Method for preparing bimetallic nanometer alloy composite material by taking graphene as carrier

A bimetallic nano-composite material technology, applied in the field of nano-inorganic materials, can solve the problems of complex preparation process, difficult to control particle size, etc., and achieve the effects of simple process, low cost and low impurity content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

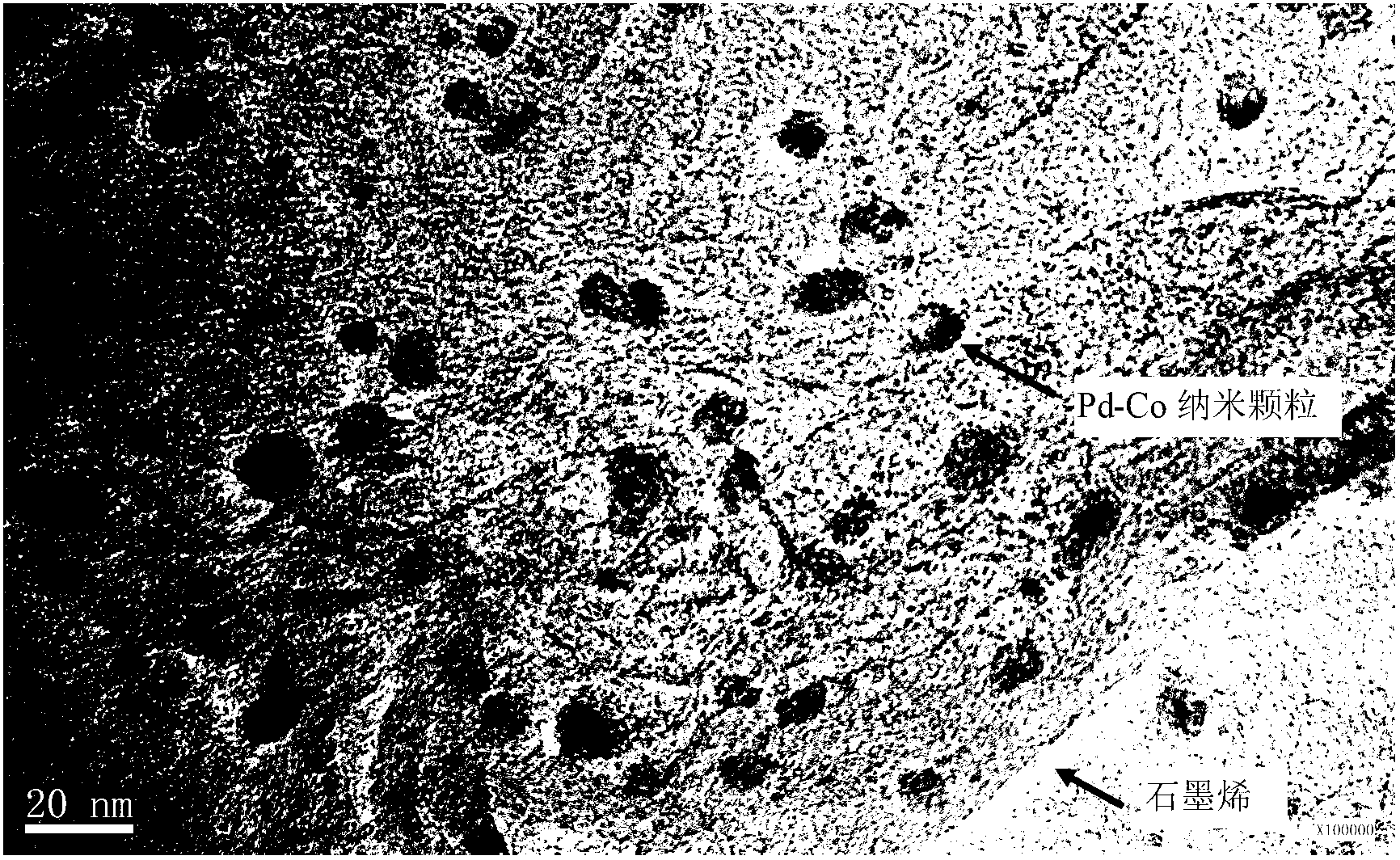

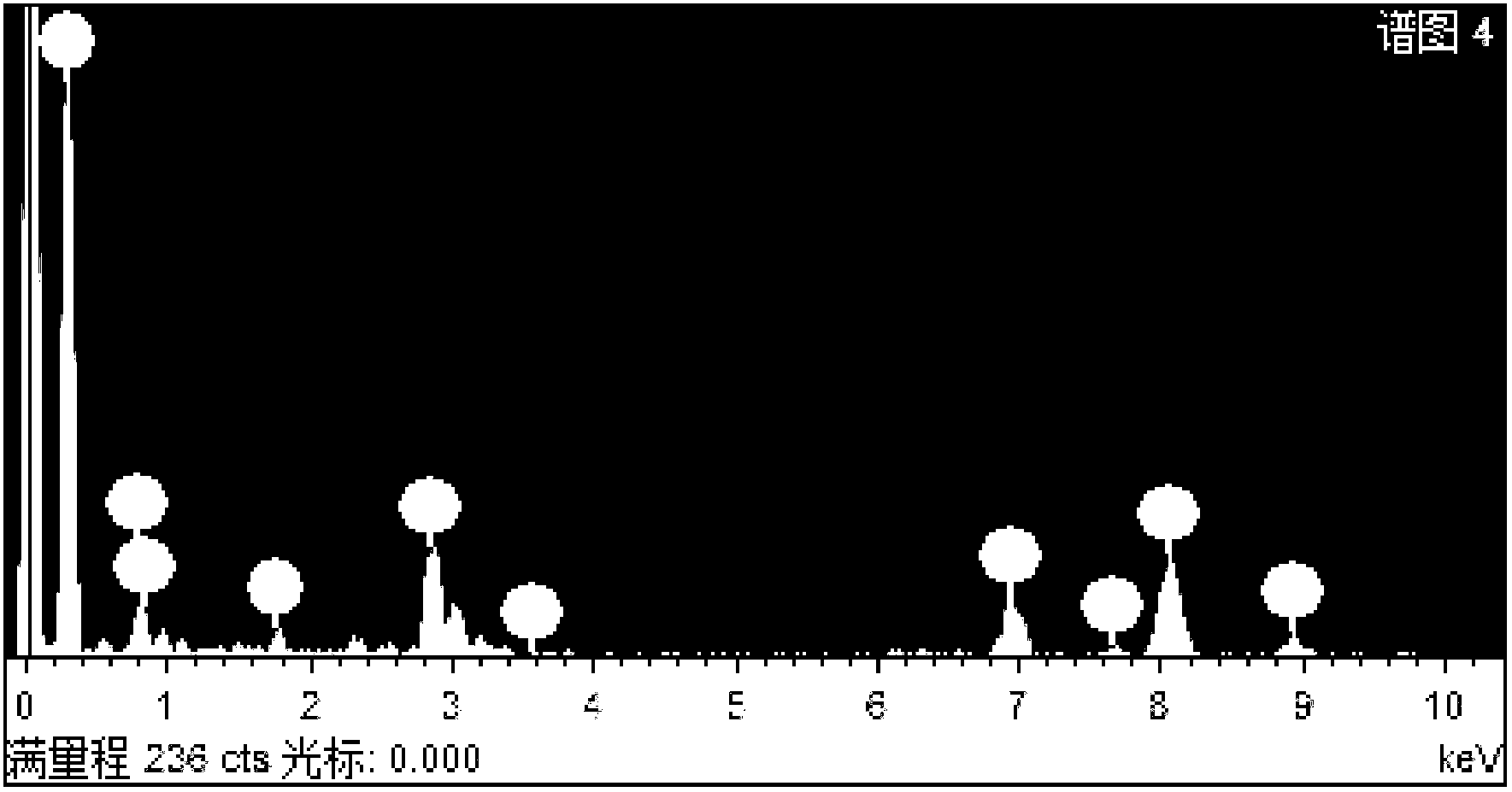

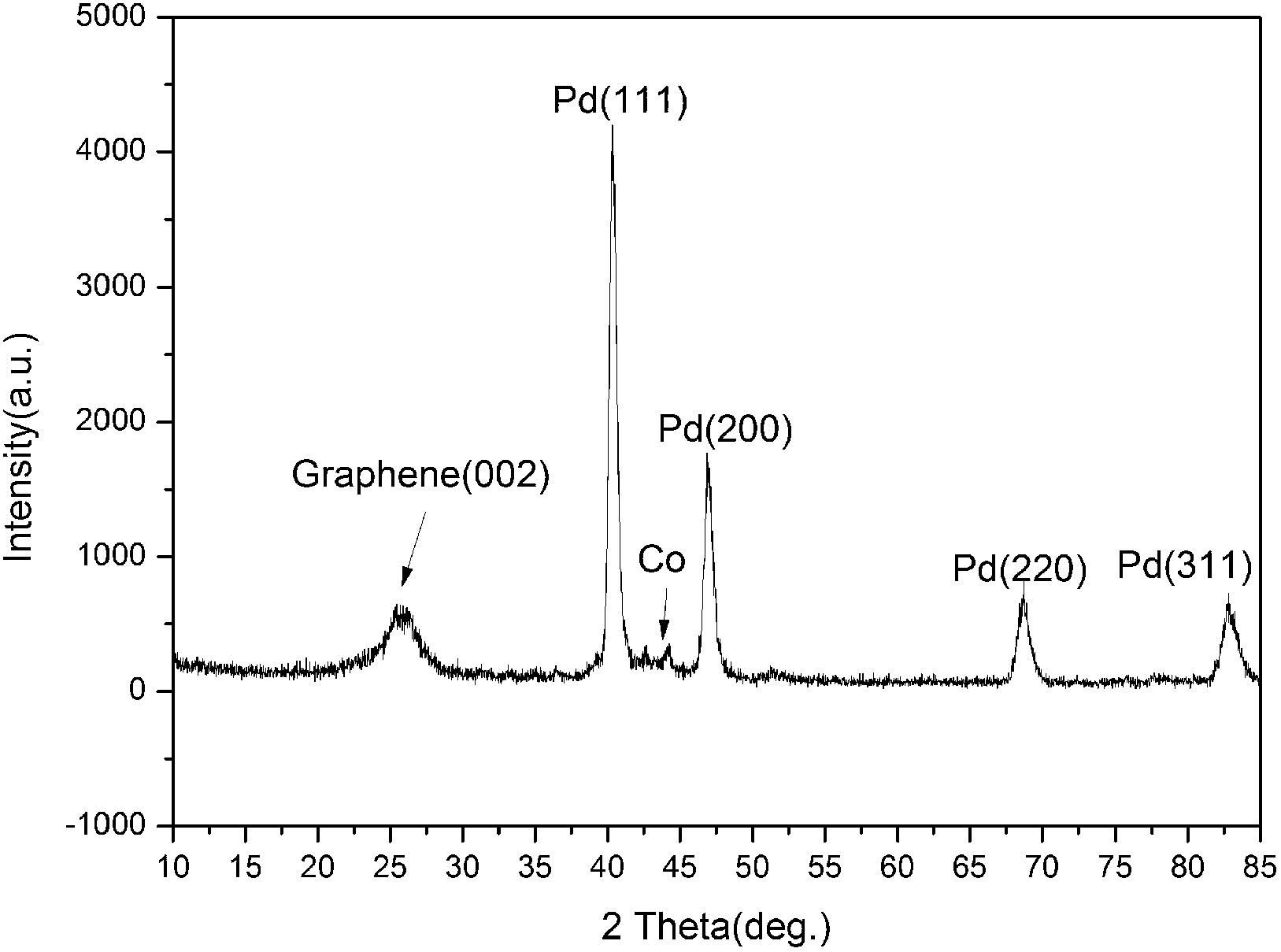

[0025] Weigh 0.282mmol PdCl 2 (AR) and 0.282mmol Co(C 4 h 6 o 4 )·4H 2 O(AR), after mixing, add to the suspension containing 0.3g graphene oxide, stir magnetically at 80-90°C for 1 hour, then slowly add 50mL ammonia water (AR) to adjust the pH>10, then add 35mL of 85% mass concentration Hydrazine hydrate solution, reacted for 4 hours under magnetic stirring, after the reaction, centrifuged to obtain a black solid, washed with deionized water until neutral, and then vacuum-dried at 60°C to obtain a black flaky solid, after grinding the black flaky solid Obtain uniform black powder;

[0026] Spread the black powder on a quartz boat, place it in the constant temperature zone of the tube furnace, raise the temperature to 300°C under nitrogen atmosphere (flow rate: 600mL / min), feed hydrogen gas (flow rate: 100mL / min), reduce and calcinate for 120 Minutes, cooled to room temperature under the protection of nitrogen (flow 600mL / min); then heated up to 500°C under nitrogen atmosp...

Embodiment 2

[0028] The preparation method of the present embodiment is the same as embodiment 1, and the difference is that the noble metal N salt is Pd(C 2 h 3 o 2 ) 2 (AR), 124 mg of nano-Pd-Co / graphene composite material (molar ratio Pd:Co=1:1) was obtained, and the loading rate of nano-Pd-Co particles was 37.5%.

Embodiment 3

[0030] The preparation method of the present embodiment is the same as that of embodiment 1, and the difference is that the noble metal N salt is Pd(NO 3 ) 2 (AR), 134 mg of nano-Pd-Co / graphene composite material (molar ratio Pt:Co=1:1) was obtained, and the loading rate of nano-Pd-Co particles was 37.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com