Patents

Literature

6263 results about "Binding force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Micron nano material composite modified water-based adhesive

InactiveCN101210157ALow shrinkageImprove performanceMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesMicro nanoExtensibility

The invention relates to an aqueous binder which is compounded and modified by micro nano material. The modified aqueous binder of the invention adopts emulsion adhesive as matrix and micro-size and nano-size inorganic powder as modifier to prepare the compound and modified aqueous binder. The method of the invention can not only enhance the interface binding force of the aqueous binder, but also greatly improve the properties of water resistance, toughness and extensibility, leading comprehensive performance of the aqueous binder to be improved.

Owner:郑旷宇

Chromium-free passivation liquid for galvanized sheet and manufacture method thereof

InactiveCN101250699AImprove bindingImprove corrosion resistanceMetallic material coating processesChromium freeSealant

The invention in particular relates to passivation solution without chrome which is used for galvanized sheets and a method thereof. The technical scheme thereof comprises: firstly, dissolving inorganic salt corrosion inhibitor, then, adding the inorganic salt corrosion inhibitor into a stirred tank, adding dispersant, organic acid, sealant, silicone-acrylate emulsion and water while stirring, then, using inorganic acid or alkali to regulate the pH value to be 2.0-5.0, and then stirring for 1-2 hours under the condition that the temperature is 20-30 DEG C, the content of the components of each liter is: the inorganic salt corrosion inhibitor 10-55g, additive 4-10g, the organic acid 5-20g, the sealant 5-30g, the silicone-acrylate emulsion 150-300g, and the rest is the water. The method of the invention can additionally form a layer of organic resin separate layer on the basis of forming an inorganic metal compound precipitation film, additionally, since the silicon compound is added, not only the binding force between a passivation layer and zinc coating can be increased, but also the corrosion resistance, the scrubbing resistance and the wear resistance of the passivation layer can be increased, and the coating treatment after passivation can not be affected.

Owner:WUHAN UNIV OF SCI & TECH

Safety shield for medical needles

Owner:SPECIALIZED HEALTH PRODS

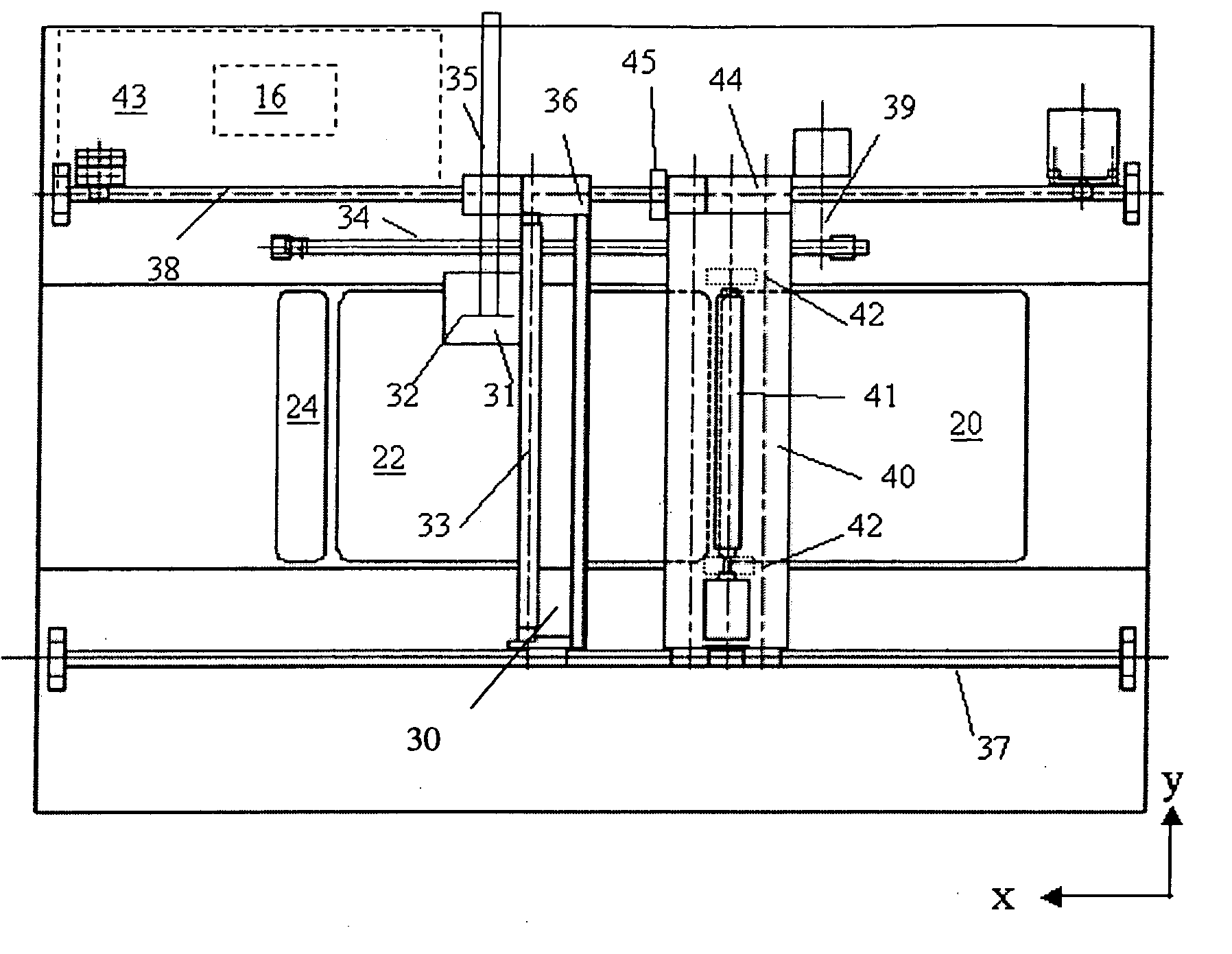

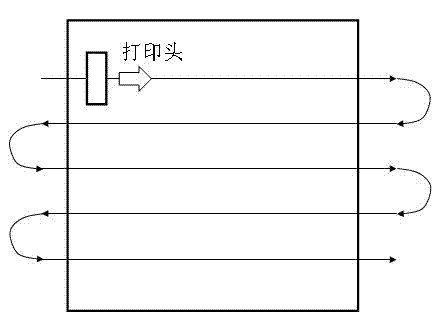

Method and apparatus for rapid prototyping using computer-printer aided to object realization

InactiveUS20050225007A1Shorten the timeIncrease printing speedConfectionerySweetmeatsComputer printingObject store

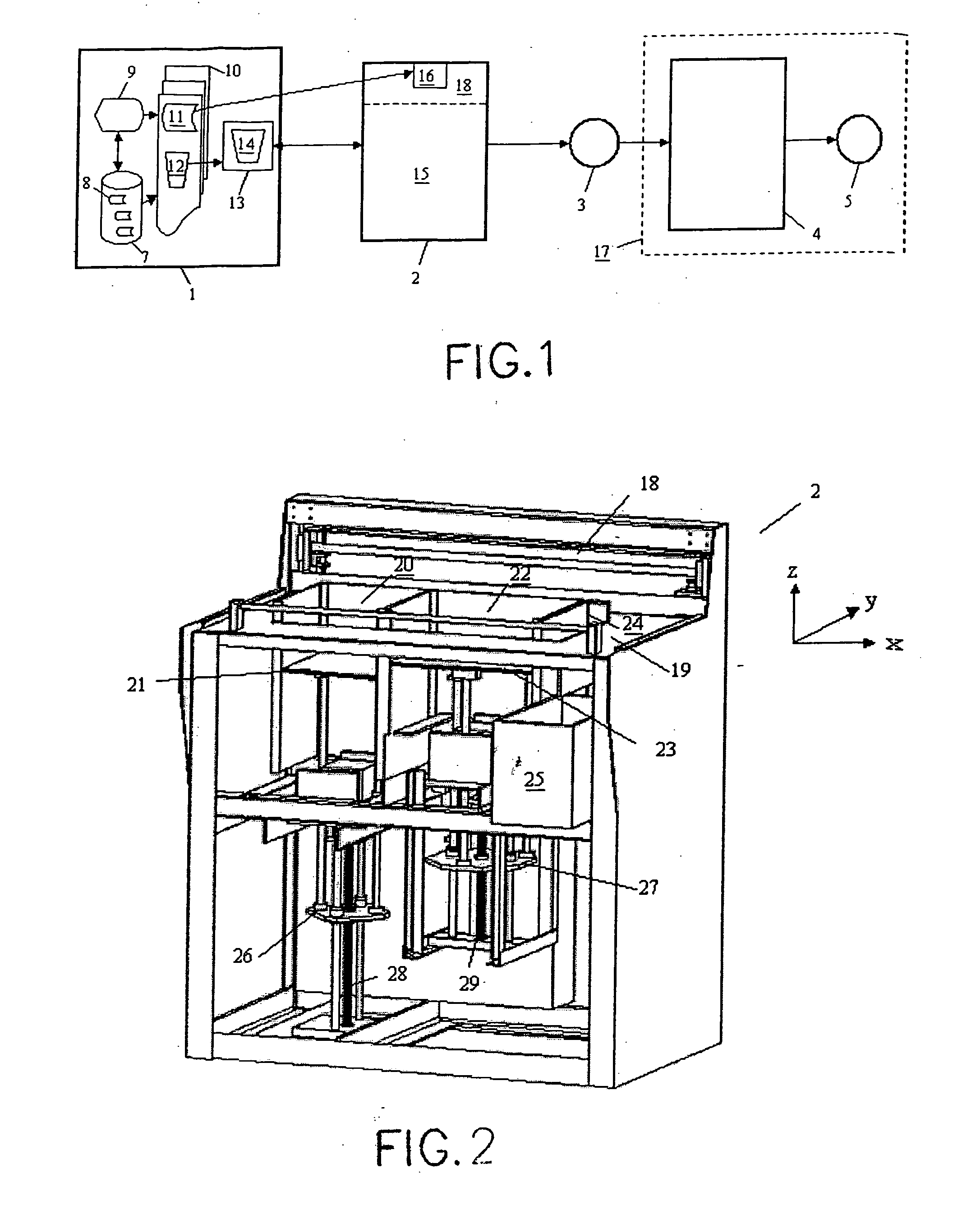

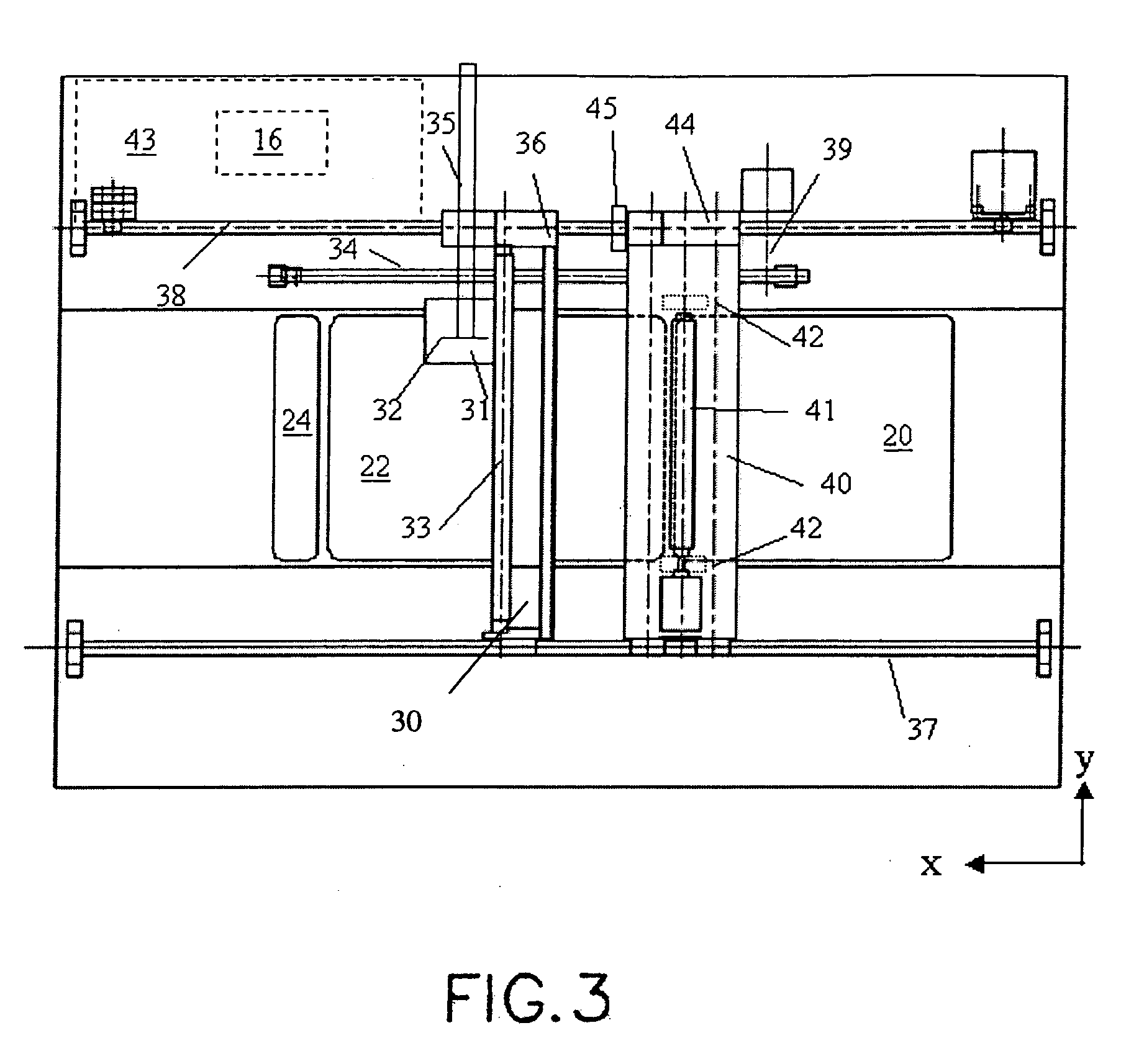

This invention applies a new computer and printer integrated technology to aid forming physical objects rapidly, and the method and apparatus are disclosed to satisfy the market requirements for a quick, reliable, safe, and inexpensive operation. The invention coverts a virtual object stored in the storage device of computer through software that slices the virtual object into many layers. The cross-section of the first layer is sent to a printer or a plotter, and the contour domain is printed or plotted by the printer or plotter. The fluid (not limited to binder) in the printer head is coated onto a layer of uniform distributed porous material which allows the powder and fluid to combine with each other; however, the combining process can be either a natural or an artificial process to enhance the binding force between the fluid and powder. After the first layer is finished, the second layer of powder is uniformly distributed on the first layer, and the contour printing process is repeated. As the printing process is repeated until all slicing layers of the model are finished, the object is stacked layer by layer sequentially. The physical object can be obtained after all the unglued powders are removed. The above-mentioned printing process not only produces monochrome objects, but also produces color objects. The machine includes components of a printer or plotter and its interface card, and x-z axis traversal driven mechanism. The operation platforms include a material supply chamber, a constructing chamber at which powder material is combined with solution, and a recycling hole. A slicing algorithm control software is used to calculate the cross-sectional contour, and the manufacture process is controlled by software and hardware interfaces.

Owner:NAT CHENG KUNG UNIV

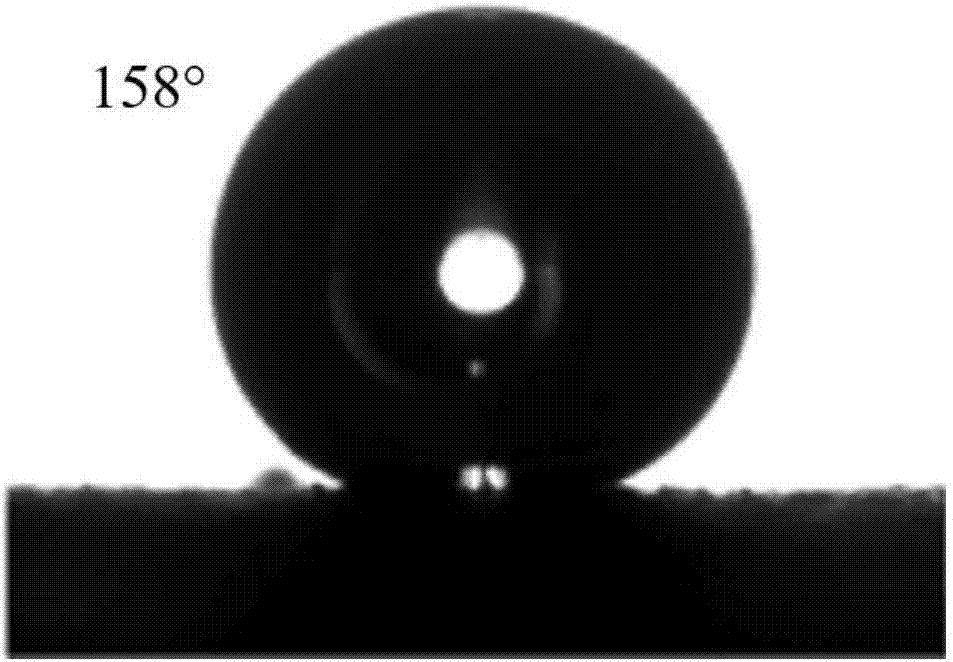

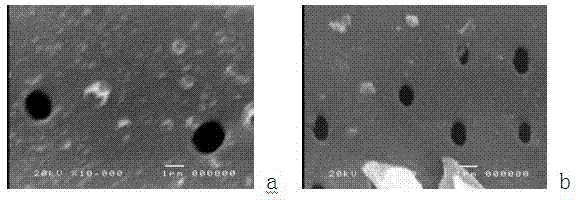

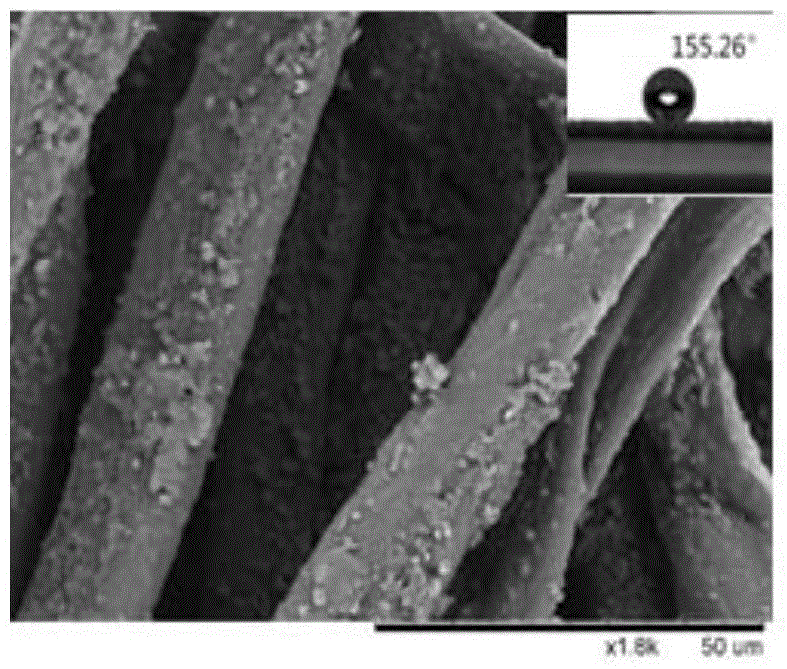

Wear-resisting super-hydrophobic coating composition as well as preparation method and application thereof

InactiveCN107987675AImprove protectionLong-term effective superhydrophobic propertiesLiquid surface applicatorsPolyurea/polyurethane coatingsMicro nanoNanoparticle

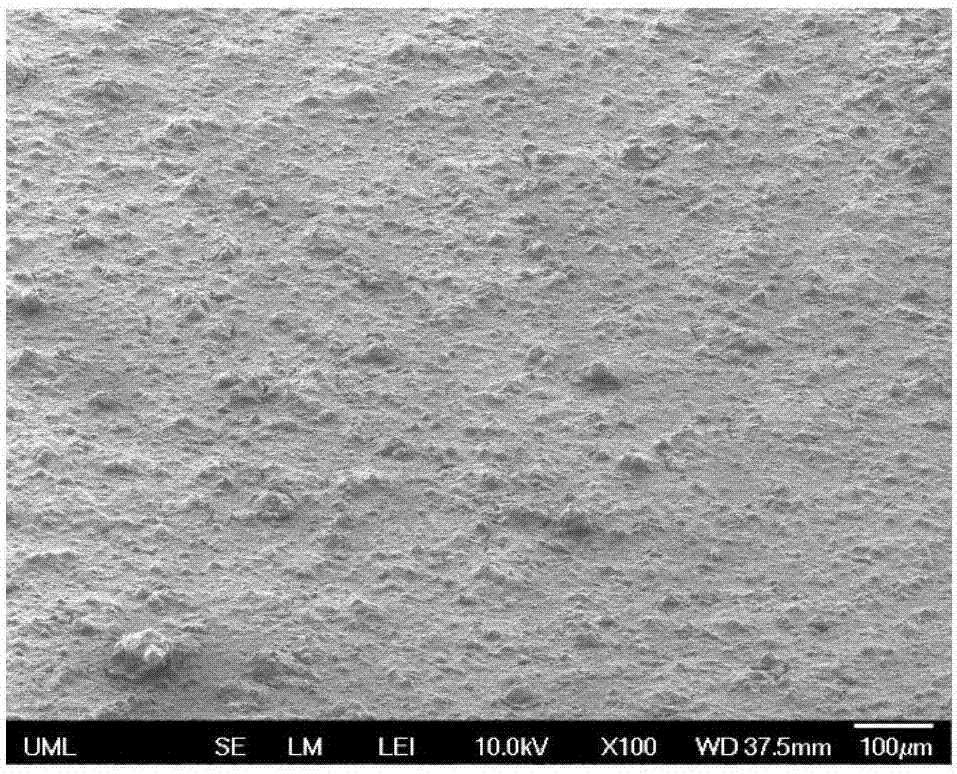

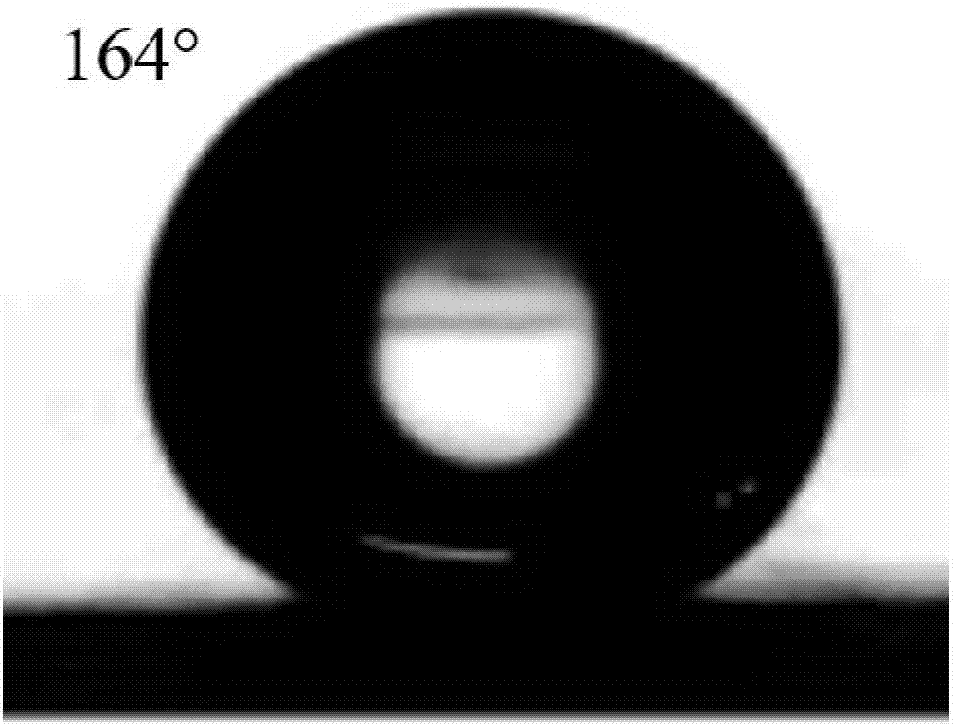

The invention relates to a wear-resisting super-hydrophobic coating composition as well as a preparation method and application thereof. The composition is prepared from a nano-material dispersion solution and a binding material dispersion solution. The nano-material dispersion solution is prepared by mixing a nanoparticle material, a hydrophobic silane coupling agent and a volatile solvent, wherein nanoparticles form a rough structure with a micro-nano dual scale through a mutual effect of the nanoparticles and the structure is dispersed in the solution of the hydrophobic silane coupling agent; the hydrophobic silane coupling agent has one or more groups and covalent bond connection is formed by the hydrophobic silane coupling agent and the micro-nano dual rough structure; meanwhile, thewear-resisting super-hydrophobic coating composition at least contains one hydrophobic group. A super-hydrophobic coating layer formed by the super-hydrophobic coating composition keeps a long-term effective super-hydrophobic property; the coating composition adopts a binding material so that the binding force between a super-hydrophobic structure and a matrix is enhanced and the protection effectof the coating layer is enhanced; a processing technology of the super-hydrophobic coating layer is simple and convenient and large-area construction is facilitated.

Owner:杭州纳微生物化学有限公司

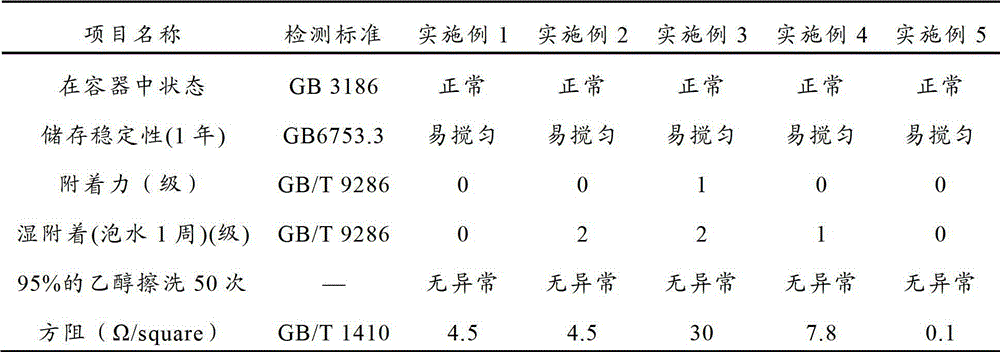

Conducting paint

ActiveCN102977742AImprove conductivityGood adhesionEpoxy resin coatingsElectrically-conductive paintsEpoxySolvent

The invention provides a conducting paint which comprises 1-8 wt% of graphene, 0.1-1 wt% of functionalized graphene, 15-30 wt% of epoxy resin and curing agent, 0.2-1.5 wt% of wetting dispersant, 0.1-0.5 wt% of defoaming agent, 0-30 wt% of conducting filler and the balance of solvent. The functionalized graphene is amino-containing functionalized graphene or sulfhydryl-containing functionalized graphene. The functionalized graphene contains amino or sulfhydryl group, and therefore, can be better dispersed in the system, and the amino or sulfhydryl group can react with epoxy group in the epoxy resin, thereby enhancing the binding force of the coating; and besides, the graphene has a flake structure and a large radius-thickness ratio and is arranged as a plurality of layers in the coated film in parallel, and therefore, the conducting paint has favorable conductivity and adhesiveness.

Owner:NINGBO GRAPHENE INNOVATION CENT CO LTD

Acidic solution for treating surface of magnesium alloy and processing method

InactiveCN101285193AFully activatedHigh activityMetallic material coating processesGlutaric acidBinding force

The invention relates to acid solution used for processing the magnesium alloy surface. The acid solution is water solution which contains acids, inhibitor and wetting agent, wherein, the acids are first acids or mixture of first acids and second acids; the first acids are selected from one type or a plurality of types among citric acids, oxalic acids, tartaric acids, methanoic acids, acetic acids, metacetonic acids, butyric acids, glutaric acids, phenylformic acids, benzene dicarboxylic acids, lactic acids, glycolic acids, glyoxylic acids and amino acids; and the second acids are hydrochloric acids and / or nitric acids. By adoption of the acid solution, the magnesium alloy surface can be fully activated; the membranous layer of a converting film which is formed on the magnesium alloy surface after chemical conversion process is compact, has erosion resistance and good binding force with a paint film. Moreover, the method is a environment-friendly method for processing the magnesium alloy surface.

Owner:BYD CO LTD

Epoxy resin-oxidized graphene composite coating and application method thereof

InactiveCN104356860AImprove corrosion resistanceImprove adhesionAnti-corrosive paintsEpoxy resin coatingsEpoxyCoated surface

The invention provides an epoxy resin-oxidized graphene composite coating. The composite coating is prepared by using oxidized graphene as a packing and adding the packing to epoxy resin coating. A coating layer prepared on the surface of a matrix by utilizing the composite coating is excellent in binding force of the matrix, and further greatly improved in corrosion resistance, so as to effectively obstruct a corrosive medium from penetrating from the surface of the coating layer to the path of the matrix. Therefore, the epoxy resin-oxidized graphene composite coating is good in application prospect, and in particular suitable for the matrix in a highly-corrosive severe environment.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Hydrophilic nano zinc based composite coating

InactiveCN101613559AStrong weather resistanceNo pollution in the processAnti-corrosive paintsPolyurea/polyurethane coatingsSilanesSolvent

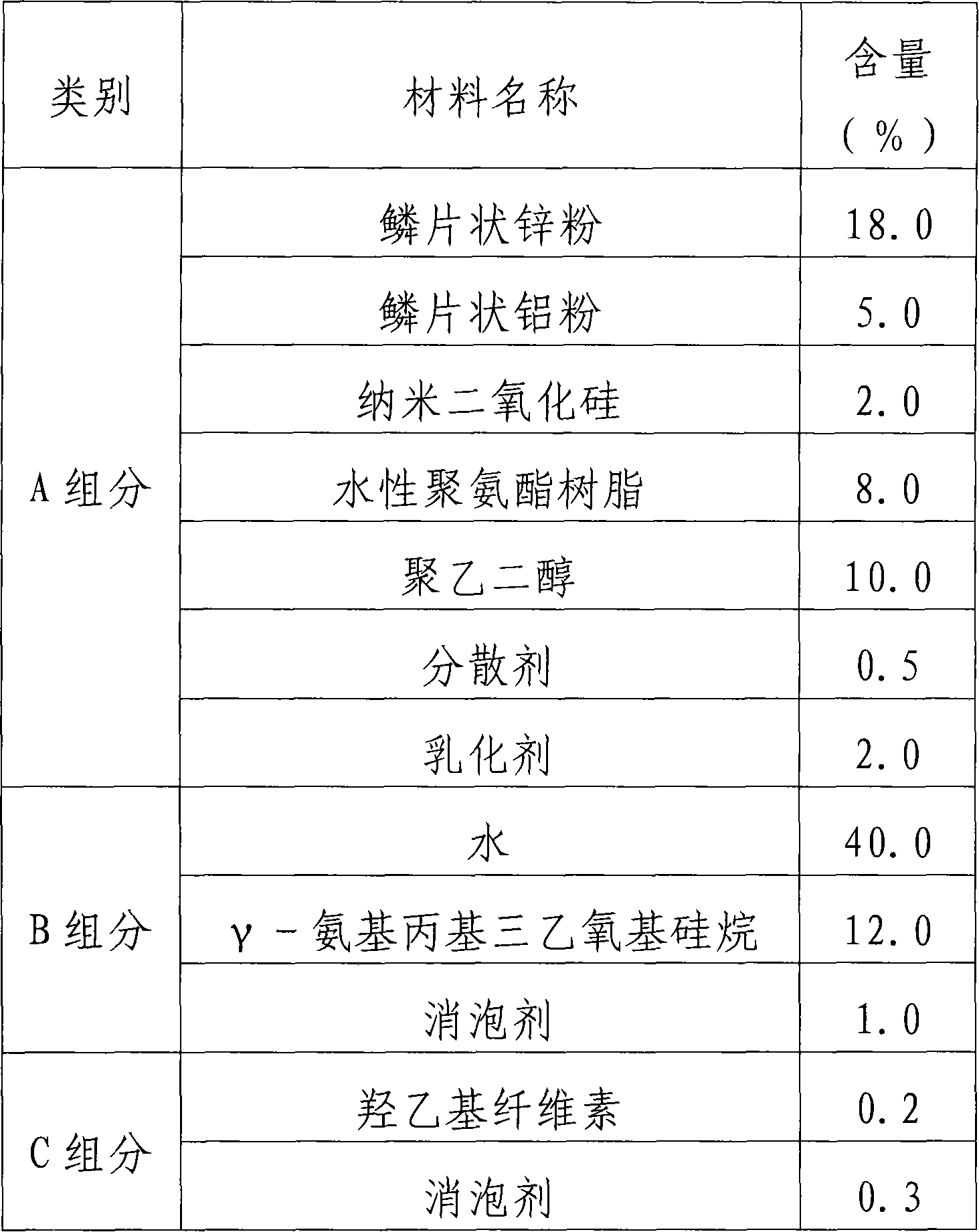

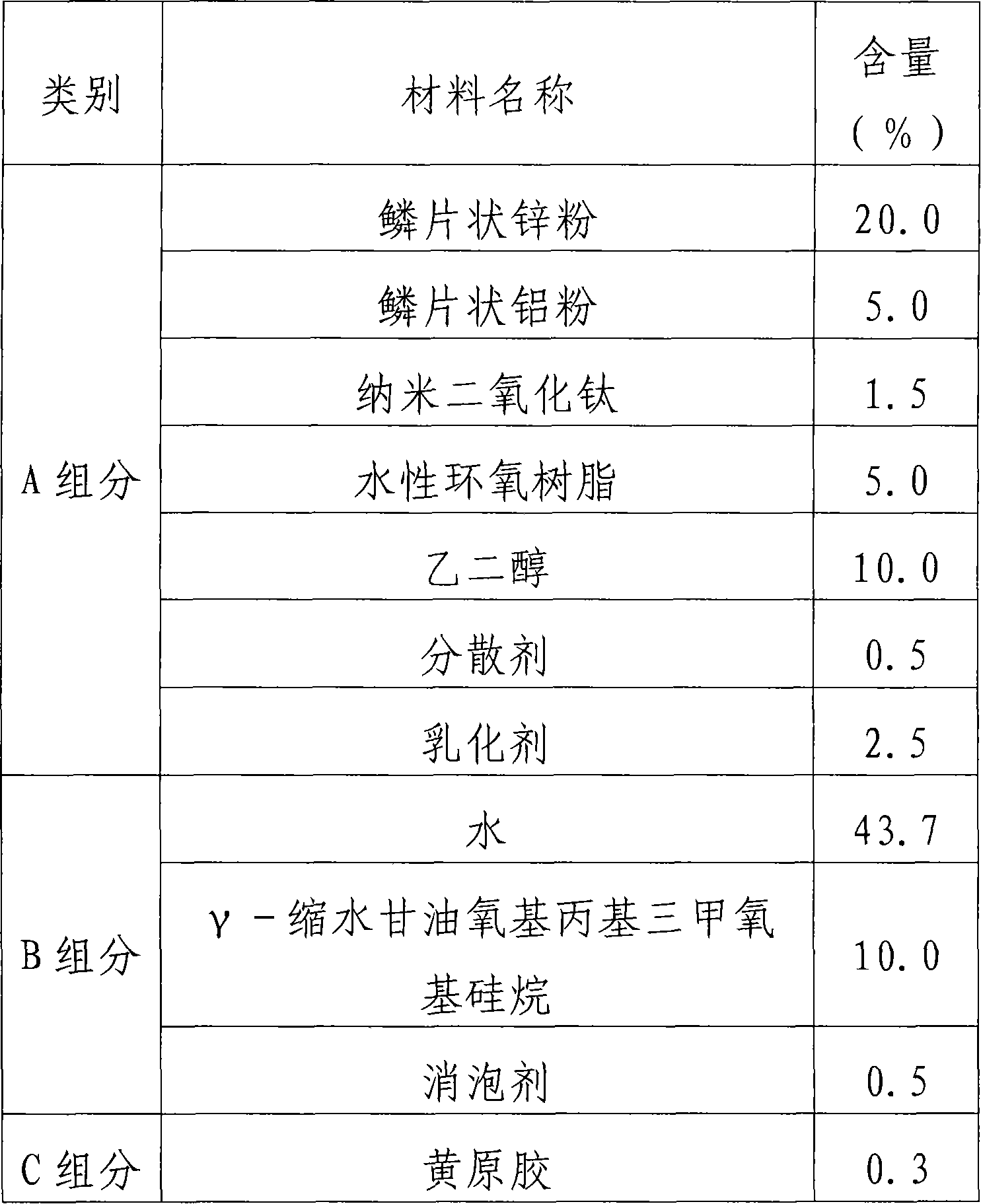

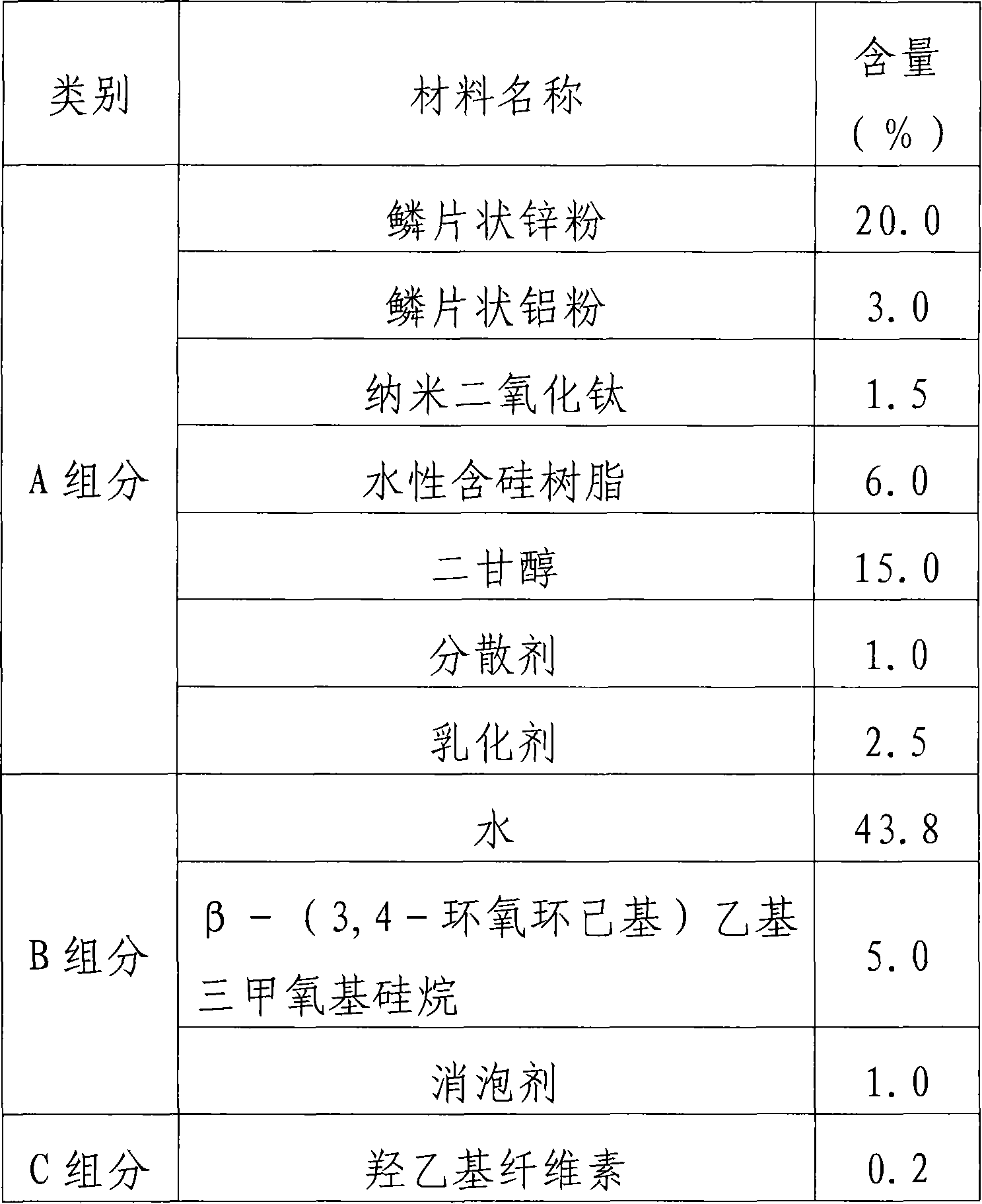

The invention belongs to the technical field of chemical engineering coatings and particularly relates to a hydrophilic nano zinc based composite coating used for preventing corrosion on the surfaces of the metal parts. The coating comprises an emulsifier, a dispersant, an antifoaming agent, scaly metallic powder, nano oxides, a silane coupler, an alcohol-type solvent, a high-molecule organic material, a thickener and 30.0 to 60.0 percent of water serving as a disperse medium. The coating can be coated by spraying, brushing, soaking and soaking-centrifugal coating and other methods, and the coating can be formed by being roasted at a temperature of about 200 DEG C for 20 minutes. Neutral salt spray corrosion resistant tests show that the neutral salt spray corrosion resistant time is more than 800h, the binding force is proved to be above level 4 (by an adhesive band test). The coating has the advantages of environmental pollution prevention, excellent metallic corrosion resistant property, economy and practicability and convenient use; and moreover, the coating can be widely used for the corrosion resistant treatment of the surface of metal parts made of iron, aluminum, copper and magnesium alloy and the like, particularly the corrosion resistant treatment of metal parts with complex geometric shapes.

Owner:YUNNAN GREAT IND DEV

Method for improving graphene and copper basal body binding force in copper-based graphene composite material

The invention provides a method for improving graphene and copper basal body binding force in a copper-based graphene composite material; and the method prepares the composite material by a spark plasma sintering technology through adding a small amount of alloy elements in a copper basal body and mixing the alloy elements with graphene. Experiments prove that the method improves the interface binding force of the basal body and a graphene reinforcement phase in the composite material; and compared with a composite material prepared by adding no alloy element, high tensile resistance is achieved. In addition, the copper-based graphene composite material with excellent heat conductivity, electricity conductivity and wear resistance can be obtained by optimizing the adding quantity of the alloy elements and the mass of the graphene, so that excellent application prospect is achieved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

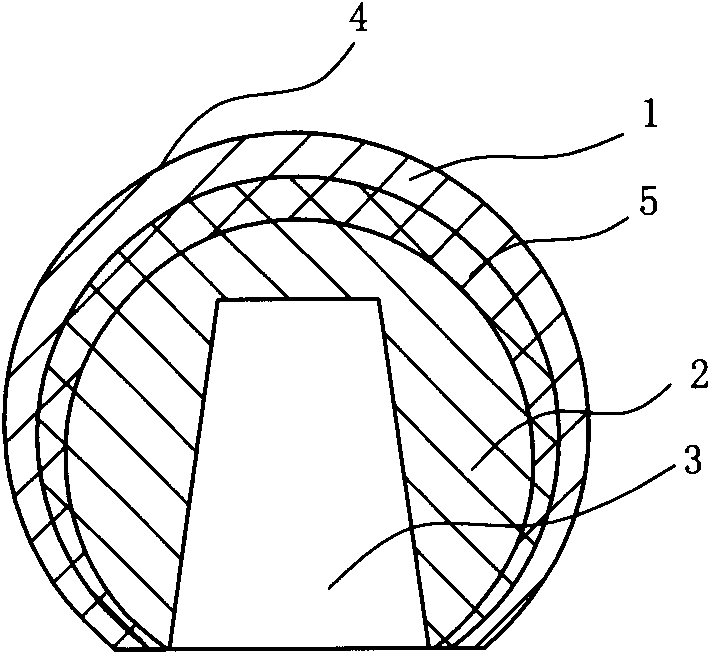

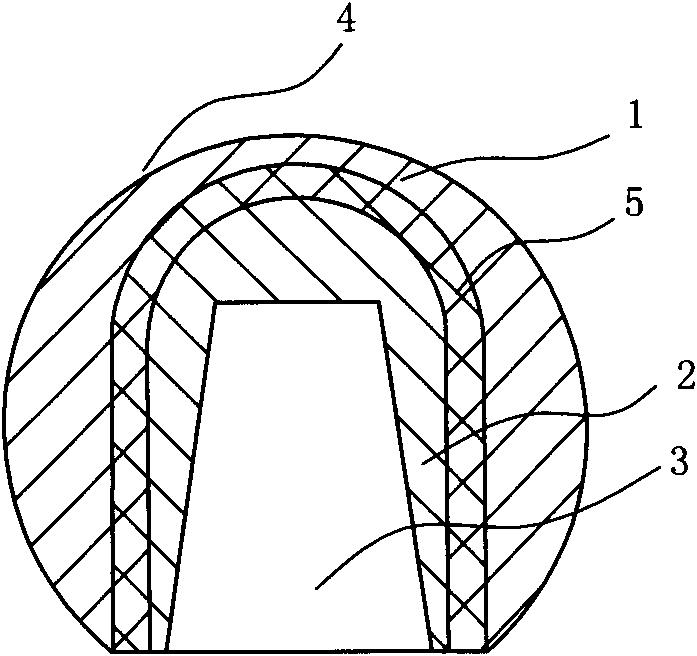

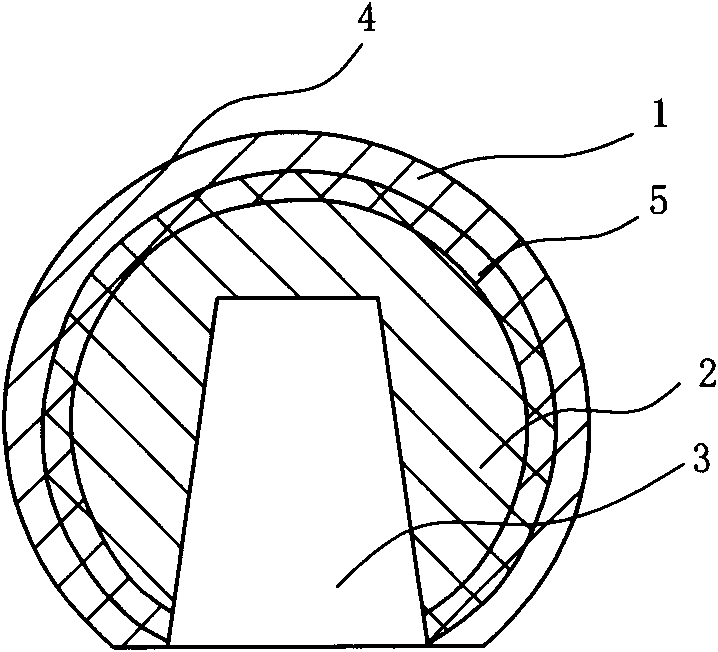

Manufacturing method of multilayer shell-core composite structural part

ActiveCN102009175AShell surface hardness is highHigh surface finishJoint implantsCeramic layered productsComposite constructionHigh surface

The invention discloses a manufacturing method of a multilayer shell-core composite structural part, which comprises the following steps of: (1) respectively preparing feed for injection forming of a core layer, a transition layer and a shell layer, wherein powder in the feed of the core layer and the powder in the feed of the shell layer are selected from one or a mixture of some of metal powder, ceramic powder, or toughened ceramic powder and are different from each other, and the powder in the feed of the transition layer is gradient composite powder; (2) respectively manufacturing blanks of the multilayer shell-core composite structural part layer by layer with a powder injection forming method; (3) degreasing the blanks; and (4) sintering the blanks to obtain the multilayer shell-core composite structural part. The multilayer shell-core composite structural part is manufactured with the powder injection forming method, and has the advantages of high surface hardness, abrasion resistance, uniform thickness of the shell layer, stable and persistent performance, strong binding force between the shell layer and the core layer due to the transition layer, good integral bending strength and good impact toughness and is difficult to crack.

Owner:SUZHOU DINGAN ELECTRONICS TECH

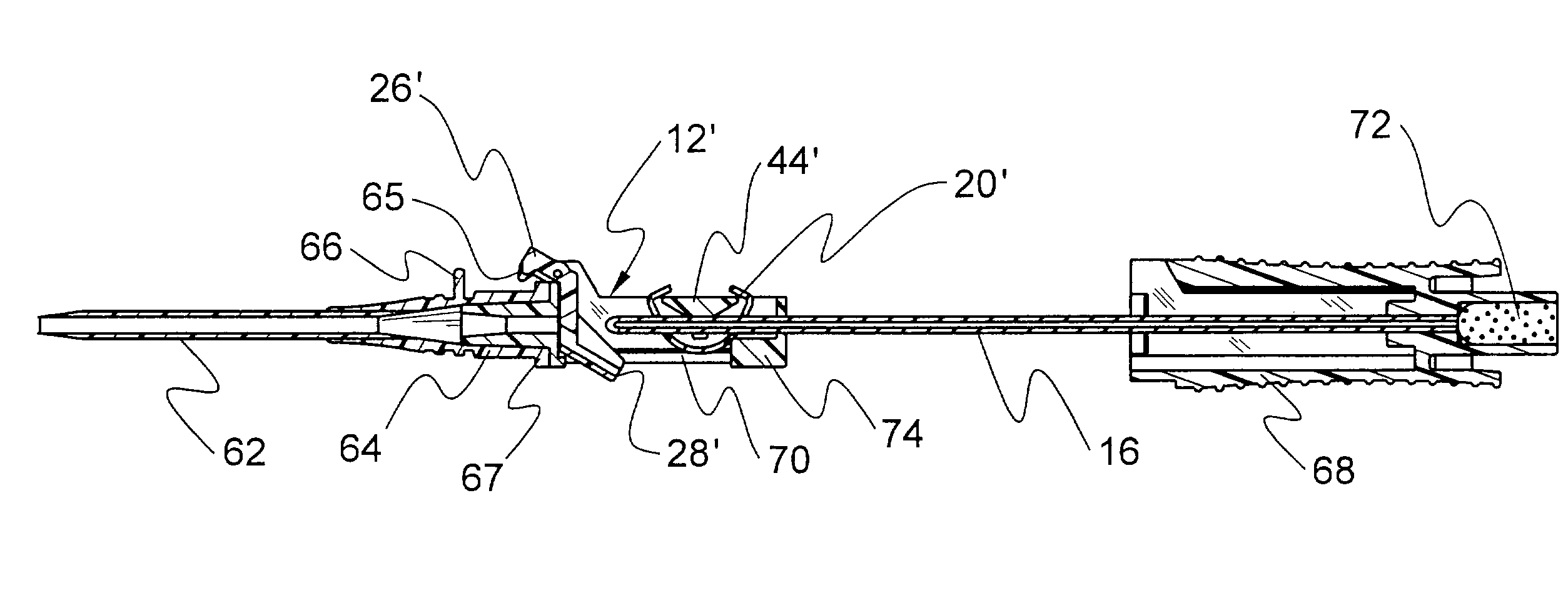

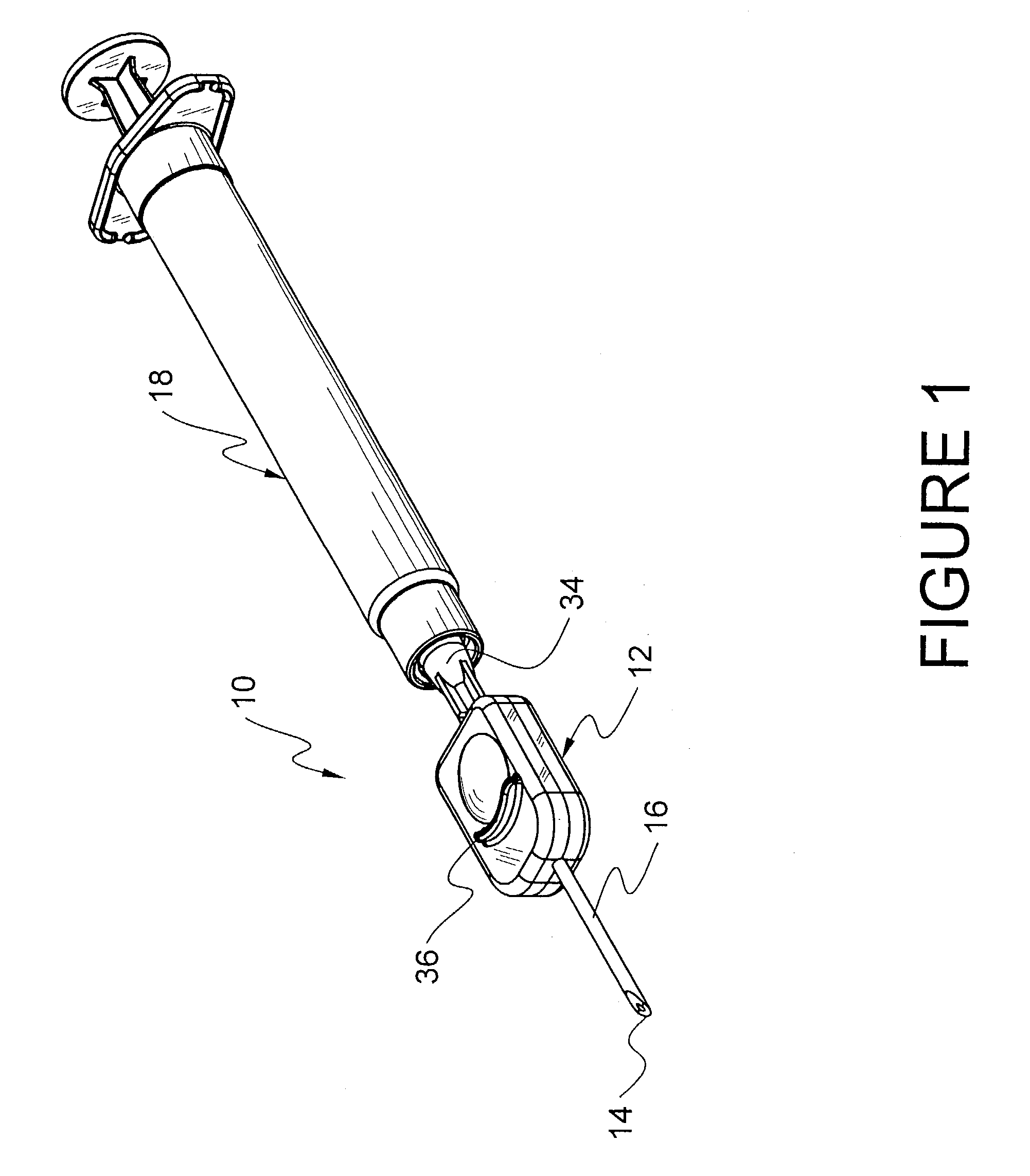

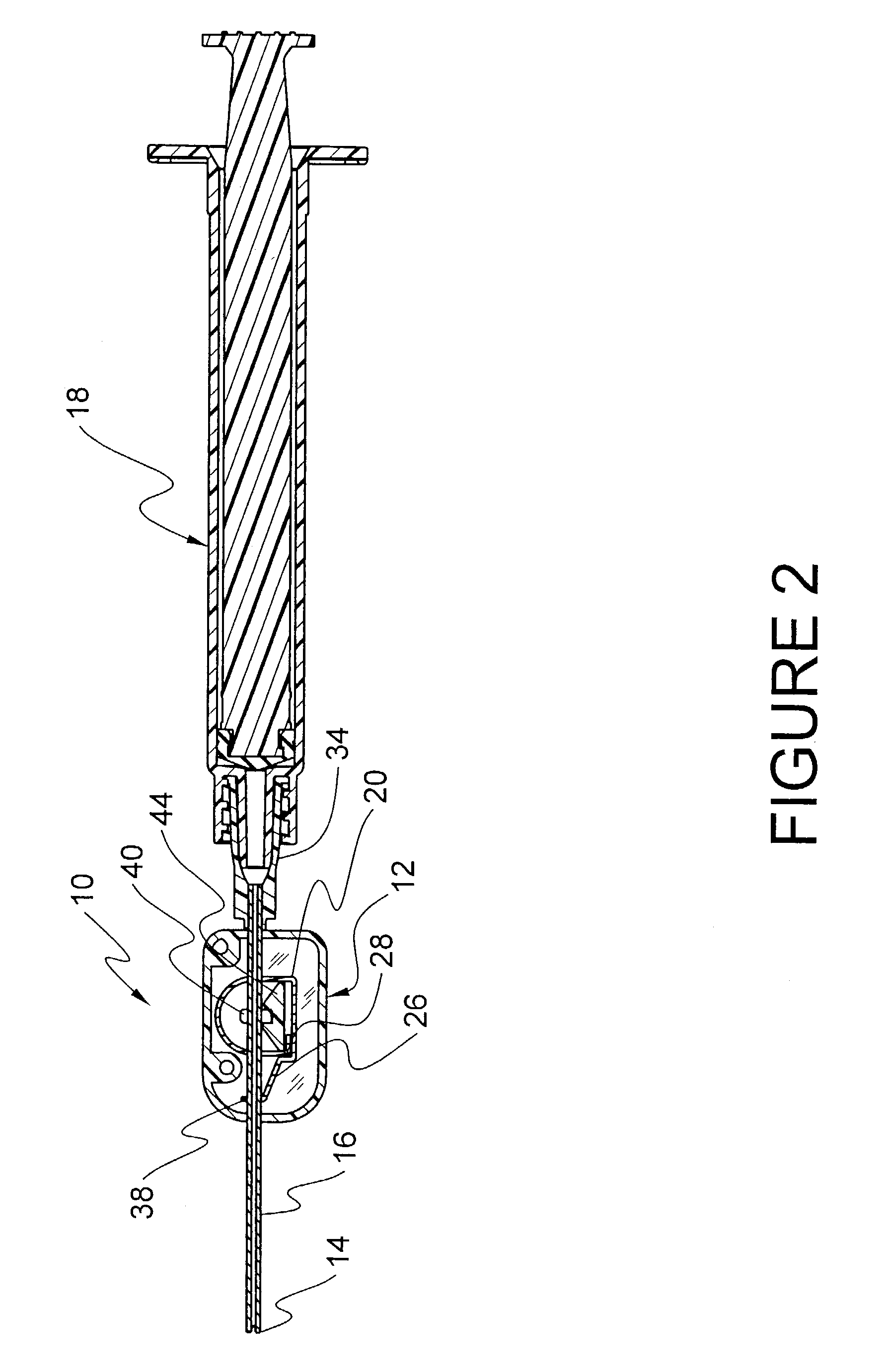

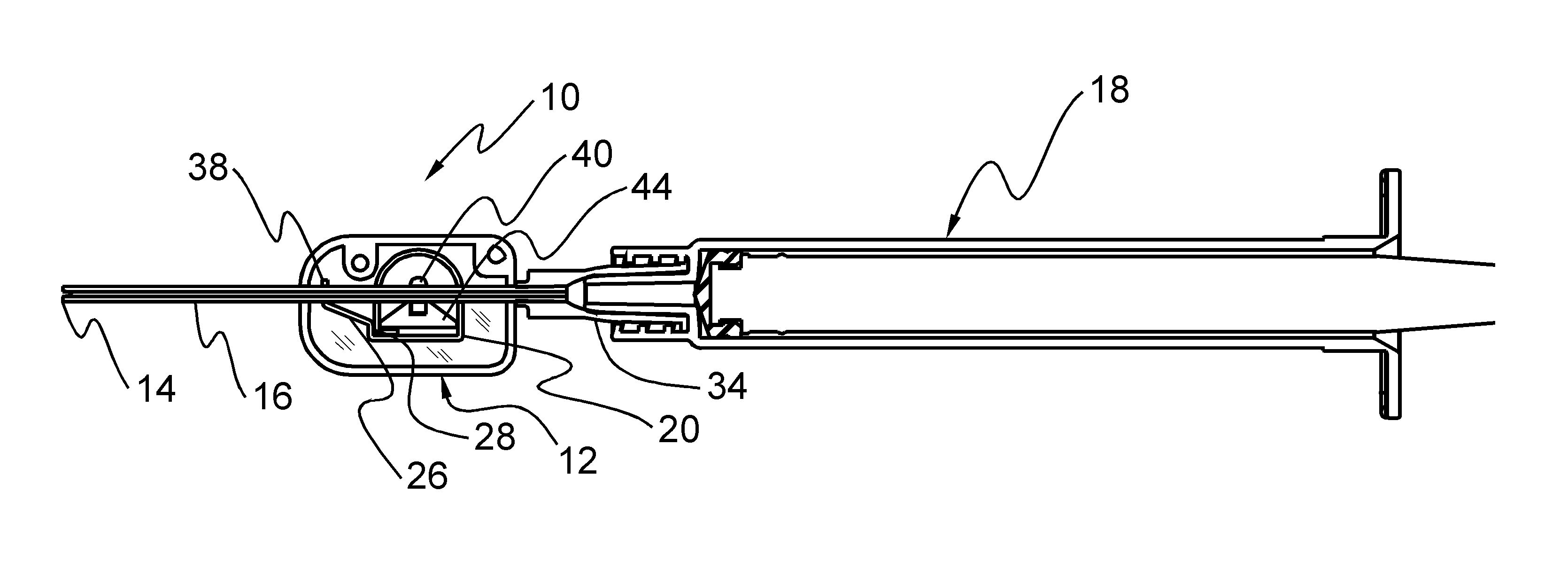

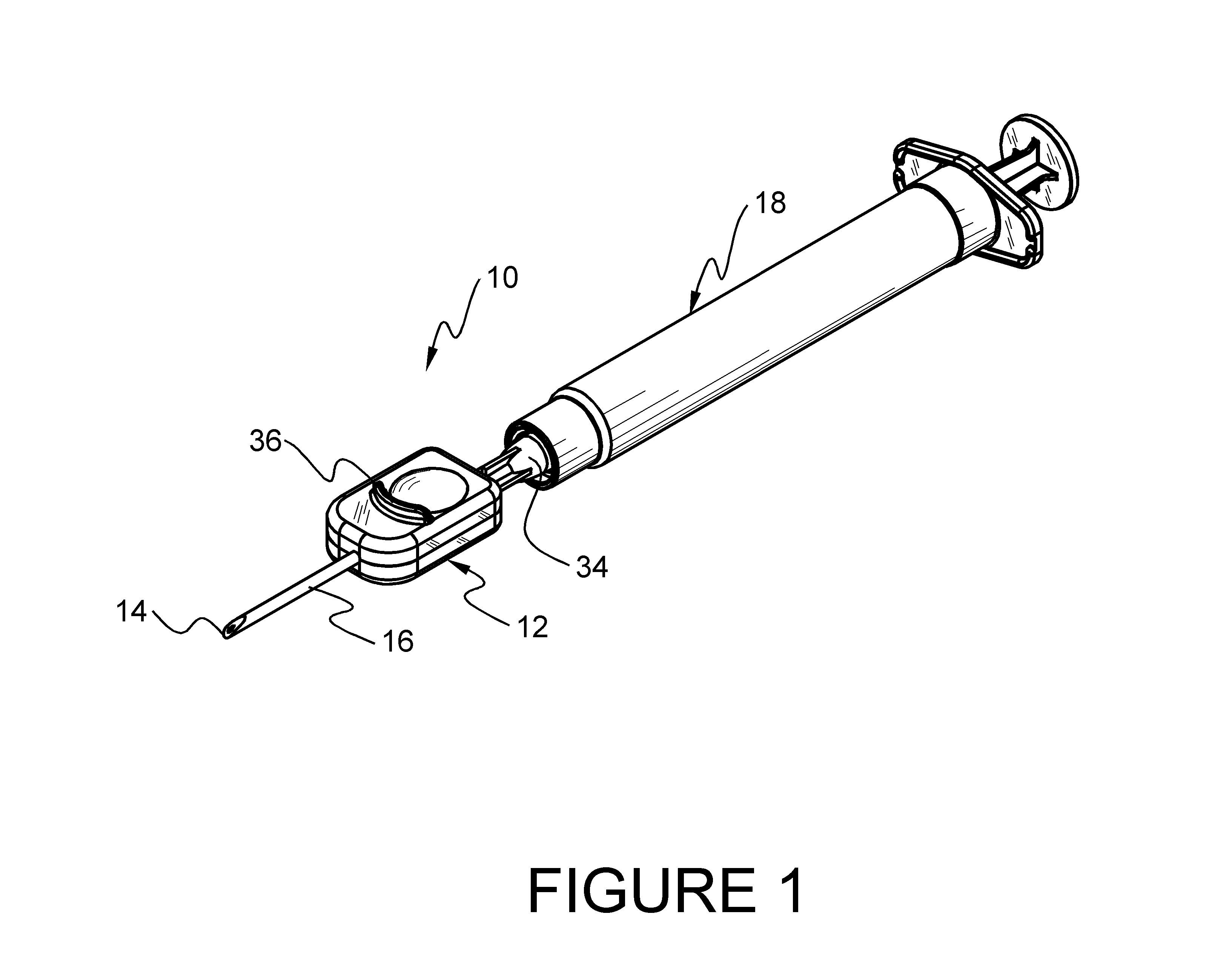

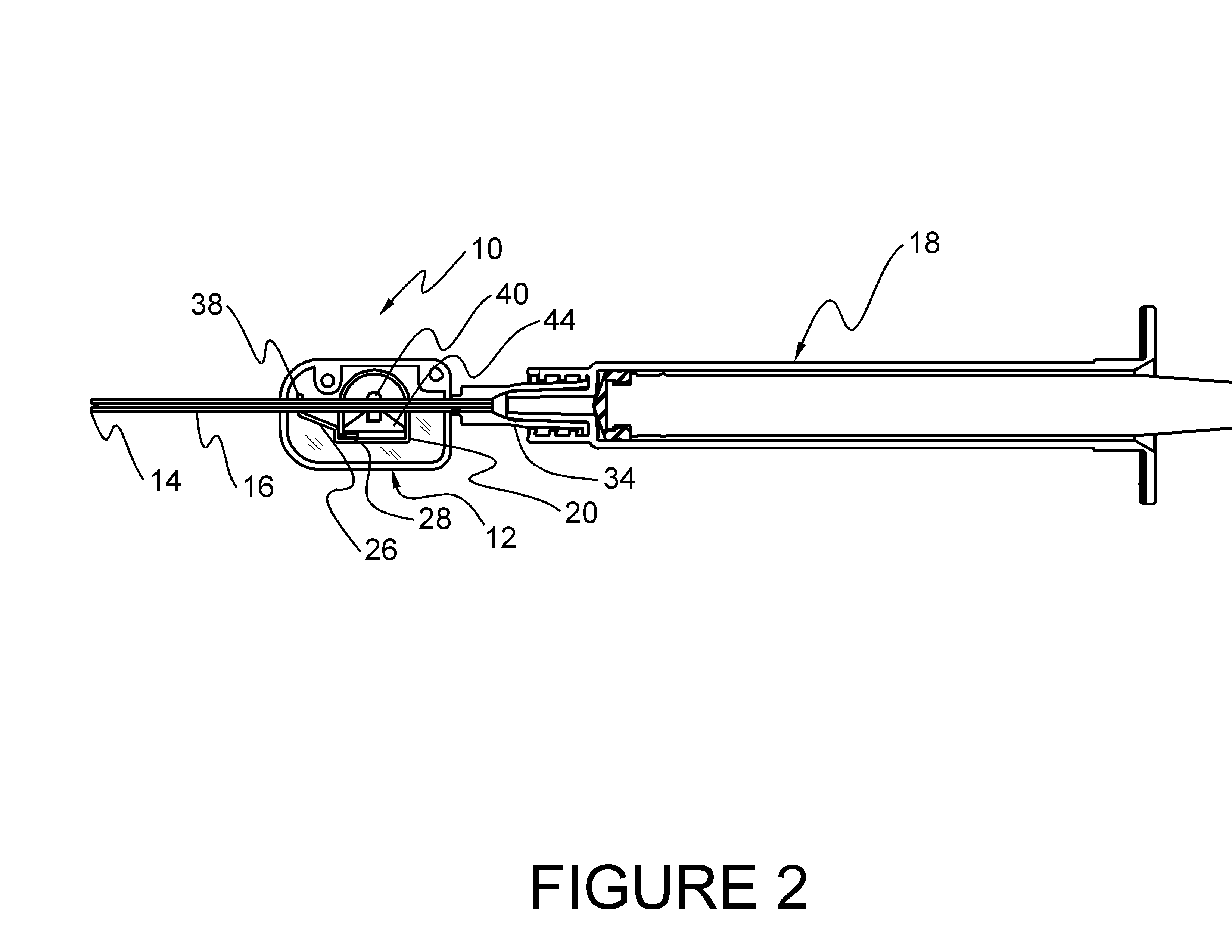

Safety shield for medical needles

InactiveUS20020151850A1Effectively and inexpensively protectsEasy to useGuide needlesSurgerySurgerySyringe needle

Owner:SPECIALIZED HEALTH PRODS

Laser cladding method for strengthening surface of piercing point

ActiveCN101519778ASolve the problem of easy falling offThickness is easy to controlMetallic material coating processesPiercing pointPre treatment

A laser cladding method for strengthening the surface of a piercing point includes the following steps of: (1) prefabricating WC / Co-base cladding powder; (2) pre-processing the surface of a piercing point workpiece, and cleaning up stain and rust; preheating for 2 to 5 hours at a temperature between 400 DEG C and 600 DEG C; (3) cladding the prefabricated composite powder fed in the way of reverse synchronization or coaxially in multiple steps by a CO2 laser; simultaneously, carrying out synchronous inert gas protection on the laser-cladding area; and (4) subsequent processing. The laser cladding method adopts laser to prepare a WC ceramic particle-strengthened Co-base composite coating on the surface of the piercing point, and the coating is metallically combined with the matrix, so the binding force between the coating and the matrix is enhanced; the maximum thickness of the coating can reach a few millimeters; and as the surfaces of WC particles are coated with Ni, the absorption of laser energy by the WC can be reduced, so that the burnout rate of the WC can be reduced in a laser melting pool. The distribution of the WC particles is uniform in the coating, the rigidity of the coating is high, consequently, the service performance of the piercing point can be improved, and the service life can be prolonged.

Owner:BAOSHAN IRON & STEEL CO LTD +1

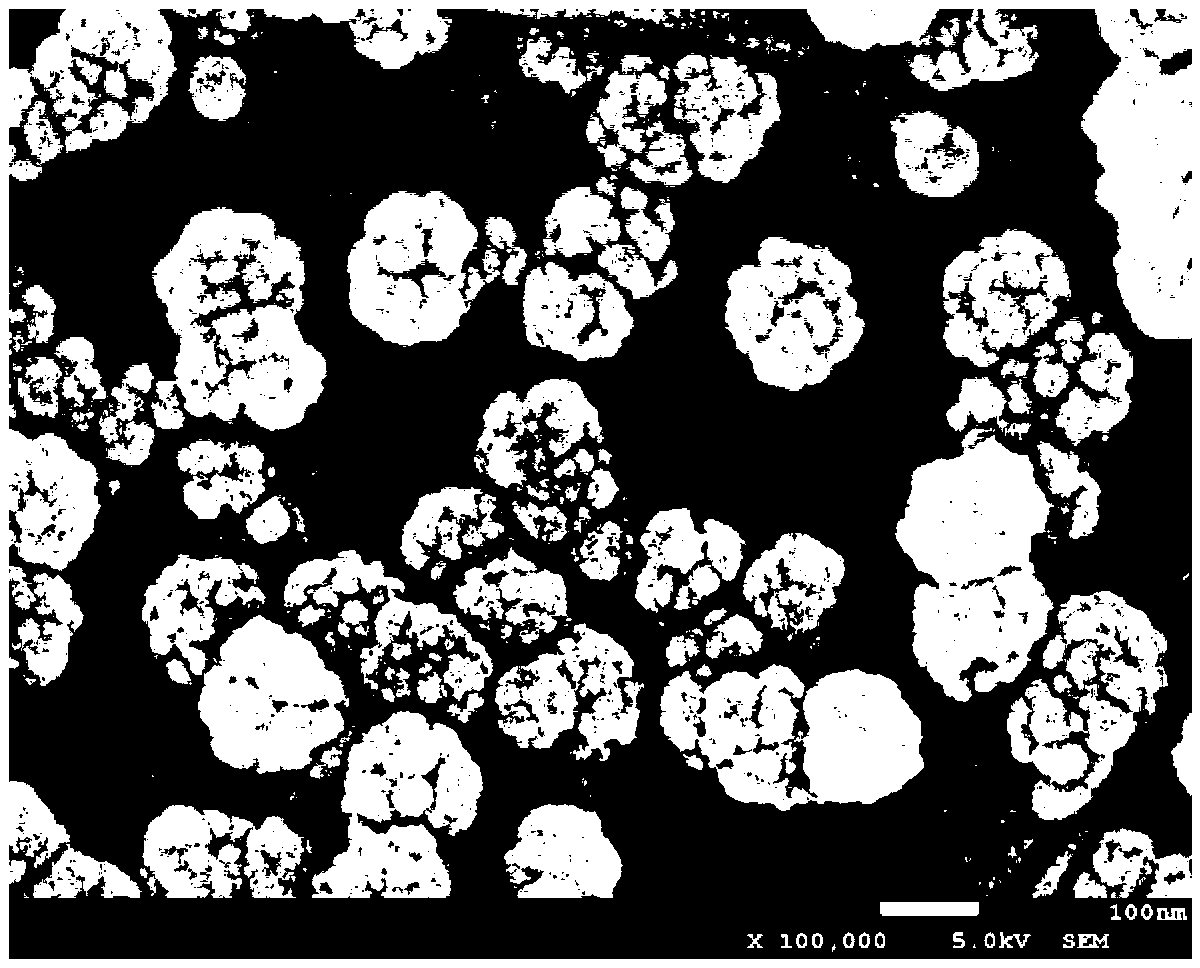

Preparation method of grapheme and ferriferrous oxide composite nanometer material

InactiveCN103274396ASolve the lack of interface binding forceResolving Particle MorphologyMaterial nanotechnologyGrapheneMicrosphereSolvent

A preparation method of a grapheme and ferriferrous oxide composite nanometer material belongs to the technical field of functional materials. The preparation method comprises the following steps: at first, oxidized grapheme is prepared by an improved chemical method; and then oxidized grapheme and ferric ions are adopted as raw materials, and are compounded through adopting a solvothermal technology to carry out one-step in-situ reduction to obtain the grapheme and ferriferrous oxide composite nanometer material. The preparation method solves the problems in the prior art that the interface binding force of grapheme and a magnetic material is insufficient, the appearances, the sizes and the magnetism of magnetic material particles are uncontrollable, and the magnetic material particles cannot be dispersed in water; the prepared composite nanometer material shows a microspheric appearance, has a loose surface and is high in specific surface area; through the change of the ratio of grapheme to the ferric ions, final magnetic property and electrical property of the composite material can be adjusted; and the controllable growth of the grapheme and ferriferrous oxide composite material is realized. The prepared grapheme and ferriferrous oxide nanometer microsheric material with magnetic and electric properties can be used in fields such as biological medicine, energy, invisibility and electronic materials.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

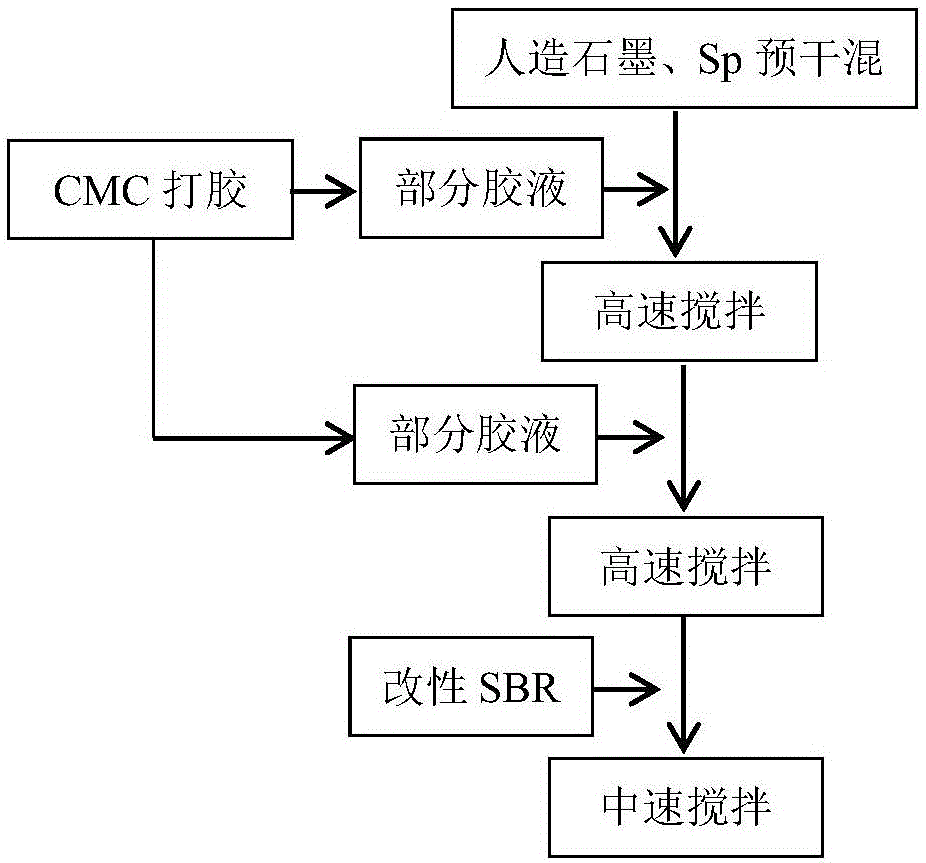

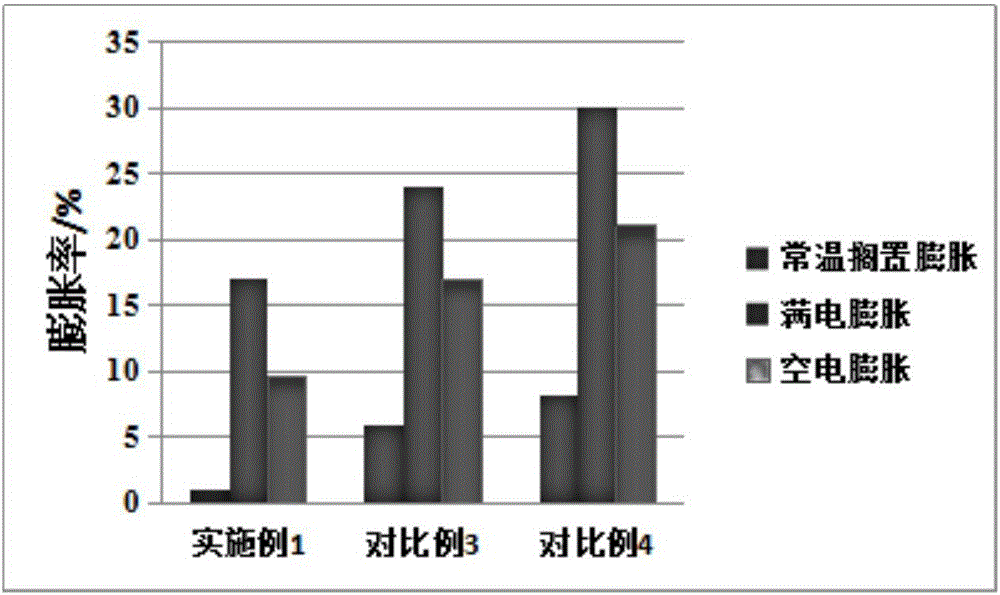

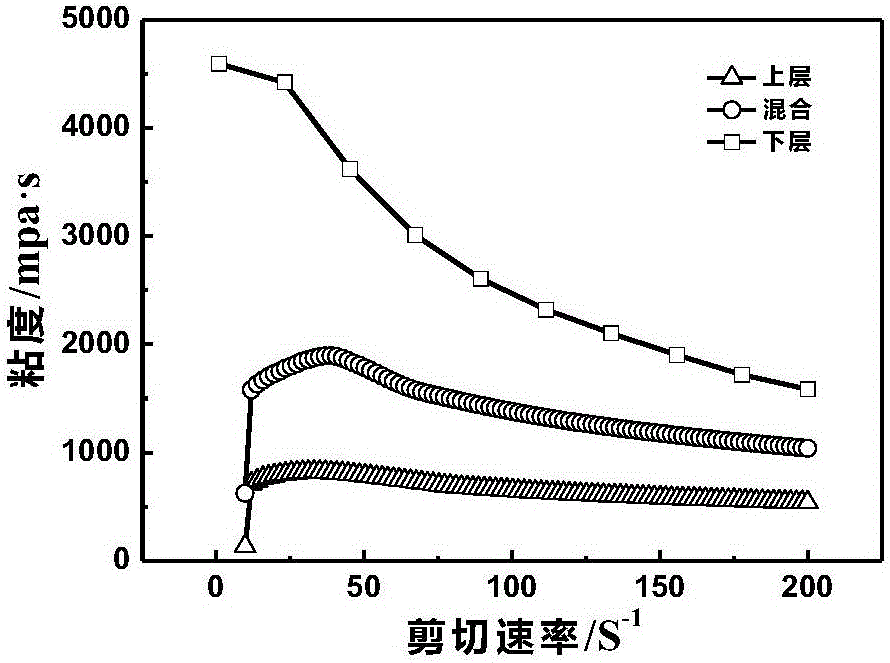

Preparation method of negative electrode slurry capable of reducing expansion of lithium ion battery

ActiveCN106159266AReduce bridgingChange structureCell electrodesSecondary cellsSlurrySodium-ion battery

The invention discloses a preparation method of negative electrode slurry capable of reducing the expansion of a lithium ion battery. The preparation method comprises the following steps of: carrying out dry blending on a negative electrode active substance and a conducting agent in advance; dissolving sodium carboxymethyl cellulose into de-ionized water to obtain a CMC (Carboxyl Methyl Cellulose) gel solution with the concentration of 1.0%-2.0%; adding one part of the CMC gel solution into a mixture of the negative electrode active substance and the conducting agent and stirring at a high speed for 0.5-1h; adding the balance of CMC gel solution and stirring at a high speed for 1-3h; adding a modified SBR (Styrene Butadiene Rubber) binding agent and stirring at a middle speed for 0.3-1h; and adjusting the viscosity. By adopting the method of carrying out the dry blending on artificial graphite and the conducting agent in advance, adding the glue solution by two times and utilizing modified SBR as the binding agent, a bridge phenomenon of the artificial graphite is reduced, a pole piece structure is changed, the binding force between grains is improved and the expansion of a negative electrode is reduced; meanwhile, the slurry sedimentation of the artificial graphite is inhibited. The preparation method of the negative electrode slurry capable of reducing the expansion of the lithium ion battery has important meanings on ternary lithium ion batteries and improvement of machinability, capacity and safety of high-capacity power batteries.

Owner:南京国轩新能源有限公司

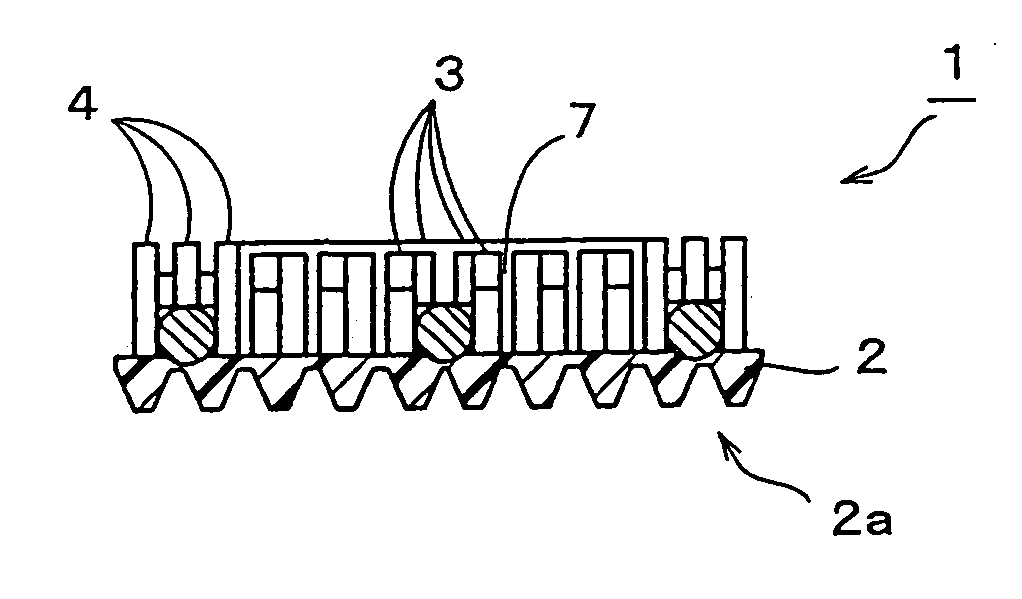

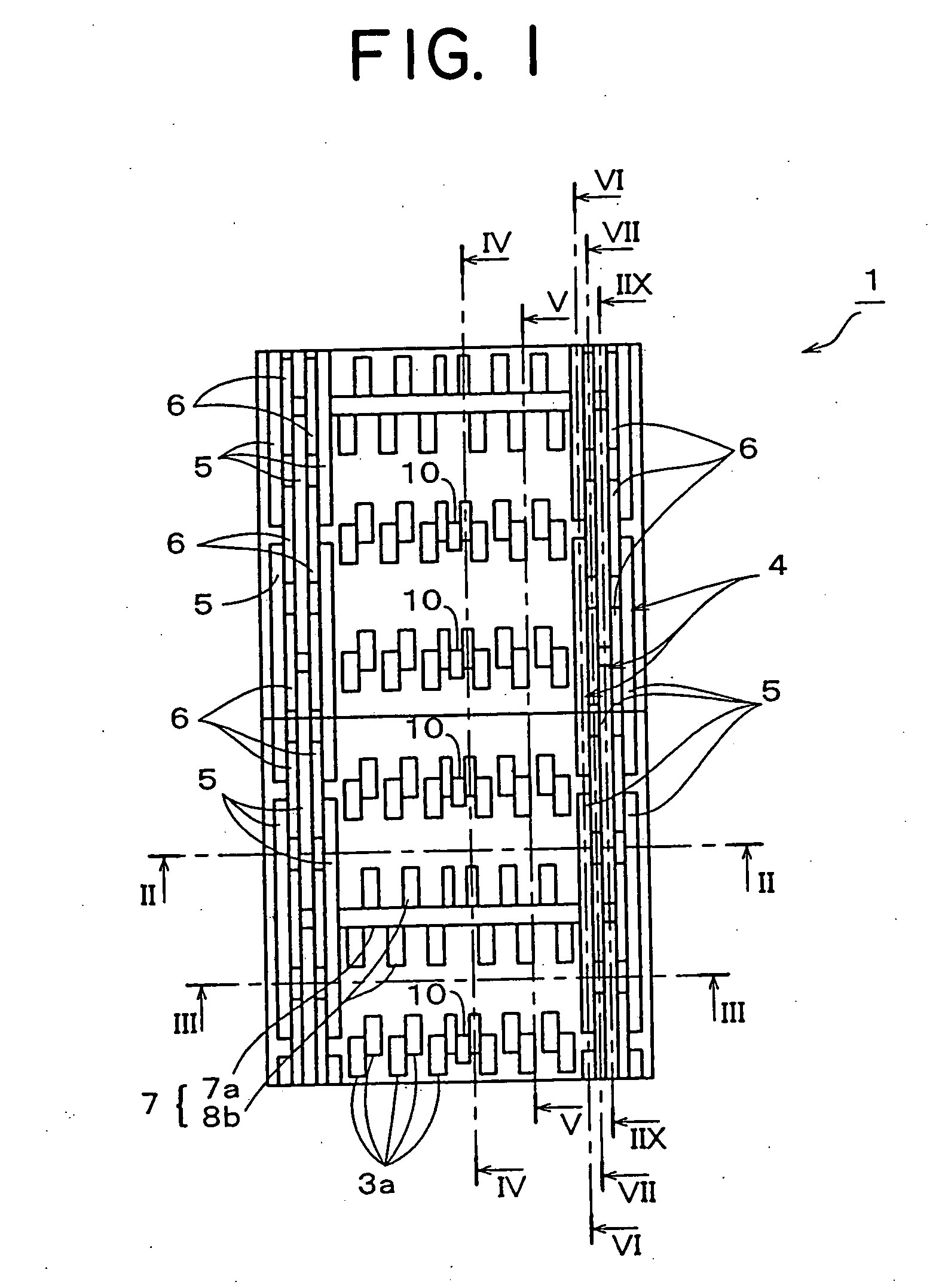

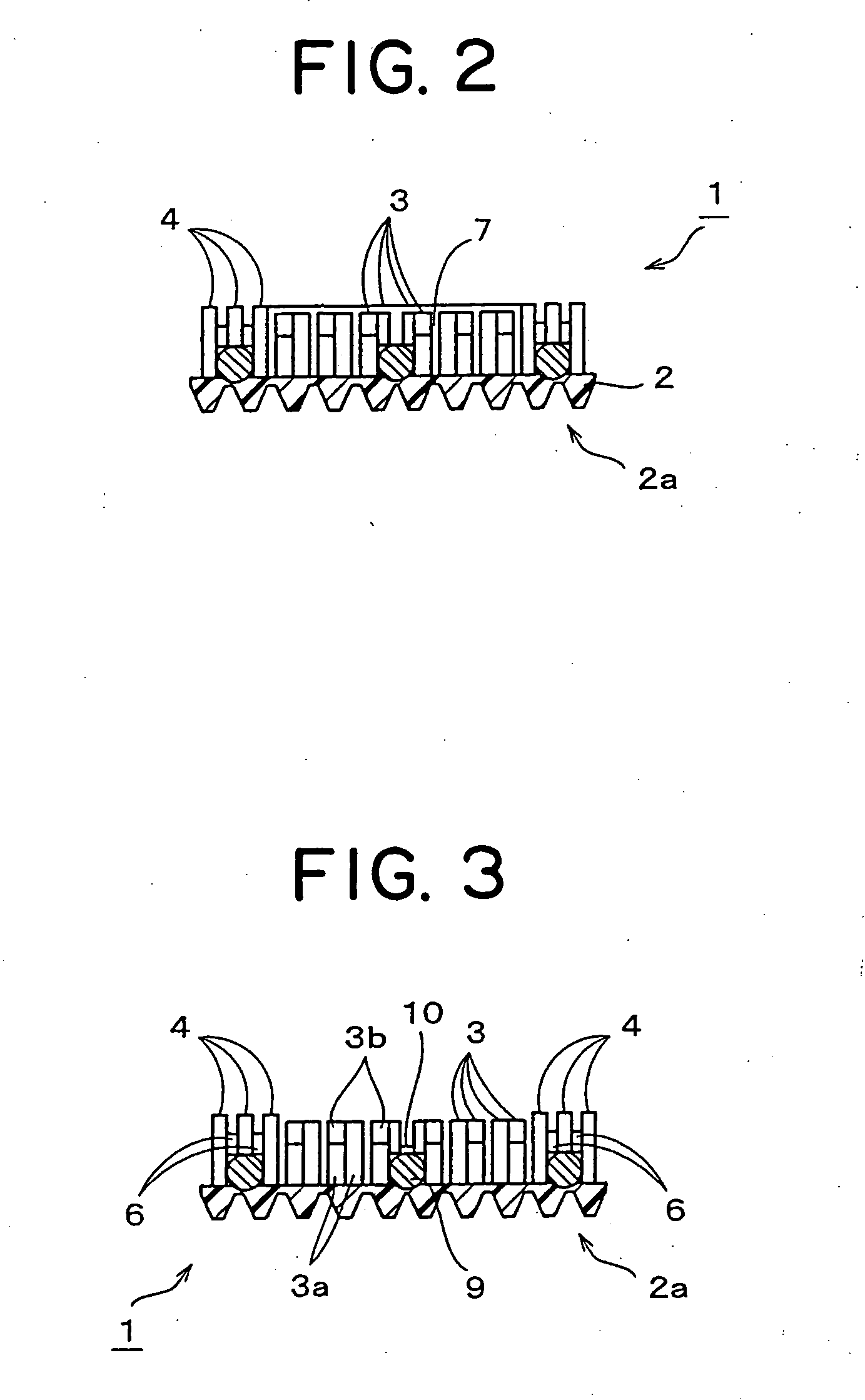

Molded surface fastener and cushion body formed integrally with the molded surface fastener

The invention provides a molded surface fastener and a cushion body formed integrally with it wherein a molded surface fastener has first resin invasion preventing means of an expandable resin material for molding a cushion body on each of right and left side edge portions along a longitudinal direction of a thermoplastic-resin base member surface, a number of engaging elements provided between the invasion preventing means, and second resin invasion preventing means for sectioning the engaging elements into desired number of regions along the longitudinal direction of the base member and extending in a width direction between adjacent sectioned regions, the second resin invasion preventing means comprising a function for engaging / disengaging a mating engaging element, thereby the molded surface fastener securing a required binding force.

Owner:YKK CORP

Method for making dimethyl silicone polymer micro flow control chip composite type optical cured resin die arrangement

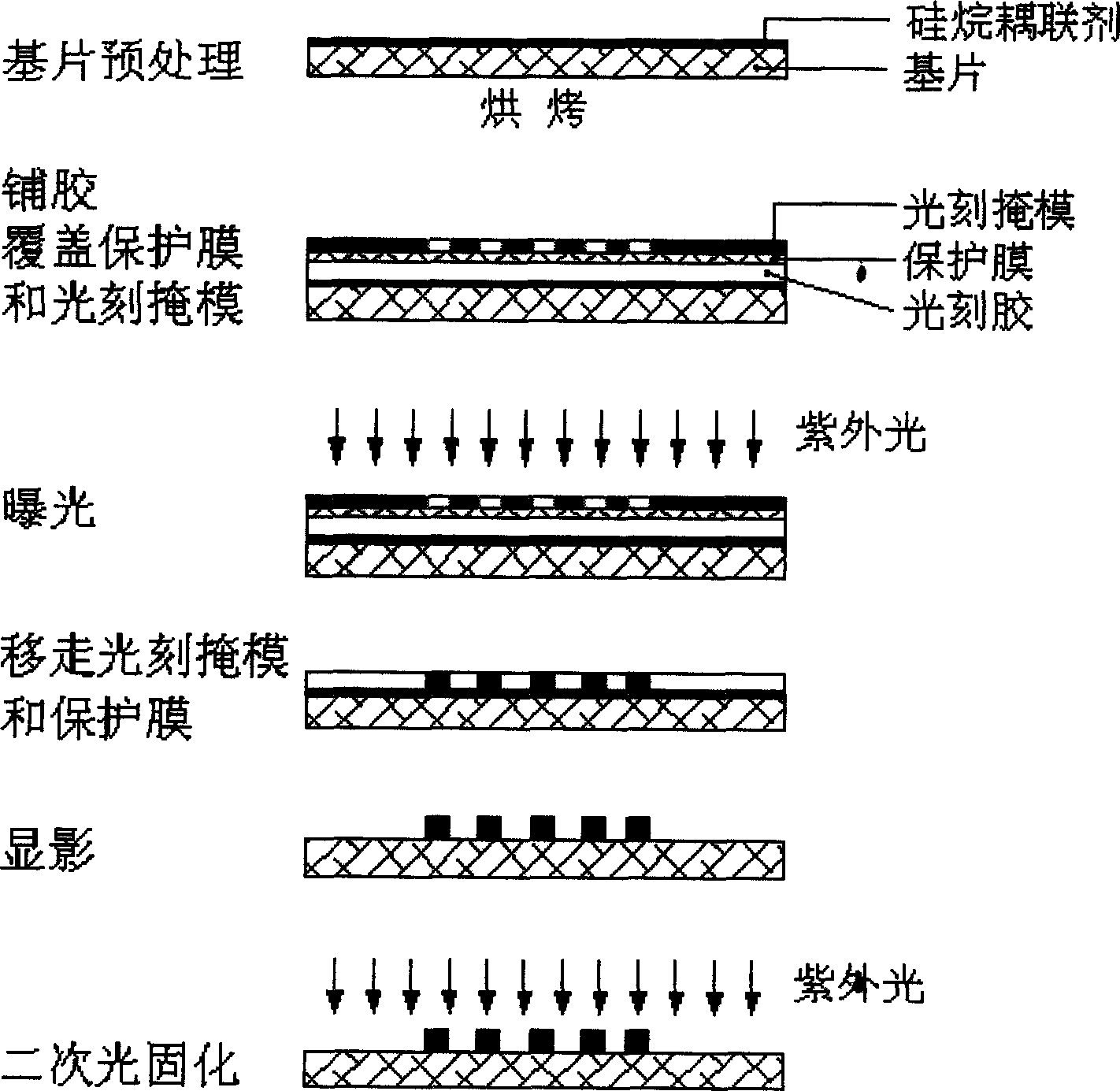

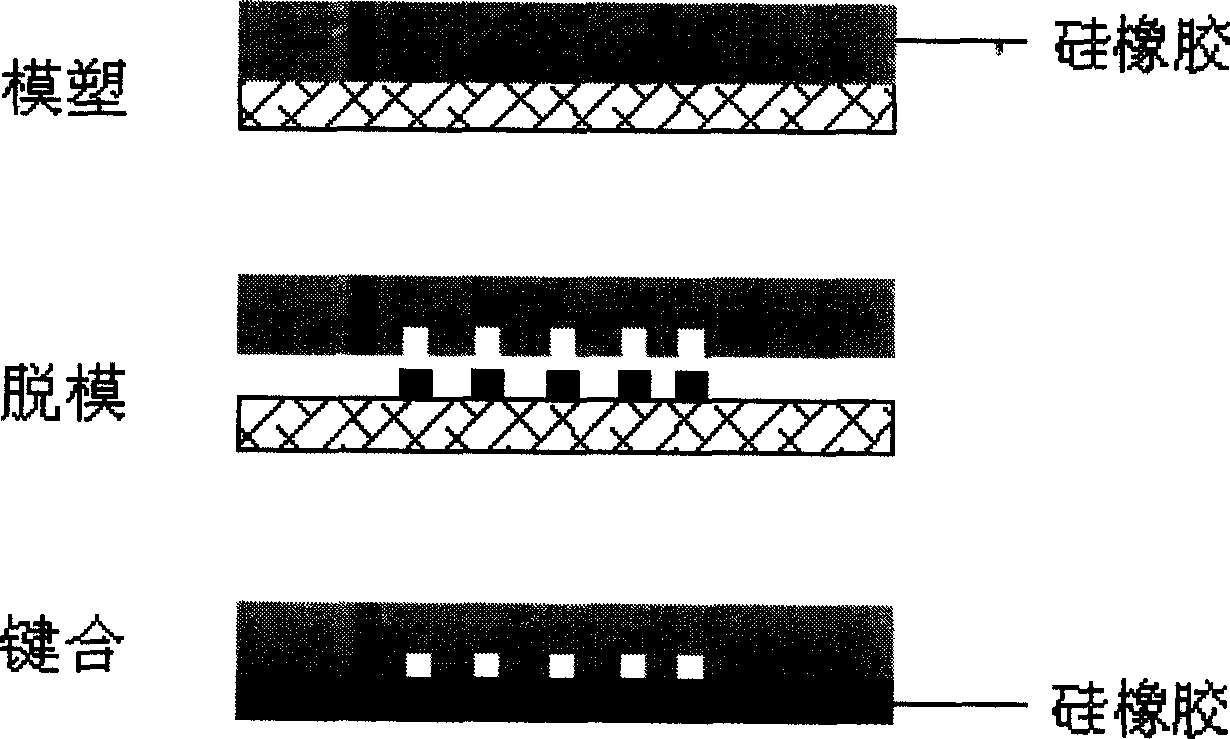

InactiveCN1621945ASolve sticking problemsHigh speedPhotomechanical exposure apparatusMicrolithography exposure apparatusEtchingSilanes

The present invention discloses the making process of composite photocuring resin mold for preparing microfluid controlling chip of polydimethyl siloxane. The present invention adopts liquid photoresist of photosensitive epoxy resin as micro mold material, quartz glass as substrate, silane coupler coating on the substrate to increase the binding force between the mold structure and the substrate, plastic film of different thickness adhered around the substrate to control the thickness of photoresist, photoetching mask of photosensitive film from laser photoset, common ultraviolet lamp or ultraviolet laser as exposure light source, F46 film as exposure protecting film, absolute alcohol as developer, vibration for clear development contour and secondary photocuring after development to raise structure strength and structure-substrate binding force. The mold is used in copying microfluid control chip, biochip, soft mold for impression etching, etc.

Owner:XI AN JIAOTONG UNIV

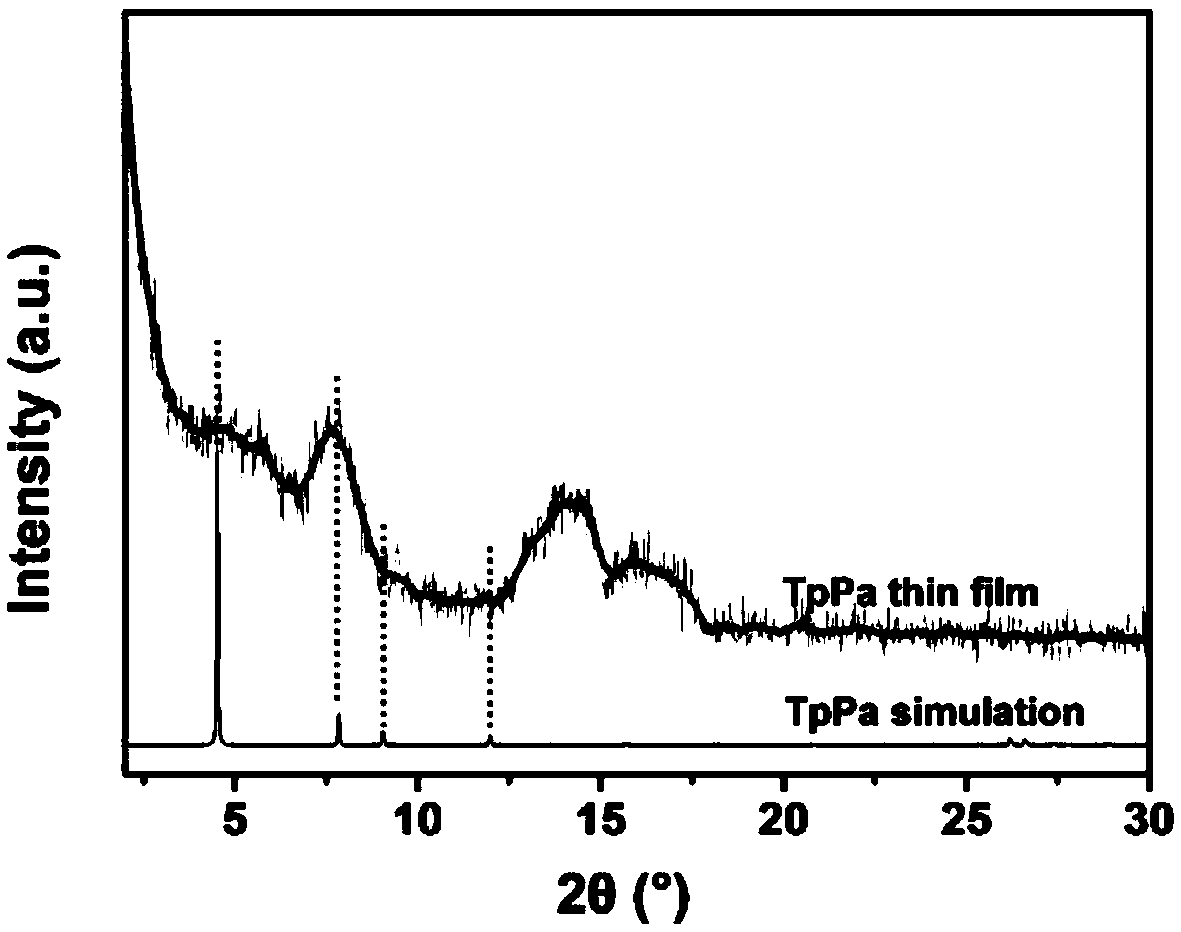

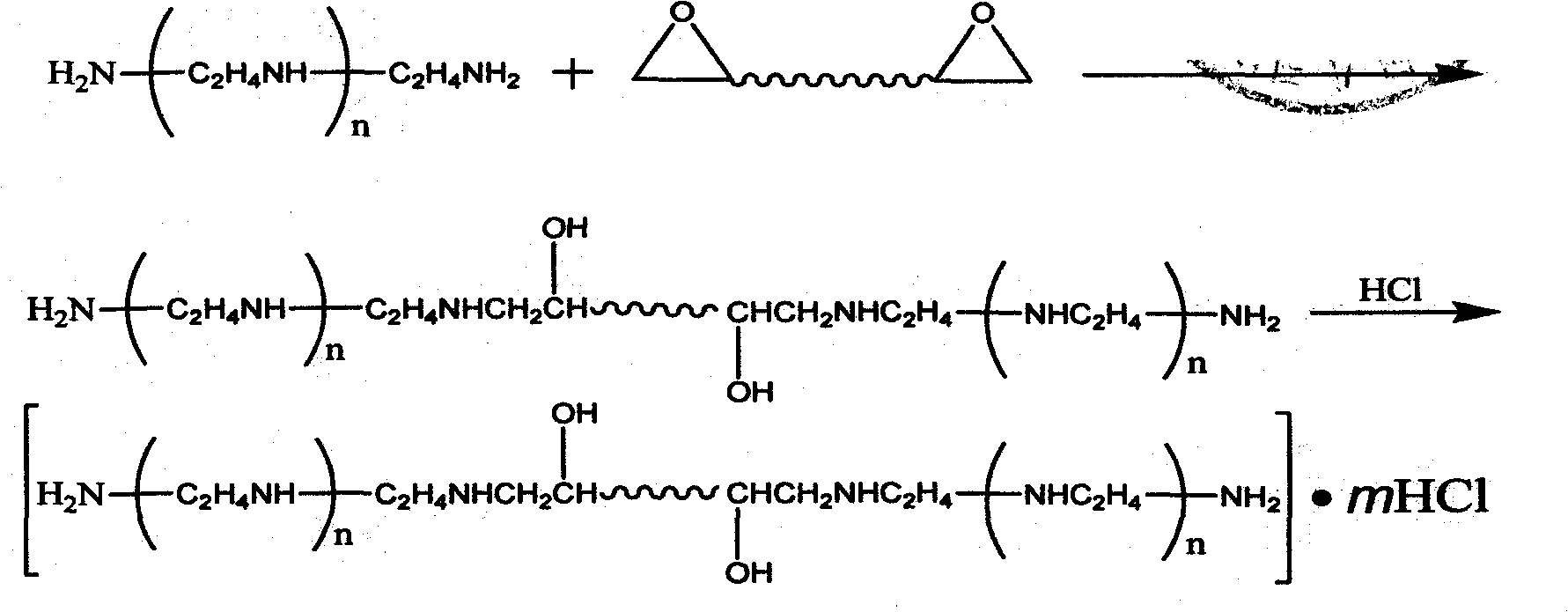

Method for preparing high-throughput covalent organic framework nano-filtration membrane on basis of interfacial polymerization

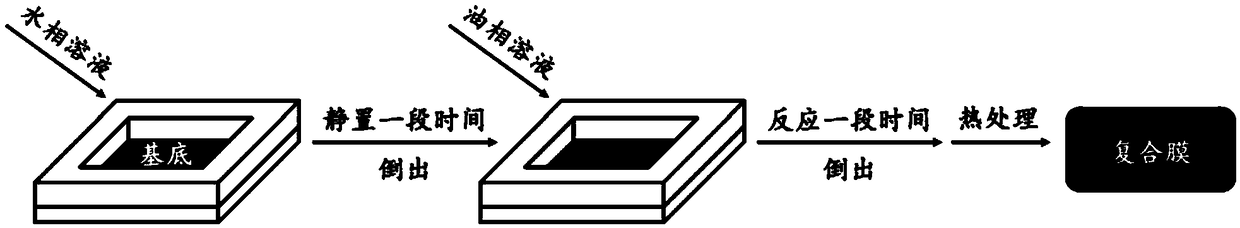

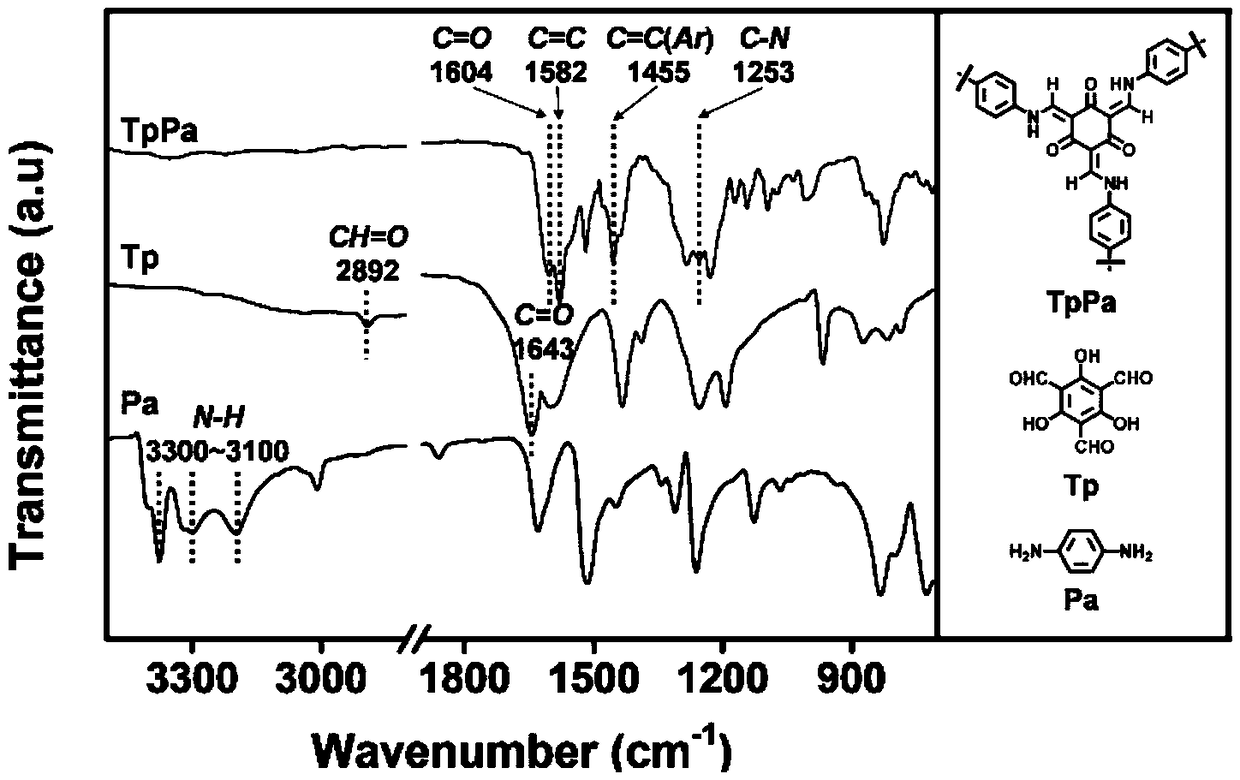

ActiveCN108889139AGood chemical stabilityHigh permeation fluxSemi-permeable membranesFiltration membraneBinding force

The invention provides a method for effectively preparing a high-throughput covalent organic framework (COFs) nano-filtration membrane on the basis of interfacial polymerization. The method comprisesthe following steps: sequentially applying an aqueous phase solution dissolved with polyamine monomers and an organic phase solution dissolved with polyaldehyde / polyketones monomers to the surface ofa porous carrier to carry out interfacial polymerization; diffusing the polyamine monomers in the aqueous phase solution saturated porous carrier to a water / oil interface to carry out schiff base reaction with polyaldehyde / polyketones in an organic phase, and gradually forming a covalent organic framework separating layer on the surface of the porous carrier by a conformal growth manner; and thencarrying out heat treatment on a composite membrane consisting of the separating layer and the porous carrier to enhance the binding force of the covalent organic framework separating layer and the porous carrier, and promoting crystallization and conversion of the covalent organic framework. The method not only is simple and convenient to operate and short in technological process, but also is well compatible with an existing process, thus, continuous product becomes possible, and the prepared composite membrane has high flux.

Owner:NANJING UNIV OF TECH

Polymer micro-sphere insulation heat-proof mortar

A polymer microsphere insulation mortar contains the following raw material by weight: the inorganic binder 15-30, lightweight aggregate 20-50, polymer microsphere 5-30, hollow fiber 0.5-3 and dispersible emulsion powder 8-20 and the method includes: fully mixing the raw material by an adding sequence of inorganic cementitious material, hollow fiber, polymer microsphere, dispersible emulsion powder and lightweight aggregate to obtain a mixture, and then blending the mixture with water to obtain a paste shape. The mortar is commonly characterized in both the thermal resistance material and the heat capacity material with high coefficient of the thermal storage, which greatly stabilizes the temperature of the insulation. The high binding force and the overall strength of the mortar and the wall substantially improve the performance of tensile, crack resistance and anti-fracture. A good barrier layer is formed in the middle of the mortar material through a mutual gradation among cement, lightweight aggregate, hollow fiber and polymer materials according to particle size, thereby reducing the hot and cold bridge in the mortar and further improving the thermal insulation performance.

Owner:金小刚

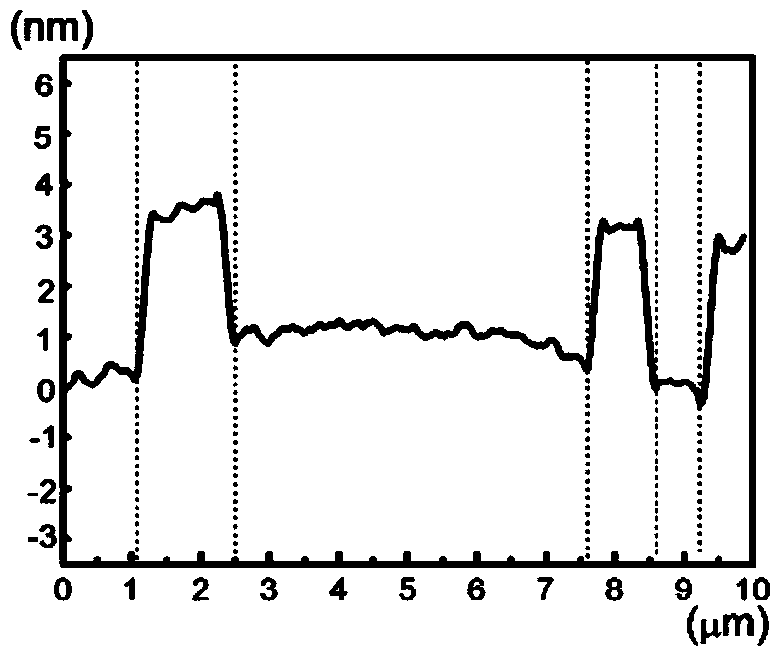

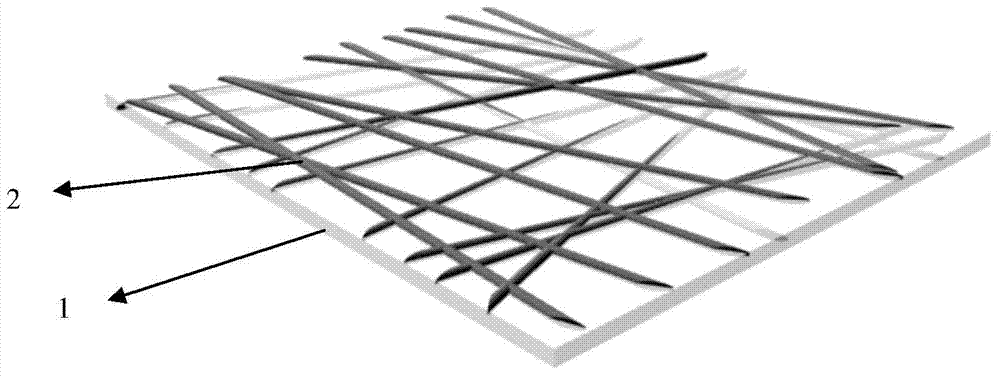

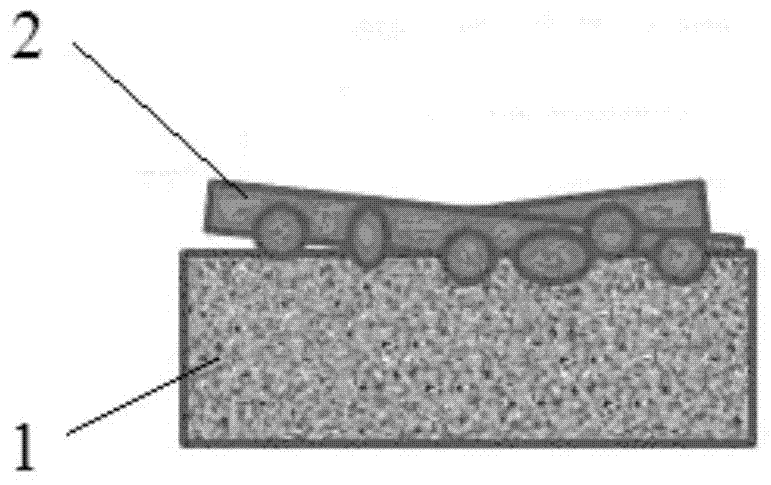

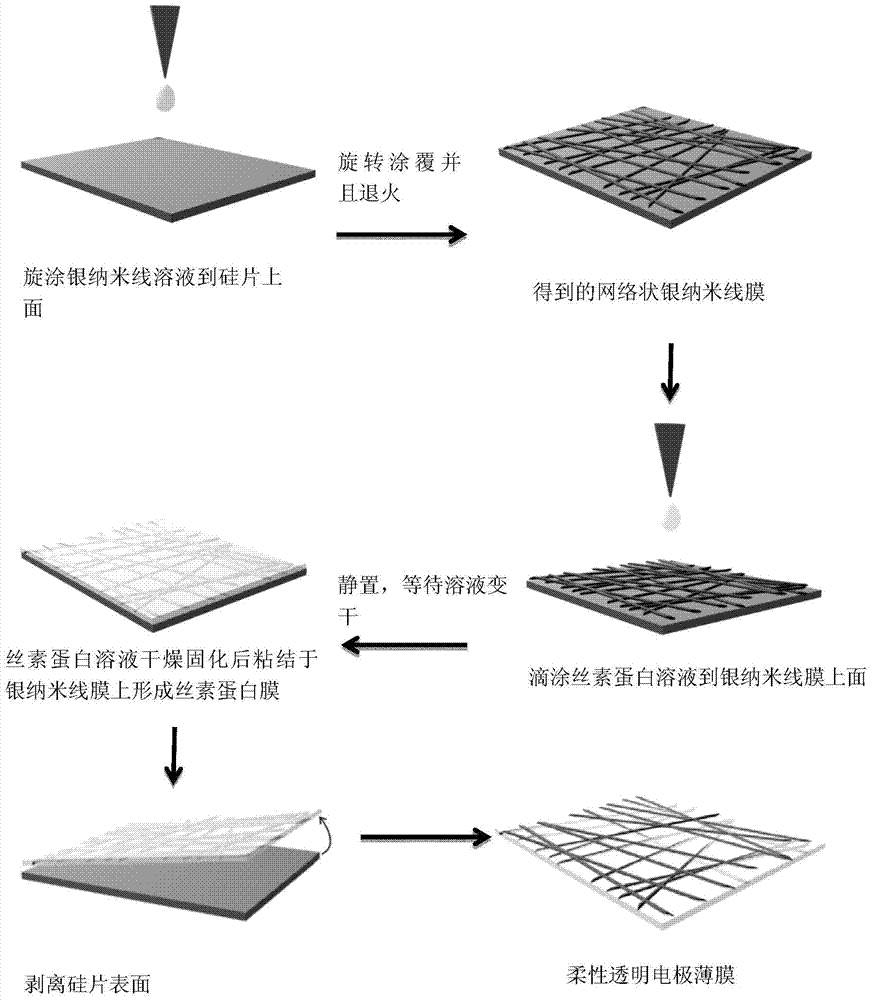

Flexible and transparent electrode film based on silk fibroin and manufacturing method and application thereof

InactiveCN103762014AGood biocompatibilityPromote degradationConductive layers on insulating-supportsIndividual molecule manipulationIrritationBiocompatibility Testing

The invention discloses a flexible and transparent electrode film based on silk fibroin which comprises a flexible supporting layer and a conducting layer and is characterized in that the conducting layer is a silver nanowire film formed by silver nanowire interwoven networks. The flexible supporting layer is a silk fibroin film, wherein silk fibroin solution is dried and solidified to adhere to the silver nanowire film through Van der Waals force to form the silk fibroin film. The electrode film has good light transmittance and conductivity at the same time and is high in flatness and binding force and good in affinity with the human body. Particularly, the silk fibroin is adopted as the supporting layer, so that the supporting layer is good in biocompatibility, biological degradability and optical performance and free of poison and irritation, the degradation process is also controllable, and the electrode film can be used in the aspects of electronic products, conductive film substrates, screens and others making intimate contact with the human body. The invention further provides a manufacturing method and application of the electrode film.

Owner:SUZHOU UNIV

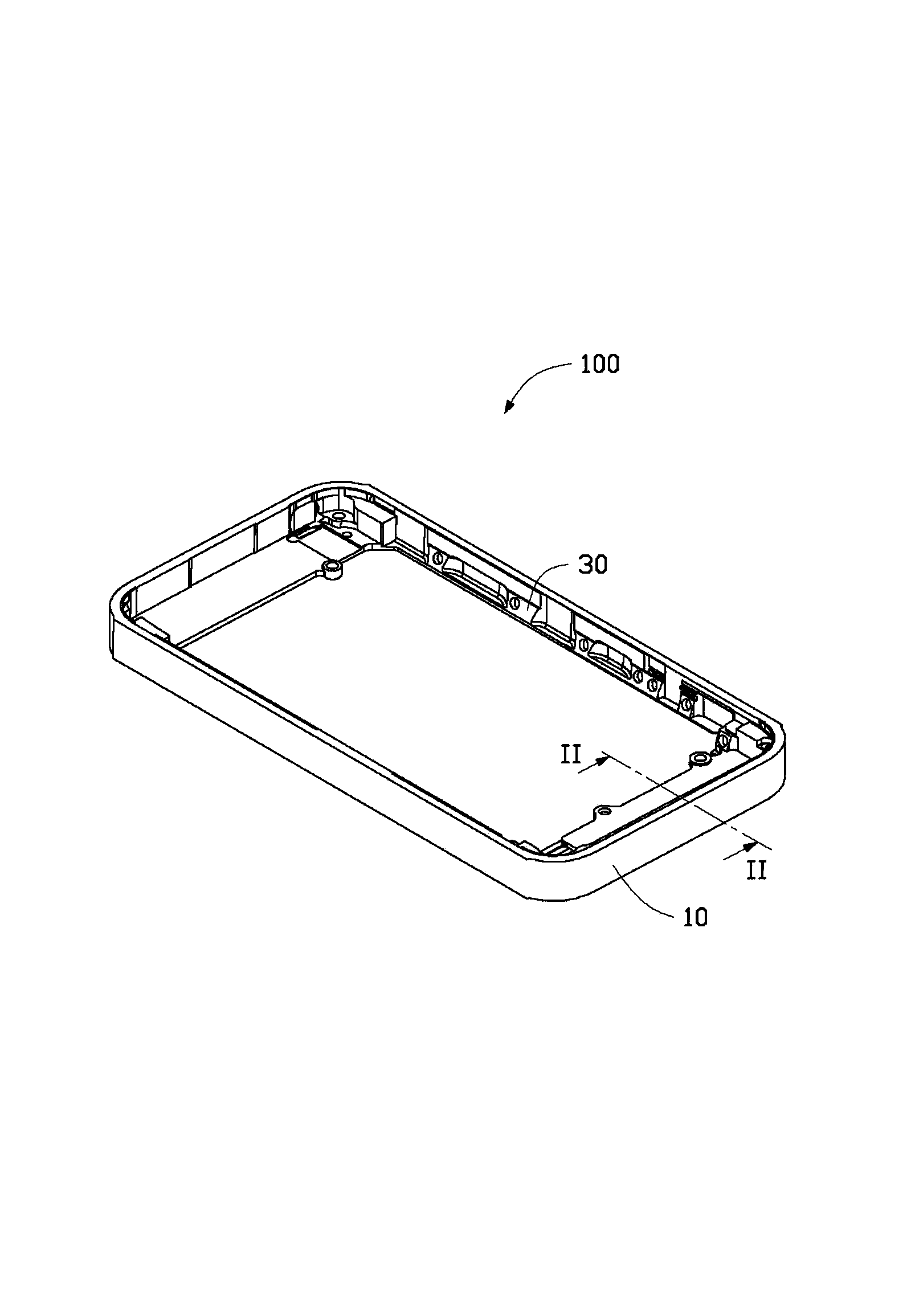

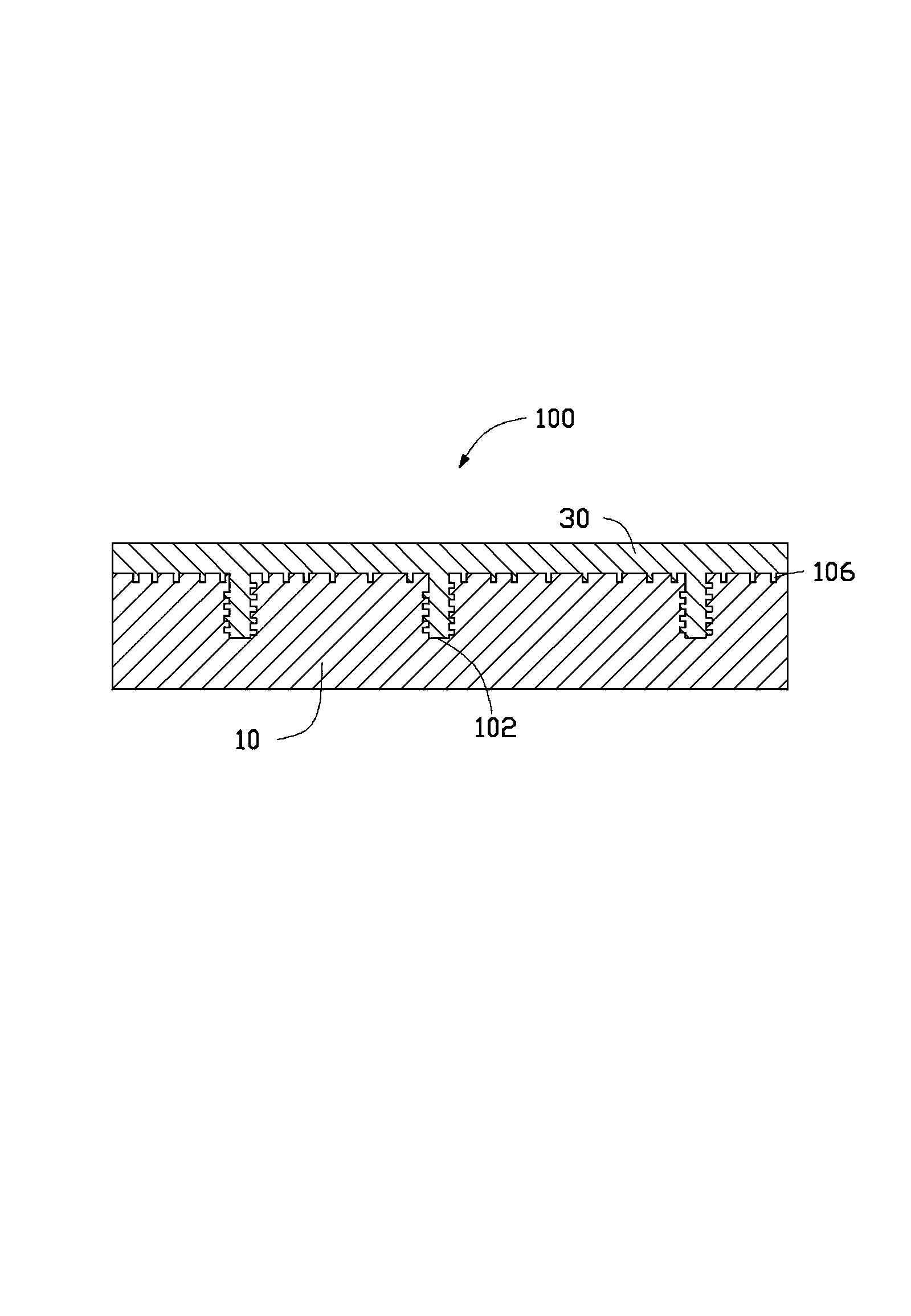

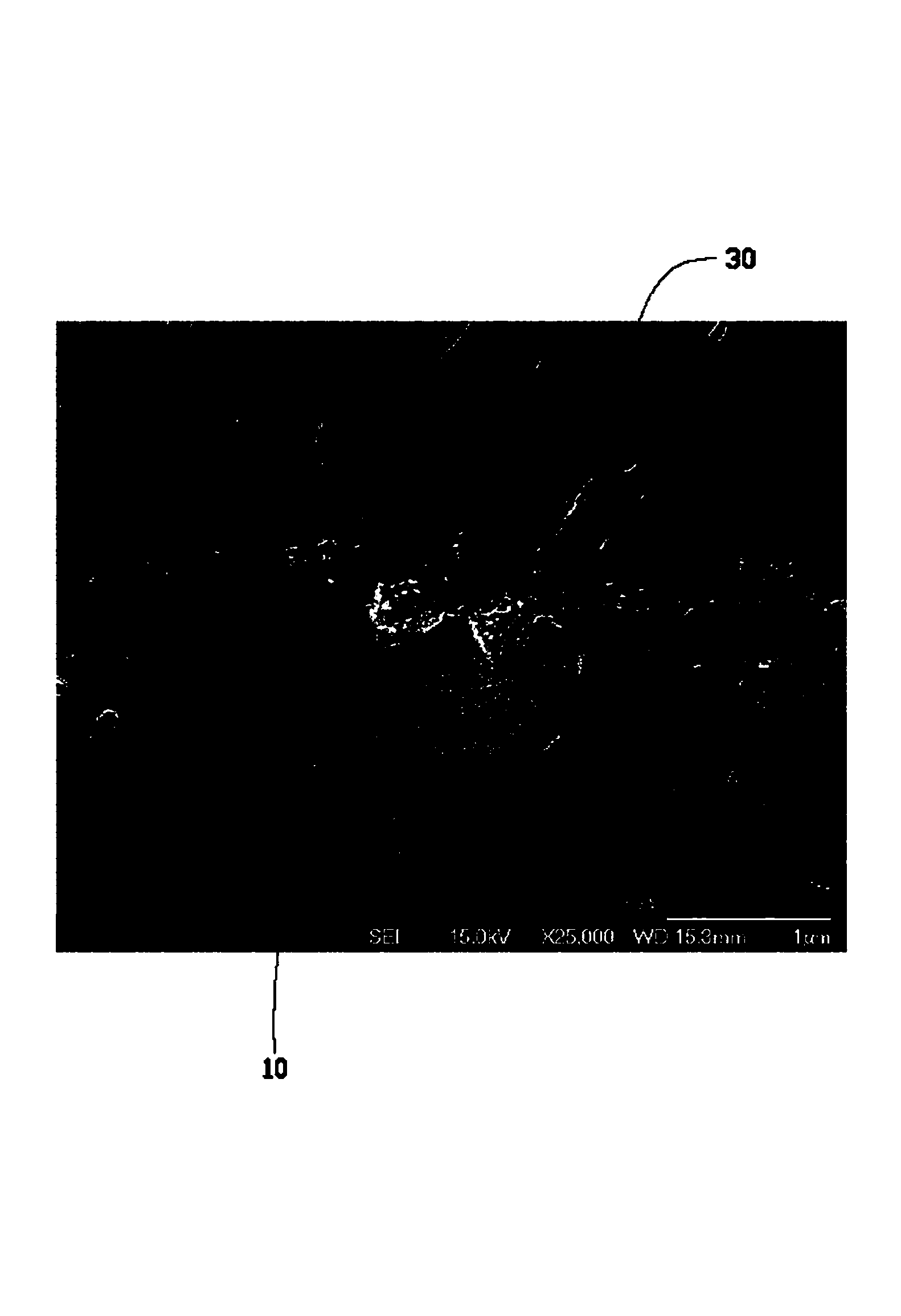

Shell and manufacturing method thereof

ActiveCN103582329AImprove bindingCasings/cabinets/drawers detailsDomestic articlesBinding forceNanopore

Owner:SHENZHENSHI YUZHAN PRECISION TECH CO LTD

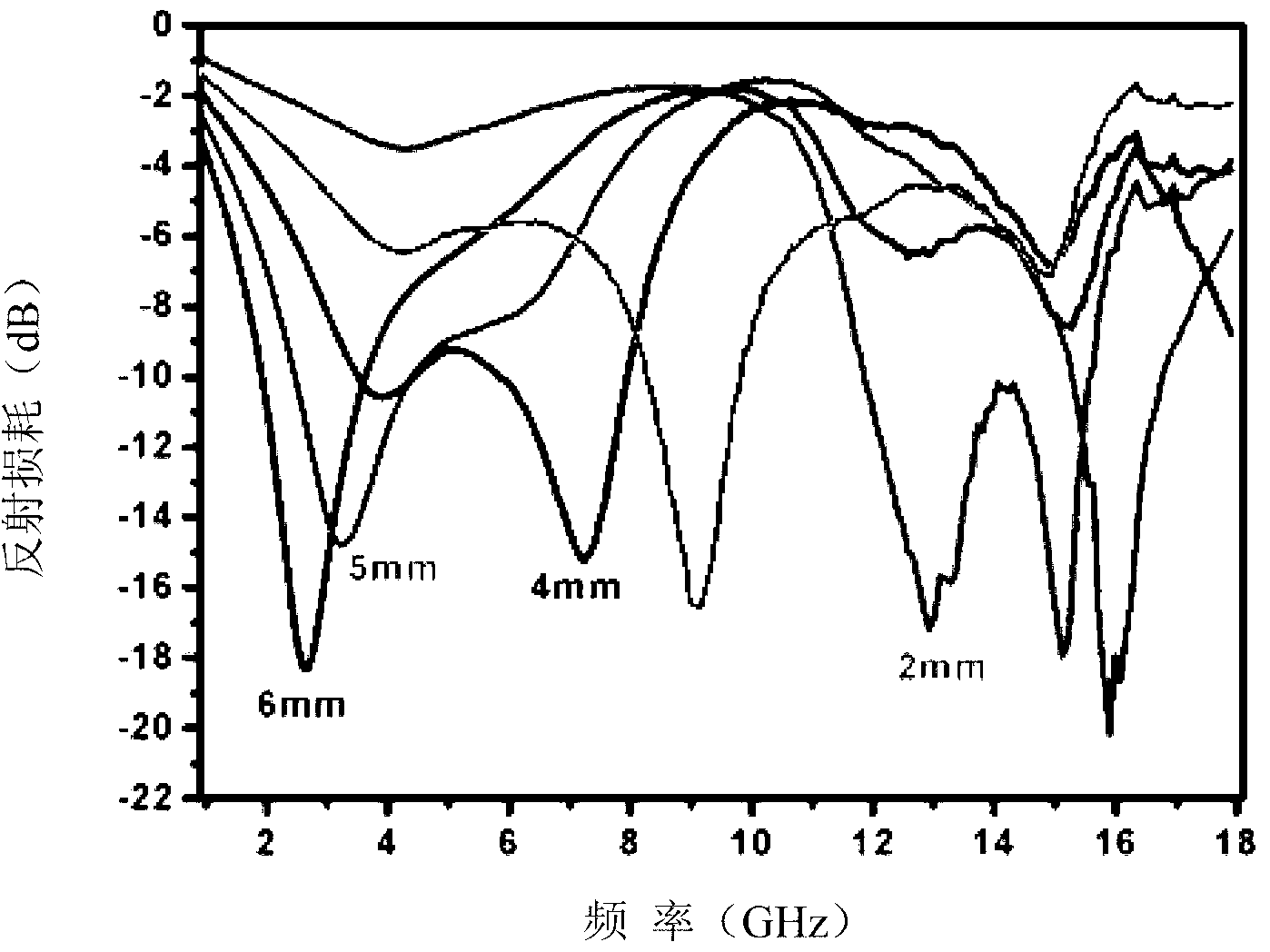

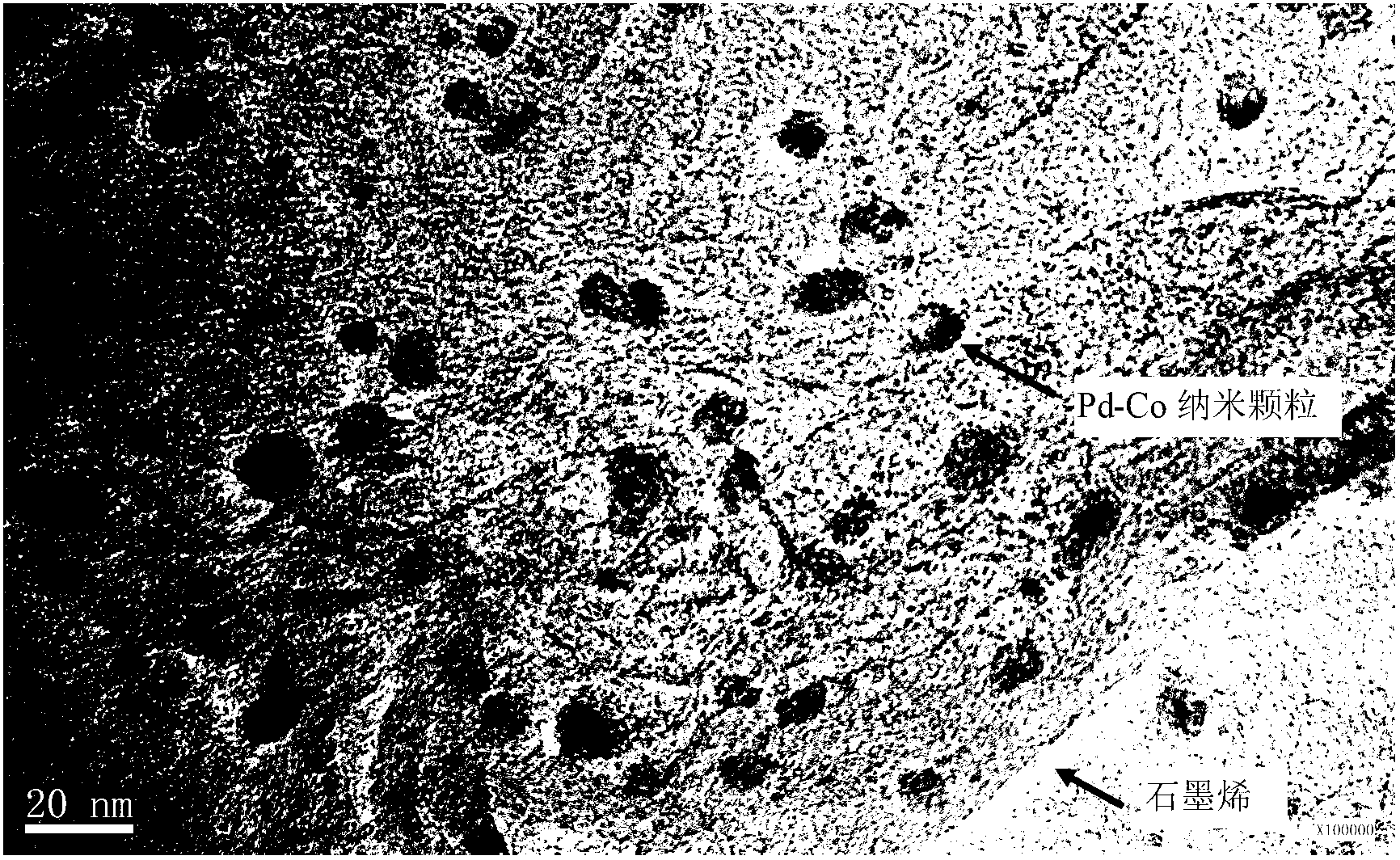

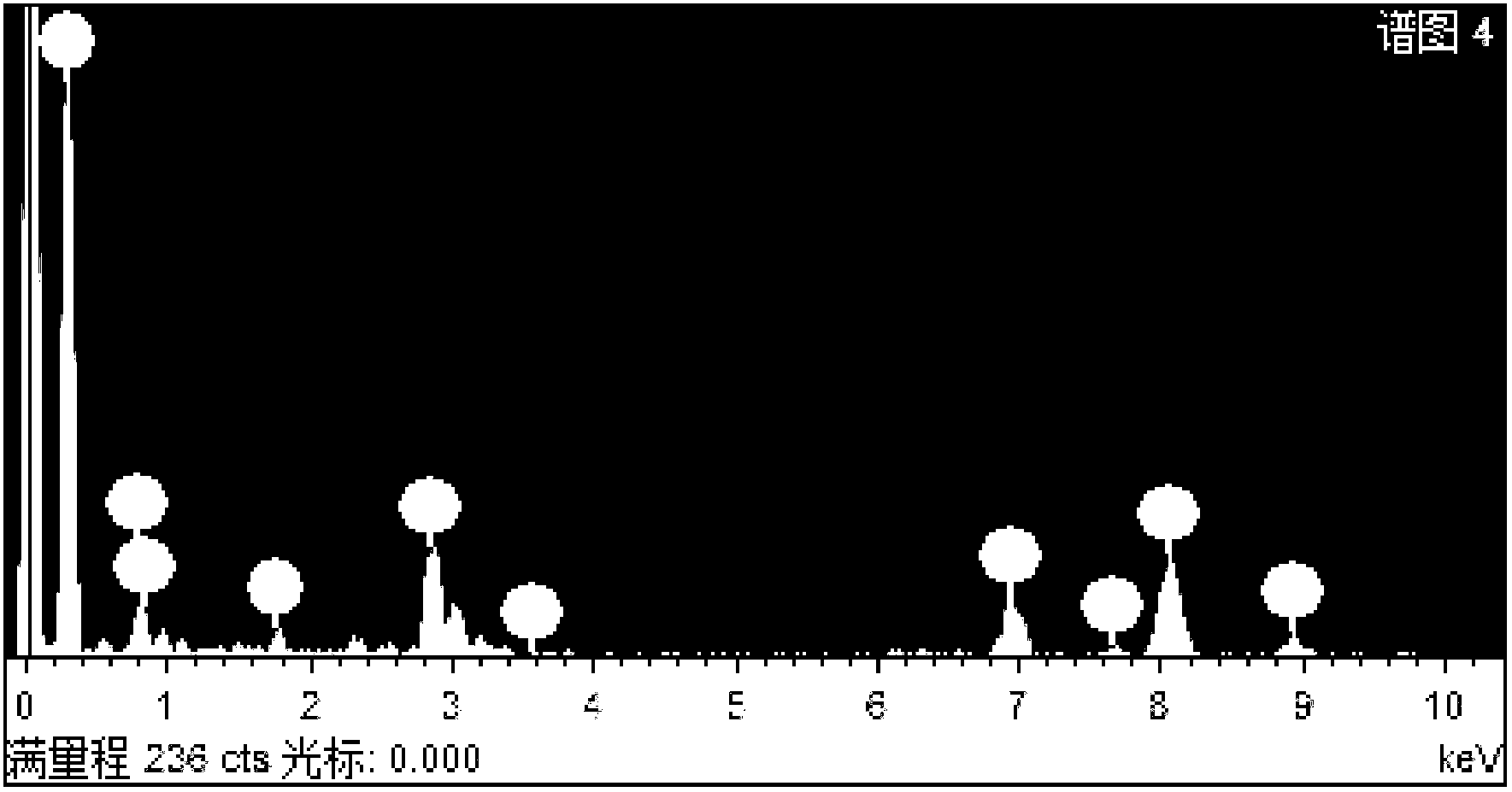

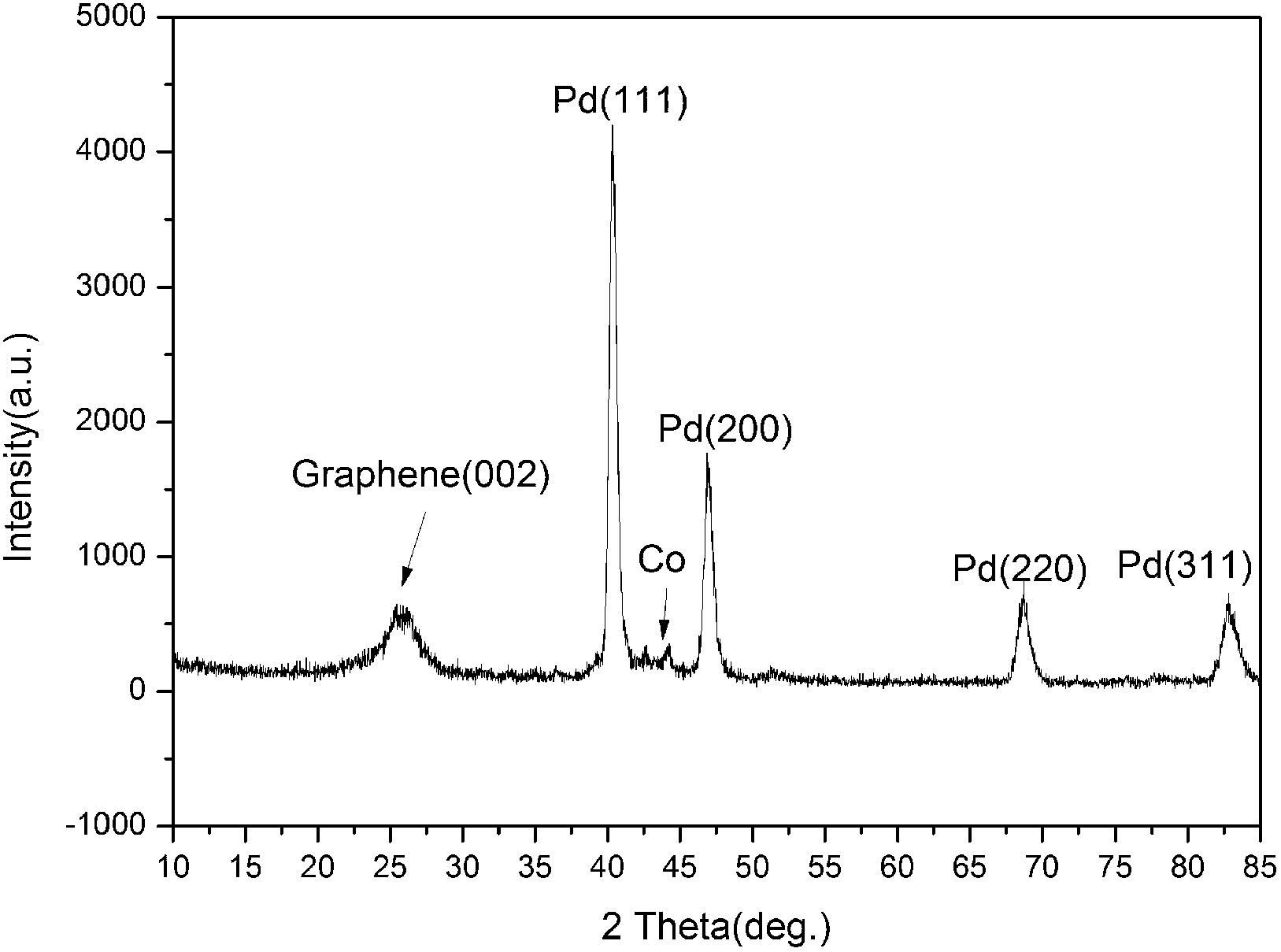

Method for preparing bimetallic nanometer alloy composite material by taking graphene as carrier

ActiveCN103007963AEvenly dispersedLow impurity contentMetal/metal-oxides/metal-hydroxide catalystsElectromagnetic shieldingAlloy composite

The invention discloses a method for preparing a bimetallic nanometer alloy composite material by taking graphene as a carrier. The method comprises the following steps of: by taking a precious metal N salt (N=Pd, Pt) and a transition metal M salt (M=Co, Ni and Cu) as precursors and taking graphene oxide as a matrix, reducing the components by employing a reducing agent; and finally, washing, filtering, drying, grinding and roasting to obtain the high-purity graphene bimetallic nanometer composite material. The composite material has high nanoparticle load capacity, stable structure, high uniformity and high dispersing property, has high binding force with the graphene and is high-efficiency in preparation method, low in cost, simple in process and suitable for industrial production. The composite material can be widely applied to the fields of magnetic targeting materials, various catalysts, electromagnetic shielding wave-absorbing materials, super-capacitor electrode materials and other related function materials.

Owner:安徽皖瑞能源科技有限公司

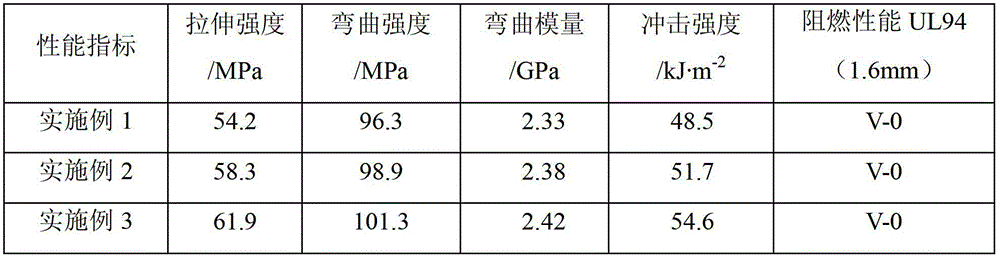

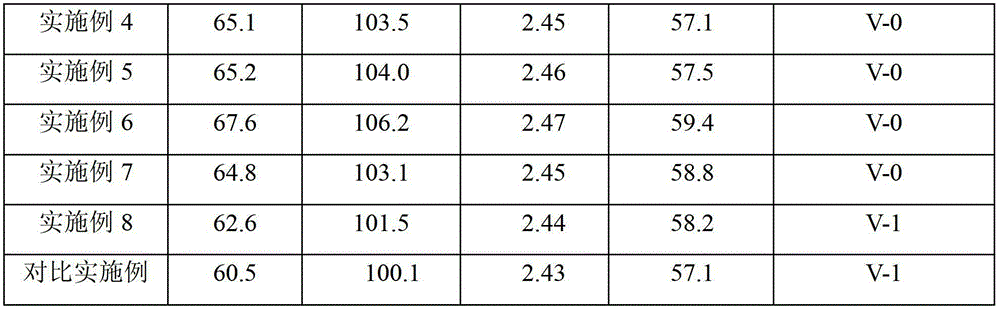

Phosphate flame-retardant PC/ABS (polycarbonate/acrylonitrile-butadiene-styrene) alloy and preparation method thereof

The invention belongs to the technical field of high-polymer alloy materials, and relates to a phosphate flame-retardant PC / ABS (polycarbonate / acrylonitrile-butadiene-styrene) alloy and a preparation method thereof. The alloy material is prepared from the following components in parts by weight: 55-75 parts of PC resin, 25-45 parts of ABS resin, 2-10 parts of compatilizer, 2-10 parts of toughening agent, 10-20 parts of flame retardant, 2-10 parts of inorganic filler, 0.1-0.5 part of antioxidant, 0.2-1.0 part of lubricant and 0.2-1.0 part of anti-dripping agent. The compatilizer, toughening agent and inorganic filler are utilized to enhance the interfacial binding force between the PC resin and ABS resin and the mechanical properties of the PC / ABS alloy. Besides, the nano silicon dioxide and other inorganic fillers added into the PC / ABS alloy can effectively perform the synergic flame-retardant function; and the anti-dripping agent in the formula can effectively inhibit the melt from dripping in the alloy material combustion process, thereby enhancing the flame retardancy of the material.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

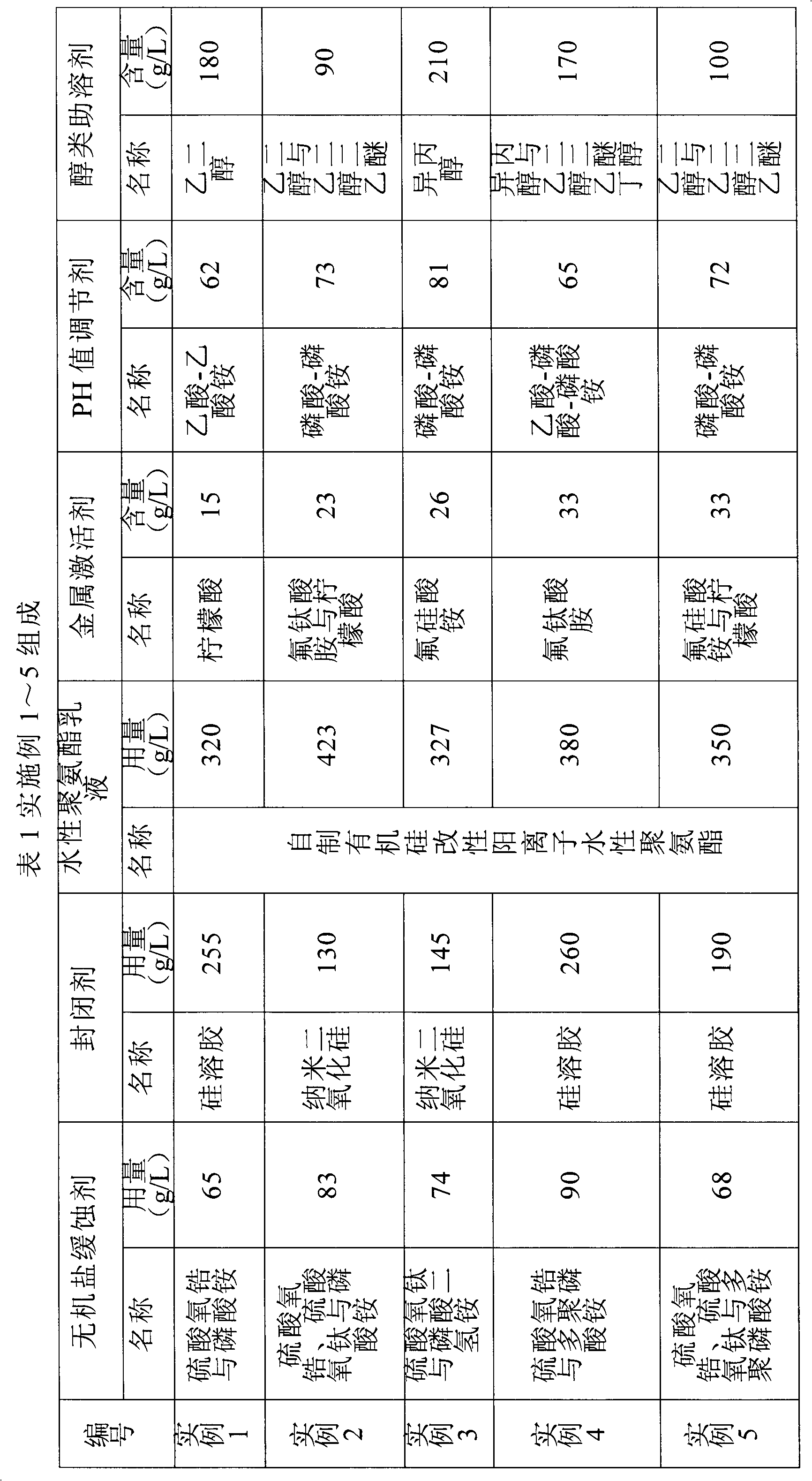

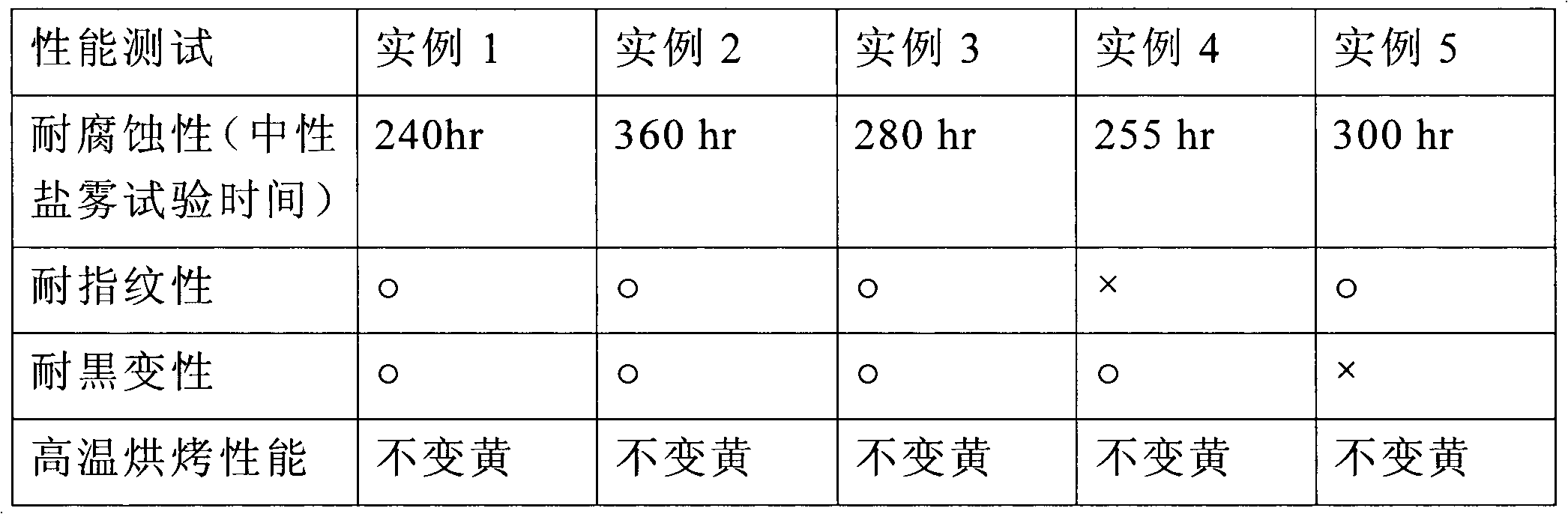

Zinc layer surface passivating treatment liquid

InactiveCN102586768AImprove bindingImprove corrosion resistanceMetallic material coating processesSolventSealant

The invention discloses zinc layer surface passivating treatment liquid. The zinc layer surface passivating treatment liquid consists of the following components by weight percent: a) 6.0 to 10.0 percent of inorganic salt corrosion inhibitor, b) 1.0 to 8.0 percent of organic acid metal activating agent, c) 6.0 to 10.0 percent of pH value regulating agent, d) 8.0 to 30.0 percent of alcohol cosolvent, e) 10.0 to 30.0 percent of silicon containing sealant, f) 30.0 to 50.0 percent of cationic or non-ionic waterborne polyurethane emulsion, and g) 0.5 to 2.0 percent of dispersing agent, defoaming agent, thickening agent and wetting agent. The film obtained by the treatment liquid has binding force with a galvanizing layer, is compact, colorless and transparent, and has high white rust resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

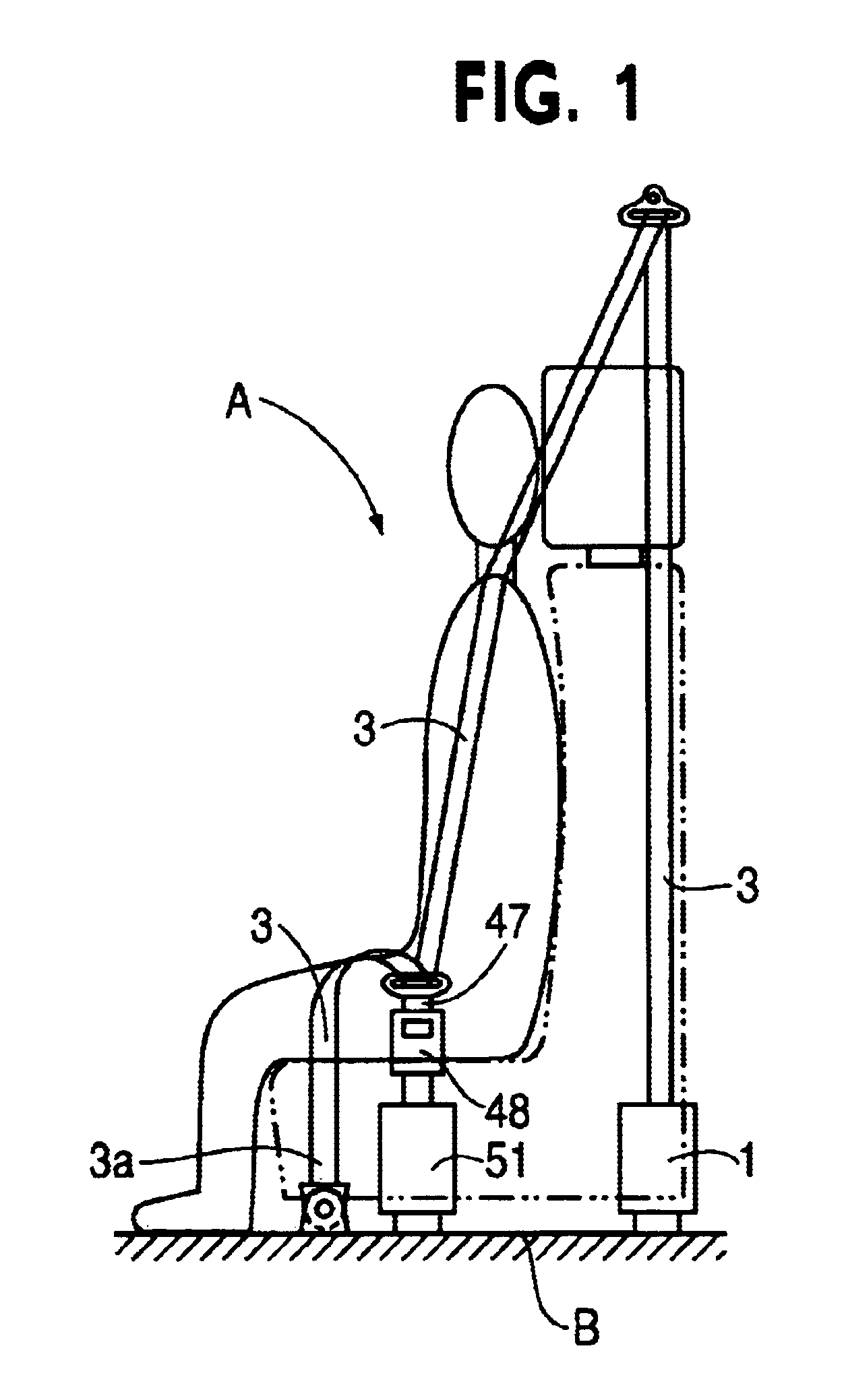

Passenger restraining protective system

InactiveUS6702326B1Easy to operate and controlEasy to installBelt retractorsPedestrian/occupant safety arrangementControl theoryBinding force

The present invention has an object to permit operation of the second pretensioner operating upon determination of a collision, irrespective of operation of the first pretensioner operating upon determination of the possibility of collision. When a vehicle body deceleration is determined not to exceed a set deceleration, possibility of collision with an obstacle is determined on the basis of a relative distance from the obstacle, a relative speed, and a vehicle speed of the subject vehicle. When the possibility of a collision is determined, a motor associated with a retractor is rotated and the webbing is retracted with a large torque until the webbing has the second set belt tension. When the vehicle deceleration is determined to be over a set deceleration, a buckle pretensioner is operated. The buckle is very strongly pulled, and the webbing is set at a third belt tension. The passenger is thus restrained by a large restraining force. At this point, the buckle pretensioner is preferentially operated irrespective of operation of the motor.

Owner:JOYSON SAFETY SYST JAPAN KK

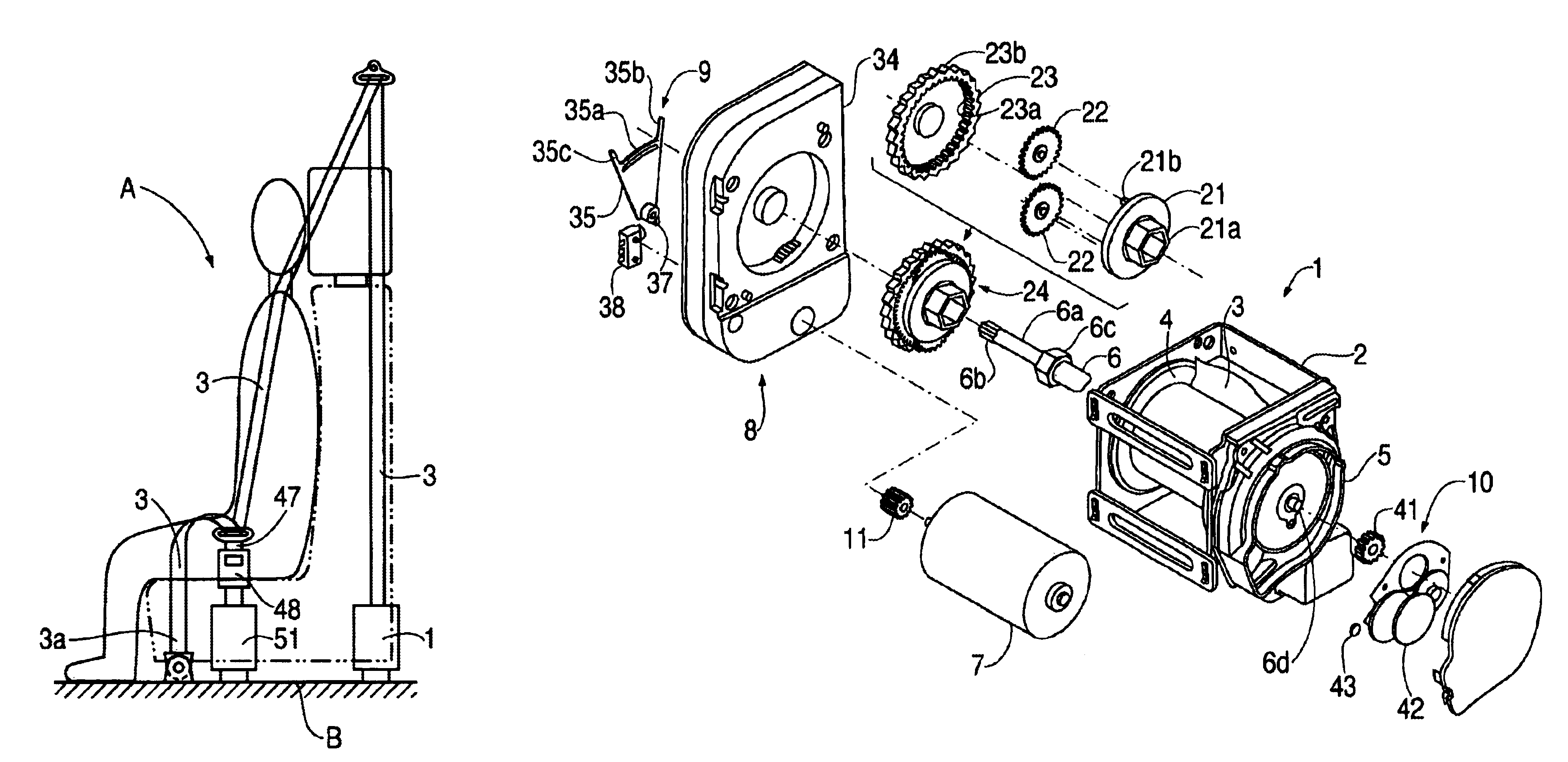

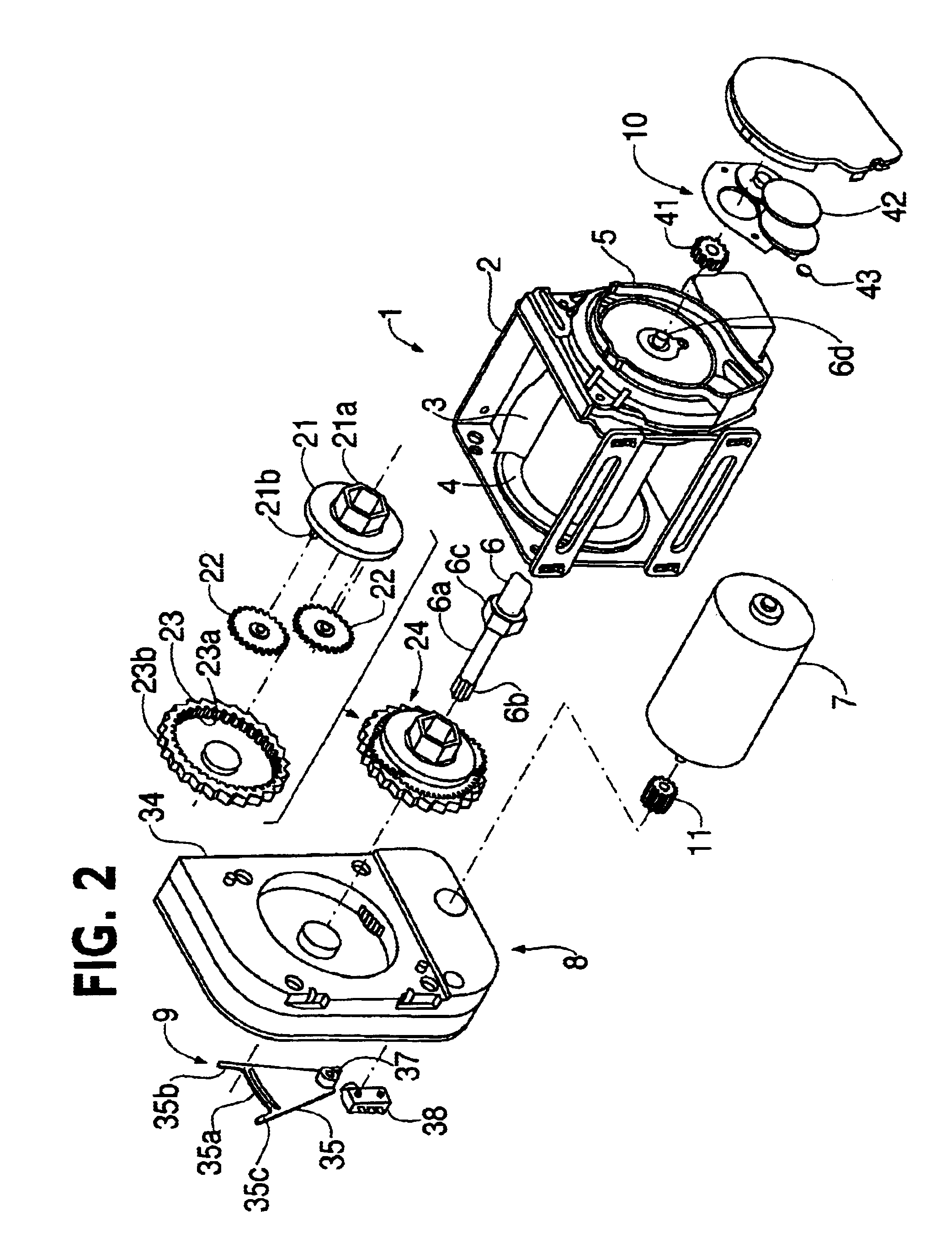

Reinforcement binding machine

A wire feed amount detection mechanism is configured by magnets mounted at an outer peripheral surface of a V-grooved drive gear of a wire feed mechanism and a magnetic sensor mounted on a body. A reinforcing bar winding turn number-setting switch is provided on the body. A control portion controls a wire feed amount of a wire feed mechanism based on a set value of the reinforcing bar winding turn number-setting switch. The number of turns of the wire around reinforcing bars can be arbitrarily set, for example, to any one of 1 to 4, and the binding can be effected with a binding force corresponding to a strength required by binding portions. As a result, with respect to those binding portions requiring a low binding force, the binding is effected with a smaller turn number, so that the amount of consumption of the wire can be saved, and besides those pipes (such as electric wiring pipes and hot water pipes) which are lower in strength than the reinforcing bars can also be bound together.

Owner:MAX CO LTD

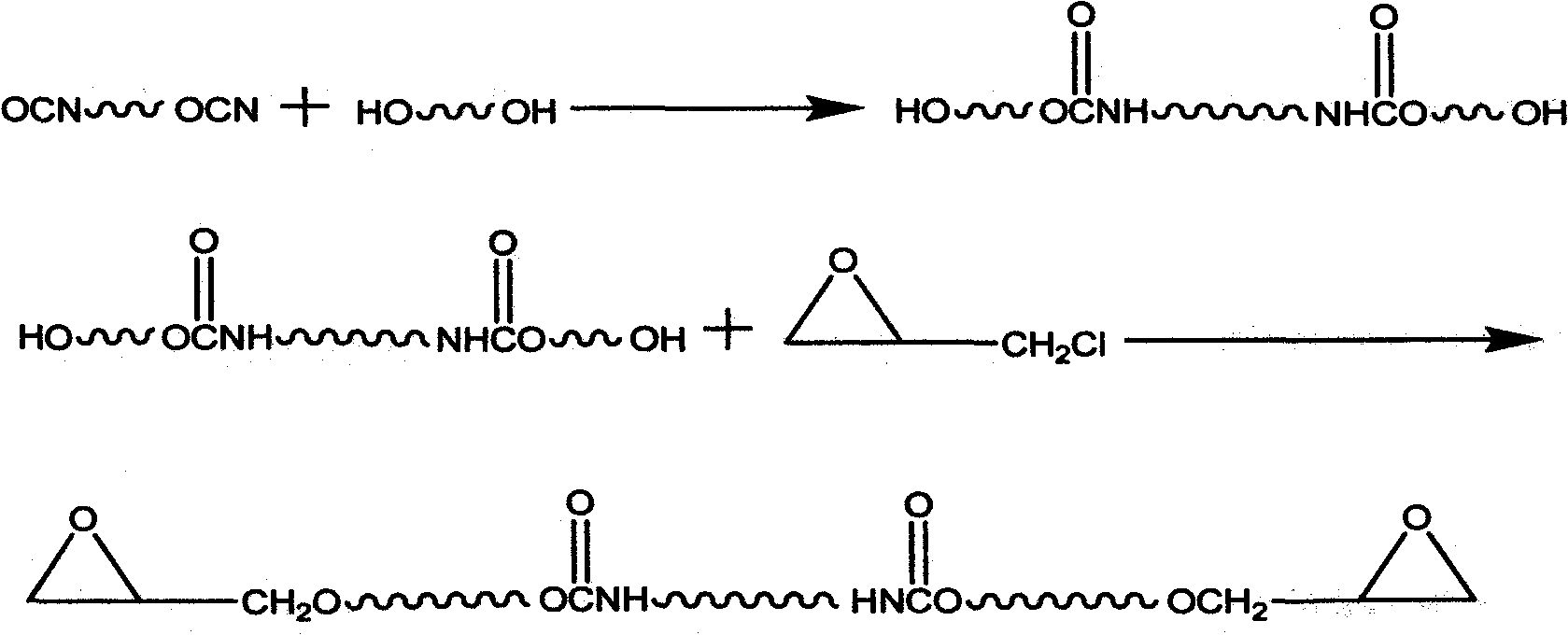

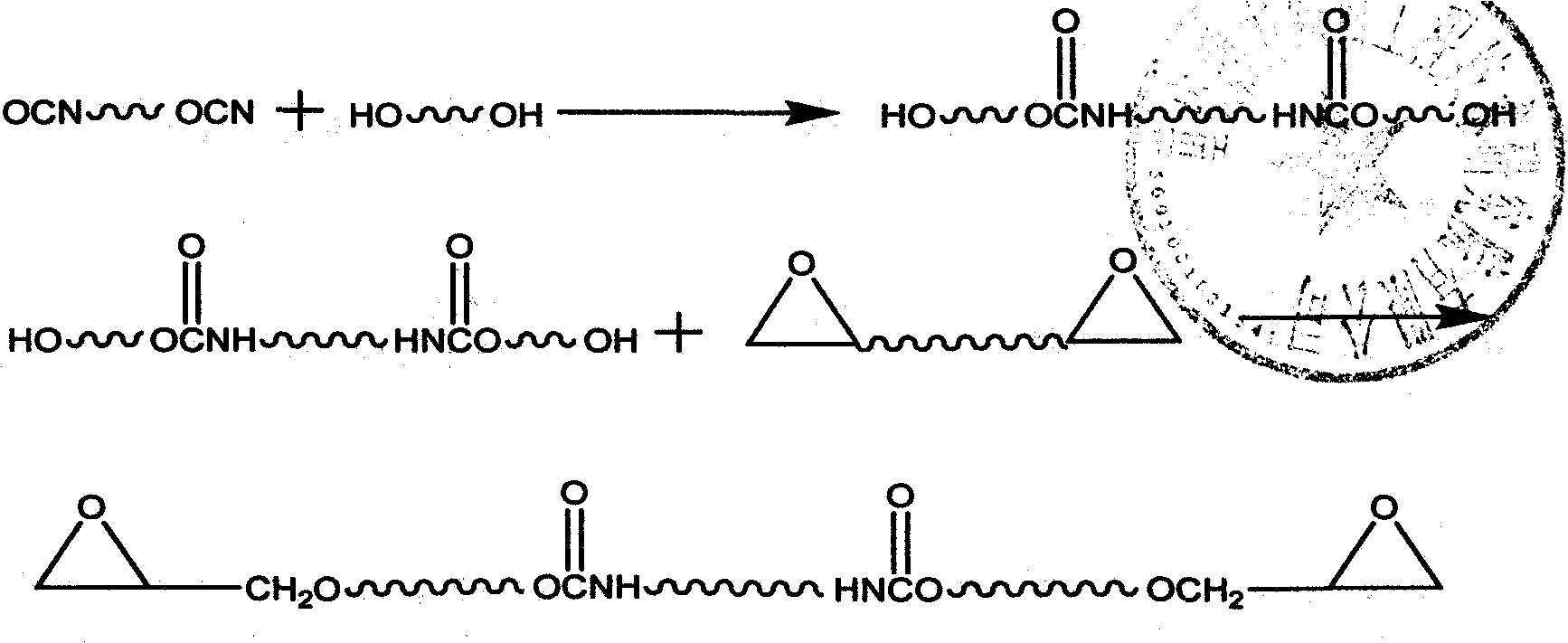

Waterborne polyurethane epoxy resin modified emulsified asphalt

ActiveCN102321372AImprove adhesionGood flexibilityIn situ pavingsBuilding insulationsEpoxyPavement maintenance

The invention relates to waterborne polyurethane epoxy resin modified emulsified asphalt, which comprises an ingredient A and an ingredient B, wherein the ingredient A is modified alicyclic amine epoxy resin curing agent aqueous solution, the ingredient B consists of the following ingredients in mass parts: 5 to 40 parts of waterborne polyurethane epoxy resin and 60 to 95 parts of emulsified asphalt, and the mass percent ratio of the ingredient A to an ingredient B is 1 / 10 to 1 / 30. During application, the ingredient A and the ingredient B are proportionably and uniformly mixed, and the waterborne polyurethane epoxy resin modified emulsified asphalt is obtained. Various indexes of the modified emulsified asphalt are all superior to those of the modified emulsified asphalt in common use in markets, good low-temperature flexibitity and high-temperature stability are realized, the brittle rupture is not easily caused under the loading effect, the adhesivity with stone materials and pavements is good, the binding force is strong, and the waterborne polyurethane epoxy resin modified emulsified asphalt can be used for pavement maintenance or can be used as cementing materials of preventive maintenance and pot hole repair materials.

Owner:CHONGQING SPECIAL ENG TECH

Active carbon immobilized imidazole ionic liquid, preparation method thereof and application thereof

InactiveCN102513063ASolve easy lossImprove bindingOther chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsActivated carbonChemical reaction

The invention discloses an active carbon immobilized imidazole ionic liquid, a preparation method thereof and an application thereof. The active carbon immobilized imidazole ionic liquid is obtained through immobilizing an imidazole ionic liquid on the surface of active carbon by a silane coupling agent. The preparation method comprises the following steps: preparing the active carbon, modifying the active carbon, silanizing the modified active carbon, and immobilizing the imidazole ionic liquid. According to the invention, the imidazole ionic liquid is firmly and chemically bonded on the active carbon, so the binding force between the ionic liquid and the active carbon is enhanced, thereby a problem of easy loss of the ionic liquid of traditional physical dipping load methods is solved. The prepared active carbon immobilized imidazole ionic liquid which can be applied to the adsorbing separation of a carbon dioxide, hydrogen sulfide, benzene and formaldehyde gas can also be used as acatalyst for a liquid phase chemical reaction, and has the advantages of adjustable adsorption performance and catalytic performance, easy recycle, environmental protection and the like.

Owner:FUJIAN AGRI & FORESTRY UNIV

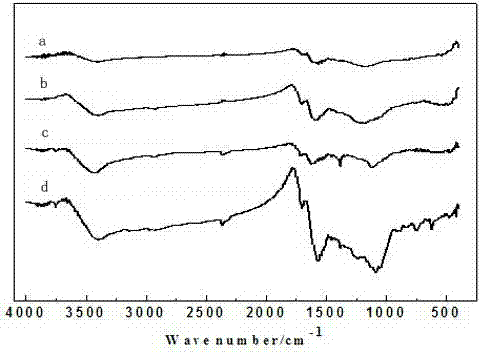

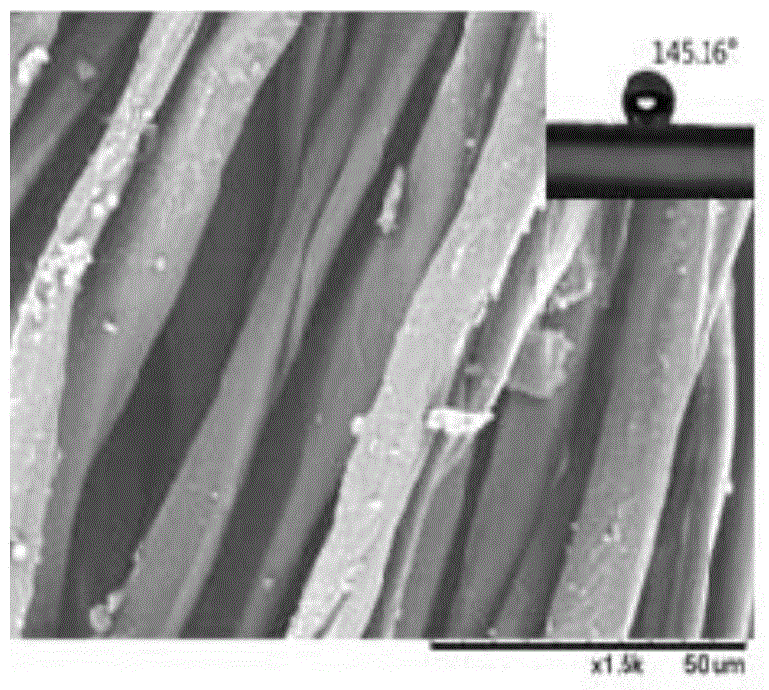

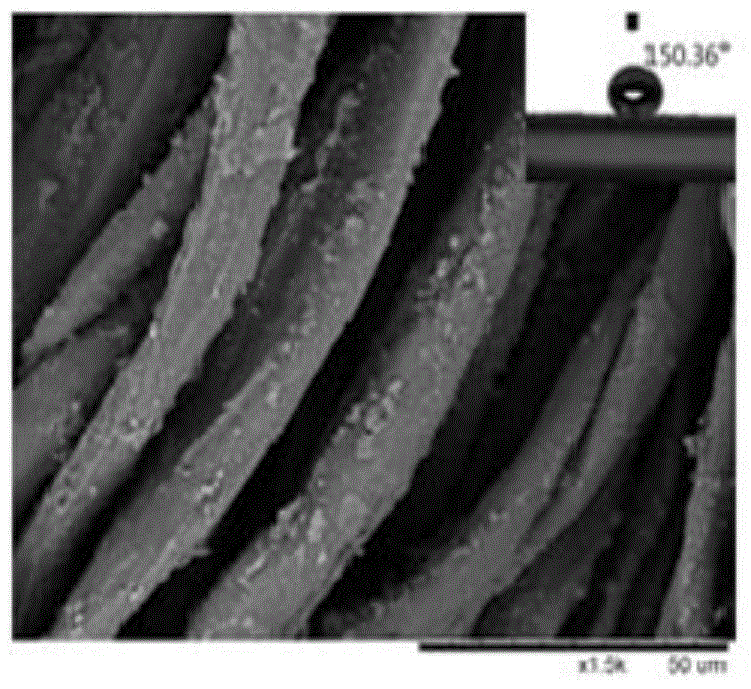

Method for preparing durable cellulose fiber fabric with super-hydrophobic surface

InactiveCN104594028AExcellent Durability Super Hydrophobic PropertiesMeet functional requirementsVegetal fibresCross-linkState of art

The invention relates to a method for preparing a durable cellulose fiber fabric with a super-hydrophobic surface. The method comprises the following three steps: preparing modified SiO2 composite sol, preparing a modified fabric and performing super-hydrophobic finishing on the fabric. The active groups are introduced into nanometer SiO2 and fiber surface, the fabric is finished by adopting a simple one-step method, the binding force between the fabric and the inorganic nanometer SiO2 is enhanced by virtue of the active groups on the fiber surface and the cross-linking effect on the modified SiO2 surface, the covalent bonding firmness between the modified sol and the surface of the modified cellulose fiber fabric is improved, and the super-hydrophobic interface of a fluoride-free cellulose fiber fabric with certain washing fastness is finally obtained. Compared with the prior art, the preparation method disclosed by the invention is economical and environmentally friendly, and the industrial production is promoted.

Owner:SHANGHAI UNIV OF ENG SCI

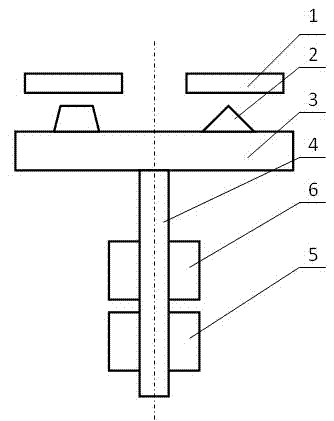

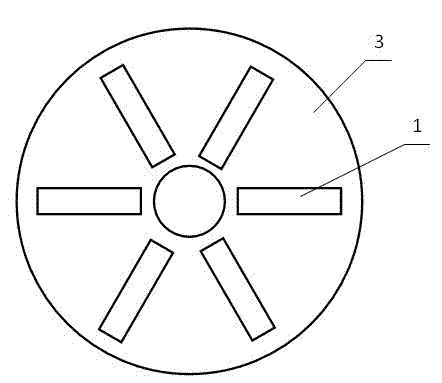

Three-dimensional (3D) printing method and 3D printing system

The invention discloses a three-dimensional (3D) printing method and a 3D printing system. Printing data information of an object is acquired, a printing material is controlled to be molded layer by layer according to the printing data information, and printing is realized. The 3D printing method is characterized by comprising the following steps: providing a circular printing platform for bearing a printing object; setting multiple printing heads on the circular printing platform, wherein multiple nozzles which are radially arranged along the circle are arranged on each printing head; and setting a synchronous control mechanism, and synchronously controlling the circular printing platform to rotate around a rotating shaft in the center of a circle and decline during printing, so that the molded printing layers form a spiral shape on the whole circular printing platform, and the position and shapes of slicing data of the printing data information in the object are consistent with the spiral layer shape of the printing object. Multi-layer synchronous printing in a printing period is realized, the printing speed is improved, and the interlayer binding force is enhanced.

Owner:SHANGHAI REALFAST DIGITAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com