Patents

Literature

594 results about "Natural dye" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Natural dyes are dyes or colorants derived from plants, invertebrates, or minerals. The majority of natural dyes are vegetable dyes from plant sources—roots, berries, bark, leaves, and wood—and other biological sources such as fungi and lichens.

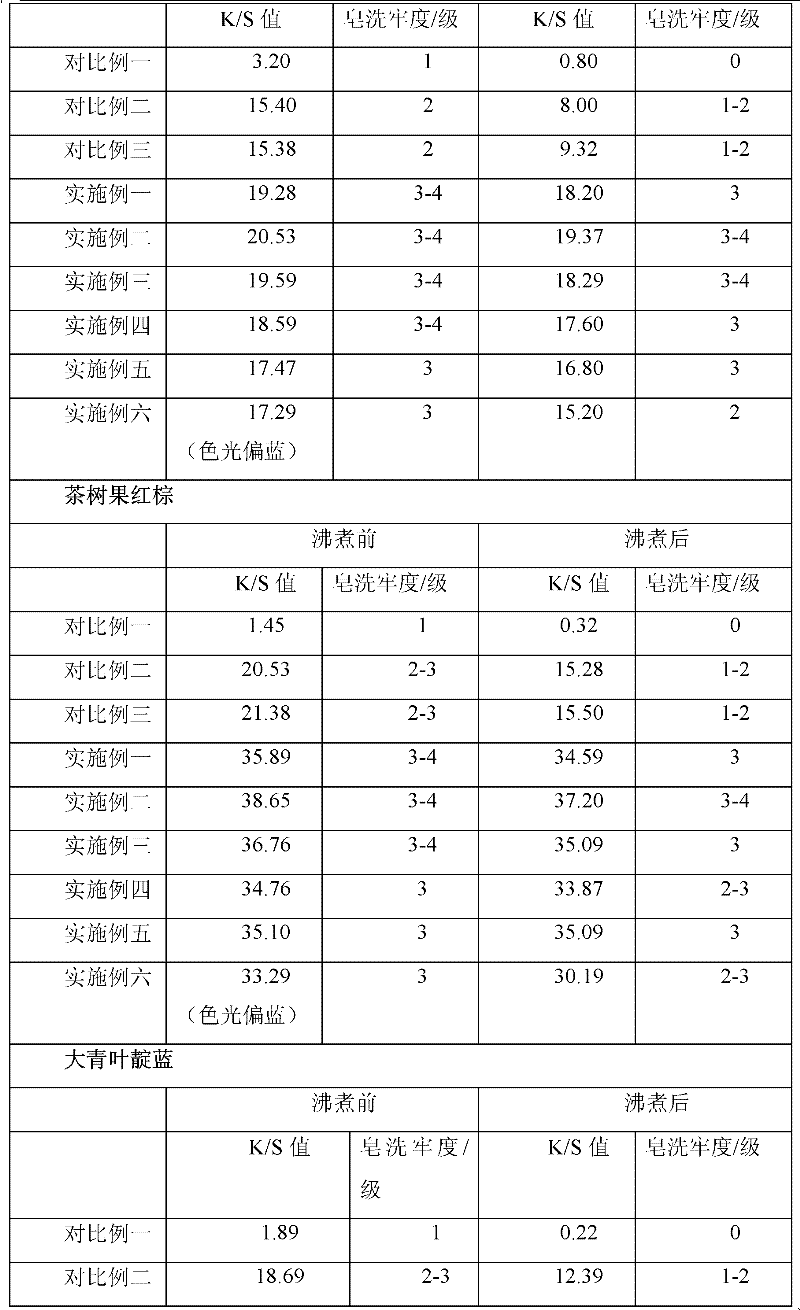

Natural dye dying method based on cotton fiber modification

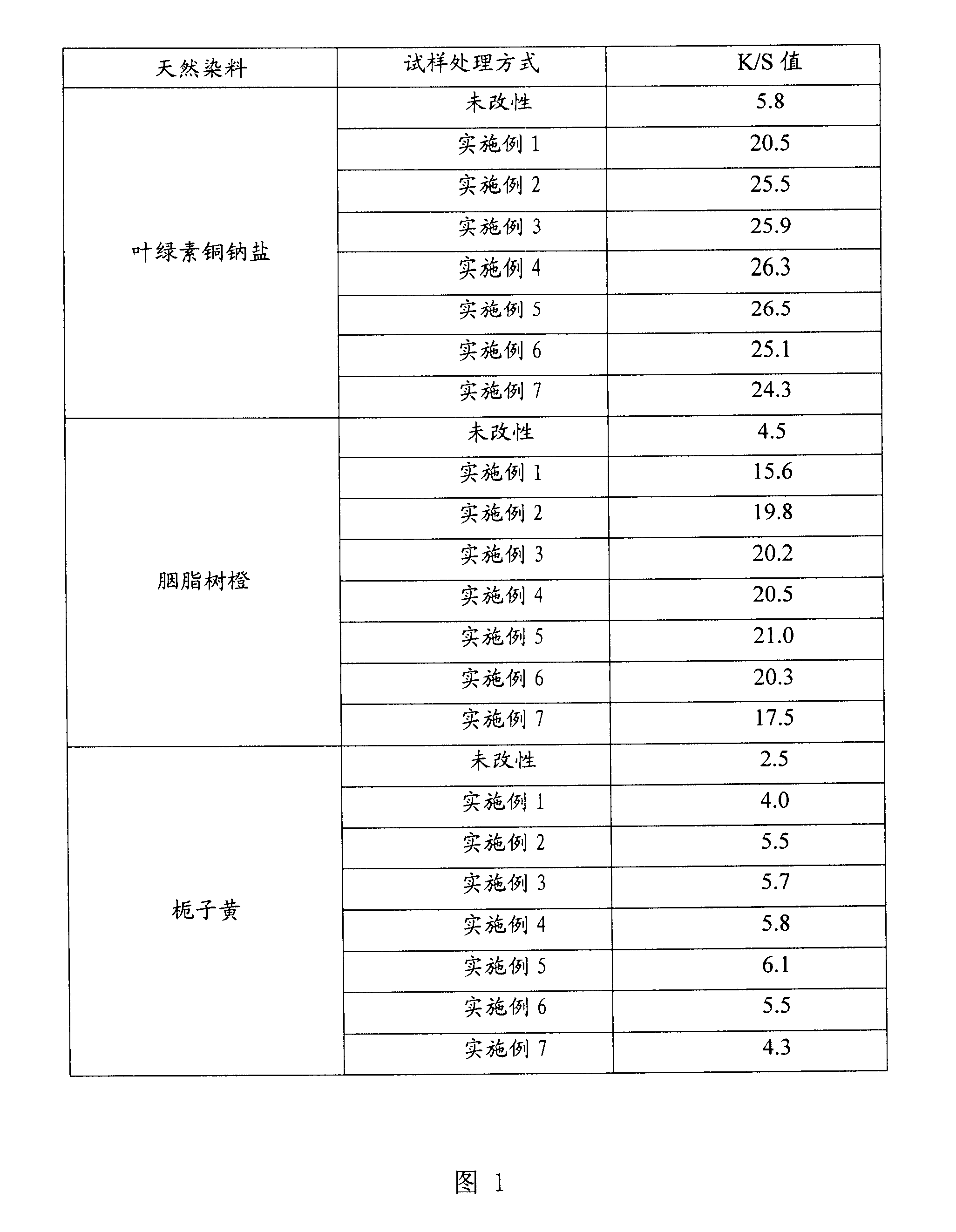

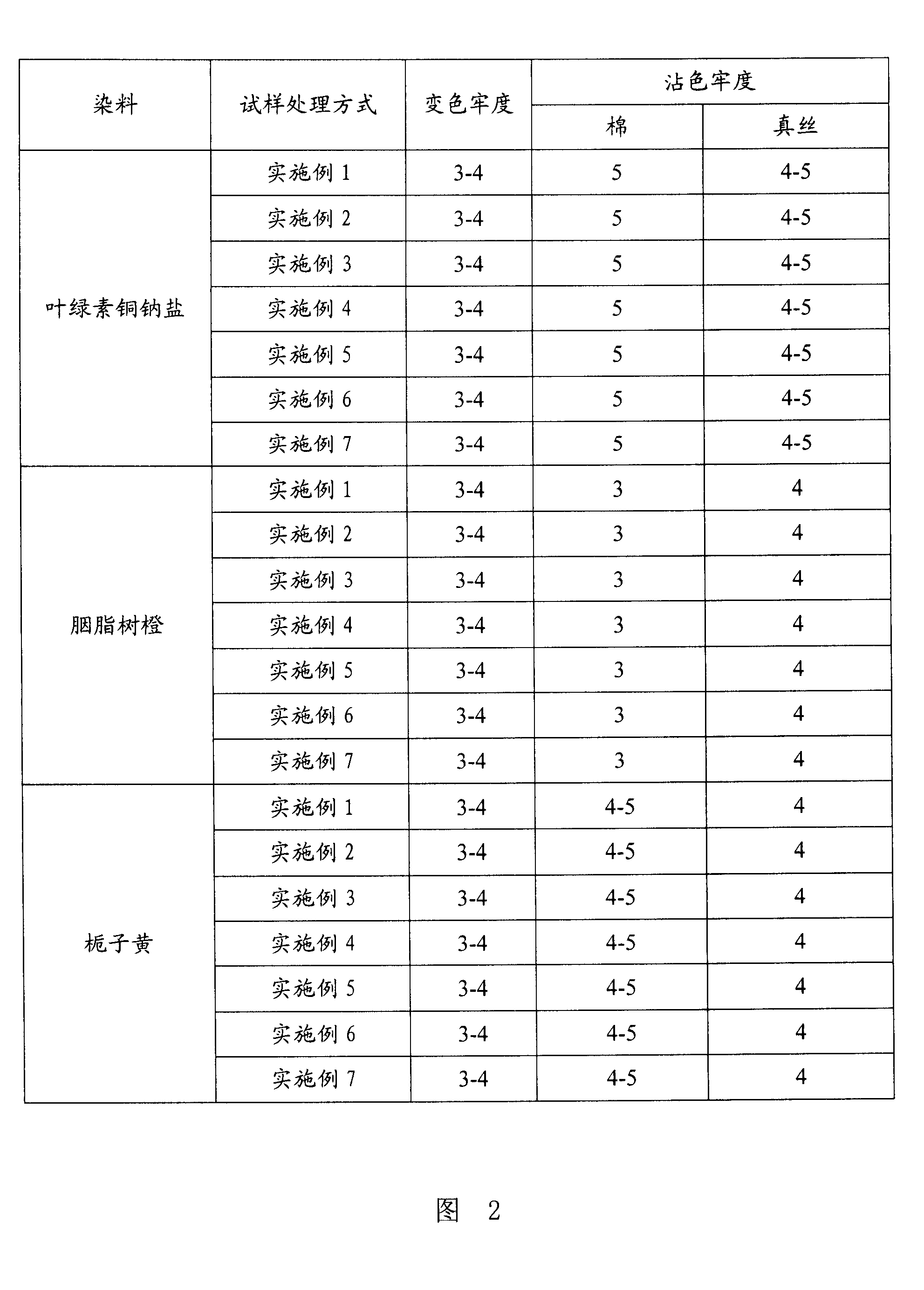

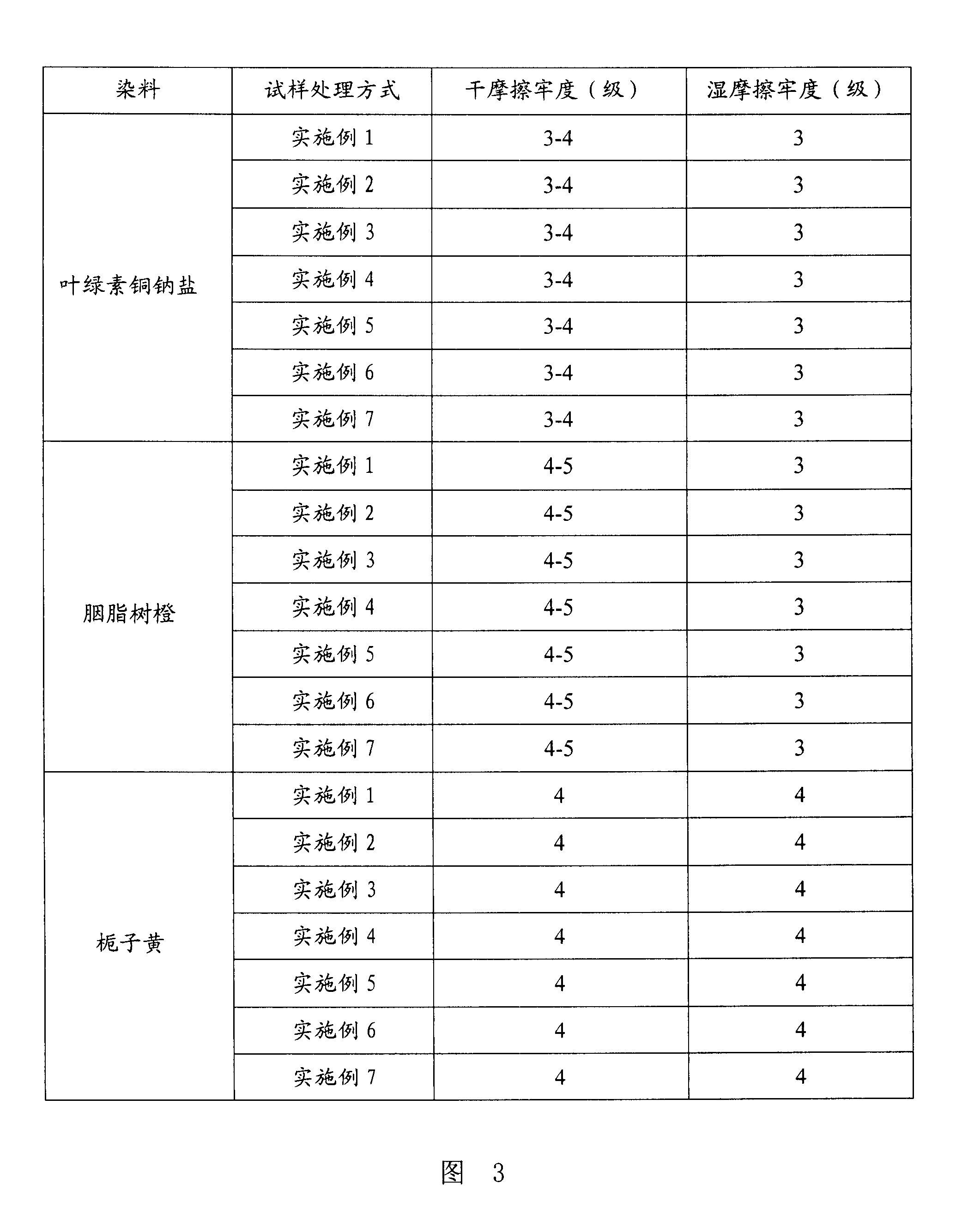

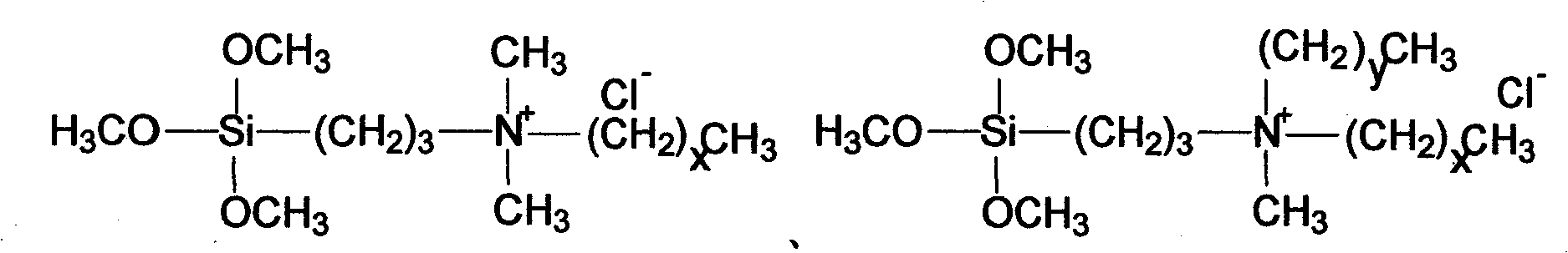

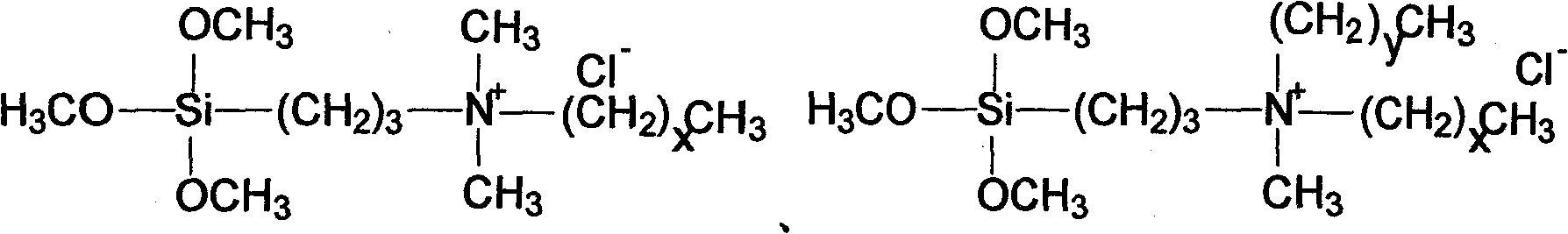

ActiveCN101187175AImprove adsorption capacityImprove dye uptakeDyeing processCotton fibreNatural dye

The invention relates to a dyeing method of natural dye material of cotton fabric, which belongs to the field of fabric dyeing and finishing technique and comprises: processing the modifying liquid by use of the modifying agent containing anode ions group, firstly modifying the cotton fabric and dyeing the fabric with the natural dyeing material, after cleaning, fulfilling the dyeing with the natural dye material of cotton fabric, wherein due to the modifying process on the cotton fabric in advance, the anode ion base is introduced into the cotton fabric to strengthen the combination ability from the cotton fabric to the natural dye material of cathode ion, which effectively improves the cotton fabric dyeing rate, color depth and dyeing evenness and distinctly improves the anti-washing and anti-abrasion firmness of the dyed cotton fabric. The process has simple operation, even dyeing and wide application prospect.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD +1

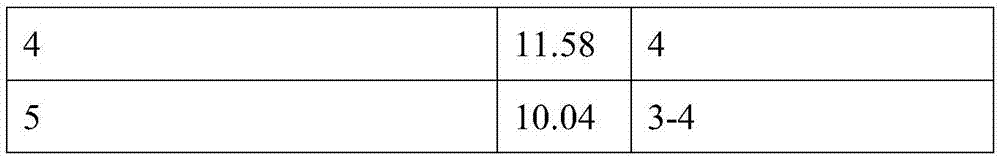

Ecological dyeing method for dyeing cotton fabric with mulberry red natural dye

InactiveCN101851868AImprove protectionNo allergic reactionDyeing processVegetal fibresEngineeringNatural dye

The invention relates to an ecological dyeing method for dyeing a cotton fabric with mulberry red natural dye, comprising the following steps: preprocessing the cotton fabric and then dyeing the preprocessed cotton fabric with the mulberry red natural dye; adding metal salt for fixation; and soaping the fabric after fixation and then fixing colors to obtain the dyed fabric with even color, wherein washing fastness can reach 3-4degrees. The ecological dyeing method has simple dyeing process, high dye-uptake, good pigment stability and wide market prospect.

Owner:CHANGZHOU GOLDEN SPRING TEXTILE +1

Method for dyeing cotton fibers by using natural dye

The invention relates to a method for dyeing cotton fibers by using a natural dye, comprising the following steps of: 1) boiling the cotton fibers and drying the cotton fibers for later use; 2) modifying the cotton fibers; 3) dyeing the cotton fibers; and 4) fixing the color of the cotton fibers, wherein the dosage of a color fixing agent is 1-5% of the mass of the cotton fibers, the temperature of color fixation is 50-85 DEG C, the color fixing agent is added to the cotton fibers obtained in step 3), the time of color fixation is 20-50 min, drying is performed after water washing, and the color fixing agent can be one or two of sodium chloride, sodium sulfite, citric acid and aluminum potassium sulfate dodecahydrate. The food-grade fixing agent is selected in the method; therefore, the troubles caused by synthetic dyes and heavy metals for the health of human are solved, and the fastness of the cotton fibers can be enhanced; as a result, the dyed cotton fibers are natural and soft in color and have no harm to the human body and the environment.

Owner:CHANGZHOU MYSUN BIOLOGICAL MATERIALS

Natural Water-Insoluble Encapsulation Compositions and Processes for Preparing Same

InactiveUS20080160084A1Prevent degradationHigh dye concentrationPowder deliveryBiocideWater insolubleFine particulate

The present invention relates to dry particulate encapsulation compositions comprising a water-insoluble matrix comprising at least 70% by weight of proteins, based on the total weight of the matrix and a moisture content of about 5 to 10% by weight, based on the total weight of the matrix and an encapsulate encapsulated in the matrix, wherein the matrix once wetted in a clear colorless aqueous solution or in mineral oil has a lightness value (L*) greater than about 40, a color vividness or Chroma (C*) lower than about 33 and a hue angle between about 70 and 90. The encapsulation compositions of the present invention are useful in encapsulating dyes, medications and vitamins. Fine particulate encapsulation compositions comprising natural dyes can be used in lieu of artificial lakes in confectionery, cosmetics and caplets color coatings.

Owner:COLAROME

Extraction of natural gromwell dye and application thereof

The invention relates to extraction of natural gromwell dye and application thereof. The extraction comprises the following steps of: crushing gromwell, ultrasonically extracting the crushed gromwell at a certain temperature by using ethanol solution as a solvent to obtain pasty natural gromwell dye, and adding an emulsifying agent into the pasty natural gromwell dye to perform emulsification so as to obtain aqueous solution of the natural gromwell dye. The natural gromwell dye used for dyeing protein, cotton, polyester fibers, yarns or fabrics has good dyeing effect. The natural dye is extracted from the gromwell, and the solvent is reclaimed for reuse, so the environment is not polluted; and the dye extraction process is simple, and the natural gromwell dye has stable quality and broad market prospect.

Owner:CHANGZHOU UNIV +1

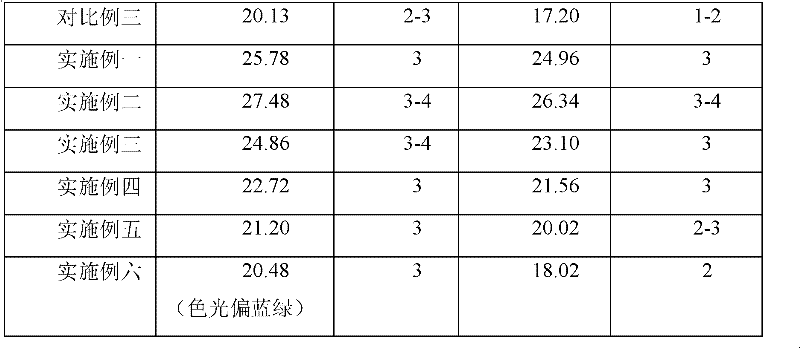

Natural dye mordanting dyeing or mordanting printing product and preparation method thereof

ActiveCN105113290AHigh color fastnessUniform base colorFibre treatmentDyeing processMordantNatural dye

The invention provides a method for preparing a natural dye mordanting dyeing or mordanting printing product. The preparation method comprises the steps of performing pretreatment on a fabric, using cation modified working solution to perform cation modification on the fabric, and obtaining cation-modified fabric; using natural dye to dye the cation-modified fabric and obtaining a natural dye dyeing fabric; using a mordant working solution or mordant working solution foam to perform mordanting dyeing or mordanting printing on the natural dye dyeing fabric at a predetermined area, performing steaming or baking at 80-180 DEG C for 10 s to 25 min, performing washing, softening and shaping, and obtaining the natural dye mordanting dyeing or mordanting printing product. The invention further provides the natural dye mordanting dyeing or mordanting printing product obtained according to the preparation method. The natural dye mordanting dyeing or mordanting printing product obtained according to the preparation method is good in color fastness and uniform in base color, the printing part is dark in color, the material loss is less, and a fabric is softer.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

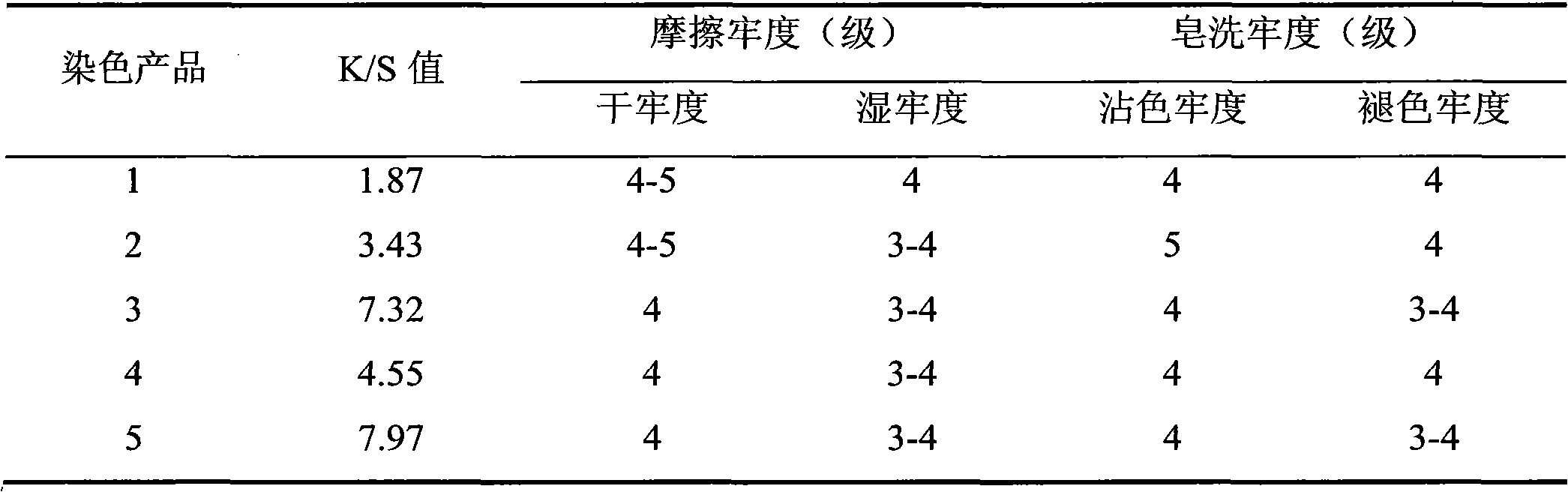

Method for dyeing cellulose fiber fabric by using suaeda salsa natural dye

InactiveCN102226315AIncrease costHigh color fastnessDry-cleaning apparatus for textilesDyeing processAcid washingRoom temperature

The invention relates to a method for dyeing cellulose fiber fabric by using suaeda salsa natural dye, and the method comprises the following processes: 1) a modification process of the cellulose fiber fabric: placing the cellulose fiber fabric into a solution containing 4-8% (o.w.f) (on weight of fabric) of cationic modifier and 4-6g / L of NaOH modifier at a bath ratio of 1:50, heating up to 70-90 DEG C at the heating-up speed of 2 DEG C / minute at room temperature, and performing reaction for 10-20 minutes; and modifying, washing the fabric with hot water, washing with cold water, carrying out acid washing, washing with cold water and drying; and 2) a dyeing process: using a direct dyeing method to dye the cellulose fiber fabric after the modification, washing with water, soaping, washing with water, and drying in the shade. The cellulose fiber fabric dyed by the method is natural and elegant in color and luster, and has the advantages of good washing fastness and rubbing fastness, suitability for industrial production, no toxicity, no harmless and no pollution free and good application prospects.

Owner:YANCHENG INST OF IND TECH

Cotton fabric high-efficiency dyeing and finishing process

InactiveCN104988713AImprove hydrophilicityImprove dye uptakeSucessive textile treatmentsLiquid/gas/vapor removalFiberInorganic salts

The invention discloses a cotton fabric high-efficiency dyeing and finishing process including modification treatment, scouring and dyeing in one bath, soaping, color fixation, post-finishing, drying, sizing, calendering, and coiling. Ultrasonic waves are used for pretreatment; at the same time, before a dyeing process, a fabric is subjected to low temperature plasma treatment, then the fiber fabric is subjected to modification treatment with 2,3-epoxypropyltrimethylammonium chloride and finally is treated by chitosan, and thus the fabric dyeing degree is increased, and the difficulty of the subsequent dyeing steps is reduced; with adopting of scouring and dyeing in one bath, the efficiency is increased, and the cost is reduced; in the dyeing process, a large amount of alkaline substances and inorganic salts are not used, natural dyes are used, and at the same time, a colophony powder is added as a color fixing agent, so that the color fixing effect is enhanced, besides, the environmental pollution is avoided, and the requirements of environmental protection are met; montmorillonite is used for flame retardant treatment on the fabric, so that the flame retardancy of the fabric is high; and with increase of anti-yellowing finishing, a final fabric does not easily turn yellow.

Owner:TAICANG SHUANGYU CHEM FIBER CO LTD

Method for extracting matural dye from external skin of walnut

The method of extracting natural dye from walnut epicarp is to extract natural active dye from walnut epicarp containing condensated tannin component in 27-30 % possessing dyeing activity in the molecular weight range of 350-2000. By means of fermenting, drying, organic solvent extracting, adsorbing, refining and other technological steps, carbon black and reddish brown dyes of purity over 90 % are prepared. The obtained dyes have fast dyeing effect and high fastness and may be used as permanent pure botanic dyes. The obtained dyes are used in dyeing hair, wool, fabric, etc.

Owner:青岛海联植物科技研究所 +1

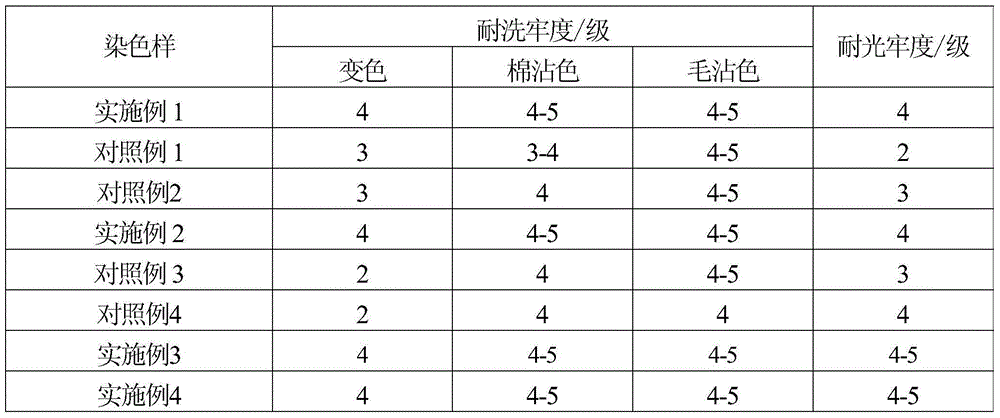

Processing method used for dyeing wool fabric with natural dye with high colour fastness

ActiveCN105625057AGood light stabilityImprove washing fastnessDyeing processAnimal fibresColour fastnessThermal water

The invention discloses a processing method used for dyeing wool fabric with a natural dye with high colour fastness. The processing method comprises following steps: wool fabric is immersed in a treating fluid containing 0.5 to 10g / L of a wetting agent for 10 to 30min, and then is taken out from the treating fluid and dried via squeezing; the treated wool fabric is subjected to dye bath in a solution containing the natural dye and 1 to 10% (owf) of a gallnut extract, temperature is increased to 75 to 98 DEG C at a speed of 1 to 5 DEG C / min, constant temperature dyeing is carried out for 30 to 90min, and then an obtained product is taken out from dye bath and washed with water, wherein pH value of the solution ranges from 3.0 to 4.5; mordanting is carried out with a metal ion mordant, wherein mordant using amount is controlled to be 2 to 8% (owf), pH value is controlled to be 3.0 to 5.0, mordanting temperature is controlled to be 50 to 70 DEG C, and mordanting time is controlled to be 40 to 80min; high temperature steam treatment with saturated steam is carried out for 10 to 30min; fabric obtained via steaming is washed with hot water for 10 to 30min, is washed with cold water, and is subjected to dehydration and dying. The washing fastness and light fastness of the wool fabric obtained via the processing method are both relatively high.

Owner:HENGYUANXIANG GRP

Natural antibacterial mould proofing detergent without petrochemical components

InactiveCN103820229AAvoid irritationAvoid harmInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsPetrochemicalNatural mineral

The invention relates to a natural antibacterial mould proofing detergent without petrochemical components. The detergent which is produced by organically combining petrochemical component-free natural plant extract, petrochemical component-free natural mineral extract and existing products processed by modern biological technologies has high safety to human bodies and the environment, is environment-friendly, is capable of efficiently resisting bacteria and mildew, has strong broad-spectrum antibacterial and mould proofing performances, especially has excellent antibacterial performance for drug resistant germs, can remove heavy metals such as lead, and AOX (adsorbable organic halide) attached to clothes and skin, and has good vegetal washing effect especially for the fabric dyed with natural dyes, and the fabric dyed with natural dyes does not fade or change color after being washed with the detergent. The natural antibacterial mould proofing detergent does not contain oxidant or fluorescent brightener, is nonirritant to the skin, is applicable to washing the fabric and clothes of children, can be used for washing tableware and vegetables, can be used as liquid soap, liquid shampoo, bath foam and the like, is environment-friendly, safe and hygienical, and is a multifunctional washing product.

Owner:祝一鸣

Natural dyestuff dyeing and finishing process of polyester fabric

The invention discloses a natural dyestuff dyeing and finishing process of polyester fabric. The natural dyestuff dyeing and finishing process of the polyester fabric comprises pretreatment, preshaping, modification treatment, dyeing, mordant removing, soaping, fixation, finishing, drying, shaping, calendering and winding. According to the natural dyestuff dyeing and finishing process of the polyester fabric, helicase and alhpa-amylase are adopted to conduct pretreatment, modification treatment is radically conducted on the performance of the polyester fabric through a acetic acid aqueous solution of chitosan, hydrogen peroxide and epoxy chloropropane, and the dyeing rate of the fabric is increased; in the dyeing process, a large amount of alkaline matter and inorganic salt are not used, a levelling agent and diffusant are added, the level-dyeing property is improved, natural dyestuff is used, therefore, environmental pollution is avoided, and requirements of green environmental protection are met; modification treatment and fire-retardant treatment are conducted on the fabric through montmorillonite, and the fire resistance of the fabric is high; anti-yellowing reagents are used in the preshaping and the shaping, and the final fabric is not prone to yellowing.

Owner:TAICANG CHENGLE CHEM FIBER

Natural dye printed product and preparation method thereof

ActiveCN104452334AHigh color fastnessDark colorDyeing processVegetal fibresWater bathsRoom temperature

The invention provides a natural dye printed product and a preparation method thereof. The preparation method comprises the following steps: performing pretreatment on fabrics to obtain pretreated fabrics; performing cation printing modifying on the pretreated fabrics at preset areas by using a cation printing modifying working solution, and cooking or roasting at 100-180 DEG C for 10 seconds to 15 minutes to obtain cation printed modified fabrics; and washing the cation printed modified fabrics with water and acid, immersing in a natural dye aqueous solution, performing water bath at the room temperature to 100 DEG C for 10 minutes to 48 hours, cooking at 100-120 DEG C for 30 seconds to 15 minutes by using steam or roasting at 100-180 DEG C for 10 seconds to 15 minutes, then washing with water, softening and shape setting to obtain the natural dye printed product. The invention further provides the natural dye printed product obtained according to the preparation method. The method for preparing the natural dye printing product disclosed by the invention can solve the problems of over standard heavy metals, hard feel, poor color fastness, light color of the printing part and the like of printing by using conventional natural dyes.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Process for dyeing cotton cheese by using natural dye

InactiveCN102080333ASolve the problem of level dyeingDyeing equipment is simpleDyeing processVegetal fibresTextile printerEngineering

The invention relates to a process for dyeing cotton cheese by using natural dye, belonging to the technical field of textile printing and dyeing. A two-step method is adopted to complete dyeing on the cotton cheese by using the natural dye, namely firstly modifying the cotton cheese by virtue of high pressure spray and then dyeing, thus the natural dye can have good dyeing depth and leveling property on one hand, on the other hand, the leveling property problem in dyeing by using the natural dye can be effectively solved.

Owner:JIANGNAN UNIV

Dyeing method for common goldenrod herb natural dye

The invention relates to a dyeing method for a common goldenrod herb natural dye. The dyeing method comprises the following steps: preparing a 2 to 20 g / I common goldenrod herb dye, and setting a dyeing temperature of 40 to 100 DEG C, a bath ratio of 1:50 to 200 and dyeing time of 10 to 90 minutes; taking a 2 to 20 g / I mordant solution, and setting a mordanting temperature of 40 to 100 DEG C and mordanting time of 10 to 90 minutes; and adding a mordant before or after natural fiber yarn or natural fiber textile is added into common goldenrod herb dye liquor or simultaneously when the natural fiber yarn or the natural fiber textile is added into the common goldenrod herb dye liquor for one-bath dyeing. The method uses the prior textile dyeing device for direct dyeing without adding devices or increasing cost. The textile dyed by the method is soft, primitive and simple and natural color, and has good dye fastness, no fading, no discoloring, good reproducibility, and chromatic aberration around a half level. The method is suitable for the industrialized production, and has no toxicity, no harm and no pollution.

Owner:DONGHUA UNIV

Method for low-temperature ultrasonic dyeing and soaping of short fiber by using Chinese herbal medicine plant dye

ActiveCN103174041AUltrasonic effect improvedGood level dyeingDry-cleaning apparatus for textilesDyeing processTextile printerFiber

The invention belongs to the field of textile printing and dyeing and particularly relates to a method for low-temperature ultrasonic dyeing and soaping of short fiber by using a Chinese herbal medicine plant dye. The method is characterized in that, during the dyeing and the soaping processes, two types and more than two types of ultrasonic waves with different frequencies are combined for assistance, wherein during the dyeing process, the frequency selection range of the ultrasonic waves is 20KHz-28KHz, the dyeing temperature is 15 DEG C-35 DEG C, the dyeing treatment time is 10-60min, and the total intensity of the multi-frequency ultrasonic waves is 0.1-0.8W / cm<2>; and during the soaping process, the frequency selection range of the ultrasonic waves is 28KHz-55KHz, the soaping temperature is 20 DEG C-35 DEG C, the soaping time is 5-30min, and the total intensity of the multi-frequency ultrasonic waves is 0.2-1W / cm<2>. Compared with the prior art, the mehtod disclosed by the invention has the advantages that, under the low-temperature condition, the ultrasonic wave effects can be improved over one time in comparison with the single-frequency ultrasonic waves, the high-temperature damages can be avoided, and the uniform dyeing property of dyeing of the natural dye can be improved.

Owner:山东锦润嘉植物染色科技有限公司

Method for dyeing protein fiber and fabric thereof with natural dye extracted from grape seeds

The invention relates to a method for dyeing with a dye extracted from a grape beverage and grape seeds as waste resources in wine industry processing, which is characterized in that a grape seed pigment solution is adopted to dye protein fiber fabrics such as wools, silks and the like with a directly dyeing method or an aluminium ion and iron ion pre-mordant dyeing method. A dyeing technology has the following parameters: the bath ratio of (25-50):1, a dye bath pH value of 3-5, the grape seed dosage of 1-6 percent (o.w.f), dyeing temperature of 30 DEG C, temperature rise rate of 1-3 DEG C / min, temperature rising to 80-100 DEG C and insulation time of 60-120min. The aluminium ion and iron ion pre-mordant dyeing method is characterized by comprising the following steps of, firstly, carrying out pre-mordant dyeing on the protein fiber fabrics by adopting aluminium ions and iron ions, and putting the protein fiber fabrics such as the wools, the silks and the like into a grape seed pigment dye bath to dye. Fabrics in different colors can be obtained by adopting different mordants. The invention can efficiently utilize grape seed waste resources and expand the application field of completely nontoxic grape seed pigments.

Owner:JIANGNAN UNIV

Method for extracting natural dye of gordon euryale seed shell and application in pure cotton dyeing

ActiveCN101775234AImprove protectionNo allergic reactionNatural dyesDyeing processUltrasonic assistedUltrasound assisted

The invention discloses a method for extracting a natural dye of gordon euryale seed shell, which is performed by the following steps: (1) pretreating raw materials; (2) performing ultrasound assisted extraction on the crushed gordon euryale seed shell; (3) performing secondary extraction on filter residue; and (4) refining natural dye of coarse gordon euryale seed shell, dissolving the natural dye of coarse gordon euryale seed shell by using deionized water, and passing through a cation macroporous absorption resin column to obtain refined brown powdery natural dye extract of the gordon euryale seed shell, wherein the dyed fabric is light brown. The application of the natural dye of gordon euryale seed shell in the pure cotton dyeing comprises the following two processes: pretreating cotton fabrics and dyeing the pure cotton, namely, (1) treating the pure cotton fabrics in a prepared pretreatment agent; and (2) dyeing by adopting the natural dye of gordon euryale seed shell, and taking out the fabrics for cleaning and drying. The method for extracting the natural dye of gordon euryale seed shell can effectively extract the natural dye by using wastes, is favorable for environmental protection, and saves energy. The clothes made by the dyed fabrics are safe and biodegradable.

Owner:CHANGZHOU UNIV

Environmental-friendly cotton fabric dyeing

InactiveCN104099788AReduce consumptionThe production process is briefBiochemical fibre treatmentDyeing processAfter treatmentPulp and paper industry

The invention discloses an environmental-friendly cotton fabric dyeing. The cotton fabric dyeing comprises the following steps: (1) pretreatment: putting grey cloth into lukewarm water to conduct pre-moistening; adding a pretreatment agent; adjusting pH value to conduct scouring and bleaching; conducting hot washing and cool washing; drying; dyeing; conducting fixation; putting the grey cloth after the pretreatment in the step (1) into water of which the bath ratio is 1:(20-30) in ordinary temperature; adding natural dyestuff, a dispersant, a mordant and a dyeing auxiliary to dye for 20 min; elevating temperature for dyeing for 20-40 min; reducing temperature and adding a fixing agent to conduct fixation; (2) after-treatment: putting the cotton fabric after dyeing into water of which the bath ratio is 1:8 at ordinary temperature; adding soap berry saponin to soak for 10-20 min; washing the cotton fabric; drying. The dyeing is simple and short in production technology, greatly shortens pretreatment time, reduces manufacturing cost, is high in fastness, easy to wash and low in water consumption, and reduces pollution to environment.

Owner:WUXI XINDA DYEING MACHINE FACTORY

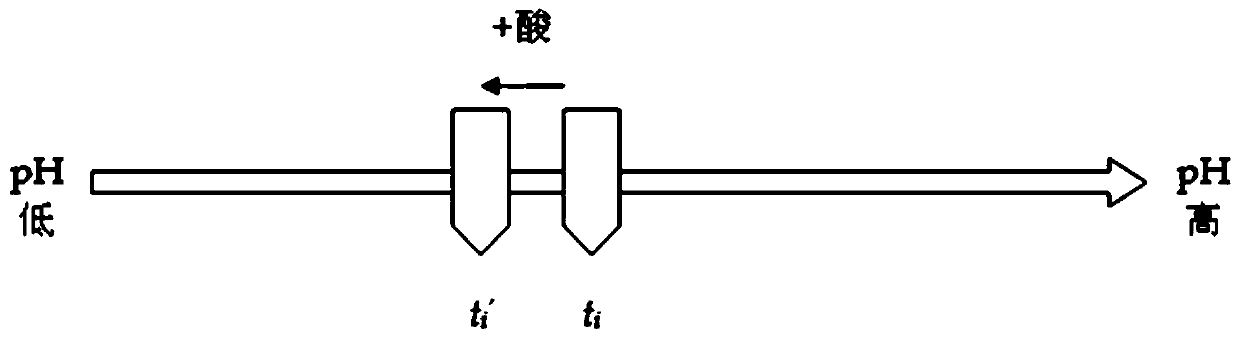

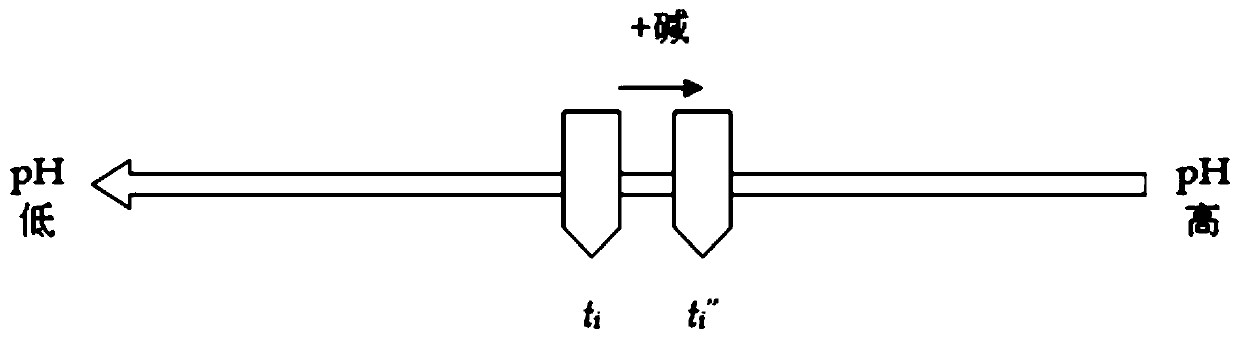

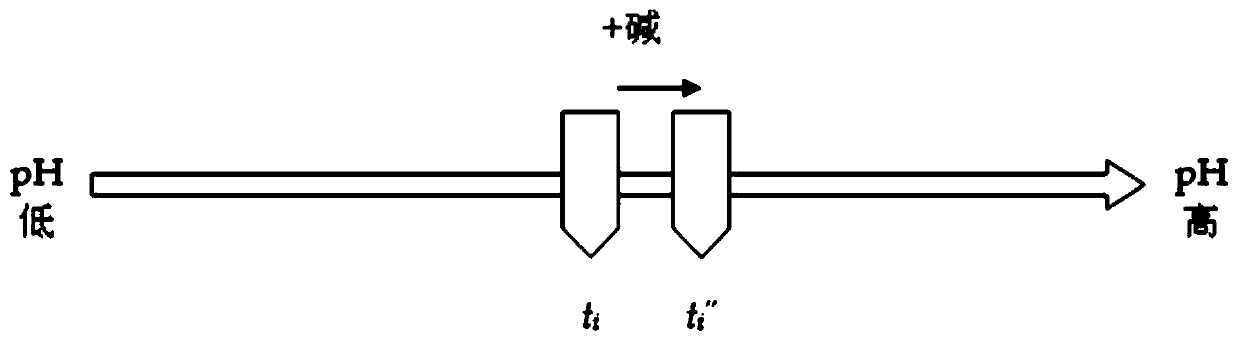

Preparation method and sensitivity regulation method of pH type food freshness indication label

ActiveCN110564013AGood biocompatibilityBenign environmental effectStampsMaterial analysis by observing effect on chemical indicatorPlasticizerColor transition

The invention discloses a preparation method and a sensitivity regulation method of a pH type food freshness indication label. The preparation method comprises: extracting a pH sensitive natural dye to obtain a pH sensitive natural dye concentrated solution; dissolving a natural polymer material in a solvent to obtain a film-forming stock solution; sequentially adding a plasticizer, a water absorbent, a phase transfer catalyst and the pH sensitive natural dye concentrated solution into the film-forming stock solution, and fully stirring until the materials are uniformly mixed and dispersed toobtain a film-forming solution; and carrying out ultrasonic deaeration on the film-forming solution, slowly pouring the film-forming solution into a culture dish, and drying the solvent to obtain thefreshness indication label. According to the present invention, the pH value of the film-forming solution in the preparation process of the indication label is adjusted according to the front-back relationship between the freshness indication label color transition point and the food spoilage point, such that the two time points are matched so as to achieve the purpose of precise indication; and the method is simple and easy to implement, and the prepared indication label has high sensitivity, has the sensitivity capable of being regulated based on food spoilage rule, and has wide application.

Owner:WUHAN UNIV

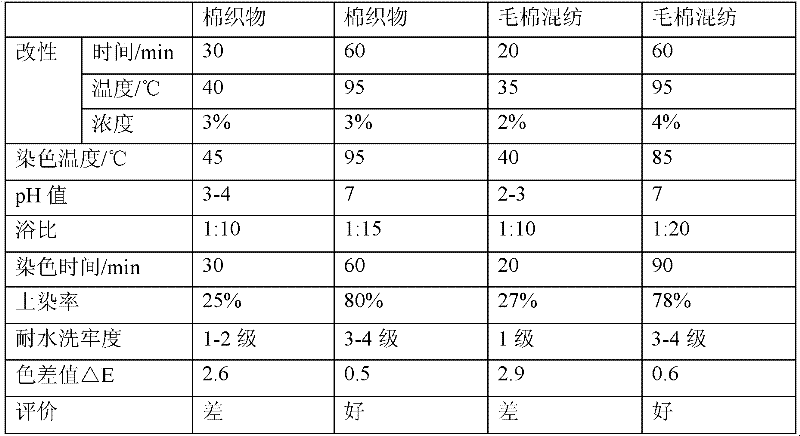

Natural dye and dyeing method thereof

The present invention relates to a natural dye of broadleaf liriope root scape, and a dyeing method for dyed media such as protein and cellulose by the natural dye. The dyeing method for the protein comprises that: the dyeing temperature is 60-95 DEG C, the pH value is 3-5, the bath ratio is 1:20-50, and the dyeing time is 30-80 minuets. The dyeing method for the cellulose comprises: (1) firstly carrying out modification: wherein the quality ratio of the natural modifier to the dyed media is 2-4%, the bath ratio is 1:15-40, the temperature is 50-95 DEG C, and the time is 60-80 minutes; (2) finally carrying out dyeing: the dyeing temperature is 70-95 DEG C, the pH value is 5-7, the bath ratio is 1:15-30, and the dyeing time is 50-90 minutes. According to the present invention, the used broadleaf liriope root scapes of the present invention are easily collected; the dyed fabric has fragrance; the method is simple, the requirements of the equipment are low, and the production process does not cause the pollution; the dyed finished product by the dyeing method of the present invention has characteristics of high dye uptake, good washing fastness resistance and small color difference.

Owner:CHANGZHOU MYSUN BIOLOGICAL MATERIALS

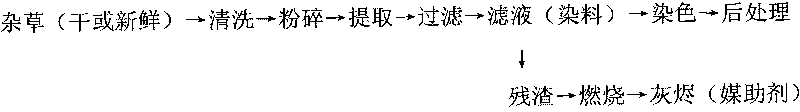

Natural plant dye, preparation method and application thereof

InactiveCN101709152ANo need to saveNo need to deal withNatural dyesDyeing processInvasive WeedsWater Hyacinths

The invention relates to the field of natural dyes, and specifically relates to a natural plant dye, a preparation method and application thereof. According to the invention, the natural plant dye is obtained by extracting vicious weeds serving as raw materials, wherein the vicious weeds are one or more in a group including chromolaena odorata, mikania cordata, water hyacinth, alternanthera philoxeroides, alternanthera pungens, spartina anglica s, ragweed, lantana camara, solanum aculeatissimum and lolium temulentum. The extraction method comprises the steps of grinding and extracting through water. The invention provides a novel scheme for utilizing exotic vicious weeds; the preparation of the natural plant dye by taking exotic invasive weeds as raw materials can protect environment and bring conomic benefits; residue produced during dye extraction can be burnt and combustion can provide a heat source for a dyeing process; and obtained ash can be used as mordanting assistants for dyeing with no storage or treatment so as to really achieve environmental protection.

Owner:INST OF PLANT PROTECTION CHINESE ACAD OF AGRI SCI

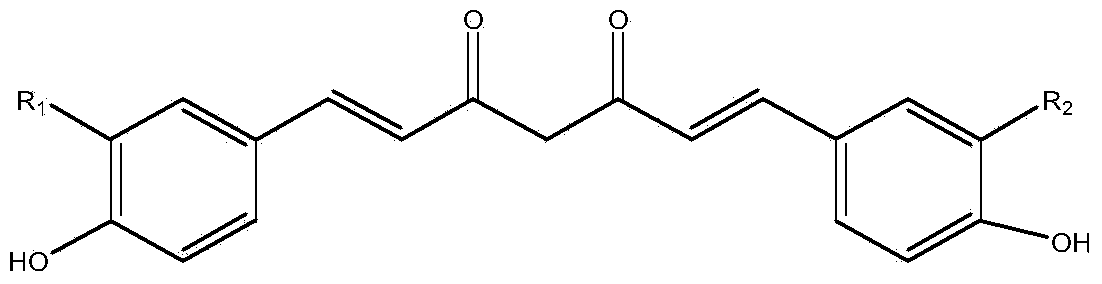

Preparing method of turmeric natural dye

The invention relates to a preparing method of turmeric natural dye. After petroleum ether mixing, ray radiation pretreatment, stirring and digestion with an extractant, vacuum concentration, recrystallization with polyol, and modification by addition of a surfactant, curcumin in a turmeric raw material is extracted and prepared into the turmeric natural dye. After being blended, the turmeric natural dye can achieve dyeing of fabric in simple and mild conditions. The method is advantageous in that: the dye preparing process is simple, the cost is low, the solvent is cheap and can be easily recovered, and the dye is stable in property and has good dyeing effects for fabric and high sun-proof fasteness.

Owner:NANJING UNIV OF TECH

Method for dyeing silk broadcloth by using plant dye solution extracted from lily

InactiveCN102587153ASafe to takeIncrease added valueDry-cleaning apparatus for textilesNatural dyesFiltrationPollen

The invention discloses a method for dyeing silk broadcloth by using the pollen of lily as a natural dye and belongs to the technical field of textile dyeing and finishing. The method comprises the following steps of: soaking fresh or dried dark-red lily pistil, heating and performing suction-filtration to obtain a dye solution; adding silk broadcloth fabric which is refined, and dyeing the silk broadcloth fabric; and adding different mordants for mordanting and thus obtaining silk fabric with different colors. The method has the advantages of low cost, simple process, high performance, high additional value, non-allergic and non-carcinogenic to skin, and the like; raw materials are inexpensive, easy to get, and reproducible; and taking of dyeing products is safe. Particularly, by taking plant ash as a mordant, pollution is avoided. The method is environment-friendly and energy-saving, and clothes which are made of fabric dyed by using the method are natural, environment-friendly and nonirritating to the skin.

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

Dyeing and finishing process of polyester-nylon composite fiber fabric

InactiveCN105019237AHigh whitenessAvoid damageBiochemical fibre treatmentHeating/cooling textile fabricsPolyesterInorganic salts

The invention discloses a dyeing and finishing process of polyester-nylon composite fiber fabric. The dyeing and finishing process of the polyester-nylon composite fiber fabric comprises pretreatment, preshaping, modification treatment, dyeing, mordant removing, soaping, fixation, finishing, drying, shaping, calendering and winding. According to the dyeing and finishing process of the polyester-nylon composite fiber fabric, helicase and alhpa-amylase are adopted to conduct pretreatment, the modification treatment is conducted before dyeing, modification is conducted on performance of the polyester-nylon fabric radically, and the dyeing rate of the fabric is increased; in the dyeing process, a large amount of alkaline matter and inorganic salt are not used, a levelling agent, substitution alkali, migration inhibitor and diffusant are added, the level-dyeing property is improved, natural dyestuff is used, therefore, environmental pollution is avoided, and requirements of green environmental protection are met; self-cleaning treatment is added in finishing, and the self-cleaning capacity, crease resistant property and fastness to washing of the fabric are improved; the whole process is environmentally friendly and free of pollution.

Owner:TAICANG TIANLONG CHEM FIBER

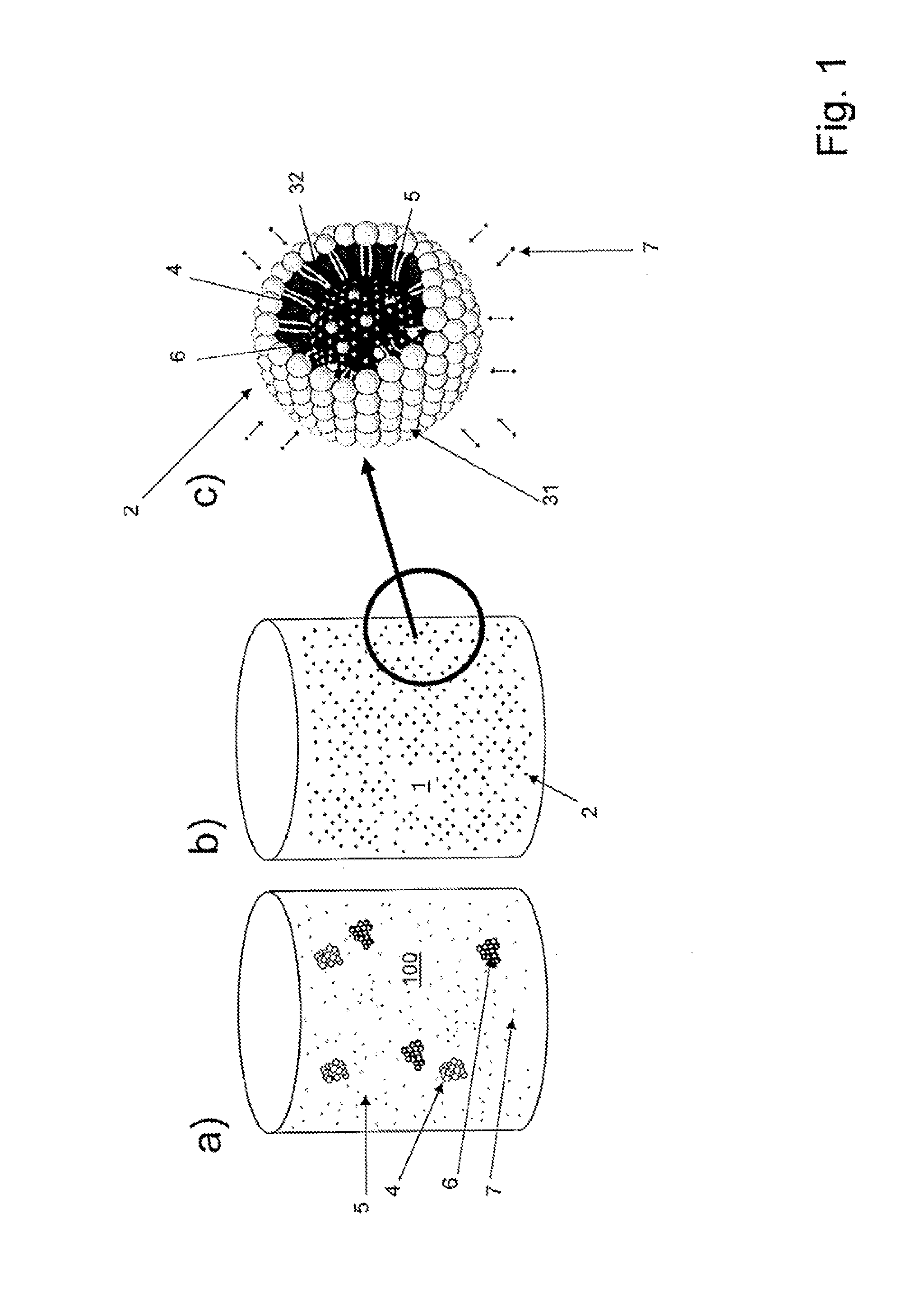

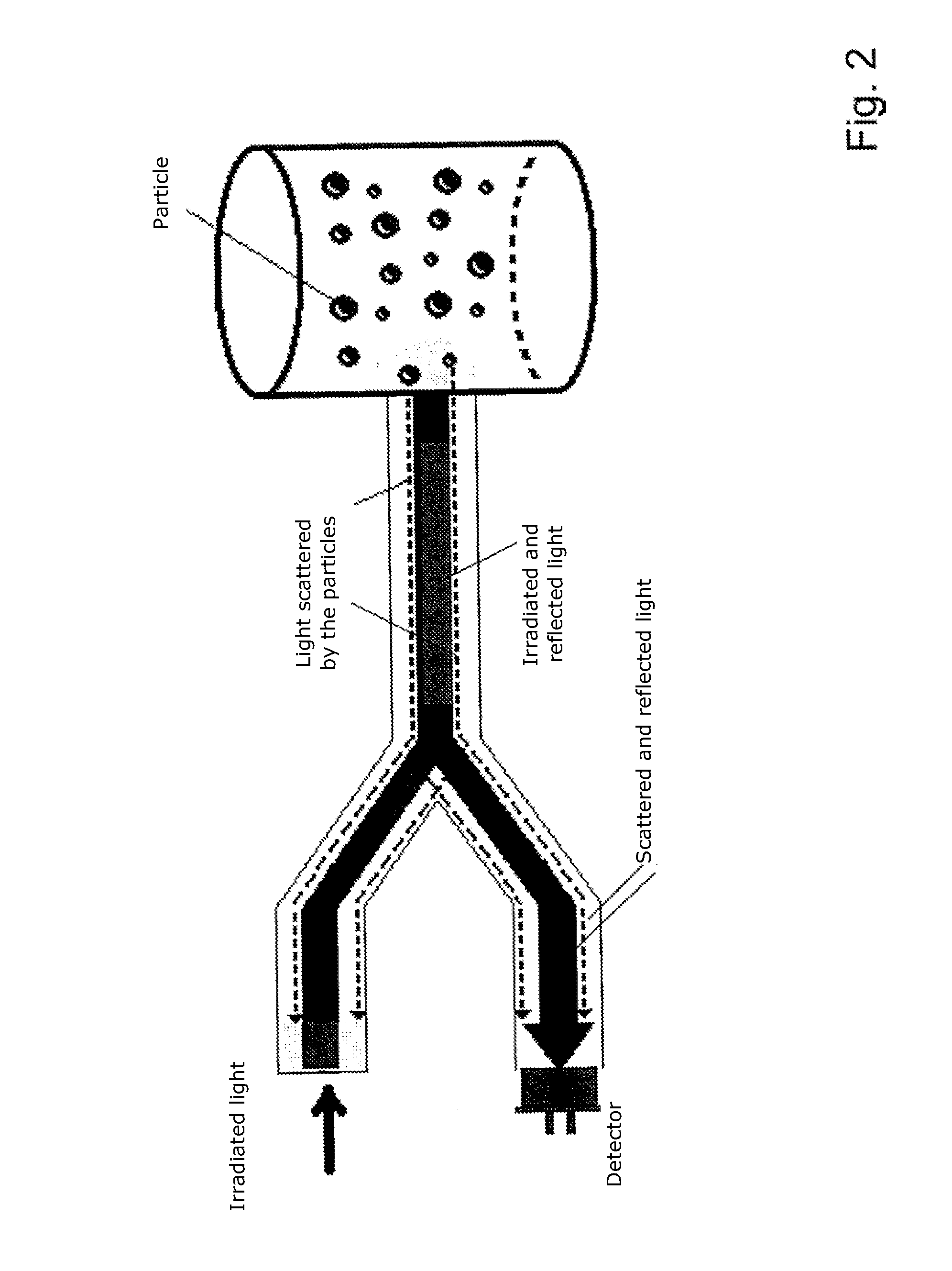

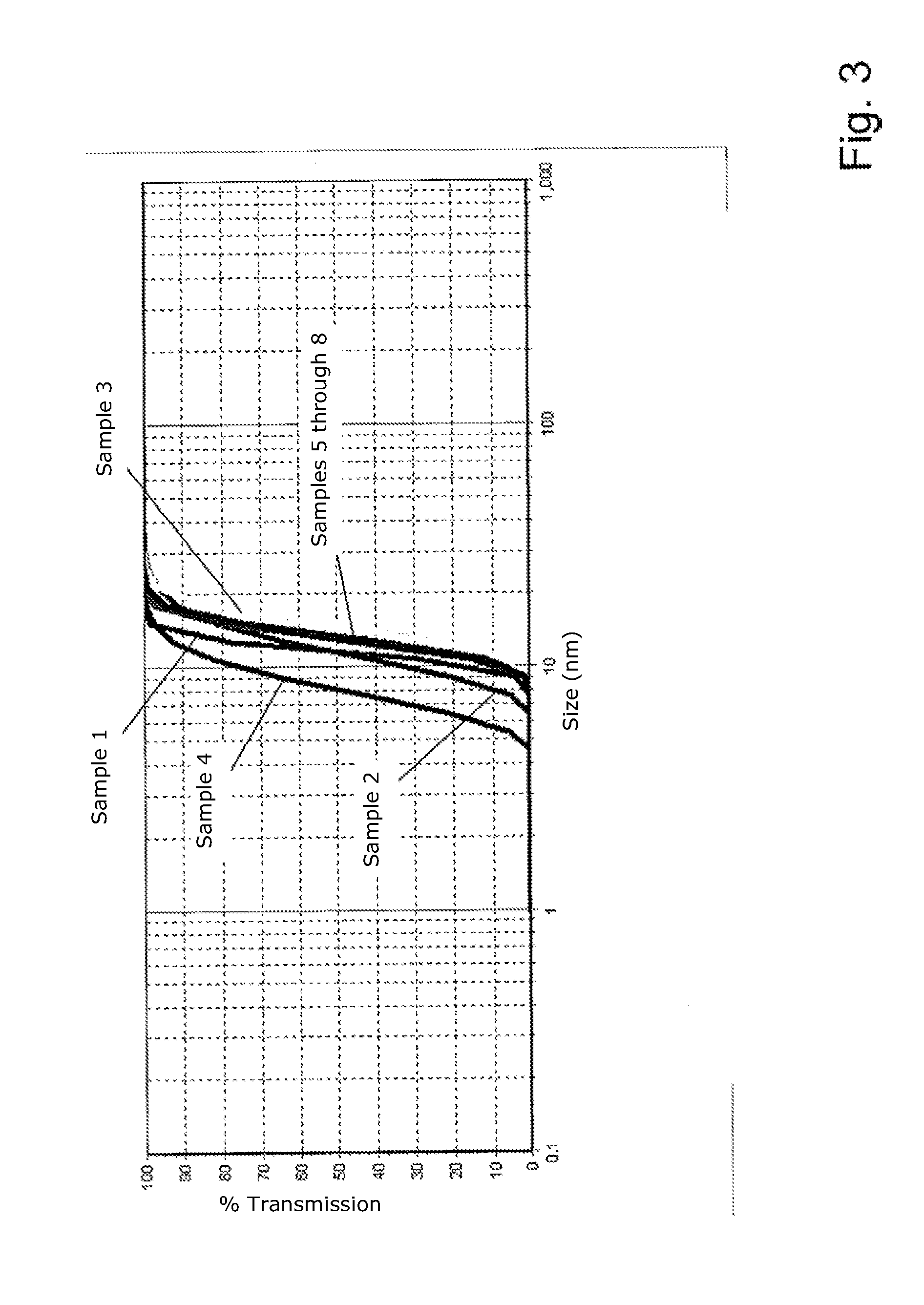

Micellarly integrated oxidation protection for natural dyes

InactiveUS20110293678A1Improve protectionPrevent oxidationCosmetic preparationsMaterial nanotechnologyAntioxidantSolvent

In order to formulate natural dyes, which are insoluble or sparingly soluble in water, in such a way that the dye is protected against oxidation, also and in particular after being incorporated into the end product with dilution, and which as a replacement for azo dyes in a beverage result in a solution which is clear to the human eye, the invention provides a solubilizate and a method for preparing a solubilizate. The solubilizate contains at least one natural dye that is insoluble or sparingly soluble in water, at least one emulsifier having an HLB value of 8 to 19, and at least two antioxidants. The dye and the antioxidants are present enclosed together in micelles.

Owner:AQUANOVA AG

Spatholobus stem natural dye preparation and its uses

InactiveCN1995151AAbundant raw materialsSimple ingredientsNatural dyesDyeing processTrisodium phosphatePhotochemistry

The invention discloses a preparing method and application of natural dye of spatholobus stem, which comprises the following steps: grinding spatholobus stem; immersing in the sodium carbonate solution with pH value at 8-10 under 95-100 deg. c for 60-90min; filtering to obtain the primary liquid of natural dye; condensing the primary liquid; solidifying; grinding; obtaining the powder-shaped natural dye.

Owner:ZHEJIANG SCI-TECH UNIV +1

Method for dyeing of loose fibre with natural dye

ActiveCN101270550AReduce pollutant contentAntibacterial health careFibre treatmentDyeing processPlant fibreAnimal fiber

The invention provides a method for dyeing a loose fiber by a natural dye, which comprises the steps of carrying out boiling, mordant dyeing, dyeing and fixation on the loose fiber. The method selects the natural dyes with corresponding variety and amount according to the dyeing color and the depth of the dyeing to dissolve in water according to a bath ratio of 1 to 20; putting the fiber through mordant dyeing into a cylinder; raising the temperature from 30 to 100 DEG C with a speed of 2 DEG C per minutes, preserving the temperature for 30 minutes and then carrying out dyeing. The method uses the natural materials during the manufacture technique of dyeing; the content of the contaminations in the waste water generated during the manufacture process is very low, thus having the advantage on sewage treatment and according with the national environment protection policy compared with the traditional technique. The invention can be applied to various loose fiber dyeing like animal fibers, plant fibers and chemical fibers, has a broad application range and the fiber dyed by using the natural dye, has excellent color brilliance and color fastness.

Owner:东阳市神农纺织品有限公司

Platable soluble dyes

Edible colored powders are formed by combining silica with a soluble dye, such as a natural dye. The colored powders can be used to color edible substrates such as particles and compressed tablets. Methods of forming the edible colored powders may include a drying step to reduce the moisture content of the colored powder.

Owner:SENSIENT COLORS

Method for padding dyed cellulose fabric with natural vegetable dye

InactiveCN107237180AIncrease dye uptakeImprove color fastness to washingDyeing processCellulosePhotochemistry

The invention discloses a method for padding dyed cellulose fabric with natural vegetable dye. The natural vegetable dye is added to water and natural vegetable dye liquor is prepared; a cationic dye fixing agent is dissolved in the natural vegetable dye liquor and a dye working solution is prepared; the to-be-dyed cellulose fabric is immersed in the prepared dye working solution, padded on a padder and immersed in a gardenia blue dye working solution for dip dyeing and then padded on the padder, and the to-be-dyed cellulose fabric is colored; the colored cellulose fabric is dried after coloring is completed, the dried colored cellulose fabric is washed with a washing agent, and flooding is removed; the washed cellulose fabric is dried and dyeing with the natural vegetable dye is completed. The method has the benefits that the dyeing amount of the natural dye can be increased, the washing color fastness can be improved, and the color of the natural dye cannot be affected.

Owner:WUHAN TEXTILE UNIV +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com