High-tenacity heat-resisting ageing-resisting chlorinated polyvinyl chloride alloy material and preparation method thereof

A technology of chlorinated polyvinyl chloride and alloy materials, which is applied in the field of high-toughness, heat-resistant and aging-resistant alloy materials and their preparation, can solve the problems of heat resistance and aging resistance decline, and achieve the improvement of aging resistance and heat resistance. Improvement and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

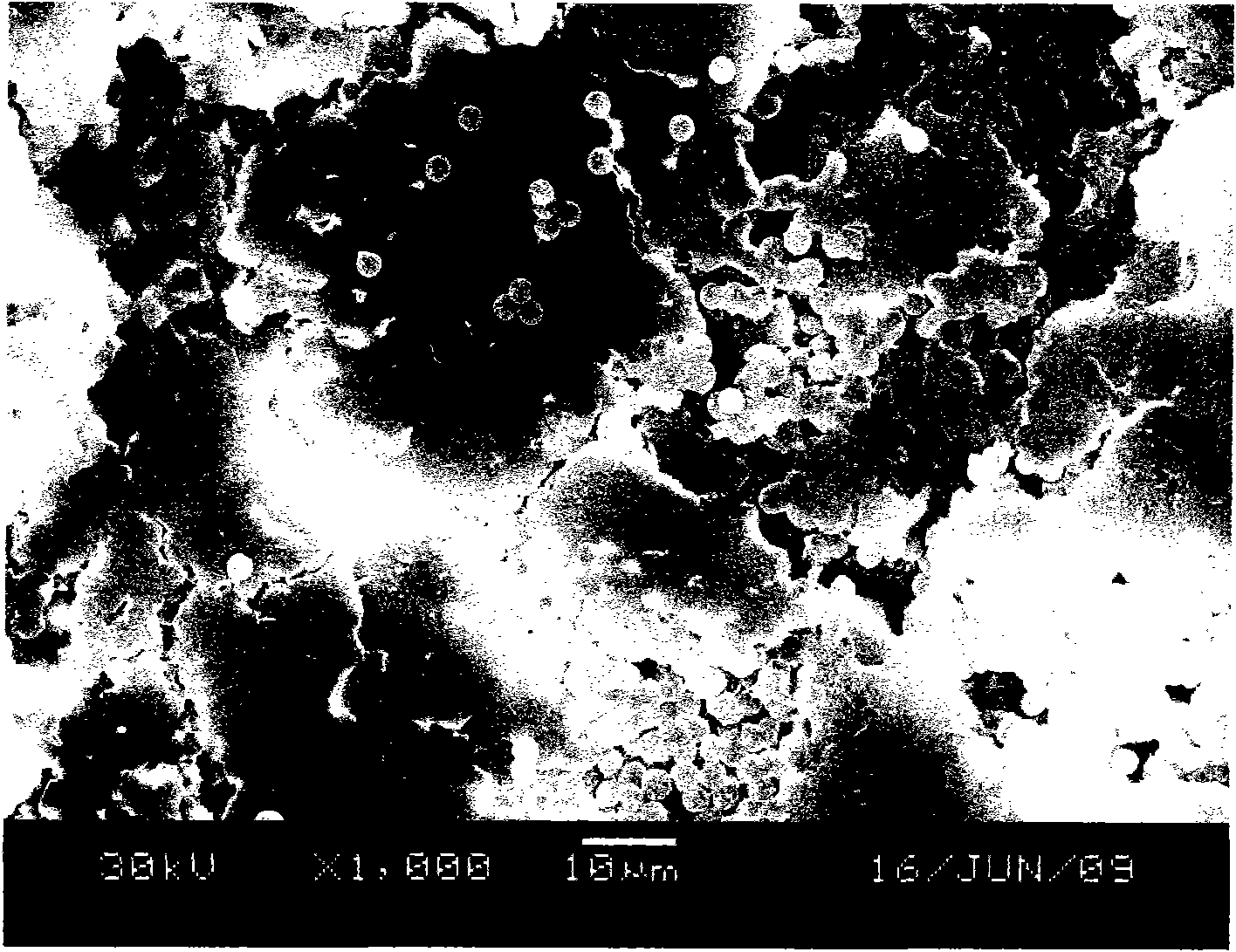

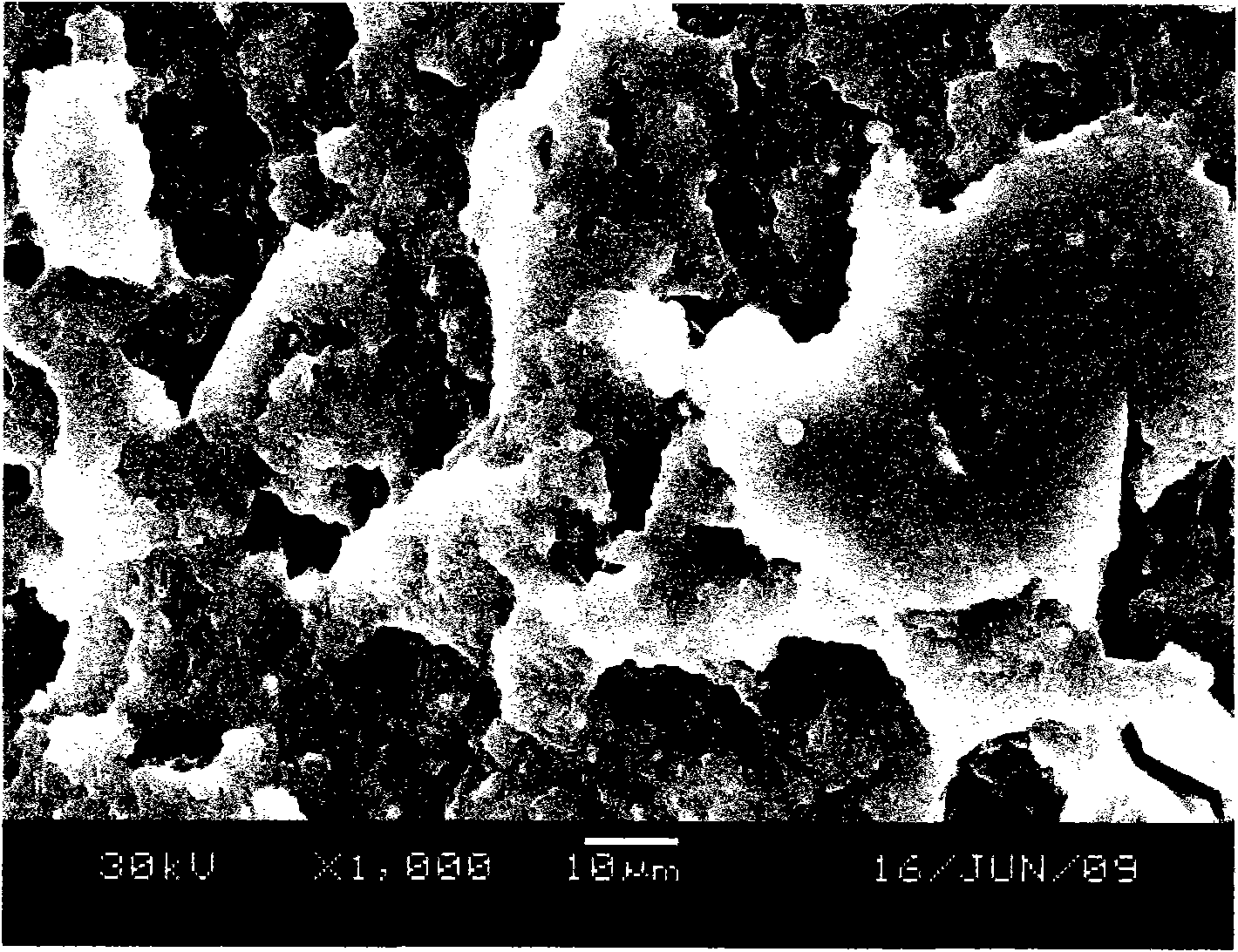

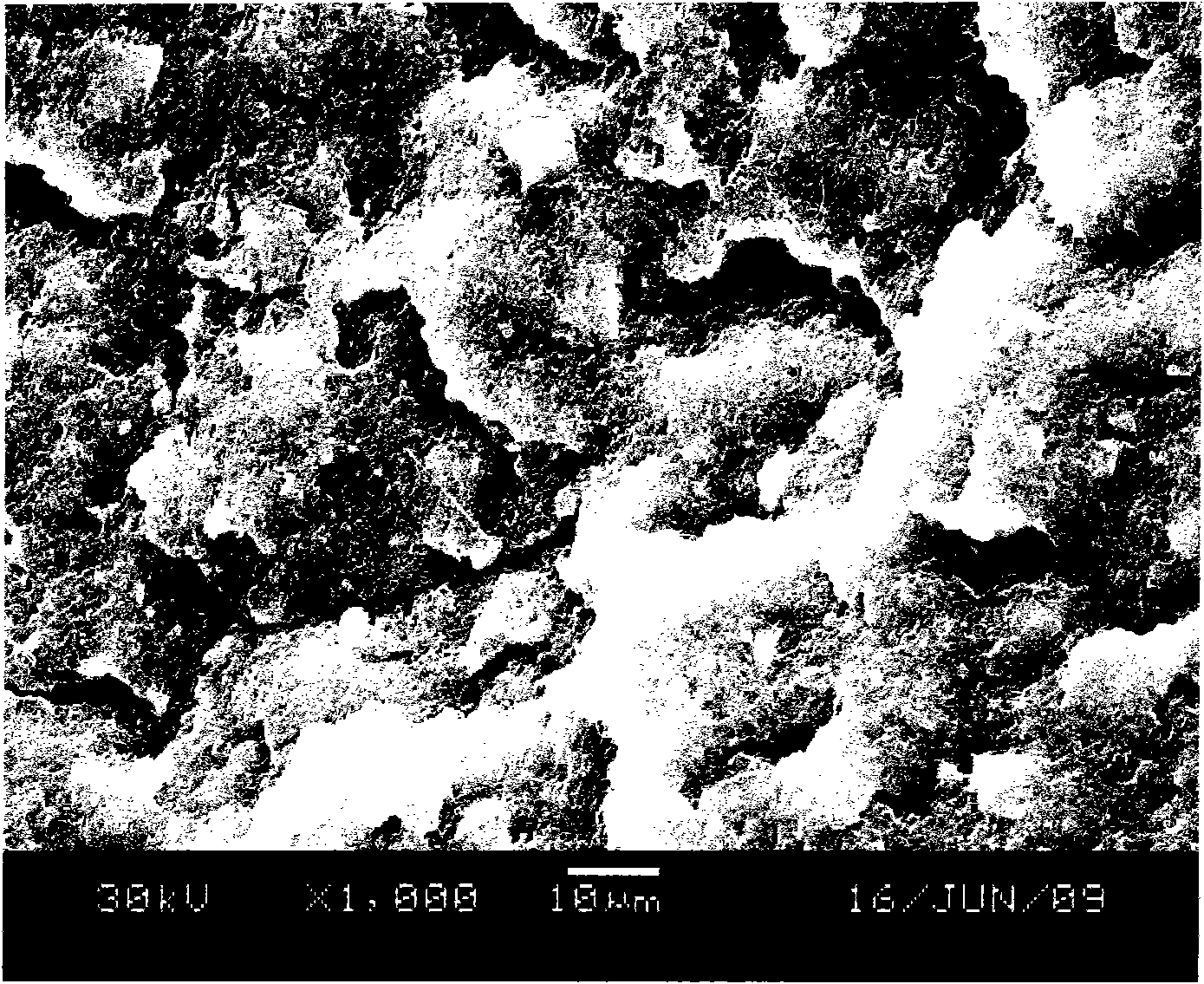

Image

Examples

Embodiment 1

[0048]100 parts of CPVC resin with 67% chlorine content and 1000 degree of polymerization, 5 parts of composite lead salt stabilizer, 0.4 part of paraffin wax, 0.7 part of polyethylene wax, 0.8 part of oxidized polyethylene wax, 10 parts of ASA, 0.5 part of hindered phenol Antioxidant BHT, 5 parts of titanate-coupling calcium carbonate, 1 part of ACR-201, stirred to 110°C with a high-speed mixer, kept for 15 minutes, cooled to room temperature, and heated at 170°C with a double-roller plasticizer Plasticize for 5 minutes, press into sheets to make 4mm plates, and make impact, tensile, and Vicat softening point test specimens. The test results are shown in Table 1.

[0049] Table 1 Performance comparison of high toughness, heat resistance and aging resistance CPVC alloy

[0050] performance

Embodiment 2

[0052] 100 parts of chlorine content is 67%, the degree of polymerization is CPVC resin of 700, 7 parts of composite lead salt stabilizer, 0.4 part of calcium stearate, 0.7 part of polyethylene wax, 0.8 part of oxidized polyethylene wax, 8 parts of ASA, 0.2 Part of hindered phenolic antioxidant 1010, 3 parts of talc powder treated with silane ester coupling, 0.5 part of ACR-401, stirred to 110°C with a high-speed mixer, kept for 20 minutes, cooled to room temperature, and granulated with conical twin-screws, Then use the injection machine to inject impact, tensile, and Vicat softening point test specimens. The test results are shown in Table 2.

[0053] Table 2 Performance comparison of high toughness, heat resistance and aging resistance CPVC alloy

[0054] performance

Embodiment 3

[0056] 100 parts of CPVC resin with a chlorine content of 67% and a polymerization degree of 1000, 3 parts of organotin stabilizers, 0.7 parts of calcium stearate, 0.4 parts of paraffin wax, 0.7 parts of polyethylene wax, 0.8 parts of oxidized polyethylene wax, 0.4 parts Stearic acid monoglyceride, 12 parts of ASA, 0.2 parts of hindered phenolic antioxidant BHT, 15 parts of rare earth coupling treated calcium carbonate, 1.5 parts of ACR-201, stirred to 110 ° C with a high-speed mixer, kept for 25 minutes, cooled to At room temperature, plasticize at 180°C for 5 minutes with a two-roller plasticizer, press into sheets to make 4mm plates, and make impact, tensile, and Vicat softening point test specimens. The test results are shown in Table 3.

[0057] Table 3 Performance comparison of high toughness, heat resistance and aging resistance CPVC alloy

[0058] performance

PUM

| Property | Measurement | Unit |

|---|---|---|

| Polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com