Polyetheretherketone composite material and method of its manufacture

A polyetheretherketone and composite material technology, which is applied in the field of composition and preparation of special engineering materials, can solve problems such as insufficient performance of polyetheretherketone, and achieve the effects of performance improvement, cost reduction and thermal conductivity improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

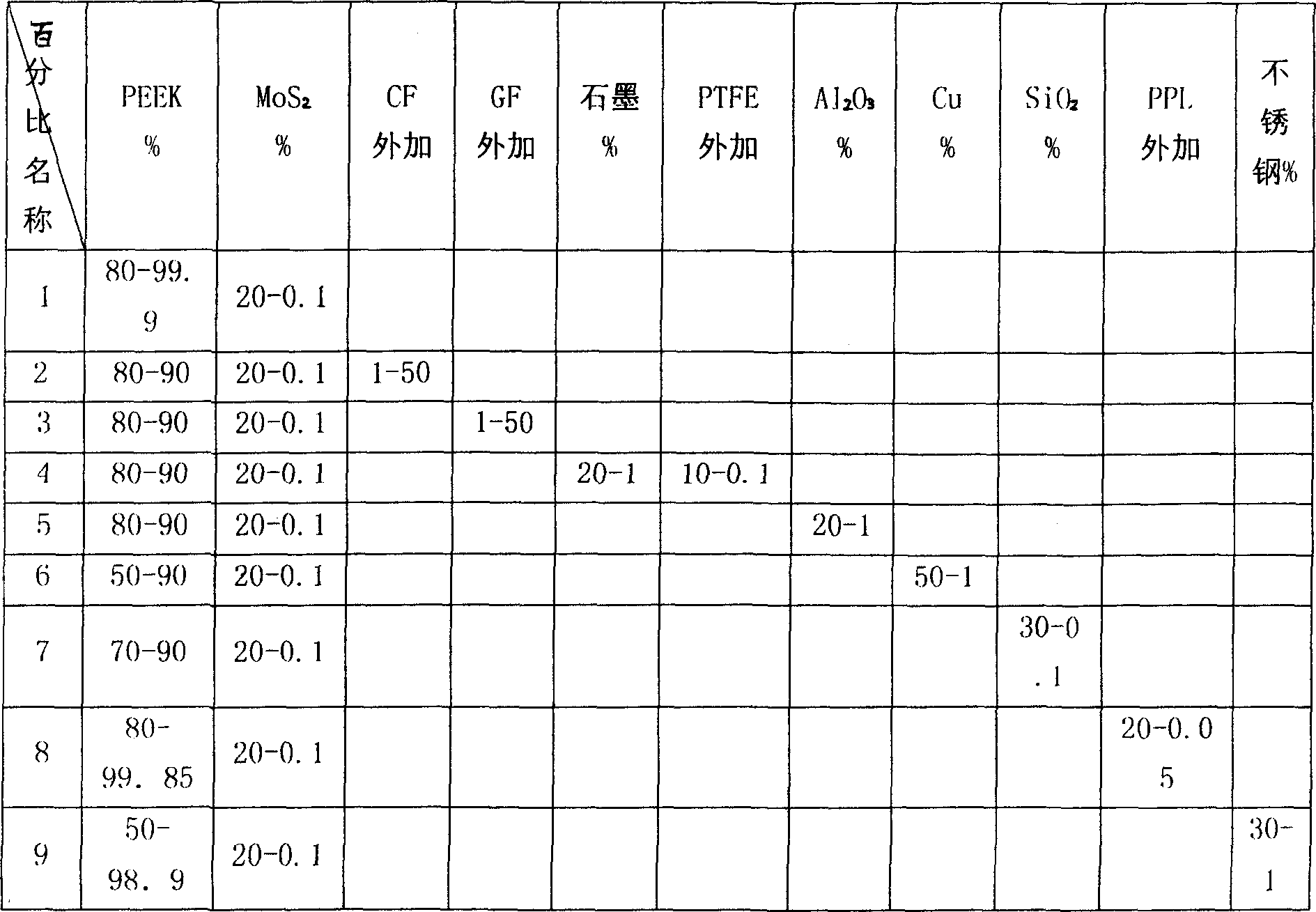

AI Technical Summary

Problems solved by technology

Method used

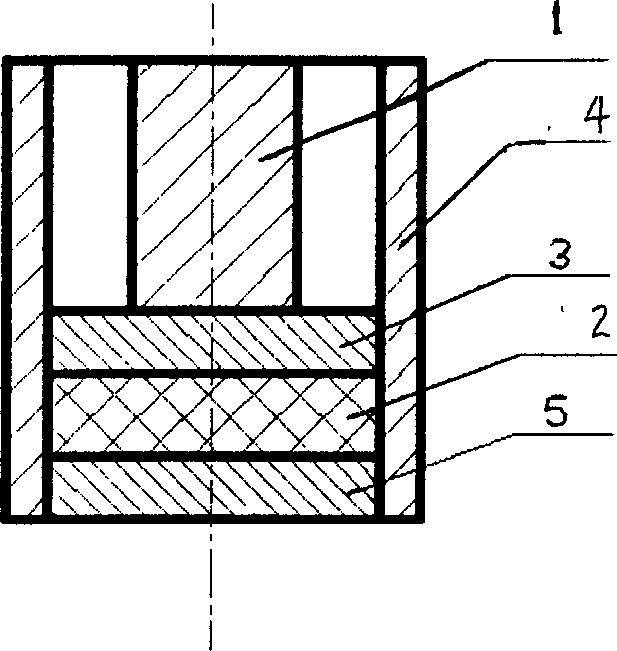

Image

Examples

preparation approach 1

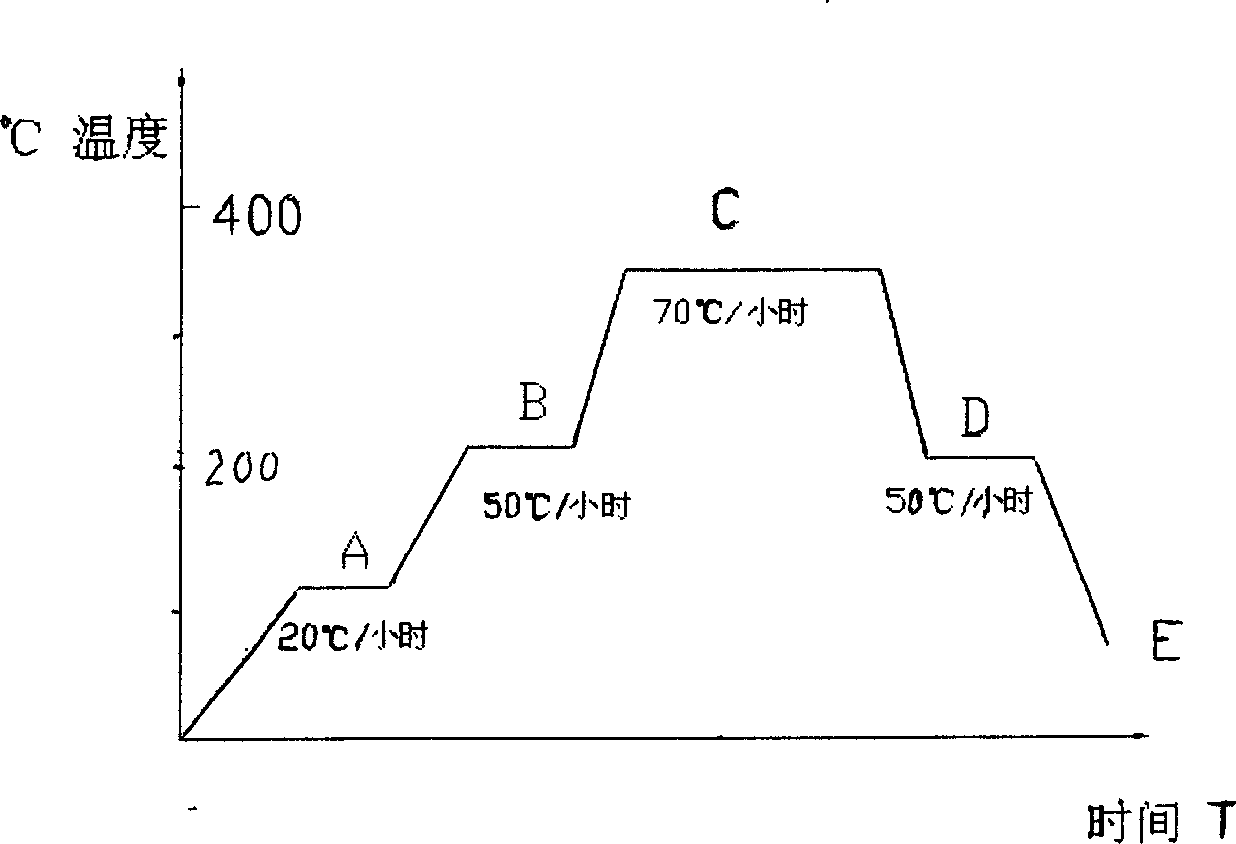

[0027] Preparation scheme 1, injection molding:

[0028] KT-PEEK composite polymer can be injection molded with a standard reciprocating screw injection molding machine. However, due to the high melting temperature, the following processing parameters need to be designed:

[0029] ① Melt cylinder temperature: In order to successfully mold KT-PEEK polymer, the cylinder heater connected to the sol cylinder of the injection molding machine must reach 400-410°C, and the injection port should be kept between 70°C-100°C between.

[0030] ②. Nozzle and cut-off system: KT-PEEK polymer has a high melting point. If the temperature drops below 343°C, the melt will solidify quickly. It is necessary to install a heater large enough at the nozzle to prevent cooling and "injection cold" materials”, this is very important.

[0031] KT-PEEK polymers are generally viscous enough to use open nozzle systems. Do not use closed nozzles because they often contain melt "dead spots" and limit injec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com