Halogen-free flame-retardant high-gloss inorganic-fiber-reinforced PC/ABS material and preparation method thereof

A technology of ABS materials and inorganic fibers, which is applied in the field of polymer material modification, and can solve problems such as the inability to apply high-gloss appearance parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

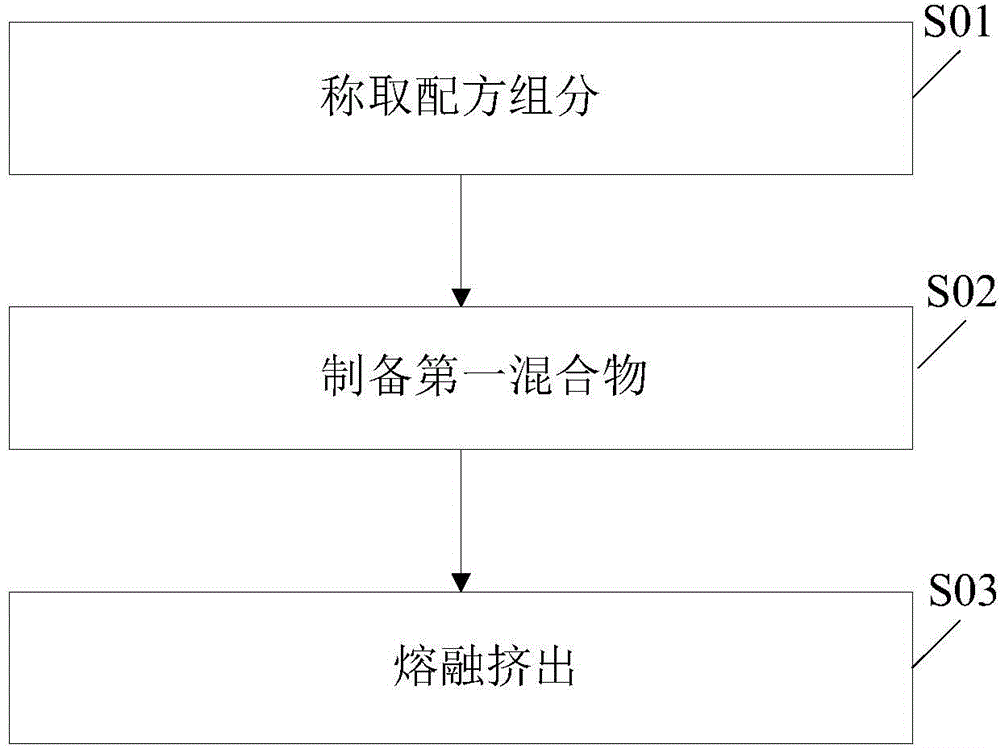

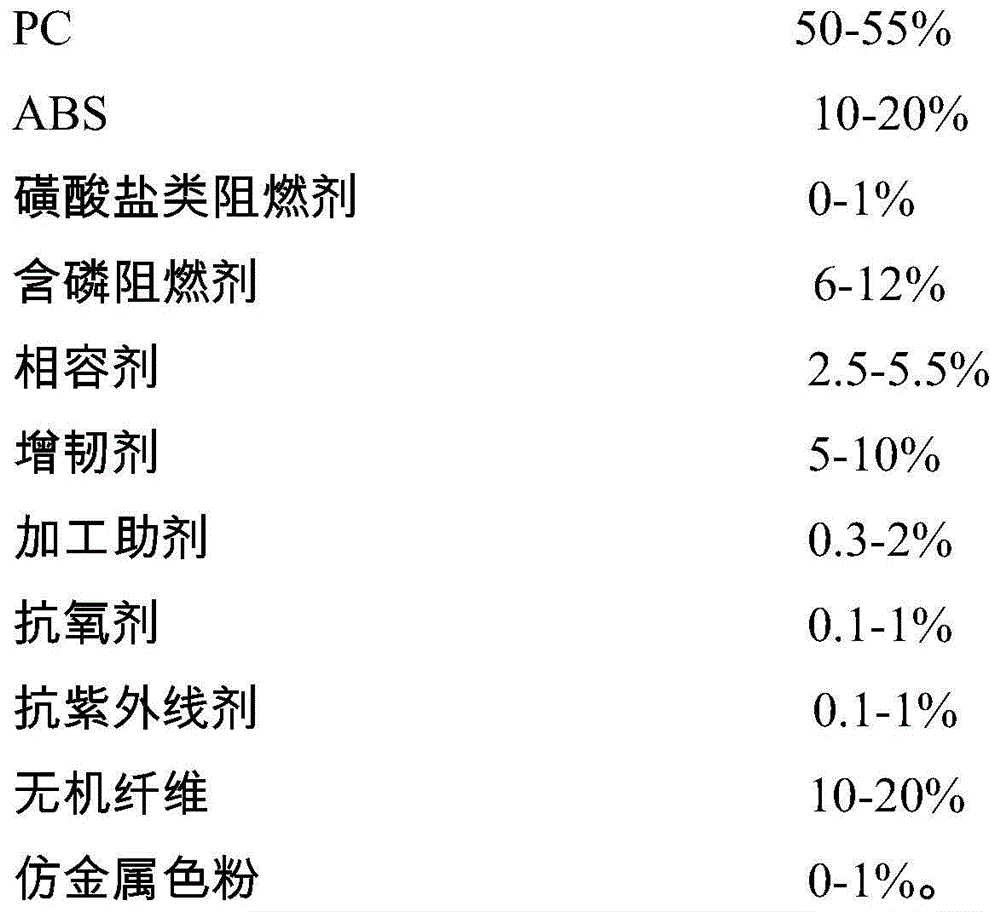

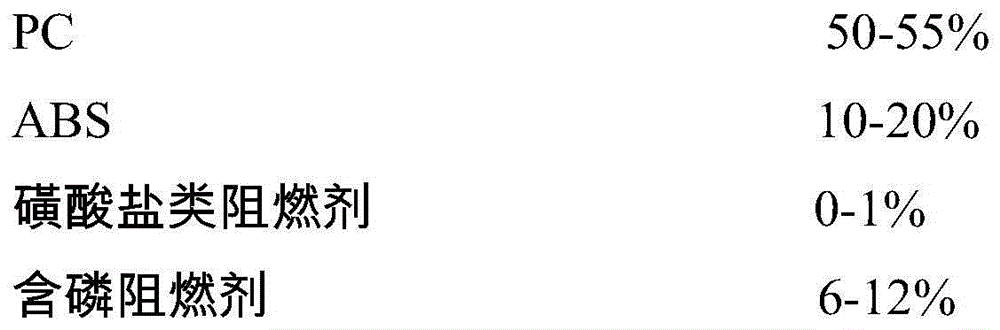

[0042] Correspondingly, the embodiment of the present invention provides a method for preparing a halogen-free flame-retardant high-gloss inorganic fiber reinforced PC / ABS material. The schematic flow chart of the preparation method is as follows figure 1 As shown, the method includes the following steps:

[0043] S01 Weighing formula components

[0044] According to the above formula of halogen-free flame-retardant high-gloss inorganic fiber reinforced PC / ABS material, weigh PC, ABS, sulfonate flame retardant, phosphorus-containing flame retardant, compatibilizer, toughener, processing aid, Antioxidant, anti-ultraviolet agent, inorganic fiber, silver powder;

[0045] S02 prepares the first mixture

[0046] Add the PC, ABS, toughening agent, processing aid, antioxidant, anti-ultraviolet agent, and silver powder weighed in step S01 into a high-speed mixer and mix at high speed for 2-10 minutes to obtain the first mixture;

[0047] S03 melt extrusion

[0048] The first mixtu...

Embodiment 1

[0055] The halogen-free flame-retardant high-gloss inorganic fiber-reinforced PC / ABS material in this example is composed of the following components by weight percentage: 55.0 parts of PC, 13.3% of ABS, 8.0% of toluene xylyl phosphate, HES-FR 0.1 %, MBS 4.0%, ABS-g-MAH 3.0%, processing aid 1.5%, antioxidant 0.5%, anti-ultraviolet agent 0.5%, stir in the mixing tank for 5 minutes, pre-treated Jushi glass fiber 988A15%, and then It is melt-extruded and granulated through a twin-screw extruder, and its processing technology is as described above.

Embodiment 2

[0057] The halogen-free flame-retardant high-gloss inorganic fiber-reinforced PC / ABS material in this example is composed of the following components by weight percentage: 55.0 parts of PC, 13.3% of ABS, 8.0% of toluene xylyl phosphate, and 0.1% of KSS , MBS 4.0%, ABS-g-MAH 3.0%, processing aid 1.5%, antioxidant 0.5%, anti-ultraviolet agent 0.5%, stir in the mixing tank for 5 minutes, pre-treated Jushi glass fiber 988A 15%, and then It is melt-extruded and granulated through a twin-screw extruder, and its processing technology is as described above.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com