Patents

Literature

9461 results about "Aging resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

As parts of the brain lose function with aging, loss of functional plasticity impairs the brain’s ability to adapt to this loss by recruiting other areas to take over these functions[13] leading to cognitive decline. Two studies support the role of resistance training in promoting functional plasticity.

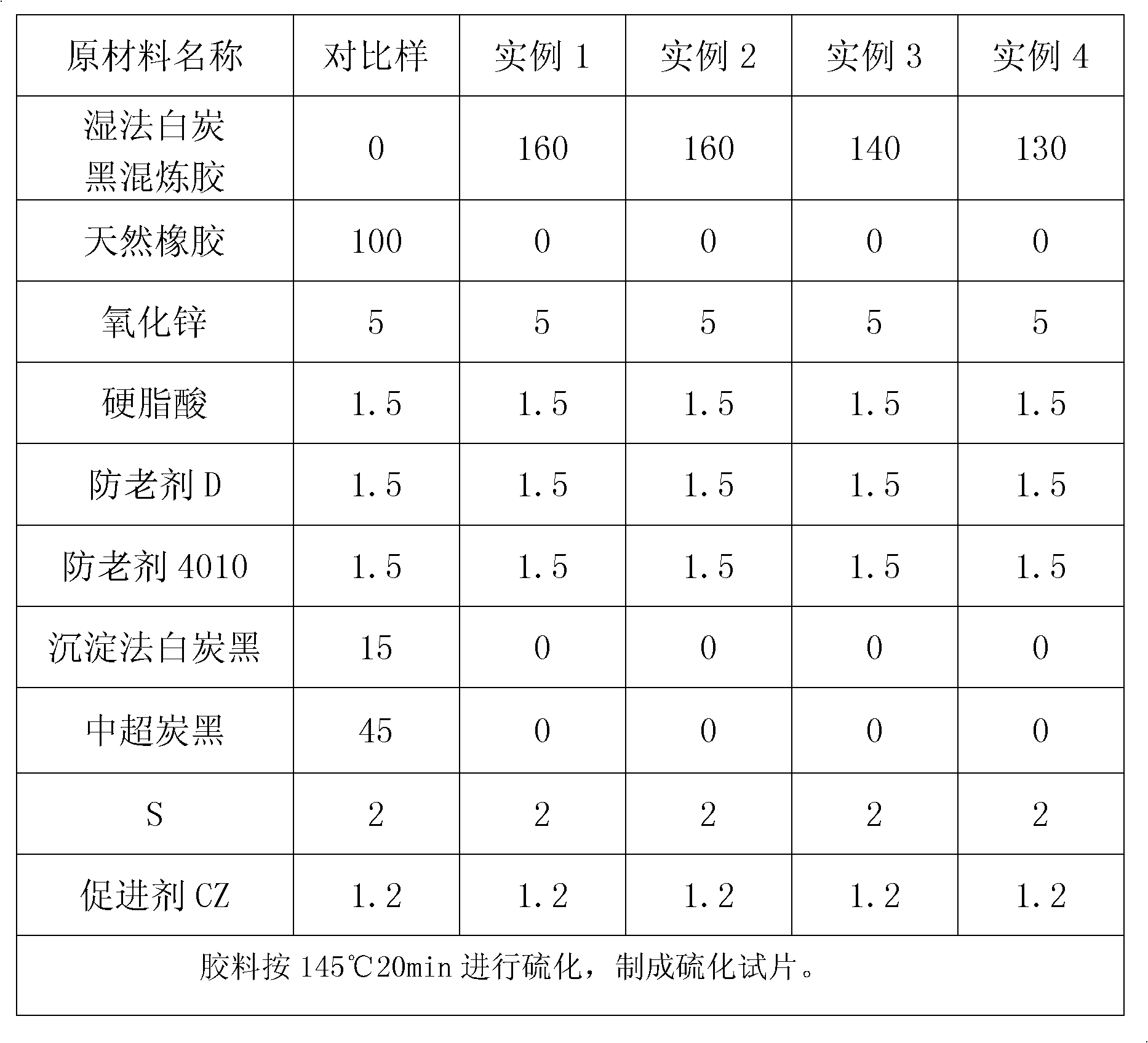

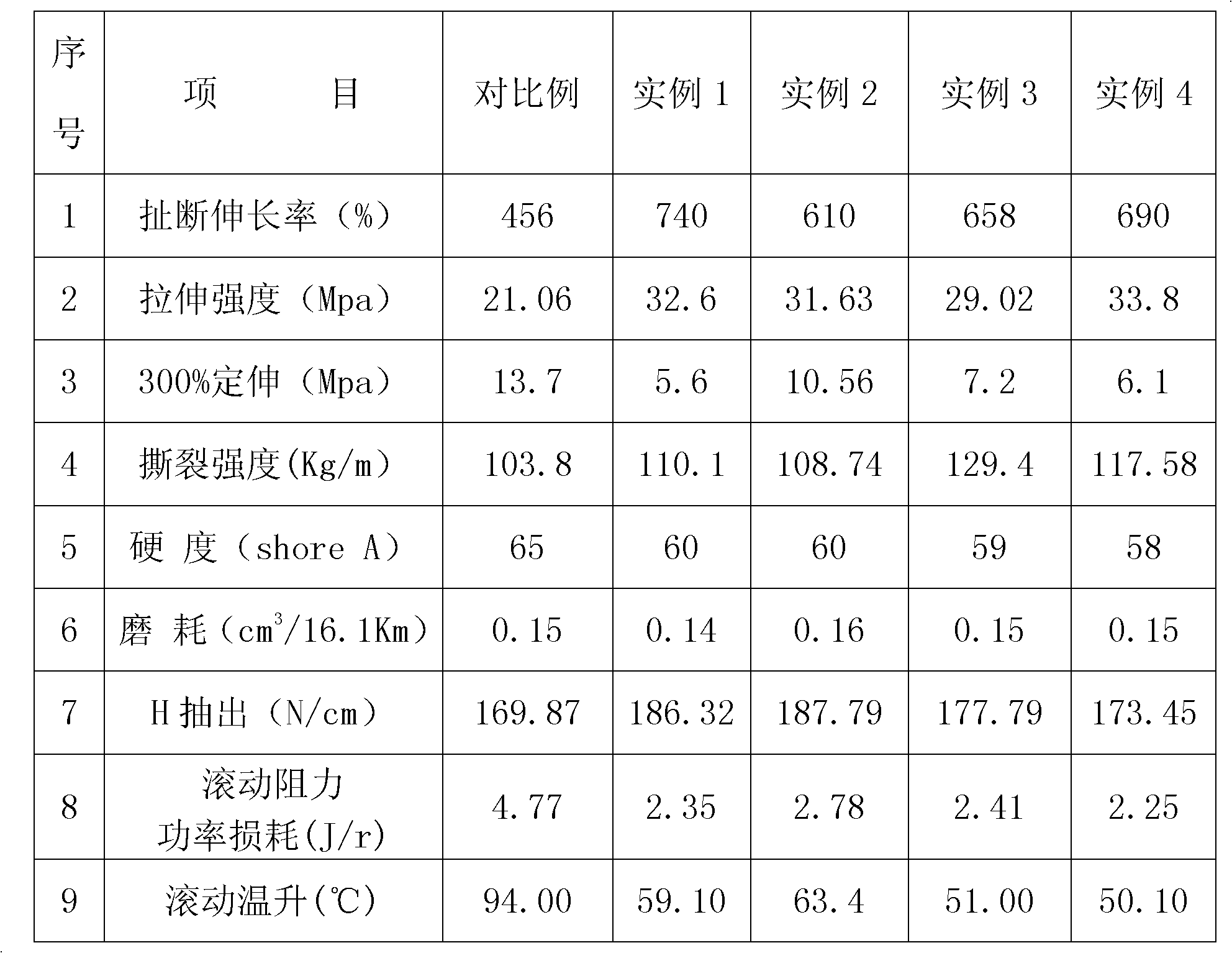

Preparation method of wet process mixed natural rubber material

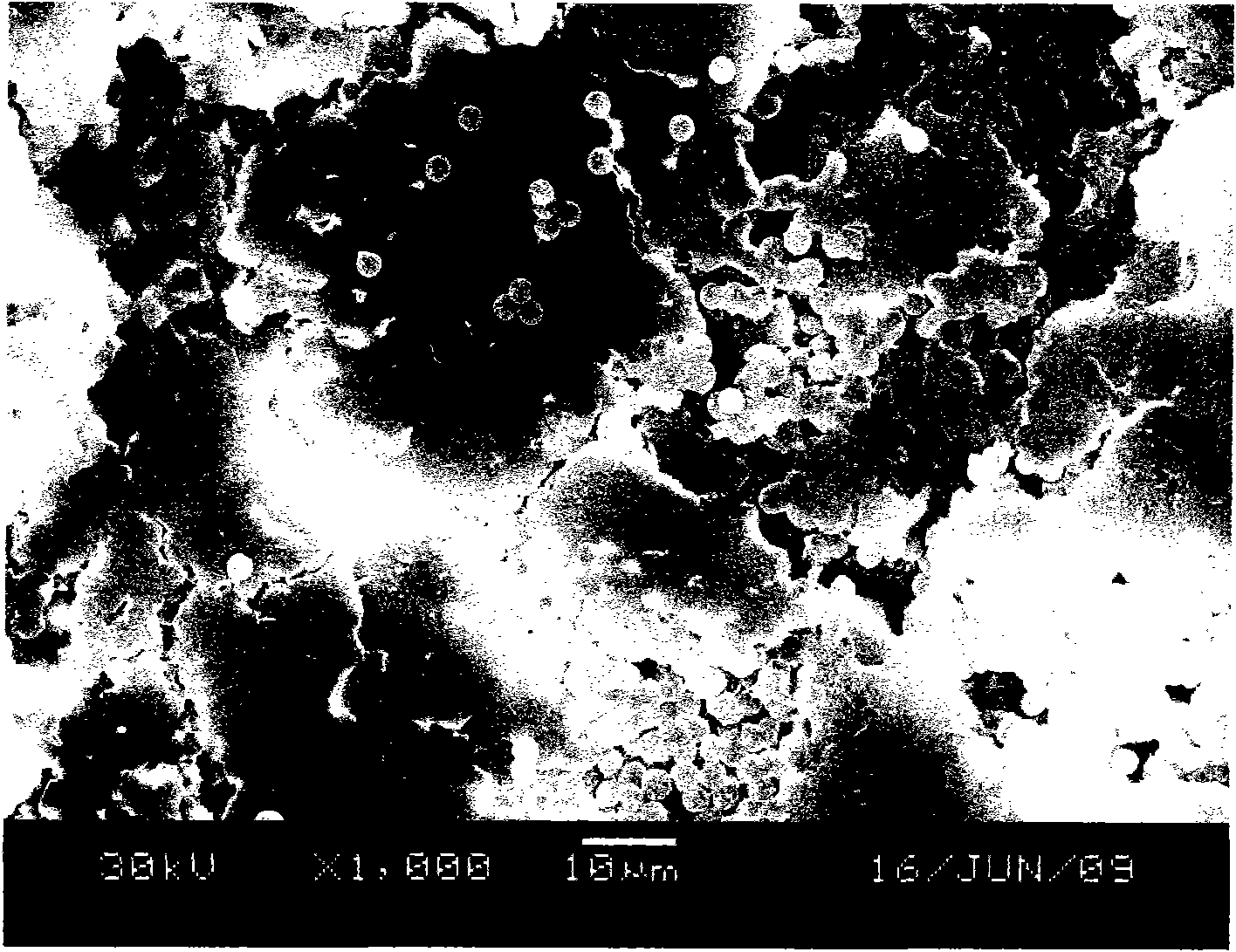

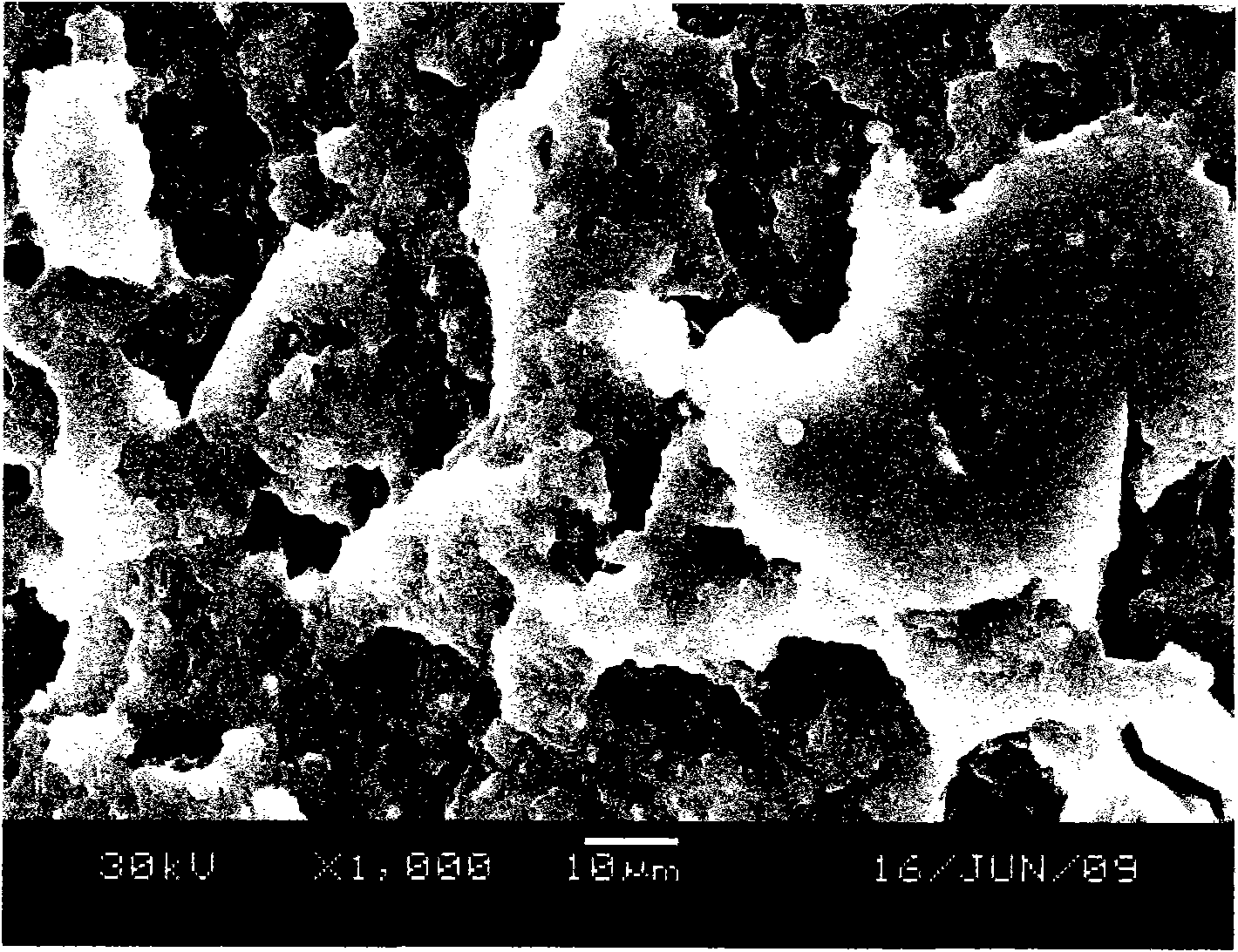

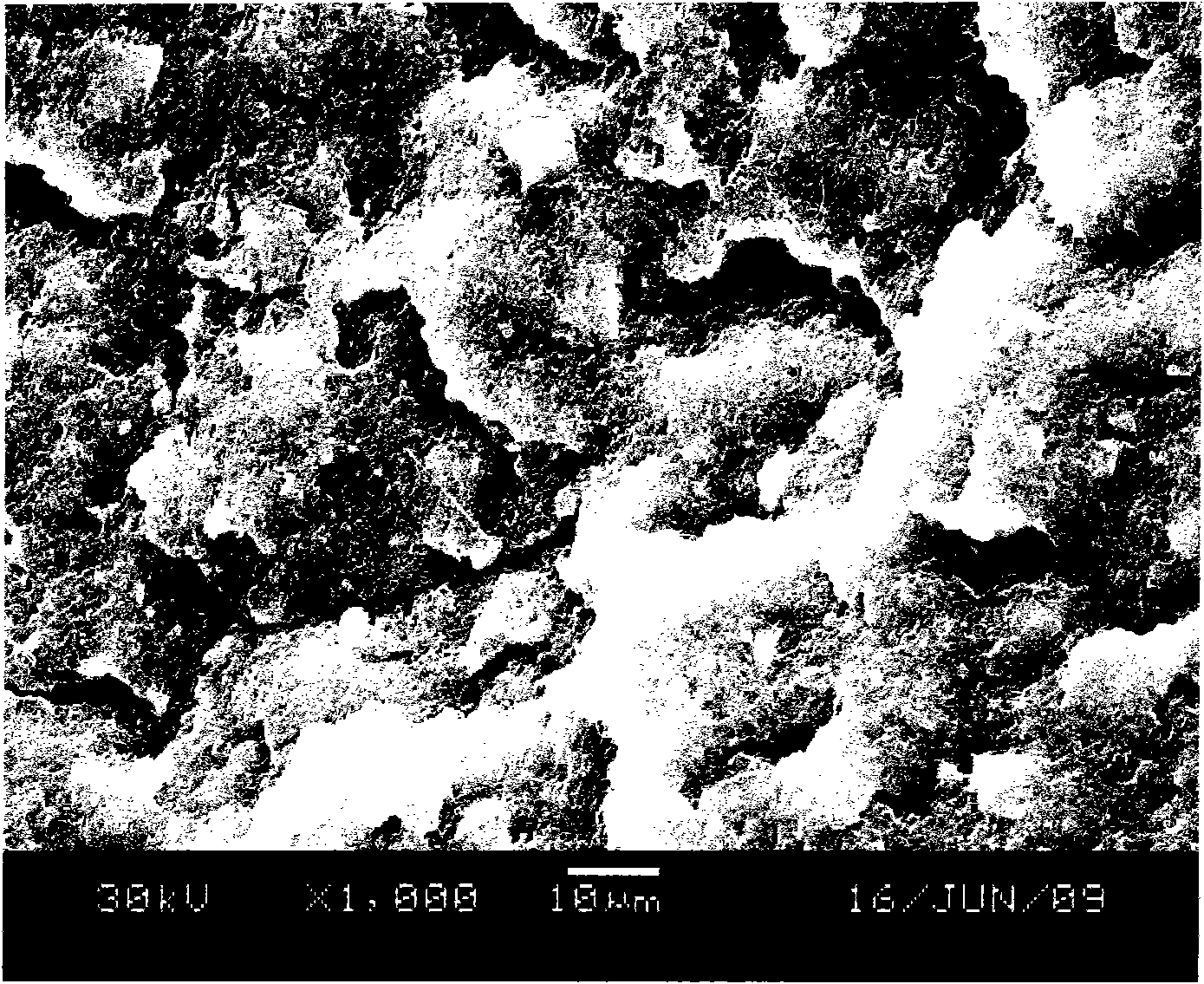

ActiveCN102153792AGood dispersionImprove uniformityRolling resistance optimizationRubber materialPolymer science

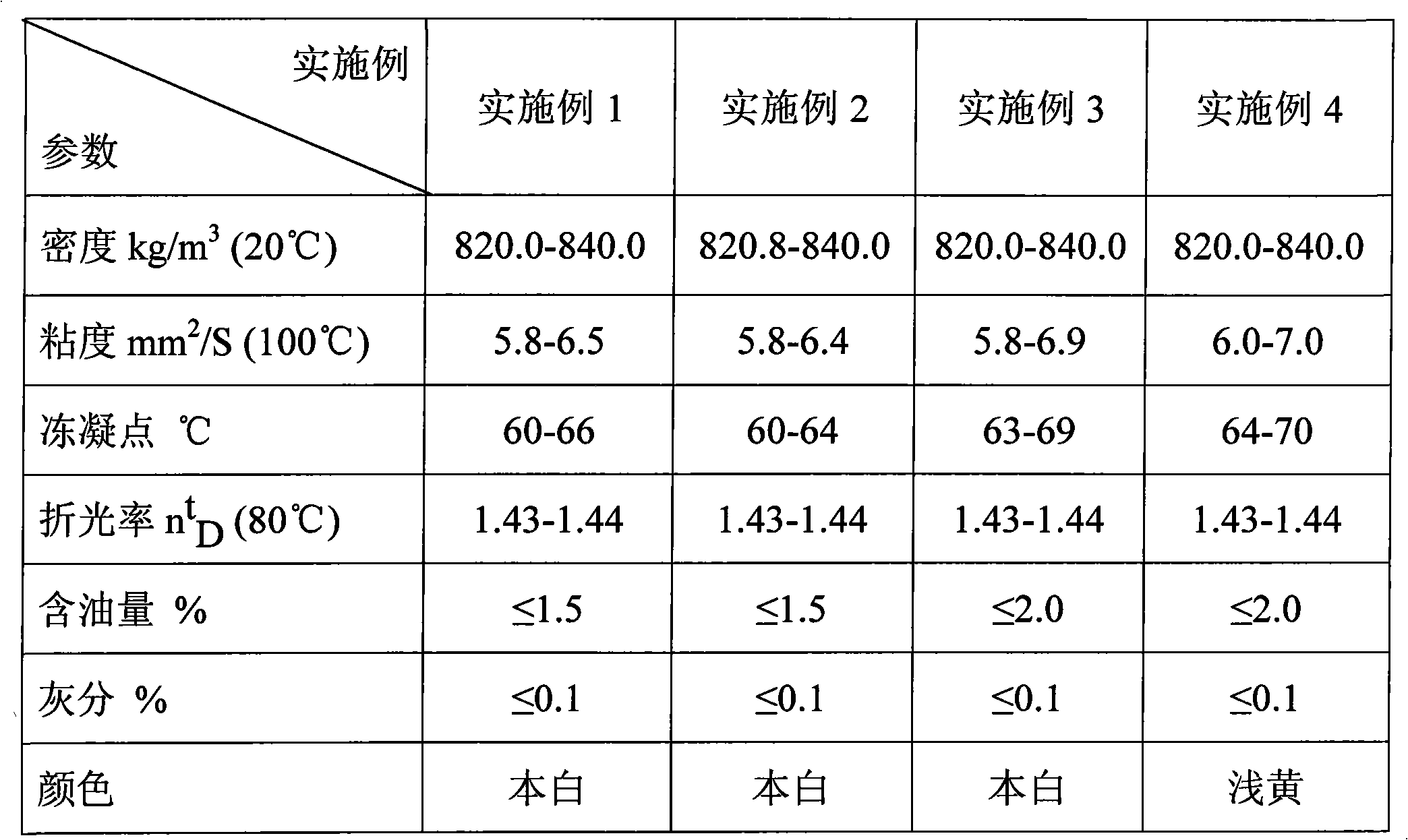

The invention relates to a preparation method of a wet process mixed natural rubber material. The method comprises the following steps of: preparing slurry and soaking 15-40 percent of dry white carbon black in 60-85 percent of deionized water; adding a coupling agent and a surfactant, uniformly mixing, grinding, preparing latex mixed liquor, extracting natural latex and adding white carbon black water dispersoid into the latex; stirring and mixing to obtain a latex mixed liquor, flocculating and adding acetic acid into the mixed liquor; performing rubber washing and dehydration by using a rubber washing machine and feeding to a rubber pelletizer for pelletizing; and feeding rubber particles into a box drying cabinet for drying. The preparation method has the advantages of simple machining process, small equipment investment, realization of various ideal performances with the most ordinary white carbon black, low dust pollution in the entire production process and energy saving. A tire manufactured with the method has small rolling resistance, low heat generation, high tensile strength, high tearing strength and high rubber material ageing resistance. Mixing of the white carbon black is performed in a liquid phase, so that the dispersivity and uniformity are enhanced.

Owner:ZHUZHOU ANBAOLINFENG NEW MATERIALS

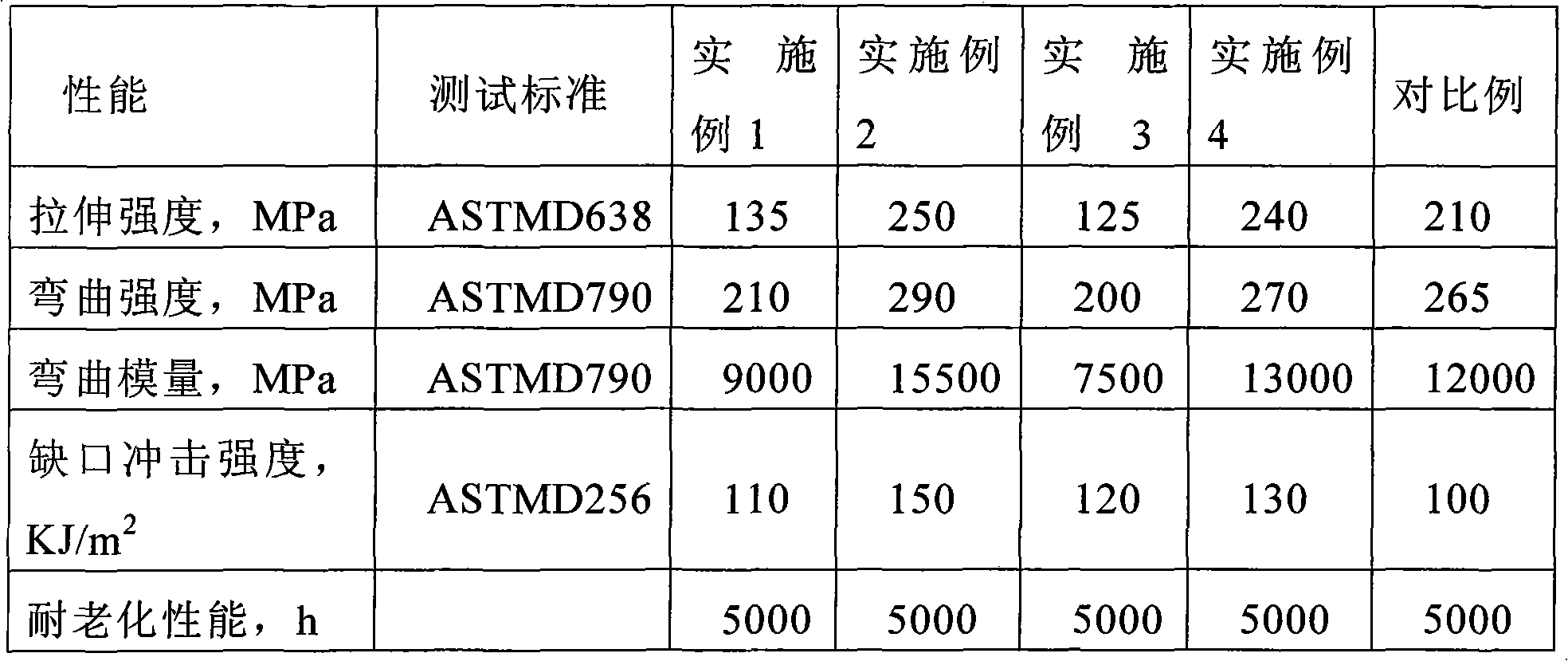

Composite material for wind power generator blade and preparation method thereof

ActiveCN101906251AGuaranteed mechanical propertiesGive full play to the high-strength and high-model characteristicsFinal product manufactureMachines/enginesState of artFiber

The invention relates to a composite material for a wind power generator blade. The composite material comprises the following components in parts by weight: 40-75 parts of thermoplastic resin component, 25-60 parts of reinforced fiber component and 0-5 parts of additive. Compared with the prior art, the invention has the advantages of meeting high strength, high modulus, ageing resistance, and the like required by a wind power generator blade.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

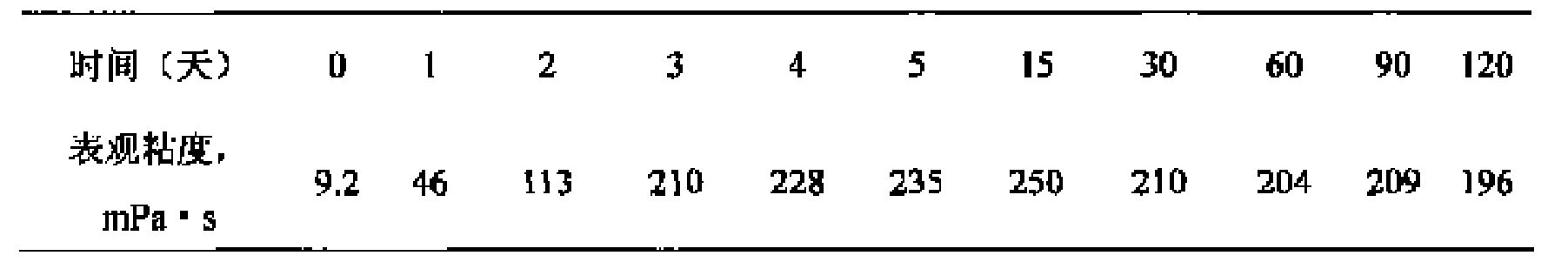

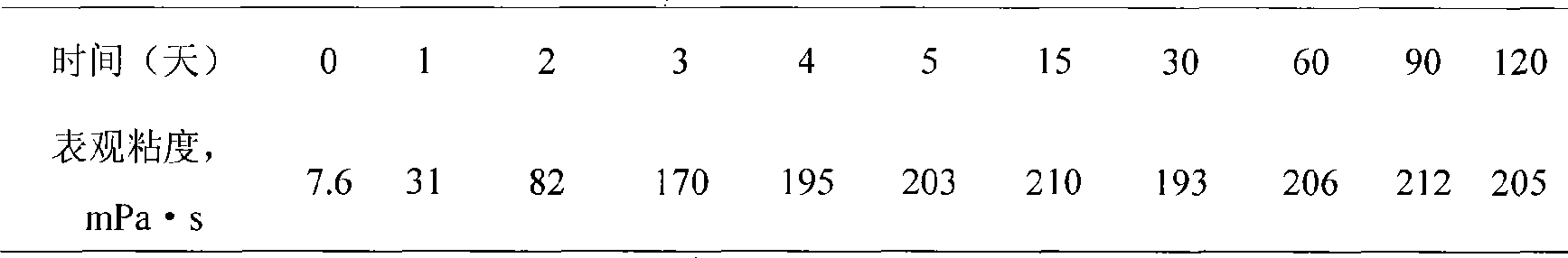

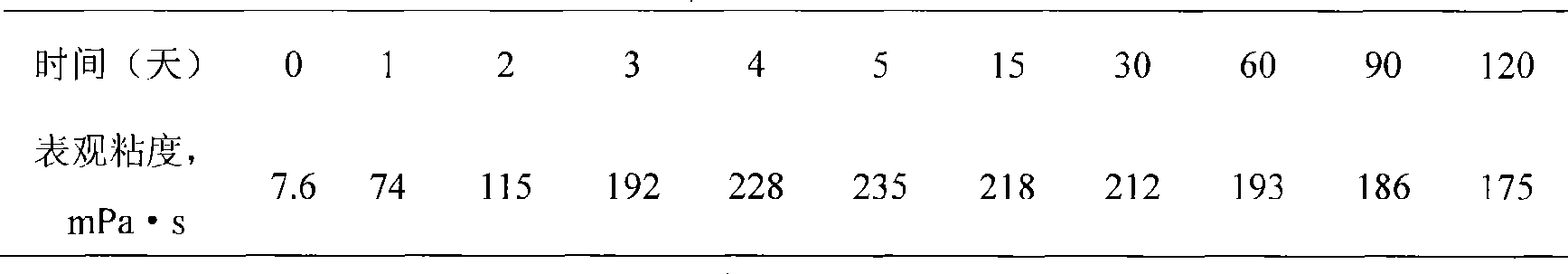

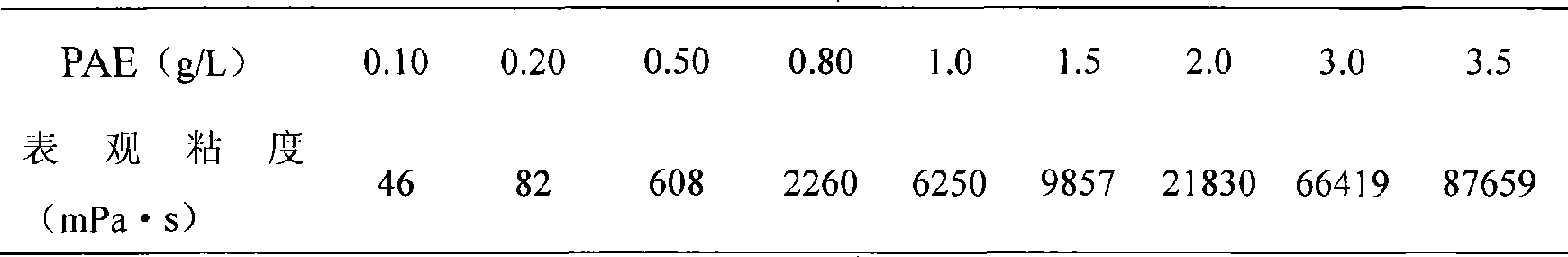

Temperature-resistant salt-resistant efficient gel, and preparation and use thereof

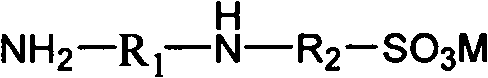

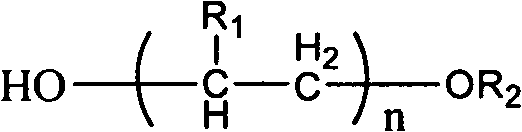

InactiveCN101475667AImprove solubilityGood viscosity increasing effectDrilling compositionSulfite saltAging resistance

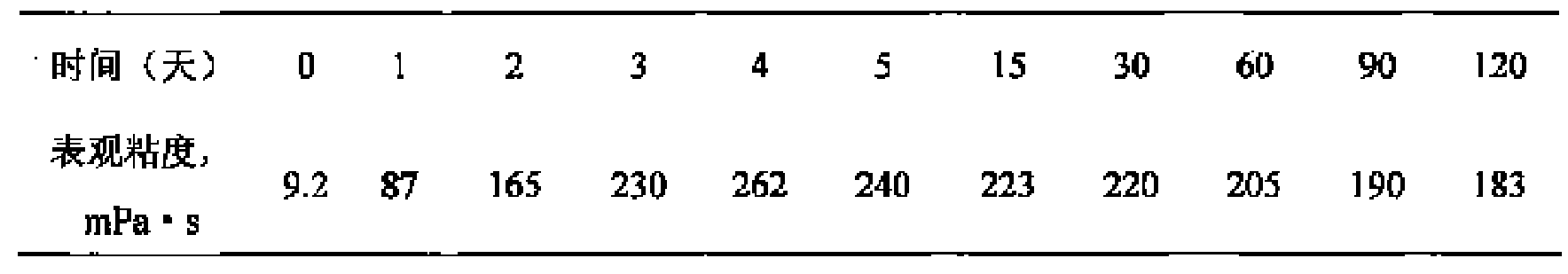

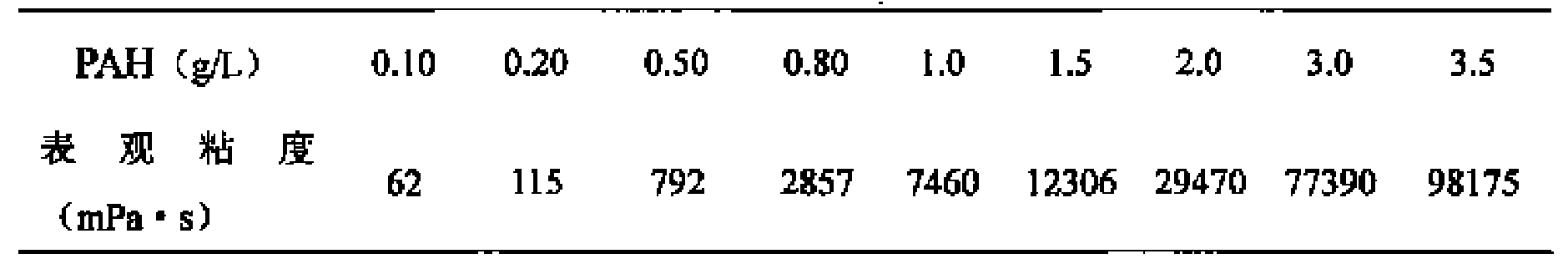

The invention discloses a temperature resistant salt tolerant high efficiency gel and a preparation method and application thereof. The preparation method is characterized in that the preparation method comprises the following steps: preparing a comb-shaped associated copolymer PAH containing macromonomers and functional hydrophobic monomers into an aqueous solution having the concentration of 0.1 to 4g / L, the crosslinking agent concentration of 0.01 to 1.0g / L, the surfactant concentration of 0.01 to 8mmol / L and the sodium sulfite thermal stabilizer concentration of 0.005 to 1.0g / L; adding the aqueous solution into a mixing container with a stirring device; stirring the aqueous solution evenly at the room temperature; regulating the pH value of the solution to be equal to between 4 and 11, and obtaining a temperature resistant salt tolerant high efficiency gel polymer solution system used for tertiary oil recovery and scavenge, displacement modification, profile modification or water shutoff. The polymer solution system has micro-crosslinking to form the gel during the flowage inside the oil reservoir. The gel has good elasticity, not easy dehydration, stable gelling performance, and excellent tackification, temperature resistance, salt tolerance, shearing resistance and ageing resistance.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

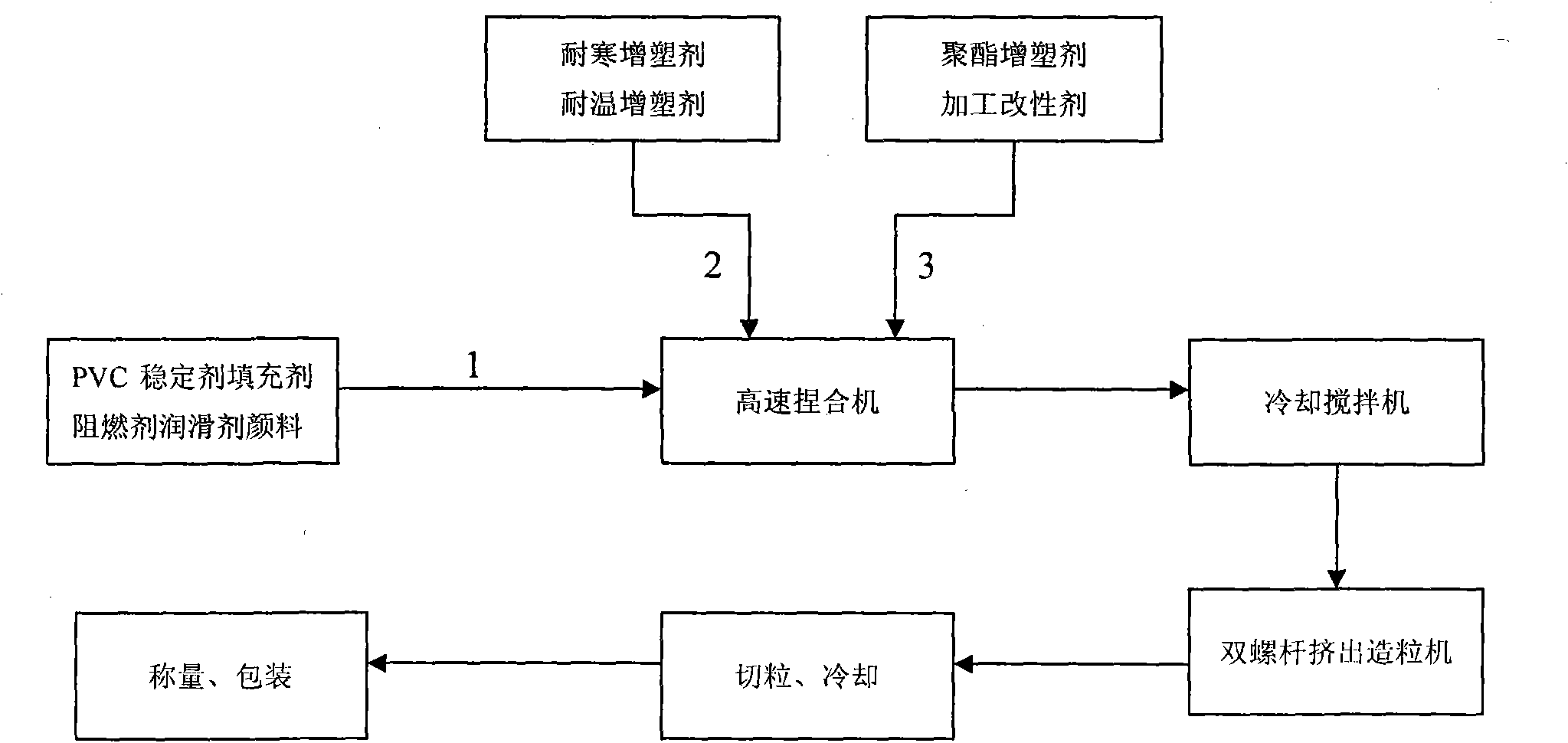

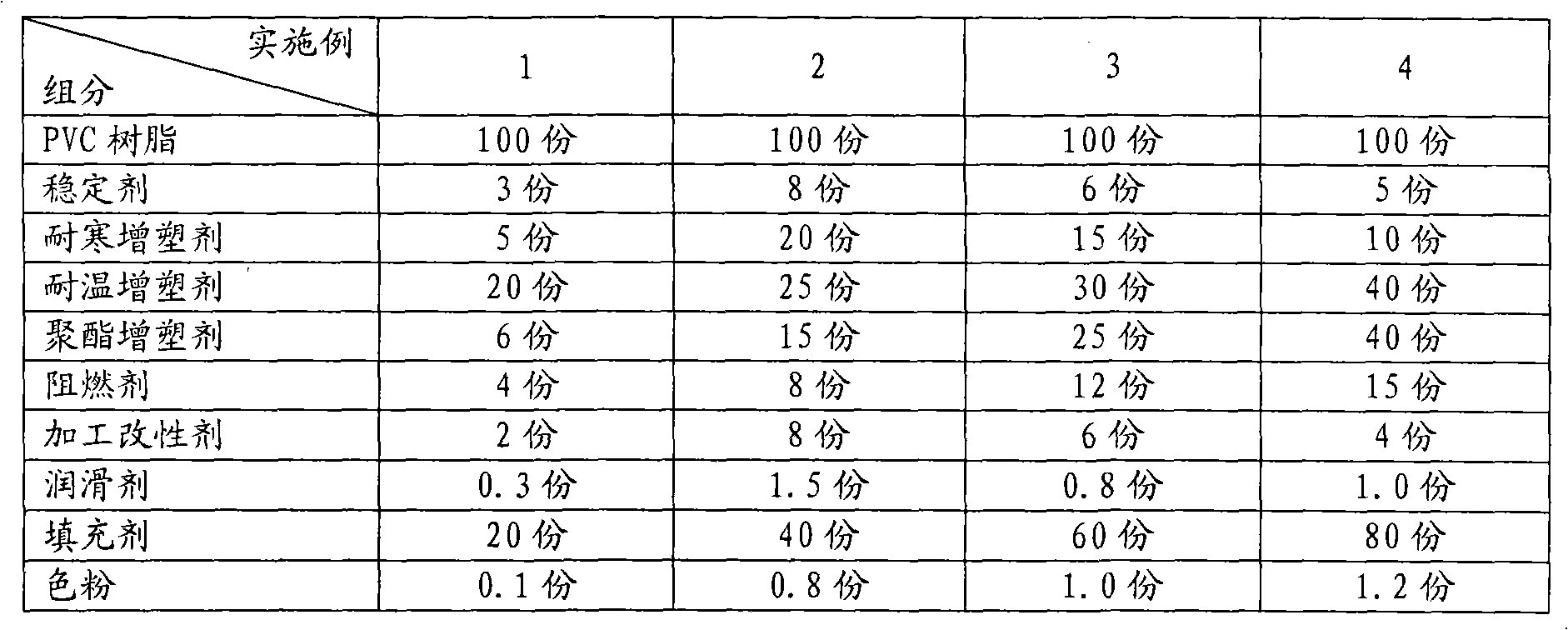

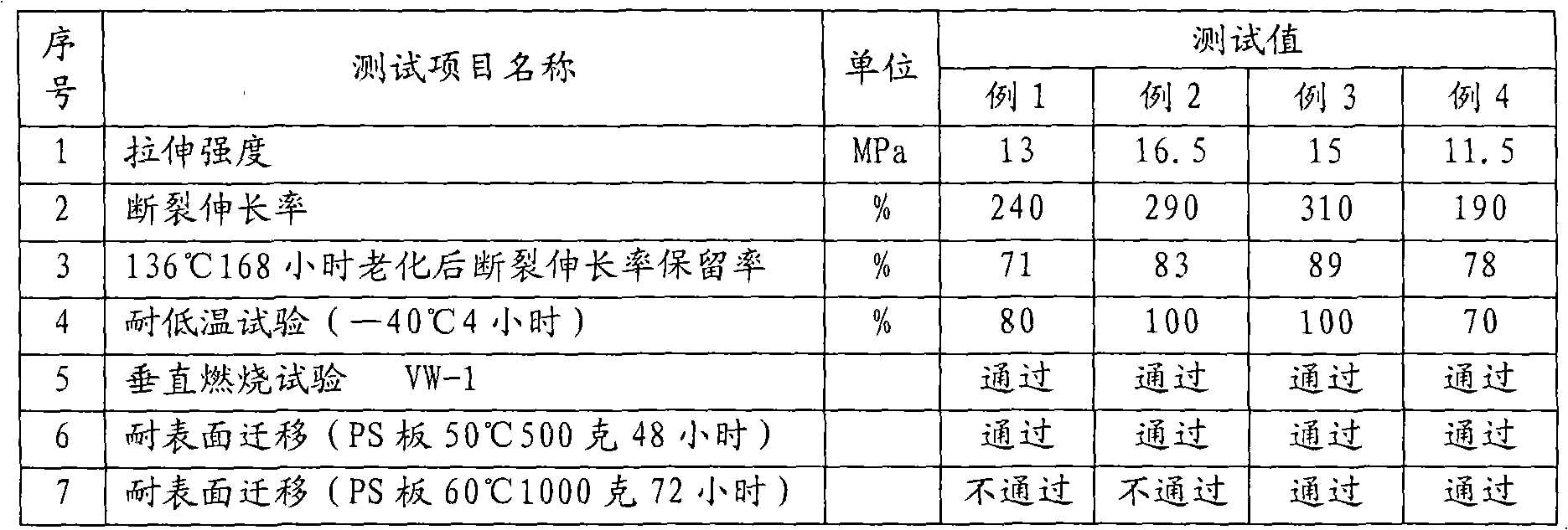

Cold-resistant temperature-resistant flame-retardant surface migration-resistant polrvinyl chloride insulating material

InactiveCN101967250AWon't breakNo migrationPlastic/resin/waxes insulatorsPolyesterEnvironmental resistance

The invention discloses a cold-resistant temperature-resistant flame-retardant surface migration-resistant polrvinyl chloride insulating material. The material comprises the following components in part by weight: 100 parts of polrvinyl chloride (PVC) resin, 5 to 20 parts of cold-resistant plasticizer, 20 to 40 parts of temperature-resistant plasticizer, 6 to 40 parts of polyester polymer plasticizer, 3 to 8 parts of environmentally-friendly heat stabilizer, 20 to 80 parts of filler, 4 to 15 parts of fire retardant, 2 to 8 parts of processing modifier, 0.3 to 1.5 parts of lubricant and 0.1 to 1.2 p[arts of toner. The polrvinyl chloride composite material of the invention has the comprehensive performance, such as low temperature embrittlement resistance, low temperature compact resistance, high temperature aging resistance, fire resistance, surface migration resistance and the like.

Owner:王长明

Production method for liner gloves aqueous polyurethane coating connection material

InactiveCN101328383ABreathableGood moisture permeabilityPolyurea/polyurethane coatingsWater basedPropanoic acid

The invention discloses a production method for insert gloves water-based polyurethane coating bonding materials. The method comprises the following steps of: under the protection of dry nitrogen, adding polyether glycols (including polyether diatomic alcohol and / or polyether triatomic alcohol) having undergone vacuum dewatering and isocyanate into a reaction vessel; heating the mixture up to between 80 and 100 DEG C for reaction after even mixing; then adding a hydrophilic chain extender such as dihydromethyl propionic acid (DMPA) and a catalyst for reaction at a temperature of between 80 and 100 DEG C; finally adding the chain extender and a solvent into the mixture for reaction at a temperature of between 55 and 65 DEG C until the NCO content of the isocyanate group does not change; discharging the reactant after temperature reduction to obtain an ionomer; neutralizing a preformed polymer with triethylamine or diethanolamine or triethanolamine and then adding water the mixed solution for emulsification to obtain water-based polyurethane latex; and carrying out reduced pressure distillation to remove the solvent and obtain the product. The synthesized water-based polyurethane resin which serves as a gloves coating has the advantages of good air and moisture permeability, excellent mechanical performance, solvent resistance, ageing resistance, resistance to corrosion caused by chemical mediators, oil resistance, resistance to hooking, cutting and piercing, excellent abrasion resistance, odorlessness, innocuous and nondestructive for contacting with skin, etc.

Owner:ANHUI UNIVERSITY +1

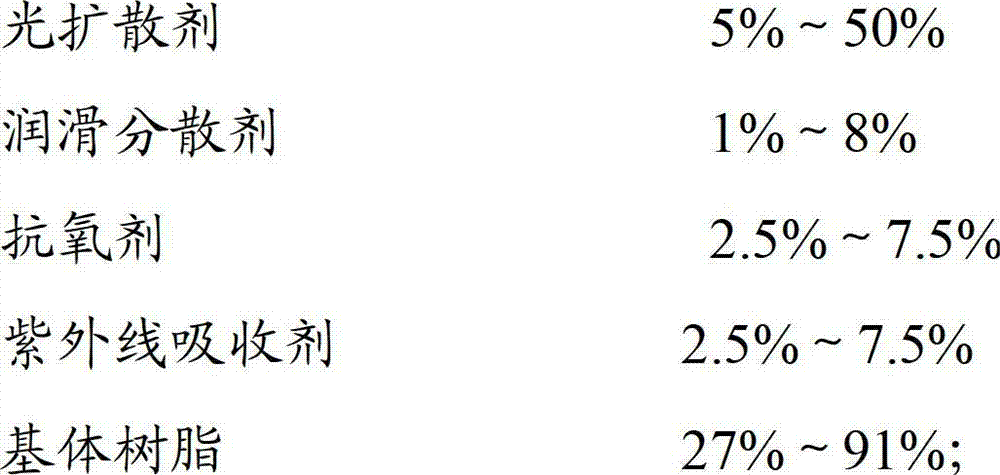

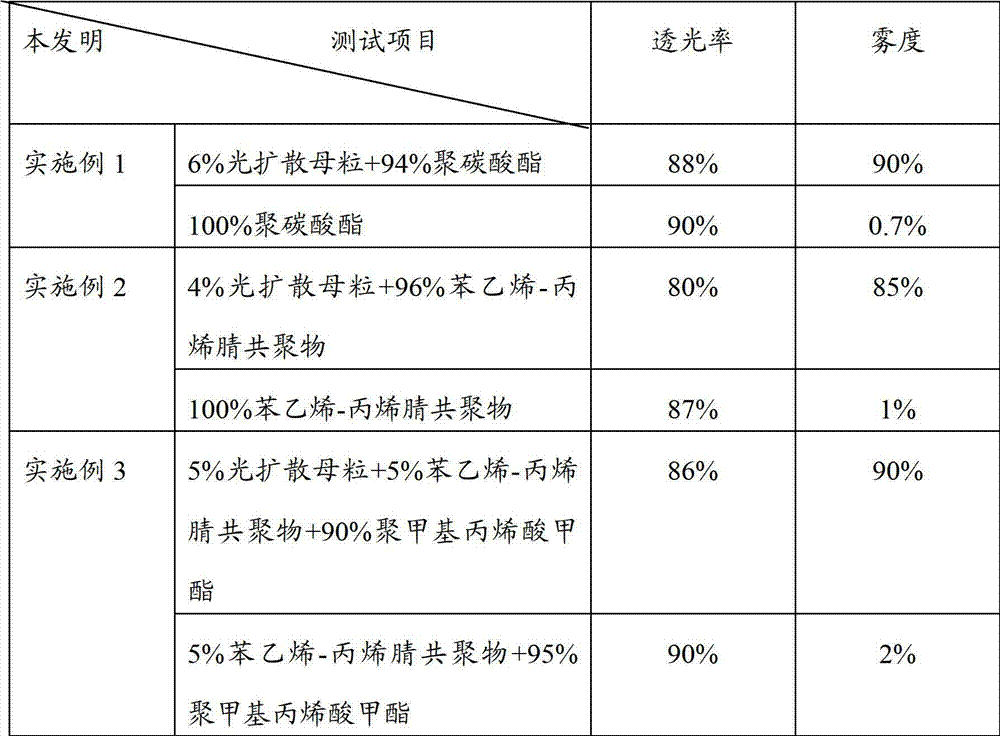

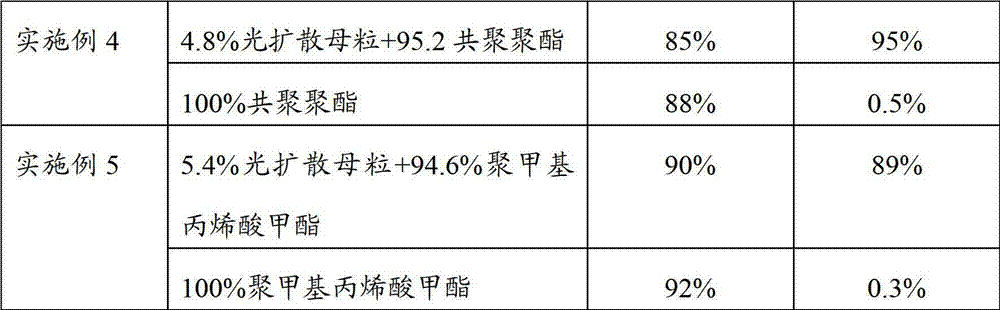

Light diffusion master batch for transparent plastics and preparation method thereof

ActiveCN103073867ASolve the problem of fragmentationAvoid the disadvantages of physical property degradationHigh concentrationAging resistance

The invention relates to the technical field of functional master batches, in particular to a light diffusion master batch for transparent plastics and a preparation method thereof. The light diffusion master batch comprises the following components in percentage by weight: 5-50% of light diffusant, 1-8% of lubrication dispersant, 2.5-7.5% of antioxidant, 2.5-7.5% of ultraviolet light absorber and 27-91% of matrix resin; after being mixed, the components are placed in an extruder for being molten and extruded; and the extruded materials are cooled, pelletized and dried to prepare the product of light diffusion master batch. The light diffusion master batch has stable properties, high transparency and high haze; and as the master batch contains a light stabilizing agent and a heat stabilizing agent with high concentrations, plastic products produced thereby have excellent ageing resistance, and are suitable for long-time use in locations of natural illumination or manual illumination.

Owner:东莞市普凯塑料科技有限公司

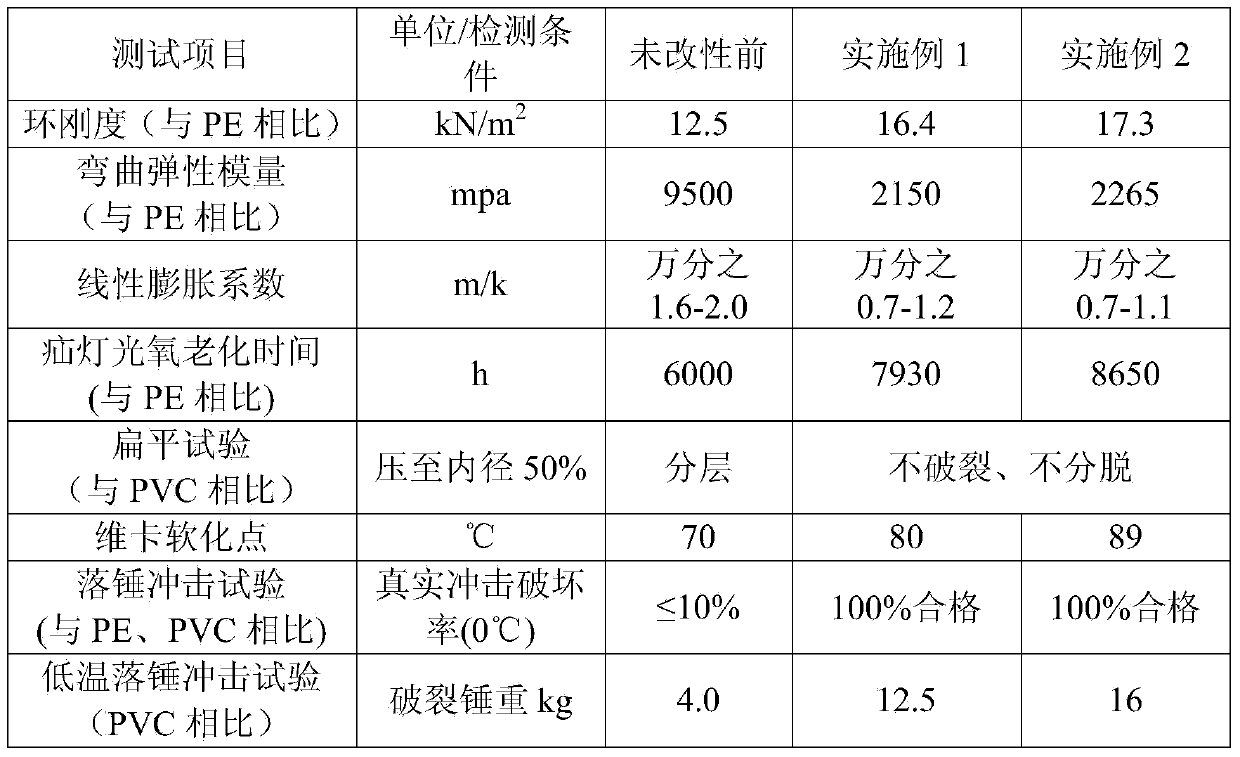

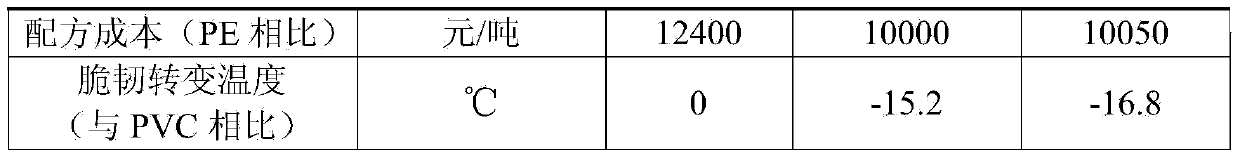

Polyethylene-polyvinyl chloride blend-modified tube and preparation method thereof

The invention belongs to the field of drainage tubes, and particularly relates to a polyethylene-polyvinyl chloride blend-modified tube and a preparation method thereof. The polyethylene-polyvinyl chloride blend-modified tube aims to solve the technical problems of poor shock strength, high sensitivity to temperature, poor ring stiffness, higher cost and short service life in the existing tube. In order to solve the technical problems, the invention provides a polyethylene-polyvinyl chloride blend-modified tube which comprises the following components in parts by weight: 50-150 parts of polyethylene resin, 50-150 parts of polyvinyl chloride resin, 10-30 parts of nano material, 0.5-5 parts of pigment, 2-20 parts of leadless stabilizer, 1-20 parts of processing assistant, 1-5 parts of lubricant, 0.5-5 parts of antioxidant, 0.5-2 parts of photostabilizer, 1-25 parts of solubilizer, 1-15 parts of impact-resistant modifier, 1-15 parts of enhancer and 0.5-10 parts of coupling agent. The polyethylene-polyvinyl chloride blend-modified tube has the advantages of higher ring stiffness, favorable toughness, aging resistance and greatly higher shock strength.

Owner:KANGTAI PLASTIC SCI & TECH GRP

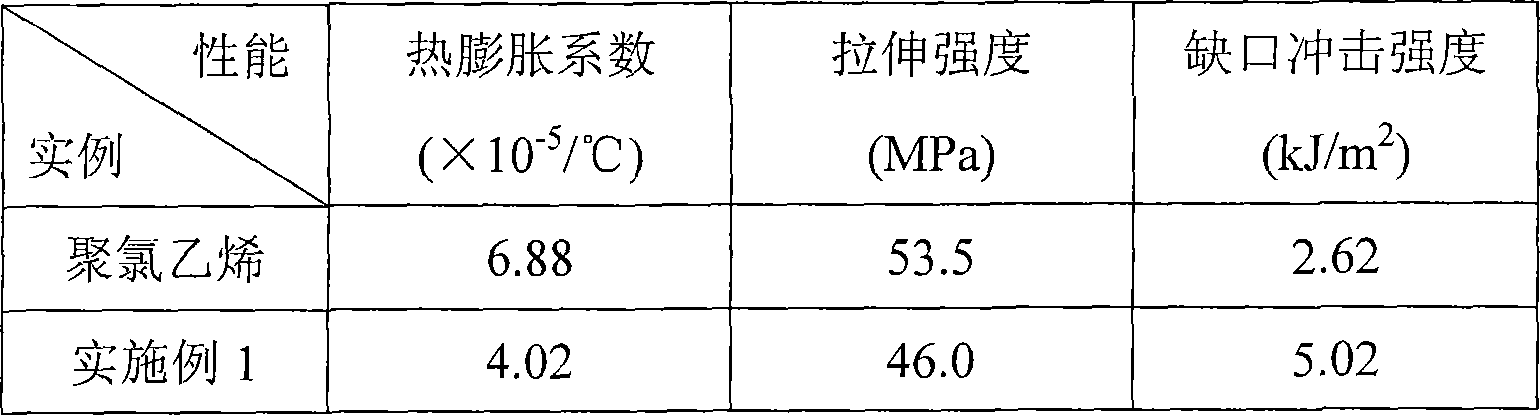

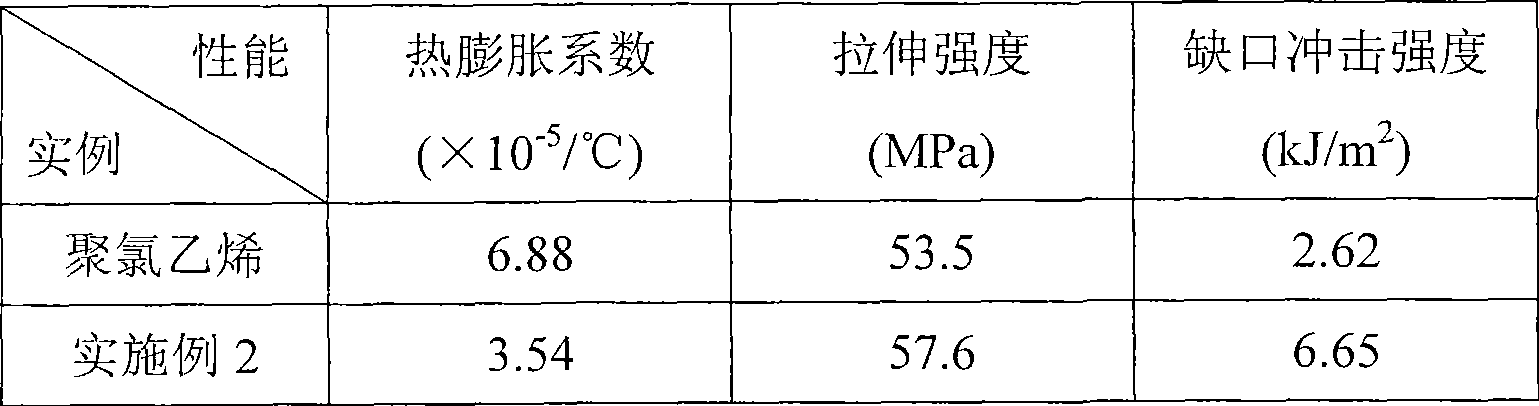

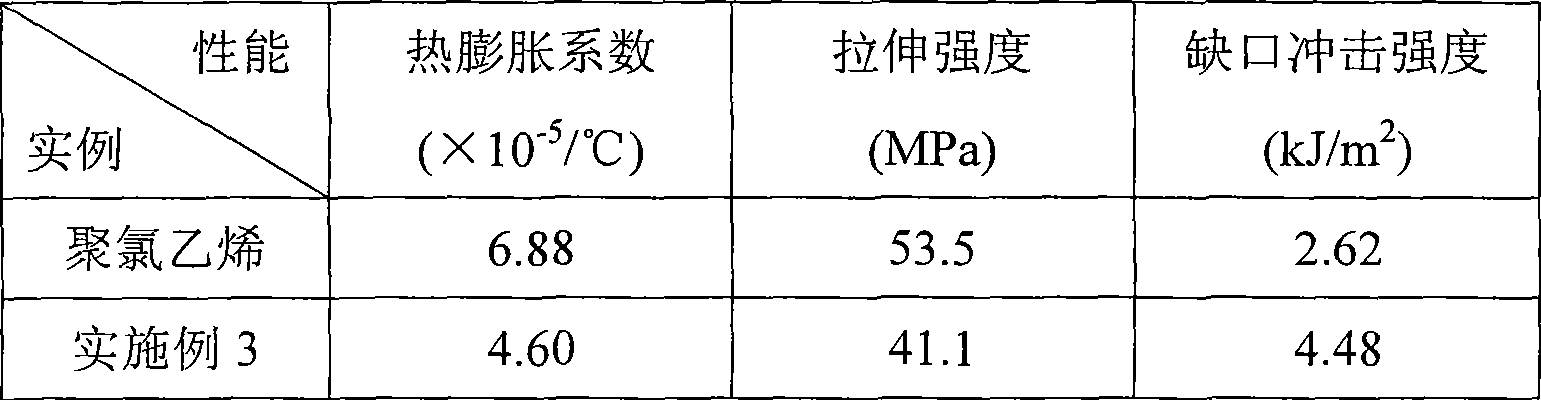

Low-expansion coefficient polyvinyl chloride alloy material and manufacturing method thereof

The invention provides a low-expansion coefficient polyvinyl chloride alloy material and a manufacturing method thereof. The ingredients of raw materials of the alloy material comprise a polyvinyl chloride substrate, a heat-resistant modifier, a heat stabilizer, a lubricator, a filler and a processing agent, and the alloy material is manufactured by a melt blending technique. The processing agent and the filler in the ingredients of the raw materials of the invention are the processing agent that is subjected to modification by a new method and the filler that is subjected to organic treatment, and by means of a mechanochemical reaction, self-plastification, toughening and reinforcement of the PVC can be combined organically to improve compatibility and dispersity of the polyvinyl chloride, the filler and heat-resistant resin, thus settling the problem about the contraction between the improvement of heat expansion performance and heat resistance of the PVC, and processing performance, strength and toughness of the PVC; the polyvinyl chloride engineering plastic with low expansion coefficient, high heat resistance, high strength, high toughness, excellent aging resistance and outstanding processing performance is manufactured; the invention has extensive industrial market prospect and the manufacturing method thereof is simple in technology, convenient in operation and control, stable in quality and high in production efficiency.

Owner:SICHUAN UNIV

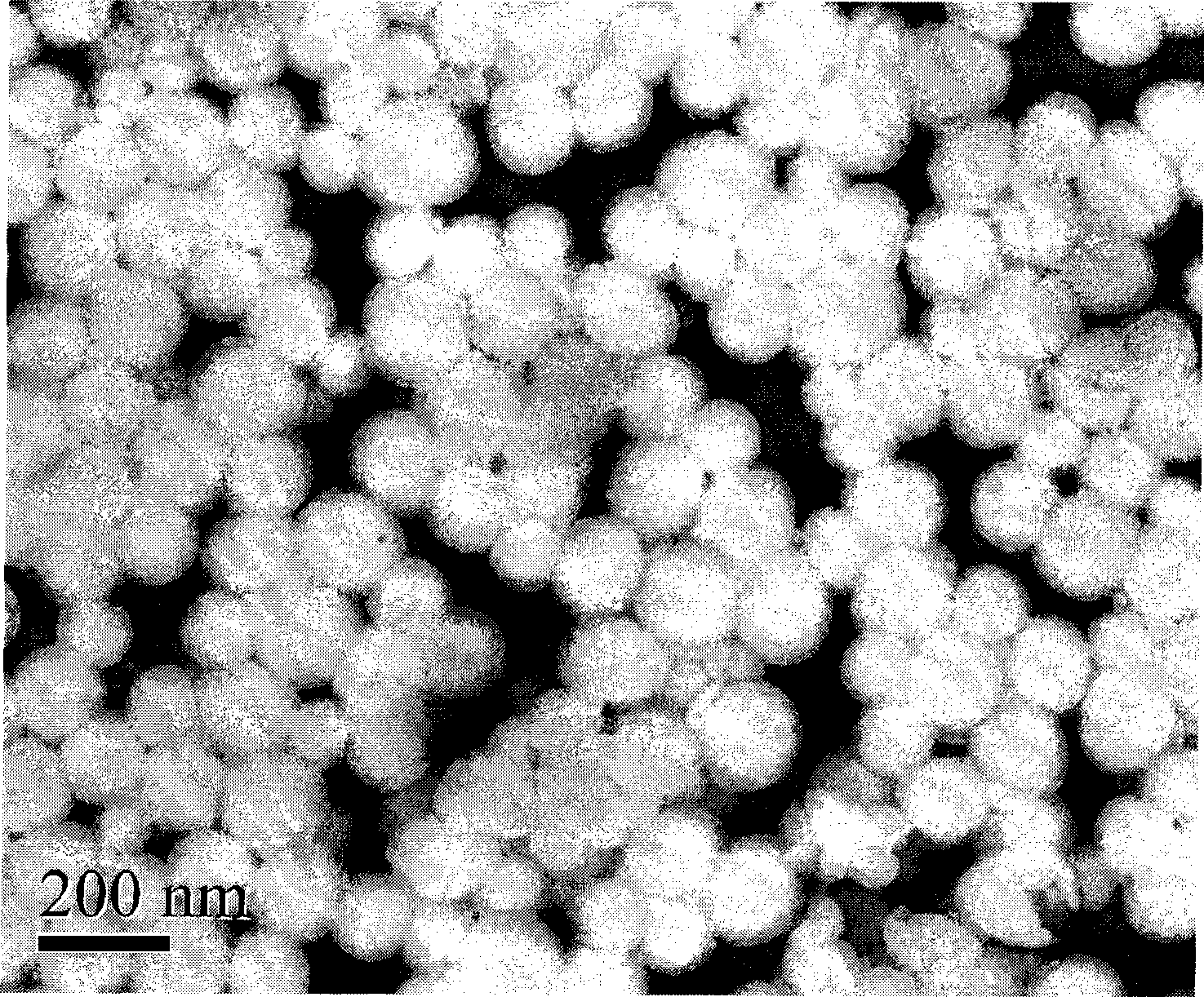

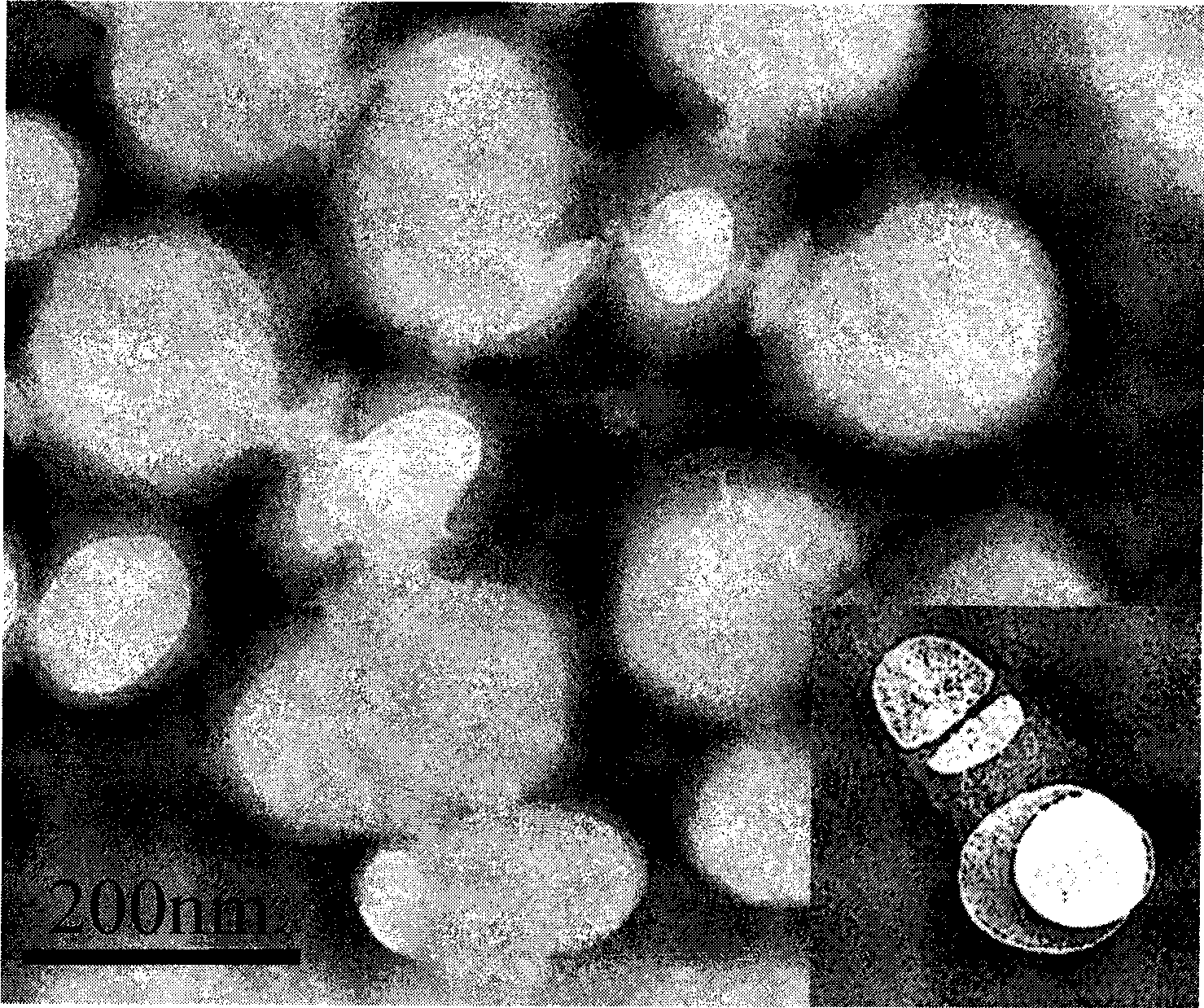

Nano silicasol / acrylic ester composite emulsion and preparation thereof

The invention discloses a nanometer silica sol / acrylic ester composite latex and a preparation method thereof. The composite latex is formed by polymerizing acrylic ester monomers with nanometer silica sol and alkylol solvent; emulsion particles in the composite latex are in a nanometer nucleus-shell structure taking silicon dioxide granules as nucleus and acrylic ester multipolymer as shells; and the preparation method adopts a seed emulsion polymerization method or in situ polymerization method. The composite latex has higher tensile-strength and tearing strength and better performances of acid durability, weather resisting property, wearing resistance, ultraviolet aging resistance, anti-pollution resistance, and the like, can be applied to various aspects of inner and outer wall dope, ground and terrace dope, ground coating of specialty sports fields, and the like, is green and environment-friendly, and has wide market foreground.

Owner:SHANGHAI SUNRISE CHEMISTRY CO LTD

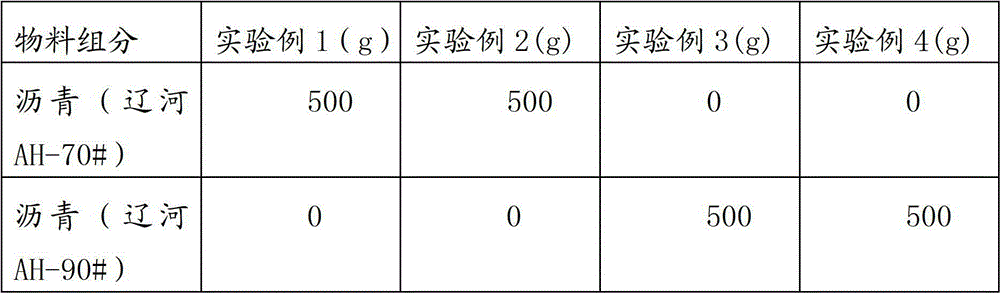

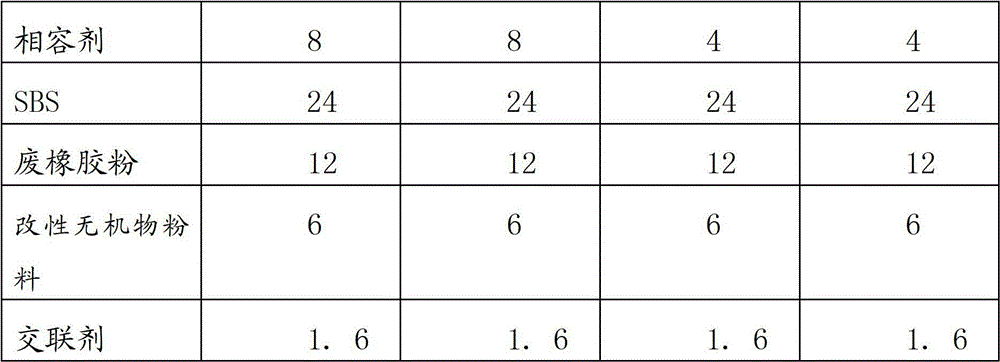

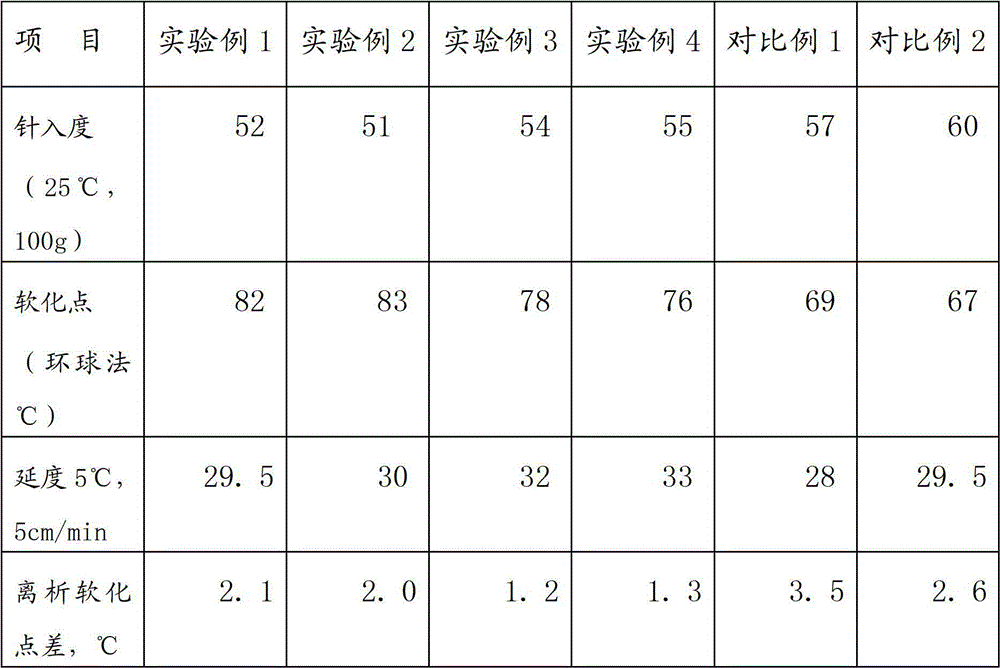

SBS (styrene-butadiene-styrene)/scrap rubber powder composite modified asphalt and preparation method thereof

InactiveCN102977621AImprove anti-aging propertiesReduce material costsBuilding insulationsHigh temperature storagePolymer science

The invention relates to an SBS (styrene-butadiene-styrene) / scrap rubber powder composite modified asphalt which comprises the following components in parts by weight: 75-96 parts of matrix asphalt, 0.5-12 parts of scrap rubber powder, 0.5-6 parts of SBS, 0.2-8 parts of modified inorganic substance powder, 0.1-8 parts of compatilizer and 0.1-3 parts of crosslinking agent. The preparation method comprises the following steps: preparing the scrap rubber powder; heating the matrix asphalt to 160-180 DEG C, adding the compatilizer while stirring, and evenly mixing; adding the SBS scrap rubber powder and modified inorganic substance powder, stirring at the speed of 1000-5000 rpm for 5-125 minutes while keeping the temperature, and adding the crosslinking agent; and quickly stirring for 20-300 minutes while keeping the temperature. The key technical indexes of the product are higher than those of the SBS modified asphalt; and the invention enhances the high / low-temperature properties and aging resistance, prolongs the high-temperature storage stabilization period, and completely satisfies the property requirements for national high-grade roads.

Owner:TIANJIN HI TECH ENVIRONMENT DEV CO LTD

Acrylic amide modified polymer micro-crosslinking gel and preparation thereof

InactiveCN101475691AImprove solubilityGood viscosity increasing effectDrilling compositionPolymer scienceSulfite salt

The invention discloses acrylamide modified polymer micro-crosslinking gel and a preparation method thereof. The preparation method is characterized in that the method comprises the following steps that: acrylamide modified polymer PAE containing functional macro monomer is prepared into an aqueous solution with the concentration between 0.1 and 4g / L, the concentration of crosslinking agent between 0.01 and 1.0g / L, the concentration of surface active agent between 0.01 and 8mmol / L and the concentration of heat stabilizer sodium sulfite between 0.005 and 1.0g / L; the aqueous solution is added in a mixing container with a stirring device and is stirred evenly at room temperature; the pH value of the solution is adjusted between 4 and 11 to prepare a polymer solution system of the acrylamide modified polymer micro-crosslinking gel used for tertiary oil recovery and displacement, oil displacement modification, profile modification or water plugging; and the polymer solution system undergoes micro crosslinking during flowing inside an oil layer to form the gel. The acrylamide modified polymer micro-crosslinking gel has ideal elasticity, difficult dehydration, stable performance and excellent performances on tackifying, temperature resistance, salt resistance, shearing resistance and ageing resistance.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Polyurethane resin composition, preparation method and application thereof

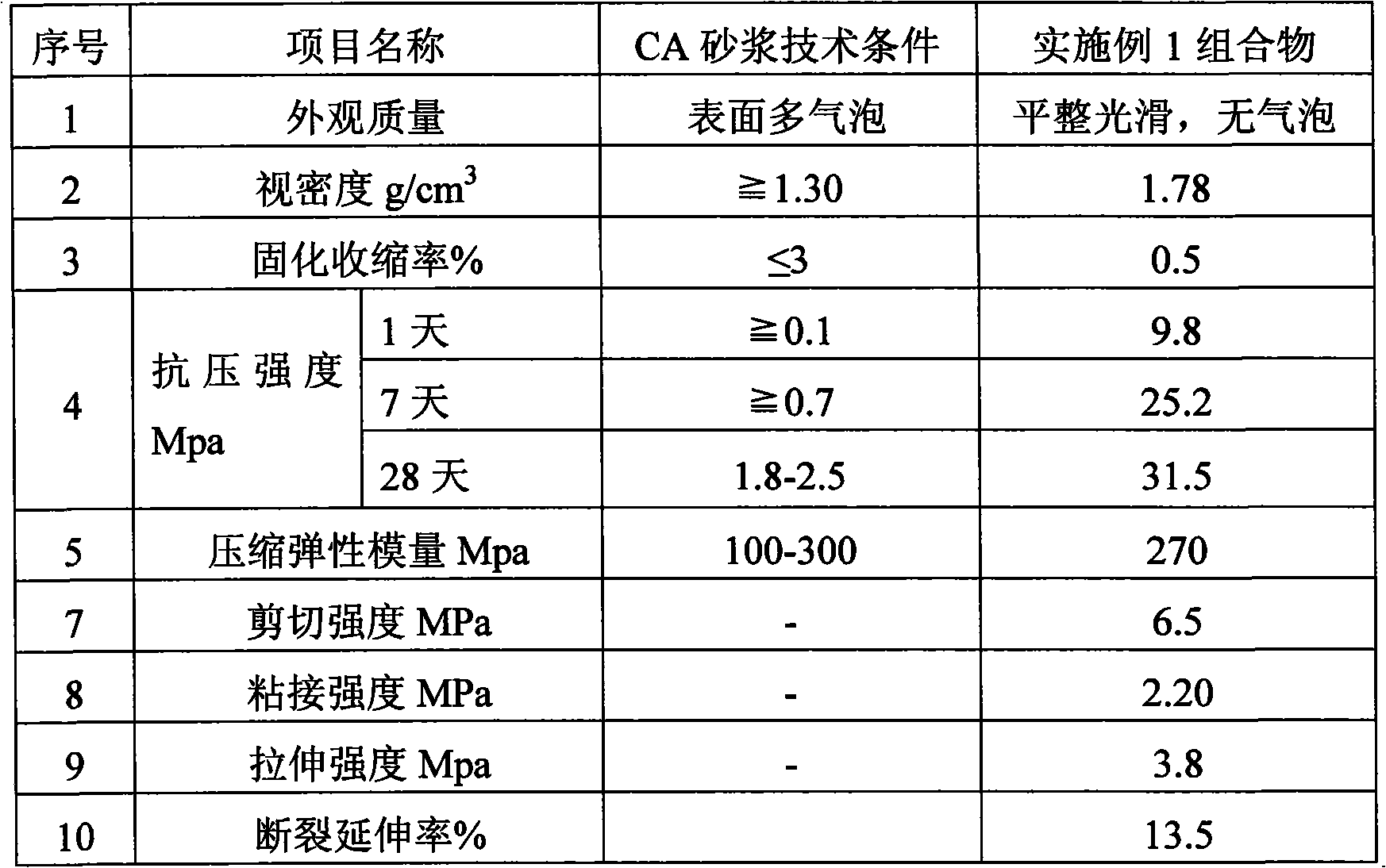

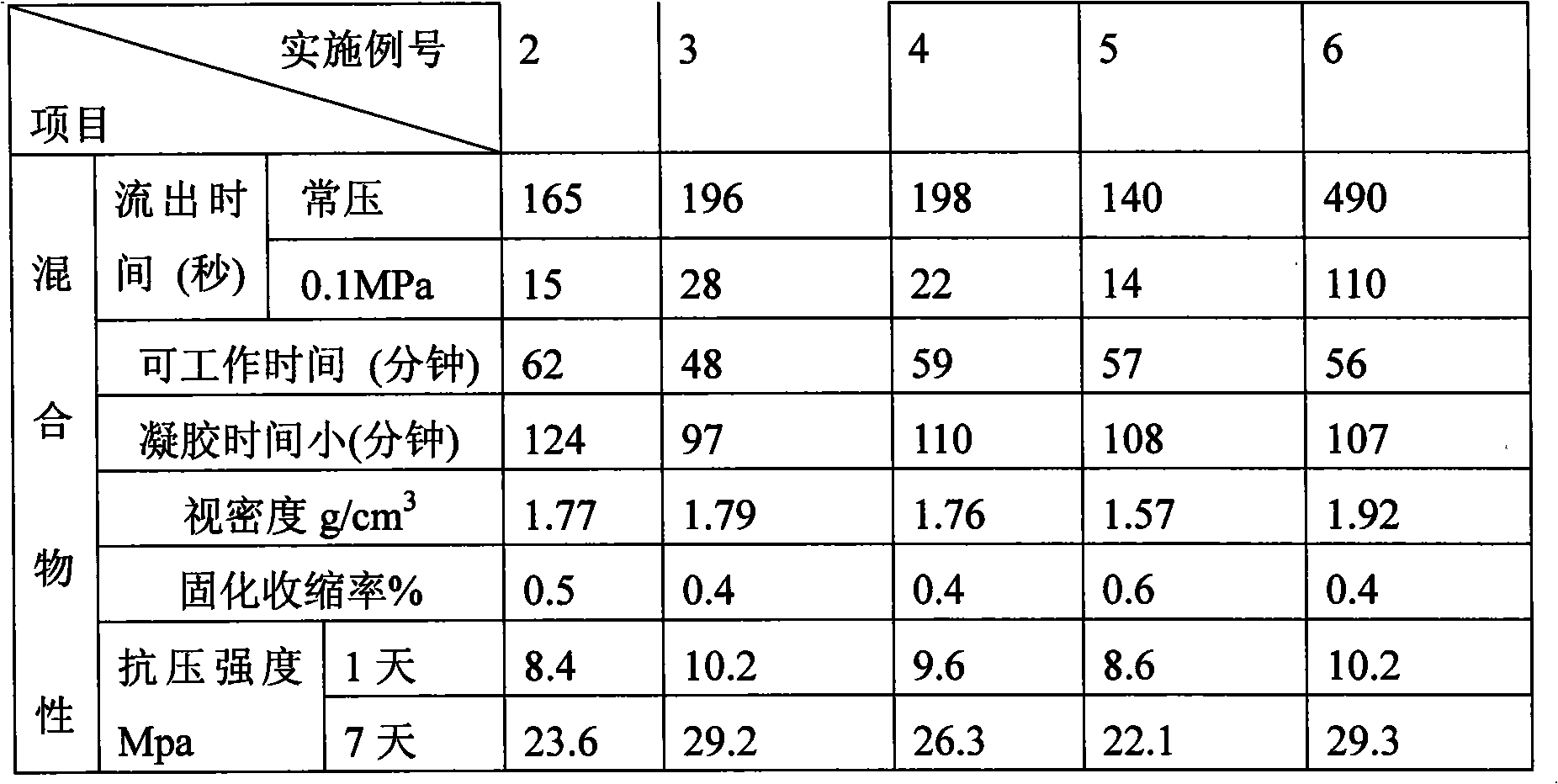

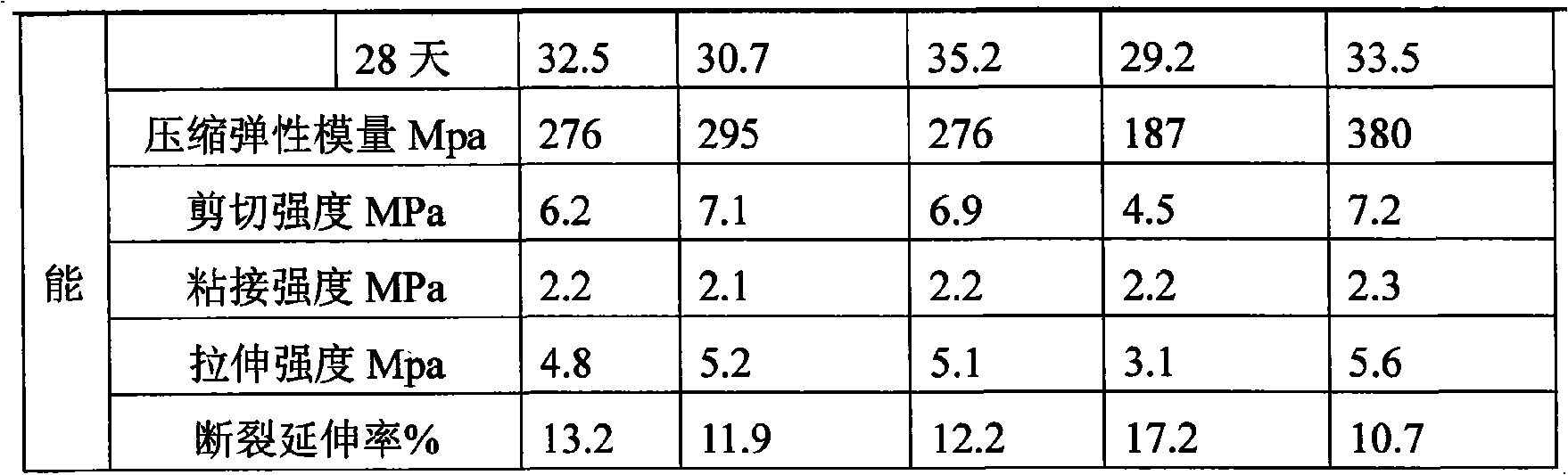

InactiveCN101735595AImprove water resistanceImprove featuresBallastwayTrack maintainencePolyolefinAlcohol

The invention provides a polyurethane resin composition, a preparation method and application thereof. The polyurethane resin composition comprises a component A and a component B, wherein the component A contains polyolein polyatomic alcohol, a plasticizer, an anti-settling agent and other auxiliary agents; the component B is isocyanate or prepolymer of the isocyanate; and the mass ratio of the A to the B is 10:1-1:10. A pouring material containing the resin composition can be used as a patching material for a cement road bed, a boss resin layer and a mortar packing layer of a railway plate-type unballasted track and has the advantages of high water resistance, ageing resistance and low temperature resistance, long service life and capability of being used at a low temperature.

Owner:METALS & CHEM RES INST CHINA ACAD OF RAILWAY SCI

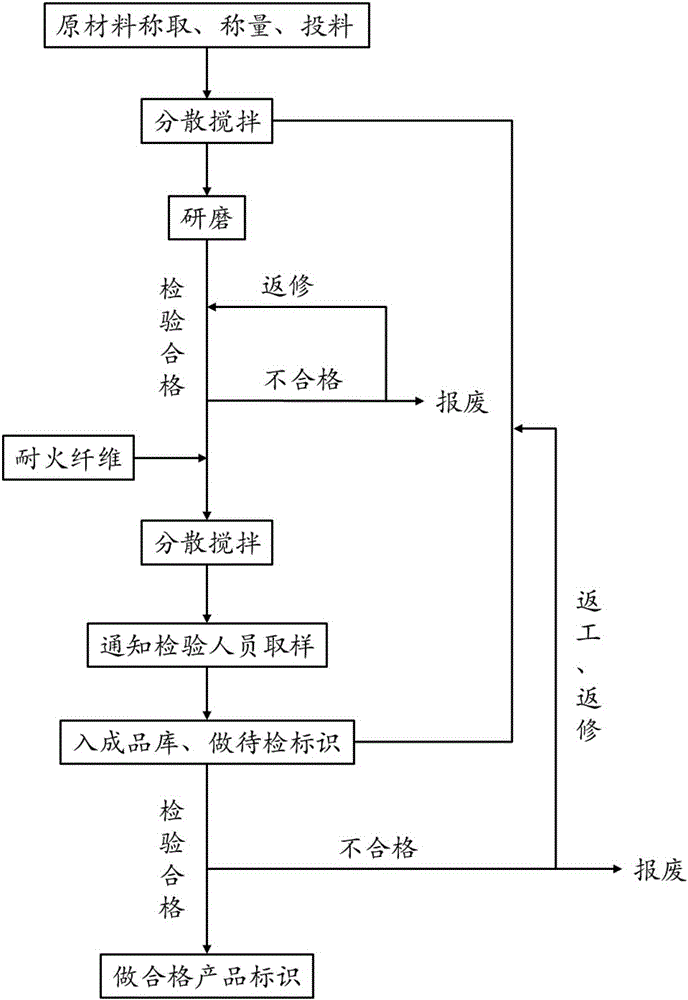

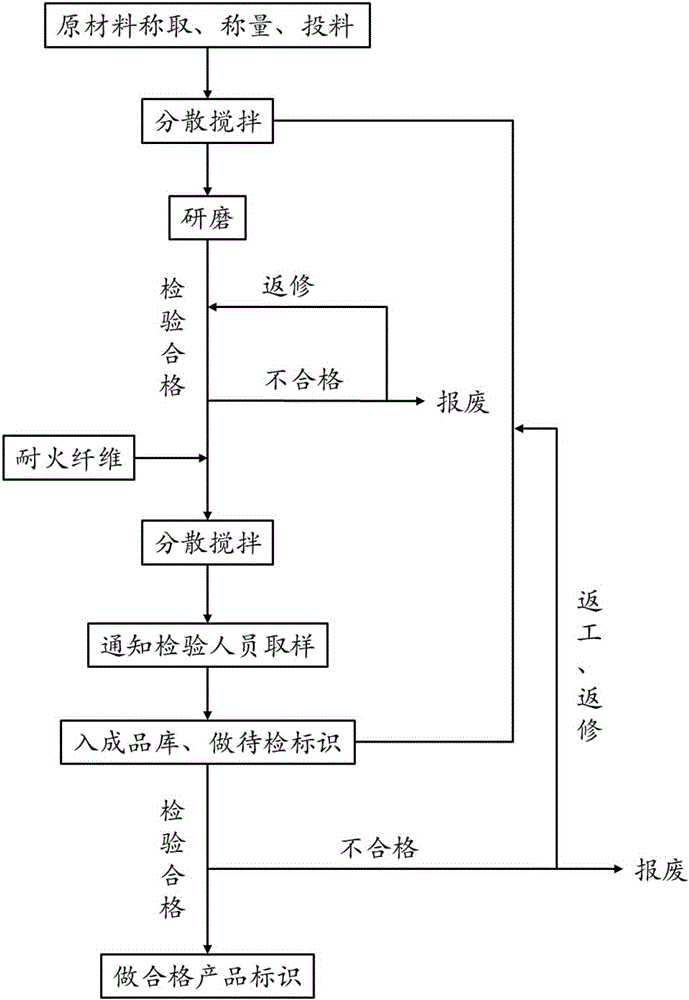

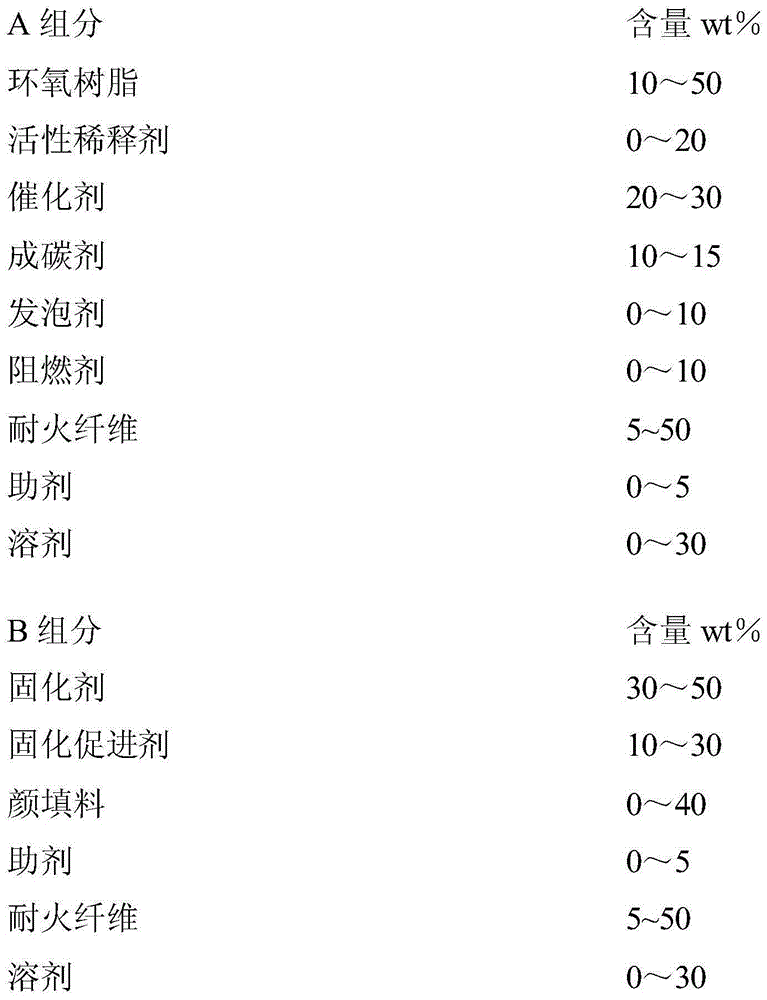

Environment-friendly epoxy intumescent fire-retardant coating and preparing method thereof

ActiveCN105238222AImprove acid resistanceGood alkali resistanceFireproof paintsEpoxy resin coatingsFiberAlkylphenol

The invention relates to an environment-friendly epoxy intumescent fire-retardant coating and a preparing method thereof, and belongs to the field of functional coatings. The environment-friendly epoxy intumescent fire-retardant coating is prepared from a component A and a component B, wherein the component A uses epoxy resin as a main film forming matter and is added with a reactive diluent, a catalyst, a carbon-forming agent, a foaming agent, fire retardant, auxiliaries and solvent, and the component B is composed of a curing agent, a curing accelerator, pigment filler, auxiliaries, refractory fibers and solvent. In the component A, the ratio of the epoxy resin to the reactive diluent is 1:1-5:1. In the component B, the ratio of the curing agent to the curing accelerator is 1:1-5:1, and the usage quantity of the refractory fibers accounts for 5-50% of the total mass. The environment-friendly epoxy intumescent fire-retardant coating is free of alkylphenol, or halogen compounds, or boron compounds or sulfocompounds. The prepared environment-friendly epoxy intumescent fire-retardant coating is good in acid resistance, alkali resistance, water resistance, ageing resistance and salt mist resistance and is particularly suitable for fire-retardant protection for maritime and severe outdoor environments, the petrochemical industry and places with hydrocarbon fire potential hazards.

Owner:MARINE CHEM RES INST

Super-high early-strength grouting material for repairing ballastless track structure of high speed railway

The invention discloses a super-high early-strength grouting material for repairing a ballastless track structure of a high speed railway, which is prepared by the following steps of: sequentially adding water, polymer emulsion, a water reducing agent, a rheology accessory agent and an antifoaming agent; adding admixture, cement, an expansion agent, a coagulator and a retarder, and stirring and blending the materials at a high speed. The parts by weight of the ingredients are as follows: 100 parts of superfine cement, 50-150 parts of admixture, 25-50 parts of redispersible emulsion powder, 3-10 parts of polymer emulsion, 5-25 parts of expansion agent, 0.1-1.0 part of carboxylic acid water reducing agent, 0.1-10 parts of coagulator, 0.1-5 parts of retarder, 0.001-0.005 parts of rheology accessory agent, 0.001 part of polyether-siloxane copolymer antifoaming agent and 20-70 parts of water. The material disclosed by the invention has the advantages of low viscosity, super-high early-strength, low cost, fatigue resistance, aging resistance and water erosion resistance, and the like, so that the material can be used for repairing the concrete gaps of ballastless tracks of high speed railways, gaps of cement asphalt mortar filling layers, cracks and damages.

Owner:四川昊龙高科轨道交通新材料科技股份有限公司

Spray polyurea elastomer for mine, preparation and construction method thereof

InactiveCN101302393ANot affected by ambient temperatureNot affected by ambient humidityLiquid surface applicatorsPolyurea/polyurethane coatingsElastomerPolyol

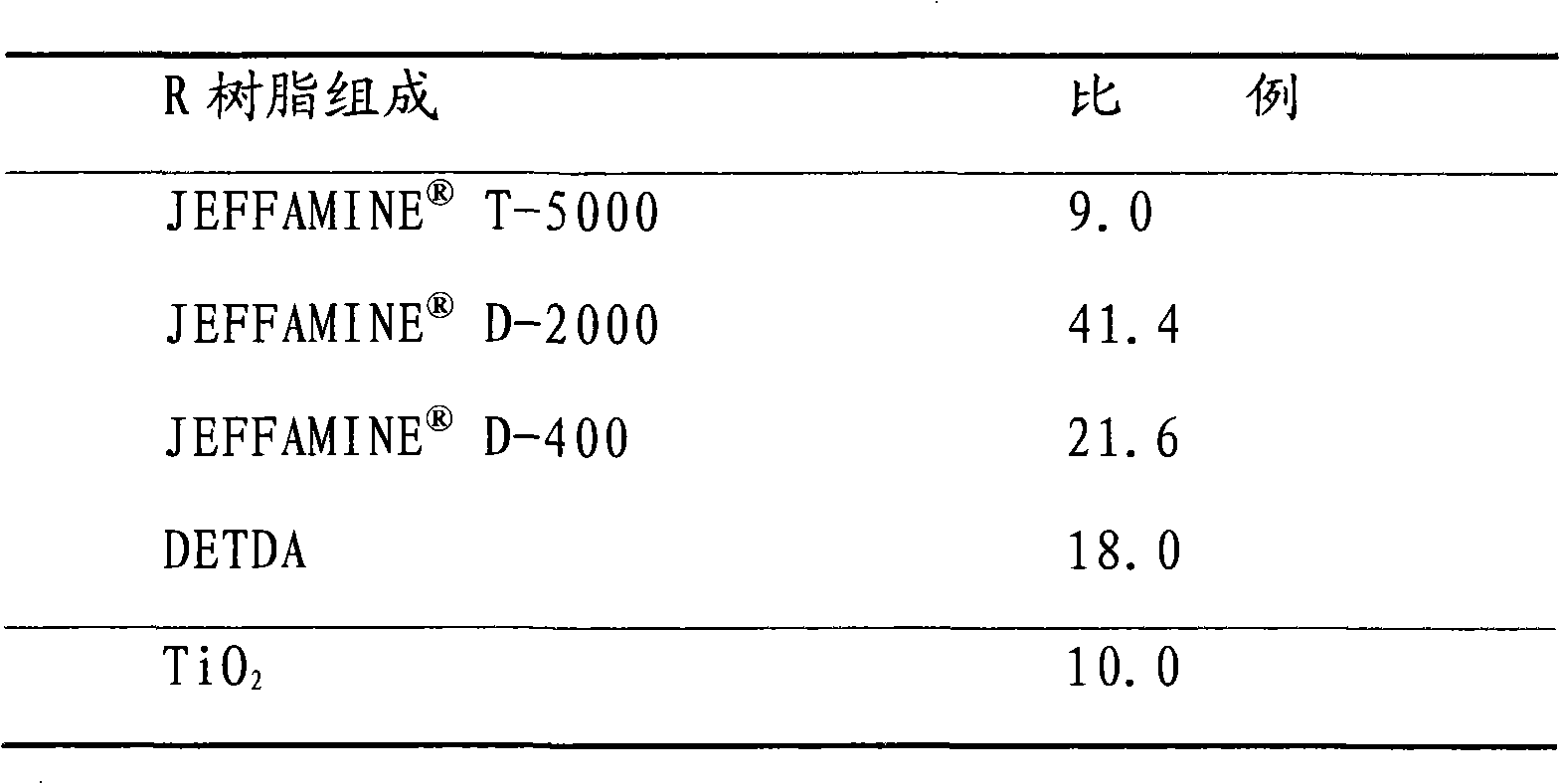

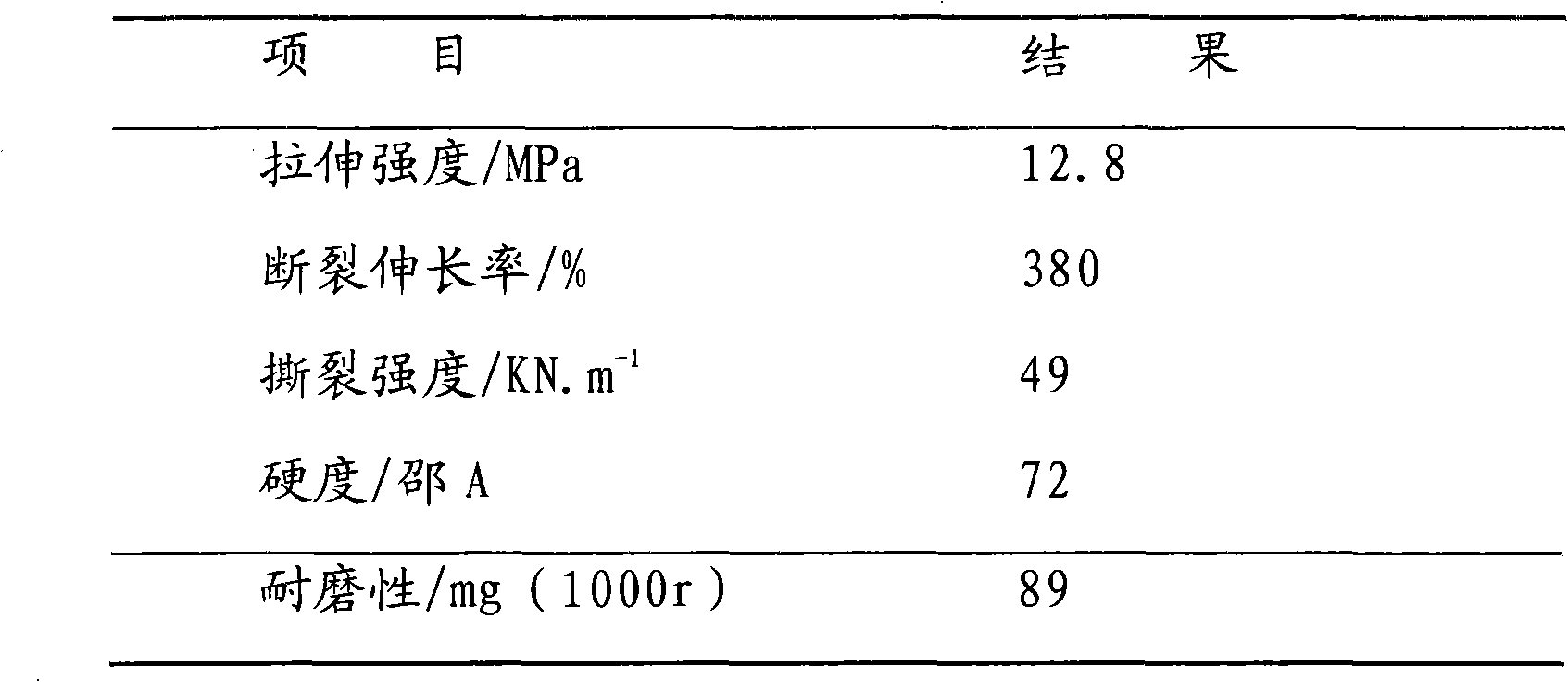

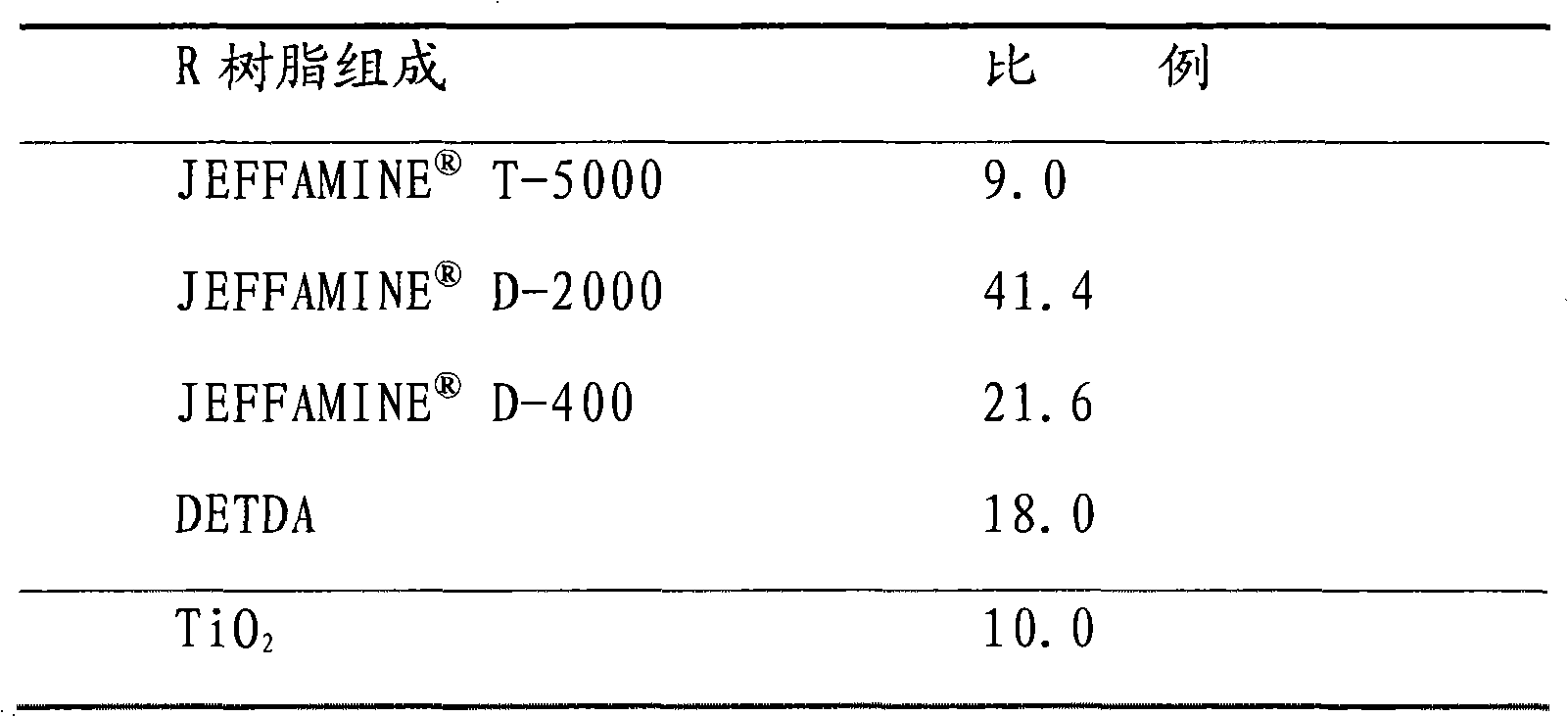

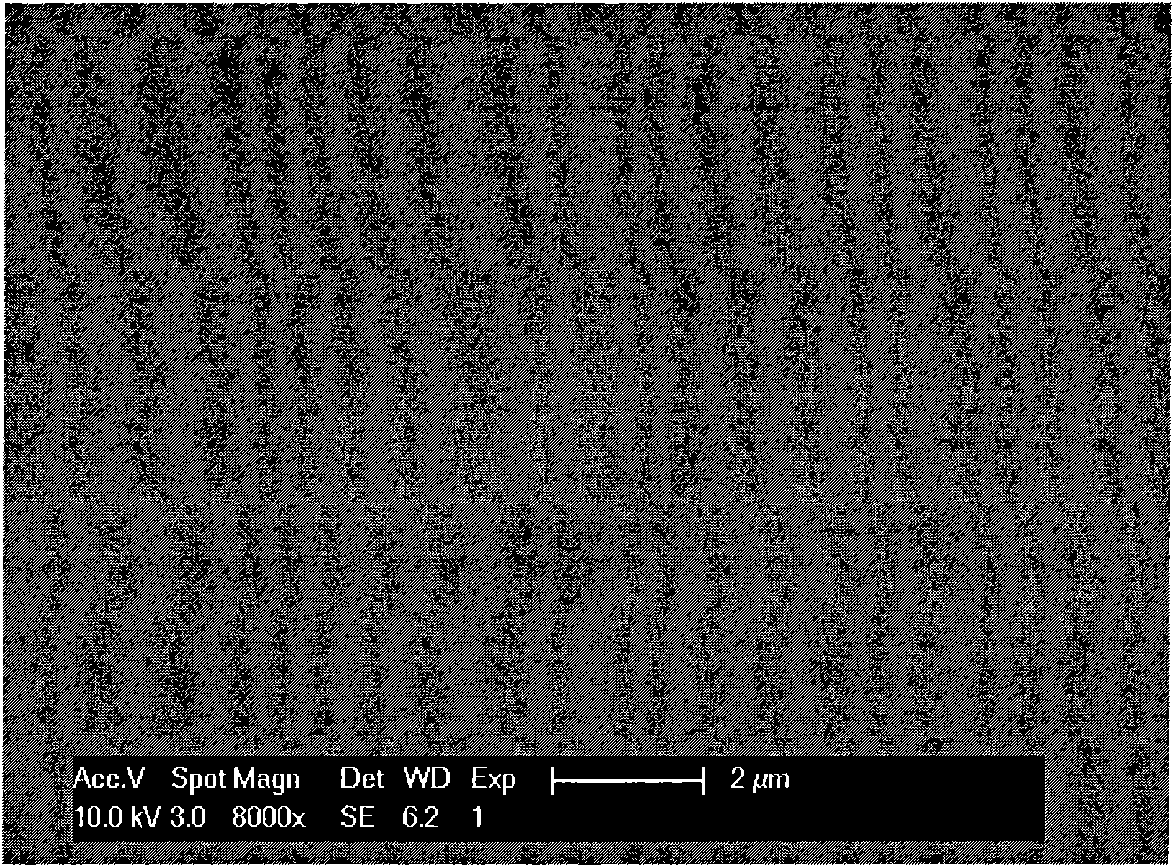

The invention provides a spraying polyurea elastomer applied to a mine, a method for making the same and a construction method. The spraying polyurea elastomer can solve the problem of poor wearing resistance in the prior art. The invention comprises the following technical proposals that: the spraying polyurea elastomer applied to the mine comprises two compositions A and R, wherein, the composition A is a semi-prepolymer synthesized by 45 to 65 portions of polyisocyanate and 35 to 55 portions of polyether polyol; the composition R comprises 55 to 80 portions of amine terminated polyether, 15 to 33 portions of chain extender and 5 to 25 portions of antiwear filler; and the compositions A and R are matched for use according to an isocyanate index of between 0.9 and 1.2. The spraying polyurea elastomer has good physical performance, high wearing resistance, good oil resistance, hydrolization resistance, bacteria resistance and aging resistance and good construction performance and can be used in a vibration sieve equipment lining, a flotation equipment lining, etc. of the mine and other application places which have high requirement on wearing resistance.

Owner:青岛佳联化工新材料有限公司

Novel nano modified antimicrobial water-based woodware paint

InactiveCN103059669ANo pollution in the processNon-flammableAntifouling/underwater paintsPaints with biocidesWater basedAcrylic resin

The invention discloses a novel nano modified antimicrobial water-based woodware paint which comprises acrylic resin emulsion, polyurethane resin emulsion, nano silica sol, nano aluminum oxide, nano titanium dioxide, nano silver, film-forming assistant, defoaming agent, wetting and dispersing agent, leveling agent, thickening agent, wax emulsion and pH regulator. The nano materials dispersed in the water-based paint enhance the hardness of the coated film, so that the coated film has excellent yellowing resistance, aging resistance and mold resistance.

Owner:高凡

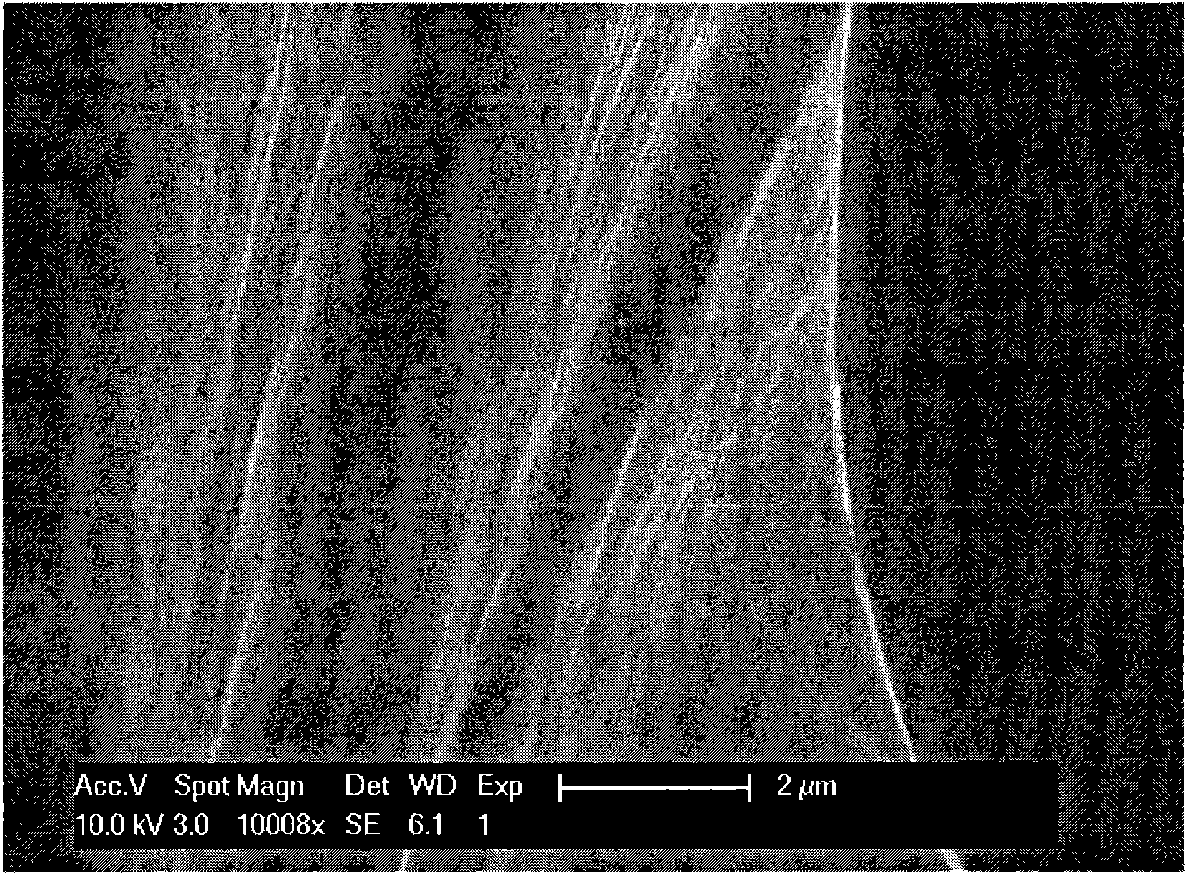

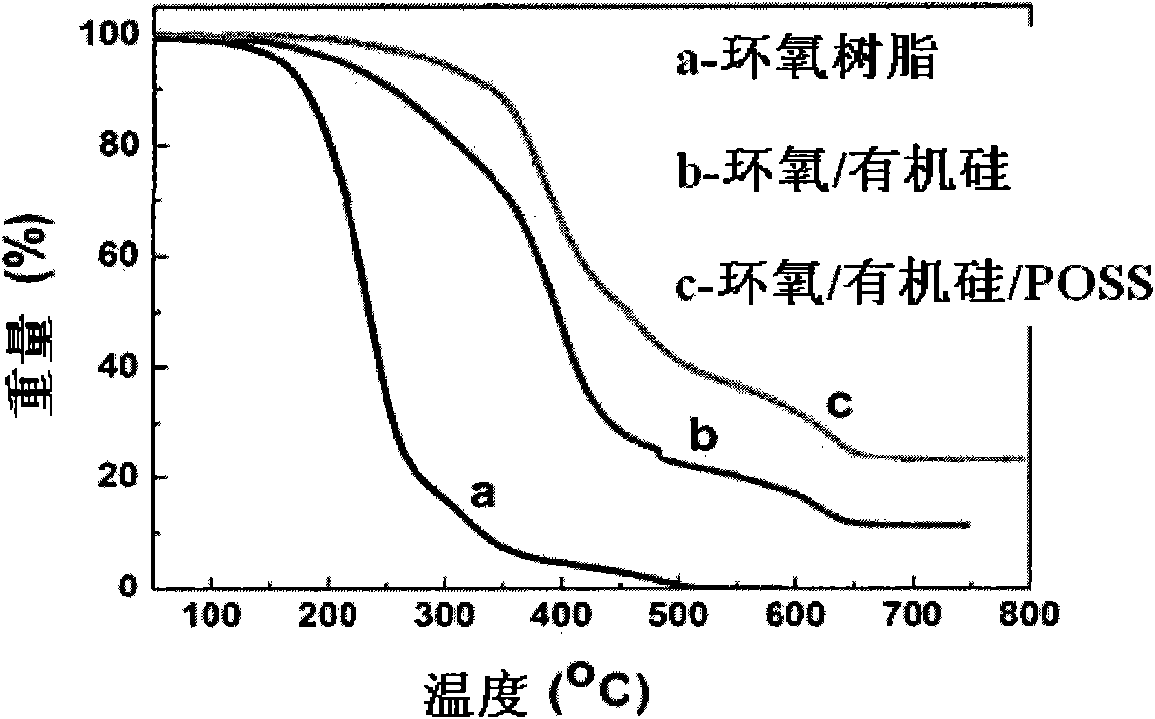

Low-stress epoxy/organic silicon/POSS nano hybrid material, and preparation method and application thereof

InactiveCN101974227AImprove thermal stabilityHigh light transmittanceEpoxy resin adhesivesEpoxy resin coatingsChemical industryEpoxy

The invention relates to the technical fields of photoelectricity and chemical industry, in particular to a low-stress epoxy / organic silicon / POSS nano hybrid material, and a preparation method and application thereof. The epoxy / organic silicon / POSS nano hybrid material comprises (a) an epoxy resin, (b) a polyorganosiloxane, (c) a cage-type polysilsesquioxane (POSS), (d) an epoxy hardener, (e) non-essential silane oxycompound and (f) non-essential assistants, wherein the polyorganosiloxane contains epoxy groups and silane oxygen groups. The cured nano hybrid system has excellent reticular cross-linked structure and does not have microphase separation. The epoxy / organic silicon / POSS nano hybrid material has the advantages of high mechanical strength, favorable heat resistance, favorable cohesive property, high chemical stability, favorable ultraviolet aging resistance, favorable optical transparency and other excellent properties, has the functions of low internal stress and pressure buffer, and can be used as an LED packaging material, optical protection material, circuit protection coating material, adhesive paint and the like.

Owner:FUDAN UNIV +1

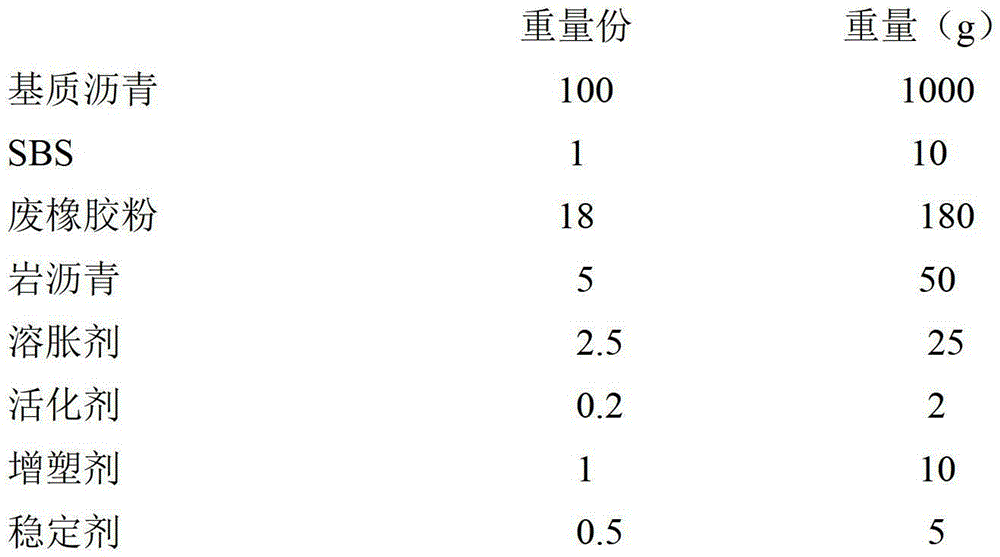

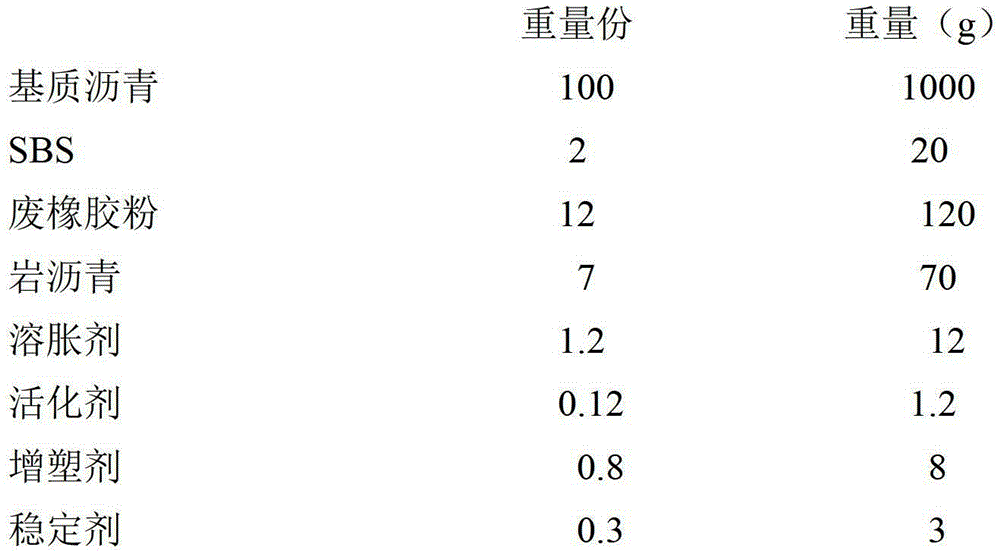

Ultraviolet aging-resistant compound modified asphalt and preparation method thereof

ActiveCN103146207AImprove anti-aging propertiesStop breakingTreatment with plural serial refining stagesBuilding insulationsPolymer modifiedPolymer science

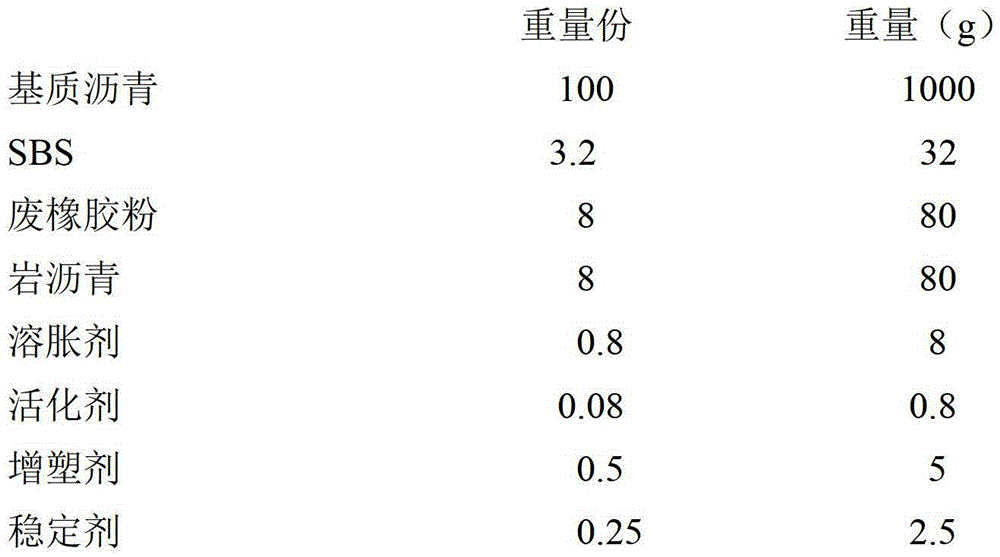

The invention belongs to the technical field of road asphalt modification and relates to an ultraviolet aging-resistant compound modified asphalt, wherein on the basis of 100 parts by weight of matrix asphalt, in parts by weight, 1-6 parts of styrene-butadiene-styrene block copolymer, 3-18 parts of waste rubber powder, 5-10 parts of rock asphalt, 0.3-2.5 parts of sweller, 0.03-0.2 part of activator, 0.1-1 part of plasticizer and 0.2-0.5 part of stabilizer are further added, wherein the sweller is furfural extract oil which is subjected to dewaxing treatment previously; the furfural extract oil contains 60wt%-88wt% of aromatic components which contain 40-65wt% of heavy aromatic hydrocarbon; and the waste rubber powder is waste rubber tire tread rubber powder having the content of carbon black between 28wt% and 58wt% and the grain diameter between 45 and 80 meshes. The ultraviolet aging-resistant compound modified asphalt provided by the invention is up to the standard of the polymer modified asphalt in performance, and the ultraviolet aging resistance of the asphalt is improved to a large extent; and waste resources are utilized.

Owner:HUBEI GUOCHUANG HI TECH MATERIAL

Epoxy resin mortar composite used for plate type fragment-free track

The invention discloses an epoxy resin mortar composite and an application of the composite for a filling material of railway plate type fragment-free track elastic adjusting layer, the epoxy resin mortar composite is composed of A, B and C three parts of materials, wherein part A is composed of the following materials according to parts by weight: 80-100 parts of epoxy resin, 1-10 parts of paint, 0-100 parts of diluent, 0-50 parts of toughening agent, 0-5 parts of ultraviolet absorbent, 0-5 parts of antioxidant, 0-2 parts of antifoaming agent and 0-5 parts of coupling agent; part B is curing agent; part C is filler, and the weight ratio of A, B and C parts is 80-100:5-100:50-600. Detection shows that the epoxy resin mortar composite provided by the invention has, for cement components, excellent adhesion stress, strong wet-heat aging resistance and chemical corrosion resistance and better elasticity and mechanical strength, thereby satisfying requirements of different climatic conditions and different construction conditions.

Owner:CHANGSHU JIAFA CHEM

Thin-wall insulated electric wire material for automobile and preparation method of electric wire material

ActiveCN102964724ACompatibility is reasonableImprove physicsPlastic/resin/waxes insulatorsInsulated cablesCombustionWear resistant

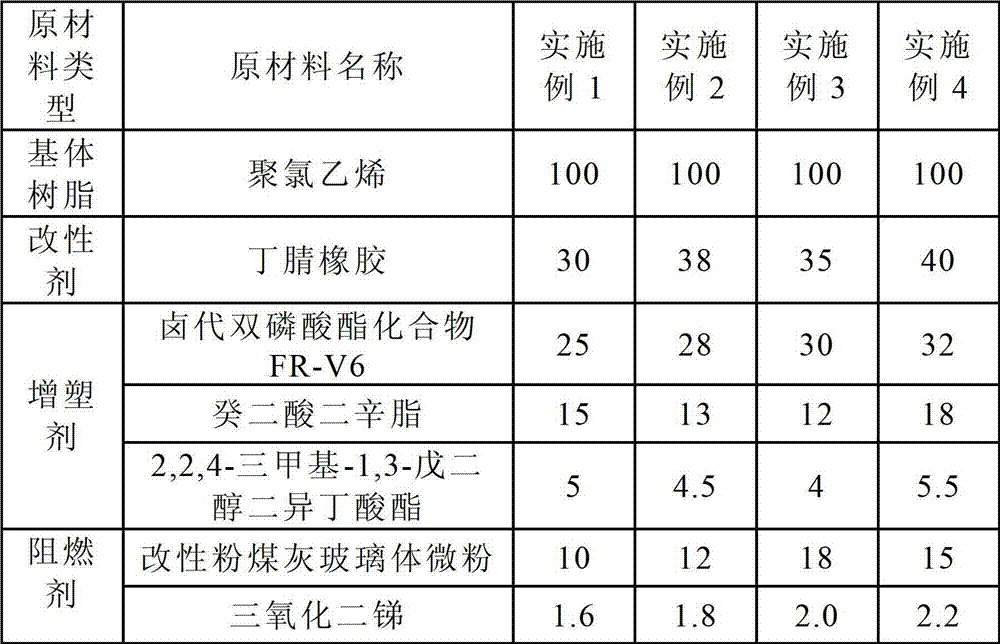

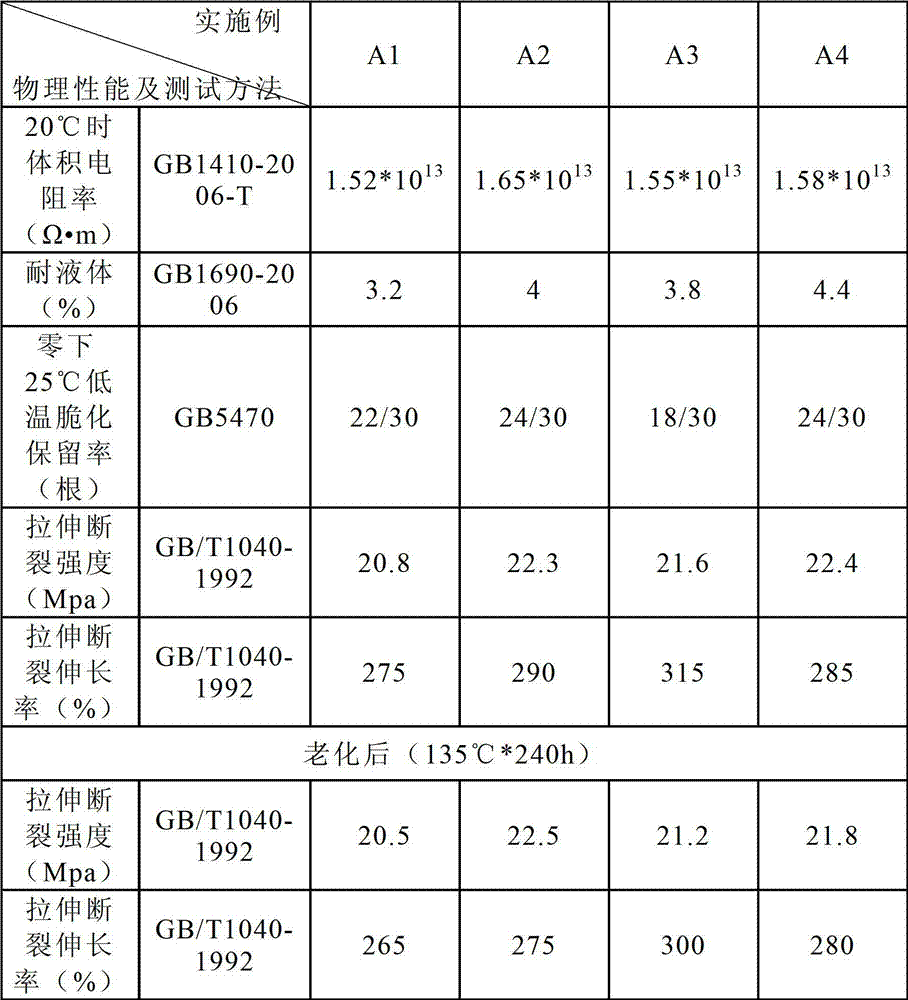

The invention relates to a thin-wall insulated electric wire material for an automobile and a preparation method of the electric wire material, belonging to the technical field of materials, and solving the problem that cable wires cannot meet long-time ageing resistance, low-temperature resistance, high-temperature resistance, high physical performance, no drop during combustion, good liquid resistance and the like simultaneously in the prior art. The cable material comprises the following ingredients in parts by weight: 100 parts of matrix resin, 30-40 parts of modifier, 40-60 parts of plasticizer, 15-25 parts of filler, 50-60 parts of flame retardant, 5-10 parts of stabilizer, 1-5 parts of wear-resistant agent, and 1-5 parts of auxiliaries, wherein the plasticizer is the mixture of halogenated biphosphate compound FR-V6, dihexyl sebacate and 2,2,4-trimethyl-1,3-pentanediol di-isobutyrate in a weight ratio of (5-10): (3-6): 1. The thin-wall insulated electric wire material for the automobile disclosed by the invention is good in physical performance, resistant to long-time ageing, and low in cost.

Owner:ZHEJIANG SHIP ELECTRONICS TECH

Starch-based edible film and preparation method thereof

InactiveCN101906220ARich sourcesReduce manufacturing costFlexible coversWrappersPliabilityStabilizing Agents

The invention relates to a starch-based edible film and a preparation method thereof. The starch-based edible film is a starch-based edible packaging film with favorable flexibility, barrier property, ageing-resistance property and heat sealing property, which is prepared by adopting the preparation method comprising the following steps of: adding a food-grade plasticizer, a lubricating agent, a reinforcing agent, a stabilizing agent and other accessories by taking stably-degraded composite modified starch as a main film-forming raw material, stirring and mixing at high speed, carrying out double-screw extrusion granulation and then carrying out single-screw extrusion casting to obtain the finished product. The invention has the characteristics of low energy consumption and high production efficiency and is suitable for industrial continuous production. The prepared film in the invention has edibility and full degradability, can be widely applied to inner packaging of foods, and avoids non-degradable food packages from polluting the environment.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Preparation method of nano-silicon-dioxide-modified water-based polyurethane

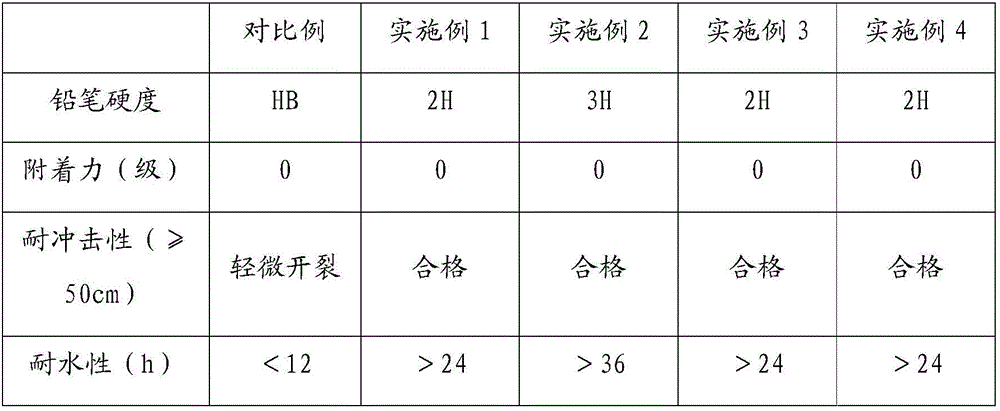

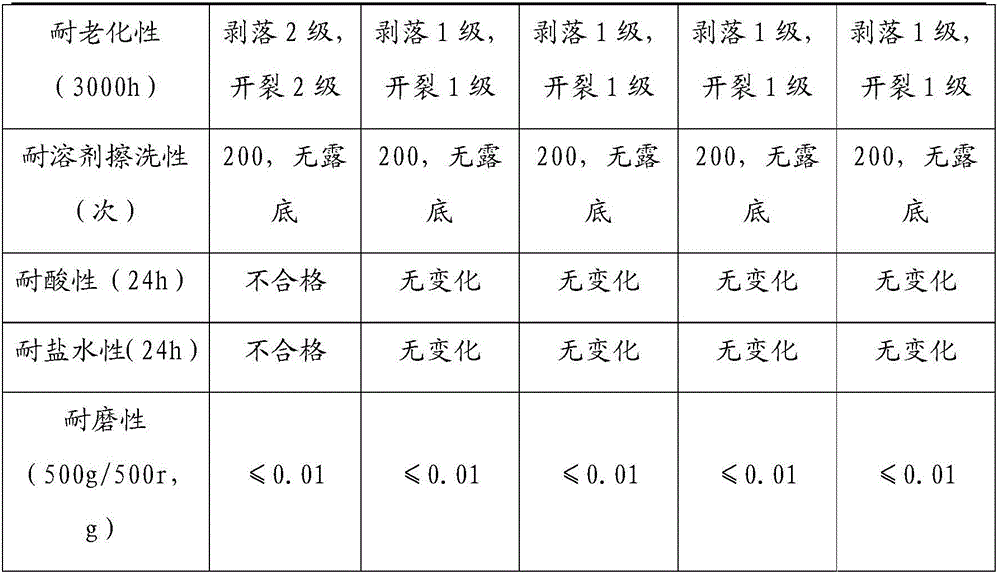

The invention discloses a preparation method of nano-silicon-dioxide-modified water-based polyurethane. The method comprises the following steps: (1) preparing a water-based polyurethane prepolymer by a conventional process; (2) silane-coupling-agent-modified nano silica sol: diluting nano silica sol with a small amount of isopropanol, mixing with a silane coupling agent, and stirring to react at normal temperature for 30 minutes, thereby obtaining the silane-coupling-agent-modified nano silica sol; and (3) adding the water-based polyurethane prepolymer obtained in the step (1) into the silane-coupling-agent-modified nano silica sol obtained in the step (2), adding deionized water and a small-molecule amine chain extender, carrying out high-speed shear emulsification and dispersion at normal temperature for 15-30 minutes, and carrying out reduced pressure distillation to remove the solvent, thereby obtaining the nano-silicon-dioxide-modified water-based polyurethane. The film formed by the resin prepared by the method has excellent hardness, adhesion, impact resistance, water resistance, aging resistance, solvent scrubbing resistance, acid resistance, saline water resistance, wear resistance and the like.

Owner:HANGZHOU JIHUA POLYMER MATERIAL CO LTD

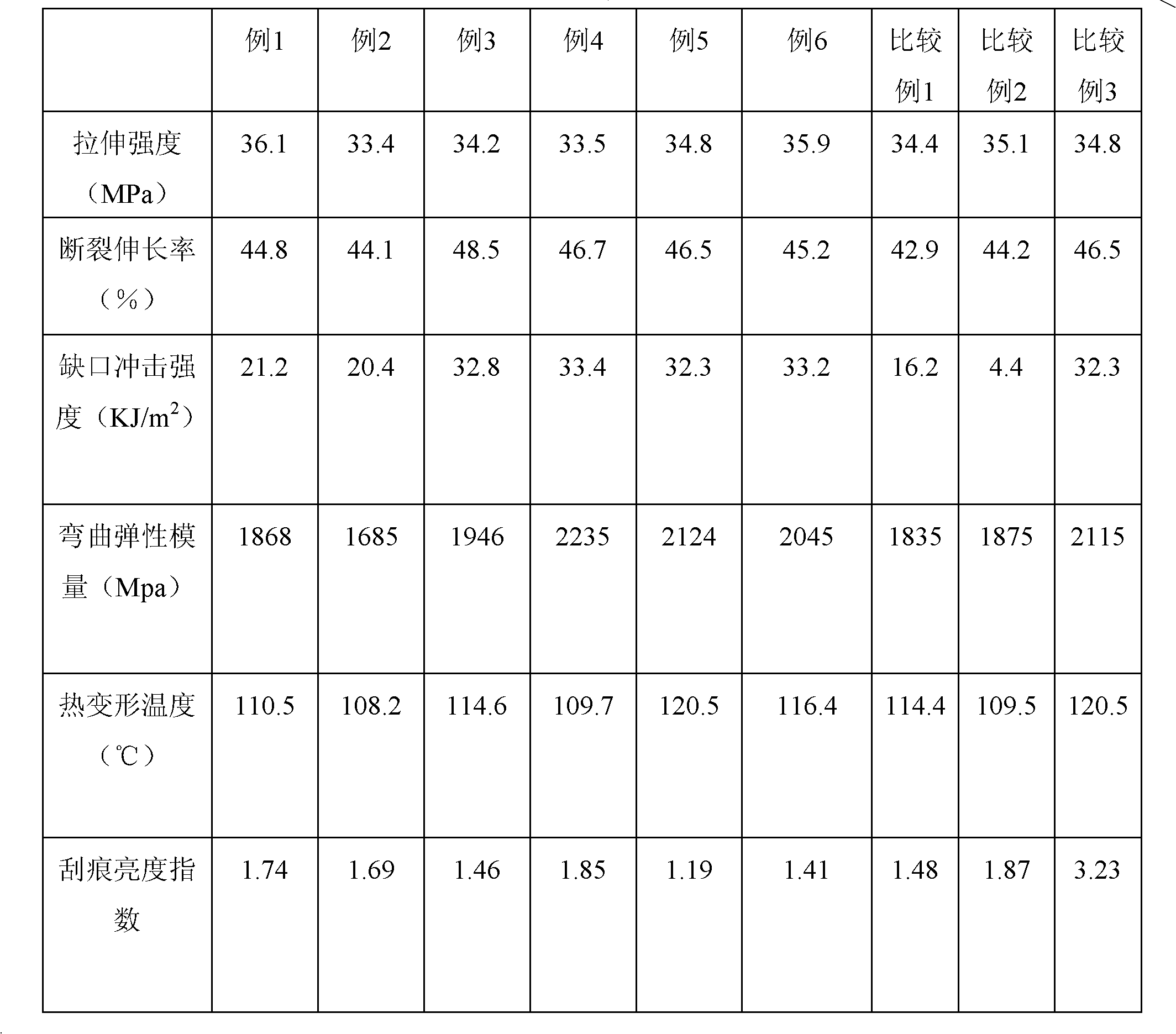

High-tenacity heat-resisting ageing-resisting chlorinated polyvinyl chloride alloy material and preparation method thereof

The invention relates to a high-tenacity heat-resisting ageing-resisting chlorinated polyvinyl chloride alloy material which comprises the following raw materials in weight parts: 100 parts of chlorinated polyvinyl chloride, 1-50 parts of impact modifier, 1.5-10 parts of thermal stabilizer, 0.1-10 parts of lubricant, 0.5-15 parts of PVC processing aid, 0.1-0.5 part of antioxidant and 0-40 parts of filler. The invention solves the problems of low heat resistance and aging resistance while improving the tenacity of CPVC in the prior art; and the Vicat softening point can vary within the range of 104 to 119 DEG C, the tensile strength can reach 45-64 MPa, and the notch impact strength can be increased by more than 200 percent.

Owner:LIAOCHENG UNIV

Preparation method of thermoplastic polyurethane elastomer

InactiveCN103059554AImprove mechanical propertiesImprove heat resistancePolyethylene glycolHydrolysis

Owner:DONGGUAN JIXIN POLYMER SCI & TECH

EVA (Ethylene Vinyl-Acetate) packaging glue film with high gas-water barrier property and preparation method thereof

InactiveCN103756579AImprove barrier propertiesImprove hydrolysis resistanceNon-macromolecular adhesive additivesFilm/foil adhesivesAntioxidantAging resistance

The invention discloses an EVA (Ethylene Vinyl-Acetate) packaging glue film with high gas-water barrier property and a preparation method thereof. The glue film is prepared from the following raw materials in parts by weight: 100 parts of an EVA copolymer, 0.5-5 parts of a crosslinking agent, 0.1-0.5 part of an antioxidant, 0.1-0.5 part of an ultraviolet absorber, 0.05-0.5 part of a light stabilizer, 0.1-3 parts of a silane coupling agent and 0.01-55 parts of a water resistant. The preparation method comprises the following steps: plastifying and extruding; stretching; drawing; rolling and the like. The glue film disclosed by the invention has the beneficial effects that the EVA glue film obtained by the invention has good gas-water barrier property and hydrolysis resistance as well as better damp-heat aging resistance.

Owner:CHANGZHOU SVECK PHOTOVOLTAIC NEW MATERIAL

Novel rubber protective wax

The invention discloses a novel rubber protective wax which comprises the following components in percentage by weight: 14-20 percent of paraffin, 55-60 percent of mixed crystal wax, 24-30 percent ofmicrocrystalline wax and 1-2 percent of polyethylene wax. The invention has favorable seal performance and can reinforce the ozone and ageing resistance of a rubber product and prolong the service life of the rubber product.

Owner:上海绿菱特种蜡制品厂

Single-component addition-type silicone rubber and preparation method thereof

The invention provides a single-component addition-type silicone rubber which is prepared by vulcanizing the following raw materials in parts by mass: 20-50 parts of vinyl polysiloxane, 3-18 parts of vinyl methyl phenyl polysiloxane, 4-20 parts of hydrogen-containing polysiloxane, 0.01-0.1 part of platinum catalyst, 0.3-2.5 parts of inhibitor, 40-60 parts of filler, 2.0-10 parts of additive and 0.5-3 parts of tackifier. The single-component addition-type silicone rubber comprises the heat-resistant additive and the filler, so that the single-component addition-type silicone rubber prepared by vulcanizing has good high temperature resistance and low temperature aging resistance. The single-component addition-type silicone rubber comprises the catalytic inhibitor, so that the single-component addition-type silicone rubber has a higher inhibitory effect, and the storage life of the single-component addition-type silicone rubber is prolonged. When the addition-type silicone rubber is vulcanized, small molecular substances are not produced, and packaging components are not corroded.

Owner:ZHUZHOU TIMES ELECTRIC INSULATION

High-elasticity waterborne polyurethane-acrylate composite resin, and preparation method and application thereof

The invention relates to a high-elasticity waterborne polyurethane-acrylate composite resin which is prepared mainly from the following raw materials: 7 to 20 parts by mass of aliphatic polyisocyanates with highly symmetrical structure, 25 to 45 parts by mass of polyether polyol, 0 to 0.03 parts by mass of polyurethane catalyst, 0 to 2 parts by mass of low molecular weight alcohol chain extender, 1 to 6 parts by mass of hydrophilic chain extender, 0.4 to 1.5 parts by mass of low molecular weight amine chain extender, 1 to 4 parts by mass of organic amine neutralizer, 20 to 60 parts by mass of (methyl) acrylate monomer and 0.08 to 1.3 parts by mass of free radical initiator. The high-elasticity waterborne polyurethane-acrylate composite resin disclosed by the invention has good mechanical property at different using temperatures. A coating prepared from the high-elasticity waterborne polyurethane-acrylate composite resin not only has excellent mechanical property, but also has excellent water resistance, alkali resistance, stain resistance and ageing resistance, so the high-elasticity waterborne polyurethane-acrylate composite resin is very suitable for preparing the single-component elastic coating in the field of buildings.

Owner:WANHUA CHEM GUANGDONG

Modified polypropylene material as well as preparation method and application thereof

InactiveCN102464830AImprove rigidityNo lack of resilienceLinear low-density polyethyleneAging resistance

The invention belongs to the technical field of high molecule modification and processing and relates to a modified polypropylene material as well as a preparation method and application thereof. The material provided by the invention comprises the following components in parts by weight: 40-50 parts of bulk polypropylene, 20-35 parts of co-polypropylene, 15-24 parts of toughening agent, 0-15 parts of linear low-density polyethylene, 8-15 parts of filler retention aid, 6-12 parts of compatilizer, 0-8 parts of scratch-resistant smoothing agent, 0.5-1 part of lubricating agent, 3.5-5 parts of composite antioxidant and 1.5-3 parts of coupling agent. Compared with the prior art, the modified polypropylene material provided by the invention has the advantages of good rigidity, ductility, improvement on impact strength, heat resistance, ageing resistance, scratch resistance and excellent processing performance. The material provided by the invention can be widely applied to various interior trim parts of automobiles.

Owner:华砻树脂股份有限公司 +1

Thermoplastic low-smoke halogen-free flame-retardant environment-friendly sheath material for power cables and preparation method thereof

ActiveCN103122097ADoes not affect physical and mechanical propertiesDoes not affect processabilityInsulated cablesPigment treatment with macromolecular organic compoundsCrack resistanceDimethyl methylphosphonate

The invention discloses a thermoplastic low-smoke halogen-free flame-retardant environment-friendly sheath material for power cables and a preparation method thereof. The thermoplastic low-smoke halogen-free flame-retardant environment-friendly sheath material for power cables comprises the following components in parts by weight: 60-80 parts of EVA (ethylene-vinyl acetate), 20-30 parts of HDPE (high-density polyethylene), 10-15 parts of EPDM (ethylene-propylene-diene monomer), 15-25 parts of compatiblizing agent, 100-150 parts of halogen-free flame retardant, 0.5-1 part of antioxidant 1035, 0.5-1 part of antioxidant DSTP, 1-2 parts of ethylene bis stearamide, 3-5 parts of DCP (dicumyl peroxide), 2-4 parts of zinc oxide, 1-2 parts of calcium stearate, 10-20 parts of dimethyl methyl phosphonate, 30-40 parts of nano kaolin, 2-3 parts of stearic acid and 0.5-1 part of isopropyl tri(dioctylpyrophosphate)titanate. The sheath material disclosed by the invention has the advantages of excellent physical and mechanical properties, excellent flame retardancy, favorable high / low temperature resistance, favorable oil resistance, favorable solvent resistance, favorable wear resistance, favorable ozone resistance, favorable aging resistance, high flexibility, crack resistance and the like, is very durable, environment-friendly and pollution-free, and can completely satisfy the requirements for modern power cables.

Owner:ANHUI HUAJIN CABLE GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com