Rare earth permanent magnet produced by applying abundant rare earth cerium (Ce) and preparation method thereof

A rare earth permanent magnet, high-abundance technology, applied in the direction of magnetic objects, inductor/transformer/magnet manufacturing, magnetic materials, etc., to reduce production costs, improve grain boundary phase distribution, and achieve cost control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The steps of the preparation method of the rare earth permanent magnet produced by using high-abundance rare earth Ce are as follows:

[0023] 1) The main phase alloy powder was prepared by quick-setting flake ingot, hydrogen explosion and jet milling;

[0024]2) Grain boundary phase supplementary alloy powder is prepared by coarse crushing and mechanical ball milling after vacuum intermediate frequency induction melting;

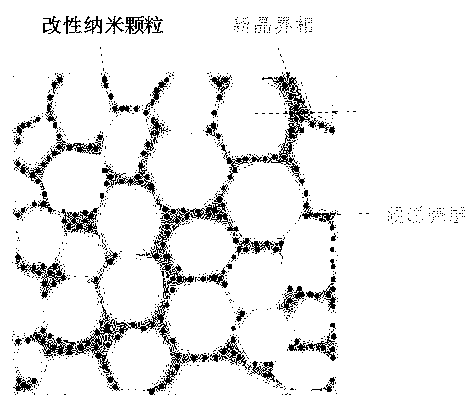

[0025] 3) The nano powder and the grain boundary phase supplementary alloy powder are evenly mixed for nano modification, and the mass fraction of the added nano powder is 0.001~10%, so as to obtain the nano modified grain boundary phase supplementary alloy powder;

[0026] 4) The main phase alloy powder and the nano-modified grain boundary phase-assisted alloy powder are evenly mixed and then subjected to magnetic field orientation pressing to obtain a green body, in which the nano-modified grain-boundary phase-assisted alloy powder accounts for 3% ...

Embodiment 1

[0030] 1) The main phase alloy powder is prepared by quick-setting scale ingot, hydrogen explosion and jet milling. The main phase alloy is expressed in atomic percentage, and its composition is (Nd 0.9 Ce 0.1 ) 12 Fe 82 B 6 ;

[0031] 2) Grain boundary supplementary alloy powder is prepared by coarse crushing and mechanical ball milling after vacuum intermediate frequency induction melting. The grain boundary supplementary alloy is expressed in atomic percentage, and its composition is Ce 72 Cu 28 ;

[0032] 3) Evenly mix the nano powder and the grain boundary phase alloy powder for nano modification, and the added nano Dy 2 o 3 The powder mass fraction is 3%, and the grain boundary phase supplementary alloy powder through nano-modification is obtained;

[0033] 4) The main phase alloy powder and the nano-modified grain boundary phase-assisted alloy powder are evenly mixed and then subjected to magnetic field orientation pressing to obtain a green body, in which the n...

Embodiment 2

[0037] 1) The main phase alloy powder is prepared by quick-setting flake ingot, hydrogen explosion and jet milling. The main phase alloy is expressed in atomic percentage, and its composition is (Nd 0.6 Ce 0.4 ) 15 Fe 78.4 Ga 0.5 Al 0.5 co 0.1 B 5.5 ;

[0038] 2) Grain boundary supplementary alloy powder is prepared by coarse crushing and mechanical ball milling after vacuum intermediate frequency induction melting. The grain boundary supplementary alloy is expressed in atomic percentage, and its composition is Nd 70 Cu 30 ;

[0039] 3) The nano-powder and the grain boundary phase-assisted alloy powder are evenly mixed for nano-modification, and the mass fraction of the added nano-Cu powder is 0.05%, and the nano-modified grain-boundary phase-assisted alloy powder is obtained;

[0040] 4) The main phase alloy powder and the nano-modified grain boundary phase-assisted alloy powder are evenly mixed, and then subjected to magnetic field orientation pressing to obtain a g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com