Patents

Literature

2031results about How to "Improve microstructure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of electrophoretic deposition of ceramic bodies for use in manufacturing dental appliances

InactiveUS6059949AHigh strengthImprove toughnessElectrolysis componentsTeeth fillingMetallurgyElectrophoresis

A method for electrophoretic deposition of ceramic particles as a green body shaped as a dental appliance, the method comprising the steps of (a) forming a suspension of the ceramic particles in a first polar solvent, the ceramic particles constituting at least about 5% of the first suspension by weight; (b) passing a direct electrical current through the first suspension, using a deposition electrode shaped as the dental appliance to form a green body; (c) coating the green body with glass particles; and (d) sintering the resultant coated body for obtaining a glass coated all-ceramic dental appliance.

Owner:CEREL CERAMIC TECH

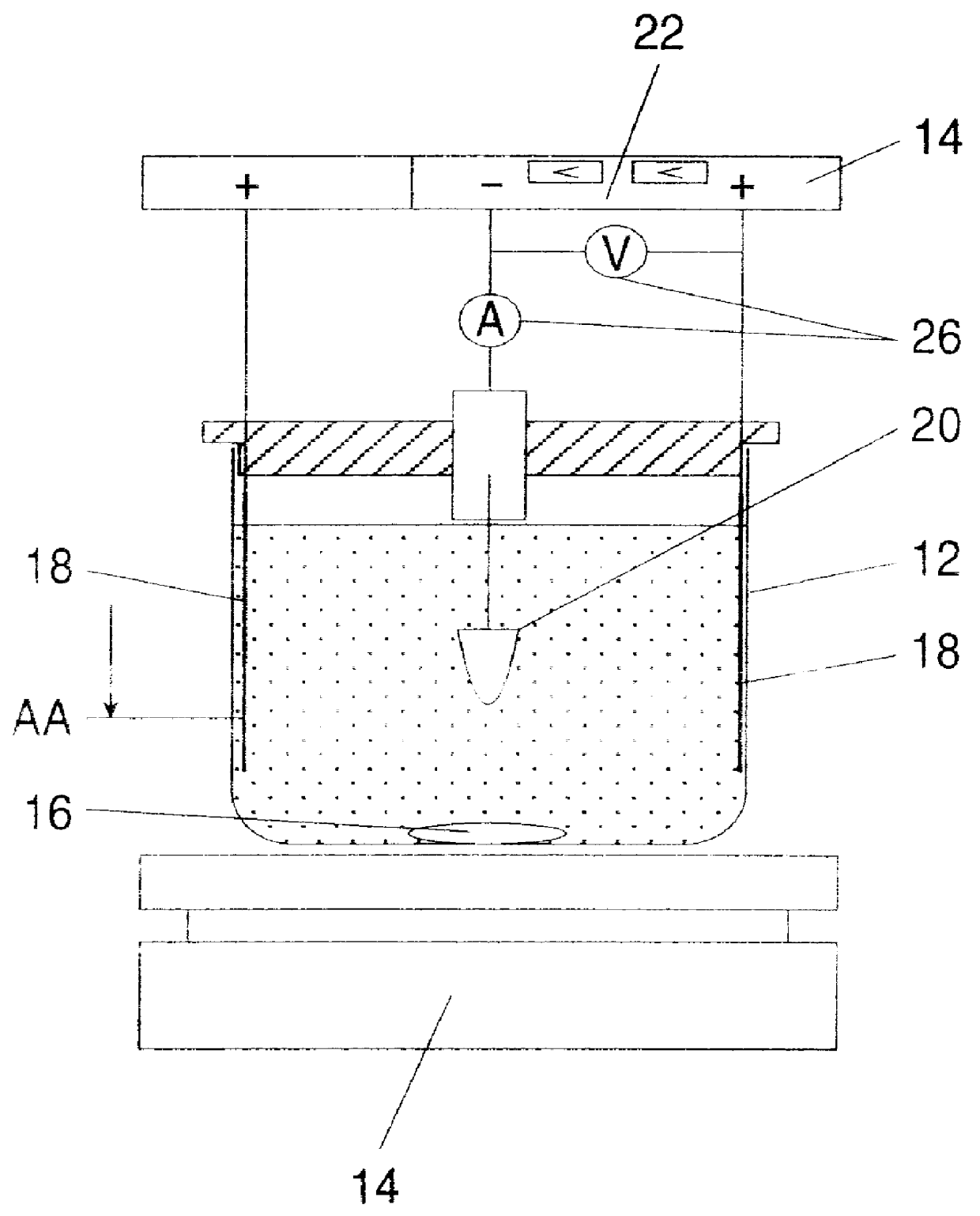

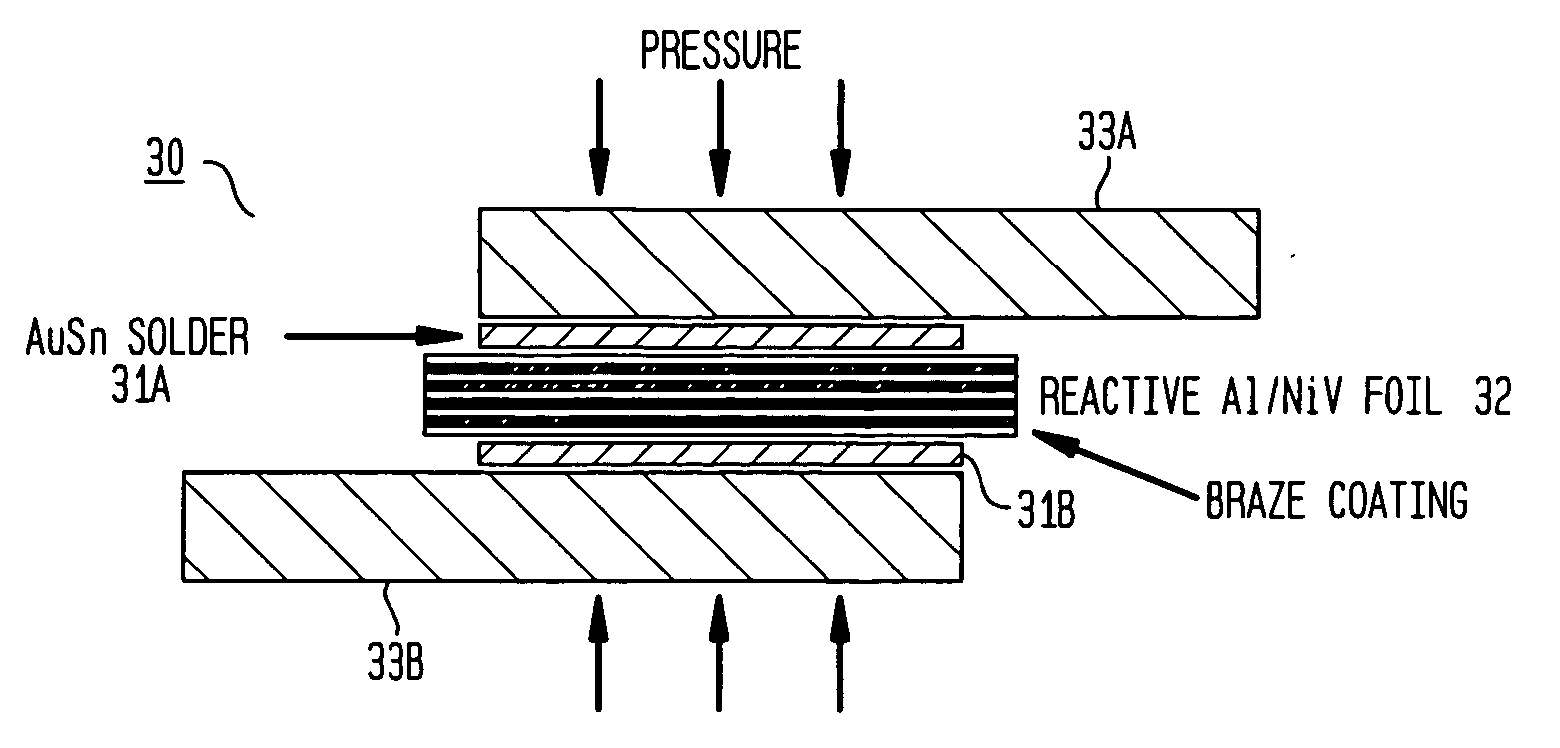

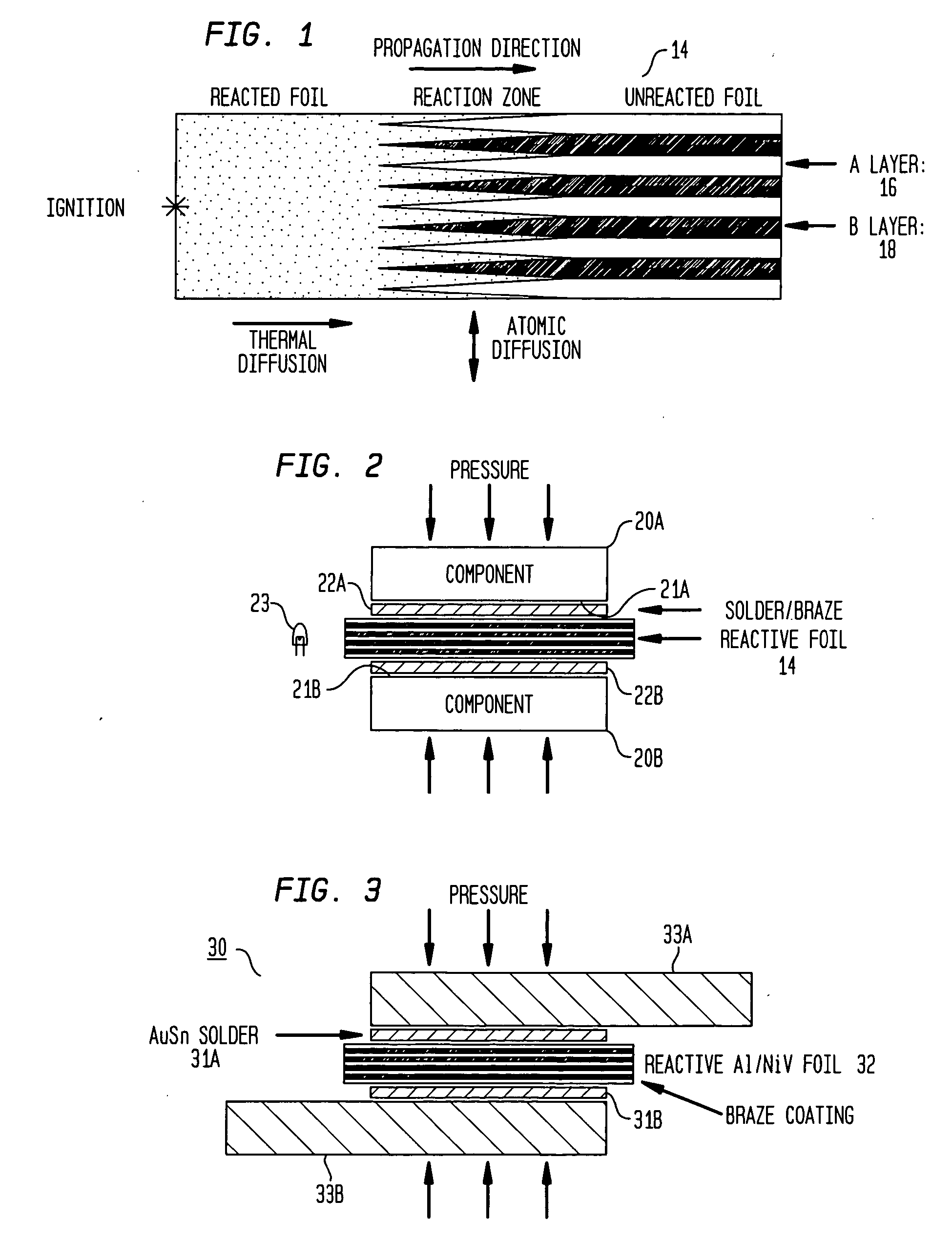

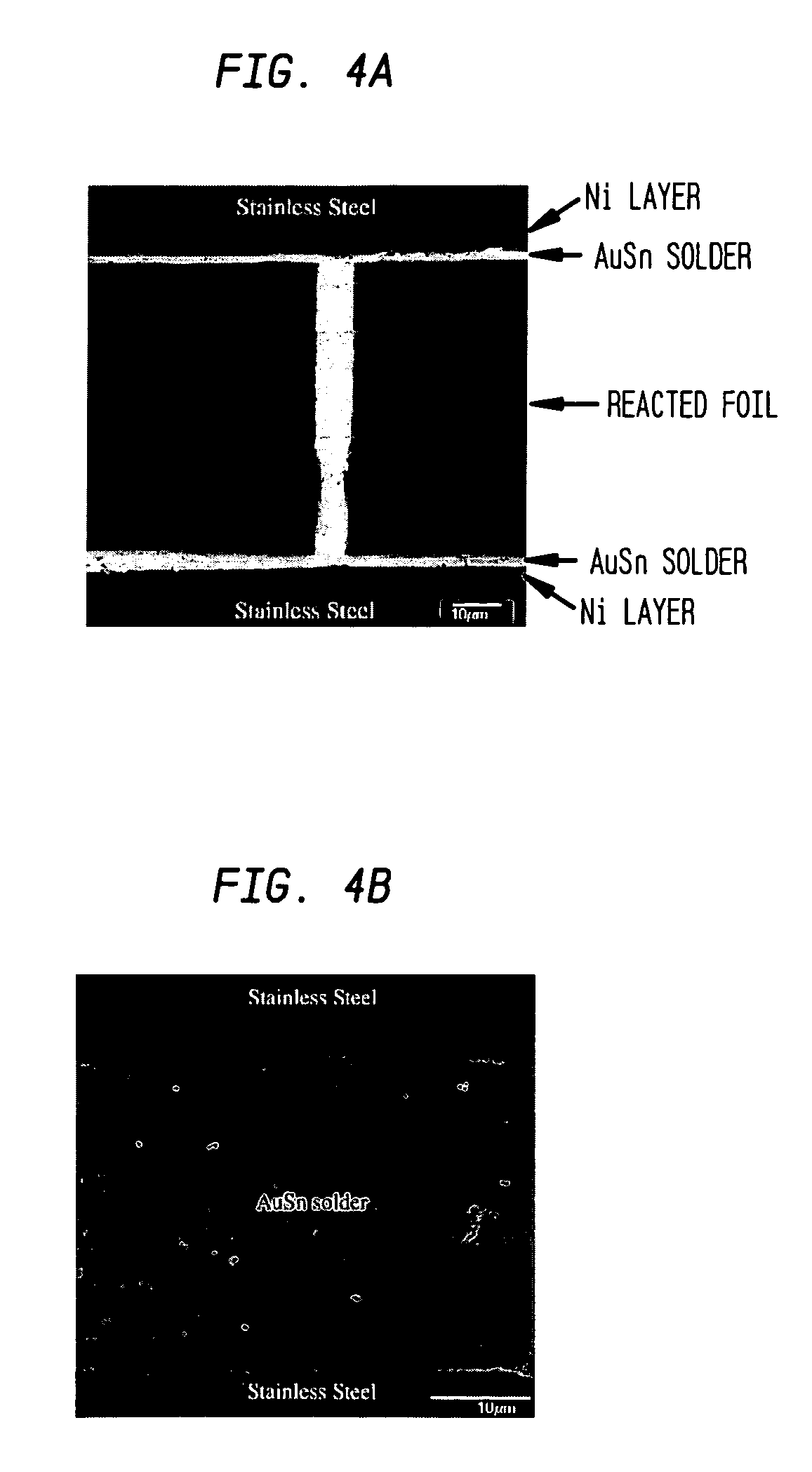

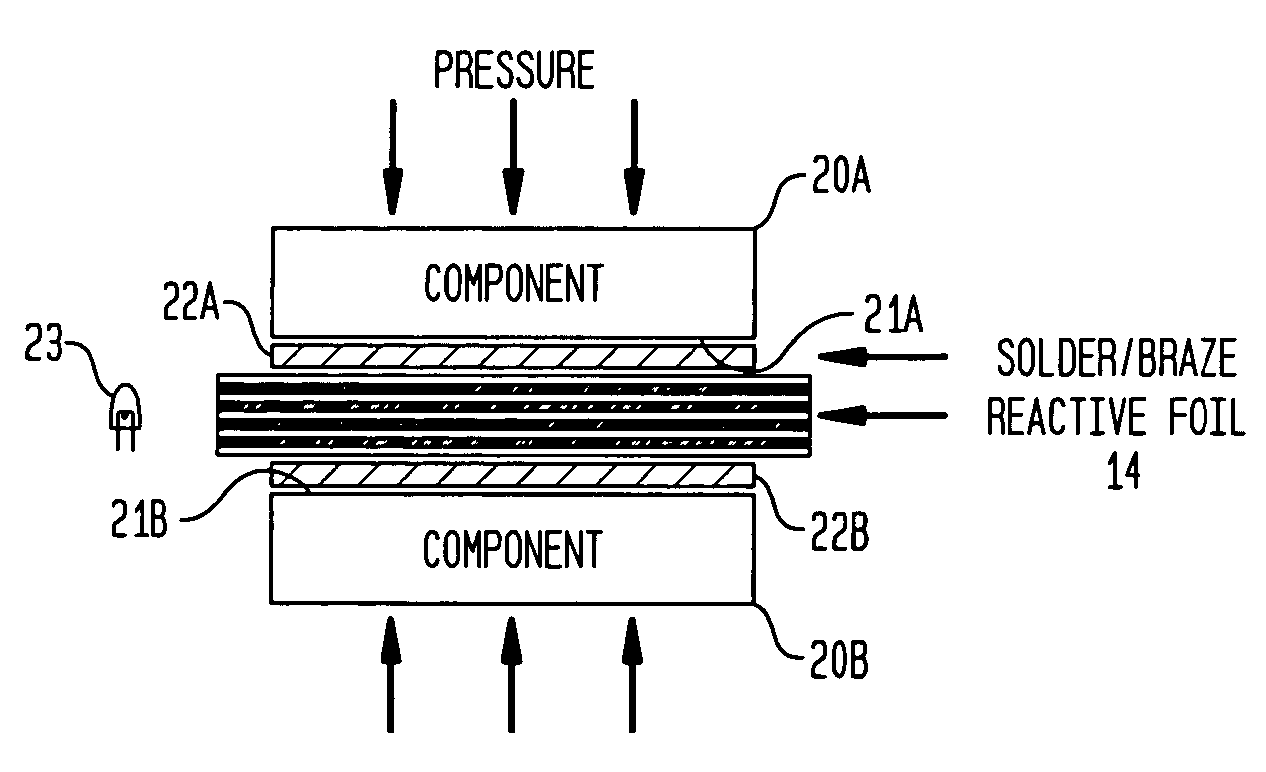

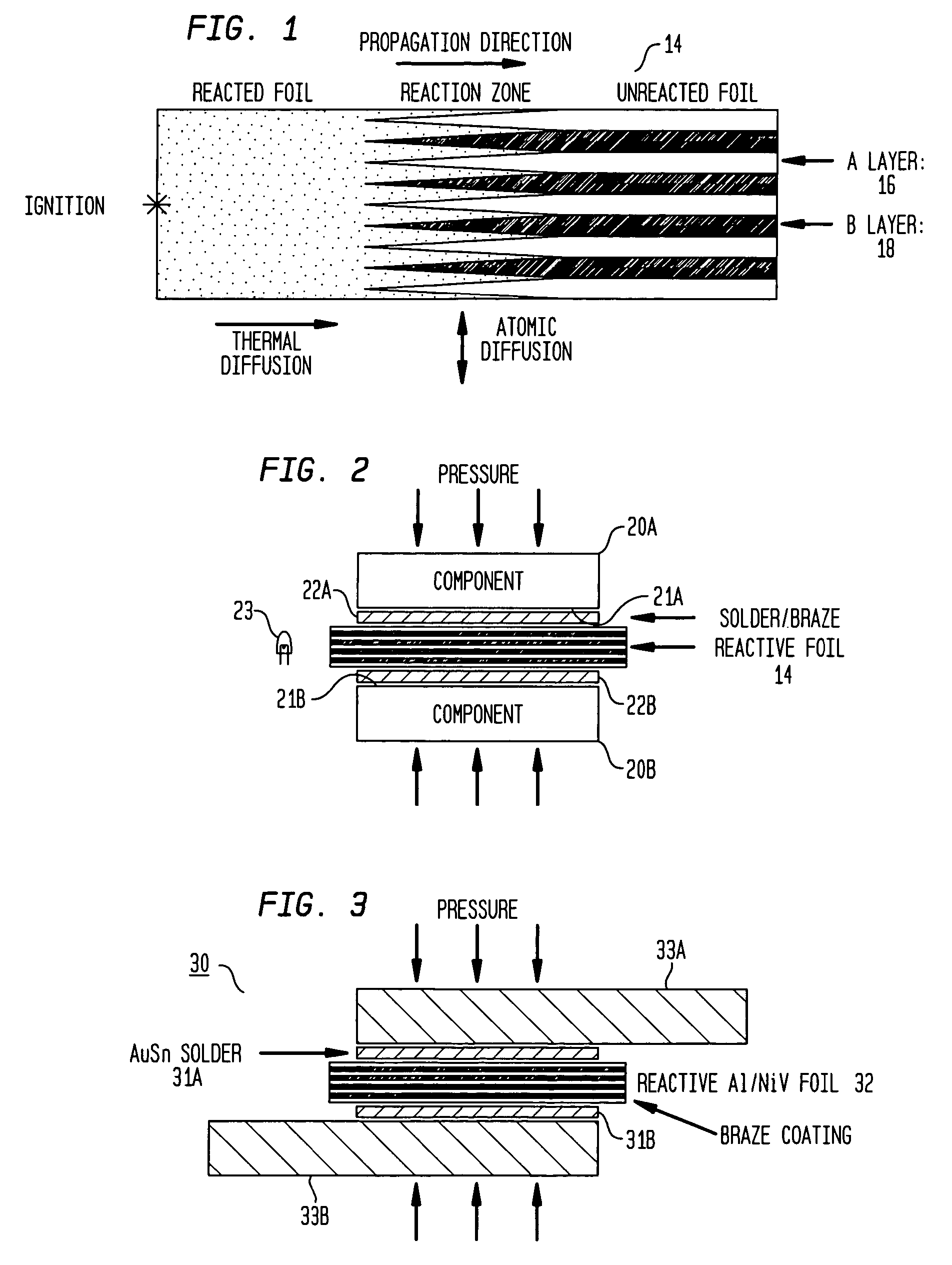

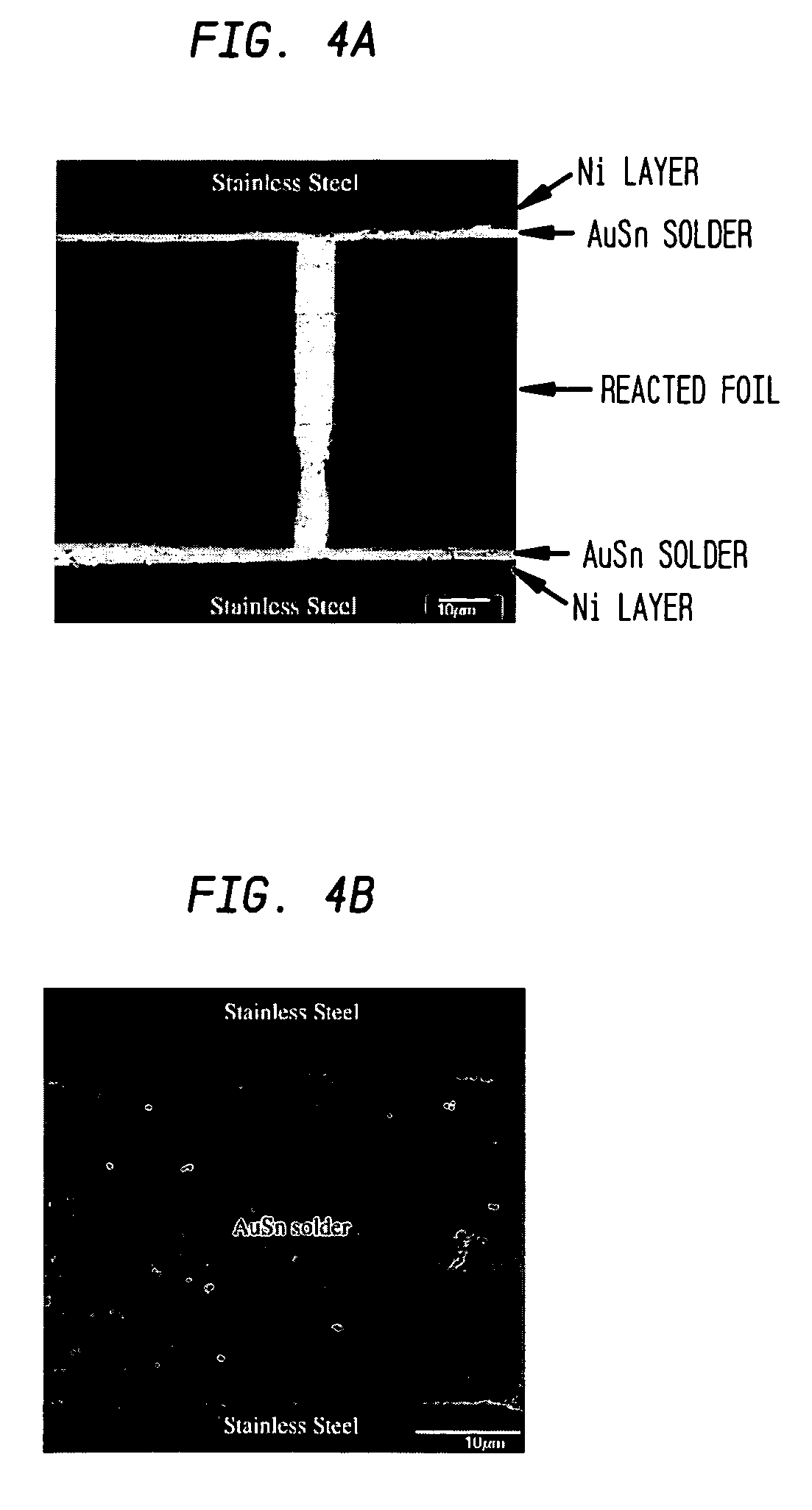

Nanostructured soldered or brazed joints made with reactive multilayer foils

InactiveUS20050051607A1Reduce coolingImprove microstructureExothermal chemical reaction heat productionVacuum evaporation coatingRoom temperatureSlow cooling

Self-propagating formation reactions in nanostructured multilayer foils provide rapid bursts of heat at room temperature and therefore can act as local heat sources to melt solder or braze layers and join materials. This reactive joining method provides very localized heating to the components and rapid cooling across the joint. The rapid cooling results in a very fine microstructure of the solder or braze material. The scale of the fine microstructure of the solder or braze material is dependant on cooling rate of the reactive joints which varies with geometries and properties of the foils and components. The microstructure of the solder or braze layer of the joints formed by melting solder in a furnace is much coarser due to the slow cooling rate. Reactive joints with finer solder or braze microstructure show higher shear strength compared with those made by conventional furnace joining with much coarser solder or braze microstructure. It is expected that the reactive joints may also have better fatigue properties compared with conventional furnace joints.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

Nanostructured soldered or brazed joints made with reactive multilayer foils

InactiveUS7361412B2Reduce coolingImprove microstructureExothermal chemical reaction heat productionVacuum evaporation coatingRoom temperatureSlow cooling

Self-propagating formation reactions in nanostructured multilayer foils provide rapid bursts of heat at room temperature and therefore can act as local heat sources to melt solder or braze layers and join materials. This reactive joining method provides very localized heating to the components and rapid cooling across the joint. The rapid cooling results in a very fine microstructure of the solder or braze material. The scale of the fine microstructure of the solder or braze material is dependant on cooling rate of the reactive joints which varies with geometries and properties of the foils and components. The microstructure of the solder or braze layer of the joints formed by melting solder in a furnace is much coarser due to the slow cooling rate. Reactive joints with finer solder or braze microstructure show higher shear strength compared with those made by conventional furnace joining with much coarser solder or braze microstructure. It is expected that the reactive joints may also have better fatigue properties compared with conventional furnace joints.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

Rare earth permanent magnet produced by applying abundant rare earth cerium (Ce) and preparation method thereof

ActiveCN103123839AReduce production and sales balancePromote the balance of production and salesInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementCost Controls

The invention discloses a rare earth permanent magnet produced by applying abundant rare earth cerium (Ce) and a preparation method of the rare earth permanent magnet produced by applying abundant rare earth Ce. Based on a double-alloy process, main phase alloy formula uses Ce to partly replace neodymium (Nd), an optimized composition design enables a main alloy to form Ce2Fe14B phase and Nd2Fe14B phase to a greatest extent, and therefore high intrinsic magnetic property is guaranteed. A brand new crystal boundary phase is prepared by a crystal boundary reconstitution technology, and high integral magnetic property and corrosion resistant property are guaranteed, and meanwhile a nanometer powder crystal modification method is supplemented, a micro organization structure of a magnet is optimized, crystal boundary distribution is improved, and the magnetic property and the corrosion resistant property are further improved. By applying abundant rare earth cerium, cost is effectively reduced, and meanwhile balance between production and marketing is promoted. Praseodymium (Pr), Nd, and the like are chosen to form a hard magnetic shell layer of a main phase boundary in a composition design of crystal phase auxiliary alloy at the same time, compared high price heavy rare earth elements of dysprosium (Dy) and terbium (Tb) with the elements, and cost control can be further achieved.

Owner:ZHEJIANG UNIV +1

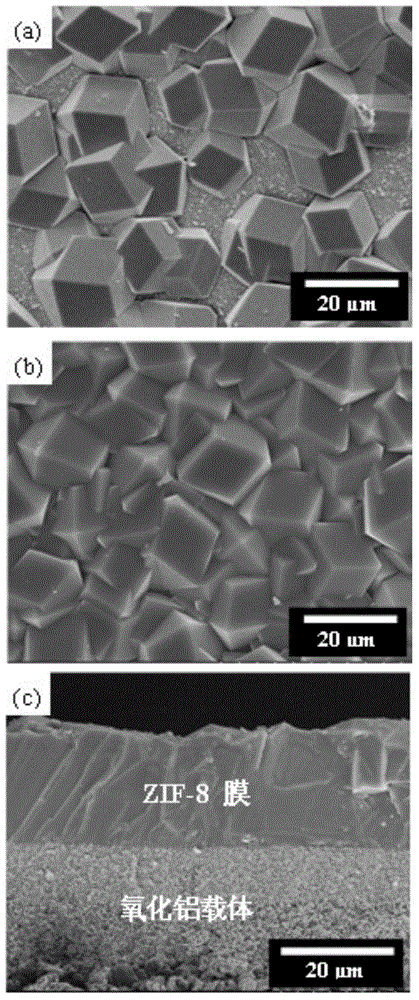

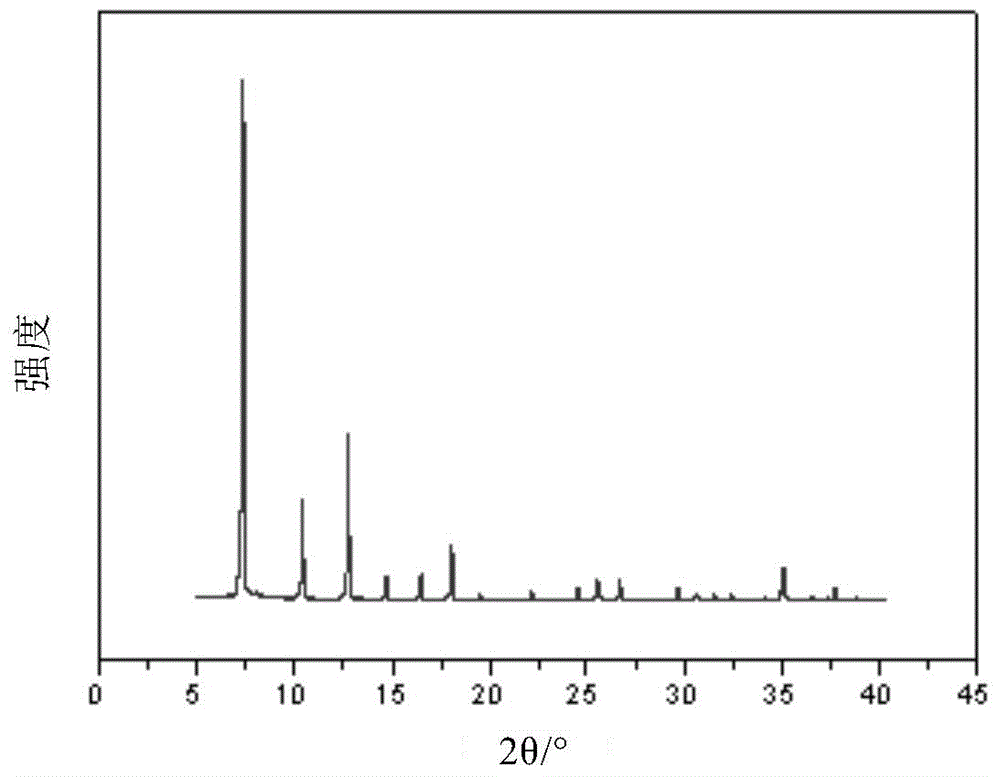

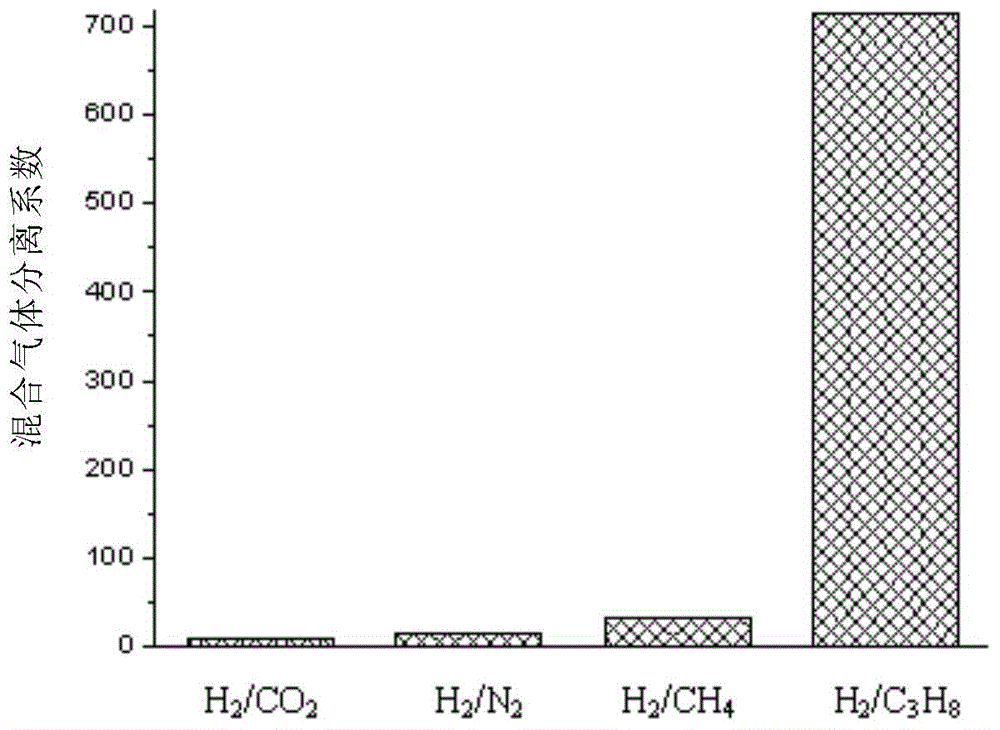

Metal organic framework membrane and preparation method and application thereof

ActiveCN104415670AImprove microstructureEasy to separateSemi-permeable membranesMicrowaveMetal-organic framework

The present invention provides a high-selection hydrogen permeation separation performance metal organic framework membrane for efficient preparation, and especially relates to a zeolite imidazole organic framework membrane, and preparation method of ZIF-8 membrane and a metal organic framework membrane prepared by the method are provided. The method comprises the following steps: using dopamine for functional modification of a solid carrier; and synthesizing the metal organic framework membrane on the surface of the functionally modified solid carrier. By preparation of the metal organic framework membrane by the method, nucleation and growth are greatly enhanced, the prepared metal organic framework membrane is homogeneous and dense, falling-off condition after membrane formation can be significantly improved, and gas separation performance is good; the method has the advantages of mild operation condition, easy industrialized amplification, environment friendliness, and strong applicability. The method can also adopts microwave heating method, the reaction time can be shortened, and the cost of industrial production can be further reduced.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

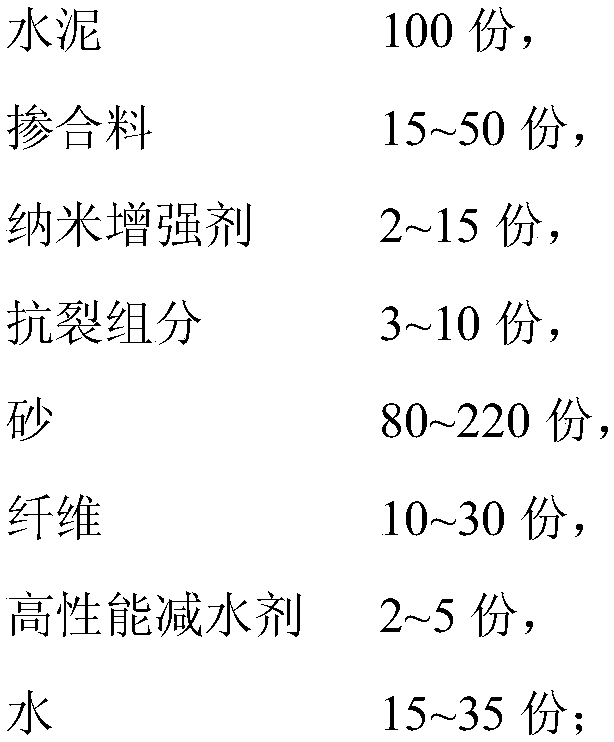

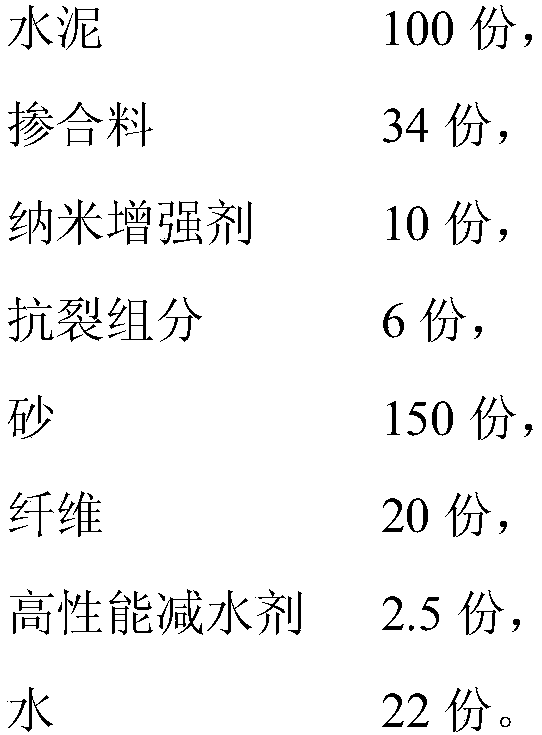

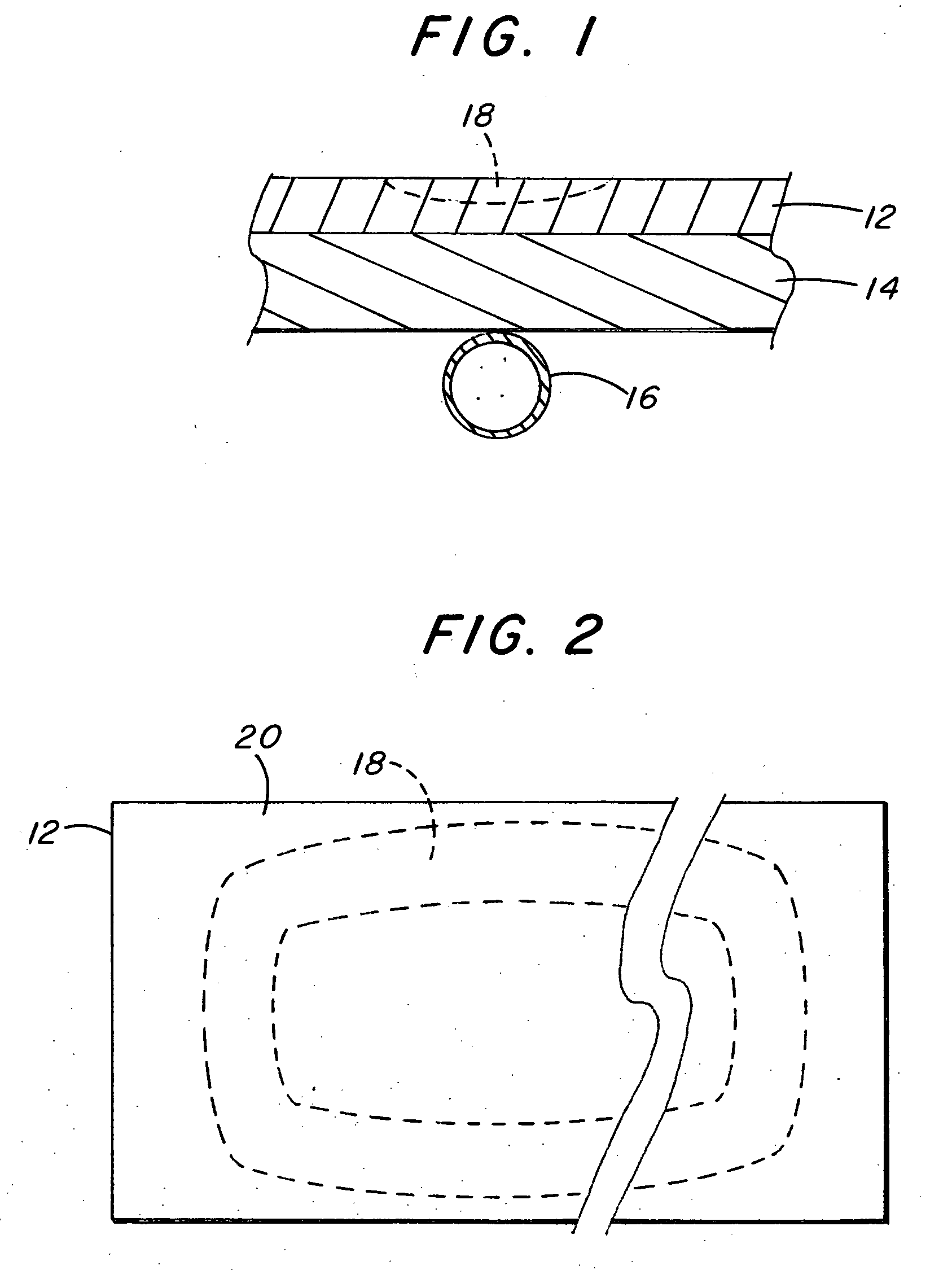

Super-high-performance cement base repairing material and preparing method thereof

The invention discloses a super-high-performance cement base repairing material and a preparing method thereof. The repairing material is prepared from, by mass, 100 parts of cement, 15-50 parts of admixture, 2-15 parts of nanometer reinforcing agent, 3-10 parts of crack resistance component, 80-220 parts of sand, 10-30 parts of fiber, 2-5 parts of high-performance water reducing agent and 15-35 parts of water. The super-high-performance cement base repairing material has super-high tensile strength, bending resistance and adhesive strength and extremely low shrinkage performance, and has excellent construction performance, high elasticity modulus and super-high durability. The material has effects of repairing, reinforcing, seepage preventing, preventing and the like, and therefore the service life of the repairing material and a structure is prolonged. In addition, the material can be used as a joint material of a structural joint.

Owner:JIANGSU SOBUTE NEW MATERIALS

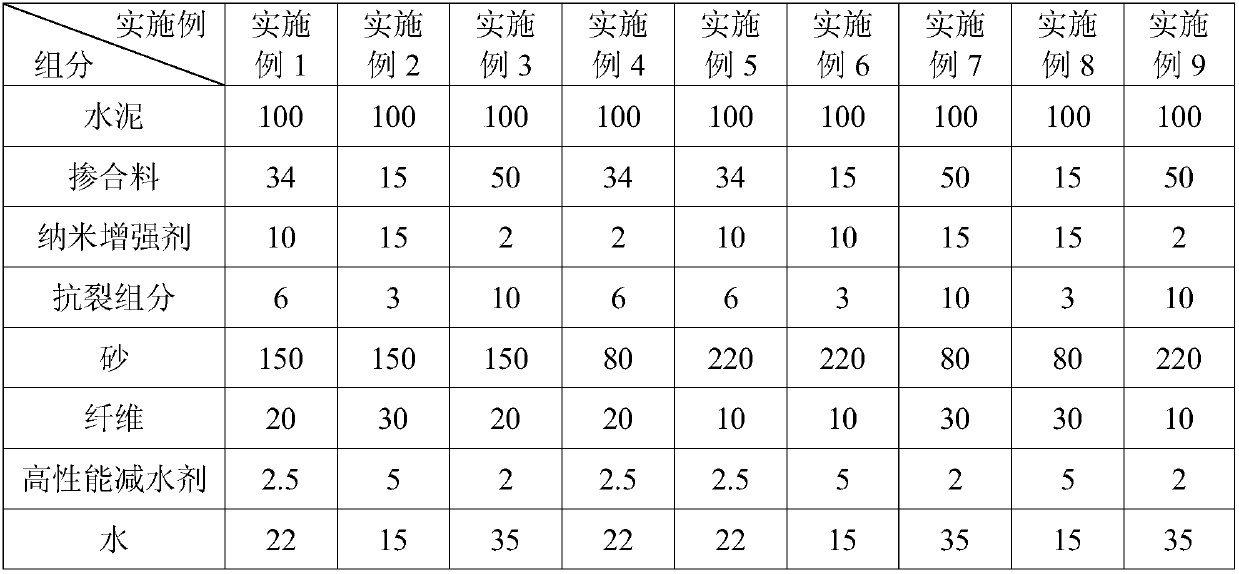

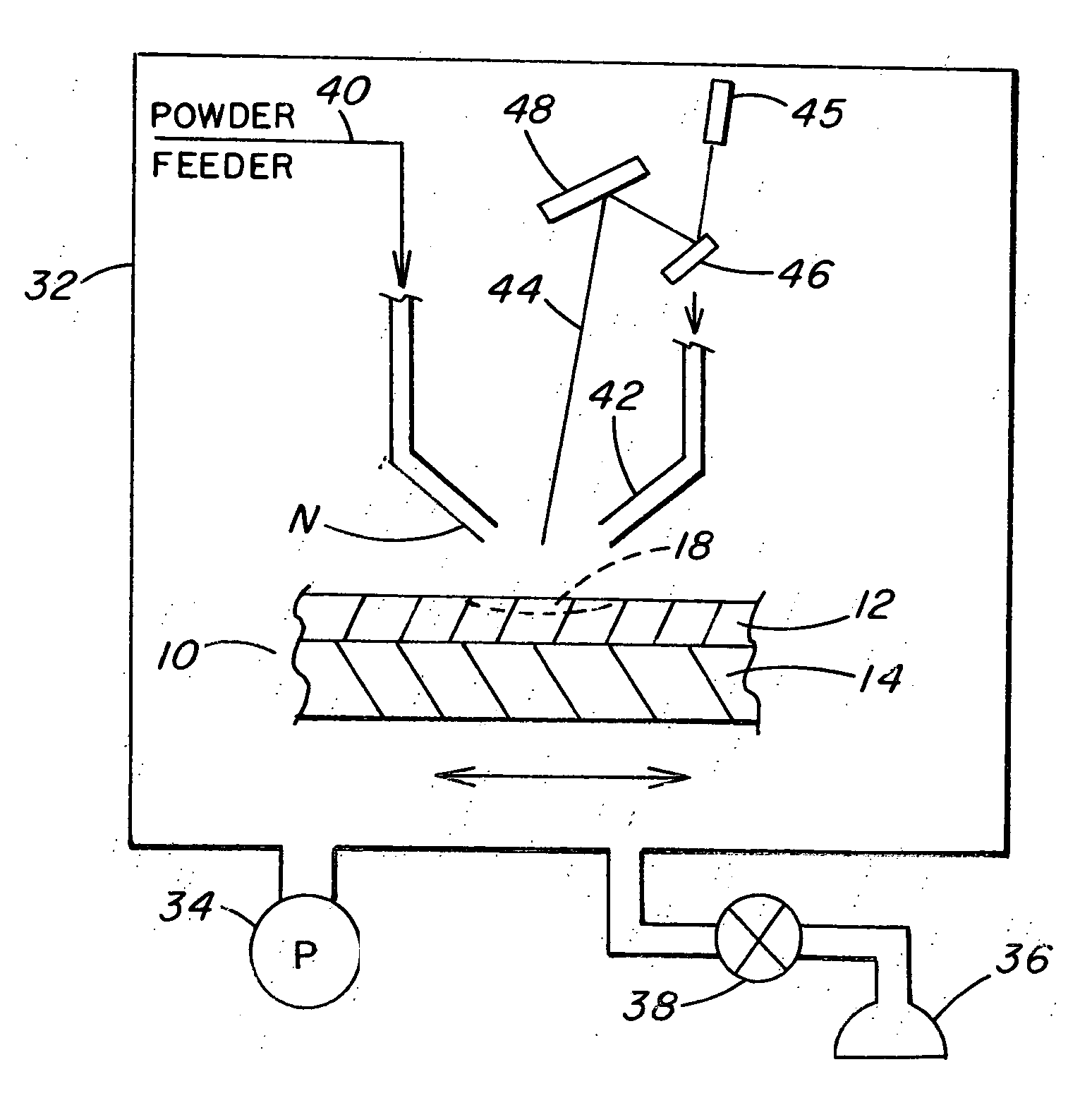

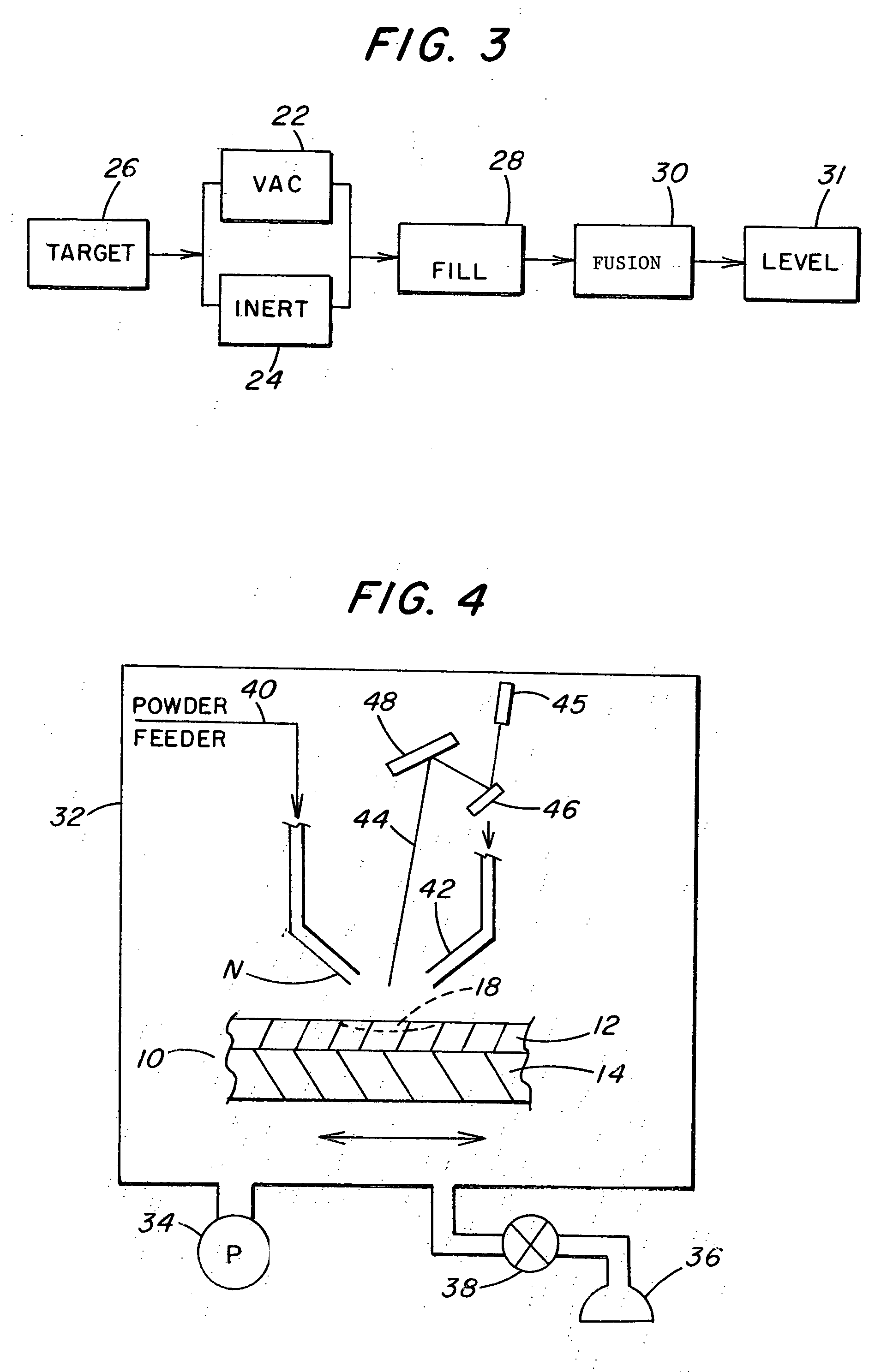

Rejuvenation of refractory metal products

InactiveUS20060032735A1Increase speedImprove microstructureCellsAdditive manufacturingMaterials scienceMetal

Refractory metal products, such as tantalum, can be rejuvenated after metal consumption in selected zones by filling the zones with powder and simultaneously applying focused radiant energy to the powder.

Owner:MATERION NEWTON INC

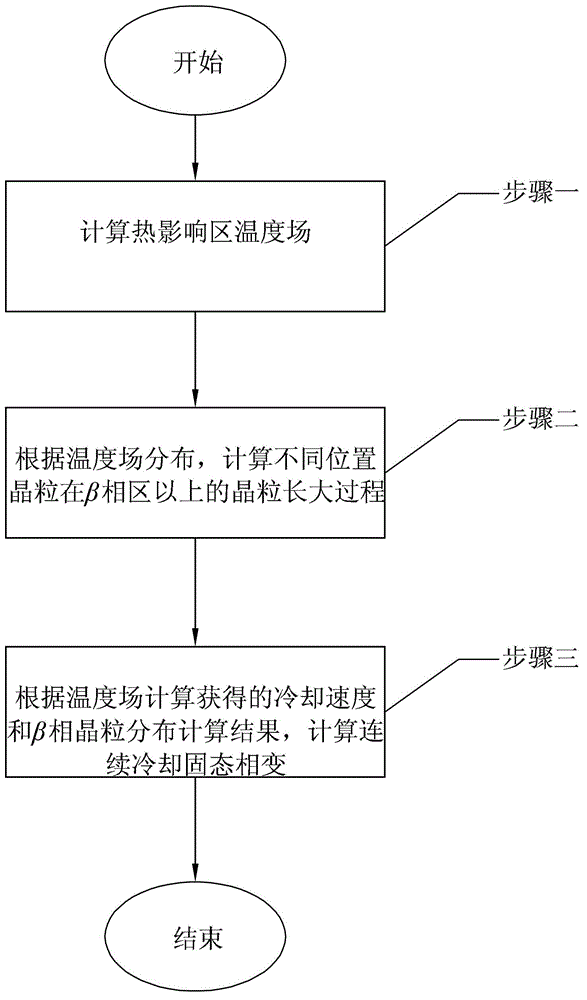

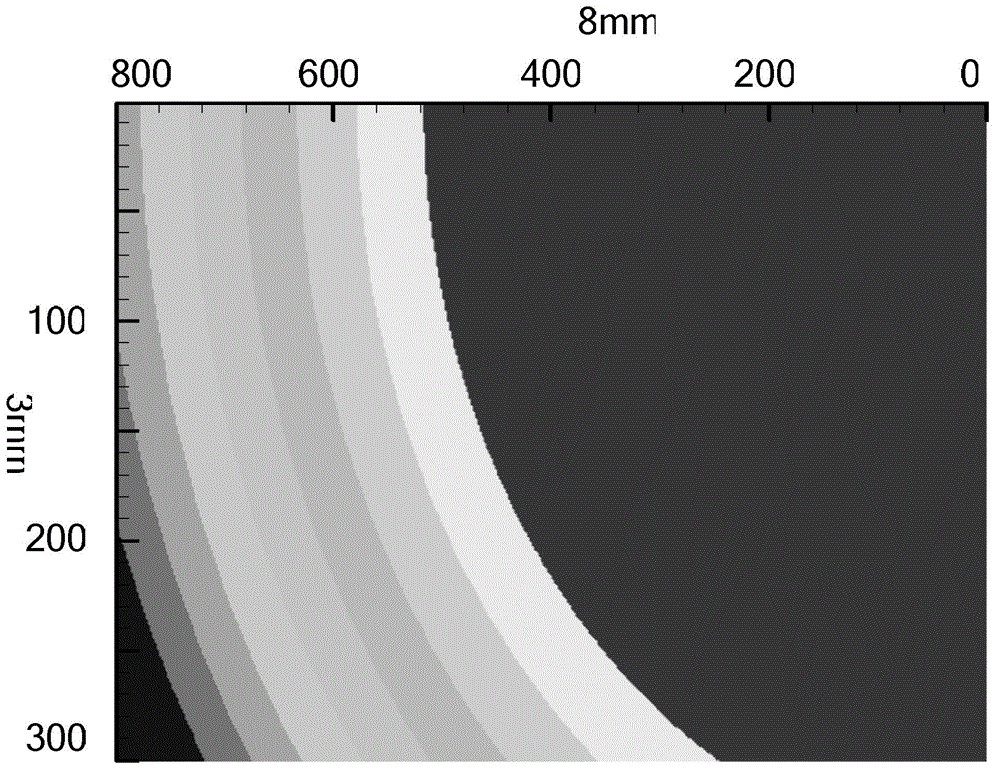

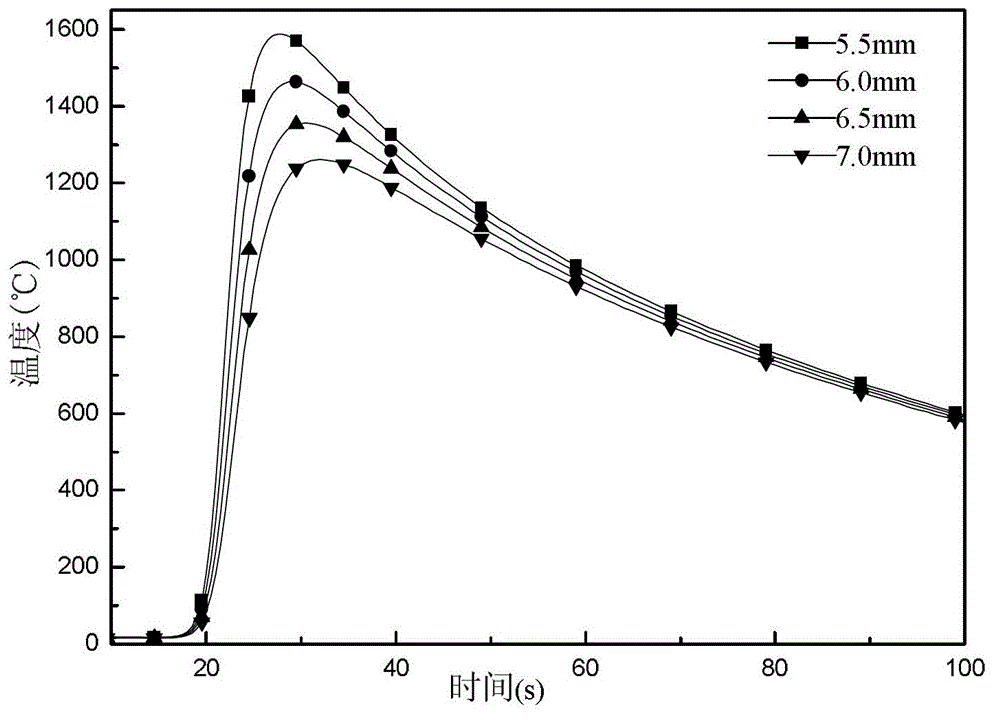

Simulation method of texture evolvement of heat affected zone in welding process

ActiveCN102750425AImprove microstructureImprove mechanical propertiesFurnace typesHeat treatment process controlHeat-affected zoneMaterials science

The invention discloses a simulation method of texture evolvement of a heat affected zone in a welding process, relating to a fine texture simulation method of a welding connector and aiming at solving the problems that the quantification of the present fine texture evolvement of a weld joint is mainly based on an experiential or half experiential deterministic model or analysis calculation, and only the texture content is calculated but the state, the size and the distribution of the texture cannot be reflected dynamically. The method comprises the following steps: step 1, calculating the temperature fields of the heat affected zone; step 2, calculating the crystalline grain growth process of crystalline grains at different positions above a beta phase zone according to the distribution of the temperature fields; and step 3, calculating continuous cooling solid state phase change according to the cooling velocity and the beta phase crystalline grain distribution calculation result obtained through the temperature field calculation. The simulation method is used for the fine texture simulation of the welding connector.

Owner:HARBIN INST OF TECH

Samarium-cobalt sintered magnet material and preparation method thereof

InactiveCN101882494ALower temperature coefficient of remanenceLower flux temperature coefficientMagnetic materialsRare earthCobalt

The invention discloses a 2:17 type samarium-cobalt sintered magnet material and a preparation method thereof. The 2:17 type samarium-cobalt sintered magnet material comprises the following raw materials in percentage by mass: 10 to 25 percent of samarium, 45 to 55 percent of cobalt, 10 to 20 percent of iron, 3 to 9 percent of copper, 1 to 3 percent of zirconium and 5 to 15 percent of at least one heavy rear earth element. Due to the selection and the proportion of the raw materials and the innovation of the sintering process, a microstructure of the magnet material is optimized, and the aims of reducing the temperature coefficient of a magnet and simultaneously maintaining higher magnetic energy product of the magnet are fulfilled, wherein the magnetic energy product of the prepared magnet is 14 to 25 MGsOe, the residual magnetism temperature coefficient is about -0.005 to -0.03 percent per DEG C, and a lower magnetic flux temperature coefficient is maintained in an environment at the temperature of between -35 and 300 DEG C.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

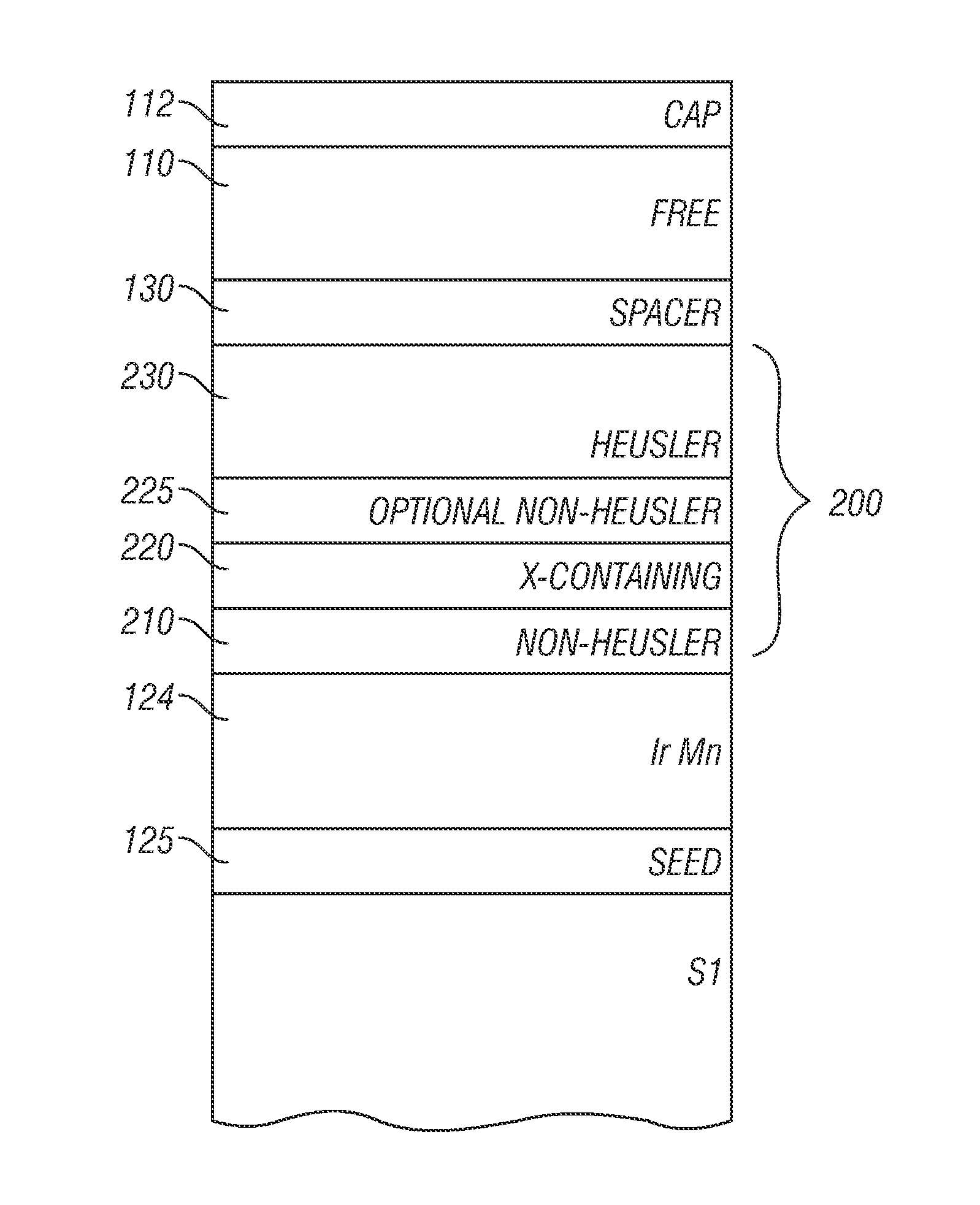

Method for making a current-perpendicular-to-the-plane (CPP) magnetoresistive sensor containing a ferromagnetic alloy requiring post-deposition annealing

InactiveUS20130236639A1Improve microstructureMagnetic measurementsMagnetic-field-controlled resistorsGiant magnetoresistanceAlloy

A method for making a current-perpendicular-to the-plane giant magnetoresistance (CPP-GMR) sensor with a Heusler alloy pinned layer on the sensor's Mn-containing antiferromagnetic pinning layer uses two annealing steps. A layer of a crystalline non-Heusler alloy ferromagnetic material, like Co or CoFe, is deposited on the antiferromagnetic pinning layer and a layer of an amorphous X-containing ferromagnetic alloy, like a CoFeBTa layer, is deposited on the Co or CoFe crystalline layer. After a first in-situ annealing of the amorphous X-containing ferromagnetic alloy, the Heusler alloy pinned layer is deposited on the amorphous X-containing ferromagnetic layer and a second high-temperature annealing step is performed to improve the microstructure of the Heusler alloy pinned layer.

Owner:WESTERN DIGITAL TECH INC

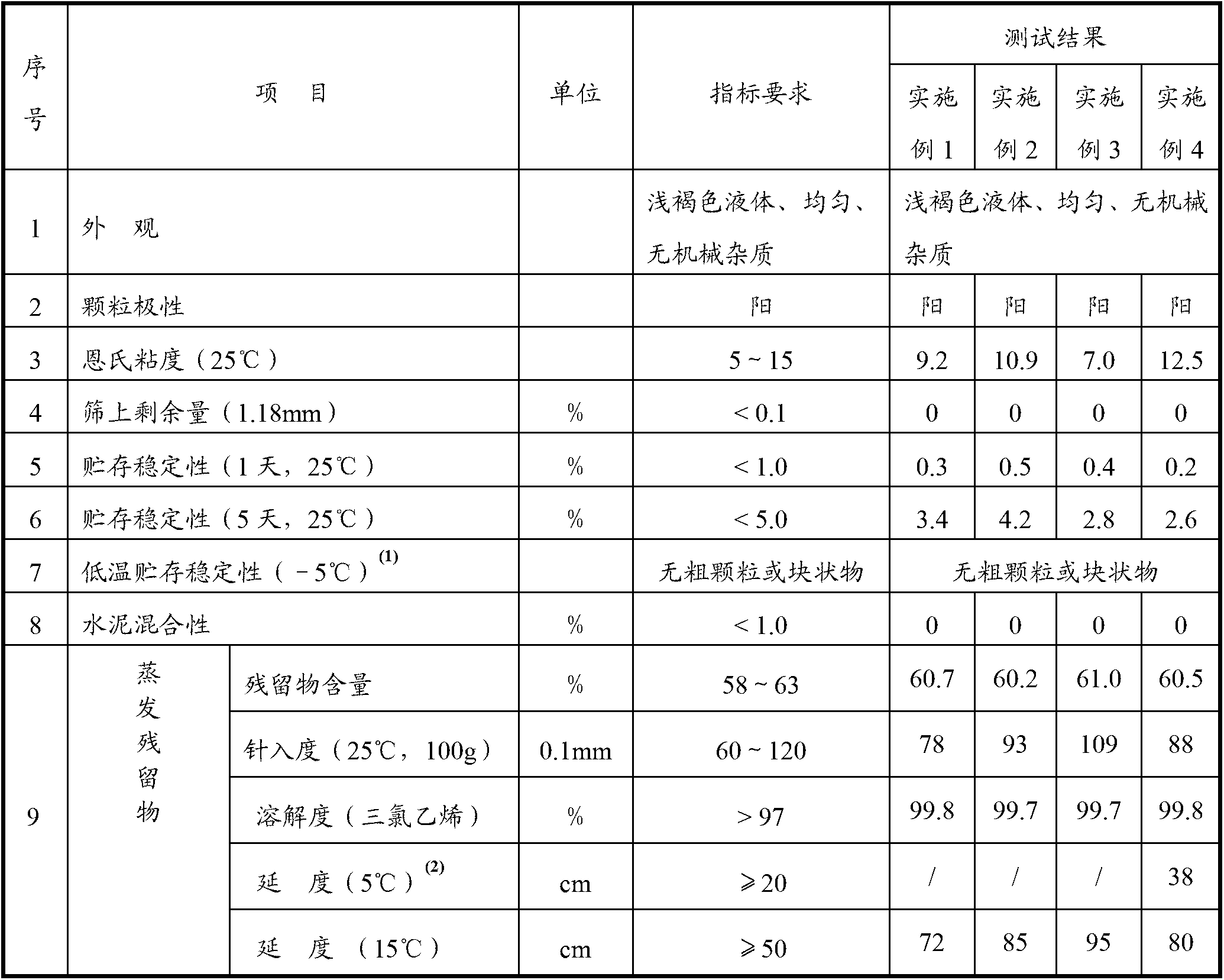

Cement-emulsified asphalt mortar for slab tracks in severe cold areas

Owner:METALS & CHEM RES INST CHINA ACAD OF RAILWAY SCI +2

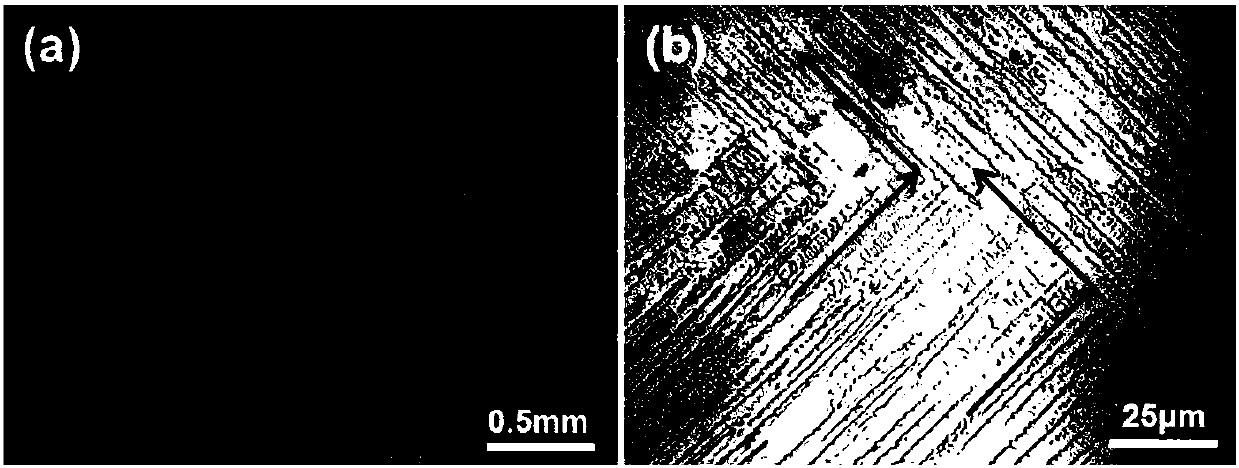

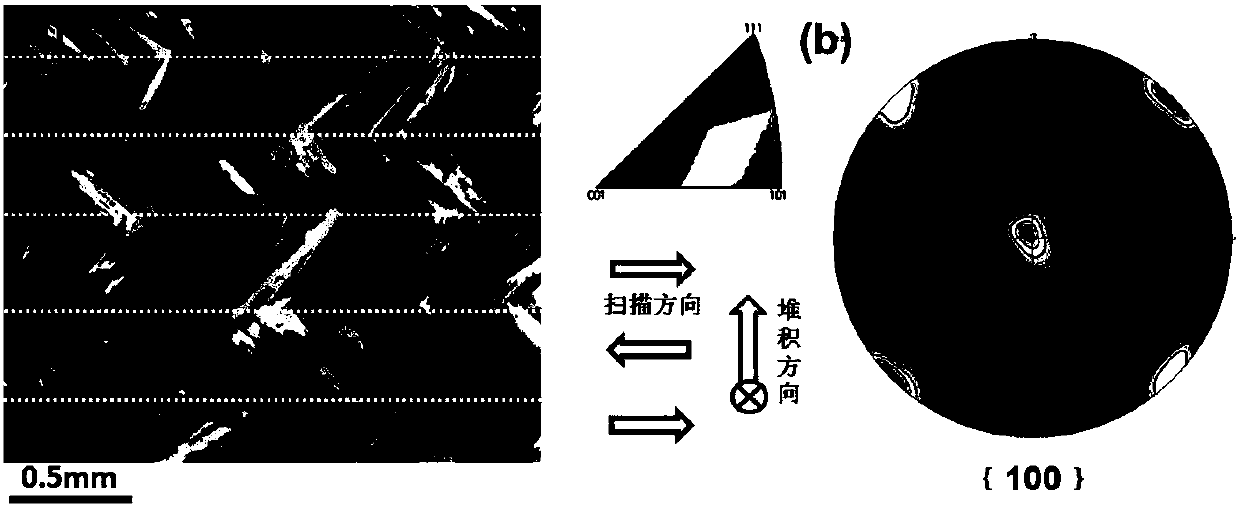

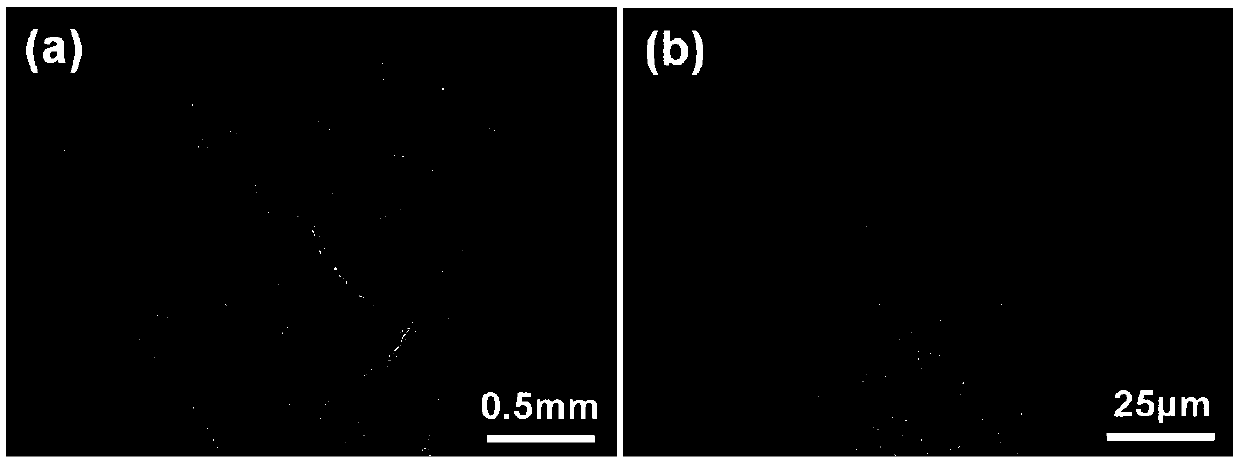

Quasi-continuous laser metal 3D printing method capable of realizing regulation of nickel base alloy crystallographic texture

ActiveCN107790717AImprove consistencyImprove microstructureAdditive manufacturing apparatusIncreasing energy efficiencyMolten bathMatch rule

The invention discloses a quasi-continuous laser metal 3D printing method capable of realizing regulation of nickel base alloy crystallographic texture. Laser output is set as a quasi-continuous lasermode, and then a laser metal 3D printing technical window is preliminarily optimized. The temperature field of a molten bath under the preliminarily optimized parameter is calculated by using a finite element heat transfer model; the temperature gradient G and the cooling rate xi of the moving boundary of the molten bath during closing of laser in a single pulse period are extracted, and the growth length L of a single pulse internal columnar dendrite is worked out according to a structure growth theoretical model; the laser parameter is optimized according to the matching rule that the ratioof the scanning speed V to pulse frequency f is 0.5-0.8L, and finally 3D printing forming is conducted according to the optimized parameter, so that a formed part with the consistent crystallographicorientation height is obtained. By regulating the heat source output mode, an effective remelting mechanism for mixed crystal or isometric crystal is introduced in the scanning direction, all columnar dendrite growth is obtained, and the consistency of grain orientation is remarkably improved.

Owner:HUNAN UNIV

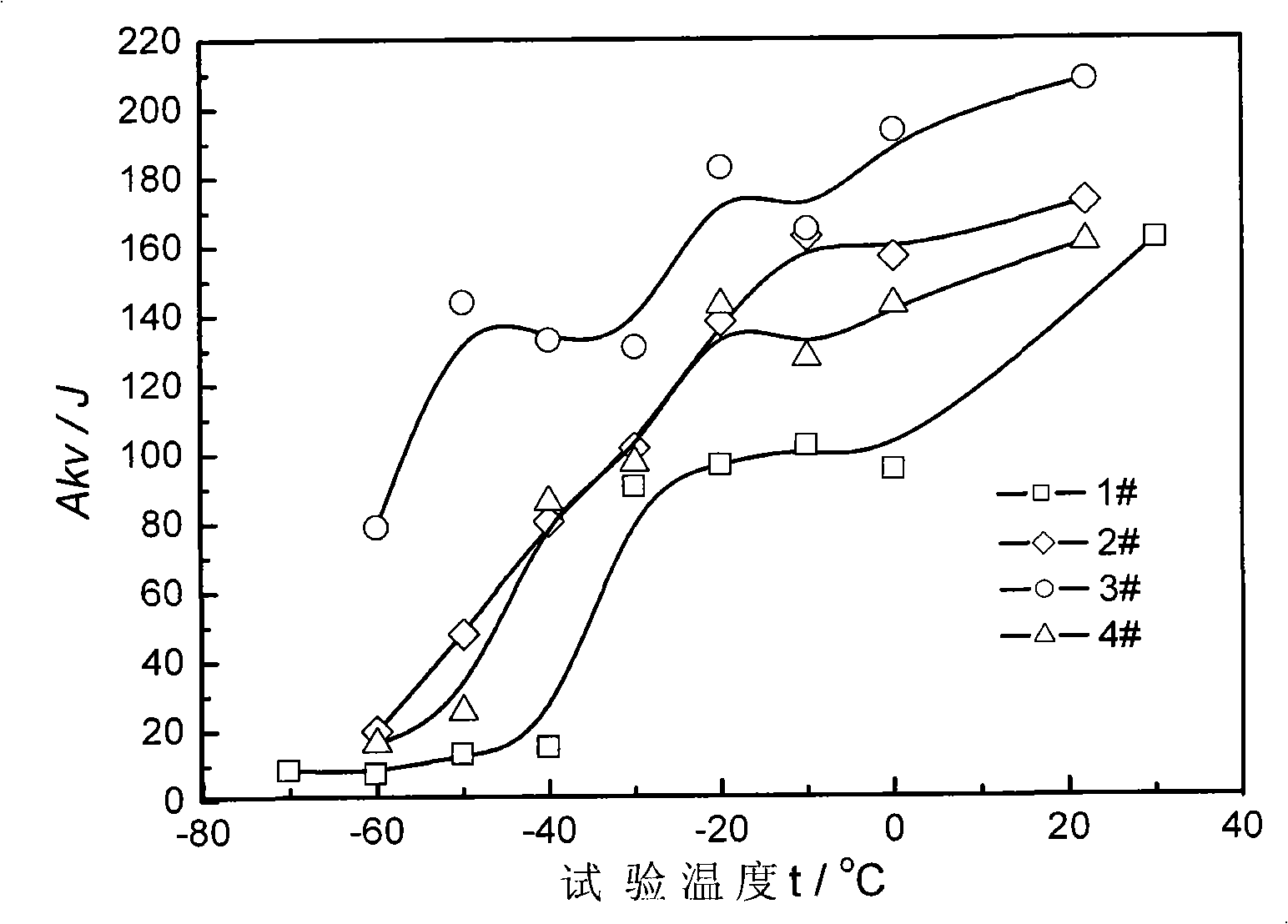

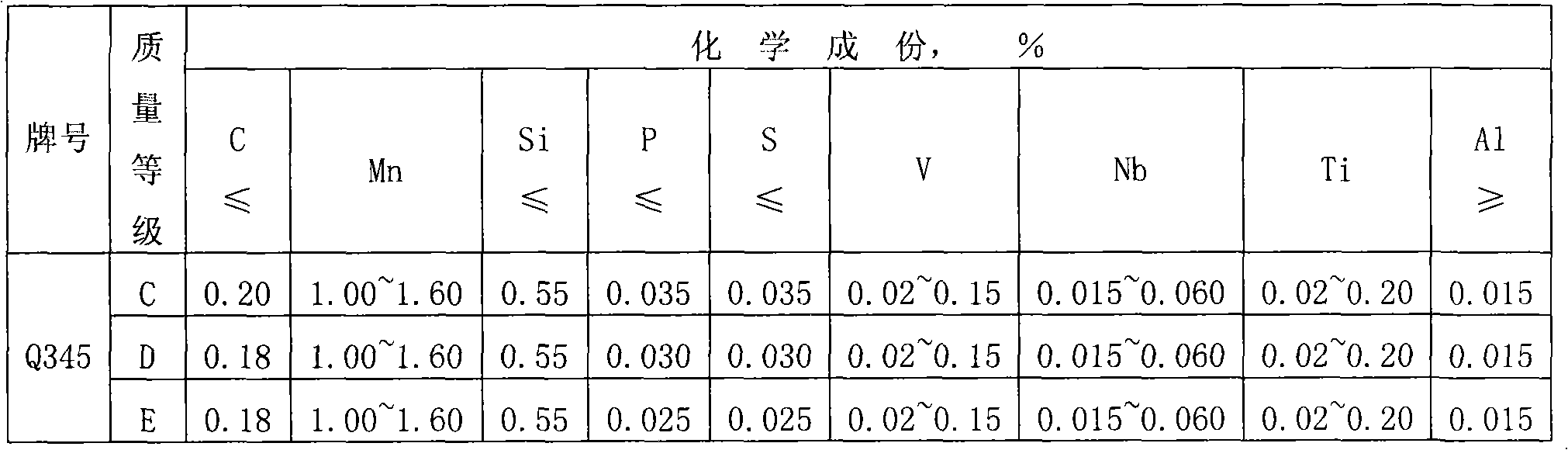

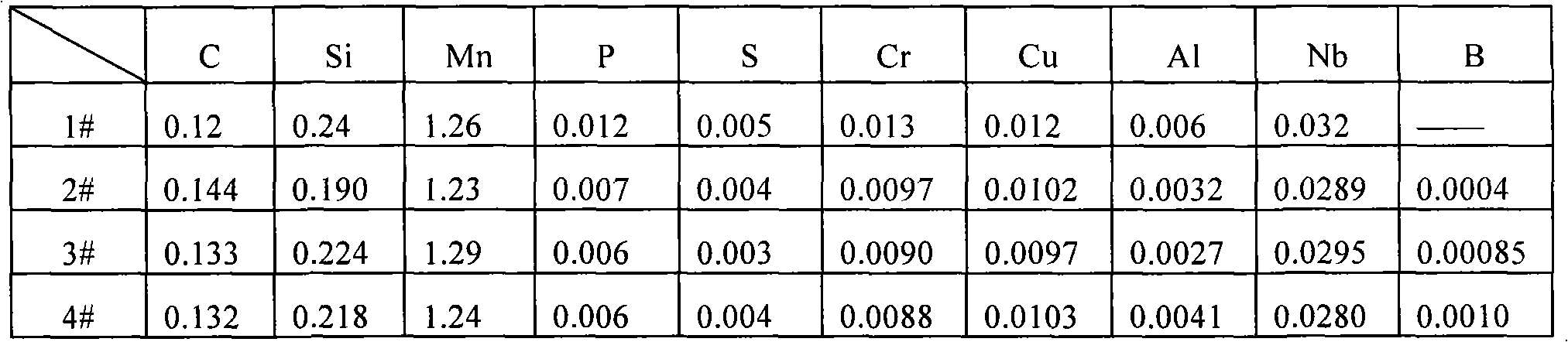

Boron-modified H-shape steel having well low-temperature impact flexibility and preparation method thereof

InactiveCN101255527AImprove mechanical propertiesImproved low temperature impact propertiesMetallurgyBoron

The invention relates to a boron-modified H type steel having good low-temperature impact toughness and the preparing method thereof. The steel is composed of 0.08 to 0.20 by weight percentage of C, 1.00 to 1.60 by weight percentage of Mn, 0.10 to 0.55 by weight percentage of Si, no more than 0.25 by weigh percentage of P, no more than 0.025 by weight percentage of S, 0.015 to 0.035 by weight percentage of Nb, 0.0005 to 0.0012 by weight percentage of B, and the balance Fe and trace impurity. During melting process, the gas content is controlled: no more than 0.004% of N, and no more than 0.0085% of O. According to the invention, the low-temperature impact toughness of Q345 H type steel is greatly improved; compared with Chinese standard, -40 DEG C AKV has a large surplus, the product quality is easy to be guaranteed; the Q345 H type steel can also be applied to regions having more severe condition.

Owner:SHANDONG IRON & STEEL CO LTD

Heat treatment technology for markedly raising comprehensive performance of aluminium alloy

InactiveCN102242325AMeet the requirements of large structural partsPractical application value of large industry5005 aluminium alloySolid solution

A heat treatment technology for markedly raising comprehensive performance of aluminium alloy is accomplished by the adoption of the following scheme: carrying out a solid solution treatment on the aluminium alloy, taking the aluminium alloy out of a furnace and carrying out water quenching, and carrying out a pre-aging treatment, cold deformation and a secondary aging treatment. Nanometer-level aging precipitation strengthening phase is formed by the pre-aging treatment, and dislocation configuration generated from the subsequent cold deformation can be changed, so as to improve the strength, ductility and toughness of the alloy; during the cold deformation, nanometer-level atomic clusters will precipitate out from solute atoms precipitated during the pre-aging treatment, or ''pinning'' air mass is formed around the dislocation structure, thus further raising the strength of the alloy. The precipitated precipitation strengthening phase is nanometer level, thus raising the ductility and toughness of the alloy and markedly enhancing the strength of the alloy on the basis of guaranteeing good plasticity. The technological process provided by the invention is simple, is convenient to operate, can be adopted to markedly raise comprehensive performance such as the strength and plasticity of the aluminium alloy and improve the corrosion resistant performance and fatigue resistant performance of the aluminium alloy, and is suitable for industrial application.

Owner:CENT SOUTH UNIV

Laser-high frequency induction composite welder and its method

InactiveCN1554510ARealize simultaneous mobile heatingImprove absorption rateHigh frequency current welding apparatusLaser beam welding apparatusMetallic materialsInductor

The present invention provides welder and welding method combining two different kinds of heat source, laser and HF inductor, and adopts real-time temperature monitor and control to overcome the demerits of common laser welding of metal material, which has low energy utilization and is likely to produce air hole. During welding, two kinds of heat source are used to heat the welded part and near part simultaneously. The welder of the present invention has laser welding head as the main body comprising integrated induction heating winding and infrared sensor. Compared with common laser welding, the present invention has greatly raised production efficiency and welding quality and can realize 2D and 3D welding.

Owner:HUAZHONG UNIV OF SCI & TECH

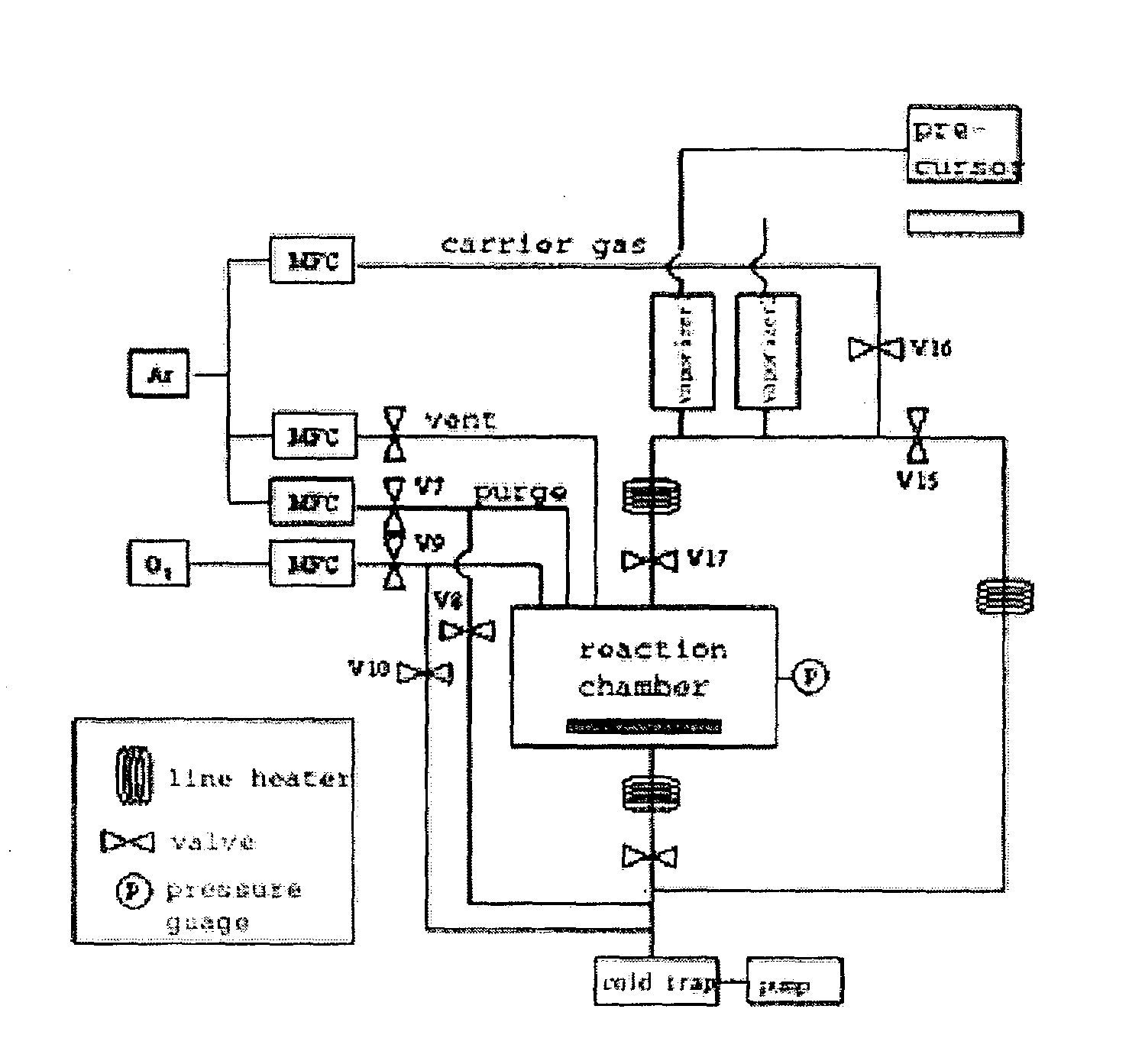

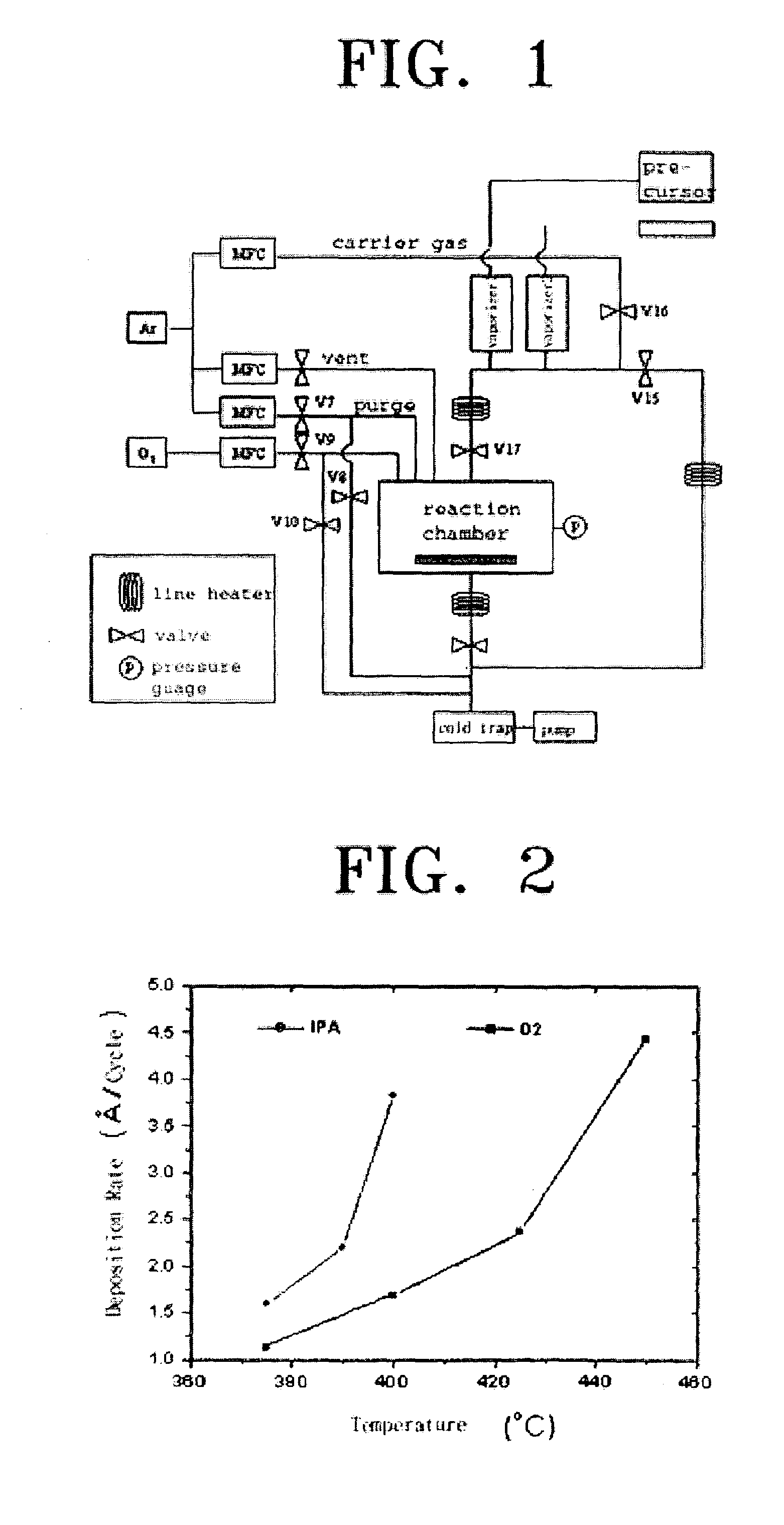

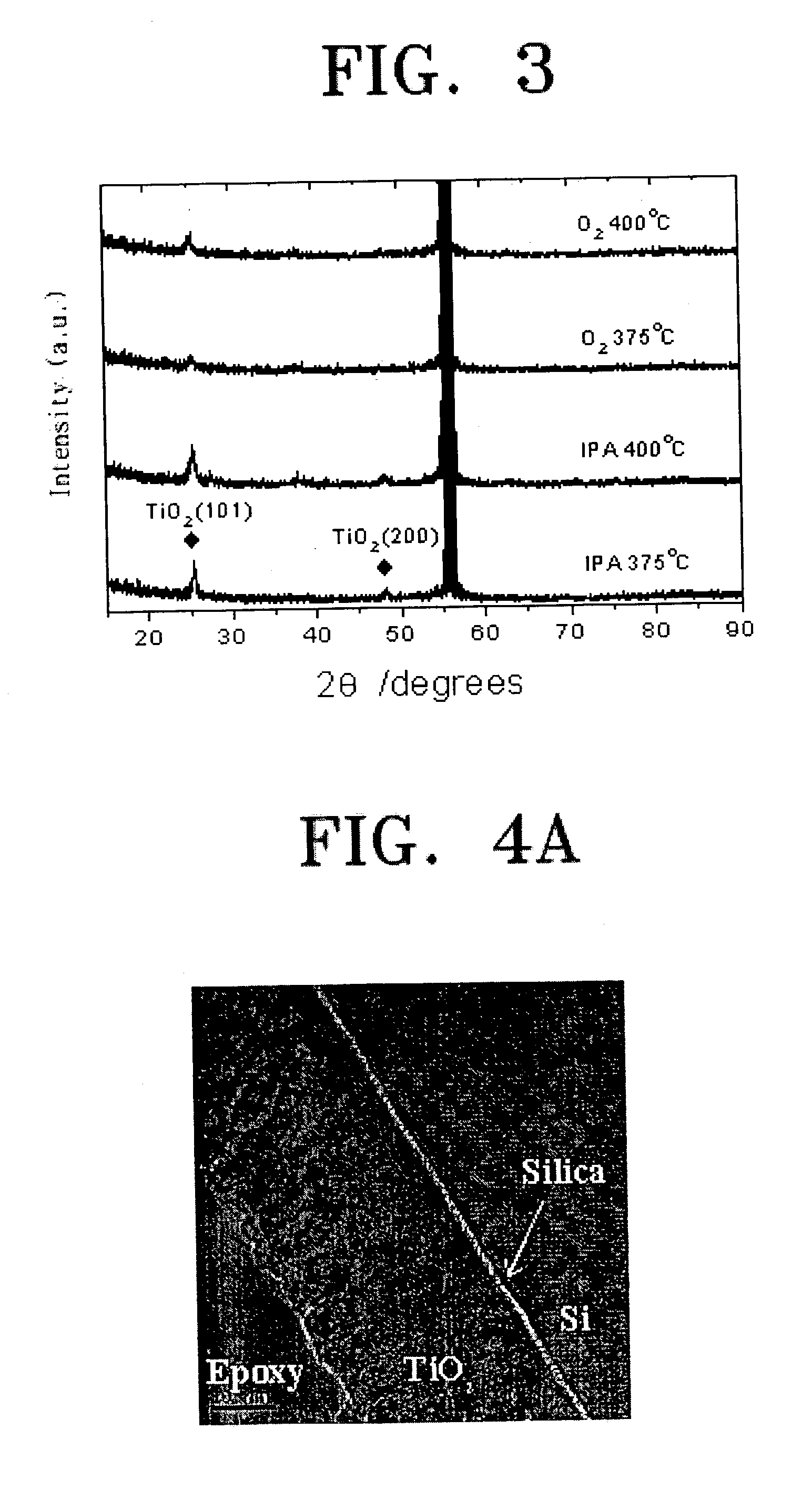

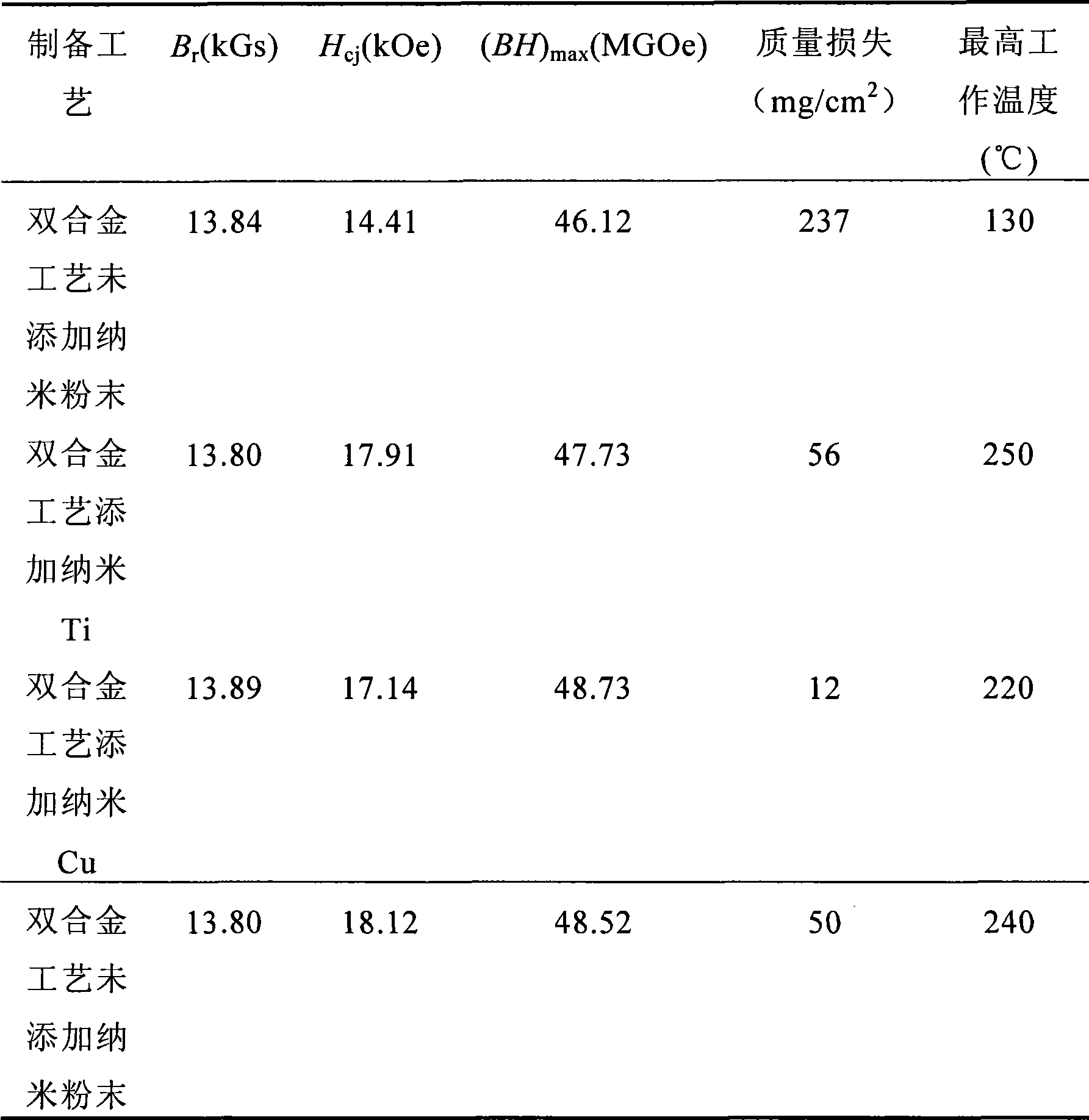

Chemical vapor deposition method using alcohol for forming metal oxide thin film

ActiveUS7135207B2Excellent leakage current characteristicFine microstructureFixed capacitor dielectricSemiconductor/solid-state device manufacturingLow leakageMicrostructure

Provided is a method for fabricating a metal oxide thin film in which a metal oxide generated by a chemical reaction between a first reactant and a second reactant is deposited on the surface of a substrate as a thin film. The method involves introducing a first reactant containing a metal-organic compound into a reaction chamber including a substrate; and introducing a second reactant containing alcohol. Direct oxidation of a substrate or a deposition surface is suppressed by a reactant gas during the deposition process, as it uses alcohol vapor including no radical oxygen as a reactant gas for the deposition of a thin film. Also, since the thin film is deposited by the thermal decomposition, which is caused by the chemical reaction between the alcohol vapor and a precursor, the deposition rate is fast. Particularly, the deposition rate is also fast when a metal-organic complex with β-diketone ligands is used as a precursor. Further, a thin film with low leakage current can be obtained as the metal oxide thin film fabrication method using a chemical vapor deposition or atomic layer deposition method grows a thin film with fine microstructure.

Owner:SAMSUNG ELECTRONICS CO LTD

High-strength high-conductivity copper alloy contact wire for rapid transit railway

ActiveCN1811998AExcellent thermal stability and corrosion and wear resistanceFine grain structureSingle bars/rods/wires/strips conductorsCable/conductor manufactureCrystalliteChromium

Owner:郑茂盛 +1

Ultrahigh-coercivity sintered neodymium-iron-boron magnet and preparation method thereof

ActiveCN103794322AImprove coercive forceAchieve magnetic hardeningPermanent magnetsInductances/transformers/magnets manufactureRare-earth elementHigh volume manufacturing

The invention discloses an ultrahigh-coercivity sintered neodymium-iron-boron magnet and a preparation method thereof. The ultrahigh-coercivity sintered neodymium-iron-boron magnet comprises a main phase and a crystal boundary adding phase. The main phase comprises low-HA main alloy and high-HA main alloy. The high magnetocrystalline anisotropy field HA main alloy and the low-HA main alloy are used as the main phase, so that the heavy rare earth element diffuses from the high-HA phase to the low-HA phase in the sintering and heat treatment process to initially improve the coercivity; in addition, alloy components and the preparation technology can be controlled at the same time, the content of Nd2Fe14B in the magnet is improved, and it is ensured that the magnet has the high magnetic energy product. The crystal boundary adding phase can further achieve crystalline grain surface magnetic hardening and improve the coercivity, the microscopic structure is optimized, and the coercivity is further improved. The preparation method of the ultrahigh-coercivity sintered neodymium-iron-boron magnet has the advantages of both a traditional dual alloy method and a single alloy crystal boundary adding method, and is easy to operate and suitable for mass production of ultrahigh-coercivity high-residual-magnetism sintered neodymium-iron-boron magnets.

Owner:ZHEJIANG UNIV +1

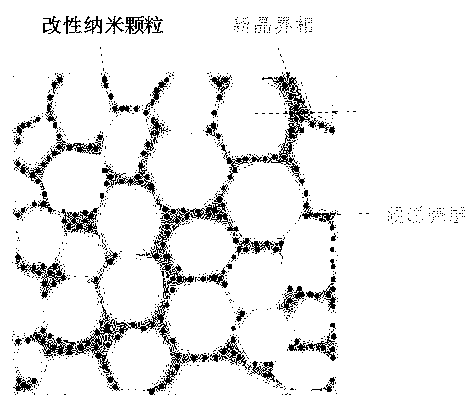

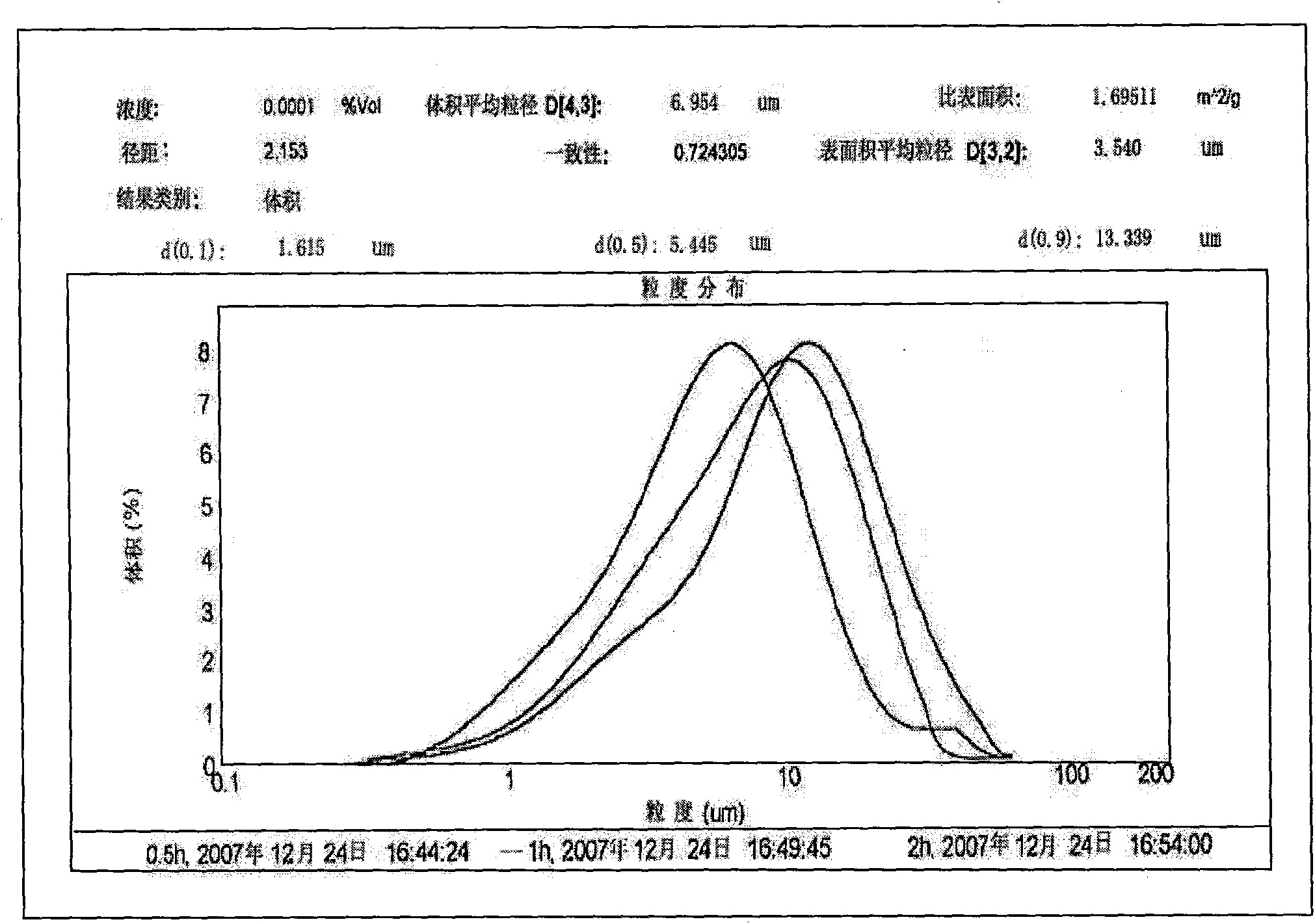

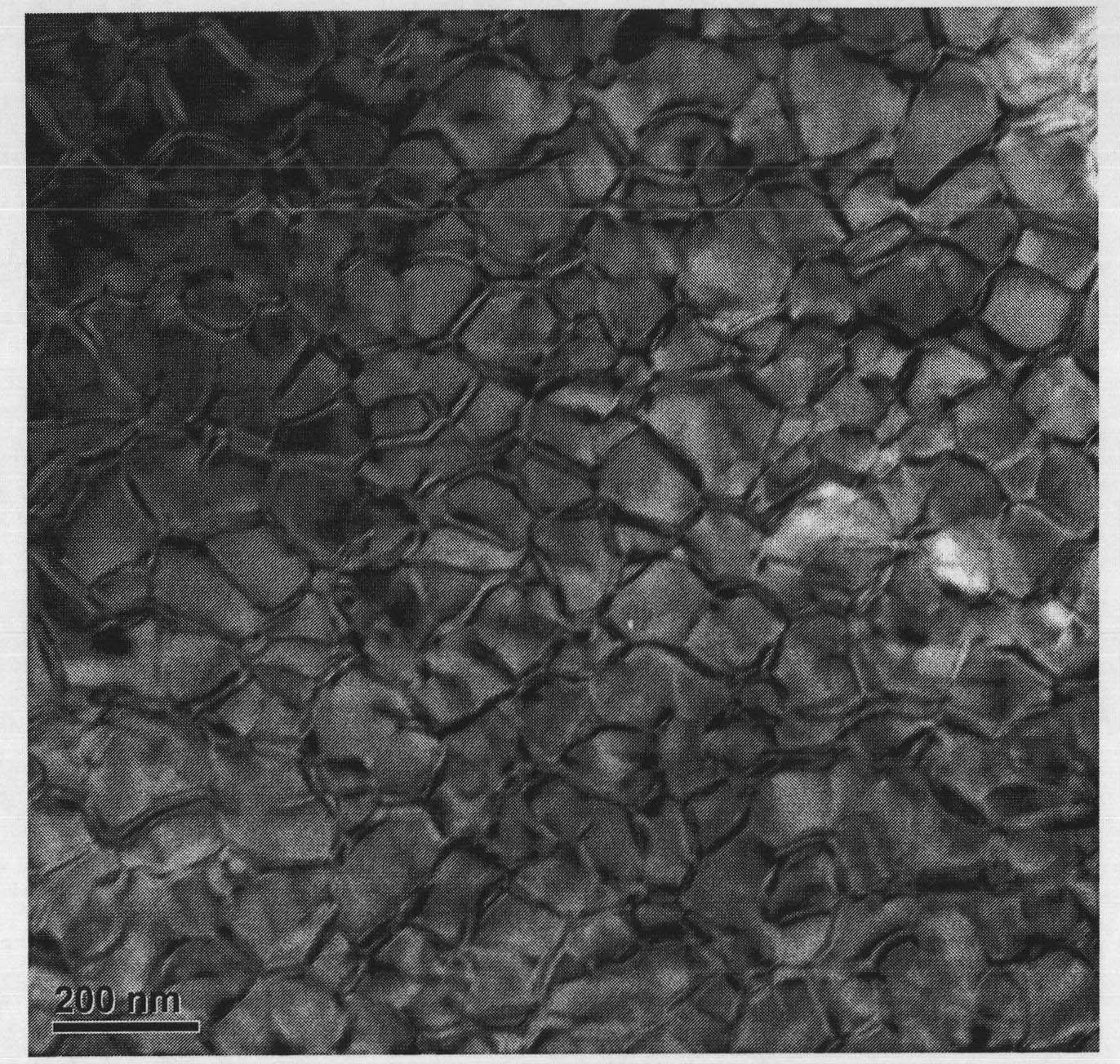

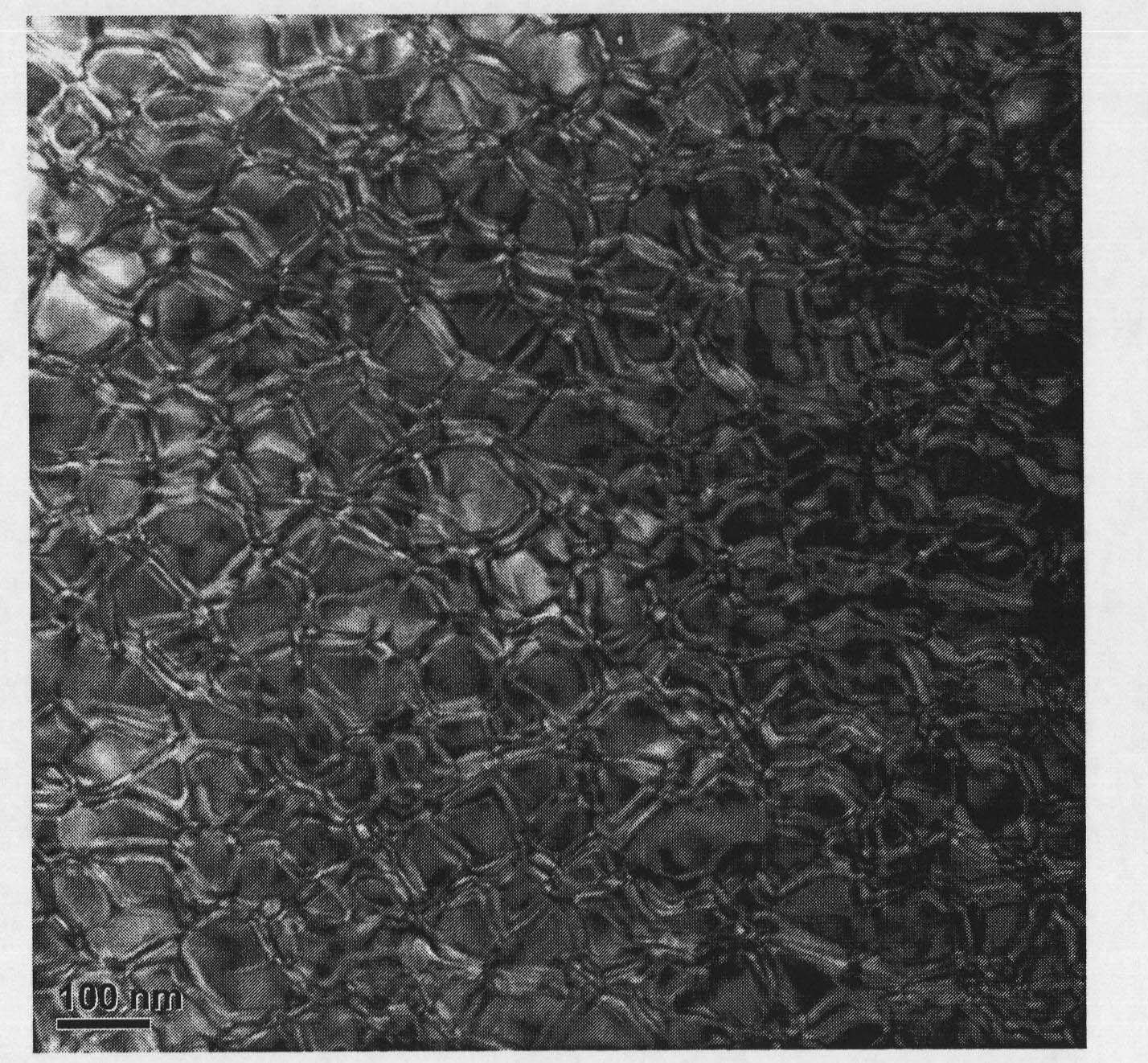

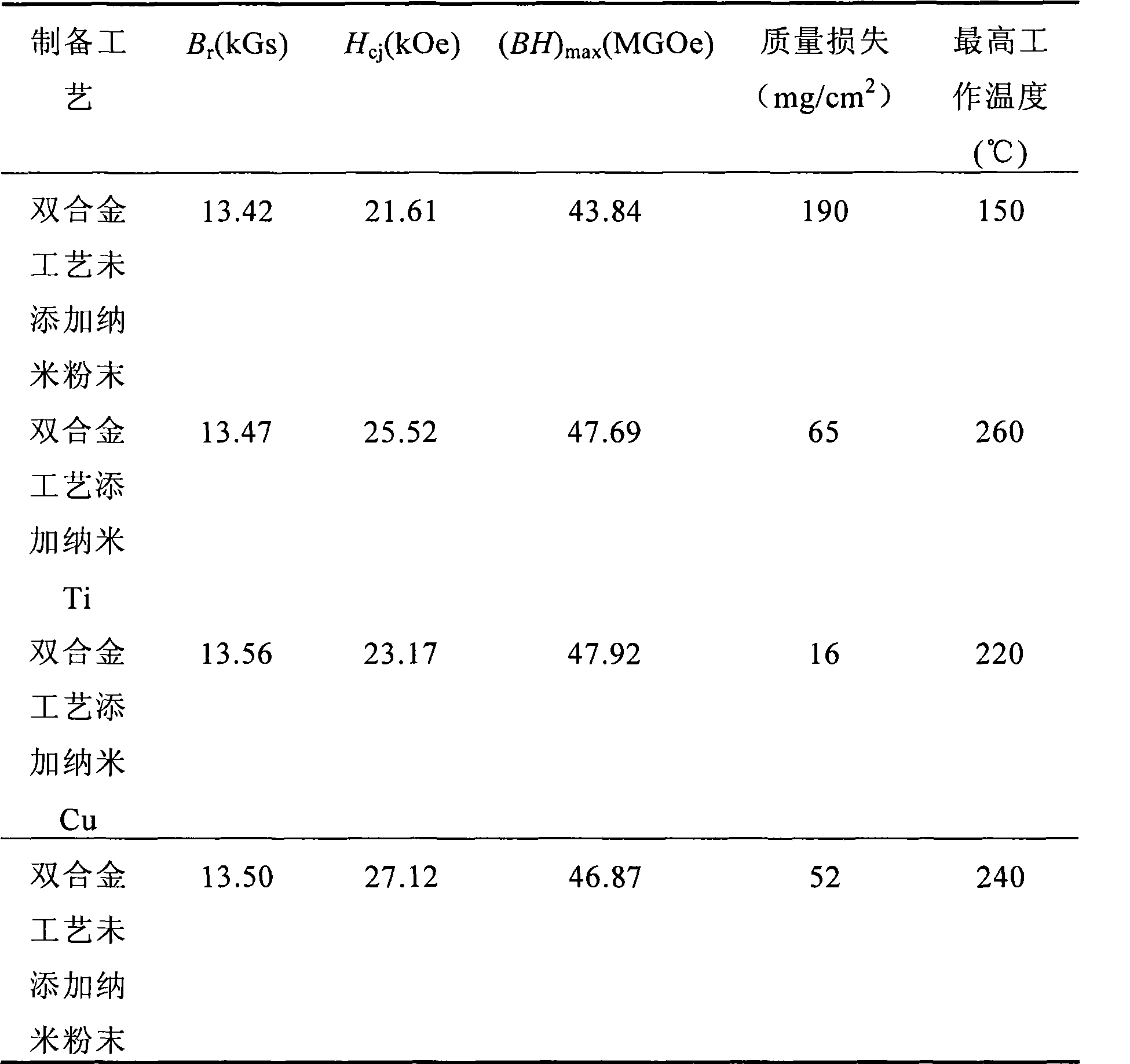

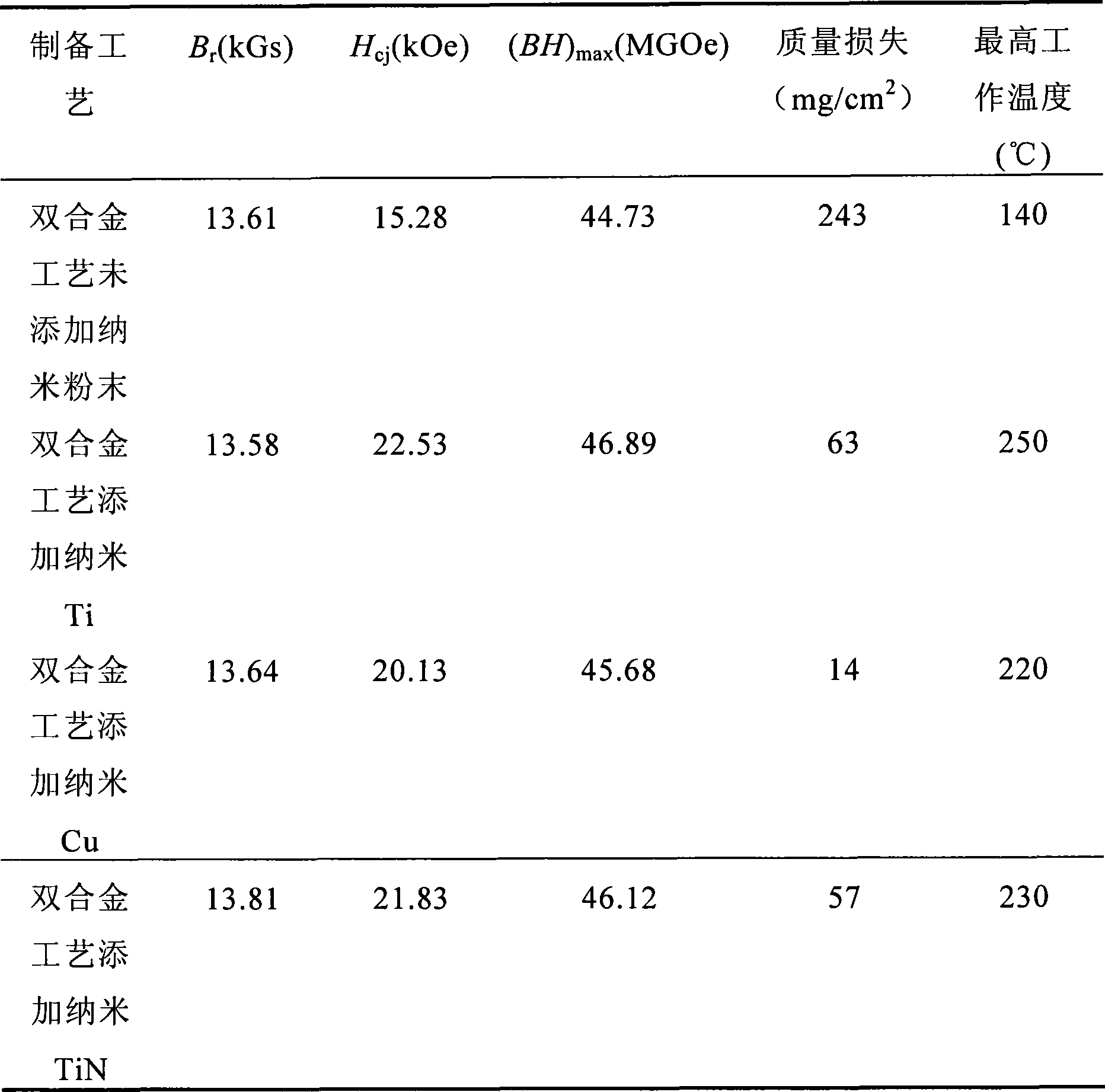

Sintered NdFeB permanent magnet with high working temperature and high corrosion resistance

InactiveCN101499346AIncrease coverageImprove microstructureInorganic material magnetismAlloyGrain boundary

The invention provides a sintered Nd-Fe-B (neodymium iron boron) permanent magnet combination with high working temperature and high corrosion resistance; the composition of the magnet comprises 80-95% of main phase alloy powder and 5-20% of nano-modified grain-boundary-phase alloy powder, taking the total weight of the permanent magnet combination in calculation; the main phase alloy powder is calculated by atomic percentage, and the composition comprises NdaFe100-a-b-cBbMc, wherein a is no less than 11 but no more than 16, b is no less than 5.4 but no more than 6.6, and c is no less than 0 but no more than 6, and M is one or more types of elements Dy, Tb, Nb, Co, Ga, Zr, and Al; and the average particle diameter of the main phase alloy powder is 3-8 mu m. The invention also provides a sintered Nd-Fe-B permanent magnet which simultaneously has high working temperature and high corrosion resistance.

Owner:ZHEJIANG UNIV +1

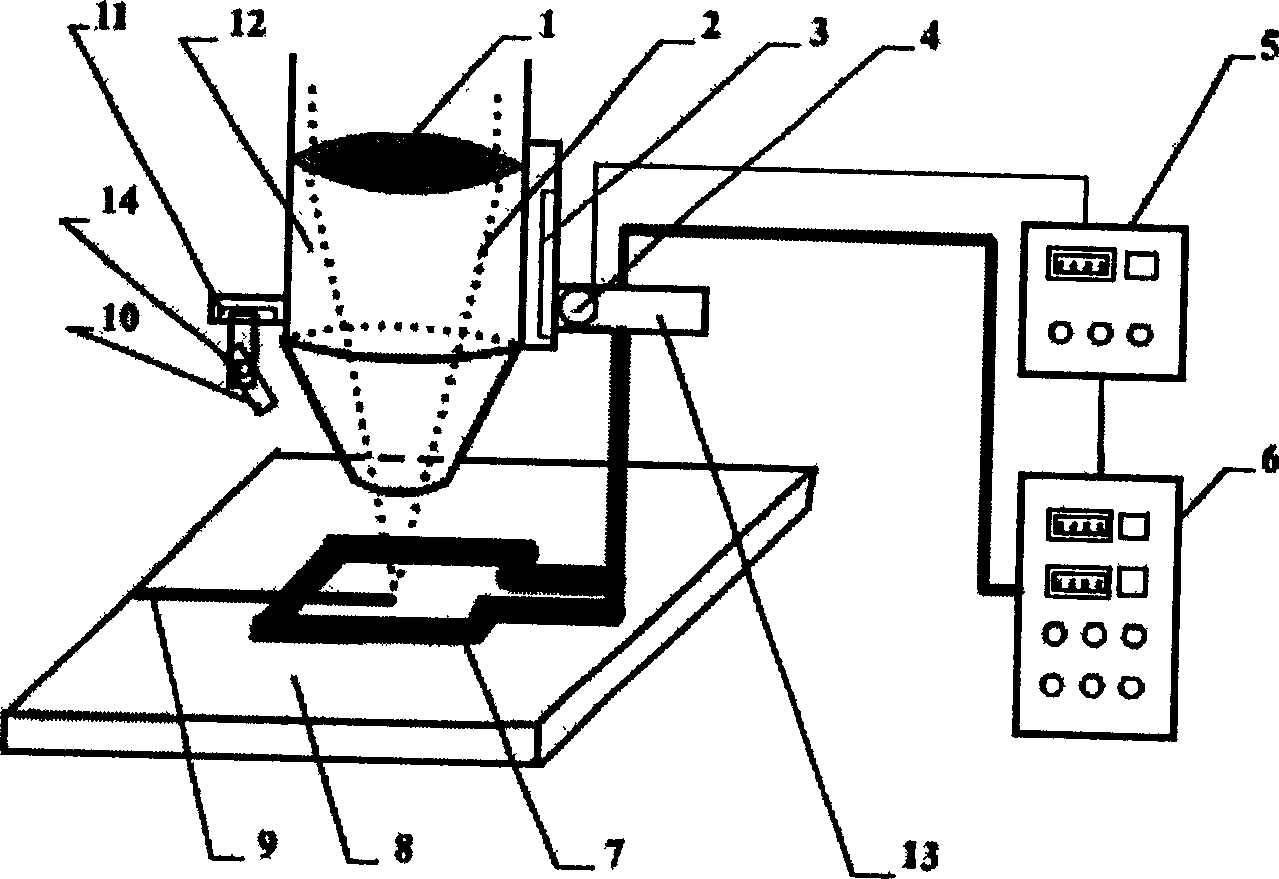

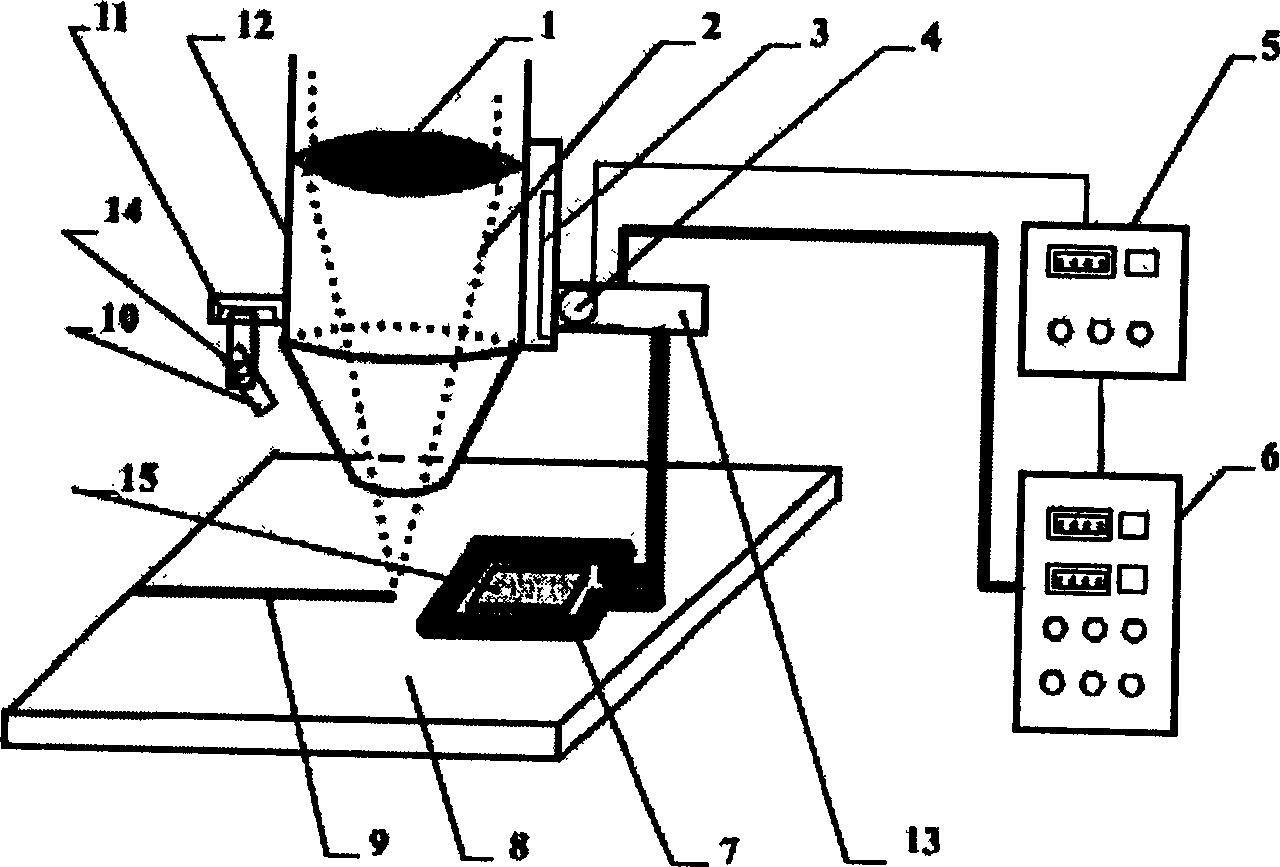

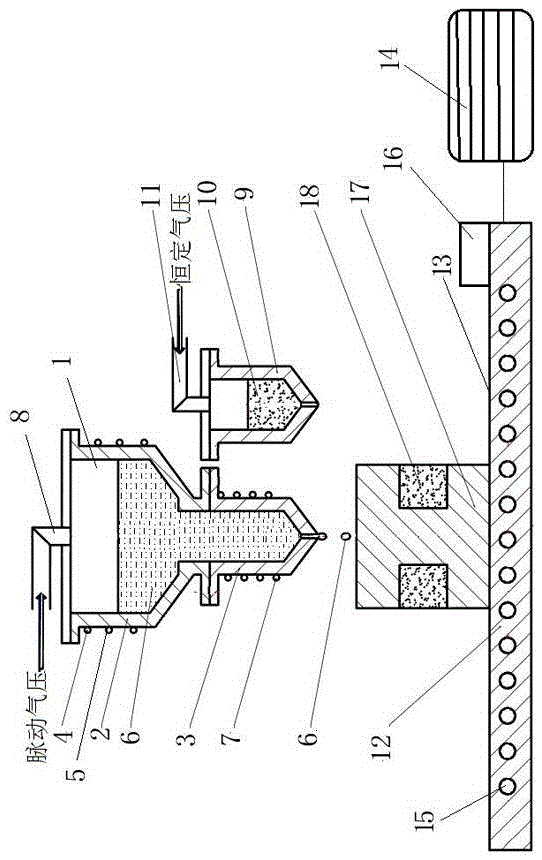

Device for realizing 3D metal printing by virtue of supporting structure

ActiveCN105618756AReasonable structureSimple structureAdditive manufacturing apparatusAutomatic controlShielding gas

The invention relates to a device for realizing 3D metal printing by virtue of a supporting structure. The device comprises a translation stage capable of moving along the X-axis, the Y-axis and the Z-axis. Heating resistance wires and a thermocouple are arranged on a base plate of the translation stage. The heating resistance wires are used for preheating the base plate, so as to enable metal droplet layers to be tightly overlapped. The thermocouple is used for realizing the measurement and the feedback control of a temperature. An electromagnetic induction heating copper pipe and a cooling water pipe are arranged outside a graphite crucible, metallic raw materials are enabled to be molten to form molten metal, the bottom of the graphite crucible is connected with a metal printing spray nozzle, a protective gas is inputted from a gas inlet pipe at the top of the graphite crucible, and under the pulse pressure, molten metal forms regular metal droplets to drip to the base plate of the translation stage. The 3D metal droplet printing is realized through the cooperation with the movement of the translation stage. A supporting material spray nozzle is adjacent to the metal printing spray nozzle. A uniform mixture of gypsum and photosensitive resin is extruded stably under the constant pressure inputted by the gas inlet pipe so as to print the supporting part of a part. The switching between metal and the supporting material is automatically recognized and controlled by a control system. The 3D metal printing device is reasonable, high in operability, high in degree of automation, high in production efficiency, and suitable for being widely popularized, and ensures the molding quality.

Owner:STATE GRID CORP OF CHINA +5

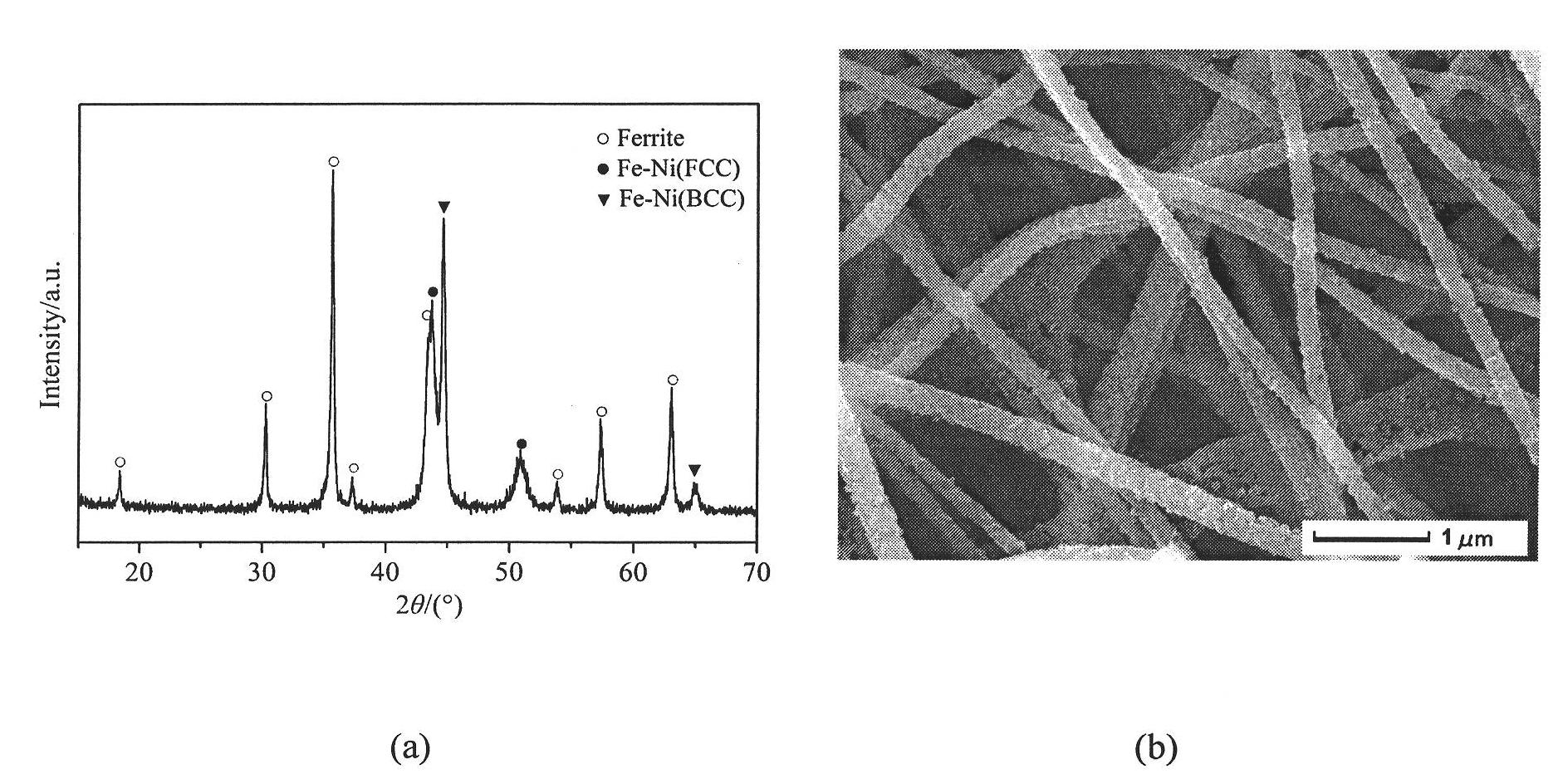

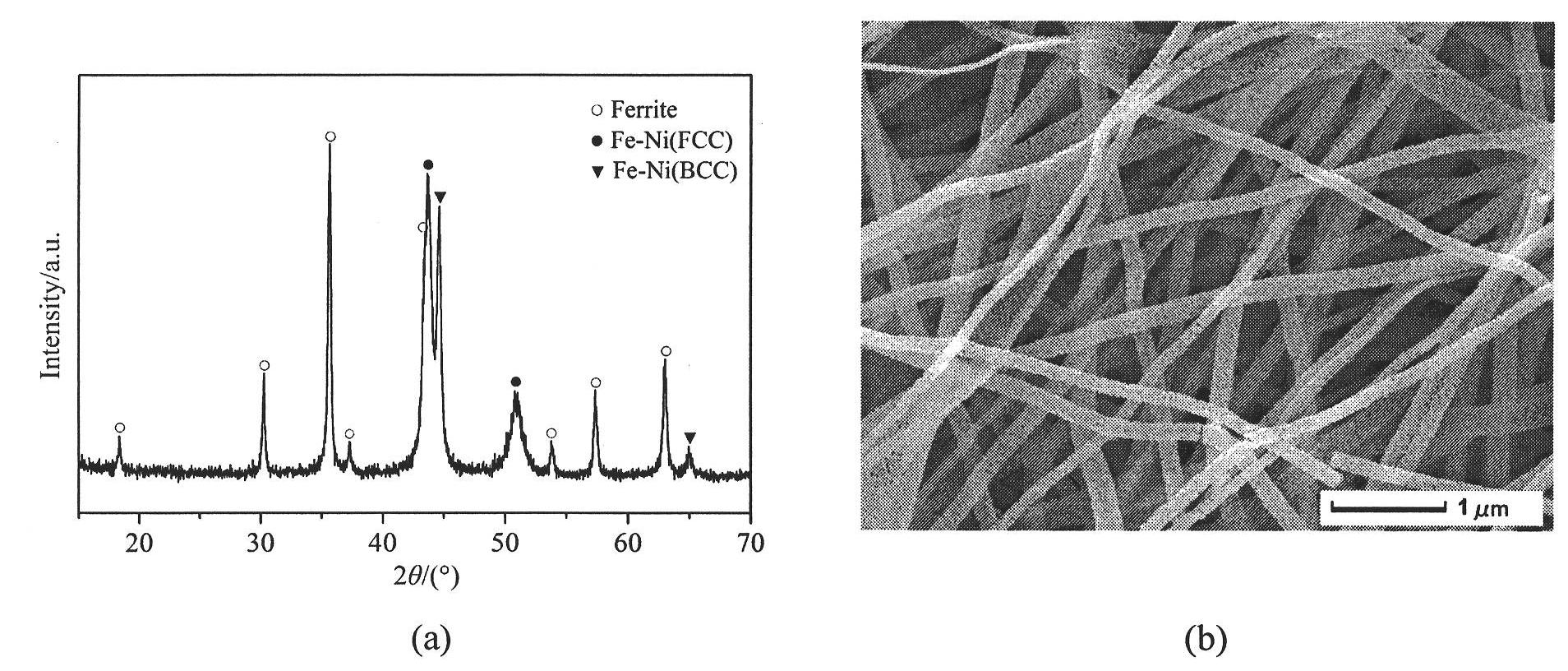

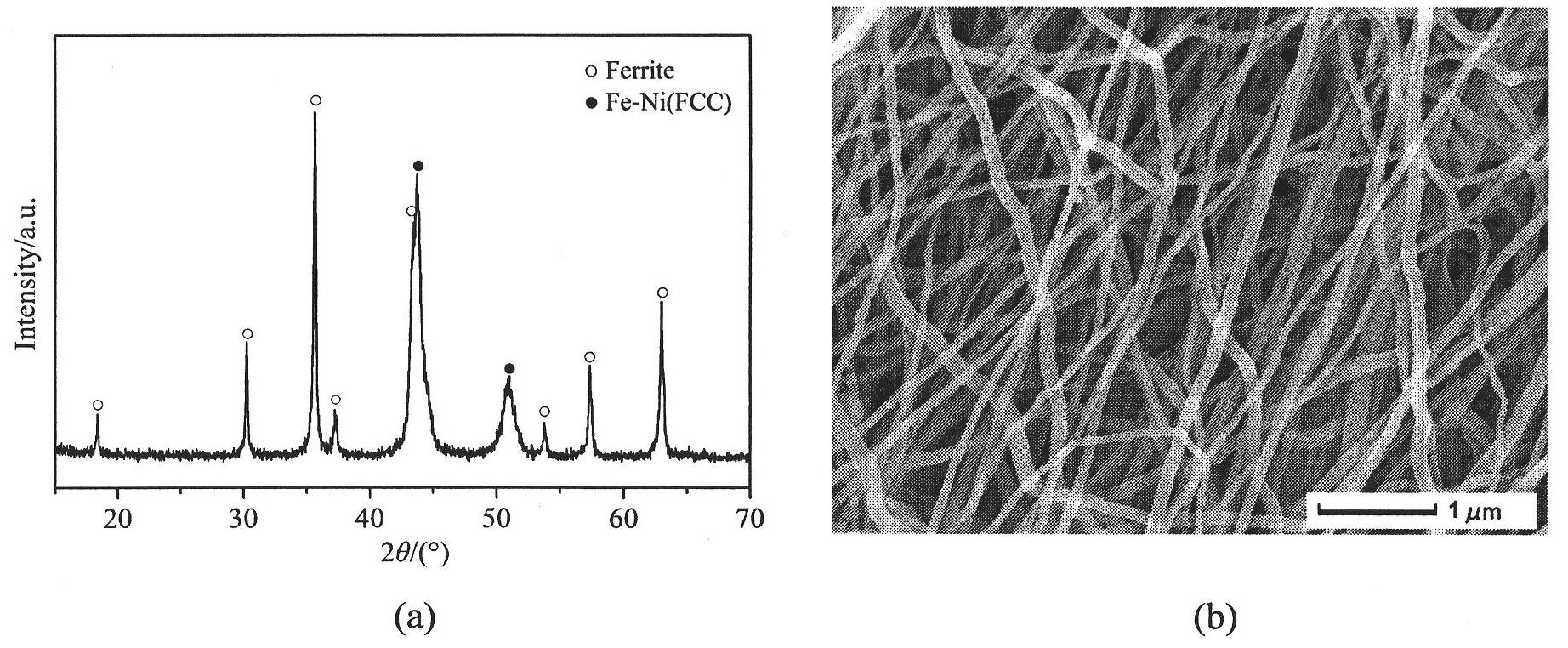

Iron-nickel alloy/nickel ferrite magnetic composite nanofiber and preparation method thereof

InactiveCN101851814ASignificant shape anisotropyAbsorb electromagnetic waves to broadenInorganic material artificial filamentsFilament/thread formingSolventAir atmosphere

Owner:JIANGSU UNIV

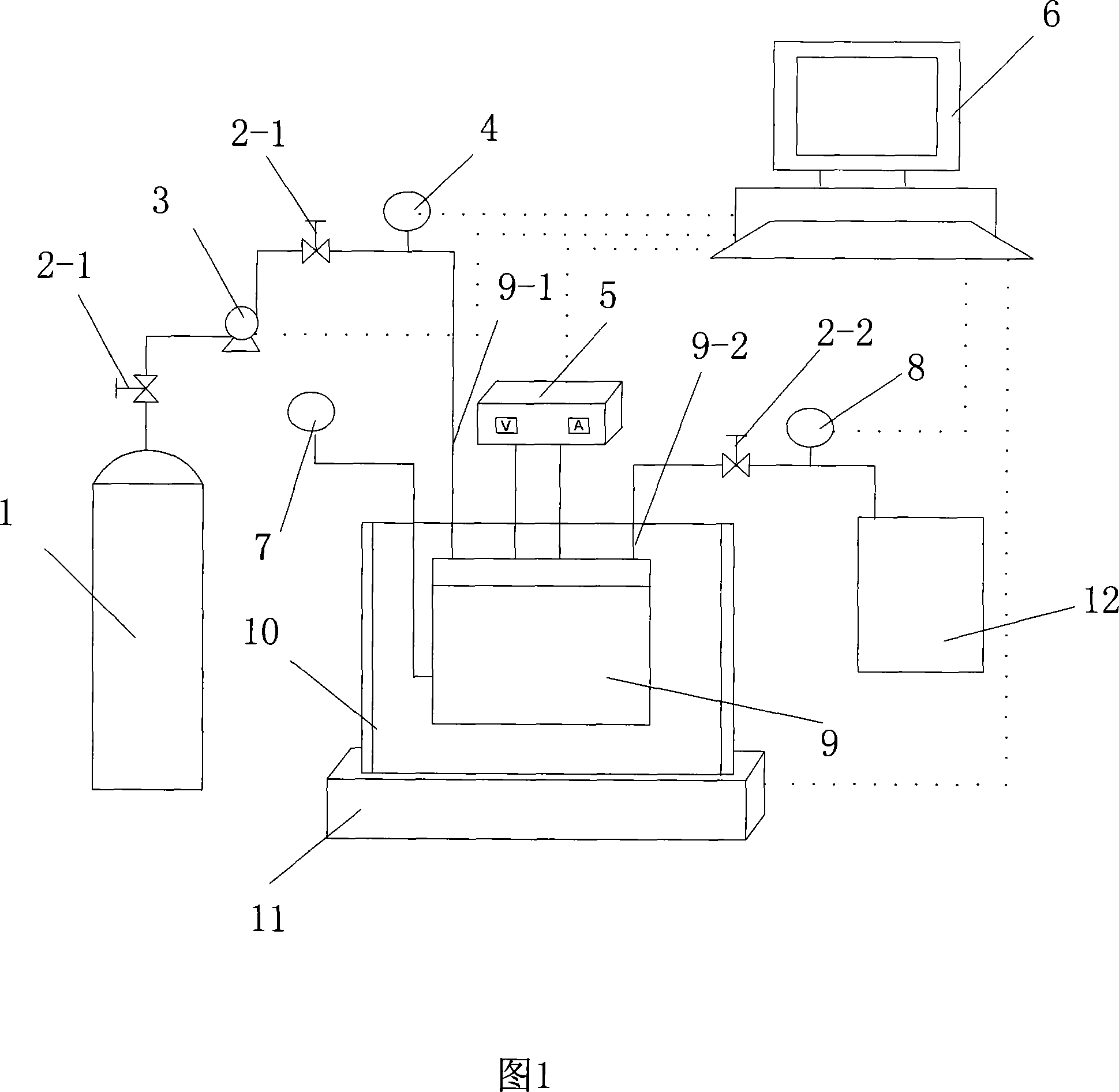

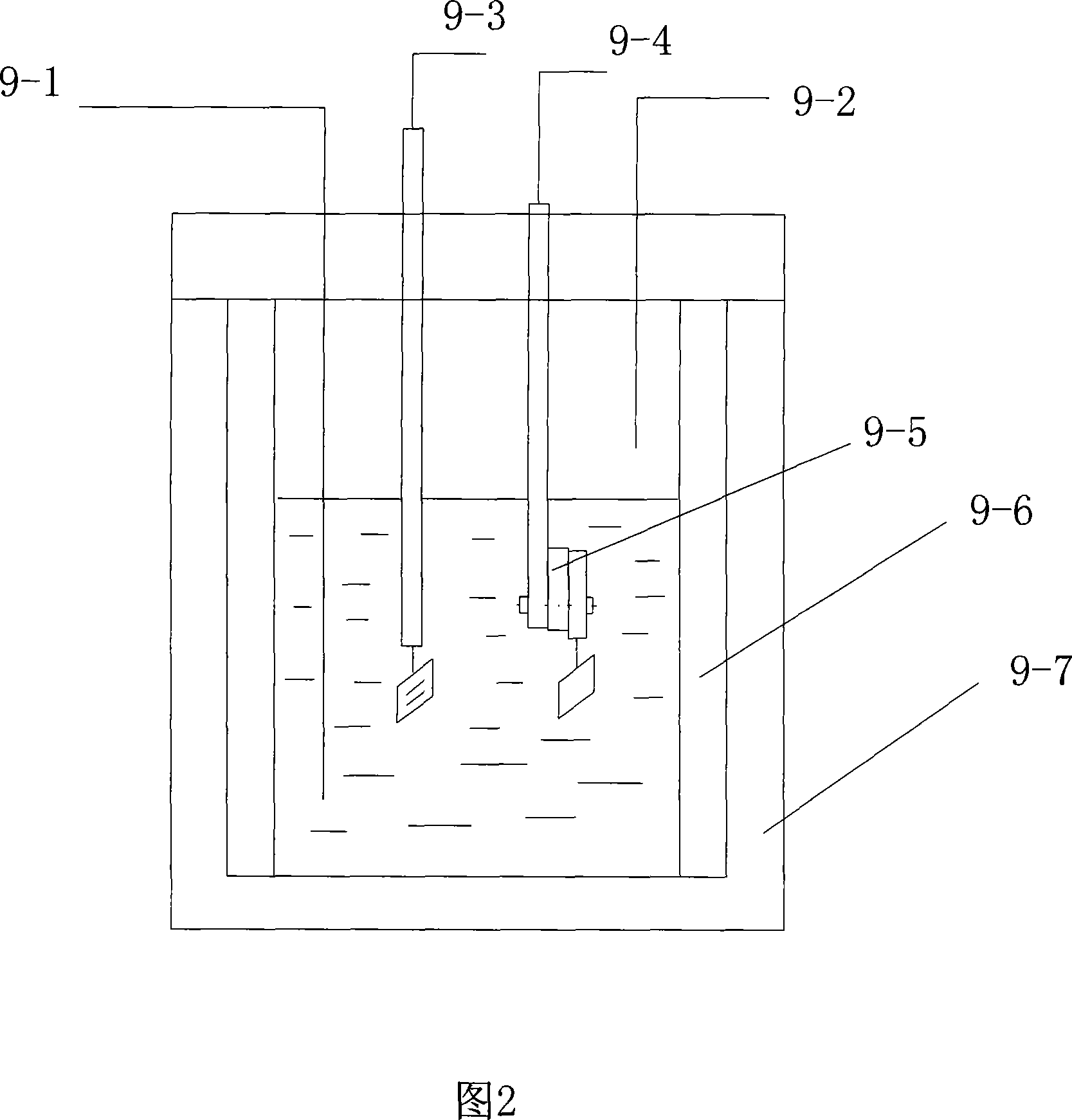

Superfine electroform technique of supercutical fluid, and equipment

InactiveCN101092716AImprove deposition conditionsQuality improvementElectroforming processesEngineeringBottle

This invention discloses process and apparatus for micro electroforming by using supercritical fluid. The process comprises: (1) generating supercritical fluid electroforming solution in the reactor of a fine deposition unit; (2) controlling the power source by a control unit, selecting appropriate electric parameters, and depositing metal ions onto the photoresist patterns of the cathode of the fine deposition unit; (3) removing residual photoresist to obtain fine component. The apparatus comprises a CO2 steel bottle, a high-pressure pump, a DC power source, a control unit, a fine deposition unit, a magnetic stirrer, a thermostatic bath, a backpressure valve and a recovery device. The method and apparatus in this invention can deposit compact, smooth and clear fine component, and the waste supercritical fluid electroforming solution can be recovered and recycled.

Owner:HAIAN GASOLINEEUM SCI RES INSTR +1

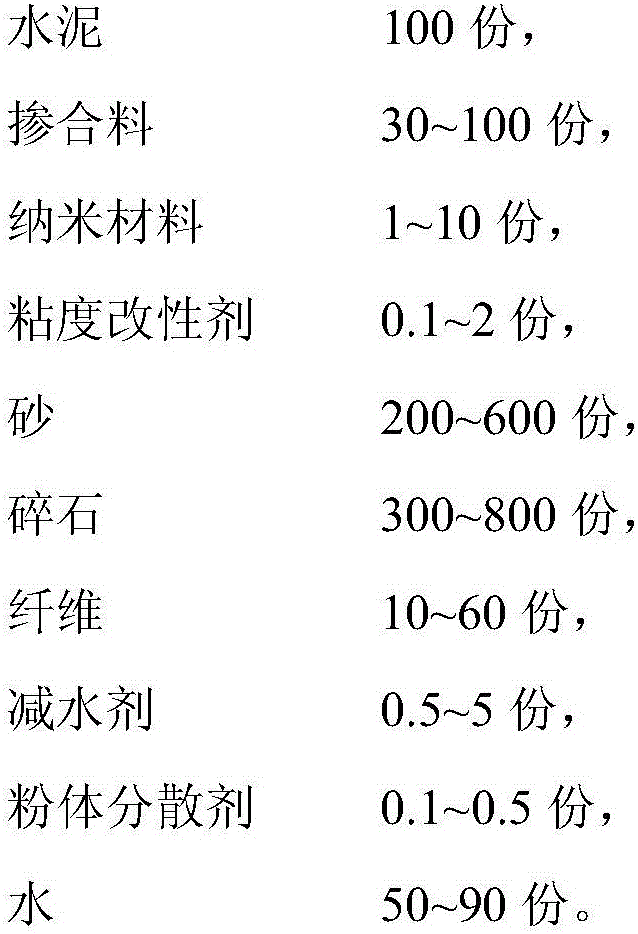

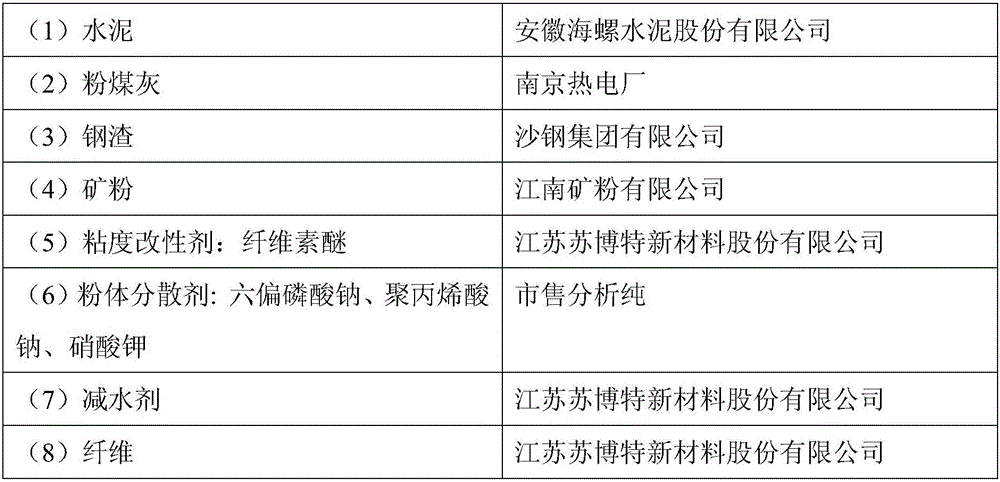

Concrete with common strength and high elastic modulus and preparation method thereof

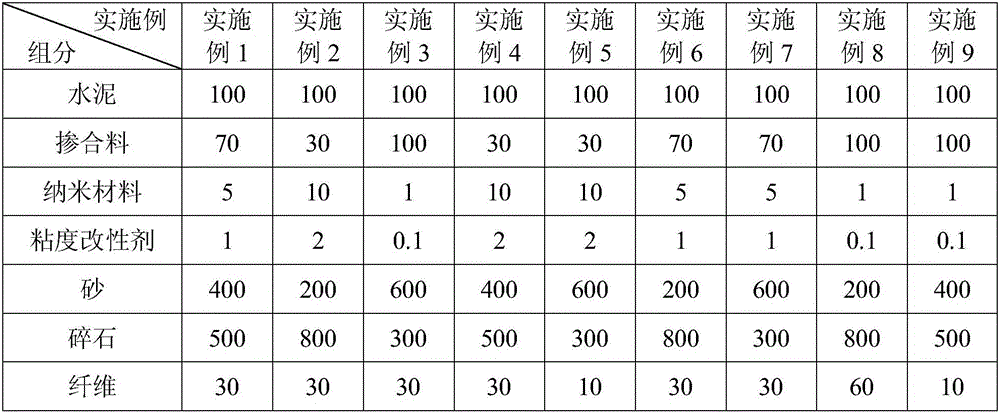

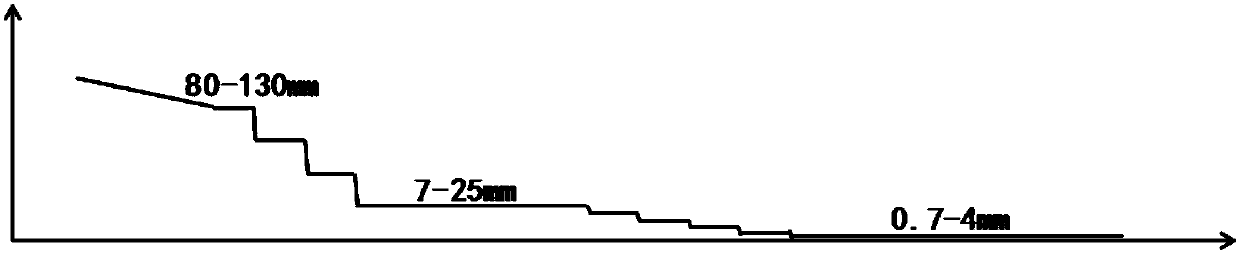

The invention discloses concrete with common strength and high elastic modulus and a preparation method thereof. The concrete with common strength and high elastic modulus, disclosed by the invention, is prepared from the following components in parts by mass: 100 parts of cement, 30-100 parts of an admixture, 1-10 parts of a nano material, 0.1-2 parts of a viscosity modifier, 200-600 parts of sand, 300-800 parts of crushed stones, 10-60 parts of fibers, 0.5-5 parts of a water reducing agent, 0.1-0.5 part of a powder dispersant and 50-90 parts of water. After the concrete with common strength and high elastic modulus, disclosed by the invention, is subjected to standard curing or natural curing for 28d, the strength grade of the concrete is C40-C50, and the elastic modulus can reach 50GPa or more; and the concrete has excellent working performance and endurance performance.

Owner:JIANGSU SOBUTE NEW MATERIALS

Slag mixed active powder concrete

Disclosed is reactive powder concrete mixed with slag, which is a novel engineering material with super-high intensity and super-high durability, particularly cement-based composite material having super-high property prepared and formed via using all kinds of industrial residue as reactive powder. Corresponding to Portland cement, proportion by weight of all composites of the concrete is: the Portland cement holding 1 part, the slag holding 0.40-0.60 part, silicon powder holding 0.20-0.35 part, quartz flour holding 0.20-0.35 part, river sand holding 1.20-1.60 parts, water holding 0.20-0.28 part and a water reducing agent holding 0.02-0.03 part.

Owner:SOUTHEAST UNIV

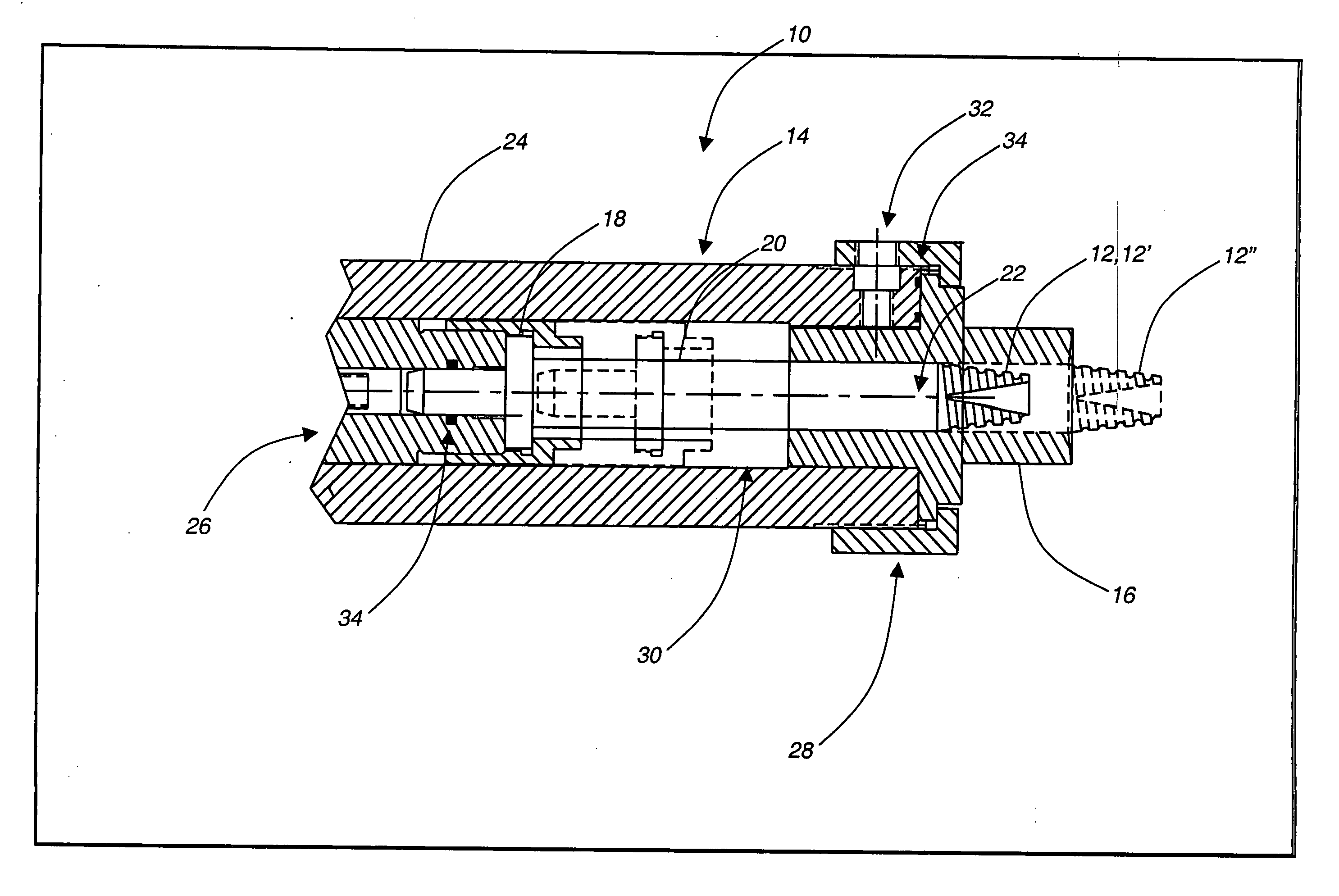

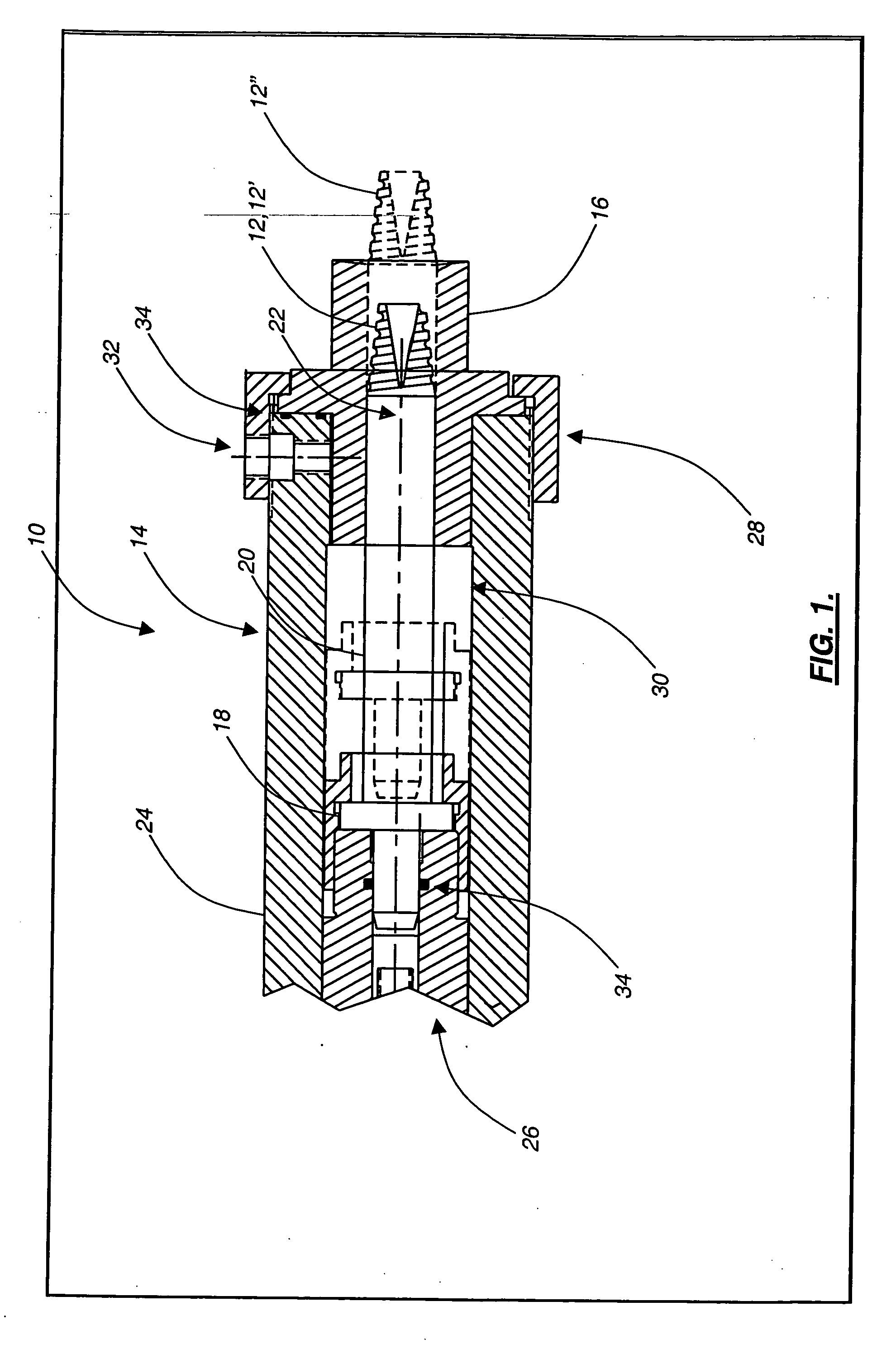

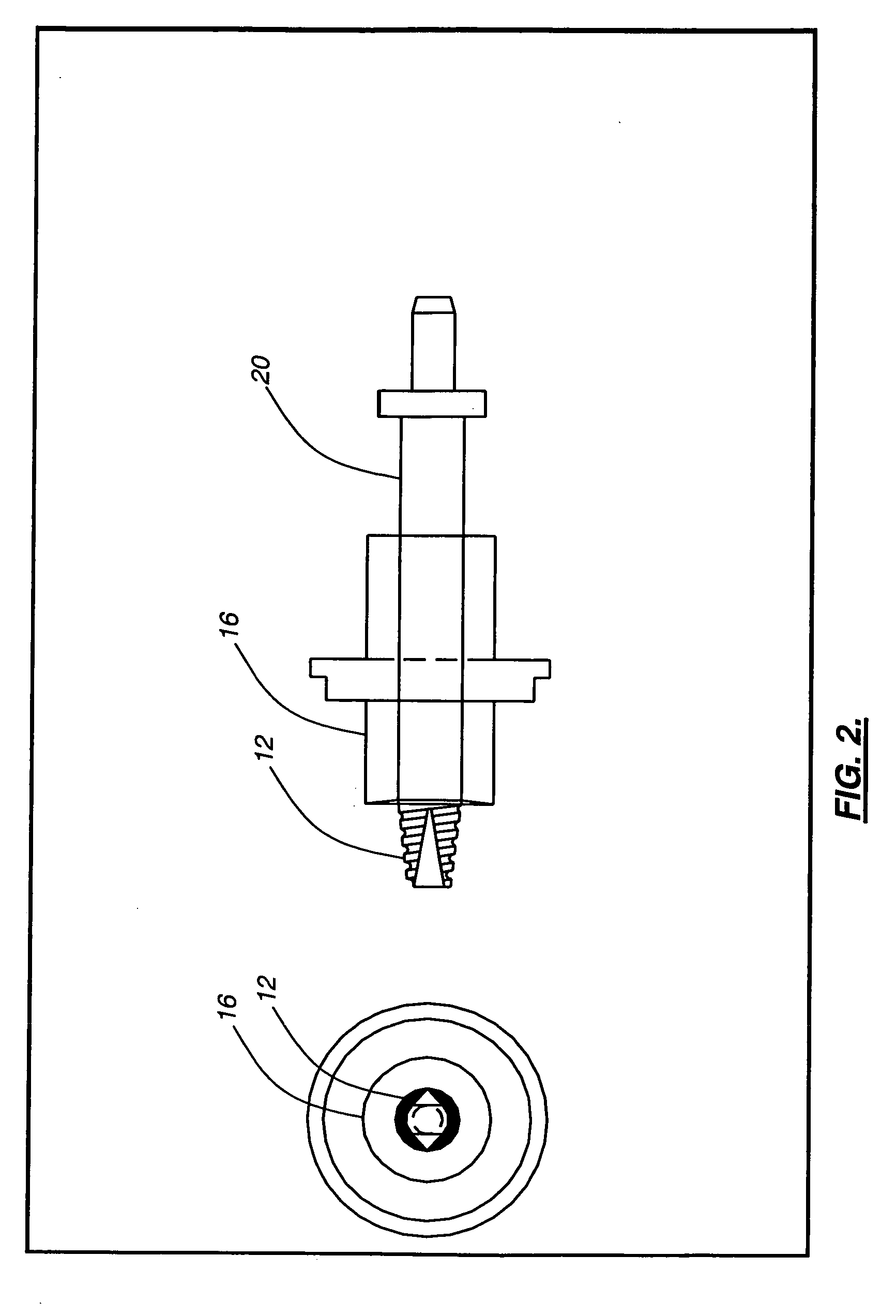

Apparatus and method for friction stir welding using a consumable pin tool

InactiveUS20060163328A1Improve mechanical propertiesImprove microstructureWelding/cutting auxillary devicesAuxillary welding devicesMulti materialMetal alloy

The present invention provides a friction stir welding apparatus operable for welding one or more metals, metal alloys, or other materials. The friction stir welding apparatus includes a pin tool holder, a shoulder having a surface coupled to the pin tool holder, and a pin tool coupled to the pin tool holder, the pin tool at least partially protruding from the surface of the shoulder, wherein the pin tool is made of a consumable pin tool material. Optionally, the shoulder rotates at a predetermined rotational speed and is retractable into / extendable from the pin tool holder at a substantially constant rate. Optionally, the shoulder is also made of a consumable shoulder material that is at least partially incorporated into the volume of a joint to be welded. The consumable shoulder material comprises a material that is the same as, similar to, or dissimilar from one or more materials comprising a workpiece to be friction stir welded. Preferably, the pin tool rotates at a predetermined rotational speed and is retractable into / extendable from the surface of the shoulder at a substantially constant rate. The consumable pin tool material is at least partially incorporated into the volume of the joint to be welded. The consumable pin tool material comprises a material that is the same as, similar to, or dissimilar from one or more materials comprising the workpiece to be friction stir welded.

Owner:GENERAL ELECTRIC CO

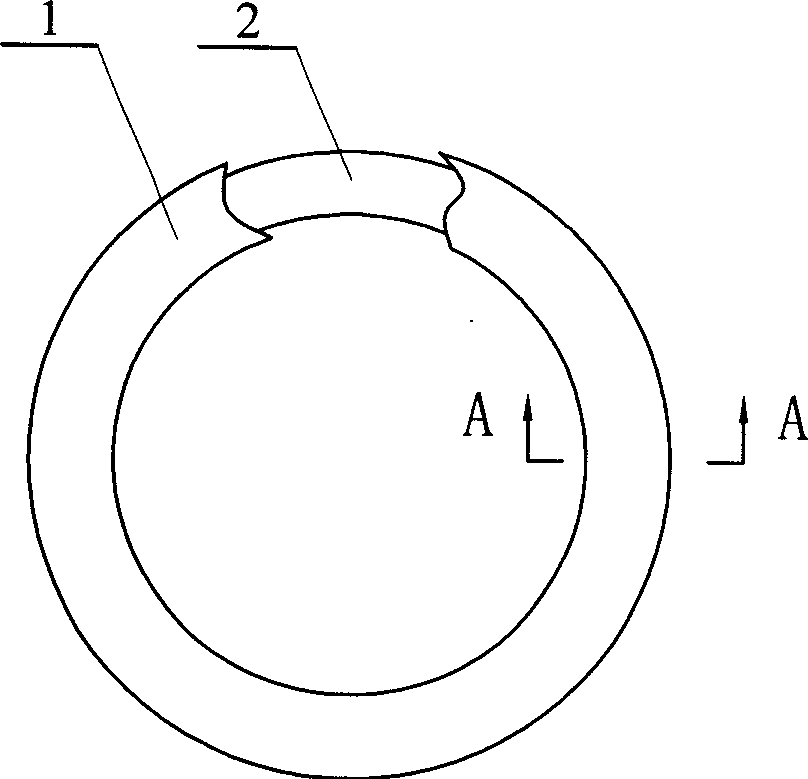

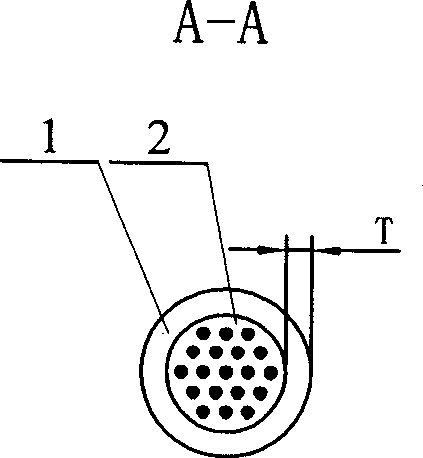

Aluminum welding ring and flux core in use for welding joint of tubes made from aluminum and aluminum alloy, and preparation method

ActiveCN1759973AAvoid adding too muchAvoid uniformityWelding/cutting media/materialsSoldering mediaChemical compositionIngot

A flux cored aluminium ring for the butt connection between two aluminium or Al-alloy tubers by soldering is composed of the shell made of Al-Si alloy foil and the core made of Al-Si alloy wire and alloy powder. Said Al-Si alloy foil (or wire) contains Al (86.5-97 Wt %), Si (3-13), Sr (0.01-0.3) and La (0.01-0.2). Said alloy powder consists of KalF4-K3AlF6 eutectic and Si powder. Its preparing steps are smelting Al-Si alloy ingot, preparing Al-Si alloy band and wire, preparing their foil and wire, grinding alloy powder, making core wire, and making flux cored ring.

Owner:浙江信和科技股份有限公司

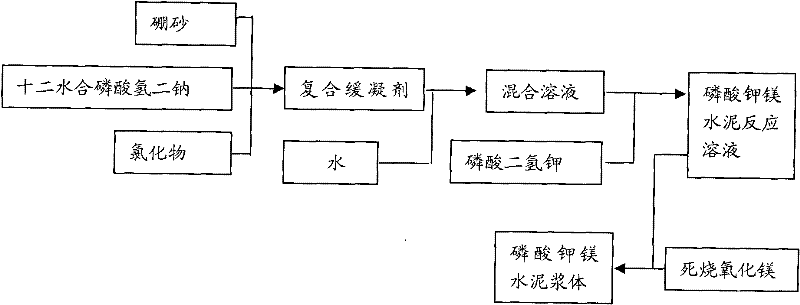

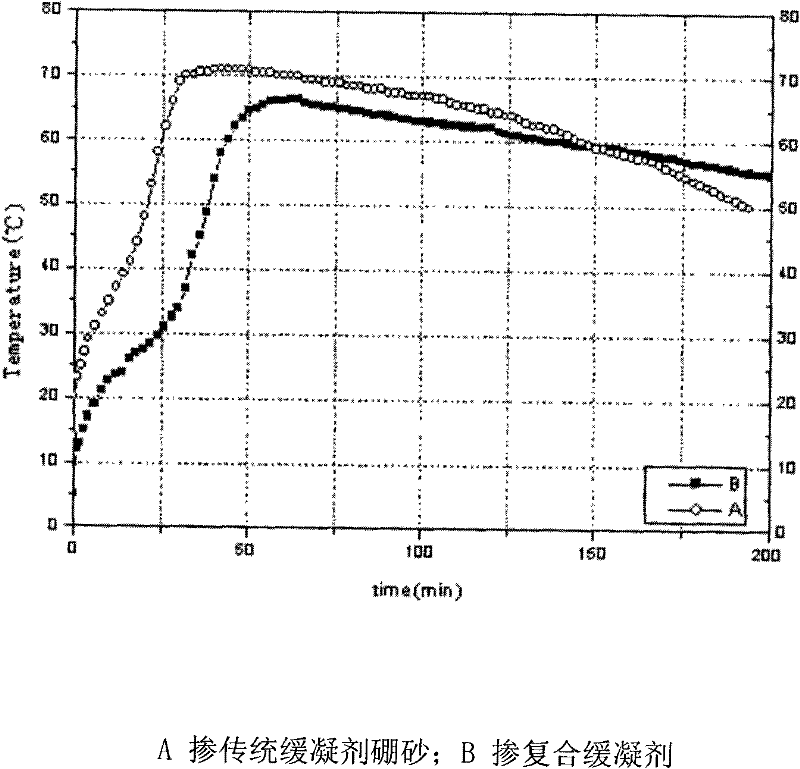

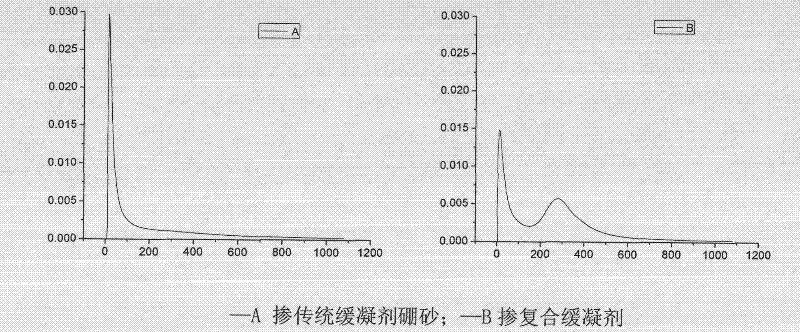

Method for controlling setting time and early hydration speed of magnesium potassium phosphate cement

InactiveCN102234200AEffective adjustment of clotting timeEffective control of clotting timeControl setOperability

The invention relates to a method for controlling the setting time and early hydration speed of magnesium potassium phosphate cement, and belongs to an early strength quick hardening cement cementing material. A composite retarder can effectively adjust the setting time of magnesium potassium phosphate cement slurry, and the setting time of the magnesium potassium phosphate cement slurry can be effectively controlled in the range of 10 minutes to 6 hours by adjusting the content of chloride and disodium hydrogen phosphate dodecahydrate in the composite retarder, so that the problems of a limited retarding effect, low operability and the like are solved; the composite retarder can change the hydration heat release characteristic of the magnesium potassium phosphate cement, the magnesium potassium phosphate cement slurry doped with the conventional retarder borax has a hydration heat release peak at the initial reaction stage and has a high heat release speed and large heat release amount, and the magnesium potassium phosphate cement doped with the composite retarder has two hydration heat release peaks and has small hydration heat release amount at the initial hydration stage; and the doped composite retarder improves the microstructure and later strength of a hardened magnesium potassium phosphate cement body, so that enough construction operable time can be ensured while the magnesium potassium phosphate cement slurry has early strength and is quickly hardened.

Owner:苏州诚开新材料有限公司

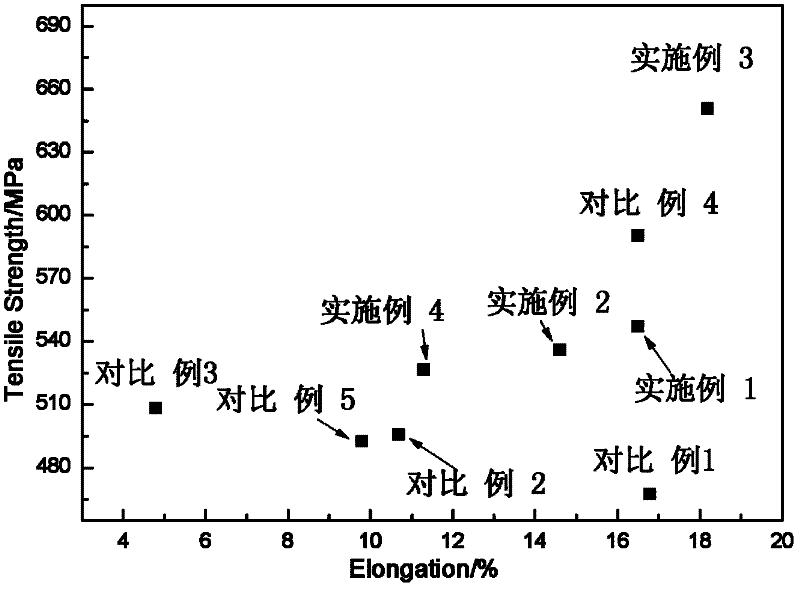

Manufacturing method of metal matrix nanocomposites with high toughness

The invention relates to the composite technical field, in particular to a manufacturing method of metal matrix nanocomposites with high toughness. According to the manufacturing method, the size, distribution, interface structure of reinforcement bodies and the metal matrix micro-structure are effectively controlled by the combined composite process of twice ball-milling, discharging plasma in situ reaction sintering and the large strain plastic deformation technology, so that ultra-fine grain metal matrix composites with evenly distributed in situ authigenic nanoparticles and good interface combination are manufactured, and good matching of intensity and toughness is obtained.

Owner:泰州赛龙电子有限公司

Method for increasing working temp and corrosion resisting property of Nd-Fe-B by adding nona silicon nitride in crystal boundary phase

InactiveCN1725394AIncrease working temperatureImprove corrosion resistanceInorganic material magnetismInductances/transformers/magnets manufactureSintered magnetsWorking temperature

This invention discloses a method for adding nm SiN in grain boundary phase to increase NdFeB working temperature and corrosion resistance including: applying casting technology for a main phase alloy to process a NdFeB ingot alloy or applying a foil rapid hardening technology to manufacture NdFeB rapid hardened foils, applying casting technology for grain boundary phase alloy to make ingot alloy or foil technology to foils or rapid extraction band by rapid extraction technology 2 powdering the two alloys, 3 adding nm SiN into the grain boundary phase alloy powder, 4, mixing them and pressing them to formation 5, sintering it in the oven to a sintered magnet.

Owner:ZHEJIANG UNIV

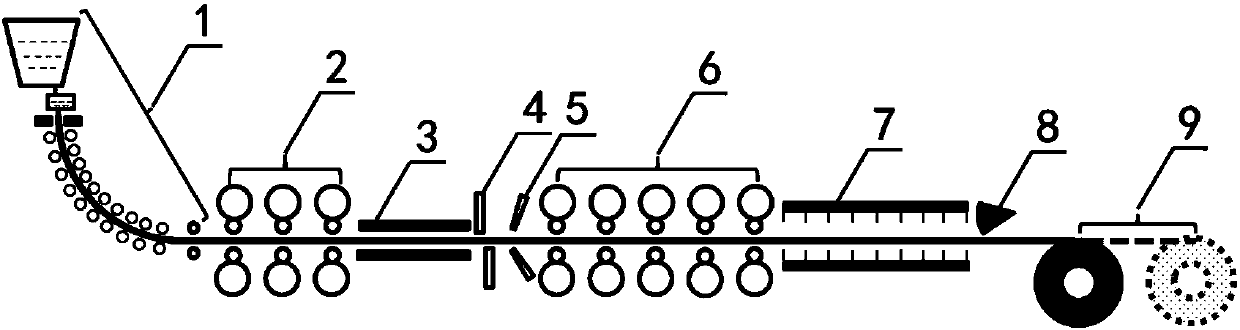

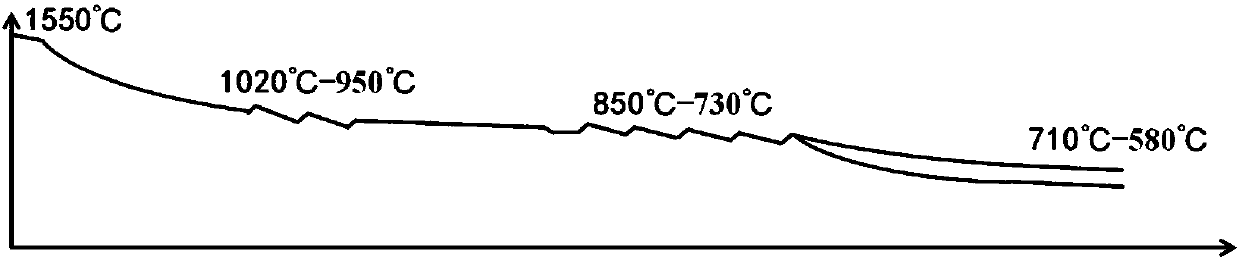

Headless continuous casting and rolling ferrite rolling method and device of low/micro-carbon steel coil for deep drawing

PendingCN107597844AReduce aging phenomenonPromote formationTemperature control deviceWork treatment devicesTemperature controlHigh pressure water

The invention discloses a headless continuous casting and rolling ferrite rolling method and device of a low / micro-carbon steel coil for deep drawing and belongs to the field of metallurgy steel rolling. According to the headless continuous casting and rolling ferrite rolling method and device of the low / micro-carbon steel coil for deep drawing, continuous casting for blank forming, rough rollingof a rough rolling unit, temperature control of a cooling channel, descaling of high-pressure water, ferrite rolling of a finishing mill group, cooling of a layer cooling device, high-speed flying shear and shunt winding and coiling of a reeling machine are carried out. By means of the method and device, the problems that heating / soaking of a heating furnace is needed before rough rolling of a conventional hot rolling process, and cooling with temperature retaining is needed due to the fact that the temperature difference of rough rolling of an austenite zone and finish rolling of a ferrite zone is large and the problems that for thin slab casting and rolling processes with CSP as a respective, heating / soaking or induction heating for temperature supplementing of a heating furnace is needed are solved, the advantages that the arrangement is compact, the investment is small, the production efficiency is high, safety and reliability are achieved, energy is saved, environmental friendliness is achieved, and the cost is reduced are achieved, and the low-carbon / micro-carbon steel coil for deep drawing is produced through headless continuous casting and rolling and ferrite rolling.

Owner:UNIV OF SCI & TECH BEIJING +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com