-thermoplastic polyimide blend system as a compatibilizer, the block polymer is beneficial to improving the compatibility of the blend system, thereby preparing the high-polymer alloy material with excellent comprehensive properties, such as mechanical properties, working properties, thermal properties and the like.

Owner:JILIN UNIV

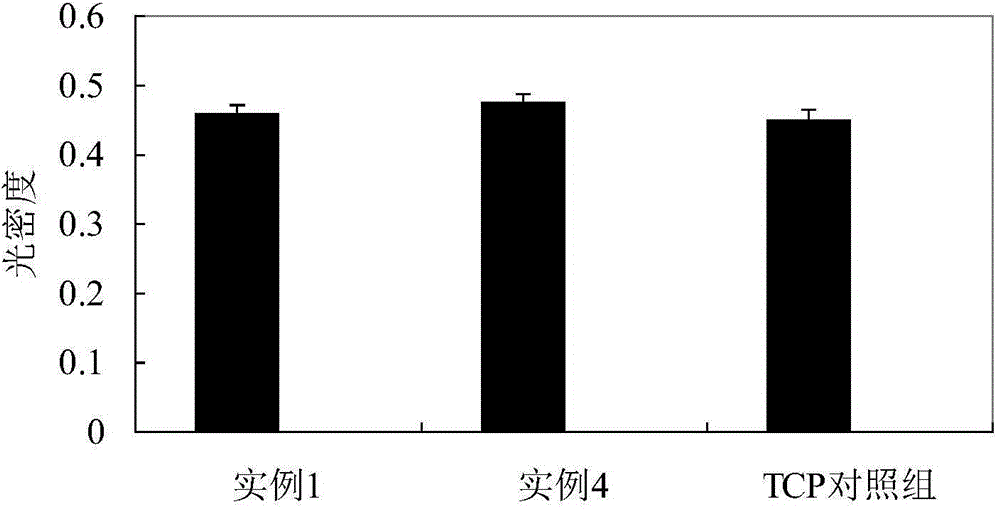

Nano-hydroxyapatite/polyether-ether-ketone composite material and bone repair body as well as preparation method and application thereof

The invention discloses a nano-hydroxyapatite / polyether-ether-ketone composite material and a bone repair body as well as a preparation method and application thereof. The preparation method of the composite material comprises the following steps: uniformly mixing 30-35wt% of 200nm-1mu m hydroxyapatite powder and 65-70wt% of 5-15mu m polyether-ether-ketone powder to obtain mixed powder; and processing the mixed powder and moulding to obtain the composite material. The composite material has good biocompatibility and bioactivity as well as mechanical properties matching the bone tissue, effectively prevents the stress shielding effect, and can stimulate bone growth, accelerate bone healing, shorten the healing time of the injury after material implantation of bone and reduce the probability of second operation. The preparation technology of the composite material can be adjusted to prepare bone repair bodies different in shape, specification and mechanical properties to meet the clinical needs. Inflammatory reaction is avoided after the implantation of the bone repair bodies, the mechanical properties are matched with human bone, negative effects such as bone repair material loosening and bone resorption are prevented, and the clinical needs for bone repair can be met.

Owner:SHENZHEN KEJU NEW MATERIAL

Antistatic high-temperature-resistant poly(ether-ether-ketone) coating and preparation method of antistatic high-temperature-resistant coating

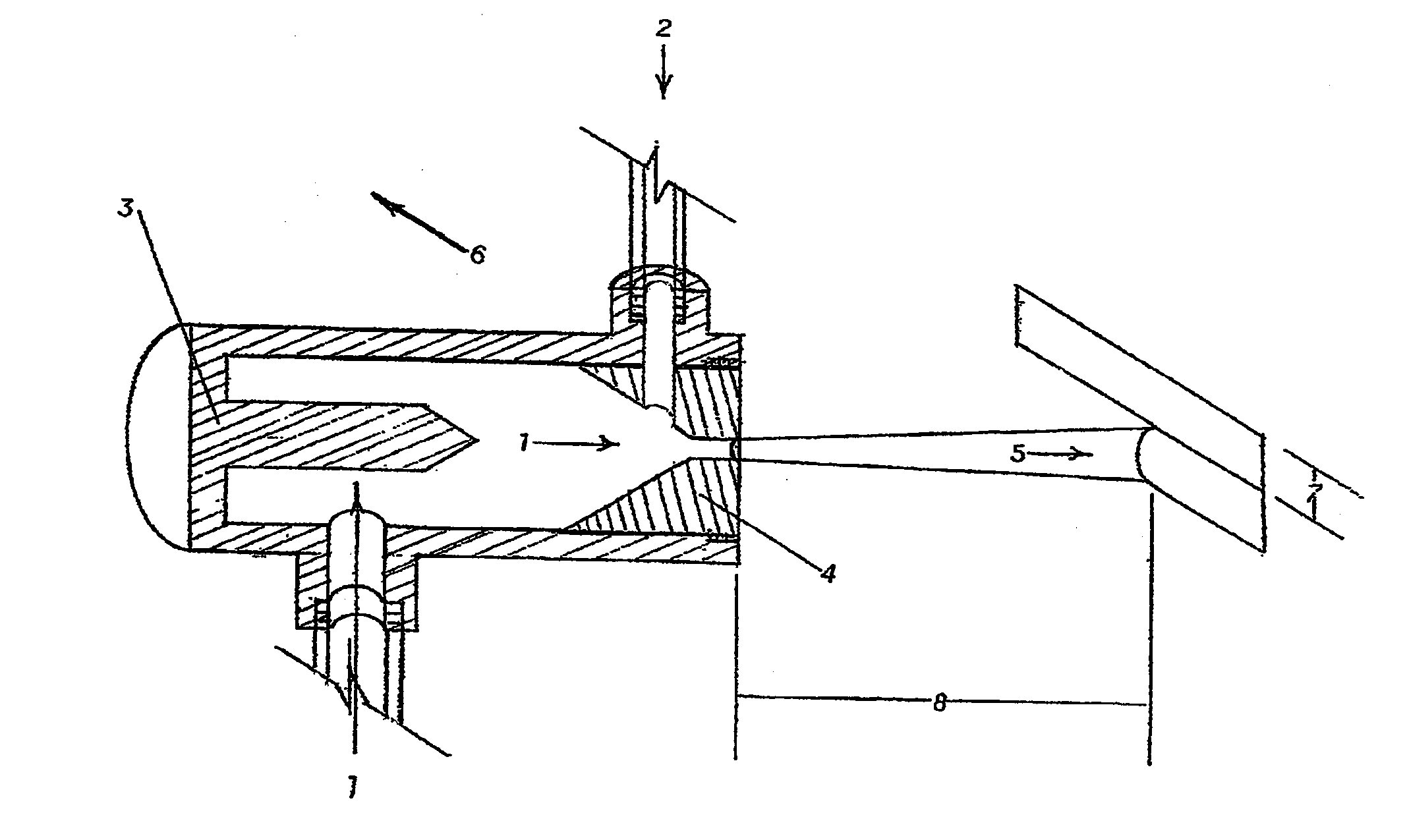

ActiveCN103194142AEasy to prepareImprove conductivityPretreated surfacesPolyether coatingsAviationPoly ether ether ketone

The invention discloses an antistatic high-temperature-resistant polyether-ether-ketone coating and a preparation method of the antistatic high-temperature-resistant coating, and belongs to the technical field of paint. The mass ratio of the polyether-ether-ketone resin to a carbon nano tube in the coating disclosed by the invention is (98.5-99.5) to (1.5-0.5). The preparation method of the coating comprises the steps of grinding and drying the polyether-ether-ketone resin; mixing with the carbon nano tube to obtain mixed paint, and spraying the mixed paint on a sanded metal plate by an electrostatic spraying technology; and curing at room temperature after melting at high temperature to obtain the antistatic high-temperature-resistant coating. The alternating current conductivity of the antistatic high-temperature-resistant coating disclosed by the invention under the frequency of 10<3>Hz is 8.09*10<-9>s / m to 7.10*10(-4)s / m, and has the antistatic function. The preparation method of the antistatic high-temperature-resistant coating disclosed by the invention is simple and convenient; the conductive padding is evenly dispersed in resin; the conductivity of the coating is improved; and the antistatic high-temperature-resistant coating can be applied to the industries such as electronics, electric appliances, aviation and petrochemical engineering.

Owner:吉林省奕彤新材料有限公司

Preparation method of composite proton exchange membrane

ActiveCN101864163AInhibit swellingImprove proton conductivityFinal product manufactureCell component detailsElectrical conductorHeteropoly acid

The invention discloses a preparation method of a composite proton exchange membrane, comprising the following steps of: sulfonating, preparing a sulfonated polyether ether ketone solution; preparing polyaniline filter liquid, preparing membrane preparing liquid, casting to form a membrane, and the like. The composite membrane is prepared by using SPEEK (sulfonated polyether ether ketone) as a basal body and PANI (Polyaniline) and HPA (Heteropoly acid) as dopants, a material source is wide and does not need to be imported, a preparation process is simple, and used instruments are simple, thereby the cost of the membrane is reduced. A hydrogen bond formed by PANI and SPEEK is used for avoiding the swelling of the SPEEK and reducing methanol penetration, and the proton conductivity of the composite membrane is improved by the HPA. By changing the composition and the ratio between an alkaline polymer and a proton conductor, the novel PEM (proton exchange membrane) reaches optimum balance among high proton conductivity, low methanol penetration and low HPA dropout rate, the proton conductivity reaches 10-2S / cm, the methanol penetration rate of the composite proton exchange membrane is a half lower than that of an Nafion 117 membrane, and the HPA wastage rate does not reach 5 percent.

Owner:SUZHOU DACHENG YOUFANG DATA TECH CO LTD

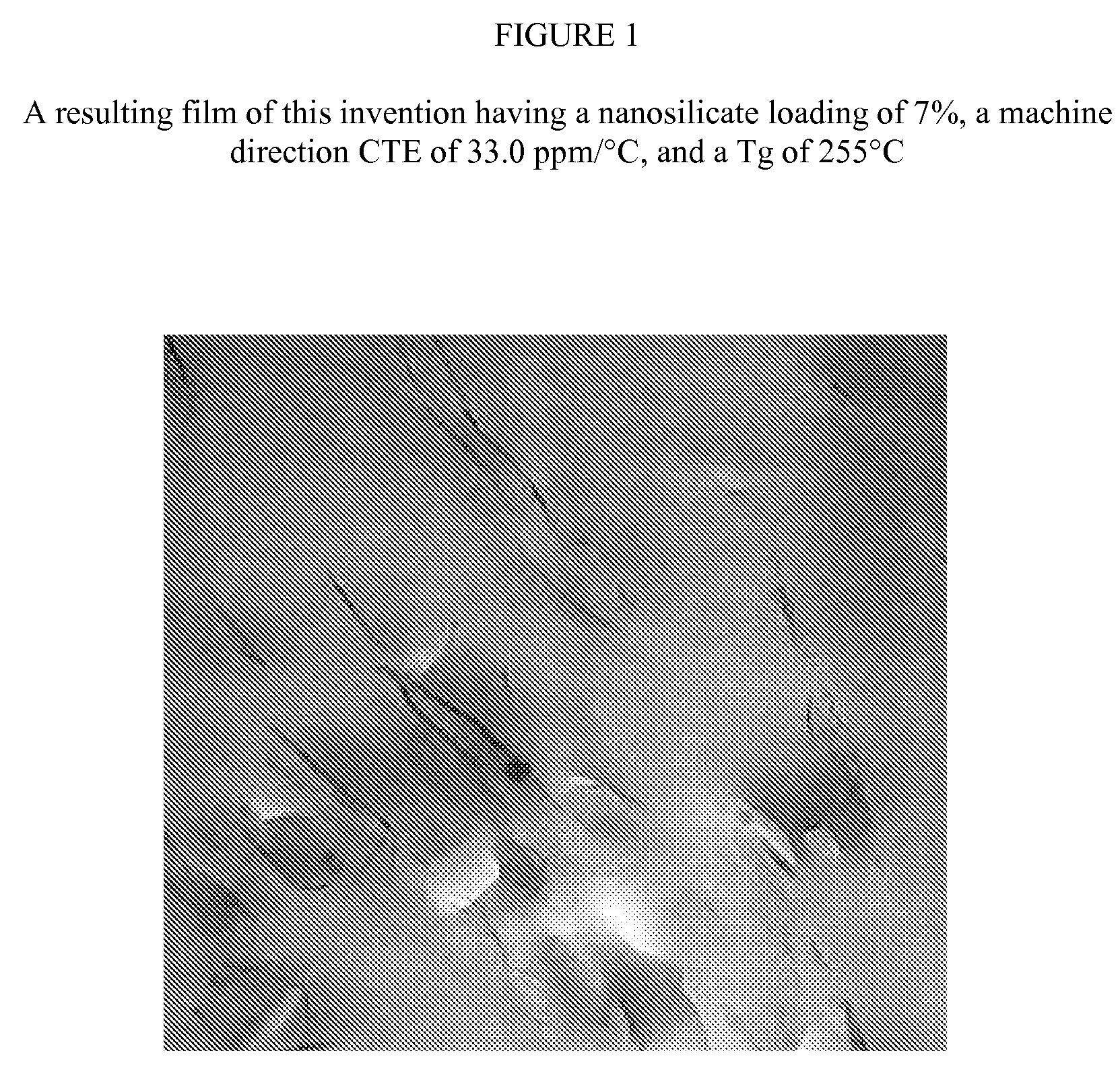

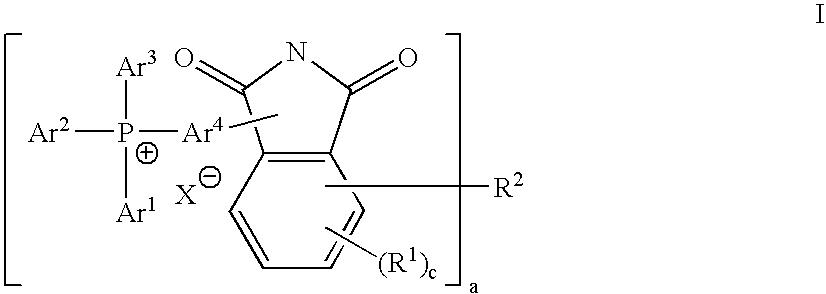

Compositions and methods for polymer composites

This invention relates to organic salt compositions useful in the preparation of organoclay compositions, polymer-organoclay composite compositions, and methods for the preparation of polymer nanocomposites. In one embodiment, the present invention provides a method of making a polymer-organoclay composite composition, said method comprising melt mixing a quaternary organoclay composition comprising alternating inorganic silicate layers and organic layers, said organic layers comprising a quaternary organic cation with a polymeric resin comprising at least one polymer selected from the group consisting of polyamides, polyesters, polyarylene sulfides, polyarylene ethers, polyether sulfones, polyether ketones, polyether ether ketones, polyphenylenes, and polycarbonates, said polymeric resin being substantially free of polyetherimides; said melt mixing being carried out at a temperature in a range between about 300° C. and about 450° C. to provide a polymer-organoclay composite composition, said polymer-organoclay composite composition being characterized by a percent exfoliation of at least 10 percent.

Owner:SABIC INNOVATIVE PLASTICS IP BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com