Patents

Literature

645 results about "Middle column" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

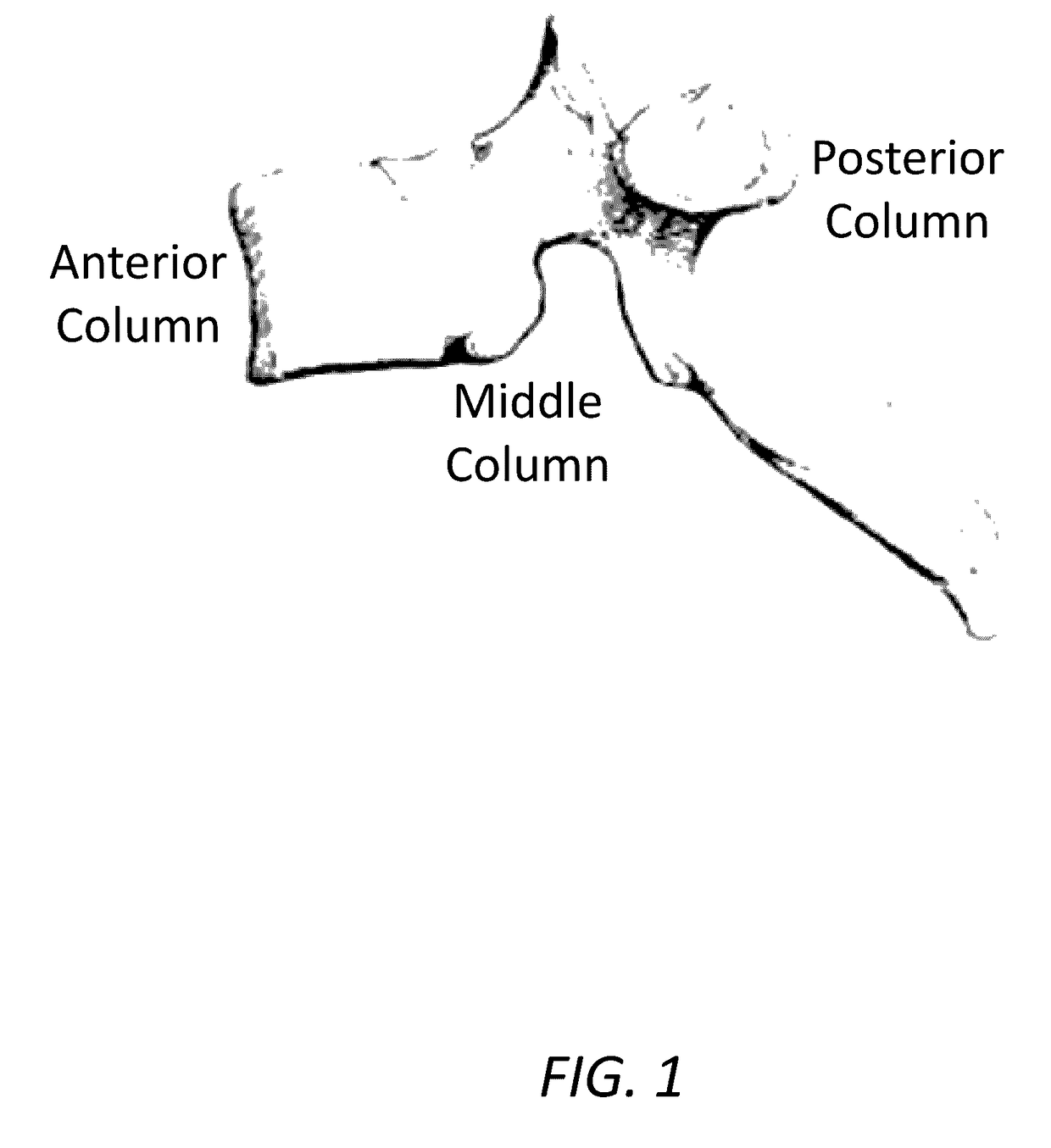

Columns. Denis divided the vertebral column into 3 vertical parallel columns based on biomechanical studies related to stability following traumatic injury. Instability occurs when injuries affect 2 contiguous columns (i.e. anterior and middle column or middle and posterior column). Obvious a 3 column injury is unstable. The three columns are:

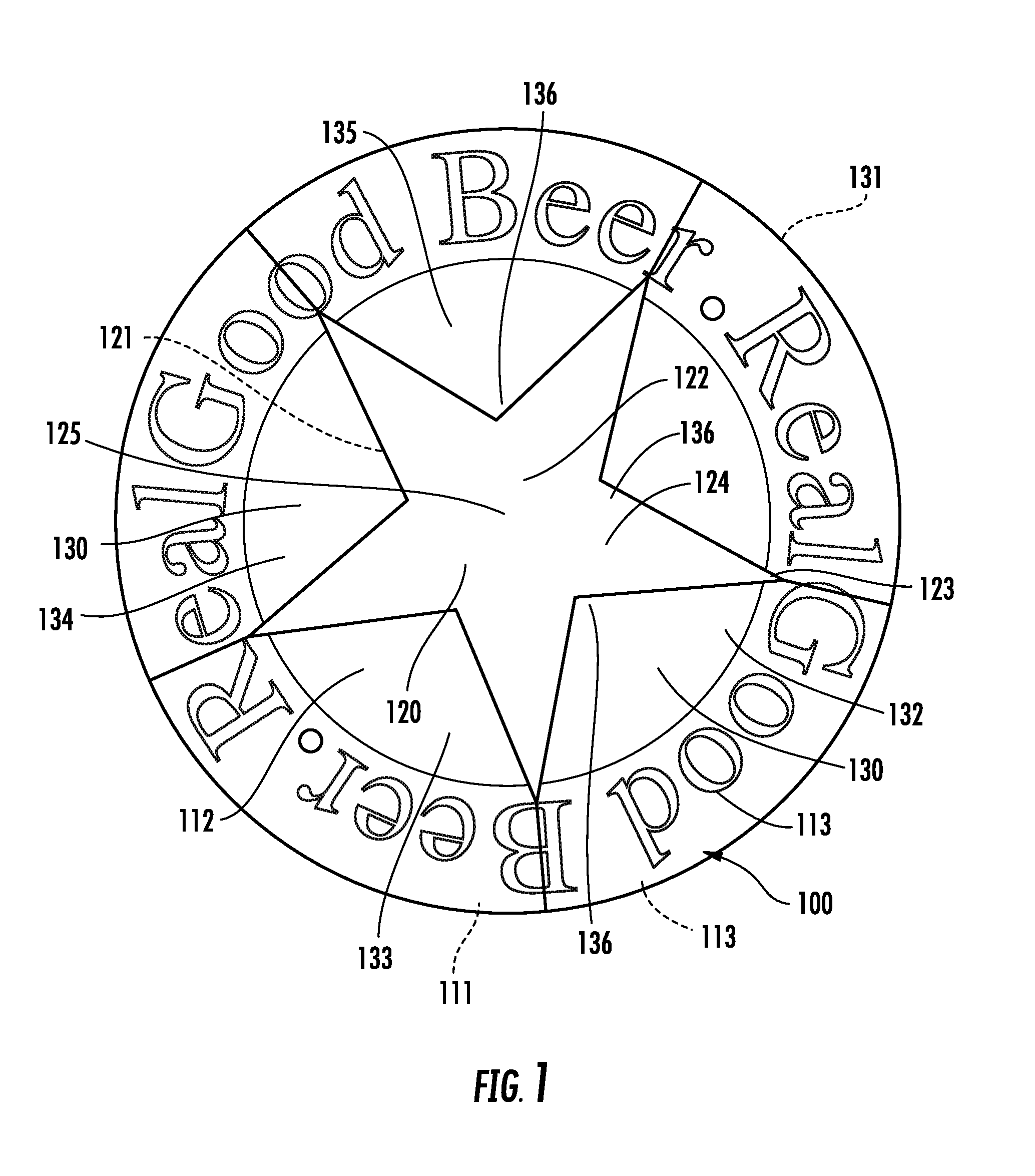

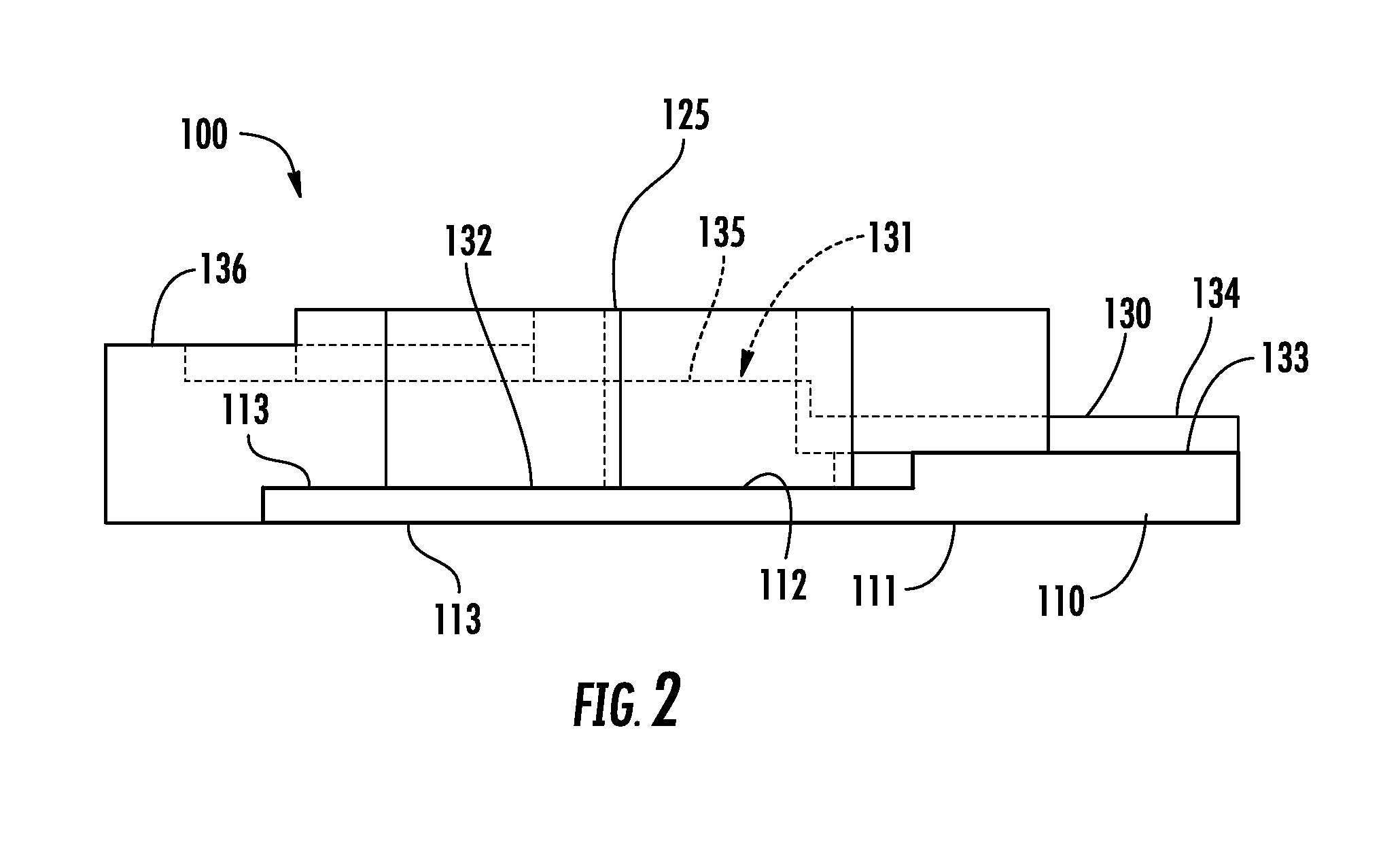

Rotatable table leveling disk

InactiveUS20120175475A1Reduce riskStabilize furnitureStands/trestlesKitchen equipmentEngineeringMechanical engineering

This invention is directed to a uni-body constructed leveling device used to shore and stabilize a furniture leg. This leveling device may include three primary components. First, it has a bottom disk having a first surface and corresponding second surface which is essentially flat and circular. Affixed to the second surface is a vertical shaft having a first end, a second end and a middle column disposed between both the first and second ends. The first end of the vertical shaft is rigidly affixed to the second surface. Lastly, a plurality of platforms are affixed to the bottom disk. Each platform has a unique elevation above the bottom disk. Moreover, each platform is essentially parallel to the second surface of the bottom disk.

Owner:MCERLANE SCOTT

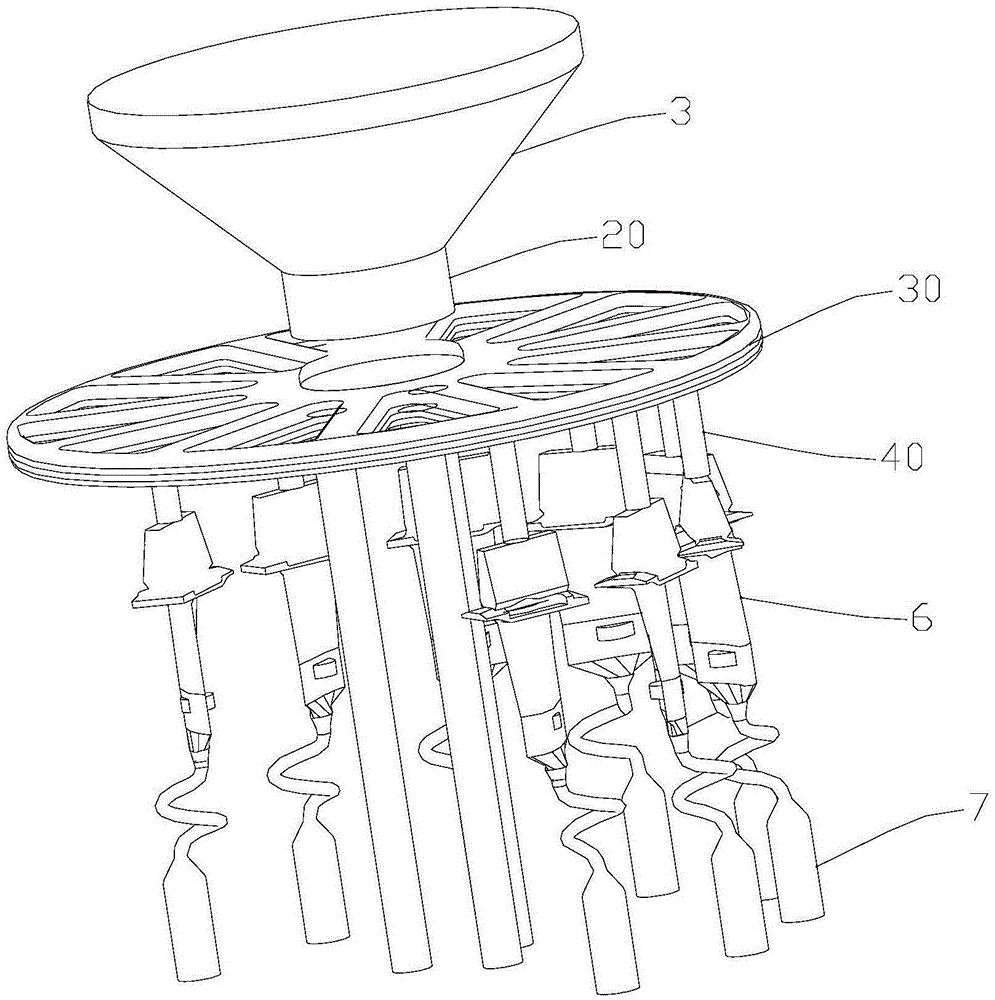

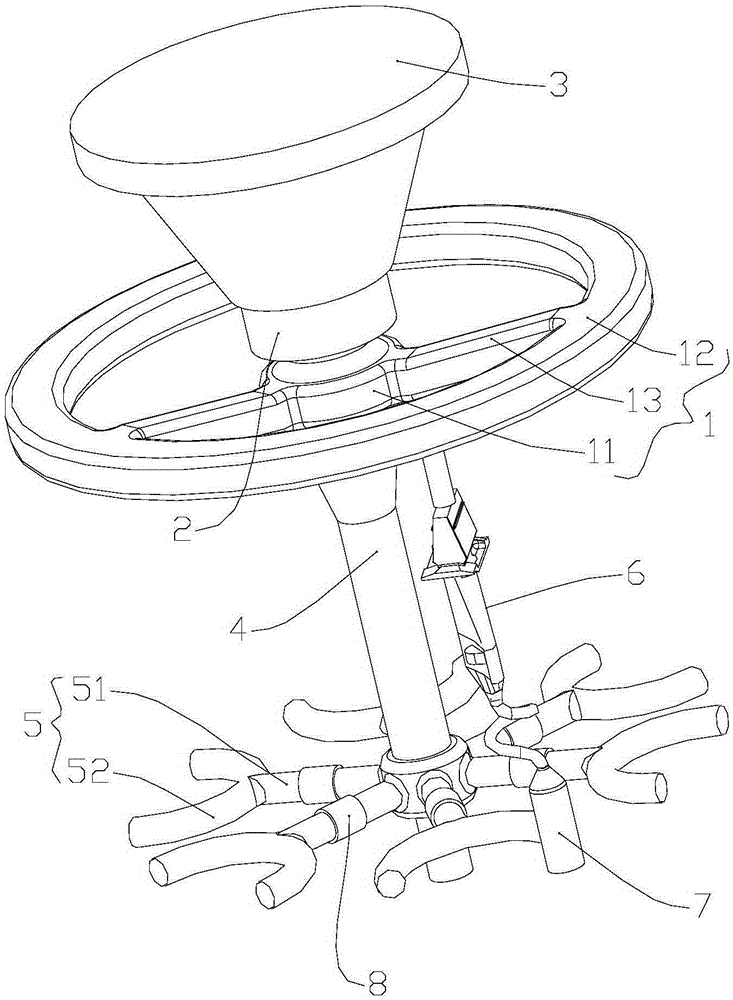

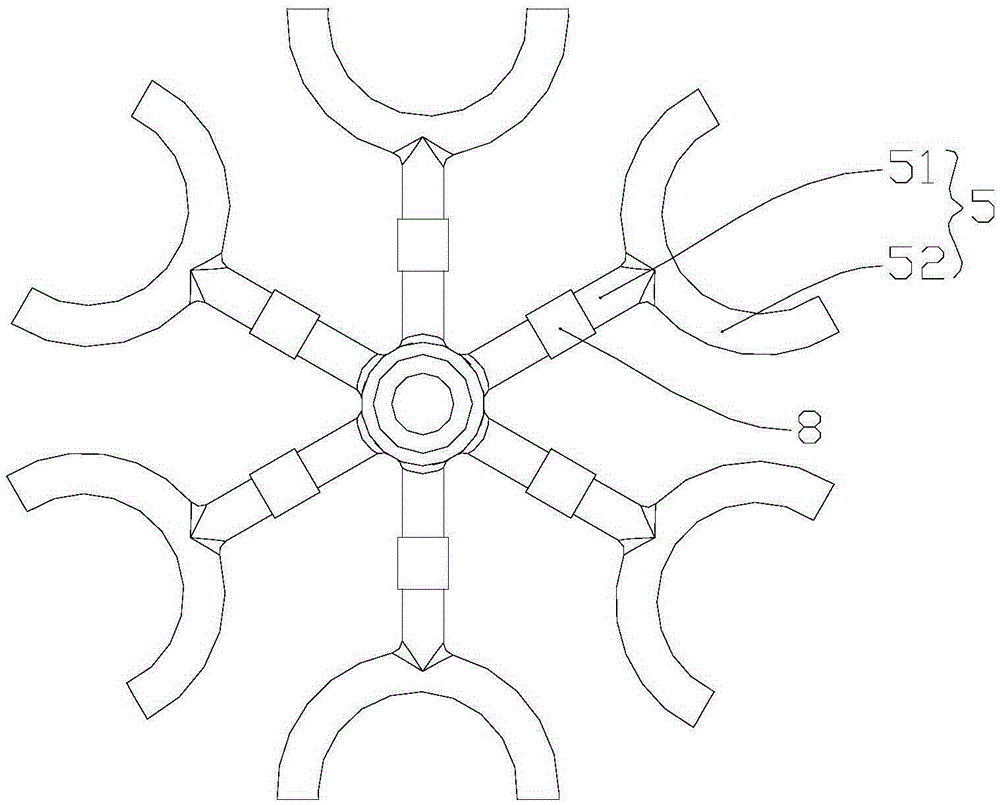

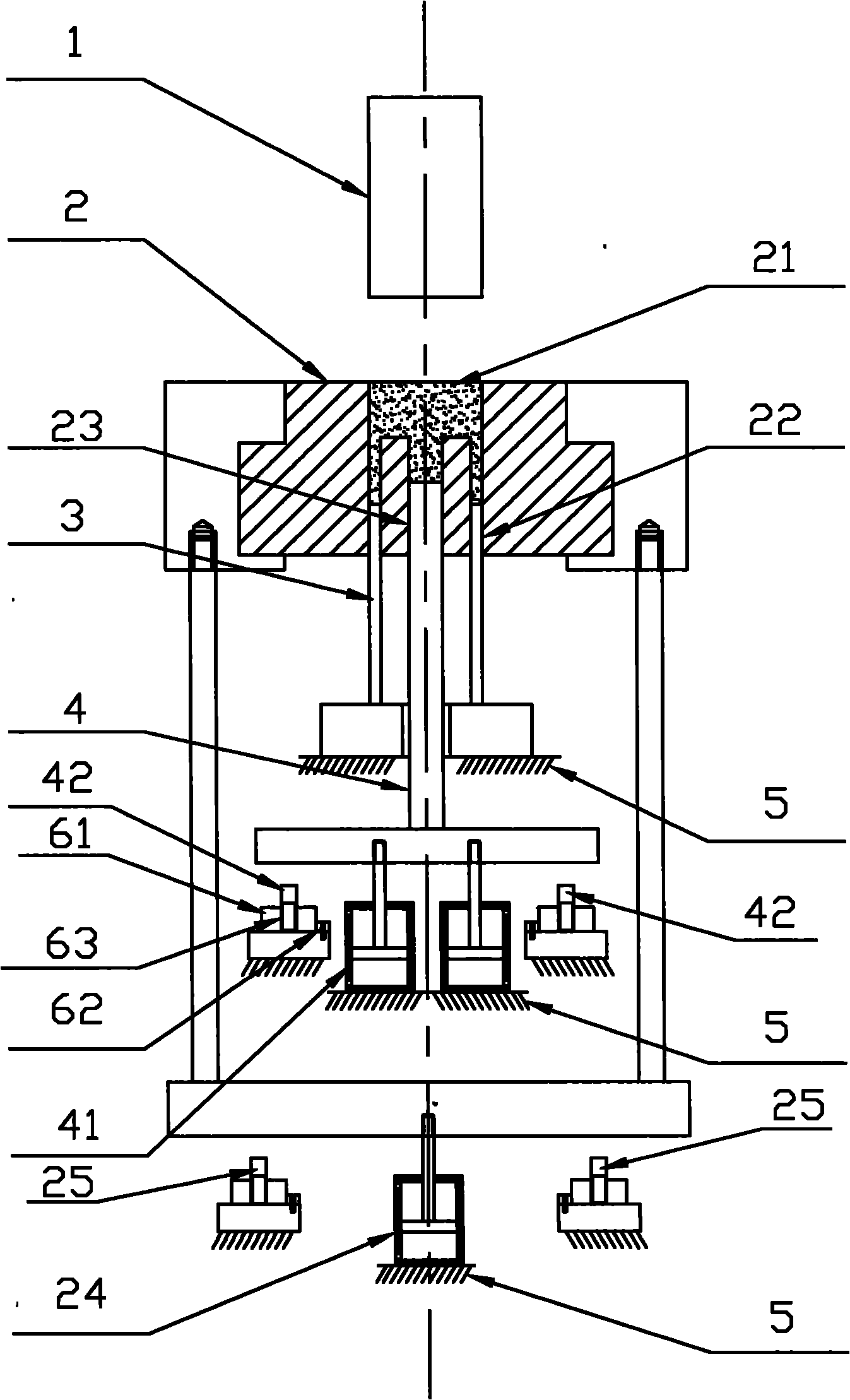

Bottom pouring type pouring system

ActiveCN105290333AGuaranteed effective lengthImprove grain orientation pass rateFoundry mouldsFoundry coresCircular discMold filling

The invention discloses a bottom pouring type pouring system. The bottom pouring type pouring system comprises a disc pouring gate which comprises a main disc pouring pipe allowing pouring liquid to pass through, a first filtering net used for filtering the pouring liquid is connected to the upper end of the main disc pouring pipe, and a pouring cup used for leading in the pouring liquid is connected to the upper end of the first filtering net; a vertically-arranged middle column pouring gate is connected to the lower end of the main disc pouring pipe, and a bottom pouring gate is connected to the bottom end of the middle column pouring gate; and a blade is connected to the disc pouring gate, a spiral crystal selecting device for molding the blade into a single crystal blade is connected to the bottom end of the blade, and the bottom end of the spiral crystal selecting device is communicated with the bottom pouring gate so as to enable the pouring liquid to enter the spiral crystal selecting device from the bottom end of the spiral crystal selecting device. In the bottom pouring type pouring system, the effective length of the spiral crystal selecting device is effectively guaranteed, the crystal orientation acceptability of the single crystal blade is improved, mold filling is stable, impact of the high-temperature pouring liquid to a ceramic core of the blade is reduced, the bottom pouring type pouring system is simple in structure, and assembling of all components of a module is easy and convenient.

Owner:CHINA HANGFA SOUTH IND CO LTD

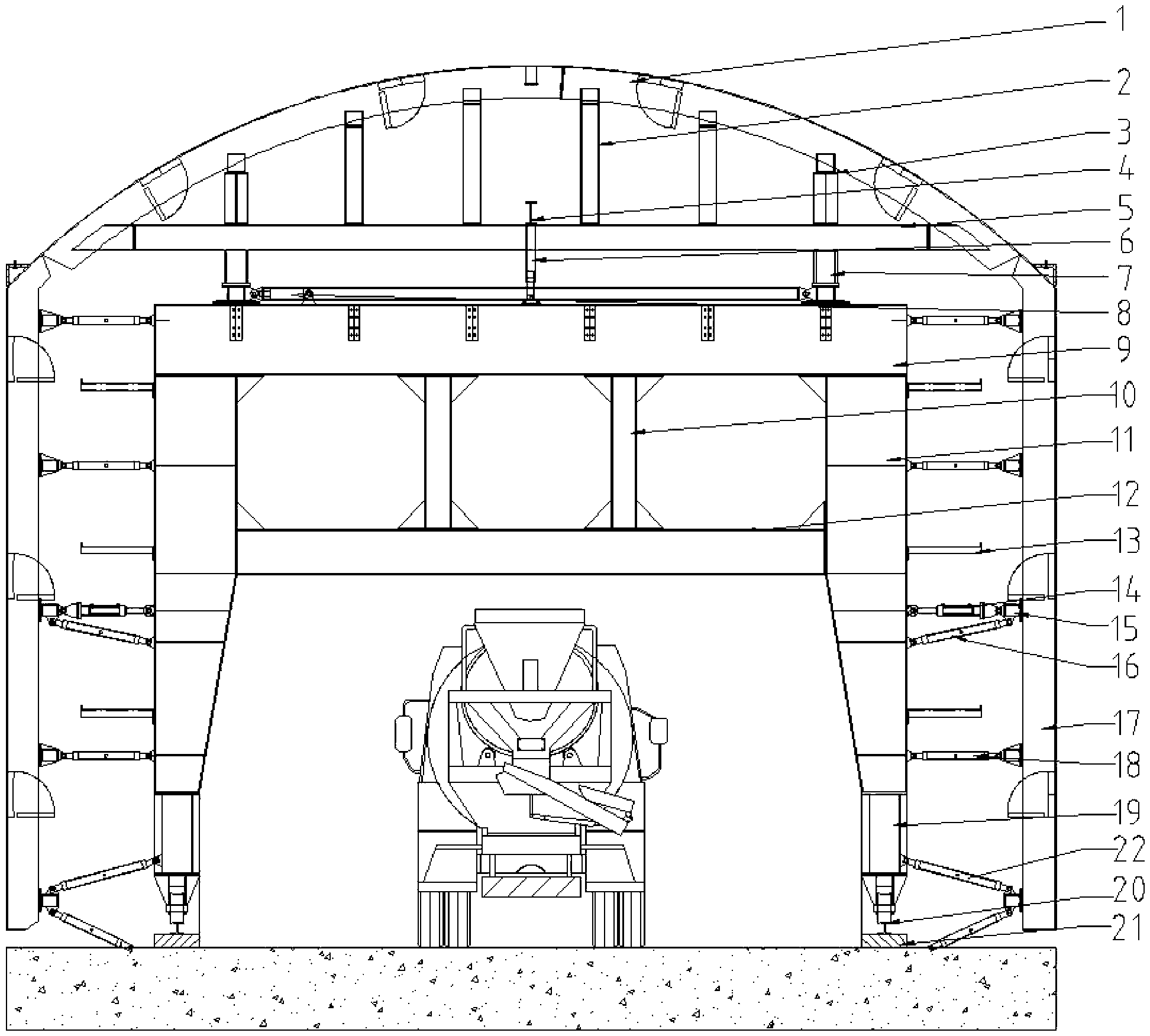

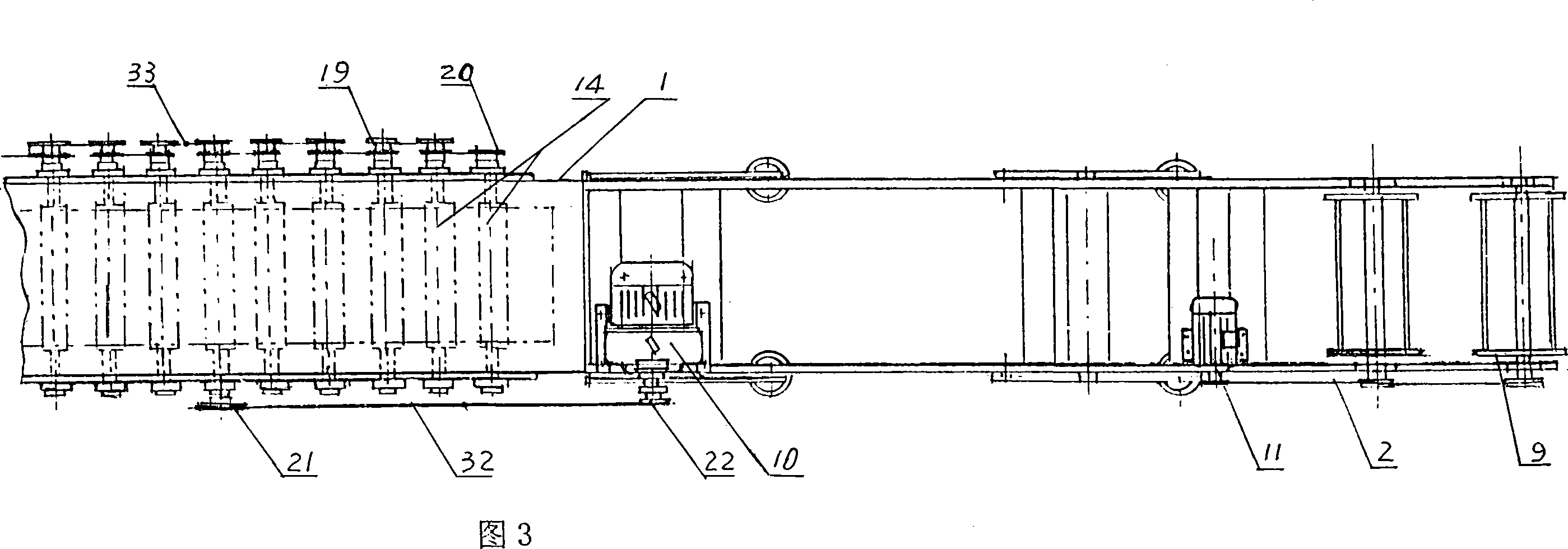

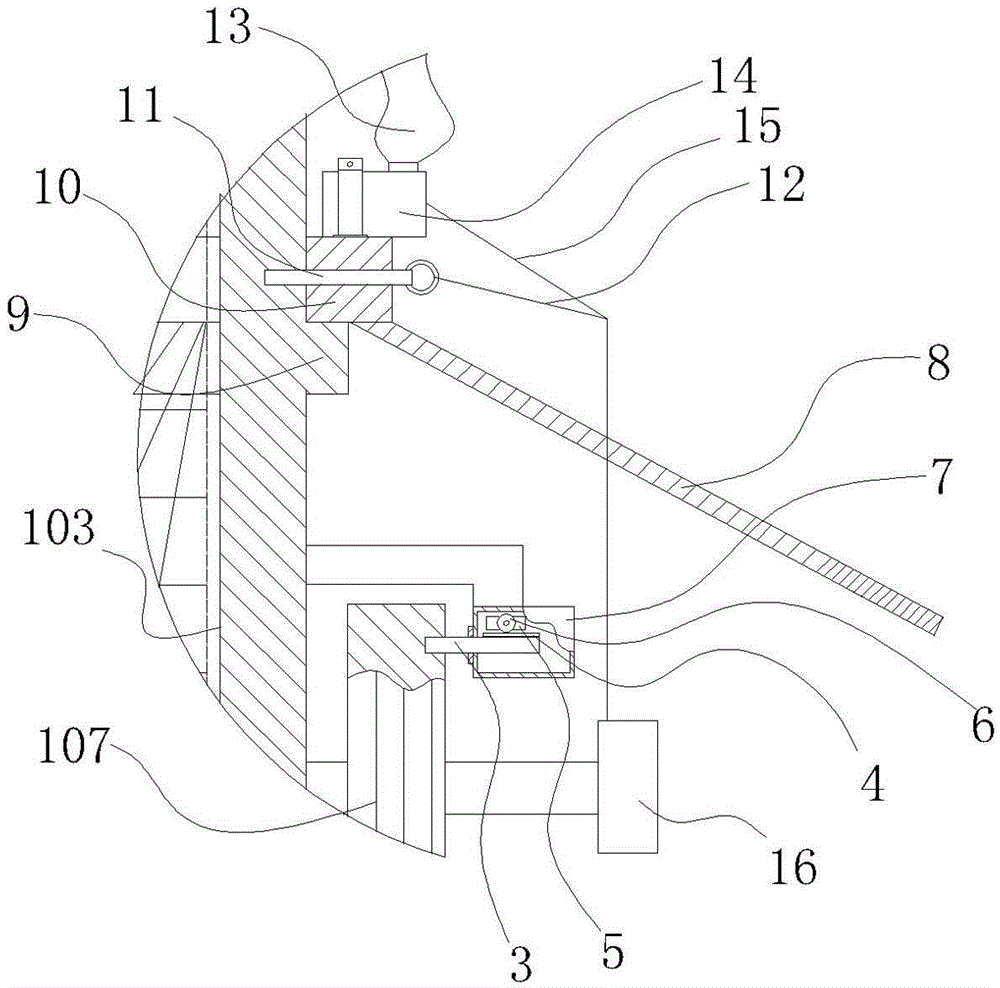

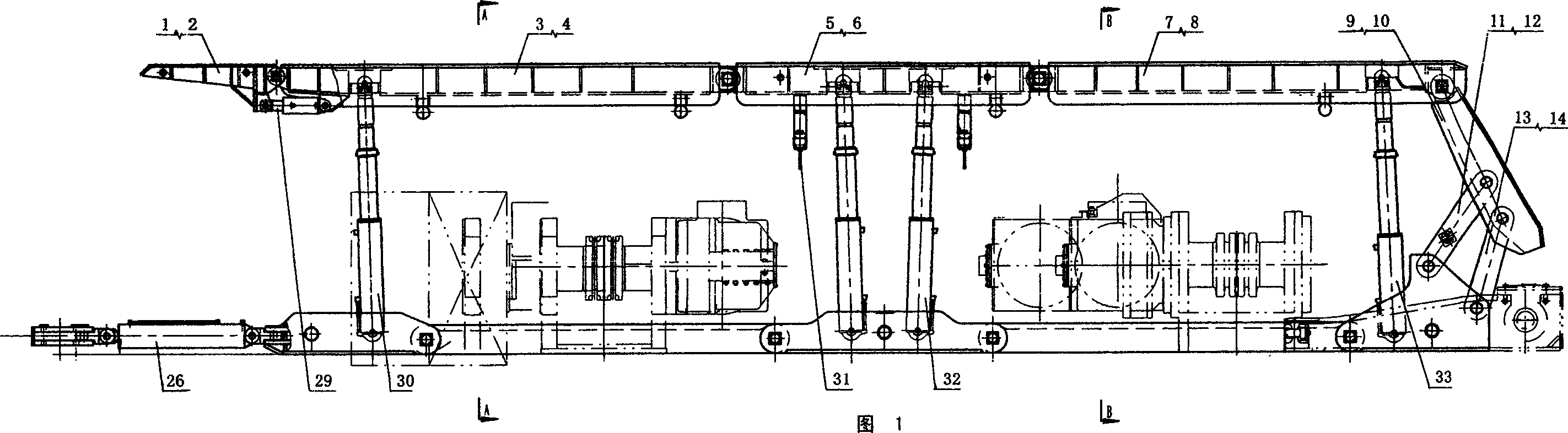

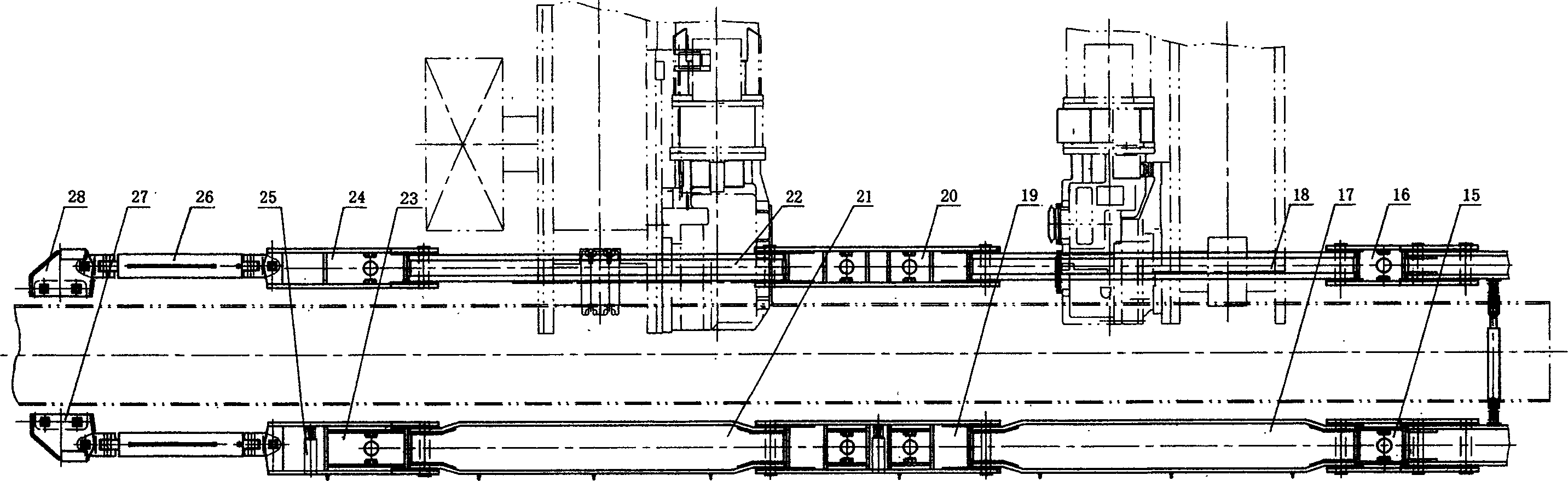

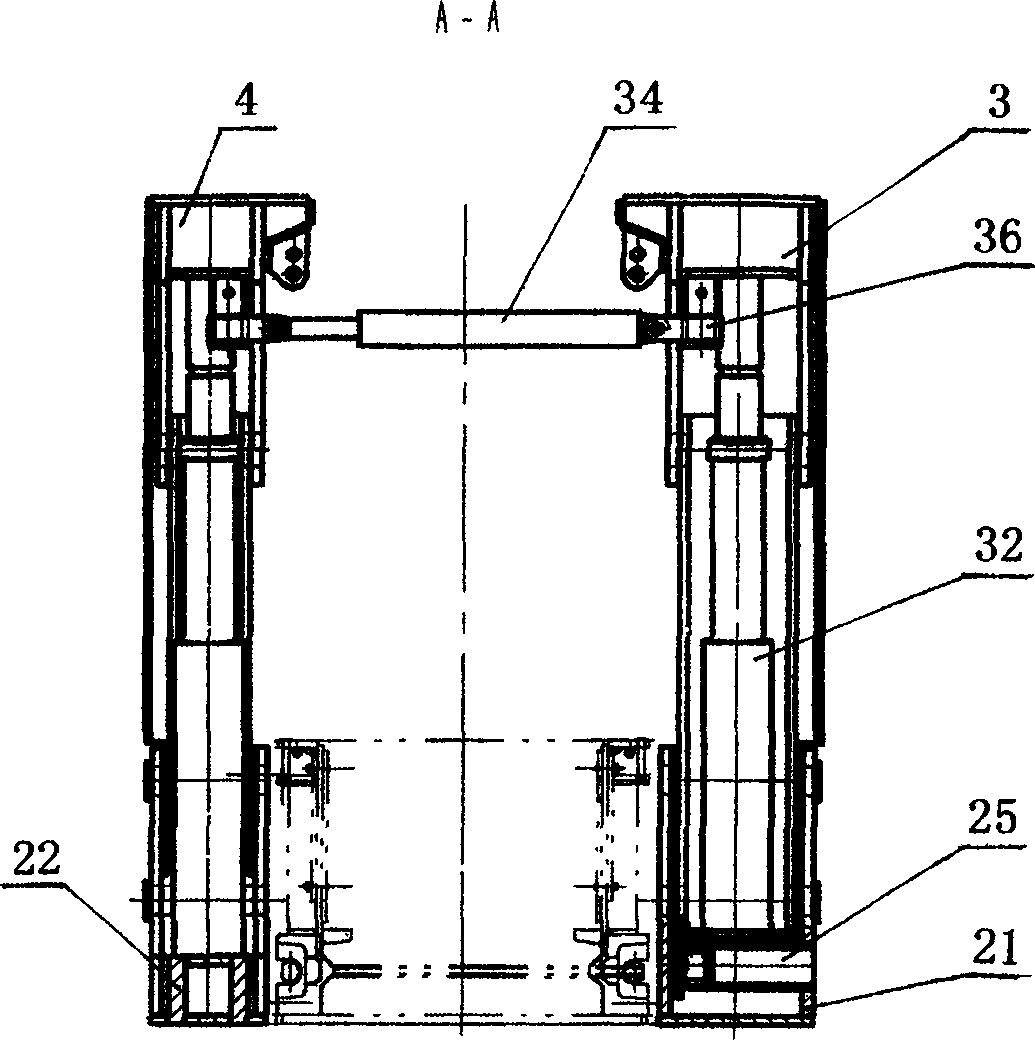

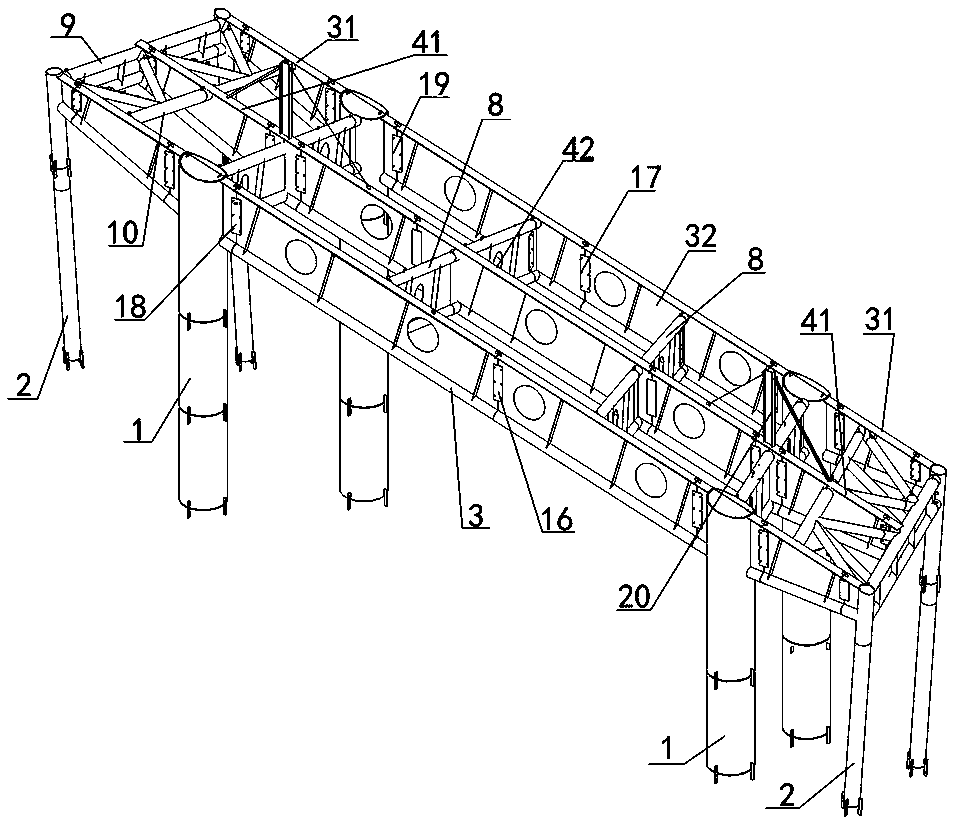

Hydraulic self-propelled steel form carrier for tunnel secondary lining operation

InactiveCN103016028AGuaranteed stabilityPrecise positioningUnderground chambersTunnel liningMiddle columnHydraulic pressure

The invention discloses a hydraulic self-propelled steel form carrier for tunnel secondary lining operation. A travelling system is driven by a hydraulic system to move on steel rails, a backform frame body assembly is erected on a platform beam through a backform column and is driven by a jacking oil cylinder, the platform beam is arranged on a gantry beam through a jack frame in the middle, the gantry beam is erected on a middle beam through a middle column, gantry columns are respectively arranged on the two end parts of the middle beam, the gantry columns and a side form assembly are provided with a plurality of side form lead screws and reinforcement lead screws, the two ends of the side form lead screws are respectively hinged with the gantry columns and the side form assembly, and a bottom longitudinal beam is arranged below the gantry columns. The gantry frame of the hydraulic self-propelled steel form carrier for tunnel secondary lining operation is a non-stress part during the construction and is only stressed during erecting form removing and travelling processes; and when the hydraulic self-propelled steel form carrier constructs or travels in a ramp tunnel, the jacking oil cylinder on the lower part of the gentry frame is used for regulating the height, so that the whole carrier body is positioned in a horizontal state and does not have forward inclining force and side inclining force, and the whole stability of the carrier is ensured.

Owner:CHANGSHA INTO MACHINERY

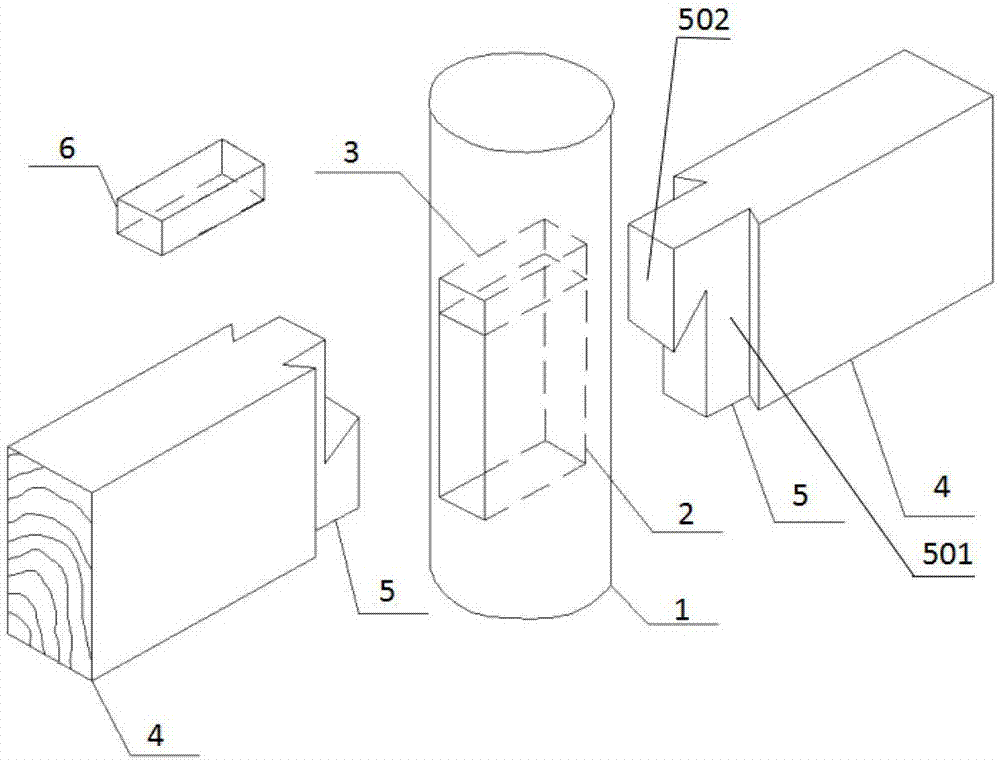

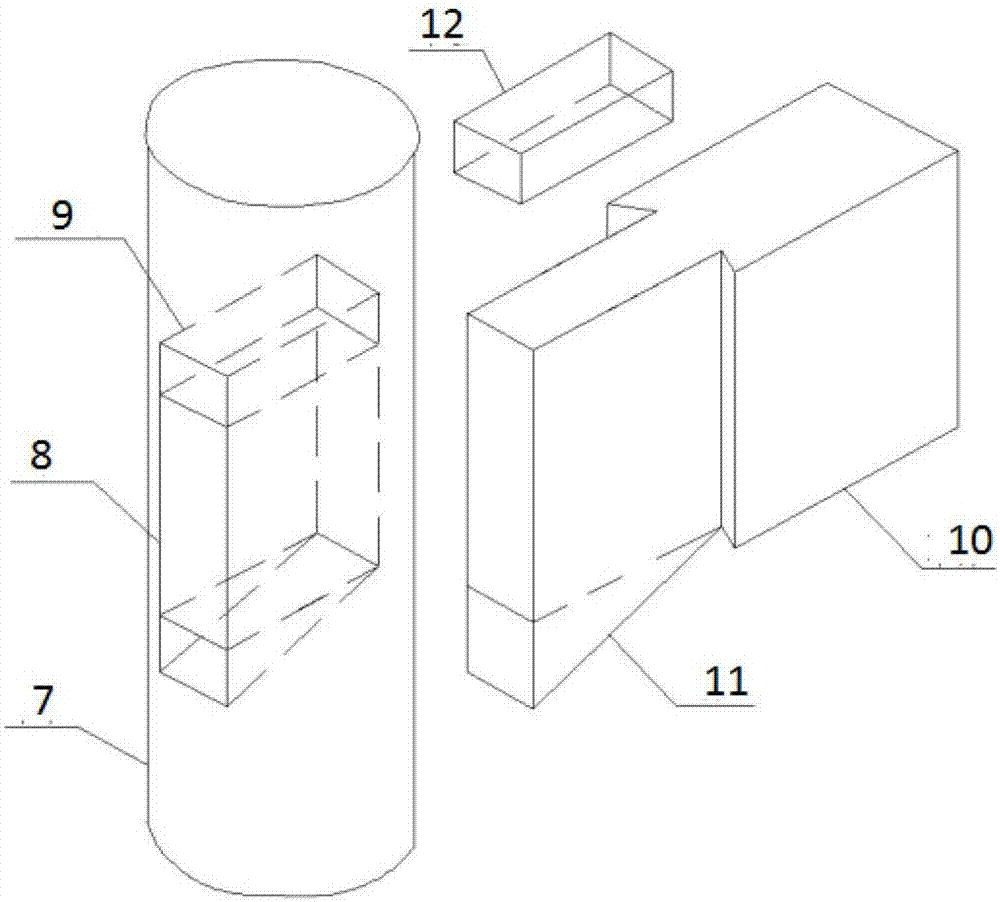

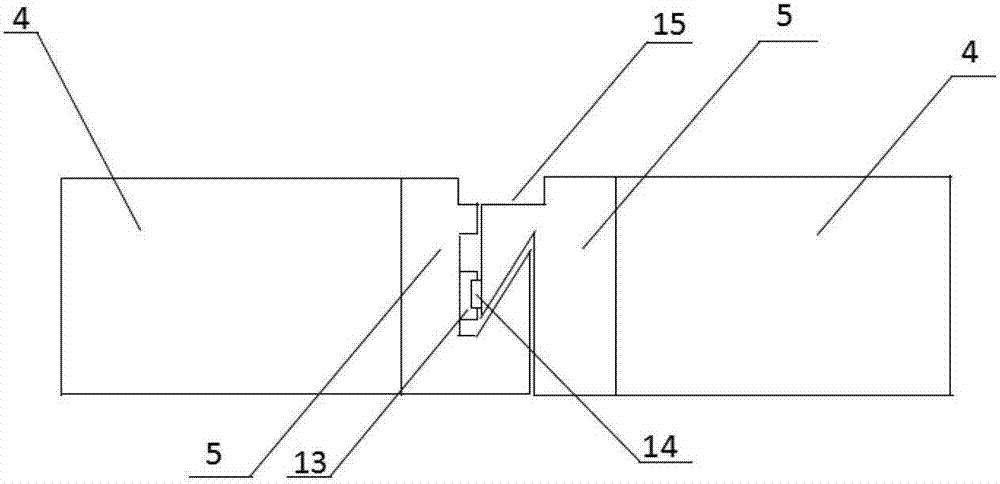

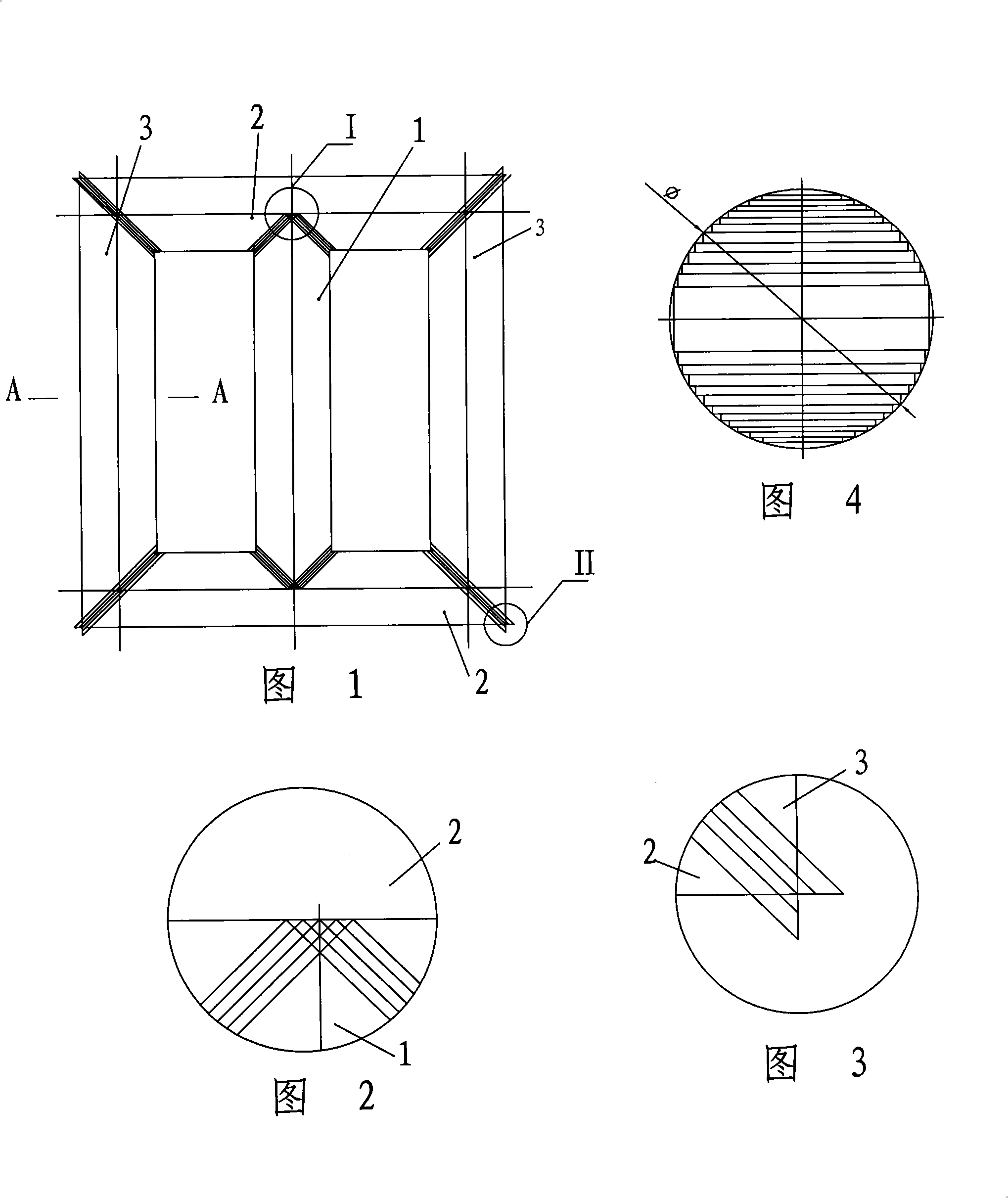

Vertical semi-dovetail tenon node connection structure for wood structure building beam column

InactiveCN106906906AReduce decreaseIncrease stiffnessBuilding constructionsMortise and tenonEngineering

The invention discloses a vertical semi-dovetail tenon node connection structure for a wood structure building beam column. In the wood structure building, the connection between a middle column and a wood beam or a side column and the wood beam adopts the vertical semi-dovetail tenon node connection structure, and knotting to each other is conducted through the tenon vertical semi-dovetail on the wood beam structure, so that the seismic horizontal bearing tensile strength of a frame is improved. Meanwhile, the vertical semi-dovetail tenon node has strong bending resistance ability. The vertical semi-dovetail tenon node is connected and applied to a wood structure farm house or a civil mixed structure, so that the seismic bearing ability of the wood structure farm house or the civil mixed structure is greatly improved; and the vertical semi-dovetail tenon node connection form makes a slight change on the basis of inheriting a traditional mortise and tenon node connection form, a nail and an iron are still not needed, the vertical semi-dovetail tenon node connection form is more suitable for drawing materials and constructing houses locally of remote mountainous areas, and the construction progress and construction quality are improved in a large degree; and meanwhile, cost of vertical semi-dovetail tenon node is low, and the cost of engineering structure can be reduced.

Owner:SOUTHWEAT UNIV OF SCI & TECH

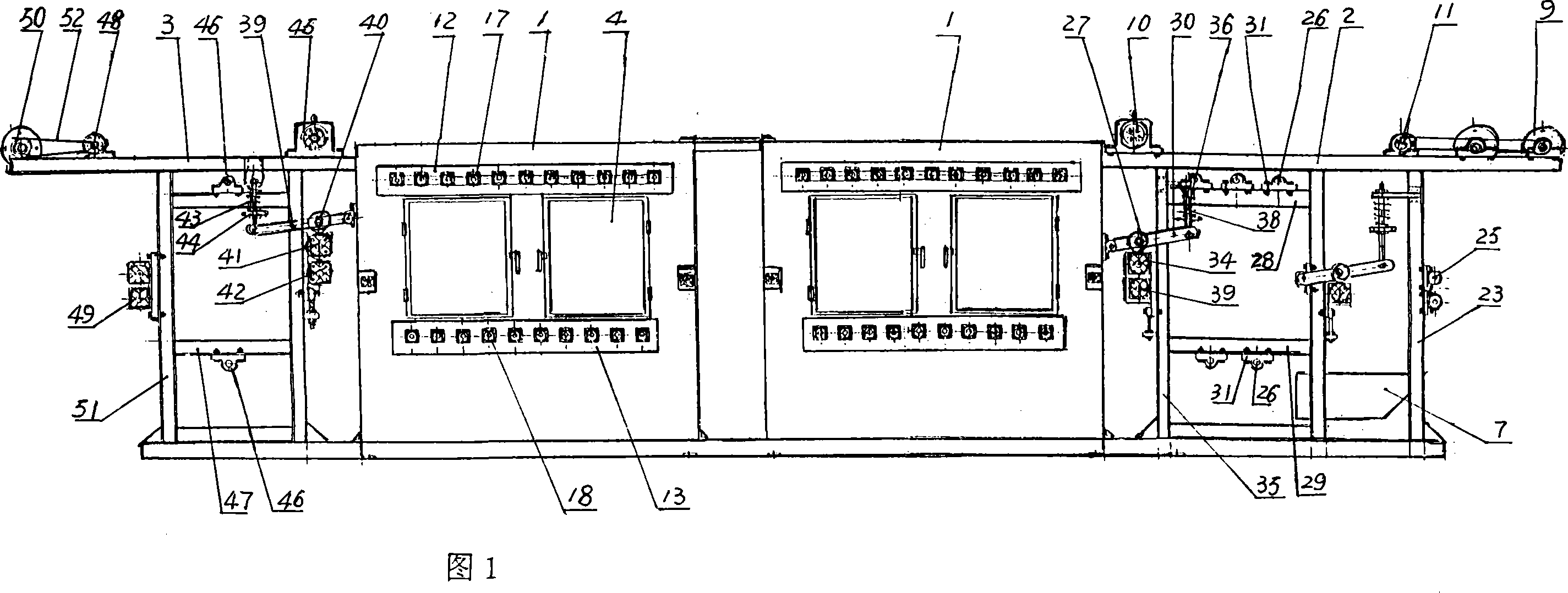

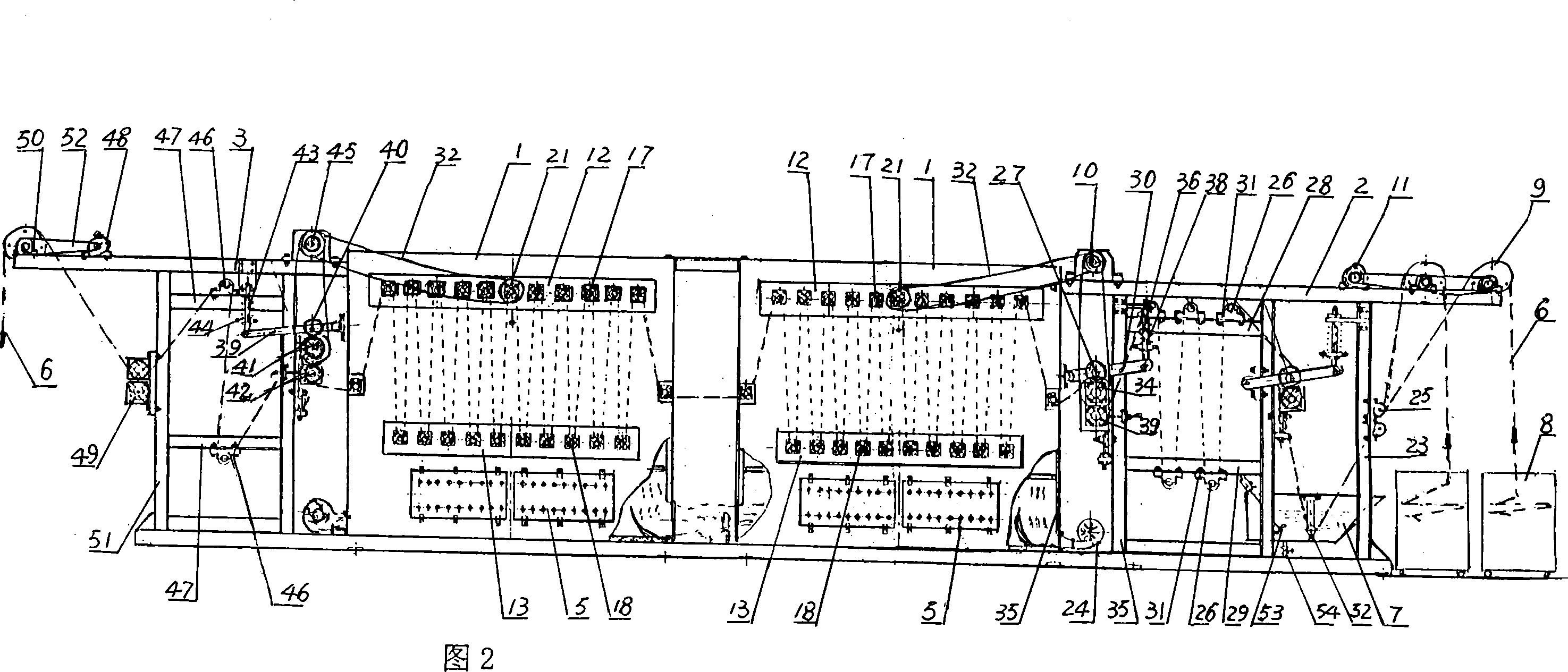

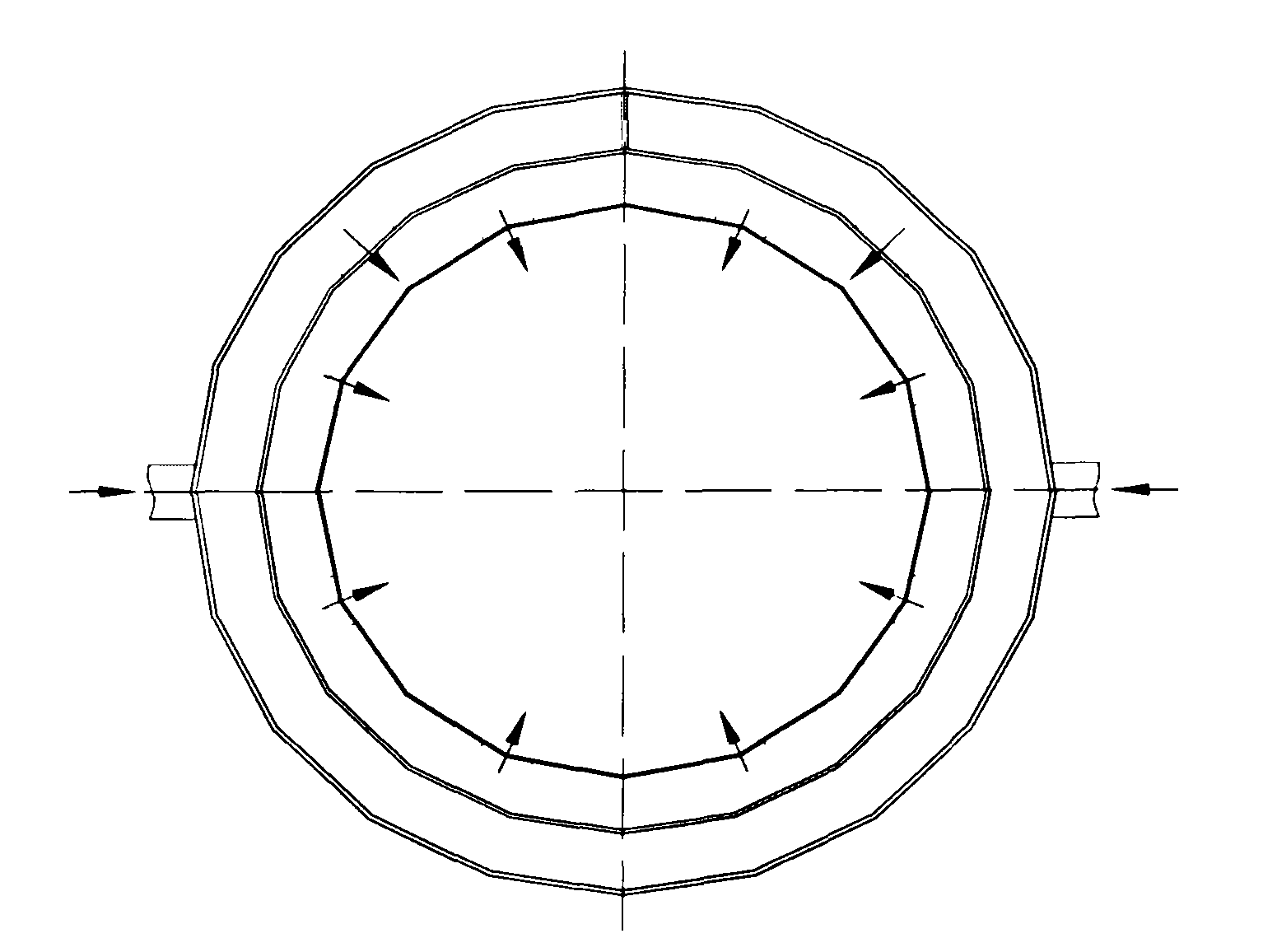

Equipment for dyeing and finishing polyester fibre flat woven tape

InactiveCN101220549ANo deformationUniform thicknessSucessive textile treatmentsTextile treatment containersPolyesterEngineering

The invention discloses a dyeing and finishing device of a terylene flat meshbelt, relating to a high speed continuous dyeing and finishing device of the terylene flat meshbelt which is a dyeing dryer that collects coloring, dyeing, fixation, drying, ironing and sizing into a whole. The device comprises a front straining trestle, a back straining trestle, a carding belt device, a staining trough, a front draughting and pressing device, a drying box, a back draughting device, a cooling device, and a tape-out device. The front straining trestle is arranged on the front of the drying box while the back straining trestle is arranged on the back of the drying box; the carding belt device comprises a meshbelt freight lorry, a squirrel cage typed carding belt drum, a speed reduction motor, and a carding belt drum; and the staining trough is arranged on the lower part of the front straining trestle; the front draughting and pressing device which is arranged on a middle column of the front straining trestle comprises a frequency control motor I, a press roll, a draughting and driving roller, a pressure adjusting rod, a pressure spring, and a pressure adjusting ejector pin; the drying box is provided with a drying chamber and a heating chamber, and the back draughting device is arranged on a back column which is on the lower part of the back straining trestle, and the cooling device is provided with a plurality of cooling rollers.

Owner:杨军

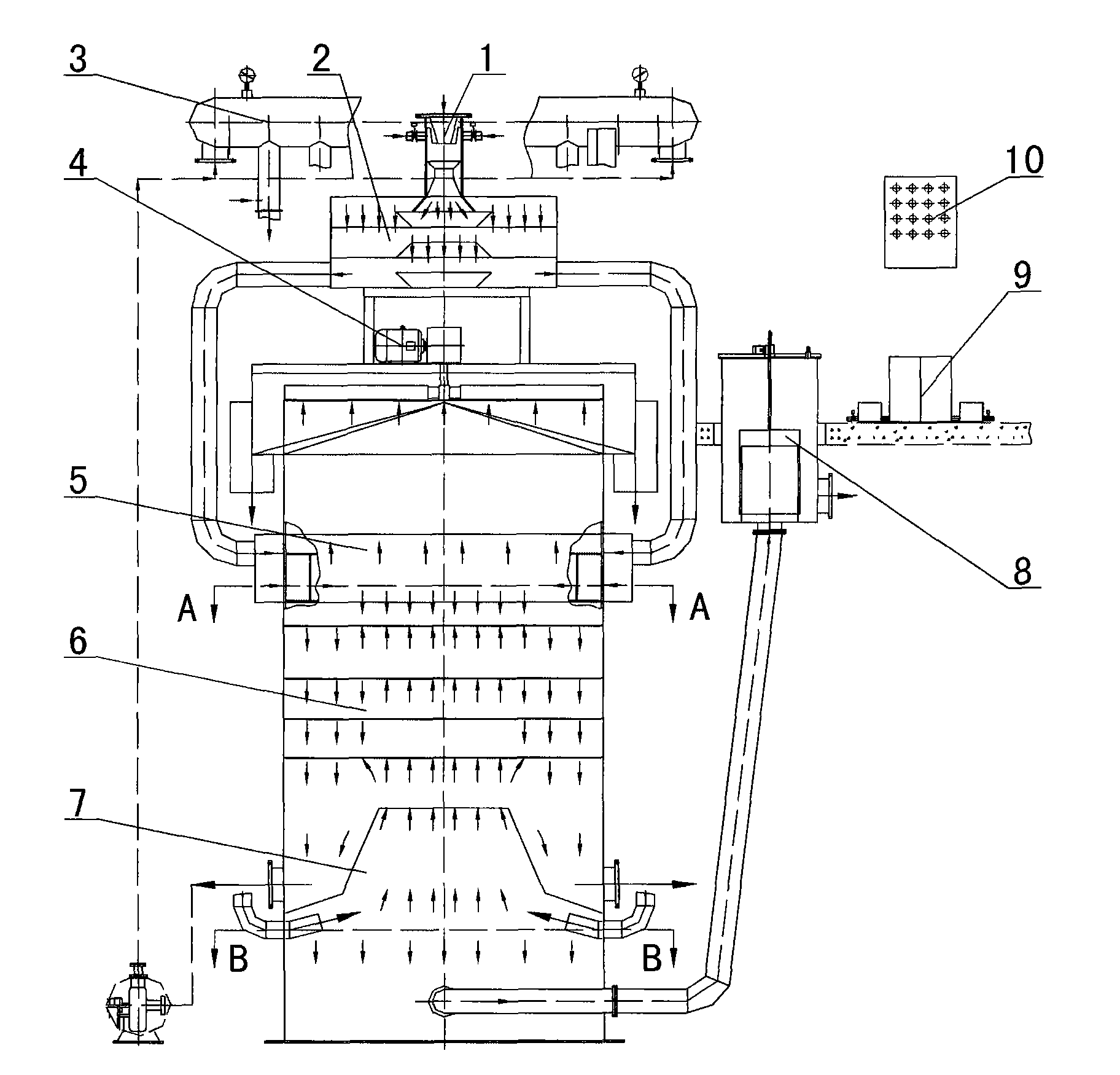

Flotation column special for floating fine flake graphite

InactiveCN102698879AFeeding kinetic energy is smallImplement static flotationFlotationElectricityProgrammable logic controller

The invention relates to a flotation column special for floating fine flake graphite, belonging to the technical field of graphite flotation; the flotation column disclosed by the invention is mainly composed of a mixing device, a static mineralizing machine, an upper column body, a scraping device, a distributor, a lower column body, a gangue discharging device, a middle column body, a dosing device and a PLC (programmable logic controller) control case; the mixing device is composed of a mixing pipe, a nozzle, a throat pipe and an expanding pipe; the static mineralizing machine is composed of a case body, a variable-diameter amplifier, a baffle board, an uniform distribution board and a discharging pipe; the upper column body is composed of an upper barrel body, a finished ore groove and a static charging device; the scraping device is composed of a motor, a decelerator, an output shaft and a scraper; and the distributor is composed of a distributing pipe, an electric valve, an electric contact pressure gauge, a circular pump and a micro-bubble generator. According to the invention, the flotation column has the advantages of good raw ore and medicament mineralizing effect, small charging kinetic energy, large cyclone force field, good flotation effect and large treatment quantity.

Owner:SHANDONG LAIWU COAL MINING MACHINERY

Novel multifunctional safe running machine

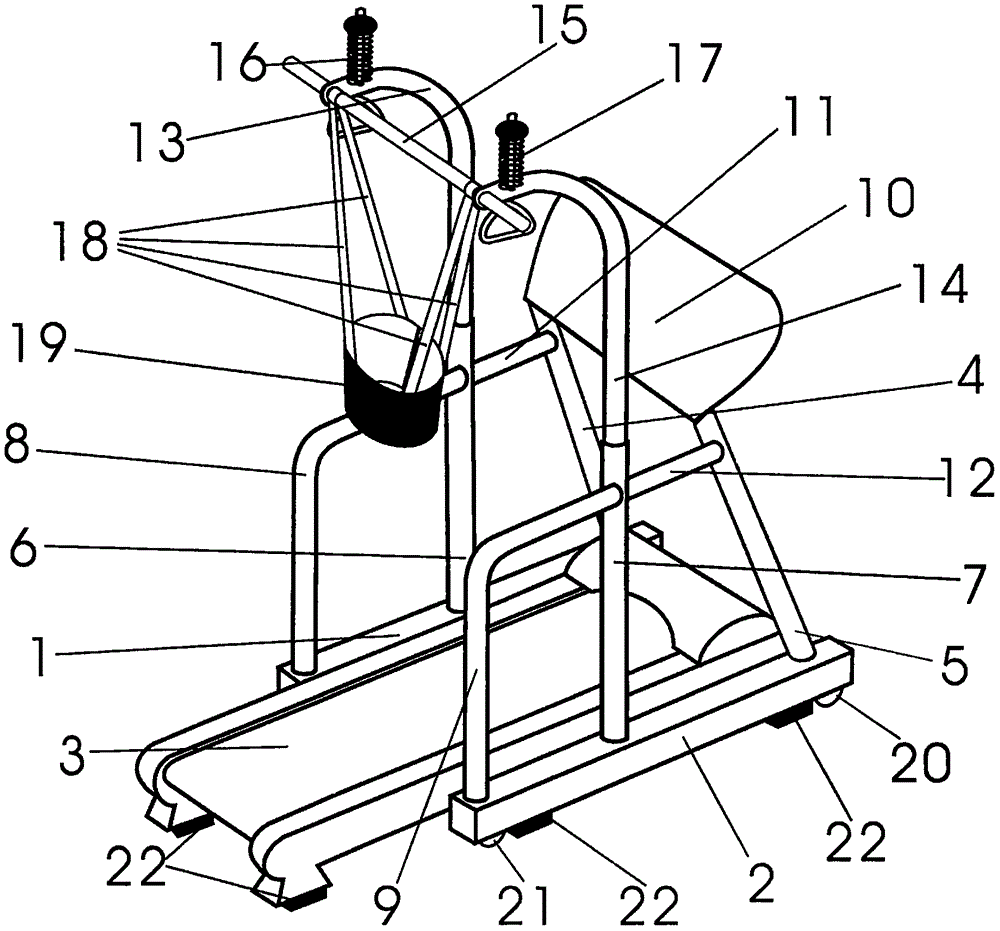

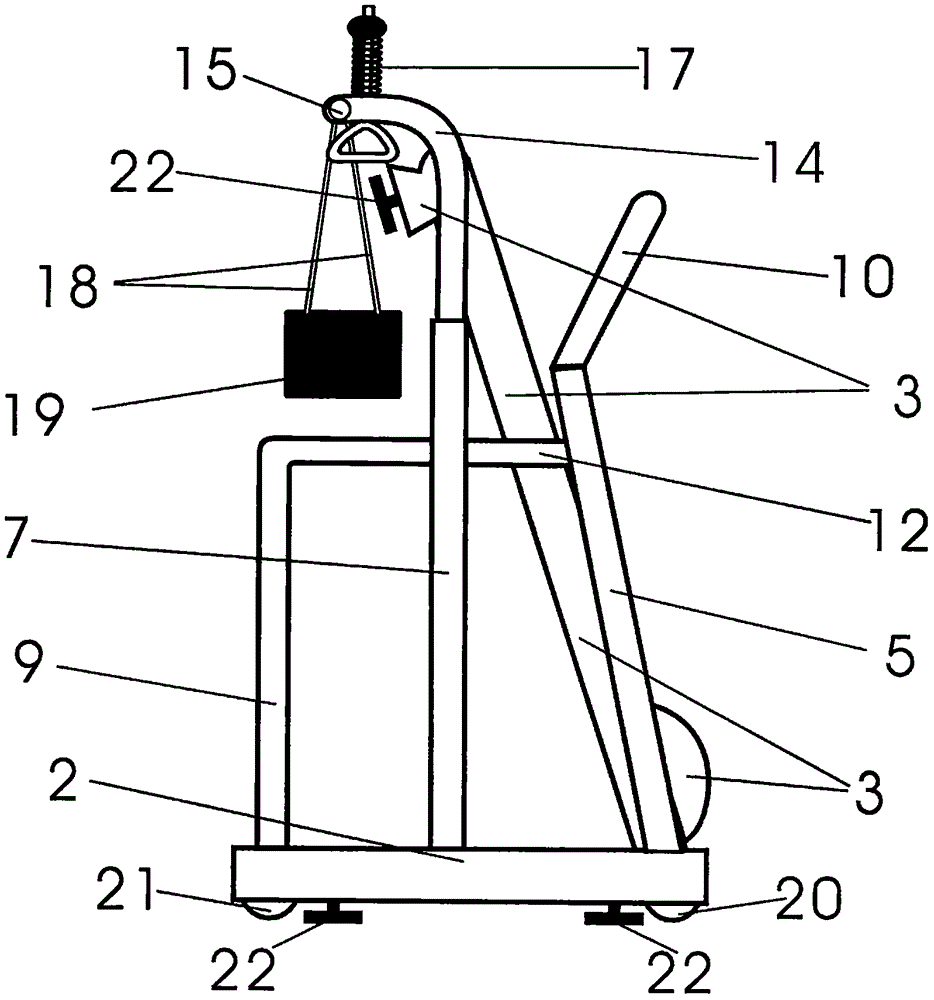

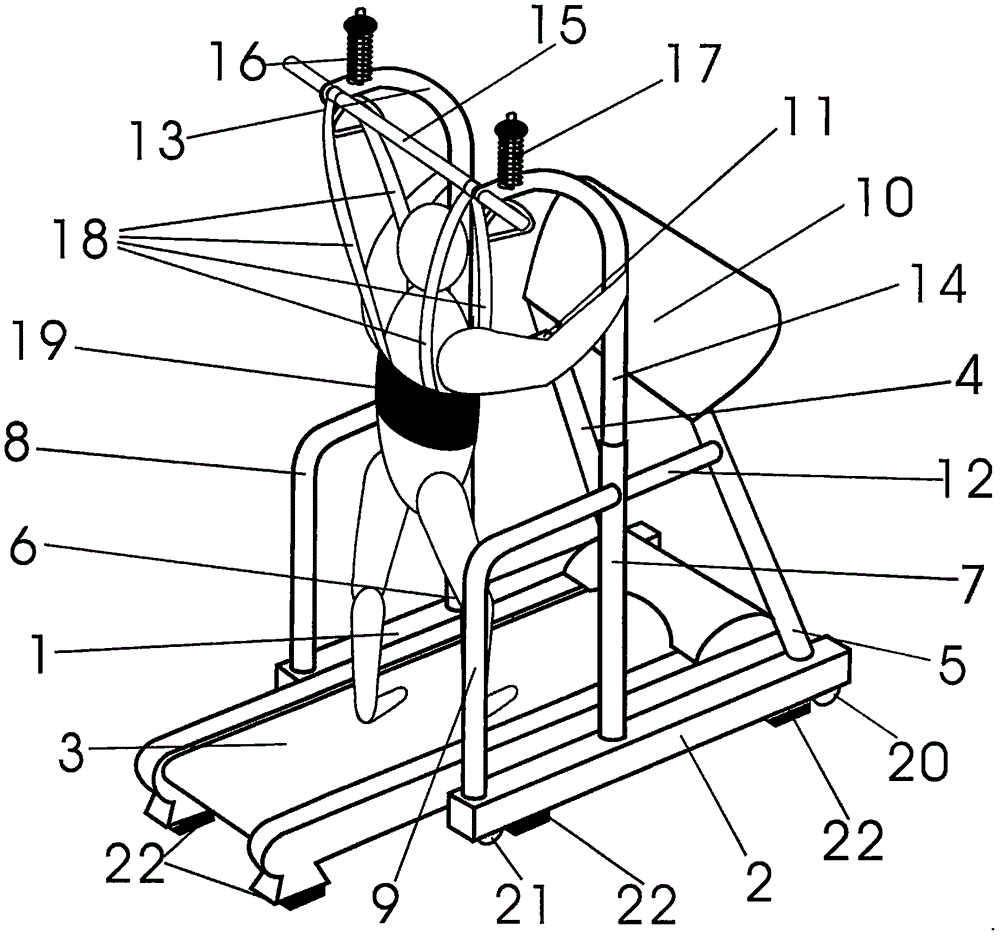

InactiveCN105797308AImprove shock absorptionEasy to move and save effortDiagnostic recording/measuringSensorsEngineeringInstrument control

The invention provides a novel multifunctional safe running machine and belongs to the field of fitness facilities. The novel multifunctional safe running machine comprises a left base frame, a right base frame, an electric running machine treadmill, a left front column, a right front column, a left middle column, a right middle column, a left horizontal armrest frame, a right horizontal armrest frame, an instrument control panel, a left connecting rod, a right connecting rod, a left vertical armrest rod, a right vertical armrest rod, a high armrest rod, a left chest expander, a right chest expander, safety belts, a chest and abdominal binding belt, front rolling wheels, rear rolling wheels and adjustable shock-absorbing pads. The novel multifunctional safe running machine is characterized in that the running machine is provided with the front rolling wheels, the rear rolling wheels and the adjustable shock-absorbing pads, adopts and has the advantages of adopting four-wheel movement, being more convenient and saving more effort in movement; the running machine is provided with the adjustable base frame shock-absorbing pads, the whole machine is movable after the shock-absorbing pads are put away, and the shock-absorbing effect is better after the shock-absorbing pads are placed or arranged; a user can do upper limb exercise through the horizontal rods and the chest expanders separately or do it while running, and the machine makes exercise more comprehensive; the running direction can be adjusted to be forward walking and forward running, or reverse walking and reverse running, or alternative performing of forward walking and forward running and reverse walking and reverse running, and the user can run with double hands in front of the chest, or behind the back or above the head or on the higher armrests so as to achieve a better exercise effect.

Owner:陈金芳

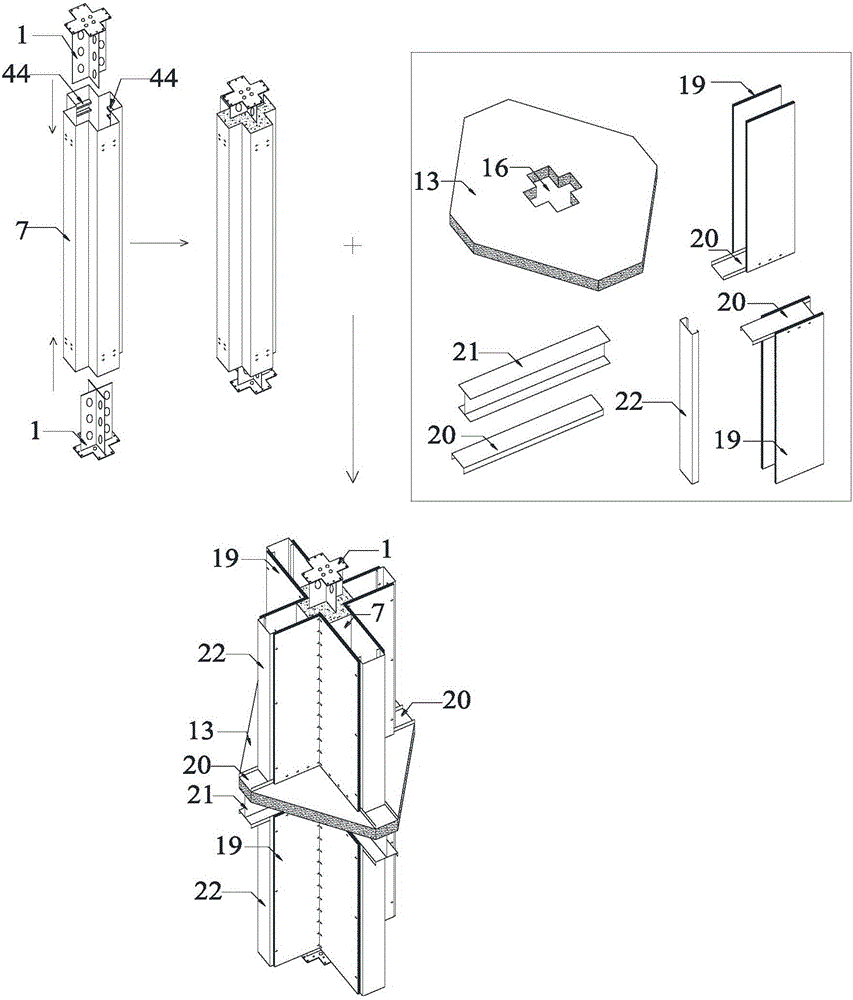

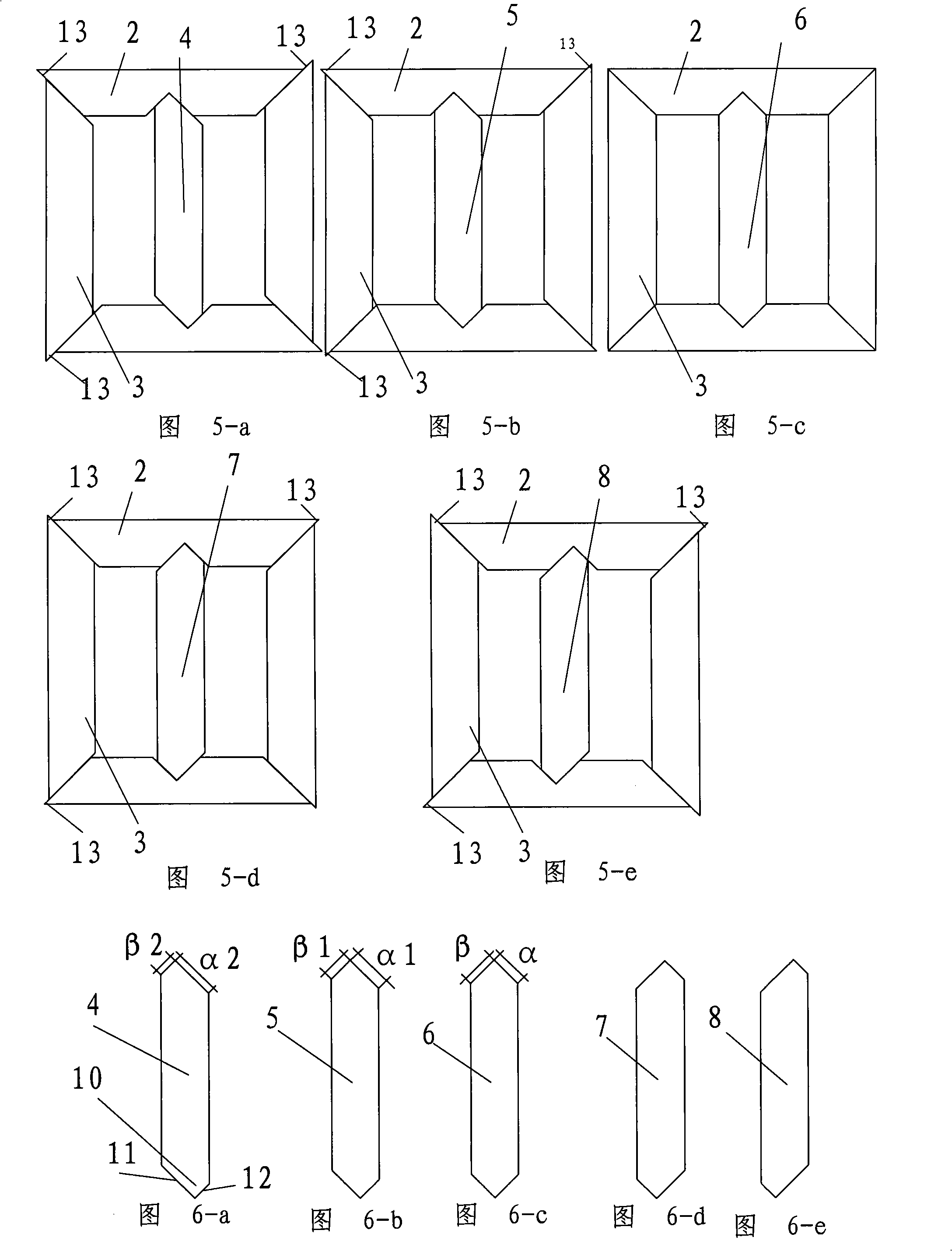

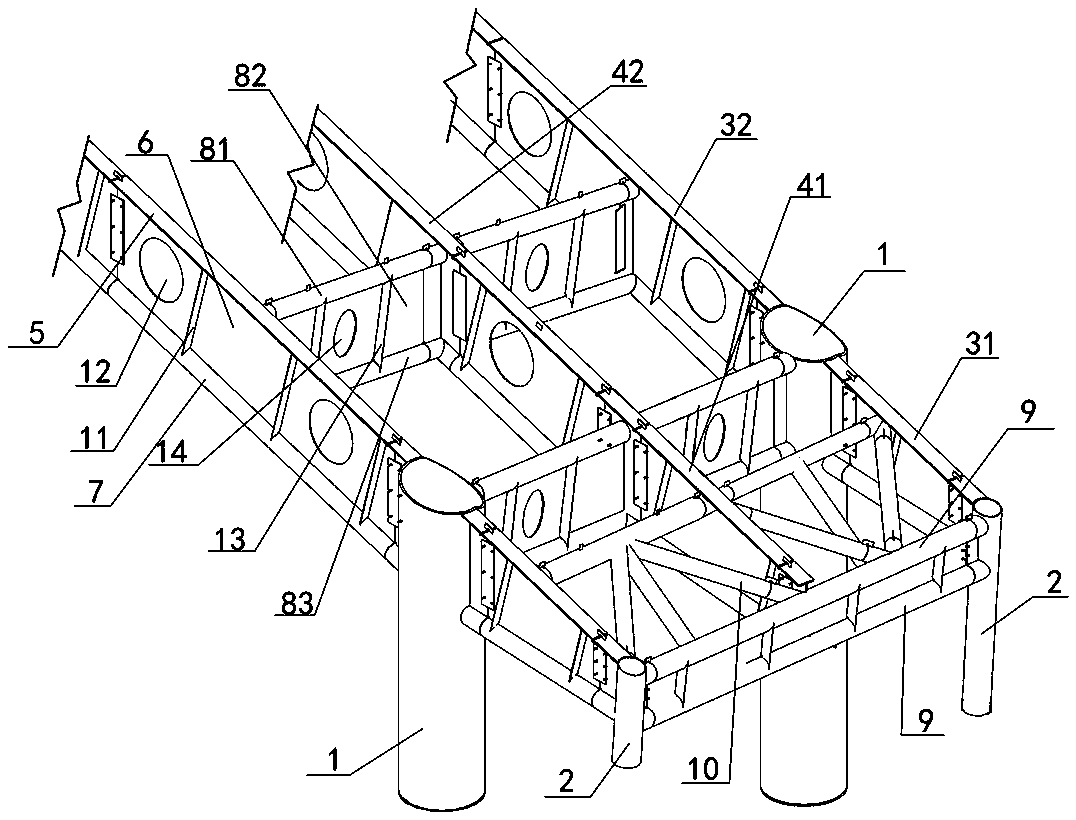

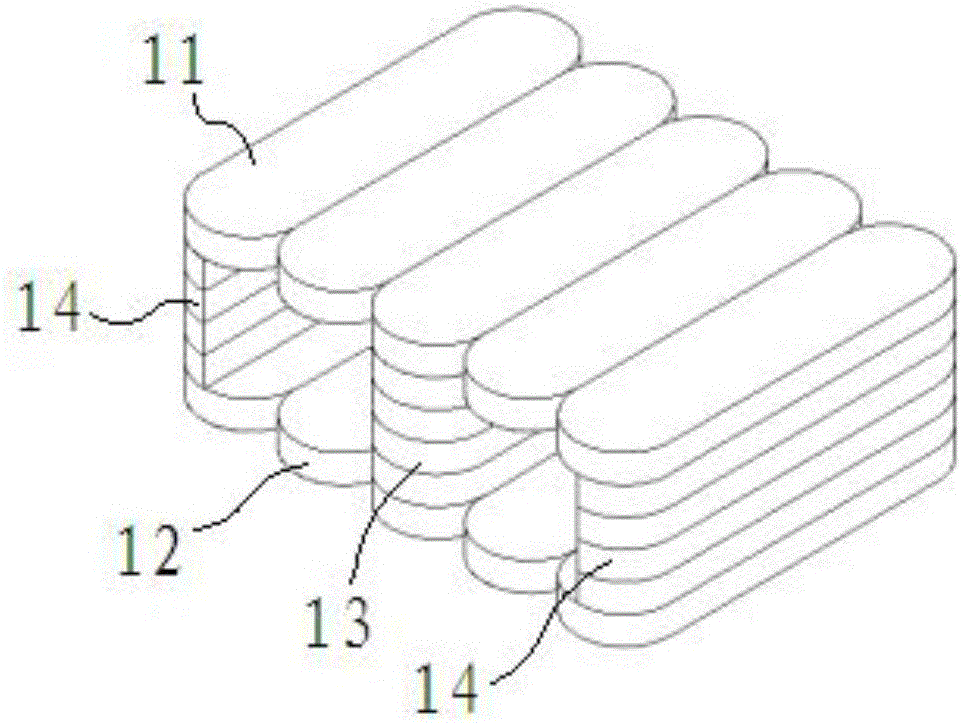

Multilayer cold-formed steel integrally prefabricated house and splicing method thereof

ActiveCN105696817AReduce on-site construction workloadHigh degree of industrializationBuilding material handlingDwelling buildingFloor slabEngineering

Owner:SOUTHEAST UNIV

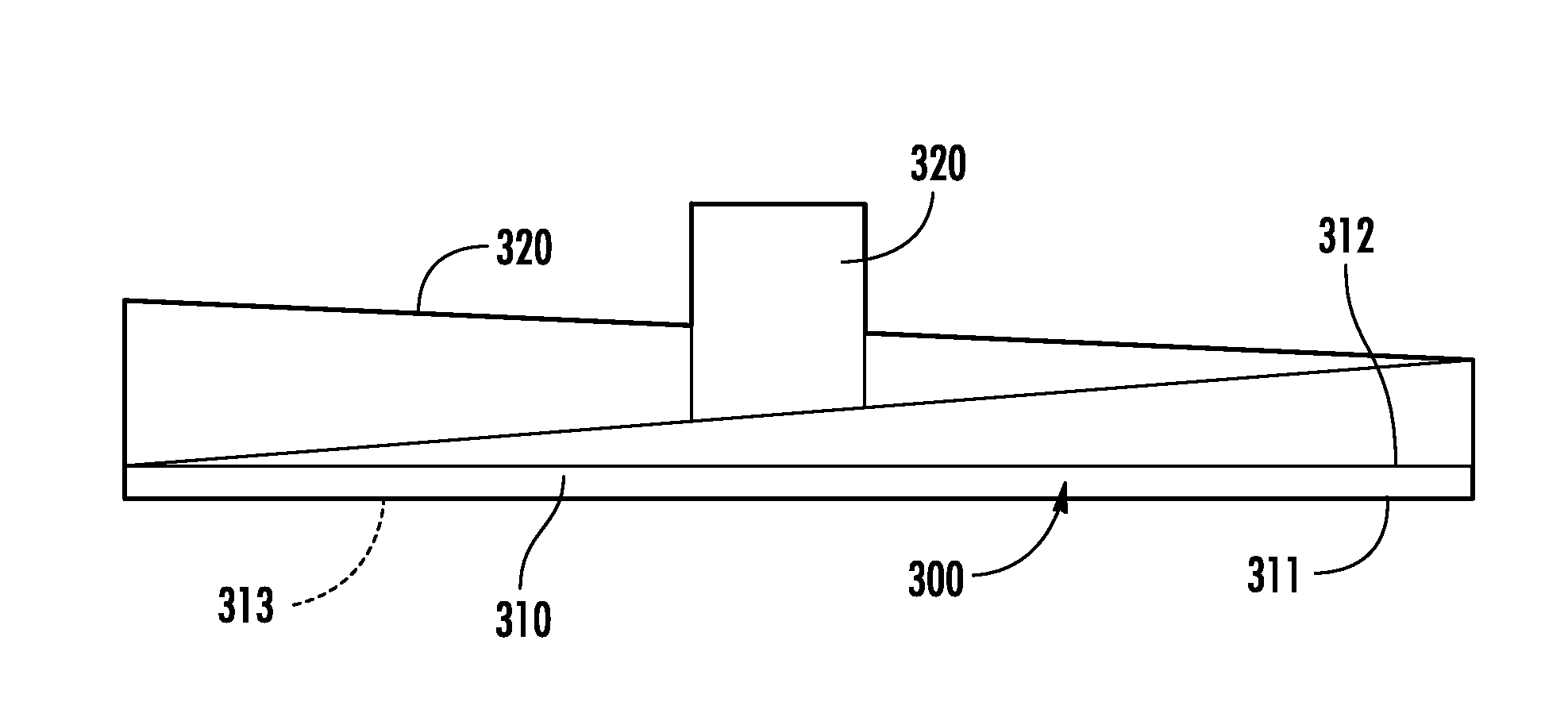

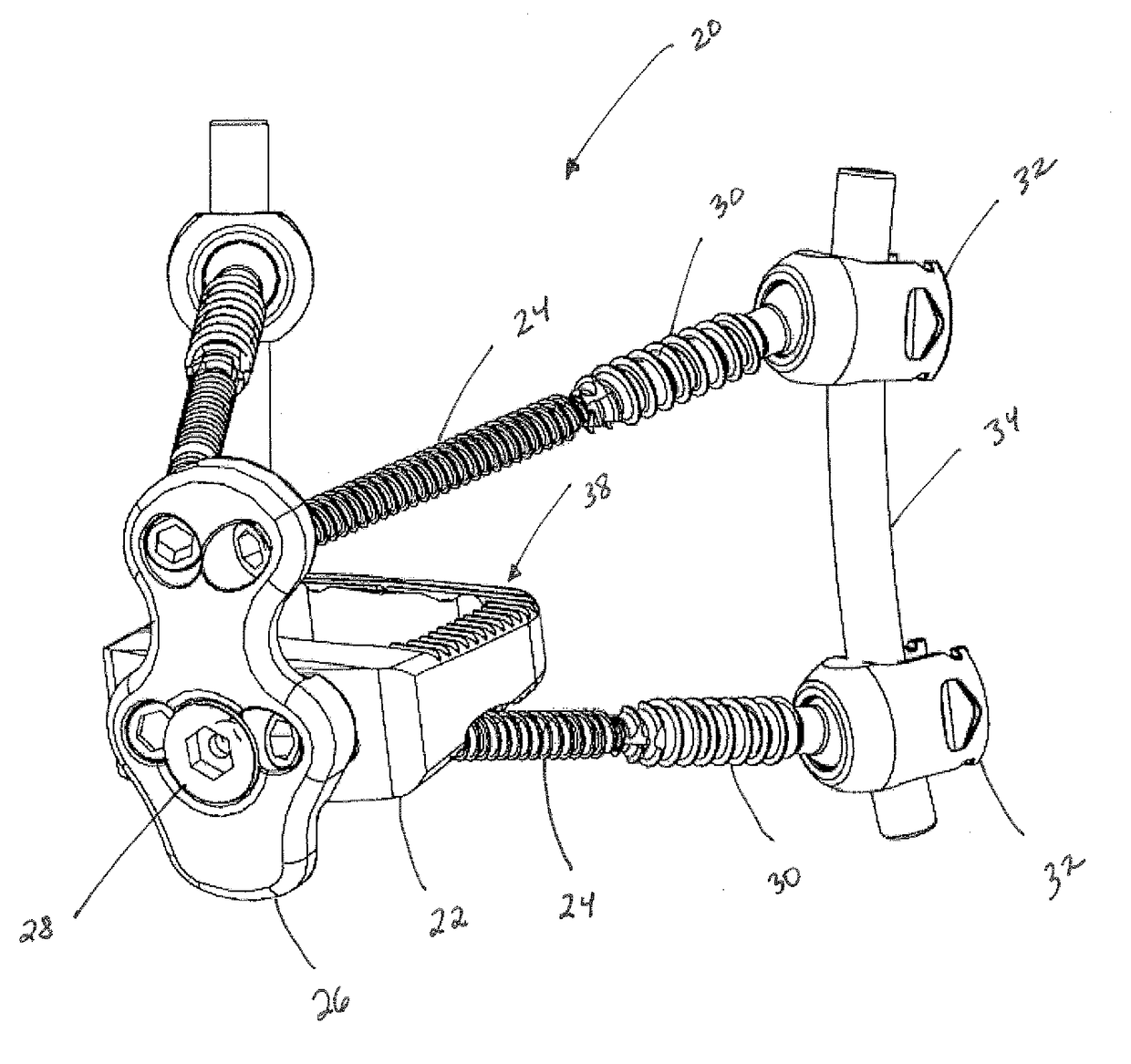

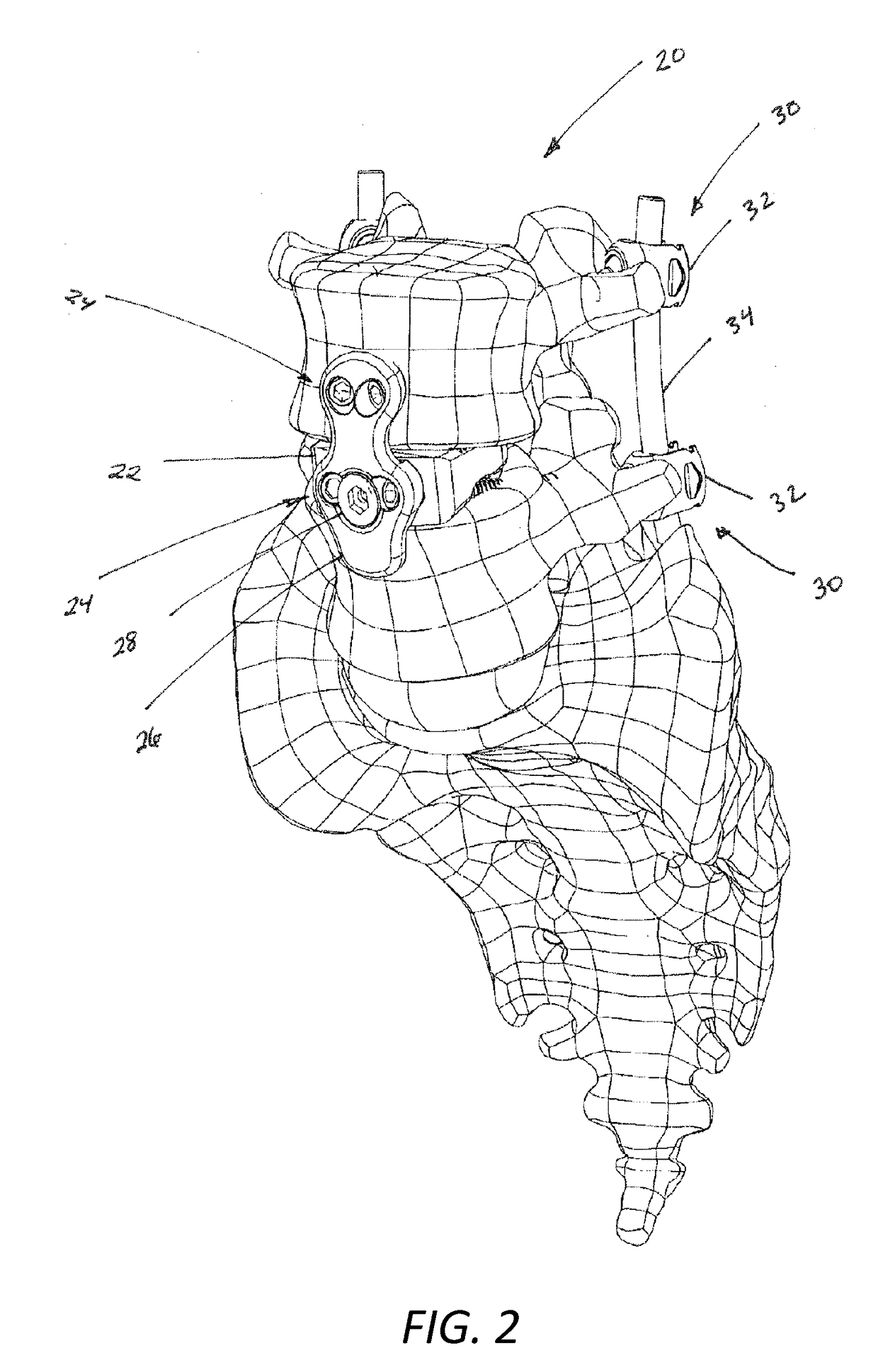

Three column spinal fixation implants and associated surgical methods

ActiveUS20170119537A1Improve operational simplicityShorten operation timeInternal osteosythesisJoint implantsSpinal columnIntervertebral space

A three column spinal fixation implant, including: an anterior cage configured to be disposed in an intervertebral space between adjacent vertebral bodies in a spine of a patient; an anterior plate coupled to the anterior cage; a pair of anterior screws coupled to the anterior cage and the anterior plate and extending posteriorly from the anterior cage and the anterior plate through a portion of one or more of the adjacent vertebral bodies and into or through posterior bony structures of the spine of the patient; a pair of anterior screws coupled to the anterior plate and extending posteriorly from the anterior plate through a portion of one or more of the adjacent vertebral bodies and into or through posterior bony structures of the spine of the patient; a plurality of posterior headbodies coupled to the anterior screws opposite the anterior cage and the anterior plate; and one or more connecting structures coupled to the plurality of posterior headbodies; wherein the three column spinal fixation implant provides structural stability to the spine of the patient across a first anterior column, a second middle column, and a third posterior column thereof.

Owner:TEPPER GIL +2

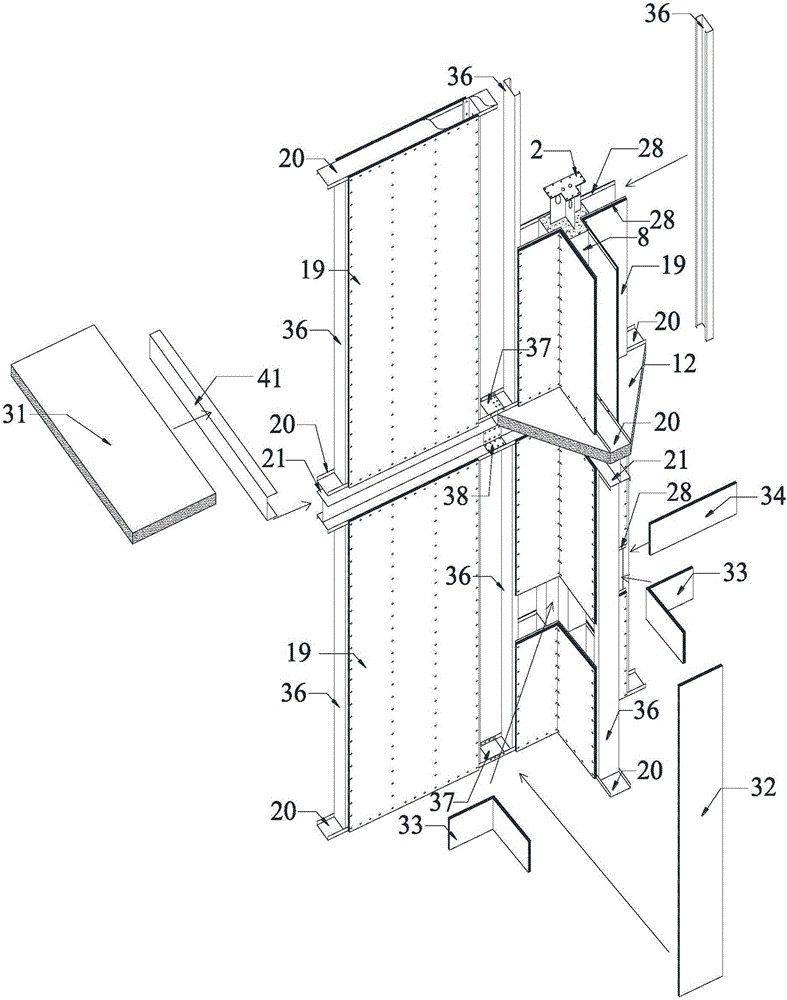

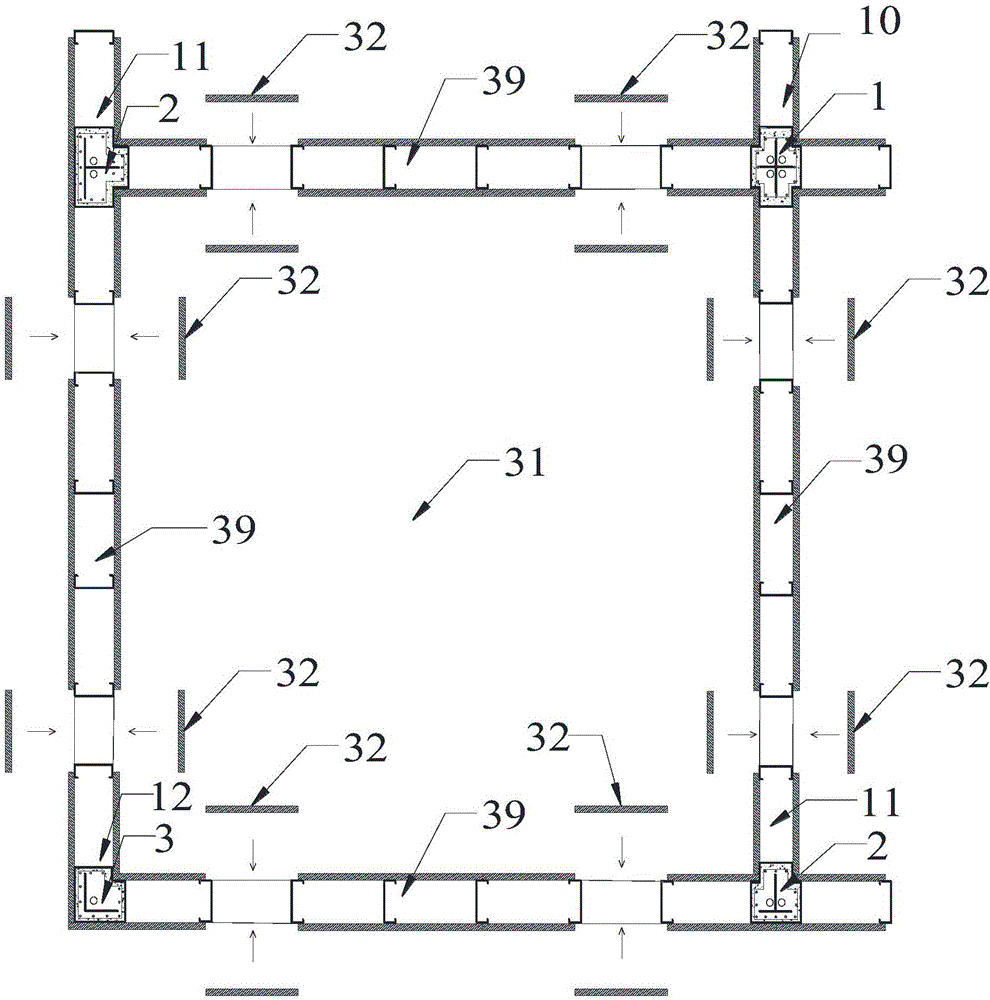

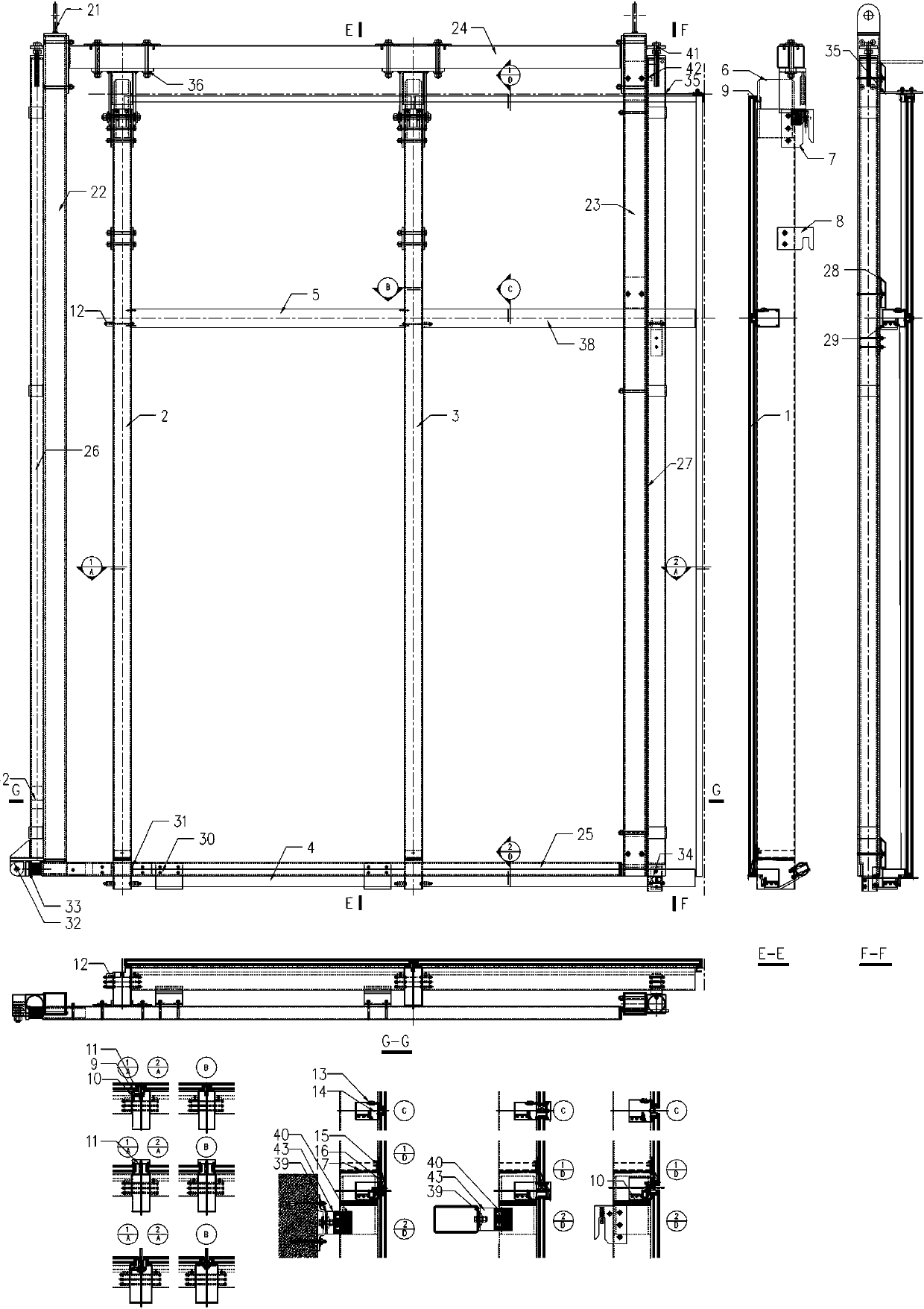

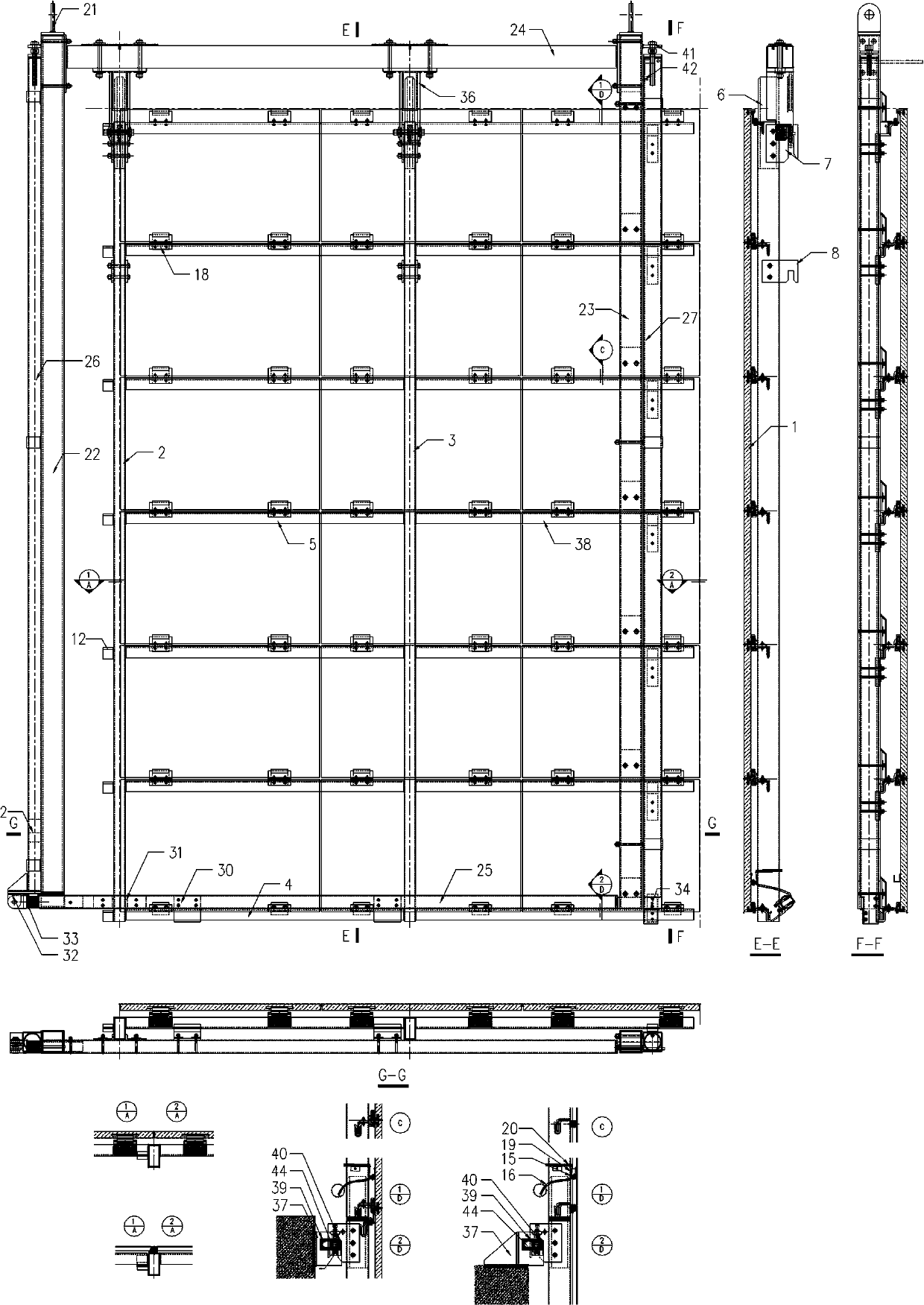

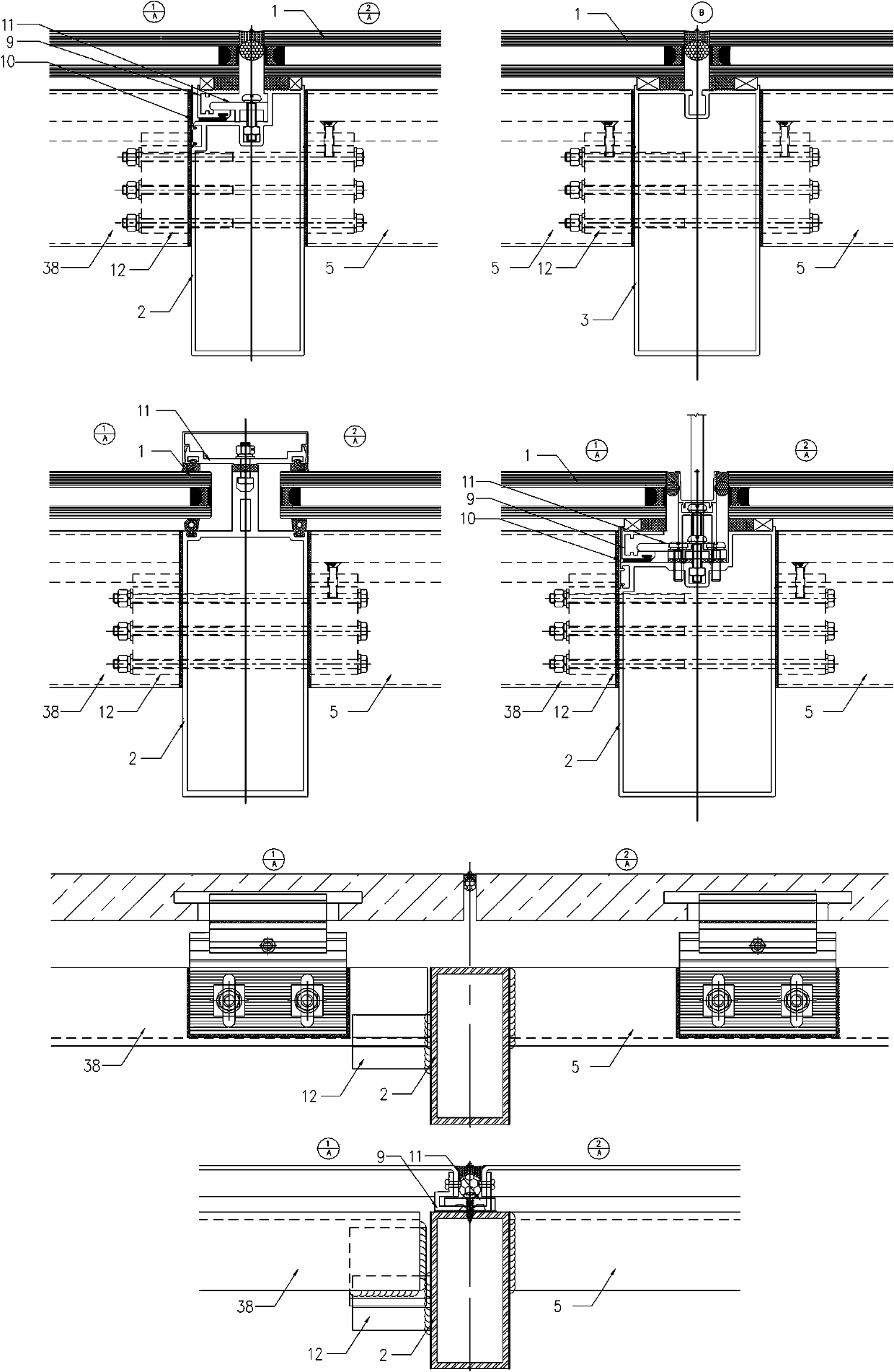

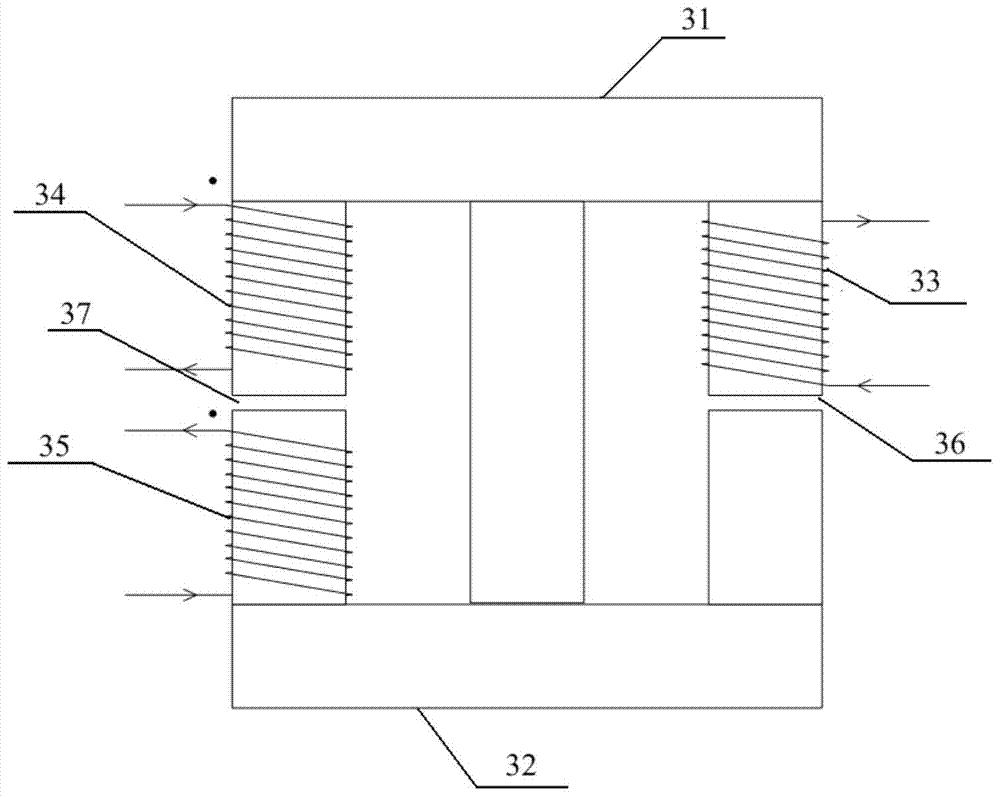

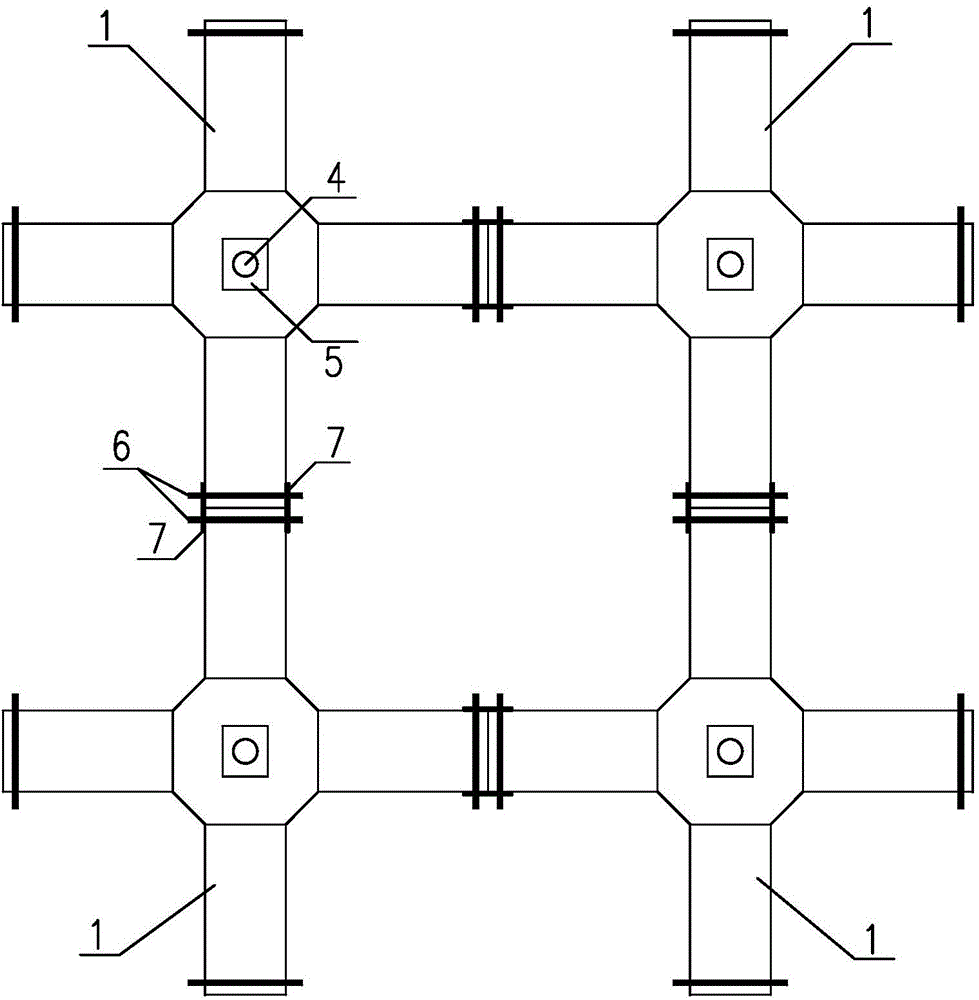

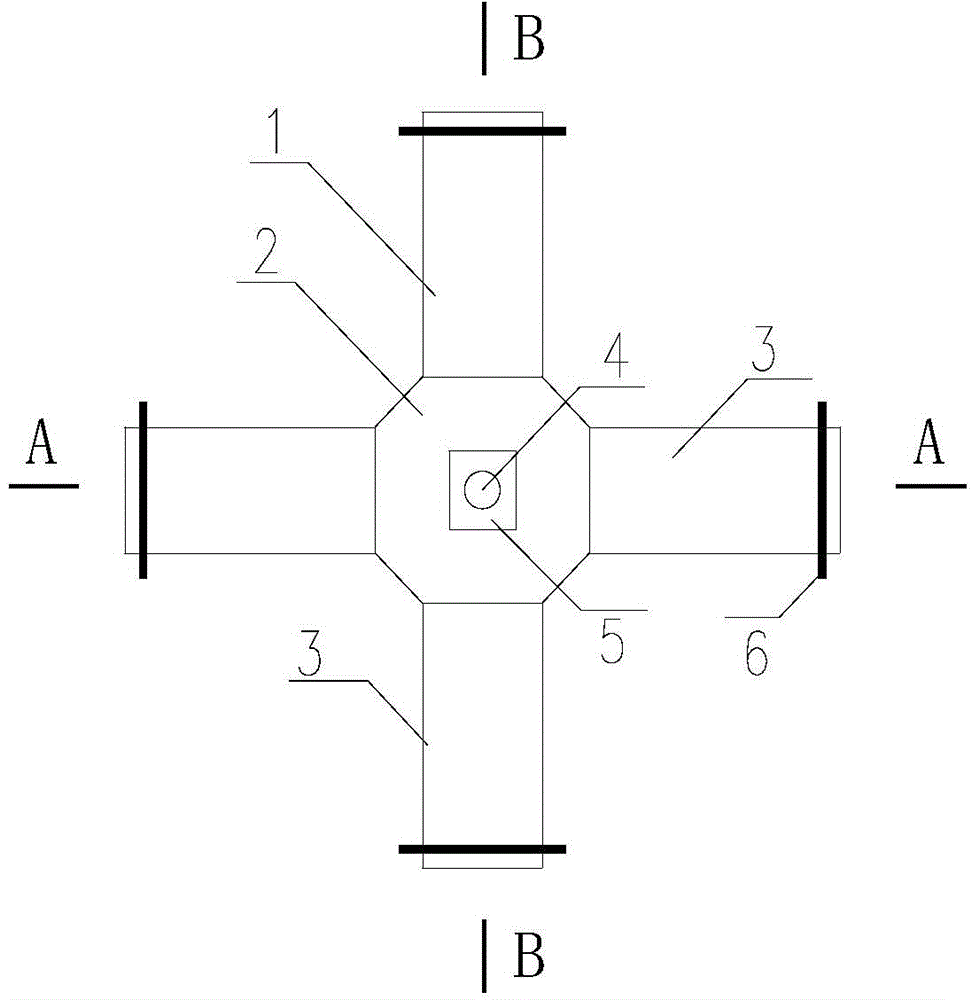

Frame type unit curtain wall adopting auxiliary installing rack, tooth profile angle and tooth profile support

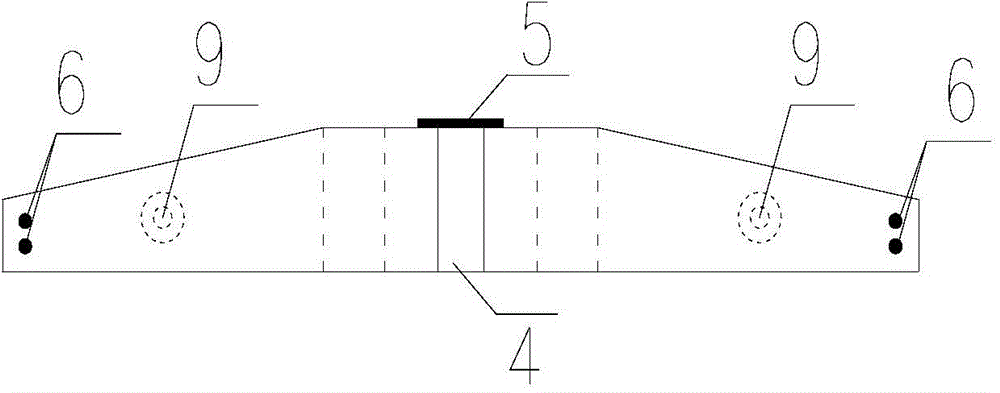

The invention relates to the field of curtain walls of buildings, in particular to a frame type unit curtain wall adopting an auxiliary installing rack, a tooth profile angle and a tooth profile support. The frame type unit curtain wall adopting the auxiliary installing rack comprises a panel (1), end columns (2), middle columns (3), end cross beams (4), middle cross beams (5), inserting cores (6), an auxiliary frame (9), a cover plate and the like. The frame type unit curtain wall adopting the auxiliary installing rack, the tooth profile angle and the tooth profile support are long in service life, low in cost, good in machinability, short in field construction period and good in sealing performance.

Owner:何志胜

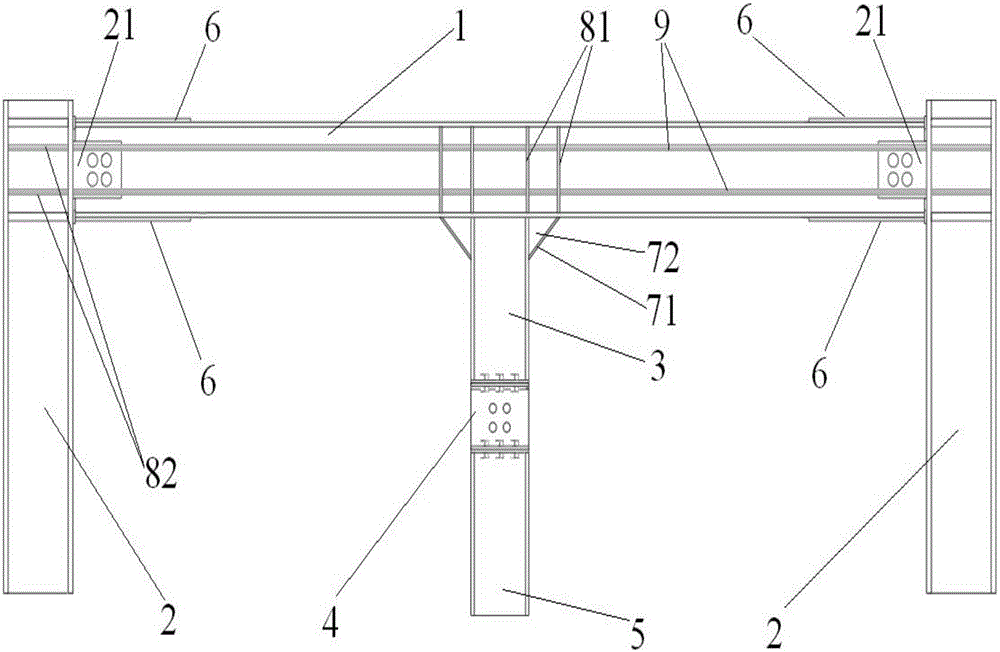

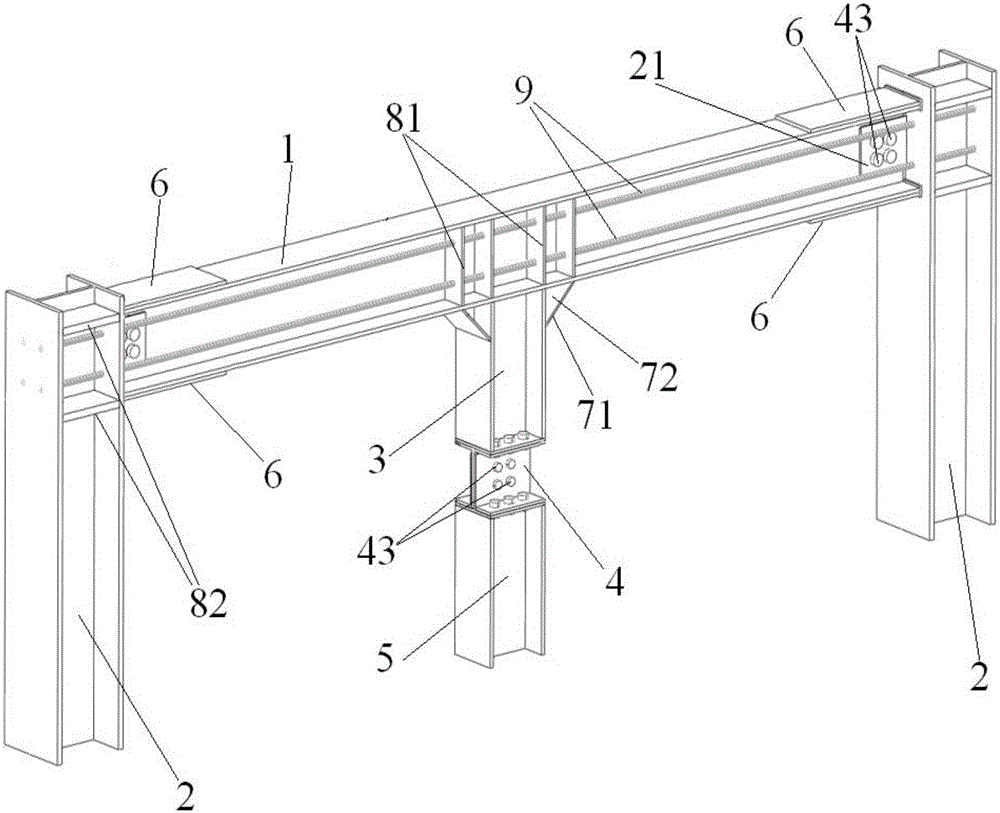

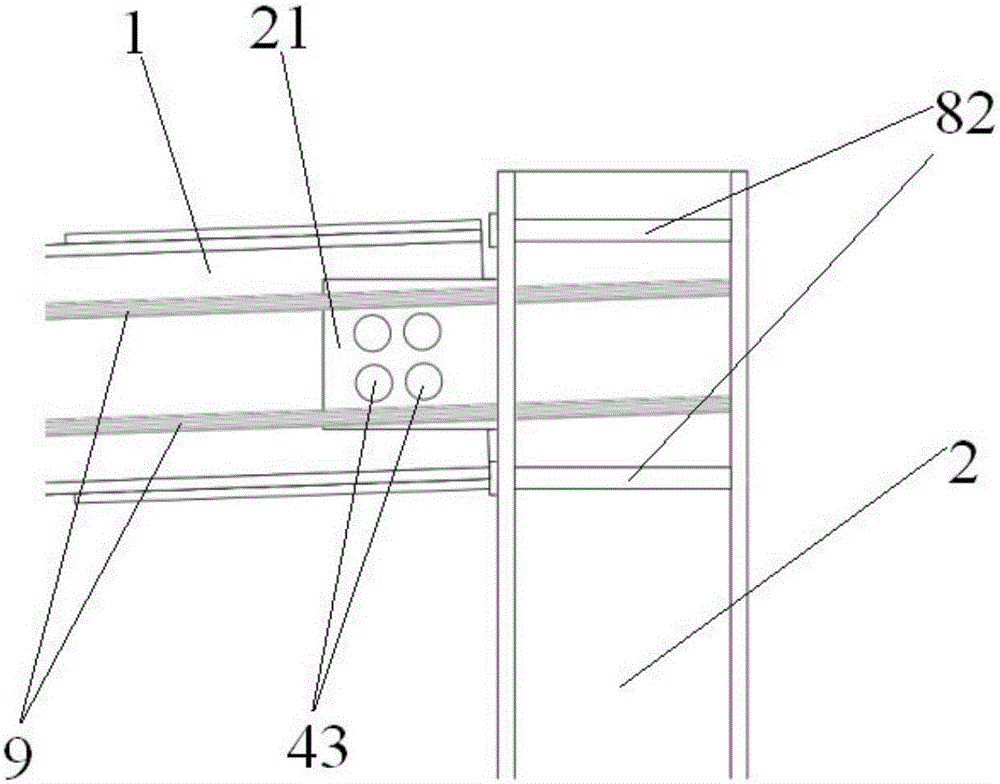

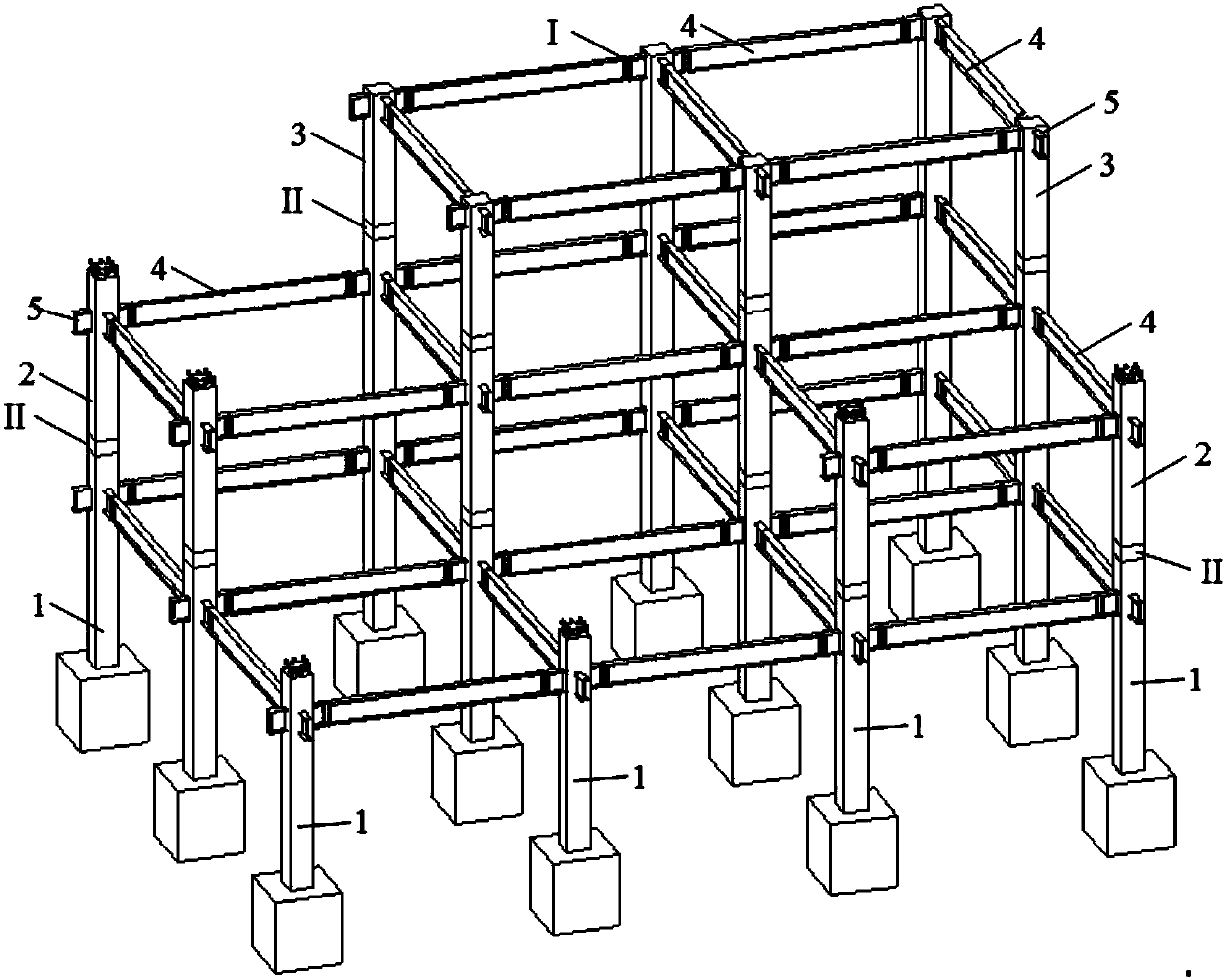

Prestressed assembled middle column steel frame recoverable in function

The invention relates to the technical field of steel structures in building industry and discloses a prestressed assembled middle column steel frame recoverable in function. The prestressed assembled middle column steel frame comprises a frame beam, two frame columns, an upper middle column, a friction energy-consuming device and a lower middle column, the frame beam is arranged horizontally, the frame columns are vertically arranged at two ends of the frame beam, the frame columns are movably connected with the frame beam, the upper middle column is vertically arranged below the frame beam, the top of the upper middle column is fixedly connected with the frame beam, and the upper middle column, the friction energy-consuming device and the lower middle column are sequentially connected from top to bottom. Rigidity of the whole steel frame can be enhanced; energy dissipation of the steel frame can be improved through the friction energy-consuming device, so that overall deformation degree of the prestressed assembled middle column steel frame is lowered greatly, in other words, inter-layer displacement angle response is reduced, stability of a whole building is improved, designing requirements are met, and safety in operation can be guaranteed.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

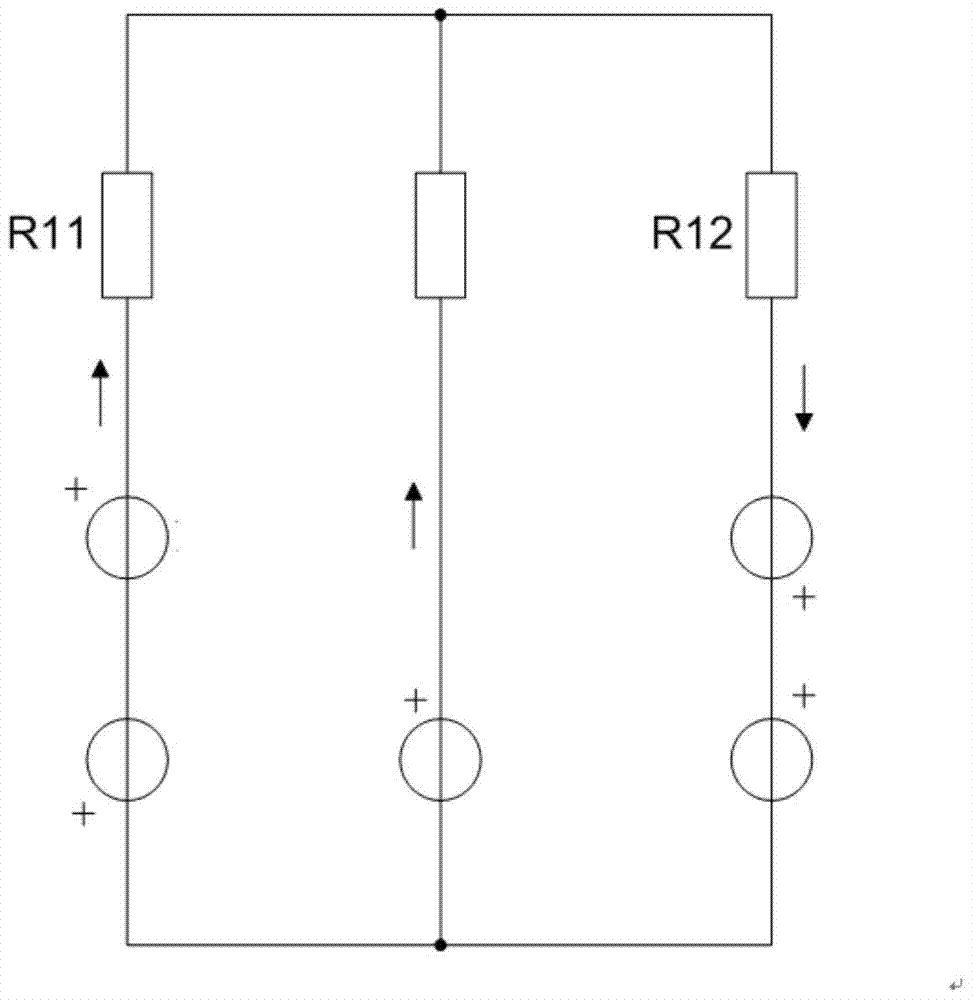

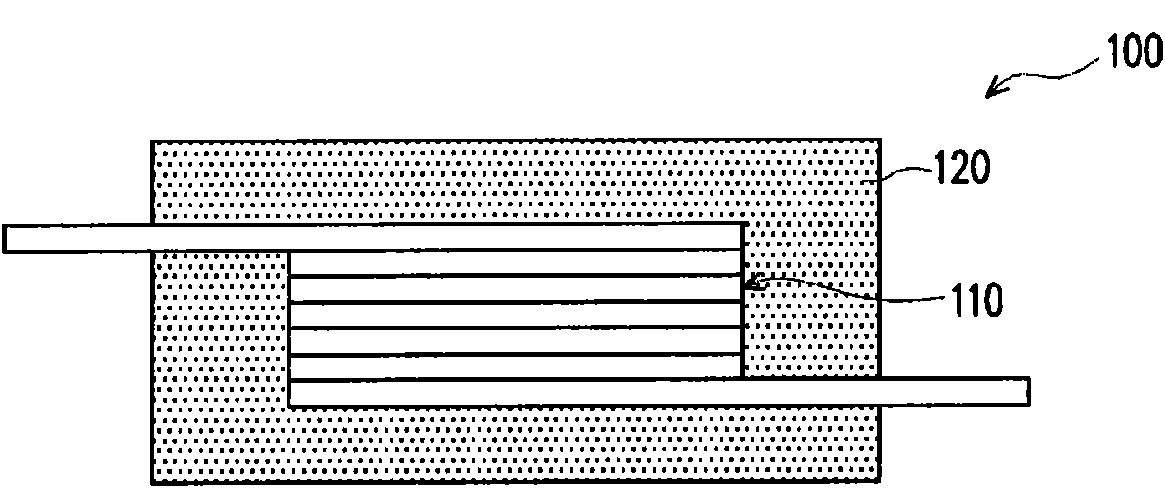

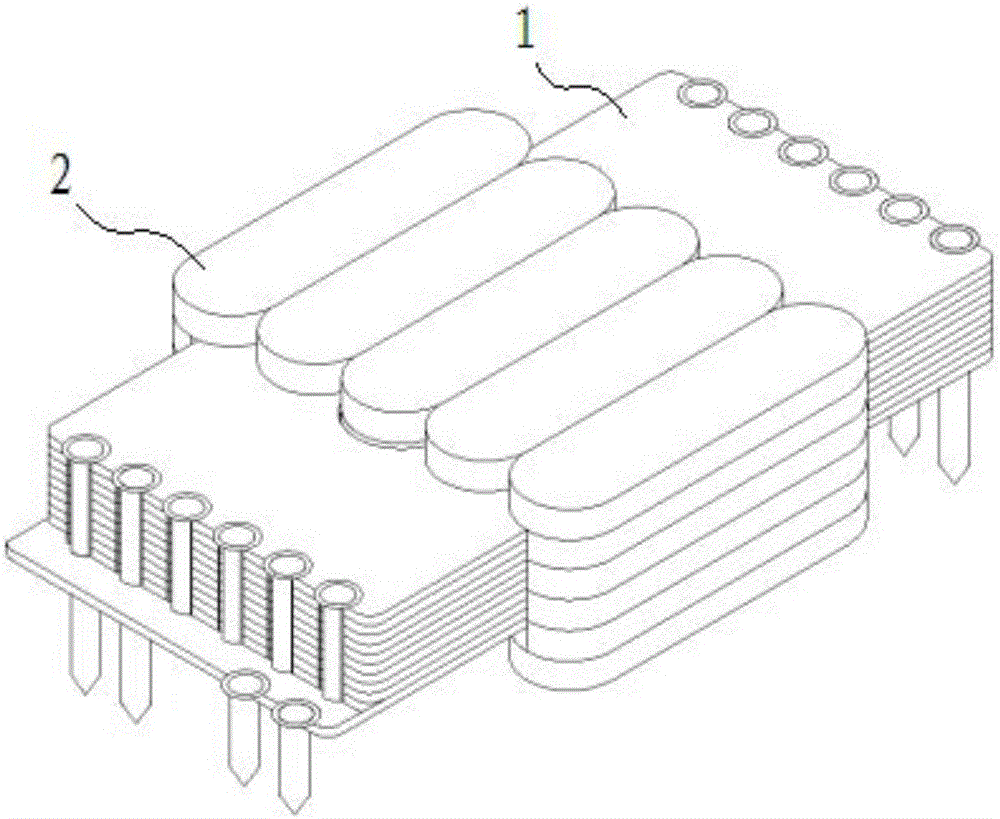

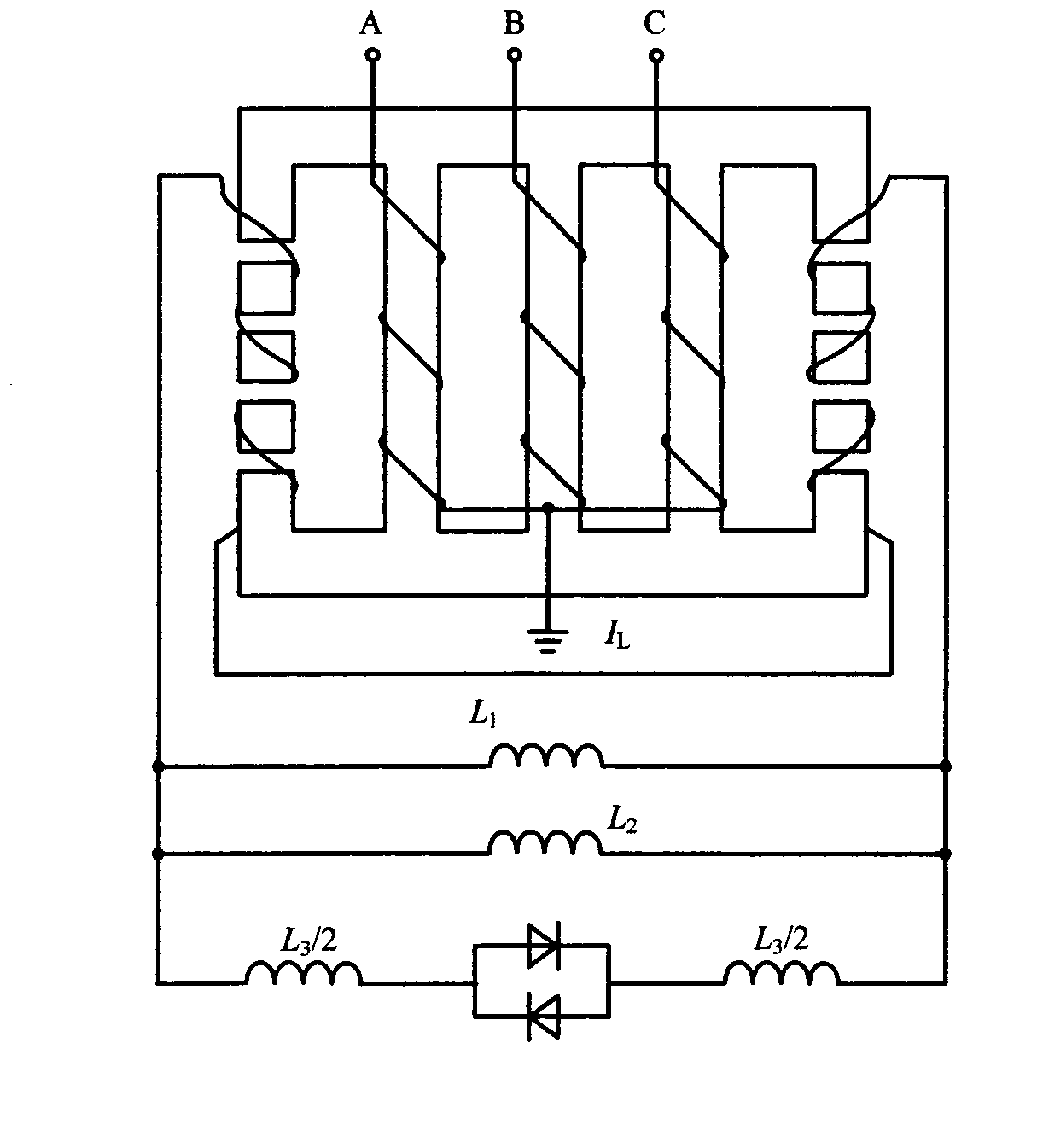

Integrated magnetic structure

InactiveCN103871716AReduce volumeImprove power densityTransformersTransformers/inductances coils/windings/connectionsTransformerEngineering

The invention discloses an integrated magnetic structure, and belongs to the technical field of electromagnetism. The integrated magnetic structure comprises a horizontal magnetic core shaped like a Chinese character Ri, first and second side column windings wound on a left side column, third and fourth side column windings wound on a right side column and a middle column winding wound on a middle column, wherein the first and third side column windings are connected and forwards coupled; the second and fourth side column windings are connected and forwards coupled. When the integrated magnetic structure is applied to the integration of a transformer and an inductor, magnetic flux generated by a winding of the inductor passes through a magnetic circuit of the transformer, so that a magnetic core material can be fully utilized, and the size of a magnetic core can be reduced; when the integrated magnetic structure is applied to the integration of a common mode choke and a differential mode choke, magnetic flux generated by a winding of the differential mode choke passes through the common mode choke part, so that the whole magnetic core is fully utilized, and the size of a filter is reduced; moreover, the common mode choke and the differential mode choke are decoupled, and can be independently regulated without influence.

Owner:TONGJI UNIV

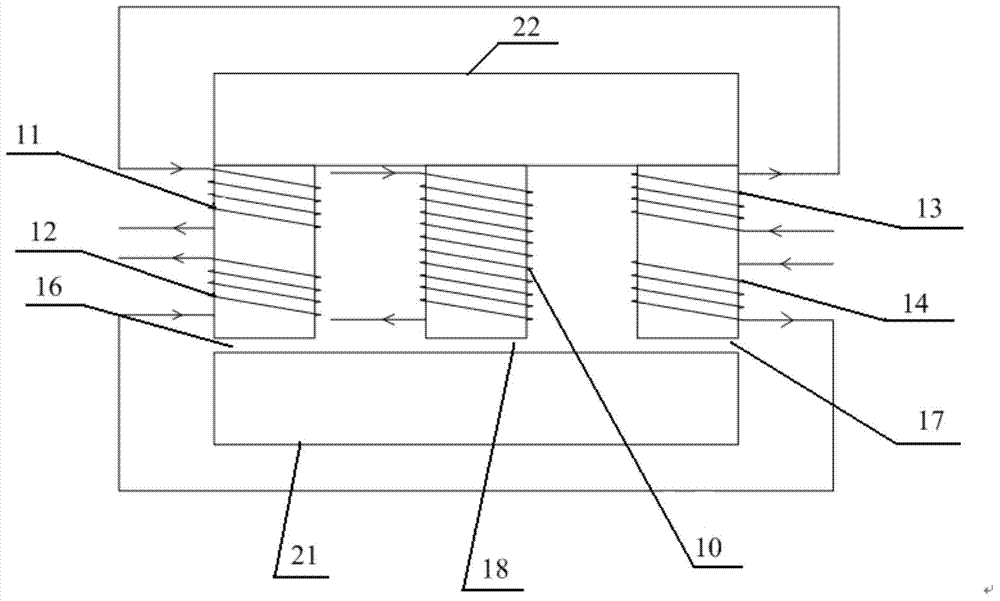

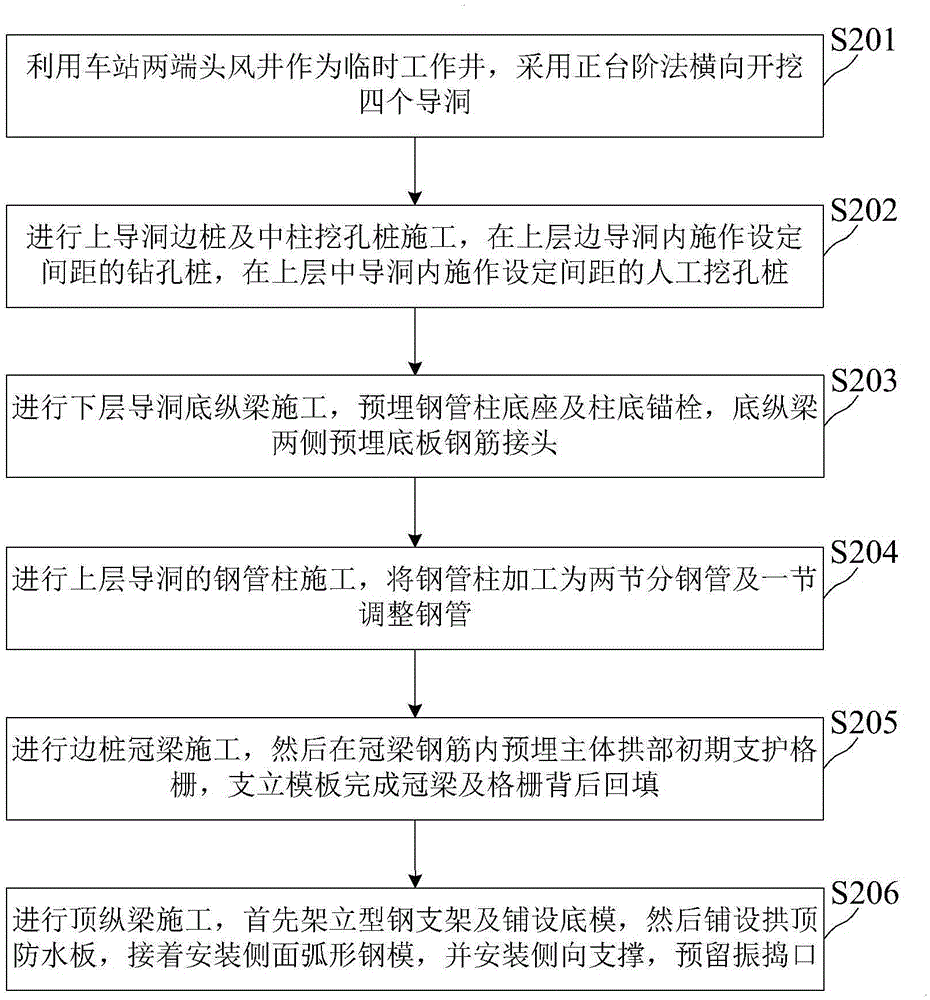

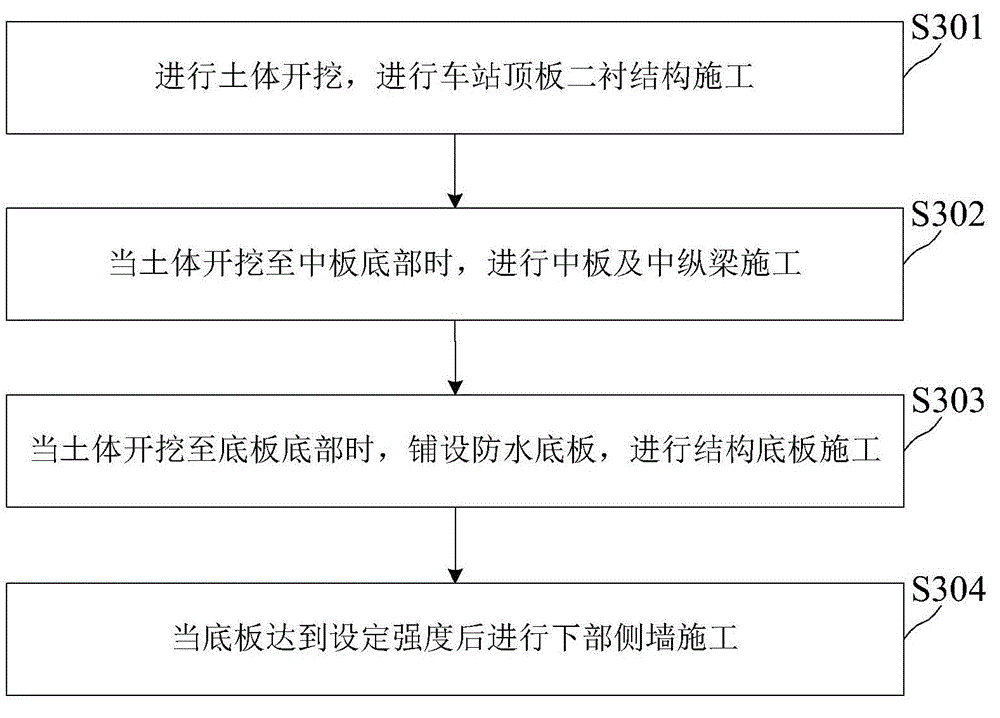

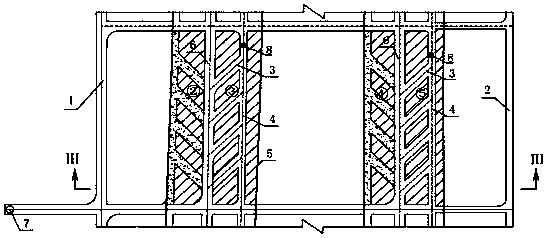

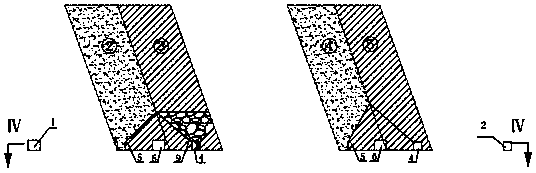

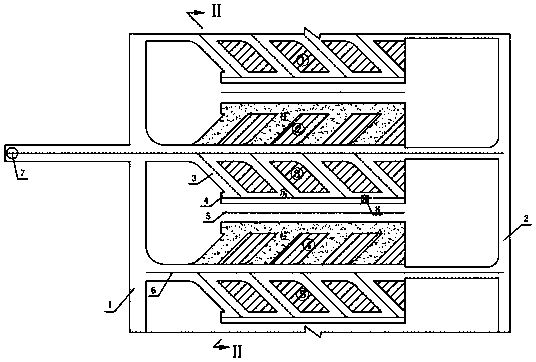

Mined metro station hole pile construction method

ActiveCN106703814AReduce the impact of settlementSave masonryUnderground chambersTunnel liningSupporting systemMetro station

Provided is a mined metro station hole pile construction method. The method comprises the steps of whole support system construction and main body second lining construction; the whole support system construction step comprises the substeps that by utilizing air shafts at the two ends of the station as temporary working wells, four pilot tunnels are transversely dug through a positive step method; upper pilot tunnel side pile and middle column hole digging pile construction is conducted, bored piles are constructed inside an upper layer side pilot tunnel at intervals, and artificial hole digging piles are constructed inside an upper layer middle pilot tunnel at intervals; lower layer pilot tunnel bottom longitudinal beam construction is conducted; upper layer pilot tunnel steel pipe column construction is conducted; side pile crown beam construction is conducted; top longitudinal beam construction is conducted; top arch initial supporting structure construction is conducted; the main body second lining construction step comprises the substeps that soil body excavation is conducted, and station top plate second lining structure construction is conducted; when a soil body is dug to the bottom of a middle plate, middle plate and middle longitudinal beam construction is conducted; when a soil body is dug to the bottom of a base plate, the waterproof base plate is laid, and structure base plate construction is conducted; lower portion side wall construction is conducted when the base plate reaches the set intensity.

Owner:HONGRUN CONSTR GROUP STOCK

Mining method for underground mine with ore-drawing roadway arranged between every two adjacent stopes

ActiveCN108625856AReduce the amount of quasi-engineeringControl mining boundariesUnderground miningBlastingTwo stepMineralogy

The invention discloses a mining method for an underground mine with an ore-drawing roadway arranged between every two adjacent stopes. The mining method comprises the steps that an ore body is divided into a plurality of ore blocks along the trend of the ore body, the length of each ore block is 40-80 m, then each ore block is divided into an ore chamber and a jamb, and a middle column is arranged between the bottoms of each ore chamber and the corresponding jamb; a hanging wall in-vein air return roadway and a footwall in-vein transportation roadway are arranged along the trend of the ore body, and the footwall in-vein transportation roadway is arranged outside the ore body and is parallel to the trend of the ore body; an orepass is arranged on the other side of the footwall in-vein transportation roadway; and when the thickness of the ore body is larger than 40 m, the ore chambers and the jambs are arranged perpendicular to the trend of the ore body, each ore-drawing roadway betweenthe bottoms of the two corresponding adjacent stopes is arranged perpendicular to the trend of the ore body, the length of each stope is equal to the length of the ore blocks, the width of each stopeis 13-20 m, the height of each stope is 40-100 m, and drilling chambers are arranged at the bottom of the upper-middle section. In the mining method, during two-step stoping, tunneling in a filling body is not needed, and the novel method is large in production capacity, small in mining project amount and efficient.

Owner:安徽大昌矿业集团有限公司

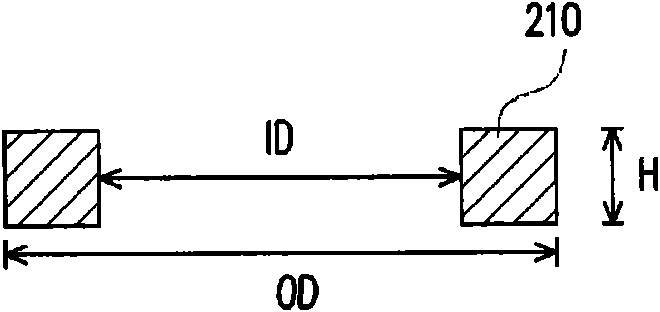

Choke

InactiveCN101789303AReduce labor costsTransformers/inductances magnetic coresInductances/transformers/magnets manufactureAlloyEngineering

The invention discloses a choke which comprises a drum-type magnetic core and at least one lead. The drum-type magnetic core comprise a middle column, a first tabular body and a second tabular body, both ends of the middle column are respectively connected with the first tabular body and the second tabular body, the drum-type magnetic core is made of an iron-contained alloy, and the lead is provided with a winding part wound around the middle column.

Owner:CYNTEC

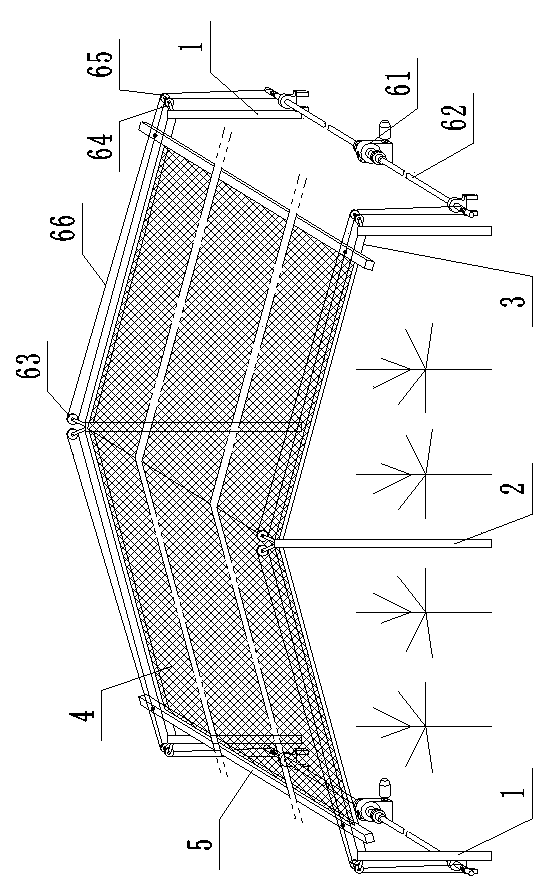

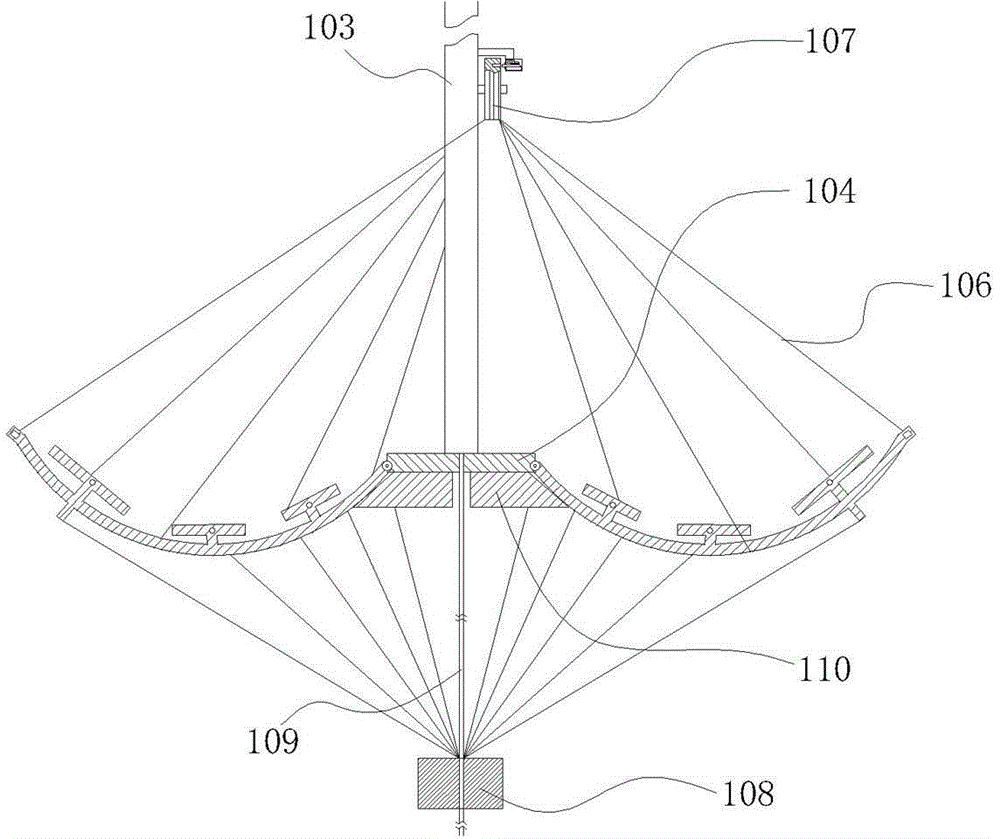

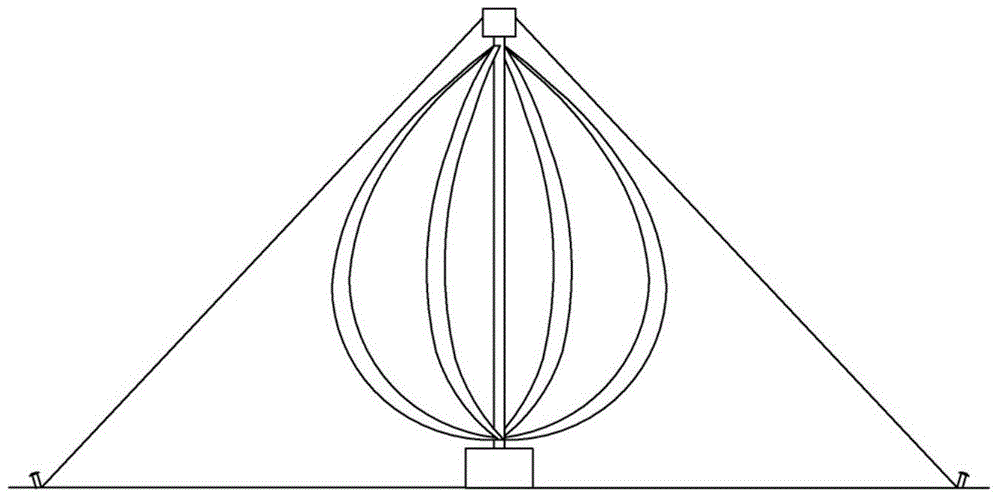

Application of sunshade net to agriculture rain shielding and fruit tree rain shed made of sunshade net

The invention belongs to the technical field of agriculture rain shielding and provides application of a sunshade net to agriculture rain shielding and a fruit tree rain shed made of the sunshade net. The fruit tree rain shed made of the sunshade net is simple in structure, low in cost and capable of preventing wind. According to the technical scheme, the shading rate of the sunshade net reaches more than 70%, the sunshade net is a round wire and ribbon-like filament interwoven net, the fruit tree rain shed made of the sunshade net comprises two rows of side vertical columns and a row of middle columns located between the two rows of side columns, each middle column is arranged corresponding to two side columns, the height of the middle column is larger than that of the side columns, two supporting ropes at vertical intervals are fixed between the top of each middle column and the tops of the two side vertical columns corresponding to the middle column respectively, the sunshade net is clamped between the two supporting ropes at the vertical intervals, and the top of the sunshade net is fixed to the middle column to form a ceiling. The fruit tree rain shed is applied to agriculture rain shielding.

Owner:SHANXI ACAD OF AGRI SCI GARDENING RES INST

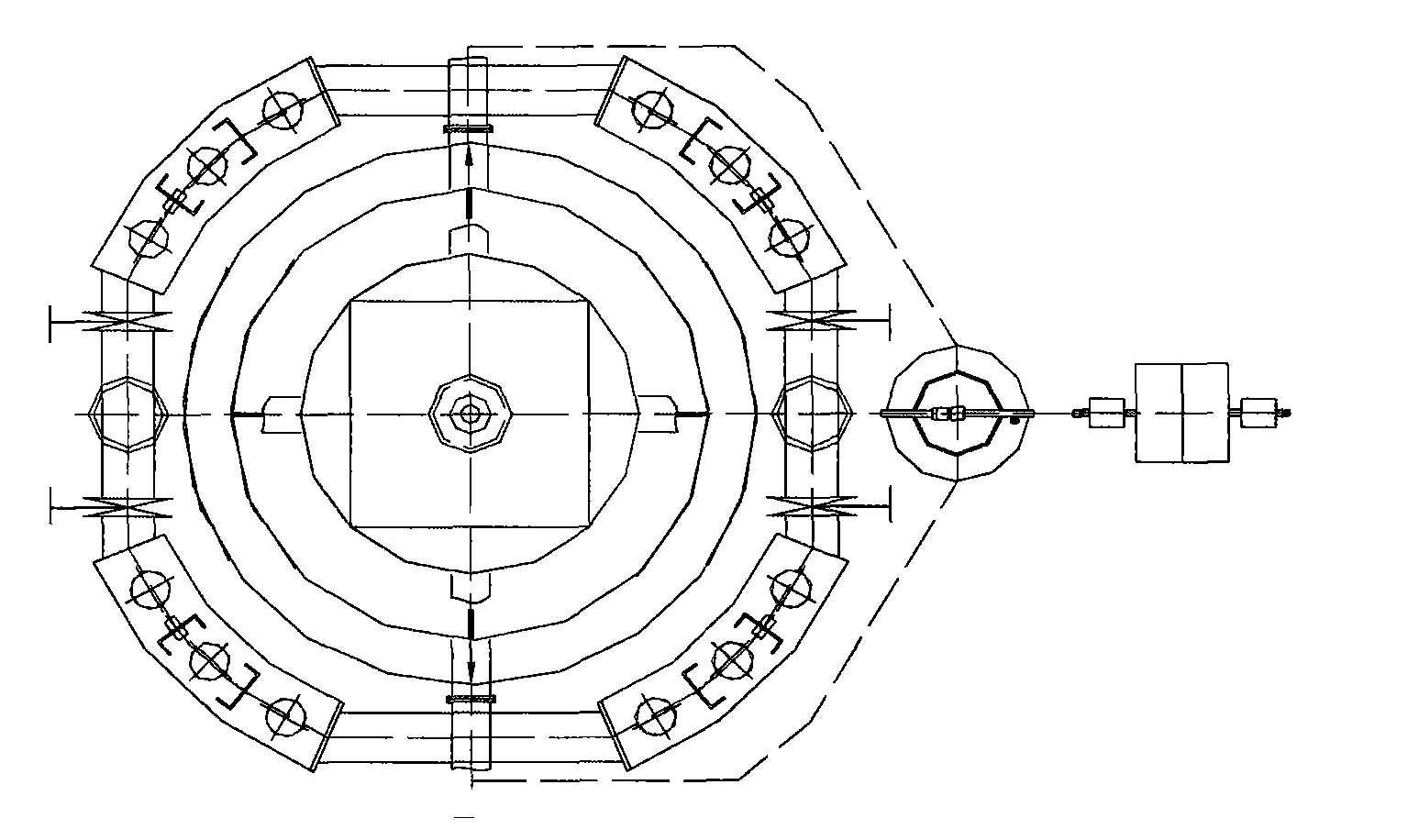

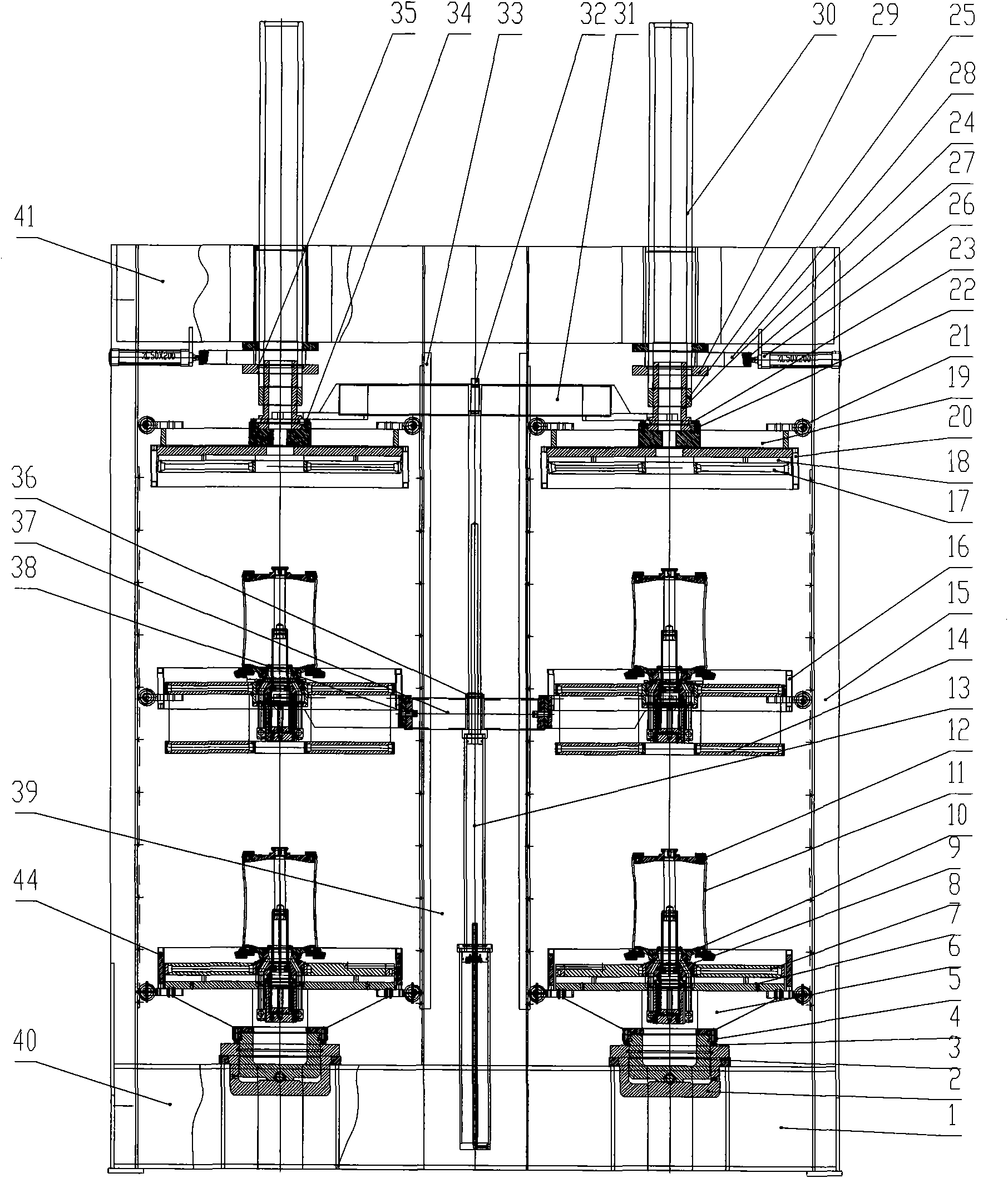

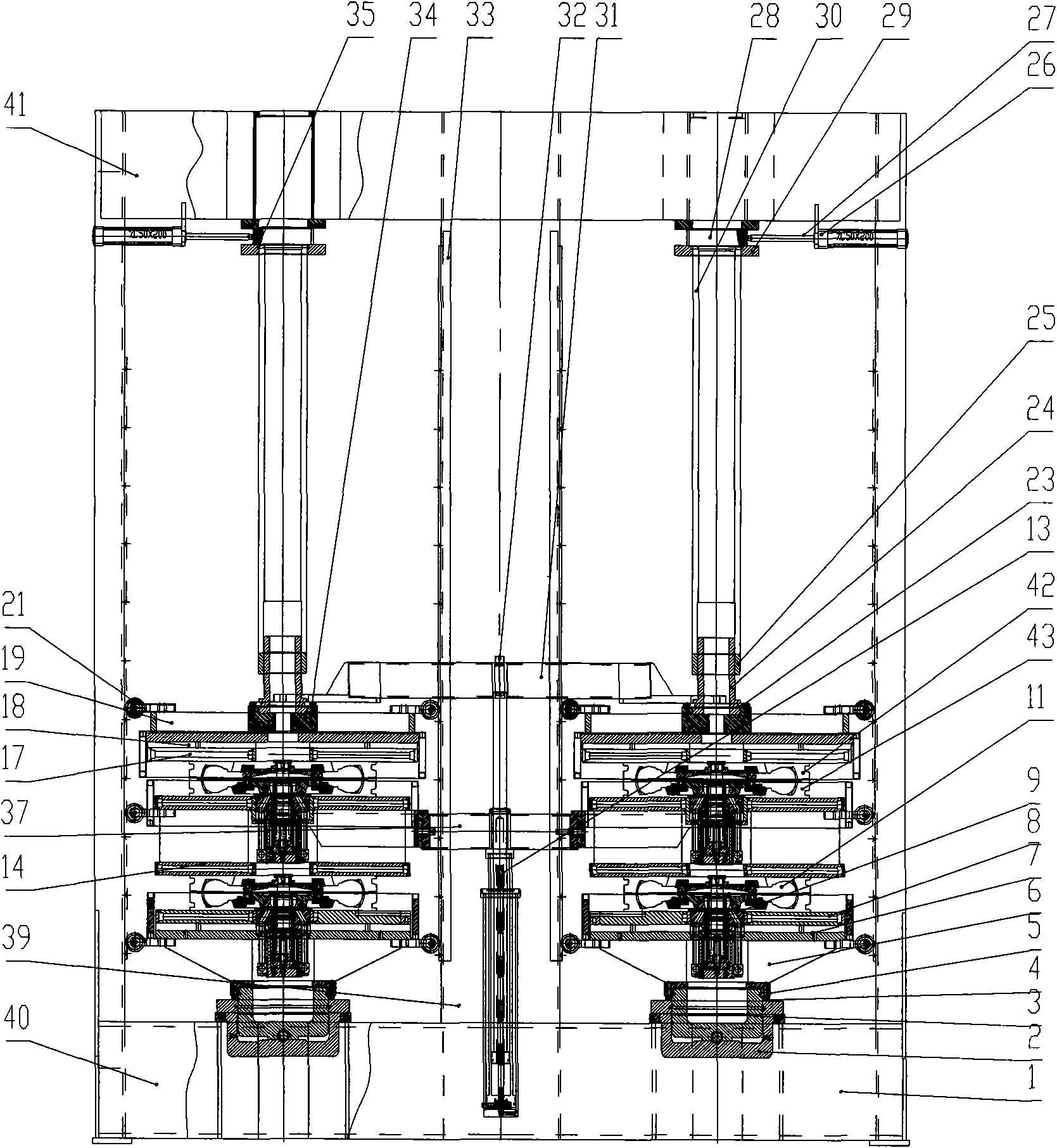

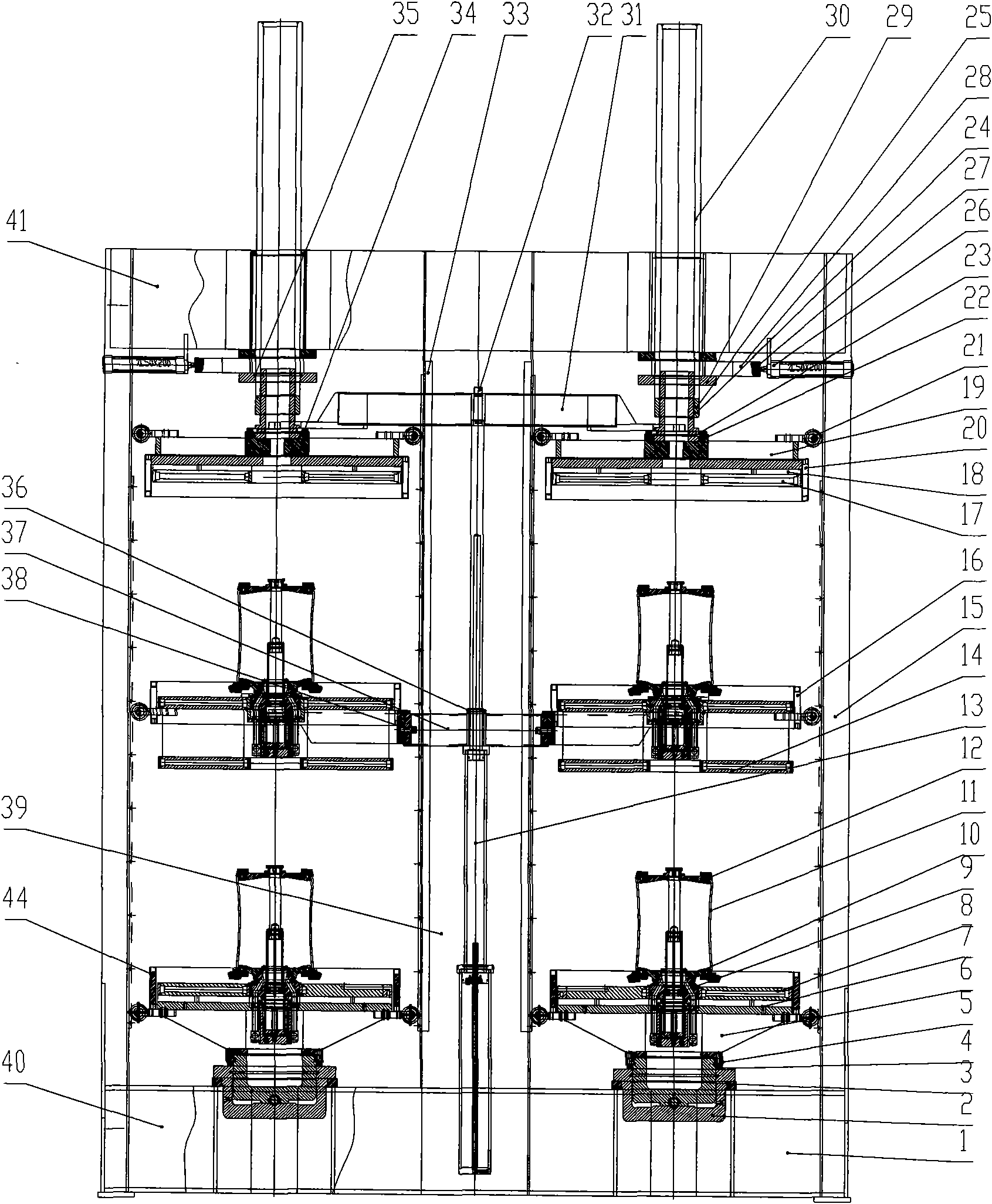

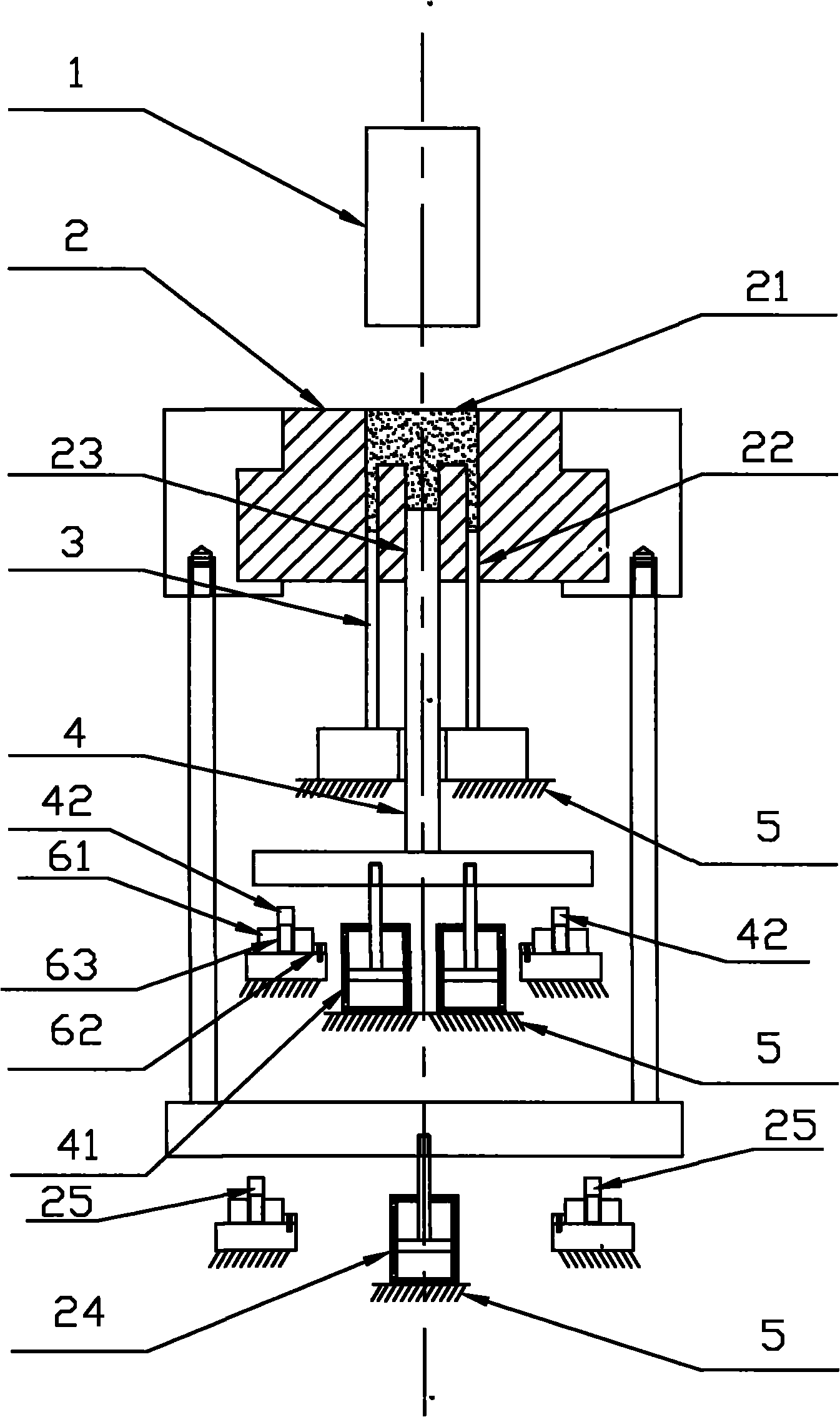

Double-station multi-level hydraulic capsule tire-forming vulcanizer

The invention relates to a double-station multi-level hydraulic capsule tire-forming vulcanizer. A stand is separated into a left station and a right station by a middle column, either station is internally provided with a set of hot-plate device which comprises devices sequentially arranged from top to bottom, i.e. a set of upper hot-plate device, at least one set of middle hot-plate device and a set of lower hot-plate device which form a multi-level structure, the upper hot-plate devices in the two stations are connected through an upper bracket arm, the middle hot-plate devices in the two sections are connected through a middle bracket arm, a plunger of a man oil cylinder is fixedly connected with a lower tray, a final-stage piston rod of a multi-level oil cylinder is fixedly connectedwith the upper bracket arm, and a middle-level piston rod of the multi-level oil cylinder is fixedly connected with the middle bracket arm. The invention opens and closes a die by adopting the lower multi-level oil cylinder, locks the die by the match of the lower short-stroke plunger-type main oil cylinder and the upper die-locking device and has the advantages of low operation and manufacture costs, small floor area, low labor intensity, good environmental protection, high safety, humanized operation, and the like.

Owner:万进学

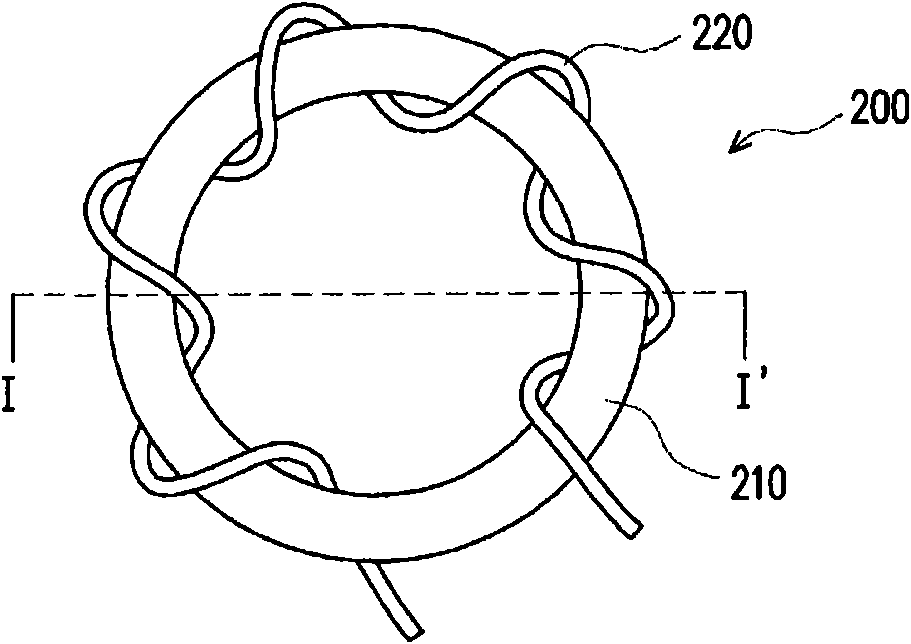

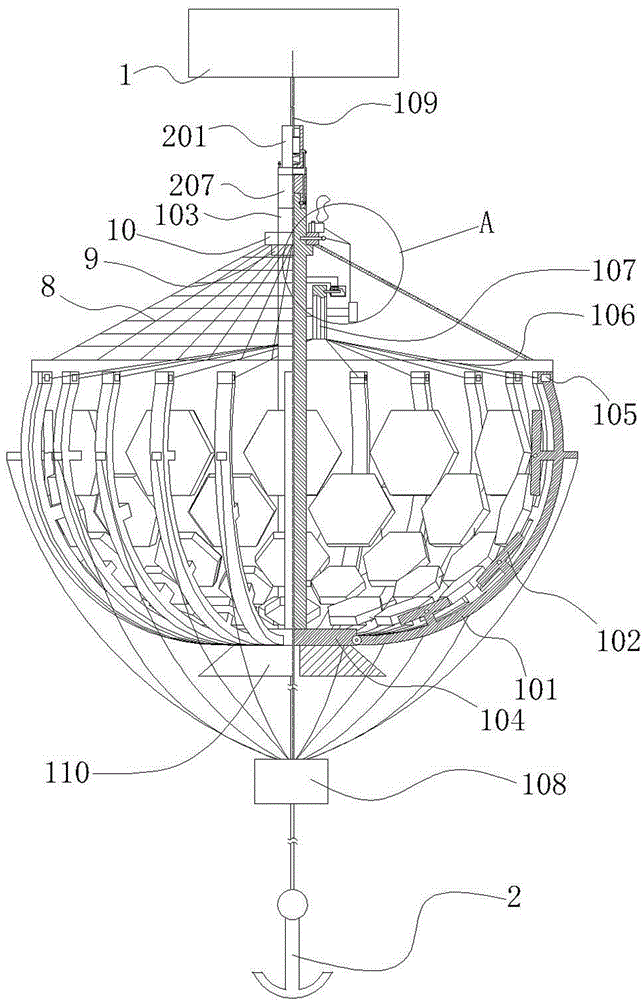

Algae reproduction device with seedling protecting function

ActiveCN104429886AExpandable growing areaStable proliferationClimate change adaptationCultivating equipmentsBrickSilica gel

The invention discloses an algae reproduction device with the seedling protecting function. The algae reproduction device with the seedling protecting function aims to overcome the defect that due to the fact that an artificial algae reproduction facility in the prior art can not protect algae seedlings sufficiently, the reproduction rate of algae is low. The algae reproduction device comprises a floater, a hanging rope, a cultivation body and a locating anchor. The cultivation body comprises a circular-ring-shaped upper frame, a base plate, a middle column, a silica gel base body of a conical surface shape, a balancing weight and algal reef bricks. The edge of the wider end of the conical structure of the silica gel base body is fixedly connected to the upper frame, and the edge of the narrower end is fixedly connected with the edge of the base plate. The algal reef bricks are laid on the surface of the inner side of the silica gel base body. The floater is connected to the top end of the middle column through the hanging rope. The bottom end of the middle column is connected with the locating anchor through the hanging rope. The algae reproduction device has the following advantages that the algae seedlings can be protected, the survival rate of the seedlings is increased, the growth space of the algae is expanded when the algae grows to a certain scale, and then the algae can be reproduced further; the yield of a unit cultivation area is easy to control, which is beneficial for industrialization of algae cultivation; when big waves invade, the algae sink automatically, and therefore loss of damage to the algae can be reduced.

Owner:ZHEJIANG OCEAN UNIV

Fabricated lattice unit for foundation pit supporting and installation method

InactiveCN104532856AWith detachableRepetitiveExcavationsBulkheads/pilesMiddle columnBuilding construction

The invention relates to a fabricated lattice unit for foundation pit supporting. The fabricated lattice unit for foundation pit supporting is characterized by comprising a plurality of lattice unit bodies which are connected through connecting structures, each lattice unit body comprises a middle column and beams arranged on the side walls of the periphery of the middle column and evenly distributed, each middle column is provided with an anchor cable hole and is connected with an anchor cable on a foundation pit through the anchor cable hole, and every two adjacent lattice unit bodies are connected through the connecting structures at the ends of the corresponding beams. Each connecting structure is composed of fixing bolts arranged at the ends of the corresponding beams and connecting plates, and through holes matched with the fixing bolts are formed in the connecting plates. The fabricated lattice unit for foundation pit supporting can be well adapted to a hard clay stratum or a mud rock stratum or other stratums, and the supporting effect of the fabricated lattice unit is reliable; construction is safe and rapid, no large machine is needed, and the prefabricated lattice unit has the advantages of being dismountable and recyclable; industrial and standard production can be achieved. By the adoption of the fabricated lattice unit for foundation pit supporting, consumption of energy resources can be reduced, labor productivity is improved, and environment protection is promoted.

Owner:GUANGXI RUIYU BUILDING TECH

Hydraulic supporter for end of widening working face

ActiveCN1786419ASimple structureReduce weightMine roof supportsProps/chocksPhysical hard workHydraulic circuit

The invention relates to synthesizing discharging face end hydraulic support. Two of them are formed a set. It is made up of left support, right support, falling preventing jack, and hydraulic circuit. The left and right support are made up of three top beams, three bases, and three columns all of with are divided into front, middle, and back. The three top beams are hinged orderly. The front top beam is hinged to canopy guard front beam and its jack. The back top beam is hinged to caving shield. The three bases are hinged orderly. It is adopted front back joining among the bases. The front base is connected to loading mechanism. The falling preventing jack is hinged between the top beams and connecting rod. The distance between the front and middle columns, middle and back columns are respectively adapted to the distance that the width of the front back scraper conveyor plus forward lead step pitch. The left support base is set side jack. The invention can realize end head supporting mechanization, reduce manual labor, increase ahead speed. Its structure is simple; weight is light; the support moving is convenient.

Owner:兖矿能源集团股份有限公司

Method for locating and overlapping center of transformer core

ActiveCN101409143AAddressing Jagged DefectsReduce biasTransformers/inductances magnetic coresInductances/transformers/magnets manufactureTransformerEngineering

The invention relates to a production technology of a transformer iron core, in particular to a central positioning and stacking method of the transformer iron core. In accordance with the technical proposal, the central positioning and stacking method of the transformer iron core comprises upper and lower yokes which are positioned at upper and lower ends of the iron core, side columns which are positioned at left and right sides of the iron core and middle columns which are positioned in the middle part of the iron core, wherein, the side columns are parallel to the middle columns; the central positioning and stacking method is characterized in that the method comprises the following steps: step 1, positioning: the positions of the middle columns, the side columns and the upper and the lower yokes are firstly positioned on a positioning support; step 2, stacking of the middle columns: a plurality of pieces of the middle columns are sequentially stacked on the positioning support; step 3, insertion: a plurality of pieces of the middle columns are all well stacked, then the stacking of the upper and the lower yokes and the side columns is started, when in stacking of the upper and the lower yokes and the side columns, the upper and the lower yokes and the side columns are stacked on the positioning support piece-by-piece according to the sequence of firstly stacking one piece of the upper and the lower yokes and then stacking one piece of the side column. The central positioning and stacking method can facilitate the packaging of the iron core and the insertion after the packaging.

Owner:WUXI PUTIAN IRON CORE CO LTD

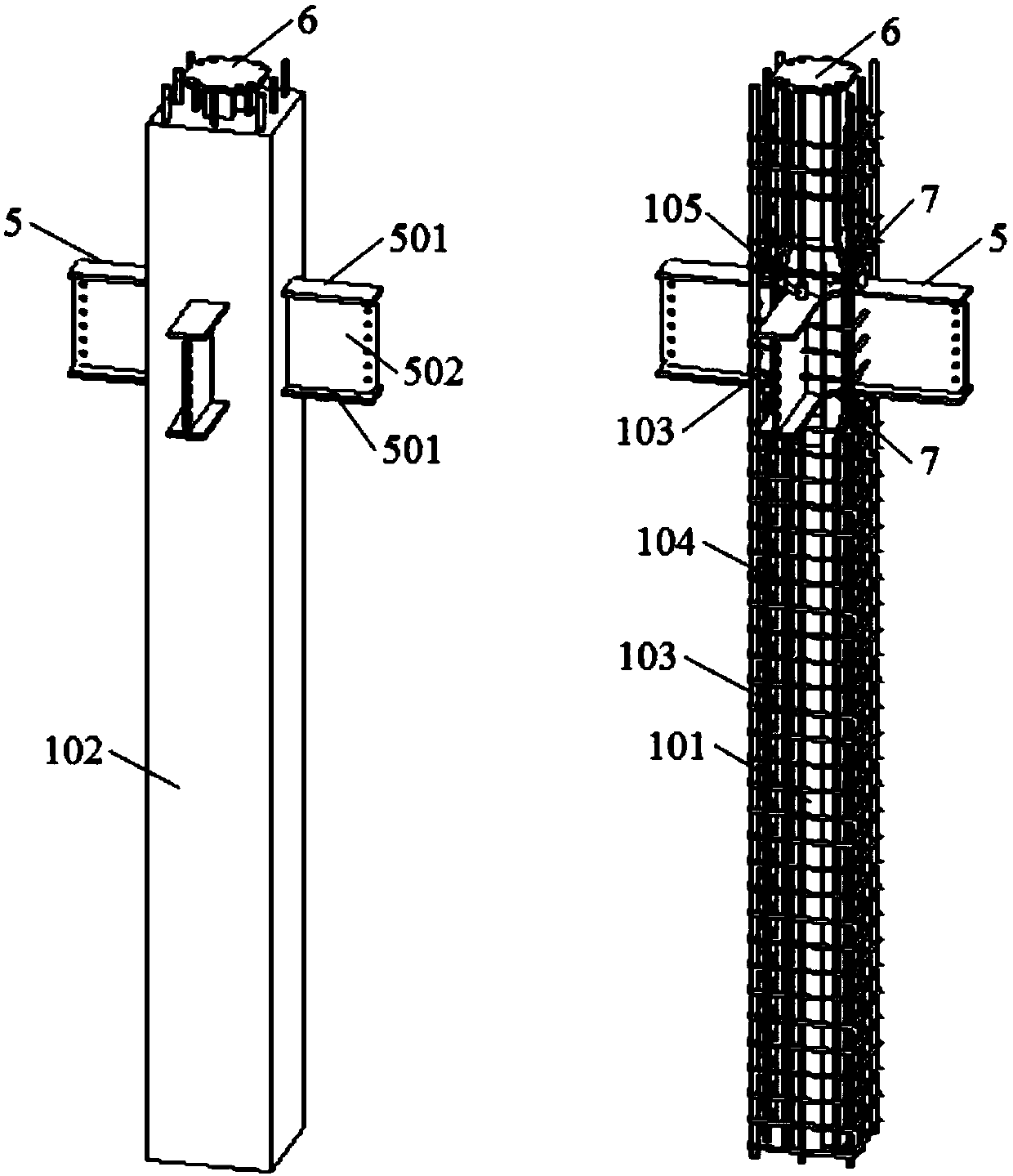

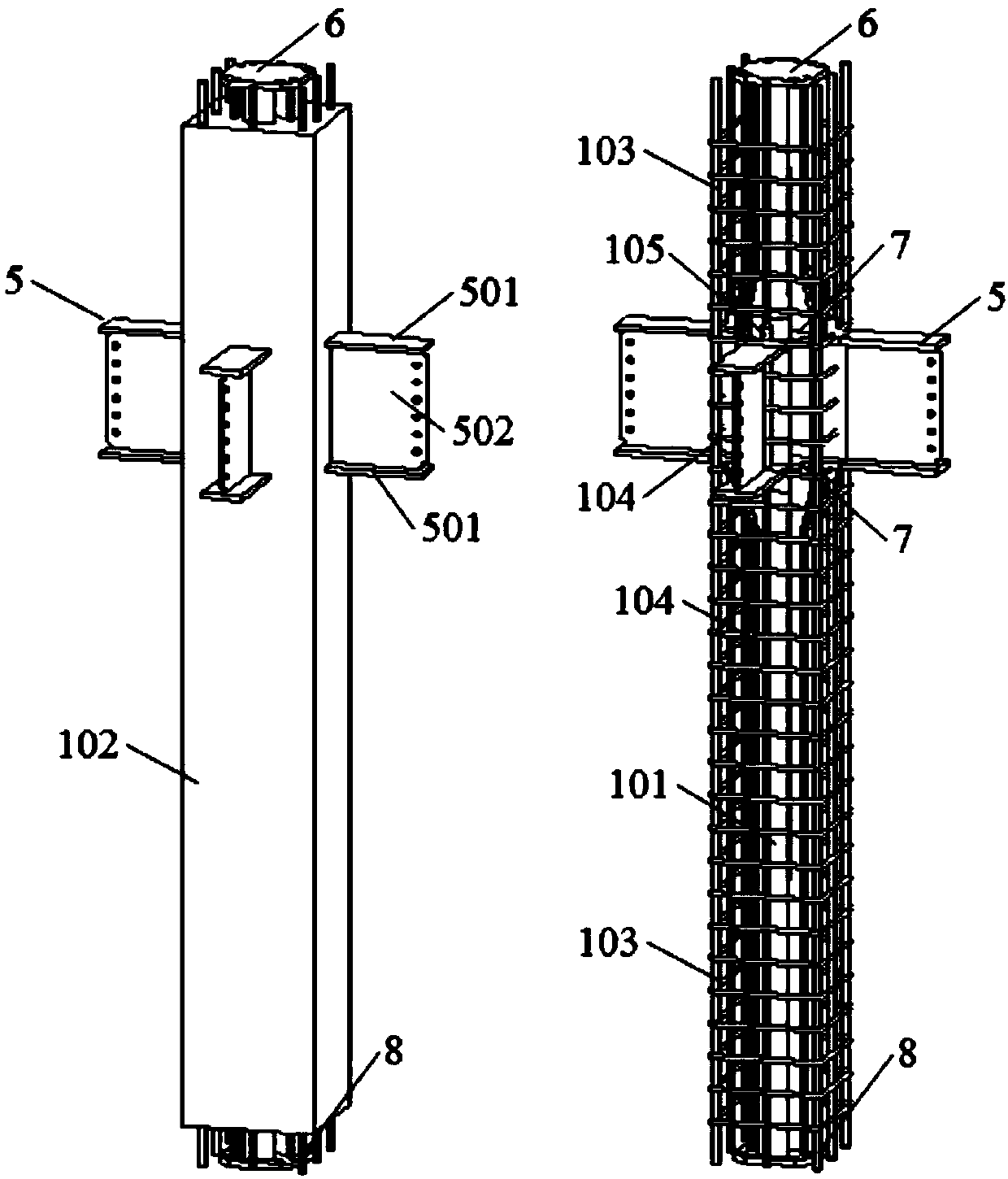

Prefabricated frame adopting combination of steel reinforced concrete columns and steel beams

PendingCN107938835AReduce weightReduce section sizeBuilding constructionsReinforced concrete columnBeam column

The invention provides a prefabricated frame adopting combination of steel reinforced concrete columns and steel beams. The prefabricated frame comprises a plurality of bottom layer column units, a plurality of middle layer column units, a plurality of top layer column units and a plurality of cross beams, and the bottom layer column units, the middle layer column units, the top layer column unitsand the cross beams are all preformed components. The upper ends of the bottom layer column units are provided with upper column connectors, and the upper ends and the lower ends of the middle layercolumn units are provided with upper column connectors and lower column connectors correspondingly. The middles of the middle layer column units are provided with beam-column connecting joints. The lower ends of the top layer column units are provided with lower column connectors, and the upper ends of the top layer column units are provided with column-column connecting joints. The two ends of the cross beams are provided with beam connectors. The components are assembled on site, the complex technological process of traditional construction in a joint area is avoided, the column connectors and the beam connectors only need to be assembled outside the joint area, and thus the construction efficiency and the engineering quality are greatly improved.

Owner:CHONGQING UNIV

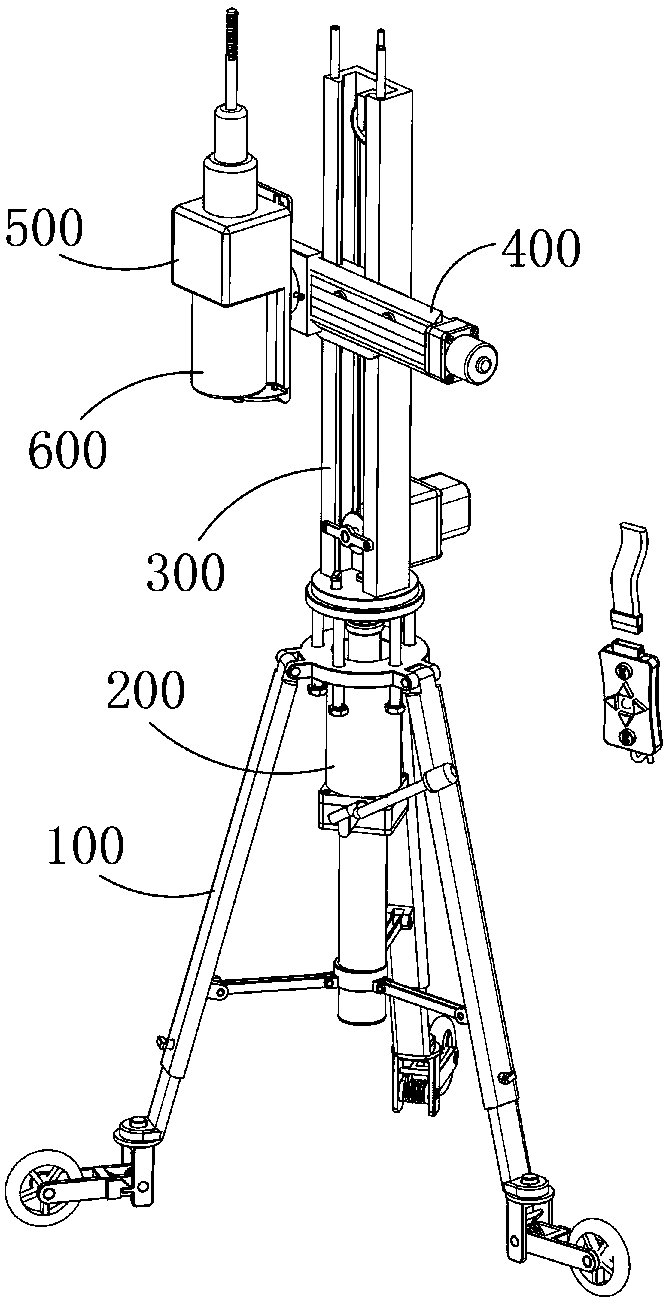

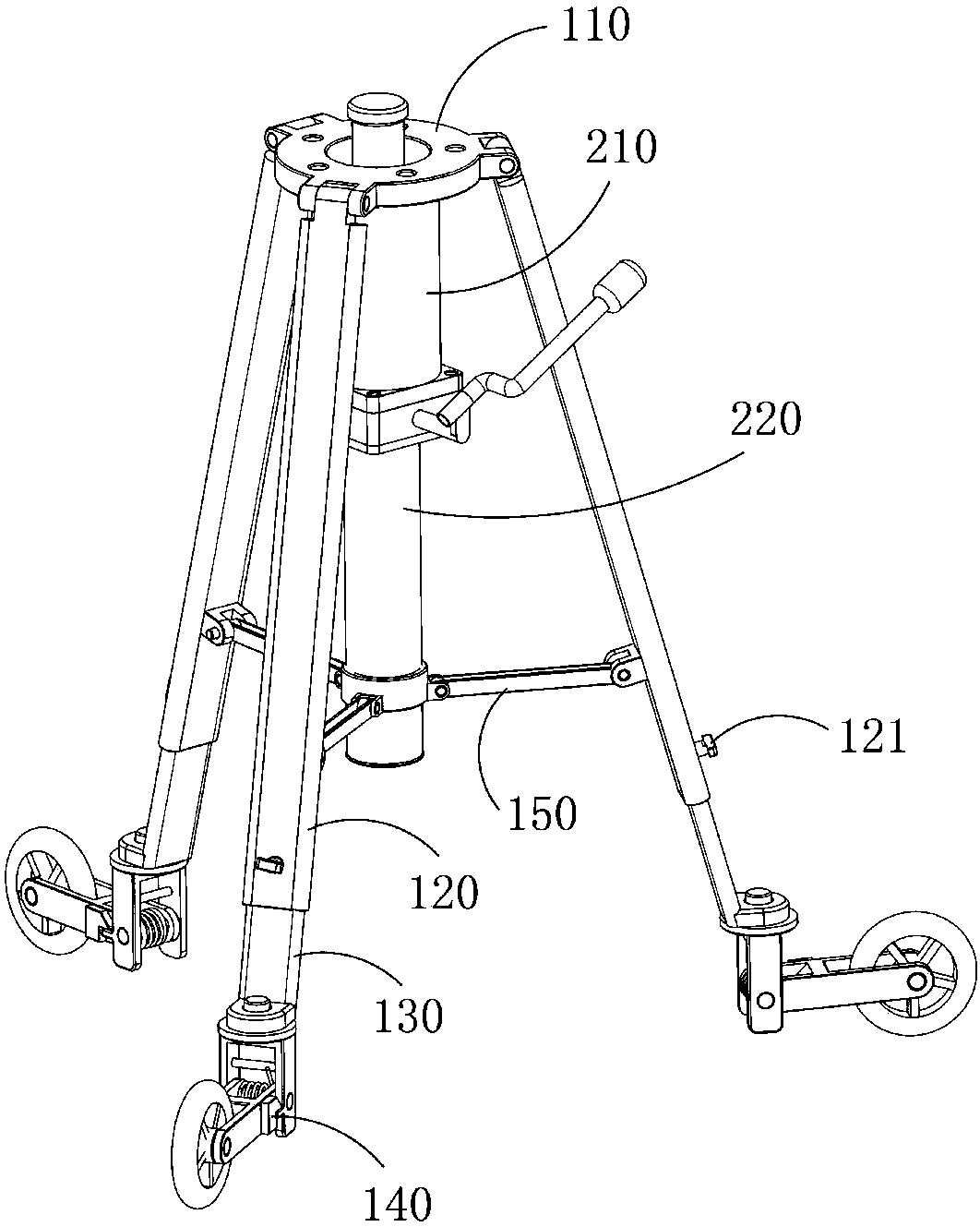

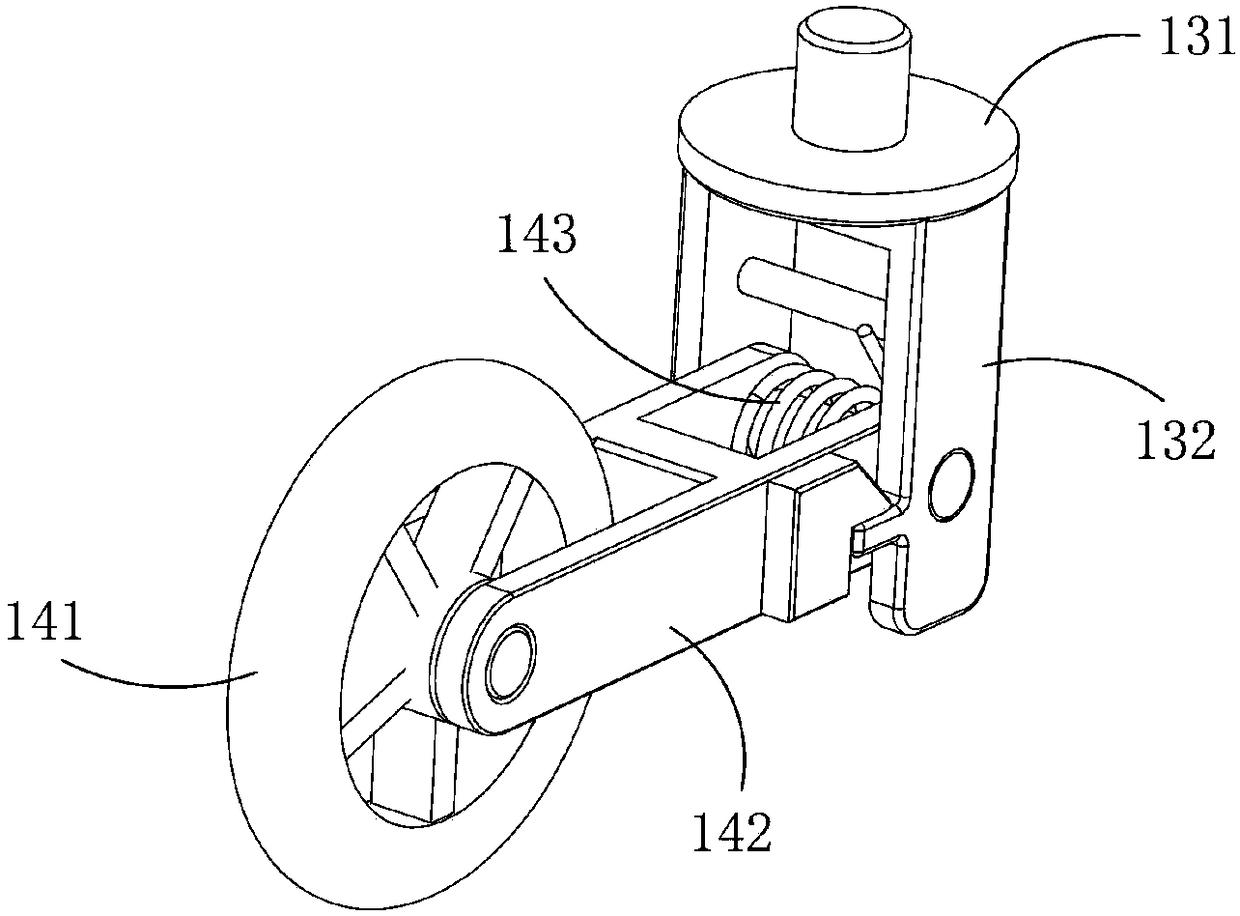

High-precision crown drilling machine used for housing construction ceiling and capable of performing continuous hole drilling

InactiveCN108453290AImprove structural strengthLabor savingWork benchesPortable drilling machinesEngineeringDrilling machines

The invention provides a high-precision crown drilling machine used for a housing construction ceiling and capable of performing continuous hole drilling. An electric drill, a supporting mechanism, ajacking mechanism, a height adjusting device and a horizontal displacement device are included; the height adjusting device is used for adjusting the height of the electric drill; the horizontal displacement device is used for adjusting the horizontal displacement of the electric drill; the supporting mechanism is matched with the jacking mechanism to support and fix the electric drill in the workstate; a fixing mechanism is arranged between the electric drill and the horizontal displacement device, and the electric drill is installed on the horizontal displacement device through the fixing mechanism; the horizontal displacement device is connected with the height adjusting device which is connected with the supporting mechanism; the jacking mechanism comprises a jack and a middle column;and a connection component used for connecting the middle column with the supporting mechanism is arranged between the middle column and the supporting mechanism.

Owner:陆永柱

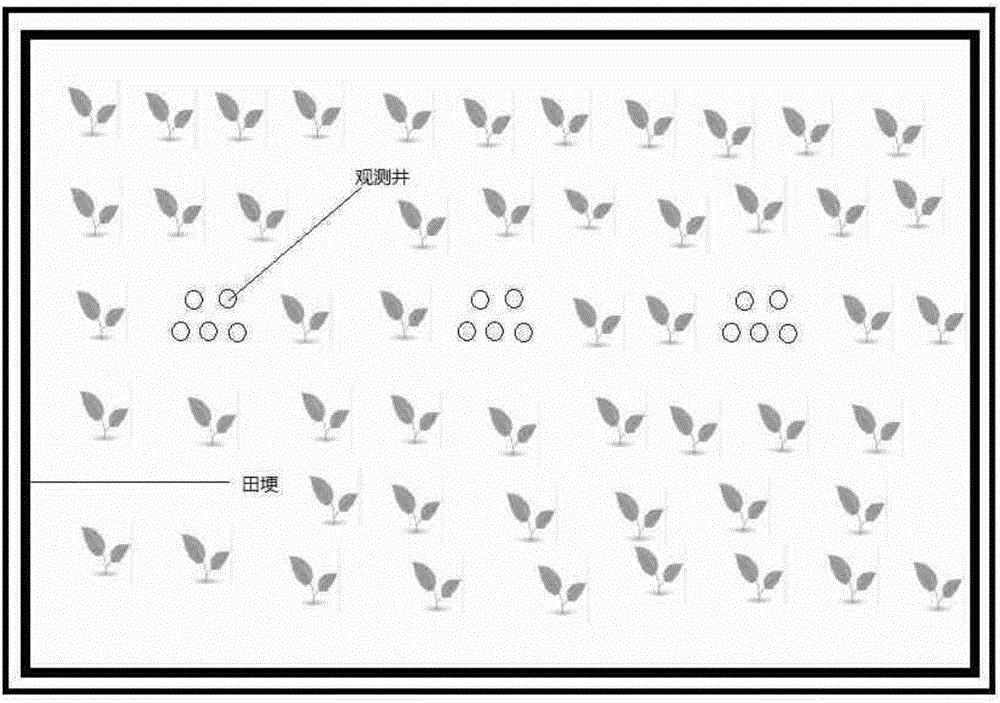

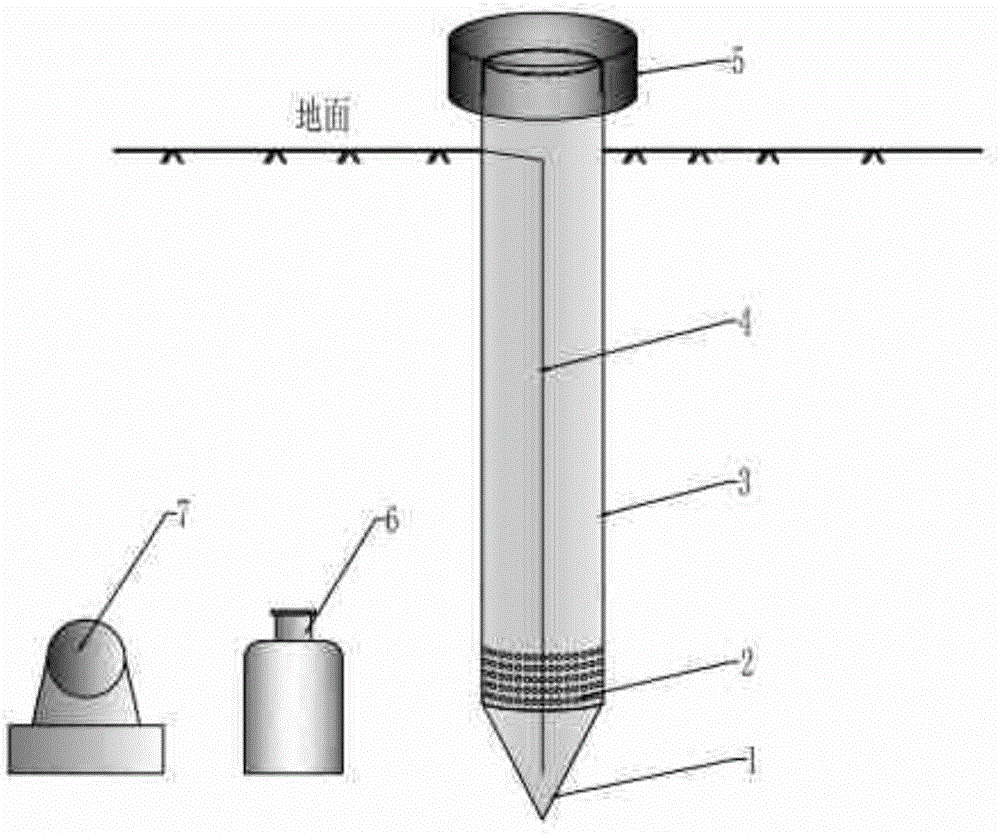

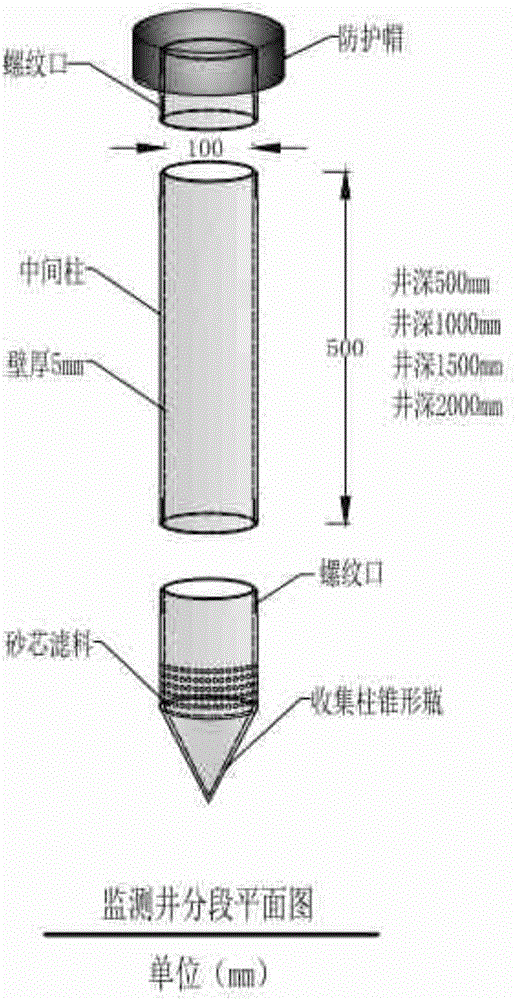

Shallow groundwater pollutant monitoring system

InactiveCN106124719AContamination is accurateMonitoring embeddingGeneral water supply conservationWithdrawing sample devicesMonitoring systemBottle

The invention discloses a shallow groundwater pollutant monitoring system. The system comprises a monitoring well and a sampling system. The monitoring well is a stainless steel combination column and comprises a collection column, a middle column and a protective column which are sequentially connected from bottom to top. The lower portion of the collection column is a cone, and the upper portion of the collection column is a cylinder, a set of thin and long seepage core filter membranes are arranged within 10 cm at the lower end of the cylinder. The sampling system comprises a water outlet pipe, a sampling bottle and a power pump, wherein the water outlet pipe is a two-way water guiding pipe, one end of the water outlet pipe stretches deep into the monitoring well, and the other end of the water outlet pipe is connected with the sampling bottle, and underground water in the monitoring well is guided into the sampling bottle through pump suction. The shallow groundwater pollutant monitoring system is applicable to research of agricultural chemical application such as pesticide, the actual field phenomenon is better reflected on the basis of the underground pollution rules, and basic parameters and data are provided for underground pollution assessment and pollution prevention.

Owner:NANJING INST OF ENVIRONMENTAL SCI MINIST OF ECOLOGY & ENVIRONMENT OF THE PEOPLES REPUBLIC OF CHINA

Soft magnetic ferrite magnetic core forming method and forming die thereof

InactiveCN101930840AReduce the overall heightReduce scrap rateInductances/transformers/magnets manufactureEngineeringVolumetric Mass Density

The invention discloses a soft magnetic ferrite magnetic core forming method. In the green compact compaction process, the raw materials are filled in a middle die forming groove, the upper punch moves downwards to precompact the powder in the forming groove; the upper punch, middle die and lower second punch move downwards to the respective preset positions so as to compact the back, feet and middle column of the product to the preset dimension and density; in the process of milling the magnetic core, the magnetic core feet are milled to the preset dimension; the middle die and lower second punch can be positioned on a die carrier in an axial sliding mode; the upper side of the middle die is provided with a forming groove, and the lower side is provided with a first lower punched hole and a second lower punched hole which are communicated with the forming groove; the first lower punch is fixed on the die carrier; the upper ends of the first lower punch and second lower punch are inserted in the first lower punched hole and second lower punched hole in an axial sliding mode; and the lower end of the upper punch is inserted in the forming groove in an axial sliding mode. The invention presets middle column air gaps in the green compact compaction process, so that it is not necessary to mill the middle column in the magnetic core milling process, thereby reducing the rejection rate of the product and saving the labor cost.

Owner:ACME ELECTRONICS KUNSHAN

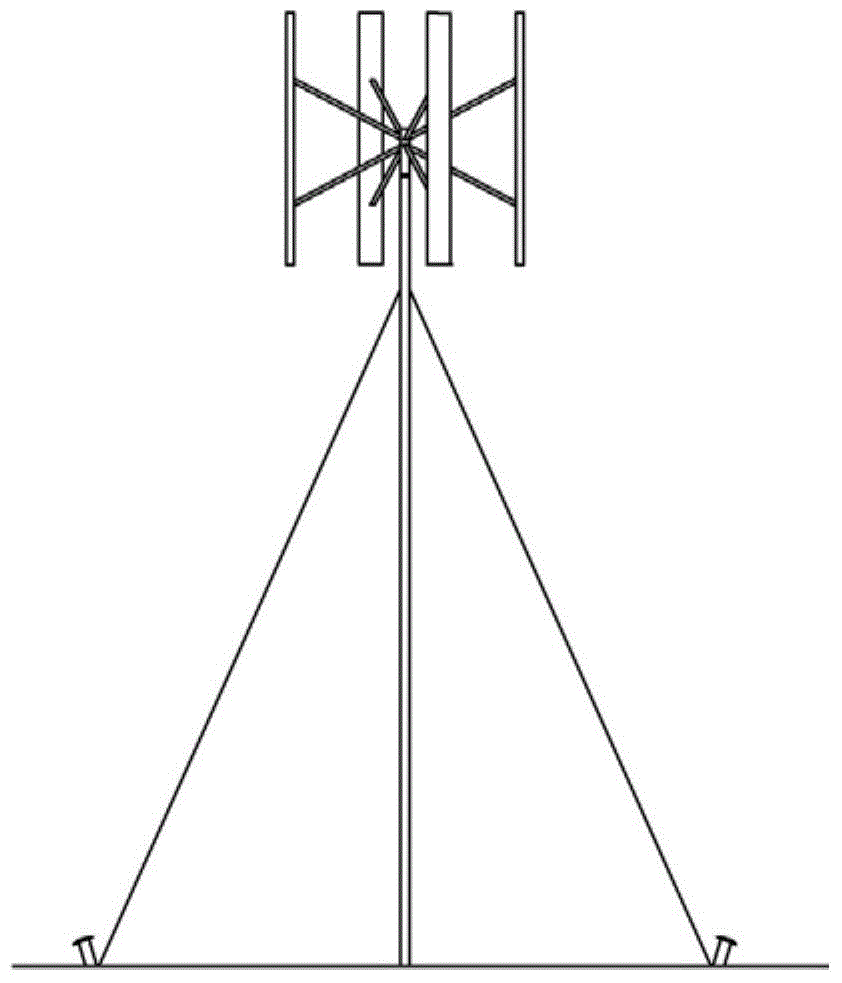

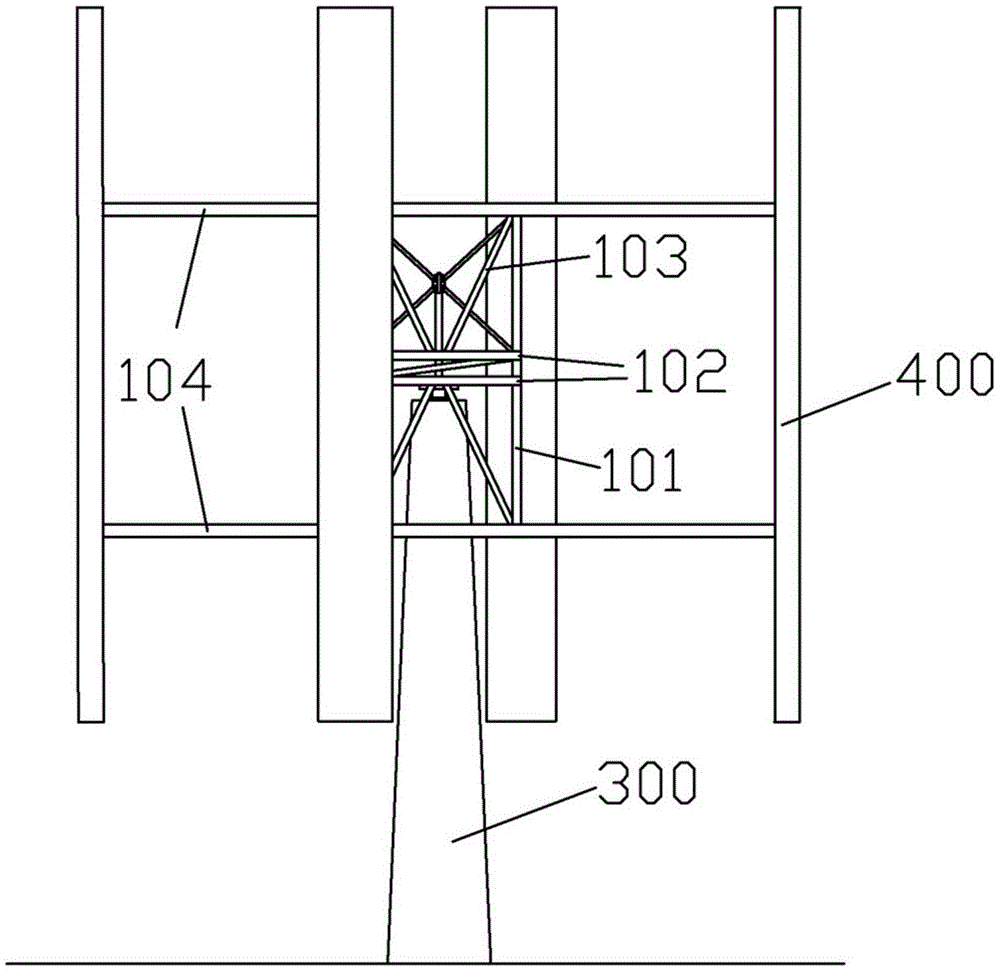

Vertical axis wind turbine and wind energy ship with same

ActiveCN104314751AExtended service lifeImprove structural strengthWind motor combinationsMachines/enginesVertical axis wind turbineTower

The invention discloses a vertical axis wind turbine and a wind energy ship with the same. The vertical axis wind turbine comprises a tower body (300), wherein a main shaft (108) which can rotate freely is arranged in the tower body (300); a cylindrical middle column body is arranged on the outer side of the main shaft (108); the middle column body is of a regular polyhedral frame structure which is formed by combining vertical columns (101) and cross beams (102), and is fixedly connected with the main shaft (108); the upper and lower groups of cross beams (102) or a plurality of upper and lower groups of cross beams (102) are provided with paddle arms (104) extending outwards; blades (400) are arranged on the paddle arms (104). The vertical axis wind turbine and the wind energy ship have the advantages of high structural strength and deformation resistance, more balanced and rational stress state, contribution to prolonging of service life of parts and high efficiency.

Owner:莫海路

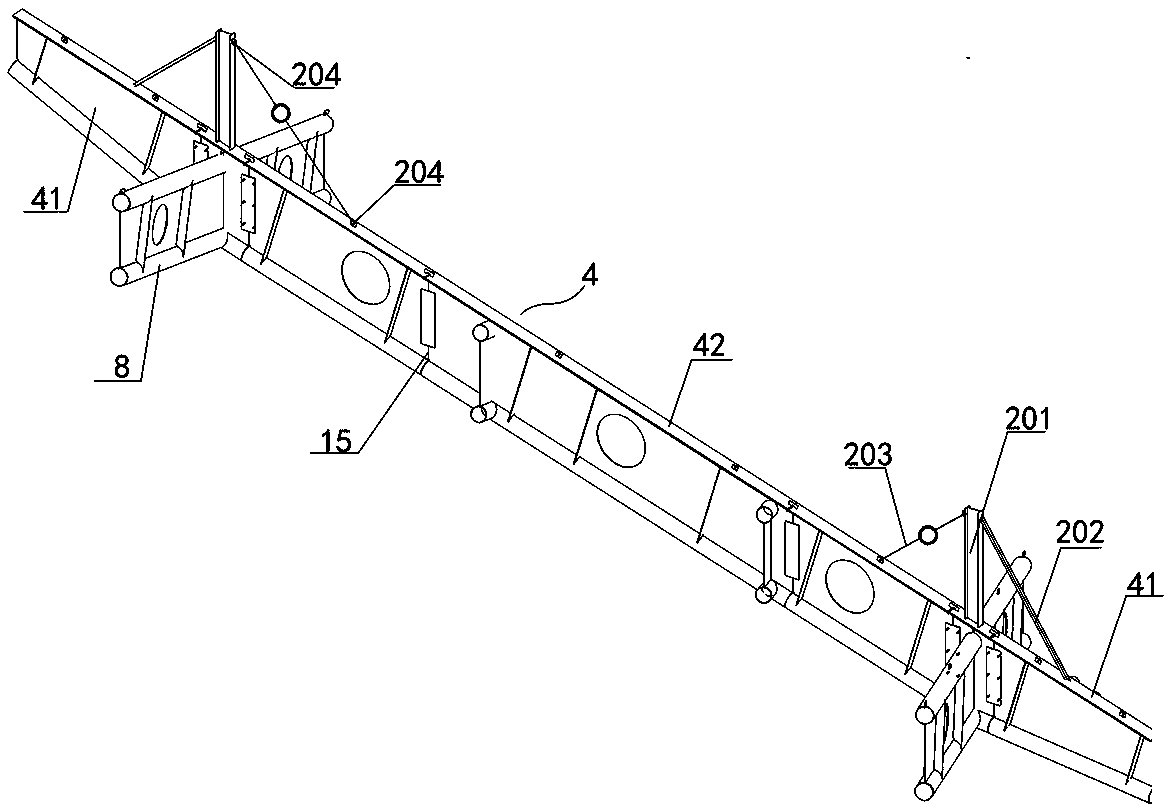

Long-span multi-section combined truss roof structural system and construction method thereof

The invention relates to a long-span multi-section combined truss roof structural system and a construction method thereof. The structural system comprises structural columns and a roof truss, whereinthe structural columns include middle columns and side columns; the roof truss comprises main trusses and secondary main trusses, the main trusses comprise side main trusses and side main trusses, the main trusses are formed by splicing main truss units, and the head end surface and tail end surface of the main truss units are oblique end surfaces and are parallel to each other; and column connecting brackets which used for connecting the roof truss and are adapted to components of the corresponding roof truss are arranged in node regions of the structural columns. According to the construction method, the roof truss and the structural columns are sectionally lifted by virtue of the cooperation with a temporary reinforcing measure. Under the condition that the construction stress is met,the structural system is improved, the construction procedure is optimized, the construction cost is saved, the mounting efficiency is improved, and the measure cost is saved.

Owner:CHINA CONSTR SECOND BUREAU INSTALLATION ENG

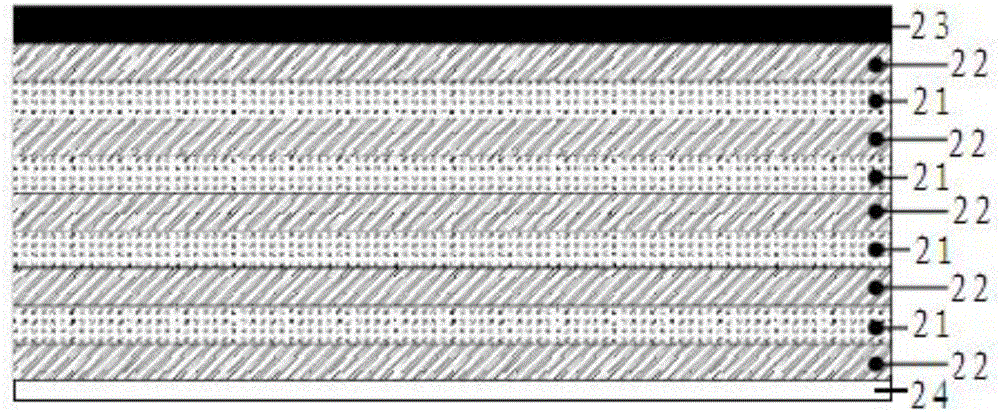

Planar transformer

ActiveCN105914011AEasy to produceIncreased reluctanceTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresMagnetic reluctanceMiniaturization

The invention discloses a planar transformer which comprises a magnetic core and a coil winding; the magnetic core comprises a top plate, a bottom plate, a middle column and two edge columns, the middle column and the two edge columns are located between the top plate and the bottom plate, the coil winding and the magnetic core are assembled together, the top plate and the bottom plate are composed of a whole magnetic block or formed by laying and splicing a plurality of unit magnetic block bodies, and the middle column and the edge columns are formed by stacking multiple unit magnetic block bodies; each unit magnetic block body is a flat strip-shaped block body, and a preset gap is formed between the two ends of the two adjacent unit magnetic block bodies which are laid and spliced. The whole magnetic core is formed by piling multiple unit magnetic block bodies, the transformer can still maintain high efficiency under high frequency, the unit magnetic block body is the flat strip-shaped block body, it is convenient to produce the magnetic core, it is beneficial to miniaturization and planarizartion, and a piled production mode is more beneficial to automated generation; the preset gap is formed between the two ends of the two adjacent unit magnetic block bodies which are laid and spliced, magnetic resistance between every two unit magnetic block bodies is increased, an edge magnetic line can be drawn close to the magnetic core, and thus diffusion flux is reduced.

Owner:SHENZHEN MAIJIRUI TECH CO LTD

Three-phase five-column arc extinction electric reactor

ActiveCN103310953ASmooth and high precisionReduce noiseTransformers/inductances coils/windings/connectionsVariable inductancesTransformerAlloy

The invention discloses a three-phase five-column arc extinction electric reactor which belongs to the technical field of transformer design and manufacture. The three-phase five-column arc extinction electric reactor realizes the integral function of ground connection and arc extinction. An amorphous alloy with an air gap is first adopted for an iron core, and the end surface of the air gap has high smooth accuracy, so the noise caused by the adjustable air gap is effectively reduced; three main windings in the middle of the iron core are in star connection, a neutral-point is directly connected to ground, the columns on two sides are provided with air gaps and form a zero sequence magnetic access with the middle column; coils are wound on the columns on two sides, and three inductive loads with different reactive resistance are provided for the columns on the two sides to realize the rough adjustment and fine adjustment of a compensating current. The advantages of high magnetic permeability and low energy consumption of the amorphous alloy are fully utilized to overcome the defects caused by direct current excitation for a long time that the system is easy to become overheated, the active loss is large, the wave distortion of the compensating current is large, and the residue is large after compensation. The three-phase five-column arc extinction electric reactor is mainly used in high-voltage and intermediate-voltage electric power systems.

Owner:JIANGSU HONGAN TRANSFORMER

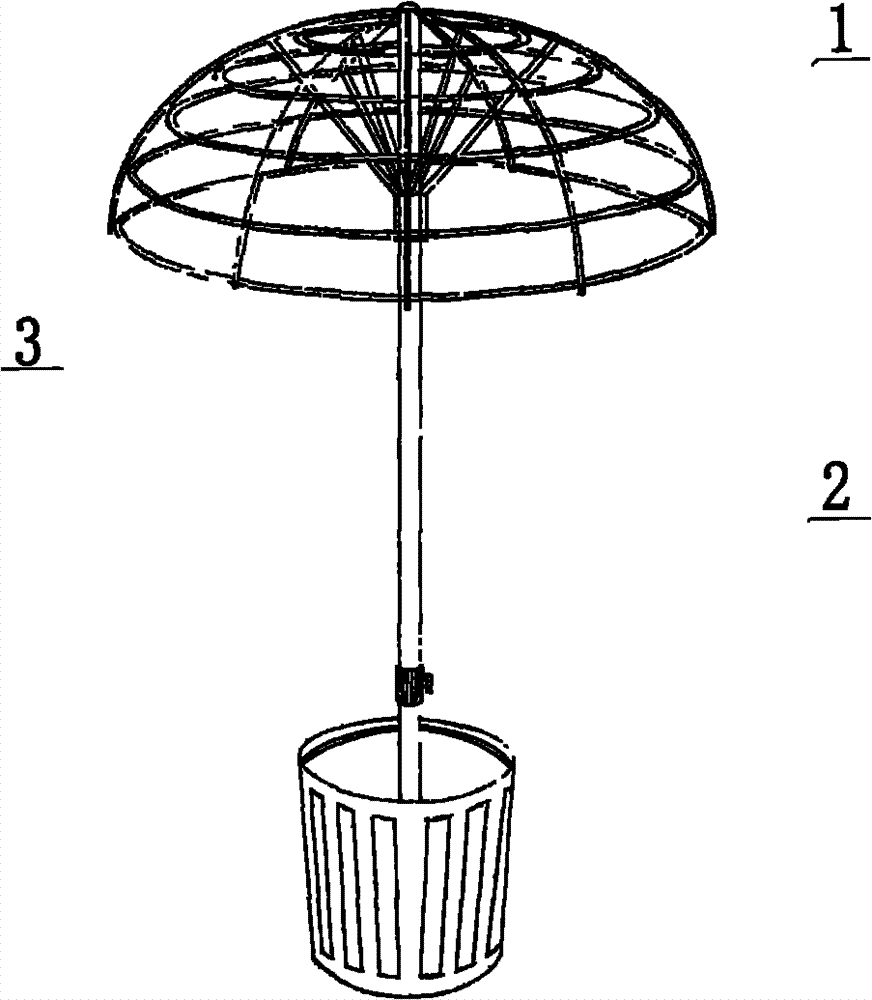

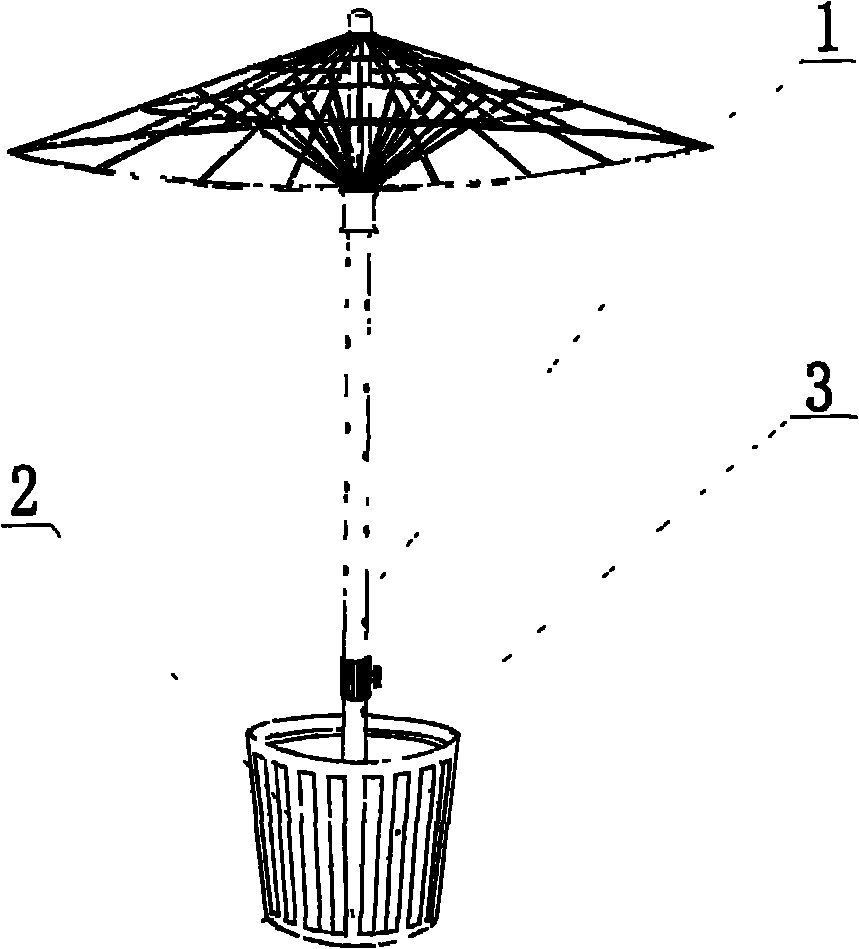

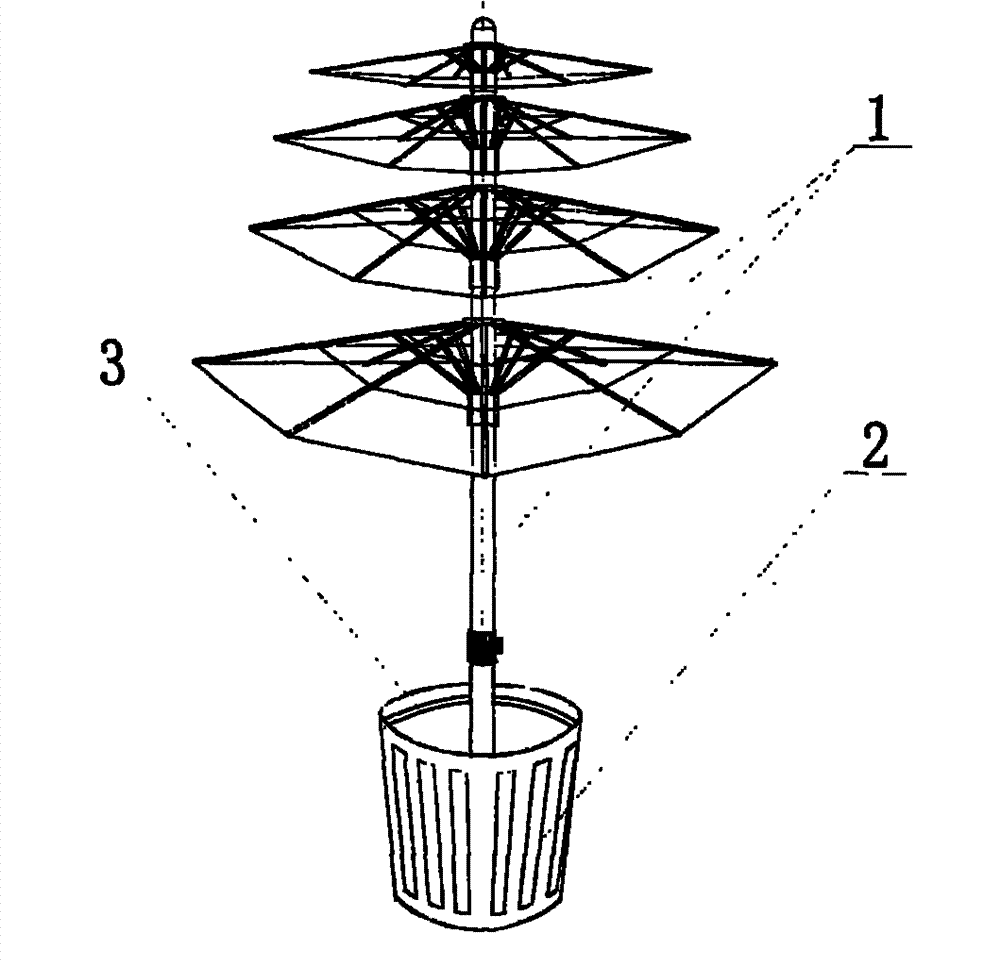

Three-dimensional cultivating frame for vine plants and method for installing same

InactiveCN102726237AEasy to climbSimple structureReceptacle cultivationPlant supportsEngineeringPlant soil

The invention provides a three-dimensional cultivating frame for vine plants and a method for installing the same. The three-dimensional cultivating frame comprises a cultivating framework (1), a base (2) and a planting soil bowl (3), wherein the cultivating framework (1) comprises a middle column (4) and a climbing top frame (5), the climbing top frame (5) is arranged at the upper end of the middle column (4), and the lower end of the middle column (4) is fixed on the base (2); and the planting soil bowl (3) is arranged in the base (2). According to the three-dimensional cultivating frame, the fixed three-dimensional structure is applied to the overall packing cultivation of vine plants, so the climbing growth of vine plants is greatly facilitated, and a fixed shape is formed; the structure is simple, and the installation and the transportation are both convenient; the materials can be repeatedly used, so the waste of resources is lowered; the three-dimensional cultivating frame is favorable for the climbing growth of vine plants, and facilitates harvesting; and the pattern of the cultivating frame is diversified so as to meet different demands. The three-dimensional cultivating frame is widely applied to the cultivation of various vine flowers, vegetables and the like, and the plants, even adult plants, cultivated by adopting the cultivating mode, can be wholly packed and moved.

Owner:重庆天开园林股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com