Prepolymer used for self-repair wear-resistant material and application of prepolymer used for self-repair wear-resistant material

A technology of wear-resistant materials and prepolymers, applied in the field of thermosetting shape memory polymers and recyclable polymers, can solve the problem that remodelable thermosetting SMPs cannot have high heat resistance, high mechanical properties, shape memory properties, and cannot be repeated Utilization, waste of resources and environmental issues, to achieve good reshaping performance, outstanding heat resistance, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of the self-repairing wear-resistant material prepolymer of the present invention is as follows:

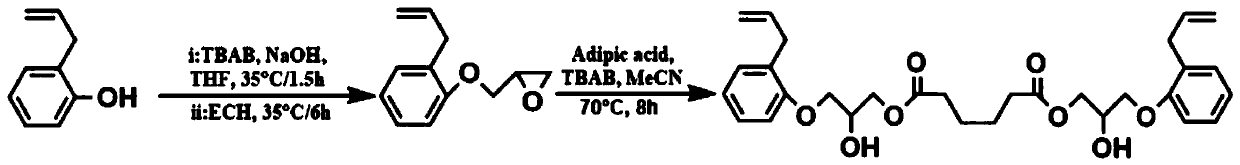

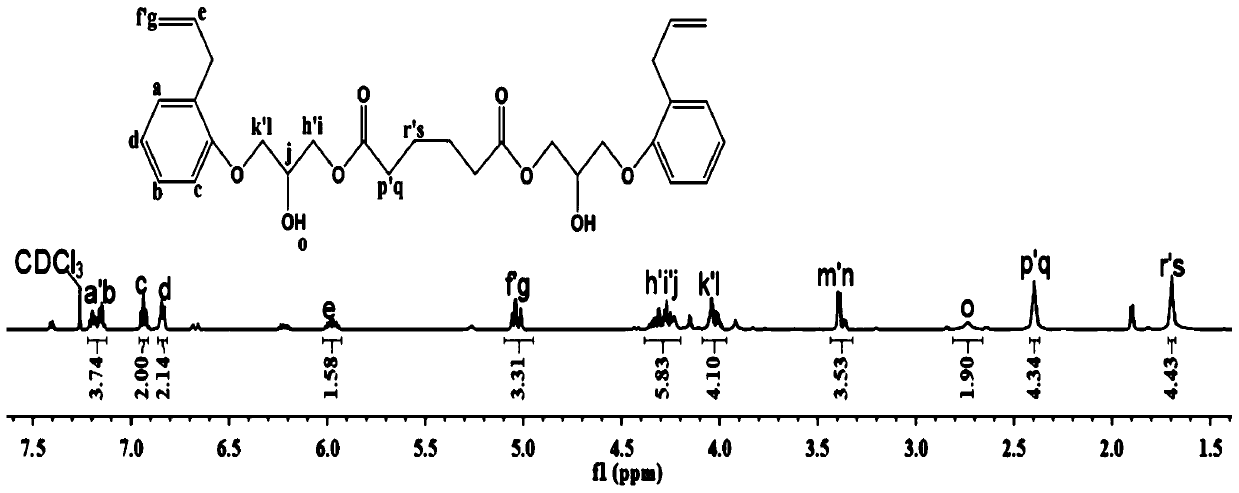

[0030] (1) In the presence of quaternary ammonium salt, react 2-allylphenyl glycidyl ether with adipic acid to prepare bis(3-(2-allylphenoxy)-2-hydroxypropyl)hexyl Diacid ester;

[0031] (2) Stir and mix bis(3-(2-allylphenoxy)-2-hydroxypropyl) adipate, bismaleimide, zinc compound, and filler system to obtain self-repairing wear-resistant Prepolymer for materials; filler system includes epoxy resin and alumina.

Synthetic example

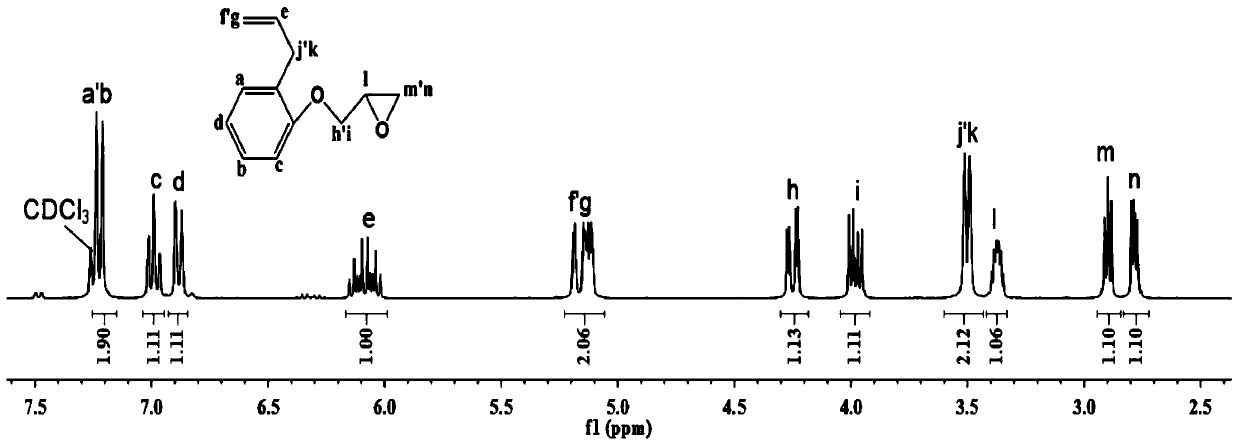

[0033] On a mass basis, mix 120g of 2-allylphenol, 140g of sodium hydroxide, 10g of tetrabutylammonium bromide and 230g of tetrahydrofuran, and insulate and react at 35°C for 1.5h under stirring conditions to obtain solution A; Slowly add 270 g of epichlorohydrin dropwise, and keep stirring at 35° C. for 6 hours to react; after the reaction, vacuum rotary evaporation removes tetrahydrofuran and epichlorohydrin to obtain a crude product. The crude product was washed successively with saturated ammonium chloride solution (200 mL×2), deionized water (200 mL×2), and finally separated and purified by chromatography to obtain a yellow transparent liquid, namely 2-allylphenyl Glyceryl ether, the yield is about 93%, its reaction formula and 1 H-NMR see attached figure 1 and 2 . In terms of mass, mix 120g 2-allylphenyl glycidyl ether, 40g adipic acid, 10g tetrabutylammonium bromide and 230g acetonitrile, and insulate and react at 70°C for 8h under stirring conditions; after the reac...

Embodiment 1

[0035] Embodiment 1 Preparation of prepolymer for self-repairing wear-resistant materials

[0036] 50g N, N'-4,4'-diphenylmethane bismaleimide, 73.41g bis(3-(2-allylphenoxy)-2-hydroxypropyl) adipate and 6.29 g (22.3 mmol) zinc acetylacetonate hydrate and 4 g filler system were mixed, stirred and pre-polymerized at 130°C for 60 min, obtained from the prepolymer for repairing wear-resistant materials, and sampled for DSC testing.

[0037] Cool the above-mentioned prepolymer for self-repairing wear-resistant materials to room temperature, put it into a mold preheated at 150°C, and perform hot pressing and post-treatment according to the following process: 150°C / 1 h / 1MPa+180°C / 2 h / 3MPa +200 ℃ / 1.5 h / 5MPa+220 ℃ / 1.5 h / 5MPa and 240 ℃ / 2 h; demold after natural cooling, that is, the self-repairing wear-resistant material, and test TG, DMA, bending strength and wear resistance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com