Patents

Literature

28892 results about "Glycerol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

This medication is used as a moisturizer to treat or prevent dry, rough, scaly, itchy skin and minor skin irritations (e.g., diaper rash, skin burns from radiation therapy).

Method of treating glutaraldehyde-fixed pericardial tissue with a non-aqueous mixture of glycerol and a C1-C3 alcohol

A method of treating a biological tissue that enables dry storage of said tissue is disclosed. In one embodiment, the method comprises contacting the biological tissue with a non-aqueous treatment solution comprising a polyhydric alcohol and a C1-C3 alcohol and removing a portion of the treatment solution from the solution-treated biological tissue. Also disclosed is biological tissue prepared using the above process and prosthetic devices made with such tissue.

Owner:EDWARDS LIFESCIENCES CORP

Pharmaceutical compositions for lipophilic drugs

InactiveUS7070802B1Good self-emulsifying performanceShelf-stableCyclic peptide ingredientsCapsule deliveryMonoglycerideCyclosporins

Stable solutions of lipophilic drugs, such as cyclosporin, forming a polar lipid self-emulsifying drug delivery system. The solutions can include lipophilic drugs, such as cyclosporin, dissolved in a polar lipid, such as having a C6-C12 fatty acid monoglyceride content of at least about 50%, surfactants and triglycerides. The composition forms a fine emulsion on exposure to water. The encapsulated dosage form of this composition needs neither a hydrophilic component nor air-tight blister packaging, and is particularly suitable for oral administration.

Owner:WATSON LAB INC

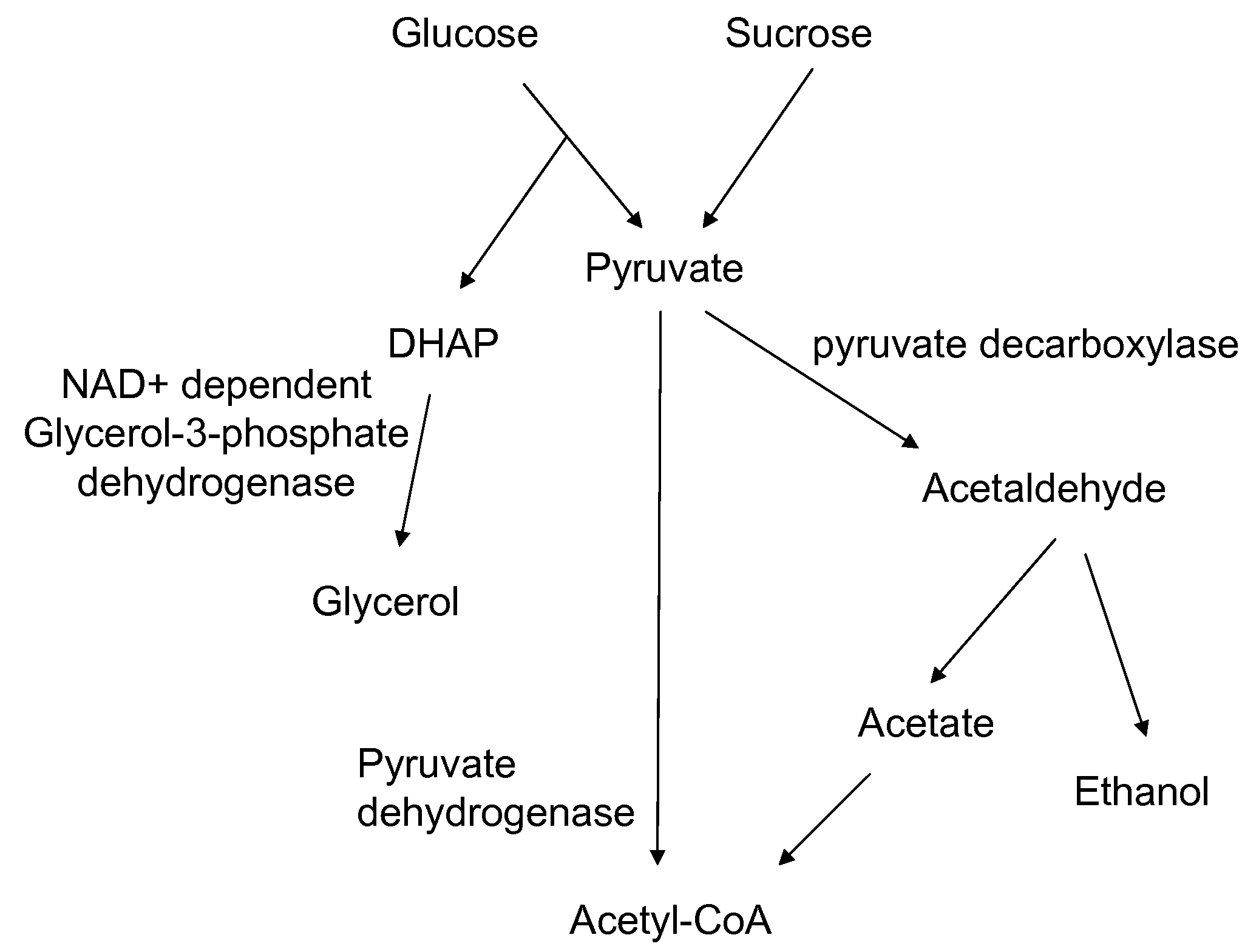

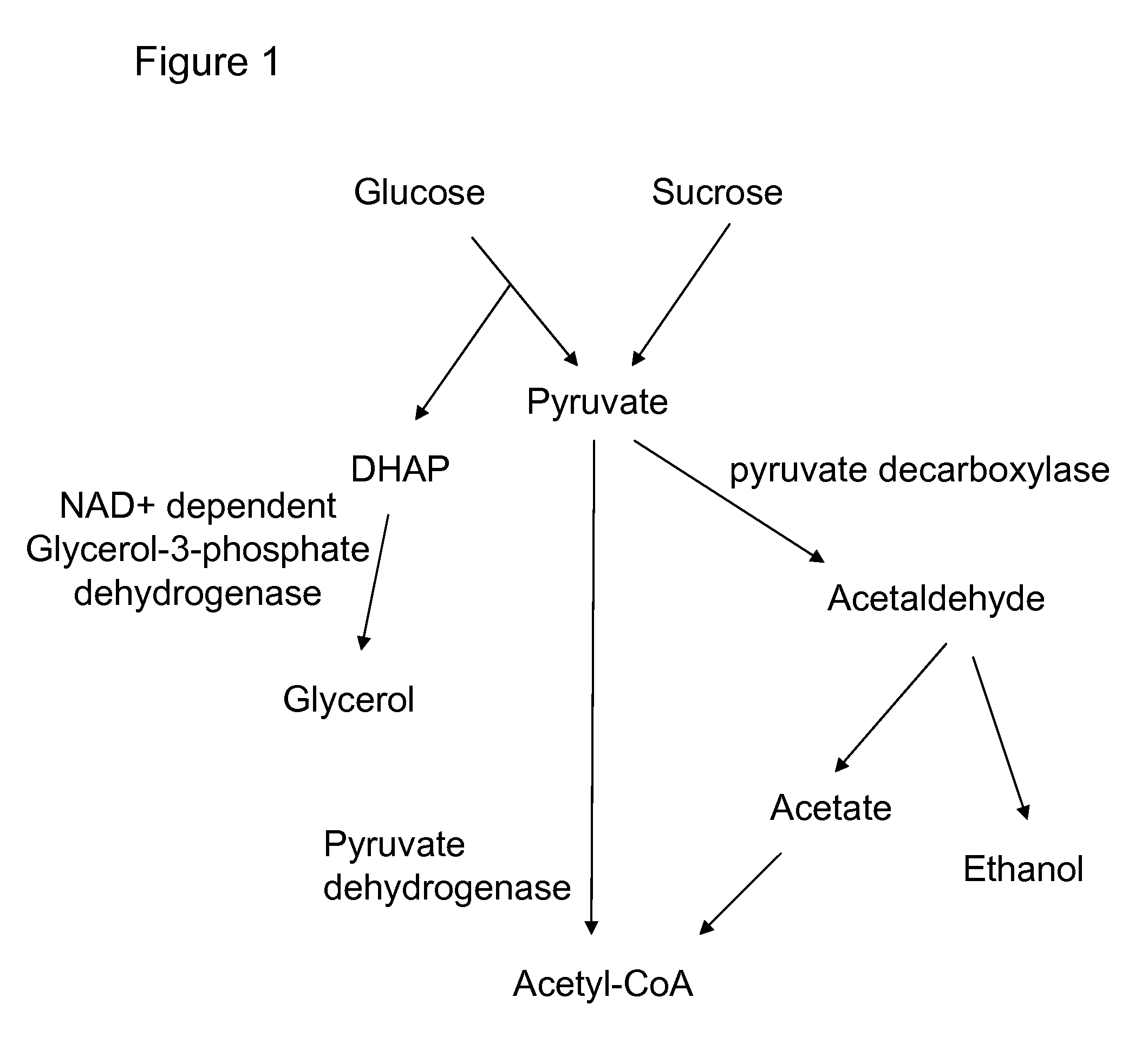

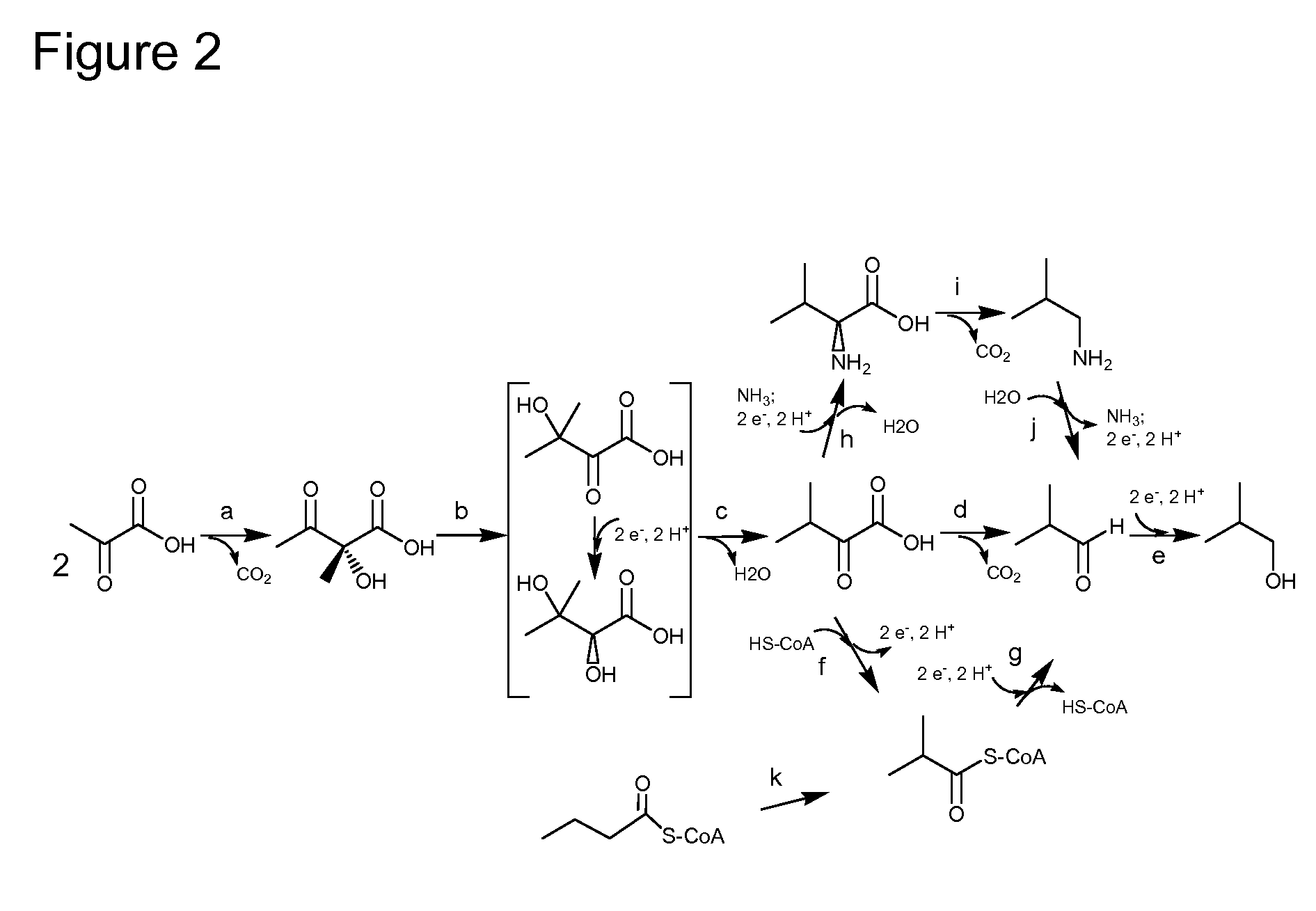

Enhanced pyruvate to acetolactate conversion in yeast

ActiveUS20090305363A1Improve throughputReduction of pyruvate decarboxylase activityFungiTransferasesYeastCytosol

A high flux in conversion of pyruvate to acetolactate was achieved in yeast through expression of acetolactate synthase in the cytosol in conjunction with reduction in pyruvate decarboxylase activity. Additional manipulations to improve flux to acetolactate are reduced pyruvate dehydrogenase activity and reduced glycerol-3-phosphate dehydrogenase activity. Production of compounds having acetolactate as an upstream intermediate benefit from the increased conversion of pruvate to acetolactate in the described strains.

Owner:GEVO INC

Oleaginous pharmaceutical and cosmetic foam

InactiveUS20070292461A1Pleasant and easy to spreadPatient compliance is goodCosmetic preparationsMetabolism disorderActive agentPolyethylene glycol

The invention relates to stable pharmaceutical or cosmetic foam compositions containing certain active agents, having unique therapeutic properties and methods of treatment using such compositions. The foamable composition includes at least one solvent comprising polyethylene glycol (PEG) or PEG derivative and mixtures thereof, or comprising propylene glycol, wherein the solvent is present at a concentration of about 70% to about 96.5% by weight of the total composition, at least a non-ionic surface-active agent at a concentration of about 0.1% to less than about 10% by weight of the total composition.

Owner:FOAMIX PHARMACEUTICALS LIMITED

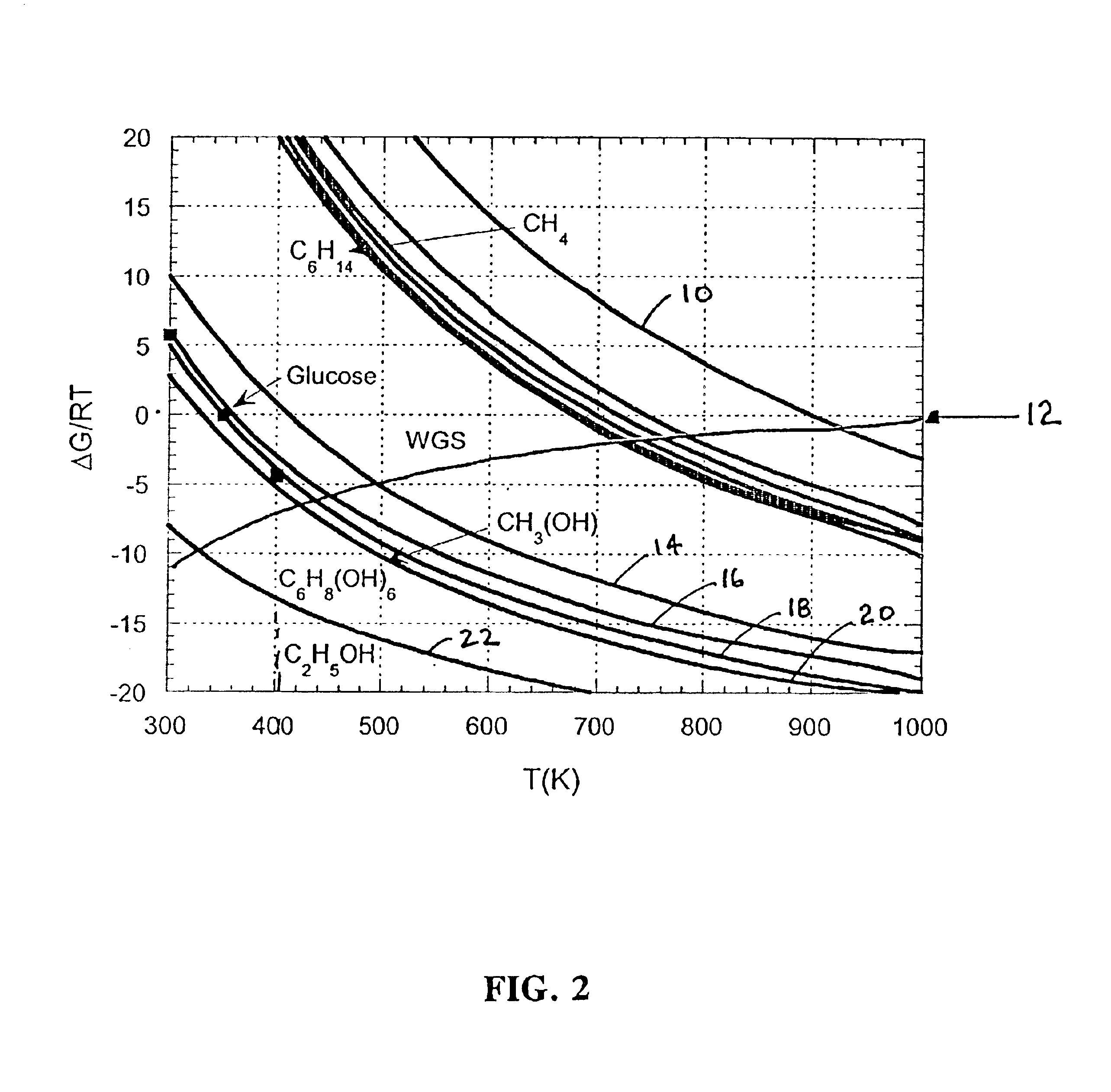

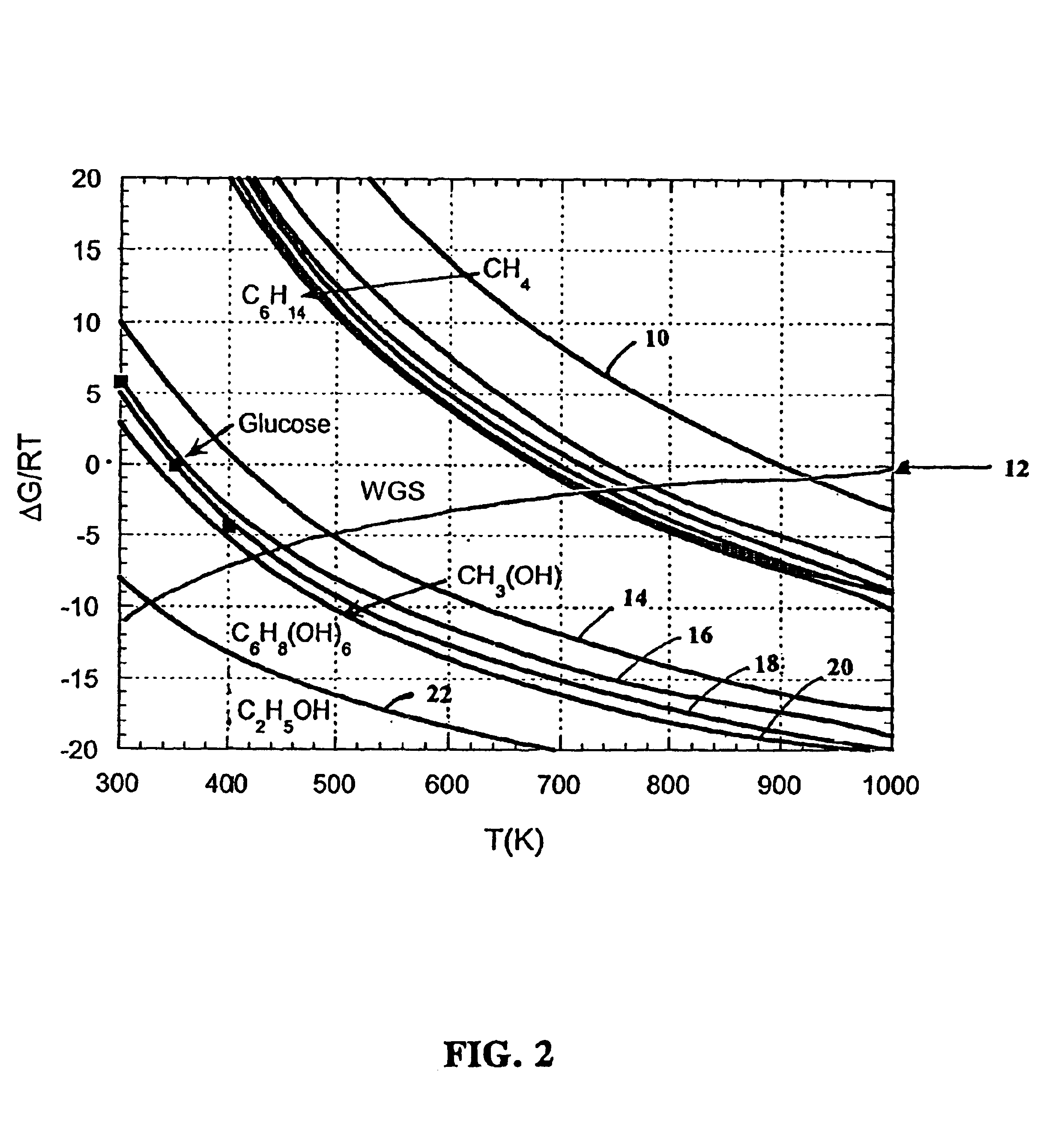

Low-temperature hydrocarbon production from oxygenated hydrocarbons

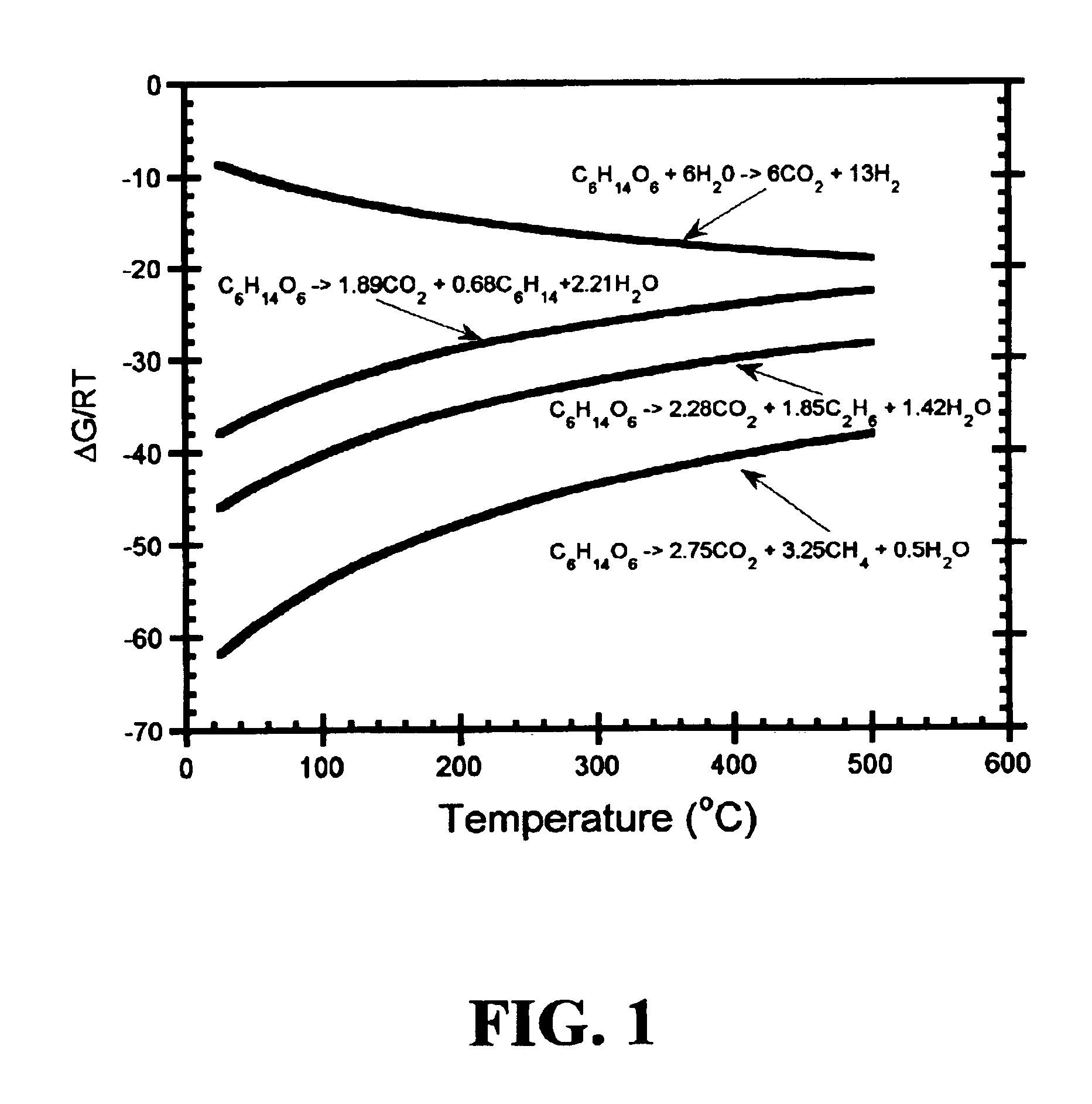

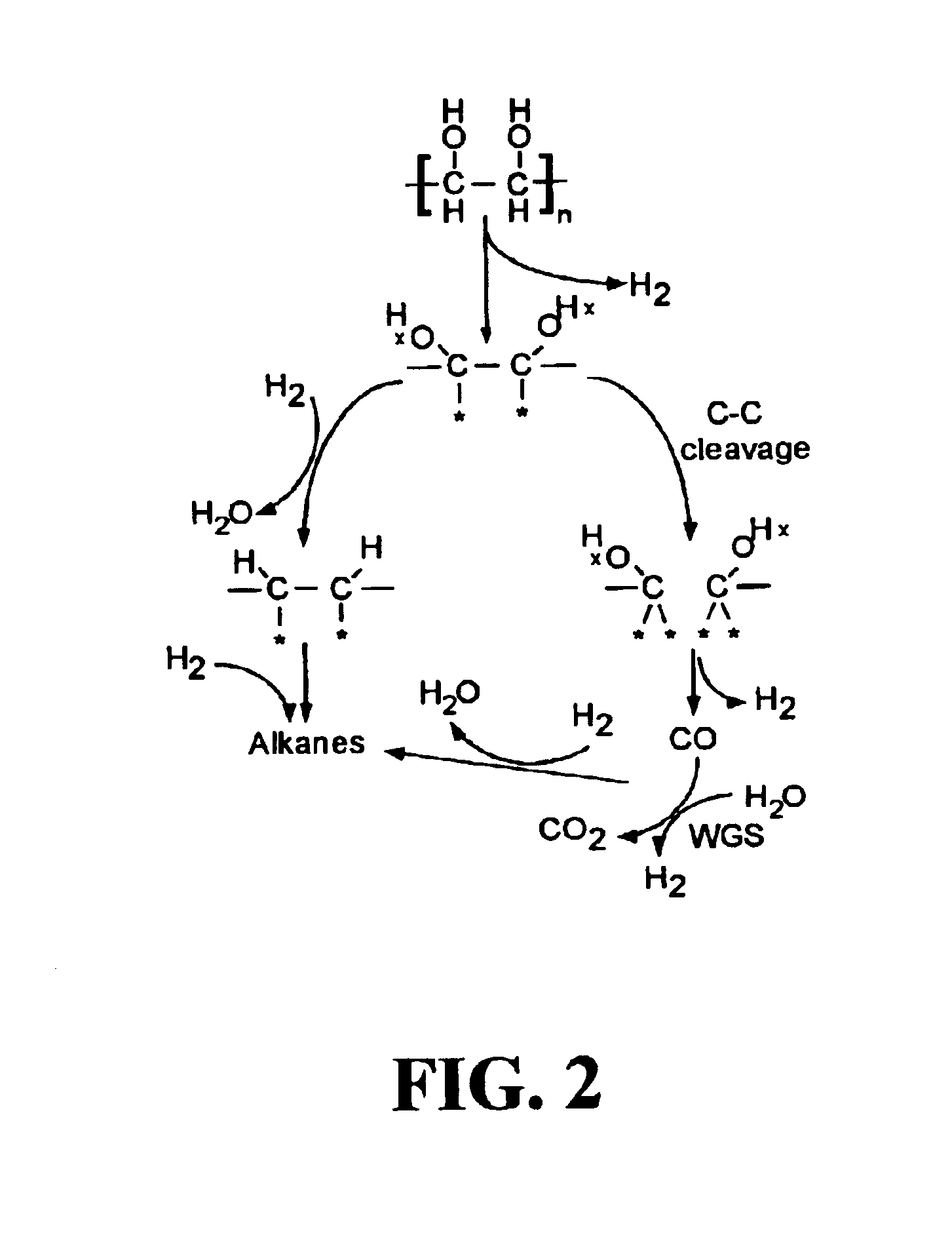

Disclosed is a method of producing hydrocarbons from oxygenated hydrocarbon reactants, such as glycerol, glucose, or sorbitol. The method can take place in the vapor phase or in the condensed liquid phase (preferably in the condensed liquid phase). The method includes the steps of reacting water and a water-soluble oxygenated hydrocarbon having at least two carbon atoms, in the presence of a metal-containing catalyst. The catalyst contains a metal selected from the group consisting of Group VIIIB transitional metals, alloys thereof, and mixtures thereof. These metals are supported on supports that exhibit acidity or the reaction is conducted under liquid-phase conditions at acidic pHs. The disclosed method allows the production of hydrocarbon by the liquid-phase reaction of water with biomass-derived oxygenated compounds.

Owner:WISCONSIN ALUMNI RES FOUND

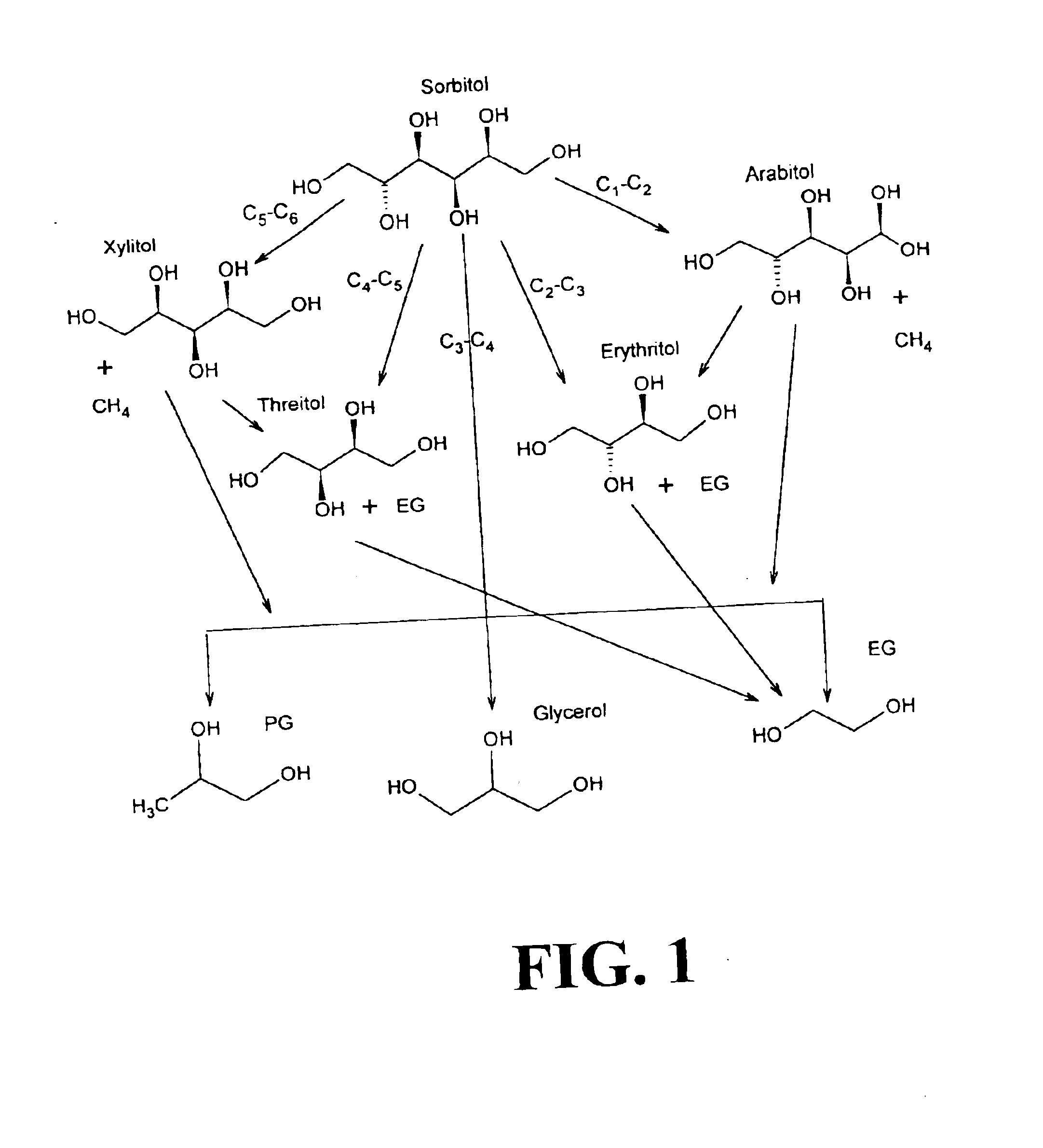

Hydrogenolysis of 6-carbon sugars and other organic compounds

InactiveUS6841085B2High selectivityHigh activityBiocideHydroxy compound active ingredientsHydrogenAlcohol sugars

Methods for hydrogenolysis are described which use a Re-containing multimetallic catalyst for hydrogenolysis of both C—O and C—C bonds. Methods and compositions for reactions of hydrogen over a Re-containing catalyst with compositions containing a 6-carbon sugar, sugar alcohol, or glycerol are described. It has been surprisingly discovered that reaction with hydrogen over a Re-containing multimetallic catalyst resulted in superior conversion and selectivity to desired products such as propylene glycol.

Owner:MICHIGAN STATE UNIV +1

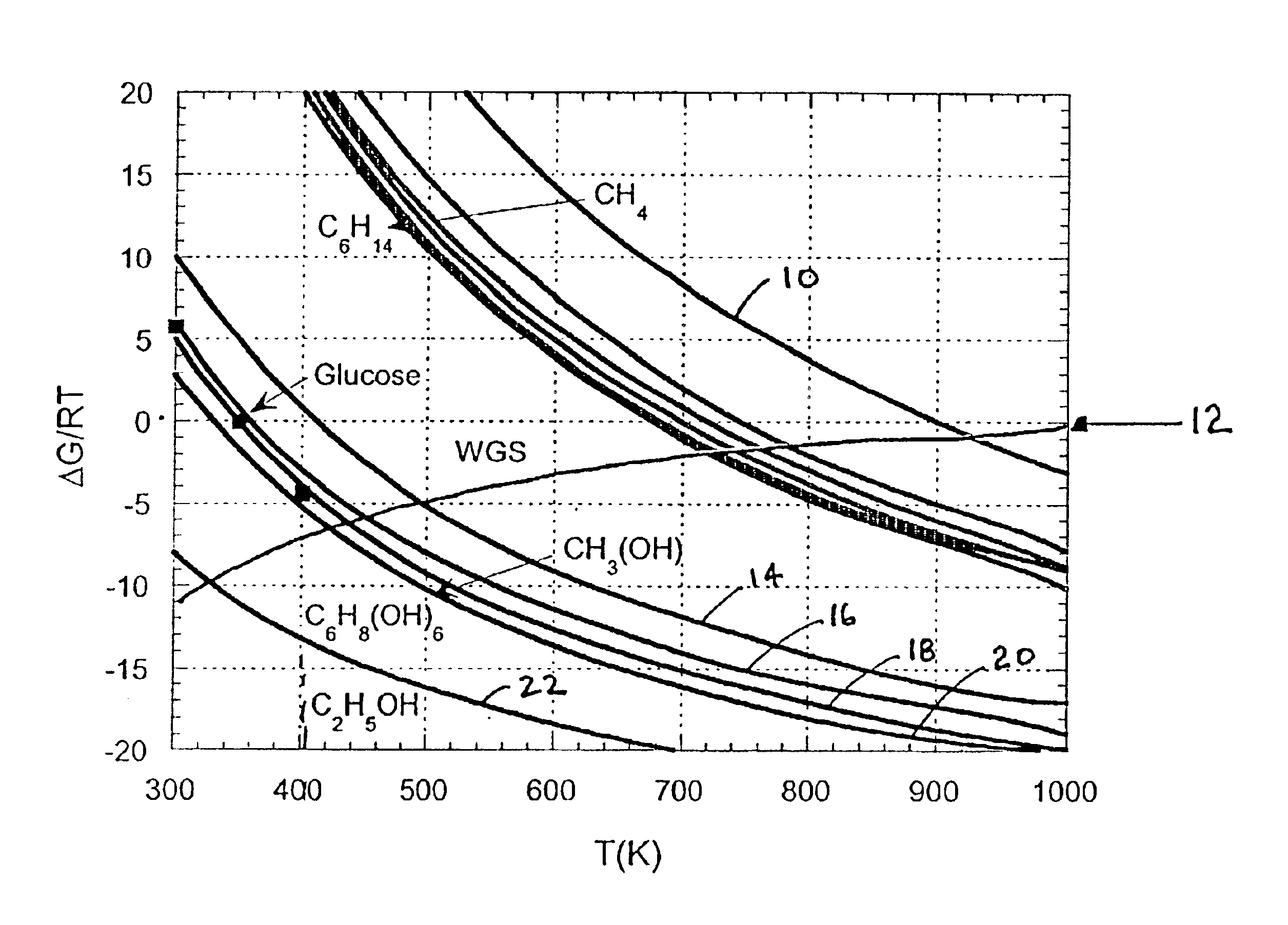

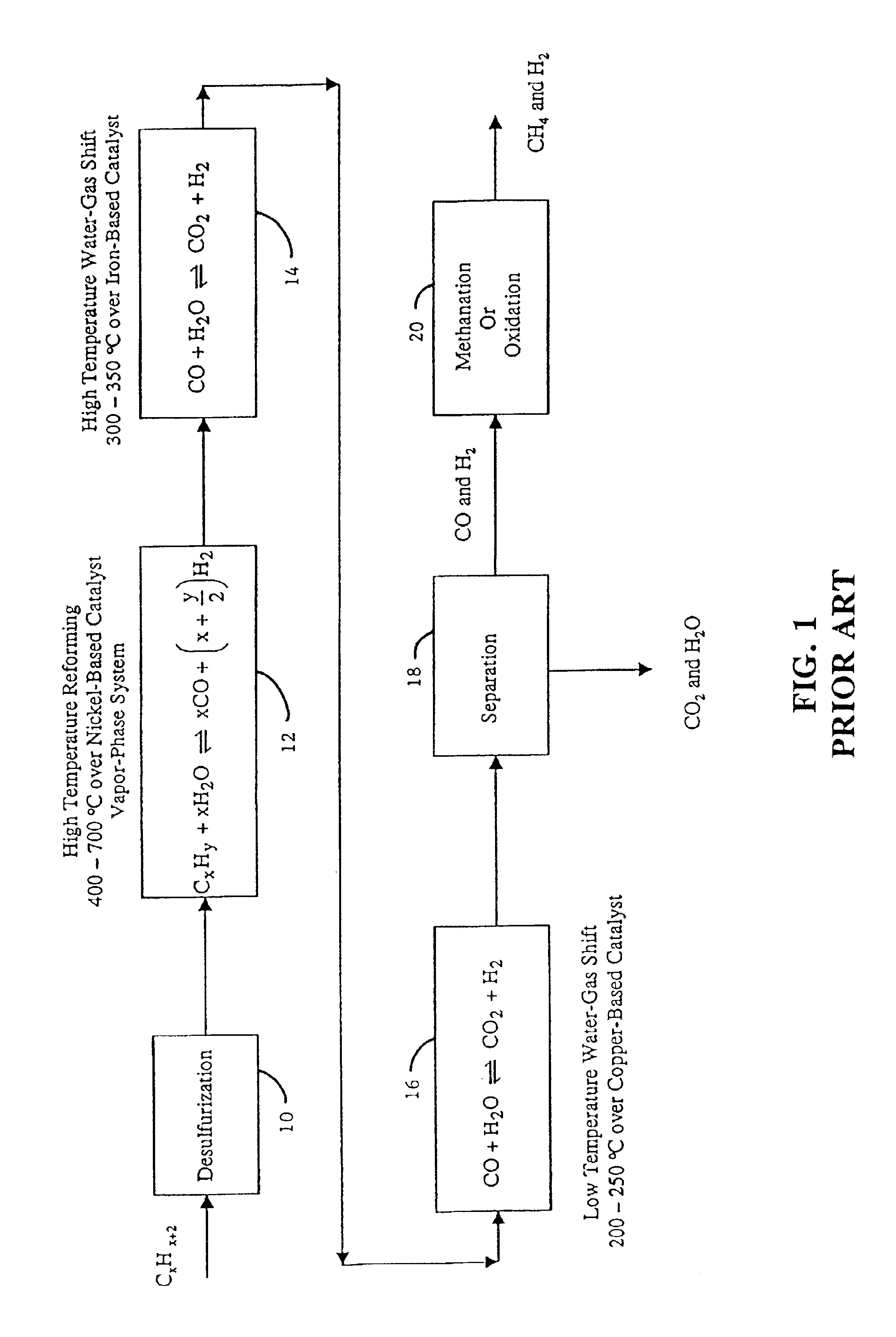

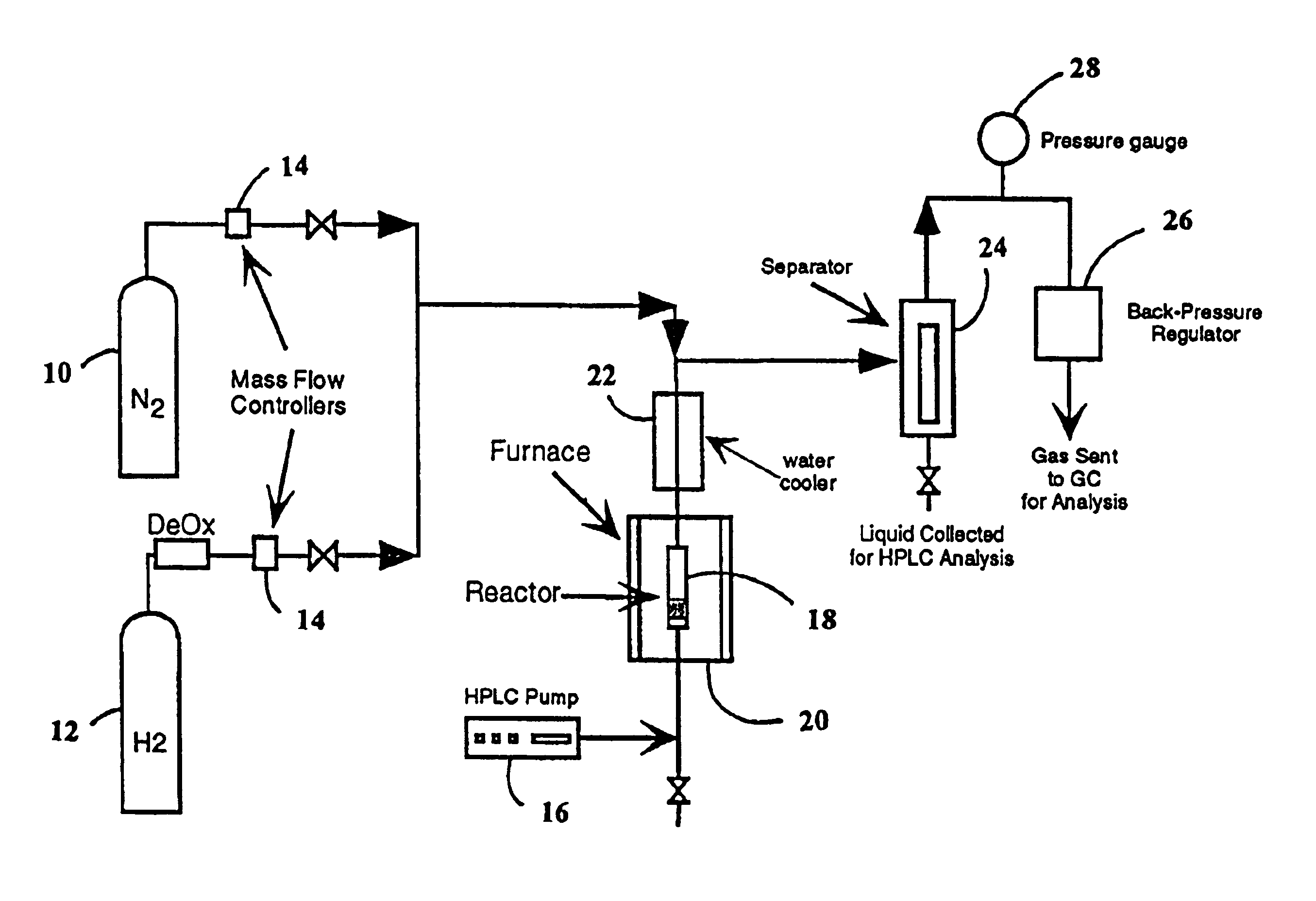

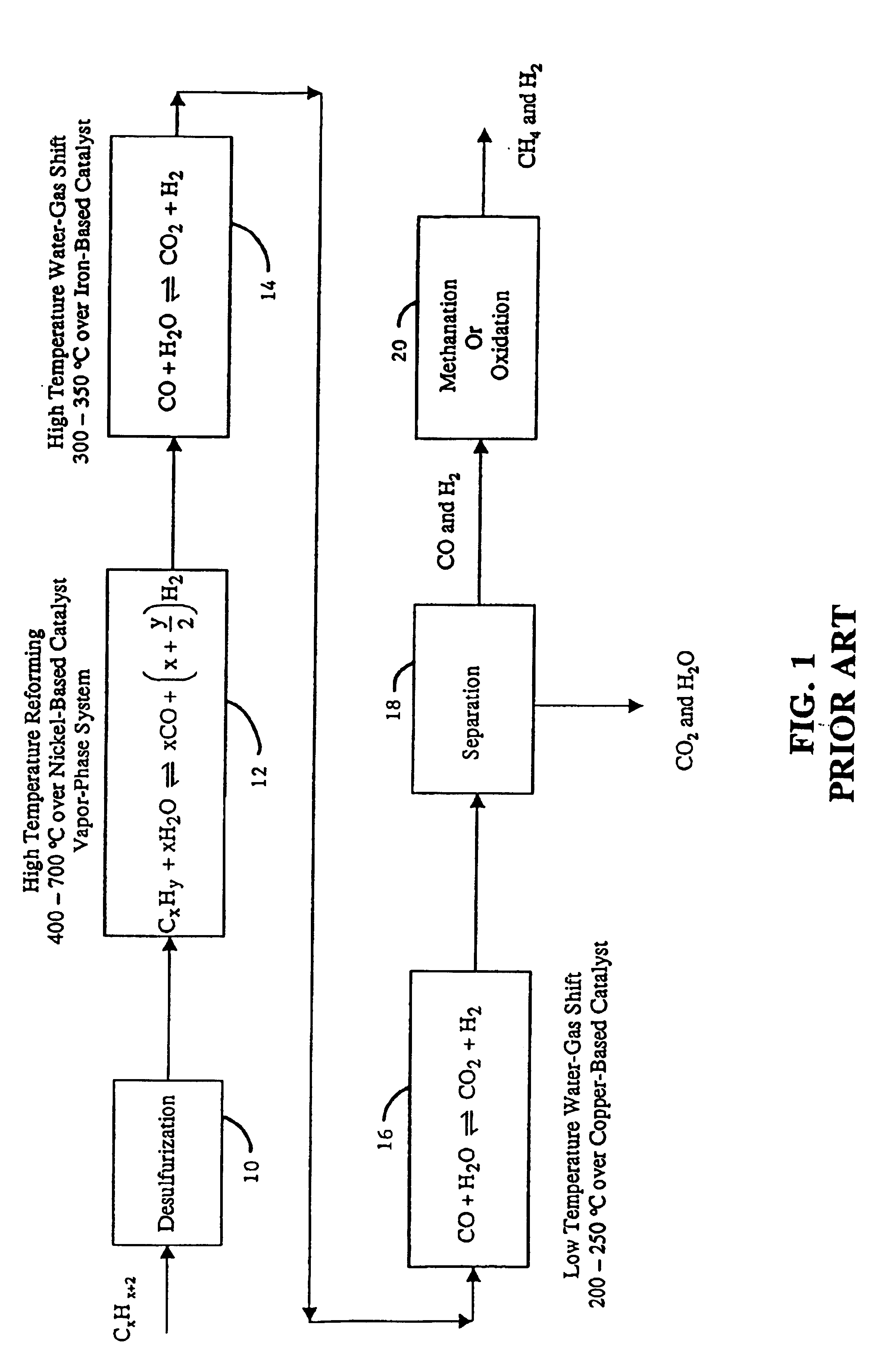

Low-temperature hydrogen production from oxygenated hydrocarbons

InactiveUS6964757B2Reduce riskWeaken energyHydrogen productionHydrogen/synthetic gas productionSteam reformingAlkane

Disclosed is a method of producing hydrogen from oxygenated hydrocarbon reactants, such as methanol, glycerol, sugars (e.g. glucose and xylose), or sugar alcohols (e.g. sorbitol). The method takes place in the condensed liquid phase. The method includes the steps of reacting water and a water-soluble oxygenated hydrocarbon in the presence of a metal-containing catalyst. The catalyst contains a metal selected from the group consisting of Group VIIIB transitional metals, alloys thereof, and mixtures thereof. The disclosed method can be run at lower temperatures than those used in the conventional steam reforming of alkanes.

Owner:WISCONSIN ALUMNI RES FOUND

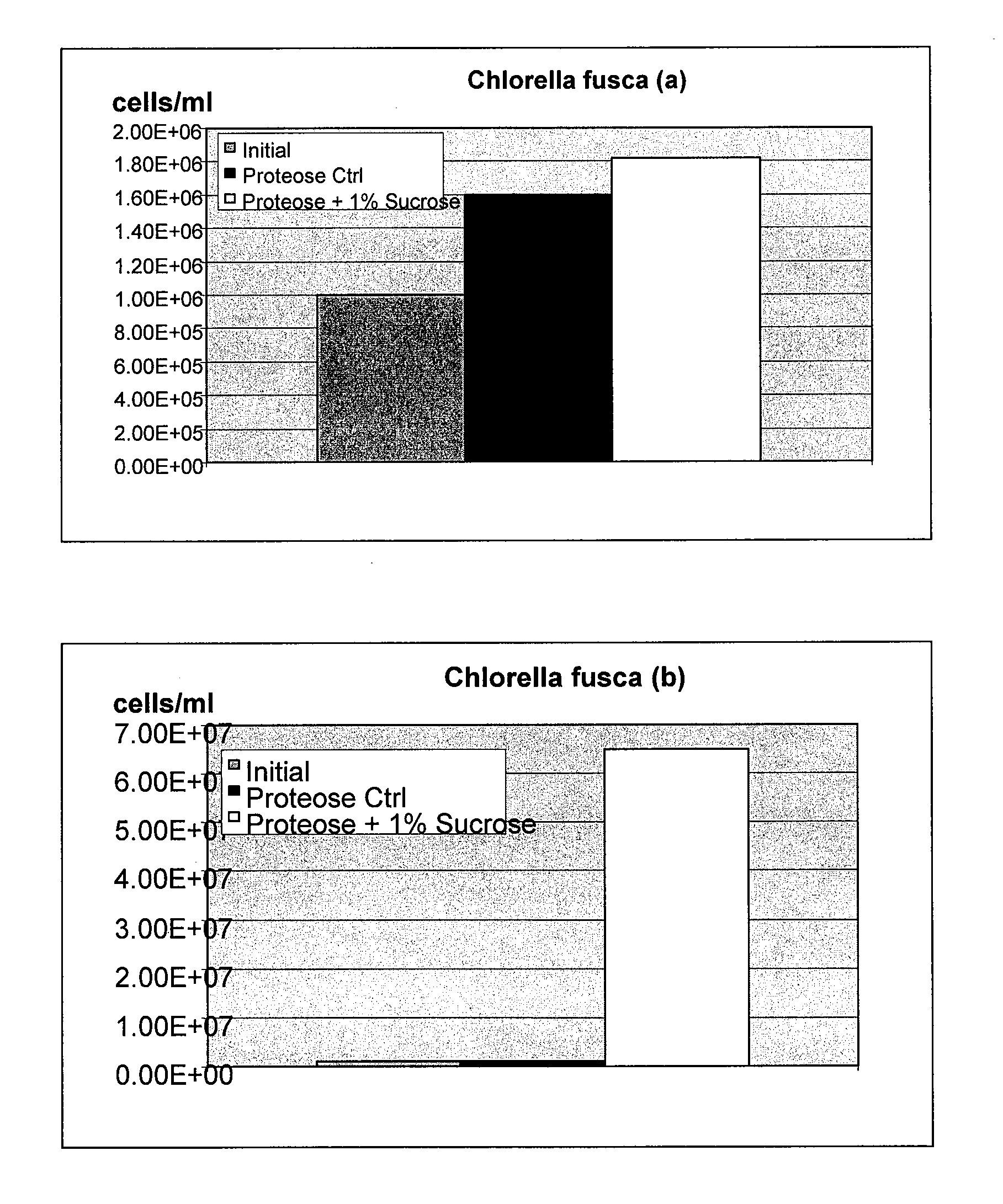

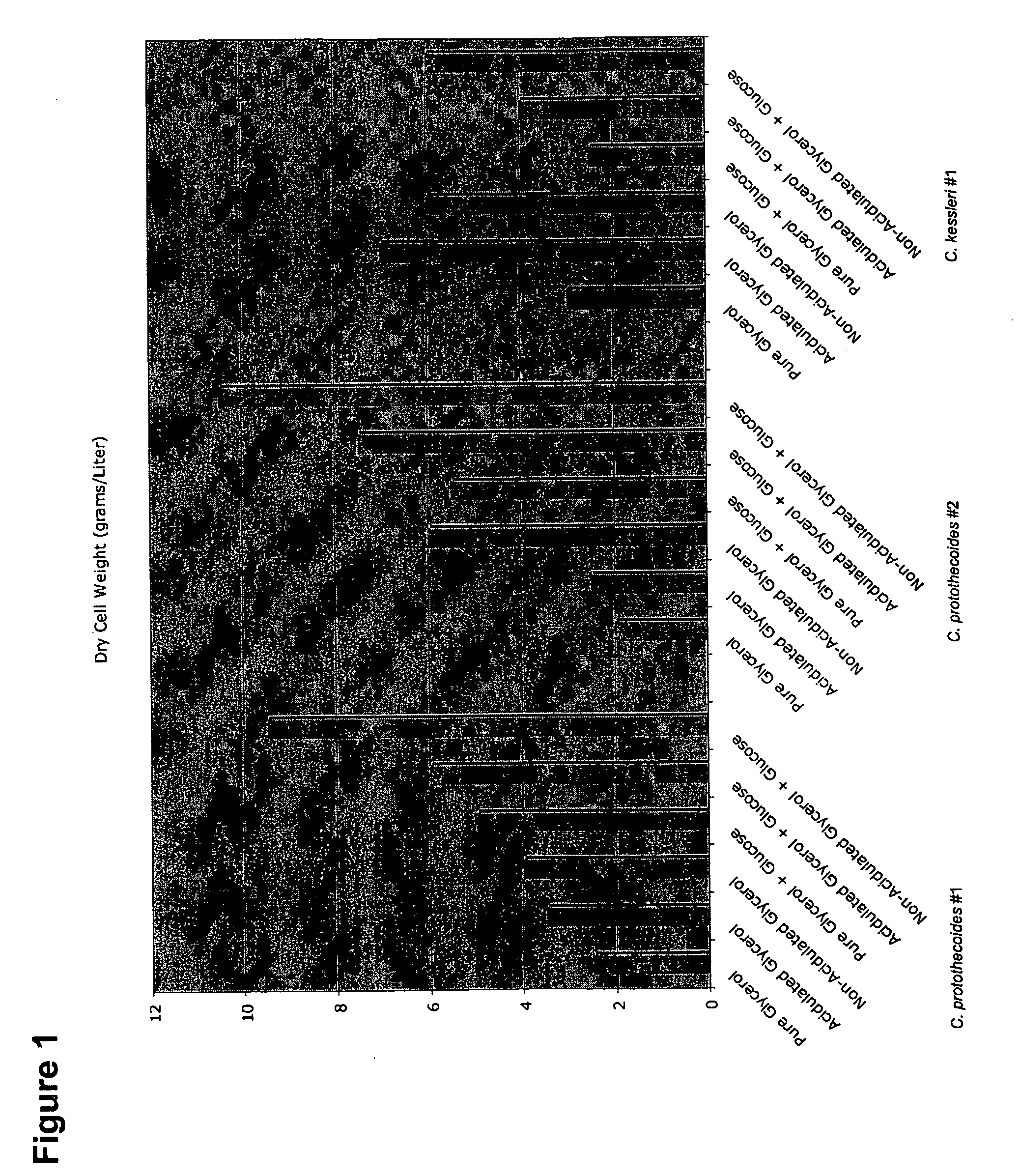

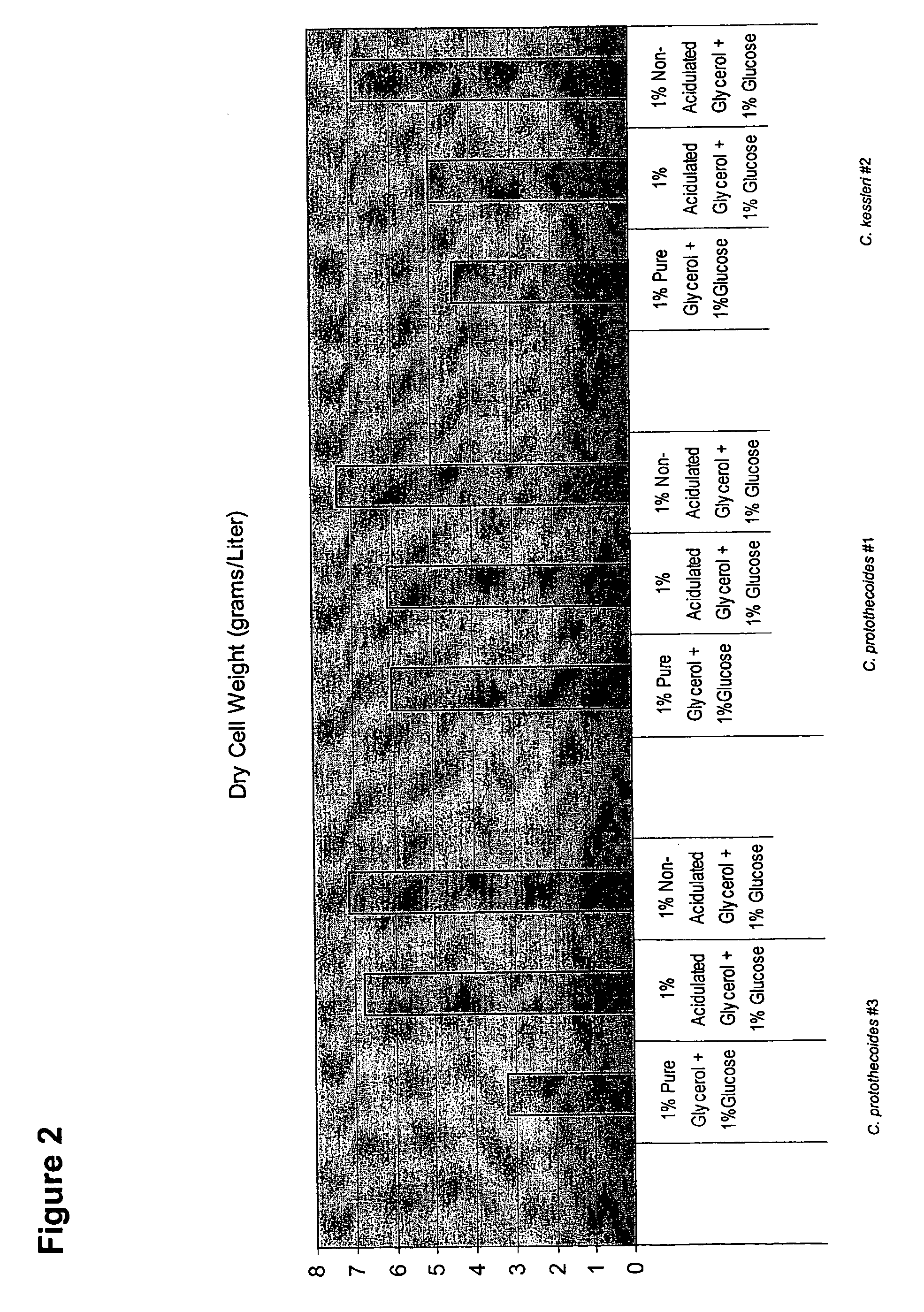

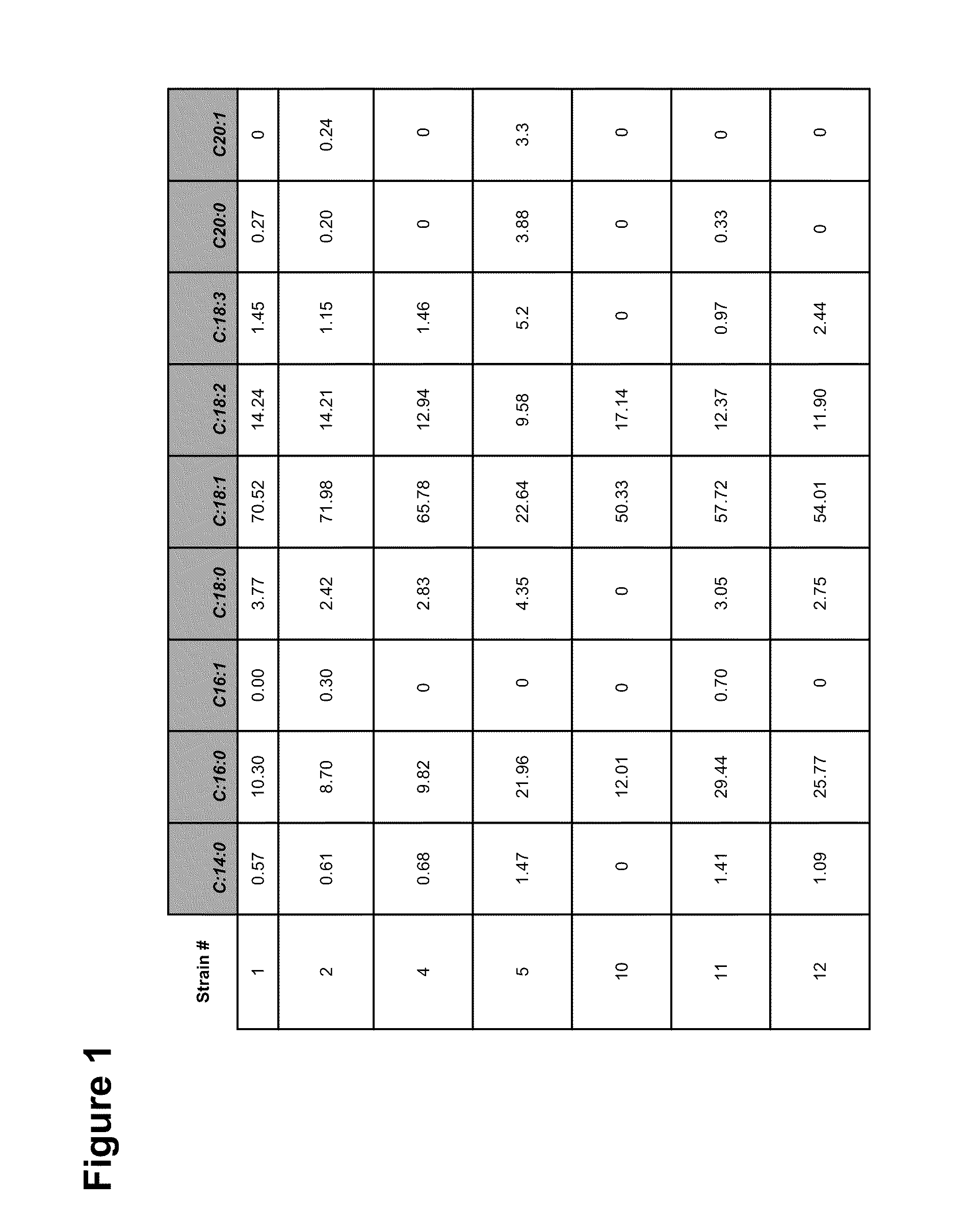

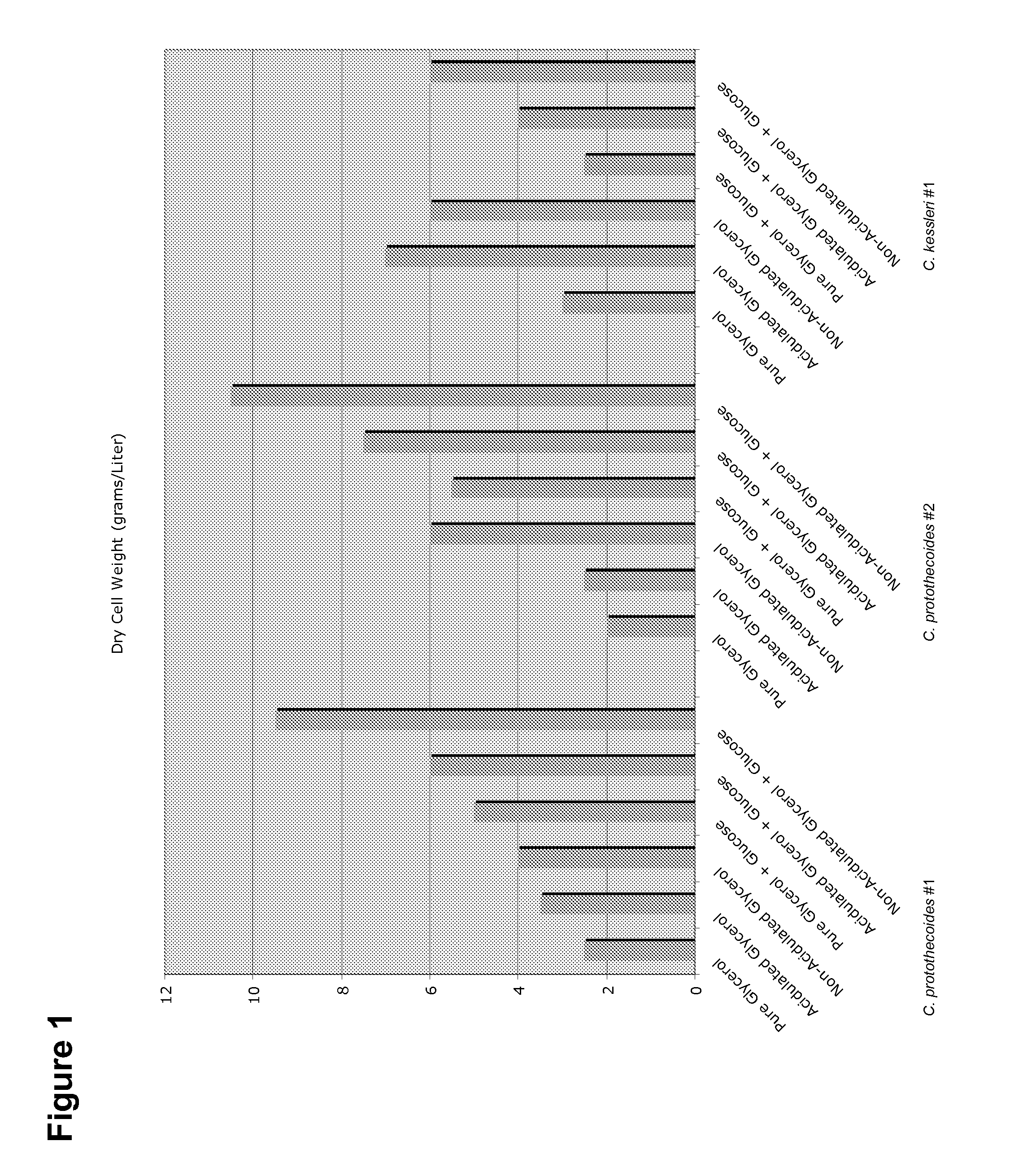

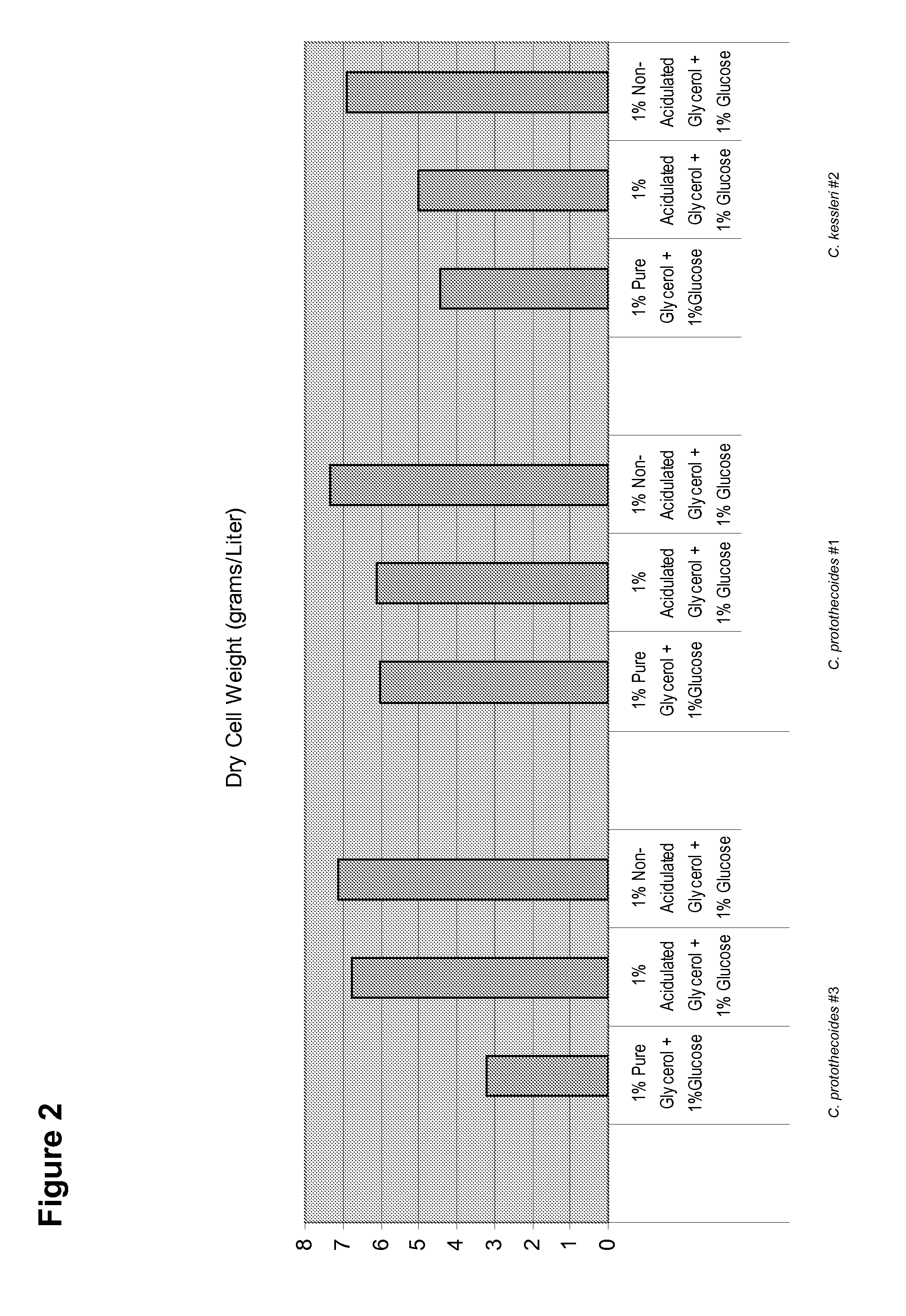

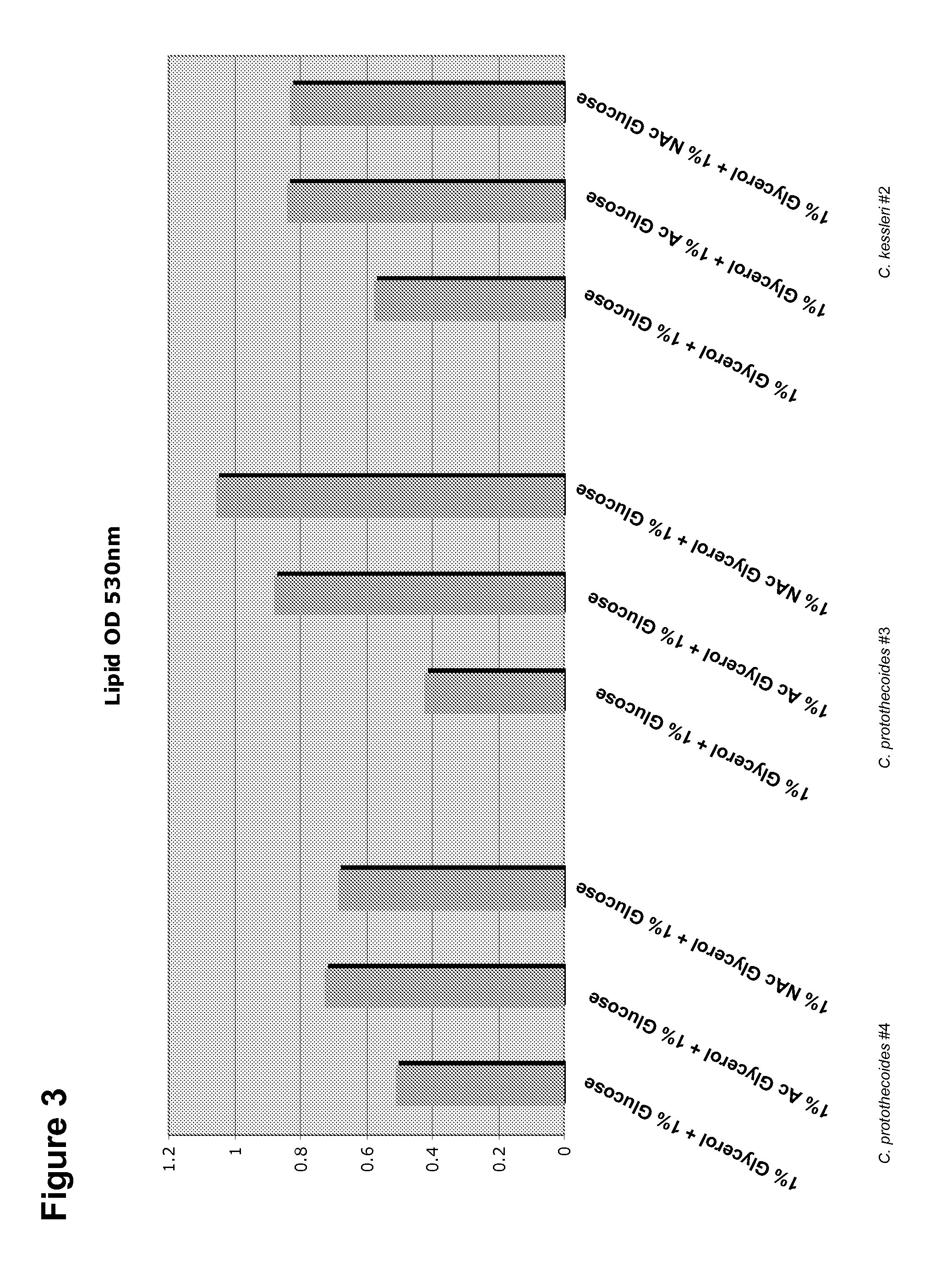

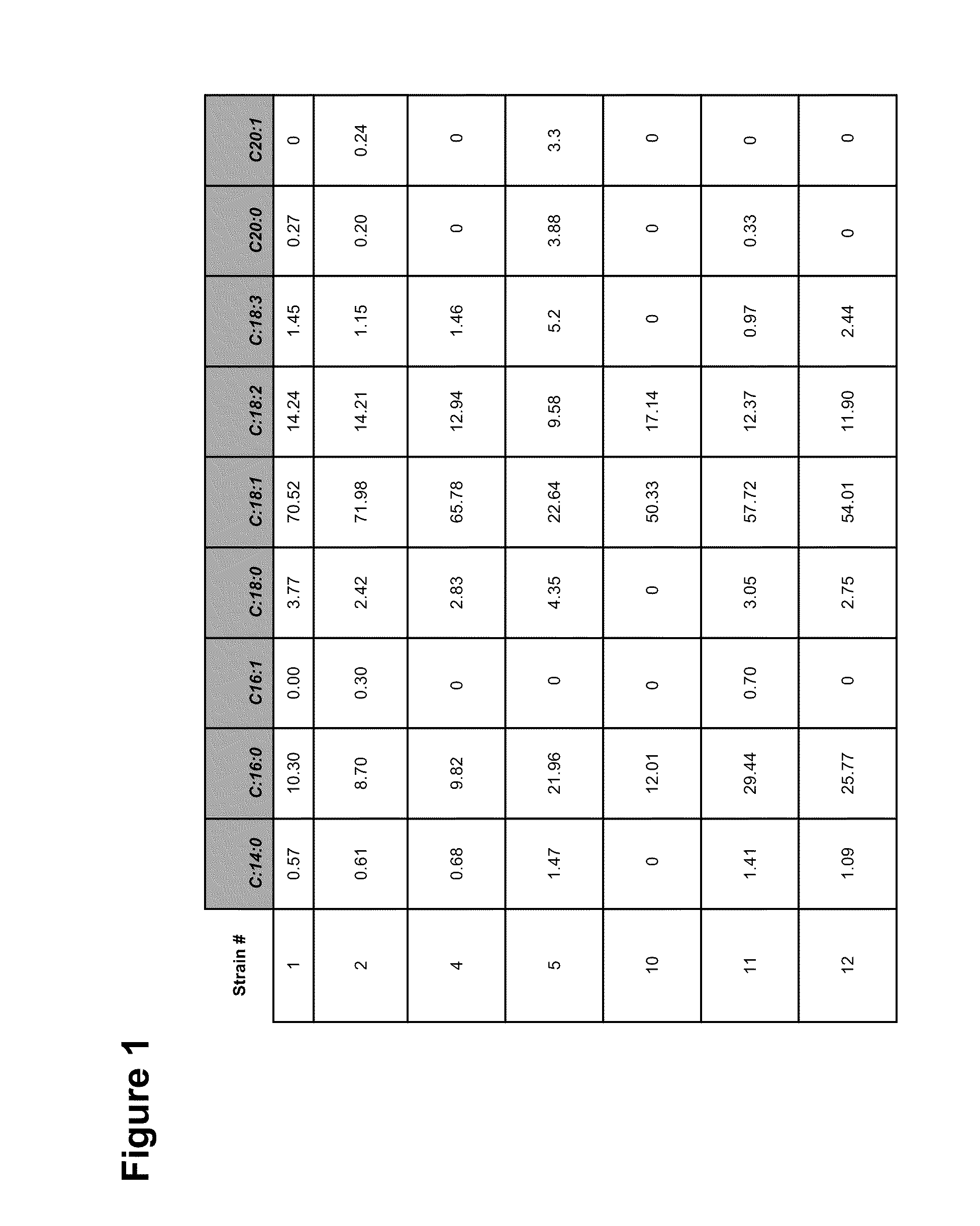

Glycerol Feedstock Utilization for Oil-Based Fuel Manufacturing

InactiveUS20090004715A1Bioreactor/fermenter combinationsFatty acid chemical modificationMicroorganismTransesterification

The invention provides methods of manufacturing biodiesel and other oil-based compounds using glycerol and combinations of glycerol and other feedstocks as an energy source in fermentation of oil-bearing microorganisms. Methods disclosed herein include processes for manufacturing high nutrition edible oils from non-food feedstock materials such as waste products from industrial waste transesterification processes. Also included are methods of increasing oil yields by temporally separating glycerol and other feedstocks during cultivation processes. Also provided herein are oil-bearing microbes containing exogenous oil production genes and methods of cultivating such microbes on glycerol and other feedstocks.

Owner:TERRAVIA HLDG INC

Low-temperature hydrogen production from oxygenated hydrocarbons

InactiveUS6964758B2High energy costWeaken energyHydrogen productionHydrogen/synthetic gas productionSteam reformingAlkane

Disclosed is a method of producing hydrogen from oxygenated hydrocarbon reactants, such as glycerol, glucose, or sorbitol. The method can take place in the vapor phase or in the condensed liquid phase. The method includes the steps of reacting water and a water-soluble oxygenated hydrocarbon having at least two carbon atoms, in the presence of a metal-containing catalyst. The catalyst contains a metal selected from the group consisting of Group VIII transitional metals, alloys thereof, and mixtures thereof. The disclosed method can be run at lower temperatures than those used in the conventional steam reforming of alkanes.

Owner:WISCONSIN ALUMNI RES FOUND

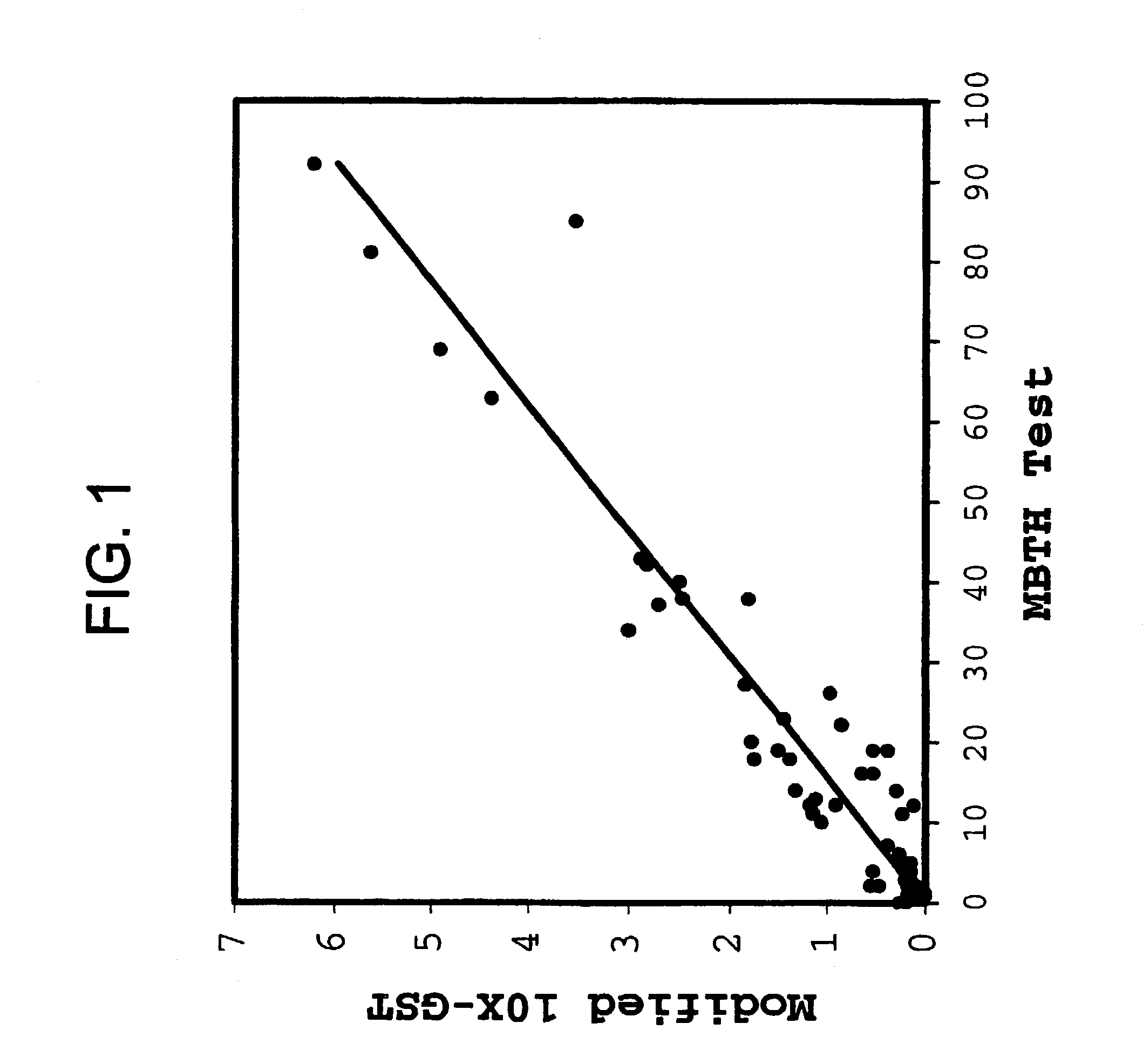

Polypeptide compositions with improved stability

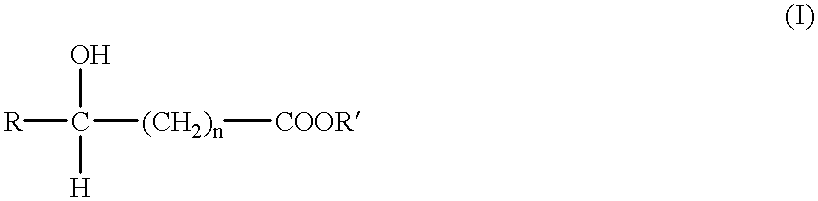

InactiveUS7022674B2Good chemical stabilityLower Level RequirementsPeptide/protein ingredientsMetabolism disorderLinear correlationGlycerol

The present invention provides means to improve the chemical stability of aqueous, parenteral pharmaceutical compositions comprising a polypeptide and glycerin. Reactive aldehydes are identified in commercial glycerins, and means for reducing such are provided. Convenient means are provided to assay for reactive aldehydes in glycerin, and a strong linear correlation between the level of reactive aldehydes in glycerin and chemical stability of compositions comprising a polypeptide and glycerin is demonstrated. The invention includes aqueous compositions comprising a polypeptide and glycerin having improved chemical stability compared to compositions previously known.

Owner:ELI LILLY & CO

Topical dermal anaesthetic

A liquid composition applied transdermally for relief of pain comprising alcohol in an amount by weight of about 57 to about 91 percent; glycerin in an amount by weight of about 1 to about 12 percent; an analgesic agent in an amount by weight of about 2 to about 28 percent, the analgesic agent comprising a derivative of salicylic acid; methylsulfonylmethane in an amount by weight of about 0.02 to 5 percent; and emu oil in an amount by weight of about 0.01 to 3 percent, the liquid composition permeating skin to relieve pain. The composition further comprising, as an additional feature, aloe vera in an amount by weight of at least about 0.05 percent and having an amount by weight of about 0.05 to 4 percent. The composition features transdermal pain relief such that a patient can apply the analgesic agent directly to an area of pain without such side effects as stomach irritation which is normally associated with aspirin. The composition may be sprayed or rolled directly onto the painful area. Because of the unique formula, the composition is safe to vital internal organs, requires no mixing before use, and is shelf stable for marketing purposes.

Owner:VELTRAN LP

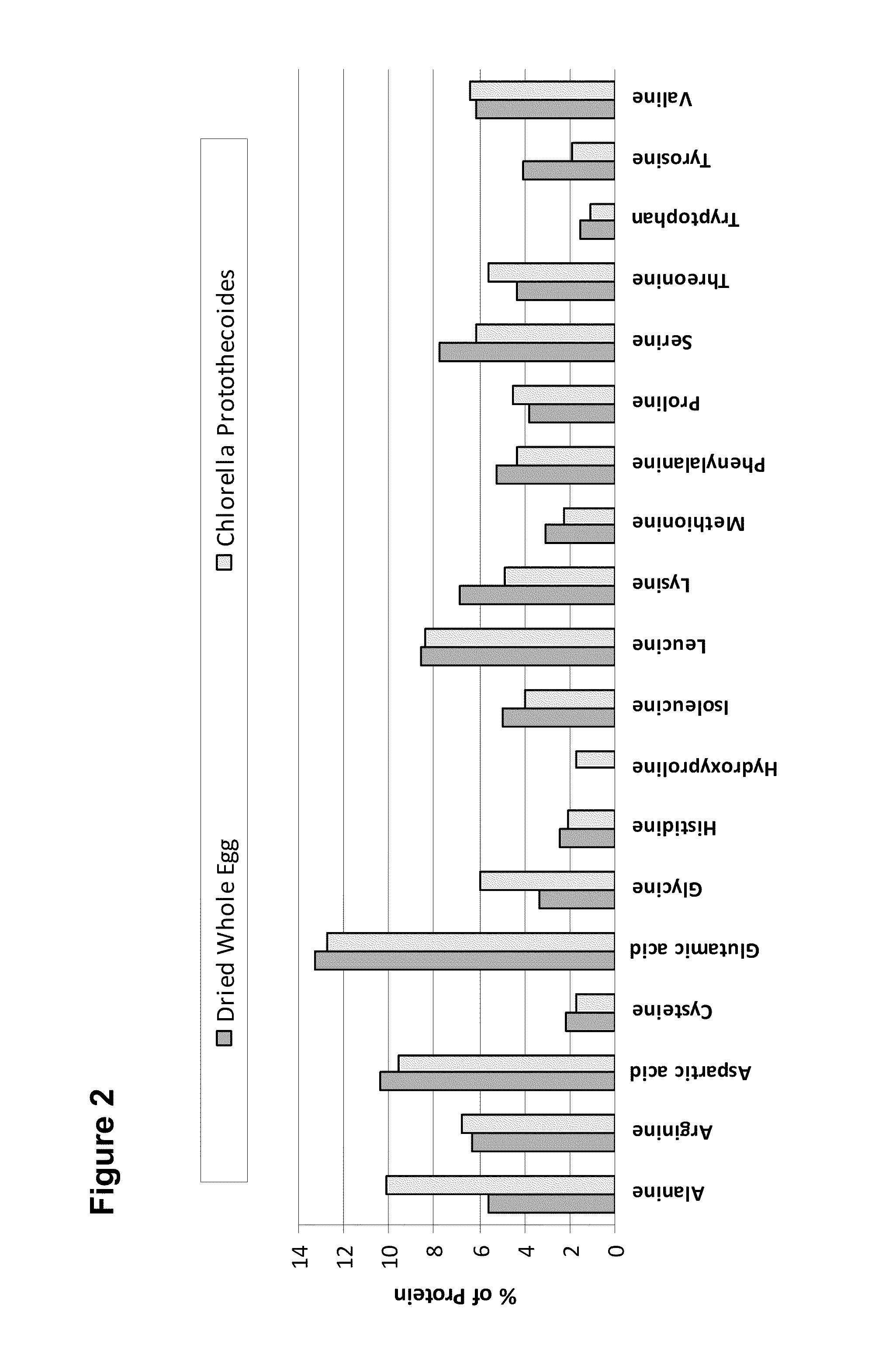

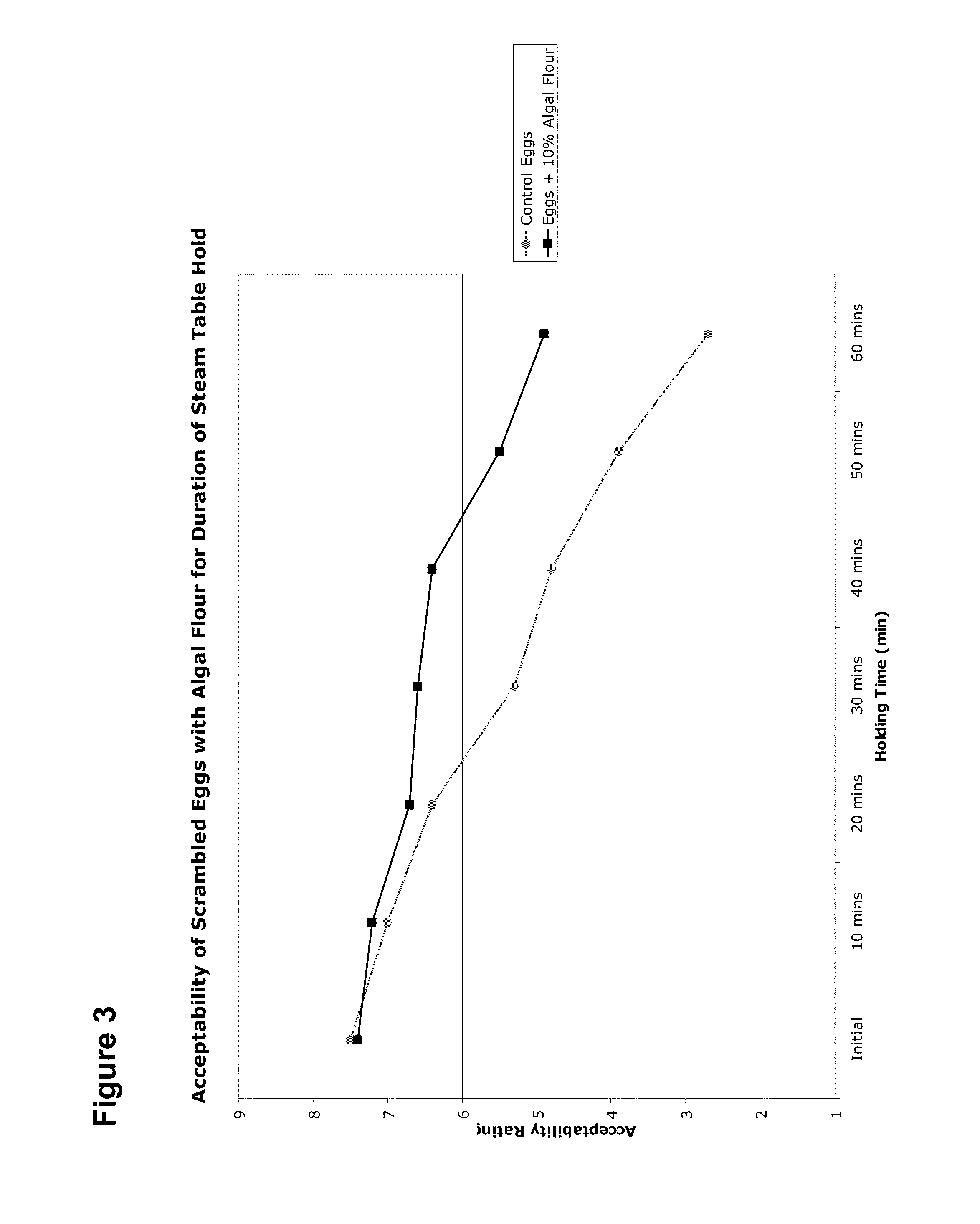

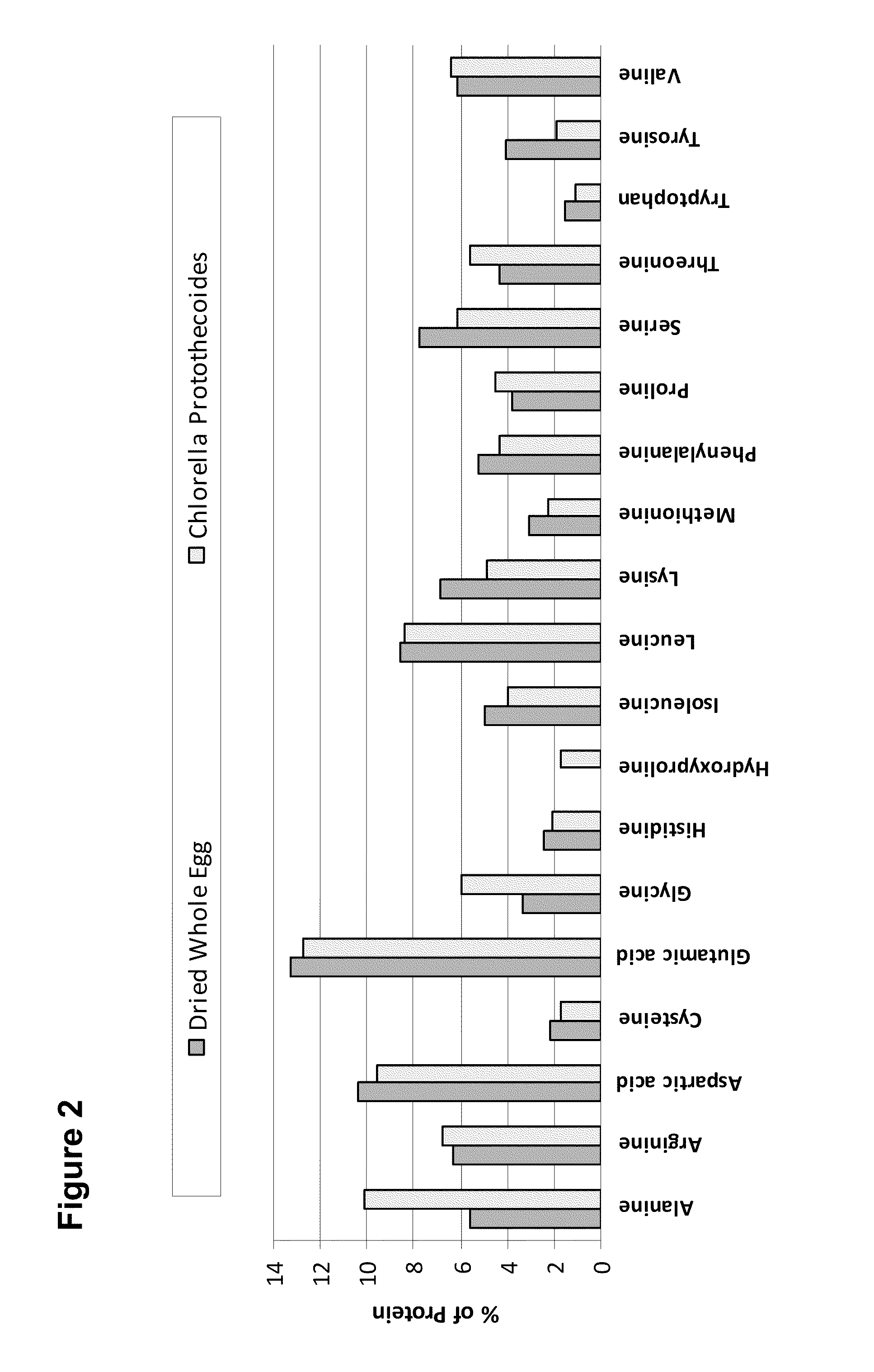

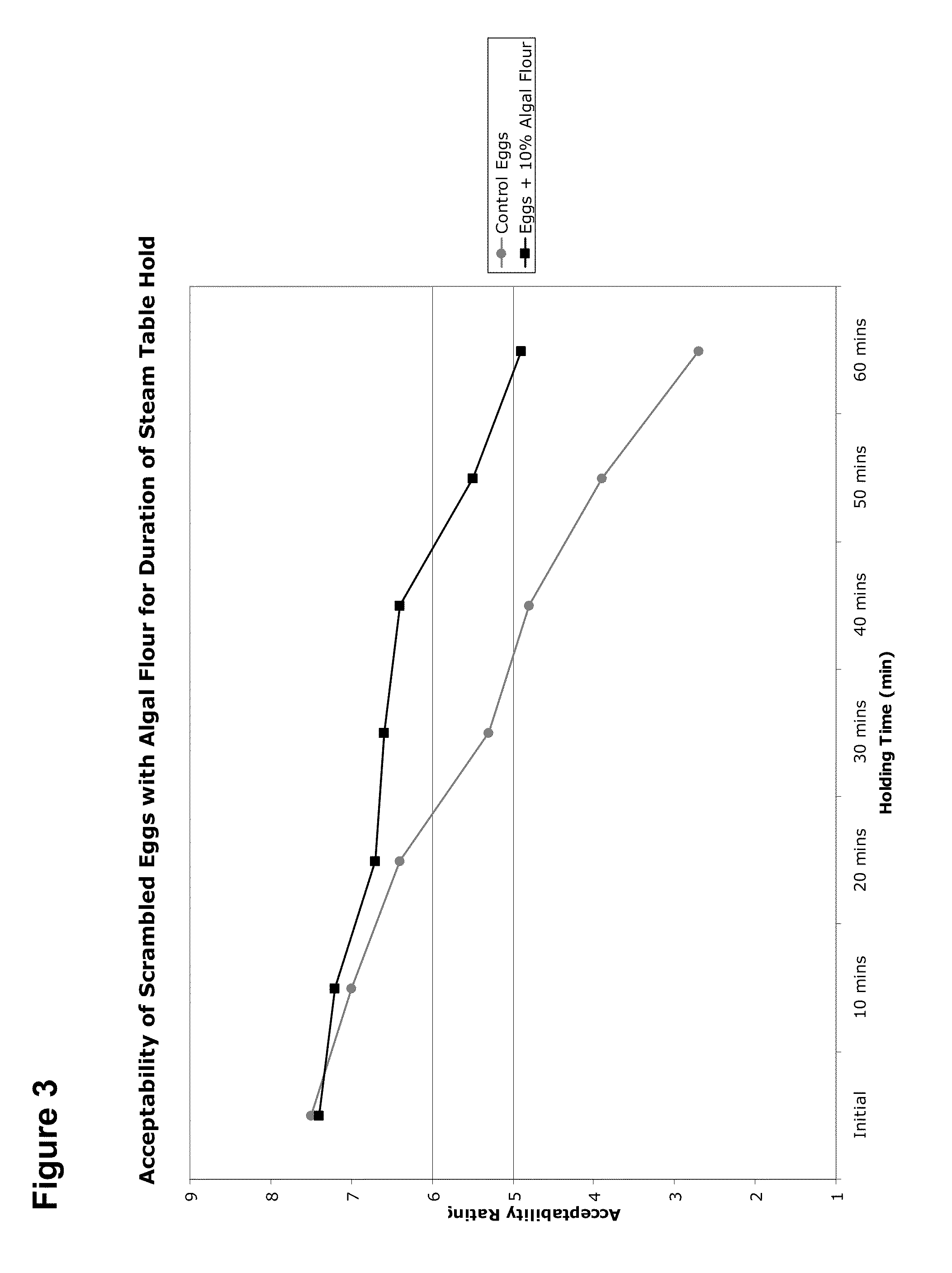

High Protein and High Fiber Algal Food Materials

The disclosed inventions include microalgal biomass high in protein and fiber, wherein the biomass has been manufactured through heterotrophic fermentation. The materials provided herein are useful for the manufacture of meat substitutes and meat enhancers, as well as other food products that benefit from the addition of digestible protein and dietary fiber. Structural properties of foods are enhanced through the use of such materials, including texture and water retention properties. High in protein and fiber food materials of the invention can be manufactured from edible and inedible heterotrophic fermentation feedstocks, including corn starch, sugar cane, glycerol, and depolymerized cellulose.

Owner:TERRAVIA HLDG INC

Hormone hydrogel rooting film

InactiveCN102599161AExtend the critical periodImprove survival rateBiocidePlant growth regulatorsSocial benefitsPolyvinyl alcohol

The invention discloses a hormone hydrogel rooting film, which is prepared by the steps of: swelling polyvinyl alcohol at normal temperature for 30min, and heating for completely dissolving polyvinyl alcohol to obtain a transparent liquid; cooling, adjusting the pH value of the solution with concentrated hydrochloric acid, adding glycerol and reacting to prepare a hydrogel liquid; and adding hormone to the hydrogel liquid and stirring. When in use, the hormone hydrogel rooting film is spread on the surface of a hard branch cutting shoot, so that a gel film is formed on the surface of the hard branch cutting shoot above the ground so as to achieve the purpose of reducing the moisture of the cutting shoot from dissipation, and a gel film is formed on the surface of the hard branch cutting shoot under the ground so as to keep a moisture state in soil and play a role of slowly releasing hormone to stimulate the rooting of the cutting shoot, thus the rooting critical stage of the hard branch cutting shoot is prolonged and the rooting survival rate of the hard branch cutting shoot is improved. The technical scheme disclosed by the invention is simple and convenient, high in raising seedling survival rate and significant in economic and social benefits, and saves seedling-raising investment by more than 10%.

Owner:濮阳市林业科学院

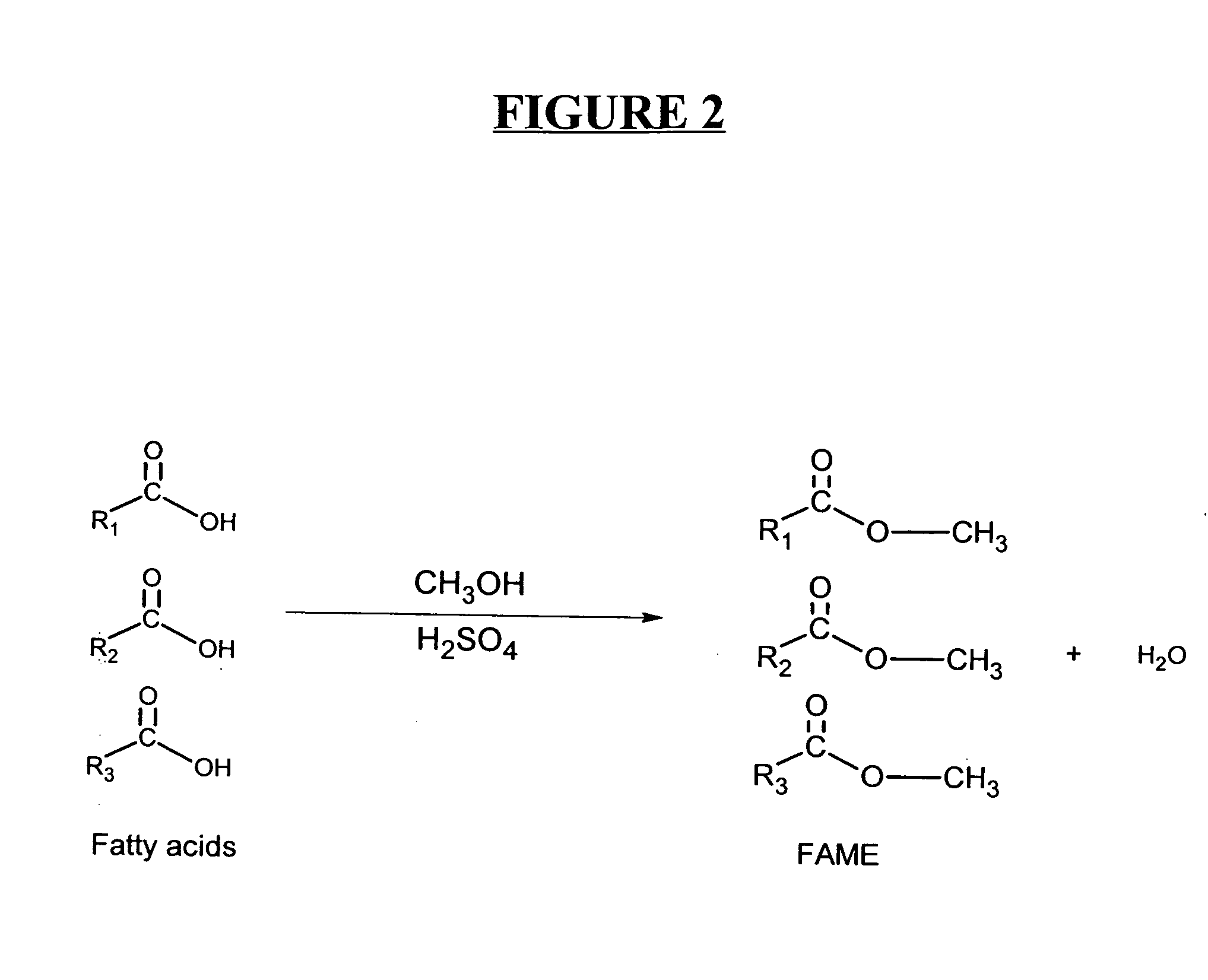

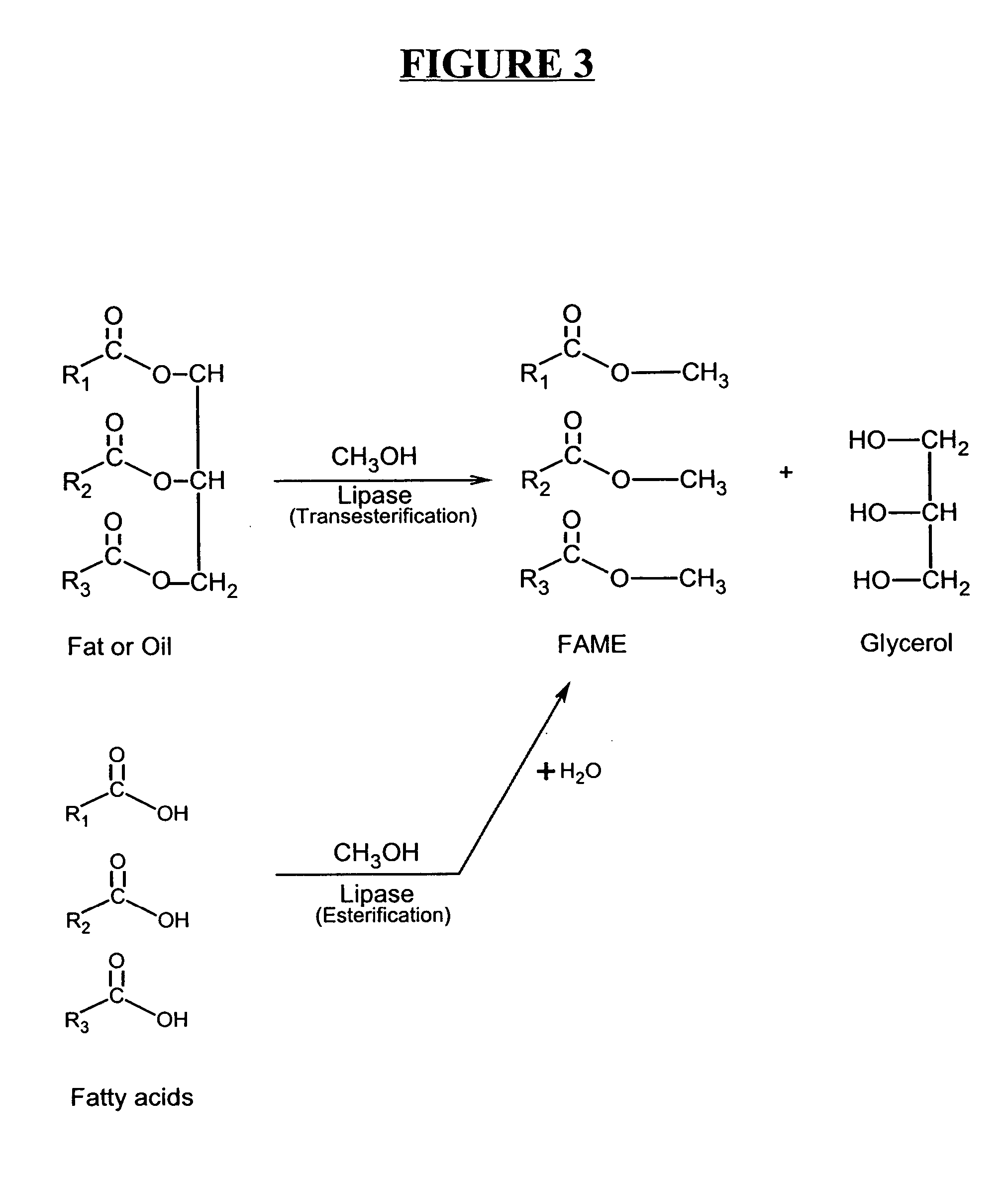

Production of biodiesel and other valuable chemicals from wastewater treatment plant sludges

ActiveUS20050112735A1Reduce the environmentPromote digestionBio-organic fraction processingByproduct vaporizationLipid formationSludge

A process for producing biodiesel has been invented by first extracting lipids from the sludges generated during primary and / or biological treatment of municipal, agricultural, and industrial wastewaters using primary, secondary, and tertiary treatments followed by the transesterification of the extracted lipids using transesterification conversion into alcohol-based esters. The resulting products from this process include biodiesel, glycerol, lipid-free proteins, various other useful chemicals and an aqueous-based substrate well suited for optimized digestion within subsequent biological digestion (either aerobic or anaerobic). The lipids extracted from the sludges containing high levels of microorganisms are phospholipids which can also be directly used as lecithin. The extraction of the lipids from the sludges will be performed using chemical extraction techniques with the transesterification of the extracted lipids accomplished using basic, acidic, and / or a combination of the two transesterification techniques.

Owner:MISSISSPPI STATE UNIV RES & TECH

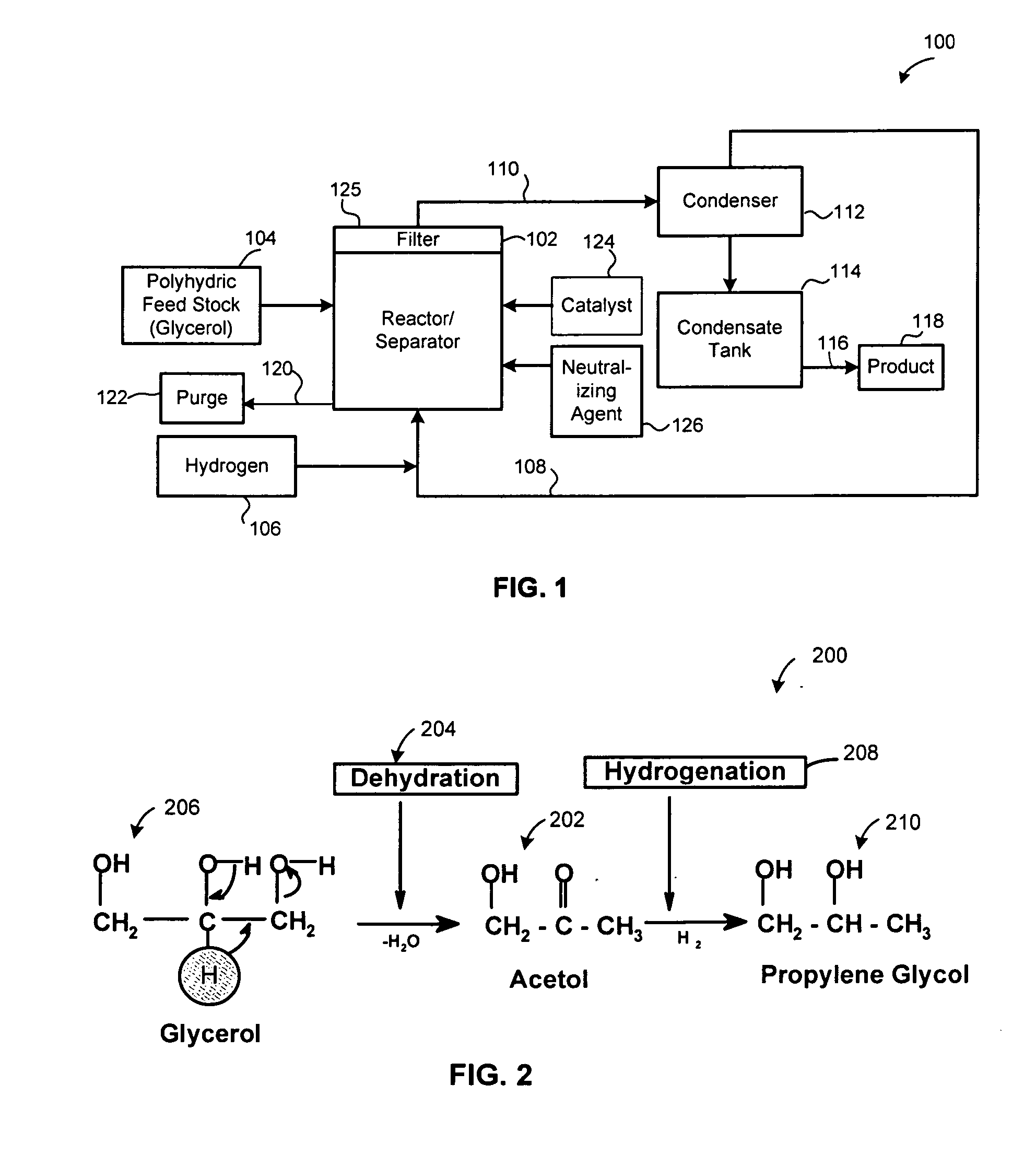

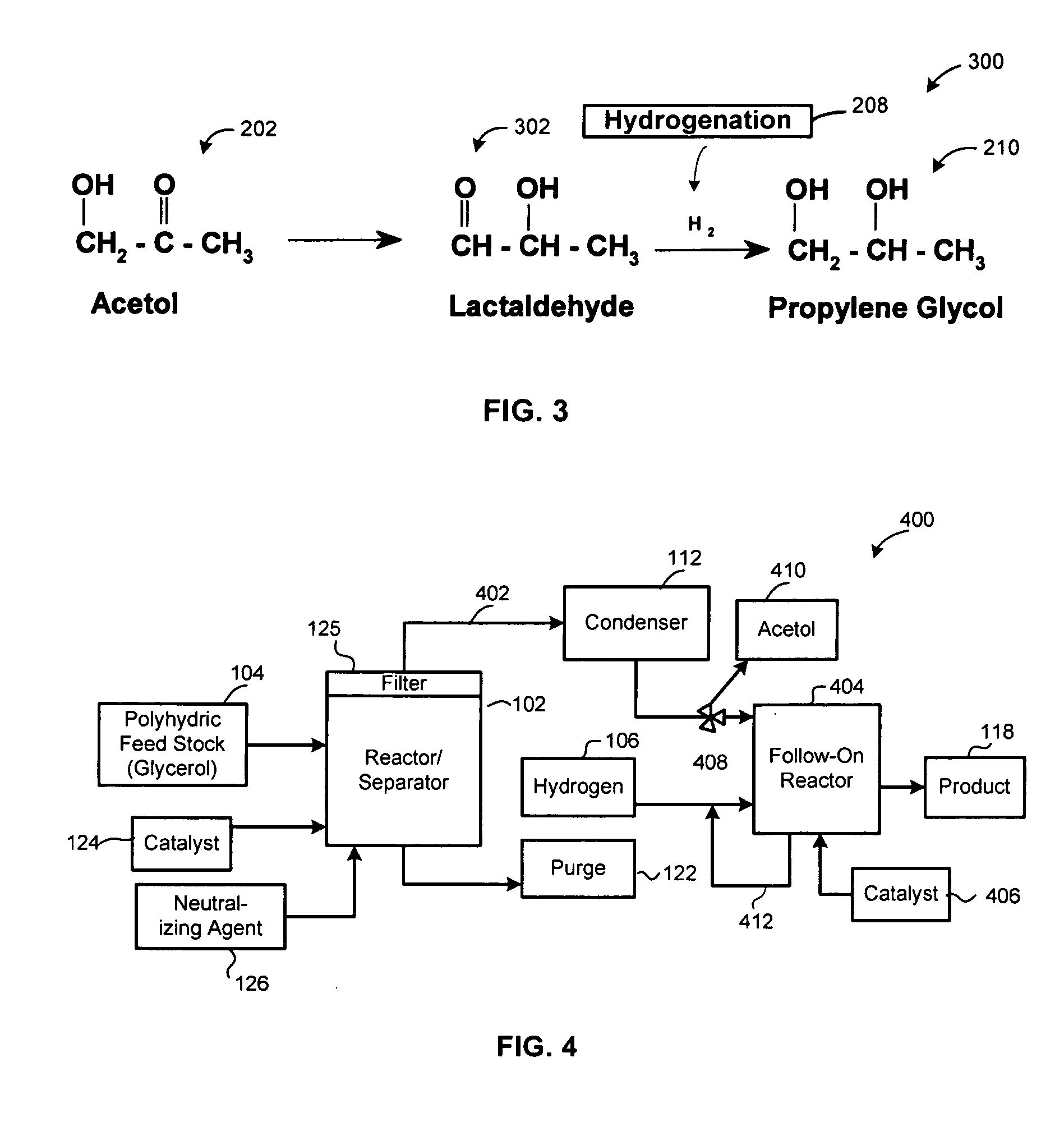

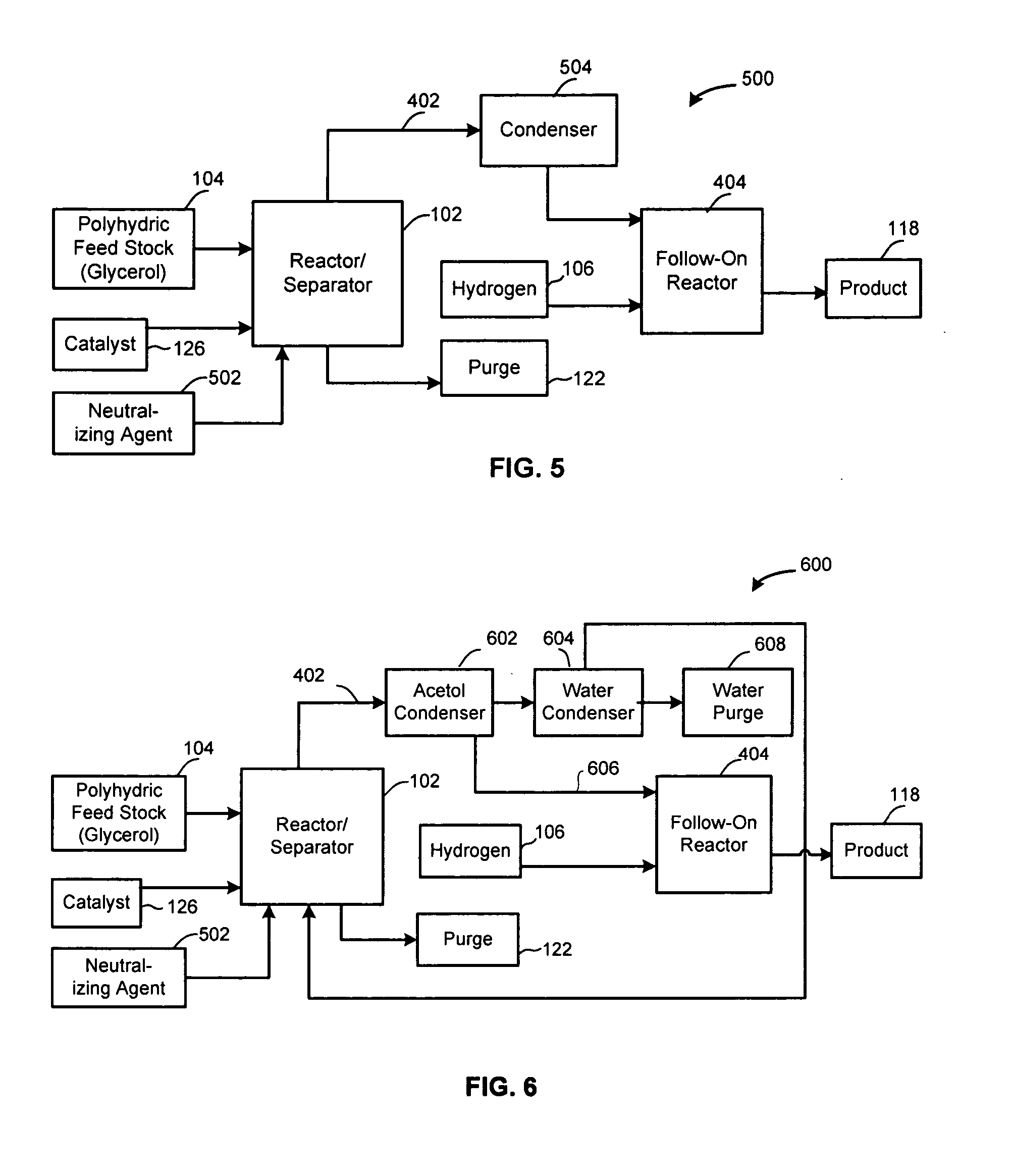

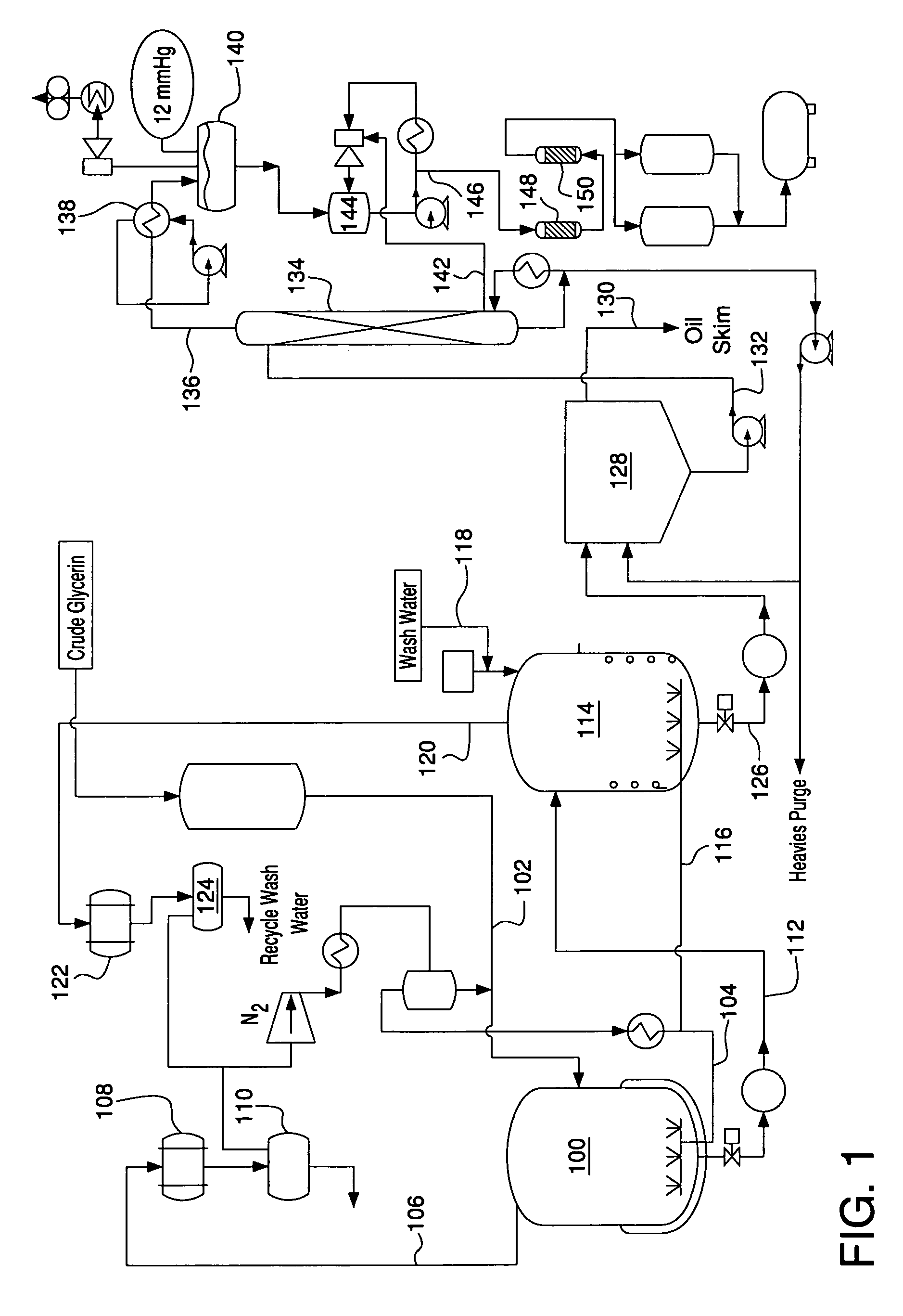

Method of producing lower alcohols from glycerol

ActiveUS20050244312A1High selectivityOrganic compound preparationOxygen compounds preparation by reductionAlcoholBoiling point

A reactive-separation process converts glycerin into lower alcohols, having boiling points less than 200° C., at high yields. Conversion of natural glycerin to propylene glycol through an acetol intermediate is achieved at temperatures from 150° to 250° C. at a pressure ranging from 1 and 25 bar. The preferred applications of the propylene glycol are as an antifreeze, deicing compound, or anti-icing compound. The preferred catalyst for this process in a copper-chromium powder.

Owner:RENEWABLE ALTERNATIVES LLC +1

Purification of glycerin

InactiveUS7126032B1Low costEfficient recyclingOrganic compound preparationOxygen compounds purification/separationAlcoholWash water

A process for purifying glycerin recovered as a byproduct of biodiesel production comprises heating a glycerin effluent stream containing a low molecular weight alcohol, water and fatty acid esters of the low molecular weight alcohol to cause transesterification of the fatty acid esters to glycerides and additional low molecular weight alcohol. The reaction mixture is sparged with nitrogen to help remove water and low molecular weight alcohol, which drives the transesterification reaction towards glyceride formation. A wash water stream may also be added to the recovered glycerin stream from biodiesel production. Either before or following the transesterification reaction, an oil layer can be separated from the recovered glycerin stream by reducing the pH of the stream to below 7. Following separation of the oil layer and transesterification the glycerin stream is flash distilled to separate glycerin from water, salts, and glycerides.

Owner:SUNOCO INC (R&M)

Gel pad and UV-curving production method thereof

The invention relates to a gel pad and a uv-curing production method thereof. This invention, including the gel bag, is characterized in that the gel bag is filled with gel which is prepared from gel monomers, a cross-linking agent and a photoinitiatorandwater prepared from the UV curving. The gel consists of monomers, cross-linking agents, cross-linking agents, photo initiators and water. The said monomer are two or more than two of an acrylic acid alkali metal salt, ester generated by methacrylic acid ,acrylamide ,methacrylamide and AMPS(2-acrylamide-2-methyl-propanesulfonic acid ). The said cross-linking agent is a non-conjugated double bond compound which is polyol(glycerol )N,N'-methylene bisacrylamide. The said photoinitiator is a cracking type initiator or a photosensitive initiator or a cationic initiator. The advantages of the method are that the production process is simple, the gel solidification is fast and the gel pad produced is flattened.

Owner:朱雪兵

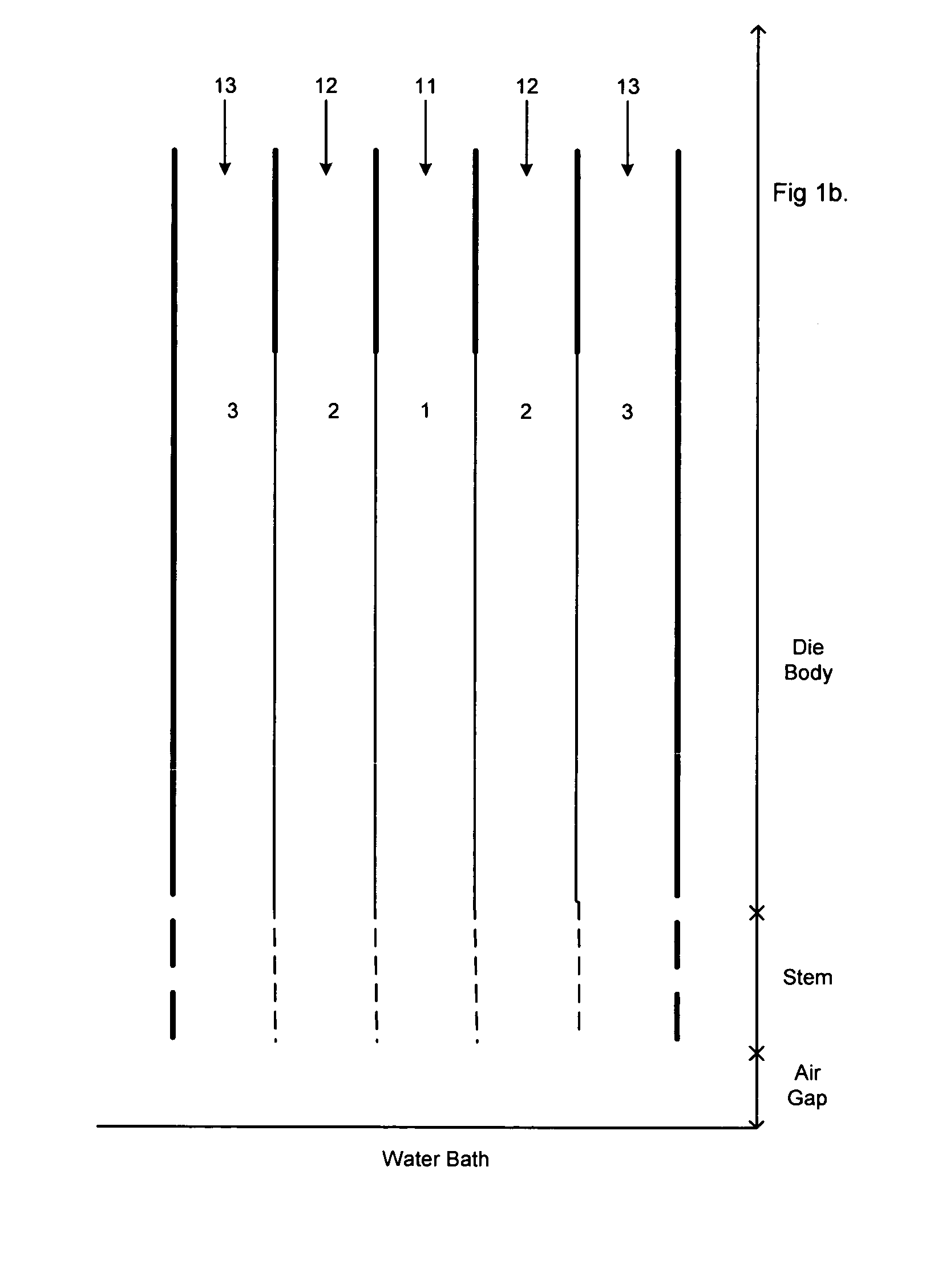

Poly(ethylene chlorotrifluoroethylene) membranes

InactiveUS7247238B2Improve permeabilityImprove integrityMembranesSemi-permeable membranesFiberGlycerol

Porous polymeric membranes including Halar (poly (ethylene chlorotrifluoroethylene)) and related compounds and the methods of production thereof which avoid the use of toxic solvents. Preferred solvents, coating agents and pore forming agents are citric acid ethyl ester or glycerol triacetate. The membranes may be in the form of a hollow fiber or flat sheet, and may include other agents to modify the properties of the membrane, such as the hydrophilic / hydrophobic balance. Leachable agents may also be incorporated into the membranes.

Owner:EVOQUA WATER TECH LLC

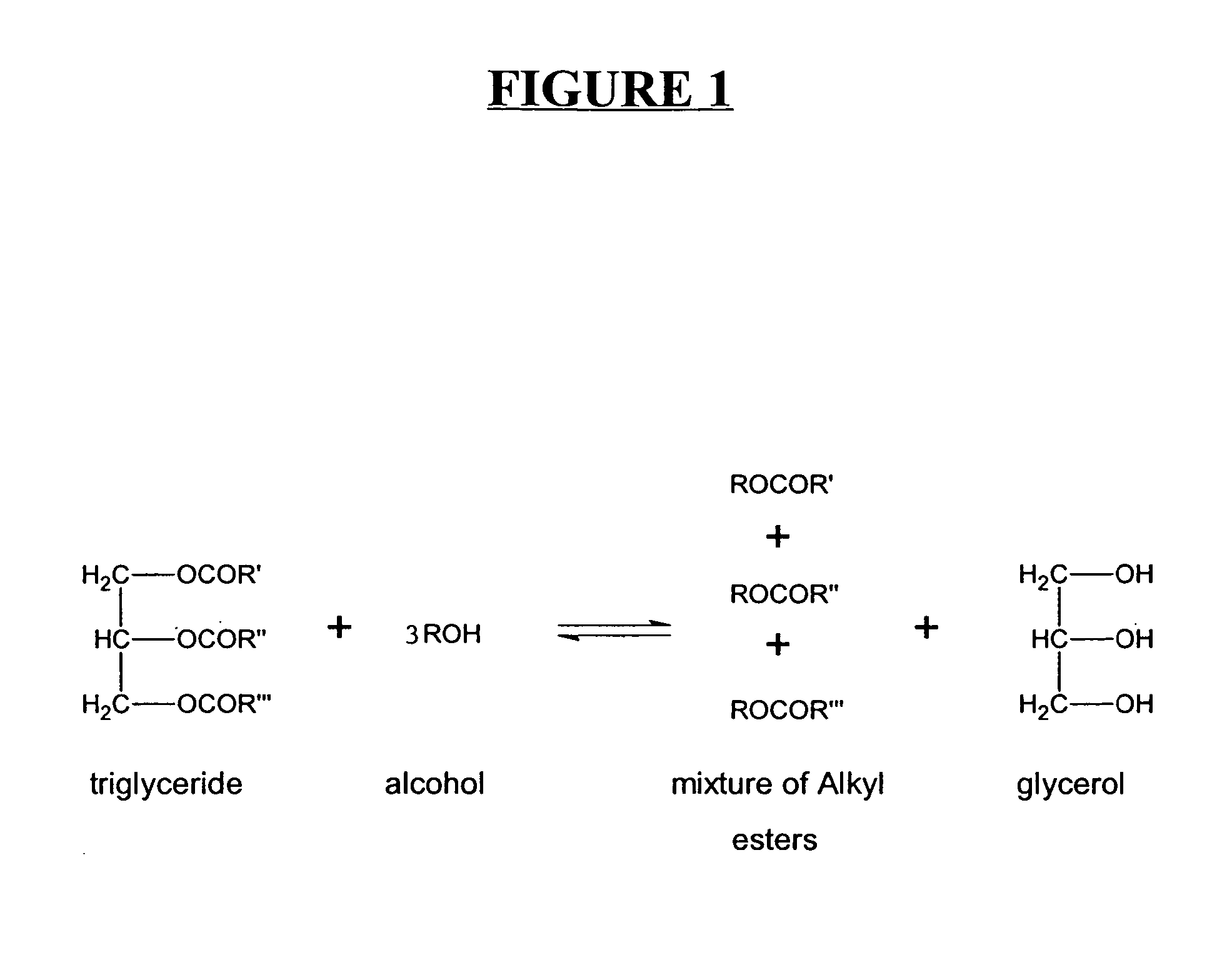

Process for producing biodiesel, lubricants, and fuel and lubricant additives in a critical fluid medium

InactiveUS6887283B1Limited mass transferImprove reaction speedFatty oils/acids recovery from wasteFatty acid esterificationBiodieselVegetable oil

A process for producing alkyl esters useful in biofuels and lubricants by transesterifying glyceride- or esterifying free fatty acid-containing substances in a single critical phase medium is disclosed. The critical phase medium provides increased reaction rates, decreases the loss of catalyst or catalyst activity and improves the overall yield of desired product. The process involves the steps of dissolving an input glyceride- or free fatty acid-containing substance with an alcohol or water into a critical fluid medium; reacting the glyceride- or free fatty acid-containing substance with the alcohol or water input over either a solid or liquid acidic or basic catalyst and sequentially separating the products from each other and from the critical fluid medium, which critical fluid medium can then be recycled back in the process. The process significantly reduces the cost of producing additives or alternatives to automotive fuels and lubricants utilizing inexpensive glyceride- or free fatty acid-containing substances, such as animal fats, vegetable oils, rendered fats, and restaurant grease.

Owner:BATTELLE ENERGY ALLIANCE LLC

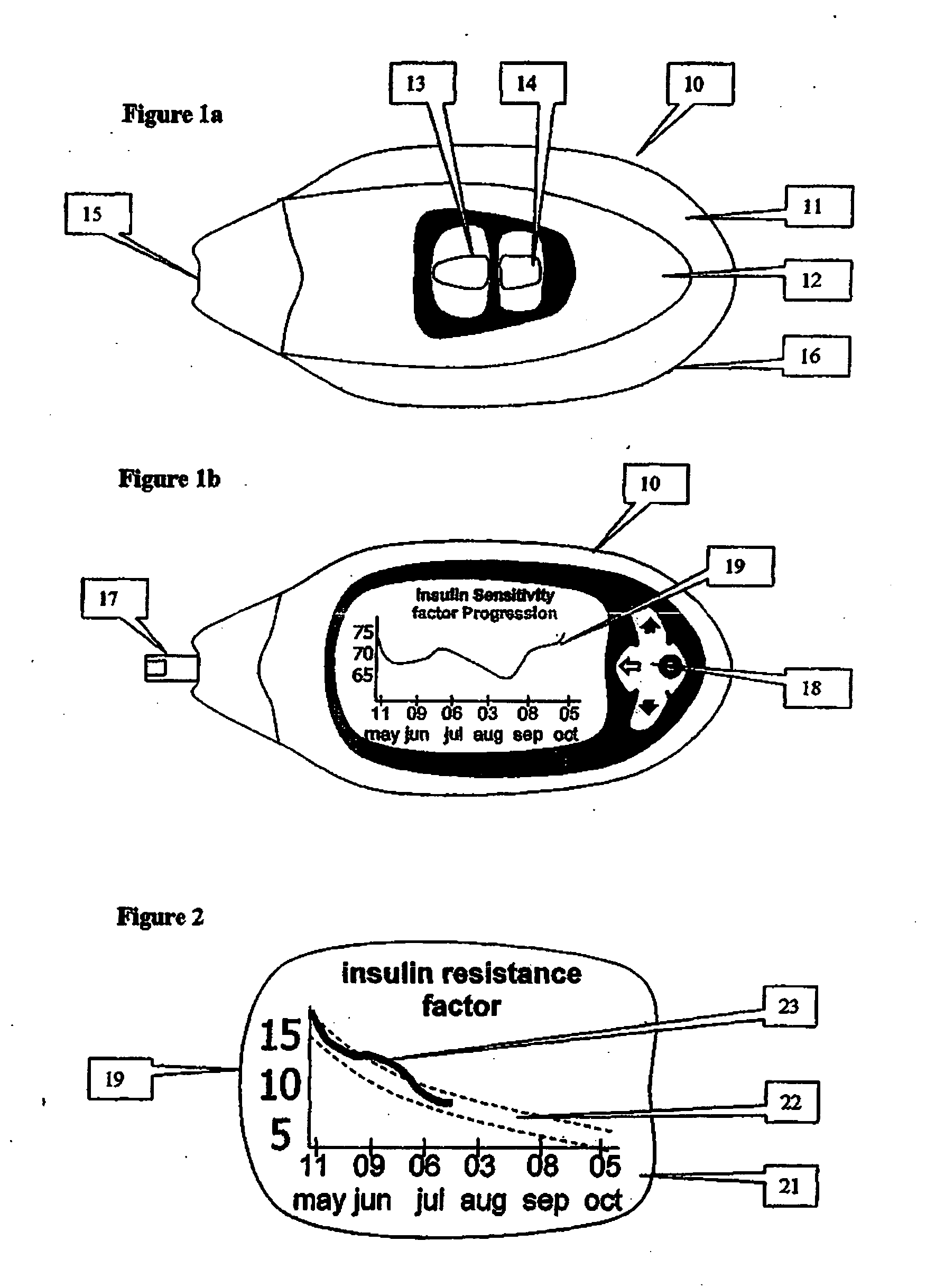

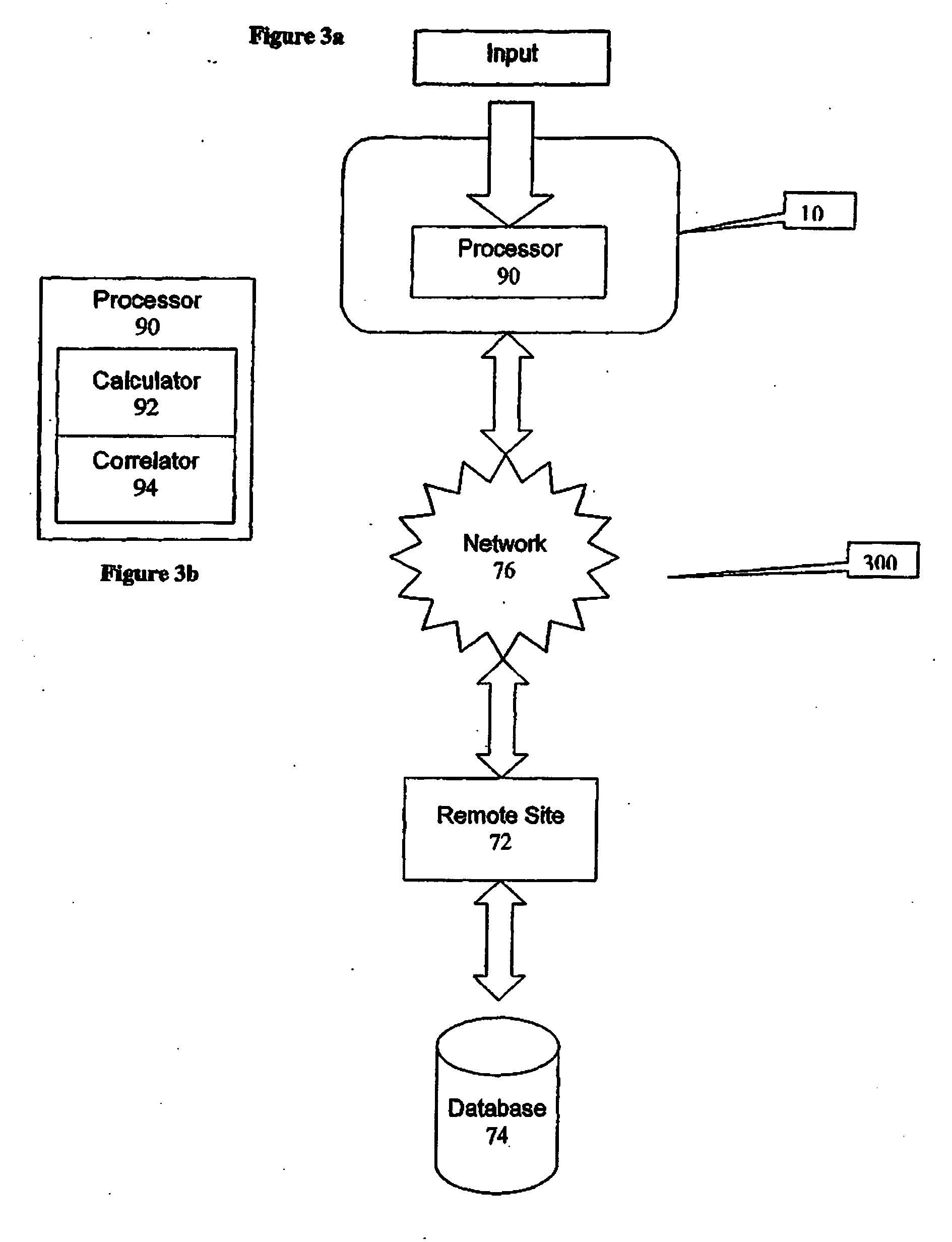

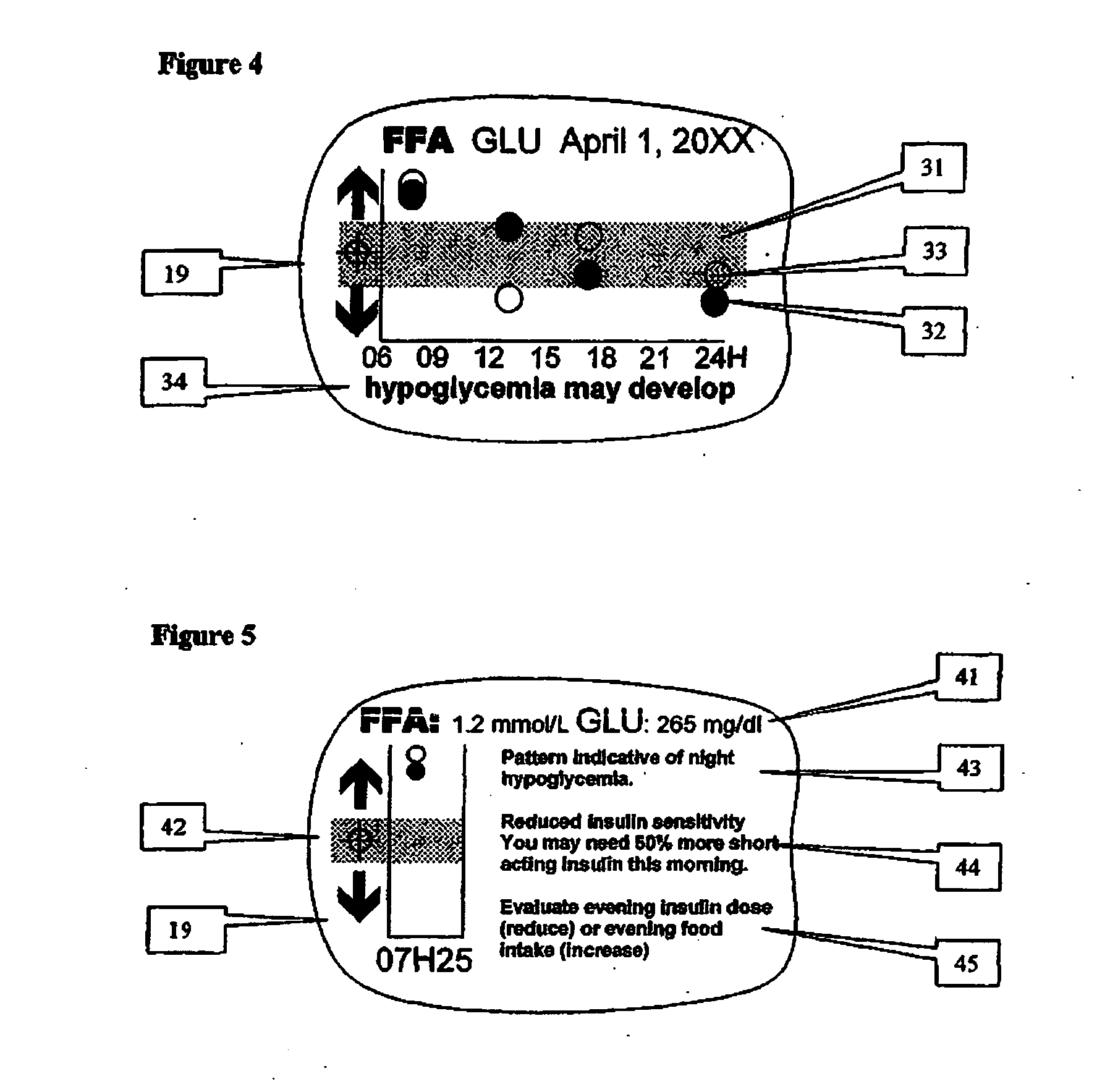

Method and device for utilizing analyte levels to assist in the treatment of diabetes

A health-monitoring device assesses the health of a user based on levels of two analytes in a biological fluid. A first analyte that is utilized to assess a user's health is a fat metabolism analyte, such as ketones, free fatty acids and glycerol, which is indicative of fat metabolism. A second analyte that is utilized is a glucose metabolism analyte, such as glucose. The levels of the two analytes may be used to assess insulin sensitivity, to detect both recent hypoglycemia and the cause of high glucose levels, and / or to guide therapeutic intervention. The dual analyte model may calculate a discrepancy between an actual insulin activity level and a theoretical insulin activity level. The dual analyte model of the present invention may be used to identify individuals at risk for metabolic syndrome, insulin resistance and non-insulin dependent diabetes, and allows monitoring of the progression of those disease states, as well as progress made by therapeutic interventions.

Owner:ABBOTT DIABETES CARE INC

Soaps Produced from Oil-Bearing Microbial Biomass and Oils

ActiveUS20090305942A1Improve efficiencyLow costSoap detergents with organic compounding agentsBiofuelsMicroorganismMicrobial oil

Soap and cosmetic products can be made from oil-bearing microbial biomass via the alkaline hydrolysis of glycerolipids and fatty acid esters to fatty acid salts. The saponified microbial oils / lipids can be combined with a variety of additives to produce compositions for use as soaps and other cosmetic products, which may also contain other constituents of the biomass, including unsaponified oils, glycerol and carotenoids, among others.

Owner:CORBION BIOTECH INC

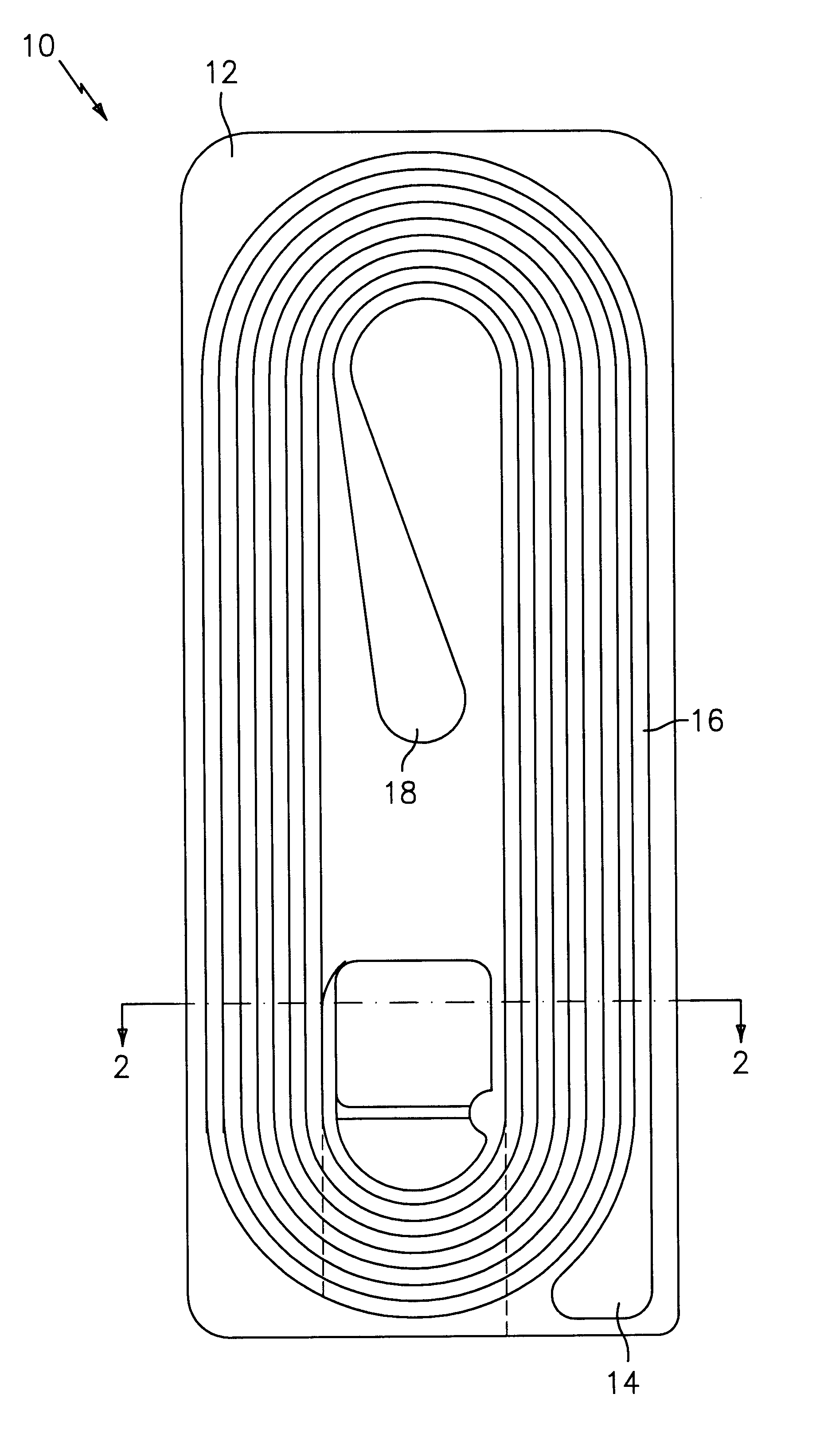

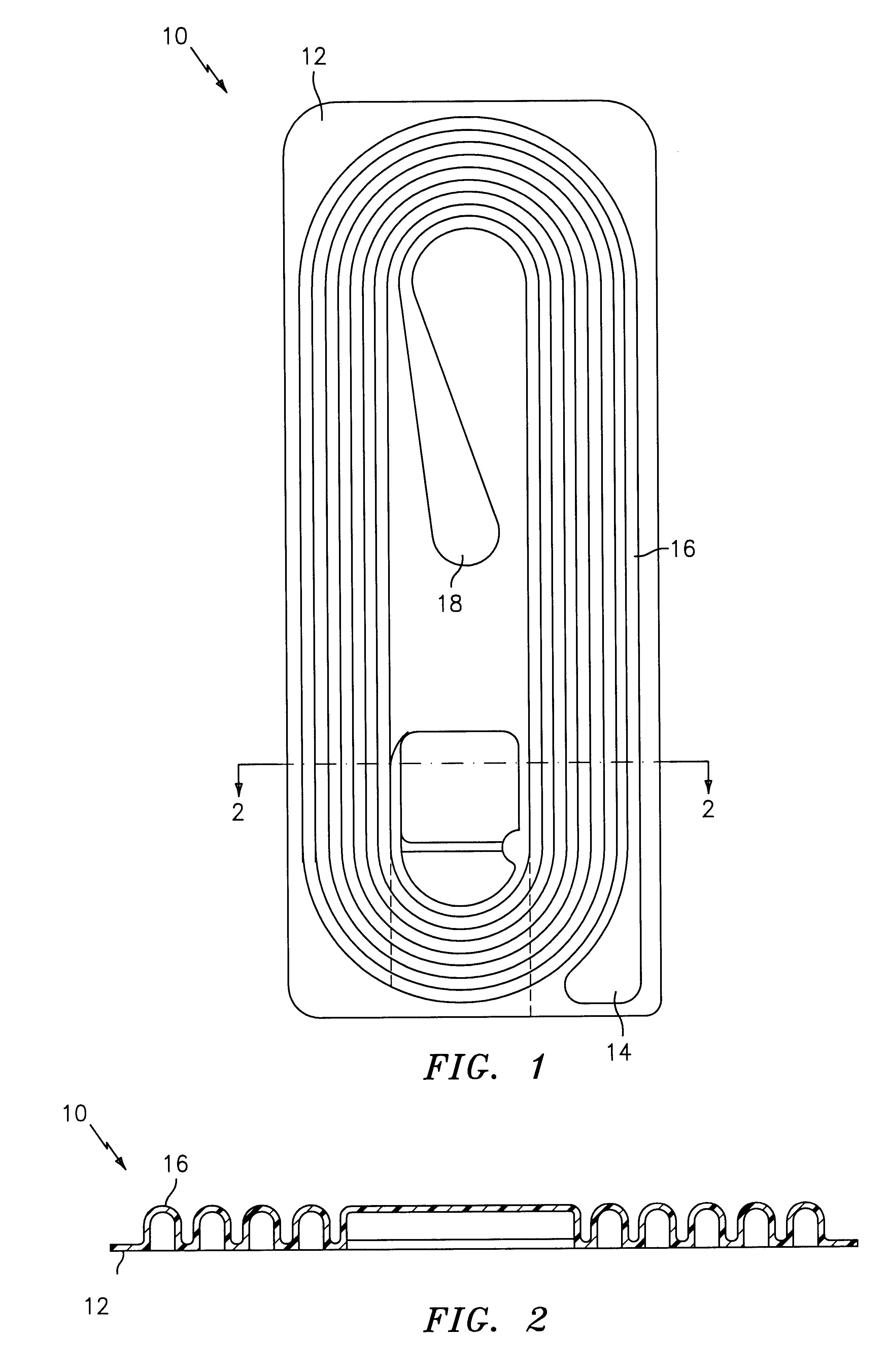

Packaged synthetic absorbable surgical elements

InactiveUS6260699B1Improved out of package handling characteristicImproving out of package flexibility and handSuture equipmentsBiocideGlycerolAbsorbable suture

Synthetic absorbable sutures are filled with a stabilizing agent, preferably a mixture of glycerol and calcium lactate, and inserted into a retainer having a narrow convoluted passageway. The retainer is inserted into an open foil pouch with a package stabilizing element such as a paper sheet filled with stabilizing agent. The package containing the suture, retainer and package stabilizing element is sterilized, aerated, equilibrated to a relatively high moisture level, and sealed. Long lengths of suture and doubled-over and tripled-over suture may be withdrawn from the retainer with low force without damaging the suture. Bends and kinks in the suture are prevented so as to provide a synthetic absorbable suture having highly desirable out of package hand and feel. The suture an removed from the package exhibits improved tissue drag characteristics.

Owner:UNITED STATES SURGICAL CORP

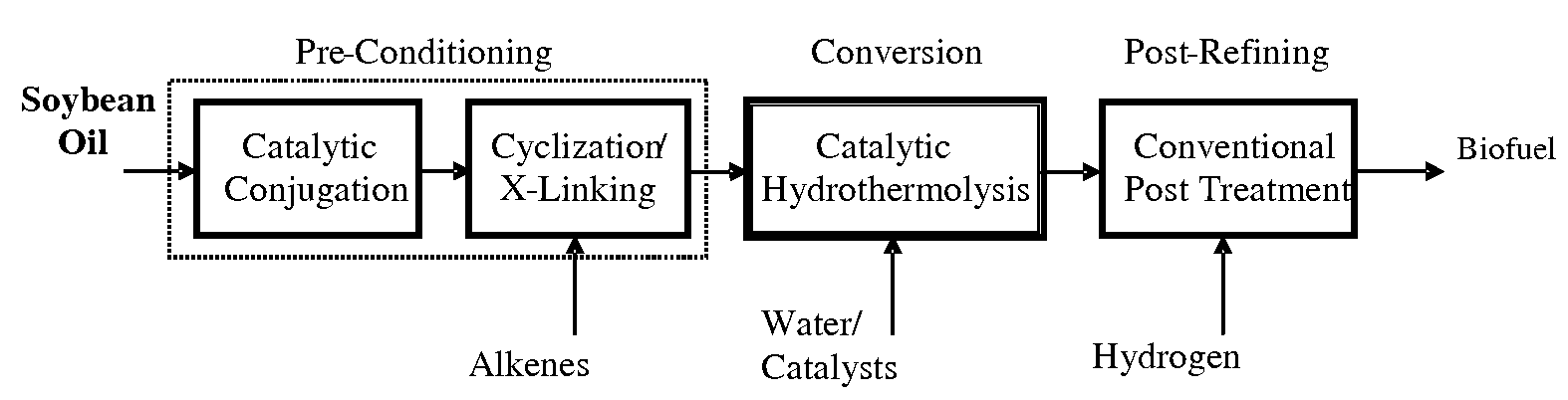

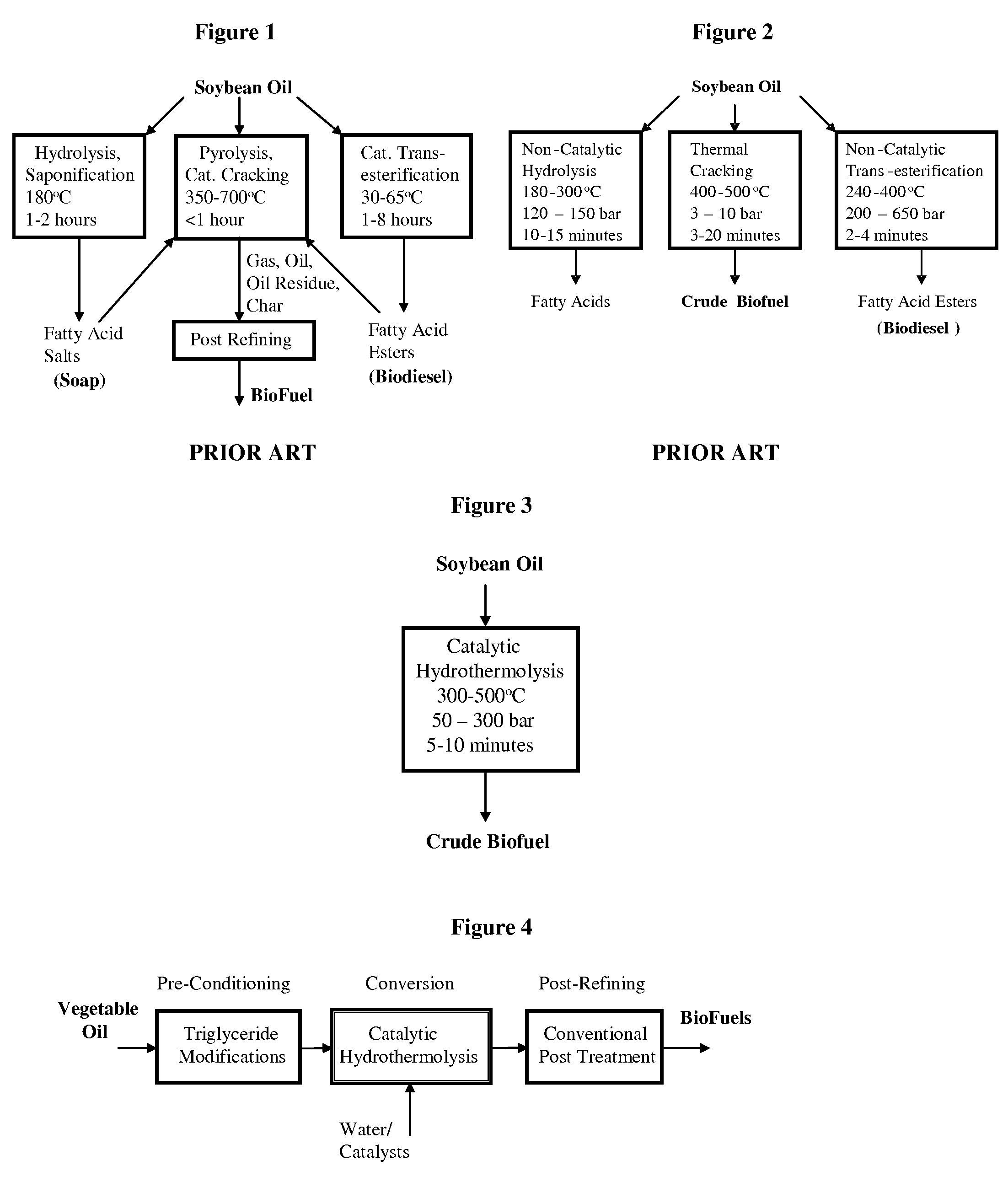

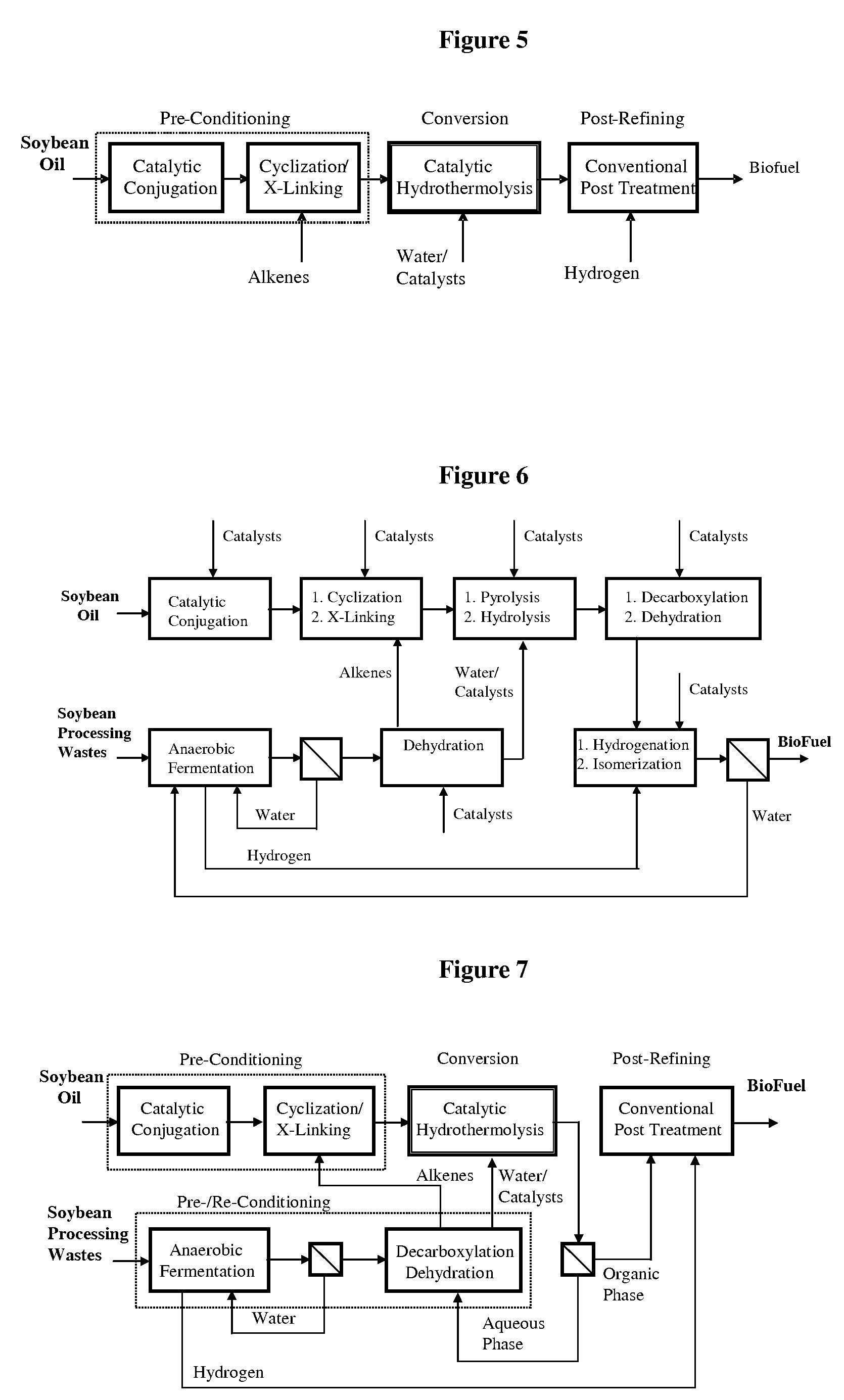

Method of converting triglycerides to biofuels

ActiveUS7691159B2Improve chemical and physical and combustion qualityImprove thermal stabilityFatty acid chemical modificationOrganic compound preparationCross-linkIsomerization

A triglyceride-to-fuel conversion process including the steps of (a) preconditioning unsaturated triglycerides by catalytic conjugation, cyclization, and cross-link steps; (b) contacting the modified triglycerides with hot-compressed water containing a catalyst, wherein cracking, hydrolysis, decarboxylation, dehydration, aromatization, or isomerization, or any combination thereof, of the modified triglycerides produce a crude hydrocarbon oil and an aqueous phase containing glycerol and lower molecular weight molecules, and (c) refining the crude hydrocarbon oil to produce various grades of biofuels. A triglyceride-to-fuel conversion process further including the steps of (a) carrying out anaerobic fermentation and decarboxylation / dehydration, wherein the anaerobic fermentation produces hydrogen, volatile acids, and alcohols from fermentable feedstocks, and the decarboxylation / dehydration produces alkenes from the volatile acids and alcohols, respectively; (b) feeding the alkenes to the cyclization process; (c) feeding the hydrogen to the post refining process; and (d) recycling the aqueous phase containing glycerol to the decarboxylation / dehydration process. A biofuel composition including straight-chain, branched and cyclo paraffins, and aromatics. The paraffins are derived from conversion of triglycerides. The aromatics are derived from conversion of either triglycerides, petroleum, or coal.

Owner:APPLIED RES ASSOCS INC

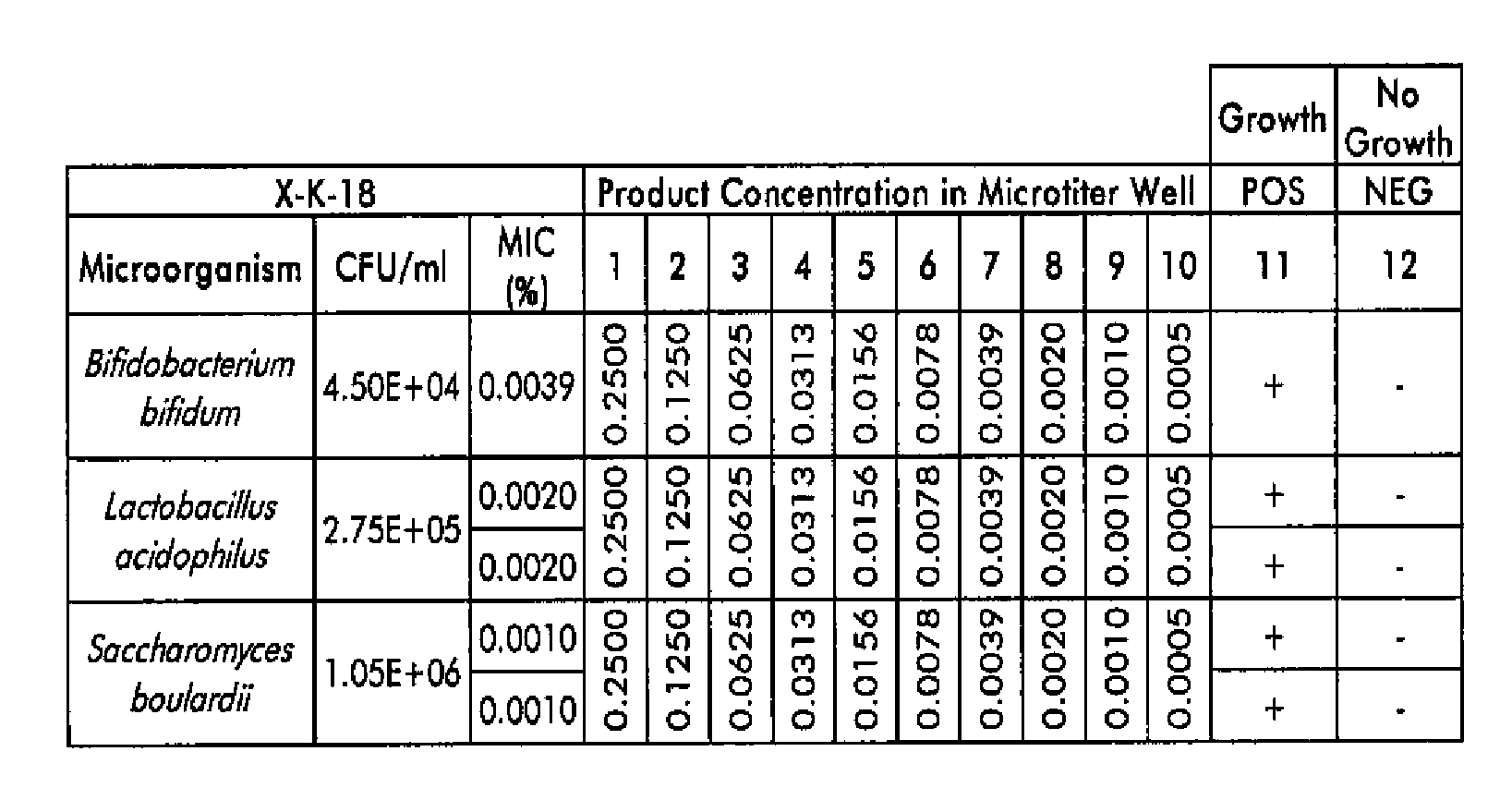

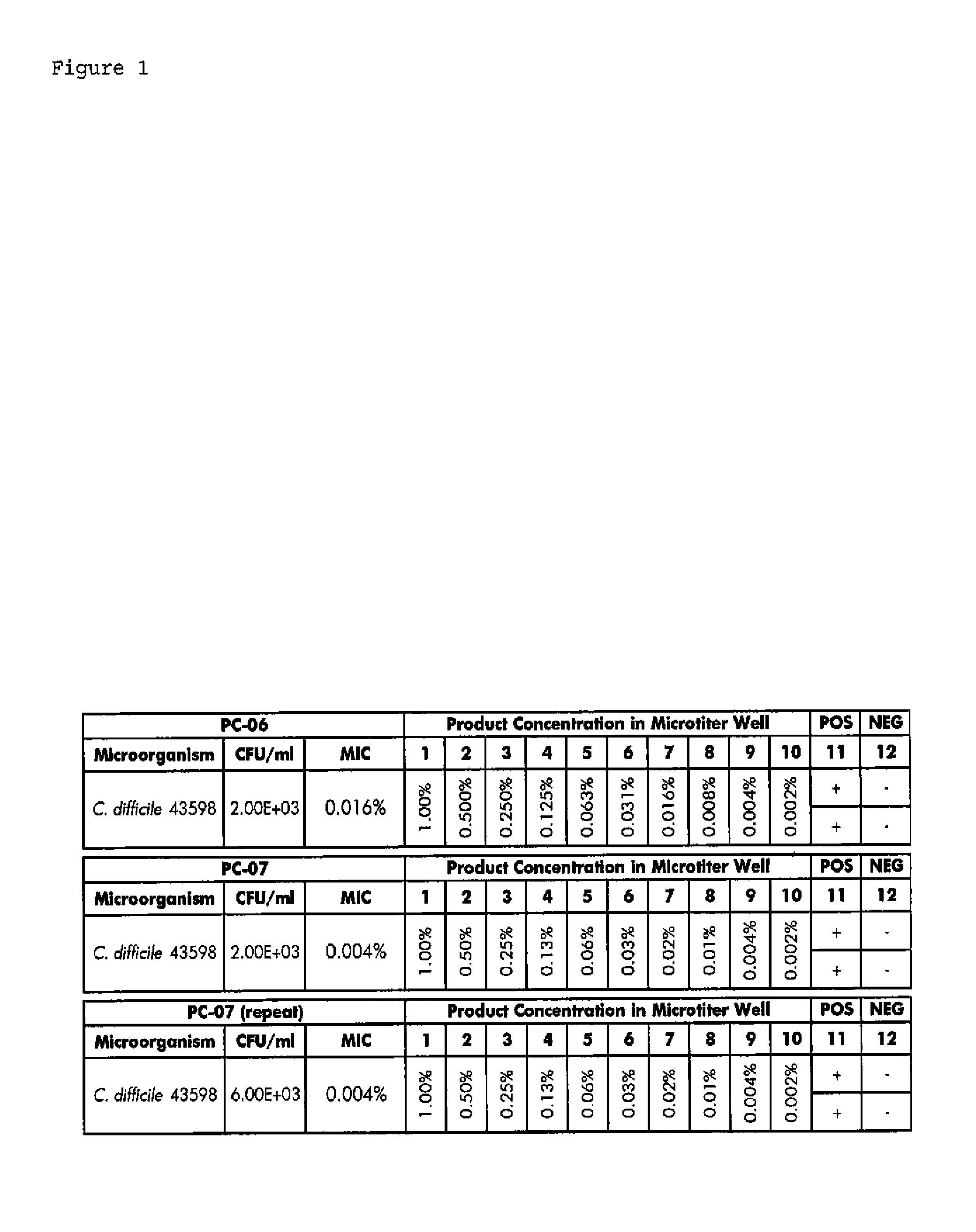

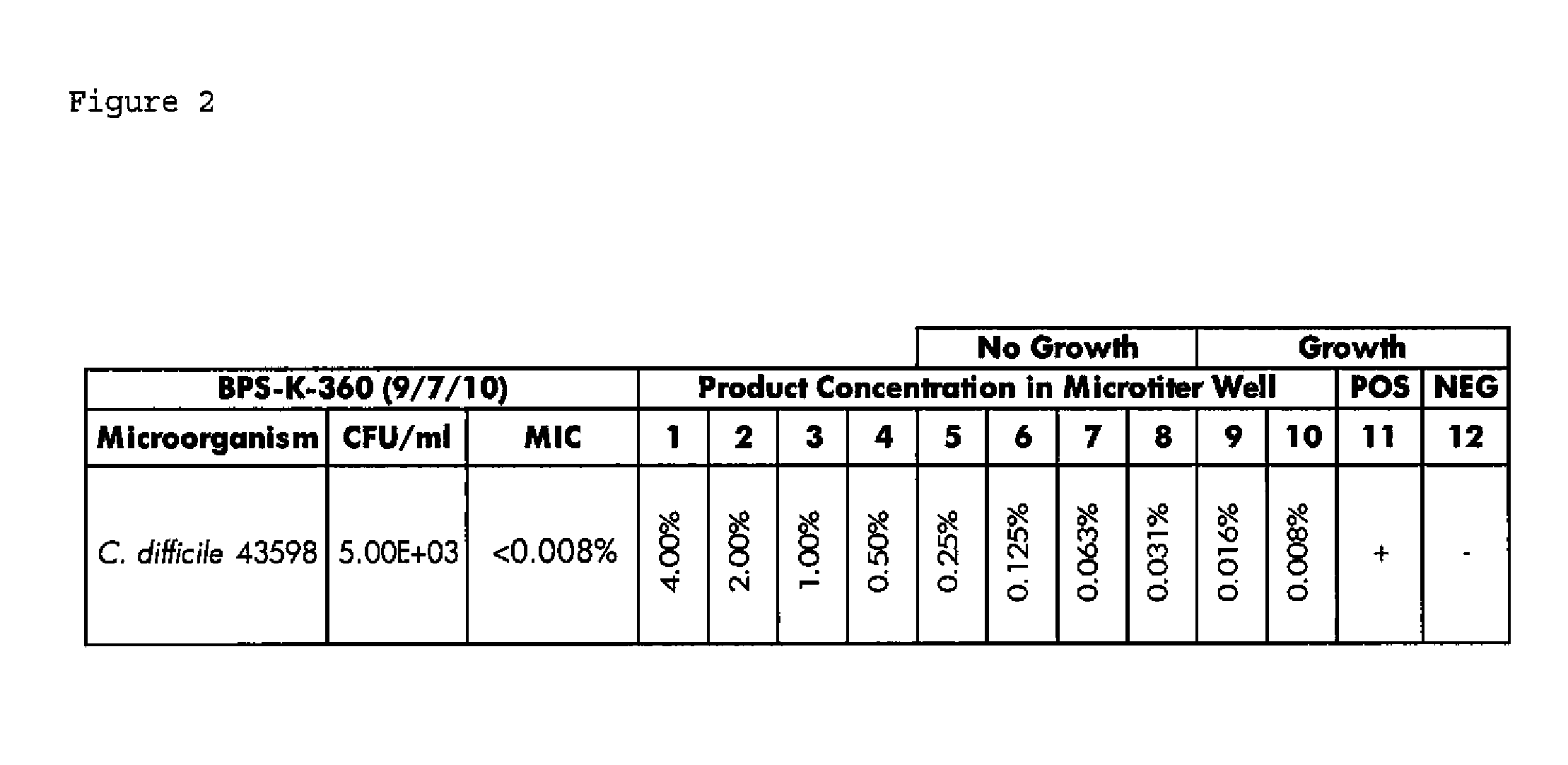

Composition and Method for Treating Infections and Promoting Intestinal Health

ActiveUS20110200570A1Improve floraPrevent bacterial growthAntibacterial agentsBiocideSuppositoryGlycerol

Compositions and methods for the treatment of intestinal infections. Compositions that include a liquid crystal mixture of an antimicrobial glycerol fatty acid ester and a polyhydric alcohol inhibit the growth of numerous deleterious intestinal pathogenic bacteria, including C. difficile. C. difficile is the causative agent in an increasing number of antibiotic-resistant bacterial infections. The formulations may be administered orally as capsules or soft gels, or alternatively as a enema, colonic, or rectal suppository. When combined with a probiotic supplement, the liquid crystal combinations reported here are able to treat an intestinal bacterial infection effectively and safely, thus promoting general intestinal health.

Owner:COPPERHEAD CHEM

Composition for oily foamable aerosol

ActiveUS20040197276A1Improve applicabilityMaintain good propertiesCosmetic preparationsToilet preparationsChemistryGlycerol

The present invention provides a composition for an oily foamable aerosol, characterized in that the composition comprises a fat or oil, and a polyglycerol fatty acid ester and / or an organic and fatty acid esters of glycerol; and an aerosol comprising the composition as defined in above and a propellant.

Owner:TAIYO KAGAKU CO LTD

Dental bleaching compositions containing sucralose

InactiveUS6322774B1Effectively disguise the bitter taste of such agents over timeAccurate quantityCosmetic preparationsImpression capsFlavouring agentGlycerol

Dental bleaching compositions that include sucralose as a non-nutritive sweetener. The bleaching agent is dispersed within a carrier, which is optimally sticky and viscous, such as a mixture of a liquid or solvent carrier and a tackifying agent. Propylene glycol and / or glycerin are especially useful liquid or solvent carriers. Flavorants may be added to enhance the taste of the dental compositions, since they will be used within a person's mouth. For best results, a flexible, thin-walled, comfortable-fitting, custom dental tray is used with the dental bleaching compositions. The dental compositions are preferably sufficiently sticky and viscous so as to adhere and retain a dental tray against a person's teeth which is designed so as to not exert significant mechanical pressure onto the person's teeth.

Owner:ULTRADENT PROD INC

Edible Oil and Processes for Its Production from Microalgae

InactiveUS20100303957A1Simple preparation conditionsFatty acid hydrogenationReady-for-oven doughsCelluloseBiotechnology

Novel triglyceride oils are provided for human consumption. Traditionally, agricultural materials such as canola, soybean, and olives have been the sources of edible oils, and such materials are limited by the geography in which these crops can be cultivated. Oils of the invention can be manufactured from edible and inedible heterotrophic fermentation feedstocks, including corn starch, sugar cane, glycerol, and depolymerized cellulose that are purpose-grown or byproducts of existing agricultural processes from an extremely broad diversity of geographic regions. The food oils disclosed herein are low in saturates, high in monounsaturates, and can be manufactured in reduced pigment form through the use of pigment-reduced microalgae strains. The food oils disclosed herein can be manufactured through the use of a variety of different types of oil-producing microalgae.

Owner:TERRAVIA HLDG INC

Environmentally benign anti-icing or deicing fluids employing triglyceride processing by-products

InactiveUS6890451B2Improve ice resistanceGreat tractionOther chemical processesTG - TriglycerideGlycerol

Deicing compositions comprised of glycerol-containing by-products of triglyceride processing processes are disclosed.

Owner:MLI ASSOC

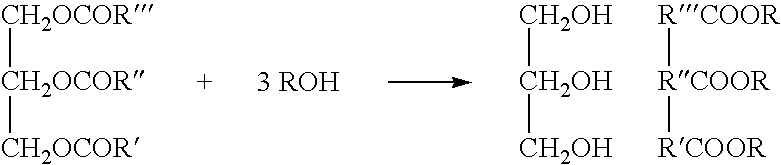

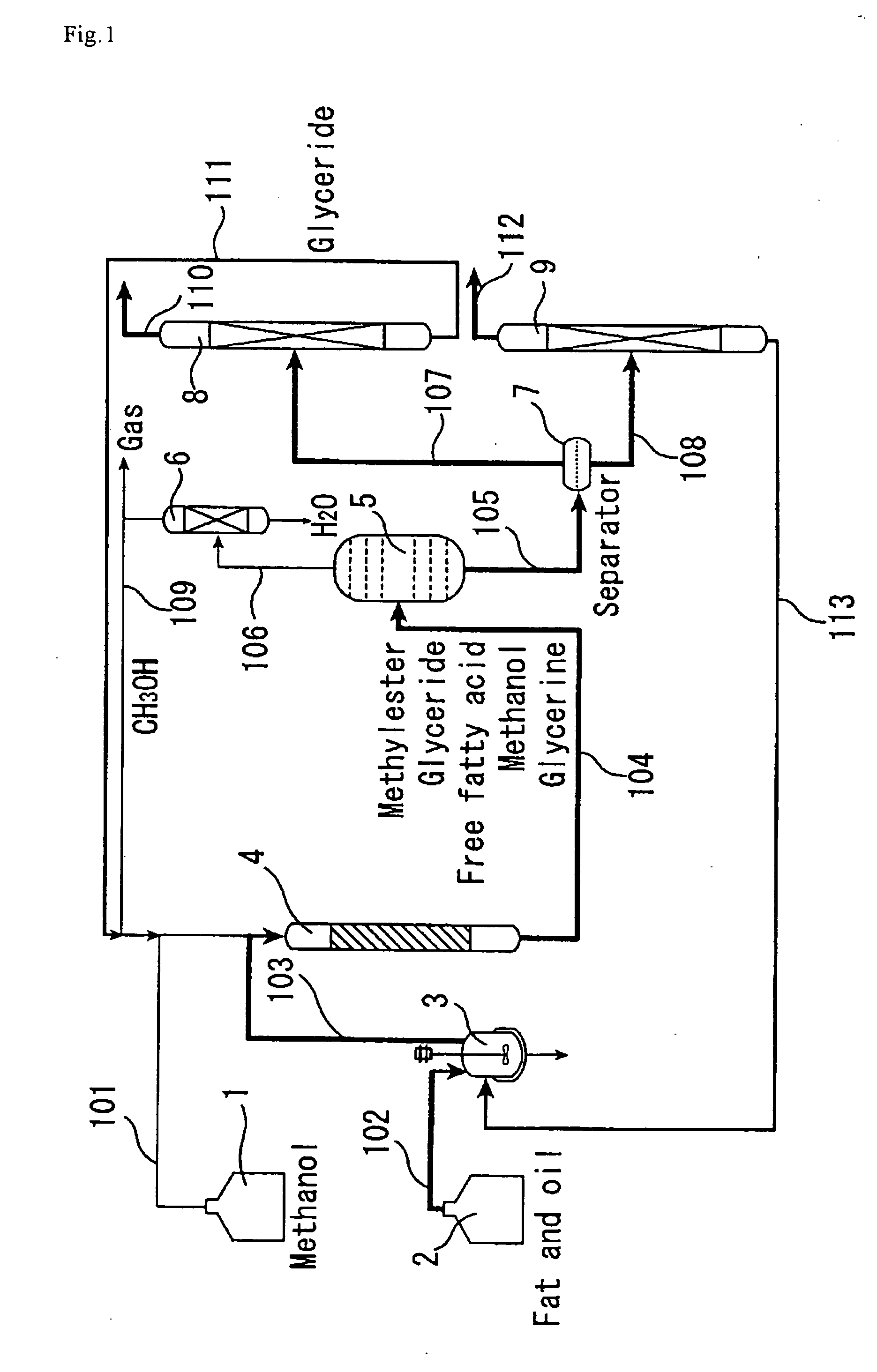

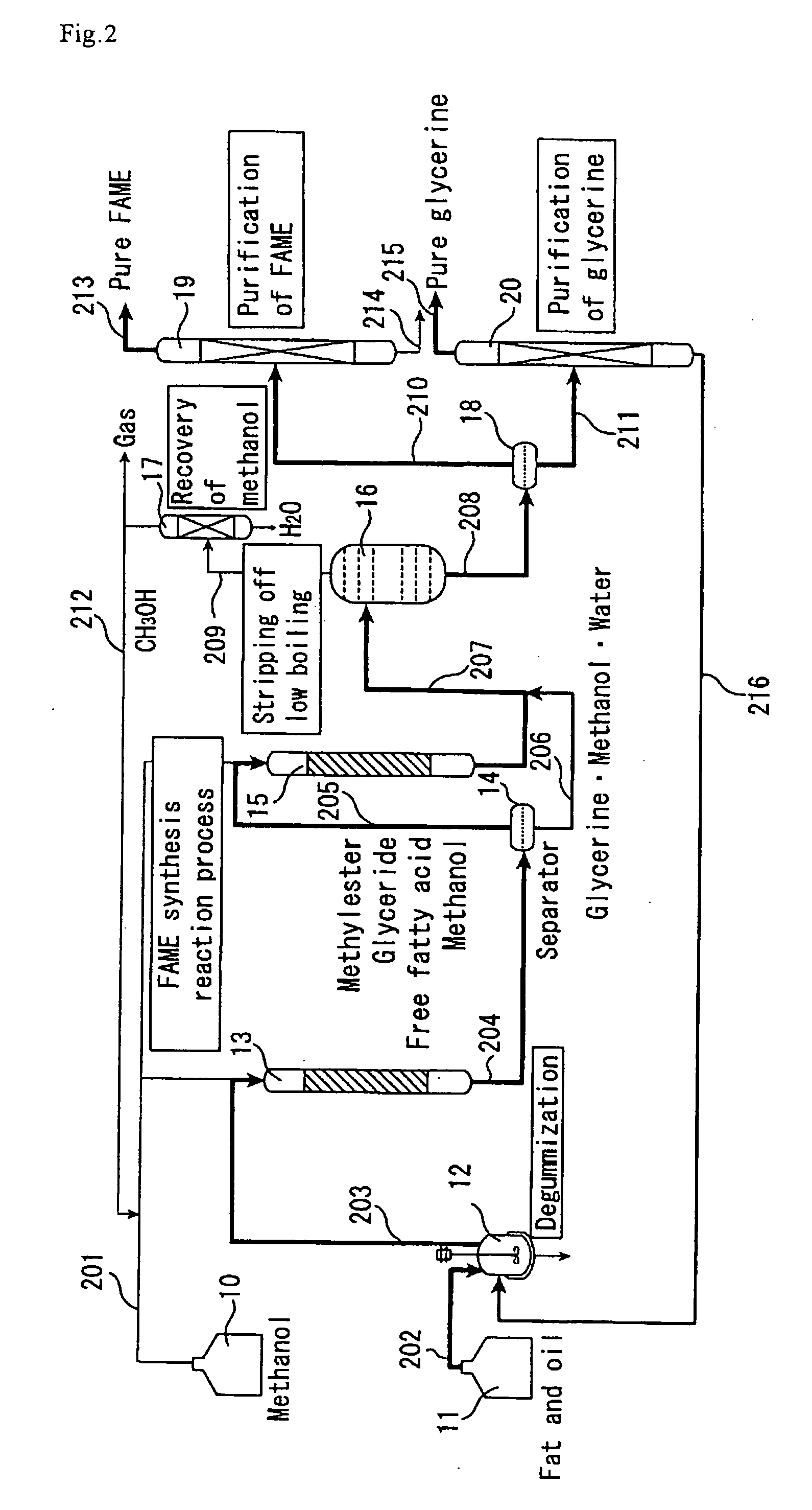

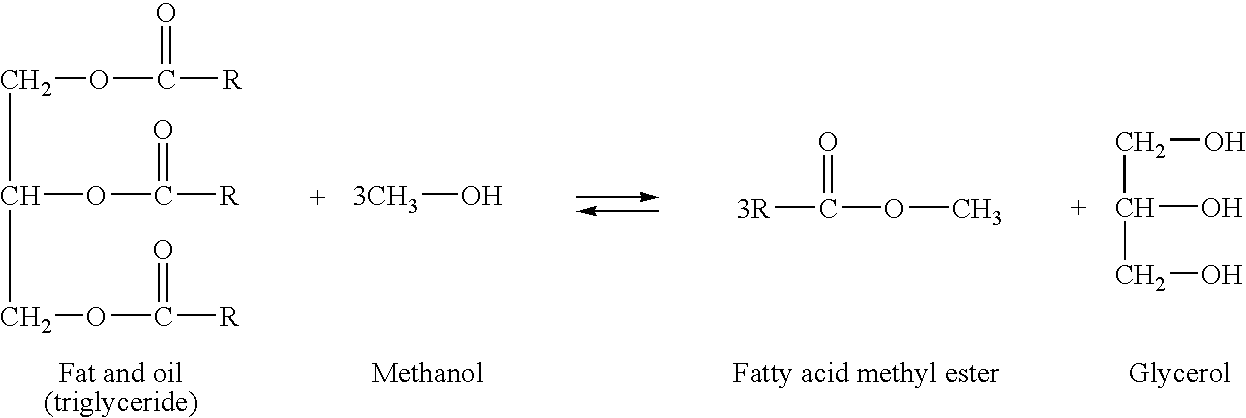

Method of production of fatty acid alkyl esters and/or glycerine and fatty acid alkyl ester-containing composition

InactiveUS20070167642A1Reduce energy consumptionIncrease contentFatty oils/acids recovery from wasteFatty acid esterificationBoiling pointGlycerol

The method of producing fatty acid alkyl esters and / or glycerine of the present invention is a method of producing high-purity fatty acid alkyl esters and / or glycerine advantageously from the energy viewpoint while reducing the energy consumption of the production, and the products can be used in various fields of application, for example in biodiesel fuels, foods, cosmetics and pharmaceuticals. The above-mentioned method of producing fatty acid alkyl esters and / or glycerine by reacting a fat or oil with an alcohol using an insoluble solid catalyst in a reaction apparatus comprising at least one reactor, comprises (a) a step of obtaining low-boiling components removed liquid by removing low-boiling components or fraction from an effluent liquid of a reactor and (b) a step of separating the fatty acid alkyl esters and glycerine from the low-boiling components removed liquid, wherein an eluted active metal component of the insoluble solid catalyst in the effluent liquid of a reactor amounts to a level not higher than 1,000 ppm.

Owner:NIPPON SHOKUBAI CO LTD

Extended binder compositions

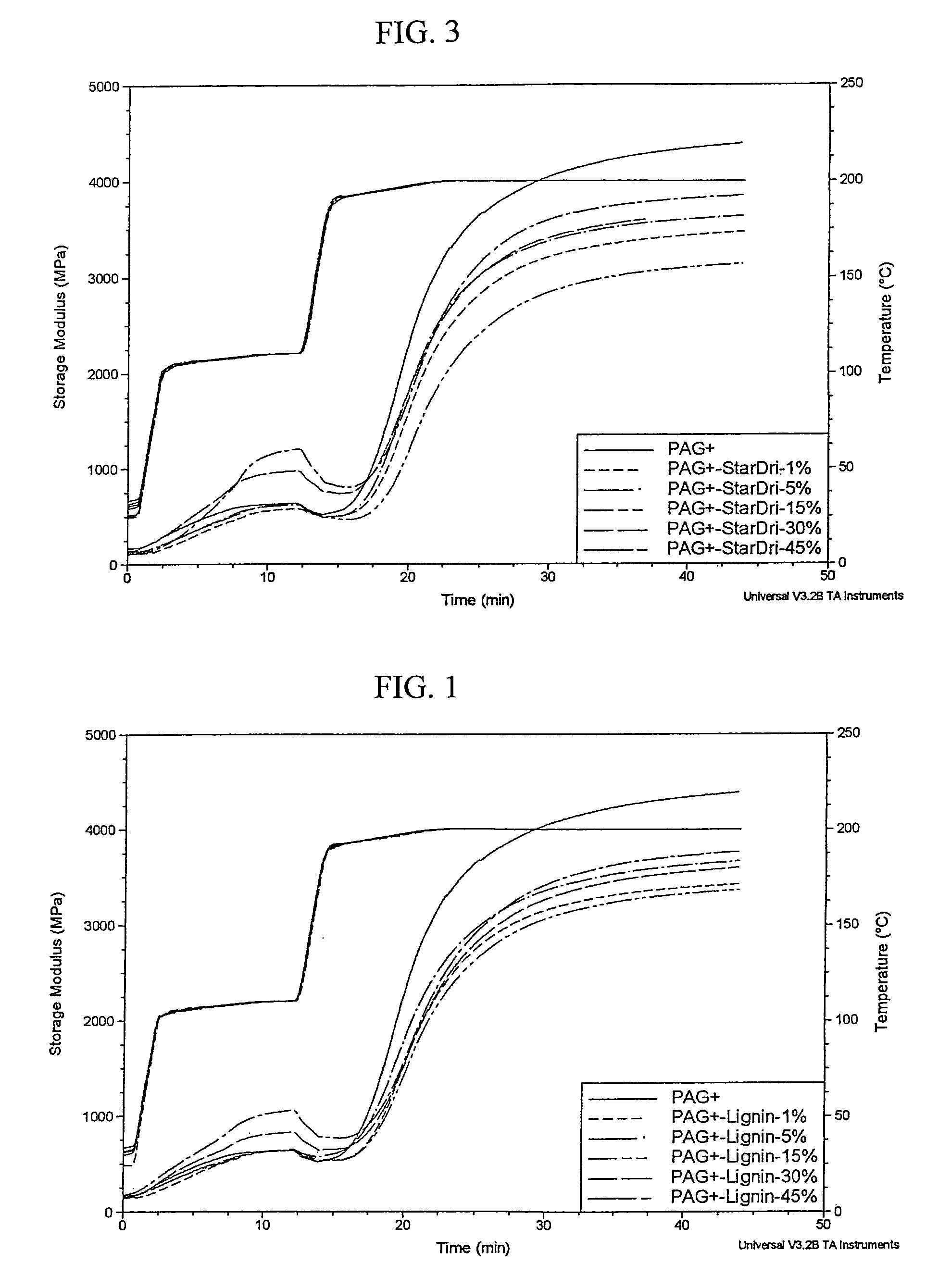

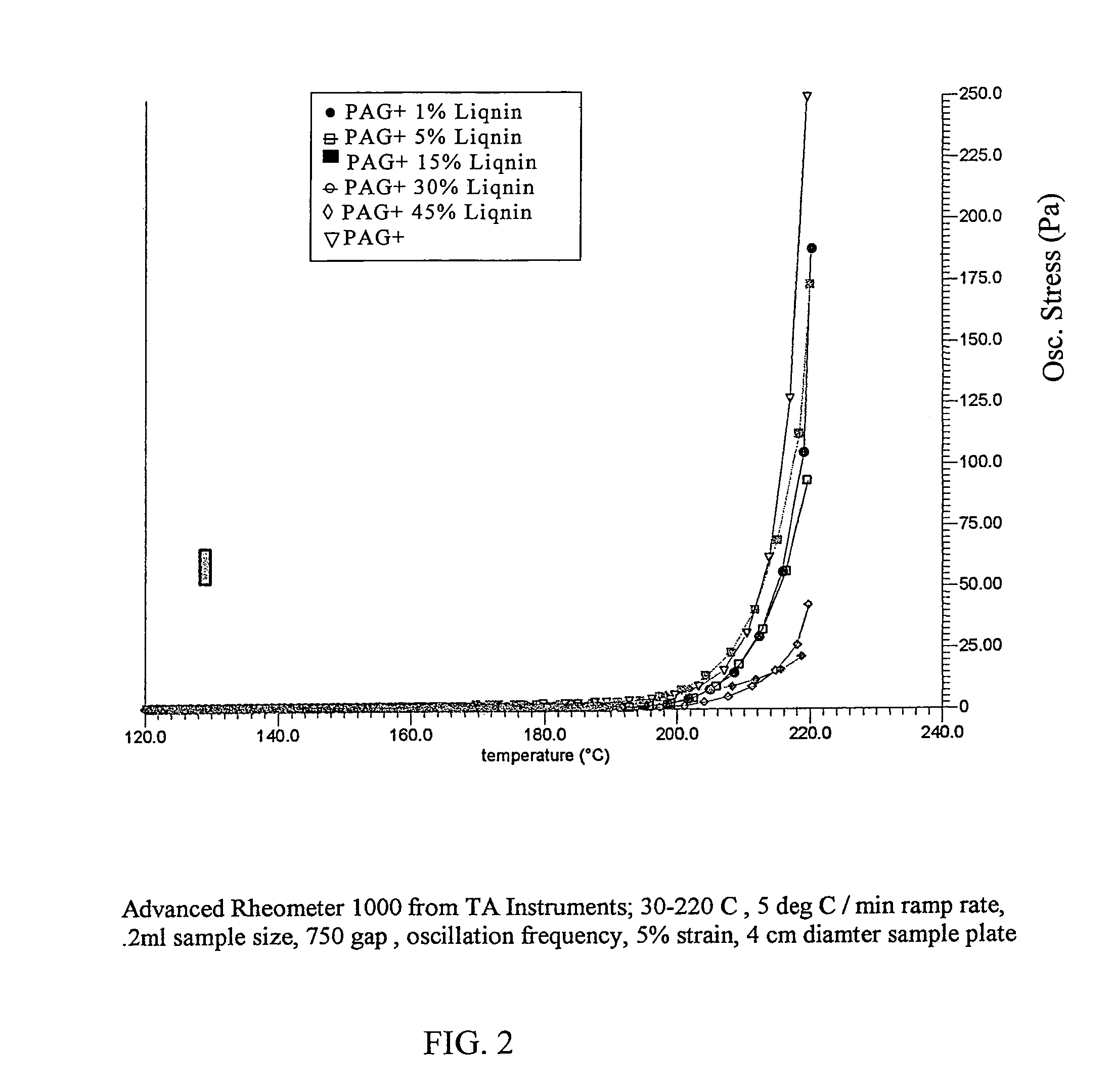

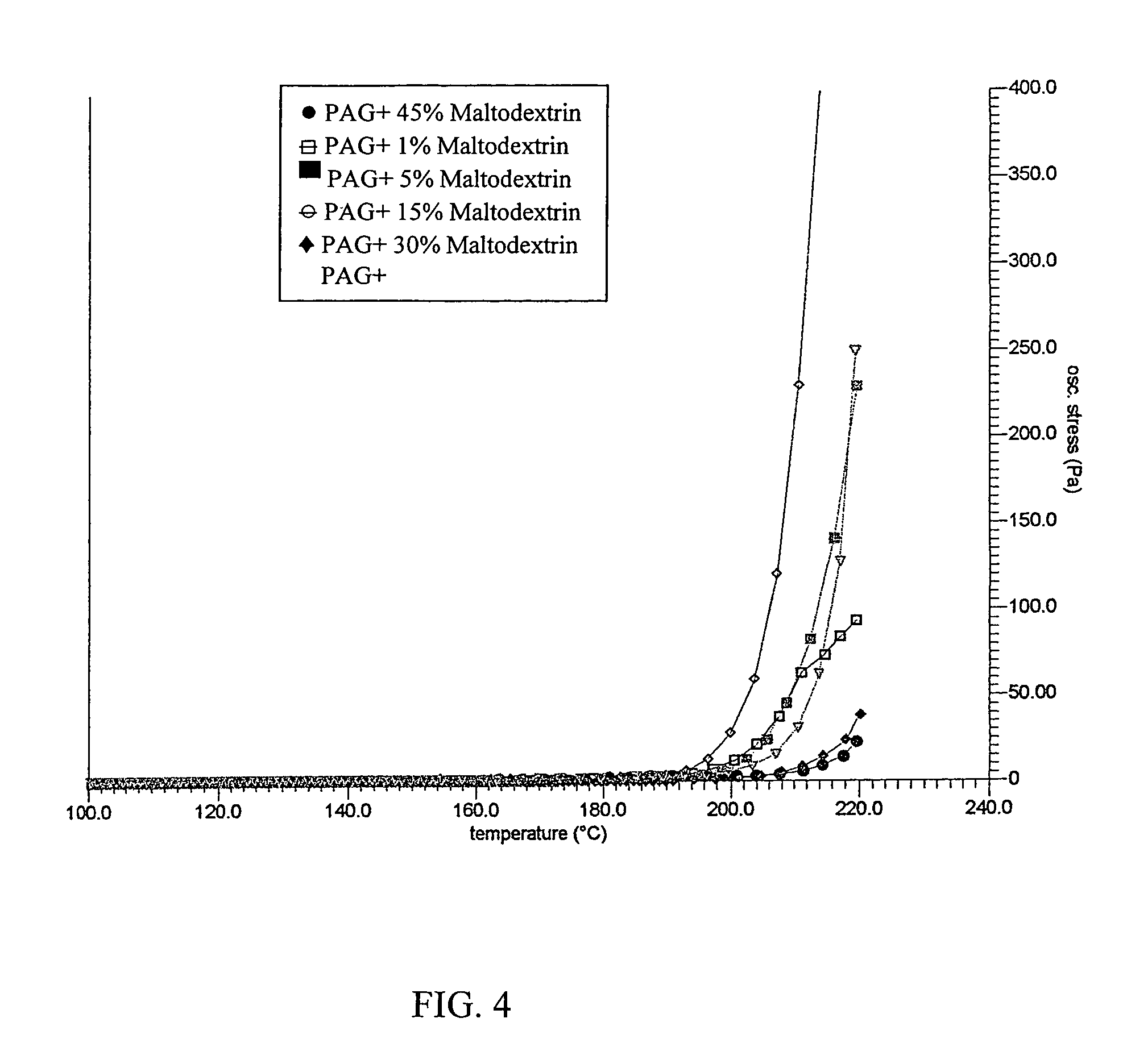

The present invention provides a variety of extended polyacrylic acid based binder compositions comprising a low molecular weight polyacrylic acid (typically hypophosphite or sulfite terminated), a crosslinking agent (such as triethanolamine or glycerol) and one or more water soluble materials, such as lignin, low molecular weight starch and soybean protein. The extended binder composition of the present invention provides a lower cost binder composition without degrading the performance and may be selected to alter one or more characteristics of the basic binder composition such binder wetting, emulsion compatibility, dust suppression and wash water flow properties.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com