Patents

Literature

127 results about "Indentation hardness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

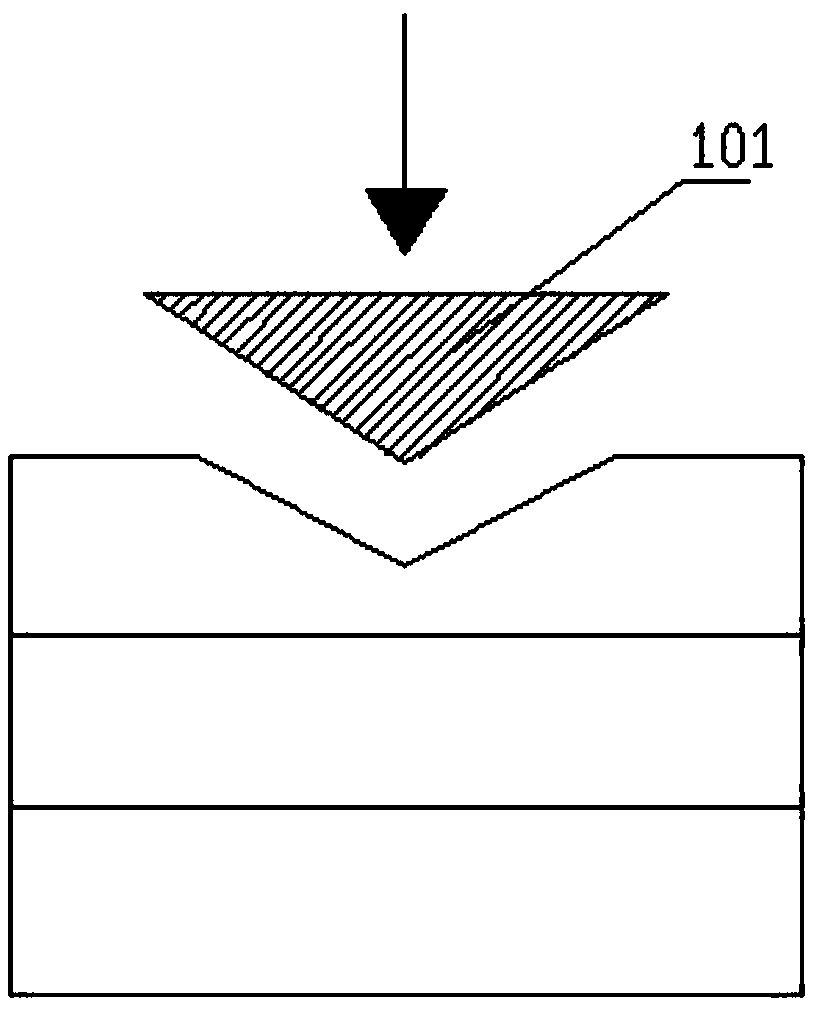

Indentation hardness tests are used in mechanical engineering to determine the hardness of a material to deformation. Several such tests exist, wherein the examined material is indented until an impression is formed; these tests can be performed on a macroscopic or microscopic scale.

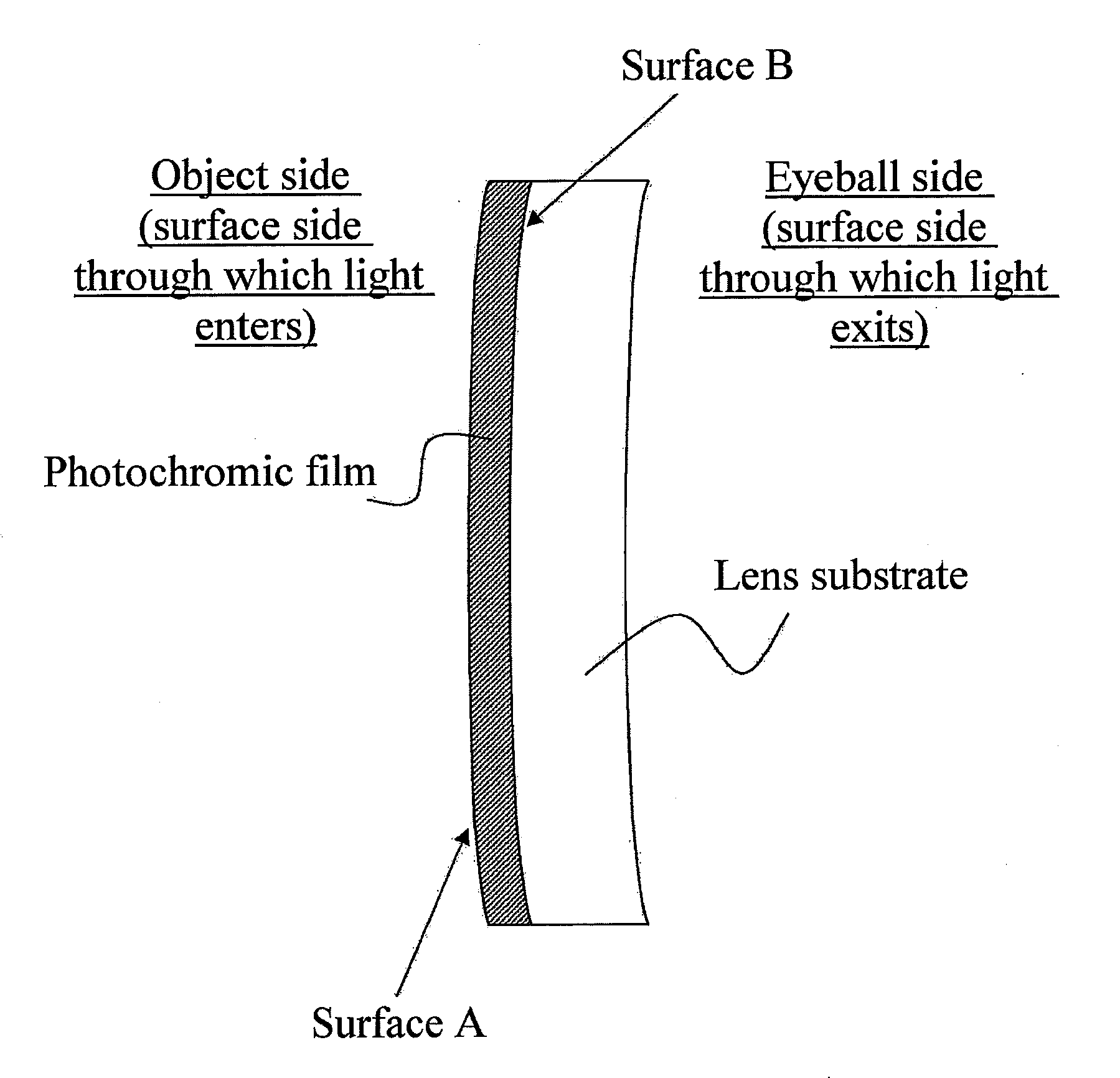

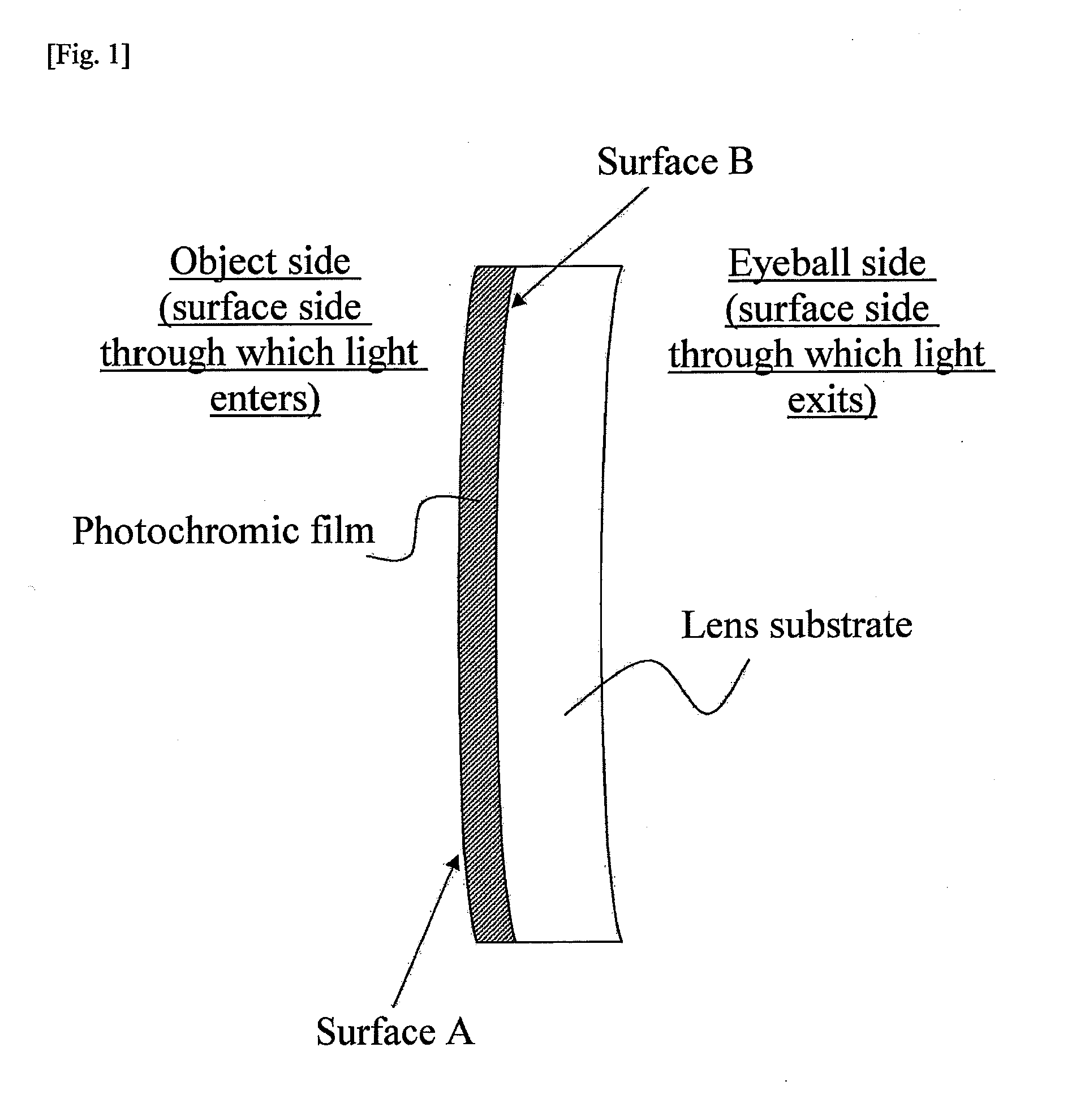

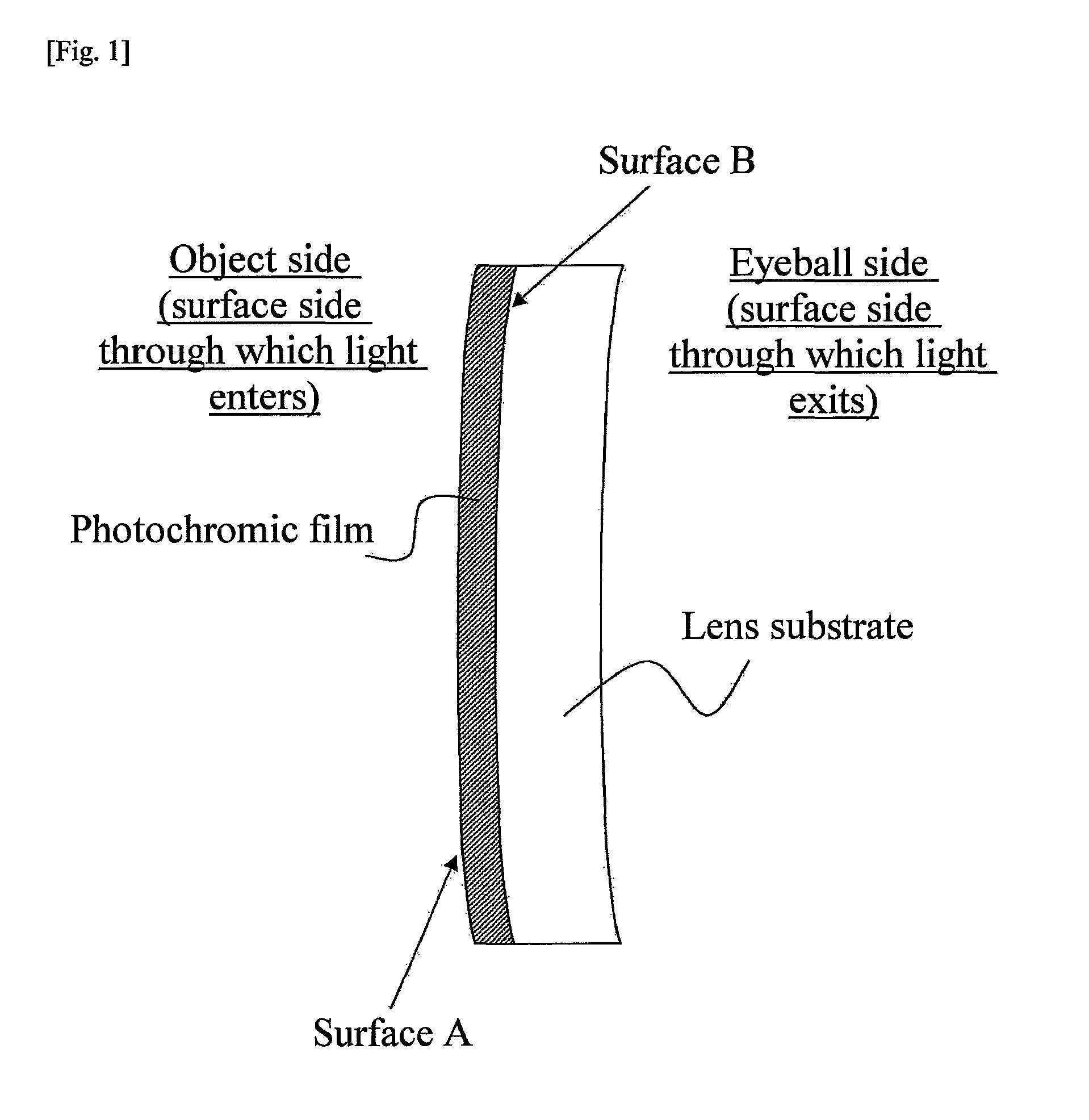

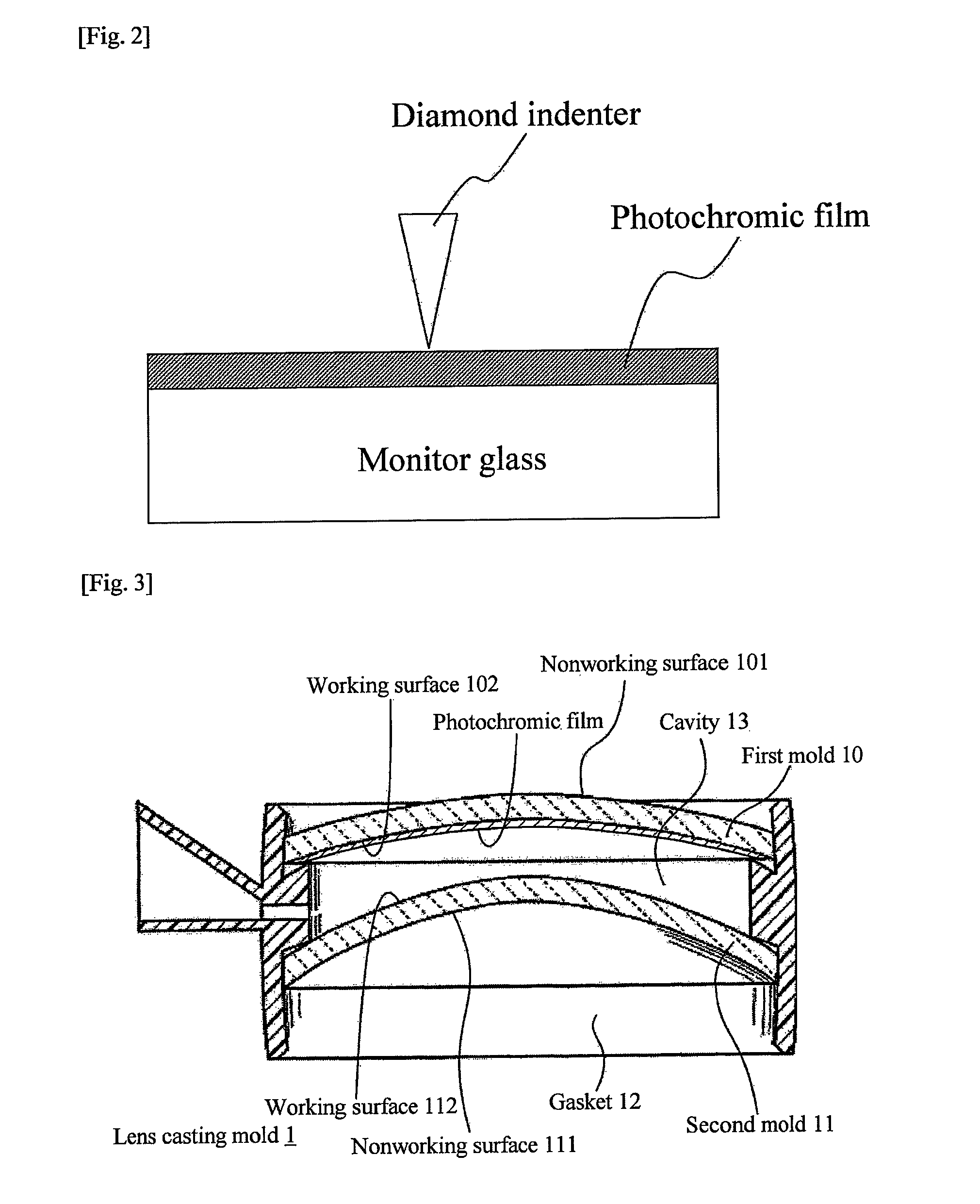

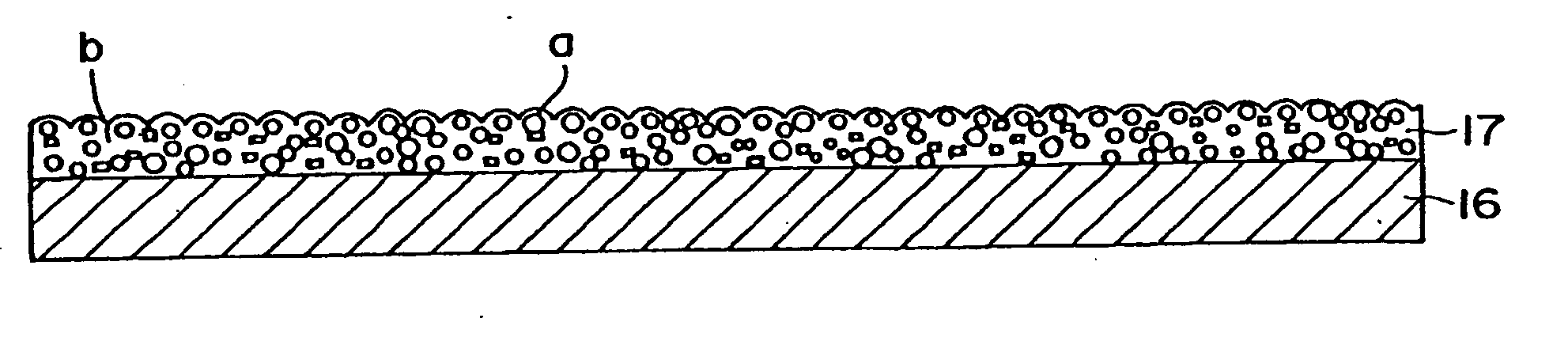

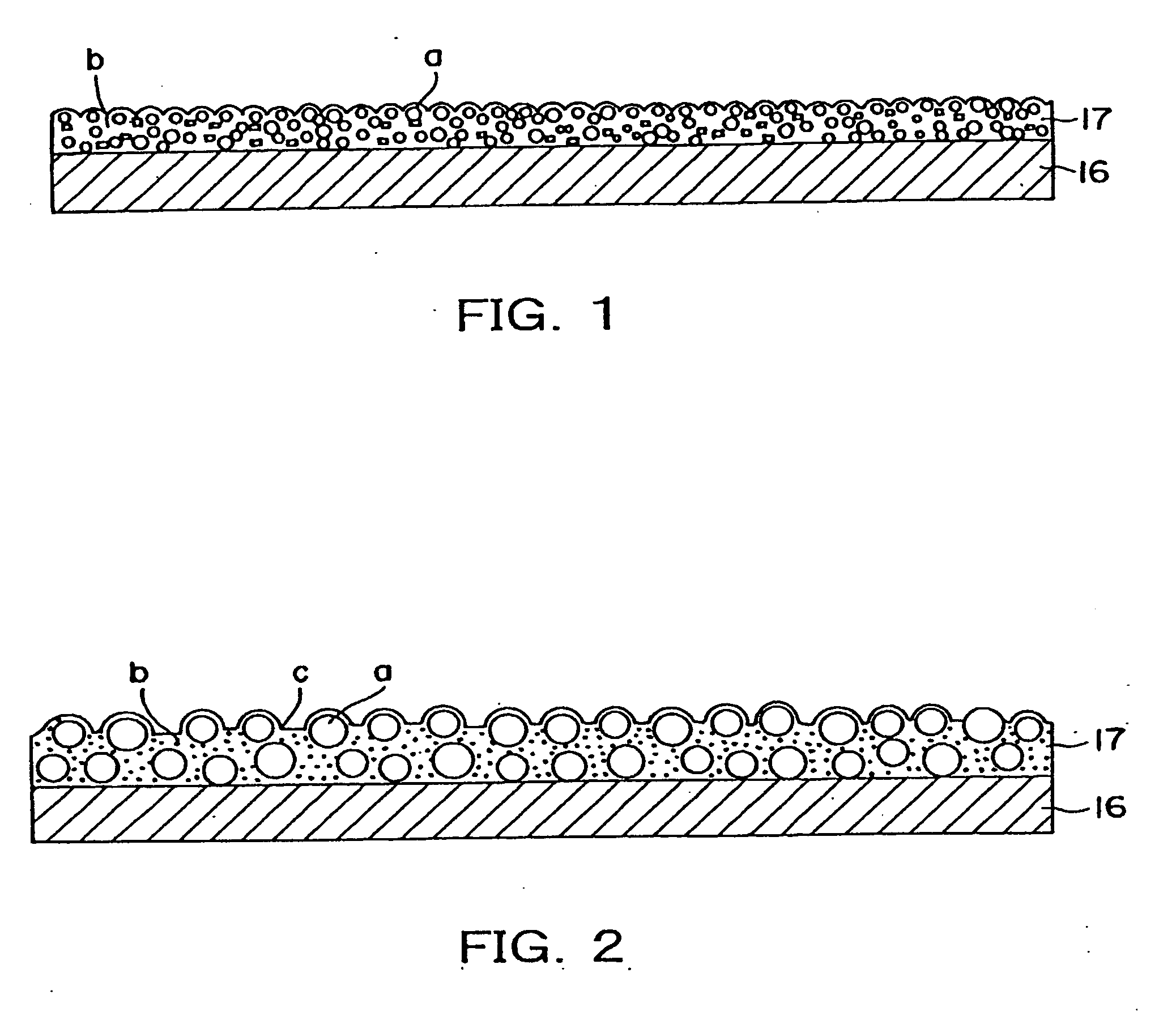

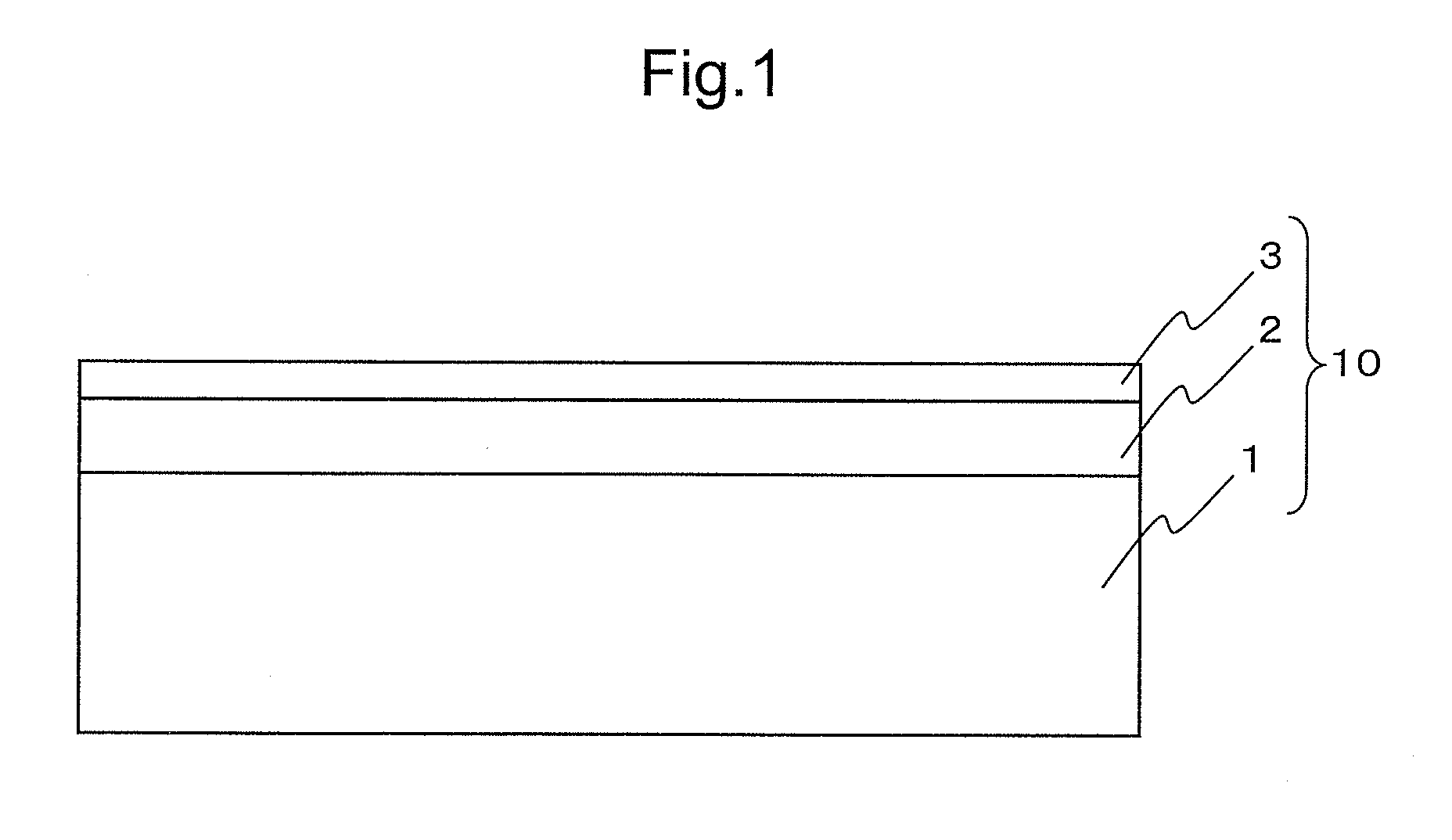

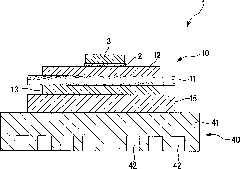

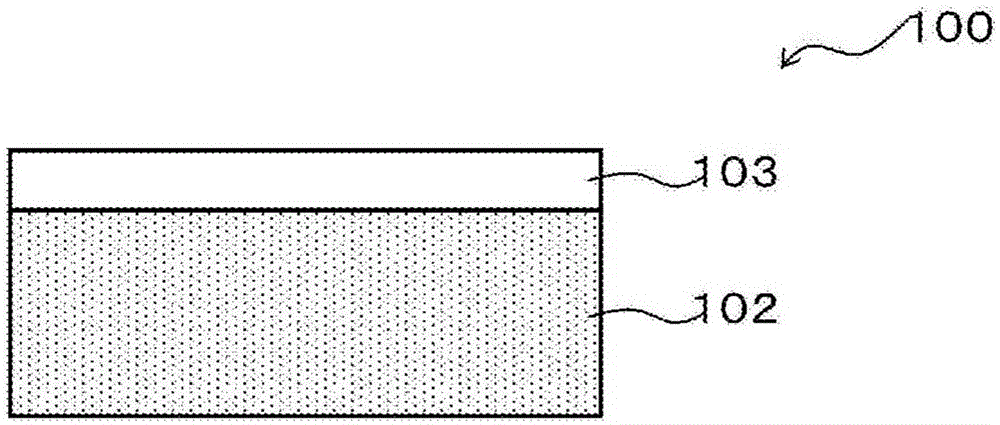

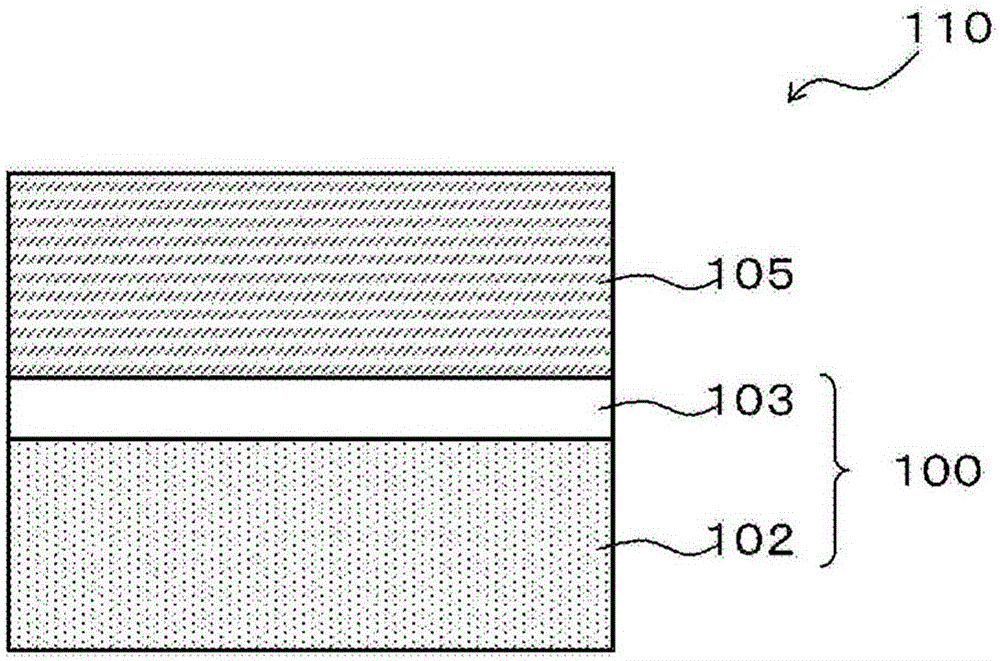

Photochromic film, photochromic lens comprising the same, and method of manufacturing photochromic lens

ActiveUS20090316246A1Good photoresponse performanceImprove featuresDecorative surface effectsOptical articlesPhotochromic lensHardness

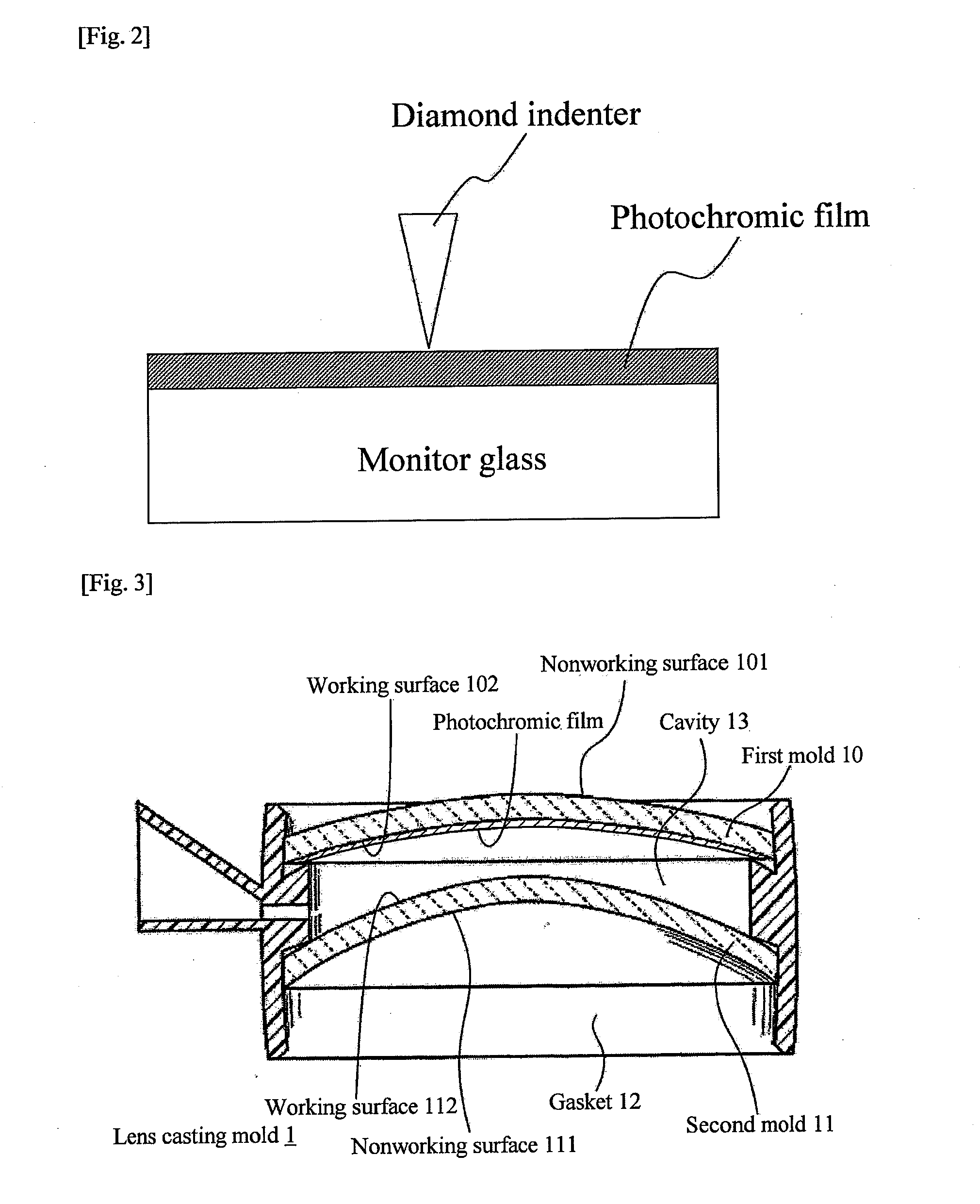

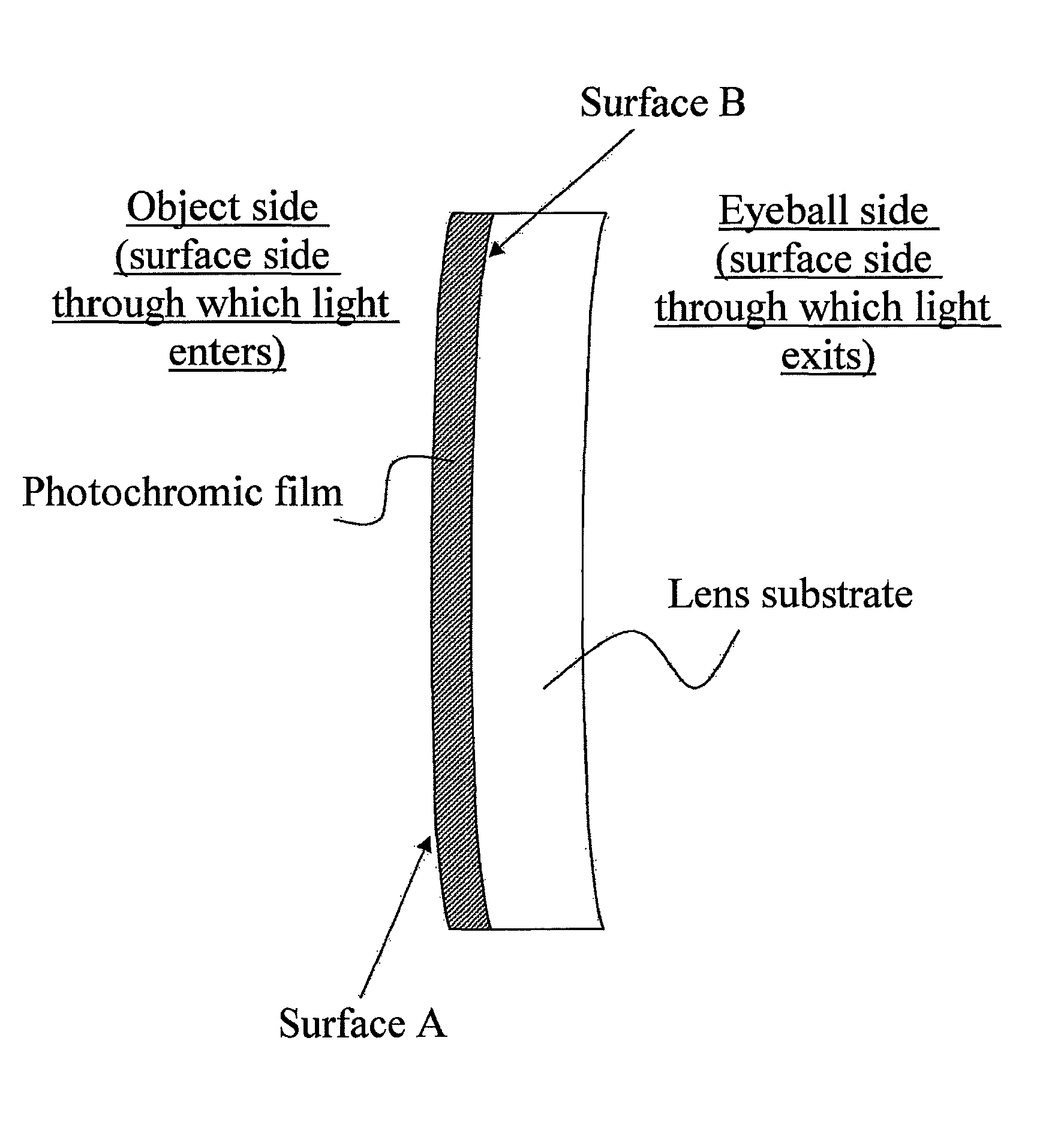

The present invention relates to a photochromic film comprising a photochromic dye and a resin component. The photochromic film has a nanoindentation hardness of equal to or greater than 800 nm on at least one of surfaces, surface A, thereof. The present invention further relates to a method of manufacturing a photochromic lens. The method of manufacturing a photochromic lens of the present invention comprises forming a photochromic film having a nanoindentation hardness ranging from 500 to 5000 nm on an outermost surface thereof as well as having a smaller nanoindentation hardness on a surface facing a first mold than that on the outermost surface by coating a photochromic liquid comprising a photochromic dye and a curable component on one surface of the first mold for formation of one of surfaces of a lens and subjecting the photochromic liquid to curing treatment, and a photochromic lens comprising a photochromic film on a lens substrate is obtained by means of the above first mold.

Owner:HOYA CORP

Photochromic film, photochromic lens comprising the same, and method of manufacturing photochromic lens

ActiveUS7999989B2Good photoresponse performanceImprove featuresOptical articlesCoatingsPhotochromic lensHardness

The present invention relates to a photochromic film comprising a photochromic dye and a resin component. The photochromic film has a nanoindentation hardness of equal to or greater than 800 nm on at least one of surfaces, surface A, thereof. The present invention further relates to a method of manufacturing a photochromic lens. The method of manufacturing a photochromic lens of the present invention comprises forming a photochromic film having a nanoindentation hardness ranging from 500 to 5000 nm on an outermost surface thereof as well as having a smaller nanoindentation hardness on a surface facing a first mold than that on the outermost surface by coating a photochromic liquid comprising a photochromic dye and a curable component on one surface of the first mold for formation of one of surfaces of a lens and subjecting the photochromic liquid to curing treatment, and a photochromic lens comprising a photochromic film on a lens substrate is obtained by means of the above first mold.

Owner:HOYA CORP

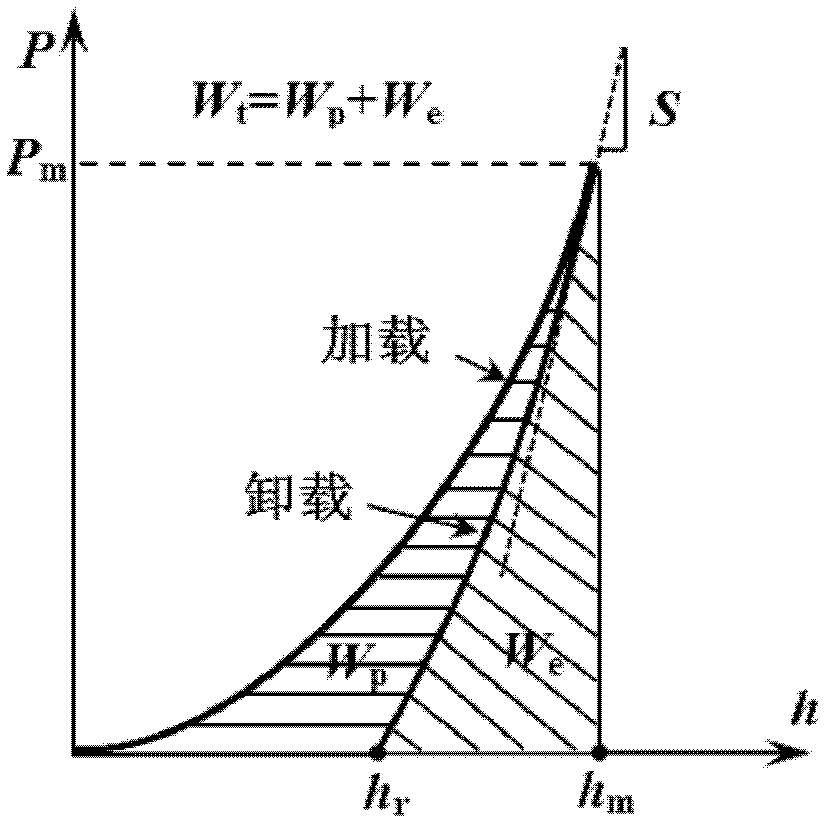

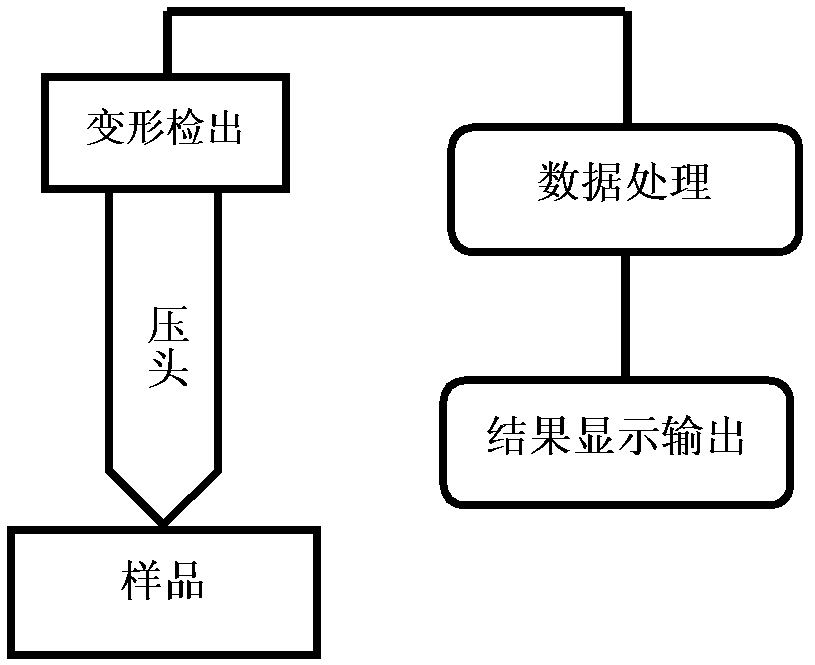

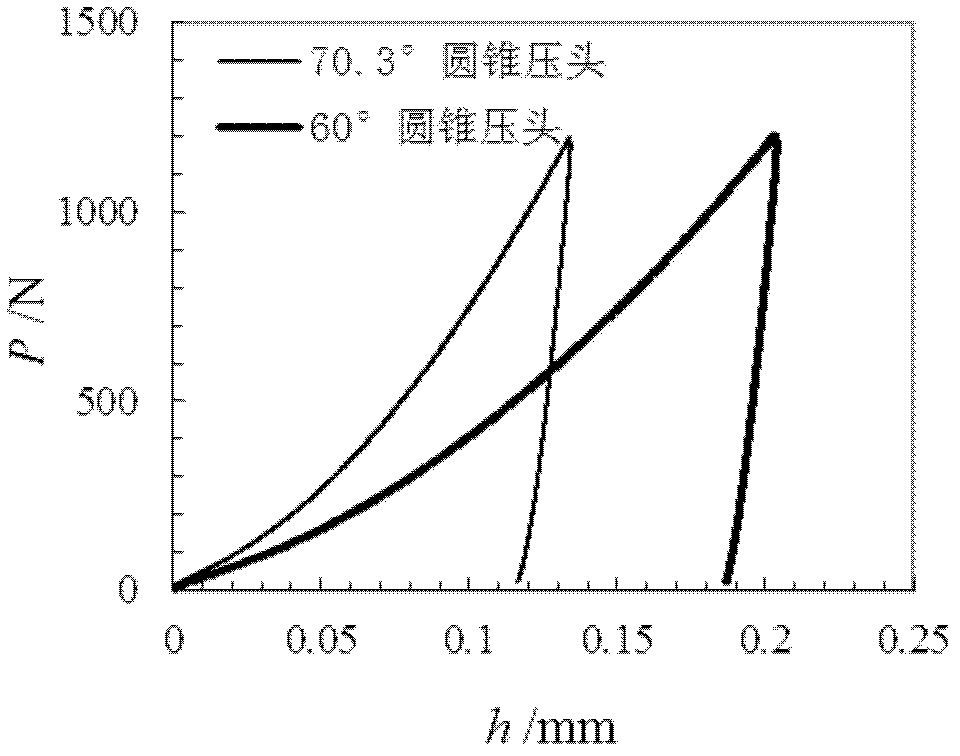

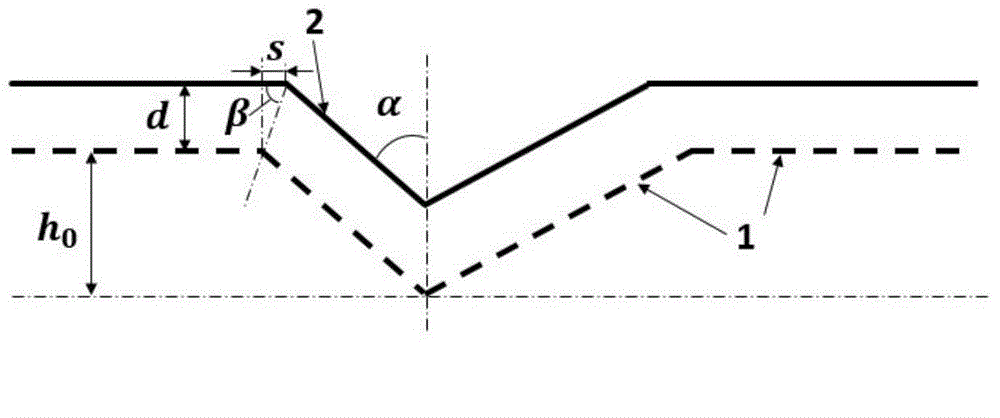

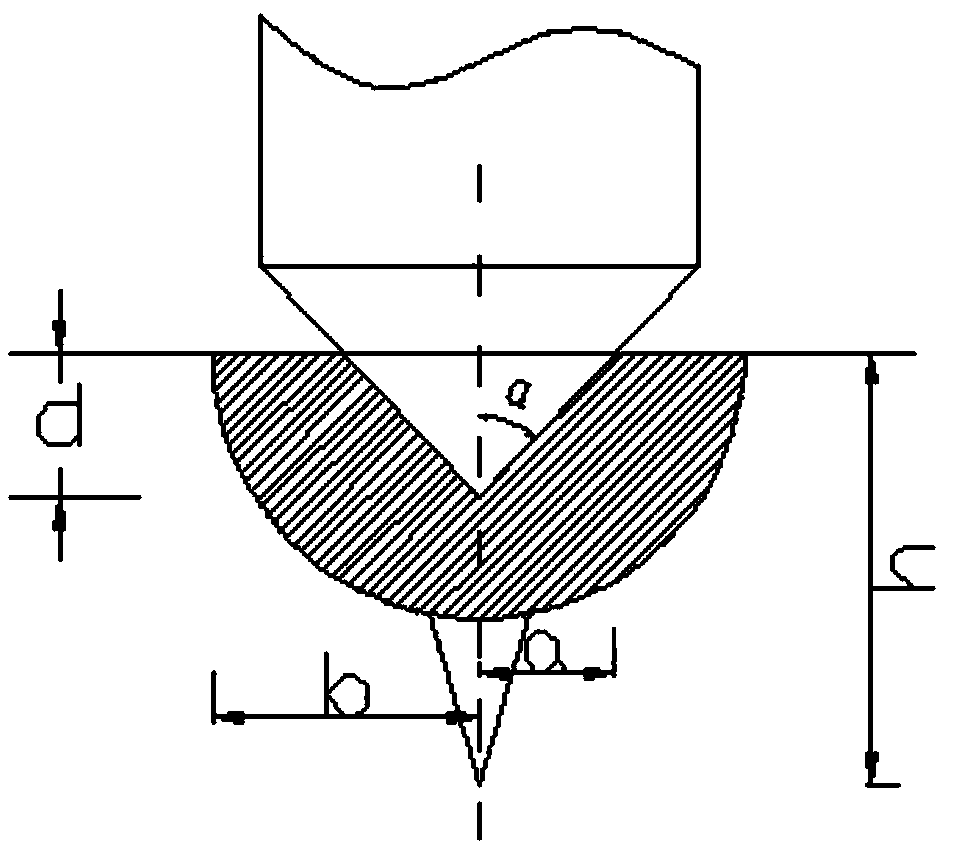

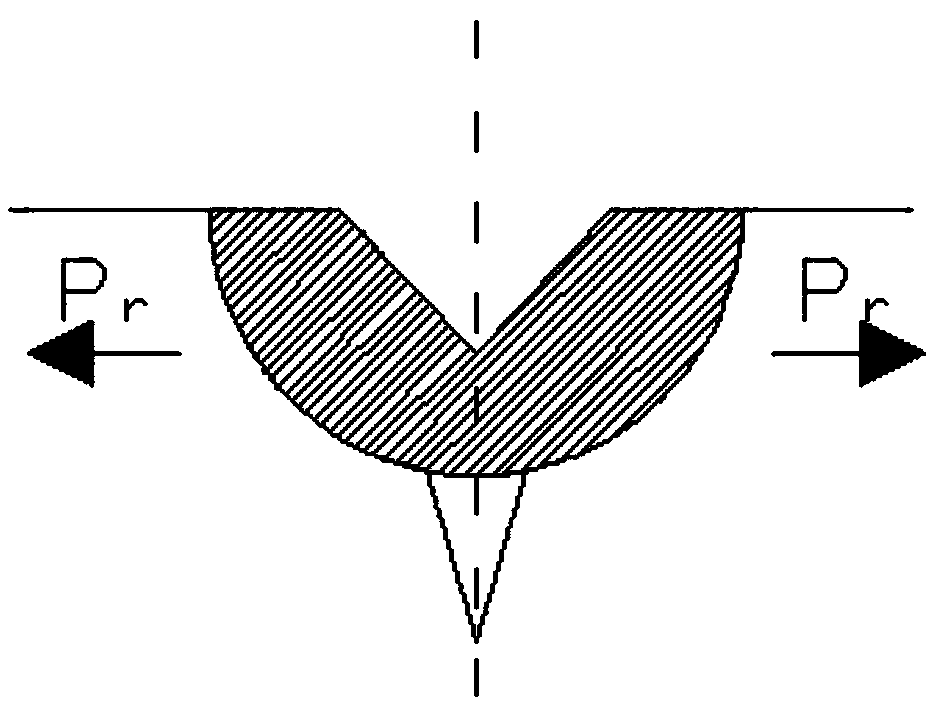

Method for forecasting uniaxial constitutive relation of material according to press hardness

The invention discloses a method for forecasting the uniaxial constitutive relation of material according to press hardness, comprising the following steps: in a press hardness detecting system consisting of a press head loading unit, a deformation detecting unit and a data processing unit, the press head loading unit presses material to be detected by press heads with different appearances, and the deformation detecting unit detects the corresponding deformation of the material to be detected and inputs into the data processing unit to obtain the constitutive parameters E, sigma y and n of forecasting material, so that the portable measurement of the uniaxial constitutive relation of the material and the serviced structural part can be realized by the simple method for forecasting the uniaxial constitutive relation of the material according to the press hardness.

Owner:SOUTHWEST JIAOTONG UNIV

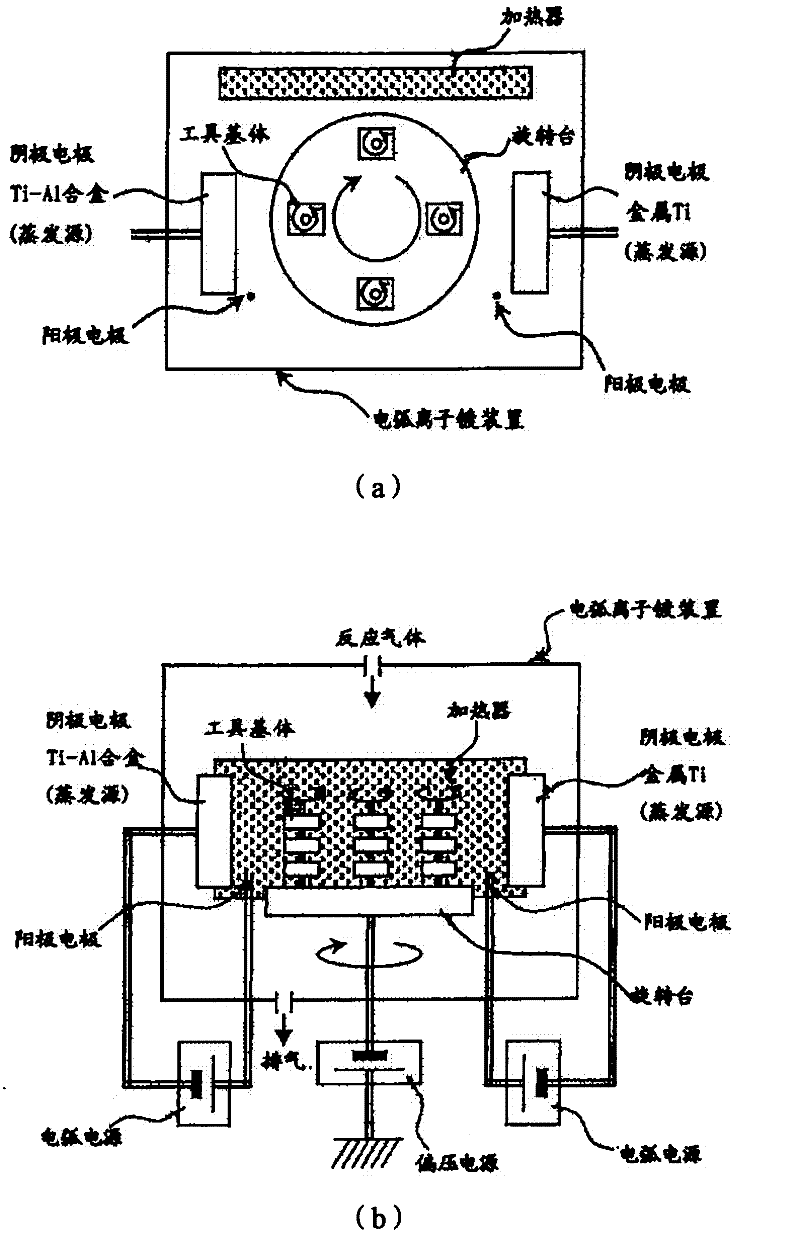

Surface-coated cutting tool

ActiveCN1845808AImprove overall lifespanAvoid chippingTransportation and packagingMilling cuttersHardnessIndentation hardness

A surface-coated cutting tool having a base material and, formed thereon, a coating film, wherein the coating film has a hard layer comprising a compound selected from among a nitride, a carbonitride, a nitroxide and a carbonitroxide of one or more first elements selected from the group consisting of metals belonging to 4a, 5a and 6a Groups of the Periodic Table and B, Al and Si, and wherein the hard layer satisfies the followings: (a) in the nano indentation hardness test, (hmax - hf) / hmax is 0.2 to 0.7, wherein hmax represents the maximum indentation depth, and hf represents the indentation depth after the removal of a load (impression depth), (b) the hard layer has a film thickness of 0.5 to 15 mum, and (c) a hardness according to the nano indentation method is 20 to 80 GPa.

Owner:SUMITOMO ELECTRIC HARDMETAL CORP

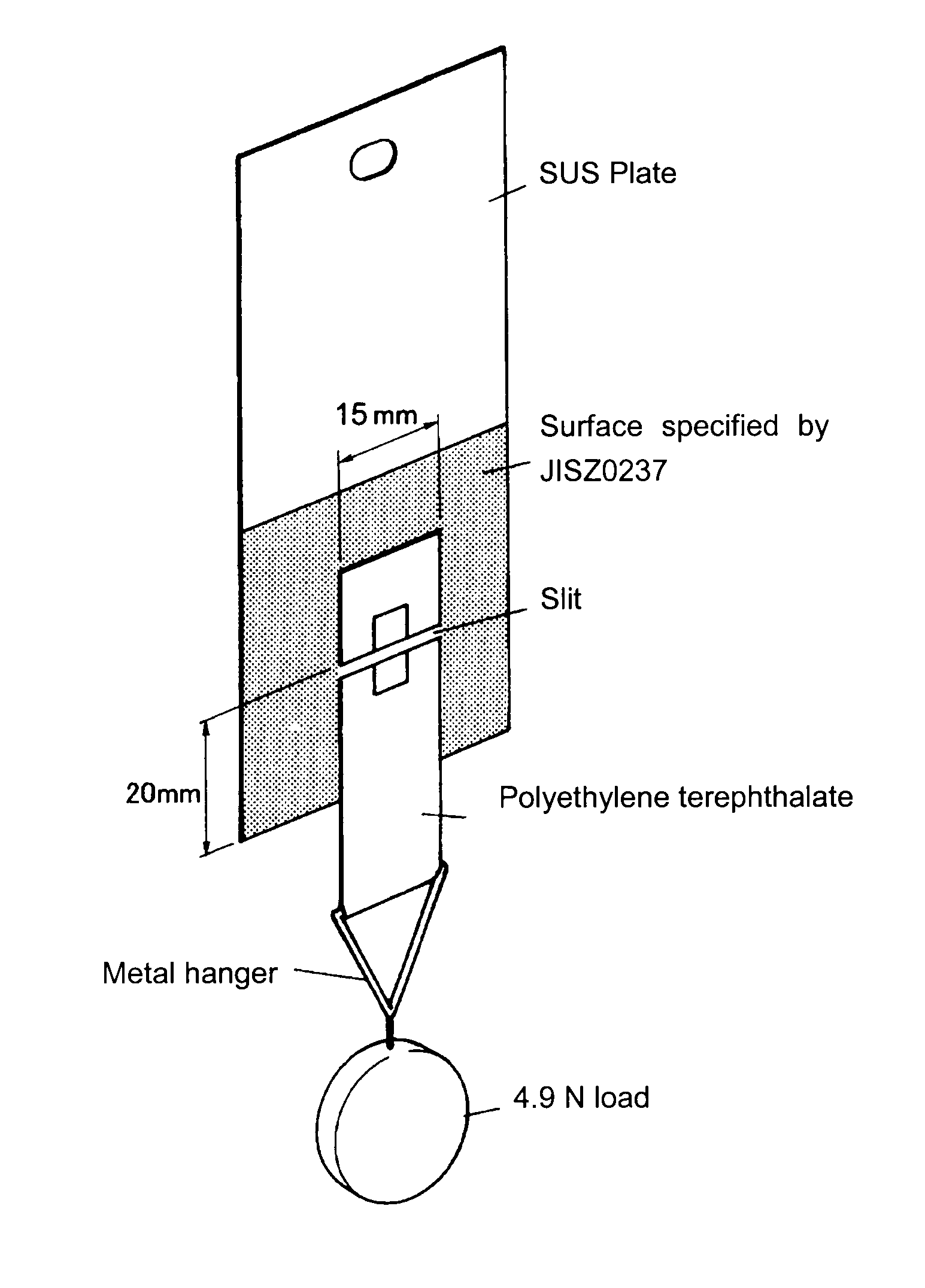

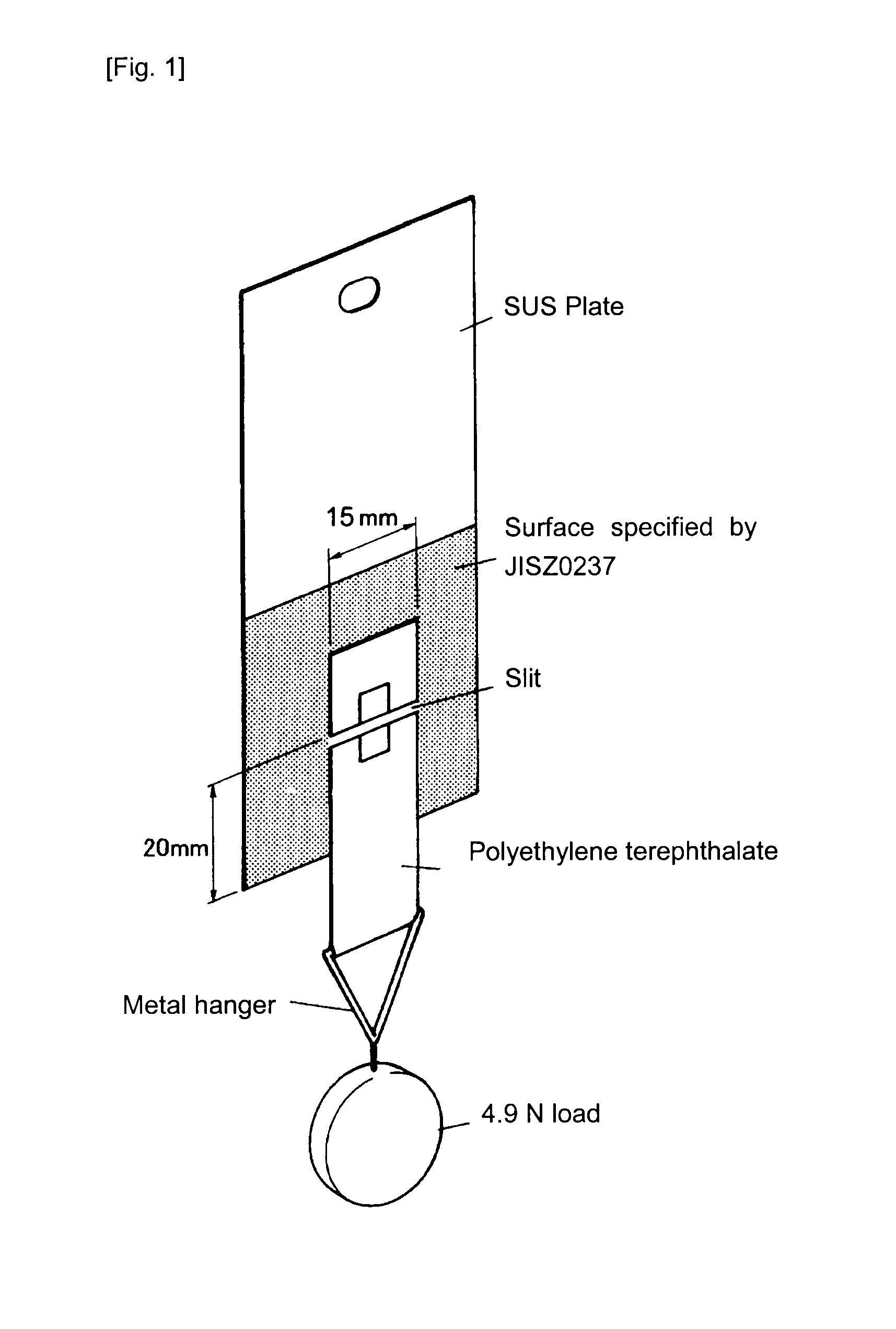

Transparent double-sided self-adhesive sheet

InactiveUS20120156456A1Improve abilitiesImprove machinabilitySynthetic resin layered productsOpticsMethacrylateMeth-

A transparent double-sided self-adhesive sheet is provided which, when bonding to an adhered, not only excels in the ability to conform to steps or surface irregularities caused by a printing site, but also excels in workability such as cutting processability. A transparent double-sided self-adhesive sheet is proposed, having an intermediate resin layer (A) and pressure-sensitive adhesive layers (B) as front and reverse side layers, each of the layers being a layer having one or more species of (meth)acrylic acid ester series (co)polymer as the base resin, in which transparent double-sided self-adhesive sheet, the shear storage elastic modulus (G′(A)) at a frequency of 1 Hz of the intermediate resin layer (A) is higher than the pressure-sensitive adhesive layers (B) in a temperature range of 0° C. to 100° C., and, the indentation hardness (ASKER C2 hardness) of the entire sheet is 10 to 80.

Owner:MITSUBISHI CHEM CORP

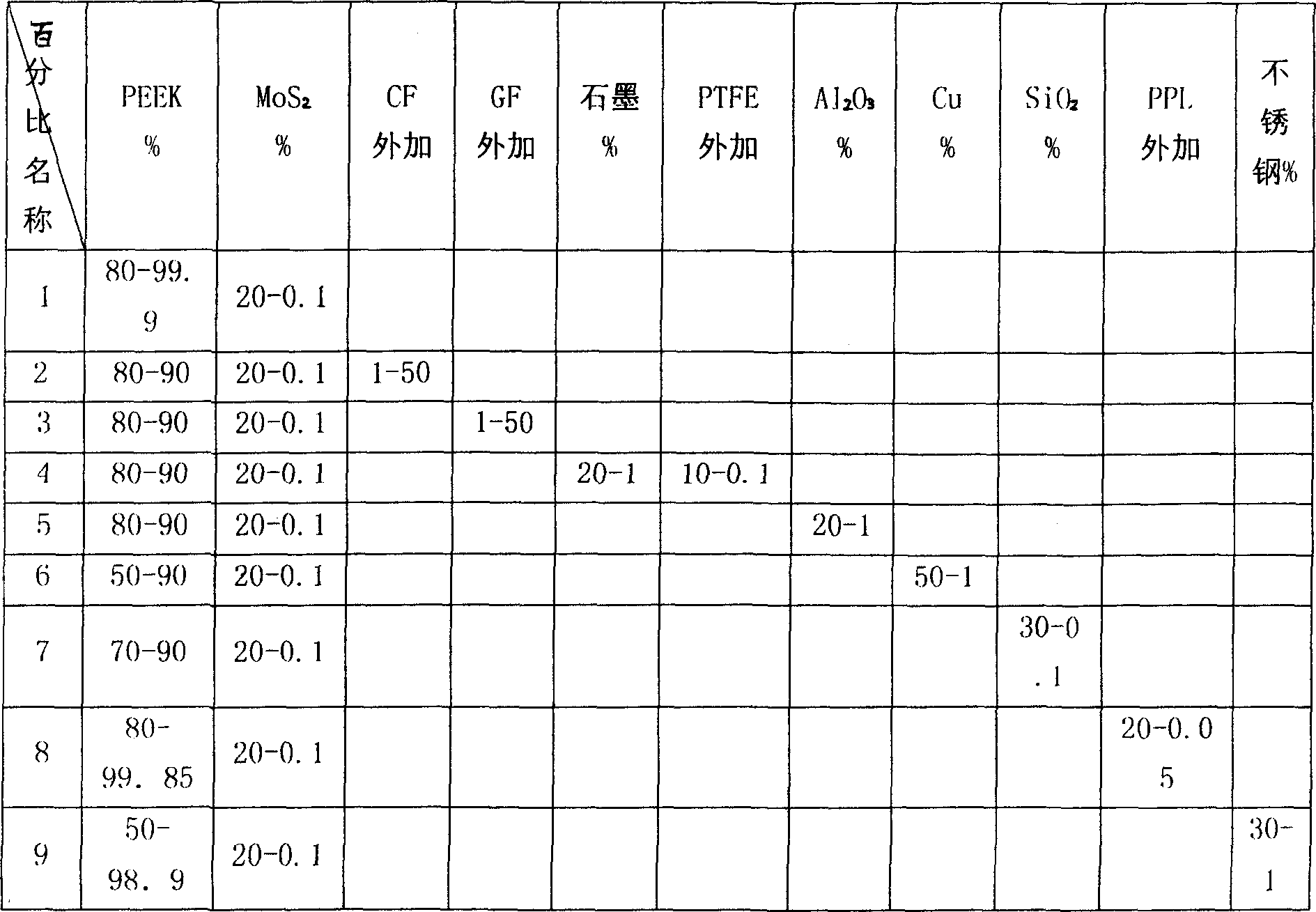

Polyetheretherketone composite material and method of its manufacture

ActiveCN1880372AImprove thermal conductivityImproved ball pressure hardnessFiberPoly ether ether ketone

This invention relates to a polyetheretherketone composite material, composed of a binary composite of polyetheretherketone and one of molybdenum disulfide, aluminium trioxide, copper powder, silica dioxide or stainless steel powder, with weight ratio of 80-99.9:0.1-20. On the base of the above weight as 100%, it continues to add polytetrafluoroethylene or polyphenyl ester, with weight ratio of 0.1-80% and 0.1-20% respectively, to form the ternary polyetheretherketone composite material. On the base of the above binary or ternary composite weight, it continues to add carbon fiber or glass fiber, with weight ratio of 0.1-50%. This invented composite material is characterized of increased thermal conductivity factor, distinct improvement of tensile strength, ball indentation hardness, frictional factor and linear expansibility, and cost reducing.

Owner:NANJING COMPTECH COMPOSITES CORP

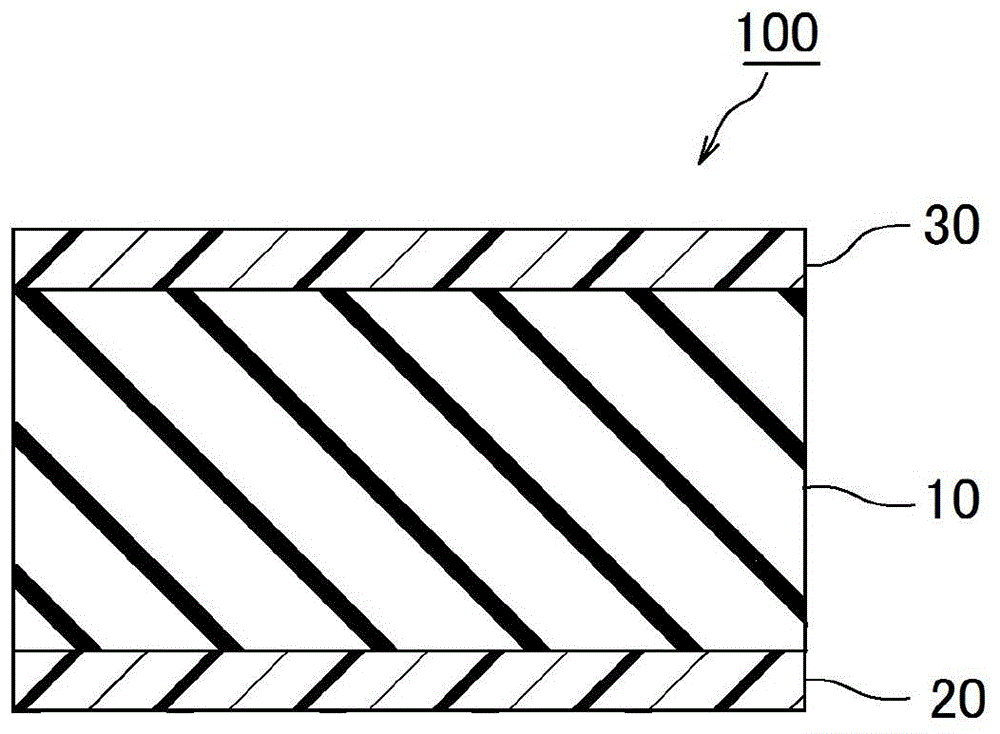

Gas-Barrier Laminate

ActiveUS20070224402A1Good printabilityExcellent gas barrier performanceSynthetic resin layered productsCellulosic plastic layered productsPolyesterAtmospheric air

A gas-barrier laminate with a plastic substrate, an inorganic thin film formed on at least one surface of the plastic substrate, and a coating layer formed by applying a coating material on a surface of the inorganic thin film, wherein said coating layer contains a polyester-based resin having a molecular weight of 3000 to 15000 and a polyurethane-based resin having a molecular weight of 8000 to 30000 at a weight ratio of 5 / 95 to 95 / 5, and said gas-barrier laminate has an oxygen permeability of not more than 25 fmol / m2 / s / Pa; and a gas-barrier laminate comprising a plastic substrate, an inorganic thin film formed on at least one surface of the plastic substrate, and a coating layer formed by applying a coating material on a surface of the inorganic thin film, wherein the gas-barrier laminate exhibits an oxygen permeability of not more than 50 fmol / m2 / s / Pa as measured with respect to a gas-barrier film obtained by laminating an unstretched polypropylene film having a thickness of 60 μm on the coating layer of the gas-barrier laminate after subjecting the gas-barrier film to hydrothermal treatment at 120° C. for 30 min, and the coating layer has either a hardness of 0.1 to 0.5 GPa as measured at 23° C. in atmospheric air by a nano-indentation hardness testing method, a hardness of 0.03 to 0.5 GPa as measured at 23° C. in water by a nano-indentation hardness testing method, or a ratio of number of carbon atoms derived from carboxyl groups to number of carbon atoms constituting the surface of the coating layer of 0.005 to 0.1.

Owner:MITSUBISHI CHEM CORP

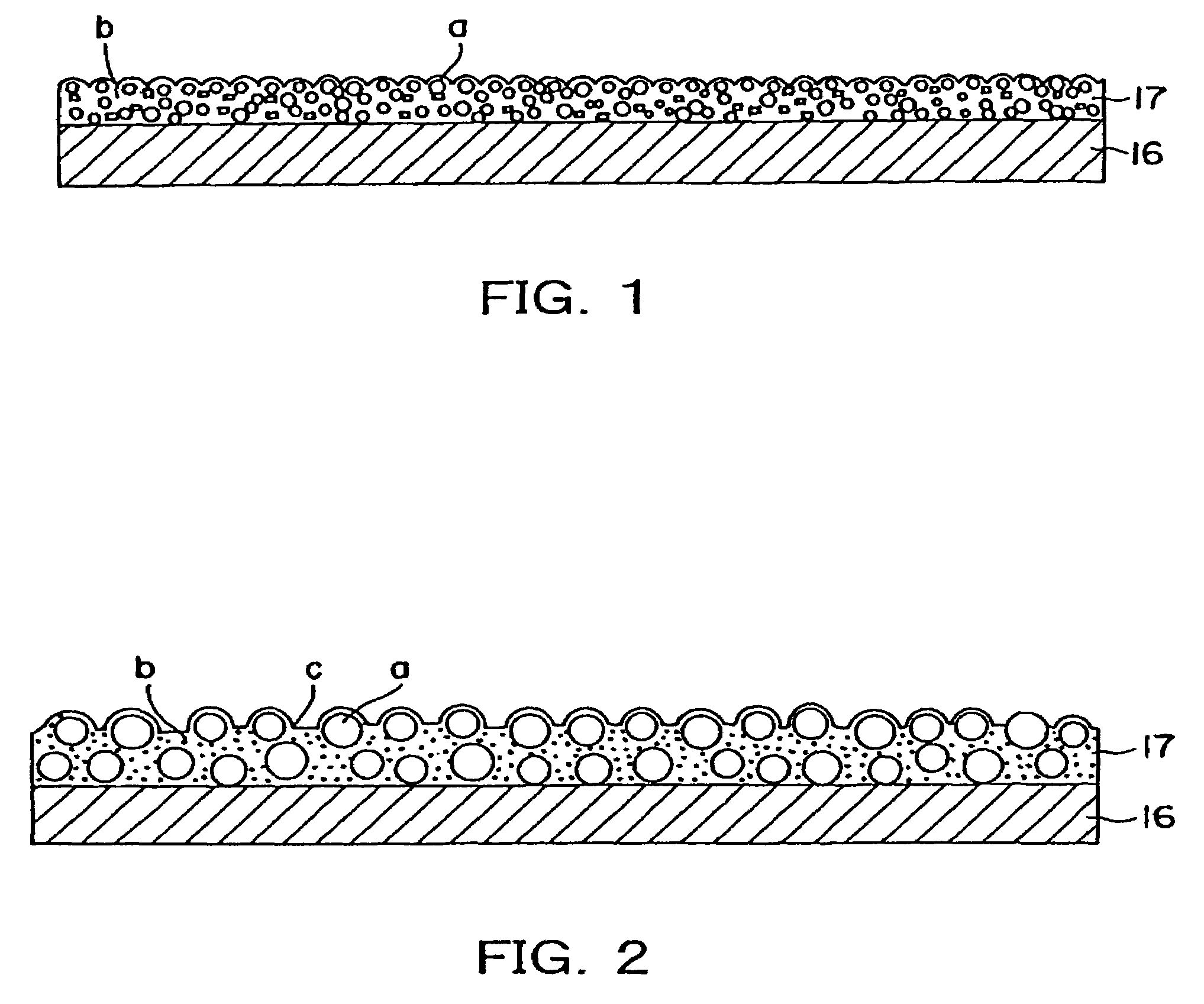

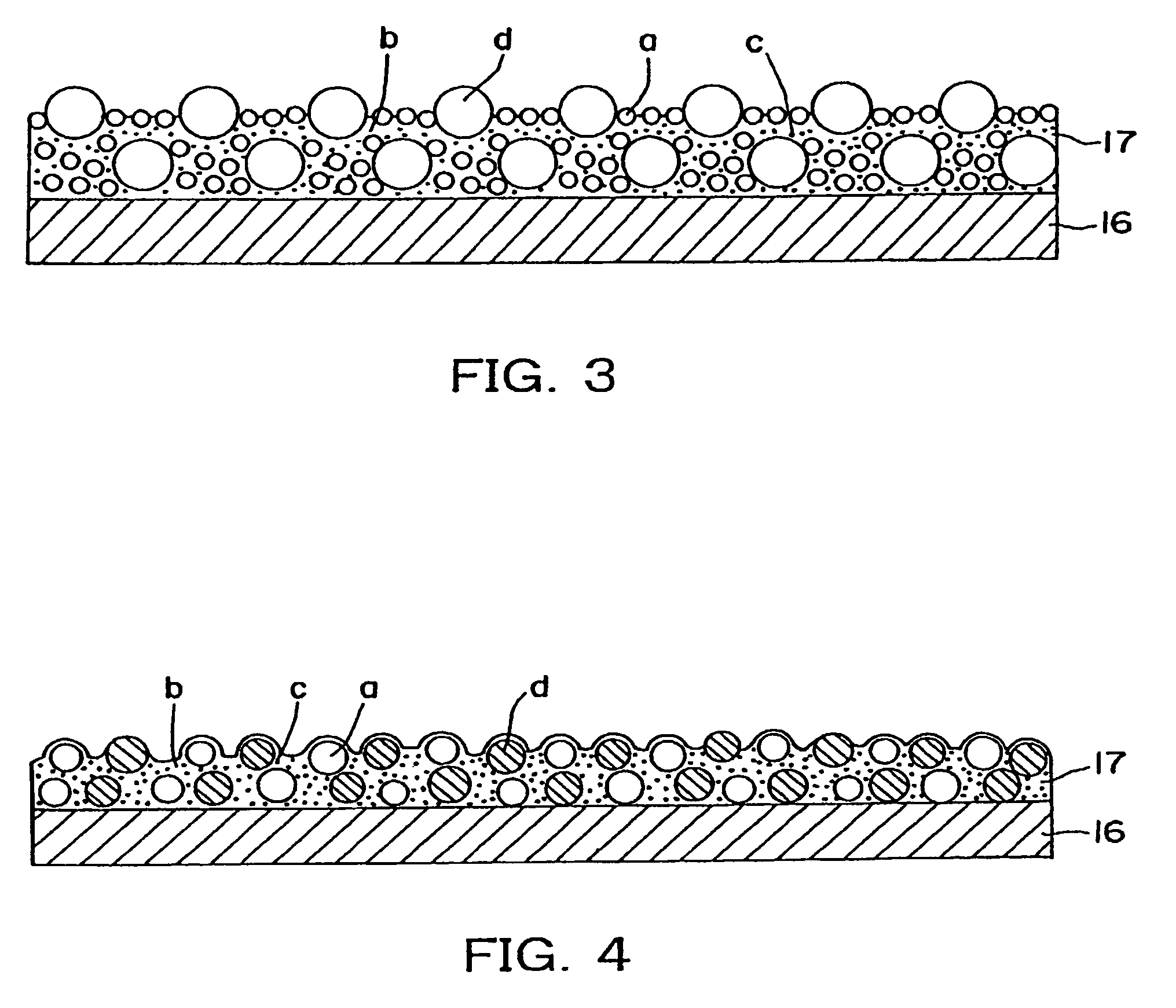

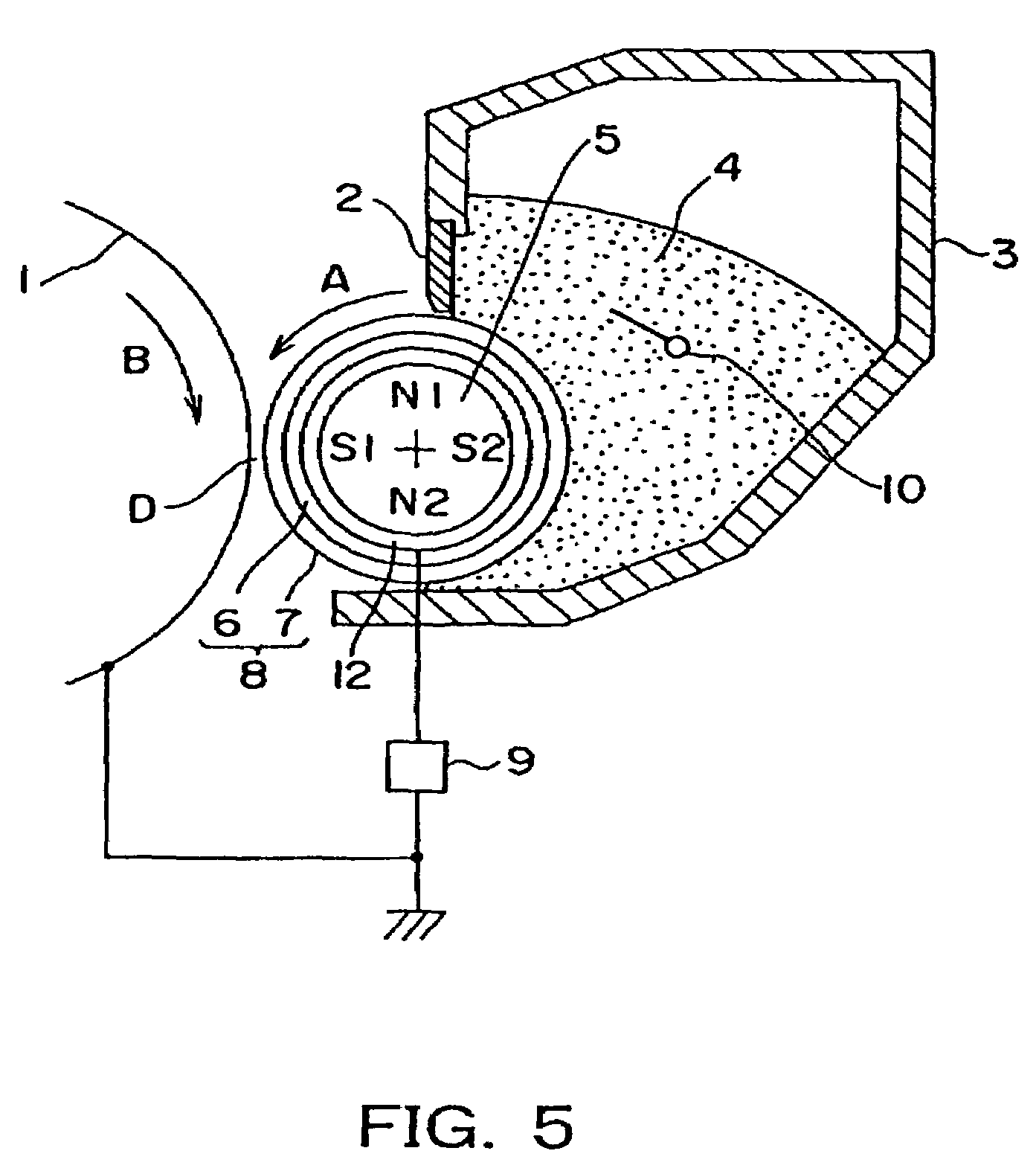

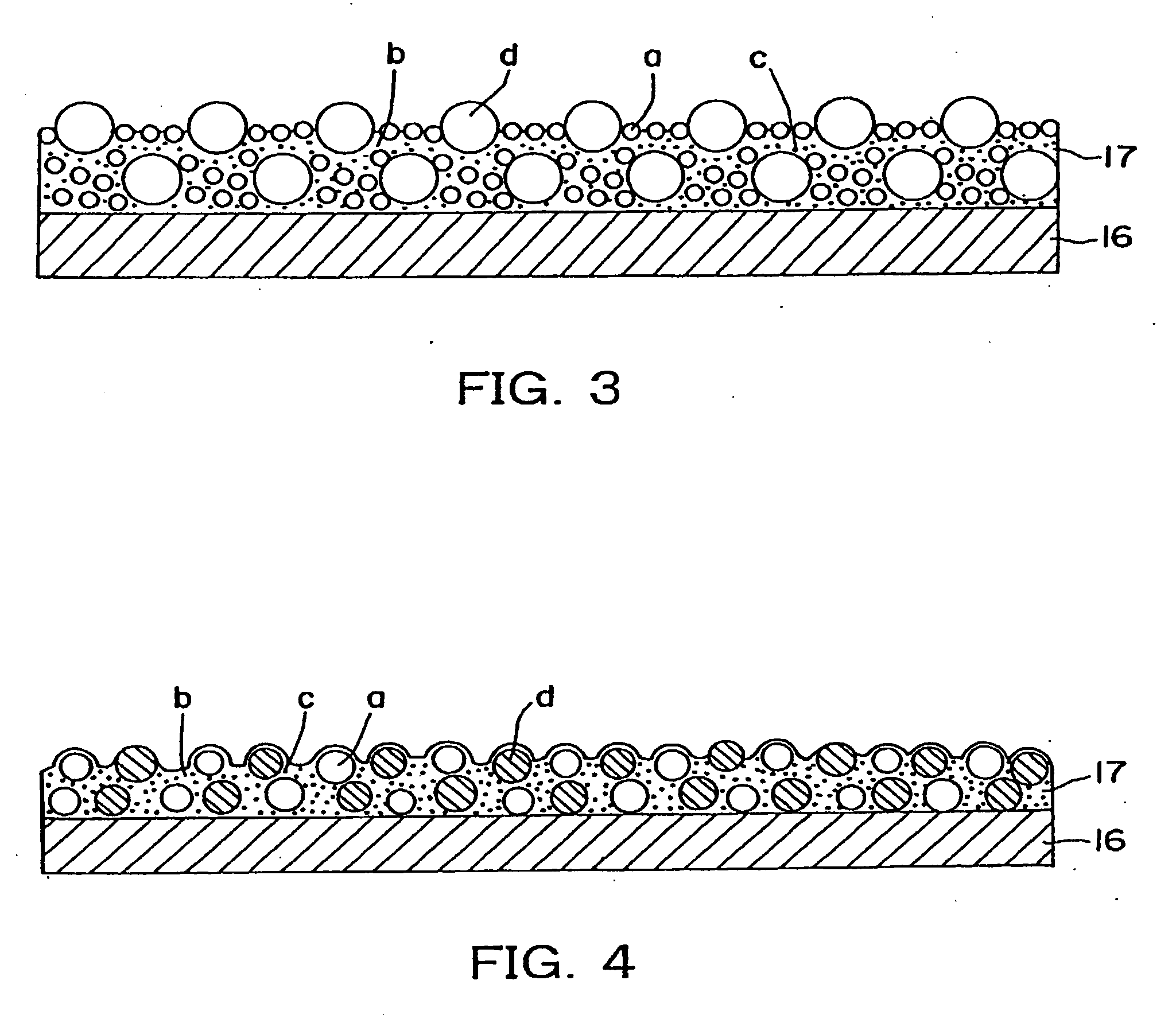

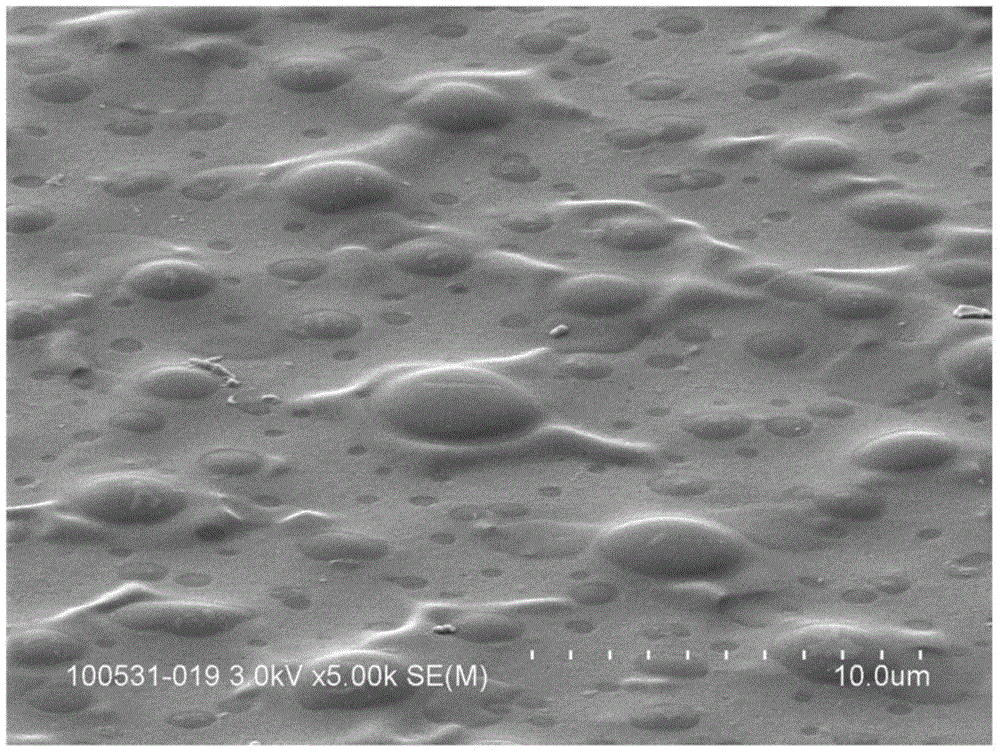

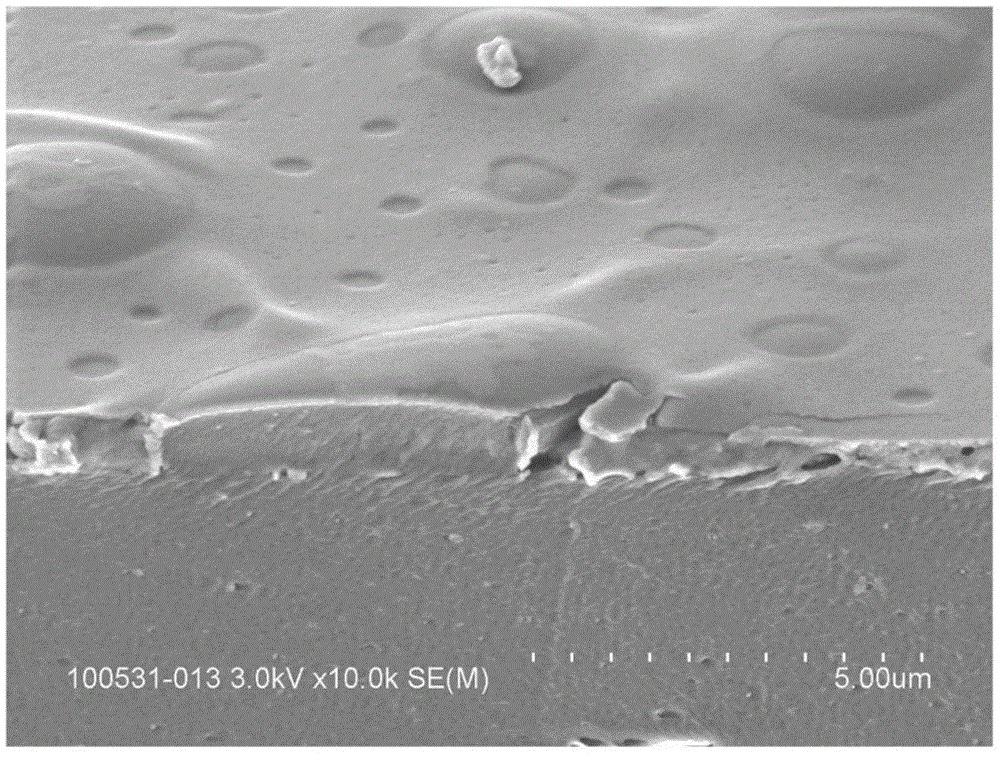

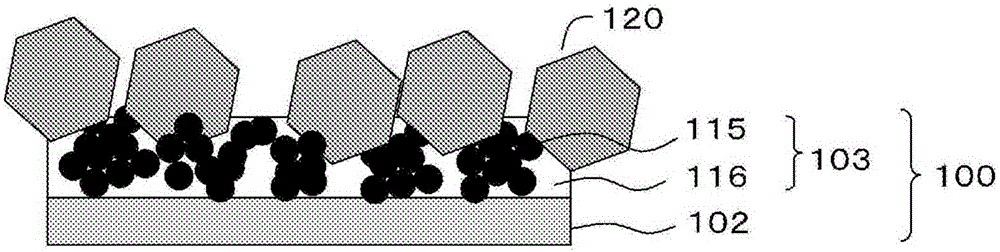

Developer carrier, developing device using the developer carrier, and process cartridge using the developer carrier

InactiveUS7361400B2High image densityReduce adhesionLayered productsElectrographic process apparatusEngineeringResin coating

Owner:CANON KK

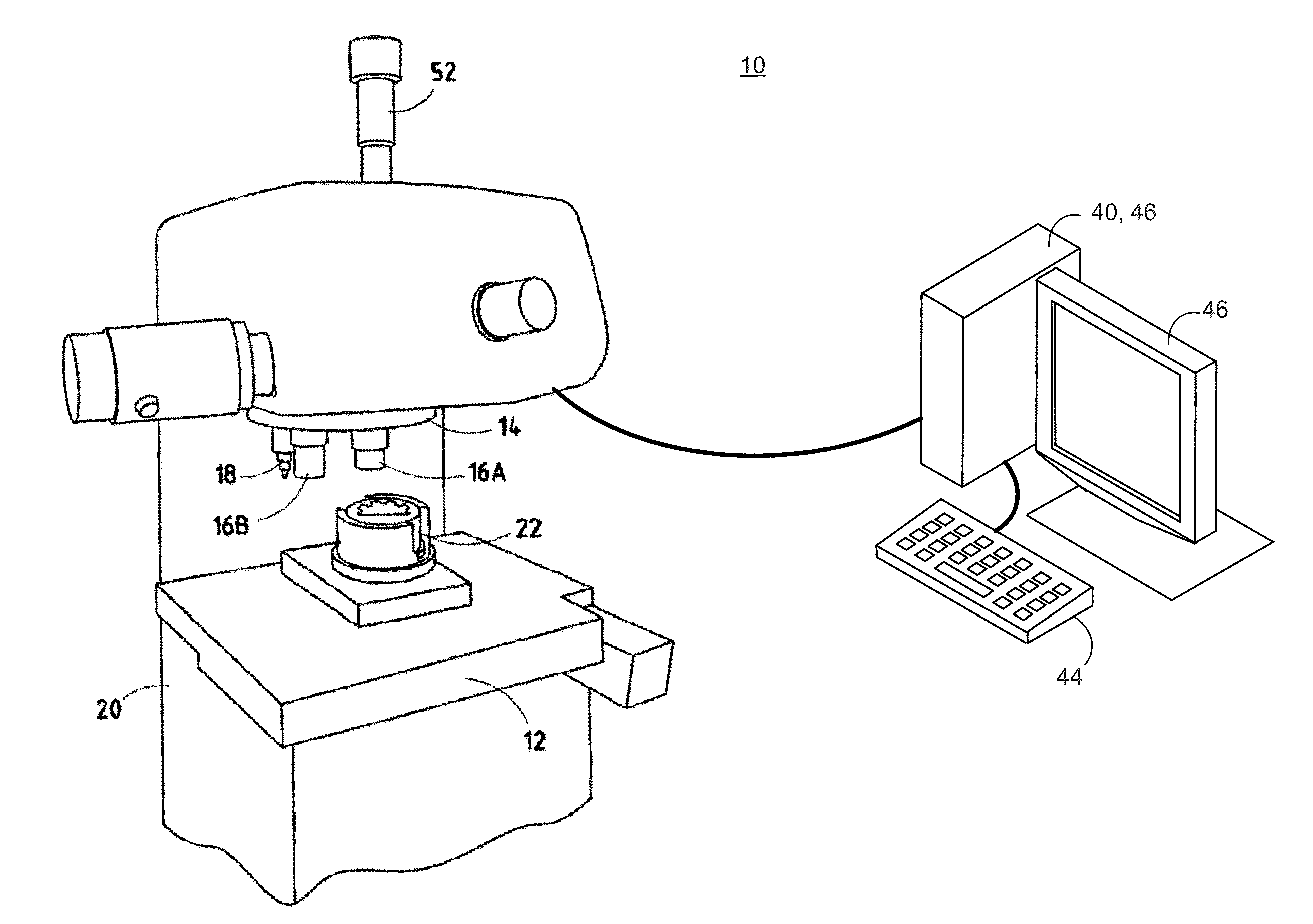

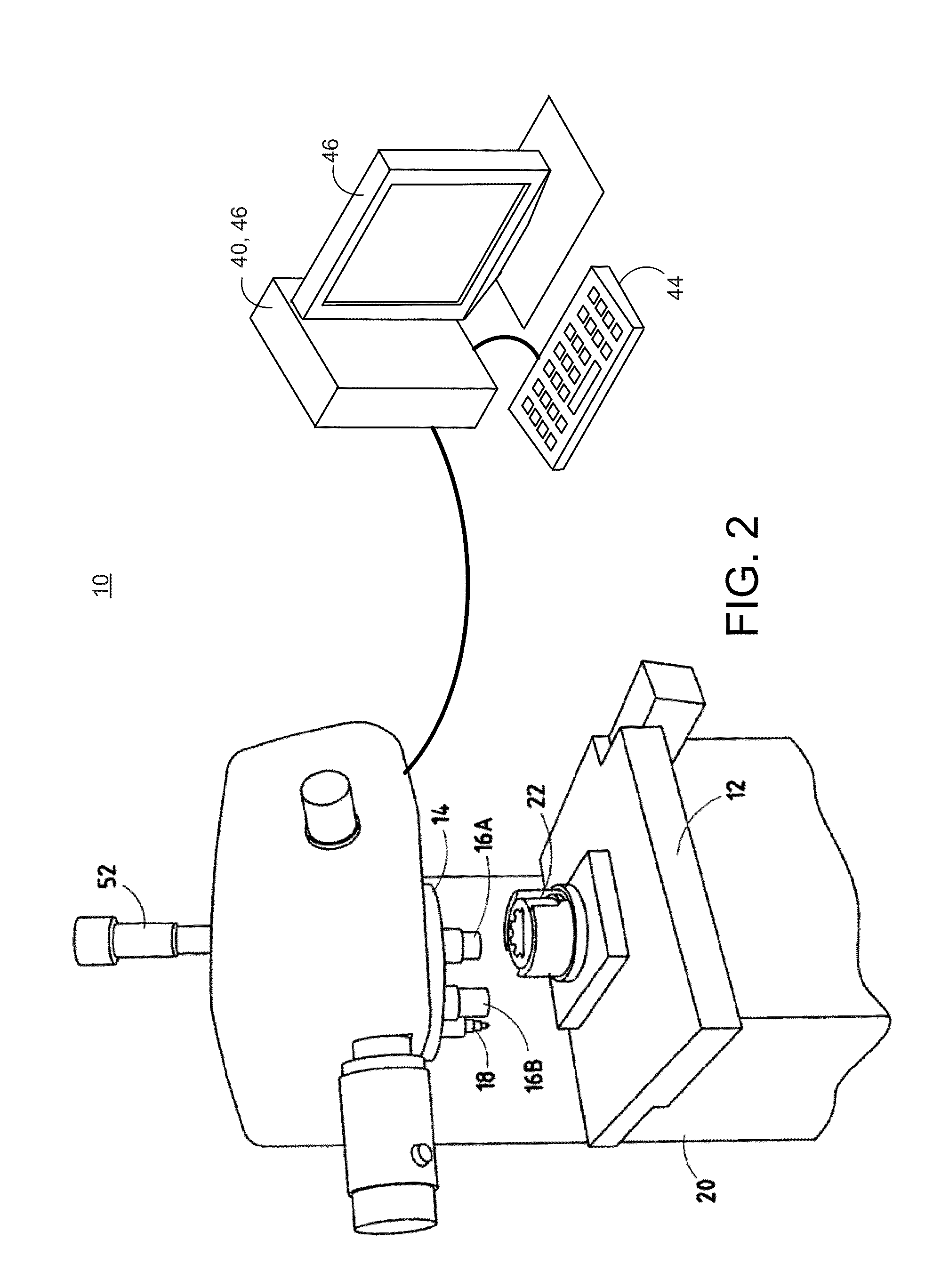

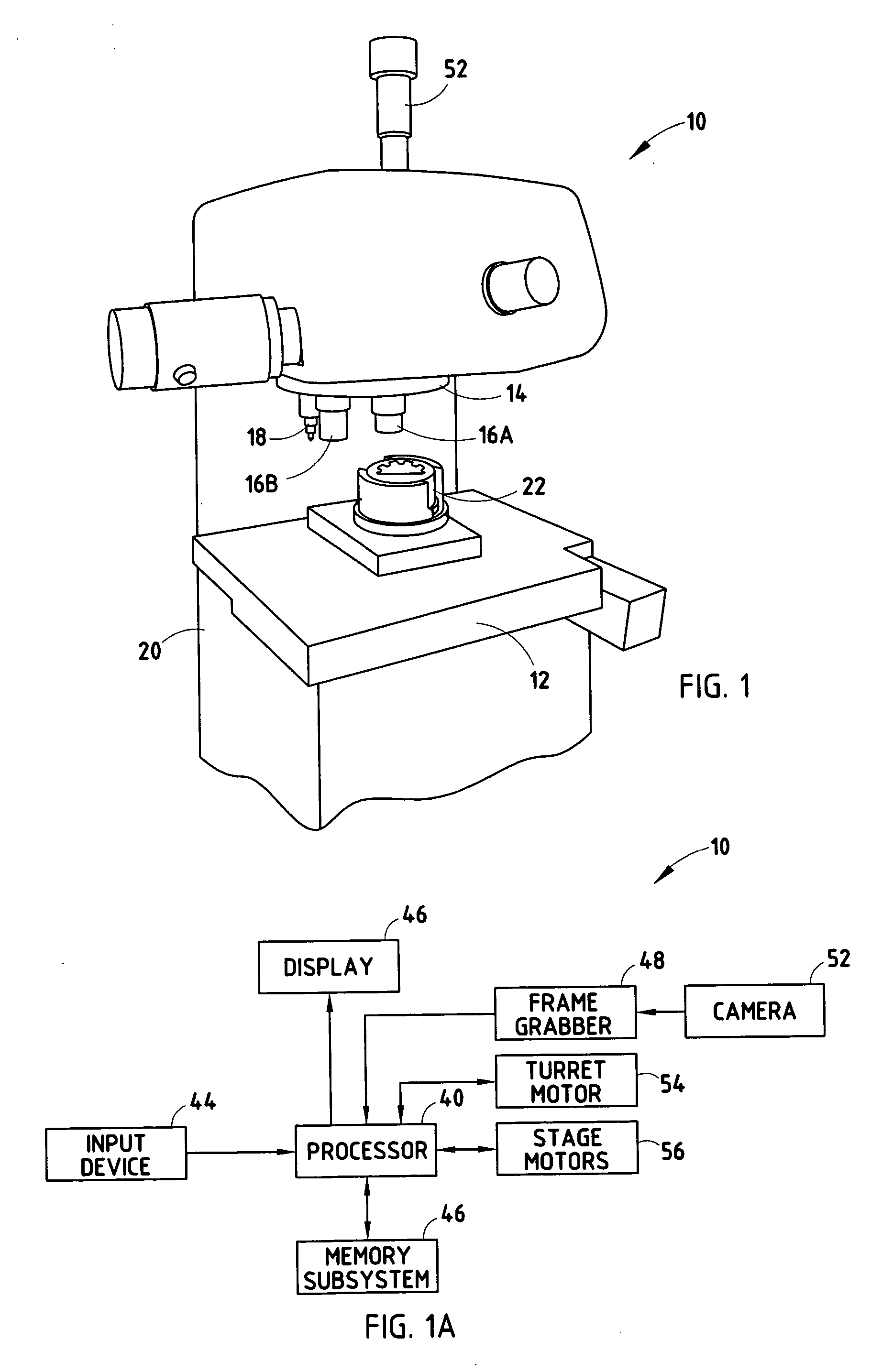

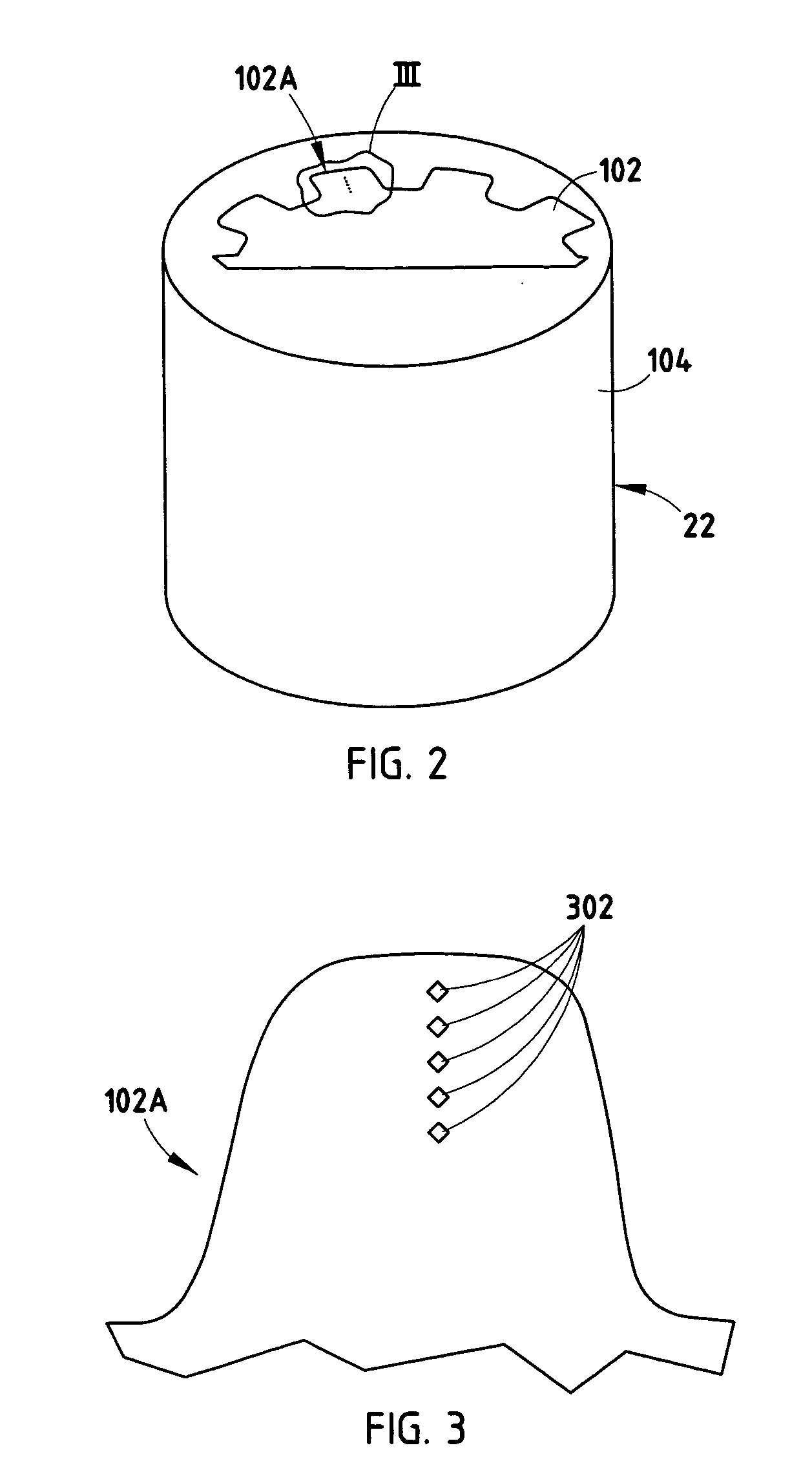

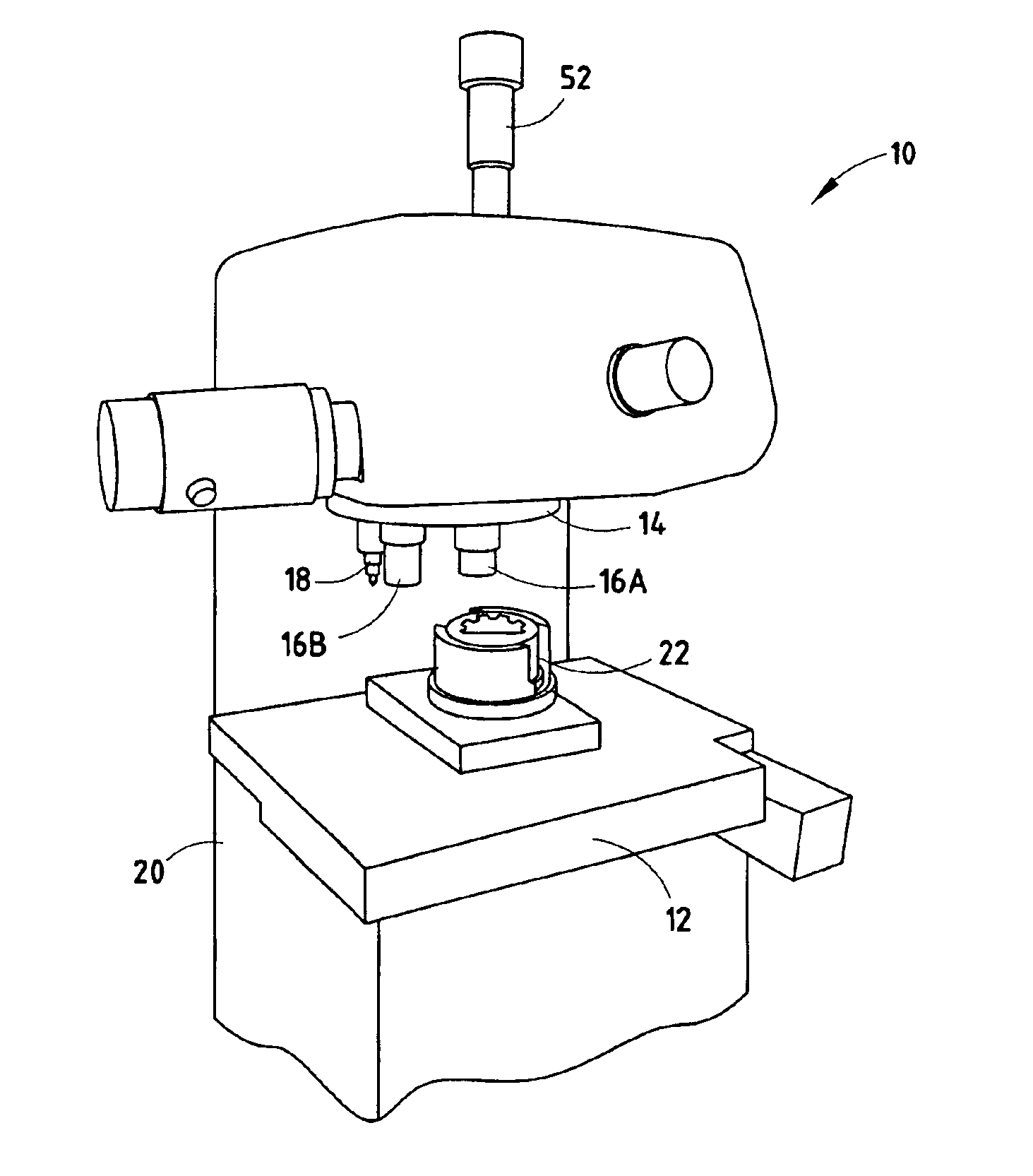

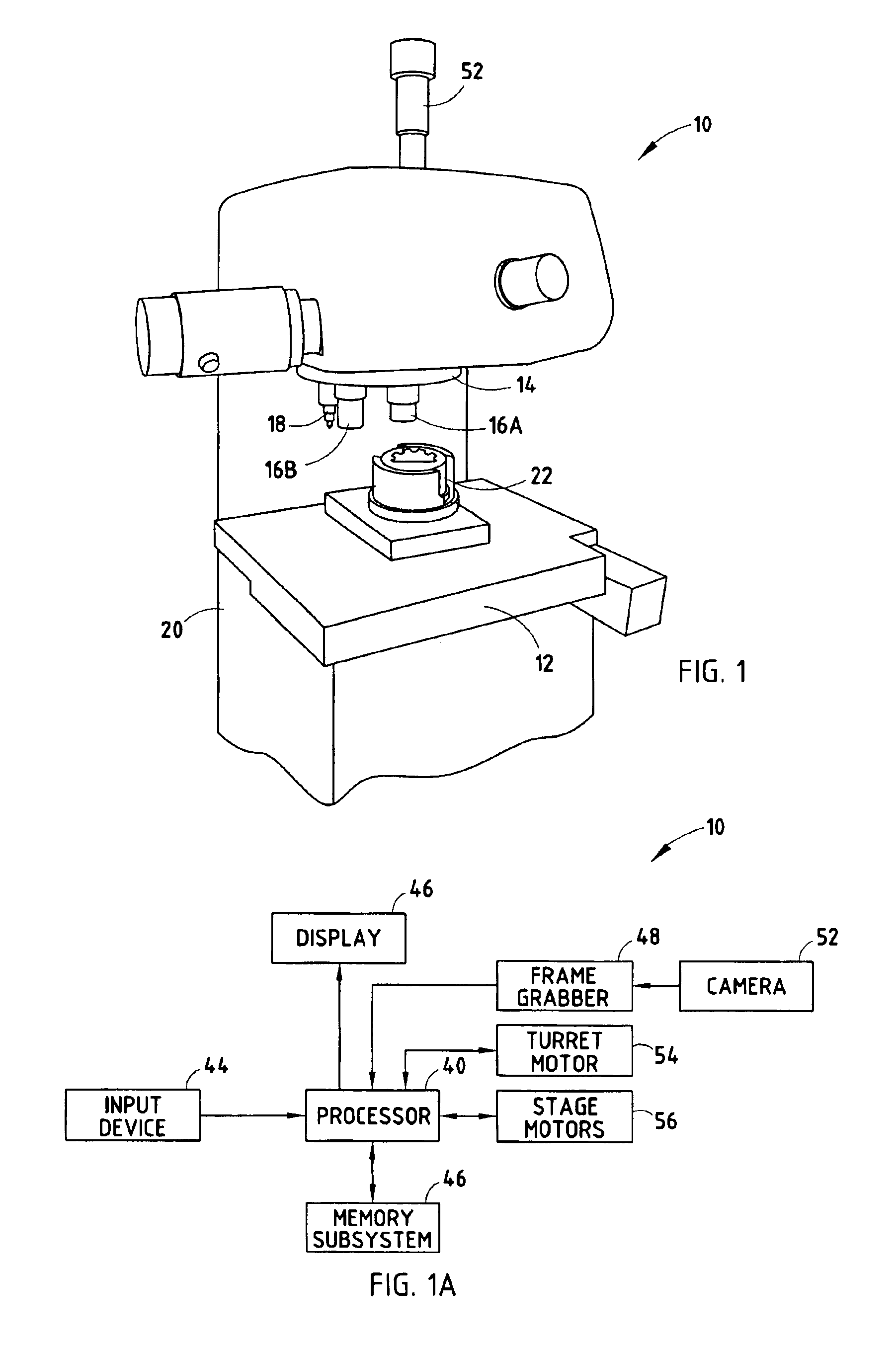

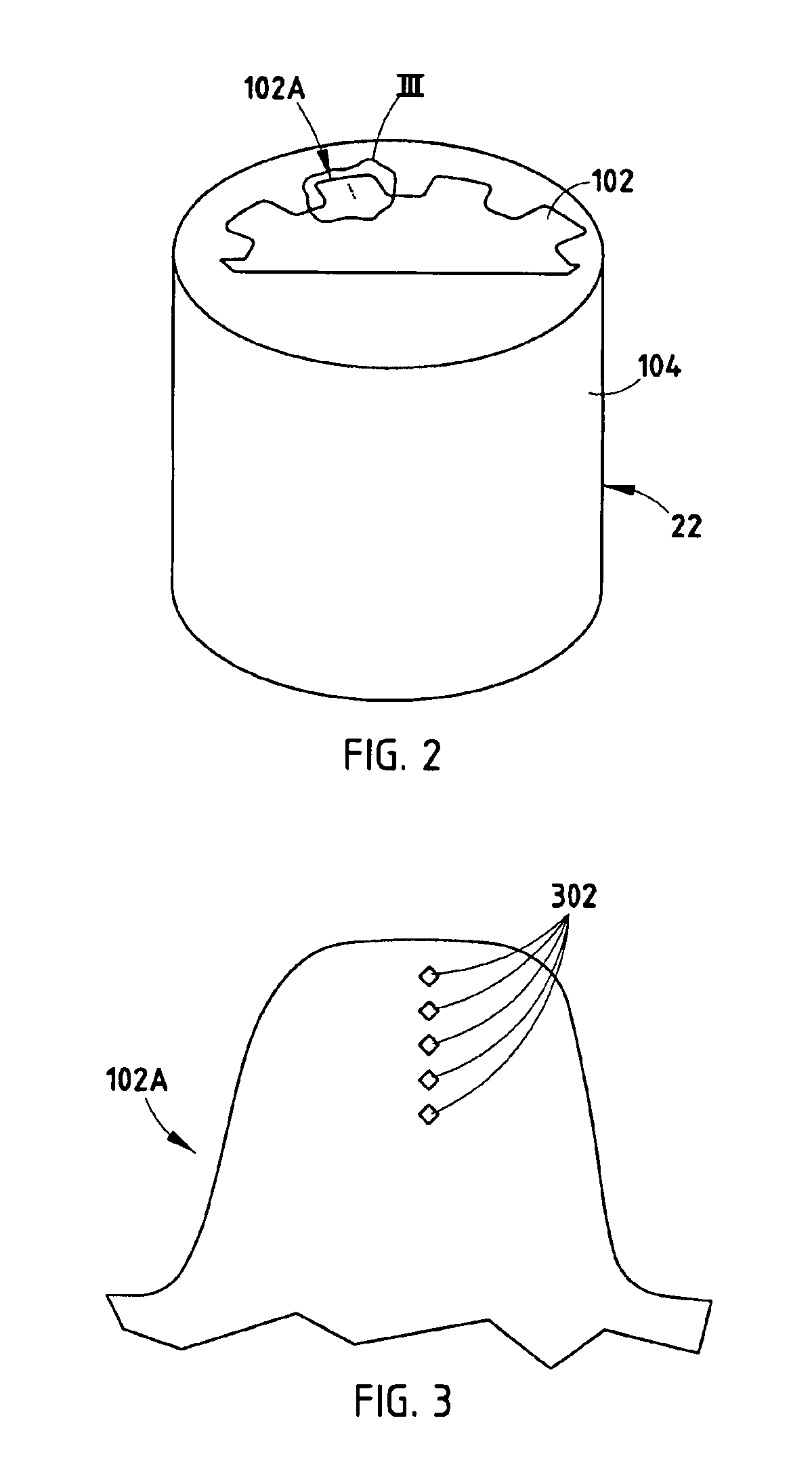

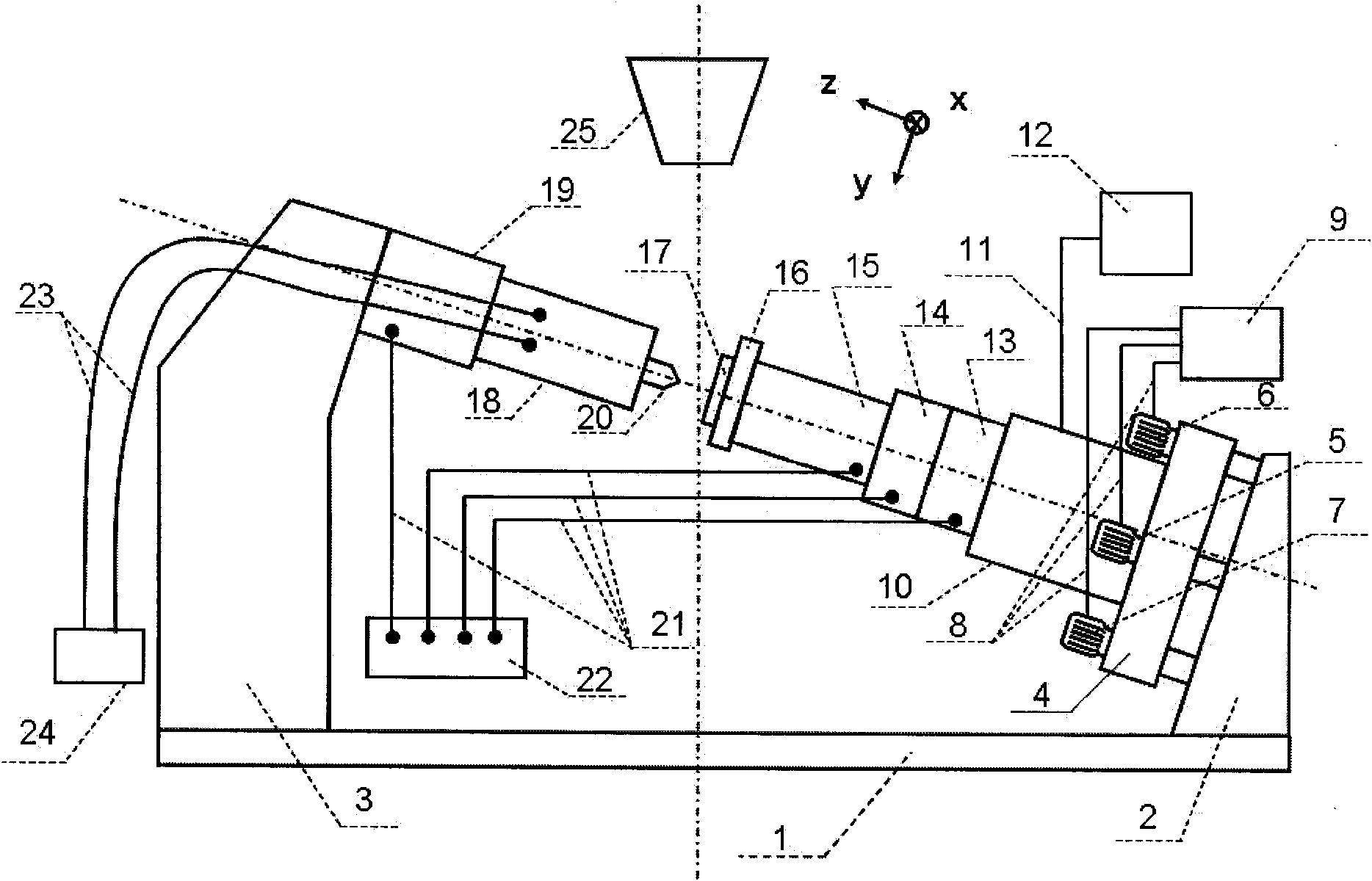

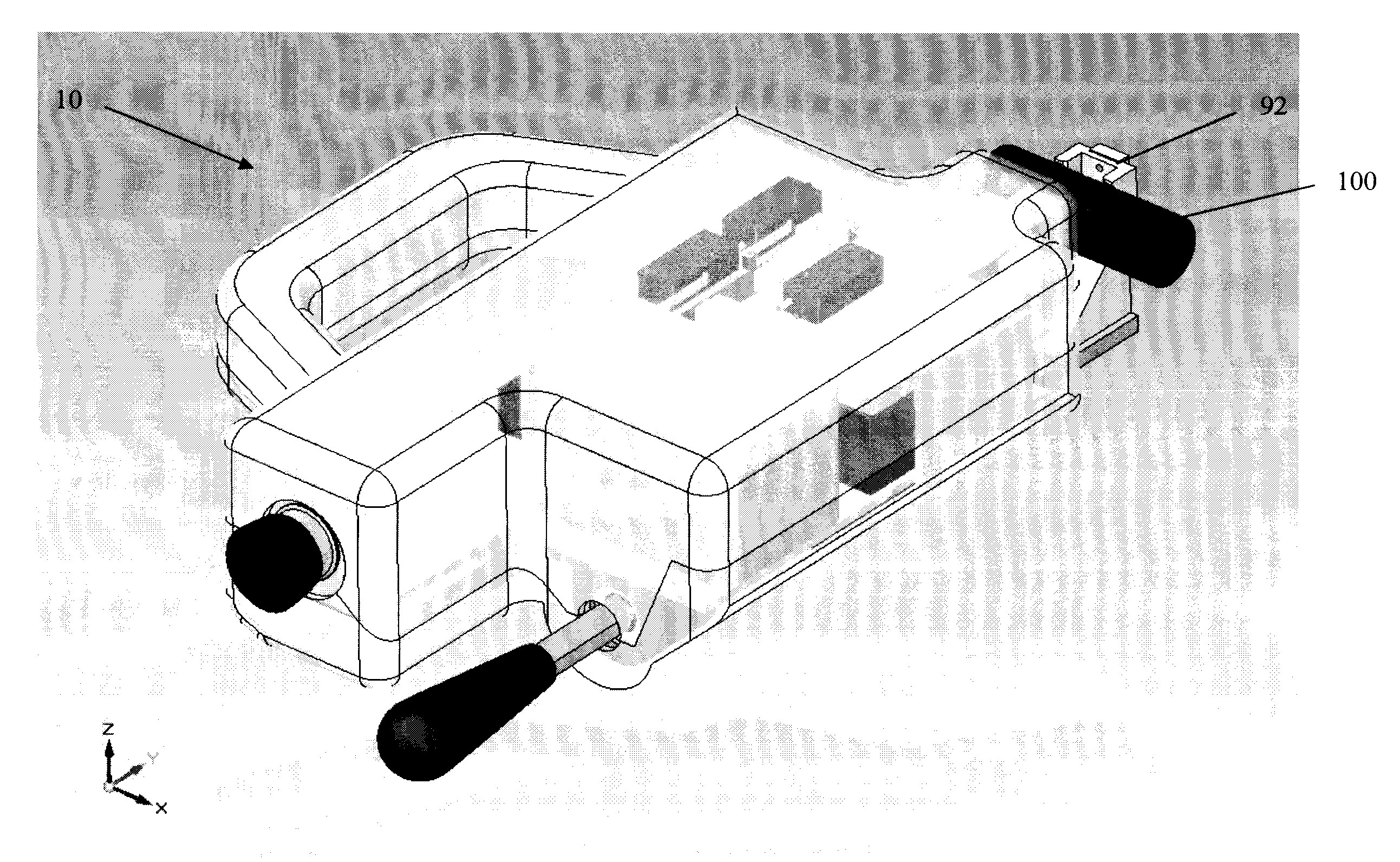

Indentation hardness test system having an autolearning shading corrector

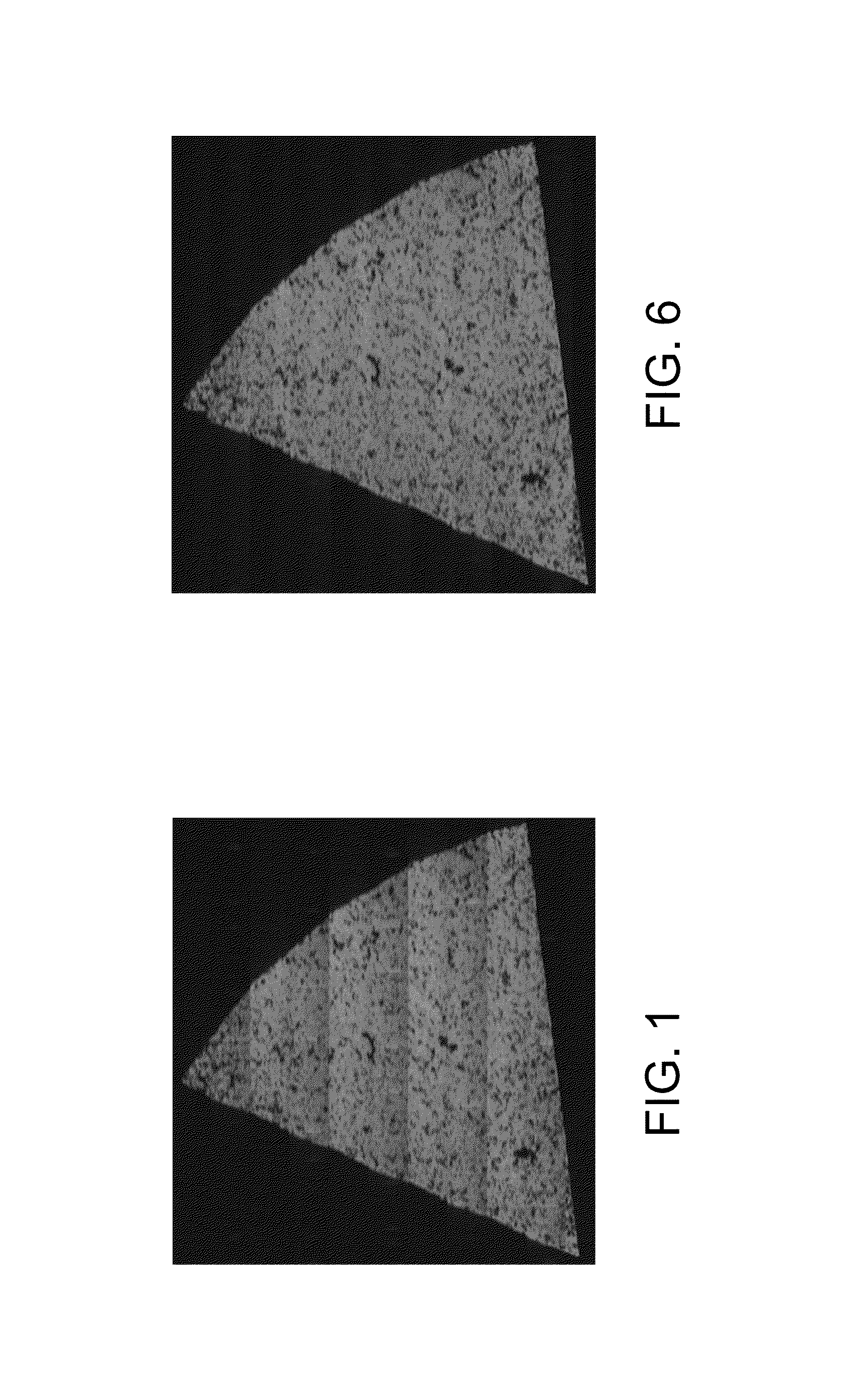

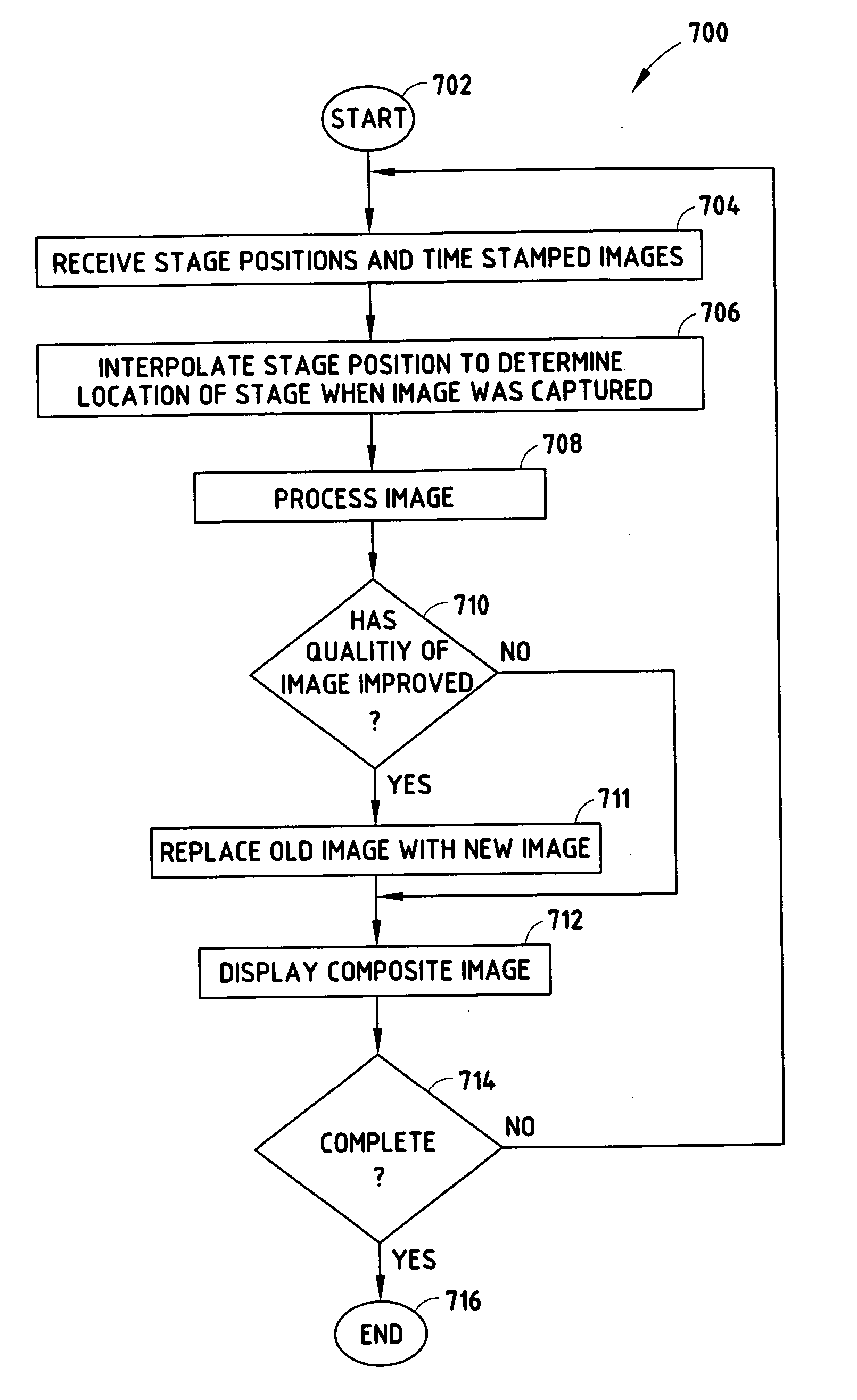

An indentation hardness test system is provided that includes: a frame including an attached indenter; a movable stage for receiving a part attached to the frame; a camera; a display; a processor; and a memory subsystem. The processor performs the steps of: (a) capturing images of different portions of the part; (b) for each image, computing an average intensity; (c) computing an average intensity across all images; (d) for each pixel, computing PixelAverageDeltan(x,y) as a function of the raw pixel data and the average pixel intensity of the image frame; (e) for each pixel, computing a correction factor using the average intensity across all images and PixelAverageDeltan(x,y); (f) performing shading correction by adjusting the raw pixel values by corresponding correction factors; and (g) generating a composite image of the part. Steps (b)-(e) may be performed on moving images while not including stationary images in the computations of those steps.

Owner:LECO CORPORATION

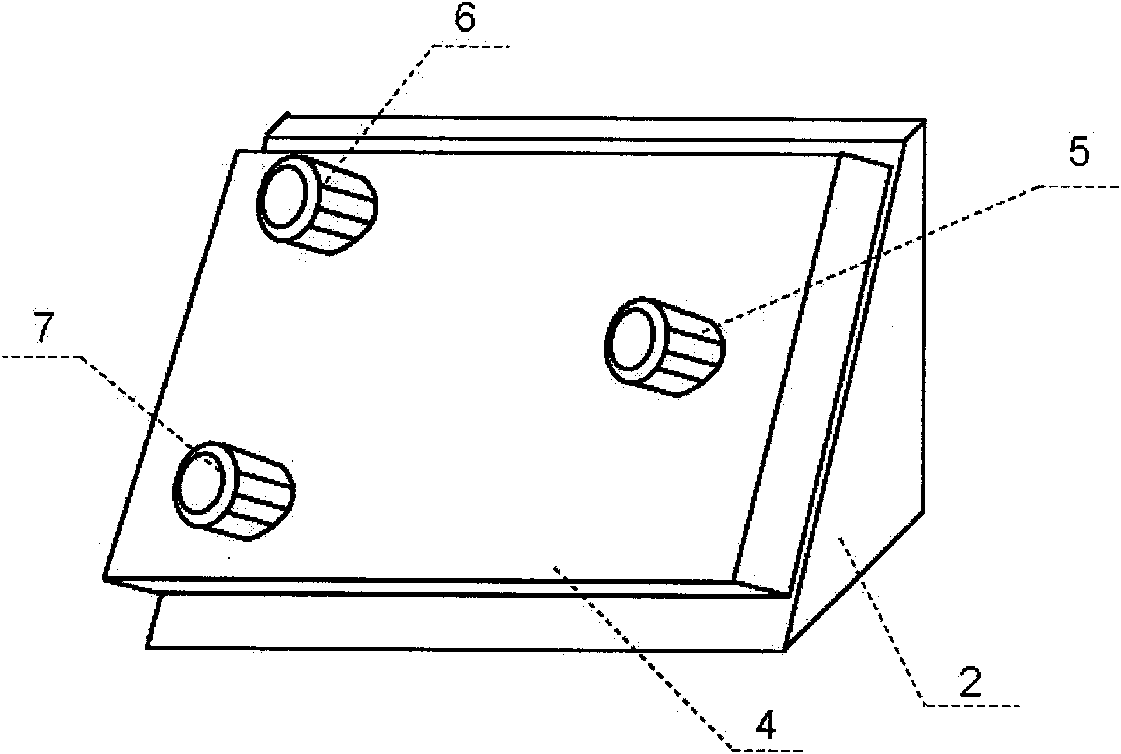

Indentation hardness test system

ActiveUS20050265593A1Material strength using tensile/compressive forcesCharacter and pattern recognitionDisplay deviceIndentation hardness

An indentation hardness test system includes a frame including an attached indenter, a movable stage for receiving a part attached to the frame, a camera, a display, a processor and a memory subsystem. The camera captures images of the part, which can then be provided on the display. The processor is coupled to the movable stage, the camera and the display, as well as the memory subsystem. The memory subsystem stores executable code that instructs the processor to capture a series of real-time images of the part using the camera, obtain associated stage coordinates for each of the images and display a composite image, which includes the series of real-time images assembled according to the associated stage coordinates, of the part.

Owner:LECO CORPORATION

Developer carrier, developing device using the developer carrier, and process cartridge using the developer carrier

InactiveUS20060275598A1High image densityQuality improvementSynthetic resin layered productsCellulosic plastic layered productsResin coatingEngineering

A developer carrier is capable of stably charging a toner over a long term without change in physical surface shape and composition. The developer carrier has at least a substrate and resin coating layer formed on a surface of the substrate. The resin coating layer includes at least graphitized particles (i) with a degree of graphitization p(002) of 0.20 to 0.95 and an indentation hardness HUT [68] of 15 to 60 or graphitized particles (ii) with a degree of graphitization p(002) of 0.20 to 0.95 and an average circularity SF-1 of 0.64 or more.

Owner:CANON KK

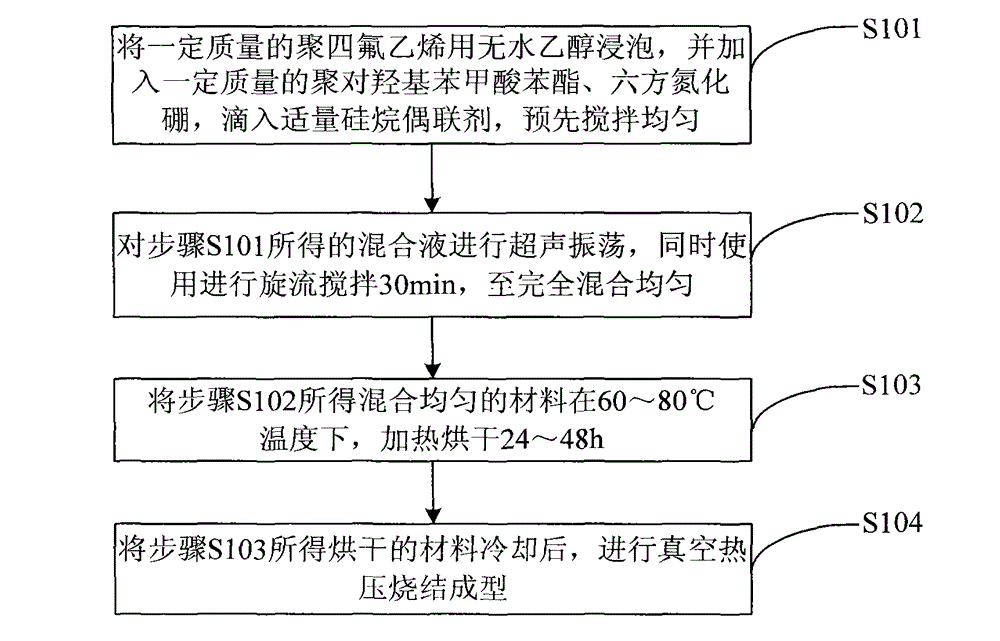

Polytetrafluoroethylene composite friction material and preparation method thereof

InactiveCN102942757ASimple production processEasy to controlOther chemical processesHexagonal boron nitrideBoron nitride

The invention belongs to the technical field of composite material preparation and provides polytetrafluoroethylene composite friction material and a preparation method thereof. The polytetrafluoroethylene composite friction material is compounded by polytetrafluoroethylene (PTFE), poly-p-oxybenzoyl (POB) and hexagonal boron nitride (HBN) respectively at mass ratio of 60%-75%, 20% and 5%-20%. The production process of the composite friction material is simple and is convenient to control and the preparation cost of the composite friction material is low; the mechanical property and the bearing capacity of the polytetrafluoroethylene composite friction material are effectively improved; the friction coefficient of the polytetrafluoroethylene composite friction material is low; and the compression strength, the ball indentation hardness and the wear resistance of the composite material are improved. The polytetrafluoroethylene composite friction material can be applied to engineering and transportation fields which require high bearing capacity and have oil-free lubrication, and has high popularization and application values.

Owner:CHINA UNIV OF MINING & TECH

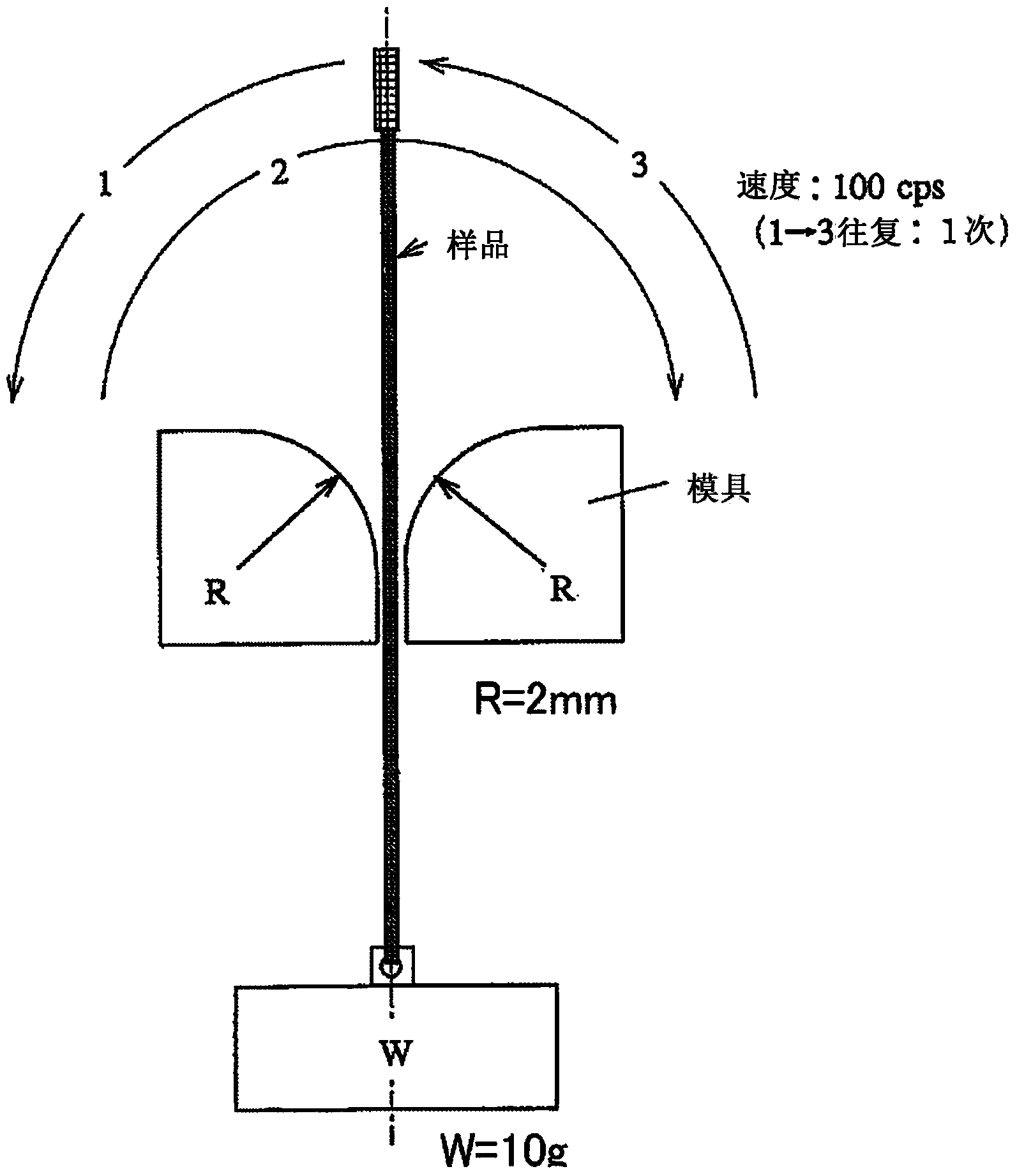

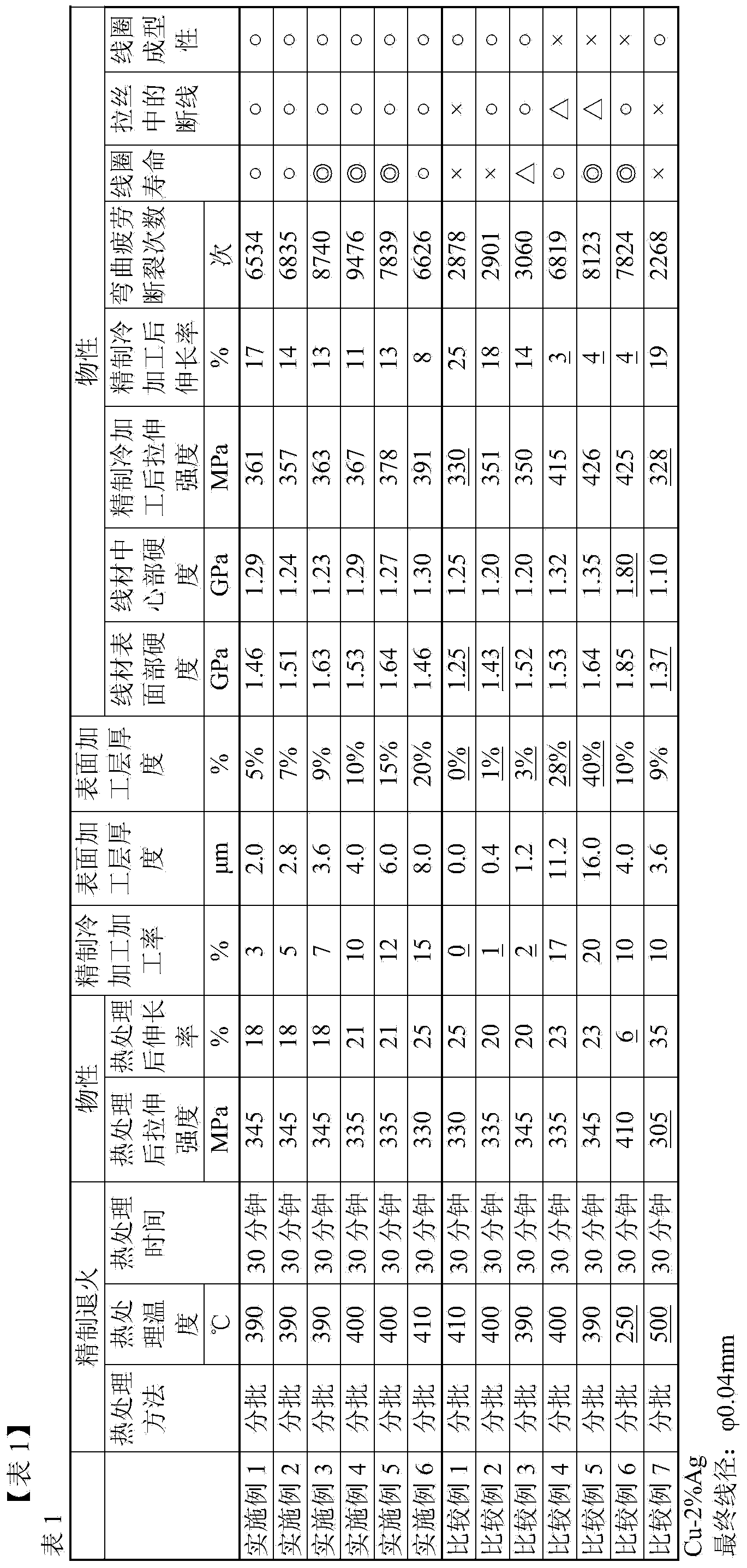

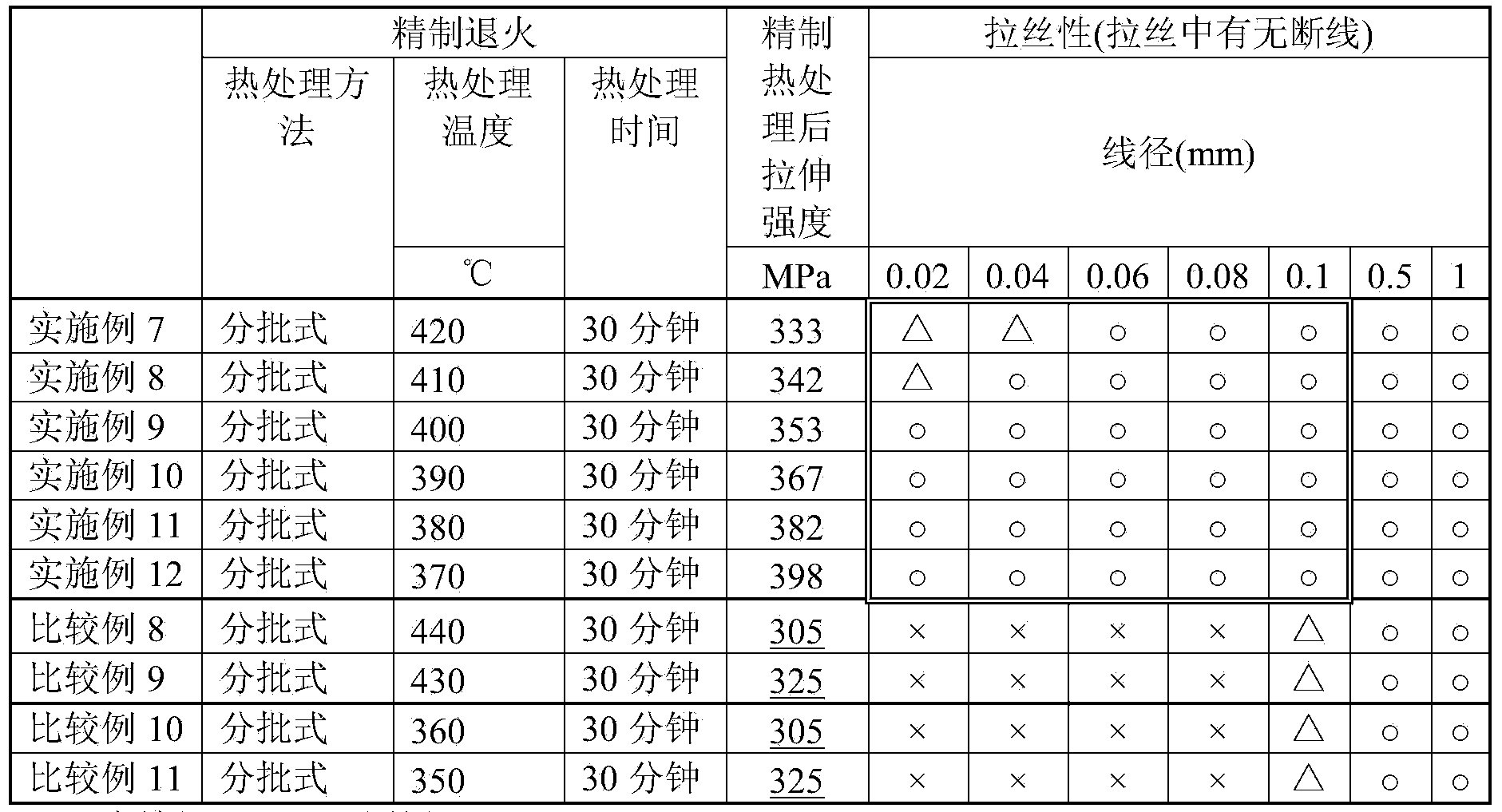

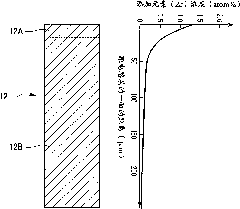

Copper-alloy wire rod and manufacturing method therefor

ActiveCN104169447AExcellent bending fatigue resistanceHigh bending fatigue resistanceSingle bars/rods/wires/strips conductorsConductive materialIndiumManganese

This copper-alloy wire rod and a manufacturing method therefor make it possible to inexpensively provide a copper-alloy wire rod that exhibits excellent elongation and flex-fatigue-resistance properties and can be used, for example, as a magnet wire. Said copper-alloy wire rod contains, by mass, 0.5% to 4% silver and 0.05% to 0.3% of each of at least one element selected from the group consisting of tin, manganese, zinc, indium, nickel, cobalt, zirconium, and chromium, with the remainder comprising copper and unavoidable impurities. This copper-alloy wire rod has a diameter or thickness of at most 0.1 mm and exhibits a nano-indentation hardness of at least 1.45 GPa in a region extending from the outer surface of the wire rod to a depth of at least 5% of the diameter or thickness of the wire rod, a nano-indentation hardness of less than 1.45 GPa in a central section, a tensile strength of at least 350 MPa, and an elongation of at least 7%.

Owner:FURUKAWA ELECTRIC CO LTD

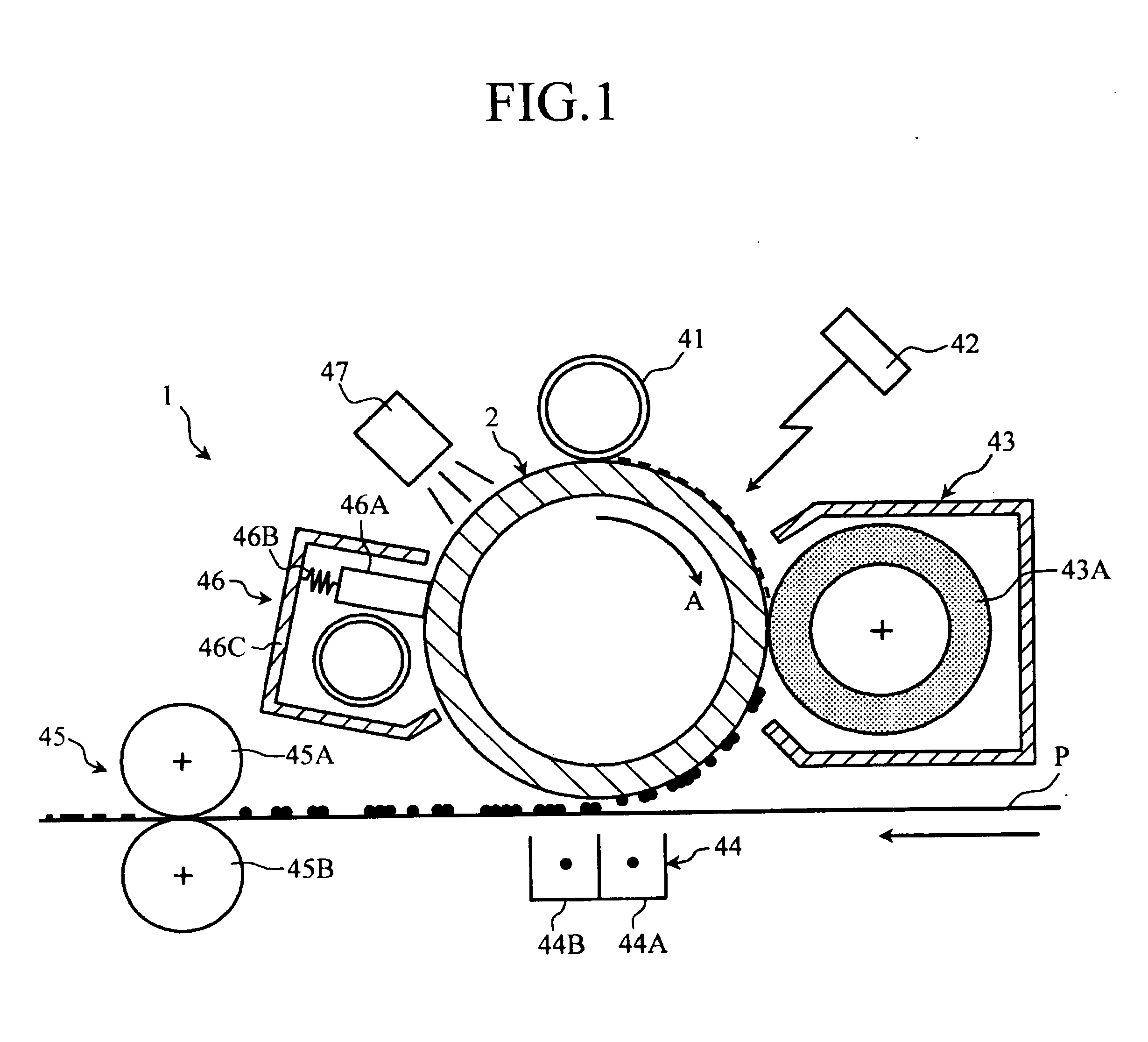

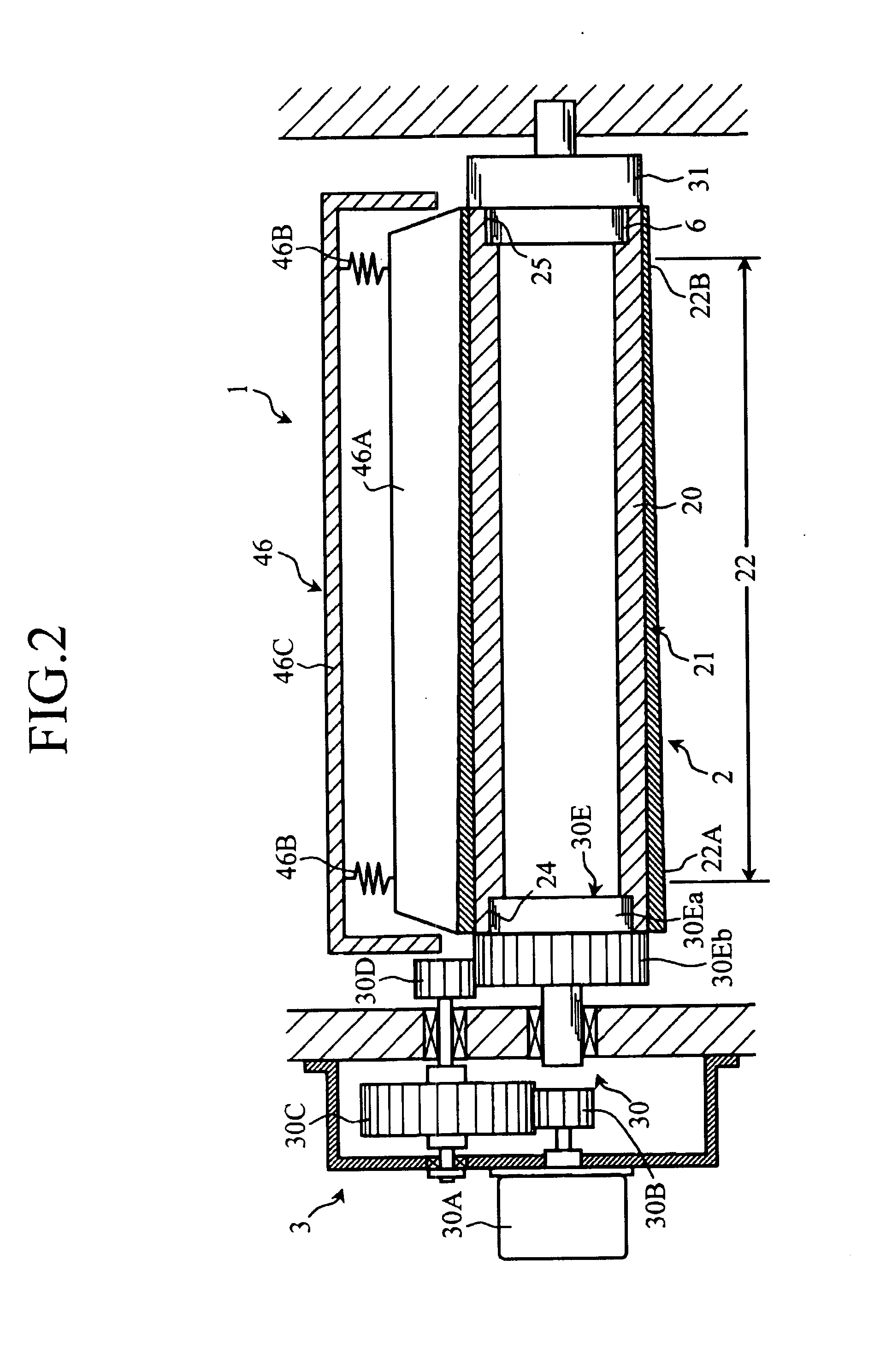

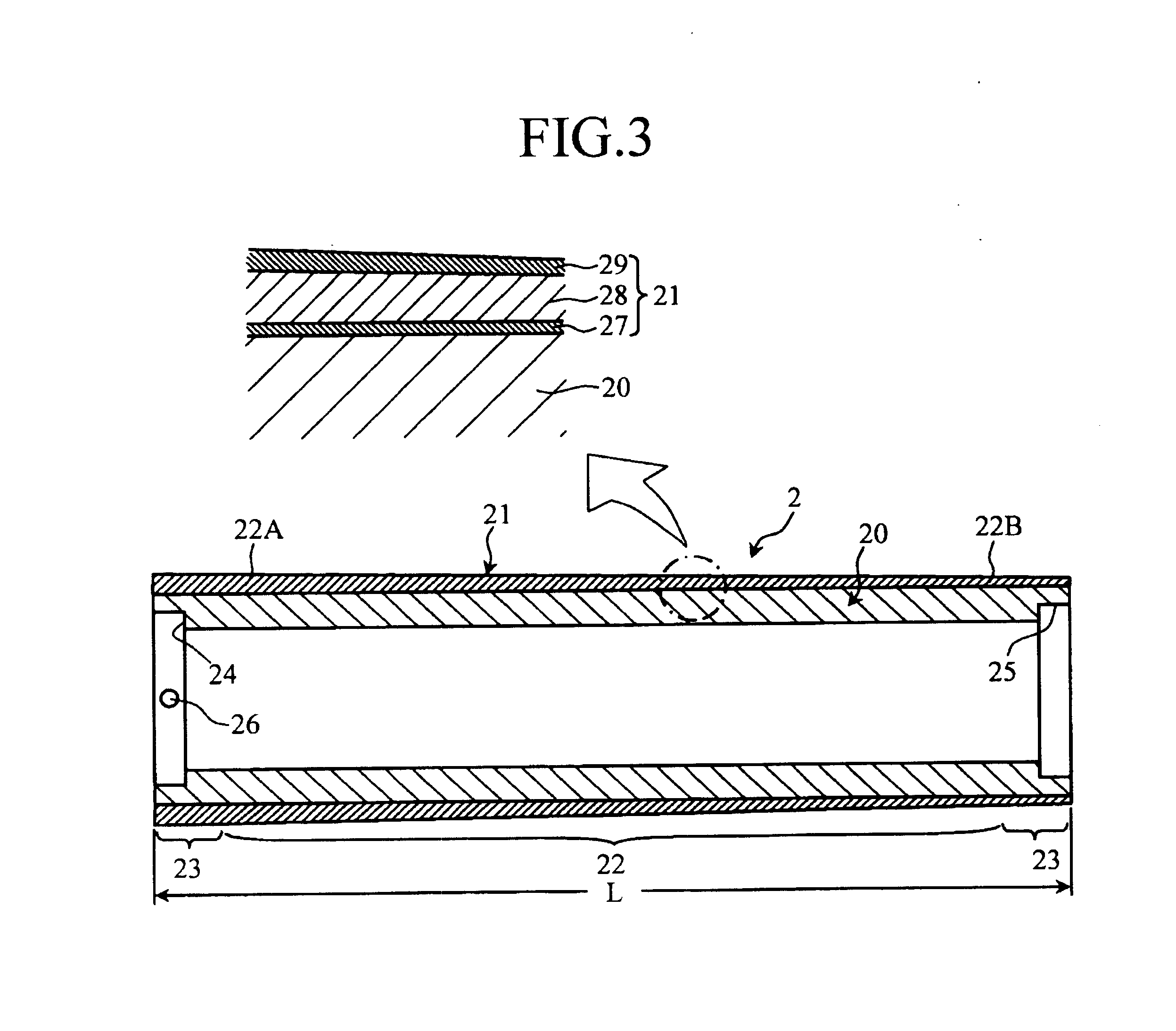

Electrophotographic photosensitive member and image forming apparatus provided with the same

The present invention relates to an electrophotographic photosensitive member and an image forming apparatus provided with the same. The electrophotographic photosensitive member includes a substantially cylindrical body and a photosensitive layer having a latent image forming area formed on the body. In the photosensitive layer incorporated in the image forming apparatus, a first end in the axial direction of the latent image forming area is pressed harder than a second end at opposite side of located opposite to the first end in the axial direction. In the photosensitive layer, thickness or dynamic indentation hardness at the first end at one side of the latent image forming area is larger than thickness or dynamic indentation hardness at the second end at opposite side of located opposite to the first end in the axial direction of the latent image forming area.

Owner:KYOCERA CORP

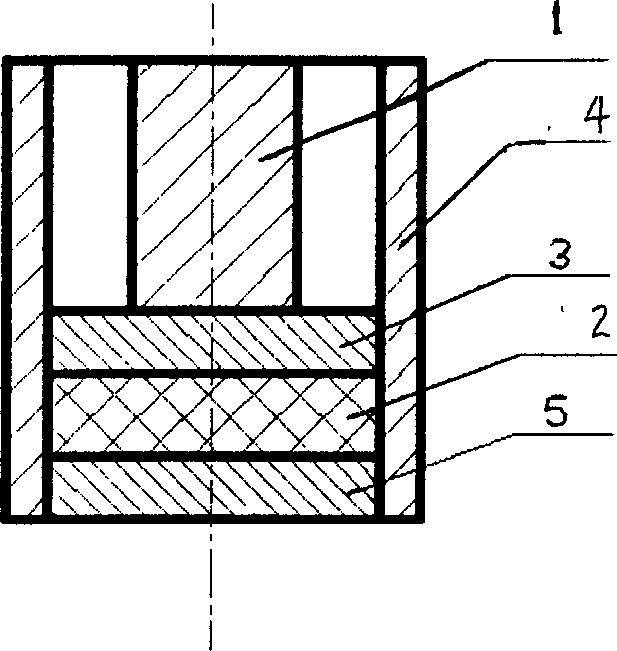

Method for sintering β-silicon nitride ceramics under normal pressure and low temperature

ActiveCN102276260AIncrease productionRaw materials are cheap and easy to getNitrogen atmosphereNitrogen gas

The invention discloses an atmospheric-pressure and low-temperature sintering method of beta-silicon nitride ceramic, comprising the following steps of: using beta-silicon nitride as a raw material, adding a sintering aid to prepare a mixed powder, and carrying out liquid phase sintering on the mixed powder at normal pressure and in nitrogen atmosphere. The sintering aid is made from the following components of: by weight, 25-35% of MgO, 10-20% of CeO2, 5-10% of AlPO4, 1-20% of Y2O3 and 25-35% of Li2CO3. The high-output beta-silicon nitride powder which is cheap and easily available is adopted in the invention; in comparison with an expensive high-purity alpha-silicon nitride powder, the beta-silicon nitride powder is used to greatly reduce the cost. By the liquid phase sintering at normal pressure and in nitrogen atmosphere with the sintering temperature being within 1600 DEG C, the method provided by the invention has low requirement of equipment so as to reduce the equipment cost. According to the silicon nitride ceramic obtained by the method, the relative density is larger than or equal to 98%, the bending strength ranges from 600Mpa to 700Mpa, and the indentation hardness reaches 7-8Gpa.

Owner:中国科学院唐山高新技术研究与转化中心

High-load-bearing low-friction polytetrafluoroethylene friction material and its manufacturing process

InactiveCN102276951AHigh mechanical strengthReduce coefficient of frictionOther chemical processesHigh loadBasalt fiber

The invention which relates to a PTFE friction material with high bearing and a low friction coefficient and a manufacturing process thereof belongs to the field of materials with high bearing and low friction coefficients and manufacturing processes thereof. The PTFE friction material which mainly comprises components of PTFE, poly-p-hydroxybenzoate, expanded graphite, a basalt fiber, a silane or titanate coupling agent and the like is manufactured by adopting a mixing technology of ultrasonic vibration-swirling and the manufacturing process of vacuum cold press sintering or vacuum hot pressing molding. The mechanical strength of the PTFE composite material is obviously increased, the friction coefficient of the PTFE composite material is reduced, and the PTFE composite material which has obvious progresses in aspects of tensile strength, ball indentation hardness, wear resistance and the like allows application demands of harsh industrial fields and transport fields of railway freight car bogies, slide slewing bearings and the like to be satisfied. The PTFE friction material of the invention has the advantages of low friction coefficient, and good bearing performance and corrosion resistance, and the manufacturing process of the PTFE friction material has the advantages of simplicity, low cost, and wide practicality.

Owner:CHINA UNIV OF MINING & TECH +1

Adhesive tape

ActiveCN104099032AInhibit residual glueEasy to take outNon-macromolecular adhesive additivesFilm/foil adhesivesLaser cuttingEngineering

The present invention provides an adhesive tape capable of suppressing rise of adhesive force even in the case of being heated due to laser cutting and the like, enabling processing such as taking out of small sheets of semiconductor components and transferring to the other adhesive tape to be easy, and capable of suppressing adhesive residue to an adherend. The adhesive tape of the present invention has an adhesive layer on at least one surface of a substrate, and indentation hardness of a surface of the adhesive layer obtained by using a nanoindentor at the temperature below 100 DEG C is more than 20.0 MPa.

Owner:NITTO DENKO CORP

Indentation hardness test system

ActiveUS6996264B2Material strength using tensile/compressive forcesCharacter and pattern recognitionComputer graphics (images)Display device

An indentation hardness test system includes a frame having a movable turret, a movable stage for receiving a part, a camera, a display, a processor and a memory subsystem. The turret includes an objective lens of a microscope and an indenter and the movable stage is configured for receiving the part to be tested. The camera captures images of the part through the microscope, which can then be provided on the display. The processor is coupled to the turret, the movable stage, the camera and the display, as well as the memory subsystem. The memory subsystem stores executable code that instructs the processor to capture and store a series of real-time images of the part using the camera, store associated stage coordinates provided by the stage for the images and display a composite image, which includes the series of real-time images assembled according to the associated stage coordinates, of the part.

Owner:LECO CORPORATION

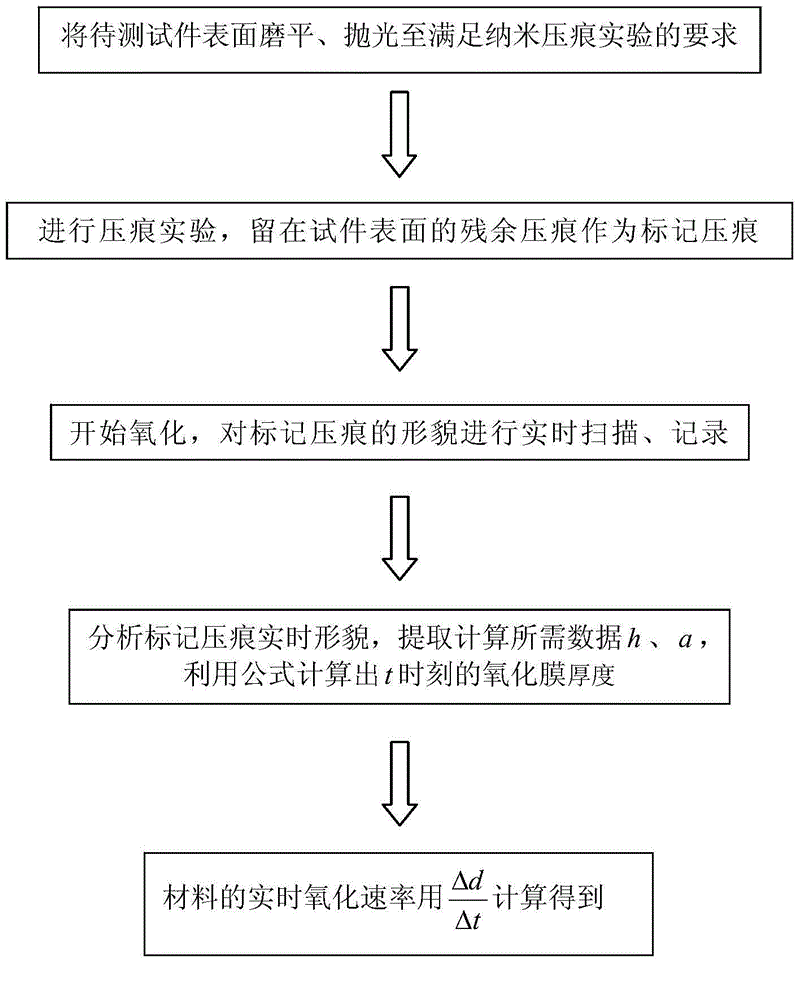

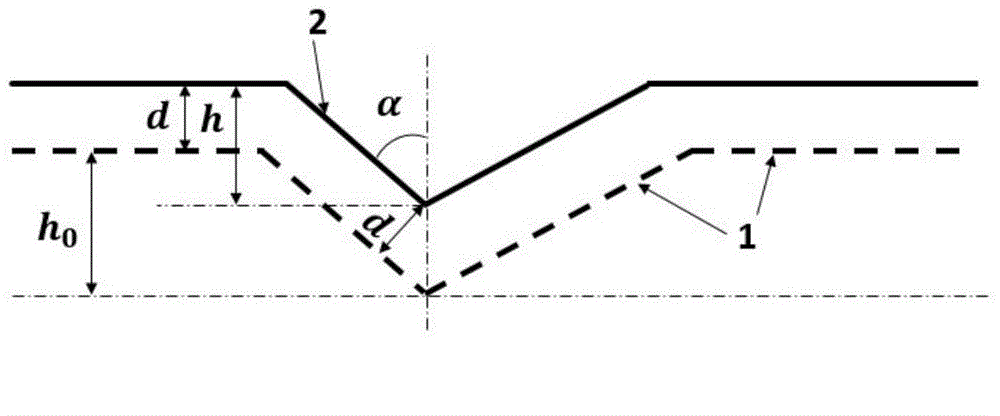

Method for real-time measurement of oxidation rate of material by using nanoindentation shape

ActiveCN104406982ARealize real-time online measurementRealize evaluationMaterial analysis by optical meansUsing optical meansMicro nanoStructural deformation

The invention relates to a method for real-time measurement of the oxidation rate of a material by using a nanoindentation shape and belongs to the technical field of engineering materials, structural deformation and mechanical experiments. The method provided by the invention is technically characterized in that the indentation shape of a surface marker of the material is scanned in real time by virtue of an imaging function of a scanning probe microscope of a nanoindentor so as to measure the room temperature of the material and the oxidation rate of the material under a high-temperature condition; the method comprises the following steps: firstly, carrying out indentation experiment on the surface of the material; using residual indentation as a mark indentation; after the material is started to be oxidized, carrying out real-time online scanning and recording on the shape of the mark indentation by virtue of the imaging function of the scanning probe microscope of the nanoindentor; analyzing the shape of the mark indentation; extracting data use for calculation; calculating by virtue of a formula so as to measure the oxidation rate of the material. The method is obtained based on a specific experimental analysis result, thereby providing a novel method for researching oxidation behaviors of materials at different temperatures at micro-nano scale.

Owner:TSINGHUA UNIV

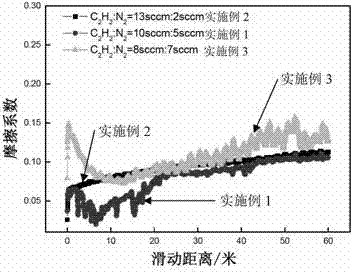

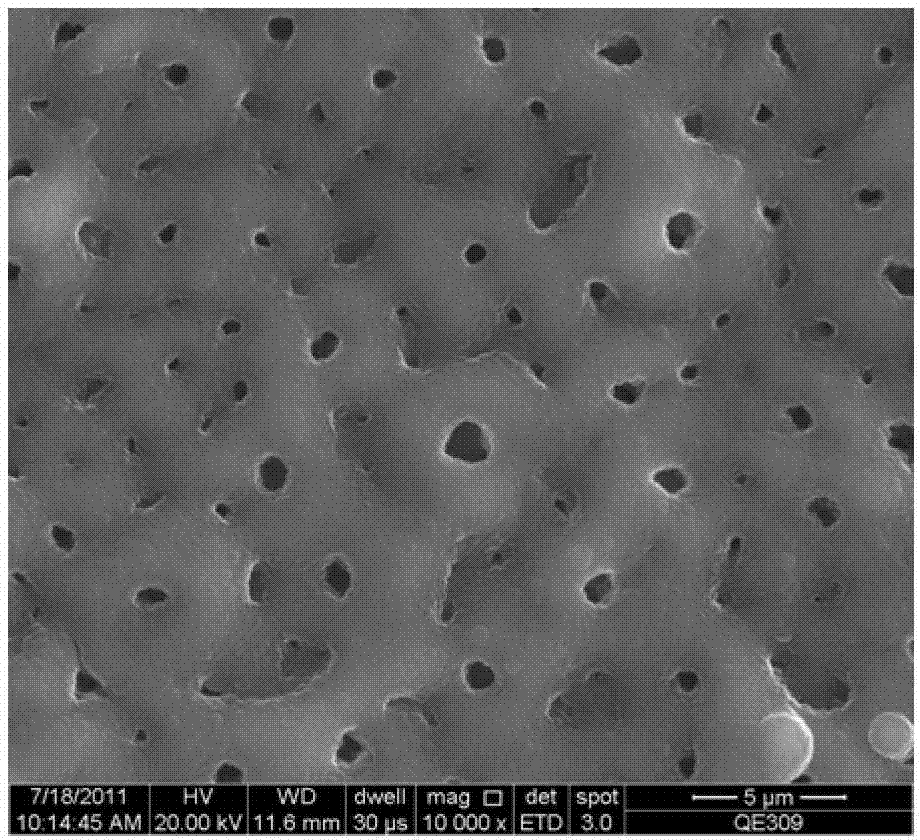

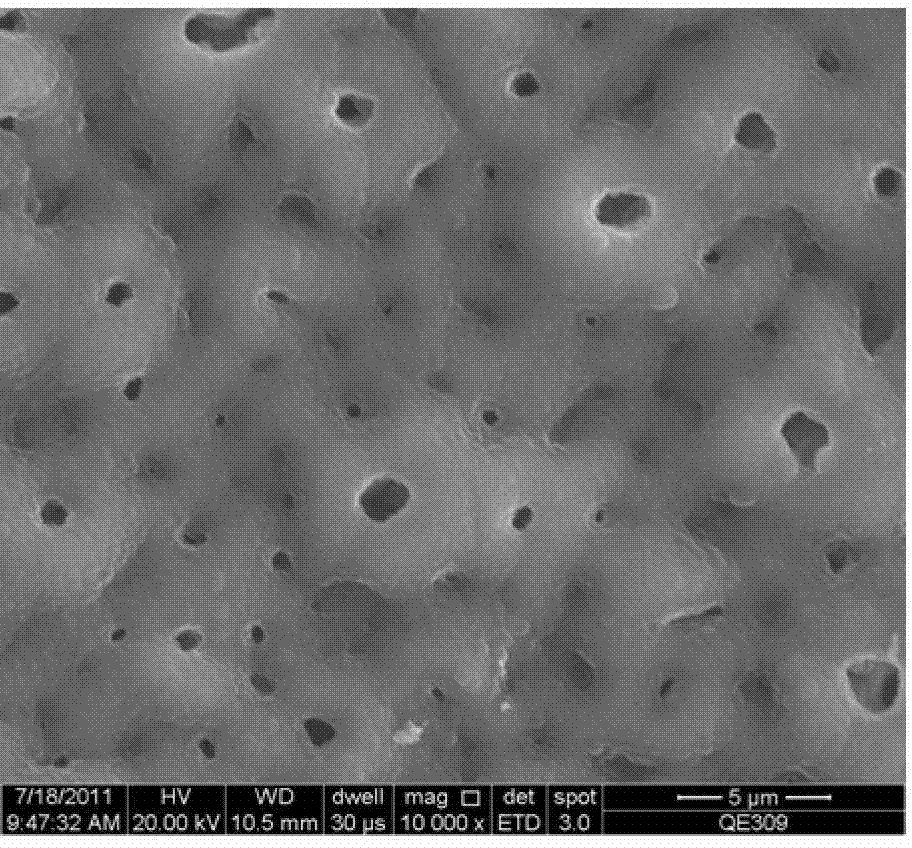

Composite coating with anti-corrosion lubricating property of surface of magnesium alloy, preparation method thereof

ActiveCN102758201AImprove performanceSimple processSuperimposed coating processMicro arc oxidationPlasma electrolytic oxidation

The invention discloses a composite coating with anti-corrosion lubricating property of the surface of magnesium alloy, which takes an MgO porous membrane as a transition layer, and the MgO porous membrane is positioned on the surface of a magnesium alloy substrate and is used for leading magnesium atoms of the surface layer of the magnesium alloy substrate to be formed in situ by adopting a micro-arc oxidation technology, and comprises (Si, N)-DLC or (Ti, N)-DLC multi-element nano-composite coating arranged on the surface of the transition layer. Compared with the prior art, the composite coating greatly improves the corrosion resistance and the wear resistance of the surface of the magnesium alloy substrate, has the nano-indentation hardness of 21-30GPa and the frictional factor with a steel ball of less than 0.15 or even less than 0.1, and is good in corrosion resistance, so that the composite coating with the anti-corrosion lubricating property has a good application prospect.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Method for quantitative detection of indentation fracture toughness of coating material

InactiveCN109406280APossibility of improving quantitative evaluation of fracture toughnessMaterial strength using tensile/compressive forcesInvestigating material hardnessCoated surfaceCrazing

The invention discloses a method for quantitative detection of indentation fracture toughness of a coating material. The method includes steps: 1) adopting a pressing head for applying pressure intensity P to the coating surface to form indentation and cracks; 2) determining a coating surface indentation modulus E, indentation hardness H and crack characteristic length c; 3) substituting the indentation modulus E, indentation hardness H, crack characteristic length c and the pressure intensity P into a formula as shown in the specification to obtain material indentation fracture toughness Kc.A method for quantitative assessment of indentation fracture toughness of the coating material can be created according to indentation cracking characteristics to provide basic data support for coating mechanical property design and environmental adaptability assessment.

Owner:CASIC DEFENSE TECH RES & TEST CENT

Transparent conductive laminate and transparent touch panel

InactiveUS20140085548A1Avoid breakingConductive layers on insulating-supportsSynthetic resin layered productsIndentation hardnessTouch panel

The purpose of the present invention is to provide a transparent conductive laminate that will not break by being bent. Another purpose of the present invention is to provide a transparent touch panel comprising such a transparent conductive laminate. A transparent conductive laminate of the present invention has a cured resin layer and a transparent conductive layer laminated on at least one face of a transparent organic-polymer substrate. The resin composition constituting the cured resin layer has a recovery rate (ηIT), which is indicated in the following formula, of 60% or less, for a cured resin layer having a thickness of 5 μm, in an indentation hardness test (testing load: 1 mN) conforming to ISO14577-1: 2002. ηIT=Welast / Wtotal×100(%) (wherein Welast is indentation work (Nm) generated by elastic returning deformation, and Wtotal is mechanical indentation work (Nm)).

Owner:TEIJIN LTD

Gas-barrier laminate

ActiveUS7910213B2Good printabilityExcellent gas barrier performanceSynthetic resin layered productsCellulosic plastic layered productsPolyesterAtmospheric air

A gas-barrier laminate with a plastic substrate, an inorganic thin film formed on at least one surface of the plastic substrate, and a coating layer formed by applying a coating material on a surface of the inorganic thin film, wherein said coating layer contains a polyester-based resin having a molecular weight of 3000 to 15000 and a polyurethane-based resin having a molecular weight of 8000 to 30000 at a weight ratio of 5 / 95 to 95 / 5, and said gas-barrier laminate has an oxygen permeability of not more than 25 fmol / m2 / s / Pa; and a gas-barrier laminate comprising a plastic substrate, an inorganic thin film formed on at least one surface of the plastic substrate, and a coating layer formed by applying a coating material on a surface of the inorganic thin film, wherein the gas-barrier laminate exhibits an oxygen permeability of not more than 50 fmol / m2 / s / Pa as measured with respect to a gas-barrier film obtained by laminating an unstretched polypropylene film having a thickness of 60 μm on the coating layer of the gas-barrier laminate after subjecting the gas-barrier film to hydrothermal treatment at 120° C. for 30 min, and the coating layer has either a hardness of 0.1 to 0.5 GPa as measured at 23° C. in atmospheric air by a nano-indentation hardness testing method, a hardness of 0.03 to 0.5 GPa as measured at 23° C. in water by a nano-indentation hardness testing method, or a ratio of number of carbon atoms derived from carboxyl groups to number of carbon atoms constituting the surface of the coating layer of 0.005 to 0.1.

Owner:MITSUBISHI CHEM CORP

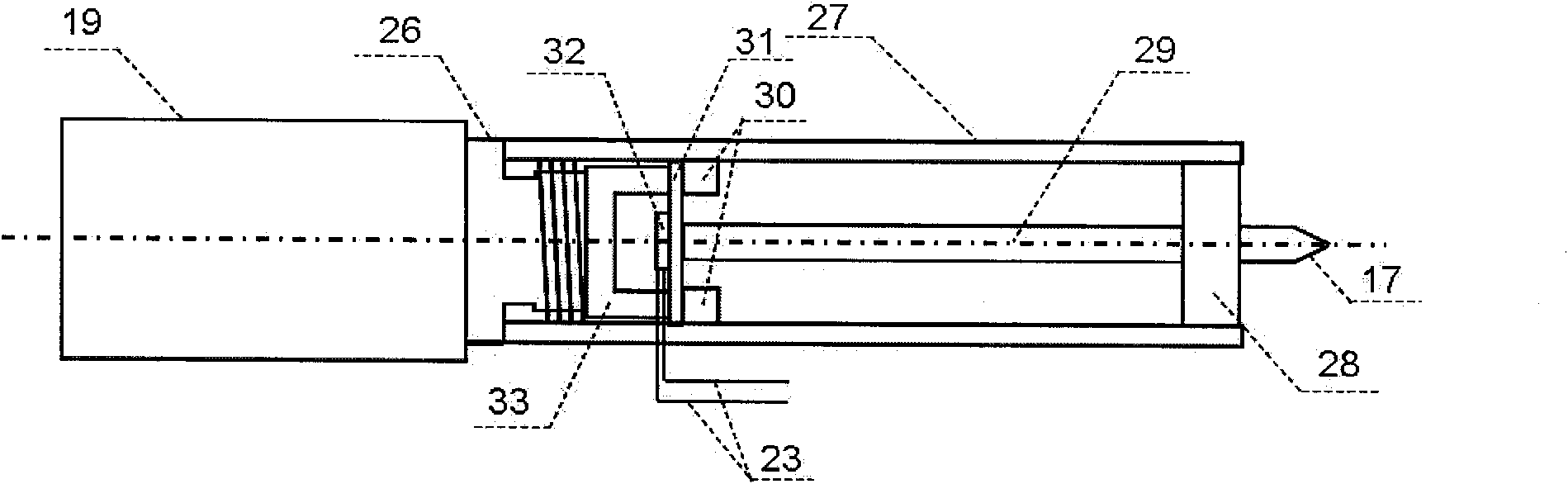

Nano indentation system based on scanning electron microscope

InactiveCN101793911AReduce the impactLow costScanning probe techniquesElectrical/magnetic solid deformation measurementStress measurementHigh resolution imaging

The invention relates to a nano indentation apparatus based on scanning electron microscope, belonging to the low nano material stress state combination property test field. The invention is characterized in that the nano indentation apparatus comprises a pedestal and a sample substrate and an indentation head supporting seat, a set of angle regulating device, a set of triaxial translation rough adjustment device and a set of triaxial micropositioner are additionally arranged on the sample substrate, so as to move a sample to 2-00Mum away from the indentation head point and cause the sample to be over against the indentation head, the micropositioner of the indentation head is utilized to realize indentation operation, point indentation depth and stress measurement is realized by a strain gage in the interior of the indentation head and a piezoresistor as well as a stress-strain tester, relation of the stress and texturing mechanism is revealed by combining an emphasis-scanning high-resolution imaging system, and the nano indentation apparatus can be used for research of optic and electric properties of material under the action of stress. The invention has simple structure, low price and reliable performance and can realize indentation operation of material and research of mechanic al properties.

Owner:BEIJING UNIV OF TECH

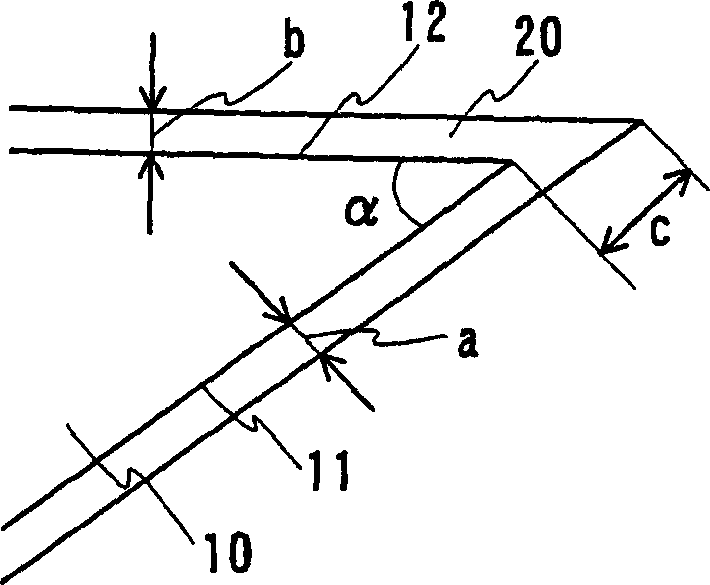

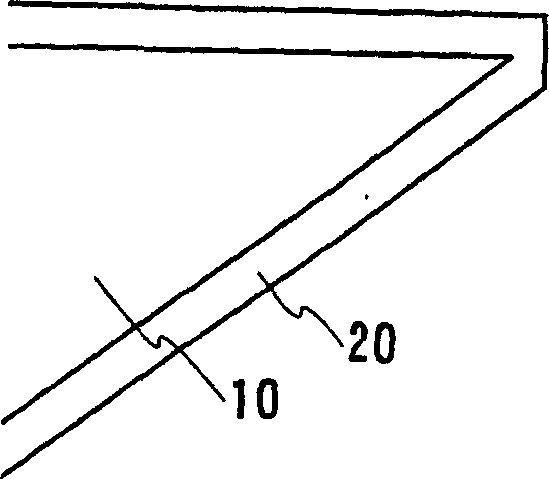

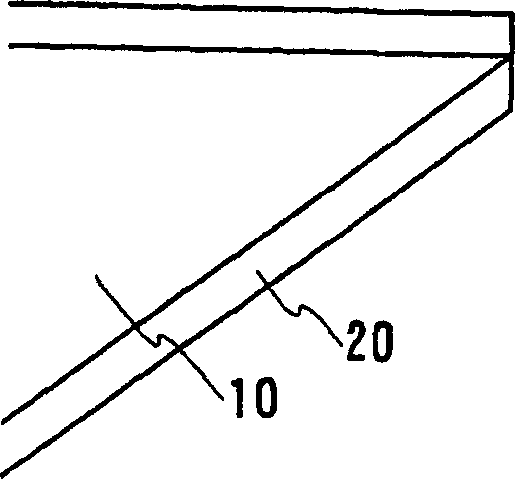

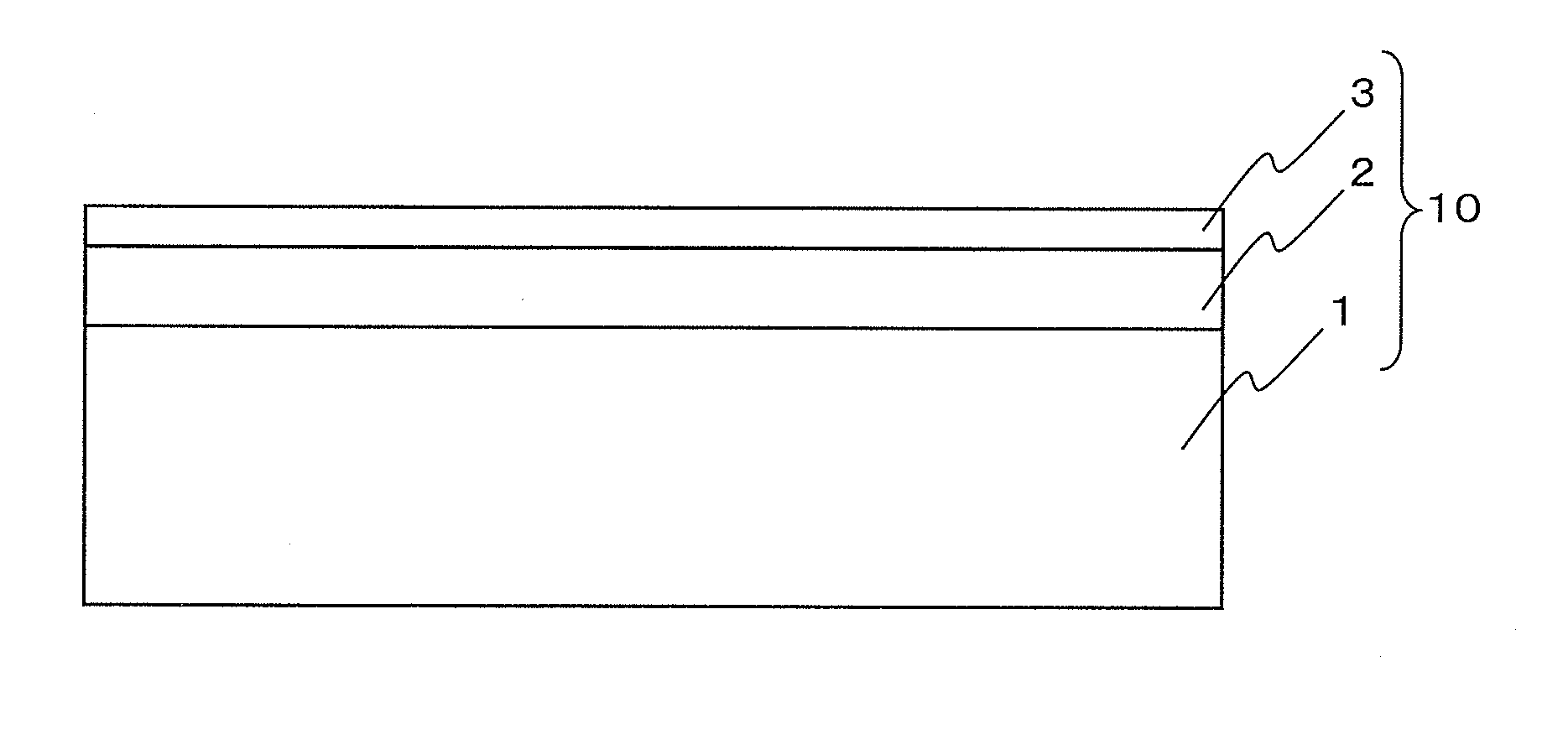

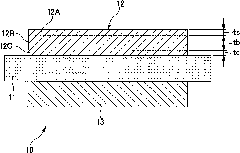

Substrate for power module, preparing method thereof, substrate with heat radiator and power module

InactiveCN102194765AImprove joint reliabilitySmall resistance to deformationPrinted circuit detailsSemiconductor/solid-state device detailsSurface layerHardness

The present invention provides a substrate for a power module, a preparing method thereof, a substrate for the power module with a heat radiator, and the power module thereof. In thermal circulation load, the power module can restrain fluctuation or corrugation on a surface of a circuit layer. Furthermore, application of a thermal stress on a joint interface between a ceramic substrate and the circuit layer can be restrained. Additionally, the substrate for the power module has excellent thermal circulation reliability. The substrate (10) for the power module is provided with an aluminum circuit layer (12) on one surface of the ceramic substrate (11), wherein, the circuit layer (12) is provided with a body layer (12B) and a hardened surface layer (12A) which is configured exposed at the surface side. The indentation hardness (Hs) of the surface of the circuit layer (12) is set in a range between 50mgf / mu m2 and 200mgf / mu m2. More than 80% of the area of the indentation hardness (Hs) becomes the hardened surface layer (12A). The indentation hardness (Hb) of the body layer (12B) is less than 80% of the indentation hardness (Hs).

Owner:MITSUBISHI MATERIALS CORP

Portable polymer tester

The present invention provides a polymer indentation method and tester that includes measuring the time taken by a polymeric material to recover a set portion of an initial deformation and use this duration as a material degradation indicator. The recovery time was found to be more sensitive to cable degradation than the specific compressive stiffness (or indenter modulus) measured during the indentation phase, and this high sensitivity was achieved for both thermally aged and irradiated polymer samples.

Owner:ATOMIC ENERGY OF CANADA LIMITED

Collector, electrode structure, nonaqueous electrolyte battery, and electricity storage component

ActiveCN105074979ALess than appearance deformationLower resistanceFinal product manufactureElectrode carriers/collectorsElectricityAluminum foil

Provided are: a collector which has little deformation in the appearance after pressing and achieves a low resistance and excellent durability; an electrode structure which uses this collector; a nonaqueous electrolyte battery; and an electricity storage component. Provided is a collector which comprises a conductive resin layer on at least one surface of an aluminum foil. The conductive resin layer contains a resin layer and conductive particles; the aluminum foil has a tensile strength of 180 MPa or more; the surface of the conductive resin layer of the collector has an indentation hardness of 600 MPa or less; and the area occupancy of the conductive particles in the surface of the conductive resin layer is 45% or more.

Owner:FURUKAWA SKY ALUMINUM CORP +1

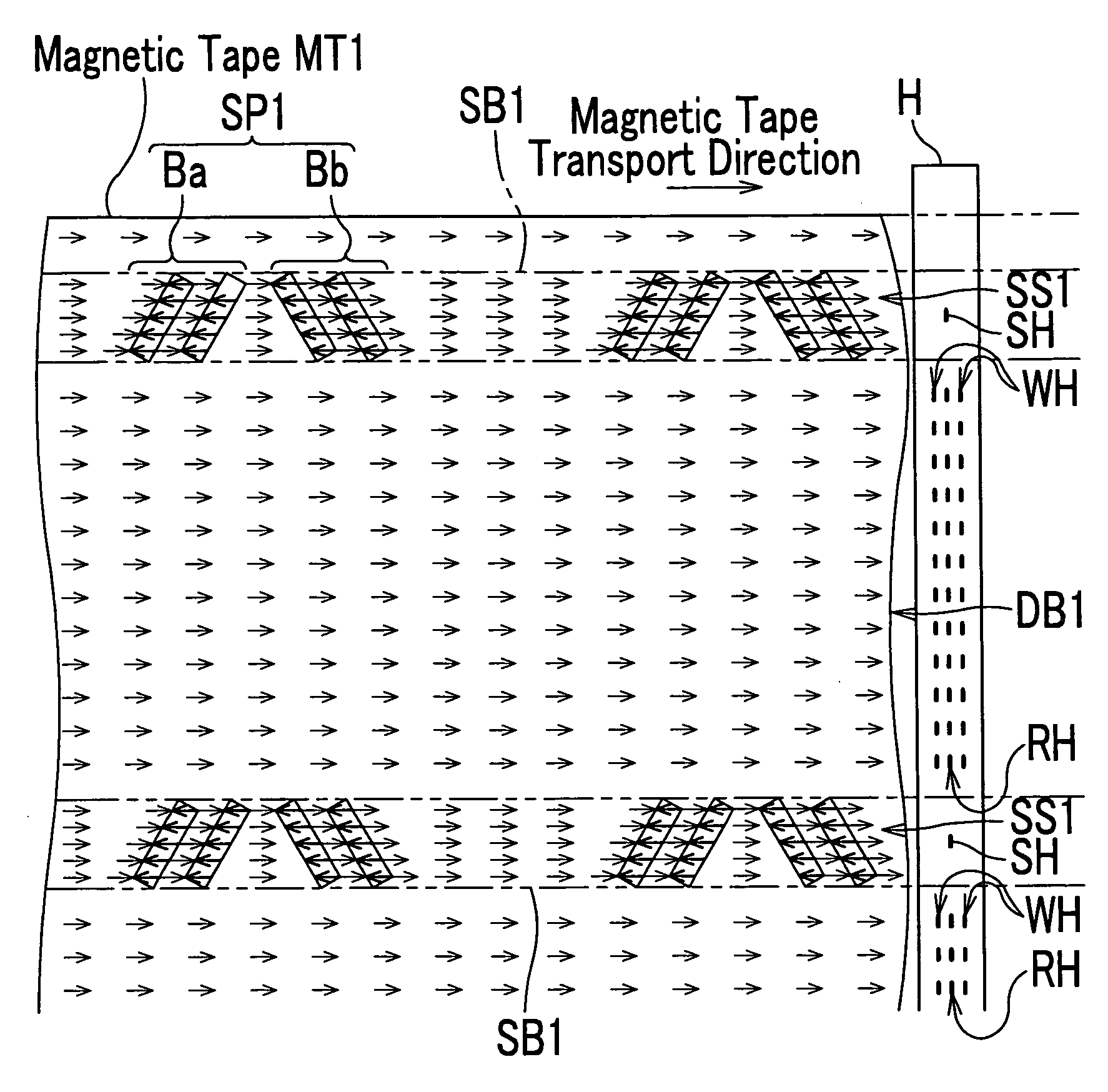

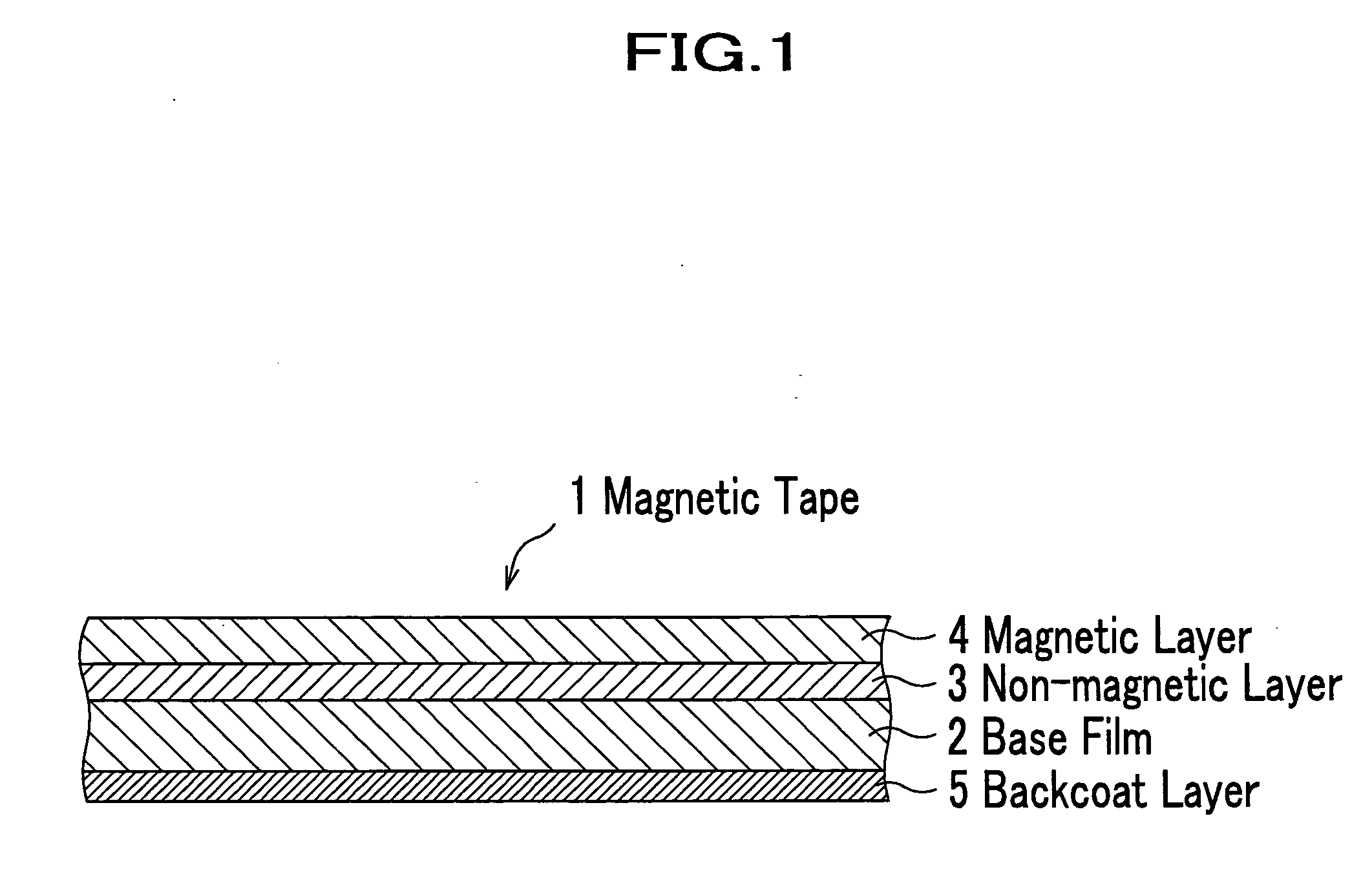

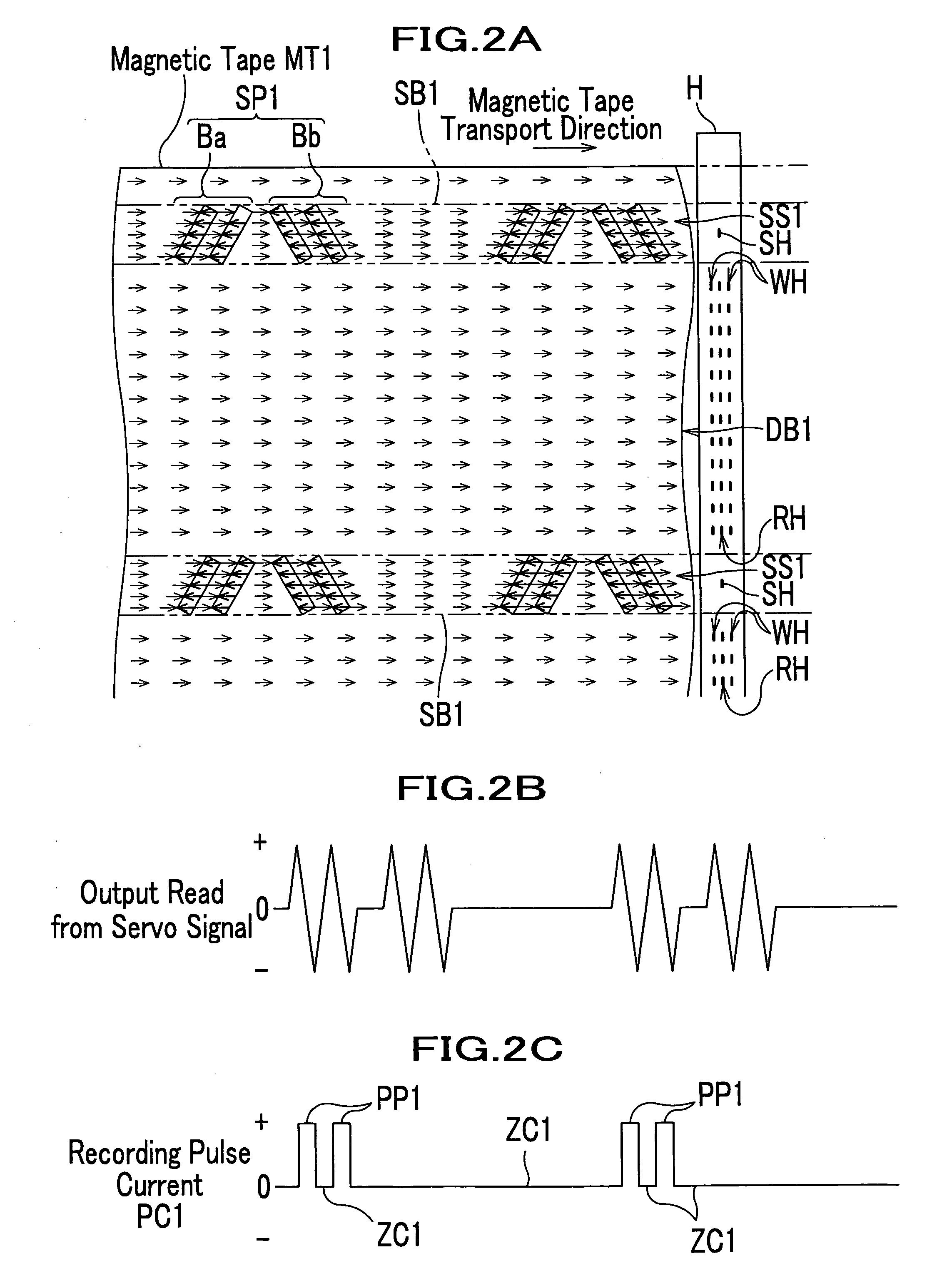

Magnetic recording medium

InactiveUS20040264025A1Increase output ratioDecrease in chip and cuttingBase layers for recording layersAlignment for track following on tapesControl theoryIndentation hardness

Disclosed is a magnetic recording medium which has a high S / N ratio of an output read from a servo signal, few deposits adhered to a head, and a low error ratio. The magnetic recording medium has a magnetic layer which includes a servo band onto which a servo signal for controlling tracking of a magnetic head is written and a data band onto which data are recorded. The servo signal is written onto the servo band which has been magnetized in one direction along length of the magnetic recording medium, by magnetizing the servo band in a direction opposite to the one direction. Further, the magnetic layer has indentation hardness of 60 to 140 Kg / mm<2>.

Owner:FUJIFILM CORP +1

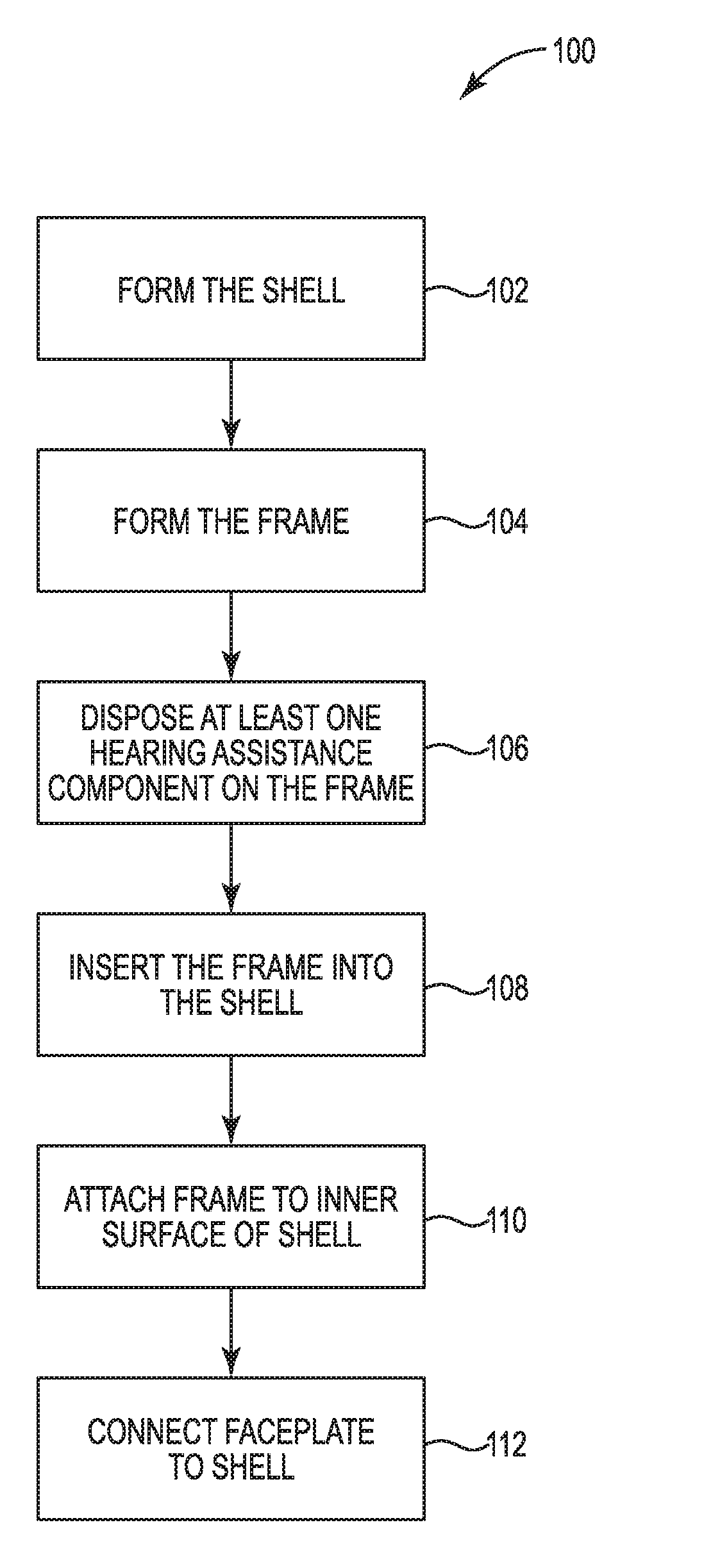

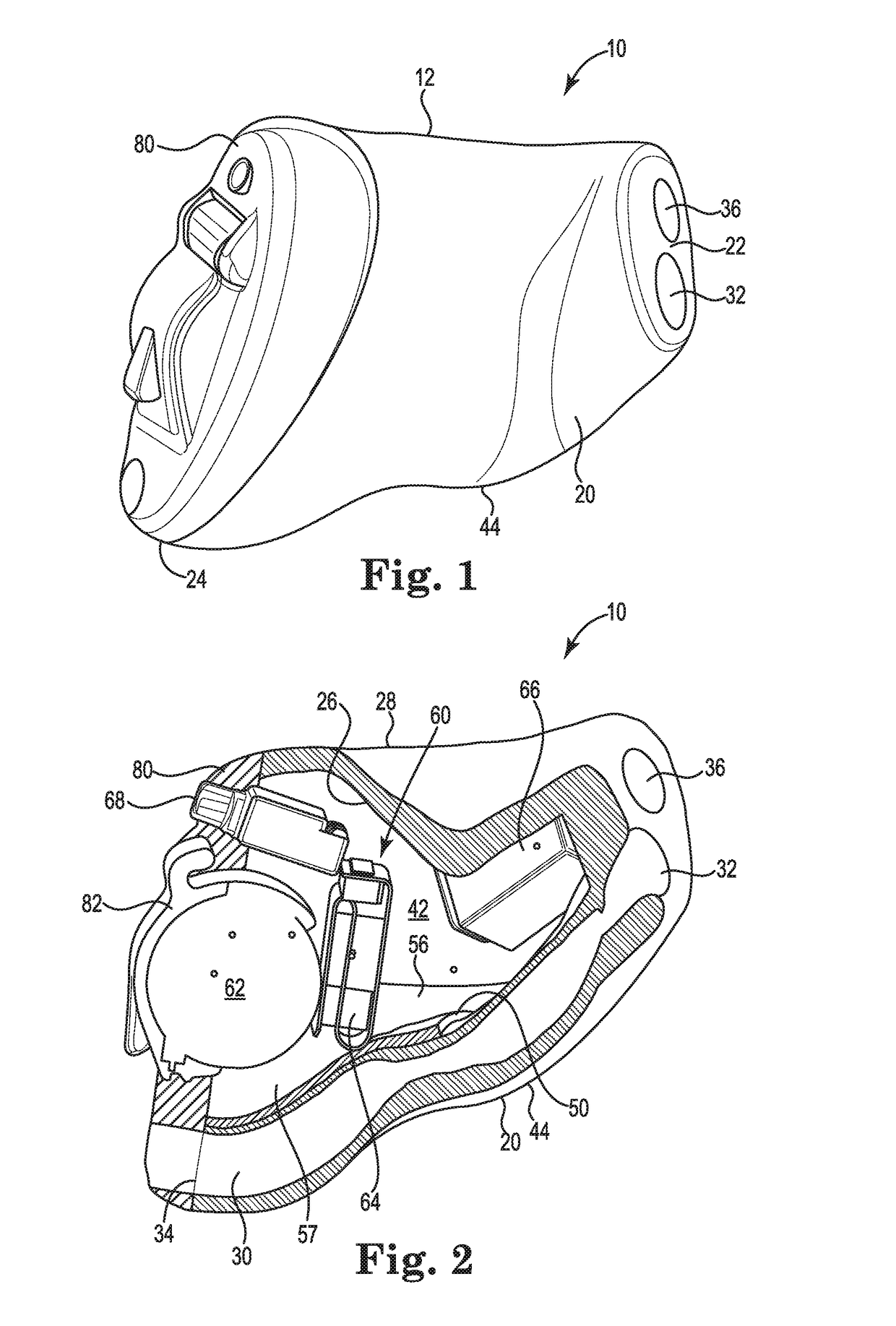

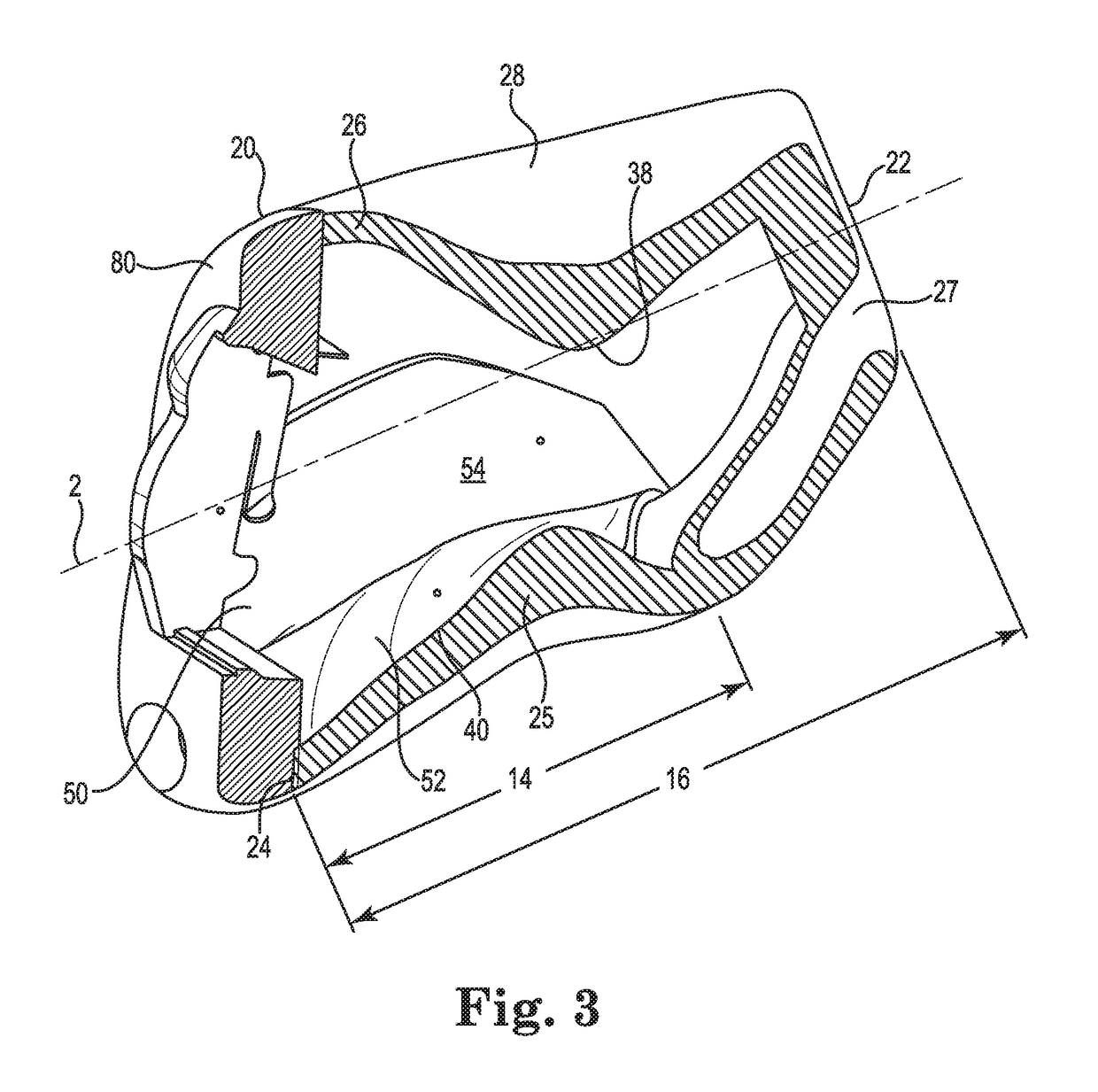

Hearing assistance device

ActiveUS20180234781A1Better conformProvide integrityCompletely in canal hearing aidsIn the ear hearing aidsHearing aidEngineering

Various embodiments of a hearing assistance device and a method of forming such device are disclosed. The device includes a housing having a shell and a frame disposed at least partially within the shell. An inner surface of the shell and at least a portion of the frame define a void. Further, an indentation hardness value of the frame is greater than an indentation hardness value of the shell. The hearing assistance device also includes hearing assistance components that are disposed at least partially within the void.

Owner:STARKEY LAB INC

Cutting tool made of surface-coated cubic boron nitride-based ultra-high pressure sintered material having high peeling resistance

ActiveCN102528104AExcellent finishing surface accuracyImprove heat resistanceLayered productsMilling cuttersUltra high pressureBoron nitride

The invention provides a cutting tool made of surface-coated cubic boron nitride-based ultra-high pressure sintered material, which develops good property of peeling resistance when high-rigidity steel undergoes high-speed cutting. The cutting tool is formed by forming hard coating layer on the surface of CBN-based ultra-pressure sintered body whose cubic boron nitride is 50-85 capacity%. The hard coating layer comprises a lower layer and an upper layer whose average layer thickness is 1.5-3Mum. The lower layer has a complex nitride layer satisfying a formula: [Ti1-XA1X]N, wherein in terms of atomic ratio, X is 0.30-0.60. The upper layer has a thin layer A and a thin layer B which is alternative and has 0.03-0.3Mum average layer thickness. The thin layer A includes a complex nitride layer satisfying a formula: [Ti1-XA1X]N, and the thin layer B includes TiN layer. The surface roughness, residual stress and nano-indentation hardness are set to be a predetermined value.

Owner:MITSUBISHI MATERIALS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com