Patents

Literature

1251 results about "Mold filling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mold filling occupies a significant position in the entire casting process. The two factors, which greatly impact the flow process, are fluidity and turbulence. Fluidity, a technological feature, reflects the ability of liquid metal to flow continuously even as it solidifies, via a given mold passage, filling it to reproduce the detailed design.

Mixed filling type thermal conductive silicone rubber composite and preparation method thereof

InactiveCN102220006APacked tightlyHigh thermal conductivityHeat-exchange elementsPolymer scienceVulcanization

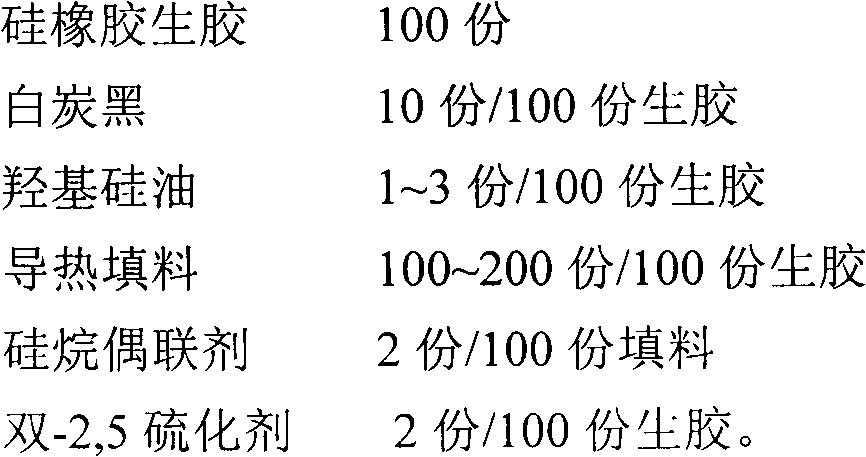

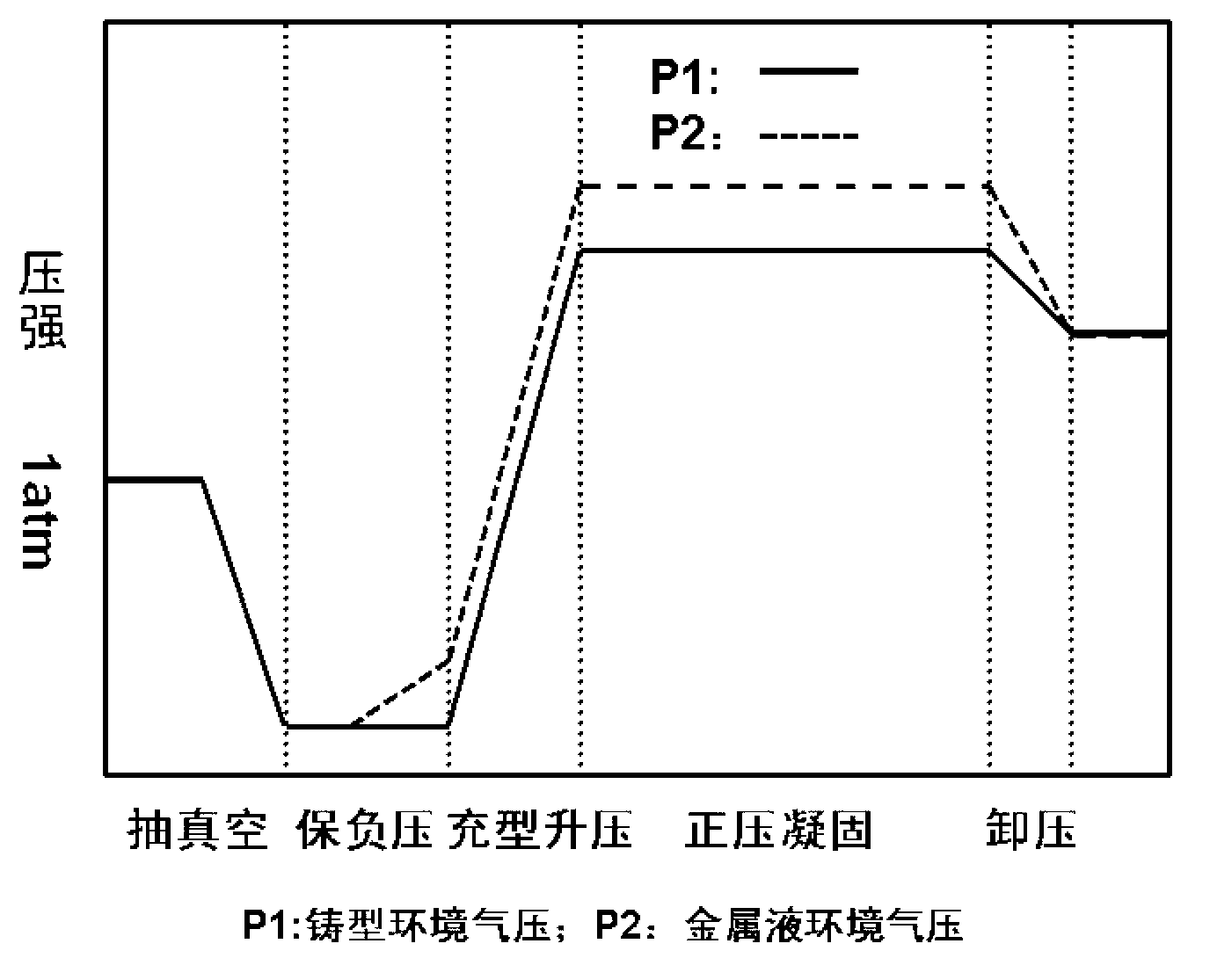

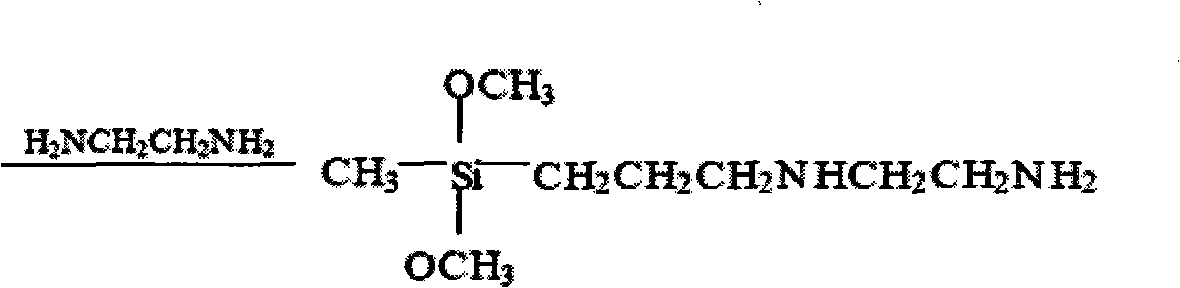

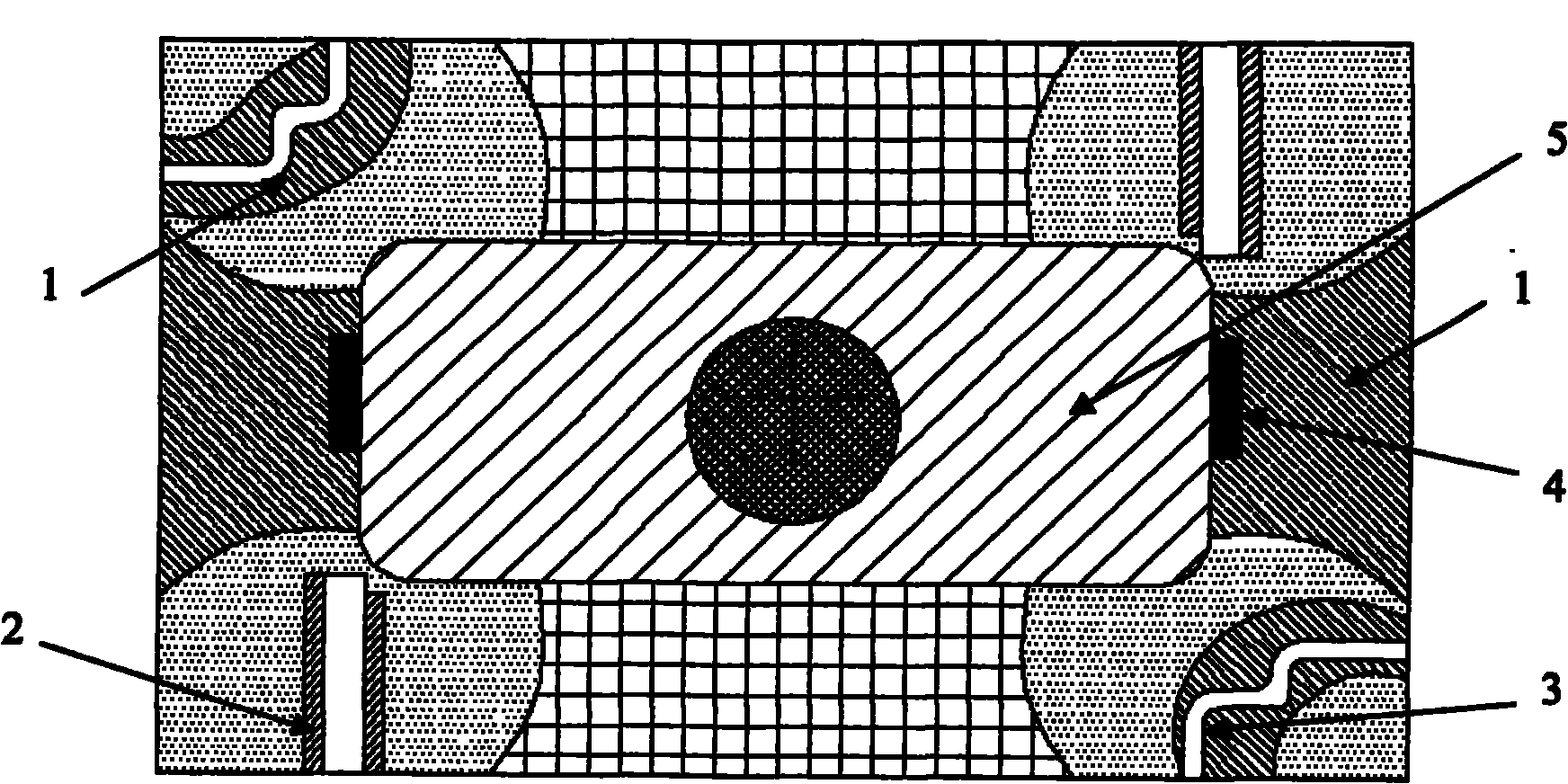

The invention discloses a preparation method of a mixed filling type thermal conductive silicone rubber composite. Raw materials comprises the following components, by mass, 100 parts of raw silicone rubber, 10 parts of white carbon black, 1 to 3 parts of hydroxy silicone oil, 100 to 200 parts of a thermal conductive filler, 2 to 4 parts of a silane coupling agent and 2 parts of a di-2,5-vulanizator. The preparation method comprises the following steps: adding raw silicone rubber to a double roller mill; adding white carbon black, the thermal conductive filler, the silane coupling agent and hydroxy silicone oil according to a formula design after roller packaging; adding a peroxide vulcanizer after repeatedly and uniformly mixing; mixing uniformly to obtain mixed silicone rubber; putting in a die and carrying out first-stage vulcanization after cold pressing mold filling; and putting a molded sample in an air blasting drier and carrying out second-stage vulcanization to obtain a finished product. In the present invention, mixed particles of SiC and AlN are employed to fill high temperature vulcanized silicon rubber, effective thermal conductive net chains are formed in silicone rubber matrixes, so the obtained heat-conducting silicone rubber composite material has a good heat conducting performance.

Owner:TIANJIN UNIV

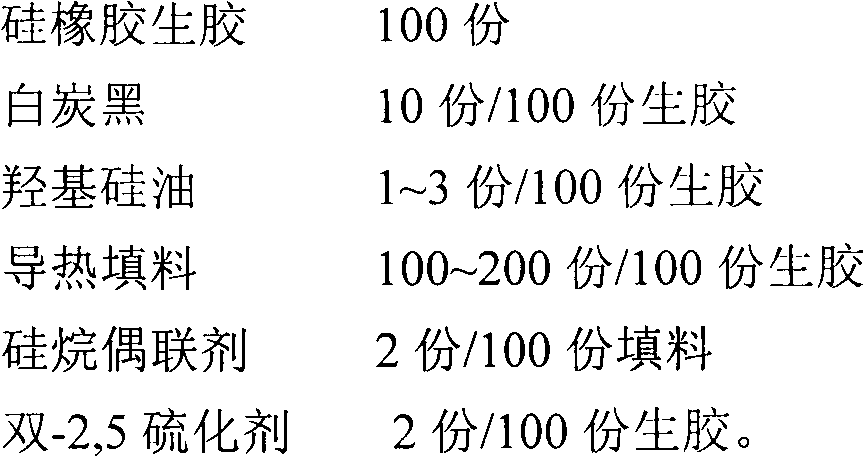

Cast magnesium alloy of low linear shrinkage

The invention discloses a cast magnesium alloy of low linear shrinkage, which belongs to the field of magnesium alloys. The magnesium alloy consists of Mg, Al, Zn, Mn, rare earth, Nb, Li and M element, wherein the materials have the following weight percentage composition: 1.5-25 percent of Al, 0.1-3.5 percent of Zn, 0.1-2.2 percent of Mn, 0.0002-16 percent of rare earth, 0.0002-4 percent of Nb, 0.0002-9 percent of Li, 0.0002-2 percent of M element and the balance Mg; and the M element is at least one of Zr, Ti, Sr, Ca, C and B. According to the heat-resistant magnesium alloy, the rare earth element and the Nb element are added into the magnesium alloy, so that the structure of beta phase is changed; the Zr element and the M element are added to refine crystal grains; due to combined action of the elements, latent heat of crystallization during alloy solidification is changed; and the magnesium alloy which has superior mold-filling capacity, low shrinkage, superior mechanical property and good machinability, fluidity and die-cast performance and is suitable for casting is obtained.

Owner:嘉兴佳斯贝特新材料有限公司

Precesion casting method for high temperature alloy complex thin-walled castings

ActiveCN102699311ASolve filling problemsReduce air permeabilityFoundry mouldsFoundry coresIntermediate frequencyMold filling

The invention discloses a precision casting method for high temperature alloy complex thin-walled castings. The method comprises the following steps of: utilizing a medium frequency induction heating power supply to melt the alloy, utilizing a medium baffle to separate an upper tank and a lower tank, and utilizing an electric hoist to elevate the upper tank when a casting mold and a liquid rising tube are installed; after the installation is completed, utilizing a gas circuit control pipeline, a vacuum system and a gas tank to realize vacuum and pressure regulation in a pressure regulating furnace. By adopting the method disclosed by the invention, stable and efficient mold filling is realized, the castings is solidified sequentially, utilization efficiency of the material can be effectively improved, and the space for near-end net shape casting can be supplied; the complex, thin-walled and integral metal castings which are difficult to cast through other molding methods can be produced, so as to solve the filling problem in the pouring process of the complex thin-walled castings, and in particular, the filling capacity for the thin-walled castings with the wall thickness of less than 3mm is greatly improved. Accurate castings with high dimensional accuracy can be obtained through high temperature alloy pressure regulating investment precision casting, and the accuracy of the casting can reach between CT4 and CT6.

Owner:SHANGHAI JIAO TONG UNIV

Ablation-resistant lightweight heatproof integrated composite material with thermal insulation function and preparation method thereof

ActiveCN109968757ALightweight withImproves ablation resistanceLamination ancillary operationsSynthetic resin layered productsFiberHeat flux

Provided is an ablation-resistant lightweight integrated composite material with a thermal insulation function. The composite material is of a sandwich structure, the middle layer adopts a chopped fiber as a reinforcing body, phenolic resin as a substrate and hollow microbeads as thermal insulation fillers, upper and lower surface layers are bonded to each other by a fiber cloth pre-impregnation material, and the three layers are cured to improve the bearing capacity and the anti-scouring capacity. The preparation method of the composite material comprises eight steps including ceramic powdertreatment, pretreatment of the chopped fiber and a fiber cloth, mixing, drying, slurry preparation, brushing or impregnation, mold filling, curing formation and demolding. The composite material can be applied to the ablation working condition of medium and low heat flux density; the composite material is formed at one time, so that the preparation cycle is short, and the cost is low; a stable ablation-resistant ceramic layer can be formed on the surface in a temperature range from 800 DEG C to 1,300 DEG C, and meanwhile, low-density fillers such as the hollow microspheres achieve a thermal insulation function. In this way, the integrated thermal insulation function under the conditions of medium and low heat flux density and oxidation is achieved.

Owner:NAT UNIV OF DEFENSE TECH

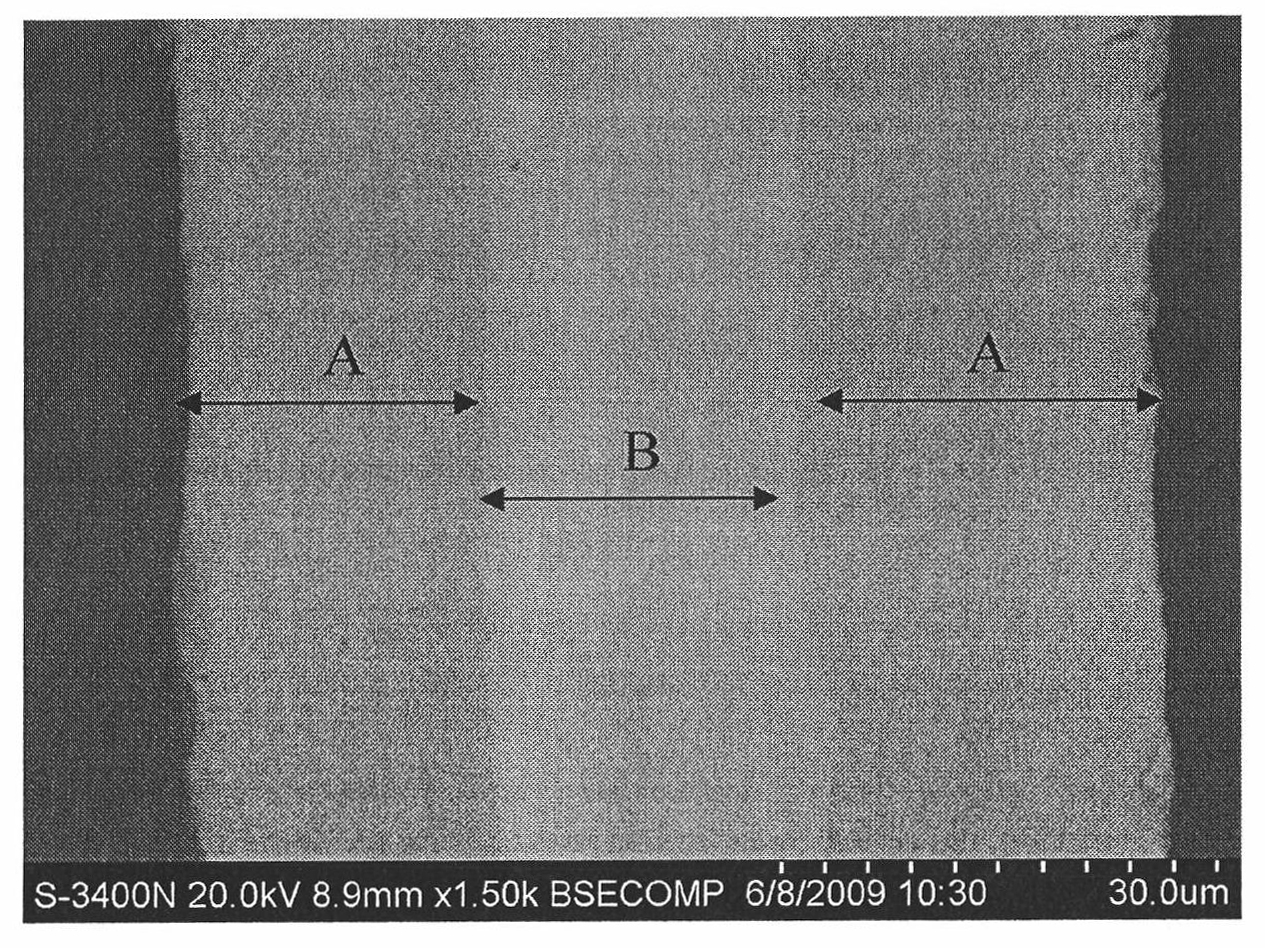

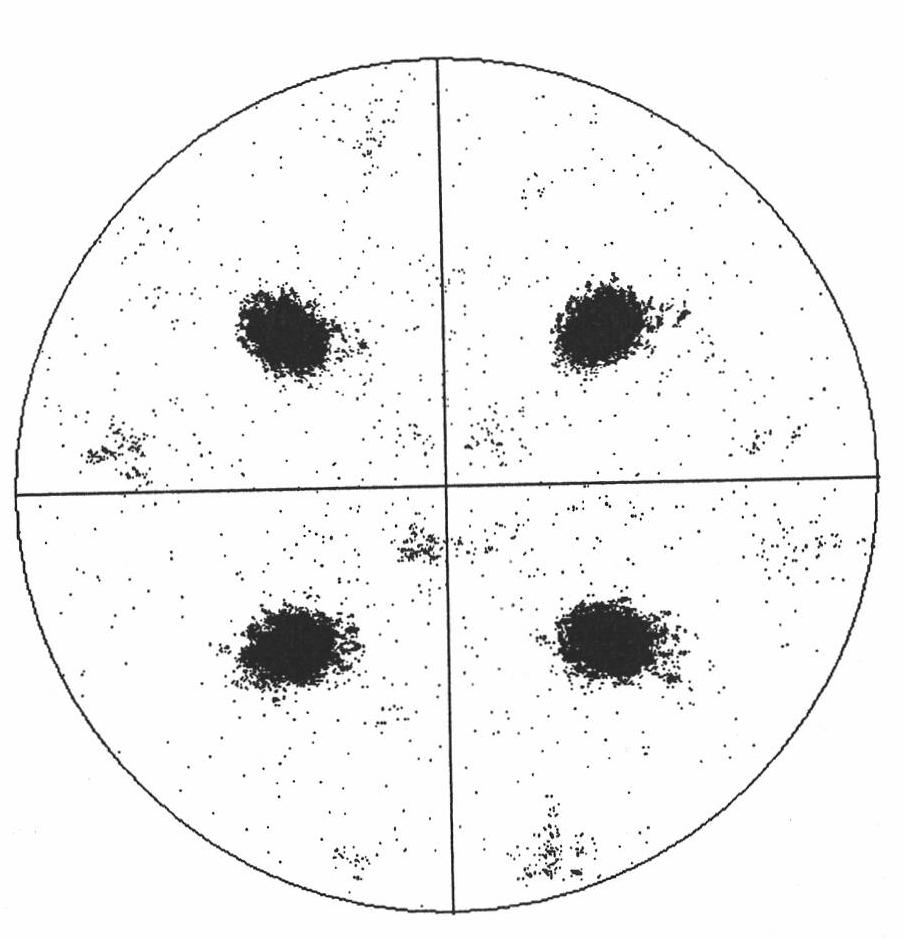

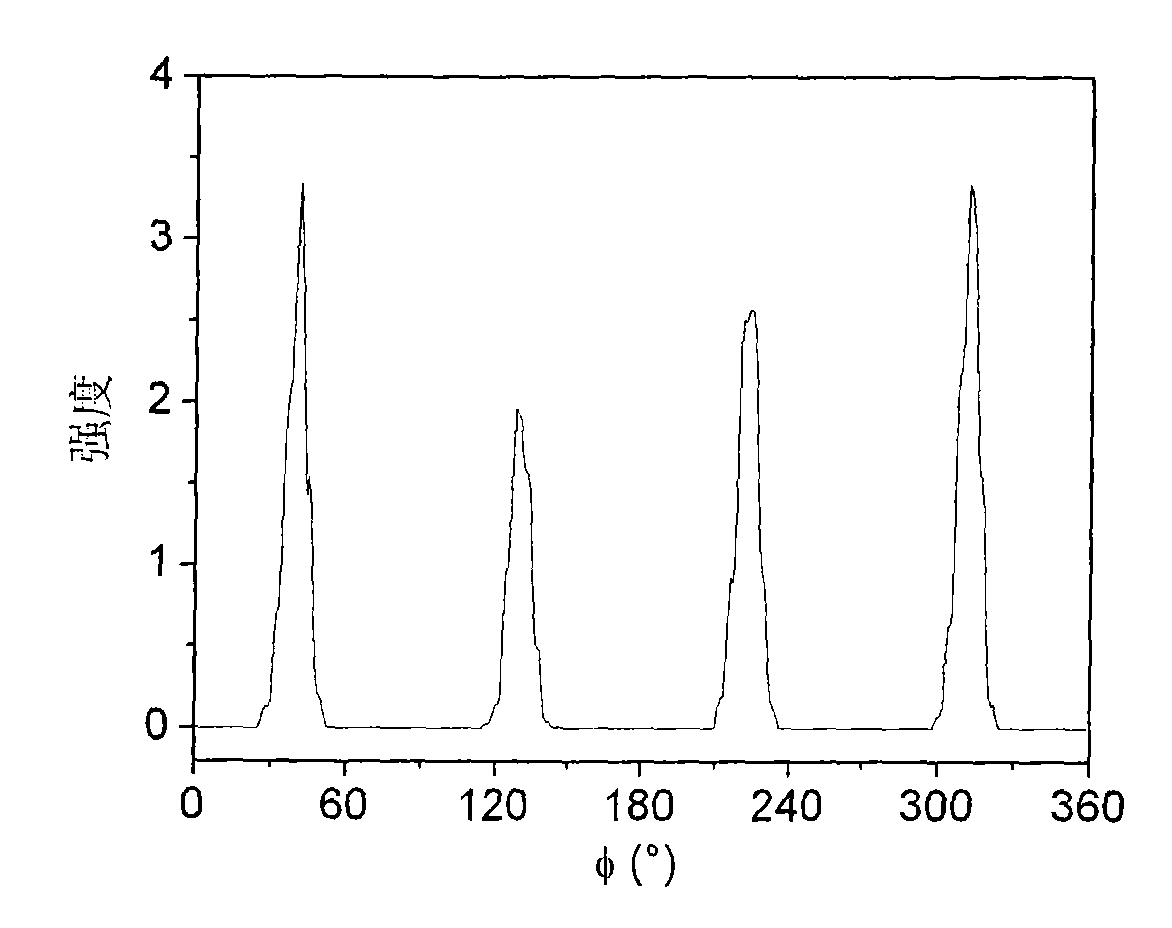

Non-magnetic cube texture Cu-based alloy composite base band and preparation method thereof

InactiveCN101786352AHigh mechanical strengthNo Magnetic GuaranteeMetal rolling arrangementsMetal layered productsSurface layerMold filling

The invention discloses a non-magnetic cube texture Cu-based alloy composite base band. The non-magnetic cube texture Cu-based alloy composite base band is prepared by compositing surface layers and a core layer and has the structure of surface layer, core layer and surface layer, wherein each surface layer is copper-nickel alloy in which the weight percentage of nickel is less than 50 percent; and the core layer is nickel-tungsten alloy in which the atomic percentage of tungsten is between 9 and 12 percent. A preparation method by using powder metallurgy comprises the following steps: (1) initial powder mixing and mold filling; (2) compressing and sintering of a composite green compact; (3) deforming and rolling of the sintered composite bullet; and (4) recrystallizing heat treatment for a cold rolling base band. The preparation method improves the mechanical strength of the whole base band and simultaneously ensures the non-magnetic performance of the whole base band; and the composite base band has high yield strength.

Owner:BEIJING UNIV OF TECH

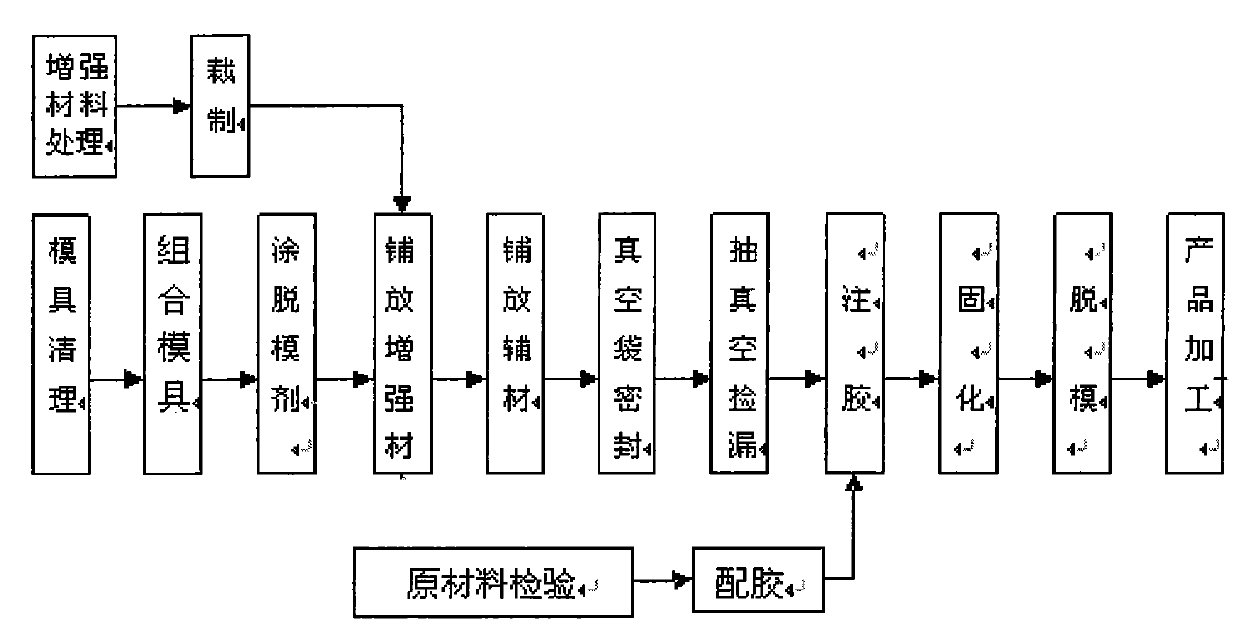

Method for forming large-sized composite material box

The invention discloses a method for forming a large-sized composite material box. The method includes the following steps that (1) a mold is prepared; (2) a plurality of layers including fiber materials are laid on the outer surface of the mold; (3) a vacuum system is arranged on the upper surface of the laid reinforcing material layer, and a glue inlet pipe and a glue outlet pipe are further arranged; (4) the whole device is wrapped with vacuum, vacuum pumping is conducted, and then air tightness is checked; (5) glue is prepared for mold filling; and (6) demolding is performed after curing, and the product is dressed and processed to be formed. By the adoption of the method, the content of fibers in the formed product is even in distribution, quality is reliable, and process repeatability is good. The whole process can only be completed through a vacuum pump, and no special equipment is required, so that investment is small, labor intensity is low, consumed labor hours is short and cost is low. The process belongs to mold closing forming, the amount of volatilization of harmful gas is small, environmental pollution can be reduced, the good health of operators can be guaranteed, and therefore popularization is facilitated.

Owner:北京玻钢院复合材料有限公司

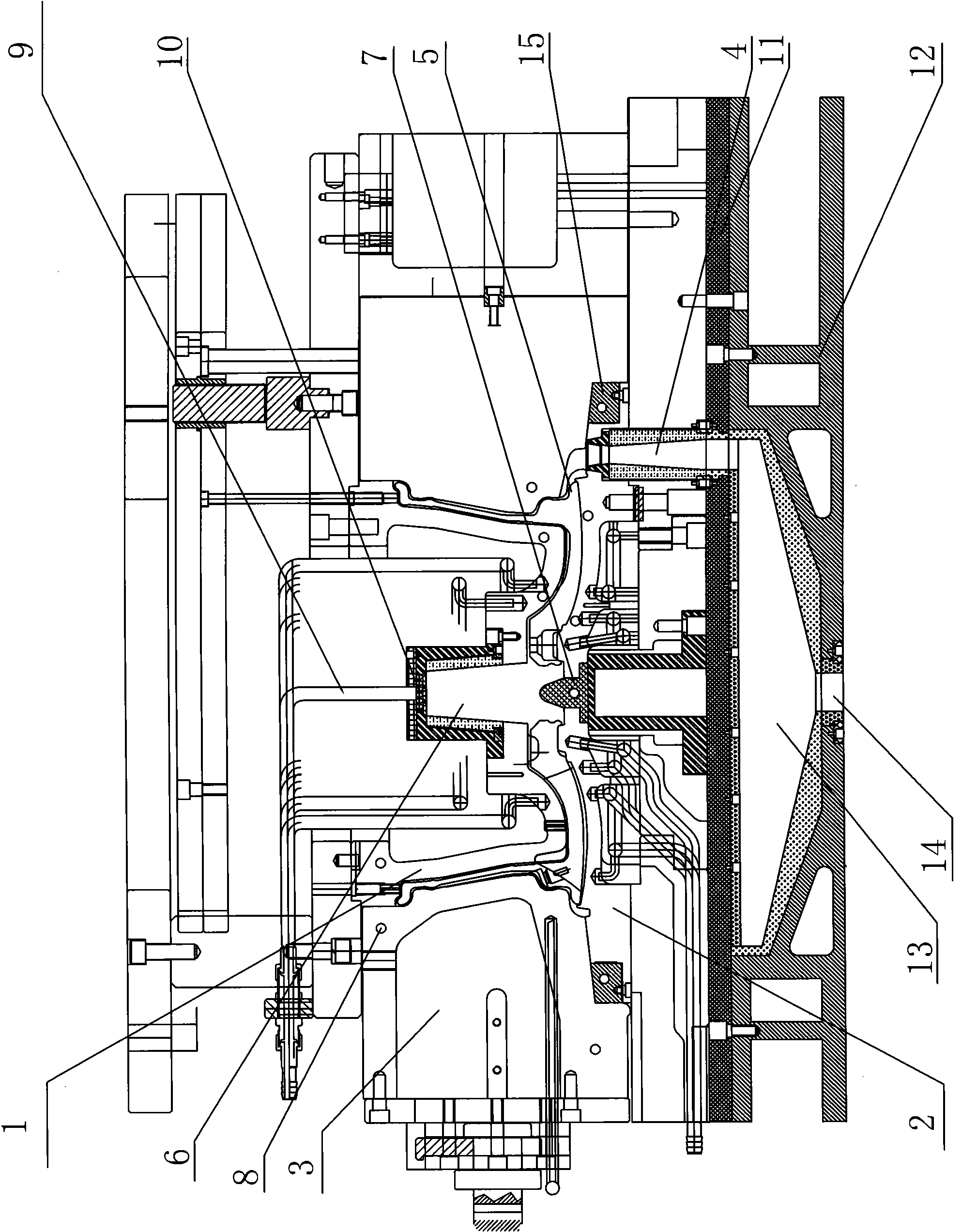

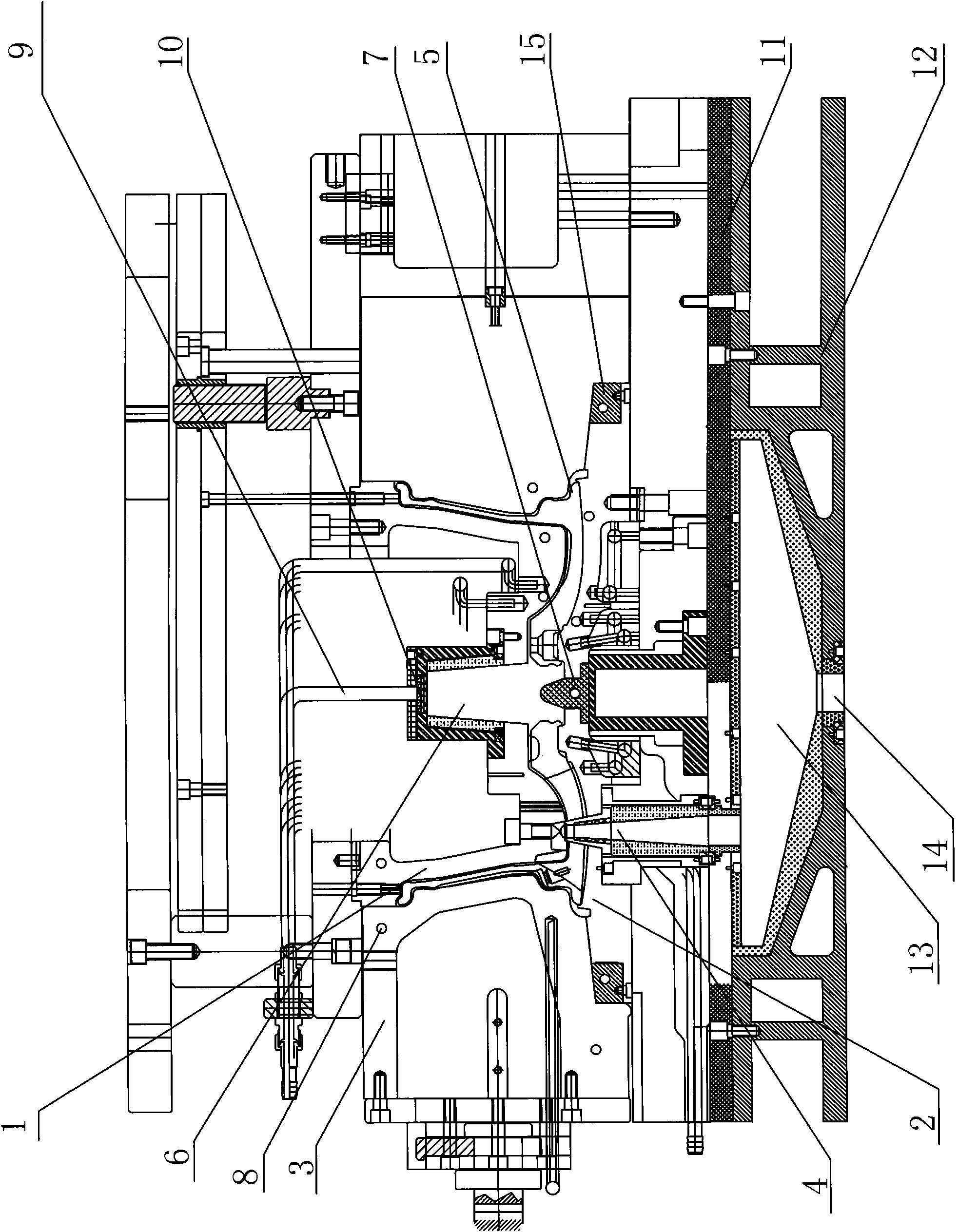

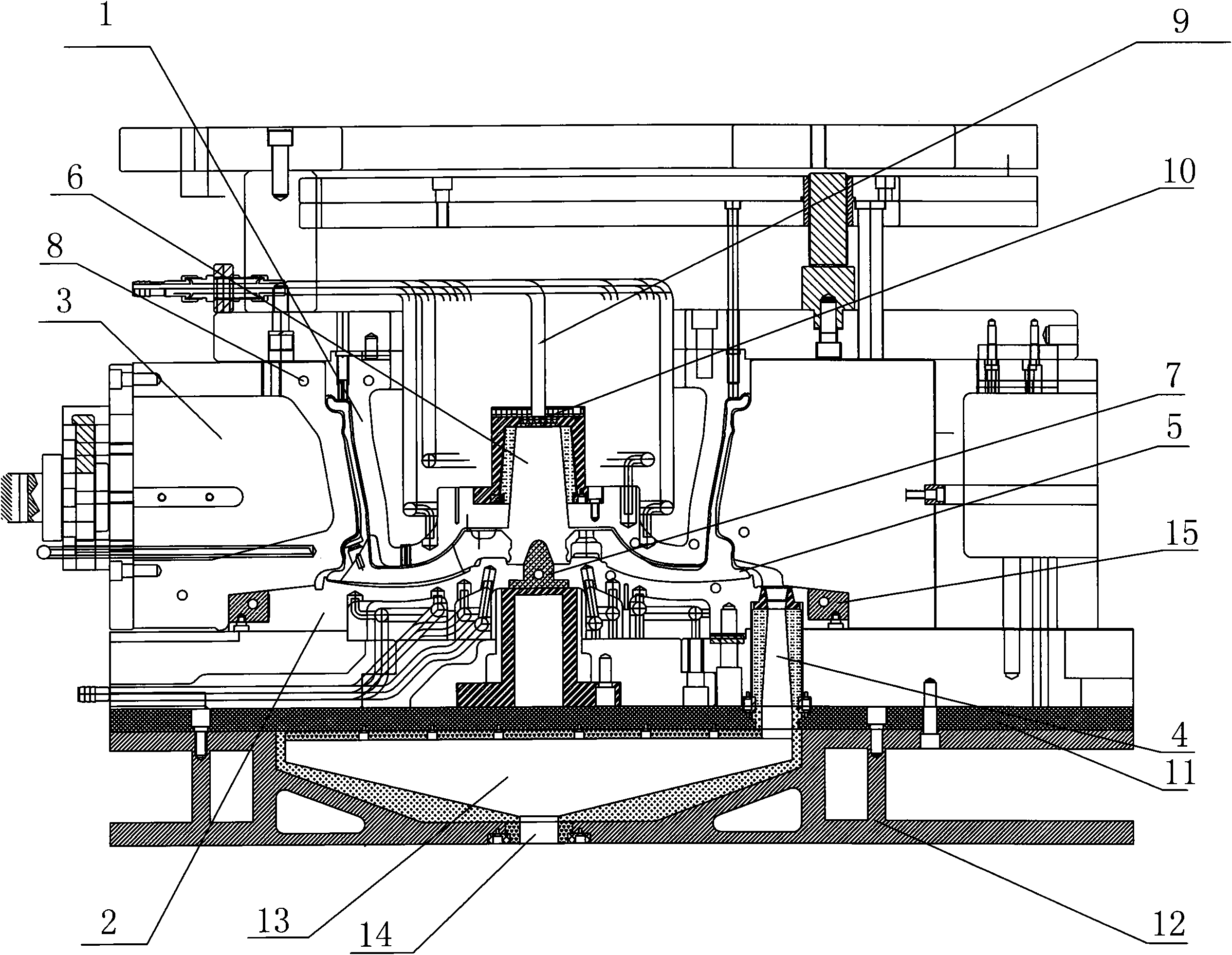

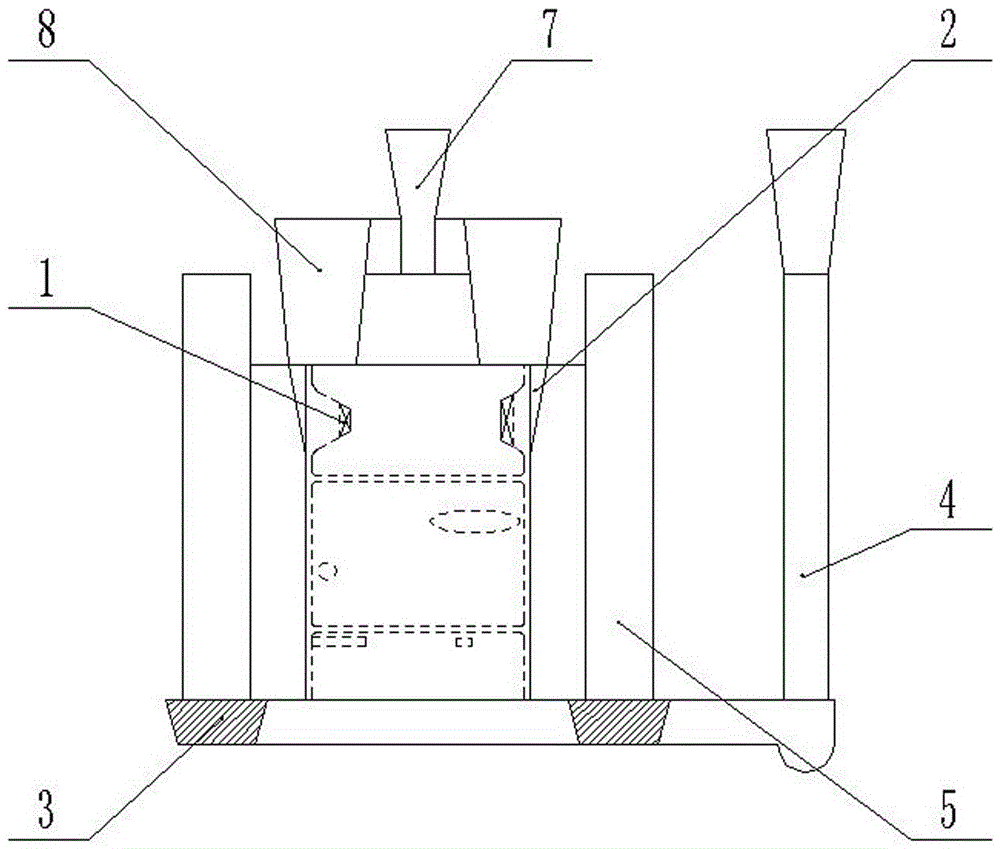

Low-pressure casting die of aluminium alloy wheel and casting method thereof

The invention discloses a low-pressure casting die of an aluminium alloy wheel and a casting method thereof. The low-pressure casting die comprises a top die (1), a bottom die (2) and a side die (3), wherein a plurality of gates (4) are arranged on the bottom die (2); the center of the top die is provided with a central riser (6) which is used for feeding; the center of the bottom die is provided with a shunt cone (7) which is used for forming the center of a wheel disc, and the gates are arranged at the outer side of the lower wheel lip of the bottom die or at the window of the bottom die. The casting method comprises the following steps of mold filling, exhausting, pressurization, cooling, feeding, aluminium liquid reflux and the like. By using the invention, the quality of casting parts is increased, the mechanical property index of produced vehicle wheel spokes and wheel centers is good, and pinholes do not easily appear on products. The invention can be suitable for occasions with high requirements for product quality, is beneficial to achieving the light weight of the products, improves production efficiency, and reduces die erosion.

Owner:何丙军 +1

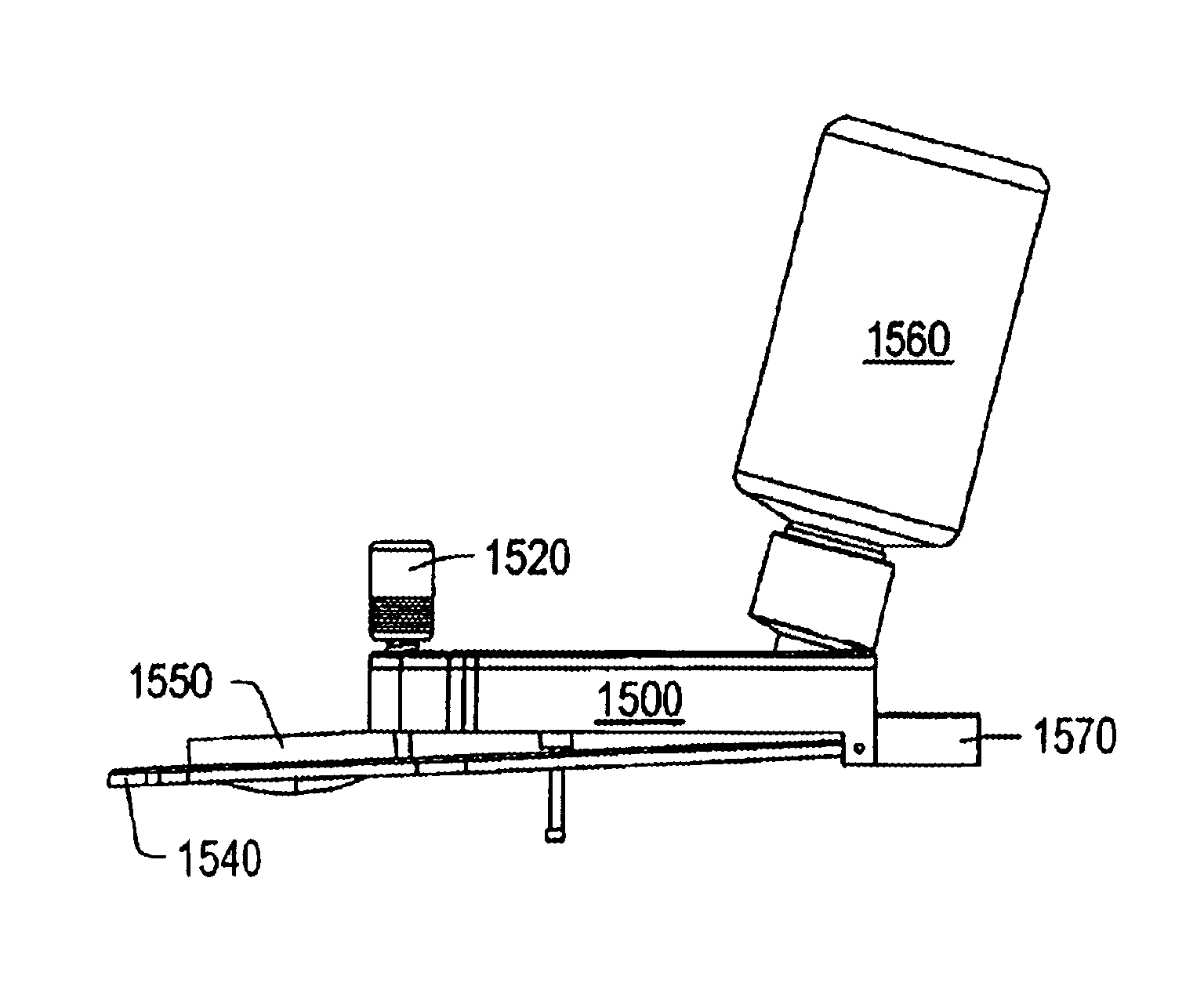

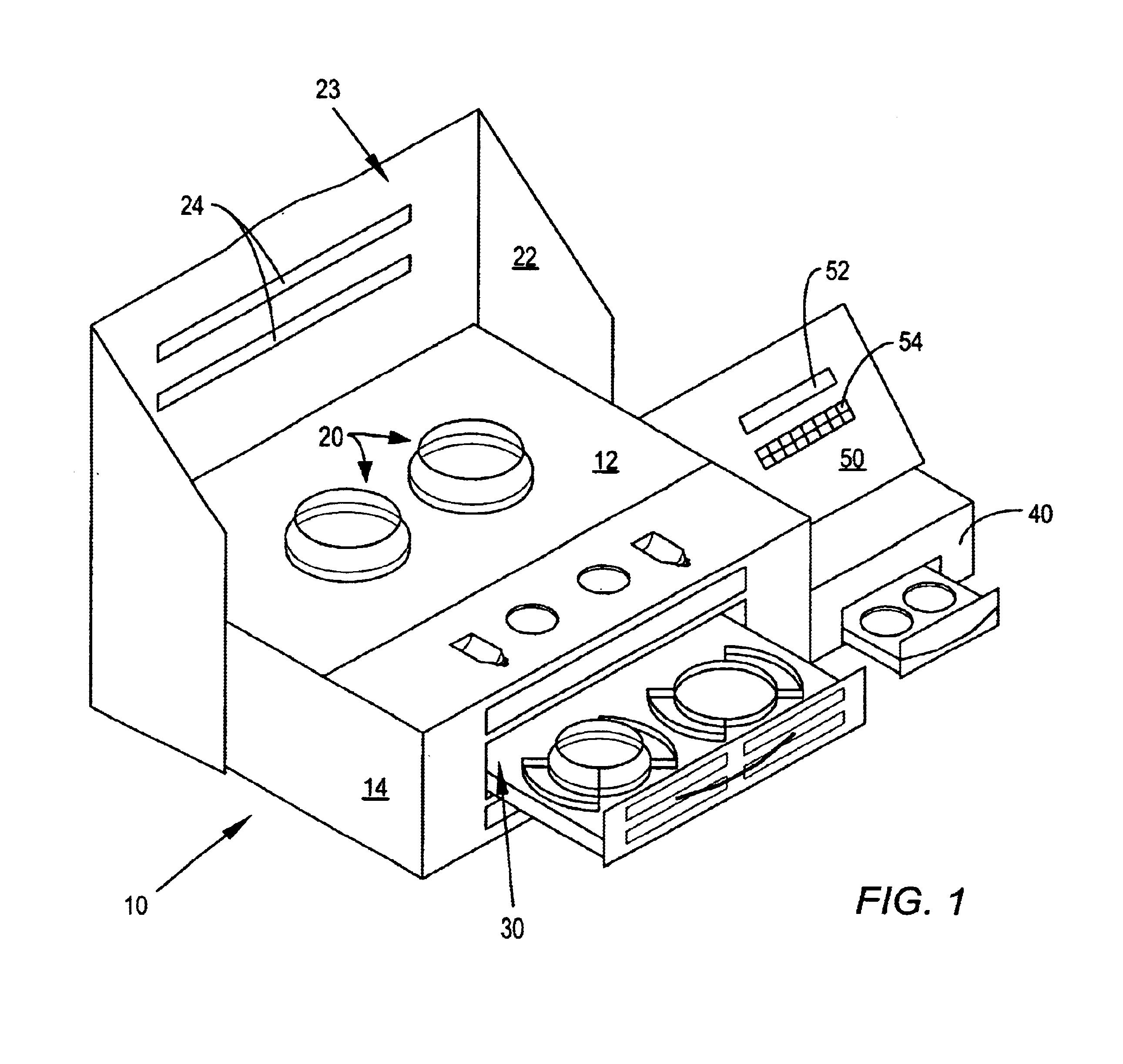

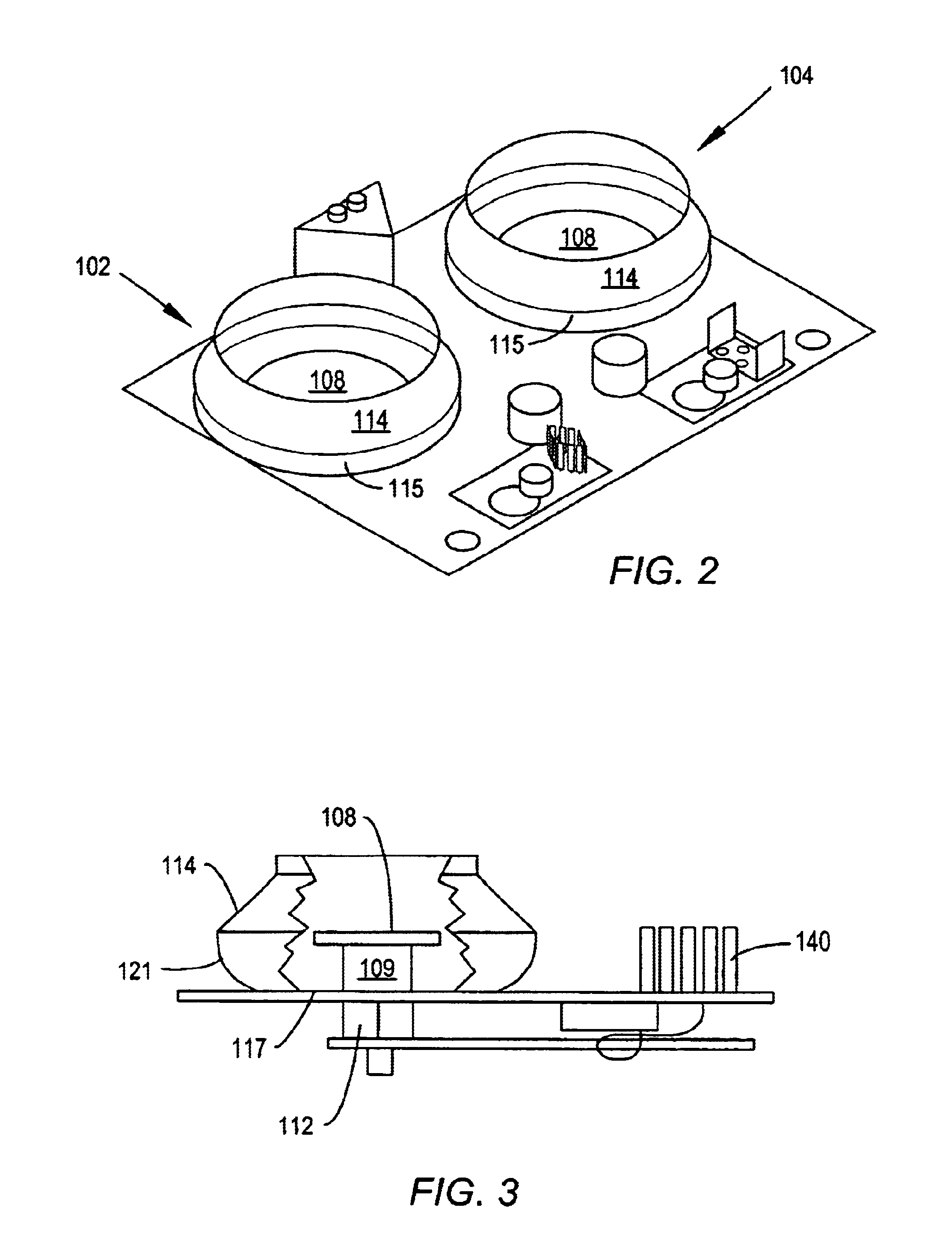

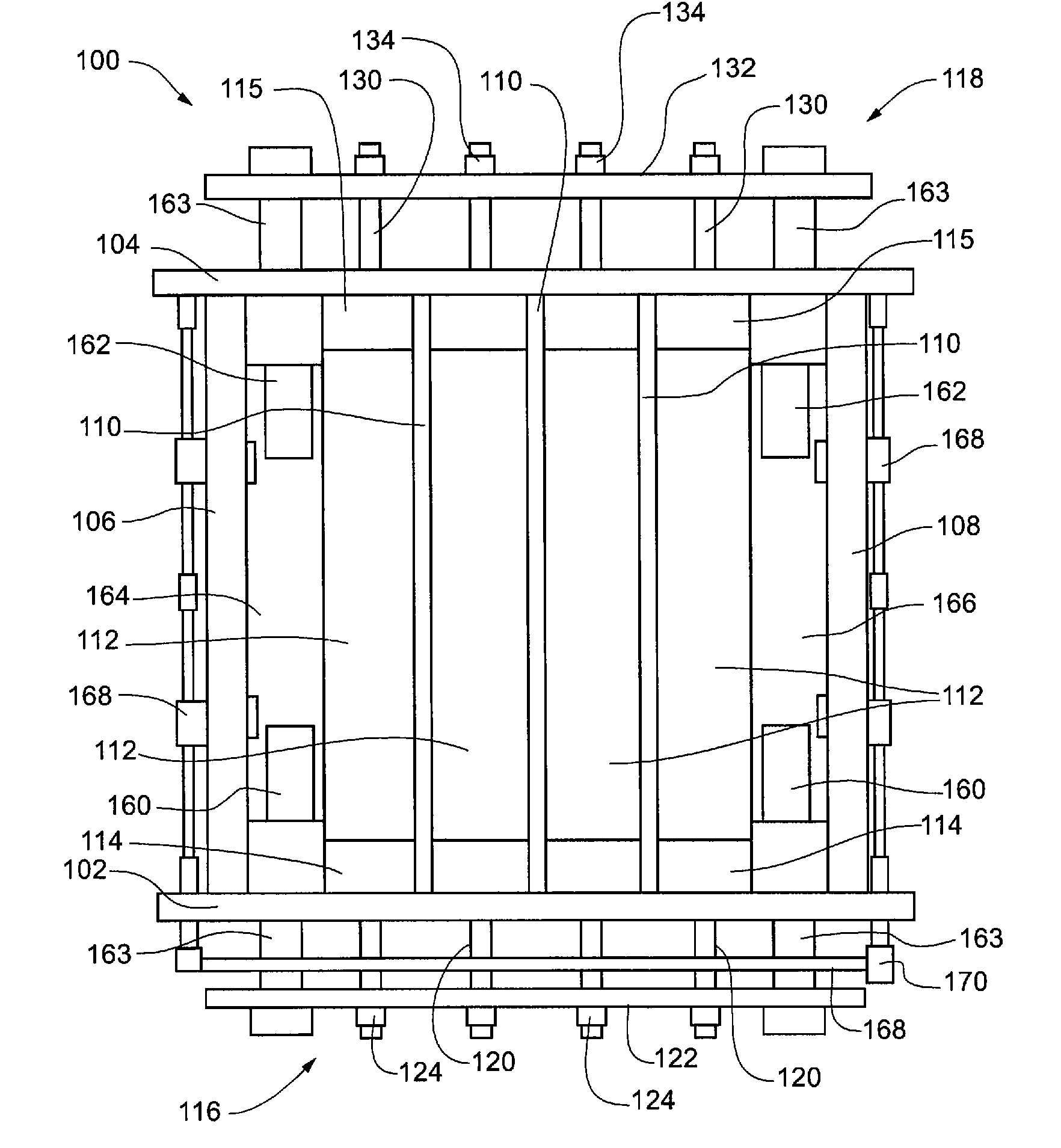

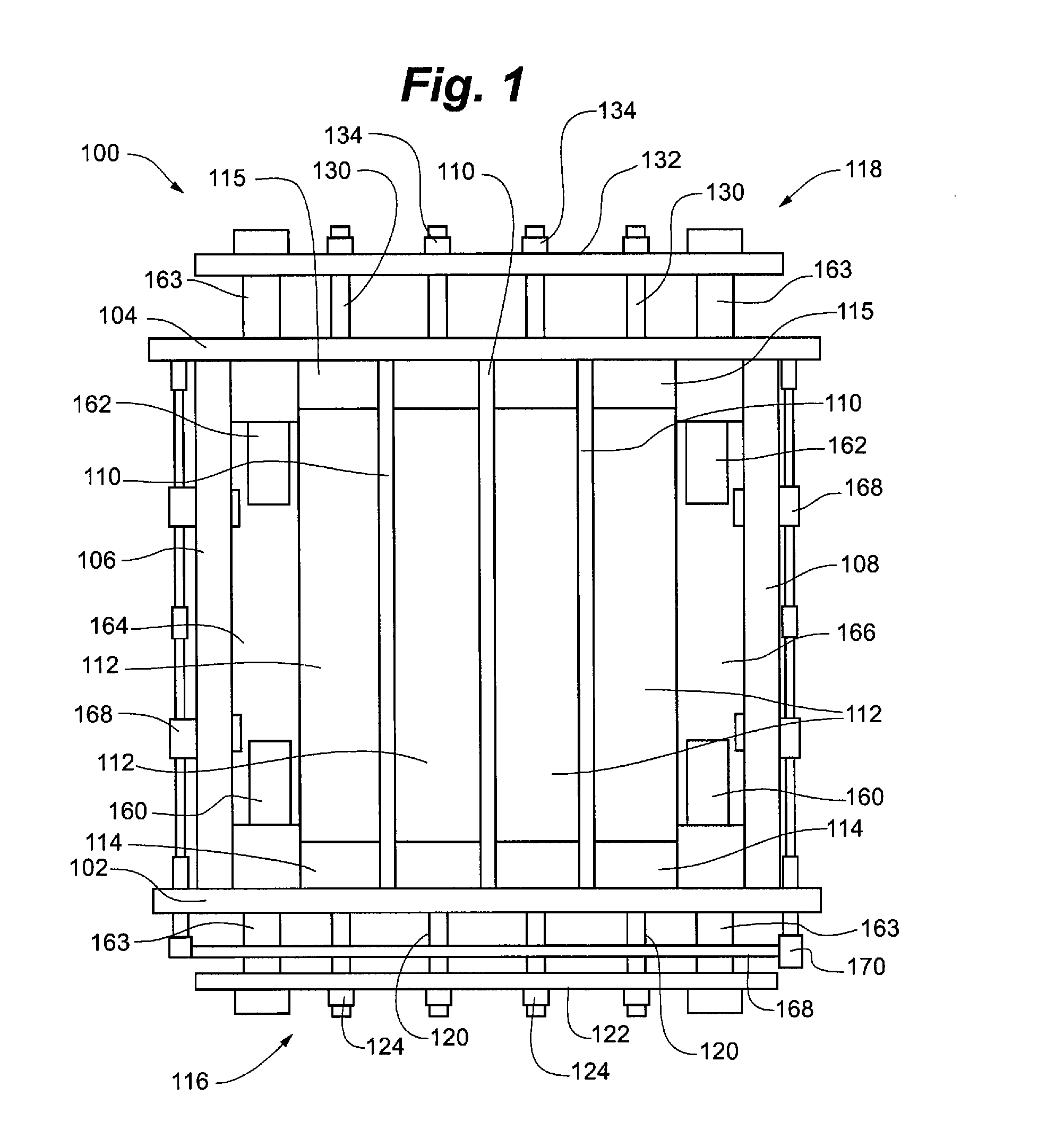

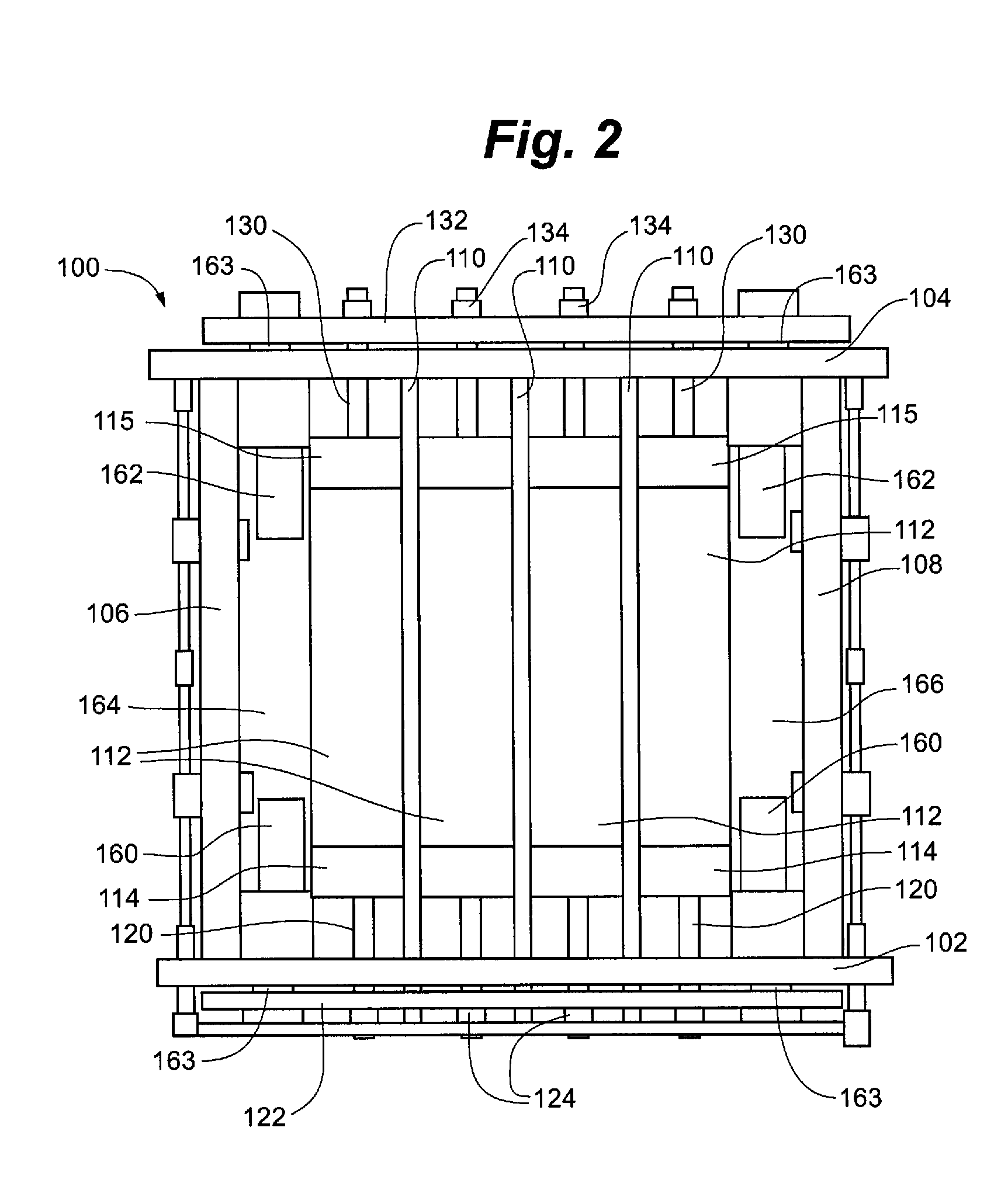

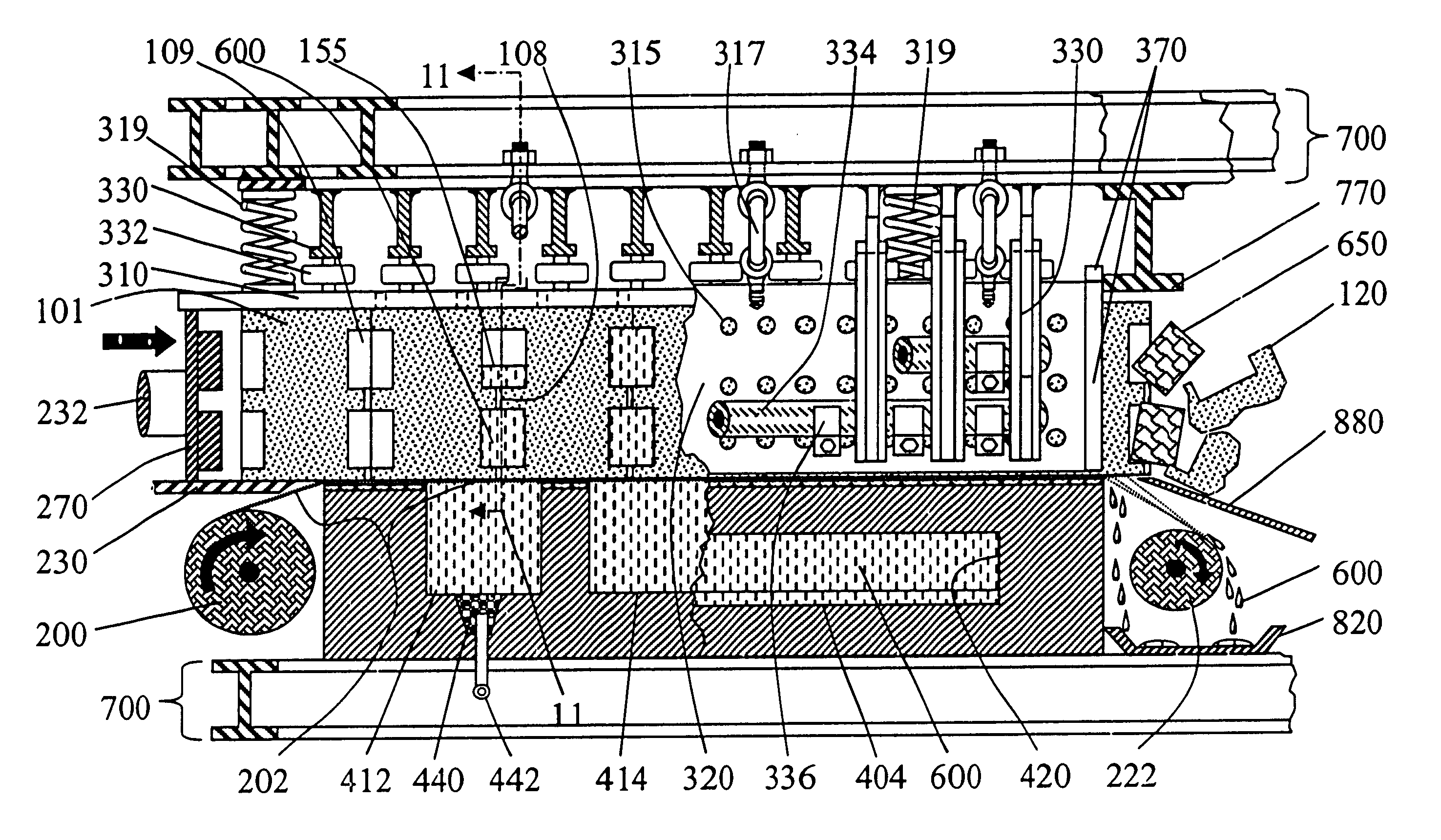

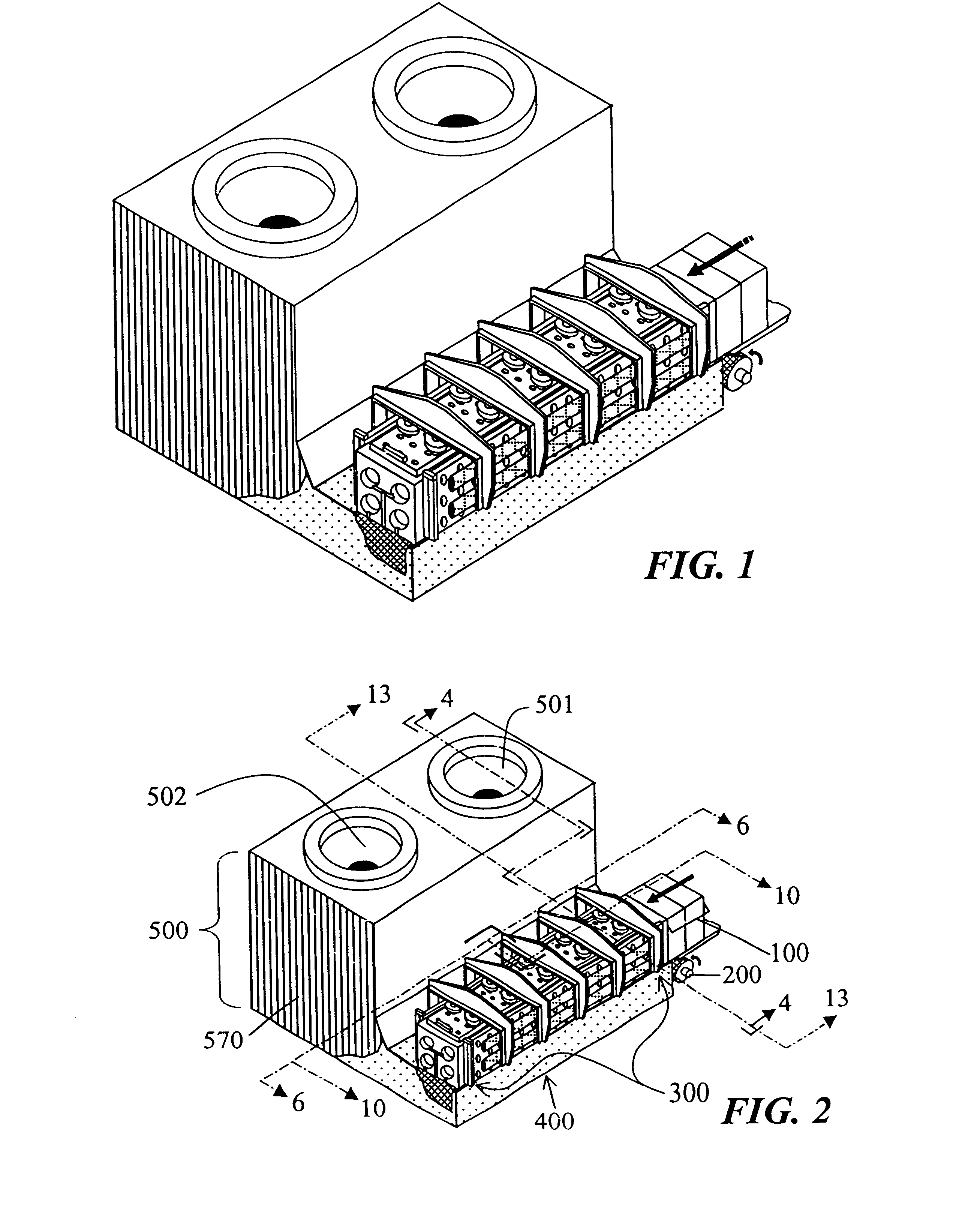

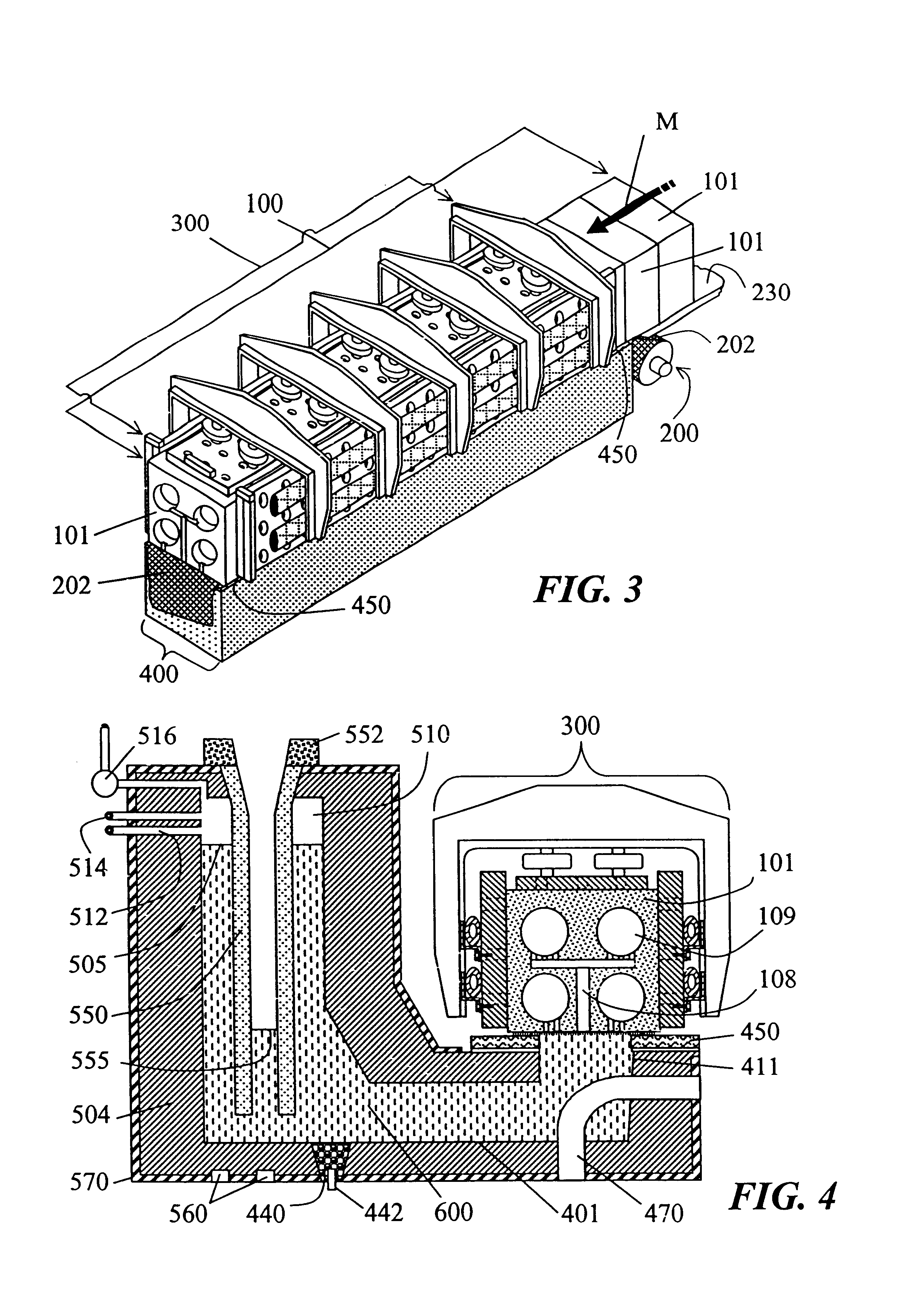

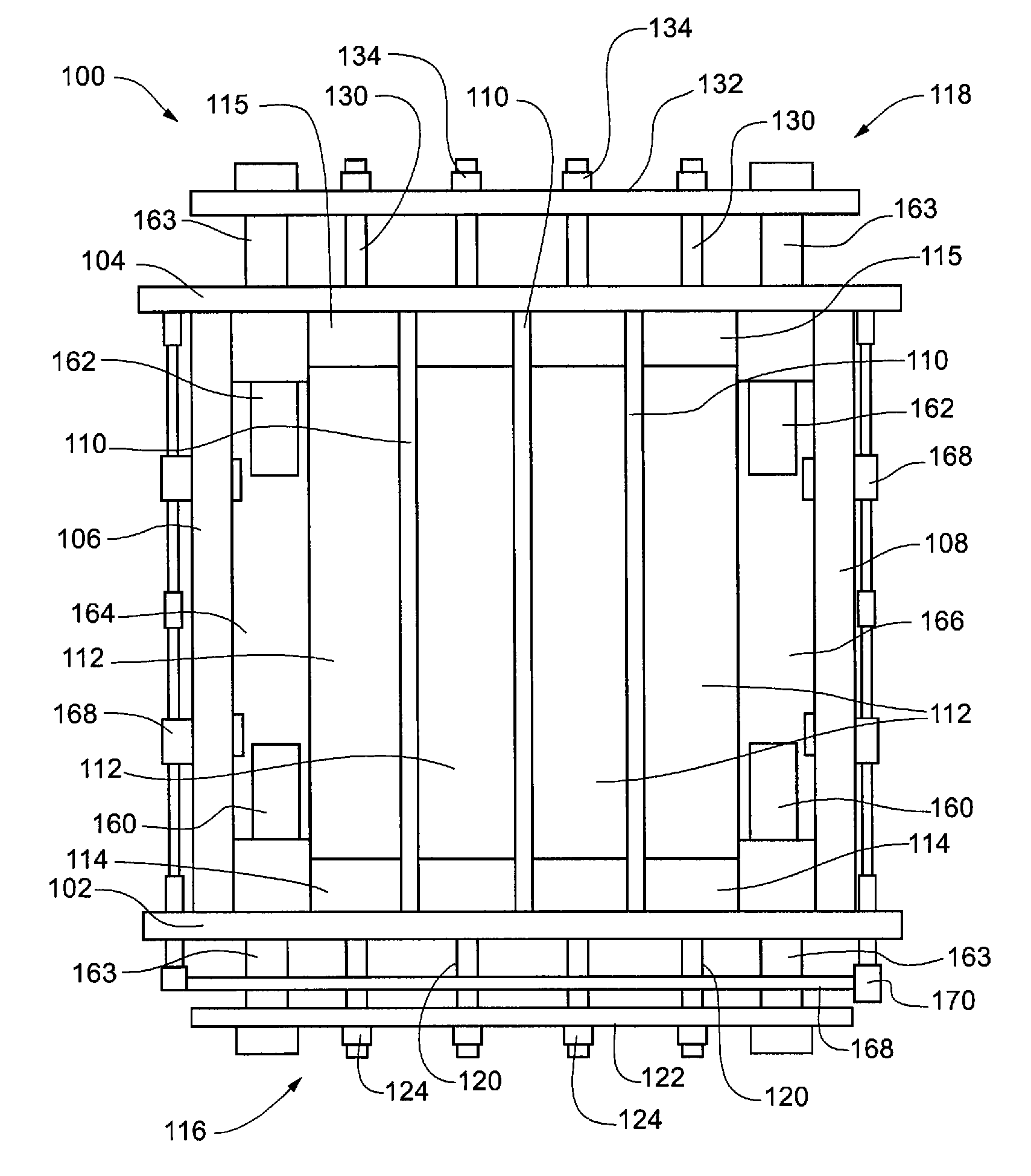

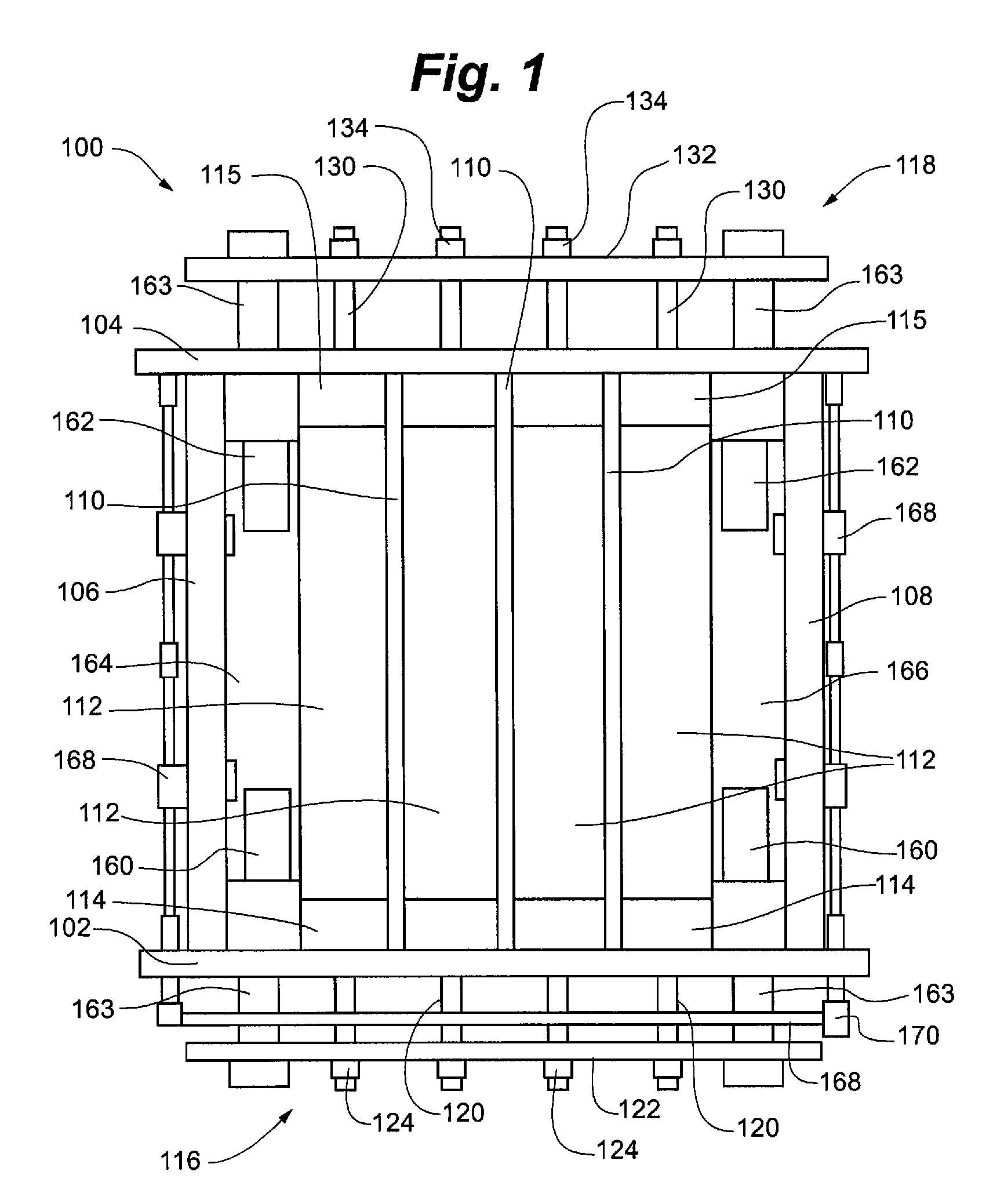

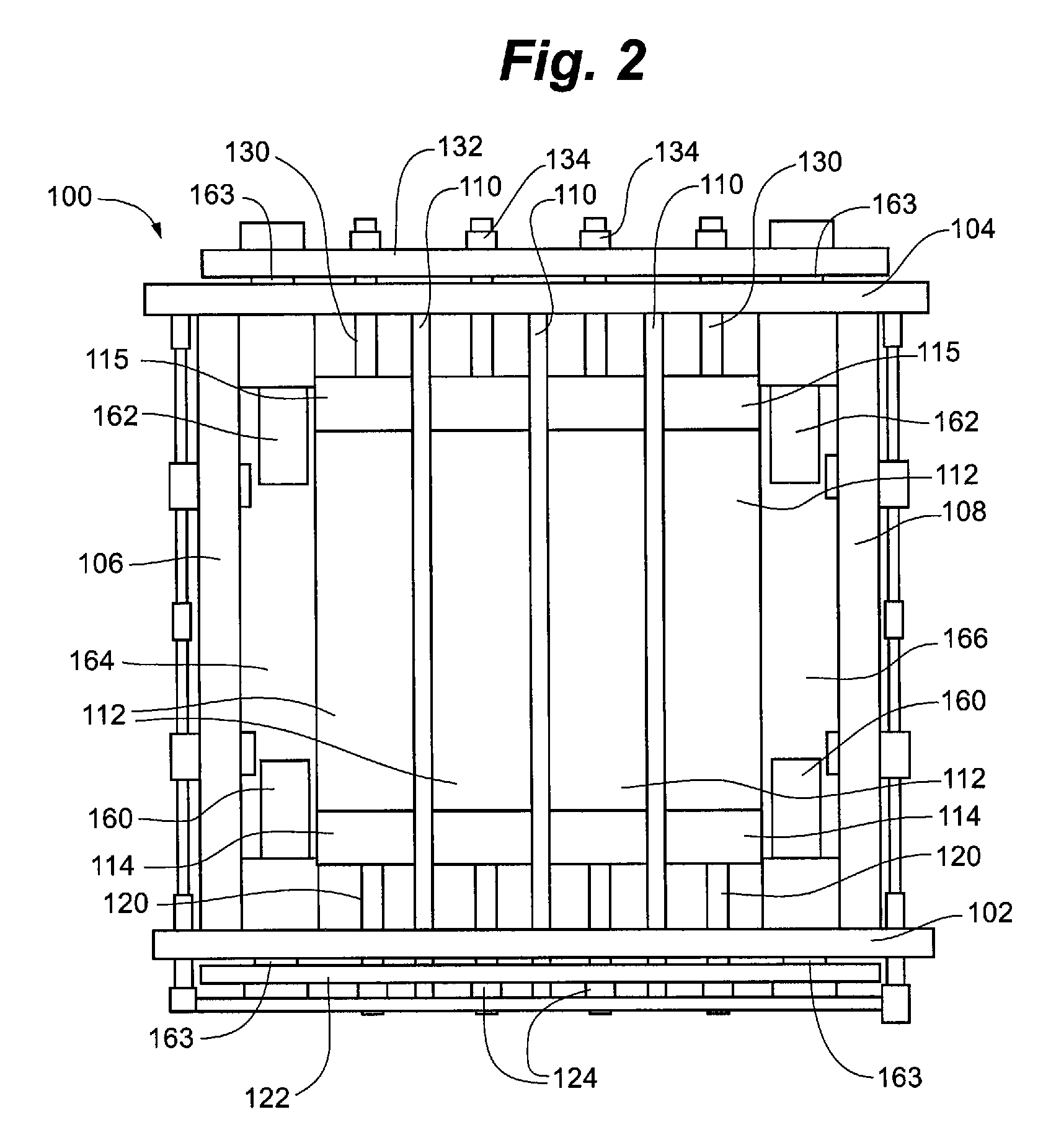

Mold filing apparatus having multiple fill stations

InactiveUS6863518B2Change colorReduce stepsOptical articlesAuxillary shaping apparatusEyeglass lensesMold filling

A high volume lens curing system is described. The high volume lens curing system may be configured to cure multiple eyeglass lenses in a continuous manner. An embodiment of a system may include a mold assembly, a lens curing apparatus, a mold filling apparatus and / or a controller.

Owner:Q2100

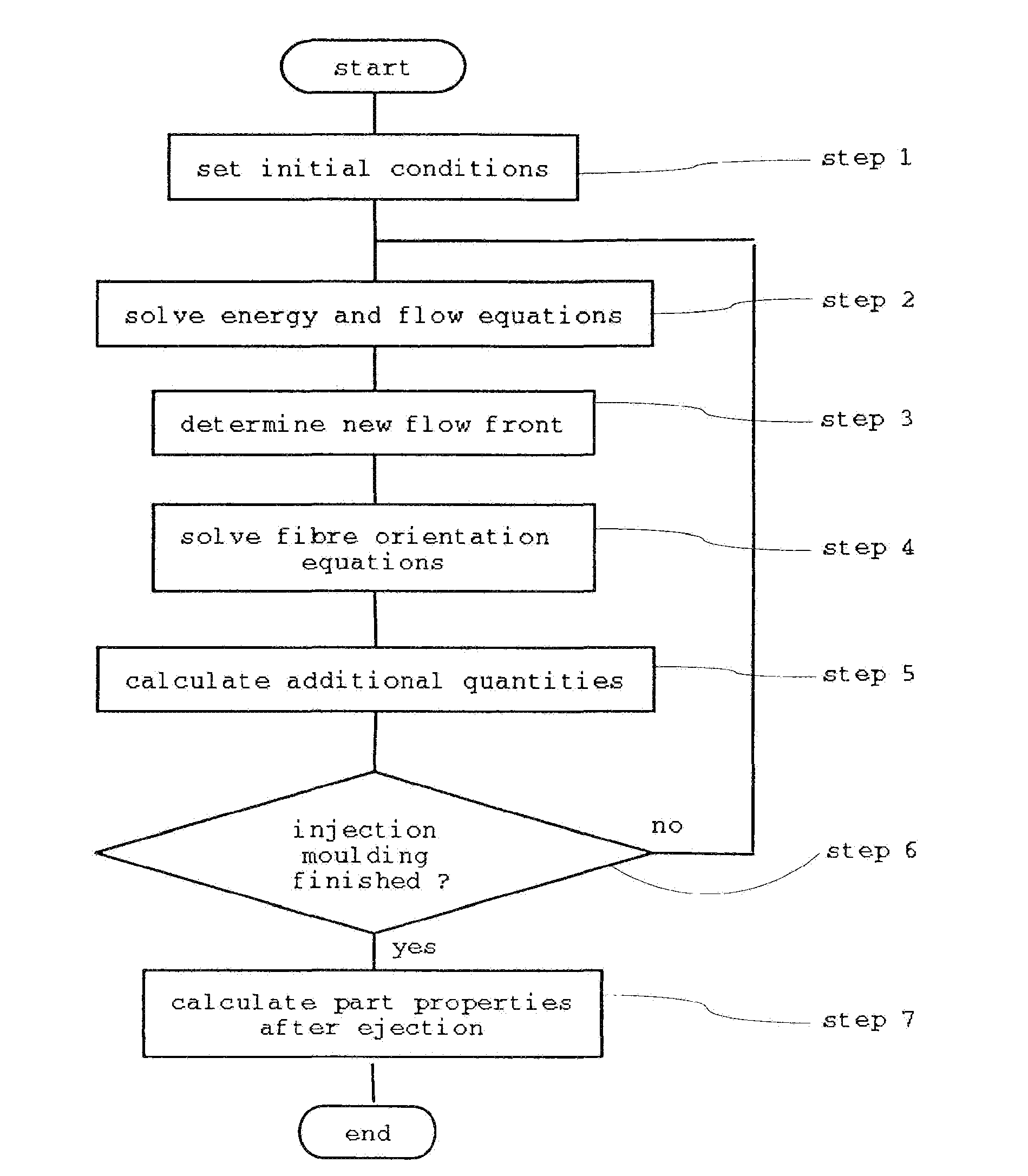

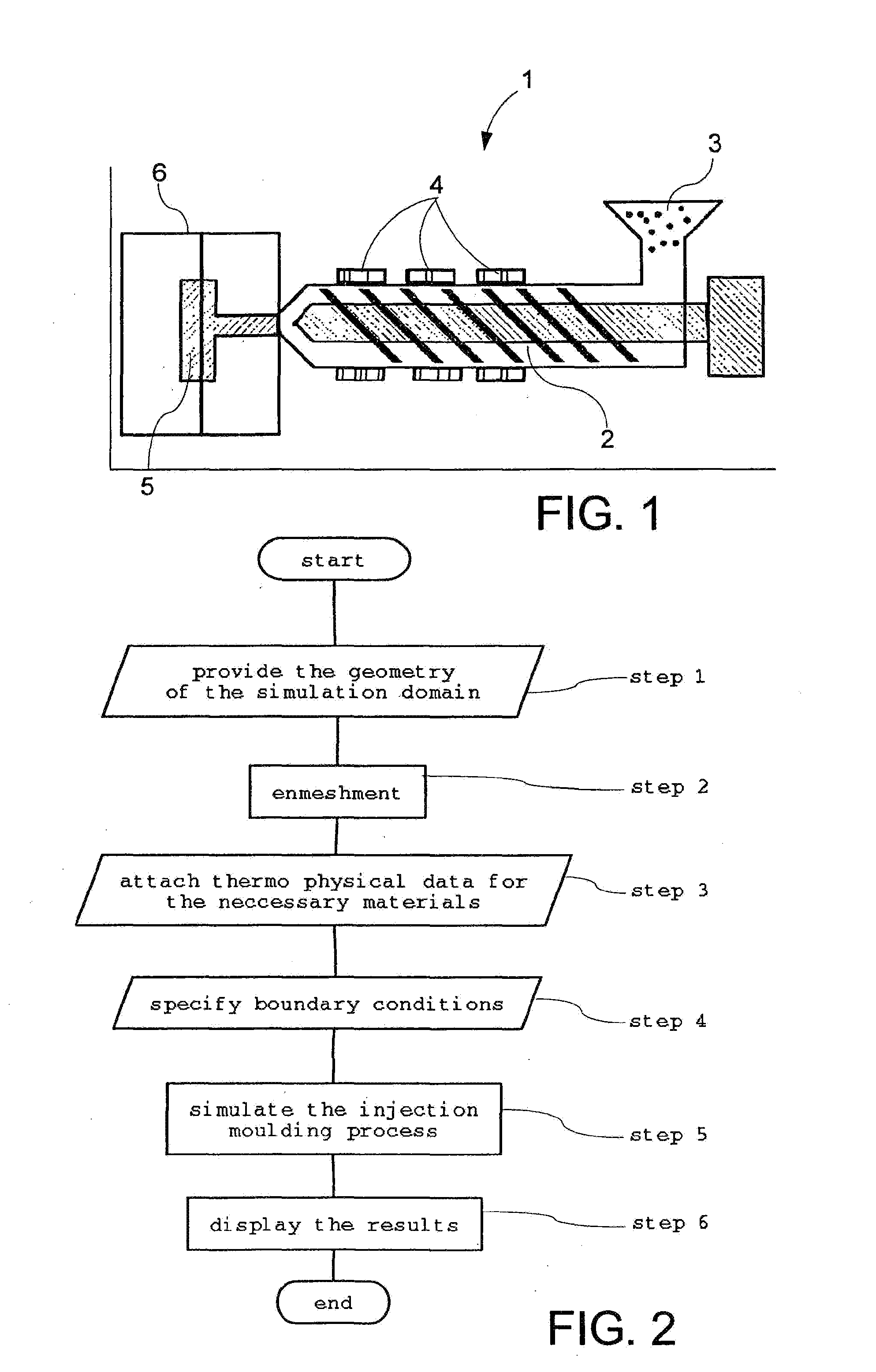

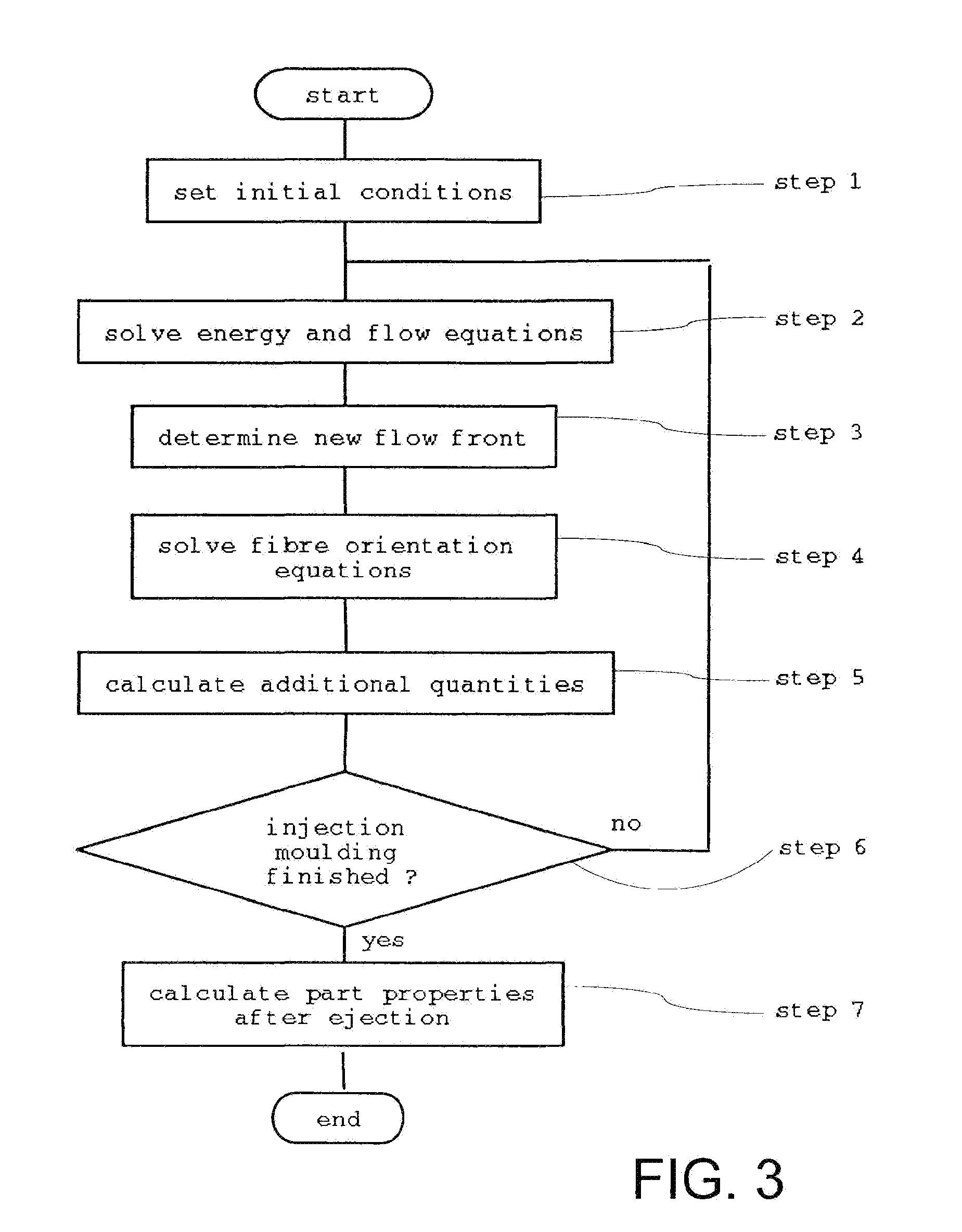

Method and Apparatus for Describing the Statistical Orientation Distribution of Particles in a Simulation of a Mould Filling Process

ActiveUS20100169062A1Less computation intensiveImprove stabilityAnalogue computers for control systemsComputation using non-denominational number representationShell moldingMold filling

A method and apparatus for describing the statistical orientation distribution of nonspherical particles in a simulation of a process wherein a mold cavity is filled with a suspension that contains a large number of nonspherical particles. The method and apparatus may be applied to the analysis of an injection molding process for producing a fiber reinforced molded polymer component or of a metal casting process for producing a fiber reinforced metal product. The results of these analyses may be used to determine tension and warping aspects of the component, and to optimize the process conditions used in the production process.

Owner:MAGMA GIESSEREITECH

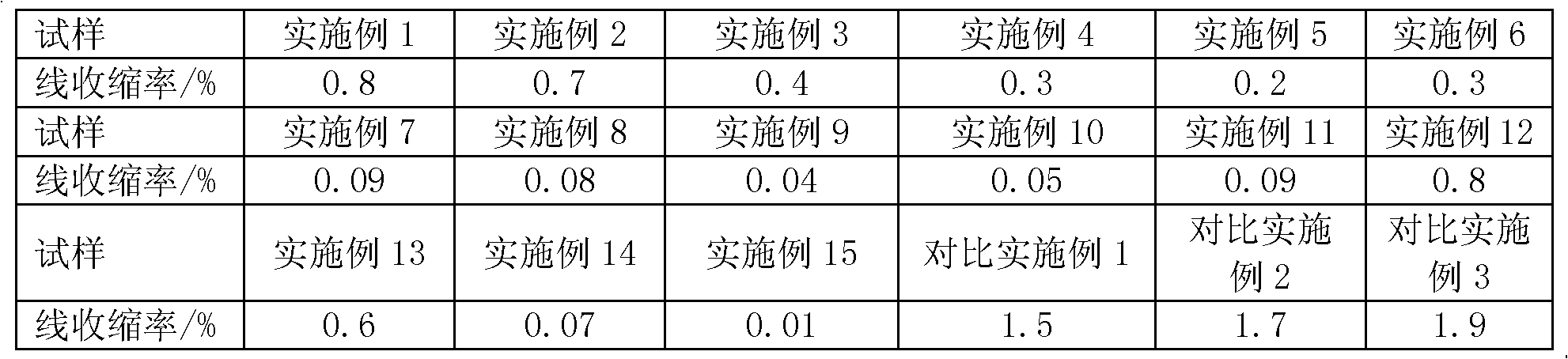

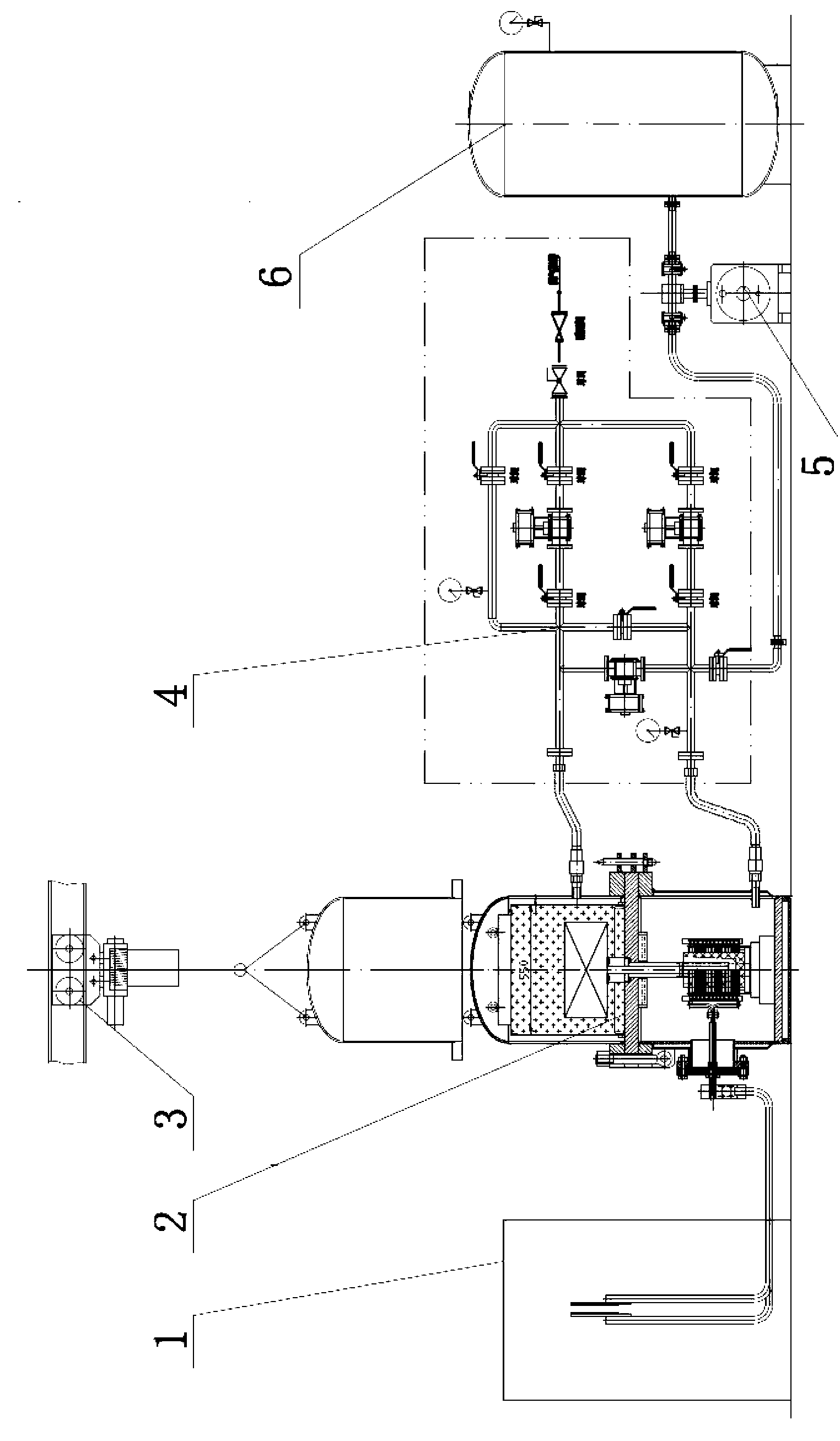

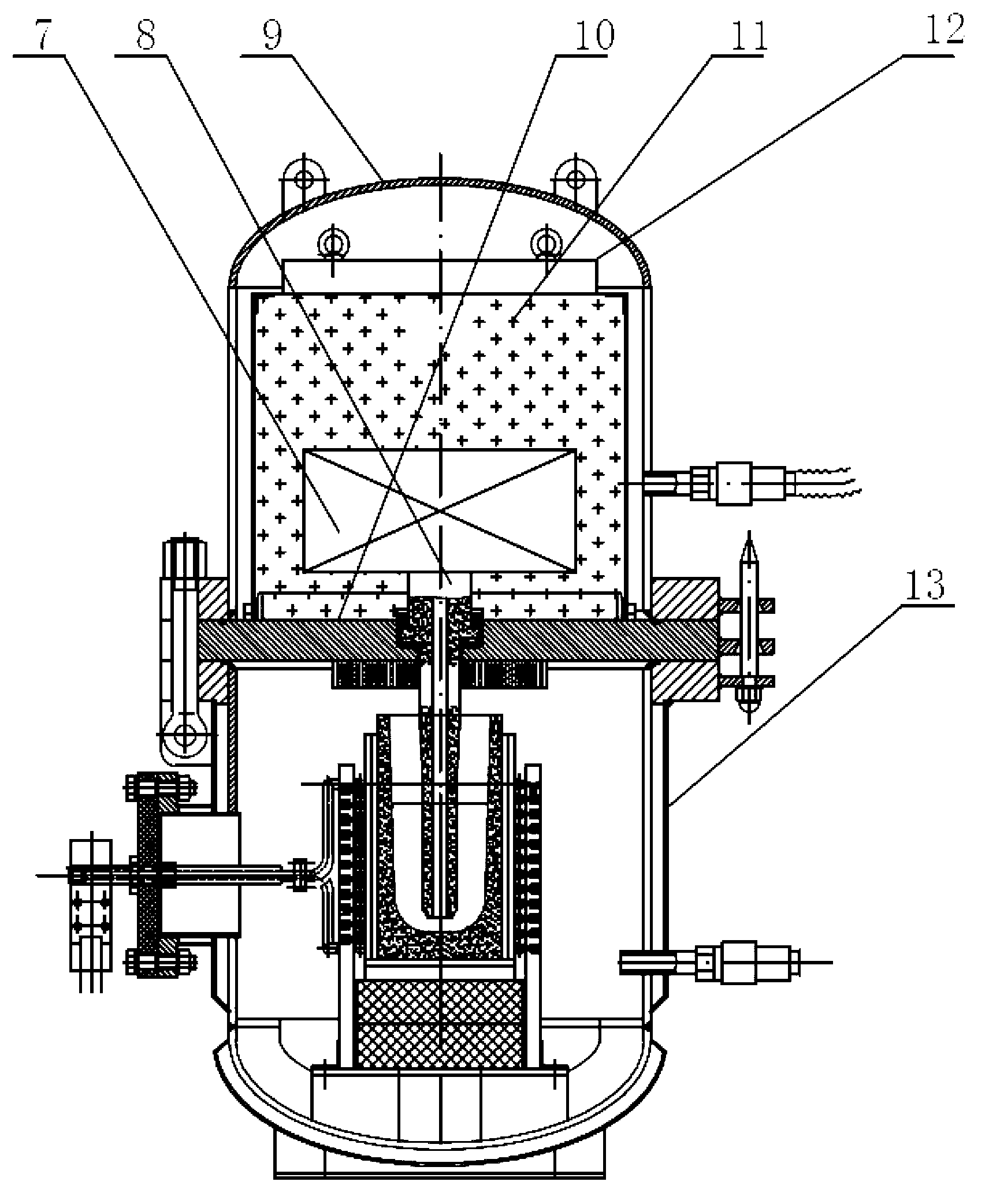

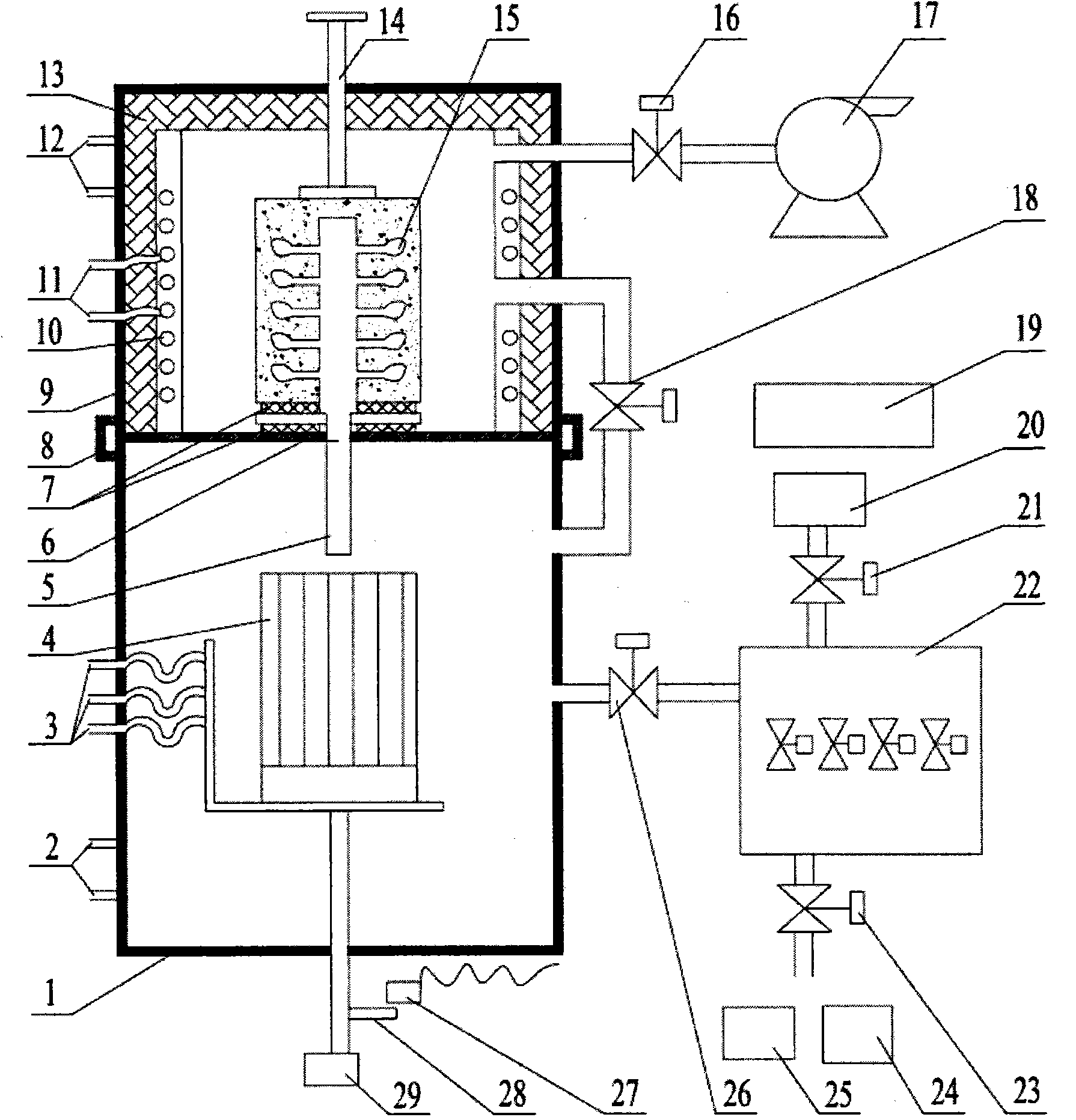

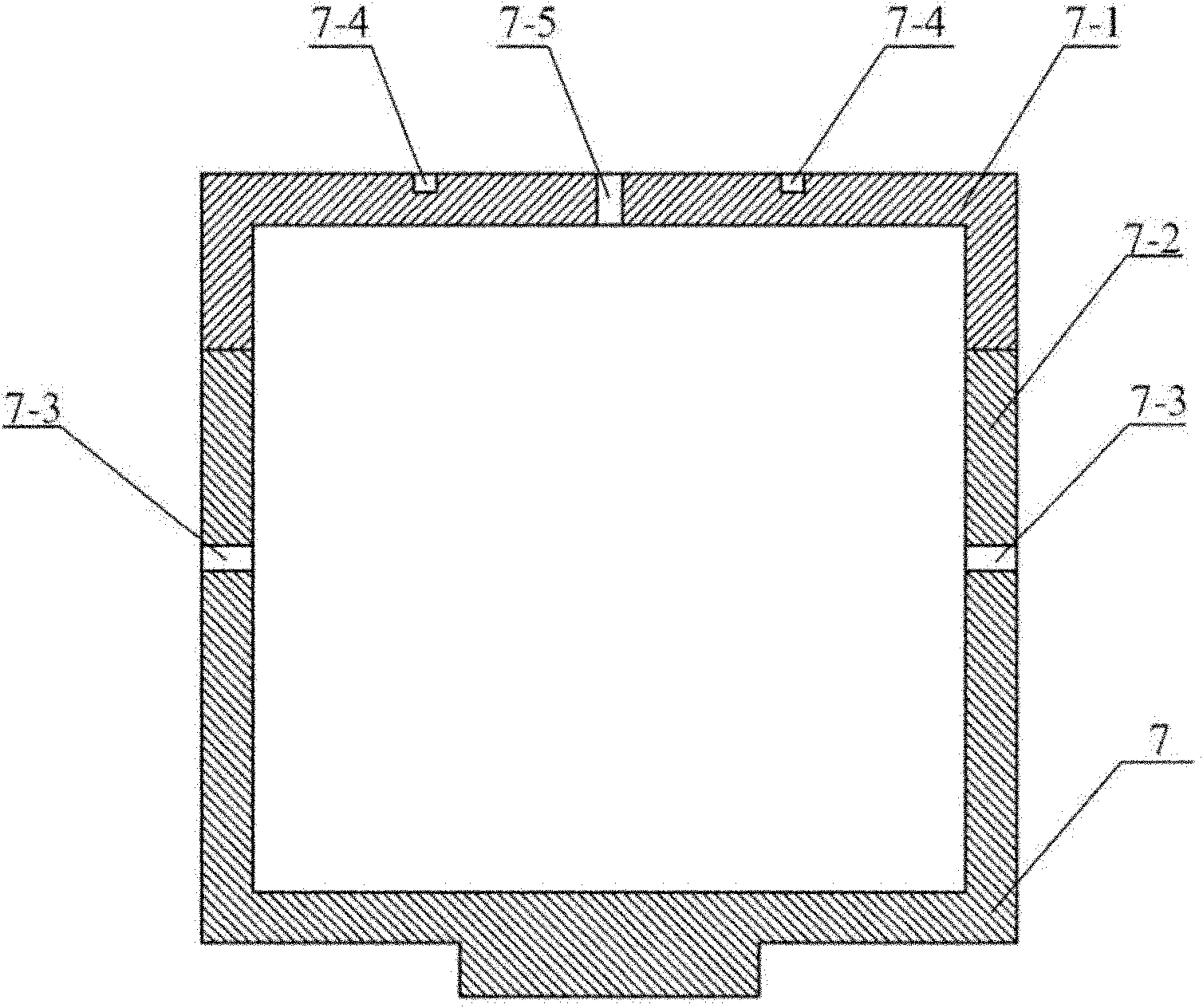

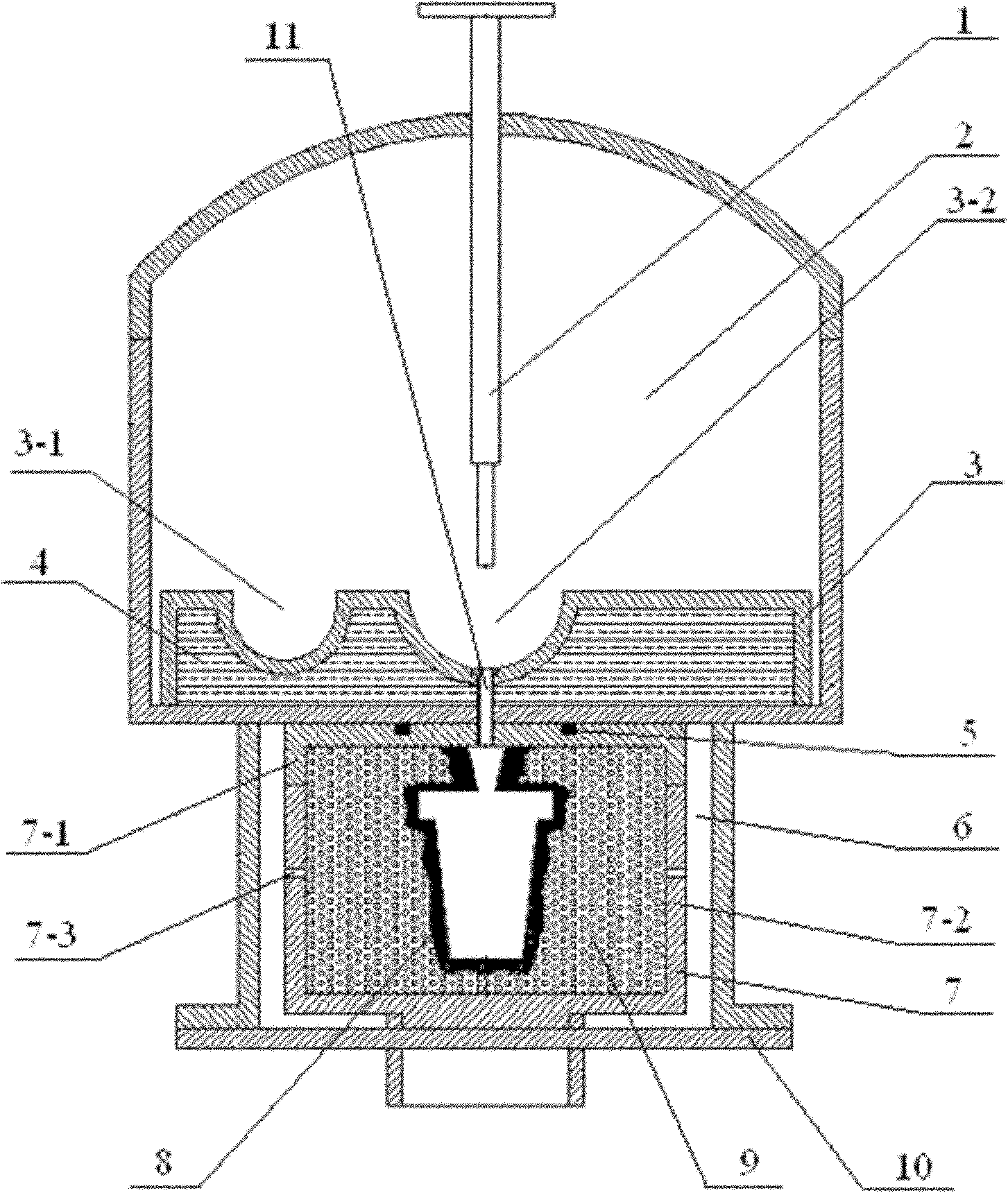

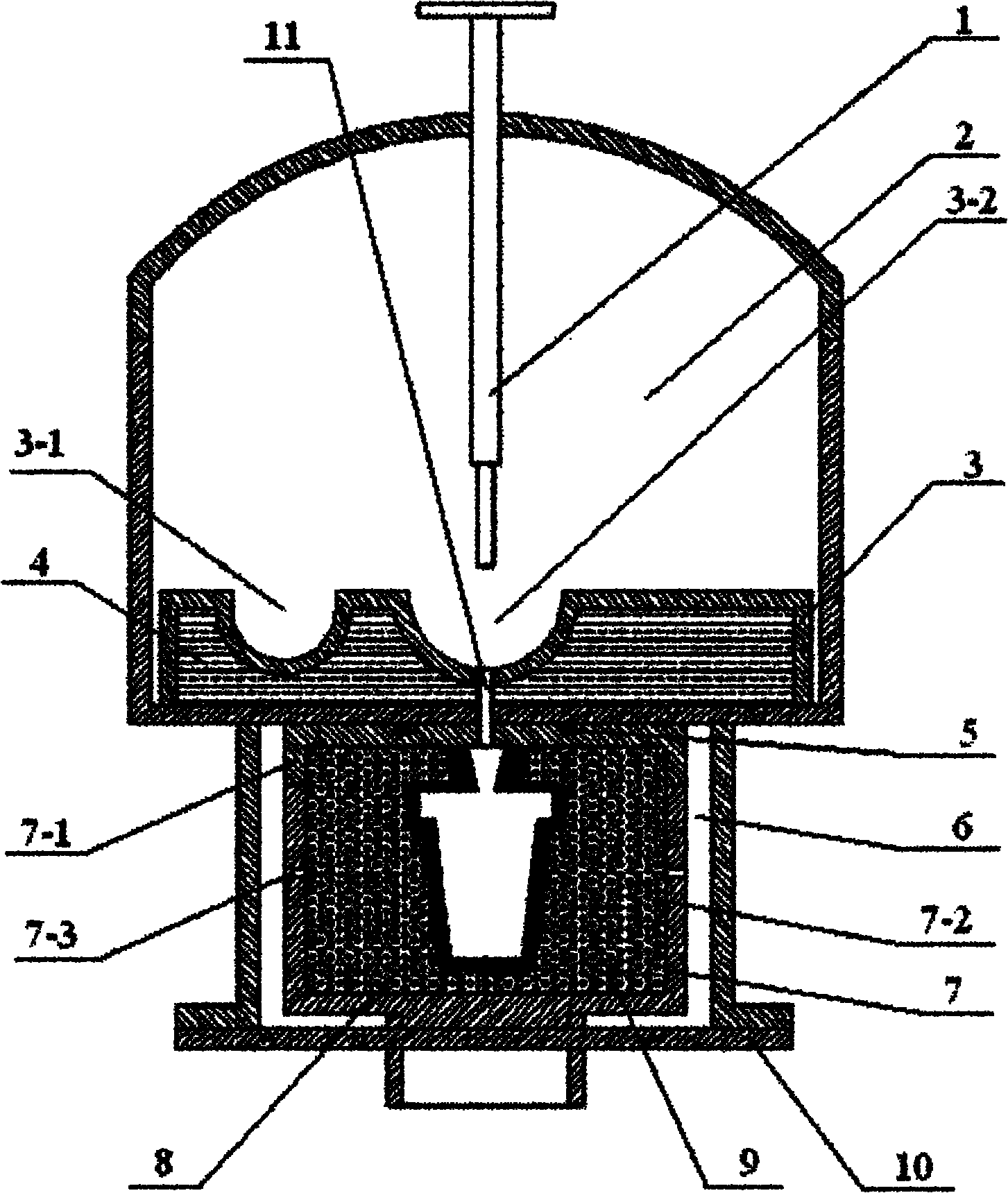

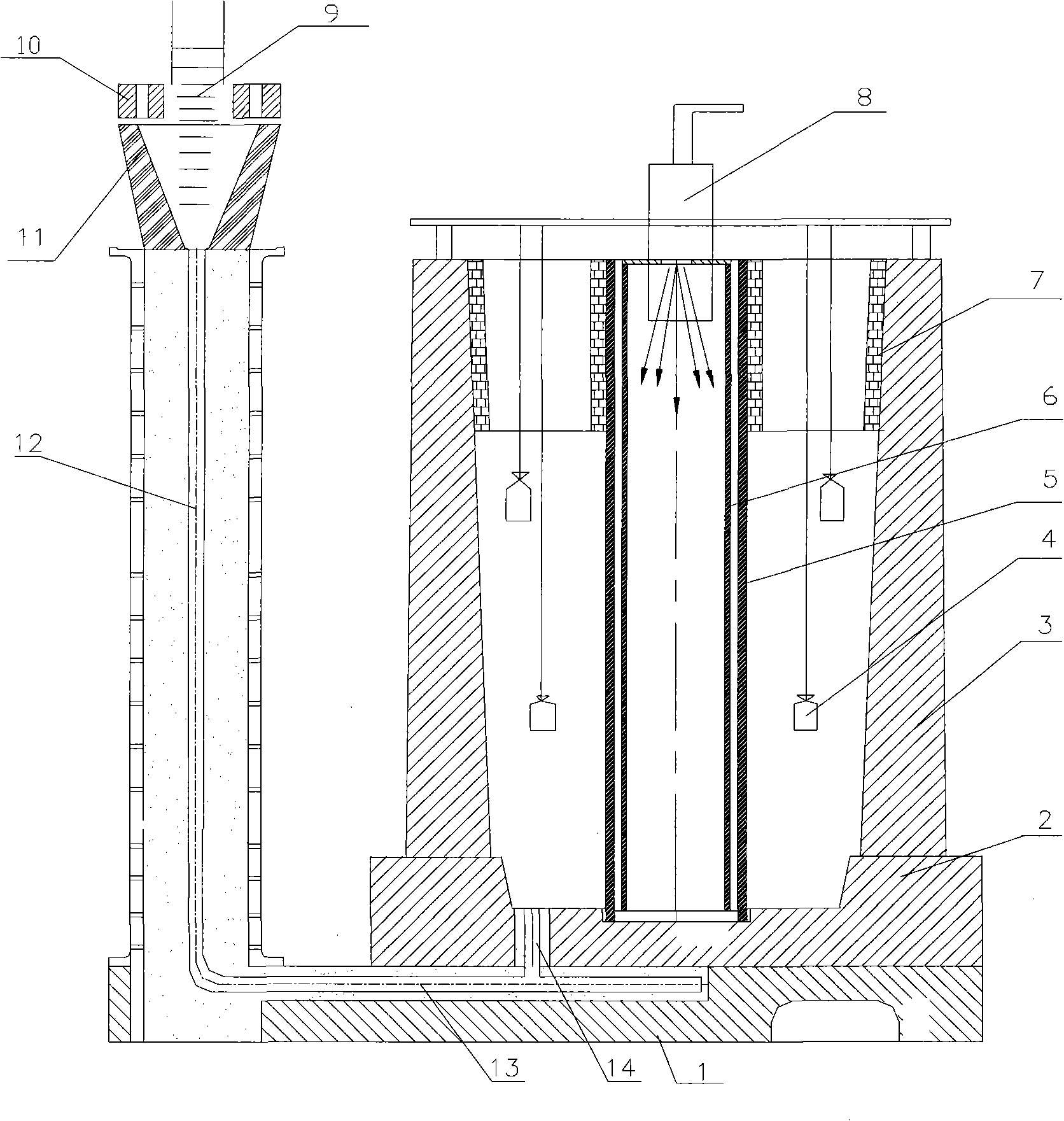

Vacuum low-pressure casting forming device for titanium alloy component

InactiveCN104028729AImprove feeding capacitySuppresses the tendency to segregate chemical componentsActuatorPressure difference

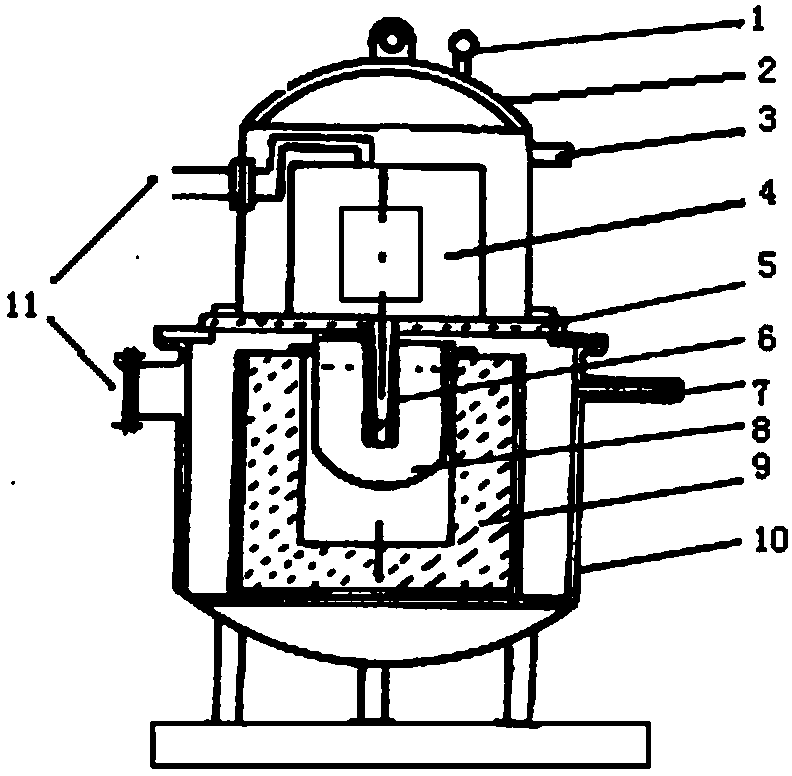

The invention provides a vacuum low-pressure casting forming device for a titanium alloy component. The vacuum low-pressure casting forming device for the titanium alloy component comprises a device body, a vacuum low-pressure casting pneumatic control system and an electronic control system. An upper chamber and lower chamber type structure is adopted by the device body, a water-cooled copper crucible is arranged in a lower chamber, a casting mold is arranged in an upper chamber, an intermediate separation plate is arranged between the upper chamber and the lower chamber, and a liquid lifting pipe is arranged on the intermediate separation plate. The vacuum low-pressure casting pneumatic control system is connected with the device body, a vacuum system and a protective gas source system, and digital combination valves are adopted as flow regulation actuators. The electronic control system is composed of an industrial control computer and a PLC. After the smelting process of titanium alloy is completed in a smelting chamber, the water-cooled copper crucible is lifted to a casting position through a lifting device, an upper chamber and lower chamber intercommunication valve is closed, the flow of protective gas fed into the lower chamber is controlled through the computer, the pressure difference between the upper chamber and the lower chamber is established, the liquid alloy is filled in the casting mold through the liquid lifting pipe under the action of the pressure difference, and the casting process is completed. Compared with traditional centrifugal casting and bottom leakage type suction casting, the mold-filling capacity and solidification feeding capacity of the titanium alloy can be improved, castings with better casting quality and thinner wall thicknesses can be obtained, and a new means is provided for batch production of minitype titanium alloy components.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Cast forming method of small titanium alloy or titanium-aluminum alloy complicated casting

InactiveCN102019401AImprove filling abilityImprove efficiencyFoundry mouldsFoundry coresMold fillingIngot

The invention relates to a cast forming method of a small titanium alloy or titanium-aluminum alloy complicated casting, belonging to the casting method of the titanium alloy or titanium-aluminum alloy casting and solving the technical problems that the gravity casting of the traditional titanium alloy member is difficult in smooth mold filling, the centrifugal casting method has complicated process, the material utilization rate is low and the metal bottom-drain type vacuum suction casting method cannot be used for casting and forming thin-walled parts with complicated shapes. The method comprises the steps of: 1. preparing a ventilating shell; 2. preparing a bottom drain type vacuum suction casting container; 3. fixing the shell in the container, fixing the container in a suction casting chamber of a smelting furnace; 4. carrying out electric arc melting on the titanium alloy or titanium-aluminum alloy raw materials to obtain a button ingot; 5. turning the button ingot to a suction casting crucible for smelting to obtain overheating melt; and 6. suction-casting and mold-filling, and cooling to finally obtain the casting. The yield by the method is not less than 90 percent; and the method is a simple near net shape forming method, can be used for preparing a titanium and titanium-aluminum alloy blade, a worm wheel, artware and other small complicated castings.

Owner:HARBIN INST OF TECH

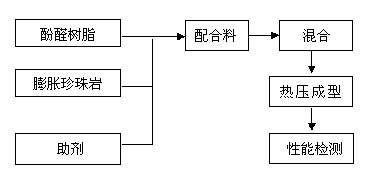

Composite heat insulation material using phenolic resin and perlite as major raw materials and preparation method of composite heat insulation material

The invention discloses a composite heat insulation material using phenolic resin and perlite as major raw materials and a preparation method of the composite heat insulation material. The phenolic resin, expanded perlite and a proper number of auxiliaries are uniformly mixed, and mold filling and hot press molding at different compression ratios are carried out. The phenolic resin adopts boron modified thermoplastic solid phenolic resin, and the consumption of the phenolic resin is 20 to 70 weight percent; the expanded perlite adopts bulk materials with the stacking density being 80 to 150kg / m<3>, and the consumption of the expanded perlite is 30 to 80 weight percent; the compression ratio is 1.25 to 2.5; and the hot press molding temperature is 200 to 240 DEG C, and the pressure maintaining time is 1.5 to 2.5 hours. The apparent density of samples is 280 to 350kg / m<3>, the heat conductivity coefficient is 0.037 to 0.068 W / (m.K), the compressive strength is 1.1 to 1.8 MPa, the rupture strength is 0.8 to 1.5MPa, and the combustion performance is in B1 level. The composite heat insulation material has the advantages of low heat conductivity coefficient of organic heat insulation materials, and high intensity and flame retardance of inorganic heat insulation materials.

Owner:XINYANG NORMAL UNIVERSITY

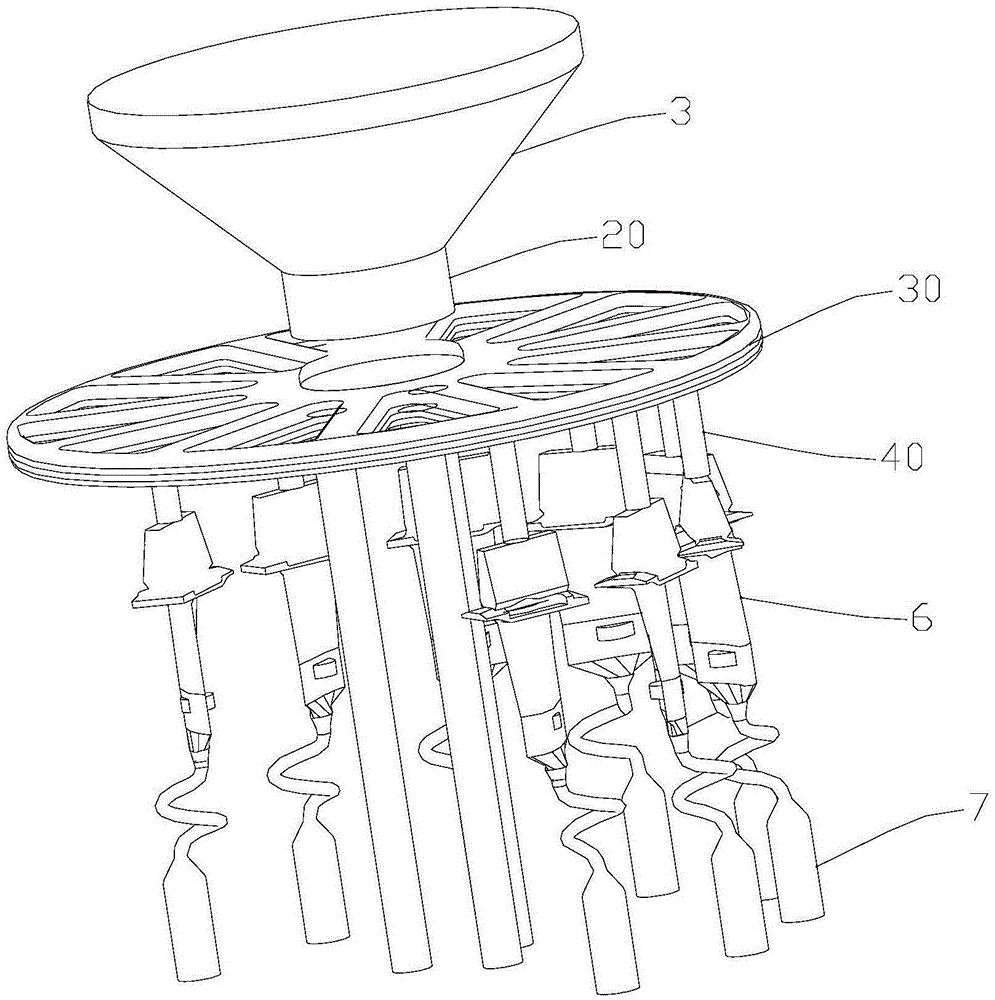

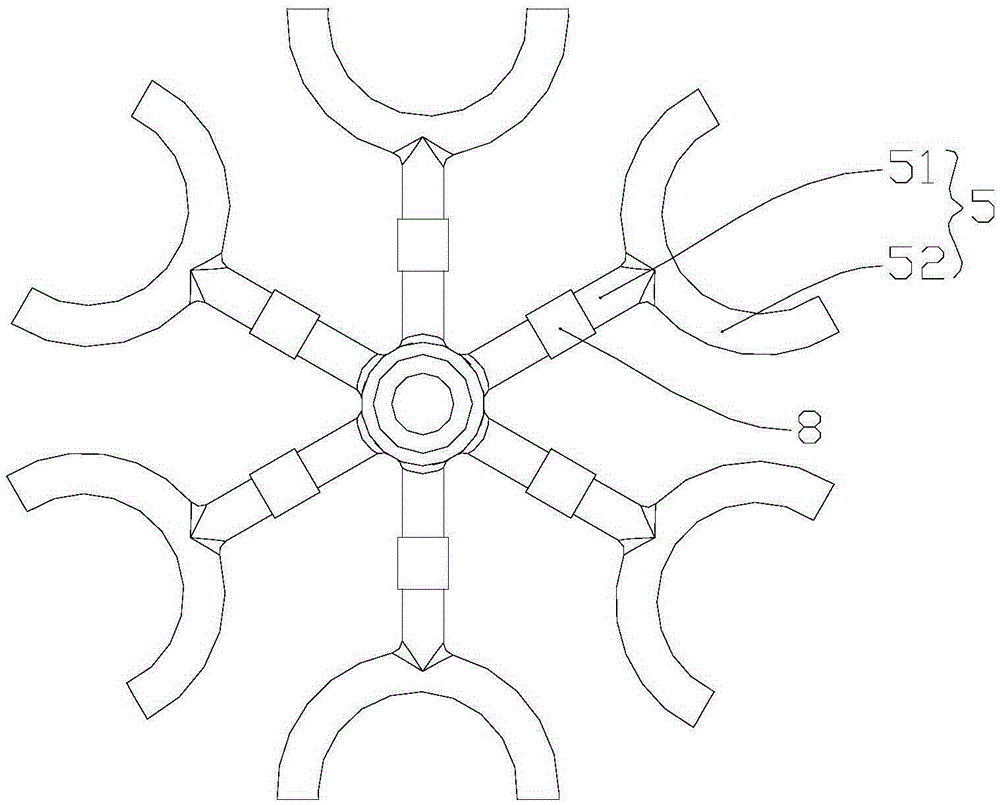

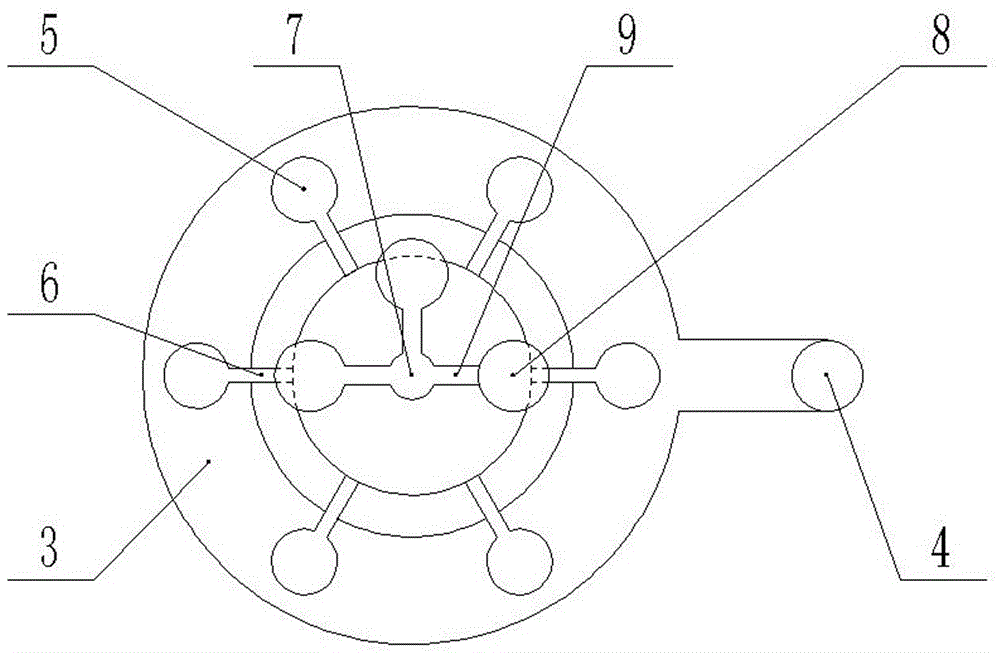

Bottom pouring type pouring system

ActiveCN105290333AGuaranteed effective lengthImprove grain orientation pass rateFoundry mouldsFoundry coresCircular discMold filling

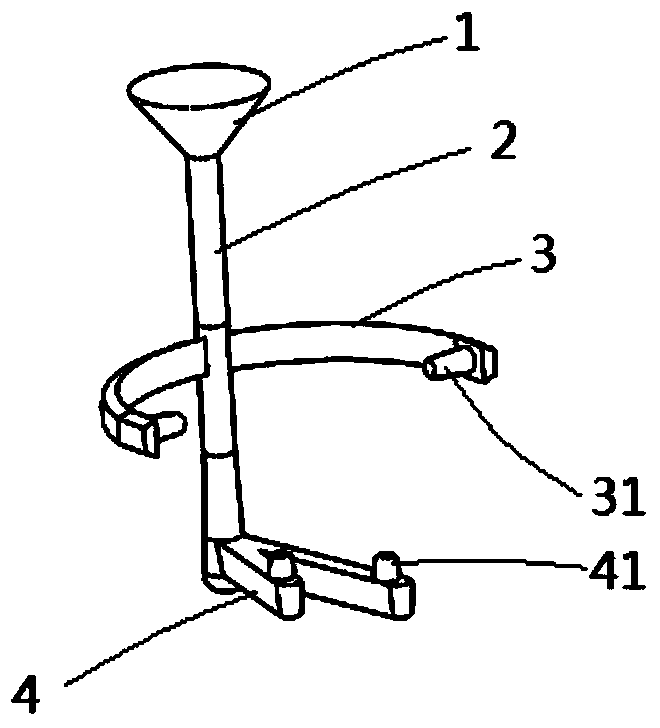

The invention discloses a bottom pouring type pouring system. The bottom pouring type pouring system comprises a disc pouring gate which comprises a main disc pouring pipe allowing pouring liquid to pass through, a first filtering net used for filtering the pouring liquid is connected to the upper end of the main disc pouring pipe, and a pouring cup used for leading in the pouring liquid is connected to the upper end of the first filtering net; a vertically-arranged middle column pouring gate is connected to the lower end of the main disc pouring pipe, and a bottom pouring gate is connected to the bottom end of the middle column pouring gate; and a blade is connected to the disc pouring gate, a spiral crystal selecting device for molding the blade into a single crystal blade is connected to the bottom end of the blade, and the bottom end of the spiral crystal selecting device is communicated with the bottom pouring gate so as to enable the pouring liquid to enter the spiral crystal selecting device from the bottom end of the spiral crystal selecting device. In the bottom pouring type pouring system, the effective length of the spiral crystal selecting device is effectively guaranteed, the crystal orientation acceptability of the single crystal blade is improved, mold filling is stable, impact of the high-temperature pouring liquid to a ceramic core of the blade is reduced, the bottom pouring type pouring system is simple in structure, and assembling of all components of a module is easy and convenient.

Owner:CHINA HANGFA SOUTH IND CO LTD

System and method for manufacturing concrete blocks

A system and method for manufacturing an uncured concrete block using the dry-cast manufacturing process includes a mold box having a pair of side walls, a pair of side plates, an open top side and an open bottom side defining a mold cavity. One or more end liners are disposed within the mold cavity and are selectively shiftable within the mold cavity with hydraulic cylinders between a first position and a second position. The end liners can be provided with a three-dimensional textured face to impart a decorative face to a side surface of the concrete block formed in the mold or can also provide blocks with a tapered face when disposed in the second position while the mold is filled with concrete. Before the block is stripped from the mold, the end liners are returned to the first position, so that the side surfaces are not damaged as the block is released.

Owner:MARSHALL CONCRETE

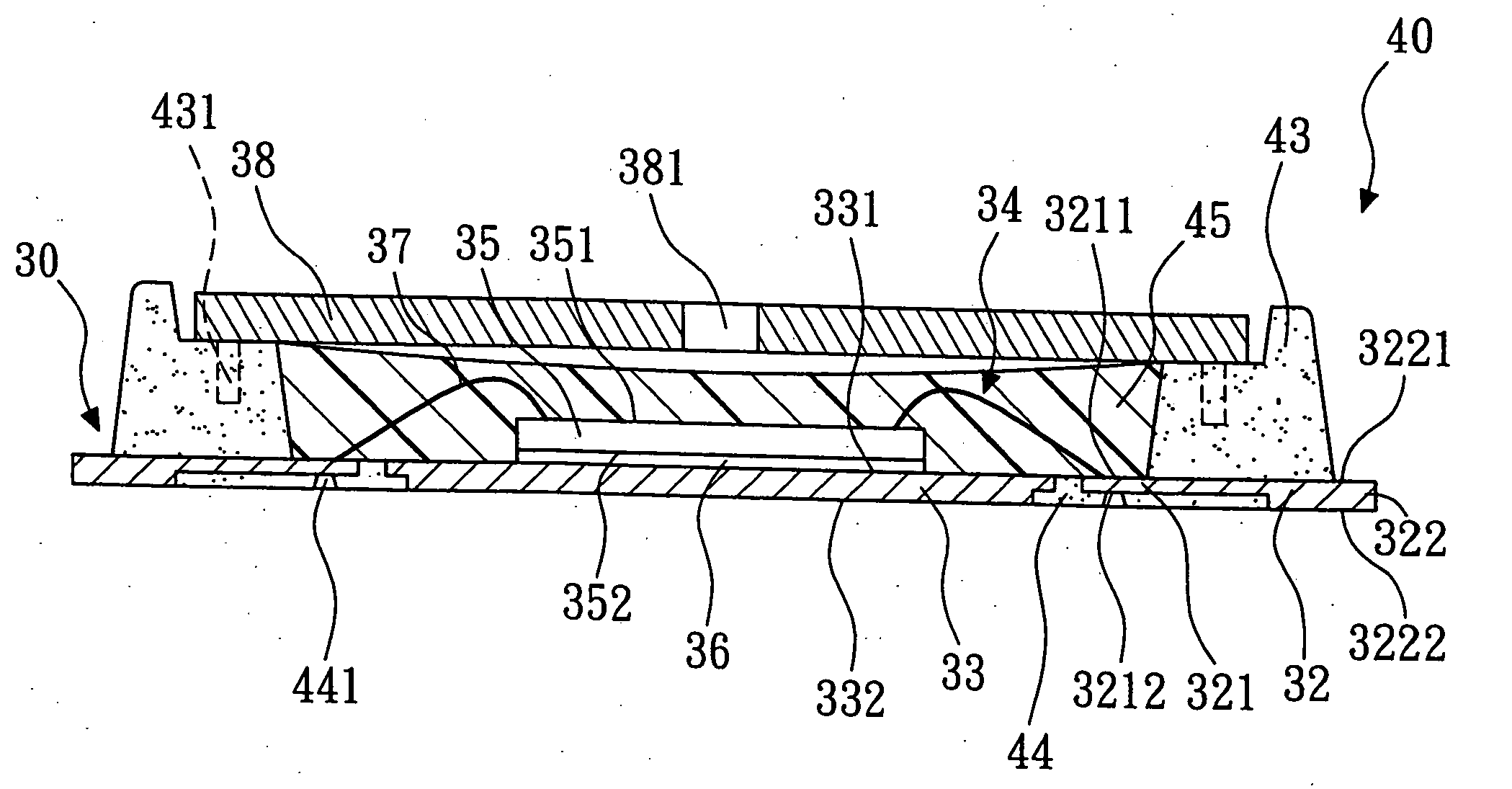

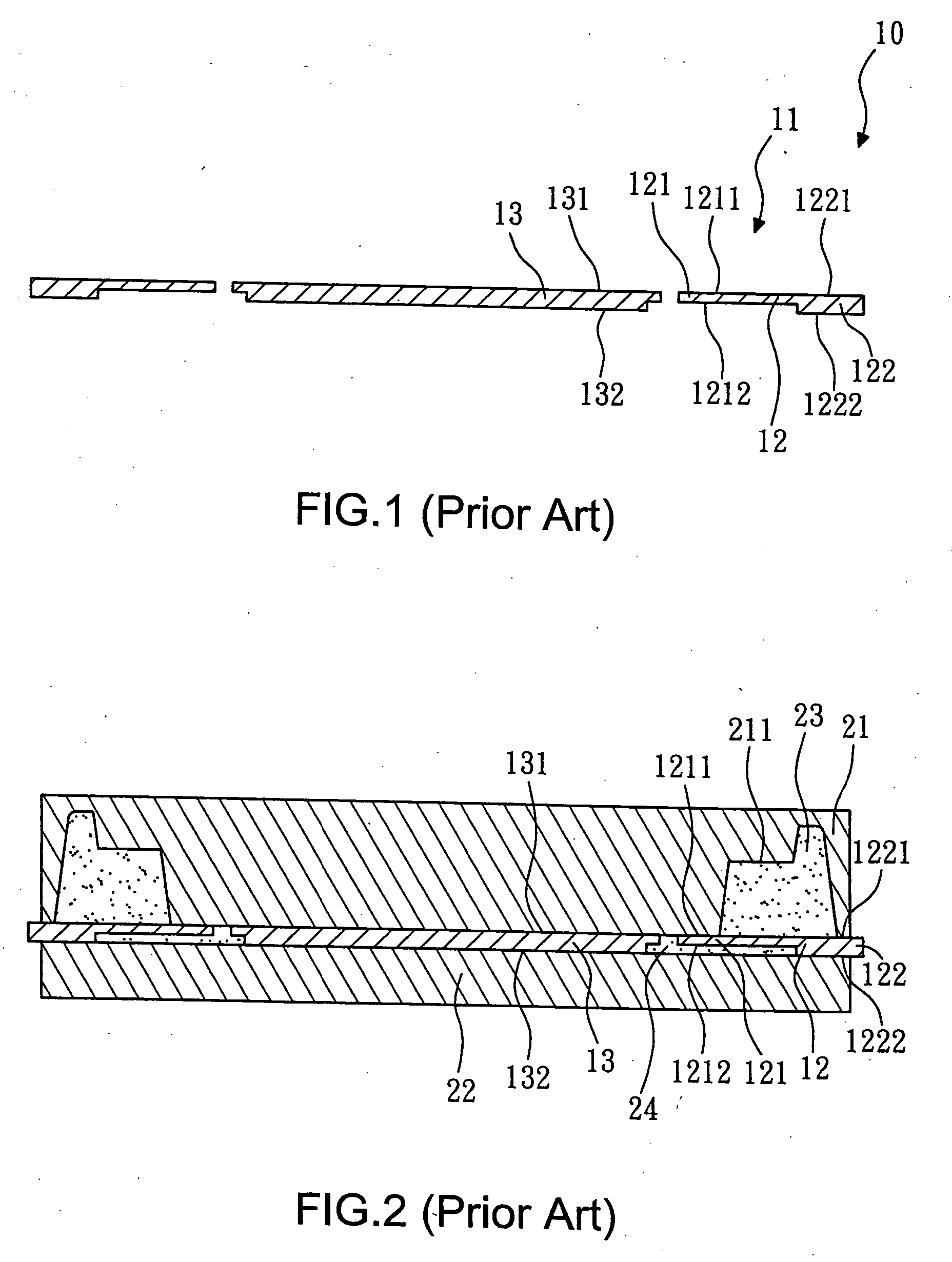

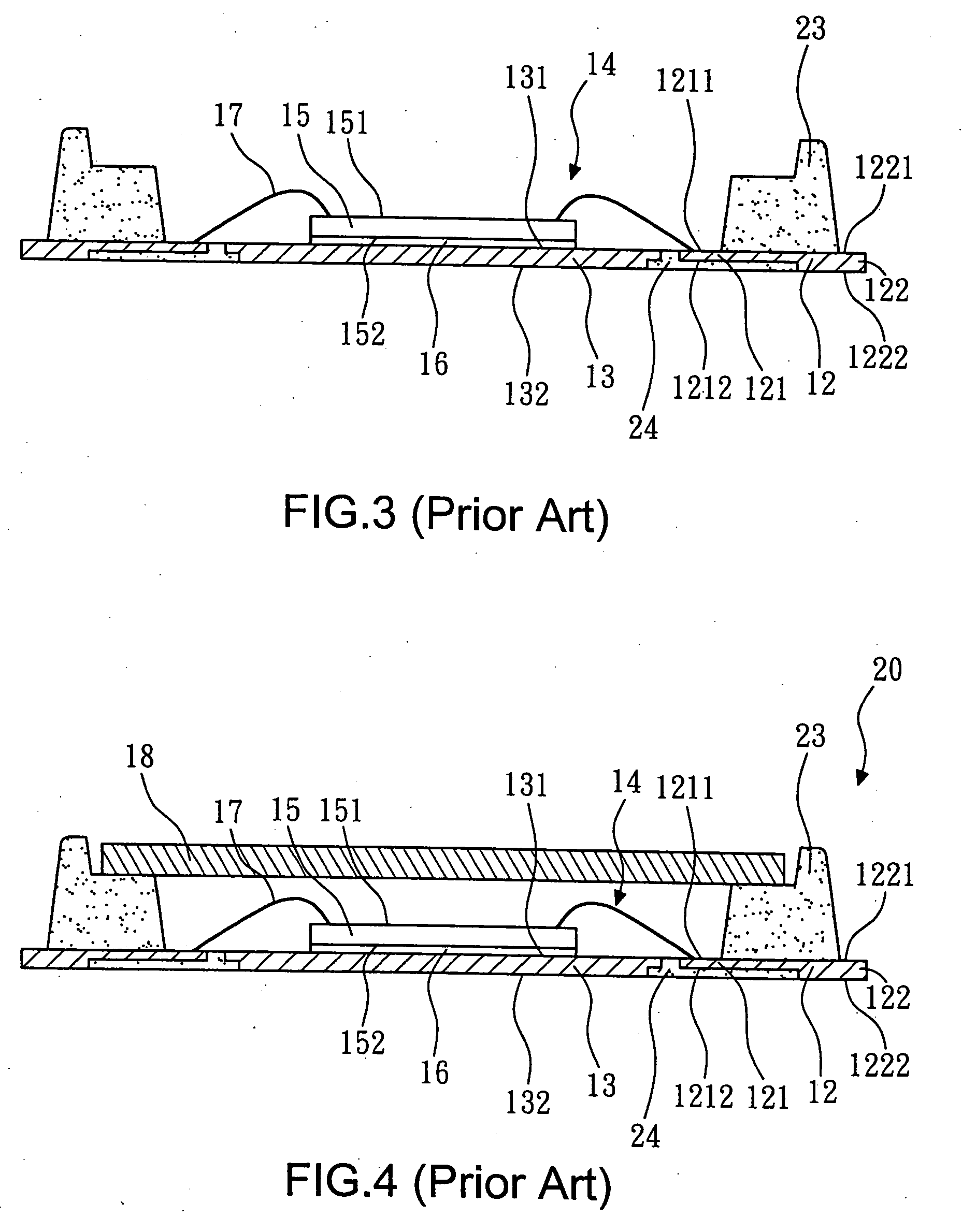

Package structure having recession portion on the surface thereof and method of making the same

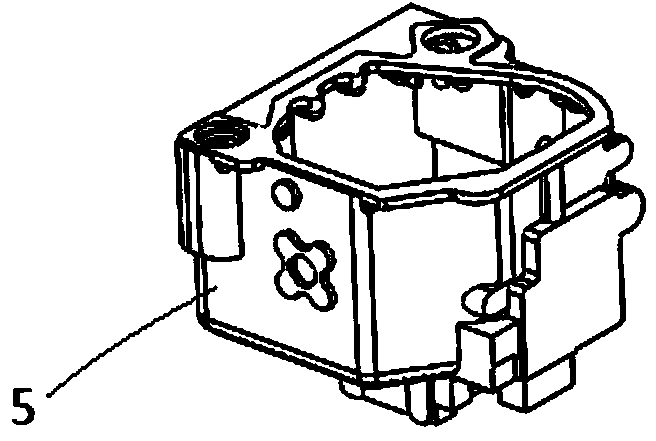

InactiveUS20070023873A1Improve production yieldBlock compoundSemiconductor/solid-state device detailsSolid-state devicesMold fillingEngineering

The present invention relates to a method for making a package structure having recession portion on the surface thereof. The method comprises: (a) providing a lead frame having a plurality of package units, each package unit having a plurality of leads and a die paddle; (b) providing an upper mold and a lower mold for clamping the lead frame, wherein the upper mold and the protruding block of the lower mold clamp the first portions of the leads so as to prevent molding compound bleeding to the upper surfaces of the first portions during mold filling operation, for improving the product yield; (c) injecting a molding compound between the upper mold and the lower mold, and forming a plurality of accommodation spaces; (d) attaching a plurality of chips onto the die paddles; (e) electrically connecting the chips to the first portions of the leads; (f) sealing the accommodation spaces; and (g) segregating the package units.

Owner:ADVANCED SEMICON ENG INC

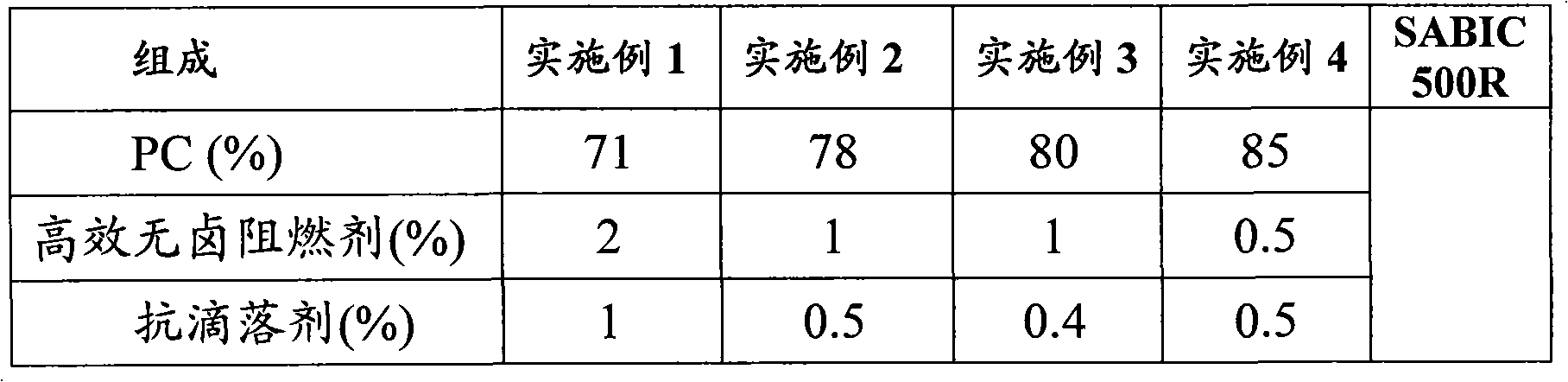

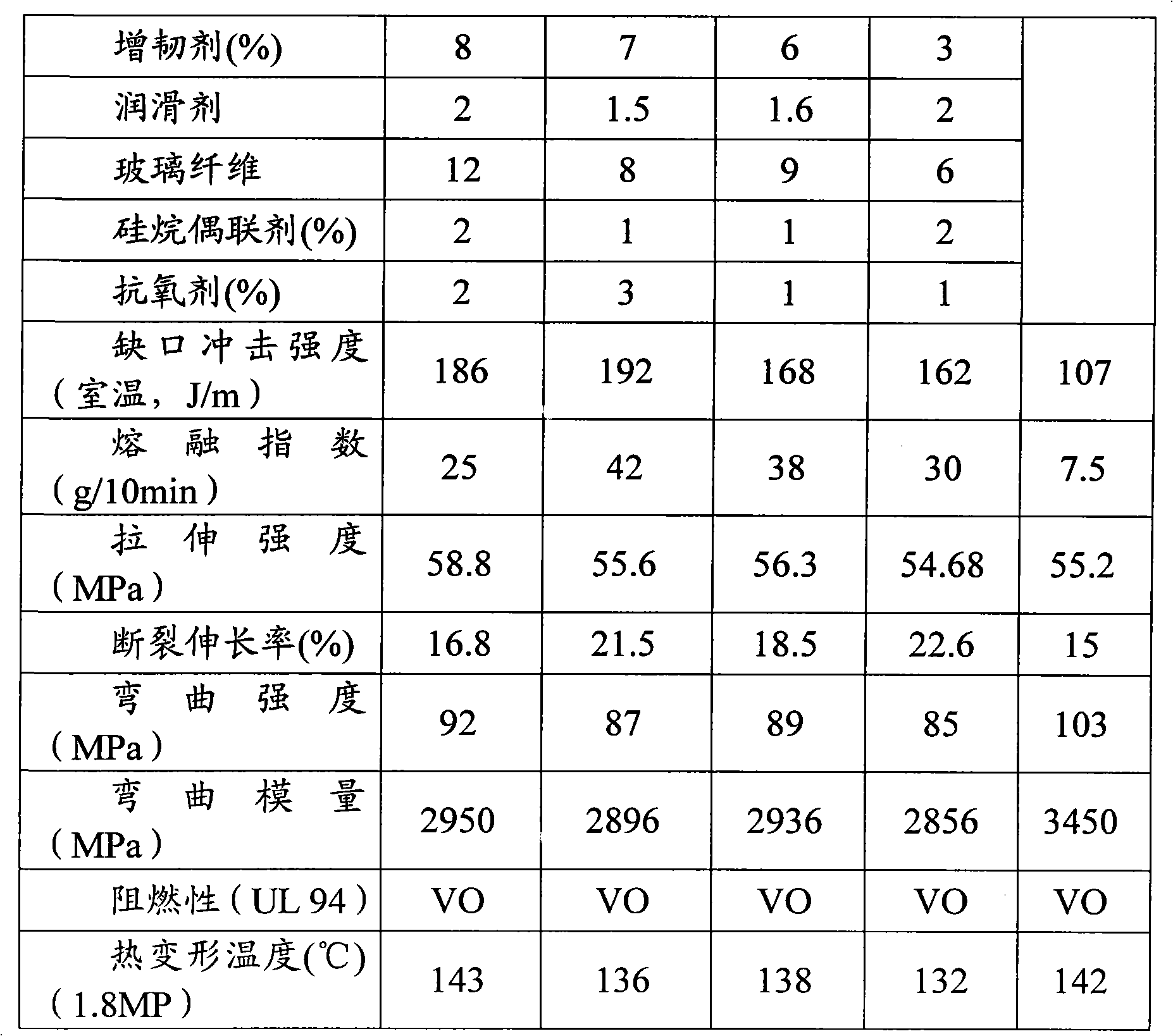

Low-smoke and zero-halogen inflaming retarding glass fiber reinforced polycarbonate composite material and preparation method thereof

The invention discloses a low-smoke and zero-halogen inflaming retarding glass fiber reinforced polycarbonate composite material and a preparation method thereof. The low-smoke and zero-halogen inflaming retarding glass fiber reinforced polycarbonate composite material comprises the following components of 70 to 85wt% of PC (Polycarbonate), 0.5 to 2wt% of high-efficiency zero-halogen inflaming retardant, 5 to 12wt% of glass fiber and 5 to 16wt% of auxiliary. The low-smoke and zero-halogen inflaming retarding glass fiber reinforced polycarbonate composite material of the invention has the advantages of good mold filling fluidity, excellent processing performance, strong bending resistance performance, high toughness, good dimensional stability, high surface glossiness, good application prospects on the aspect of liquid crystal display television die set products.

Owner:SHENZHEN KEJU NEW MATERIAL

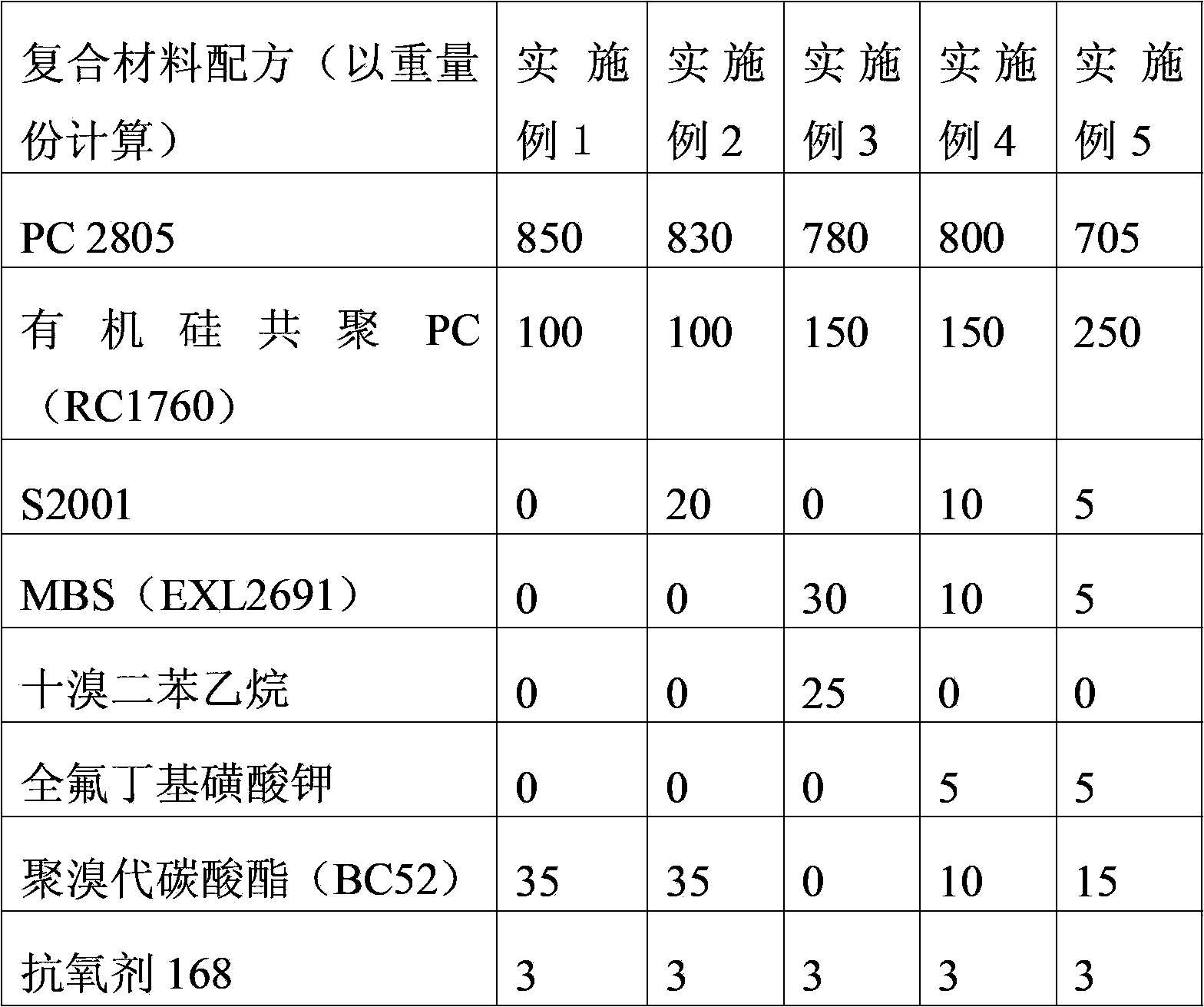

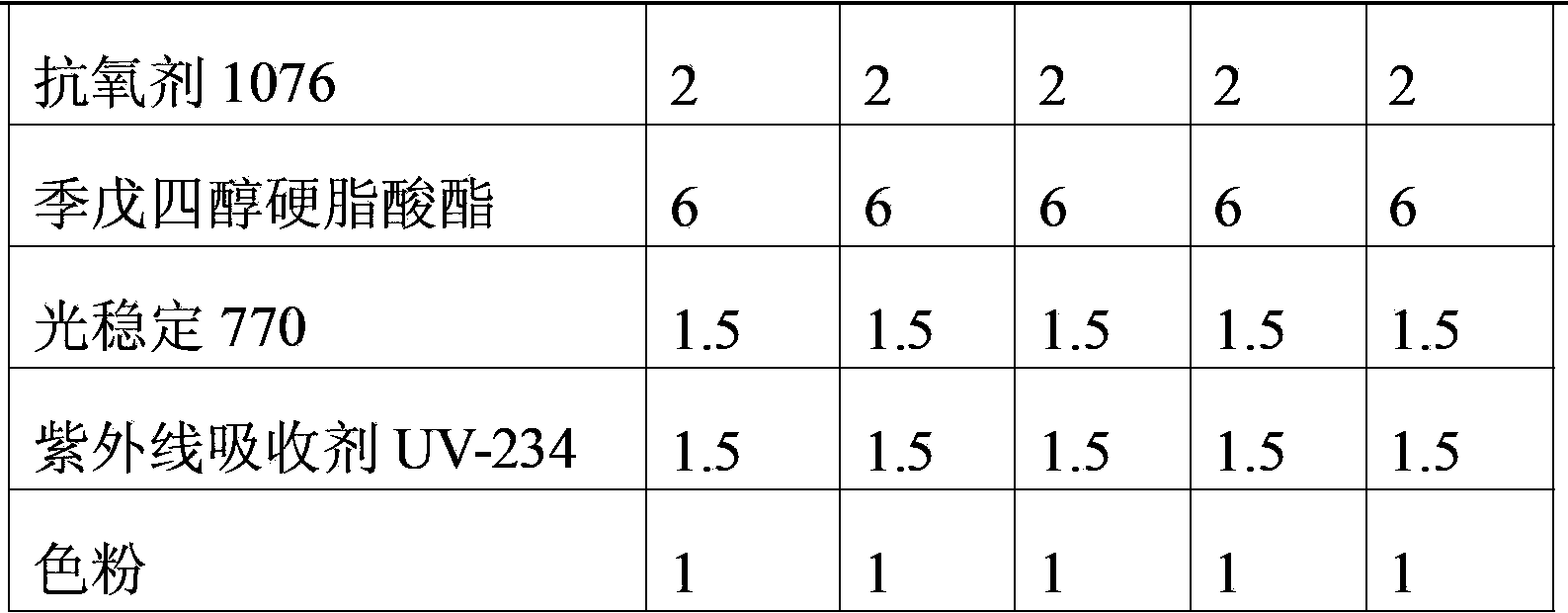

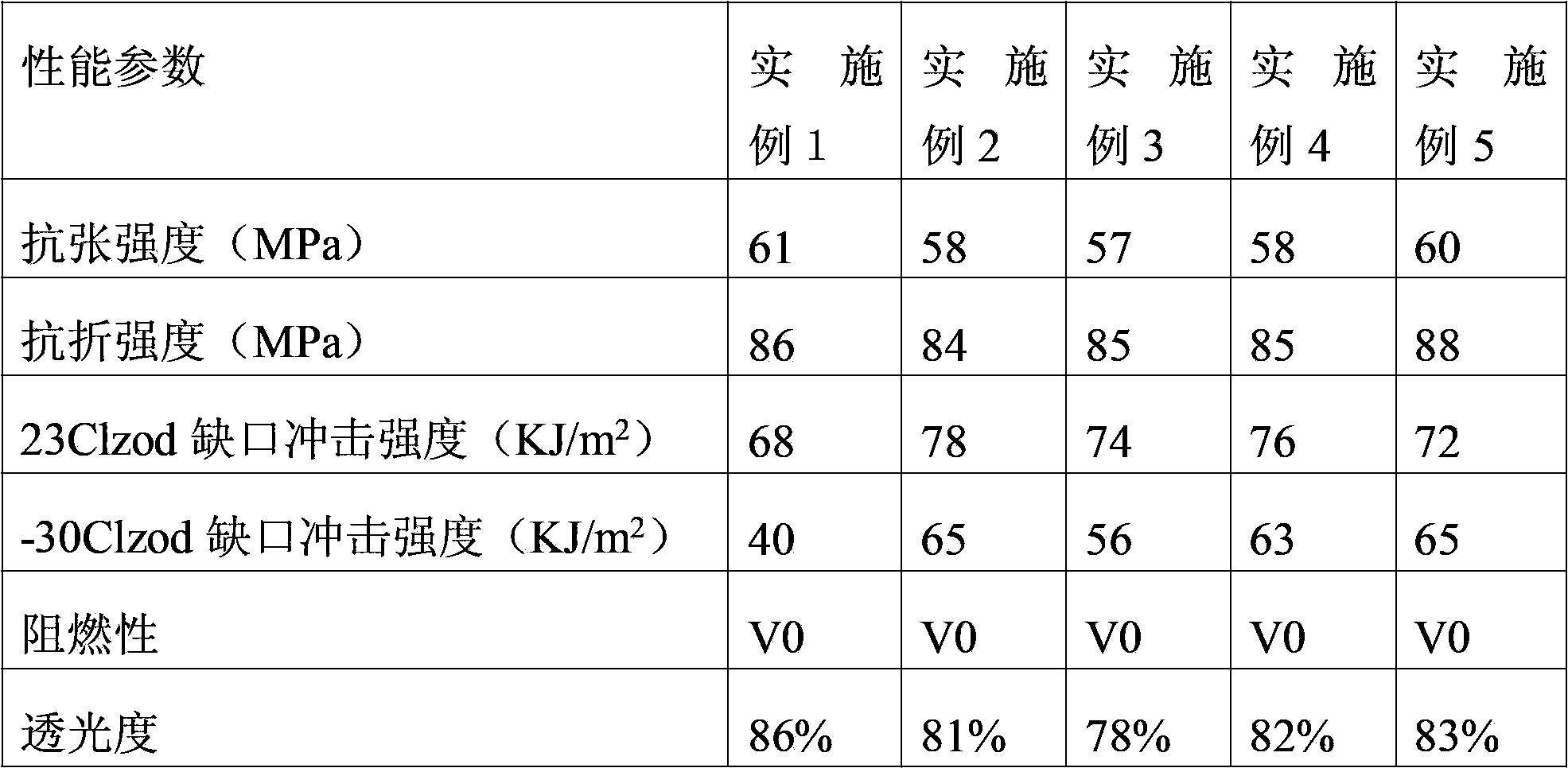

High-transparency low-temperature-impact-resistant flame-retardant polycarbonate composite material and preparation method thereof

ActiveCN103788610AImprove low temperature impact resistanceEnhance and improve low temperature impact resistanceMold fillingPotassium

The invention discloses a high-transparency low-temperature-impact-resistant flame-retardant polycarbonate composite material and a preparation method thereof. The composite material comprises following components by weight: 700-850 parts of polycarbonate resin, 100-250 parts of organosilicone co-polymer PC, 0-30 parts of a low-temperature-impact modifying agent and 10-14 parts of a flame retardant. The low-temperature-impact modifying agent is one of an organosilicone type flexibilizer and an acrylate type flexibilizer or a mixture of the organosilicone type flexibilizer and the acrylate type flexibilizer. The flame retardant is one of or a mixture of several compounds selected from decabromodiphenylethane, poly(bromocarbonate), potassium perfluorobutane sulfonate or diphenylsulfonesulfonate. The organosilicone co-polymer PC is polycarbonate resin obtained by copolymerization of bisphenol A and organosilicone and has a relative molecular weight of 20000-30000. The preparation method of the composite material is also provided. According to the composite material and the preparation method, the low-temperature-impact-resistant performance of the PC resin is largely enhanced, and the composite material has excellent flame retardance and can preserve the high transparency of the material itself. In addition, the material has advantages of easy mold filling, low processing temperature, short processing and forming period, and the like.

Owner:SHANGHAI CHANGWEI JINCI ENG PLASTIC

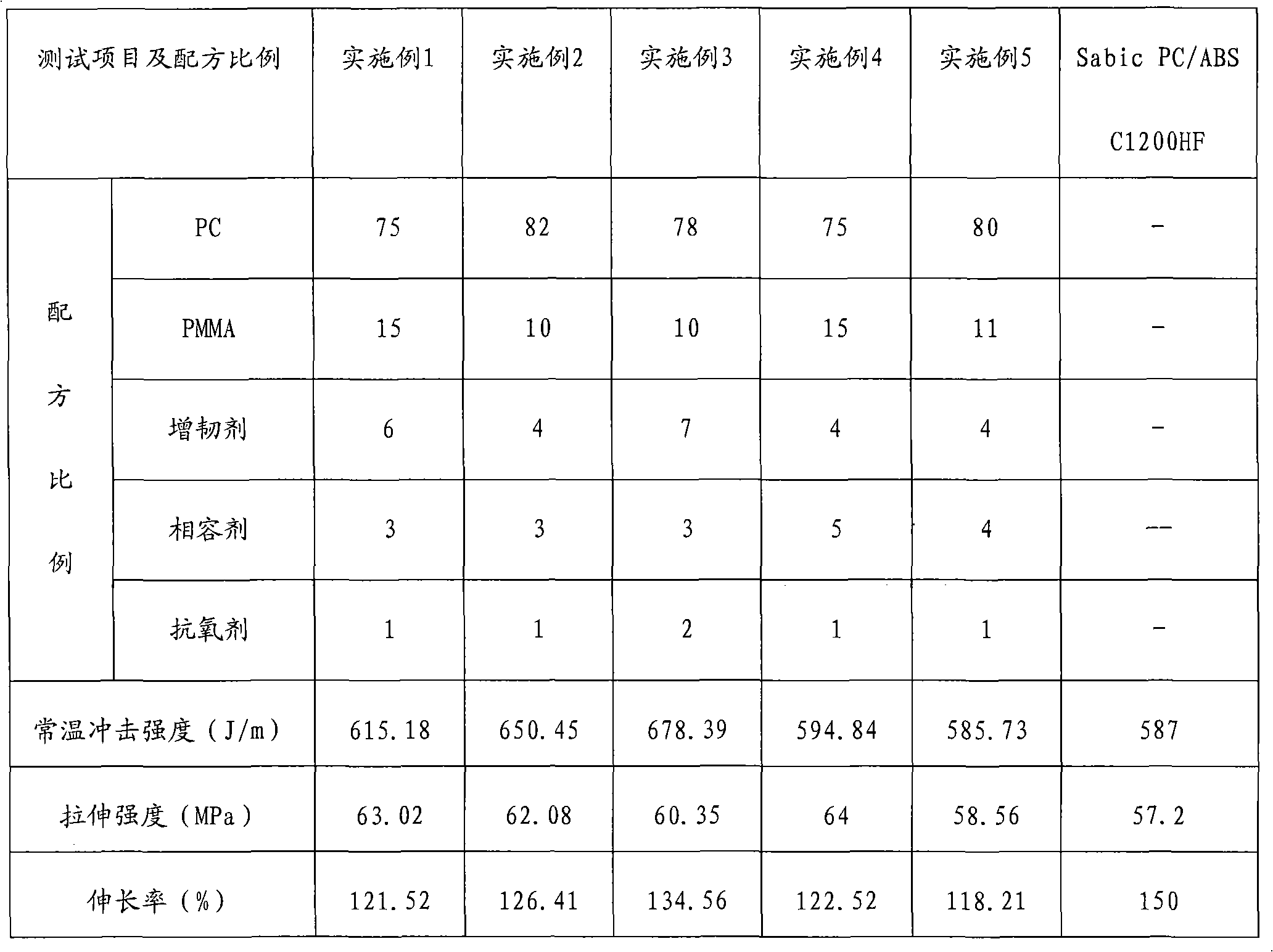

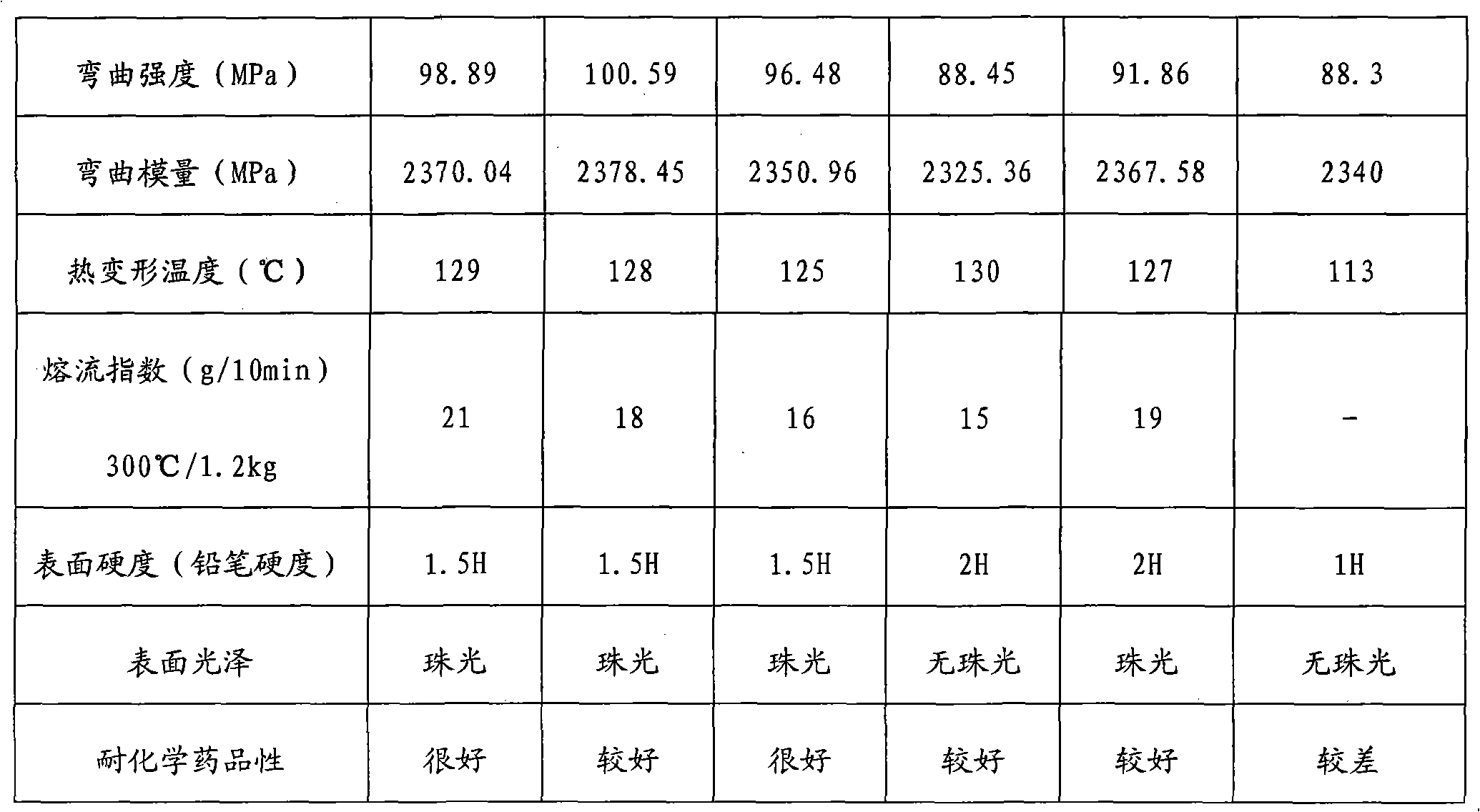

PC/PMMA alloy and preparation method thereof

The invention relates to a PC / PMMA alloy and a preparation method thereof. The PC / PMMA alloy comprises the following components by weight percent: 75-82% of PC, 10-15% of PMMA, 4-10% of toughener, 3-5% of compatibilizer and 1-2% of antioxidant. The PC / PMMA alloy has the advantages of good mold filling flowability, excellent processing performance, high impact resistance, chemical resistance, high hardness and difficult scratching, and can adjust the transmittance of the PC / PMMA and the surface pearlescent color according to the needs, and be used as housings of communication devices with higher surface hardness and used for packaging foods with higher requirements on the surface luster.

Owner:SHENZHEN KEJU NEW MATERIAL

Automotive and aerospace materials in a continuous, pressurized mold filling and casting machine

Owner:HERRON DAVID J

Solidification and feeding method for complicated annular thin-wall shell steel casting

The invention discloses a solidification and feeding method for a complicated annular thin-wall shell steel casting. By means of the solidification and feeding method, the problem that in the casting process of existing complicated annular thin-wall steel castings, shrinkage porosity, shrinkage cavities and crack defects are prone to occur is resolved. The solidification and feeding method comprises the following steps that a, steel casting sand mold cavity is made; b, annular transverse runners and a straight runner are made on the steel casting sand mold cavity, slag collecting cylinders are arranged on the upper surfaces of the annular transverse runners, gap inner runners are arranged between the slag collecting cylinders and the outer wall of the steel casting sand mold cavity, a feeding auxiliary sprue and top risers are arranged on the upper portion of the steel casting sand mold cavity, and a gap auxiliary runner is arranged between each top riser and the feeding auxiliary sprue; c, during pouring, the film forming pouring temperature of molten metal is 1500 DEG C-1520 DEG C; and d, when the molten metal level reaches the upper portions of the top risers, melt metal pouring is stopped on the straight runner, and the molten metal enters the steel casting sand mold cavity through the feeding auxiliary sprue until pouring is completed. The whole mold filling process is stable, no disturbance exists, and the phenomena of pores and dreg inclusion defects are avoided.

Owner:SHANXI PINGYANG IND MACHINERY

Die-casting aluminium alloy

InactiveCN1607261AMake up for the disadvantage of about 45% higher densitySave electricityMold fillingManganese

A aluminium alloy for press casting very thin parts (0.7-1.2 mm) is composed of (by weight) 10.0-14.0 % of silicon, 2.5-4.5 % of copper, 0-2.0 % of nickel, 0-1.5 % of manganese, the total content of nickel and manganese keeps in 0.5-2.0 %. The alloy castability (mold filling ability) increases by more than 20 %. Under high pressure press casting, 0.7-1.2 mm wall casting can be made and can be used as casing of 3C products, also the cost is reduced by more than 20-30 % compared with magnesium alloy.

Owner:ALLOY MATERIALS LAB

System and method for manufacturing concrete blocks

A system and method for manufacturing an uncured concrete block using the dry-cast manufacturing process includes a mold box having a pair of side walls, a pair of side plates, an open top side and an open bottom side defining a mold cavity. One or more end liners are disposed within the mold cavity and are selectively shiftable within the mold cavity with hydraulic cylinders between a first position and a second position. The end liners can be provided with a three-dimensional textured face to impart a decorative face to a side surface of the concrete block formed in the mold or can also provide blocks with a tapered face when disposed in the second position while the mold is filled with concrete. Before the block is stripped from the mold, the end liners are returned to the first position, so that the side surfaces are not damaged as the block is released.

Owner:MARSHALL CONCRETE

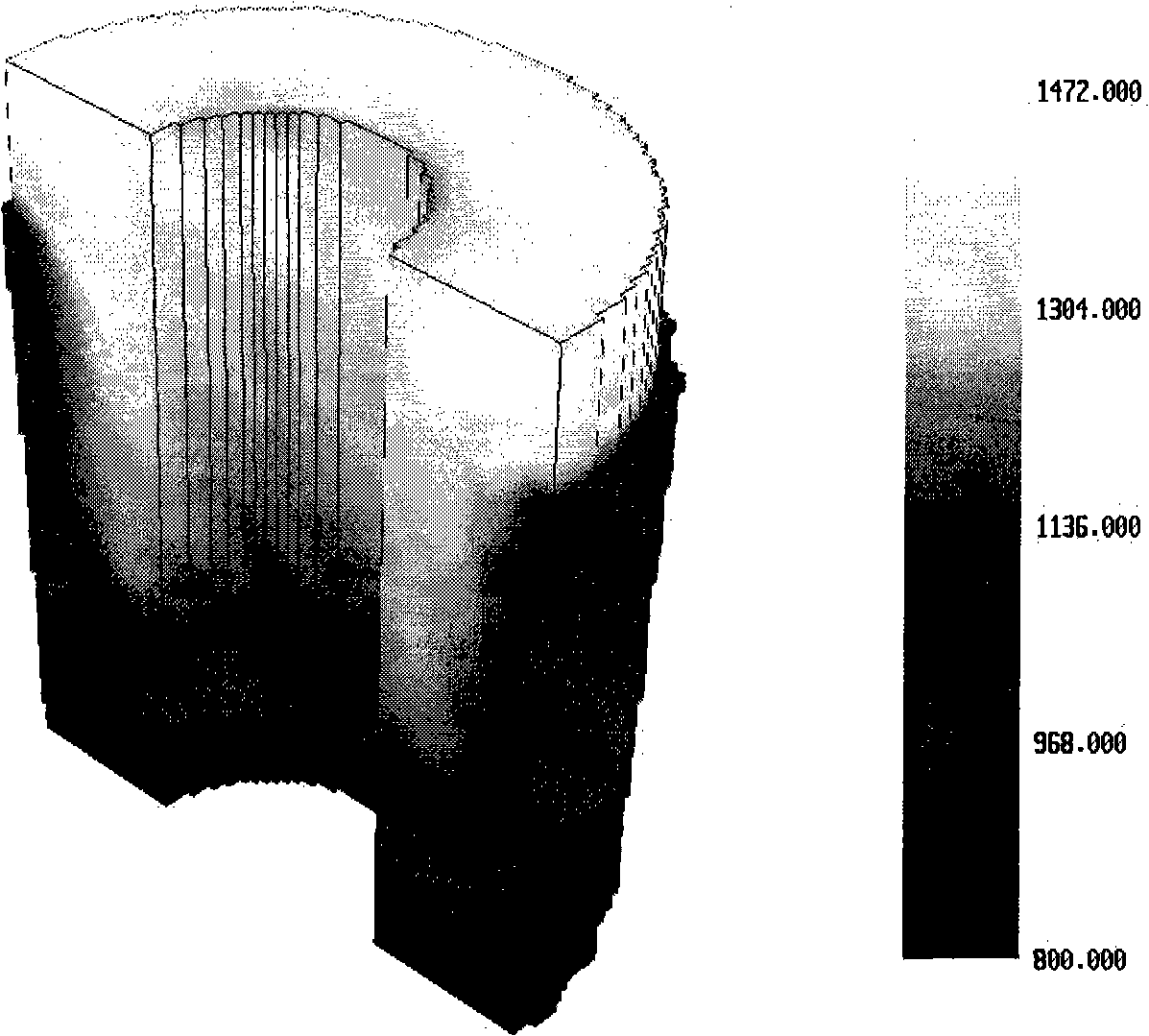

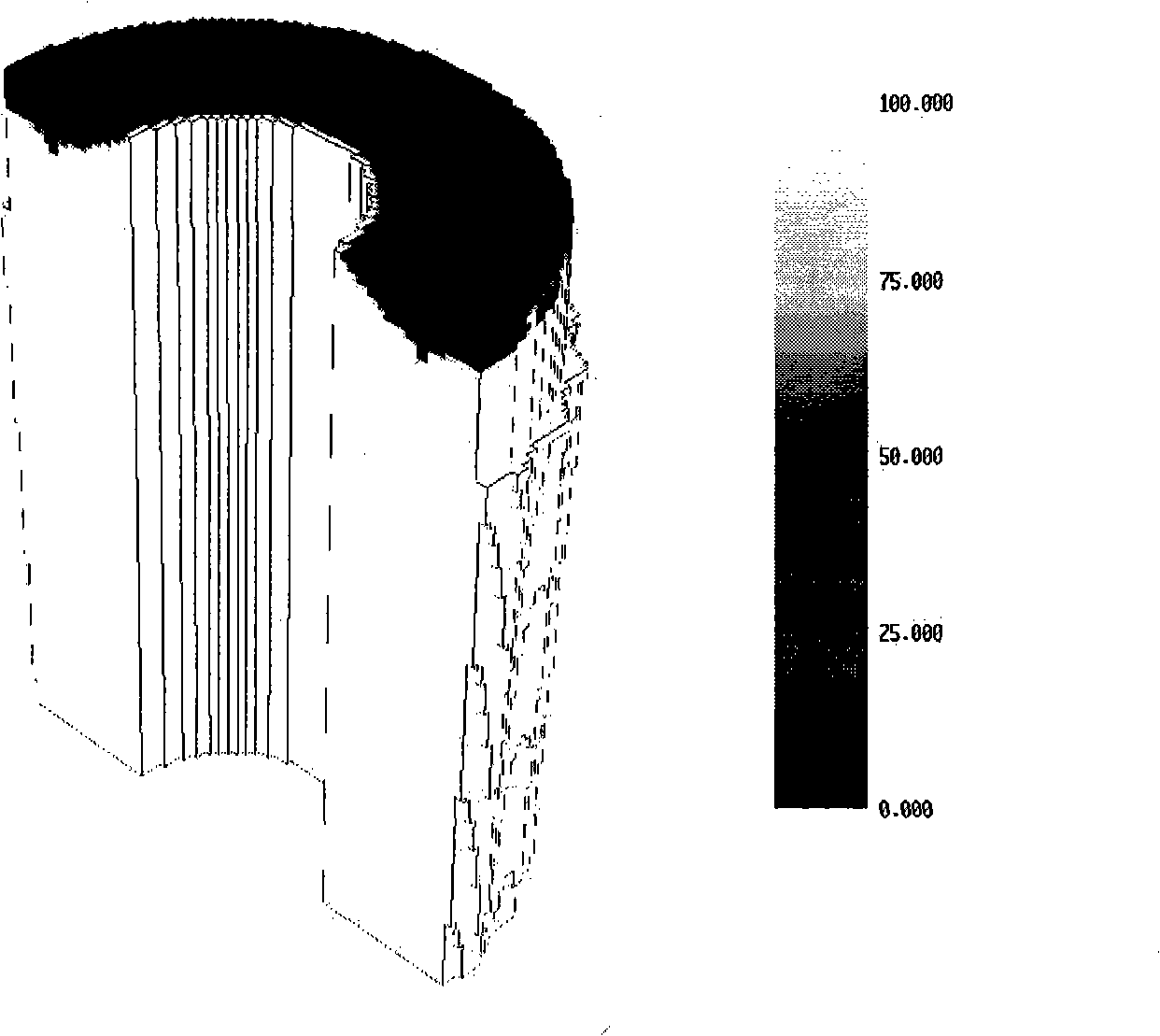

Method for casting thin-shell nodular-cast-iron turbocharger

The invention relates to a method for casting a thin-shell nodular-cast-iron turbocharger, in particular to a method for casting the thin-shell nodular-cast-iron turbocharger and the like products, which is characterized by comprising the following steps of: process method design, three-dimensional model design of the casting process, mold-filling / solidifying simulation, analysis treatment for a simulated result, selection of mold materials, mold assembling simulation, molding, core making, mold assembling, molten iron melting, spheroidizing inoculation, and pouring. The process method provided by the invention is unique, which can solve the problem of shrinkage porosity because the partially overlarge part of an inner cavity cannot be fed by a riser, and can ensure the dimensional accuracy of air cavity, water cavity and oil cavity which are intersected one another in the inner cavity of the casting shell.

Owner:KOCEL EQUIP +1

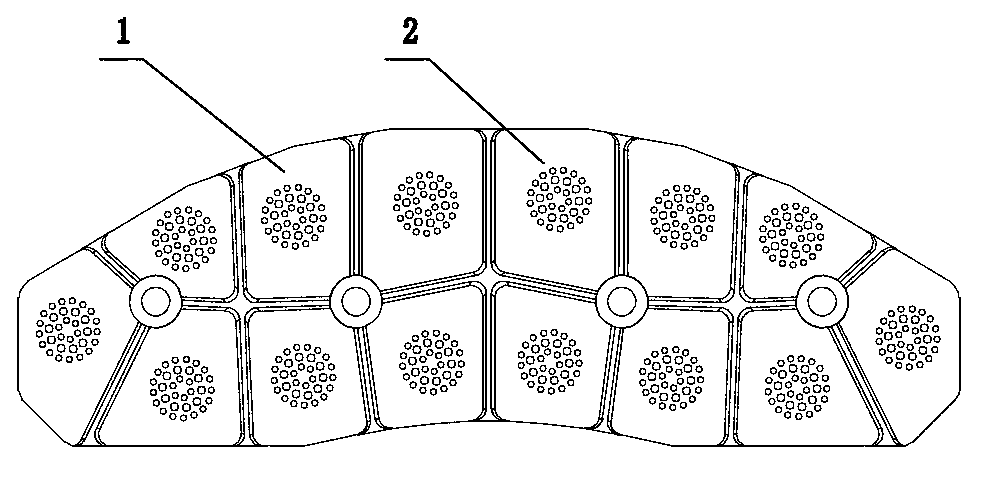

Ceramic/metal composite material brake lining for high-speed train and preparation method of ceramic/metal composite material brake lining

ActiveCN103075445AReduce movementConvenient engineering preparationBraking membersFriction liningThermal decaySlurry

The invention provides a ceramic / metal composite material brake lining for a high-speed train and a preparation method of the ceramic / metal composite material brake lining, and belongs to the technical field of high-speed brake. The existing high-speed train brake lining has the defects that the thermal stability is poor, the friction factor is low, the abrasion rate is high, the thermal decay resistance is poor, and the service life is short. The ceramic / metal composite material brake lining comprises friction blocks, a base plate and a heat radiation fin, wherein the friction blocks are made of ceramic block reinforced metal composite materials, the gap width among the friction blocks is 3 to 8mm, the ceramic block is obtained through sintering ceramic posts of a certain rule and connected ceramic biscuits of ceramic substrates connected with the ceramic posts, and the connected ceramic biscuits can be formed in modes of slurry filling, gel mold filling, molding pressing, isostatic pressing and the like. The preparation method provided by the invention comprises the following steps including ceramic block sintering, surface treatment, brake lining casting, precise processing and heat treatment. The ceramic / metal composite material brake lining has the characteristics that the thermal stability is good, the friction factor is high, the abrasion rate is low, the thermal decay resistance is good, the service life is long, and the like, and the effective braking can be realized on 380km / h high-speed trains.

Owner:浙江天乐新材料科技有限公司

Self-adaptive casting mould manufacture method for casting

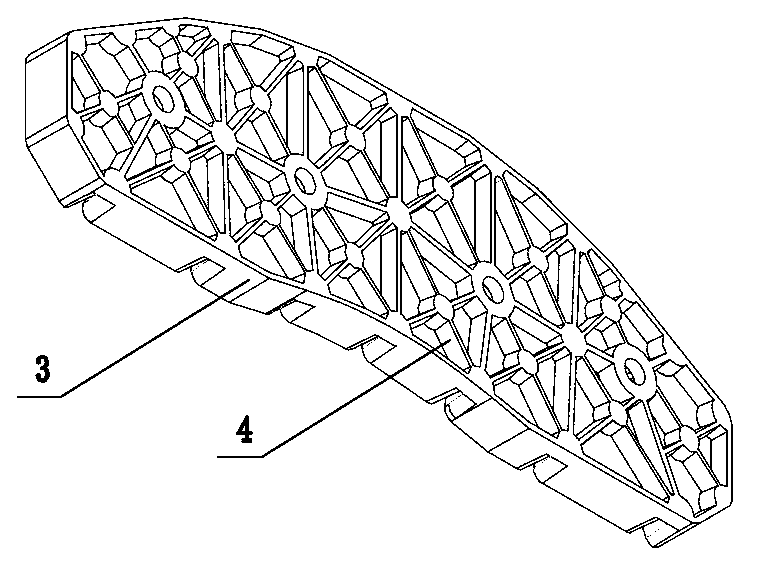

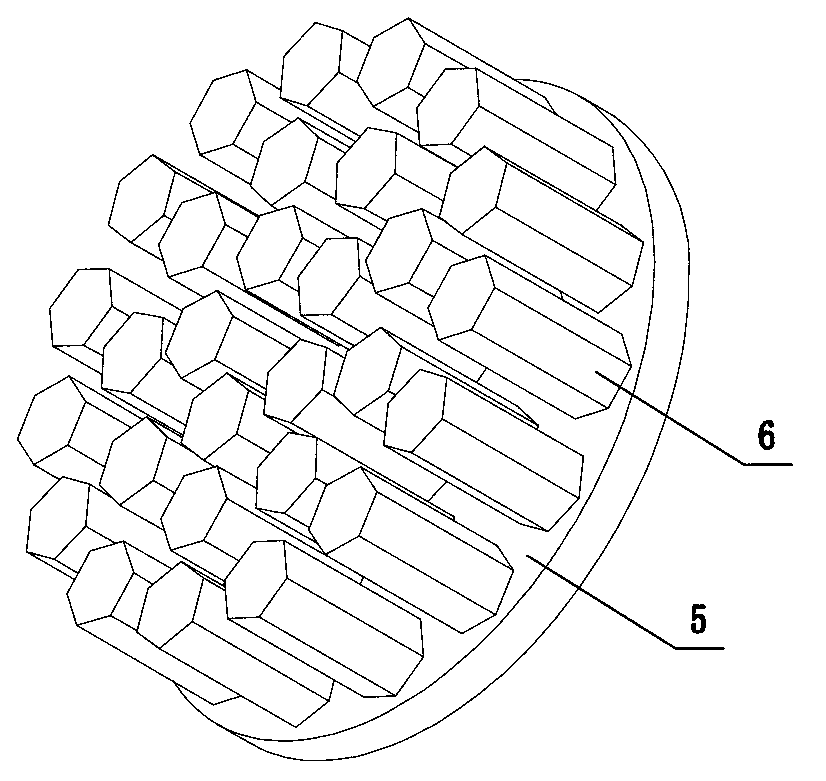

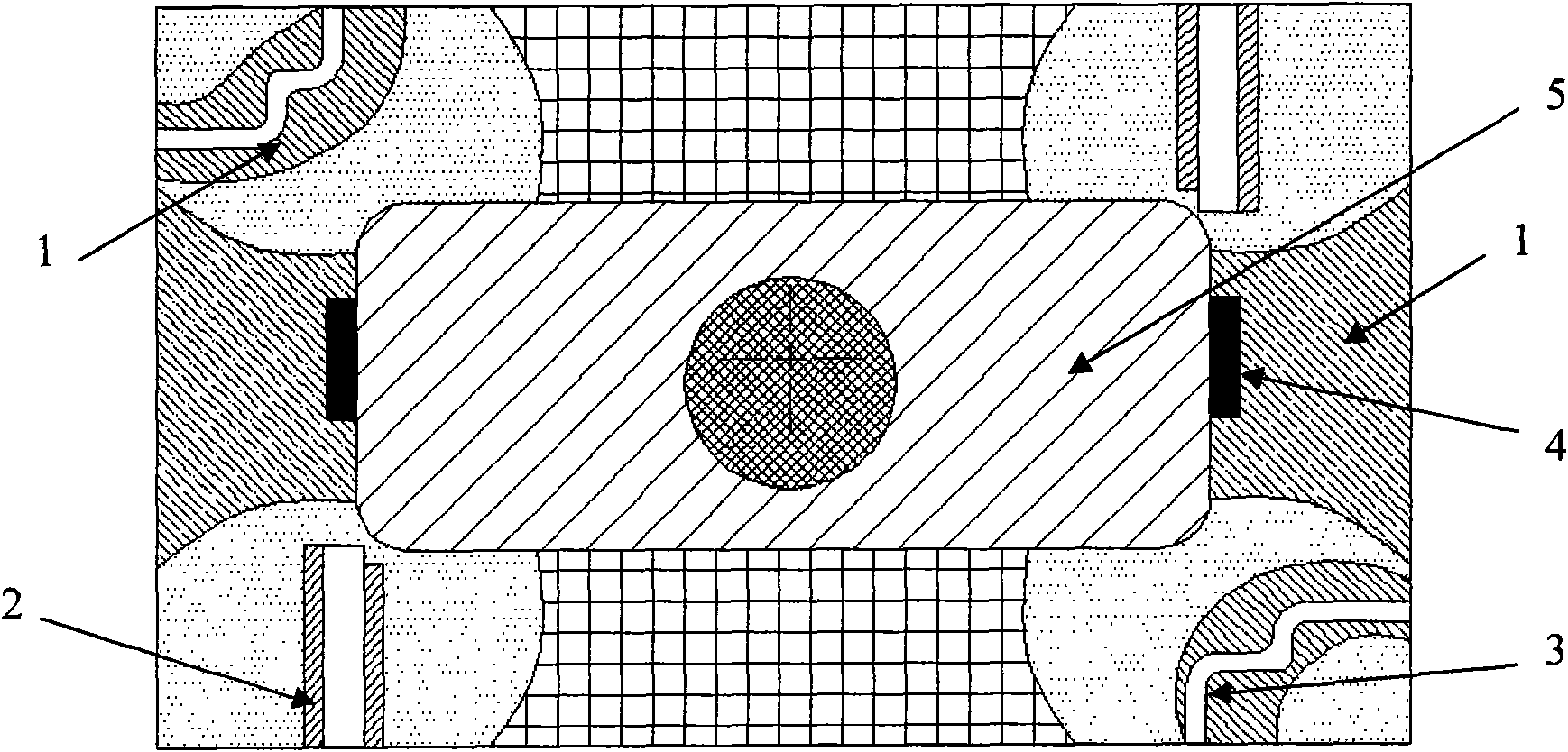

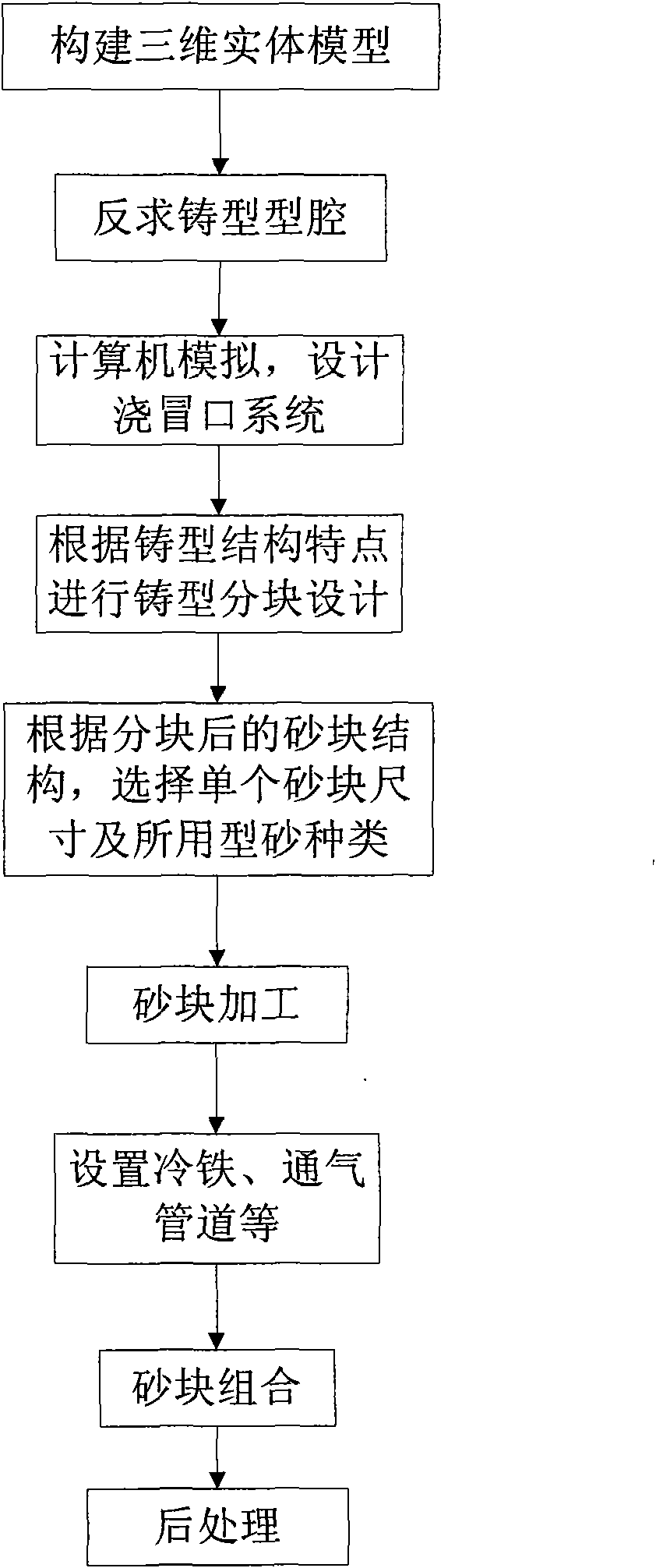

ActiveCN101992272AReduce preparationQuick cutFoundry mouldsFoundry coresNumerical controlMold filling

The invention relates to a self-adaptive casting mould manufacture method for a casting, which belongs to the technical field of casting and numerical control machining. The method of the invention comprises the following steps of: constructing a three-dimensional solid model of a casting mould according to a casting drawing and reversely solving a cavity of the casting mould; carrying out sand block partitioning design according to the structural characteristics of the casting mould; manufacturing a sand mould (core) in blocks by selecting different mould sand materials, such as zircon powder, mullite powder, quartz sand, and the like; adding cold iron, a cooling pipeline, and the like into different parts of the casting mould according to a simulating result of pouring solidification; processing the sand mould (core) in blocks; and after forming the mould (core), post processing and forming a final poured casting mould. The type and the shrinking percentage of molding sand for each sand block are determined according to a simulating result of a stress field and a temperature field during mold filling and solidification processes. Finally, the size of sand blocks required to be mixed is determined so as to establish the casting mould of each sand block. The invention can singly design each casting mould (mould sand material can be different) according to the structural characteristics and local solidification characteristics of the casting and greatly improves the flexibility and the operability of casting mould design and the adaptability of the casting. The self-adaptive casting mould manufacture method is especially suitable for the manufacture of a single casting and small-mass castings.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

Plaster casting method for large-sized complex thin-walled magnesium alloy part

ActiveCN104209497ASolve Oxidation ProblemsImprove filling abilityFoundry mouldsFoundry coresVacuum castingMold filling

The invention relates to a plaster casting method for a large-sized complex thin-walled magnesium alloy part. The method comprises the following steps of coating the surface of an assembled form with a coating in situ, and arranging shapeless cold iron on a hot spot part, wherein a mixture for manufacturing the shapeless cold iron comprises the following components in percentage by mass: 1.25 percent of phenolic resin, 0.4 percent of toluenesulfonic acid, 1 to 1.5 percent of boric acid, 2 percent of bentonite and the balance of 70 to 140-mesh chromite sand; pouring a casting in an adjustable pressure casting device, arranging a plaster mold poured by the form at the casting position of the adjustable pressure casting device, filling a tank with dry air or a CO2 atmosphere with SF6 content of 0.1 to 1.0 percent, and performing vacuum casting and pressurized solidification, wherein the casting temperature is 710 to 750 DEG C, vacuum degree for primary mold filling is minus 0.6Mpa to minus 0.8Mpa, and the solidification pressure is 0.020 to 0.025Mpa. According to the method, oxidization can be prevented, the mold filling capability can be improved, shrinkage cavities and shrinkage porosities in the casting are reduced, and the obtained magnesium alloy casting is higher in density.

Owner:山西银光华盛镁业股份有限公司

Evanescent mode pouring system of speed changing box body

The invention discloses an evanescent mode pouring system of a speed changing box body. The evanescent mode pouring system is provided with a sprue, wherein the sprue is sequentially communicated with a pouring cup, a first cross gate and a second cross gate from top to bottom, and the first cross gate and the second cross gate are respectively communicated onto the sprue along the radial direction of the sprue; the end part, away from of the sprue, of each of the first cross gate and the second cross gate is respectively provided with a first inner gate pouring port and a second inner gate pouring port. The pouring system is adopted for pouring a casting, so that the mold filling time is shortened, and the heat loss is reduced; moreover, the shrinkage porosity and cavity weakness can be greatly reduced, and the casting quality can be effectively improved.

Owner:HEFEI UNIV OF TECH

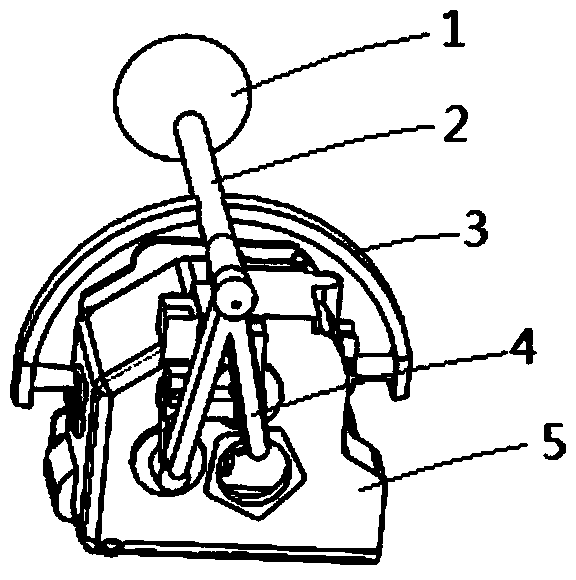

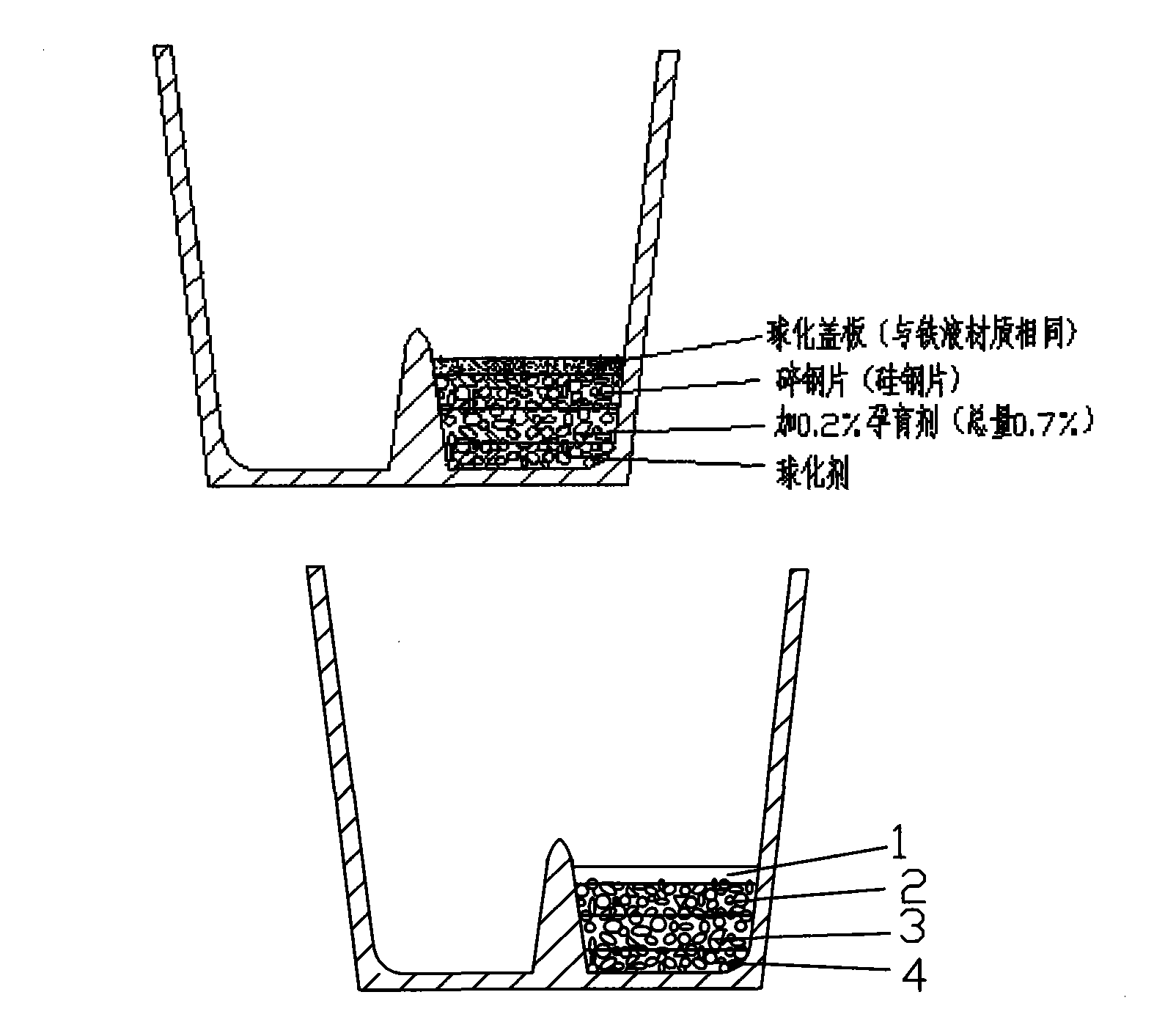

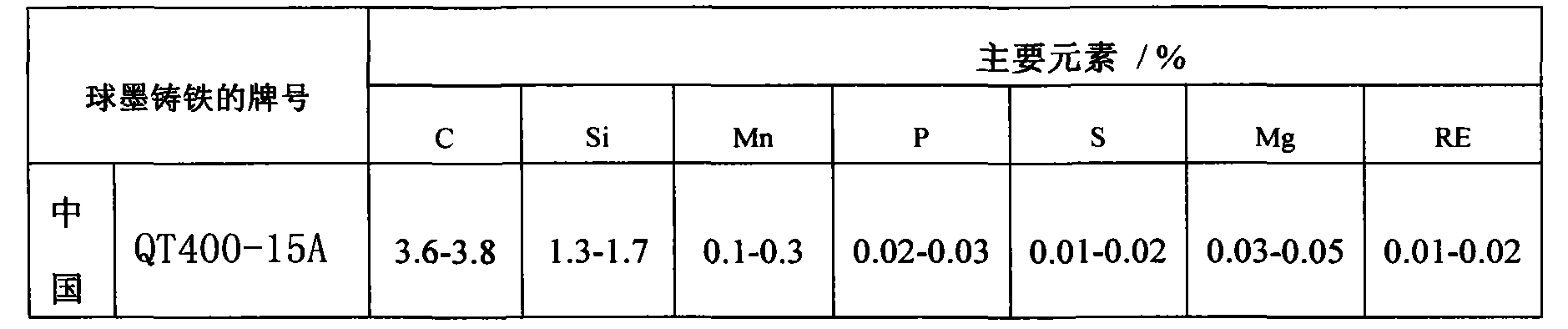

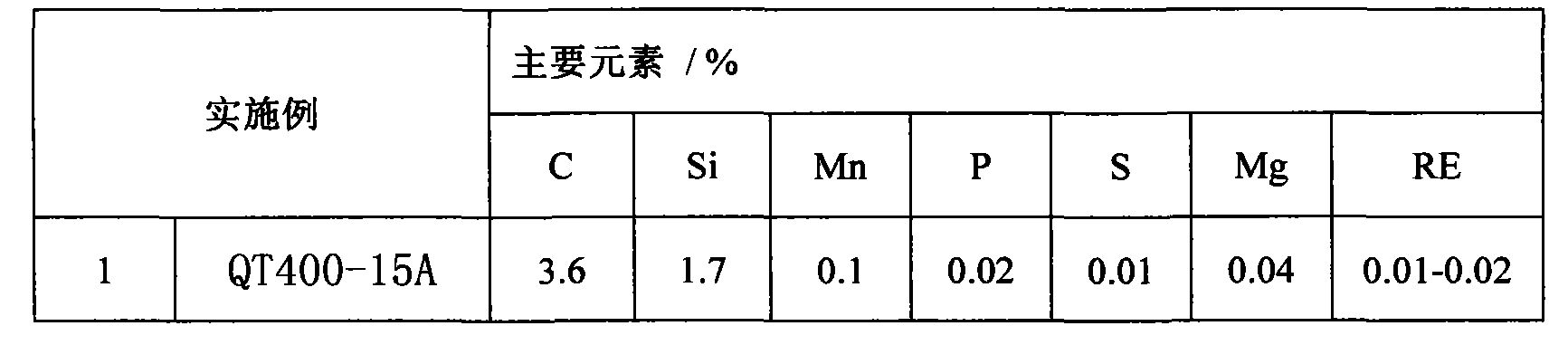

Method for integrally casting large-sized V-shaped diesel engine body by utilizing nodular cast iron

The invention discloses a method for integrally casting a more-than-25-ton large-sized diesel engine V-shaped body by utilizing nodular cast iron. The method comprises the following steps of A1, smelting the nodular cast iron in a smelting furnace, and adding bariumsili and metallurgical carborundum pretreatment agent after the smelting; A2, placing a spheroidizing agent into a bottommost layer of a dam-type spheroidizing ladle, utilizing a nucleating agent to cover a second layer, and utilizing a low-maganese low-alloy broken steel sheet to completely cover and compact a third layer; A3, adding a calcium-barium nucleating agent, charging the melted iron in one step to carry out the tapping metal-stream inoculation, realizing the nucleating effect while carrying out the spheroidizing treatment on charged melted iron, and carrying out the pouring pretreatment on the melted iron in the ladle; A4, placing the metal-stream inoculation agent into a funnel to carry out the pouring metal-stream inoculation; and A5, finally pouring the melted iron with the temperature being more than or equal to 1400 DEG C into a sand box, forming a cast by mold filling and solidifying the melted iron under the feeding of the feeder head liquid metal, and carrying out the heat treatment by utilizing the waste heat of the cast.

Owner:宜宾普什联动科技有限公司

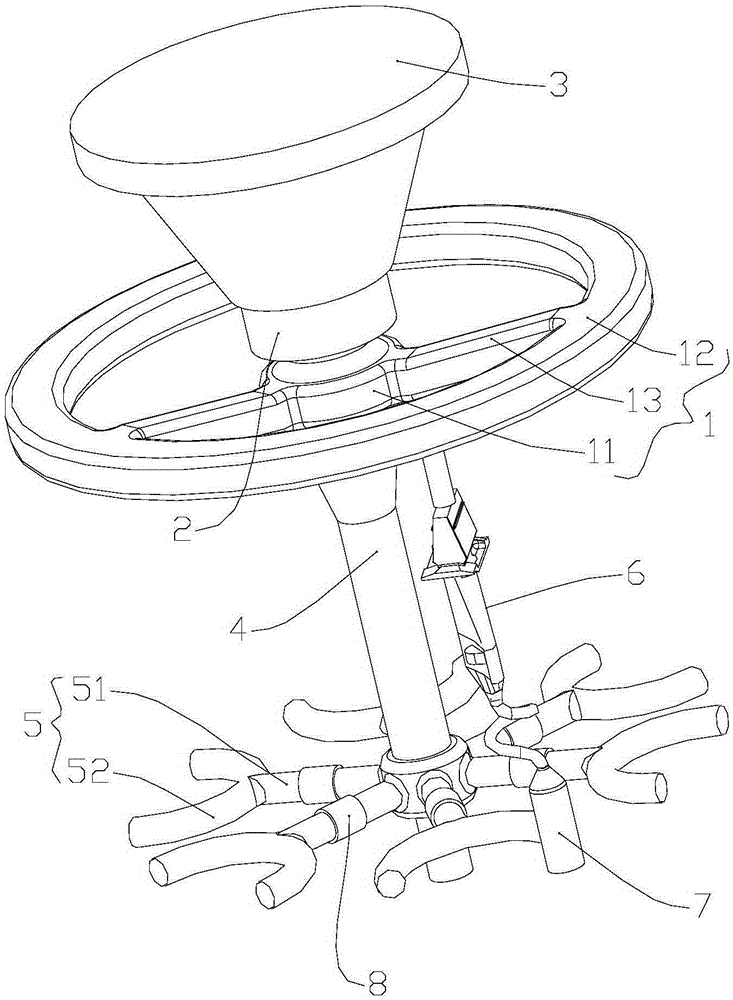

Low-pressure casting preparation method of aluminum alloy auxiliary frame

InactiveCN106925756AImprove inner qualityImprove mechanical propertiesChemical compositionMold filling

The invention discloses a low-pressure casting preparation method of an aluminum alloy sub-frame, including the design of the chemical composition of the aluminum alloy material, the refinement treatment of alloy smelting and modification, the assembly of sand molds, the transfer of pressure-time curves, low-pressure casting molding, and casting heat treatment processes. Firstly, the aluminum alloy is prepared according to the percentage of weight and composition, put into the crucible melting furnace for melting, refining and modification and refinement treatment, assemble the sand mold on the crucible furnace of the low-pressure casting machine and align the sprue with the rising pipe, and call the pressure time curve , low-pressure pressure filling and pressure maintaining to solidify the sub-frame castings to obtain aluminum alloy sub-frame castings, and then perform T6 heat treatment on the castings to obtain aluminum alloy sub-frames that can be loaded into the test and collect data requirements.

Owner:CHINA FIRST AUTOMOBILE

Process for manufacturing low-aliquation large-scale hollow steel ingot

InactiveCN101293273AReduce segregationIncrease profitFoundry mouldsIngot casting plantsAir volumeMold filling

The invention relates to a technology for casting a large hollow steel ingot, in particular to a method for manufacturing a low segregation large hollow steel ingot. The manufacturing method is applicable to the process for manufacturing the large hollow steel ingot which is less than 250 tons, made of various materials and has various models and specifications. Besides, computer simulation technique is utilized for reasonably designing an steel ingot mould and a gating system, steel structure nesting core pore-forming technology, large air flow cooling technology, injecting stream protection technology and metal liquid early-stage covering technology are mainly adopted in the manufacturing method, thus guaranteeing stability of ingot mold filling, reducing secondary oxide inclusion and improving the purity of the steel ingot. The large air flow cooling technology and the steel structure nesting core pore-forming technology guarantee the operability of casting process, control the segregation position of ingot, reduce the defects of shrinkage cavity and looseness and improve the utilization ration of the hollow steel ingot. By adopting the manufacturing method, the problems that a taper core can not be taken out easily and an inner core body is deformed in the manufacturing process of the large hollow steel ingot are solved, meanwhile, the segregation problem of large hollow steel ingot is relieved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com