Patents

Literature

46531 results about "Hydrochloric acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrochloric acid or muriatic acid is a colorless inorganic chemical system with the formula HCl:H2O and is a ionically bonded acid. Hydrochloric acid has a distinctive pungent smell. It is classified as strongly acidic and can attack the skin over a wide composition range, since the hydrogen chloride completely dissociates in aqueous solution.

Methods and systems for operating an aerosol generator

InactiveUS20050217666A1Improve security levelImprove delivery efficiencyAntibacterial agentsOrganic active ingredientsDiseaseAmikacin

A method of treating a patient with a pulmonary disease, where the method includes delivering a dose of aerosolized medicament intermittently to a ventilator circuit coupled to the respiratory system of the patient. Also, a method of treating a patient with a pulmonary disease, where the method includes taking the patient off a ventilator, and administering to the patient, a nebulized aerosol comprising from about 100 μg to about 500 mg of a medicament. Additionally, an aerosolized medicament for the treatment of a pulmonary disease, where the medicament includes amikacin mixed with an aqueous solution having an adjusted pH from about 5.5 to about 6.3. The pH is adjusted by adding hydrochloric acid and sodium hydroxide to the aqueous solution.

Owner:NOVARTIS AG

Method for preparing lithium cobaltate by directly using invalid lithium ion battery

InactiveCN102030375AReduce dispersionHigh purityCell electrodesCobalt compoundsElectrical batteryPotassium hydroxide

The invention provides a method for preparing lithium cobaltate by directly using an invalid lithium ion battery. The method comprises the following steps: crushing the invalid lithium ion battery or scraps generated when a lithium cobaltate battery is produced by a mechanical crusher at normal temperature; adding water and one or more of acetic acid, sulfuric acid, hydrochloric acid or nitric acid to produce mixed aqueous solution of the battery scraps and acid; filling the mixed aqueous solution into a hermetic pressure reactor, and controlling the temperature in the reactor to be between 50 and 150 DEG C; introducing or adding one leaching additive of sulfur dioxide or hydrogen, or adding hydrazine hydrate; stirring and leaching, cooling, and filtering; adding one precipitator of sodium carbonate, potassium carbonate and ammonium carbonate, or adding composite precipitator consisting of one of the sodium carbonate, the potassium carbonate and the ammonium carbonate and one of sodium hydroxide and potassium hydroxide to obtain mixture of lithium carbonate, cobalt carbonate and cobalt hydroxide; drying and calcining at high temperature to produce a lithium cobaltate product. The method is particularly suitable for the treatment scale of medium-sized and small enterprises, and is an effective method for directly materializing cobalt secondary resources.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Hormone hydrogel rooting film

InactiveCN102599161AExtend the critical periodImprove survival rateBiocidePlant growth regulatorsSocial benefitsPolyvinyl alcohol

The invention discloses a hormone hydrogel rooting film, which is prepared by the steps of: swelling polyvinyl alcohol at normal temperature for 30min, and heating for completely dissolving polyvinyl alcohol to obtain a transparent liquid; cooling, adjusting the pH value of the solution with concentrated hydrochloric acid, adding glycerol and reacting to prepare a hydrogel liquid; and adding hormone to the hydrogel liquid and stirring. When in use, the hormone hydrogel rooting film is spread on the surface of a hard branch cutting shoot, so that a gel film is formed on the surface of the hard branch cutting shoot above the ground so as to achieve the purpose of reducing the moisture of the cutting shoot from dissipation, and a gel film is formed on the surface of the hard branch cutting shoot under the ground so as to keep a moisture state in soil and play a role of slowly releasing hormone to stimulate the rooting of the cutting shoot, thus the rooting critical stage of the hard branch cutting shoot is prolonged and the rooting survival rate of the hard branch cutting shoot is improved. The technical scheme disclosed by the invention is simple and convenient, high in raising seedling survival rate and significant in economic and social benefits, and saves seedling-raising investment by more than 10%.

Owner:濮阳市林业科学院

Oil based compositions and method for temporarily sealing subterranean zones

InactiveUS6887833B2High viscosityLow viscosityOther chemical processesFlushingOrganoclayHydrochloric acid

The present invention provides oil based compositions and methods of using the compositions for temporarily sealing subterranean zones. The compositions are basically comprised of oil, a hydratable polymer, an organophilic clay, a water-swellable clay, and an acid soluble material such as calcium carbonate. These compositions will form a viscous gel when contacted with water. The gelled mass may then be dissolved with an acidic fluid, such as 15% hydrochloric acid.

Owner:HALLIBURTON ENERGY SERVICES INC

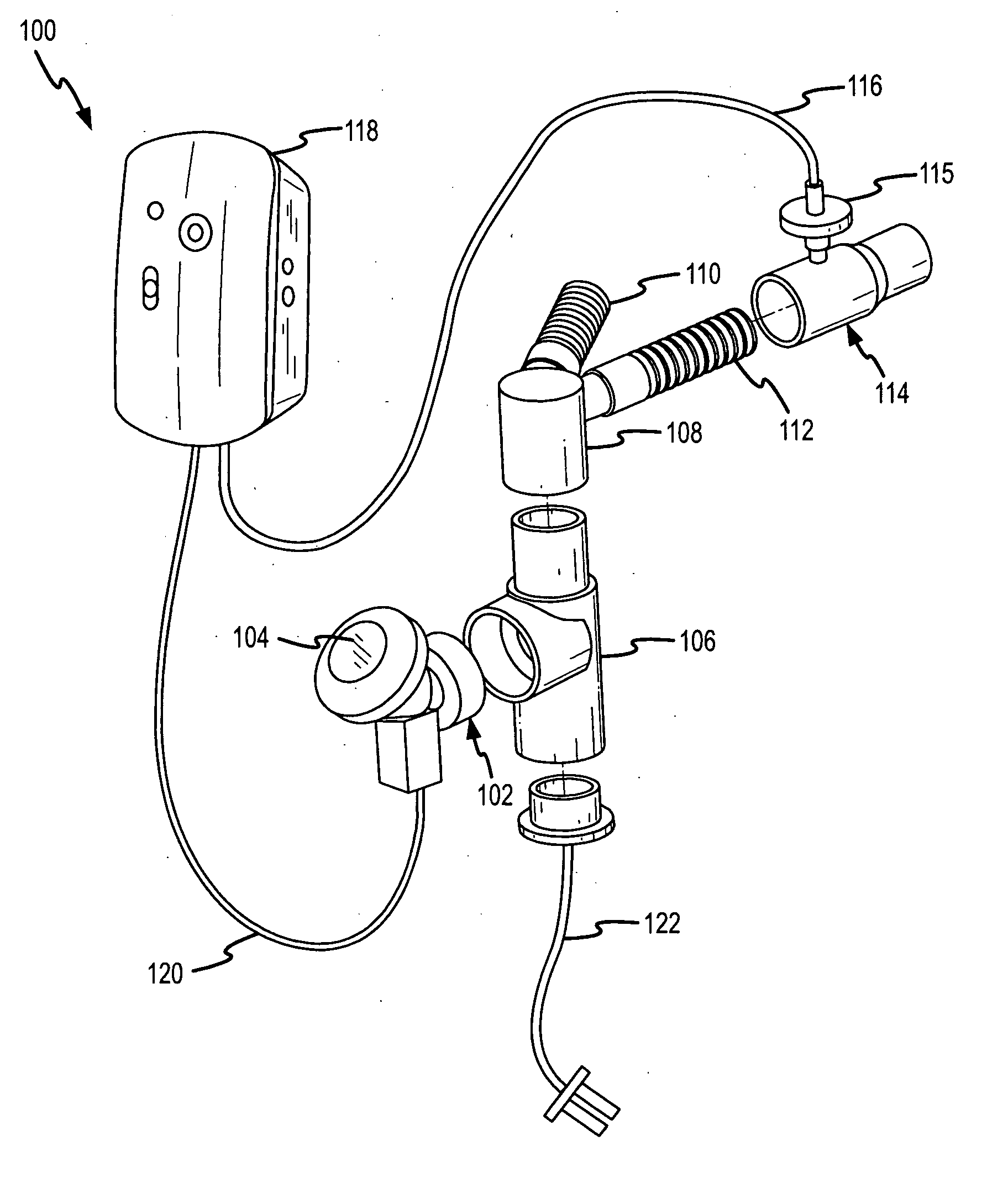

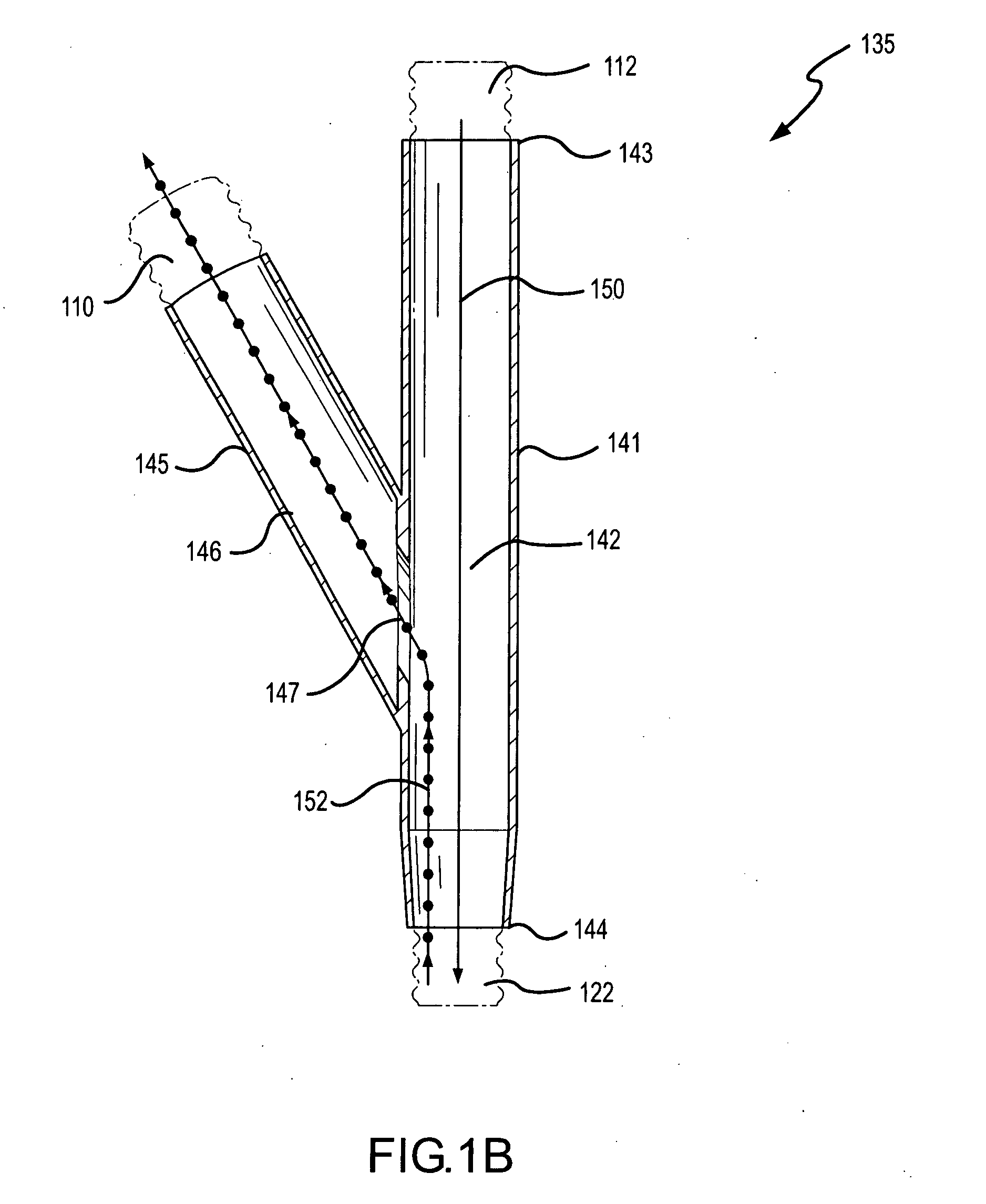

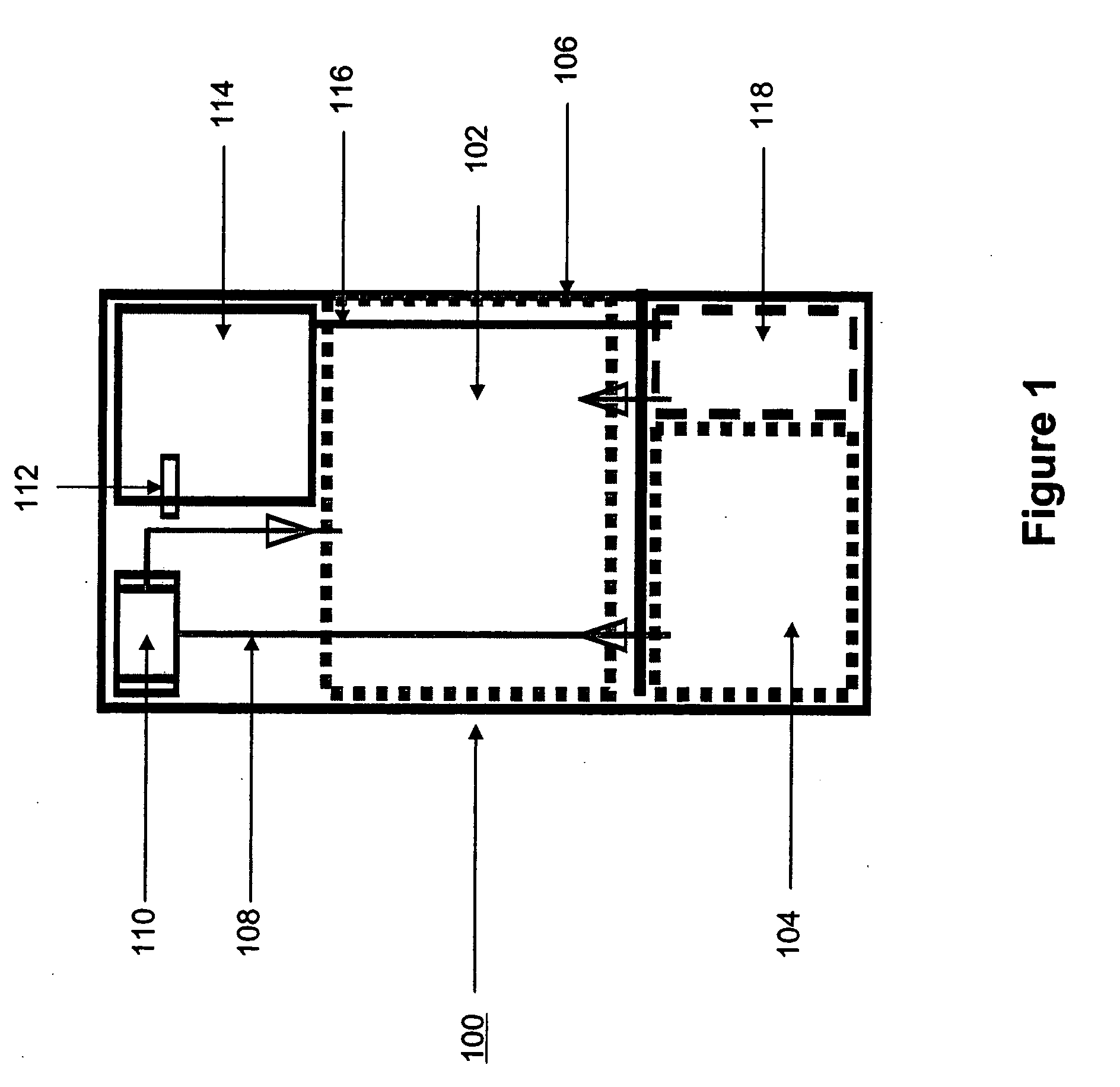

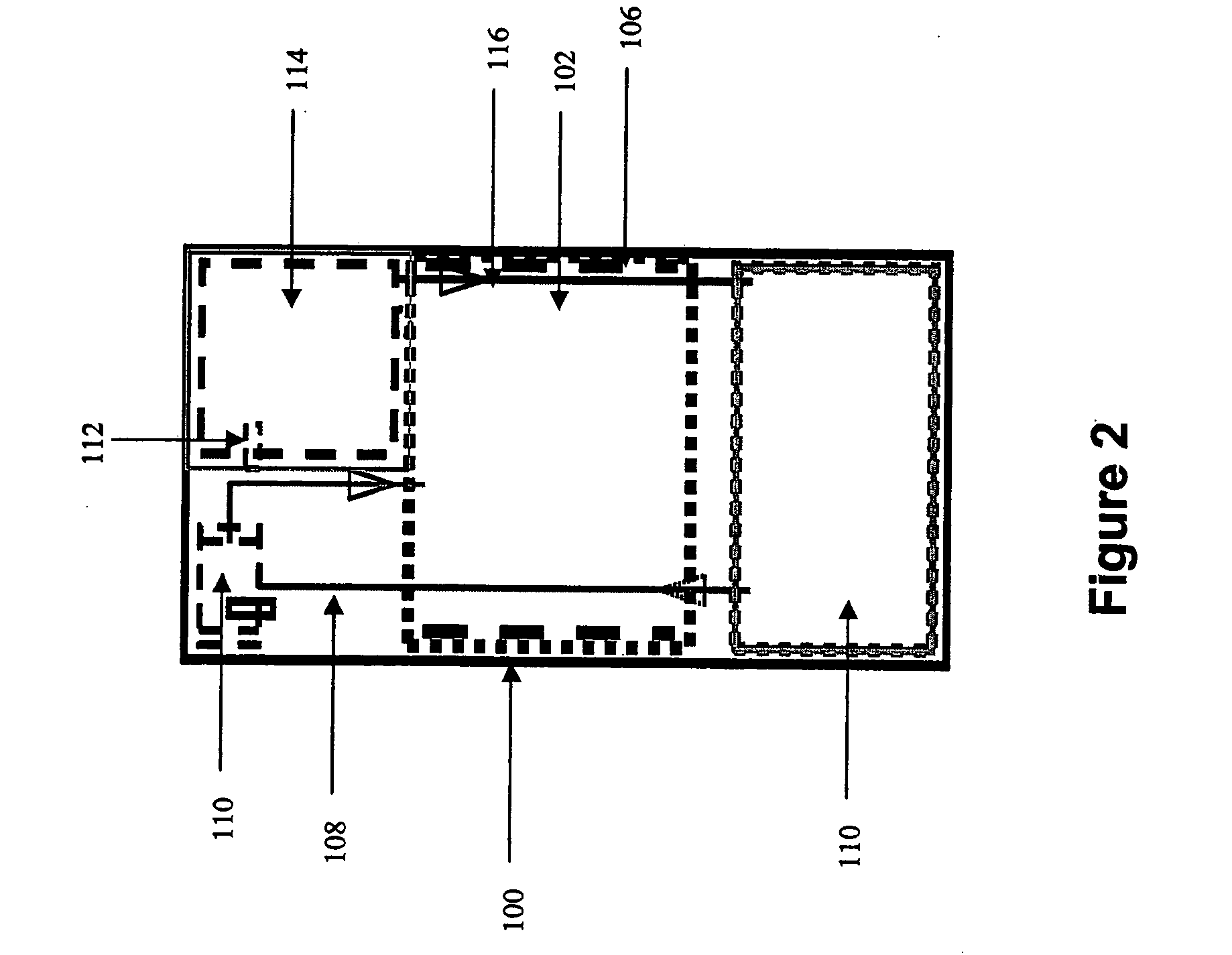

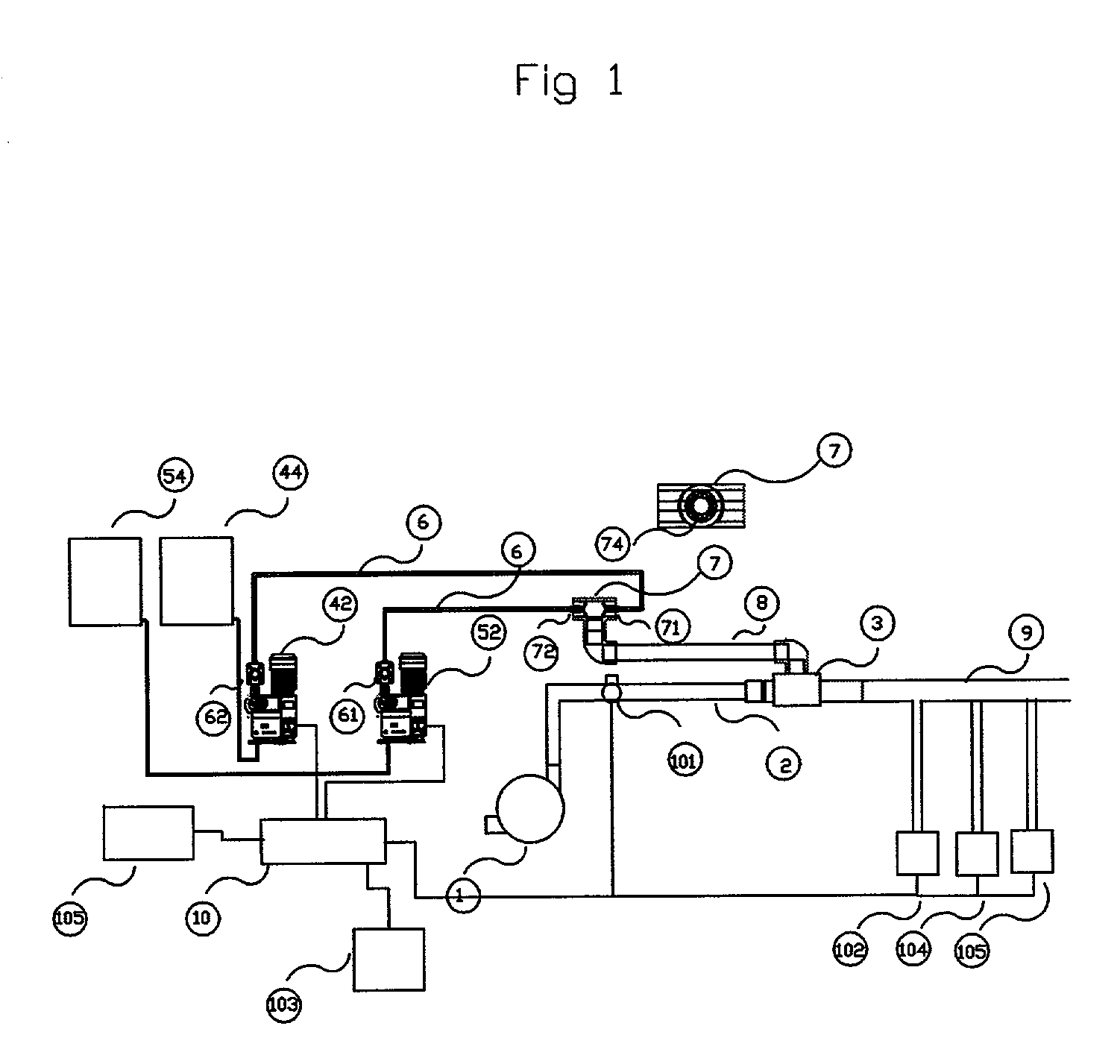

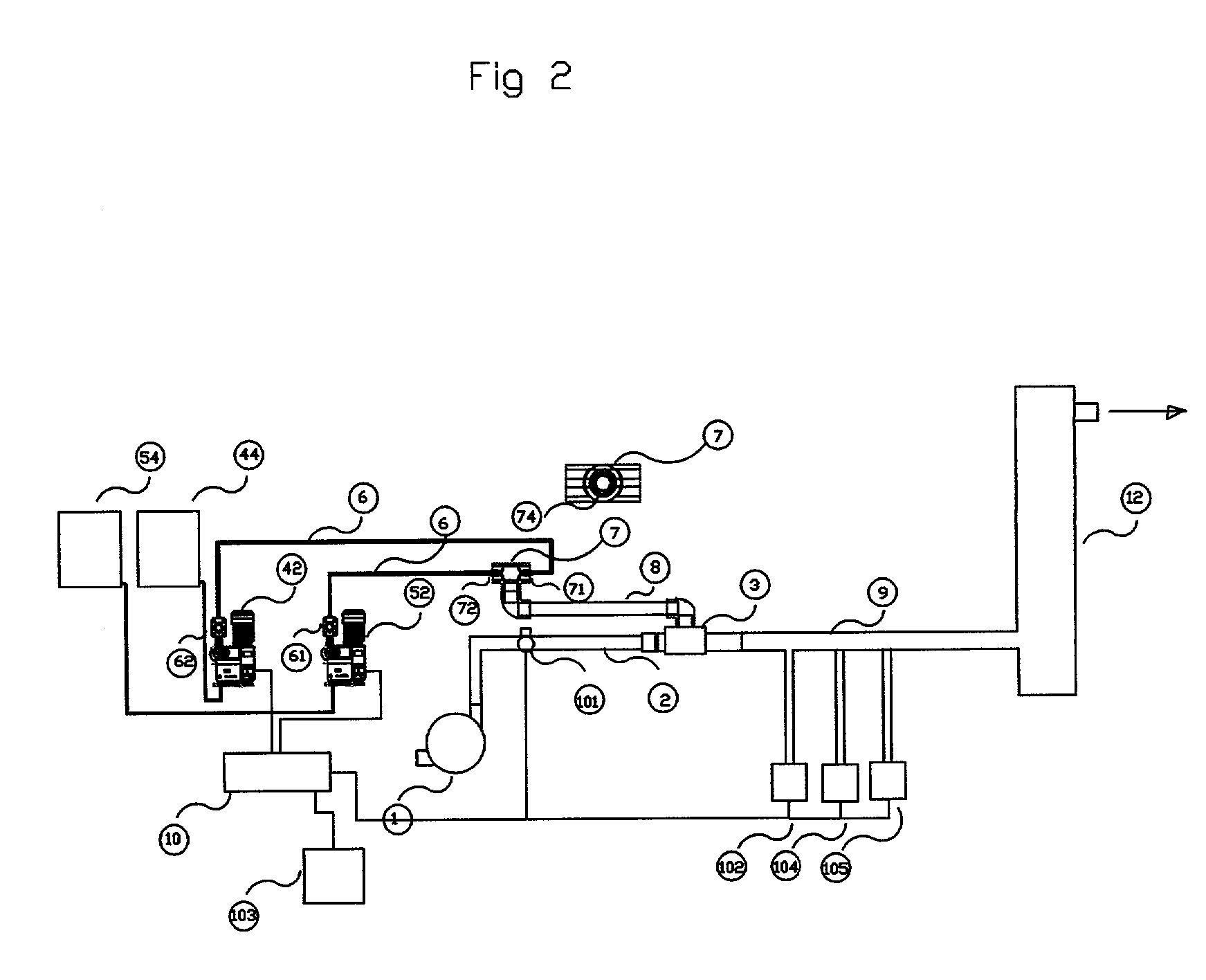

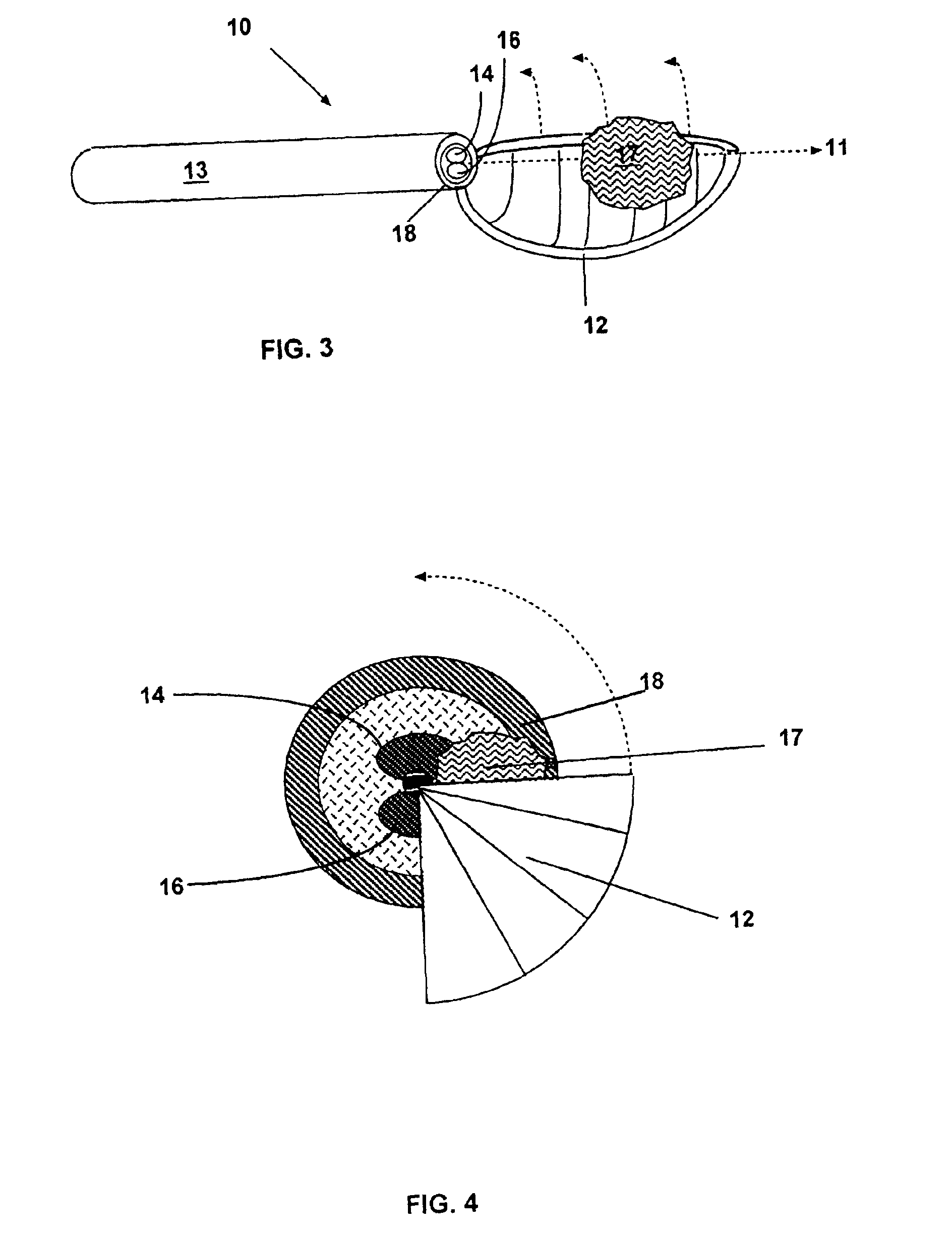

Systems and methods for hydrogen generation from solid hydrides

InactiveUS20050238573A1Regulate rateReactant parameters controlHydrogen productionO-Phosphoric AcidAlkaline earth metal

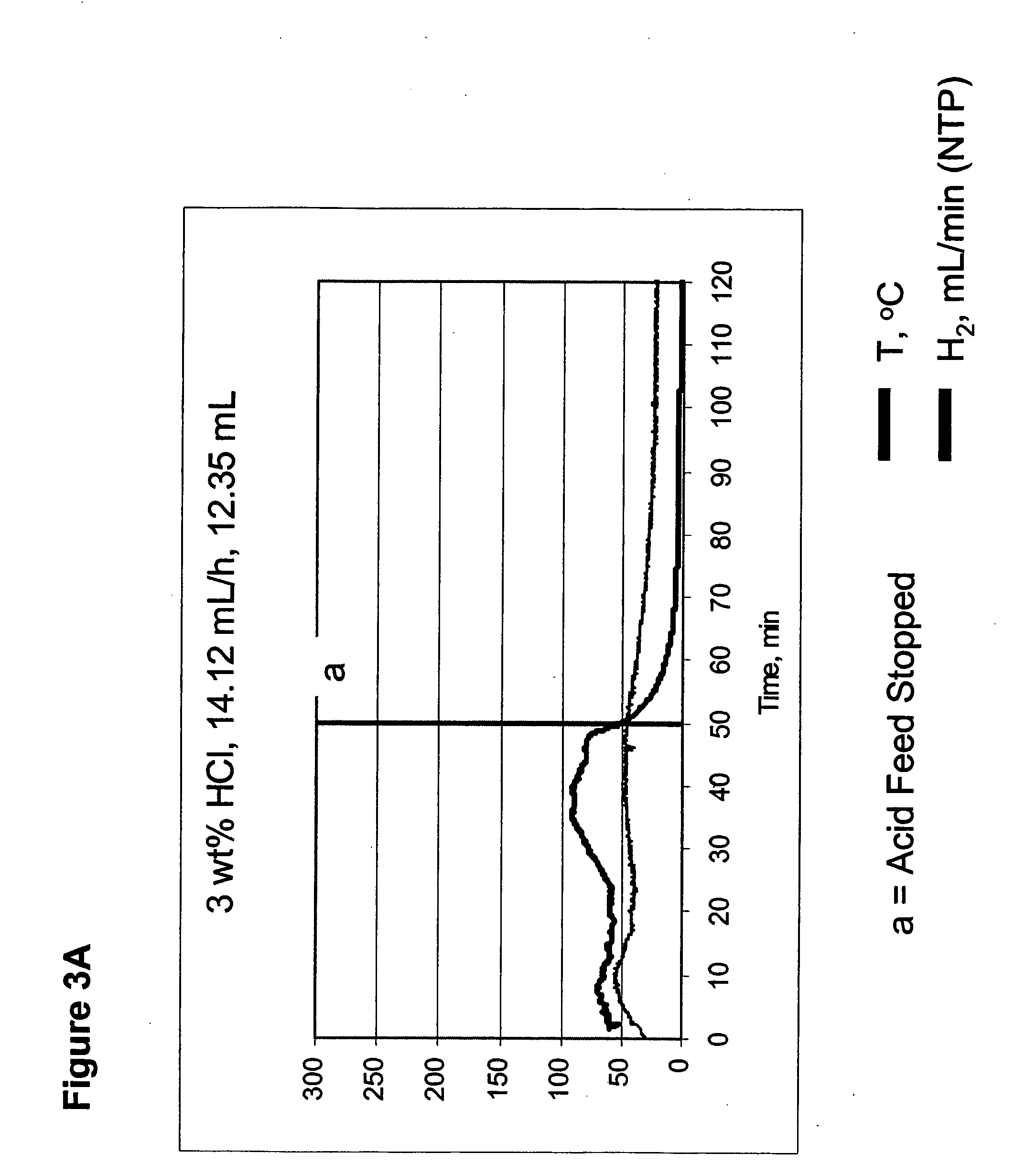

A system is disclosed for hydrogen generation based on hydrolysis of solid chemical hydrides with the capability of controlled startup and stop characteristics wherein regulation of acid concentration, acid feed rate, or a combination of both control the rate of hydrogen generation. The system comprises a first chamber for storing a solid chemical hydride and a second chamber for storing an acidic reagent. The solid chemical hydride is a solid metal borohydride having the general formula MBH4, where M is selected from the group consisting of alkali metal cations, alkaline earth metal cations, aluminum cation, zinc cation, and ammonium cation. The acidic reagent may comprise inorganic acids such as the mineral acids hydrochloric acid, sulfuric acid, and phosphoric acid, and organic acids such as acetic acid, formic acid, maleic acid, citric acid, and tartaric acid, or mixtures thereof.

Owner:MILLENNIUM CELL

Oxide etching method

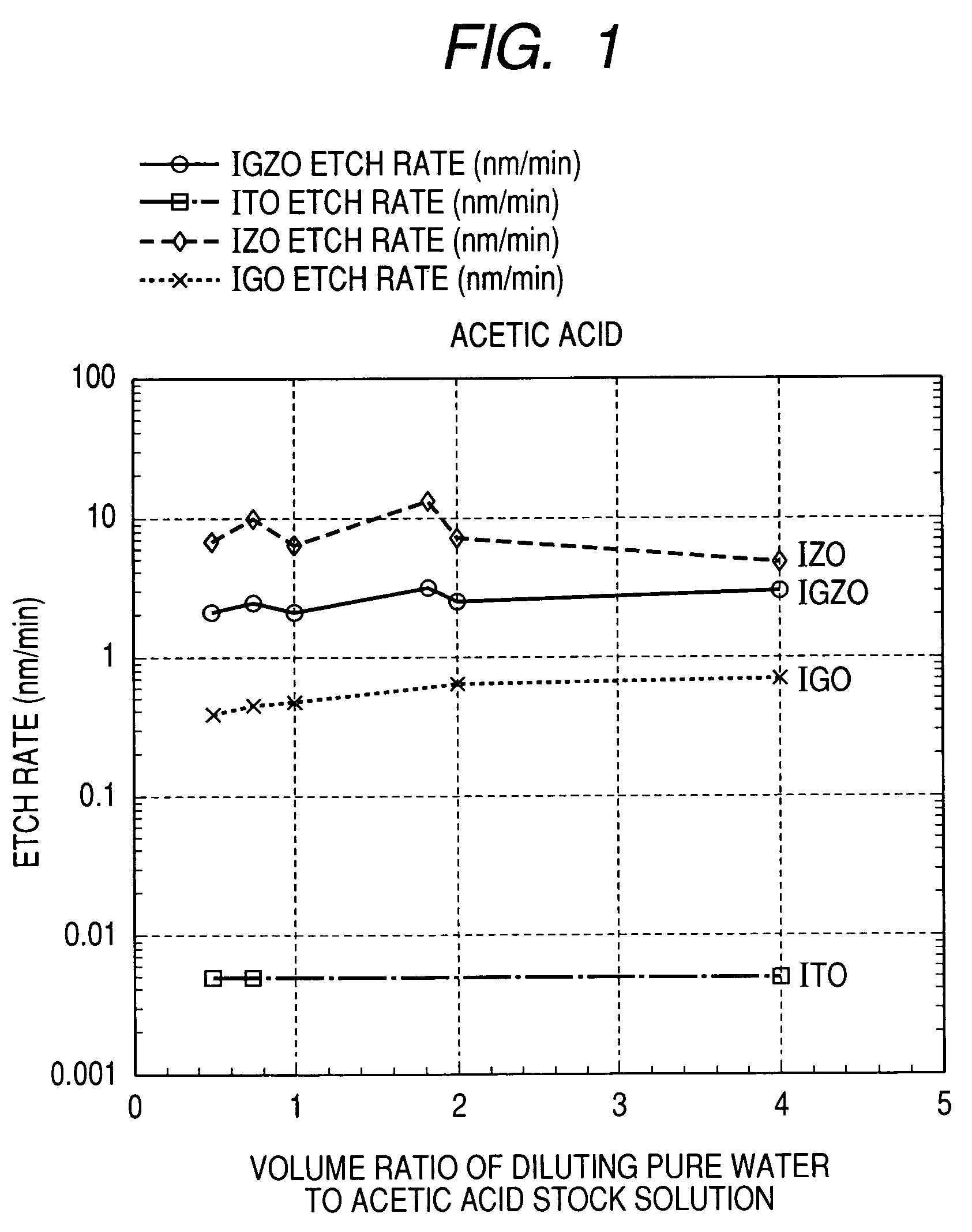

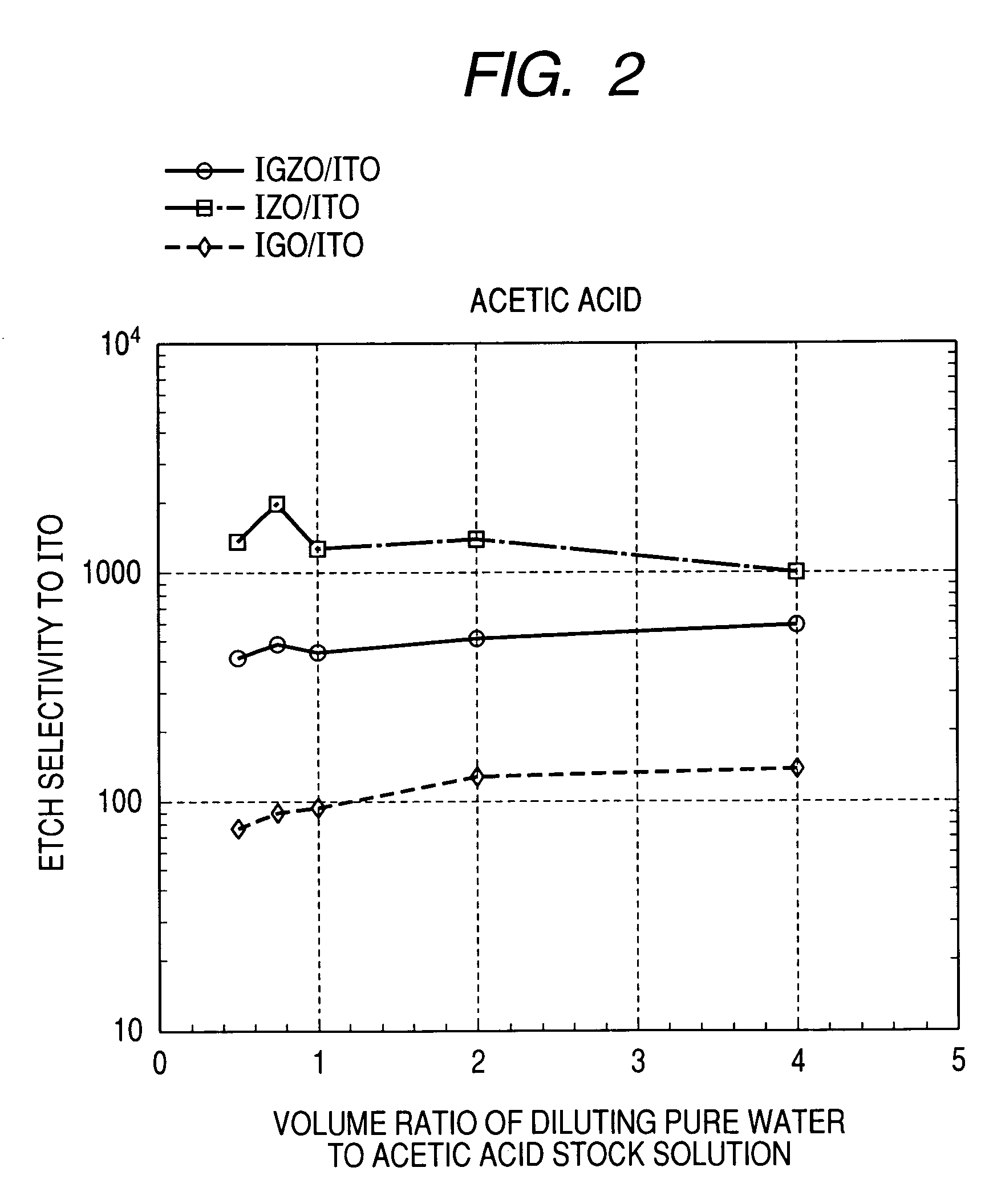

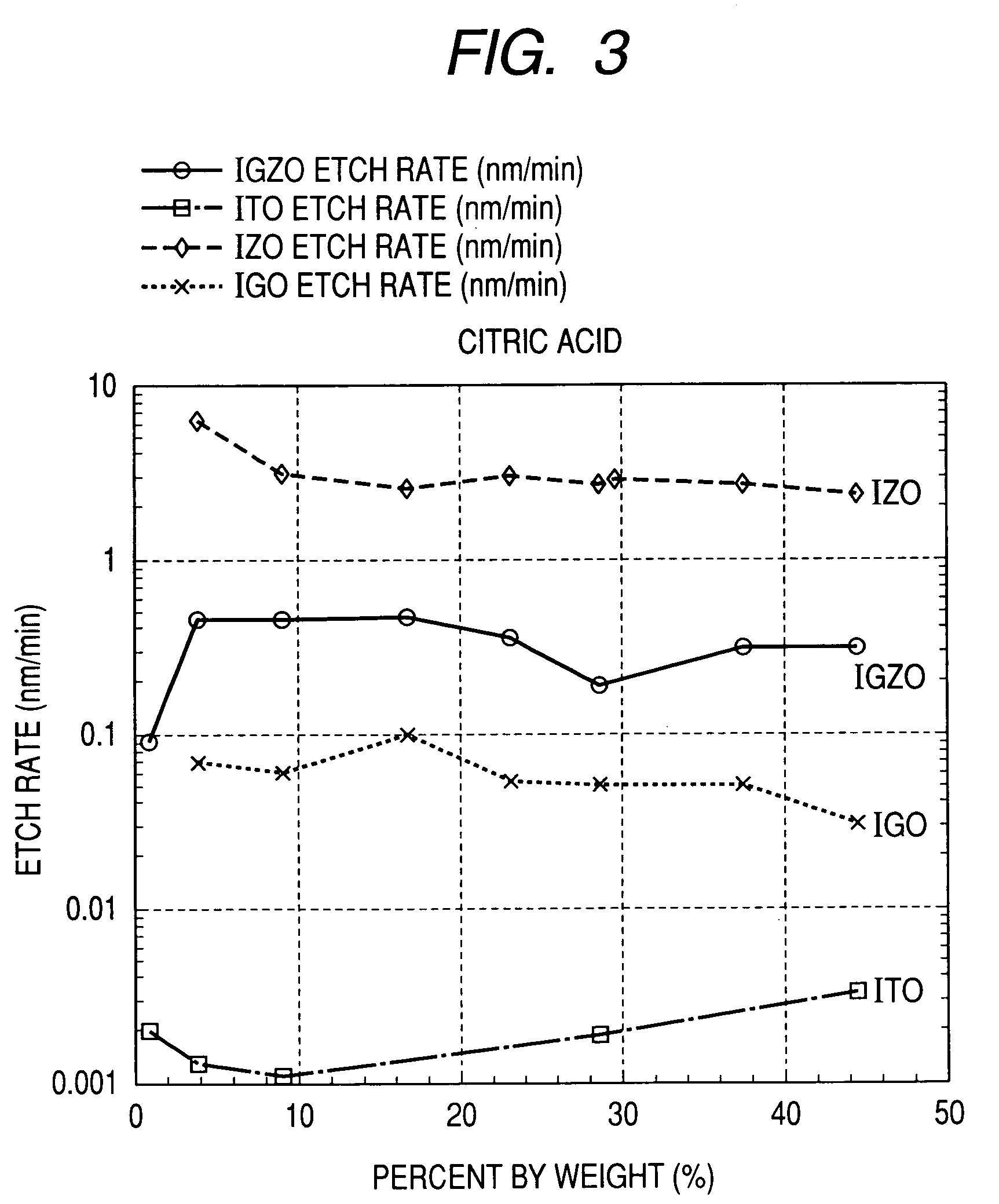

InactiveUS8168544B2Precise and easy etchingPrecise and highly selective wet etchingDecorative surface effectsFinal product manufactureAcetic acidEtching

There is provided an etching method of an amorphous oxide layer containing In and at least one of Ga and Zn, which includes etching the amorphous oxide layer using an etchant containing any one of acetic acid, citric acid, hydrochloric acid, and perchloric acid.

Owner:CANON KK

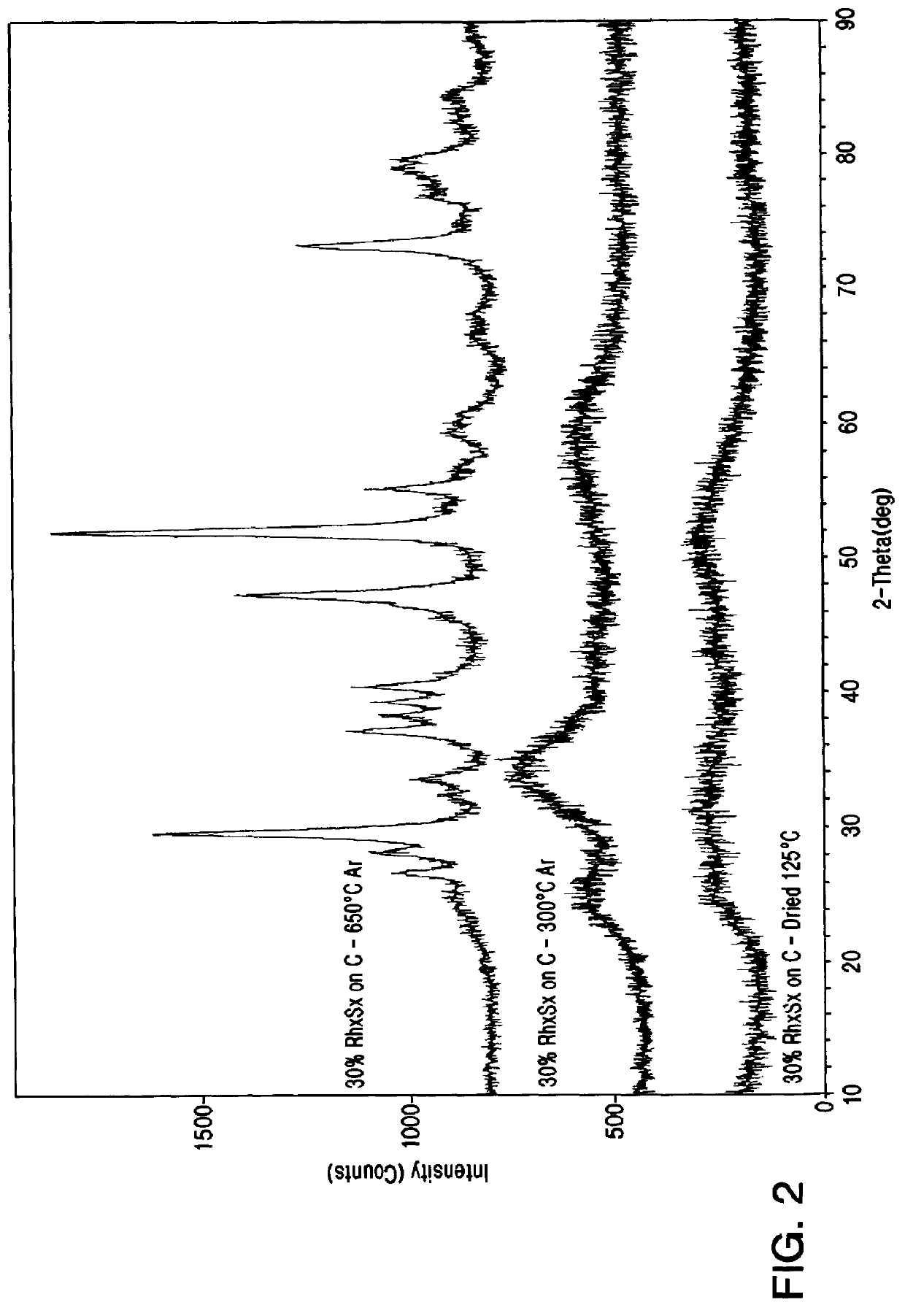

Rhodium electrocatalyst and method of preparation

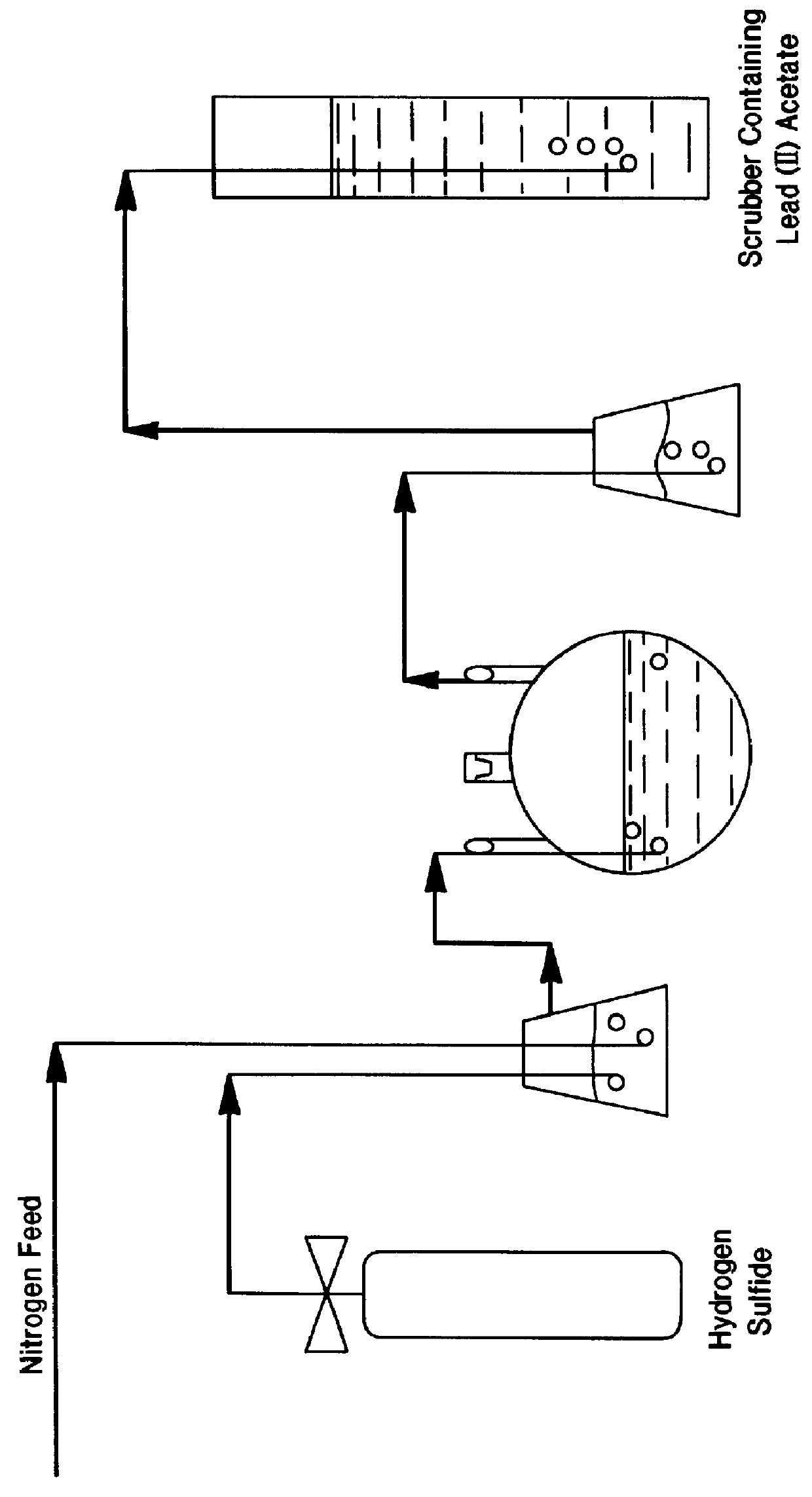

The invention relates to a novel rhodium sulfide catalyst for the reduction of oxygen in industrial electrolyzers. The catalyst is highly resistant towards corrosion and poisoning by organic species, thus resulting particularly suitable for use in aqueous hydrochloric acid electrolysis, when technical grade acid containing organic contaminants is employed.

Owner:DE NORA SPA

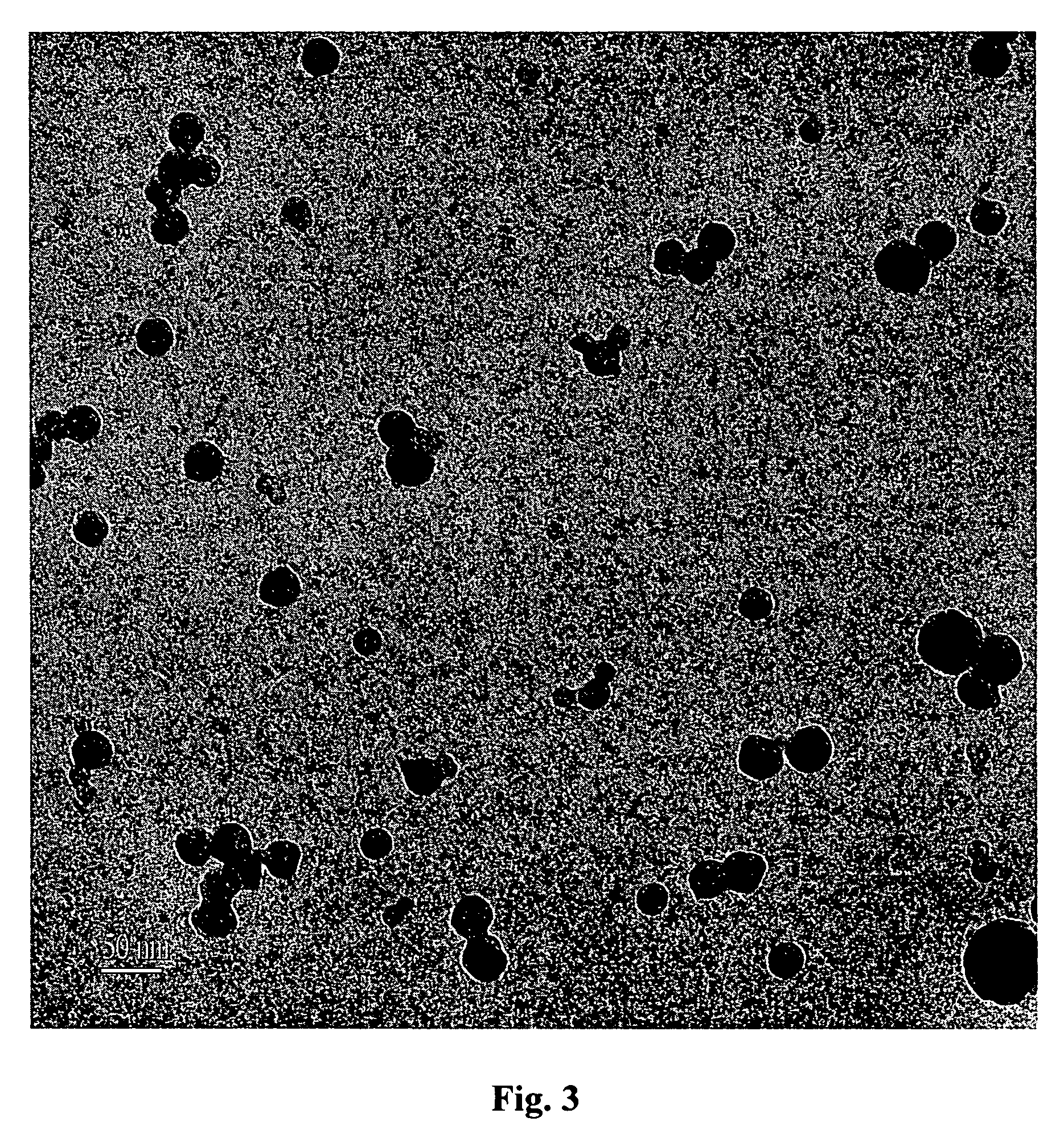

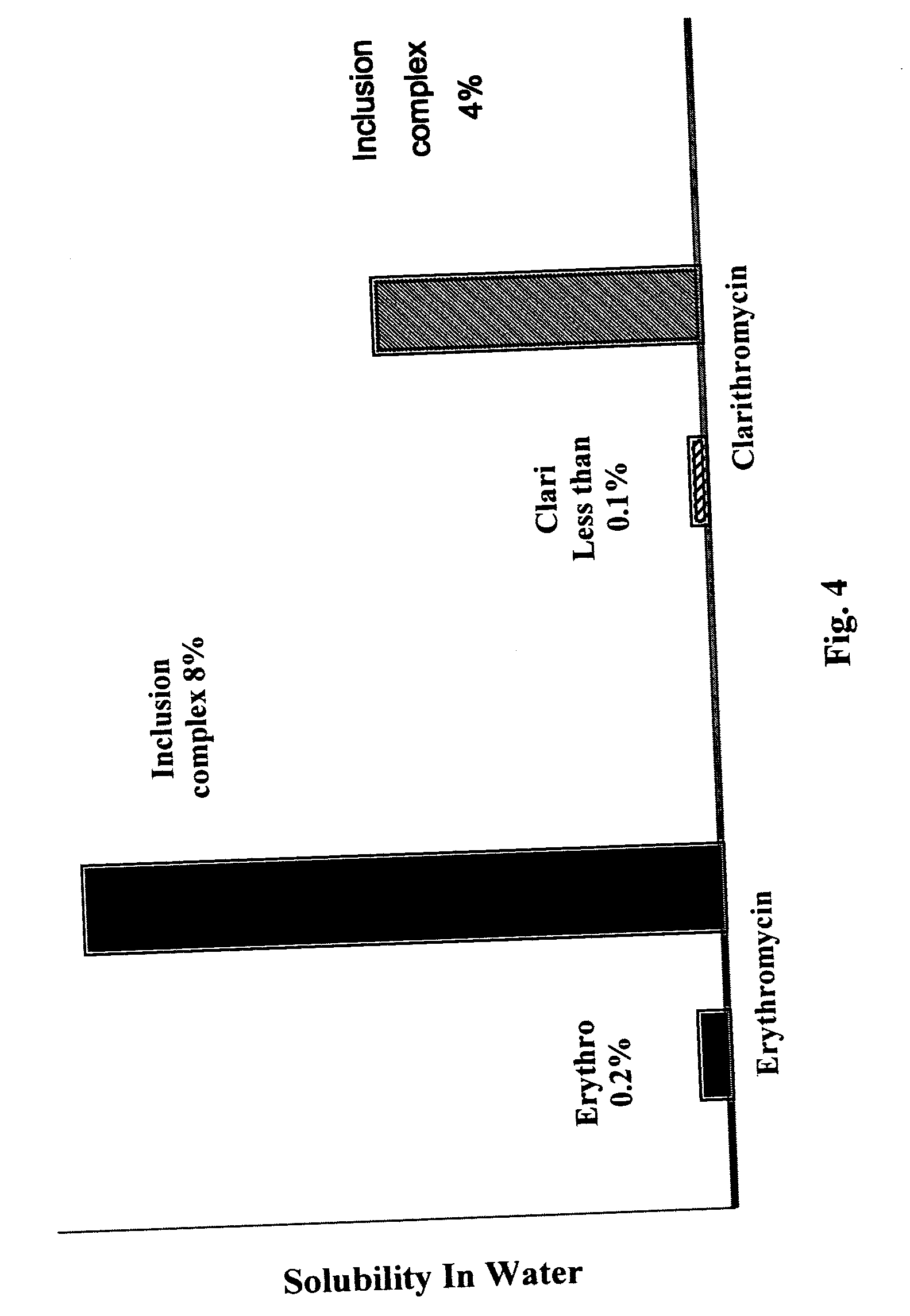

Water soluble nanoparticles and method for their production

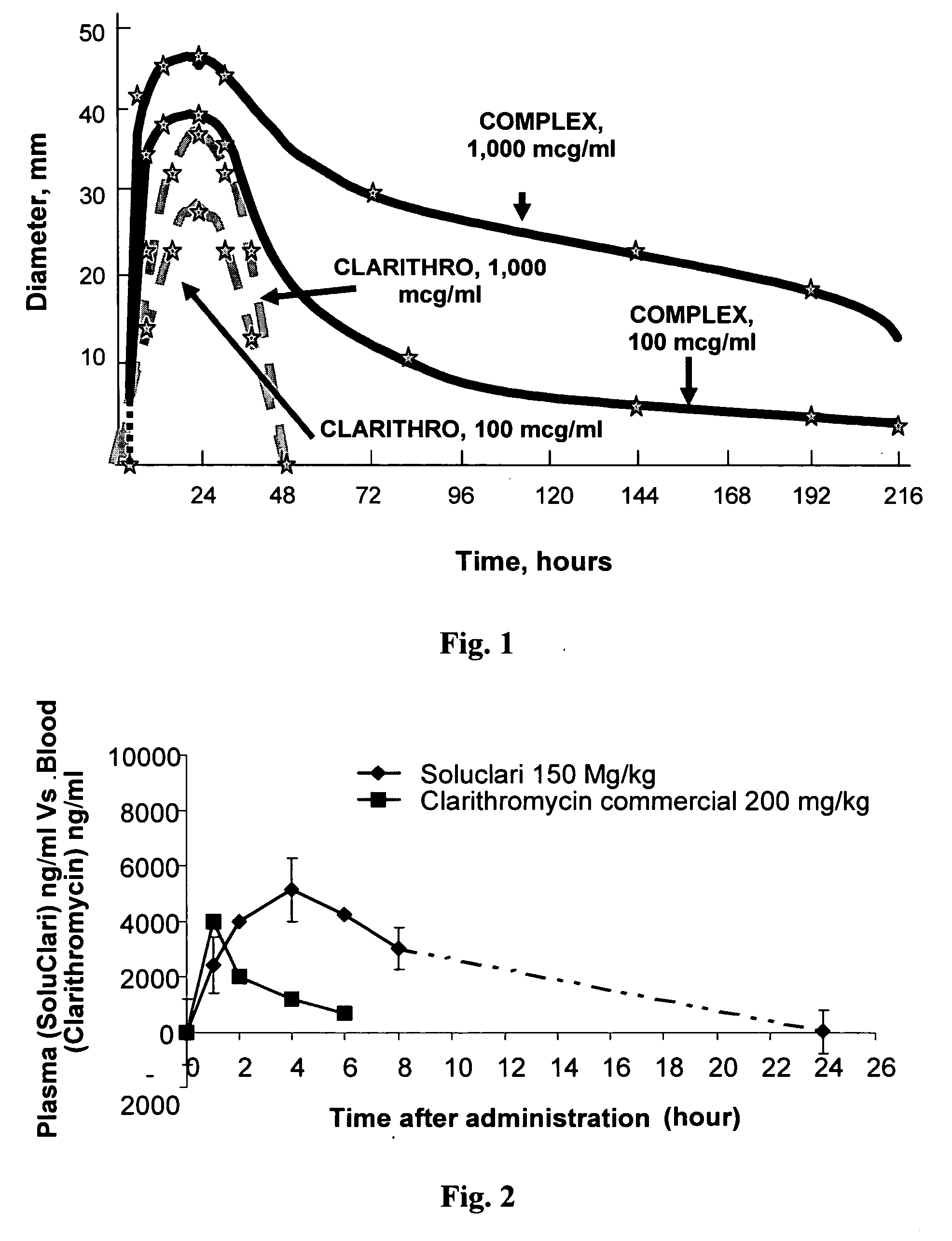

InactiveUS20050191359A1Readily bioavailableLow costPowder deliveryBiocidePolymer scienceNanoparticle

Hydrophilic dispersions of stable nano-sized particles are provided comprising: (a) a water-insoluble or water-soluble active compound, wherein said active compound is selected from the group consisting of a macrolide antibiotic, donepezil hydrochloride, an azole compound and a taxane; and (b) an amphiphilic polymer which wraps said active compound in a non-crystalline manner to form a nano-sized molecular entity in which no valent bonds are formed.

Owner:SOLUBEST

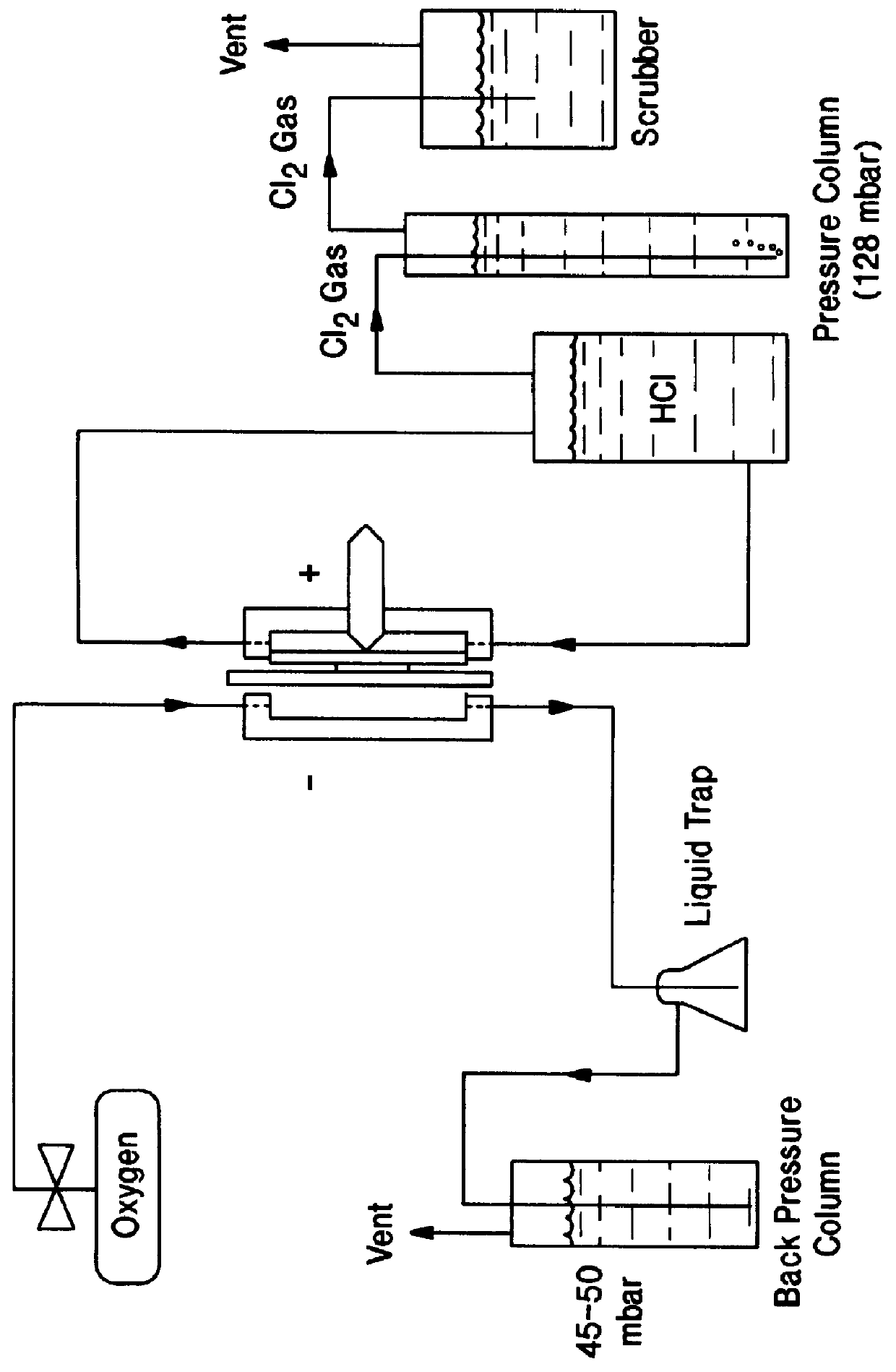

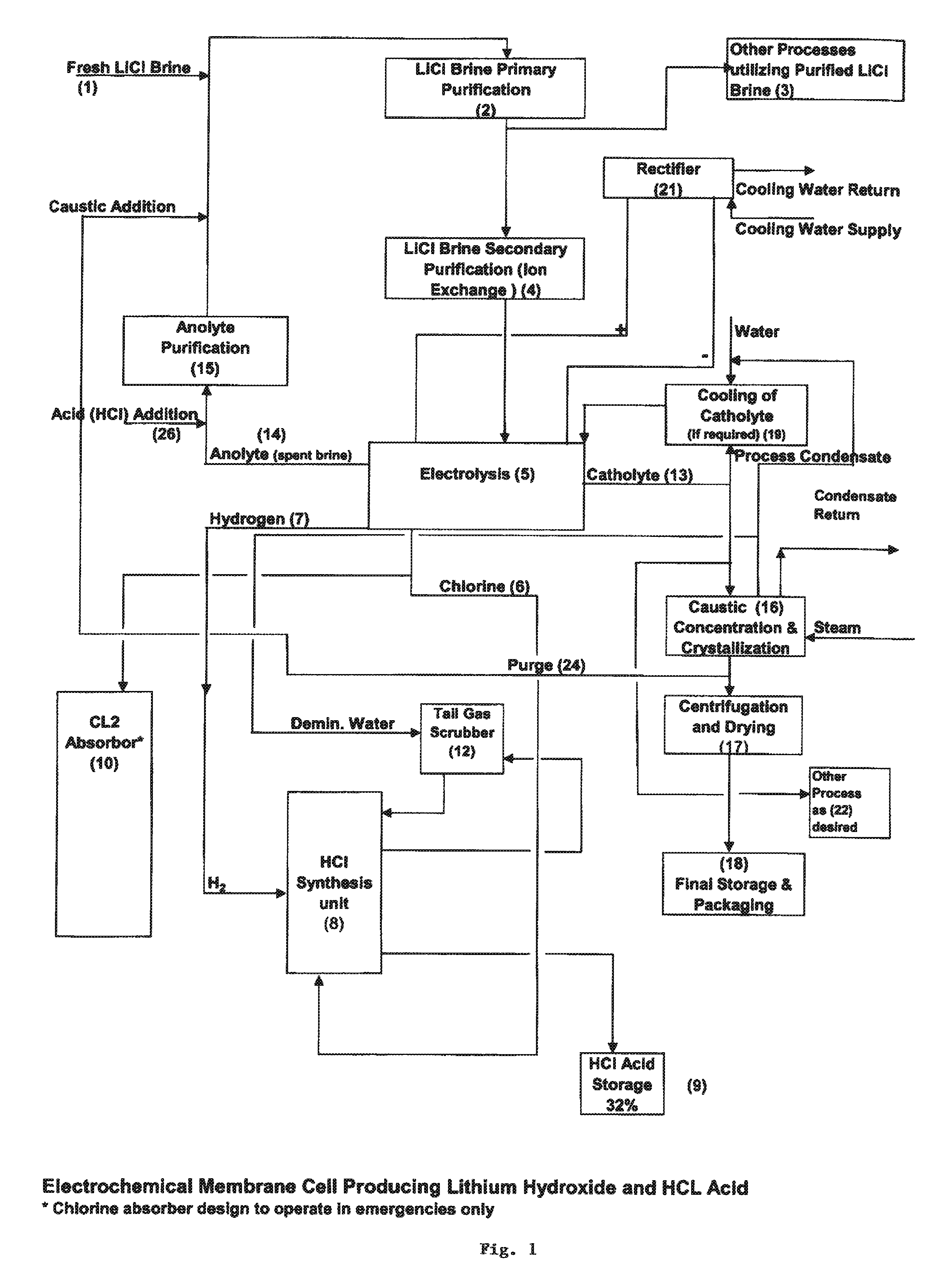

Method of making high purity lithium hydroxide and hydrochloric acid

InactiveUS20110044882A1Simple and economical processEasy to convertElectrolysis componentsEnergy inputElectrolysisIon exchange

The present invention relates to a process for producing high purity lithium hydroxide monohydrate, comprising following steps: concentrating a lithium containing brine; purifying the brine to remove or to reduce the concentrations of ions other than lithium; adjusting the pH of the brine to about 10.5 to 11 to further remove cations other than lithium, if necessary; neutralizing the brine with acid; purifying the brine to reduce the total concentration of calcium and magnesium to less than 150 ppb via ion exchange; electrolyzing the brine to generate a lithium hydroxide solution containing less than 150 ppb total calcium and magnesium, with chlorine and hydrogen gas as byproducts; producing hydrochloric acid via combustion of the chlorine gas with excess hydrogen and subsequent scrubbing of the resultant gas stream with purified water, if elected to do so; and concentrating and crystallizing the lithium hydroxide solution to produce lithium hydroxide monohydrate crystals.

Owner:ROCKWOOD LITHIUM INC

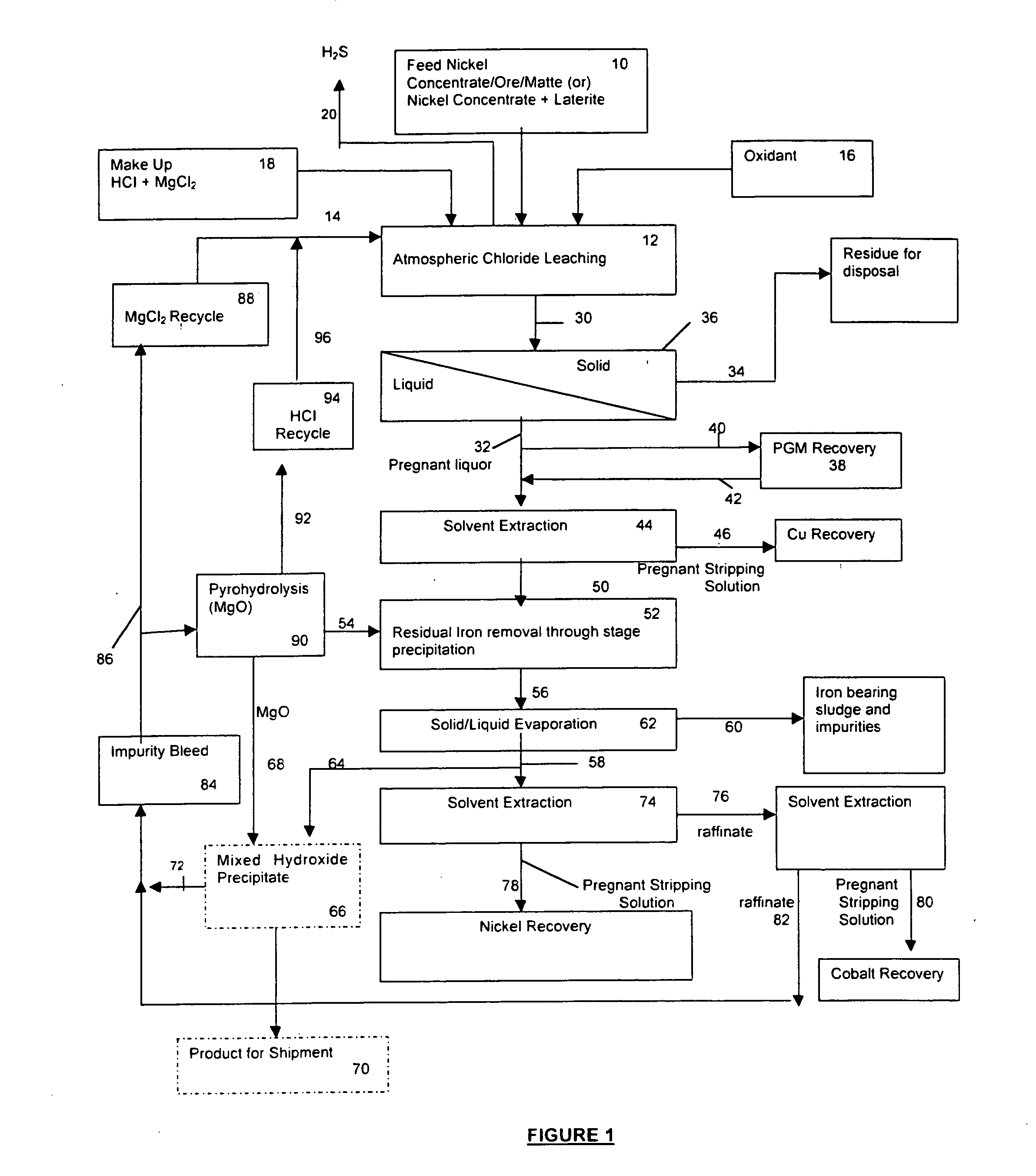

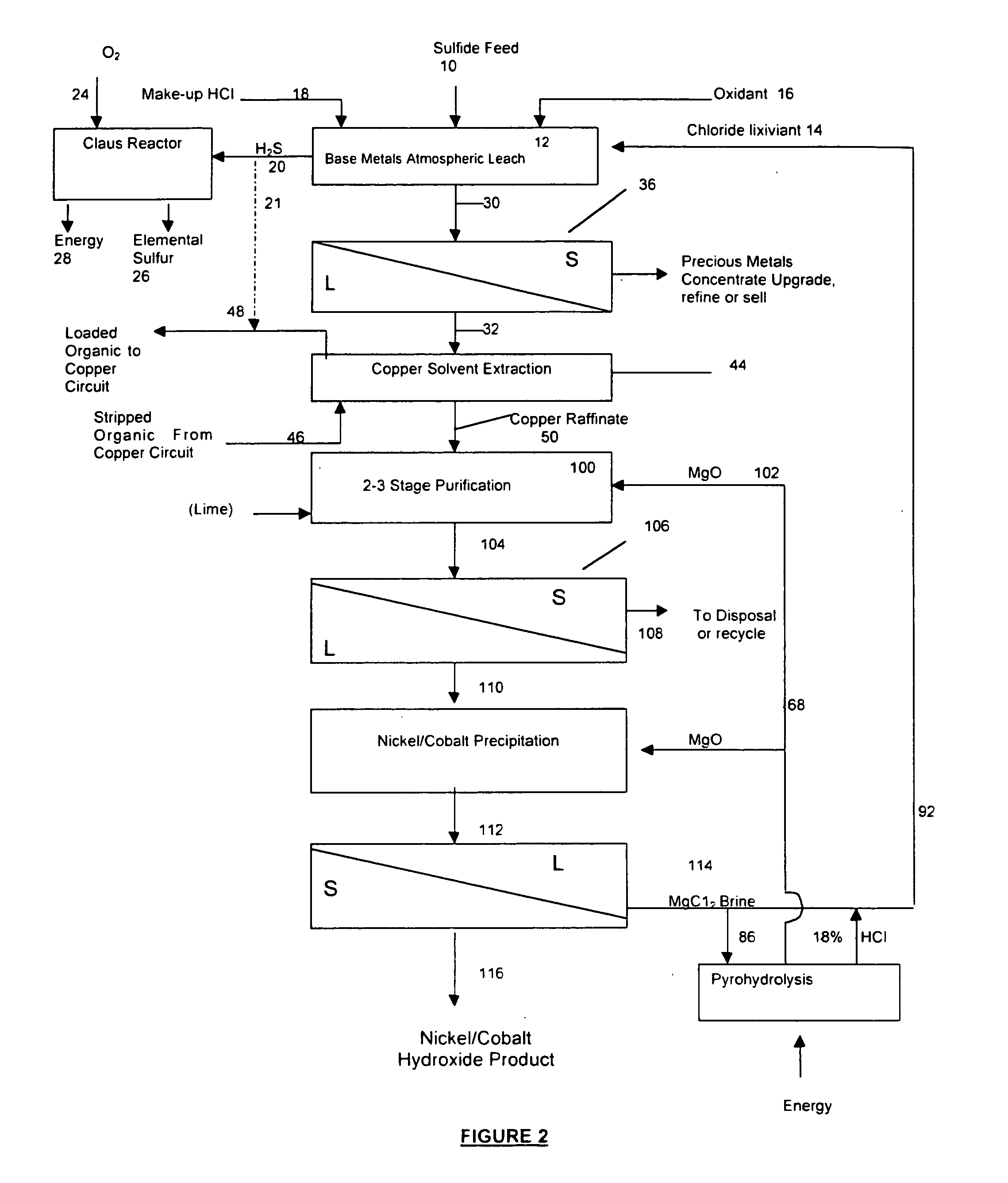

Process for the recovery of value metals from base metal sulfide ores

InactiveUS20050118081A1Simple gas/liquidReduce the amount requiredSulfur compoundsSolid sorbent liquid separationSulfideDissolution

A process for leaching a value metal from a base metal sulfide ore, comprising the step of leaching the ore with a lixiviant comprising a chloride, an oxidant and hydrochloric acid is disclosed. The leaching is controlled, by use of low concentrations of hydrochloric acid and a redox potential, to effect formation of hydrogen sulfide from the base metal sulfide ore. The hydrogen sulfide is stripped from the leach solution, thereby reducing the amount of sulfate generated in the leach to very low levels. The leaching may also be conducted to limit the co-dissolution of platinum group metals and gold with the base value metals. The leach forms a value metal-rich leachate and a solids residue. The solids residue may be subsequently leached to recover the platinum group metals and gold. The value metal-rich leachate can be is oxidized and neutralized to recover the value base metals. In an embodiment, the chloride is magnesium chloride and lixiviant solution is regenerated.

Owner:JAGUAR NICKEL INC

Low-temperature smoke denitration SCR (silicon controlled rectifier) catalyst and preparation method

ActiveCN102114424ARich pore structureLarge specific surface areaDispersed particle separationCatalyst activation/preparationSilicon-controlled rectifierManganese oxide

The invention relates to a low-temperature smoke denitration SCR (silicon controlled rectifier) catalyst, which comprises a carrier, a manganese oxide, and composite oxide of one or more of Ce, Zr, Ti, Co, Fe and Cu, the mass content of manganese is 0.1-66 percent, and the total mass content of the Ce, Zr, Ti, Co, Fe or / and Cu is 0-50 percent; and glass fiber and / or kieselguhr is used as the carrier, wherein the glass fiber of the carrier is calcined for 2-4 hours at temperature of 400-600 DEG C, then placed in a nitric acid, sulfuric acid or hydrochloric acid solution with mass concentration of 5-40 percent for acidizing for 1-8 hours, washed by distilled water to be neutered, dried at temperature of 80-120 DEG C, and crushed to have the fineness of 20-325 meshes. The catalyst uses the glass fiber and the kieselguhr as the carriers, so that the dispersion effect of nanoparticles and specific surface area of the catalyst are increased, the high adsorptive capacity and strong heat resistance and corrosion resistance capacity are achieved, stronger toxic resistance capacity to sulfur dioxide and stream contained in the smoke is realized, the invention can be used for 10-200 DEG C of low temperature smoke denitration, and has strong water resisting and sulphur toxic resisting capacities.

Owner:GUODIAN SCI & TECH RES INST +1

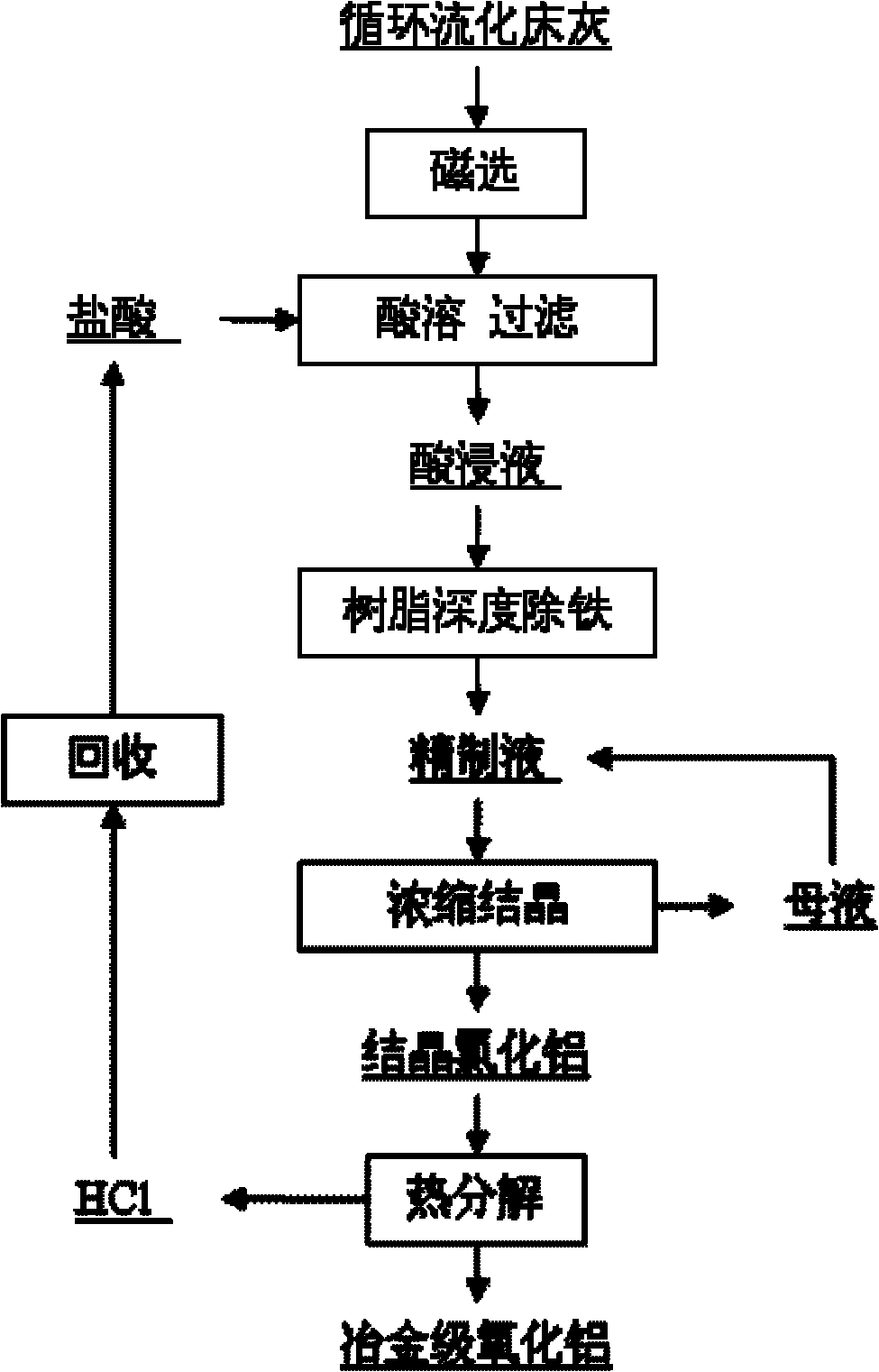

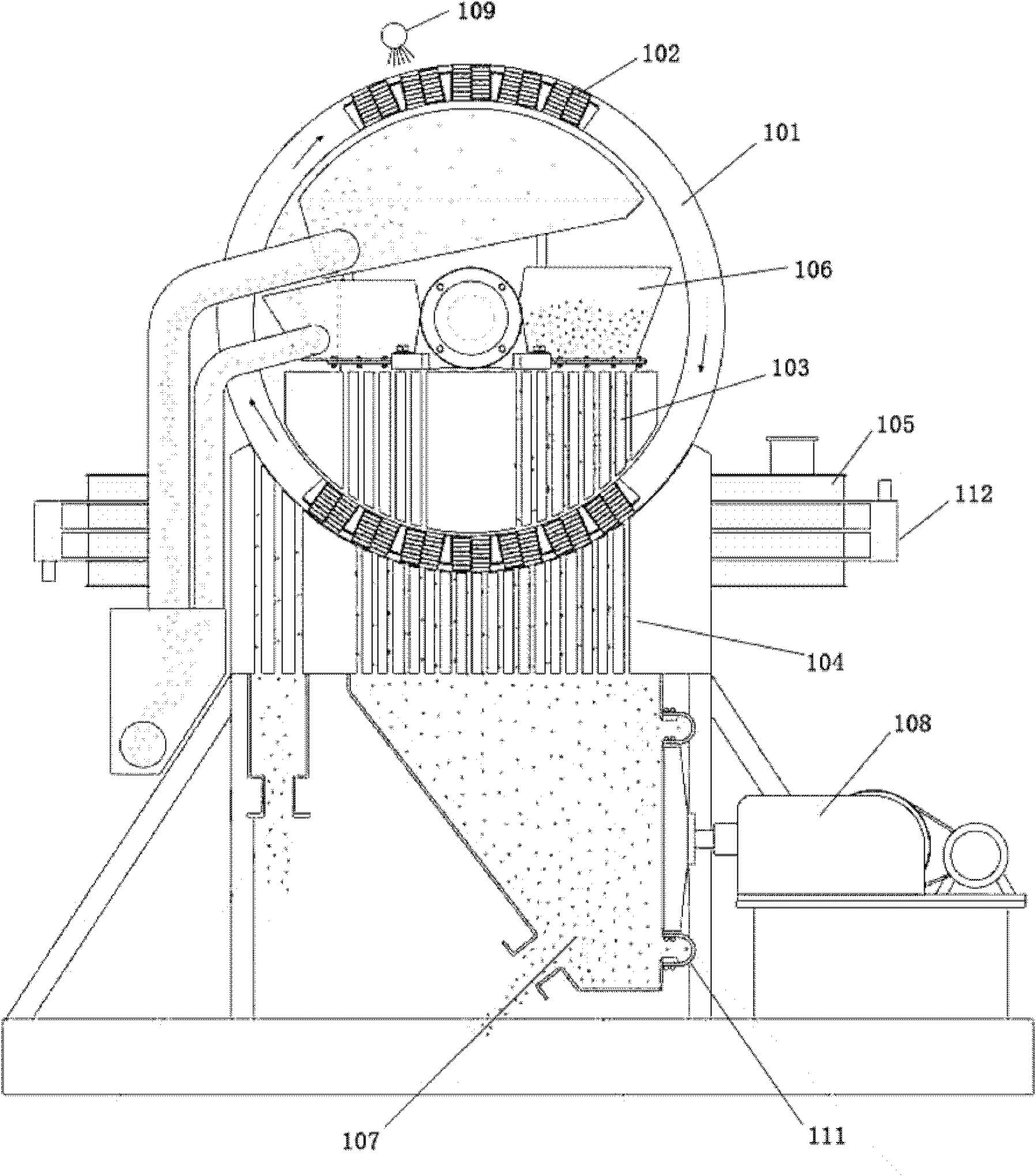

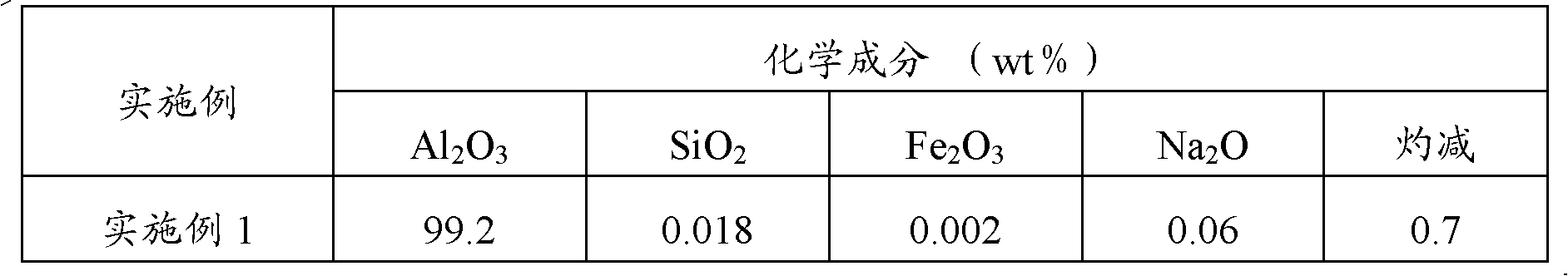

Method for preparing metallurgy-level aluminum oxide by using fluidized bed pulverized fuel ash

ActiveCN102145905AHigh extraction rateReduce manufacturing costSolid waste disposalTransportation and packagingAluminium chloridePulverized fuel ash

The invention discloses a method for preparing metallurgy-level aluminum oxide by using fluidized bed pulverized fuel ash as a raw material. The method comprises the following steps of: a) grinding the pulverized fuel ash, and removing iron by a wet magnetic separation method; b) reacting the pulverized fuel ash subjected to magnetic separation with hydrochloric acid to obtain hydrochloric acid immersion liquid; c) allowing the hydrochloric acid immersion liquid to pass through a large pore type cation resin column for further iron removal to obtain refined aluminum chloride solution; d) concentrating the refined aluminum chloride solution, and crystallizing to obtain an aluminum chloride crystal; and e) calcining the aluminum chloride crystal and decomposing to obtain the metallurgy-level aluminum oxide. The method has a simple process and an easily-controlled production process, and is high in aluminum oxide extraction efficiency, low in production cost and stable in product quality.

Owner:CHINA SHENHUA ENERGY CO LTD

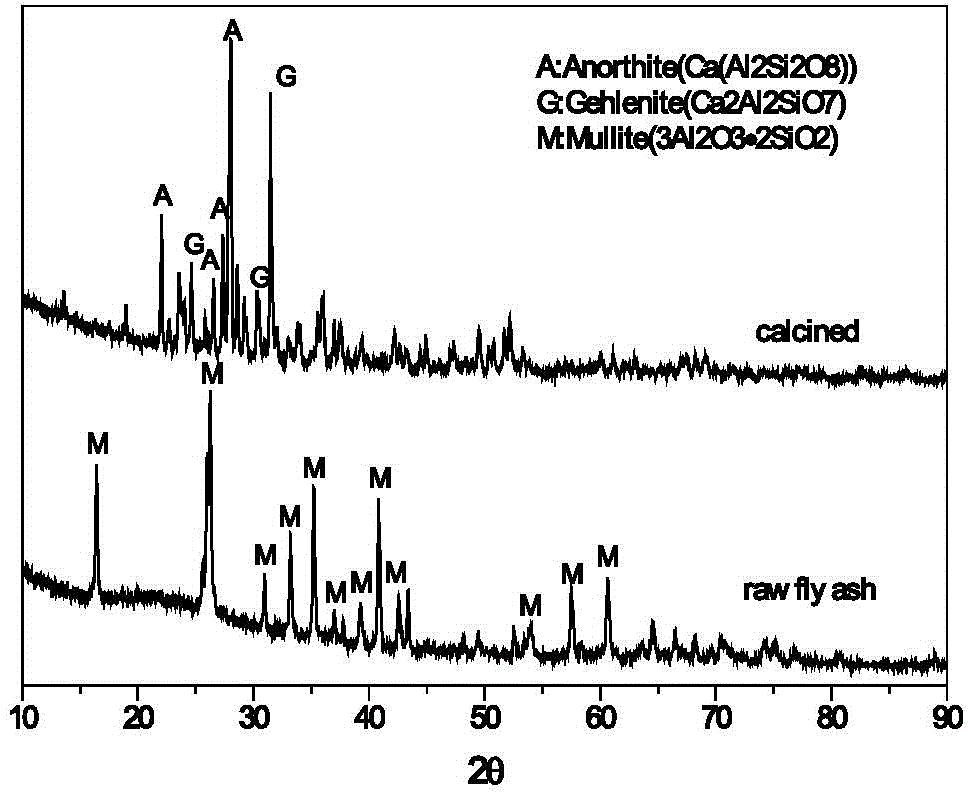

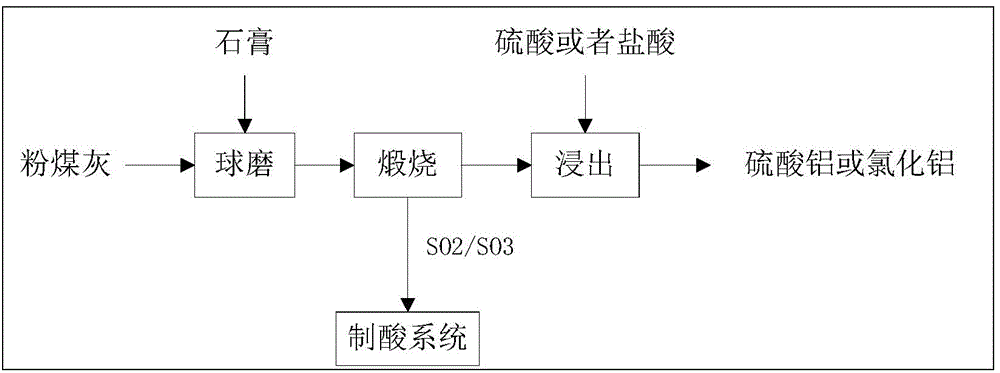

Method for cooperative activation of fly ash and decomposition of gypsum for recovery of sulfur resource

The invention provides a method for cooperative activation of fly ash and decomposition of gypsum for recovery of a sulfur resource. According to the method, solid waste, i.e., fly ash, discharged by a coal-fired power plant or coal-fired boiler is used as a raw material, a certain proportion of desulfurized gypsum discharged by the coal-fired power plant or waste phosphogypsum produced in the phosphorus chemical industry is added and mixed with the fly ash, then the obtained mixture is subjected to ball milling, and activation and calcination at a temperature of 950 to 1450 DEG C are carried out for 5 to 180 min; calcium sulfate in the gypsum are almost totally decomposed after calcination, and produced gas contains sulfur dioxide or sulfur trioxide which can be used as feed gas for preparation of sulfuric acid; and calcination enables solid fly ash to be activated, leaching with a sulfuric acid or hydrochloric acid solution is carried out at a temperature of 50 to 100 DEG C, and the leaching rate of alumina is greater than 80%. The method provided by the invention has the advantages that since all the raw materials are solid waste, the purpose of treating the waste by using the waste is achieved; elemental sulphur in the gypsum can be recovered; and the fly ash can be activated and activity of the fly ash can be improved, so a high alumina recovery rate at a low temperature can be realized. With the method, high-efficiency extraction of alumina in the fly ash is realized; the sulfur resource in the gypsum is recovered; shortage in industrial sulphur in the sulfuric acid industry in China is compensated; and the method has good economic benefits and wide industrial application prospects.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

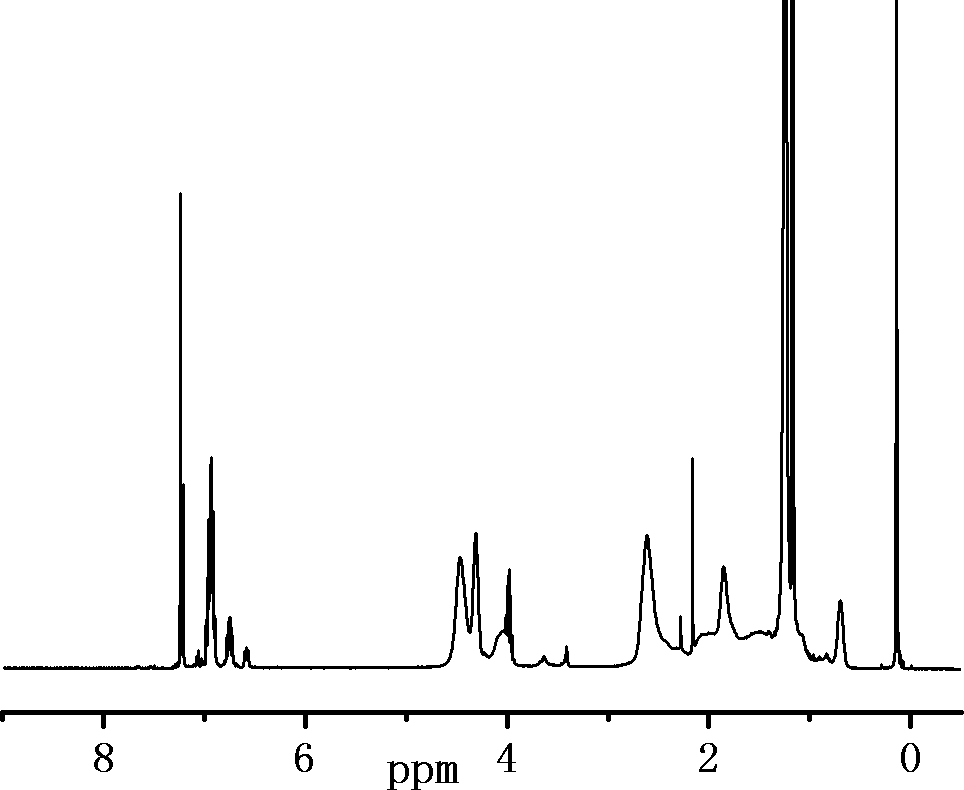

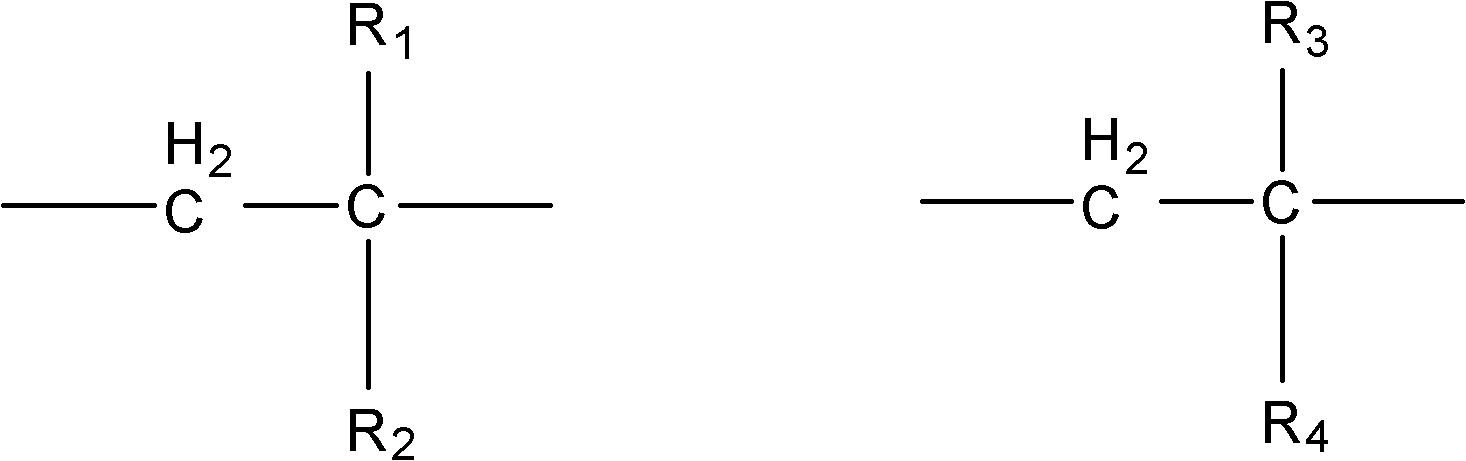

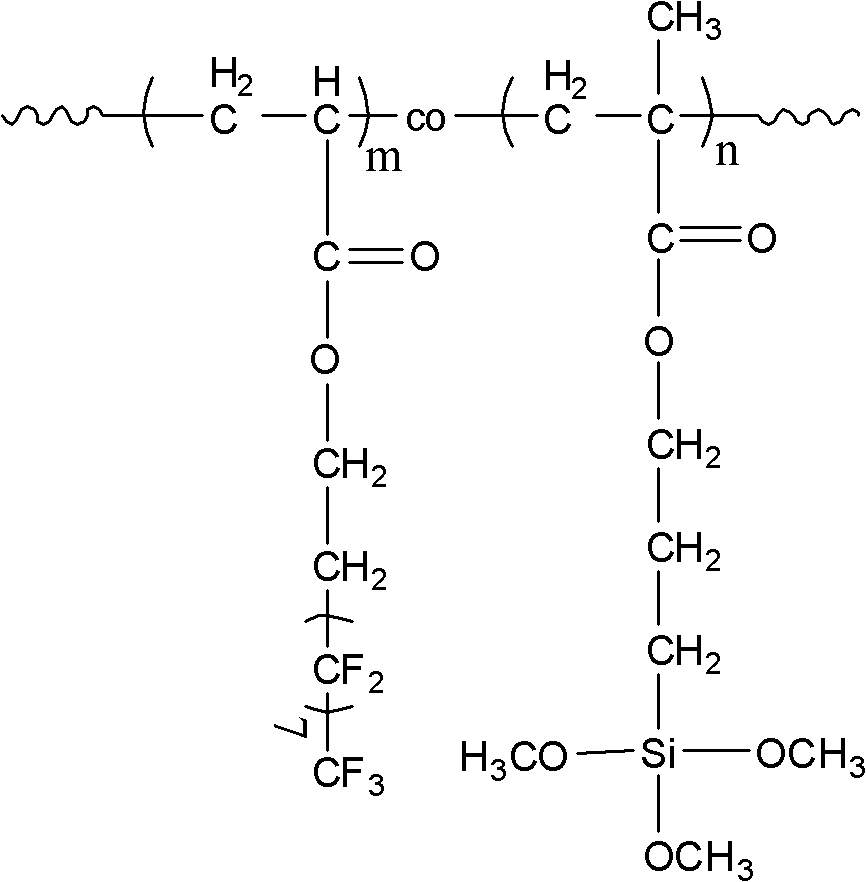

Super-amphiphobic polymer and super-amphiphobic surface prepared from super-amphiphobic polymer

InactiveCN102432742AGood scrub resistanceAccelerated corrosionWater-repelling agents additionPaper/cardboardPolymer scienceMicrosphere

The invention belongs to the field of macromolecule super-amphiphobic materials and discloses a super-amphiphobic polymer and a super-amphiphobic surface. The super-amphiphobic polymer is a random copolymer composed of structural units shown as a formula I and a formula II. The super-amphiphobic surface is obtained by comprising the following steps of: pre-processing a substrate material; placinga micro-balloon in a fluorine-containing solvent, and ultrasonically dissolving to obtain a micro-balloon supernatant solution; adding the super-amphiphobic polymer, a hydrochloric acid tetrahydrofuran solution and water into the micro-balloon solution while stirring, placing the substrate material, and reacting for 5-24 h; and taking out the substrate material, washing by using the fluorine-containing solvent, methanol and water in turn, drying in vacuum, and obtaining the super-amphiphobic surface. The super-amphiphobic polymer disclosed by the invention can give good surface hydrophobic ability and oleophobic ability to the substrate. Because the polymer has the characteristics of the fluorine-containing polymer so that the polymer can be chemically bonded with the surface of the substrate, the obtained super-amphiphobic surface has good scrubbing resistant property and corrosion resistant property.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

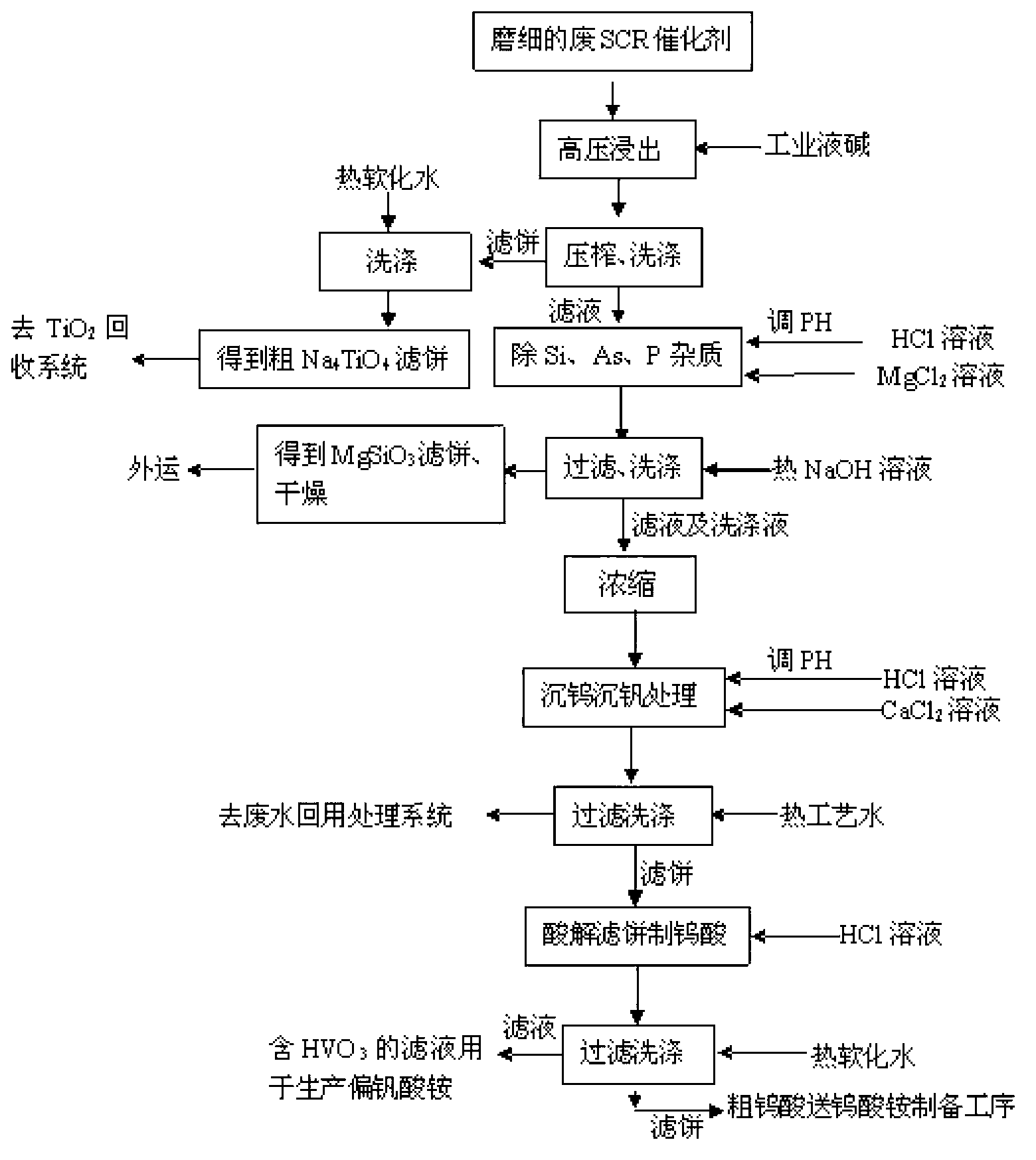

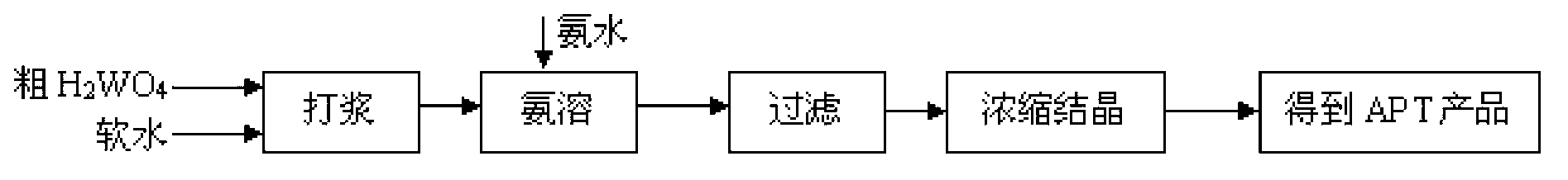

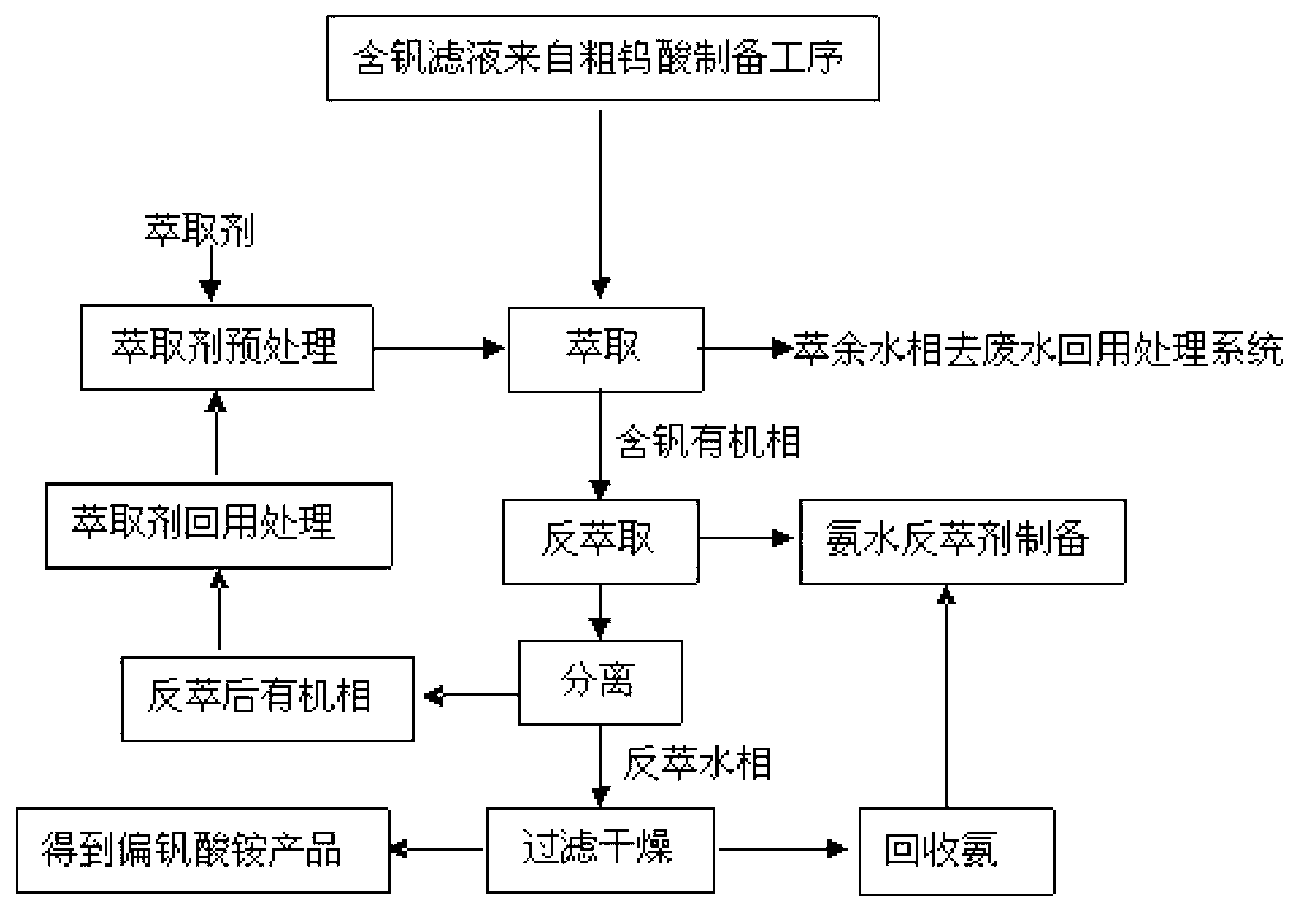

Recovery process of honeycomb type selective catalytic reduction (SCR) waste catalyst containing tungsten, vanadium and titanium

InactiveCN102936039AHigh purityHigh recovery rateTitanium dioxideVanadium compoundsHigh concentrationAmmonium paratungstate

The invention discloses recovery process of honeycomb type selective catalytic reduction (SCR) waste catalyst. The process includes the following steps: a, preprocessing the SCR waste catalyst and leaching at the high temperature and under high pressure; b, adding hydrochloric acid into leaching liquid, adjusting pH, and removing impurities; c, adding hydrochloric acid into the leaching liquid, reacting, calcining and preparing rutile titanium dioxide; d, preparing ammonium paratungstate; e, preparing ammonium metavanadate; and f, recycling and treating waste water. Main products of ammonium paratungstate, ammonium metavanadate and rutile titanium dioxide obtained in the process are high in purity and recovery rate. By-products of silicon magnesium slags, salty mud, high-concentration sodium chloride liquid and barium sulfate dregs are high-purity harmless useful goods. The process is free of harmful secondary pollutant emission, environment-friendly and capable of circulating, has high economical and social benefit and is practicable.

Owner:曾瑞

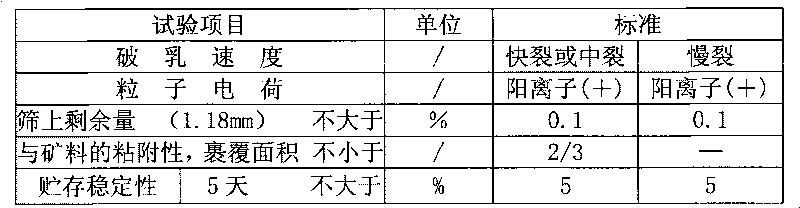

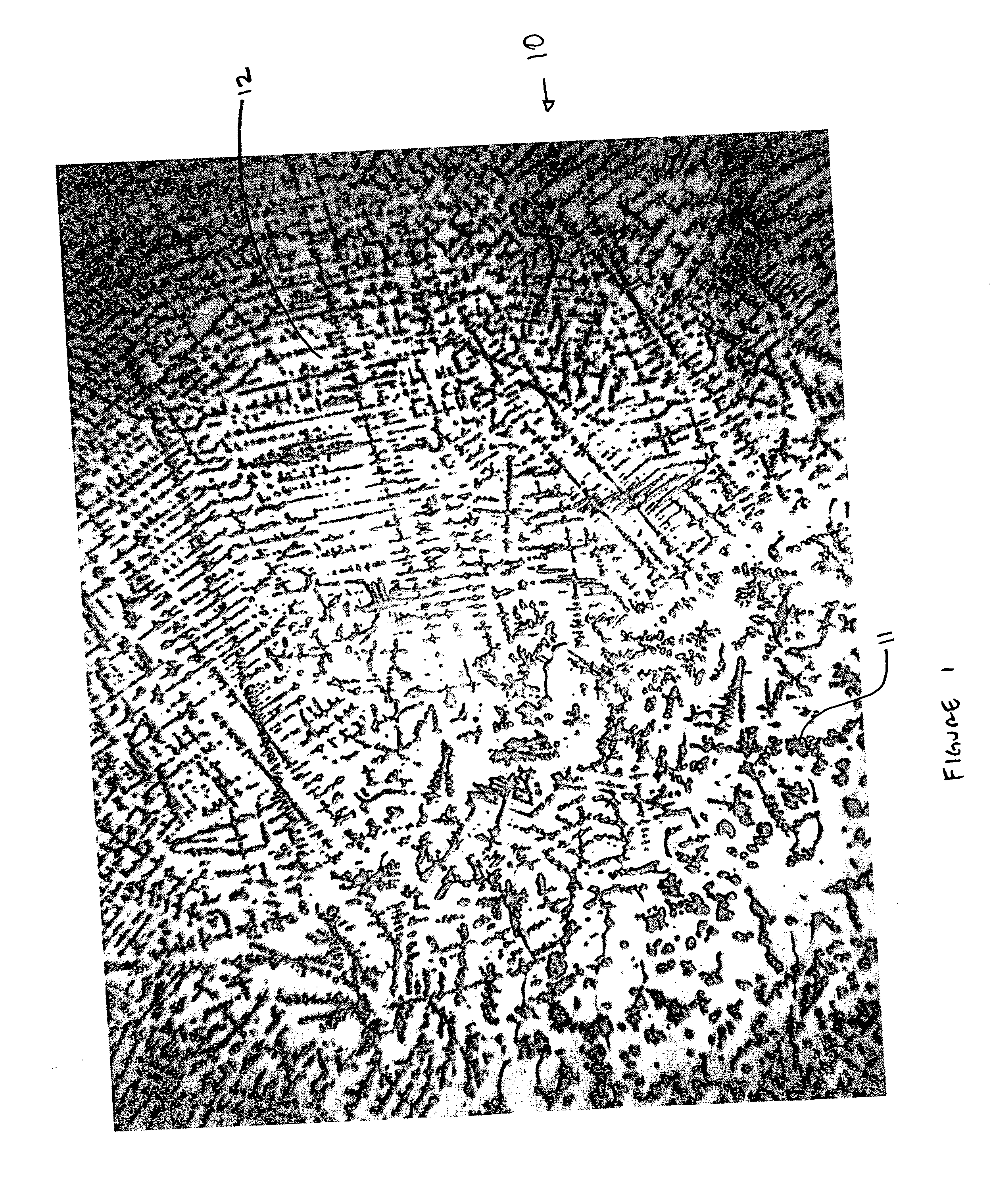

Cationic asphalt emulsifier and preparation method and application thereof

ActiveCN101745340AWide selectionWide applicabilityTransportation and packagingMixingChloroacetic acidsFatty alcohol

The invention relates to cationic asphalt emulsifier and preparation method and application thereof. The main agent of the cationic asphalt emulsifier is prepared through the reaction of quaternarization reagent and intermediate at molar ratio of 0.5-3:1, wherein the intermediate is produced in the reaction of organic acid mixture and organic amine at molar ratio of 1: 1-3. The adjuvant agent of the cationic asphalt emulsifier is the combination of, based on the main agent by weight, 0.1-2.5% of nonionic surfactant and 0.1-2.5% of modifier. The organic acid mixture is the mixture of linear, branched or naphthene-containing organic acid with small relative pace steric effect and organic acid with big relative space steric effect at molar ratio of 1: 3- 3: 1. The quaternarization reagent is epichlorohydrin, hydrochloric acid, chloromethane, dimethyl sulfate or chloroacetic acid. The modifier is one or more of aluminum sulfate, ammonium chloride and calcium chloride and the nonionic surfactant is fatty alcohol-polyoxyethylene ether. The emulsifier has no bad effects to the property of the asphalt, has wide application range and can satisfy different construction conditions.

Owner:PETROCHINA CO LTD +1

Particle electrode for efficiently removing various organic compounds and preparation method thereof

InactiveCN103539229AImprove current efficiencyImprove stabilityWater contaminantsWater/sewage treatmentEmulsionFiltration

The invention discloses a particle electrode for efficiently removing various organic compounds and a preparation method thereof. The preparation method comprises the following steps of adding AgNO3 to isopropanol to obtain a solution A, adding treated Al2O3 to the solution A, filtering the solution to obtain a particle B and micro-emulsion X, and obtaining a particle D after washing the particle B with ethanol; adding the particle D to X to obtain a particle F after filtration; utilizing Ce(NO3)2, NiCl2, CuCl2, isopropanol and concentrated hydrochloric acid to prepare solutions B, C, D, E and F; adding the particle F to the solution B to obtain a particle I through filtration; adding the particle I to the solution C to obtain a particle J through filtration, washing the particle J with ethanol, and drying the particle J, thus obtaining a particle K; adding the particle K to the solution D to obtain a particle L through filtration, washing the particle L with ethanol, and drying the particle L, thus obtaining a particle M; adding M to E to obtain a particle N through filtration, washing the particle N with ethanol, and drying the particle N, thus obtaining a particle O; adding the particle O to the solution F to obtain a particle P through filtration, washing the particle P with ethanol, and drying and roasting the particle P for four hours, thus obtaining the needed particle electrode.

Owner:BEIJING NORMAL UNIVERSITY

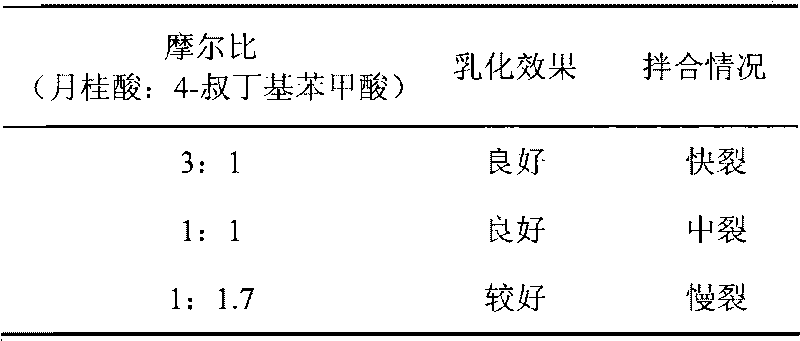

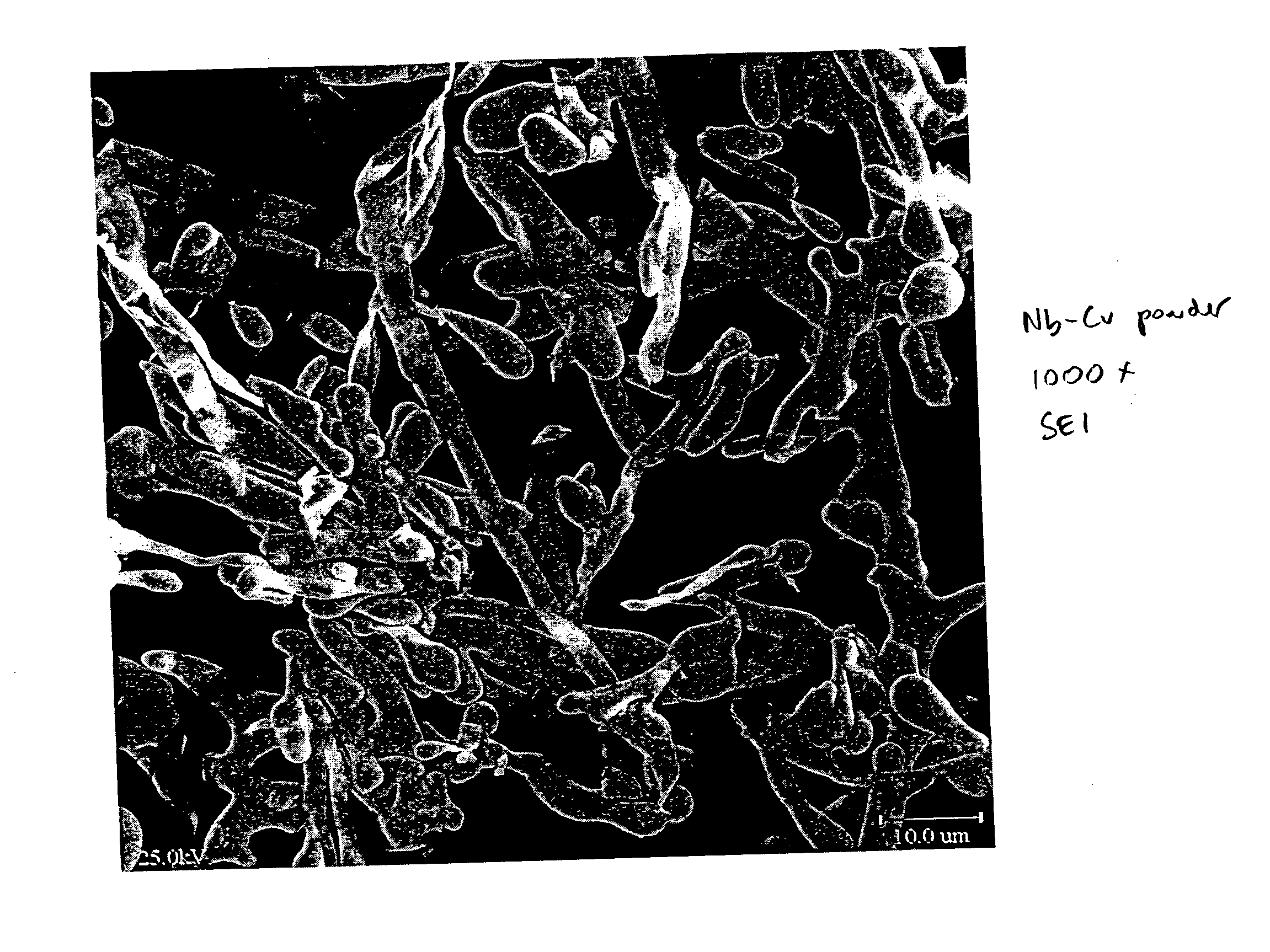

Method for producing metal fibers

InactiveUS20050000321A1Transportation and packagingMetal-working apparatusO-Phosphoric AcidMetal fibers

A method of producing metal fibers including melting a mixture of at least a fiber metal and a matrix metal, cooling the mixture to form a bulk matrix comprising at least a fiber phase and a matrix phase and removing at least a substantial portion of the matrix phase from the fiber phase. Additionally, the method may include deforming the bulk matrix. In certain embodiments, the fiber metal may be at least one of niobium, a niobium alloy, tantalum and a tantalum alloy and the matrix metal may be at least one of copper and a copper alloy. The substantial portion of the matrix phase may be removed, in certain embodiments, by dissolving of the matrix phase in a suitable mineral acid, such as, but not limited to, nitric acid, sulfuric acid, hydrochloric acid and phosphoric acid.

Owner:ATI PROPERTIES

Method for synthesizing polyoxymethylene dimethyl ether

The invention relates to a method for synthesizing polyoxymethylene dimethyl ether. The invention mainly solves the following problems of the prior art that: in the process of synthesizing polyoxymethylene dimethyl ether, catalyst separation is difficult, the material conversion rate is low, and product selectivity is poor. The method adopts methanol and trioxymethylene as materials, the reactiontemperature is 70 DEG C to 200 DEG C, the reaction pressure is 0.5MPa to 6MPa, the materials react with super solid acidic catalyst by way of contact, so that the polyoxymethylene dimethyl ether CH3O(CH2O)nCH3 is produced, wherein the used catalyst is selected from solid superacids. By weight part, the polyoxymethylene dimethyl ethe comprises the following components: (a) 20 to 70 parts of acid selected from sulfuric acid, hydrochloric acid or peroxosulfuric acid or at least one of salt thereof; (b) 30 to 80 parts of carrier selected from at least one of ZrO2, TiO2, SiO2, Fe2O3, SnO2, WO3 andAl203. The method effectively solves the problems, and can be used in the industrial production of polyoxymethylene dimethyl ether.

Owner:CHINA PETROLEUM & CHEM CORP +1

Recovery of common salt and marine chemicals from brine

InactiveUS6776972B2High purityLow costGeneral water supply conservationSeawater treatmentSaline waterEvaporation

A new process for recovery of common salt, potassium chloride, concentrated magnesium chloride with enriched bromide, and high purity magnesia from brine in an integrated manner, said process comprises preparation of calcium chloride by reaction of hydrochloric acid generated in the process with limestone, desulfatation of brine with calcium chloride, production of sodium chloride of superior quality in solar pans, solar evaporation of bittern thereby producing carnallite and end bittern, processing carnallite through established processes to produce potassium chloride, recovering end bittern containing highly concentrated magnesium chloride and enriched bromide and calcination of a part of the end bittern after solidification to produce high purity magnesia and hydrochloric acid utilizable in the process.

Owner:COUNCIL OF SCI & IND RES

Method for producing metal fibers

Owner:ATI PROPERTIES

Process and apparatus for the generation of chlorine dioxide using a replenished foam system

InactiveUS20030031621A1Reduce operating costsReadily availableChlorine dioxideChlorine dioxideAlkali metal

An aqueous solution of metal chlorate, mineral acid and a reducing agent are continuously or intermittently sprayed, in a pattern to achieve intimate mixing, into a spherical chamber creating an aqueous foam reaction mixture generating chlorine dioxide which is removed in a direction 90 degrees to the axis of the spray nozzles. A baffle plate may be used to reduce the open cross sectional area of the exit port to increase reaction efficiency. The reactants are a mineral acid and an alkali metal chlorate or chloric acid and a reducing agent such as hydrogen peroxide. The mineral acid is either diluted or concentrated sulfuric acid, hydrochloric acid, acetic acid, nitric acid or a blend thereof. The ratio of acid is greater than one and less than 3 kg acid per kg of ClO2 formed. The chlorine dioxide may be removed with a stripper column.

Owner:GRAVITT ALAN +1

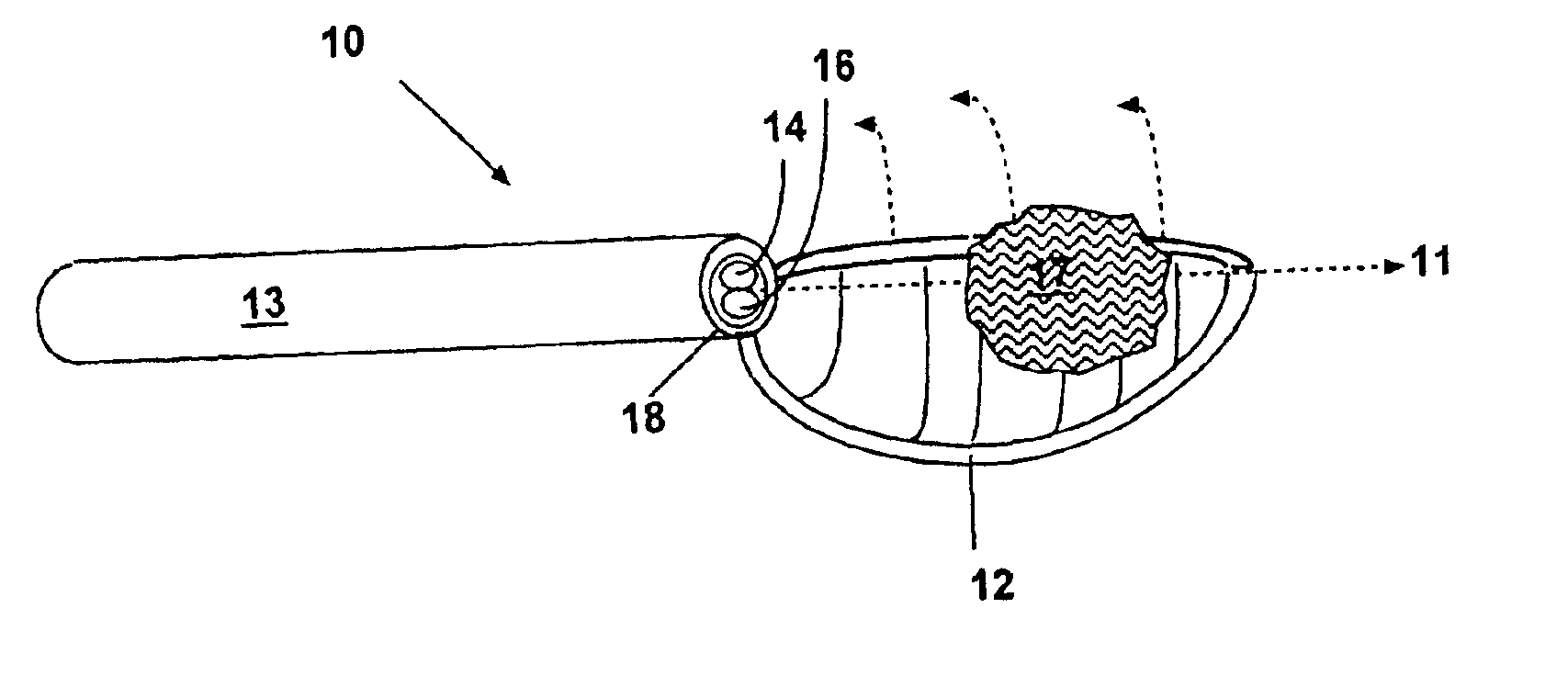

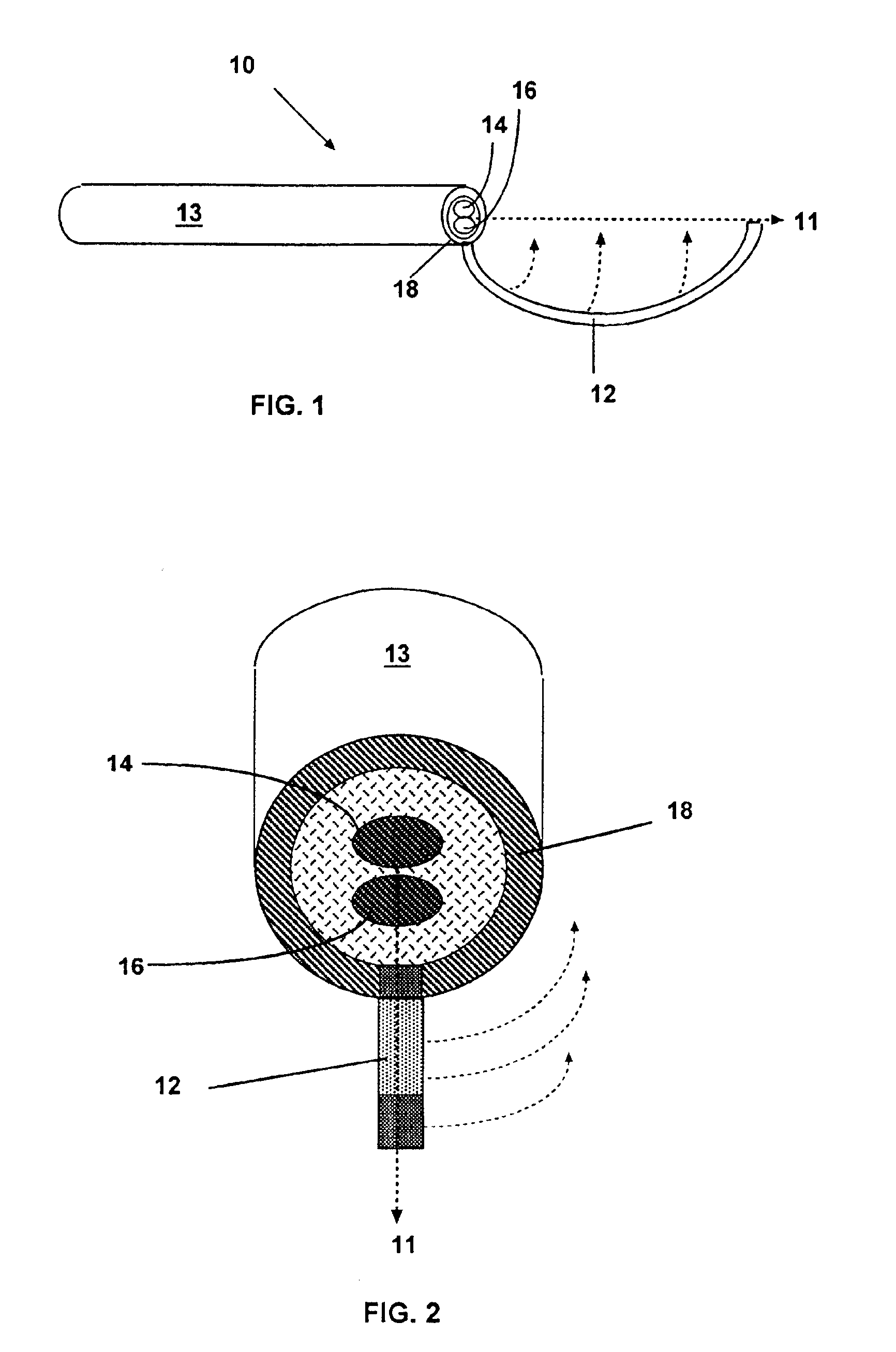

Methods and devices for the in situ dissolution of renal calculi

Methods and devices for at least reducing the mass of, if not dissolving, renal calculi in situ are provided. In the subject methods, a renal calculus is contacted, e.g. flushed, with an acidic dissolution solution in situ, where the acidic dissolution solution is a solution of a strong, inorganic acid, e.g. hydrochloric acid. In many embodiments, the renal calculus is first enclosed in an isolated local environment of a device prior contact with the dissolution solution. Also provided are novel devices and kits for practicing the subject invention.

Owner:CARDINAL HEALTH SWITZERLAND 515 GMBH

Acidic solution for treating surface of magnesium alloy and processing method

InactiveCN101285193AFully activatedHigh activityMetallic material coating processesGlutaric acidBinding force

The invention relates to acid solution used for processing the magnesium alloy surface. The acid solution is water solution which contains acids, inhibitor and wetting agent, wherein, the acids are first acids or mixture of first acids and second acids; the first acids are selected from one type or a plurality of types among citric acids, oxalic acids, tartaric acids, methanoic acids, acetic acids, metacetonic acids, butyric acids, glutaric acids, phenylformic acids, benzene dicarboxylic acids, lactic acids, glycolic acids, glyoxylic acids and amino acids; and the second acids are hydrochloric acids and / or nitric acids. By adoption of the acid solution, the magnesium alloy surface can be fully activated; the membranous layer of a converting film which is formed on the magnesium alloy surface after chemical conversion process is compact, has erosion resistance and good binding force with a paint film. Moreover, the method is a environment-friendly method for processing the magnesium alloy surface.

Owner:BYD CO LTD

Lercanidipine salts

The present invention relates to new addition salts of lercanidipine comprising lercanidipine and an acid counterion wherein the acid counterion is selected from the group consisting of: (i) inorganic acids, (ii) sulfonic acids, (iii) monocarboxylic acids, (iv) dicarboxylic acids, (v) tricarboxylic acids, and (vi) aromatic sulfonimides, with the proviso that said acid counterion is not hydrochloric acid.

Owner:RECORDATIE IRELAND LTD

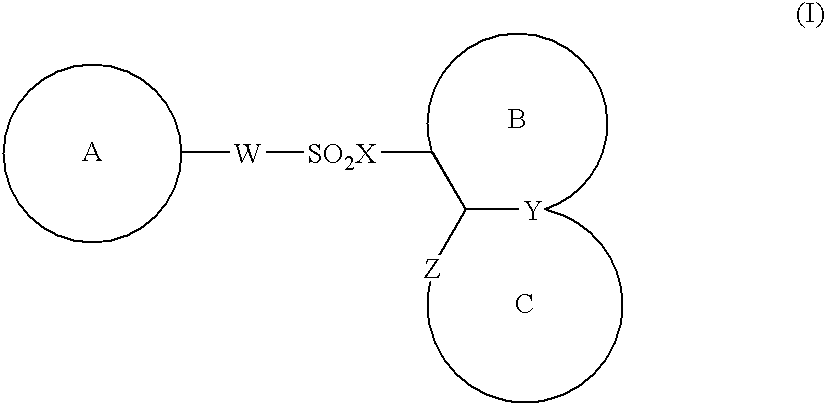

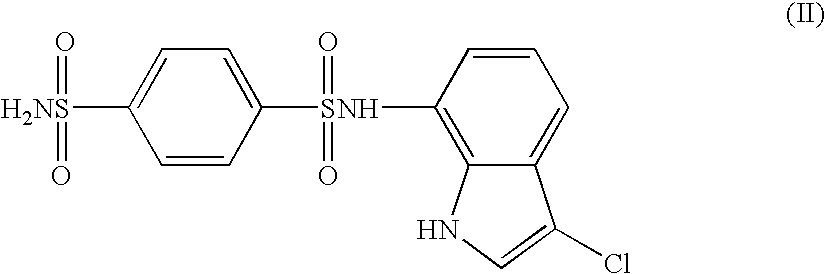

Medicinal compositions for concomitant use as anticancer agent

InactiveUS20030215523A1Good synergyEliminate side effectsHeavy metal active ingredientsBiocideCarboplatinAnticarcinogen

The present invention provides a medicinal composition having an excellent antitumor activity. That is, it provides a medicinal composition comprising a sulfonamide compound, a sulfonate compound or a salt of them, which is represented by the following formula: (wherein ring A represents an aromatic ring which may have a substituent group; ring B represents a 6-membered unsaturated hydrocarbon ring which may have a substituent group etc.; ring C represents a 5-membered hetero-ring containing one or two nitrogen atoms, and the ring C may have a substituent group; W represents a single bond or -CH=CH-; X represents -NH- etc.; and Y represents a carbon atom or a nitrogen atom; and Z represents -NH- etc.), particularly N-(3-chloro-1H-indol-7-yl)-4-sulfamoylbenzenesulfonamide or a salt thereof, combined with at least one substance selected from (1) irinotecan hydrochloride trihydrate; (2) mitomycin C; (3) 5-fluorouracil; (4) cisplatin; (5) gemcitabine hydrochloride; (6) doxorubicin; (7) taxol; (8) carboplatin; (9) oxaliplatin; (10) capecitabine; and (11) a salt of the above-mentioned (1) to (10).

Owner:EISIA R&D MANAGEMENT CO LTD

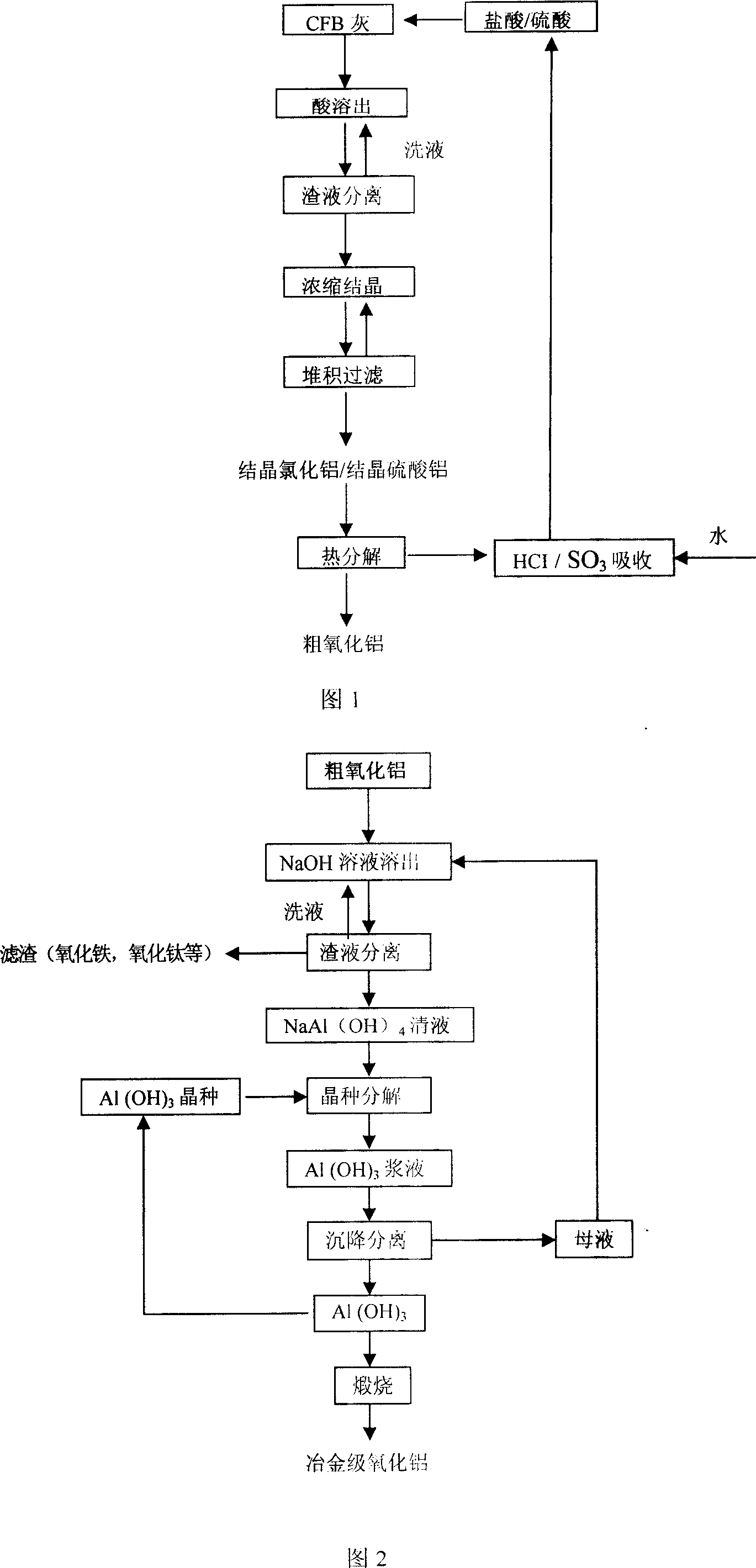

Preparation method of alumina

ActiveCN1927716AReduce pollutionReduce consumptionAluminium oxide/hydroxide preparationAluminium oxides/hydroxidesAluminium hydroxideDecomposition

The process of preparing alumina includes: the reaction of flyash from circular fluidizing bed and acid to obtain aluminum chloride solution, eliminating silicon impurity, concentrating to crystallize and heating to decompose and to obtain crude alumina product; reaction of crude alumina product and hot alkali solution to obtain sodium aluminate solution; eliminating iron, titanium and other impurity, adding aluminum hydroxide crystal seed into sodium aluminate solution for seed separating decomposition to obtain aluminum hydroxide precipitate; and final calcining aluminum hydroxide to obtain metallurgical alumina. The normal pressure process has no any cosolvent added, and the alumina product has Al2O3 content up to 98 %. The process has small sodium hydroxide consumption, reuse of most of sodium hydroxide, simple operation, low cost, low power consumption, capacity of reducing flyash pollution and other advantages.

Owner:SHENHUA ZHUNGER ENERGY

Method for Treating a Subterranean Formation

Acidizing methods for subterranean formations formed of predominantly siliceous material as well as acidizing compositions. Some methods include injecting into a predominantly siliceous subterranean formation, an aqueous acidic mixture formed by blending an aqueous liquid, a fluoride source, and an effective amount of an alkane sulfonic acid, preferably methane sulfonic acid, to adjust the pH of the fluid where the alkane sulfonic acid where the alkane group may be an unbranched, a branched or a cyclic alkyl residue. Hydrofluoric acid (HF) may not be added to the fluid in some embodiments as the fluoride source, such as the case for an HF free fluid, and, in some instances, hydrochloric acid is not added to the fluid to adjust pH. Also described are compositions containing an aqueous acidic mixture formed by blending an aqueous liquid, a fluoride source, and an effective amount of an alkane sulfonic acid to adjust pH.

Owner:SCHLUMBERGER TECH CORP

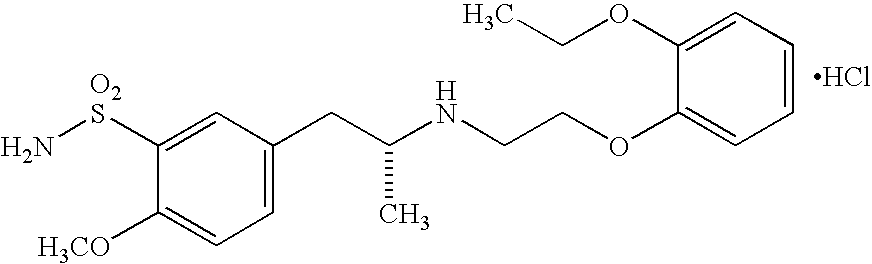

Formulations of a nanoparticulate finasteride, dutasteride or tamsulosin hydrochloride, and mixtures thereof

Described are nanoparticulate compositions of finasteride, dutasteride, tamsulosin hydrochloride, or a combination thereof. The formulations exhibit unexpectedly prolonged release and can be maintained in a depot for release to a patient for a period of up to six months.

Owner:ELAN PHRMA INT LTD

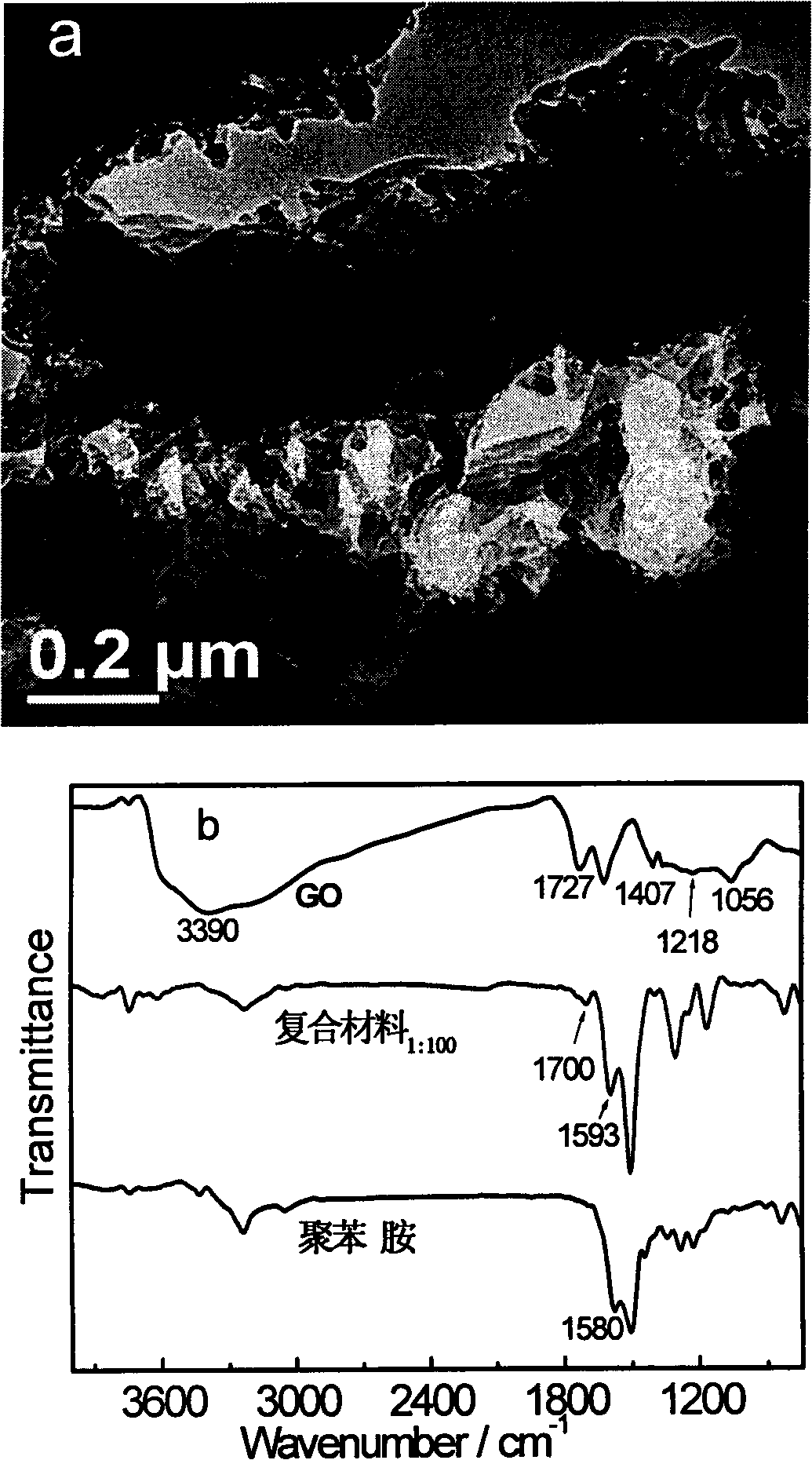

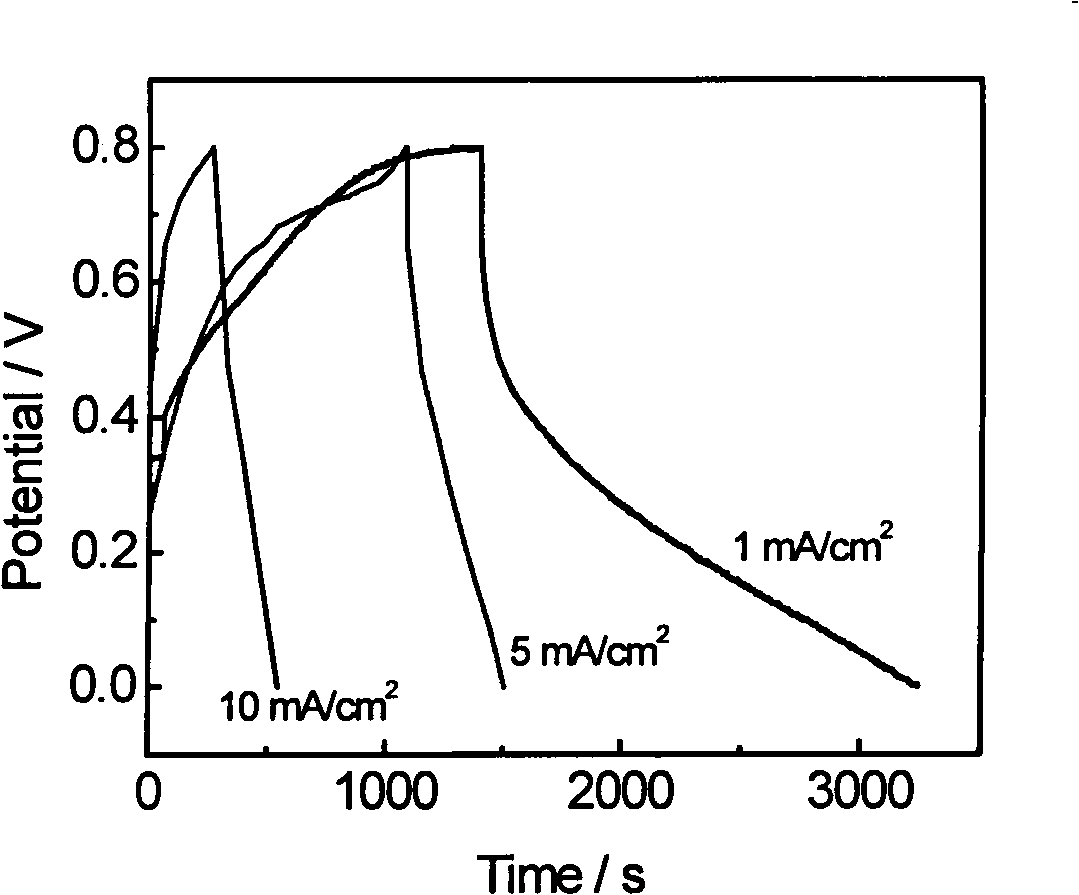

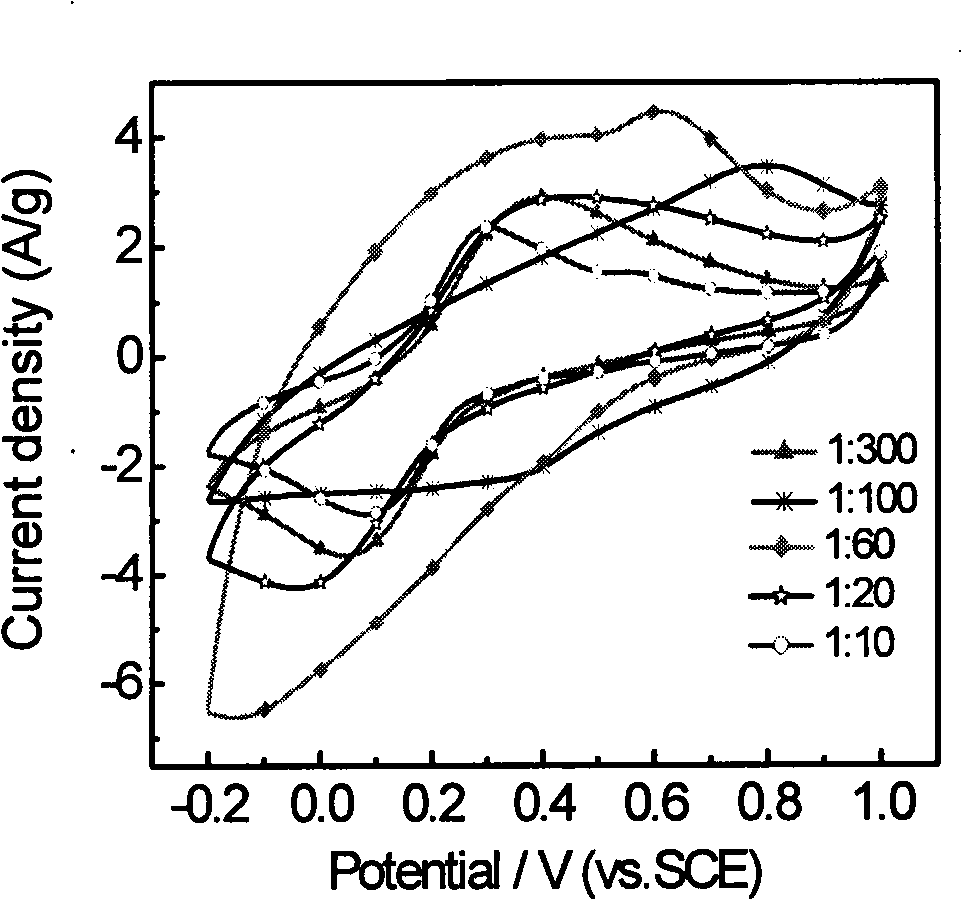

Oxidized grapheme/polyaniline super capacitor composite electrode material and preparation method and application thereof

ActiveCN101527202AImprove double layer capacitanceExcellent supercapacitor performanceElectrolytic capacitorsHybrid capacitor electrodesPolyaniline compositeAniline

The invention discloses an oxidized grapheme / polyaniline super capacitor composite electrode material and the preparation method and the application thereof. The preparation method comprise the following steps: firstly, adding oxidized graphite to water for ultrasonic dispersion so as to form an oxidized grapheme solution with uniformly dispersed single pieces; at room temperature, dropping aniline to the obtained oxidized grapheme solution for continuous ultrasonic dispersion to from a mixed solution; at a low temperature condition, adding hydrogen peroxide, ferric trichloride and a hydrochloric acid solution dropwise to the mixed solution, and stirring the solution for polymerization; and after the reaction is finished, centrifugating, washing and roasting the obtained mixed solution in vacuum to obtain the oxidized grapheme / polyaniline super capacitor composite electrode material which is used as the electrode material of an electricity storage system of a super capacitor and a battery. The oxidized grapheme / polyaniline super capacitor composite electrode material with good electrochemistry performance is obtained by the method, and the specific capacity of the oxidized grapheme and the polyaniline is greatly improved. In addition, the addition of the oxidized grapheme improves the charge and discharge service life of the polyaniline.

Owner:NANJING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com