Dynamic polymer with hybrid cross-linking network

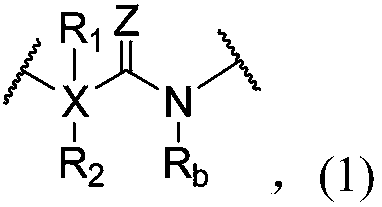

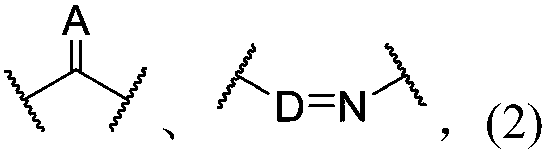

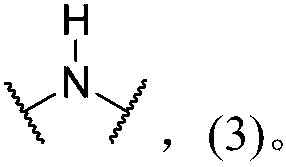

A hybrid cross-linking and polymer technology, applied in the field of smart materials, can solve problems such as non-recycling and recycling, difficulty in bond breaking, etc., and achieve rich environmental responsiveness, good dynamic effects, and excellent self-healing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0170] The preparation method of a kind of dynamic polymer ionic liquid gel of the present invention preferably comprises the following steps: the raw material of the dynamic polymer that prepares hybrid cross-linked network is added in ionic liquid, makes the prepared hybrid cross-linked network The mass fraction of the dynamic polymer is 0.5-50%. The covalent cross-linking is carried out by the appropriate means, and after the reaction is completed, it is naturally cooled to form a dynamic polymer gel. The ionic liquids mentioned above are generally composed of organic cations and inorganic anions. The cations are usually alkyl quaternary ammonium ions, alkyl quaternary ions, 1,3-dialkyl substituted imidazolium ions, N-alkyl substituted pyridinium ions, etc. ; Anions are usually halide ions, tetrafluoroborate ions, hexafluorophosphate ions, and CF 3 SO 3 - , (CF3SO 2 ) 2 N - 、C 3 f 7 COO - 、C 4 f 9 SO 3 - 、CF 3 COO - , (CF 3 SO 2 ) 3 C - , (C 2 f 5 SO 2 ...

Embodiment 1

[0222] 3-allyl-1,2-phenylenediamine and 4-mercapto-2-pyrrolidone were mixed according to a molar ratio of 1:1, and 0.2wt% of photoinitiator benzoin dimethyl ether (DMPA) was added, and after stirring fully, put The compound 1a was prepared by ultraviolet irradiation in an ultraviolet crosslinking apparatus for 4 h.

[0223]

[0224] Weigh the reaction material A in parts by weight: 12 parts of N,N'-di-tert-butylethylenediamine, 4 parts of compound 1a, 0.3 parts of 1,6-hexanediol, 0.3 parts of tris(3-aminoethyl) Amine, 0.2 parts of dibutyltin dilaurate, 0.2 parts of triethylenediamine, 0.1 parts of silicone oil, 5 parts of methylene chloride, and 3 parts of water were added to the container, and the Stir evenly under the same conditions; Reaction material B: 12 parts of 1,4-cyclohexane diisocyanate, add to the container, and stir evenly under the condition of material temperature 35°C and stirring speed 200r / min; then the reaction material A and the reaction material B is...

Embodiment 2

[0228] Tris(3-aminoethyl)amine and ethyl isocyanate were mixed according to equimolar ratio, dissolved in 200mL of dichloromethane, and then 0.1 part of dibutyltin dilaurate and 0.1 part of triethylenetetramine were added as catalyst to prepare band Urea-based diamine compound 2a.

[0229]

[0230] Weigh the reaction material A in parts by weight: 15 parts of N,N'-di-tert-butyldecanediamine, 6 parts of compound 2a, 0.5 parts of 1,6-hexanediol, 0.1 part of glycerol, 0.2 parts of dilaurel Add dibutyltin dibutyltin, 0.2 parts of triethylenediamine, 0.1 parts of silicone oil, 5 parts of dichloromethane, and 3 parts of water into the container, and stir evenly at a material temperature of 35°C and a stirring speed of 200r / min; Material B: 12 parts of hexamethylene diisocyanate, added to the container, stirred evenly under the condition of a material temperature of 35°C and a stirring speed of 200r / min; then the reaction material A and the reaction material B were mixed accordi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com