Method for forming large-sized composite material box

A composite material and molding method technology, which is applied in the field of large-size composite material box molding, can solve the problems of low strength utilization rate of wet hand lay-up molding materials, poor reliability of batch production process, and complicated process realization, and achieve cost reduction. low cost, reliable quality and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below:

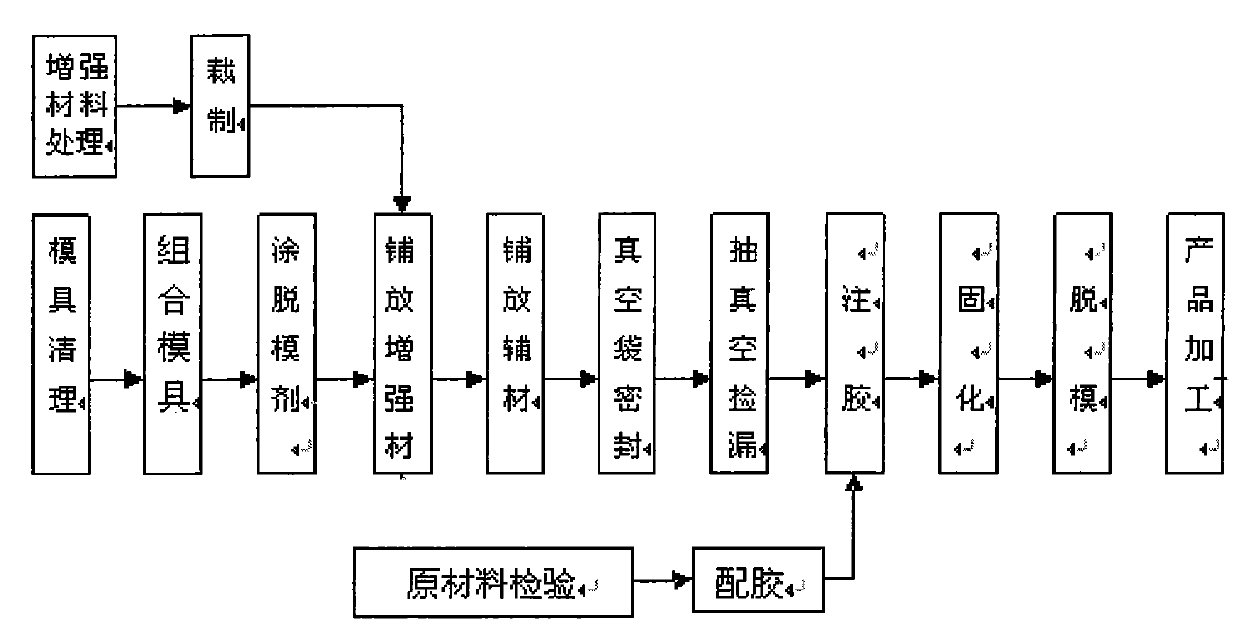

[0030] Such as figure 1 Shown, the present invention will describe vacuum infusion process in detail below by the forming process of quadrilateral launching box, and its forming process comprises the following steps, its process flow figure 1 Shown:

[0031] 1) Mold preparation: wipe the surface of the mold with alcohol, and then spray on the surface of the mold 15 Sealer and release 818 release agent.

[0032] 2) Lay reinforcement material: Lay the dried reinforcement material on the mould, wherein the reinforcement material consists of laying glass fiber fabric, balsa wood, PVC foam board and PU foam board in sequence. The specific laying sequence is: first lay 4-20 layers of glass fiber fabric, preferably 10 layers; then lay balsa wood, PVC foam board and PU foam board on the glass fiber fabric in a conventional way, and then lay 4 - 20 layers of fiberglass fabric, optimally laid in 10 layers.

[0033] 3)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com