Patents

Literature

37results about How to "Not carcinogenic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ecological dyeing method for dyeing cotton fabric with mulberry red natural dye

InactiveCN101851868AImprove protectionNo allergic reactionDyeing processVegetal fibresEngineeringNatural dye

The invention relates to an ecological dyeing method for dyeing a cotton fabric with mulberry red natural dye, comprising the following steps: preprocessing the cotton fabric and then dyeing the preprocessed cotton fabric with the mulberry red natural dye; adding metal salt for fixation; and soaping the fabric after fixation and then fixing colors to obtain the dyed fabric with even color, wherein washing fastness can reach 3-4degrees. The ecological dyeing method has simple dyeing process, high dye-uptake, good pigment stability and wide market prospect.

Owner:CHANGZHOU GOLDEN SPRING TEXTILE +1

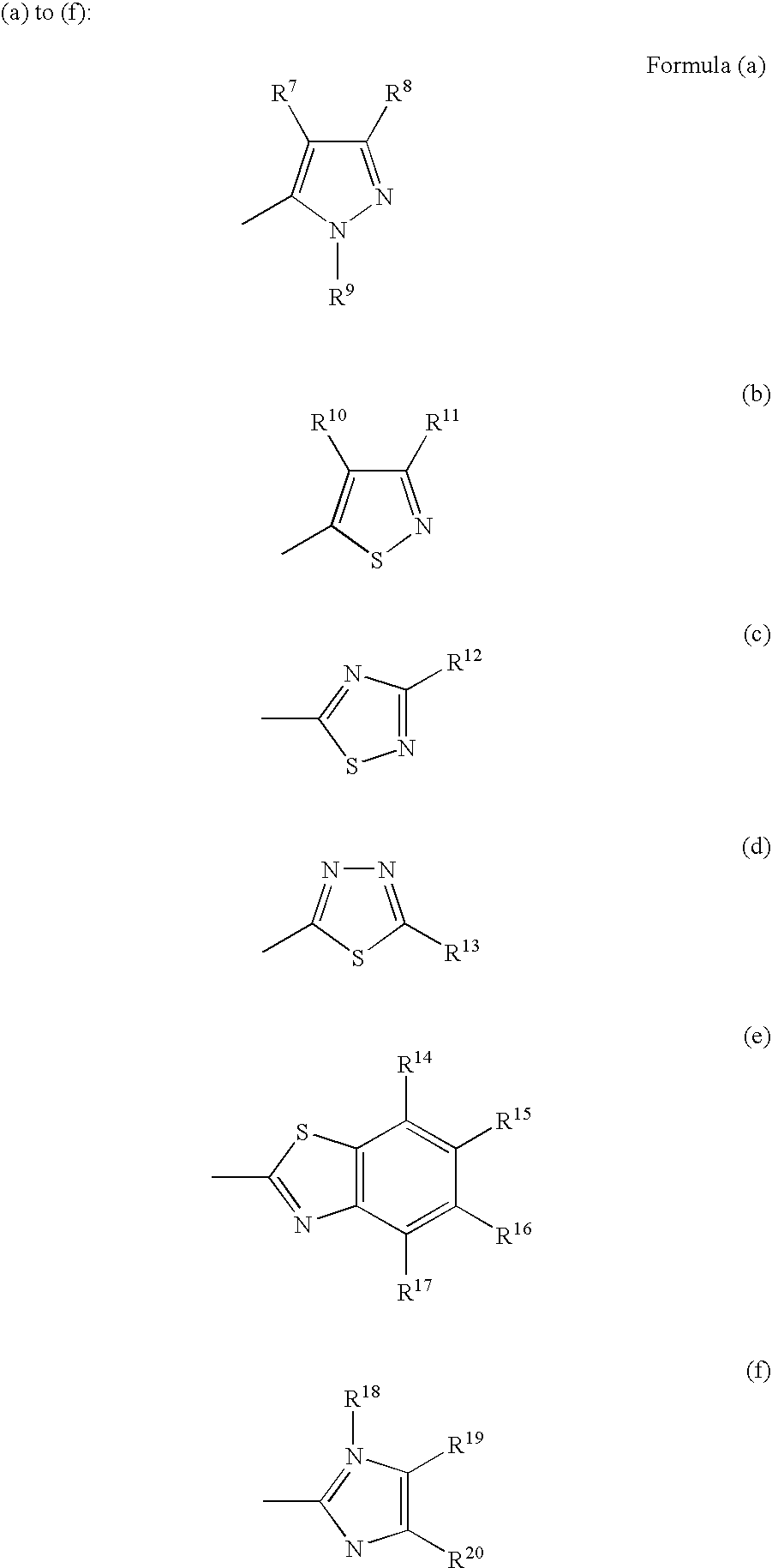

Method for preparing photinia fruit natural dye and application of photinia fruit natural dye

The invention relates to the field of natural dyes and application thereof and aims to provide a method for preparing a photinia fruit natural dye and application of the photinia fruit natural dye. The preparation method comprises the following steps of: (1) washing and airing fresh photinia fruits and dried photinia fruits, and mechanically crushing the fruits; and (2) adding the crushed photinia fruits into aqueous solution of ethanol for reflux extraction, raising the temperature of the extract to between 70 and 90 DEG C, keeping the temperature, filtering and distilling under reduced pressure to make the volume of concentrated solution 1 / 6 to 1 / 2 of the original volume of the extract so as to obtain the concentrated photinia fruit natural dye. The method for preparing the photinia fruit natural dye has the advantages of simple extraction technology, extraction efficiency obviously higher than that of ethanol reflux and other methods, and no environmental pollution in the extraction process; and the extract has the advantages of good color fastness to protein fibers, capacity of increasing color spectrum after dyeing by using environment-friendly dye mordant treatment, gentle color and safe wear of the dyed fabrics without carcinogenic, teratogenetic actions or anaphylactic reaction, high ecological environment compatibility, biodegradation, low price, full utilization of natural resources and wide market prospect.

Owner:ZHEJIANG SCI-TECH UNIV

Preparation of anthocyanin dye and application of anthocyanin dye in cellulosic fiber fabric dyeing

InactiveCN105348851AImprove extraction efficiencyQuality improvementNatural dyesDyeing processWarm waterDistillation

The invention discloses a preparation method of a natural anthocyanin dye. The preparation method comprises the following steps: pounding the plant raw material containing anthocyanin pigment to form plant raw material slurry; adding acidified ethanol water into the plant raw material slurry, and carrying out ultrasonic extraction; adding petroleum ether with the same volume into the obtained anthocyanin extracting solution; carrying out reduced pressure distillation on the ethanol water layer obtained through liquid separation, so as to obtain a natural anthocyanin dye concentration solution. The invention further provides a method for dyeing fabric through the natural anthocyanin dye prepared through the method. The method comprises the following steps: carrying out modification treatment on the cellulosic fiber fabric; weighing the natural anthocyanin dye concentration solution with the weight 2-20% of that of the fabric; weighing a metal mordant with the weight 2-10% of that of the fabric; adding water to form dye liquor with the bath ratio of (1: 50)-(1: 100); after wetting the modified fabric with warm water, dyeing for 60-90 minutes at the temperature of 40-80 DEG C; after dyeing, taking out the fabric, washing, and drying at the temperature of 45-55 DEG C.

Owner:ZHEJIANG SCI-TECH UNIV

Preparation method of silk fibre with function of removing formaldehyde

The invention discloses a preparation method of silk fibre with a function of removing formaldehyde, mainly comprising the following steps: (1) dissolving procyanidin with the weight equivalent to 8-12 percent of the silk fibre into water, adding 0.2-0.5 milliliters of glacial acetic acid per each litre of water into the solution and uniformly stirring, adding ferrous sulphate into the solution according to the mass ratio of the ferrous sulphate to the procyanidin of 1 to 1-3 and stirring, adding a sodium bicarbonate solution into the solution to regulate the pH value of the mixing solution to 5-8, increasing the temperature of the mixing solution to 50-60 DEG C, and preserving the heat of the mixing solution for 20-40 minutes; (2) adding 0.5 gram of peregal O and 2-10 grams of salt intoeach litre of the obtained mixing solution and uniformly stirring; (3) adding the silk fibre into the obtained mixing solution and processing for 1-12 hours under the conditions that temperature is 25-90 DEG C and liquor ratio is 1 to 20-40, and then taking the silk fibre out and washing and drying the silk fibre. The obtained silk fibre can enable the removal rate of the formaldehyde contained inindoor air to achieve more than 75 percent.

Owner:ZHEJIANG SCI-TECH UNIV

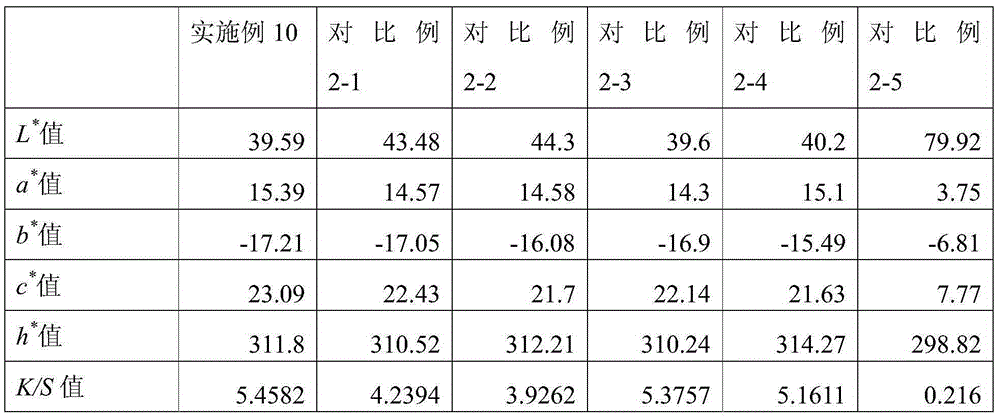

Production method for craft paper

ActiveCN104153230AHigh whitenessReduce yieldPaper recyclingWaste paper working-upPapermakingCellulase

The invention belongs to the technical field of papermaking, relates to a production method for craft paper, and aims to solve the problem of difficulty in the production of feather-weight, strong-strength and high-whiteness craft paper under the condition of not using wood pulp. The production method for the craft paper comprises steps of a MOW pretreatment step for forming surface pulp and lining pulp, an OCC pretreatment step for forming core pulp and prime pulp, and a step for subsequently treating the surface pulp, the lining pulp, the core pulp and the prime pulp, and is characterized in that the MOW pretreatment step comprises the following steps: a, simultaneously performing pulping and biological enzyme deinking on MOW, and b, performing heat dispersion on MOW, wherein the step a comprises a step of adding 1,600 to 1,800 IU / ml cellulase, Na2SiO3 and NaOH into MOW pulp at the mass concentration of 10 to 15 percent for pulping under the condition of 40 to 50 DEG C, wherein the mass concentration of the cellulase, the Na2SiO3 and the NaOH is 0.01 to 0.05 percent, 0.5 to 1.0 percent and 0.5 to 1.0 percent respectively, and the pulping time is 10 to 20 min. Due to the adoption of the technical scheme, the method can effectively solve the technical problem.

Owner:ZHEJIANG JINGXING PAPER

Method for preparing water chestnut hull natural dye and uses thereof

InactiveCN101182391AProtection of interestsSave resourcesNatural dyesDyeing processWater ChestnutsFerrous salts

The invention discloses a preparation method and application of natural dye of water caltrop shell thereof. The water caltrop shell is smashed and then is added into 5 times to 10 times of aqueous solution to be dipped; after the water caltrop shell is fully wetted, sodium hydroxide, sodium carbonate or sodium phosphate is added until the pH of the solution is adjusted to be 8 to 13; the temperature is raised to be between 90 DEG C and 100 DEG C and then is kept for 60 minutes to 90 minutes; the solution is filtered; the filter residue is continuously dipped, extracted and filtered with the alkali solution with the pH of 8 to 13; the solution after two times of dipping and extraction is combined to prepare the stock solution of the natural dye; the stock solution is contracted, solidified and smashed to prepare the natural dye of powder shape. No mordant, mixed rare earth chloride, metal aluminum salt or metal ferrous salt is used for dying products of natural silk or wool. First cation modifier is used for modification; then the natural dye of water caltrop shell is used for dying cotton products. The invention has the advantages of the simple process, the high efficiency, the stable quality and the broad market prospects.

Owner:ZHEJIANG SCI-TECH UNIV +1

Antirusting agent

InactiveCN101519777AThe synthesis method is simpleNo deteriorationMetallic material coating processesSodium phosphatesMildew

The invention relates to an antirusting agent which is characterized by comprising the following components by weight percent: 1.5 to 2 of calcined soda, 0.5 to 1 of trisodium phosphate, 0.3 to 1 of sodium propionate, 0.5 to 0.7 of trimeric sodium phosphate, and the balance of water. The antirusting agent has the advantages of integration of rust resistance, sterilization, mildew resistance and cleanness, as well as good antirusting effect, wide sterilization spectrum, good sterilization effect, long antirusting and bacteriostasis control period, innocuity, insipidity, no simulation to skin, no corrosion to base metal, no pollution to part surface, no bond, convenient operation, economy, practicality, no environment pollution, stable property, no easy metamorphism, easy storage, no flammability, and the like.

Owner:李玉微 +1

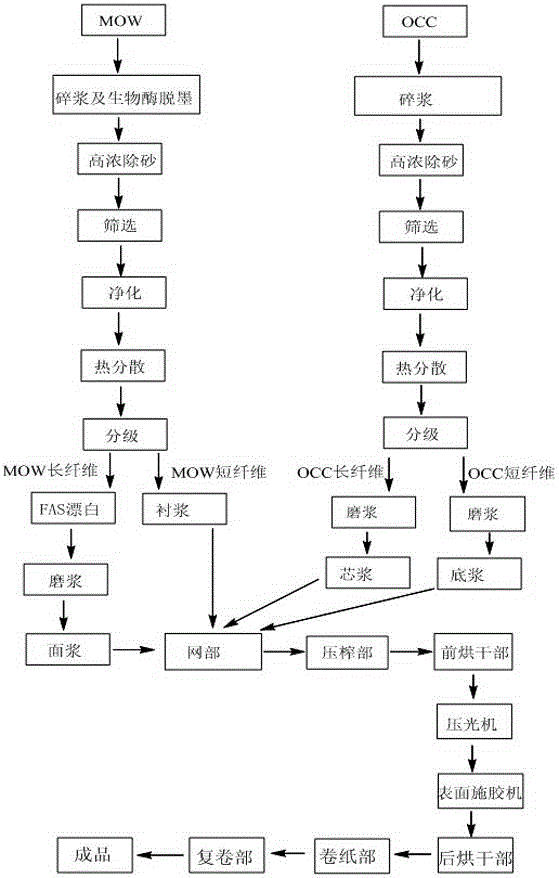

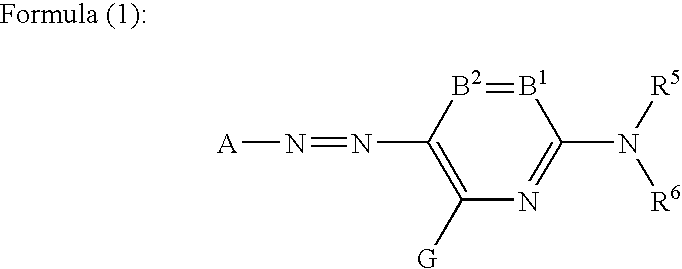

Ink for inkjet recording and method for inkjet recording

InactiveUS20050162492A1Excellent toneHigh fastnessMonoazo dyesMeasurement apparatus componentsOrganic solventImaging quality

An inkjet recording ink comprising an aqueous medium having dissolved or dispersed therein a magenta dye selected from azo dyes, wherein the magenta dye is a dye having an oxidation potential more positive than 1.0 V (vs SCE) and at the same time, a water-miscible organic solvent having a vapor pressure of 2,000 Pa or less at 20° C. is contained; and an inkjet recording method using the ink. By virtue of such a constitution, an inkjet recording ink and an inkjet recording method are provided, which can ensure high ejection stability, good color hue of the obtained image, no drying of the ink at the ink jet head, excellent fastness to light and water, image quality free from defective such as fineline bleeding under high-humidity condition, and good preservability of the image under severe conditions, and furthermore can ensure high storability and high ejection stability even after aging for a long time or under severe conditions.

Owner:FUJIFILM CORP +1

Engine oxygen-rich fuel

InactiveCN103965973ANo restriction on straw typeLess investment in productionLiquid carbonaceous fuelsFuel additivesHydrogenAlcohol

The present invention relates to an engine oxygen-rich fuel, which is formed by mixing an active hydrogen-free and oxygen-containing organic matter and an additive, wherein the active hydrogen-free and oxygen-containing organic matter comprises but is not limited to a ketone substance, an ether substance, an ester substance and an acetal substance, the ester substance content is 0-99.99%, the content of other substances is 0-100%, and the additive content is 0-10%. According to the present invention, the product can be separately used, and can further be used by mixing with a fossil fuel and an alcohol based fuel according to an arbitrary ratio so as to improve combustion quality; and the oxygen-rich fuel has characteristics of complete combustion, environmental-friendliness on environment, human body and engines, and low cost, and is the ideal fuel for replacing the existing fossil energy source.

Owner:张永钢 +1

Preparation method of real silk fabric having uvioresistant function

ActiveCN104894862ASimple processIncrease productivityAnimal fibresEcological environmentHypersensitive response

The invention relates to the field of preparation of functional textile fabrics and aims at providing a preparation method of a real silk fabric having an uvioresistant function. The method comprises the following steps: uniformly mixing a sanguisorba officinalis extract, a mordant, anhydrous sodium sulphate and water to prepare a finishing liquid; putting the real silk fabric in the finishing liquid for treating for 50-80min under the conditions that the pH value is 4-6 and the temperature is 60-80 DEG C; and after the finishing is finished, washing the raw real silk fabric clean and drying so as to obtain the real silk fabric having the uvioresistant function. The invention provides the environment-friendly novel technology for preparing the real silk fabric having the uvioresistant function; the extract is fixedly attached to the raw real silk fabric so that the real silk fabric has the uvioresistant function. The method is simple, the treatment process can be carried out on a dyeing and finishing device and therefore the production efficiency is improved; the fabric can come into direct contact with the skin, is good in safety, is free of carcinogenic and teratogenic effects or anaphylactic reaction, is good in compatibility with ecological environments, is biodegradable, is a novel environment-friendly product and is wide in application range.

Owner:ZHEJIANG SCI-TECH UNIV

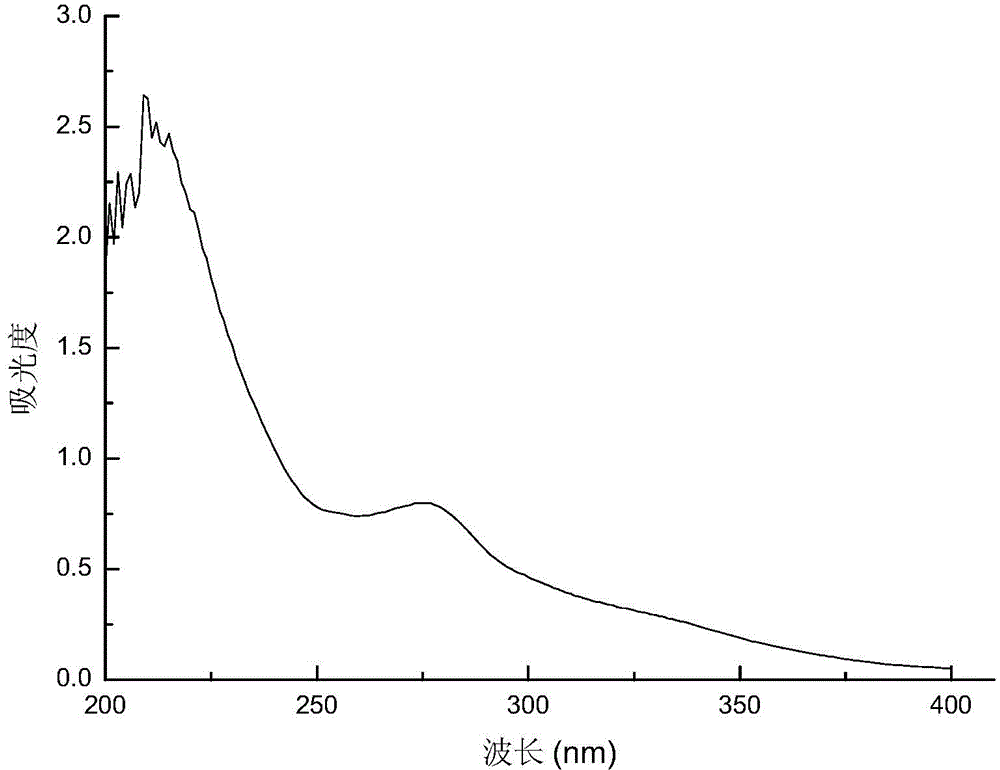

Hydrogen peroxide air disinfector

The technical solution of the invention discloses a hydrogen peroxide air disinfector, which comprises an evaporator, an injection pump, a compressor, an airflow generator, and a nozzle, the evaporator is provided with a liquid-filling inlet, an air inlet, and an air outlet, the injection pump is used for injecting hydrogen peroxide liquid, the injection pump is connected to the liquid-filling inlet of the evaporator, the compressor is connected to the liquid-filling inlet and used for generating air pressure, the airflow generator is connected to the air inlet and used for jetting airflow into the evaporator, the nozzle is mounted in the liquid-filling inlet, and the nozzle is connected to the injection pump ad the compressor. The toxicity of hydrogen peroxide in the hydrogen peroxide airdisinfector is extremely low, and hydrogen peroxide does not have carcinogenicity; and hydrogen peroxide is easy to decompose, can be completely self-degraded, and does not have any toxic and side effects on the human body. The concentration of produced hydrogen peroxide gas is high, and highly efficient sterilization can be realized. The gasification degree of the produced hydrogen peroxide gasis high, the produced hydrogen peroxide gas can be kept in the gaseous state for a long time without being condensed on the surface of an object, and thereby the corrosion of color plates or other materials by the produced hydrogen peroxide gas is reduced.

Owner:上海汉尼生物技术有限公司

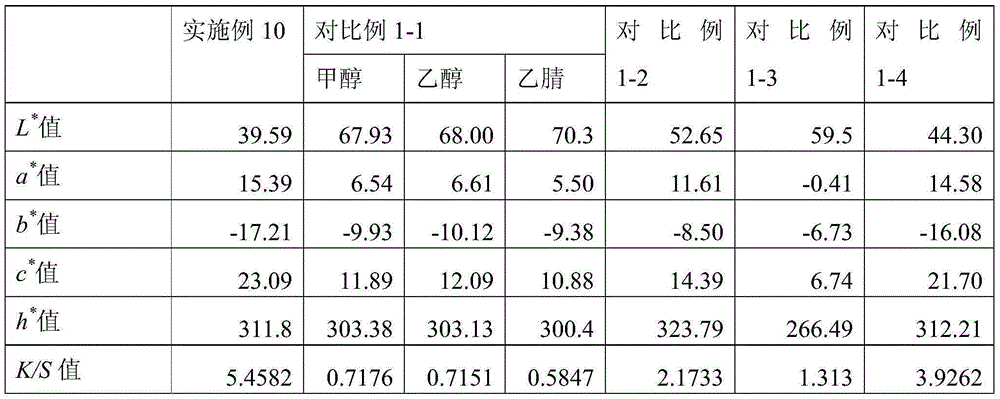

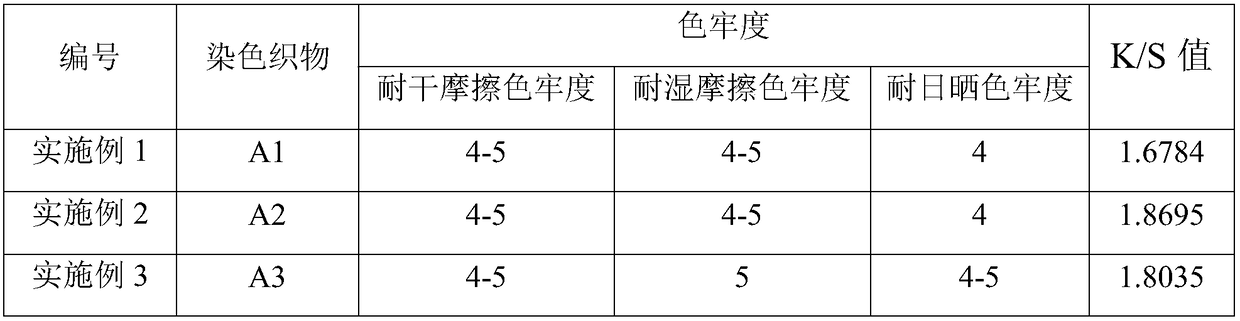

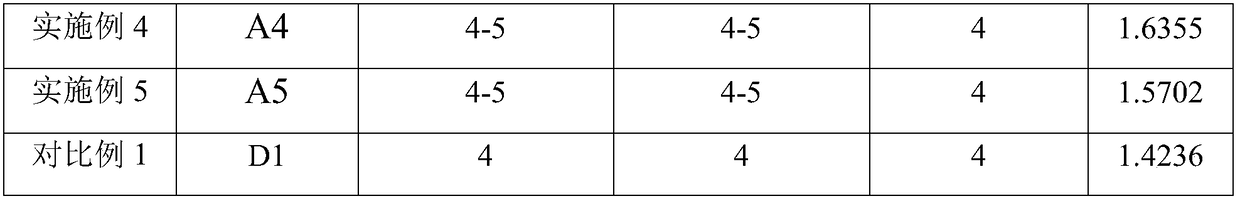

Method for extracting natural dye from rubia cordifolia as well as natural dye prepared by the method and dyeing method

InactiveCN108912729AHigh extraction rateImprove dyeing effectNatural dyesDyeing processDistillationFreeze-drying

The invention relates to the field of natural dye extracting and dyeing, discloses a method for extracting natural dye from rubia cordifolia as well as the natural dye prepared by the method and a dyeing method. The method for extracting natural dye from rubia cordifolia comprises the following steps: washing, drying and crushing rubia cordifolia roots, and extracting the obtained crushed materials in an alkaline aqueous solution; and sequentially performing suction filtration, distillation and freeze-drying on the obtained extracting liquor. The rubia cordifolia natural dye prepared by the method for extracting natural dye from rubia cordifolia has an obvious and relatively good dyeing effect; and specially, the dyed sample in deeper in surface color, and is better in color firmness.

Owner:WUHAN TEXTILE UNIV

Natural dye and dyeing method

The invention provides natural dye and a dyeing method. The natural dye is prepared in the step as follows: after being aired and smashed, senecio cineraria petals are added to water and subjected toultrasonic extraction. The natural dye has stronger affinity for various fabrics and has the advantages of high dyeing coloring rate, good color fastness and concise process, and meanwhile, the fabrics are endowed with special healthcare performance, and the natural dye has broad application prospects.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Preparation method and use of garden burnet natural dye

ActiveCN104910642AImprove dyeing effectImprove performanceNatural dyesDyeing processEcological environmentDistillation

The invention relates to a dye preparation technology and provides a preparation method and use of garden burnet natural dye. The preparation method of the garden burnet natural dye comprises crushing garden burnet rhizome dried in the sun, adding the garden burnet rhizome powder into an ethanol aqueous solution, carrying out reflux extraction at a temperature of 50-70 DEG C for 0.5-2h to obtain extract, filtering the extract and carrying out reduced pressure distillation to obtain the concentrated garden burnet natural dye. The garden burnet natural dye has excellent dyeing effects on protein fibers and a fabric. Through treatment by different mordants, different colors and good color fastness are obtained. The garden burnet natural dye is a natural plant dye with excellent performances. The preparation method has simple extraction processes, short time and no environment pollution in extraction. The fabric dyed by the garden burnet natural dye has a soft color, good color fastness and wear safety, does not cause cancers, malformation or anaphylactic reaction, has good ecological environment compatibility and is biodegradable. The garden burnet natural dye has a low price, fully utilizes natural resources and has a wide market prospect.

Owner:ZHEJIANG SCI-TECH UNIV

Preparing method and application of gnetum montanum natural dye

InactiveCN109971207AImprove performanceImprove dyeing effectNatural dyesDyeing processAqueous sodium hydroxideNatural fiber

The invention relates to a coloring agent, in particular to a preparing method and application of a gnetum montanum natural dye, and belongs to the technical field of dye preparation. The method includes the steps of cutting dried gnetum montanum into small pieces, adding the small pieces to a sodium hydroxide water solution, conducting extraction for 60-120 minutes at 80-100 DEG C to obtain an extraction solution, filtering the extraction solution, and conducting vacuum concentrating to obtain the concentrated gnetum montanum natural dye. The gnetum montanum natural dye is applied as the coloring agent for cotton fabrics, silk fabrics or chinlon fabrics and is also suitable for other natural cellulose and regenerated cellulose fabrics such as ramie, flax, viscose, bamboo fiber and modal fabrics and other natural protein and regenerated protein fiber fabrics such as wool, cashmere, rabbit hair and soy protein fiber fabrics.

Owner:浙江恒生印染有限公司

Technology for purifying life waste water for generation and reusing

InactiveCN1648068AEfficient removalEfficient degradationWater/sewage treatment by flocculation/precipitationWater/sewage treatment by oxidationWater qualitySewage

The technological process of treating domestic sewage for reuse includes the following steps: pre-treatment through adding strong oxidant in pre-treating pond, coagulation and reaction under stirring, and deposition in deposition pond for 1-2 hr; conventional physical and chemical purification; and secondary sterilizing treatment. The said process can degrade organic pollutant in domestic sewage efficiency, eliminate harmful and toxic matters and bacteria, and eliminate carcinogenic and mutagenic matters, and the treated water may be reused. The present invention is especially suitable for purifying water from swimming pool, bath room, etc.

Owner:金增鲁

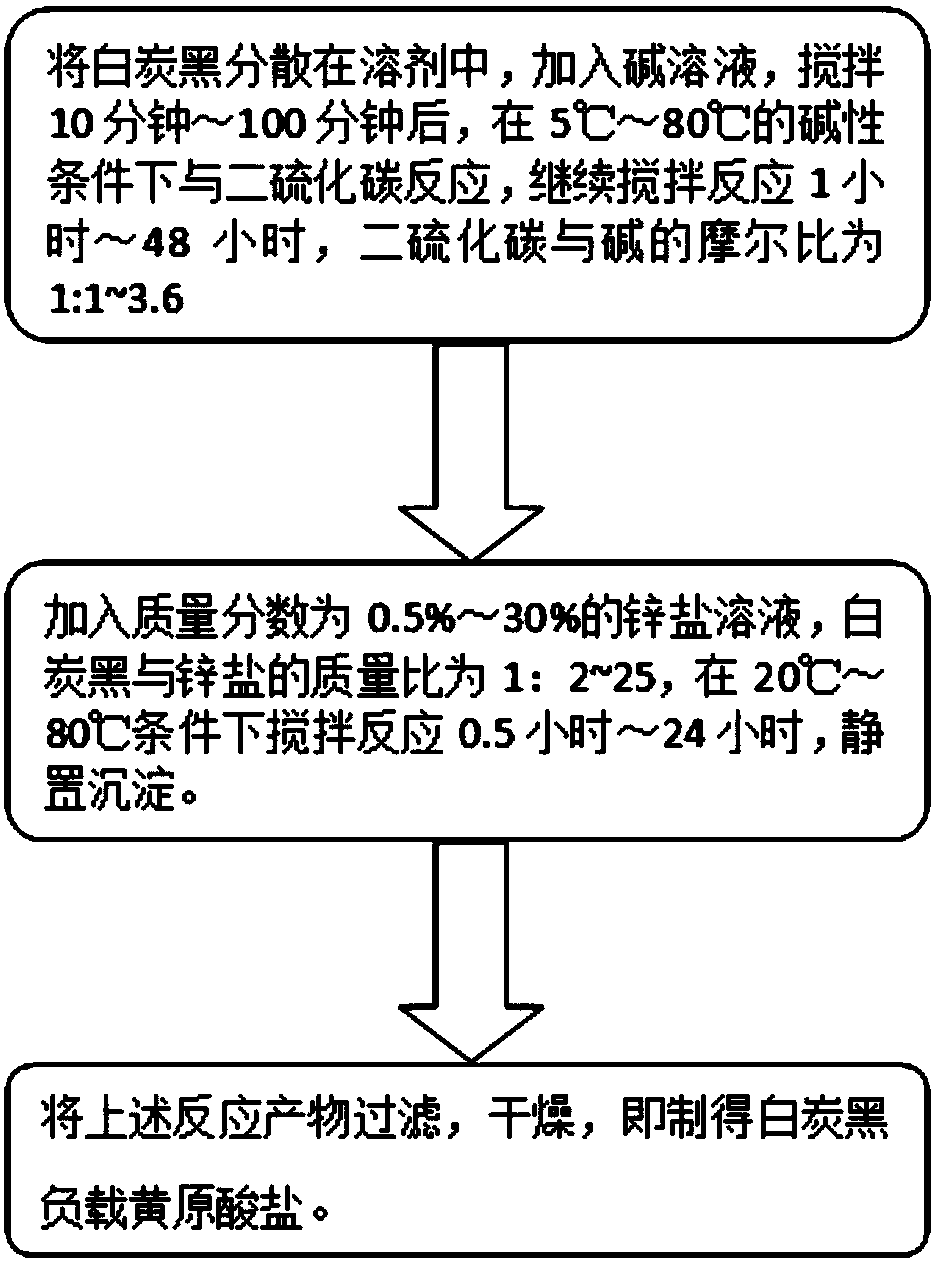

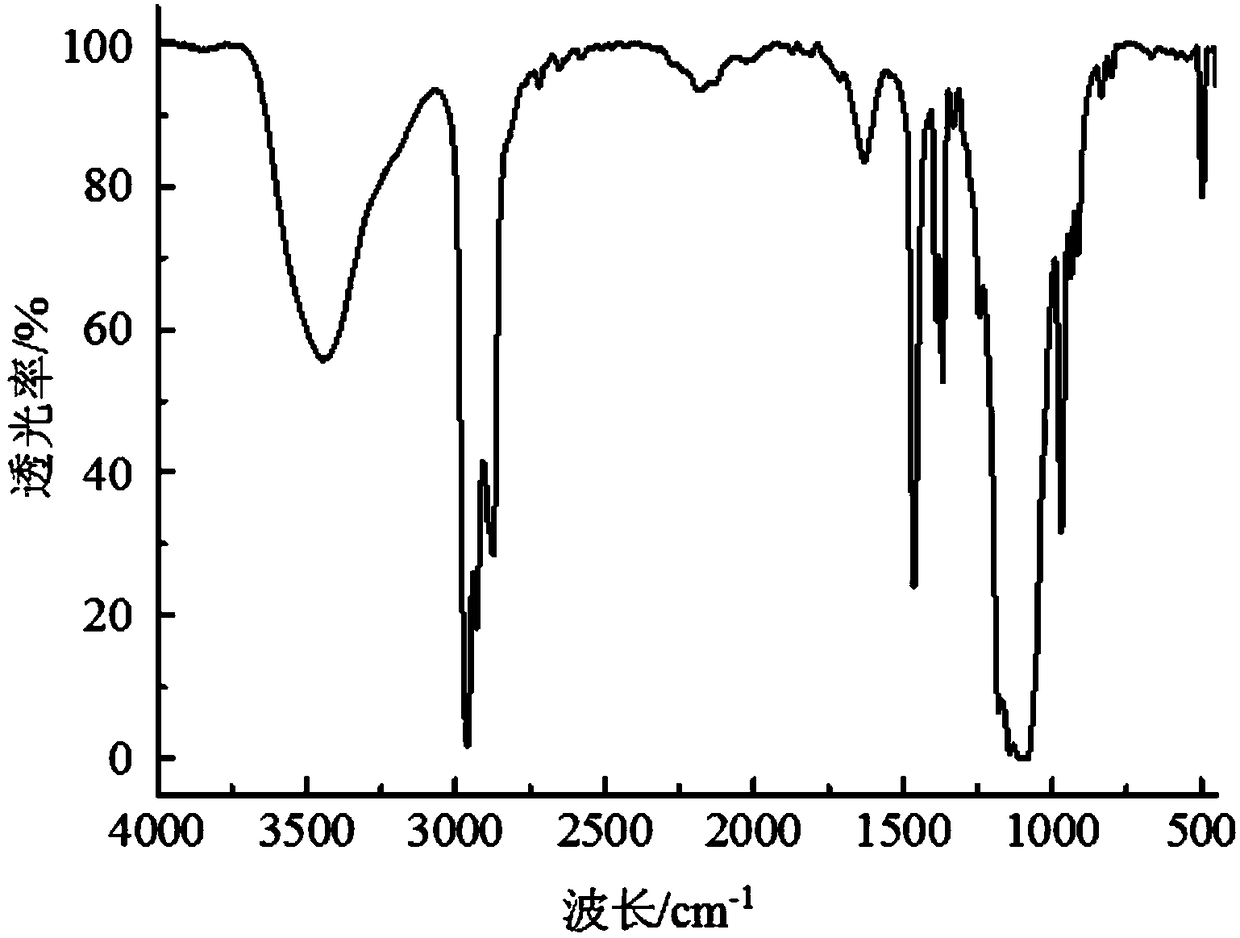

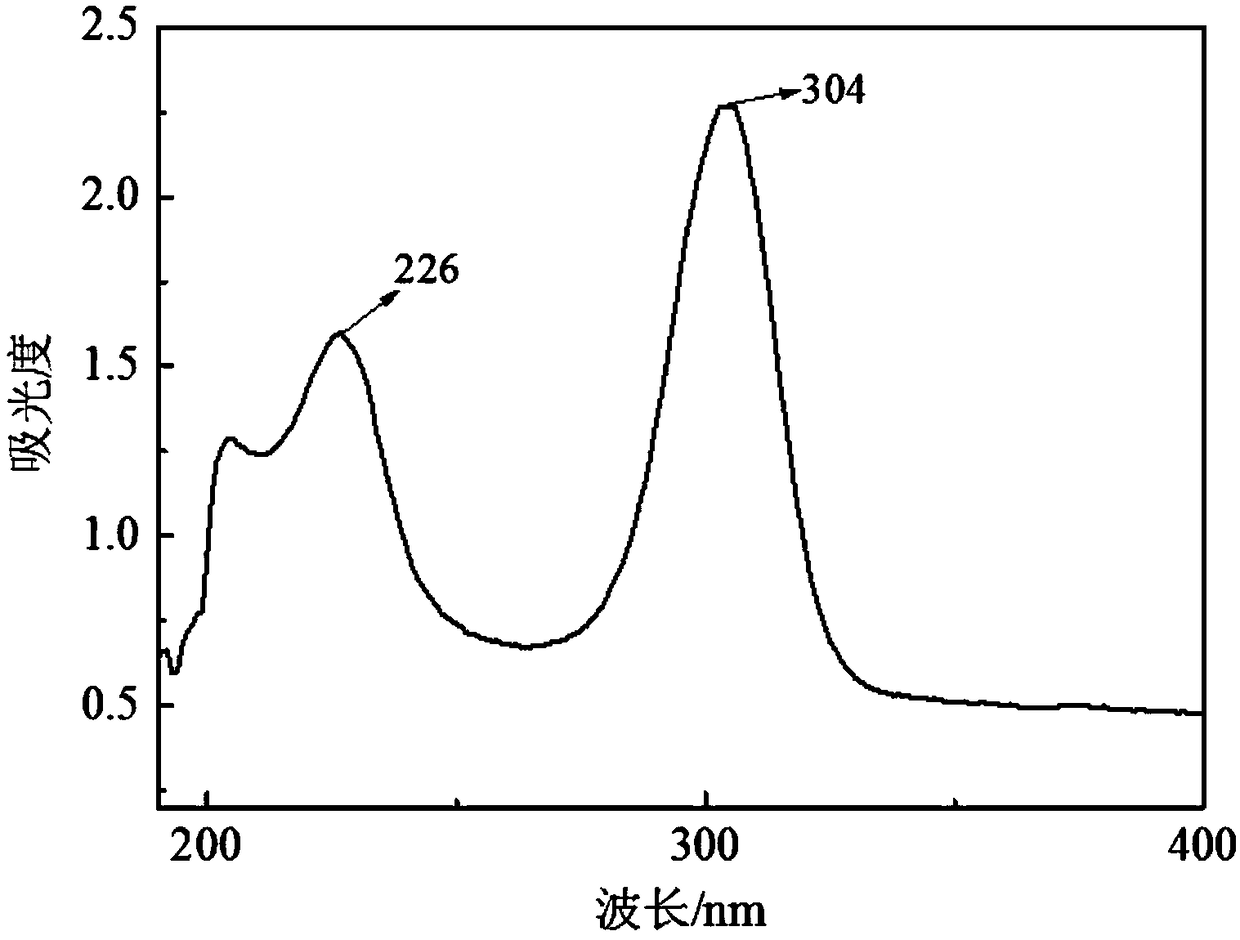

White carbon black-loaded xanthogenate as well as preparation method and application thereof

InactiveCN108129697AImprove thermal stabilityEfficient vulcanization acceleration functionVulcanizationNitrosamine

The invention relates to white carbon black-loaded xanthogenate as well as a preparation method and application thereof. The preparation method comprises the following steps: dissolving white carbon black subjected to modified treatment into a solvent, adding an alkaline solution, stirring for 10 to 100 minutes, reacting with carbon disulfide at 5 to 80 DEG C and under the alkaline condition, andcontinuously stirring for 1 to 48 hours, wherein the molar ratio of the carbon disulfide to the alkali is 1:(1-3.6); adding a zinc salt solution with the mass percentage of 0.5 to 30 percent, stirringunder the condition of 20 to 80 DEG C for 0.5 to 24 hours, and performing static settlement, wherein the mass ratio of the white carbon black to the zinc salt is 1:(2-25); and filtering and drying the reaction product to prepare the loaded xanthogenate, wherein the structure is as follows: the white carbon black serves as a carrier, and the oxygen atom in -OH on the surface of the white carbon black is connected with carbon atom in the xanthogenate (the formula is as shown in the description). In the rubber formula, the white carbon black-loaded xanthogenate is added to serve as a vulcanization accelerator, good vulcanization effect can be achieved, nitrosamine is not generated in the rubber vulcanization and product use processes, and the white carbon black-loaded xanthogenate is an efficient, non-toxic and environment-friendly novel rapid vulcanization accelerator.

Owner:HAINAN UNIVERSITY

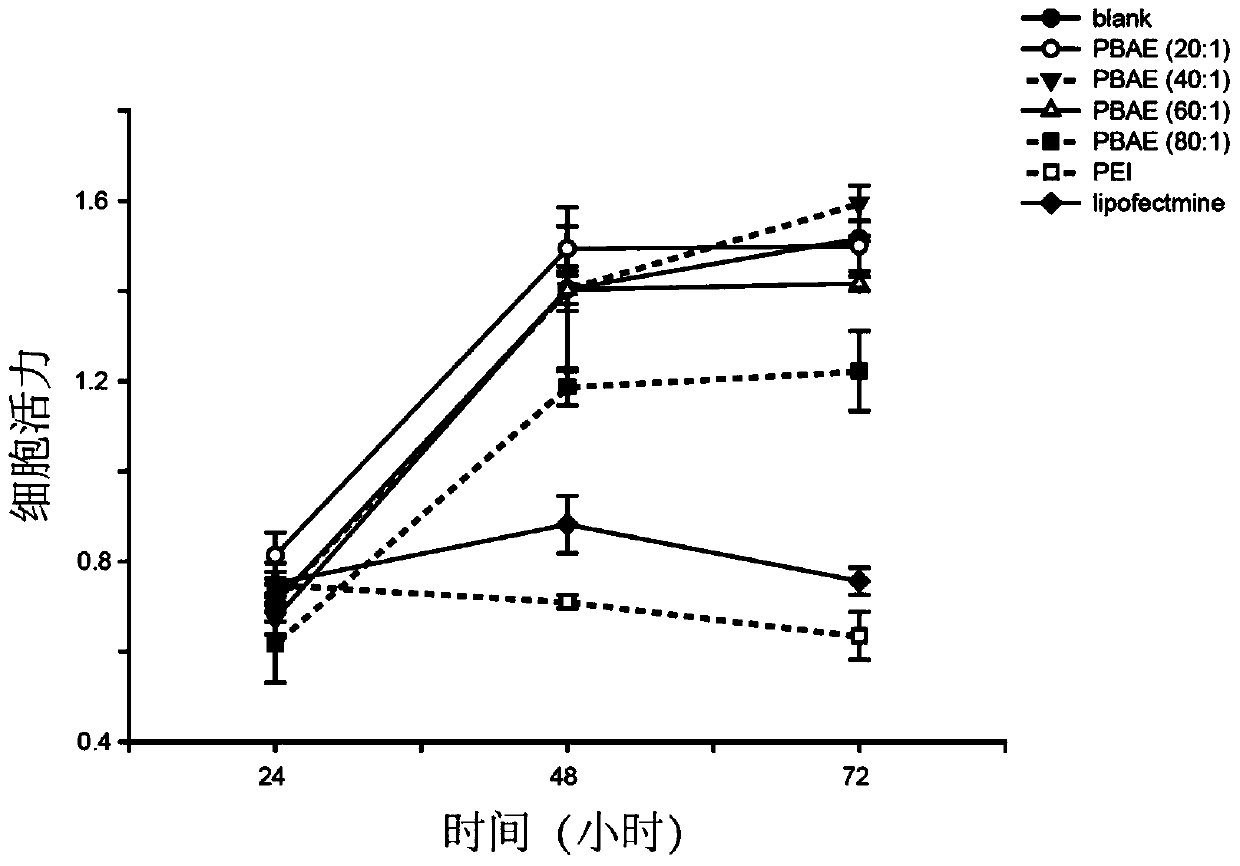

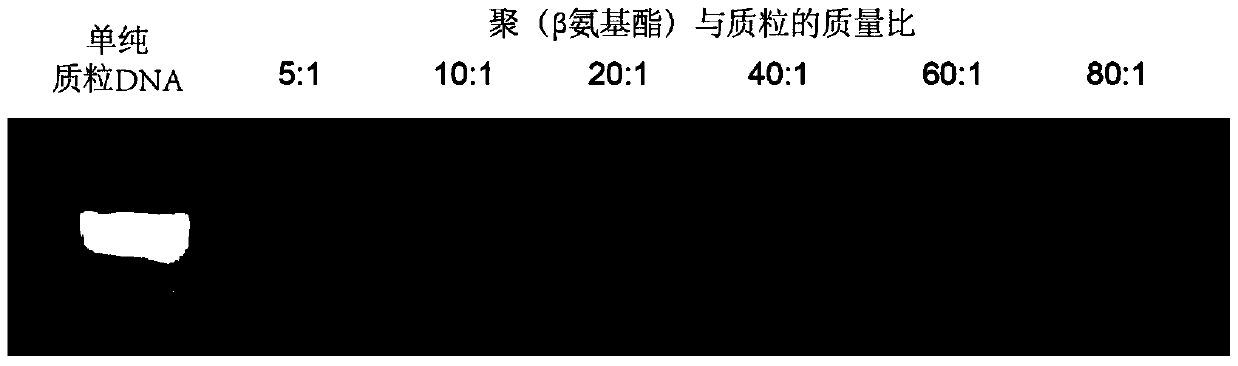

A nanoparticle preparation for treating HPV infection and preparation method thereof

ActiveCN105535994BHPV targeting is goodPromote absorptionOrganic active ingredientsPowder deliveryHuman papilloma virusSide effect

The invention relates to a nanoparticle preparation for treating HPV (Human Papilloma Virus) infection and a preparation method of the nanoparticle preparation. The nanoparticle preparation for treating the HPV infection is prepared from a poly(beta amino ester) polymer and a recombinant plasmid DNA (Deoxyribonucleic Acid) for knocking out or knocking down the HPV in a targeting manner. The nanoparticle preparation disclosed by the invention takes the poly (beta amino ester) polymer and the recombinant plasmid DNA for knocking out or knocking down the HPV in a targeting manner as main raw materials and has the advantages of good specificity, high transfection efficiency, low toxic or side effects and the like.

Owner:TONGJI HOSPITAL ATTACHED TO TONGJI MEDICAL COLLEGE HUAZHONG SCI TECH

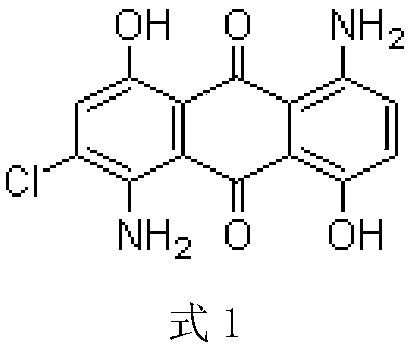

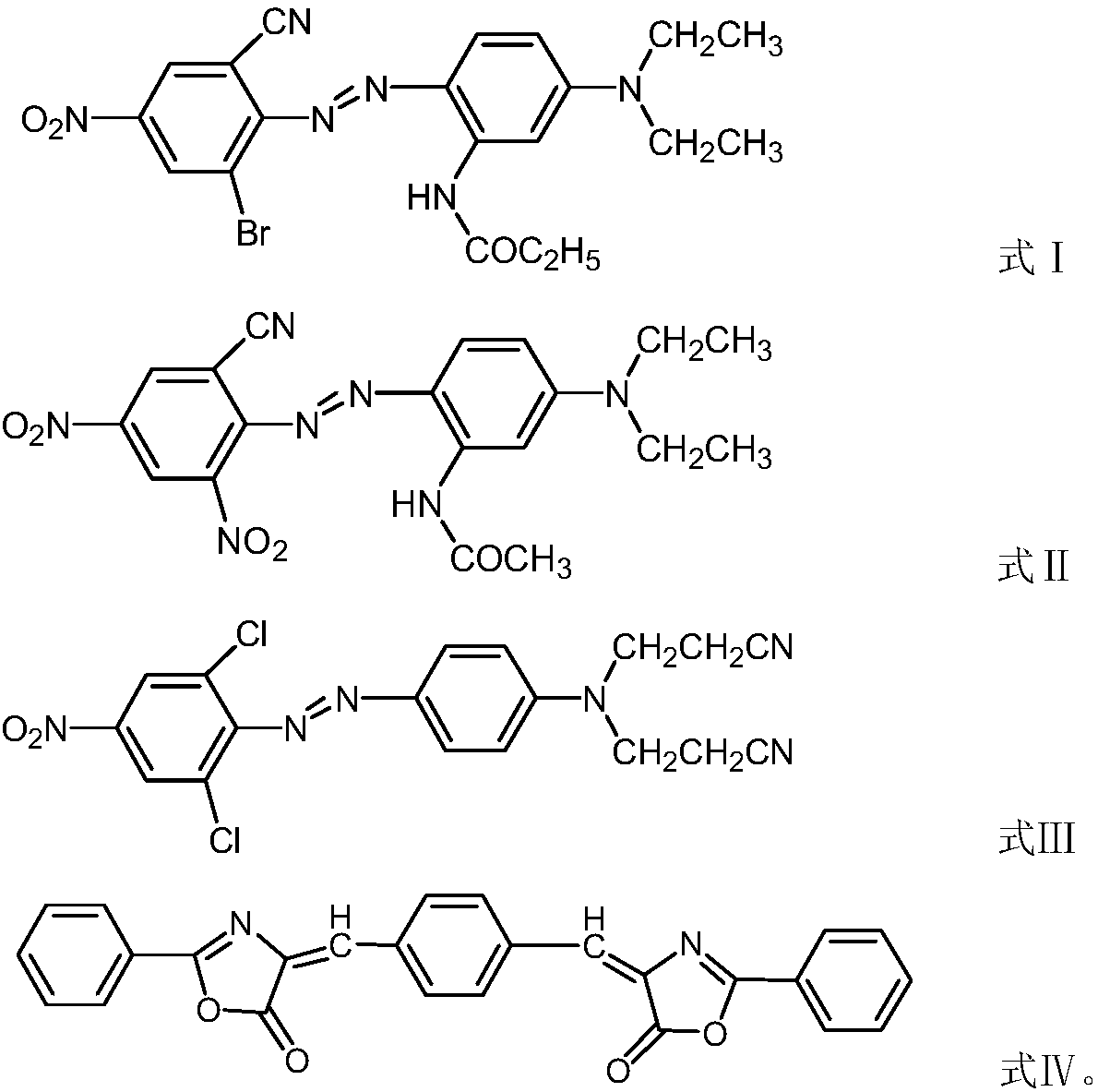

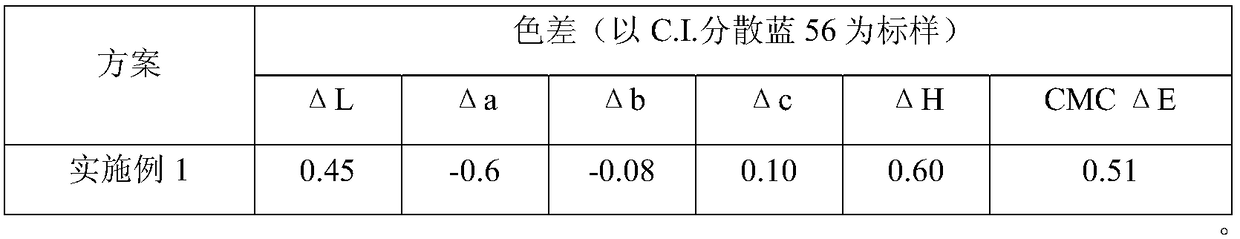

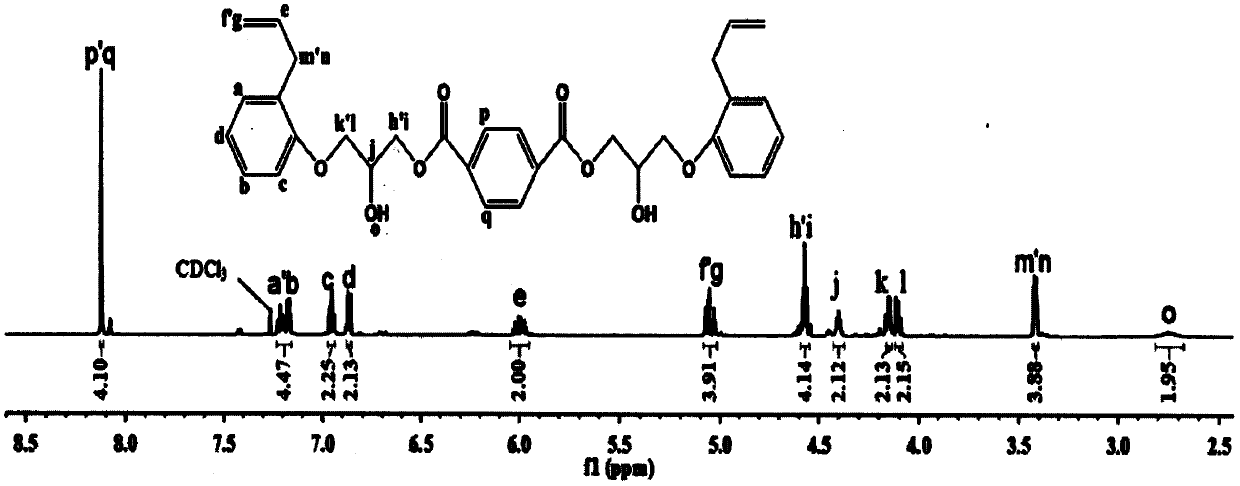

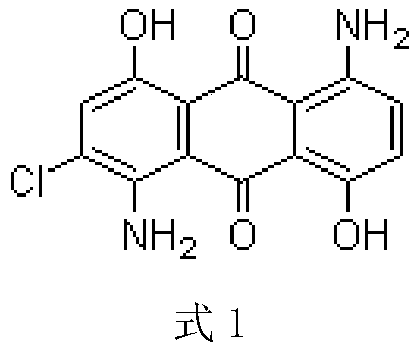

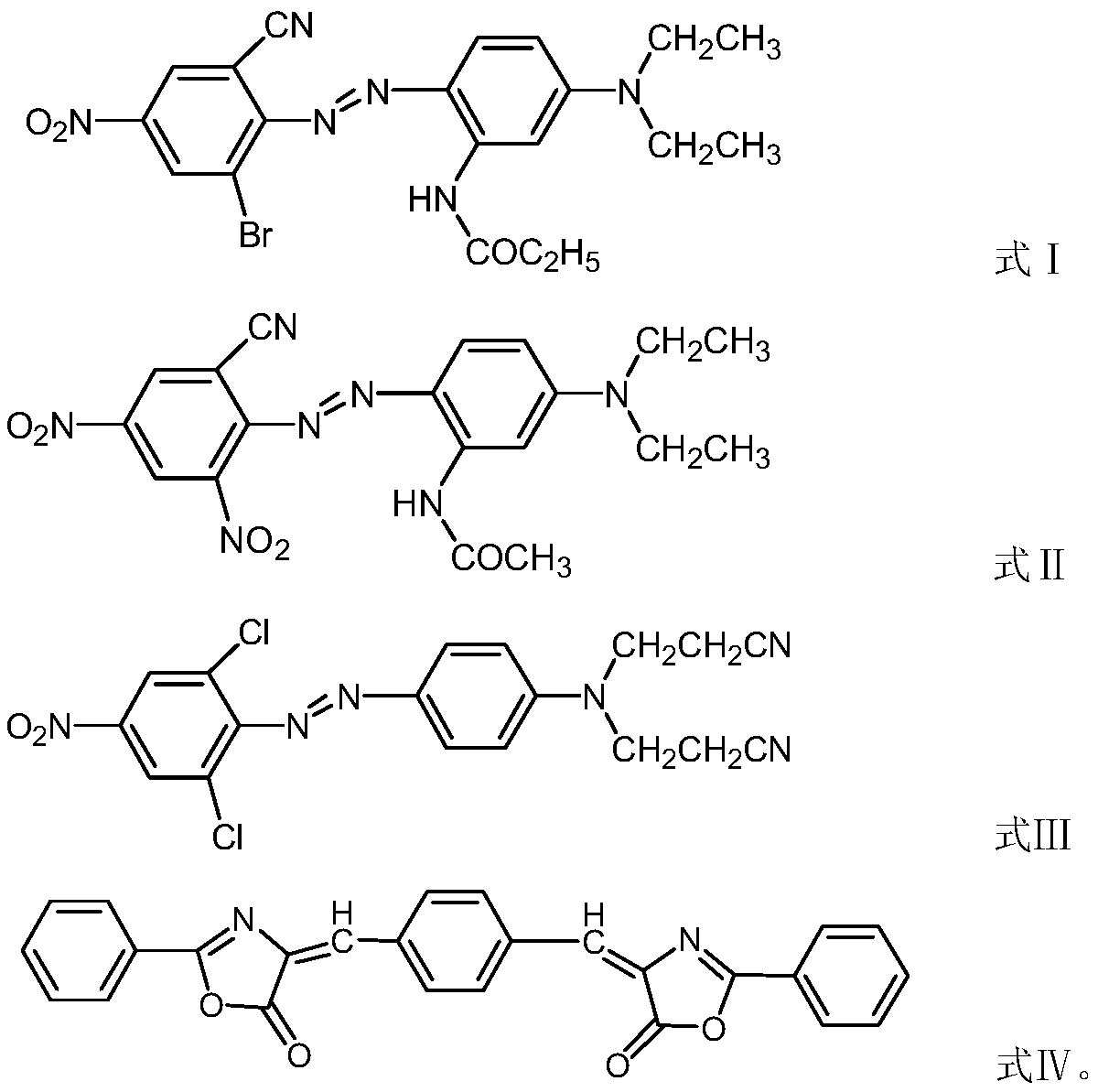

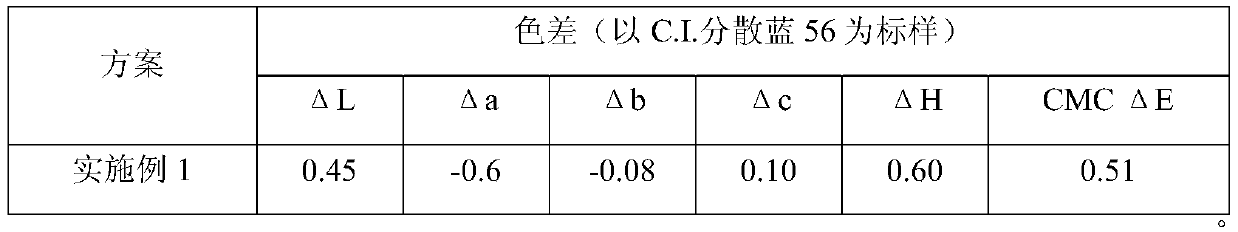

Disperse dye composition and preparation and application methods thereof

ActiveCN109486239AReduce dosageIncrease lifting powerOrganic dyesDyeing processDisperse dyePhotochemistry

The invention discloses a disperse dye composition and preparation and application methods thereof. The disperse dye composition is composed of a component A, a component B, a component C and a component D at a certain ratio, which are added with a certain quantity of additives. The prepared disperse dye composition has the same shade with C. I. disperse blue 56, and when applied to dyeing polyester and polyester blended fabric, has the advantages of being higher in washing fastness and sublimation fastness, better in built-up property, lower in price, safer and more environmentally friendly and accordingly can replace the C. I. disperse blue 56 for dyeing production of hydrophobic fabric, especially polyester.

Owner:SHAOXING UNIVERSITY

Cottonseed hull natural dye extraction method and dyeing application

ActiveCN105949819AHigh pigment contentIncreased dyeable rangeNatural dyesDyeing processAqueous sodium hydroxideAqueous ethanol

The invention discloses a cottonseed hull natural dye extraction method and dyeing application and belongs to the application field of natural dyes. The extraction method includes the steps that cottonseed hulls are smashed into powder and soaked in a sodium hydroxide aqueous solution for 2 h, the cottonseed hull powder obtained after filtering is frozen to -20 DEG C, after being taken out, the cottonseed hull powder is immediately added into an ethanol aqueous solution with the mass being 3-5 times that of the cottonseed hull powder, the mass fraction being 40-60% and the temperature being 60-70 DEG C for heat preservation and ultrasonic extraction, filtering is conducted after extraction to obtain an extraction solution, and rotary concentration and drying are conducted to obtain the powder, namely, a cottonseed hull natural dye. The dye is good in dyeing color fastness on protein type cloth, the cloth is safe to wear, and carcinogenic and teratogenetic effects or anaphylaxis is avoided; compatibility with the ecological environment is good, and the dye is biodegradable. The raw material, namely, the cottonseed hulls, is wide in source, the price is low, natural resources are fully used, and market prospects are very wide.

Owner:山东巧妻食品科技有限公司

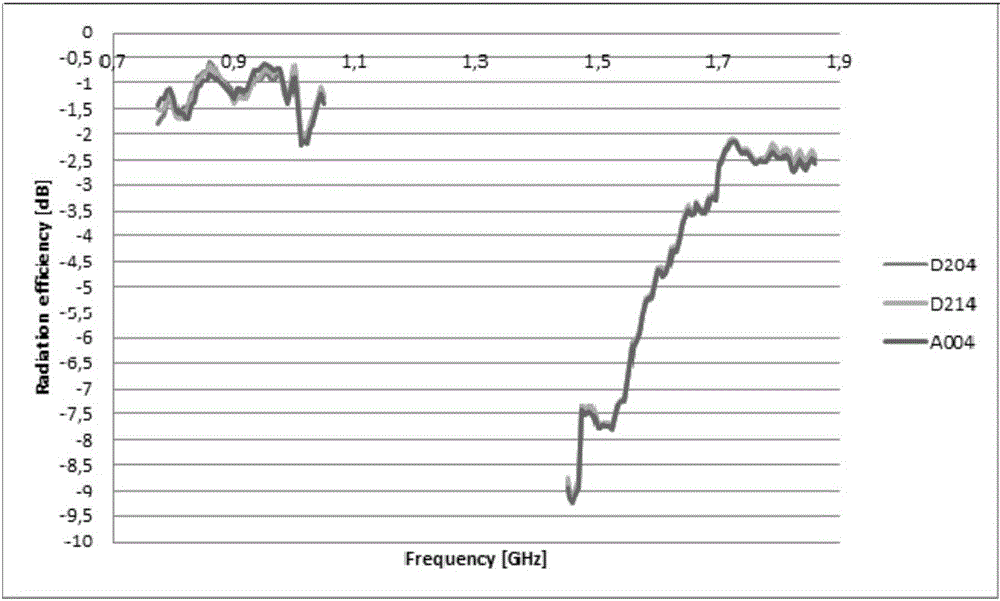

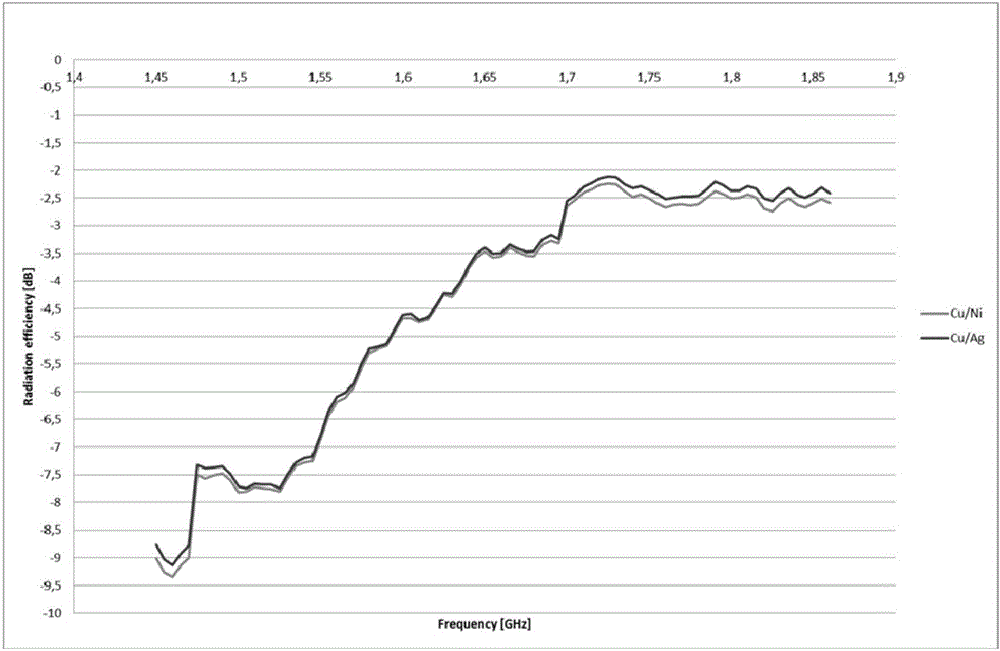

LDS antenna with silver coatings and manufacturing method of LDS antenna

InactiveCN105063583AImprove corrosion resistanceImprove conductivityRadiating elements structural formsLiquid/solution decomposition chemical coatingCopper coatingAntenna element

The invention relates to an LDS antenna with silver coatings. The LDS antenna comprises an antenna element and the coatings. The coatings are composed of the first coating and the second coating. The first coating is a silver coating or a copper coating, and the second coating is a silver coating. The first coating is arranged on the surface of the antenna element, and the second coating is arranged on the surface of the first coating. The invention further relates to a manufacturing method of the LDS antenna with the silver coatings. The LDS antenna with the silver coatings and the manufacturing method of the LDS antenna have the beneficial effects that the performance of the antenna can be improved; safety, better electrical conductivity and the better anti-corrosion property are achieved; welding can be achieved; raw materials are saved; and the total cost is low.

Owner:SHENZHEN SUNWAY COMM

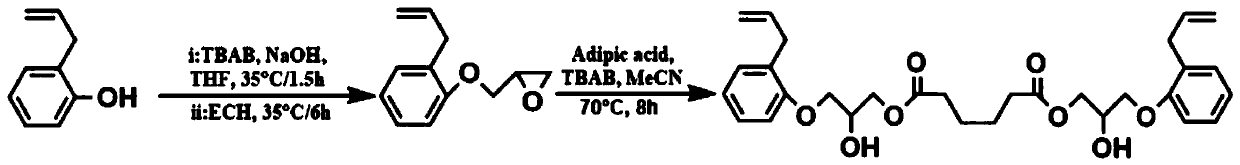

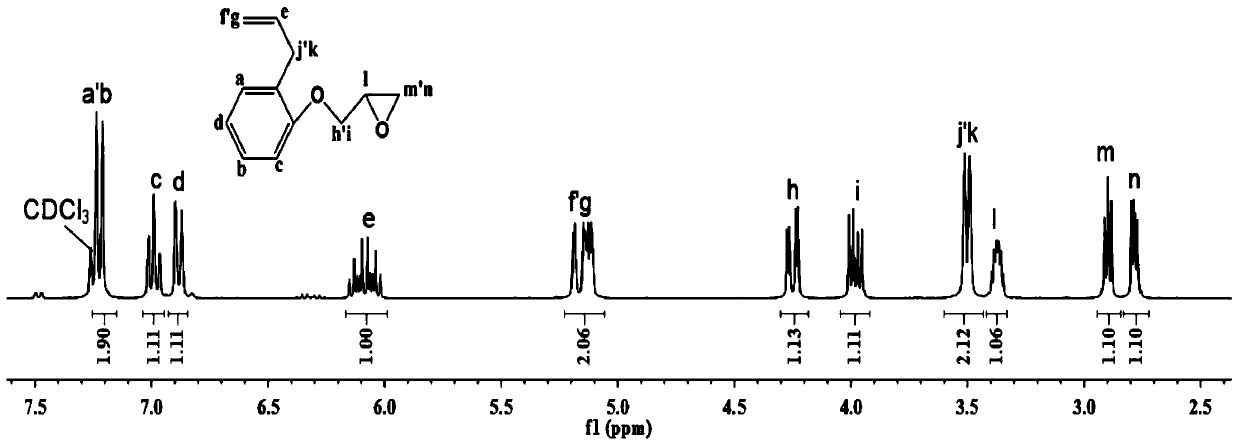

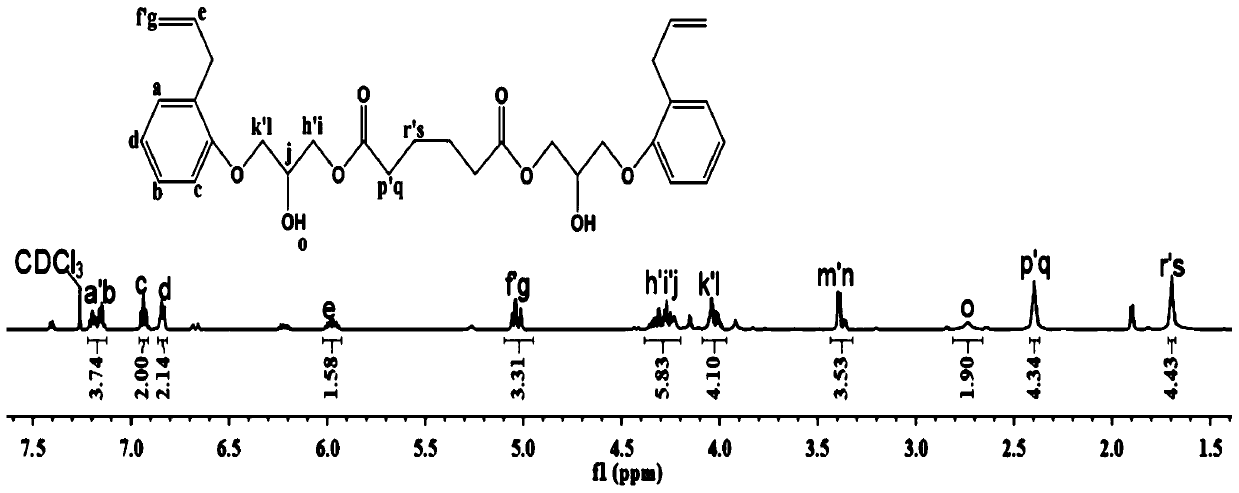

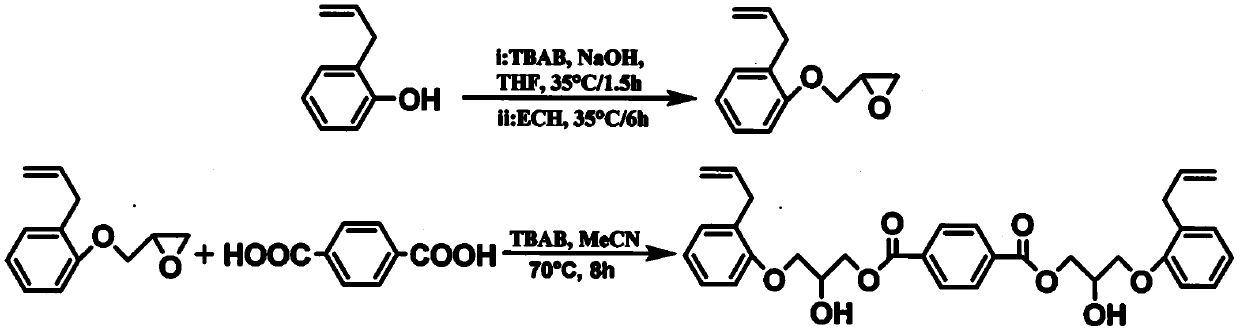

Prepolymer used for self-repair wear-resistant material and application of prepolymer used for self-repair wear-resistant material

ActiveCN110724380AExcellent shape memory performanceGood remodeling propertiesOrganic compound preparationCarboxylic acid esters preparationPolymer sciencePtru catalyst

The invention discloses a prepolymer used for a self-repair wear-resistant material and application of the prepolymer used for the self-repair wear-resistant material. Specific production comprises blending 2-allylphenyl glycidyl ether and adipic acid in acetonitrile, under a condition of a quaternary ammonium salt as a catalyst, carrying out an esterification reaction to obtain bis(3-(2-allylphenoxy)-2-hydroxypropyl)adipate containing a reversible dynamic group; and then evenly mixing the bis(3-(2-allylphenoxy)-2-hydroxypropyl)adipate, bismaleimide and aluminium oxide to obtain the prepolymer, and conducting curing to produce the self-repair wear-resistant material. The self-repair wear-resistant material produced from the prepolymer not only has good wear resistance performance, thermalresistance performance and mechanical performance, but also can be remoulded under a hot-pressing condition, and has wide application prospects.

Owner:江苏立一新材料科技有限公司

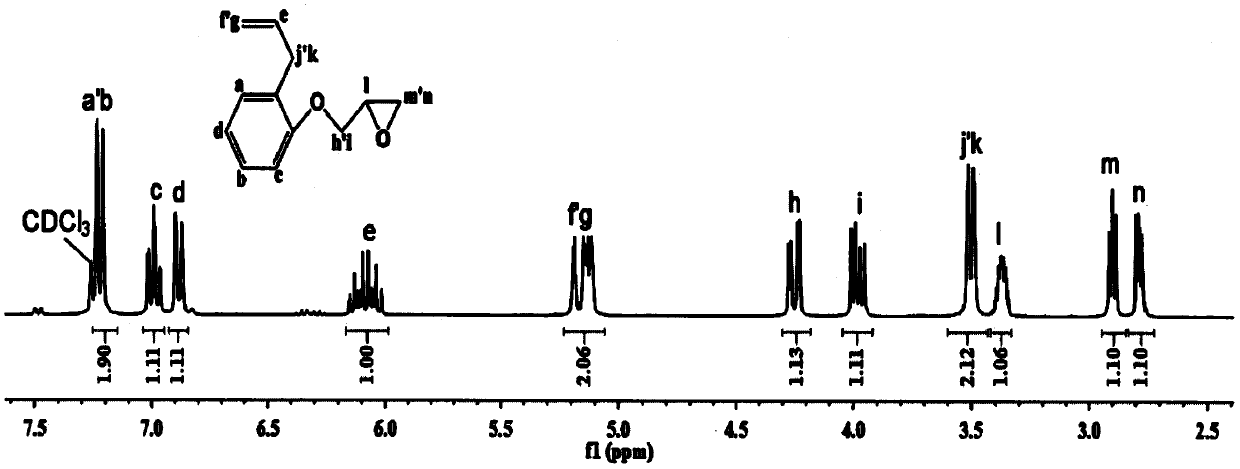

Electronic material and use thereof

ActiveCN110713616AExcellent dielectric propertiesExcellent shape memory performanceOrganic compound preparationCarboxylic acid esters preparationPolymer sciencePtru catalyst

The invention discloses an electronic material and an application thereof. The preparation method specifically comprises the following steps: blending 2-allyl phenyl glycidyl ether and terephthalic acid in acetonitrile, and carrying out esterification reaction with quaternary ammonium salt being a catalyst, so as to obtain bis(3-(2-allylphenoxy)-2-hydroxypropyl)terephthalate containing reversibledynamic groups; and then uniformly mixing bis(3-(2-allylphenoxy)-2-hydroxypropyl)terephthalate with bismaleimide, polyphenyl ether coated mesoporous silica and a solvent, and then impregnating the mixture with glass cloth to prepare the electronic material. The electronic material not only has good dielectric property and heat resistance, but also can realize remodeling under a hot-pressing condition, and has a wide application prospect.

Owner:SUZHOU YIKETAI ELECTRONICS MATERIAL

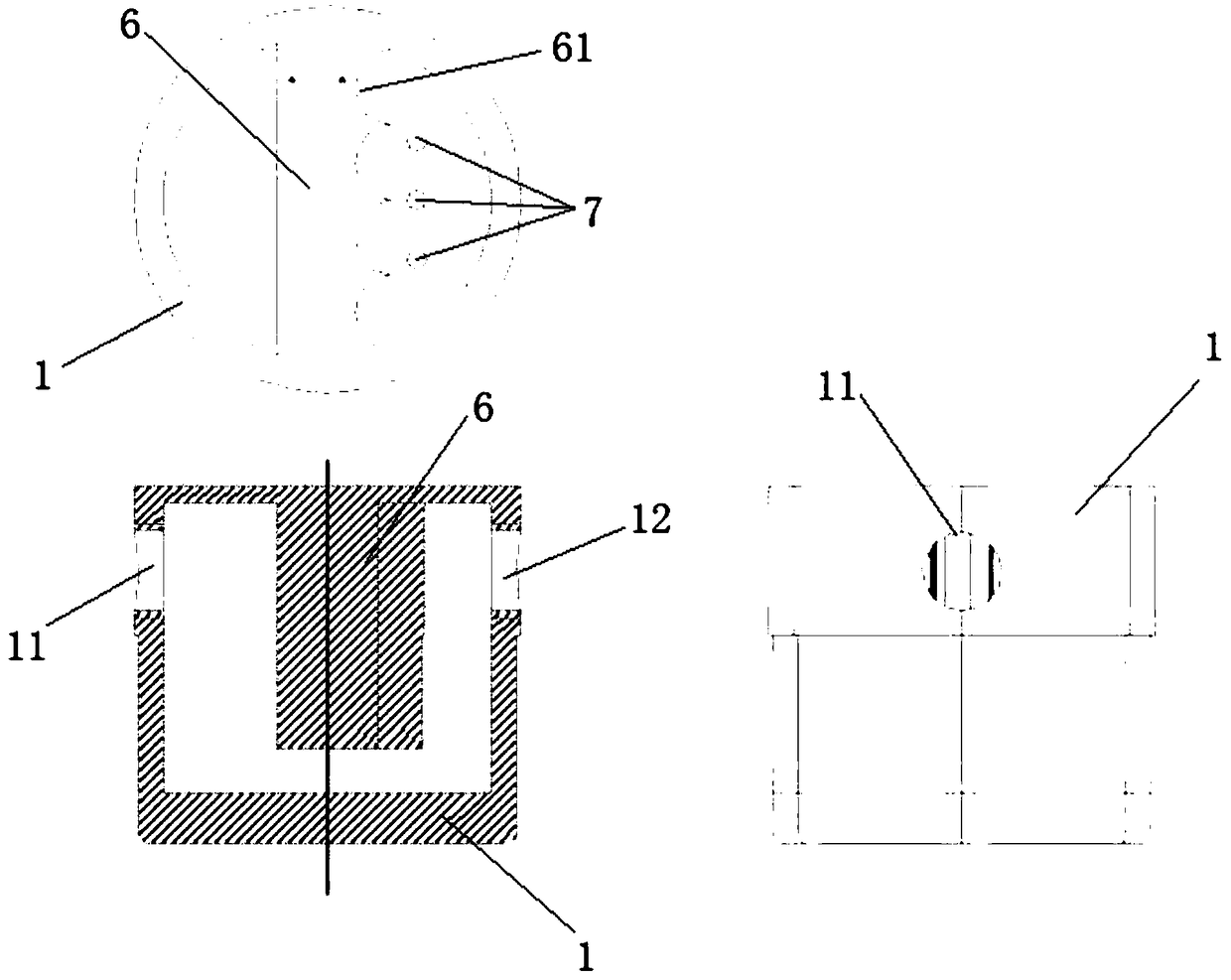

Method for accurately detecting liquid-based fungi by using pelleter

InactiveCN114459844AImprove solubilityReduced disulfide bondsPreparing sample for investigationFluorescence/phosphorescenceBiotechnologyMicroscopic observation

According to the method for accurately detecting the liquid-based fungi by using the pelleter, the special coloring agent is added with phycocyanobilin or phycoerythrin with excellent fluorescence, is red, purple blue and blue protein with strong fluorescence, is derived from algae substances such as blue-green algae or red algae, is natural and non-toxic, and can be used for accurately detecting the liquid-based fungi. Compared with a common staining agent, the fluorescent staining agent is better in fluorescent effect, safer, free of carcinogenesis and suitable for staining for fungus detection; based on a liquid-based flaking technology of a centrifugal method, a centrifugal oscillation method is adopted, fungi are separated into single fungal cells without adhesion, most of human cells and other bacteria in leucorrhea are subjected to enzymolysis after digestion, only the fungal cells are left on a slice after thin-layer filtration, and the cells are in a suspension state after oscillation, so that the liquid-based flaking is realized. Cells dyed by the dyeing agent are clear and distinguishable, and microscopic observation is facilitated.

Owner:HUBEI KANGQIANG MEDICAL DEVICES CO LTD

A special plastic bag for artificial intelligence to identify commodities

Owner:HENAN MECHANICAL & ELECTRICAL VOCATIONAL COLLEGE

Plant dyeing method for textile fabric

PendingCN111979798AIncrease optionalityKeep healthyDyeing processPulp and paper industryIndustrial engineering

The invention discloses a plant dyeing method for textile fabric. The plant dyeing method for the textile fabric includes the steps of plant color paste preparation, grey fabric processing, dyeing liquid preparation, dyeing and dyeing postprocessing. According to the disclosed plant dyeing method for the textile fabric, pure vegetable dyes are selected to carry out printing and dyeing on grey fabric, the method has the characteristics of being friendly to the human body and the environment, a plant dyeing technology is applied to clothing products, the optionality of consumers can be increased, and the physical health of the consumers can be guaranteed.

Owner:FUJIAN FYNEX TEXTILE SCI & TECH

Drug formula for treating bovine diarrhea

InactiveCN109316585AGood treatment effectLow costDigestive systemAluminium/calcium/magnesium active ingredientsSide effectMedicine

The invention discloses a drug formula for treating bovine diarrhea, and relates to the field of veterinary drugs. The drug formula for treating bovine diarrhea is prepared from talcum, poria cocos, sand-fried rhizoma atractylodis macrocephalae, pericarpium citri reticulatae, cauliflower, fructus tsaoko, stir-fried rhizoma dioscoreae, rhizoma zingiberis preparata, and folium sennae. The raw materials are processed and ground into thin powder, and then are mixed uniformly according to a mass ratio, and the mixture is evenly divided into three parts. The three parts are separately mixed with water and then filled into the stomach of a sick cow in the morning, at noon and at night respectively. The drug formula has a good effect on treating bovine diarrhea. The raw materials are all natural Chinese herbals, the cost is low, the toxic and side effects are small, the residues are less, and the drug formula cannot cause cancer, malformation, mutation or resistance to drugs.

Owner:HEILONGJIANG BAYI AGRICULTURAL UNIVERSITY

A kind of disperse dye composition and its preparation method and application

ActiveCN109486239BReduce dosageIncrease lifting powerOrganic dyesDyeing processDisperse dyePolymer science

The invention discloses a disperse dye composition and preparation and application methods thereof. The disperse dye composition is composed of a component A, a component B, a component C and a component D at a certain ratio, which are added with a certain quantity of additives. The prepared disperse dye composition has the same shade with C. I. disperse blue 56, and when applied to dyeing polyester and polyester blended fabric, has the advantages of being higher in washing fastness and sublimation fastness, better in built-up property, lower in price, safer and more environmentally friendly and accordingly can replace the C. I. disperse blue 56 for dyeing production of hydrophobic fabric, especially polyester.

Owner:SHAOXING UNIVERSITY

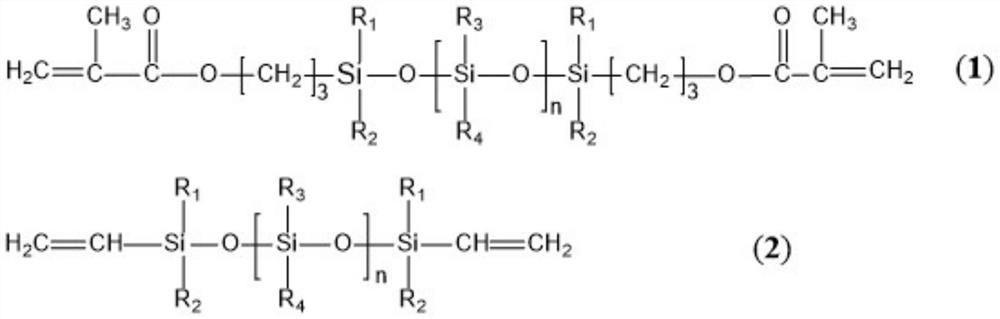

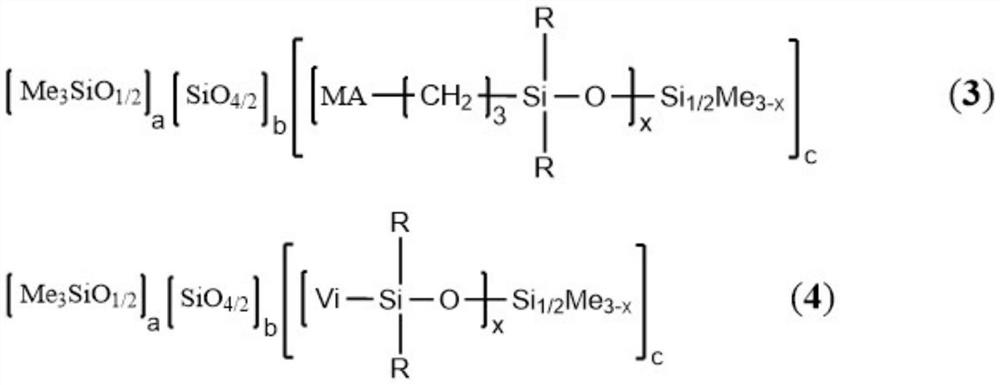

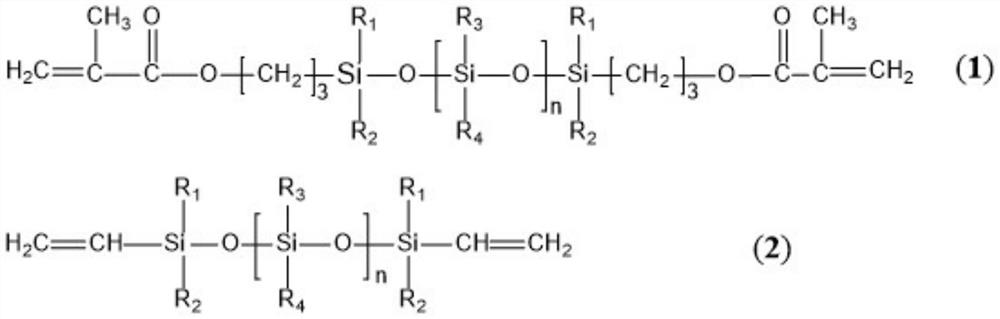

A kind of UV/moisture dual fast curing polysiloxane adhesive composition

ActiveCN110713818BIncreased mechanical bond strengthImprove curing depthNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer scienceOrganometallic catalysis

The invention relates to a polysiloxane adhesive composition with UV / moisture double fast curing, which comprises: (A) 100 parts by weight of diorganopolysiloxane, (B) 5-100 parts by weight of organic modified (C) 0.5-5 parts by weight photoinitiator, (D) 0.001-2 parts by weight organometallic catalyst. The invention has the characteristics of fast ultraviolet curing rate, short moisture curing time, low VOC, high transparency, excellent bonding performance and long storage period. The adhesive composition involved in the invention can be applied to display screens, touch screens and optical devices, circuit board protection, chip protection, and motor sealing.

Owner:王安

Preparation method of compound real silk fabric

InactiveCN108099296AImprove matchGood radiation protectionSynthetic resin layered productsLight resistant fibresUltravioletMaterials science

The invention provides a preparation method of a compound real silk fabric. According to the preparation method, nano silver fibers are used as warp yarns and ice cold cool fibers are used as weft yarns; the weft density is 8 to 15 threadspieces / cm and the warp density is 25 to 40 threadspieces / cm; the ice cold cool fibers are fibers of 75D polyester filaments and 75D viscose filaments and are spun into a bottom surface fabric of an anti-radiation fabric, and the thickness of the bottom surface fabric is 0.35mm to 0.40mm; a nickel layer is plated on the obtained bottom surface fabric and the thickness of the nickel layer is 0.08 to 0.15mm; the plated bottom surface fabric of the anti-radiation fabric is connected with a real silk fabric with an anti-ultraviolet function in a weft knittingplain stitch manner to obtain the anti-ultraviolet compound real silk fabric. According to the method provided by the invention, the selection and matching of raw materials are optimized on the basisof a traditional method and production conditions are strictly controlled; the prepared compound real silk fabric has a better anti-radiation effect; the compound real silk fabric is more ventilated and comfortable when being directly worn on a body and has washability and a wide application prospect.

Owner:大连率为环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com