Patents

Literature

208 results about "Total investment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Simple Definition: Total investments means the total invested capital (particularly money) in every investment vehicle (paper assets such as stocks, mutual funds, 401k plan, trust accounts in the banks, time deposits, bonds or real estate properties, and business) you participated. For further explanation, keep on reading.

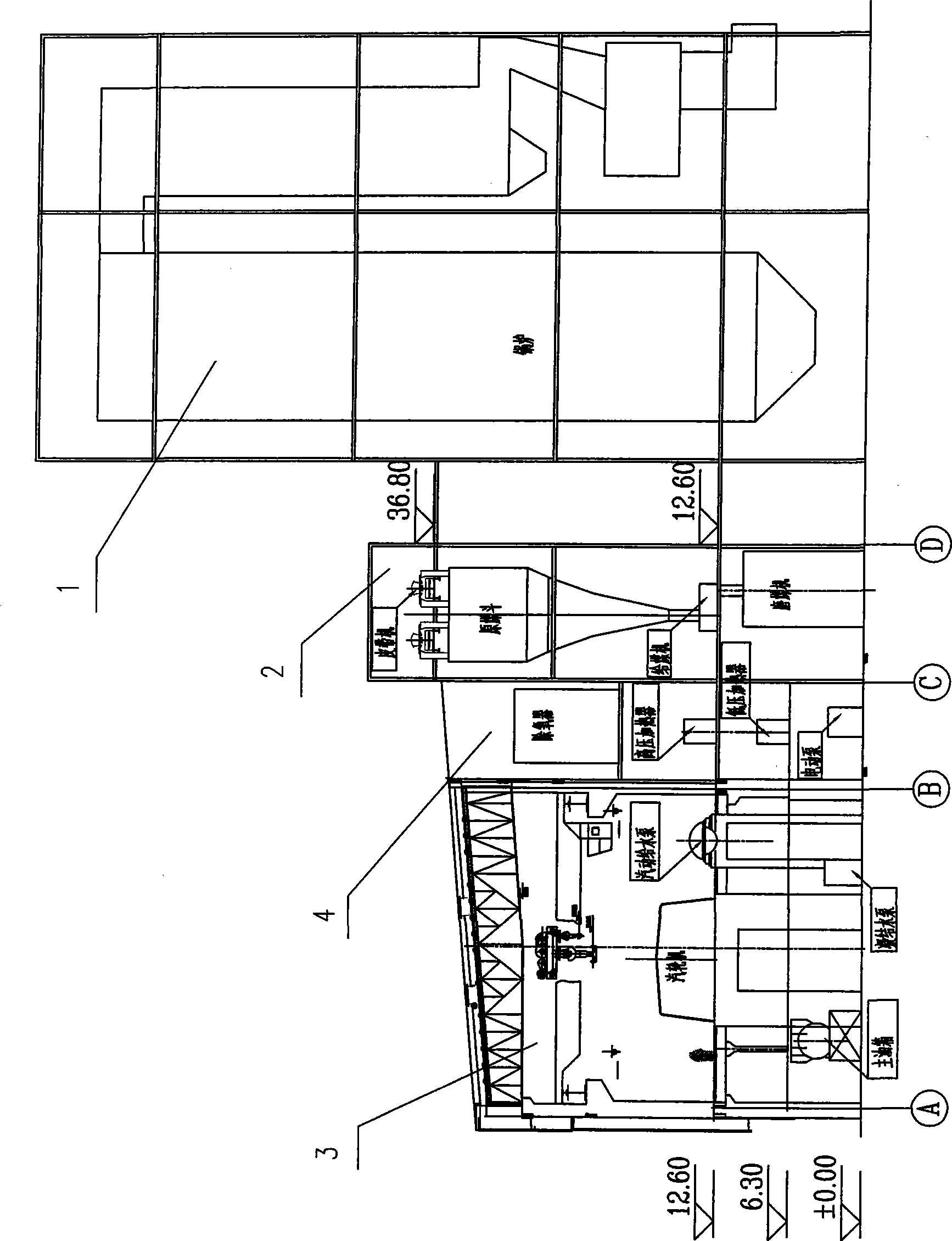

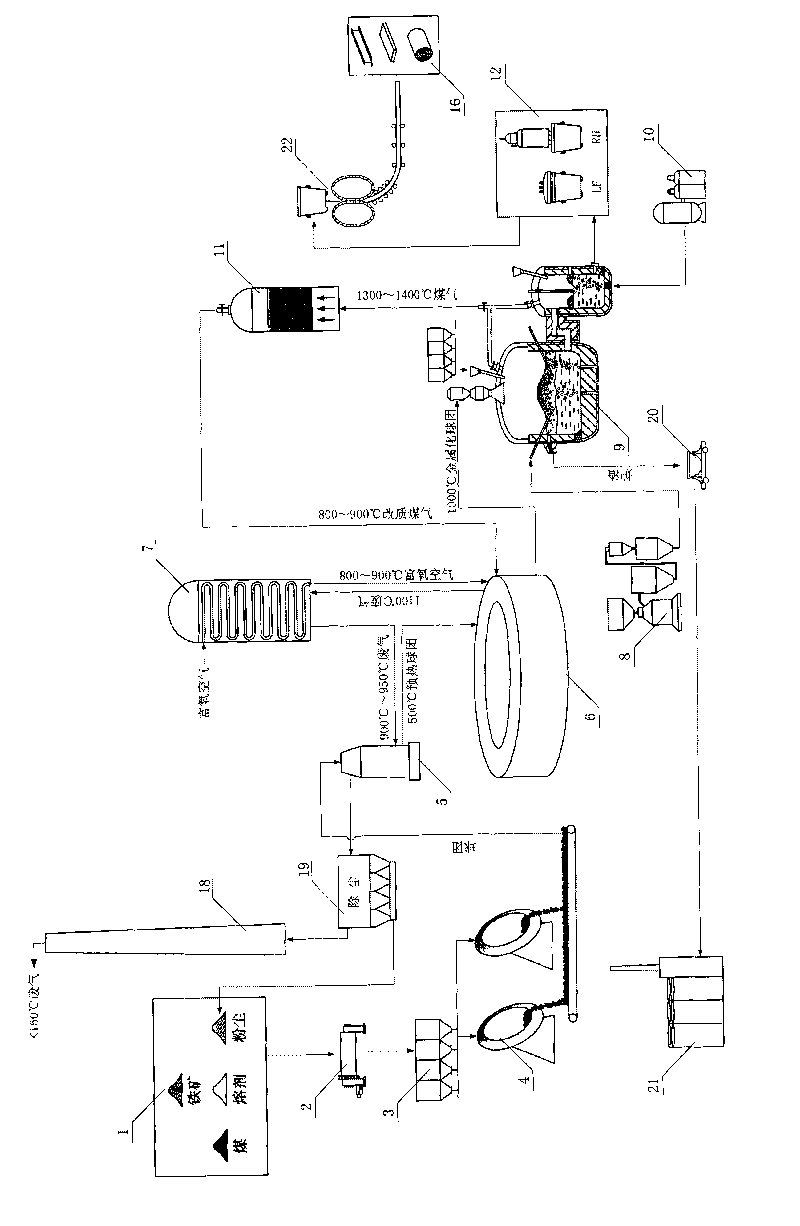

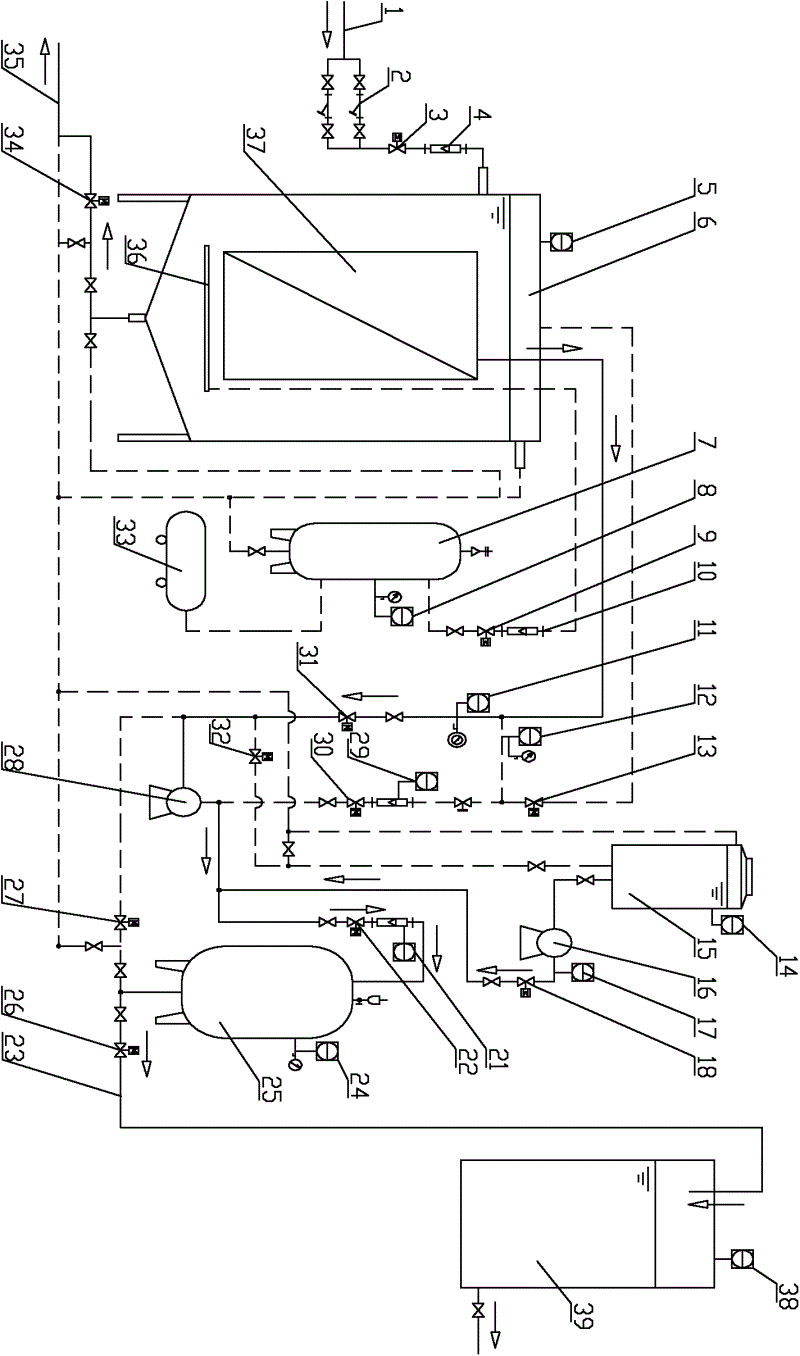

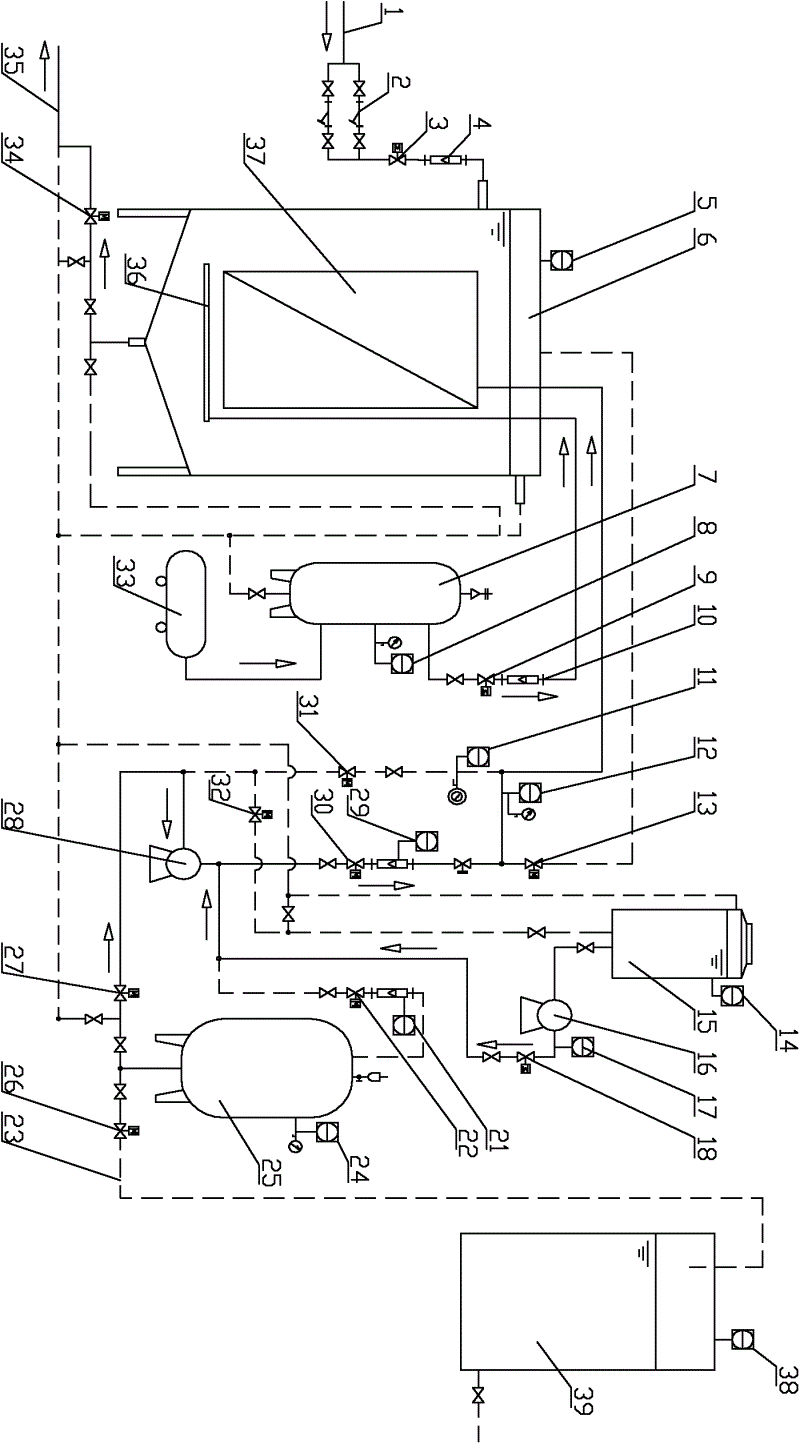

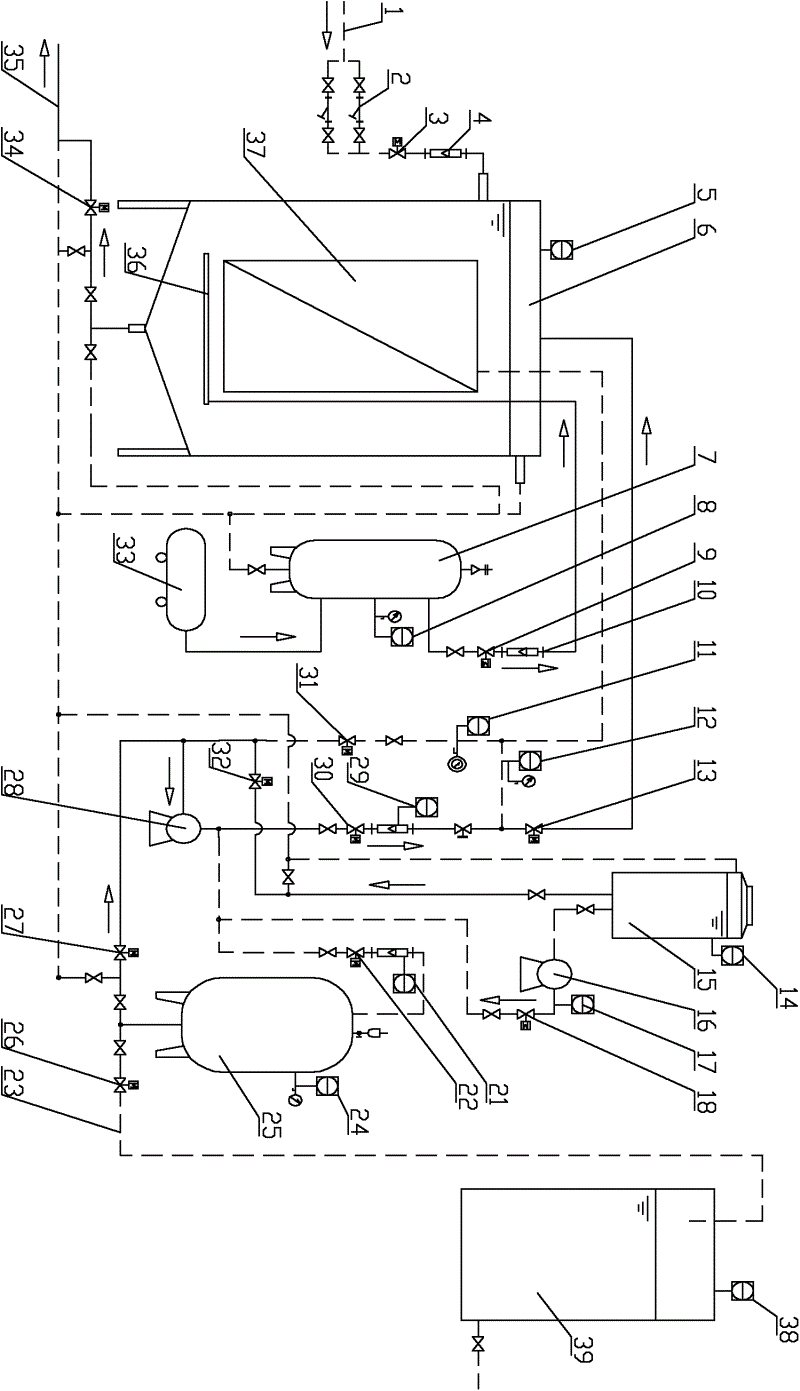

A coal dressing method and system of four-product jigging primary cleaning, secondary head coal small simplified heavy medium reelecting

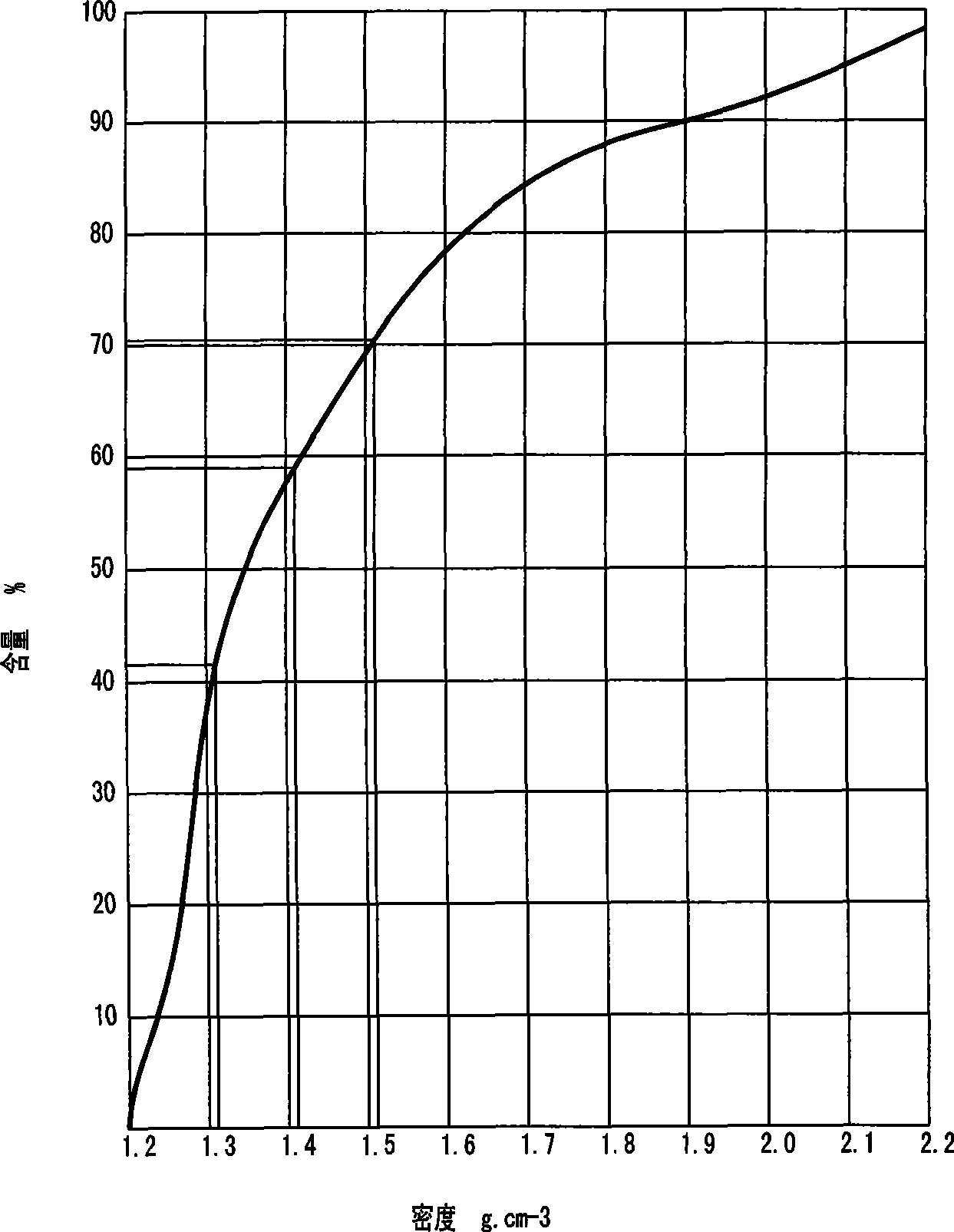

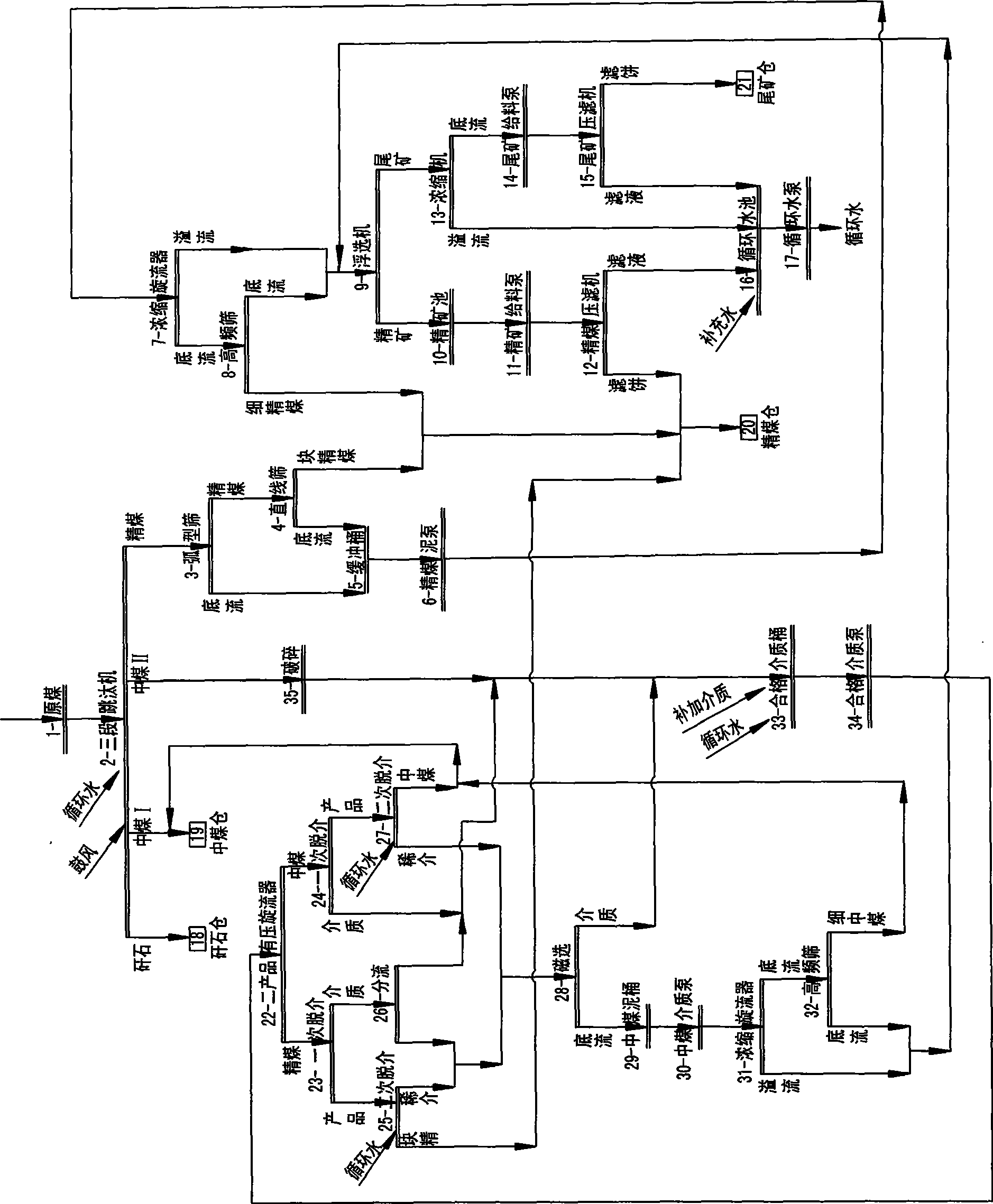

ActiveCN101530824AReduce investmentLow operating costSievingScreeningTotal investmentSeparation technology

The invention discloses a coal dressing method and system of four-product jigging primary cleaning and secondary head coal small simplified heavy medium reelecting. The invention is a coal dressing method and system that selects the secondary head coal product through the four-product jigging technique and then reelects the secondary head coal with small simplify heavy medium separation technology. The adoption of the invention to select coal is characterized by less total investment, simpler system and lower operational expense, which can improve the stability of the system, reduce the powerconsumption, simplify the managing and maintaining work. The method can be easily realized with present technical merits, which is beneficial to be popularized in the middle and small coal washeries where the management level is low and if the method is used in oversize coal washeries, the cost for washing is lower.

Owner:JINYITONG SCI ANDTECH BEIJING CO LTD

Optimal design method for production line layout

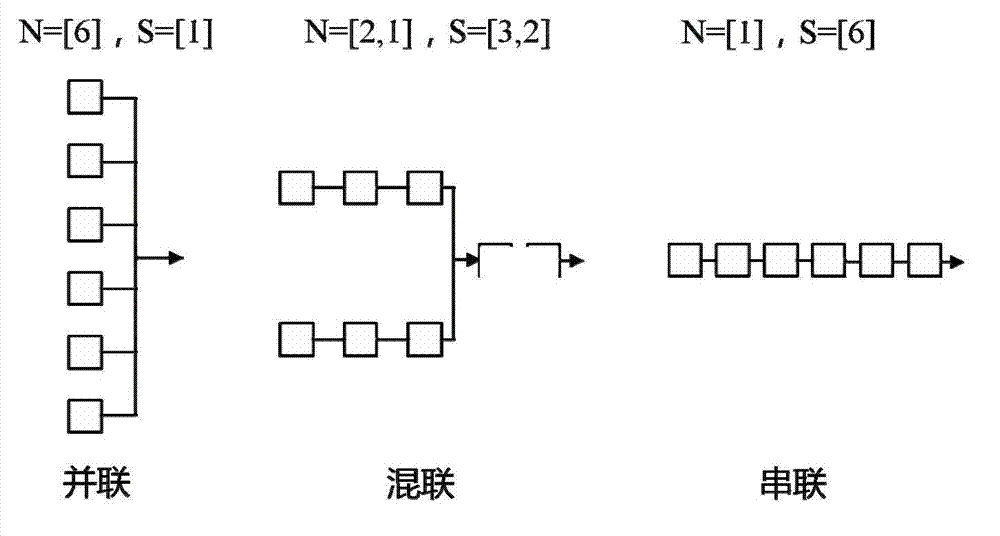

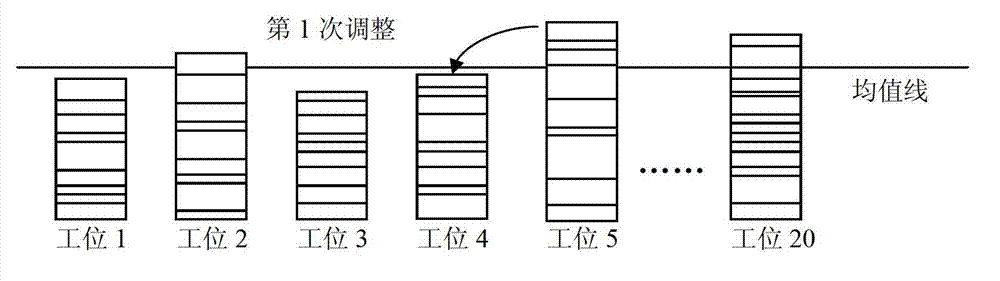

ActiveCN103049801AReduce the impact of volatilityIncrease production capacityForecastingProduction lineTotal investment

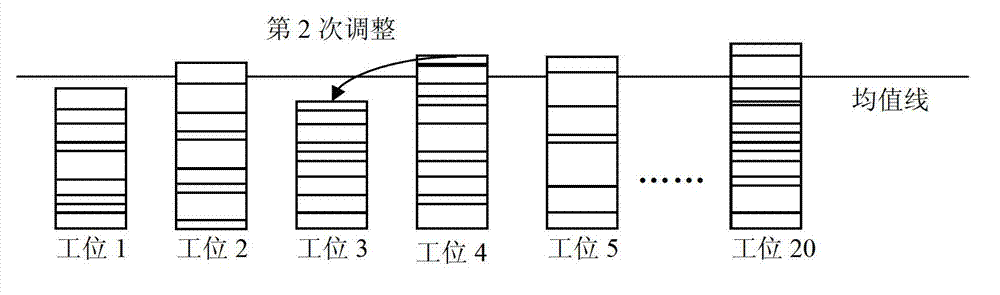

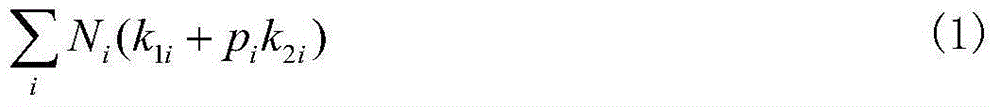

The invention relates to the field of engineering manufacture, in particular to an optimal design method for production line layout. The technical problem that the influence of production fluctuation on production efficiency cannot be reduced by the conventional method so as to reduce enterprise benefits is solved. According to the scheme, the optimal design method for new production line layout mainly comprises the following steps of: acquiring the labor house data of original sub-procedures; generating functional segments and a station number by adopting a line balancing planning method, so that the cycle time of a single line in each functional segment is shortest; when total investment C is determined, finding all N and S combinations consistent with a constraint condition by using an enumeration method; calculating the cycle time of each functional segment; calculating the overall cycle time of each [N, S] scheme; and performing calculation according to the steps, and when the total investment C is determined, determining a scheme with the shortest cycle time in all the [N, S] schemes as a target scheme. The method can be used for the design of the new production line layout and the modification of the conventional production line layout.

Owner:四川长虹智能制造技术有限公司

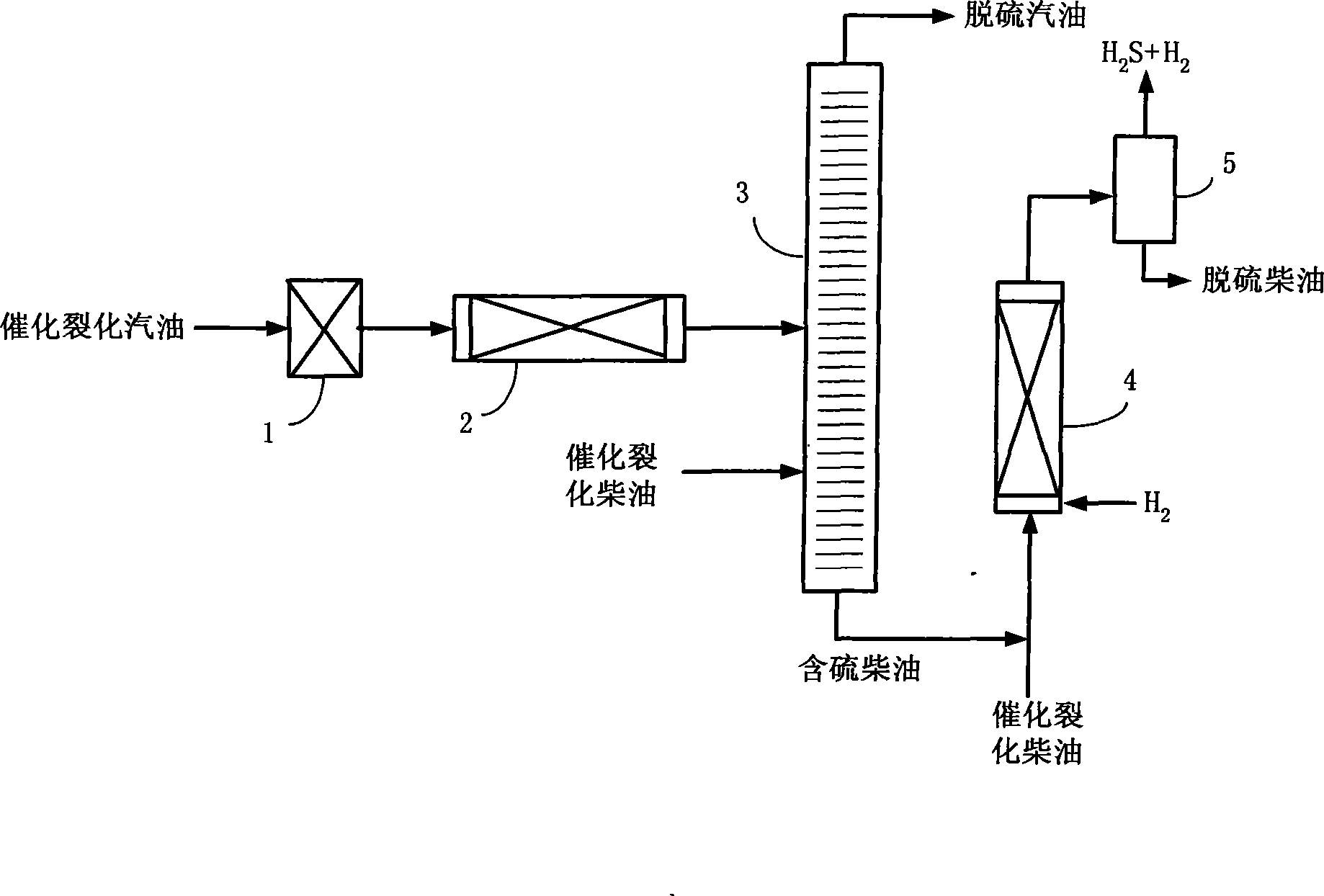

Device and method for catalytically cracked gasoline and diesel oil coupling desulfurization

InactiveCN101220295AHigh boiling pointNo loss of octaneTreatment with hydrotreatment processesTotal investmentDistillation

The invention relates to a device and a method for coupling and decarbolizing of catalytic cracking gasoline and kerosene, wherein a feed inlet of a preprocessor of the catalytic cracking gasoline is connected with a head tank of the catalytic cracking gasoline through a gasoline feeding pump; a discharge hole is connected with an inlet of a thiophene sulfide alkylation reactor through a pipeline; the outlet of an alkylation reactor is connected with the middle part of a sulfur transferring fractionating tower through the pipeline; a catalytic cracking kerosene input port is arranged at a stripping section of the fractionating tower and is connected with a catalytic cracking kerosene storage tank by the feeding pump; a desulfurated gasoline outlet is arranged on the top of the fractionating tower; a sulf-kerosene outlet is arranged at the bottom of the fractionating tower and is connected to a kerosene hydrodesulfurizing device through the pipeline; a product outlet arranged at the upper end of a kerosene hydrogenation plant is connected with a gas-liquid separator through the pipeline; a desulfurated kerosene outlet is arranged at the lower end of the gas-liquid separator. The invention has the advantages that through a corporate distillation of gasoline and kerosene, sulfur in the gasoline is transferred into the kerosene, and sulfur in gasoline fraction is desorbed without losing octane value, thus omitting the process of gasoline hydrodesulfurizing and lowering total investment and operation expenses.

Owner:TIANJIN UNIV

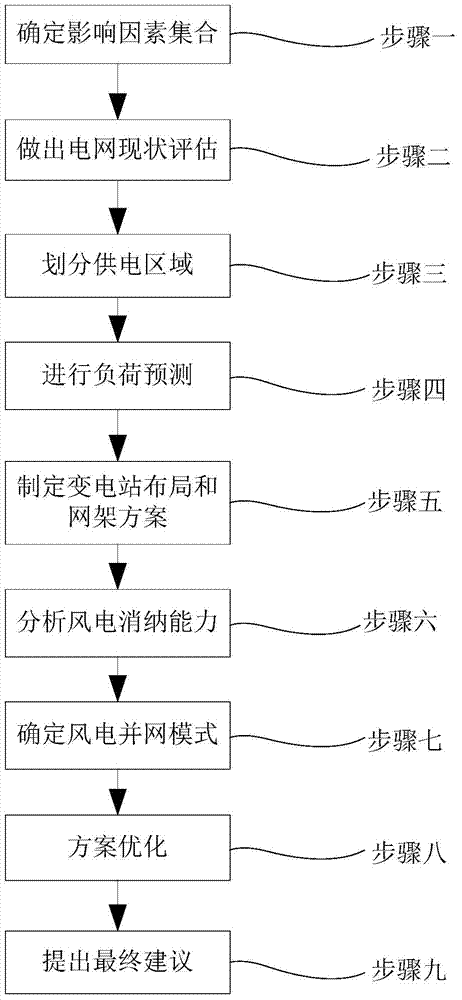

Method of intertidal zone wind power for accessing power grid

ActiveCN103577901AExcellent total investment costMeet safe and stable operation requirementsForecastingInformation technology support systemElectricityTotal investment

The invention discloses a method of intertidal zone wind power for accessing a power grid. The method comprises the following steps: step 1, determining an influence factor set; step 2, evaluating the power grid state; step 3, dividing the planning area into supply districts which are of different layers, connected but independent; step 4, carrying out load prediction, and performing load characteristic analysis and prediction with some emphasis; step 5, formulating a transformer substation layout and a wire frame scheme; step 6, analyzing wind power consumption capacity in the planning area and each supply district; step 7, determining wind power integration mode of the intertidal zone wind power access applicable for each power supply district; step 8, carrying out scheme optimization; step 9, providing the final suggestion. By virtue of the method, in the power grid planning phase, the wind power resource characteristics and the power grid operation requirements can be both considered about to realize that the total investment cost for power grid construction is optimized.

Owner:STATE GRID CORP OF CHINA +1

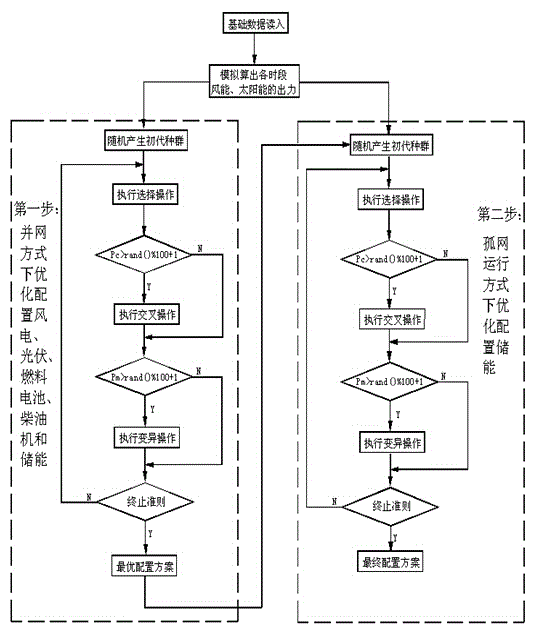

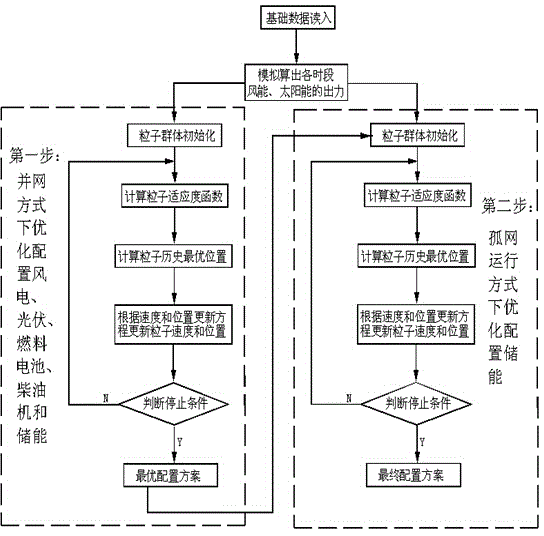

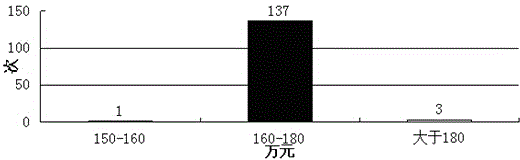

Optimization programming and evaluation method of micro-grid power supply

InactiveCN104881716AAchieve wellImprove optimization effectForecastingTotal investmentMathematical model

The invention discloses an optimization programming and evaluation method of a micro-grid power supply. Under grid connection and island operation modes, a mathematical model of distributed power supply optimization programming in a microgrid is established respectively. Constraint conditions of diesel generator starting and operation are considered so that optimization configuration of scientific wind power, photovoltaic and fuel cells, a diesel generator and an energy storage capacity is acquired. A heredity and particle swarm algorithm is used to carry out optimization programming on the power supply in the microgrid. A programming scheme evaluation method including a stable power supply duty ratio, total investment, a time-shifting electric quantity of energy storage, power supply capacity adequacy and longest running time of the diesel generator is established. Correctness of a programming method and rationality of a programming result are guaranteed.

Owner:POWER GRID PLANNING RES INST OF GUIZHOU POWER GRID CO LTD

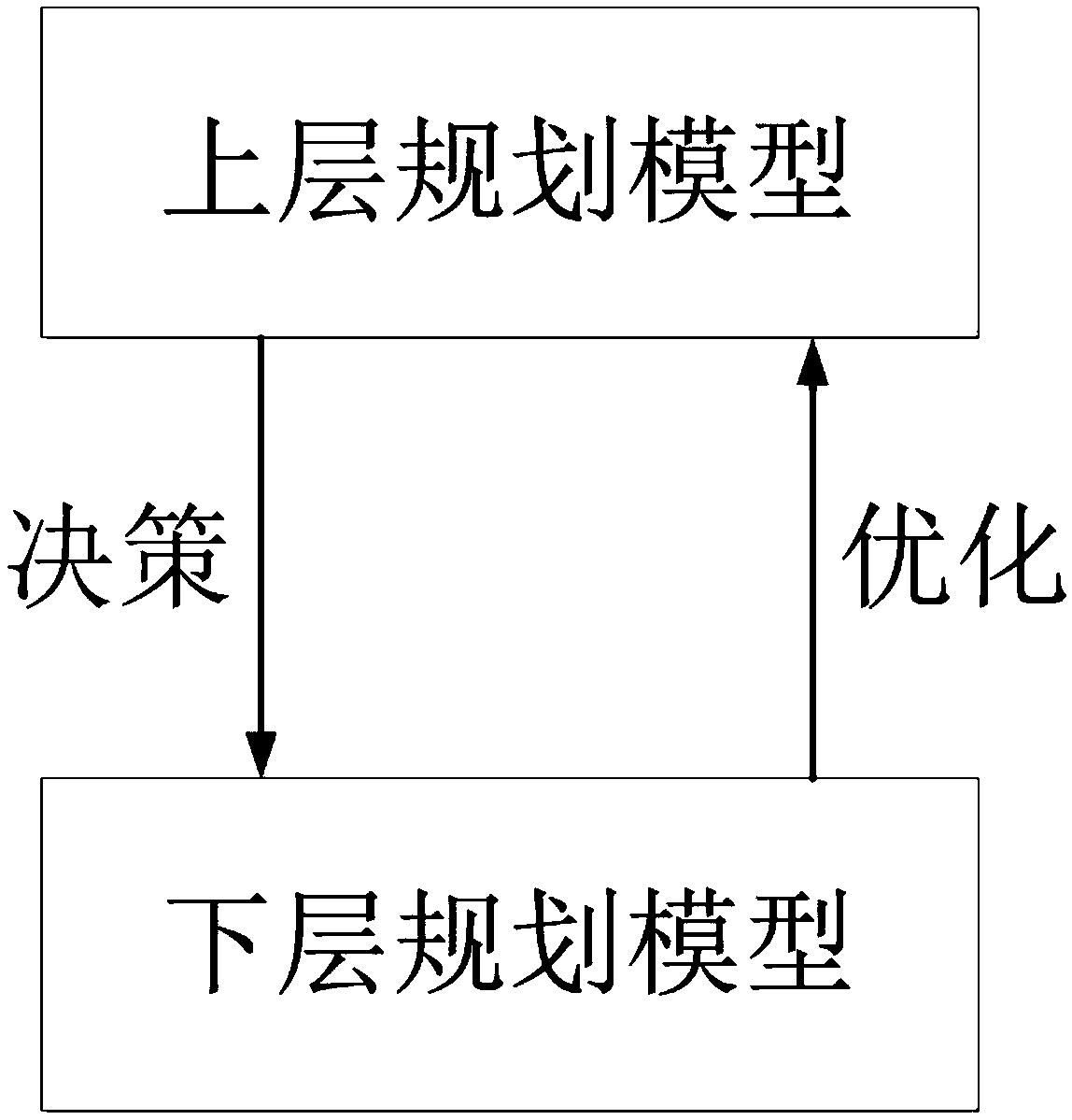

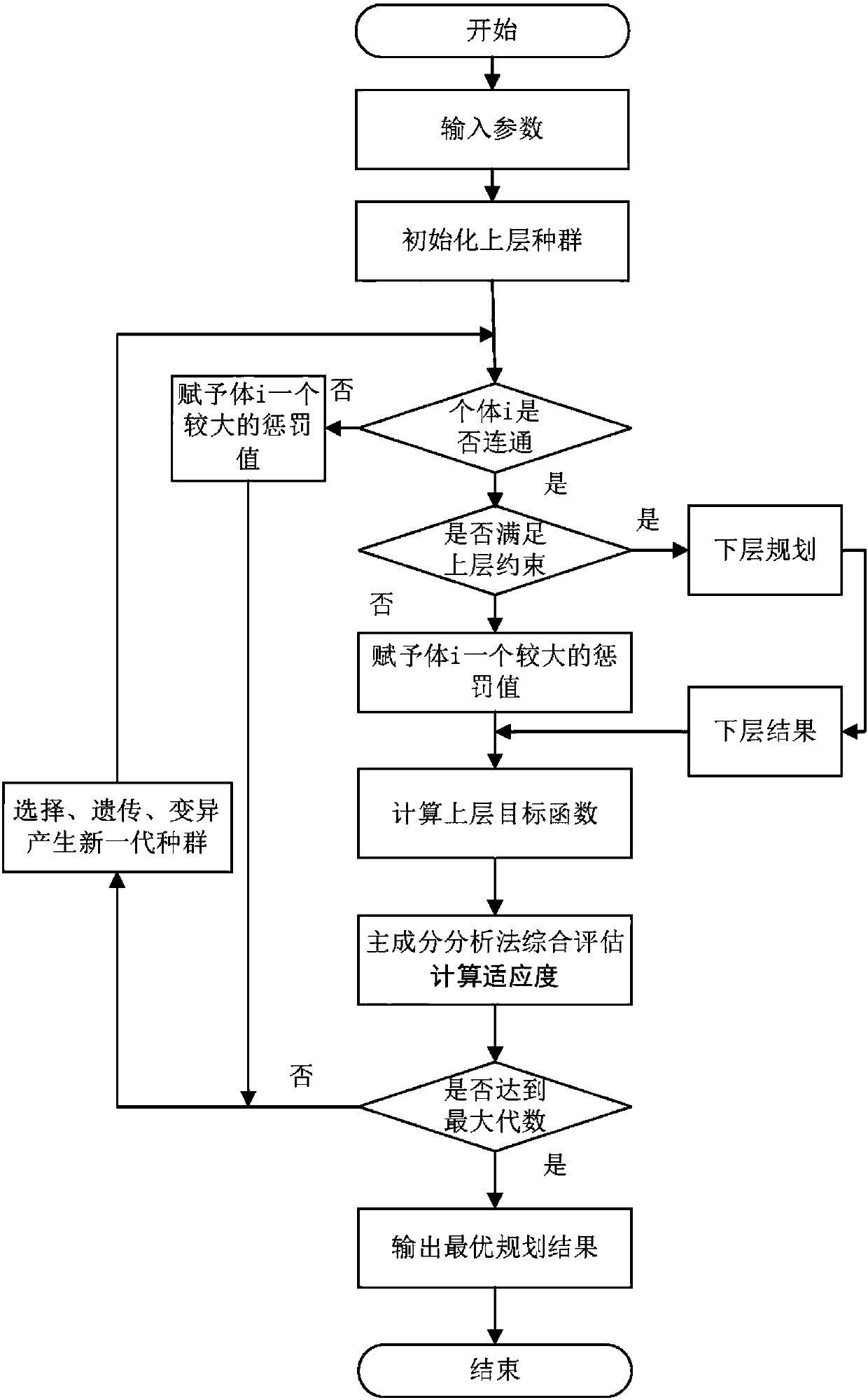

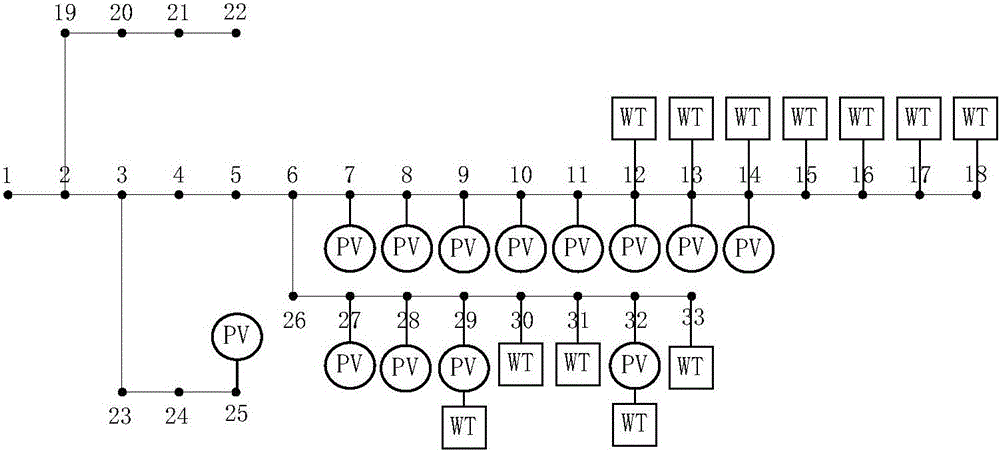

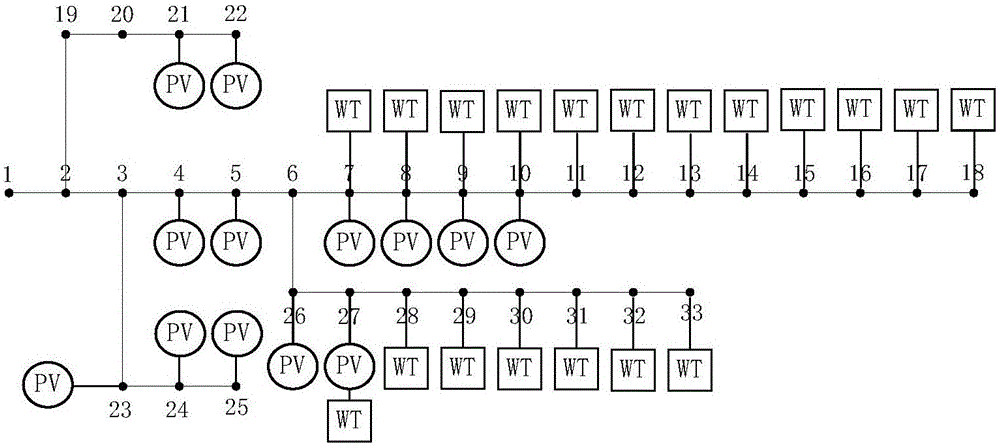

Power transmission planning under high proportion clean energy access

ActiveCN107679658AEffectively reflect the ability to embrace renewable energyForecastingInformation technology support systemTotal investmentElectric power system

The invention discloses a power transmission planning under high proportion clean energy access. The power transmission planning under high proportion clean energy access includes the steps: establishing and solving double layer planning models to obtain a planning scheme which enables the upper and lower layers of planning models to be relatively optimal, wherein as the upper layer planning modeltakes the line to be established, the flexibility unit to be established and the flexibility resource calling quantity as variables and takes the total investment of planning and the grid frame flexibility index as the target function to make decisions, the decision result is transmitted to the lower layer planning model through a system admittance matrix; and at the same time, through operationverification of different simulation scenes, the lower layer planning model takes the volume of the flexibility unit to be established and the flexibility calling quantity as the variables to optimizethe flexibility index and flexibility unit configuration, and returns the optimized flexibility index and flexibility unit configuration to the upper layer planning model through the calling total quantity of the flexibility resources and the construction volume of the adjustable unit to be established, so as to influence the variable parameters of the upper layer planning model. Therefore, the power transmission planning under high proportion clean energy access can effectively reflect the capability of accepting renewable energy sources of the electric power system, and can be adapted to the relatively higher proportion of renewable energy sources grid connection demand.

Owner:STATE GRID SICHUAN ECONOMIC RES INST

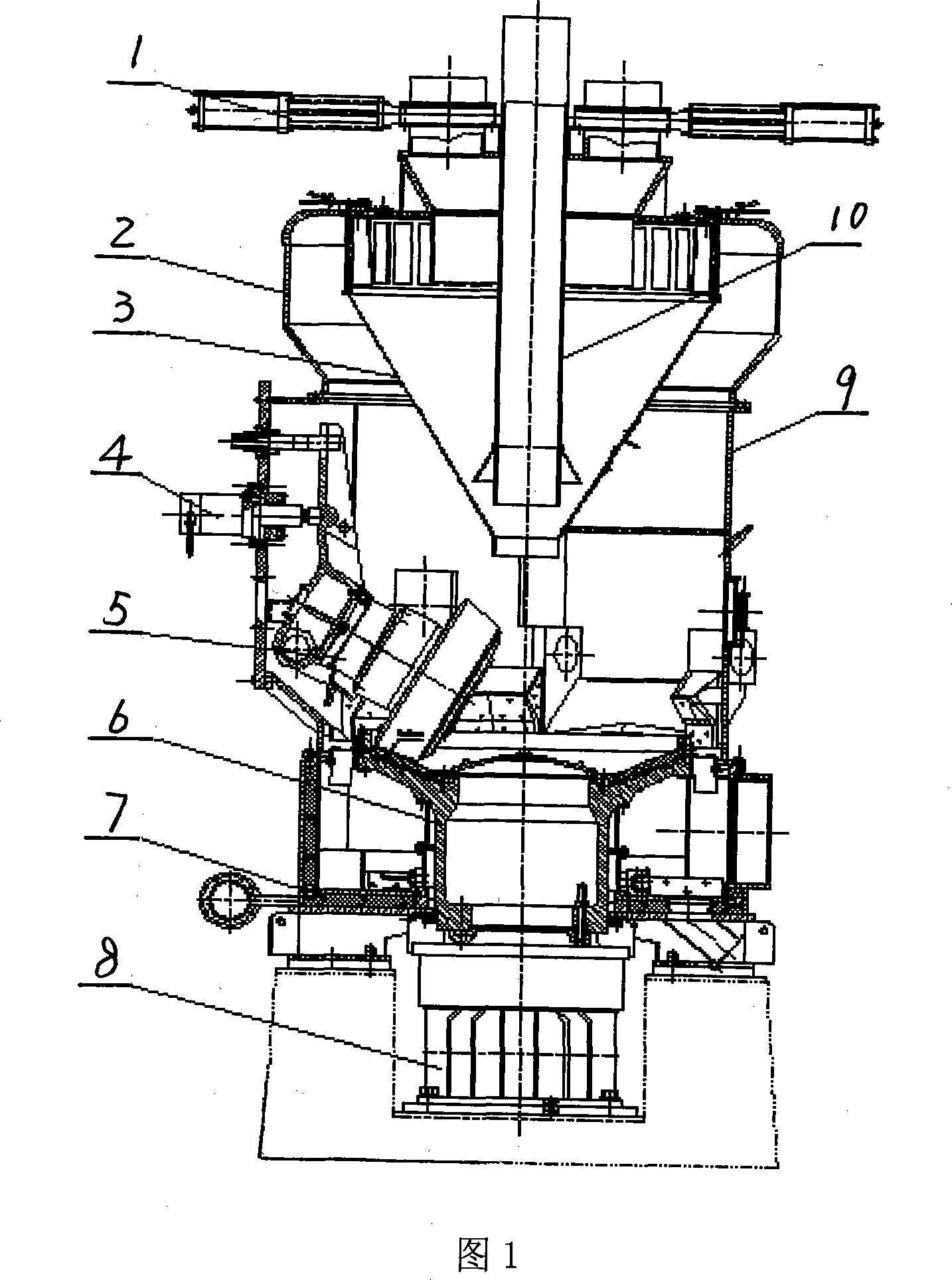

Roller type medium speed mill

InactiveCN101125306AExtended service lifeLower the altitudeGrain treatmentsChemical industryImpeller

The present invention relates to a roller type mill with medium speed used for the electric power plant, metallurgy, chemical industry and cement powder making filed. The working principle is that: the milling bowl and the impeller device are rotated in a clockwise manner under the driving of the reducer, and the material falls to the milling bowl by the central falling coal tube, and then moves towards outside along the radial direction under the action of the centrifugal force, and a layer of material bed is formed on the milling bowl, and the material bed is through under the milling roller equipment which can rotate around the shaft. At this time, the milling force produced by the loading unit is pressed on the material by the rotating milling roller. The material is milled to the powder between the milling bowl liner and the milling roller. The material moving in a radial and surround manner carries the powder to pass the edge of the milling bowl to enter the transmission medium channel. The invention is of a novel and scientific design, which adopts hydraulic pressure turning to loading protecting the material with strong adaptability. The milling roller adopts the cone shaped roller shape, and using the special tool directly to turn the outside of the machine body for exchanging the milling roller sleeve, the milling roller bearing and the milling roller oil seal. Exchanging and overhauling the milling bowl liner is convenient, and the inner installing type coal powder separator structure is improved to the hopper shape, and the service life of the coal powder separator is prolonged, and the invention reduces the height of the milling machine and weight as well as the total investment of the project.

Owner:LIAONING HEAVY EQUIP & TECH

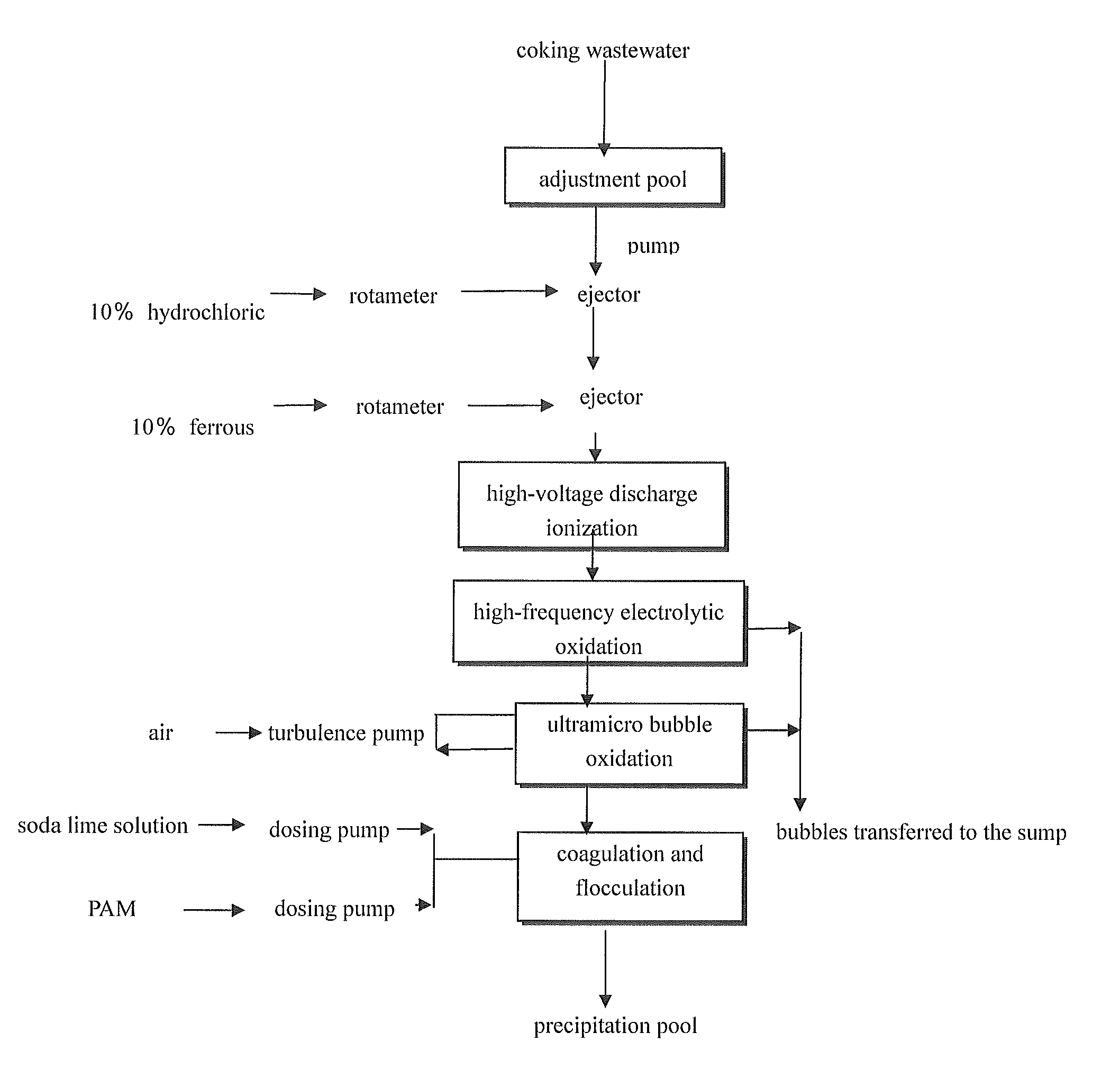

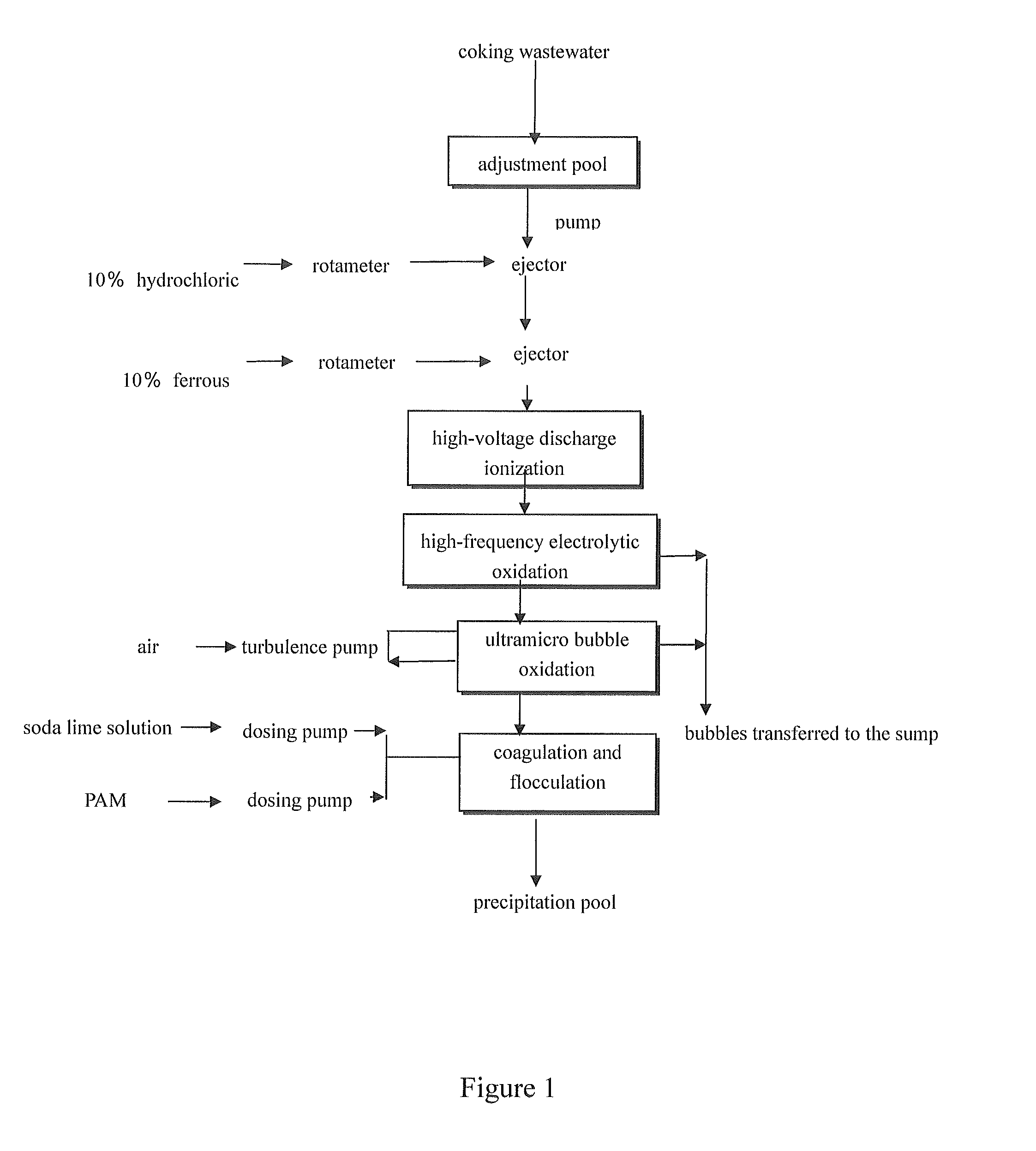

Method integrating electrochemical oxidation and flocculation processes for pre-treatment of coking wastewater

ActiveUS20110220585A1Pollution indices in the wastewater drop dramaticallyTotal investment on equipments and operation expenditureWaste water treatment from metallurgical processSedimentation separationHigh concentrationTotal investment

A new method that integrates electrochemical oxidation and flocculation processes for removing ammonia nitrogen in coking wastewater is disclosed in this invention. It comprises steps as follow: first, adjusting the PH of coking wastewater and adding Fe2+ into the wastewater; then leading the wastewater containing Fe2+ through such 5 areas as pulsed high-voltage discharge oxidation area, pulsed high-frequency DC electrolytic oxidation area, microbubble oxidation area, flocculation area and precipitation area in succession. High-voltage pulse and high-frequency pulse are two different mechanisms for achieving strong oxidation. With help of both solid and liquid catalysts, these two oxidations can work synergistically. The recalcitrant organic chemicals are effectively destroyed and satisfactorily removed out of wastewater. The high-concentration coking waster pretreated with this method will meet Chinese highest discharge standard as long as the routine biochemical treatment is applied thereafter. The total investment on equipments and operation expenditure of the whole system is economically modest, which, together with its highly efficient treatment performance, ensures its extensive application in the field of wastewater treatment.

Owner:NANJING UNIV

Method for optimizing and configuring power supply of grid-connection-mode microgrid

The invention relates to a method for optimizing and configuring a power supply of a grid-connection-mode microgrid, which belongs to the field of the optimization planning of an electric network. (when a power output constraint and quality constraint condition of a power supply in the microgrid is satisfied, the configuration capacity of each distributive power supply of each type is optimized and selected, the power construction expense, the operation expense and the damage of the microgrid under the grid-connection mode are adequately considered, a minimal total investment sum is adopted as a target function, a penalty function is introduced, the improved particle swarm optimization is used for solving the function, adaptability of a particle swarm is calculated by utilizing the penalty function when the constraint condition is not satisfied, and an optimal result is enabled to fall in the constraint range). For the operation characteristics of the grid-connection-mode microgrid, complementation of the inner power supply of the microgrid and the traditional power supply of a large grid as well as randomness of wind-optical resource and fluctuation of a load are considered, so that the economical performance of the power investment is optimal when the microgrid under the grid-connection mode satisfies the constraint condition.

Owner:WUHAN UNIV

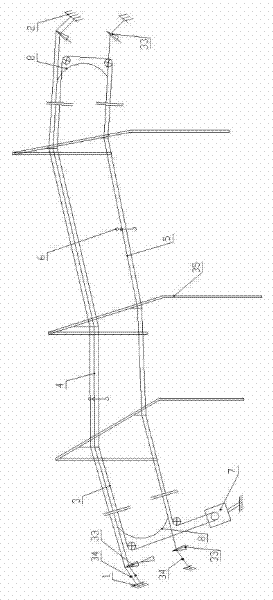

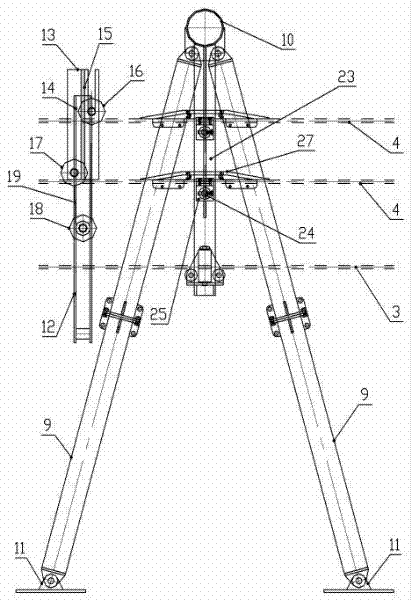

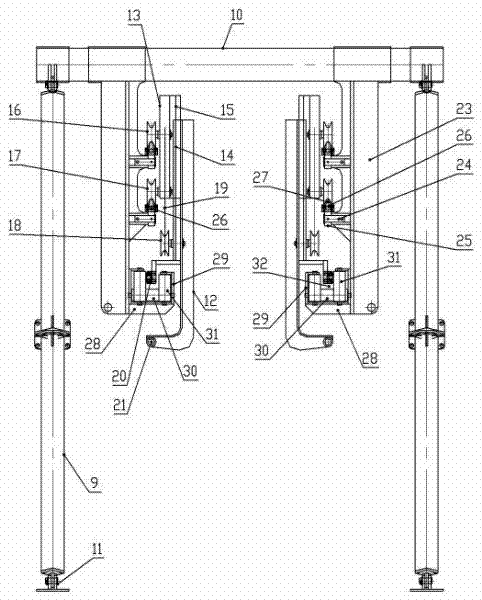

Double-cable circular curved cableway transportation system

ActiveCN102259649AImprove delivery efficiencyImprove securityRope railwaysTransport systemTotal investment

The invention discloses a curve cableway transporting system of double-cable circulating type, which comprises two groups of ground anchors, supporting devices, a dragging cable, two load bearing cables, one or two empty-return cables, a freight trolley and a dragger. The dragging cable is connected with the dragger to form an annular circulating loop, the two load bearing cables are arranged in parallel up and down, the one or two empty-return cables and the load bearing cables are respectively mutually connected at positions near the adjacent two groups of ground anchors through a corner slid rail, the dragging cable is arranged below the two load bearing cables and the one or two empty-return cables, and the load bearing cables or empty-return cables on the two sides of each supportingdevice are provided with an included angle. According to the curve cableway transporting system of double-cable circulating type disclosed by the invention, a cableway construction line is shortened in some regions, and multiple times of loading, unloading, dumping and transporting do not needed during transportation; and the curve cableway transporting system of double-cable circulating type disclosed by the invention has the advantages of reasonable design, convenience for installing, large freight volume, large altitude difference, large span, high transportation efficiency, high safety coefficient, low total investment, low operation cost and the like, and has large popularization and application values.

Owner:STATE GRID CORP OF CHINA +2

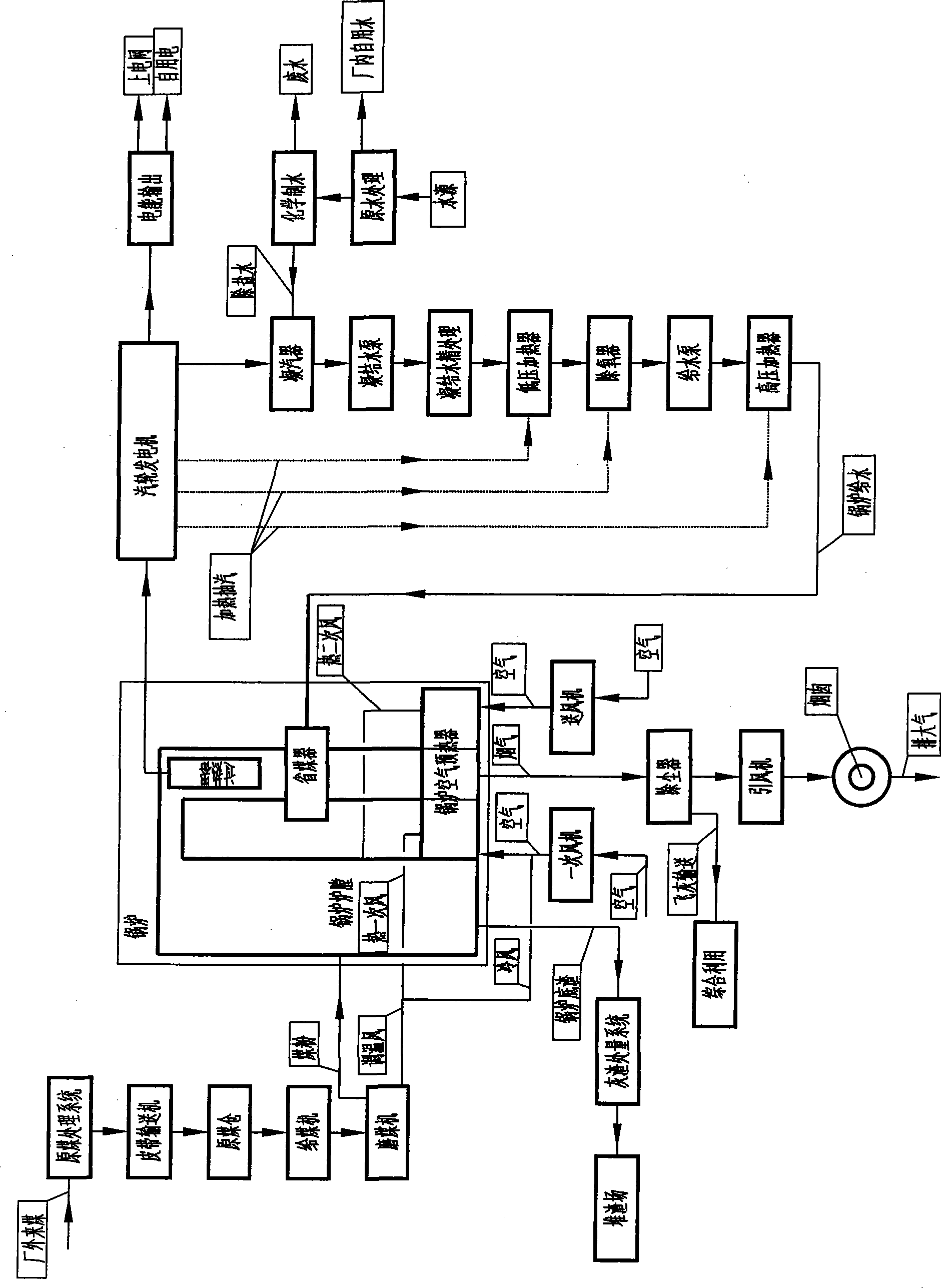

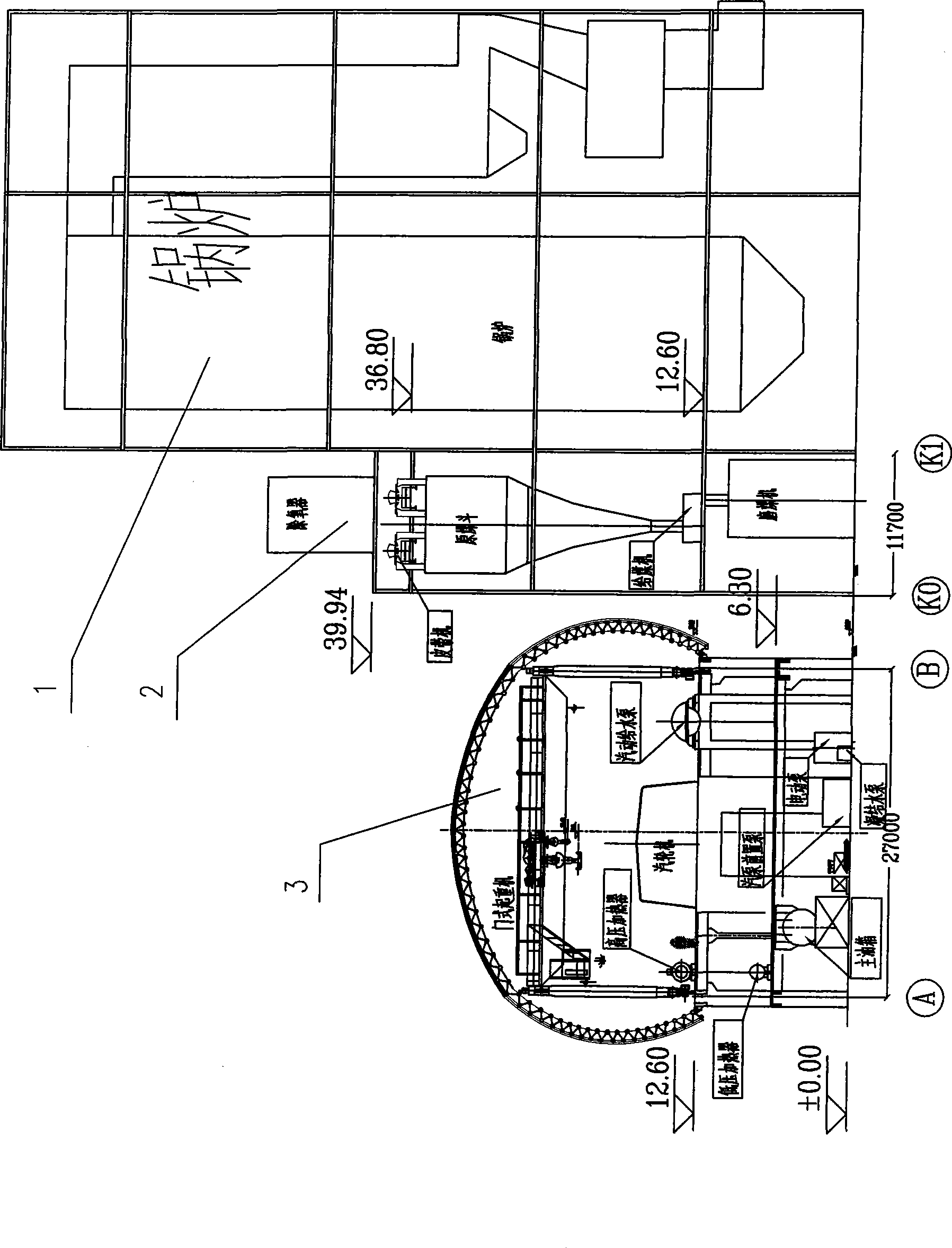

Main power zone island type arrangement of thermal power generation plant

InactiveCN101481958AReduce distanceReduce dosageIndustrial buildingsReinforced concreteTotal investment

Owner:上海电气工程设计有限公司

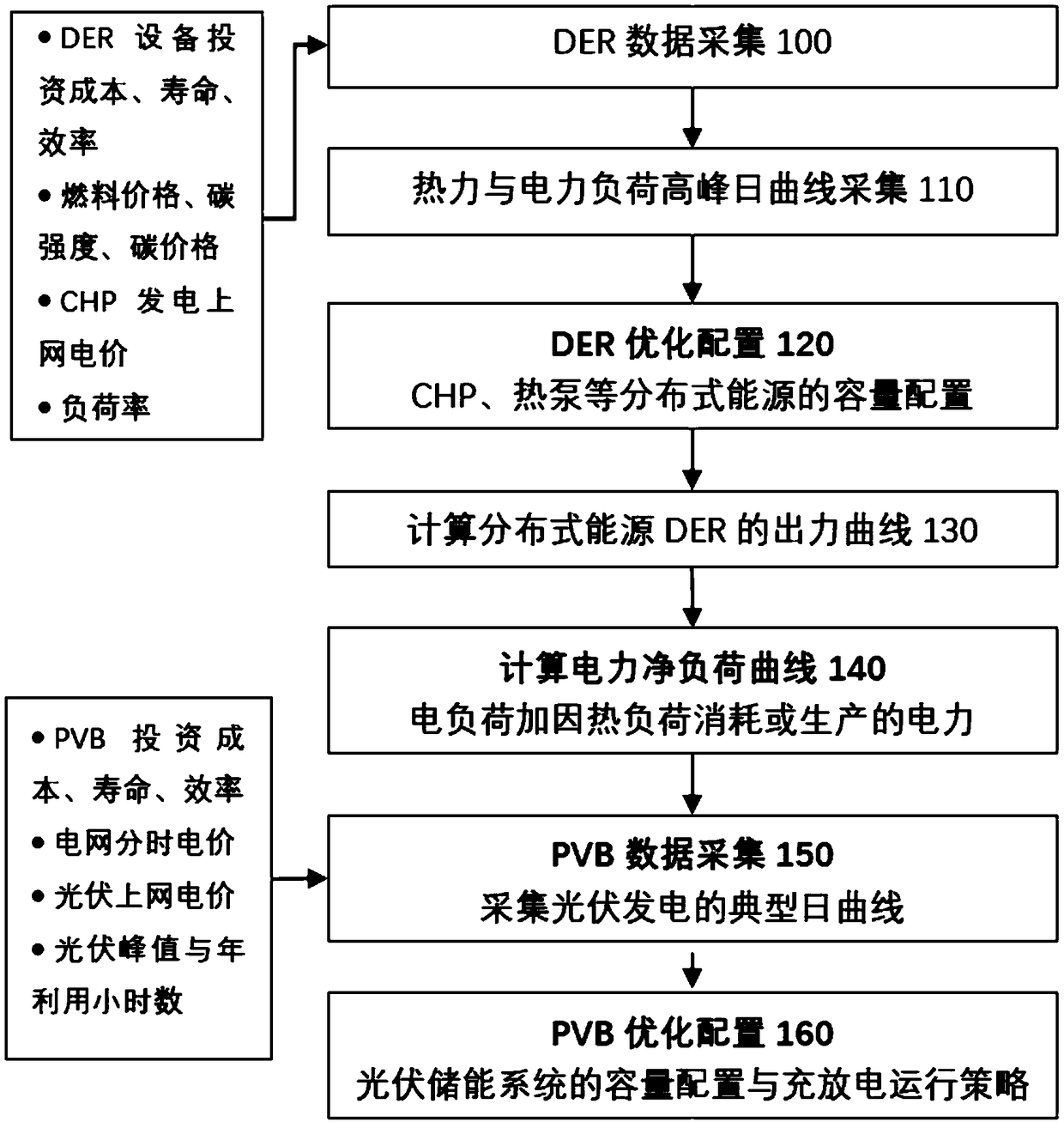

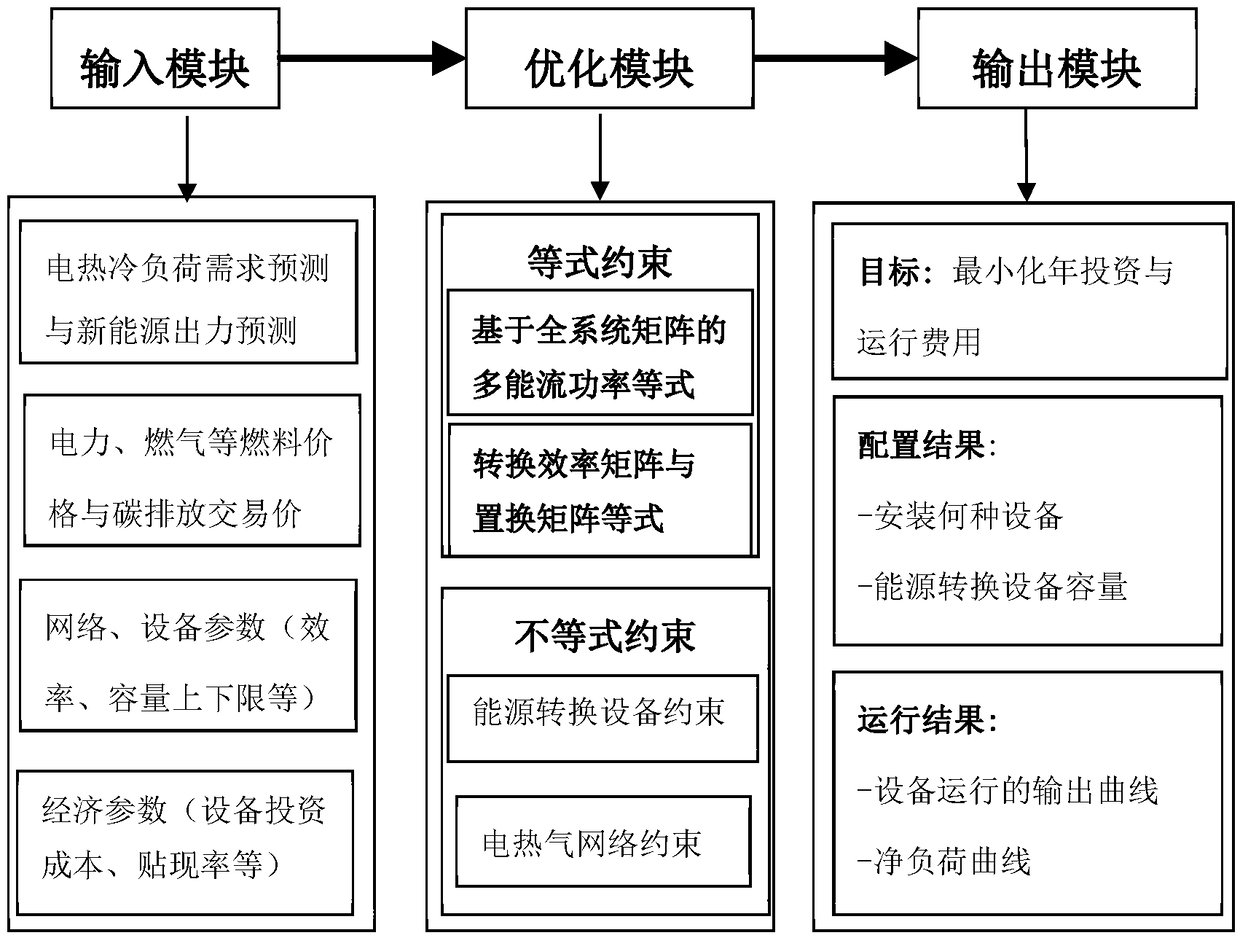

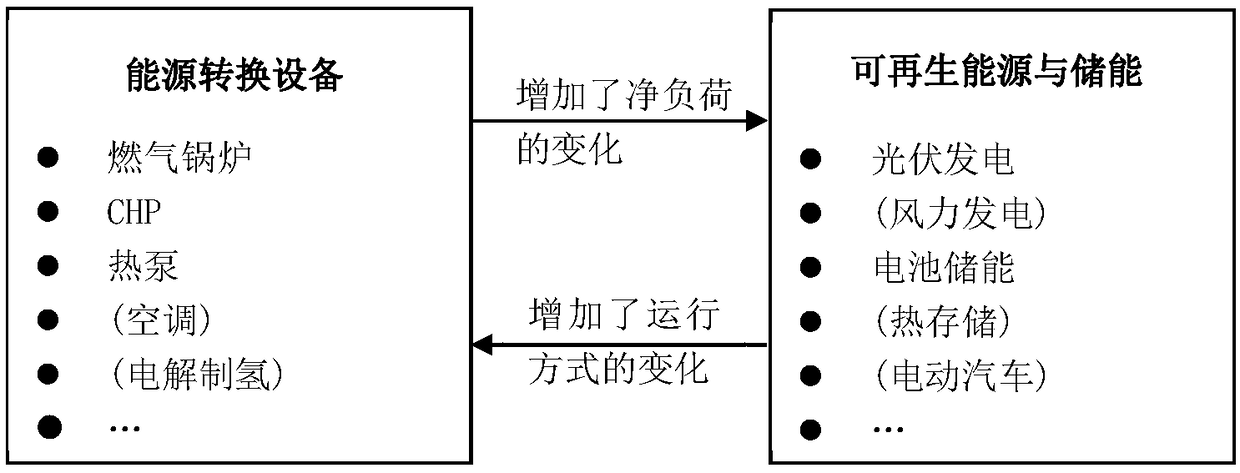

Capacity configuration and operation optimization method for combination of photovoltaic energy storage and distributed energy

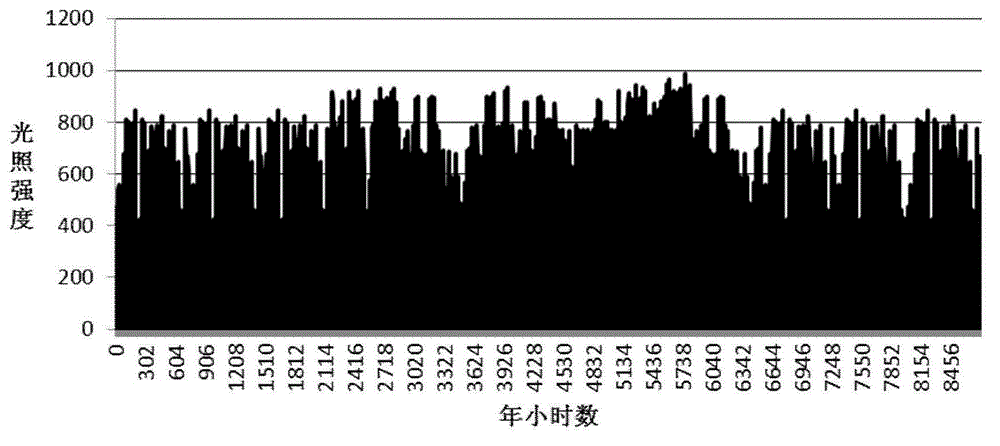

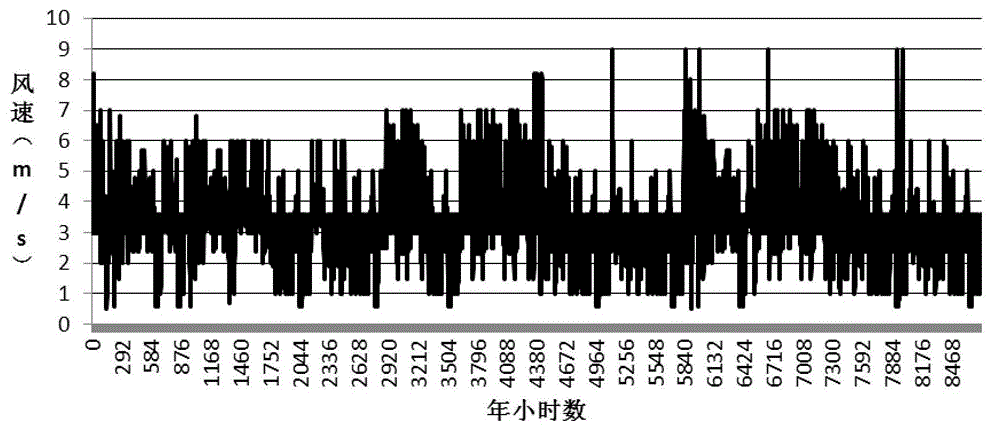

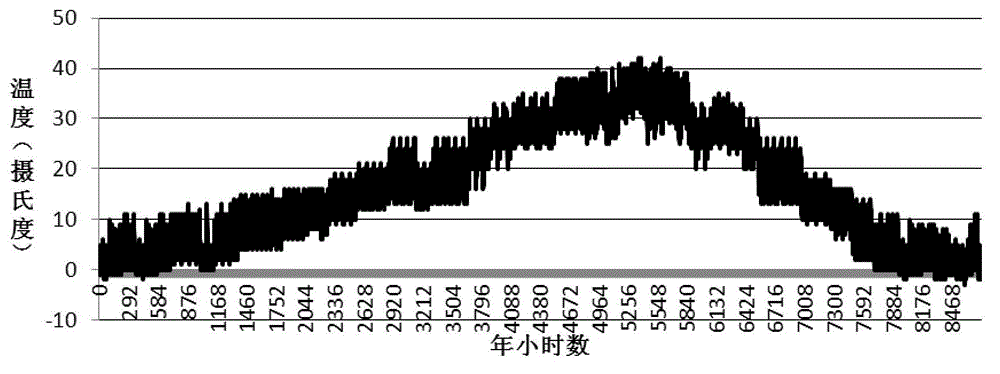

ActiveCN109510224ASingle network parallel feeding arrangementsEnergy storageNameplate capacityTotal investment

The invention relates to a capacity configuration and operation optimization method for combination of photovoltaic energy storage and distributed energy. The method comprises the following steps: (1)collecting the basic data of a distributed energy system and thermodynamic and electric load data curves accurate to hours of one year; (2) configuring the capacity of energy conversion equipment inthe distributed energy system with the optimization objective of minimizing the total annual investment and operating cost of the distributed energy system; (3) determining the operation optimizationoutput curve of the distributed energy system; (4) determining an electric net load curve; (5) collecting the basic data of a photovoltaic energy storage system; (6) according to the basic data of thephotovoltaic energy storage system and the electric net load curve, optimizing the rated power of battery energy storage, rated capacity of battery energy storage and charging / discharging strategiesin the photovoltaic energy storage system with the objective of minimizing the annual total investment and operating cost of photovoltaic energy storage system. Compared with the prior art, the methodof the invention is fast and comprehensive and the result is accurate and reliable.

Owner:SHANGHAI JIAO TONG UNIV

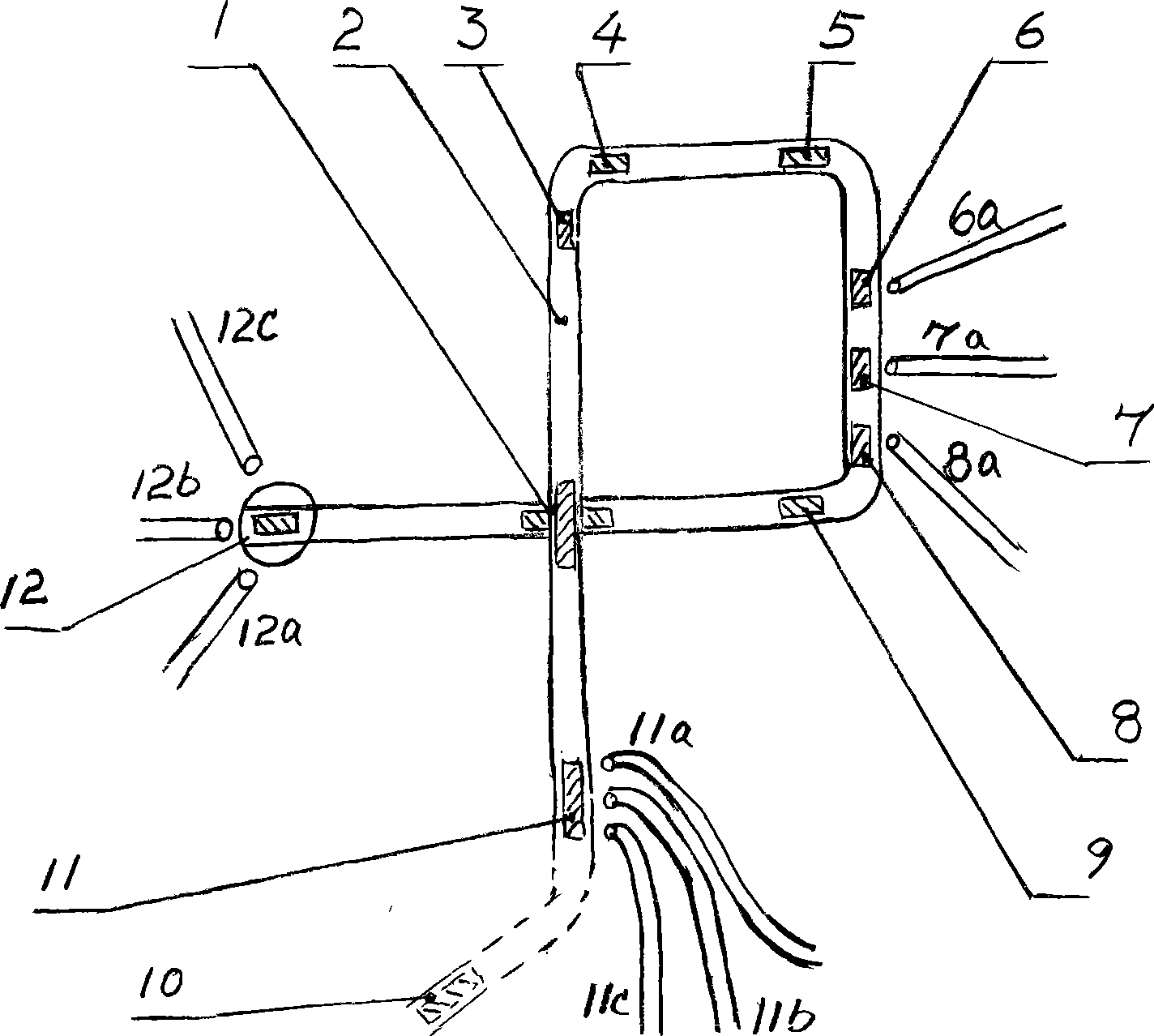

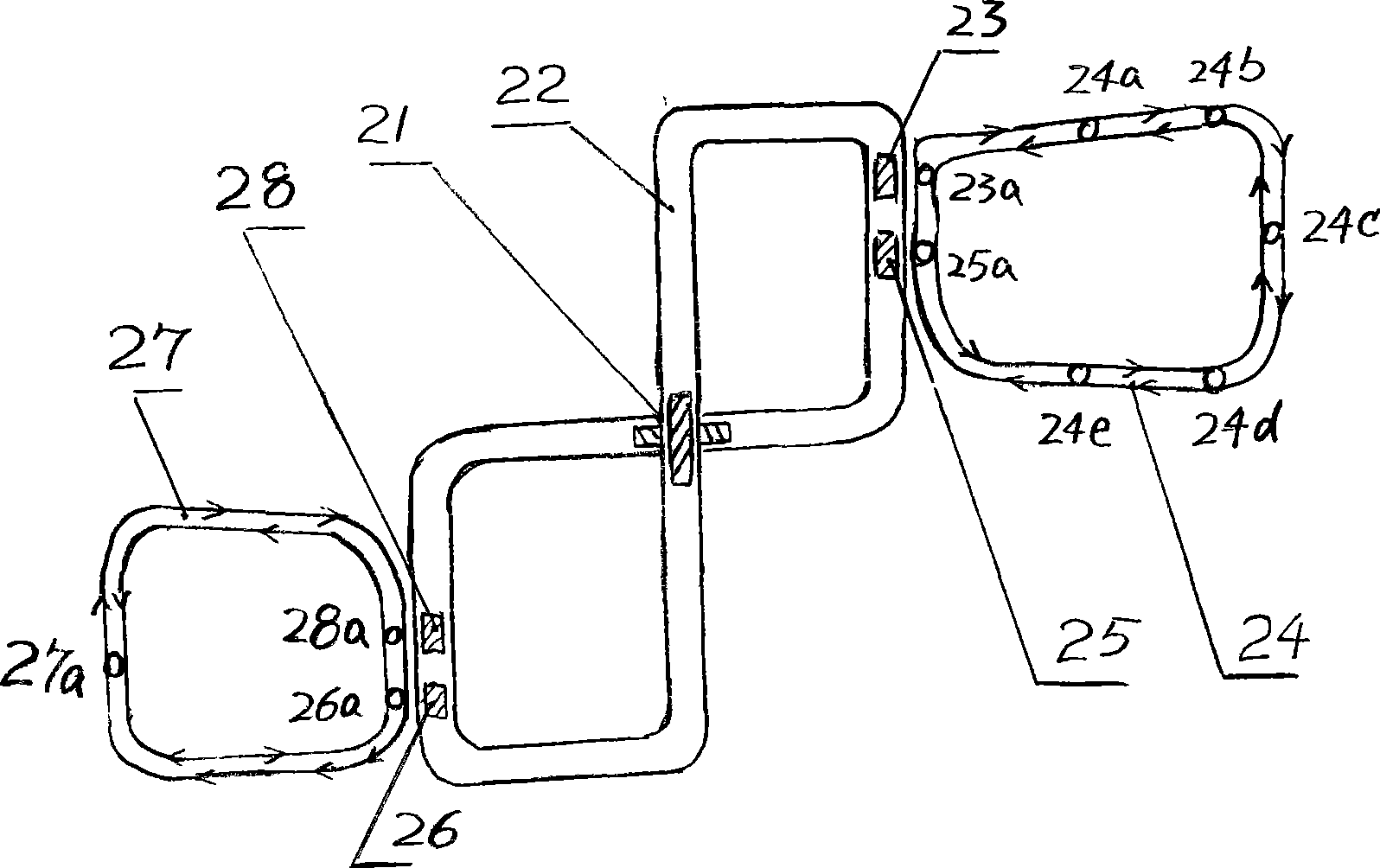

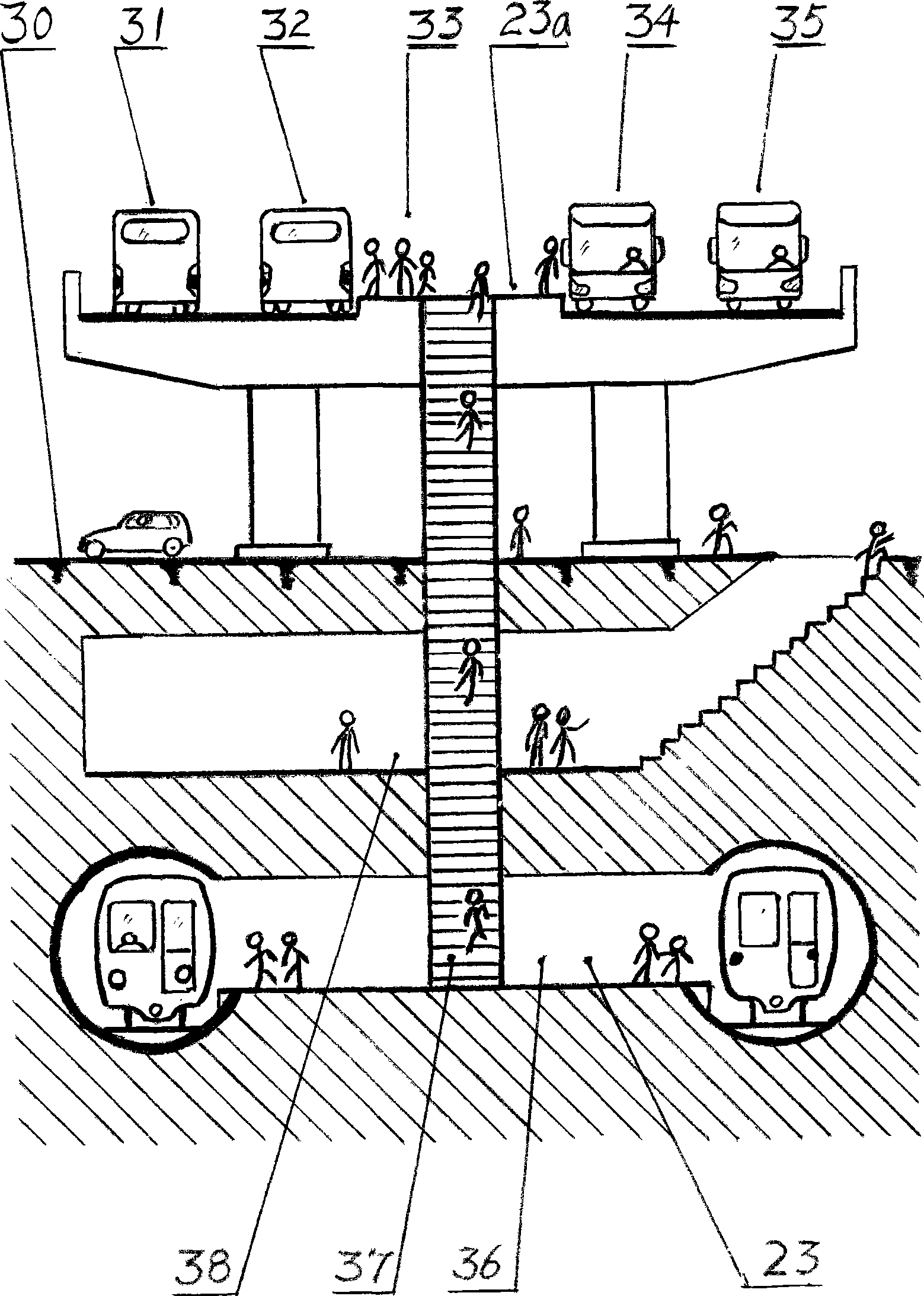

Twisting ring linear city rail traffic route

InactiveCN101435178AIncrease the lengthExpand the concatenated areaRoadwaysRailway componentsTotal investmentTraffic network

The invention relates to torsion circular urban rail transmit routes, mainly solving the problem that the urban track routes under programming and building plan have low route-net density among main cities while having extremely long route in the overall urban rail programming, and the total investment is extremely high. The technical proposal is that: an urban rail operation route with an uplink route and a downlink route is provided with at least one loop formed by the self torsion of the route, and the loop is provided with at least one transfer station of the route, the upper layer and the lower layer of which are separated and form vertical crossing, and which can provide vertical transfer for the passengers. The matching of the torsion circular subway of the main cities and the parallel high rise express way of suburban areas forms a backbone public traffic network of big cities.

Owner:田耕

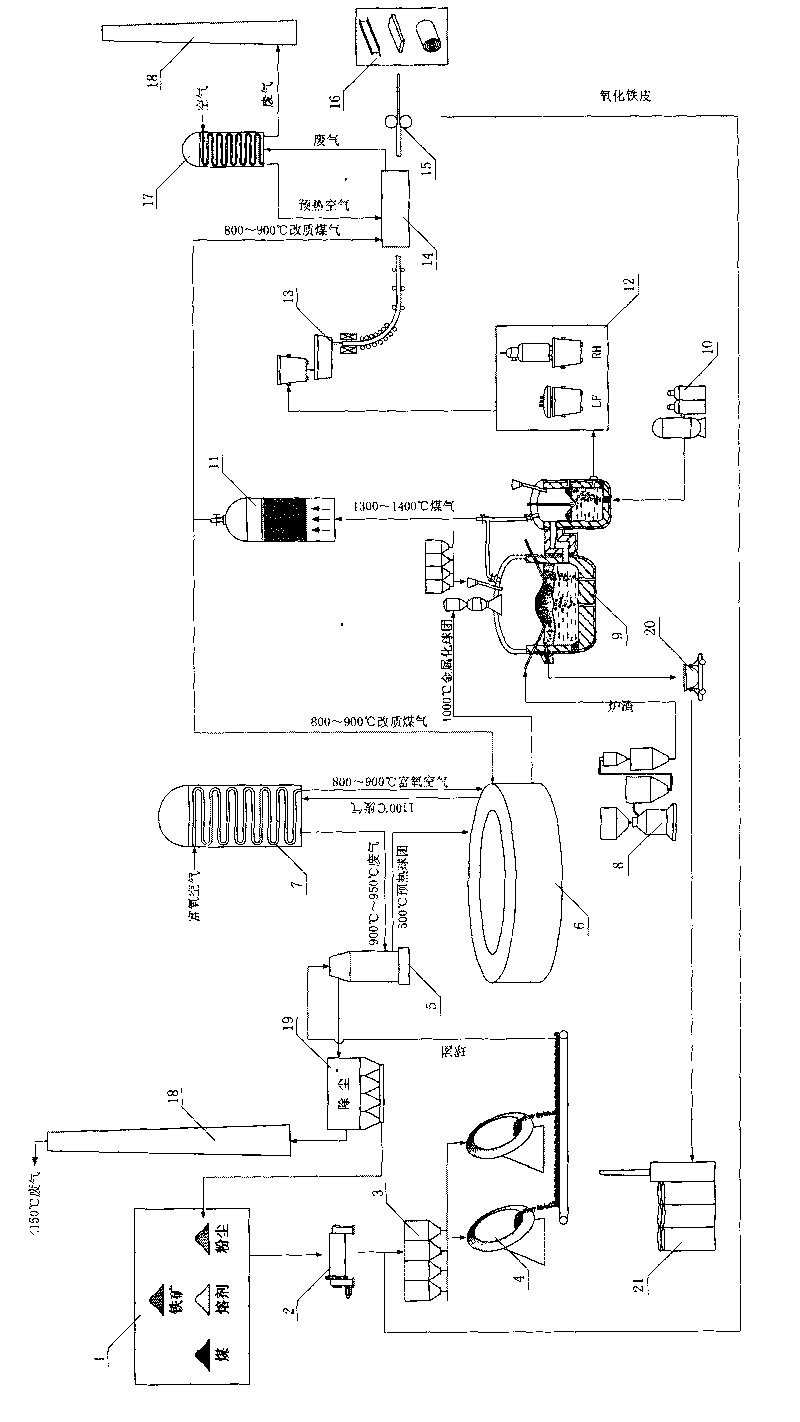

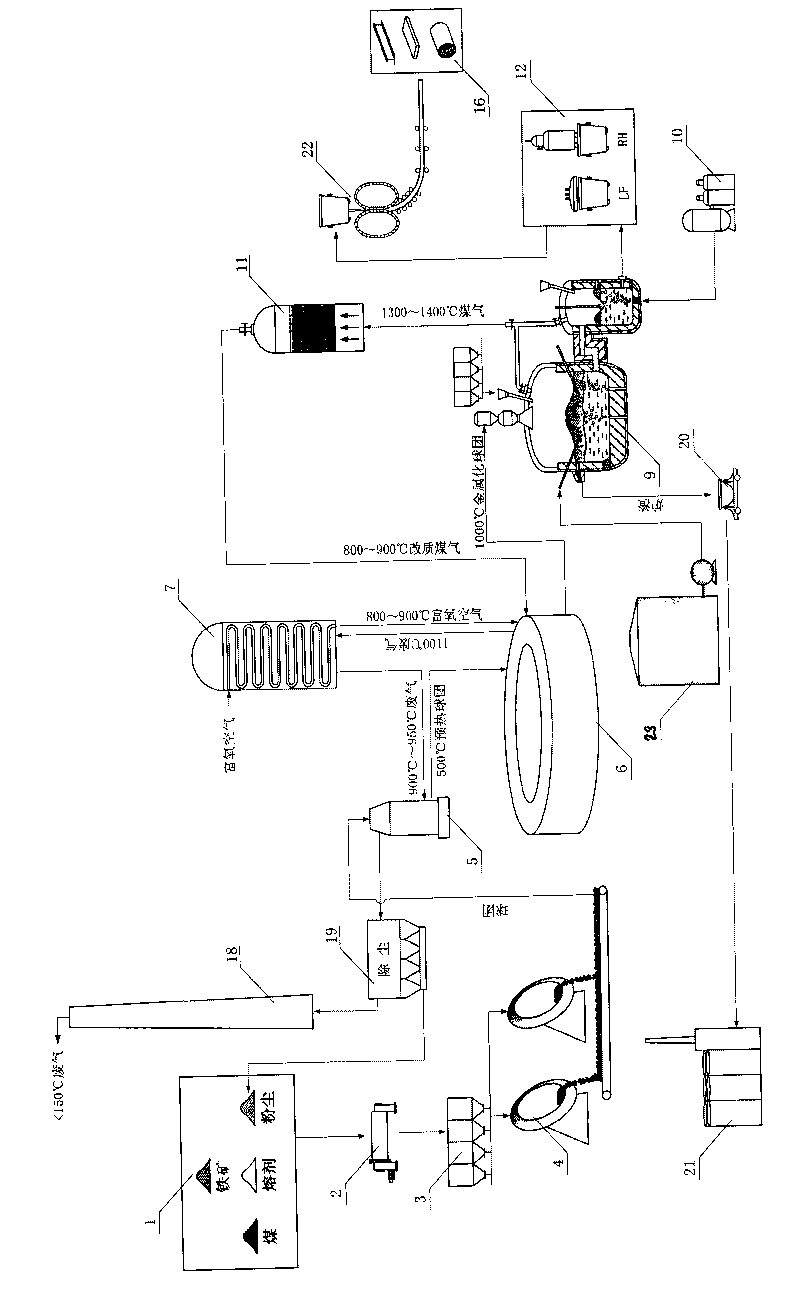

Short-flow rotary hearth furnace continuous steelmaking method comprehensively utilizing resources

InactiveCN101724727AReduce consumptionIncrease profitFurnace typesGas emission reductionSteelmakingTotal investment

The invention relates to a short-flow environment-friendly plant for steel production with a rotary hearth furnace continuous steelmaking method and equipment as the cores and with noncoking coal or natural gases as the main energy. Coal dust (natural gases, etc.) and oxygen are jetted into a continuous steelmaking furnace to smelt high temperature pre-reduced metallized pellets provided by the rotary hearth furnace to realize continuous steelmaking, and the molten steel is directly manufactured into the finished products by cast-rolling integration equipment after being refined or is manufactured into the finished products by traditional continuous casting and steel rolling. Meanwhile, the high temperature coal gas generated by a continuous steelmaking furnace is used for the pre-reduced pellets provided by the rotary hearth furnace after being reformed and the other part of high temperature reformed coal gas can be used for traditional continuous casting and steel rolling heating furnaces. The heat of the high temperature waste gas in the rotary hearth furnace is cascade-utilized to preheat the oxygen-enriched air and the pellets for the rotary hearth furnace. The high temperature waste gas in the steel rolling heating furnace is used for preheating the air for the heating furnace. The iron-containing dust is recycled and the steel slag and other dust are used for manufacturing cement. Therefore, the plant has high comprehensive utilization efficiency of energy, low energy consumption, low production cost, less emission and small total investment, and saves land.

Owner:LAIWU IRON & STEEL GRP +1

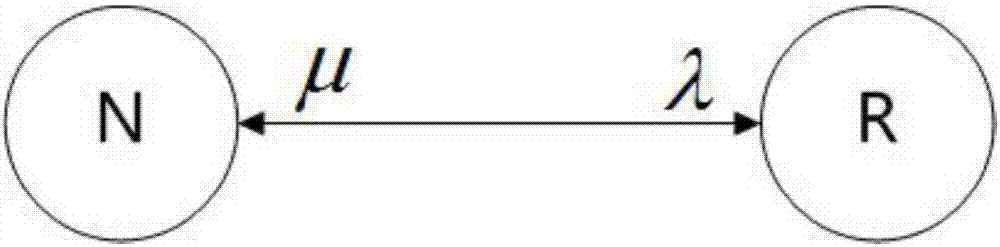

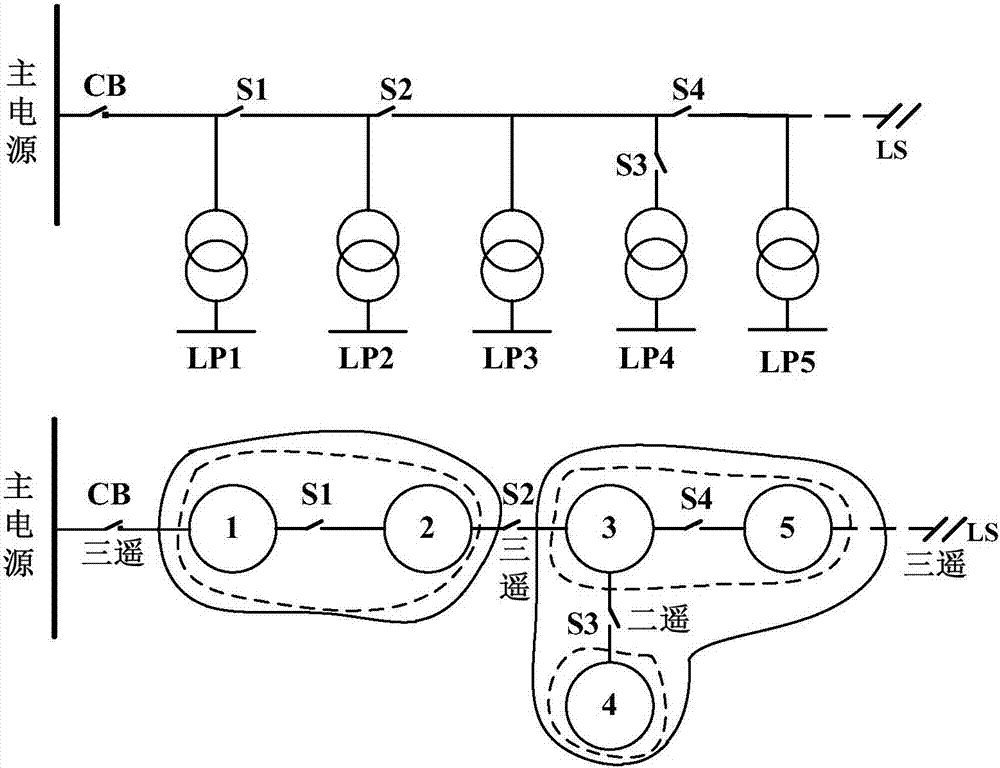

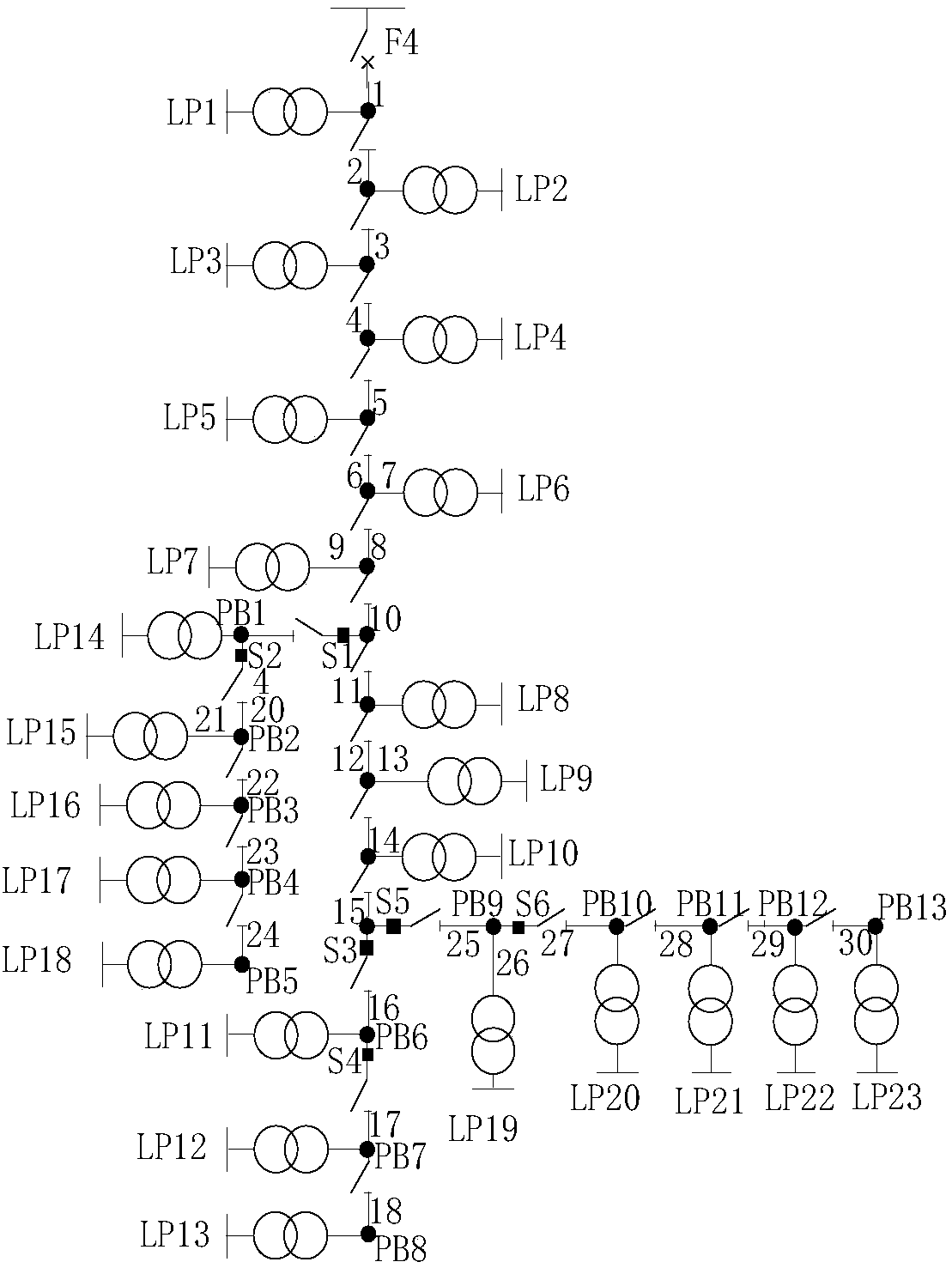

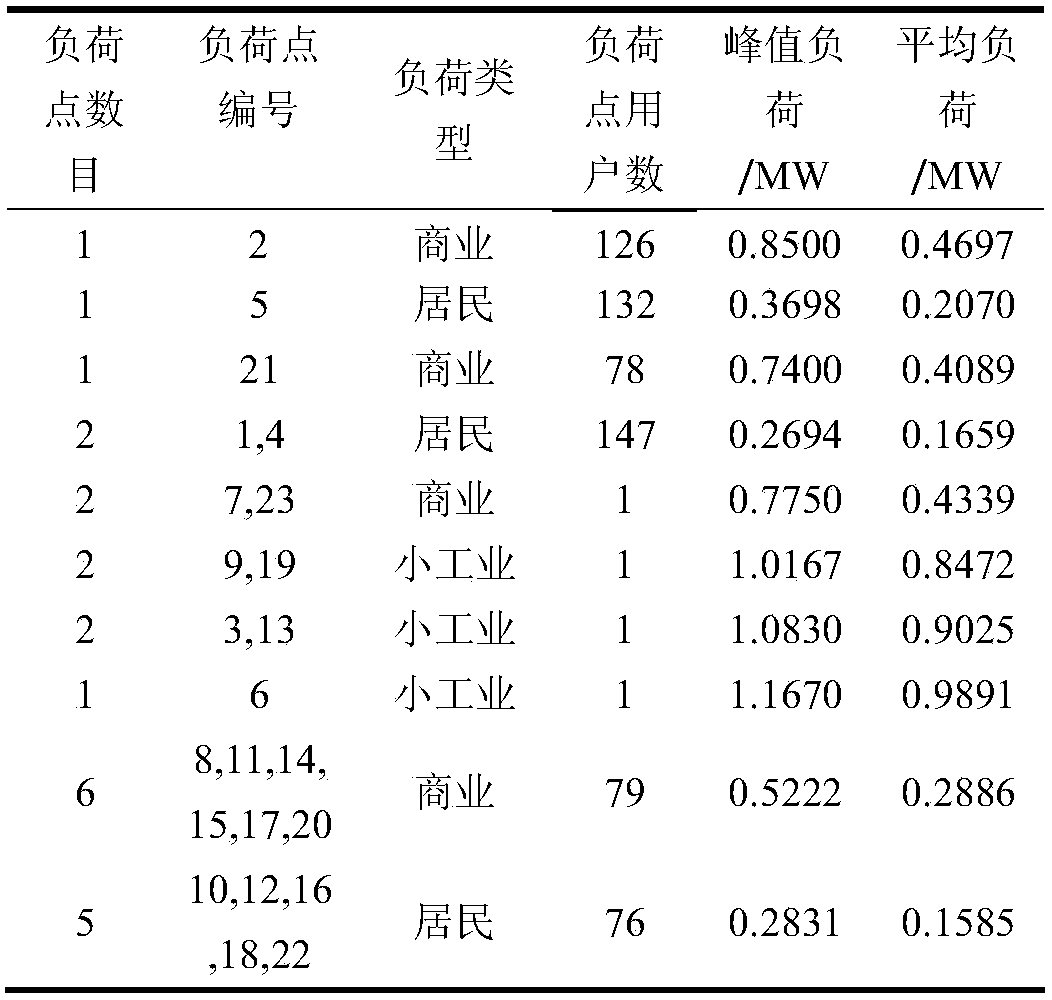

Optimal configuration method for feeder terminals based on genetic algorithm

ActiveCN107545516ANumber of solutionsTroubleshoot configuration issuesData processing applicationsEmergency protective circuit arrangementsConsequence analysisTotal investment

The invention provides an optimal configuration method for feeder terminals based on an genetic algorithm, which is characterized in that an objective function is built according to the total investment of two-remote feeder terminals and three-remote feeder terminals under constraint conditions of a power supply reliability index of a power distribution network and power failure time of a load point, reliability evaluation is performed by adopting a fault consequence analysis method, influences imposed on the reliability of a power distribution system and the power failure time of a load pointby the two-remote feeder terminals and the three-remote feeder terminals are sufficiently considered, and finally the objective function is solved in an optimized manner by adopting the genetic algorithm. The optimal configuration method can solve a configuration problem in number and position of the two-remote feeder terminals and the three-remote feeder terminals, and provides a reference for scientifically and reasonably performing power distribution automation plan design and transformation.

Owner:CHINA ELECTRIC POWER RES INST +3

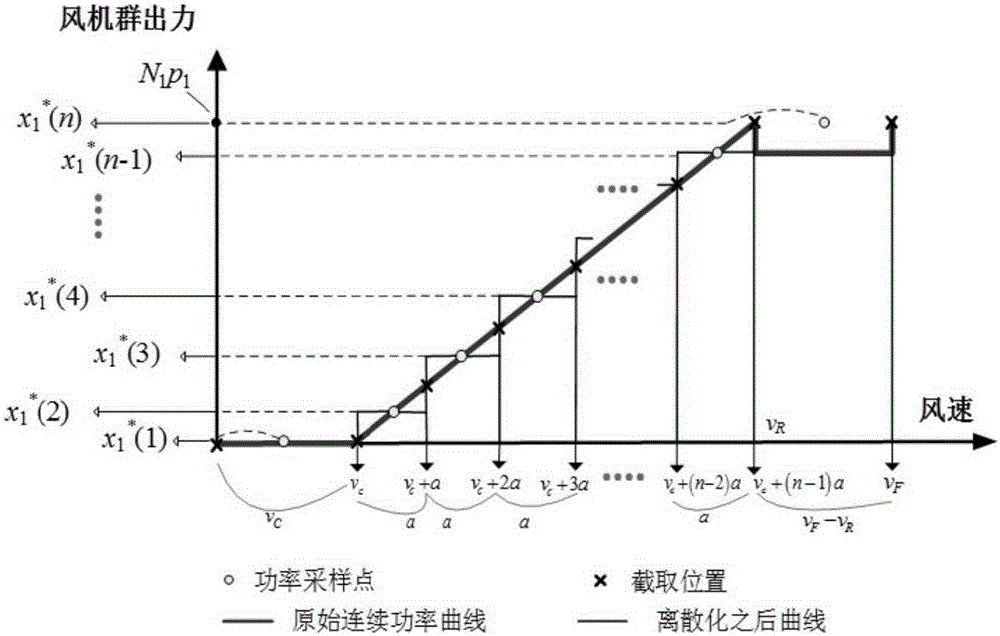

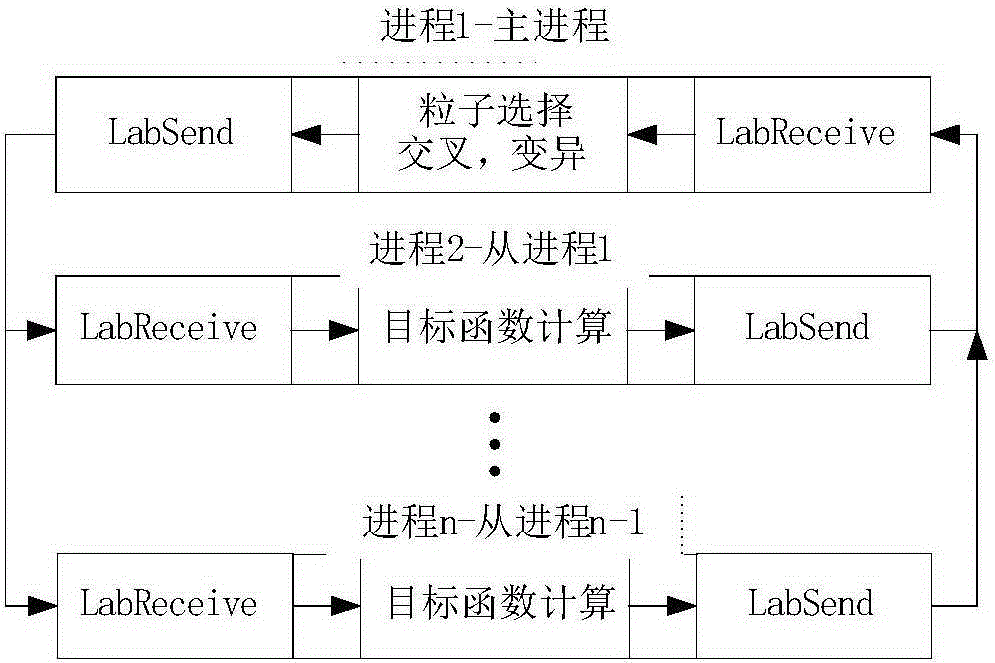

Quantitative optimal configuration method of wind-solar hybrid power system based on discrete probability model

InactiveCN105207573AOptimal solution set fastFast operationPV power plantsSingle network parallel feeding arrangementsProbit modelTotal investment

The invention discloses a quantitative optimal configuration method of a wind-solar hybrid power system based on a discrete probability model. The method is characterized in that discrete probability distribution is utilized to show random variation factors in the system, and a multi-objective optimization model is established with maximum electric energy adequacy and minimum power supply system total investment and voltage out-of-limit probability being optimization objectives; then, a probabilistic load flow algorithm is subjected to partial improvement, expectation value and increment of a discrete random variable are studied separately, and through moment calculation and semi-invariant conversion, and by applying series approximation, probability distribution of the node voltage and the system electric energy adequacy is obtained, and furthermore, objective functions can be calculated more efficiently and quickly; and finally, the method adopts a parallel-acceleration non-dominated sorting genetic algorithm having an elitist strategy to solve a Pareto optimal solution set of the optimization objectives. Compared with a conventional optimal configuration method, the method can reflect the running state of the system comprehensively, and provides more complete information for policy makers.

Owner:ZHEJIANG UNIV

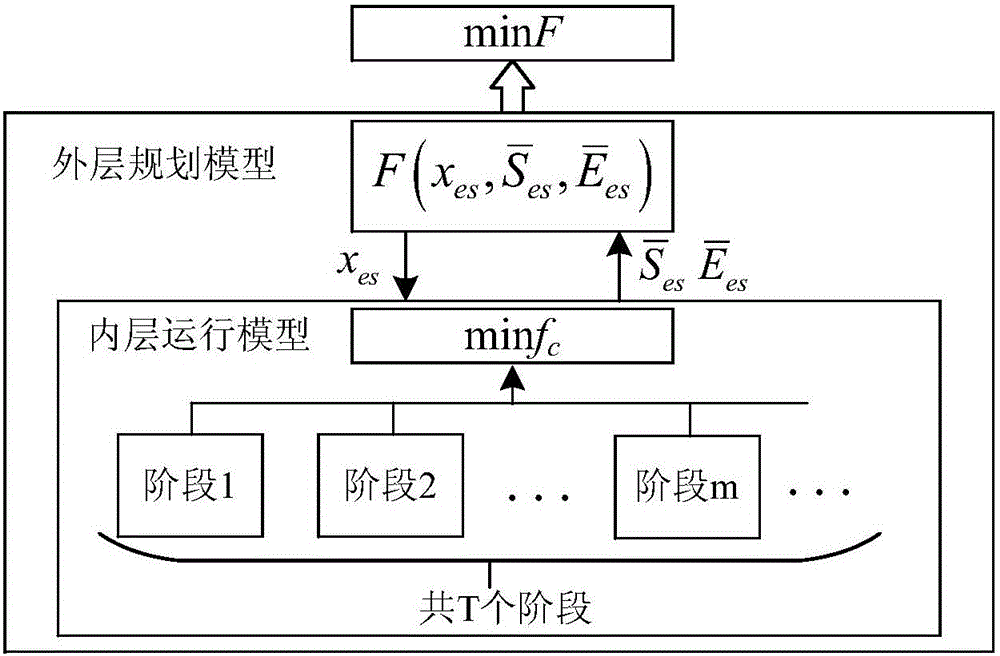

Double-layer hierarchical optimization configuration method of energy storage system in active power distribution network

ActiveCN106374515APreserve double featureImprove optimization effectAc network load balancingRunning economyTotal investment

The invention relates to a double-layer hierarchical optimization configuration method of an energy storage system in an active power distribution network. The double-layer hierarchical optimization configuration method comprises the steps of building an outer-layer planning model, wherein total investment cost is taken as a target, year is taken as minimum planning unit, and optimization objects are installation position and installation capacity of the energy storage system; and building an inner-layer running model, wherein optimal running economy is taken as a target, day / hour / minute is taken as minimum running unit, and an optimization object is a running control variable of storage energy. An optimal solution of the outer-layer planning model is figured out by mutual relation between the inner-layer running model and the outer-layer planning model, and optimization configuration of the energy storage system in the active power distribution network is further achieved. With regard to unfavorable influence of a distributed power supply on the power distribution network, two different time scale problems of running control and planning design are combined, so that the configuration of the energy storage system can be reasonably optimized, and the economy of the power distribution network is improved.

Owner:STATE GRID CORP OF CHINA +2

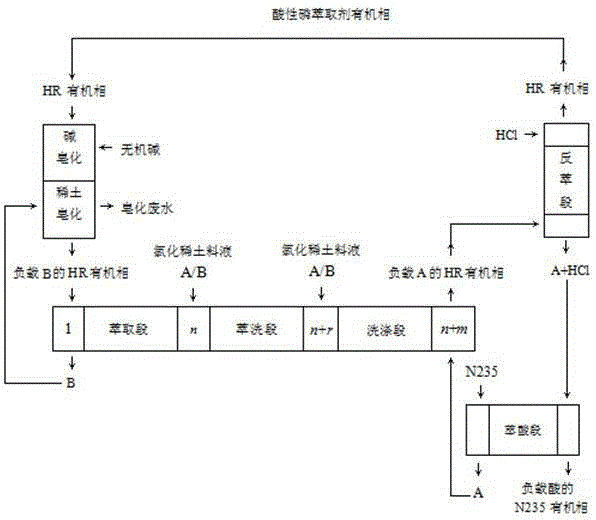

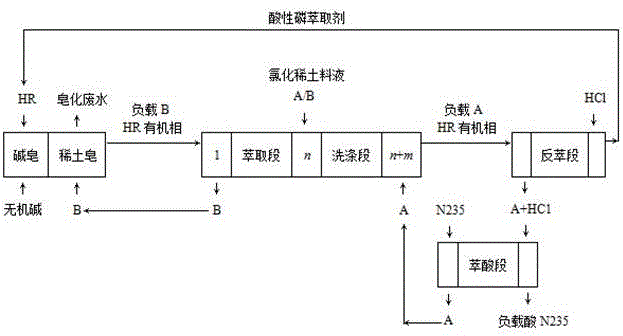

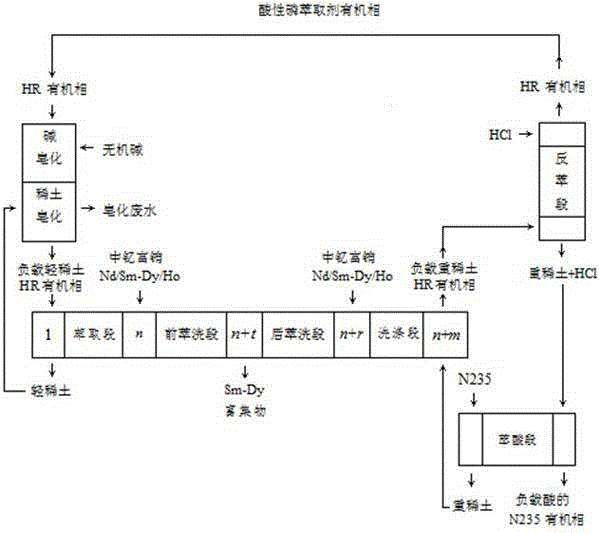

Two-feeding-opening fully-loaded rare earth fractional extraction separation process method

InactiveCN104561546AReduce acid and alkali consumptionHigh degree of greeningProcess efficiency improvementSide effectTotal investment

The invention discloses a two-feeding-opening fully-loaded rare earth fractional extraction separation process method. According to the method, P507 serves as a rare earth extracting agent; in a two-feeding-opening fractional extraction separation process, an acid extraction section which takes N235 as an acid extracting agent and takes trioctyl phosphate as an N235 organic phase demulsifying agent is arranged, and the side effect of hydrogen ions can be eliminated through the acid extracting effect of the N235, so that not only is the rare earth separation coefficient not reduced, but also the extracting amount of rare earth in a two-feeding-opening fractional extraction system is not lower than the saponification amount of the rare earth. Compared with the existing two-feeding-opening fractional extraction process, the consumption of acid and alkali in a rare earth separation process can be greatly reduced, wherein the consumption amount of an alkaline reagent is reduced by 39 to 51 percent, and the consumption amount of hydrochloric acid can be reduced by 17 to 26 percent; the waste water discharging amount in the rare earth extraction separation process is greatly reduced; the green degree of rare earth separation is greatly improved; the stage number of extracting tanks can be reduced by 32 to 38 percent; the total investment of the rare earth extraction separation process is reduced. Therefore, the separation cost is remarkably reduced.

Owner:NANCHANG HANGKONG UNIVERSITY

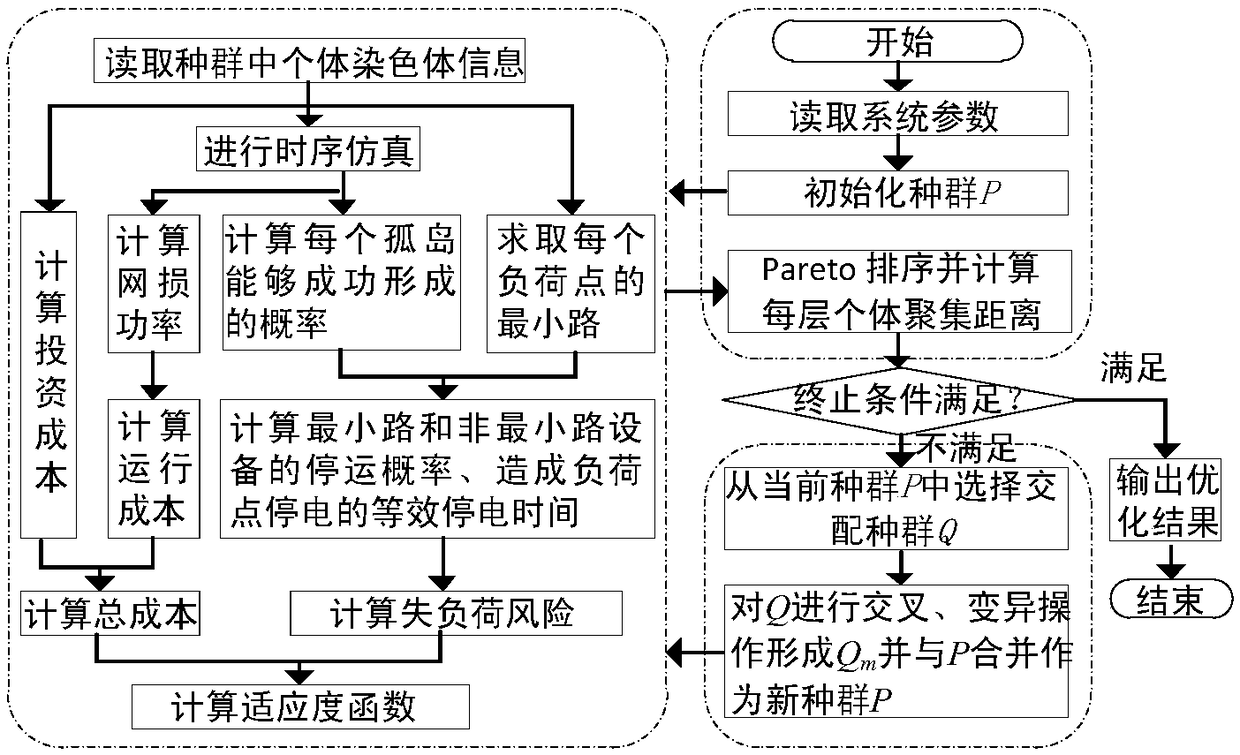

A collaborative planning method of optical/storage and planning islands for distribution networks considering the risk of loss of load

InactiveCN109149622AImprove computing efficiencyMeet the needs of reliability calculation accuracyEnergy industrySingle network parallel feeding arrangementsTotal investmentNew energy

With the implementation of national new energy policy and electric power system reform, a large number of distributed energies are connected to the distribution network in various forms. In order to ensure the reliability of power supply for power users, power grid enterprises need to consider the uncertainty of new energy sources and provide them with the necessary backup, but to some extent, this reduces the utilization rate of equipment. In order to avoid this negative effect, the distribution network should adopt active operation strategy under the condition of fault, and fully dispatch distributed energy to participate in fault recovery, in order to improve the load rate of distribution network equipment. The invention establishes a programming model which takes the total investment cost is minimum, the risk of losing load is minimum as multi-objective, voltage stability, power flow does not cross line and the like as constraint conditions, and adopts a programming model based onNSGA-II, the multi-objective evolutionary algorithm is used to solve the problem. The range of planned islands and the location and capacity of photovoltaic and energy storage batteries in the islandsare taken into account in the planning. The validity of the model and the method established by the invention is verified by simulation.

Owner:国网山西省电力公司经济技术研究院 +1

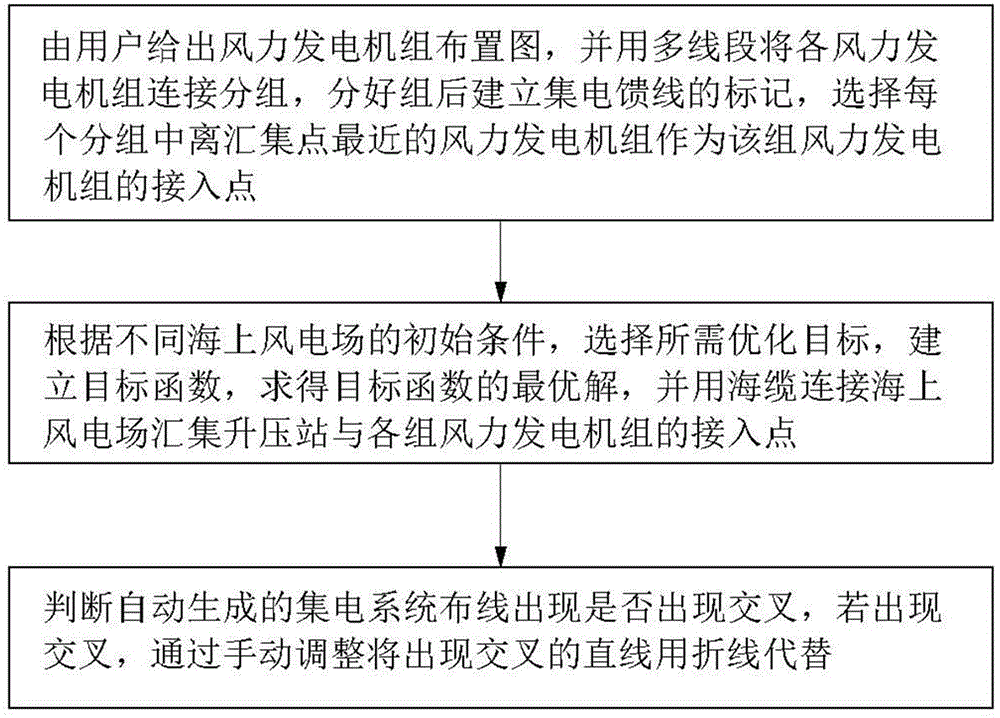

Method for selecting address of converging booster station of offshore wind plant

ActiveCN104537427AImprove controllabilityImprove engineering applicabilityForecastingTotal investmentCollection system

The invention relates to a method for selecting an address of a converging booster station of an offshore wind plant. The method comprises the steps of connecting and grouping wind generating sets by wires according to an arrangement diagram of the wind generating sets given by a user, establishing a mark of each segment of current collection feeder line, and selecting the wind generating set of each group of wind generating sets closest to a converging point as an access point of the group of wind generating sets; according to initial conditions of different offshore wind plants, selecting a target to be optimized, establishing an objective function, obtaining the optimal solution of the objective function so as to minimum the total investment of a wind plant electric system, and connecting the converging booster station of the offshore wind plant with the access point of each group of wind generating sets by a sea cable; and judging whether automatically generated current collection system wiring is crossing, if yes, adjusting by hands to replace the crossing straight lines with fold lines.

Owner:TSINGHUA UNIV +1

Technological method of full load fractional extracting and separating rare earths

InactiveCN104532022AReduce acid and alkali consumptionHigh degree of greeningProcess efficiency improvementSeparation factorWater discharge

The invention relates to a technological method of full load fractional extracting and separating rare earths. According to the technological method disclosed by the invention, P507 or P204 serves as a rare earth extractant; in a fractional extraction separation technology, N235 serves as an acid extraction agent, and a mixed alcohol serves as an acid extraction segment of an N235 organic phase regulator; an easily-extracted rare earth component solution with a pH value to be 1-4 serves as a washing solution; by virtue of the acid extraction action of the N235 in the acid extraction segment, the side effects of hydrogen ion washing are eliminated, so that the separation factor of the rare earths is ensured not to be lowered, and the extraction quantity of the extractant in a fractional extraction system is also ensured. Compared with the traditional fractional extraction separation technology, the acid and alkali consumption in the process of the rare earth separation technology can be greatly lowered, wherein the consumption of a basic reagent is lowered by 34-62 percent, and the consumption of hydrochloride is lowered by 16-29 percent; the waste water discharge in the process of the rare earth extraction separation technology is greatly reduced, the greening degree of rare earth separation is greatly increased; the grade amount of extraction tank is reduced by 22-46 percent, the total investment of the rare earth extraction separation technology is lowered; the separation cost is greatly lowered.

Owner:NANCHANG HANGKONG UNIVERSITY

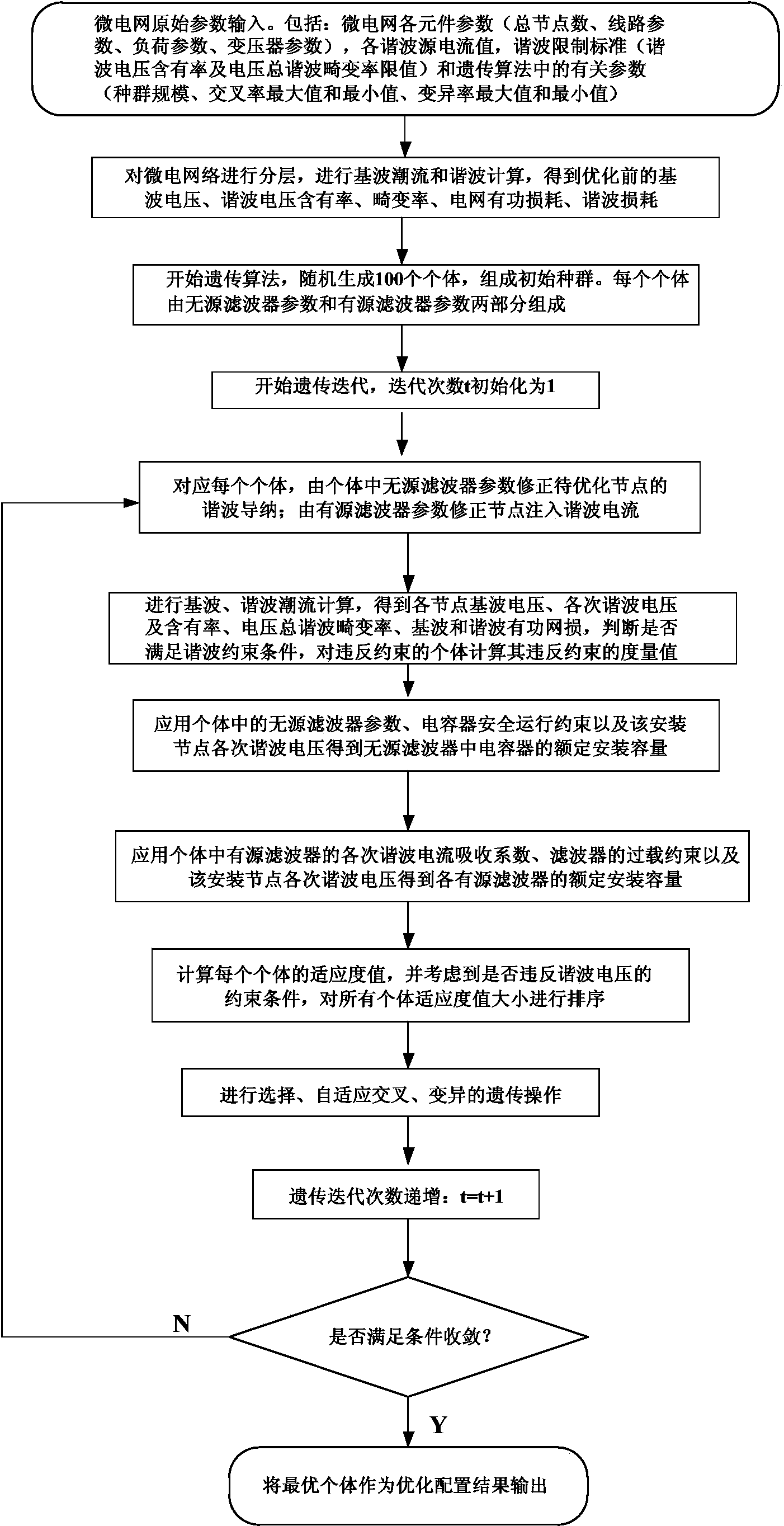

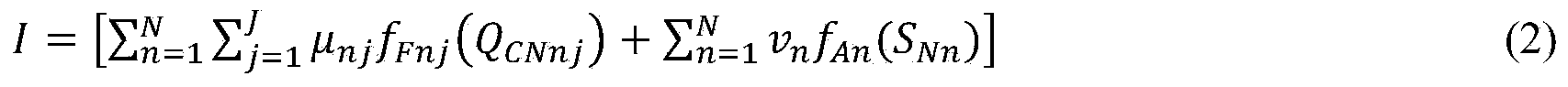

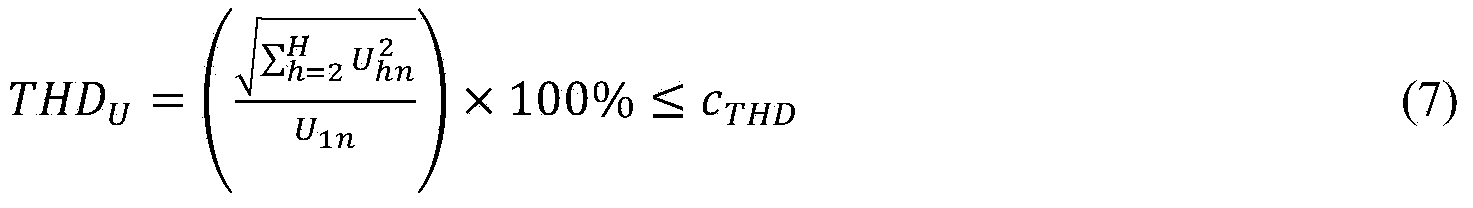

Optimizing configuration method for micro-grid filters

ActiveCN103972892AThe total investment cost is smallHarmonic suppressionHarmonic reduction arrangementAc network to reduce harmonics/ripplesTotal investmentControl theory

The invention provides an optimizing configuration method for micro-grid filters. The method comprises the following steps of setting up optimizing configuration objective functions of the micro-grid filters, determining optimizing configuration constraint conditions of the micro-grid filters, and adopting a self-adaptation genetic algorithm and a differential evolution algorithm to adapt to carry out optimizing configuration on the micro-grid filters. The method can be used for optimizing the installation position, the installation type, the installation class number and the parameter of the passive and active filters in a whole micro-grid operating with harmonic wave source loads; on the premise that harmonic wave currents meet the constraint conditions and the filters operate safely, the total investment cost of the filters can be reduced, and the harmonic waves can be effectively restrained.

Owner:STATE GRID CORP OF CHINA +3

Nd/Sm-Dy/Ho group separation process method of medium-yttrium europium-enriched ore

InactiveCN104561613AIncrease throughputHigh degree of greeningProcess efficiency improvementTotal investmentRare earth

The invention discloses an Nd / Sm-Dy / Ho group separation process method of a medium-yttrium europium-enriched ore. P507 is used as a rare earth extracting agent, medium-yttrium europium-enriched ore is used as a raw material, a third outlet is formed in an extraction washing section of a two-inlet-three-outlet fractional extraction system and an acid extraction section with N235 as an acid extracting agent and TBP as a demulsifier is arranged between a washing section and a reverse extraction section; the side effects of hydrogen ions is eliminated by virtue of the acid extraction effect of N235. Compared with the existing Nd / Sm-Dy / Ho group separation process of the medium-yttrium europium-enriched ore, the acid and base consumptions during the rare earth separation process can be significantly reduced, wherein the consumption of a basic reagent is decreased by 58.2%-64.5% and the consumption of hydrochloric acid is decreased by 22.7%-34.2%; the wastewater discharge amount during the extraction and separation of rare earth is significantly reduced and the environmental friendliness degree for separating rare earth is significantly increased; the number of stages of an extraction tank can be reduced by 12.7%-22.2% and the total investment of rare earth extraction and separation processes is decreased; and the quality of heavy rare earth products is improved.

Owner:NANCHANG HANGKONG UNIVERSITY

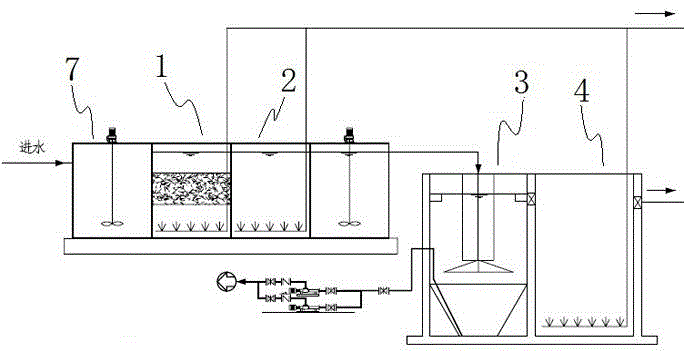

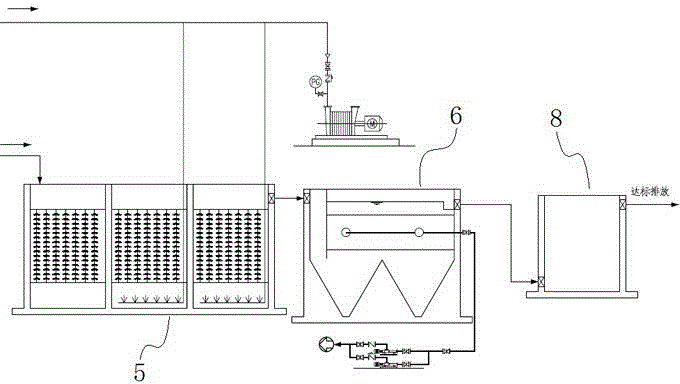

Biochemical treatment process for high salinity wastewater

ActiveCN104150608AQuantity maximizationEfficient degradationBiological water/sewage treatmentStart timeTotal investment

The invention discloses a biochemical treatment process for high salinity wastewater. In order to solve the problem of treating high salinity wastewater with relatively low operating cost and total investment, the biochemical treatment process for high salinity wastewater comprises the following steps: 1) obtaining halotolerant bacteria and attaching the halotolerant bacteria on filler in a reactor; 2) preparing simulated wastewater; 3) acclimatizing the halotolerant bacteria, wherein the simulated wastewater is mixed with the high salinity wastewater in different proportions to prepare various acclimatizing wastewater, and in the starting process of the reactor, the halotolerant bacteria are acclimatized by virtue of the various acclimatizing wastewater according to a sequence of the content of the simulated wastewater in the acclimatizing wastewater from high to low, so that the starting time of the reactor is shortened; 4) directly treating the high salinity wastewater by virtue of the acclimatized halotolerant bacteria. By virtue of acclimation and culture combined with a biological multiplying technology, the halotolerant bacteria are maximized in quantity, specialized in flora and efficient in degrading capability, so that organic pollutants in water are effectively degraded.

Owner:深圳永清水务有限责任公司

Methods and vehicles utilizing financial instruments for funding retained obligations

A method and vehicle for finding retained obligations in accordance with the principles of the present invention comprises pooling of investments from investors in an investment vehicle. No single investor's assets will be traced in any manner, including for purposes of measuring or allocating gain or loss. The investors share any gain or loss in accordance with their interest in the investment vehicle. The investment vehicle invests its assets with a preference for financial instruments of one or more interest holders of the investors; provided, that there is no requirement that the investment vehicle must buy a specific amount of any interest holders' financial instruments, or buy any interest holders' financial instruments at any specific time and the investment vehicle will not guarantee that a specific amount of contribution in the investment vehicle will equal a specific investment in financial instruments of an interest holder. The holding of financial instruments of any single interest holder does not make up a significant portion of the total investment of the investment vehicle. In one preferred embodiment, the method and vehicle for funding retained obligations in accordance with the present invention is directed to an investment vehicle for captive insurance companies, where the investment vehicle preferably invests in the financial instruments of a policyholder or the ultimate parent and / or subsidiaries and / or affiliates of a captive insurance company.

Owner:DEARDEN KAREY B

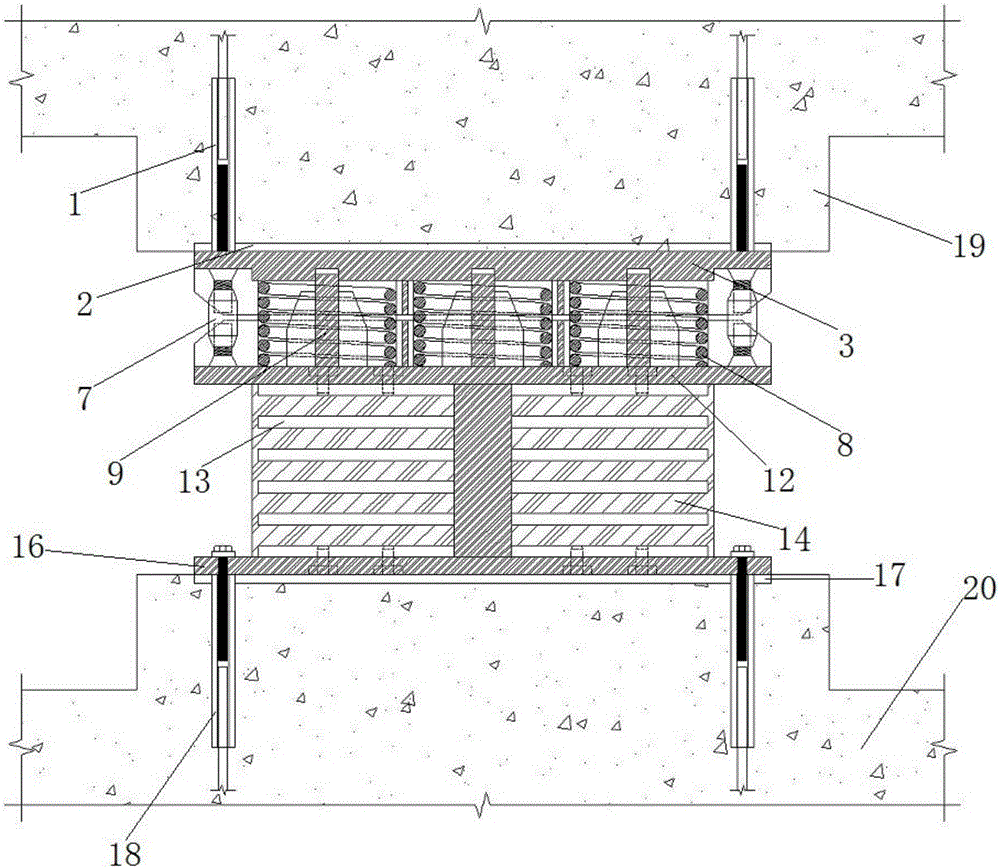

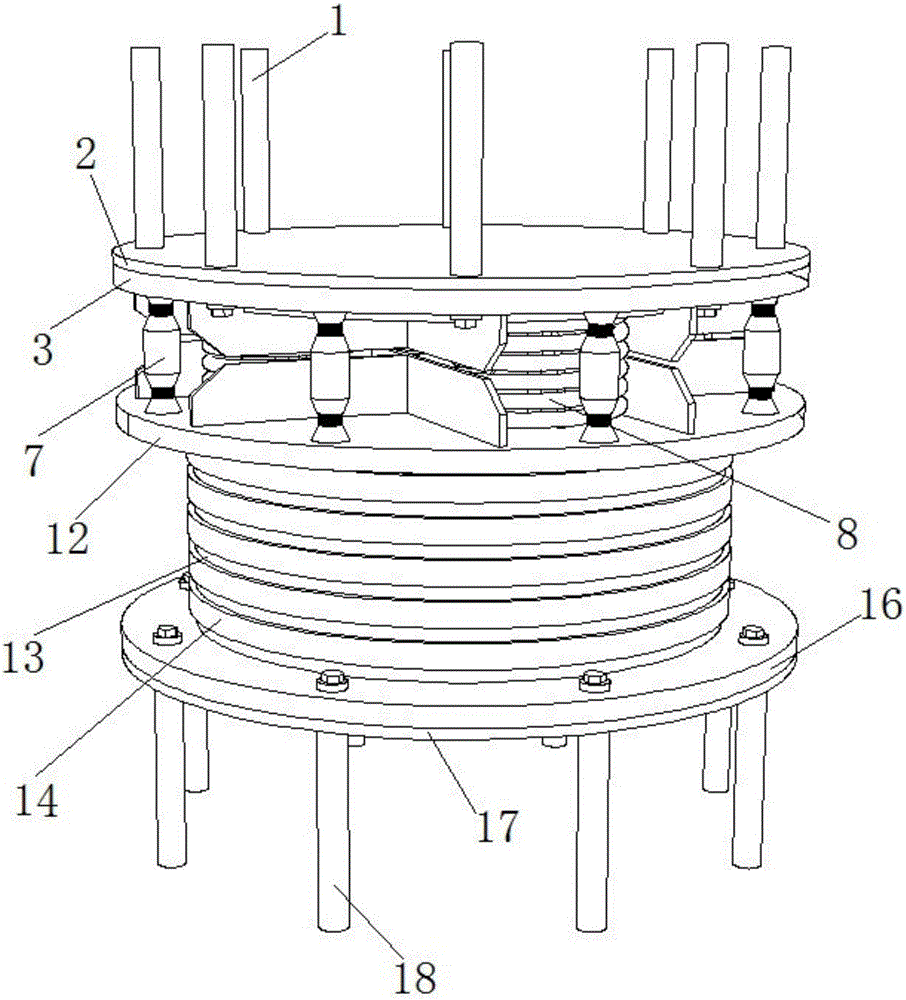

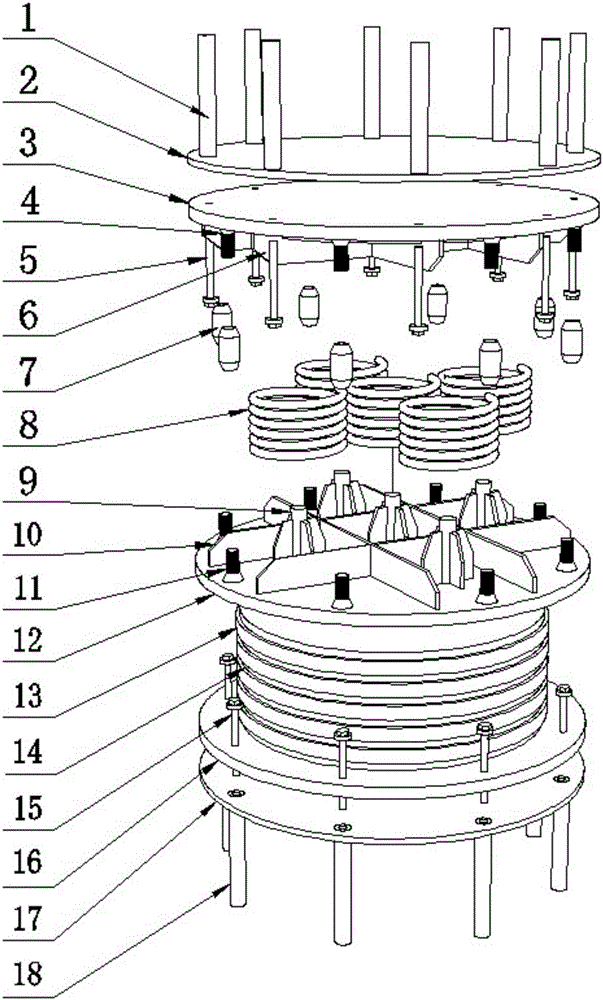

Device for isolating horizontal earthquake and vertical vibration for building

The invention discloses a device for isolating horizontal earthquake and vertical vibration for a building. The device comprises a vibration isolation device and an earthquake isolation device, wherein the vibration isolation device comprises an upper roof, a vertical spring array, a horizontal limiting bolt screw and a middle plate; the upper roof is connected with an upper buttress pre-buried positioning plate through a connection component; the vertical spring array is composed of multiple springs and arranged between the upper roof and the middle plate; the springs sleeve the outer side of the horizontal limiting bolt screw; the horizontal limiting bolt screw is fixed on the upper surface of the middle plate; the lower surface of the middle plate is fixedly connected with the earthquake isolation device; the earthquake isolation device comprises multiple layers of thin-layer rubber, multiple layers of thin-layer steel plates and a lower bottom plate; the thin-layer rubber layers are overlapped, and the thin-layer steel plates are clamped between every two adjacent rubber layers; and the lower bottom plate is connected with the lower buttress pre-buried positioning plate through a connection device. According to the invention, the functions of horizontal earthquake isolation and vertical vibration isolation can be realized at the same time; and moreover, the cost of the device is relatively low, and total investment in vibration isolation and earthquake isolation can be greatly reduced.

Owner:BEIJING INST OF ARCHITECTURAL DESIGN

Erigeron breviscapus planting and field managing method

InactiveCN103988706AGuaranteed small investmentSolve labor difficultiesHorticultureDiseaseTotal investment

An erigeron breviscapus planting and field managing method belongs to a medicinal plant cultivating technique. By the erigeron breviscapus planting and field managing method, the whole planting process of erigeron breviscapus can be managed and controlled through subtle changes of the procedures such as land selecting, ploughing, ditching, film covering, seed dressing, sowing, fertilizing, weed removing, watering, and disease preventing. Thus, the most serious problems in an existing erigeron breviscapus planting process are solved, the emergence rate is greatly improved, and the mortality is reduced. Physical and manual weed removal is utilized in the whole planting process, so that the weed removal cost is greatly reduced, and the difficulty with labor using is solved. The most serious problem of root rot, the most headache, is fundamentally solved. Small investment, large output and high yield of farmers are guaranteed. Calculated by per acre, the total investment is 3000 yuan, the output generally reaches 3000-4500kg; if the price is 3 yuan per kilogram, the gain is 9000-135000 yuan, and the net income is 6000-9000 yuan.

Owner:云南绿高生物科技有限公司

Integrated water purification and supply method and system

ActiveCN102616954AReduce sedimentationReduce flocculationSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisTreatment effectDisinfectant

The invention discloses an integrated water purification and supply method, which comprises the following processing steps of: (1) extracting raw water and injecting it into a membrane filtration device for treatment; (2) injecting the effluent water treated by the membrane filtration device into a water storage tank through a water pump; (3) adding a disinfectant into the water storage tank for disinfection treatment; and (4) outputting the disinfected water in the water storage tank directly for water supply. The invention also discloses a corresponding integrated water purification and supply system. The system of the invention maximumly optimizes the system configuration, and substantially saves the total investment and operating cost while ensuring the treatment effect, thus improving popularization and application in the water treatment industry. With two functions of water purification and water supply, the system provided in the invention is a feed water treatment systems and apparatus characterized by effluent water quality consistent with national standards, simple operation, convenient operation management, small floor space, low construction cost, and low running cost.

Owner:GUANGZHOU MUNICIPAL ENG DESIGN & RES INST CO LTD

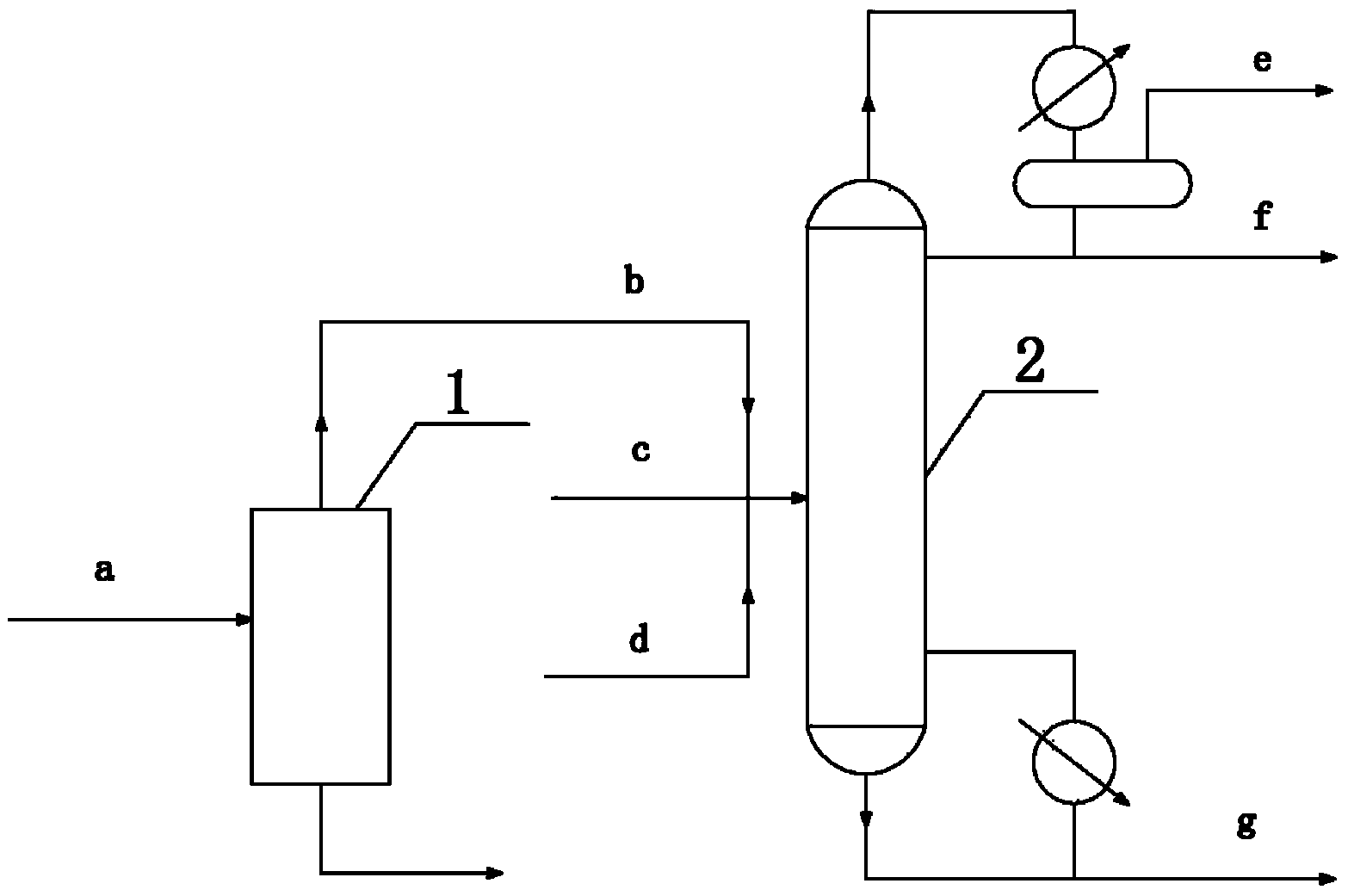

Equipment and method for preparing chlorosilane from silane through reverse disproportionation

ActiveCN103708471AReduce riskIncrease profitChemical industryHalogenated silanesTotal investmentSilanes

The invention relates to equipment and a method for preparing chlorosilane from silane through reverse disproportionation. the method comprises the following steps of introducing the tail gas of a polycrystalline silicon reduction furnace, trichlorosilane (or dichlorosilane) and silicon tetrachloride to the reverse disproportionation reaction section for a reverse disproportionation reaction in the presence of a catalyst at the reaction temeperature of 30-80 DEG C and reaction pressure of 0.1-5MPa in a feeding mole ratio of silicon tetrachloride to trichlorosilane (or dichlorosilane) to the feed silane is (3-1000): (0.1-5): 1, so as to generate dichlorosilane; carrying out reverse disproportionation reaction on the generated dichlorosilane and excessive silicon tetrachloride to generate trichlorosilane; discharging the trichlorosilane and hydrogen from the top of the tower and separating in a tower top condenser; and discharging the excessive silicon tetrachloride from the bottom of a rectifying tower. According to the invention, the non-decomposed silane is synthesized into the trichlorosilane through the reverse disproportionation process without a silane storage tank. As a result, the production danger of preparing polycrystalline silicon by the silane method is reduced, and the utilization rate of the raw materials is increased and the total investment on the process is reduced.

Owner:TIANJIN UNIV

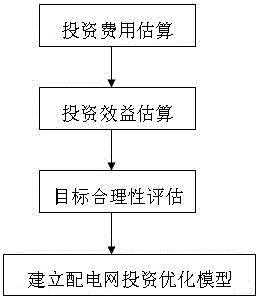

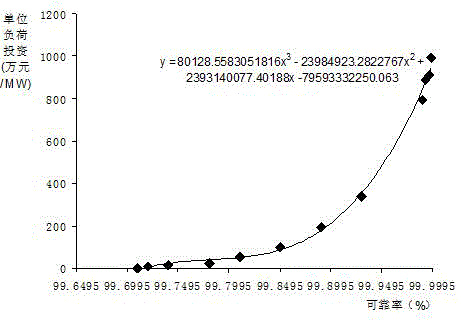

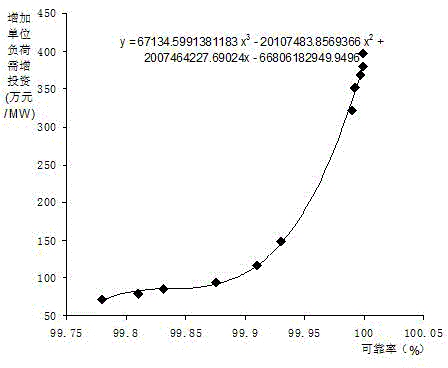

Reliability and economy-coordinated optimization method of power distribution network planning and investment

ActiveCN104680253ASolve planning problemsImprove capital operation efficiencyForecastingSystems intergating technologiesUnit loadTotal investment

The invention discloses a reliability and economy-coordinated optimization method of power distribution network planning and investment. The method firstly determines unit load reliability improving costs and unit load increasing costs, then determines investment benefits of corresponding sub-regions, and finally establishes a power distribution network investment optimization distribution model with the goal of maximizing the investment benefits. The method comprises the following steps: (1) estimation of investment costs: estimating a reliability improving investment cost and a unit load increasing cost and an overall investment cost; (2) estimation of investment benefits: proposing the concept of a ratio of output value to unit electric energy consumption, evaluating the economic benefits generated by unit electrical energy in this region; (3) estimation of target reasonableness: determining the reasonableness of annual target power supply reliability setting according to the relationship between the total investment cost and the budget; (4) establishment of a reliability and economy-coordinated investment optimization model: taking different types of power supply loads in all regions as optimization variables, taking the maximum investment benefits of the whole region as the optimization target, and taking the investment budget as the constraint.

Owner:STATE GRID CORP OF CHINA +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com