Patents

Literature

128results about How to "Has antistatic effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Spray coating type fire-retardant antistatic polyurethane elastomer and preparation method thereof

ActiveCN103709362ALow viscosityImprove liquidityFireproof paintsPolyurea/polyurethane coatingsCarbon nanotubeSpray coating

The invention discloses a spray coating type fire-retardant antistatic polyurethane elastomer and a preparation method thereof. The spray coating type fire-retardant antistatic polyurethane elastomer comprises an A component and a B component, wherein the A component is composed of 40-60 parts of isocyanate and 40-60 parts of phosphorus-containing flame-retardant polyol, and the B component is composed of 0-30 parts of chain extender, 0-30 parts of polyether polyol, 10-75 parts of amine-terminated polyether, 0-30 parts of carbon nanotube slurry, 0-3 parts of pigment and 0-3 parts of assistant. The preparation method comprises the following steps: adding the phosphorus-containing flame-retardant polyol into a reaction kettle, heating up to 110 DEG C, vacuumizing for 3 hours, cooling to 30 DEG C, adding the isocyanate, heating up to 105 DEG C, and reacting for 3 hours to obtain a semi-prepolymer A component; sequentially adding the ingredients of the B component into a stirring tank, stirring uniformly, and grinding the mixture in a sand mill for 2.5 hours to prepare the B component; spray-coating the A component and the B component onto a surface through a high pressure spray coating machine, and quickly curing to form. According to the spray coating type fire-retardant antistatic polyurethane elastomer disclosed by the invention, film forming matters are stable, no fire retardant is separated out and the durability is good; a spray coating type fire-retardant antistatic material prepared by the preparation method disclosed by the invention has both fire resistance and anti-static function, so that the material is suitable for application on flame-retardant and explosion-proof occasions.

Owner:QINGDAO ADVANCED MARINE MATERIAL TECH

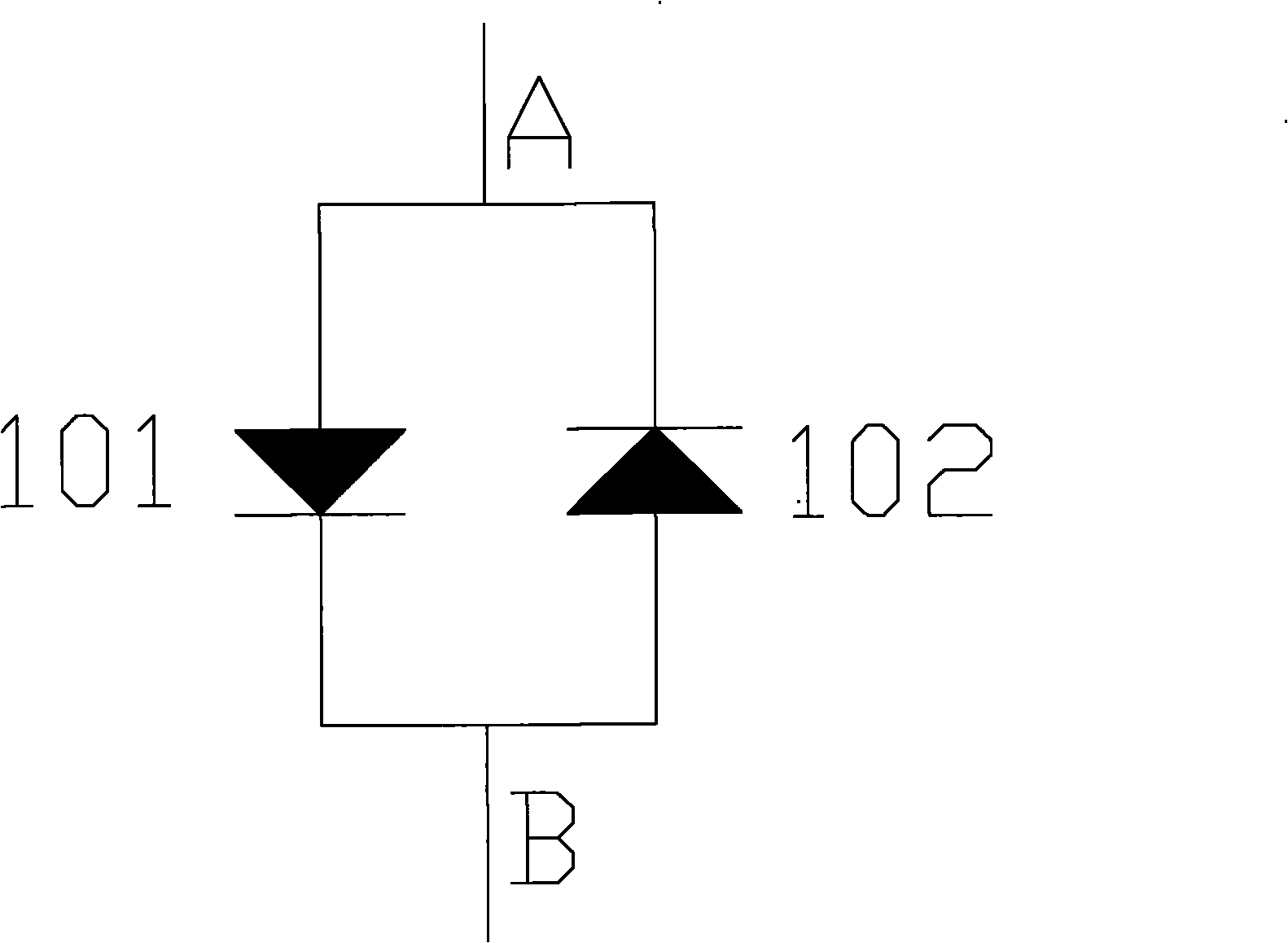

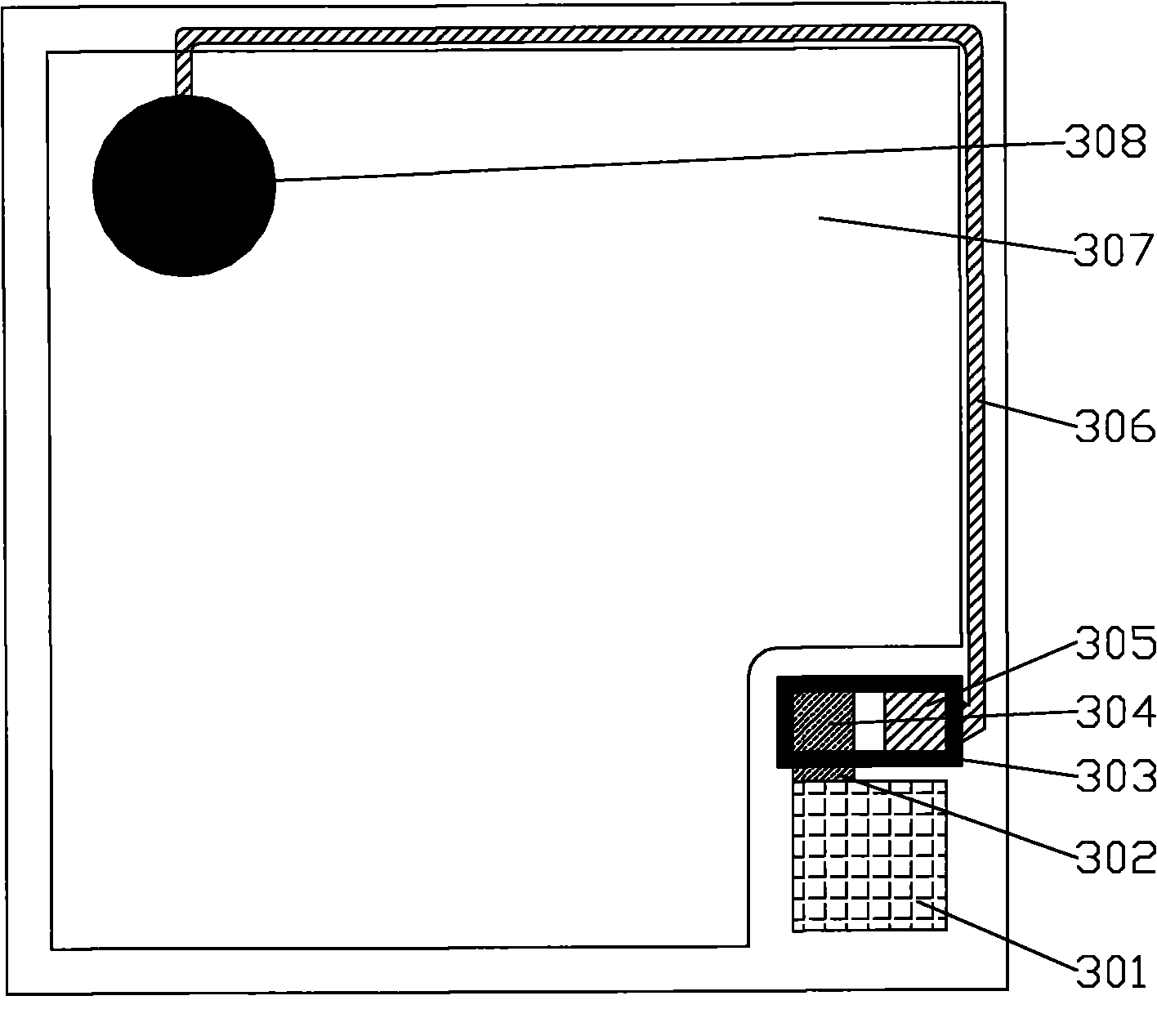

Light emitting diode element capable of preventing electrostatic damage

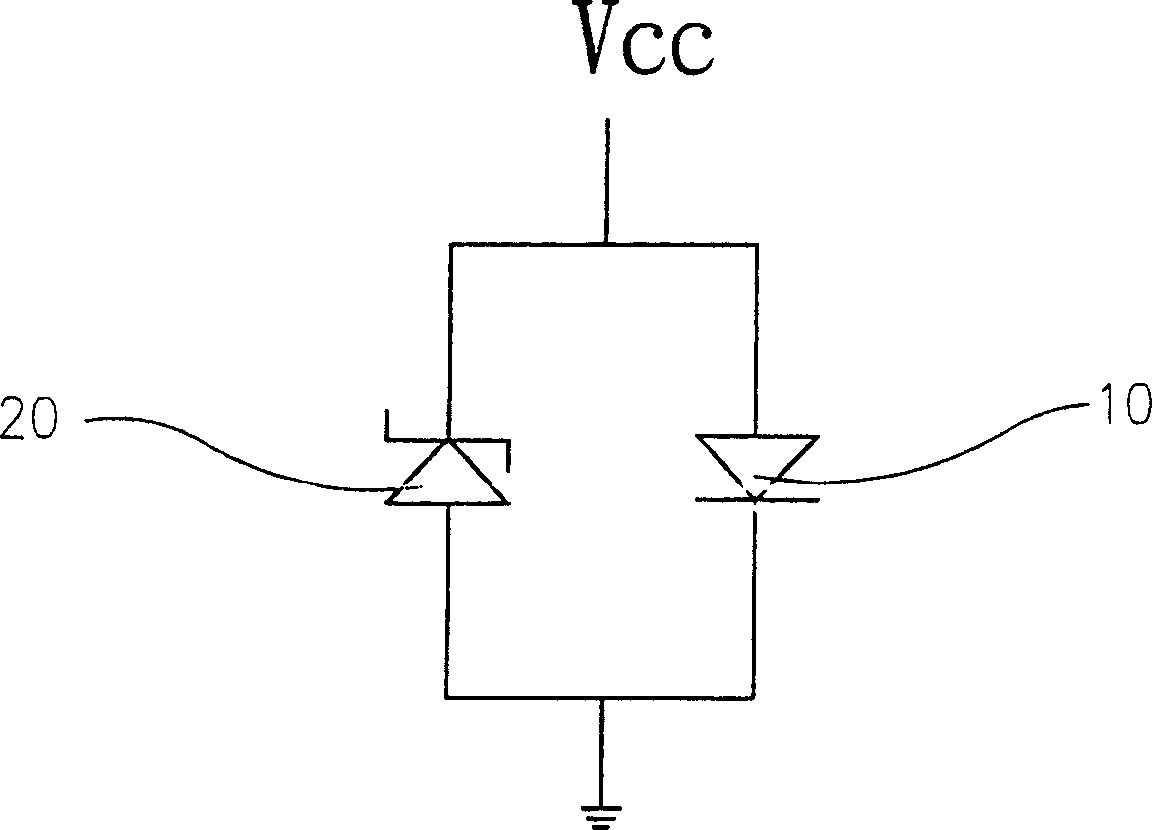

InactiveCN1558451AHas antistatic effectThe production process is simpleSemiconductor/solid-state device detailsSolid-state devicesElectrostatic dischargeEngineering

The invention relates to a light-emitting diode element, in particular a light-emitting diode element capable of preventing electrostatic damage, wherein a surface insulation substrate is provided with at least a first power supply circuit and at least a second power supply circuit, the first power supply circuit can be electrically connected to the LED first electrode of a light-emitting diode and an eSD second electrode of a static electricity resistant protection element, and the second power supply circuit can be electrically connected to the LED second electrode of a light-emitting diode and an eSD first electrode of a static electricity resistant protection element.

Owner:OPTO TECH

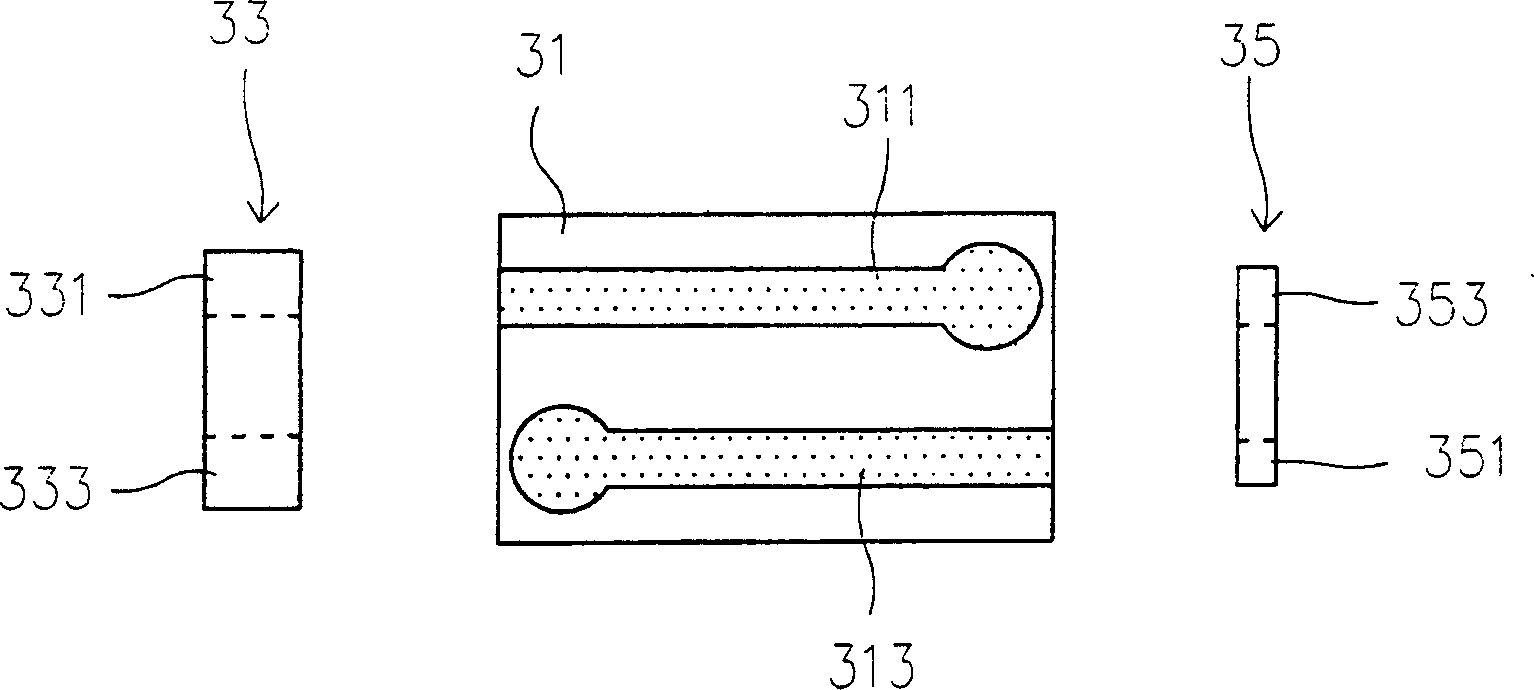

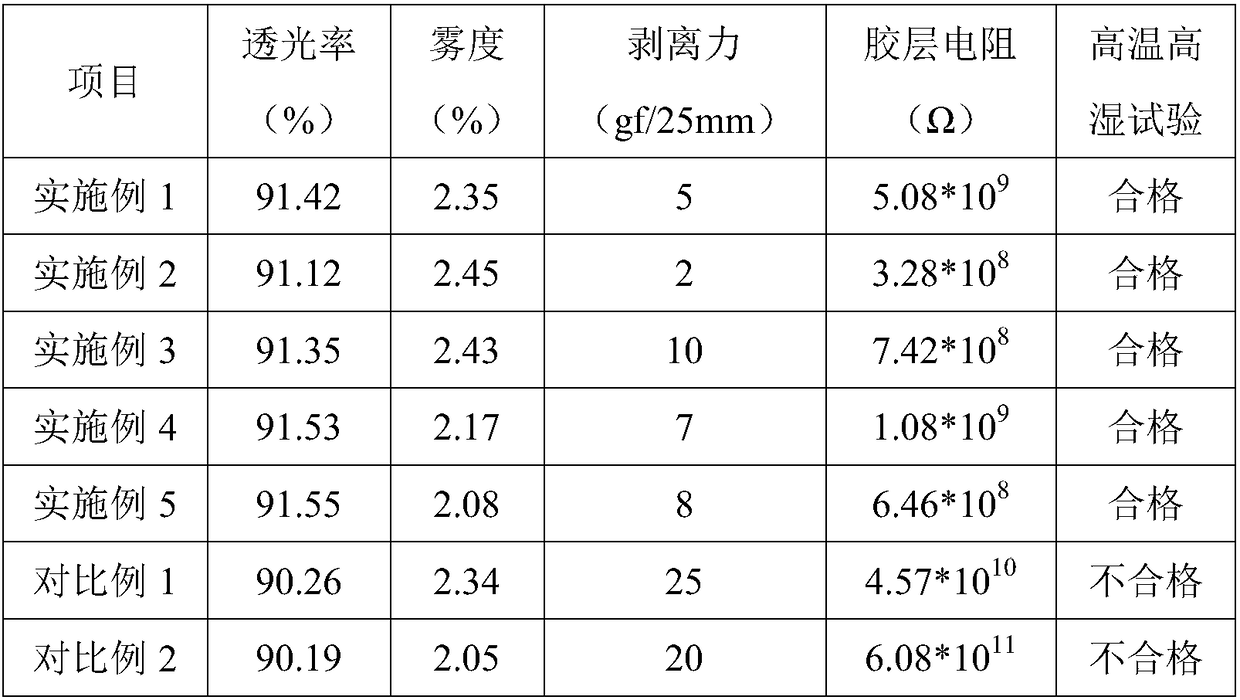

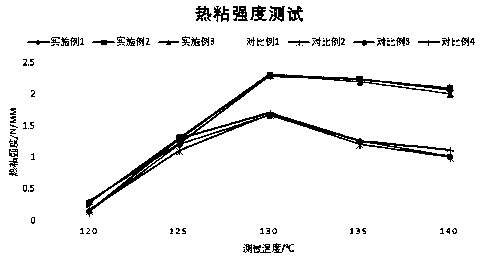

Preparation method of pressure sensitive adhesive for polaroid protection film and protection film thereof

InactiveCN108384476ASave glue dispensing processLow costNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolyesterTectorial membrane

The invention discloses a preparation method of a pressure sensitive adhesive for a polaroid protection film and a protection film thereof. The pressure sensitive adhesive is prepared from the following raw materials in parts by weight: 10 to 40 weight parts of soft monomers, 5 to 15 weight parts of hard monomers, 2 to 6 weight parts of fluorine containing acrylate monomers, 0.8 to 3 weight partsof crosslinking monomers, 0.8 to 2 weight parts of vinylsilane, 0.5 to 2 weight parts of anti-static agents, 0.5 to 1.5 weight parts of initiators and 80 to 190 weight parts of solvents. The pressuresensitive adhesive can be directly covered on the surface of a polyester film; the additional addition of the curing agents and the anti-static agents is not needed; the adhesive layer resistance is 1010 ohm or less; the anti-static performance is realized. When the polaroid protection film adhesive layer is pasted on the surface of a polaroid, after the high-temperature and high-humidity tests for 500h, the protection film and the polaroid are tightly attached; no bubble bulges exist; no adhesive is remained when the protection film is torn away; defects such as hard shadow do not exist.

Owner:昆山乐凯锦富光电科技有限公司 +1

Waterfree car washing type fresh maintenance agent and its prepn. method

InactiveCN1834215ASolve poor stabilitySimple production processNon-ionic surface-active compoundsOrganic detergent compounding agentsSolventChemistry

This invention provides a method for manufacturing a washing-free retreading and maintaining agent for tyres, which does not need water washing before application on tyres, thus saving water resources. The agent is composed of RHODORSIL EIP emulsion 10-50%, nonionic surfactant 0.2-2.5%, triethanolamine 0.5-5.0%, ethylene glycol 1.0-6.0%, BS-12 0.3-1.6%, solvent oil 1.0-6.0%, ammonia solution 0.3-1.5%, preservative 0-0.1%, dyestuff 0-0.005%, and deionized water as balance. The agent has such advantages as simple process, stable property, and easy usage and is environmentally friendly.

Owner:王士奎

Environment-friendly water-based ink

An environment-friendly water-based ink comprises the following components by mass percent: 12-22% of alcohol-soluble modified acrylic resin, 10-20% of alcohol-soluble modified aldehyde ketone resin, 35-55% of a diluents, 6-12% of methyl ether, 12-20% of pigment, and 2-5% of a functional auxiliary agent. The environment-friendly water-based ink provided by the invention is an alcohol-soluble gravure ink, adopts more than 95% of alcohol as the auxiliary agent to realize gravure production, is stable in ink performance, uniform in texture, strong in tinting strength, not easy to precipitate, and similar with the printing effect of the traditional offset printing, and has certain antistatic function.

Owner:JIANGSU DAREGLOBAL PRINTING CO LTD

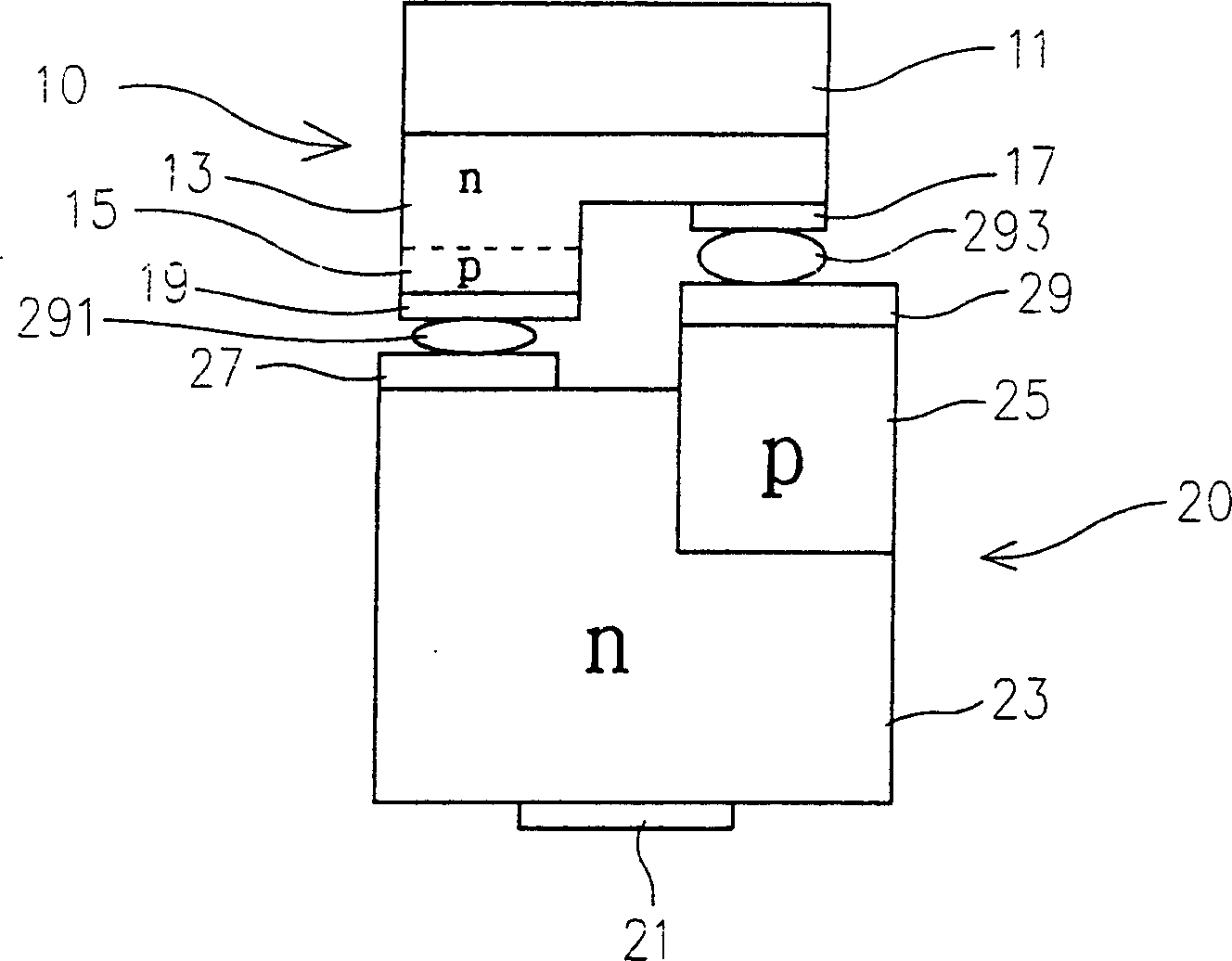

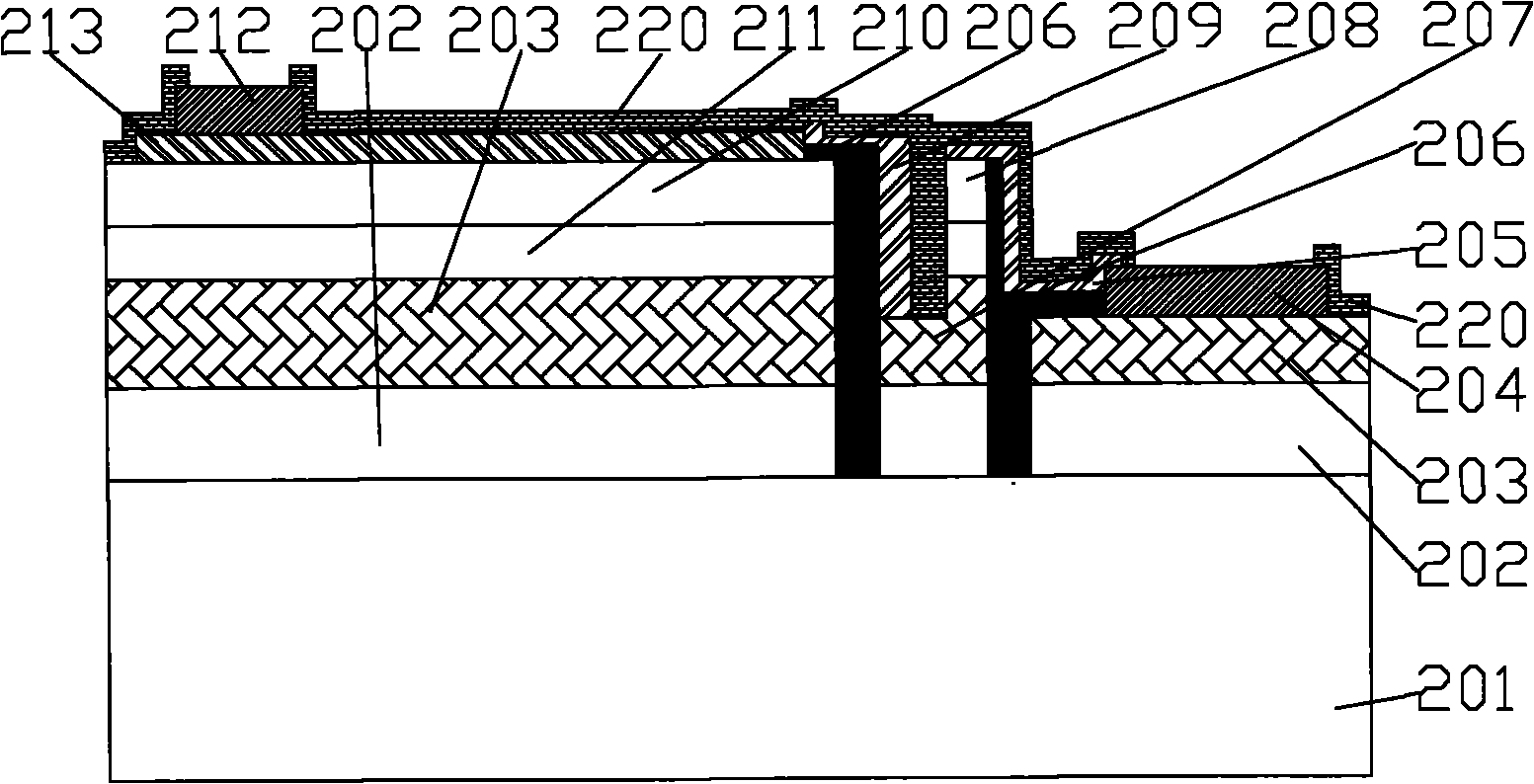

Antistatic gallium nitride based luminescent device and manufacturing method thereof

InactiveCN101916769ASimplify the production processImprove product yieldSolid-state devicesSemiconductor/solid-state device manufacturingMultiple quantumGallium nitride

The invention discloses an antistatic light-emitting diode device structure and a manufacturing method thereof. The method comprises the following steps: growing a buffer layer, an N-shaped gallium nitride layer, a luminescent layer multiple quantum well (MQW) structure and a P-shaped gallium nitride layer on a sapphire substrate in sequence; etching an epitaxial layer between a light-emitting diode and a protection diode on the substrate; manufacturing the P electrode and the N electrode of the light-emitting diode; respectively connecting the P electrode and N electrode of the light-emitting diode with the N electrode and P electrode of the protection diode; and integrating the protection diode and the light-emitting diode in a light-emitting diode device on the basis of not changing the existing gallium nitride base epitaxial structure, thus improving antistatic capacity of products, reducing parallel protected diodes in packaging subsequent products, reducing working procedures, and lowering product cost.

Owner:HC SEMITEK CORP

Nano antistatic finishing agent, preparation method and application

The present invention discloses a nano antistatic finishing agent, its preparation method and application. The described finishing agent contains alumina sol, PVA whose content is 0.1-0.5 wt% of alumina sol weight and non-ionic surfactant whose content is 0.1-1 wt% of alumina sol weight. Said invention adopts nano-size inorganic material, so that it can obtain good antistatic effect.

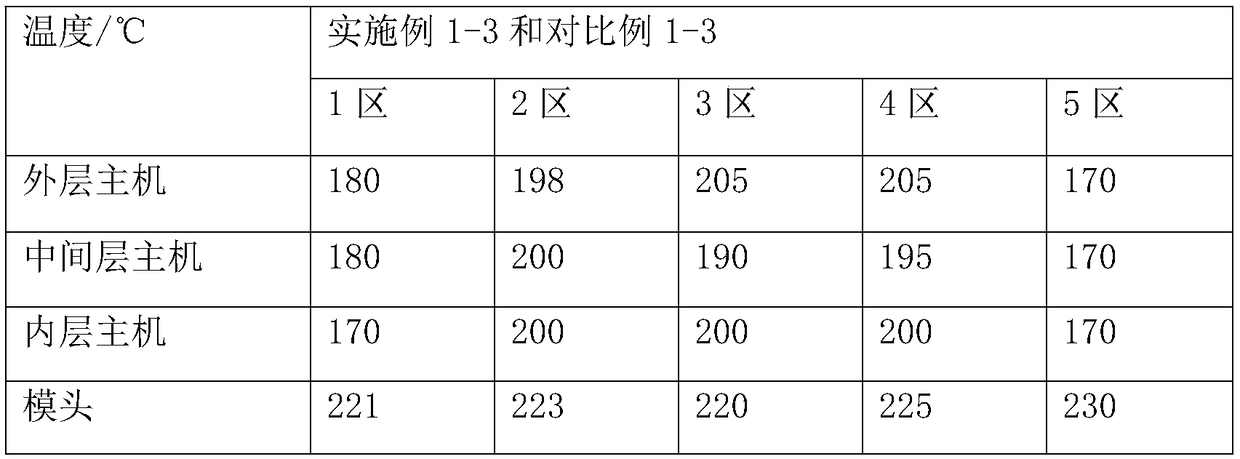

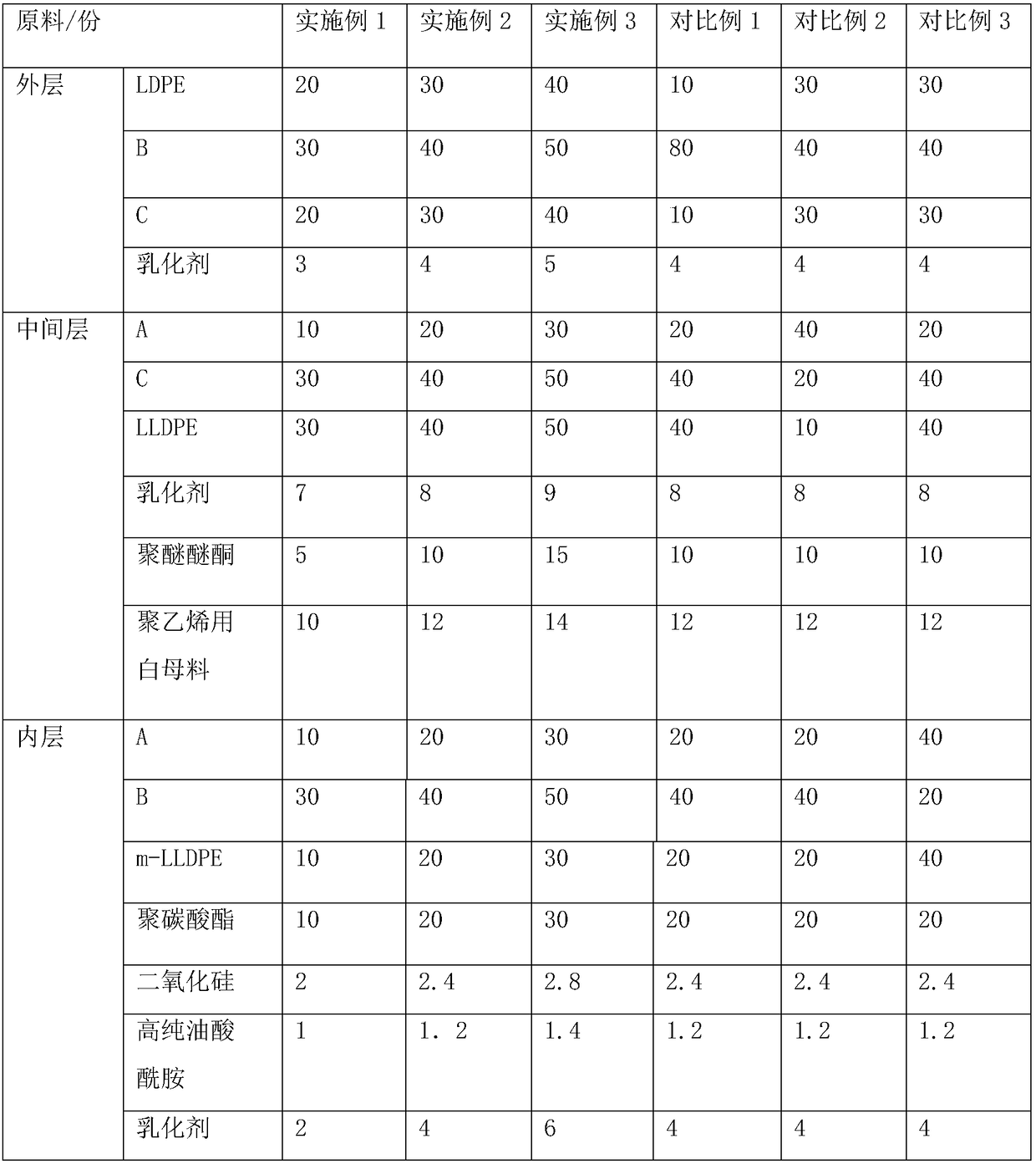

Polyethylene film for automatic packaging and preparation method thereof

ActiveCN108773137AAnti-pollutionComposite strongSynthetic resin layered productsLow-density polyethyleneLinear low-density polyethylene

The invention discloses a polyethylene film for automatic packaging. The polyethylene film comprises an outer layer, an intermediate layer and an inner layer which are sequentially laminated. The outer layer is prepared from the following substances in parts by weight: 20-40 parts of low density polyethylene (LDPE), 30-50 parts of linear low density polyethylene (LLDPE), and 20-40 parts of LLDPE with melt index of 1.1 g / 10 min and density of 0.920 g / cm<3>. The intermediate layer is prepared from the following substances in parts by weight: 10-30 parts of LDPE, 30-50 parts of LLDPE with melt index of 1.1 g / 10 min and density of 0.920 g / cm<3>, and 30-50 parts of LLDPE with melt index of 2.4 g / 10 min and density of 0.921 g / cm<3>. The inner layer is prepared from the following substances in parts by weight: 10-30 parts of LDPE, 30-50 parts of LLDPE, and 10-30 parts of LLDPE. The invention solves the problem that the polyethylene film has lower thermal viscosity and higher bag breaking rate.

Owner:青岛东海包装产业有限公司

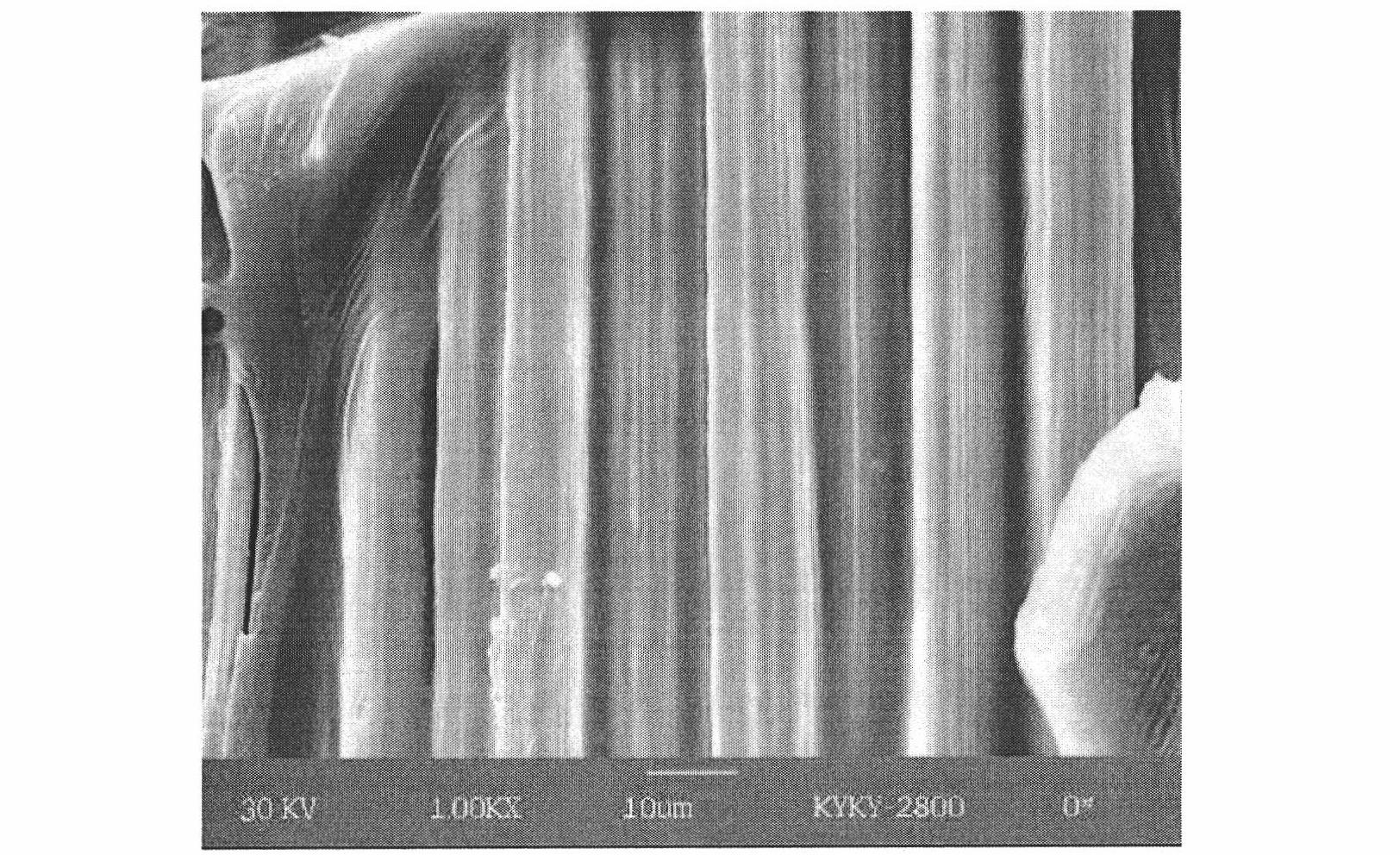

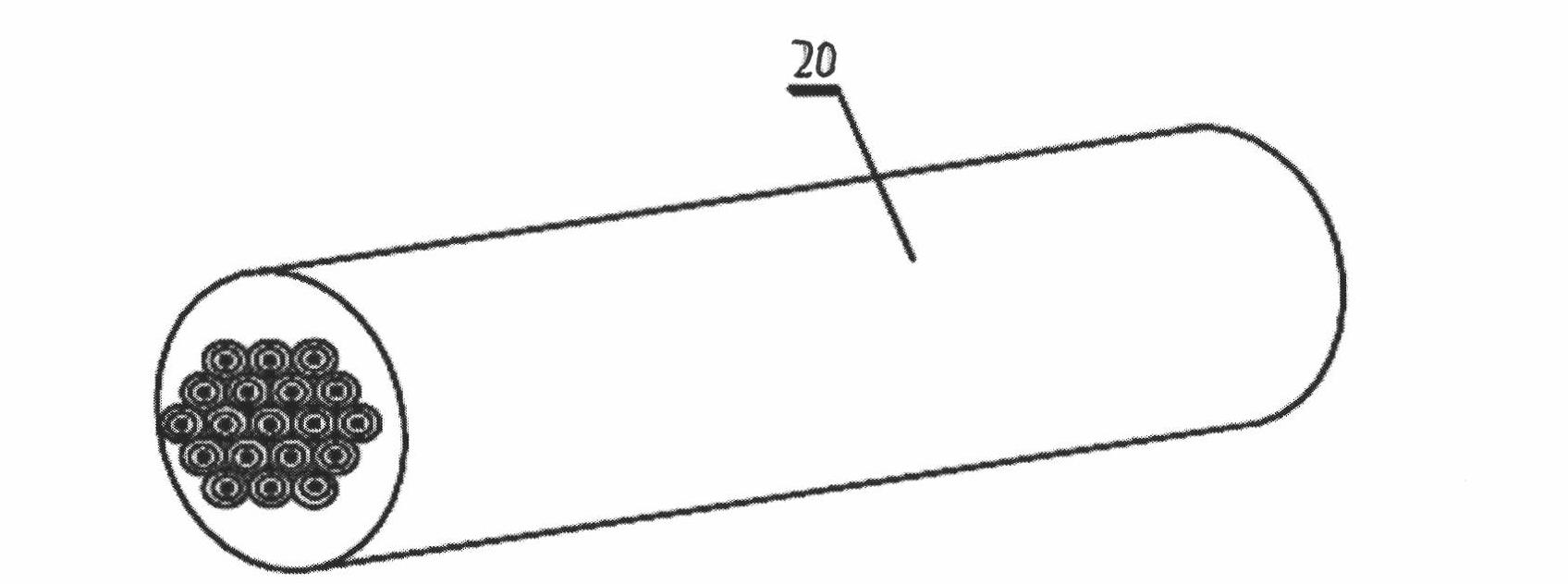

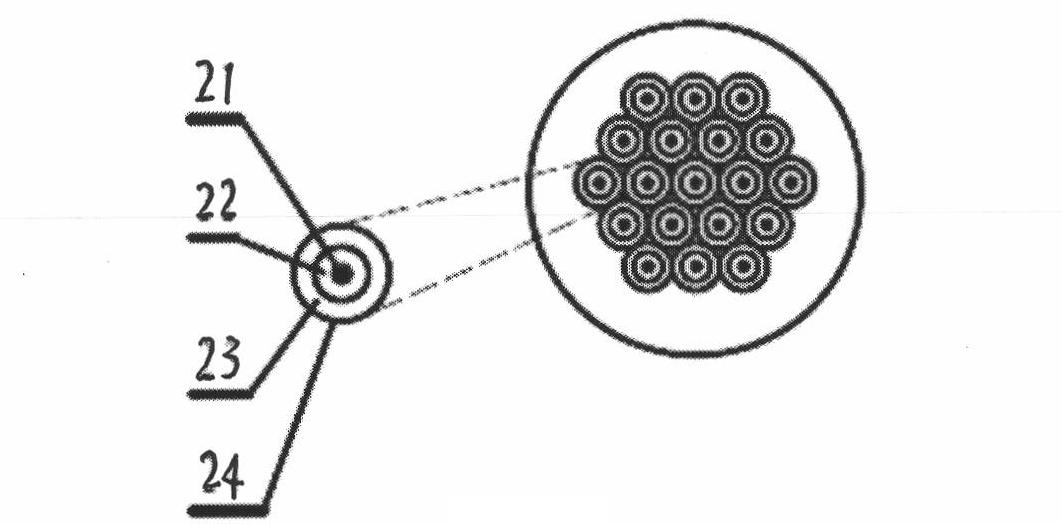

Preparation method of conductive plastics master batch containing stainless steel fibers

ActiveCN101840745AElectromagnetic shielding effect hasHas antistatic effectNon-conductive material with dispersed conductive materialCable/conductor manufactureElectromagnetic shieldingStainless steel fiber

The invention discloses a preparation method of a conductive plastics master batch containing stainless steel fibers. The stainless steel fibers in the plastics master batch are isolated by macromolecular materials and completely packed by the macromolecular materials. When the plastics master batch as raw materials is mixed with plastics for secondary granulation or a conductive plastic work-piece is formed, the stainless steel fibers can resist high shear force when the plastics are processed, and are easily and uniformly dispersed in the plastic work-piece and overlap to each other to form a three-dimensional conductive network. By adopting the conductive plastics master batch, the ideal antistatic and electromagnetic screen effects can be achieved under the circumstance of low content of the stainless steel fiber.

Owner:HUNAN HUITONG ADVANCED MATERIALS

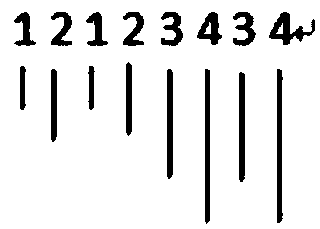

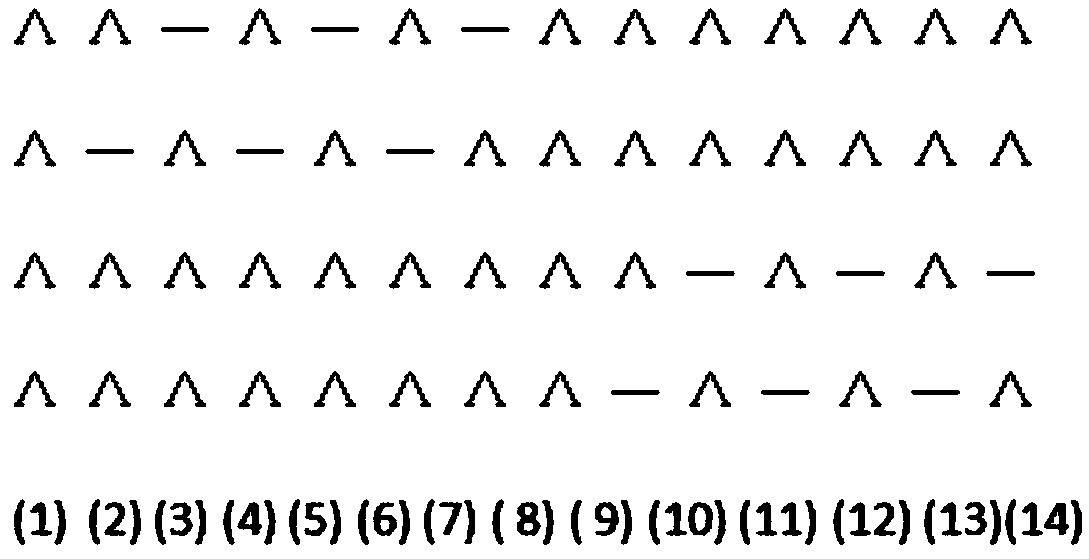

Polyester spandex super-quick-drying knitted fabric and processing method thereof

ActiveCN109056171AAchieve the effect of moisture absorption and quick dryingSoftSolvent-treatmentWeft knittingFiberPolyester

The invention discloses a polyester spandex super-quick-drying knitted fabric and a processing method thereof. The fabric is woven through a special weaving method with complete-extinction super-fine-denier polyester fibers with the filament number of 1.1-1.7 D and spandex fibers as the raw materials, and the close-fitting surface of the fabric is provided with dotted jacquard protrusions capableof guiding moisture in one direction. The processing method includes the steps of conducting weaving through a four-track single-side knitting machine, wherein four needles 1, 2, 3 and 4 are adopted;forming one loop through fourteen paths; conducting post-processing through polyester keratase. By means of the special weaving structure, the close-fitting surface has a small protrusion jacquard effect, the contact area of the close-fitting surface and a human body is reduced, and the movable friction coefficient is reduced; the dotted protrusion jacquard part making contact with skin has a one-way moisture guide function, and the water expanding capacity is improved. The complete-extinction super-fine-denier polyester fibers are selected as the raw material, the surface area of the fibers is increased, subsequent fibers have a certain anti-UV effect, and the knitted fabric has the advantages of being soft in color and luster, good in deep dyeing performance, high in textile drapability,strong in shielding performance and the like.

Owner:SHANGHAI JIALE

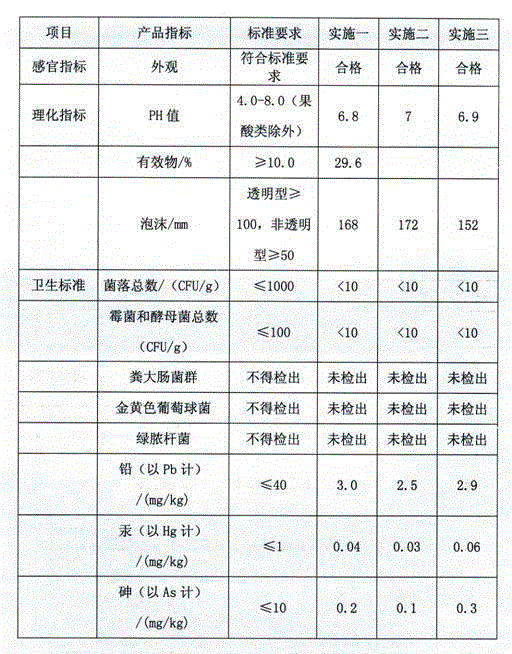

Tea bran shampoo

InactiveCN104434613AClean hairHas anti-inflammatory and anti-disease effectsCosmetic preparationsHair cosmeticsAdditive ingredientPolyethylene glycol

The invention discloses a tea bran shampoo, and belongs to the technical field of bath supplies. The effective ingredients of the tea bran shampoo are prepared from the following raw materials in percentage by weight: 23-25% of tea bran extract, 1-3% of tea oil, 1-2% of guar gum quaternary ammonium salt, 0.3-0.6% of ethylene glycol stearate, 0.7-1% of polyethylene glycol bisstearate, 0.85-1.23% of white vinegar and the balance of water. The tea bran shampoo disclosed by the invention is reasonable and simple in raw material components, convenient and practical; various unnecessary additives are reduced, thus the tea bran shampoo is more natural and safer, and has the great functions of cleaning, nourishing, preventing hair loss and resisting diseases.

Owner:广西三椿生物科技有限公司

Halogen-free organic phosphorus-nitrogen expandable flame retardant and application thereof to flame-retardant paint

InactiveCN102504645AGood physical and chemical propertiesGood light stabilityCoatingsFoaming agentPorous carbon

The invention provides a halogen-free organic phosphorus-nitrogen expandable flame retardant and an application thereof to flame-retardant paint. A preparation method of the halogen-free organic phosphorus-nitrogen expandable flame retardant comprises the following steps of: mixing 1 part by weight of phosphorus pentoxide with 1-3 parts by weight of phosphoric acid; under a stirring condition, adding 0.5-1 part by weight of a char forming agent and 2-4 parts by weight of a foaming agent in sequence into a mixture; adding an amine compound for neutralizing till the pH value is 5-7; and drying filter residues to obtain the halogen-free organic phosphorus-nitrogen expandable flame retardant. Anti-static flame-retardant paint is prepared by uniformly mixing 15-35 percent by weight of the halogen-free organic phosphorus-nitrogen expandable flame retardant into ordinary paint. The expandable flame retardant has a phosphorus-nitrogen synergistic effect. In the expandable flame retardant, phosphorus and nitrogen are taken as flame retardants of flame retardant elements. During burning of a high polymer containing the type of flame retardants, a uniform porous carbon foam layer can be formed on the surface; and the foam layer has the advantages of heat insulation, oxygen insulation, smoke inhibition, prevention of fused drops and good flame retarding and smoke inhibiting functions.

Owner:UNIV OF SCI & TECH OF CHINA

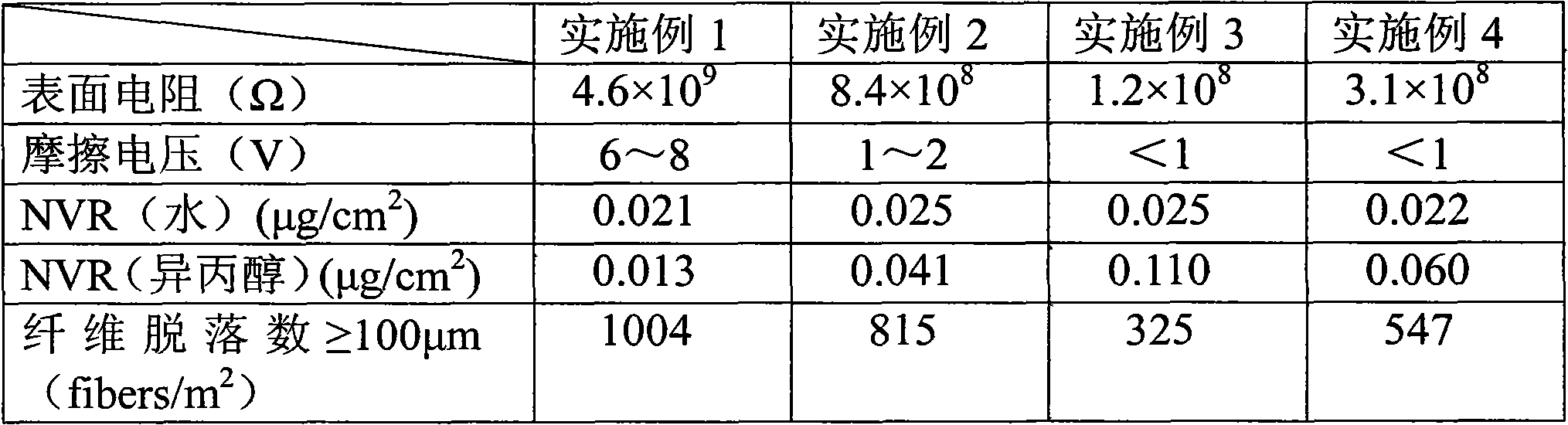

Antistatic wear-resistant non-woven fabric for manufacturing dust-free wiping paper and treatment method thereof

ActiveCN102383307AHas antistatic effectImprove antistatic performanceNon-woven fabricsVegetal fibresCellulosePolyester

The invention discloses an antistatic wear-resistant non-woven fabric for manufacturing dust-free wiping paper and a treatment method thereof. The antistatic wear-resistant non-woven fabric is cellulose filament non-woven fabric of which the surface is coated with an antistatic coating, or spun-laced non-woven fabric formed by combining cellulose staple fibers and polyester staple fibers in different proportions, wherein the antistatic coating is a melamine resin coating combined with an antistatic agent with an active group. The treatment method comprises the following steps of: (1) preparing an antistatic coating solution; (2) coating the antistatic coating solution on non-woven fabric with a dip-coating process; (3) drying the non-woven fabric containing the antistatic coating solution; and (4) packaging the dried non-woven fabric in rolls to obtain the antistatic wear-resistant non-woven fabric. The antistatic wear-resistant non-woven fabric has the advantages of durable antistatic performance, high wear resistance, low probability of fiber breakage by hooking in use and fewer fallen fibers. The treatment process is simple; and the antistatic agent can be firmly combined on the surface of the non-woven fabric without polluting a product.

Owner:SHENZHEN SELEN SCI & TECH CO LTD +1

Screen detergent

InactiveCN102517173AHigh human safetyImprove securityOrganic non-surface-active detergent compositionsNon-surface-active detergent solventsChemical solutionDissolution

The invention provides a screen detergent. The screen detergent comprises 3-8% of dipropylene glycol dimethyl ether, 1-3% of a quaternary ammonium salt, 20-25% of ethanol, and the balance deionized water. The screen detergent which adopts above chemical solutions with high safeties to human bodies has the characteristics of effective dissolution and removal of dirt on the screen, screen degerming, and antistatic effect possessing, so screen cleaning requirements by people are reached.

Owner:WUJIANG DEZUO DAILY CHEM PROD

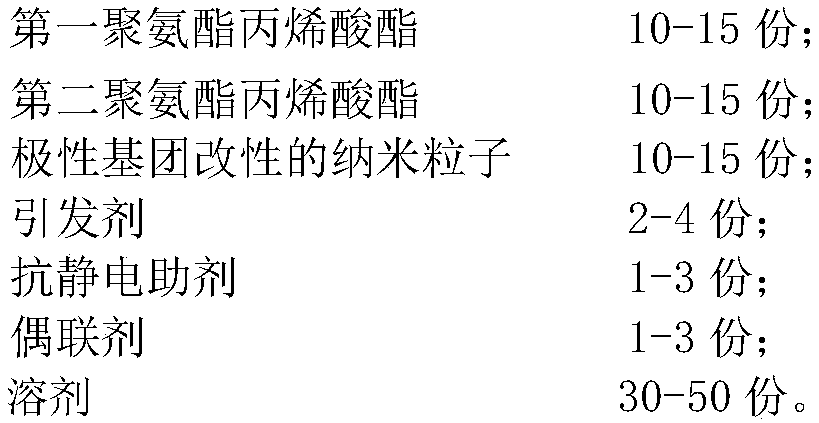

Ultraviolet curable anti-fog glue and preparation method thereof

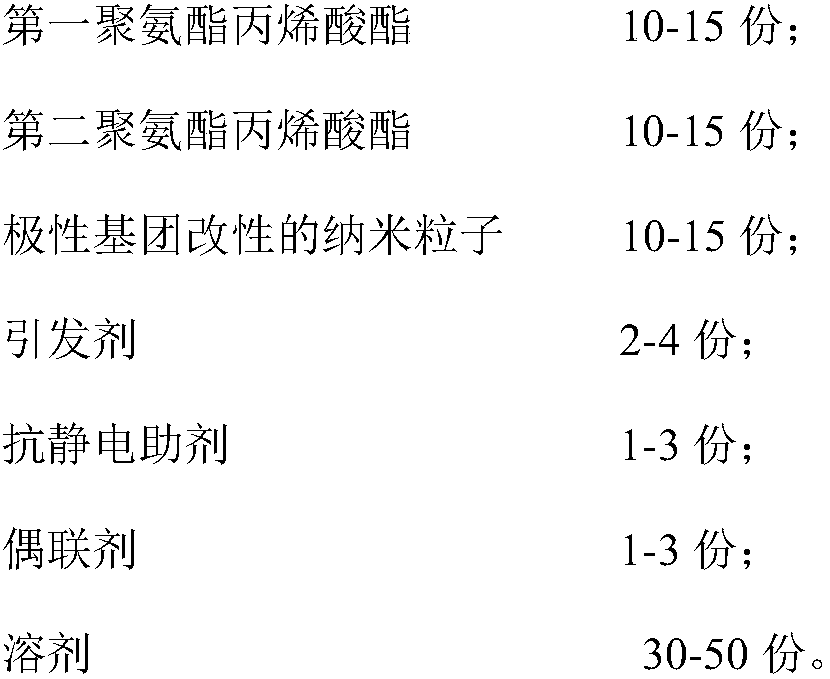

InactiveCN109251716AHas antistatic effectImprove wear resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAntistatic agentNanoparticle

The invention provides an ultraviolet curable anti-fog glue, which is characterized by comprising the following components by weight: 10-15 parts of first polyurethane acrylate; 10-15 parts of secondpolyurethane acrylate; 10-15 parts of polar group modified nanoparticles; 2-4 parts of an initiator; 1-3 parts an antistatic assistant; 1-3 parts of a coupling agent; and 30-50 parts of a solvent. Theultraviolet curable anti-fog glue provided by the invention adopts modified particles to combine photocurable resin, not only increases the anti-fog effect, but also improves the surface hardness andmechanical strength, and has excellent wear resistance. The coupling agent is added between the particles and the resin to well connect the particles and the resin, effectively improves the wear resistance of the resin, and at the same time improves the adhesion. The added antistatic agent endows the film with antistatic effect and prevents the film from adsorbing dust.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

Fabric softener

InactiveCN104562651AGood effectRaw materials are easy to getFibre treatmentSodium silicatePropylene glycol

The invention discloses a fabric softener which comprises the following components in parts by weight: 10-20 parts of propylene glycol, 10-15 parts of essential oil, 3-9 parts of trimethylamine, 2-5 parts of acrylamide, 5-10 parts of sodium silicate, 2-8 parts of polyoxyethylene ether, 4-10 parts of octamethyl tetrasiloxane and 50-80 parts of water. The softener disclosed by the invention is good in service effect, readily available in raw materials, high in binding force with fibers, high-temperature-resistant and washing-resistant, the fabric surface is not damaged, and an excellent soft effect and smooth handfeel can be achieved. Moreover, the synthetic fiber has a certain antistatic effect, and the wear resistance and tearing strength of the fabric can be improved.

Owner:江苏紫石化工科技有限公司

Anti-static inflaming retarding fabric

InactiveCN103556352AHas antistatic effectFlame retardantMelt spinning methodsWoven fabricsFiberPolyester

The invention discloses anti-static inflaming retarding fabric which is formed by interweaving warp and weft. The warp is made of polyester inflaming retarding fiber, and the weft is made of anti-static fiber. Phosphorus content of the polyester inflaming retarding fiber is 0.45-0.65%. The anti-static fiber is formed by two-for-one twisting polyester conductive fiber and cotton fiber. The anti-static inflaming retarding fabric has the durable and efficient inflaming retarding property and has a good anti-static property.

Owner:SUZHOU WILDER IND & TRADE

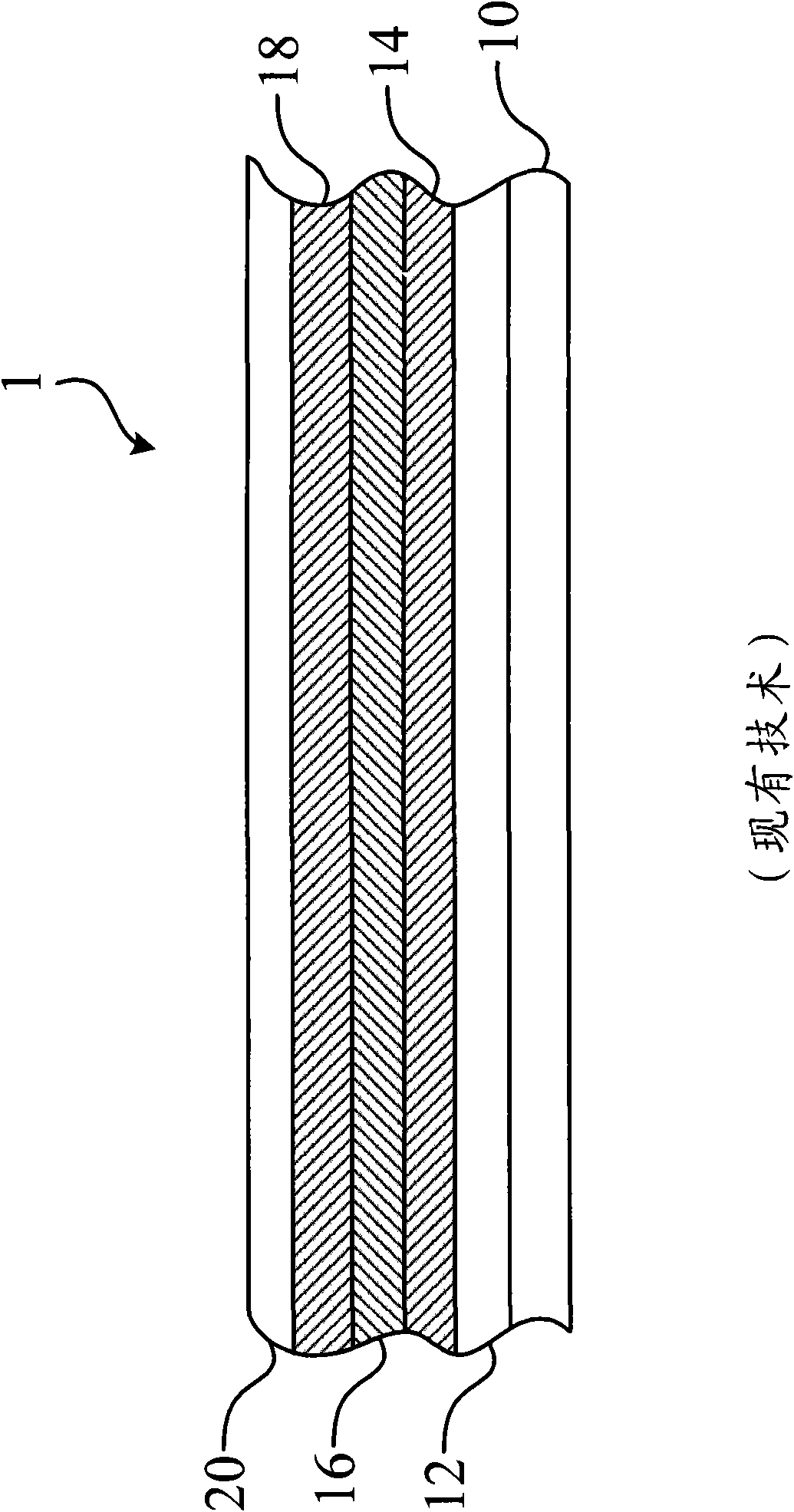

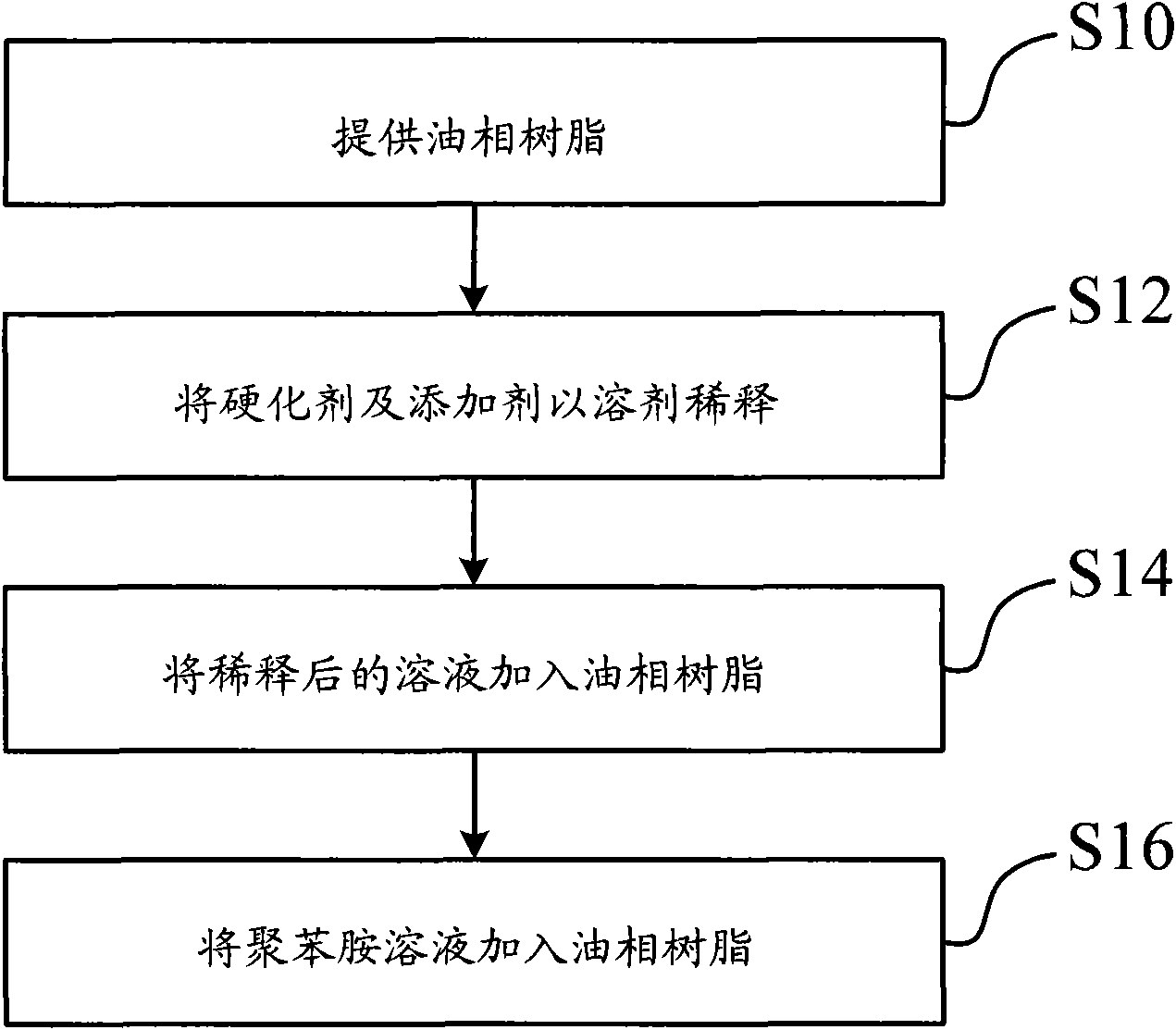

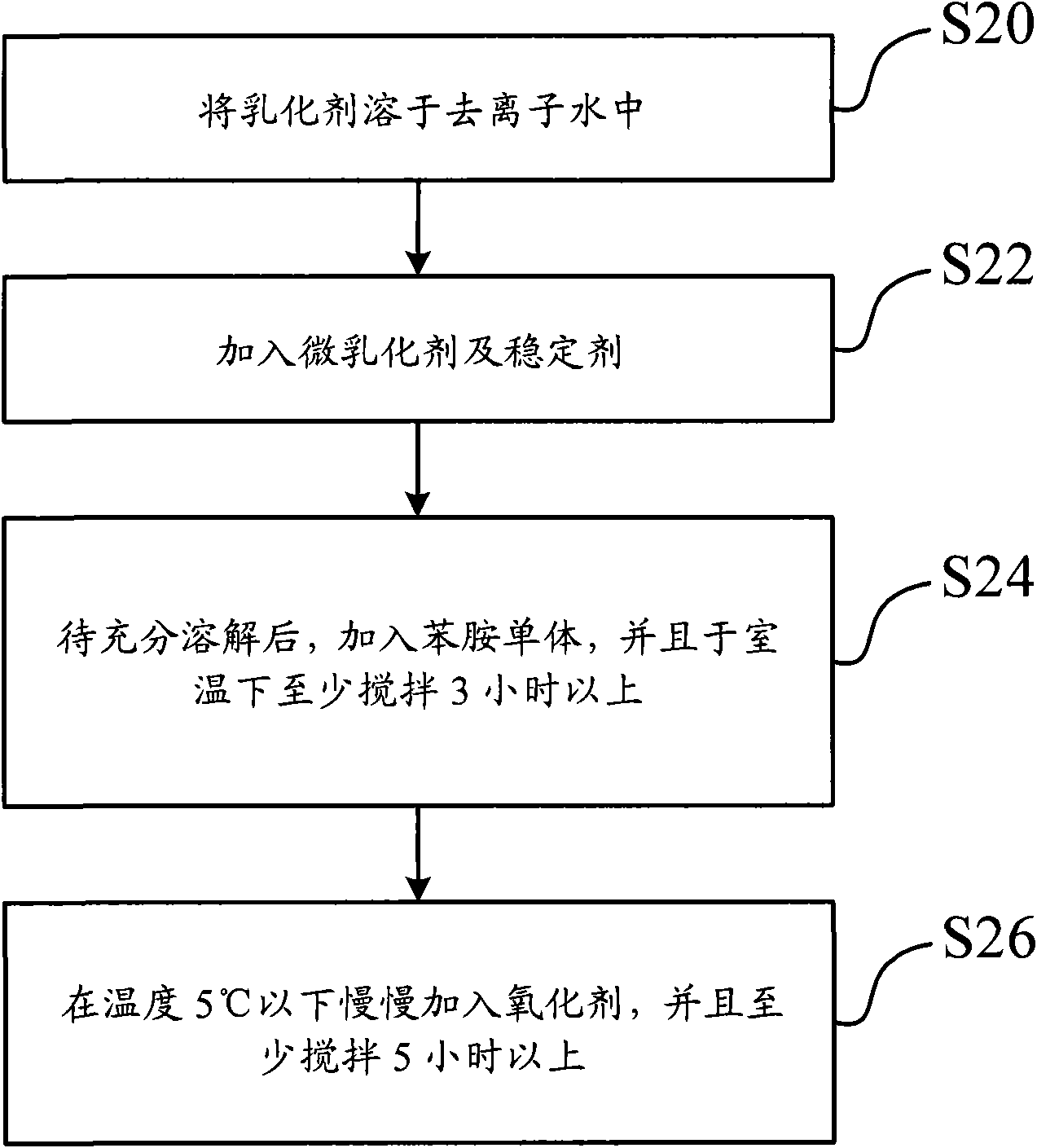

Pressure sensitive adhesive and manufacture method thereof

InactiveCN101591515AHas antistatic effectAvoid stickingNon-macromolecular adhesive additivesLayered productsOil phaseSolvent

The invention discloses a pressure sensitive adhesive and a manufacture method thereof. The manufacture method of the pressure sensitive adhesive comprises the following steps: (a) providing oil-phase resin; (b) dissolving a hardener and an additive in solvent and adding the diluted solution to the oil-phase resin; and (c) adding a polyaniline solution with the fixed content over 0.06 percent to the oil-phase resin. Accordingly, the pressure sensitive adhesive with the antistatic effect can be obtained.

Owner:DAXON TECH INC

Antibacterial waterproof electrostatic-resisting environment-friendly fabric

ActiveCN103879109AWaterproof and breathableGood for healthSynthetic resin layered productsWoven fabricsSurface layerChitin formation

The invention relates to fabric, and provides antibacterial waterproof electrostatic-resisting environment-friendly fabric which is good in antibacterial effect and electrostatic-resisting effect and has a waterproof function. The antibacterial waterproof electrostatic-resisting environment-friendly fabric comprises an antibacterial fabric layer, a fiber layer which is arranged on the inner layer of the antibacterial fabric layer and a hydrophilic composite polyurethane film which is arranged on the surface layer of the antibacterial fabric layer, wherein the antibacterial fabric layer is formed by blending and weaving 10-14 parts by weight of bamboo fibers, 1-5 parts by weight of chitin fibers and 70- 75 parts by weight of cotton fibers, the fiber layer is interwoven of warp yarn and weft yarn according to a two-up one-bottom manner, the warp yarn is blended and woven of 16 to 20 parts by weight of color cotton fiber yarns and 80 to 84 parts by weight of tencel fibers, and the weft yarn is interwoven of weft yarn A and weft yarn B.

Owner:晋江万兴隆染织实业有限公司

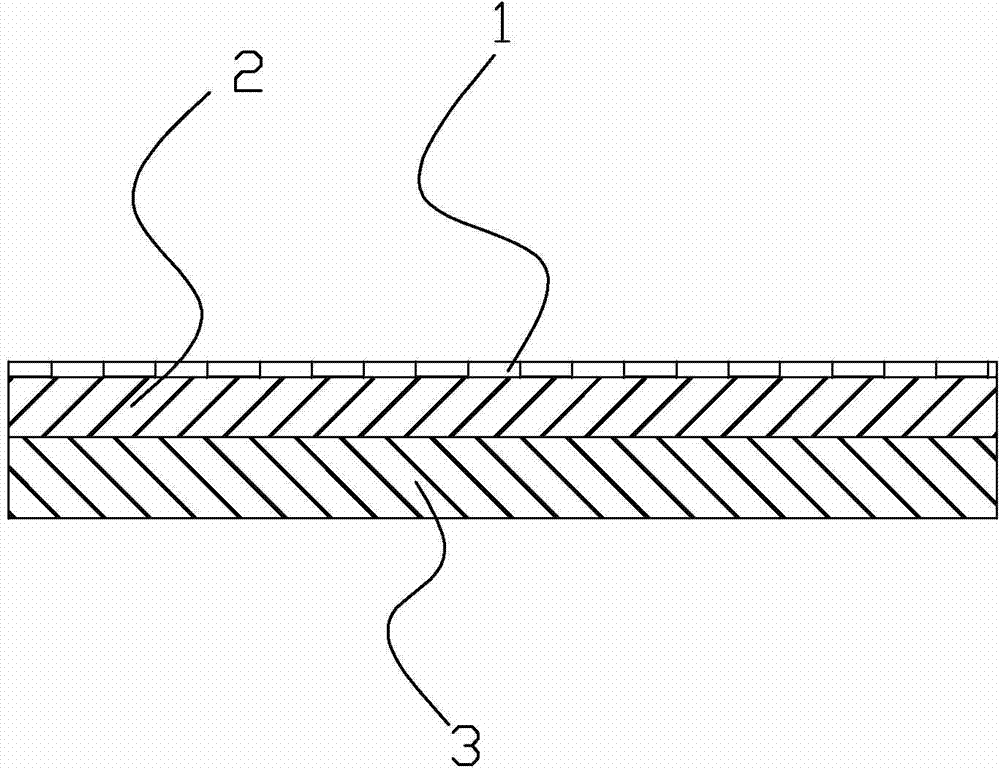

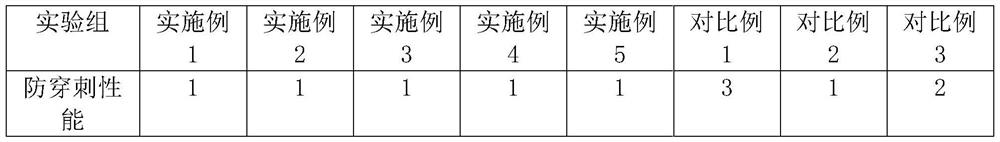

Wear-resistant anti-puncture fabric and processing technology thereof

InactiveCN113529428AReduce manufacturing costExcellent shape retention, wrinkle resistanceTextiles and paperPolyesterEthyl acetate

The invention discloses a wear-resistant anti-puncture fabric and a processing technology thereof. The wear-resistant anti-puncture fabric comprises a polyester base cloth; an anti-puncture layer is arranged on the surface of the polyester base cloth, and the surface of the anti-puncture layer is coated with a wear-resistant coating; the anti-puncture layer is formed by spinning ultra-high molecular weight polyethylene fibers; and the wear-resistant coating is prepared from the following raw materials in parts by weight of 50-60 parts of modified epoxy resin, 5-7 parts of a curing agent, 6-7 parts of a plasticizer and 3-4 parts of a diluent, and the modified epoxy resin is prepared from E40 epoxy resin, tetraethoxysilane, ethanol, ethyl acetate and a catalyst. Compared with the prior art, the polyester fabric is used as the base cloth of the product, the production cost of the product can be reduced, and polyester has excellent wrinkle resistance and shape retention and has certain mechanical strength, elastic recovery capacity, thermoplasticity and stability, so that the polyester is selected as the base cloth, and the effects of the product in various aspects can be improved.

Owner:东台市东驰服装有限公司

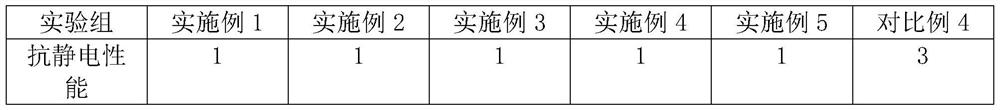

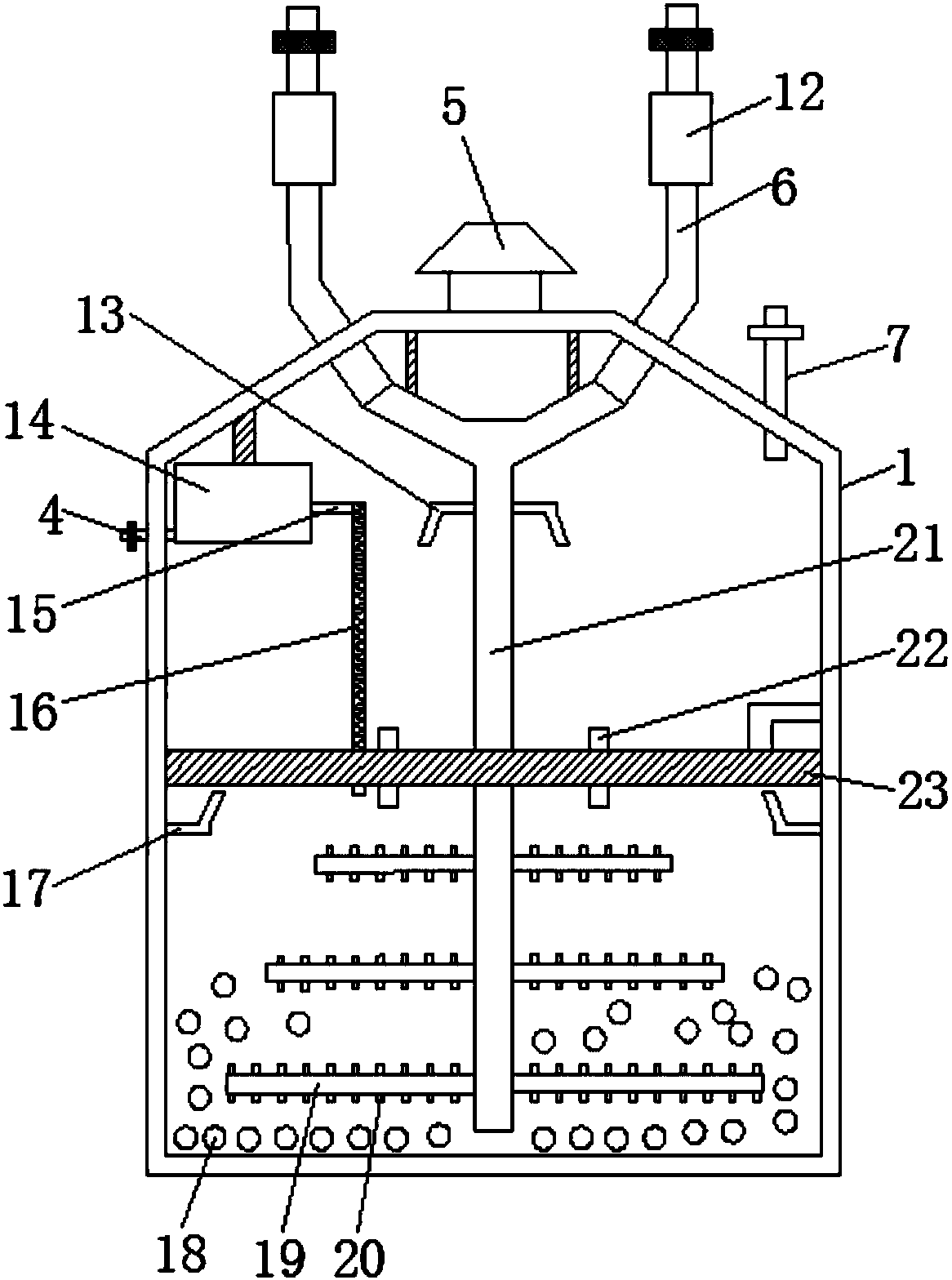

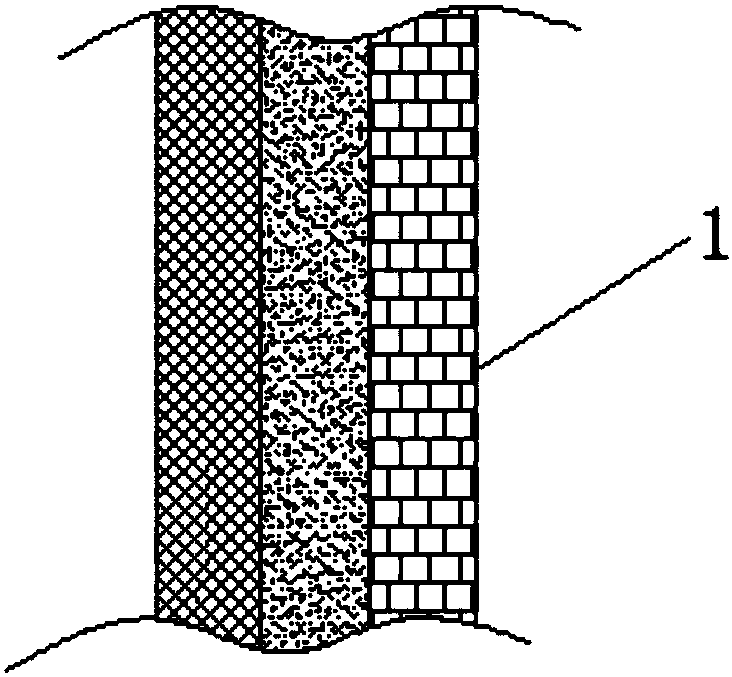

Efficient and durable storage container

InactiveCN109928103AReduce static electricityImprove securityLarge containersUnderwater structuresEngineeringLiquid storage tank

The invention discloses an efficient and durable storage container. The efficient and durable storage container has high quality and comprises a container, wherein a ceiling is horizontally arranged inside the container; the upper end of the interior of the container is connected to a mixed liquid storage tank through a bracing frame; a mixed liquid passage is arranged at one side of the mixed liquid storage tank; a joining passage is arranged at one side, far away from the mixed liquid passage, of the mixed liquid storage tank; a soft channel is arranged at one end, far away from the mixed liquid storage tank, of the joining passage; a transparent cover is arranged on the top end of the container; two entering liquid passages are symmetrically arranged at the upper end of the container; agas exchanging device is also inserted in the upper end of the container; and a temperature reducing instrument is arranged on each entering liquid passage. The efficient and durable storage container is practicable, stable, simple and convenient to operate, safe, efficient, and durable in use, can also treat internal liquid and has a high promotion value.

Owner:陕西海嵘工程项目管理有限公司

Medical nursing cushion

InactiveCN106309053ASimple structureGood breathability and water absorptionNursing bedsAbsorbent padsSurface layerBULK ACTIVE INGREDIENT

The invention relates to a medical nursing cushion, belonging to the field of medical supplies. The adopted technical scheme is as follows: the medical nursing cushion comprises a surface layer and a bottom layer made of a non-woven fabric material, wherein an absorbing layer is arranged between the surface layer and the bottom layer, a breathable layer is arranged between the bottom layer and the absorbing layer, a flocking paste fluff layer composed of cotton or synthetic fibers is arranged between the surface layer and the absorbing layer, active ingredients of a silver ion solution and a Chinese herbal medicine solution steep the flocking paste fluff layer, and a support layer with air vent holes is arranged between the bottom layer and the breathable layer. The medical nursing cushion has the advantages that the structure is simple and reasonable, the breathability and water absorption are good, the cushion body integrates the soft and hard properties and is suitable for turning over of patients, and meanwhile, the medical nursing cushion has the effect of resisting bacteria, tearing and static electricity.

Owner:蒋满珍

Hair conditioner

InactiveCN103705399AImprove performanceWon't tangleCosmetic preparationsHair cosmeticsGlycerolStearyltrimethylammonium chloride

Embodiments of the present invention disclose a hair conditioner, wherein the hair conditioner comprises, by mass, octadecyl trimethyl ammonium chloride, glycerol, propylene glycol, hexadecanol, polyoxyethylene sorbitan, glyceryl monostearate, a small amount of essence and a pigment, and the balance of deionized water. According to the present invention, the dry combing property and the wet combing property can be improved so as to make hair do not tangle, and the antistatic effect is provided, such that hair can not flutter.

Owner:广东柏亚化妆品有限公司

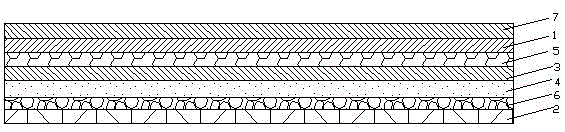

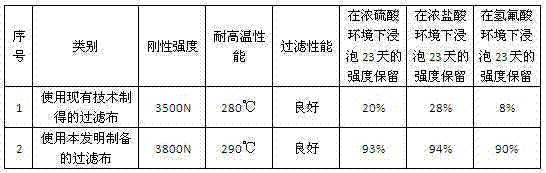

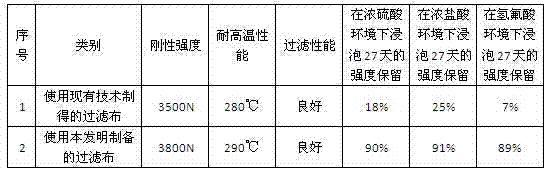

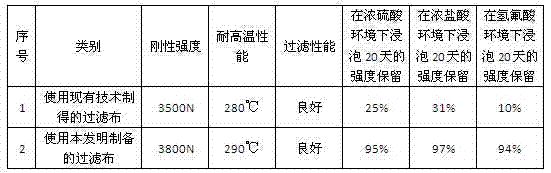

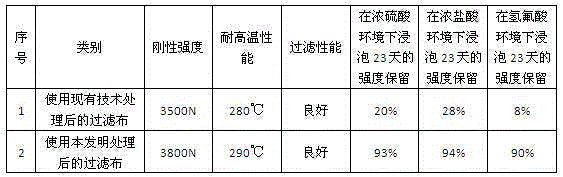

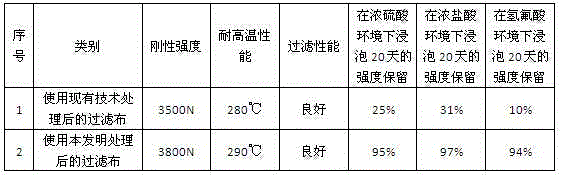

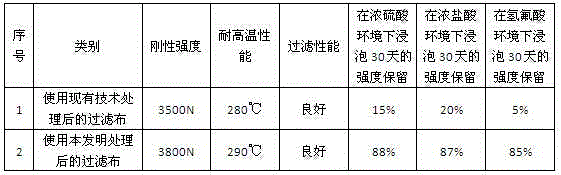

Preparation method for ECR (e-glass of chemical resistance) glass fiber filter cloth

ActiveCN104707400APromote environmental protectionImprove acid resistanceFibre treatmentLiquid/gas/vapor removalStrong acidsTemperature resistance

The invention discloses a preparation method for ECR (e-glass of chemical resistance) glass fiber filter cloth. The preparation method comprises the following steps: a, arranging warp yarns on a weaving warp beam disk head through a warping machine; b, bulking and loosening weft yarns through a bulked yarn machine; c, weaving the prepared warp yarns and weft yarns into filter base cloth through a weaving machine; d, enabling the filter base cloth to pass through boiling hot water in a hot cleaning machine unit at a speed of 3-8 m / min for performing hot cleaning, and then enabling the filter base cloth to pass through hot air with a temperature of 380-420 DEG C at the same speed for performing combustion; e, coating the filter base cloth with a surface treatment agent; f, drying the filter base cloth coated with the surface treatment agent, and finally obtaining the ECR glass fiber filter cloth. Therefore, the glass fiber filter cloth can resist corrosion of strong-acid substances such as concentrated sulfuric acid, concentrated hydrochloric acid, hydrofluoric acid and the like, and the rigid strength, high temperature resistance and filtering effect of the glass fiber filter cloth also can be improved.

Owner:SICHUAN FIBERGLASS GRP

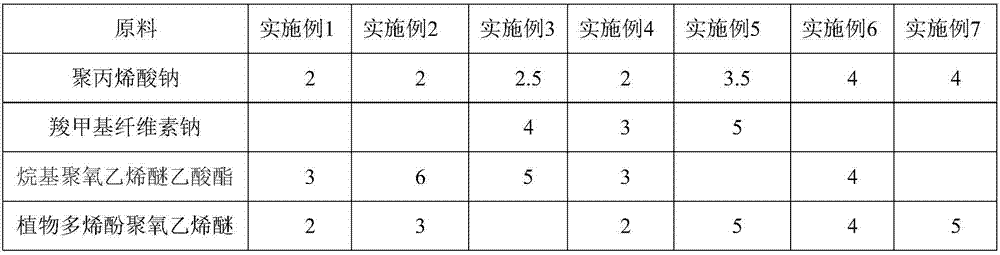

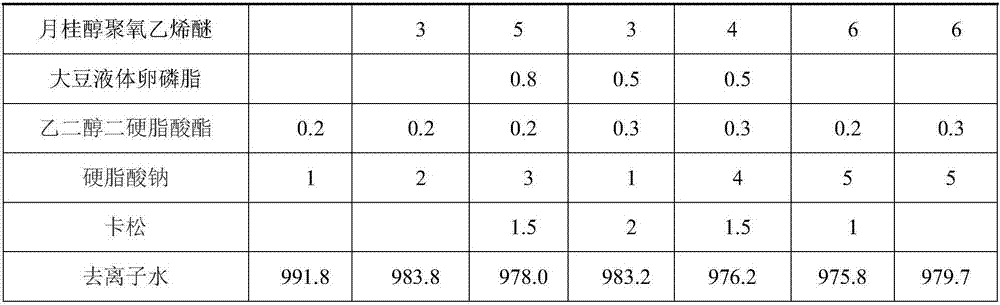

Car wash cleaning solution and preparation method thereof

ActiveCN106398886BEasy to useSave waterOrganic detergent compounding agentsSurface-active detergent compositionsSodium stearateSURFACTANT BLEND

A car-wash cleaning solution and a preparation method therefor. The car-wash cleaning solution contains sodium polyacrylate, a surfactant, sodium stearate, ethylene glycol distearate and deionized water, in which the surfactant is any two or three of alkyl polyoxyethylene ether acetate, phytocene polyoxyethylene ether and lauryl alcohol polyoxyethylene ether.

Owner:LINKAGE AUTOMOBILE SERVICES CO LTD

Softener for chemical and blended fabric and preparation method thereof

InactiveCN105113225AEasy to useRaw materials are easy to getFibre treatmentPentaerythritolTemperature resistance

The invention discloses a softener for chemical and blended fabric. The softener for the chemical and blended fabric is prepared from, by mass, 20-30 parts of fatty alcohol-polyoxyethylene ether, 40-45 parts of pentaerythritol aliphatic ester, 25-30 parts of trimethylamine, 15-25 parts of Turkey red oil, 20-25 parts of propylene glycol and 40-45 parts of deionized water. The softener for the chemical and blended fabric has the advantages that the using effect is good, the fabric surface is not damaged, the raw materials are easy to obtain, the binding force with fibers is high, the high temperature resistance, washing resistance and wearing resistance are achieved, and the excellent softening effect and smooth hand feel can be achieved; in addition, synthetic fibers can have the certain anti-static effect, and the wearing resistance and tearing strength of the fabric can also be improved.

Owner:SUZHOU SHUNTANG CHEM FIBER

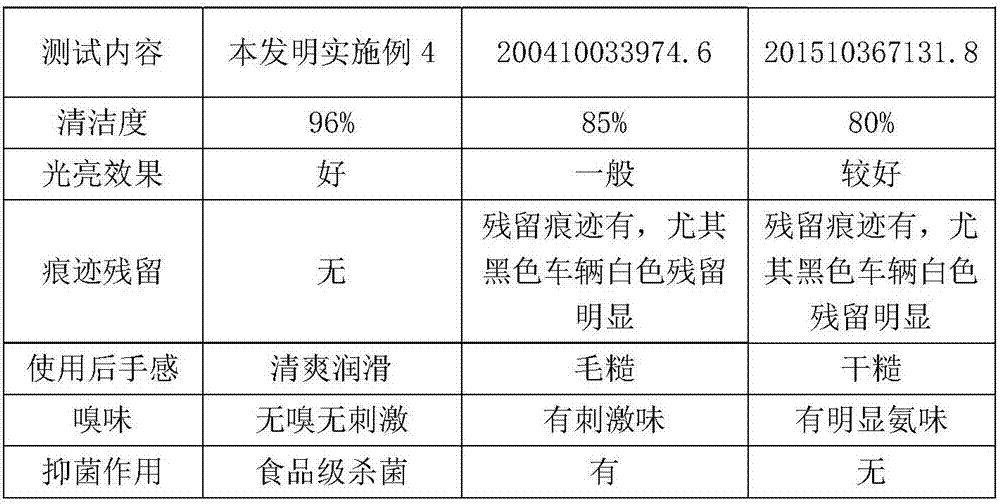

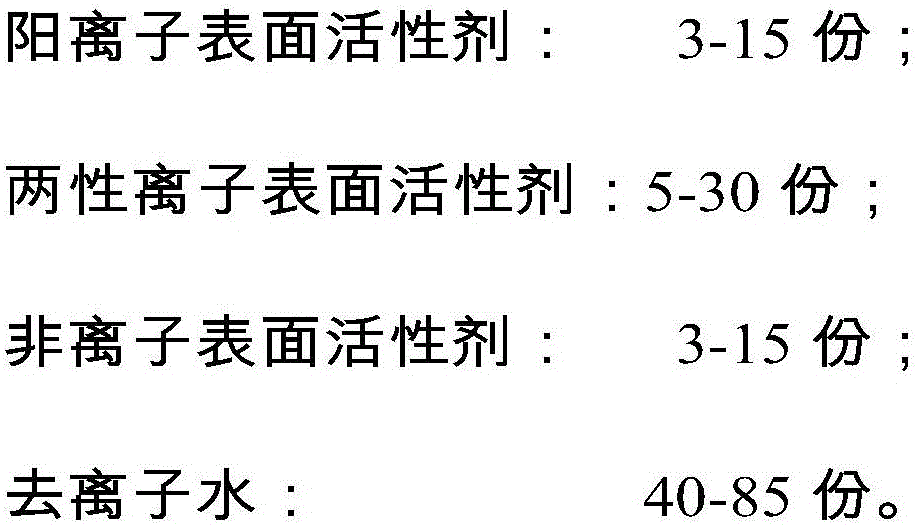

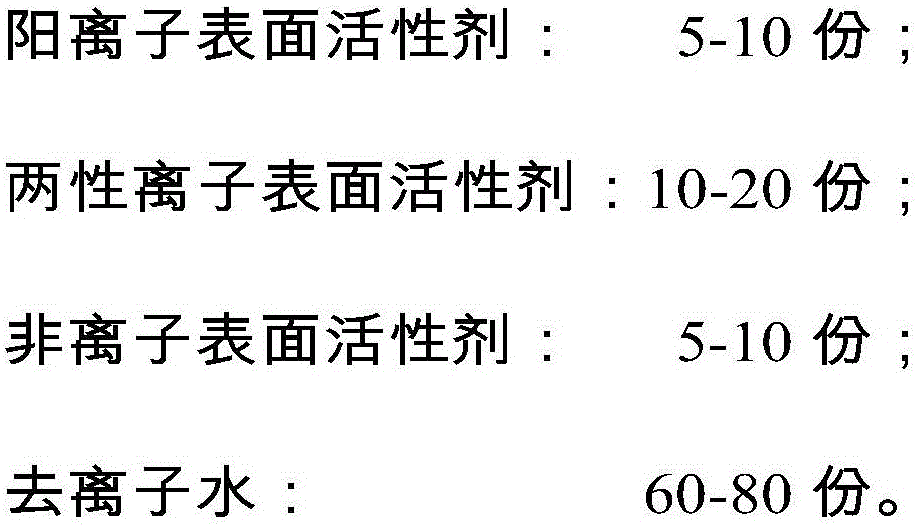

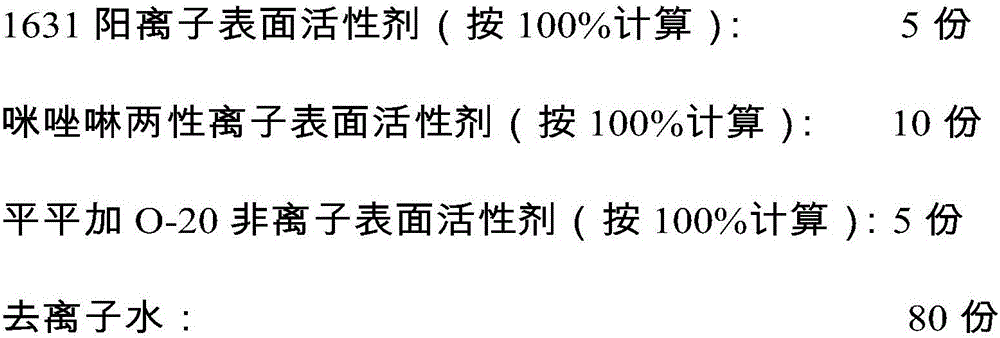

Antistatic agent as well as preparation method and application thereof

InactiveCN105755187AReduce adverse effectsSimple and fast operationLeather surface finishingAntistatic agentActive agent

The invention provides an antistatic agent which is prepared from the following components in parts by weight: 3-15 parts of cationic surface active agent, 5-30 parts of zwitterionic surfactant, 3-15 parts of a nonionic surfactant and 40-85 parts of deionized water. The antistatic agent provided by the invention is resistant to hard water, formic acid and ethanol-tolerant, can be mixed with a cationic substance, has a certain soft effect and a smooth effect, and ensures that a fleece is anti-static and smooth in hand feeling and a leather board is soft. The invention also provides a preparation method of the antistatic agent. The preparation method comprises the following steps: adding deionized water, heating, adding the cationic surface active agent, the zwitterionic surfactant and the nonionic surfactant without precedence order, and stirring. According to the method provided by the invention, a specific mixing mode is used, the antistatic agent is prepared under a mild condition, the operation is simple and convenient, and the stability and the reproducibility are good. The invention also provides application of the antistatic agent.

Owner:BEIJING FANBO CHEM

Surface treating agent for glass fiber filter cloth and preparation method of surface treating agent

The invention discloses a surface treating agent for glass fiber filter cloth. The surface treating agent comprises the following components in percentage by mass: 1-5% of a water-repellent and oil-resistant agent, 0.5-2% of a softening agent, 0.1-0.5% of inorganic pigment, 0.01-0.1% of a fluorocarbon surfactant, 2-5% of an acid-resistant adhesive, 2-10% of PTFE dispersing liquid and the balance of softened water. By using the surface treating agent, not only can the glass fiber filter cloth resist to the corrosion of strong-acid substances such as concentrated sulfuric acid, concentrated hydrochloric acid and hydrofluoric acid, but also the rigid strength, high-temperature resistance and filtering effect of the glass fiber filter cloth can be improved.

Owner:SICHUAN FIBERGLASS GRP

Antistatic water-soluble latex paint

InactiveCN104650704AHas antistatic effectMeet environmental protection production standardsPolyurea/polyurethane coatingsEmulsion paintsPolyethylene glycolThick fluid

The invention aims to prepare an antistatic water-soluble latex paint which is characterized by being composed of following chemical raw materials: a cationic surfactant dodecyl dimethyl benzene chloride as an antistatic agent, a nonionic surfactant nonylphenol polyoxyethylene ether as an emulsifying agent, high carbonic acid diethanolamide polyoxyethylene ether as an anti-hard water-dispersing agent, a wetting agent high carbonic acid polyethylene glycol ester, a film-forming agent polyurethane, a film-forming agent polyethyl acetate, a nonionic surfactant ethylene glycol polyether as a defoaming agent, acrylic acid silicone oil emulsion as a flatting agent, Cassion as a preservative, ethylene glycol as an anti-freezing agent, hydroxyl cellulose as a thickening agent, calcium carbonate as a whitening agent and pure water. The latex paint has an antistatic effect, is a milky-white thick fluid, is free of generation of foam when being vibrated, is 6-8 in pH, is good in stability, is quite low in human skin irritation and toxin, needs to be stored at an environmental temperature higher than 10 DEG C. The preparation method is free of waste gas, waste water and solid waste and is in conformity with a national environmental production standard.

Owner:TIANJIN BOLAIEN TECH DEV

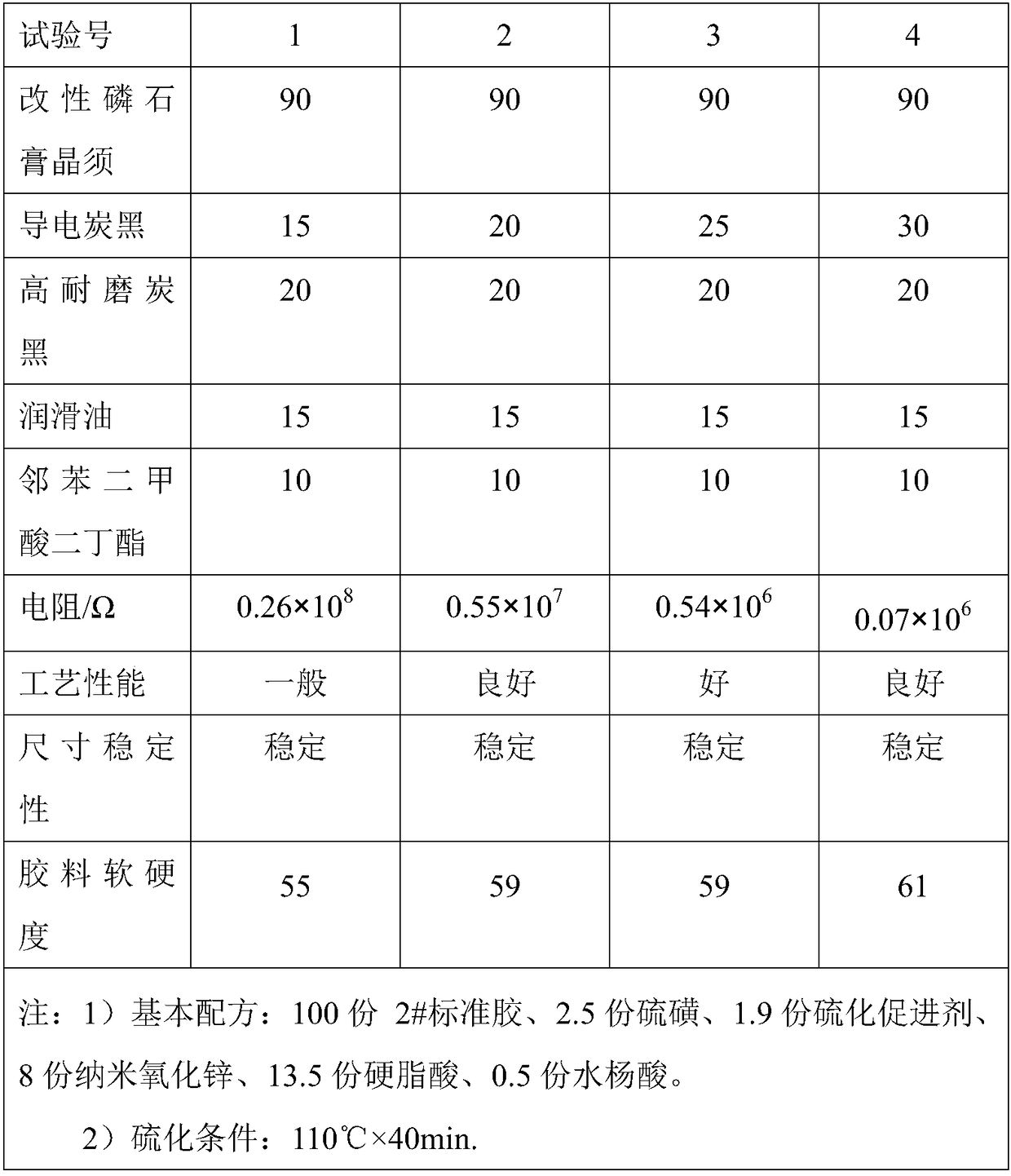

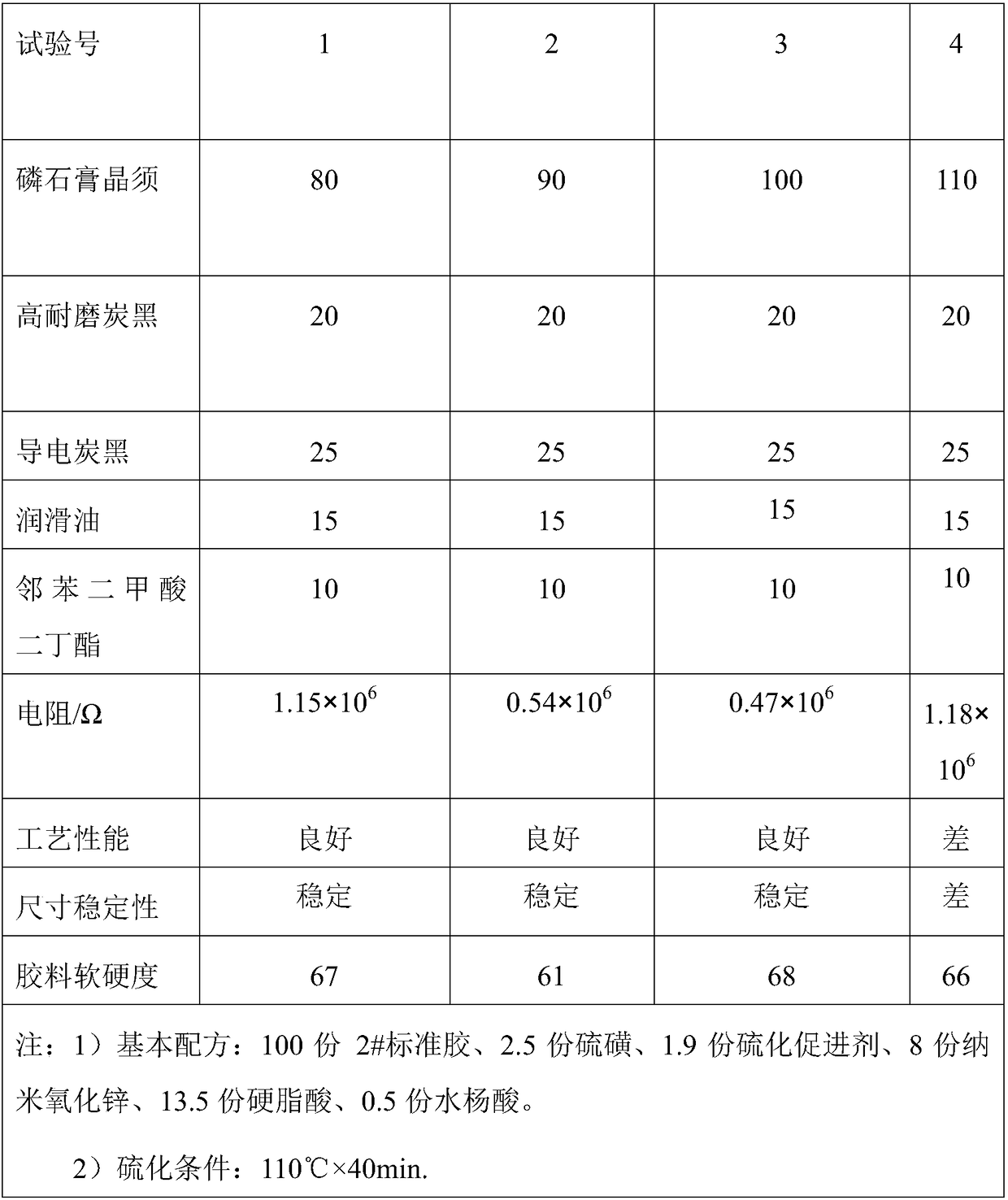

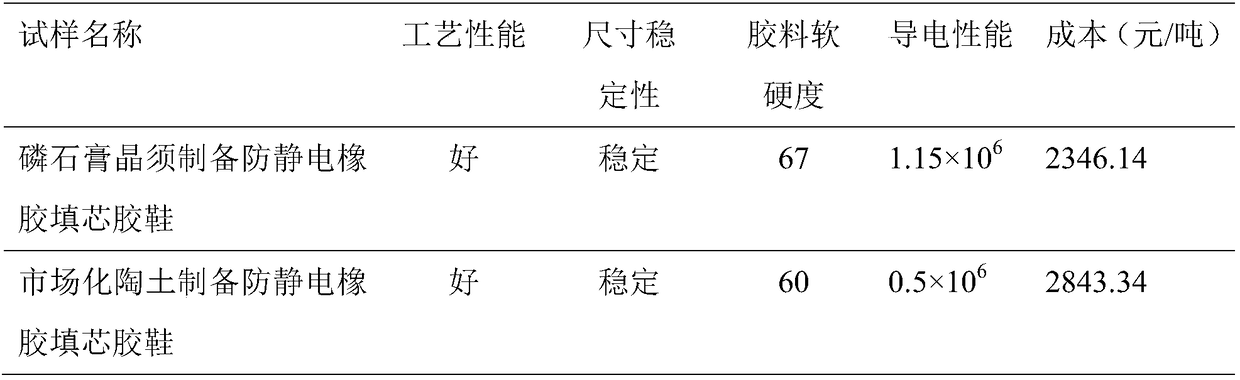

Antistatic rubber core-filling rubber shoe rubber material prepared from phosphorus gypsum whiskers and preparation method

The invention discloses an antistatic rubber core-filling rubber shoe rubber material prepared from phosphorus gypsum whiskers and a preparation method. The antistatic rubber core-filling rubber shoerubber material is prepared from the following raw materials in parts by weight: 95 to 115 parts of standard rubber, 2 to 3 parts of sulfur, 1.7 to 2 parts of vulcanization accelerant, 7 to 9 parts ofnano zinc oxide, 11 to 15 parts of stearic acid, 80 to 110 parts of phosphorus gypsum whiskers, 0.4 to 0.6 part of salicylic acid, 18 to 22 parts of high-wear-resistant carbon black, 20 to 25 parts of conducting carbon black, 13 to 18 parts of engine oil and 8 to 12 parts of dibutyl phthalate. The preparation method comprises the following steps: plasticating the number-2 standard rubber in an open-type rubber mixing mill at the temperature of 20 to 50 DEG C until wechsler plasticity is 0.55 to 0.60, adding other formulas such as sulfur and vulcanization accelerator; then uniformly turning and mixing the rubber material, eliminating bubbles, forming a rubber sheet, and naturally cooling the rubber sheet to the room temperature; and vulcanizing, thus obtaining the antistatic rubber core-filling rubber shoe rubber material. By adopting the antistatic rubber core-filling rubber shoe rubber material, the technical problems that the rubber core-fill rubber material is easy to generate aggregates or condensate and the dispersion effect is poor can be solved.

Owner:GUIZHOU NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com