Patents

Literature

460 results about "Ag element" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of forming an oxide film

InactiveUS6960812B2Improve performanceReduce the temperatureSolid-state devicesVacuum evaporation coatingAlkali ionsSputtering

A method of forming an oxide film and a method of manufacturing an electronic device utilizing the oxide film is disclosed. A silicon oxide film is formed on a substrate by sputtering. Therefore, the film formation is carried out at a low temperature. The sputtering atmosphere comprises an oxidizing gas and an inert gas such as argon. In order to prevent fixed electric charges from being generated in the film and to obtain an oxide film of good properties, the proportion of argon is adjusted to 20% or less. Alternatively, a gas including halogen elements such as fluorine is added to the above sputtering atmosphere at a proportion less than 20%. Hereupon, alkali ions and dangling bonds of silicon in the oxide film are neutralized by the halogen elements, whereby a fine oxide film is obtained.

Owner:SEMICON ENERGY LAB CO LTD

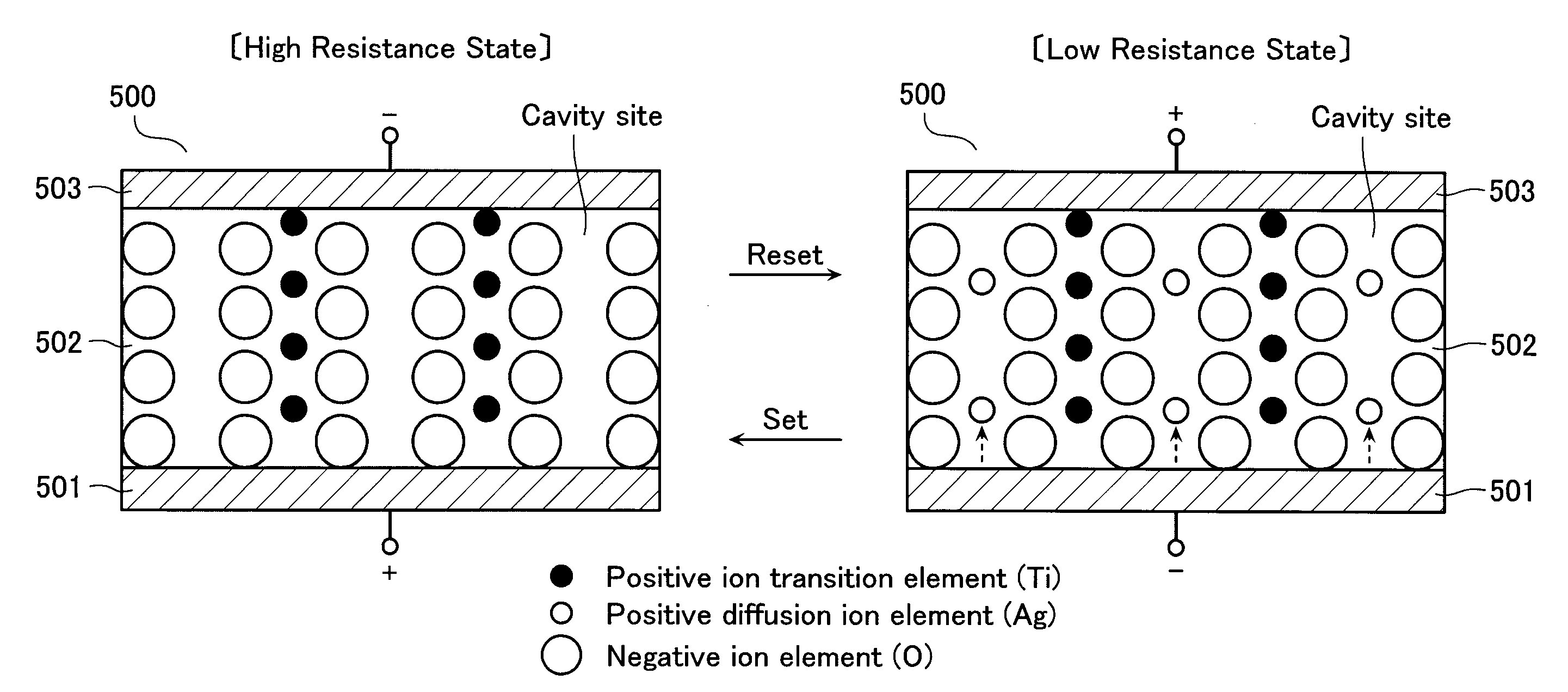

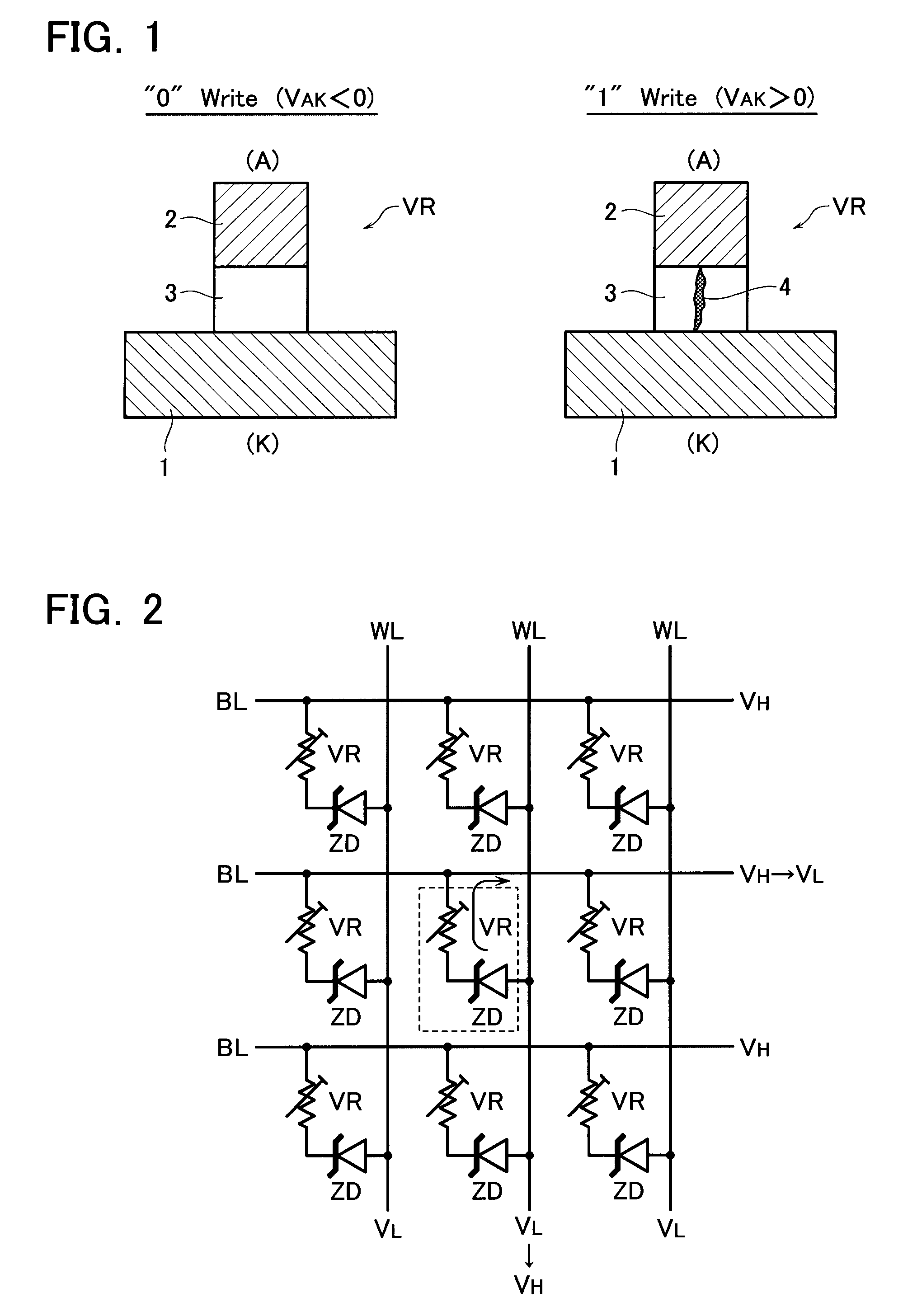

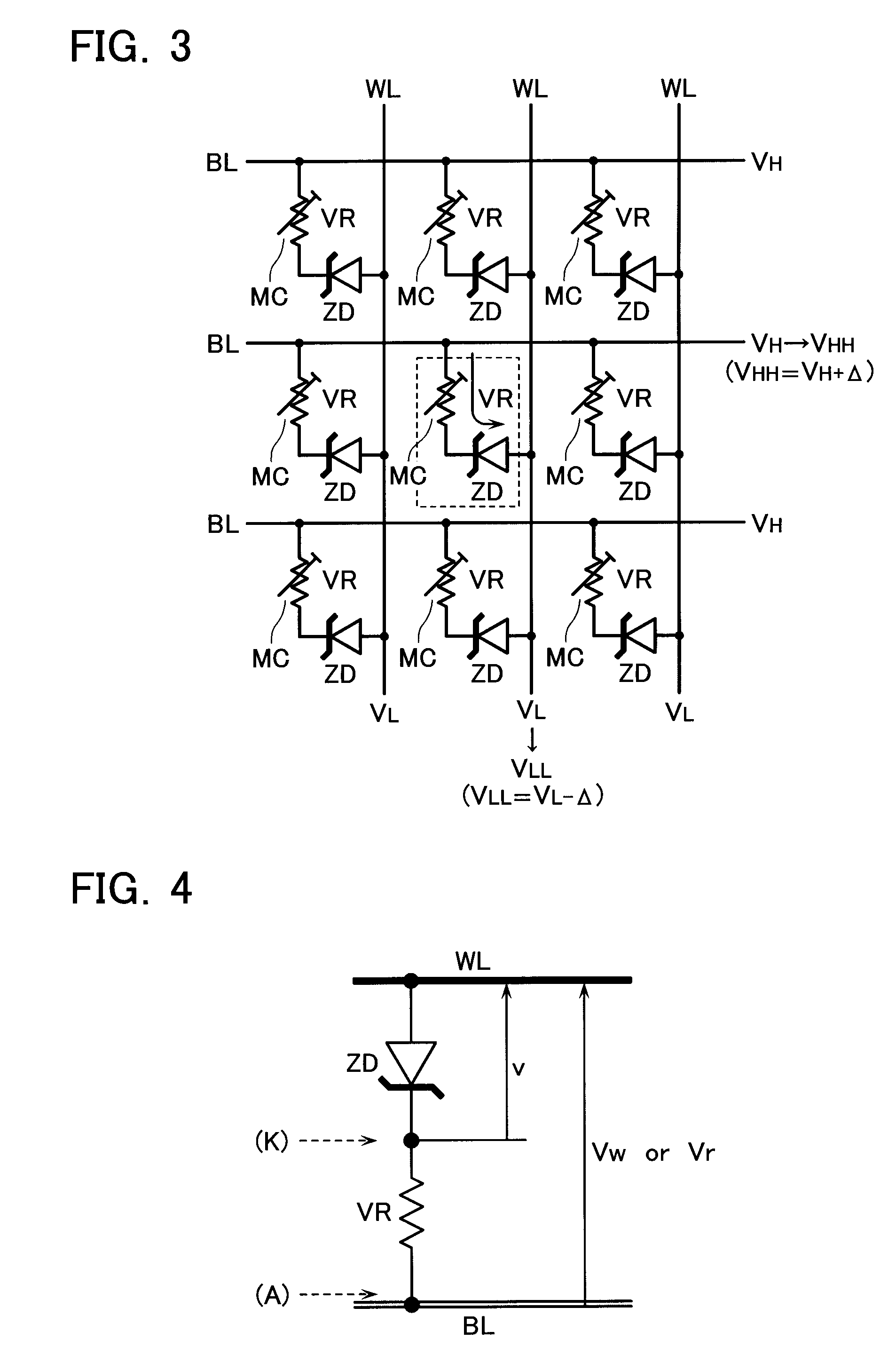

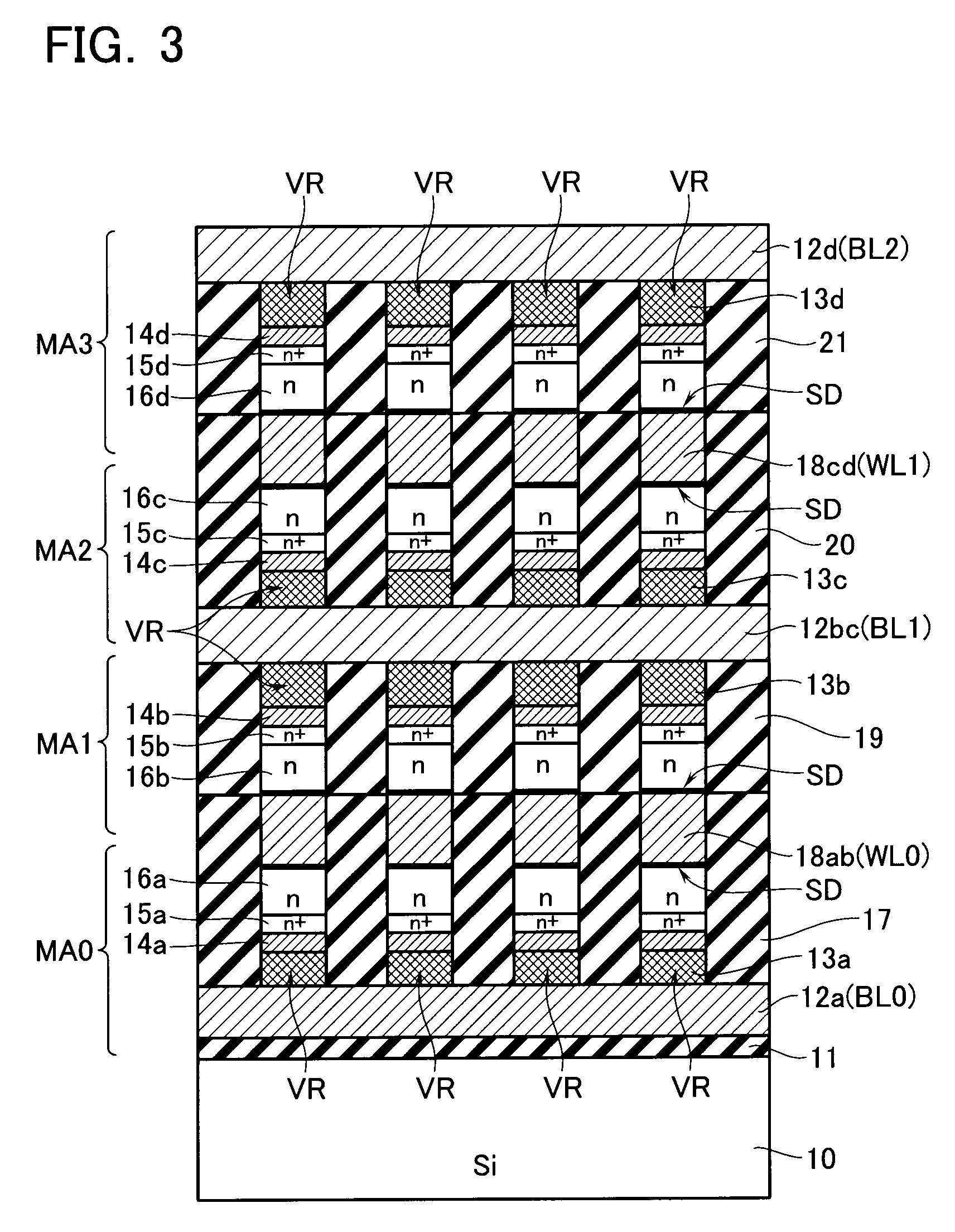

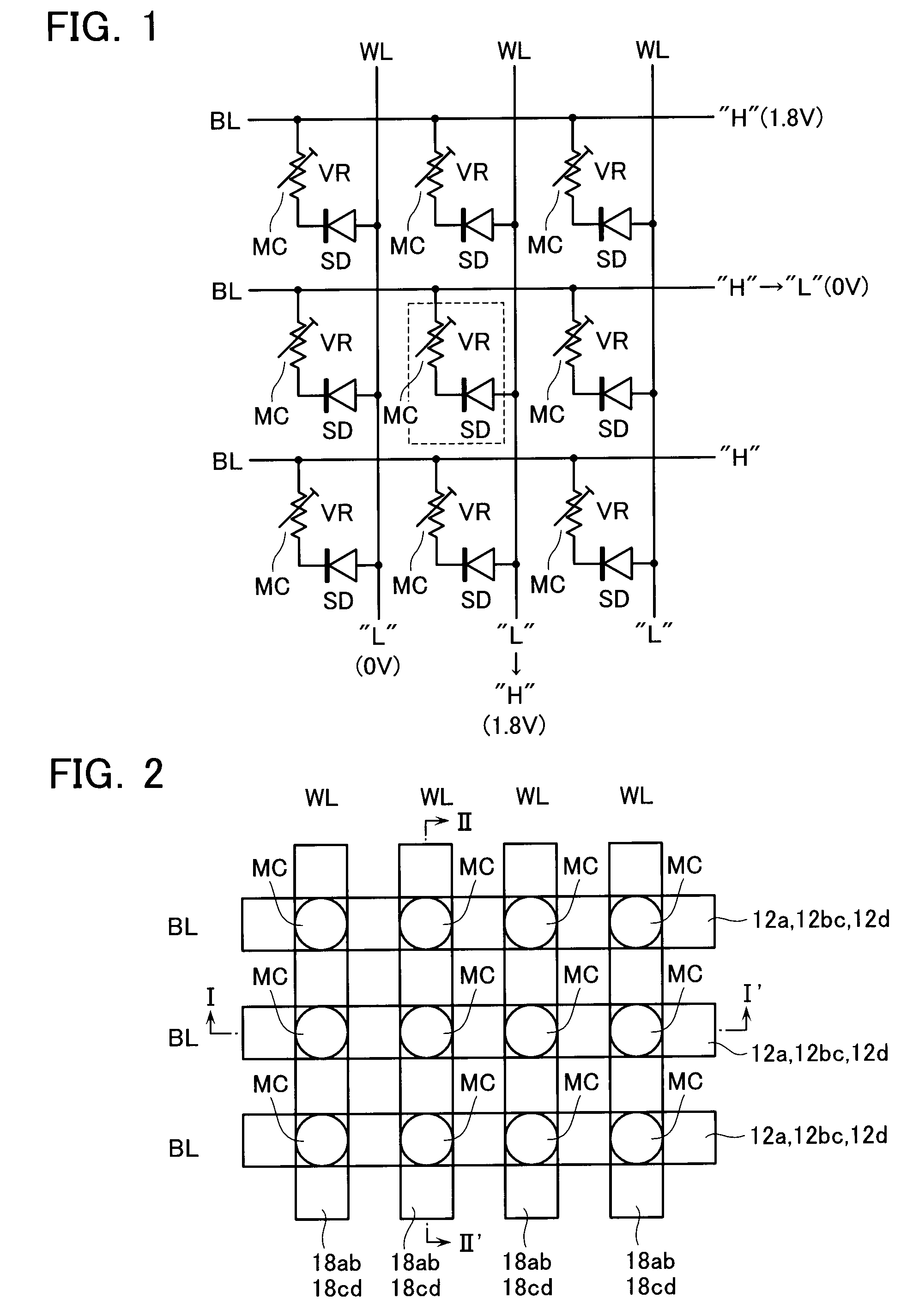

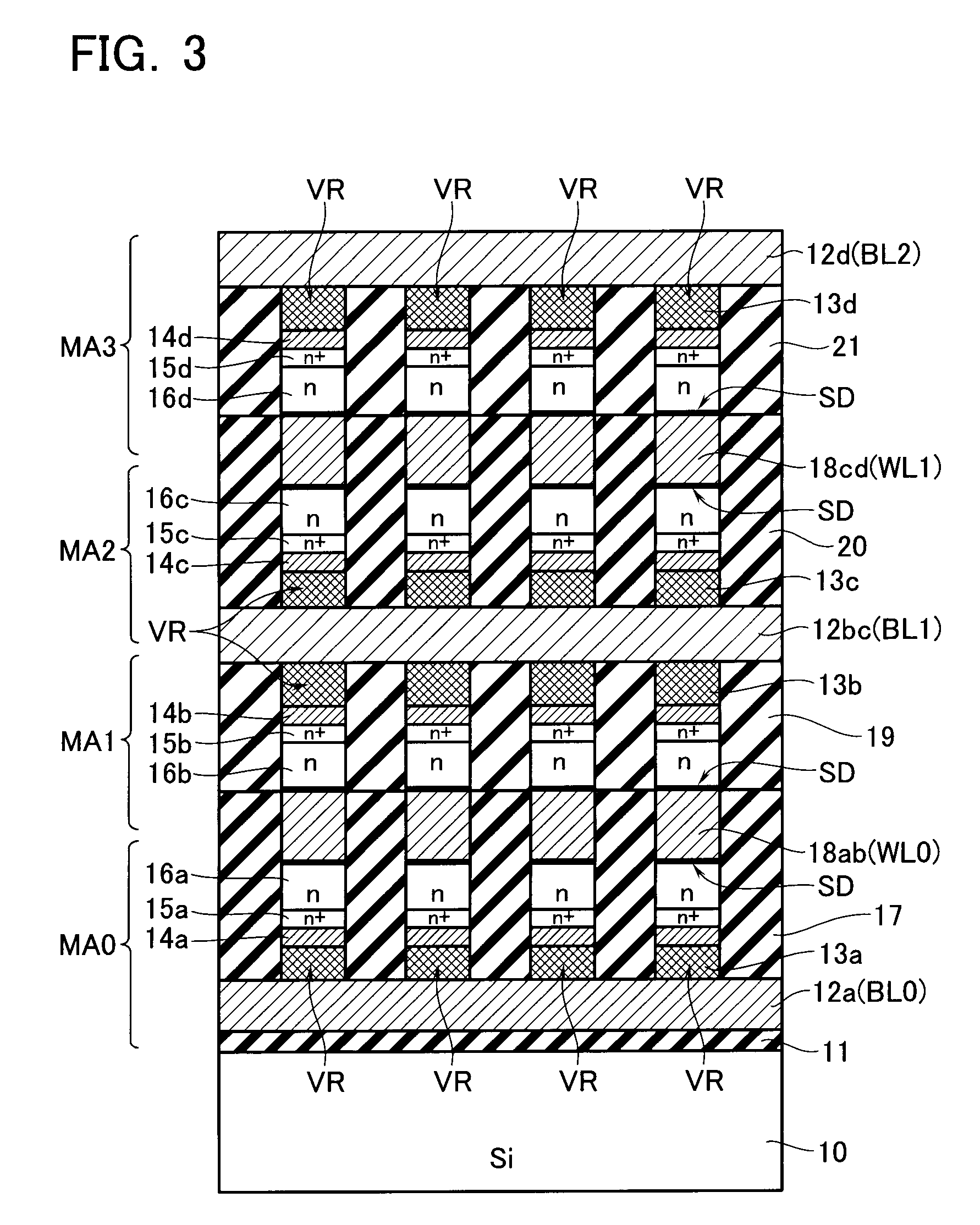

Resistance change memory device having a variable resistance element with a recording layer electrode served as a cation source in a write or erase mode

A resistance change memory device including: a semiconductor substrate; at least one cell array formed above the semiconductor substrate to have a stack structure of a variable resistance element and an access element, the variable resistance element storing a high resistance state or a low resistance state in a non-volatile manner, the access element having such an off-state resistance value in a certain voltage range that is ten times or more as high as that in a select state; and a read / write circuit formed on the semiconductor substrate, wherein the variable resistance element includes: a recording layer formed of a composite compound containing at least one transition element and a cavity site for housing a cation ion; and electrodes formed on the opposite sides of the recording layer, one of the electrodes serving as a cation source in a write or erase mode for supplying a cation to the recording layer to be housed in the cavity site.

Owner:TOSHIBA MEMORY CORP

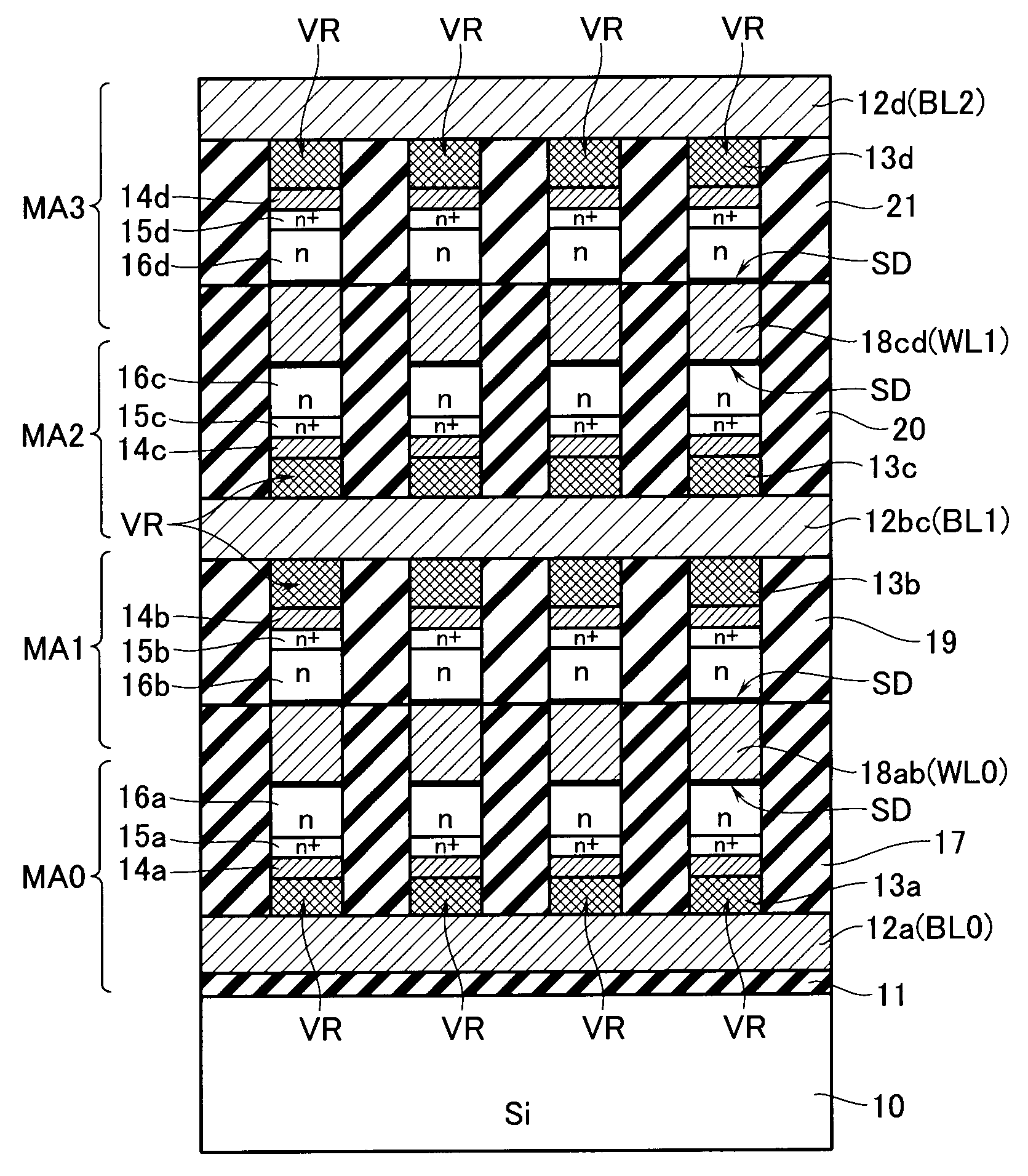

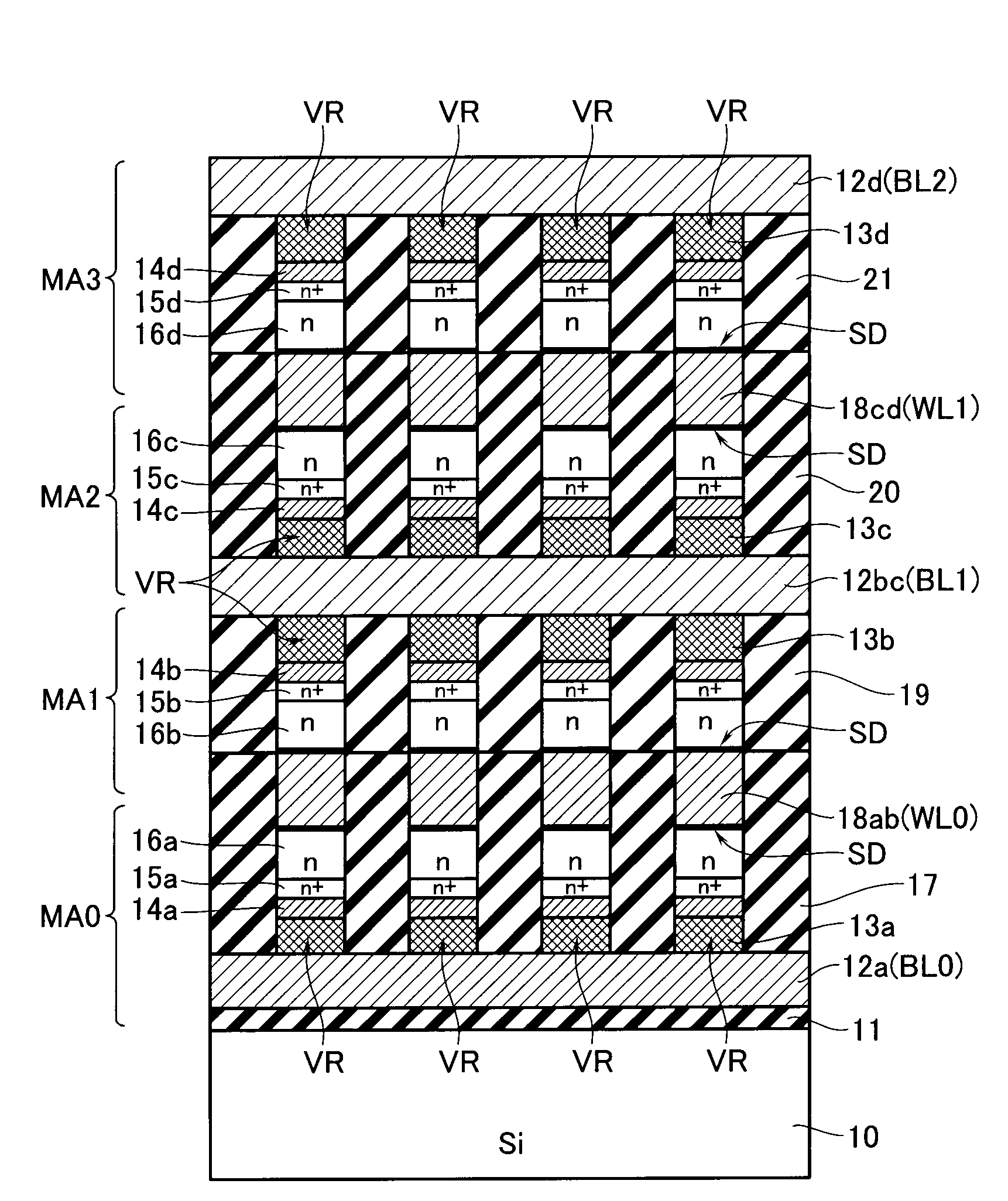

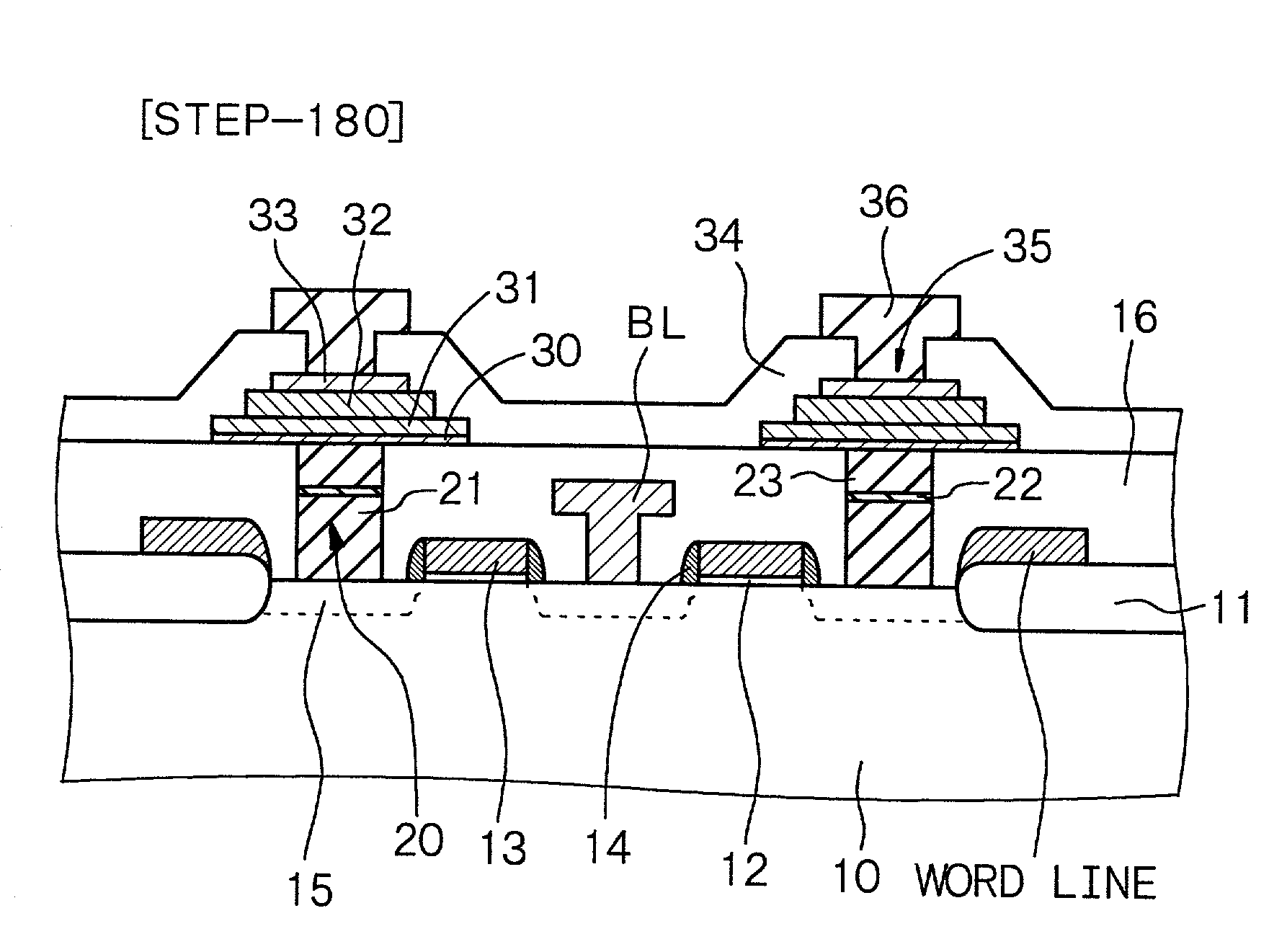

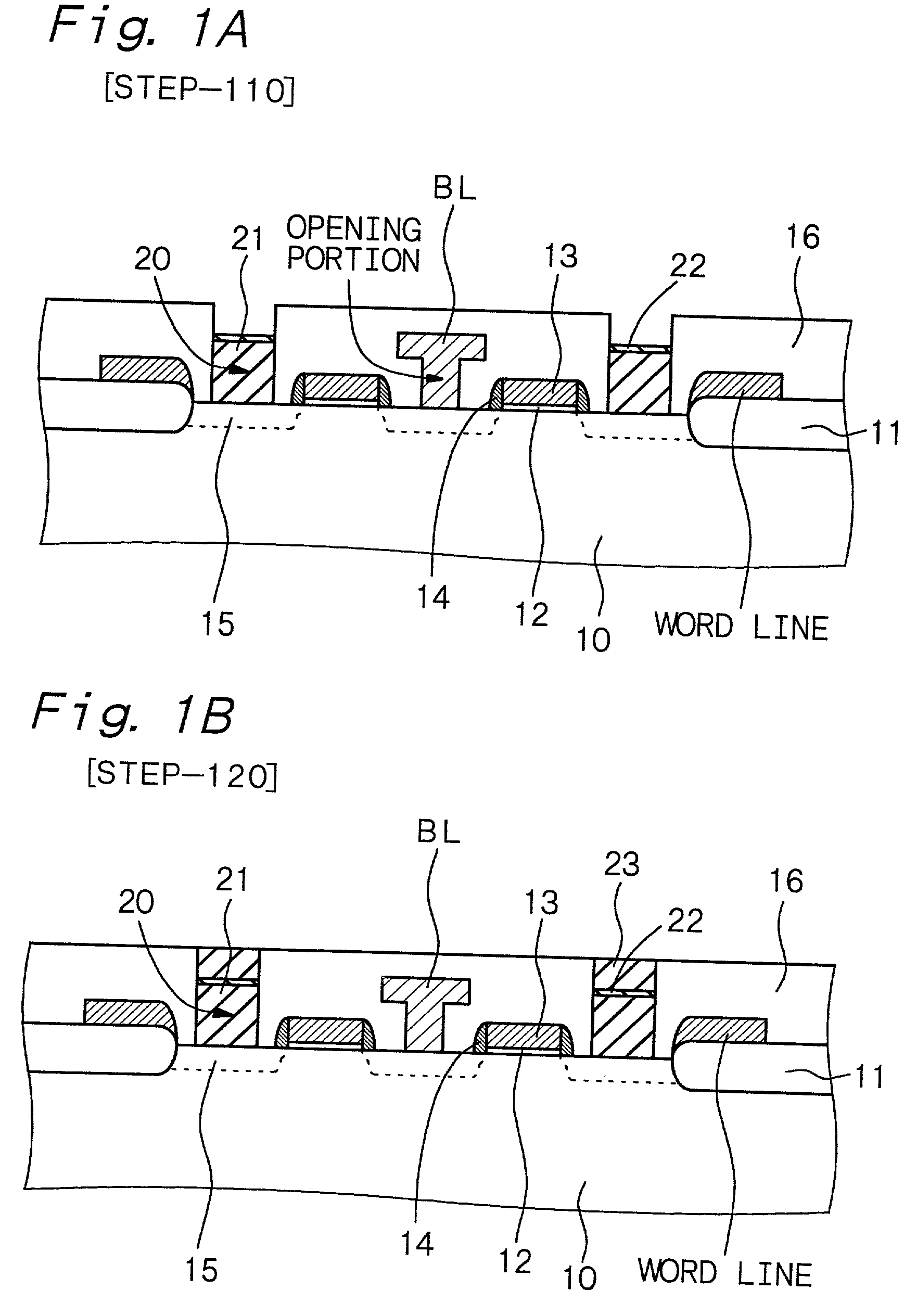

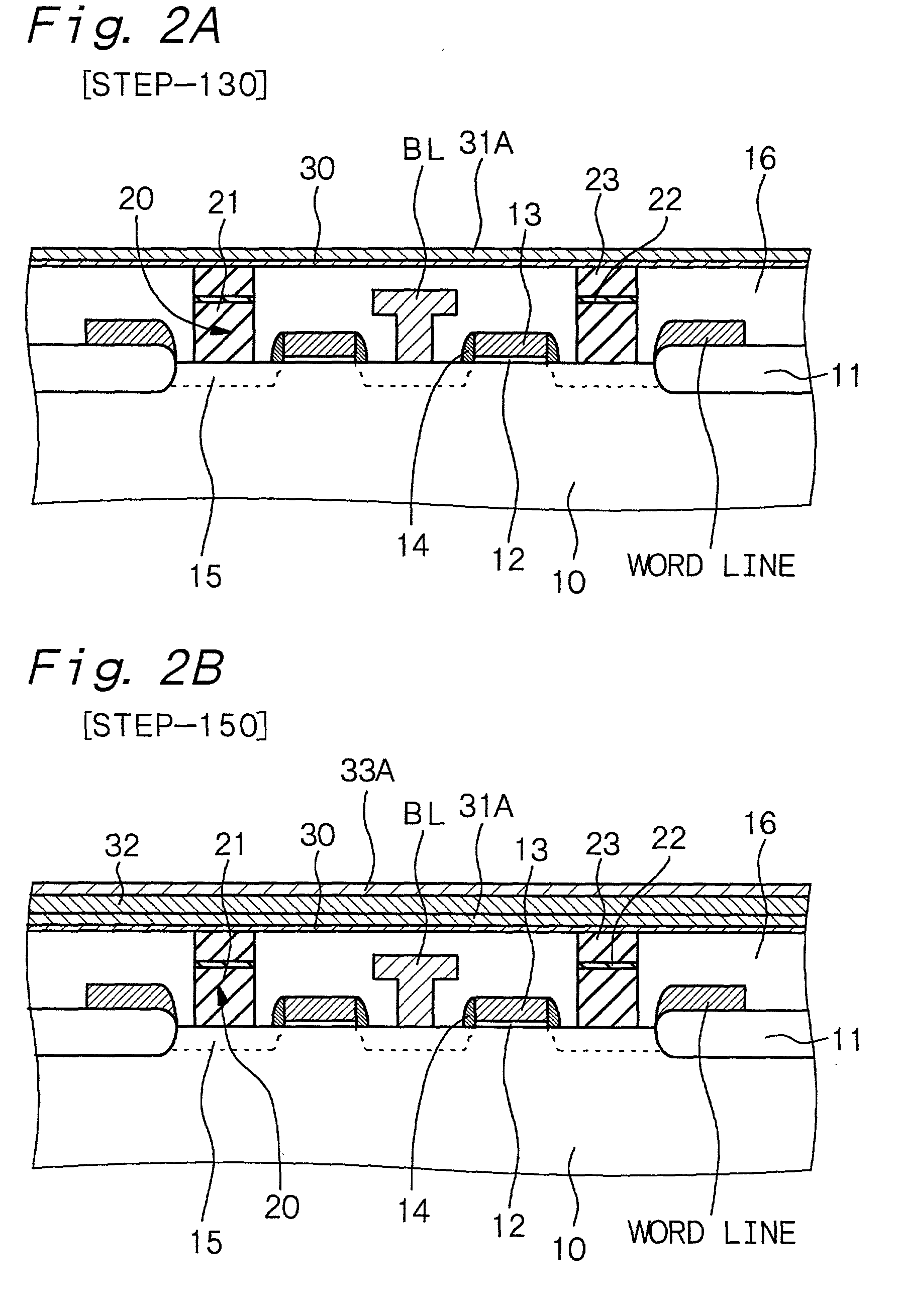

Resistance change memory device

A resistance change memory device including: a semiconductor substrate; cell arrays stacked above the substrate, bit lines word lines; a read / write circuit formed on the semiconductor substrate; first and second vertical wirings disposed to connect the bit lines to the read / write circuit; and third vertical wirings disposed to connect the word lines to the read / write circuit, wherein the memory cell includes a variable resistance element for storing as information a resistance value, which has a recording layer formed of a first composite compound expressed by AxMyOz (where “A” and “M” are cation elements different from each other; “O” oxygen; and 0.5≦x≦1.5, 0.5≦y≦2.5 and 1.5≦z≦4.5) and a second composite compound containing at least one transition element and a cavity site for housing a cation ion.

Owner:TOSHIBA MEMORY CORP

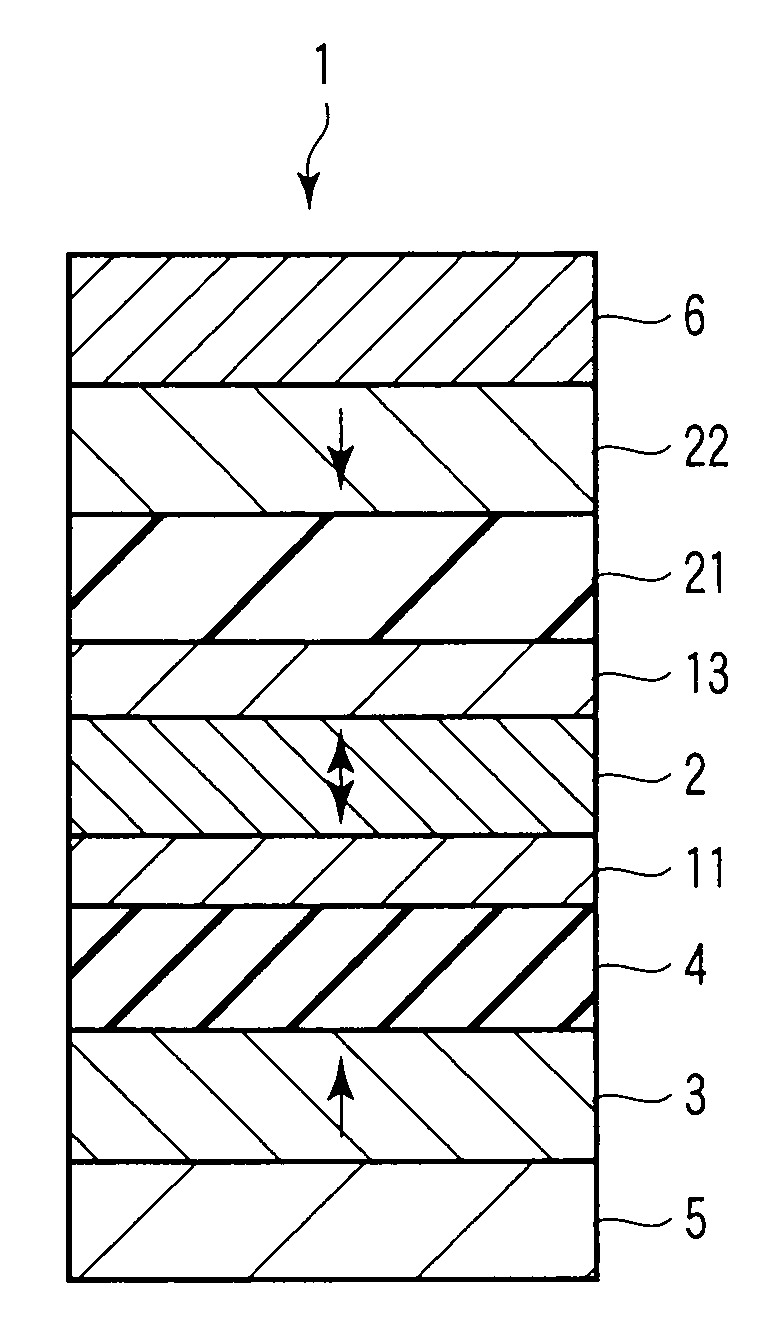

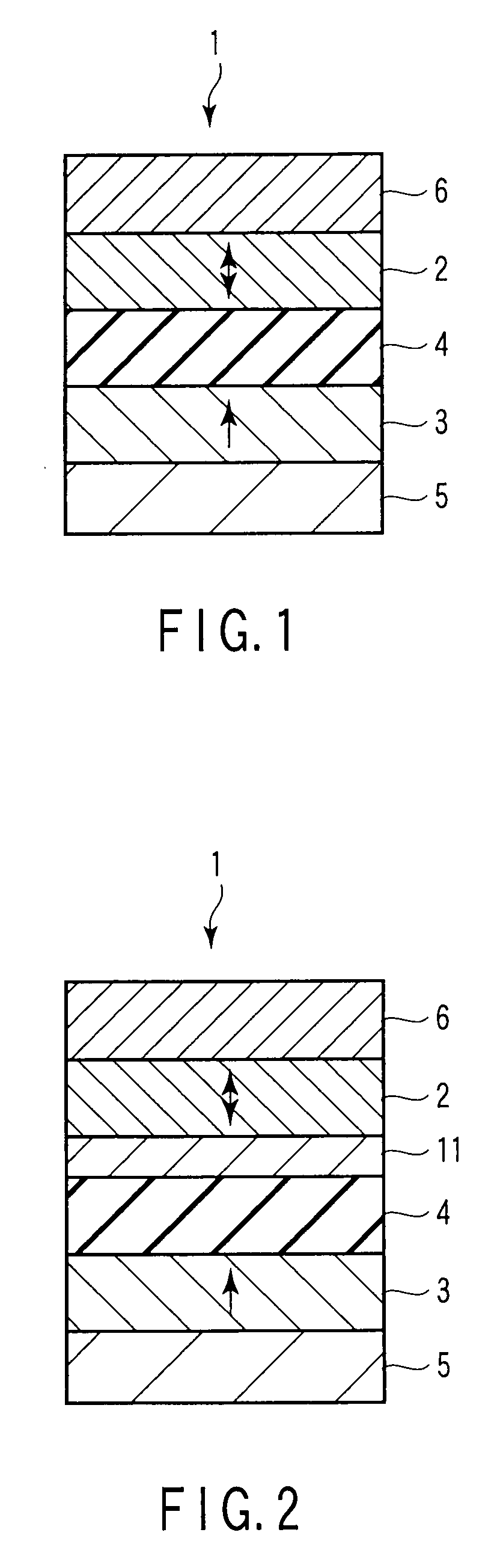

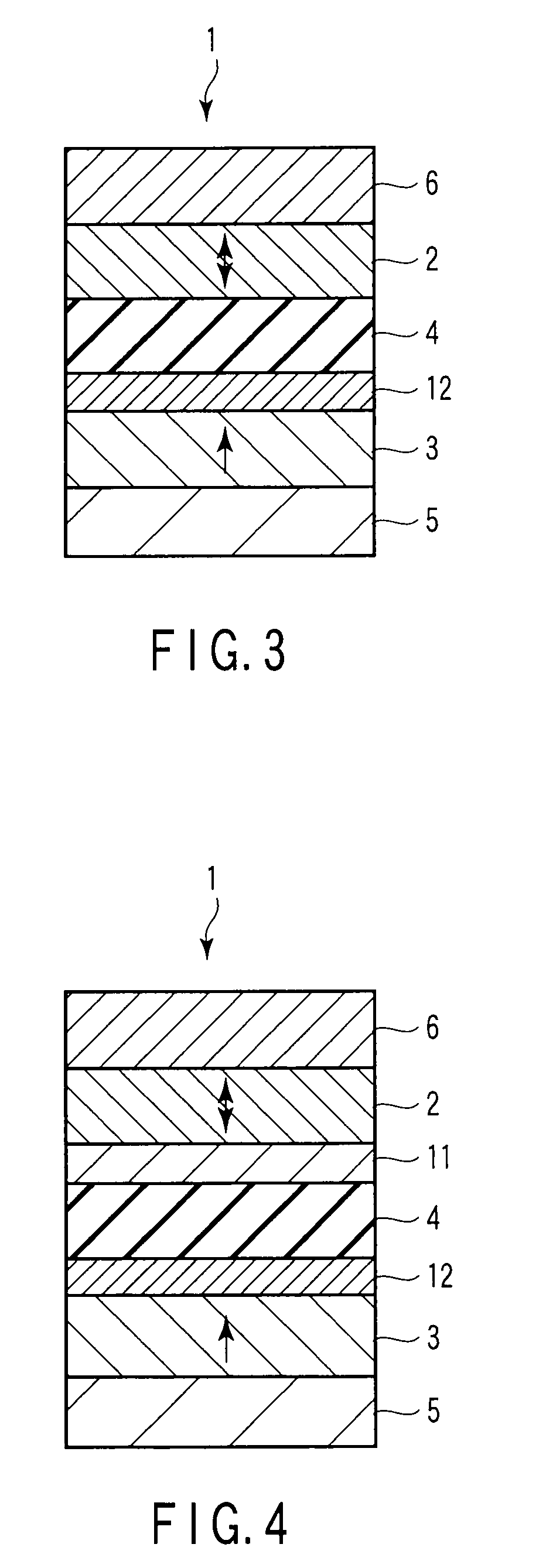

Magnetoresistance effect element and magnetoresistive random access memory using the same

A magnetoresistive effect element includes a first magnetic layer, a second magnetic layer, and a first spacer layer. The first magnetic layer has an invariable magnetization direction. The second magnetic layer has a variable magnetization direction, and contains at least one element selected from Fe, Co, and Ni, at least one element selected from Ru, Rh, Pd, Ag, Re, Os, Ir, Pt, and Au, and at least one element selected from V, Cr, and Mn. The spacer layer is formed between the first magnetic layer and the second magnetic layer, and made of a nonmagnetic material. A bidirectional electric current flowing through the first magnetic layer, the spacer layer, and the second magnetic layer makes the magnetization direction of the second magnetic layer variable.

Owner:KIOXIA CORP

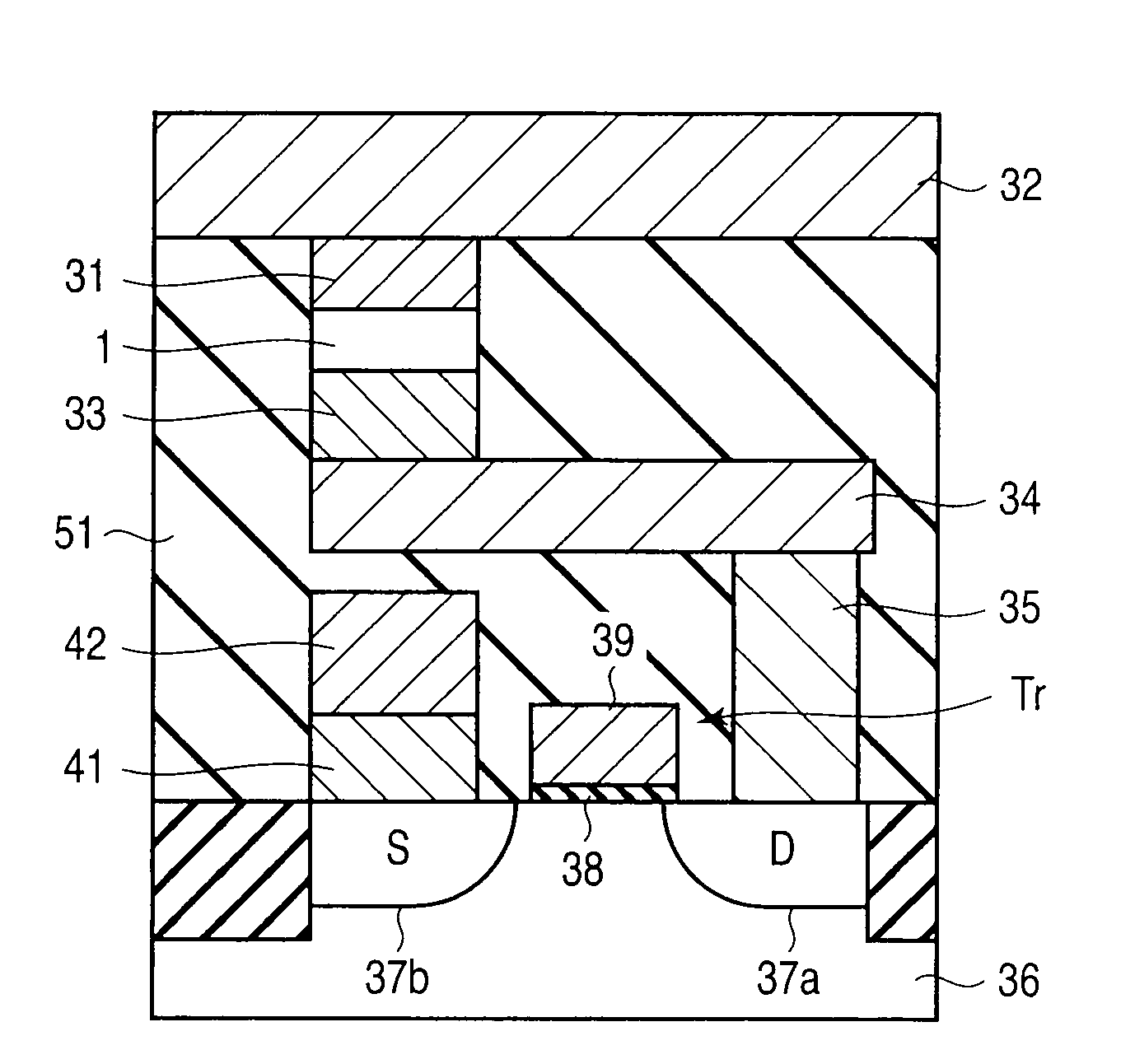

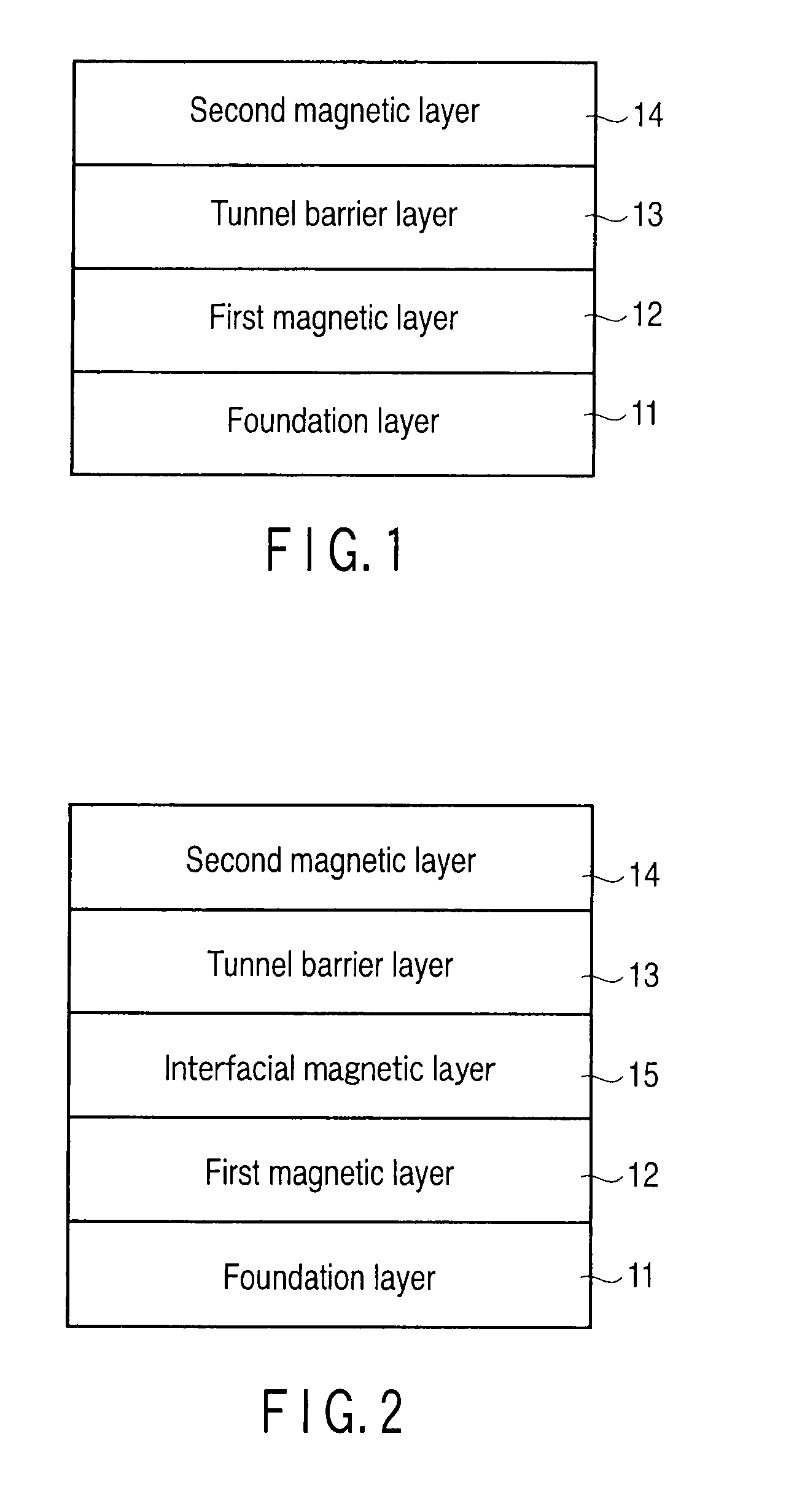

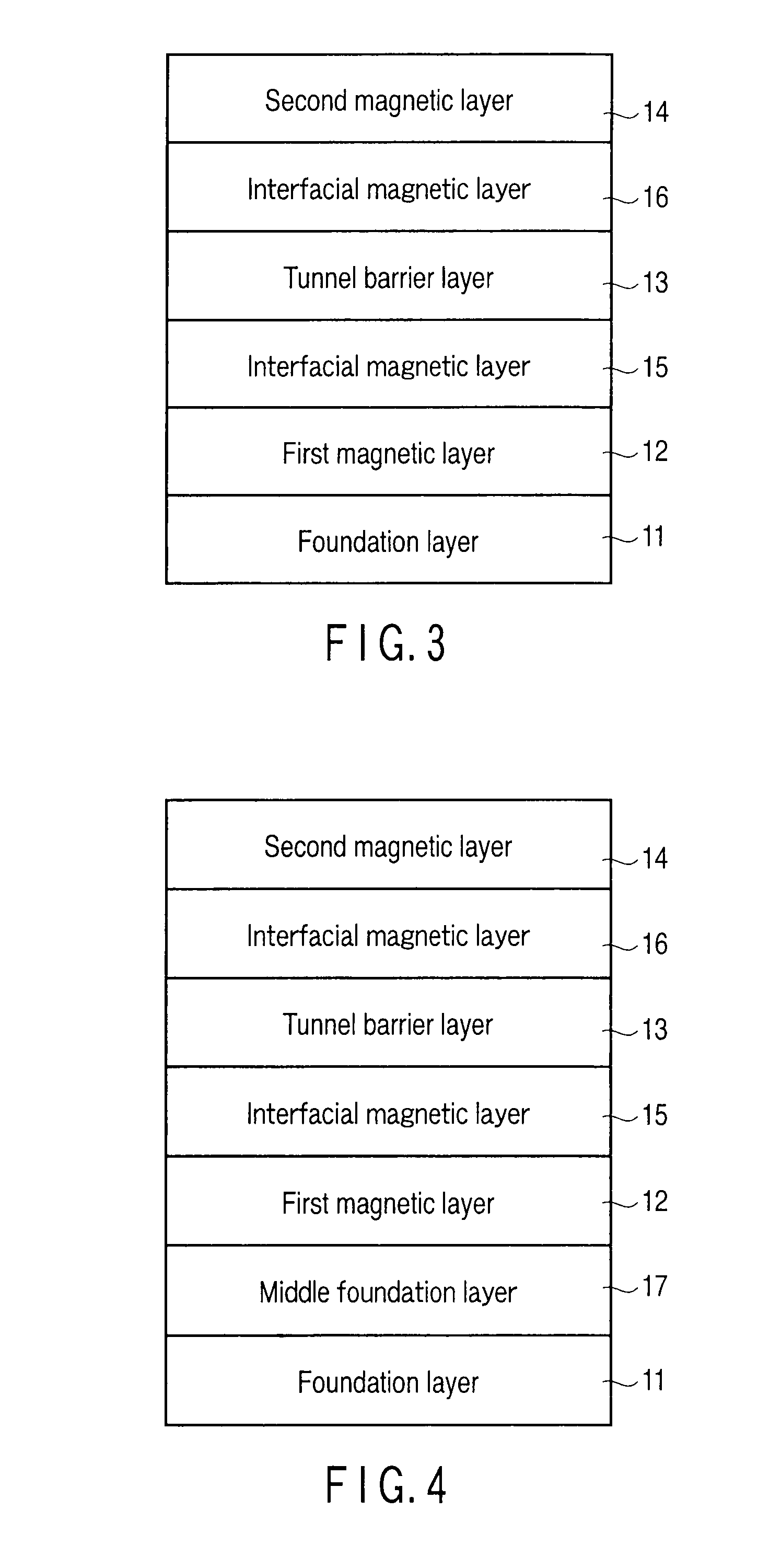

Magnetoresistive element and magnetic random access memory

A magnetoresistive element includes a foundation layer, a first magnetic layer on the foundation layer, a tunnel barrier layer on the first magnetic layer, and a second magnetic layer on the tunnel barrier layer. The first magnetic layer is made of a ferromagnetic metal containing one or more elements selected from a first group consisting of Co, Fe, and Ni, and one or more elements selected from a second group consisting of Cu, Ag, Au, Pd, Pt, Ru, Rh, Ir, and Os. The foundation layer is made of a metal containing one or more elements selected from a third group consisting of Al, Ni, Co, Fe, Mn, Cr, and V.

Owner:KK TOSHIBA

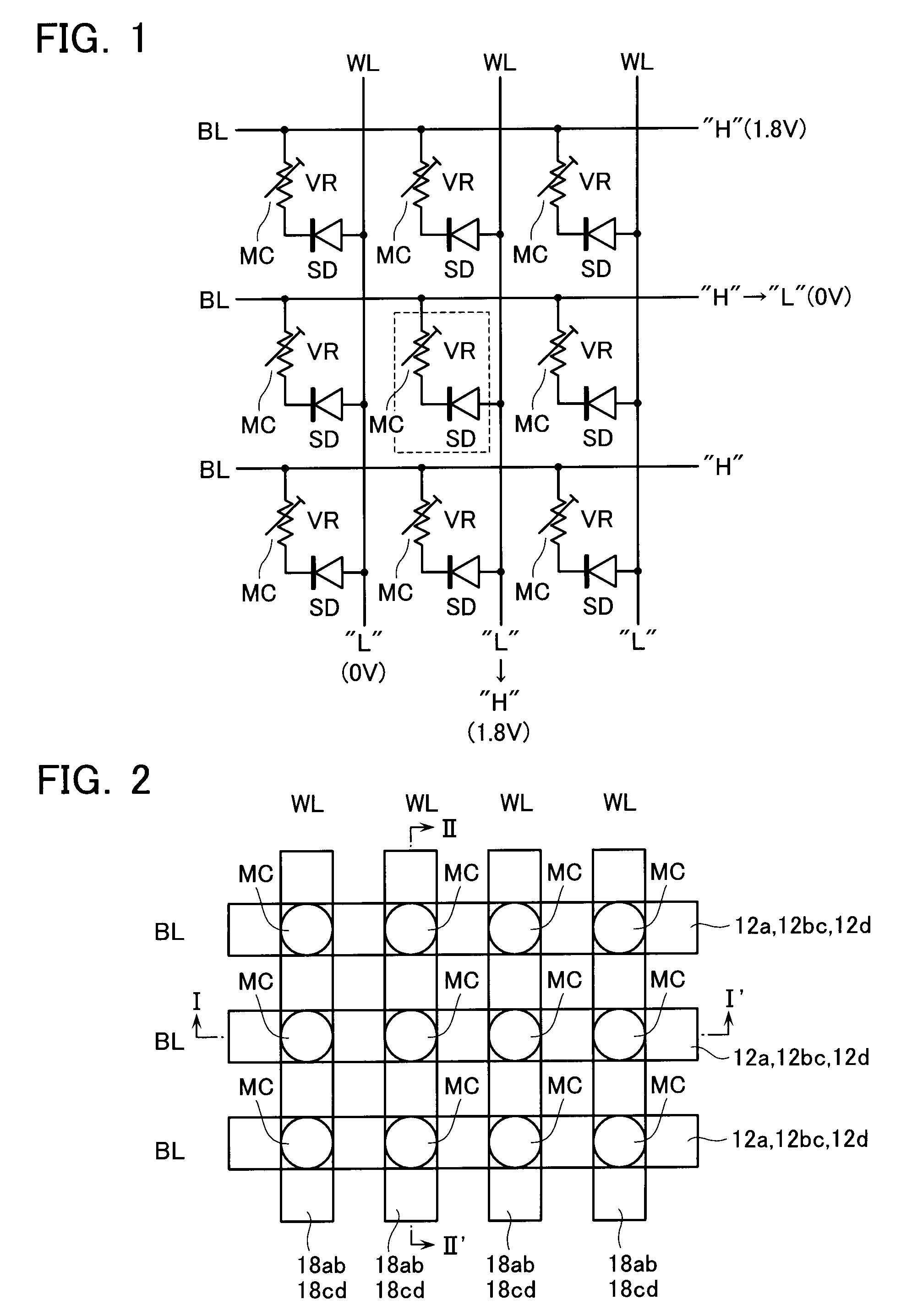

Resistance change memory device

A resistance change memory device including: a semiconductor substrate; cell arrays stacked above the substrate, bit lines and word lines; a read / write circuit formed on the semiconductor substrate; first and second vertical wirings connecting bit lines to the read / write circuit; and third vertical wirings connecting word lines to the read / write circuit, wherein the memory cell includes a variable resistance element. The variable resistance element has: a recording layer formed of a composite compound containing at least one transition element and a cavity site for housing a cation ion; and electrodes formed on the opposite sides of the recording layer, one of the electrodes serving as a cation source in a write or erase mode for supplying a cation to the recording layer to be housed in the cavity site therein.

Owner:TOSHIBA MEMORY CORP

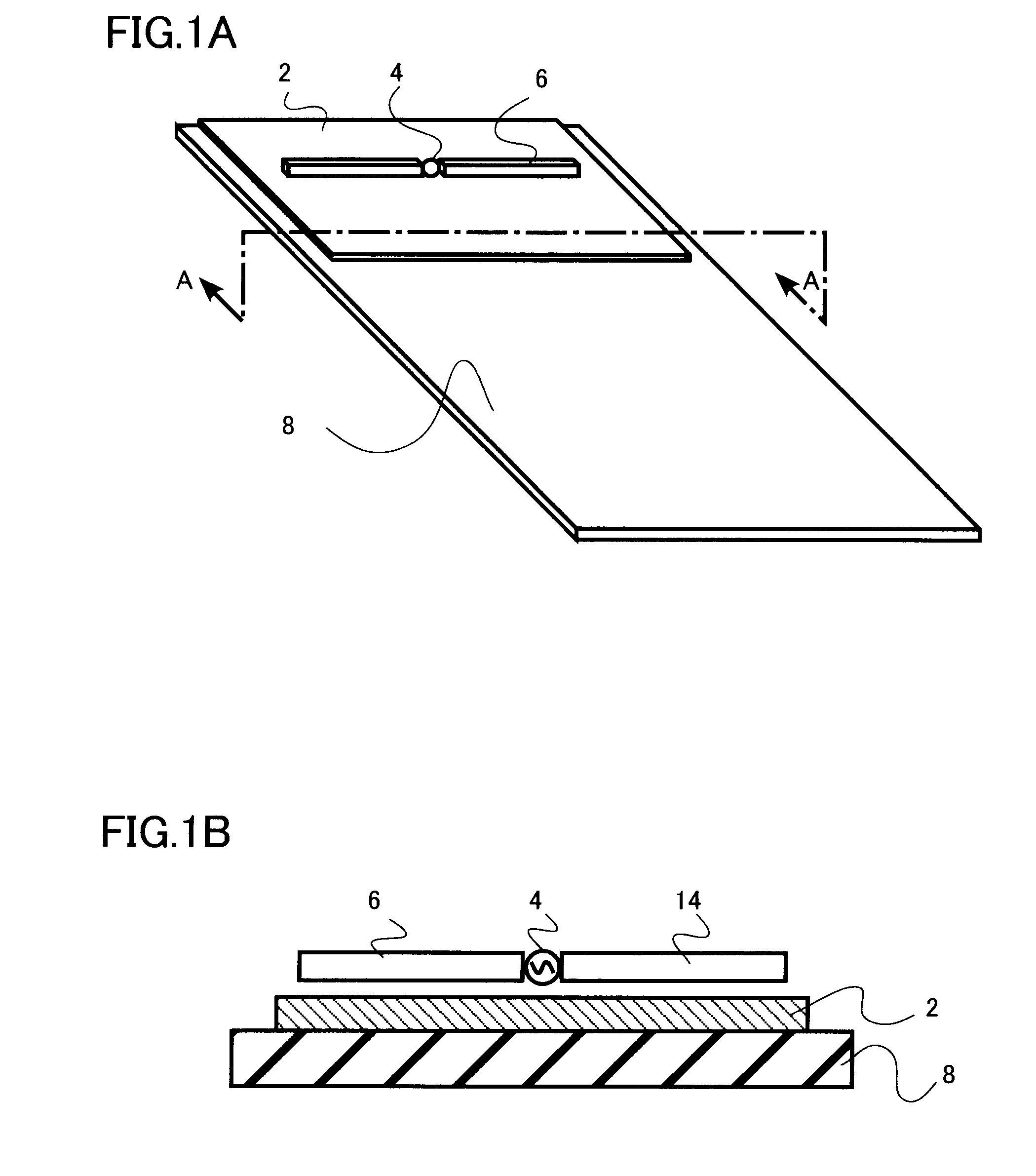

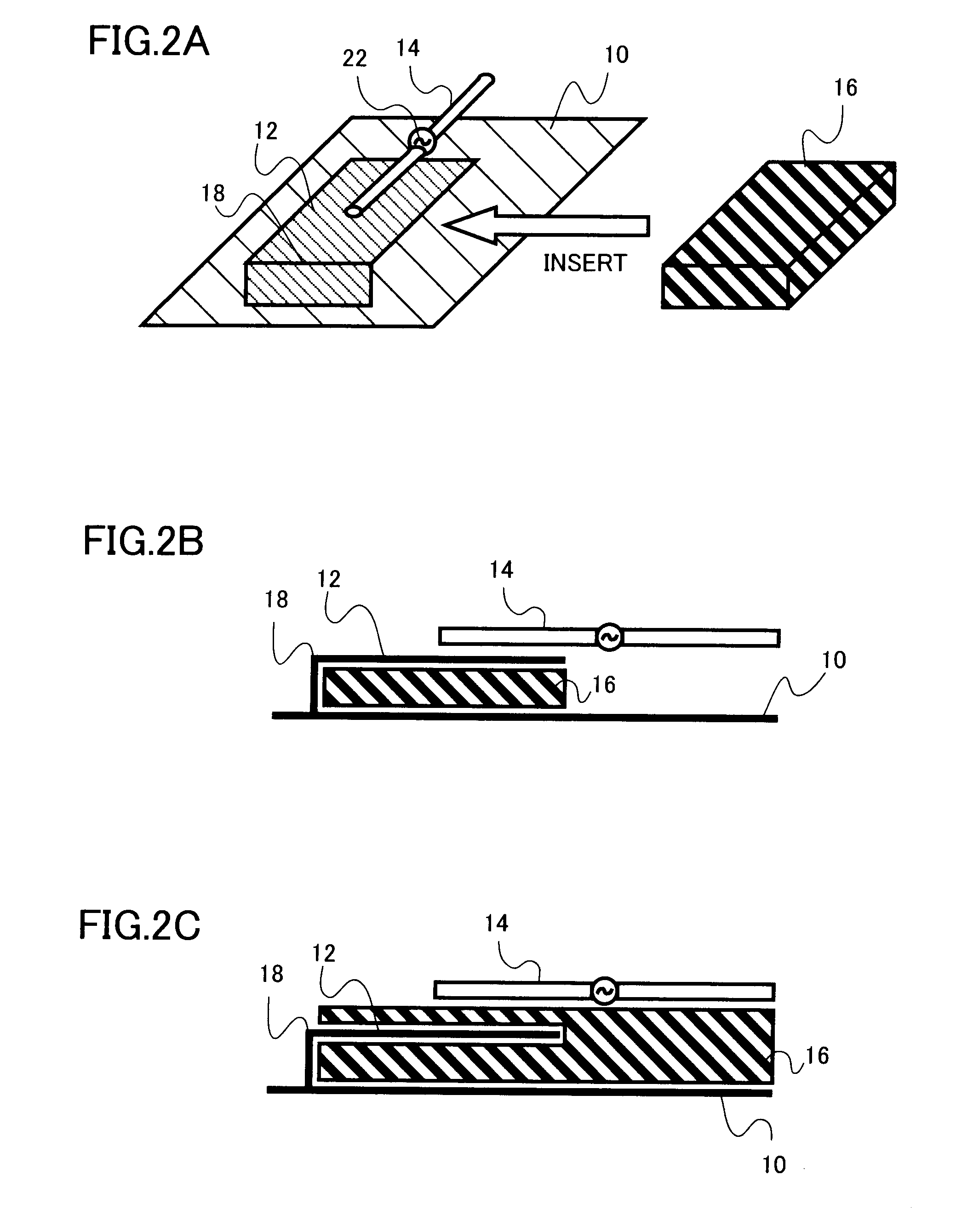

Optical recording medium

InactiveUS20040157158A1High sensitivityReduce reproductionMechanical record carriersPhotomechanical apparatusRecording layerOptical recording

An optical recording medium includes a substrate and a recording layer in which data can be recorded by projecting a laser beam thereonto, the recording layer including a first recording film containing an element selected from the group consisting of Si, Ge, Sn, Mg, In, Zn, Bi and Al as a primary component and a second recording film containing Cu as a primary component and 10 to 30 atomic % of Al as an additive. The thus constituted optical recording medium has an excellent initial recording characteristic and can store recorded data in a good condition over the long term.

Owner:TDK CORPARATION

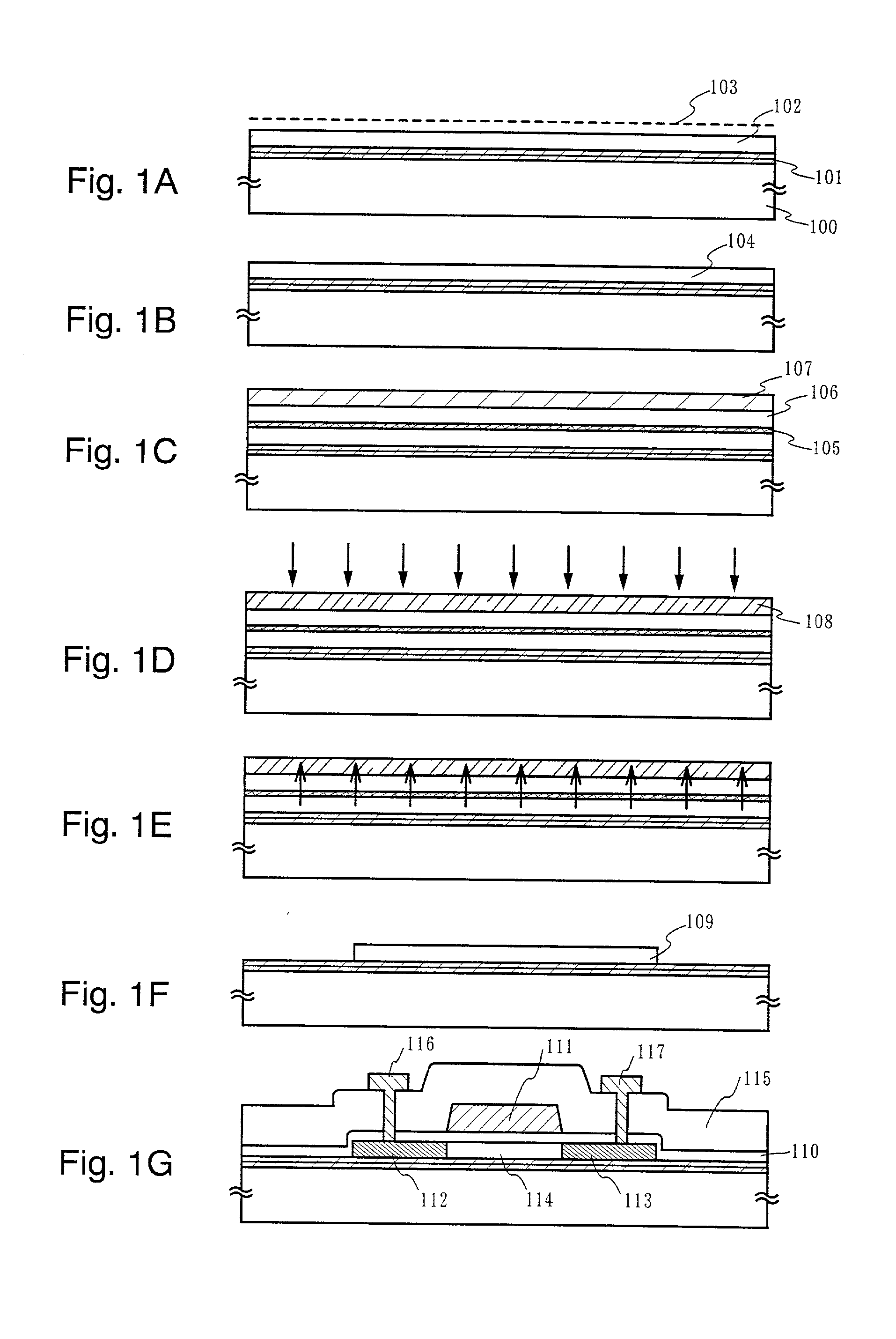

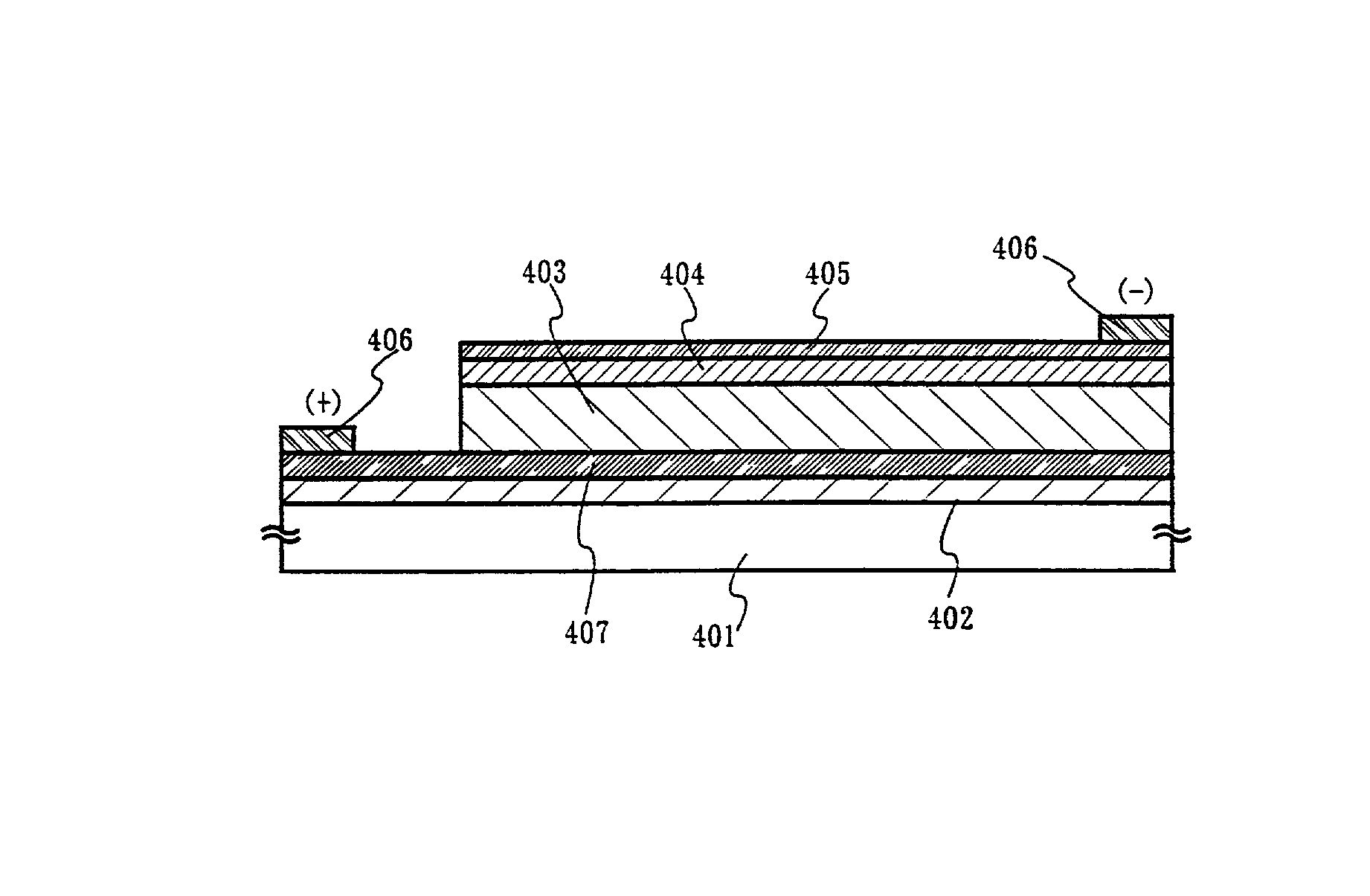

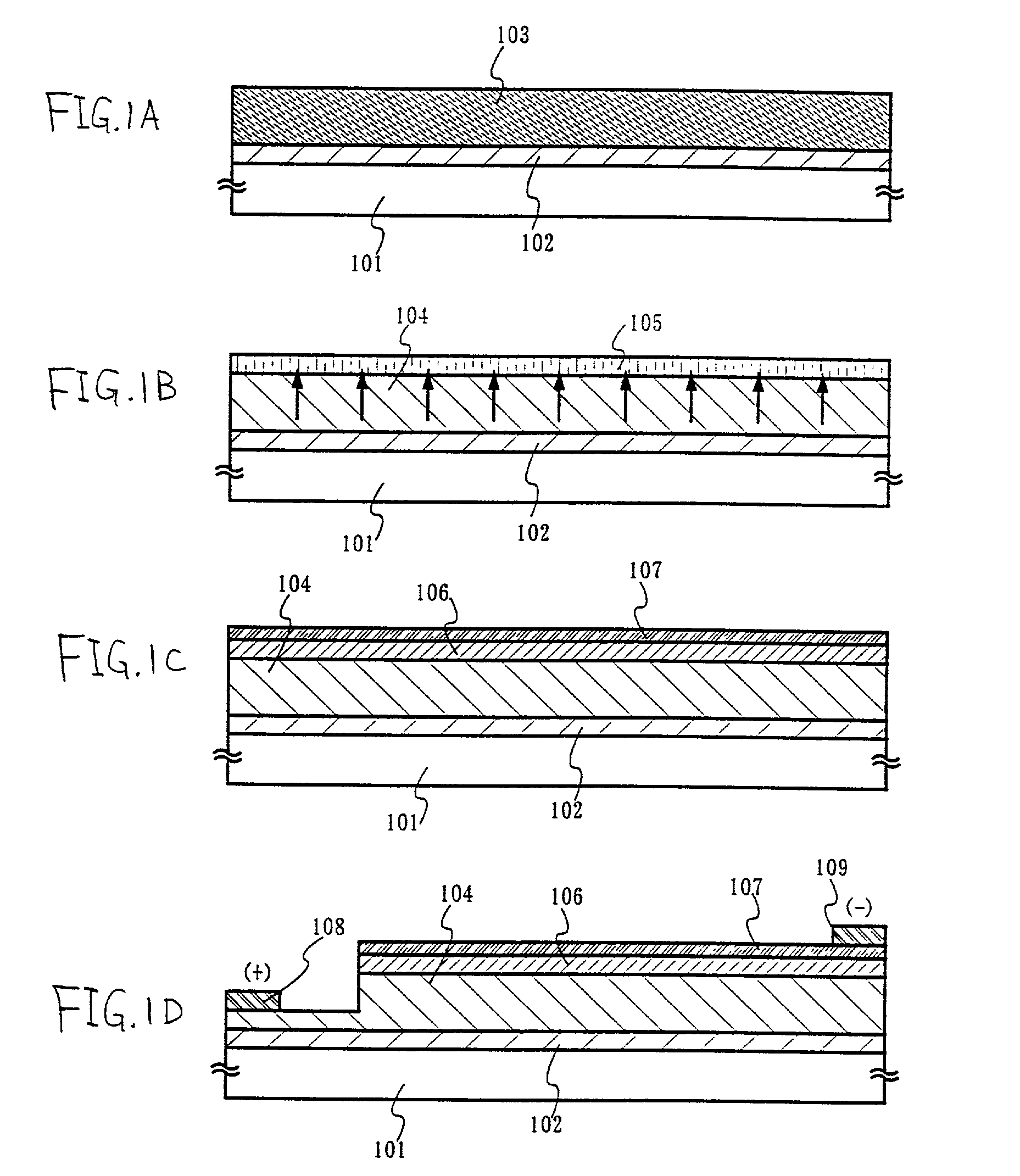

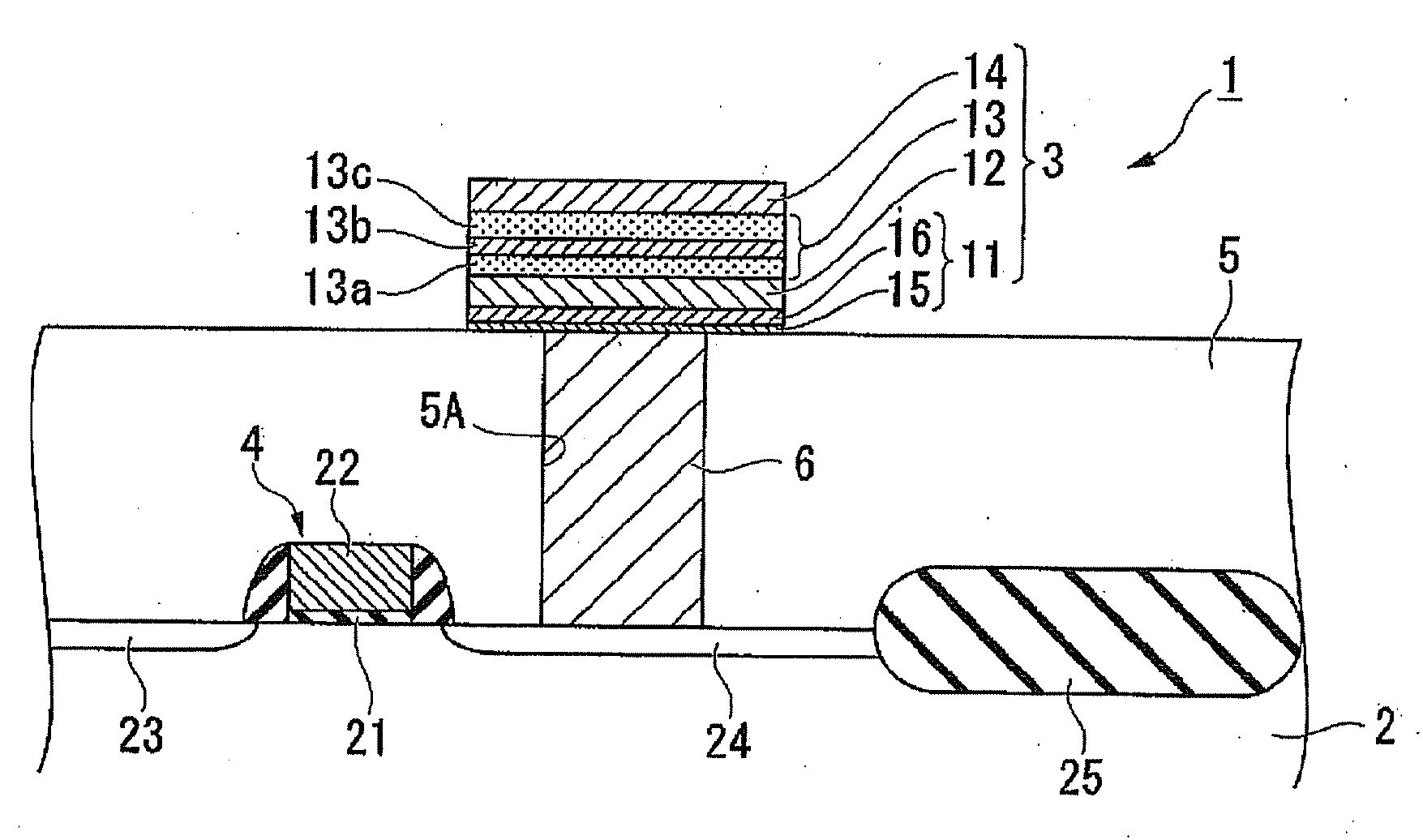

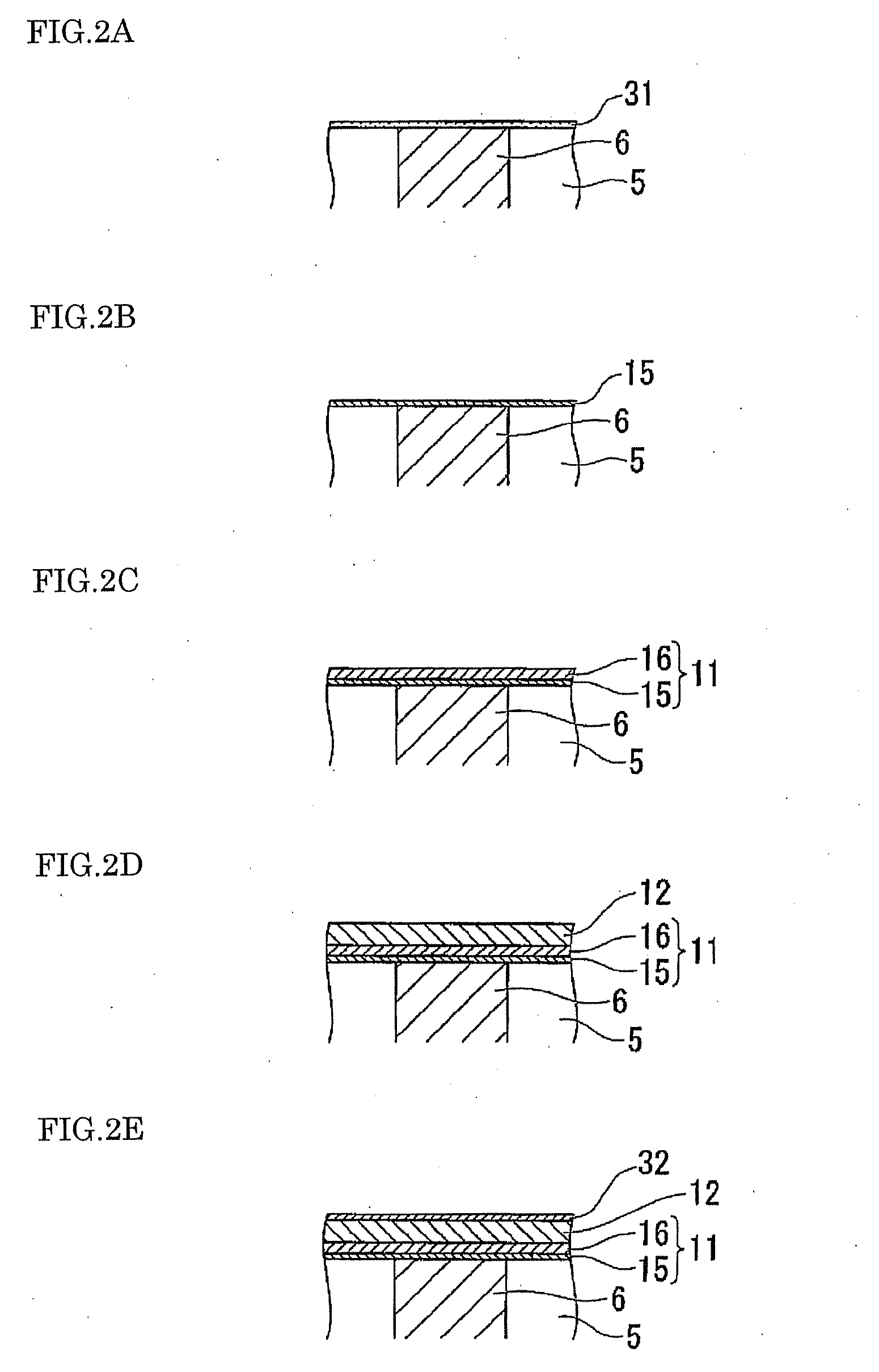

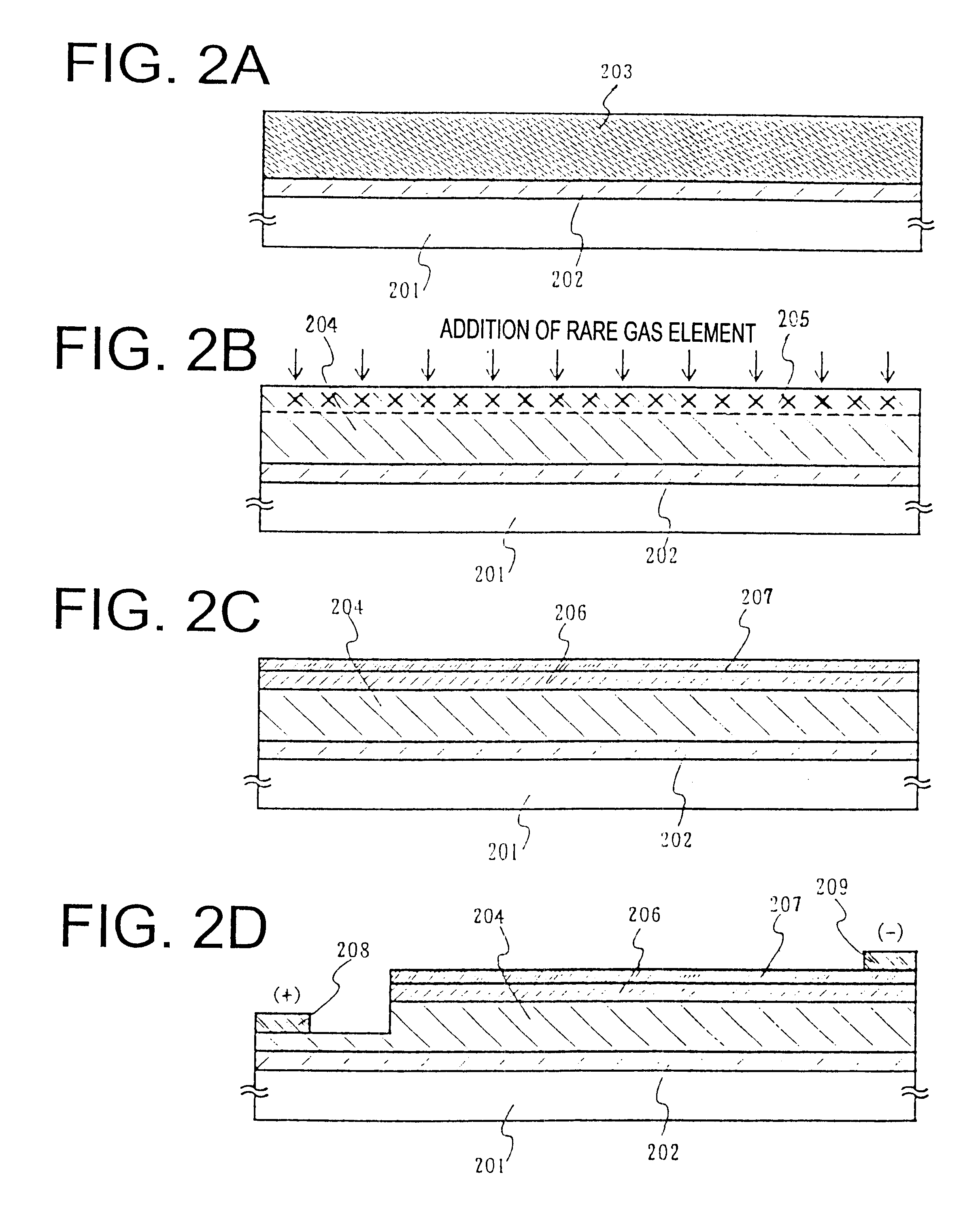

Method of manufacturing a semiconductor device

InactiveUS20020151120A1Inhibited DiffusionImprove efficiencyTransistorSolid-state devicesElectrical conductorCrystal structure

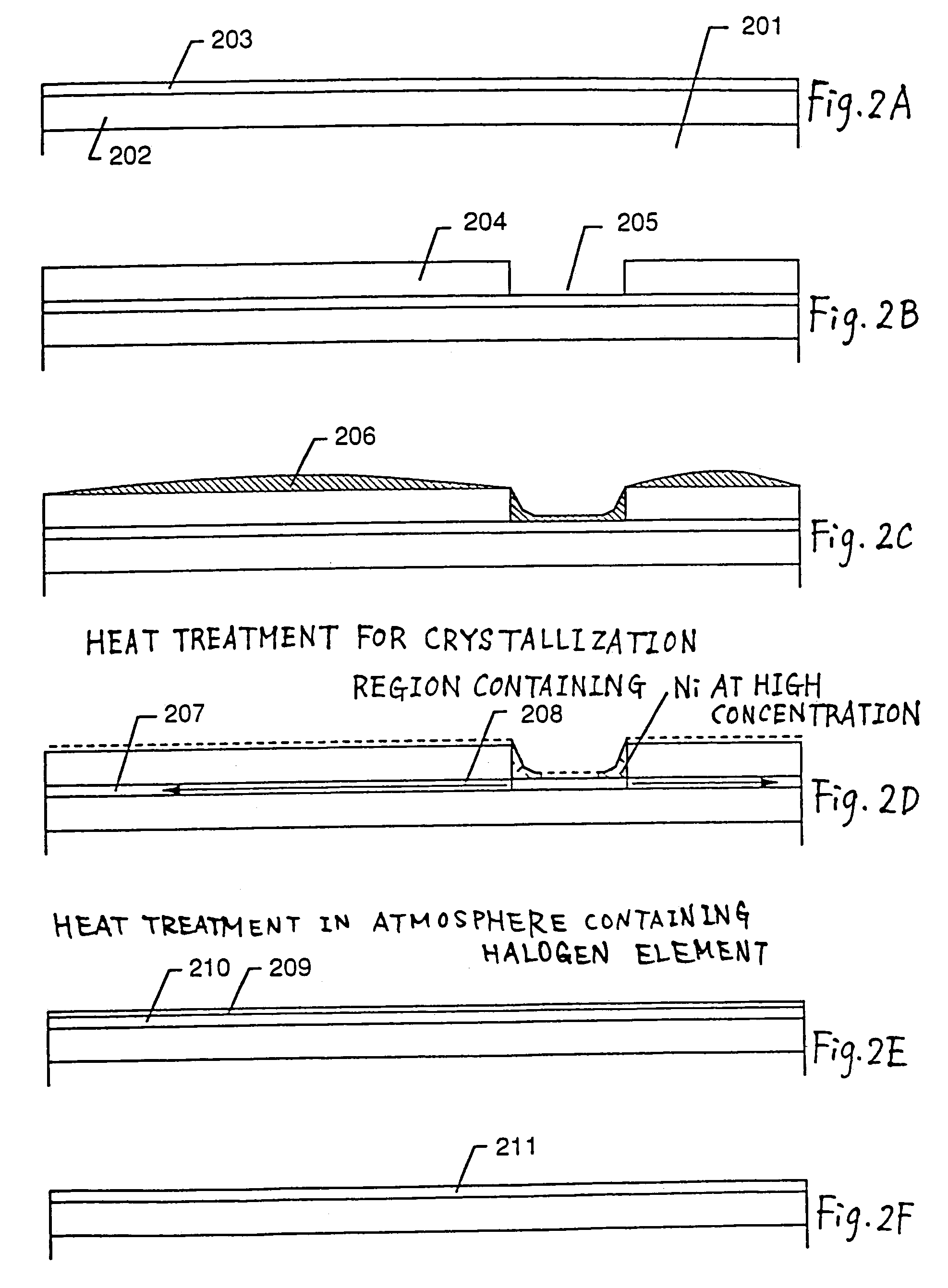

An object is to reduce the number of high temperature (equal to or greater than 600° C.) heat treatment process steps and achieve lower temperature (equal to or less than 600° C.) processes, and to simplify the process steps and increase throughput in a method of manufacturing a semiconductor device. With the present invention, a barrier layer, a second semiconductor film, and a third semiconductor film containing an inert gas element are formed on a first semiconductor film having a crystalline structure. Gettering is performed and a metallic element contained in the first semiconductor film passes through the barrier layer and the second semiconductor film by a heat treatment process, and moves to the third semiconductor film. The second semiconductor film and the third semiconductor film are then removed, with the barrier layer used as an etching stopper.

Owner:SEMICON ENERGY LAB CO LTD

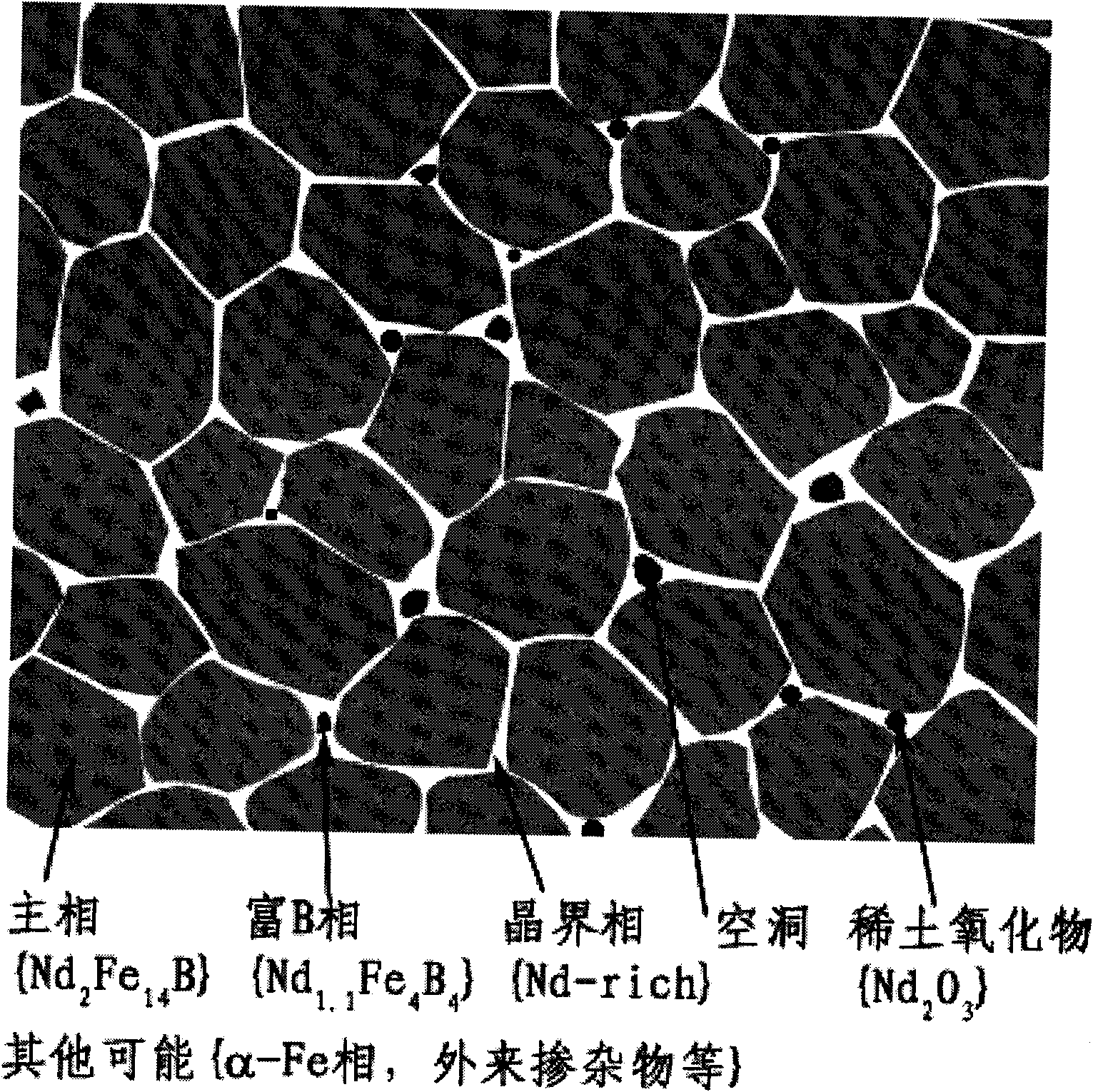

Rare earth permanent magnet produced by applying abundant rare earth cerium (Ce) and preparation method thereof

ActiveCN103123839AReduce production and sales balancePromote the balance of production and salesInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementCost Controls

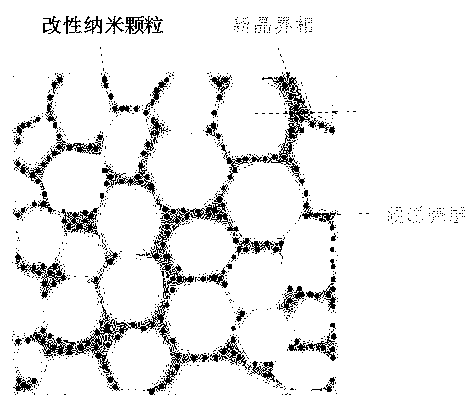

The invention discloses a rare earth permanent magnet produced by applying abundant rare earth cerium (Ce) and a preparation method of the rare earth permanent magnet produced by applying abundant rare earth Ce. Based on a double-alloy process, main phase alloy formula uses Ce to partly replace neodymium (Nd), an optimized composition design enables a main alloy to form Ce2Fe14B phase and Nd2Fe14B phase to a greatest extent, and therefore high intrinsic magnetic property is guaranteed. A brand new crystal boundary phase is prepared by a crystal boundary reconstitution technology, and high integral magnetic property and corrosion resistant property are guaranteed, and meanwhile a nanometer powder crystal modification method is supplemented, a micro organization structure of a magnet is optimized, crystal boundary distribution is improved, and the magnetic property and the corrosion resistant property are further improved. By applying abundant rare earth cerium, cost is effectively reduced, and meanwhile balance between production and marketing is promoted. Praseodymium (Pr), Nd, and the like are chosen to form a hard magnetic shell layer of a main phase boundary in a composition design of crystal phase auxiliary alloy at the same time, compared high price heavy rare earth elements of dysprosium (Dy) and terbium (Tb) with the elements, and cost control can be further achieved.

Owner:ZHEJIANG UNIV +1

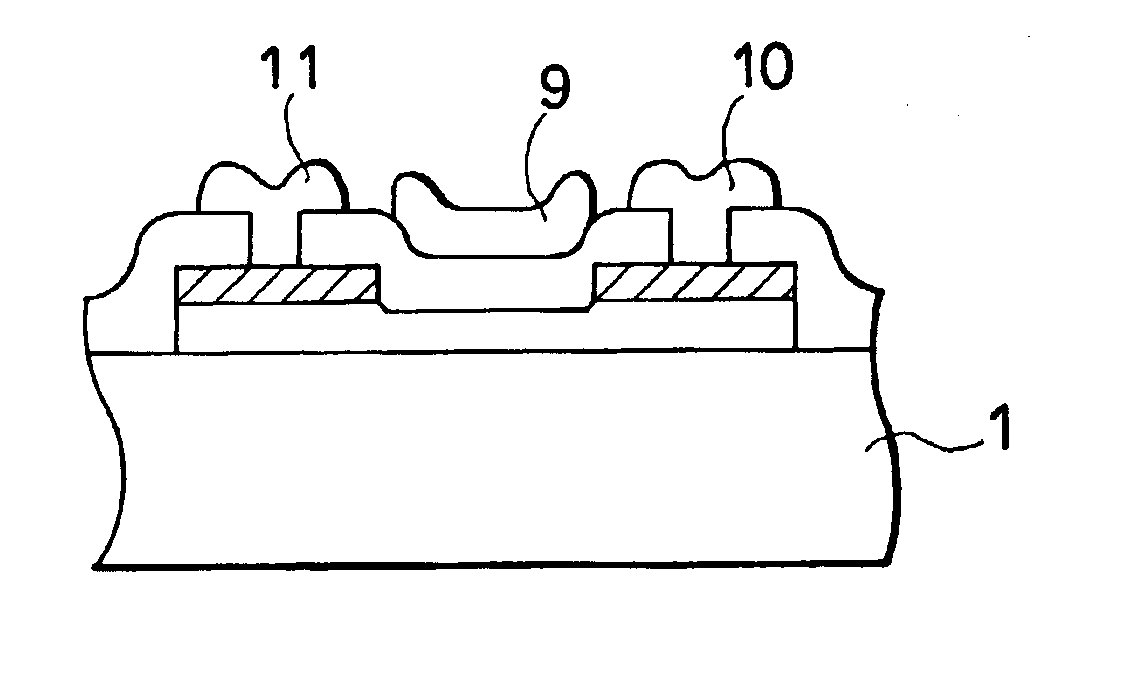

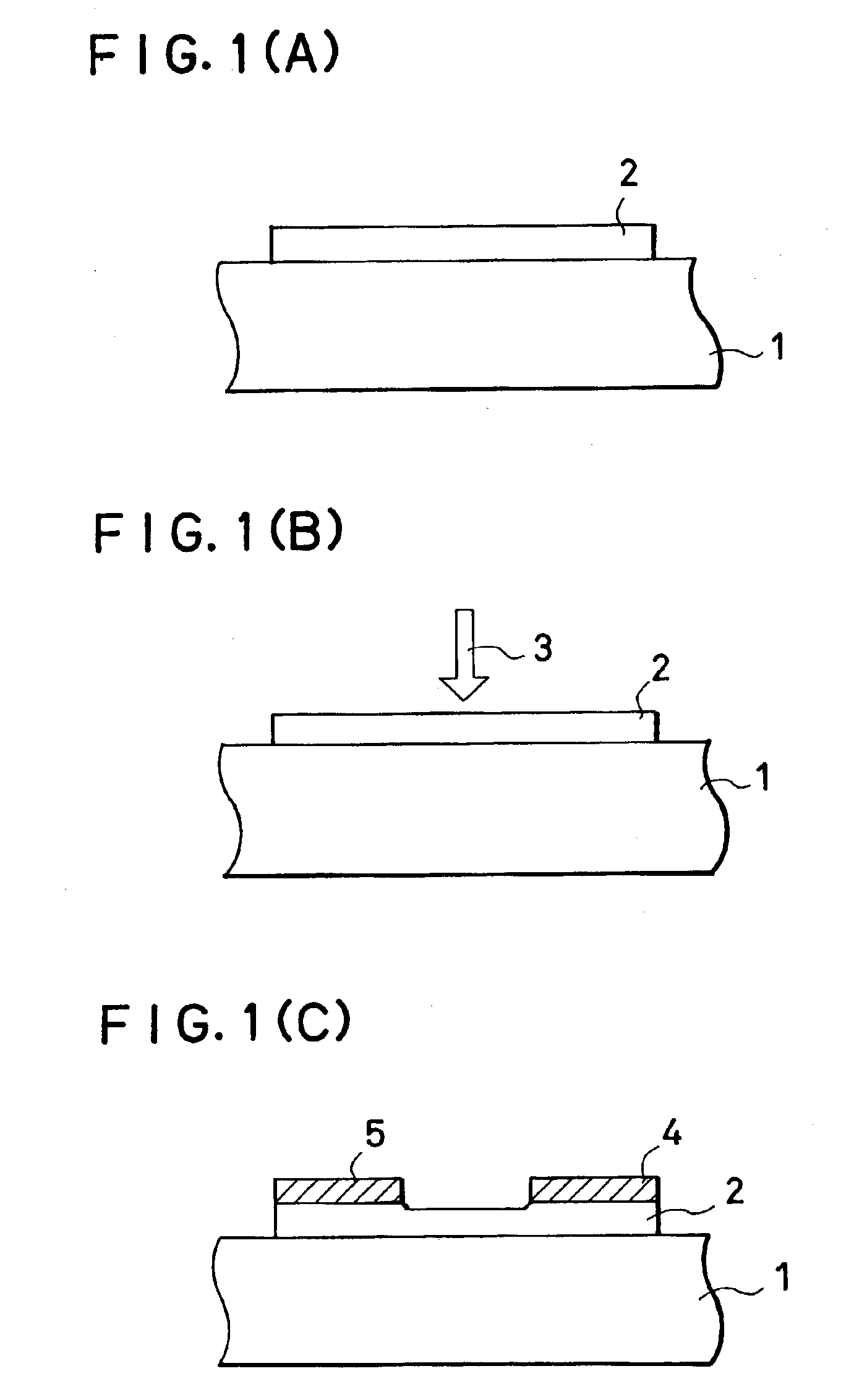

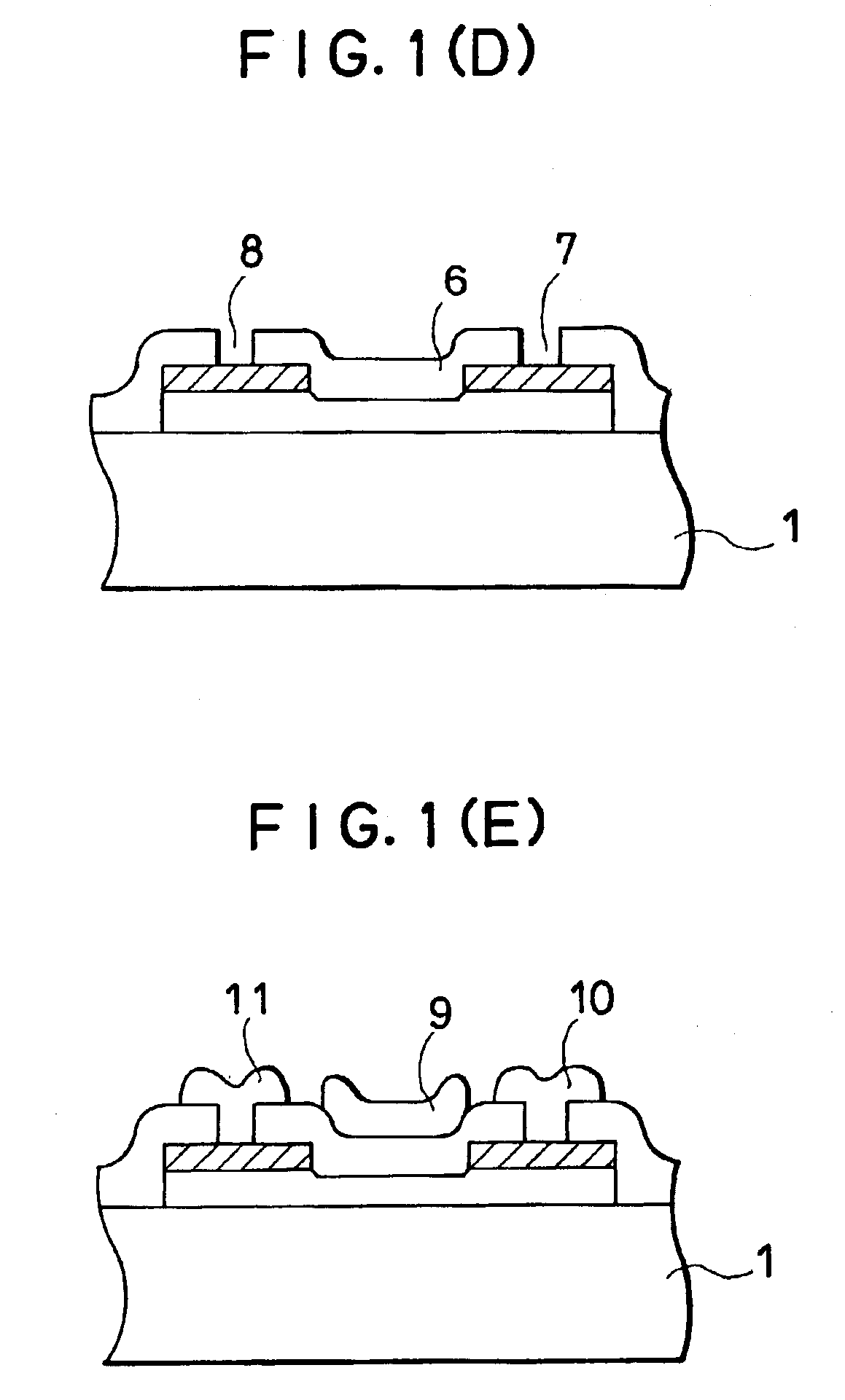

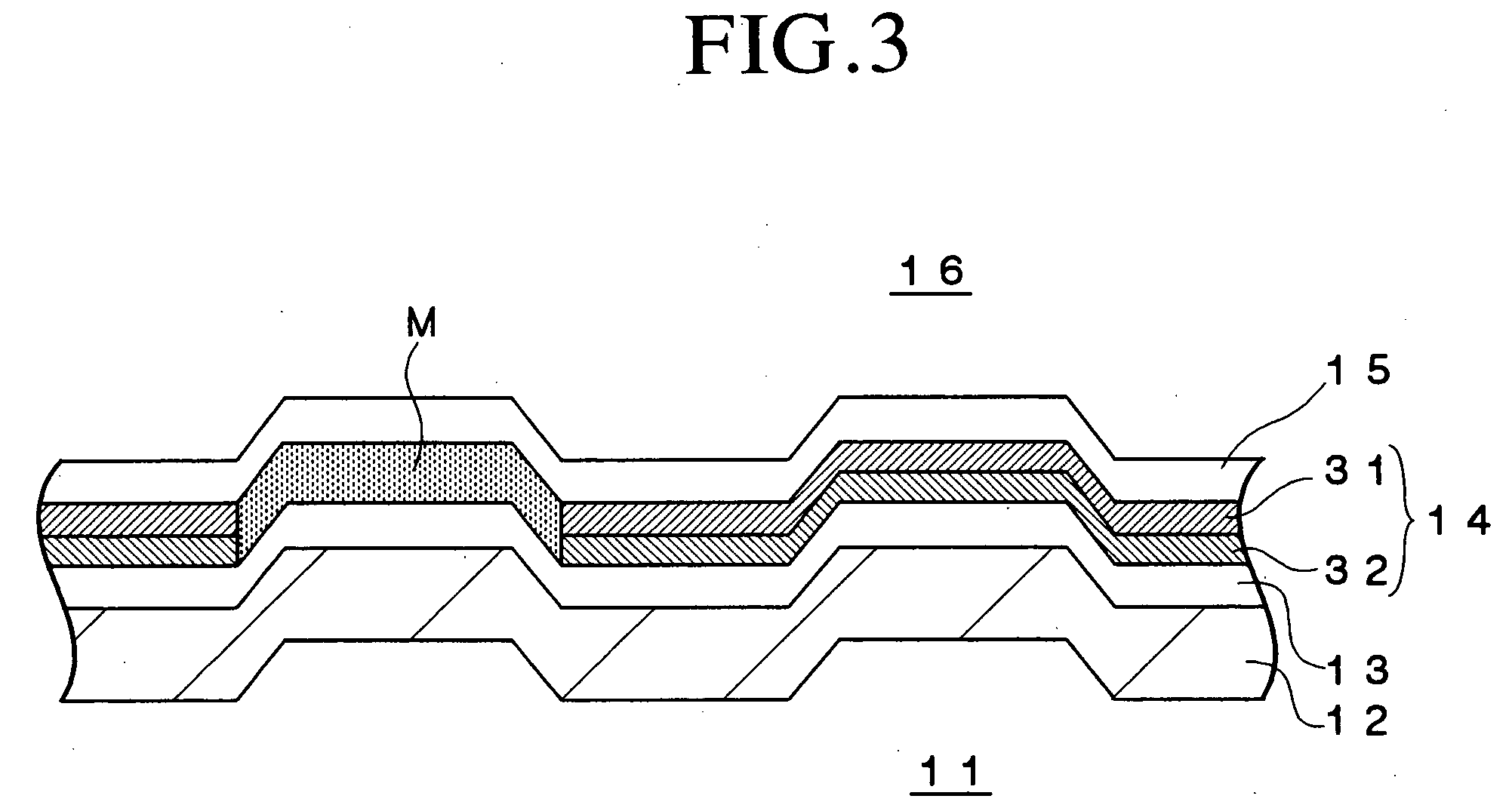

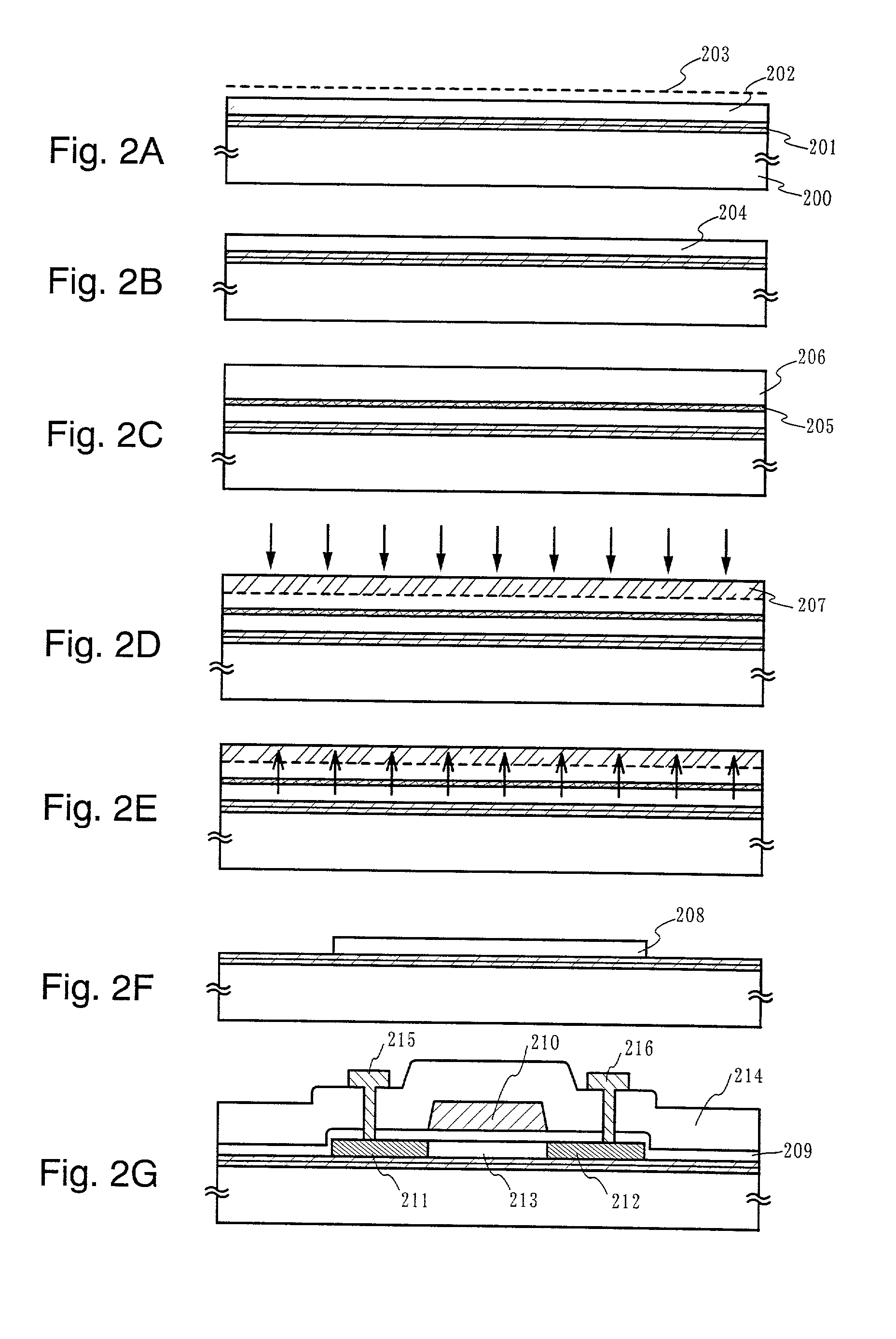

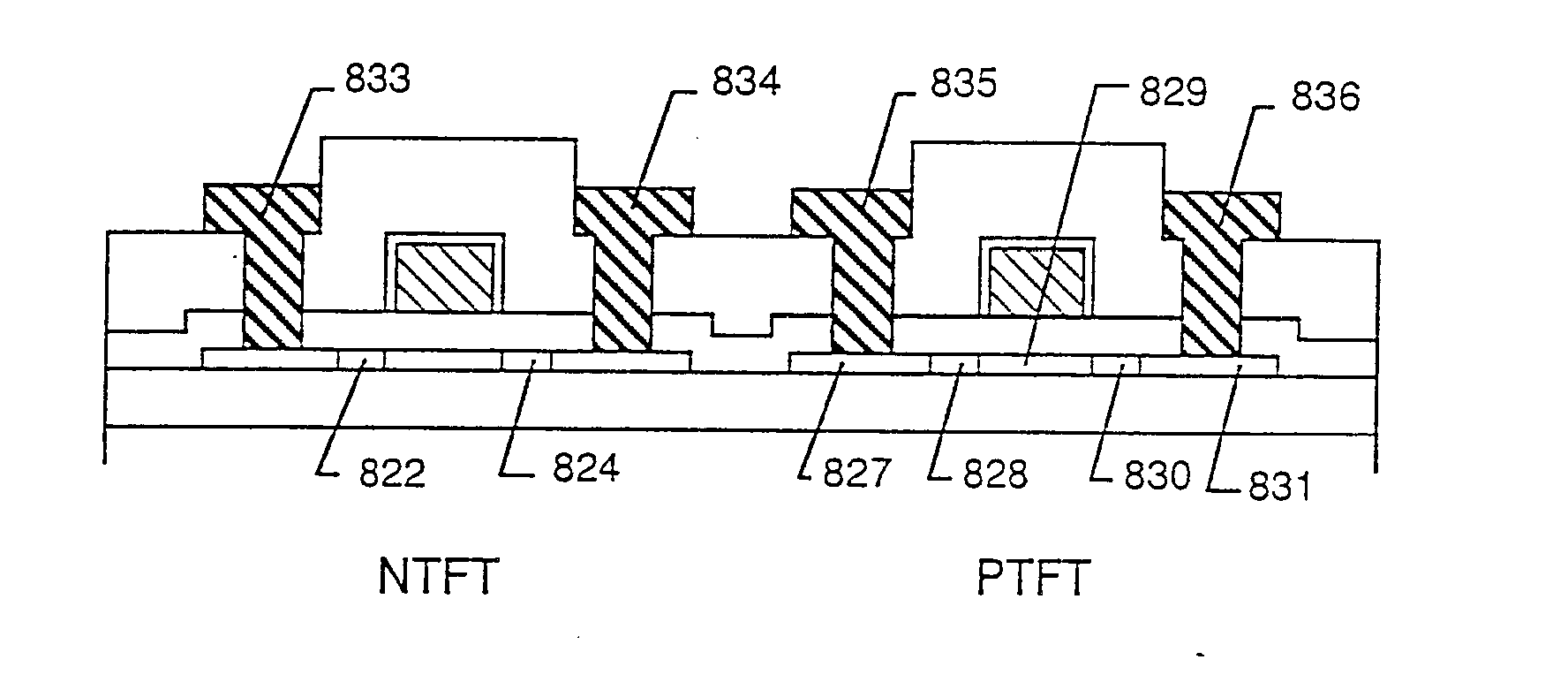

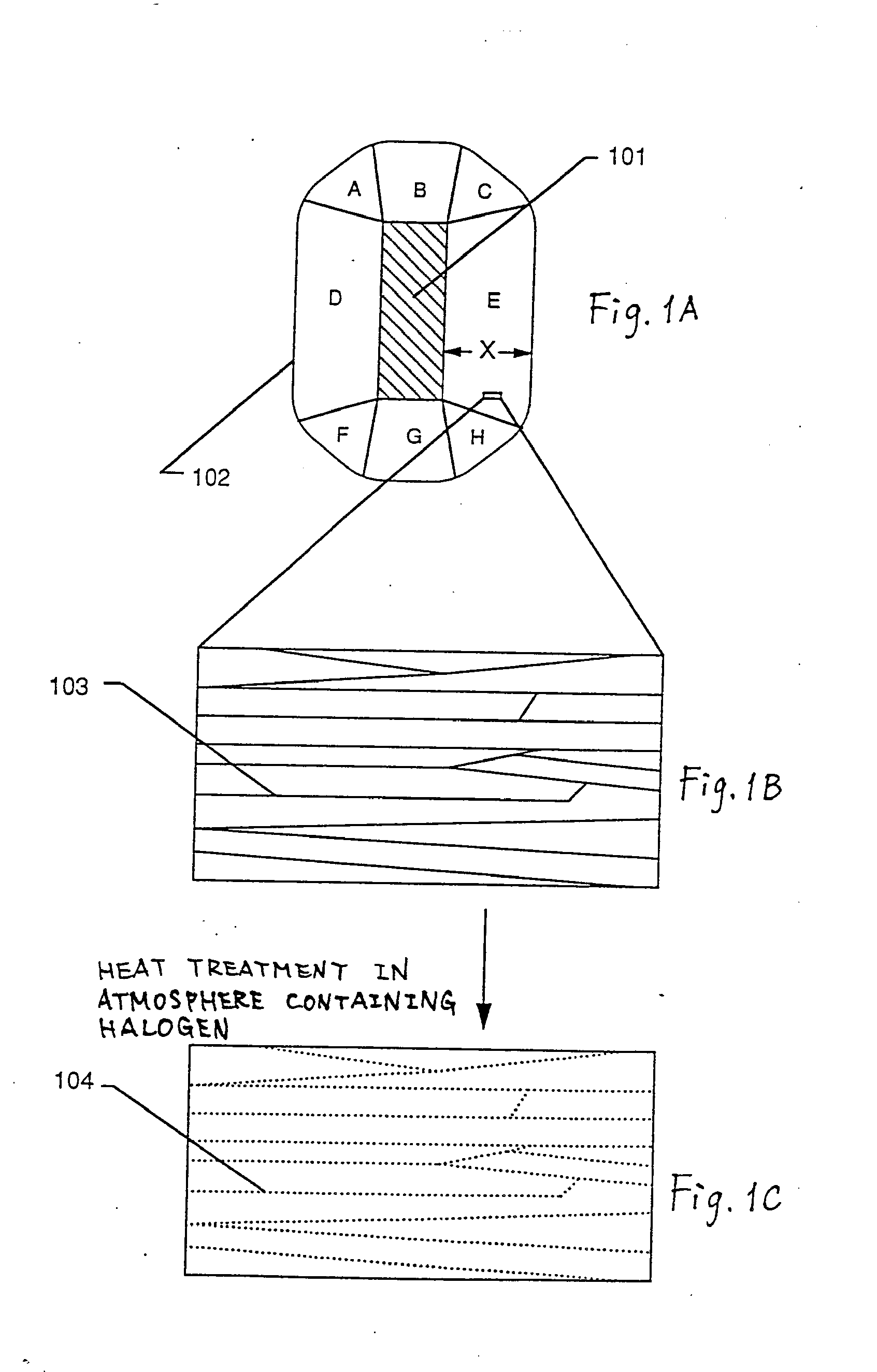

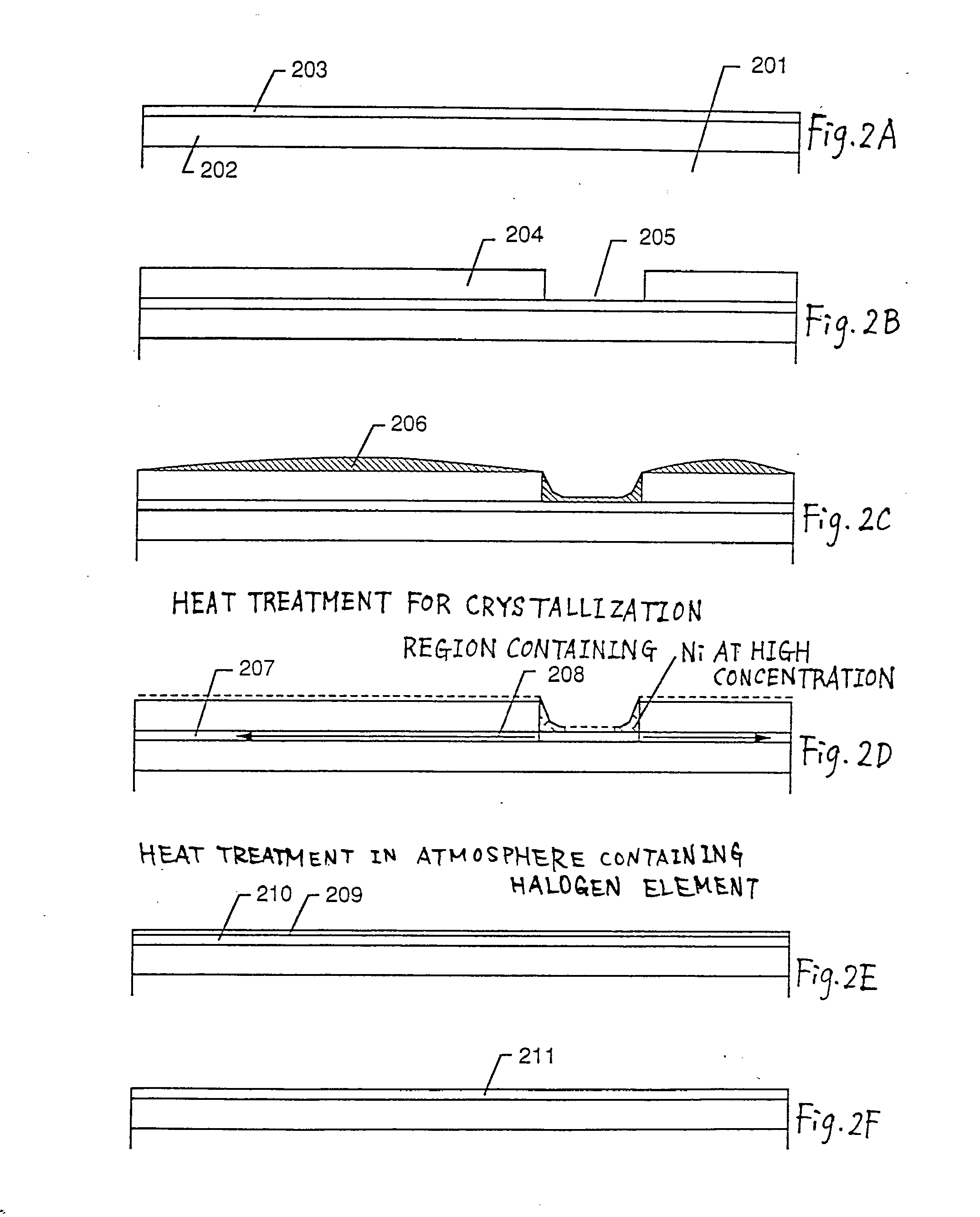

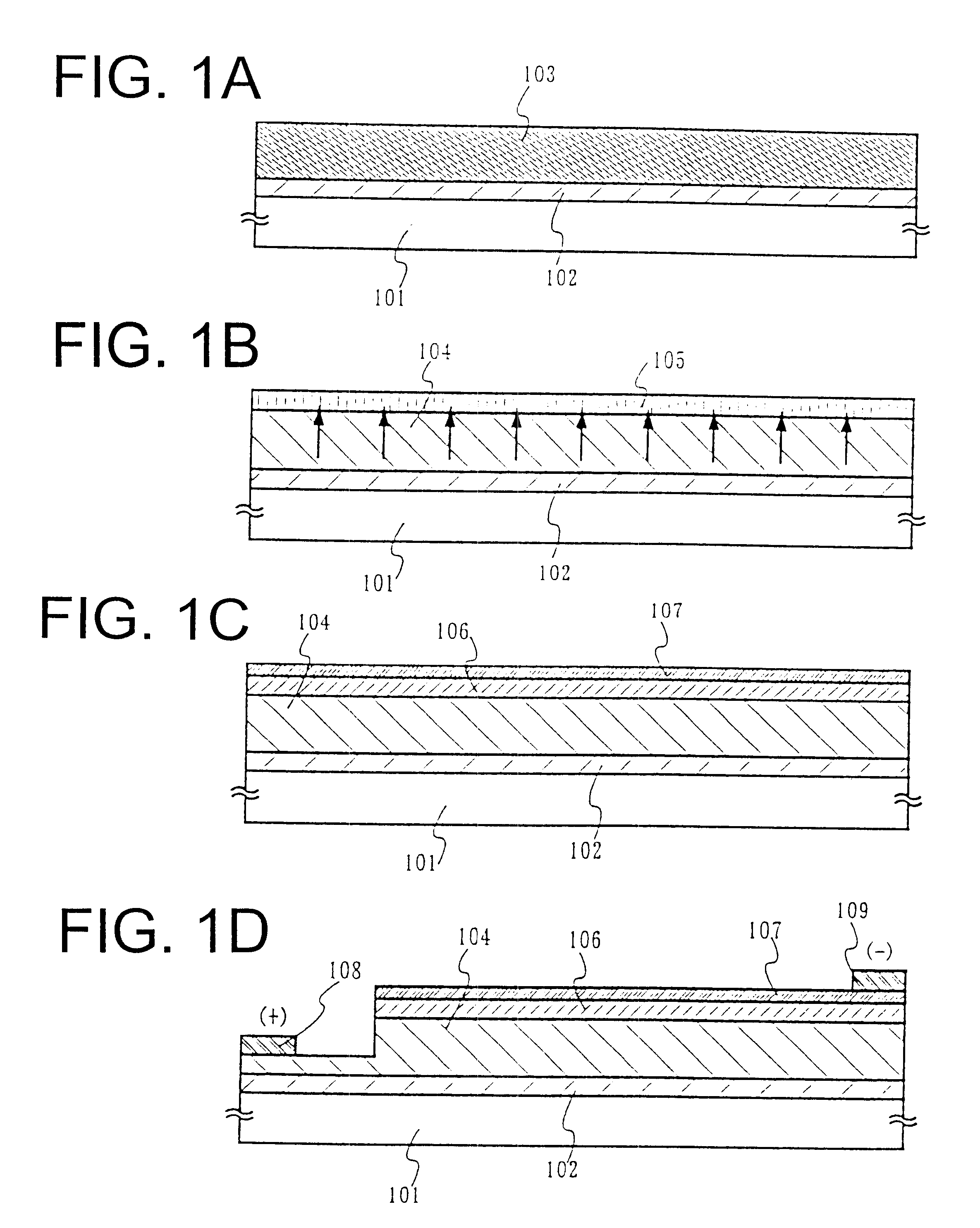

Semiconductor thin film and method of manufacturing the same and semiconductor device and method of manufacturing the same

InactiveUS7172929B2Avoid problemsImprove performanceTransistorSolid-state devicesSingle crystalCrystallinity

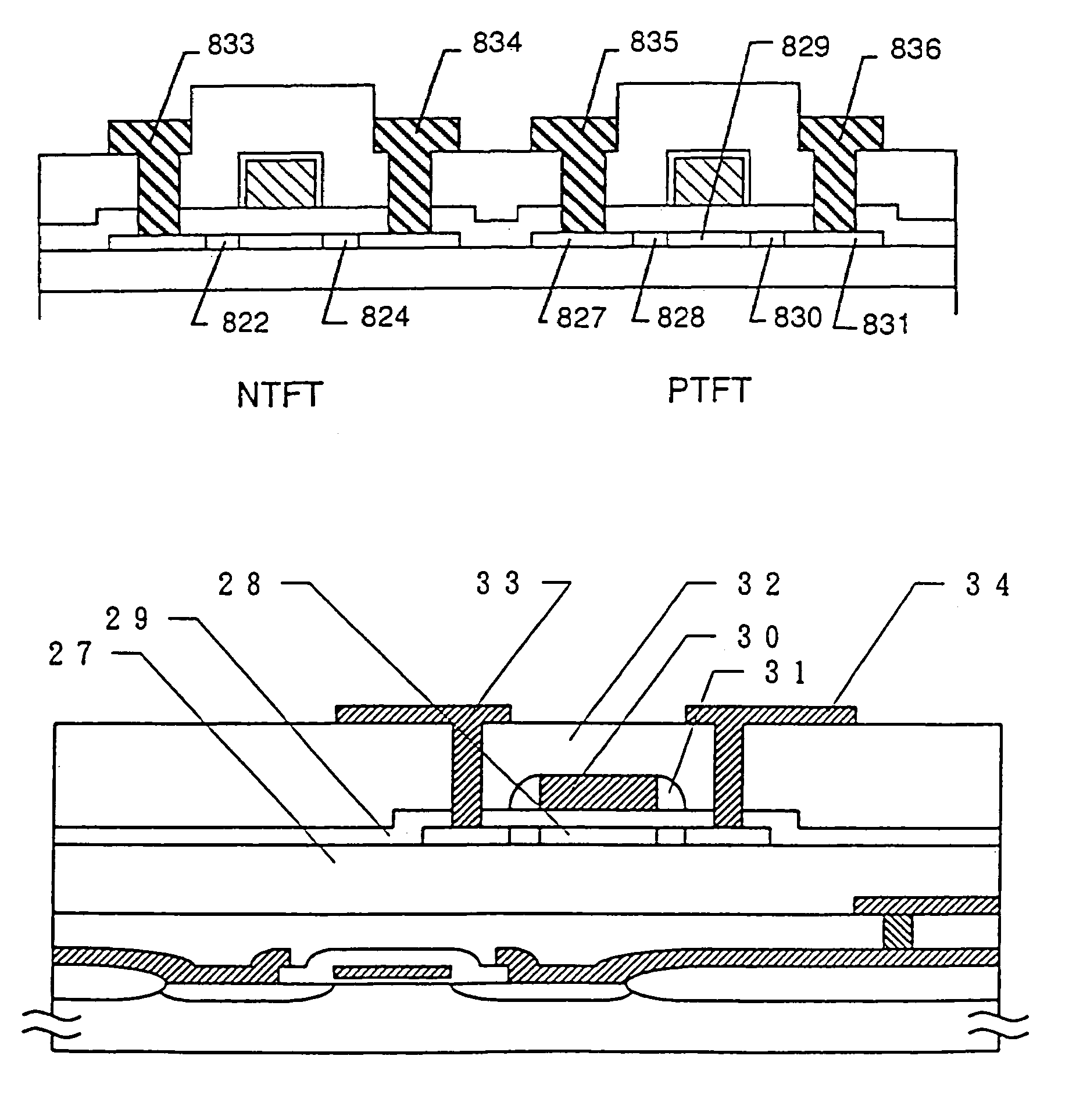

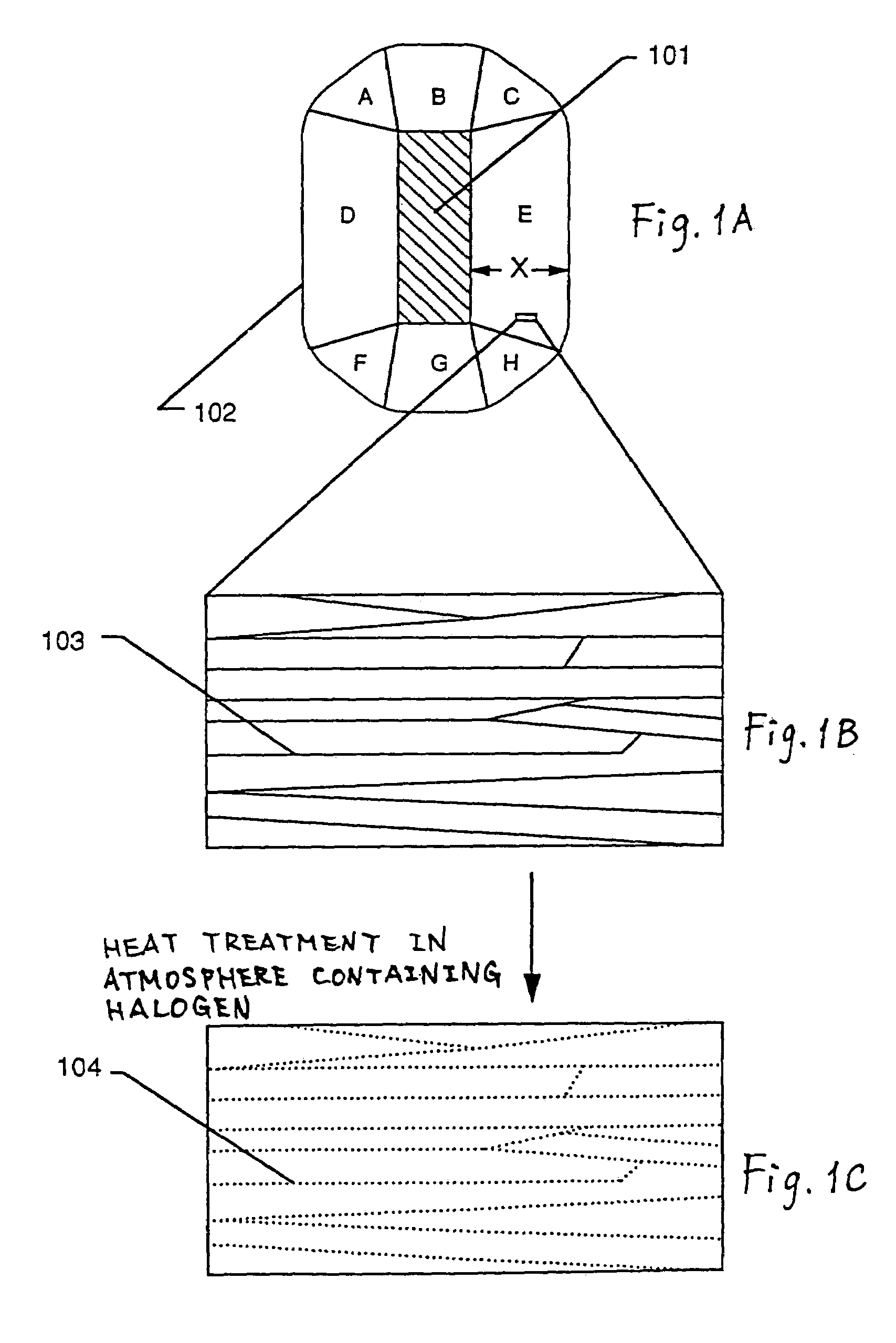

A thin film semiconductor transistor structure has a substrate with a dielectric surface, and an active layer made of a semiconductor thin film exhibiting a crystallinity as equivalent to the single-crystalline. To fabricate the transistor, the semiconductor thin film is formed on the substrate, which film includes a mixture of a plurality of crystals which may be columnar crystals and / or capillary crystal substantially parallel to the substrate. The resultant structure is then subject to thermal oxidation in a chosen atmosphere containing halogen, thereby removing away any metallic element as contained in the film. This may enable formation of a mono-domain region in which the individual columnar or capillary crystal is in contact with any adjacent crystals and which is capable of being substantially deemed to be a single-crystalline region without presence or inclusion of any crystal grain boundaries therein. This region is for use in forming the active layer of the transistor.

Owner:SEMICON ENERGY LAB CO LTD

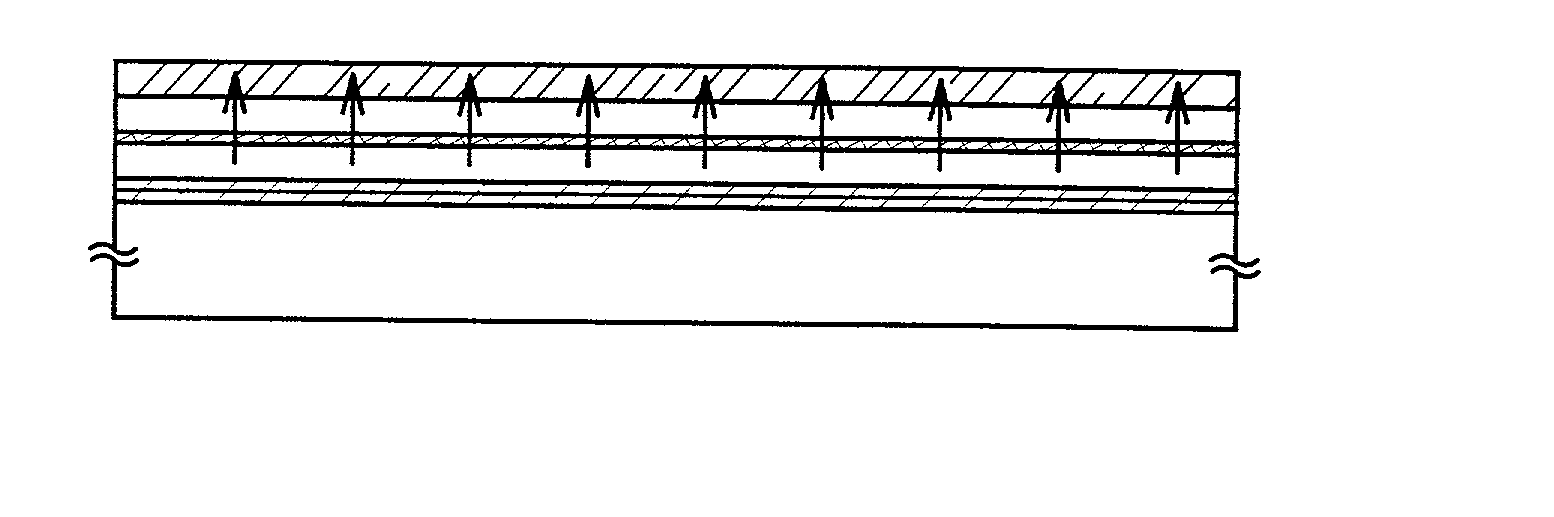

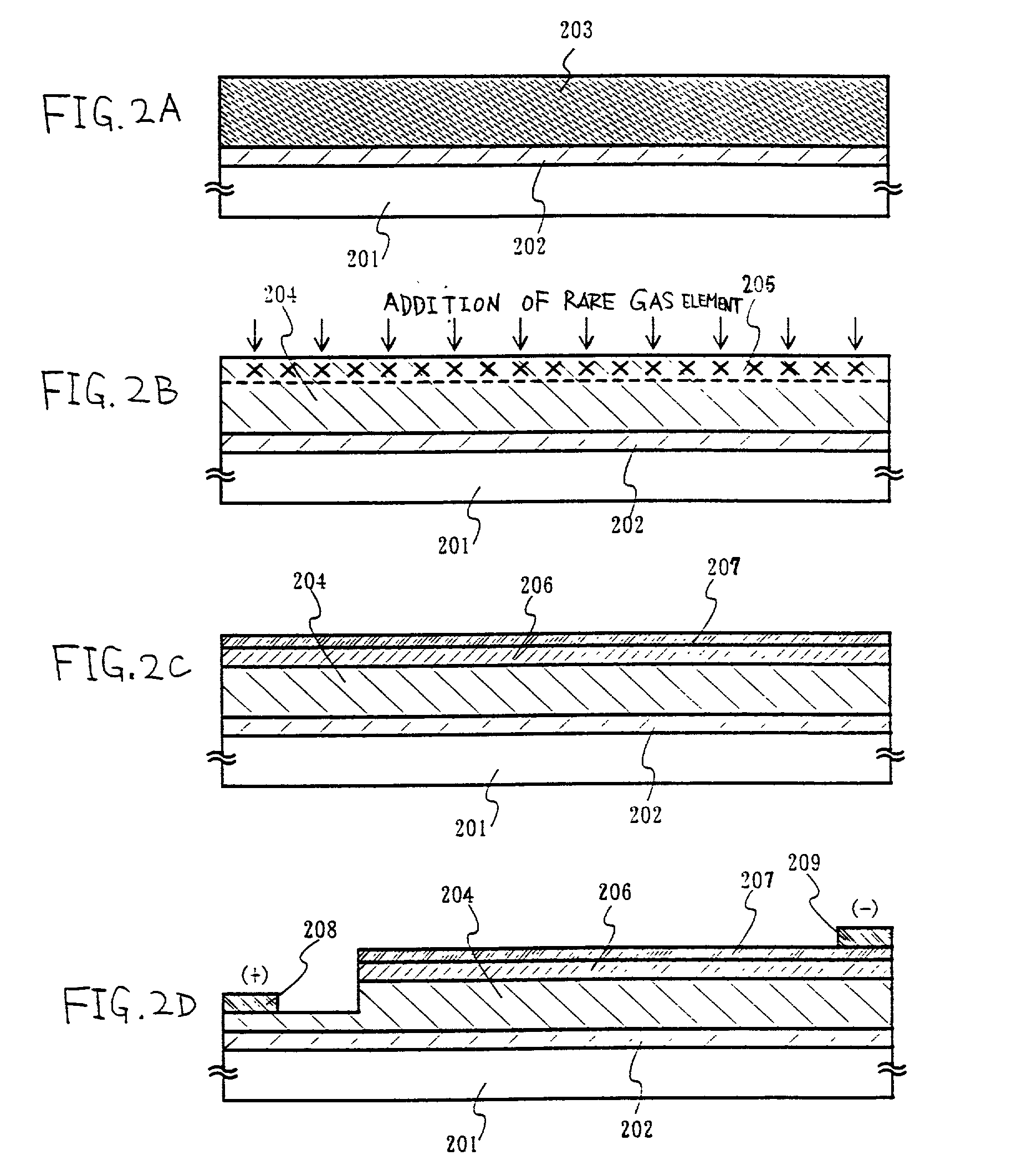

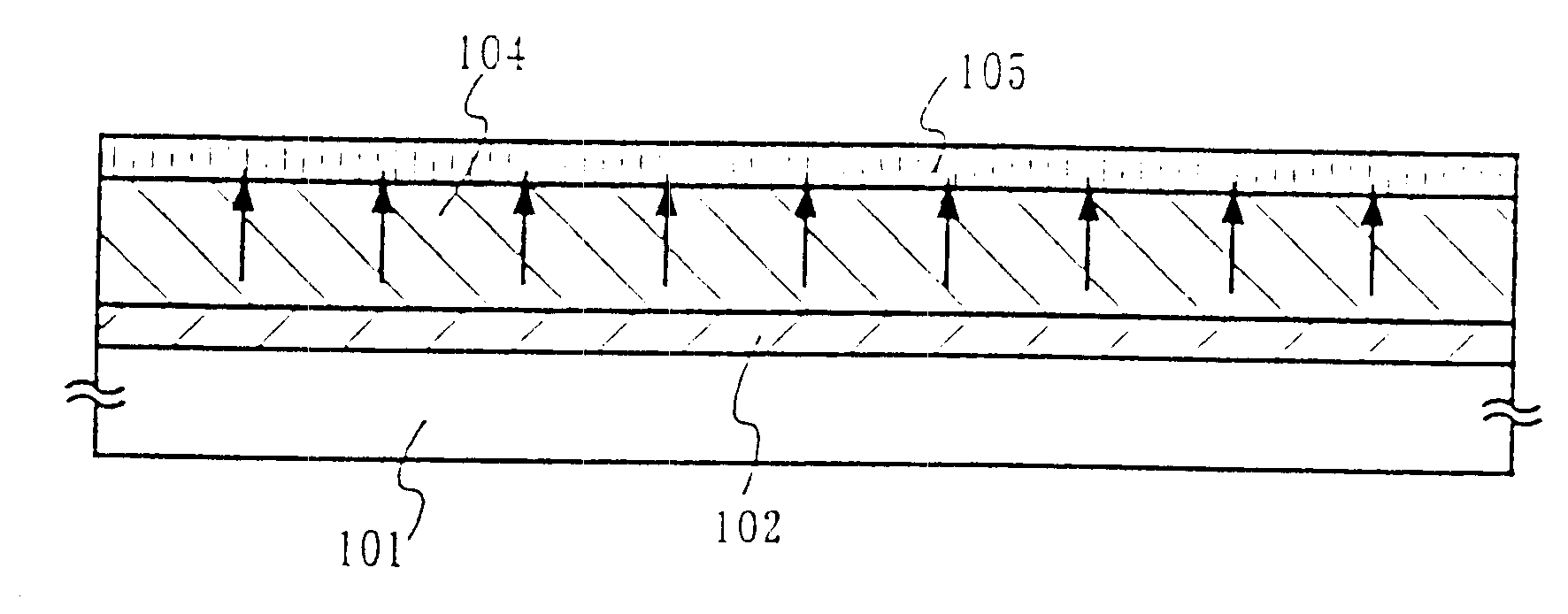

Process for producing a photoelectric conversion device

InactiveUS20020102764A1Rapid thermal annealing (RTA)Polycrystalline material growthFrom solid stateElectrical conductorNoble gas

A catalyst element remaining in a first semiconductor film subjected to a first heat treatment (crystallization) is moved and concentrated / collected by subjecting a second semiconductor film which is formed on the first semiconductor film and contains a rare gas element to a second heat treatment. That is, the rare gas element is incorporated into the second semiconductor film to generate a strain field as a gettering site.

Owner:SEMICON ENERGY LAB CO LTD

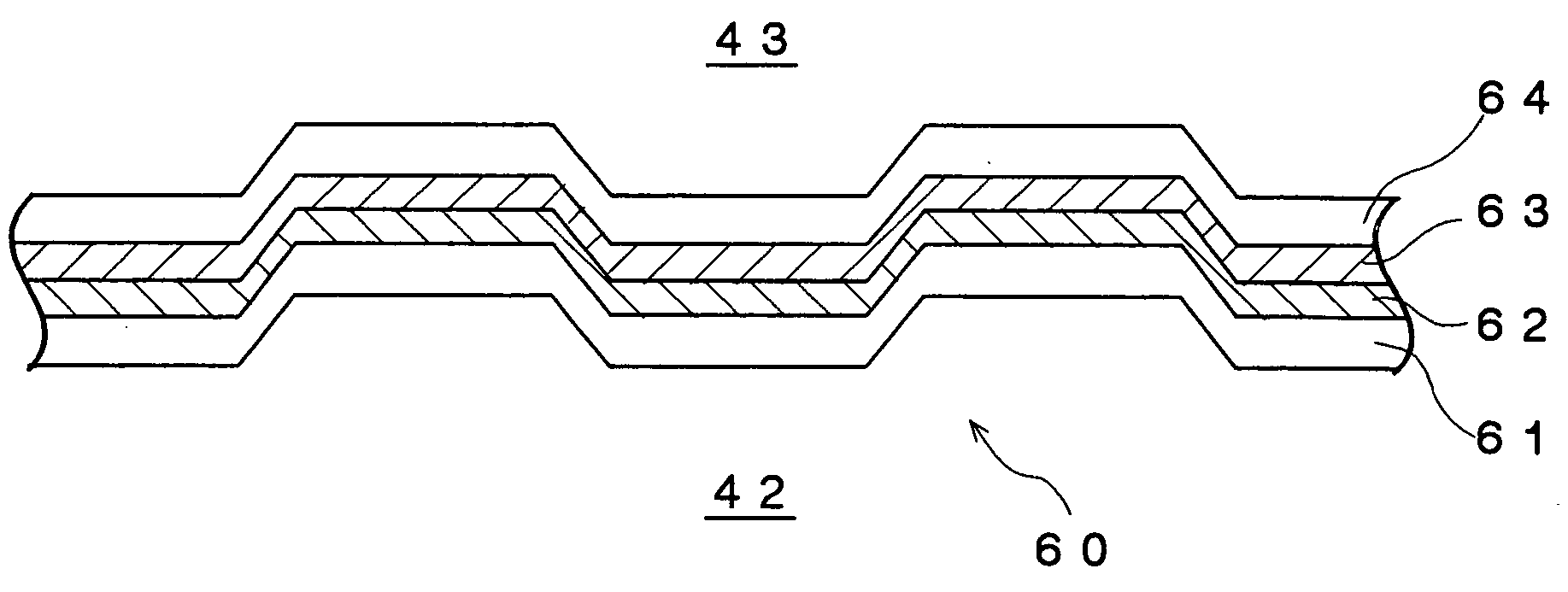

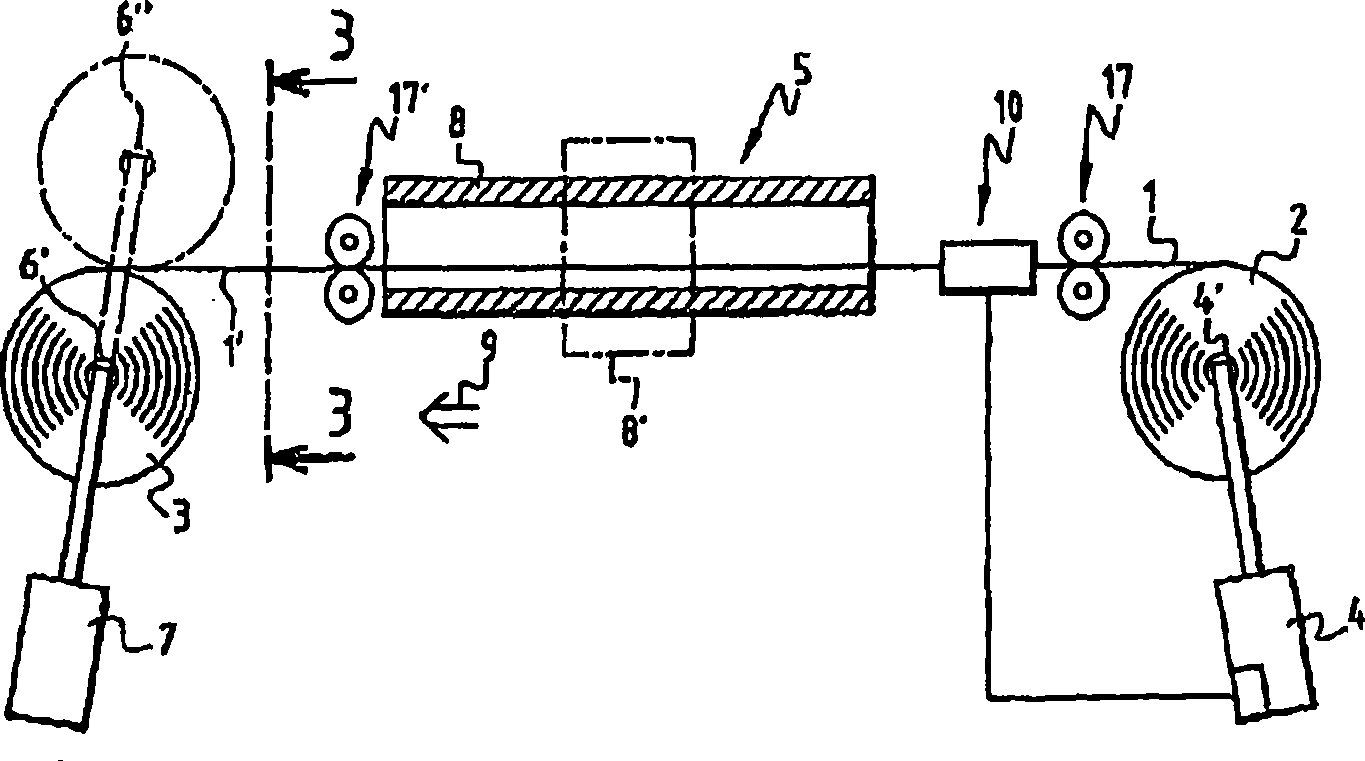

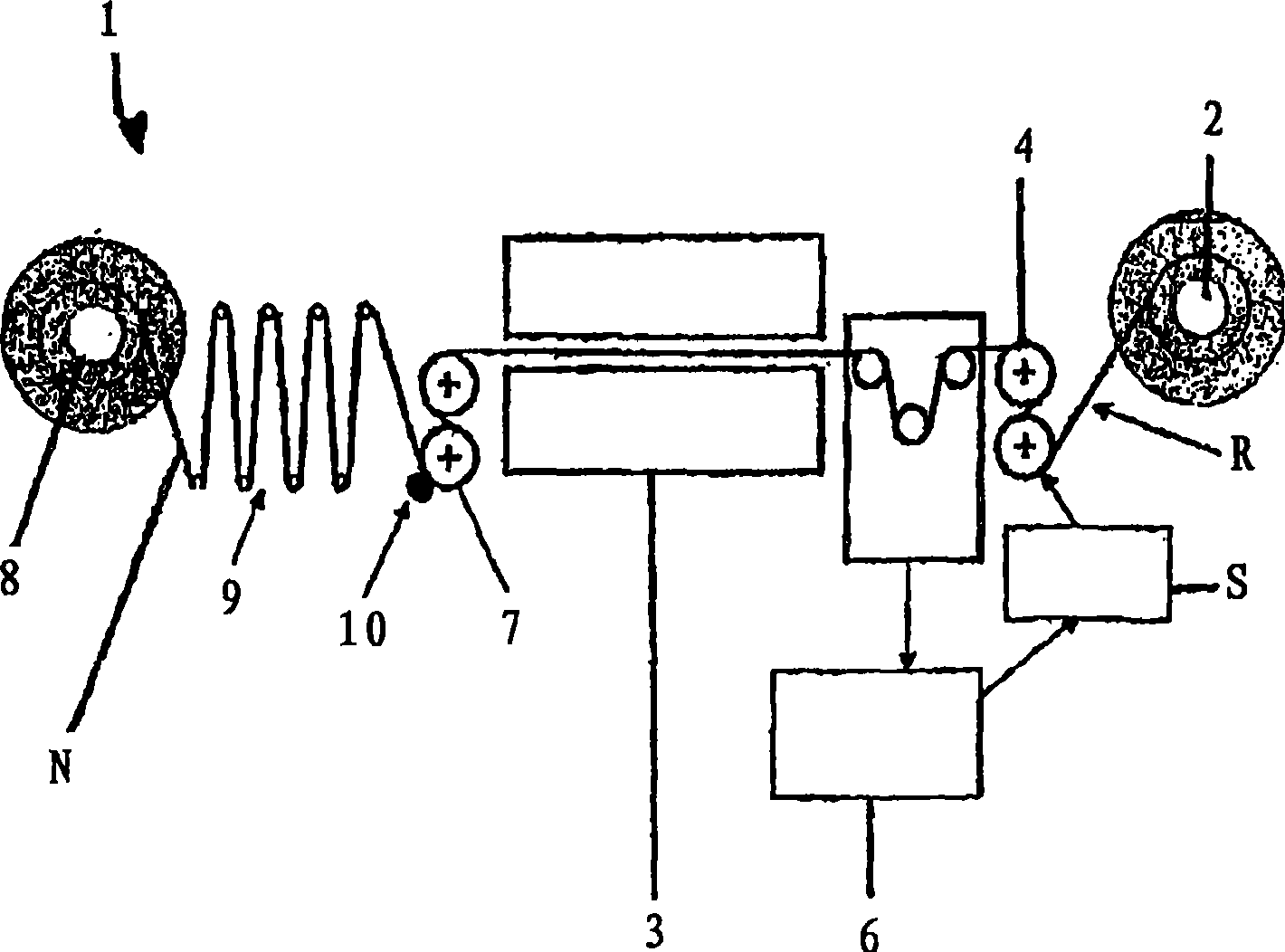

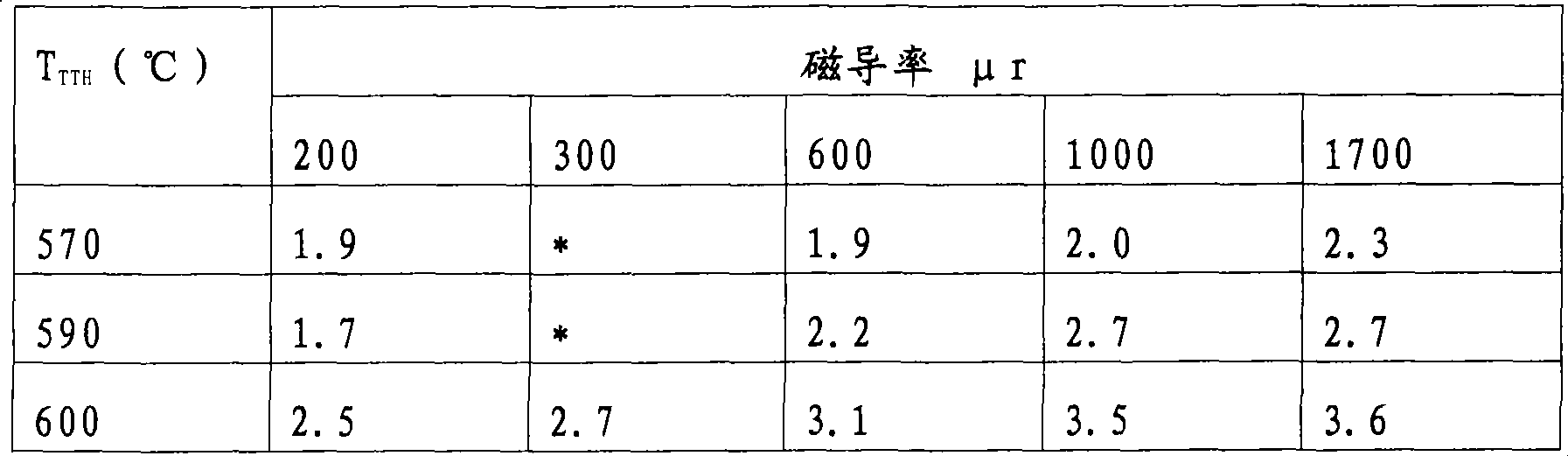

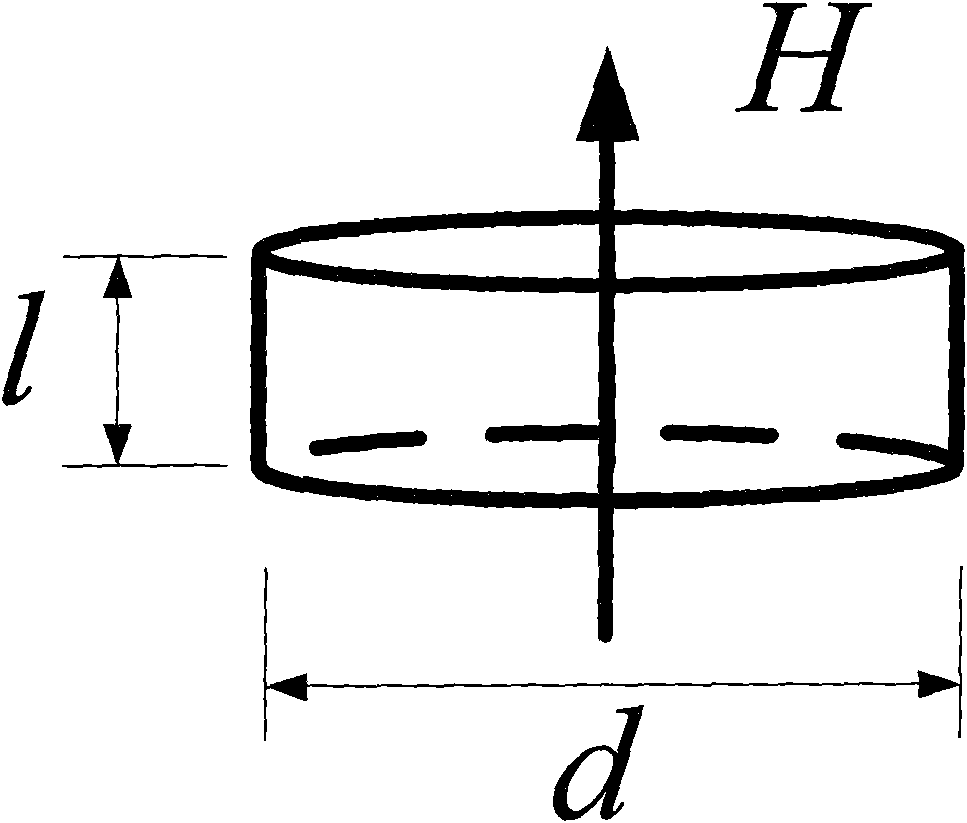

Method of producing a strip of nanocrystalline material and device for producing a wound core from said strip

The invention relates to a method of producing a strip of nanocrystalline material which is obtained from a wound ribbon that is cast in an amorphous state, having atomic composition [Fe1-a-bCoaNib]100-x-y-2-alpha-beta-gamma Cu<x>Si<y>BzNbalphaM'betaM''gamma, M' being at least one of elements V, Cr, Al and Zn, and M being at least one of elements C, Ge, P, Ga, Sb, In and Be, with: a <= 0.07 and b = 0.1, 0.5 <= x <=1.5 and 2 <= a <= 5, 10 <= y <= 16.9 and 5 <= z <= 8, beta <= 2 and gamma <= 2. According to the invention, the amorphous ribbon is subjected to crystallisation annealing, in which the ribbon undergoes annealing in the unwound state, passing through at least two S-shaped blocks under voltage along an essentially longitudinal axial direction of the ribbon, such that the ribbon is maintained at an annealing temperature of between 530 DEG C and 700 DEG C for between 5 and 120 seconds and under axial tensile stress of between 2 and 1000 Mpa. The tensile stress applied to the amorphous ribbon, the displacement speed of the ribbon during annealing and the annealing time and temperature are all selected such that the cross-section profile of the strip is not in the form of Omega and the maximum deflection of the cross-section of the strip is less than 3% of the width of the strip and preferably less than 1% of the width. The invention also relates to the strip and the core thus obtained and to the device used to implement the method.

Owner:IMPHY ALLOYS

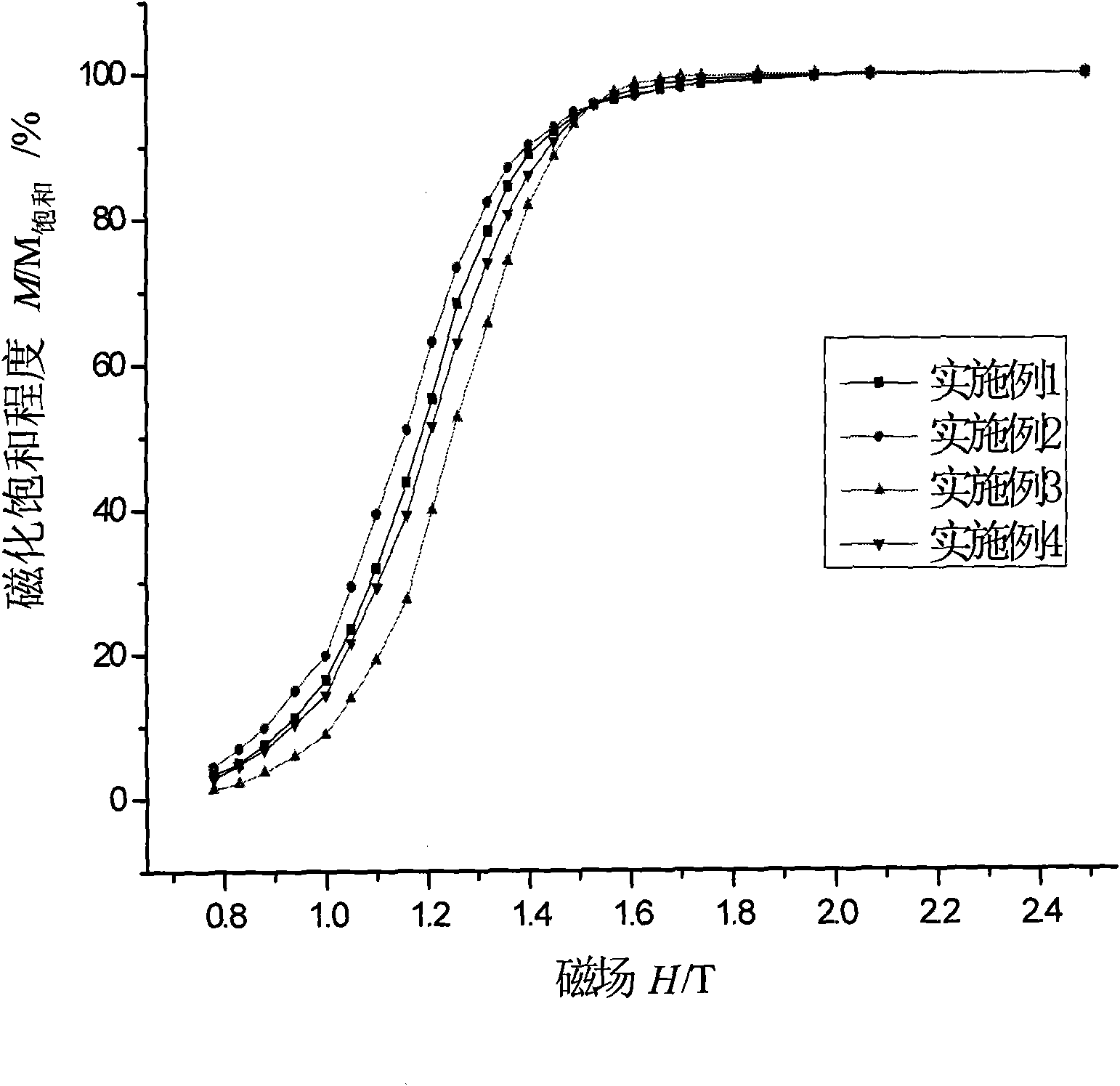

Sintered NdFeB rear-earth permanent magnet with fine magnetization characteristic and manufacturing method thereof

ActiveCN101872668AImprove microstructureGood orientationInorganic material magnetismInductances/transformers/magnets manufactureMetallurgyMagnetization

The invention relates to a sintered Nd-Fe-B rear-earth permanent magnet with fine magnetization characteristic, comprising the following components: (R1a, R2b) Fe100-a-b-c-d McBd, wherein R1 is Nd, or comprising Nd and at least one element of rear-earth elements selected from Sc, Y, La, Ce, Pr, Pm, Sm and Eu; R2 comprises Yb and at least one element of rear-earth elements selected from Tb, Dy, Gd, Ho, ErTm and Lu; and M comprises Cr and at least one element of rear-earth elements selected from Co, Cu, Al, Cr, Ga, Nb, Ti, V, Mn, Sn, Ca, Mg, Pb, Sb, Zn, Si, Ni, Mo, W and Ta. In the invention, the sintered Nd-Fe-B easy to charge magnetism to be saturated is manufactured when the magnetic circuit is at open state, and the method is low in cost, simple, and easy to realize large-scale industrial production.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH +1

Semiconductor thin film and method of manufacturing the same and semiconductor device and method of manufacturing the same

InactiveUS20070252206A1Improve reliability and performanceHigh crystallinityTransistorSolid-state devicesOptoelectronicsSingle crystal

A thin film semiconductor transistor structure has a substrate with a dielectric surface, and an active layer made of a semiconductor thin film exhibiting a crystallinity as equivalent to the single-crystalline. To fabricate the transistor, the semiconductor thin film is formed on the substrate, which film includes a mixture of a plurality of crystals which may be columnar crystals and / or capillary crystal substantially parallel to the substrate. The resultant structure is then subject to thermal oxidation in a chosen atmosphere containing halogen, thereby removing away any metallic element as contained in the film. This may enable formation of a mono-domain region in which the individual columnar or capillary crystal is in contact with any adjacent crystals and which is capable of being substantially deemed to be a single-crystalline region without presence or inclusion of any crystal grain boundaries therein. This region is for use in forming the active layer of the transistor.

Owner:SEMICON ENERGY LAB CO LTD

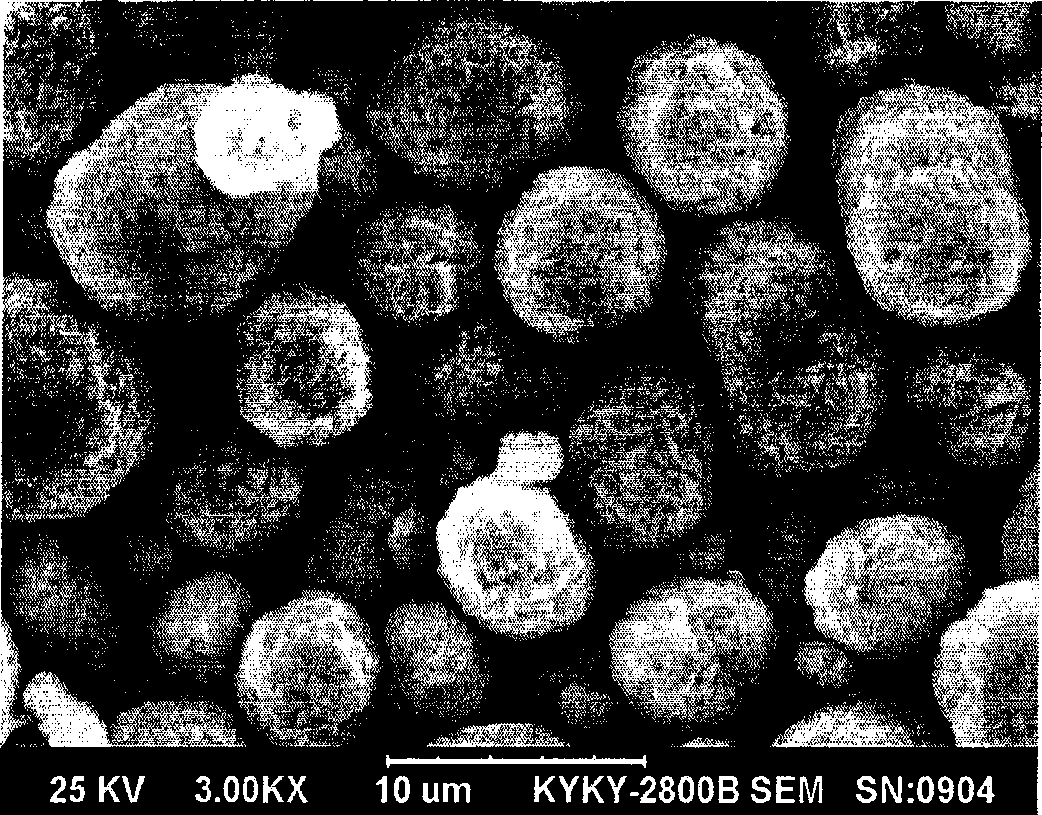

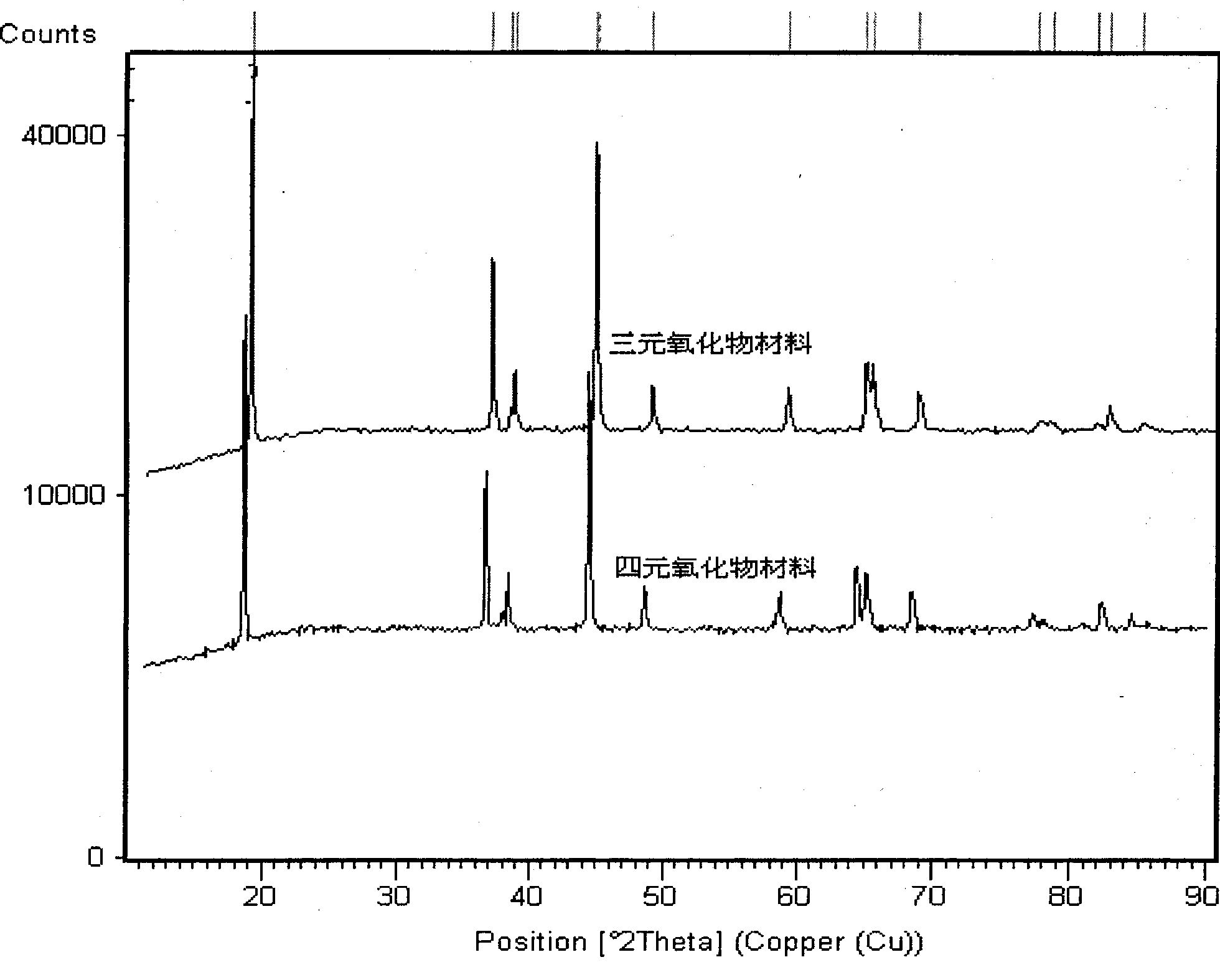

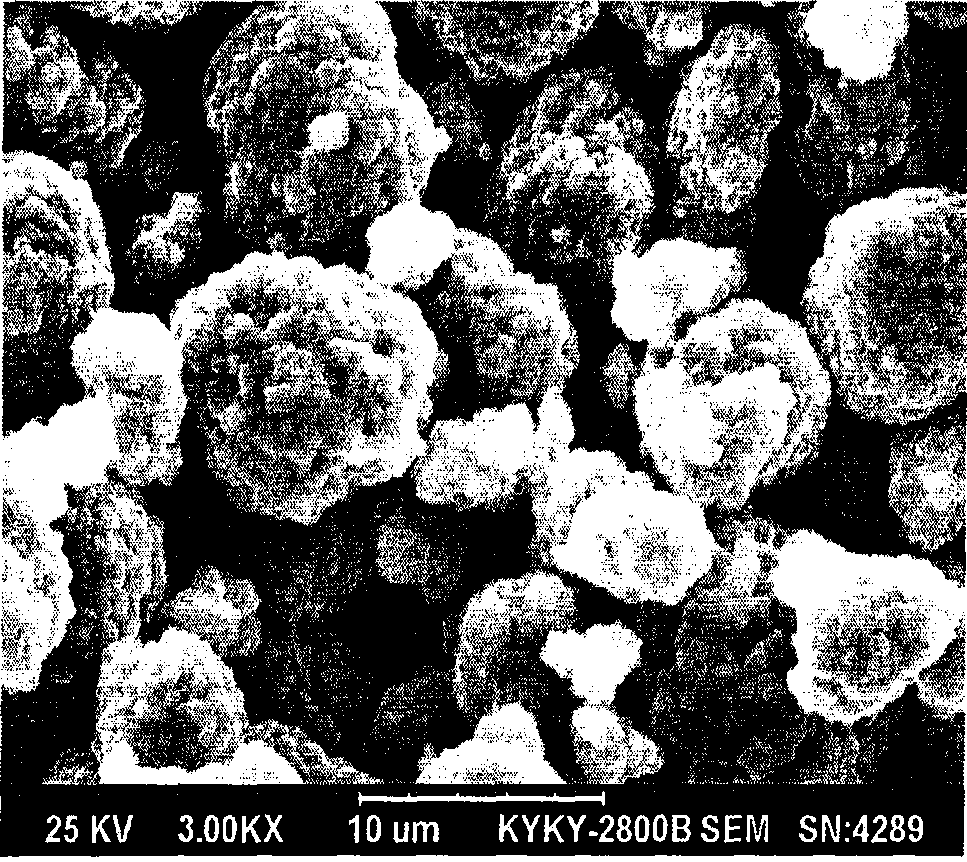

Metal oxide lithium ionic cell positive pole material and preparation thereof

ActiveCN101483265ALow raw material costReduce manufacturing costElectrode manufacturing processesLithium compoundsElectrochemistryLithium-ion battery

The invention discloses a metal oxide lithium ion battery positive material and a preparation method thereof. The problem to be solved is to improve the electrochemistry property of the positive material. The material formula of the invention is LiNi1-x-y-zMnxCoyMzO2, wherein the x+y+z is less than 1, or a quaternary or a quinary metal oxide material of the LiNi1-x-y-z-rMnxCoyMzNrO2, wherein the x+y+z+r is less than 1, and the M and N are selected from one of the Al, Ti, Cr, Mg, V, Zn and Zr, x is equal to 0.01-0.8, y is equal to 0.01-0.8, z is equal to 0.01-0.8 and r is equal to 0.01-0.8. The preparation method comprises: preparing a precursor mixture, mixing and sintering. Comparing with the prior art, the invention prepares the oxide lithium ion battery material by a liquid phase multi-element mixing reaction, a mixing method and a solid state sintering method, the maximum discharging capacity is larger than 150mAh / g, the primary coulomb efficiency is more than 90, the capacity conservation rate after 300 cycles is more than 95 The metal oxide lithium ion battery positive material is suitable for industrial scale production.

Owner:BTR NEW MATERIAL GRP CO LTD

Self-cleaning antibacterial ceramic glaze and preparation method and ceramic product thereof

The invention discloses a self-cleaning antibacterial ceramic glaze and a preparation method and a ceramic product thereof. The key of the self-cleaning antibacterial ceramic glaze provided by the invention is that the ceramic glaze contains Ti element and Ag element. The ceramic glaze comprises the following components in percentage: 52-72% of SiO2, 5-9% of Al2O3, 6-10% of CaO, 2-6% of K2O, 0.5-1.5% of Na2O, 0.5-3% of ZnO, 1-3% of Li2O, 4-8% of Ti2O, 1-3% of V2O5 and 1-5% of Ag2O3. The ceramic product of the invention comprises a ceramic noumenon, which is characterized by containing a self-cleaning antibacterial ceramic glaze layer on the surface of the ceramic noumenon. The composition of the invention is suitable to be adopted in primary glazing process, and the surface of the ceramic glaze has high flatness, fined and delicate crystalloid, good smooth finish, no needle pole, extremely soft and good glass like and smooth in touch and reaches the self-cleaning antibacterial effect of ultra smooth glaze layer enamel.

Owner:广东澳丽泰陶瓷实业有限公司

Method for manufacturing ultrafine carbon fiber and field emission element

Owner:SEMICON ENERGY LAB CO LTD

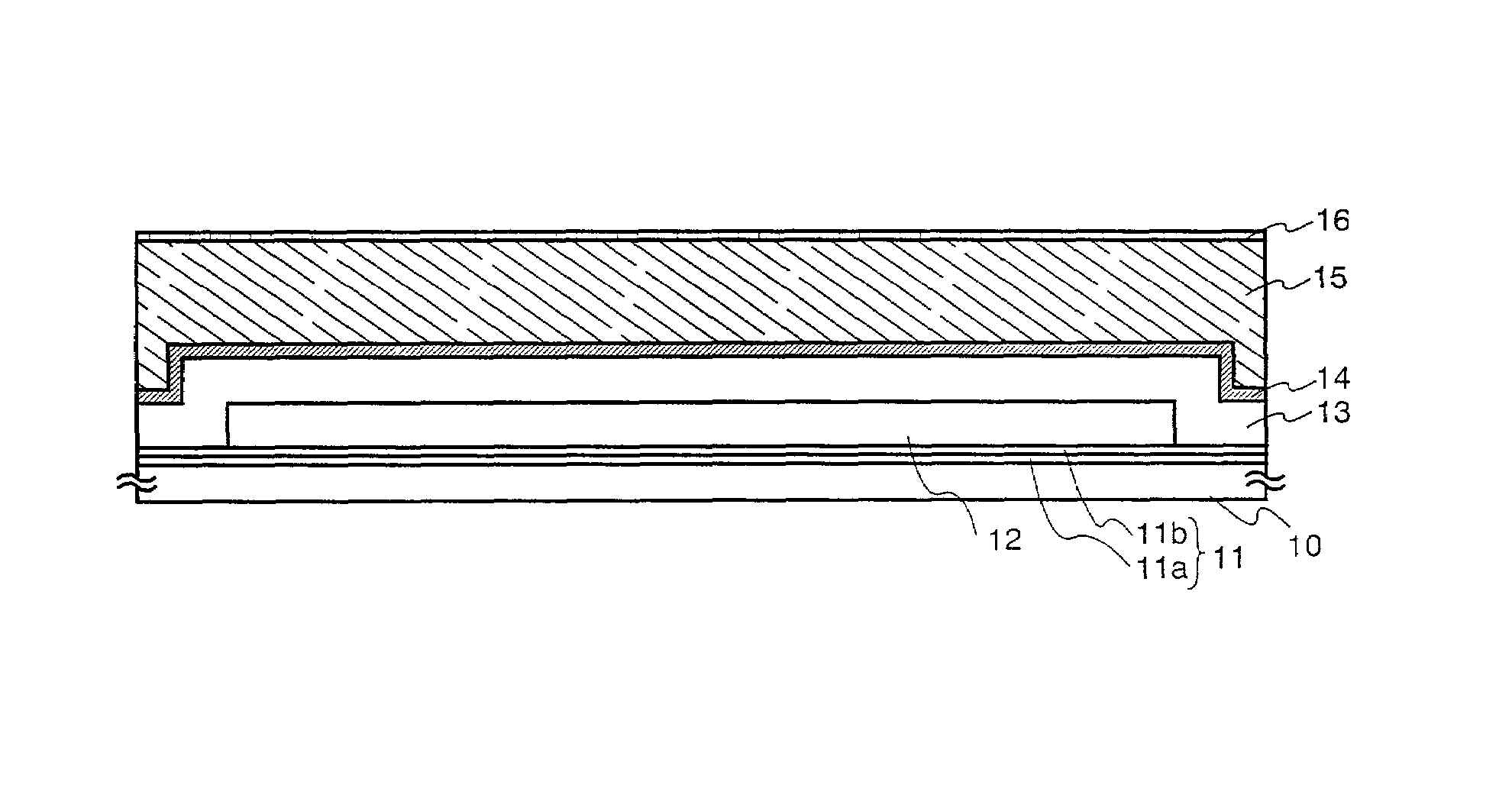

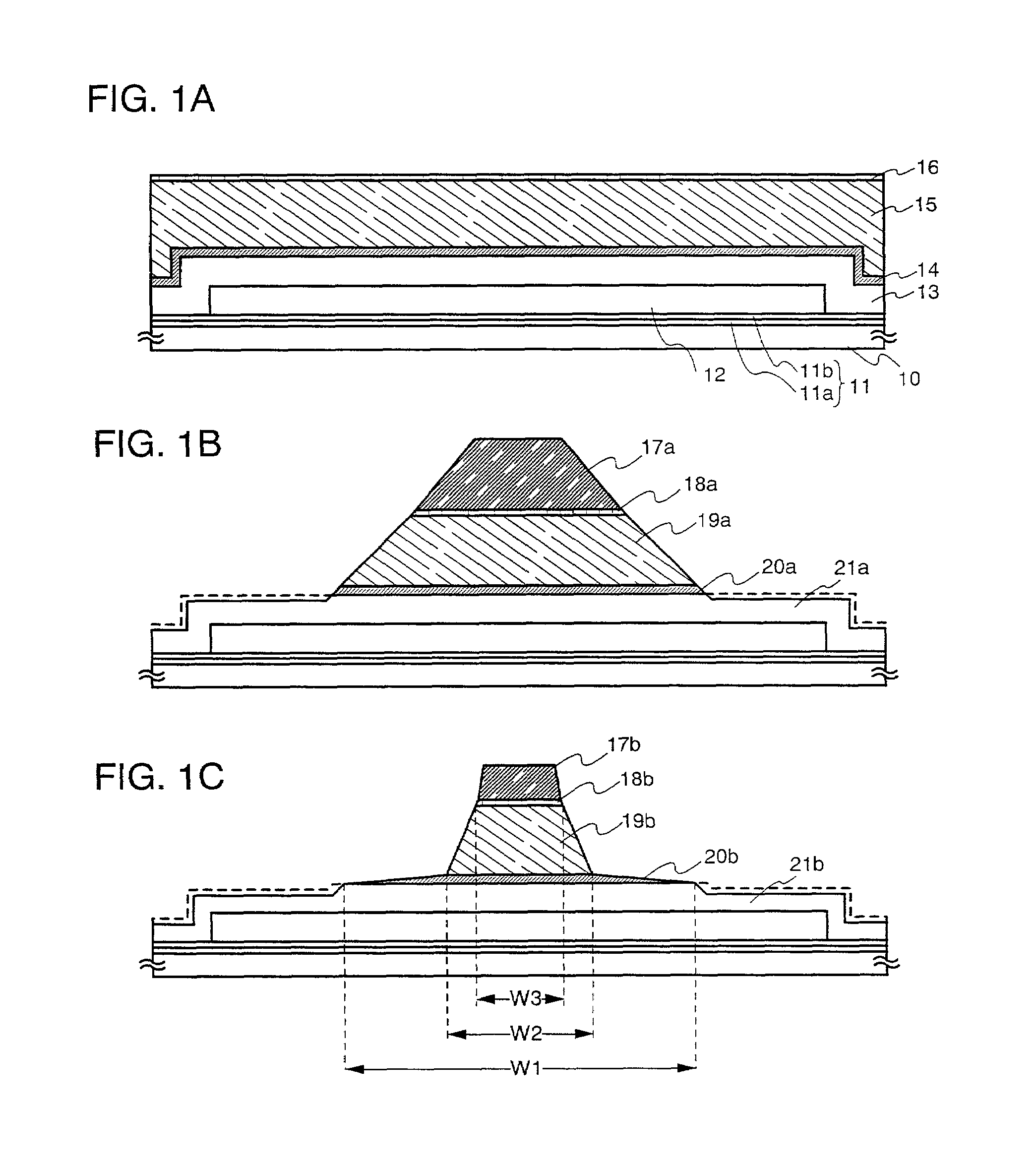

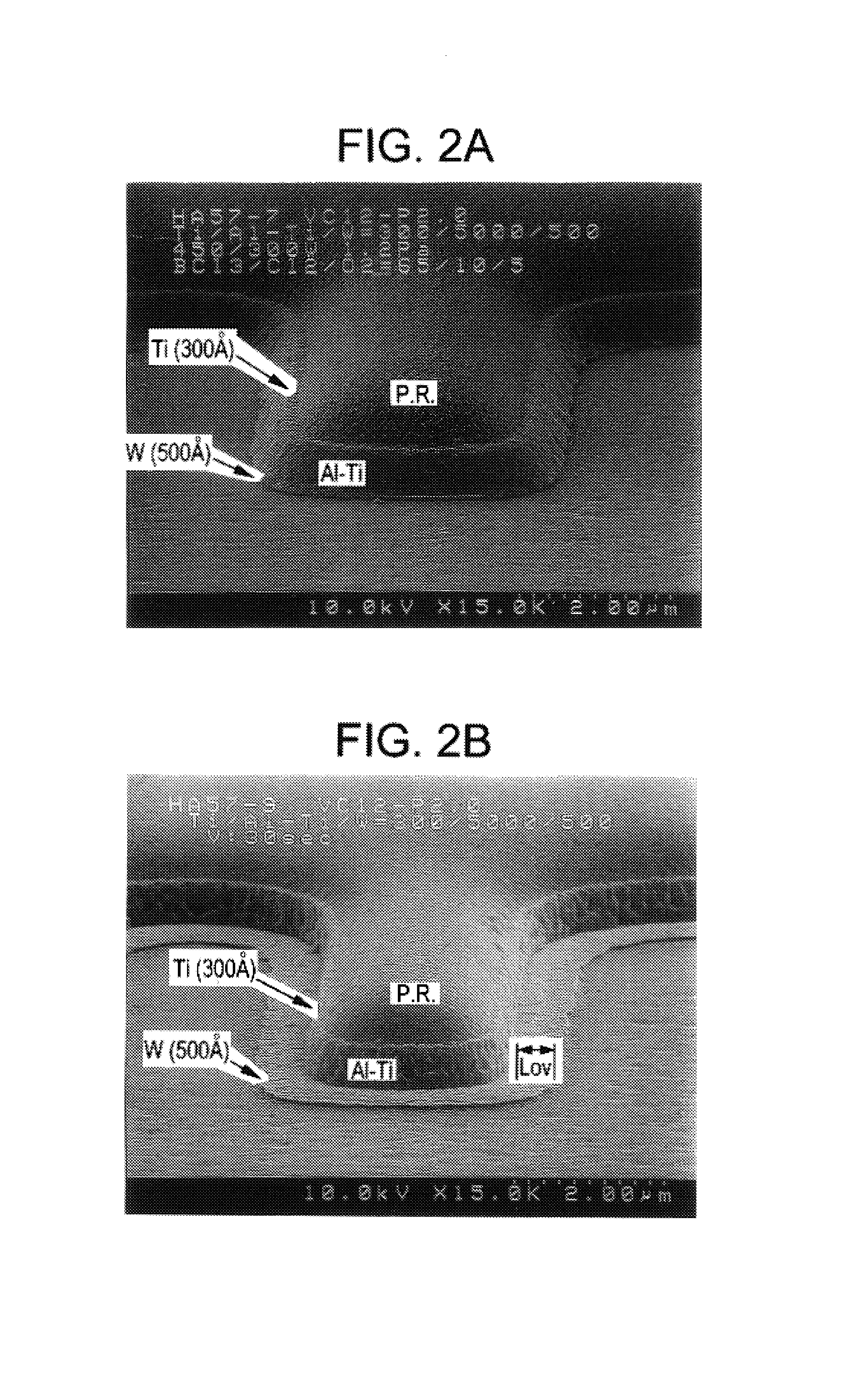

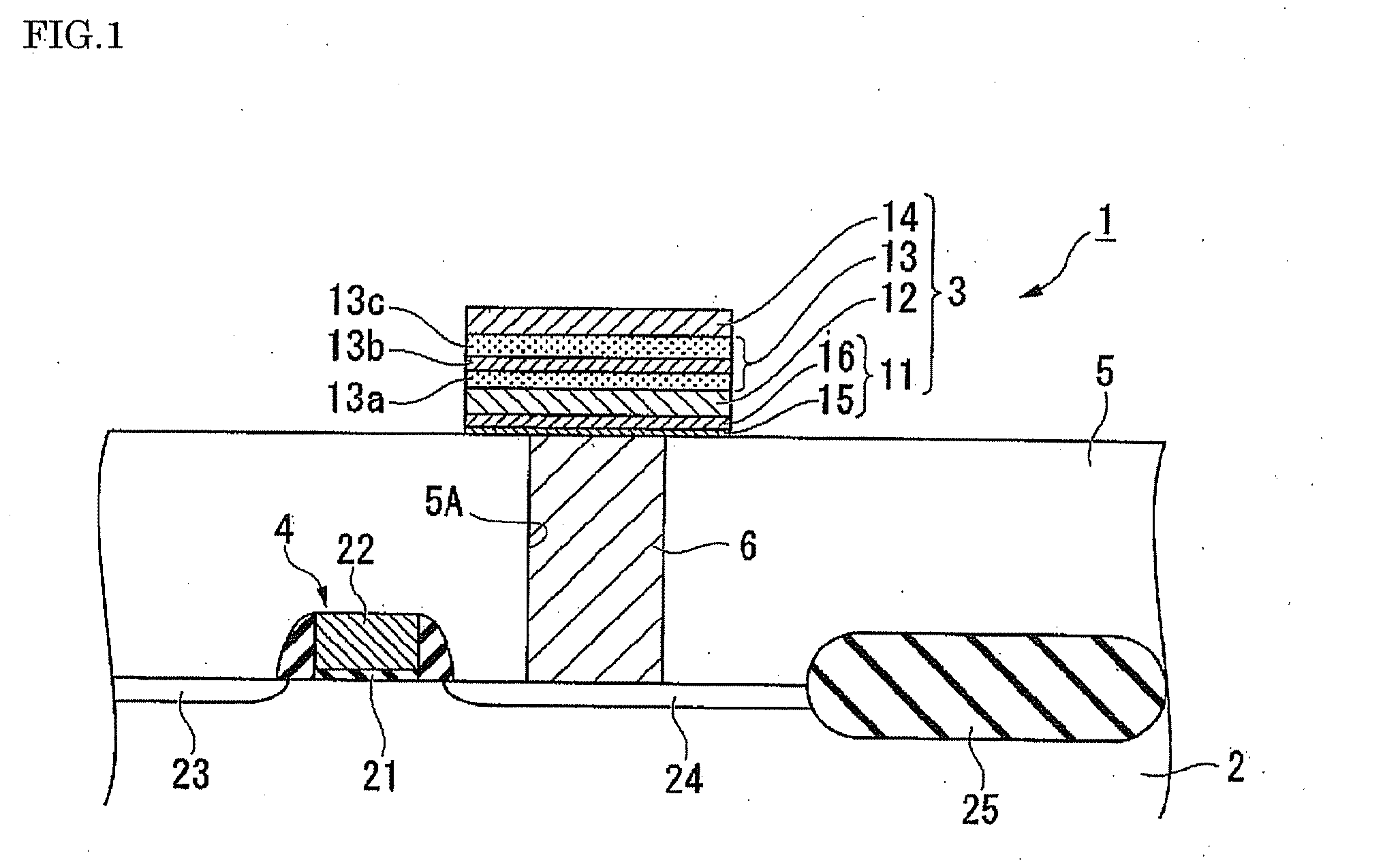

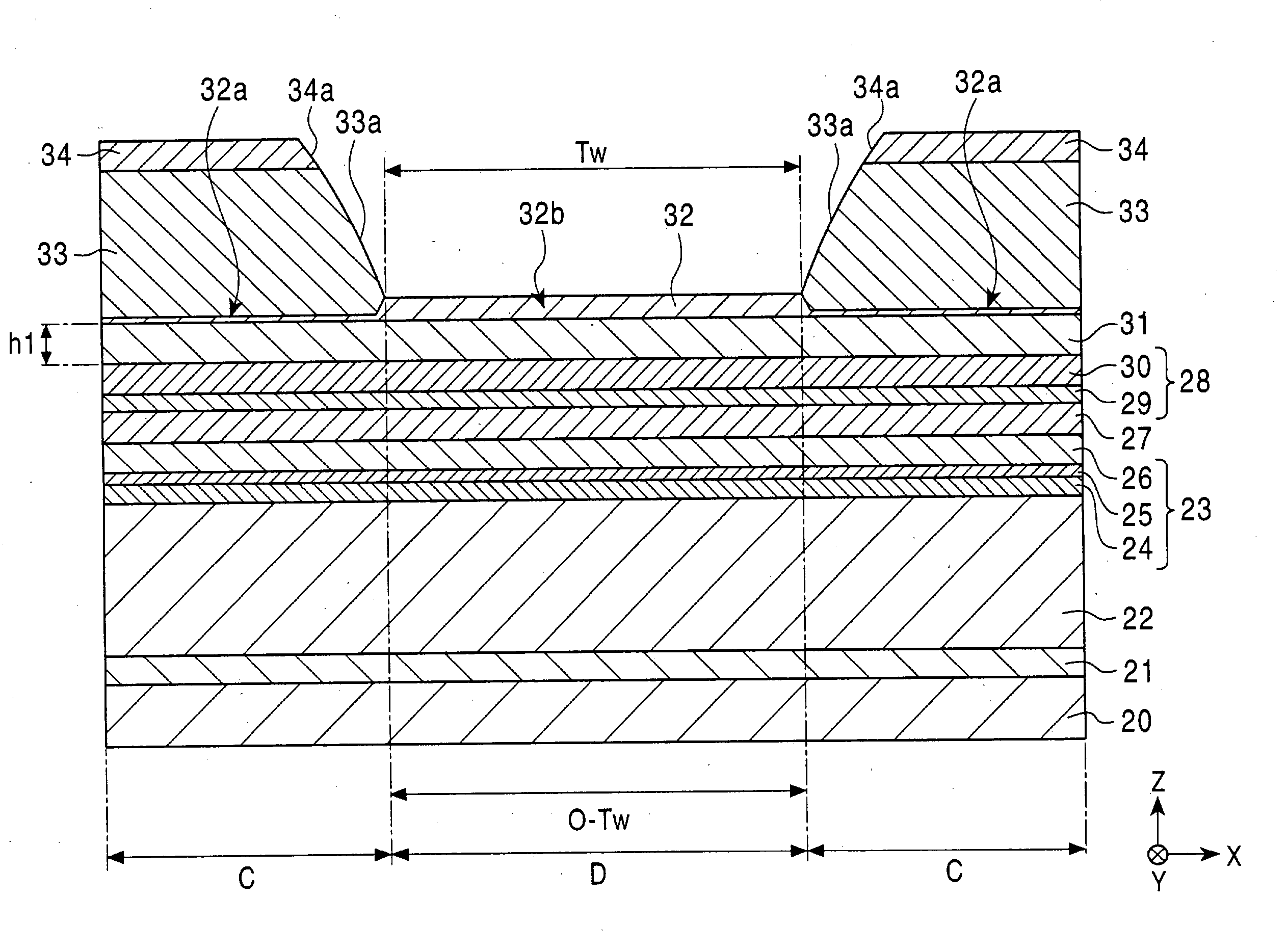

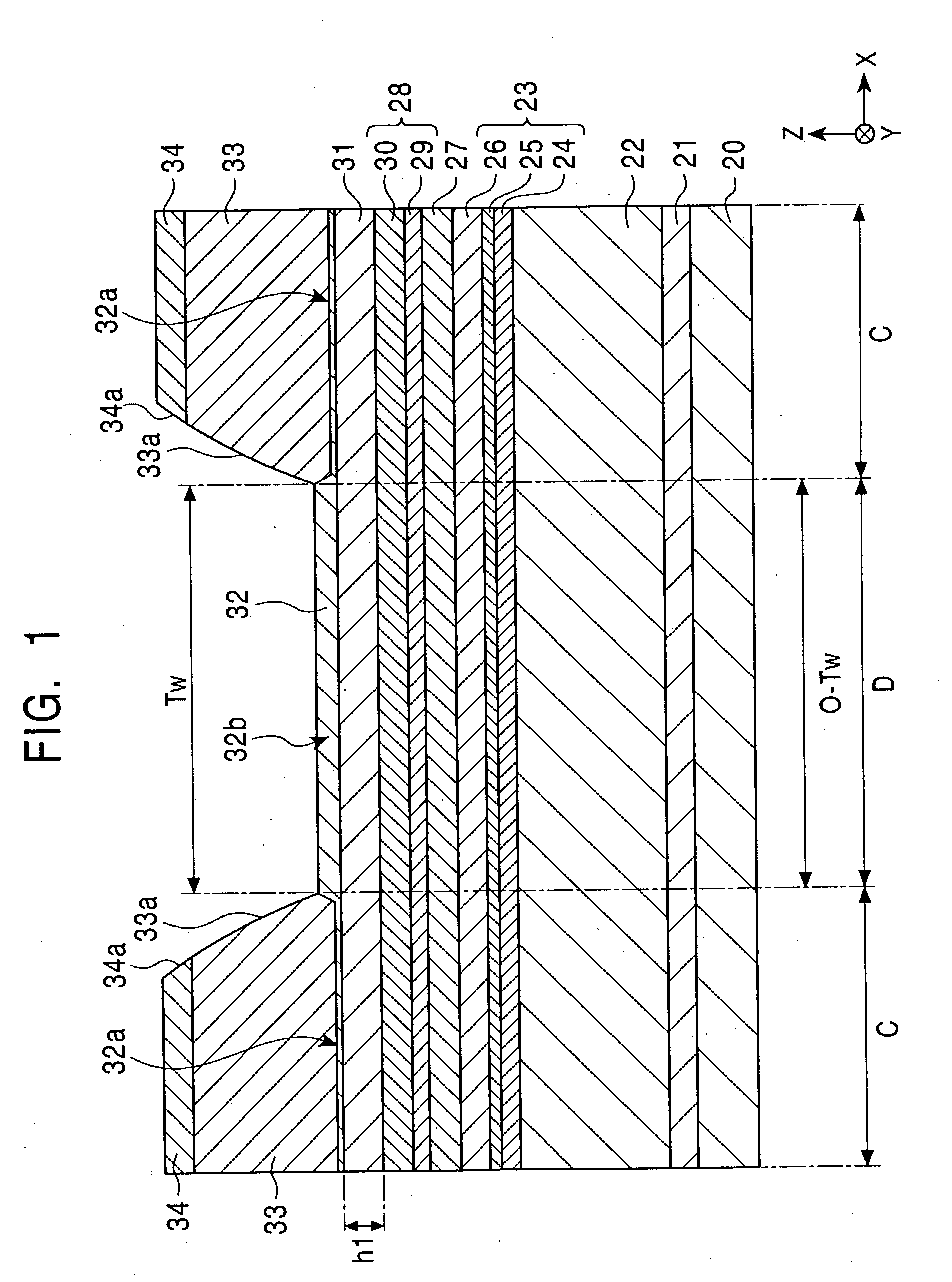

Wiring and method of manufacturing the same, and wiring board and method of manufacturing the same

InactiveUS7169710B2Lower resistanceHigh melting pointTransistorSemiconductor/solid-state device detailsAg elementLayered structure

The wiring of the present invention has a layered structure that includes a first conductive layer (first layer) having a first width and made of one or a plurality of kinds of elements selected from W and Mo, or an alloy or compound mainly containing the element, a low-resistant second conductive layer (second layer) having a second width smaller than the first width, and made of an alloy or a compound mainly containing Al, and a third conductive layer (third layer) having a third width smaller than the second width, and made of an alloy or compound mainly containing Ti. With this constitution, the present invention is fully ready for enlargement of a pixel portion. At least edges of the second conductive layer have a taper-shaped cross-section. Because of this shape, satisfactory coverage can be obtained.

Owner:SEMICON ENERGY LAB CO LTD

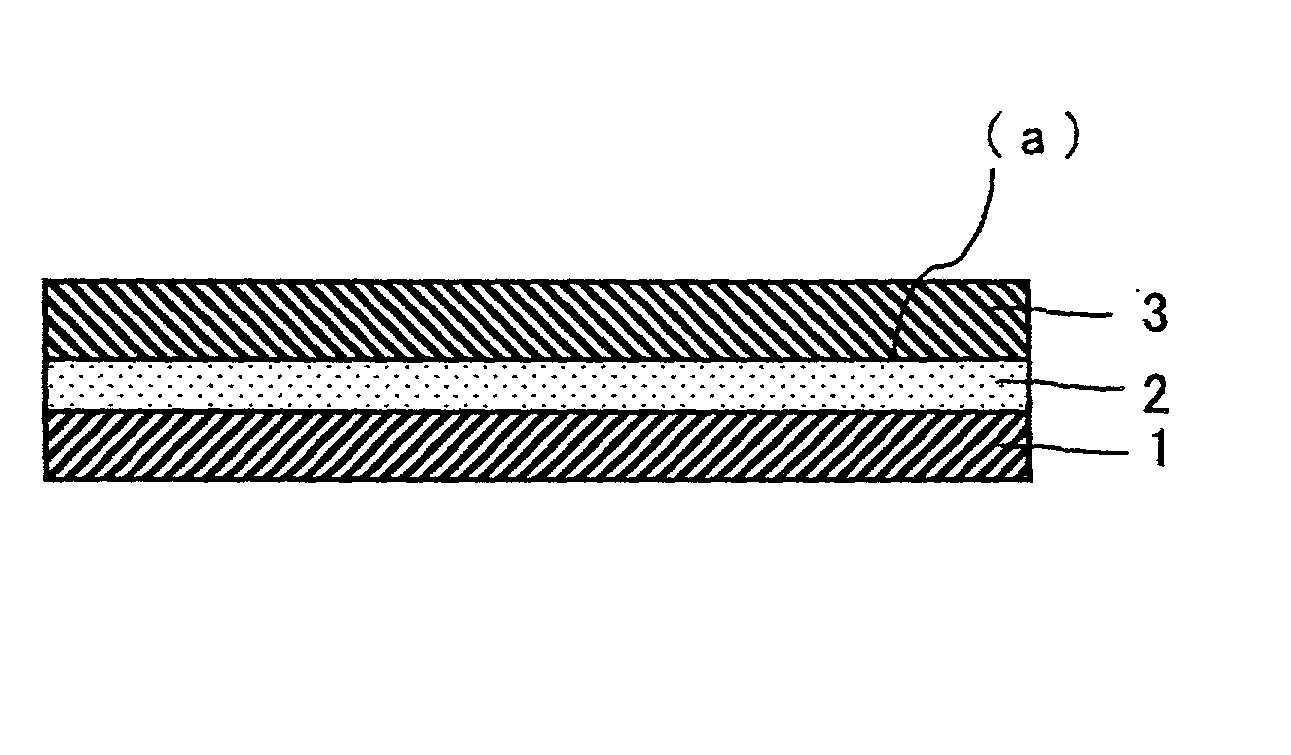

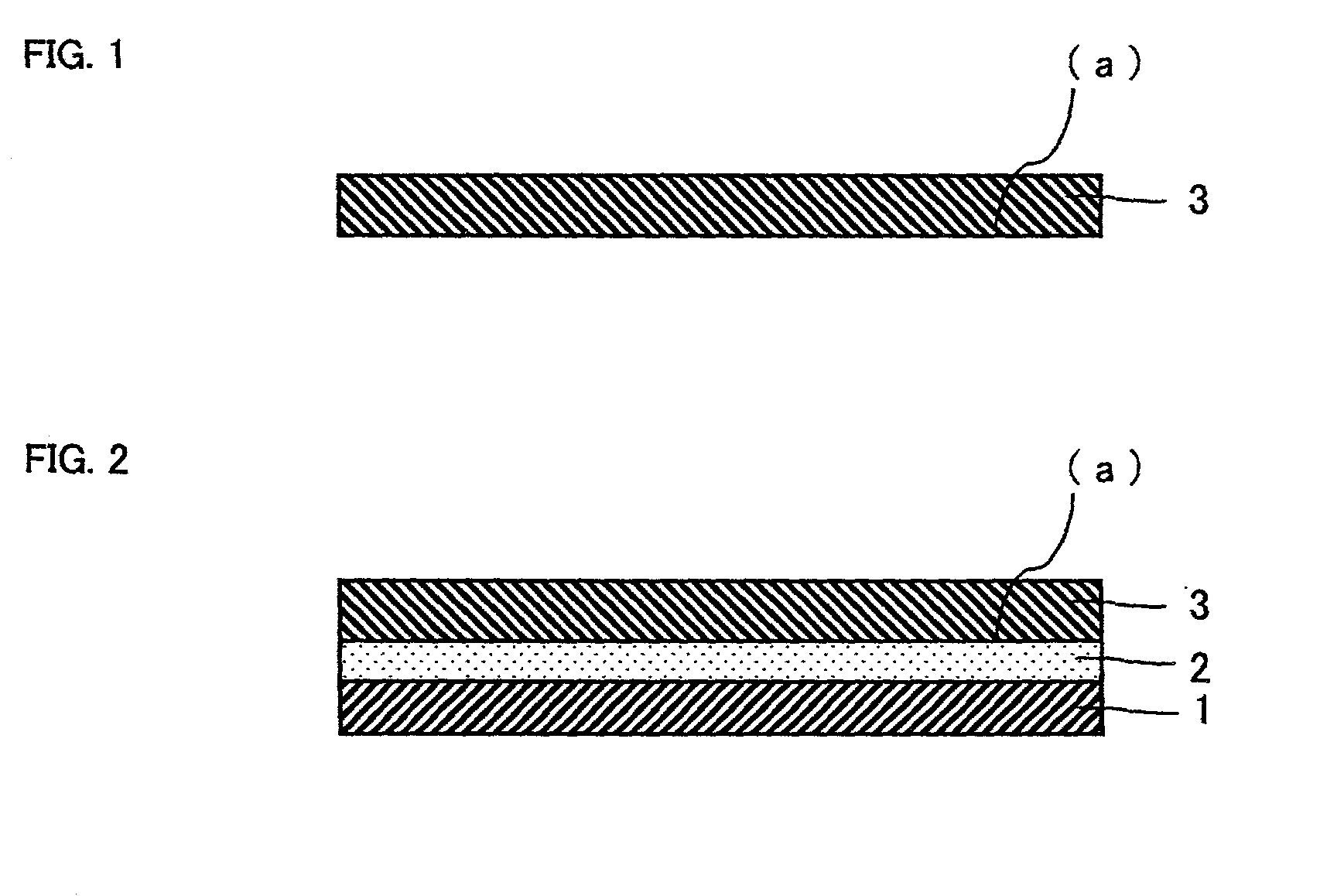

Ferroelectric capacitor and its manufacturing method

InactiveUS20080225569A1Reduce roughnessReduce leakage currentThin/thick film capacitorSolid-state devicesFerroelectric thin filmsCrystal structure

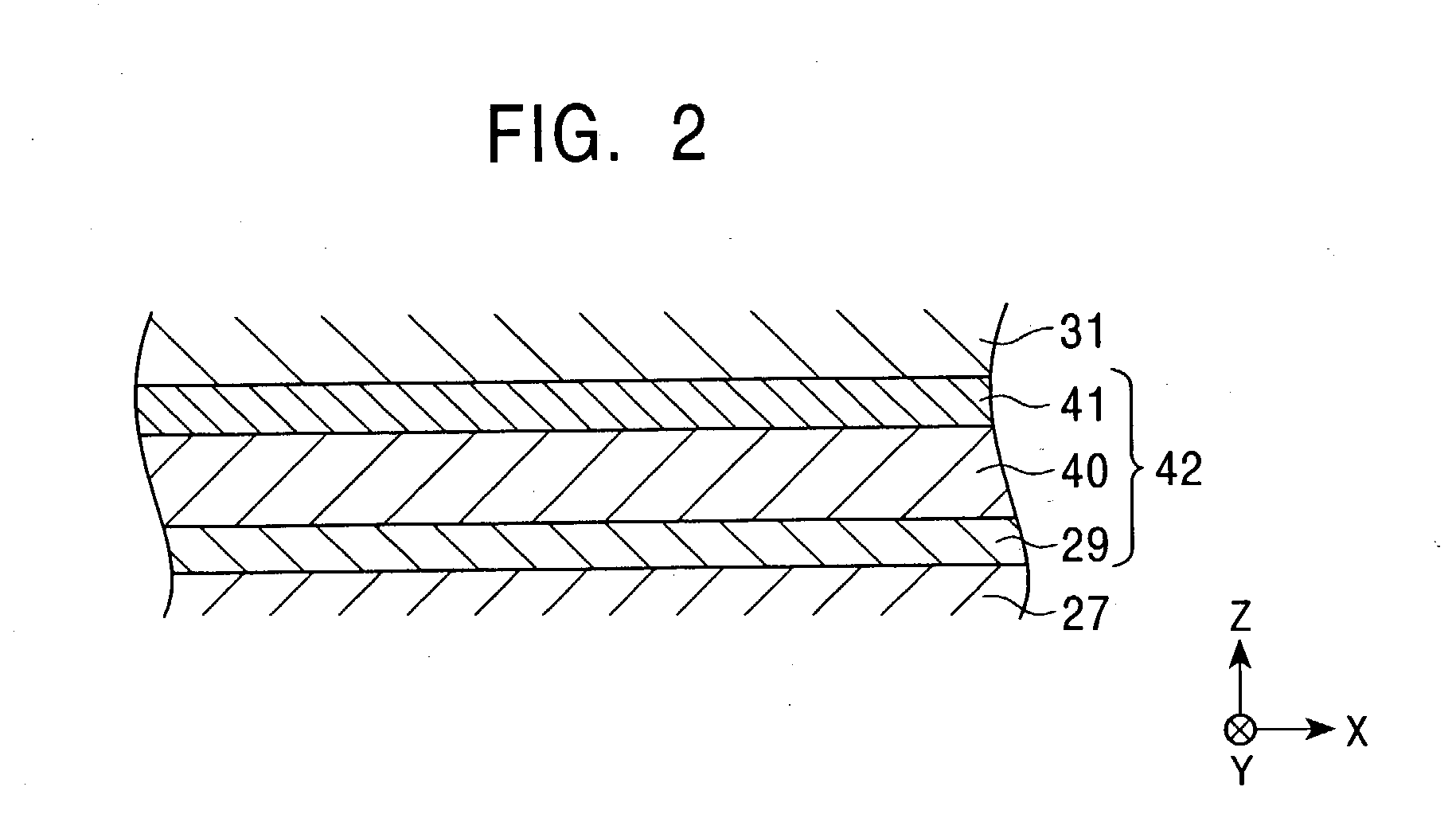

A ferroelectric capacitor includes: a ferroelectric film, and a lower electrode and an upper electrode interposing the ferroelectric film, wherein the ferroelectric film includes a first ferroelectric layer of ferroelectric material having a perovskite type crystal structure expressed by a general formula ABO3 formed by a metal organic chemical vapor deposition method, a second ferroelectric layer of ferroelectric material in which a part of B site element in ferroelectric material having a perovskite type crystal structure expressed by a general formula ABO3 is replaced with Nb, and a third ferroelectric layer of ferroelectric material having a perovskite type crystal structure expressed by a general formula ABO3 formed by a sol-gel method, which are sequentially laminated from the side of the lower electrode.

Owner:SEIKO EPSON CORP

Process for producing a photoelectric conversion device

InactiveUS6686262B2Rapid thermal annealing (RTA)Polycrystalline material growthFrom solid stateNoble gasElectrical conductor

Owner:SEMICON ENERGY LAB CO LTD

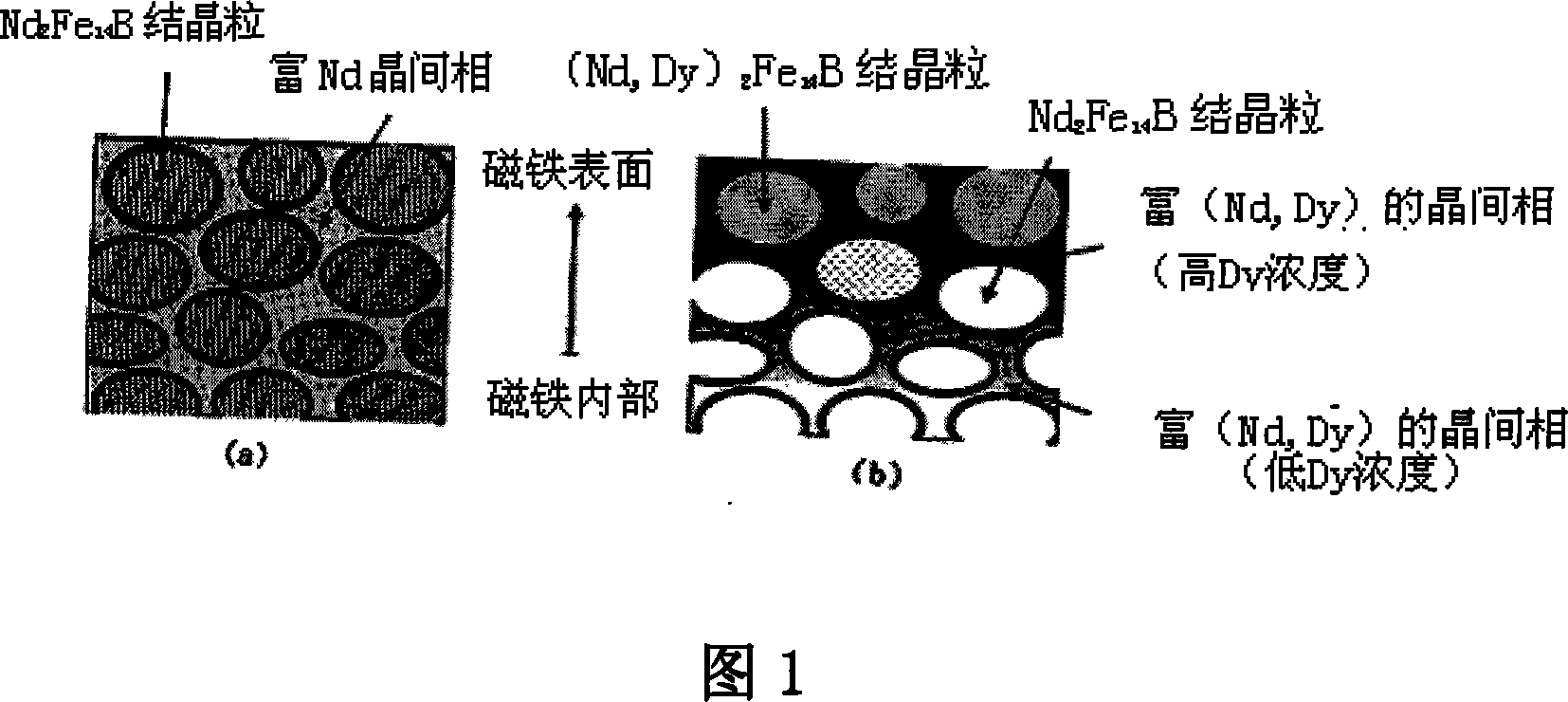

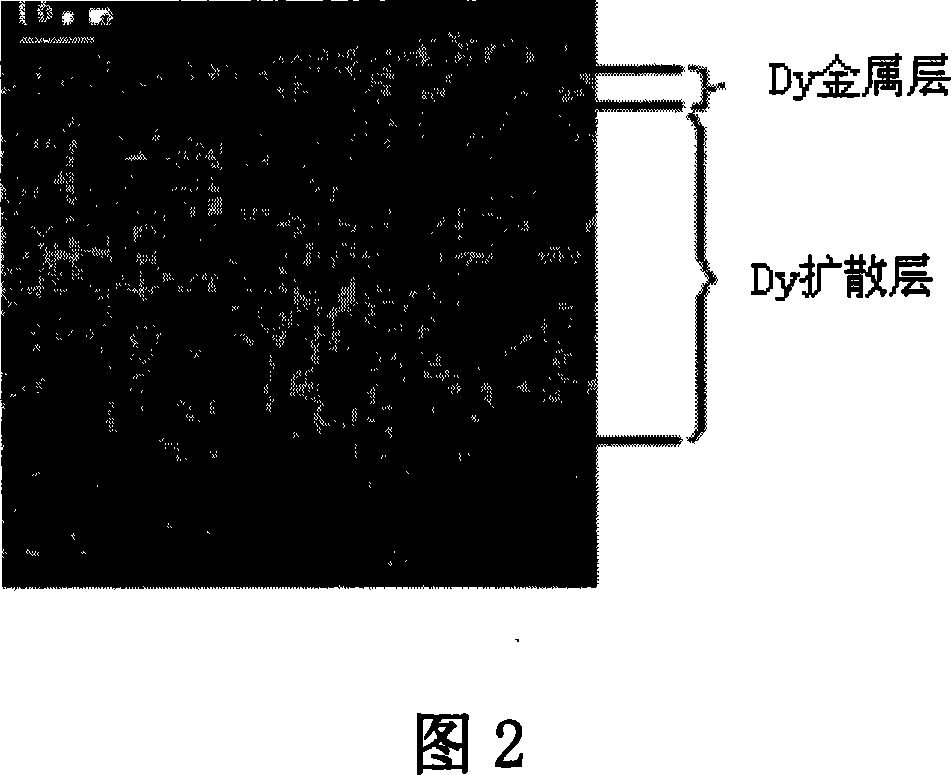

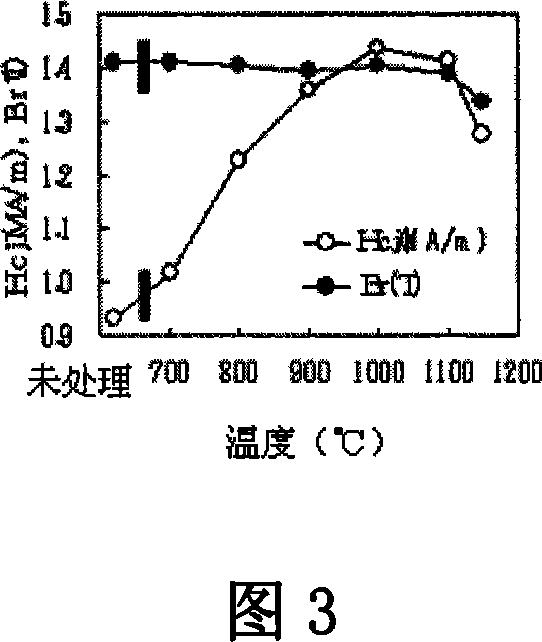

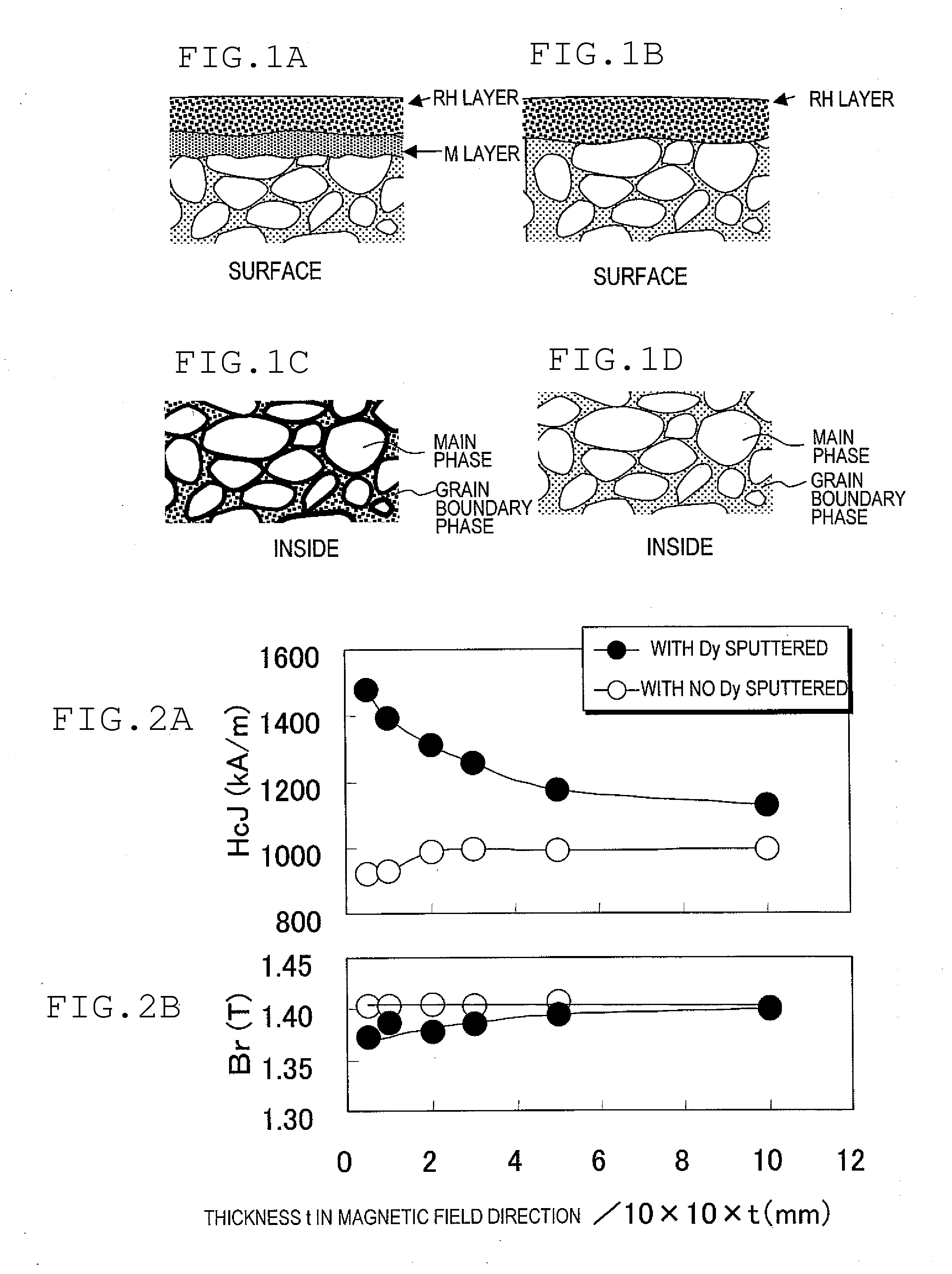

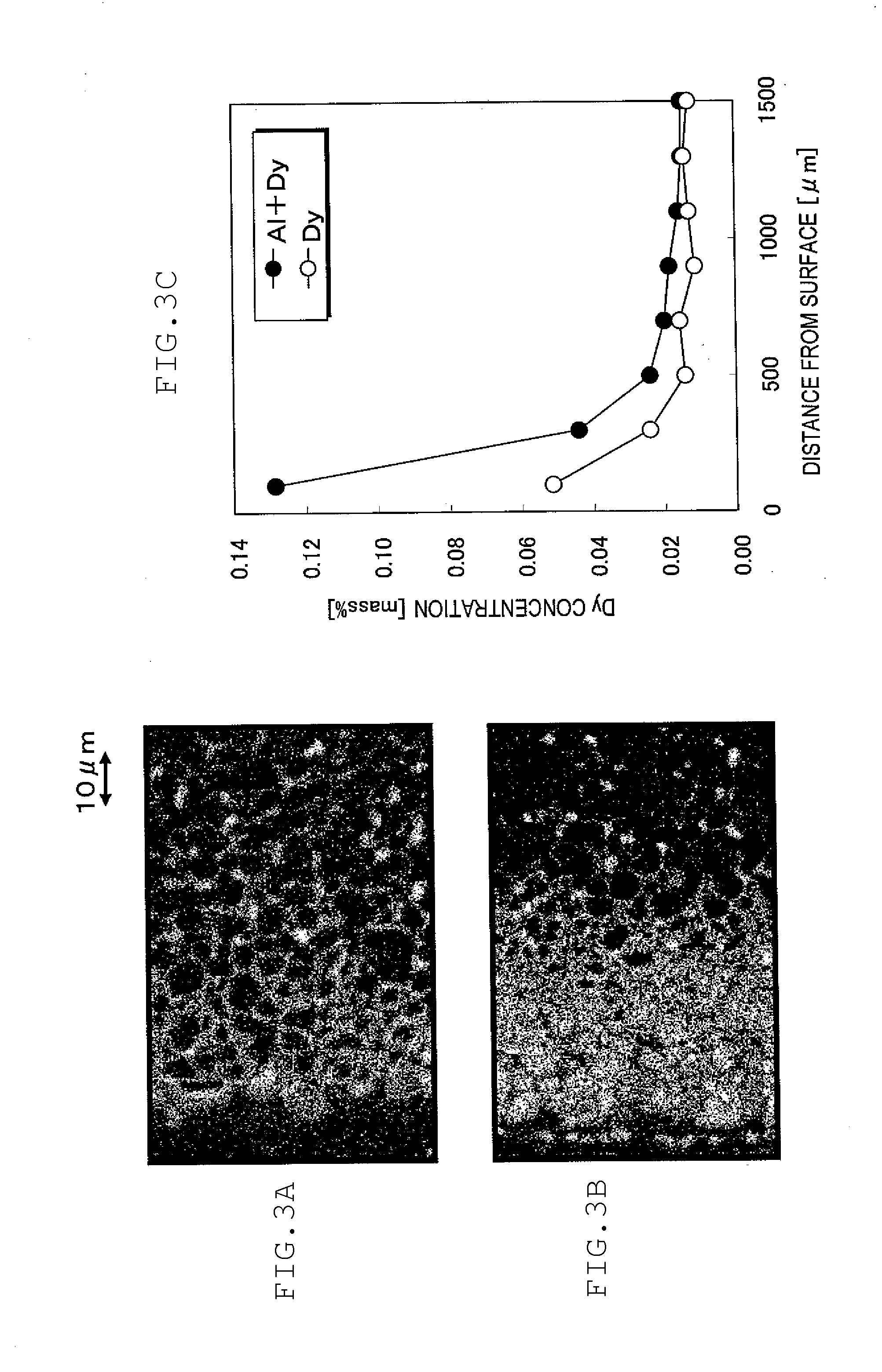

Nd-fe-b magnet with modified grain boundary and process for producing the same

InactiveCN101076870AIncrease the coercive forceEasy to demagnetizeInorganic material magnetismInductances/transformers/magnets manufactureReduction treatmentSintered magnets

In the conventional process, a coercitivity increase is realized by effecting selective presence of, for example, Dy metal in crystal grain boundary zones of sintered magnet. However, as this process employs a physical film forming technique using a vacuum vessel, such as sputtering, there has been a difficulty in mass productivity in the performing of vast quantities of magnet treatment. Further, from the viewpoint, for example, that an expensive high-purity Dy metal or the like must be employed as a film forming material, there has been a drawback in magnet cost. There is provided a method of modifying the grain boundary of Nd-Fe-B magnet, characterized in that a fluoride, oxide or chloride of metal element M (M: Pr, DY, Tb or Ho) is subjected to reduction treatment so that there is effected diffusion infiltration of the metal element M from the surface of Nd-Fe-B sintered magnet having an Nd rich crystal grain boundary phase surrounding the circumferential part of Nd2Fe14B main crystal into the grain boundary phase.

Owner:JAPAN SCI & TECH CORP +1

Transparent protective film for polarizing plate, process for producing the same, polarizing plate, and optical film and liquid crystal display using polarizing plate

InactiveUS20020186461A1Facilitate adhesion surfaceNo deformationPolarising elementsNon-linear opticsTectorial membraneLiquid-crystal display

A transparent protective film for polarizing plate being provided via an adhesive layer on at least one surface of a polarizer, wherein a ratio of constituent elements (oxygen ratio / carbon ratio) on the polarizer-adhering surface of the transparent protective film for polarizing plate, which is determined by X-ray photoelectron spectrometry, is larger than 0.75 has facilitate adhesion surface and no deformation without problems attributable to saponification.

Owner:NITTO DENKO CORP

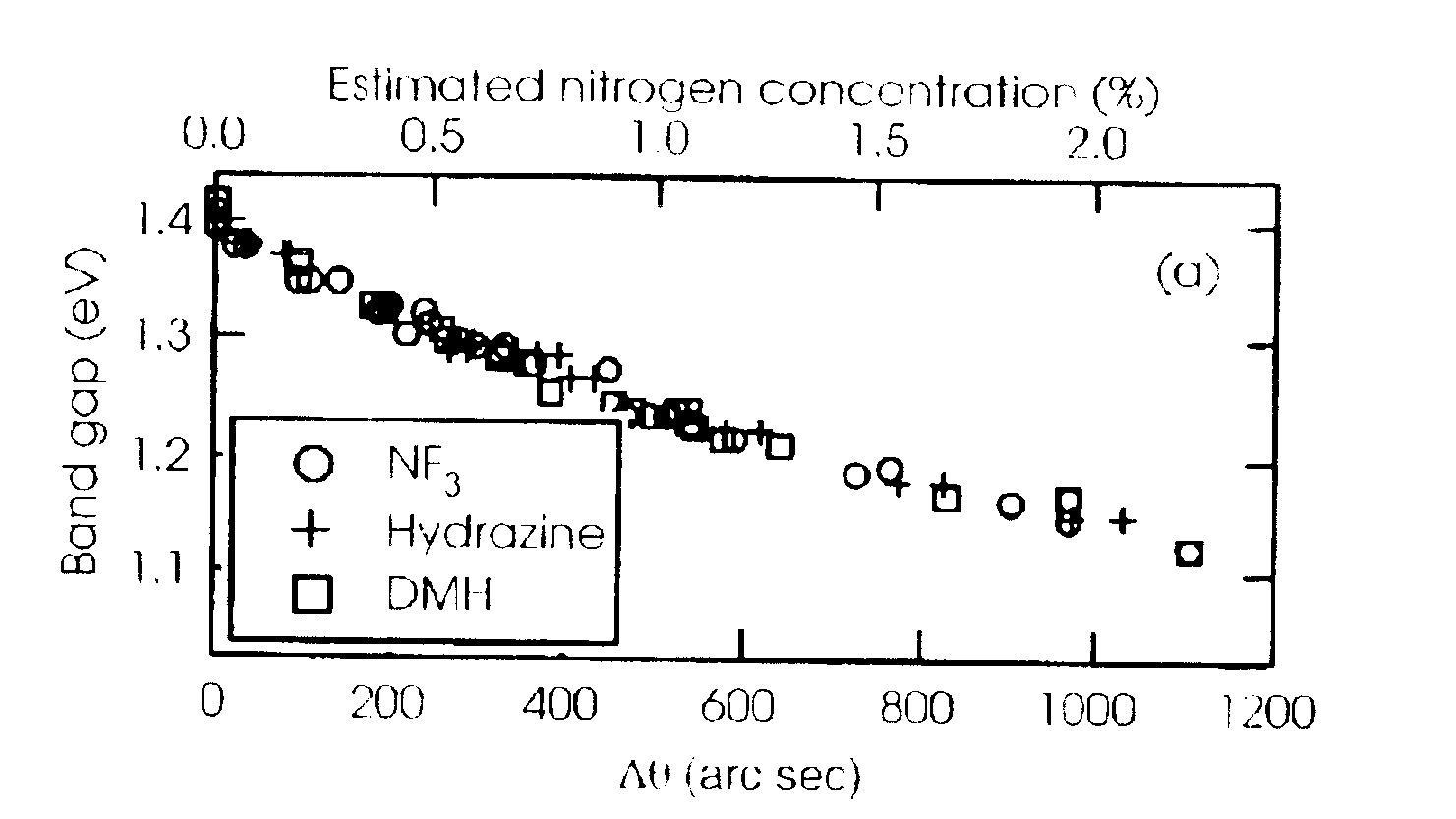

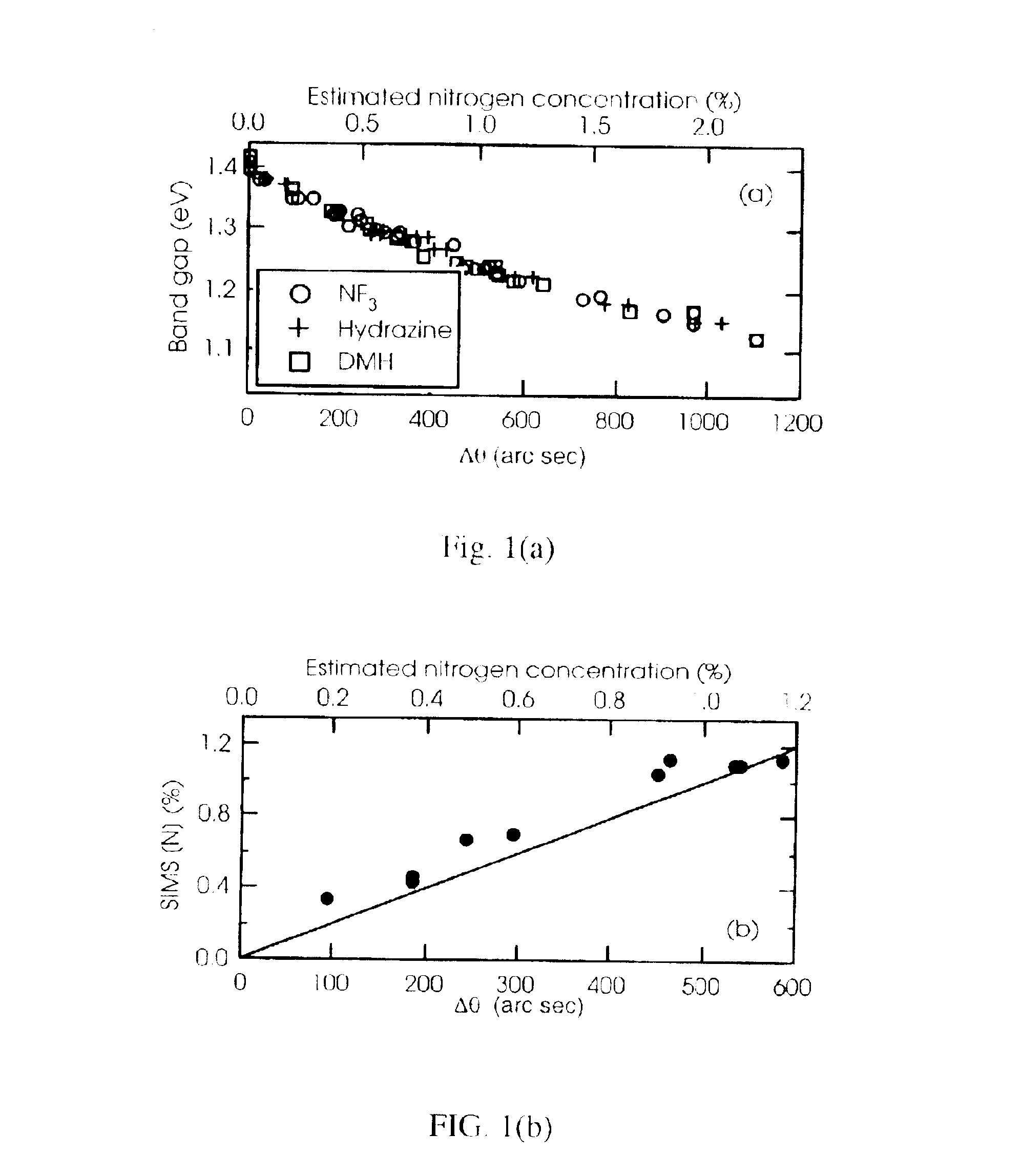

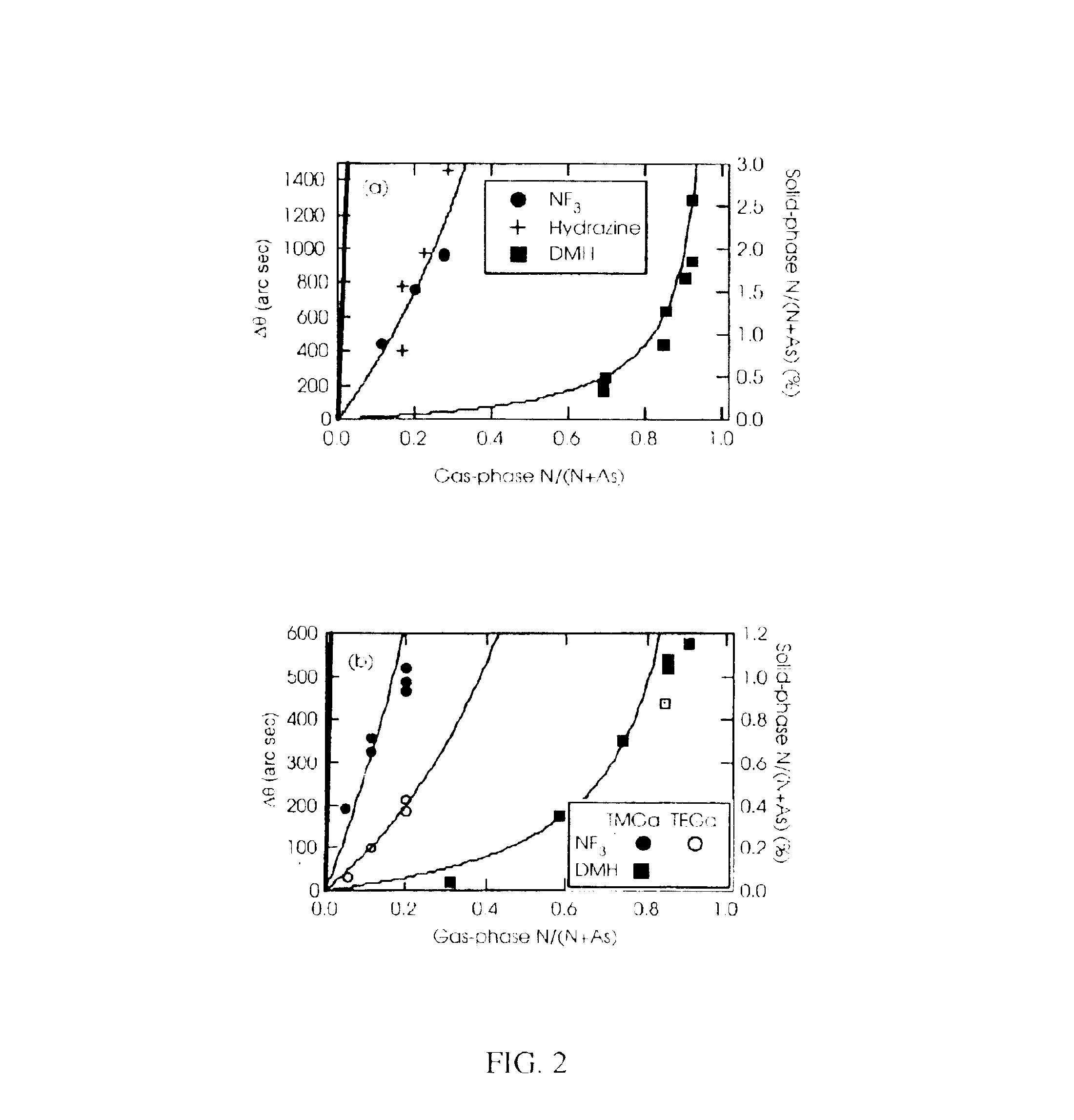

Method of preparing nitrogen containing semiconductor material

InactiveUS6787385B2Polycrystalline material growthSemiconductor/solid-state device manufacturingSemiconductor materialsNitrogen

Owner:ALLIANCE FOR SUSTAINABLE ENERGY

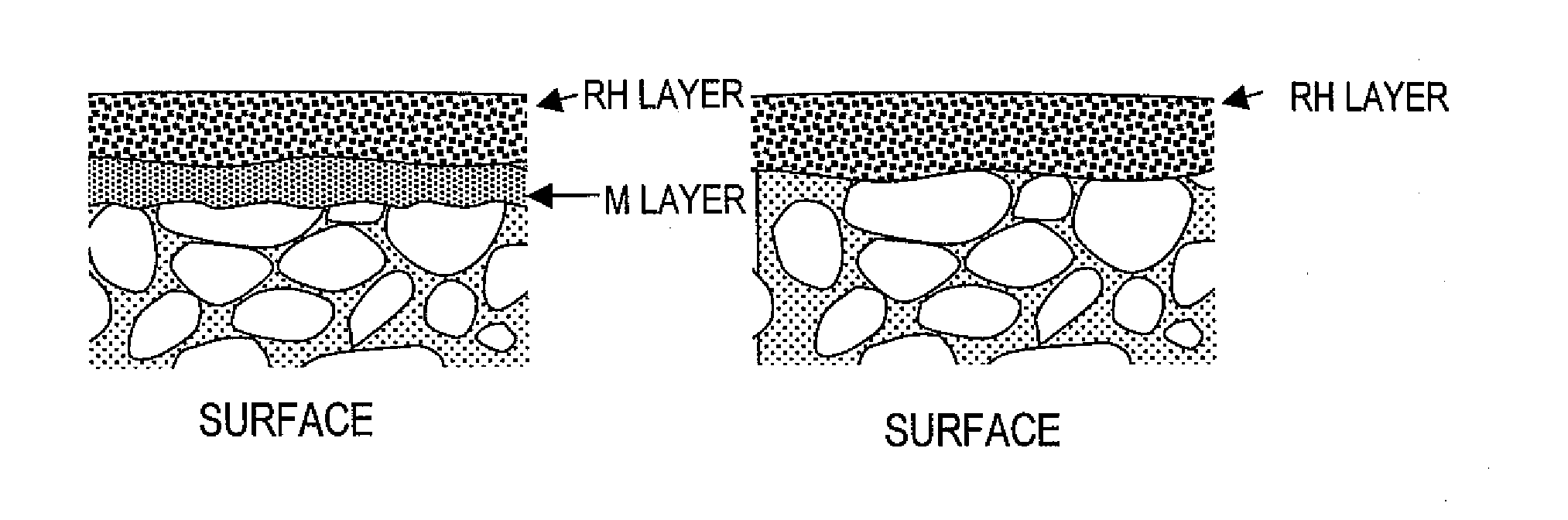

R-Fe-B RARE-EARTH SINTERED MAGNET AND PROCESS FOR PRODUCING THE SAME

ActiveUS20100231338A1Easy to useImprove remanenceVacuum evaporation coatingSputtering coatingRare-earth elementSintered magnets

First, an R—Fe—B based rare-earth sintered magnet body including, as a main phase, crystal grains of an R2Fe14B type compound that includes a light rare-earth element RL, which is at least one of Nd and Pr, as a major rare-earth element R is provided. Next, an M layer, including a metallic element M that is at least one element selected from the group consisting of Al, Ga, In, Sn, Pb, Bi, Zn and Ag, is deposited on the surface of the sintered magnet body and then an RH layer, including a heavy rare-earth element RH that is at least one element selected from the group consisting of Dy, Ho and Tb, is deposited on the M layer. Thereafter, the sintered magnet body is heated, thereby diffusing the metallic element M and the heavy rare-earth element RH from the surface of the magnet body deeper inside the magnet.

Owner:HITACHI METALS LTD

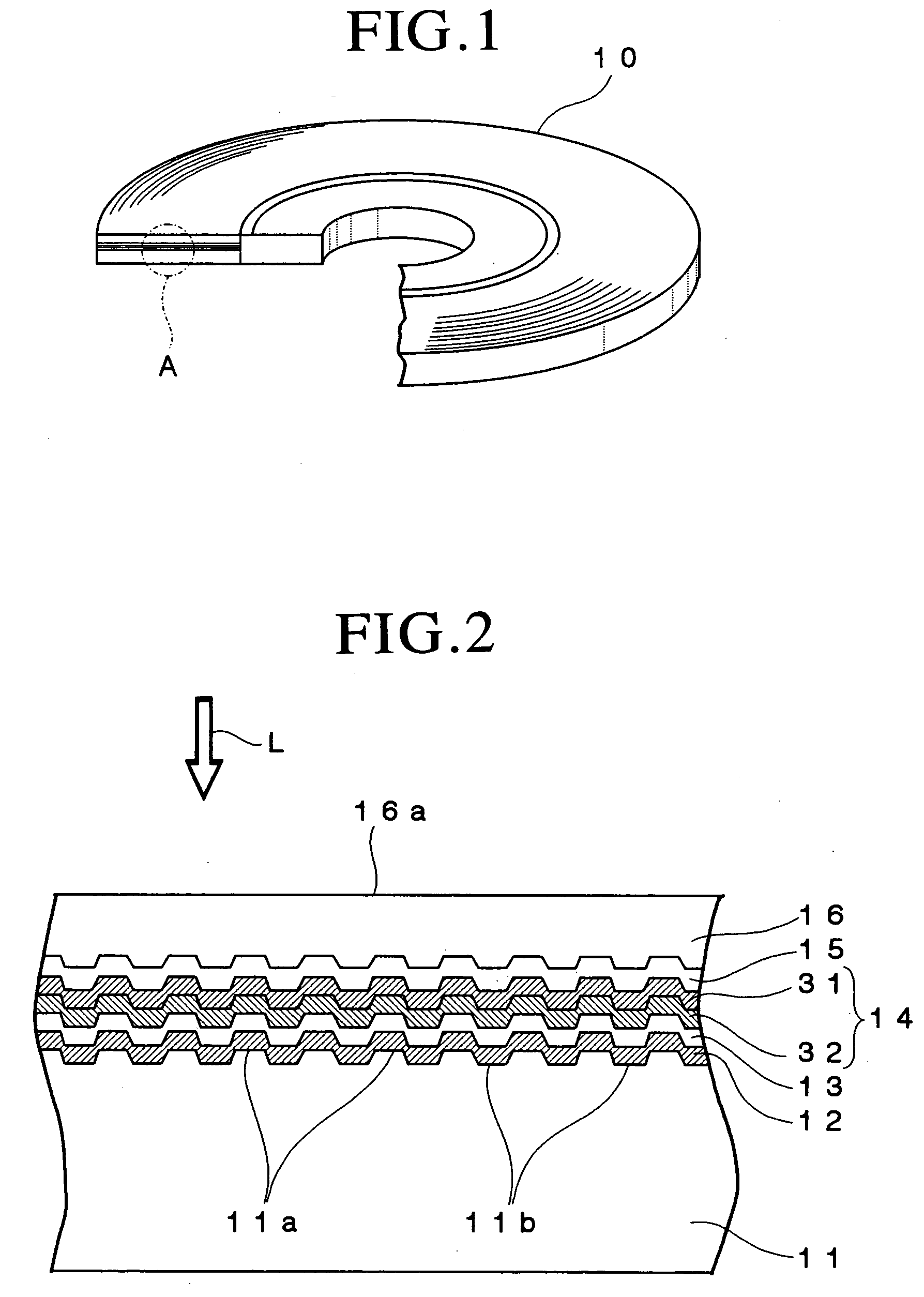

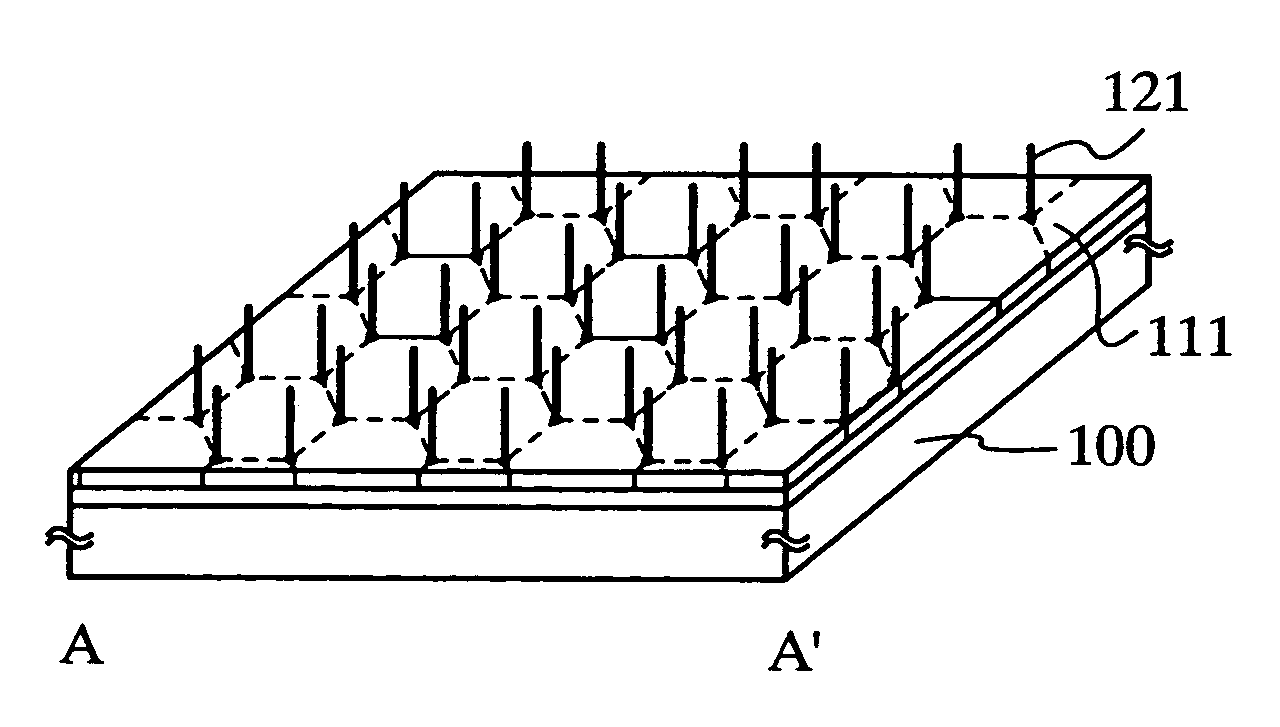

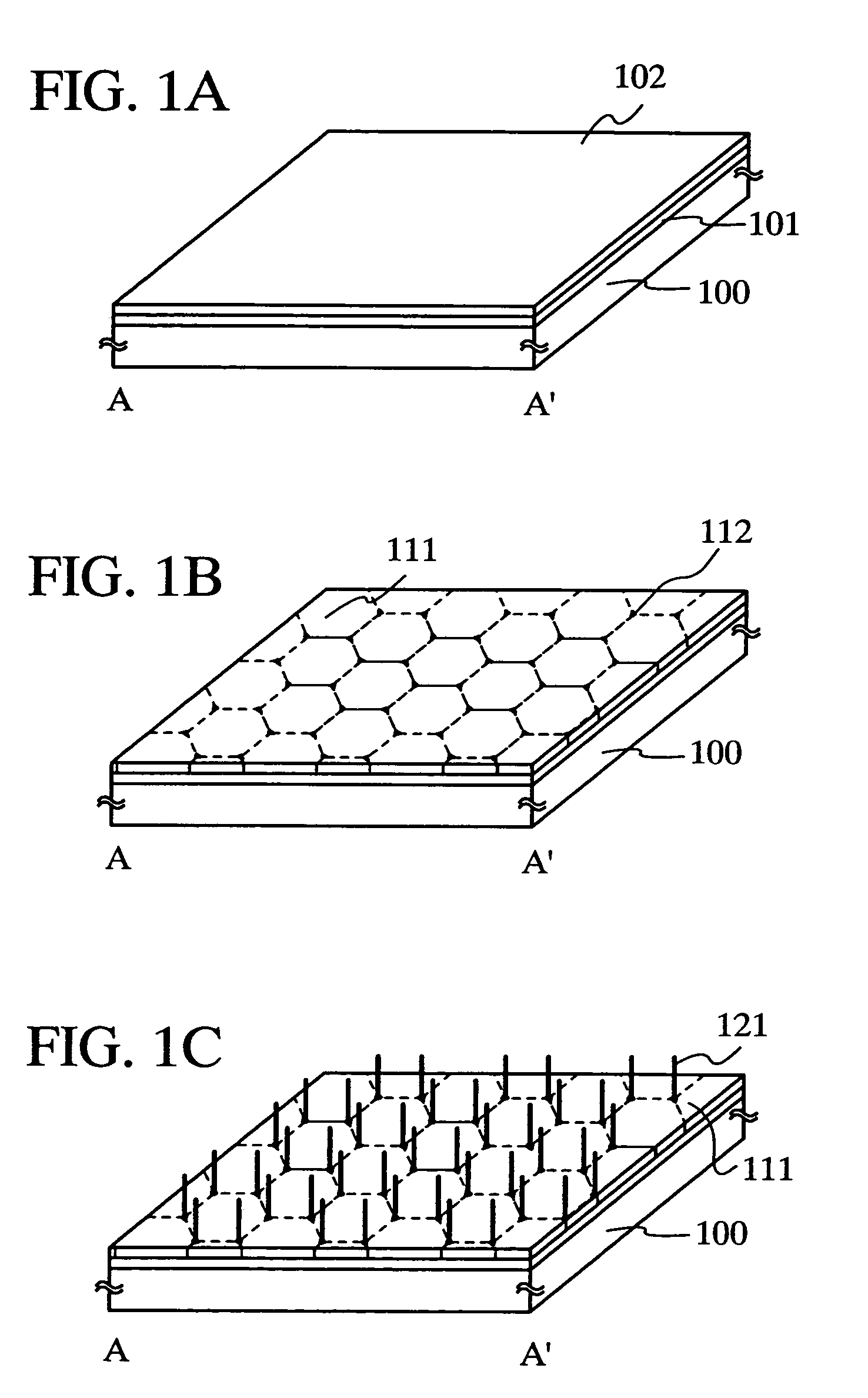

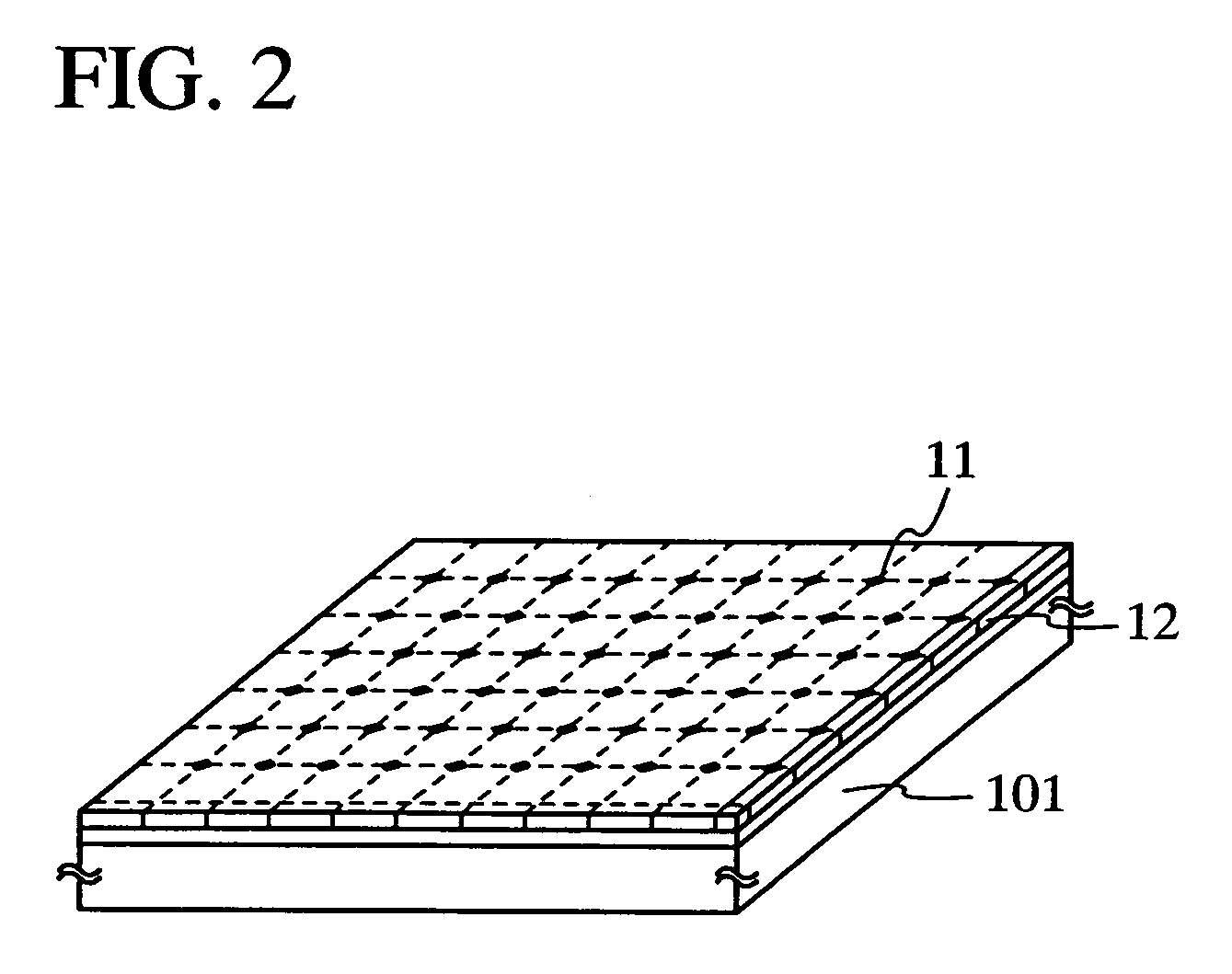

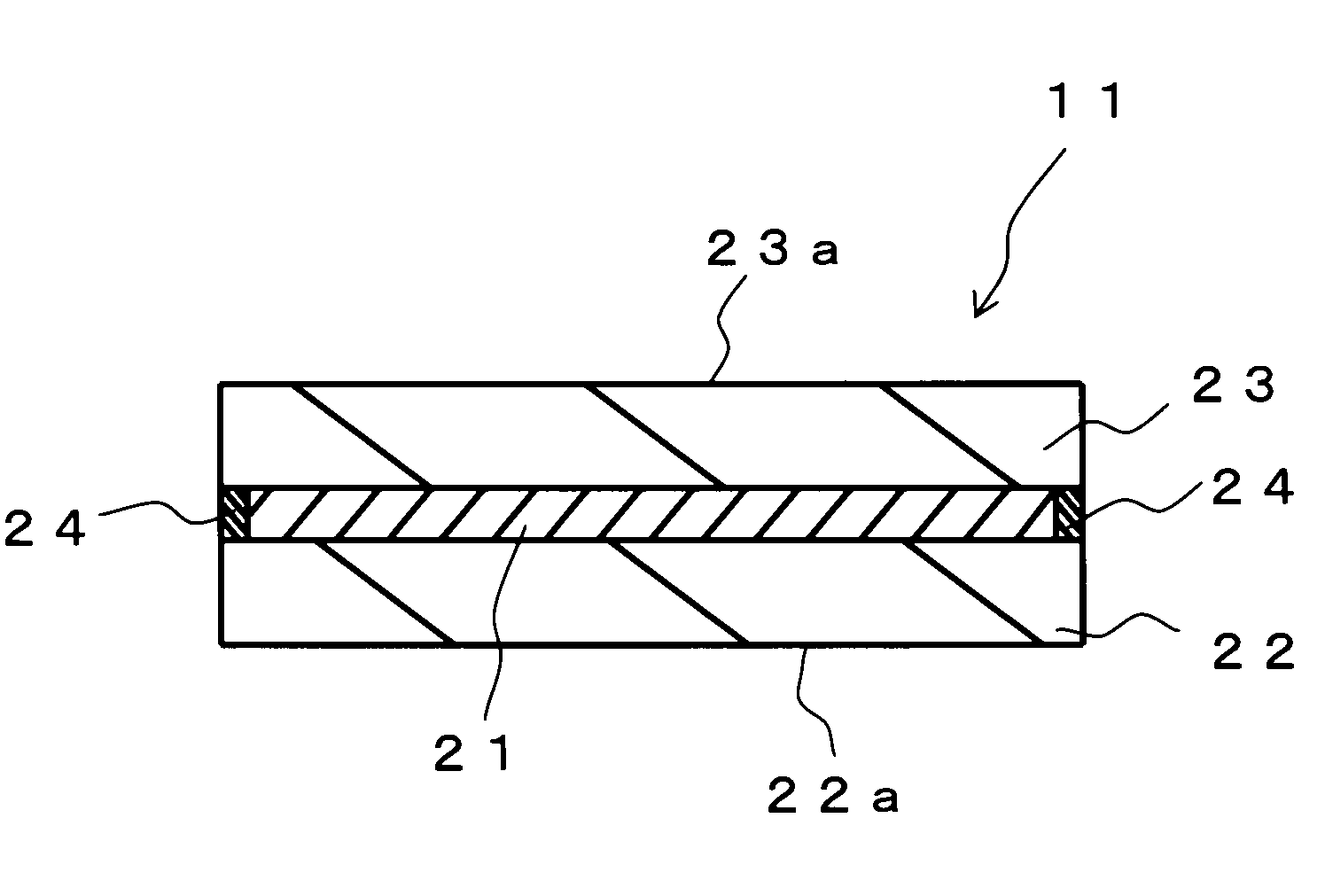

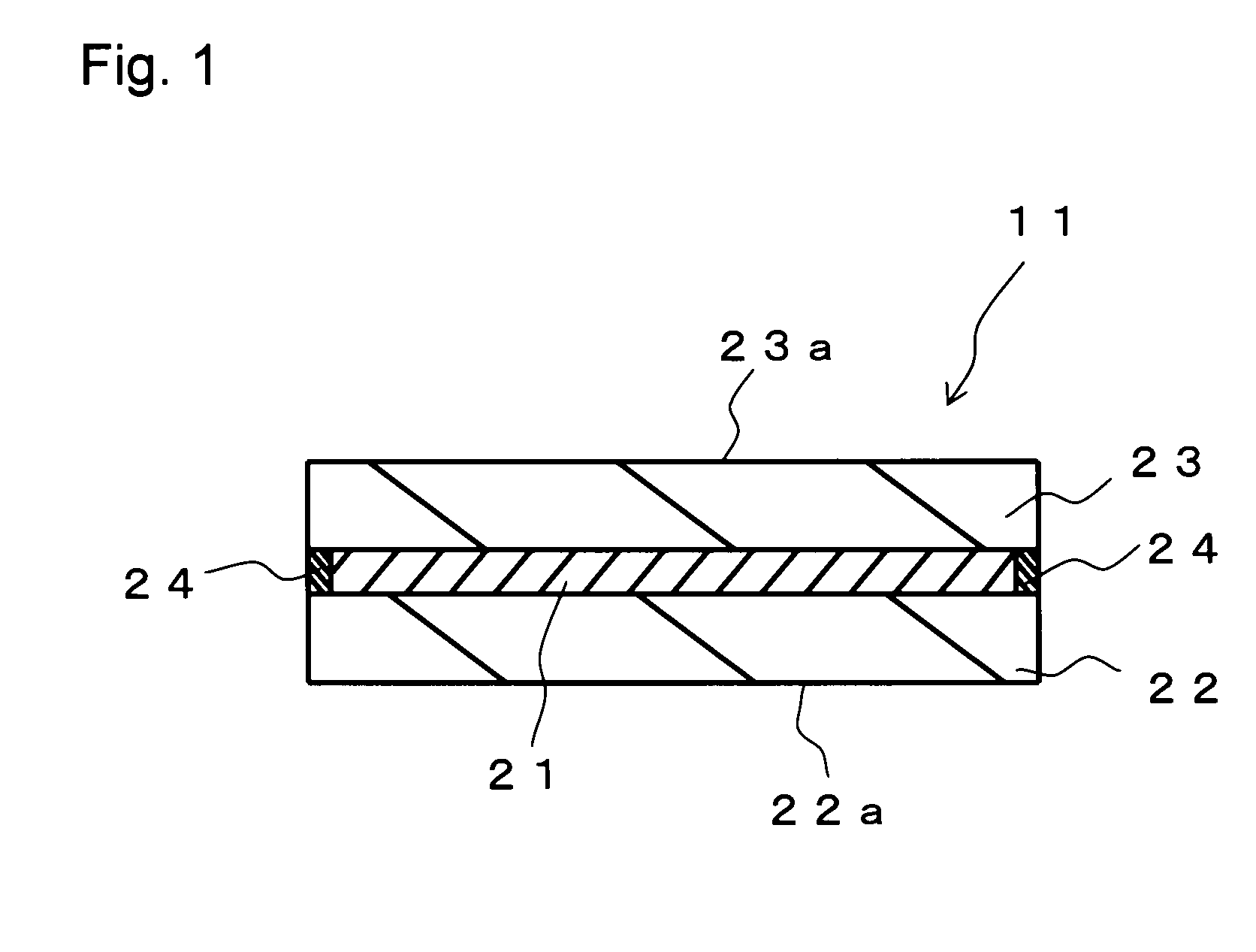

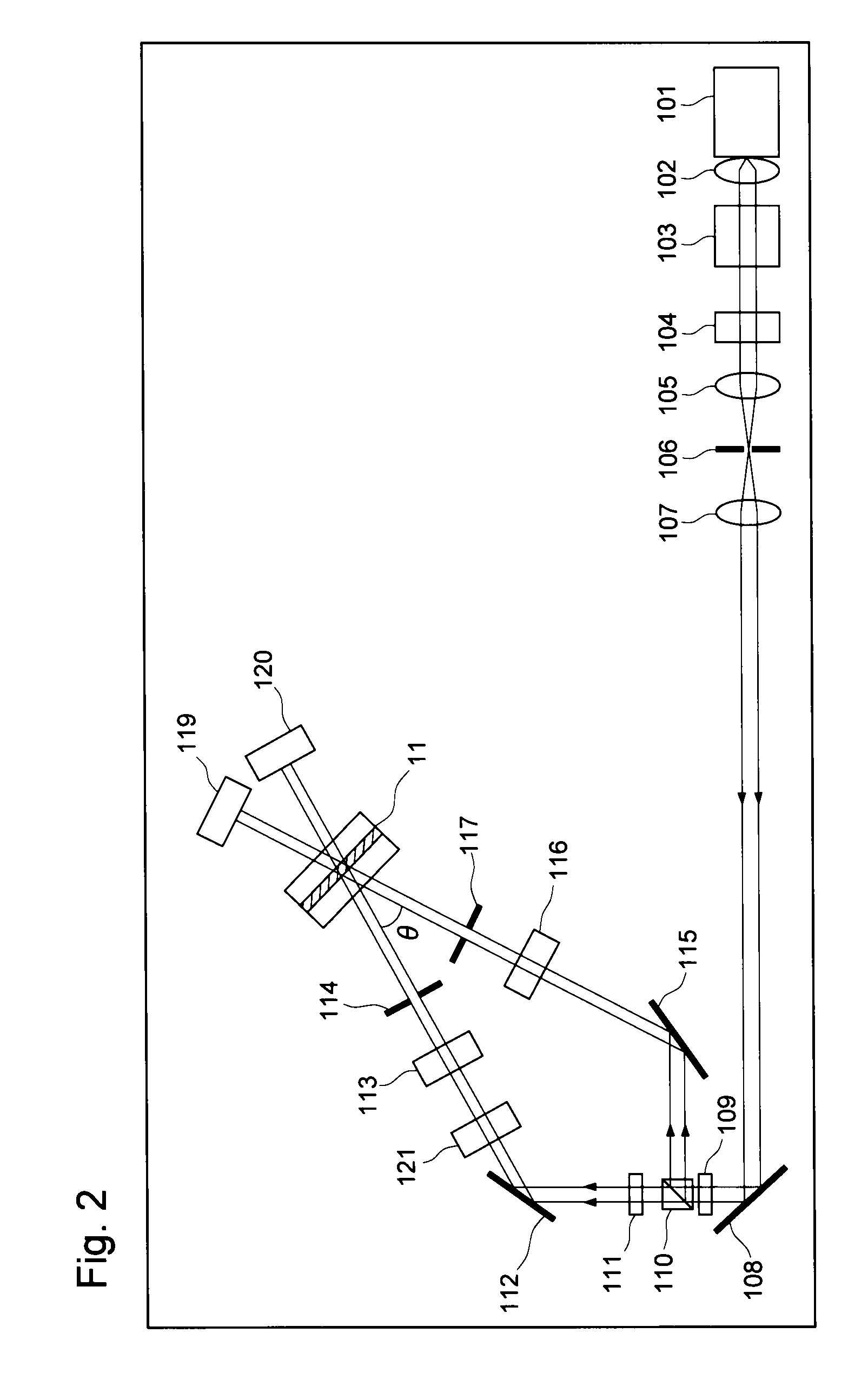

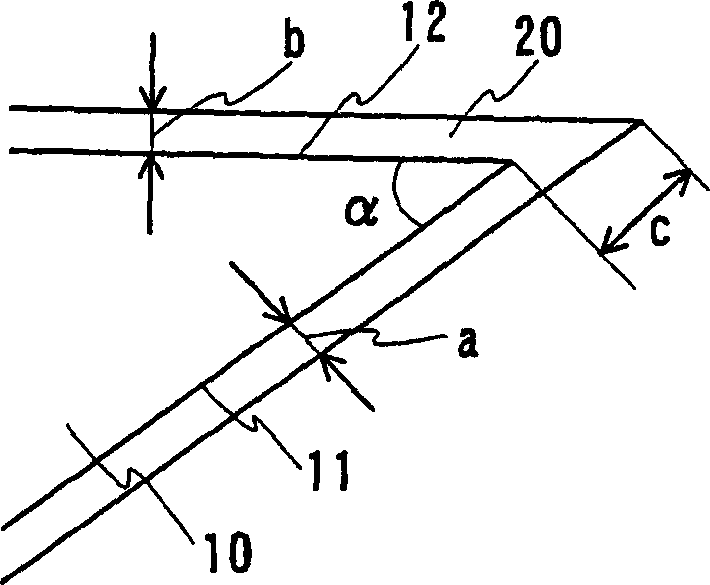

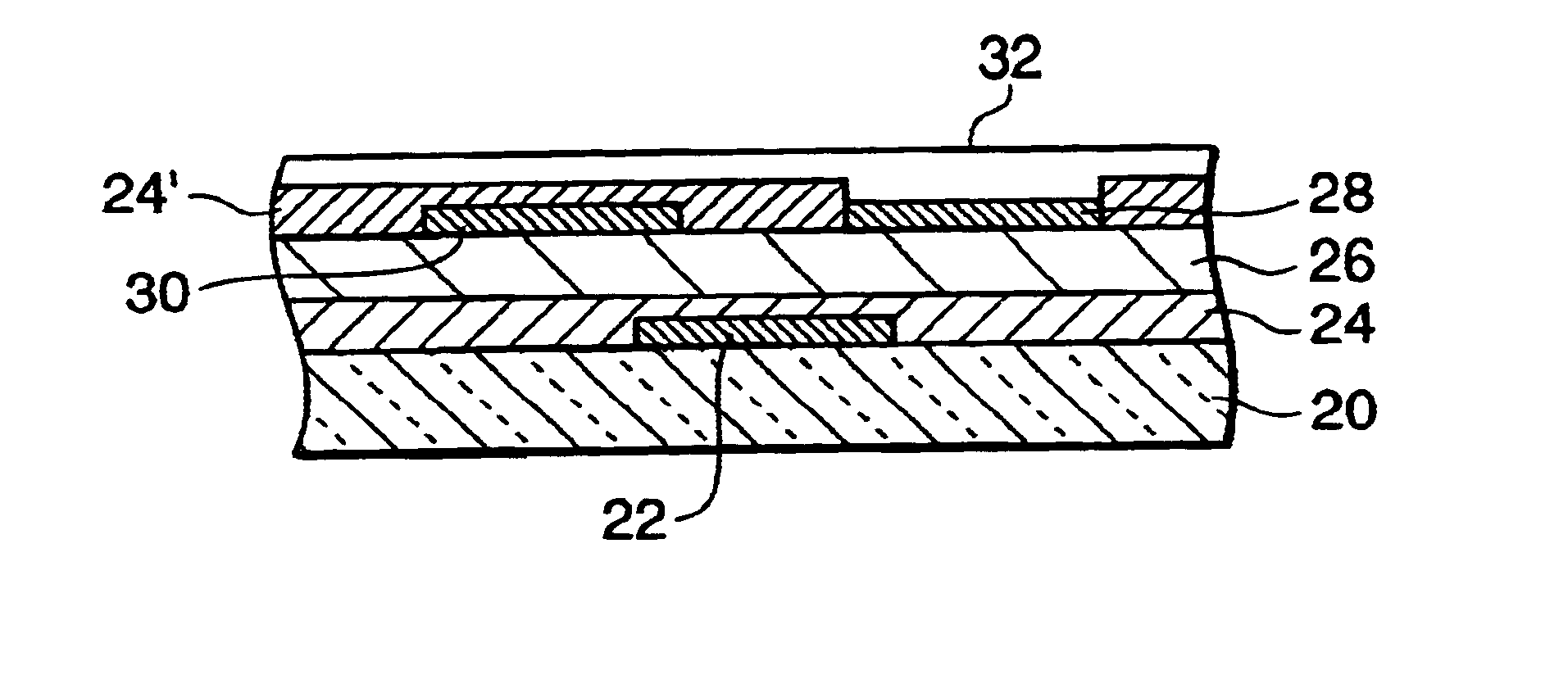

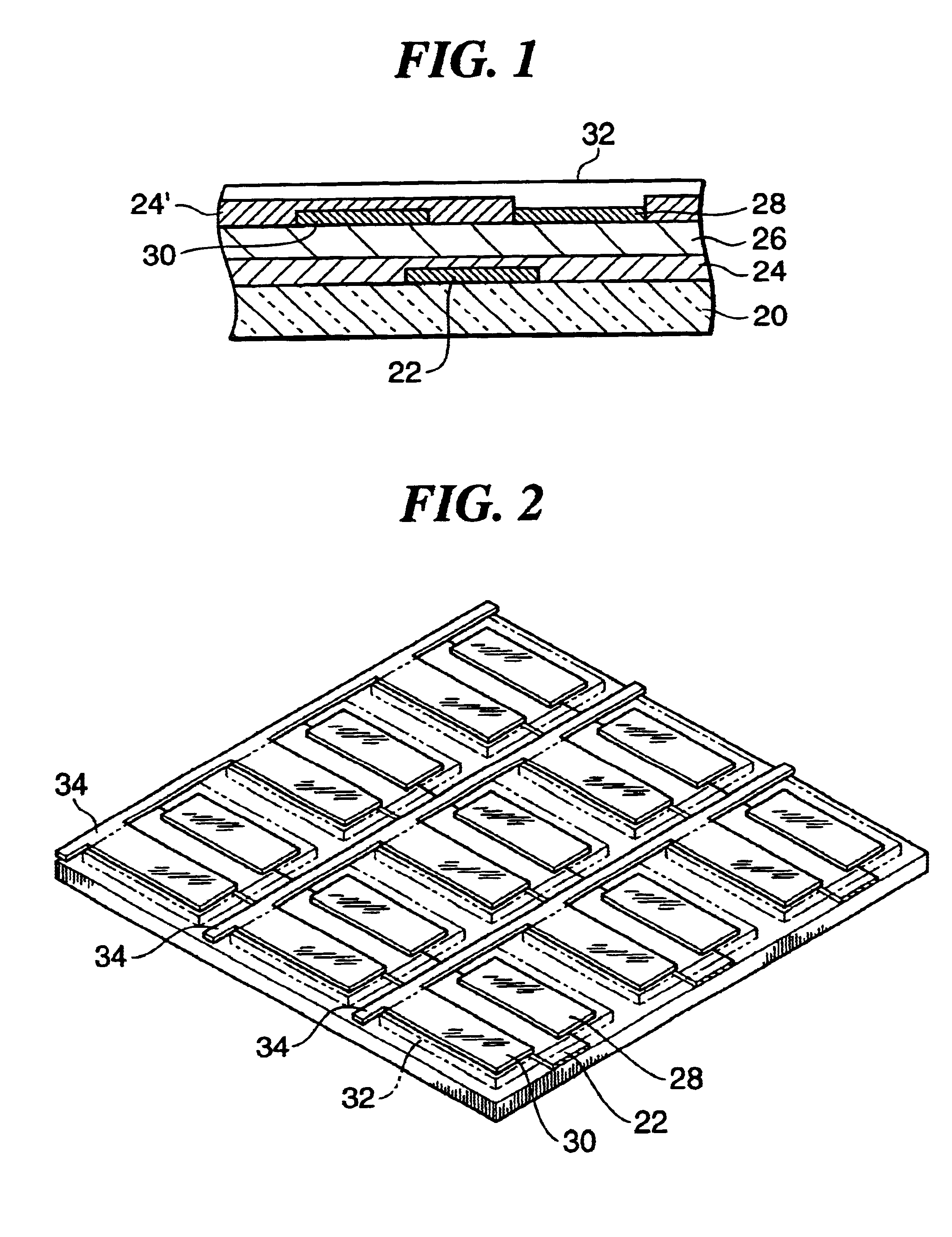

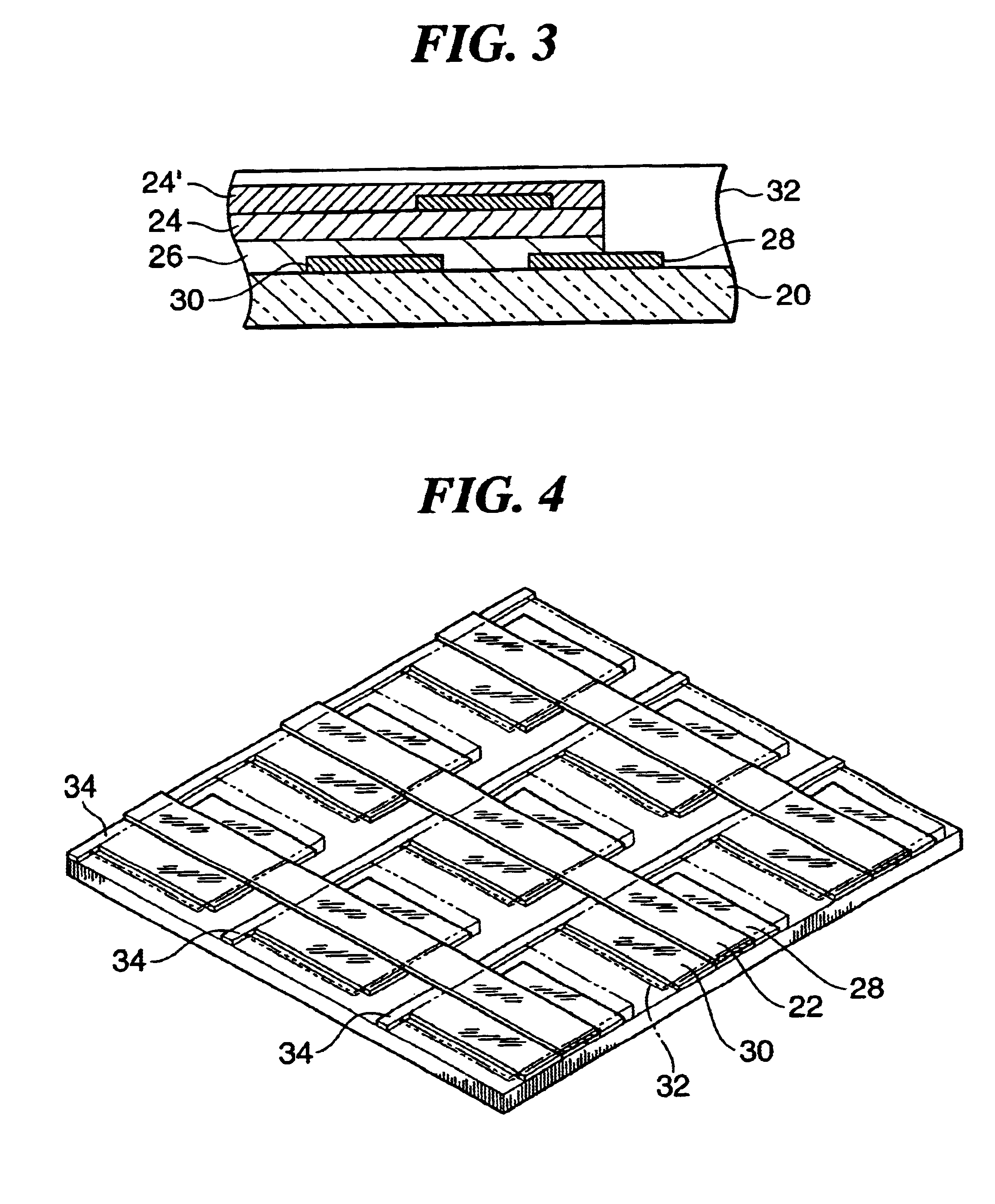

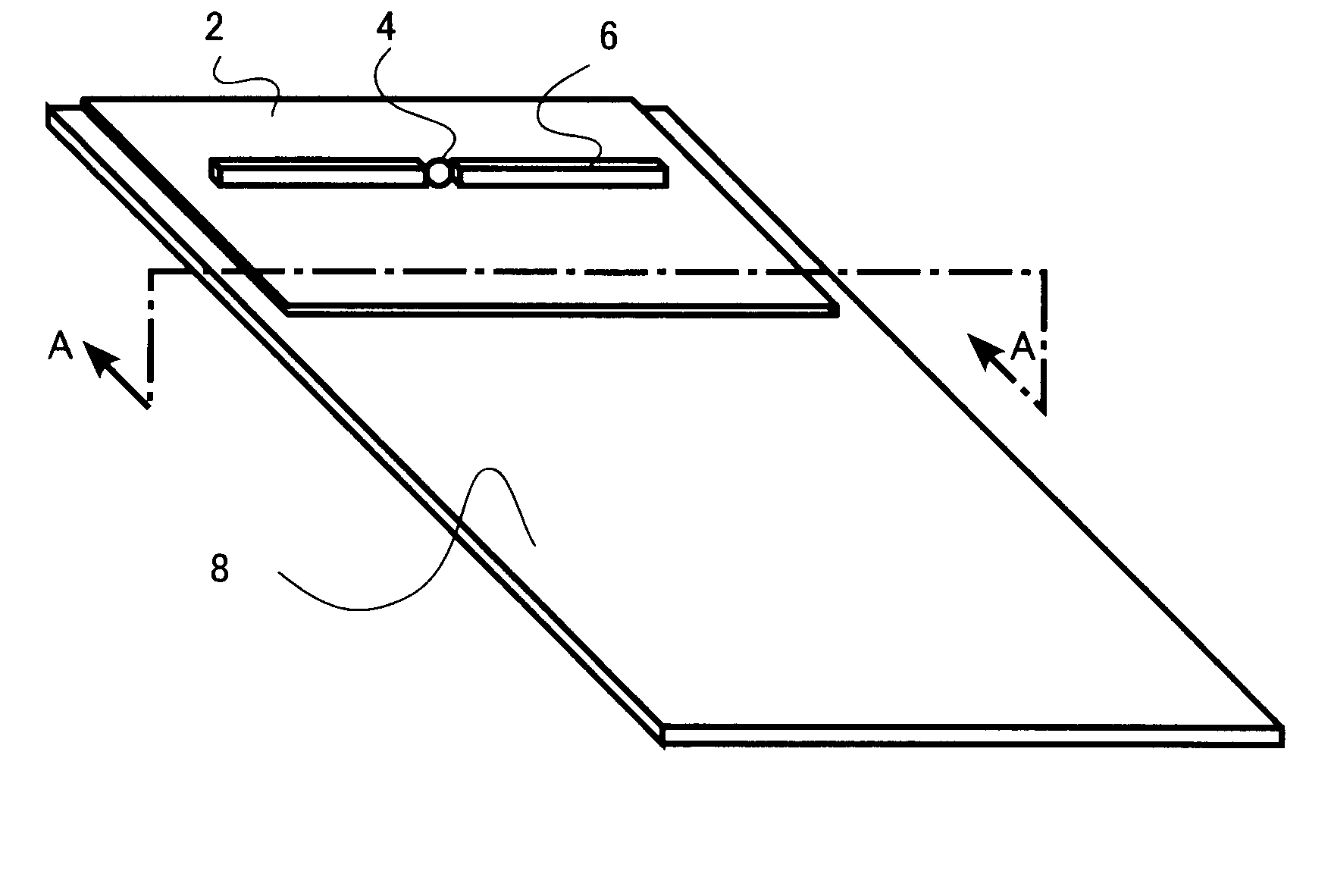

Method for producing silicon-containing complex oxide sol, method for producing silicon-containing hologram recording material, and hologram recording medium

InactiveUS20090186281A1Reduce lightAbsorption of lightPhotomechanical apparatusHydrolysateRecording layer

The present invention provides a method for producing a homogeneous complex oxide sol comprising Si and a metal other than Si as metal elements, and a method for producing a Si-containing hologram recording material using a homogeneous complex oxide sol. A method for producing a complex oxide sol comprising Si and a metal other than Si as metal elements, the method comprising: mixing a silanol compound with an alkoxide compound of a metal other than Si so that the silanol compound is reacted with the alkoxide compound, thereby yielding a precursor of a complex oxide, and adding water to the complex oxide precursor so as to hydrolyze an alkoxyl group bonded to the metal other than Si, and then making the resulting hydrolysate undergo a condensation reaction, thereby forming a complex oxide. A hologram recording medium (11) having a hologram recording layer (21) comprising the hologram recording material obtained by the production method.

Owner:TDK CORPARATION

Surface-coated cutting tool

ActiveCN1845808AImprove overall lifespanAvoid chippingTransportation and packagingMilling cuttersHardnessIndentation hardness

A surface-coated cutting tool having a base material and, formed thereon, a coating film, wherein the coating film has a hard layer comprising a compound selected from among a nitride, a carbonitride, a nitroxide and a carbonitroxide of one or more first elements selected from the group consisting of metals belonging to 4a, 5a and 6a Groups of the Periodic Table and B, Al and Si, and wherein the hard layer satisfies the followings: (a) in the nano indentation hardness test, (hmax - hf) / hmax is 0.2 to 0.7, wherein hmax represents the maximum indentation depth, and hf represents the indentation depth after the removal of a load (impression depth), (b) the hard layer has a film thickness of 0.5 to 15 mum, and (c) a hardness according to the nano indentation method is 20 to 80 GPa.

Owner:SUMITOMO ELECTRIC HARDMETAL CORP

Magnetic sensing element comprising antiferromagnetic layer laminated on free magnetic layer

Changes of the direction of magnetization at the central region of the free magnetic layer is facilitated by using a layer comprising a magnetic material having a small exchange stiffness constant such as the NiFe layer comprising the NiaFeb alloy (a and b are represented in at %, and satisfy the relation of a>80 and a+b=100) and NiFeX layer (X is at least one element selected from Mn, Cu, Zn, Ti, Al, Ge, Si, Cr, V, Sn, Ir, Ru, Nb, Sb, W, Mo, Os and Ta) for the magnetic material layer of the free magnetic layer.

Owner:TDK CORPARATION

Semiconductor memory device

InactiveUS20020196654A1Prevent peelingImprove adhesionSolid-state devicesSemiconductor/solid-state device manufacturingAlkaline earth metalEngineering

A semiconductor memory device comprising; (A) a transistor, (B) a capacitor member formed above said transistor through an insulating interlayer, said capacitor member comprising a lower electrode, a capacitor layer formed of a high-dielectric-constant material or a ferroelectric material and an upper electrode, (C) a contact plug formed in said insulating interlayer, for electrically connecting the lower electrode formed on the insulating interlayer with the transistor, and (D) a diffusion barrier layer formed between the lower electrode and the contact plug, said semiconductor memory device further comprising (E) an adhesion layer formed at least between the lower electrode and the diffusion barrier layer, and said adhesion layer consisting of an alloy that contains a noble metal element as a main component, and contains, as a component, a metal element that differs from any one of the noble metal element, an alkali element and an alkaline earth metal element and that contains no oxygen atom.

Owner:SONY CORP

Thin film transistor and display device having the same

A thin film transistor has, on a transparent substrate, a transparent semiconductor layer containing nitrogen, hydrogen and one or more elements selected from Al, Ga and In, a transparent source electrode and a transparent drain electrode at least partially in contact with the transparent semiconductor layer, and a transparent gate electrode.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Core-shell magnetic material, method of manufacturing core-shell magnetic material, device, antenna device, and portable device

ActiveUS20100060538A1Improve featuresRadiating elements structural formsInorganic material magnetismRare-earth elementNitrogen

The present invention provides a core-shell magnetic material having an excellent characteristic in a high frequency band, particularly, in a GHz band. The core-shell magnetic material includes: core-shell magnetic particles including magnetic metal particles and an oxide coating layer, the magnetic metal particle containing magnetic metal selected from the group of Fe, Co, and Ni, nonmagnetic metal selected from the group of Mg, Al, Si, Ca, Zr, Ti, Hf, Zn, Mn, a rare-earth element, Ba, and Sr, and an element selected from carbon and nitrogen, and the oxide coating layer being made of an oxide containing at least one nonmagnetic metal as one of the components of the magnetic metal particle; and oxide particles existing at least a part between the magnetic metal particles and containing nonmagnetic metal selected from the group of Mg, Al, Si, Ca, Zr, Ti, Hf, Zn, Mn, a rare-earth element, Ba, and Sr, and in which nonmagnetic metal / magnetic metal (atomic ratio) in the particles is higher than that in the oxide coating layer.

Owner:KK TOSHIBA

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com