Antistatic agent as well as preparation method and application thereof

A technology of antistatic agent and active agent, which is applied in the field of antistatic agent and its preparation, can solve the problems of dye discoloration, light fastness reduction, large dosage, etc., and achieve the effect of soft skin, excellent hygroscopicity, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

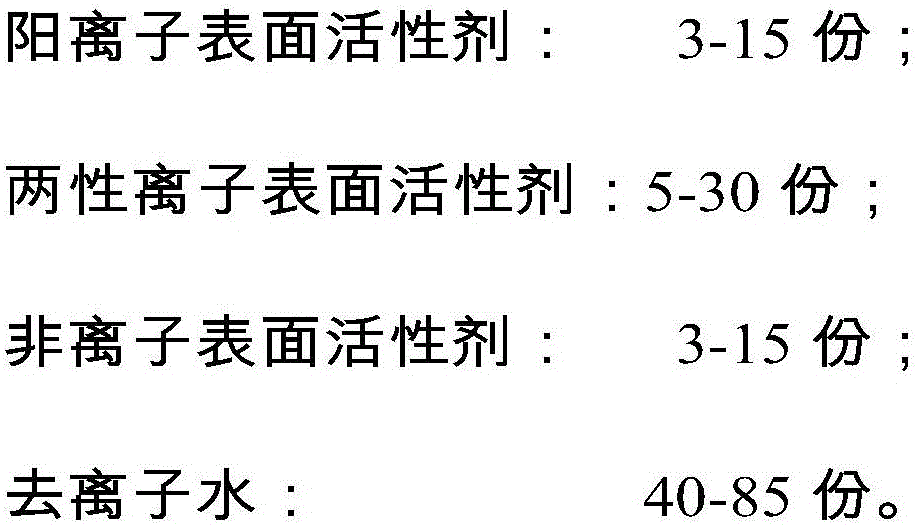

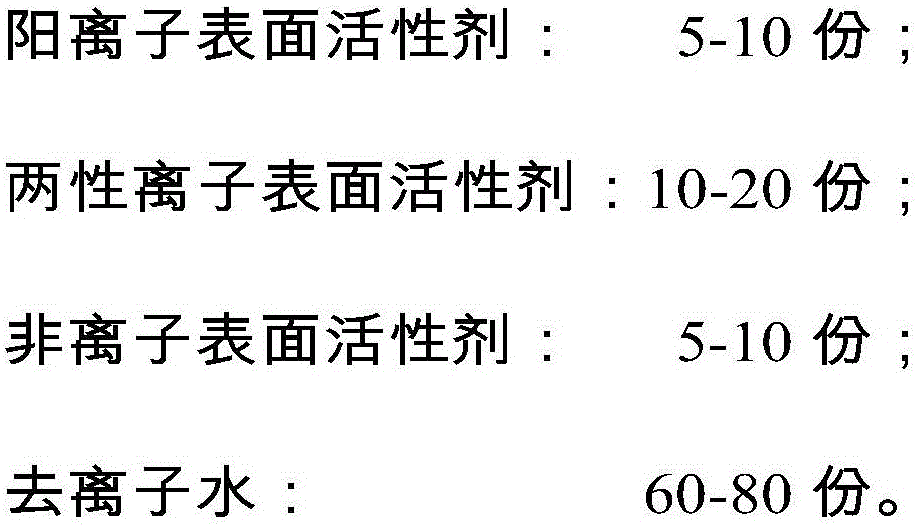

Method used

Image

Examples

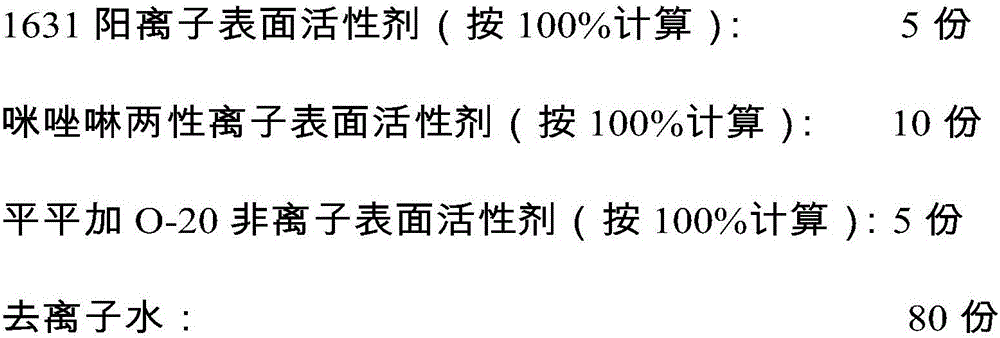

Embodiment 1

[0037]

[0038] Prepared by mixing and compounding. First, add the required weight of deionized water into the steam heating reaction tank, and heat it to 40°C-50°C. Then add cationic surfactant, zwitterionic surfactant and nonionic surfactant in no particular order. After all the addition is completed, mix for 30 minutes at 40°C-50°C by controlling the stirring speed at 15-30 rpm through a frequency converter, and then discharge.

Embodiment 2

[0040]

[0041] Prepared by mixing and compounding. First, add the required weight of deionized water into the steam heating reaction tank, and heat it to 40°C-50°C. Then add cationic surfactant, zwitterionic surfactant and nonionic surfactant in no particular order. After all the addition is completed, mix for 30 minutes at 40°C-50°C by controlling the stirring speed at 15-30 rpm through a frequency converter, and then discharge.

Embodiment 3

[0043]

[0044] Prepared by mixing and compounding. First, add the required weight of deionized water into the steam heating reaction tank, and heat it to 40°C-50°C. Then add cationic surfactant, zwitterionic surfactant and nonionic surfactant in no particular order. After all the addition is completed, mix for 30 minutes at 40°C-50°C by controlling the stirring speed at 15-30 rpm through a frequency converter, and then discharge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com