Welding pad structure for ball grid array packaging chip and multilayer printed circuit board for mobile phone

A ball grid array and multi-layer printing technology, which is applied to printed circuit components, electrical connection printed components, circuits, etc., to achieve the effect of reducing design difficulty, improving core competitiveness, and reducing the number of layers or series

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementations and examples of the present invention will be described in detail below in conjunction with the accompanying drawings. The described specific examples only use the specification parameters of 0.4mm pitch BGA packaging devices to explain the present invention, and are not intended to limit the specific implementation of the present invention. Way.

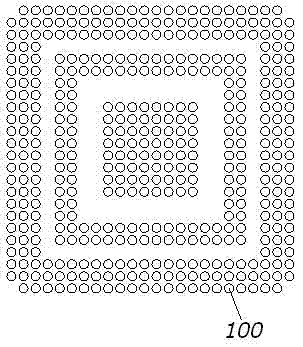

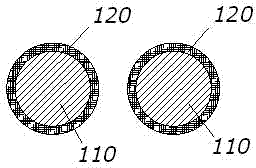

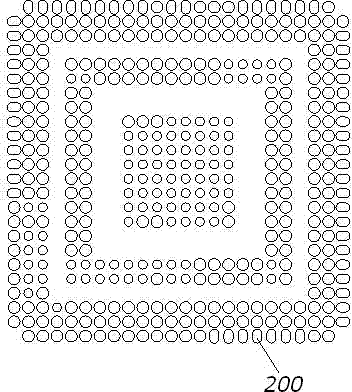

[0026] A pad structure of a ball grid array packaged chip of the present invention is arranged on the surface of a printed circuit board. One of its specific implementation methods is as follows: image 3 As shown, it includes a square ring grid array formed by a plurality of welding spots arranged at intervals; wherein, non-circular welding spots 200 are arranged in the outermost ring of welding spots of the grid array. At the same time, not all the solder joints 200 in the outermost circle of the grid array are set as non-circular solder joints 200 , and only need to be set in the solder joints ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com