Method for industrialized production of high-purity neodymium oxide

A neodymium oxide, high-purity technology, applied in chemical instruments and methods, preparation/processing of rare earth metal oxides/hydroxides, rare earth metal compounds, etc., can solve problems such as high production costs, complicated equipment, and cumbersome operations. Achieve the effect of low cost, low cost, and less rare earth in the groove

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Rare earth-enriched material solution of lanthanum, cerium, praseodymium and neodymium is prepared. The material liquid is obtained from the light rare earth components after grouping neodymium and samarium of the southern ionic rare earth mine. Molar concentration of total rare earths = 0.70 moles per liter, pH = 2. Its composition is shown in Table 1.

[0026] Table 1. The composition of the rare earth enriched material liquid of lanthanum, cerium, praseodymium and neodymium

[0027] rare earth oxide

La

Ce

Pr

Nd

SM

Ho-Lu

Y

weight ratio(%)

24.5

4.49

11.6

59.5

<0.001

<0.001

<0.001

[0028] (2) Prepare the organic phase. The volume ratio of P507 and sulfonated kerosene is 40:60. The degree of alkali saponification of the organic phase was 36%.

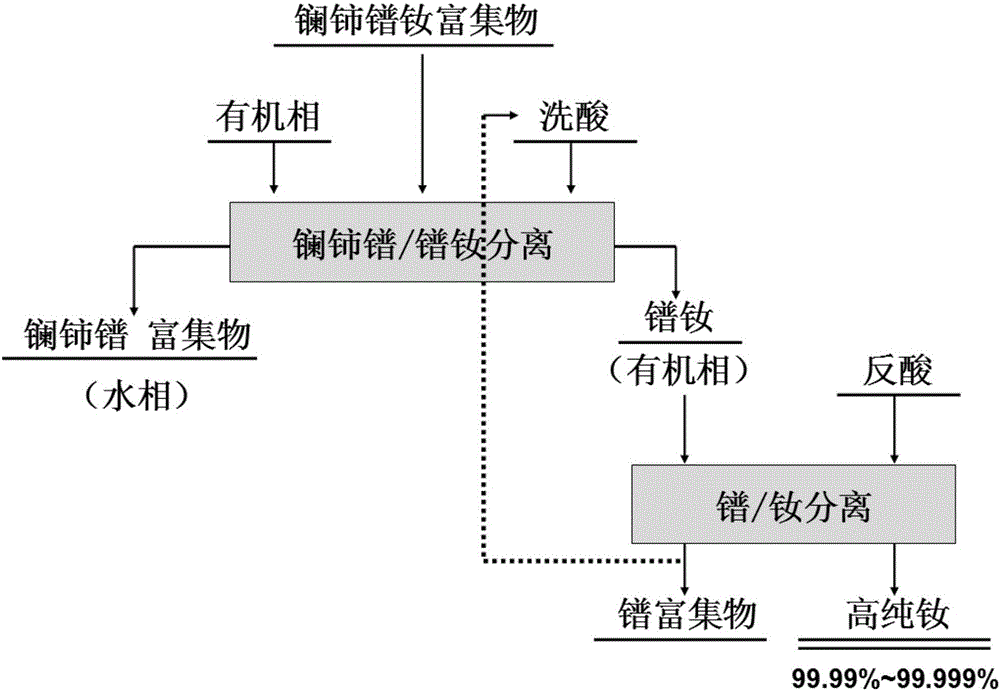

[0029] (3) The enriched material liquid of lanthanum cerium praseodymium and neodymium is mixed with the organic phase, and extracted by the lanthanum...

Embodiment 2

[0035] (1) Rare earth-enriched material solution of lanthanum, cerium, praseodymium and neodymium is prepared. The feed liquid is taken from the light rare earth component of a factory in the north. Molar concentration of total rare earths = 1.0 moles per liter, pH = 1. Its composition is shown in Table 1.

[0036] Table 1. The composition of the rare earth enriched material liquid of lanthanum, cerium, praseodymium and neodymium

[0037] rare earth oxide

La

Ce

Pr

Nd

SM

Ho-Lu

Y

weight ratio(%)

24.09

54.21

3.59

18.10

<0.001

<0.001

<0.001

[0038] (2) Prepare the organic phase. The volume ratio of P507 and sulfonated kerosene is 30:70. The degree of alkaline saponification of the organic phase was 30%.

[0039] (3) The enriched material liquid of lanthanum cerium praseodymium and neodymium is mixed with the organic phase, and extracted by the lanthanum cerium praseodymium / praseodymium neodymium fuzzy extr...

Embodiment 3

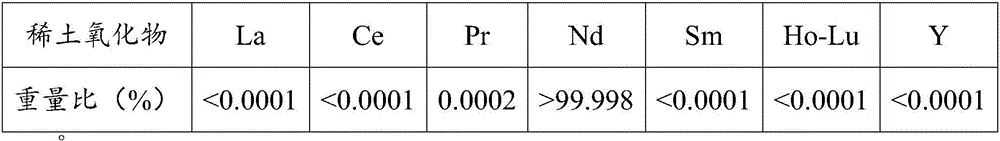

[0045] (1) Rare earth-enriched material solution of lanthanum, cerium, praseodymium and neodymium is prepared. The feed liquid is taken from a company's praseodymium and neodymium enrichment, the molar concentration of the dissolved total rare earths is 1.20 moles per liter, and the pH is 1. Its composition is shown in Table 1.

[0046] Table 1. The composition of the rare earth enriched material liquid of lanthanum, cerium, praseodymium and neodymium

[0047] rare earth oxide

La

Ce

Pr

Nd

SM

Ho-Lu

Y

weight ratio(%)

1.18

2.87

23.50

72.45

<0.001

<0.001

<0.001

[0048] (2) Prepare the organic phase. The volume ratio of P507 to sulfonated kerosene is 20:80. The degree of alkali saponification of the organic phase was 26%.

[0049] (3) The enriched material liquid of lanthanum cerium praseodymium and neodymium is mixed with the organic phase, and extracted by the lanthanum cerium praseodymium / praseodymium neo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com