Patents

Literature

96 results about "Color loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aqueous compositions comprising polymeric duller particle

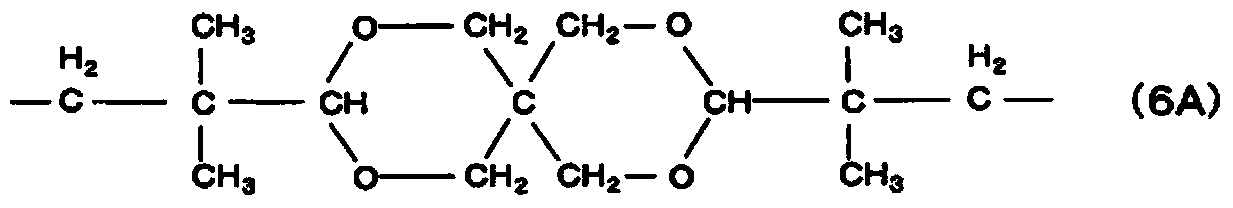

ActiveUS7829626B2Limit scopeImprove consistencyLiquid surface applicatorsLayered productsSingle stageTert-butyl acrylate

The present invention provides aqueous matte coating compositions comprising a binder component B) and a polymeric duller component A) composed of particles of one or more multi-stage copolymer or single stage crosslinked (co)polymer, e.g. crosslinked t-butyl (meth)acrylate, the duller component particles A) having an average diameter of 1-20 μm. Components A) and B) are compatible. Preferably, the duller component A) is acrylic; more preferably, components A) and B) are acrylic. The aqueous compositions provide matte coatings having haptic or feel (soft touch) properties, film and appearance properties, including burnish resistance and low color loss.

Owner:ROHM & HAAS CO

Aqueous compositions comprising polymeric duller particle

ActiveUS20070218291A1Improve clarityGood “hand feel”Liquid surface applicatorsLayered productsMeth-Single stage

The present invention provides aqueous matte coating compositions comprising a binder component B) and a polymeric duller component A) composed of particles of one or more multi-stage copolymer or single stage crosslinked (co)polymer, e.g. crosslinked t-butyl (meth)acrylate, the duller component particles A) having an average diameter of 1-20 μm. Components A) and B) are compatible. Preferably, the duller component A) is acrylic; more preferably, components A) and B) are acrylic. The aqueous compositions provide matte coatings having haptic or feel (soft touch) properties, film and appearance properties, including burnish resistance and low color loss.

Owner:ROHM & HAAS CO

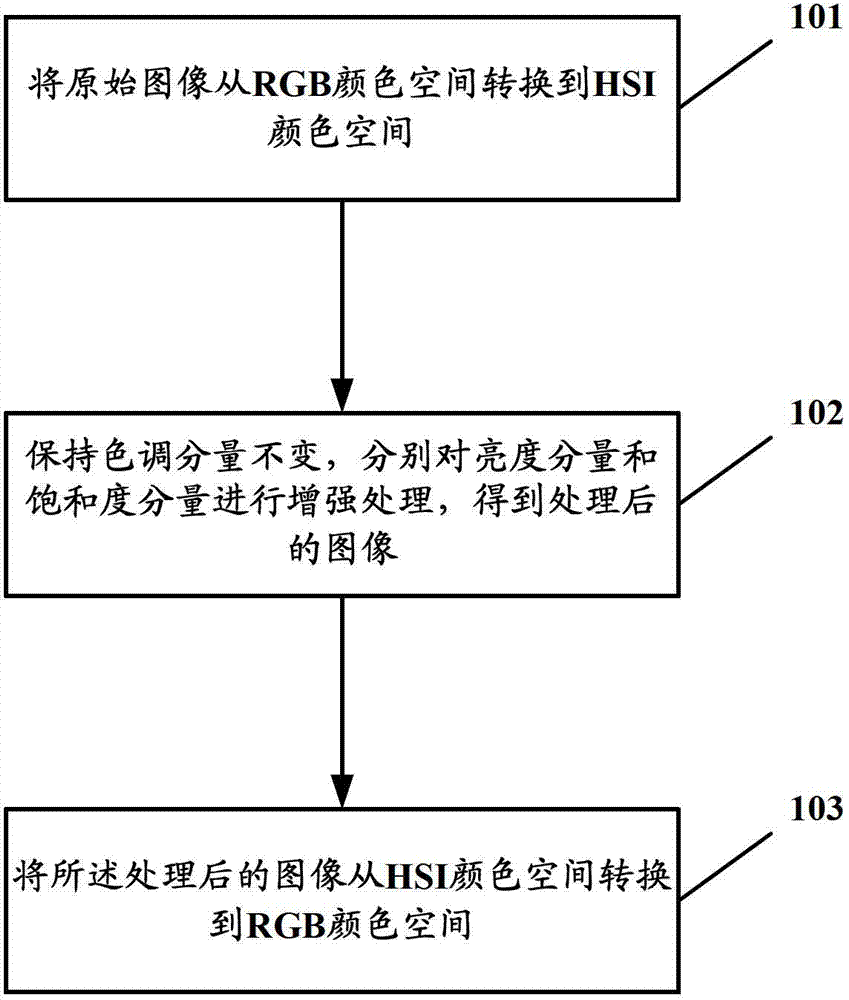

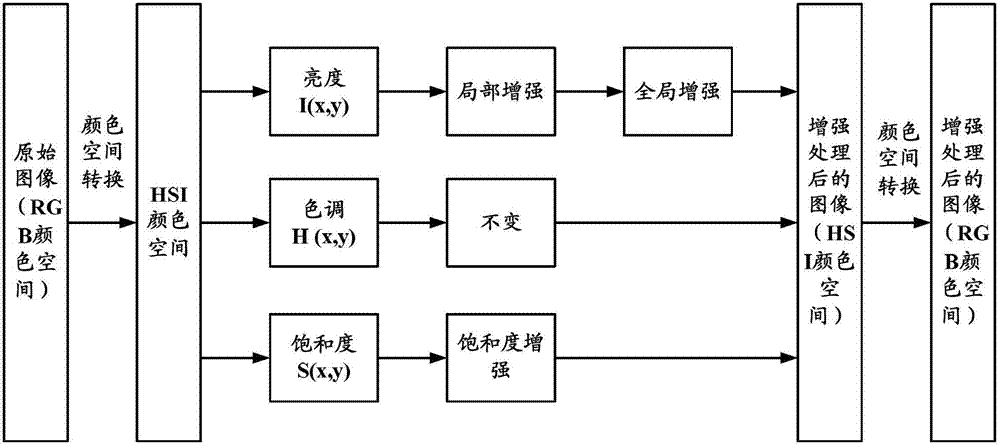

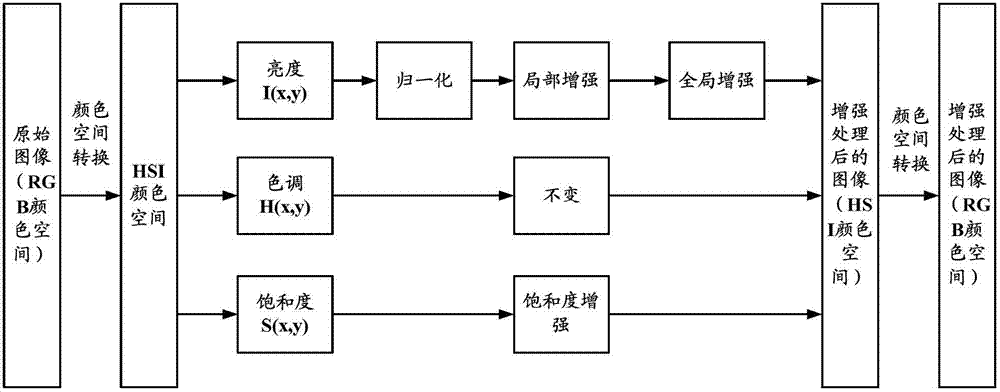

Image reinforcement method, image reinforcement device and display device

InactiveCN102779330ASuitable for visual characteristicsAvoid the defect of color lossImage enhancementPictoral communicationDisplay deviceHue

The invention provides an image reinforcement method, an image reinforcement device and a display device. The image reinforcement method comprises the steps of: converting an original image from a RGB (red-green-blue) color space into an HIS (Hue-Saturation-Intensity) color space; maintaining the tone component, and respectively performing reinforcement processing on the brightness component and the saturation level component to obtain a processed image; and converting the processed image from the HIS color space into the RGB color space. The image reinforcement method provided by the invention converts the image from the RGB color space into the HIS color space to perform the reinforcement processing so as to avoid the defect of color loss.

Owner:BOE TECH GRP CO LTD +1

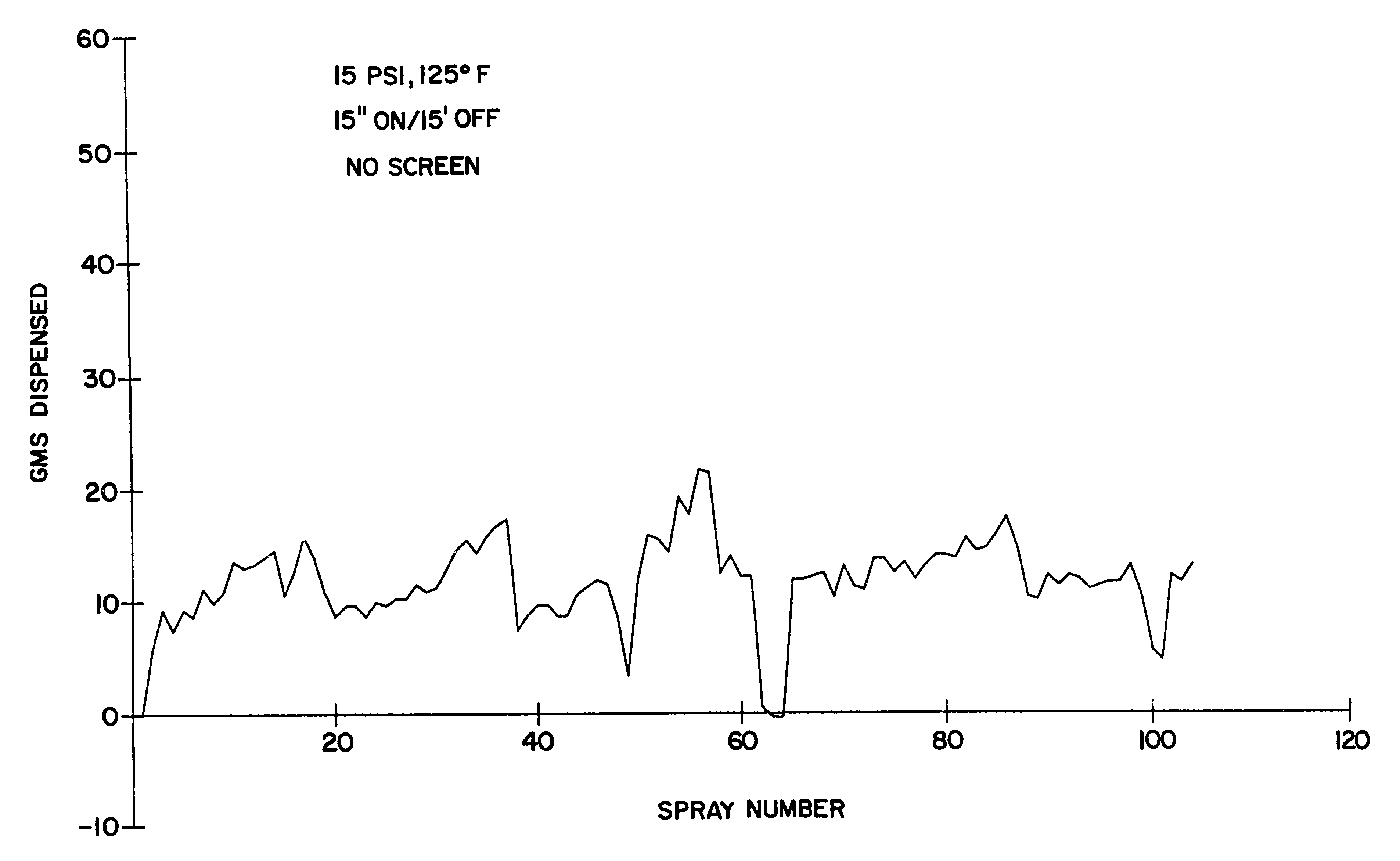

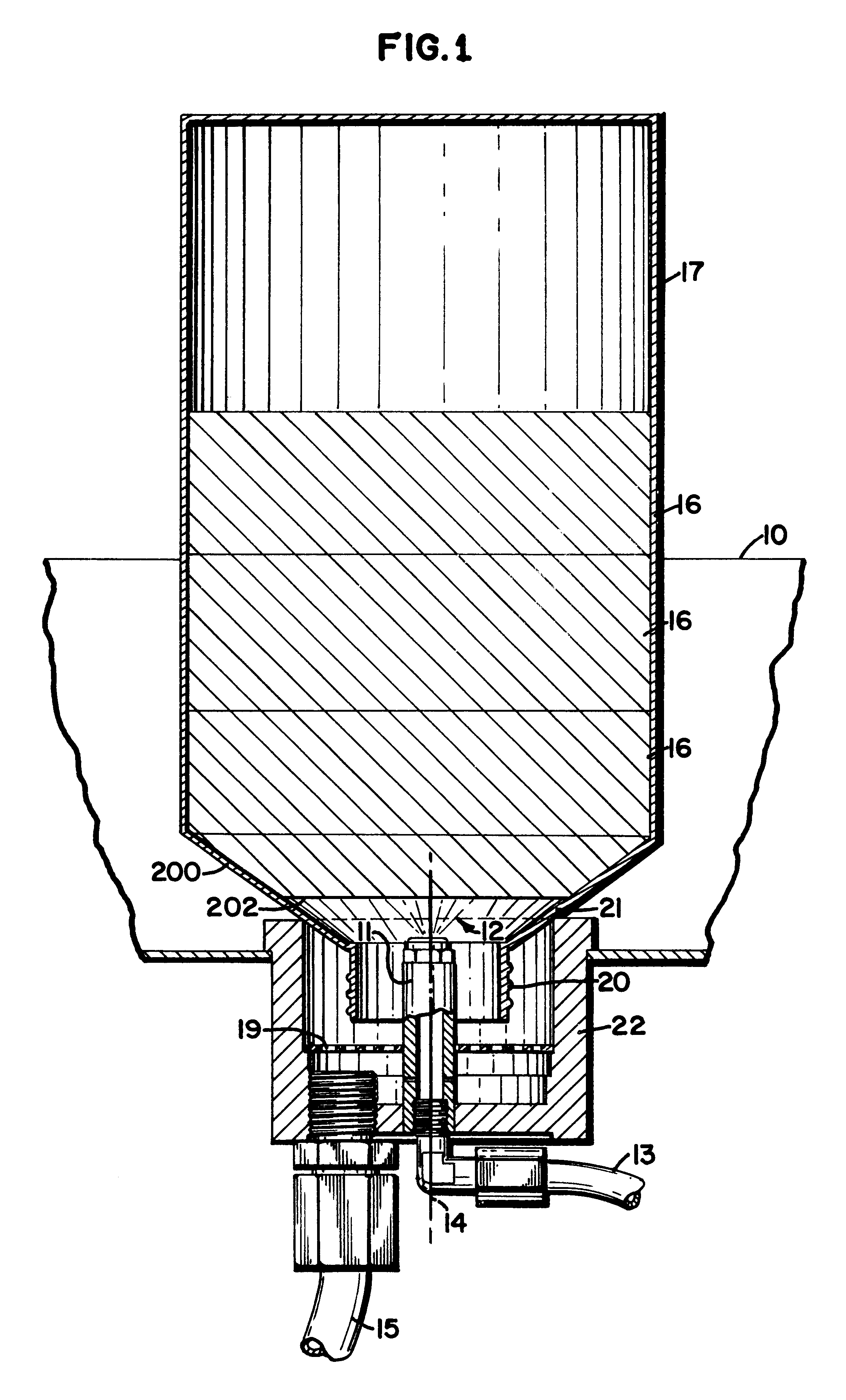

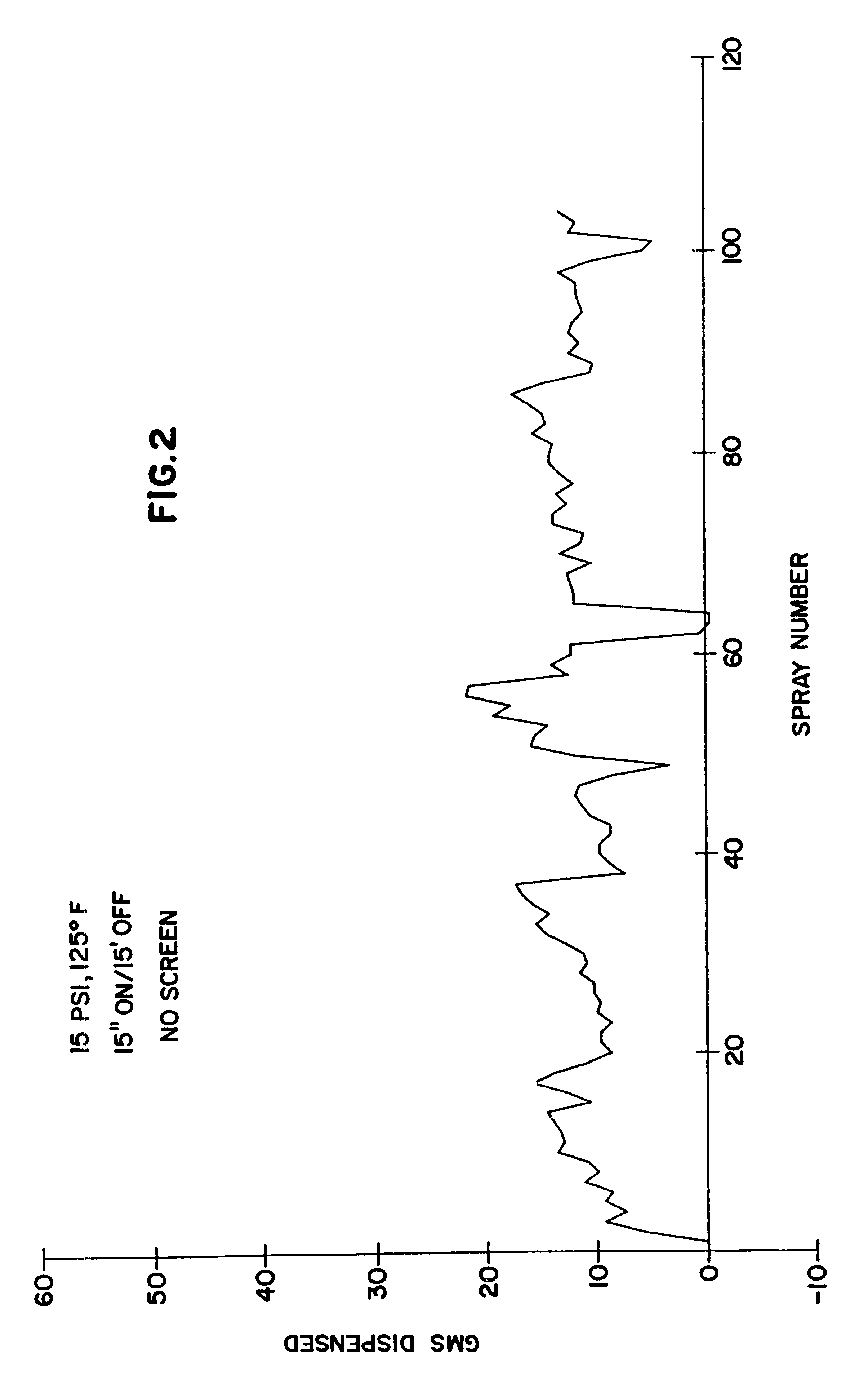

Shaped solid comprising oxidant bleach with encapsulate source of bleach

InactiveUS6589443B1Trend downReduce harmful effectsOxygen/ozone/oxide/hydroxideOther chemical processesParticulatesBrick

Aqueous bleach solutions can be made by directing a spray of water onto a bulk or shaped solid (brick, tablet, block, etc.) comprising a continuous solid phase of an encapsulated source of an active halogen bleach or a solid comprising a source of an oxidizing active halogen bleach, and an encapsulated oxidizing halogen bleach source. Such shaped solids can be used to dispense uniform quantities of an aqueous bleach concentrate to bleaching locus such as a washing machine. The tablets can be made from the encapsulated bleach or from a powder mixture of a particulate, granulated or powdered unencapsulated source of active oxidizing bleach and an encapsulated source of active oxidizing bleach by forming the powder mixture into a desired shape. Such a shaped solid bleach can be packaged in a container and can then be contacted with an aqueous spray in a dispenser to create a solution of active bleach for cleaning bleaching processes. The presence of the encapsulate in the solid with the powder reduces the tendency of the solid to absorb water which can be wicked through the solid to pass water through the solid into adjacent solids. Substantial proportions of absorbed water can cause the tablets to crack, crumble and to periodically dispense uneven, substantially large and undesirable concentrations of active bleach into a wash or bleach cycle. Such large amounts of halogen can cause corrosion of metal machine or dispenser parts, clothing damage, can cause pinholing or other fabric damage, can result in color loss or change, or can result in other undesirable effects in either the dispenser, washing machine or the cleaned item.

Owner:ECOLAB USA INC

Macromolecule color masterbatch and preparation method thereof

The invention discloses a macromolecule color masterbatch which is composed of the following components in percentage by weight: a, 30-60% of carrier resin, b, 5-15% of pigment, c, 4-8% of dispersed lubricant, d, 1-3% of compatilizer and e, 15-25% of other additives. The component e comprises an antistatic agent, a protective agent, a heat stabilizer and an antibacterial agent. The preparation method comprises the following steps of: mixing each component in proportion and placing the mixture in a high-speed mixer; secondly, mixing for 5-20 minutes at the rotate speed of 1000-1500r / min (revolutions per minute); thirdly, carrying out melt blending by adopting a double-screw extruder or an internal mixer as the temperature is at 150-250 DEG C; and fourthly, shearing and mixing by a screw or a rotor as the rotate speed of the screw is 80-300r / min, finally extruding in the extruder, cooling, drying and pelleting to prepare the color masterbatch. The macromolecule color masterbatch has the advantages of anti-static electricity, invariant color, no color loss and uniform color and luster, and the process is clean and environmentally-friendly.

Owner:胡君

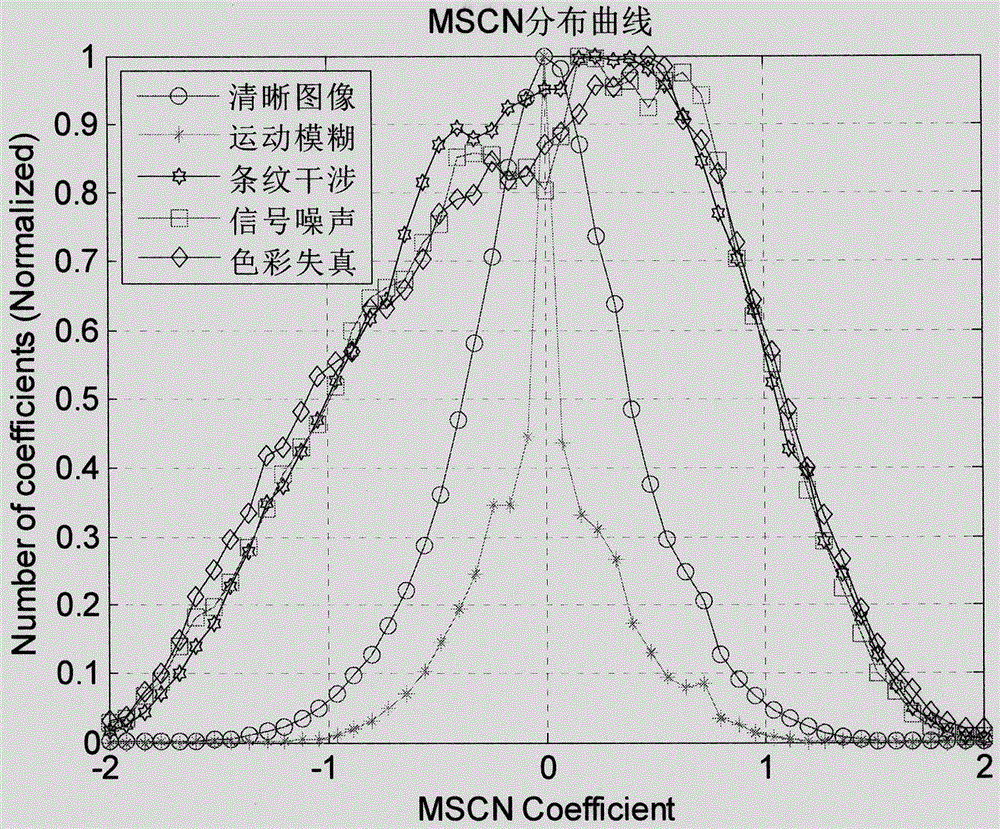

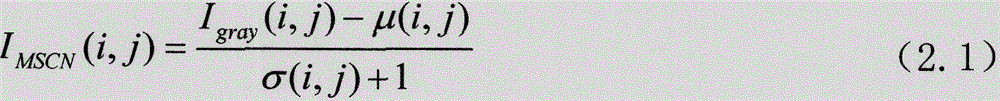

Quality blind evaluation method for unmanned aerial vehicle image

InactiveCN106447646ASolve the problem of lack of training set for blind evaluationEase of evaluationImage analysisGaussian beamImaging quality

The present invention relates to a quality blind evaluation method for an unmanned aerial vehicle image. The method comprises the steps: S1, obtaining an unmanned aerial vehicle image, and performing analysis at three aspects of the image information structure character, the image information integrity and the image information color character; constructing the corresponding quality evaluation measurement; and constructing a standard MVG model by employing a multi-Gaussian beam model, and finally obtaining the quality equal division of the whole image by employing a mean value method. On the basis of comprehensively analyzing the classic no-reference image quality evaluation method and unmanned aerial vehicle image features, aiming at the unmanned aerial vehicle image multi-distortion and mixture problem, the quality blind evaluation method for an unmanned aerial vehicle image extracts three types of quality feature factor sets capable of showing the unmanned aerial vehicle image multi-distortion scenes for perception expression for three types of main distortion of information entropy integrity, structure information changing and color loss.

Owner:中国人民解放军陆军军官学院

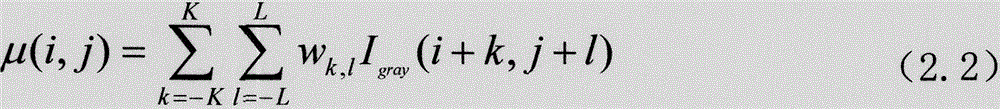

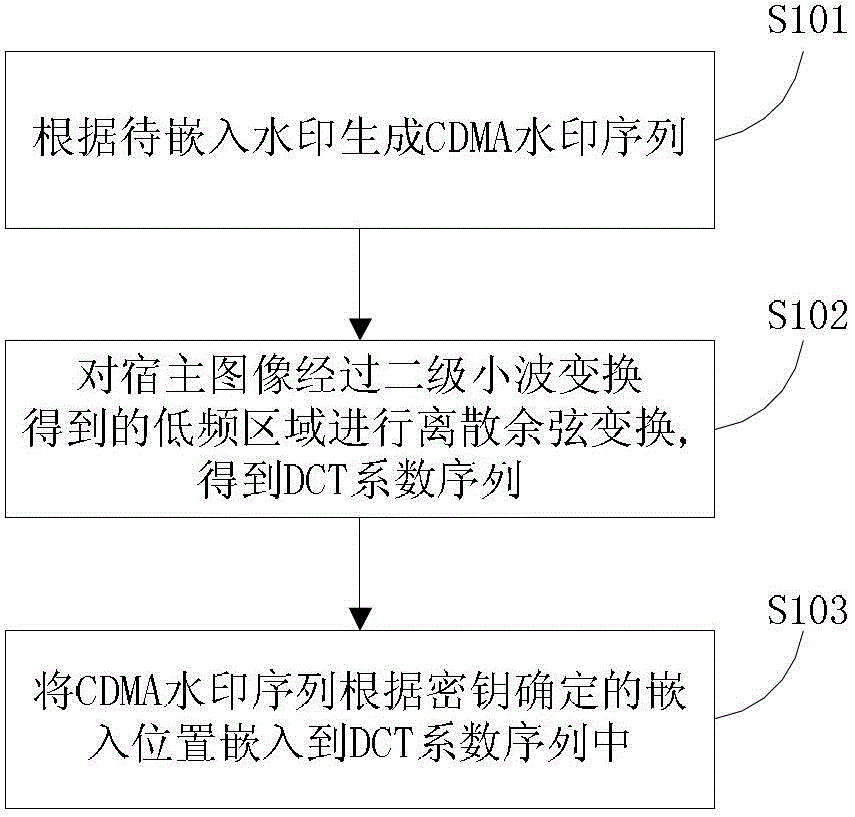

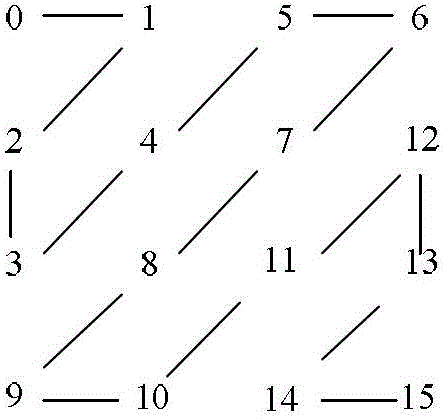

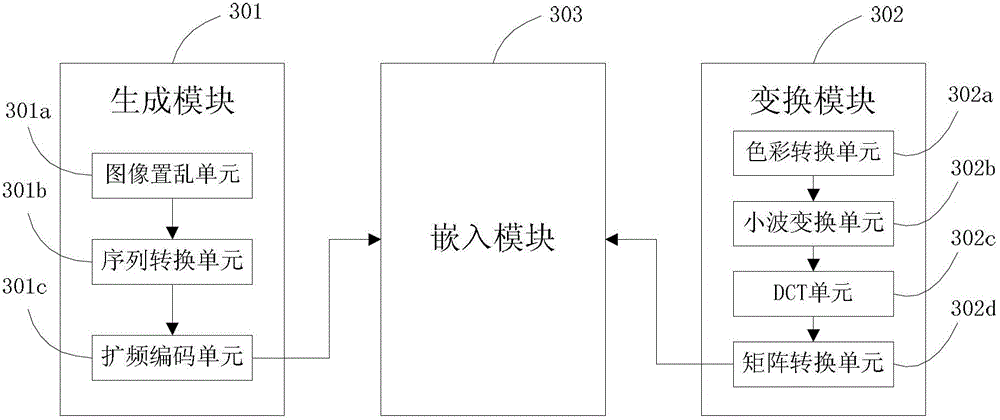

Method and device for embedding and extracting digital watermarking

ActiveCN102750660ANo lossImprove robustnessImage data processing detailsPattern recognitionLab color space

The invention discloses a method and device for embedding and extracting digital watermarking. The method comprises the steps of: conducting discrete cosine transform (DCT) to a low-frequency area obtained by generating a CDMA (Code Division Multiple Access) watermarking sequence and carrying out discrete wavelet transform (DWT) to a host image; embedding the CDMA watermarking sequence into a medium-high frequency DCT coefficient sequence determined by a secret key. No color loss can be ensured in color mode translation by embedding watermarking in the LAB color space of the image, the robustness and invisibility of the watermarking can be improved by adding watermarking onto the DWT and DCT transformed coefficient of the image, and the capacity of the watermarking can be increased through the CDMA coding technique.

Owner:京北方信息技术股份有限公司

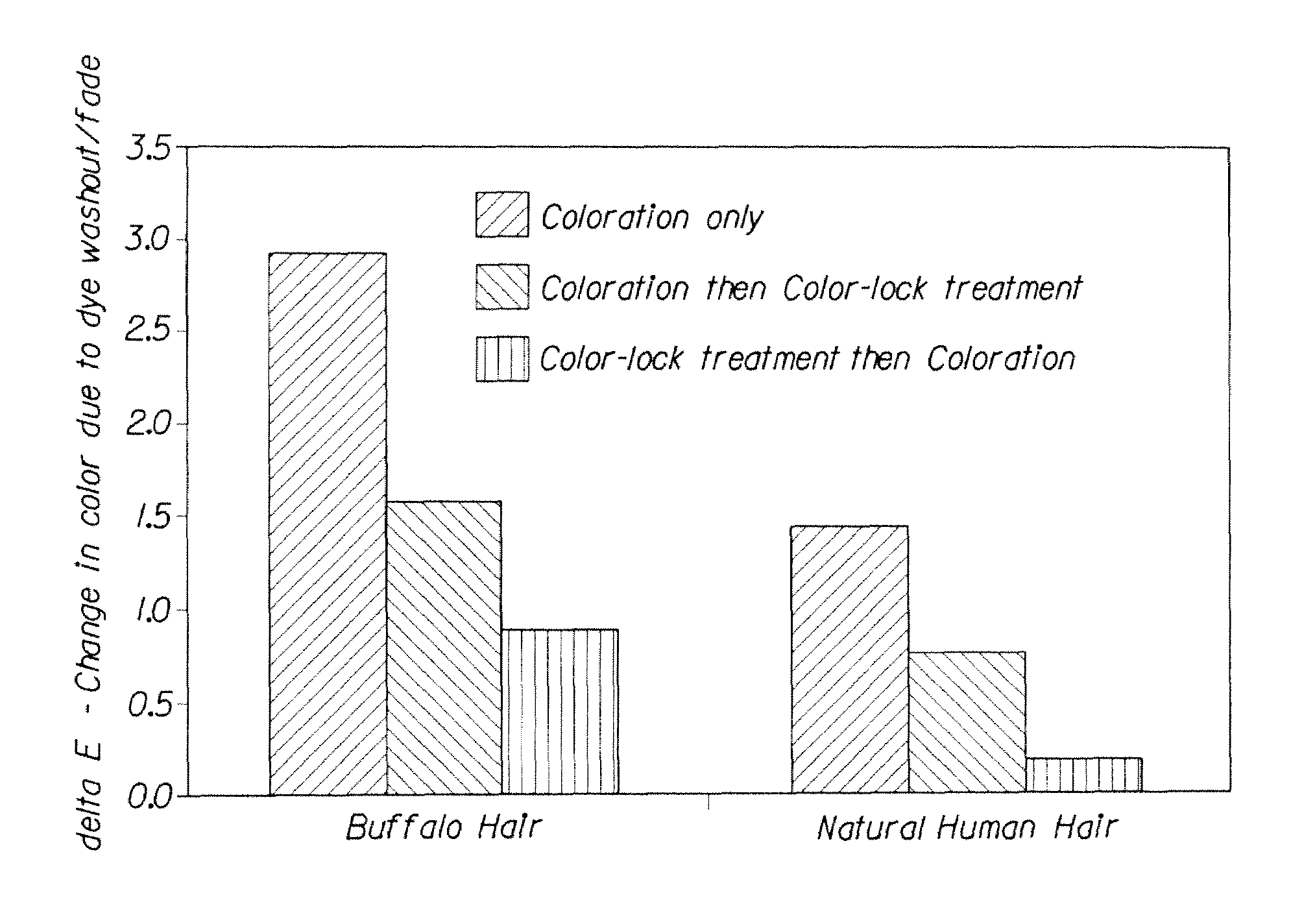

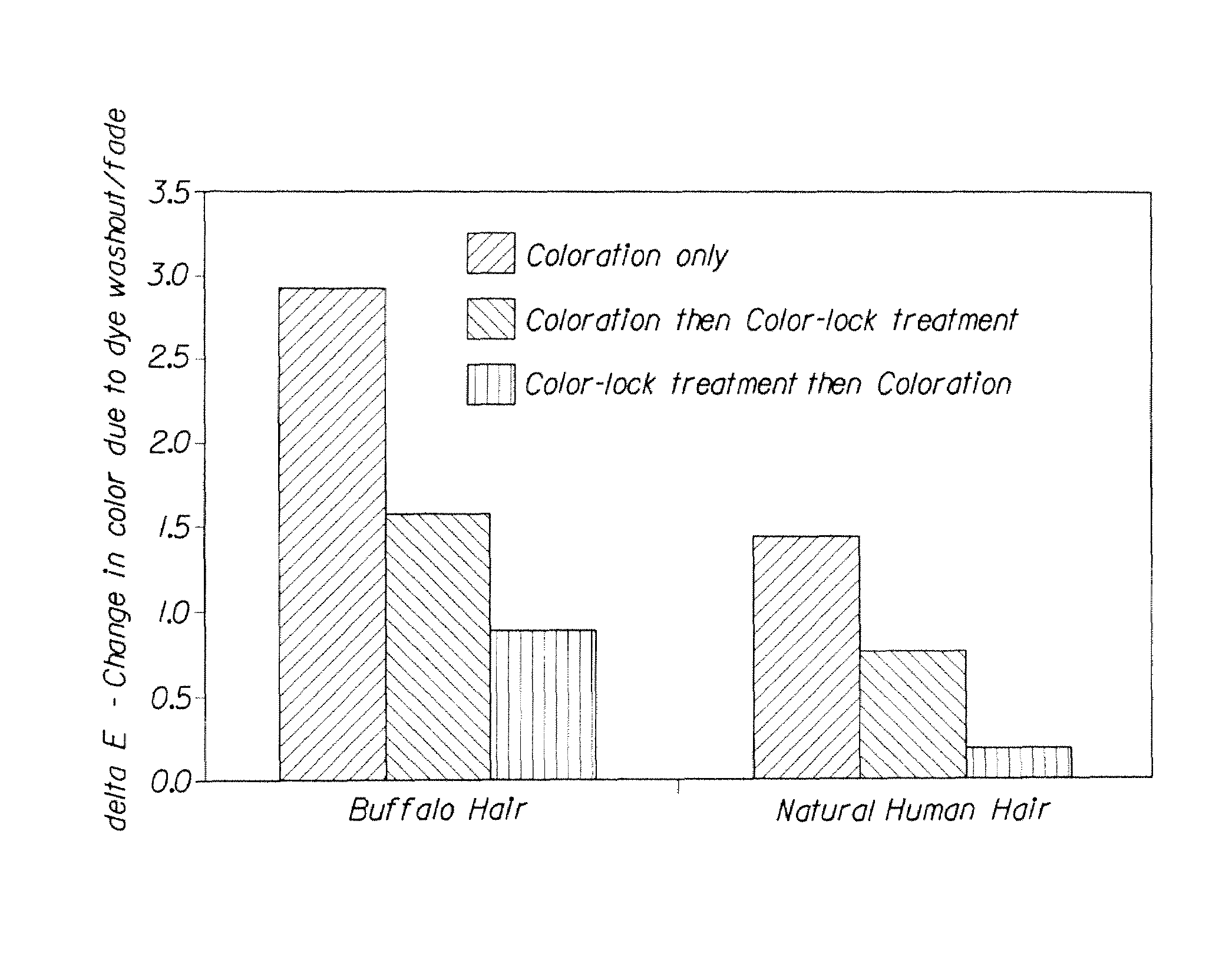

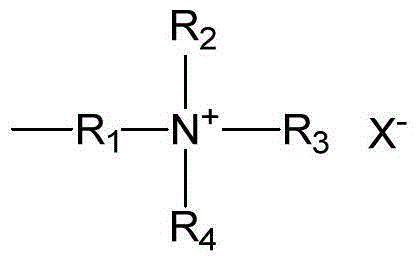

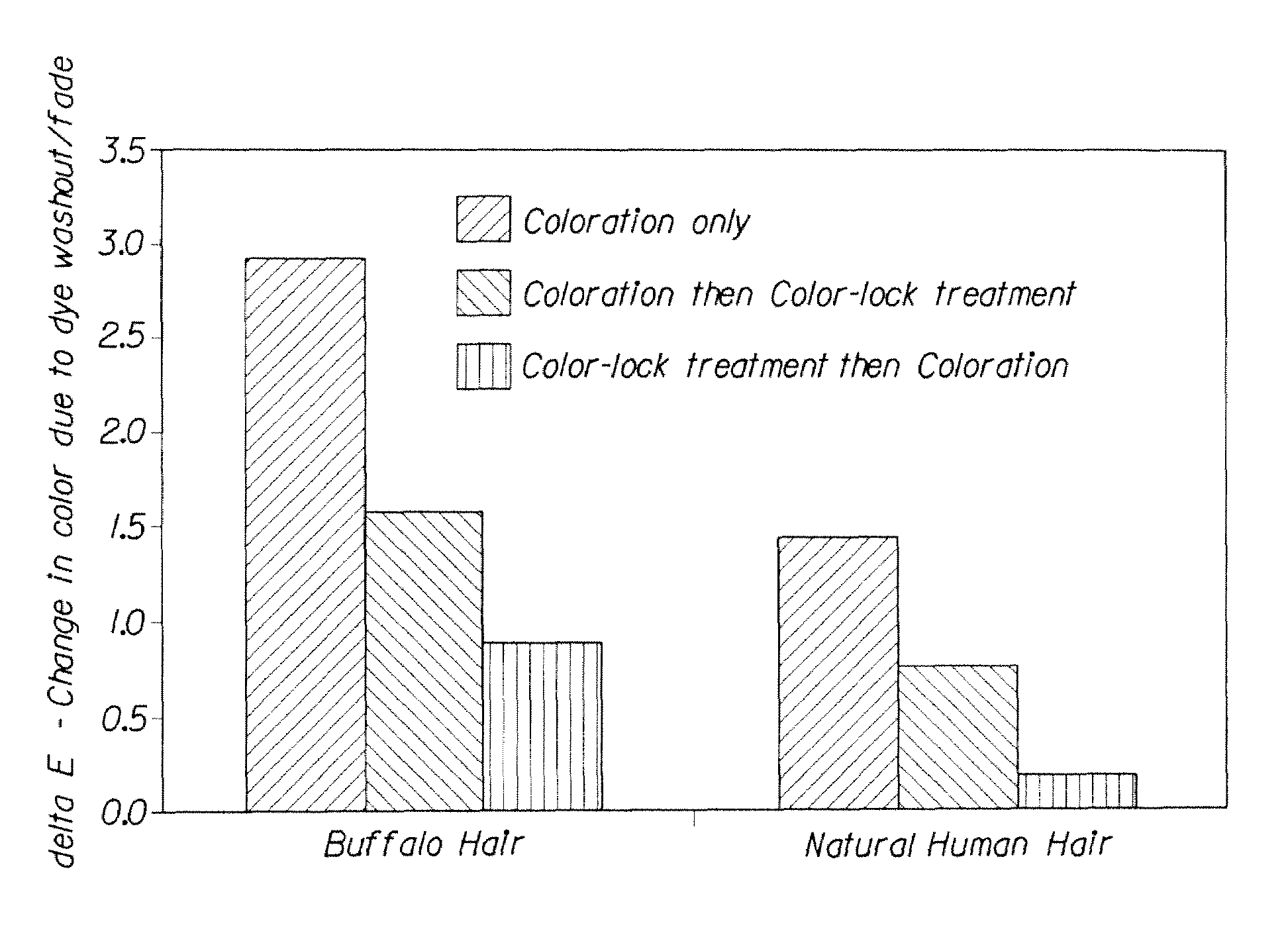

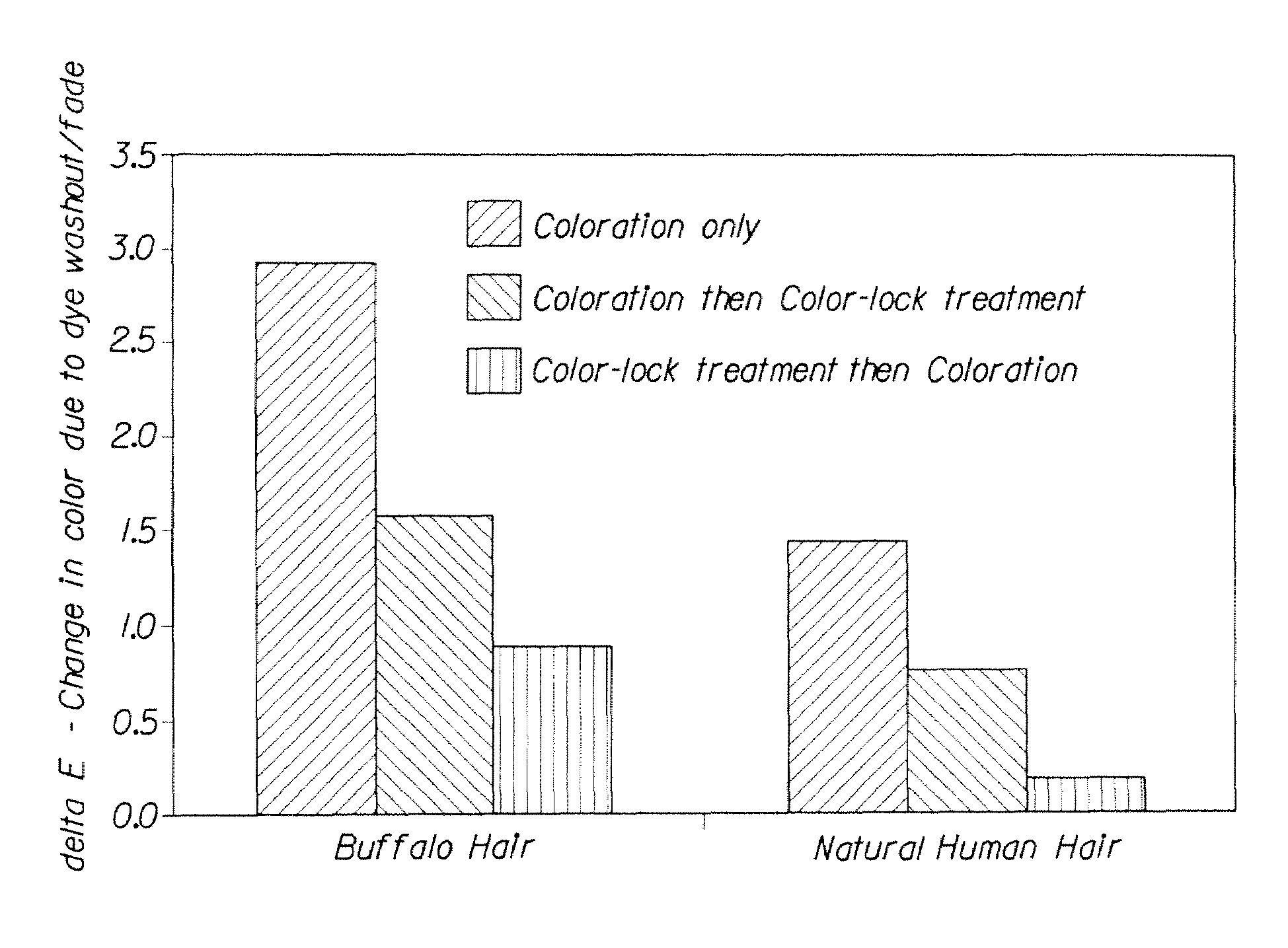

Composition and process for coloring hair

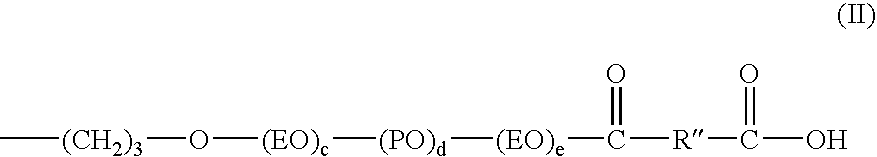

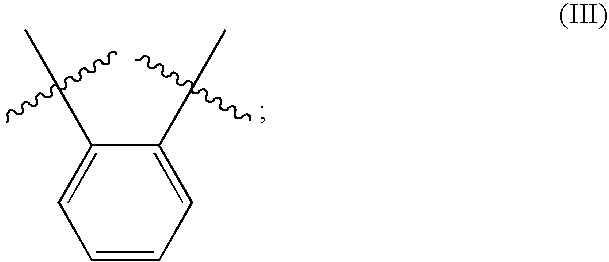

A composition, kit and process for dyeing hair fibers in a manner which inhibits color loss during subsequent shampooing involving contacting the hair fibers with a composition containing: (a) at least one polyamine having at least two amino groups; (b) at least one anionic silicone; and (c) at least one dye component chosen from a direct dye and an oxidation dye, and wherein the dyed hair fibers inhibit color loss resulting from subsequent shampooing of the dyed hair fibers.

Owner:LOREAL SA

Composition and process for coloring hair

A composition, kit and process for dyeing hair fibers in a manner which inhibits color loss during subsequent shampooing involving contacting the hair fibers with a composition containing: (a) at least one polyamine having at least two amino groups; (b) at least one anionic silicone; and (c) at least one dye component chosen from a direct dye and an oxidation dye, and wherein the dyed hair fibers inhibit color loss resulting from subsequent shampooing of the dyed hair fibers.

Owner:LOREAL SA

Process for styling dyed hair and inhibiting its color loss during shampooing

A process for styling dyed hair fibers in a manner which inhibits subsequent color loss during shampooing involving contacting the dyed hair fibers with a composition containing: (a) at least one polyamine compound having at least two amino groups; (b) at least one anionic silicone; (c) at least one film-forming polymer; and (d) optionally, at least one surfactant, and wherein (a) is present in the composition in an amount sufficient to inhibit color loss during shampooing.

Owner:LOREAL SA

Process for styling dyed hair and inhibiting its color loss during shampooing

A process for styling dyed hair fibers in a manner which inhibits subsequent color loss during shampooing involving contacting the dyed hair fibers with a composition containing: (a) at least one polyamine compound having at least two amino groups; (b) at least one anionic silicone; (c) at least one film-forming polymer; and (d) optionally, at least one surfactant, and wherein (a) is present in the composition in an amount sufficient to inhibit color loss during shampooing.

Owner:LOREAL SA

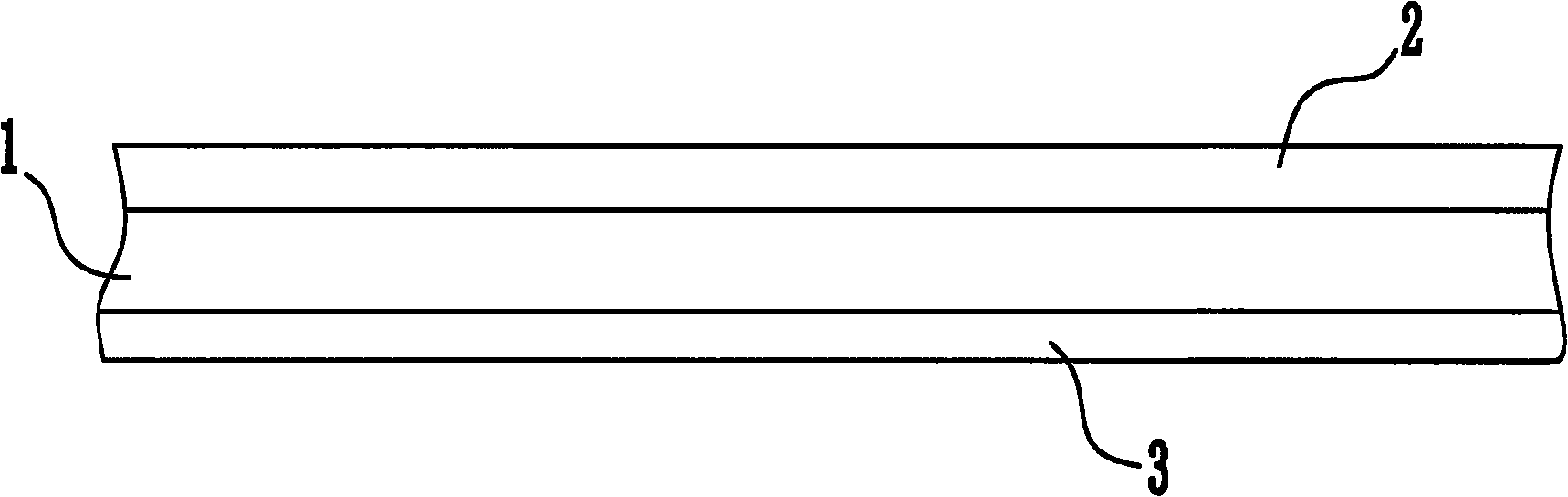

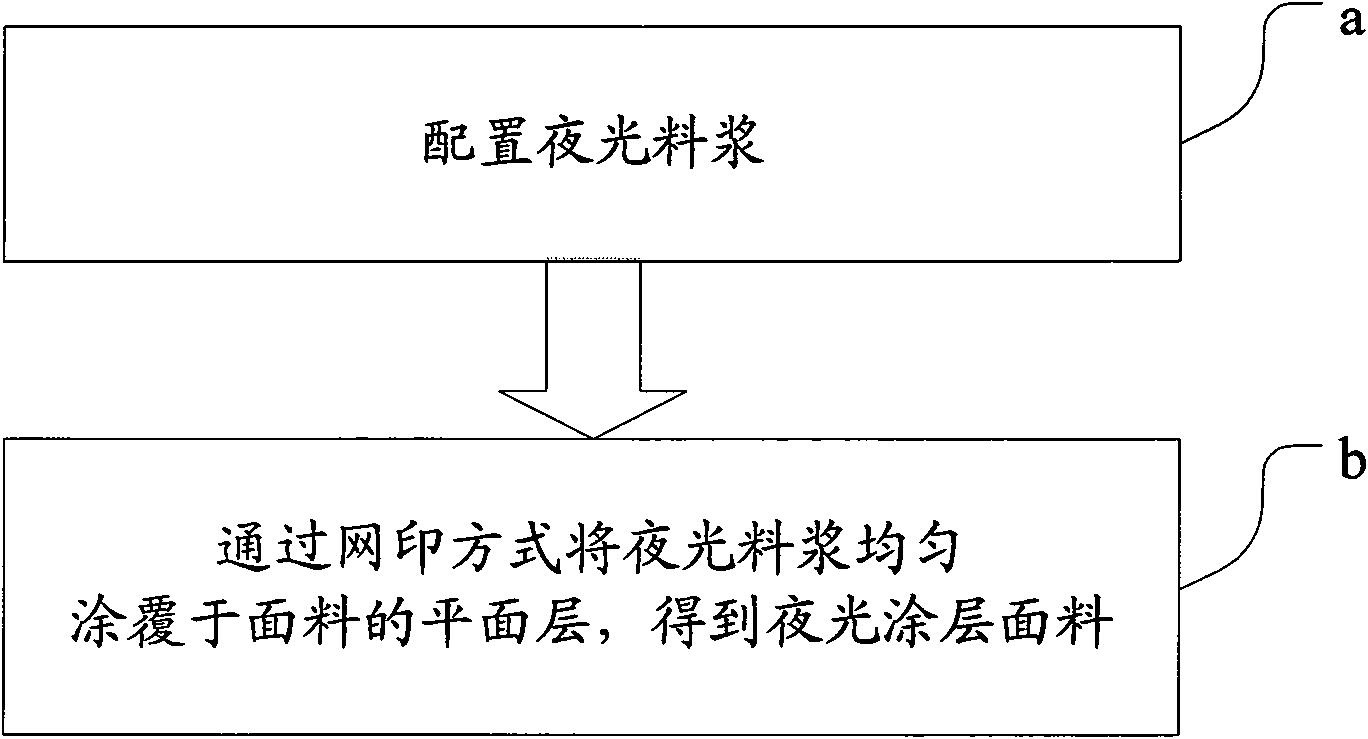

Luminous coating fabric and processing method thereof

The invention discloses luminous coating fabric and a processing method thereof. The method comprises the following steps of: a, preparing luminous slurry: adding 30 to 40 percent luminous powder solvent into 60 to 70 percent inorganic pigment hydrosol, stirring the mixture uniformly, then adding 50 percent color fixing agent, 10 percent stabilizing agent, 15 percent thickening agent and 15 percent softening agent into the mixture in turn for harmonious blending, and stirring the mixture for 1 to 2 hours; and b, uniformly coating the luminous slurry on the plane layer of fabric in a screen printing mode, and then thermally baking the fabric at the temperature of between 130 and 150 DEG C and the row speed of 35 to 40 meters per minute to obtain the luminous coating fabric. Compared with the prior art, because the luminous powder is dyed on the fabric in the screen printing mode, the luminous coating fabric provided by the invention has the advantages of good air permeability, good handfeel, fading resistance, color loss resistance, cleaning property and the like; the processed fabric has no essential difference compared with the fabric before processing, so the texture of the fabric is not affected; and the processed fabric has no toxicity, harm or radioactivity, can be continuously luminous for over 10 hours in dark, can be infinitely recycled, and has stable luminous performance.

Owner:顾军

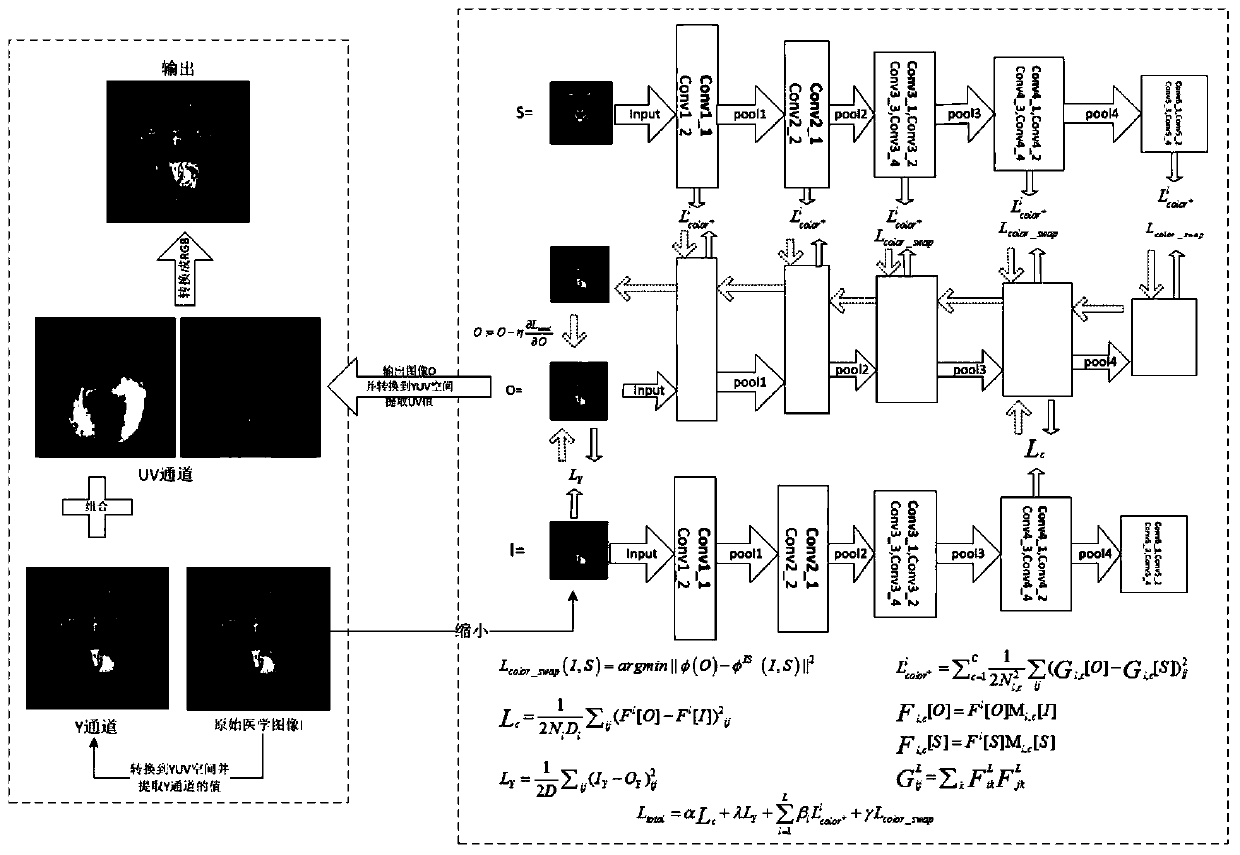

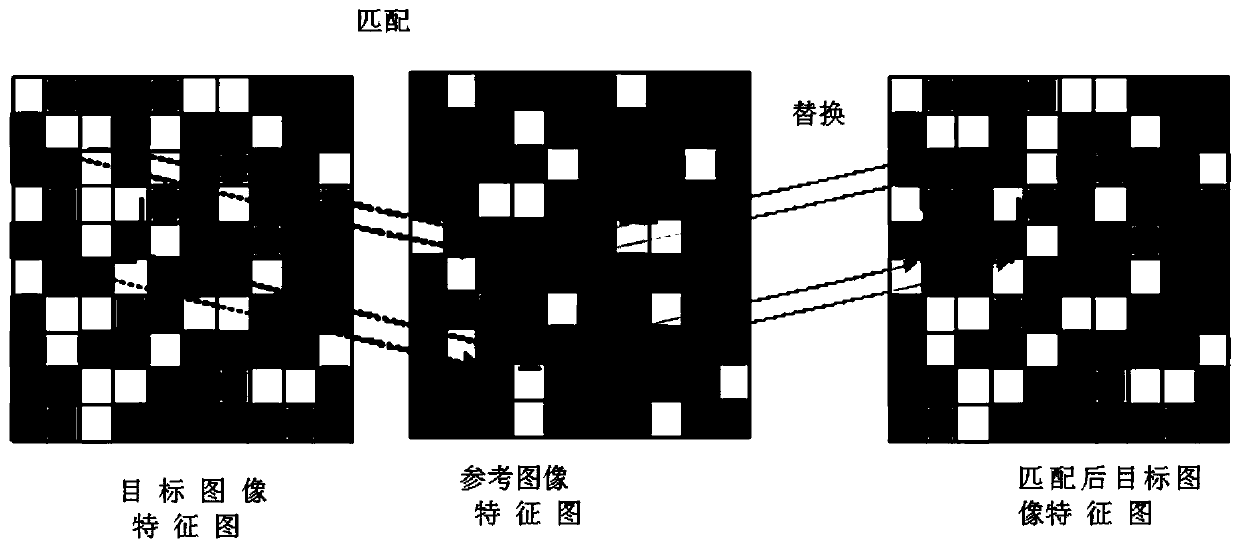

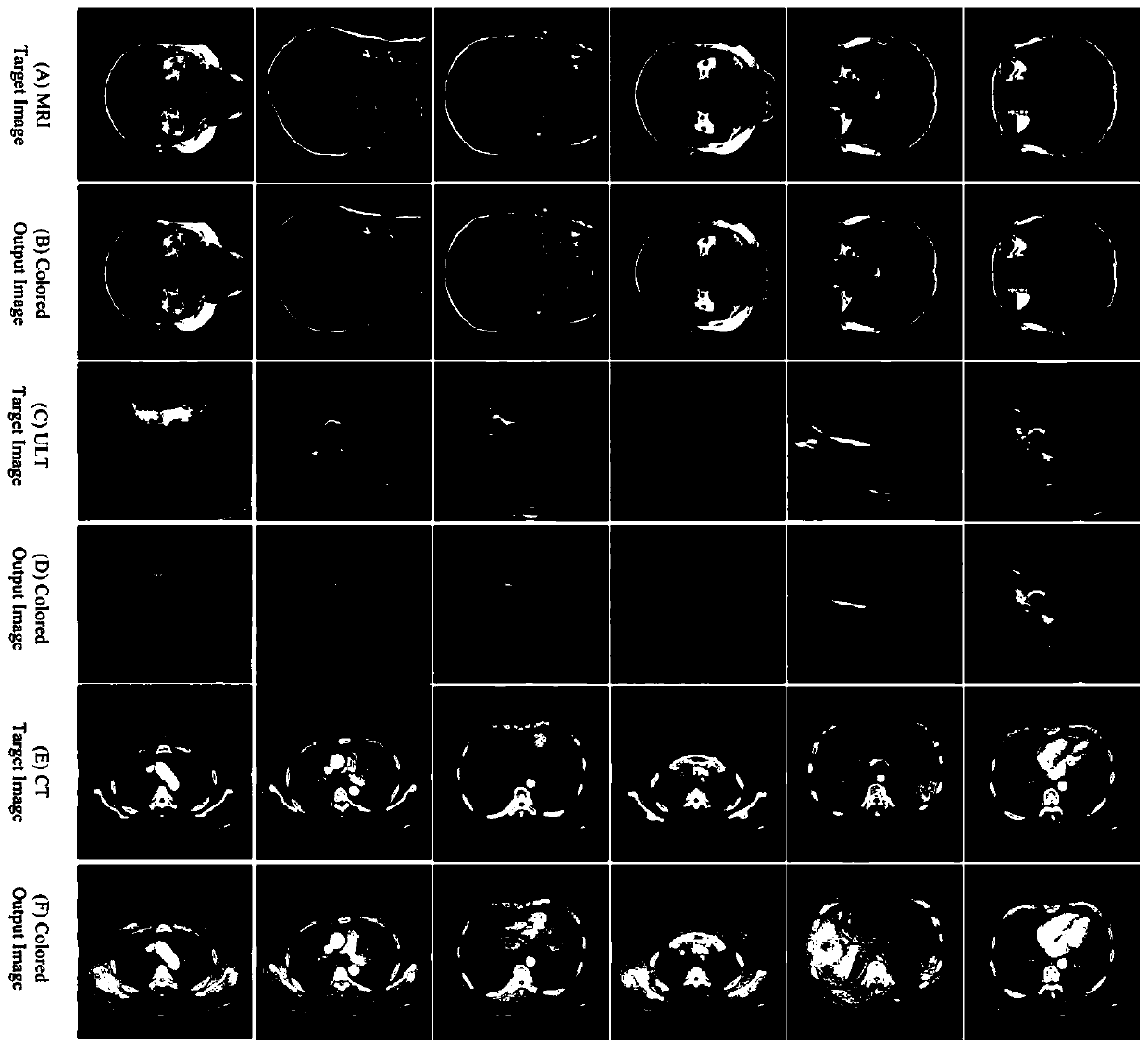

Medical image coloring method based on depth color migration

PendingCN110458906AFast convergenceSolve the problem of coloringImage enhancementImage analysisPattern recognitionReference image

The invention discloses a medical image coloring method based on depth color migration. The method comprises the following steps: randomly initializing an initial image, coloring the medical image byusing a deep neural network in combination with a color migration idea; extracting depth features of the medical image, the reference image and the initial image through a deep neural network; and then constructing content loss, color loss, spatial relationship loss and texture detail loss, calculating the gradient of total loss relative to the pixels of the initial image, and iteratively updatingthe initial image by utilizing the gradient until the initial image is matched with the color of the reference image and the texture structure of the target image at the same time; then reconstructing a color medical image by utilizing the color information and the brightness information of the initial image and the original medical image in the YUV space. According to the invention, the medicalimage with color information can be generated, the texture structure of the original medical image is provided, and the original diagnostic significance is maintained.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

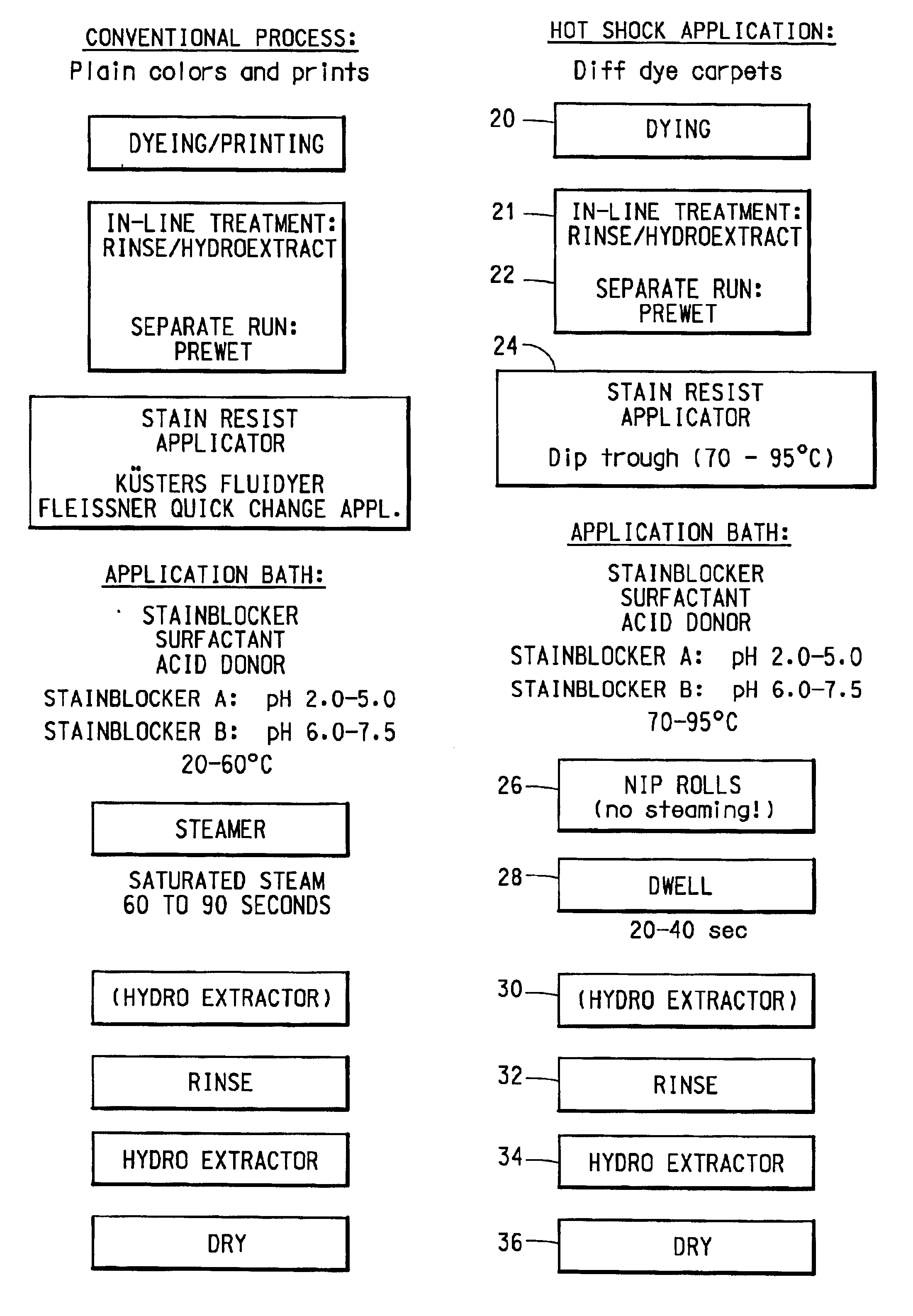

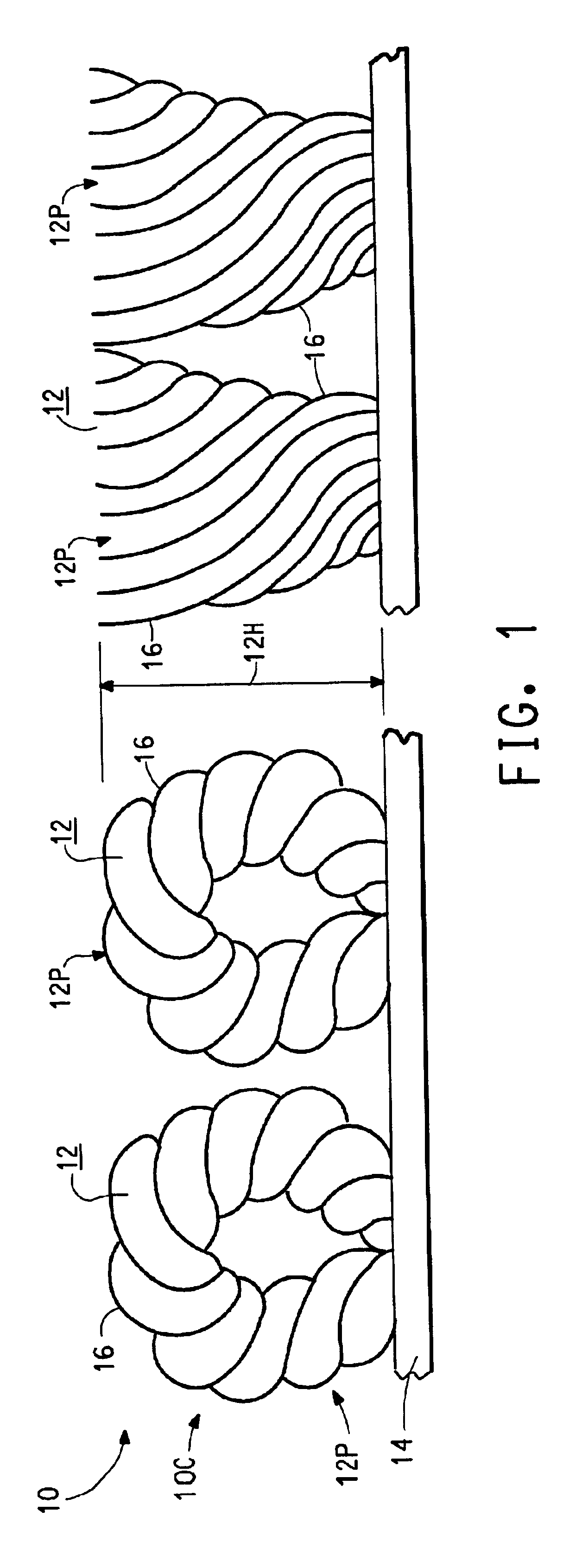

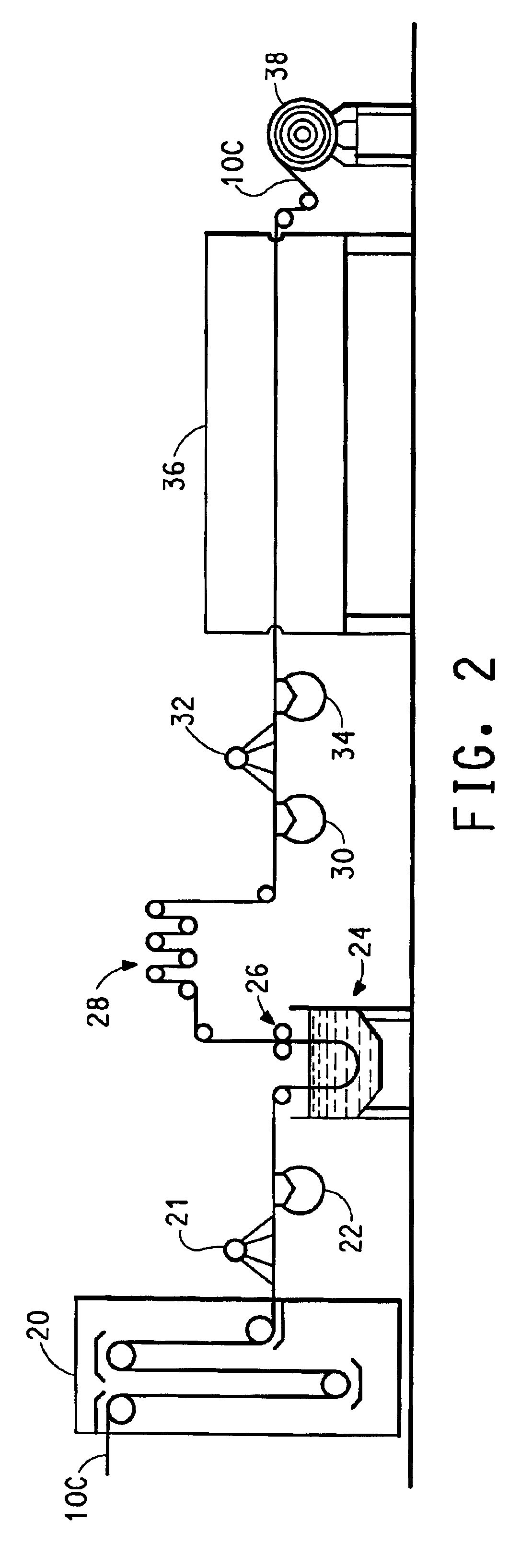

Method of imparting stain resistance to a differentially dyeable textile surface and the article produced thereby

A method of treating articles having a textile surface (such as broadloom carpets or carpet tiles) with a stainblocker composition is disclosed.A pile surface structure having pile elements containing nylon yarns having both acid dyeability and cationic dyeability is dyed with both acid dye and cationic dye and then passed through a hot stainblocker treatment bath and a cooling zone. Substantially the entire height of each pile element is coated with a stainblocker composition whereby the pile surface structure has a stain resistance of 9 or higher on the AATCC Red 40 Stain Scale. The resulting pile surface has good color separation and stability, and no color loss from the catatonically dyeable yarns.

Owner:DUPONT DE NEMOURS GMBH +1

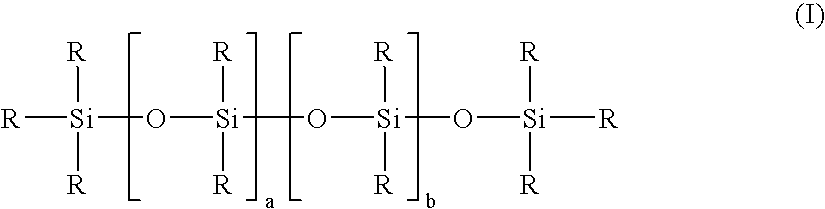

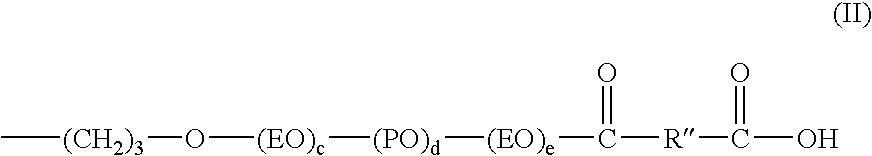

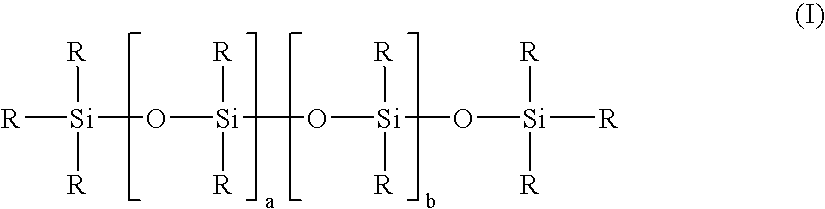

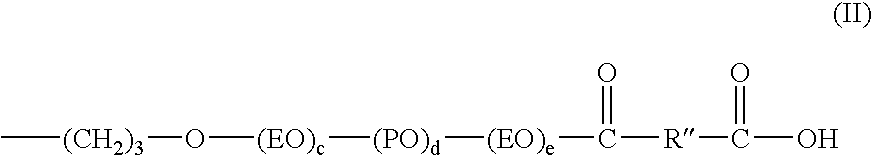

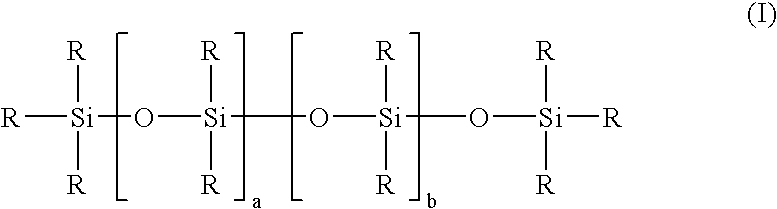

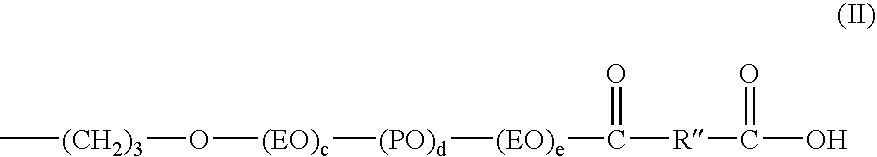

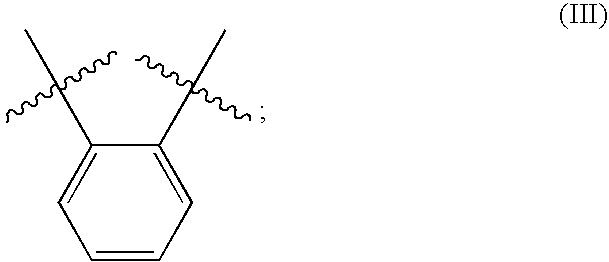

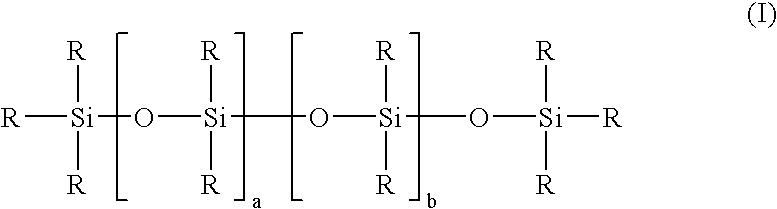

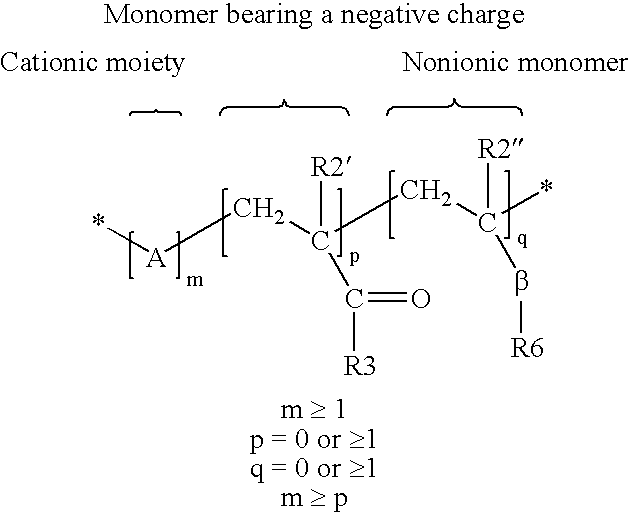

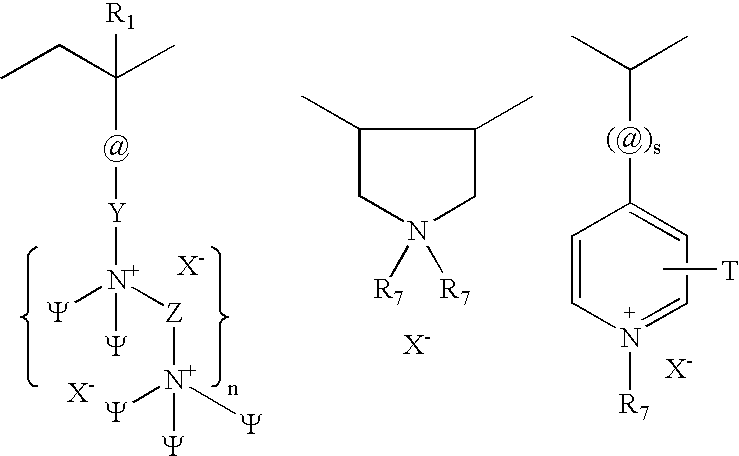

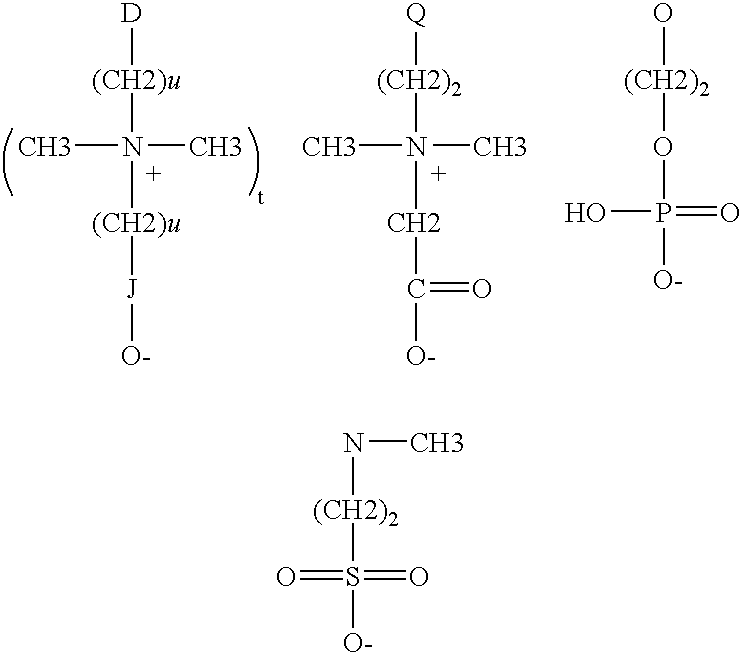

Method for Preventing Color Loss in Oxidatively Dyed Hair

InactiveUS20090049623A1Inhibit coloringColor lossCosmetic preparationsHair cosmeticsPolymer chemistryColor loss

A method for preventing color loss from oxidatively dyed hair comprising the steps of: a) contacting said hair with a shampoo composition, said shampoo comprising: from about 5% to about 50% of an anionic surfactant; from about 0.025% to about 5% by weight of a synthetic cationic polymer having a cationic charge density of at least about 3 meq / gm, wherein said synthetic cationic polymer form lyotropic liquid crystals upon combination with said anionic surfactant; and water; and b) rinsing said composition from said hair. An article of manufacture comprises the shampoo composition and is promoted to consumers.

Owner:THE PROCTER & GAMBLE COMPANY

Method and Composition for Maintaining Hair Dye Color

A method of preventing color loss from dyed hair comprising the application of a hair care composition comprising from about 0.1% to about 20% of a sulfoalkyl(meth)acrylate compound, an alkylacetamido(meth)acrylate, or a mixture thereof, and a dermatologically acceptable carrier wherein the sulfoalkyl(meth)acrylate compound and the alkylacetamido(meth)acrylate undergo polymerization inside the hair fibers.

Owner:THE PROCTER & GAMBLE COMPANY

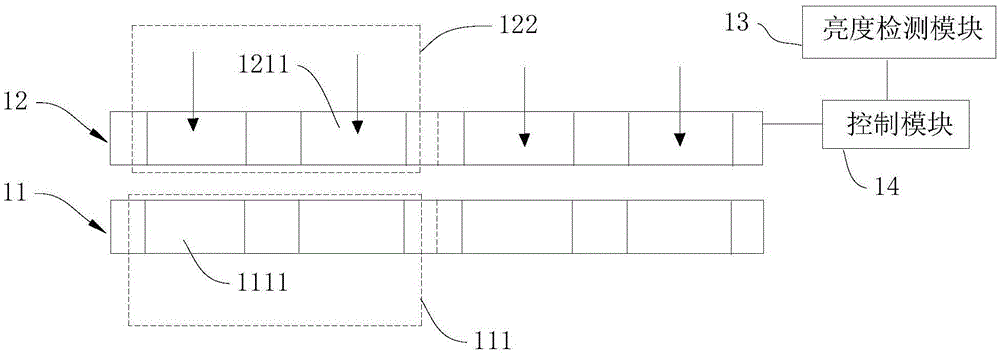

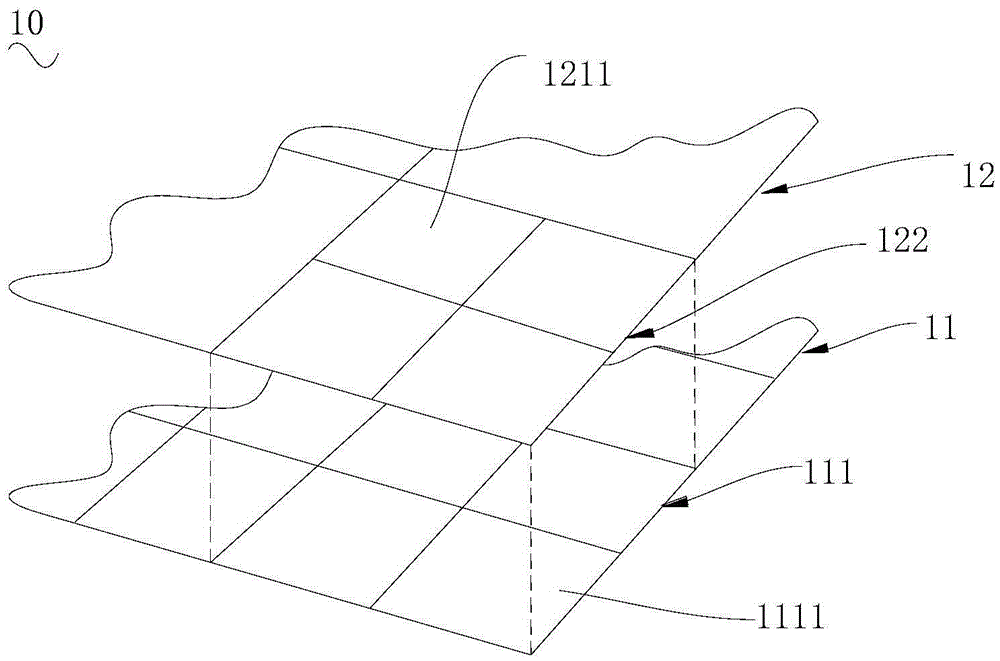

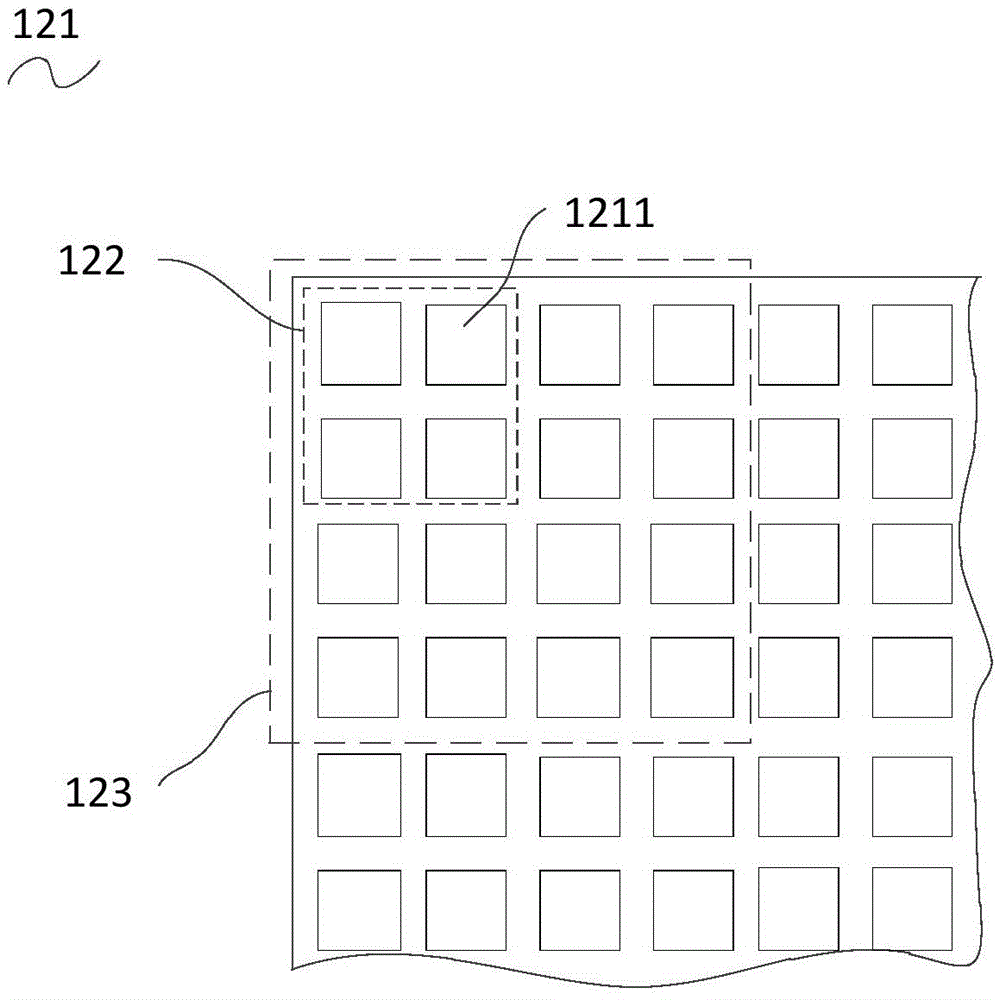

Image sensor, method for adjusting imaging quality of image sensor and imaging device

ActiveCN105578079AReduce noiseReduce lossesTelevision system detailsPicture signal generatorsSignal-to-noise ratio (imaging)Imaging quality

The invention discloses an image sensor, including: a photosensitive pixel array having a plurality of photosensitive pixel units, an optical filter, a brightness detection module and a control module. Each photosensitive pixel unit includes M photosensitive pixels; the optical filter includes a filtering unit array having a plurality of filtering modules, each filtering module includes N filtering unit that cover N photosensitive pixel units, and each filtering unit includes filtering subunits corresponding to M photosensitive pixels; the brightness detection module obtains an ambient brightness parameter; and the control module is used for judging whether the ambient brightness parameter is smaller than a first preset threshold value, determining the filtering subunit to be switch according to the ambient brightness parameter when the parameter is judged to be smaller than the first preset threshold value, and switching the filtering subunit to be switched to white. Thus, an image with a high signal to noise ratio, high definition and few noisy points is obtained under low brightness, and image color loss can be reduced as much as possible. The invention also discloses a method for adjusting the imaging quality of the image sensor, an imaging device, an imaging method and a mobile terminal.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Bamboo wood making method, dyeing method, dyeing water, and preparation method of dyeing water

ActiveCN104385407ASimple processEasy to implementWood treatment detailsWood veneer joiningFiberHigh pressure

The invention relates to bamboo wood processing, and especially relates to a bamboo sheet making method, a dyeing method, a dyeing water, and a preparation method of the dyeing water. The bamboo wood dyeing method comprises the following steps: 1, drying: drying bamboo board splints to adjust the water content to 6-10%; and 2, permeating: putting the dried bamboo board splints in a pressure furnace, sealing the pressure furnace, pumping the dyeing water into the pressure furnace through a high pressure pump until the pressure reaches 4-6MPa, allowing the dyeing water to permeate into the bamboo board splints along bamboo fibers, maintaining the pressure for 2-3d, detecting the pressure in the pressure furnace through a detector, automatically pumping the dyeing water into the pressure furnace through the high pressure pump if the pressure is too low, and automatically stopping the high pressure pump if the pressure reaches a predetermined value. The dyeing method has the advantages of simple process and easy enforcement, allows the dyeing water to permeate into and be attached to the core of bamboo wood along the bamboo fibers in the dyeing process in order to make the color loss of the bamboo wood difficult, and is in favor of producing colorful bamboo products.

Owner:浙江安吉双虎竹木业有限公司

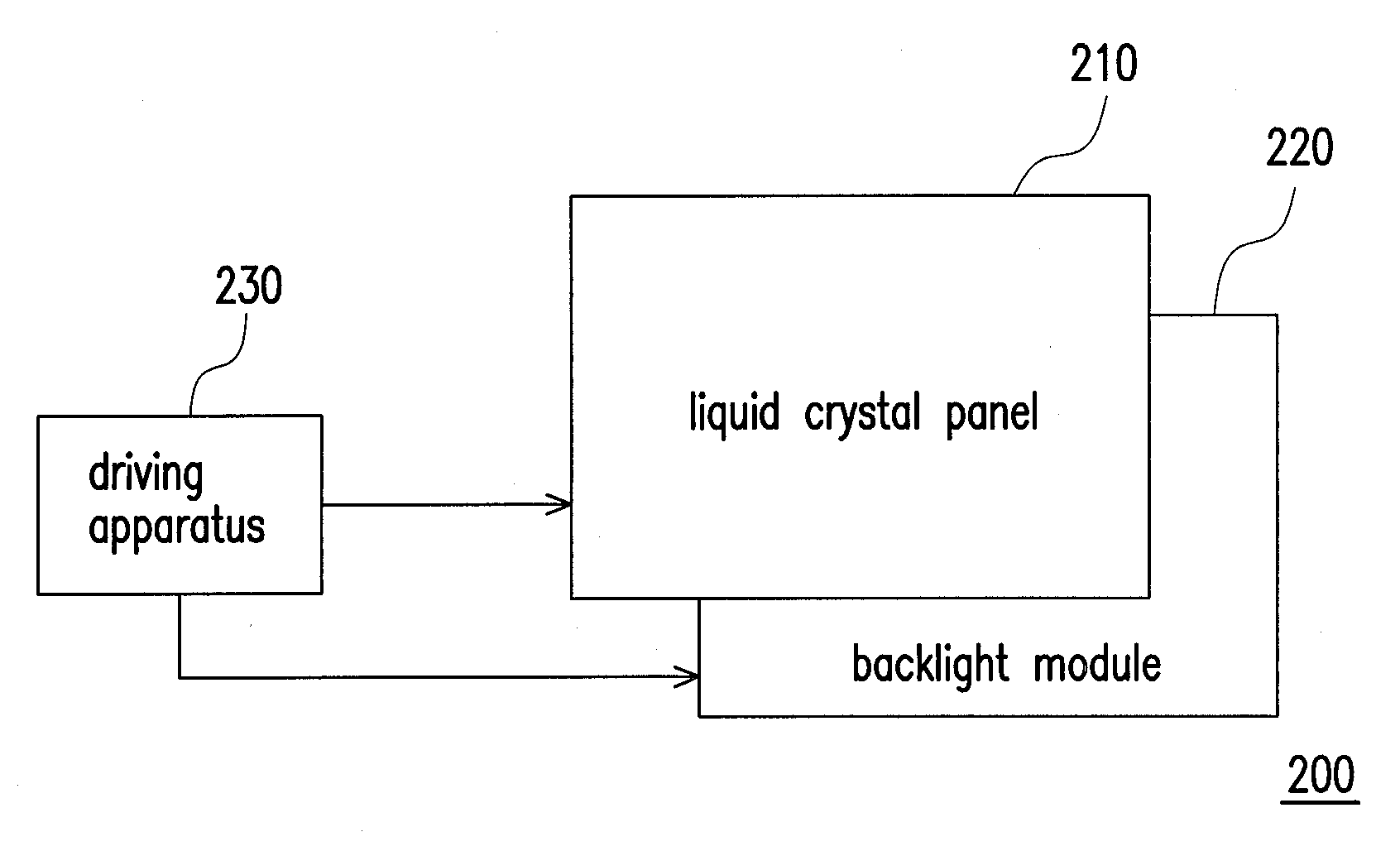

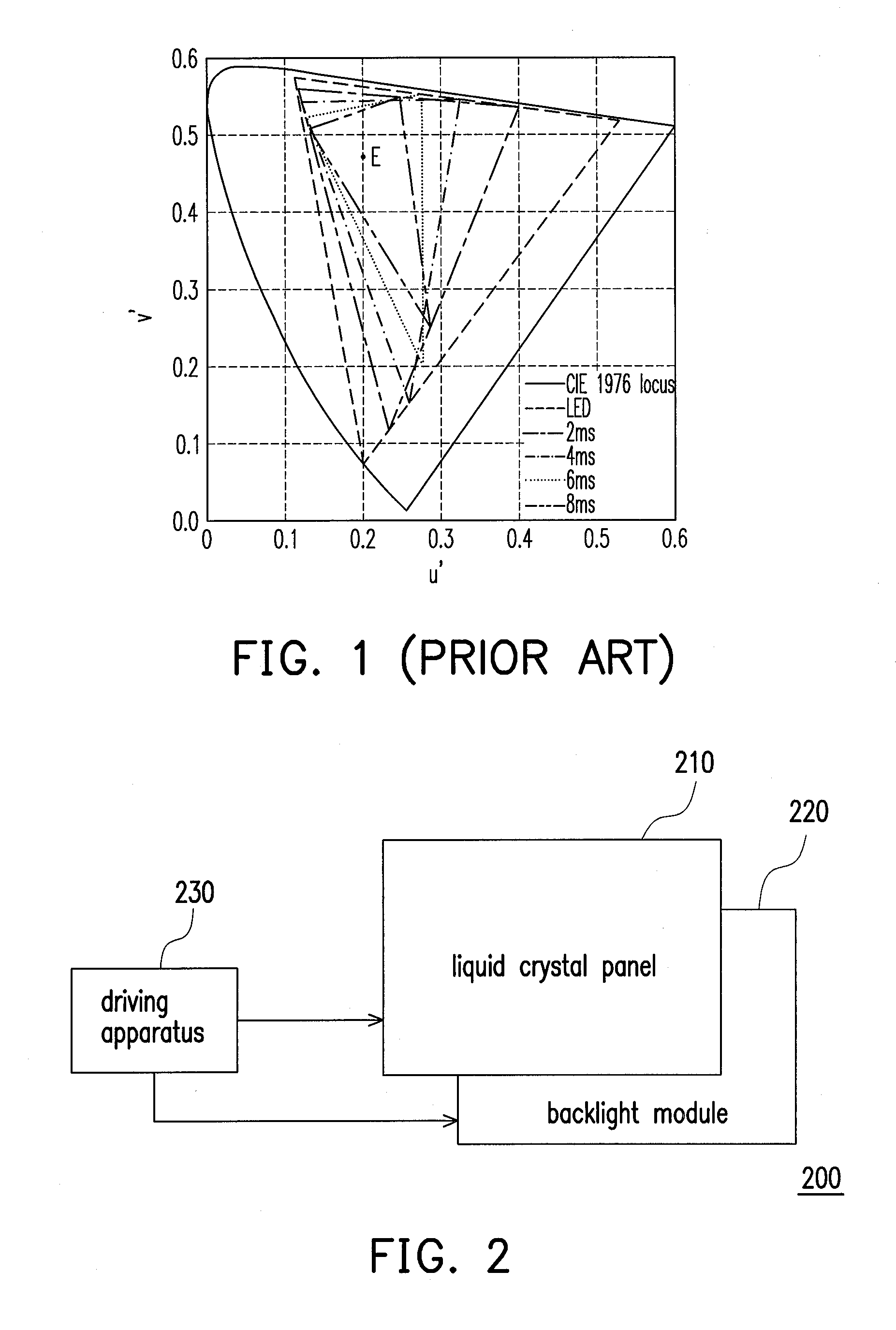

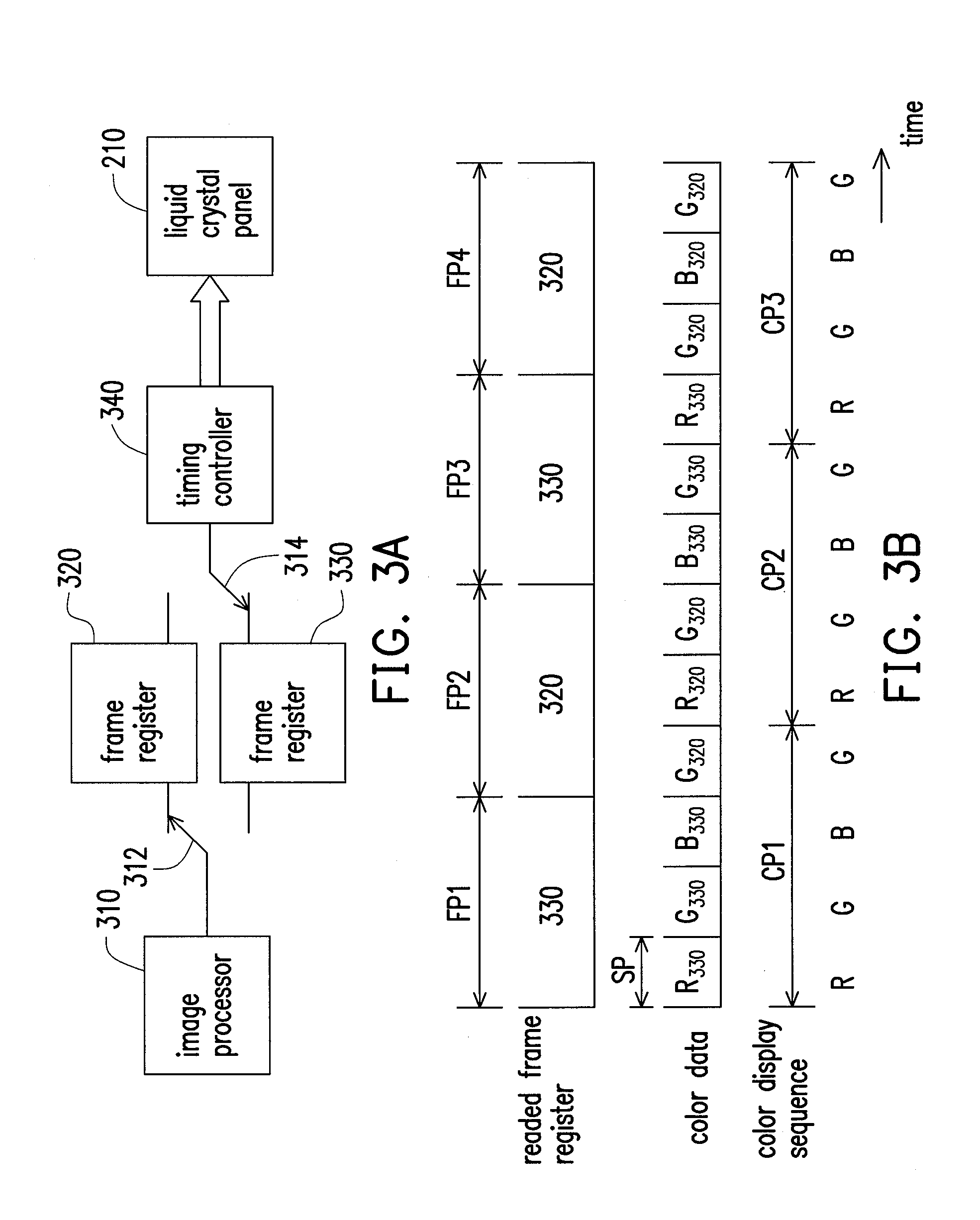

Driving apparatus, driving method and liquid crystal display using the same

InactiveUS20100039367A1Improve the problemGood colorStatic indicating devicesRecord information storageLiquid-crystal displayDisplay Order

A driving apparatus, a driving method and a liquid crystal display (LCD) using the same are provided, wherein the method includes the following steps of: setting a color display sequence, wherein the color display sequence is RGBG, RGRB or RBGB; alternately reading frame data from a first frame register and a second register according to a frame period having three field periods; and sequentially displaying four color data in a cycle period having four field periods according to the color display sequence and the read frame data. By utilizing the method in the present invention, color loss of a field sequential color display occurred in a lower temperature environment is improved.

Owner:CHUNGHWA PICTURE TUBES LTD

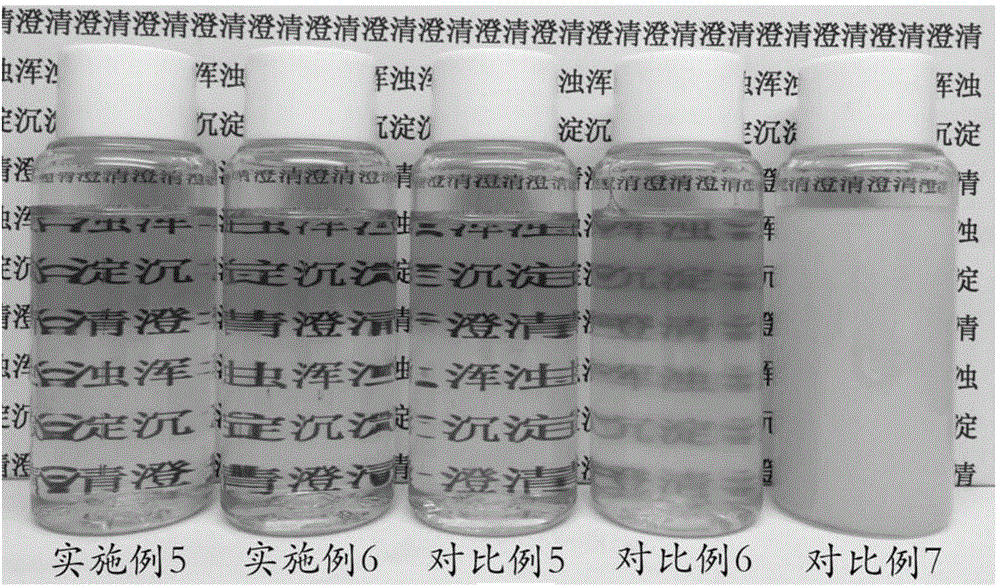

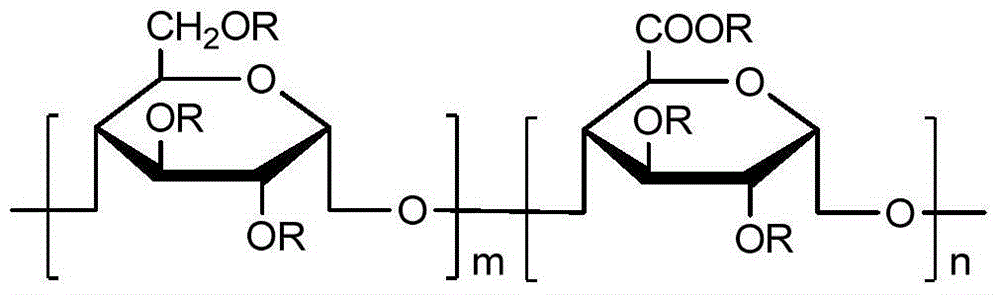

Liquid textile washing agent composition and method for improving color protection performance of liquid textile washing agent composition

ActiveCN104531406AGood color protectionReduce cross-color phenomenonDetergent mixture composition preparationSurface-active non-soap compounds and soap mixture detergentsWhitening AgentsOptical brightener

The invention discloses a liquid textile washing agent composition and a method for improving a color protection performance of the liquid textile washing agent composition. The composition contains a cation hydroxypropyl oxidized starch derivative; and the cation substitution degree is 0.20-1.00 and the number-average molecular weight of a polymer is 1000000-4000000. The cation hydroxypropyl oxidized starch derivative has a textile color fixing effect and also can prevent an anti-cross-color phenomenon from occurring between colored textiles. More importantly, cation hydroxypropyl oxidized starch has good compatibility with an anion surfactant and a fluorescent whitening agent; and the liquid textile washing agent composition has a good washing and stain-removing capability. According to the liquid textile washing agent composition and the method for improving the color protection performance of the liquid textile washing agent composition, disclosed by the invention, the washing function can be provided for a consumer, the color loss of the textiles and the mutual color crossing between the textiles are remarkably reduced, and the colors of the textiles keep bright.

Owner:GUANGZHOU LIBY

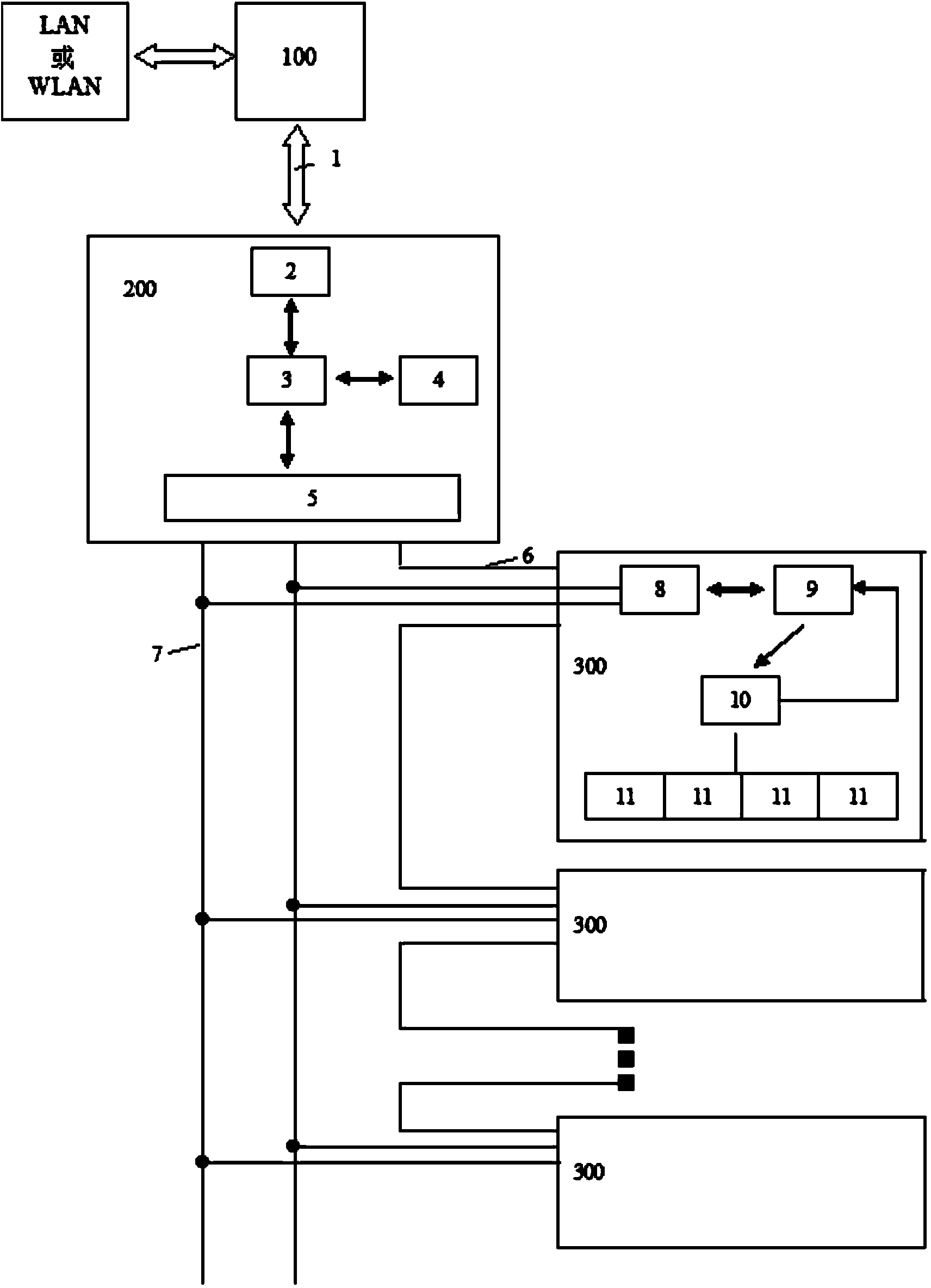

Bus-system LED display system point-by-point fault detection method and application thereof

ActiveCN104267719AAvoid destructionWith remote monitoringStatic indicating devicesElectric testing/monitoringColor lossNetworking cables

The invention relates to a bus-system LED display system point-by-point fault detection method and the application thereof. The method is based on a parallel bus-system LED lighting control system. The system is composed of an upper computer, an LED controller and a plurality of LED lamps which are connected in parallel and controlled by the LED controller. The LED controller is connected with the upper computer through an optical fiber or a network cable. The LED controller is composed of a TCP / IP communication module, a center processor, an information storage module (which is selectable) and a first communication module. Each LED lamp is composed of a second communication module, a processor and data storage module, a display monitoring module and a display module, wherein the second communication module of the LED lamp is connected with the first communication module of the LED controller through an address writing line and a communication bus. The system has the functions of remote monitoring, fault detection, fault feedback, automatic fault shielding, brightness adjustment, automatic encoding and the like, and managers can grasp system working conditions immediately; due to the fact that the system has the automatic fault shielding function, fault points are in the perfectly-black state, and damage caused by color loss, flashing and other phenomena on the whole picture vision is avoided.

Owner:SHANGHAI GRAND LIGHT

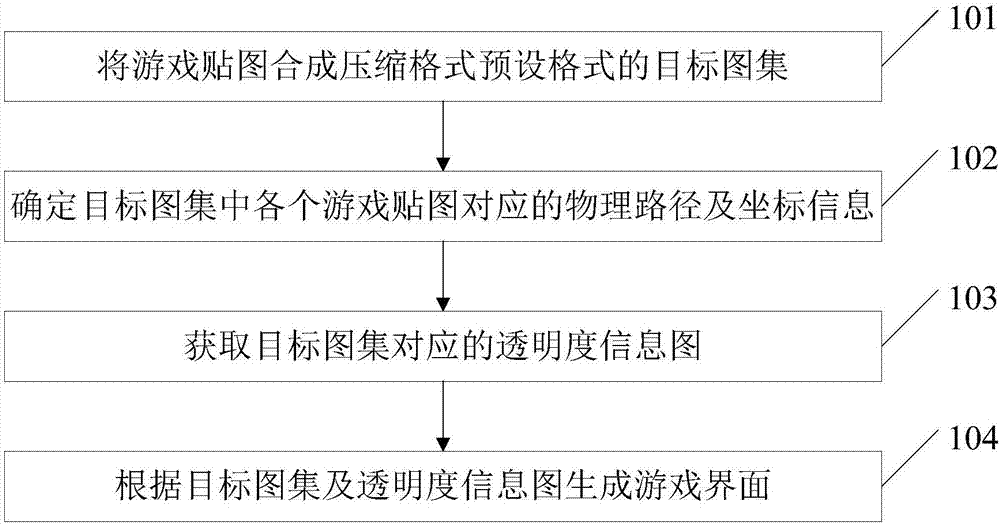

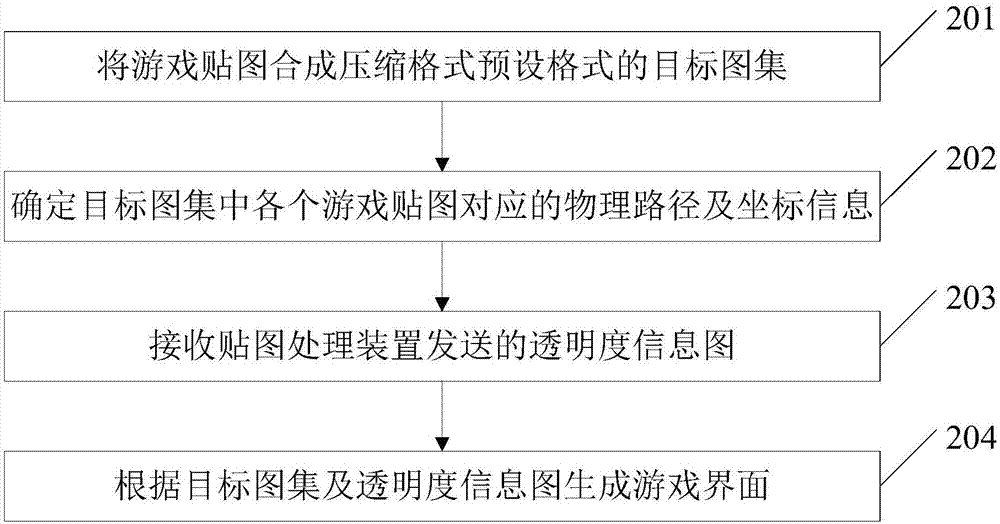

Game interface generation method and game interface generation device

An embodiment of the invention discloses a game interface generation method for reducing color loss and improving game interface display effects. The method includes: composing game images into a target image set in a compressed format which is a target format, wherein the target image set does not include target transparency information of the game images; determining a physical patch and coordinate information corresponding to each game image in the target image set, wherein the physical paths are used for acquiring the target transparency information of the game images; acquiring transparency information graph corresponding to the target image set, wherein the transparency information graph is generated according to the target transparency information and the coordinate information; generating and displaying a game interface according to the target image set and the transparency information graph.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Method and composition for maintaining hair dye color

ActiveUS7981167B2Preventing color lossInhibit coloringCosmetic preparationsHair removalFiberHair dyes

Owner:PROCTER & GAMBLE CO

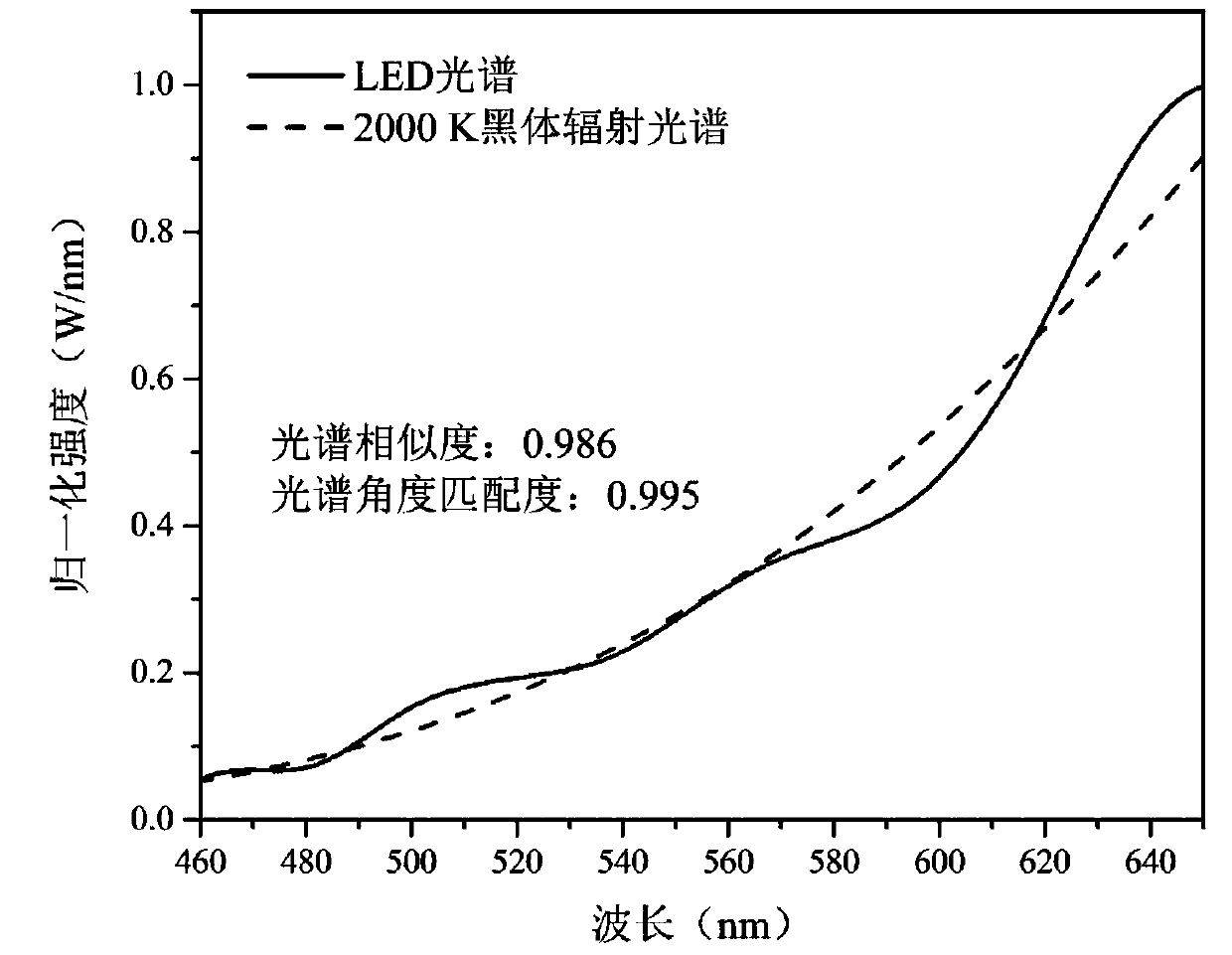

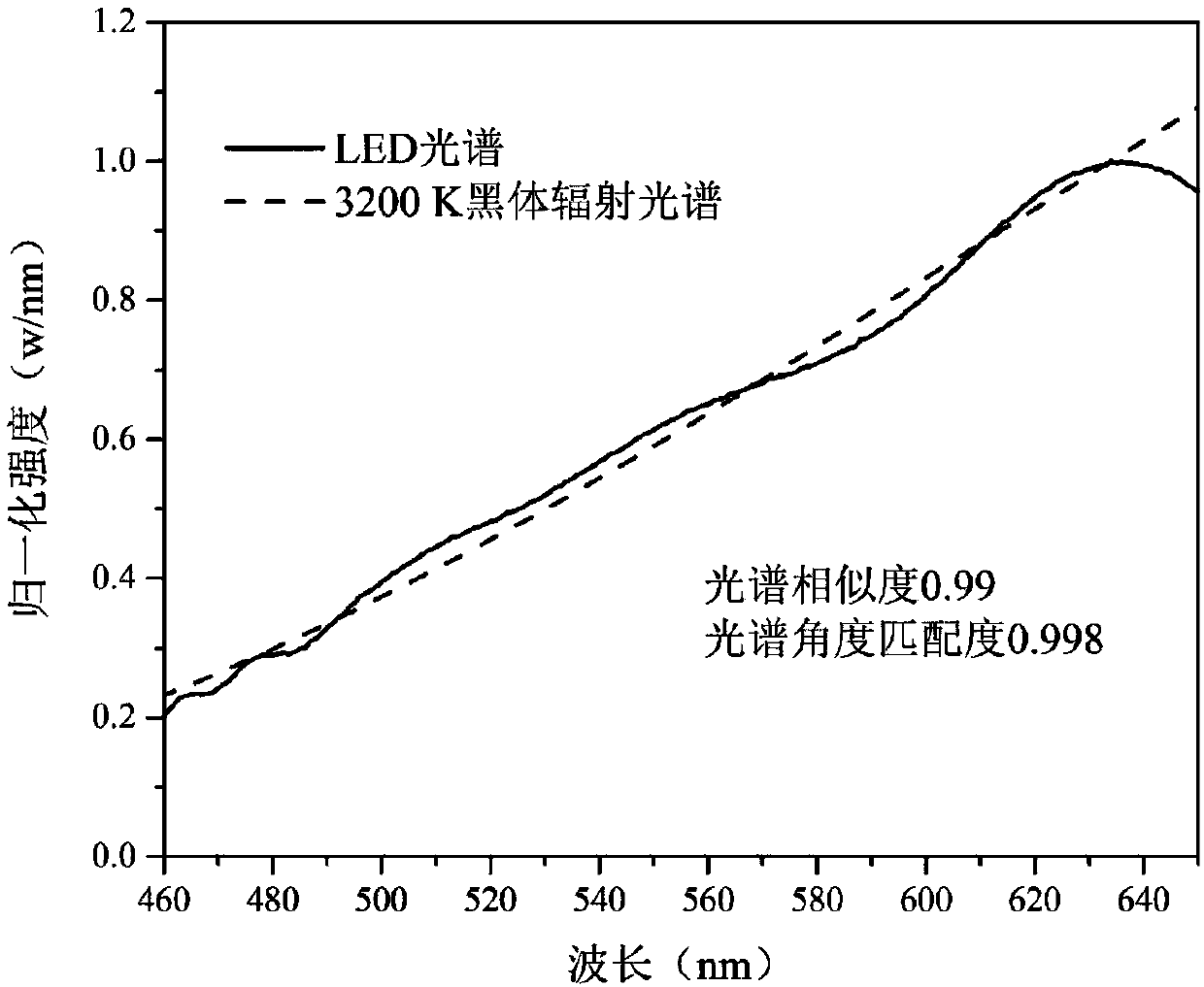

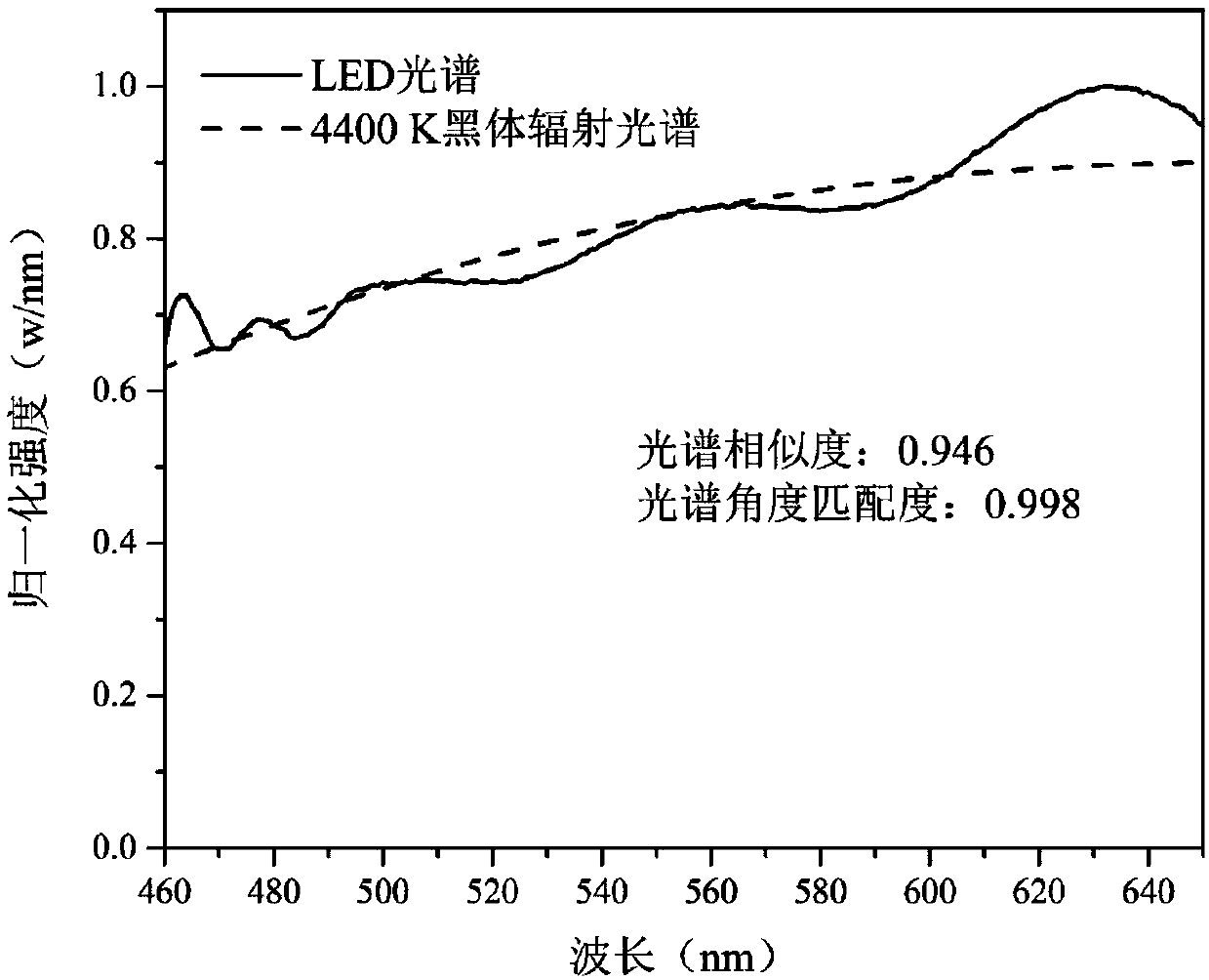

LED light source capable of simulating blackbody radiation spectrum, making method thereof and application

ActiveCN107623064ANo missing colorAvoid harmSemiconductor/solid-state device testing/measurementSemiconductor devicesPhosphorHigh intensity

The invention discloses an LED light source capable of simulating a blackbody radiation spectrum, a making method thereof and application, which belong to the technical field of LEDs and solve the problems that the existing LED light source has much blue light, color loss exists in the spectrum and a human vision system is damaged. The LED light source comprises a blue LED chip; the blue LED chipis coated with glue containing phosphor powder or the blue LED chip is placed in a shell which is already coated with glue containing phosphor powder; and the phosphor powder contains 485-500 nm cyanphosphor powder, 520-540 nm yellowish-green phosphor powder and 645-660 nm red phosphor powder. The LED light source is a continuous spectrum in the range of visible light, not any color loss happens,the highest intensity of the spectrum is not the blue light, the similarity and the angle matching degree between the spectrum and the target blackbody radiation spectrum are both close to 1 in the visible light range, the color temperature range of the spectrum is 1500-6000K, and the LED light source can be used as a health light source.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

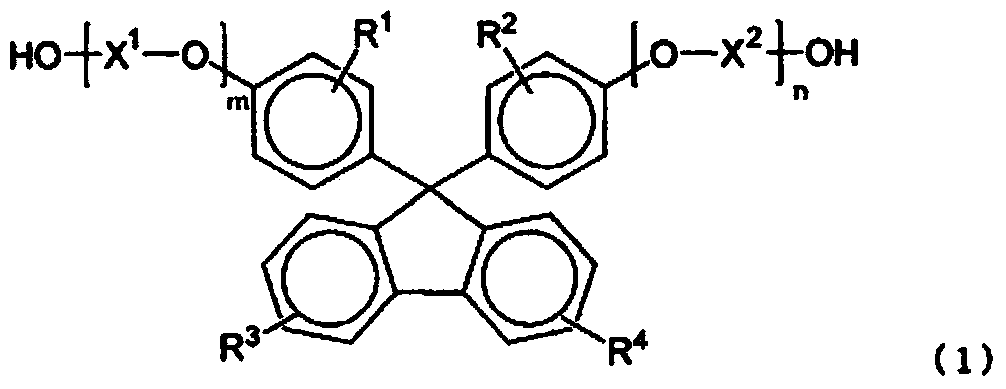

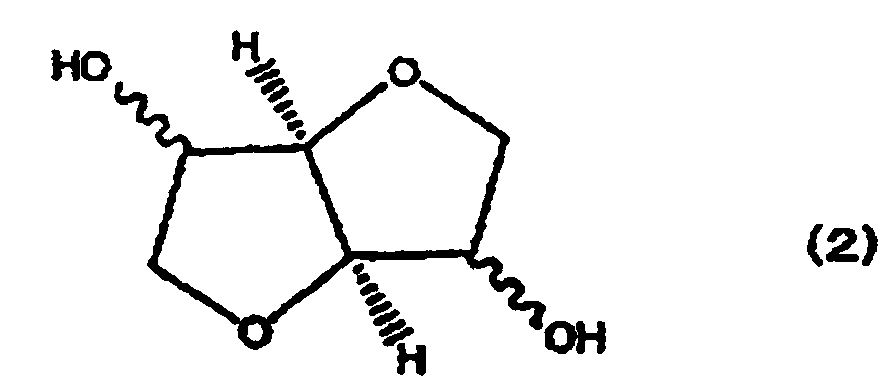

Phase difference film, circularly polarizing plate using same, and image display device

ActiveCN104067151AReduce loadNot prone to decolorizationElectroluminescent light sourcesSolid-state devicesColor shiftPhase difference

Owner:MITSUBISHI RAYON CO LTD +1

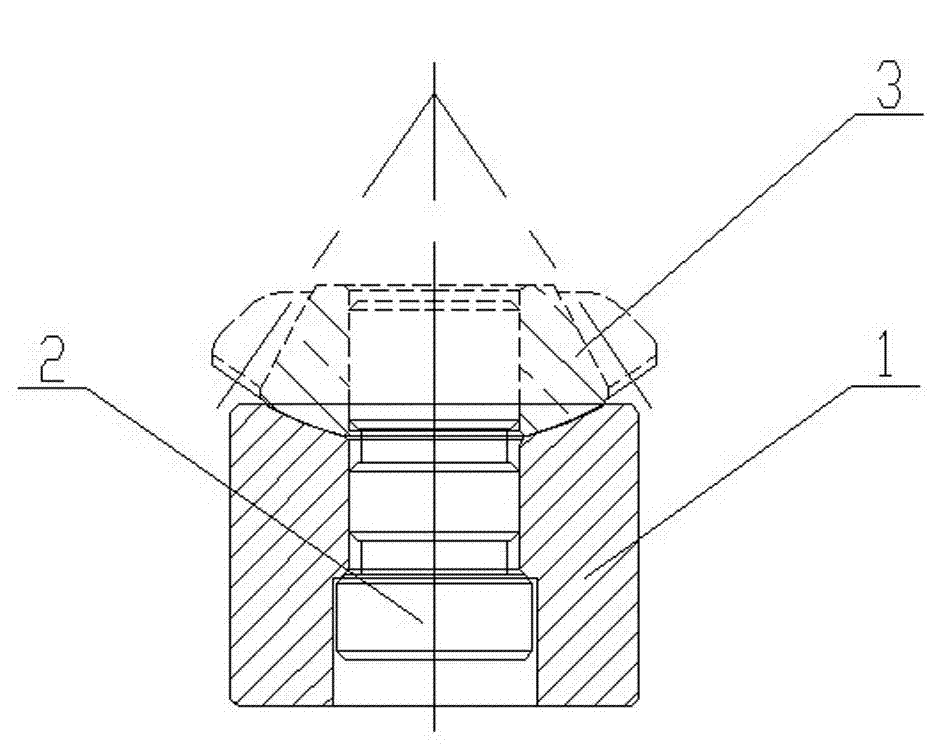

Spherical shape gauge for bevel planet gear

InactiveCN102853804APrecise positioningSimple and fast operationMeasurement devicesGear wheelEngineering

The invention discloses a spherical shape gauge for a bevel planet gear. The spherical shape gauge for the bevel planet gear comprises a cavity plate and a mandrel. The cavity plate is axially provided with three concentric conjoined cavities. The top of the cavity plate is provided with a spherical cavity, the bottom of the cavity plate is provided with a process hole, and a middle axial through hole of the cavity plate penetrates through the spherical cavity and the process hole. The mandrel is a cylindrical shaft inserted into the axial through hole of the cavity plate, the top segment of the mandrel is exposed from the spherical cavity of the cavity plate, and accordingly an axial positioning rotary structure for workpieces to be measured is formed. The area of contact of the spherical surface of the workpiece with the cavity plate can be displayed better during detection by pre-coating the spherical surface of the workpiece and inserting the workpiece on the mandrel to rotatably positionally contact with the cavity plate, and the quantity of the contact area can be determined according to color loss of the spherical surface by demounting the workpiece. The spherical shape gauge is high in detection precision and efficiency in positioned detection, and can objectively reflect actual mass of the workpiece.

Owner:JIANGSU PACIFIC PRECISION FORGING +1

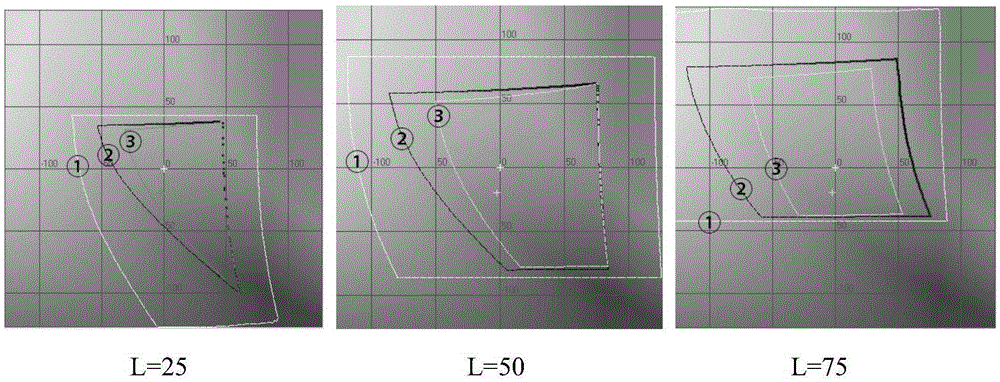

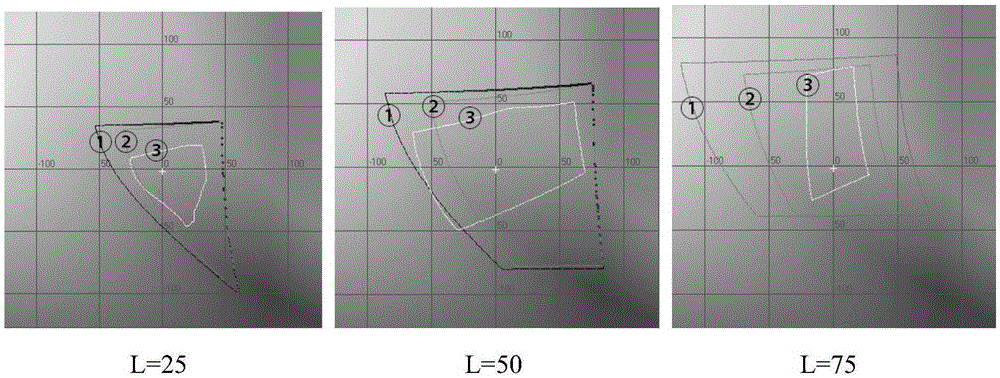

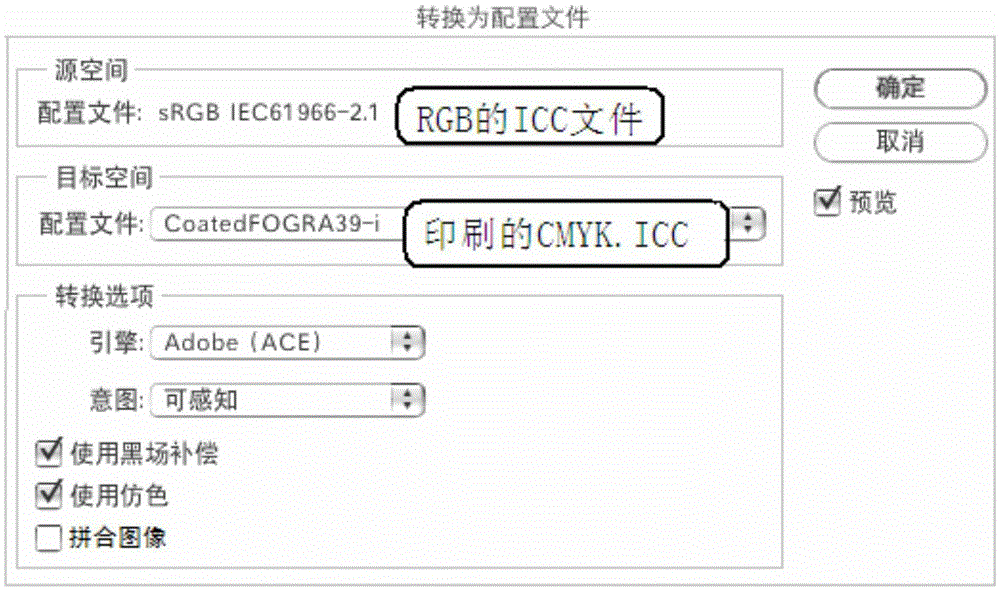

ICC file manufacturing method of converting RGB color mode to CMYK color mode

InactiveCN105262930AMake up for domestic gapsReduce color lossPictoral communicationPrinting inkComputer science

Provided is an ICC file manufacturing method of converting an RGB color mode to a CMYK color mode, comprising: using the ICC file editor in an ICC file generator to open an ICC file, and modifying the ICC file with a 360% printing ink amount, wherein changing the output of the C channel, the M channel, the Y channel and the K channel of CMYK in inputting 100% to be 95.0, 90.0, 90.0 and 85.0; modifying gray balance data, and respectively adjusting the M and Y channels to be 19 when the C channel is 25; adjusting the M and Y channels to be 40 when the C channel is 50; respectively adjusting the M and Y channels to be 64 when the C channel is 75; and determining employing long black or short black to generate black print according to a print object, and finishing if meeting color picture inspection standards, or else returning. The method can manufacture ICC conversion files suitable for Chinese printing environments, and is used for domestic printing environments to greatly reduce color loss in color transmission processes on different devices.

Owner:BEIJING SUNRAINBOW CULTURE & ARTS DEV CO LTD

Compositions for laundering and subsequently drying delicate garments without incurring any damage and methods to use them

InactiveCN102333853AInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsOrganic solventProtein fiber

The present invention relates to compositions and methods for wet-cleaning, in professional or household washing machine equipment, and subsequent drying in a tumbler dryer, of garments made of protein-fibers (animal based fibers) such as wool, cashmere, silk and other sensitive fibers. Using water and certain additives instead of organic solvents, these compositions enable the cleaning, including oil stains removal, and subsequent drying without incurring dimensional changes, shrinkage, surface damages, dye or color loss of dry clean only labeled garments or other delicate garments labeled for special care.

Owner:法瑞波兹・德乌迪安

Hair Smoothing and Protection Treatment

Hair treatments including a reactive amino-modified silicone elastomeric waterborne-emulsion and / or a waterborne hydrophilic silicone copolymer are provided. Methods include using the hair treatments alone, in conjunction with each other, and in combination with other hair care products, such as shampoo or hair color. Hair is protected against color loss, heat, humidity, chemicals, and frizz while shine, smoothness, and manageability are increased.

Owner:UNIQUE HAIR SOLUTIONS

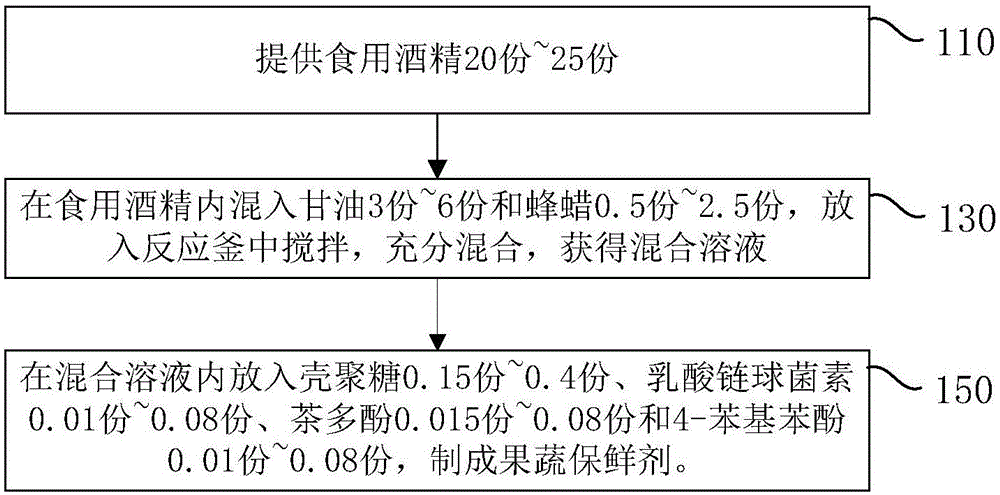

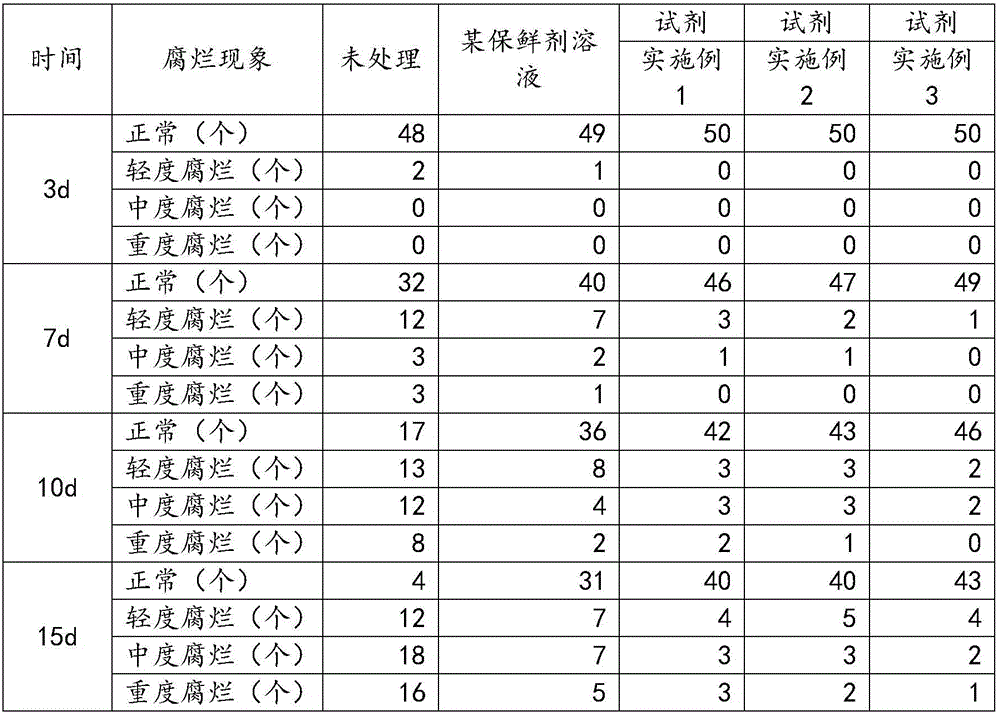

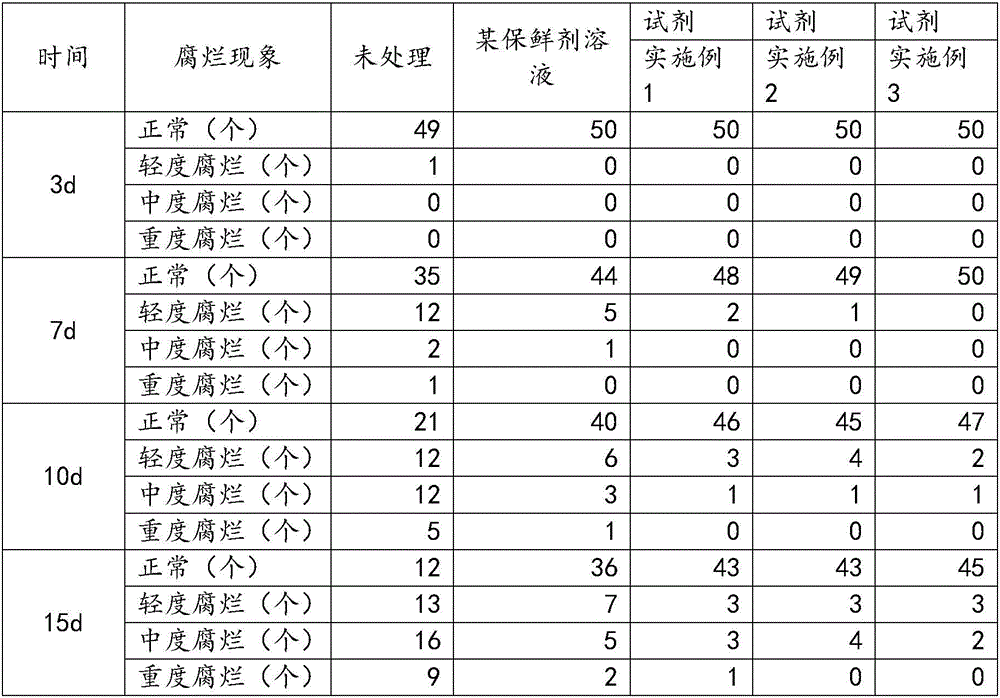

Fruit and vegetable fresh-keeping agent and preparation method thereof

InactiveCN106472664ANatural colorExtended shelf lifeFood ingredient as encapsulating agentFruits/vegetable preservation by coatingAlcoholPolyphenol

The invention relates to a fruit and vegetable fresh-keeping agent and a preparation method thereof. The fruit and vegetable fresh-keeping agent comprises the following components: 3-6 parts of glycerin, 20-25 parts of edible alcohol, 0.15-0.4 parts of chitosan, 0.01-0.08 parts of nisin from streptococcus lactis, 0.015-0.08 parts of tea polyphenol, 0.01-0.08 parts of 4-phenylphenol, and 0.5-2.5 parts of beeswax. The method is characterized in that edible alcohol, nisin from streptococcus lactis, and 4-phenylphenol in the fresh-keeping agent can effectively kill the bacteria and resist corrosion, the glycerin and beeswax can form a protection film on the surface of the fruit and vegetable, so that moisture loss of the fruit and vegetable is prevented, tea polyphenol can avoid color loss of the fruit and vegetable, and the color of the fruit and vegetable is more natural. The fruit and vegetable fresh-keeping agent can prolong the preservation period of the fruit and vegetable, so that the fruit and vegetable is fresher and more tasty, and the cost is low.

Owner:广东广垦绿色农产品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com