Method for extracting natural dye of gordon euryale seed shell and application in pure cotton dyeing

A technology of natural dyes and extraction methods, which is applied in the field of extraction of natural dyes from Gorgon husks and dyeing of pure cotton, to achieve the effects of simple extraction process, low cost and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Weigh 100 grams of air-dried gorgon shells, crush them mechanically to 30 mesh, add 60% ethanol, and extract at 40°C with an ultrasonic power of 500W for 40 minutes, filter to obtain the filter residue and the filtrate containing natural dye; filter the filter residue with 90% After leaching with ethanol at 60°C for 60 minutes, filter, combine the filtrate obtained twice, and distill and solidify under reduced pressure to obtain the natural dye of thick Gorgon shell; For the resin column, the flow rate is controlled at 1 ml / min. After the Gorgon husk natural dye solution flows out, the resin column is washed with deionized water to remove the residue, and then eluted with ethanol with a pH value of 4 and 60%. The obtained eluent is concentrated, solidified and pulverized by vacuum distillation, and the ethanol is recovered to obtain the refined powder natural dye of Gorgon husk.

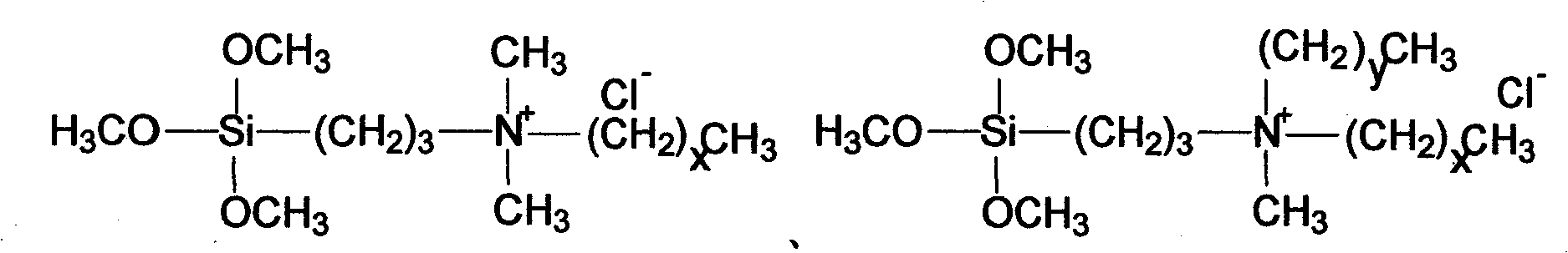

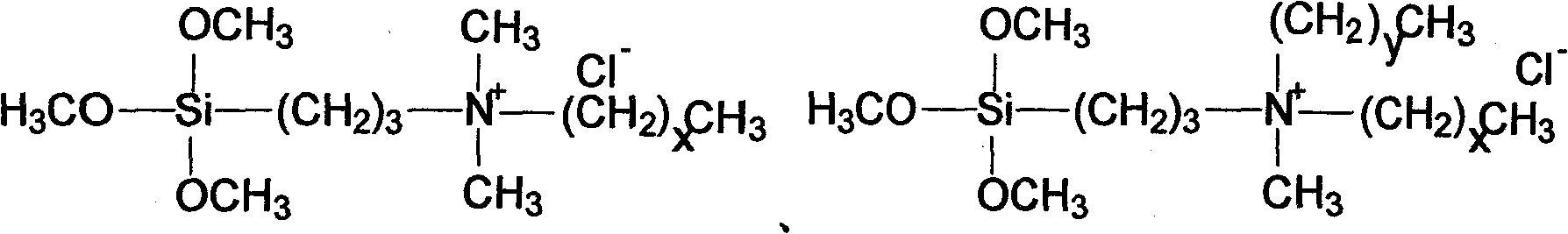

[0019] Prepare the pretreatment agent solution: 2 g / L cationic modifier, 4 g / L sodium hydr...

Embodiment 2

[0024] Weigh 100 grams of air-dried gorgon shells, crush them mechanically to 50 mesh, add 75% ethanol, and extract at 50°C with an ultrasonic power of 600W for 60 minutes, filter to obtain the filter residue and filtrate containing natural dye; filter the residue with 80% After leaching with ethanol for 50 minutes at 70°C, filter, combine the filtrates obtained twice, and distill and solidify under reduced pressure to obtain natural dyes from thick gorgon shells; after dissolving the natural dyes in thick gorgon shells with deionized water, add cationic macropores For the resin column, the flow rate is controlled at 1.5 ml / min. After the Gorgon husk natural dye solution flows out, the resin column is washed with deionized water to remove the residue, and then eluted with ethanol with a pH value of 5 and 50%. The obtained eluent is concentrated, solidified and pulverized by vacuum distillation, and the ethanol is recovered to obtain the refined powder natural dye of Gorgon husk...

Embodiment 3

[0030] Weigh 100 grams of air-dried gorgon shells, crush them mechanically to 60 mesh, add 80% ethanol, and extract at 50°C with an ultrasonic power of 1000W for 70 minutes, filter to obtain the filter residue and filtrate containing natural dyes; filter the filter residue with 75% After leaching with ethanol for 50 minutes at 80°C, filter, combine the filtrate obtained twice, and distill and solidify under reduced pressure to obtain the natural dye of thick Gorgon shell; For the resin column, control the flow rate at 2 ml / min. After the Gorgon husk natural dye solution flows out, rinse the resin column with deionized water to remove the residue, and then elute with 90% ethanol with a pH value of 5. The obtained eluent is concentrated, solidified and pulverized by vacuum distillation, and the ethanol is recovered to obtain the refined powder natural dye of Gorgon husk.

[0031] Prepare the pretreatment agent solution: 5 g / L cationic modifier, 5 g / L sodium hydroxide, the bath r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com