Patents

Literature

3618 results about "River sand" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low cost active powder concrete and preparation thereof

InactiveCN101486554ALow raw material costReduce maintenance costsSolid waste managementMixing operation control apparatusFiberSlag

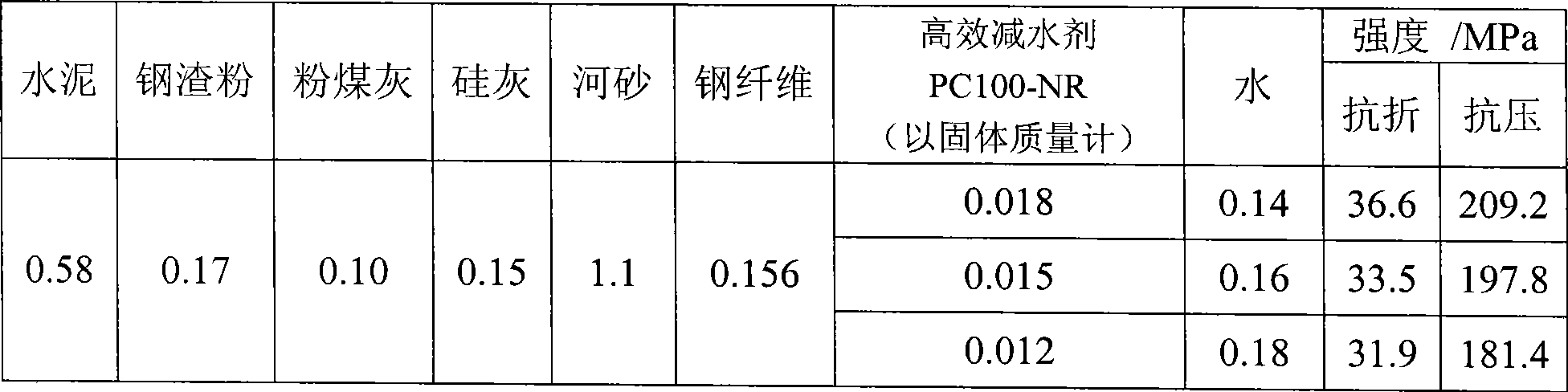

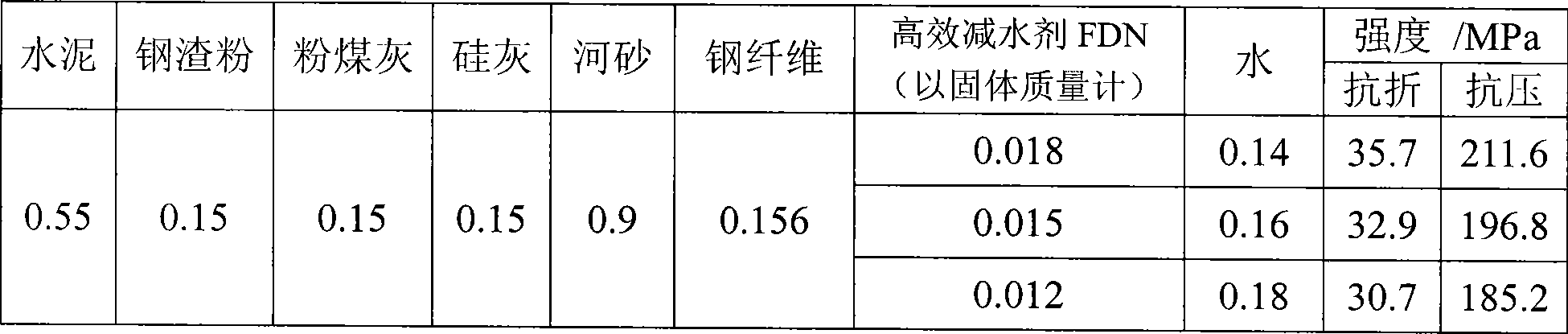

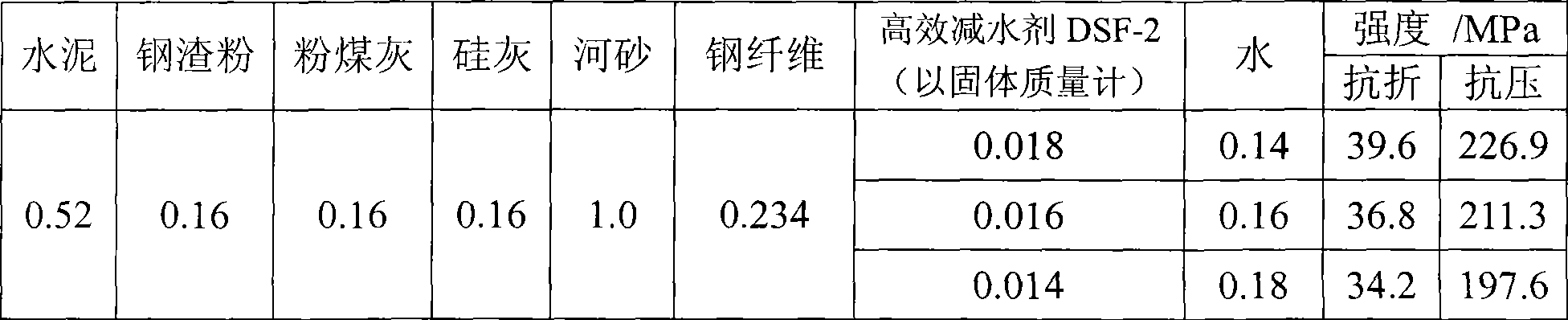

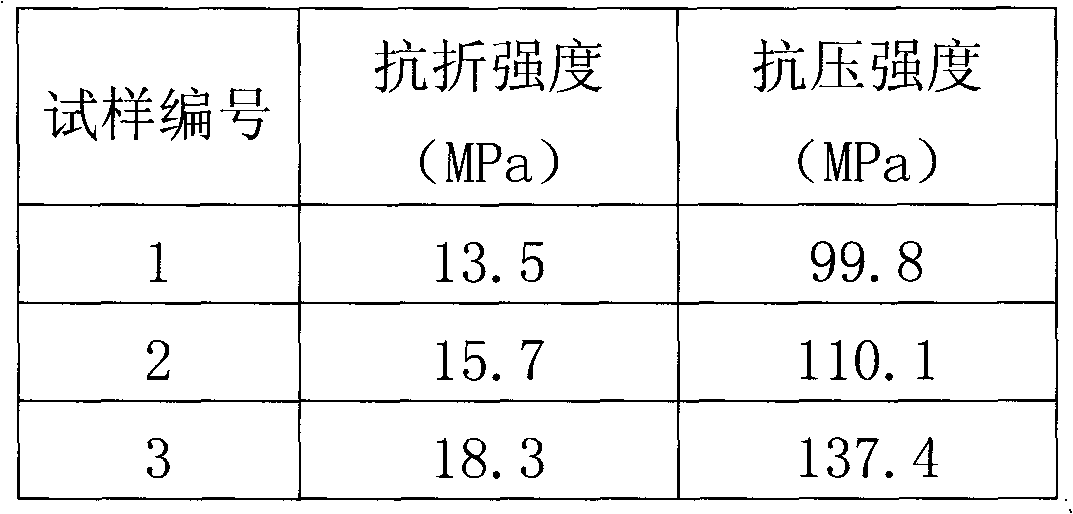

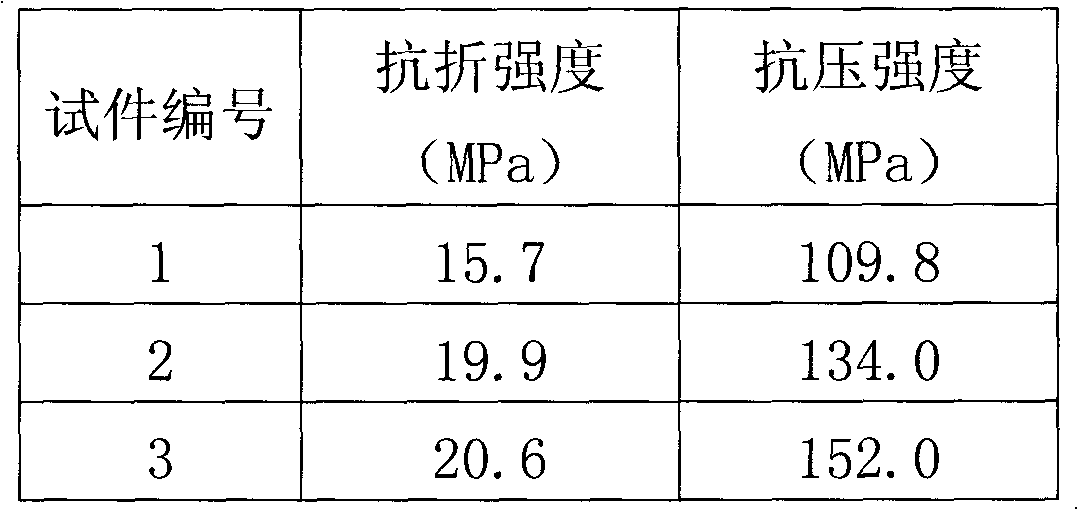

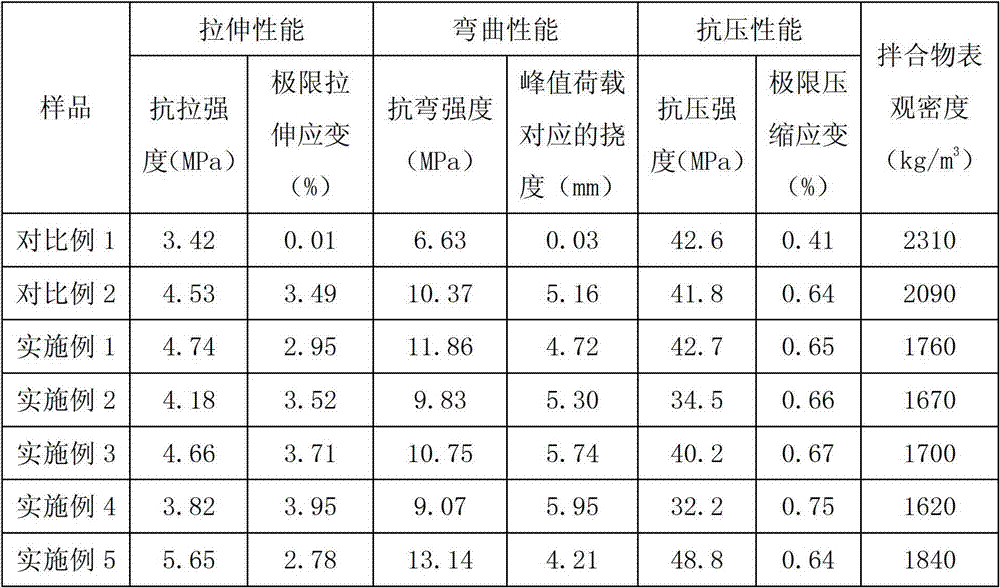

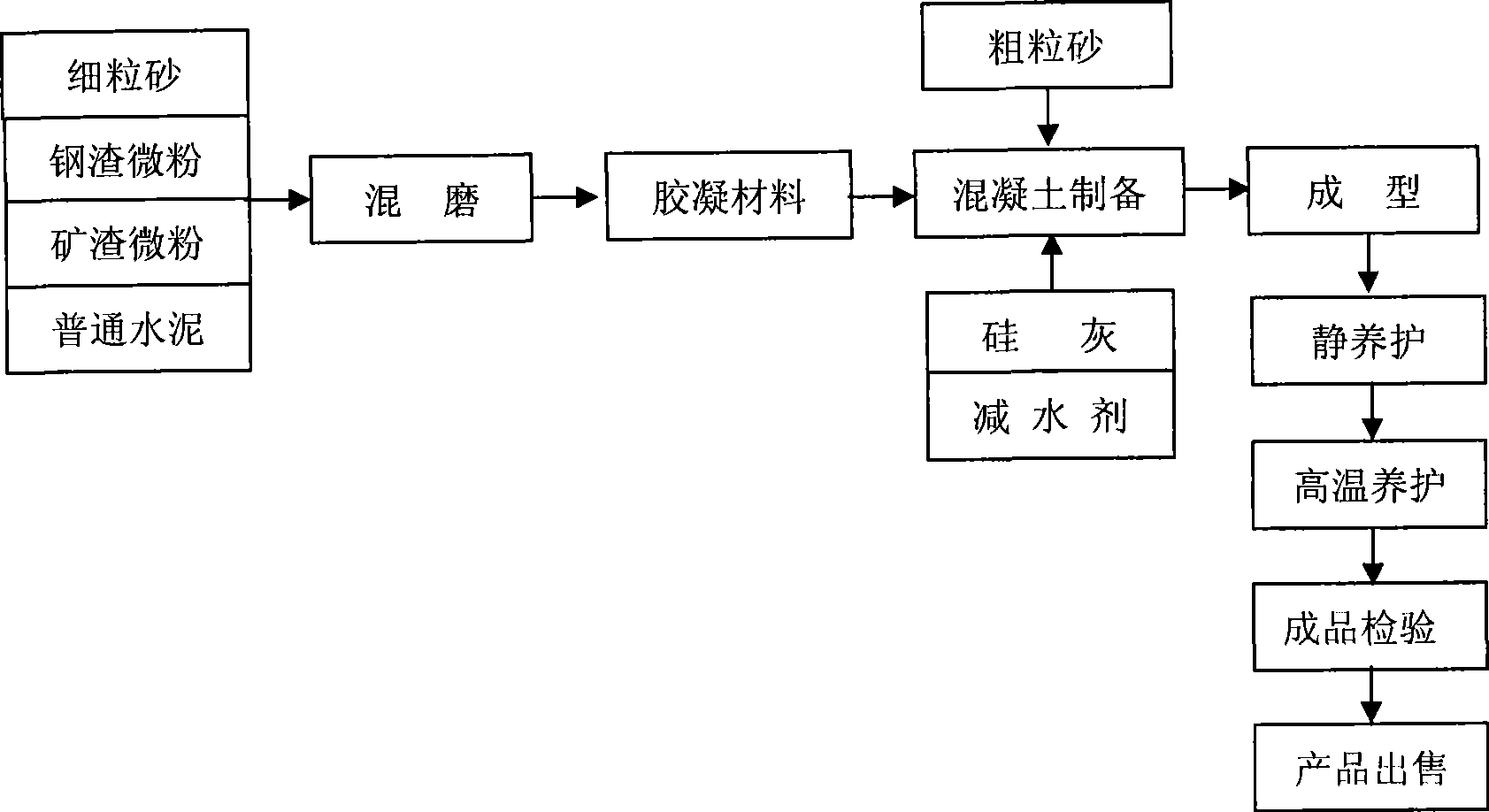

The invention discloses active powder concrete which is prepared by Portland cement, steel slag powder, fly ash, silicon ash, effective water reducing agent, river sand, mixing water and steel fiber with the mass ratios of 0.52 to 0.58 : 0.16 to 0.18 : 0.10 to 0.16 : 0.13 to 0.16 : 0.012 to 0.018 : 0.9 to 1.1 : 0.14 to 0.18 : 0.156 to 0.234. The preparation method thereof is as follows: each component is sequentially added into a stirring machine for being uniformly stirred and shaped; then after the components are maintained, the temperature is raised to 80 to 90 DEG C at the temperature rising speed of 15 to 20 DEG C / h and then constant temperature maintaining is carried out for 72 to 96h; then, the components are cooled to room temperature at the cooling speed of not more than 20 DEG C / h to obtain the active powder concrete product. The invention employs the industrial wastes like steel slag powder and fly ash to replace quartz powder, partial cement and silicon ash, and employs thin river sand to replace quartz sand to prepare the active powder concrete of 200 grade under the maintaining conditions of normal pressure below 100 DEG C, thus not only being capable of remarkably reducing the material cost and the shaping maintaining cost, but also playing important roles on saving resources and energies, protecting the environment and promoting sustainable development as a large amount of industrial waste slag is used.

Owner:WUHAN UNIV OF TECH

Technological process for preparing active powder concrete by using iron tailing

A technological process for preparing active powder concrete by using iron tailing is characterized by performing screening and mechanical-chemical activation to iron tailing, using partial iron tailing after screening as fine aggregate of the active powder concrete, using activated tailing as component of the active powder concrete, and preparing the active powder concrete. The invention substitutes partial cement, quartz powder and silica fume with mechanically-activated iron tailing and fly ash or slag, and quartz sand or river sand with screened iron tailing fine aggregate, and prepares high-strength active powder concrete under standard curing or high-temperature high-pressure curing condition; and compared with conventional method, the invention reduces raw material cost, improves iron tailing comprehensive utilization rate, reduces natural resource consumption amount, and promotes development of ecological environment protection and circular economy promotion.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

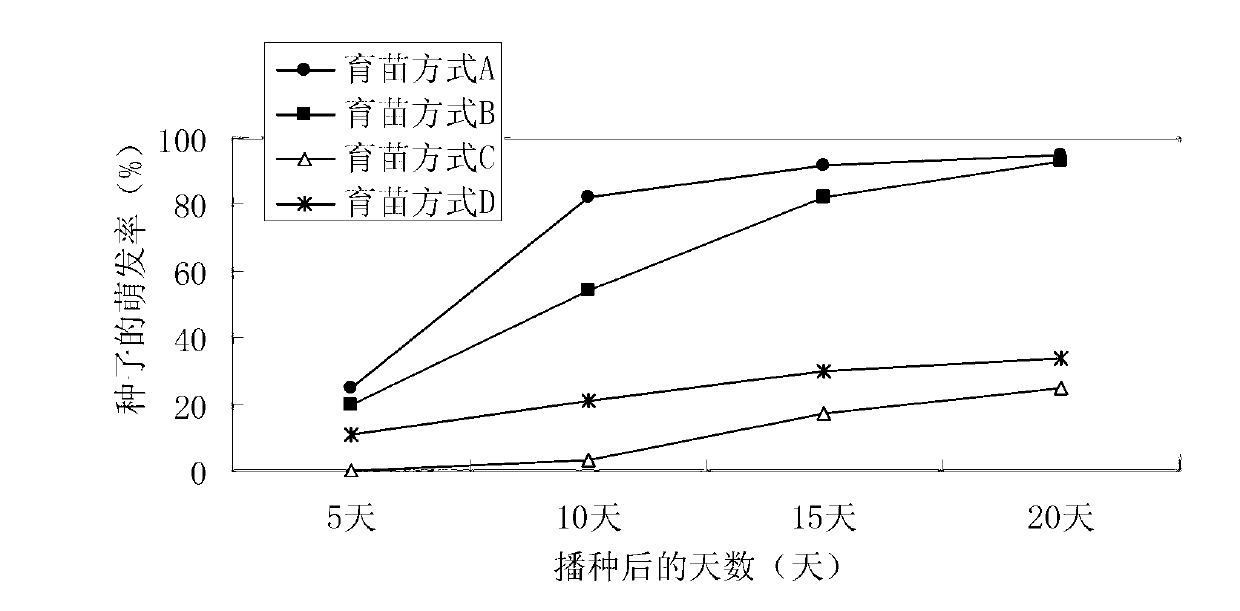

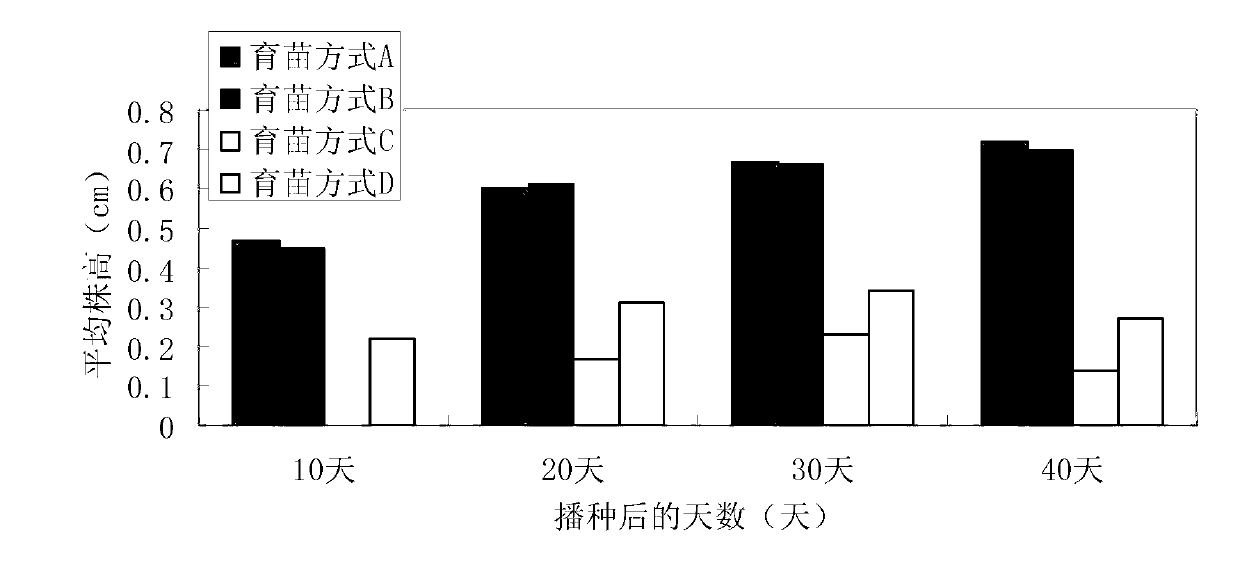

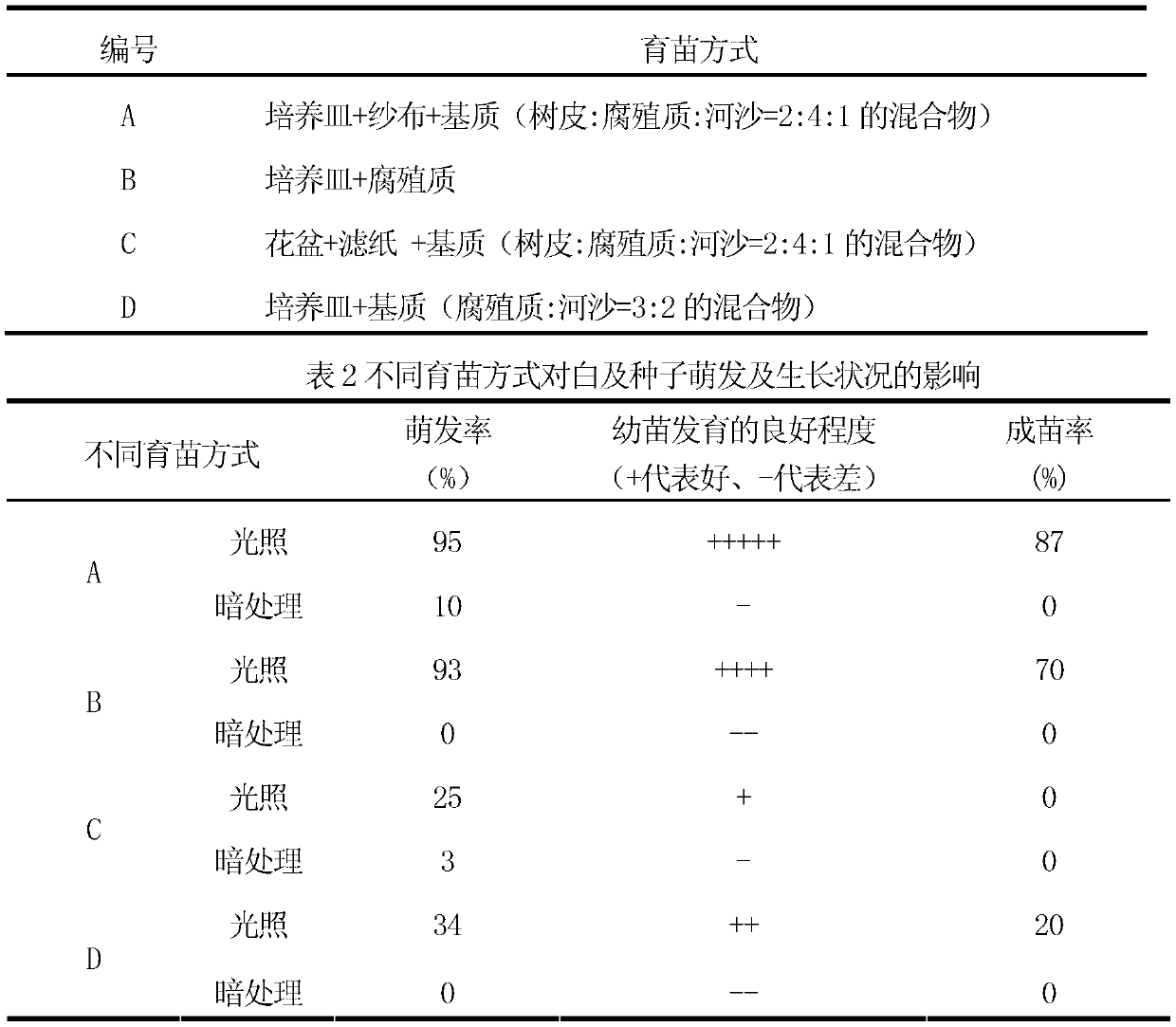

Bletilla striata rapid propagation seedling cultivation method

ActiveCN103270863ASolve the problem of quality degradationImprove germination rateSeed coating/dressingHorticultureRiver sandGermination

Provided is a bletilla striata rapid propagation seedling cultivation method. Fermented bark and a mixture of humus and river sand serve as a base material, the base material is laid on a seedling cultivation vessel, 1-2 layers of gauze is laid on the base material, water is poured to soak the base material, bletilla striata seeds are sown on the gauze, a transparent plastic film is utilized to wrap the seedling cultivation vessel, and the seedling cultivation vessel is placed in an artificial intelligent cultivation box to grow seedlings and strengthen the seedlings. The bletilla striata rapid propagation seedling cultivation method breaks through a traditional corm planting and cultivation mode of bletilla striata, the quality degeneration problem existing in vegetative propagation is resolved, and a new path is created for sexual propagation seedling cultivation of the bletilla striata genus of orchidaceae. The bletilla striata rapid propagation seedling cultivation method is simple in operation, low in cost and short in seedling cultivation period; the germination rate reaches up to 90%, the planting percent is 70%-80%, and good practical popularization significance is provided for large-scale propagation seedling cultivation of the bletilla striata.

Owner:SHAANXI NORMAL UNIV

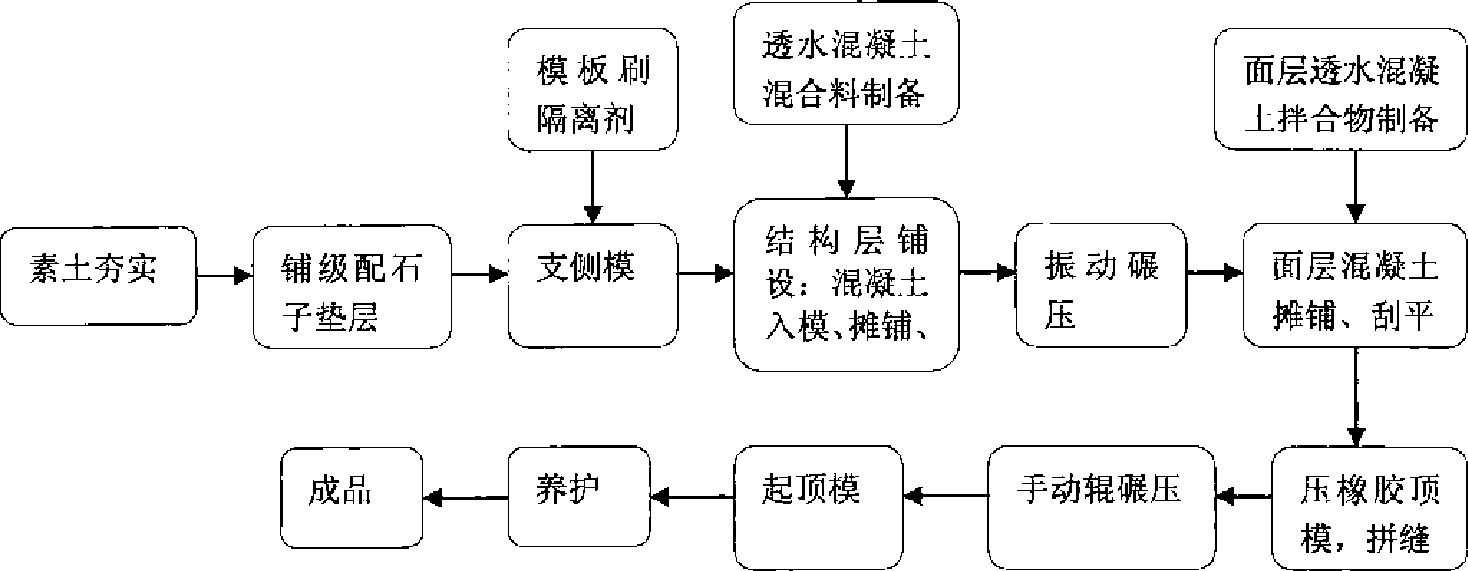

Pervious concrete and construction method thereof

ActiveCN104402339AImprove workabilityIncreased intensityIn situ pavingsRoad surfaceUltimate tensile strength

The invention discloses pervious concrete and a construction method thereof. The pervious concrete comprises the following raw materials in percentage by weight: 13.1-15.9% of cement, 12.7-15.6% of river sand, 59.6-66.0% of stones, 3.7-3.9% of water and 4.5-5.0% of admixtures, wherein the admixtures comprise the following raw materials in percentage by weight: 45-50% of ultrafine mineral powder, 15-20% of heavy calcium carbonate, 15-20% of gypsum powder, 3-5% of polypropylene fiber, 5-10% of a polycarboxylate water reducing agent, 4.2-8.4% of adhesive powder and 2-5% of a pigment. The pervious concrete provided by the invention has relatively high water permeability, strength and durability; after the pervious concrete is applied to a practical engineering, the pervious concrete can greatly improve the problem of poor drainage of a hardened road surface, so that the development of the pervious concrete can be promoted.

Owner:TIANYUAN CONSTR GROUP

Melon raise seedling or stalk cultivation ground mass and method for manufacturing same

InactiveCN101248738ASeedlings grow wellLow costBio-organic fraction processingOrganic fertiliser preparationLivestock manureDiammonium phosphate

The invention relates to a medium for culturing fruits and vegetables or cultivating straw, which is characterized in that the medium consists of materials of the following volume proportion: 35-80 percent of straw leavening, 0.2-0.5 percent of chemical fertilizer, and 19.5-64.8 percent of base material, wherein, the base material is one or more of grass carbon, perlite or vermiculite, or either grass carbon or river sand. The invention provides a manufacturing method for the medium culturing fruits and vegetables or cultivating straw, which includes: 1) fermentation of the straw; 2) proportioning of materials. The manufacturing method adds a small amount of excrement of animals and even ferments with organic material-decomposing agent; the decomposed mixture is mixed with the grass carbon and fertilizer (three-element compound fertilizer or carbamide, ordinary superphosphate, diammonium phosphate) according to certain proportion to prepare the seedling culture or cultivation medium; the growth of the fruit and vegetable seedlings are good, the cost is reduced and the dependence on mineral is reduced at the same time.

Owner:山东商道生物科技股份有限公司

High-volume slag self-leveling mortar

InactiveCN102173711AGood deformabilityStable deformation abilitySolid waste managementRiver sandSlag

The invention discloses a high-volume slag self-leveling mortar and belongs to the field of building materials. The high-volume slag self-leveling mortar comprises the following ingredients in percentage by weight: 10 to 25 percent of ordinary Portland cement, 5 to 16 percent of aluminate cement, 4 to 7 percent of gypsum, 10 to 32 percent of slag miropowders, 30 to 42 percent of slag sand, 0.1 to 0.3 percent of high-efficiency water-reducing agent, 0.15 to 0.3 percent of setting retarder, 0.1 to 0.2 percent of water-retaining agent, 0 to 0.05 percent of defoaming agent and 1 to 3 percent of latex powders. Instead of river sand or artificial quartz sand and heavy calcium carbonate powders, slag miropowders and slag sand are widely used in self-leveling mortar, so as to improve the performance of self-leveling mortar, reduce the cost of self-leveling mortar products and reduce the slag accumulation and environmental pollution.

Owner:WUHAN IRON & STEEL (GROUP) CORP

Cement-based self-leveling mortar

The invention relates to cement-based self-leveling mortar, which is prepared from the following raw materials in percentage by weight: 35 to 40 percent of No.425 ordinary portland cement, 10 to 15 percent of No.42.5 rapid hardening sulphoaluminate cement, 15 to 18 percent of heavy calcium carbonate, 0.45 to 1 percent of high polymer, 0.15 to 0.3 percent of water reducing agent, 0.15 to 0.3 percent of early strength agent, 0.15 to 0.3 percent of retarder, 0.15 to 0.3 percent of thickener and the balance of fine river sand with the fineness modulus of 1.2 to 1.5. Compared with other traditional cement self-leveling mortar, the self-leveling mortar has the characteristics of higher fluidity, higher leveling property, high early strength and the like.

Owner:CHENGDU JIAXIN TECH

Cement-based grouting material and preparation method thereof

The invention relates to a cement-based grouting material and a preparation method thereof. The cement-based grouting material comprises a component A, a component B and a component C, wherein the component A comprises the following components by weight part: 80 to 90 parts of epoxy resin, 1 to 10 parts of diluents, 0 to 1 part of defoaming agent and 1 to 5 parts of coupling agent; the component B comprises a water-soluble amine curing agent with an emulsification function; the component C comprises the following components by weight part: 30 to 50 parts of cement, 2 to 4 parts of ultrafine mineral powder, 0 to 1 part of silica micropowder, 2 to 4 parts of expanding agent, 0 to 1 part of water-reducing agent and 40 to 60 parts of river sand; and the weight ratio among the component A, the component B and the component C is (60 to 100) : (90 to 150) : (400 to 800). Mechanical indexes, such as compressive strength, breaking strength and the like, of the cement-based water-soluble epoxy resin grouting material are far more excellent than those of the common cement grouting material.

Owner:天津天盈新型建材有限公司

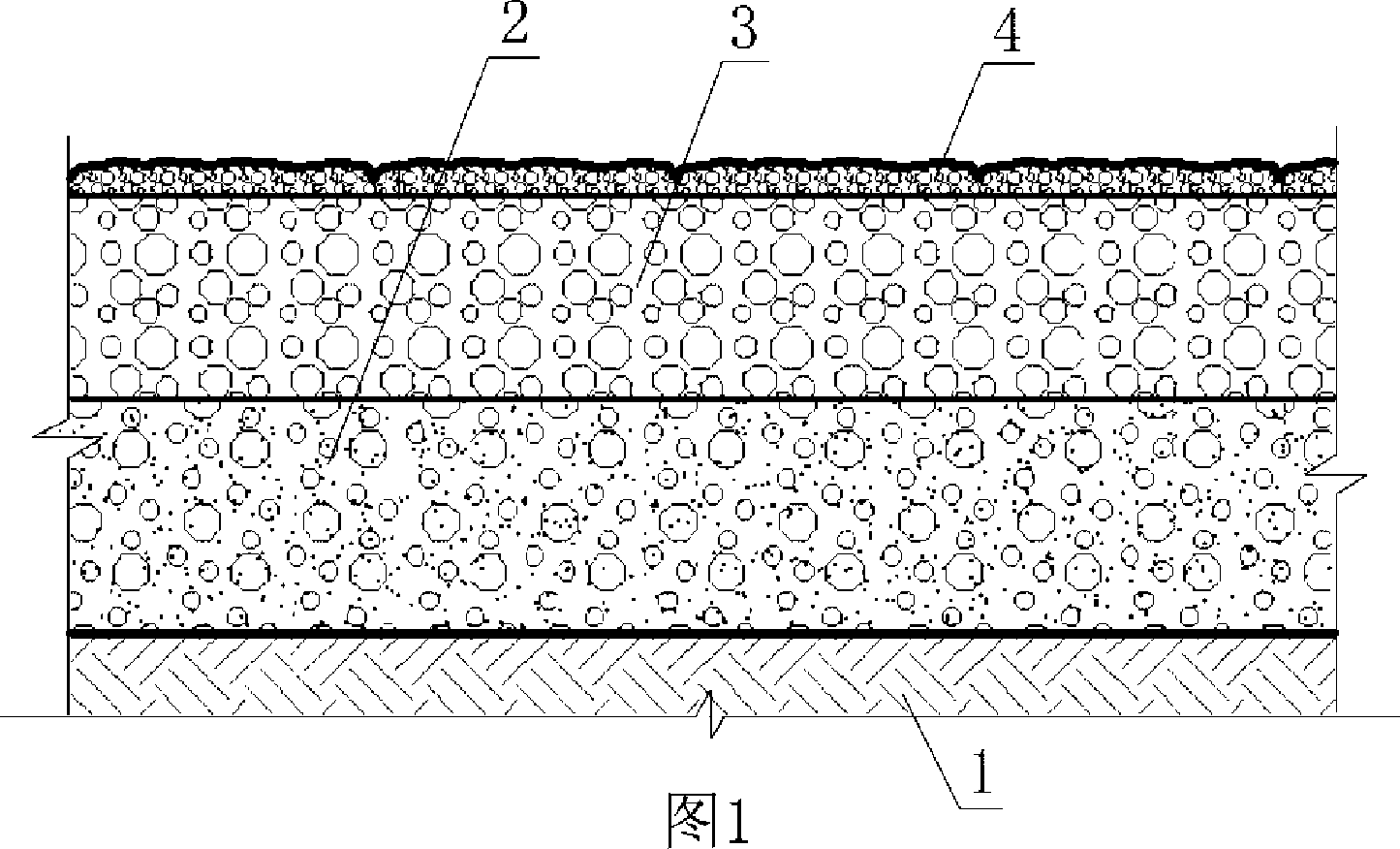

Double layer sandwich foamed concrete composite solid wall plate

InactiveCN1987008AShort demoulding timeIncrease productivityConstruction materialSolid waste managementFiberFoam concrete

A dual-layer sandwich-type solid wall slab is composed of two surficial thin cement slabs and a foam concrete core layer. It is proportionally made of fast hardening sulphoaluminate cement, powdered coal ash, river sand, fibers, hydrogen peroxide as foaming agent, and stabilizer. Its advantages are light weight, high surface strength and high insulating effect.

Owner:贵州华骏集团节能环保材料有限公司

Flower nutrient soil and preparation method thereof

InactiveCN103553767AImprove the cultivation effectRich in nutrientsFertilizer mixturesActivated sludgeMicroorganism

The invention belongs to the technical field of soil, and specifically relates to flower nutrient soil and a preparation method thereof. The flower nutrient soil comprises the following components in parts by mass: 30-35 parts of leaf mold, 25-30 parts of garden soil, 25-30 parts of river sand, 10-15 parts of activated sludge, 5-10 parts of bone meal, 10-15 parts of decayed farmyard manure, 10-15 parts of sawdust and 2-5 parts of active microorganisms. By using the technical scheme, the flower nutrient soil disclosed by the invention is rich in nutrient substances and short in fermentation time; leaf mold, garden soil, river sand and activated sludge are mixed, so that the flower nutrient soil is good in water retention and nutrient preserving capability, good in soil permeability, and low in cost; and by using the flower nutrient soil, flowers are robust and good cultivation effect is achieved.

Owner:DANYANG RUIQING GARDEN ENG

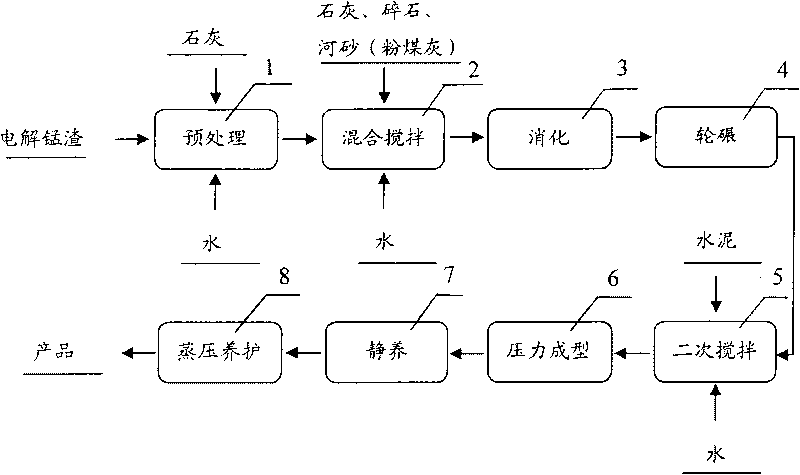

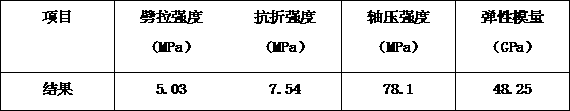

Preparation method of electrolytic manganese slag autoclaved brick

The invention provides a preparation method of an electrolytic manganese slag autoclaved brick. The method comprises the following steps: after preprocessing the electrolytic manganese slag, adding river sand (or fly ash), broken stone and lime in proportion; and stirring, assimilating, rolling, molding, standing, autoclaving and curing, and the like to obtain the electrolytic manganese slag autoclaved brick. The product meets the corresponding index requirements of Autoclaved Sand-lime Brick (GB11945-1999) or Fly Ash Brick (JC239-2001) for a first quality product with the strength level of more than 15MPa. The method has simple technology, high product quality, low production cost and good social, economic and environmental benefits.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Dry powder mortar of mine tailings

InactiveCN101560083ALow costEmission reductionSolid waste managementEcological environmentResource utilization

The invention relates to dry powder mortar of mine tailings, which comprises the following components in portion by weight: 40 to 60 portions of copper tailing sand or iron tailing sand, 20 to 30 portions of river sand, 10 to 30 portions of low-clinker silicate cement, and 0.5 to 1.5 portions of water-retaining thickening agent. The dry powder mortar is suitable for masonry, plastering, ground and common waterproof engineering. By using the low-clinker cement to replace the prior common silicate cement and using the tailing sand to partially replace the river sand, the dry powder mortar reduces the discharge of carbon dioxide and the consumption of sand river resources, realizes the resource utilization of solid wastes such as mine refuses, steel slag, tailings and the like, and protects the ecological environment.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

High-toughness inspection well concrete and method for preparing same

The invention discloses high-toughness inspection well concrete which comprises the following components in parts by weight: 350-400 parts of ordinary portland cement, 60-90 parts of fly ash, 20-30 parts of calcined red mud, 50-80 of slag powder, 2-4 parts of distearoyl isopropyl aluminate, 20-30 parts of styrene-acrylic emulsion, 100-120 parts of straw ash, 30-40 parts of modified rubber powder, 1,000-1,200 parts of crushed limestone, 500-600 parts of river sand, 140-160 parts of water and 5-8 parts of naphthalene high-efficiency water reducing agent. By adjusting the formula, improving the process and coating the slag powder by the straw, the properties such as the water penetration resistance, high temperature resistance and strength of the concrete are improved. The high-toughness inspection well concrete prepared by adopting the method has good toughness, high strength, strong impact resistance, good water penetration resistance and good durability and can be used for various high-level and large-span engineering used in the severe conditions.

Owner:FEIXI WANXI CEMENT PROD

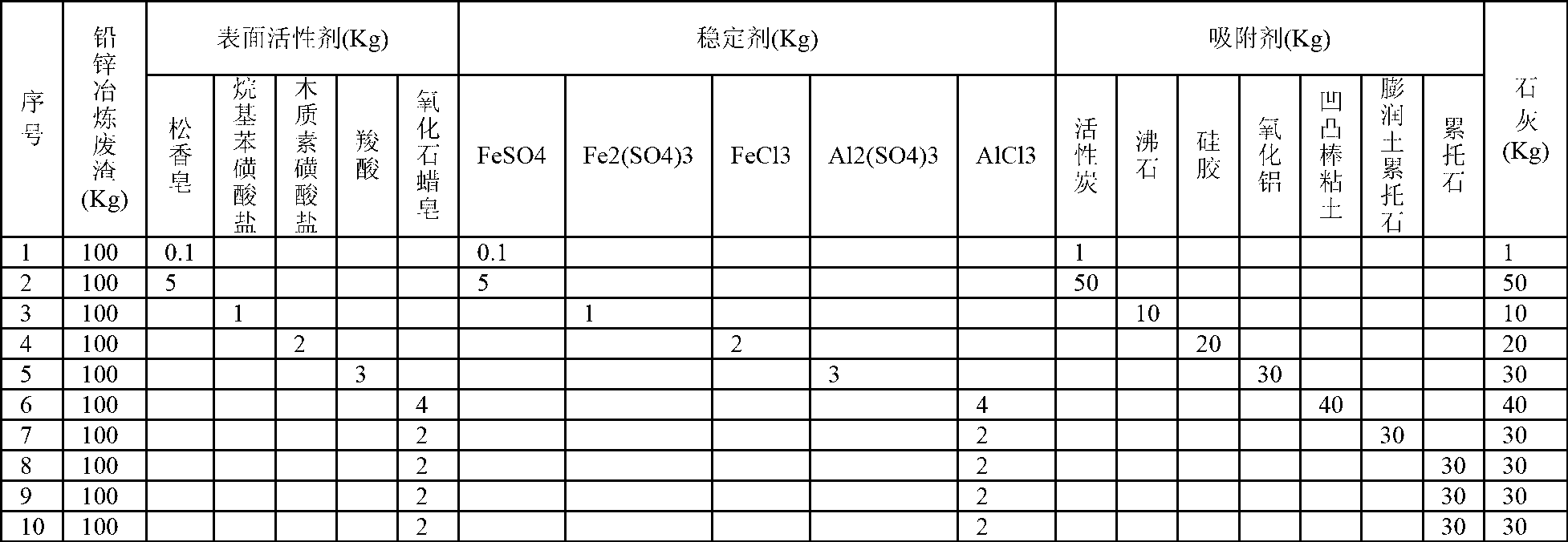

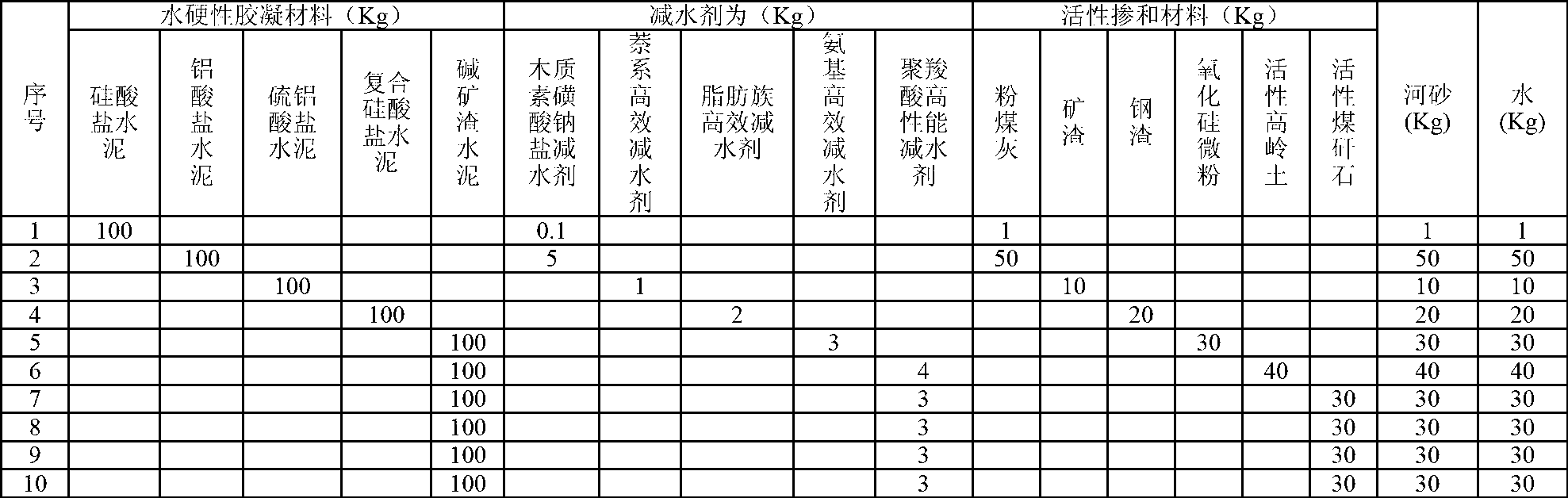

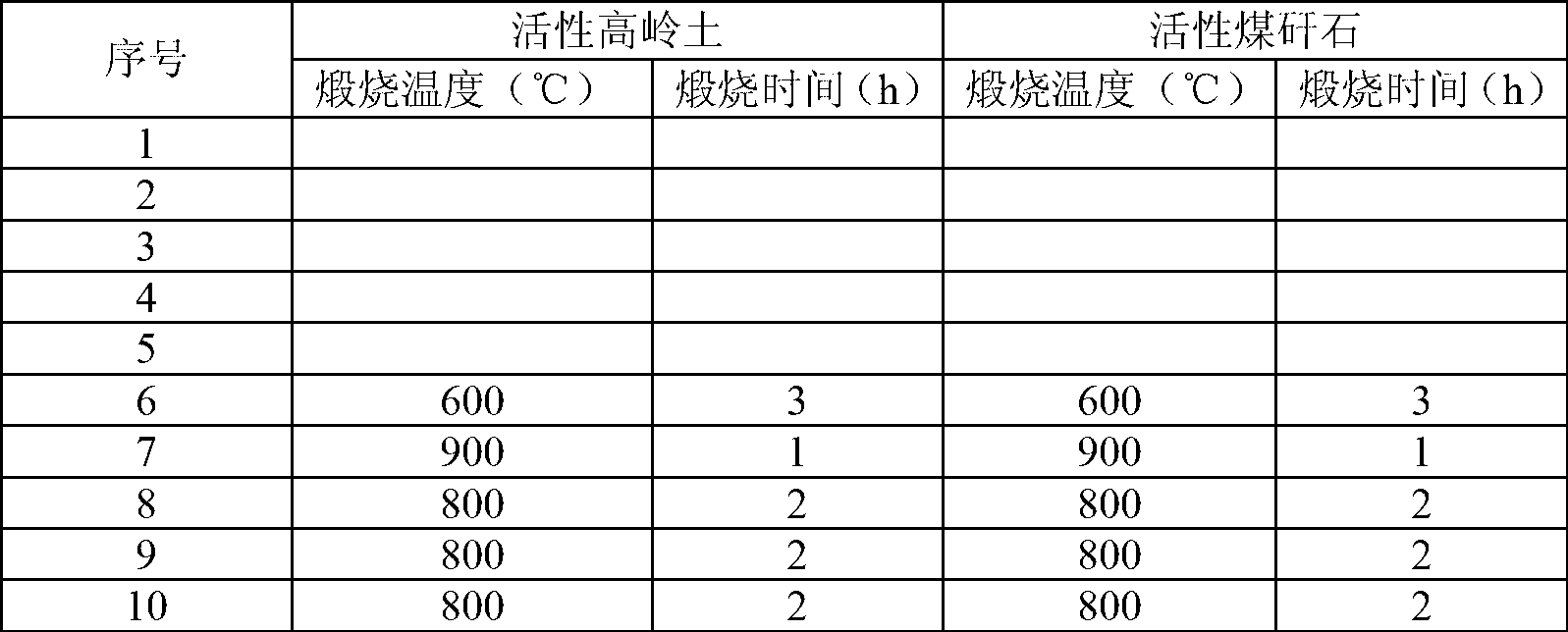

Solidification treatment process of smelting waste of lead and zinc

InactiveCN103011726AImprove workabilityImprove compactnessSolid waste managementSlagRoom temperature

The invention discloses a solidification treatment process of smelting waste of lead and zinc. The solidification treatment process is characterized in that surface active agent, stabilizing agent, adsorbent and lime are added into and mixed uniformly with the smelting waste of lead and zinc; water-reducing agent, active blending material, river sand and water are added into and mixed uniformly with the hydraulic binding material; the pretreated smelting waste of lead and zinc is added into the pretreated hydraulic binding material, placed for 24 hour under room temperature after uniformly stirred and formed, then demoulded and stored in a slag storeroom. The solidification treatment process has the characteristics of good solidification effect, simple process, low cost, easy-to-get raw material, and the like.

Owner:SHAANXI UNIV OF TECH

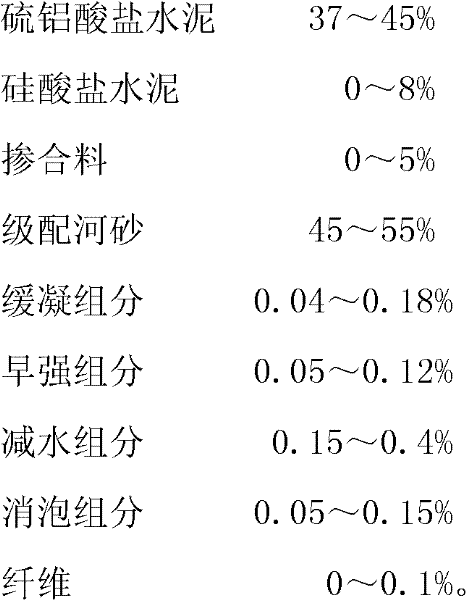

High speed railway bridge bearing anchoring mortar material

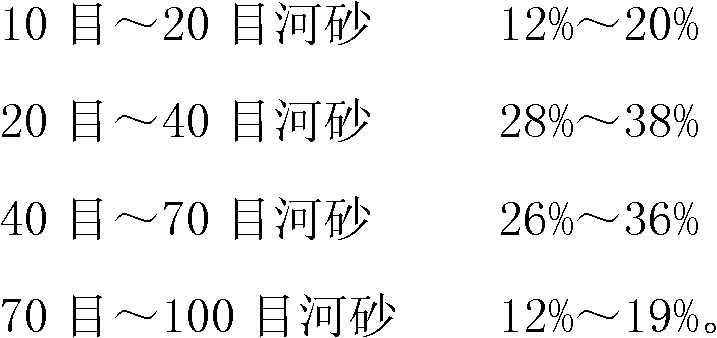

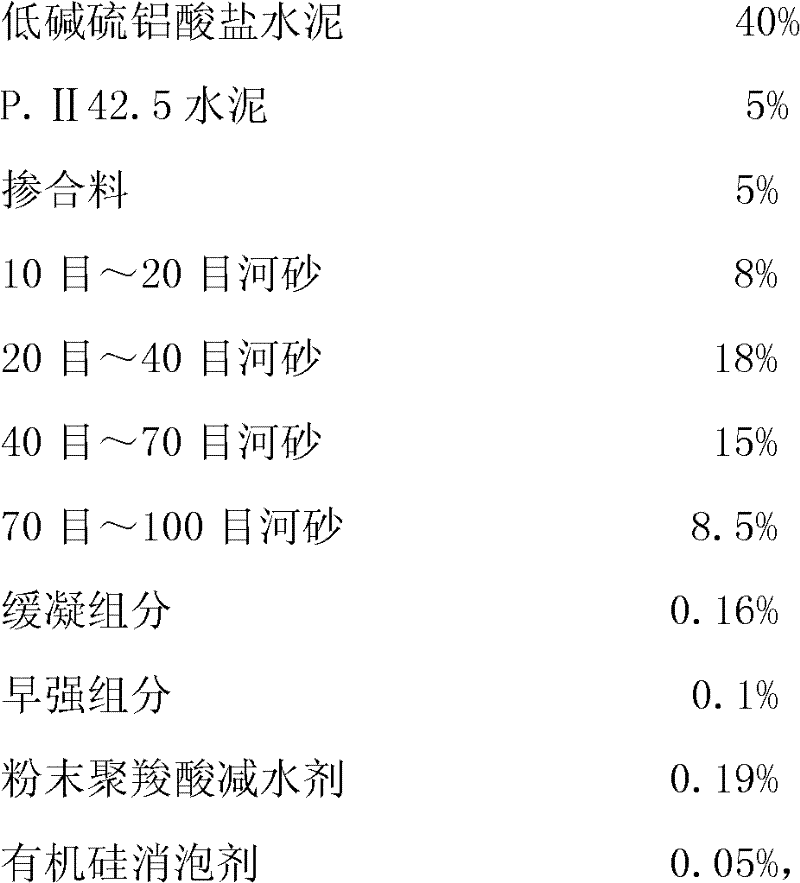

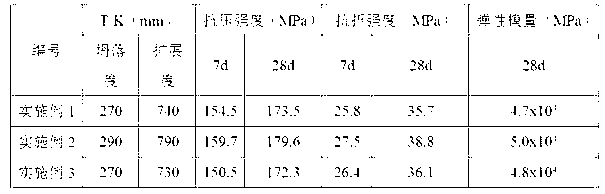

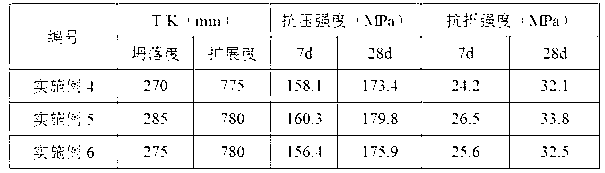

The invention discloses a high speed railway bridge bearing anchoring mortar material with is blended from components of, by weight: 37 to 45% of sulphoaluminate cement, 0 to 8% of Portland cement, 0 to 5% of an addition, 45 to 55% of graded river sand, 0.04 to 0.18% of a solidification retarder, 0.05 to 0.12% of an accelerant, 0.15 to 0.4% of a water reducing component, 0.05 to 0.15% of a defrothing component, and 0 to 0.1% of fiber. The material provided by the invention is specially used in anchoring and grouting of high speed railway bridge pot rubber bearings. The material has characteristics of good fluidity, high early strength, good filling properties, no strength reversing in later stage, low cost, convenient application, and the like. The material also can be applied in large equipment installation and pavement rush-repairing.

Owner:ANHUI ZHONGTIE ENGINEER MATERIAL SCI & TECH CO LTD

Potting nutrient soil

InactiveCN103553769ARich in nutrientsImprove water and fertilizer retention performanceFertilizer mixturesSolubilityGLYCYRRHIZA EXTRACT

The invention relates to the field of plant nutrient soil, and particularly relates to nutrient soil for a potted plant. The potting nutrient soil comprises the following active ingredients in parts by weight: 50-70 parts of needle-point leaf soil, 10-20 parts of chitosan, 5-10 parts of plant ash, 5-10 parts of pine bark, 1-3 parts of slaked lime, 10-20 parts of wormcast, 5-10 parts of river sand, 5-15 parts of bone meal, 2-5 parts of active microorganism, and 0.5-1.2 parts of liquorice. By adopting the technical scheme, the potting nutrient soil has the beneficial effects that the potting nutrient soil is rich in nutrient substances, good in water retention and nutrient preservation properties, good in soil permeability, and low in cost, potted plant can be directly placed in the potting nutrient soil for growth, the potting nutrient soil is high in nutrition value, rich in various mineral substances of calcium, phosphorus and the like, and can continuously provide nutrition. The potting nutrient soil is convenient to use, incapable of causing any environment pollution, good in solubility, popular with potted class, and has a broad market development space.

Owner:溧阳市甜园景观设计工程有限公司

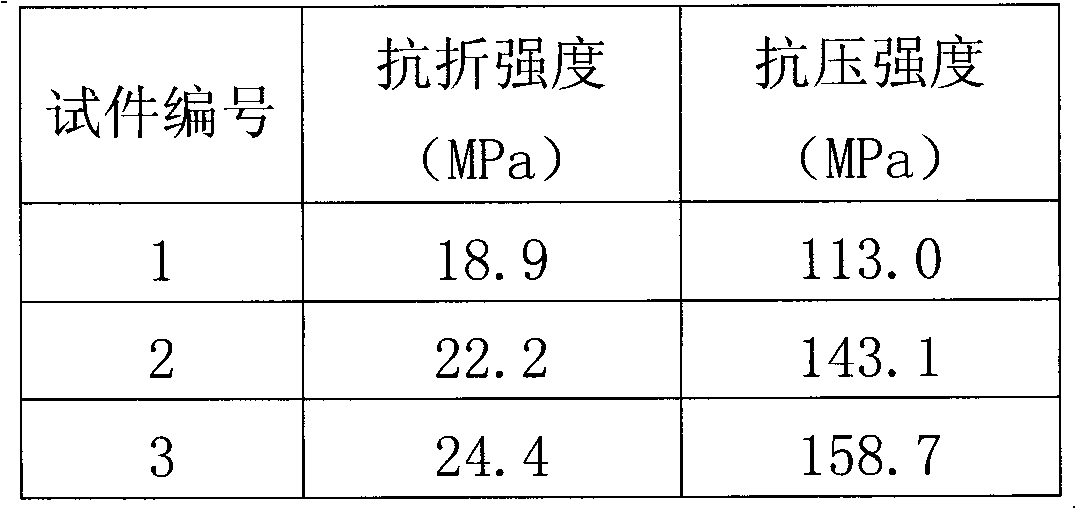

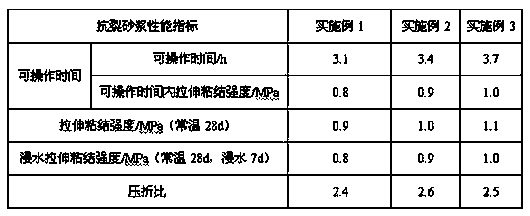

Reactive powder concrete for reinforcing buildings as well as preparation method and construction method thereof

ActiveCN103274652AHigh compressive strengthHigh bonding strengthMicrosphereUltimate tensile strength

The invention discloses a reactive powder concrete for reinforcing buildings as well as a preparation method and the construction method thereof. The reactive powder concrete comprises the following raw material constituents in parts by weight: 50 to 80 parts of cement, 15 to 40 parts of fly ash microsphere, 5 to 13 parts of silica fume, 35 to 80 parts of river sand, 20 to 65 parts of quartz sand, 10 to 20 parts of water, 10 to 30 parts of steel fibre and 1 to 2 parts of chemical additive. The reactive powder concrete has the advantages of good fluidity, strong plasticity, good cohesive property with an existing structure, similar linear expansion coefficient with an existing concrete structure, high strength, wide raw material source, reliable technology, durable service, low in cost and simple construction technology. In addition, the RPC material poured at later stage and the existing structure are closely integrated as a whole, resulting from contraction performance of the reactive powder concrete during the process of hardening, and the integrity of the structure is enhanced; all that is needed is to carry out conventional maintenance on the reactive powder concrete after forming, the prospective reinforcement effect can be achieved, and curing condition is the same as that of the normal premixed concrete.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD +1

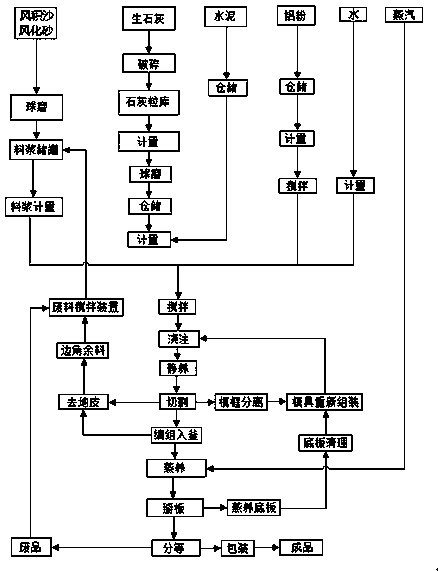

Autoclaved aeolian sand aerated concrete building block and wallboard

The invention provides an autoclaved aeolian sand aerated concrete building block and wallboard which are prepared by the following method: performing ball milling on aeolian sand or weathered sand to obtain slurry with the mass percentage concentration of 50 to 70%; crushing quick lime, grinding into quick lime powder; mixing aluminum powder; according to mass percentage, respectively taking cement, the slurry and the quick lime powder for mixing into a base material, proportionally adding the aluminum powder and gypsum, and stirring evenly to obtain finished product slurry; according to an autoclaved aerated concrete building block production process in the prior art, pouring, curing and cutting to form a green body or a workblank, removing wastes on the green body or the workblank, grouping into a reactor; performing autoclaving and maintaining and other processes, and packaging qualified products to obtain the autoclaved aeolian sand aerated concrete building block or wallboard; collecting produced waste to prepare waste slurry; and adding the waste slurry into the finished product slurry for using again. The concrete building block and wallboard can be prepared into building and environmental protection materials with good performances by comprehensive utilization of the aeolian sand and the weathered sand, and the river sand and ore sand collection and waste of resources can be reduced.

Owner:JINGTAI FUHAI SUNSHINE BUILDING MATERIAL

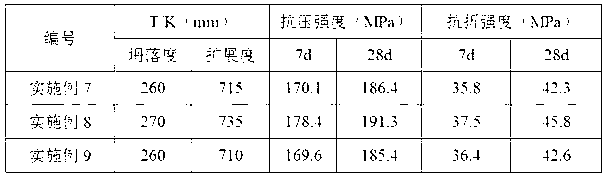

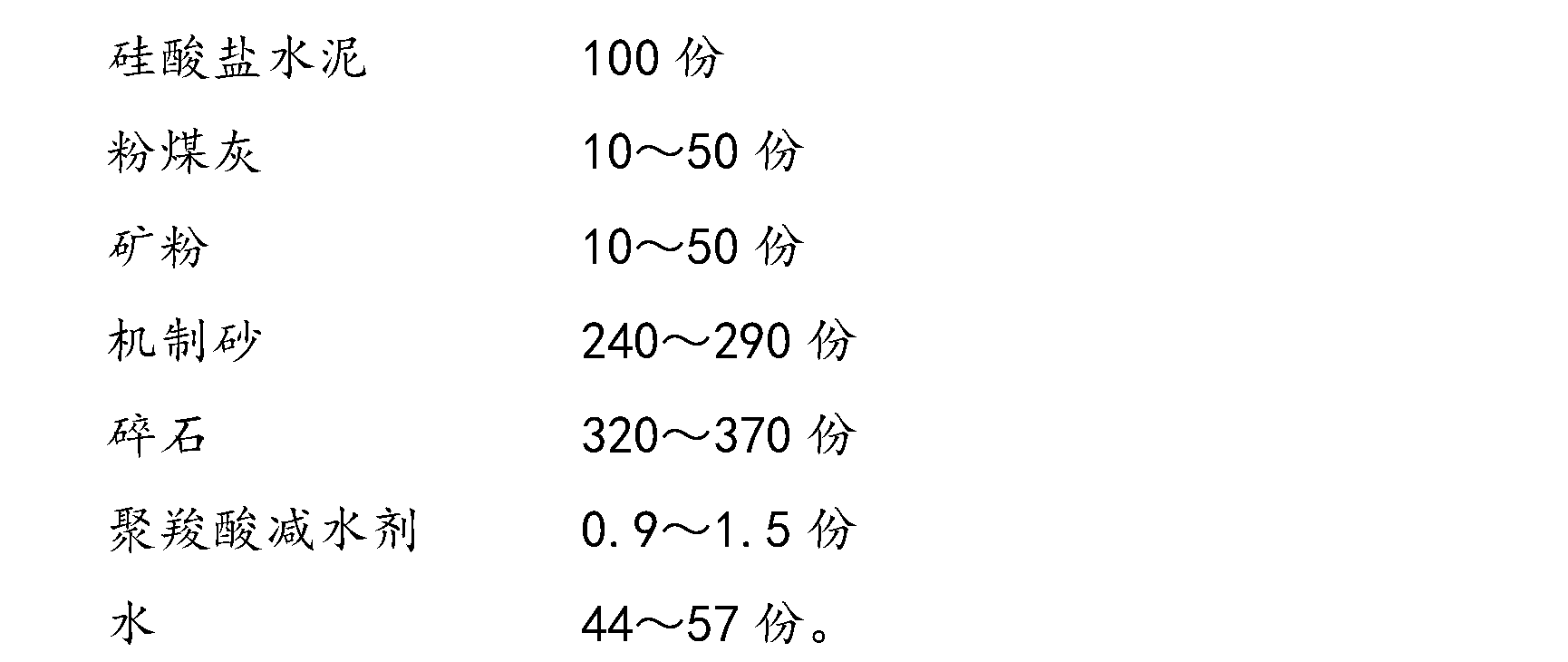

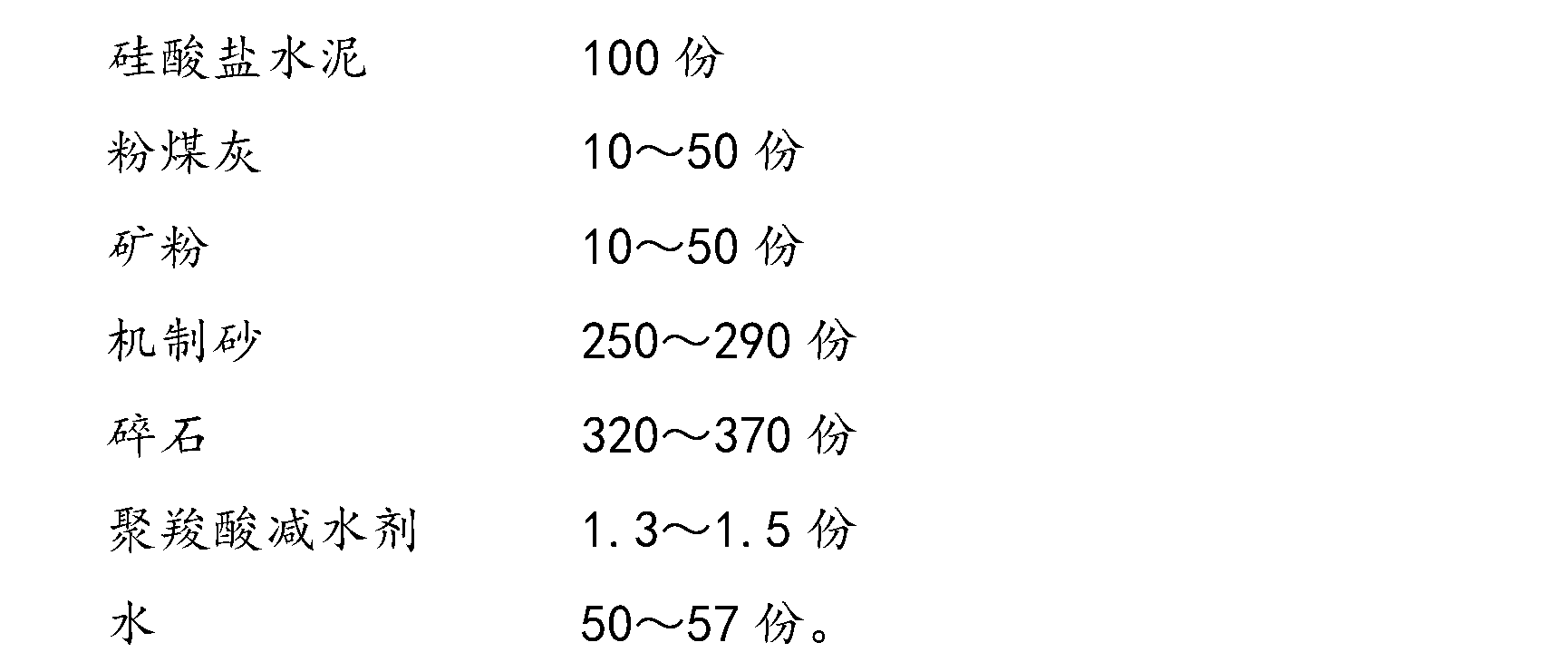

High-performance machine-made sand marine concrete and preparation method thereof

The invention discloses high-performance machine-made sand marine concrete and a preparation method thereof. The machine-made sand marine concrete comprises the following raw material components in parts by weight: 100 parts of portland cement, 10-50 parts of fly ash, 10-50 parts of mineral powder, 240-290 parts of machine-made sand, 320-370 parts of broken stone, 0.9-1.5 parts of a polycarboxylate water reducer, and 44-57 parts of water. The machine-made sand marine concrete disclosed by the invention has the characteristics of being convenient to construct, low in cost, good in working performance, high in early-stage and middle-later-stage mechanical property, excellent in durability, good in volume stability, and strong in pumpability, and is close to or even higher than river sand marine concrete in the aspects of concrete performance and technical indexes; and according to the machine-made sand marine concrete, the defects of shortage of river sand resources, instable quality, high price and the like are overcome, and the technical problems of machine-made sand in the fields of preparation and performance research for marine concrete are solved.

Owner:宁波市高等级公路建设指挥部 +2

Concrete with functions of crack resistance and infiltration resistance

InactiveCN104386959AReduce porosityImprove pore structureSolid waste managementCrack resistanceDiethylenetriamine

The invention discloses concrete with the functions of crack resistance and infiltration resistance. The concrete comprises the following raw materials in part by weight: 70-100 parts of cement, 400-500 parts of macadam, 50-70 parts of river sand, 40-50 parts of fly ash, 30-60 parts of mine residues, 5-20 parts of coal slack, 20-50 parts of basalt fibers, 5-15 parts of polypropylene fibers, 5-20 parts of glass fibers, 6-13 parts of expanded perlite, 20-80 parts of nanometer silicon dioxide, 5-15 parts of nano calcium carbonate, 1-3 parts of sodium dodecyl sulfate, 3-6 parts of zinc stearate, 2-5 parts of zinc borate, 3-7 parts of sodium citrate, 0.5-1.4 parts of acetyl tributyl citrate, 0.7-1.3 parts of diethylenetriamine, 3-10 parts of a water reducing agent, and 80-100 parts of water. The concrete disclosed by the invention has the advantages of good crack resistance, excellent infiltration resistance and good durability.

Owner:WUWEI HENGJI COMML CONCRETE

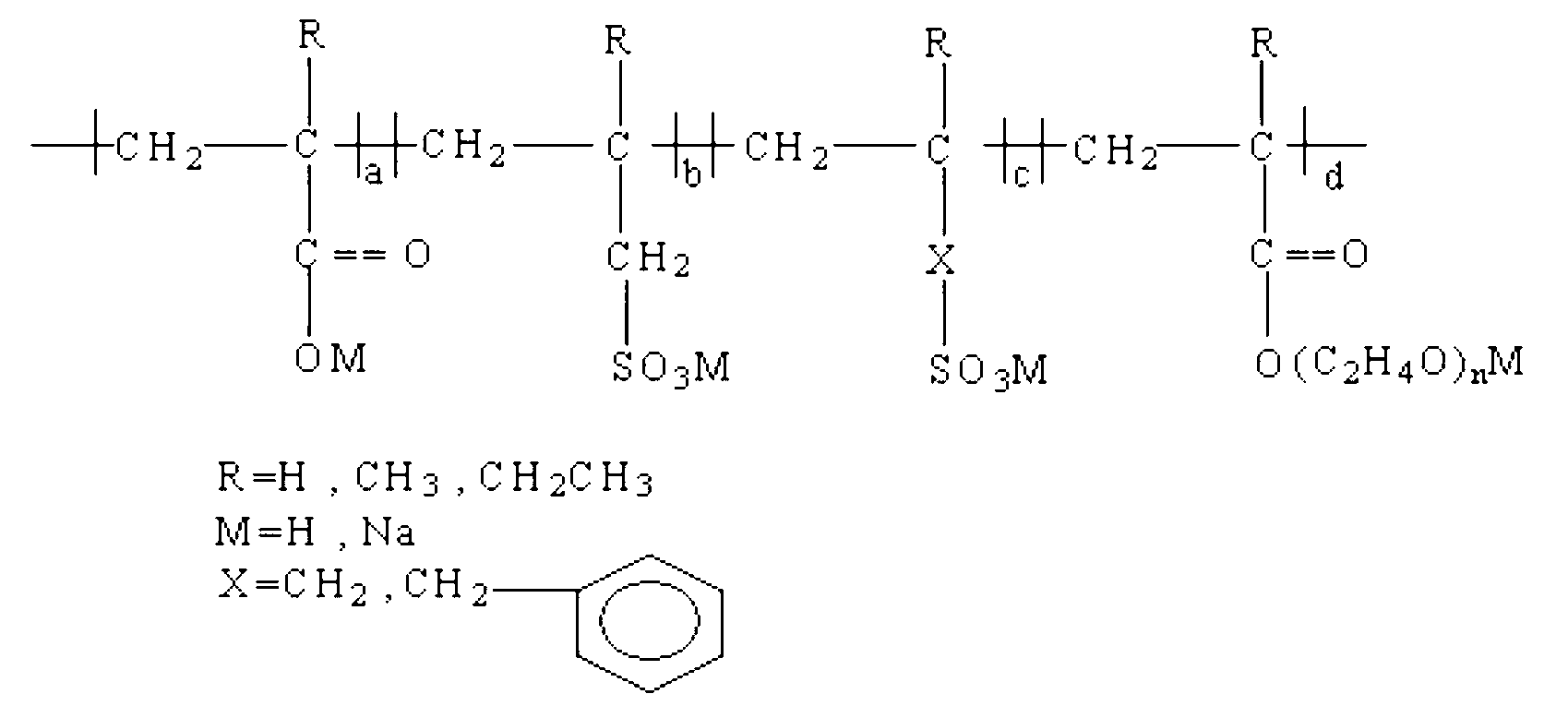

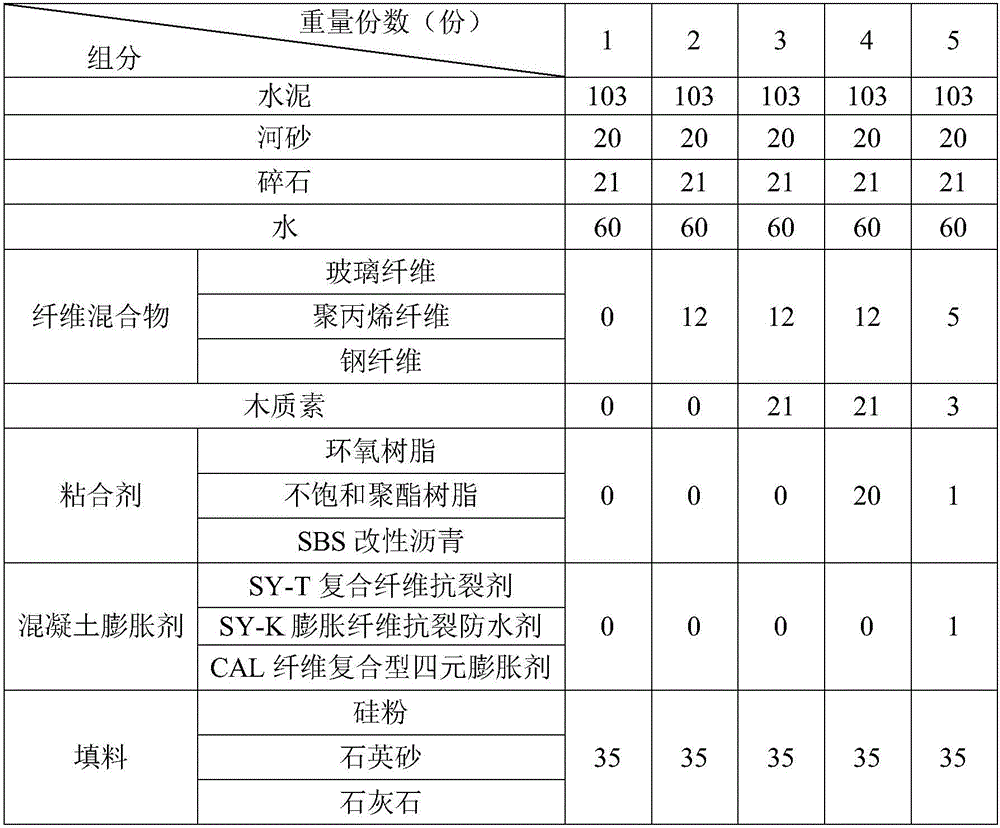

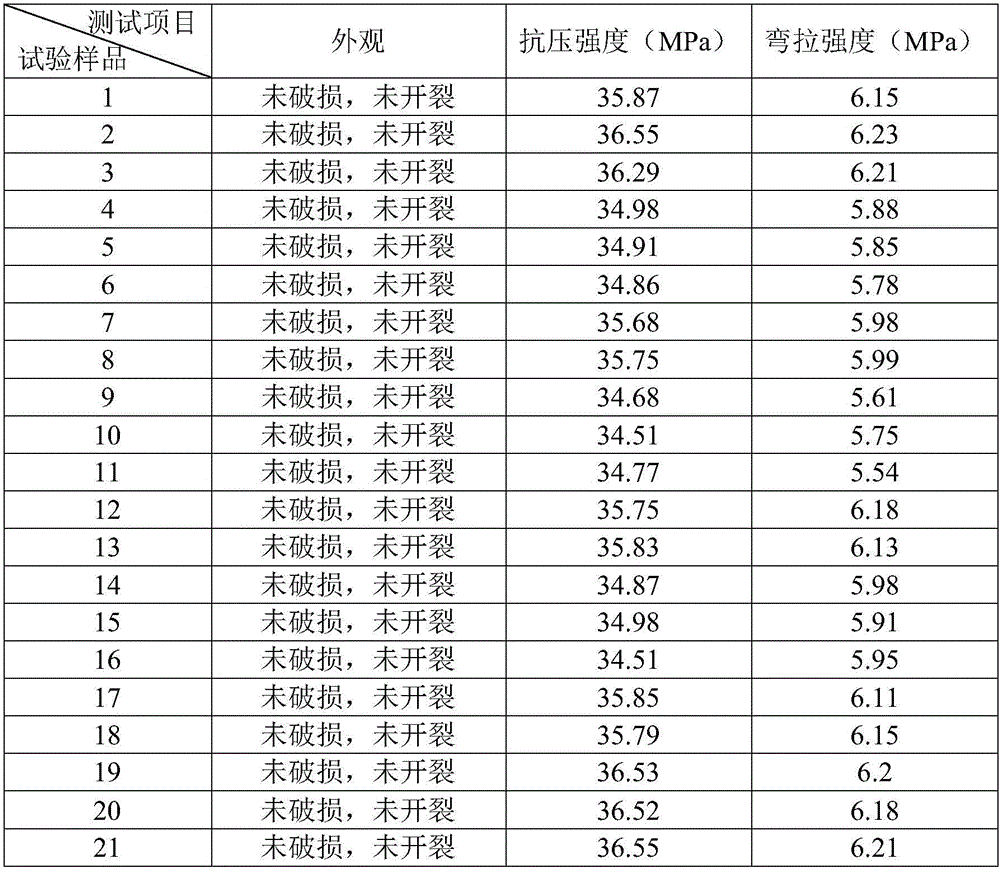

Concrete and preparation method thereof

The invention discloses concrete and a preparation method thereof. The concrete is prepared from components in parts by weight as follows: 103-133 parts of cement, 20-36 parts of river sand, 21-31 parts of gravel, 45-60 parts of water, 12-23 parts of a fiber mixture, 21-33 parts of lignin, 20-36 parts of an adhesive, 12-18 parts f a concrete expansive material and 35-51 parts of padding, wherein the fiber mixture comprises two or more of glass fibers, polypropylene fibers and steel fibers; the adhesive comprises at least two of epoxy resin, unsaturated polyester resin and SBS (styrene butadiene styrene) modified asphalt; the padding comprises silica powder, quartz sand and limestone; the concrete expansive material comprises at least two of an SY-T complex fiber anti-crack agent, an SY-K expansive fiber anti-cracking waterproof agent and a CAL fiber compound type four-element expanding agent. The concrete has the advantages of better cold resistance, stability and durability and low probability of cracking.

Owner:北京城建九混凝土有限公司

Light high-crack-resistance cement concrete

InactiveCN103030355ALow densityImprove seismic performanceSolid waste managementCrack resistancePolyvinyl alcohol

The invention provides light high-crack-resistance cement concrete which comprises the following materials in parts: 20-50 parts of cementing material, 10-20 parts of junked tire rubber grains, 0.08-0.3 parts of silane coupling agent, 20-40 parts of river sand, 10-20 parts of water, 0.3-0.6 parts of water reducing agent and 0.8-2 parts of polymeric fiber, wherein the cementing material comprises the following materials in parts: 60-80 parts of cement, 10-30 parts of fly ash, 5-10 parts of silicon ash and 3-8 parts of fine limestone powder, and the polymeric fiber comprises the following materials in parts: 70-90 parts of polyvinyl alcohol fiber and 10-30 parts of polypropylene fiber. According to the light high-crack-resistance cement concrete, a junked tire is recycled, and the density of the concrete is reduced greatly at the same time; the shock resistance and the deformation resistance of the concrete are improved greatly; an ordinary concrete brittle failure mode is changed; and strain hardening is achieved.

Owner:CHANGAN UNIV

Phosphorus slag powder doped dry powdered anti-crack mortar

Owner:TONGJI UNIV

Ceramic tile capable of releasing negative oxygen ions and preparation method thereof

The invention discloses a ceramic tile capable of releasing negative oxygen ions and a preparation method thereof. The ceramic tile is prepared from the following raw materials in parts by weight: 38-56 parts of river sand, 22-34 parts of fluorite, 18-26 parts of volcanic, 10-20 parts of dolomite, 24-36 parts of modified clay, 15-25 parts of magnesite ore, 12-18 parts of tourmaline, 10-15 parts of hexacyclic stone, 8-14 parts of medical stone, 5-10 parts of stove ash residue, 6-12 parts of talcum powder, 4-8 parts of shell powder, 3-6 parts of barium carbonate and 2-4 parts of zinc oxide. The tourmaline, the hexacyclic stone, the medical stone and the like are added into the ceramic tile, so that the ceramic tile can release negative oxygen ions beneficial to human health for a long time, can obviously enhance blood circulation, promote metabolism, improve immunity and soothe mind and body, has an effect of bacteriostat and sterilization and has an obvious deodorization function, the indoor air can be purified, and the indoor air quality is improved.

Owner:安徽省亚欧陶瓷有限责任公司

Antibacterial aerated brick and making method thereof

InactiveCN103833278AImprove foam stabilization performanceGuaranteed StrengthCeramicwareBrickPhosphoric acid

Owner:广州市明忠建筑材料有限公司

Artificial reef preparation with metallurgy slag as principal raw material

ActiveCN101475348AReduce manufacturing costImprove the living environmentSolid waste managementPisciculture and aquariaSlagSquare meter

The invention relates to a method for preparing an artificial fishing rock by using metallurgy residues as main materials, which belongs to the technical field of metallurgy residues treatment. The method is characterized by comprising the following steps: firstly, sieving and grading sea sand or river sand; secondly, mixing and grinding 0 to 20 percent of the obtained sand with the particle diameter of less than 5 millimeters with 10 to 80 percent of steel slag, 0 to 80 percent of mine refuse and 10 to 70 percent of cement clinker until the specific surface area is more than 350 square meters per kilogram; thirdly, mixing 20 to 70 percent of the mixture with 20 to 50 percent of the sieved coarse sand with the particle diameter of more than 5 millimeters and 0 to 40 percent of stones; and fourthly, obtaining the concrete artificial fishing rock with high and strong performance after high temperature maintenance. The artificial fishing rock has the advantages that the artificial fishing rock with high and strong performance is prepared by using the metallurgy residues as the main materials to remarkably reduce the preparation cost of the fishing rock, and the living environment for the aquatic lives around the fishing rock is fundamentally improved because the pH value of the concrete pore solution of the prepared fishing rock is close to that of sea water.

Owner:SHOUGANG CORPORATION

Ultrahigh-strength concrete and preparation method thereof

The invention discloses ultrahigh-strength concrete which comprises the following components in parts by weight: 300-350 parts of cement, 270-315 parts of composite mineral admixture, 30-35 parts of composite expanding agent, 96-112 parts of water, 680-720 parts of river sand, 1012-1080 parts of gravel, 13.2-14.0 parts of polycarboxylic acid high-efficiency water reducing agent, 4.4-4.7 parts of plastic retaining agent and 0.18-0.21 part of defoaming agent, wherein the composite mineral admixture is prepared from 42-49 parts of ore powder, 150-175 parts of fly ash, 30-35 parts of silica fume, 18-21 parts of zeolite powder and 30-35 parts of wollastonite powder. The invention is characterized in that the 60d concrete compression strength is 140-160 MPa, the 60d splitting tensile strength is 9.2-10.2 MPa, extruded concrete can achieve self-compaction effect within 3 hours, and the 14d self-shrinkage value is less than 0.05%.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD

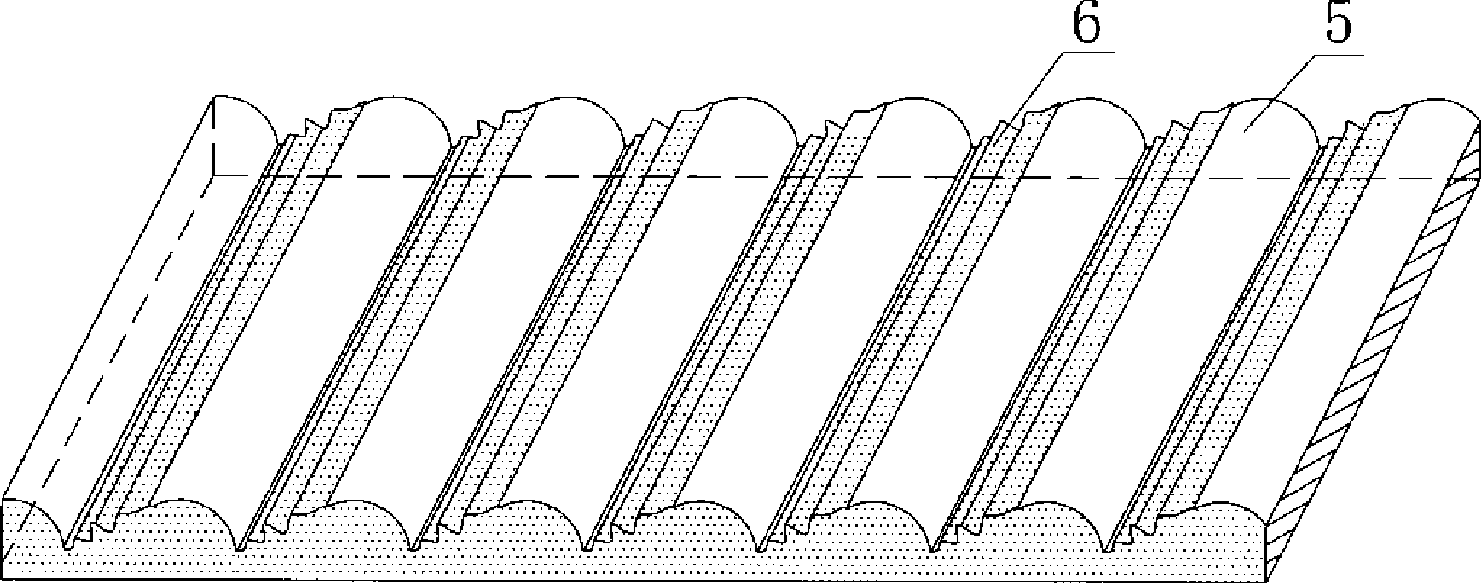

Stone texture-like permeable concrete ground and construction method thereof

InactiveCN101392484AGood water permeabilityMeet the use requirementsIn situ pavingsSolid waste managementSurface layerCrushed stone

The invention relates to a stone-simulating pervious concrete floor and a construction method thereof. The concrete floor includes a tamped foundation, a crushed stone layer, a pervious concrete structural layer and a pervious concrete surface layer from bottom to top; the pervious concrete surface layer is a stone-simulating pervious concrete surface layer, which adopts the following materials and weight ratio: 2100-2300kg / m<3> of river sand; 325-335kg / m<3> of cement; 39-41kg / m<3> of silicon power; 24-26kg / m<3> of Grade I coal ash; 3.4-3.6kg / m<3> of water reducer and 78-80kg / m<3> of tap water. The invention leads the pervious concrete road surface to have water permeability and decoration simultaneously, and improves the water-permeable and air-permeable effect of the concrete road surface on the premise of ensuring the strength of the road surface and having the texture of the concrete road surface.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +3

Steam-press air-entrainment concrete self-heat conserving building block by using sand of Yellow River and preparation method

The invention relates to a steam-press air-entrainment concrete self-heat conserving building block by using sand of Yellow River, which comprises the Yellow River sand and waste fly ash after the coal is burned in a power plant; the concrete self-heat conserving building block comprises the following components by weight percentage: 55-63% of the Yellow River sand, 5-16% of fly ash, 12.5-15% of quicklime, 2.5-3.0% of slaked lime, 1.0-2.0% of desulfurized gypsum, 0.08-0.12% of aluminum powder paste, 0.02-0.04% of foam stabilizer and the balance of cement. The building block takes the cheap Yellow River sand as a raw material, and has the advantages of light unit weight, strong processability, low heat conduction coefficient and good self-heat conserving effect.

Owner:HENAN XIAN NEW BUILDING MATERIALS

Ecological type nanometer super high performance cement based composite material and preparation method thereof

The invention discloses an ecological type nanometer super high performance cement based composite material and preparation method thereof, and the composite material comprises the following ingredients: cement: 19.2%-26.9%; industrial waste residue: 11.5-19.2%; nanometer SiO2: 0.38-1.92%; nanometer CaCO3: 0.38%-1.92%; additive: 0.8-1.2%; river sand: 38.4%-55.5%; copper facing steel fiber: 3.0%-9.0%; water: rest. The invention provides an ecological type nanometer super high performance cement based composite material and preparation method thereof, and compared with the same technique, the invention has the advantages of high cost performance, simple preparation technology, ecological environmental protection, etc. Because of composite superposed effect of nanometer ingredient and industrial waste residue, and the mechanical properties of the cement based composite material at early stage and later stage are improved, thereby improving the mechanical properties and the endurance performance of the cement based composite material.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com