Patents

Literature

322 results about "Vicat softening point" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vicat softening temperature or Vicat hardness is the determination of the softening point for materials that have no definite melting point, such as plastics. It is taken as the temperature at which the specimen is penetrated to a depth of 1 mm by a flat-ended needle with a 1 mm² circular or square cross-section. For the Vicat A test, a load of 10 N is used. For the Vicat B test, the load is 50 N.

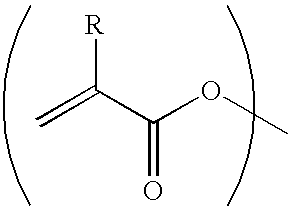

Polymer blend for matte injection moulded parts

The invention relates to a polymer mixture, comprising a) a polymer matrix which is composed of a (meth)acrylate(co)polymer or of a mixture of (meth)acrylate(co)polymers with a Vicat softening point VSP (ISO 306-B50) of at least 104° C. and / or of a (meth)acrylimide(co)polymer, b) an impact modifier which is based on crosslinked poly(meth)acrylates and which does not have covalent bonding to the polymer matrix a), c) from 1 to 15% by weight of plastics particles composed of crosslinked polymers based on polymethyl methacrylate, on polystyrene and / or on polysilicones. The polymer mixture can be used to obtain injection mouldings with matt surfaces and Vicat softening points VSPs (ISO 306-B50) of at least 90° C.

Owner:EVONIK ROEHM GMBH

Preparation method of super-strong high temperature-resistant chlorinated polyvinyl chloride tubes

ActiveCN102134360ADoes not show brittlenessExcellent low temperature toughnessRigid pipesPolymer scienceChlorinated polyvinyl chloride

The invention discloses a preparation method of super-strong high temperature-resistant chlorinated polyvinyl chloride tubes, which is characterized in that the tubes are made by the following steps: 75 to 100 portions of chlorinated polyvinyl chloride resin, 0 to 25 portions of vinyl chloride resin, 3 to 10 portions of ABS, 1 to 8 portions of acrylic acid resin, 3 to 8 portions of bismaleimides, 1 to 5 portions of plasticizing accelerator, 1 to 5 portions of compatibilizer, 10 to 25 portions of engineering plastics, 1 to 3 portions of lubricant, 1 to 5 portions of nanometer materials, 4 to 8 portions of stabilizing agent, 2 to 15 portions of filler, 0 to 1 portion of cross-linking agent, 1 to 5 portions of processing modifier and 3 to 10 portions of impact modifier are mixed and blended according to weight proportion, and then extruded by a mould. Compared with the prior art, the super-strong high temperature-resistant chlorinated polyvinyl chloride tubes has the advantages of being high in vicat softening point, being capable of meeting the high-temperature requirement of more than 120 DEG C, and having good anti-aging performance, antiflaming and insulation performance, and compression resistance, and long service life.

Owner:SHANGHAI YUANZHOU PIPE

Compositely modified polypropylene and its prepn process

The composite modified polypropylene material has the raw material composition comprising polypropylene 100 weight portions, nanometer inorganic material 0.1-10 weight portions, elastomer 1-10 weight portions, beta-crystal nucleator 0.1-0.5 weight portions, antioxidant 0-1.5 weight portions, and compatibilizing agent 0.2-3 weight portions. The composite modified polypropylene material possesses raied tensile strength, high impact strength and high heat resistance.

Owner:ZHEJIANG UNIV

High-tenacity heat-resisting ageing-resisting chlorinated polyvinyl chloride alloy material and preparation method thereof

The invention relates to a high-tenacity heat-resisting ageing-resisting chlorinated polyvinyl chloride alloy material which comprises the following raw materials in weight parts: 100 parts of chlorinated polyvinyl chloride, 1-50 parts of impact modifier, 1.5-10 parts of thermal stabilizer, 0.1-10 parts of lubricant, 0.5-15 parts of PVC processing aid, 0.1-0.5 part of antioxidant and 0-40 parts of filler. The invention solves the problems of low heat resistance and aging resistance while improving the tenacity of CPVC in the prior art; and the Vicat softening point can vary within the range of 104 to 119 DEG C, the tensile strength can reach 45-64 MPa, and the notch impact strength can be increased by more than 200 percent.

Owner:LIAOCHENG UNIV

Impact-Resistant Poly(Meth)Acrylate Moulding Masses With High Thermal Stability

The invention relates to a polymer mixture, based on the (meth)acrylate (co)polymer components a.), b.), c.) and / or d.) according to claim 1, where a test specimen produced from the polymer mixture simultaneously has the following properties:a tensile modulus (ISO 527) of at least 2 500 MPa,a Vicat softening point VSP (ISO 306-350) of at least 110° C.,an impact resistance (ISO 179-2D, flatwise) of at least 30 kJ / m2, anda melt index MVR (ISO 1133, 230° C. / 3.8 kg) of at least 1.0 cm3 / 10 at leastThe invention further relates to injection mouldings and to the use of the polymer mixture for production of injection mouldings.

Owner:EVONIK ROEHM GMBH

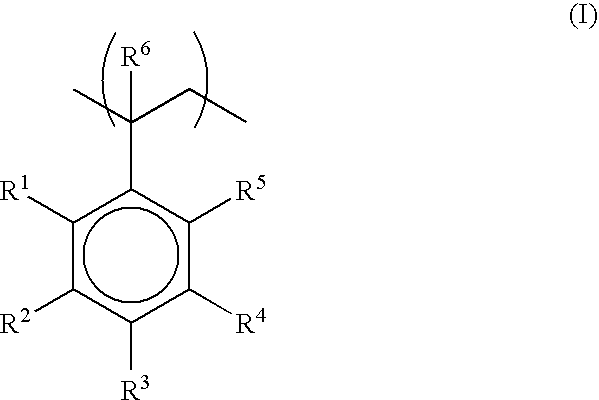

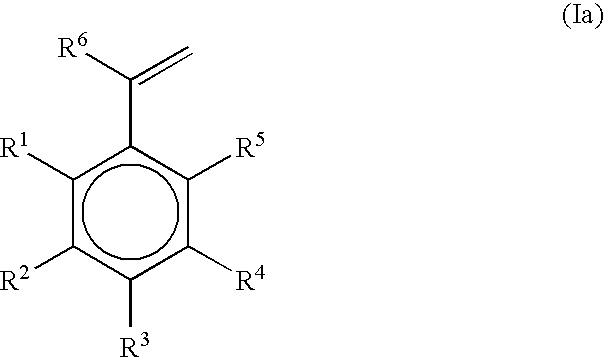

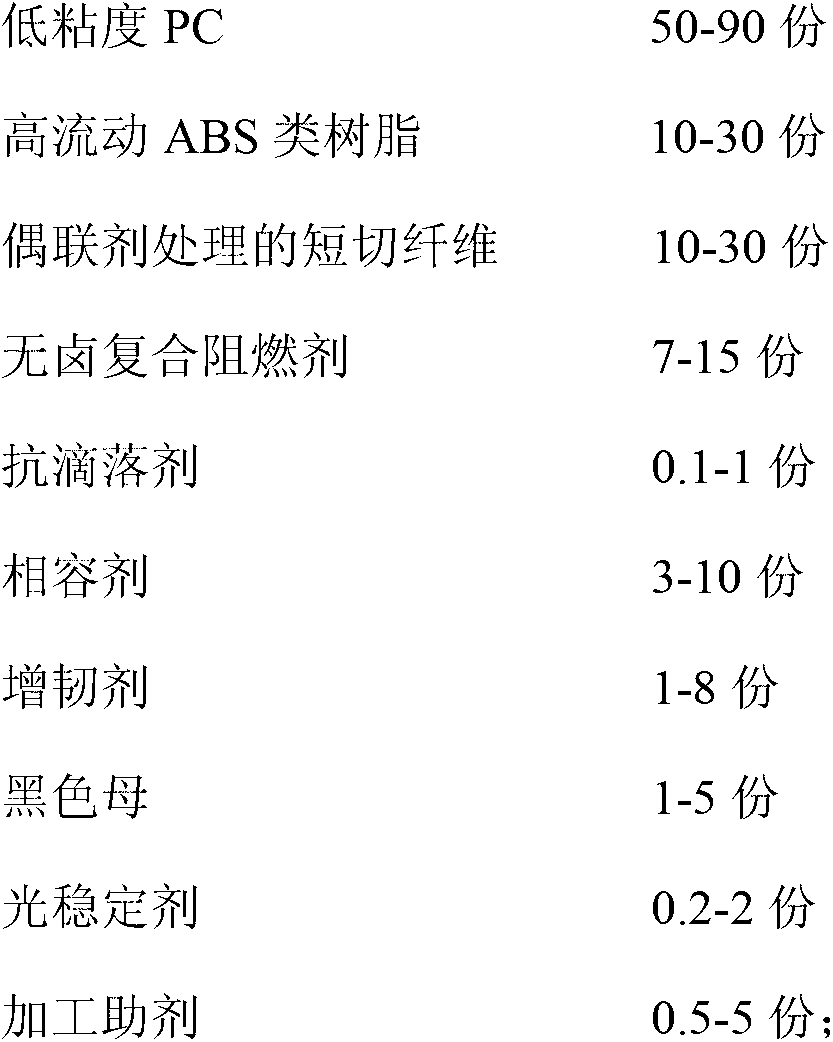

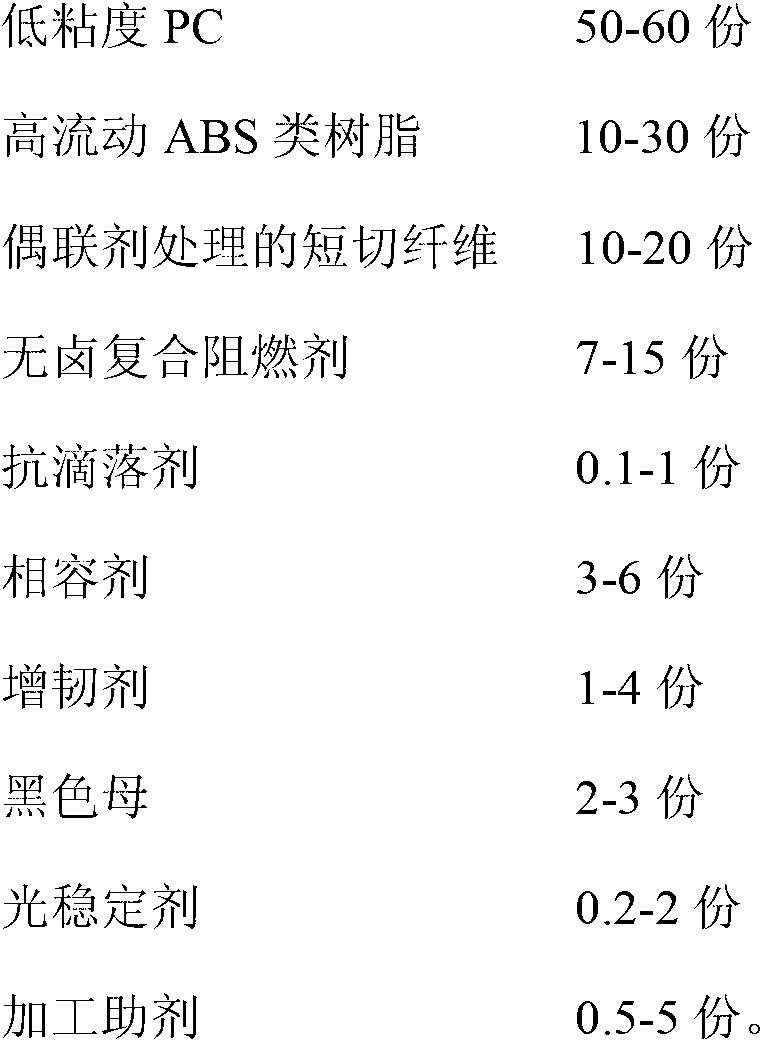

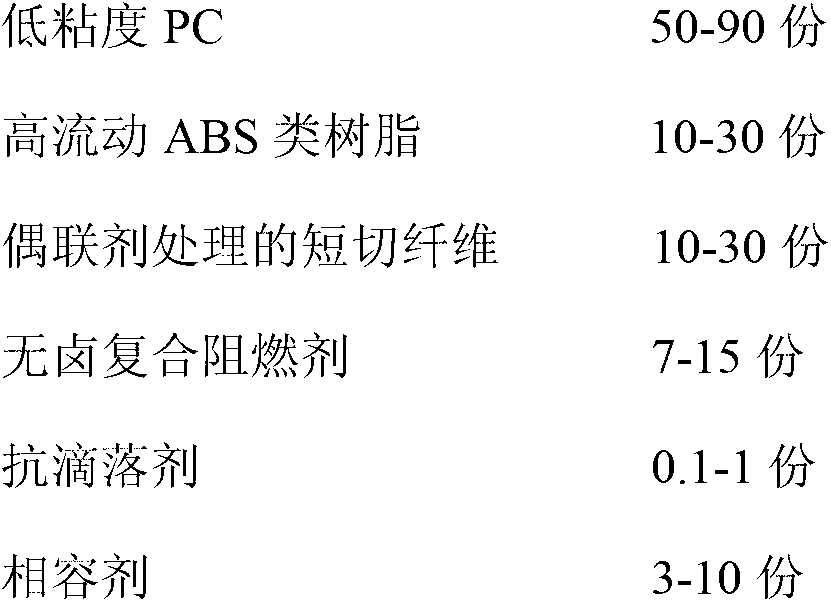

Flame-retardant glass fiber reinforced PC (Polycarbonate)/ABS (Acrylonitrile Butadiene Styrene) composite material and preparation method thereof

The invention relates to a flame-retardant glass fiber reinforced PC (Polycarbonate) / ABS (Acrylonitrile Butadiene Styrene) composite material and a preparation method thereof. The preparation method comprises the steps of: respectively and fully drying low-viscosity PC, high-flow ABS resin, chopped fibers treated by using silane coupling agent, a halogen-free composite flame retardant, an anti-dripping agent, a black color base and a processing agent; fully mixing other raw materials except for the alkali-free chopped fibers treated by using the silane coupling agent in a high-speed mixer according to a proportion; then feeding the raw material into a double-screw extruder; laterally adding the alkali-free chopped fibers treated by using the silane coupling agent; and mixing, extruding, drawing, cooling, grain-sized dicing, and drying to obtain a finished injection molding raw material. The preparation method of the flame-retardant glass fiber reinforced PC / ABS composite material, disclosed by the invention, keeps certain impact intensity and rational MFR (Melt Flow Rate), thermal distortion temperature, vicat softening point and the like of the material while obtaining high intensity, high rigidity and flame retardant properties by selecting an assistant and proportions of the raw materials reasonably and adding the fibers as well as the flame retardant.

Owner:SHANDONG UNIV +1

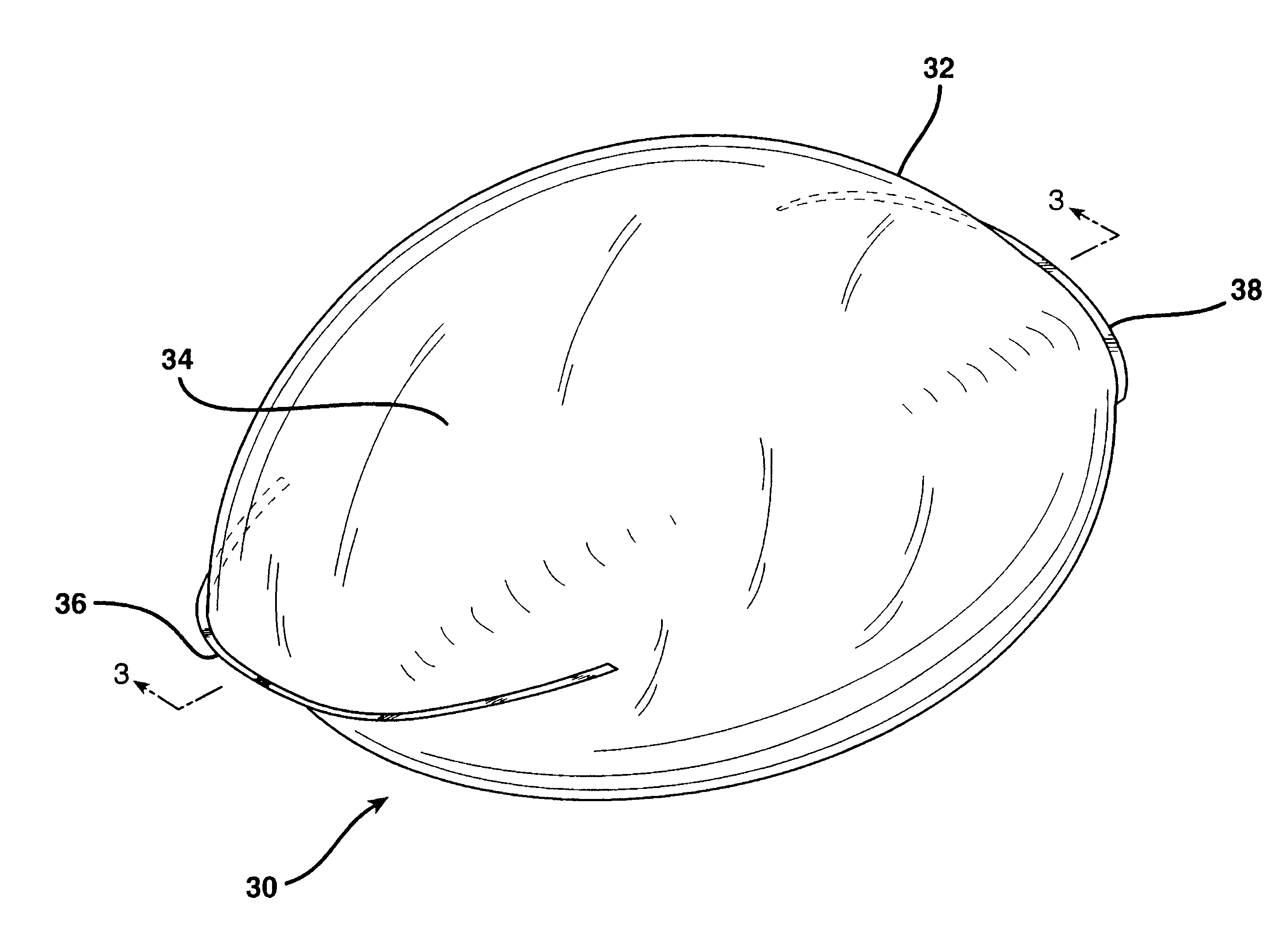

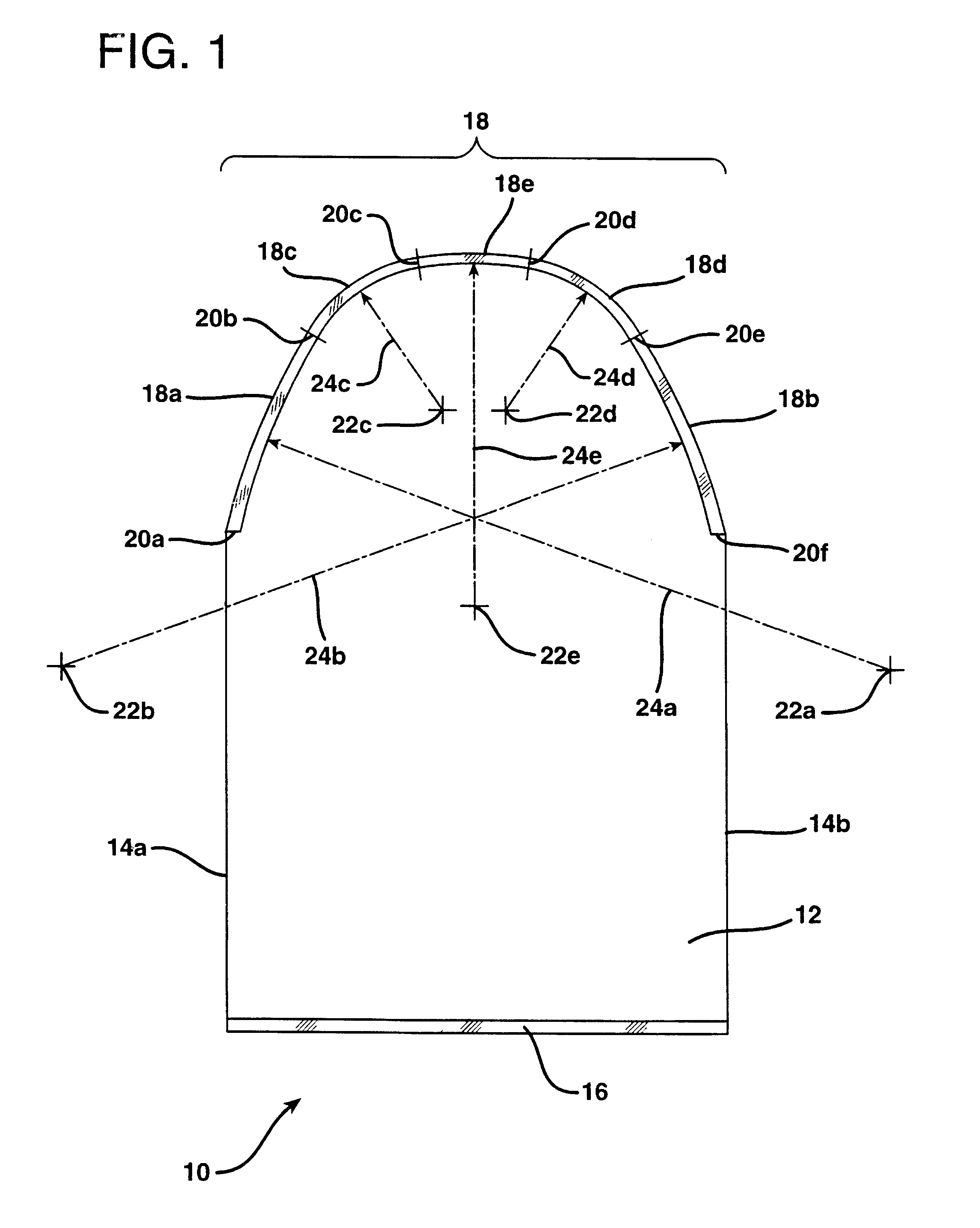

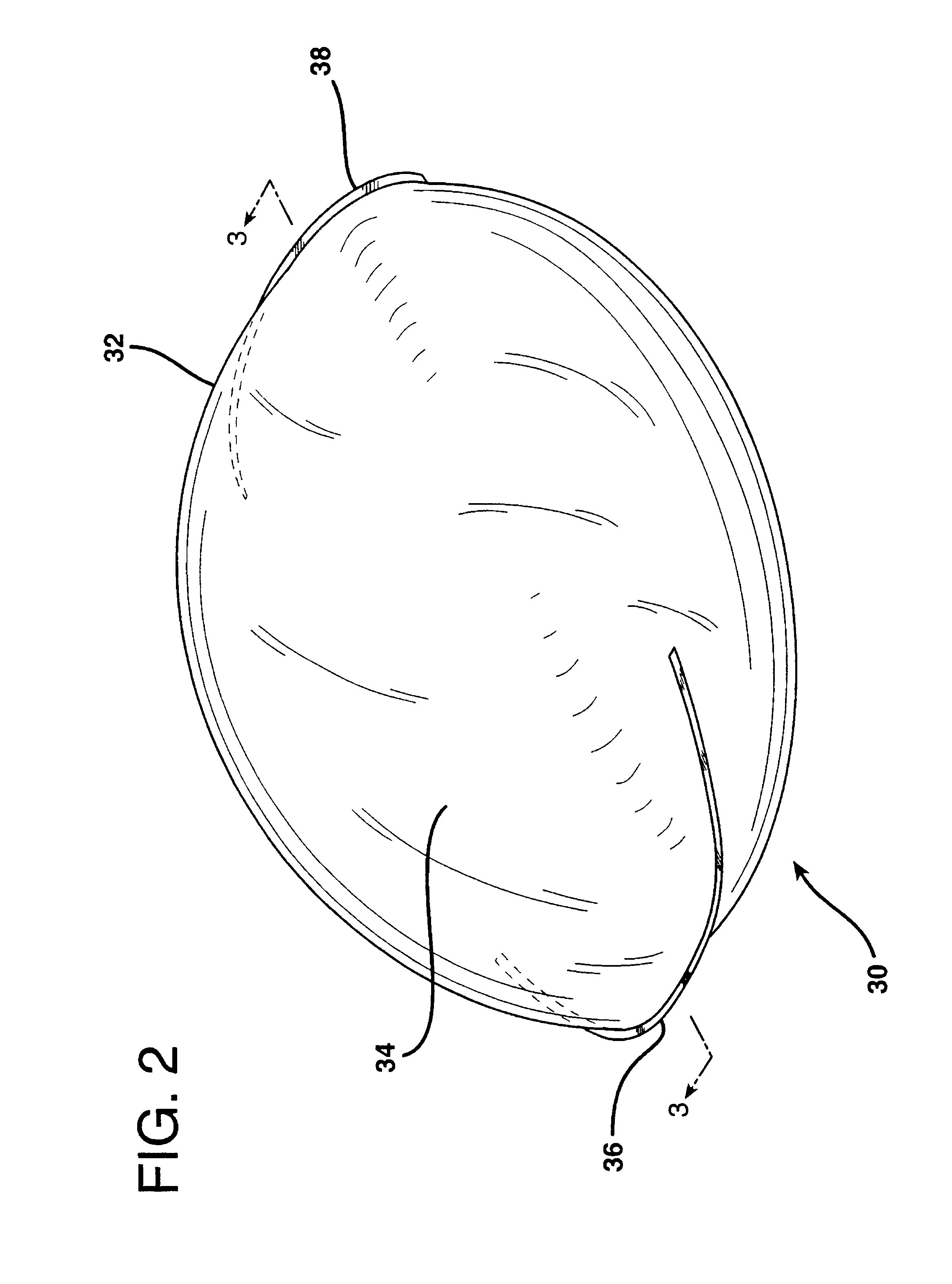

Package with contoured seal

A packaged food article includes a meat product and a thermoplastic, heat shrinkable film. The film includes a meat-contact layer that contains a polymer which includes mer units derived from a C2-C4 alpha-olefin. The film is sealed so as to form a bag which encloses the meat product. At least one of the seals defines an arc which includes at least four segments. Each of the segments has a radius of curvature which differs from the radius of curvature of any adjoining segment. When the packaged food article is subjected to a temperature of from about 50° C. up to about the Vicat softening point of the polymer of the meat-contact layer, the packaged food article takes the general shape of a poultry breast.

Owner:CRYOVAC INC

High calcium carbonate filled herd polyvinyl chloride material

A hard polyvinyl chloride material filled by more calcium carbonate is prepared from nano (or micron)-class calcium carbonate as filler, polyvinyl chloride resin, thermal stabilizer, lubricant, impact modifier, and titanium oxide powder through fusing, mixing and extruding out. Its advantages are high tension strength, elongation for break, impact strength and vicat softening point.

Owner:EAST CHINA UNIV OF SCI & TECH

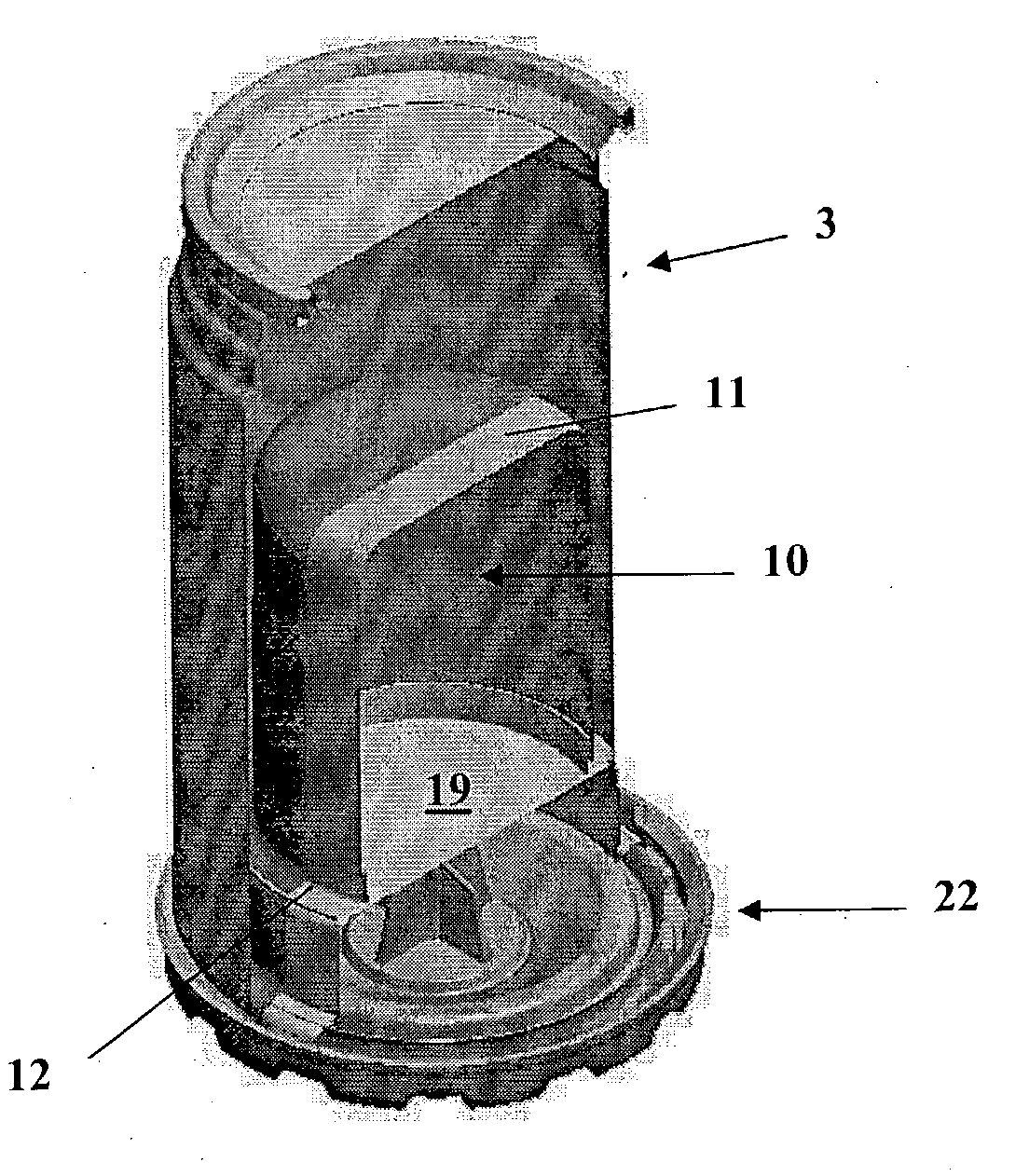

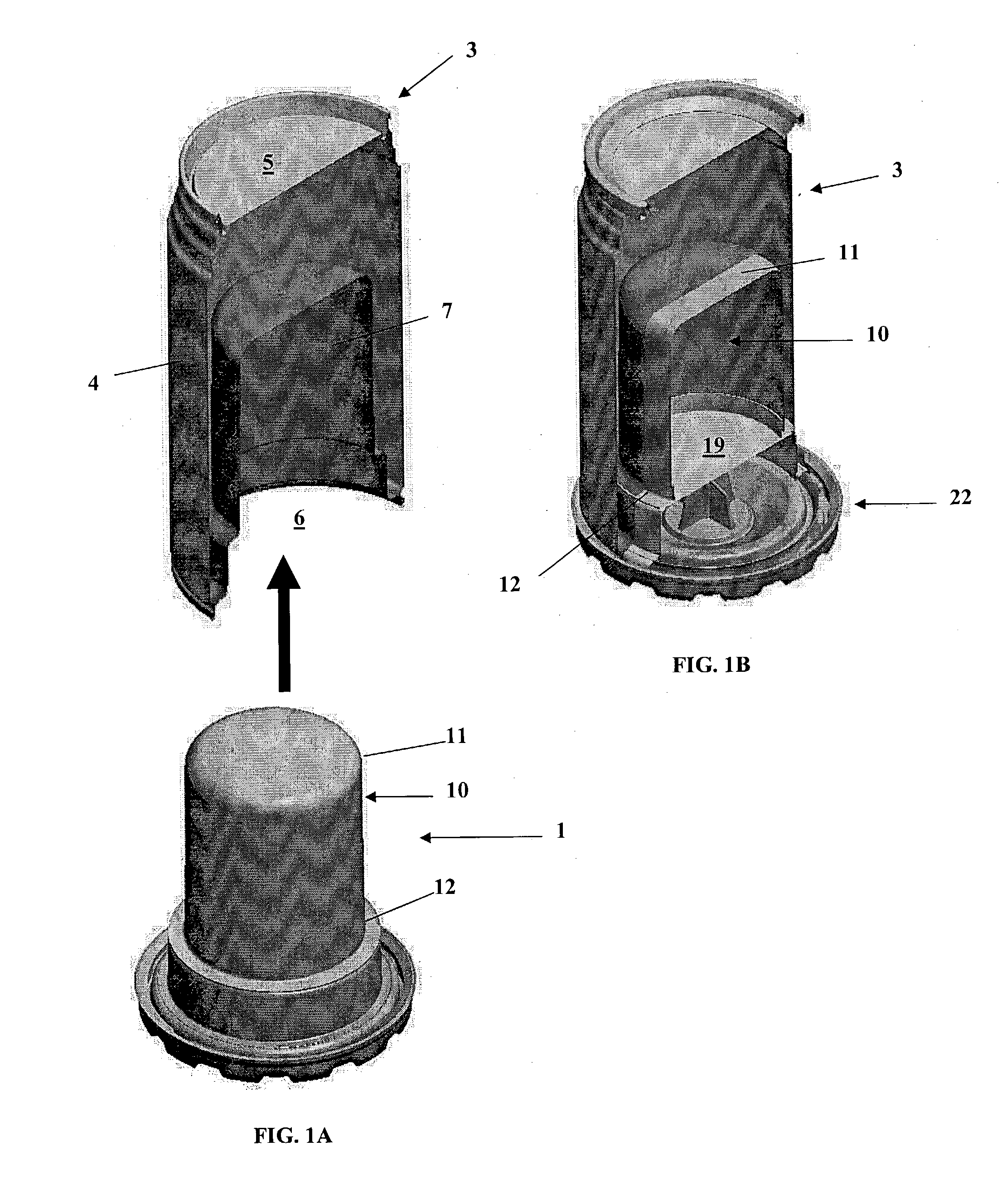

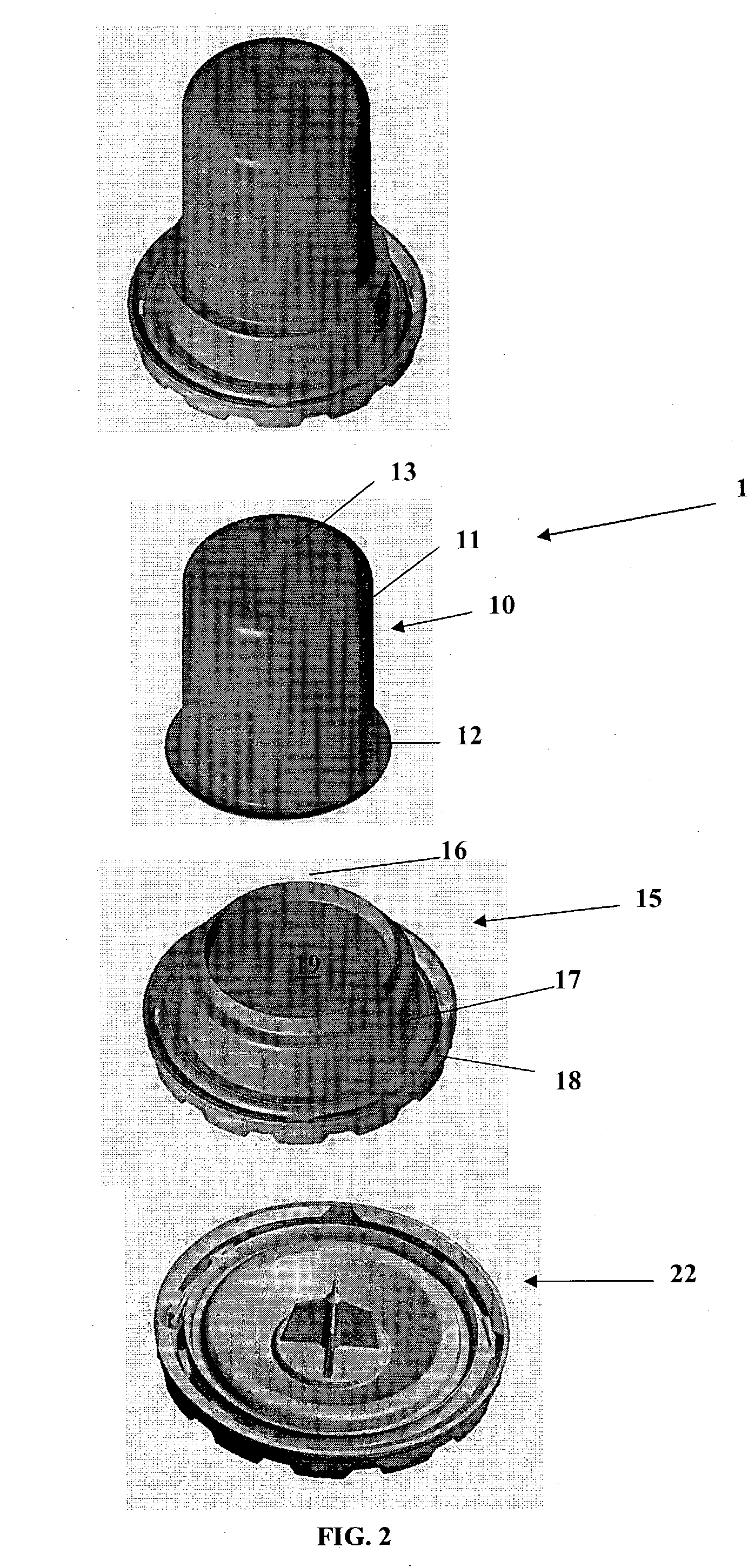

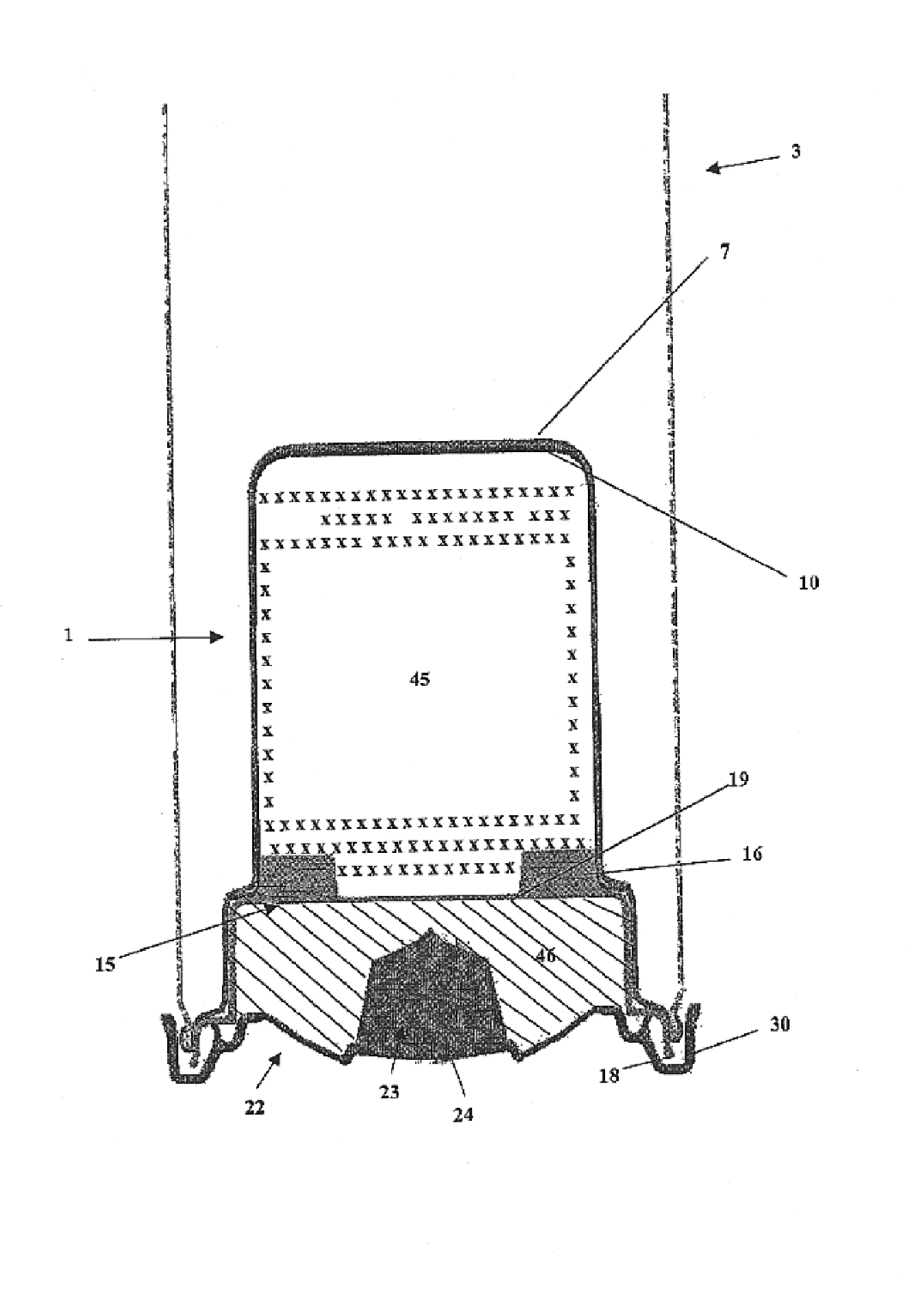

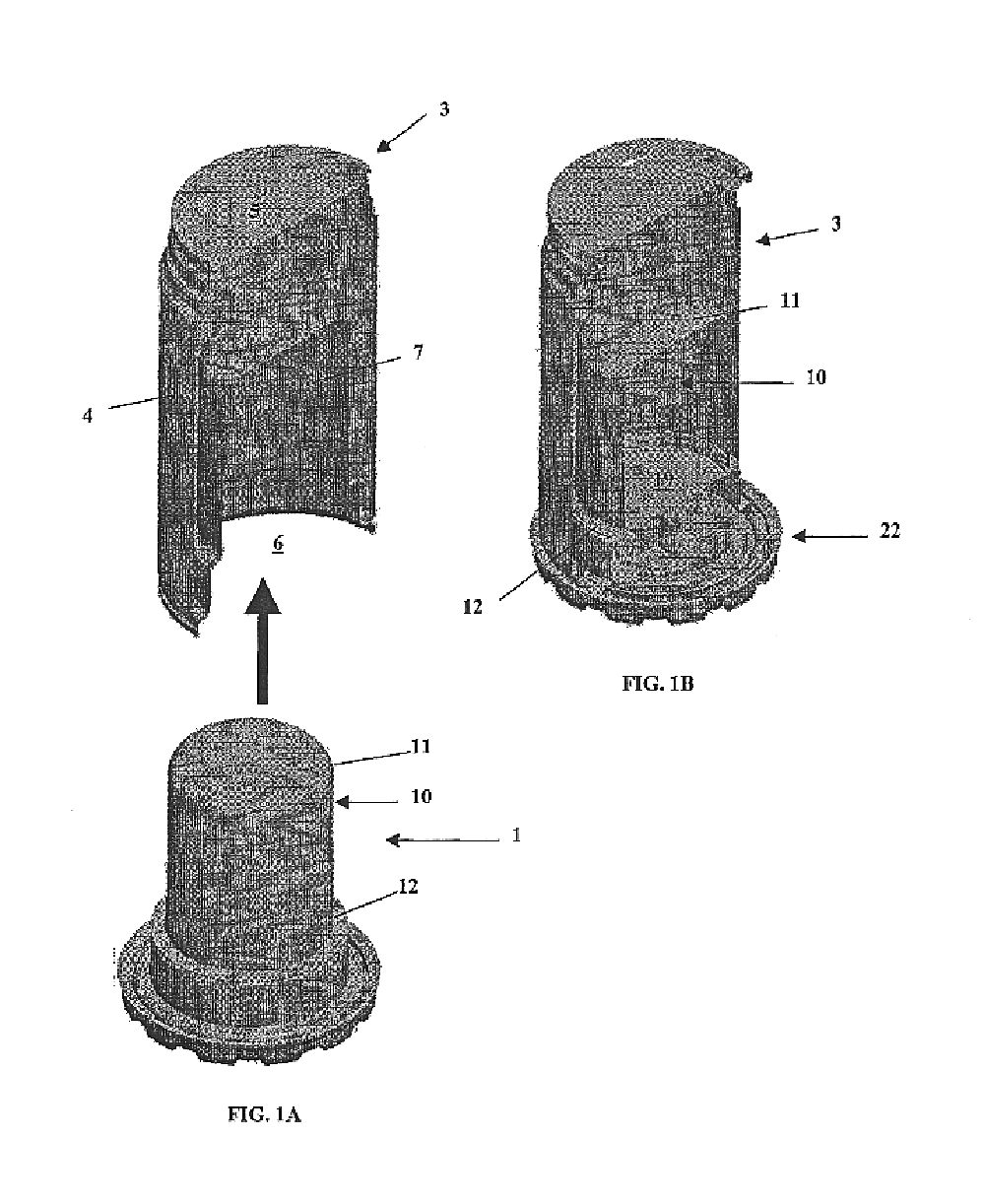

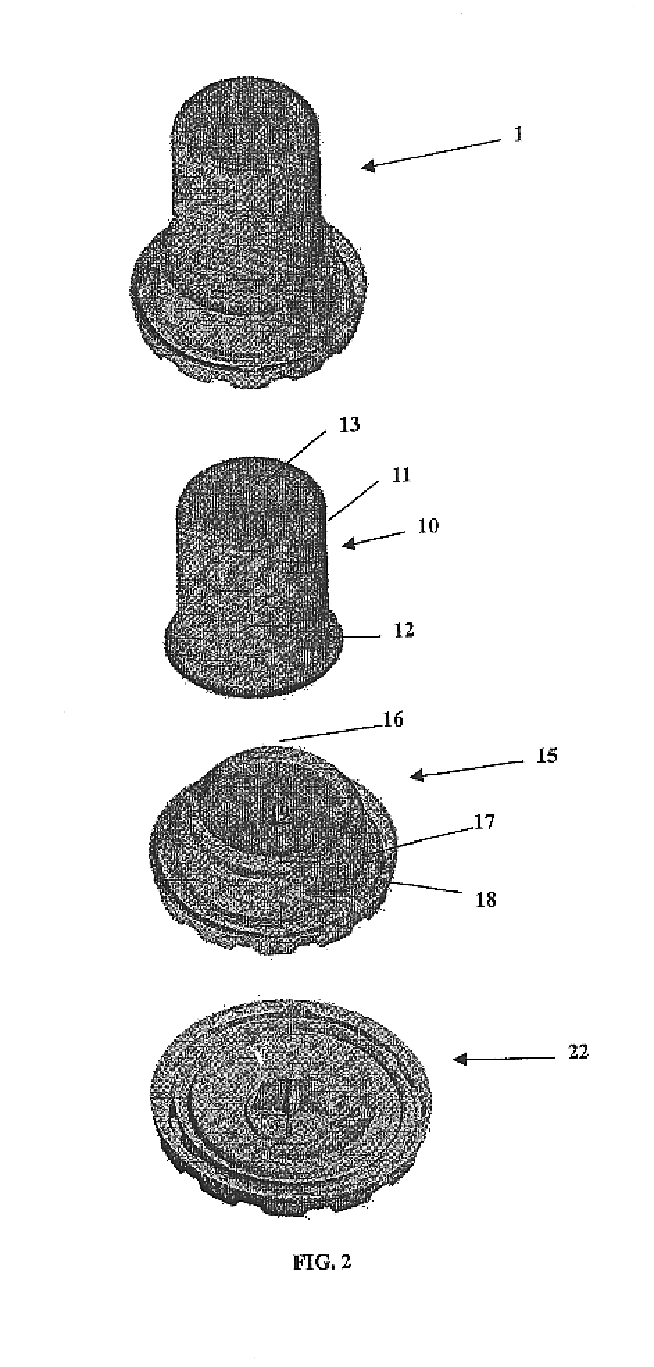

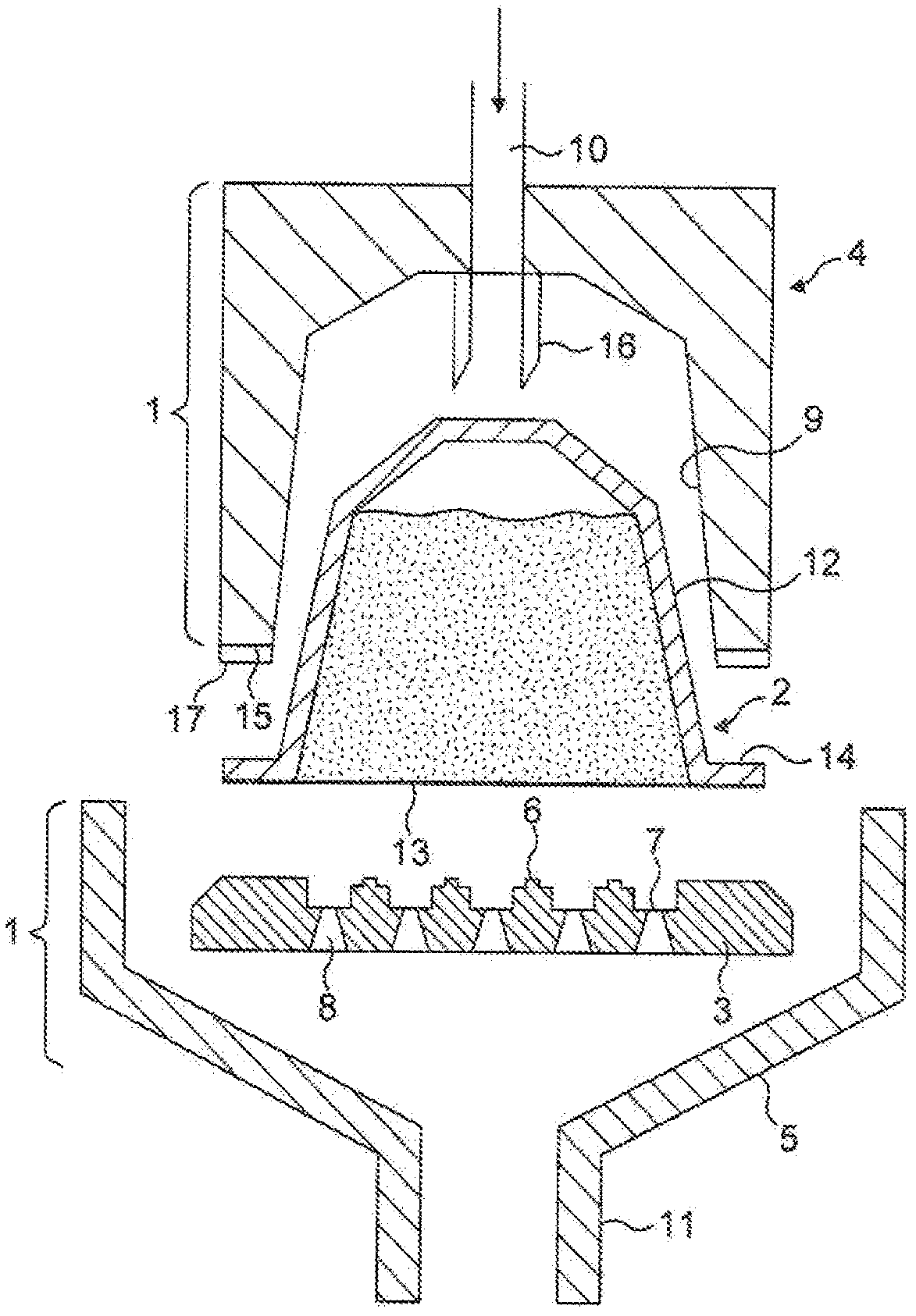

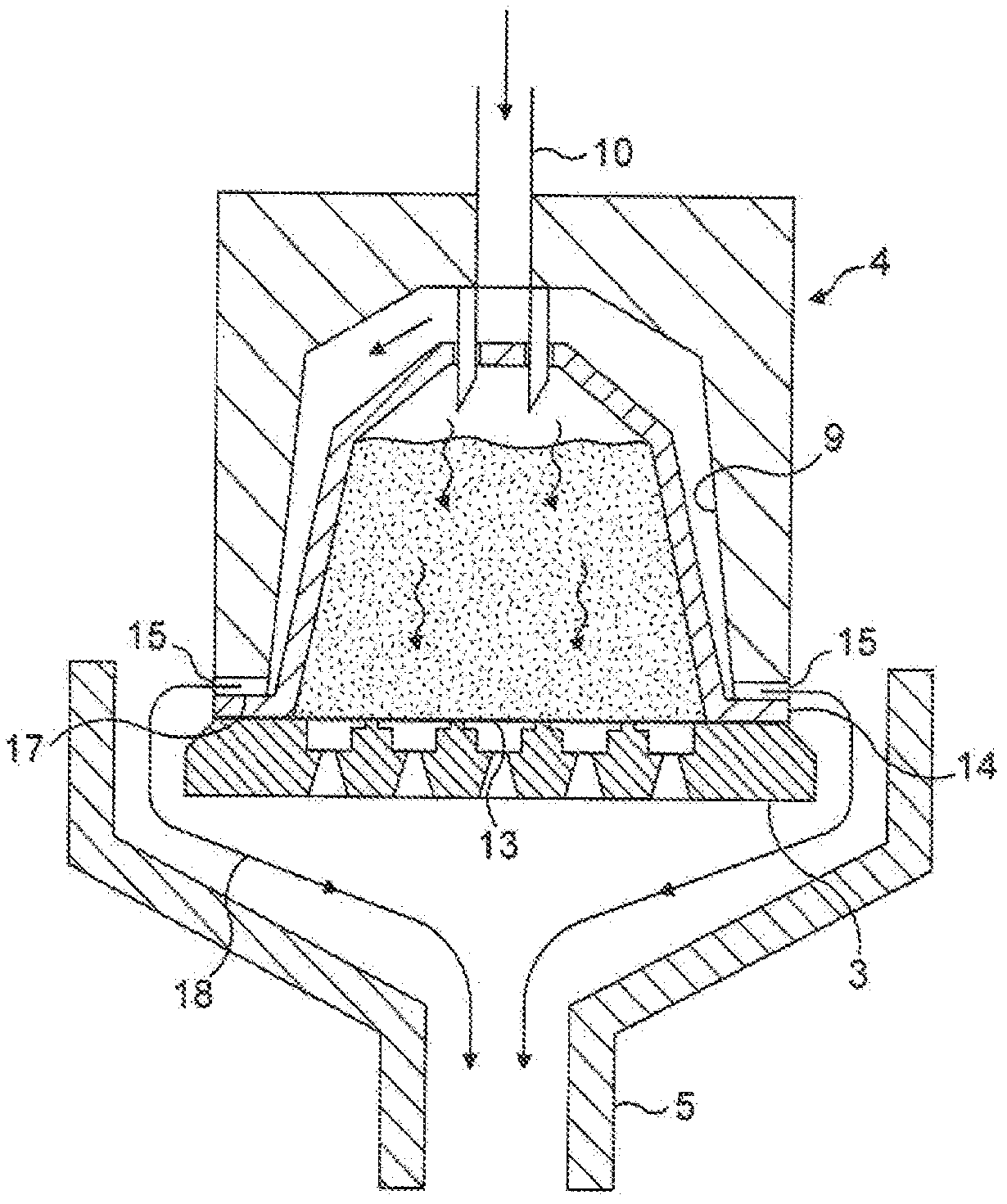

Insertable thermotic module for self-hearing can

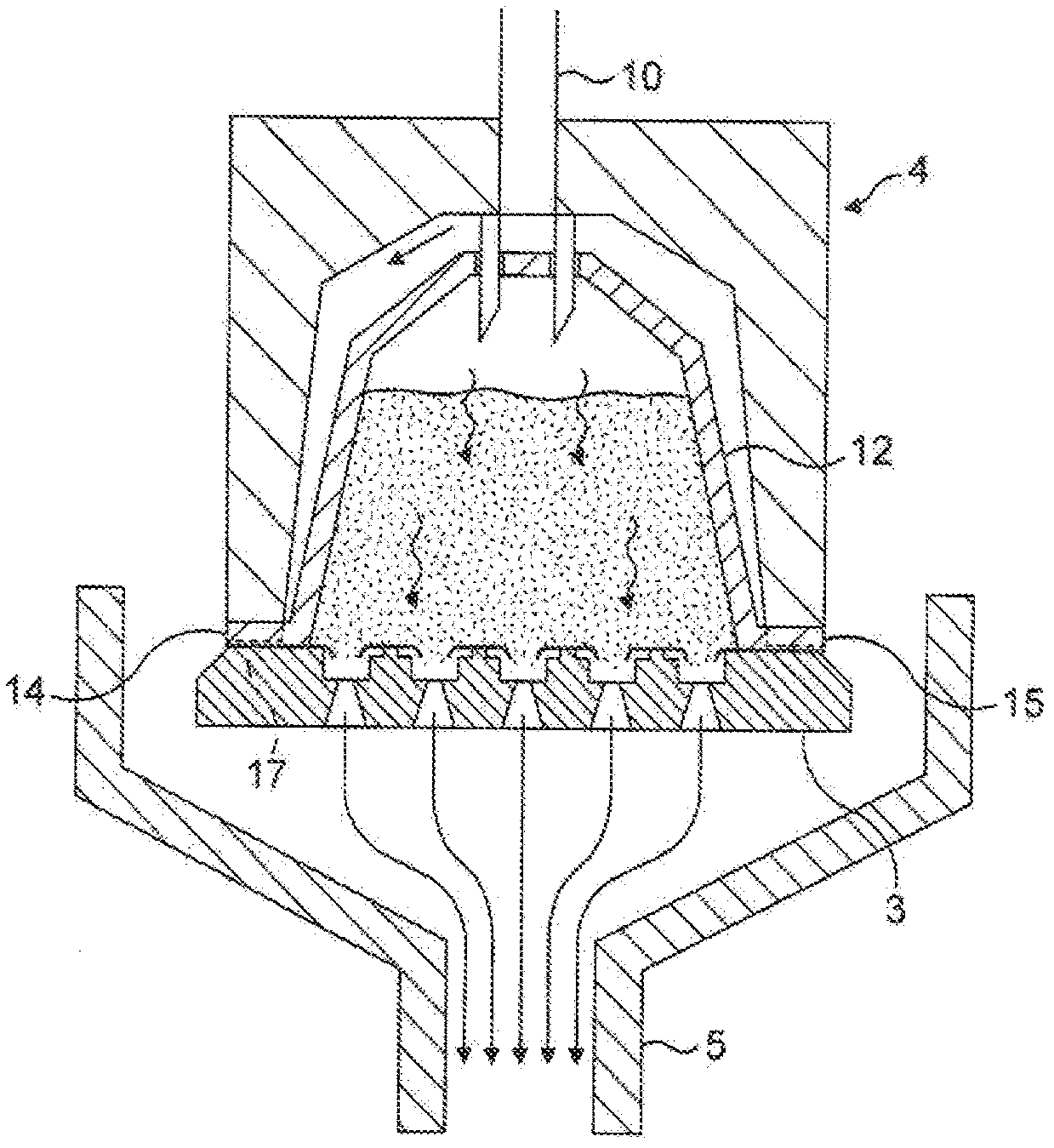

InactiveUS20030205224A1Sufficient thinnessLow pour pointExothermal chemical reaction heat productionDomestic cooling apparatusChemical reactionActuator

A thermic module for a self-heating container. The container includes a bottom end with a cavity having internal walls formed therein for receiving the thermic module. The thermic module will be comprised of a first cup having plastic walls and containing a first chemical reactant. The module will also include a second cup containing a second chemical reactant and a dividing wall positioned between the first and second cups such that the first and second chemical reactants cannot mix. An end cap will be positioned below the second cup and will retain the second chemical reactant within the second cup. An actuator for puncturing the dividing wall will be positioned between the end cap and the dividing wall. Finally, the walls of the first cup are formed of a plastic of sufficient thinness and having a sufficiently low Vicat Softening Point such that the plastic walls will expand into contact with the internal walls of the container cavity upon mixing of the first and second chemical reactants.

Owner:HOT CAN INTPROP

Random-copolymerization polypropylene toughening modified material and preparation method thereof

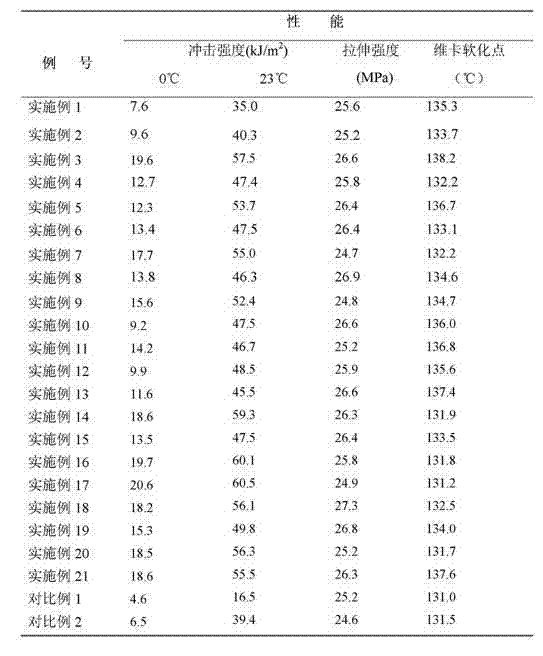

The invention discloses a random-copolymerization polypropylene toughening modified material which is formed by carrying out melt blending modification on the following components in parts by weight: 100 parts of random-copolymerization polypropylene, 0-15 parts of polypropylene homopolymer, 5-20 parts of ethylene copolymer, 2.5-12 parts of modifying master batch and 0.1-0.4 part of antioxidant. The tensile strength of the material is 24.7-27.3MPa, the notch impact strength at 23 DEG C is 35.0-60.5 kJ / m<2>, the notch impact strength at 0 DEG C is 7.6-20.6 kJ / m<2>, and the Vicat softening point is 131.2-138.2 DEG C. The invention also discloses a preparation method of the random-copolymerization polypropylene toughening modified material. The random-copolymerization polypropylene toughening modified material disclosed by the invention has favorable rigidity / toughness balance performance and heat resistance, can be widely used in the industries of construction materials, furniture, automobiles, electric appliances, electronics, electric appliances and the like, and can be used for preparing various profiles, tubes, films, sheets, plates, injection molding parts and the like. Besides, the preparation method is simple, can shorten the molding processing time, and can also lower the energy consumption and the production cost, thereby having high practicality.

Owner:SICHUAN UNIV

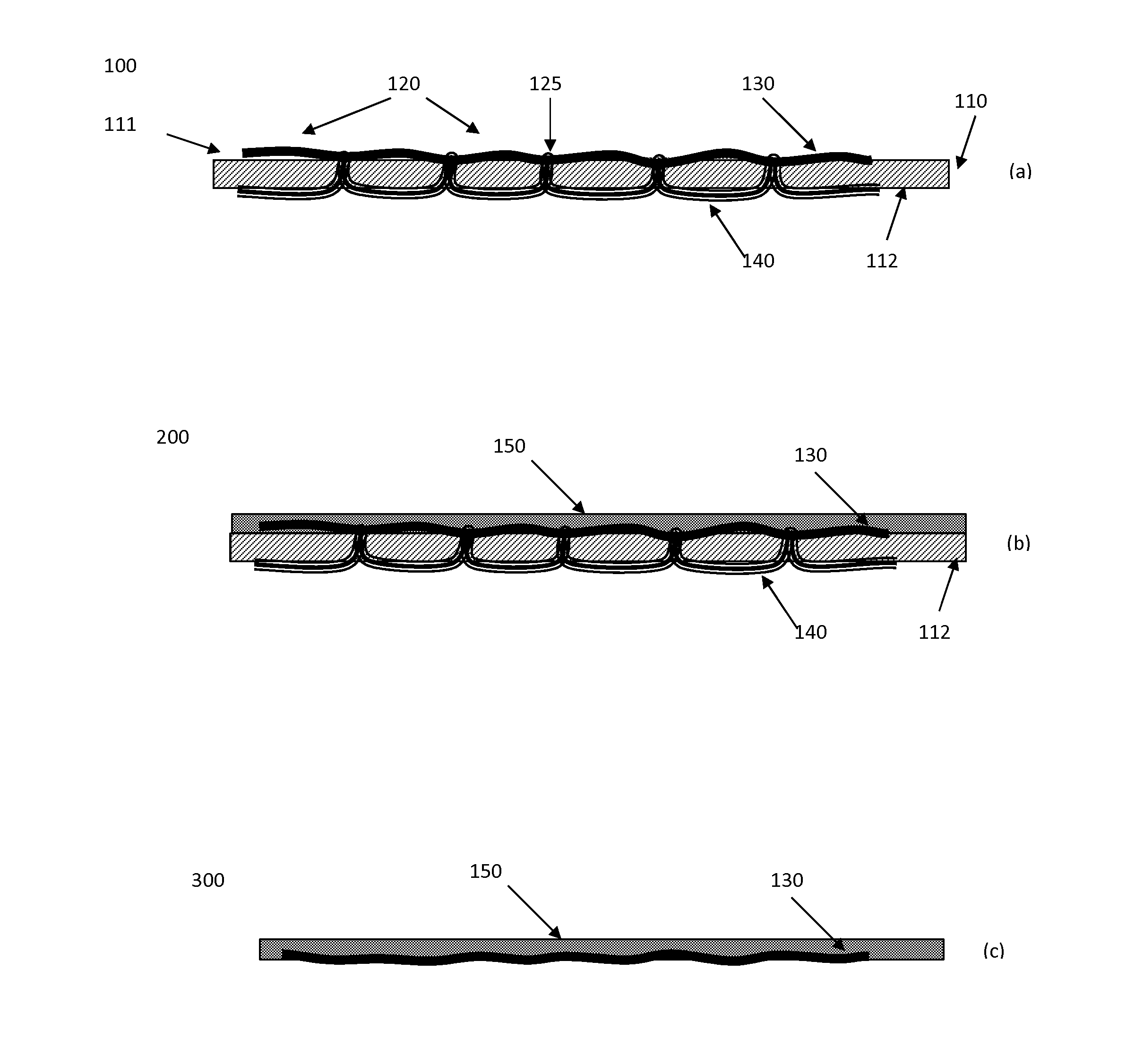

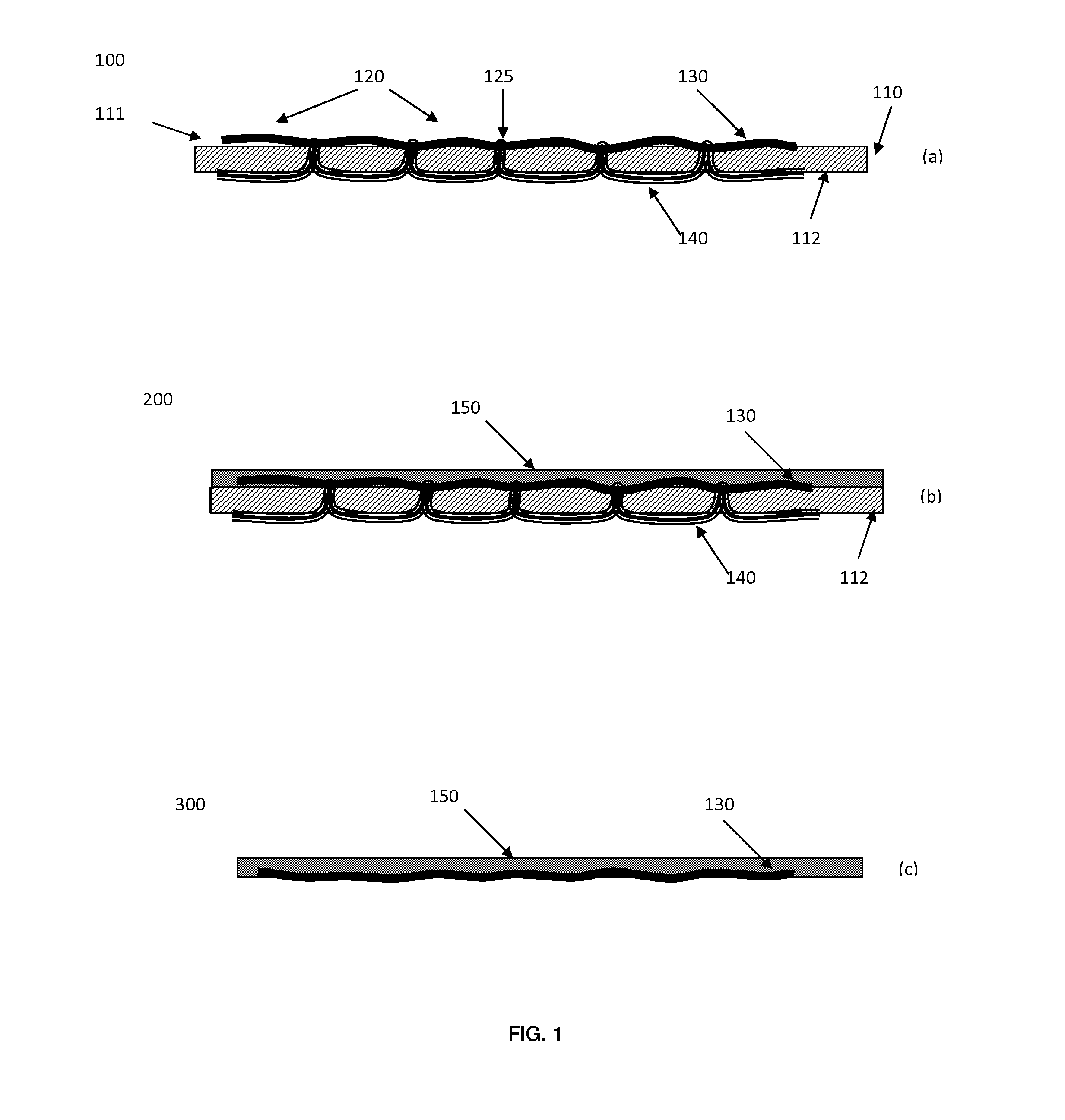

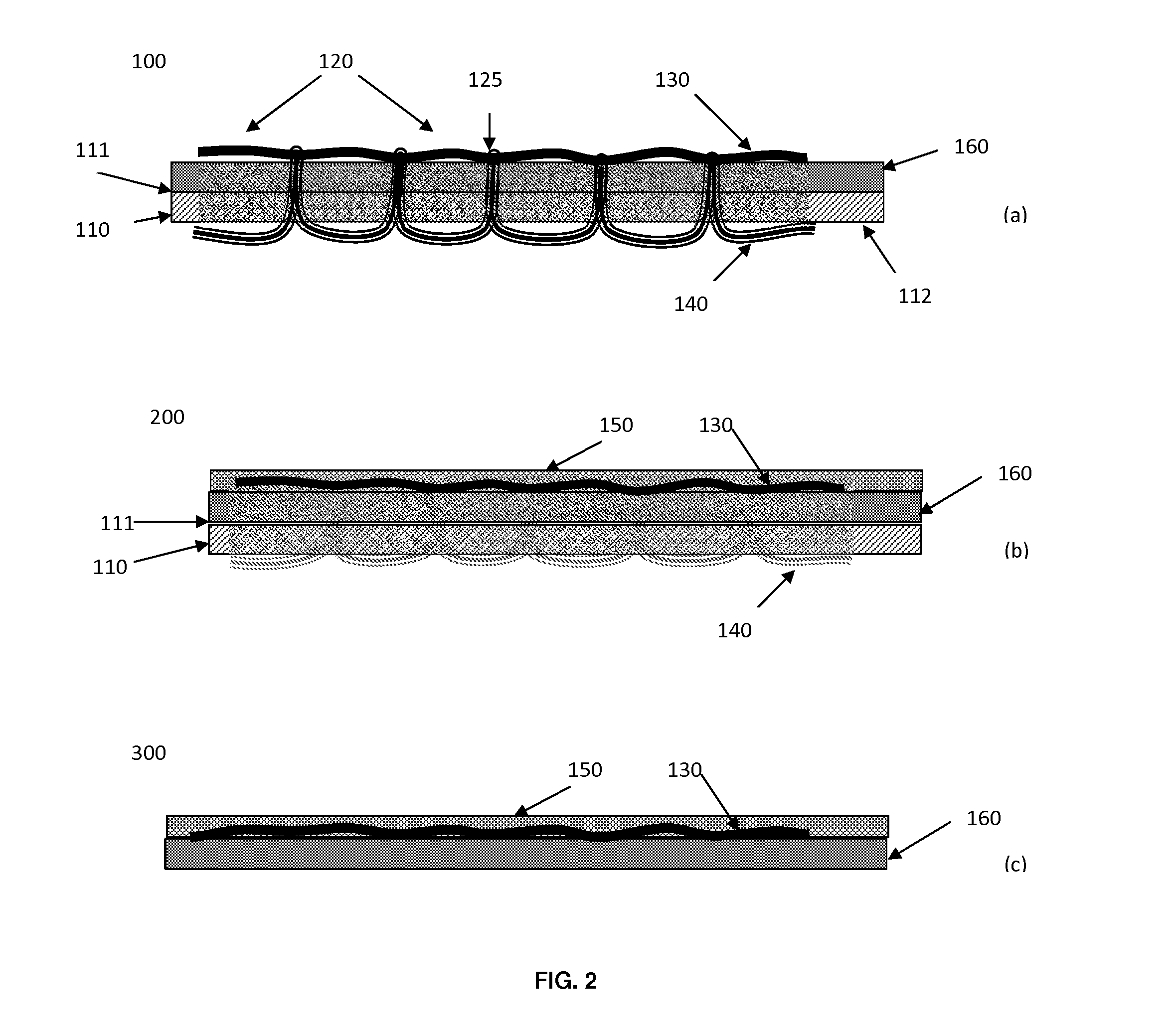

Electrically conductive textile assemblies and manufacture thereof

InactiveUS20160194792A1Less intrusiveLow costCircuit bendability/stretchabilityWeft knittingConductive textileEngineering

There is provided a method of making a conductive assembly for use in textiles, the method comprising providing a composite material comprising: a temporary substrate having a first surface and a second surface opposite the first surface; a stitching pattern comprising a plurality of lockstitches on the temporary substrate, such that a conductive thread is disposed at the first surface of the temporary substrate and a thermo-fusible thread is disposed at the second surface; and an insulating layer comprising an adhesive on top of at least part of the conductive thread on the first surface, the adhesive having an activation temperature which is higher than the Vicat softening point, as measured by method A120 of ASTM D1525, of the thermo-fusible thread; and heating the insulating layer and thermo-fusible thread to the activation temperature and curing the adhesive in the insulating layer of the composite material, thereby securing the conductive thread to the insulating layer. Articles according to the process are also provided.

Owner:MAS INNOVATION

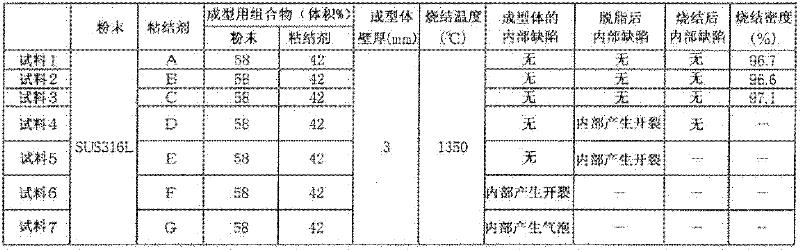

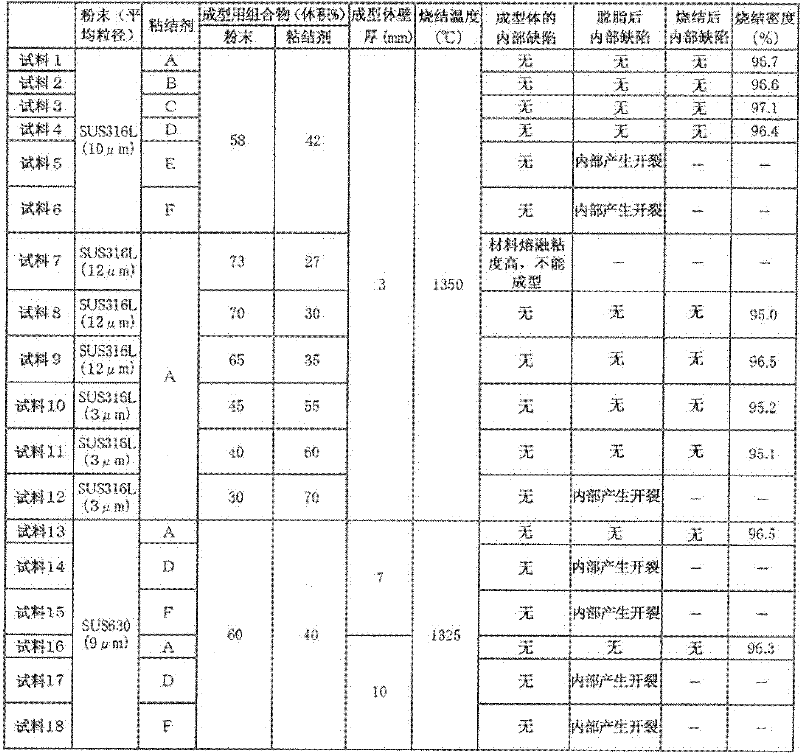

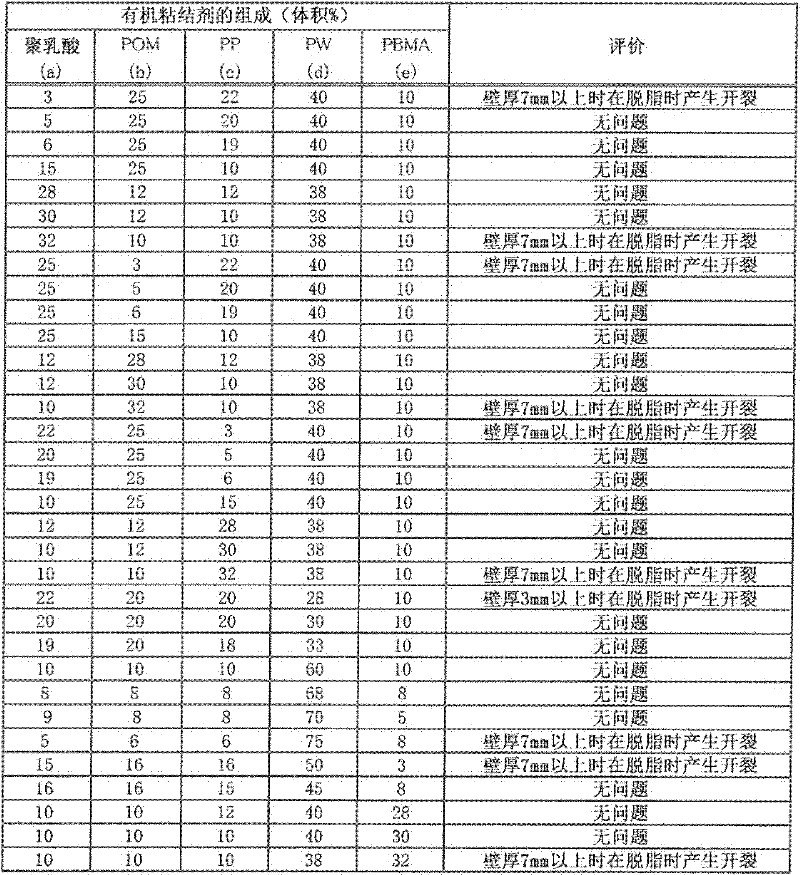

Injection molding composition

InactiveCN102355967ANo bloatingNo crackTransportation and packagingMetal-working apparatusPolyoxymethyleneMetal powder

Disclosed is an injection molding composition which has high thermal decomposability and rarely suffers from degreasing deformation when heated. The injection molding composition is capable of providing a good degreased body in a short time even in cases where a molded body has a large thickness. Specifically disclosed is an injection molding composition which is composed of a sinterable metal powder and an organic binder. The injection molding composition is characterized in that the organic binder is composed of (a) a polylactic acid, (b) a polyoxymethylene, (c) a polypropylene, (d) an organic compound having a viscosity at 150 DEG C of not more than 200 mPas, and (e) a thermoplastic resin having a Vicat softening point of not more than 130 DEG C.

Owner:IHI CORP

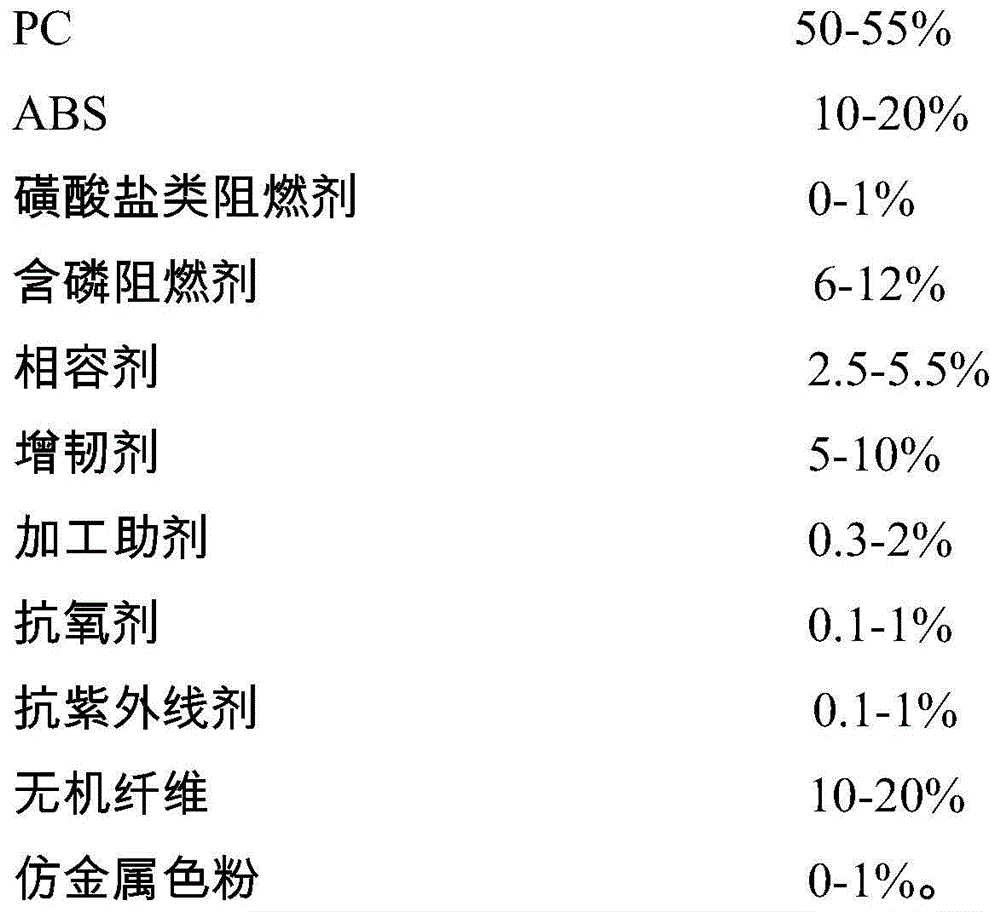

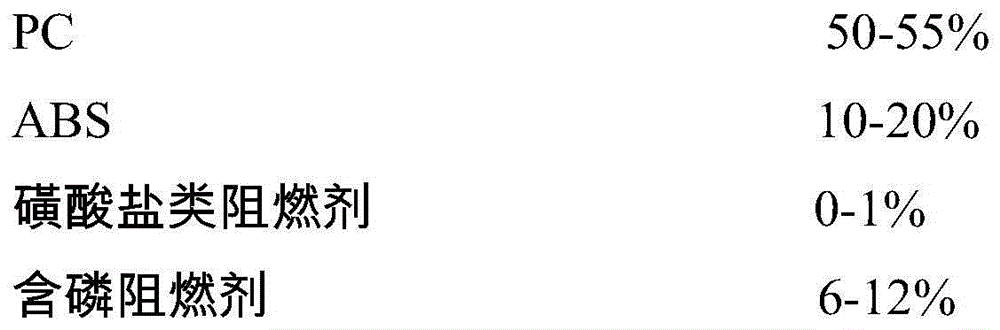

Halogen-free flame-retardant high-gloss inorganic-fiber-reinforced PC/ABS material and preparation method thereof

InactiveCN104403295AGuaranteed impact strengthReasonable Melt Flow RatePolymer scienceThermal deformation

The invention belongs to the technical field of modification of high polymer materials and provides a halogen-free flame-retardant high-gloss inorganic-fiber-reinforced PC / ABS material and a preparation method thereof. The halogen-free flame-retardant high-gloss inorganic-fiber-reinforced PC / ABS material is prepared from raw materials in percentage by weight as follows: 50-55% of PC, 10-20% of ABS, 0-1% of a sulphonate flame retardant, 6-12% of a phosphorus-containing flame retardant, 2.5-5.5% of a compatilizer, 5-10% of a toughening agent, 0.3-2% of a processing aid, 0.1-1% of an antioxidant, 0.1-1% of an anti-ultraviolet agent, 10-20% of inorganic fibers and 0-1% of a metal-imitating toner. According to the halogen-free, flame-retardant, high-gloss and inorganic-fiber-reinforced PC / ABS material, the aid and all the raw materials are reasonably selected and matched, the fibers and the flame retardants are added, through reasonably optimized screw combination, high-gloss, high strength, high rigidity and flame retardant properties are obtained, meanwhile, the halogen-free, flame-retardant, high-gloss and inorganic-fiber-reinforced PC / ABS material has certain impact strength and the reasonable melt flow rate, the reasonable thermal deformation temperature, the reasonable Vicat softening temperature and the like, and a high-gloss mirror effect can be realized.

Owner:ANHUI KEJU NEW MATERIALS

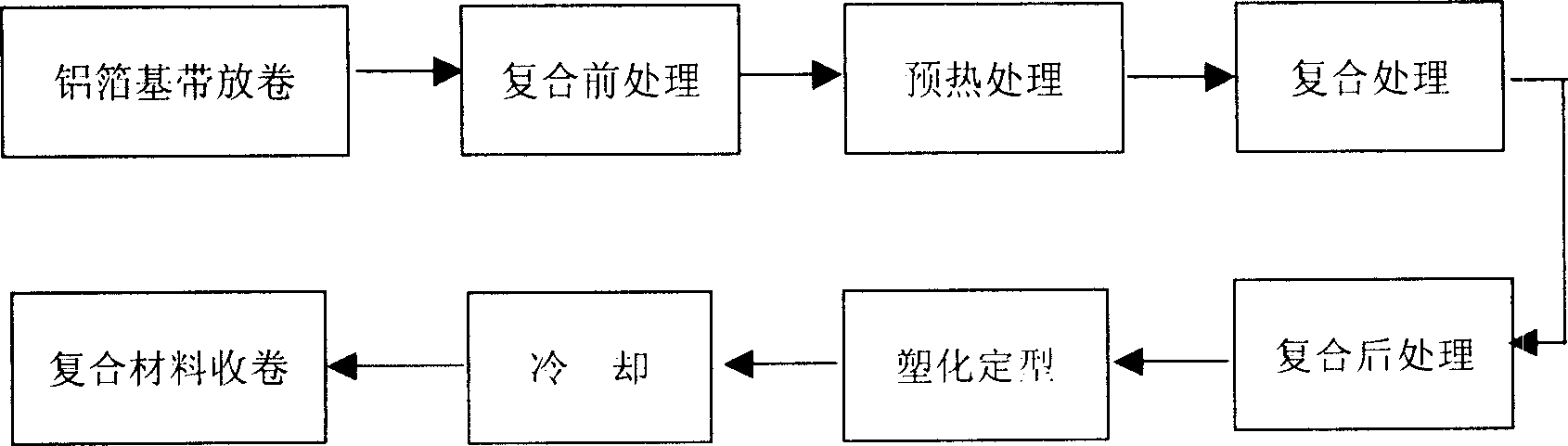

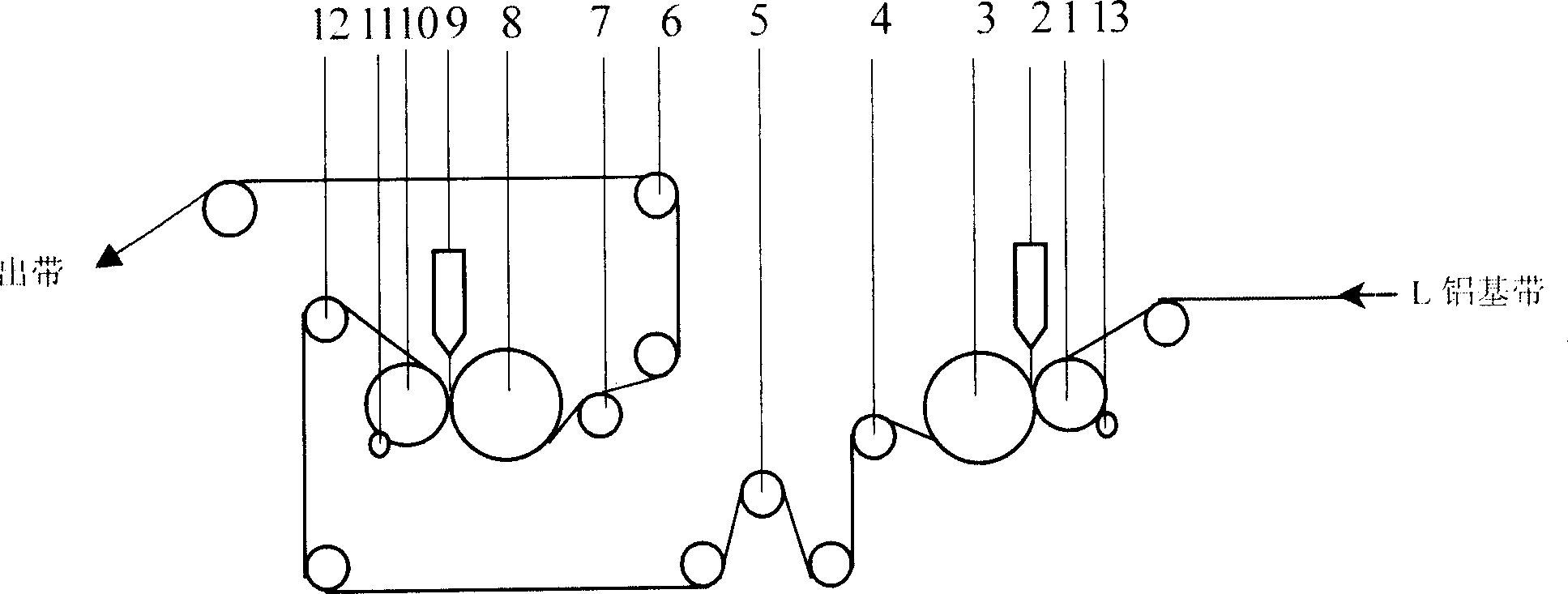

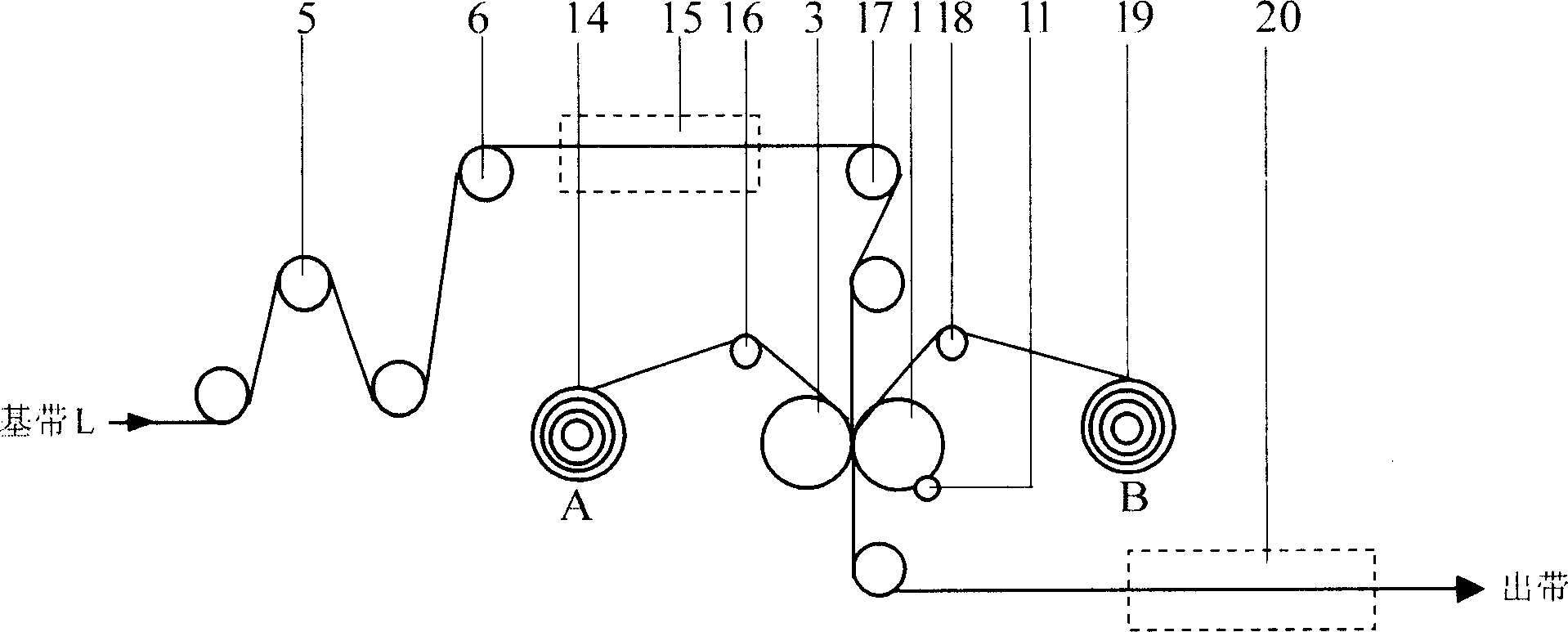

Method for mfg. sub light smooth type aluminium plastic compound band

ActiveCN1792605AReduce weightSave materialSynthetic resin layered productsBeltsPlastic filmAluminum foil

A process for preparing the dull and smooth aluminum-plastic band includes such steps as choosing an aluminum foil as basic band, pre-treating, extruding out at least one plastic film layer onto one or two surfaces of basic band, rolling while heating, and heat-treating by controlling the temp between Vicat softening point and fusion point for obtain dull and smooth surface. It can be used for optical cable or electric cable for high moisture tight effect.

Owner:上海网讯新材料科技股份有限公司

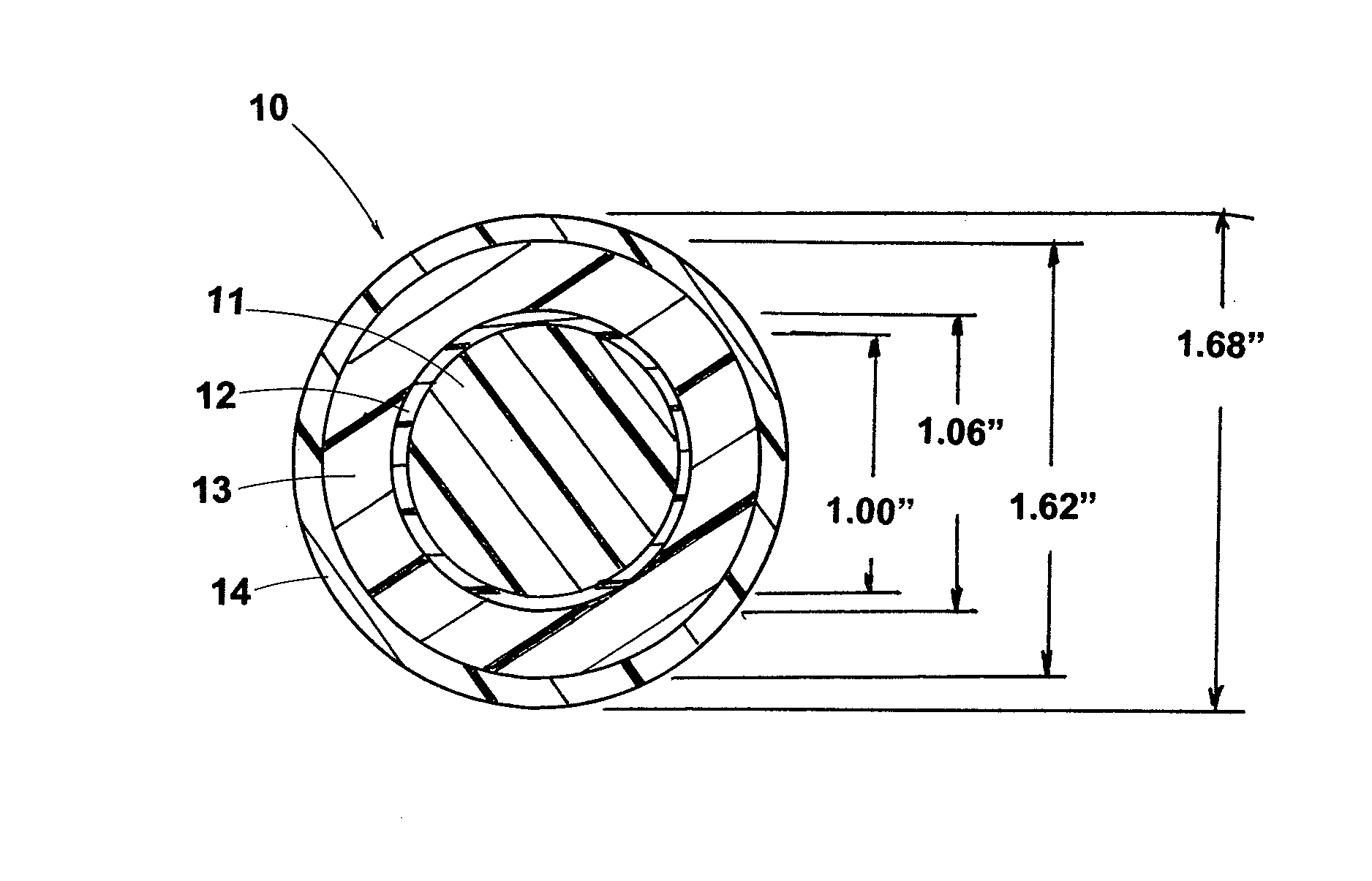

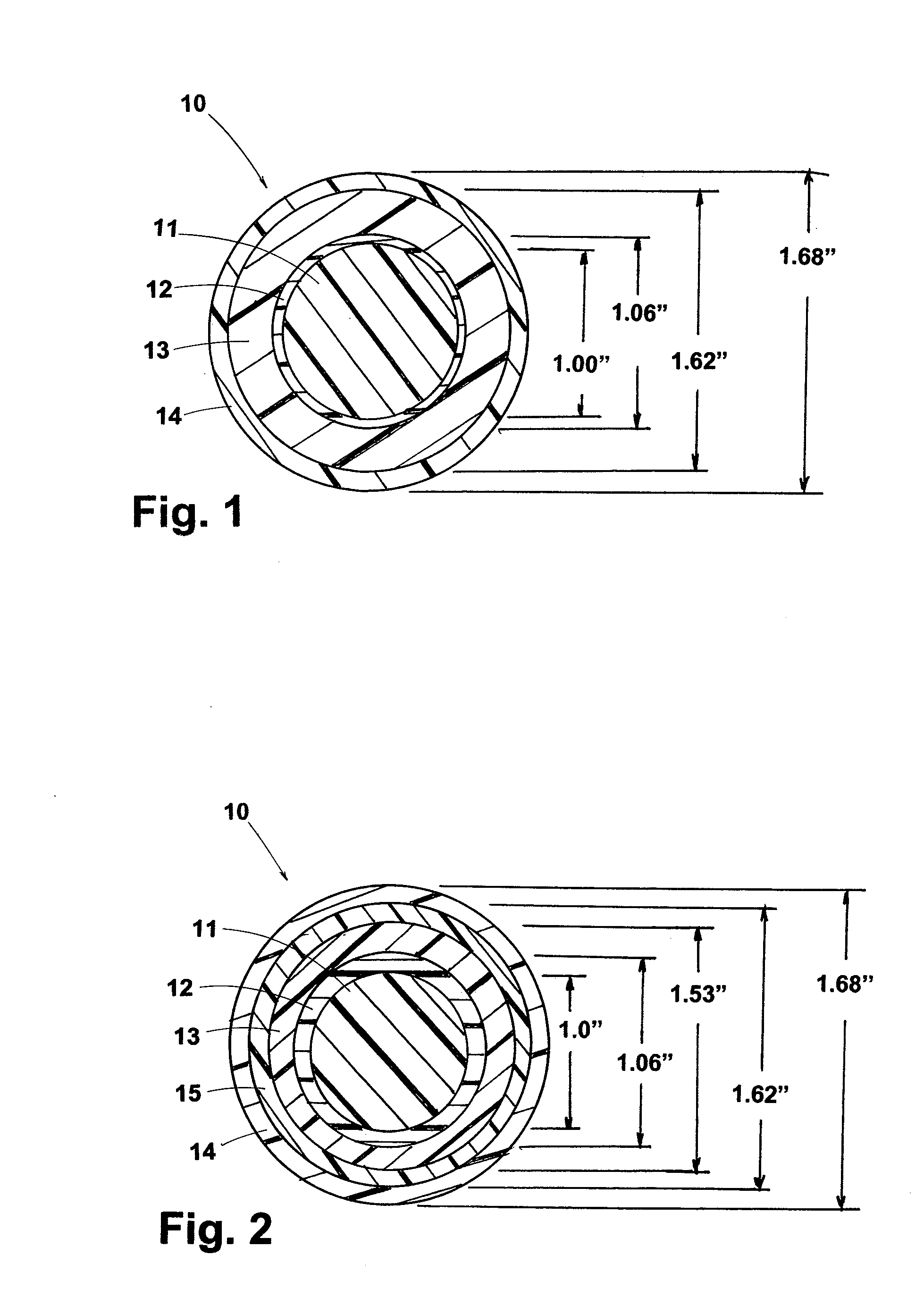

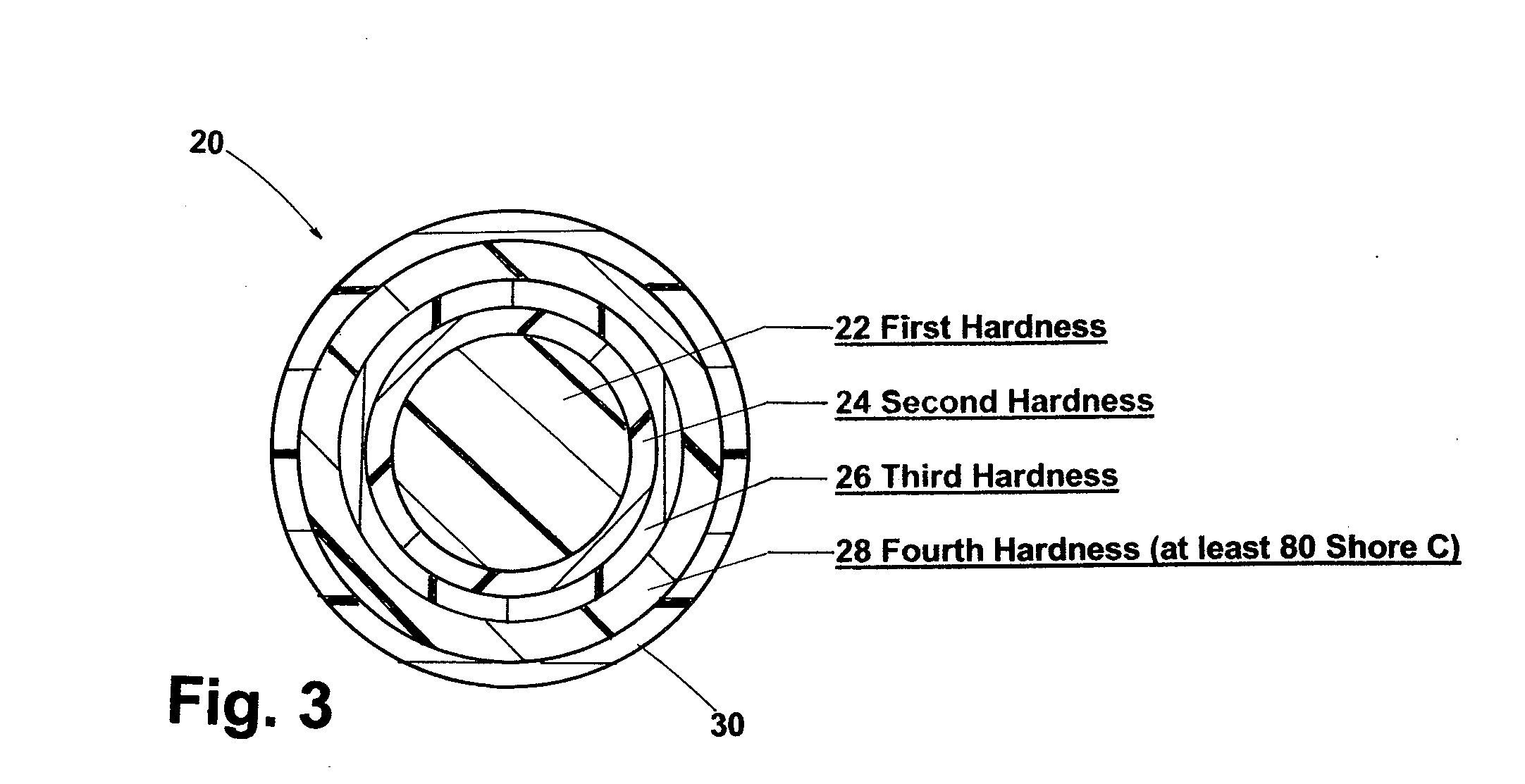

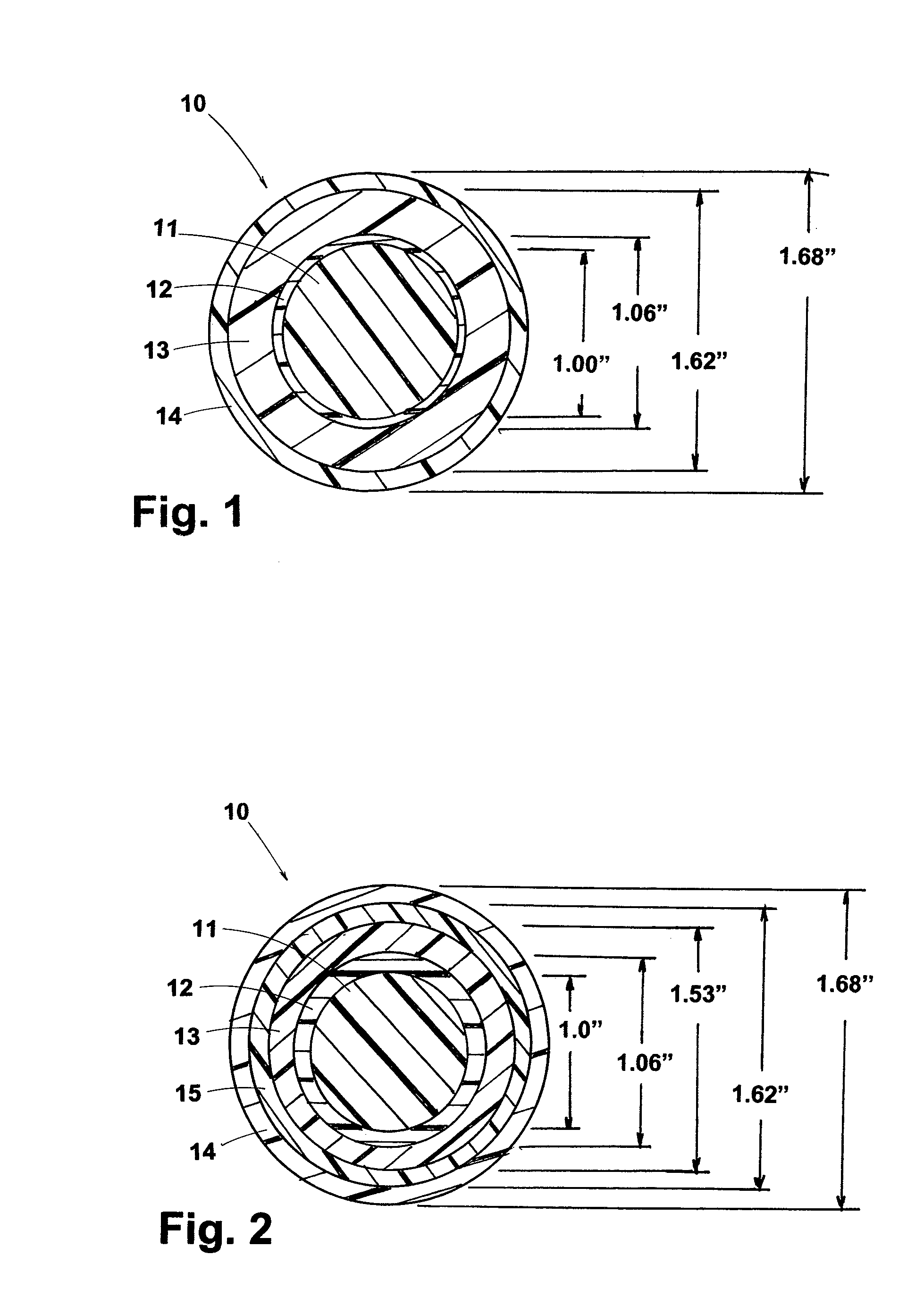

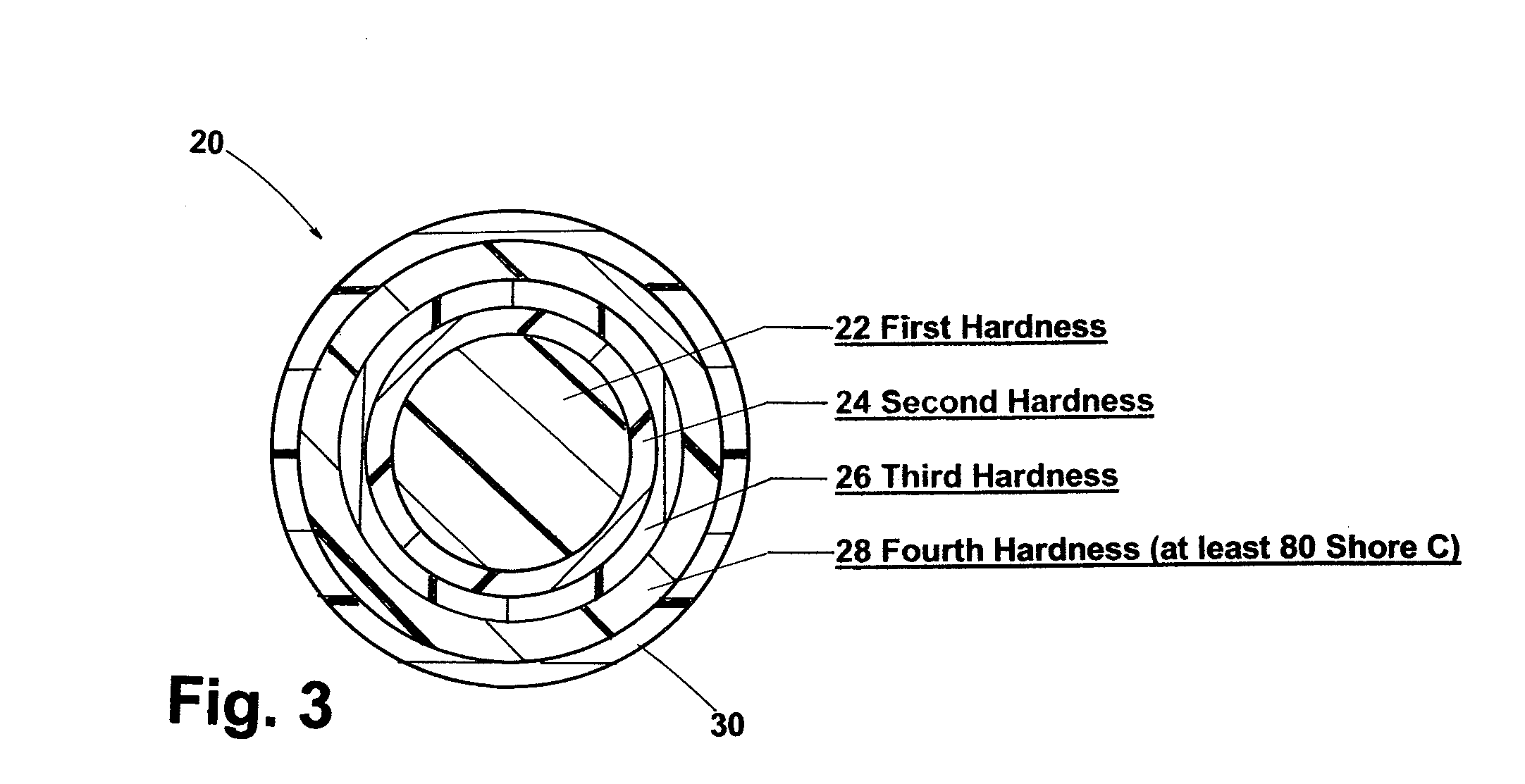

Golf ball with head resistant shield layer

The present invention is directed to a golf ball comprising a shield layer having heat resistant properties to facilitate compression molding of a thermosetting polybutadiene-comprising layer over at least one thermoplastic layer. The invention utilizes a thermoplastic inner core comprising of a low vicat highly neutralized ionomer material having a low melting point of less than 100° C., and a Shore C surface hardness of less than 80 and a compression of less than 70, wherein a shield layer is placed around the low vicat softening point temperature thermoplastic to shield it from the high heat necessary to mold a thermoset material about it.

Owner:ACUSHNET CO

Heat resistant polylactic acid-base composite material and its prepn process

The present invention relates to one kind of heat resistant polylactic acid-base composite material and its preparation process. The polylactic acid-base composite material is prepared with polylactic acid 100 weight portions, fiber 5-50 weight portions, antioxidant 0.5-3 weight portions, heat stabilizer 0.5-3 weight portions and vinyl radical polyfunctional monomer 1-10 weight portions, and through mixing, pelletizing in a double screw extruder, drying, injection molding and irradiation cross-linking with a Co-60 source or an electronic accelerator. It has the Vicat softening point raised from 55-80 deg.c to 150 deg.c.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Bonded polyolefine resin composition

ActiveCN101074305AReduce degradation reactionIncrease reaction rateLinear low-density polyethylenePolyolefin

An adhesive poly-olefin resin composite consists of grafted polypropylene 0.1-40 wt% ( MFR 1-40 wt%), polypropylene 20-48 wt% ( MFR 0.3-40 wt%), linear low-density polythene 20-40 wt% ( MFR 0.8-10 wt%), high-density polypropylene 10-30 wt% ( MFR 2-5 wt%), multi-polymer of ethylene and octane 1-20 wt% in proportion of 1:1 ( MFR 0.5-30 wt%) and polystyrene 1-10 wt%. Grafted polypropylene is unsaturated carboxylic acid, anhydride or carboxylic ester as the first grafting monomer, styrene is the second grafting monomer, the grafting rate of unsaturated carboxylic acid, anhydride or carboxylic ester of polypropylene is 1-10 wt%. It has excellent binding performance with steel, iron and aluminum, peeling strength is >=80 N / 10 mm, and softening point is >=120 degree(GB 1613-90). It can be used for chemical container and pipeline.

Owner:PETROCHINA CO LTD

Polymer mixture and the utilization thereof for injection molded parts

ActiveUS7371795B2Improve liquidityAvoid lack of toughnessPaper coatingDomestic articlesPolymer scienceInjection moulding

The invention relates to a polymer mixture based on the (meth)acrylate (co)polymer components a), b), c), and / or d) according to claim 1, where a test specimen produced from the polymer mixture simultaneously has the following properties:I. a tensile modulus (ISO 527) of at least 2600 MPa,II. a Vicat softening point VSP (ISO 306-B50) of at least 109° C.,III. an impact strength (ISO 179-2D, flatwise) of at least 17 kJ / m2, andIV. a melt index MVR (ISO 1133, 230° C. / 3.8 kg) of at least 1.5 cm3 / 10 min.The invention further relates to injection mouldings and to the use of the polymer mixture for producing injection-moulded parts.

Owner:ROHM GMBH

Insertable thermotic module for self-heating can

InactiveUS6962149B2Exothermal chemical reaction heat productionDomestic cooling apparatusChemical reactionComputer module

Owner:HOT CAN INTPROP

Oriented cook-in film with good interply adhesion

InactiveUS6294264B1High bonding strengthUnified specificationsFlexible coversWrappersAcetic acidFatty food

A multilayer film suitable for cook-in end use includes an outer layer that includes a homo- or co-polymer of propylene and, directly adhered to the outer layer, a layer that includes at least one of: (a) an ethylene / alkyl acrylate copolymer having a high melting point, (b) propylene / alpha-olefin copolymer having a lower propylene mer content than the outer layer and having a high Vicat softening point, and (c) an ethylene / vinyl acetate copolymer with at least 15% vinyl acetate mer content. The film exhibits good seal strength and good adhesion between the two layers, even in areas where the film is sealed, even after the film is oriented, even when the film is subjected to the elevated temperatures involved in cook-in procedures, and even where the film is subjected to, e.g., grease from fatty foods. The film also can include one or more other layers including, for example, bulk layers, O2-barrier layers, and / or abuse layers.

Owner:CRYOVAC ILLC

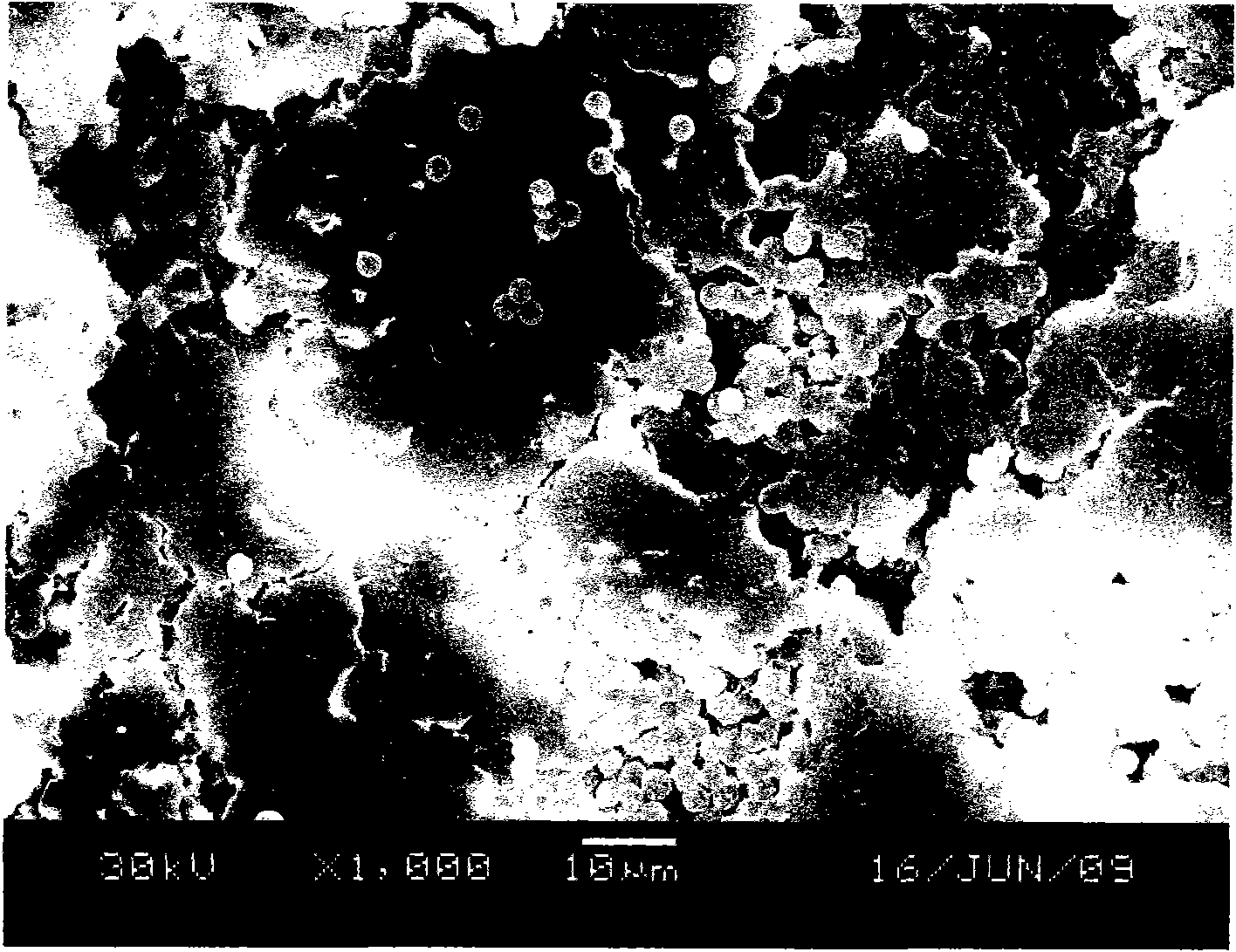

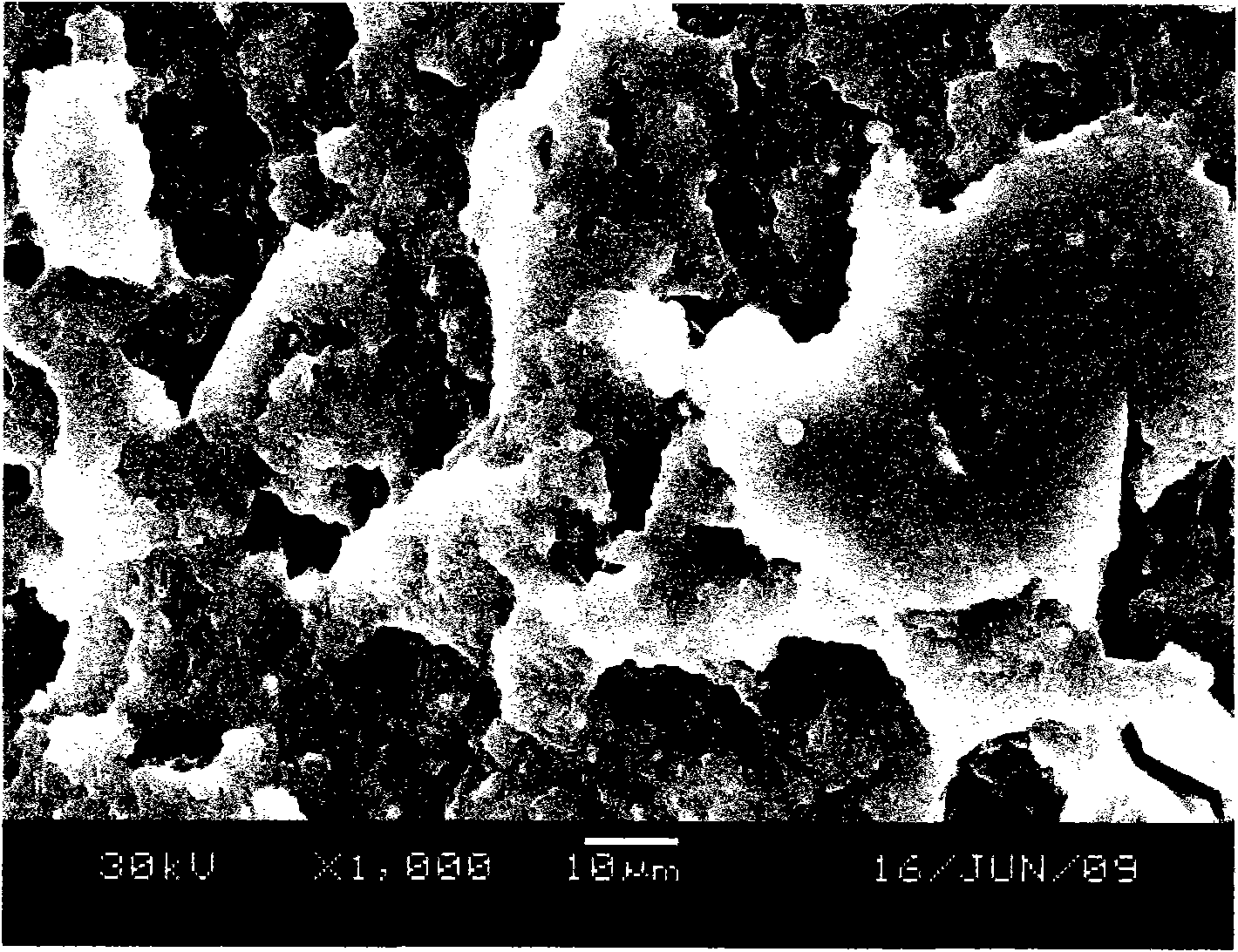

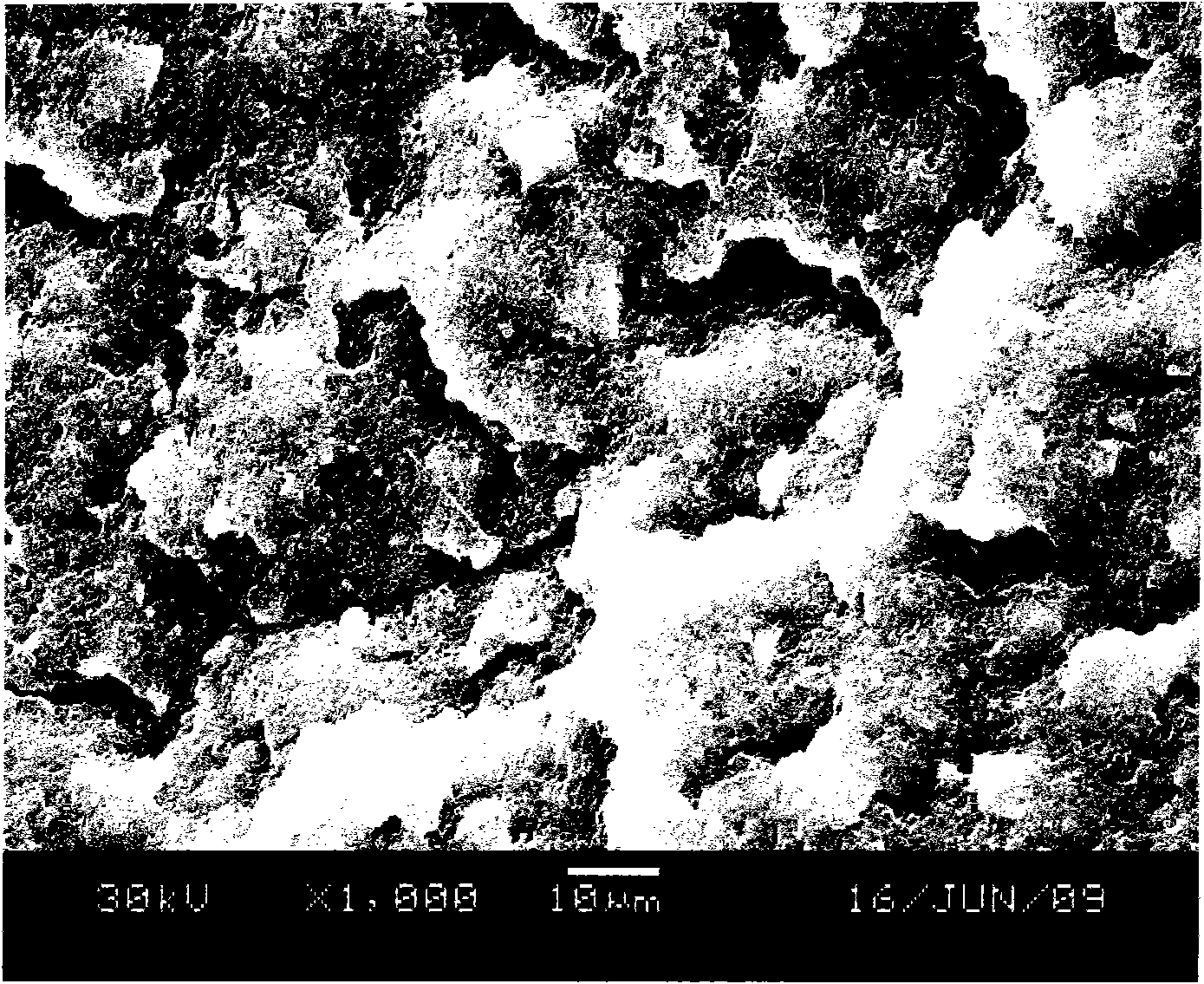

Polymer blend for matte injection moulded parts

The invention relates to a polymer mixture, comprisinga) a polymer matrix which is composed of a (meth)acrylate (co)polymer or of a mixture of (meth)acrylate (co)polymers with a Vicat softening point VSP (ISO 306-B50) of at least 104° C. and / or of a (meth)acrylimide (co)polymer,b) an impact modifier which is based on crosslinked poly(meth)acrylates and which does not have covalent bonding to the polymer matrix a),c) from 1 to 15% by weight of plastics particles composed of crosslinked polymers based on polymethyl methacrylate, on polystyrene and / or on polysilicones.The polymer mixture can be used to obtain injection mouldings with matt surfaces and Vicat softening points VSPs (ISO 306-B50) of at least 90° C.

Owner:ROEHM GMBH & CO KG

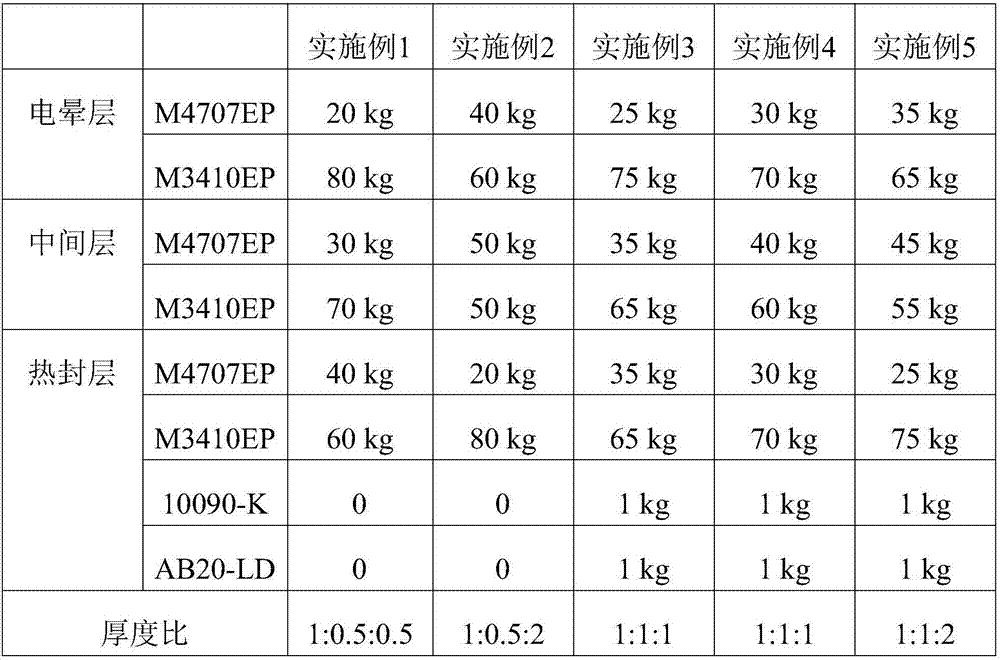

Polyethylene film resistant to high-temperature steaming and production process of polyethylene film

ActiveCN107283980AHigh mechanical strengthHigh hot viscosityLamination ancillary operationsSynthetic resin layered productsComposite filmPolymer science

The invention provides a polyethylene film resistant to high-temperature steaming and a production process of the polyethylene film. The polyethylene film comprises a corona layer, a middle layer and a heat sealing layer, wherein raw materials of the corona layer, the middle layer and the heat sealing layer comprise metallocene medium-density polyethylene and metallocene high-density polyethylene independently; the difference between the vicat softening point and the melting point of each of metallocene medium-density polyethylene and metallocene high-density polyethylene does not exceed 10 DEG C. The polyethylene film has high mechanical strength, excellent optical performance, low-temperature freezing performance, high heat-sealing strength, high thermo-viscous force, a wide heat-sealing window, low odor, resistance to steaming for 30 min at the temperature of 121 DEG C and other excellent performance and can be used as an inner material of a composite film resistant to high-temperature steaming.

Owner:永新股份(黄山)包装有限公司

Nanometer random olefin copolymer/montmorillonite composite material and its prepn

ActiveCN101020776AImprove mechanical propertiesImproved hydrostatic resistancePolyolefinMontmorillonite

The nanometer random olefin copolymer / montmorillonite composite material consists of grafting polyolefin base montmorillonite master batch 5-10 wt% and random olefin copolymer 90- 95 wt%. The nanometer random olefin copolymer / montmorillonite composite material has completely stripped montmorillonite master batch and homogeneously dispersed montmorillonite. It has high mechanical performance, including tensile strength over 25 MPa, bending strength over 30 MPa and elongation at break up to 140 %; Vicat softening point up to 130 deg.c(10N); and high static hydraulic pressure tolerance.

Owner:杭州鸿雁管道系统科技有限公司 +1

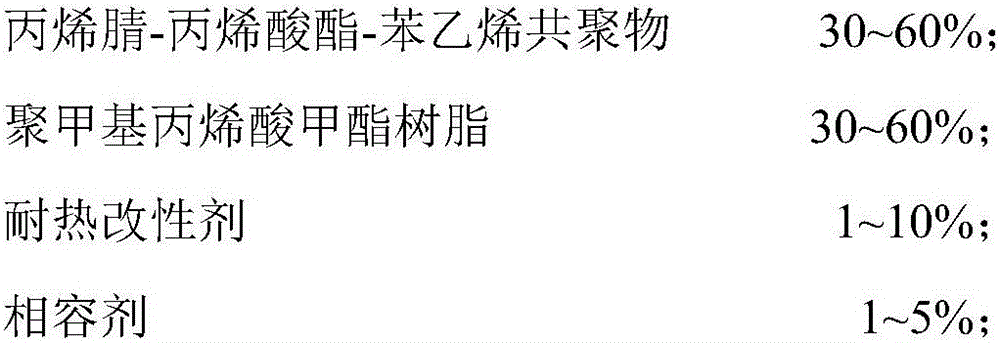

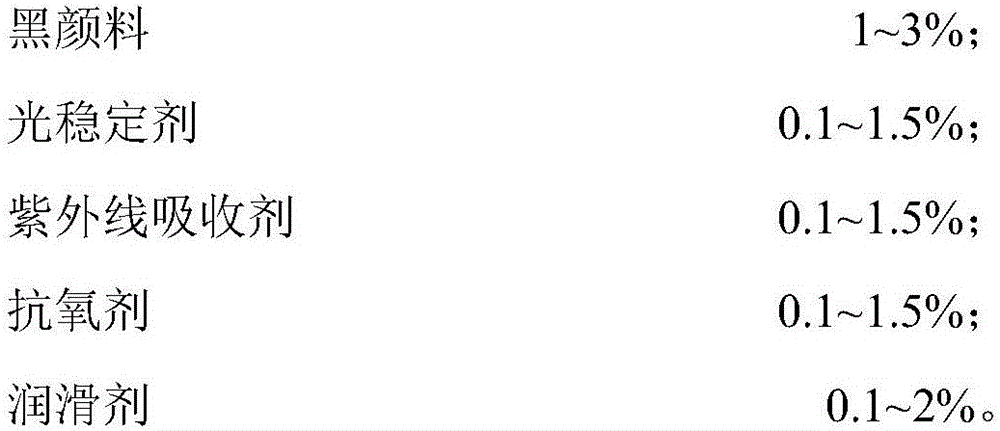

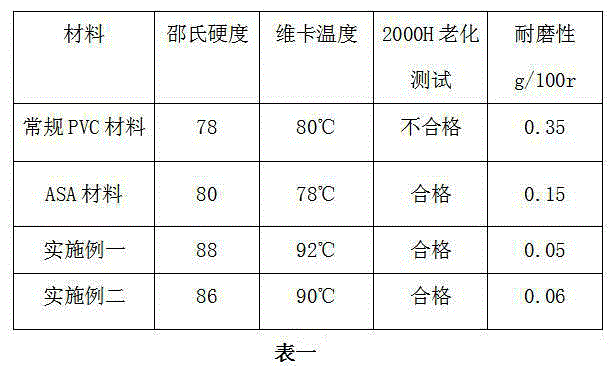

High-heat-resistant high-weatherability ASA/PMMA (acrylonitrile-styrene-acrylonitrile and polymethyl methacrylate) composite and preparation method thereof

The invention discloses high-heat-resistant high-weatherability ASA / PMMA (acrylonitrile-styrene-acrylonitrile and polymethyl methacrylate) composite and a preparation method thereof, belongs to the field of material modification, and is intended to solve the problem that existing PMMA / ASA alloy resin has Vicat softening point of <100 DEG C and is unable to meet the demand for heat resistance in products and unable to be applied to an environment having high requirement on heat resistance. The composite comprises, by weight, 30-60% of ASA, 30-60% of PMMA, 1-10% of a heat-resistant modifier, 1-5% of a compatibilizer, 1-3% of a black pigment, 0.1-1.5% of a photostabilizer, 0.1-1.5% of an ultraviolet absorbent, 0.1-1.5% of an antioxidant, and 0.1-2% of a lubricant. Actual application shows that the ASA / PMMA composite has excellent heat resistance and weatherability, high surface gloss and good comprehensive properties, has Vicat softening point of 100 DEG C and above, man have effectively extended applicable range, and has a promising application prospect.

Owner:SICHUAN COREMER CO LTD

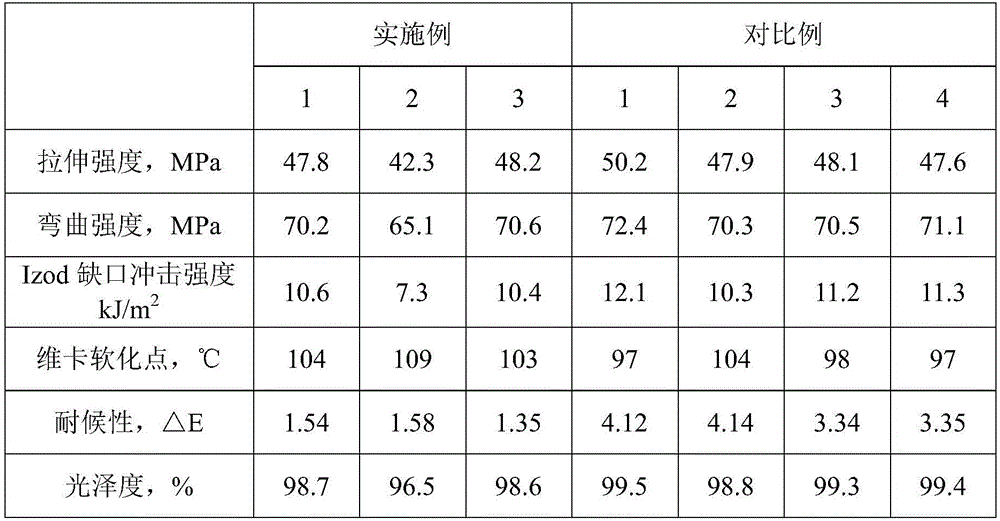

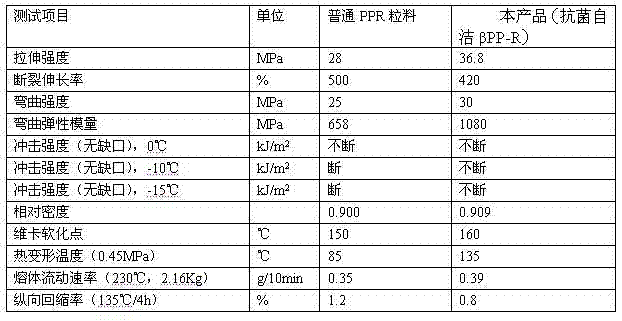

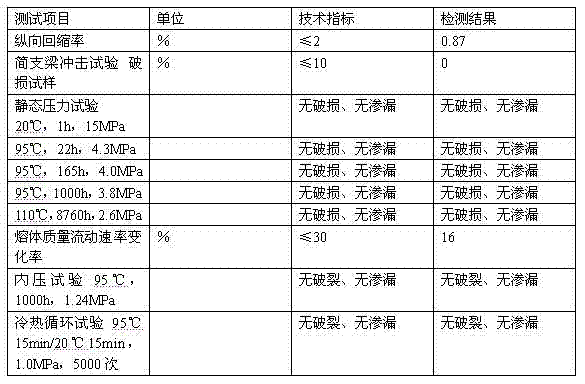

Self-cleaning antibacterial beta-crystal form PP-R cold-hot water pipe material and preparation method thereof

InactiveCN102226028AGood room temperatureImprove low temperature impact strengthRigid pipesThermal deformationInjection molding machine

The invention relates to a self-cleaning antibacterial beta-crystal form PP-R cold-hot water pipe material. The preparation method comprises the following steps of mixing calcium stearate and lanthana, adding pimelic acid into the mixture to cause a reaction, then adding nano-calcium carbonate into the reaction products obtained from the previous step and stirring uniformly to obtain a composite beta-crystal form nucleating agent, mixing orderly PP-R4220 resin, white oil 10, the composite beta-crystal form nucleating agent and anti-oxidants to produce a mixture, feeding the mixture into a parallel double screw extruder to produce beta PP-R resin particles, adding a silver ion salt and a zinc ion salt into nano-titanium dioxide, then mixing the nano-titanium dioxide, the beta PP-R resin particles and poly propylene wax to form a mixture, feeding the mixture into a parallel double screw extruder to produce a composite antibacterial mother material, and mixing uniformly the beta PP-R resin particles, the composite antibacterial mother material, poly propylene wax, methyl phenyl silicone oil and ultra -fine talc powder to form a mixture, feeding the mixture into an extruder or an injection machine to produce a self-cleaning antibacterial beta-crystal form PP-R cold-hot water pipe material. The material has the advantages of high usage temperature of 95 DEG C, high compressive strength, high thermal deformation temperature, high Vicat softening point, good self-clean performance and antibacterial effects.

Owner:HUBEI YANGTIAN PLASTIC PROD CO LTD

Heat resistant smoke inhibiting polyvinyl chloride composition and its preparation method

InactiveCN1651505AImprove heat resistanceImprove toughnessHeat deflection temperaturePolyvinyl chloride

A process for preparing the smoke-inhibiting refractory polyvinyl chloride composition features that the multiple elements componding technique is used to improve the high-temp resistance to toughness of PVC, and the two kinds of high-toughness and -rigidity materials are used as its modifier. Its product has excellent high-temp resistance, flame-retarding nature, smoke inhibition and weatherability.

Owner:CHINA PETROLEUM & CHEM CORP

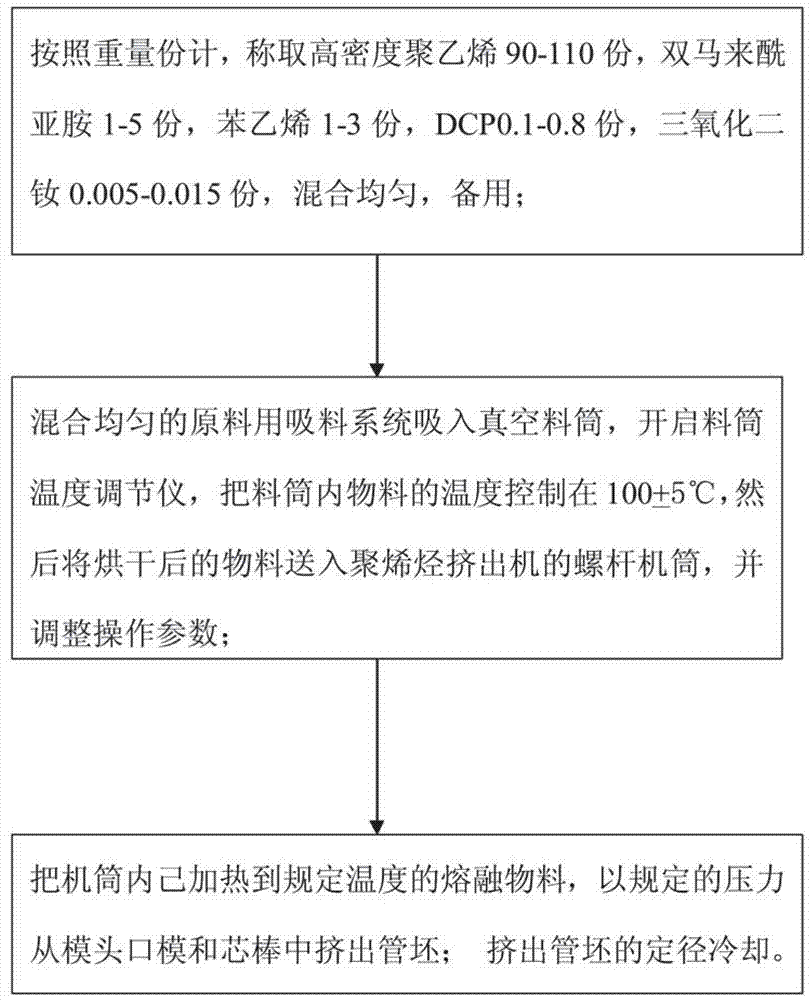

Anticorrosive, wax-proof and high-temperature-resistant polyethylene tube for oil extraction and preparation method of polyethylene tube

The invention relates to a polyethylene liner tube, particularly to an anticorrosive, wax-proof and high-temperature-resistant polyethylene tube for oil extraction and a preparation method of the polyethylene tube. The anticorrosive, wax-proof and high-temperature-resistant polyethylene tube comprises the following components in parts by weight: 90-110 parts of high-density polyethylene, 1-5 parts of bismaleimide, 1-3 parts of styrene, 0.1-0.8 part of DCP (Dicumyl Peroxide) cross-linking agent, and 0.005-0.015 part of neodymium oxide; and the polyethylene tube is manufactured by a screw cylinder of a polyolefin extruder. The vicat softening point of the prepared polyethylene tube is at 135 DEG C; the polyethylene tube with the use temperature capable of reaching 130 DEG C is applicable to an oil extraction pipe in an oil well which is 2000-3000m deep; and compared with a modified nylon oil extraction pipe applied to the oil extraction pipe below 2000m, the polyethylene tube provided by the invention is characterized in that the cost is low and the acid resistance is good.

Owner:济南赛辰高分子材料有限公司

Ultrahigh-weather-resistance PVC (polyvinyl chloride) coextruded surface material and manufacturing method thereof

ActiveCN104893143AHigh surface hardnessIncrease temperatureWeather resistanceChlorinated polyvinyl chloride

The invention an ultrahigh-weather-resistance PVC (polyvinyl chloride) coextruded surface material and a manufacturing method thereof, belonging to the field of composite materials. The ultrahigh-weather-resistance PVC coextruded surface material comprises the following components in parts by mass: 40-60 parts of PVC powder, 20-50 parts of CPVC (chlorinated polyvinyl chloride), 10-20 parts of calcium carbonate powder, 0.4-6 parts of stabilizer, 4-7 parts of impact modifier, 1-3 parts of lubricant, 0.4-0.9 part of anti-ultraviolet agent, 0.4-0.9 part of antioxidant, 0.5-1 part of antistatic agent, 3-6 parts of whisker and 3-6 parts of toner. By adjusting the formula, the material has comparable weather resistance with ASA (acrylonitrile-styrene-acrylate), and has higher surface hardness and Vicat softening point temperature. The material is low in cost, does not need to depend on import, and can obviously lower the production cost. The production cost of the product is only about one half of that of the ASA material. The product can be widely used in surface coextrusion of PVC door / window profiles, PVC wood-plastic profiles and PVC tiles to enhance the physical properties and colorfulness of the product.

Owner:DONGGUAN BETTO WOOD NEW MATERIAL TECH CO LTD

Golf ball with heat resistant shield layer

Owner:ACUSHNET CO

Capsule and method for preparing a beverage such as coffee from said capsule

Capsule for the preparation of a beverage in beverage preparation device comprising: a cup-shaped body comprising a cavity containing a beverage ingredient and a flange-like rim extending outwardly from the base of said body, a delivery wall connected to the flange-like rim, characterized in that the flange-like rim is formed of is a polymer material chosen in grade having a Vicat softening point (ISO 10350) between about 30 and 100 DEG C, preferably between 40 and 90 DEG C or apolymer chosen in grade comprising a glass transition temperature (Tg) between 30 and 80 DEG C,preferably between 40 and 60 DEG C.

Owner:SOC DES PROD NESTLE SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com