Technological method of full load fractional extracting and separating rare earths

A process method and rare earth technology, which are applied in the fields of fractional extraction and separation of rare earths, and full-load fractionation extraction and separation of rare earths, to achieve the effects of eliminating adverse side effects, reducing acid-base consumption and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

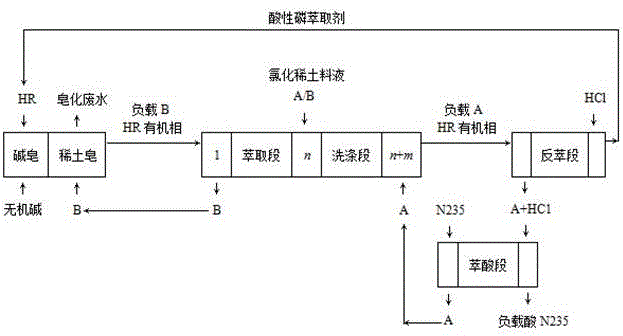

Method used

Image

Examples

Embodiment 1

[0026] Full-load fractional distillation extraction ~ Nd / Sm ~ group separation of yttrium-europium-rich ore

[0027] 1) Rare earth liquid

[0028] The rare earth chloride aqueous solution of medium yttrium and europium-rich ore is used as the feed solution, the rare earth concentration in the rare earth feed solution is 1.5 M, and the pH value is 3. In terms of rare earth elements, the molar fraction of light rare earth elements (La~Nd) is 0.55, and the molar fraction of medium and heavy rare earth elements (Sm~Lu and Y) is 0.45.

[0029] 2) Rare earth extraction organic phase

[0030] The rare earth extraction organic phase is a kerosene solution of P507, and the volume percentage concentration of P507 is 36%; it is added to the fractionation extraction system in the form of light rare earth saponification organic phase, and the saponification degree is 35%.

[0031] 3) Washing liquid

[0032] The washing solution is an aqueous solution of medium and heavy rare earth eleme...

Embodiment 2

[0045] Separation of lanthanum and cerium by fractional distillation under full load

[0046] 1) Rare earth liquid

[0047] The aqueous solution of lanthanum and cerium chloride was used as the feed solution, the rare earth concentration in the rare earth feed solution was 1.0 M, and the pH value was 5. In terms of rare earth elements, the mole fraction of lanthanum is 0.40, and the mole fraction of cerium is 0.60.

[0048] 2) Rare earth extraction organic phase

[0049] The organic phase of rare earth extraction is kerosene solution of P204, and the concentration of P204 is 30% by volume; it is added to the fractionation extraction system in the form of lanthanum saponified organic phase, and the degree of saponification is 40%.

[0050] 3) Washing liquid

[0051] The washing solution is an aqueous solution of cerium, which is obtained from the aqueous phase at the outlet of the acid extraction section; the rare earth concentration in the washing solution is 0.8696 M, and ...

Embodiment 3

[0064] Separation of Praseodymium and Neodymium by Fractional Distillation at Full Load

[0065] 1) Rare earth liquid

[0066] The aqueous solution of praseodymium and neodymium chloride was used as the feed solution, the rare earth concentration in the rare earth feed solution was 0.8 M, and the pH value was 2. In terms of rare earth elements, the mole fraction of praseodymium is 0.30, and the mole fraction of neodymium is 0.70.

[0067] 2) Rare earth extraction organic phase

[0068] The rare earth extraction organic phase is a sulfonated kerosene solution of P507, and the volume percentage concentration of P507 is 30%; it is added to the fractionation extraction system in the form of praseodymium saponification organic phase, and the saponification degree is 45%.

[0069] 3) Washing liquid

[0070] The washing solution is an aqueous solution of neodymium, which is obtained from the aqueous phase at the outlet of the acid extraction section; the rare earth concentration i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com