Patents

Literature

2055results about "Leather surface finishing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anti-calcification treatments for heart valves and vascular grafts

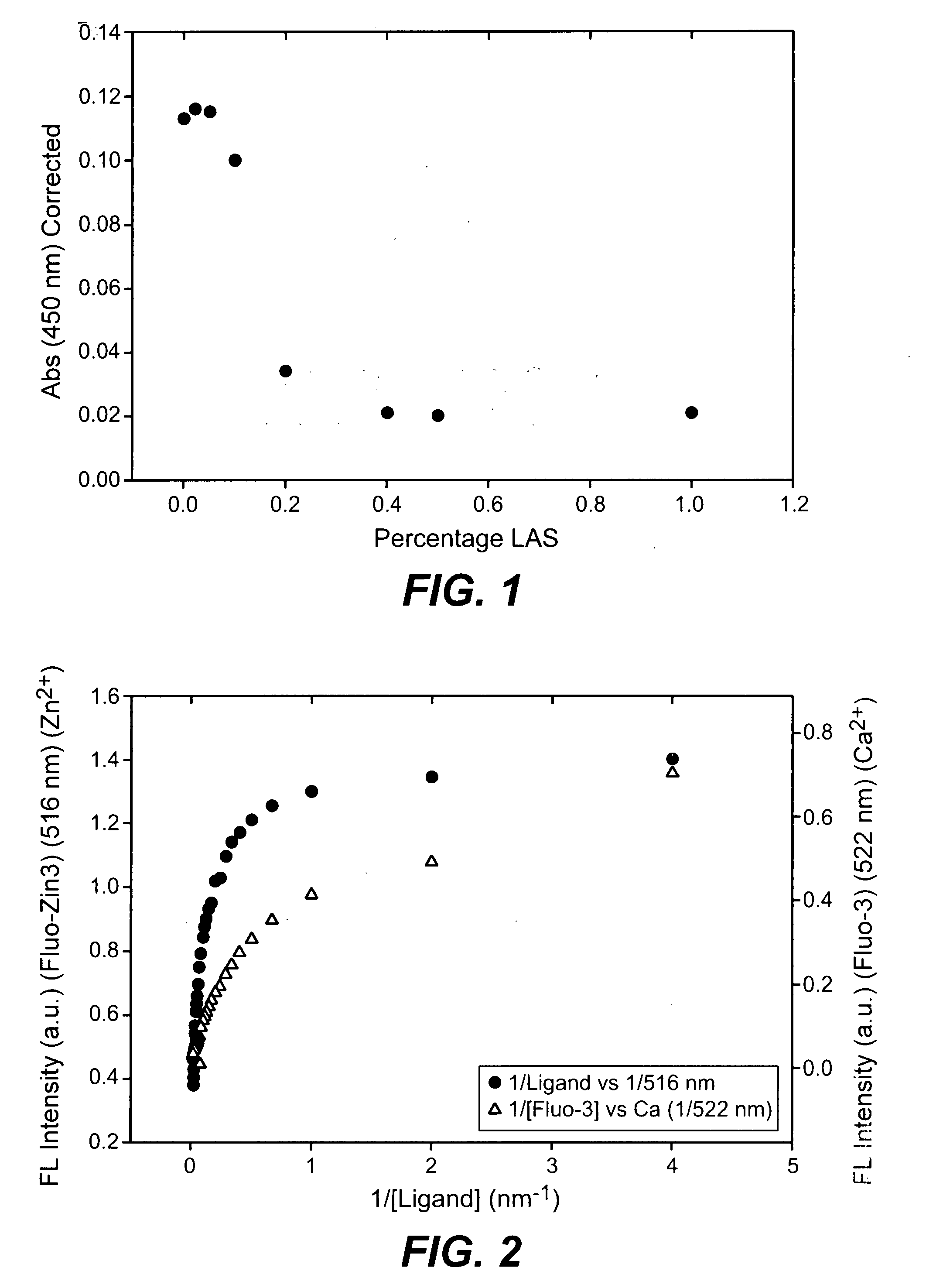

InactiveUS20060047343A1Reduces calcification potentialReduce calcificationSuture equipmentsHeart valvesCalcificationProsthesis

The present invention provides processes for fixation of biological tissue and / or post-fixation treatment of such tissue that result in modified tissues with reduced susceptibility to in vitro calcification when used in prosthetic devices. The invention also relates to calcification resistant biological tissue and to methods of using such tissue.

Owner:OVIATT HENRY W +1

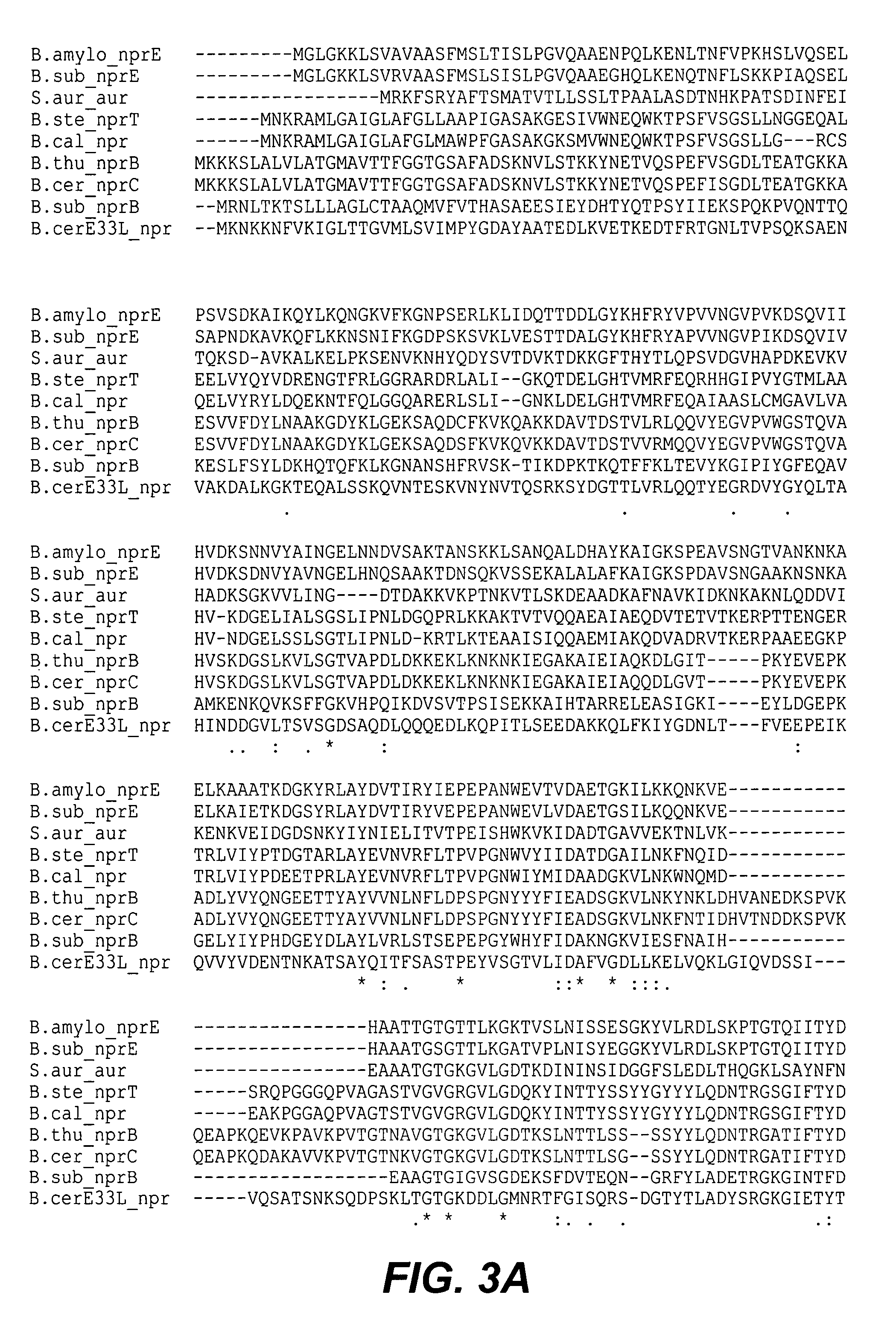

Use and production of storage-stable neutral metalloprotease

InactiveUS20080293610A1Good storage stabilityImprove performanceBacteriaFermentationBiologyGenus Bacillus

The present invention provides methods and compositions comprising at least one neutral metalloprotease enzyme that has improved storage stability. In some embodiments, the neutral metalloprotease finds use in cleaning and other applications. In some particularly preferred embodiments, the present invention provides methods and compositions comprising neutral metalloprotease(s) obtained from Bacillus sp. In some more particularly preferred embodiments, the neutral metalloprotease is obtained from B. amyloliquefaciens. In still further preferred embodiments, the neutral metalloprotease is a variant of the B. amyloliquefaciens neutral metalloprotease. In yet additional embodiments, the neutral metalloprotease is a homolog of the B. amyloliquefaciens neutral metalloprotease. The present invention finds particular use in applications including, but not limited to cleaning, bleaching and disinfecting.

Owner:DANISCO US INC +1

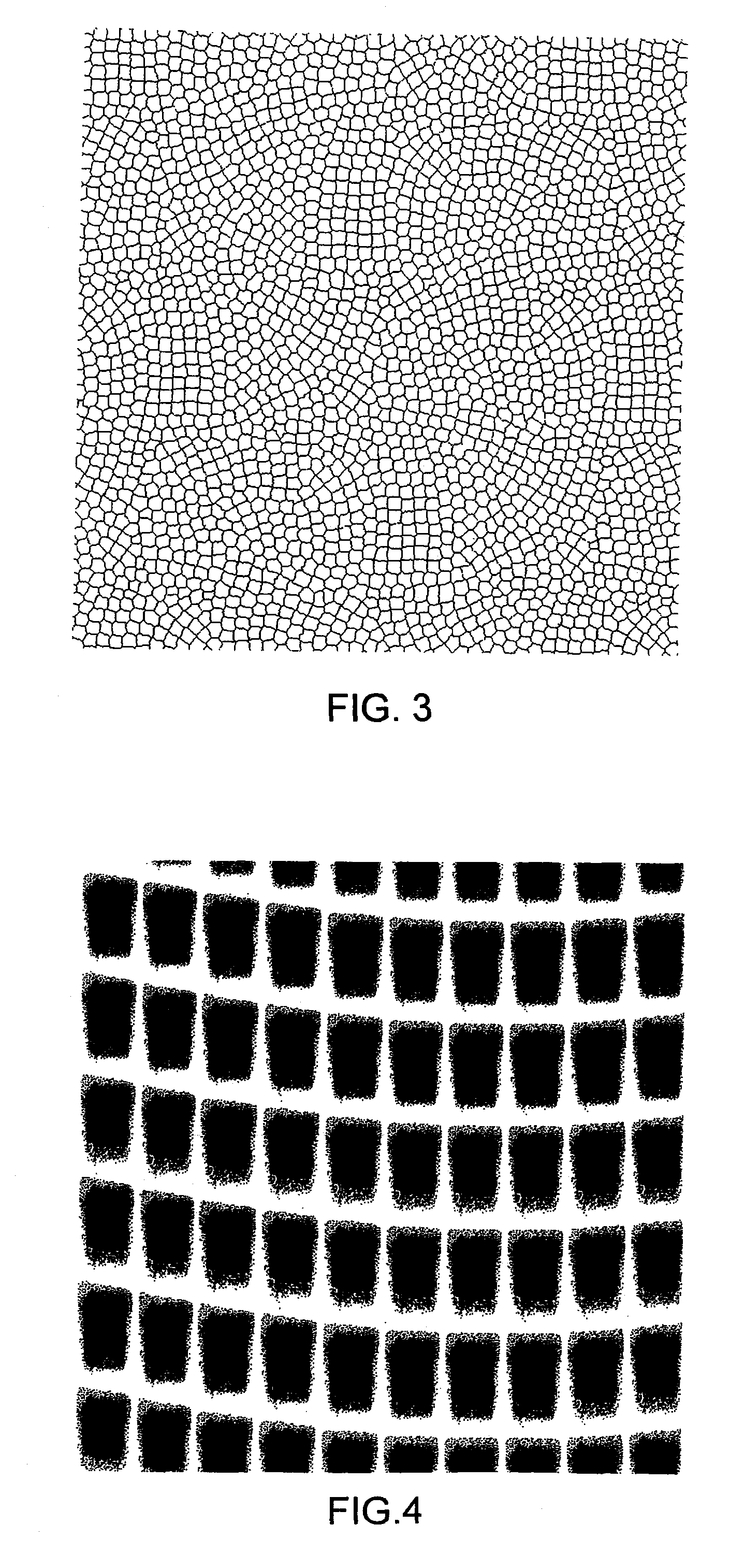

Aqueous compositions comprising polymeric duller particle

ActiveUS7829626B2Limit scopeImprove consistencyLiquid surface applicatorsLayered productsSingle stageTert-butyl acrylate

The present invention provides aqueous matte coating compositions comprising a binder component B) and a polymeric duller component A) composed of particles of one or more multi-stage copolymer or single stage crosslinked (co)polymer, e.g. crosslinked t-butyl (meth)acrylate, the duller component particles A) having an average diameter of 1-20 μm. Components A) and B) are compatible. Preferably, the duller component A) is acrylic; more preferably, components A) and B) are acrylic. The aqueous compositions provide matte coatings having haptic or feel (soft touch) properties, film and appearance properties, including burnish resistance and low color loss.

Owner:ROHM & HAAS CO

Hydrocarbon extenders for surface effect compositions

Owner:THE CHEMOURS CO FC LLC

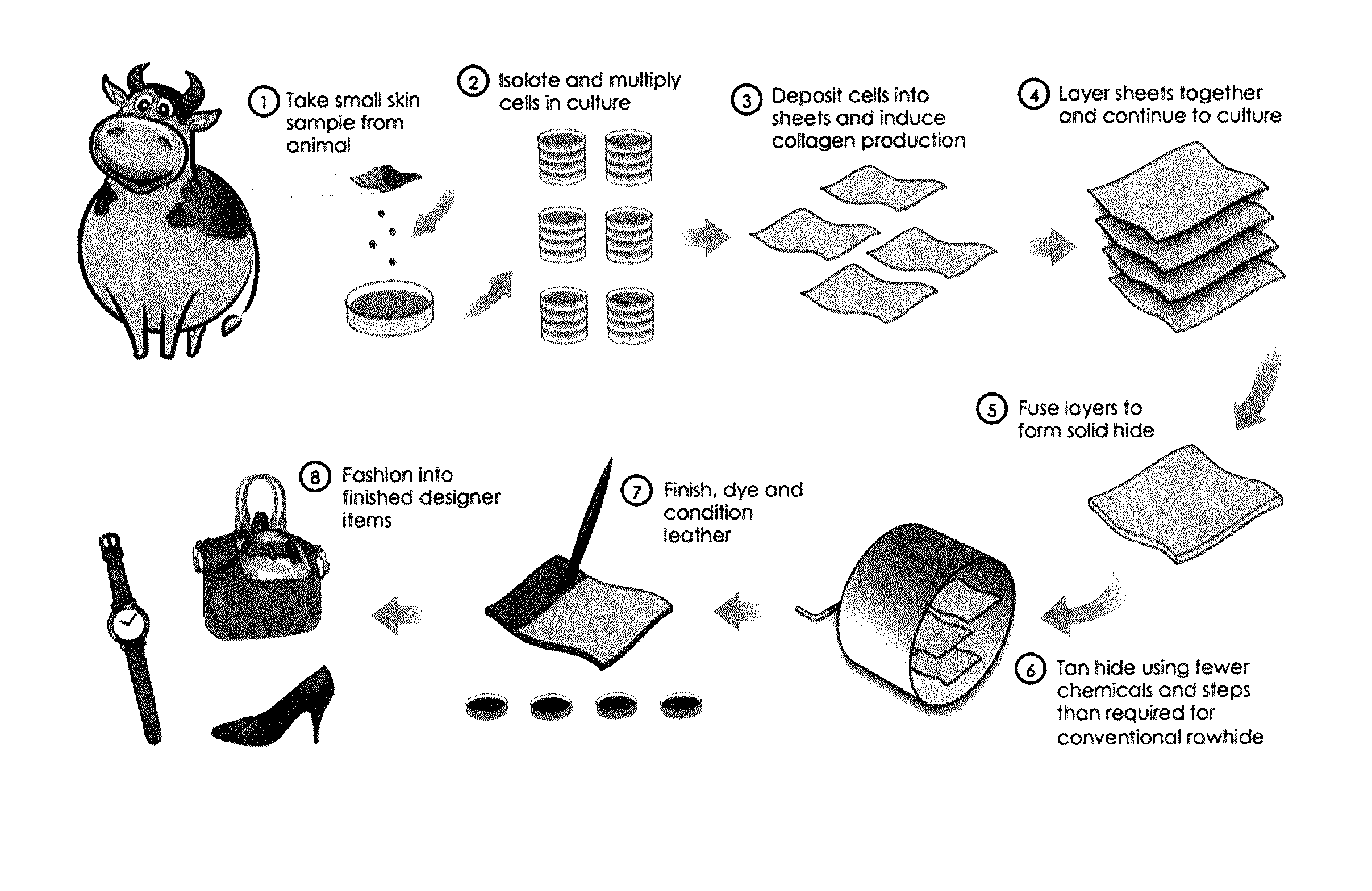

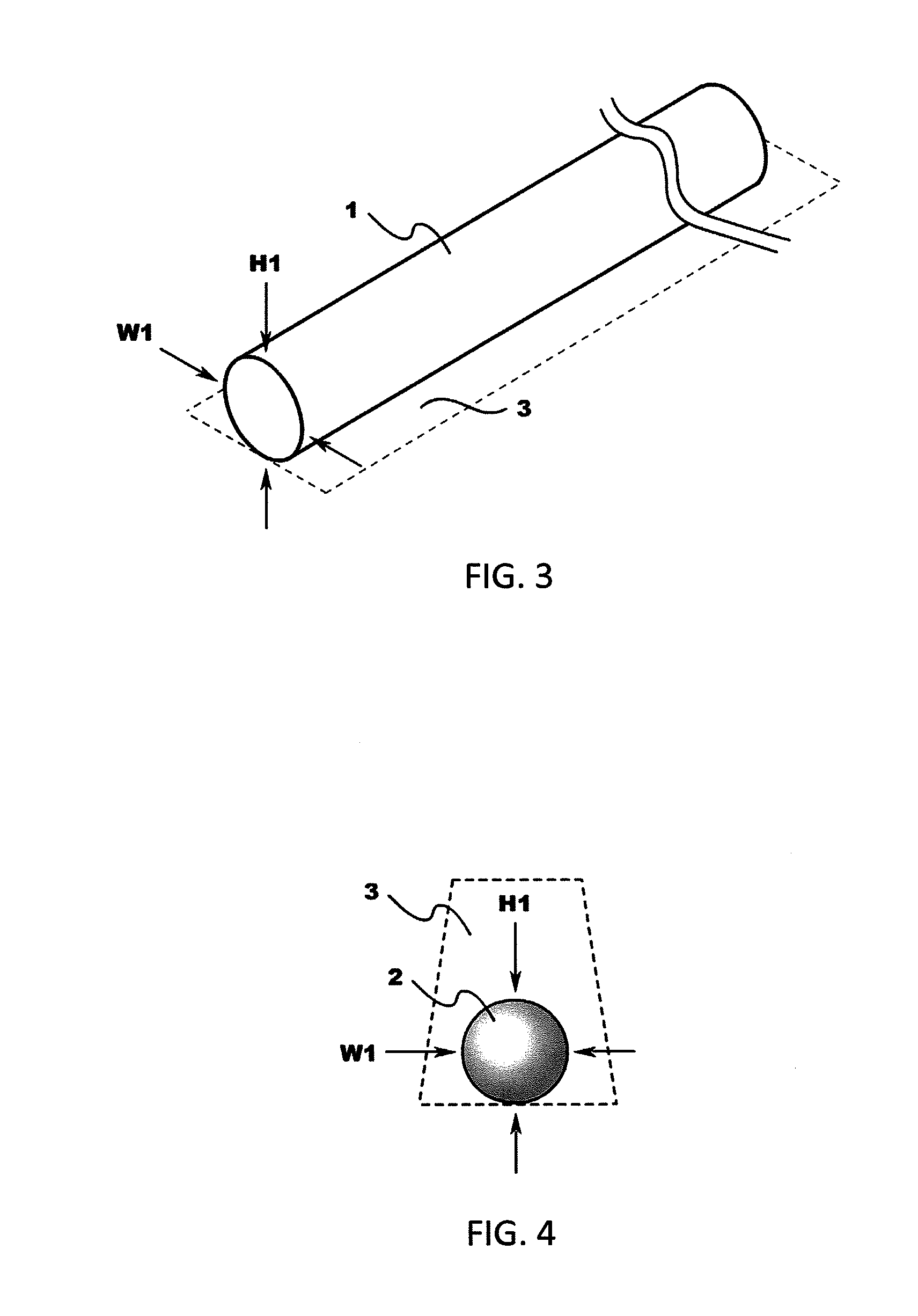

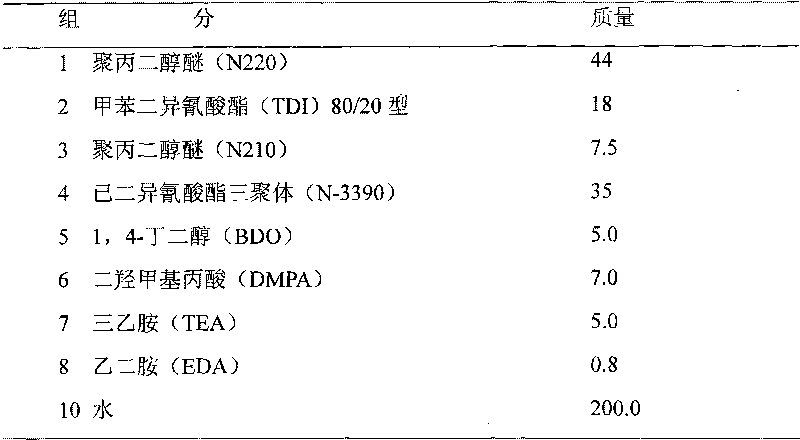

Engineered leather and methods of manufacture thereof

Engineered animal skin, hide, and leather comprising a plurality of layers of collagen formed by cultured animal collagen-producing (e.g., skin) cells. Layers may be formed by elongate multicellular bodies comprising a plurality of cultured animal cells that are adhered and / or cohered to one another; wherein the elongate multicellular bodies are arranged to form a substantially planar layer for use in formation of engineered animal skin, hide, and leather. Further described herein are methods of forming engineered animal skin, hide, and leather utilizing said layers of animal collagen-producing cells.

Owner:MODERN MEADOW INC

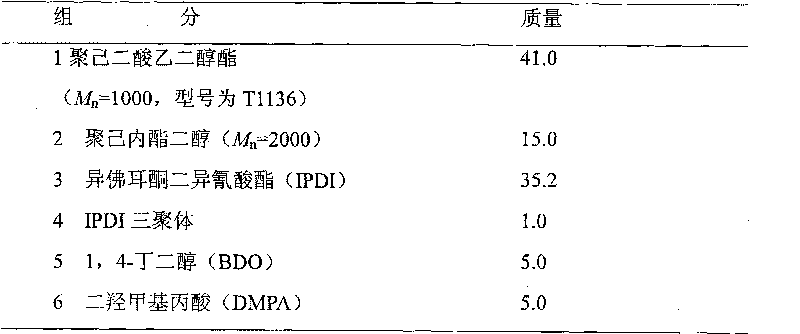

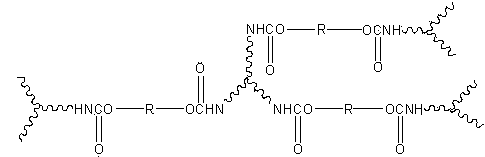

Preparation method and application of modified polyurethane aqueous dispersions of polyisocyanate curing agents

InactiveCN101696262ASimple processEasy to operatePolyurea/polyurethane coatingsLeather surface finishingPolyesterSolvent

The invention discloses a preparation method and application of modified polyurethane aqueous dispersions of polyisocyanate curing agents. The preparation method comprises the following steps of: carrying out prepolymerization reaction by using polyester polyol, vulcabond monomer and a polyisocyanate curing agent; reacting with a hydrophilic chain-extending agent and a micro-molecule chain-extending agent to obtain polyurethane prepolymer containing hydrophilic groups (carboxyl or sulfonic groups) and isocyanate(NCO)-terminated groups; neutralizing the polymer into salt, and then dispersing the salt into water; and preparing the modified polyurethane aqueous dispersions of the polyisocyanate curing agents by the chain extending of a polyamine chain-extending agent. The modified polyurethane aqueous dispersions of the polyisocyanate curing agents have self-crosslinking function at room temperature, and the self-crosslinking density is over 85%. Compared with non-modified polyurethane aqueous dispersions prepared under the same condition, the modified polyurethane aqueous dispersions have superior film forming property, water resistance, alcohol resistance, pollution resistance, cold resistance, dry / wet rubbing resistance and chemical solvent resistance; and coating films have especially high drying speed, high hardness increment speed and high final hardness.

Owner:SOUTH CHINA UNIV OF TECH

Polyurethane-polyurea dispersions based on polyether-polycarbonate-polyols

The invention relates to new, hydrolysis-stable, aqueous polyurethane-polyurea dispersions based on polyether-polycarbonate-polyols, to a process for preparing them and to their use in coating materials.

Owner:BAYER MATERIALSCIENCE AG

Aqueous compositions comprising polymeric duller particle

ActiveUS20070218291A1Improve clarityGood “hand feel”Liquid surface applicatorsLayered productsMeth-Single stage

The present invention provides aqueous matte coating compositions comprising a binder component B) and a polymeric duller component A) composed of particles of one or more multi-stage copolymer or single stage crosslinked (co)polymer, e.g. crosslinked t-butyl (meth)acrylate, the duller component particles A) having an average diameter of 1-20 μm. Components A) and B) are compatible. Preferably, the duller component A) is acrylic; more preferably, components A) and B) are acrylic. The aqueous compositions provide matte coatings having haptic or feel (soft touch) properties, film and appearance properties, including burnish resistance and low color loss.

Owner:ROHM & HAAS CO

Preparation method of matting leather water-based polyurethane coating agent

ActiveCN103740250AGood light stabilityGood compatibilityFibre treatmentPolyurea/polyurethane coatingsWater basedCross-link

The invention provides a preparation method of a matting leather water-based polyurethane coating agent. According to the preparation method, a polyurethane A component with a cross-linked structure and a large particle size is synthesized, and is mixed with a B component with a small particle size. The A component possesses many molecular branched chains, size of micellar particles is relatively large, and specific gravity of the A component is less than that of the component B; so that the A component will float on film surface, roughness of the film surface is relatively high, delustering effect is achieved, no delustering agent is needed, excellent transparency is obtained after coating, and no influence on leather substances is caused as the delustering effect is achieved.

Owner:SICHUAN DOWELL SCI & TECH INC

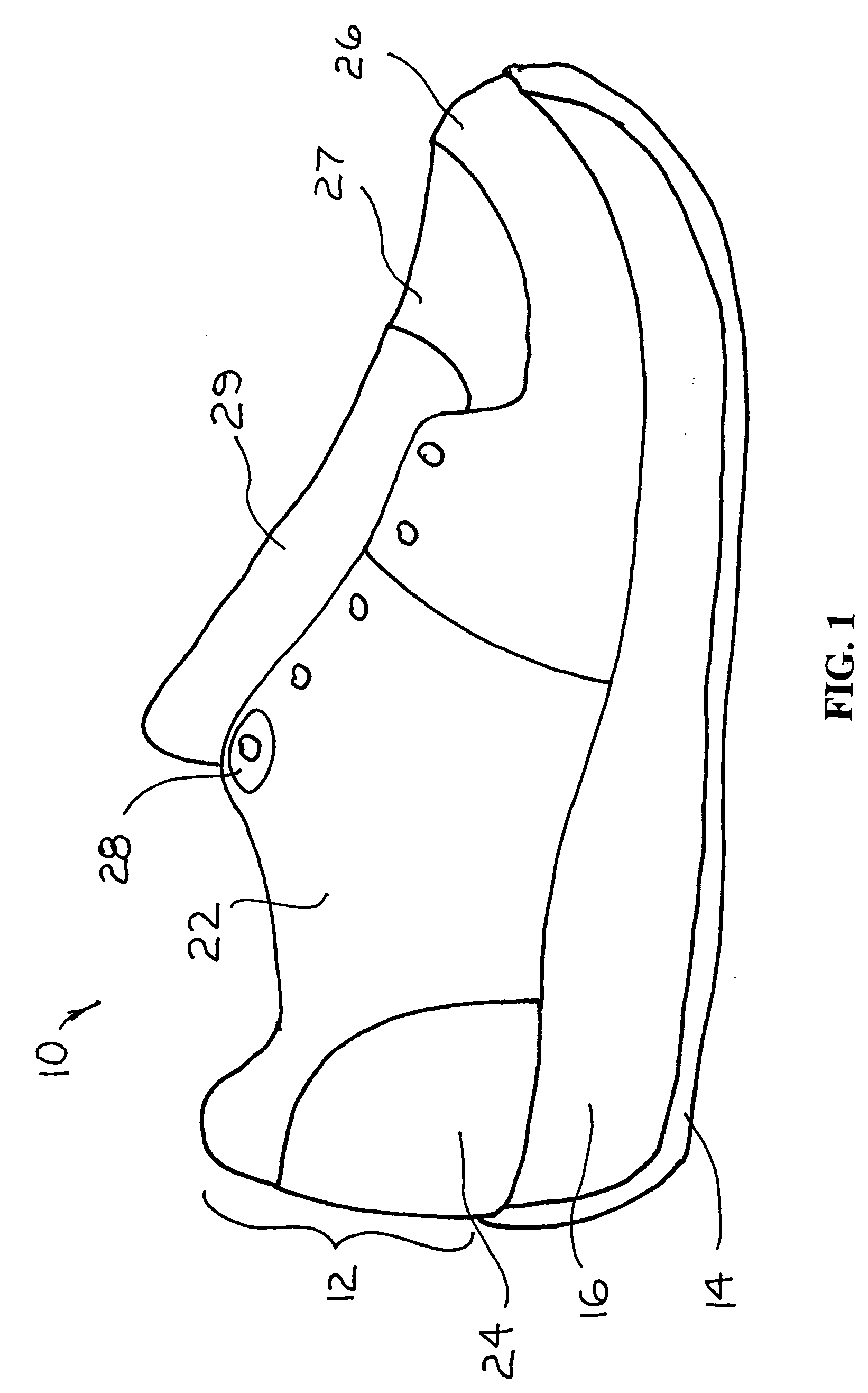

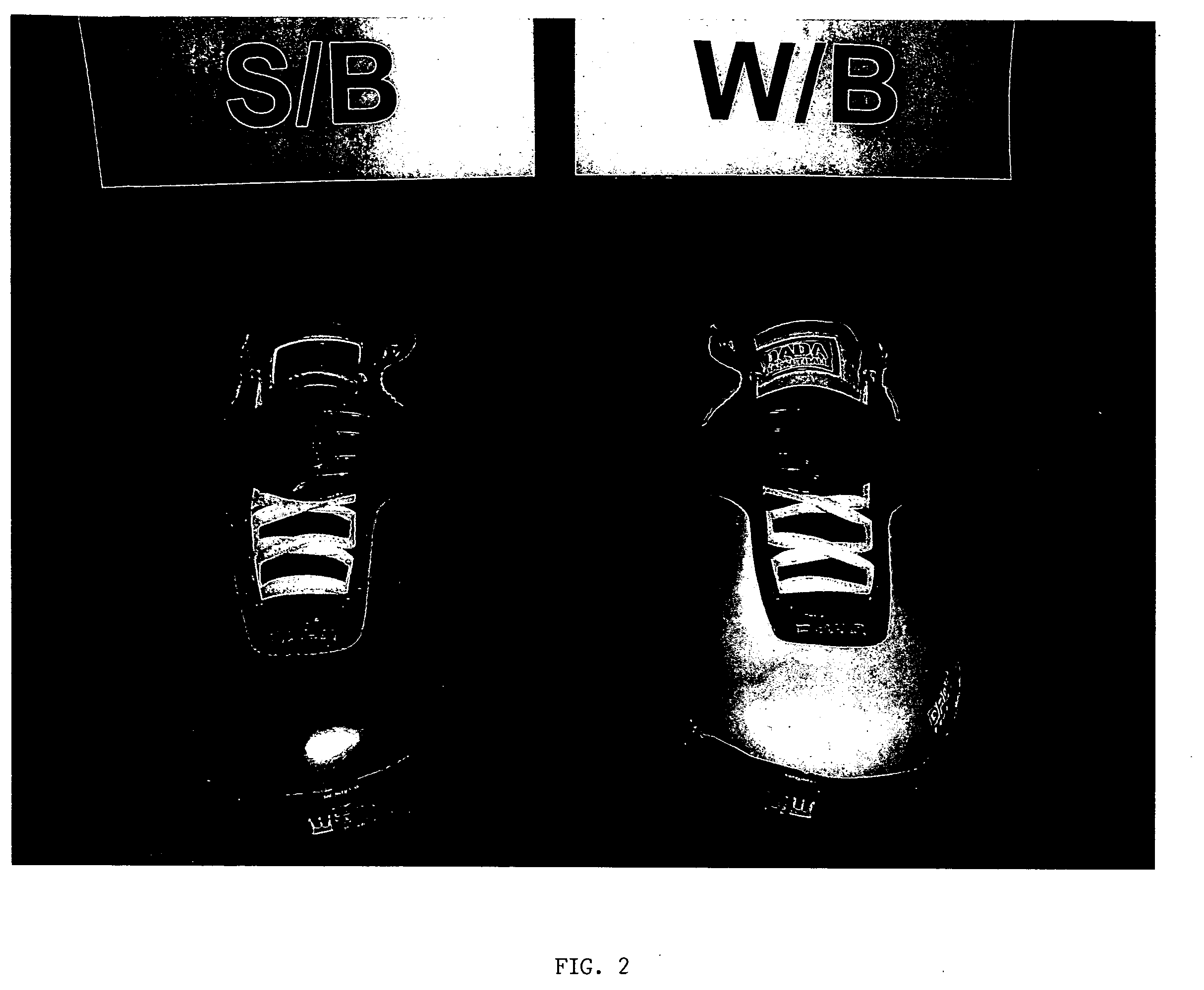

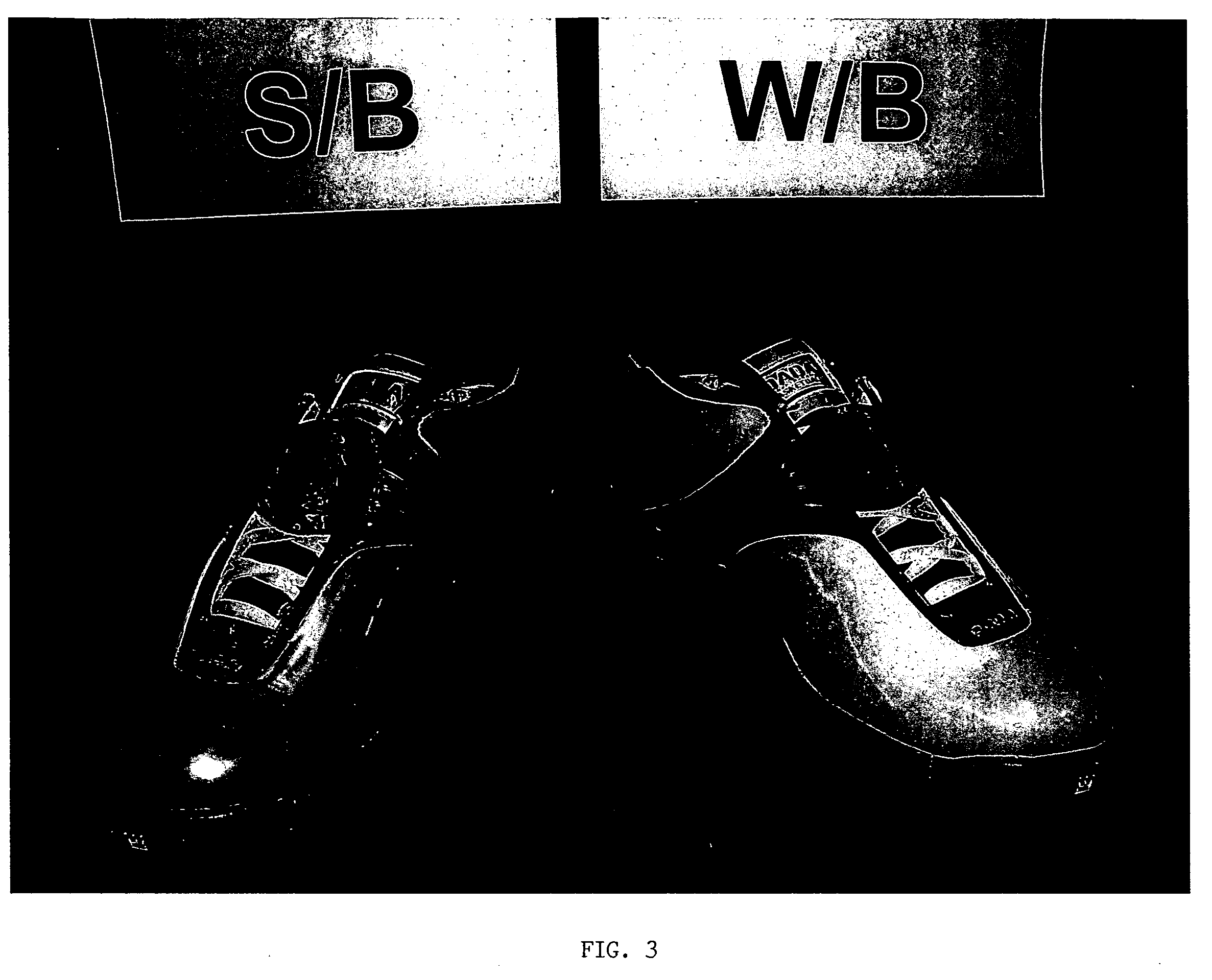

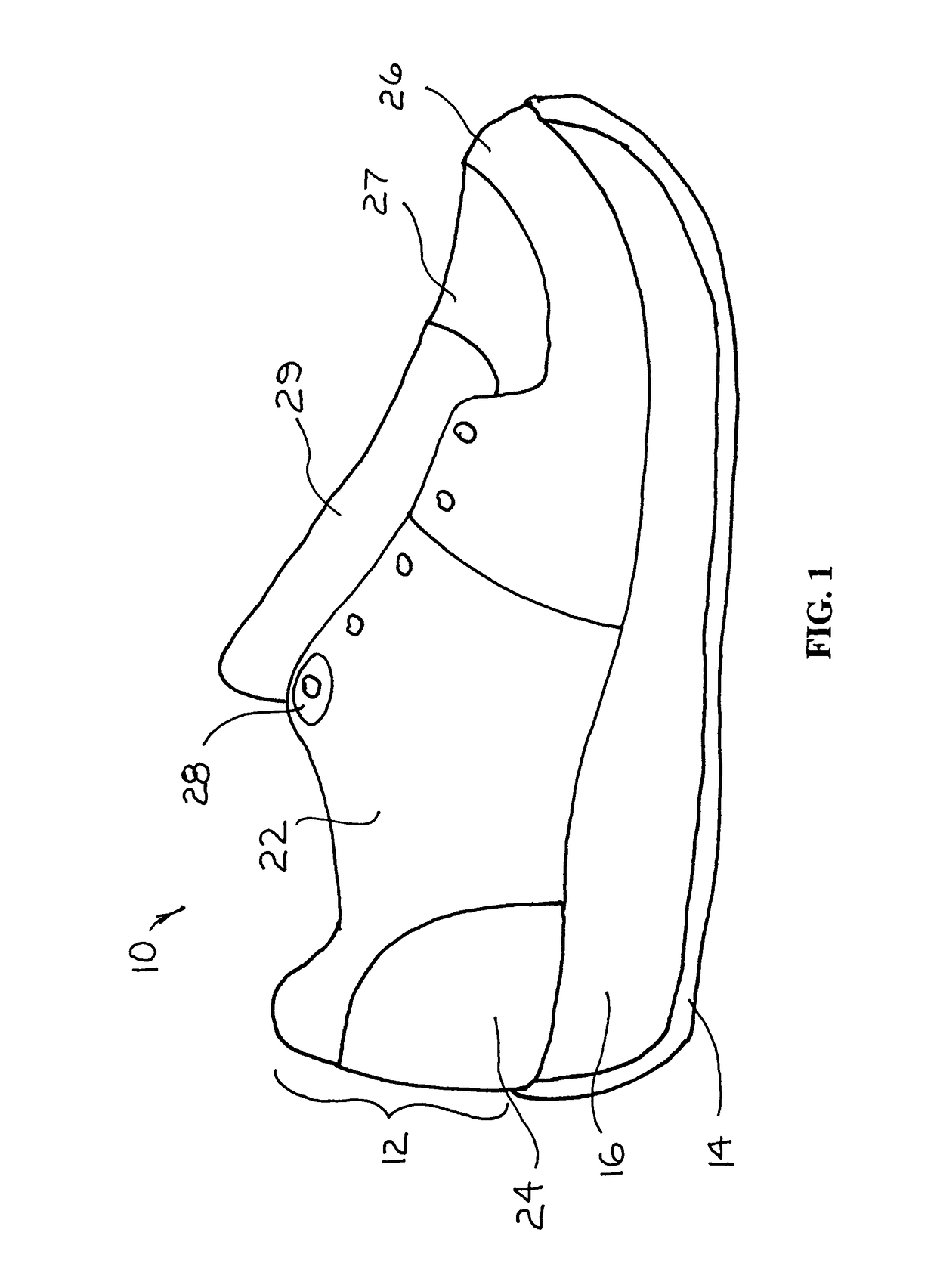

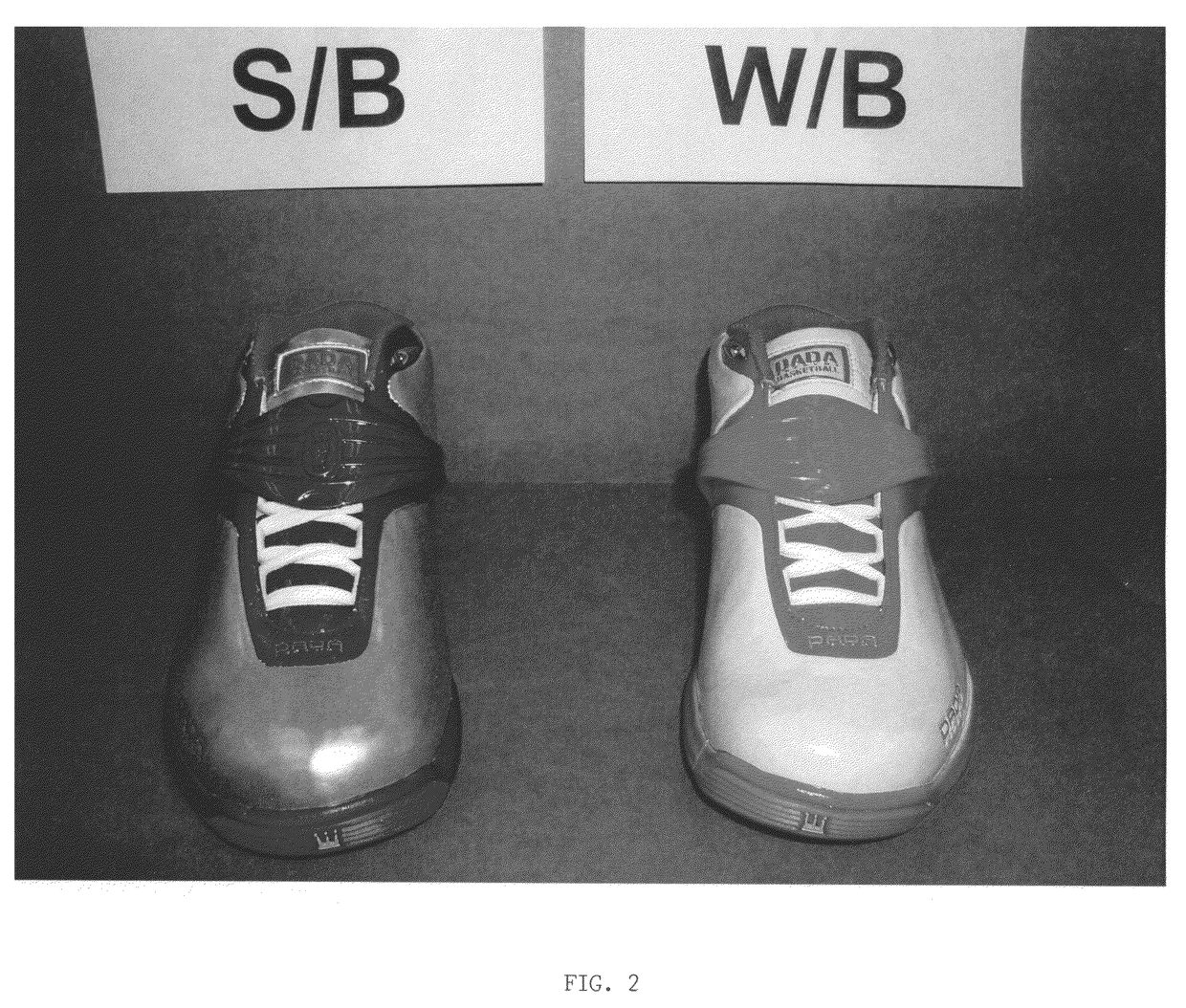

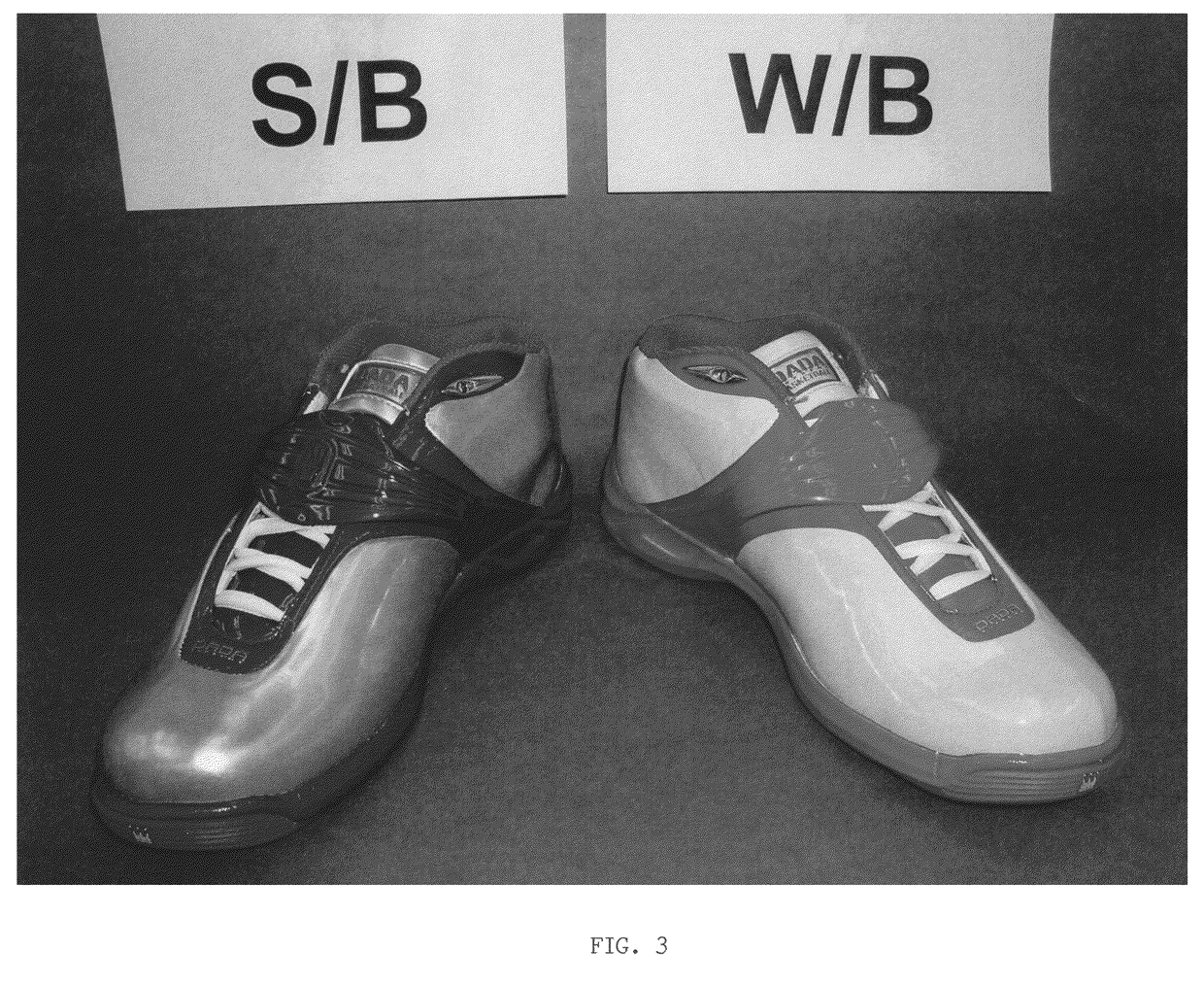

Color harmonization coatings for articles of manufacture comprising different substrate materials

Color harmonization is provided for articles of manufacture comprising different substrate materials. A coating composition is selected that can be applied to the different substrate materials while maintaining substantially uniform visual characteristics of the article. The substrates may include flexible materials such as natural leather, synthetic leather, vinyl, foam, textiles and the like. Examples of articles of manufacture include footwear, automotive upholstery and automotive interiors.

Owner:PPG IND OHIO INC

Production technology of cow skin nappa leather

ActiveCN105132596AUniform leatherImprove leather yieldLeather manufacturingTanning treatmentFiberManufacturing technology

The invention relates to the technical field of the leather manufacturing technology, and provides a production technology of cow skin nappa leather. A series of problems that due to the fact that the structure of the abdomen and the part between the ribs and the hips of the cow skin is thin and fiber is woven loosely, in the processing process, the part of the abdomen and the part between the ribs and the hips are prone to being excessively loose, the part deviation is large, and face loosening is likely to happen are solved through the production process of the cow nappa soft-face leather. The integral procedure of the technology is simple, easy to achieve, convenient to operate and practical. The grain on the abdomen and the part between the ribs and the hips is easy to open in the tan preprocessing working section of the cow skin through tanning preprocessing, retanning processing and post-tanning mechanical processing, and the whole skin body fiber is even and loose. Even and slow tanning is carried out in the tanning working section, step-by-step and multi-time even filling is carried out in the retanning working section, the whole cow skin leather is even and consistent in the manner that filling is conducted after loosening, the leather is soft but not loose, and the leather yield and the utilization rate of finished cow skin are greatly increased.

Owner:XINGYE LEATHER TECH CO LTD

Hydrocarbon extenders for surface effect compositions

ActiveUS20060052556A1Comparable and superior durabilityFibre treatmentPaper coatingPolymer scienceMonomer

A polymer extender composition for use with fluorochemical repellents, said composition comprising monomers copolymerized in the following percentages by weight: (a) from about 60% to about 94% of a monomer, or mixture of monomers, of the formula I: [CH3—(CH2)p][CH3(CH2)n]CHCH2—OC(O)—C(R)═CH2 (I), and (b) from about 5% to about 20% of a monomer, or mixture of monomers, of the formula II: H—(OCH2CH2)m—O—C(O)—C(R)═CH2 (II) wherein each R is independently H or CH3; n is 1 to 10; p is 1 to 20 and m is 2 to 10 is disclosed.

Owner:THE CHEMOURS CO FC LLC

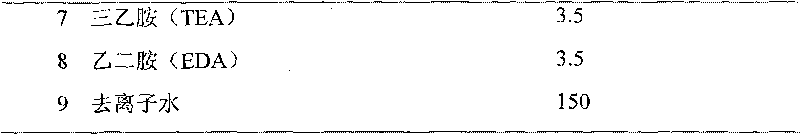

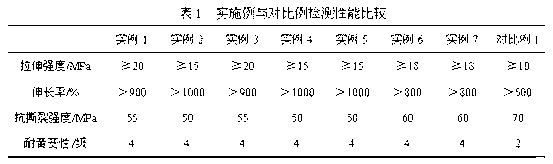

Aqueous polyurethane dispersoid for coating yellowing-resistant leather and preparation method thereof

InactiveCN102924683AGood yellowing resistanceEasy to preparePolyurea/polyurethane coatingsLeather surface finishingPolyurethane dispersionPolymer science

The invention discloses an aqueous polyurethane dispersoid for coating yellowing-resistant leather. The aqueous polyurethane dispersoid is prepared through the following steps: performing reaction on polyalcohol, a diisocyanate mixture and a crosslinking agent to generate a prepolymer with -NCO terminal group, wherein the diisocyanate mixture consisting of dicyclohexylmethane diisocyanate and isophorone diisocyanate is taken as a starting material; adding a hydrophilic chain extender into the prepolymer, further reacting and extending the chain by micromolecular dihydric alcohol; and neutralizing by using triethylamine and dispersing into water to obtain the aqueous polyurethane dispersoid. According to the aqueous polyurethane dispersoid prepared by the method, the yellowing-resistant level can reach more than level 4, the tensile strength is more than or equal to 15 MPa, the elongation ratio is more than or equal to 800 percent and the tearing strength is more than or equal to 50 MPa. The coated leather has soft and natural luster and plump and moist handfeel.

Owner:山西省应用化学研究所

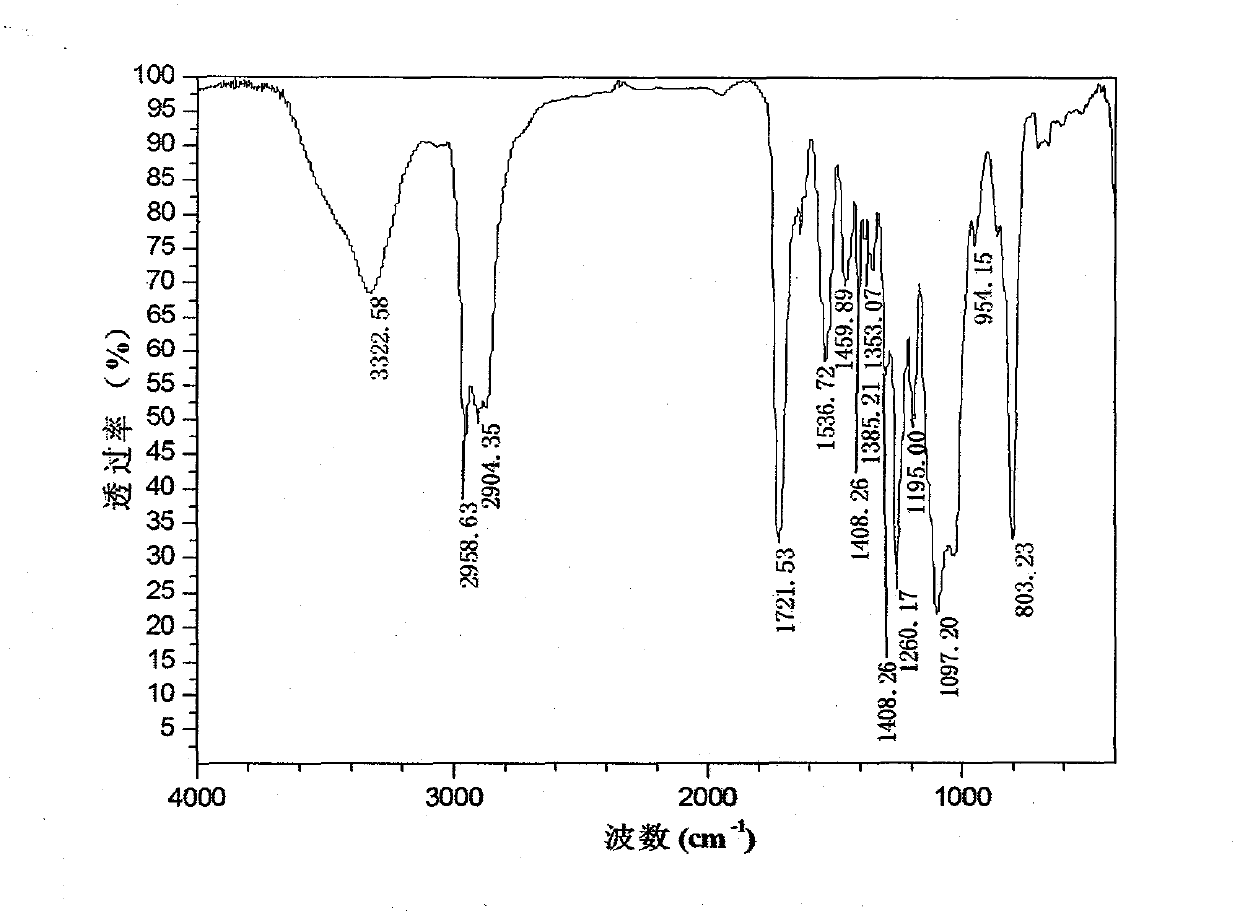

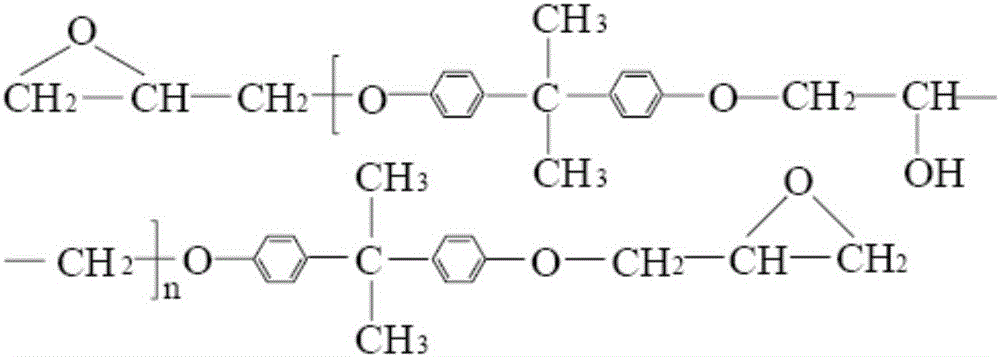

Photosensitive fluorosilicone segmented urethane acrylate oligomer and preparation method thereof

ActiveCN102993404AIncrease photosensitivityGood high resistanceFibre treatmentCoatingsOrganic solventOligomer

The invention relates to a photosensitive fluorosilicone segmented urethane acrylate oligomer and a preparation method of the photosensitive fluorosilicone segmented urethane acrylate oligomer. The preparation method comprises the steps of: (1) adding a fluorinated acrylate monomer and dialkylol amine into a reactor for reaction for 2-6hours at 20-50 DEG C; (2) adding organic silicon, polyisocyanate and a catalyst into the reactor for reaction for 0.25-2hours at 30-60 DEG C; (3) adding a second step product, a first step product, polyisocyanate and the catalyst into the reactor for reaction for 0.25-1hour at 30-60 DEG C; (4) carrying out reaction of a third step product, olefine acid-hydroxyl ester compounds, a polymerization inhibitor and the catalyst for 2-6hours at 30-80 DEG C; and (5) reducing the temperature and cooling to room temperature, discharging, and keeping in a dark place for later use. The invention has the beneficial effects that (1) the synthesized oligomer has the characteristics of better photosensitiveness, high and low temperature resistance, chemical medium resistance, resistance to pollution, flexibility and the like; (2) a ultraviolet cured leather finishing agent prepared by the oligomer has better adhesive force and low temperature hard fold resistance, does not contain organic solvents, is pollution-free and belongs to an environment-friendly material; and (3) the oligomer is simple in synthetic method, mild in reaction condition and easy to operate.

Owner:BEIJING UNIV OF CHEM TECH +1

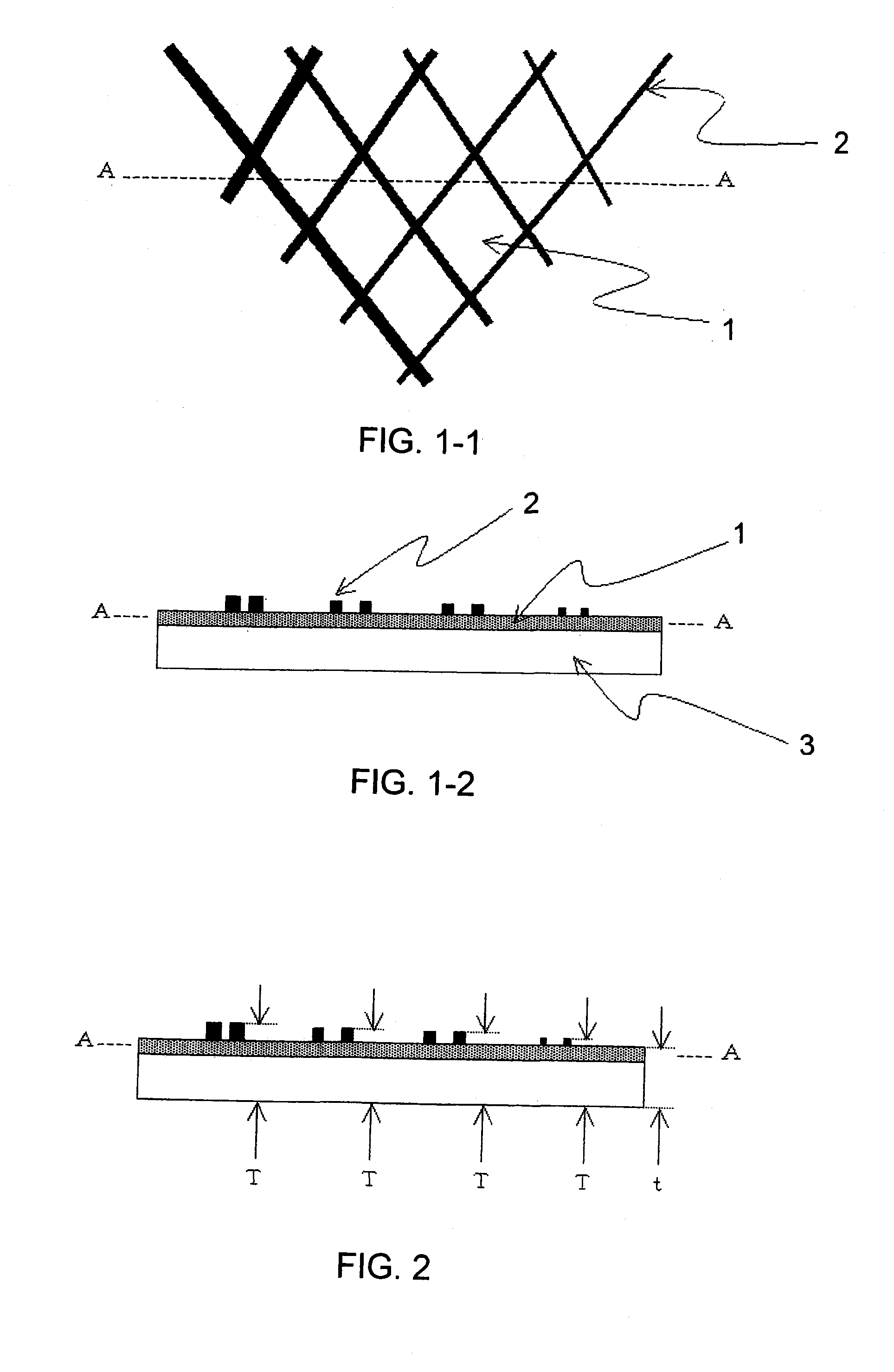

Three-dimensionally patterned natural leather

A natural leather having a three-dimensional pattern formed on the surface thereof is provided. The three-dimensionally patterned natural leather permits a minute three-dimensional expression such as small dots and thin lines, is high in the degree of freedom of the three-dimensional pattern, can retain the three-dimensional pattern even with the lapse of time and retain the characteristics peculiar to the natural leather. The three-dimensional pattern is formed by a resin portion which covers by coating the surface of an undercoating layer of the natural leather partially in a pattern shape. The resin portion has a maximum thickness of 20 to 400 μm.

Owner:SEIREN CO LTD

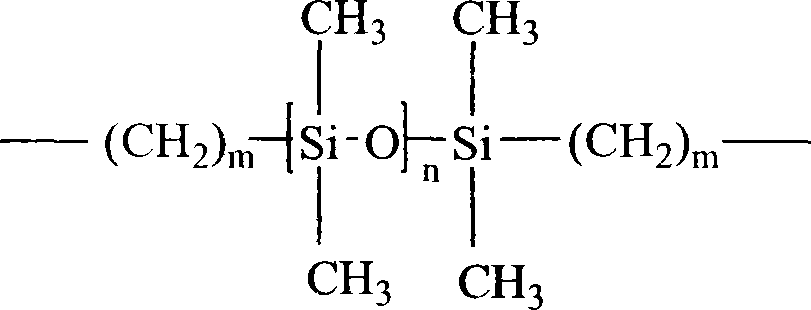

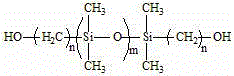

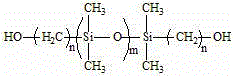

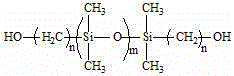

Organic silicon modified waterborne polyurethane leather coating agent and preparation method

InactiveCN104356342AMake up for the defects of poor mechanical propertiesImprove water resistancePolyurea/polyurethane coatingsLeather surface finishingSolventCastor oil

The invention discloses an organic silicon modified waterborne polyurethane leather coating agent which comprises the following raw materials in parts by weight: 30-50 parts of polyether polyol, 10-30 parts of isocyanate, 1-8 parts of castor oil, 0.1-11 parts of end hydroxyalkyl polydimethylsiloxane, 0.01-1 part of a catalyst, 1-10 parts of a hydrophilic chain extender, 5-25 parts of an organic solvent, 1-5 parts of a salt-forming agent, 1-3 parts of a small-molecule chain extender and 120-250 parts of deionized water. Correspondingly, the invention further provides a method for preparing the organic silicon modified waterborne polyurethane leather coating agent. By adopting the organic silicon modified waterborne polyurethane leather coating agent, properties such as the water resistance, the cold resistance, the solvent resistance and the surface property of synthesized waterborne polyurethane are all remarkably improved, the process is simple, the operation is convenient, the prepared emulsion is uniform and stable, no sediment is generated in the water dispersion and storage process, a coating film is transparent and bright, and the application prospect in leather coating is wide.

Owner:FOSHAN CENT FOR FUNCTIONAL POLYMER MATERIALS & FINE CHEM

Aqueous polyurethane and preparation method thereof

ActiveCN102532463AMacromolecular chain lengthGood film flexibilityFibre treatmentPolyurea/polyurethane coatingsPropanoic acidOrganic solvent

The present invention provides a preparation method for aqueous polyurethane. The method comprises the following steps: mixing aliphatic diisocyanate, an aliphatic polyol, dimethylol propionic acid and a catalyst, and carrying out a reaction to obtain a prepolymer; adding a neutralizing agent to the prepolymer, and carrying out a stirring reaction to obtain an intermediate product; adding water and a chain extender to the intermediate product, stirring and dispersing to obtain the aqueous polyurethane, wherein the chain extender is polyoxyethylene polyamine or polyoxypropylene polyamine. The invention further provides the aqueous polyurethane prepared by the method. According to the present invention, the bulk polymerization method is adopted, the use of the organic solvent is not required, and no environmental pollution is generated; the polyoxyethylene polyamine or the polyoxypropylene polyamine is adopted as the chain extender, and is used for emulsion chain extending, such that the obtained polyurethane emulsion has good film-forming flexibility, the mechanical property of the obtained polyurethane can not be reduced, the large R value is not required, and the final produced polyurethane film is soft.

Owner:SICHUAN DOWELL SCI & TECH INC

Manufacturing process of semi-vegetable tanned wrinkled leather of cow leather

InactiveCN102080134AQuality assuranceReduce contentTanning treatmentPre-tanning chemical treatmentPulp and paper industryHexavalent chromium

The invention relates to a manufacturing process of the semi-vegetable tanned wrinkled leather of cow leather, which comprises the working procedures of initial tanning, deacidifying, vegetable tanning, filling and dry finishing. In the method provided by the invention, firstly tanning is carried out on raw hide by a small quantity of chromium tanning agent and then by a vegetable tanning agent, thereby under the premise of guaranteeing the quality of the leather, greatly reducing the content of chromium in tanning waste liquid, lightening the pollution of the chromium to the environment and effectively inhibiting the generation of hexavalent chromium through the vegetable tanning agent in the leather; and meanwhile, the granule surface of the leather is tightened through the working procedures of dry finishing and coating, and natural winkles are formed on the granule surface, thereby covering the injury of the granule surface of the leather and improving the additional value of the leather.

Owner:锦兴皮业科技有限公司

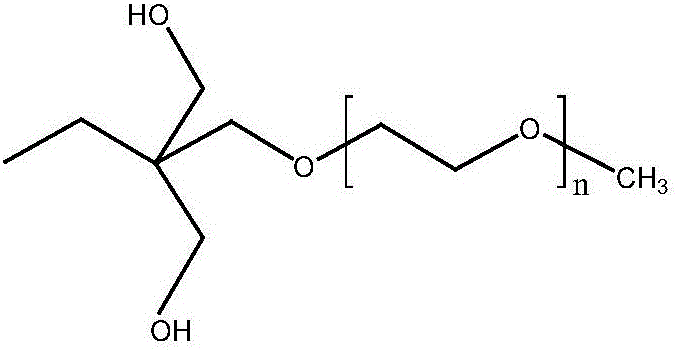

Epoxy modified anionic/nonionic waterborne polyurethane resin and preparation method thereof

ActiveCN106496485AImprove cohesive energyImprove water resistancePolyurea/polyurethane coatingsLeather surface finishingEpoxyPolyol

The invention relates to the technical field of preparation of modified waterborne polyurethane, in particular to epoxy modified anionic / nonionic waterborne polyurethane resin and a preparation method thereof. The preparation method comprises the steps: mixing a macromolecular polyol and a nonionic hydrophilic chain extender, heating to 70-80 DEG C, adding diisocyanate and a catalyst, and holding the temperature and stirring for reaction for 1 to 3 h to obtain a prepolymer; adding an anionic hydrophilic chain extender and a macromolecular polyol, stirring for reaction at 60 to 70 DEG C for 1 to 3 h to obtain a hydrophilic chain extender prepolymer; adding epoxy resin solution, stirring for reaction at 60 to 70 DEG C for 2 to 4 h to obtain epoxy modified prepolymer; cooling, and adding a salt agent to form a salt by neutralizing; adding water for emulsifying; adding polyamine for reaction for 10 to 60 min to obtain the epoxy modified anionic / nonionic waterborne polyurethane resin which has excellent resistance to hydrolysis and resistance to low temperature, high film strength, and excellent mechanical properties, and can be used as a leather finishing agent.

Owner:GUANGZHOU HUMAN CHEM

Method for preparing polyacrylate/nano-SiO2 compound coating agent by using reactive emulsifier

InactiveCN101831230AImprove electrical performanceGood optical performanceCoatingsLeather surface finishingAdhesivePolymer chemistry

The invention relates to a method for preparing polyacrylate / nano-SiO2 compound coating agent which is suitable for bottom layer coating in clothing leathers and instep leathers, by using a reactive emulsifier. The polyacrylate has excellent optical stability, chemical resistance and favorable adhesive property and is widely used as an adhesive, a coating film-forming agent, a functional film, and a medical polymer and in the fields of water treatment and the like, but polyacrylate emulsion has the defects of embrittlement at low temperature, stickiness and strength loss at high temperature, easy after tack and the like, which restrict the application range and the use value of the polyacrylate emulsion. In the invention, the polyacrylate / nano-SiO2 compound coating agent is prepared by substituting conventional emulsifier with reactive emulsifier by utilizing the nanometer effect of an inorganic nanometer material and synchronously adopting a conventional emulsion polymerization method and a sol-gel method. The compound coating agent prepared by the invention has fine granules, excellent adhesive force, good filling capacity, strong water resistance and flexible and transparent formed film, and meanwhile, the damages to the human body and the environment, which are caused by the use of large amount of emulsifiers, are reduced.

Owner:SHAANXI UNIV OF SCI & TECH

In situ fluoropolymer polymerization into porous substrates

The present invention relates to in situ polymerization of fluoropolymer into porous substrates, to improve resistance to wear, tear and creep, decay, and degradation by wetting, staining and warping, and to improve durability while maintaining the appearance of the substrate.

Owner:THE CHEMOURS CO FC LLC

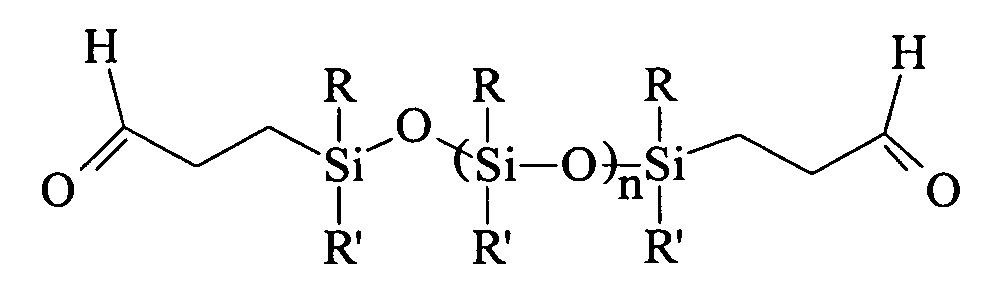

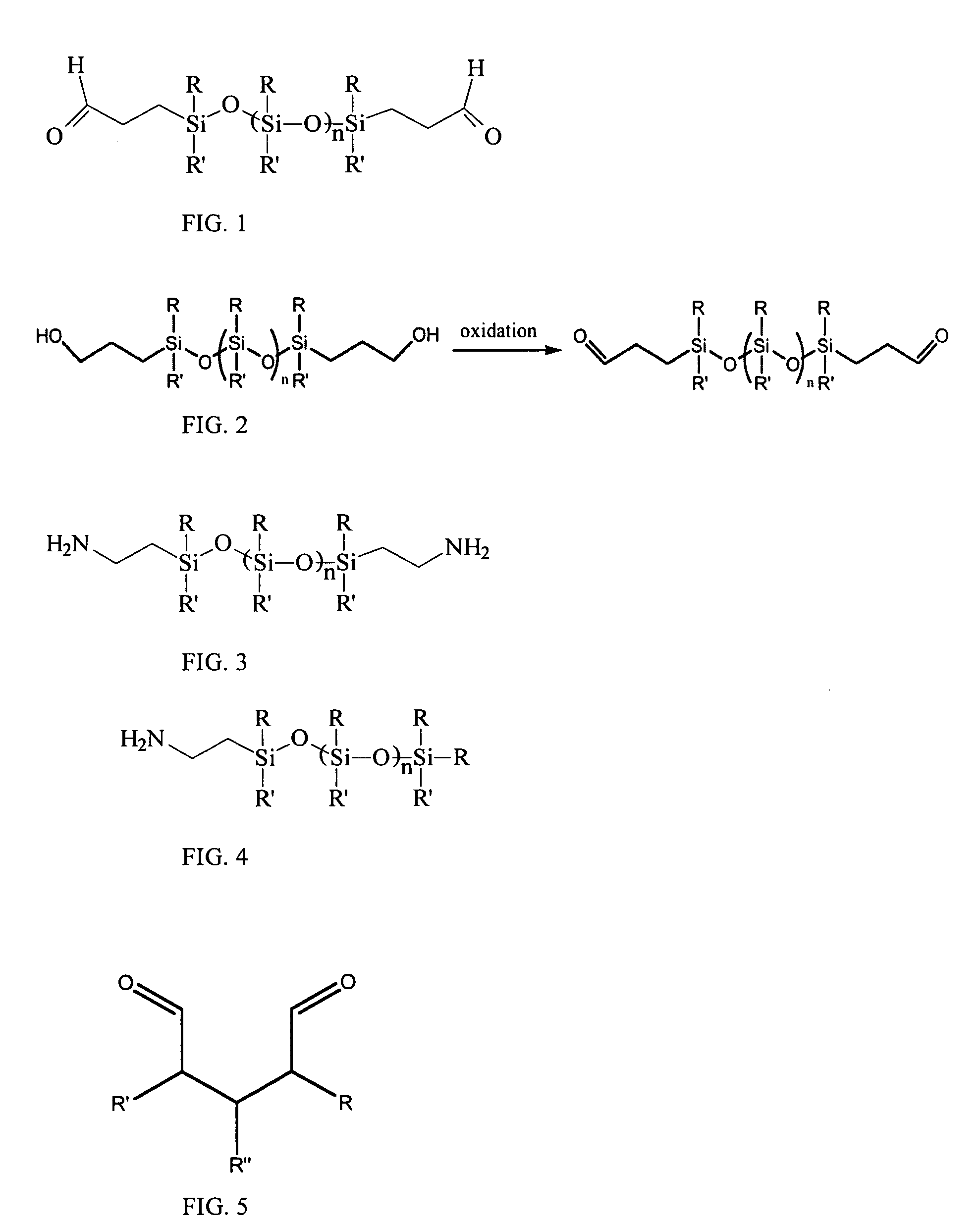

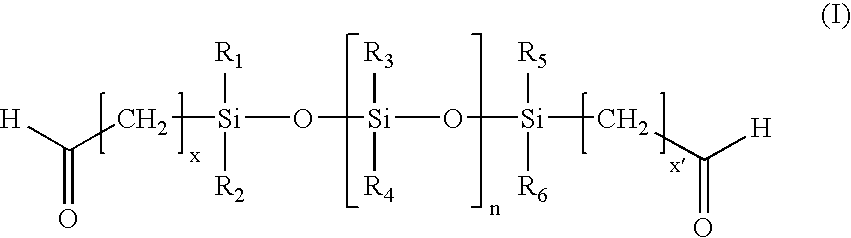

Polysiloxane-modified gelatin leather finishing agent and preparation method thereof

ActiveCN103087631AAntibacterialImprove performanceProtein coatingsLeather surface finishingWater basedEpoxy

The invention relates to a polysiloxane-modified gelatin leather finishing agent and a preparation method thereof. The preparation method comprises the steps: dissolving gelatin into water to be prepared into aqueous solution, adjusting the pH of the solution to be 6-12 at 40-70 DEG C, and adding a surfactant, wherein the usage amount of the surfactant is 2-20% the mass of the gelatin; continuing stirring, adding Si-O-Si repetitive unit-containing epoxy-polysiloxane continuously or in batches, wherein the usage amount of the epoxy-polysiloxane is 1.5-10 times the mass of the gelatin; and reacting for 12-24h at 40-70 DEG C to obtain water-based and emulsion type epoxy-polysiloxane-modified gelatin leather finishing agent.

Owner:QILU UNIV OF TECH

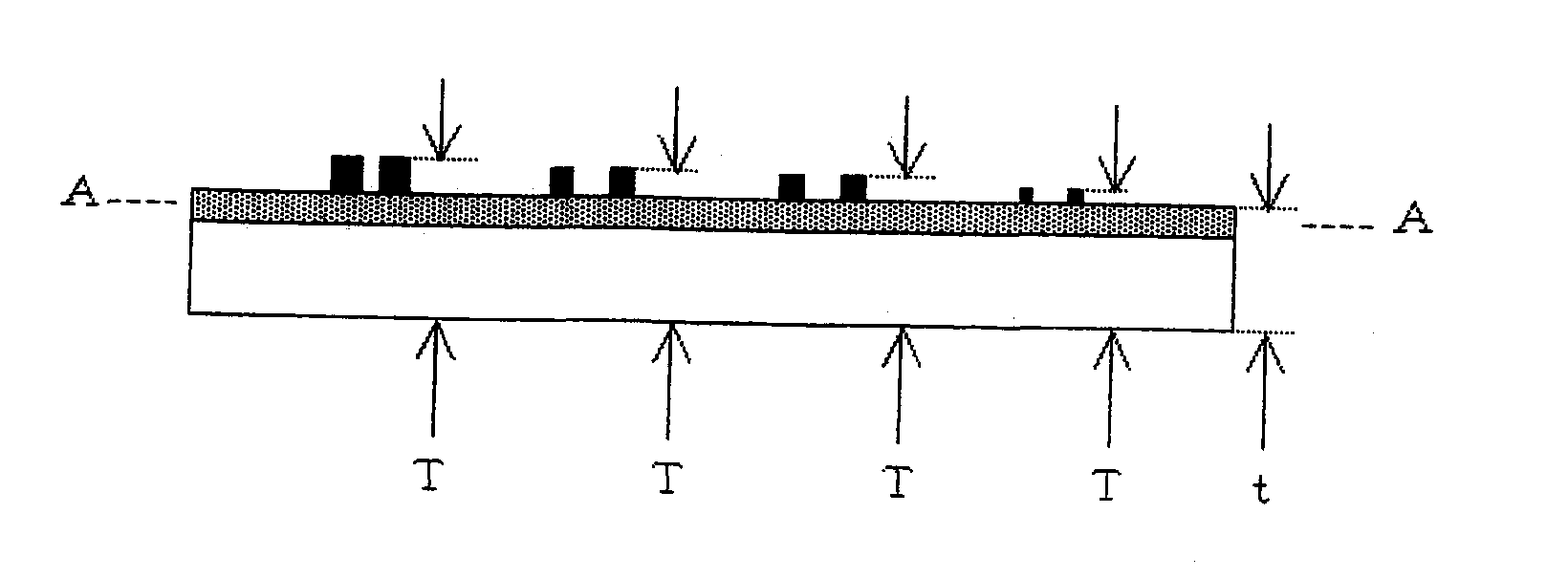

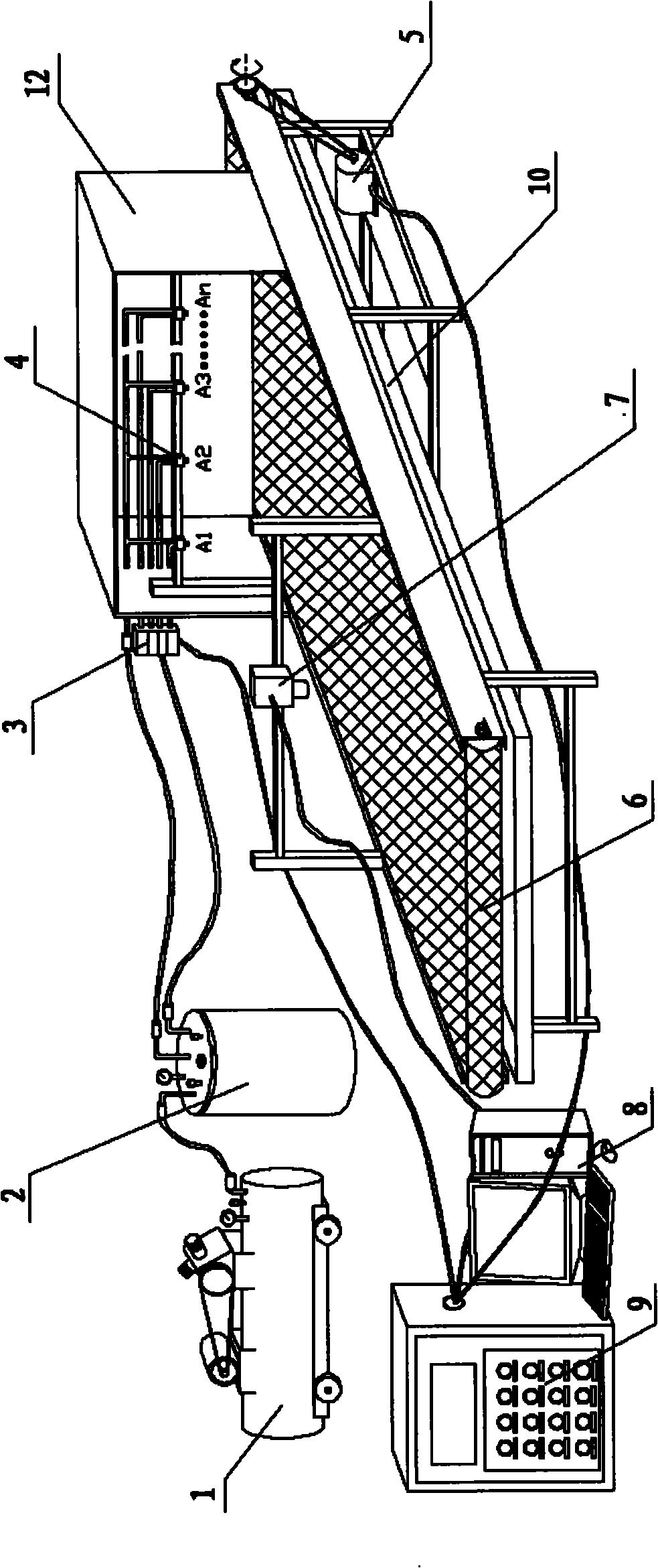

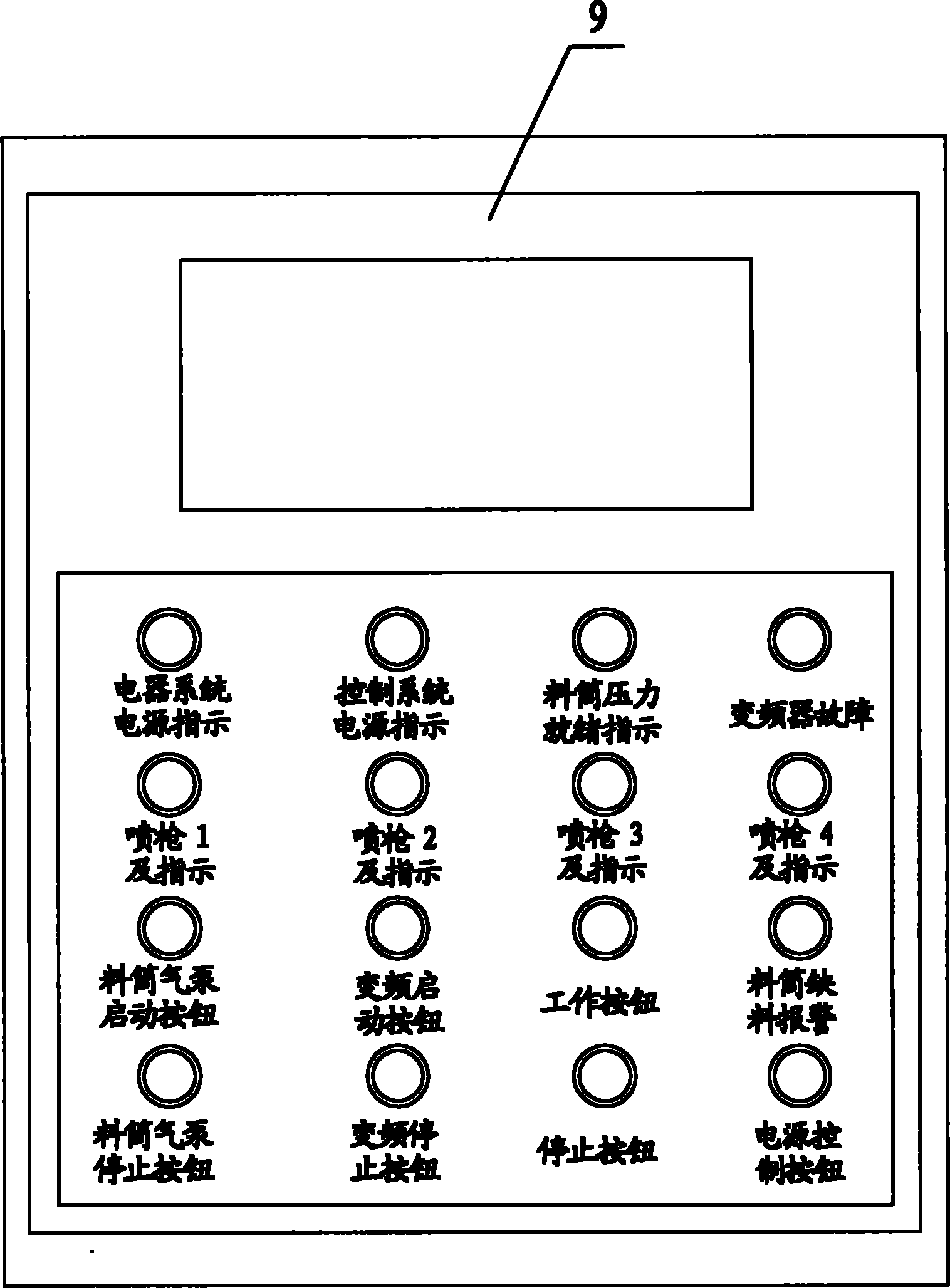

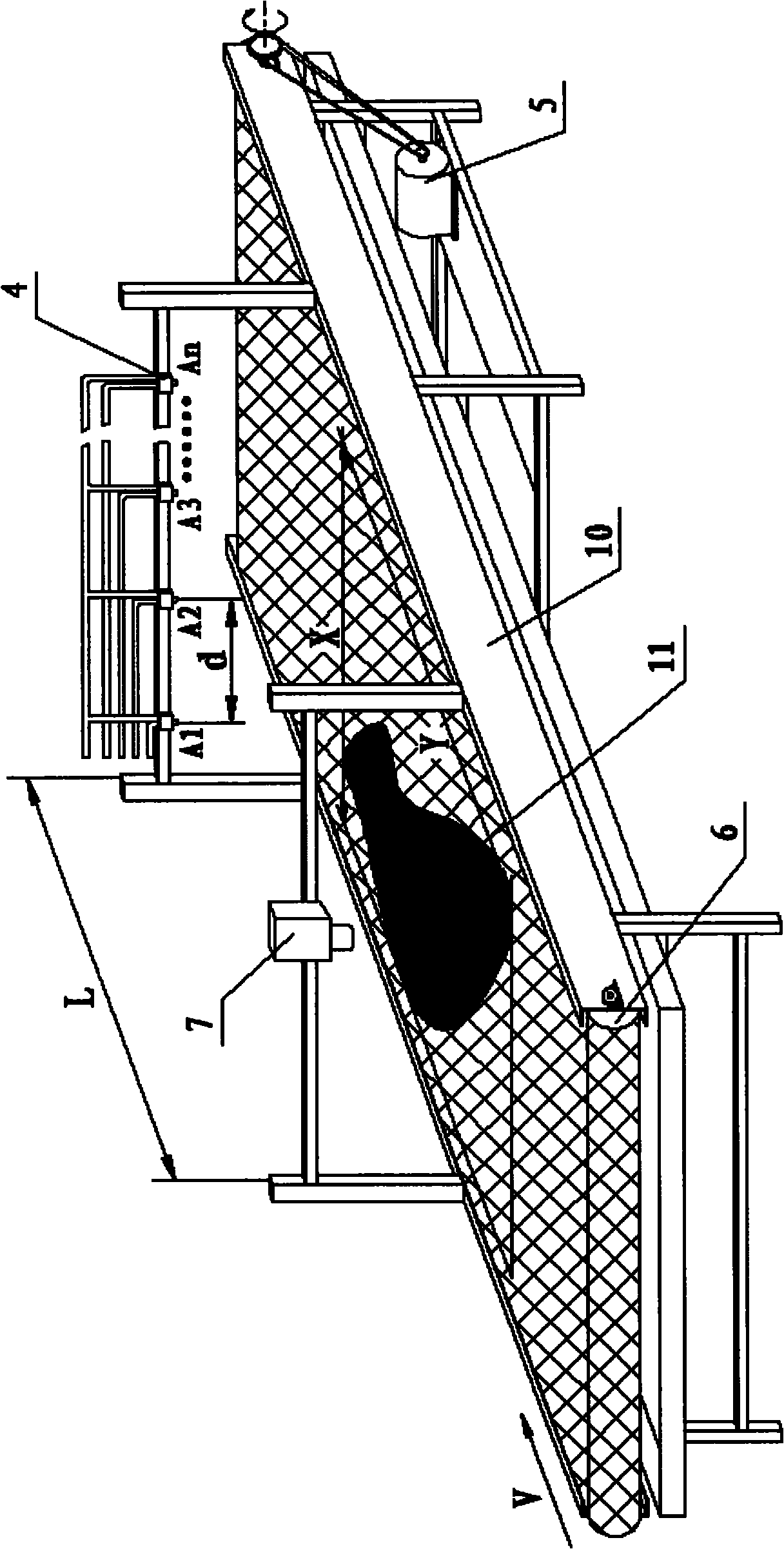

Automatic leather coating machine and automatic coating method

InactiveCN101934257ARealize automatic opening and closingRealize automatic and precise controlSpraying apparatusLeather surface finishingStart timeAutomatic control

The invention discloses an automatic leather coating machine and an automatic coating method. The automatic coating method comprises the following steps: dividing the coating width of the coating machine into a plurality of coating areas, and at least one spray gun is arranged on each coating area; before coating, acquiring shape information of leather to analyze the coating area of the leather, and coating-start time and total coating time of the spray gun of the coating area; and controlling the coating gun in each coating area to coat at the coating-start time, and stopping coating when the total coating time is used up. The machine and the method realize automatic control of leather coating so as to save usage of coating, and flexibly realize systematic control by changing program so as to greatly reduce production cost, improve product quality and production efficiency, and meet the requirement of modern society to environmental protection and safety on industrial production.

Owner:浙江温州轻工研究院

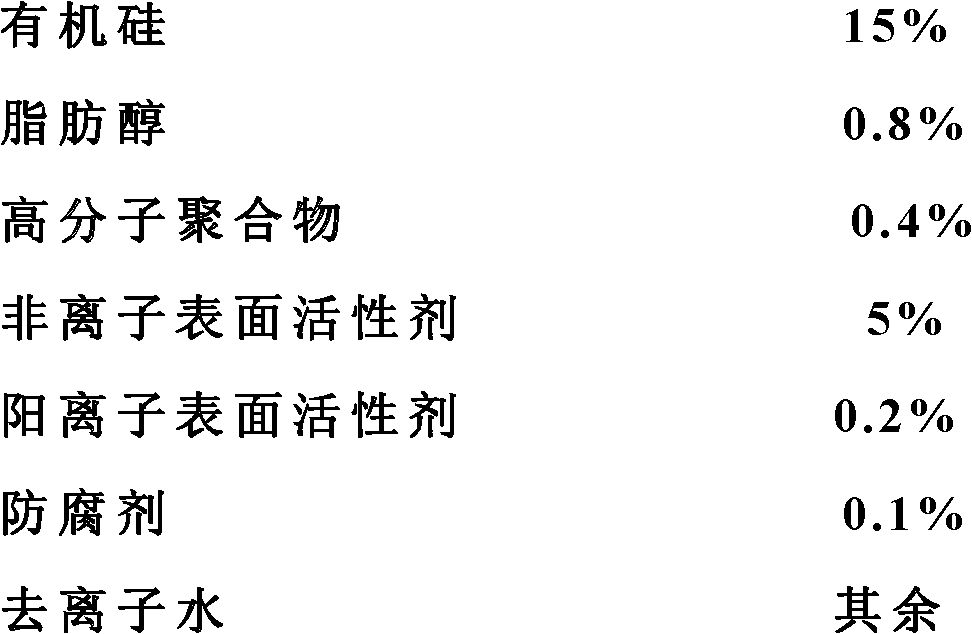

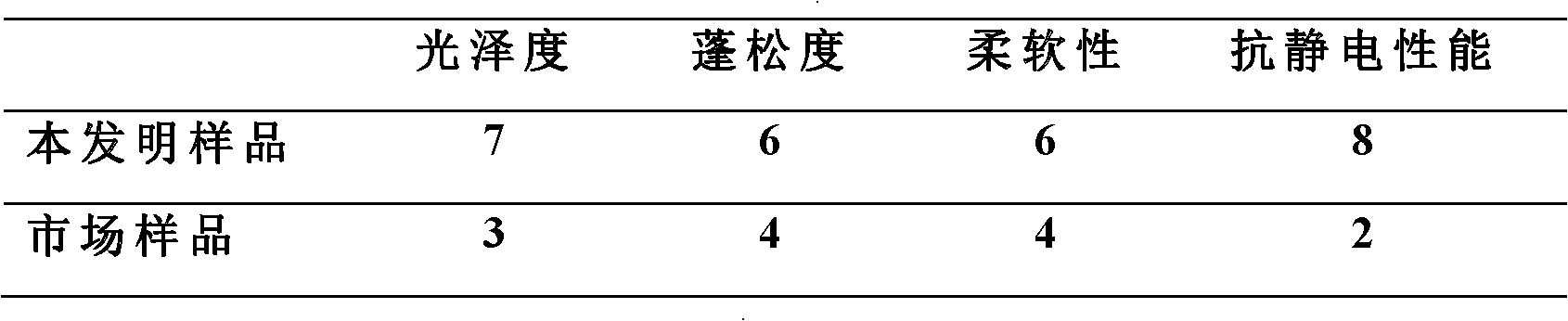

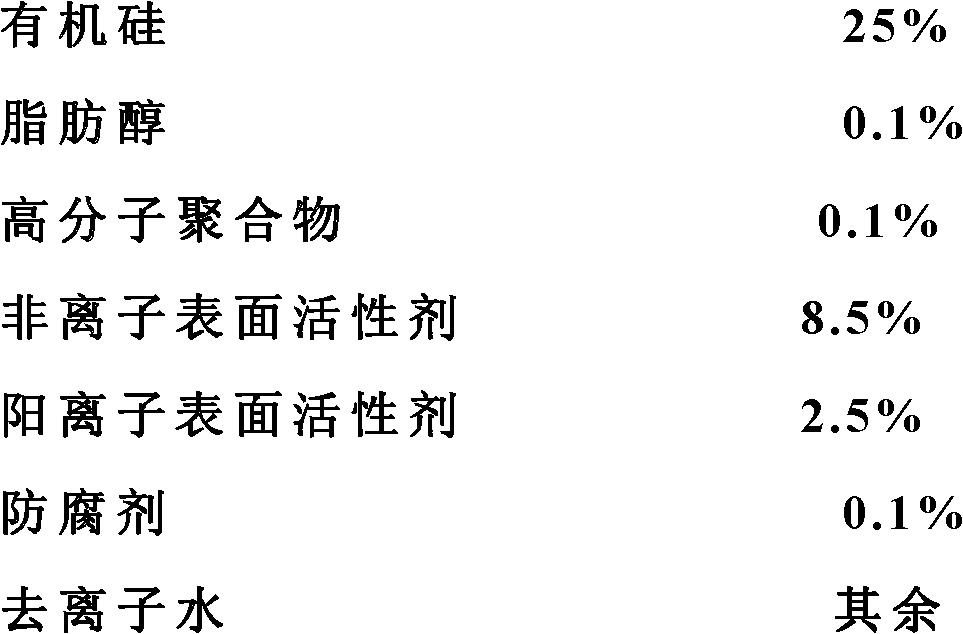

Fur brightener composition and preparation method and application thereof

ActiveCN102634285AHigh glossImprove antistatic performancePolishing compositionsLeather surface finishingPreservativeFatty alcohol

The invention discloses fur brightener composition, which is characterized by comprising, in weight percentage, 5-30% of organosilicone, 0-3% of fatty alcohol, 0.1-3% of high polymer, 1-10% of nonionic surfactant, 0-5% of cathodic or anodic surfactant, 0-1% of preservative and the balance of deionized water. Fur cover treated with the fur brightener composition has well color, looseness, softnessand electrostatic resistance.

Owner:天津泰研科技发展有限公司

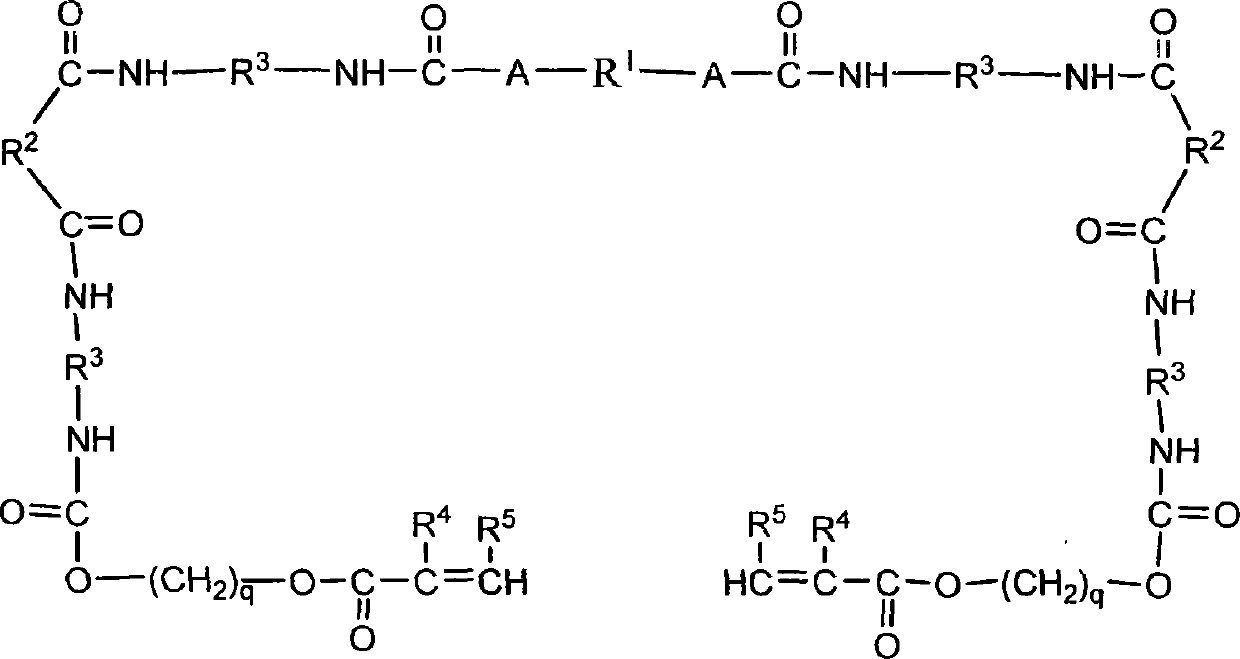

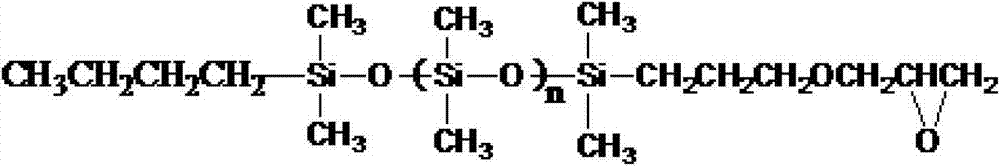

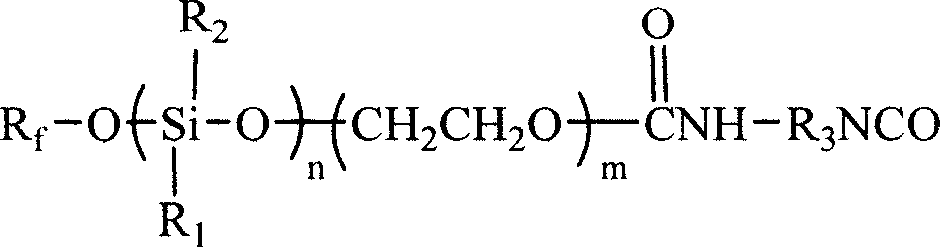

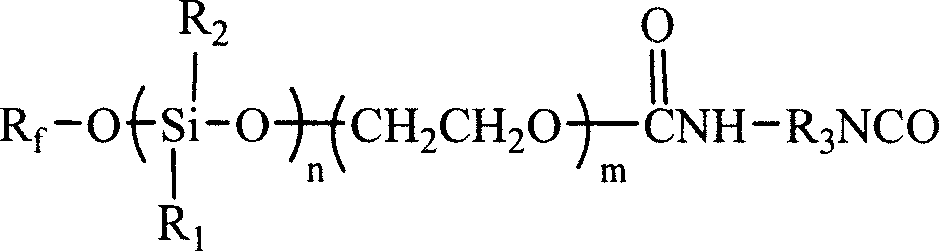

Waterproof, grease proof treating compound of fluorine silicon modified polyurethane, and preparation method

ActiveCN101003946AImprove mechanical stabilityAcid-base stability without limitationFibre typesLeather surface finishingFiberChemical structure

The present invention relates to a fluorosilicone modified polyurethane water-proofing oil-proofing finishing agent and its preparation method. Said invention also provides its chemical structure formula. It is characterized by that it uses perfluor-olefin, hydroxyl silicon oil, epoxyethane and diisocyanate as raw material and makes them undergo the process of synthesis treatment so as to obtain the invented emulsion-fluorosilicone modified polyurethane water-proofing oil-proofing finishing agent.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

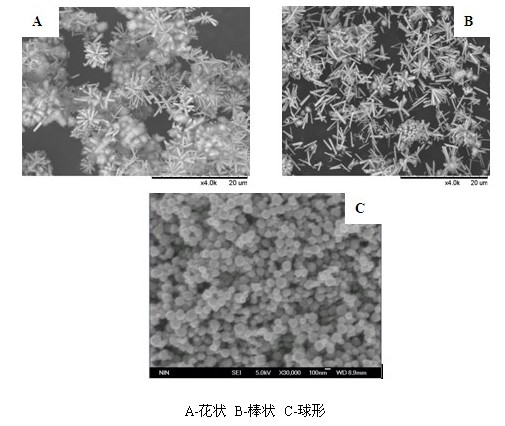

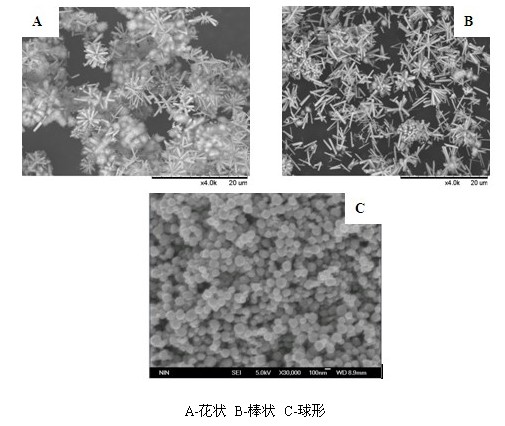

Polyacrylate/nanometer ZnO composite finishing agent and preparation method thereof

ActiveCN102304316ASolve the defect of "hot sticky and cold brittle"Improve water resistanceCoatingsLeather surface finishingPolymer sciencePOLYMER SUBSTANCE

The invention relates to a polyacrylate / nanometer ZnO composite finishing agent suitable for the base coating of clothing leathers, instep leathers and corrected leathers and a preparation method of the polyacrylate / nanometer ZnO composite finishing agent. The polyacrylate / nanometer ZnO composite finishing agent comprises the following raw materials by weight: 22wt%-28wt% of acrylic ester monomer, 2wt%-5wt% of emulsifying agent, 0.4 wt%-0.8 wt% of initiating agent, 0.2wt%-1.5 wt% of nanometer ZnO, 0.6 wt%- 5wt% of water-solubility high polymer materials, and the rest of deionized water. The preparation method comprises the following steps of: firstly, carrying out surface modification on the nanometer ZnO by adopting a water-solubility high molecular polymer, enabling the nanometer ZnO tobe uniformly dispersed in a water solution, then triggering the acrylic ester monomer to polymerize in site, and preparing the polyacrylate / nanometer ZnO composite finishing agent. Compared with the pure polyacrylate emulsion, the polyacrylate / nanometer ZnO composite finishing agent has the advantages that the water tolerance, the elongation at break, the air permeability and the water vapor permeability of a finished leather sample are all substantially increased.

Owner:SHAANXI UNIV OF SCI & TECH

Process for producing leather

ActiveCN102586497ARelieve pressureLow costLeather manufacturingPre-tanning chemical treatmentEngineering

The invention relates to the field of the manufacture of leather and provides a process for producing the leather. The production cost is reduced by changing the formula of the process. The process comprises the following steps of: preparing a crust, milling the crust, toggling, tumbling, trimming, patching, buffing, blowing dust and cleaning, spraying cations, tumbling for the second time, spraying, repairing corners, tumbling for the third time, trimming for the second time, rolling, obtaining G gloss, pressing a plate, spraying for the second time, obtaining water gloss, tumbling for the fourth time, milling for the second time, staking, tumbling for the fifth time, and spraying a handle agent.

Owner:XINGYE LEATHER TECH CO LTD

Self-extinction polyurethane resin and preparation method thereof

ActiveCN104193946AWith matting effectSimple processFibre treatmentPolyurea/polyurethane coatingsCross-linkAlcohol

The invention provides a self-extinction polyurethane resin and a preparation method thereof. The resin is mainly prepared from raw materials such as polyether polyol, isocyanate, dihydric alcohol, crylic acid grafting substances, a hydrophilic chain extender, a cross-linking agent and 5-7 parts of an amino chain extender. According to the self-extinction polyurethane resin provided by the invention, as the crylic acid grafting substances which can absorb light can extinct light in a chemical manner, leather coated with the self-extinction polyurethane resin has the light extinction effect with natural color and gloss, and meanwhile through the addition of the crylic acid grafting substances, the water resistance and the solvent resistance of the self-extinction polyurethane resin are greatly improved.

Owner:SHANDONG TIANQING TECH DEV

Color harmonization coatings for articles of manufacture comprising different substrate materials

Color harmonization is provided for articles of manufacture comprising different substrate materials. A coating composition is selected that can be applied to the different substrate materials while maintaining substantially uniform visual characteristics of the article. The substrates may include flexible materials such as natural leather, synthetic leather, vinyl, foam, textiles and the like. Examples of articles of manufacture include footwear, automotive upholstery and automotive interiors.

Owner:PPG IND OHIO INC

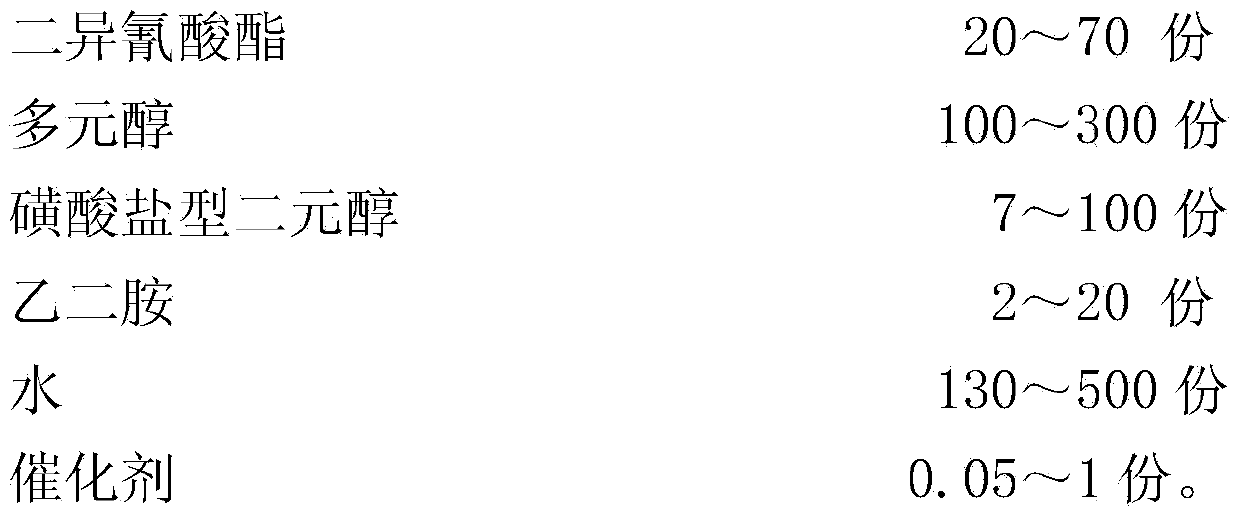

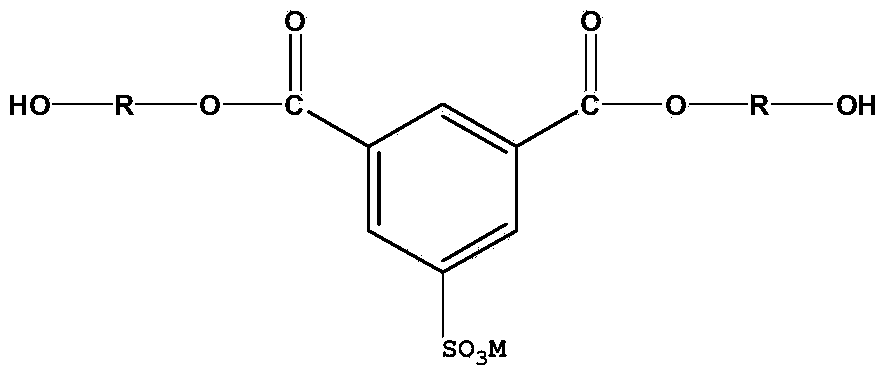

Sulfonate type water-based polyurethane emulsion and preparation method thereof

InactiveCN103626953AOmit the step of neutralization and salt formationSimple stepsPolyureas/polyurethane adhesivesPolyurea/polyurethane coatingsEthylenediamineWater based

The invention belongs to the technical field of water-based polyurethane emulsion, and discloses a sulfonate type water-based polyurethane emulsion and a preparation method thereof. The sulfonate type water-based polyurethane emulsion comprises the following components in parts by mass: 20-70 parts of diisocyanate, 100-300 parts of polyol, 7-100 parts of sulfonate type dihydric alcohol, 2-20 parts of ethylenediamine, 130-500 parts of water and 0.05-1 part of catalyst. The synthesis method disclosed by the invention is simple and environment-friendly and has relatively low cost; by adopting the method, the emulsion with high solid content is easy to prepare, and the prepared emulsion has good stability; an adhesive film has relatively good water resistance and heat resistance. The emulsion disclosed by the invention can be used as a coating, an adhesive, a leather finishing agent and the like, and has broad application prospects.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com