Reactive powder concrete for reinforcing buildings as well as preparation method and construction method thereof

A technology of active powder and concrete, which is applied in the field of active powder concrete for building reinforcement and its preparation and construction. It can solve the problems of difficult reinforcement materials, high cost, and easy to fall off when used, and achieve good adhesion, strong plasticity, increase the overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to better understand the present invention, the content of the present invention will be further clarified below in conjunction with the embodiments, but the content of the present invention is not limited to the following embodiments.

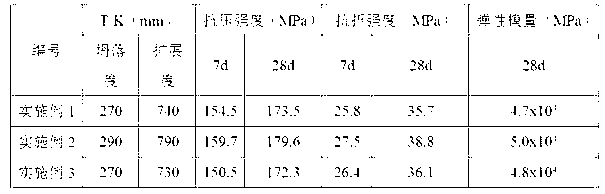

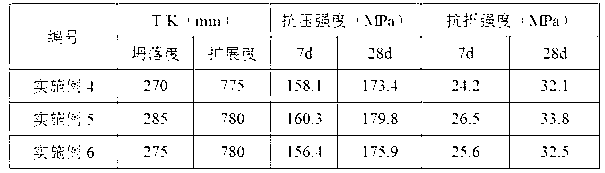

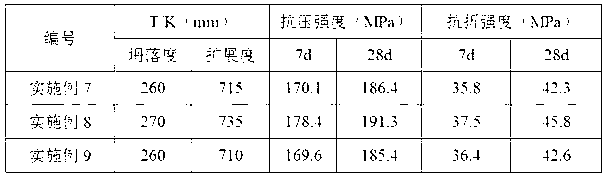

[0040] In Examples 1 to 3, this kind of reactive powder concrete for building reinforcement, the proportions of raw materials in parts by weight are shown in Table 1.

[0041] Table 1 The proportion of raw materials in parts by weight

[0042] Numbering water cement Fly ash beads Silica Fume River sand Quartz sand Steel fiber Chemical additives Powder / fine aggregate Example 1156522.812.27030171.8 1:1 Example 215702196535171.8 1:1 Example 3 15702196040171.8 1:1

[0043] among them:

[0044] The cement is ordinary Portland cement with a strength grade of 42.5;

[0045] The fly ash beads are white or light gray fly ash beads, the loss on ignition is less than 1%, and the specific surface area is ≥10000cm 2 / g;

[0046] Silica fume is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com