Patents

Literature

390results about How to "Does not change color" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aqueous texture wallpaper paint and method for making same

The invention relates to a watercraft texture wallpaper paint, characterized in that the invention comprises the following components: 31 percent to 35 percent of styrene-acrylic emulsion, 23.94 percent of superfine weight calcium, 1 percent to 2 percent of nano-titanium dioxide, 10 percent to 18 percent of titanium pigment, 8 percent to 9.8 percent of calcined kaolin, 1.2 percent to 1.8 percent of ethylene glycol, 0.2 percent to 0.5 percent of hydroxyethylcellulose, 0.8 percent to 1.5 percent of film forming additive, 0.15 percent to 0.25 percent of multi-functional additive, 0.3 percent to 0.5 percent of dispersant, 0.1 percent to 0.2 percent of wetting agent, 0.15 percent to 0.21 percent of defoamer, 0.08 percent of anticorrosion and insecticide, 0.8 percent to 2 percent of thickener and 20 percent to 22 percent of water. The invention is the watercraft texture wallpaper paint, is environment-friendly, has strong elastic tension, has good covering and anti-cracking effect on the fine cracking of wall, and has good scrape resistance performance, greatly enhancing the degree of wall surface protection; meanwhile, the invention still has strong waterproof performance, without color-changing and decortication and mildew and can fully solve the common problems existing in wall decoration.

Owner:佛山市顺德区清大润彩涂料有限公司

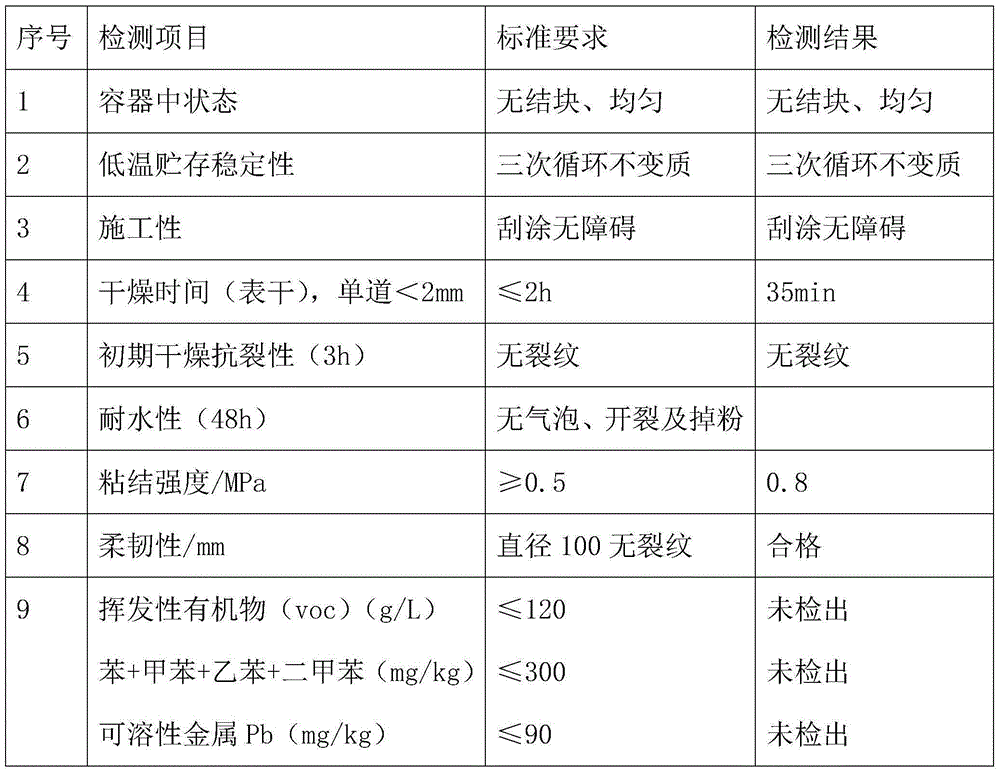

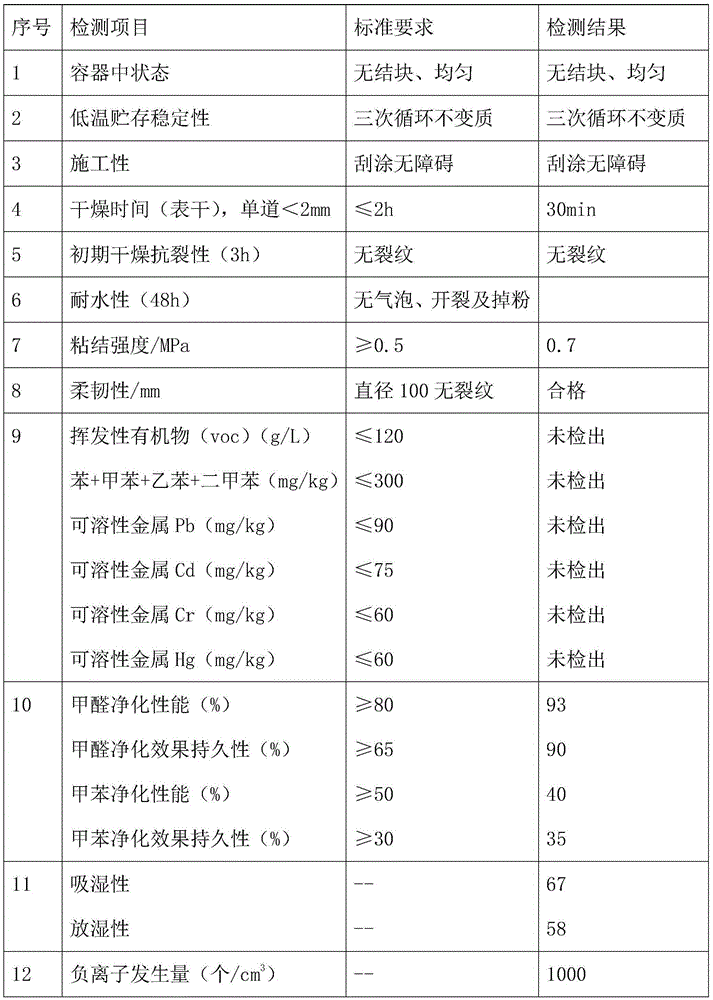

Environment-friendly humidifying diatom ooze coating

InactiveCN105131739AImproved adhesion and moisture absorptionImprove water permeability and breathabilityCoatingsEmulsionChemistry

The invention discloses an environment-friendly humidifying diatom ooze coating. The coating is prepared from silica sol / benzene-acrylic compound emulsion, pure acrylic emulsion, modified diatom ooze, light calcium carbonate, lithopone, anion powder, sodium alginate, dispersing agents SN-5040, ethylene glycol, wetting agents AP-680, alcohol ester-12, propylene glycol monomethyl ether acetate, thickening agents, flatting agents, defoaming agents, sterilization and mildew prevention agents and deionized water. The environment-friendly humidifying diatom ooze coating has the effects of absorbing moisture, releasing moisture, cleaning air and releasing anions, harmful ingredients in indoor air can be absorbed, and the environment protection and healthy effects are achieved.

Owner:TIANCHANG YINHU PAINT

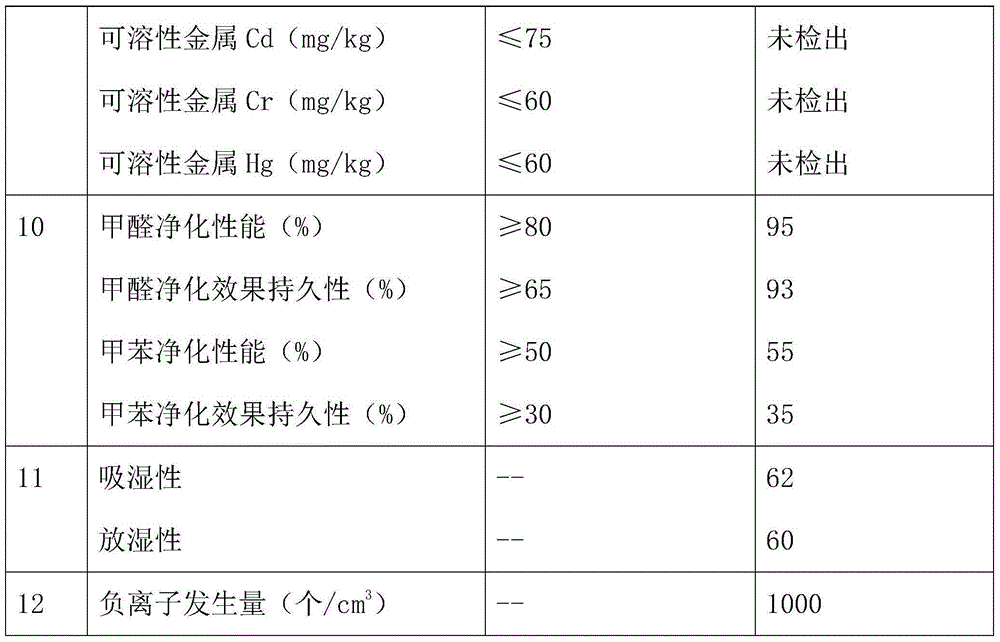

Method for multifunctional water-based ink

The invention provides a multifunctional water-based ink, which comprises the following components by weight percent: 25 to 35 percent of water-soluble acrylic resin, 10 to 20 percent of paint, 3 to 10 percent of silicon oxide, 15 to 25 percent of water, 5 to 15 percent of complex solubilizer, 5 to 10 percent of neutralizing agent, 1 to 3 percent of emulsifier, 0.2 to 1 percent of antifoaming agent, 5 to 9 percent of dispersant, 0.2 to 1 percent of antistatic agent, and 0.1 to 1 percent of anti mildew agent. The multifunctional water-based ink is a novel printing water-based ink which is nontoxic, odorless and low in comprehensive price, and has watertight, anti-mildew and antistatic functions and other functions.

Owner:HUNAN DIMENSION INTELLIGENT TECH CO LTD

Dyeing method for common goldenrod herb natural dye

The invention relates to a dyeing method for a common goldenrod herb natural dye. The dyeing method comprises the following steps: preparing a 2 to 20 g / I common goldenrod herb dye, and setting a dyeing temperature of 40 to 100 DEG C, a bath ratio of 1:50 to 200 and dyeing time of 10 to 90 minutes; taking a 2 to 20 g / I mordant solution, and setting a mordanting temperature of 40 to 100 DEG C and mordanting time of 10 to 90 minutes; and adding a mordant before or after natural fiber yarn or natural fiber textile is added into common goldenrod herb dye liquor or simultaneously when the natural fiber yarn or the natural fiber textile is added into the common goldenrod herb dye liquor for one-bath dyeing. The method uses the prior textile dyeing device for direct dyeing without adding devices or increasing cost. The textile dyed by the method is soft, primitive and simple and natural color, and has good dye fastness, no fading, no discoloring, good reproducibility, and chromatic aberration around a half level. The method is suitable for the industrialized production, and has no toxicity, no harm and no pollution.

Owner:DONGHUA UNIV

A whitening moisturizing composition

InactiveCN1875916AIncrease profitImprove absorption rateCosmetic preparationsToilet preparationsVitamin CMedicine

The invention relates to a skin whitening and moisture preserving composition, wherein its components include (by w / w ratio) nano level vitamin C liposome 30-35%, nano level vitamin A liposome 12-15%, nano level vitamin D-bepanthen liposome 5-8%, nano level vitamin E liposome 10-12%, and nano level nicotilamide liposome 7-9%.

Owner:广州市采诗化妆品有限公司

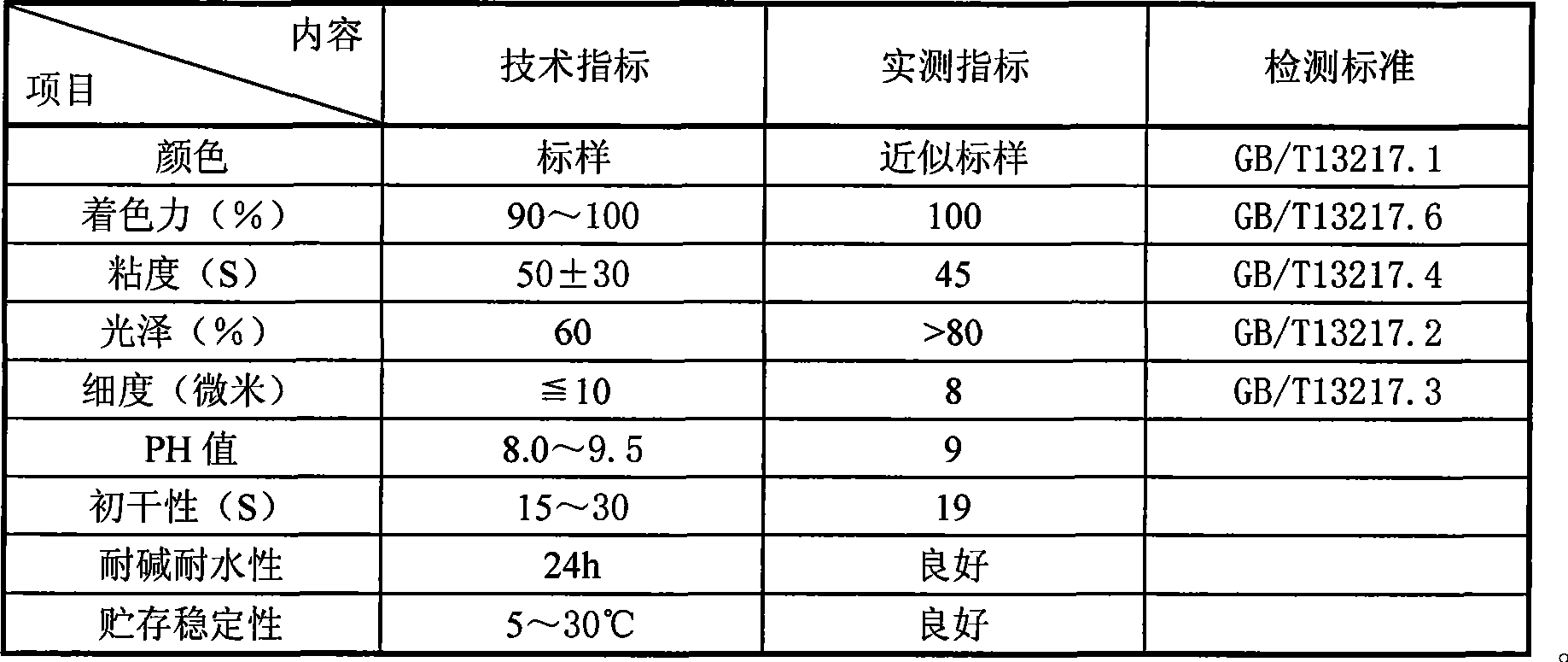

Paper historical relic deacidifying and reinforcing protective material and preparation method thereof

The invention discloses a paper historical relic deacidifying and reinforcing protective material. The paper historical relic deacidifying and reinforcing protective material consists of a solvent and an active component, wherein the active component is a compound formed by chelating a metal ion with starch or hydroxyl contained cellulose. In addition, the invention also discloses a preparation method of the paper historical relic deacidifying and reinforcing protective material. According to the protective material provided by the invention, deacidification and reinforcing treatment are combined, so that the protective material has the excellent comprehensive protective performances of safety, simplicity, convenience, durability, no membrane formation and the like, so that the paper historical relic is deacidified and reinforced once; the operation is simplified, and meanwhile, the obvious and durable reparation effect can be obtained. The preparation method is simple and is beneficial to popularization and application, the cost is low, and the use is safe, simple and convenient.

Owner:广州乾程化工科技发展有限公司

Automatic continuous production process for producing diesel oil with waste oil through catalytic cracking method

InactiveCN102585896AGuaranteed uniformitySolve the problem of not being able to feedTreatment with plural serial stages onlyLiquid hydrocarbon mixture productionWaste oilFuel oil

The invention relates to the technical field of waste oil comprehensive utilization and fuel oil processing, particularly to an automatic continuous production process for producing diesel oil with waste oil through a catalytic cracking method. The production process comprises the following process steps: 1, the waste oil is pretreated; 2, the pretreated waste oil is subjected to hot cracking and catalytic cracking, so as to obtain crude oil, wherein the catalytic cracking comprises liquid-phase catalysis and gas-phase catalysis; 3, the crude oil is fractionated; and 4, the finished product is obtained through refining and filtering. The invention has the advantages that gelatine, asphaltene, sulfide, oxide, unsaturated hydrocarbon and the like can be well removed, so that the finished oil is clear and transparent, has a pure smell, and cannot deteriorate after being stored for a long time; viscosity and pipeline blockage are avoided in the production process, the production process is simple, the conditions are easy to control, the investment is low, the results are quick, the efficiency is high, the use is simple, and the operation is convenient.

Owner:HANGZHOU LVHUI ENERGY TECH

Reinforced textile type glass fiber treating compound and preparation thereof

The invention provides an impregnating compound for reinforced textile glass fibers, which takes novel organic polymer materials as a main body. The impregnating compound comprises the following compositions by weight percentage: 5 to 10 percent of polyvinyl acetate emulsion, 1 to 4 percent of polyester emulsion, 2 to 8 percent of epoxy resin, 0.2 to 2 percent of polyurethane emulsion, 0.01 to 0.2 percent of lubricant, 0.1 to 0.5 percent of coupling agent, 0.05 to 0.3 percent of antistatic agent, 0.2 to 3 percent of surfactant, 0.05 to 1 percent of acetic acid, and the balance being deionized water. The impregnating compound has good convergence, lubricity, film-forming property and antistatic property; the glass fibers which are treated by the impregnating compound have the characteristics of bending resistance, flexibility, tensile resistance, good solubility with resin and so on; and the impregnating compound is suitable for treating the surfaces of various reinforced textile glass fibers.

Owner:上海世鹏聚氨酯科技发展有限公司

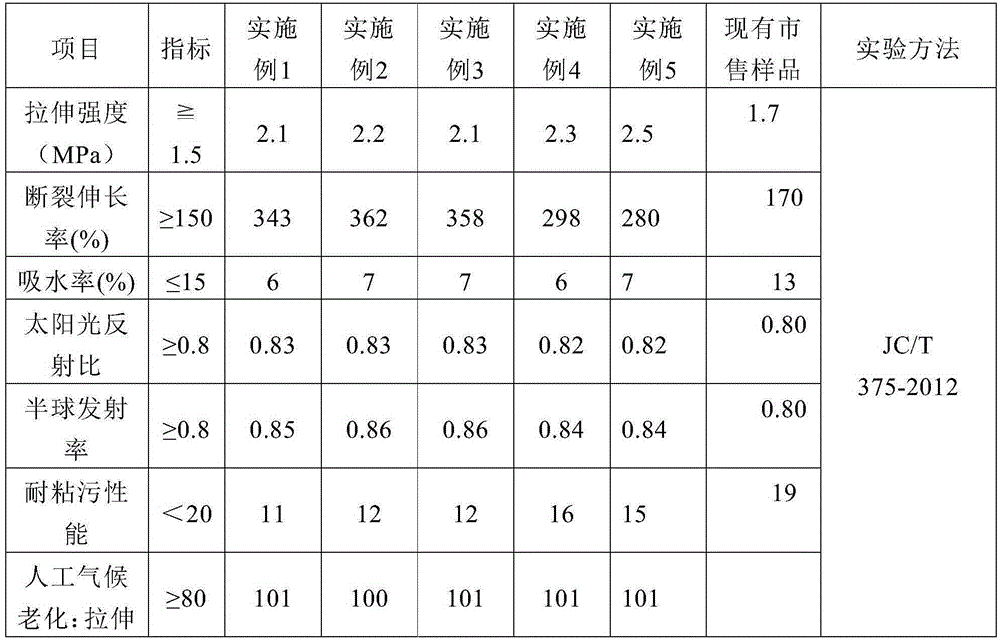

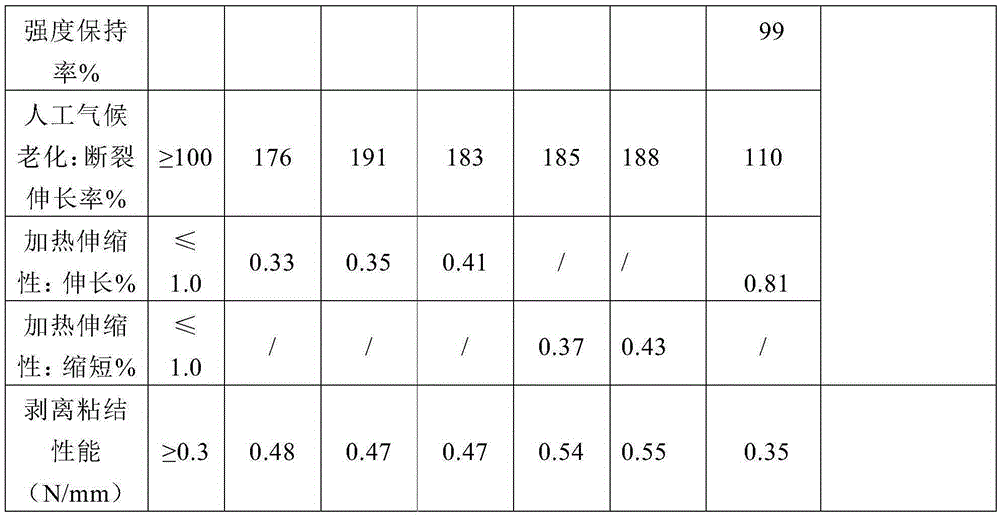

Compound-type metal roof thermal-insulation waterproof coating and preparing method thereof

ActiveCN105331220AEfficient conductionUniform conductionAntifouling/underwater paintsPaints with biocidesThermal insulationHeat conducting

The invention relates to a compound-type metal roof thermal-insulation waterproof coating and a preparing method thereof. The compound-type metal roof thermal-insulation waterproof coating is composed of a surface layer coating and a base layer coating. The surface layer coating is prepared from water, dispersing agents, antifoaming agents, pigment, hollow glass beads, inorganic-thixotropy thickening agents, inorganic filler, silicone-modification acrylic emulsion, acrylic emulsion, film forming assistants, pH value regulation agents, thickening agents and antifreeze agents; the base layer coating is prepared from water, dispersing agents, antifoaming agents, pigment, heat-conducting functional filler, inorganic-thixotropy thickening agents, inorganic filler, acrylic emulsion, pH value regulation agents, thickening agents and antifreeze agents. Compared with the prior art, the problems that bonding of a present waterproof material and a metal base material is not firm, aging is prone to occurrence and the service life is limited are solved, and the compound-type metal roof thermal-insulation waterproof coating has the advantage of integrating water proofing, protection, rust protection and thermal insulation.

Owner:上海北新月皇新材料集团有限公司

Self-cleaning antifouling inter wall paint

InactiveCN105131772AImprove water resistanceGood weather resistanceAntifouling/underwater paintsPaints with biocidesEmulsionFluorocarbon

The invention discloses a self-cleaning antifouling inter wall paint. The inner wall paint comprises raw materials: modified fluorocarbon emulsion, pure acrylic emulsion, light calcium carbonate, calcined kaolin, diatomite powder, forsterite powder, nano-stannic oxide, magnesium sulfate, hydroxyethyl cellulose, a dispersant SN-5040, a multifunctional auxiliary agent AMP-95, 2,2,4-Trimethyl-1,3-pentanediol monoisobutyrate, an antifoaming agent CF-16, negative ion-anti-microbial additives, sodium hexametaphosphate, a leveling agent L-150, a stain resistant agent JZM-1, glycol, mildew inhibitors, wetting agents and deionized water. The coating film of the inter wall paint is compact, and the inter wall paint is hydrophobic and oleophobic and has strong antifouling performance and self-cleaning capability. The coating effect is good and construction is convenient.

Owner:TIANCHANG YINHU PAINT

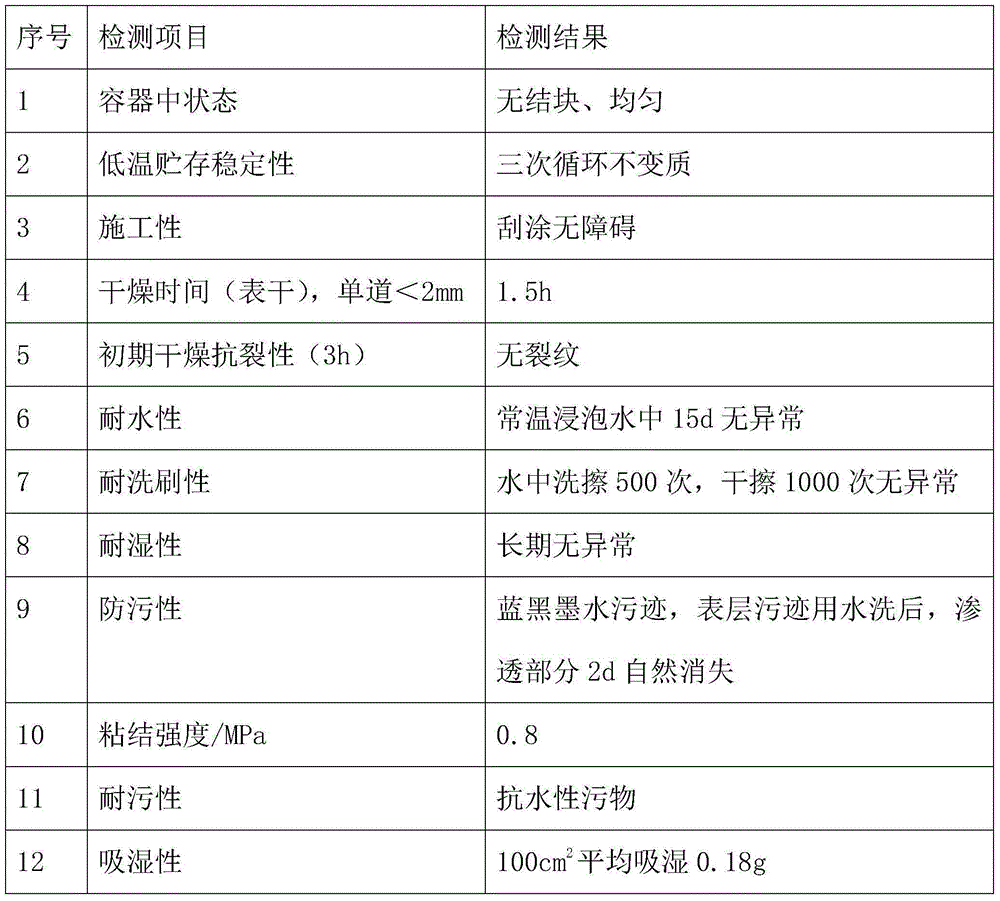

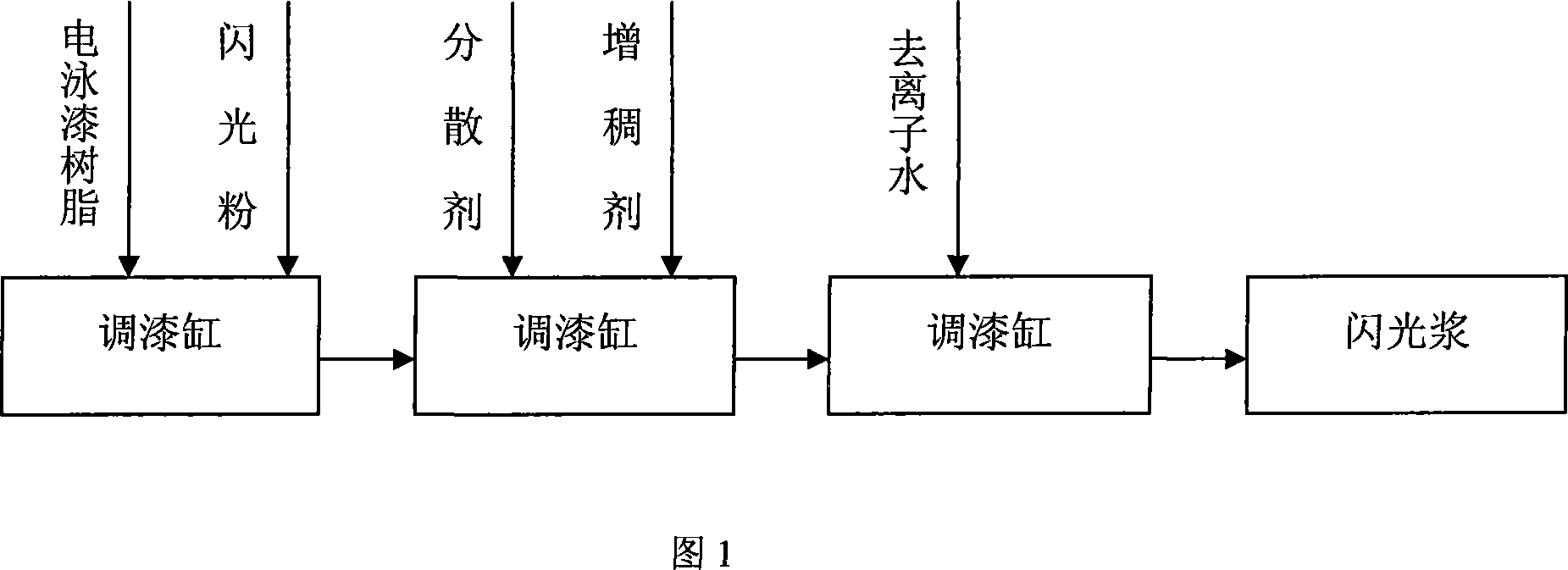

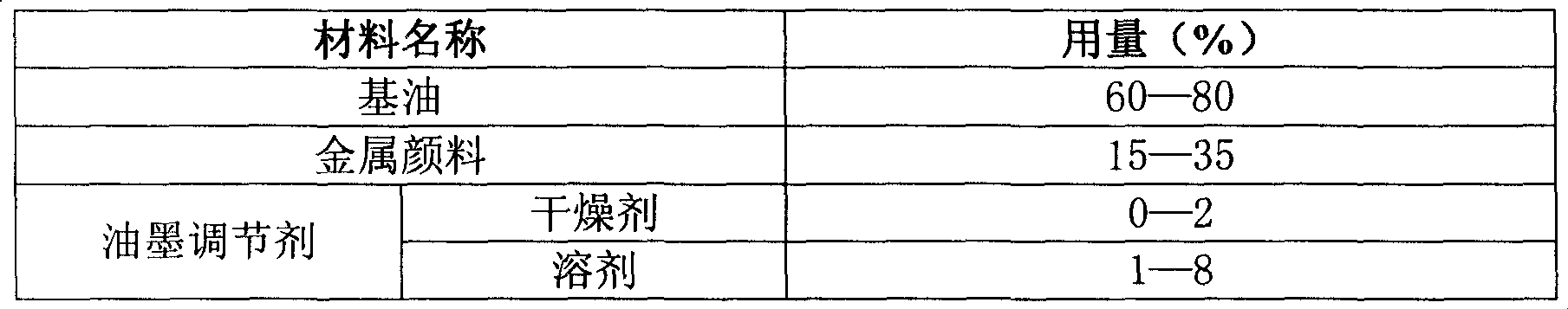

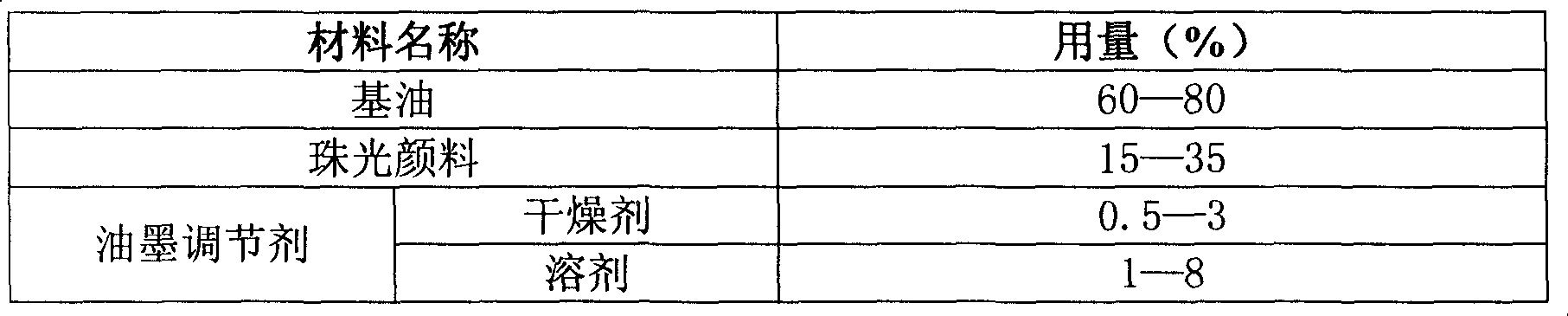

Flash electrophoretic paint and its prepn process

ActiveCN101089103AGood toughnessHigh hardnessPolyurea/polyurethane coatingsPaints for electrolytic applicationsSolventChemistry

The present invention discloses one kind of flash electrophoretic paint and its preparation process. The flash electrophoretic paint is compounded with the materials including resin as the base material 1000-1500 weight portions, flash powder 15-200 weight portions, dispersant 5-50 weight portions, thickener 5-100 weight portions, color paste 50-300 weight portions and deionized water 2000-4000 weight portions. The electrophoretic paint film formed with the flash electrophoretic paint and through an electrophoresis process has high toughness, high hardness, bright beautiful color, no discoloring and excellent corrosion resistance. The electrophoretic paint may be used to replace available paint combination of electrophoretic primer, color primer and coating varnish, and this results in short technological path and low cost. In addition, the water-thinned electrophoretic paint is environment friendly.

Owner:武汉双虎涂料股份有限公司

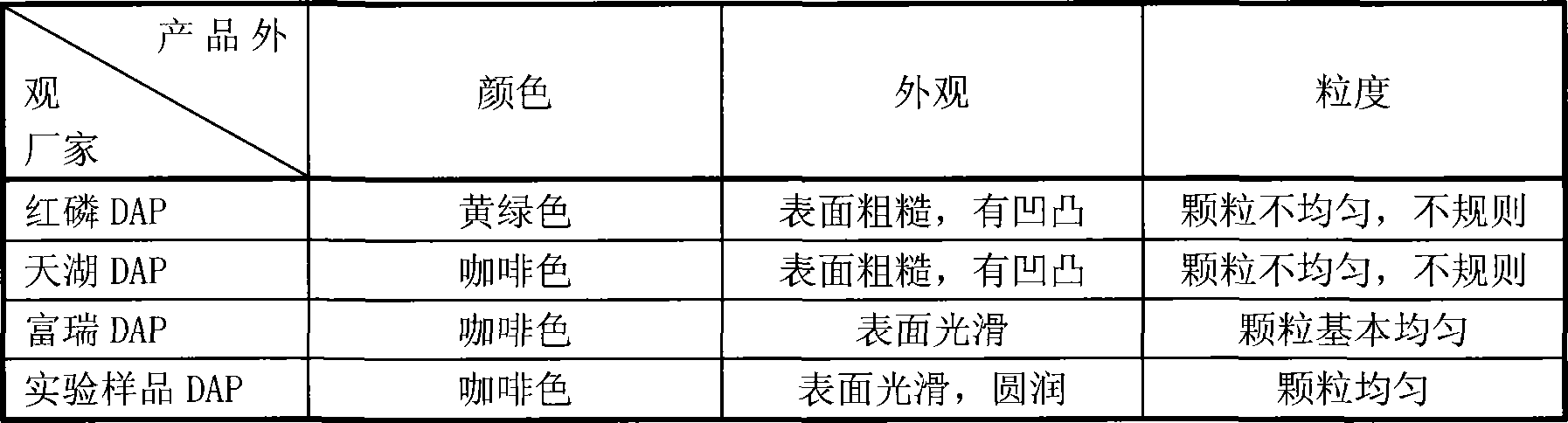

Method for dyeing phosphorus complex fertilizer

InactiveCN101234926AComponents that do not changeUniform colorFertiliser formsFertilizer mixturesDiammonium phosphatePhosphoric acid

The invention relates to a method for processing chemical fertilizer, in particular to a method for dyeing chemical fertilizer. The invention includes the preparation, addition, dyeing, and granulation of colorant, and comprises the following steps: A. adding weighted colorant into a phosphoric acid tank, an acid pump outlet or a pre-neutralization slot for producing phosphate compound fertilizer; B. mixing water solution with phosphate compound fertilizer for dyeing; C. spraying the slurry for granulation after dyeing. The method for dyeing chemical fertilizer is mainly used for appearance dyeing of various nitrogen and phosphate fertilizers and products, and can dye coffee on products evenly and effectively. The dyed products with high-quality appearance color do not have discoloration and color change so as to hit the target of unifying product color. Compared with that imported from America, diammonium phosphate dyed through the method for dyeing chemical fertilizer has the equal and even better color. As coffee color products sell well in the market, the invention can reduce sales cost.

Owner:云南云天化国际化工有限公司

Colored oily fertilizer anti-caking agent prepared from inorganic pigment and application of colored oily fertilizer anti-caking agent

The invention relates to a colored oily fertilizer anti-caking agent prepared from inorganic pigment and application of the colored oily fertilizer anti-caking agent. The colored oily fertilizer anti-caking agent comprises the following ingredients in percentage by mass: 2-4% of iron oxide red, iron oxide yellow, iron oxide blue, iron oxide green, iron oxide purple, iron oxide brown or iron oxide black and 98-96% of an oily anti-caking agent, and is prepared by uniformly milling and mixing such ingredients by adopting a horizontal mill. The colored oily fertilizer anti-caking agent is applied to fertilizer coating, and 1.0-1.6 kilograms are used in each ton of a fertilizer, so that a corresponding color of red, yellow, blue, green, purple, brown or black is shown in the appearance of the fertilizer. The colored oily fertilizer anti-caking agent with the corresponding color of red, yellow, blue, green, purple, brown or black is provided for fertilizers with different appearance colors, so that inside and outside colors of the fertilizer are consistent, color difference and materials with inconsistent colors are avoided; the colored oily fertilizer anti-caking agent is stable and uniform in color, strong in coating capability, resistant to light and heat, colorfast and non-discoloring, can also be used as a fertilizer variety distinguishing and anti-counterfeiting mark, and is low in use cost and good in anti-caking performance.

Owner:HUBEI FORBON TECH

Special modified rosin resin for road marking paint and preparation method of special modified rosin resin

InactiveCN103360952AStrong absorption capacityImprove thermal stabilityRosin coatingsNatural resin chemical modificationLacquerAntioxidant

The invention discloses a special modified rosin resin for road marking paint and a preparation method of the special modified rosin resin. The modified rosin resin comprises the following raw materials in percentage by weight: 67.4%-84.8% of gum rosin, 10%-18% of glycerol, 2%-8% of fumaric acid, 3%-6% of lauric acid, 0.1% - 0.3% of antioxidant and 0.1% - 0.3% of ultraviolet light absorber. The preparation method of the special modified rosin resin comprises the following steps of: adding the gum rosin to a reaction kettle, introducing nitrogen, heating so as to dissolve rosin, adding the fumaric acid, the antioxidant, the glycerol and the lauric acid so as to carry out polymerization esterification reaction, then adding the ultraviolet light absorber, uniformly stirring, and cooling to a room temperature, thus obtaining the product. The modified rosin resin produced by the method can be used for ensuring the strong adhesive force of coatings and has good flexibility and the advantages of cost conversation and environmental protection.

Owner:GUANGXI ZHONGCHANG RESIN

Micro-emulsified biological diesel and preparation method thereof

The invention particularly relates to micro-emulsion biological diesel oil and a process for preparation thereof. The technical proposal is that the component and content of the micro-emulsion biological diesel oil comprise biological diesel oil 50-70wt%, compound emulsifier 1-10wt%, carbinol 10-30wt%, cosolvent 1-5wt%, water 5-15wt% and ethanolamine 0.1-1wt%. The process for preparing the micro-emulsion biological diesel oil comprises the following specific steps: adding compound emulsifier in biological diesel oil according to the content of the above each component, adding mixed solution of carbinol, water and cosolvent after completely dissolving through stirring, stirring 20-60min, getting ethanolamine, and adjusting to be transparent. The process for preparation of the invention has the advantages of simple technique, low production cost and environmental friendly. The micro-emulsion biological diesel oil which is prepared has the advantages of transparency, nondiscolouring, long stabilization time and excellent oil saving property, which is not layered in long term.

Owner:WUHAN UNIV OF SCI & TECH

Color smoking treatment technology for wood modification face layer

ActiveCN105729597ADrying helpsGood for smokingWood treatment detailsThermal wood treatmentVacuum pumpingSmoking treatment

The invention discloses a color smoking treatment technology for a wood modification face layer. The color smoking treatment technology comprises the specific steps that firstly, to-be-treated wood is stacked and is blown through hot air; secondly, a layer of alcohol is brushed on the surface of the wood, cleaning is conducted through a sodium carbonate solution, then thorough scrubbing is conducted through water, and the wood modification face layer is obtained; thirdly, the overall wood is immersed in a phosphoric acid solution and taken out to be aired dry; fourthly, the wood is subjected to smoking, and the wood is subjected to further baking smoking through fuel materials; fifthly, the wood is placed in a heat treatment box to be tidily placed, rapid temperature rising is conducted, vacuum pumping is carried out, then slow temperature rising is conducted, and drying is conducted till absolute dry is achieved; sixthly, the surface of the wood subjected to heat treatment is wiped thoroughly through water; seventhly, the surface of the modification face layer is coated with a wood modification agent; and eighthly, the surface of the wood modification agent is coated with a layer of protective paint again. According to the color smoking treatment technology, physical treatment and oil paint treatment are combined, the permanency of the wood color is guaranteed, the wood waterproofness is guaranteed as well, and the wood is free of toxicity, environment-friendly, safe and sanitary.

Owner:JIANGSU KENTIER WOOD

Hot curing solder resistant printing-ink composition

The invention relates a hot-set solder resisting ink composition for production of printed circuit board which is prepared by combining some of heat hardening resin 30-70% (weight ratio), curing agent 2-8%, deflocculating agent 5-30% and filler 0-30%. The printed circuit board made from the hot-set solder resisting ink composition provided by the invention possesses good heat-proof quality, fast adherence, high degree of glossiness, and less odor.

Owner:DAHUA GROUP

Multifunctional black master batch for polypropylene resin and preparation method thereof

The invention discloses a multifunctional black master batch for polypropylene resin. The multifunctional black master batch comprises the following components in percentage by weight: 25-35 percent of pigment carbon black, 1-4 percent of a carbon nanotube, 2-6 percent of a compatilizer, 2-8 percent of an aging-proof agent, 15-25 percent of a dispersing lubricating agent and 35-45 percent of carrier resin, wherein the carbon nanotube and the pigment carbon black construct an anti-static system together; and the aging-proof agent and the pigment carbon black construct an aging-proof system together. Polypropylene is effectively prevented from aging, and the requirements of coloring, color retention and dust pollution prevention on a one-step molded polypropylene external decorative part for black electrical appliances are met. The preparation method comprises the following steps of: adding the pigment carbon black, the carbon nanotube, the compatilizer, the aging-proof agent, the dispersing lubricating agent and the carrier resin into a high-speed mixer for mixing; feeding into a dual-screw extruder for extruding; and cooling, drying, granulating and packing to obtain a needed master batch. The multifunctional black master batch has the characteristics of small using amount of the carrier resin, low consumption of a master batch molding antioxidant and simple feeding in a molding process of downstream materials, and can be widely applied to colorization of polypropylene resin.

Owner:NANHUA UNIV +1

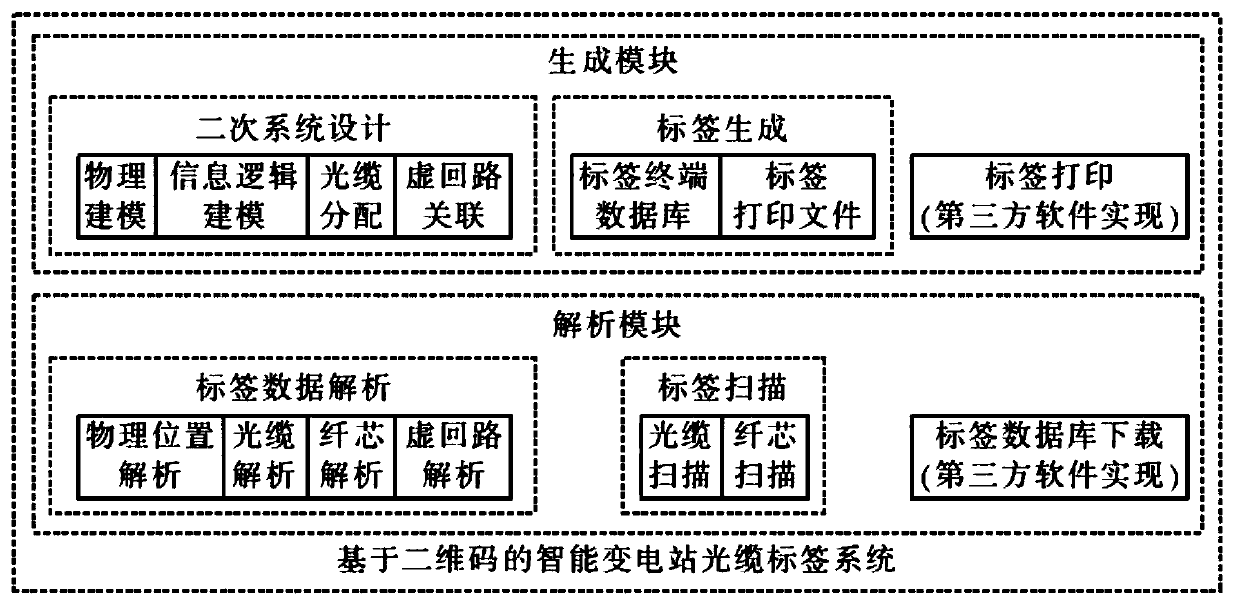

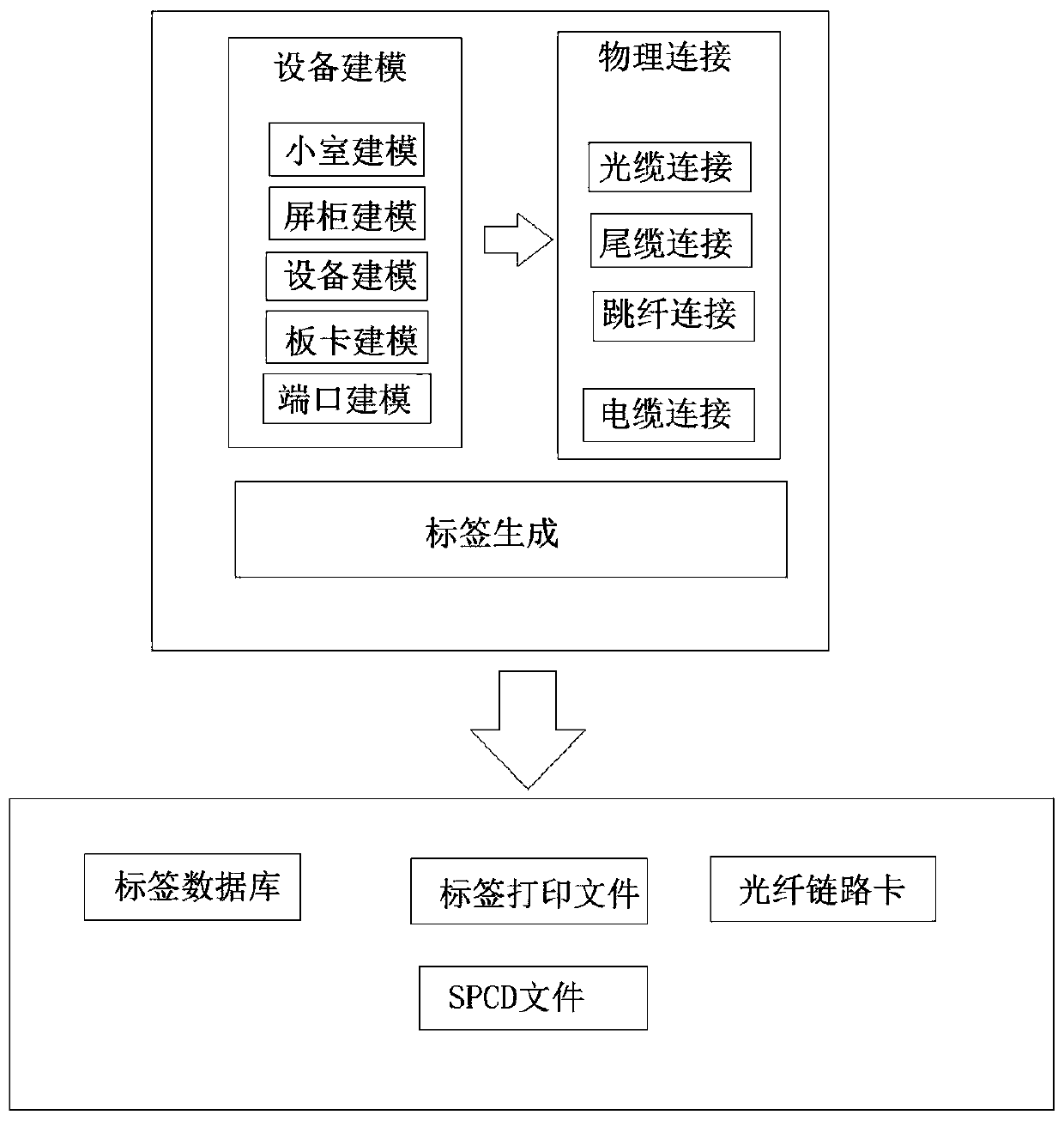

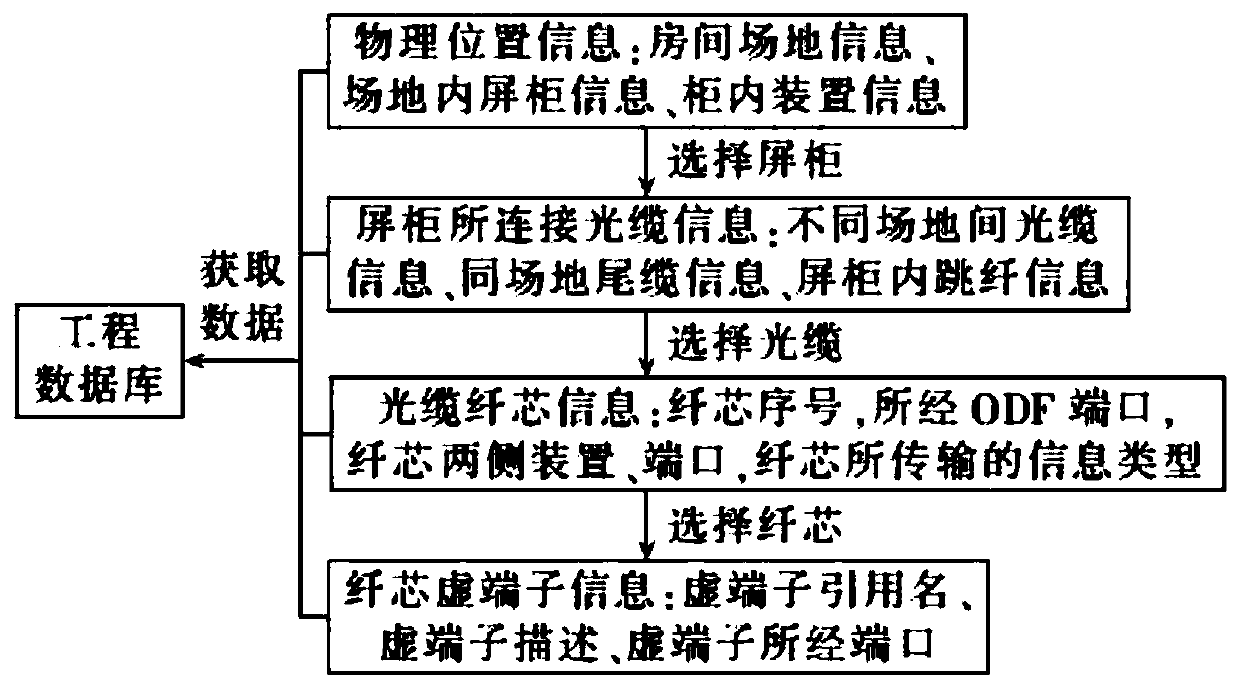

Intelligent label system

PendingCN110782047AImprove debugging efficiencyImprove operation and maintenance efficiencyStampsData processing applicationsComputer hardwareSmart substation

The invention discloses an intelligent label system. The intelligent label system comprises a generation module and an analysis module, the generation module stores designed secondary circuit physicalinformation and logic information into a database, generates a label file and prints a two-dimensional code label; the analysis module takes a two-dimensional code as an entrance, the connection information of the optical cable and the virtual loop information transmitted in the optical cable are rapidly displayed through a handheld terminal in a field scanning mode, the signal searching time isshortened from several minutes to several seconds, and scanning and watching are achieved. By scanning the two-dimensional code on the optical cable label, the physical connection information of the optical cable fiber core and the virtual loop information transmitted in the fiber core can be quickly positioned, and the debugging, operation and maintenance efficiency is improved. The advantage ofdigitization of the secondary circuit design of the intelligent substation is fully utilized, the problem that secondary circuit principle information cannot be visually obtained in field work of theintelligent substation can be effectively solved, and virtual-real correspondence of a process layer physical circuit and a logic circuit is accurately achieved.

Owner:小波科技有限公司

Anionic diatom ooze internal wall coating

InactiveCN105236835AGood weather resistanceImprove water resistanceHydroxypropylmethyl celluloseEmulsion

The invention discloses an anionic diatom ooze internal wall coating comprising following raw materials: organic silicon-modified styrene-acrylic emulsion, pure acrylic emulsion, diatomite, vermiculite powder, perlite powder, nano titanium dioxide, an anionic additive, a silane coupling agent KH-560, a silane coupling agent KH-570, sodium hexametaphosphate, alcohol ester-12, propylene glycol methyl ether, polysorbate, sodium tripolyphosphate, hydroxypropyl methyl cellulose, propylene glycol, AMP-95, a defoaming agent, a mildew-proofing agent and deionized water. The anionic diatom ooze internal wall coating not only can clean air and release anions but also can absorb certain harmful substances in indoor air. The coating is environment-friendly and healthy.

Owner:TIANCHANG YINHU PAINT

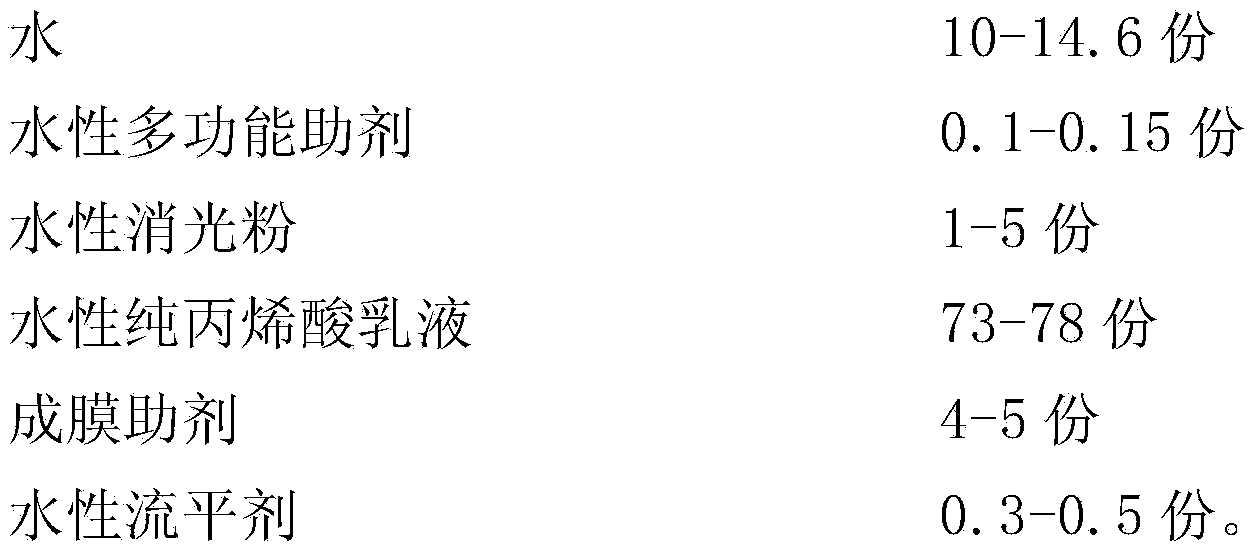

Outdoor aqueous woodenware matte clean finishing coat and its preparation method

The invention relates to a woodenware paint and a preparation method, and especially relates to an outdoor aqueous woodenware matte clean finishing coat and its preparation method, which belong to the paint field for building decoration. The provided outdoor aqueous woodenware matte clean finishing coat comprises the following raw materials by weight: 10-14.6 parts of water, 0.1-0.15 parts of aqueous multifunctional auxiliary agent, 1-5 parts of aqueous flatting silica, 73-78 parts of aqueous pure acrylic acid emulsion, 4-5 parts of film forming auxiliary agent and 0.3-0.5 parts of aqueous levelling agent. The prepared outdoor aqueous woodenware matte clean finishing coat has excellent weatherability, can protect base materials from being destroyed; the usage is simple, the construction tolerance is wide and the application scope is wide.

Owner:SKSHU PAINT

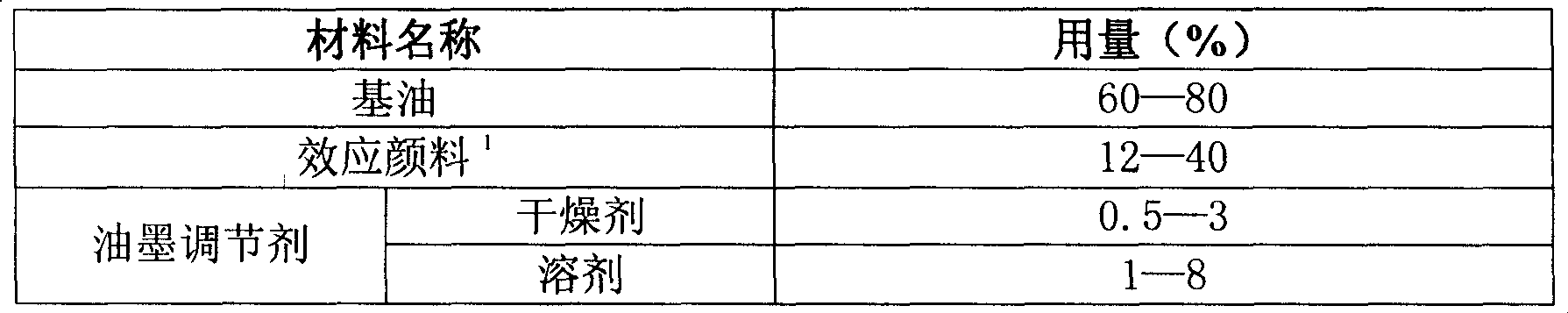

Ink vehicle composition for water-scraped without set-off intaglio

ActiveCN101362870AGood storage stabilityDoes not change colorInksOther printing apparatusAcid valueColor saturation

The invention provides a composite of linking materials, which is suitable for a water-washing non-smearing curved gravure ink. The composite consists of the following three components: component A: isocyanate-modified alkyd with a weigh percentage of 10 to 70 percent; component B: m-phenylene alkyd and / or modified m-phenylene alkyd with a weight percentage of 5 to 40 percent; component C: at least one phenolic resin oil modified by seed fat with a weight percentage of 10 to 70 percent; besides, the acid value of the composite of the linking materials is 10 to 30mgKOH / g and the viscosity is 4 to 16Pa.S / 40DEG C. The invention also provides a water-washing non-smearing curved gravure ink which mainly adopts the linking materials which improve the storage stability and the printing property of the ink, obviously improves the color saturation and lustrousness of a printed product and is beneficial to improving the anti-fake effect of the printed product.

Owner:CHINA BANKNOTE PRINTING & MINTING

Litopenaeus vannamei preservative and preparation and use method thereof

InactiveCN103947739AGuaranteed edible safetyChange colorMeat/fish preservation using chemicalsChitosan nanoparticlesPreservative

The invention discloses a litopenaeus vannamei preservative which is characterized by being prepared from the following raw materials in parts by weight: 15 parts of nano chitosan, 5-7 parts of ascorbic acid (Vc), and 1 part of phytic acid, wherein the nano chitosan is prepared by adopting a following method: adding chitosan in 1% acetic acid solution to prepare 0.5mg / mL chitosan solution, regulating pH value to 3.4-4.8 by using 1 mol / L NaOH solution; and dropwise adding 1mg / mL sodium tripolyphosphate solution in the chitosan solution so as to obtain a mixed solution, ensuring that the mass ratio of the sodium tripolyphosphate to the chitosan reaches 1:2, magnetically stirring the mixed solution at a room temperature for 60min continuously, and crosslinking to chitosan nano particles through ionic reaction. The nano chitosan is compounded with the phytic acid and the ascorbic acid, so that a synergistic effect can be developed, and a relatively good refreshing effect is achieved in comparison with that of a manner of singly using the nano chitosan, the phytic acid and the ascorbic acid. The compound preservative disclosed by the invention is excellent in antibacterial effect, and is capable of enabling meat of litopenaeus vannamei to keep delicious and keeping the attractive appearance in a storage period.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

Anti-aging heat radiation paint for LED lamp and preparation method thereof

The invention provides an anti-aging heat radiation paint for an LED lamp, wherein the paint is prepared by the raw materials by weight: 25-28 parts of aniline presence of formaldehyde resin, 20-25 parts of E-12 epoxy resin, 6-8 parts of 2-methyl methacrylate, 3-4 parts of tetraethylenepentamine, 15-18 parts of aluminum nitride powder, 1-2 parts of graphite alkene, 1-2 parts of carbon nanotube, 4-5 parts of titanium dioxide, 1-2 parts of barium sulfate, 2-3 parts of zinc oxide, 4-5 parts of glycol, 2-3 parts of silane coupling agent KH-550, 10-12 parts of phthalate, 1-2 parts of chromic oxide(Cr_2O_3), 12-14 parts of ethyl acetate, 8-10 parts of xylene, and 4-5 parts of film-forming auxiliary agent. Aluminum nitride powder is added to make the paint have advantages of high heat conductive rate and good heat radiation effect; titanium dioxide is added to make the paint have excellent anti-aging effect; under daylight irradiation, the paint has advantages of sunlight resistance, no cracking, no color change, and acid and alkali resistance; graphite alkene and carbon nanotube are added to make the paint have advantages of easy construction, greatly enhance the heat conduction effect of the paint, and improve the pot-opening effect of the paint.

Owner:天长市天泰光电科技有限公司

Agaricus bisporus film-free preservative and use thereof

InactiveCN102177960ANo pollution in the processChange colorFruit and vegetables preservationVitamin CAdditive ingredient

The invention discloses an agaricus bisporus film-free preservative and use thereof. The agaricus bisporus film-free preservative is an aqueous solution of the following components in percentage by mass: 1.2 to 2.5 percent of low-molecular-weight(1,000 to 3,000) chitosan oligosaccharide, 0.4 to 0.6 percent of citric acid, 0.4 to 0.6 percent of sodium chloride, 0.2 to 0.3 percent of vitamin C, 0.0001 to 0.0003 percent of cysteine. Compared with the agaricus bisporus preservative in the prior art, the agaricus bisporus film-free preservative disclosed by the invention has the prominent advantages that: the edible low-molecular-weight chitosan oligosaccharide is used as a main ingredient; film is not formed; color is not changed; the operation is convenient; the shelf period can be prolonged by 3 to 5 days at normal temperature (25 DEG C) and by 15 to 20 days at a low temperature (5 DEG C); and the preservative is edible, pollution-free, environment-friendly and low in cost.

Owner:LIANYUNGANG ACAD OF AGRI SCI

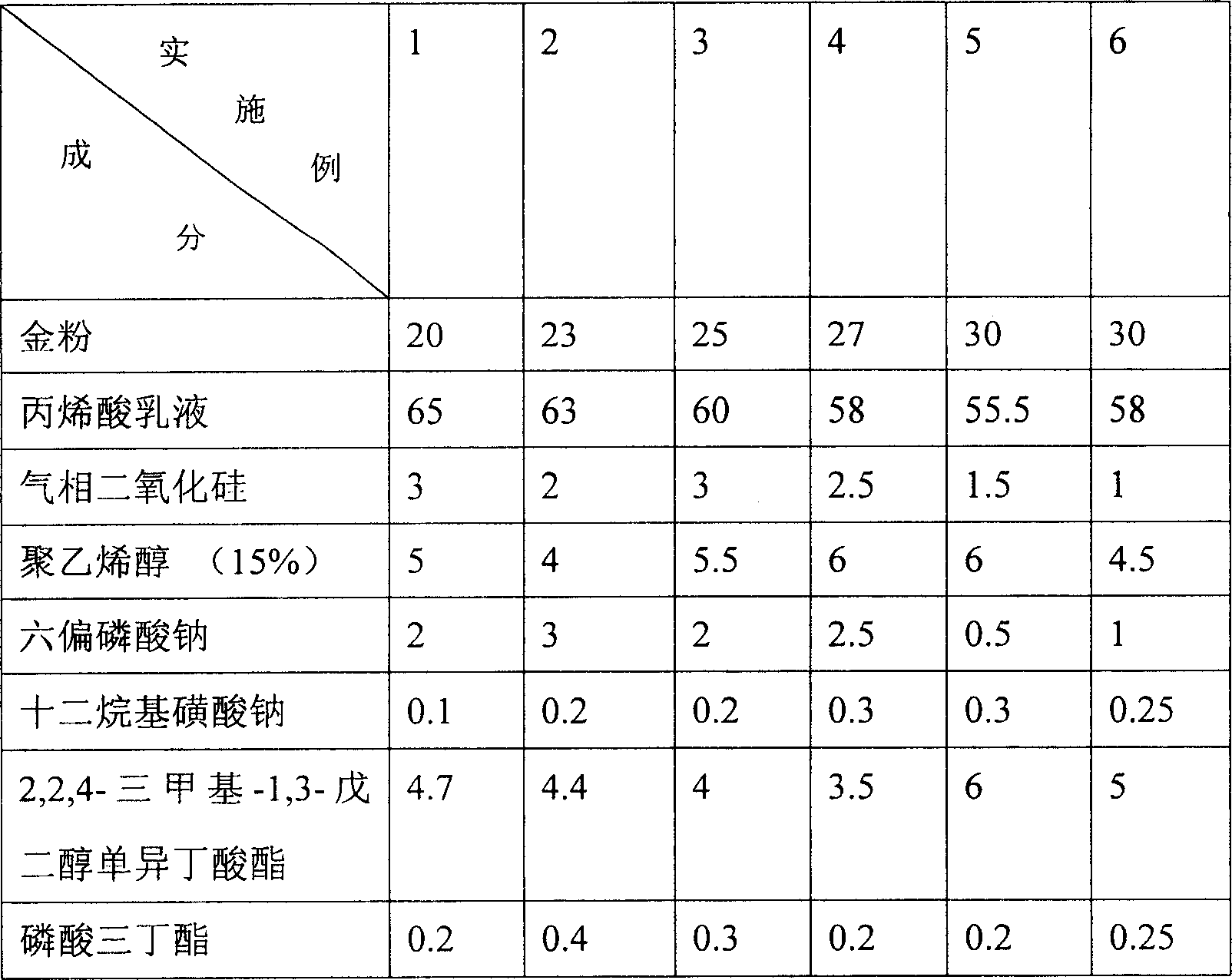

Water-soluble gold and silver inks, and preparation method

This invention relates to a method for preparing water-soluble Au / Ag ink, which comprises: Au / Ag powder 20-30 wt.%, acrylic acid emulsion 55-65 wt.%, 15% polyvinyl alcohol 4-6 wt.%, gaseous SiO2 1-3 wt.%, dispersant 2-4 wt.%, wetting agent 0.3-1.0 wt.%, film-forming agent 3-5 wt.% and antifoam 0.2-0.4 wt.%. The water-soluble Au / Ag ink has such advantages as high water leakage resistance, high adhesiveness, high corrosion resistance, high electrostatic resistance, good anti-aging capacity, no color change, no fading, simple application process, no toxicity to operators, no environmental pollution, no flammability and no explosion. The water-soluble Au / Ag ink can be used to paint packages of cigarette and food as a substitute for Al / Pt composite paper.

Owner:常德市东正环保材料科技有限公司

Making method of luminous fire label

The invention provides a making method of a luminous fire label, and the making method is as follows: performing ball milling on raw materials potash feldspar, soda feldspar, chinastone, pyrophyllite, diopside, kaolin, alumina ore, Xinyang soil, black clay and sodium potassium feldspar to obtain slurry, using a drying tower to dry until the moisture is less than 6.5% to obtain powder, using a press to press the powder into a blank mold; burning the blank mold at the high temperature of 1200-1250 DEG C to obtain a ceramic tile with the moisture absorption rate of 1%+ / -0.5; printing patterns with different labels on the ceramic tile surface by a screen printing plate screen printing way, and then entering into a roller kiln at 1200 DEG C for firing. The luminous fire label prepared by the method can resist the high temperature of 1200 DEG C without damage to the label, and the luminous fire label can really play the effects of protecting people's life and guiding correct escape routes.

Owner:爱瑞科新材料(淄博)有限公司

Production method for fireproof, flame-resistant, medium-density fiber closet plate

InactiveCN109304787AAlleviate the contradiction between supply and demandHigh hardnessNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesFiberSizing

The invention discloses a production method for a fireproof, flame-resistant, medium-density fiber closet plate. The method comprises the steps of (1) preprocessing of raw materials, (2) screening, (3) steaming and boiling for softening, (4) grinding, (5) sizing and drying, (6) prepressing, (7) hot pressing, (8) sawing and sanding, (9) veneering and hot pressing and (10) edge cutting. In this way,a finished product is obtained. The method disclosed by the invention is characterized in that eucalyptus barks and branches and waste leftover bits and pieces left after panel manufacture are takenas main raw materials, other miscellaneous wood is added and waste is recycled, so wood resources can be utilized fully and effectively; and modified paraffin and flame-resistant urea-formaldehyde resin adhesive are added, so resistance of the product to fire and flame is greatly enhanced. The medium-density fiber cabinet plate is highly resistant to fire, flame and water and low in the content offormaldehyde, so the product is a safe and environment-friendly closet plate.

Owner:广西横州丽冠环保材料有限公司

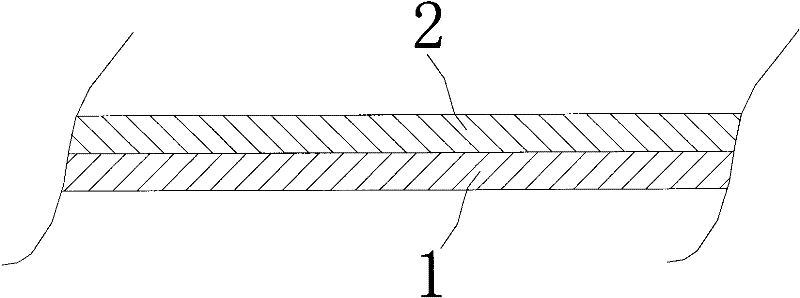

Termination adhesive tape and manufacture method thereof

InactiveCN102250562AMeet application needsLow costFilm/foil adhesivesEster polymer adhesivesIsooctyl acrylateBenzoyl peroxide

The invention relates to the technical field of adhesive tapes, and particularly relates to a termination adhesive tape and a manufacture method thereof. The termination adhesive tape comprises a base tape and a glue layer located on the base tape, wherein the glue layer is an acrylic glue layer, which is composed of the following raw materials in parts by weight: 1-5 parts of butyl acrylate, 5-12 parts of vinyl acetate, 40-60 parts of ethyl acetate, 20-35 parts of iso-octyl acrylate, 0.5-2 parts of hydroxyethyl methacrylate, 1-3 parts of acrylic acid, 2-4 parts of toluene and 0.1-0.4 part of benzoyl peroxide. The manufacture method sequentially comprises the following steps: A. preparing the acrylic glue: titrating toluene-dissolved benzoyl peroxide used as an initiator to a mixed solution of butyl acrylate, vinyl acetate, ethyl acetate, iso-octyl acrylate, hydroxyethyl methacrylate and acrylic acid at the temperature of 80 DEG C, and ensuring the titration time of 2 hours and self-reaction time of 2.5 hours; and B. applying the acrylic glue on the base tape, sequentially drying, cooling and coiling. The termination adhesive tape provided by the invention has the advantages of low cost, beautiful appearance, simple manufacture process and good electrolyte resistance.

Owner:东莞市苏粤电子包装材料有限公司

Health white spirit containing beneficial functional component

ActiveCN101007992ADoes not change colorDoes not affect the tasteOrganic active ingredientsMetabolism disorderBisulfideDaidzein

The invention discloses a health- caring wine containing good effective element. The wine with alcohol degree being 15- 75 (V / V %) comprises maltol, borneo camphor, cedrol, dimethyl trisulfide, dimethyl bisulfide, ligustrazine, daidzein, crust and puerarin, which not only changes wine color, but aslo does not influence waste, no toxic action. The health- care wine can improve bloos circulation, reduce blood pressure, reduce blood fat and promote circulation of qi and relieve pain, resist tumor and cause head pain after excessive drink.

Owner:SICHUAN TUOPAI SHEDE WINE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com