Patents

Literature

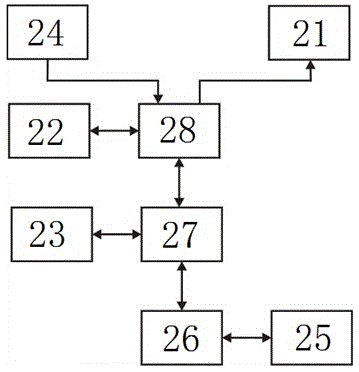

36results about How to "Eliminate immobility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

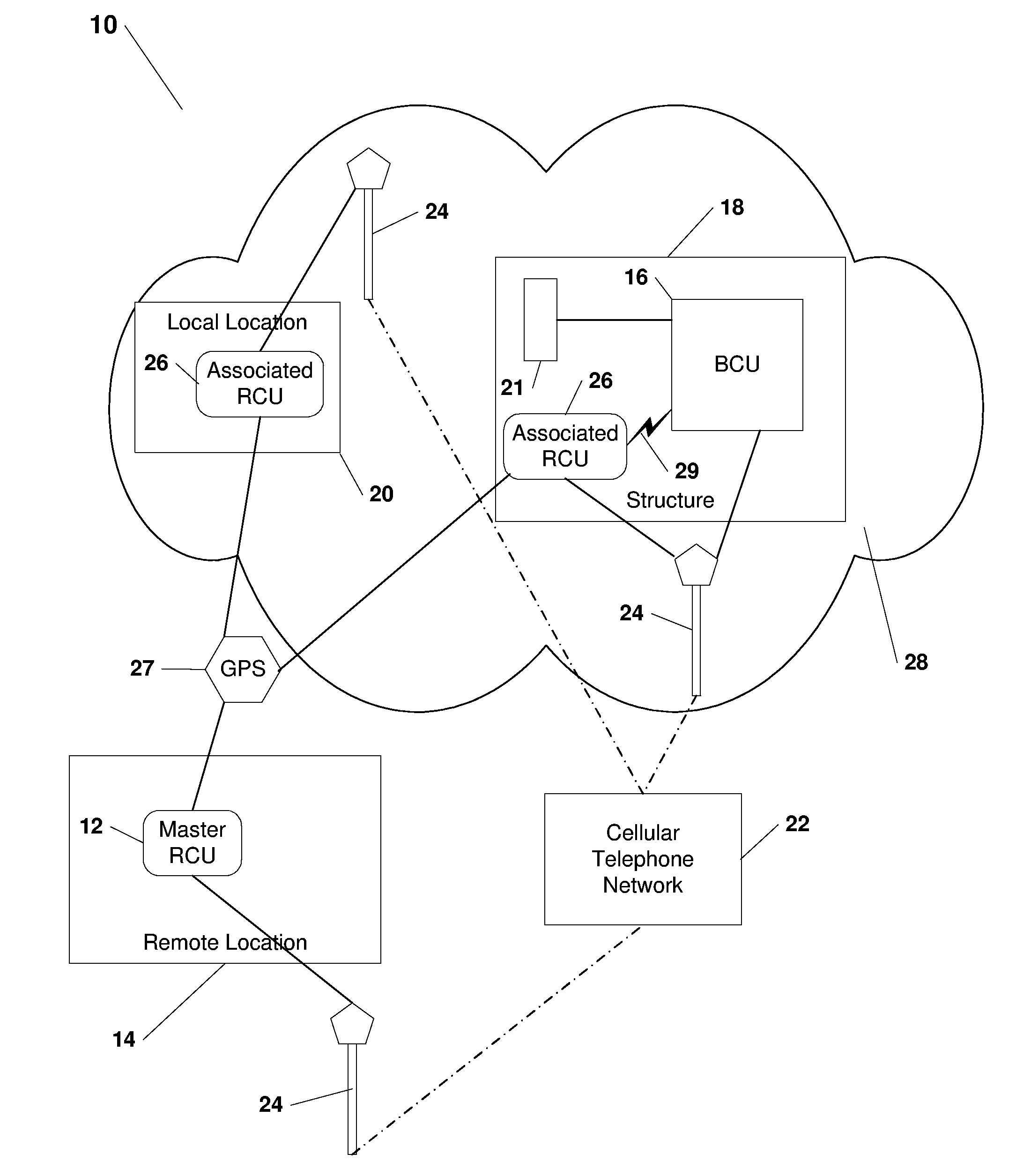

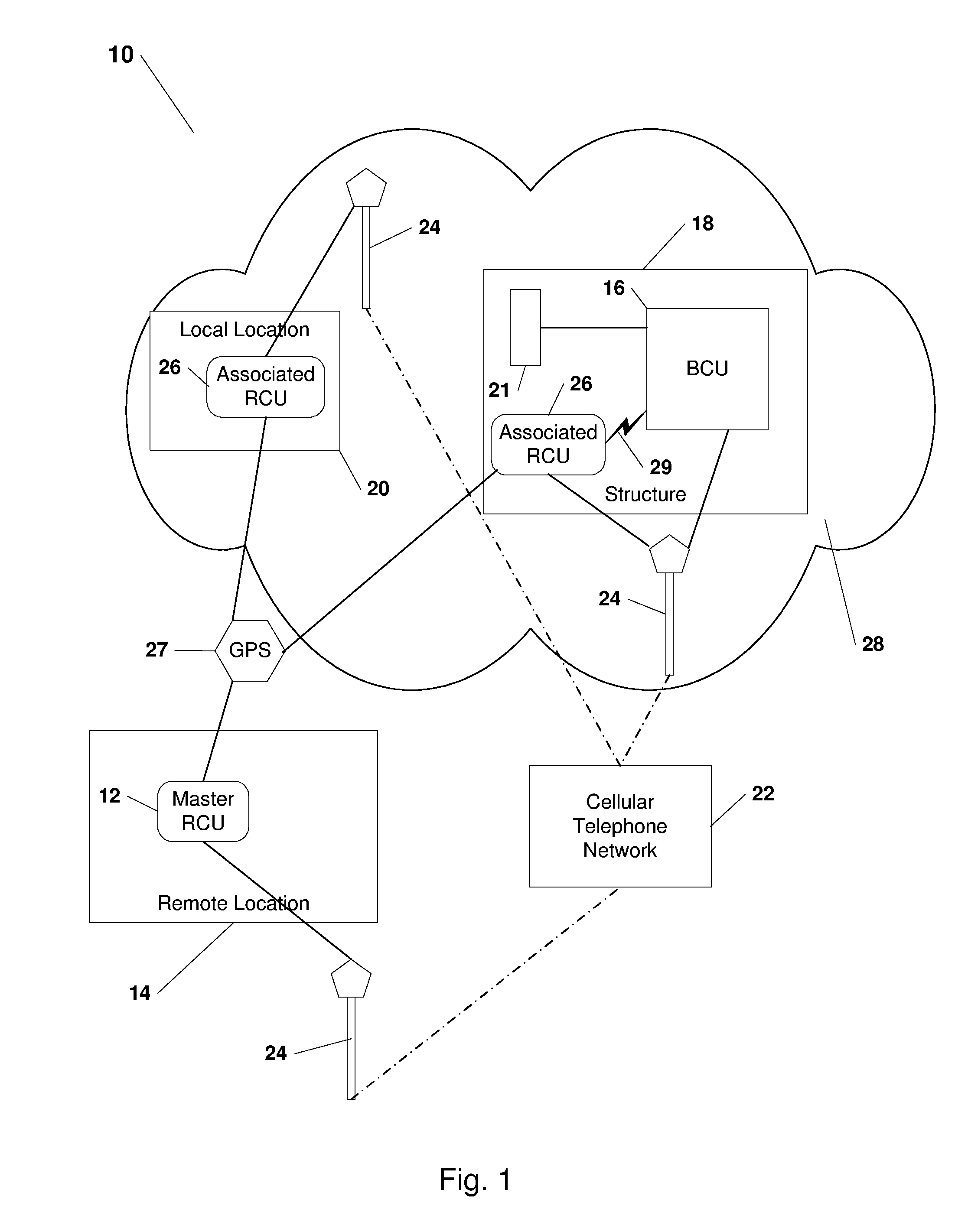

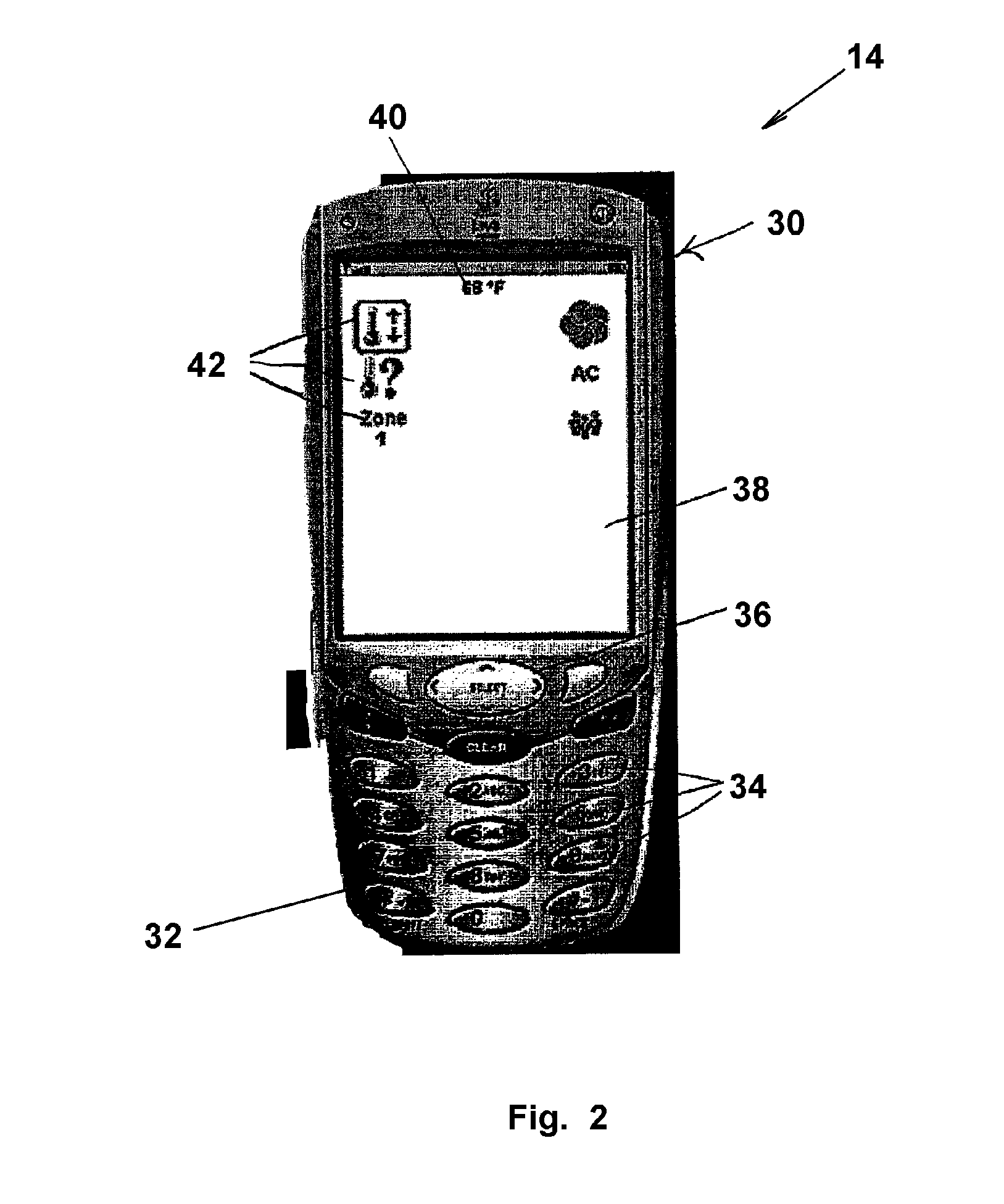

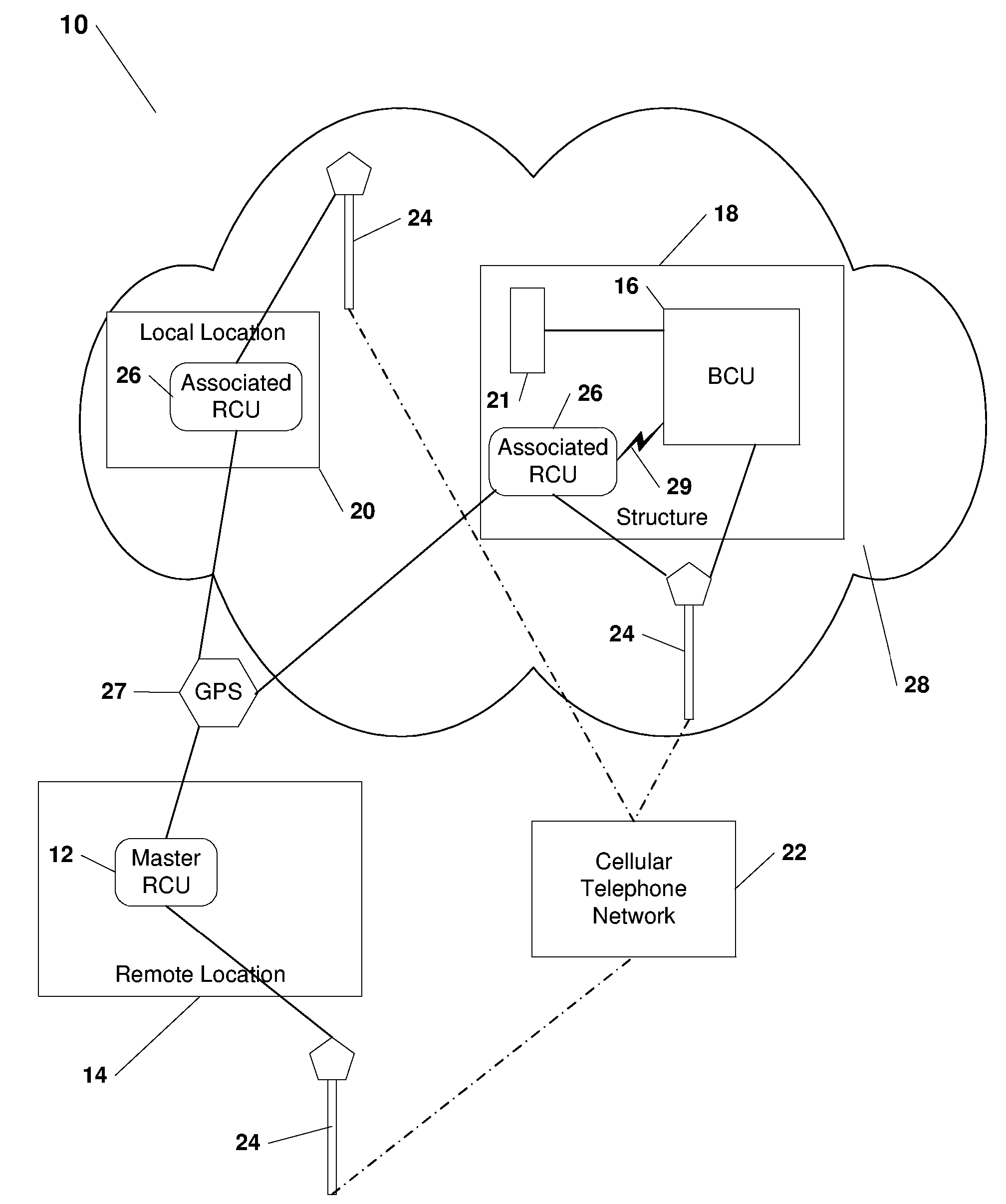

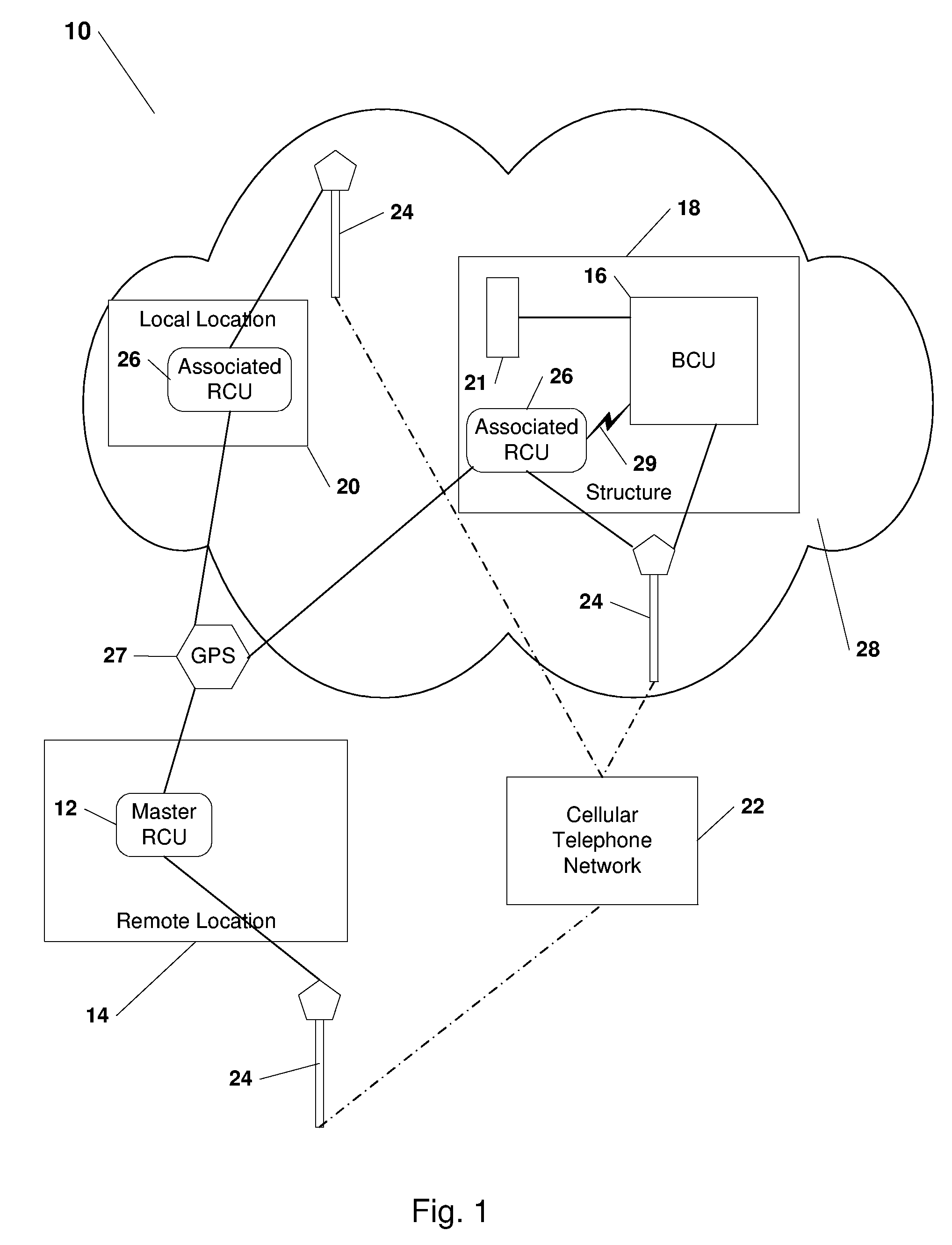

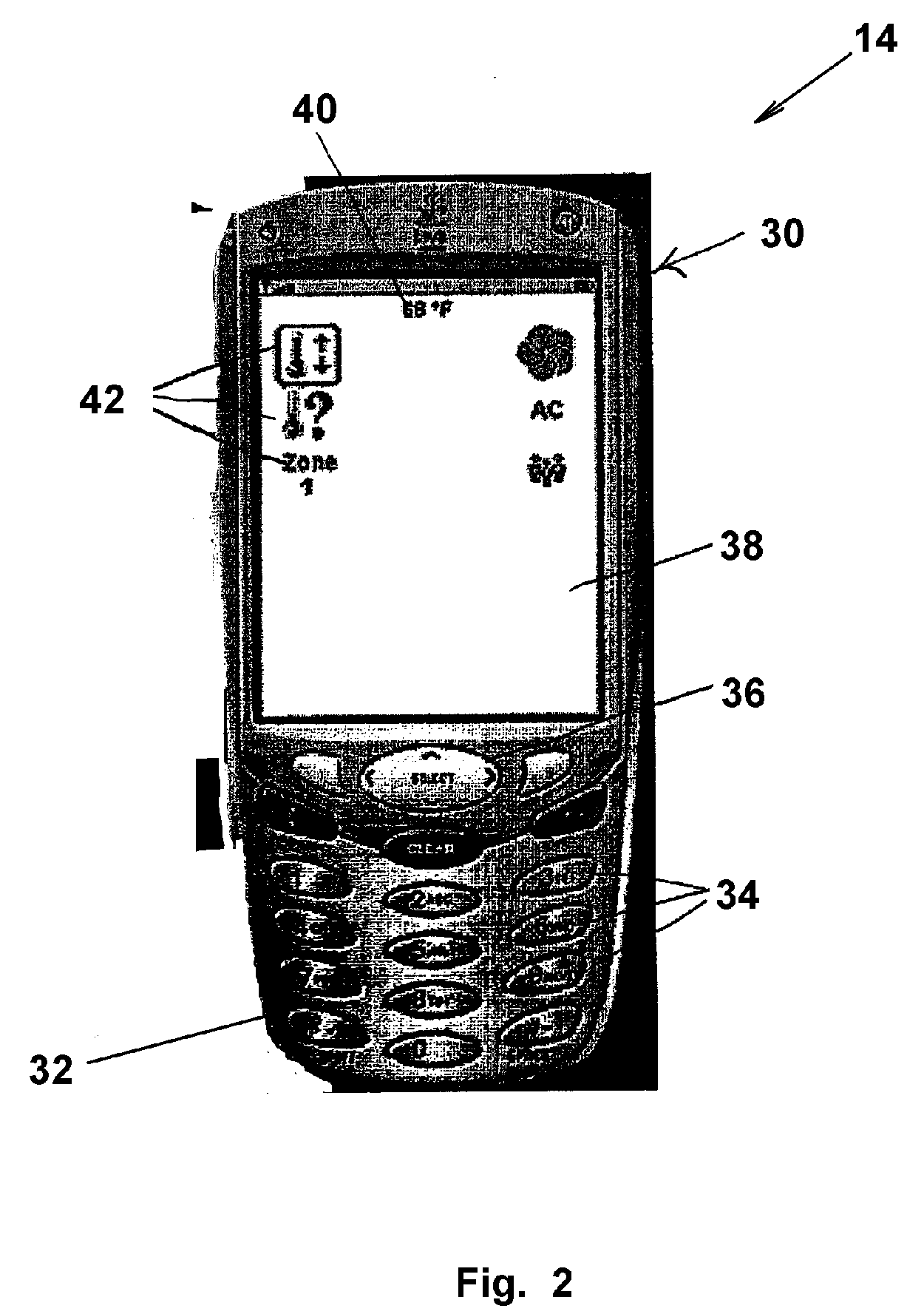

Ubiquitous connectivity and control system for remote locations

InactiveUS6990335B1Eliminate immobilityEliminate limitationsMechanical apparatusLighting and heating apparatusControl systemThermostat

A thermostat control system for monitoring and controlling environmental characteristics of a building includes a base station unit and a remote access unit continuously interfacing through instant wireless private direct connectivity. The system also includes a plurality of sensors that measure the environmental characteristics and provide the thermostat unit with the measurements.

Owner:UBIQUITOUS CONNECTIVITY

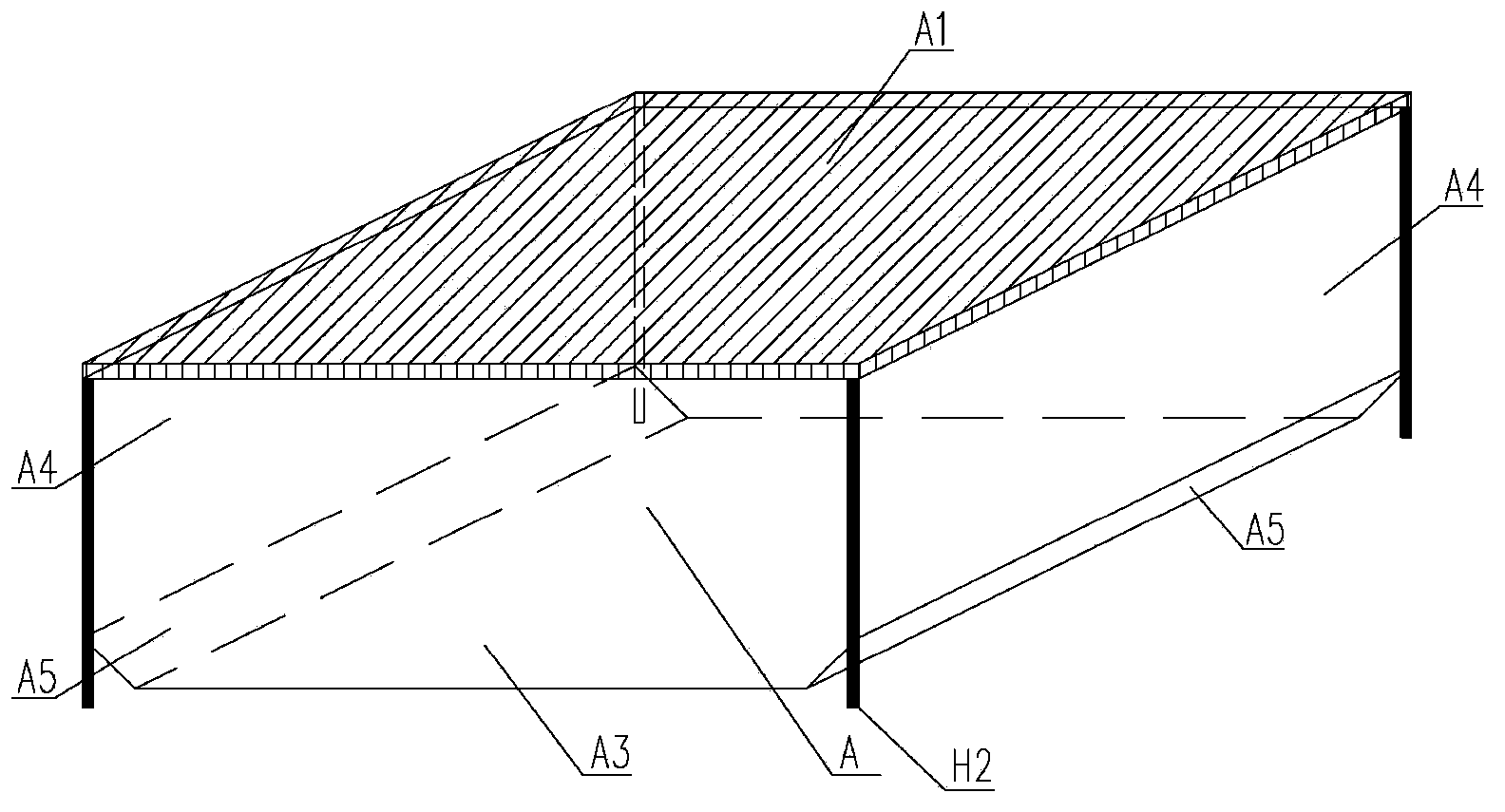

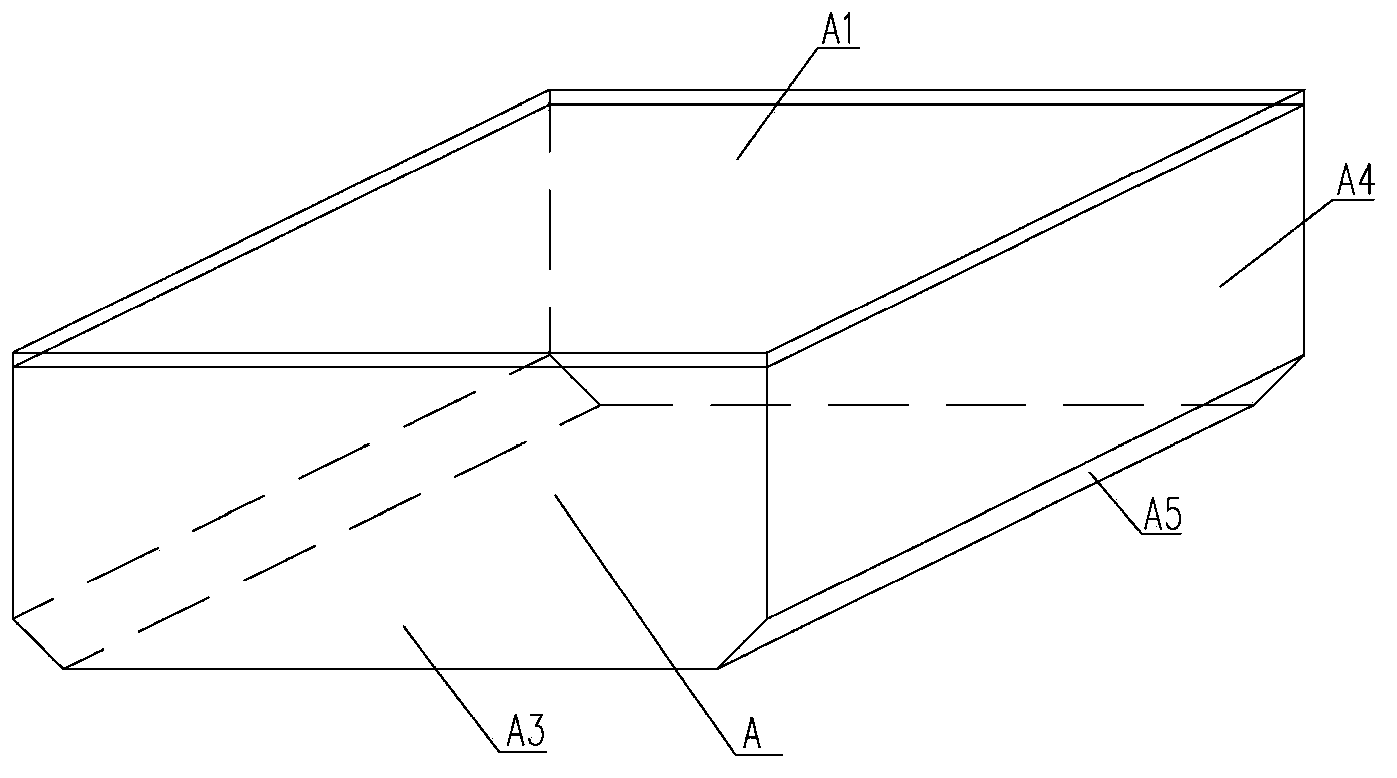

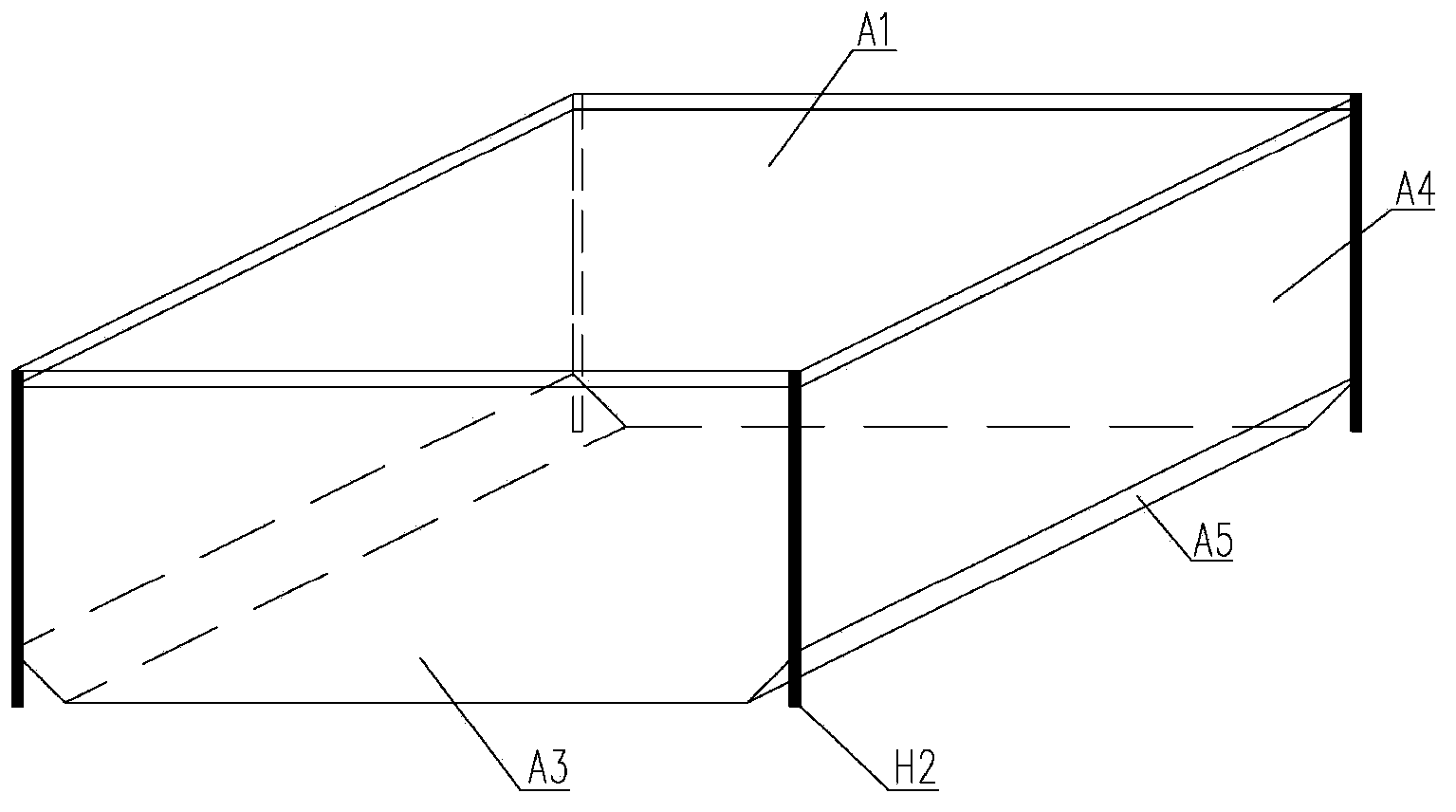

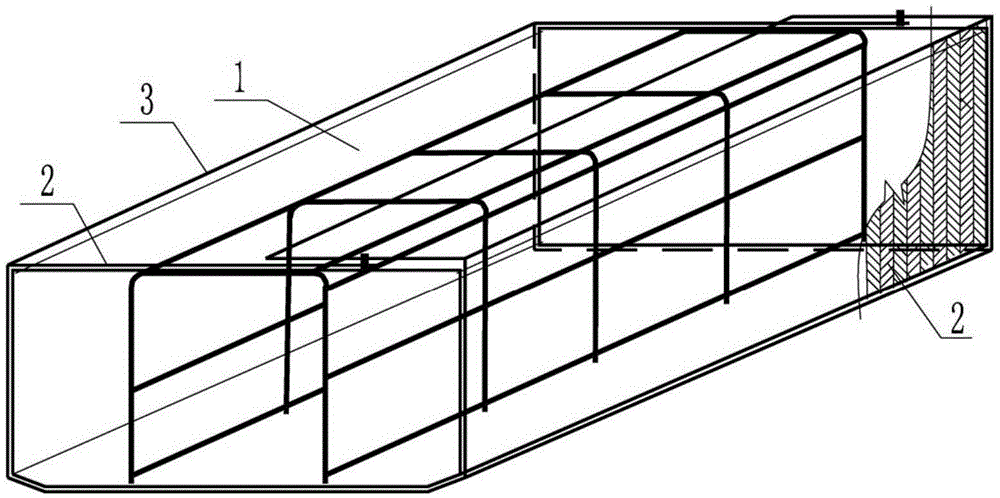

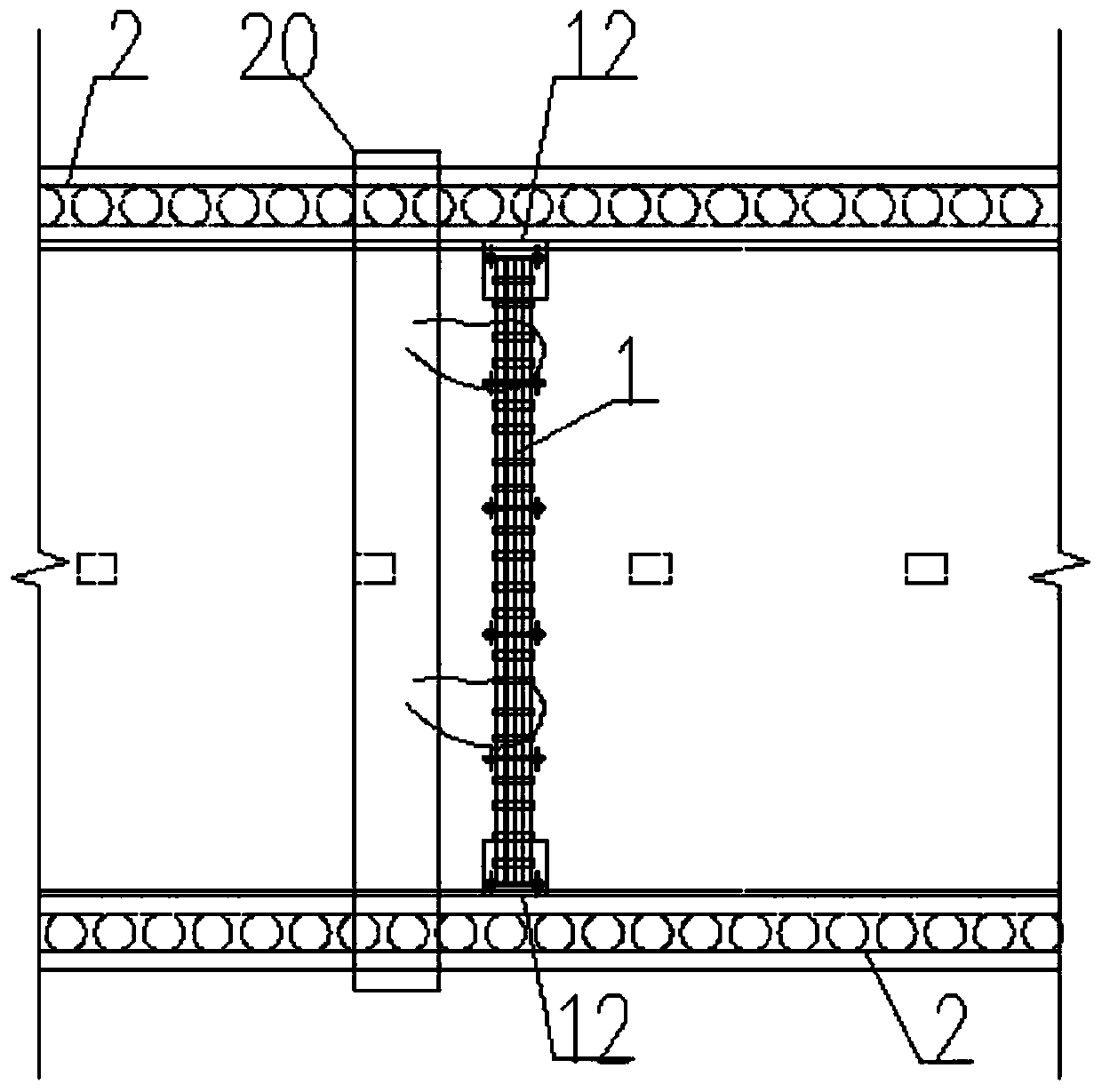

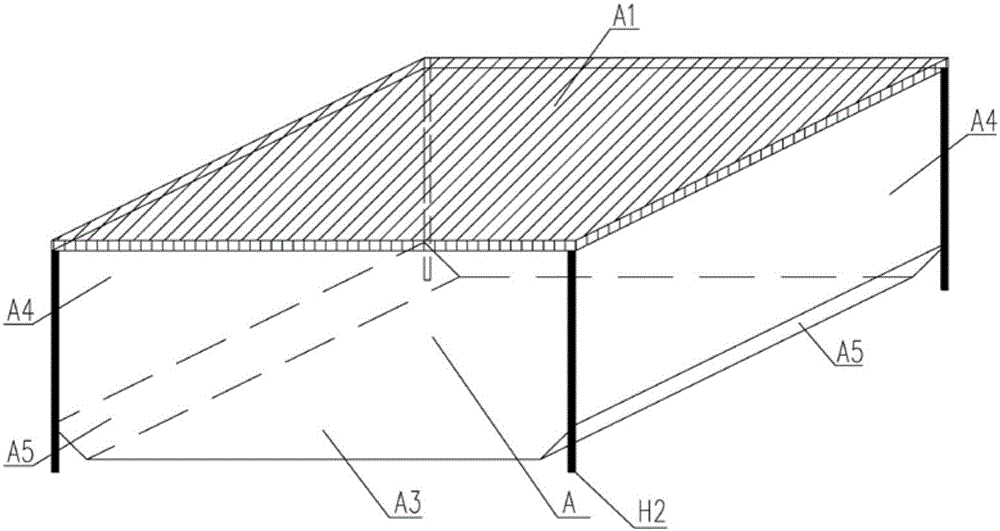

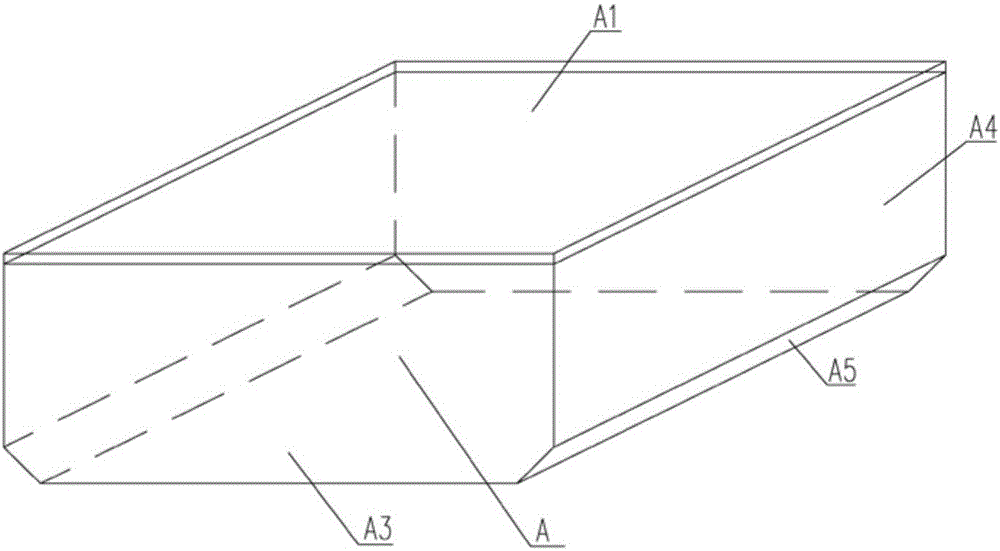

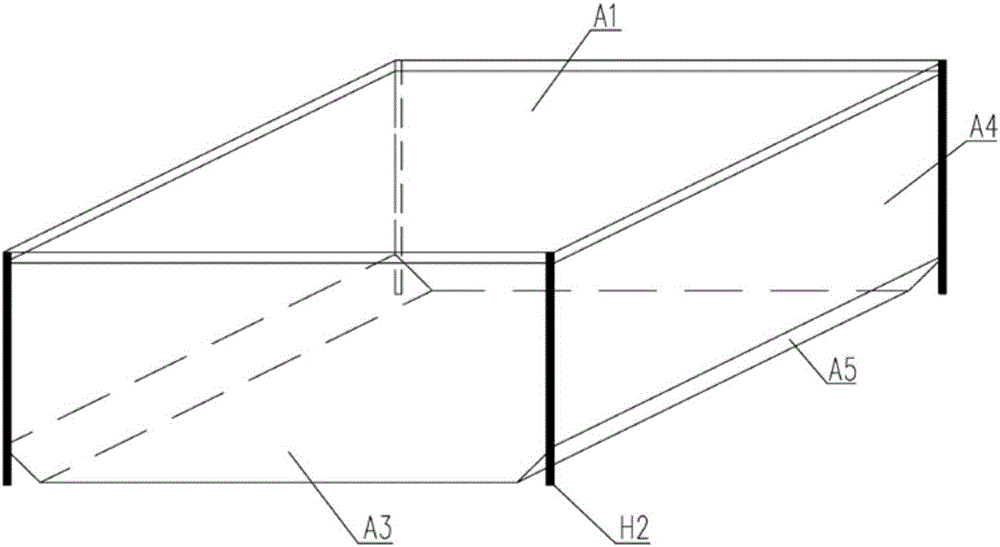

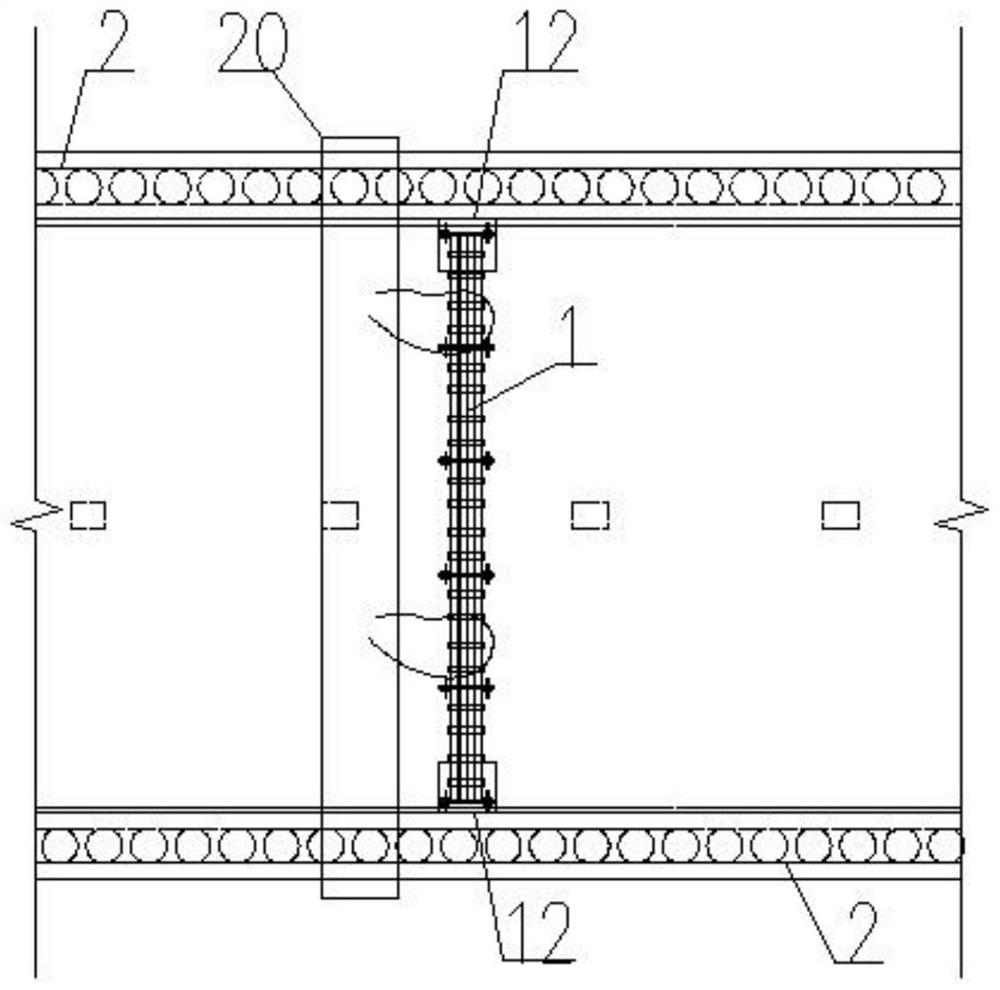

Netlike box-shaped component for forming holes in cast-in-situ hollow floor

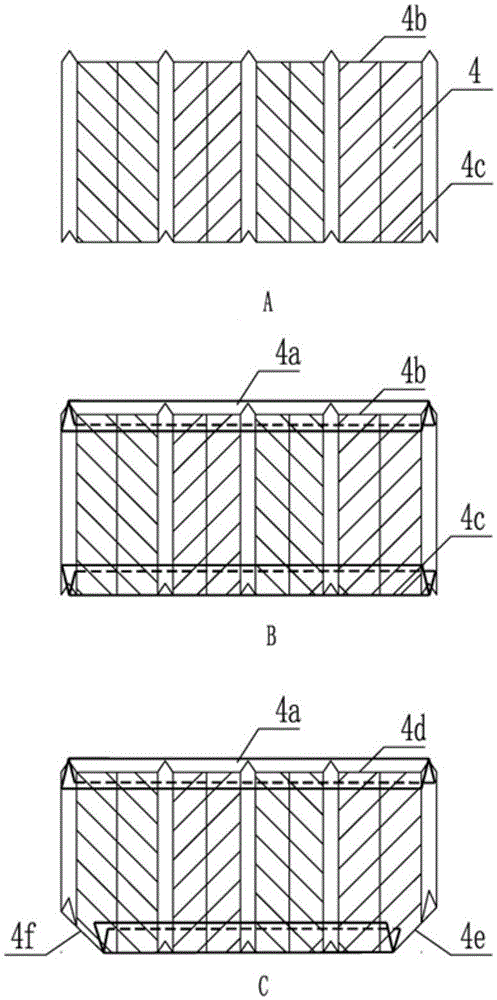

The invention provides a netlike box-shaped component for forming holes in a cast-in-situ hollow floor. The netlike box-shaped component is formed by combining a box roof, a box body (side wall) and a box bottom; the box roof is compounded with cement mortar or styrofoam or a board; the box body and the box bottom are manufactured by netlike bodies; each netlike body comprises a netlike board, reinforcing ribs and connecting nets; the netlike board, the reinforcing ribs and the connecting nets form an interacting integral structure; the area of a grid in the netlike board is smaller than 120 mm<2>; the reinforcing ribs are V-shaped; the reinforcing ribs are higher than 3mm; the space between the reinforcing ribs in each netlike body is larger than 30mm; the netlike box-shaped component is formed by combining at least two netlike bodies; at least two structural inclined planes are arranged at corners of the box bottom and the box body of the netlike box-shaped component; the netlike bodies of the netlike box-shaped component are made of steel or plastic. The unsealed netlike box-shaped component replaces a fully-sealed hollow filling body and a solid filling body as a hole forming technology of the conventional cast-in-situ hollow floor, so that technical defects of the existing hollow floor are effectively solved.

Owner:王本淼 +1

Ubiquitous connectivity and control system for remote locations

InactiveUS20060105760A1Eliminate immobilityEliminate limitationsMechanical apparatusLighting and heating apparatusControl systemEngineering

Owner:UBIQUITOUS CONNECTIVITY

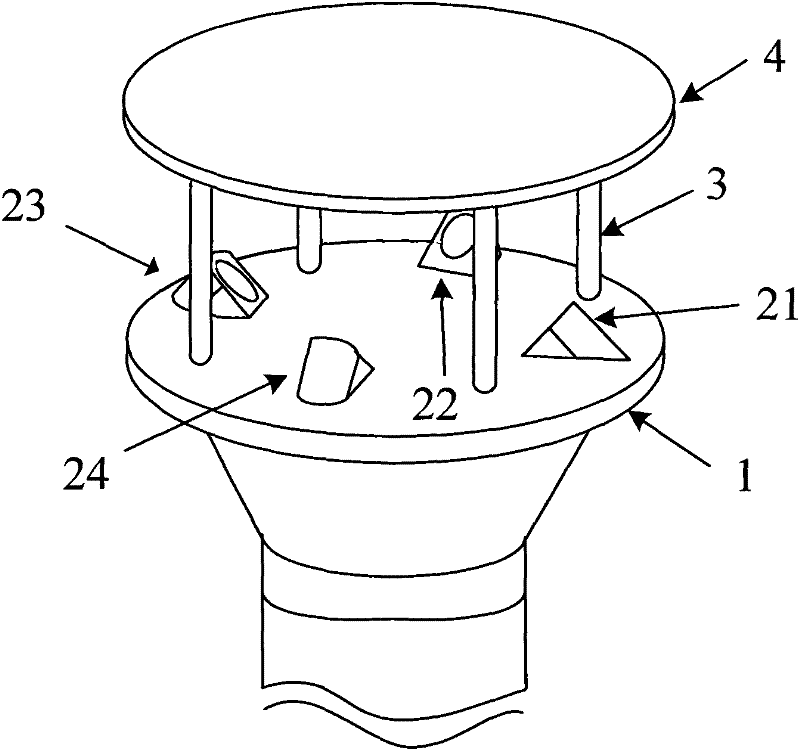

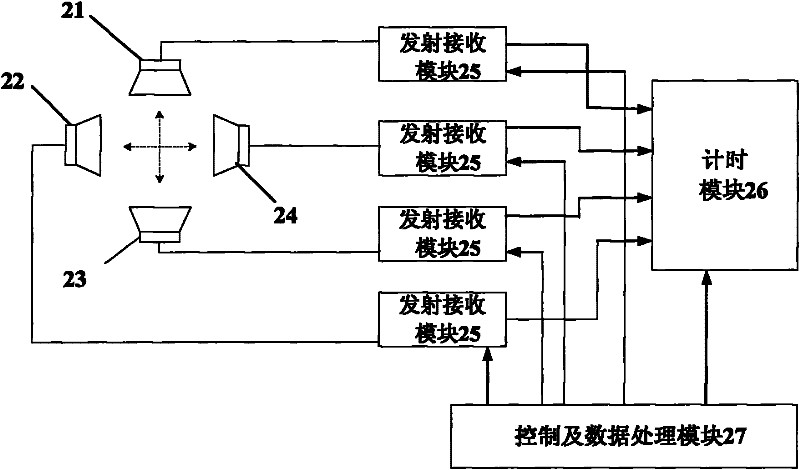

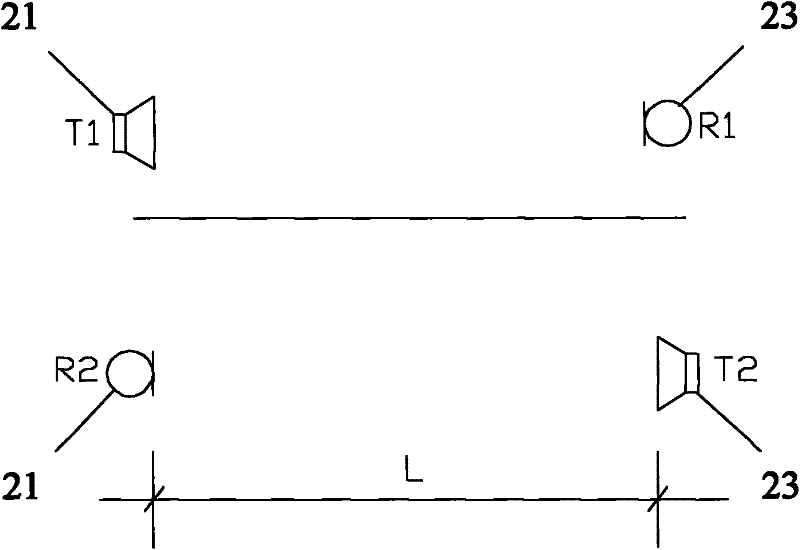

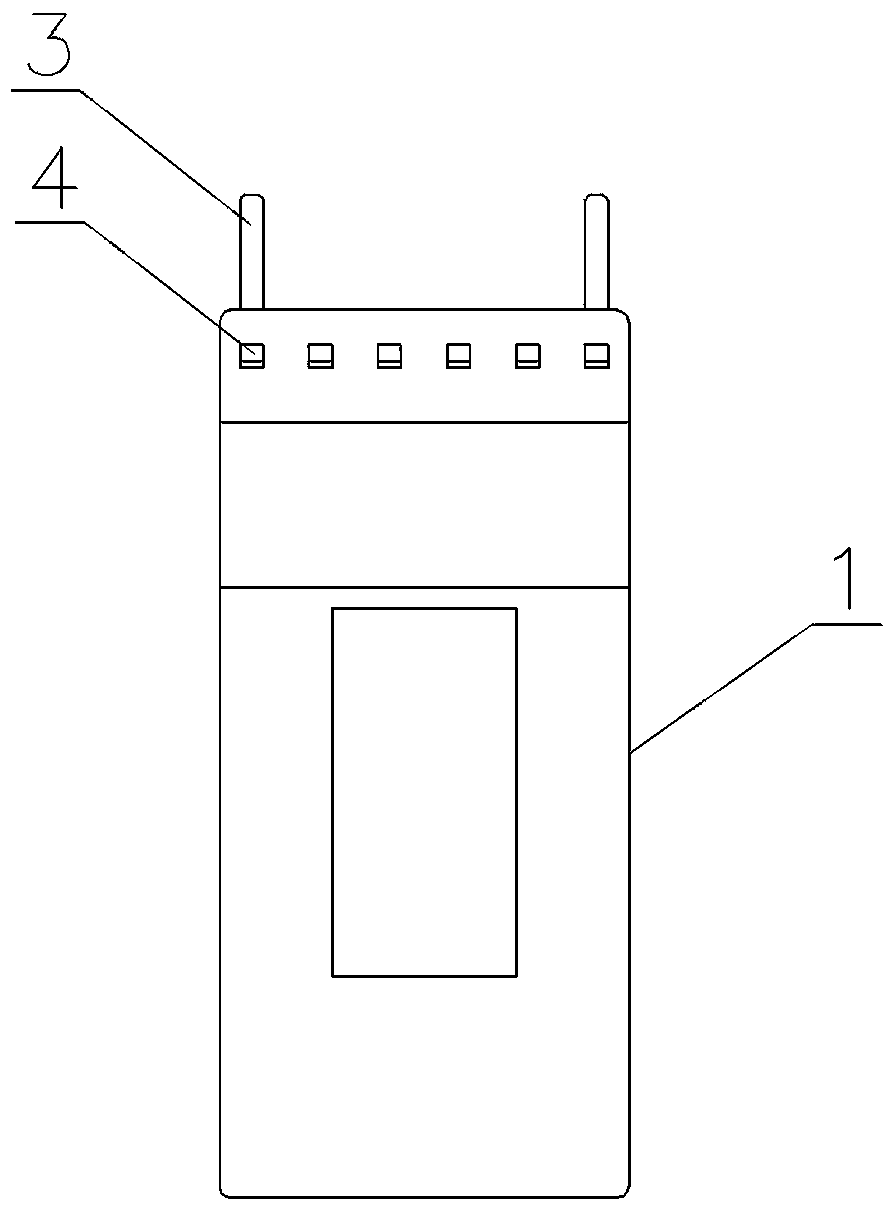

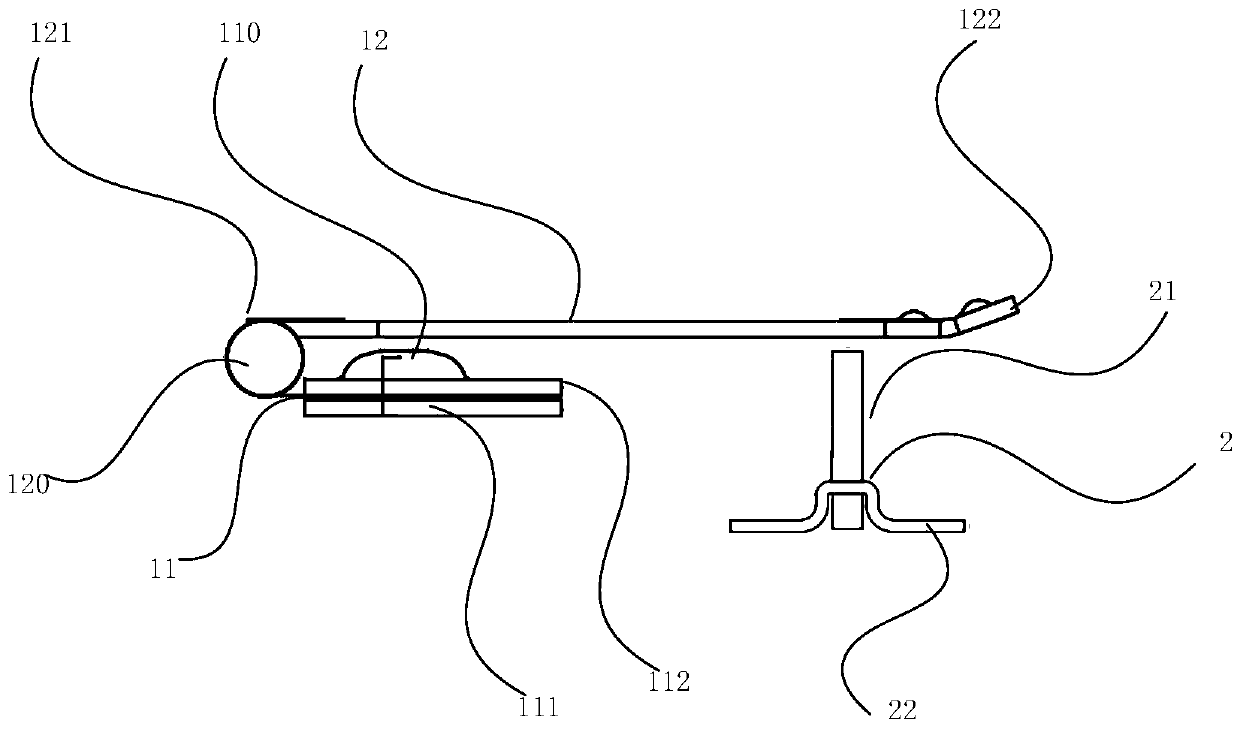

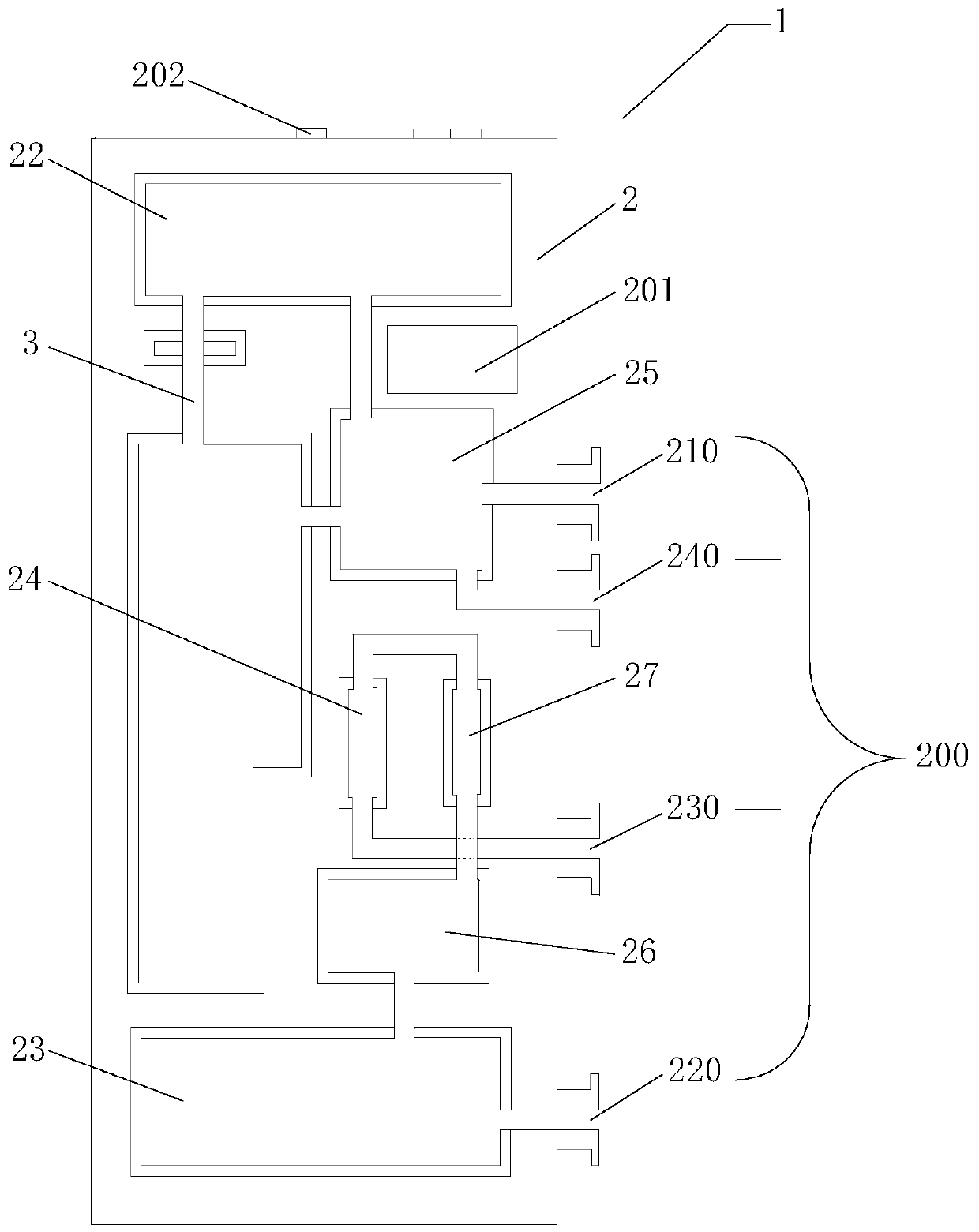

Reflective ultrasonic anemoscope and measuring method thereof

InactiveCN102288781AEliminate immobilityEliminate strengthIndication/recording movementFluid speed measurementUltimate tensile strengthUltrasound probe

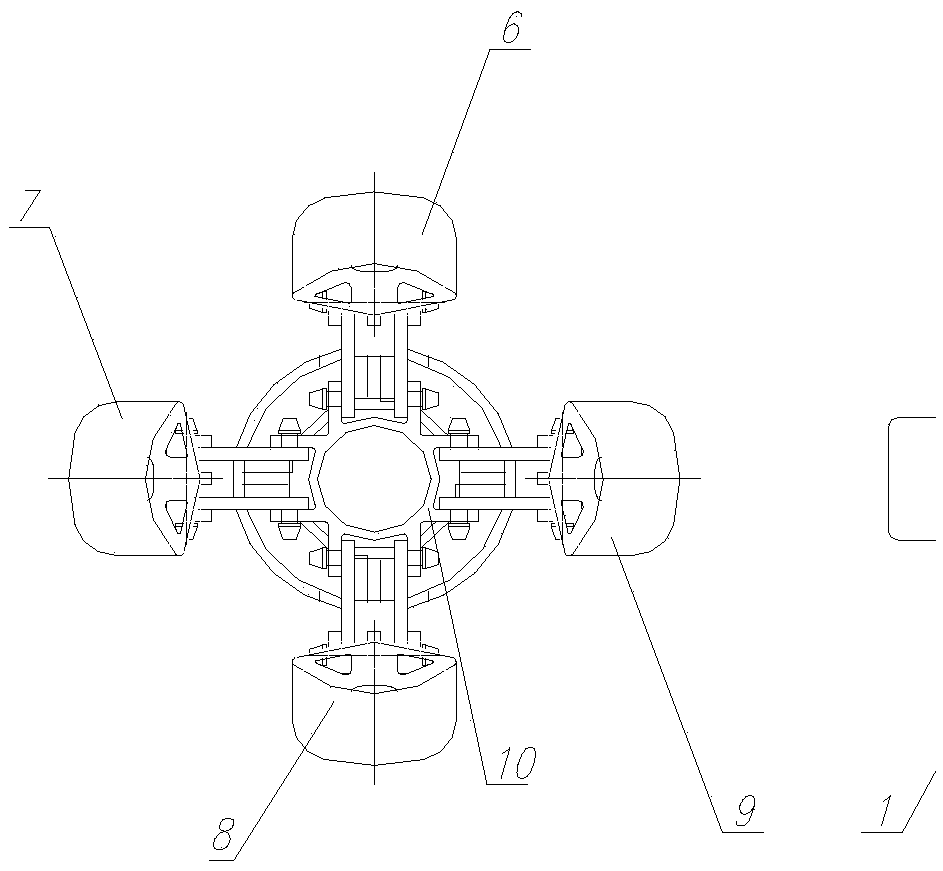

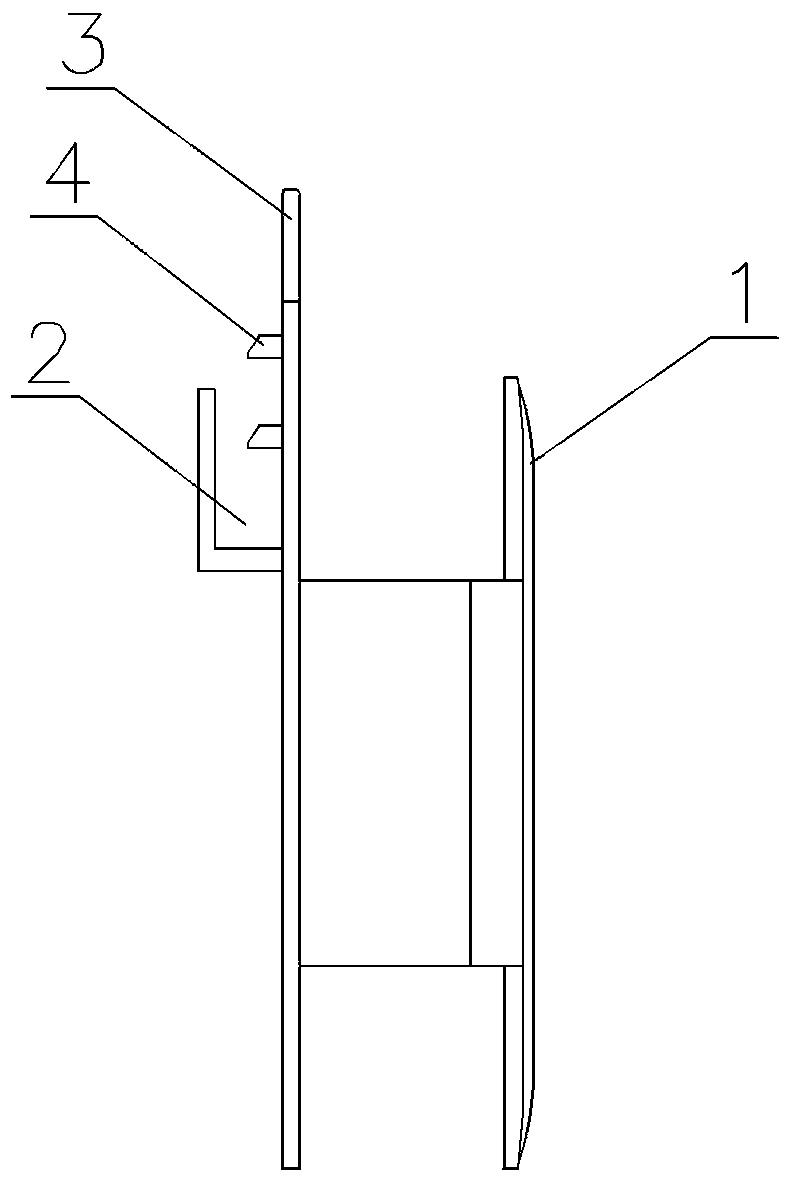

The invention discloses a reflective ultrasonic anemoscope and a measuring method thereof. The reflective ultrasonic anemoscope comprises four parts, namely a probe mounting seat (1), ultrasonic probes (21, 22, 23 and 24), a bracket (3) and a reflecting surface (4), wherein the four ultrasonic probes (21, 22, 23 and 24) are fixedly arranged on the probe mounting seat (1), are divided into two groups and are arranged on two orthogonal axes; and various ultrasonic probes (21, 22, 23 and 24) transmit ultrasonic signals in turn, and opposite ultrasonic probes (21, 22, 23 and 24) receive signals reflected by the reflecting surface (4). A wind speed value and a wind direction value are solved by a vector composition method. The reflective ultrasonic anemoscope eliminates influence on measurement due to a difficultly fixed measuring structure and great change of signal intensity along with the wind speed.

Owner:北京东方迪码科技有限公司

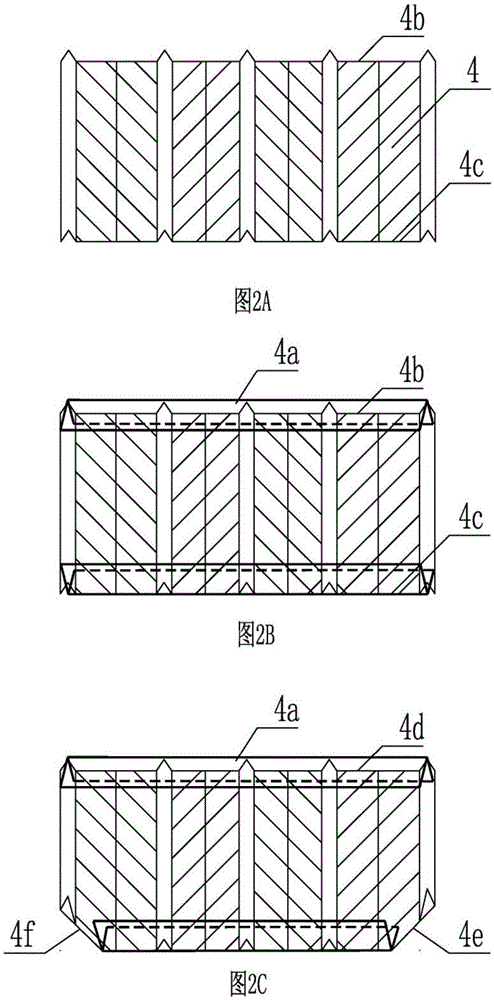

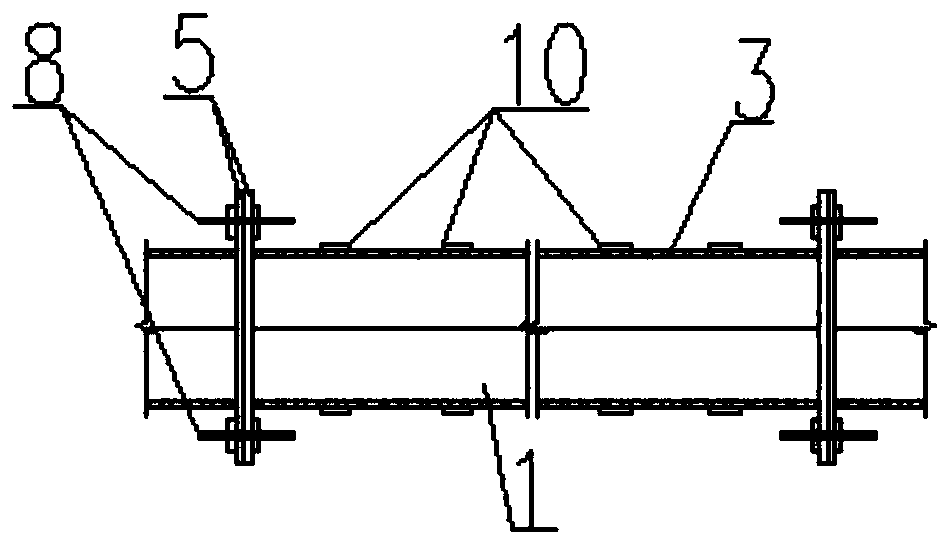

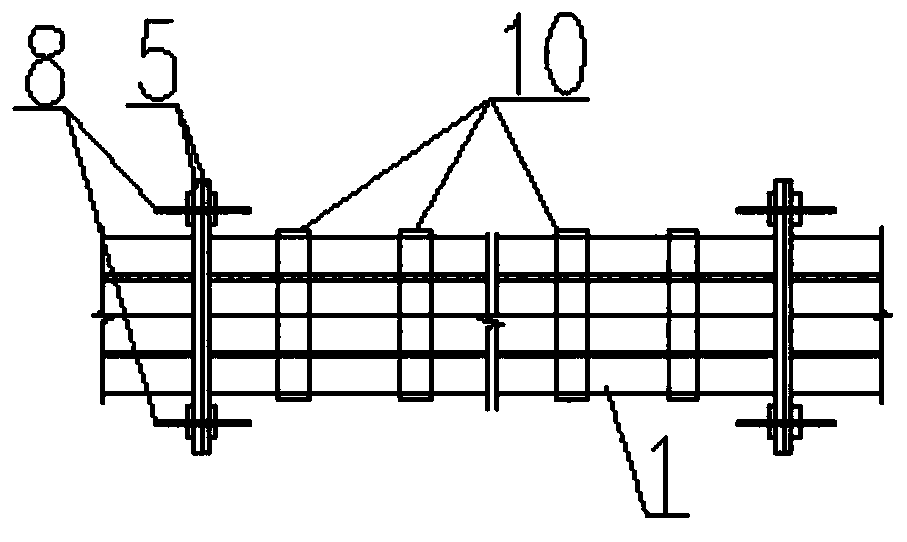

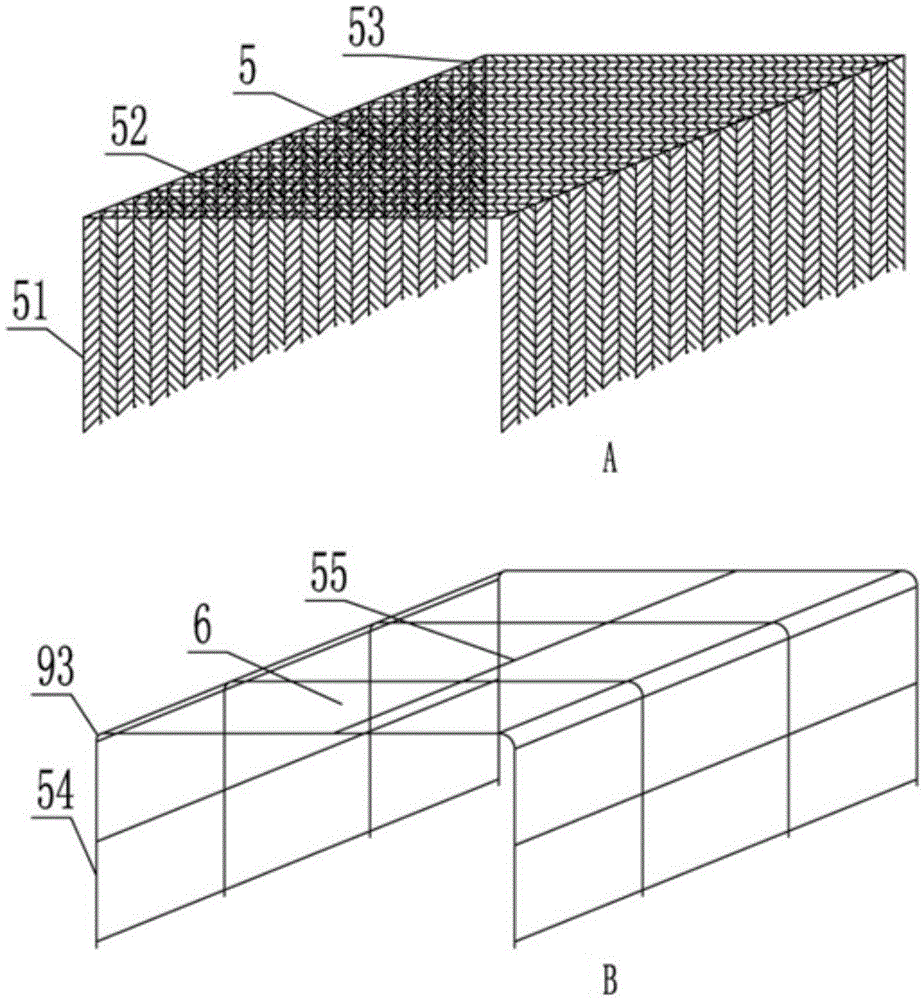

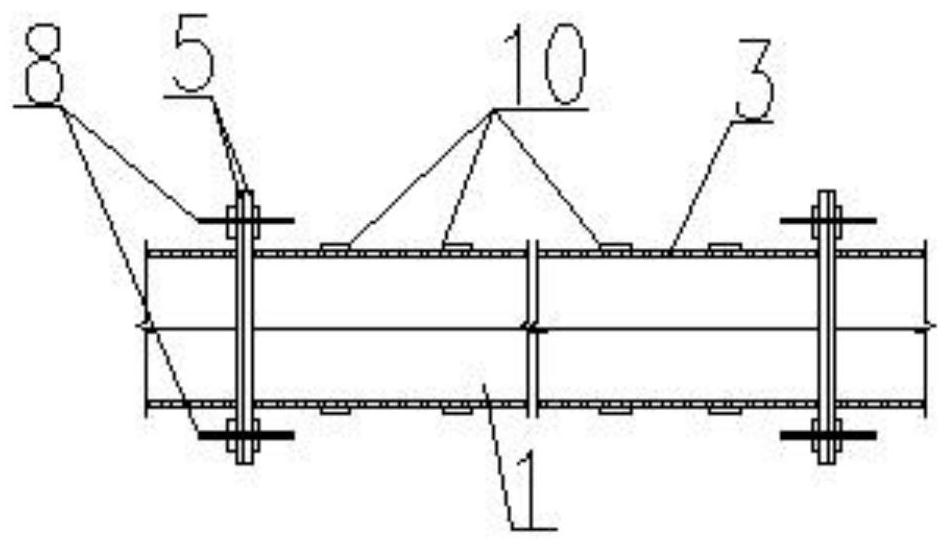

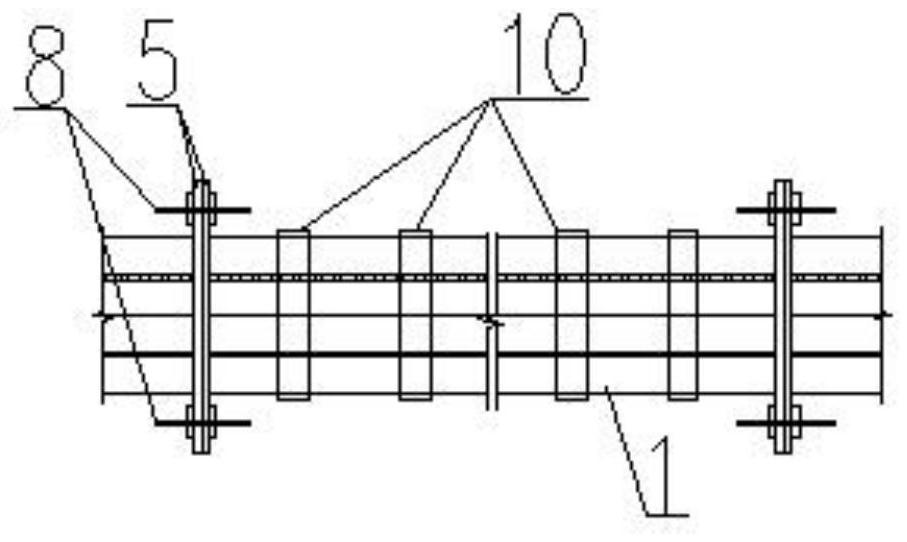

Ribbed steel engraved mesh for cast-in-place cavity floor

InactiveCN105421663AInhibitionFast productionFloorsBuilding reinforcementsSheet steelMetallic materials

The invention provides a ribbed steel engraved mesh for a cast-in-place cavity floor. The ribbed steel engraved mesh is composed of an engraved mesh, a supporting mesh and an engraved end mesh; the engraved mesh, the supporting mesh and the engraved end mesh all are made of a pure metal material; the engraved mesh forms a periphery of the ribbed steel engraved mesh; the engraved end mesh closes the ribbed steel engraved mesh and the supporting engraved mesh to form an engraved end section shape of the ribbed steel engraved mesh; the supporting mesh controls a height of an internal space of the ribbed steel engraved mesh; the engraved mesh and the engraved end mesh are fabricated from steel mesh bodies, and each steel mesh body comprises steel sheet dilated mesh holes, a V-shaped rib and a steering connecting piece; the dilated mesh holes on two sides of the steering connecting pieces are not in the same direction; the V-shaped rib is greater than 6mm high; at least four measuring fixed marks are formed by pressing on the V-shaped rib of the steel mesh body of the engraved mesh in a vertical direction; and the supporting mesh is a steel mesh body or a reinforcing mesh body; the ribbed steel engraved mesh is used for casting the cavity floor, and the ribbed steel engraved mesh is directly buried in concrete cast in place at edges of a cavity to achieve a suppression effect on temperature cracks of the floor.

Owner:王本淼 +2

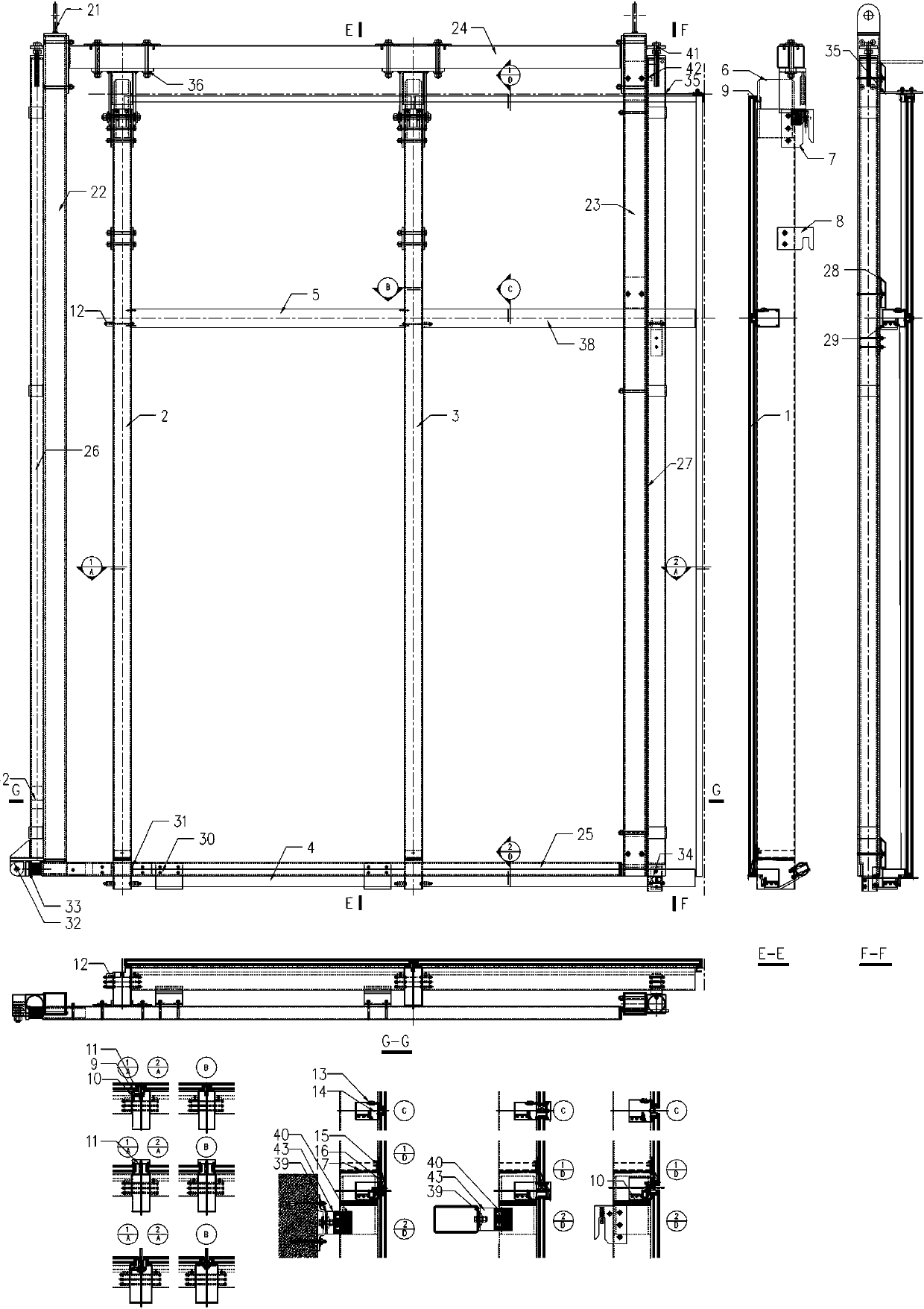

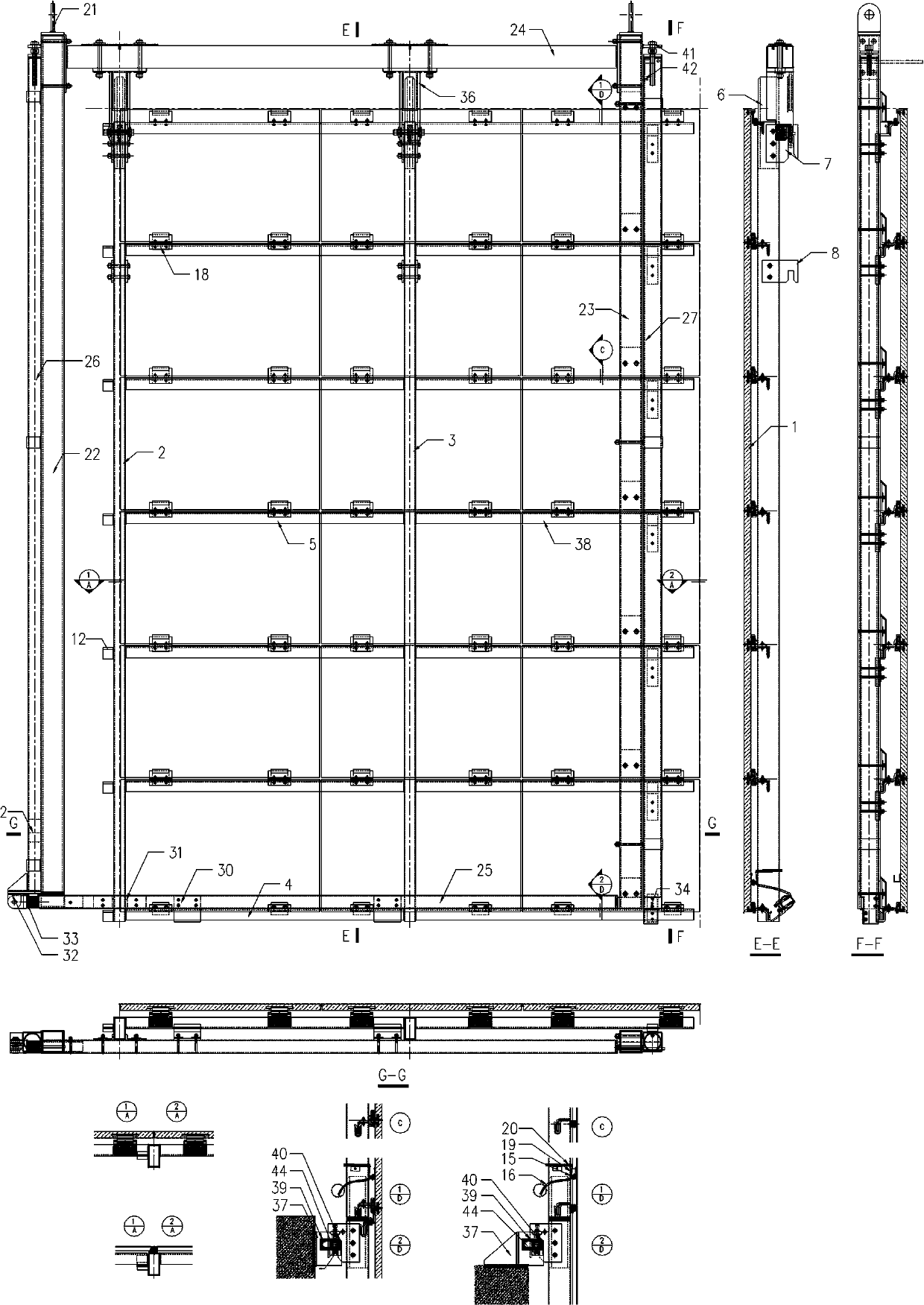

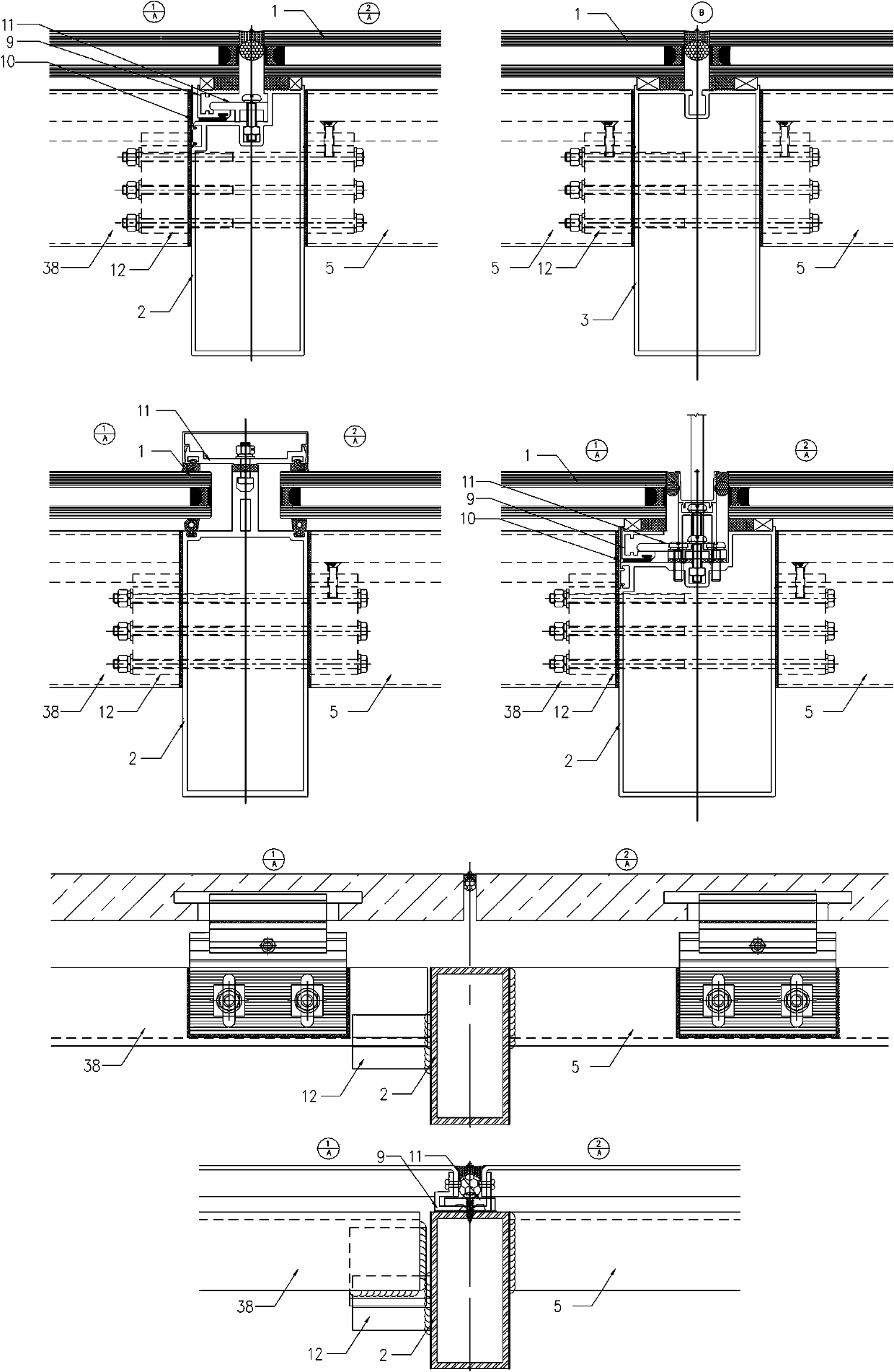

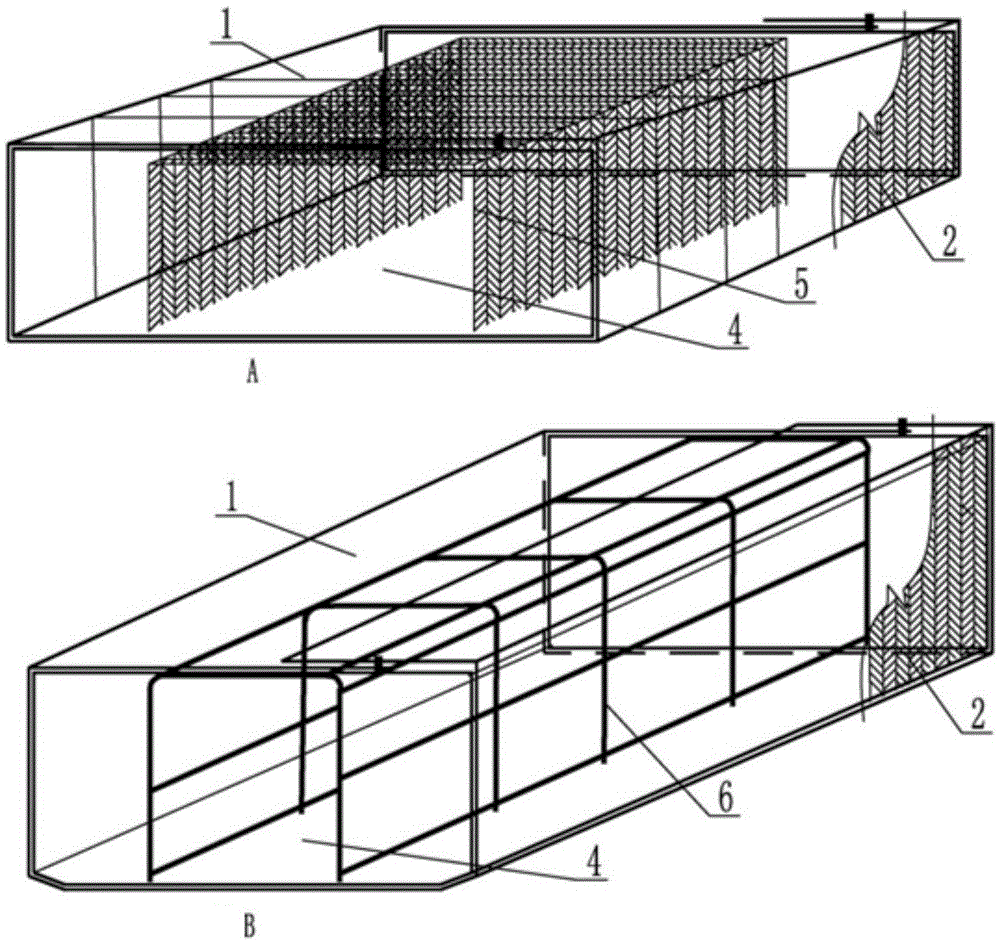

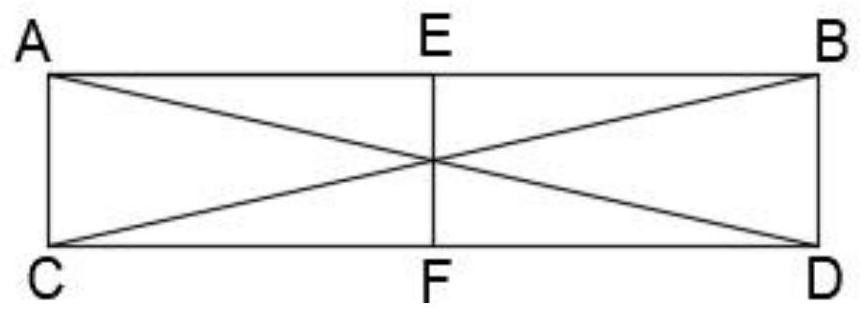

Frame type unit curtain wall adopting auxiliary installing rack, tooth profile angle and tooth profile support

The invention relates to the field of curtain walls of buildings, in particular to a frame type unit curtain wall adopting an auxiliary installing rack, a tooth profile angle and a tooth profile support. The frame type unit curtain wall adopting the auxiliary installing rack comprises a panel (1), end columns (2), middle columns (3), end cross beams (4), middle cross beams (5), inserting cores (6), an auxiliary frame (9), a cover plate and the like. The frame type unit curtain wall adopting the auxiliary installing rack, the tooth profile angle and the tooth profile support are long in service life, low in cost, good in machinability, short in field construction period and good in sealing performance.

Owner:何志胜

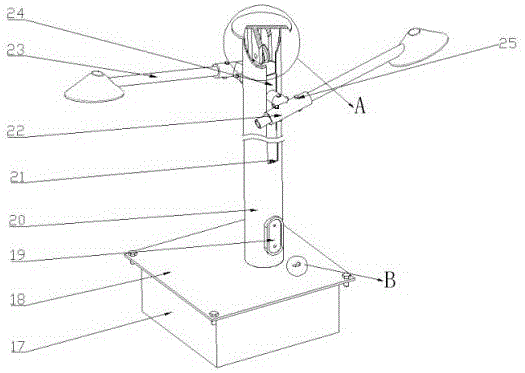

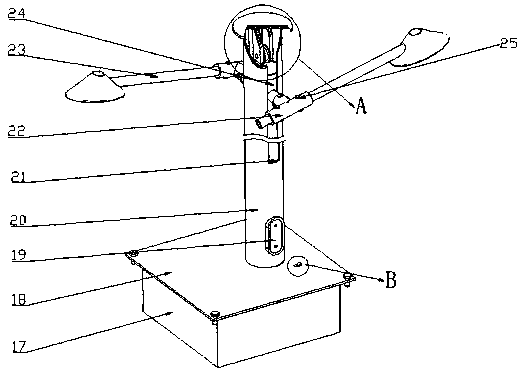

Electric adjustable type lifting streetlamp

ActiveCN106195836AEliminate immobilityEliminate disadvantages that are not easy to repairMechanical apparatusLighting support devicesSelf lockingEngineering

The invention discloses an electric adjustable type lifting streetlamp which comprises a hollow lamp post, a lamp arm arranged on the top of the hollow lamp post and a lamp head arranged on the end part of the lamp arm; a base box is fixedly arranged on the bottom of the hollow lamp post; a motor is fixedly arranged inside the base box; the motor is in transmission connection to a reduction mechanism through a motor shaft; a winding drum is arranged on the rotary shaft of the reduction mechanism; a slide block is arranged inside the hollow lamp post in a matched manner; the slide block is fixedly connected to the lamp arm through a slide slot in the side of the hollow lamp post; a slide wheel is arranged above the inner part of the hollow lamp post; the slide wheel is fixedly arranged on a slide wheel supporting base; a steel wire rope is wound on the winding drum; and the steel wire rope is fixedly connected to the slide block through the slide wheel. The electric adjustable type lifting streetlamp has the beneficial effects that: multiple limiting mechanism are adopted, and are used to realize lifting and self-locking safety by utilizing self-locking functions of worms and gears, limiting functions of ratchets and pawls, a regulating function of a limiting regulator and the like, so that maintenance safety can be guaranteed.

Owner:ZHEJIANG UNIV OF TECH

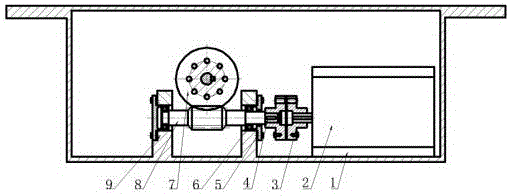

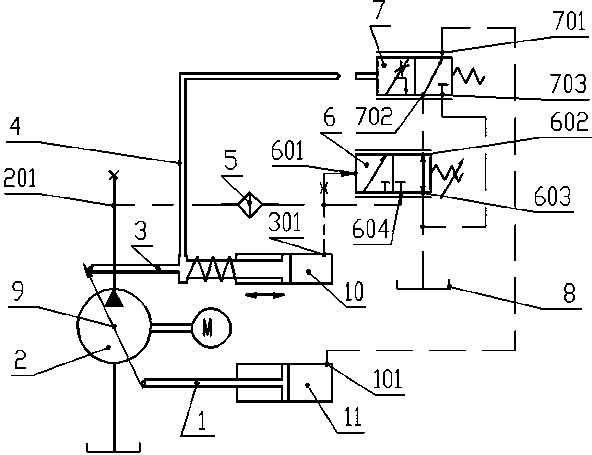

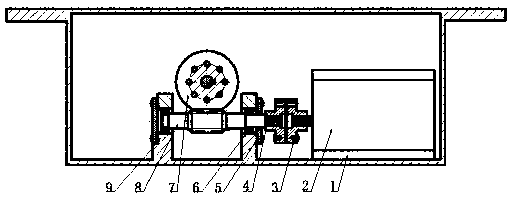

Constant-pressure control device and method for hydraulic pump

ActiveCN104179734AReduce displacementRelieve pressureServomotor componentsServomotorsFuel tankHydraulic pump

The invention discloses a constant-pressure control device and method for a hydraulic pump. An oil inlet of a fine filter is communicated with an oil discharge port of the hydraulic pump, an oil outlet of the fine filter is communicated with a constant-pressure control valve port P and a rodless cavity of a small variable piston at the same time, a constant-pressure control valve port A is communicated with a shock reducing valve port P, a constant-pressure control valve port T is communicated with a shock reducing valve port T and an oil tank at the same time, a constant-pressure control valve control port is communicated with the constant-pressure control valve port P through internal fixing damping, and a shock reducing valve port A is communicated with a rodless cavity of a large variable piston; a feedback rod is fixedly connected with the small variable piston, so that when pressure at the oil discharge port of the hydraulic pump is higher than pressure set by a proportional spring of a constant-pressure control valve, the feedback rod can be driven by the small variable piston to move to contact with a valve spool of a shock reducing valve and push the valve spool to move to the communicating station of the shock reducing valve port P and the shock reducing valve port T; when pressure at the oil discharge port of the hydraulic pump is lower than pressure set by the proportional spring of the constant-pressure control valve, the feedback rod can be separated from the valve spool of the shock reducing valve.

Owner:ZHEJIANG DETAI ELECTROMECHANICAL ENG

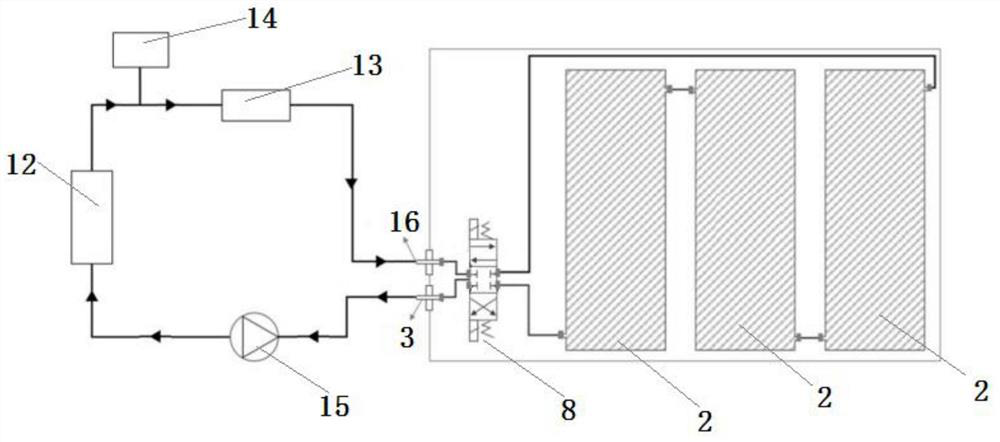

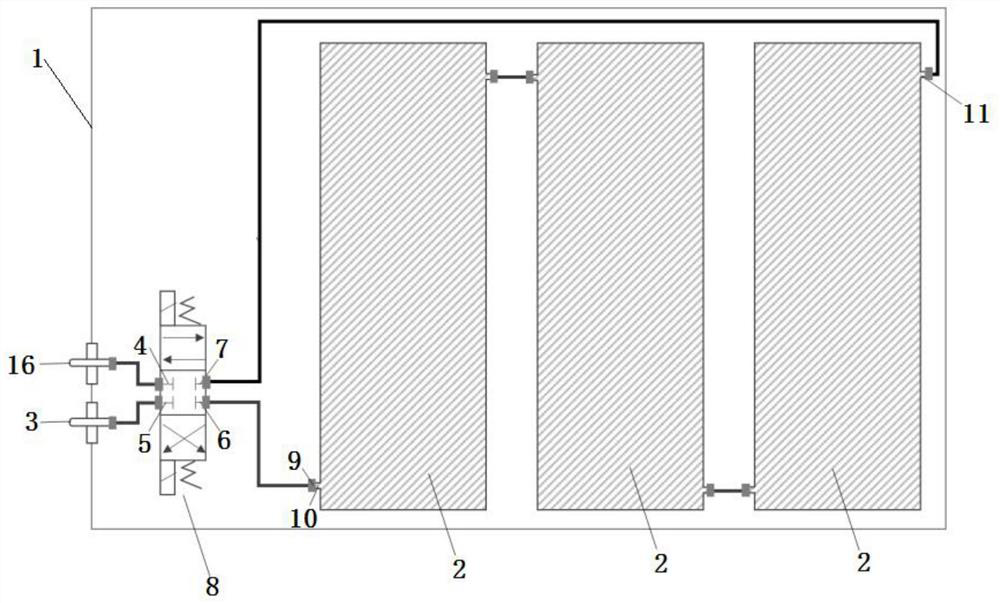

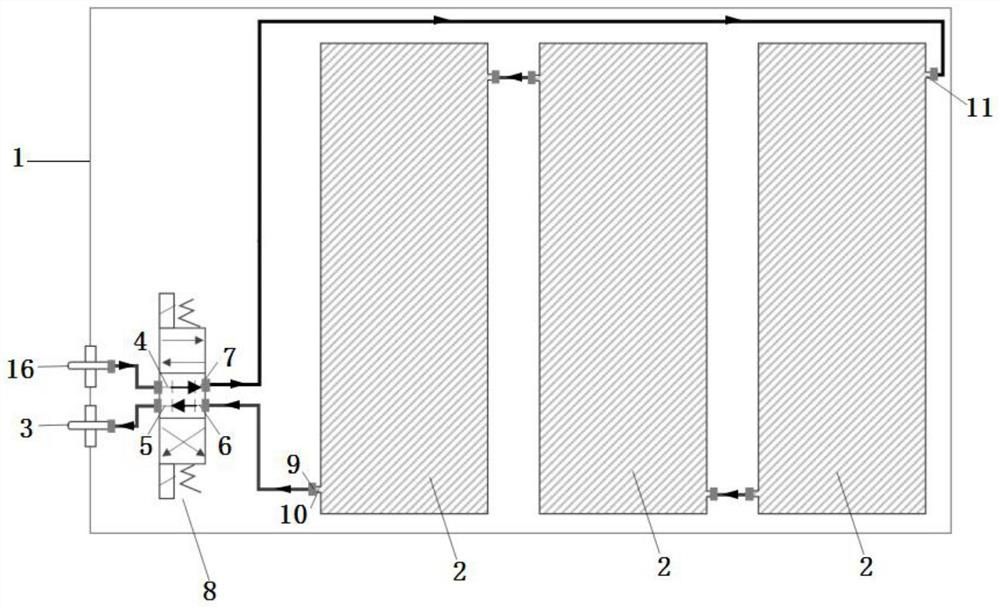

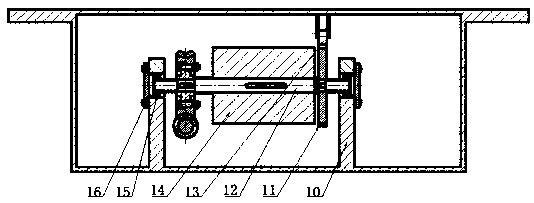

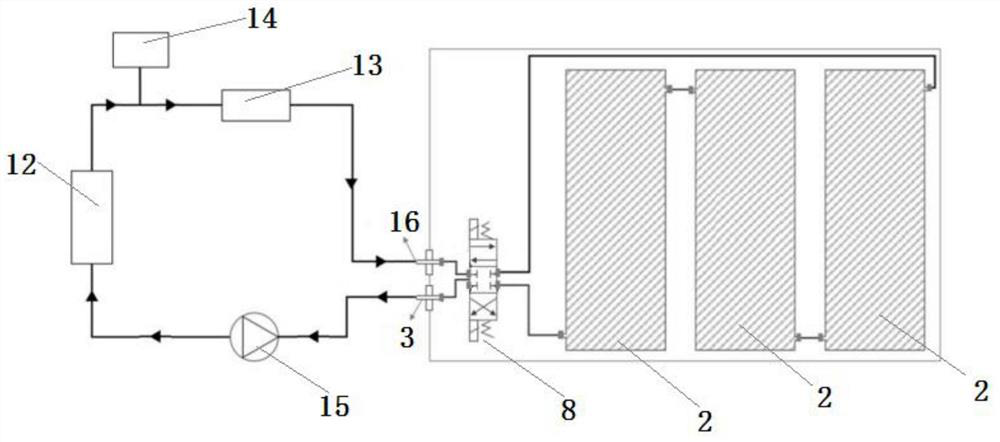

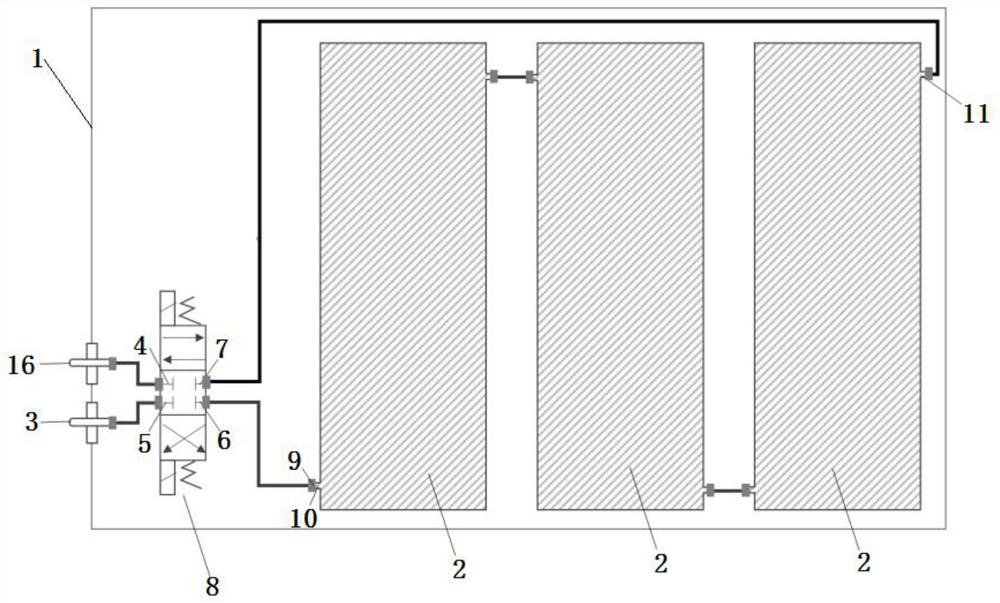

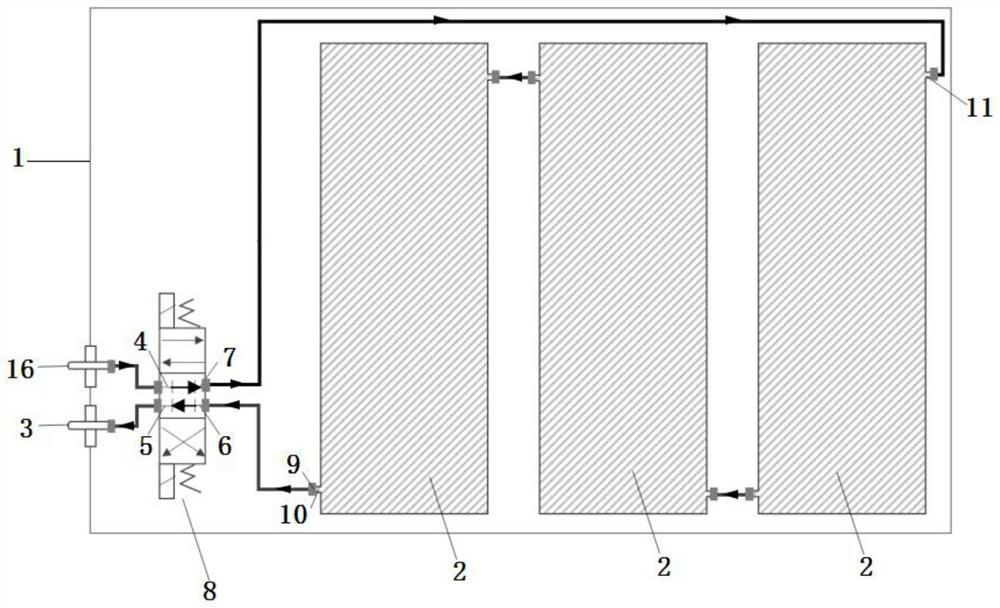

Cooling liquid flow direction controllable battery pack, battery pack thermal management system and control method

ActiveCN112151912AGuaranteed balanceReduce thermal variabilitySecondary cellsPropulsion by batteries/cellsPower batteryControl engineering

The invention discloses a cooling liquid flow direction controllable battery pack, a battery pack thermal management system and a control method. The battery pack comprises a battery pack shell and aliquid cooling plate arranged in the battery pack shell, and the battery pack shell is provided with a battery pack water inlet and a battery pack water outlet; and the liquid cooling plate comprisesa first liquid cooling plate pipe connector and a second liquid cooling plate pipe connector which are located on the left side and the right side of the liquid cooling plate, and a cooling liquid flow channel is formed between the first liquid cooling plate pipe connector and the second liquid cooling plate pipe connector. A steering device which is connected with the first liquid cooling plate pipe connector and the second liquid cooling plate pipe connector through pipelines and can change a flowing direction of a cooling liquid in the cooling liquid flow channel is further arranged in thebattery pack shell; and the steering device comprises a device water inlet connected with the battery pack water inlet through the pipeline and a device water outlet connected with the battery pack water outlet through the pipeline. According to the invention, long-standing temperature distribution fixity is eliminated, a heat dissipation difference of battery pack monomers is reduced, a service life of the power battery is prolonged, and the performance of the power battery is improved.

Owner:DONGFENG MOTOR CORP HUBEI

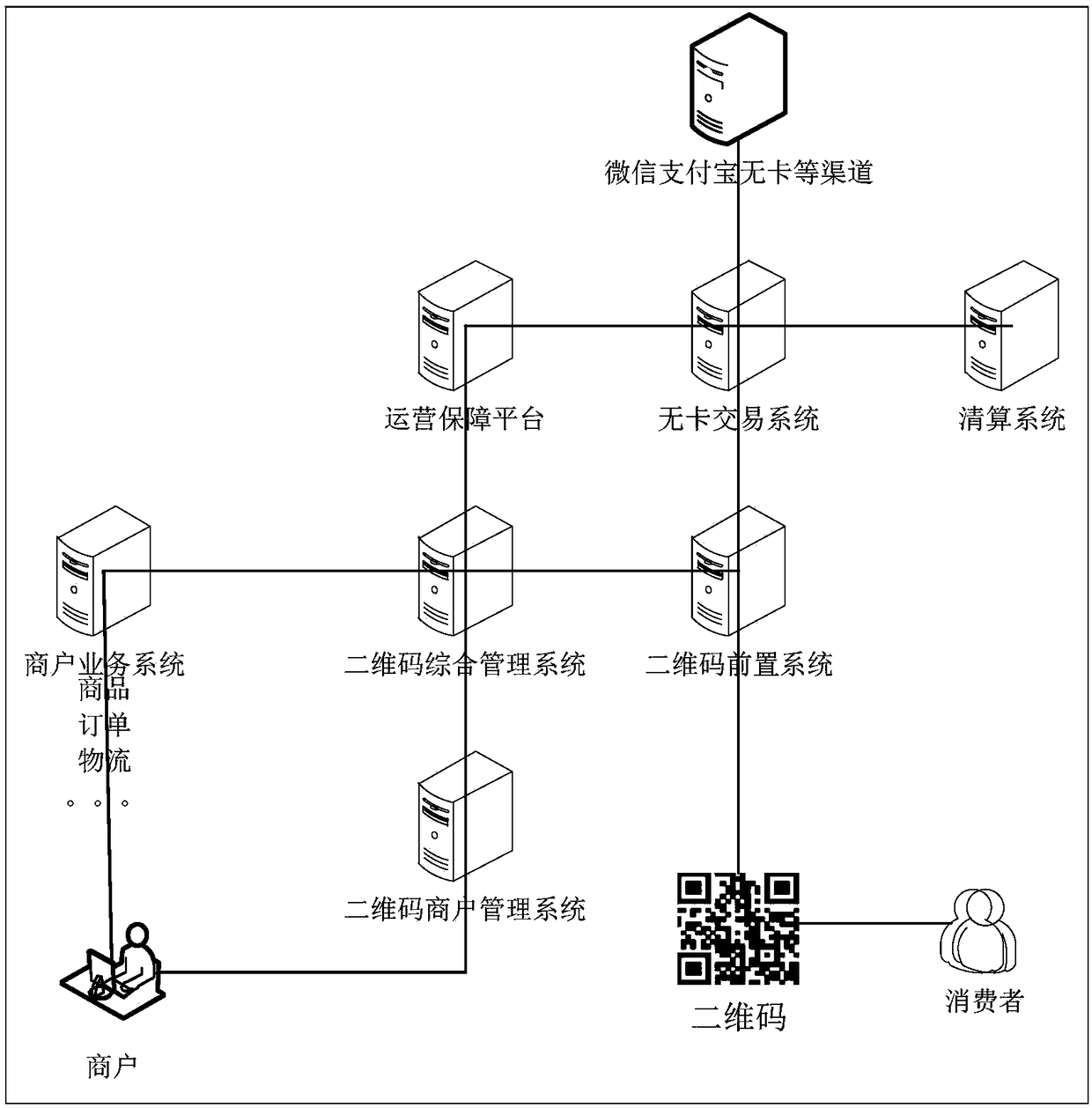

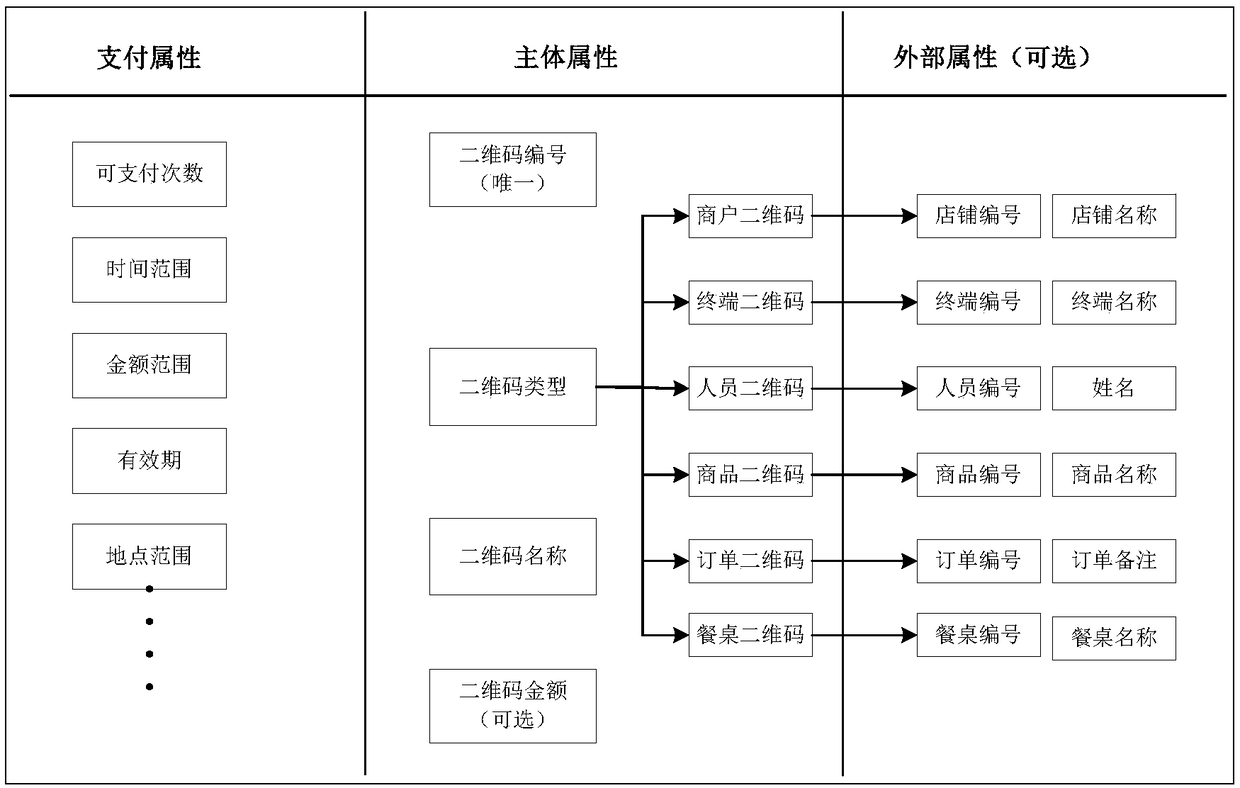

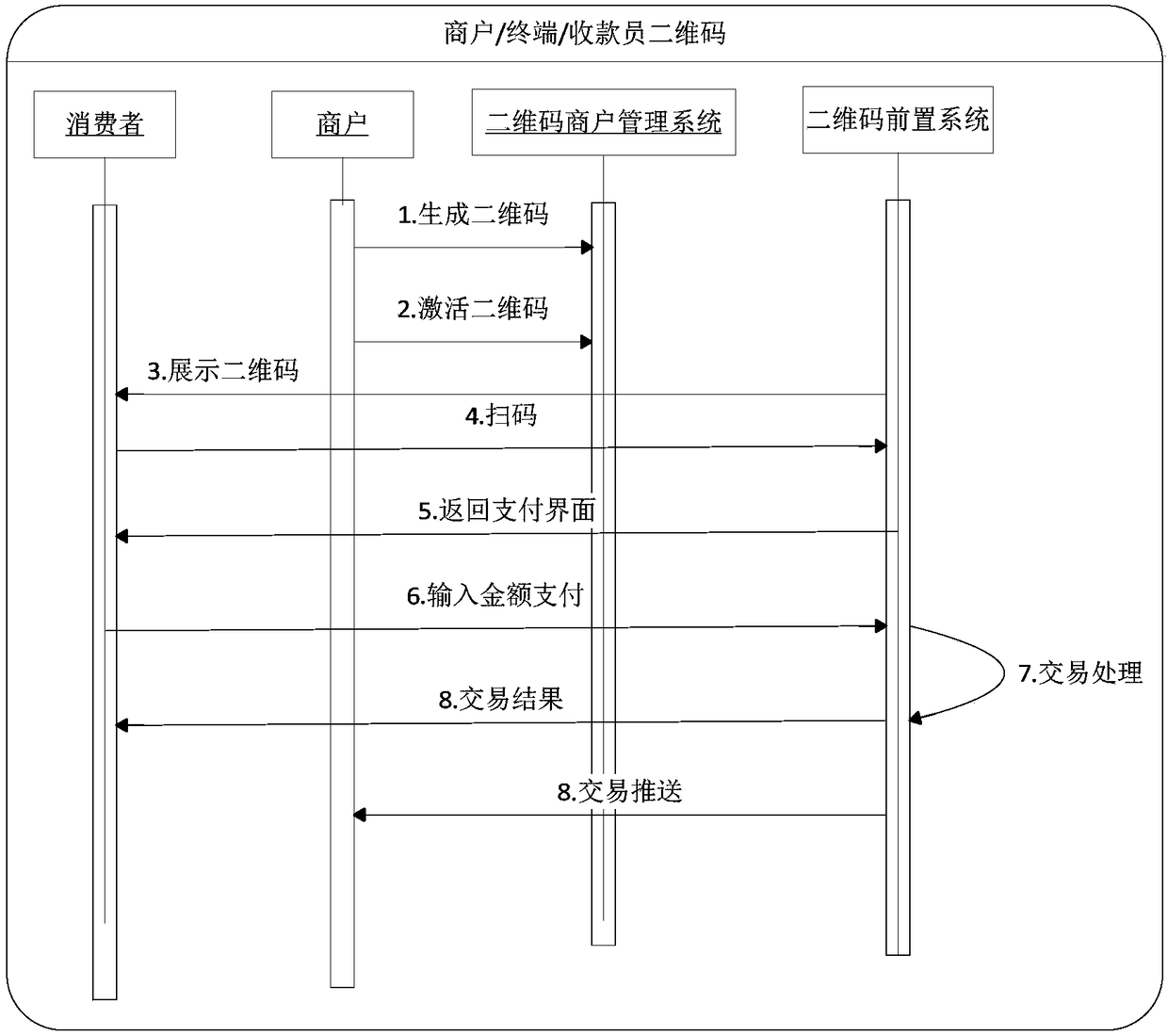

Two-dimensional code payment transaction processing platform

InactiveCN108171507AFlexible and convenient configurationConvenient and flexible configuration associationProtocol authorisationCommunication interfaceRisk Control

The invention discloses a two-dimensional code payment transaction processing platform comprising a two-dimensional code integrated management system, a two-dimensional code merchant management systemand a two-dimensional code front system. The two-dimensional code integrated management system is provided with a communication interface in communication connection with a merchant terminal system and a first configuration module used for configuring the attributes of a two-dimensional code. The two-dimensional code merchant management system is provided with a second configuration module used for configuring the attributes of a two-dimensional code. The attributes of a two-dimensional code include payment and subject attributes. The two-dimensional code front system is used for displaying aconfigured two-dimensional code, triggering the jump of a corresponding payment interface when the displayed two-dimensional code is being scanned, displaying the corresponding payment interface, andprocessing a transaction according to the payment information input on the payment interface. Through the use of the platform, configuration association can be carried out on the attributes of two-dimensional codes, so that the risk control ability of payment transaction can be improved, the compatibility of the platform can be improved, cost can be reduced, and a sufficient data basis can be provided for the subsequent management and analysis of two-dimensional codes. The platform of the invention can be widely applied to the field of payment transaction.

Owner:GUANGDONG JUNXIANG BUSINESS SERVICE

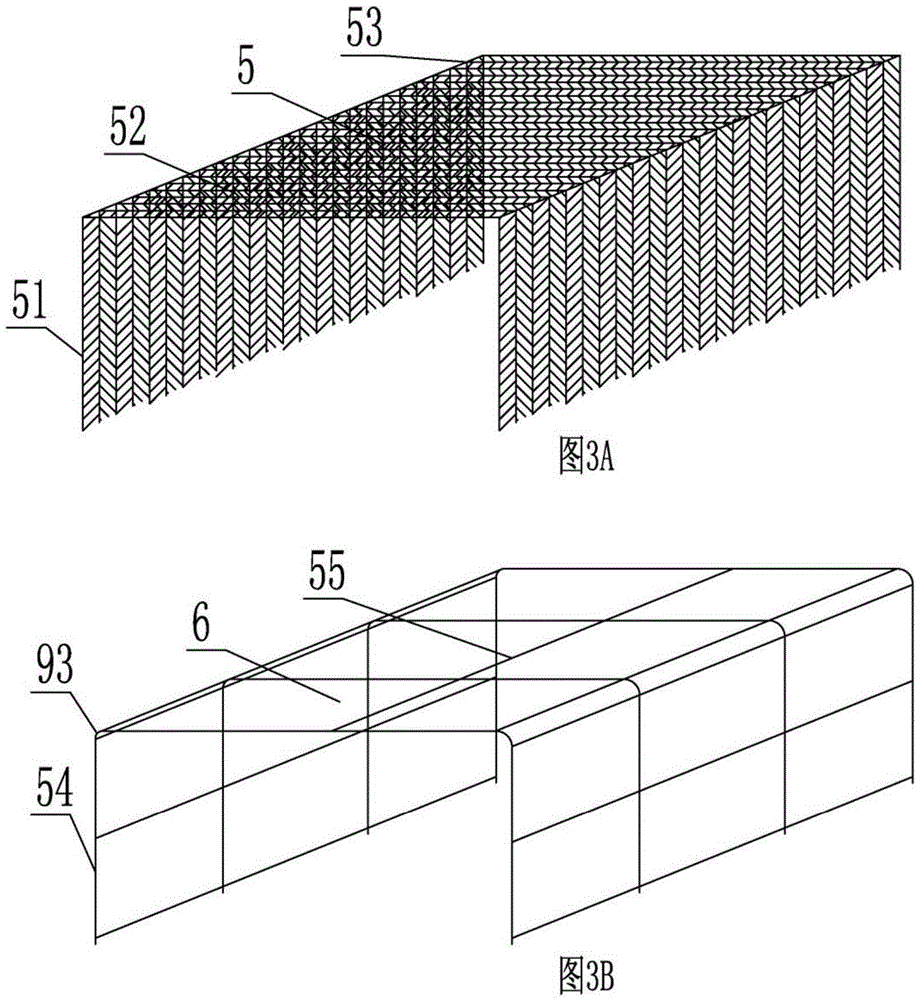

Foundation pit assembling type support structure and support construction method

ActiveCN111395351AEliminate immobilityEliminate widthExcavationsArchitectural engineeringEnvironmentally friendly

The invention provides a foundation pit assembling type support structure. The support structure comprises multiple prefabricated support segments and further comprises a switching piece and a tensioning component, wherein each prefabricated support segment comprises a support section and two end plates, and the two end plates of each prefabricated support segment are located at two end positionsof the corresponding support section respectively; every two adjacent prefabricated support segments are spliced through the end plates, the prefabricated support segments located at the end positionsare provided with sealing plates, and the sealing plates are detachably connected with the corresponding end plates; and the tensioning component is located at the outer side of cast-in-place concrete. The invention further provides a support construction method. The assembling type support structure is adopted in the method. The assembling type support structure is formed by splicing the multiple prefabricated support segments, so that the integrity is good, the requirement for bearing compressive stress can be met, and non-deformability is strong; and the structure can be recovered to be used repeatedly and is environmentally friendly and convenient to construct.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

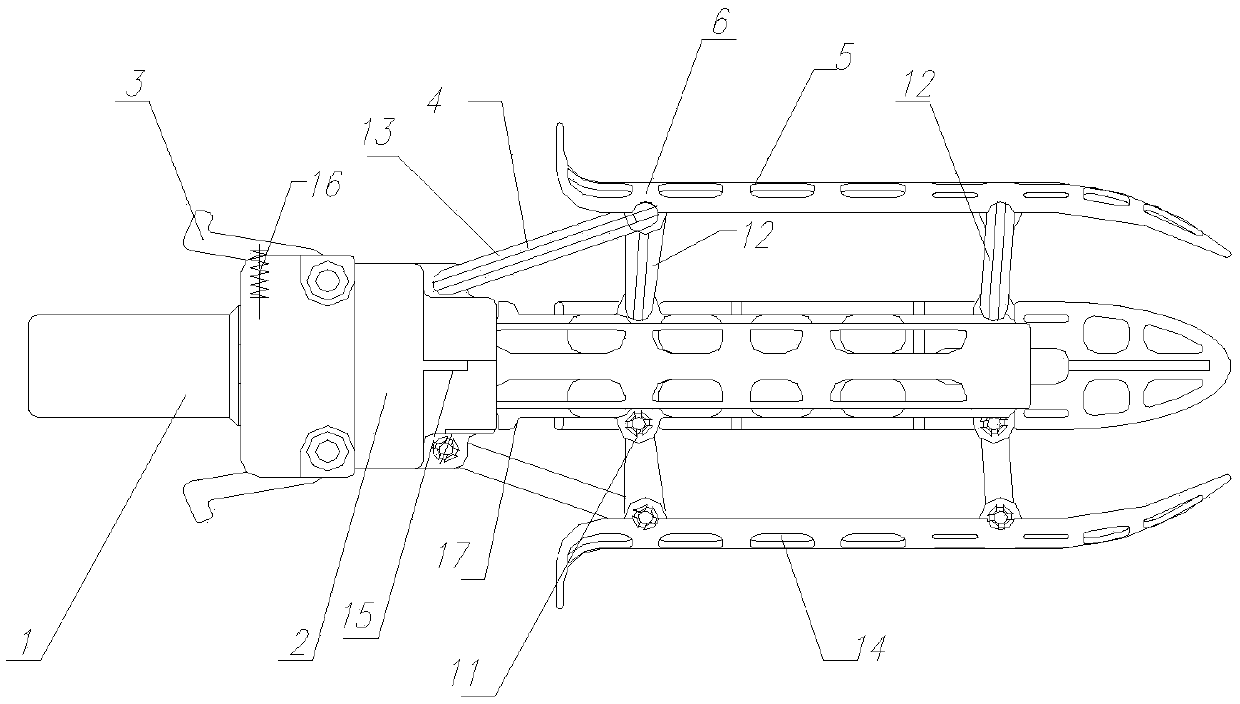

Disposable use vagina retractor

The invention provides a disposable vagina retractor. The retractor comprises a main tube, a movable sleeve, a pawl and an expansion piece, the movable sleeve and the pawl sleeve the outer side of themain tube, the movable sleeve is connected with the expansion piece through a connecting rod, and the retractor eliminates the fixed and large size of a current device, and reduces the pain of a patient; the defects that expected care and treatment cannot be conducted on a covering part and the like are overcome; the retractor is safe and reliable, is convenient to use, is low in technical requirements, avoids possible vaginal injuries and cross-infection, improves medical effects and work efficiency, can safely, effectively and easily check the vagina and cervix opening of the patient. In combination with relevant medical cleaning equipment, the patient is cleaned and cared or treated with medications by spraying a cleaning solution or a medical treatment solution through the retractor.

Owner:上海国颂医疗科技有限公司

Ribbed steel mesh hollow for cast-in-situ hollow floor slab

The invention discloses a ribbed steel mesh hollow for a cast-in-situ hollow floor slab. The ribbed steel mesh hollow consists of a hollow mesh, a supporting mesh, a hollow end mesh, wherein the hollow mesh, the hollow end mesh and the supporting mesh are made of a pure metal material; the hollow mesh forms the periphery of the ribbed steel mesh hollow; the hollow end mesh closes the ribbed steel mesh hollow and the supporting mesh to form a hollow end section shape of the ribbed steel mesh hollow; the supporting mesh controls the height of the interior space of the ribbed steel mesh hollow; the hollow mesh and the hollow end mesh are made of a steel mesh body; the steel mesh body comprises steel plate enlarging mesh holes, a V-shaped rib and a reversing connecting sheet; the enlarging mesh holes in the two sides of the reversing connecting sheet are in different directions; the V-shaped rib has the height of greater than 6mm; at least four measuring shaping marks are pressed in the vertical direction of the V-shaped rib of the steel mesh body of the hollow mesh; the supporting mesh is made of a steel mesh body or a steel bar mesh body. The hollow floor slab is cast by using the ribbed steel mesh hollow, and the ribbed steel mesh hollow is directly cast in situ into concrete on the edge of a hollow, so that a temperature crack of the floor slab is inhibited.

Owner:王海崴 +2

A reticulated box-shaped component for forming holes in cast-in-place hollow floor

The invention provides a netlike box-shaped component for forming holes in a cast-in-situ hollow floor. The netlike box-shaped component is formed by combining a box roof, a box body (side wall) and a box bottom; the box roof is compounded with cement mortar or styrofoam or a board; the box body and the box bottom are manufactured by netlike bodies; each netlike body comprises a netlike board, reinforcing ribs and connecting nets; the netlike board, the reinforcing ribs and the connecting nets form an interacting integral structure; the area of a grid in the netlike board is smaller than 120 mm<2>; the reinforcing ribs are V-shaped; the reinforcing ribs are higher than 3mm; the space between the reinforcing ribs in each netlike body is larger than 30mm; the netlike box-shaped component is formed by combining at least two netlike bodies; at least two structural inclined planes are arranged at corners of the box bottom and the box body of the netlike box-shaped component; the netlike bodies of the netlike box-shaped component are made of steel or plastic. The unsealed netlike box-shaped component replaces a fully-sealed hollow filling body and a solid filling body as a hole forming technology of the conventional cast-in-situ hollow floor, so that technical defects of the existing hollow floor are effectively solved.

Owner:王本淼 +1

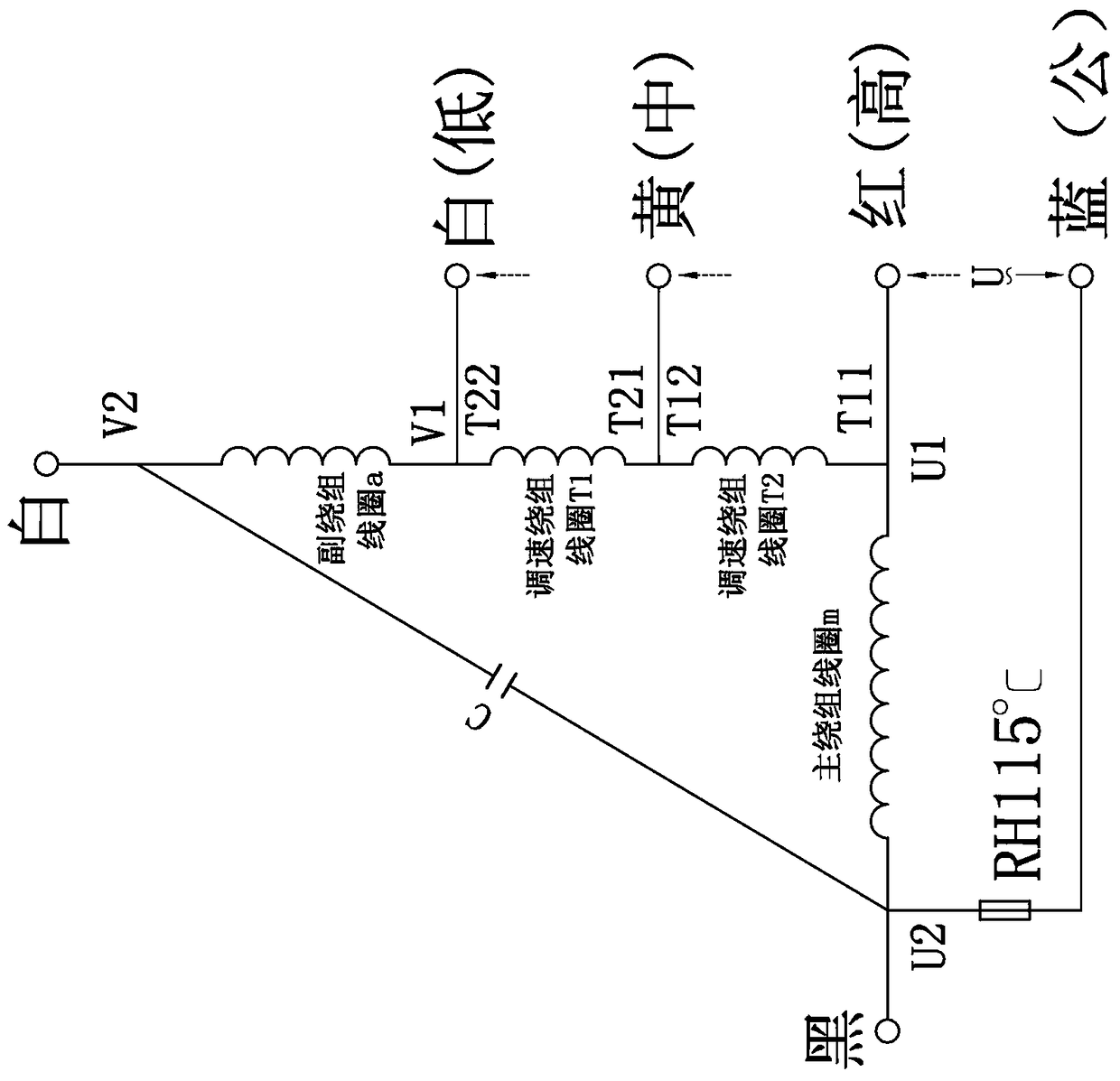

A Winding Wiring and Wiring Structure for Single-phase Asynchronous Motor

ActiveCN104953776BAvoid direct contactAvoid complicatedAsynchronous induction motorsWindings conductor shape/form/constructionEngineeringConductor Coil

Owner:河北超亚电子科技股份有限公司

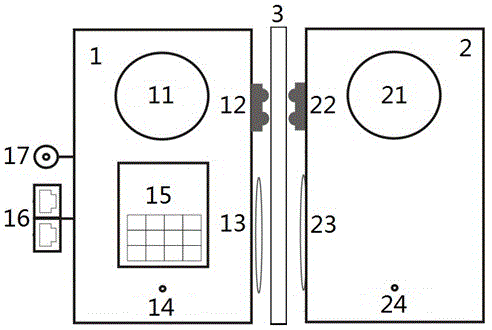

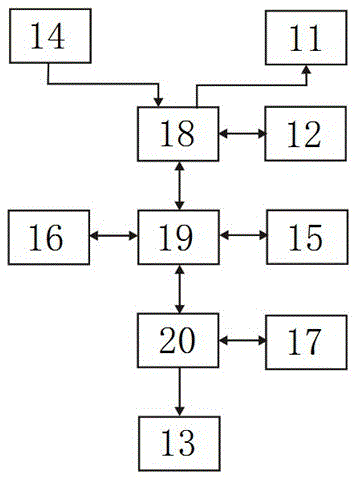

A window intercom device and method based on infrared carrier transmission signal powered by magnetic induction

ActiveCN103763027BEliminate immobilitySpeech is clearly intelligibleCircuit arrangementsClose-range type systemsPunchingWireless transmission

The invention discloses a window talkback device and method of an infrared carrier wave transmission signal based on powering of magnetic induction. An auxiliary talkback device power supply is charged in a magnetic induction mode and the infrared wireless transmission technology is adopted in audio transmission between a main talkback device and an auxiliary talkback device. The window talkback device and method of the infrared carrier wave transmission signal based on powering of the magnetic induction are mainly applied to occasions of counter window inside-outside talkback such as banks and hospitals and used for finishing audio double-direction synchronous transmission of the inside of the window and the outside of the window. In addition, an outdoor machine is designed to be a wireless panel, so that fixing by pasting or punching and wire laying in installation is omitted. The microphone-rod-free panels which are identical in appearance are adopted in the main talkback device and the auxiliary talkback device and a full duplex hands-free manner is adopted in the talkback process, so that voices of two sides can be clearly distinguished even if both sides talk at the same time.

Owner:世邦通信股份有限公司

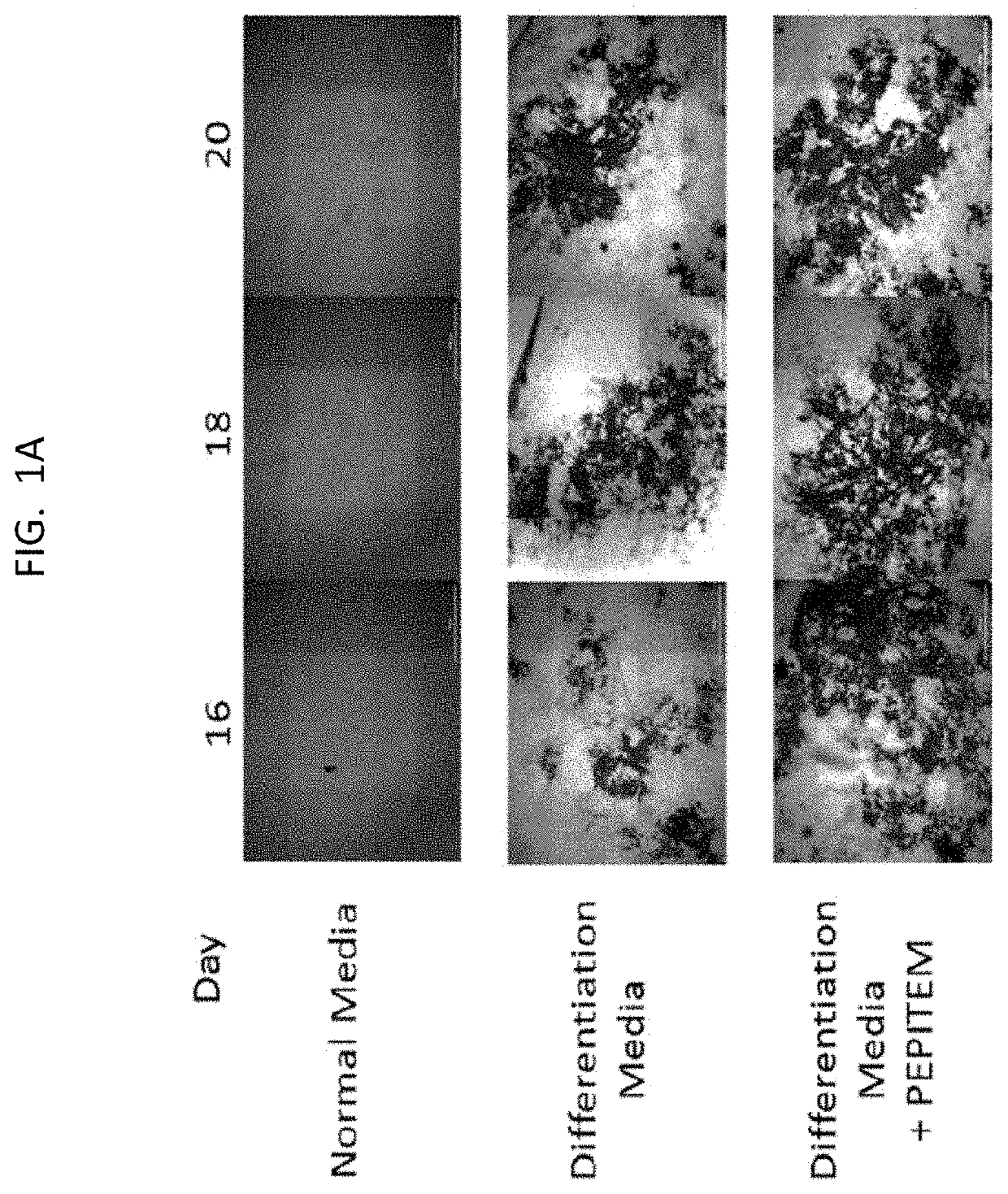

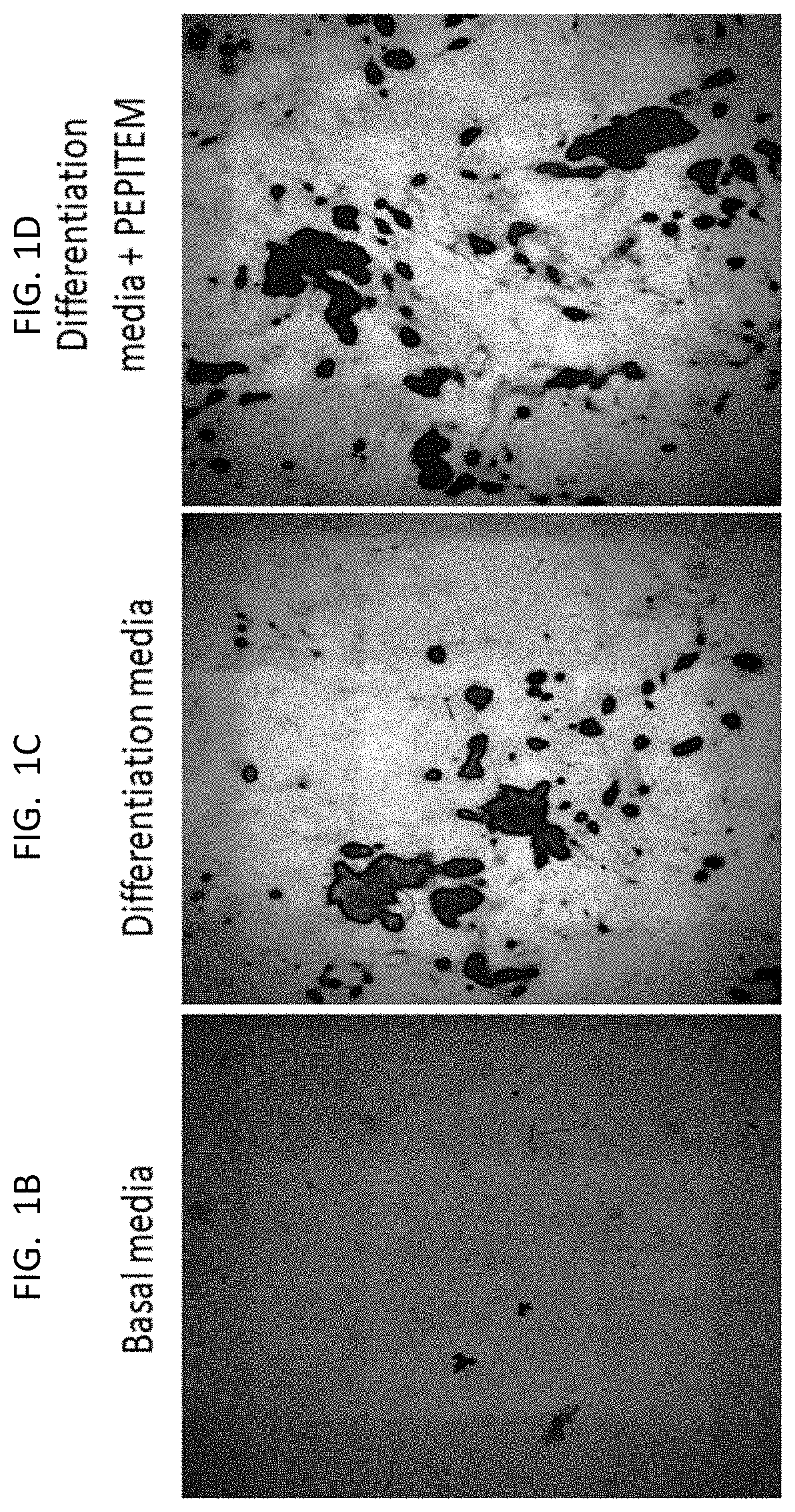

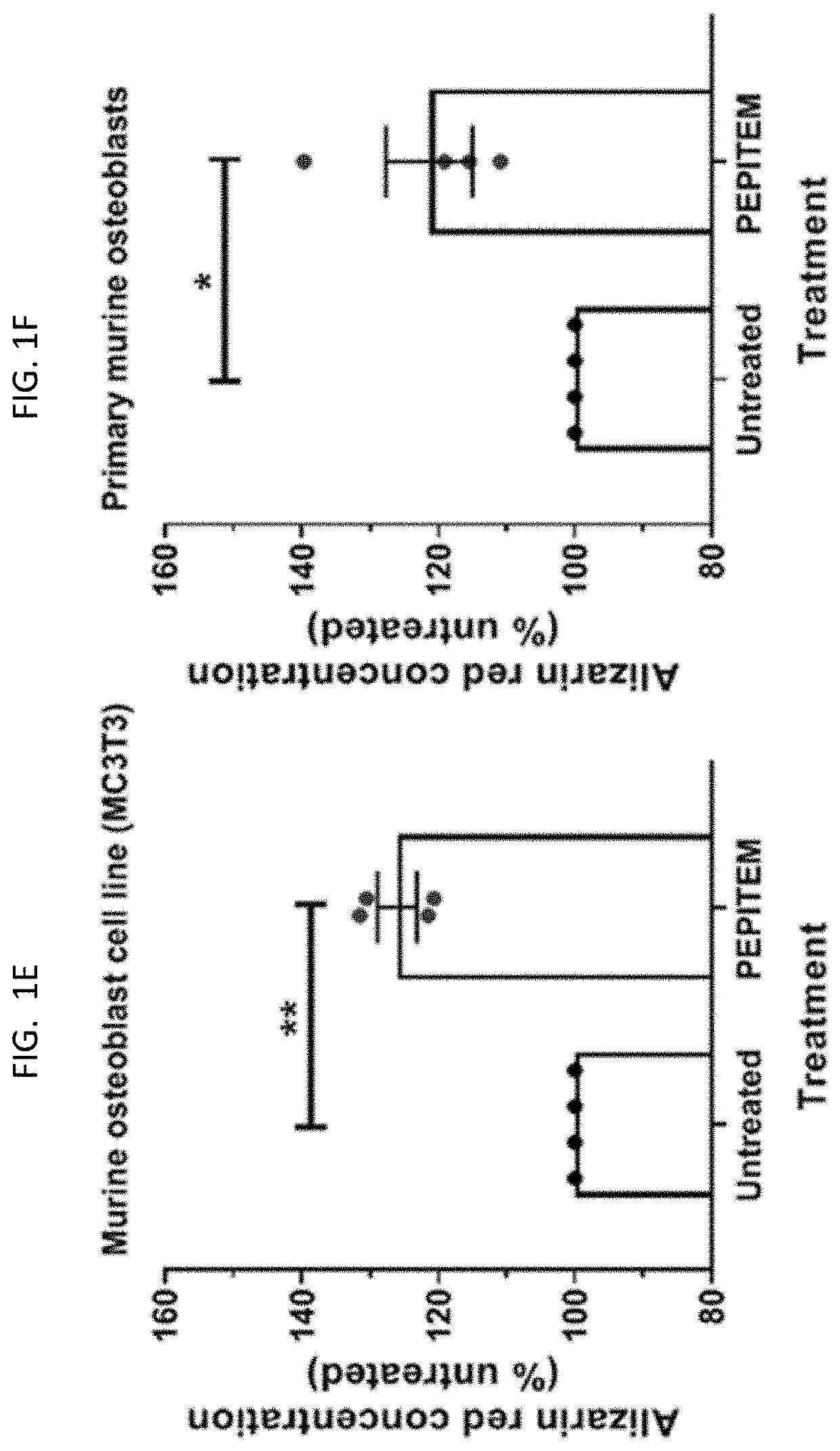

Bone disease treatment

PendingUS20210100870A1Reducing bone lossAvoid a lotPeptide/protein ingredientsSkeletal disorderOsteocytePharmacology

The present invention concerns methods of reducing bone loss and / or stimulating bone production comprising administering an effective amount of a peptide comprising the amino acid sequence SVTEQGAELSNEER (SEQ ID NO:1), or variants thereof, to a patient and / or bone cells. The present invention also concerns methods of treatment and / or prophylaxis of musculoskeletal loss and / or damage in a patient, comprising administering an effective amount of the peptide.

Owner:THE UNIV OF BIRMINGHAM

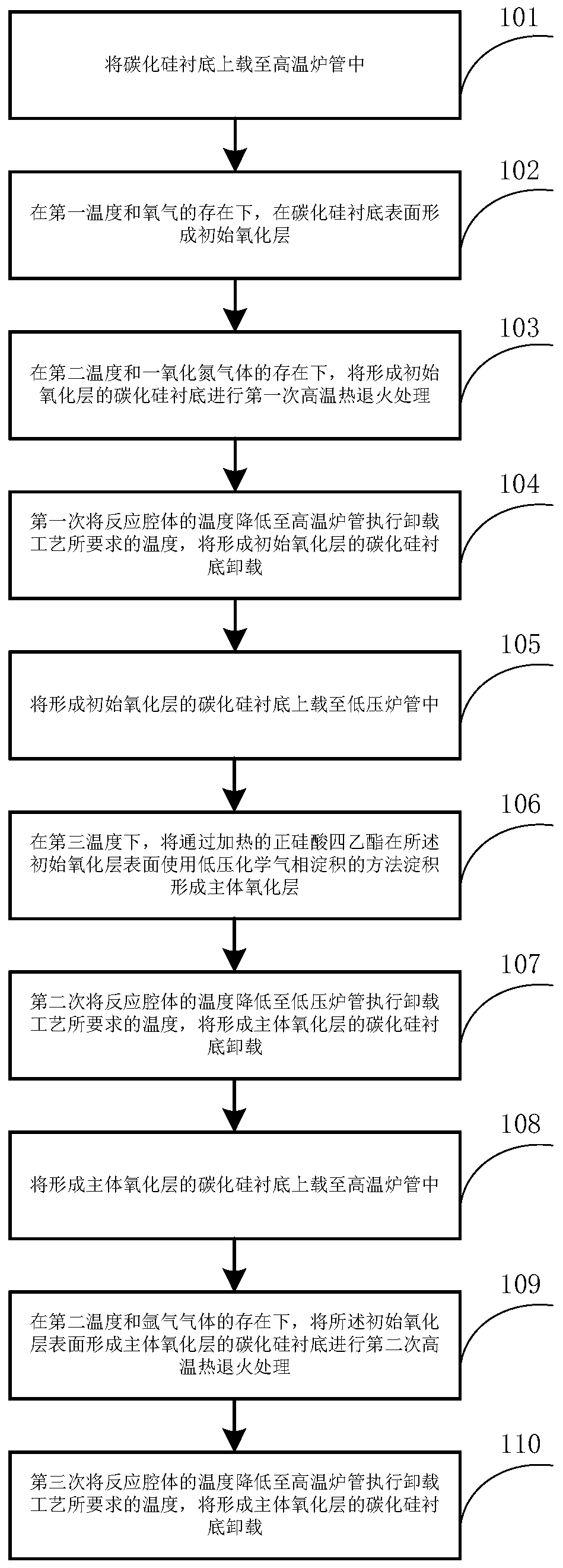

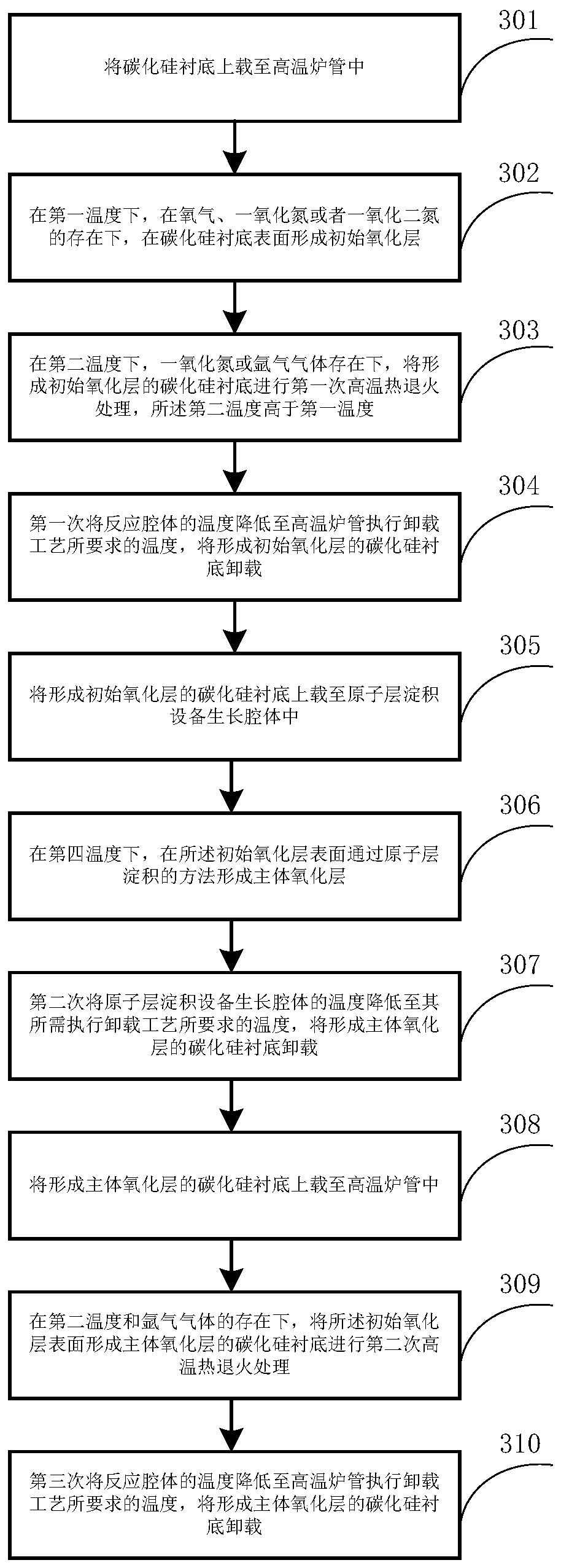

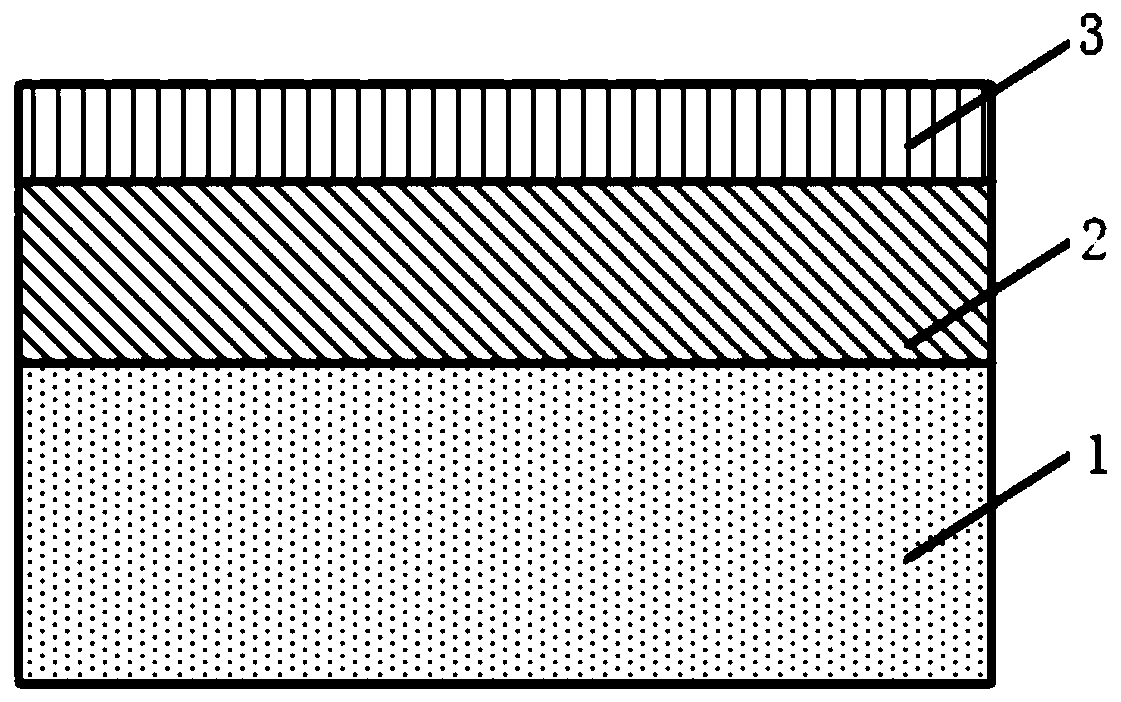

Method of fabricating gate oxide layer on silicon carbide material

InactiveCN110783174AReduce the total amount of chargingQuality improvementSemiconductor/solid-state device manufacturingCarbide siliconArgon atmosphere

The invention provides a method of fabricating a gate oxide layer on a silicon carbide material. The method comprises the following steps of: (1) loading a silicon carbide substrate into a high-temperature furnace tube, (2) forming an initial oxide layer on the surface of the silicon carbide substrate at a first temperature in an oxygen atmosphere, (3) carrying out first high-temperature thermal annealing treatment on the silicon carbide substrate at a second temperature in an argon atmosphere, (4) unloading the silicon carbide substrate, (5) loading the silicon carbide substrate to a cavity of a low-pressure furnace tube, and forming a main body oxide layer at a third temperature by using a low-pressure chemical vapor deposition method, (6) unloading the silicon carbide substrate, (7) loading the silicon carbide substrate into the high-temperature furnace tube, (8) carrying out second high-temperature thermal annealing treatment on the silicon carbide substrate at a second temperaturein an argon atmosphere, and (9) unloading the silicon carbide substrate. According to the method, the interface state density and the fixed charge quantity of the oxide layer can be effectively reduced, so that the performance of the gate oxide layer is improved.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

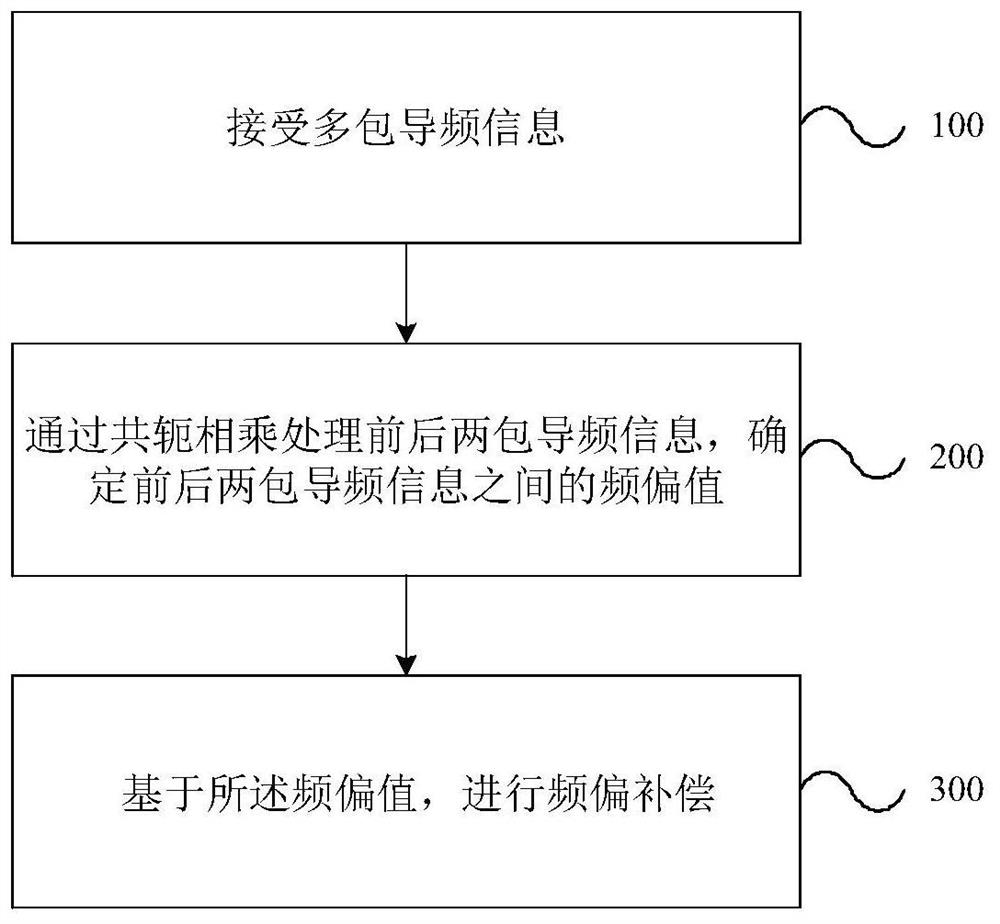

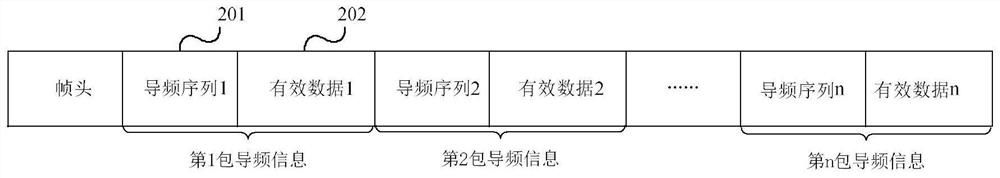

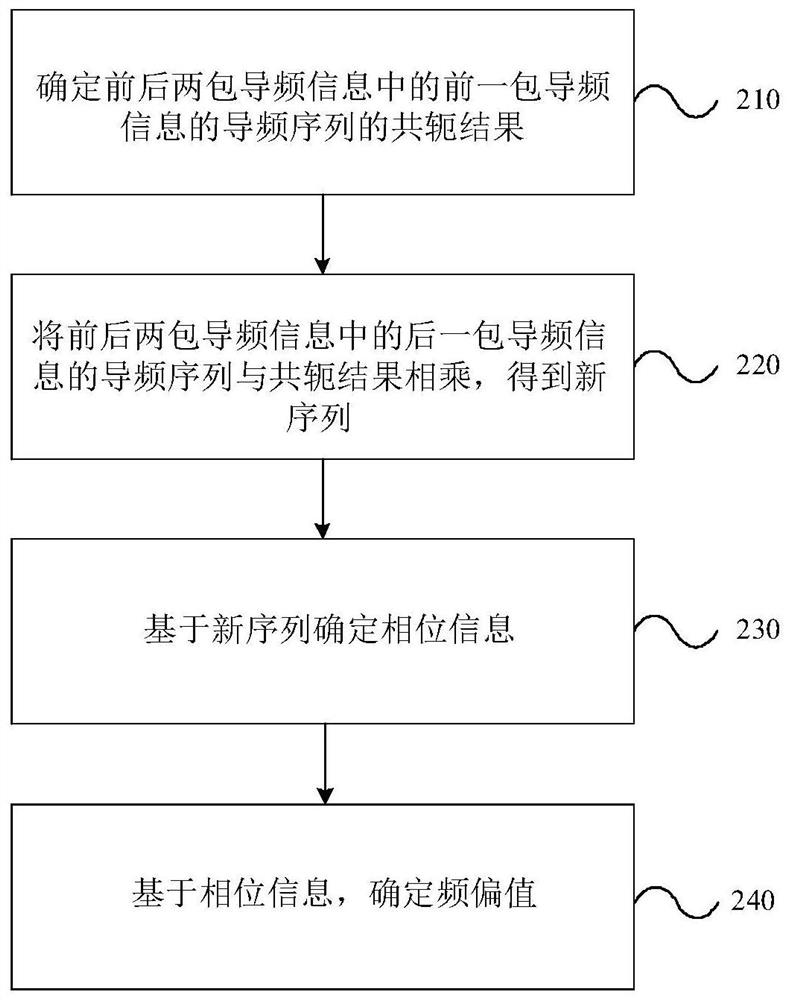

Frequency offset correction method and receiver

ActiveCN111585924BEliminate immobilityCarrier regulationMultiple carrier systemsTime domainTelecommunications

An embodiment of the present invention provides a frequency offset correction method and a receiver, wherein the method includes: receiving multiple packets of pilot information; processing two packets of pilot information through conjugate multiplication, and determining the two packets of pilot information A frequency offset value between information; performing frequency offset compensation based on the frequency offset value. The receiver is used to execute the above method. The frequency offset correction method and receiver of the embodiments of the present invention do not occupy or waste any frame structure resources, and at the same time perform frequency offset estimation in the time domain, which is simpler and faster, and is more suitable for the use environment of frequency domain equalization.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

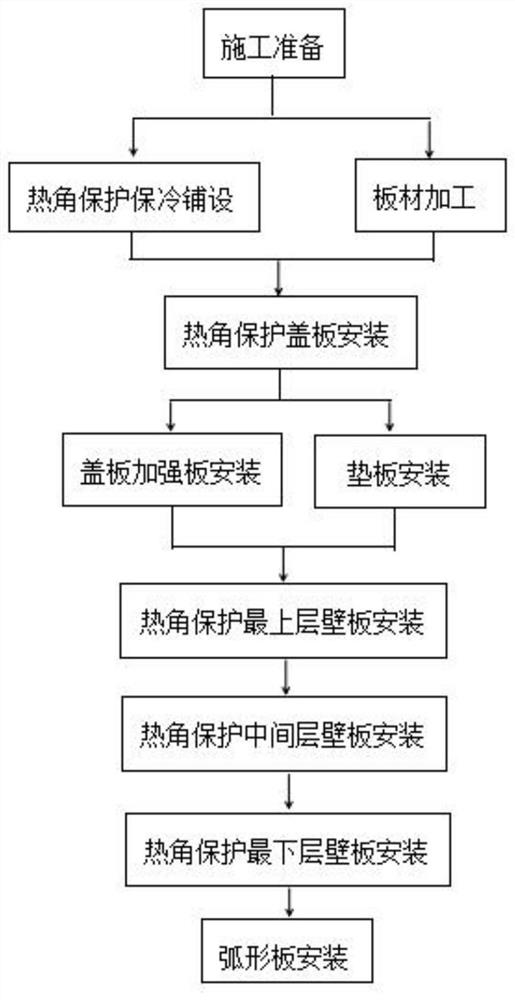

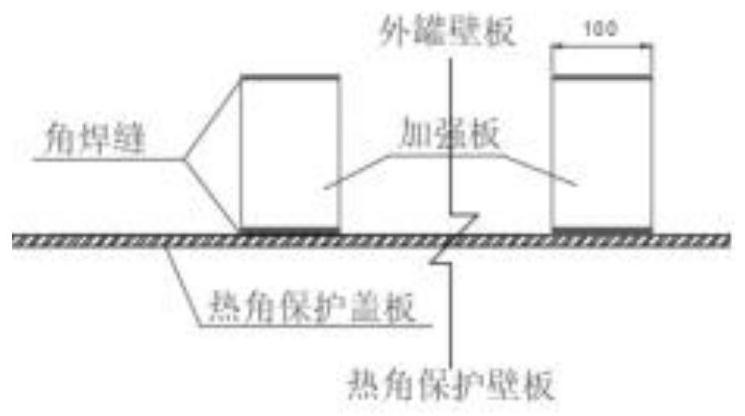

LNG bimetal full-capacity storage tank hot corner protection upside-down construction method

PendingCN113266757AEliminate immobilitySmall amount of deformationVessel mounting detailsVessel wallsBrickArchitectural engineering

The invention belongs to the technical field of bimetal full-capacity storage tanks, and particularly relates to an LNG bimetal full-capacity storage tank hot corner protection upside-down construction method. The method comprises the steps of construction technology process, material and equipment, quality control, safety measures and environmental protection measures, the construction technology process comprises the steps of construction preparation, hot corner protection cold insulation laying, plate machining, hot corner protection cover plate installation, base plate installation, uppermost-layer hot corner protection wall plate installation, lower-layer hot corner protection wall plate installation, arc-shaped plate installation, inspection and testing, the step of hot corner protection cold insulation laying comprises the following operation steps that S1, before foam glass bricks are laid, dirt on the surface of the inner side of an outer tank wall is removed, and the surface is dry, free of dust and free of oil contamination; and S2, the foam glass bricks are pasted by adopting special low-temperature-resistant glue, all the contact faces are firmly pasted by adopting a full-coating mode, and the low-temperature-resistant glue should be fully coated. According to the construction method, the hot corner protection wall plate is installed through an inverted installation method, inclined support fixing is not needed, and the deformation generated in the construction process is extremely small.

Owner:CHINA RAILWAY 18TH BUREAU GRP CO LTD +1

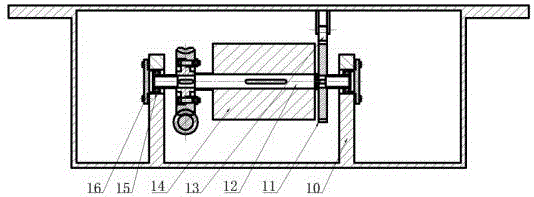

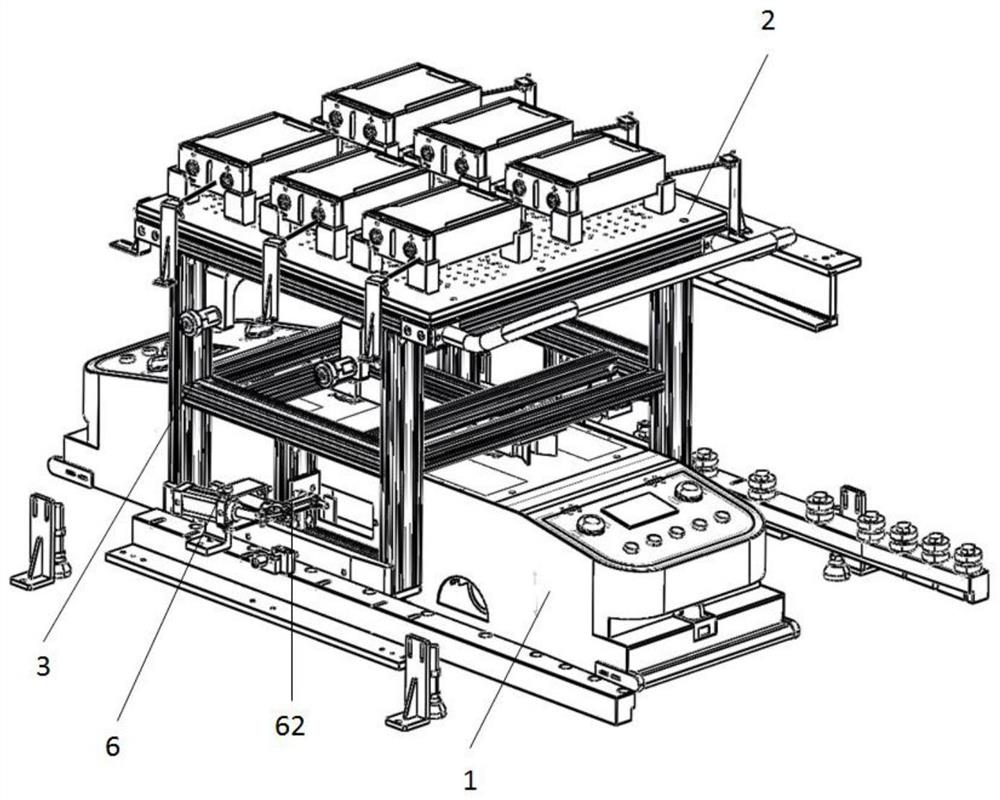

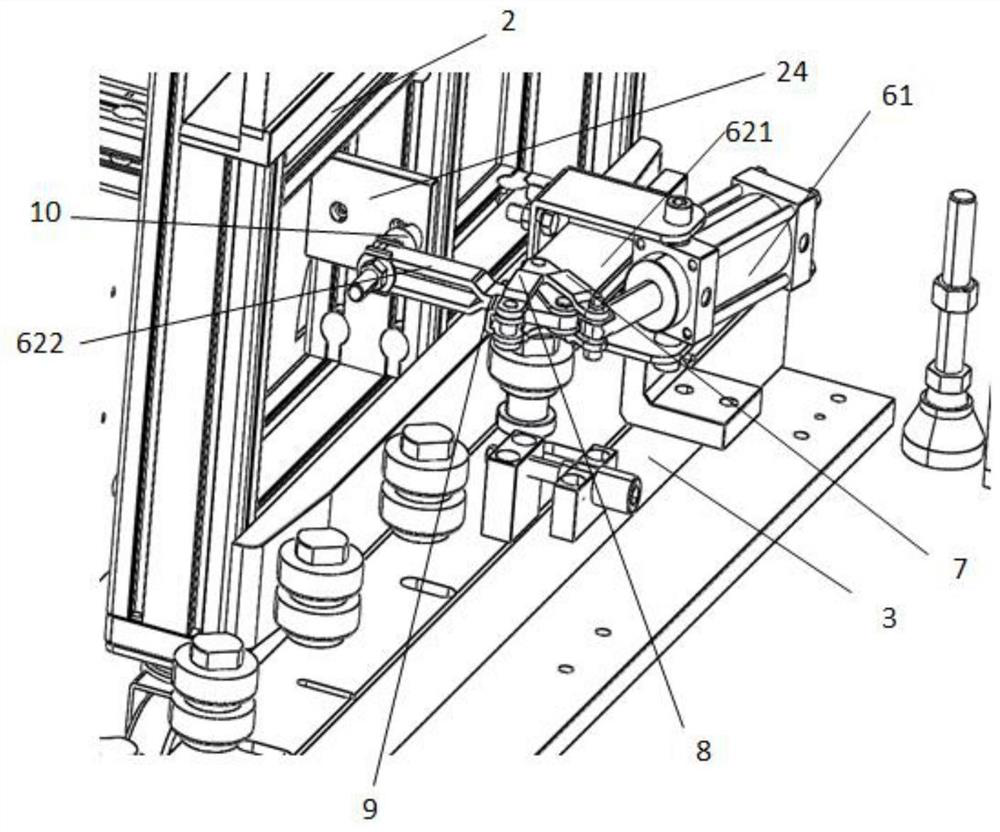

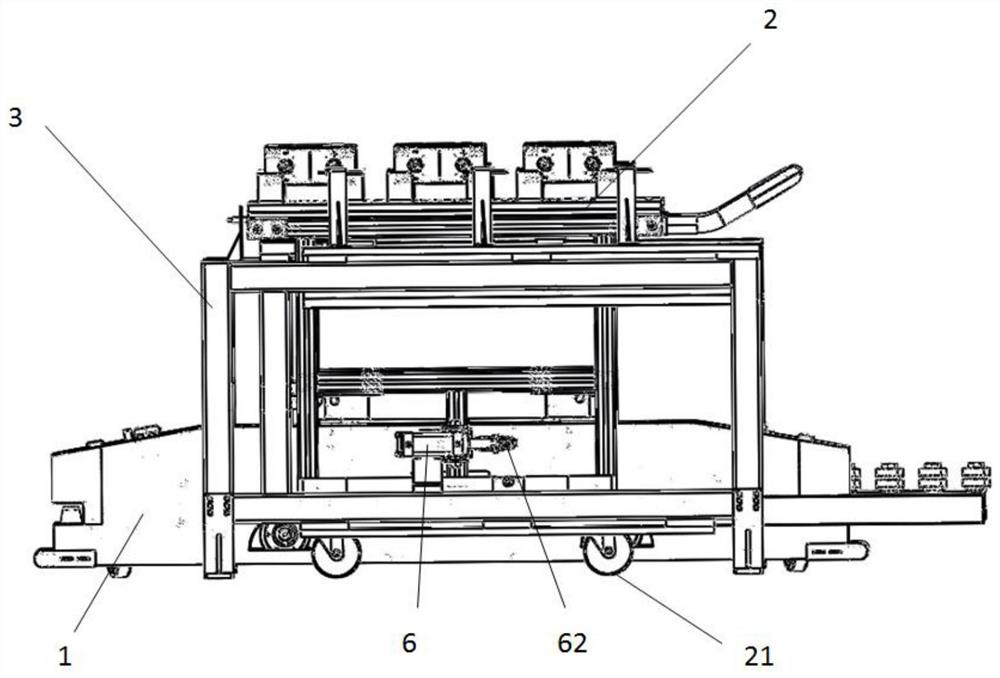

Positioning bearing mechanism for moving unit and fixing method

PendingCN112810725AImprove work efficiencyEliminate distractionsItem transportation vehiclesMechanical engineeringControl theory

Owner:SUZHOU YIMEIDE TECH CO LTD

Foundation pit prefabricated support structure and support construction method

ActiveCN111395351BEliminate immobilityTo meet the compressive stressExcavationsArchitectural engineeringEnvironmentally friendly

The invention provides a foundation pit assembled support structure, which includes a plurality of prefabricated support segments, and also includes a transition piece and a tensioning assembly, each of the prefabricated support segments includes a support segment and two end plates, two of which are The end plates are respectively located at two end positions of the support section, two adjacent prefabricated support sections are spliced by the end plates, and the prefabricated support section at the end position has a seal. The sealing plate is detachably connected to the corresponding end plate, and the tensioning assembly is located outside the cast-in-place concrete; a support construction method is also provided, which adopts the above-mentioned assembled support structure. In the present invention, the prefabricated support structure is formed by splicing a plurality of prefabricated support segments, the integrity is good, it can withstand compressive stress, has strong deformation resistance, and can be recycled and reused, which is environmentally friendly and convenient for construction.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

A high-temperature and high-line pressure microeutectic method to enhance the strength of PTFE-based membranes

ActiveCN112297475BExcellent abrasion resistanceImprove toughnessWind energy generationFlat articlesComposite filmMembrane surface

Owner:CHINA THREE GORGES CORPORATION +2

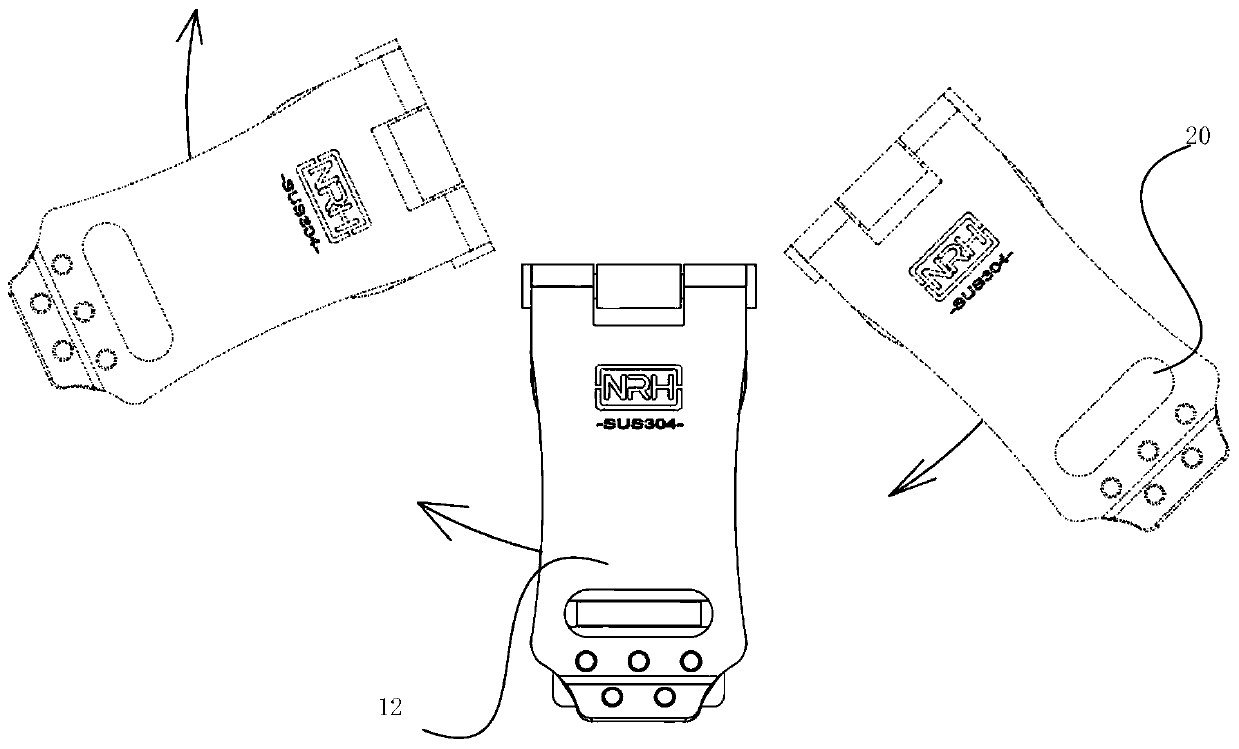

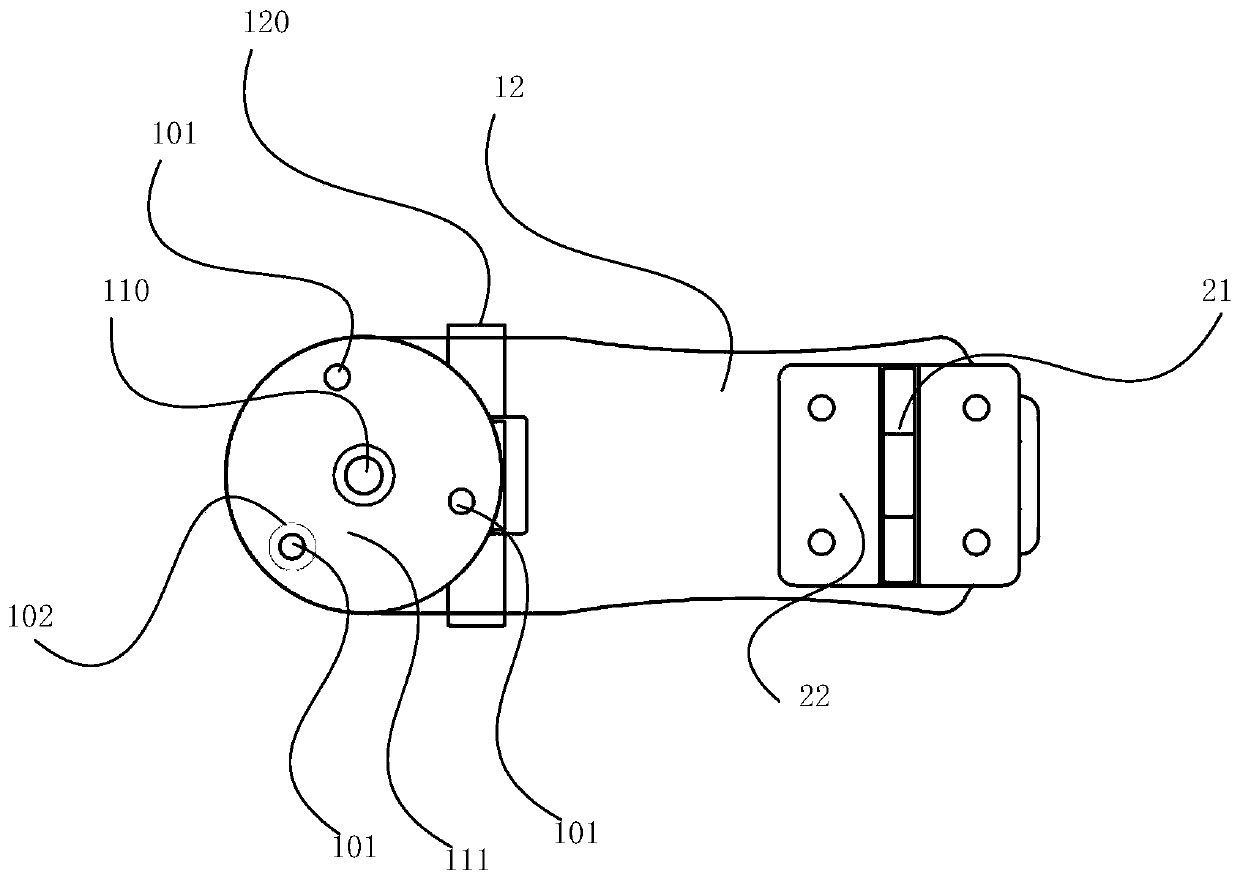

Multi-angle mounted hasp mechanism capable of automatically returning

PendingCN110005279AAvoid human body scratches and collisionsEliminates fixed mounts and non-resettablePadlocksScratchingEngineering

The embodiment of the invention relates to a multi-angle mounted hasp mechanism capable of automatically returning. The multi-angle mounted hasp mechanism comprises a hasp base and a hasp body movablyconnected with the hasp base, wherein the hasp base comprises a mounting base and a connecting panel, the connecting panel and the mounting base are movably connected through a rotatable mechanism toenable the connecting panel to rotate at multiple angles relative to the mounting base, and the hasp body is connected with the connecting panel through a movable connecting part; and the hasp mechanism also comprises a padlock device matched with the hasp body, the padlock device comprises a lug panel and a lug mounting seat used for fixing the lug panel, and the hasp body is provided with a through hole through which a lug passes. According to the embodiment of the hasp mechanism, the connecting panel is movably connected with the mounting base through the rotatable mechanism, so that the connecting panel rotates at multiple angles relative to the mounting base; and the hasp body is tightly attached to a product to be provided with the hasp body through the gravity to avoid scratching and collision of the human body, and 360-degree rotation of the connecting panel and an installation plate eliminates the defects of fixed installation and reset incapability of a traditional hasp.

Owner:上海纳汇五金制品有限公司

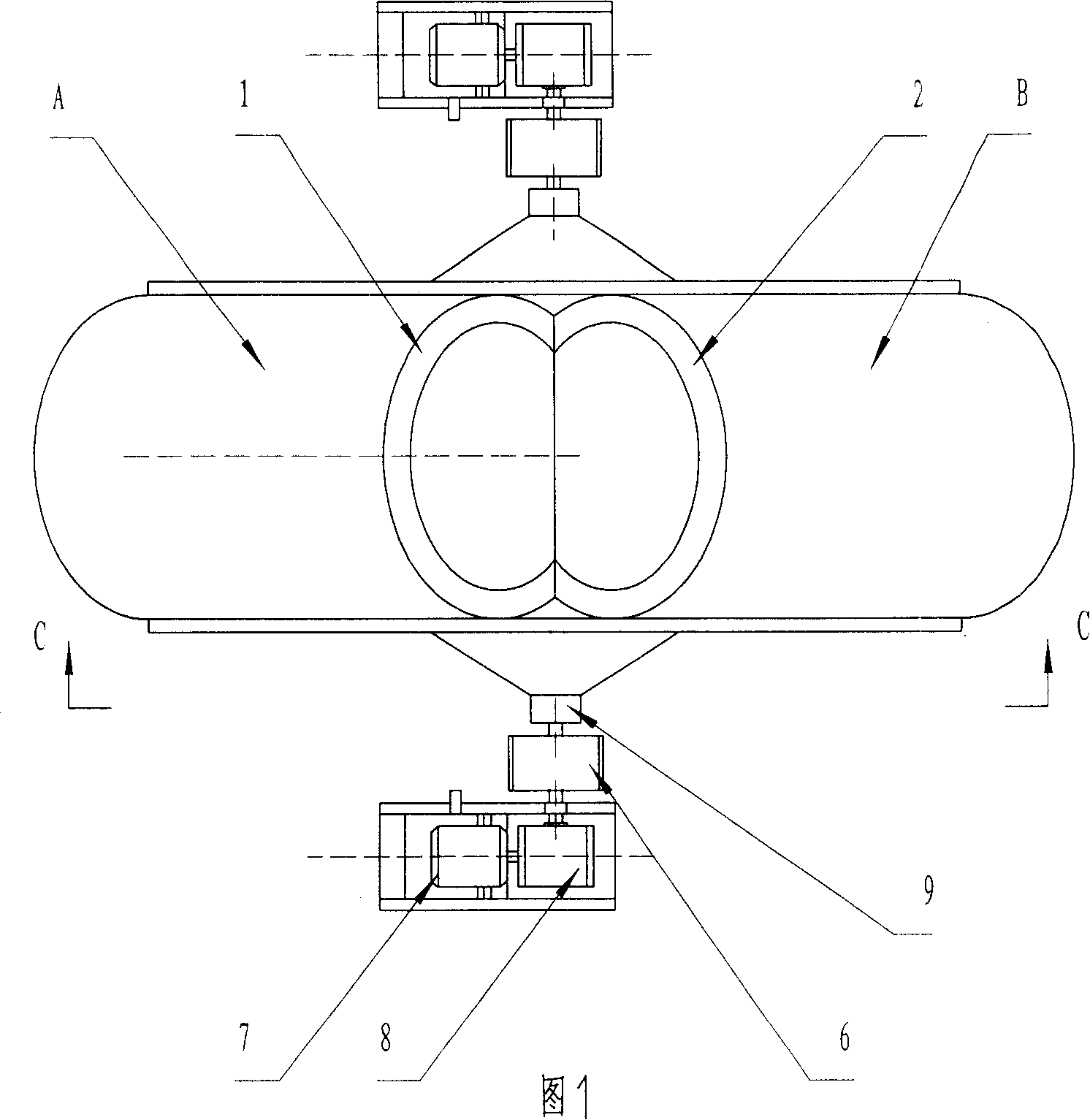

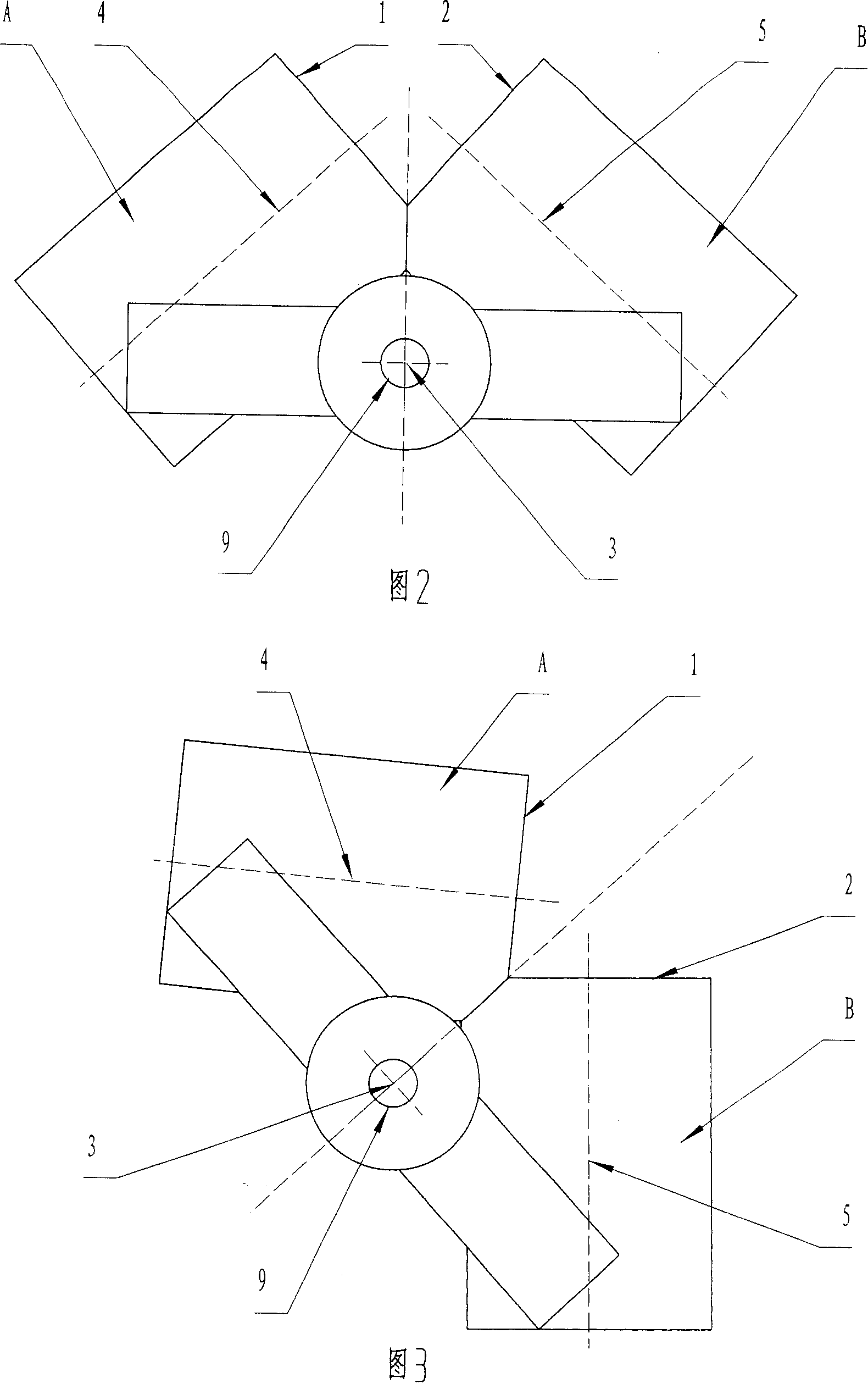

Heat-exchanging ladle-to-ladle method for producing low-carbon, micro-carbon iron alloy

This invention relates to a heat bag exchange method for producing low carbon and micro-carbon Fe alloys including the following steps: 1, connecting the orifices of heat exchange reaction bag A and B used in heat exchange to a connection bag, setting a driving unit driving the connecting bag to rotate around its shaft, 2, inpouring melt ore material being exchanged into bag A with a recovery agent, 3, starting the driving unit to pour all materials in bag A into bag B and pouring the melt materials poured in bag B before hand back to bag A and circulating the steps, 4, finishing the outgoing operation after meeting the requirement of heat exchange of bags, which reduces the exchange time.

Owner:羊实

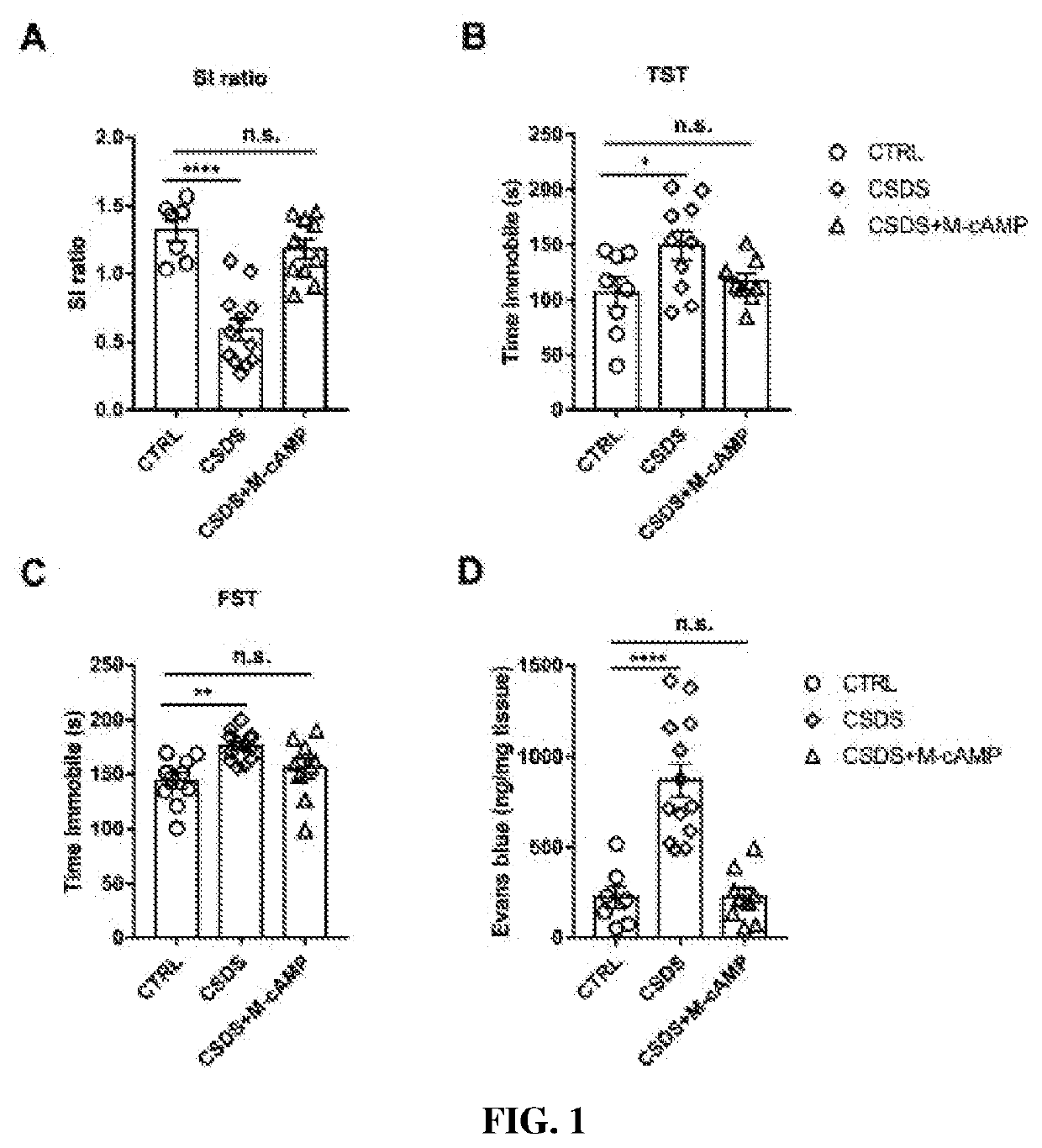

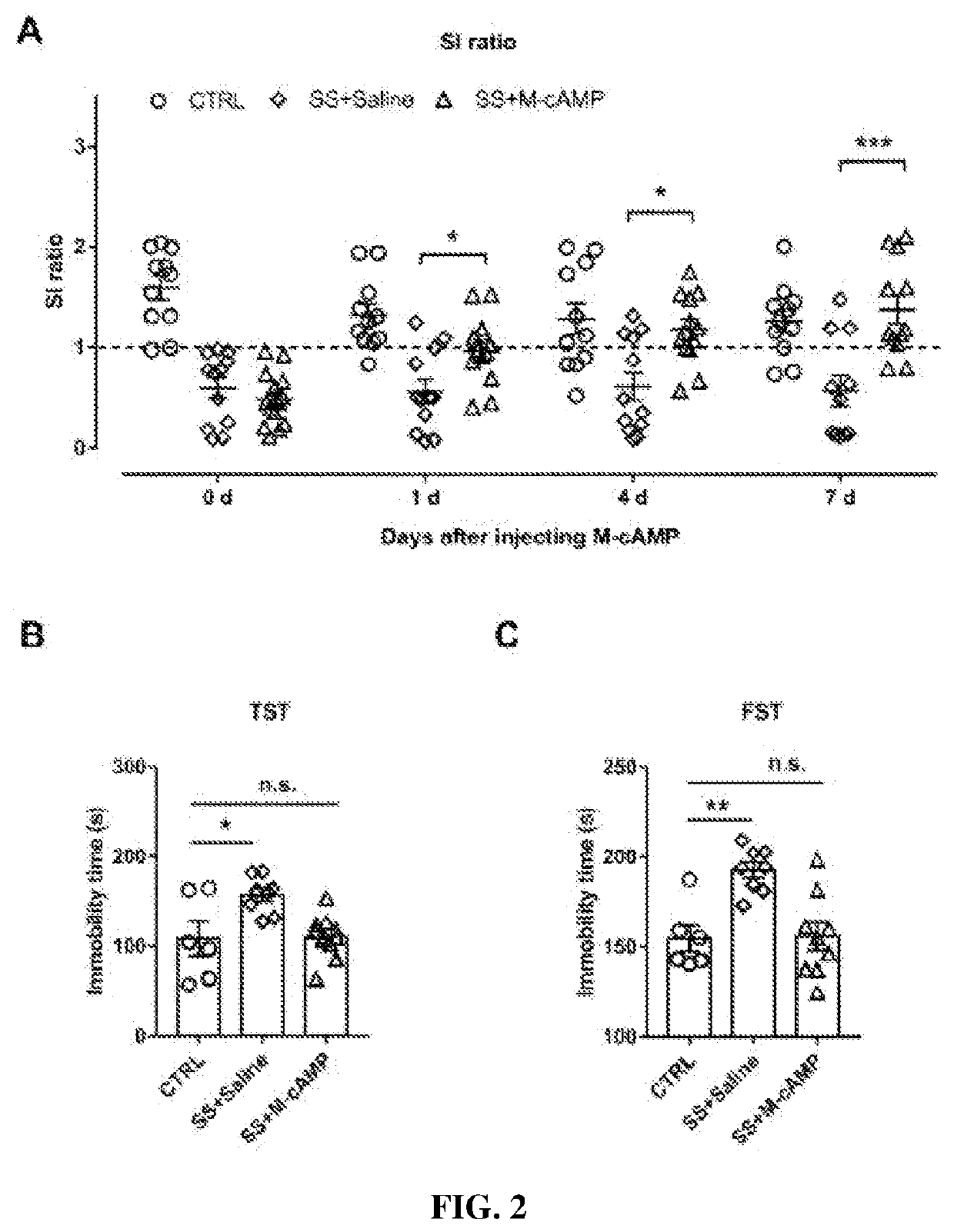

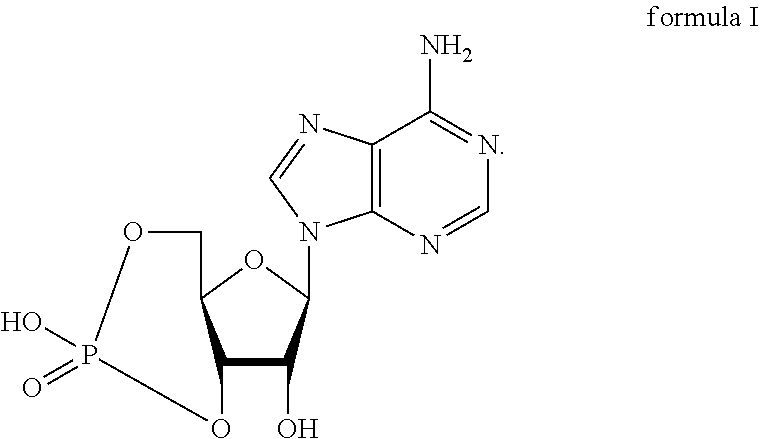

Use of cyclic adenosine monophosphate, derivative or prodrug thereof in preparation of drug for preventing and/or treating depression

InactiveUS20210369756A1Increase the transmembrane ability of cyclic adenosine monophosphateDestructionOrganic active ingredientsNervous disorderAdenosinePsychiatry

The disclosure discloses a use of cyclic adenosine monophosphate (cAMP), derivative or prodrug thereof in preparation of drug for preventing and / or treating depression. Using the established model of depressed mice caused by social defeat stress, cAMP is intraperitoneally injected upon constructing the model or directly injected into the nucleus accumbens brain region of depressed mice after modeling, which can significantly improve the depression-like behavior of mice. The disclosure discloses the prevention and treatment effect of cAMP on depression, and provides a candidate drug with new mechanism for clinical prevention and treatment of depression.

Owner:CHINA PHARM UNIV

Electric Adjustable Lifting Street Light

ActiveCN106195836BEliminate immobilitySmooth liftMechanical apparatusLighting support devicesEngineeringSelf locking

The invention discloses an electric adjustable type lifting streetlamp which comprises a hollow lamp post, a lamp arm arranged on the top of the hollow lamp post and a lamp head arranged on the end part of the lamp arm; a base box is fixedly arranged on the bottom of the hollow lamp post; a motor is fixedly arranged inside the base box; the motor is in transmission connection to a reduction mechanism through a motor shaft; a winding drum is arranged on the rotary shaft of the reduction mechanism; a slide block is arranged inside the hollow lamp post in a matched manner; the slide block is fixedly connected to the lamp arm through a slide slot in the side of the hollow lamp post; a slide wheel is arranged above the inner part of the hollow lamp post; the slide wheel is fixedly arranged on a slide wheel supporting base; a steel wire rope is wound on the winding drum; and the steel wire rope is fixedly connected to the slide block through the slide wheel. The electric adjustable type lifting streetlamp has the beneficial effects that: multiple limiting mechanism are adopted, and are used to realize lifting and self-locking safety by utilizing self-locking functions of worms and gears, limiting functions of ratchets and pawls, a regulating function of a limiting regulator and the like, so that maintenance safety can be guaranteed.

Owner:ZHEJIANG UNIV OF TECH

Thermal management system and control method for coolant flow to controllable battery pack

ActiveCN112151912BGuaranteed balanceReduce thermal variabilitySecondary cellsPropulsion by batteries/cellsPower batteryHeat management

The invention discloses a heat management system and a control method for cooling liquid flowing to a controllable battery pack, comprising a battery pack shell and a liquid cooling plate arranged in the battery pack shell, and a battery pack water inlet and a battery pack water inlet are arranged on the battery pack shell The water outlet of the battery pack, the liquid cooling plate includes a first liquid cooling plate tube interface and a second liquid cooling plate tube interface located on the left and right sides thereof, and a The coolant flow channel, the battery pack housing is also provided with a steering device that communicates with the first liquid-cooled plate tube interface and the second liquid-cooled plate tube interface through pipelines, and can change the flow direction of the coolant in the coolant flow channel. The steering device It includes a device water inlet connected to the battery pack water inlet through pipelines and a device water outlet connected to the battery pack water outlet through pipelines. The present invention eliminates the fixedness of temperature distribution that has existed for a long time, reduces the difference in heat dissipation of battery pack monomers, and improves the service life and performance of the power battery.

Owner:DONGFENG MOTOR CORP HUBEI

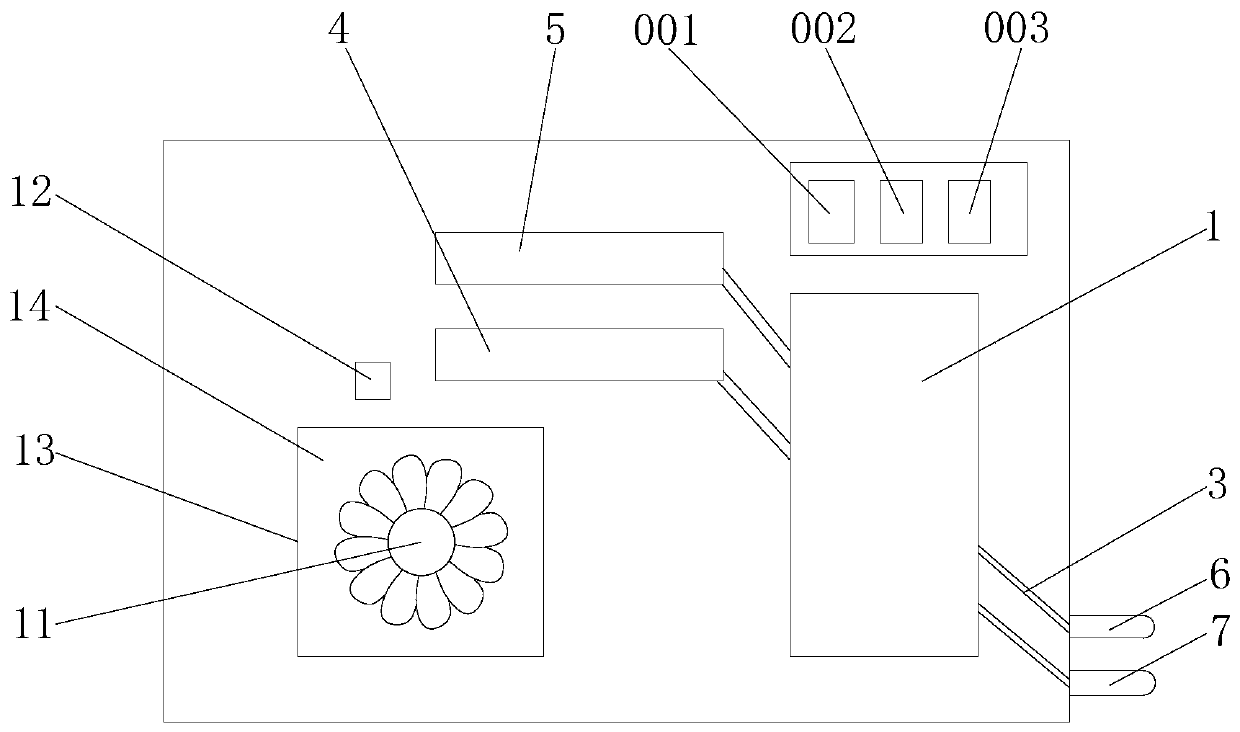

Household air conditioner with centrifugal compressor assembly

PendingCN109827351AEasy to adjustSmall installation sizeCompressorCompression machines with non-reversible cycleCollocationVapor–liquid separator

The invention relates to the technical field of household air conditioners, in particular to a household air conditioner with a centrifugal compressor assembly. The household air conditioner comprisesa machine case. The centrifugal compressor assembly is arranged in the machine case. The centrifugal compressor assembly comprises two shells. Each shell is internally provided with a centrifugal compressor groove, a gas-liquid separator groove, a liquid storage tank groove, an expansion valve groove, a dryer groove and a one-way valve groove, and the above grooves are formed in the shell througha CNC machining center. The centrifugal compressor assembly achieves the effect of the extremely high energy efficiency through arrangement of a centrifugal compressor, and the cop can reach up to 7.0 or more. Meanwhile, the centrifugal compressor assembly integrates a great number of parts of an existing air conditioner, and the parts are integrated into one assembly; modularization of the compressor is realized. The energy efficiency ratio of the household air conditioner is increased finally, and the installation size of an air conditioner host machine is effectively reduced. Industrial automatic production of air conditioners, personalized customization of users, free collocation of the functions and full intelligent application of the air conditioner can be realized.

Owner:AGAF REFRIGERATION TECH (WUXI) CO LTD

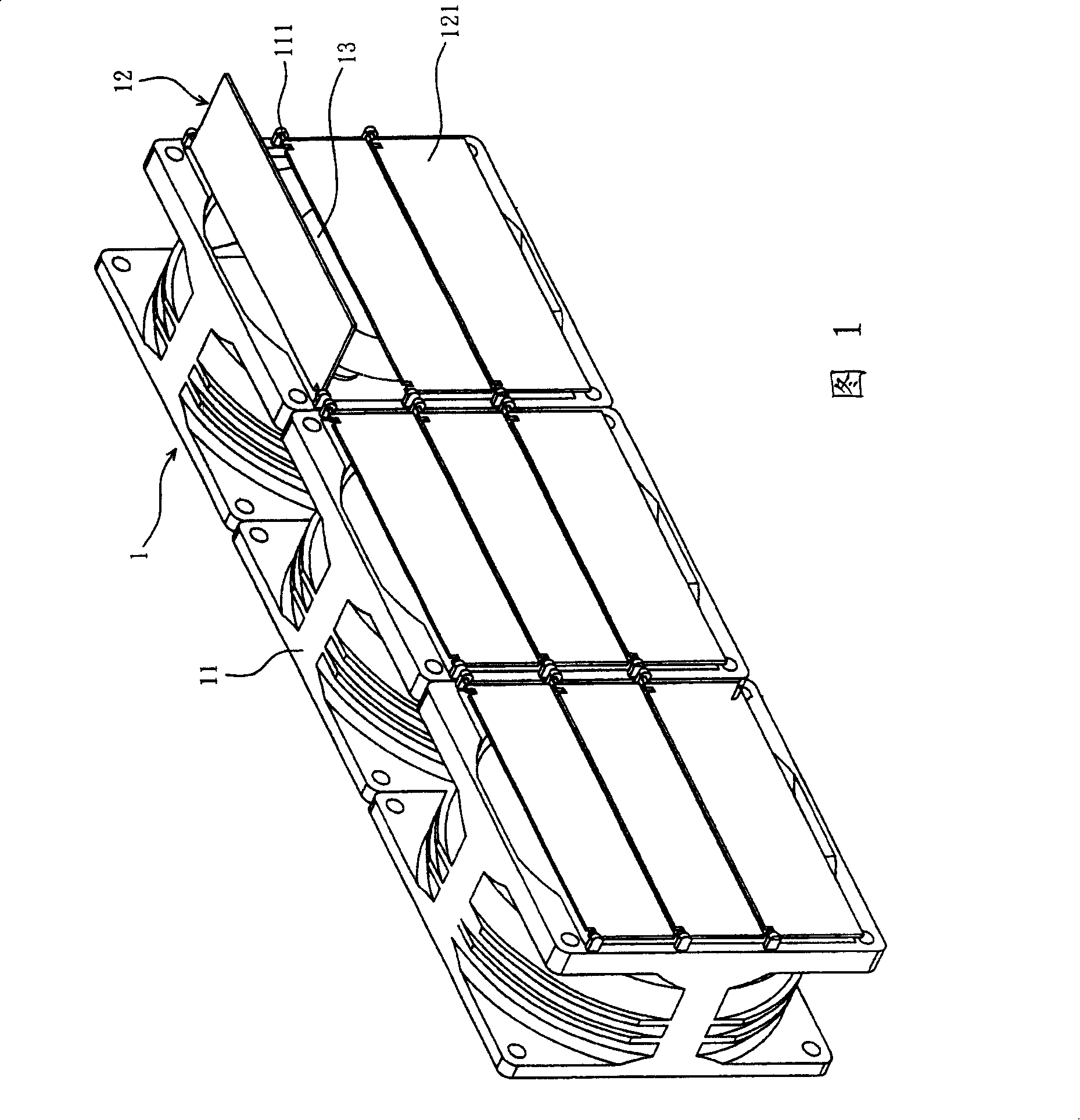

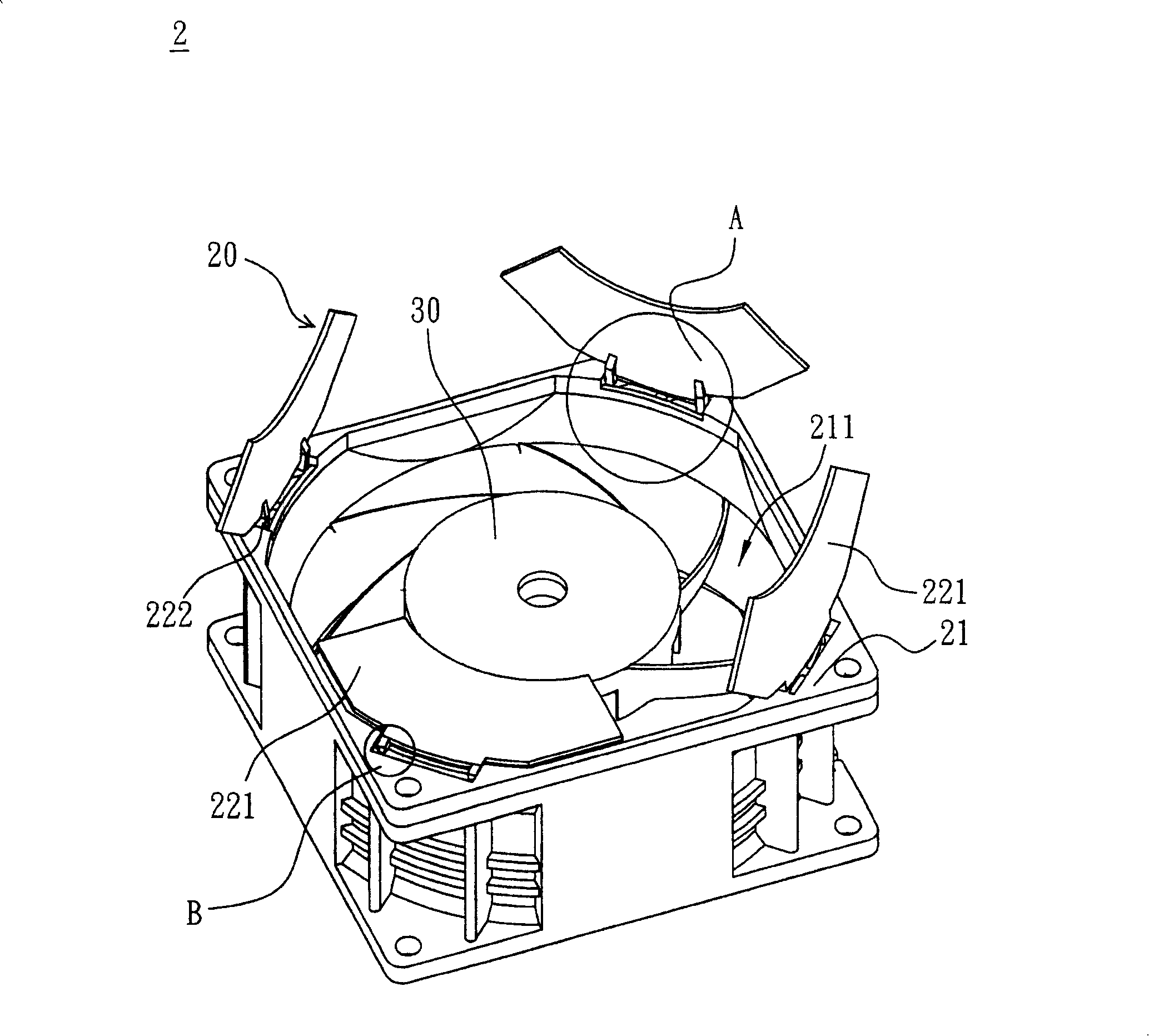

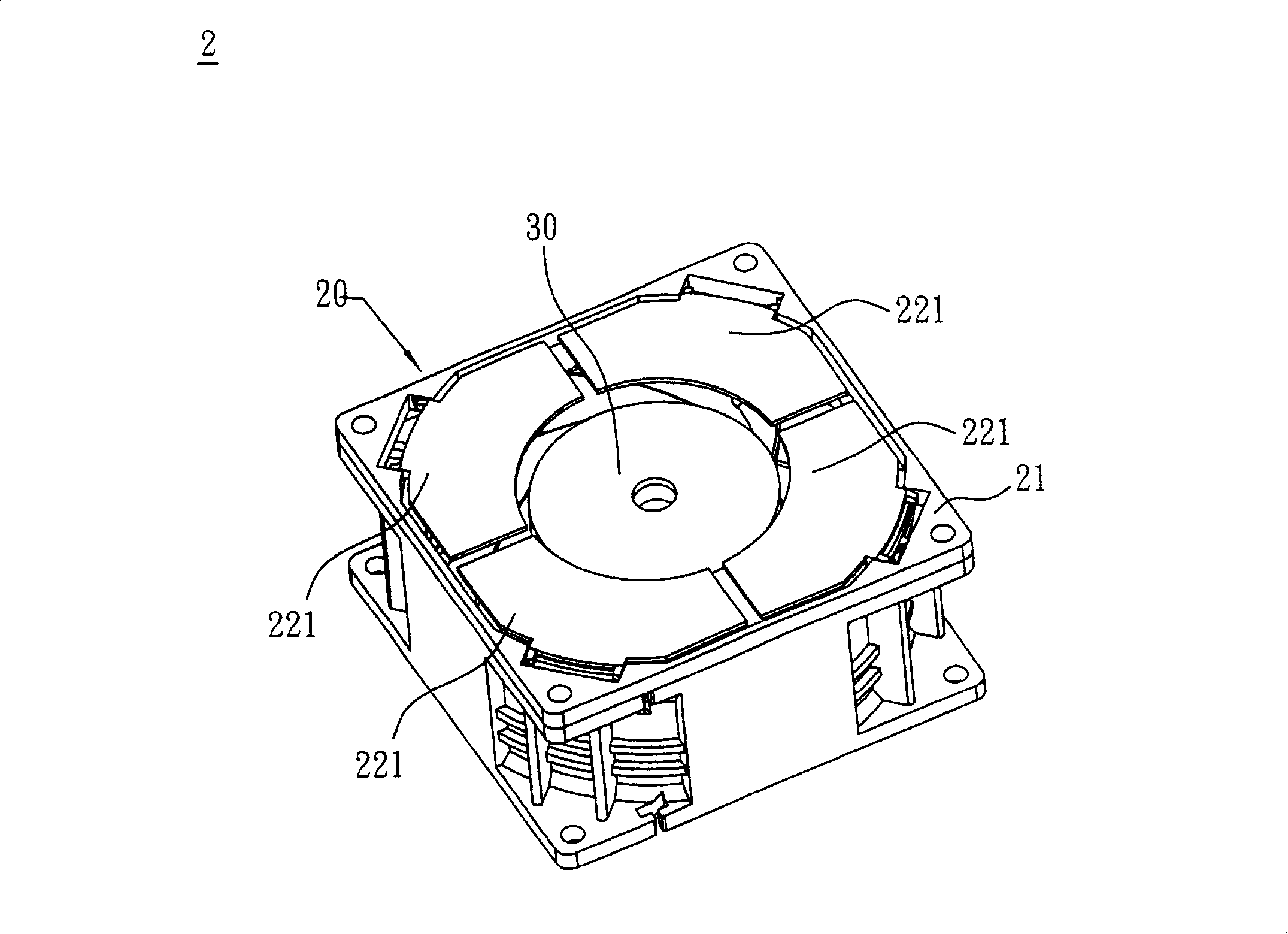

Fan with fan window structure and fan frame thereof

InactiveCN101210576ASimple structureSimplify the manufacturing processPump componentsPump installationsImpellerEngineering

The invention discloses a fan, which is composed of an impeller, a motor and a fan frame. The motor is connected with and drives the impeller to rotate; the fan frame contains the impeller and the motor, as well as a frame body and a fan window structure which is connected with an air outlet side of the frame body and which is provided with a plurality of window leaf blades and a plurality of connecting pieces; and the connecting pieces respectively enable the window leaf blades to connect with corners of the frame body.

Owner:DELTA ELECTRONICS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com